Non-woven self-wrapping acoustic sleeve and method of construction thereof

A self-curling, sleeve technology that can be used in packaging, electrical circuits or fluid lines, vehicle components, etc., to solve problems such as cost and expensive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

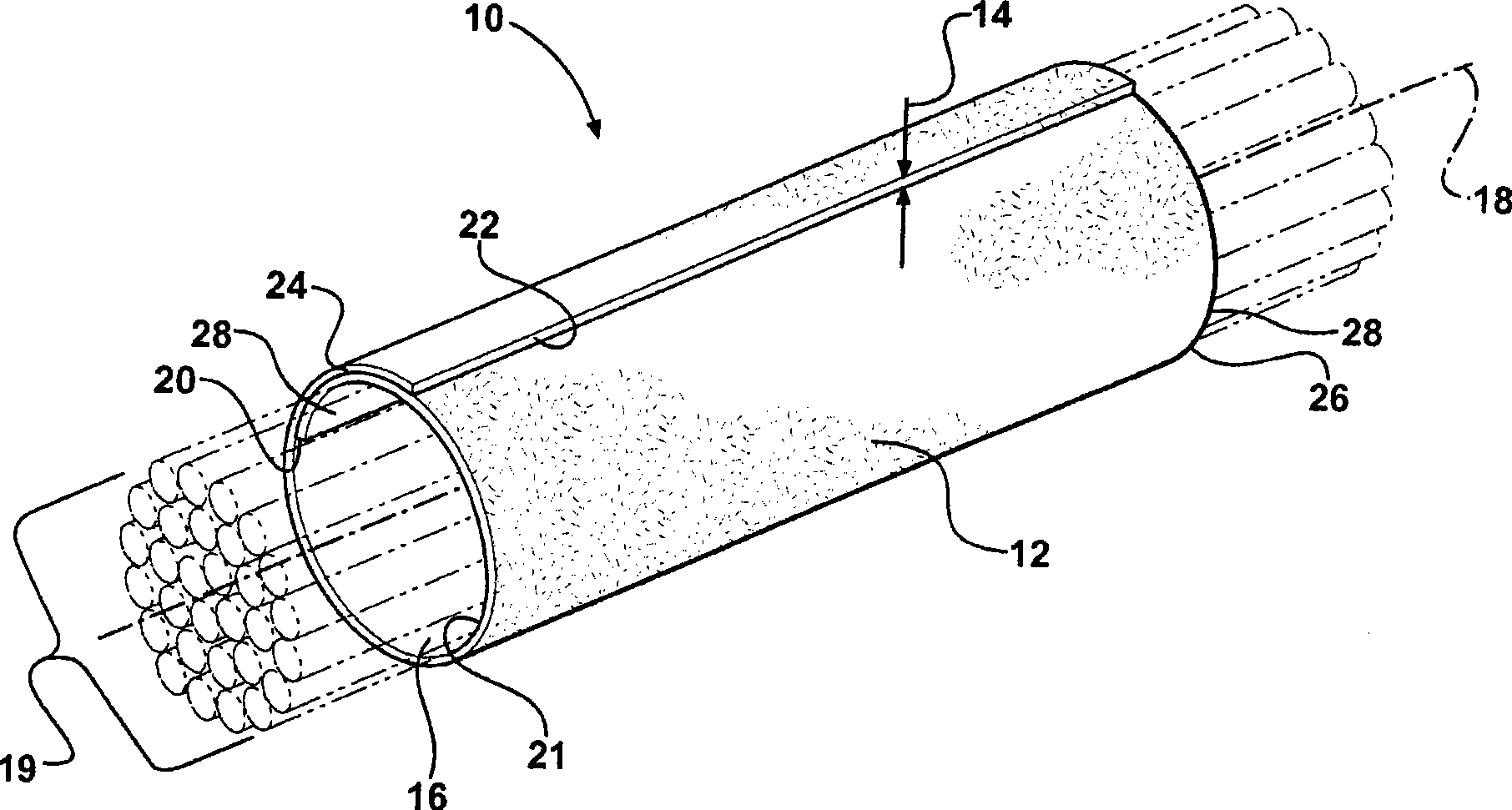

[0016] Referring to the drawings, Figure 1 shows a nonwoven sleeve 10 made in accordance with a preferred embodiment of the present invention. The sleeve 10 has a wall 12 fabricated from a nonwoven material and shaped as a self-coiling tubular structure to define an enclosed lumen 16 when it is in a self-coiling state. The lumen 16 is tubular and easily accessible along the longitudinal axis 18, so that elongated members such as electrical wires 19 or harnesses can be easily inserted radially into the lumen 16 towards the axis 18, and vice versa, as in maintenance During this time, it is removed from the chamber 16. The nonwoven material forming said wall 12 is an abrasion resistant, flexible, resilient, noise reducing polyester material, which in the preferred embodiment is formed, by way of example and not limitation, of PET. Accordingly, the sleeve 10 is well adapted to protect the elongate member 19 within the cavity 16 against wear and damage, while also preventing the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com