Metallurgical slag sampling device and usage thereof

A sampling device and slag technology, applied in sampling devices, sampling, measuring devices, etc., can solve the problems of unstable sampling quality, high-temperature slag easily sticky and mixed impurities, harsh working environment, etc., to improve quality stability and The success rate of sampling, the improvement of metallurgical automation, and the effect of simple and easy to use methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

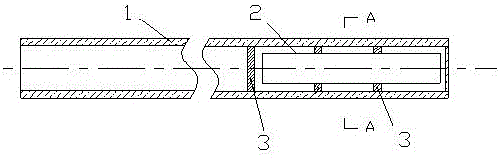

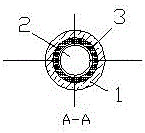

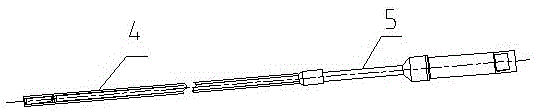

[0026] The slag sampling device 4 of the present invention is composed of a protective casing 1 , a vacuum sampling core 2 and mud material 3 .

[0027] As shown in the figure, the protective sleeve 1 is a paper sleeve, the lower end of the protective sleeve 1 is closed, and the upper end is open. The outer diameter of the protective sleeve 1 matches the front sampling positioning part of the sampling actuator. The protective sleeve 1 is installed on the sampling positioning rod of the sampling actuator or the manual sampling tool, and the protective sleeve 1 and the inner sealing mud 3 are used to protect the vacuum sampling core 2 during the sampling process.

[0028] The figure shows that the length of the protective sleeve 1 is greater than the length of the vacuum sampling core 2, and the wall thickness of the protective sleeve 1 is 5-8mm. The surface layer of the protective sleeve 1 will be burned during the sampling process, but it will not affect its Strength of protec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com