Patents

Literature

163results about How to "Improve the working environment on site" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

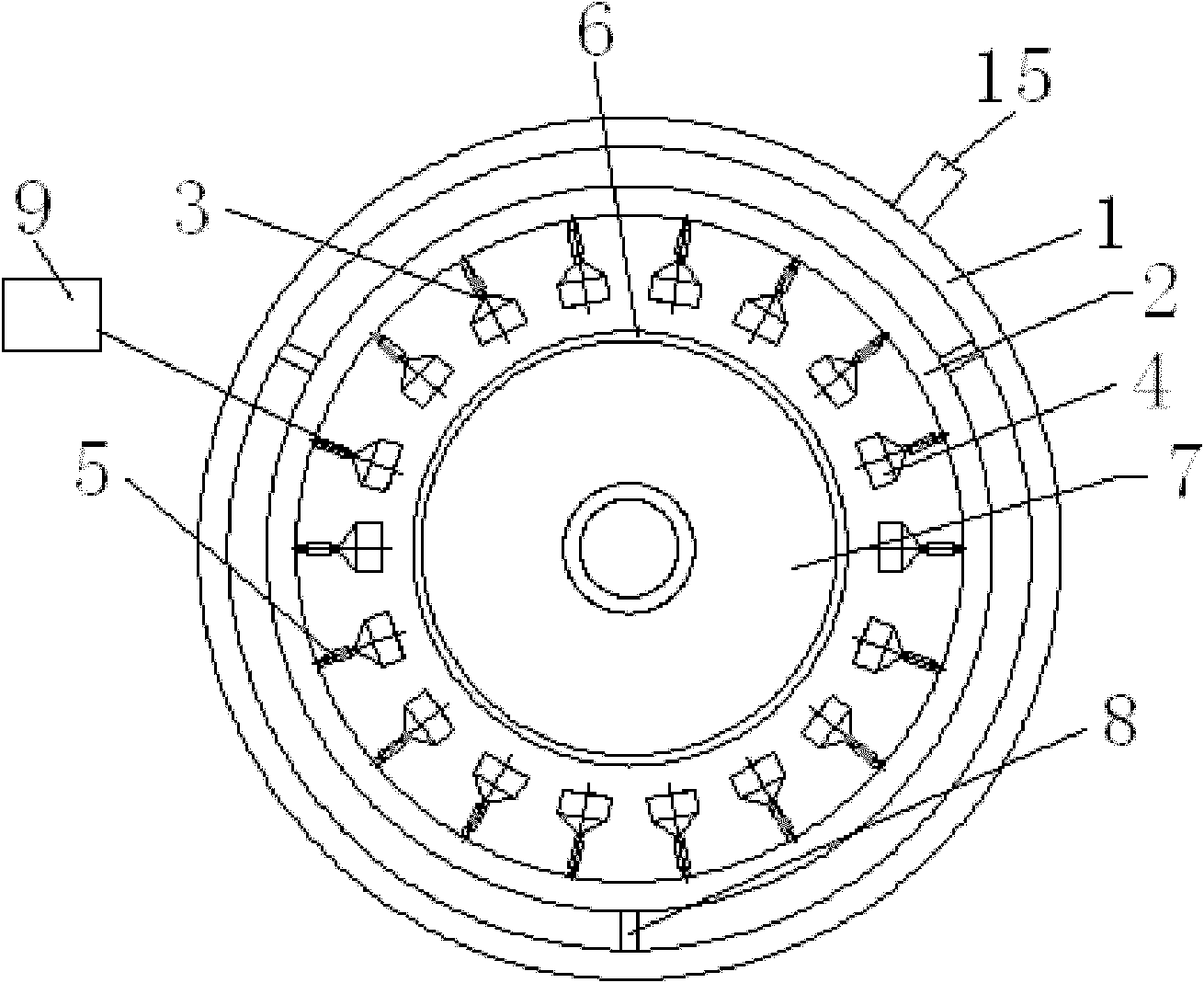

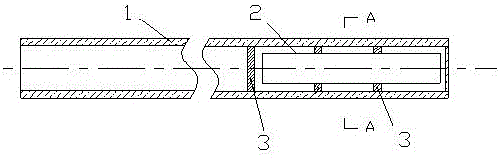

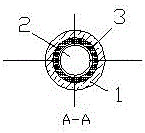

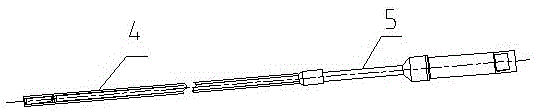

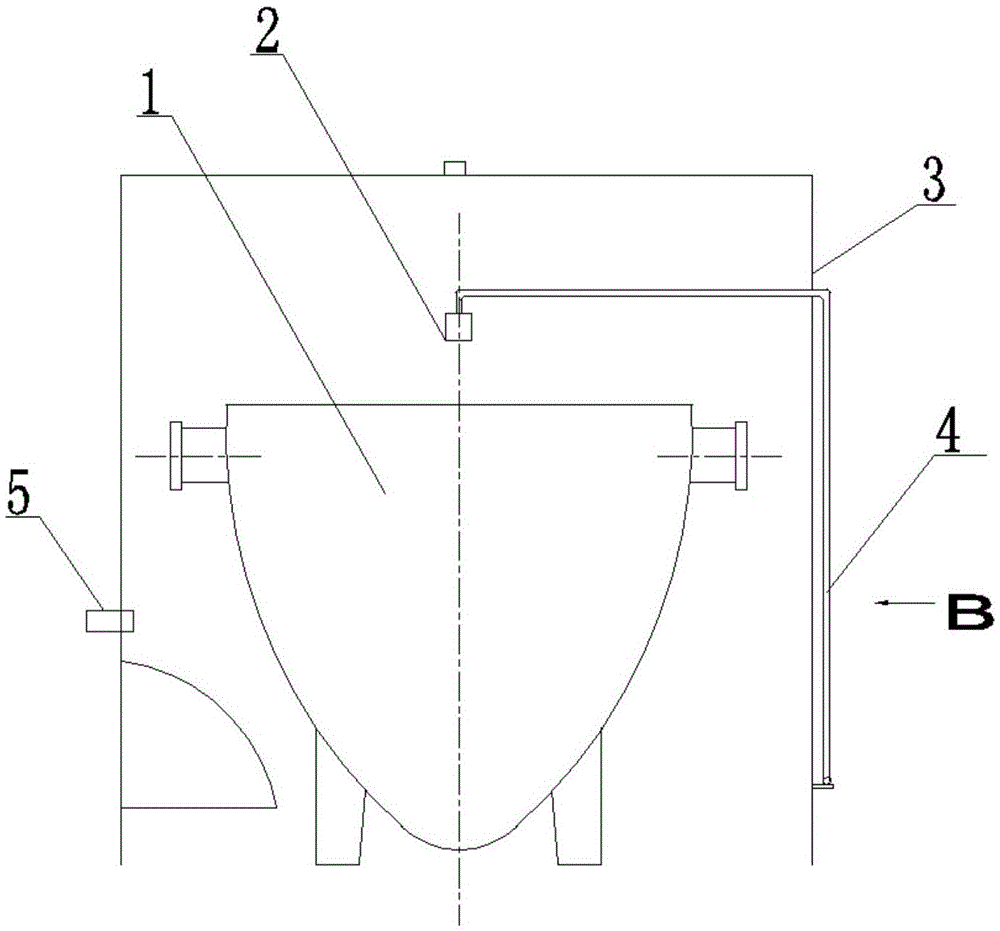

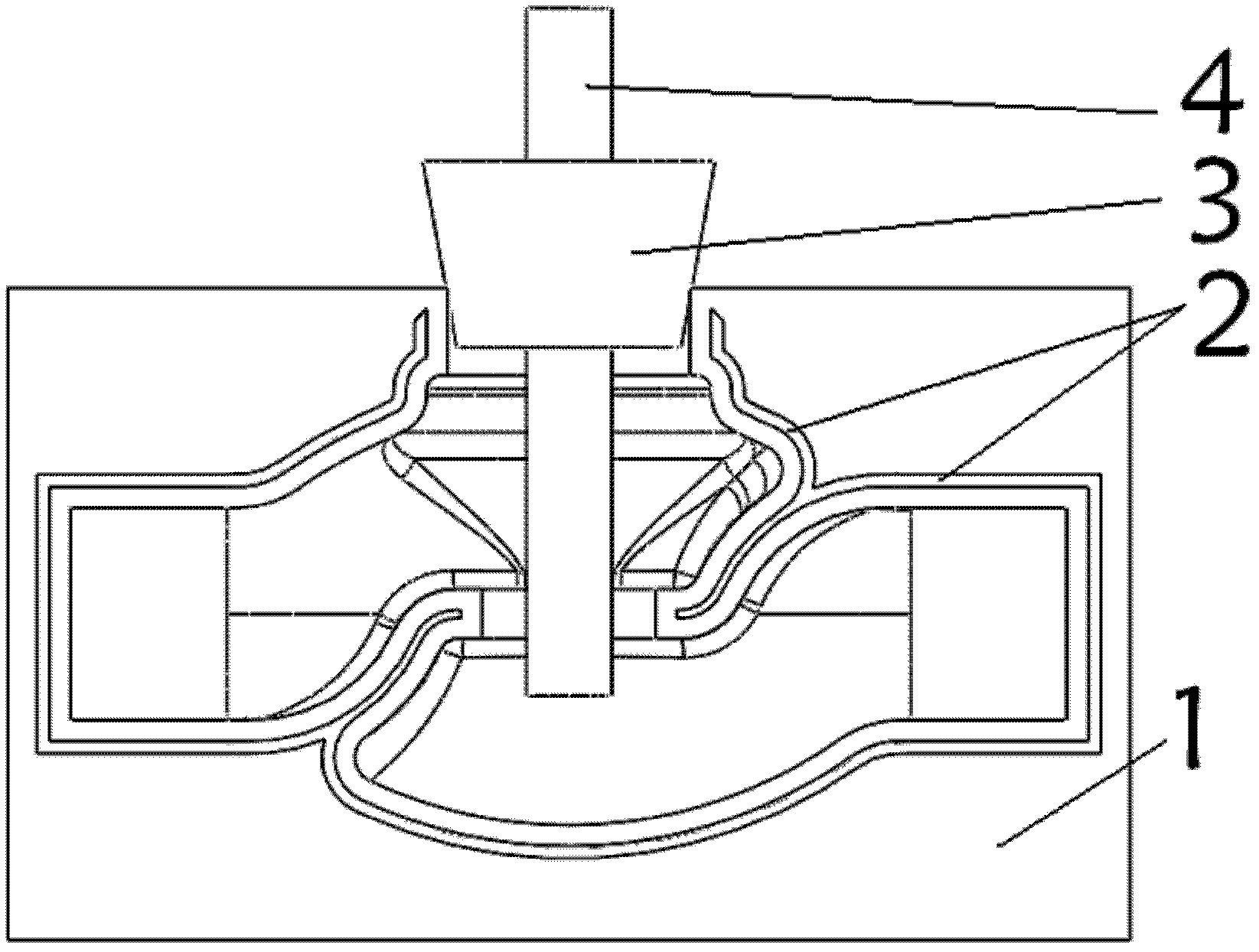

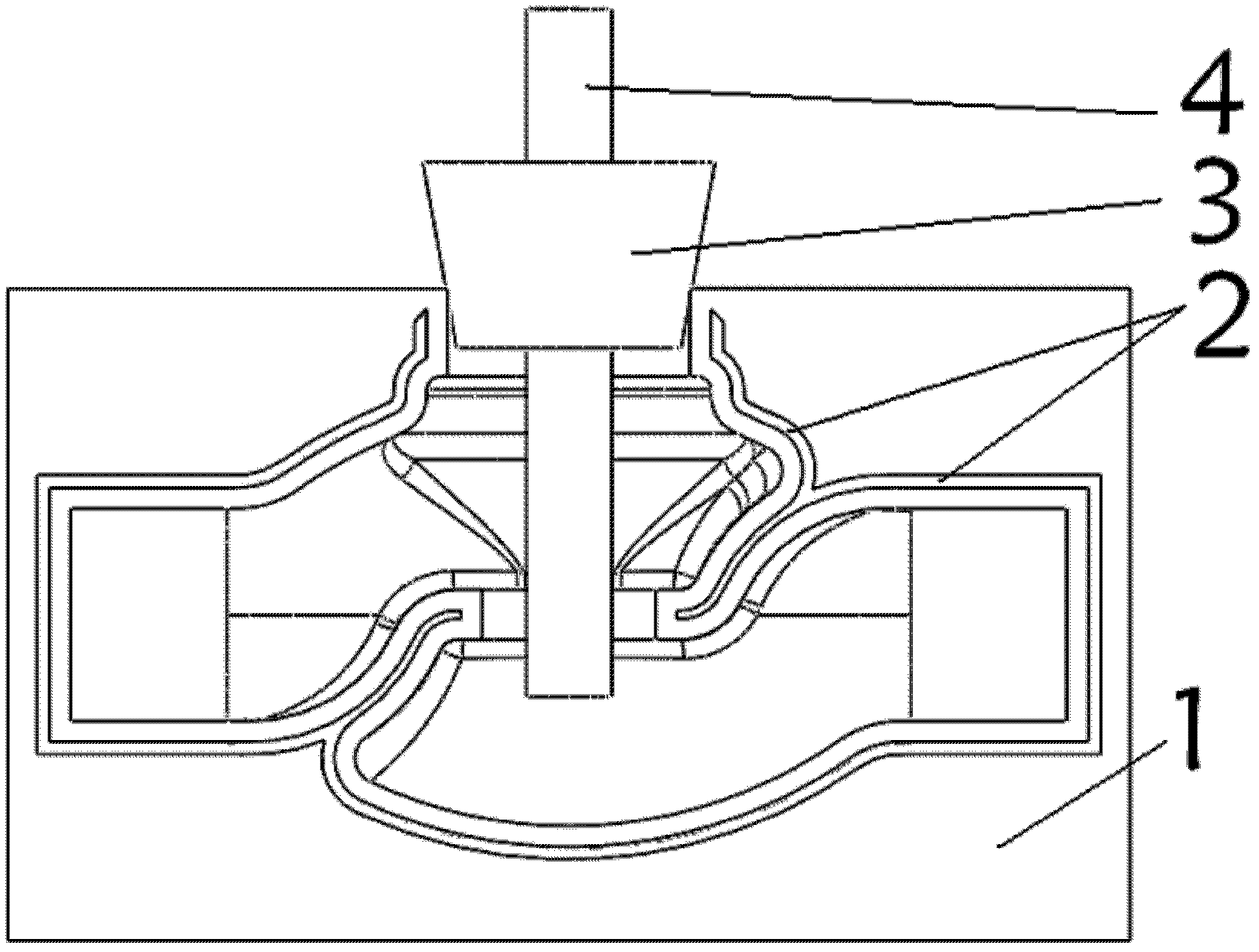

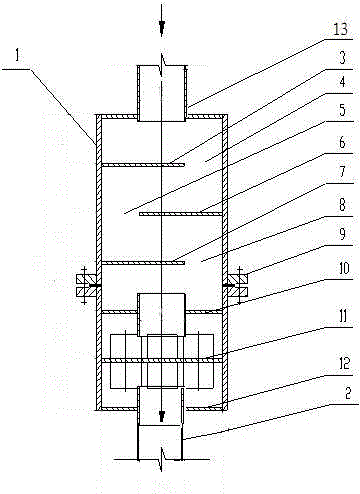

Wheel quenching device

ActiveCN102102139AImproved hardness gradientOptimize the adjustment methodFurnace typesHeat treatment furnacesQuenchingAbnormal structure

The invention provides a wheel quenching device applied to the technical field of metal heat treatment. The wheel quenching device comprises an outer ring tube (1), an inner ring tube (2), a cooling device (3) and a control device (9) for controlling the start / stop of the wheel quenching device. The wheel quenching device is characterized in that: the cooling device (3) comprises a nozzle (4) anda nozzle branch pipe (5); the nozzle branch pipe (5) is connected with the inner ring tube (2); and the nozzle (4) is connected with the nozzle branch pipe (5) and has a structure capable of being aligned with a wheel rim (6). By the technical scheme, the wheel quenching device has the advantages that: 1, the depth of an abnormal structure layer of the wheel rim is reduced; 2, the hardness gradient of the section of the wheel rim along the radial direction is improved; 3, the nozzle adjusting mode is improved, so that the adjustment is simple, and the quenching quality is improved; and 4, water splashing is reduced, the work environment for workers in field is improved, the work environment for equipment is improved and the maintenance cost of electric equipment is reduced.

Owner:MAANSHAN IRON AND STEEL COMPANY

Water-based paint of lost foam for iron casting, and production method of water-based paint

ActiveCN103447454ARaw materials are uniqueImprove securityFoundry mouldsFoundry coresWater basedSodium Bentonite

The invention relates to a water-based paint of lost foam for iron casting. The water-based paint is characterized by comprising the following raw materials: high bauxite, precious peal powder, brown aluminum oxide, sodium bentonite, polyacrylamide, a polyvinyl acetate emulsion, maltodextrin, silica sol, sodium hexametaphosphate, tributyl phosphate, sodium pentachlorophenate, OP-10 active agent and water. A production method of the water-based paint comprises the steps: pretreating the sodium bentonite, pretreating the polyacrylamide and the maltodextrin, adding the water, the sodium pentachlorophenate, the tributyl phosphate and the sodium hexametaphosphate into a high-speed dispersion kettle, stirring and then sequentially adding the sodium bentonite slurry and a polyacrylamide and maltodextrin pretreatment solution into the dispersion kettle, sequentially adding the polyvinyl acetate emulsion and the silica sol into the dispersion kettle, sequentially adding the OP-10, the high bauxite, the precious pearl powder and the brown aluminum oxide to the dispersion kettle under a stirring state, and conducting high-speed dispersion for 30 minutes after completing the feeding. The water-based paint is unique in the raw materials, environment-friendly, high in coating strength, anti-cracking, good in permeability, and free from carbon lack of castings.

Owner:共享新材料(山东)有限公司

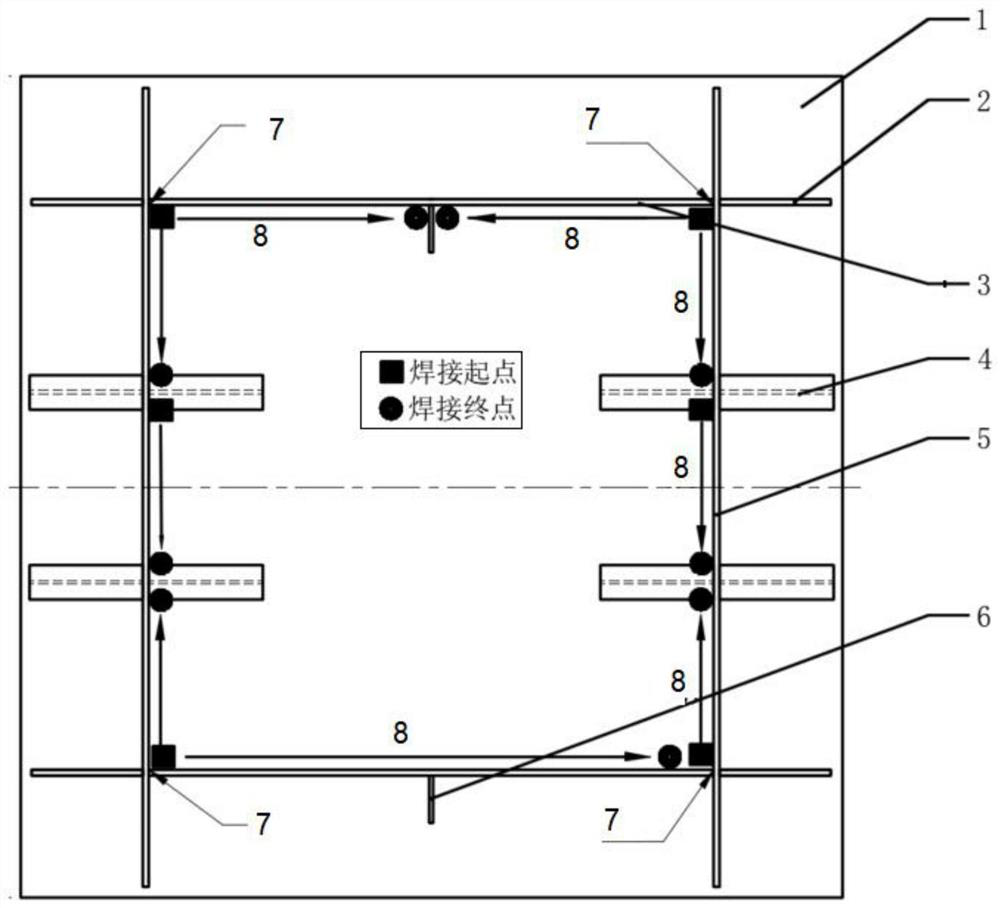

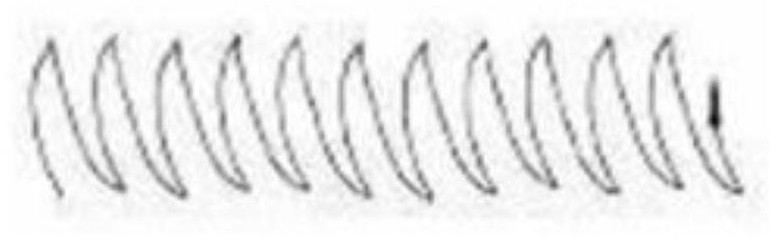

Middle assembling robot welding process for ship

InactiveCN112743206AImprove welding qualityImprove welding efficiencyElectrode supporting devicesWelding accessoriesFillet weldStructural engineering

The invention discloses a middle assembling robot welding process for a ship. The middle assembling robot welding process comprises the following steps that a, preparation before welding is conducted, specifically, after a workpiece is moved to a welding position, the workpiece is checked; B, after the workpiece is in place, weld joints are positioned, and the welding sequence and the starting point and the ending point of each weld joint are determined; C, the angle of a welding gun is adjusted, the welding gun with a gooseneck part having a bending angle is adopted by the welding gun, reaches the starting points and the ending points of the weld joints, and flat fillet welding and vertical fillet welding are completed; D, after the welding is conducted for a certain time, welding gun cleaning, wire shearing and oil spraying procedures are started, and the welding gun is prevented from being blocked; and e, after the welding of all welding seam robots is completed, the appearance and size of the welding joints need to be detected. In the welding process, electric arc tracking is adopted, and automatic welding of straight angle and vertical fillet weld of the assembly component in the ship is achieved under the cooperative use of a specific robot welding posture, a welding process, a welding sequence and a swing mode.

Owner:上海中船临港船舶装备有限公司 +1

Method for preparing TC4 titanium alloy wire

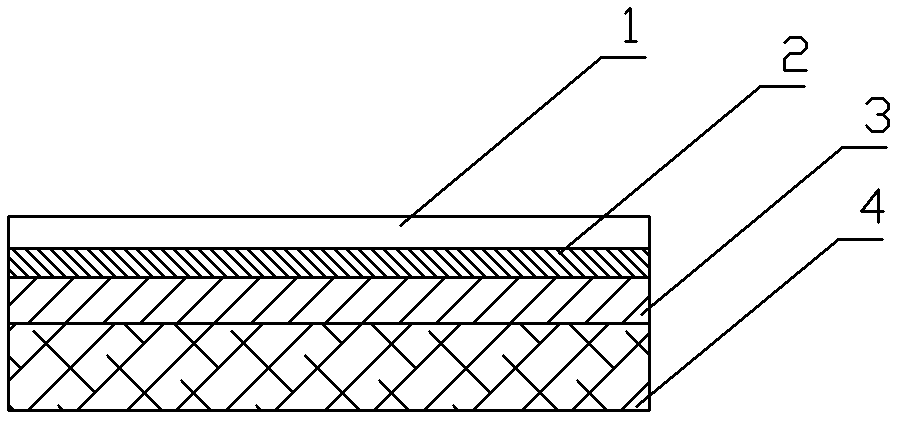

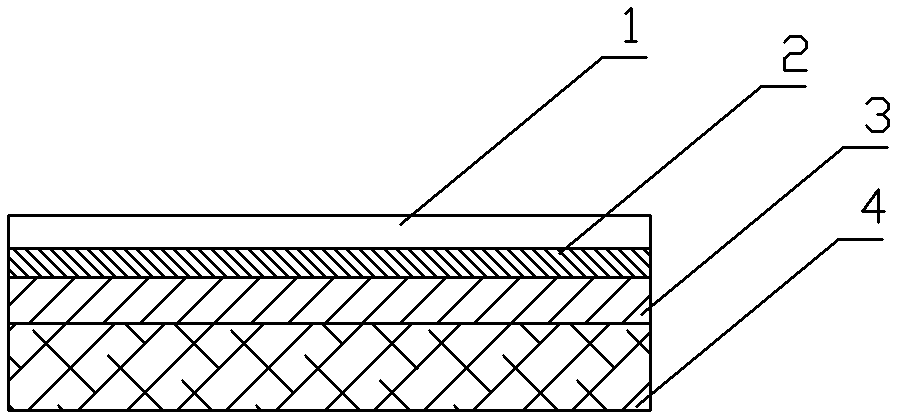

InactiveCN103406386ASave energyImprove the working environment on siteLiquid surface applicatorsCoatingsTectorial membraneTitanium alloy

The invention provides a method for preparing TC4 titanium alloy wire, which comprises the following steps: after annealing, placing an annealed titanium alloy wire blank into a container containing coating agent for heating and stewing, so as to ensure that the titanium alloy wire blank is coated by a protecting film layer; then placing the titanium alloy wire blank onto a linear wire drawing machine for continuous cold drawing. Through the adoption of the process, the linear velocity of the titanium alloy wire blank can be 16 to 40 m / min during cold drawing, so that the production efficiency is greatly improved; the yield is high; both the dimensional precision and surface quality of the titanium alloy wire are effectively guaranteed.

Owner:BAOJI ZHONGYUAN METAL PROCESSING

Lining machining method

ActiveCN101979889ADoes not affect manufacturabilityImprove surface roughnessBearing componentsPunchingWorking environment

The invention discloses a lining machine method, which comprises the following copper-based double-metal steel strip processing steps: 1) feeding; 2) punching to form hasps; 3) punching to form a U shape; 4) rounding; 5) finely rounding; 6) milling excircle; and 7) boring inner circle. The method is characterized in that the step 5 of finely rounding, the step 6 of milling excircle and the step 7of boring inner circle are accomplished by one extrusion process for forming the required surface roughness and wall thickness of the lining. The method has high economy and high processing property and can improve an on-site working environment greatly.

Owner:湖北安达精密工业有限公司

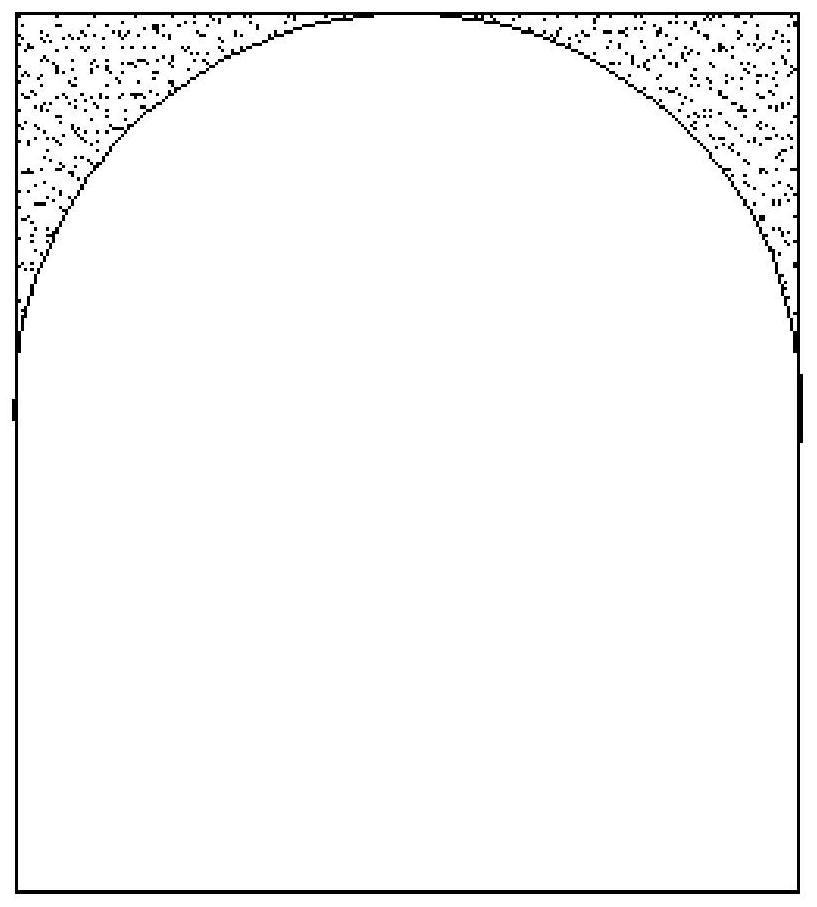

Construction method of main line fabricated secondary lining in subway underground excavation section

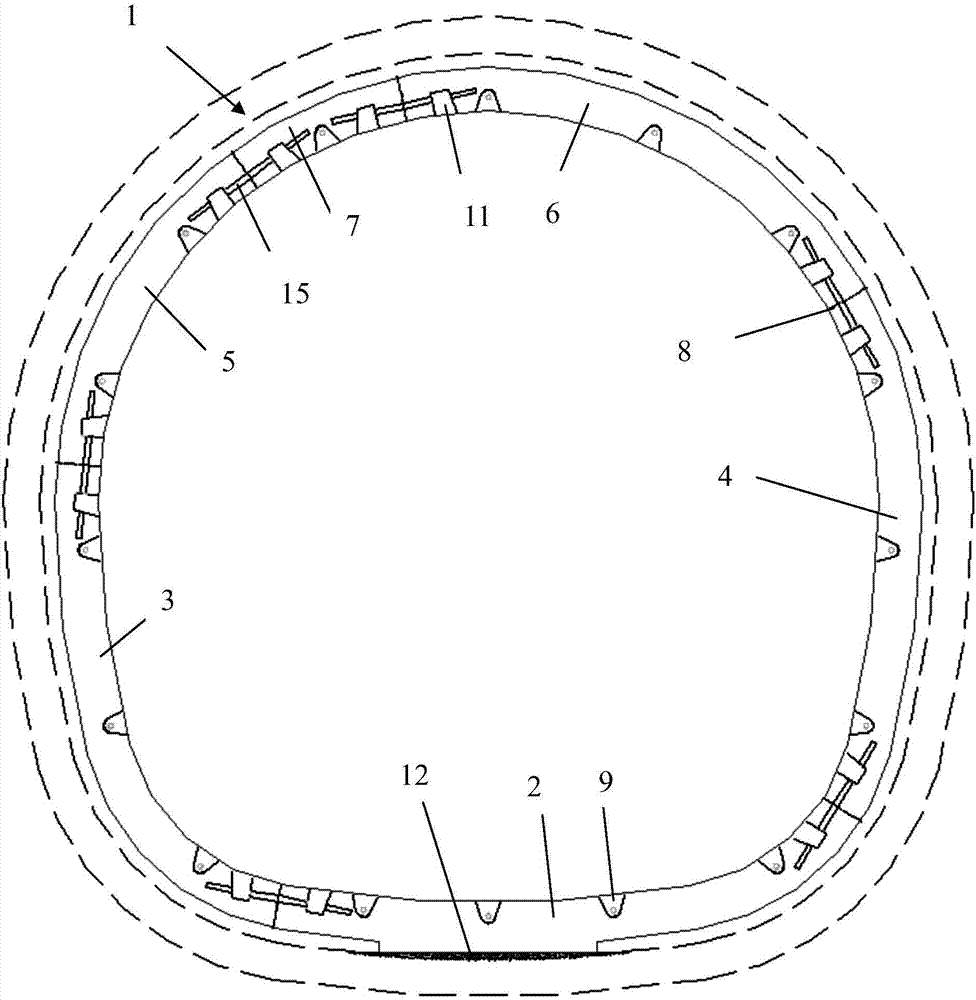

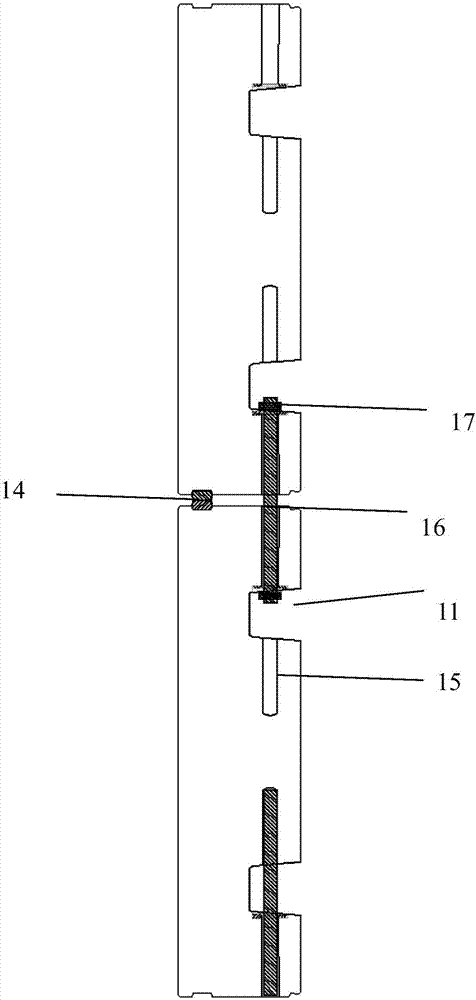

ActiveCN106930777AImprove mechanical propertiesImprove construction efficiencyUnderground chambersTunnel liningEngineeringBuilding construction

The invention provides a construction method of a main line fabricated secondary lining in a subway underground excavation section. Construction of a tunnel secondary lining structure is completed in a subway underground excavation section of a structure subjected to primary supporting by means of the method that starting and receiving of a prefabricated pipe piece assembling device and conveying of materials such as a prefabricated pipe piece are conducted through a conventional vertical shaft and a cross channel, and assembling of the prefabricated pipe piece is conducted through a dedicated pipe piece assembling device, flexibility of an underground excavation tunnel is combined, meanwhile the mechanical level and construction work efficiency of an underground excavation secondary lining are improved, an on-site operation environment is improved, safety of on-site operation is improved, the water-proof quality is improved, and industrial production is achieved.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

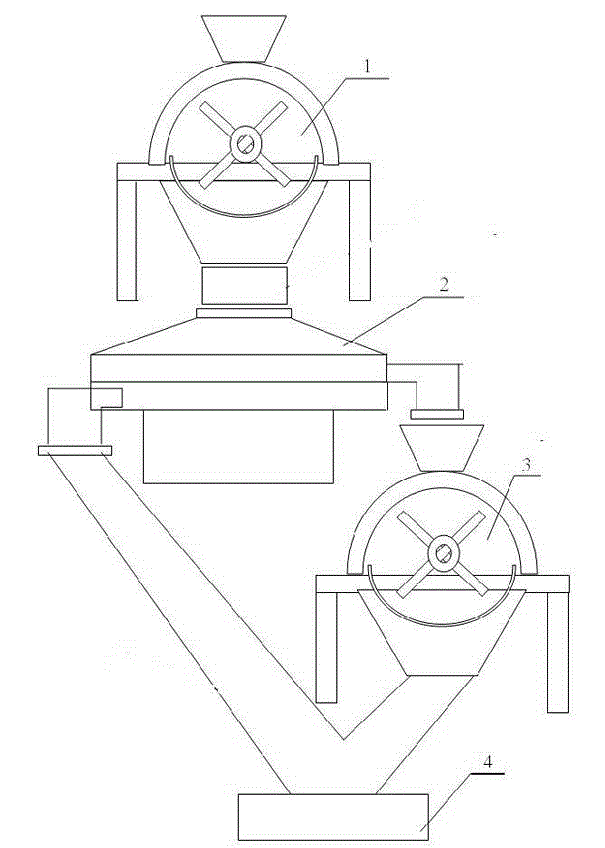

Granularity sorting method for epoxy molding compound powder material

ActiveCN102941140AThe crushing method is reasonableStrong maneuverabilityGrain treatmentsPulverizerSieve

The invention discloses a granularity sorting method for an epoxy molding compound powder material. The method comprises the following steps of: smashing the material through a first-stage hammer type smashing machine, sorting the smashed material in a double-layer sorting sieve, and pouring the fine powder material into a collector from a material outlet at the lower layer through a screen of the double-layer sorting sieve; and screening out rough powder material through the double-layer sorting sieve, smashing the rough powder material again in a two-stage hammer type smashing machine, and directly putting the smashed powder material into the collector. The smashing method is rational and high in operability; the material is smashed twice; moreover, a smashing machine screen and a sorting sieve screen which have different mesh size are adopted, so that powder materials in different granularity distribution ranges can be obtained; the granularity of the powder material is well controlled; the production efficiency is high; the material during production is high in powder flowability, so that a bridge is difficultly formed in a system; large particles and dust can be reduced; and the field working environment is improved.

Owner:灌云县瑞聚电子商务商行

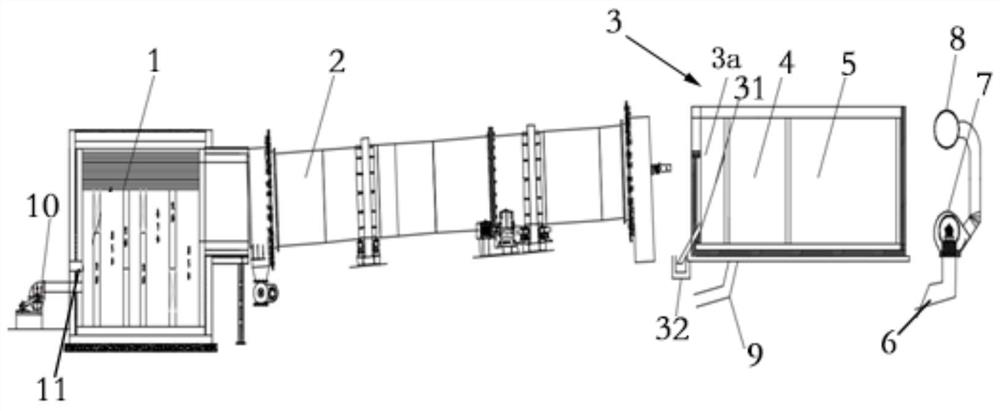

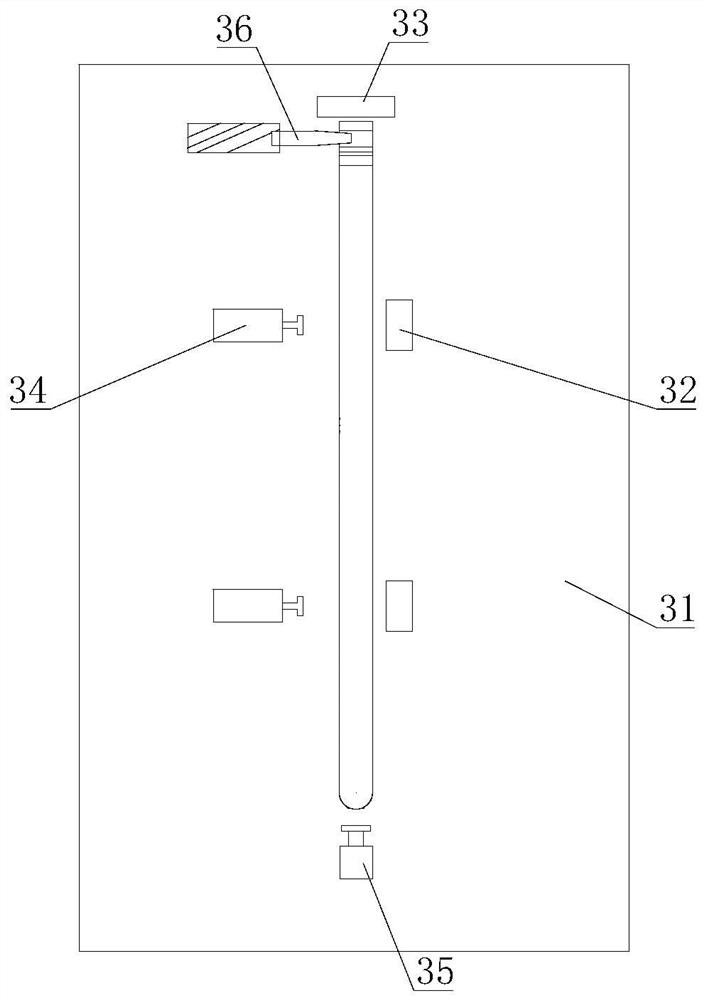

Jacking type sand core microwave drying device

InactiveCN108007096AAvoid Sealing DefectsPrevent leakageSand dryingDrying solid materials with heatMicrowaveEngineering

The invention relates to a jacking type sand core microwave drying device. The drying device mainly comprises a microwave drying cavity, a jacking assembly and a sand core tray, wherein the jacking assembly comprises two supporting stand columns and a jacking sealing bracket arranged between the two supporting stand columns; a vertical linear rail is arranged on each supporting stand column; the jacking sealing bracket is jacked and descended on the supporting stand columns through the vertical linear rails; an inner roller way is arranged on the jacking sealing bracket, and is used for beingmatched with a outer roller way to carry and transport the sand core tray; the microwave drying cavity is located above the supporting stand columns; the bottom of the microwave drying cavity is provided with a feeding opening; when the jacking sealing bracket ascends, the jacking sealing bracket is in sealing connection with the feeding opening. Through matching and sealing of the jacking sealingbracket and the upper microwave drying cavity, microwave leakage prevention is carried out, the problem of microwave leakage is effectively solved, and 3D printing sand core flow coating and automatic drying after dip coating are efficiently realized.

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

Metallurgical slag sampling device and usage thereof

InactiveCN105784418ADoes not affect protection strengthChange the face of backwardnessWithdrawing sample devicesMetallurgical slagMolten steel

A metallurgical slag sampling device and usage thereof belong to the technical field of metallurgy and are useful in online sampling of high-temperature molten metallurgical slag on a production site. The technical scheme of the invention includes: the metallurgical slag sampling device comprises a paper protection sleeve and a glass vacuum sampling core; the vacuum sampling core is mounted in the protective sleeve and fixed via pug; a sampling actuator holds the protective sleeve and extends into slag on the surface of molten steel, after a moment of standing, the slag sampling device is taken out of the slag and cooled, and a slag sample is submitted for inspection after completely solidifying. The invention is innovation on metallurgical slag sampling processes, and the backward situation of present metallurgical slag sampling is changed. The metallurgical slag sampling device and usage thereof of the invention are simple and feasible, a field operation environment and labor intensity of workers are improved effectively, quality stability and sampling success rate of high-temperature slag sampling are improved, online automatic sampling for metallurgical high-temperature slag is achieved, and further increase in the metallurgical automation level is facilitated.

Owner:SHIJIAZHUANG IRON & STEEL

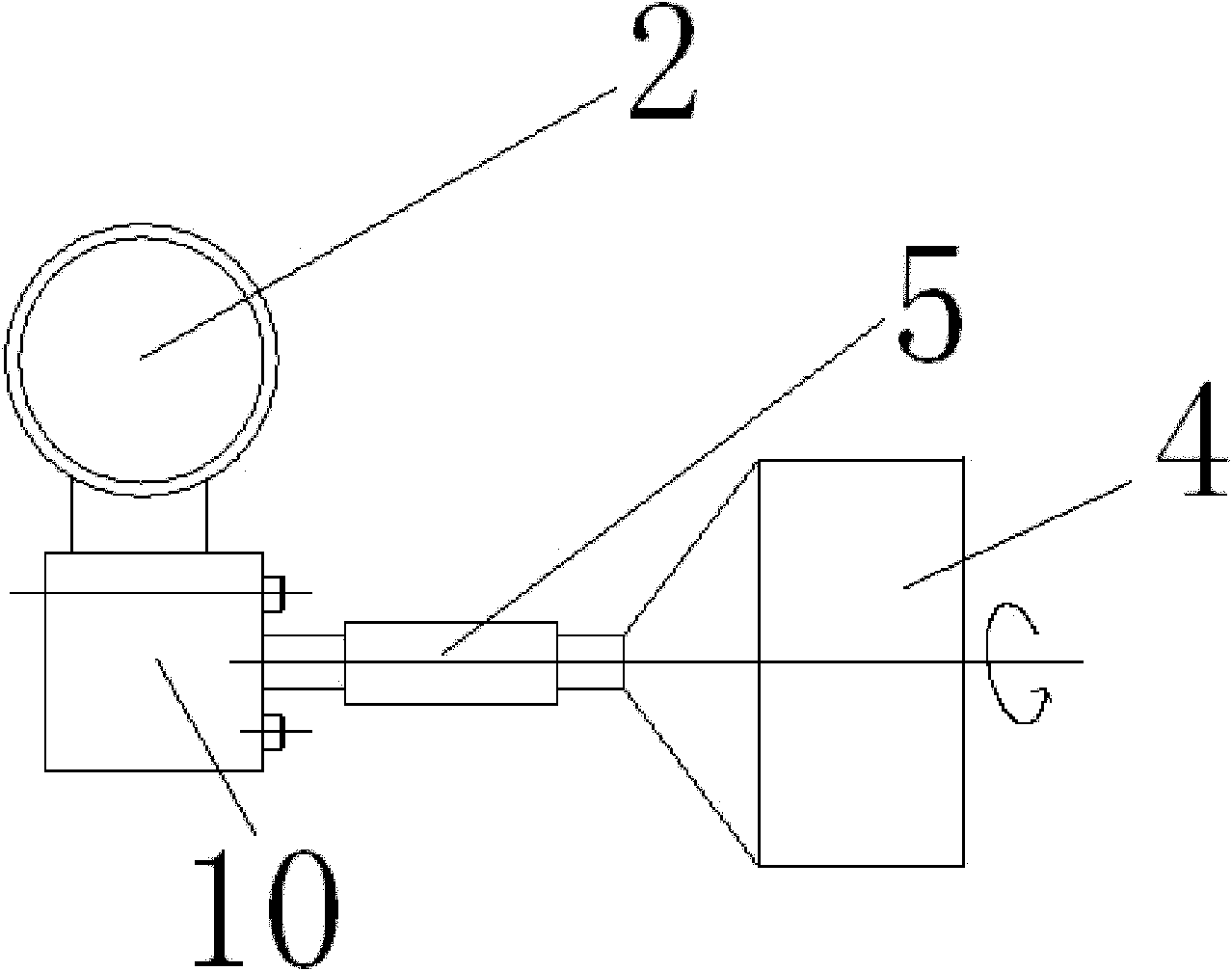

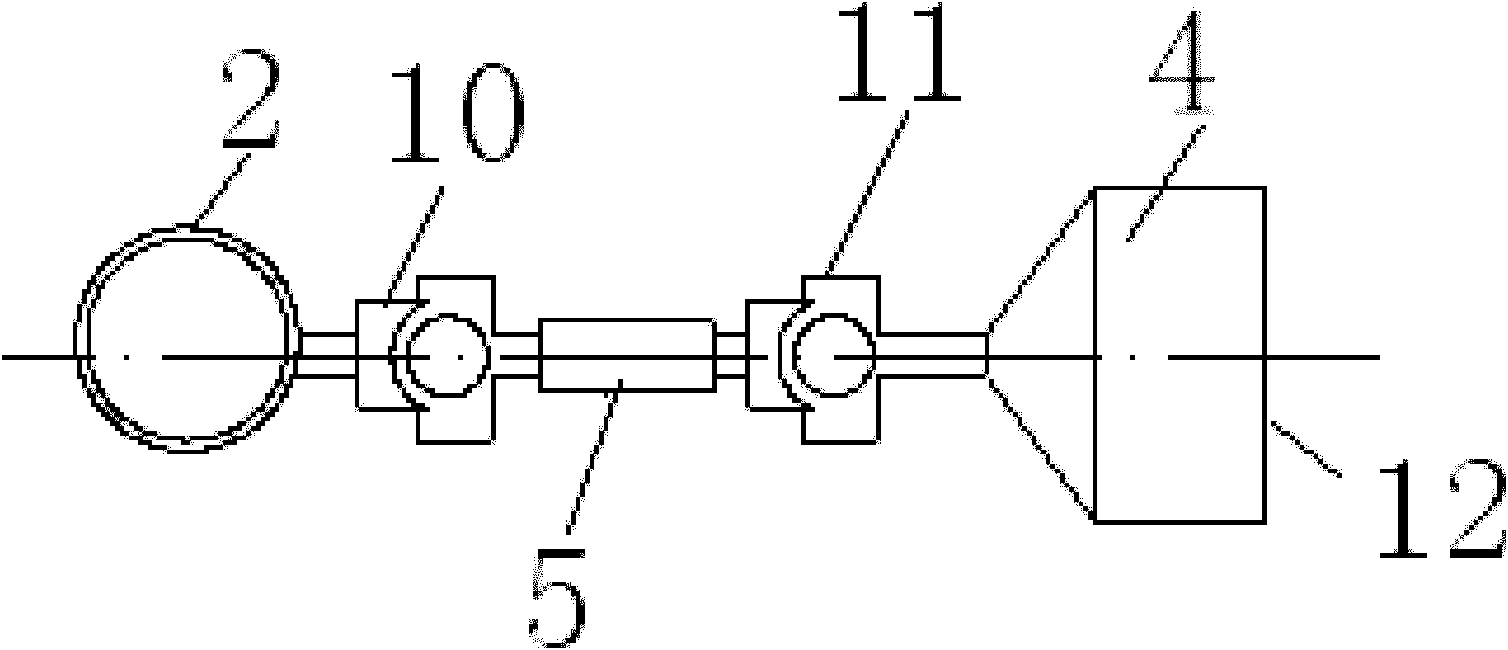

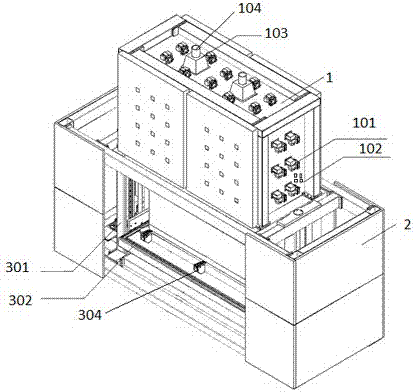

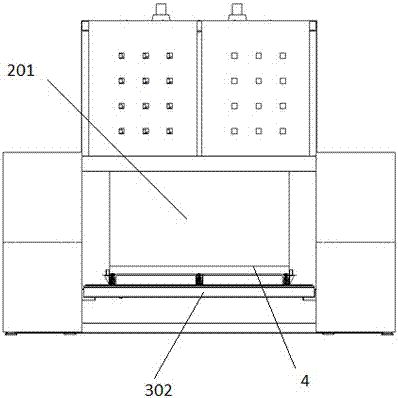

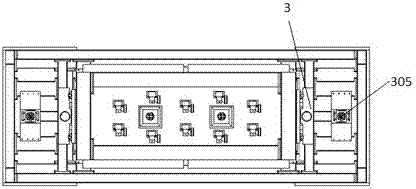

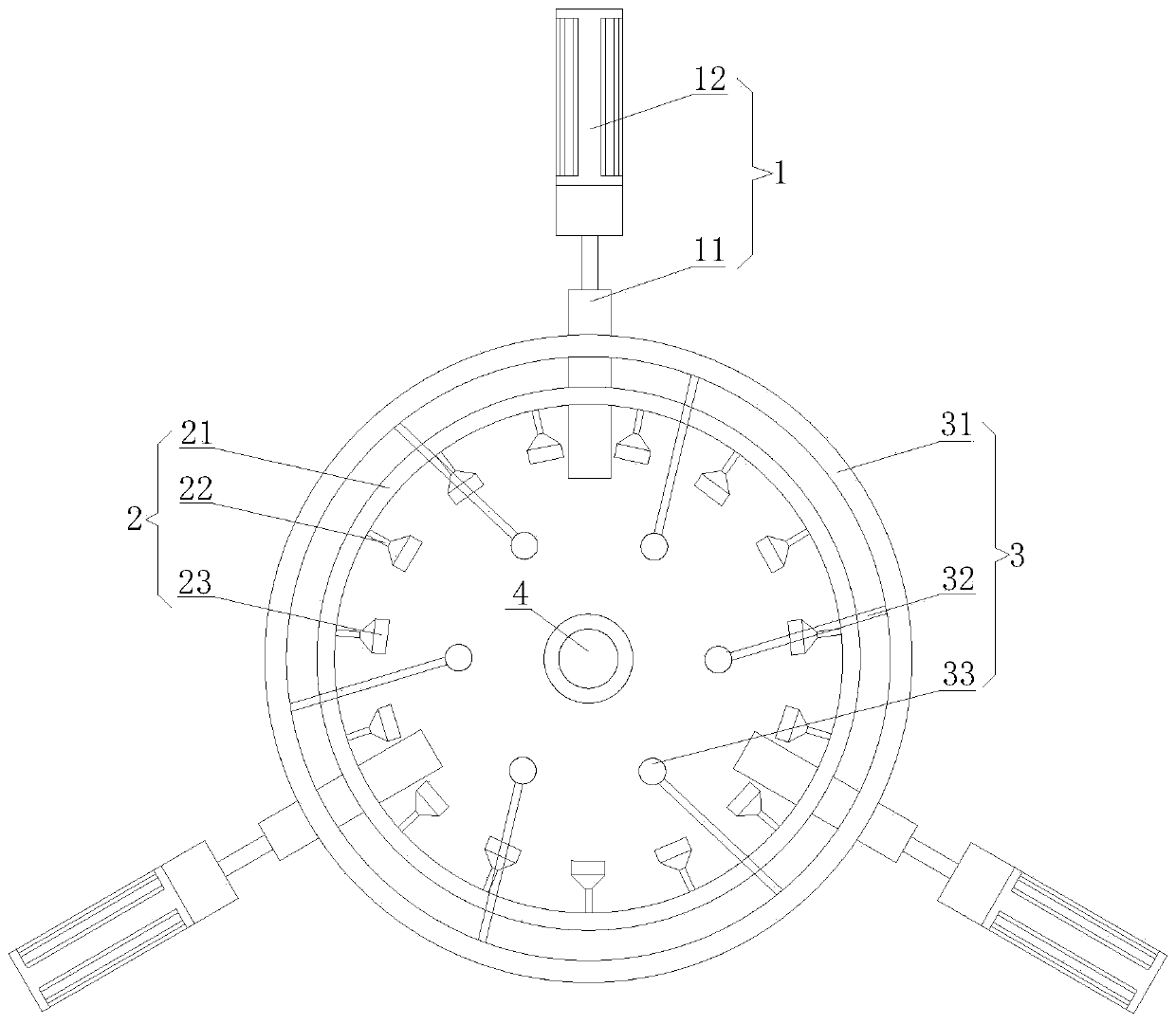

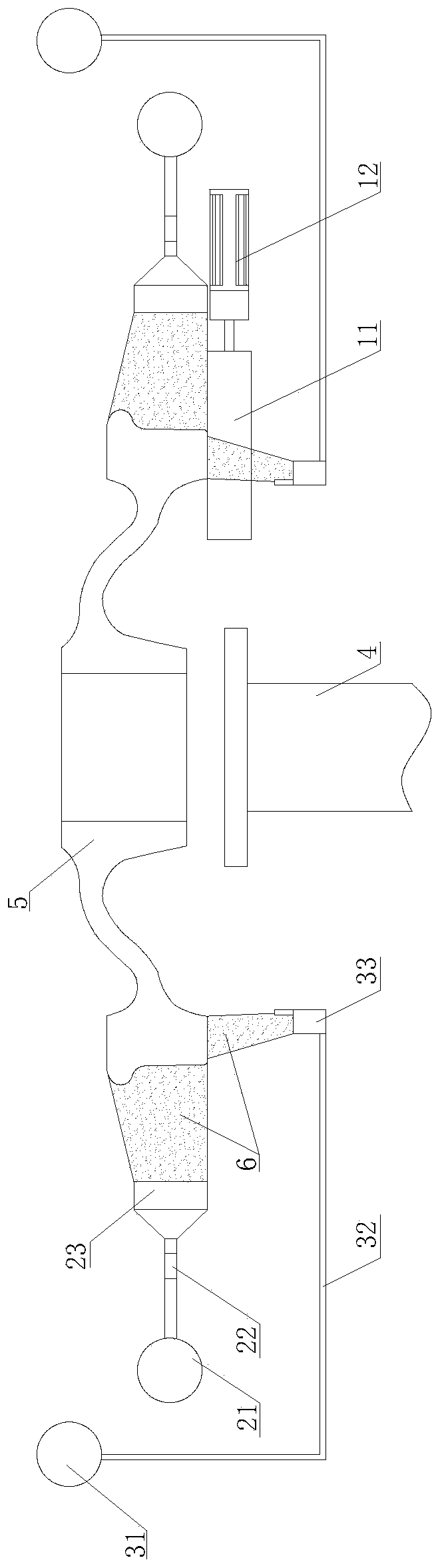

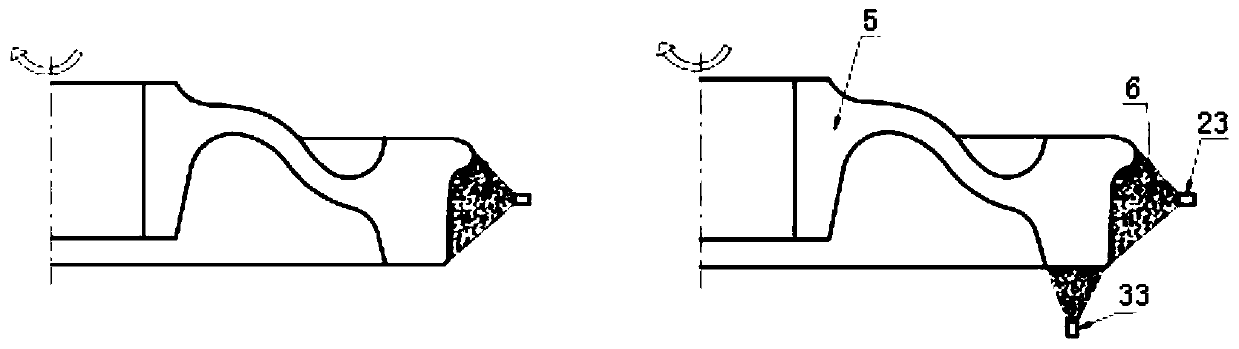

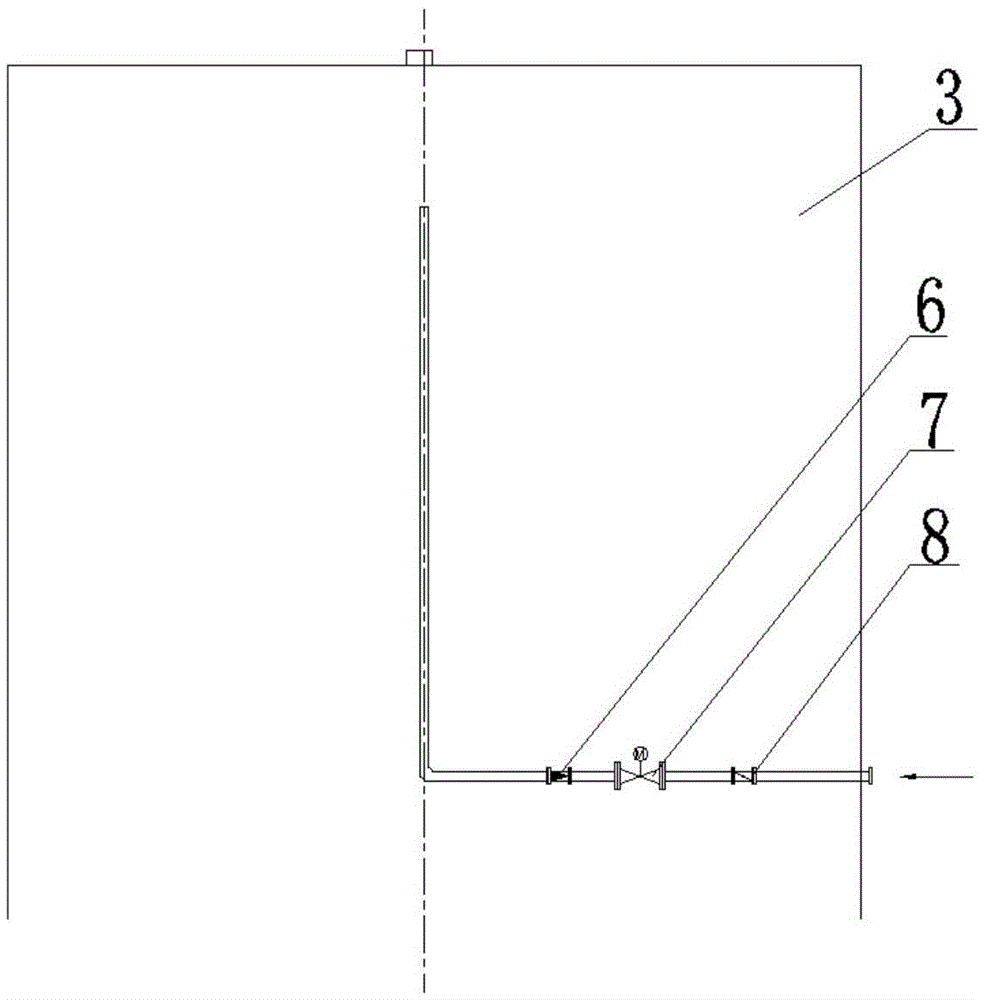

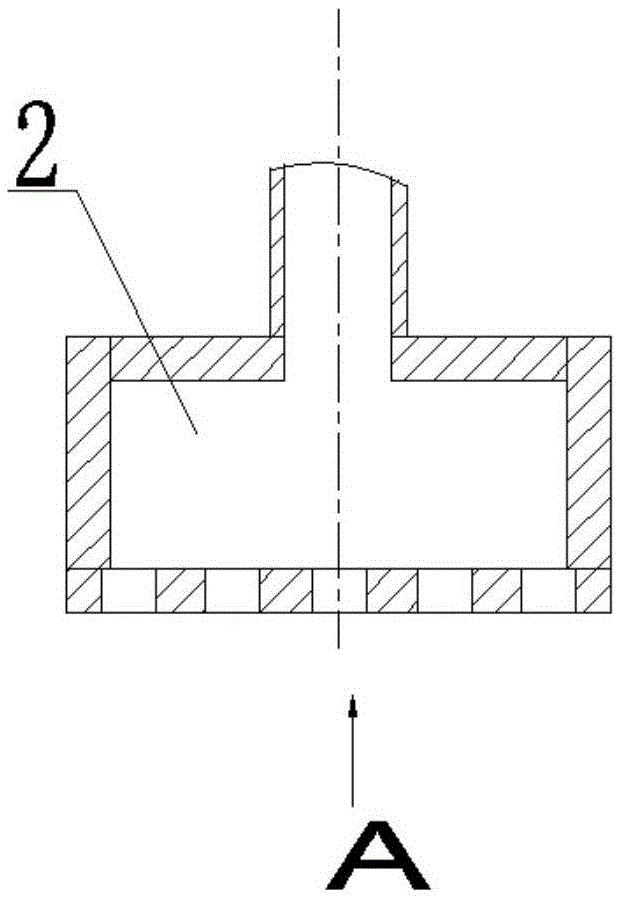

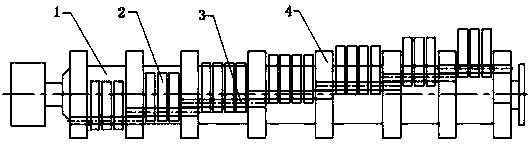

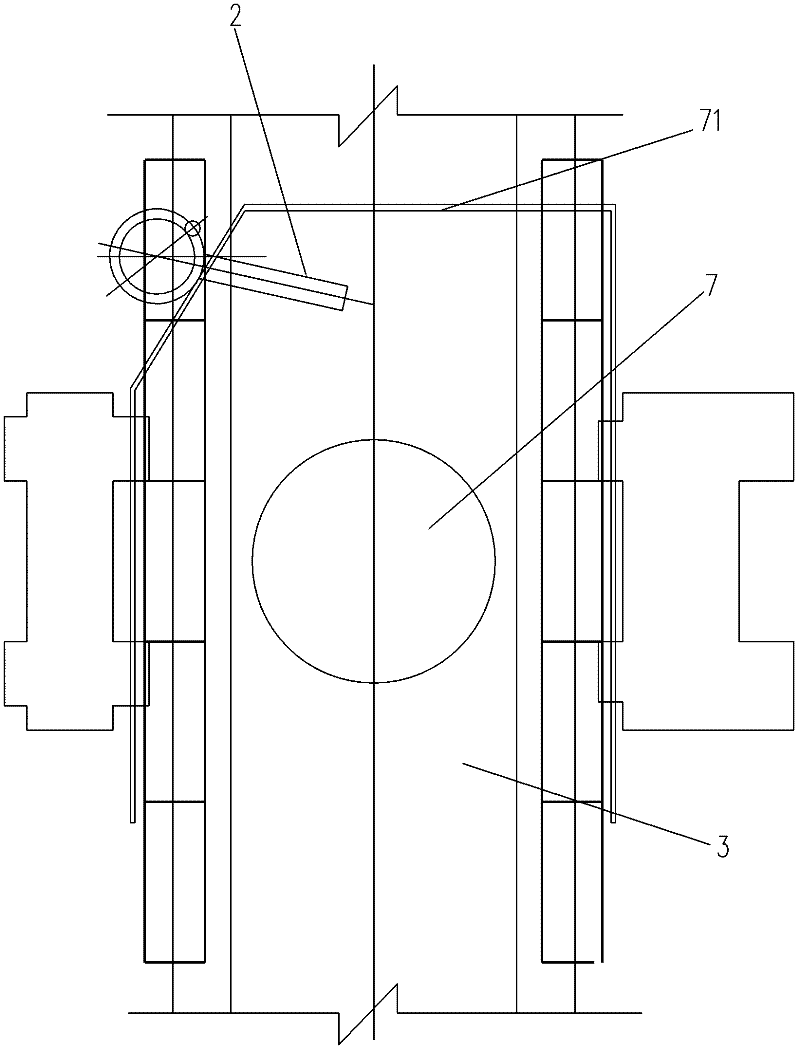

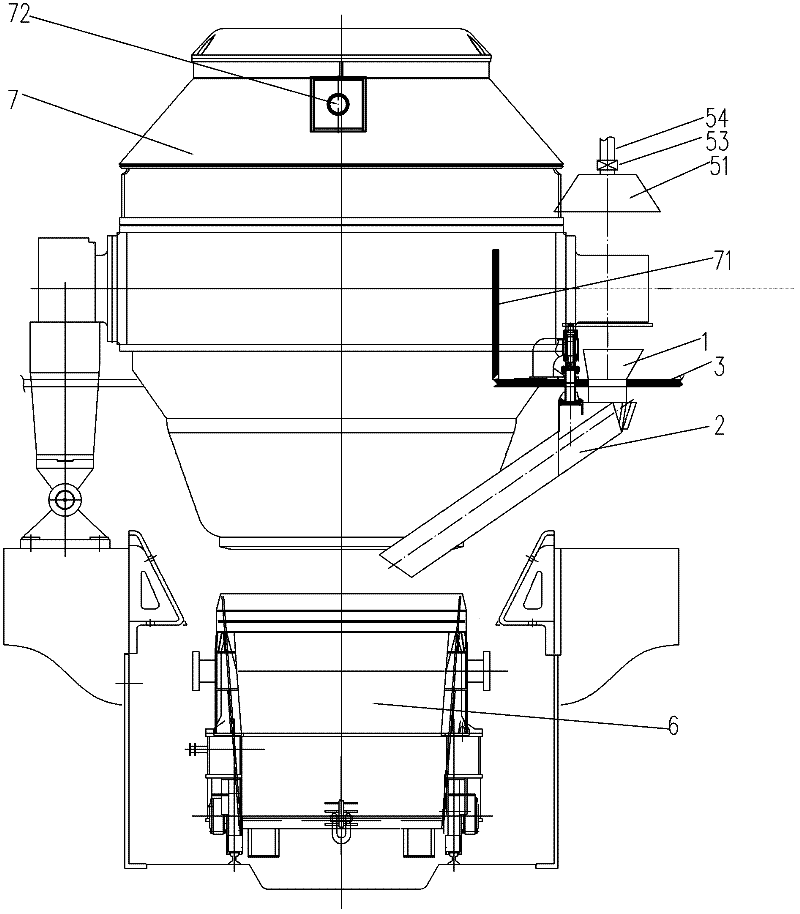

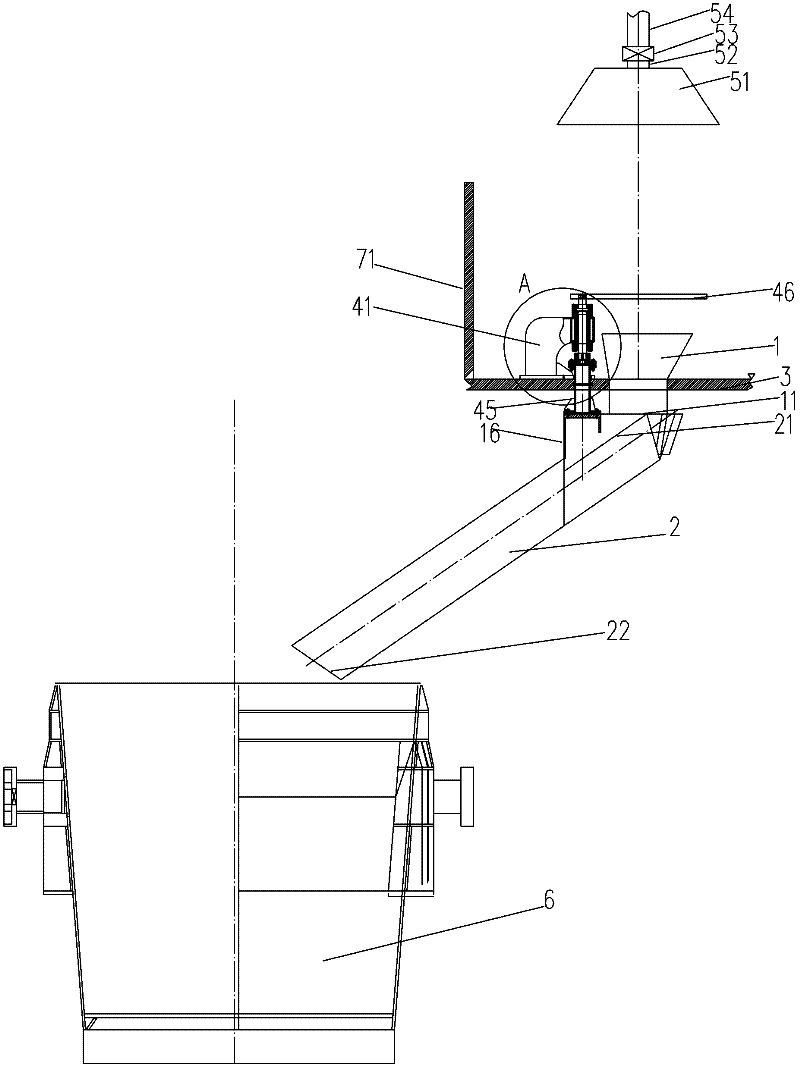

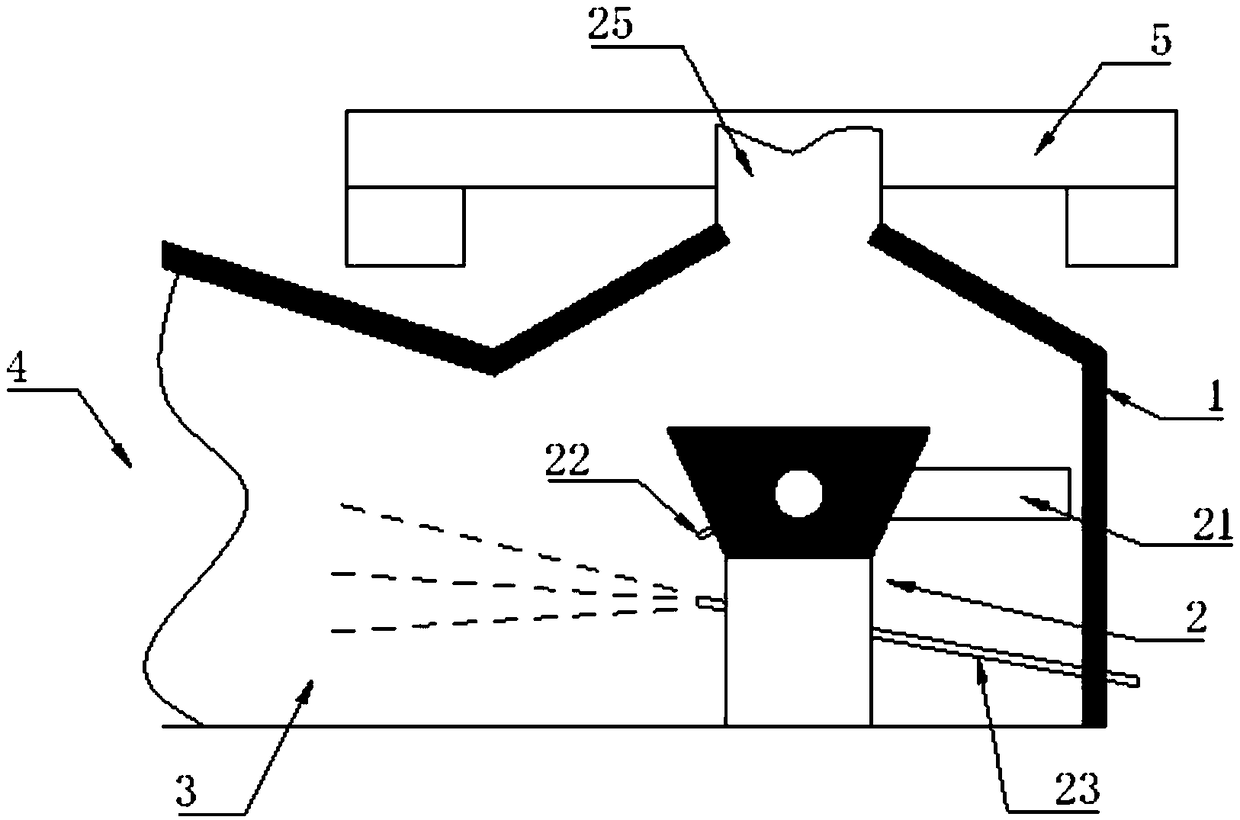

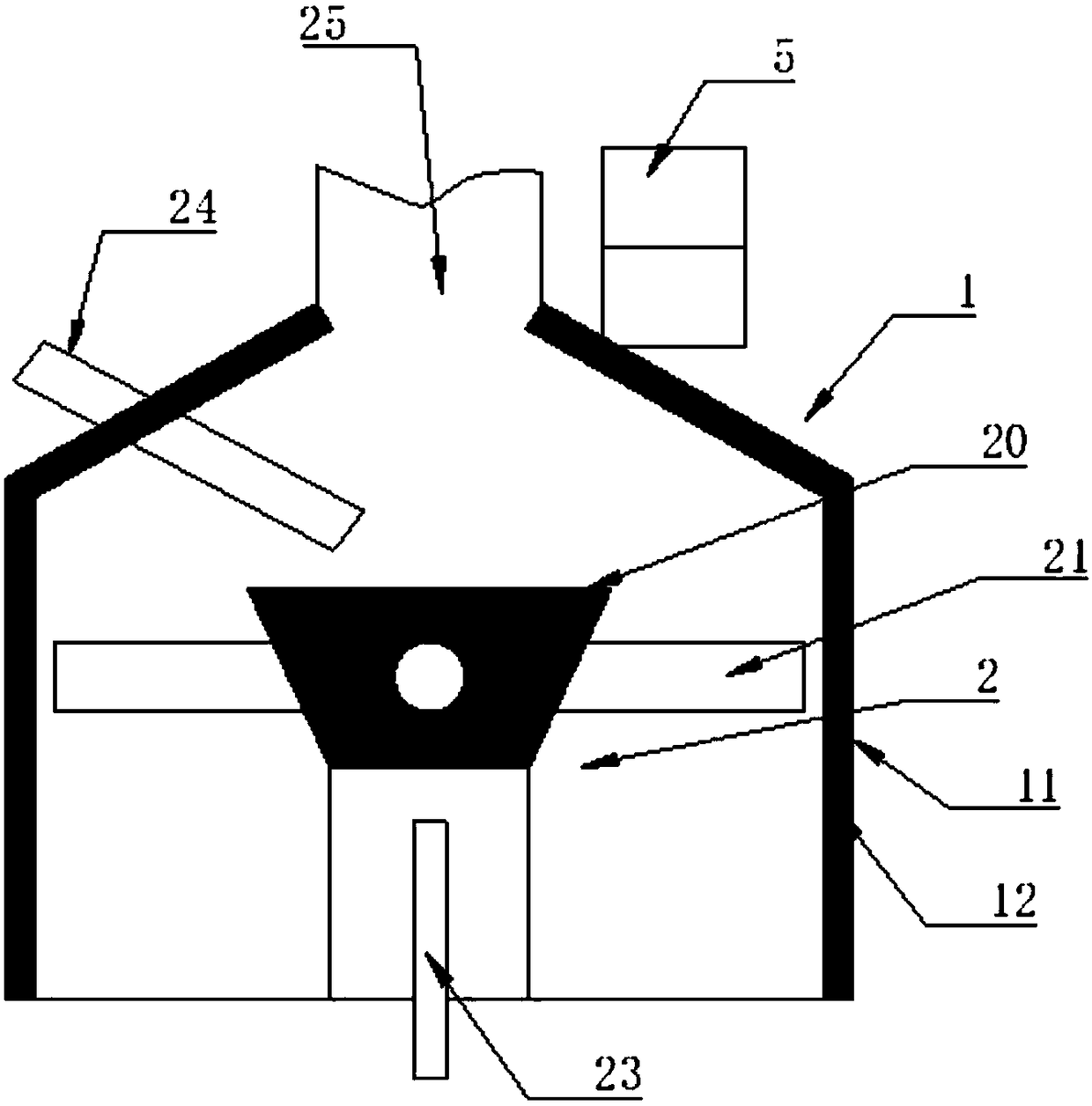

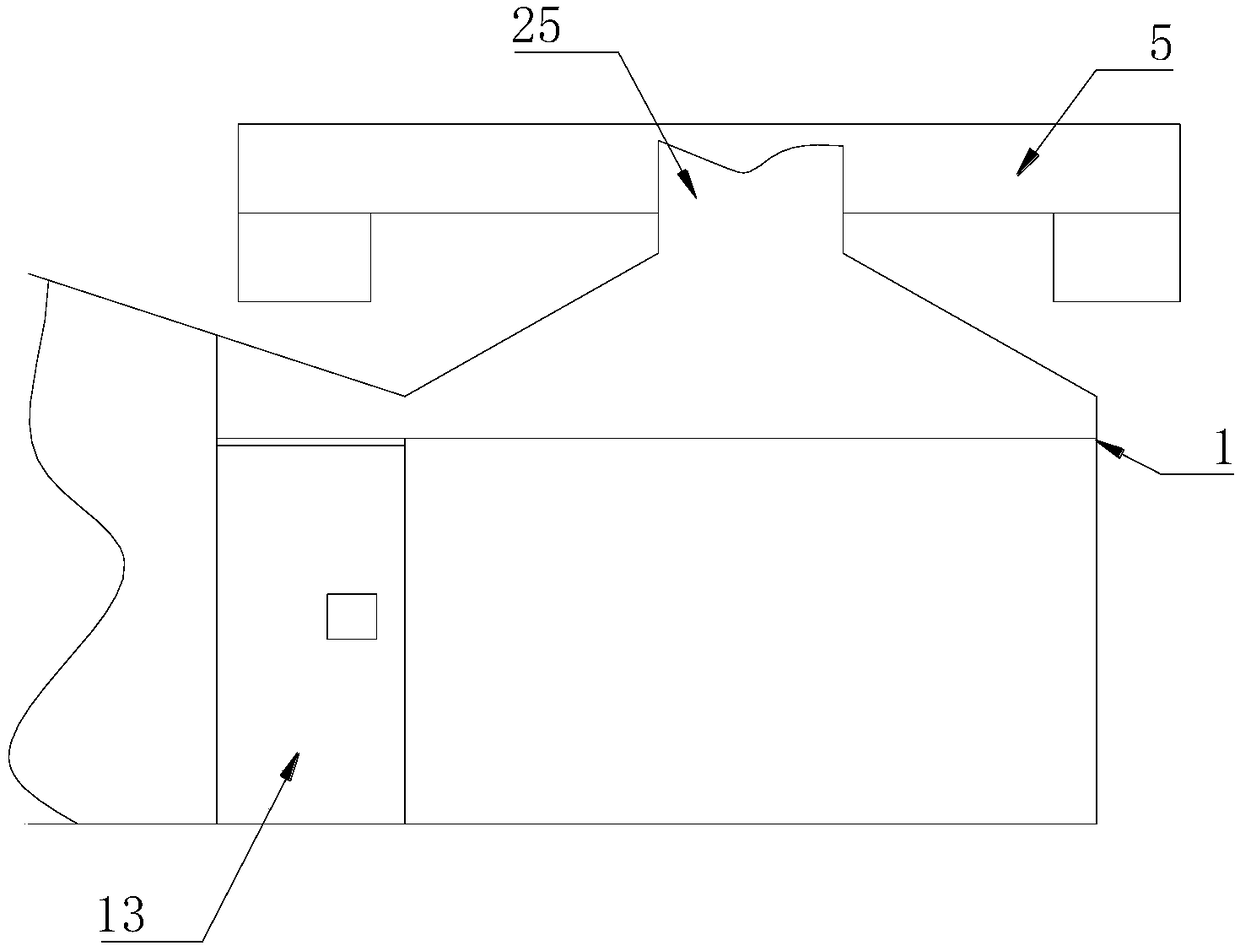

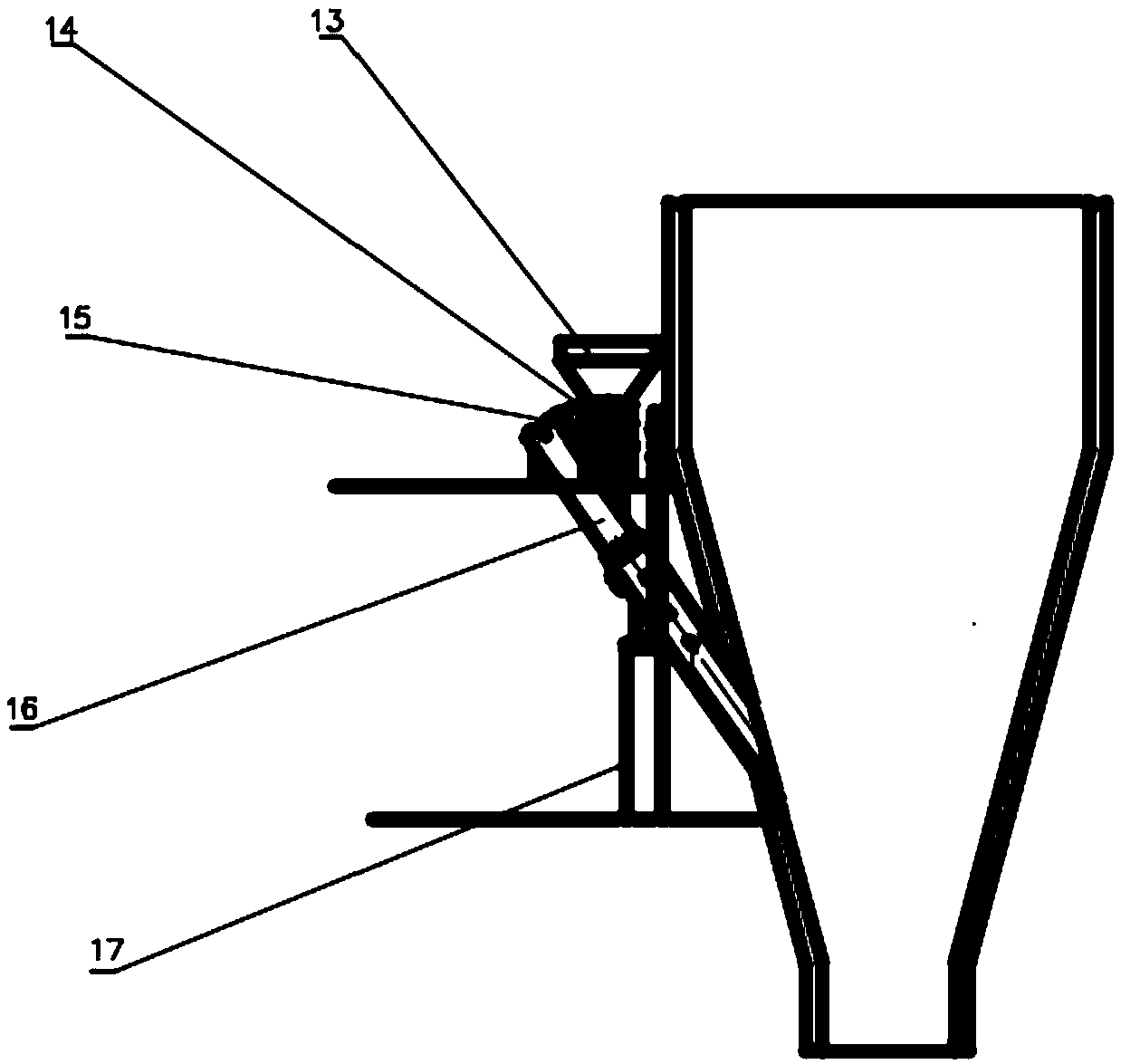

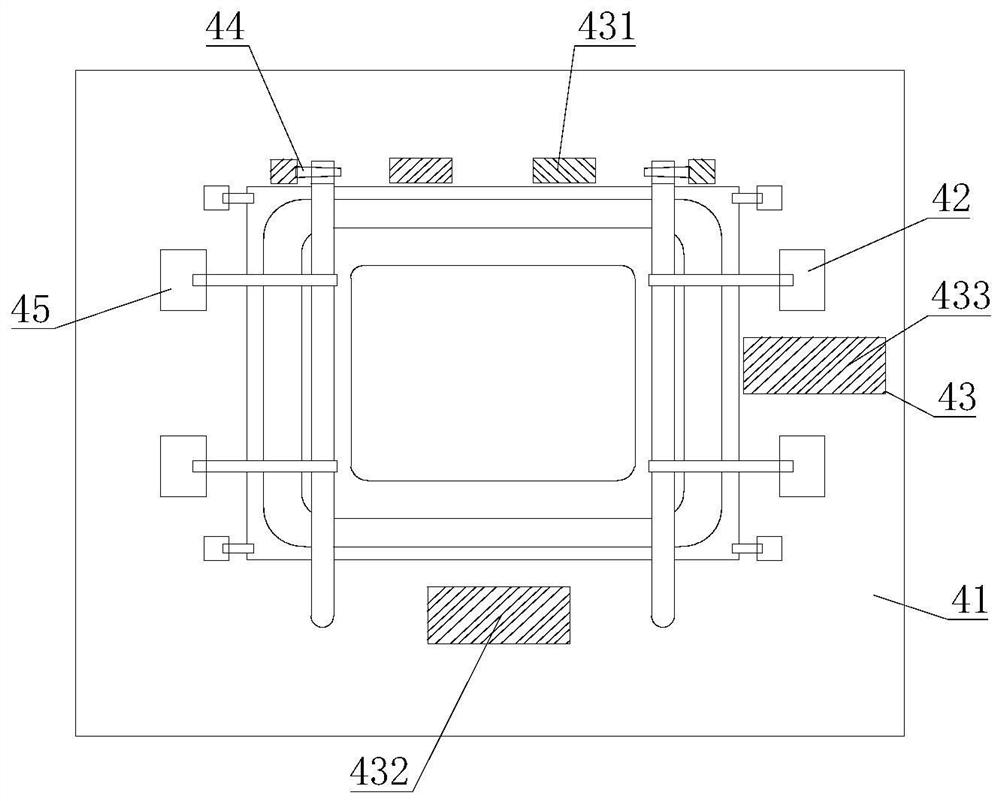

Double-sided quenching cooling device for train wheel

PendingCN110317943AHardness dispersion is smallIncrease cooling areaFurnace typesHeat treatment furnacesSpray nozzleEngineering

The invention discloses a double-sided quenching cooling device for a train wheel. The double-sided quenching cooling device for the train wheel comprises a wheel rotary driving device, a middle ringwater spraying device, a lower ring water spraying device and a wheel jacking device; a placed wheel is jacked up by the wheel rotary driving device; the wheel rotary driving device consists of a carrier roller and a motor reduction box assembly; the carrier roller is mounted on an output shaft of the motor reduction box assembly; the middle ring water spraying device consists of a middle ring water pipe, middle hoses and middle nozzles; the middle ring water pipe is connected with each middle nozzle for spraying cooling water towards a wheel tread through the corresponding middle hose; the lower ring water spraying device consists of a lower ring water pipe, lower hoses and lower nozzles; and the lower ring water pipe is connected with each lower nozzle for spraying cooling water towardsthe outer rim surface of the wheel through the corresponding lower hose. According to the double-sided quenching cooling device for the train wheel, the tread and the outer rim surface of a wheel rimare simultaneously subjected to water spraying cooling, namely, the method of increasing the cooling area of the rim and improving the cooling speed of the rim can improve the strength and the hardness and the wear resistance of the wheel without reducing the plasticity and the toughness.

Owner:MAANSHAN IRON & STEEL CO LTD

Dripping and pulverizing control device and dripping and pulverizing treatment method for steelmaking reducing slag

The invention discloses a dripping and pulverizing control device and a dripping and pulverizing treatment method for steelmaking reducing slag. The dripping and pulverizing control device comprises a slag pot, a spray nozzle, a water inlet pipe and a dust cover. The dust cover covers the slag pot and the spray nozzle, spray regions of the spray nozzle correspond to an opening of the slag pot, one end of the water inlet pipe is communicated with a water source, and the other end of the water inlet pipe is communicated with the spray nozzle; a temperature measuring instrument is arranged in the dust cover, and an electric regulating valve is arranged on the water inlet pipe. The dripping and pulverizing control device and the dripping and pulverizing treatment method for the steelmaking reducing slag have the advantages that the dust emission can be obviously reduced in steelmaking reducing slag treatment procedures, dust flying can be effectively controlled, field operation environments can be obviously improved, the steel slag treatment safety can be greatly improved, the labor intensity can be relieved, and the cost can be controlled.

Owner:GUANGDONG HUAXIN ENVIRONMENTAL PROTECTION TECH CO LTD

Use method of ice core during precision casting

The invention discloses a precision casting mould making technology by using an ice core. The technology is as follows: firstly, manufacturing an ice core with a required size and shape by a method using a specific mould to condense water; secondly, taking out the obtained ice core from the mould, and putting the ice core into an appointed environment to store for later use; during mould making, installing the ice core into the mould, injecting wax, cooling, and fusing a mold core to obtain a wax mould, wherein, during wax injecting, the wax injecting temperature and pressure are regulated to realize rapid mold filling, so that surface cold shut caused by chilling can be avoided and size deviation caused by mold core fusing can be reduced; and finally, casting an obtained mould casing by using different casing coating technologies. By using the technology disclosed by the invention, the environmental pollution is eliminated, the production cycle is shortened, the resource waste is avoided, the on-site work environment is improved, the problems caused by chilling and mold core fusion are solved, and the stability of cast quality is enhanced.

Owner:安徽应流铸业有限公司

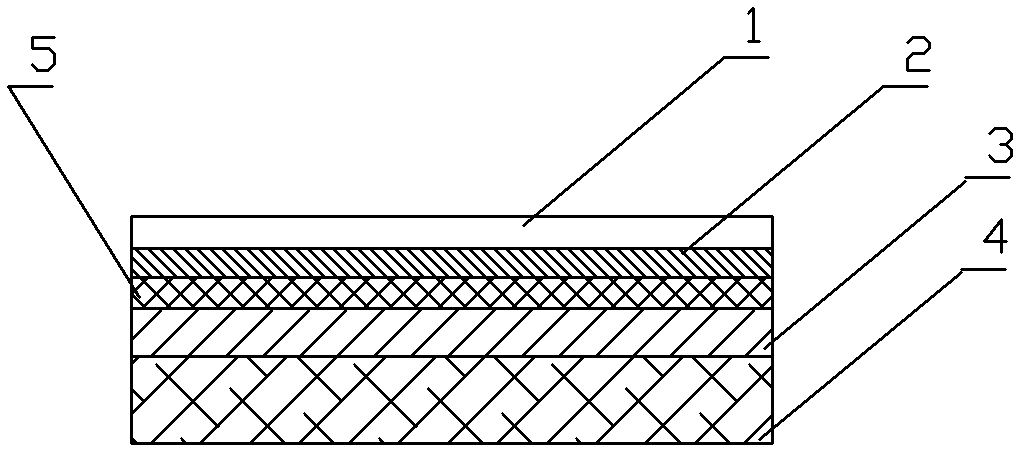

Surface treatment method by directly sticking transfer film to ultrafine fiber napped leather

The invention discloses a surface treatment method by directly sticking a transfer film to ultrafine fiber napped leather, which is characterized in that the method comprises the following processing steps: 1) preparing transfer film coiled material, ultrafine fiber napped leather coiled material and a hot-pressing laminating machine; 2) pulling the transfer film and ultrafine fiber napped leather aligned into a double-roll of the hot-pressing laminating machine, and performing hot pressing and rolling, wherein a carrier layer of the transfer film contacts a hot roller and an adhesive layer of the transfer film contacts the ultrafine fiber napped leather; 3) continuously pulling the ultrafine fiber napped leather and the transfer film out of the double-roll, thereby sticking the transfer film to the ultrafine fiber napped leather at this time; and 4) peeling the carrier layer to obtain the finished product. The product obtained by the treatment method of the invention has soft and smooth handfeel, and can be kept on subsequent processes such as lacquering, silk-screen printing, transfer printing, embossing and the like. The surface treatment method of the invention has a simple process and no environmental issues of solvent consumption and recovery, saves a great amount of equipment investment and energy consumption, and improves the site working conditions. Therefore, the surface treatment method of the invention is a desirable substitute of the prior art.

Owner:张放

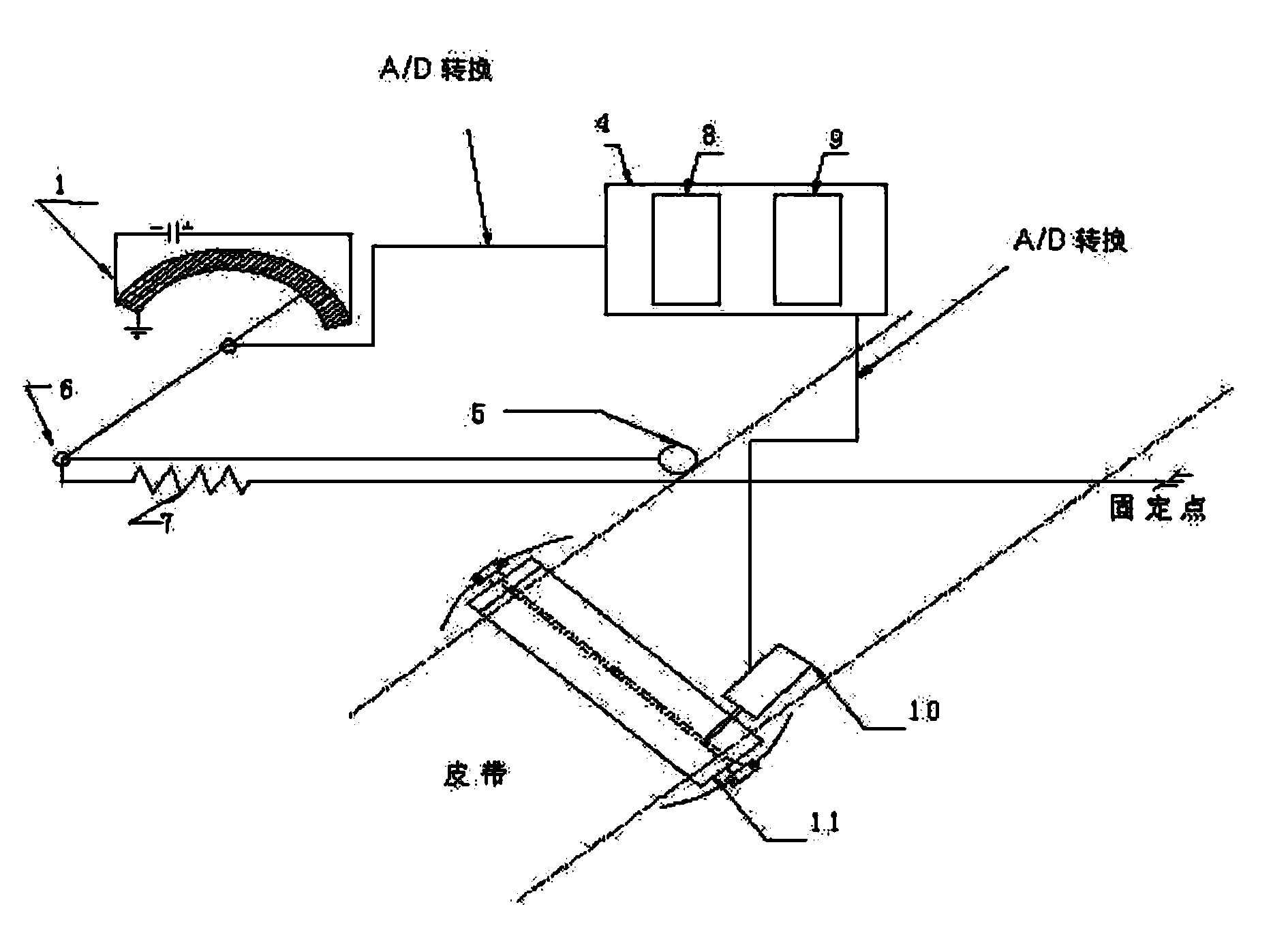

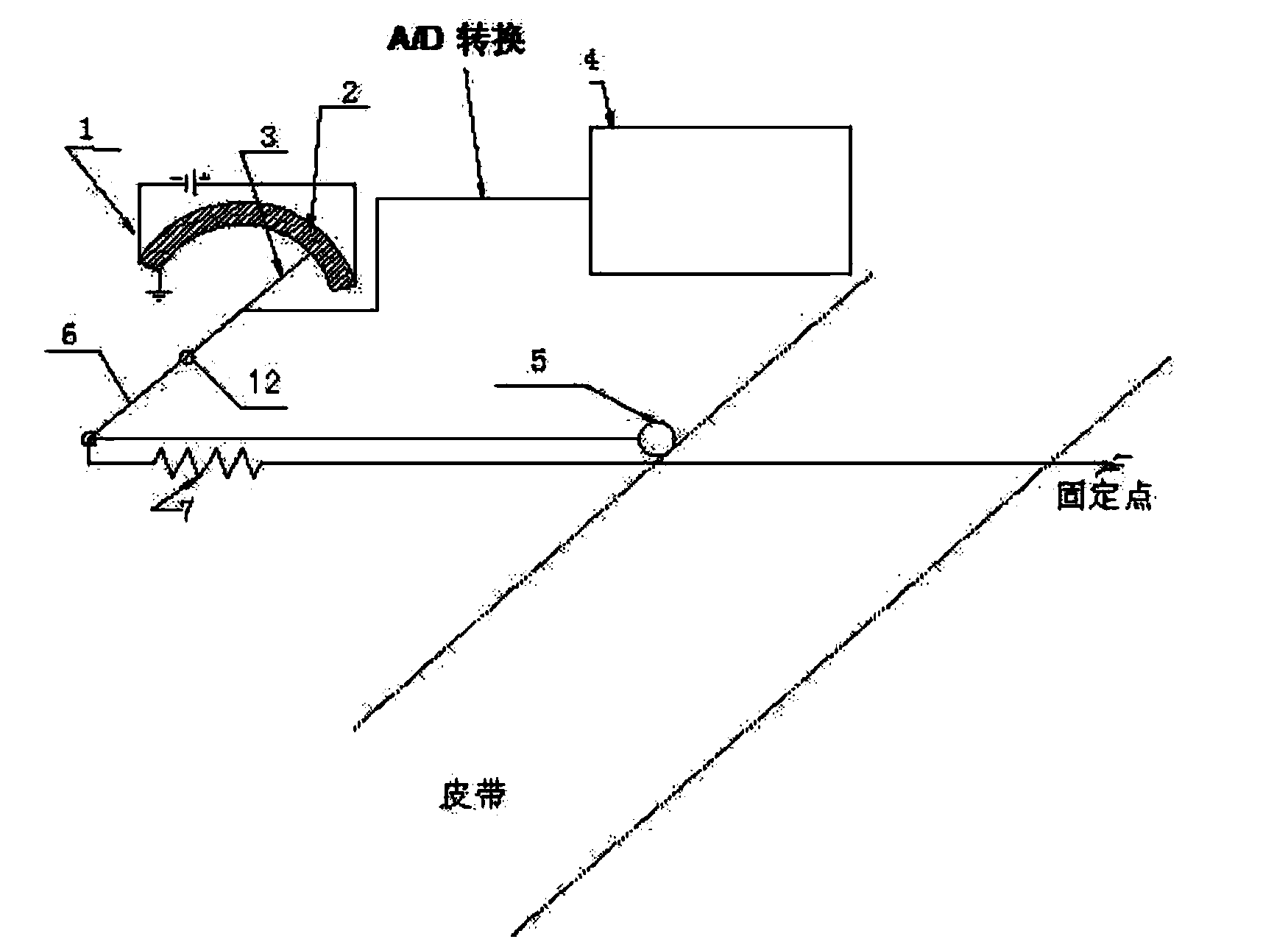

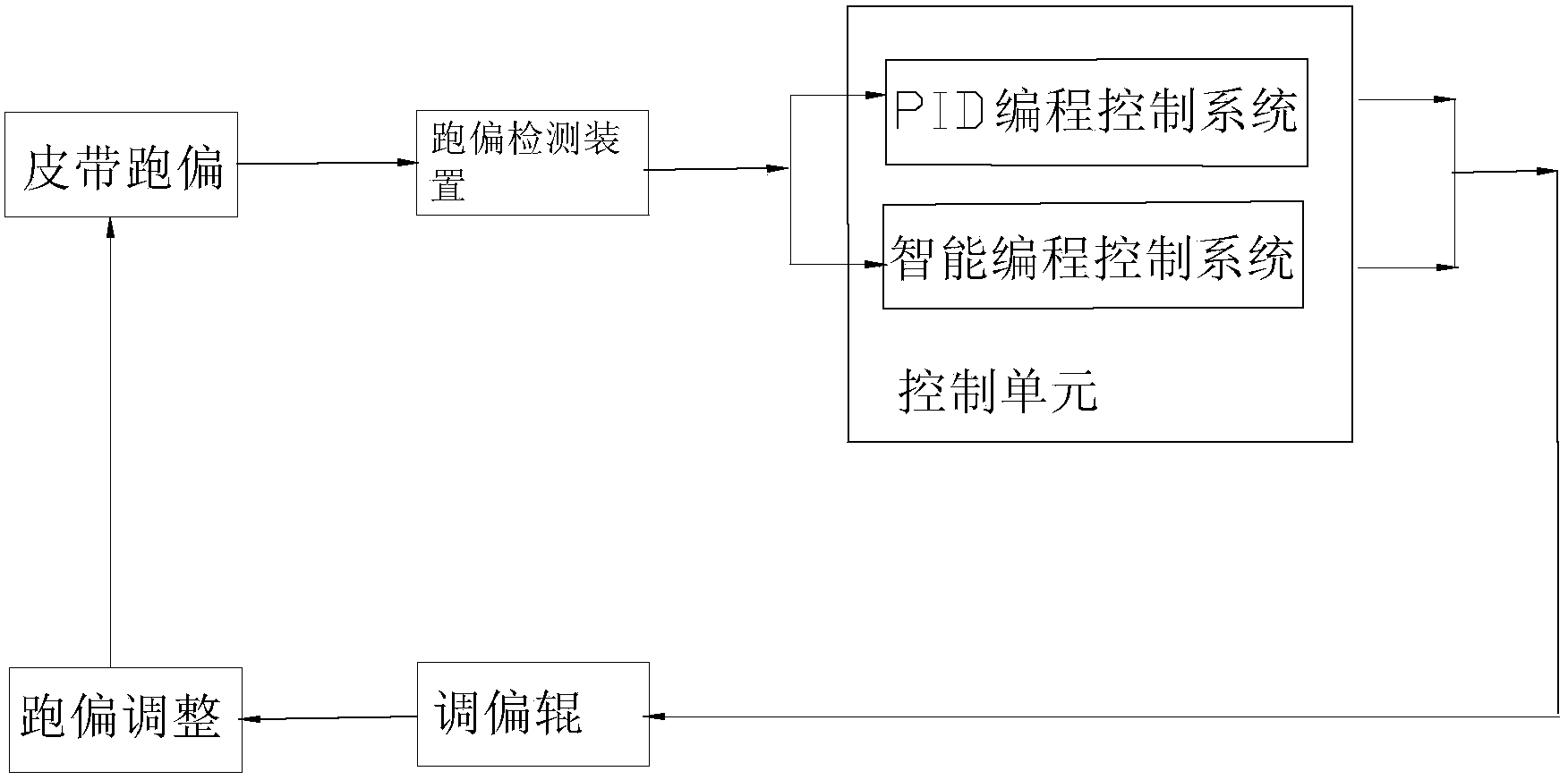

Belt deviation intelligent correcting system and correcting method for belt conveyor

ActiveCN103449141AImprove excessive deviationReduce wearConveyorsControl devices for conveyorsTransducerEngineering

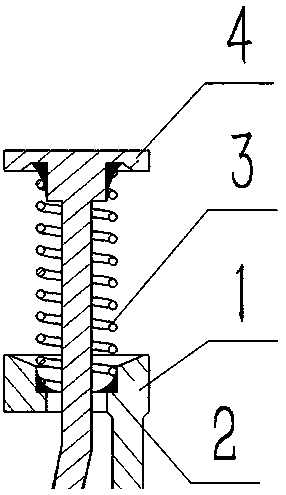

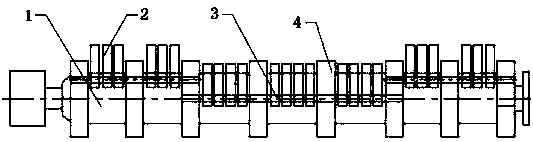

The invention discloses a belt deviation intelligent correcting system and a belt deviation intelligent correcting method for a belt conveyor. Belt deviation detection devices are arranged at the head part, in the middle and at the tail part of a belt; the belt deviation detection devices output signals, the signals output by the belt deviation detection devices are connected with a control unit by A / D (Analog to Digital) conversion, the control unit outputs signals, and the signals output by the control unit are connected with deviation regulation screw drivers to drive deviation regulation rollers by A / D conversion; each belt deviation detection device comprises a posentiometric displacement transducer which is arranged on a belt frame and is formed by a slider and a winding; the middle part of each slider is provided with a fixed shaft; one end of each slider is in line contact with the corresponding winding and the other end of the slider is connected with the tail part of a movable sliding rod which is provided with a roller at the head part and is sleeved with an automatic return spring and one end of the automatic return spring; the rollers are arranged at one side of the belt to be in contact with the belt; the other ends of the automatic return springs are fixed on a frame at the other side of the belt; and when the belt is deviated, the rollers push the sliding rods to move to drive the sliders to slide on the windings by taking the fixed shafts as the centers and voltage difference signals are generated and are output to the control unit by A / D conversion.

Owner:ANSTEEL GRP MINING CO LTD

Preparation method of solder for magnetron cathode assembly

ActiveCN111098061AEvenly distributedGood dynamic fluidityWelding/cutting media/materialsSoldering mediaMetallurgySlurry

The invention discloses a preparation method of a solder for a magnetron cathode assembly. The preparation method is characterized by comprising the following steps of (1) material selecting; (2) proportioning; (3) grinding and uniform mixing; (4) preparing of an organic carrier; and (5) preparing of solder slurry. The preparation method is simple in production process, low in cost and easy to realize automation.

Owner:佛山市海欣光电科技有限公司

Segmented type deburring roller

InactiveCN103978341AEasy to replaceReduce impactWelding/cutting auxillary devicesAuxillary welding devicesFlangeContinuous casting

The invention relates to a segmented type deburring roller. The segmented type deburring roller comprises a roller body, centrifugal swinging blocks and connecting shafts. Flanges are arranged on the roller body. Each centrifugal swinging block is provided with a through hole deviating from the center of the centrifugal swinging block. The connecting shafts penetrate through the through holes in the centrifugal swinging blocks and are fixed to the flanges. The rotation diameter, existing when each centrifugal swinging block is swung, of the centrifugal swinging block is larger than the rotation diameter, existing when each flange rotates, of the flange. The axis of each connecting shaft and the axis of the roller body are parallel to each other. One or more connecting shafts which are adjacent axially are grouped into one section. The connecting shafts of the same section are coaxial. The connecting shafts of every two adjacent sections are not coaxial. The segmented type deburring roller is small in vibration, low in noise, convenient to use, long in service life and capable of effectively eliminating oxidizing slag and burrs, left during flame cutting, of continuous casting sheet billets.

Owner:JIGANG GRP

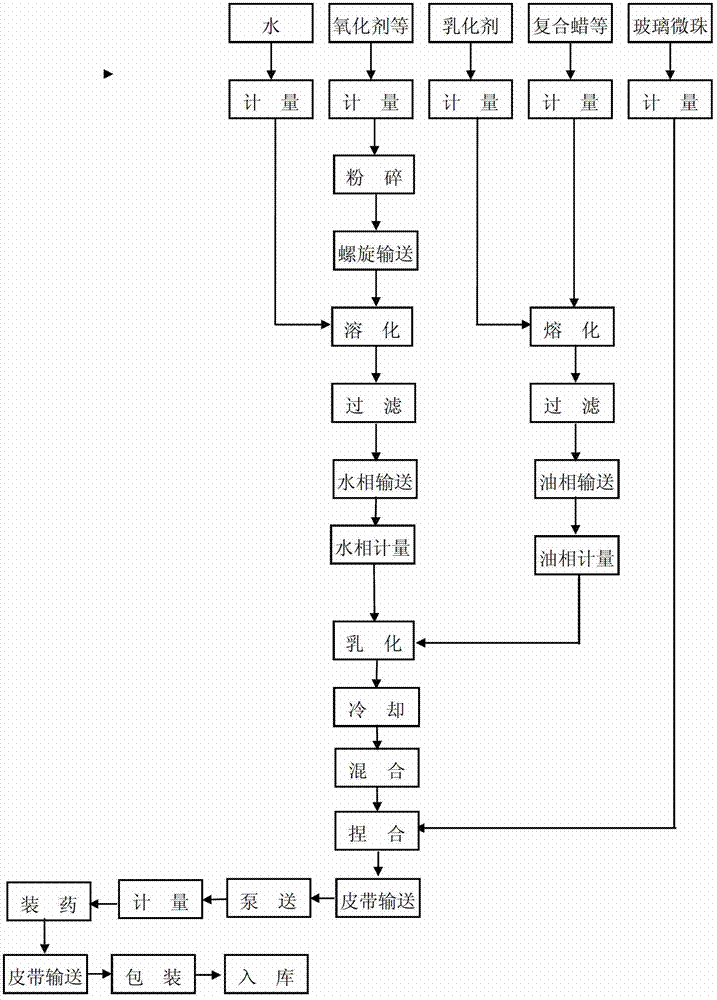

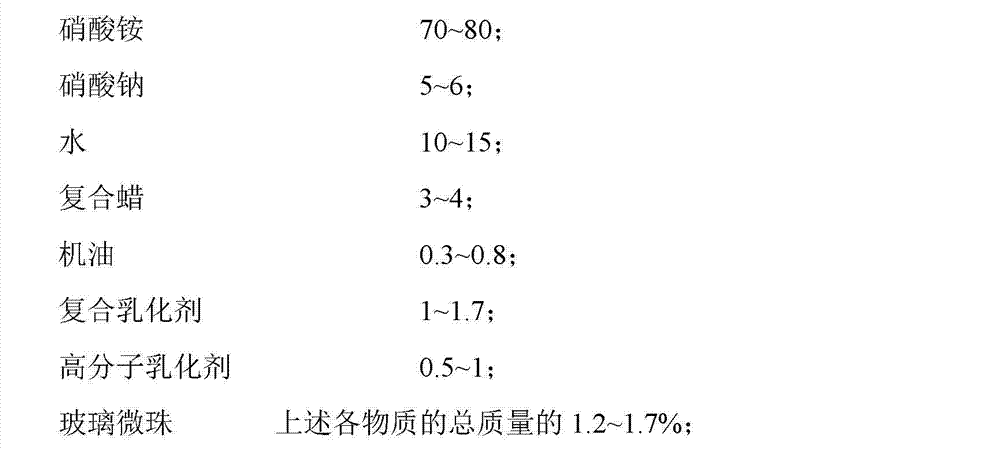

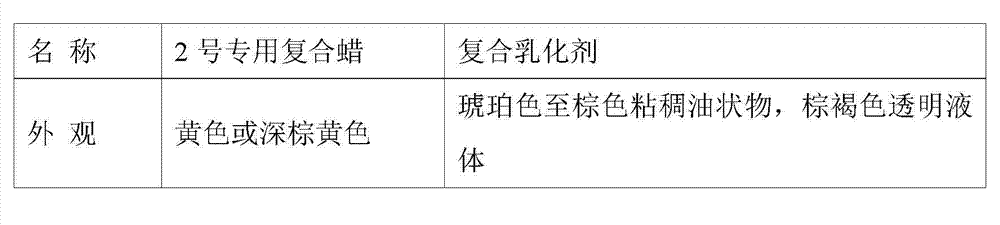

Emulsion explosive and preparation method thereof

ActiveCN103172477ALong storage periodReduce storage costsExplosive working-up apparatusNon-explosive/non-thermic compositionsWaxBurst effect

The invention relates to an emulsion explosive and a preparation method thereof. The emulsion explosive comprises the following components in parts by weight: 70-80 parts of ammonium nitrate, 5-6 parts of sodium nitrate, 10-15 parts of water, 3-4 parts of composite wax, 0.3-0.8 part of engine oil, 1-1.7 parts of composite emulsifying agent, 0.5-1 part of polymer emulsifying agent and 1.2%-1.7% (based on total weight of the components) of glass beads, wherein the composite emulsifying agent is a mixture of Span 80 and T152 emulsifying agent in a weight ratio of 6 to 4. According to the emulsion explosive disclosed by the invention, various indexes satisfy the relevant national regulations, and the performances reach three international standards, the gap distance for sympathetic detonation reaches 5, the performance quality of the explosive is improved and the burst effect is ideal. Moreover, the high polymer emulsifying agent is added to the explosive formula, so that the storage period of the emulsifying explosive is prolonged to one year from half a year, and therefore, the storage cost of the explosive is reduced. Meanwhile, the composite wax and the engine oil are used in the formula, so that the price is low, the resources are extensive and the production cost is reduced.

Owner:TIANJIN HONGTAI CHEM

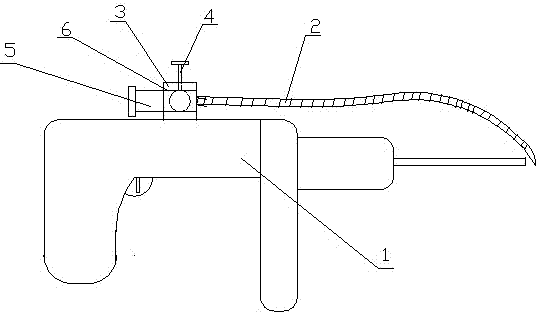

Percussion drill with liquid spraying device

InactiveCN104722807ANormal temperatureExtended service lifePortable percussive toolsPortable power-driven toolsPhysical healthEngineering

The invention belongs to the technical field of electronic products, and particularly provides a percussion drill with a liquid spraying device. The percussion drill comprises a percussion drill shell, a mounting seat is mounted in the middle of the upper end face of the percussion drill shell, and the right portion of the mounting seat is fixedly connected with a universal pipe nozzle, so that the problem that existing percussion drills are not provided with liquid spraying devices is solved. When the percussion drill works, an external liquid delivery pipe is directly inserted into a quick joint to be connected with the liquid spraying device, so that quickness and convenience are realized; position of a universal pipe can be adjusted according to needs, and liquid with pressure flows out from the nozzle to be mixed with dust timely, so that air pollution of a working site is reduced; the liquid plays a role in cooling and lubricating, so that temperature of a drill bit is maintained normal, service life of the drill bit is prolonged, and faults caused by frequent replacement are avoided; normal working is guaranteed, environment of the working site is improved, physical health of operating personnel is benefited, and working efficiency is improved.

Owner:XIAN YUHUA IND DEV

Converter alloy charging mechanism

The invention discloses a converter alloy charging mechanism, comprising a converter, a steel placing operation platform, a steel water tank, a receiving hopper, a blanking hopper, and a rocker rotary unit, wherein, the steel placing operation platform is arranged around the converter, the back side, left side and right side of the converter are respectively provided with a water cooling coaming plate, the water cooling coaming plates are fixed on the steel placing operation platform, the receiving hopper is arranged on the steel placing operation platform at the outer side of the water cooling coaming plate, the blanking hopper is arranged the lower end of the rocker rotary unit. When in a normal blanking position, the receiving port of the blanking hopper is located just below the discharge port of the receiving hopper, and the blanking port of the blanking hopper is located just above the steel water tank, According to the invention, by respectively arranging the water cooling coaming plate at the back side, left side and right side of the convertor, the invention avoids the slag splashing out to damage people; by arranging the receiving hopper and the blanking hopper, the alloy slips into the steel water tank through the blanking hopper, and no splashing of molten steel is generated, thus the situation that operator is in the face of the splashing of molten steel when the operator directly charges the alloy can be avoided, and the personal injury is avoided.

Owner:储鸿文 +2

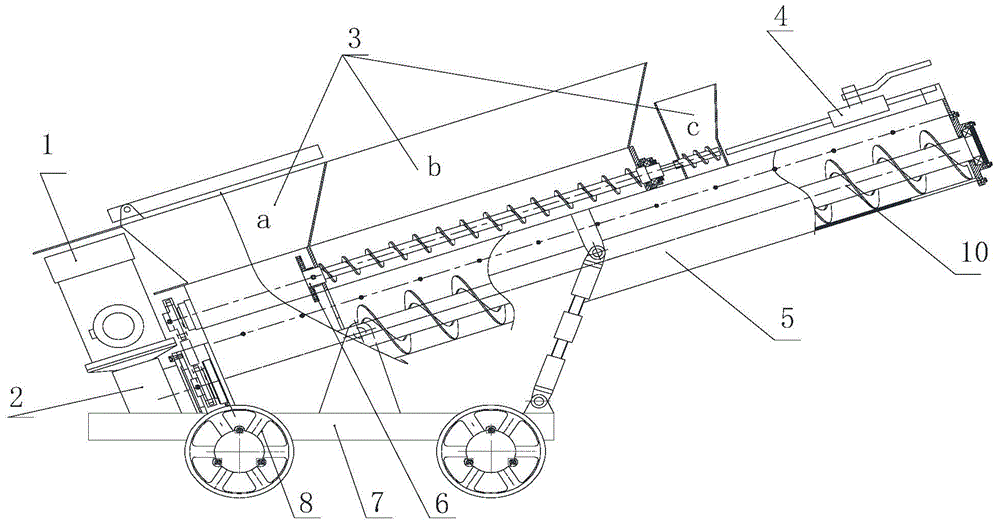

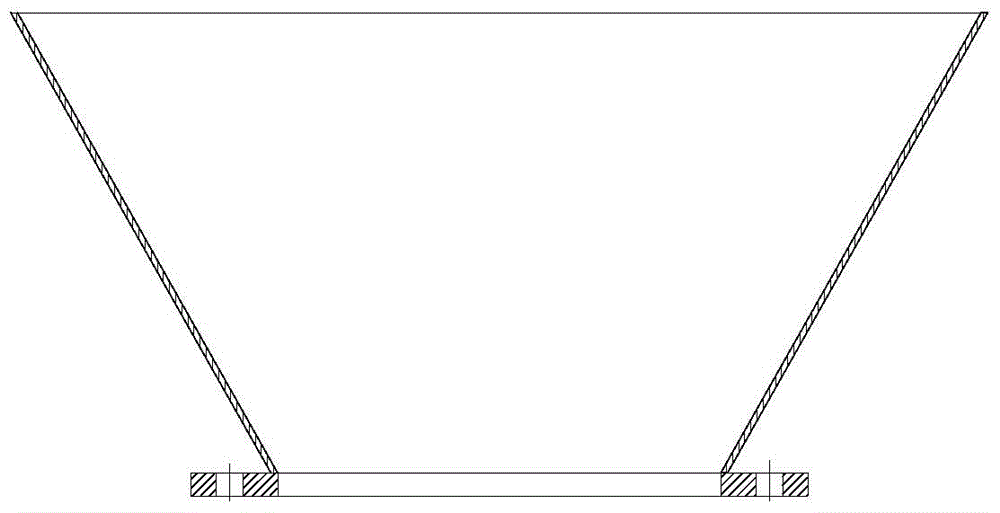

Mining spiral feeder

ActiveCN104819001AGood transportabilityExcellent fill factorUnderground chambersTunnel liningEngineeringCam

The invention discloses a mining spiral feeder. The mining spiral feeder is composed of a body, a frame and wheels; the body is hinged to the frame; the wheels for moving back and forth are symmetrically mounted at the bottom of the frame. The body comprises an explosion-proof motor, a burdening mechanism and a water spraying device, all of which are located on the same inclined surface; the explosion-proof motor is mounted at the bottom end of the body and used for driving a cam vibrating screen mechanism and a stirring conveying trough. The cam vibrating screen mechanism is arranged under the burdening mechanism; the stirring conveying trough is arranged under the cam vibrating screen mechanism; the burdening mechanism is communicated with the stirring conveying trough by use of the cam vibrating screen mechanism. The mining spiral feeder has the advantages of reducing the underground operating personnel, saving the material cost, reducing the labor intensity of workers and improving the field operating environment; meanwhile, the guniting feeding is also even and the guniting quality is improved certainly.

Owner:SHANDONG UNIV OF SCI & TECH

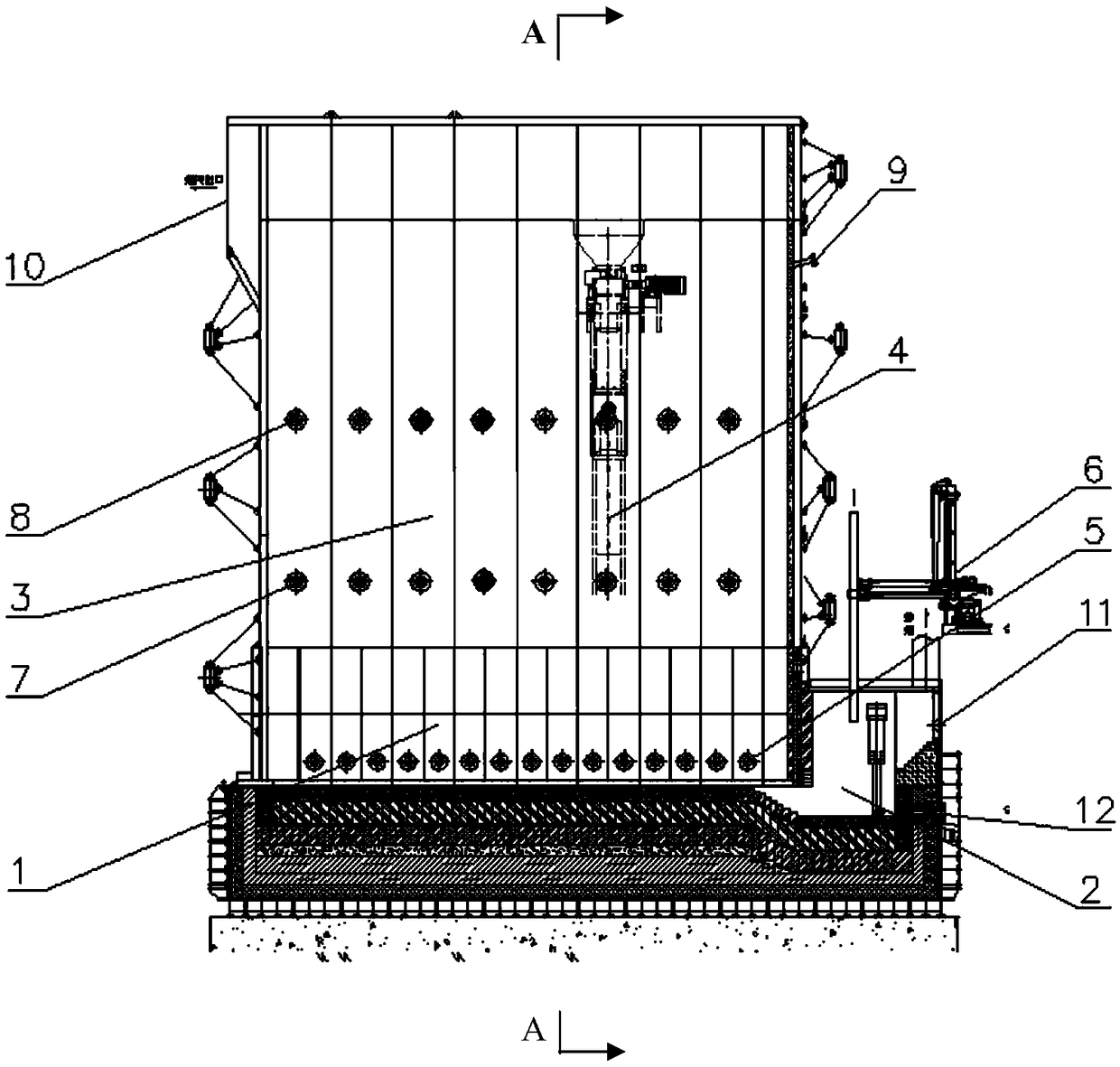

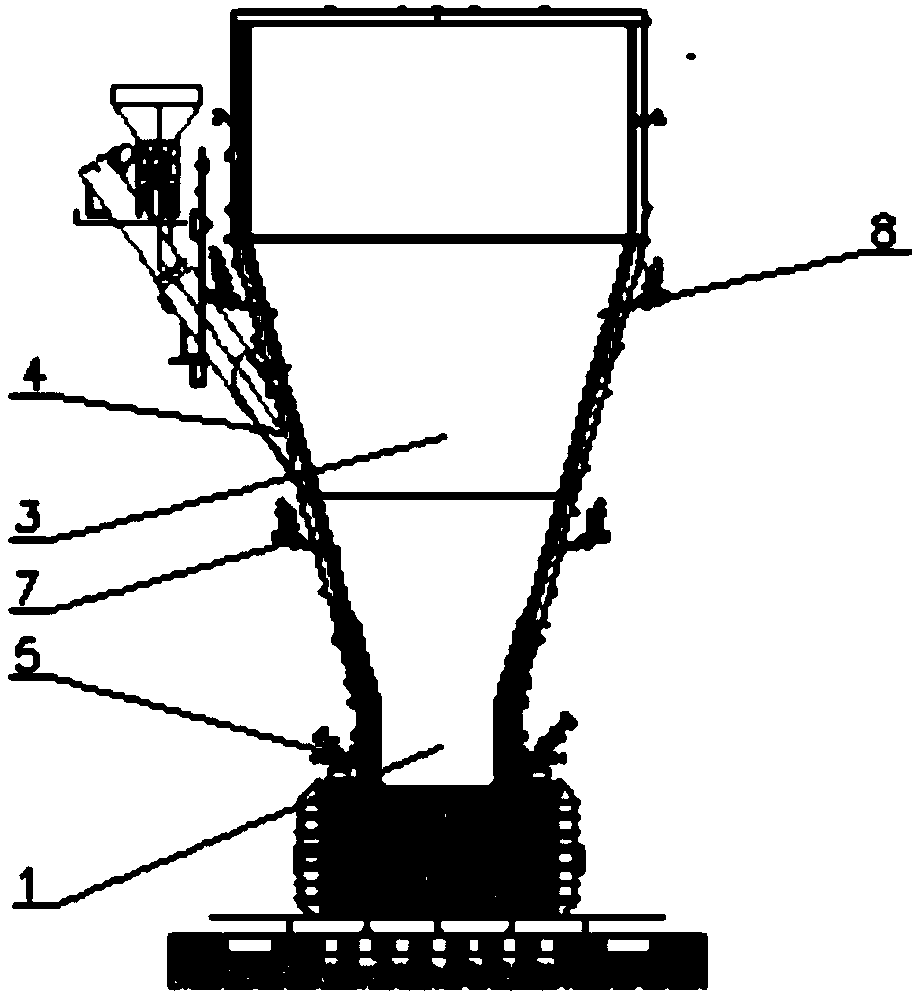

Fusion ceramic sand production equipment

PendingCN109163557AAvoid pollutionGuaranteed cleanlinessCrucible furnacesWaste heat treatmentClosed systemClosed cavity

The invention discloses fusion ceramic sand production equipment. The fusion ceramic sand production equipment comprises a smelting furnace and a cooling bin. A sealing cover is arranged on the periphery of the smelting furnace. An opening is formed in the sealing cover and is in communication connection with an inlet of the cooling bin, accordingly, a closed cavity is formed by the cooling bin and the sealing cover, and the fusion ceramic sand is produced in the cavity. A closed system is composed of the sealing cover, a blowing way and the cooling bin, the high temperature generated by the smelting furnace is isolated from an operator through the sealing cover, safety of the operator is ensured, and environment friendliness is achieved; and cleanliness of ceramic fusion casting sand is guaranteed, the field operation environment is improved, and the production efficiency is improved.

Owner:山西沁新能源集团股份有限公司

Technology for coupling utilization and co-processing of organic and inorganic hazardous wastes

InactiveCN109402414AEfficient use ofReaching the goal of benefiting waste and not producing waste"Crucible furnacesIndirect carbon-dioxide mitigationSmelting processEngineering

The invention provides a technology for coupling utilization and co-processing of organic and inorganic hazardous wastes. The technology comprises the following steps: 1) pretreating raw materials; 2)blending and loading materials; 3) smelting in a smelting furnace; 4) treating exhaust gas. According to the invention, various organic and inorganic hazardous wastes are pretreated and blended and then are put into the smelting furnace for co-processing; the effective utilization of resources is extremely realized and the purpose of 'controlling pollution, generating no pollution, utilizing wastes and generating no wastes' is achieved in the manner of coupling utilization and co-processing of organic and inorganic hazardous wastes; an oxygen-enriching strengthening smelting process is adopted by the smelting furnace; a single system can be adopted for treating 100000t / a various inorganic hazardous wastes and 100000t / a various organic hazardous wastes; the total processing capacity is 200000t / a; the purpose of 'large-volume and multi-varieties' co-processing of various organic and inorganic hazardous wastes is achieved.

Owner:杨文

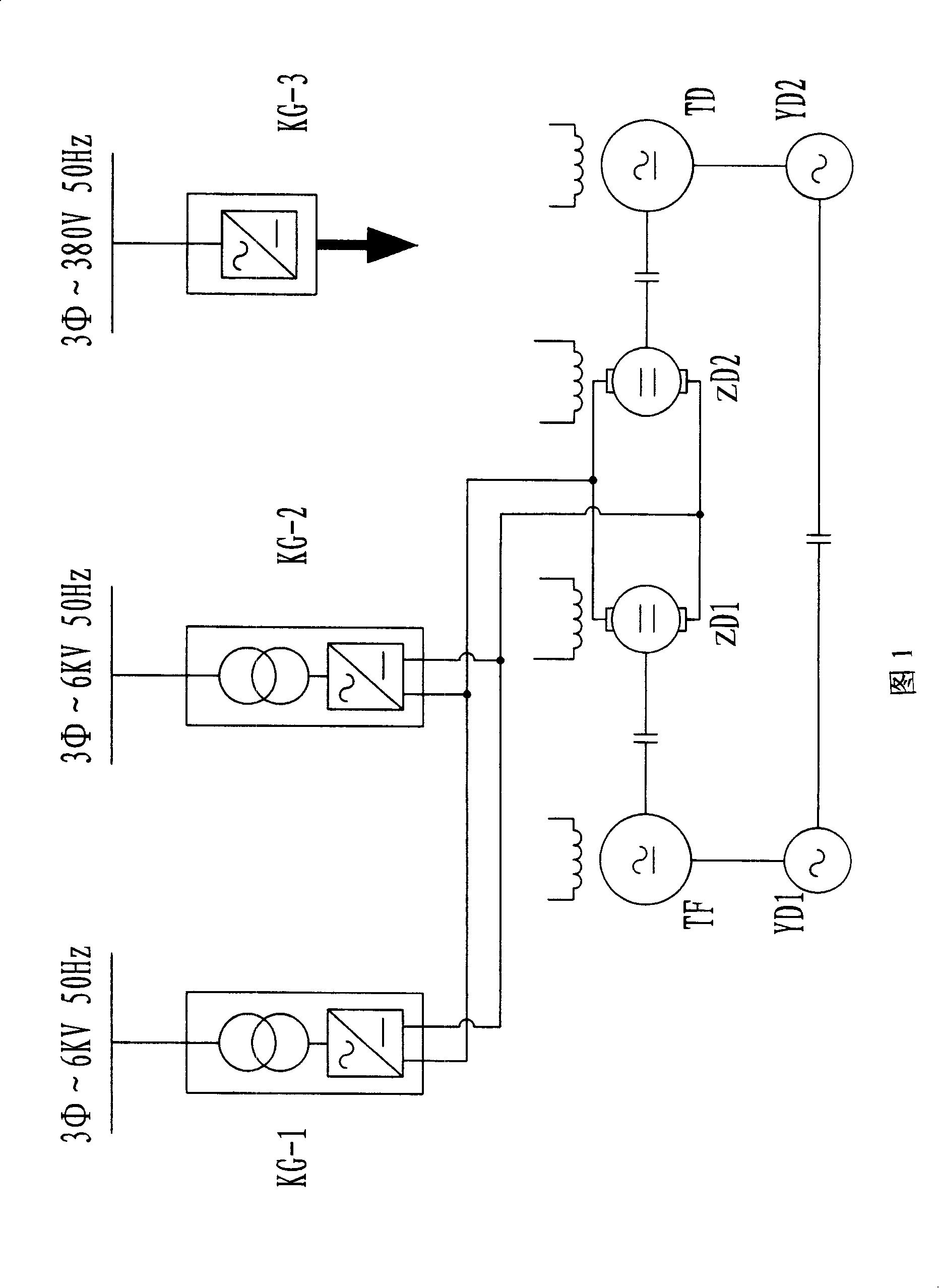

Electric motor dynamic load control device

InactiveCN101216534ASimple control systemEasy to controlDynamo-electric machine testingHigh energyControl system

The invention relates to a dynamic load control device of motor, which belongs to the field of electric drive control technology, in particular to a dynamic operation test control device of motor. The invention solves the problems of prior control device, such as large impulse current to a power grid, high energy consumption in test and inconvenient adjustment of load power. The technique scheme of the invention is that the invention includes a DC speed regulating device and a frequency-variable feedback power supply, and the DC speed regulating device provides a working power supply for the frequency-variable feedback power supply. Compared with prior art, the invention has the advantages of (1) optimized control system and control process; (2) stable start of equipment to prevent overlarge impulse current to the power grid in the start process of the equipment; (3) significant energy saving effect; and (4) improved field working environment.

Owner:HUBEI OUAN ELECTRICAL

Filtrate flow-guiding silencer

ActiveCN104307230AReduce water flow rateReduce dispersionFiltration separationWork performanceEngineering

The invention discloses a filtrate flow-guiding silencer. The filtrate flow-guiding silencer comprises a drum body, wherein the top end of the drum body is connected with a liquid inlet pipe, the upper part in the drum body is provided with a flow-guiding device, the flow-guiding device is composed of filtrate baffles interlaced and fixedly connected to the inner wall of the drum body, and an S-shaped flow-guiding area is formed among the filtrate baffles; the lower part in the drum body is provided with the silencer, the tail end of the silencer is connected with a filtrate drainage pipe, the silencer device is composed of three layers of silencing drums, each layer of silencing drum is fixedly connected to the inner wall of the drum body. The filtrate vapor and water mixture is buffered and silenced in the filtrate water emission process, so that the liquid speed is reduced, the emission is uniform, and the sound wave produced by compressing air high-pressure blast can be dispersed; the noise is eliminated, the working performance of a filter press is improved, the field operation environment is optimized, and the staff work load is lightened.

Owner:JINCHUAN GROUP LIMITED

Flue gas utilization system, flue gas utilization process and high-temperature combustion treatment system

PendingCN111692877AReduce the amount of entryAvoid fireCarbon compoundsRotary drum furnacesCombustion chamberCarbonization

The invention relates to a flue gas utilization system, a flue gas utilization process and a high-temperature combustion treatment system. The flue gas utilization system is applied to the high-temperature combustion treatment system, the high-temperature combustion treatment system comprises a combustion chamber and a rotary kiln, wherein the combustion chamber is provided with a natural gas burner and an air distribution device. The flue gas utilization system comprises a flue gas settling device, a discharge flue, a high-temperature induced draft fan, an outlet flue, a return flue and a return fan, wherein the return flue communicates with the flue gas settling device, and the return fan arranged on the combustion chamber introduces part of flue gas in the flue gas settling device intothe combustion chamber of the high-temperature combustion treatment system from the return flue to combust combustible volatiles in the flue gas so as to generate heat. The flue gas utilization systemcan effectively solve the problems that an existing rotary kiln is high in energy consumption, a combustion chamber needs to be continuously provided a heat source, flue gas in an incineration chamber is insufficient in combustion, flue gas is not effectively utilized, and flue gas enters the combustion chamber and is difficult to ignite, and can be applied to the carbonization process of activated carbon to produce activated carbon.

Owner:INNER MONGOLIA PURUIFEN ENVIRONMENTAL SCI ANDTECH

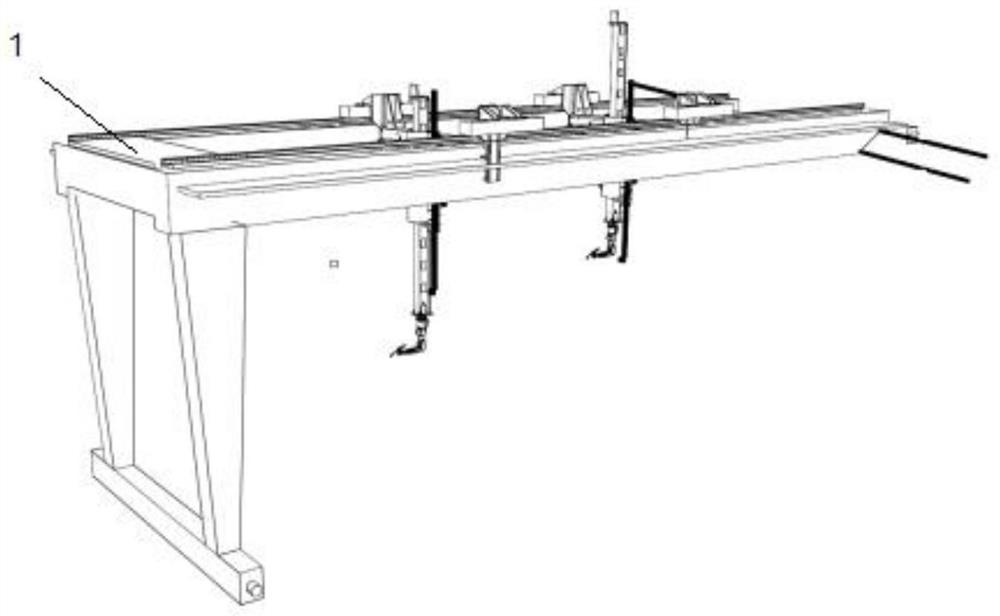

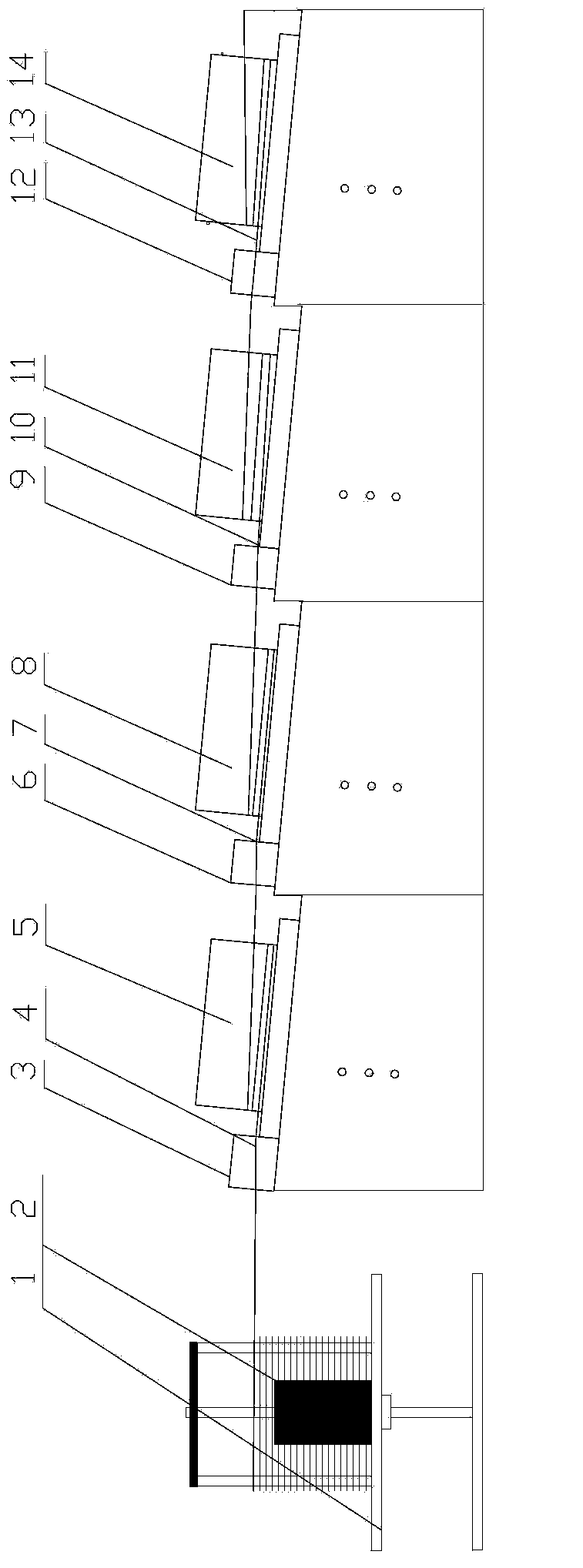

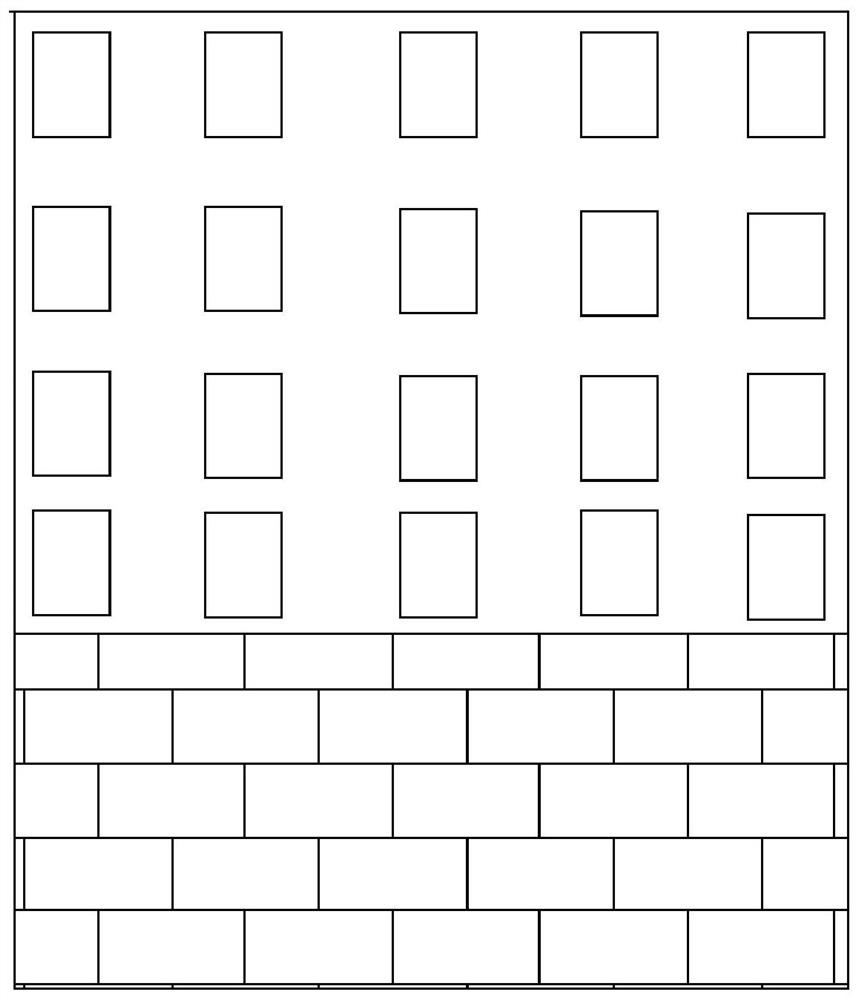

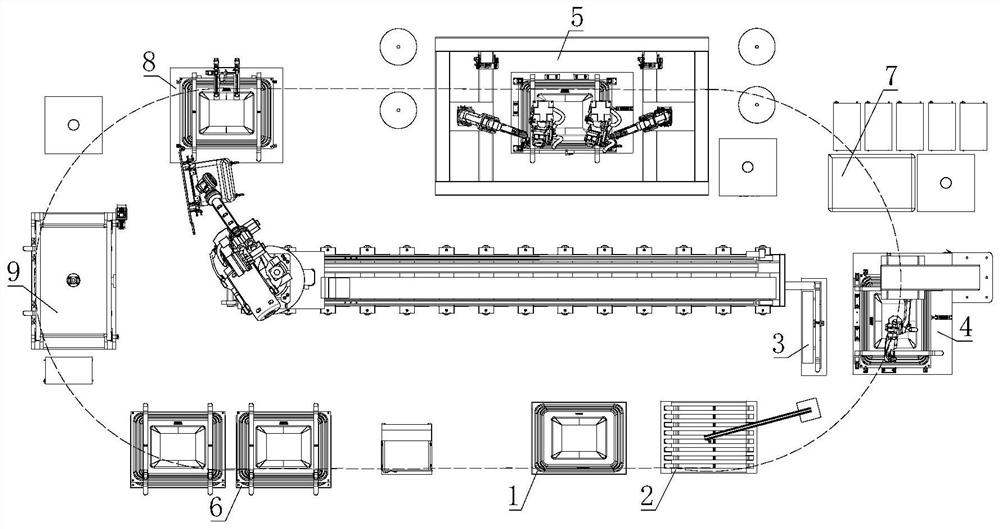

Automatic production system for railway wagon lower side door assembly

InactiveCN112809252AReduce bad luckIncrease the level of automationWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringSpot welding

The invention belongs to the technical field of lower side door production systems, and particularly relates to an automatic production system for a railway wagon lower side door assembly. According to the technical scheme, the automatic production system for the railway wagon lower side door assembly comprises a door plate feeding area, a hinge feeding area, a hinge pre-positioning device, a resistance spot welding device, an automatic welding device and a stacking area which are sequentially arranged, and welding manipulators are installed on the resistance spot welding device and the automatic welding device; the automatic production system further comprises a track, and a plurality of transfer robots for transferring materials are mounted on the track; the hinge pre-positioning device comprises a pre-positioning platform, and a plurality of hinge fixing and positioning check blocks used for positioning hinges and a plurality of hinge clamping air cylinders used for clamping the hinges are installed on the pre-positioning platform. The automatic production system for the railway wagon lower side door assembly can ensure that the hinges are accurately positioned on the resistance spot welding device.

Owner:CRRC MEISHAN

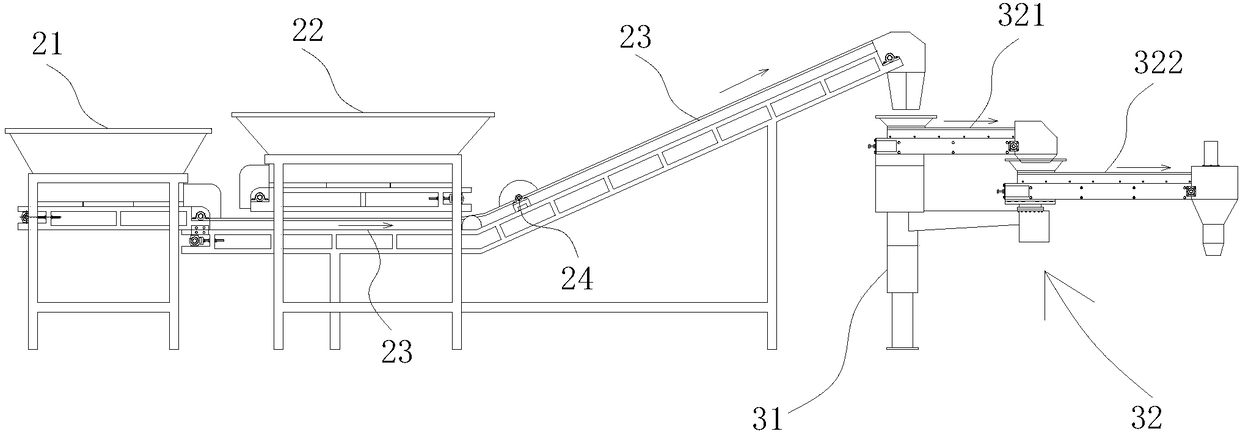

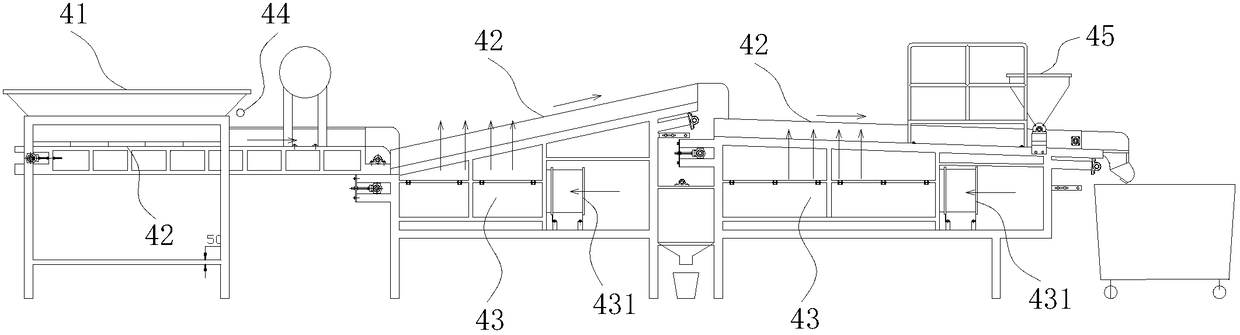

Intermittent intelligent wine brewing system and wine brewing method

InactiveCN108384699ALower installation heightAvoid uneven mixingAlcoholic beverage preparationCombustion chamberDistillation

The invention relates to an intermittent intelligent wine brewing system and a wine brewing method. The wine brewing system includes a first material stirring unit, a second material stirring unit, arice steamer storage unit, a mixed combustion vapor supply unit and a fermented grain airing and cooling unit; the first material stirring unit includes a fermented grain hopper, a grain hopper, a grain and water stirring device, a first conveyor belt and a second conveyor belt; the second material stirring unit includes a material mixing hopper, a bran hopper and a third conveyor belt; the rice steamer storage unit comprises a bracket and a spiral feeding mechanism for loading auxiliary materials into distillation rice steamers; the mixed combustion vapor supply unit includes a boiler for supplying vapor to the distillation rice steamers in which the auxiliary materials are stored; the boiler includes a combustion chamber composed of an upper layer bran husk combustion cavity, a middle layer marsh gas combustion cavity and a lower layer coal combustion cavity; the fermented grain airing and cooling unit includes a fermented grain hopper, a fourth conveyor belt and a blowing box. By means of the wine brewing system and the wine brewing method, not only can materials be uniformly blended, correspondingly the wine discharging amount is greatly increased, and the wine brewing qualityis ensured; moreover, continuous automatic operation can also be achieved, and the wine brewing efficiency is greatly improved.

Owner:ANHUI YINGJIA TRIBUTE WINE

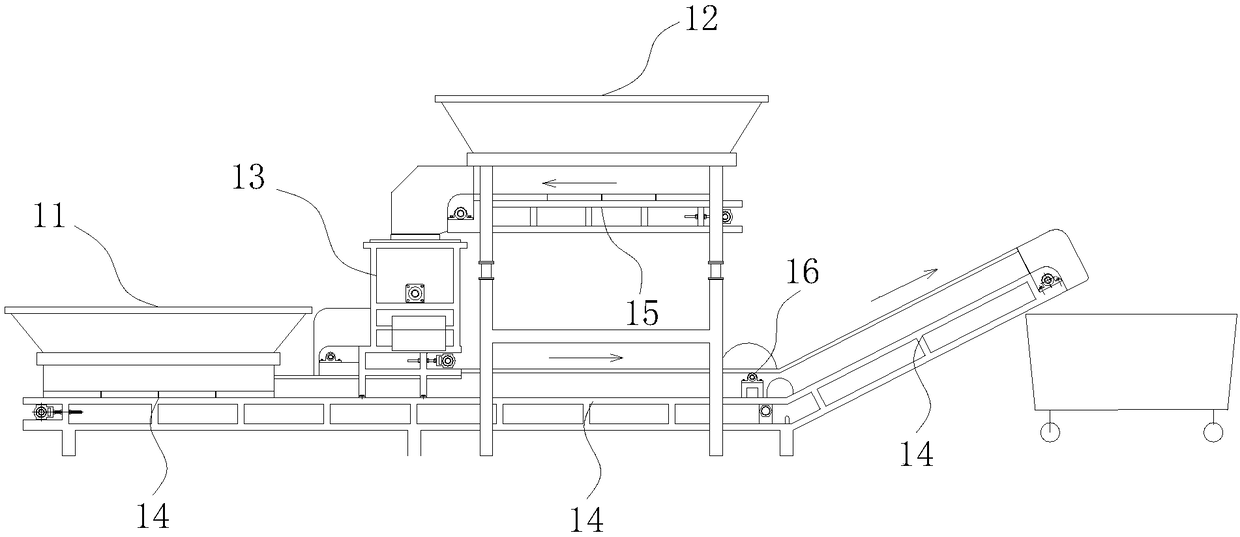

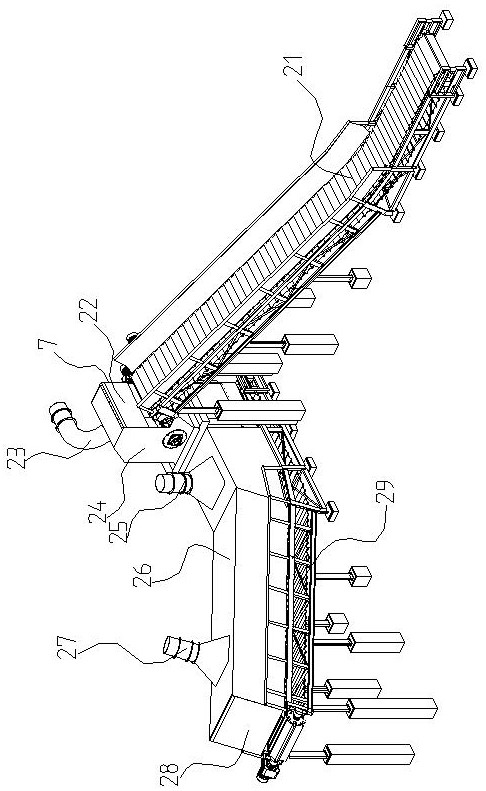

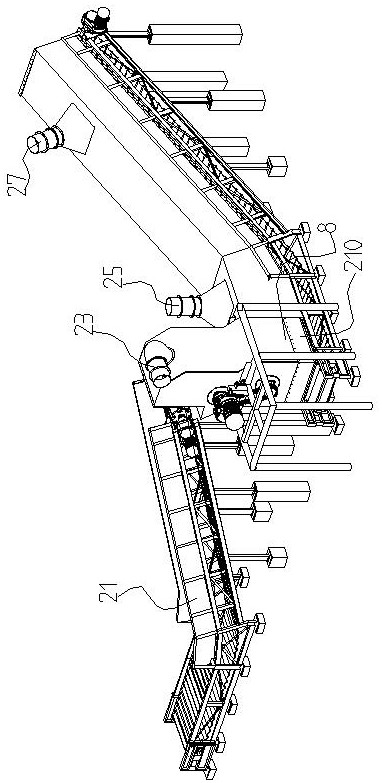

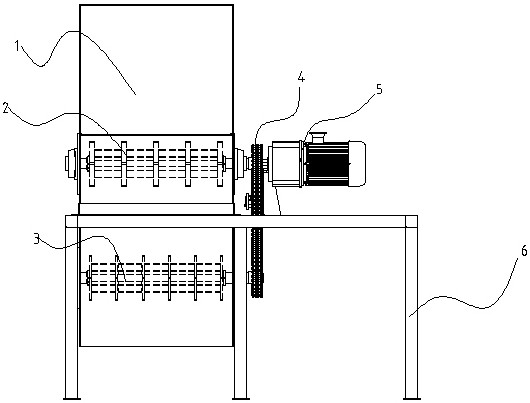

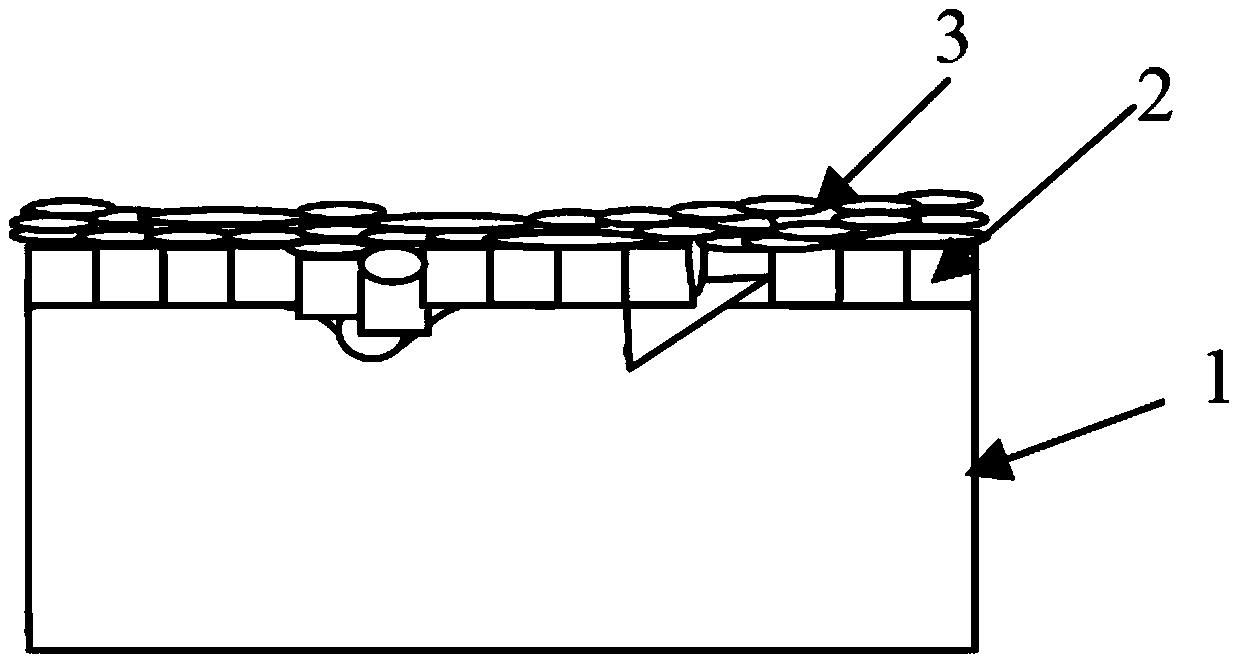

Waste paper bale breaking system based on vertical bale breaking machine

ActiveCN112278477ASpread out fastSimple structureUnpacking by cuttingDust controlProcess engineering

The invention discloses a waste paper bale breaking system based on a vertical bale breaking machine. The waste paper bale breaking system comprises the vertical bale breaking machine. The vertical bale breaking machine is mainly composed of a shell and paper breaking rollers arranged in the shell. The paper breaking rollers include the upper paper breaking rollers and the lower paper breaking rollers which are arranged in the shell in parallel up and down, the upper paper breaking rollers and the lower paper breaking rollers are connected through a transmission chain to rotate in the same direction, and the upper paper breaking rollers and the lower paper breaking rollers are each provided with a bale breaking fly-cutter structure. A feeding port is formed in the upper portion of the shell and connected with a feeding conveyor, the feeding end of the feeding conveyor is connected with an iron wire removing conveyor, waste paper on the iron wire removing conveyor is longitudinally stacked and baled, and a waste paper bale breaker is arranged between the feeding conveyor and the iron wire removing conveyor. A discharging port is formed in the bottom of the shell and is connected with a discharging conveyor. By optimizing the bale breaking machine and the aspects of feeding, dust removal and the like, the bale breaking efficiency is greatly improved, the service life of equipmentis prolonged, and the field operation environment is improved.

Owner:ZHENGZHOU LEIZHAN TECH PAPER MACHINERY

Preparation process of acid-base compound Magni coating

InactiveCN105506688AReduce production line operating costsUniform coatingChloride potassiumPre treatment

The invention discloses a preparation process of an acid-base compound Magni coating and relates to a metal surface antiseptic treatment process. The preparation process comprises the procedure of pretreatment conducted before coating, preparation of the coating and treatment conducted after coating, wherein the procedure of preparation of the coating comprises the steps of firstly, conducting potassium chloride galvanization on the surface of a workpiece, and then conducting zincate galvanization, wherein the steps of 21, potassium chloride galvanization, 22, washing III, 23, zincate galvanization, 24, washing IV, 25, film removal and 26, washing V are included; the procedure of treatment conducted after coating comprises the steps of 31, ultralow chromium passivation, 32, washing VI and 33, drying. According to the preparation process of the acid-base compound Magni coating, the potassium chloride galvanization process and the zincate galvanization process are combined together, product quality can be well stabilized, production efficiency is greatly improved, production line operation cost is lowered, the coating on the surface of a product prepared through the preparation process is uniform, surface quality is good, the preparation process has the advantages that the coating speed is high, drying can be conducted easily, product defects are few, the service life of the product is prolonged, the ultralow chromium passivation process is adopted, sewage treatment cost is lowered, and the preparation process is easy to use and popularize.

Owner:GUANGXI LIUZHOU LONGFA METAL SURFACE TREATMENT TECH

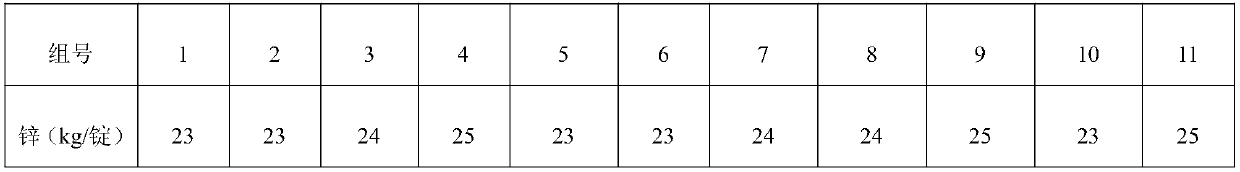

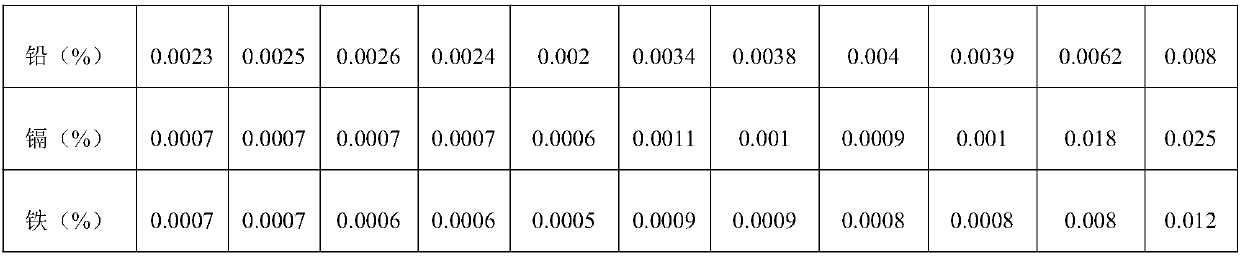

Electrolytic additive formula for improving zinc sulfate solution electrolyzed zinc quality and production environment and application method

InactiveCN107858703AImprove concentration polarizationDispersedElectrolysis componentsPhotography auxillary processesPolyethylene glycolAlloy

The invention belongs to the technical field of electrolytic zinc optimization, and provides an electrolytic additive formula for improving zinc sulfate solution electrolyzed zinc quality and the production environment and an application method. The method comprises the steps that a zinc sulfate solution is adopted as an electrolyte, a lead-silver alloy plate is used as an anode plate, and a calendered aluminum plate is used as a cathode plate; when the density of zinc on the calendered aluminum plate is reduced, a bone glue solution is added into the electrolyte; and polyacrylamide, polyethylene glycol, sodium methylene dinnaphthalene sulfonate are prepared to be a polyacrylamide solution, a polyethylene glycol solution and a sodium methylene dinnaphthalene sulfonate solution respectively, and the prepared solutions are added into the electrolyte correspondingly. By adopting the formula, the technical problems that the zinc sulfate solution electrolyzed zinc produced by a common cobalt removal process adopting reagents is poor in quality, high in lead and iron content and low in ingot casting recovery rate are solved; meanwhile, the field environment is improved, and the environment pollution is reduced; and adverse factors influencing the quality of zinc electrolyzing and electric energy consumption in the electrolysis operation can be eliminated by adopting the using method,so that the quality of the electrolytic zinc and the operating environment are greatly improved.

Owner:四川四环锌锗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com