Patents

Literature

411results about How to "Solve intractable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

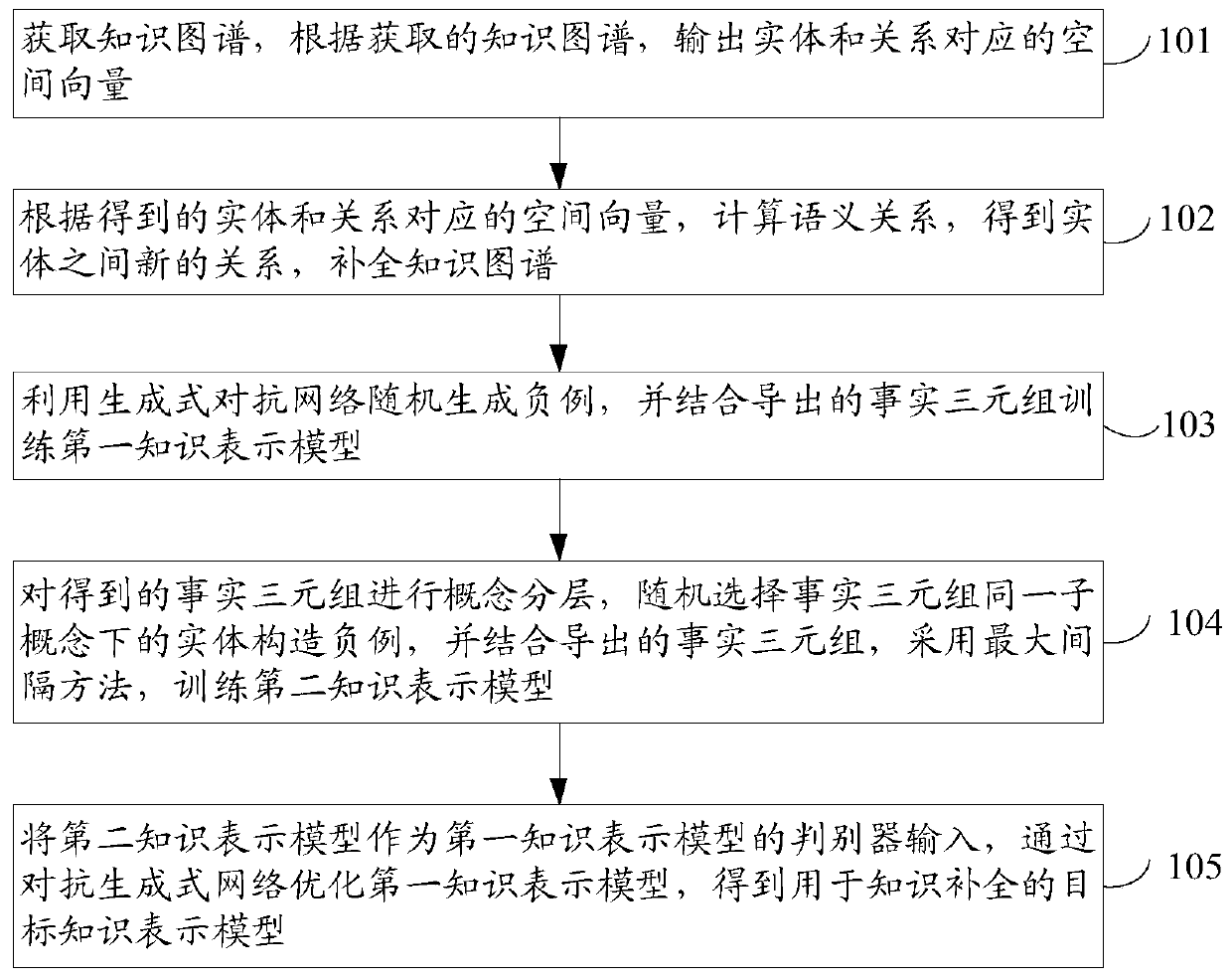

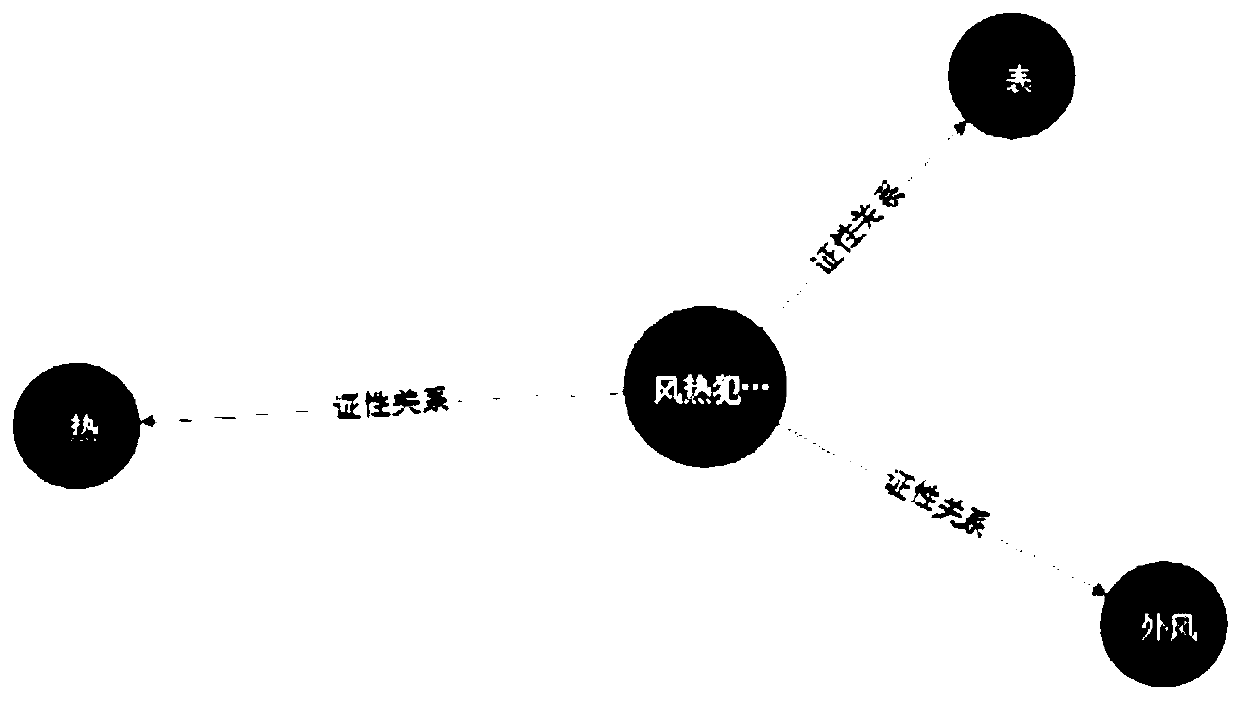

Knowledge complementing method and device for knowledge graph

ActiveCN110147450AAvoid competition for the same vector space pointSolve the meaningless problem of negative examplesSpecial data processing applicationsSemantic tool creationGenerative adversarial networkKnowledge engineering

The invention provides a knowledge complementing method and device for a knowledge graph, which can solve the problems that negative examples are meaningless and the 1-N relation is difficult to process in the whole knowledge complementation process.. The method comprises the steps of determining a space vector corresponding to an entity and a relationship; calculating a semantic relationship according to the entities and the space vectors corresponding to the relationships to obtain a new relationship between the entities, and complementing the knowledge graph; randomly generating a negativeexample by using the generative adversarial network, and training a first knowledge representation model in combination with the derived fact triple; performing concept layering on the obtained fact triple, randomly selecting entities under the same sub-concept of the fact triple to construct a negative example, and training a second knowledge representation model by adopting a maximum interval method in combination with the derived fact triple; and taking the second knowledge representation model as a discriminator input of the first knowledge representation model, and optimizing the first knowledge representation model through the adversarial generative network to obtain a target knowledge representation model for knowledge completion. The invention relates to the field of knowledge engineering.

Owner:UNIV OF SCI & TECH BEIJING

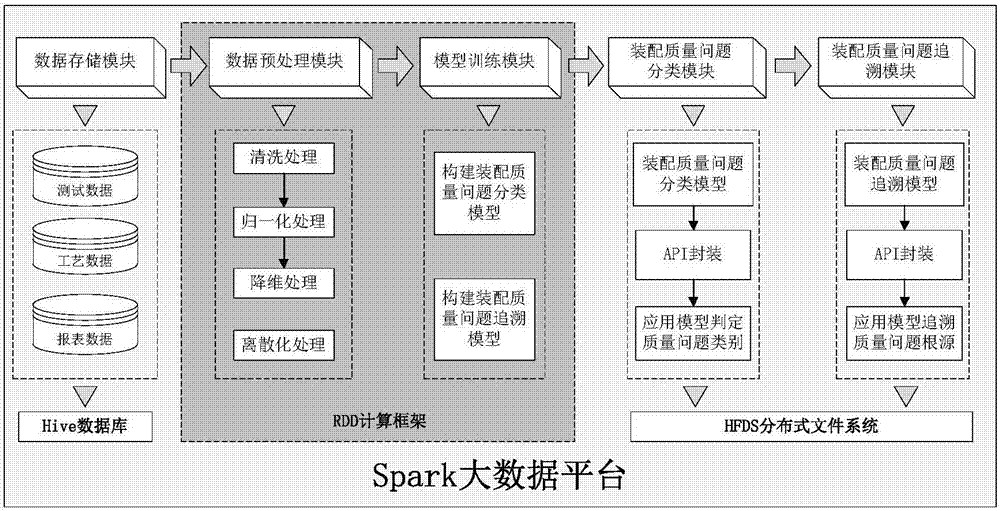

Circuit breaker assembly quality problem tracing system and method based on large data analysis

InactiveCN107451666AEnsure safetySolve intractableCharacter and pattern recognitionResourcesComputer scienceData pre-processing

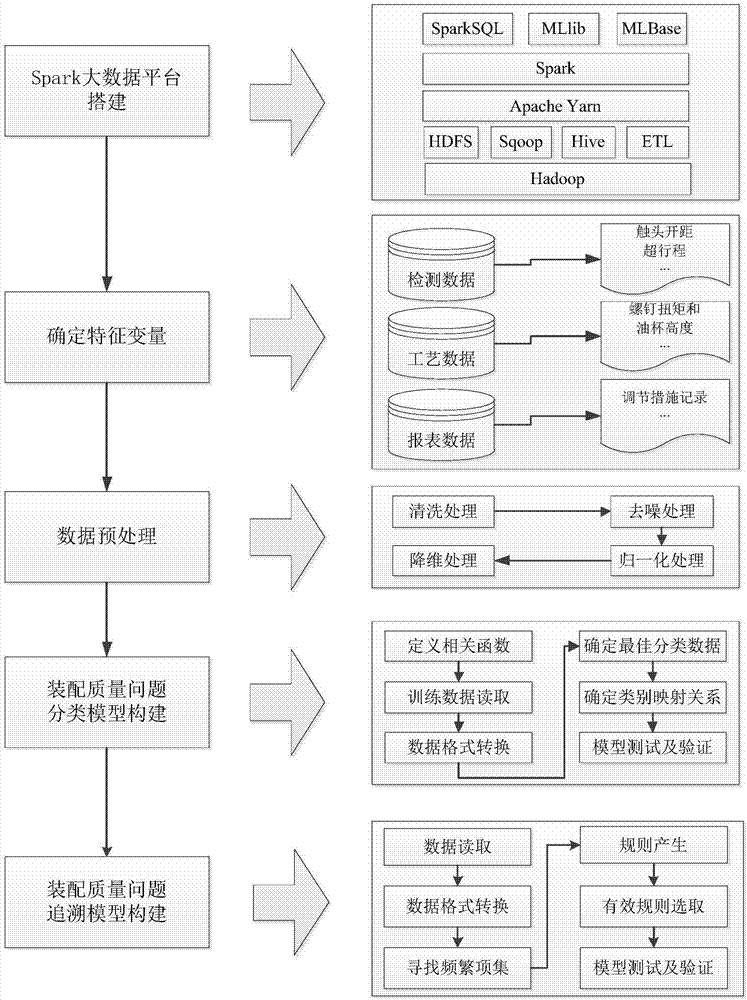

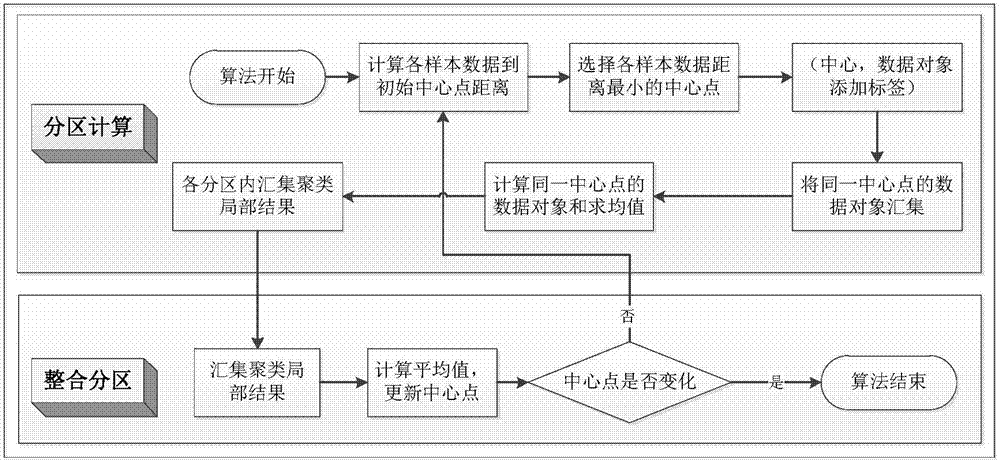

The invention discloses a circuit breaker assembly quality problem tracing system and method based on large data analysis. The problem that an ancillary system cannot meet the requirement of massive data analysis in a circuit breaker assembly production process is solved. The new idea of quality circuit breaker assembly quality problem tracing is provided from the aspect of data mining. The method comprises the steps that Spark is used to build a large data analysis platform; data preprocessing is carried out in combination with business; K-Means is used to build an assembly quality problem classification model based on distance; an Apriori association rule algorithm is used to build an influential factor analysis model; and assembly quality problem tracing is realized. The assembly quality problem classification model completes the deficiencies of mechanism classification or experience classification from the aspect of data characteristics. According to the invention, the system and method are capable of storing and analyzing massive data, have the advantages of high-performance redundancy, real-time and efficient data analysis and storage, are used for circuit breaker assembly quality problem tracing, and provide suggestions and references for circuit breaker assembly quality production.

Owner:XIDIAN UNIV

High-concentration wastewater zero-discharging method

ActiveCN105198143ARealize in-depth treatment and even zero discharge problemsEfficient reverse osmosis treatmentEnergy based wastewater treatmentMultistage water/sewage treatmentHigh concentrationReverse osmosis

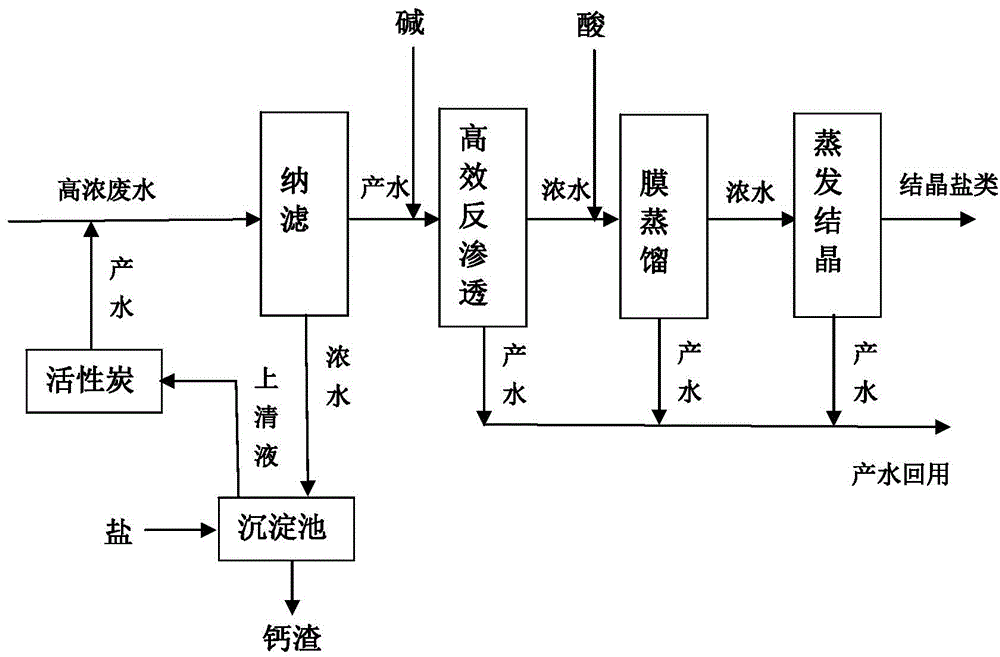

The invention relates to the field of industrial wastewater treatment, in particular to a high-concentration wastewater zero-discharging method. Accoridng to the method, a 'nanofiltration + efficient reverse osmosis + membrane distillation + evaporative crystallization' method is adopted to treat high-concentration wastewater. Firstly, nanofiltration is adopted to remove hardness, multivalent ions and parts of organic matter in the high-concentration wastewater so as to obtain nanofiltration producing water and nanofiltration concentrated water, then an efficient reverse osmosis technology is adopted to conduct deep concentration treatment on the nanofiltration producing water, deep concentration treatment is conducted on the obtained efficient reverse osmosis concentrated water through membrane distillation to obtain membrane-distillation concentrated water, further evaporative crystallization treatment is performed to enable salt solids in the membrane-distillation concentrated water to crystallize out, and centralized drying disposal is performed, wherein salt is added into the nanofiltration concentrated water to perform precipitation treatment so as to obtain calcium residues, supernate obtained after precipitation is subjected to activated carbon adsorption and then is mixed with the high-concentration wastewater, and the mixed liquid is fed into a nanofiltration unit for circular treatment. By means of the high-concentration wastewater zero-discharging method, water resources are recycled to the most degree while the problem of high-concentration wastewater discharging is solved, and zero discharging of high-concentration wastewater is basically achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Intelligent lump coal dry method inverted separation system

InactiveCN105537145AAvoid the problem that the force surface is small and it is difficult to blow through the high-frequency solenoid valveAvoid the problem that it is difficult to blow through the high-frequency solenoid valveSortingSolenoid valveSpray nozzle

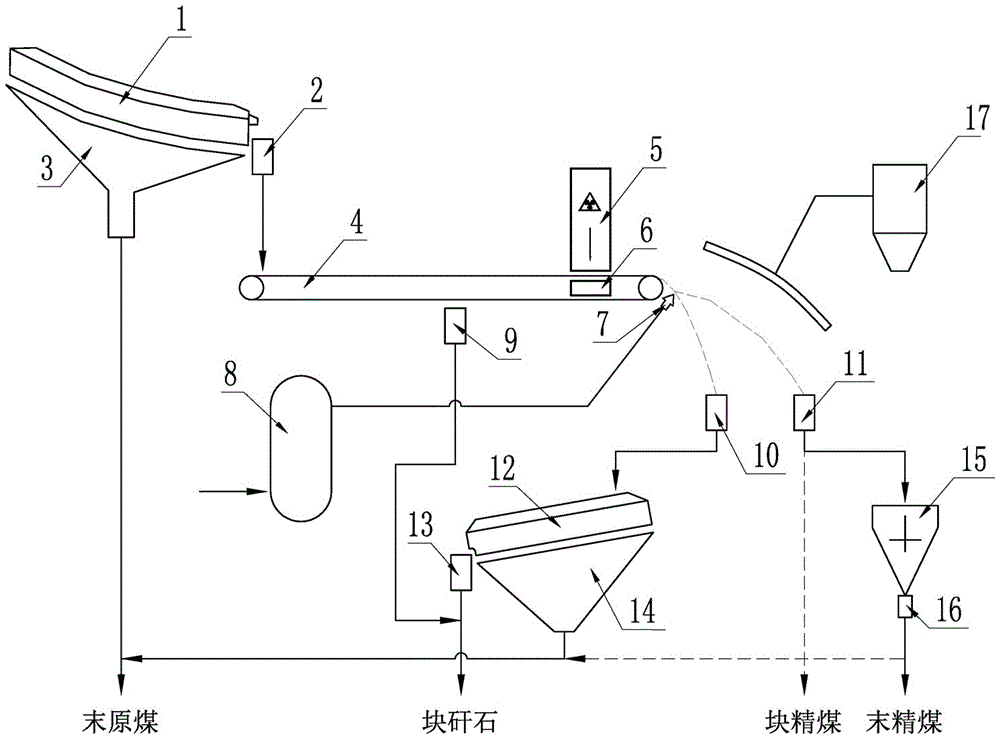

The invention aims to provide an intelligent lump coal dry method inverted separation system. After supplied raw coal materials are screened through a raw coal classifying screen, raw lump coal enters an intelligent dry separation machine, and are identified by X-rays as clean coal, gangue and other things. The intelligent lump coal dry method inverted separation system is characterized in that conventional gangue blowing operation of intelligent dry separation is turned into coal blowing operation, and the intelligent dry separation machine enables an air spray nozzle which corresponds to the clean coal and is controlled by a high-frequency solenoid valve to be opened according to identifying information of the X-rays, so that the clean coal deviates from the raw coal movement trail, and the clean coal is separated from the gangue and the other things. The intelligent dry separation machine is a dry method separation device which utilizes the rays to conduct intelligent identifying separation on minerals, the clean coal and the gangue are identified according to the difference of the capacities of the clean coal and the gangue for absorbing the rays, and the air spray nozzle serves as an execution mechanism. According to the invention, the intelligent lump coal dry method inverted separation system can be applied to coal preparation plants with a large amount of gangue and a plurality of overlarge blocks and other things so that the problem that an existing conventional intelligent dry method gangue removal system is difficult to handle with overlarge blocks and other things can be solved, and the air consumption and the energy consumption can be reduced.

Owner:TIANJIN MEITENG TECH CO LTD

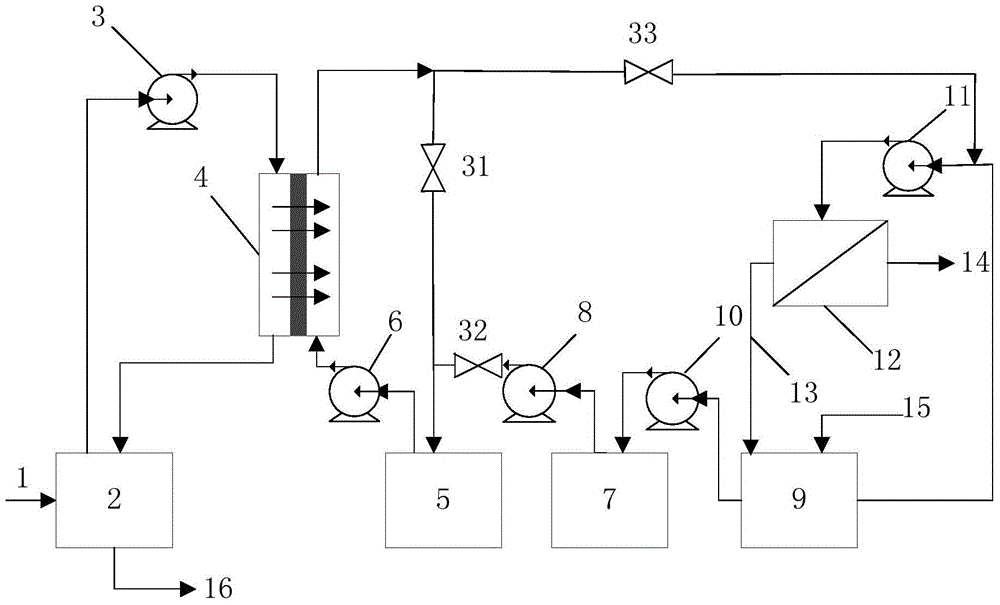

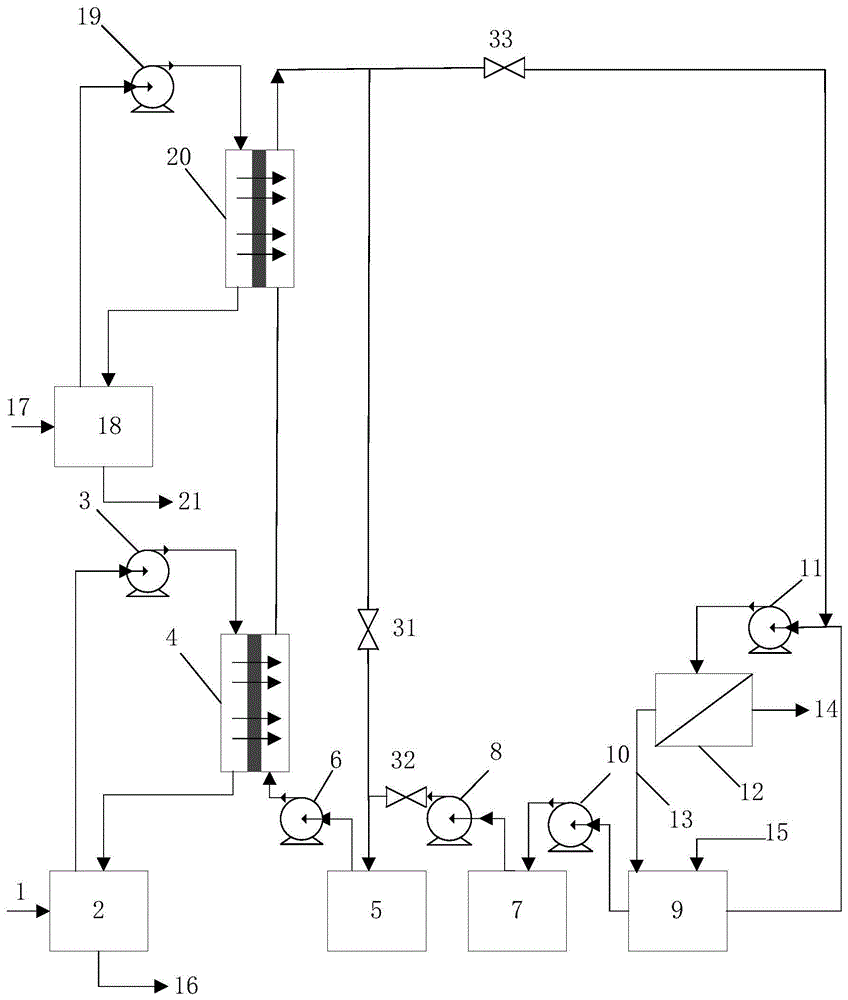

Forward osmosis coupled membrane distillation wastewater treatment apparatus and method thereof

ActiveCN104591457AEfficient use ofSimple methodWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentWater resourcesWastewater

The invention provides a forward osmosis coupled membrane distillation wastewater treatment apparatus and a method thereof. The apparatus includes a first stage forward osmosis unit or a second stage forward osmosis unit and a membrane distillation unit. The above forward osmosis unit is composed of a forward osmosis raw water pool, a forward osmosis raw water pump, a forward osmosis membrane module, a forward osmosis driving liquid pool and a forward osmosis driving liquid pump; the membrane distillation unit is composed of a membrane distillation thick water raw water pool, a membrane distillation thick water pump, membrane distillation, a membrane distillation water heating pool, a membrane distillation thick water raw water pump, a membrane distillation water feeding pump and a membrane distillation assembly; and the forward osmosis unit is connected with the membrane distillation unit through a pipeline and a valve. The method comprises the following steps: high salinity wastewater treated by the membrane distillation unit is used as a forward osmosis driving liquid, membrane distillation thick water is diluted through continuous concentration of forward osmosis feeding liquid side raw water, the diluted membrane distillation thick water returns to the membrane distillation unit and is continuously treated, and above steps are cycled. The apparatus and the method effectively solve the treatment problem of the membrane distillation thick water, and maximally recover the water resource in the wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

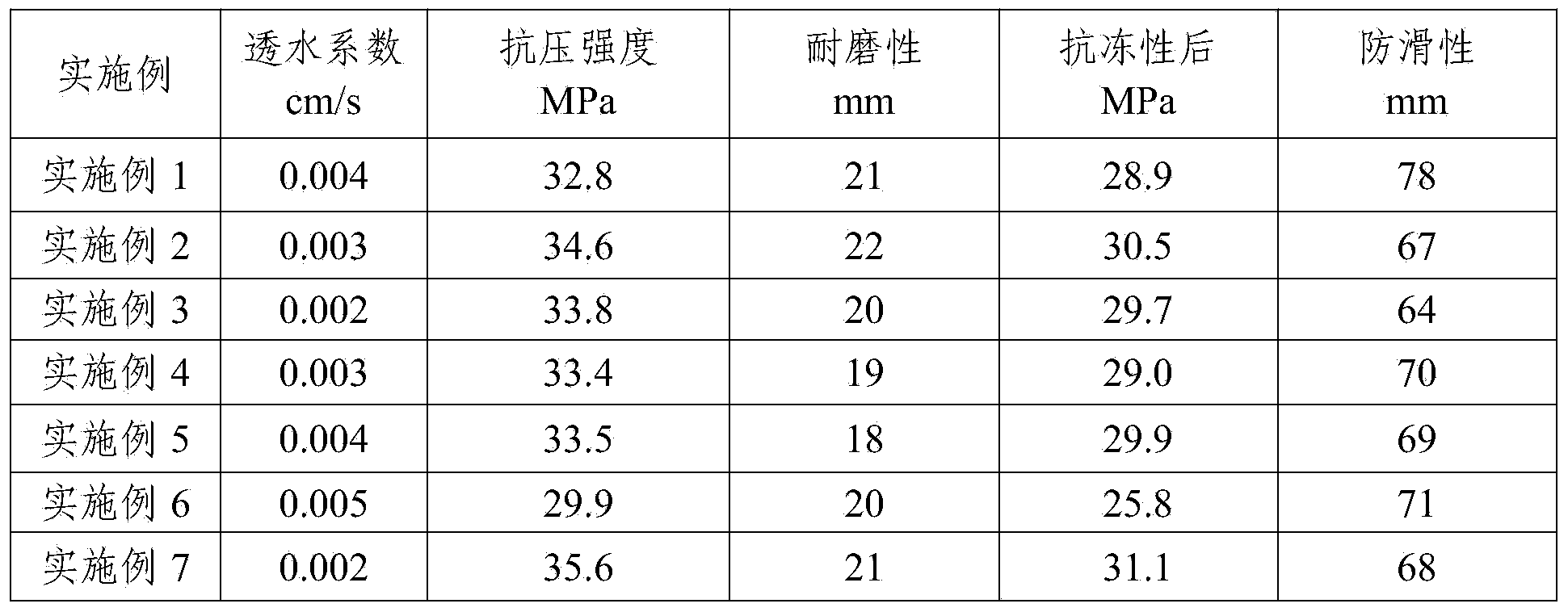

Multi-pore high-strength sintering permeable floor brick

InactiveCN105330318ASolve intractableHigh porosityCeramic materials productionCeramicwarePolyvinyl alcoholSlag

The invention discloses a multi-pore high-strength sintering permeable floor brick. The multi-pore high-strength sintering permeable floor brick is prepared from, by weight, 40-43 parts of sewage plant sludge, 6-7 parts of rice hulls, 4-5 parts of potassium feldspar powder, 10-12 parts of fly ash, 10-12 parts of water glass, 29-31 parts of basalt rubble, 5-6 parts of sawdust, 9-11 parts of mesoporous silica, 0.8-1 part of a silane coupling agent kh560, 3-4 parts of polyvinyl alcohol fibers, 7-9 parts of blast furnace slag and 2-3 parts of chemical waste gypsum powder. According to the multi-pore high-strength sintering permeable floor brick, the mesoporous silica, the sawdust and the polyvinyl alcohol fibers are added in preparation of the brick, and a composite through hole structure can be formed through sintering molding after technological modification; in addition, multiple pores distributed densely are obtained by reasonably regulating the particle size of mixed aggregates; meanwhile, the product is high in compressive strength, firm, durable and high in permeable coefficient.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

Bayer process red mud and gangue porous sintered brick and production method thereof

InactiveCN103030372ARegular appearance qualityNo deformationCeramic materials productionCeramicwareTunnel kilnBrick

The invention discloses a Bayer process red mud and gangue porous sintered brick and a production method thereof. The porous sintered brick is prepared from the following raw materials: 60 to 75 parts of Bayer process red mud; 25 to 35 parts of gangue; 2 to 6 parts of tailings or wastes in chemical plants; and 0.5 to 3 parts of pore-forming agent. The preparation method of the brick comprises the following steps: after dehydrating the Bayer process red mud, mixing and uniformly stirring the Bayer process red mud and other ground raw materials, aging for 1 to 3 days, and adding water to stir aged powder in a stirring machine so as to obtain mud; carrying out extrusion forming on the mud under the extrusion pressure of 1.5 to 2.5MPa by adopting a stiff-plastic process so as to obtain a semi-finished product which accords with the specified dimension and the specified shape; and drying a mold brick and sintering the mold brick in a tunnel kiln to obtain the Bayer process red mud and gangue porous sintered brick. The product reaches the national strength standard of the sintered bricks. In the technology, the total use amount of industrial wastes is close to 100 percent; a large number of farmlands are saved; land resources are effectively protected; and the Bayer process red mud and gangue porous sintered brick and the production method thereof accord with the national policies of saving energy and reducing emission and have obvious environmental benefits, social benefits and economic benefits.

Owner:HENAN POLYTECHNIC UNIV

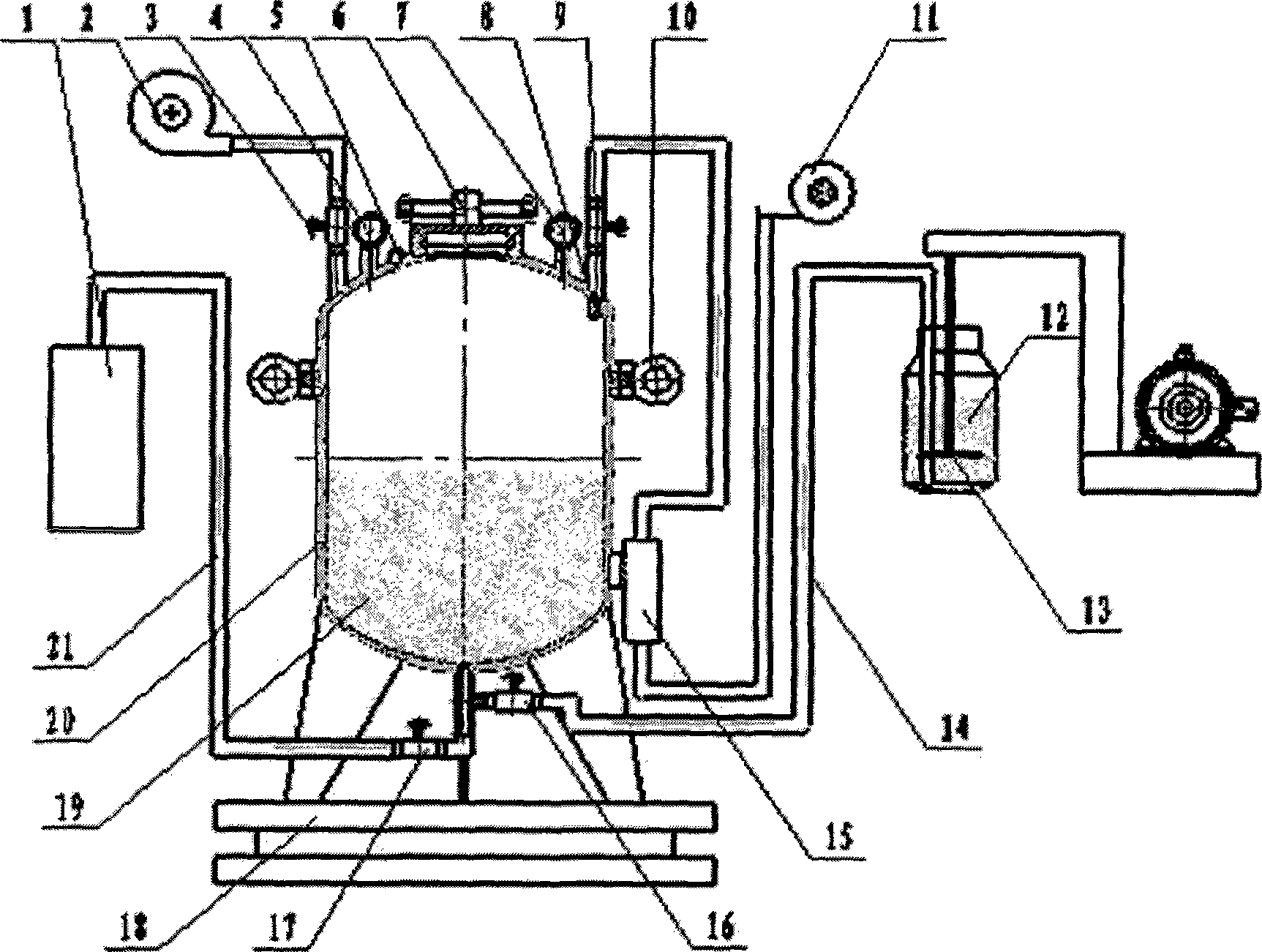

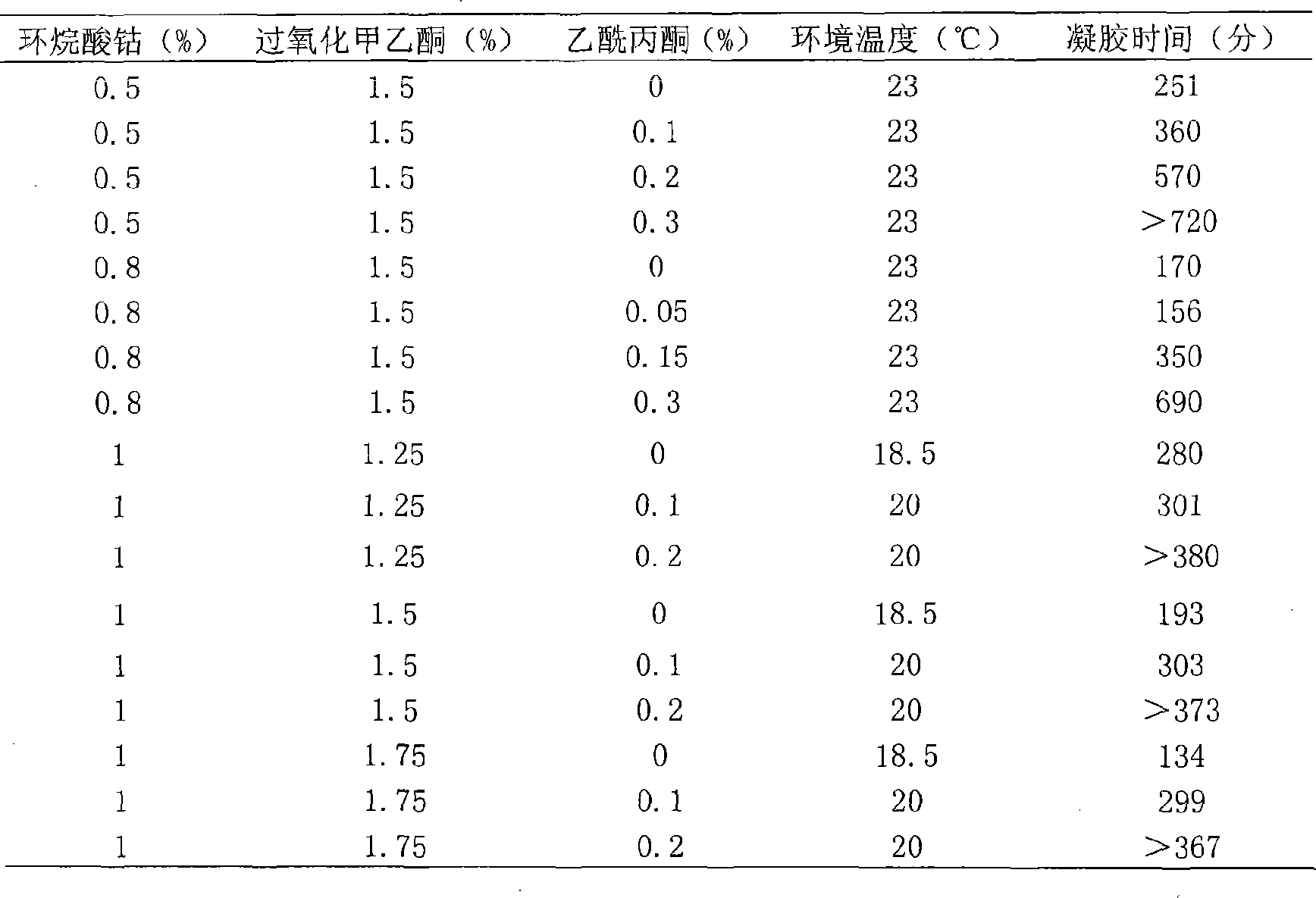

Re-injection process and equipment for poured resin adhesive solution when discharging air bubbles during composite material RTM molding process

The invention discloses a process for re-injecting resin adhesive liquid discharged from exhaust bubble in composite material RTM moulding process and a device thereof; the process comprises the steps as follows: the resin adhesive liquid is filtered by a screen mesh and collected to a material barrel added with retarder to be stirred; the evenly stirred resin adhesive liquid is sucked into a tank under the pull of vaccum, the tank is vacuumized and de-foaming is carried out on the resin adhesive; pressure is injected into the tank in which the resin adhesive liquid is stored after de-foaming, under the effect of the pressure, the resin adhesive liquid after de-foaming is injected into a mould; meanwhile pressure is continuously injected into the tank at the filling speed of 5-2000g / min; finally residual resin adhesive liquid in the empty tank after filling and in the pipeline connecting the mould with the tank is cleaned. The pipeline is positioned between the mould and the tank. The device comprises a sealed tank, a discharge nozzle connected with the tank, an air inlet pipeline, the mould and the material barrel. The invention can effectively reduce the production cost, save energy and reduce emission, and reduce the emission of waste material; in addition, the invention has remarkable economic and social benefits and is conducive to popularization and application.

Owner:北京玻钢院复合材料有限公司

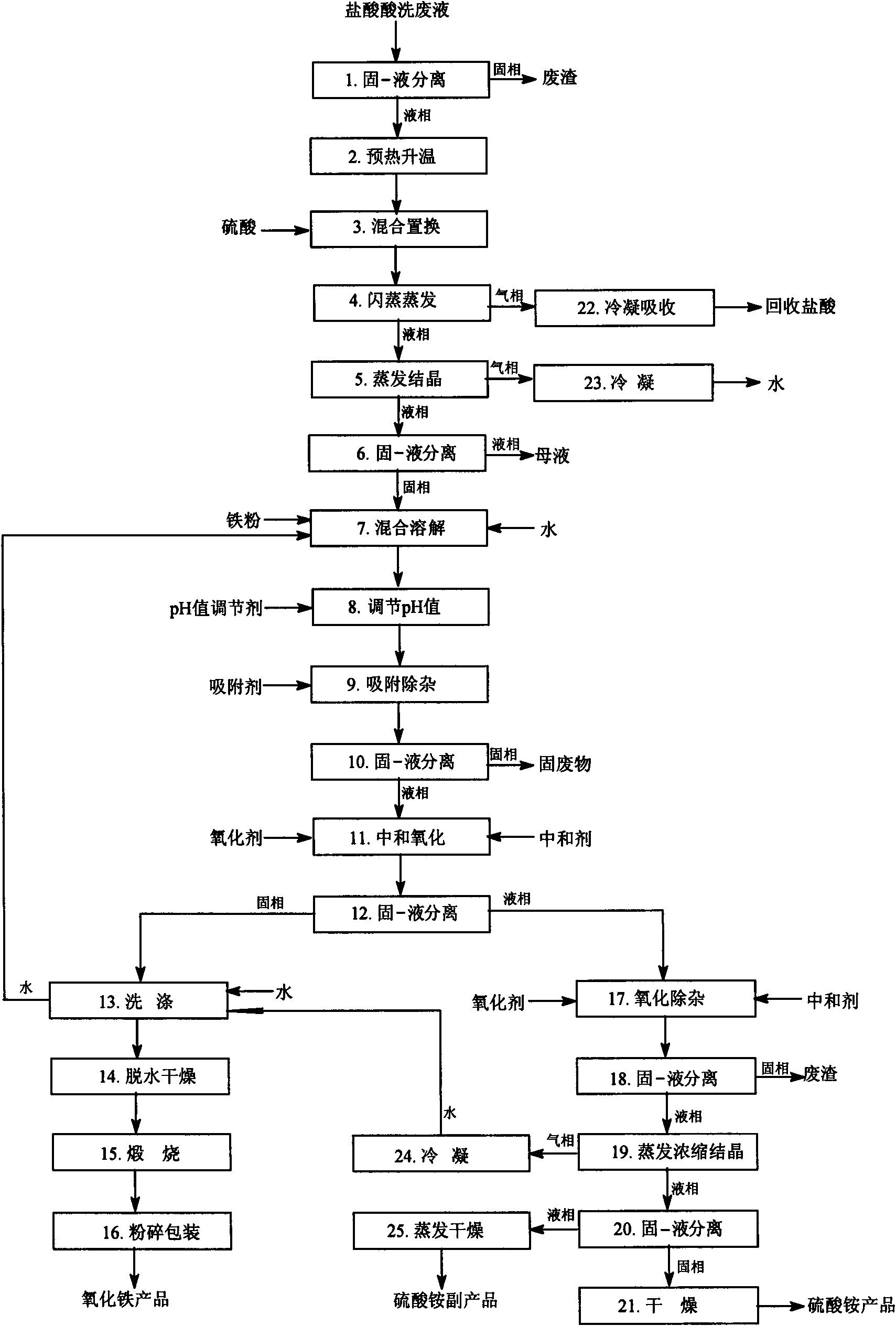

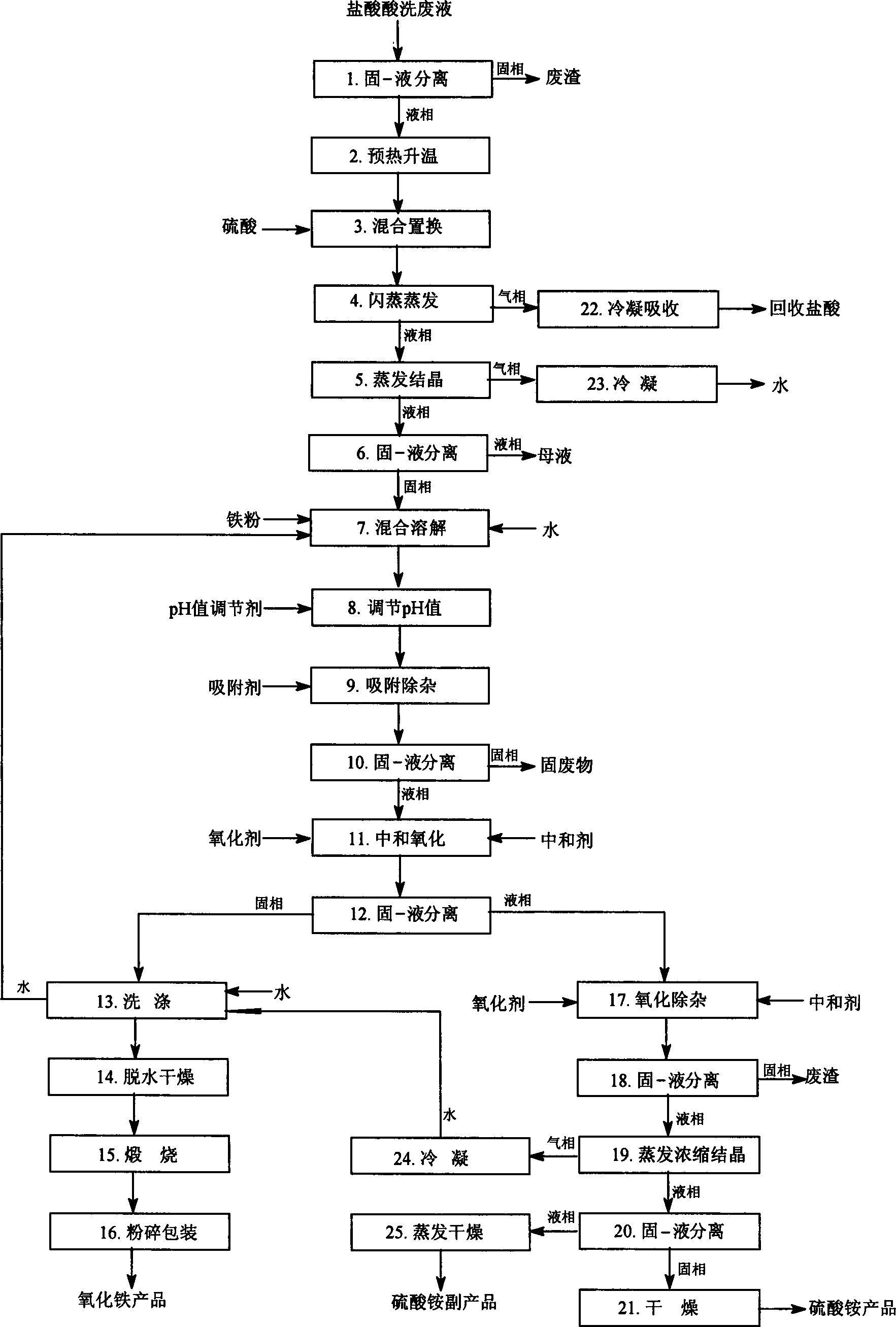

Hydrochloric acid pickling waste liquid resource integrated utilization method for preparing iron oxide and ammonium sulfate

InactiveCN102689930AFull replacementWell mixedChlorine/hydrogen-chlorideEnergy inputEvaporationImpurity

The invention relates to a hydrochloric acid pickling waste liquid resource integrated utilization method for preparing iron oxide and ammonium sulfate. Iron-containing hydrochloric acid pickling waste liquid obtained from a pickling treatment process, which uses hydrochloric acid solution as a pickle to remove surface oxides on a steel element, is used as a raw material. The method comprises the following steps of: (1) solid-liquid separation; (2) preheating and heating; (3) miscible displacement; (4) flash evaporation; (5) evaporation and crystallization; (6) solid-liquid separation; (7) mixing and dissolving; (8) pH adjusting; (9) adsorption for impurity removal; (10) solid-liquid separation; (11) neutralization and oxidation; and (12) solid-liquid separation. A liquid phase material is further used for preparation of an ammonium sulfate product, and a solid phase material is further used for preparation of an iron oxide product; besides, ammonium sulfate by-products can be prepared in further preparation of the ammonium sulfate product. The invention has advantages of reasonable technology, simple method, environment-friendliness, energy saving, low preparation cost, good product quality and high utilization rate of valuable components.

Owner:江苏江盛南节能科技有限公司

Method for preparing glyceryl polyether glycol

The invention discloses a method for preparing glycerol-based polyether polyol. Firstly, crude glycerol, a by-product of biodiesel, is refined to obtain refined glycerol which is used as an initiator together with other low-molecular-weight polyol and amines or used as the initiator alone; and with the existence of an alkaline catalyzer, the refined glycerol is reacted with oxidized alkene to obtain the polyether polyol. In the invention, the crude glycerol, the by-product of the biodiesel, is used as the raw material for producing the polyether polyol, thus having low cost, good product properties and being capable of meeting the requirements of producing polyurethane materials.

Owner:JURONG NINGWU CHEM

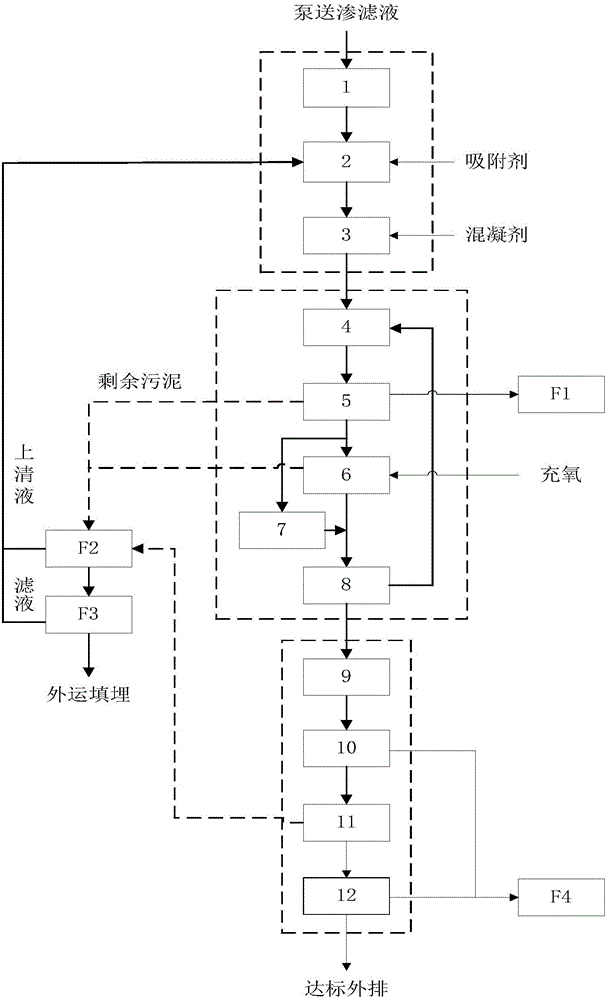

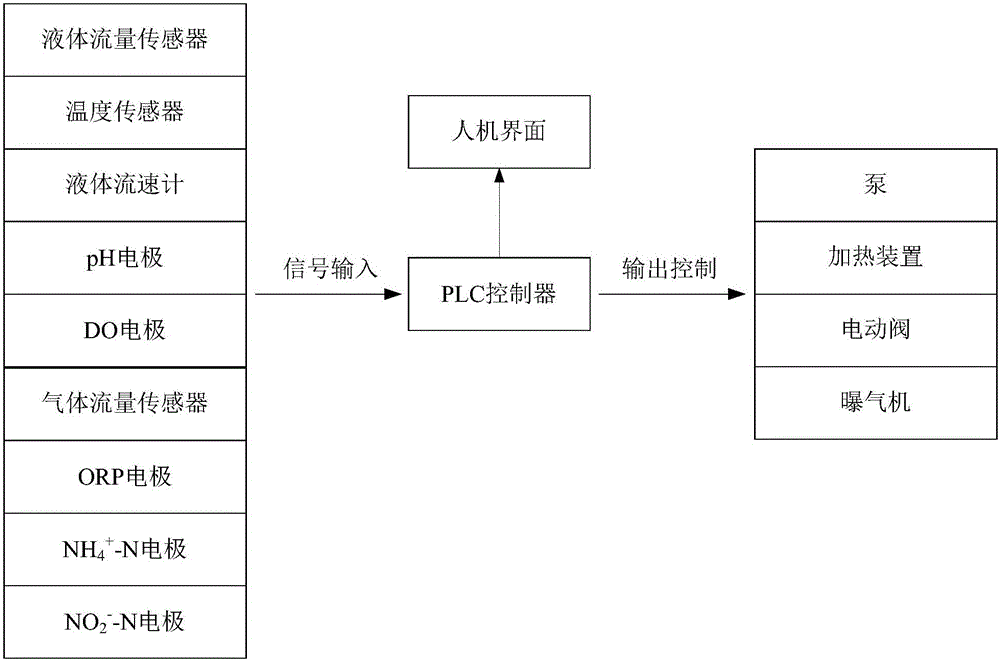

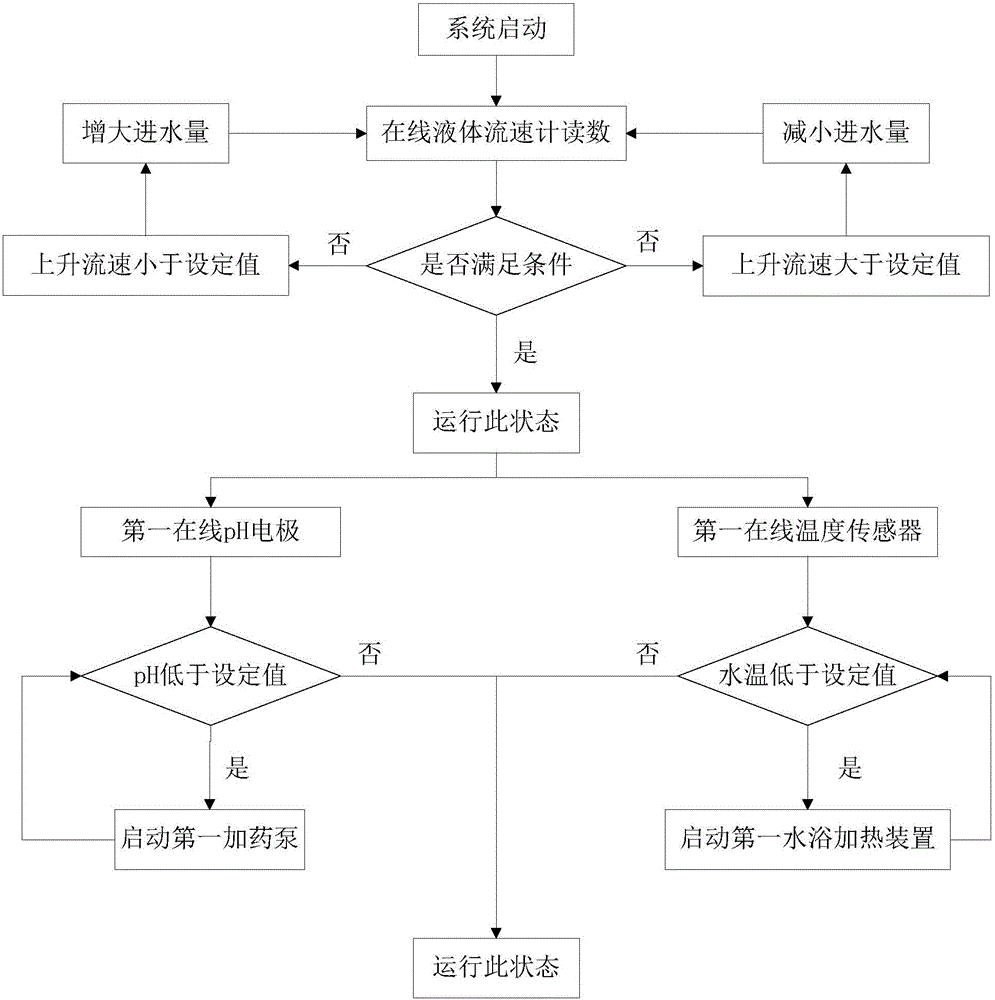

Anaerobic-autotrophic nitrogen removal-ozone oxidation coupling landfill leachate whole flow process zero emission processing process

ActiveCN105776775AReduce outputImprove nitrogen removal efficiencyWaste based fuelTreatment with anaerobic digestion processesNitrationTotal nitrogen

The invention provides a landfill leachate processing process. Landfill leachate sequentially passes through a pretreatment system, a main body biological treatment system and a deep treatment system; the pretreatment system consists of a regulating pool, an adsorption pool and a coagulating pool; wastewater is pretreated sequentially through the devices; outlet water enters the main body biological treatment system; the main body biological treatment system comprises an anaerobic EGSB (expanded granular sludge bed) reactor, an A / O short-range nitratlon reaction pool and an anaerobic ammonia oxidation UASB (upflow anaerobic sludge blanket) reactor; the treatment devices perform real-time regulation control through a PLC (programmable logic controller) control system for denitrification decarbonization reaction; the outlet water enters the deep treatment system for further treatment; the deep treatment system comprises a secondary coagulating pool, a primary homogeneous catalysis ozone oxidation reaction pool, a MBR (meane biological reactor) secondary biological reaction pool and a secondary homogeneous catalysis ozone oxidation reaction pool; finally, organic matters, total nitrogen and ammonia nitrogen of the outlet water reach the discharge standard. The landfill leachate processing process has the advantages that efficient denitrification and carbon removal are realized; the energy is saved; the consumption is reduced; the operation is stable; meanwhile, the goal of zero concentrated liquid generation is realized.

Owner:SHANGHAI BI ZONE ENVIRONMENTAL EQUIP & ENG

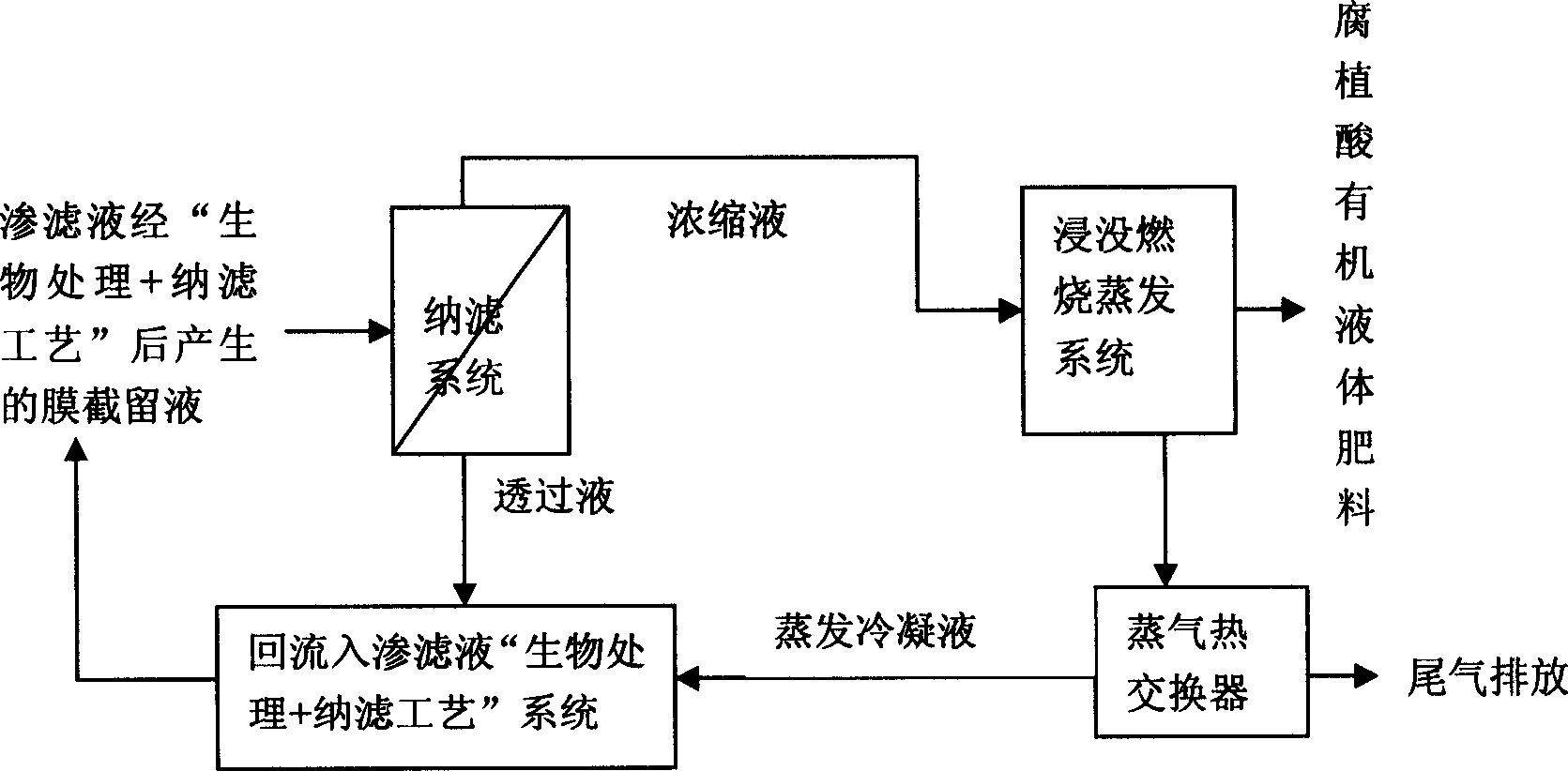

Resource process of inflitration liquid

InactiveCN1724419ASolve intractableOptimizing Process ParametersClimate change adaptationWater/sewage treatment bu osmosis/dialysisCombustionFilter system

A process for reclaiming the seeped liquid of garbage includes such steps as biologic treating, filtering by nano-membrane, pumping it in nano-filter system to obtain concentrated liquid and transmitted liquid, and flowing the concentrated liquid in an immersion-combustion evaporating system for concentrating and cleaning to obtain organic liquid fertilizer.

Owner:TSINGHUA UNIV

Energy-saving sintering water-permeable brick adding with coal residues

The invention discloses an energy-saving sintering water-permeable brick adding with coal residues. The energy-saving sintering water-permeable brick adding with the coal residues is prepared from, by weight, 40-43 parts of sludge of sewage treatment plants, 6-7 parts of rice husks, 4-5 parts of potash feldspar powder, 10-12 parts of fly ash, 10-12 parts of water glass, 3-4 parts of calcium fluoride, 5-6 parts of glycerin, 18-20 parts of shale, 14-16 parts of coal residues, 2.5-3.5 parts of coke powder, 1.5-2 parts of paraffin, 9-11 parts of alumina-chrome slags and 5-6 parts of calcium carbonate. According to the energy-saving sintering water-permeable brick adding with the coal residues, treated coal residue and shale mixed coarse aggregate is added, the plasticity index of a brick body can be increased, a green brick is made to be denser, and the strength and durability of the green brick are improved. According to the water-permeable brick prepared through sintering, the combustible feature of the coal residues can be utilized, coal resources are saved, and the brick is friendly to the environment; meanwhile, the energy-saving sintering water-permeable brick adding with the coal residues is good in durability, high in permeation coefficient and capable of saving energy and protecting the environment.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

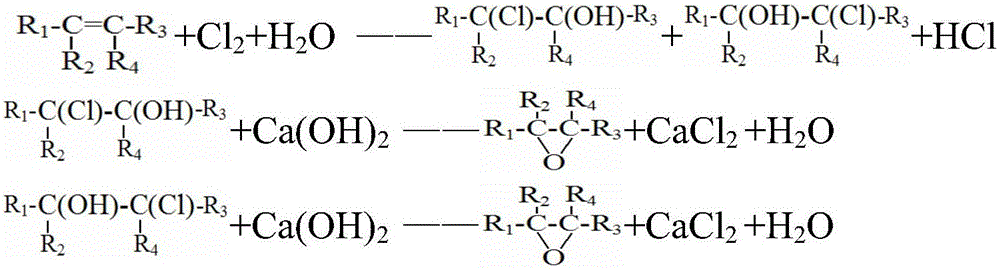

Method for preparing halogenohydrin and epoxide

ActiveCN106518624AEasily damagedSolve intractableWater contaminantsDispersed particle separationHalogenWastewater

Owner:JIANGXI SUKEER NEW MATERIAL

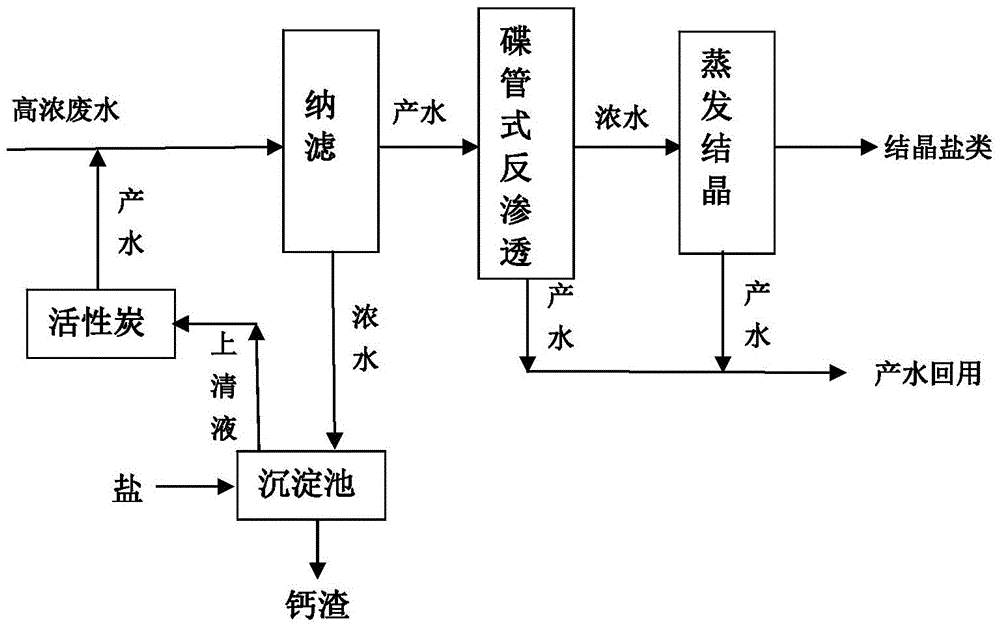

High concentration wastewater zero-emission method

ActiveCN105621769ASolve the problem of advanced treatment and even zero dischargeEasy for reverse osmosis treatmentMultistage water/sewage treatmentEnergy based wastewater treatmentHigh concentrationReverse osmosis

The present invention relates to the field of industrial wastewater treatment, and specifically relates to a high concentration wastewater zero-emission method. According to the high concentration wastewater zero-emission method, nanofiltration, disc tube reverse osmosis (dt-ro) and evaporation crystallization are used for treatment of high concentration wastewater. Firstly the nanofiltration is used for removing hardness and other multivalent ions and some organic matters in wastewater, then the disc tube reverse osmosis (dt-ro) is used for deep concentration treatment of the high concentration wastewater with the hardness and some organic matters being removed, and salt solids in concentration water are crystallized by evaporation crystallization treatment of reverse osmosis concentration water after disc tube reverse osmosis deep concentration treatment, and then are concentrated for drying treatment. The disc tube reverse osmosis producing water and the evaporation and crystallization producing water produced in the treatment process both can be reused in the production process. According to the high concentration wastewater zero-emission method, the high concentration wastewater emission problem can be solved, meanwhile the recovery of water resources is maximized, and high concentration wastewater zero-emission is basically realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

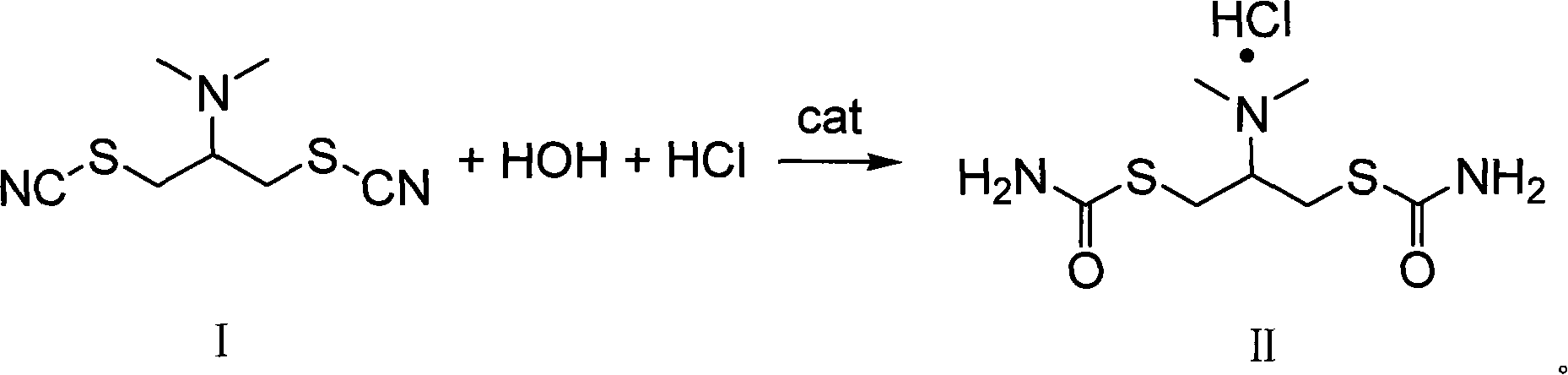

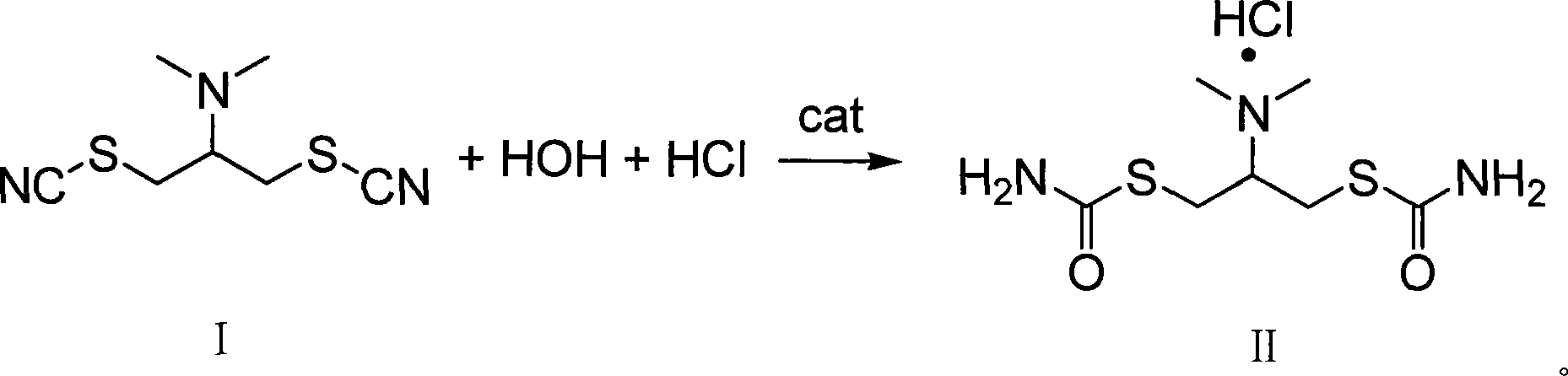

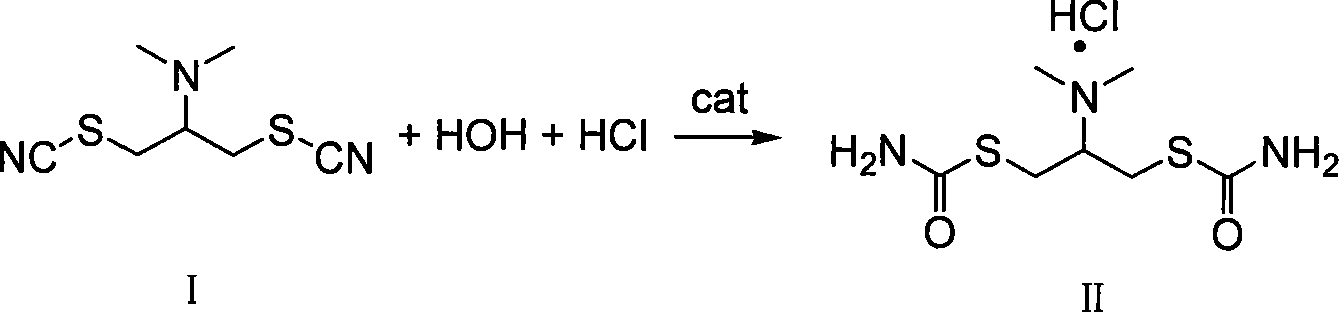

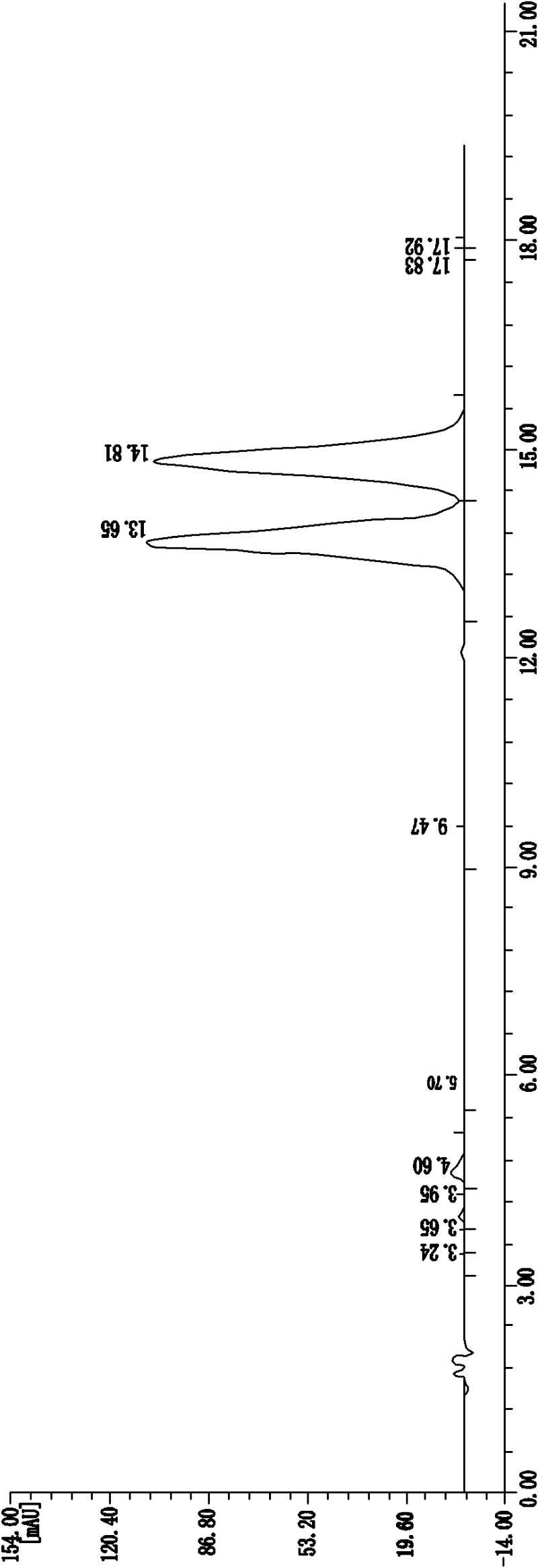

Cartap environment-friendly type preparing method

InactiveCN101103725ATaking into account the costTaking toxicity into accountBiocideOrganic chemistryAlcoholWastewater

The invention discloses an environmental protection preparation method for cartap hydrochloride; rhodanide solution, water and catalyst are arranged inside a reactor, and chlorine hydride gas is input in the reactor for hydrolysis reaction for 15 to 24 hours under -18 to 25 DEG C, so that the cartap hydrochloride can be produced. The hydrolysis processing technique of the invention firstly adopts a hydrolyst method instead of a methyl alcohol alcoholysis for solving the problems of the exhaust gas and waste water from the prior processing technique, furthermore, the hydrolysis rate can reach 95 percent, the quality stability of the cartap hydrochloride product is good, and the processing to the recovery solvent and the mother liquor has unparalleled advantages than the prior art, which fully embodies the call of nation on energy saving and pollutants discharge reduction, thereby the invention has a great social and economic efficiency.

Owner:JIANGSU TIANRONG GROUP

Manufacturing method of proPiconazole

ActiveCN102225935AEmission reductionPrecise meteringOrganic chemistryChemical recyclingPropiconazoleBromine

The invention discloses a manufacturing method of proPiconazole. The manufacturing method comprises that 2,4-dichloroacetophenone and 1,2-pentanediol undergo a cyclization reaction, and then bromine and the reaction products of the cyclization reaction undergo a bromination reaction to form 2-bromomethyl-(2,4-dichlorophenyl)-4-propyl-1,3-dioxolane. The manufacturing method is characterized in that solid heteropolyacid catalysts are utilized in the cyclization reaction, and are filtered and recycled after the cyclization reaction is finished; then the bromination reaction is caused and the 2-bromomethyl-(2,4-dichlorophenyl)-4-propyl-1,3-dioxolane, 1,2,4-triazole and potassium carbonate undergo a condensation reaction to form the proPiconazole after the bromination reaction is finished. Through the manufacturing method, new impurities which can be introduced because catalysts take part in a bromination reaction are reduced. In the invention, because a potassium triazole preparation process, a condensation reaction process and a solvent removing process are carried out simultaneously during a condensation reaction, problems of long reaction time and adhesion of 1,2,4-triazole on a kettle are solved, and a reaction time and a production cost are reduced.

Owner:山东潍坊双星农药有限公司

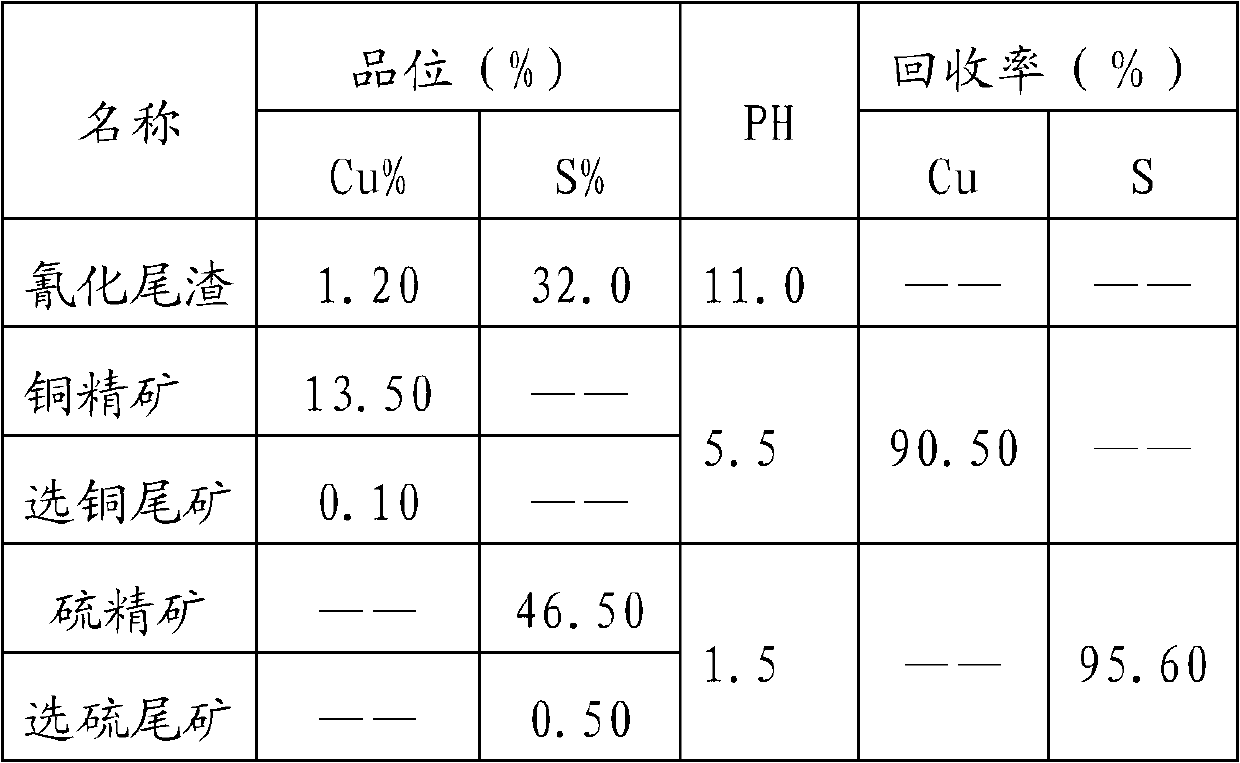

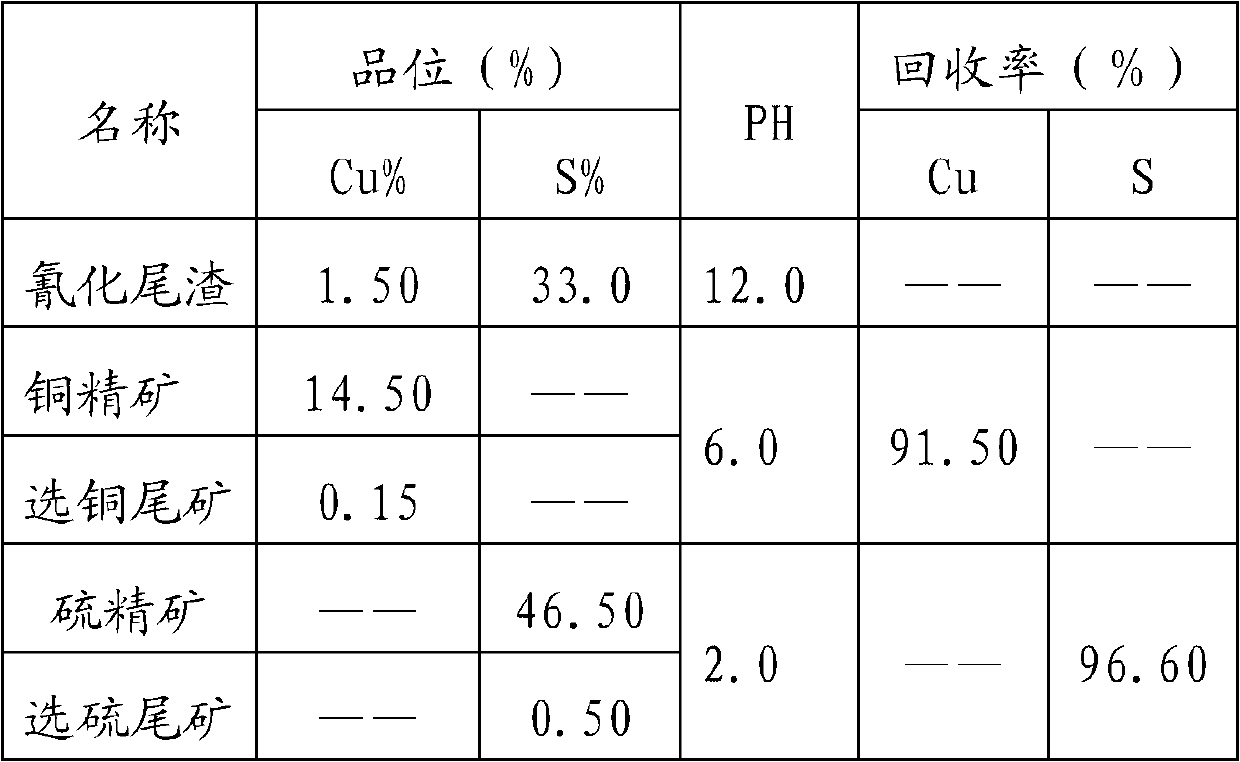

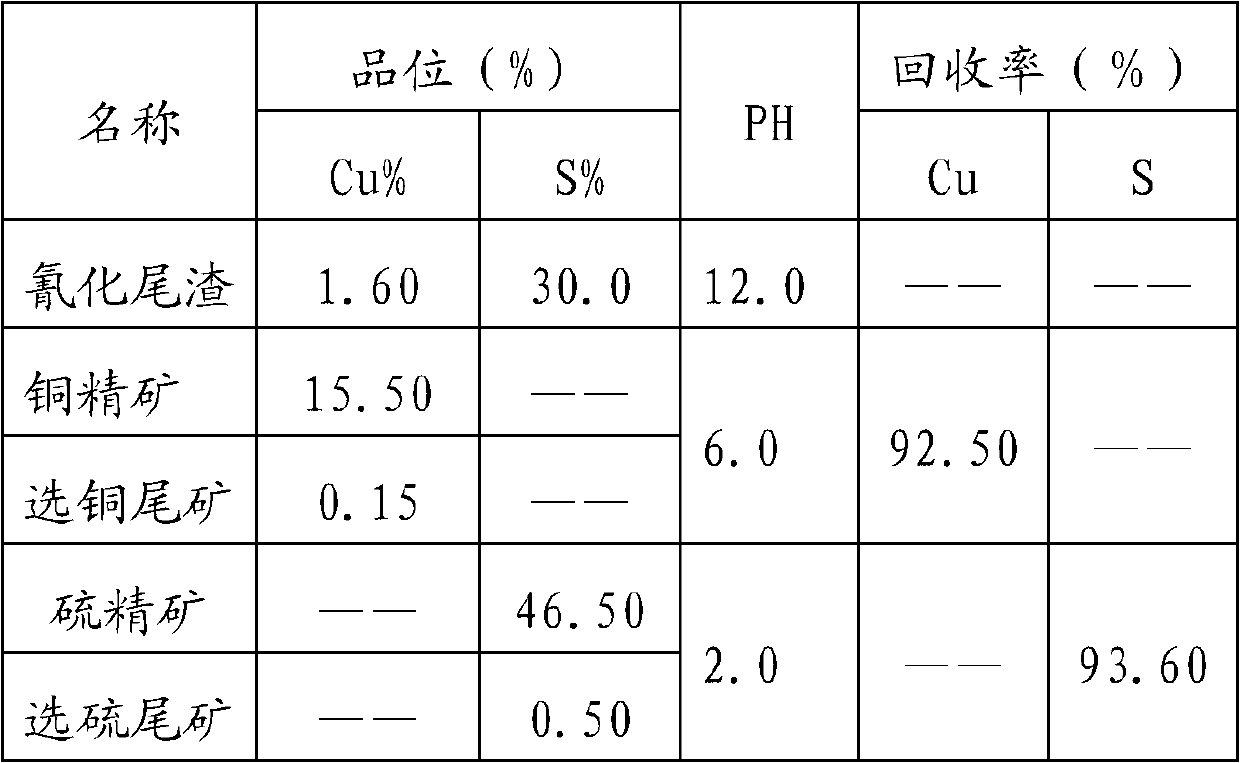

Method for circulative and comprehensive utilization of waste acids generated in acid preparation process through smoke smelting

InactiveCN102787233ASolve intractableImprove the efficiency of comprehensive recyclingSulfur-trioxide/sulfuric-acidProcess efficiency improvementChemistrySulfuric acid

The invention relates to a method for circulative and comprehensive utilization of waste acids generated in the acid preparation process through smoke smelting, and belongs to the technical fields of acid preparation through acid smelting, copper concentrate flotation from cyaniding tailings, and liquid purification of a sulfur concentrate flotation system. According to the invention, the circulative and comprehensive utilization of the waste acids generated in the acid preparation process through the smoke smelting is formed through mixing the waste acids with the cyaniding tailings to control the suitable pH value for floating copper concentrate, floating sulfur concentrate and returning a floatation system liquid to the acid preparation process through the smoke smelting. The method completely combines the comprehensive utilization of the waste acids output in the production of sulfuric acid with the comprehensive recovery technology of a plurality of elements from the cyaniding tailings, and effectively solves technical problems comprising the difficult treatment and difficult comprehensive recovery of the waste acids. The whole process flow of the method is basically circulated in a closed manner through a full wet method, so the circulative and comprehensive utilization efficiency of the waste acids is substantially improved, the zero discharge of wastewater is realized, and the pollution to the surrounding environment is reduced, thereby the economic benefits of enterprises are improved.

Owner:SHANDONG GUODA GOLD

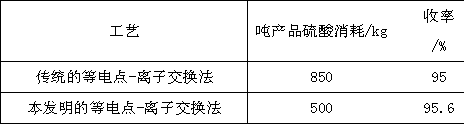

Glutamic acid separating and extracting technology

ActiveCN103224454ALow costReduce consumptionOrganic compound preparationAnimal feeding stuffIon exchangeEconomic benefits

The invention discloses a glutamic acid separating and extracting technology. The technology is characterized in that glutamic acid in the isoelectric point liquid of glutamic acid is separated and extracted through adopting an ion exchange method, an acid solution not an alkali solution is directly used to elute for generation after the ion exchange resin adsorption of the glutamic acid, and an eluate obtained after the ion exchange returns to an isoelectric operation for glutamic acid extraction. Compared with traditional technologies, the technology disclosed in the invention has the advantages of saving of a large amount of an acid and an alkali, reduction of the production cost and the environmental pollution, and economic benefit improvement.

Owner:内蒙古阜丰生物科技有限公司

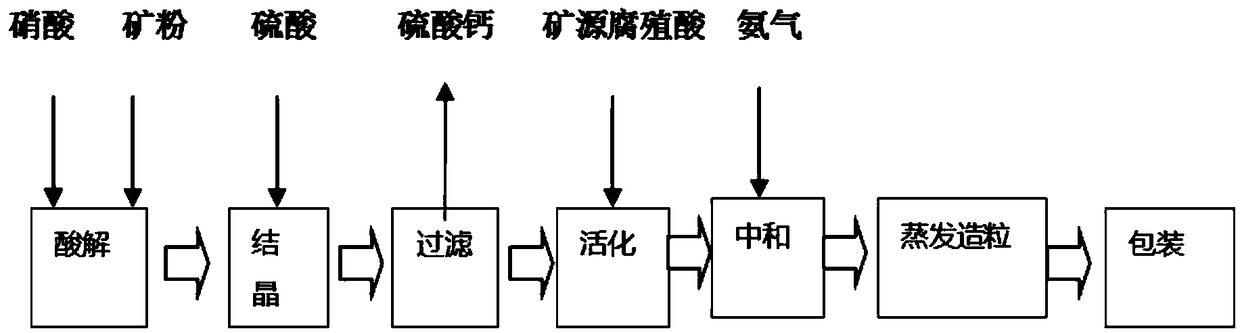

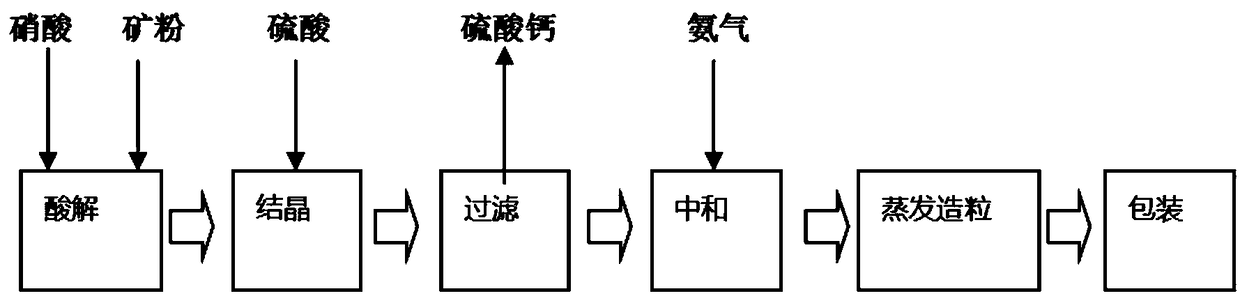

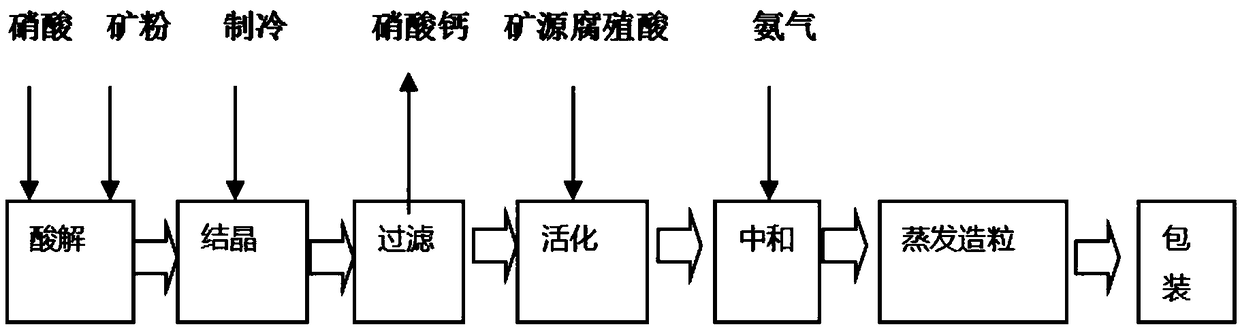

Nitryl fertilizer containing activated mineral resource humic acid and preparation method thereof

InactiveCN109485527AIncrease contentImprove solubilityCalcareous fertilisersMagnesium fertilisersPelletizingSolubility

The invention provides a nitryl fertilizer containing activated mineral resource humic acid and a preparation method thereof. The method comprises the following steps: mixing nitric acid with an inorganic mineral, dissolving the inorganic mineral, and separating insoluble substances to obtain an acidolysis liquid; adding mineral resource humic acid to the acidolysis liquid, adding excessive nitricacid for activation, adding alkali into the activated acidolysis liquid to neutralize residual nitric acid, evaporating and concentrating, pelletizing or milling powder, and drying to obtain the nitryl fertilizer. A composite fertilizer is prepared by adopting the mineral resource humic acid and the inorganic mineral, nitric acid is added for activation, and after activation, nitryl groups are added to humic acid molecules, to convert the mineral resource humic acid from large molecules to small molecules, and therefore, the content of humus is reduced, the contents of ulmic acid and fulvic acid are increased, the solubleness is improved, and the fertilizer efficiency is improved; the preparation method is improved on the basis of an original process, without increasing a too complex production line, and thus has the advantages of being convenient, simple, and easy for production.

Owner:郑利

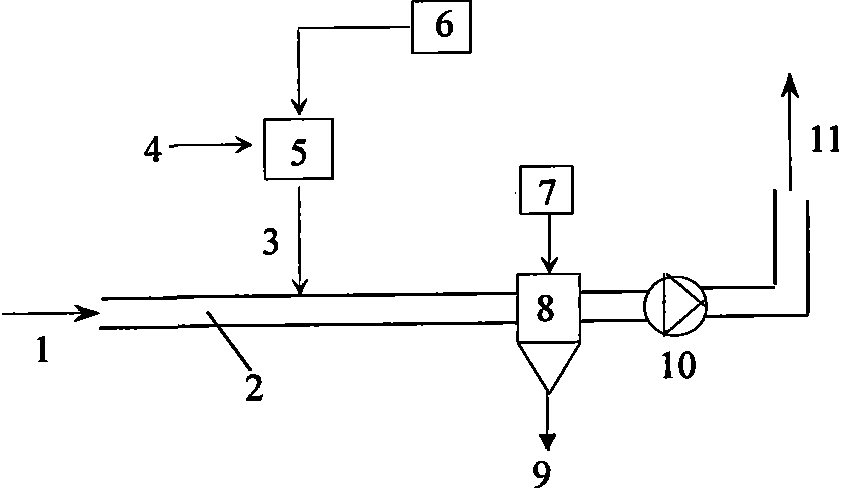

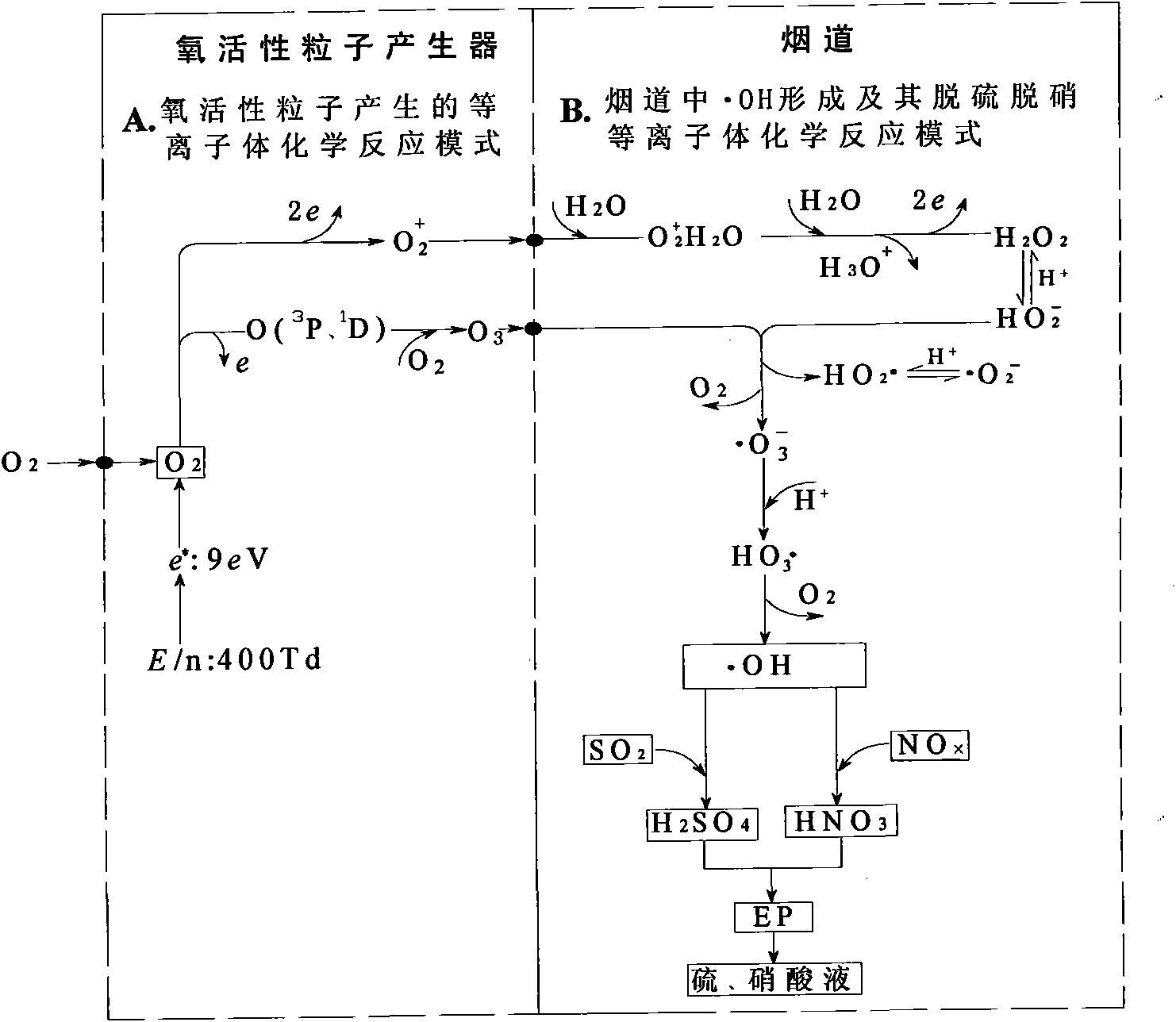

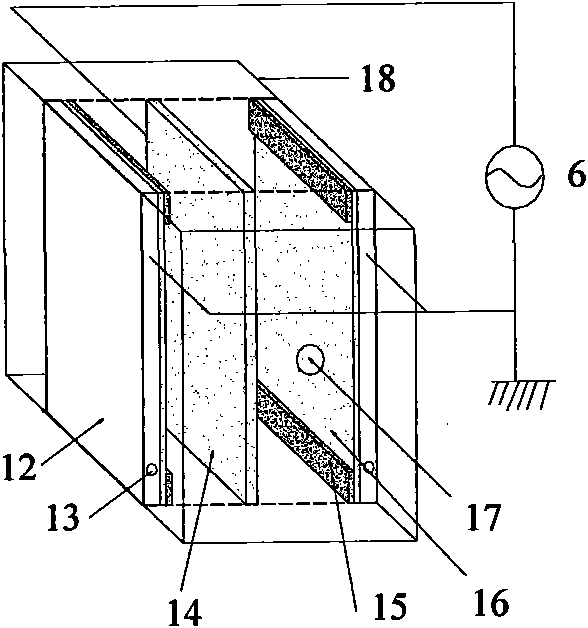

Oxidation sweetening and denitration method for hydroxyl radical of oxygen active particles injected in flue duct

InactiveCN101961596AFast chemical reactionShort processGas treatmentDispersed particle separationOxygenActive particles

The invention discloses an oxidation sweetening and denitration method for hydroxyl radical of oxygen active particles injected in a flue duct, belonging to the technical field of gas ionization discharging, plasma chemistry and environmental engineering application. The invention is characterized in that the oxygen active particles (O<2+>, O3, O(<1>D), O(<3>P)) with the concentration of 80 to 400 mg / L are injected the flue, wherein the O<2+> reacts with the H2O in the flue gas to form the HO2<->initiator, and the oxygen active particles and the HO2<->initiator are subjected to the plasma reaction to form the.OH within the reaction time of 1 mu s to 1 ms. The.OH oxidizes and removes the SO2 and the NOx in the flue gas to generate the submicron acid mist with the reaction time of 1 to 1 s, then the charge coagulation is performed to collect the mixing acid liquid, and finally the sulfuric acid and the nitric acid are separated and purified by chemical methods, wherein the acid resource recovery rate is 50 to 98%. The invention has the effects and the advantages of solving the problems of the existing desulphurization and denitration method of the flue gas, realizing the novel recycling and dry desulphurization and denitration method without using catalysts, absorbent and reducing agents, and generating any re-contaminative by-product and any negative effect to the environment.

Owner:DALIAN MARITIME UNIVERSITY

Ferro-nickel slag water permeable brick for pavements and preparation method of water permeable brick

ActiveCN104163596AEfficient resource utilizationSolve intractable problemsSolid waste managementBrickResource utilization

The invention relates to the technical field of building materials and particularly relates to a ferro-nickel slag water permeable brick for pavements and a preparation method thereof. A great deal of ferro-nickel slag is mixed into the adopted raw materials, so that the resource utilization of the ferro-nickel slag is remarkable, the treatment cost is reduced, a problem that the ferro-nickel slag is difficult to treat is effectively solved, and the environmental pollution is reduced; a modifier gypsum is introduced, so that part of a gel material can be effectively substituted by virtue of active ferro-nickel slag micro powder; by controlling the total mixing amount of the ferro-nickel slag in the water permeable brick to be over 75% and adding an activator, the breaking strength and the compressive strength as well as various indexes of the prepared ferro-nickel slag water permeable brick for pavements are guaranteed, the national comprehensive utilization industrial policy of the waste resources are fulfilled, and a great deal of the ferro-nickel slag can be treated, and thus the production cost and the energy consumption are reduced.

Owner:贵州省建筑材料科学研究设计院有限责任公司 +1

Method for producing electrolytic manganese metal by replacing partial ammonia water with manganese dregs for neutralization deironing

InactiveCN101307463ASave manganese ore consumptionHigh manganese recoveryPhotography auxillary processesSide productCarbonic acid

The invention discloses a method for producing electrolytic manganese metals by utilizing manganese residues to replace partial ammonia water for neutralization deferrization, which resolves the problems existing in western Liaoning that in the process of producing electrolytic manganese metals, because the iron content of manganese ores in western Liaoning is high, more acid leach is needed in order to achieve better yield, but in the process of neutralization, the consumption of ammonia water is too big to ensure the ammonia balance of a system. The method comprises the processes of leaching, chemical combination, purification, electrolysis and post treatment, etc., wherein during the process of leaching and chemical combination, the manganese carbonate ore powders, the manganese dioxide ore powers, the sulfuric acids and the ammonia water are used as raw materials; the method is characterized in that the manganese residues are added to replace partial ammonia water for neutralization deferrization. The method resolves the problem of the ammonia balance in the process of producing electrolytic manganese metals by western Liaoning carbonic acid manganese ores, and side products-manganese residues which are generated along with the production of manganese in our company are fully utilized, thereby saves the consumption of manganese ores, improving the recover rate of manganese, simultaneously saving the consumption of ammonia water and lowering product cost.

Owner:CITIC JINZHOU METAL +1

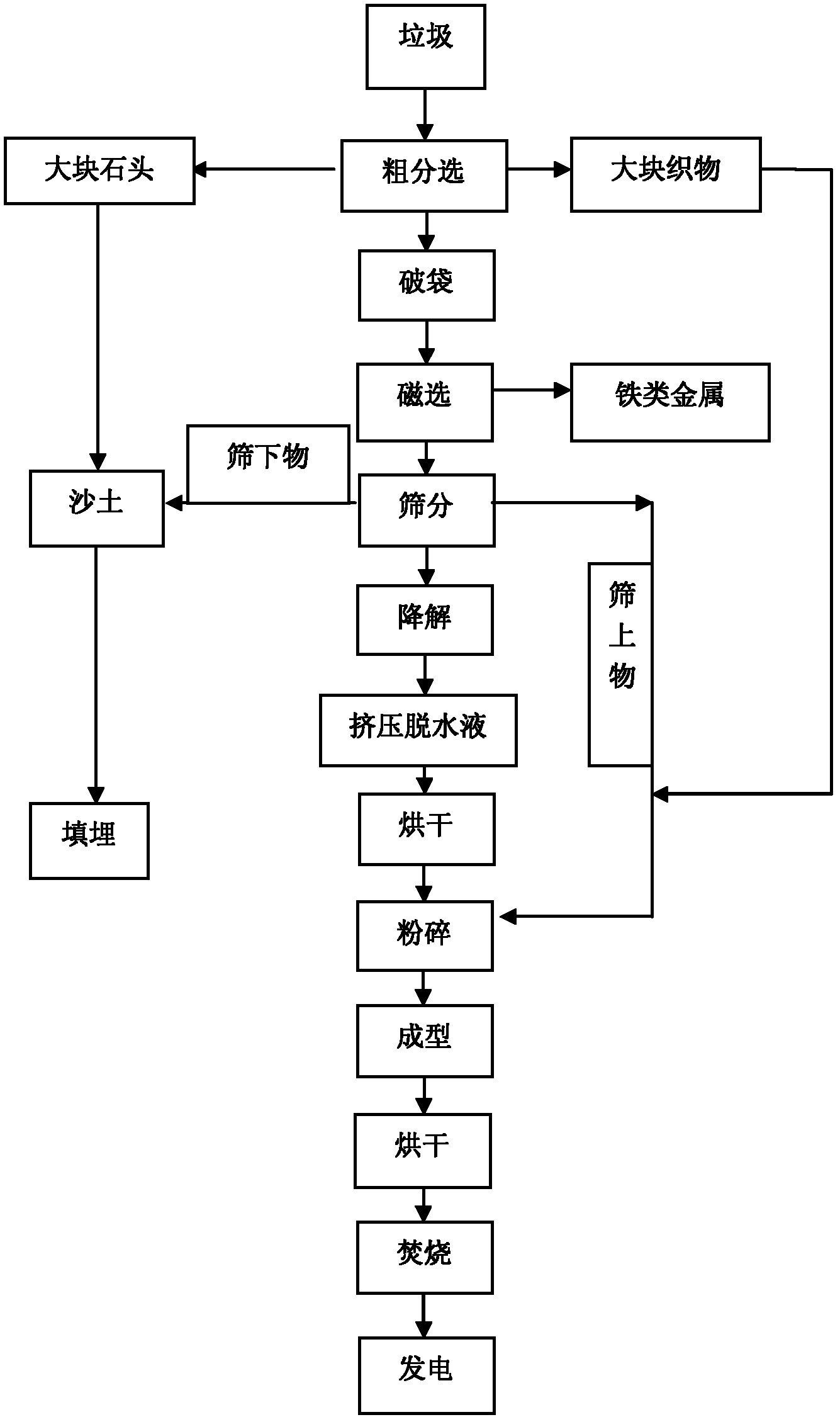

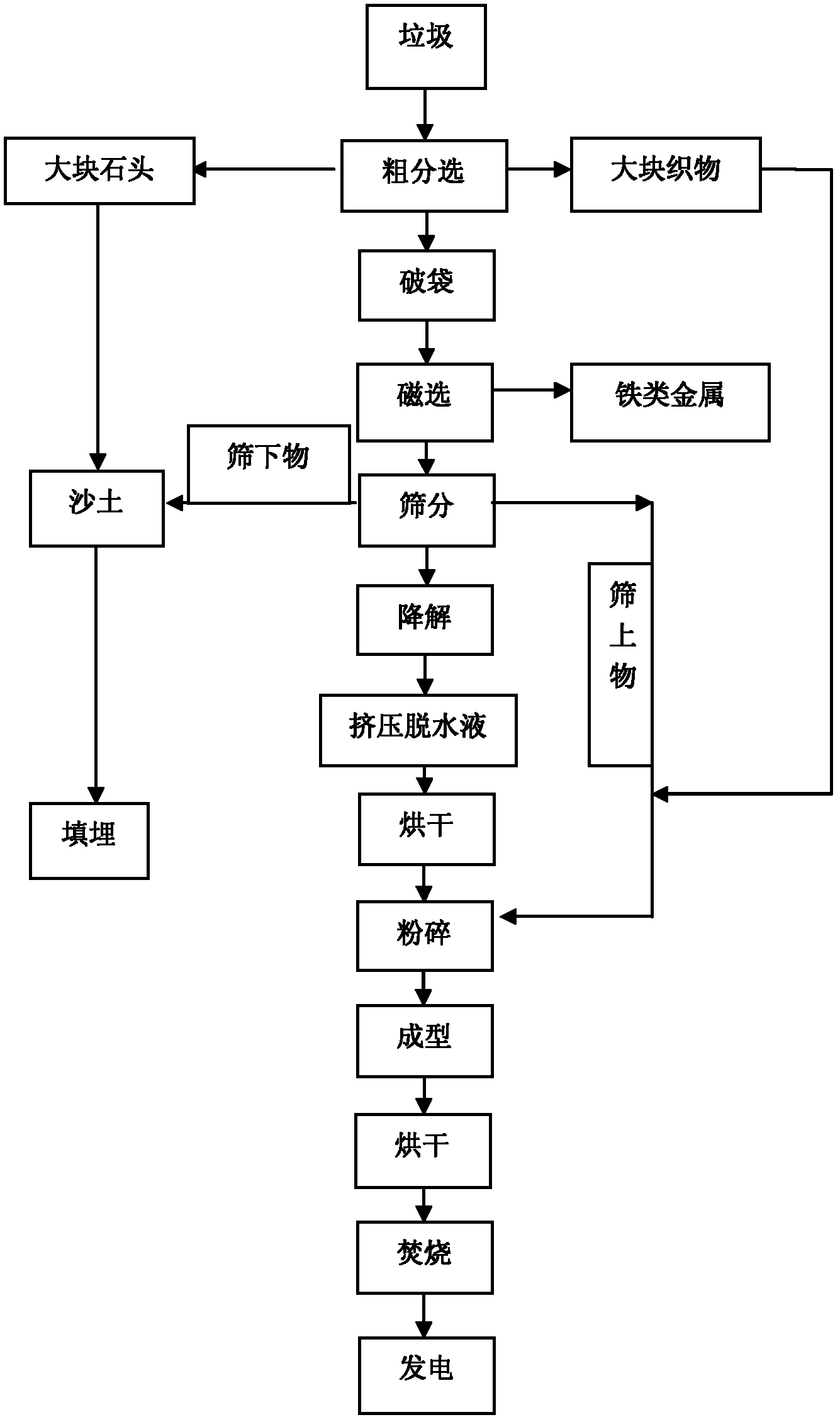

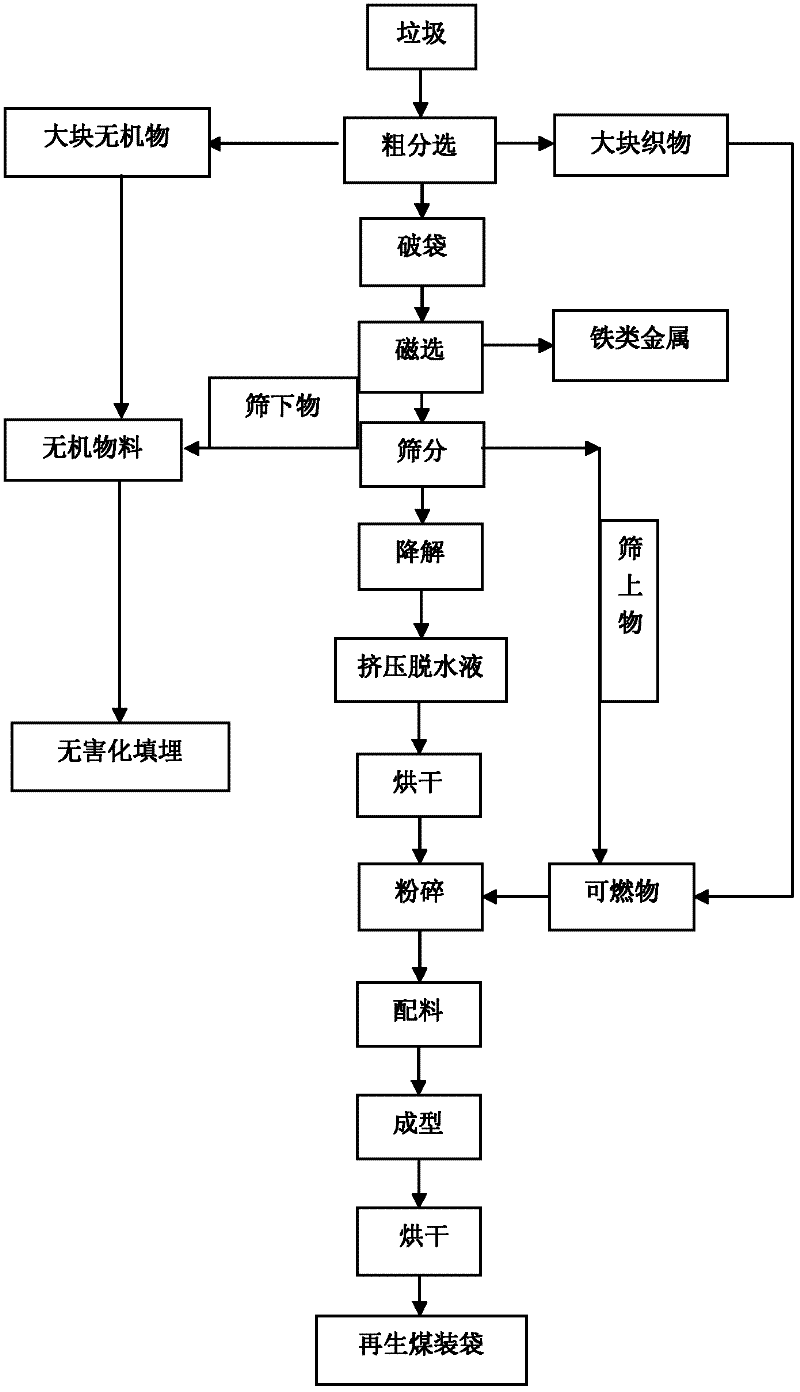

High-efficiency incineration power generation system for municipal solid waste

A high-efficiency incineration power generation system for municipal solid waste, comprising the following steps: (1) rough separation; (2) breaking the plastic bag to disperse the internal materials; (3) magnetic separation, separating ferrous metals ; (4) Screening; the material under the screen (sand) is harmlessly landfilled, and the material on the screen is directly crushed; (5) degradation, the material in the screen is degraded, (6) extrusion dehydration; (7) drying (8) crushing; (9) molding; (10) incineration; (11) power generation; slag can be made into burn-free bricks. The invention not only solves the problem that municipal solid waste is difficult to handle, but also turns it into a renewable fuel block with high calorific value, which becomes a new energy source, has small investment and occupied area, short processing cycle and low operating cost.

Owner:TIANJIN DEWEI ENVIRONMENTAL PROTECTION ENG EQUIP

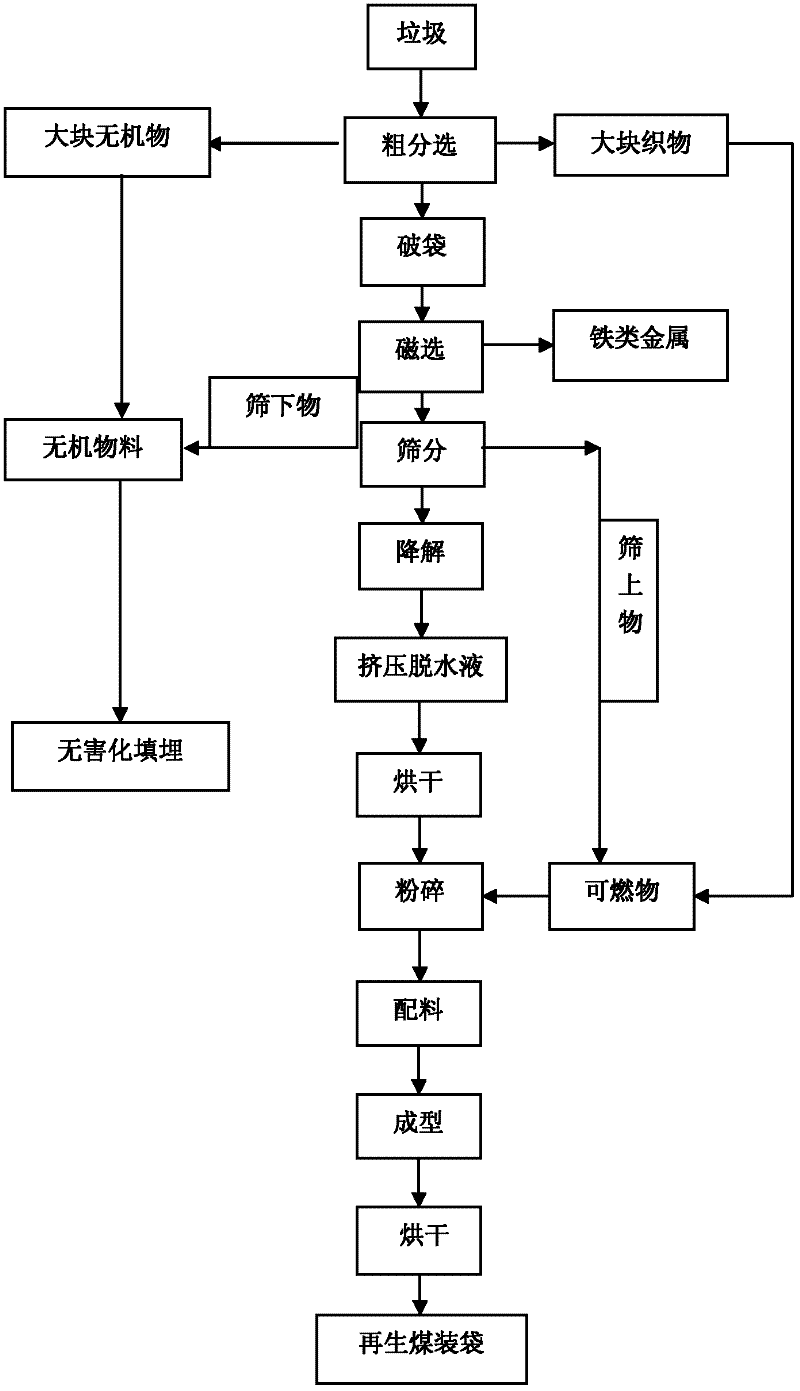

Method of preparing regenerated coal from municipal solid waste

InactiveCN102311833ANo secondary pollutionStable combustionSolid waste disposalBiofuelsFossil fuelCoal

Provided is a novel method of preparing regenerated coal from municipal solid waste. The method comprises the following steps: (1) crude sorting; (2) bag break; (3) magnetic separation; (4) screening; (5) degradation; (6) extruding dehydration; (7) drying; (8) crushing; (9) preparation of materials; (10) molding; (11) drying; (12) packaging of regenerated coal. The invention enables the problem of difficult disposal of municipal solid waste to be solved and the regenerated coal to be prepared from the municipal solid waste, and the regenerated coal has the advantages of a high heat value, no secondary pollution and stable combustion, thereby realizing resource utilization; the regenerated coal can be used to substitute fossil fuels, thereby enabling a great amount of national resources to be saved and actually turning the waste into the valuable; the method provided in the invention has the advantages of small investment and occupied land area, a short treating period and low operational cost.

Owner:TIANJIN DEWEI ENVIRONMENTAL PROTECTION ENG EQUIP

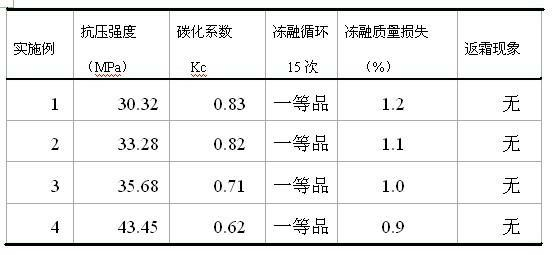

Red-mud non-fired non-steamed paving brick and preparation method thereof

The invention discloses a red-mud non-fired non-steamed paving brick and a preparation method thereof. The red-mud non-fired non-steamed paving brick is prepared by raw materials: by weight, 30-65 parts of red mud, 0-30 parts of coal ash, 2-25 parts of cement, 12-20 parts of aggregate and 1-5 parts of modifier. The red-mud non-fired non-steamed paving brick has the advantages that the raw materials are mixed with a large quantity of industrial slag, and the problem that the industrial slag is difficult to be disposed is effectively solved, 2, the modifier is mixed, and the problem of return frosting of a non-fired red-mud product is effectively solved, and 3, a small amount of cement is introduced, accordingly, total mixture of the industrial slag such as the red mud, the coal ash and thelike in the non-fired non-steamed paving brick is higher than 60%, a large amount of industrial slag can be consumed, cost is low, and energy consumption is saved. Various indexes of the produced red-mud non-fired non-steamed paving brick can achieve and meet specified national standards of paving bricks.

Owner:贵州省建筑材料科学研究设计院有限责任公司 +1

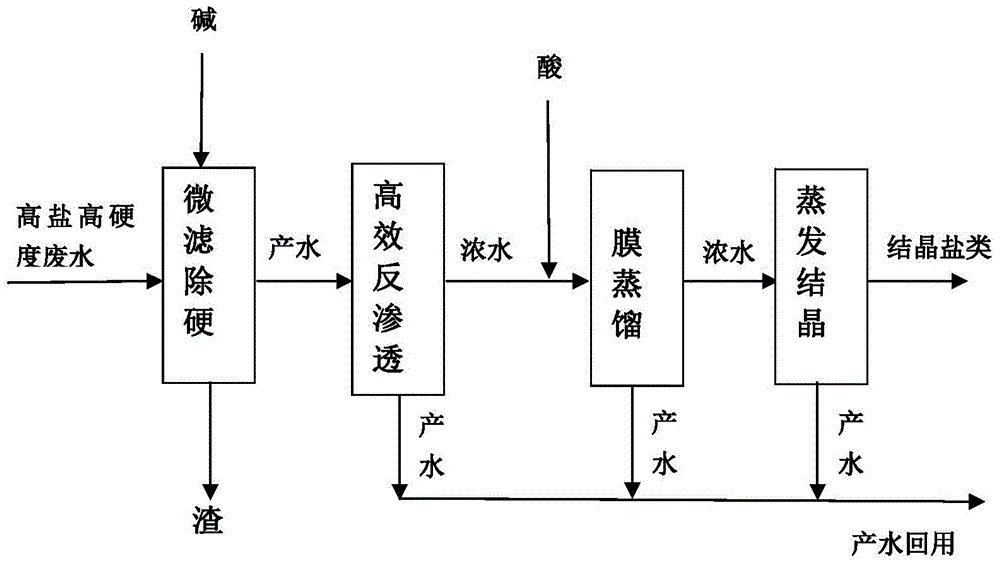

High-salinity high-hardness wastewater zero-discharging method

ActiveCN105198144AAchieving zero emissionsGuarantee continuous and stable operationMultistage water/sewage treatmentReverse osmosisWater resources

The invention relates to the field of industrial wastewater treatment, in particular to a high-salinity high-hardness wastewater zero-discharging method. According to the method, a 'microfiltration and hardness removal + efficient reverse osmosis + membrane distillation + evaporative crystallization' method is adopted to treat high-salinity high-hardness wastewater. Firstly, a microfiltration and hardness removal technology is adopted to remove hardness of the high-salinity high-hardness wastewater, then an efficient reverse osmosis technology is adopted to further concentrate the wastewater without hardness so as to obtain efficient reverse osmosis producing water and efficient reverse osmosis concentrated water, deep concentration is conducted on the efficient reverse osmosis concentrated water through membrane distillation to obtain membrane-distillation producing water and membrane-distillation concentrated water, evaporative crystallization treatment is further conducted on the membrane-distillation concentrated water to enable salt solids in the concentrated water to crystallize out, and centralized drying disposal is performed. The efficient reverse osmosis producing water, the membrane-distillation producing water and evaporative-crystallization producing water produced in the treating process can be reused for a production process, water resources are recycled to the most degree while the problem of wastewater discharging is solved, and zero discharging of high-salinity high-hardness wastewater is basically achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hardened cement body dirt cleaning agent and usage method thereof

InactiveCN104804906AOvercome erosion damageEasy to cleanSurface-active non-soap compounds and soap mixture detergentsCleaning using liquidsChemical reactionCleansing Agents

The invention belongs to the technical field of chemical cleaning, and particularly relates to a hardened cement body dirt cleaning agent and a usage method thereof. The cleaning agent comprises raw materials as follows: water, glycolic acid, oxalic acid, a surfactant, a corrosion inhibitor, a penetrating agent, a scaling inhibitor, a rust inhibitor, a coloring agent and a thickening agent. The cleaning agent is sprayed onto thin-layer hardened cement body dirt and can quickly penetrate into the hardened cement body dirt to have chemical reactions and form fluffy substances, the cementing force of cement is decreased, and the hardened cement body dirt can be easily removed when washed with clear water after a period of time. The cleaning agent has the outstanding characteristics that the cleaning agent is non-toxic, harmless, capable of avoiding corrosion to base body materials such as metal equipment and the like, low in harm to operators and the like, can be widely applied to cleaning of house wall surface cement dirt, hardened cement body dirt on experimental equipment or cement stains on articles for daily use and the like, and has good economic benefit and environmental benefit.

Owner:TONGJI UNIV

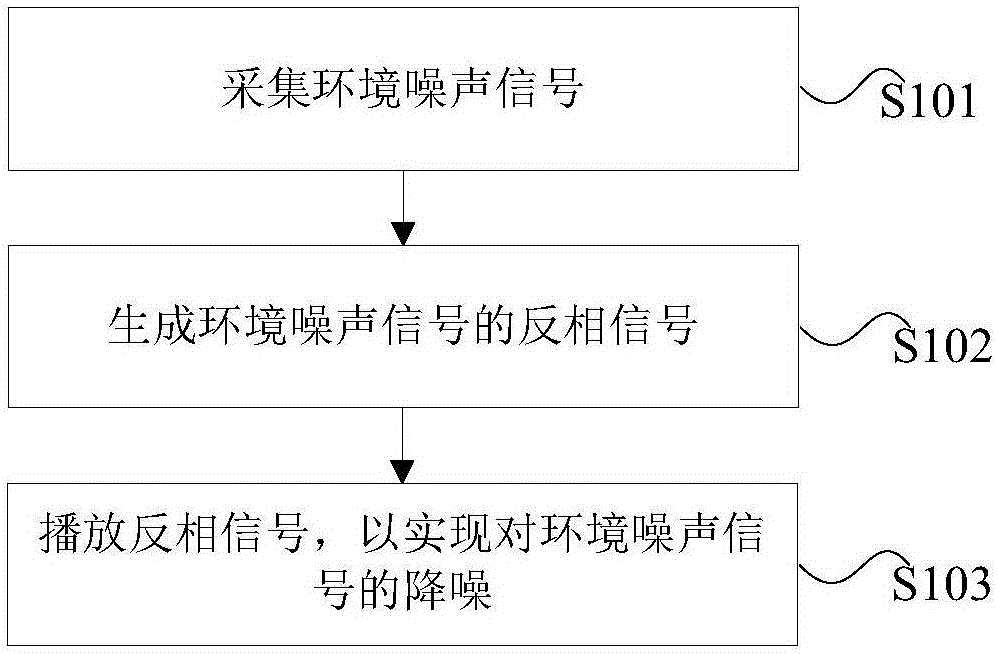

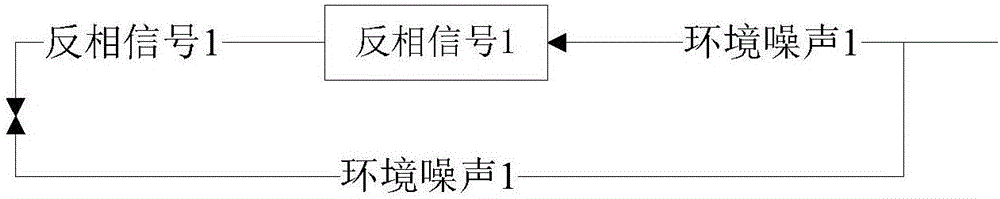

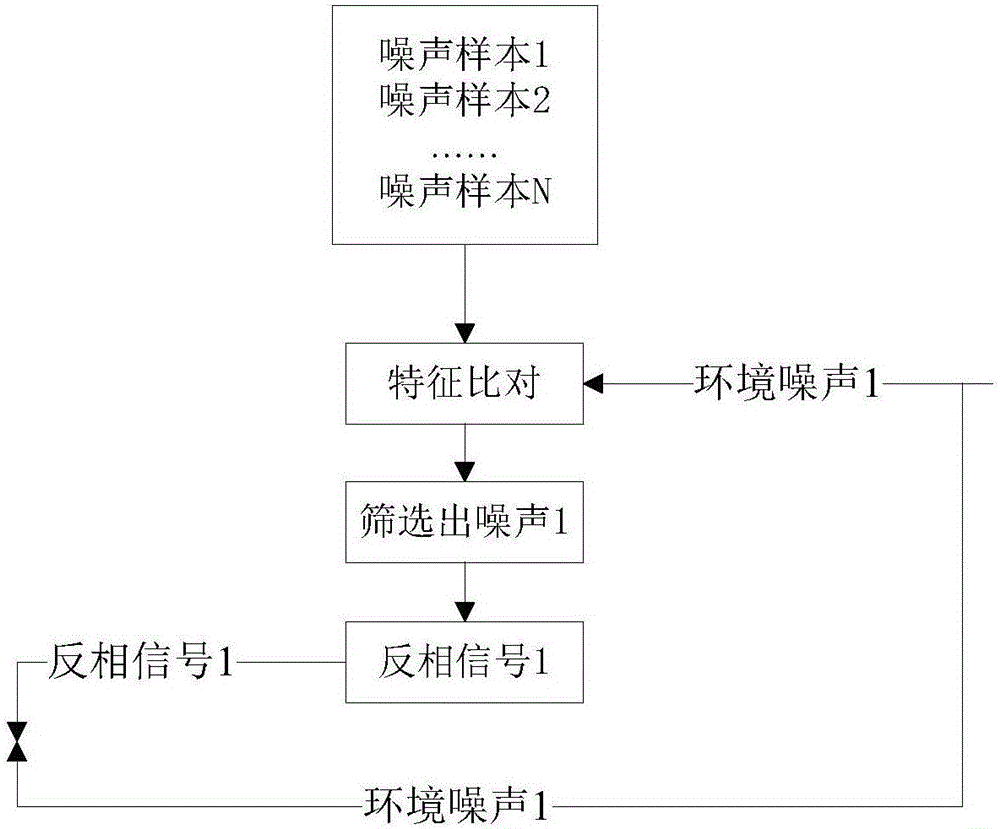

Denoising method and device

InactiveCN106303783AAchieve noise reductionSolve intractable problemsEarpiece/earphone noise reductionEnvironmental noiseEngineering

The invention provides a denoising method and device. The method comprises the steps of collecting environment noise signals; generating inversion signals of the environment noise signals; and playing the inversion signals, thereby denoising the environment noise signals. Through application of the method and the device, the problem that environment noise is difficult to eliminate is solved, and the environment noise is denoised.

Owner:BEIJING JINRUIDELU TECH

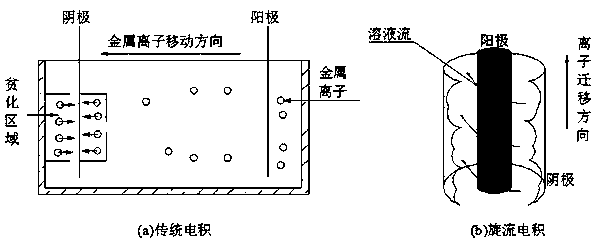

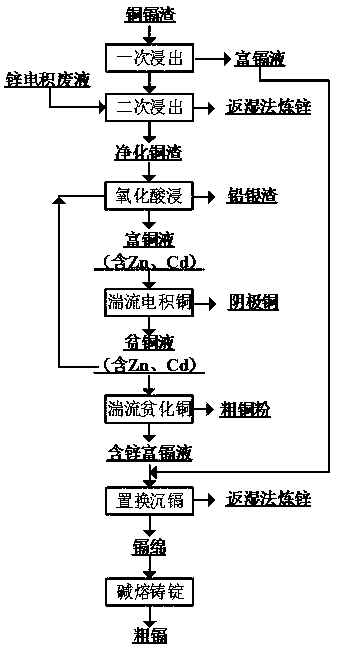

Method for recovering valuable metals from copper-cadmium slag of zinc hydrometallurgy

ActiveCN107557589AEfficient recyclingRealize resourceful and harmlessPhotography auxillary processesProcess efficiency improvementPressure oxidationZinc

The invention relates to a method for recovering valuable metals from copper-cadmium slag of zinc hydrometallurgy, and belongs to the technical field of zinc hydrometallurgy in nonferrous metallurgy.The method comprises the following steps: primary leaching is carried out on the copper-cadmium slag to obtain a cadmium-rich solution and primary leaching slag; the obtained primary leaching slag issubjected to secondary leaching with a zinc electrodeposition waste solution as a leaching solution to obtain purified copper slag and a secondary leaching solution; normal-pressure oxidation acid leaching is carried out on the purified copper slag to obtain lead-silver slag and a copper-rich solution containing Zn and Cd; turbulence electrodeposition is carried out on the obtained copper-rich solution containing Zn and Cd, metal copper can be produced at a cathode after the turbulence electrodeposition, and a residual solution obtained after the electrodeposition is a copper-poor solution containing Zn and Cd; a part of the copper-poor solution containing Zn and Cd can be returned to the normal-pressure oxidation acid leaching process, and after active copper powder is added into the other part of the copper-poor solution containing Zn and Cd for precipitation and filtration, turbulence electrodeposition is carried out to obtain crude copper powder and a zinc-containing cadmium-rich liquid with the copper content no more than 2g / L; and finally, zinc powder replacement and alkali fusion casting are carried out to obtain a crude cadmium ingot. According to the method, the storage problem of the copper-cadmium slag as dangerous waste is solved.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com