RTM change mold for changing root diameters of fan blade molds and change method of RTM change mold

A technology of fan blades and moulds, which is applied to household appliances, other household appliances, and household components, etc., which can solve the problems of high cost, achieve the effects of small dimensional tolerance, fast switching, and improved change efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific examples.

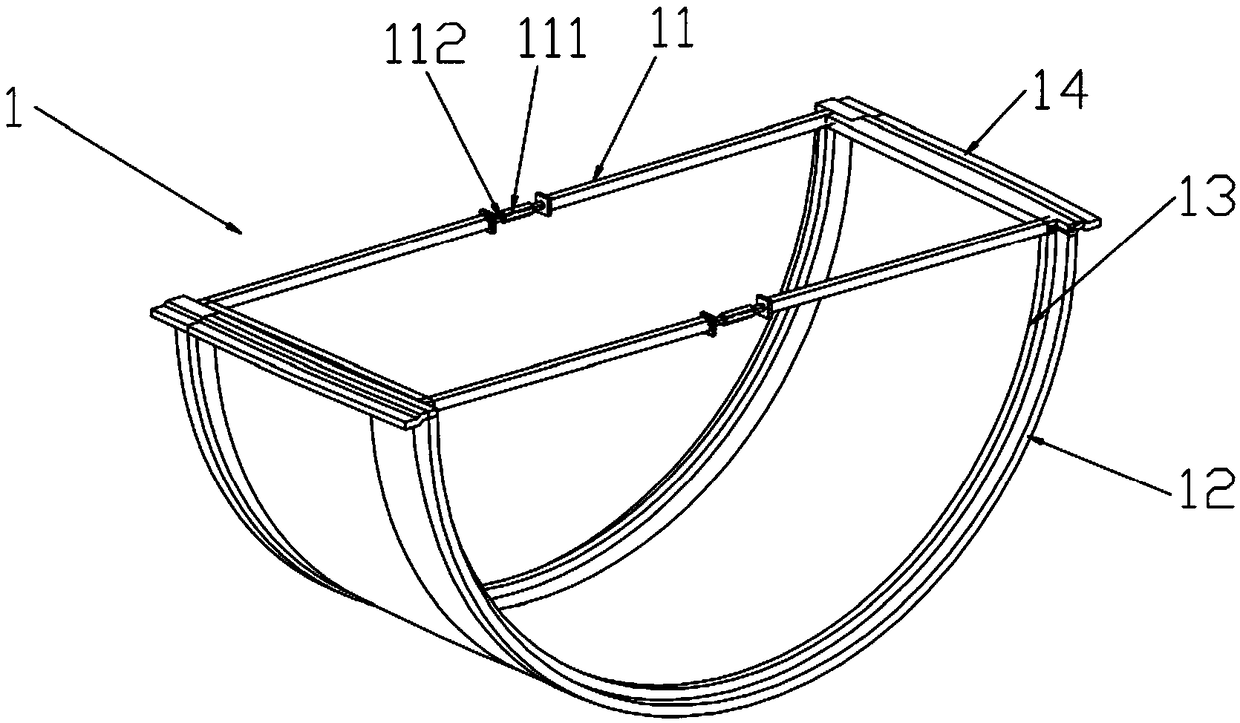

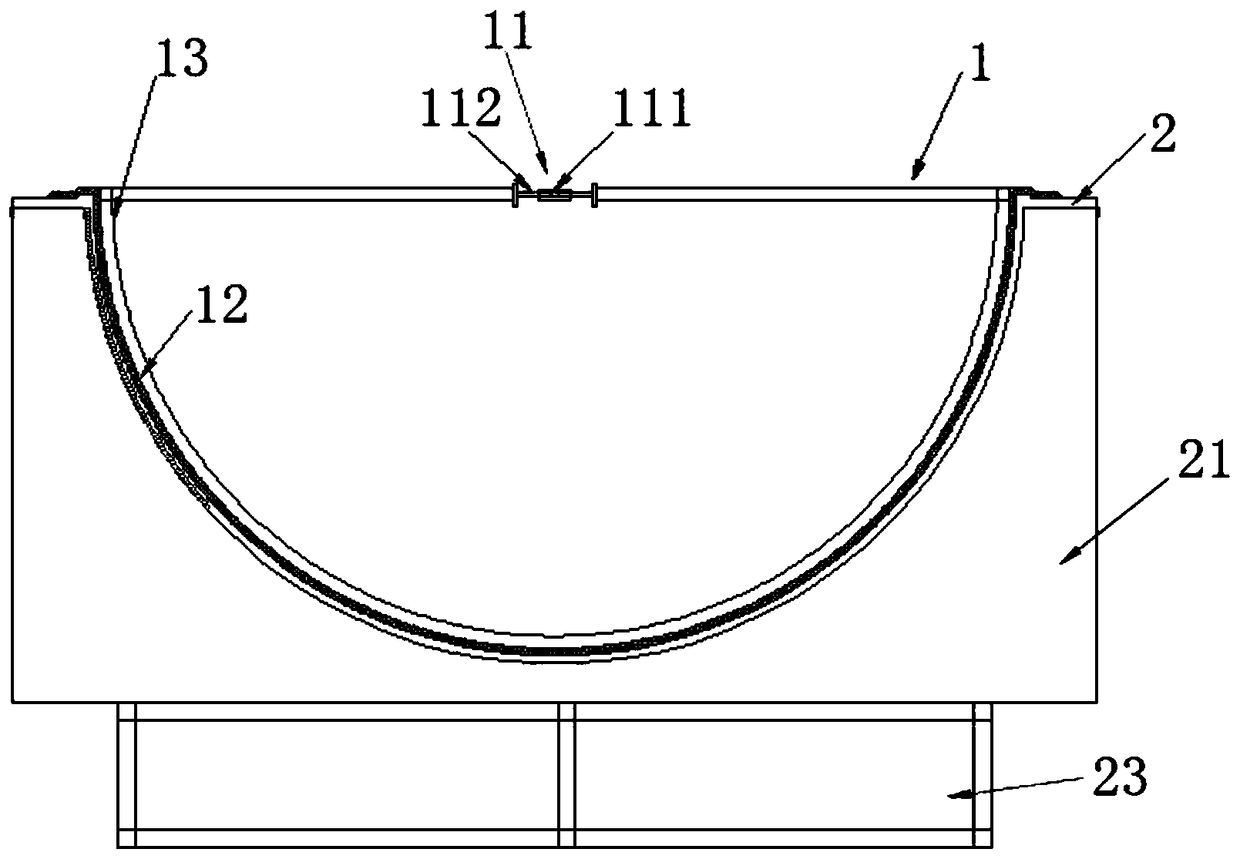

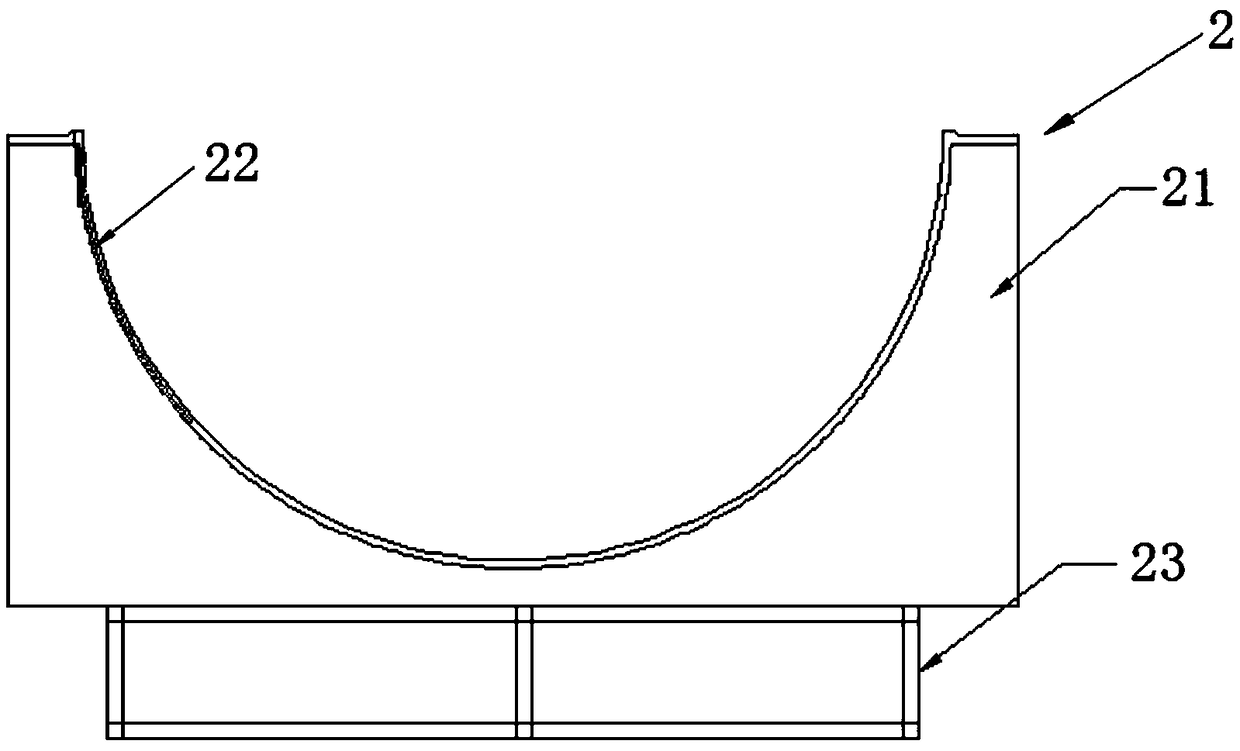

[0019] see Figure 1 to Figure 3 As shown, the root diameter of the fan blade mold provided by this embodiment changes the RTM mold, including the RTM mold shell 12 made of the RTM mold male mold 2 and the RTM mold diameter adjustment rod 11, and the RTM mold shell 12 is based on the RTM mold male mold. The shape and size of the root surface of the blade mold of mold 2 is formed by one-time vacuum infusion, forming a structure with 20mm balsa wood in the middle, 5 layers of 1200 four-axis cloth on the upper and lower sides, and a semicircle that adapts to the shape of the blade root. Surface, the inner surface of the RTM mold shell 12 is hand-laid with a 60*60*3mm square tube 13 to strengthen the strength of the RTM mold shell 12, and the two ends of the opening of the RTM mold shell 12 extend outward horizontally with mounting flanges Side 14, the RTM mold diameter adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com