Hydrochloric acid pickling waste liquid resource integrated utilization method for preparing iron oxide and ammonium sulfate

A technology of pickling waste liquid and iron oxide, which is applied in chemical instruments and methods, iron oxide, ammonium sulfate, etc., can solve the problems of increasing production costs, difficult application of harmless treatment, and increasing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

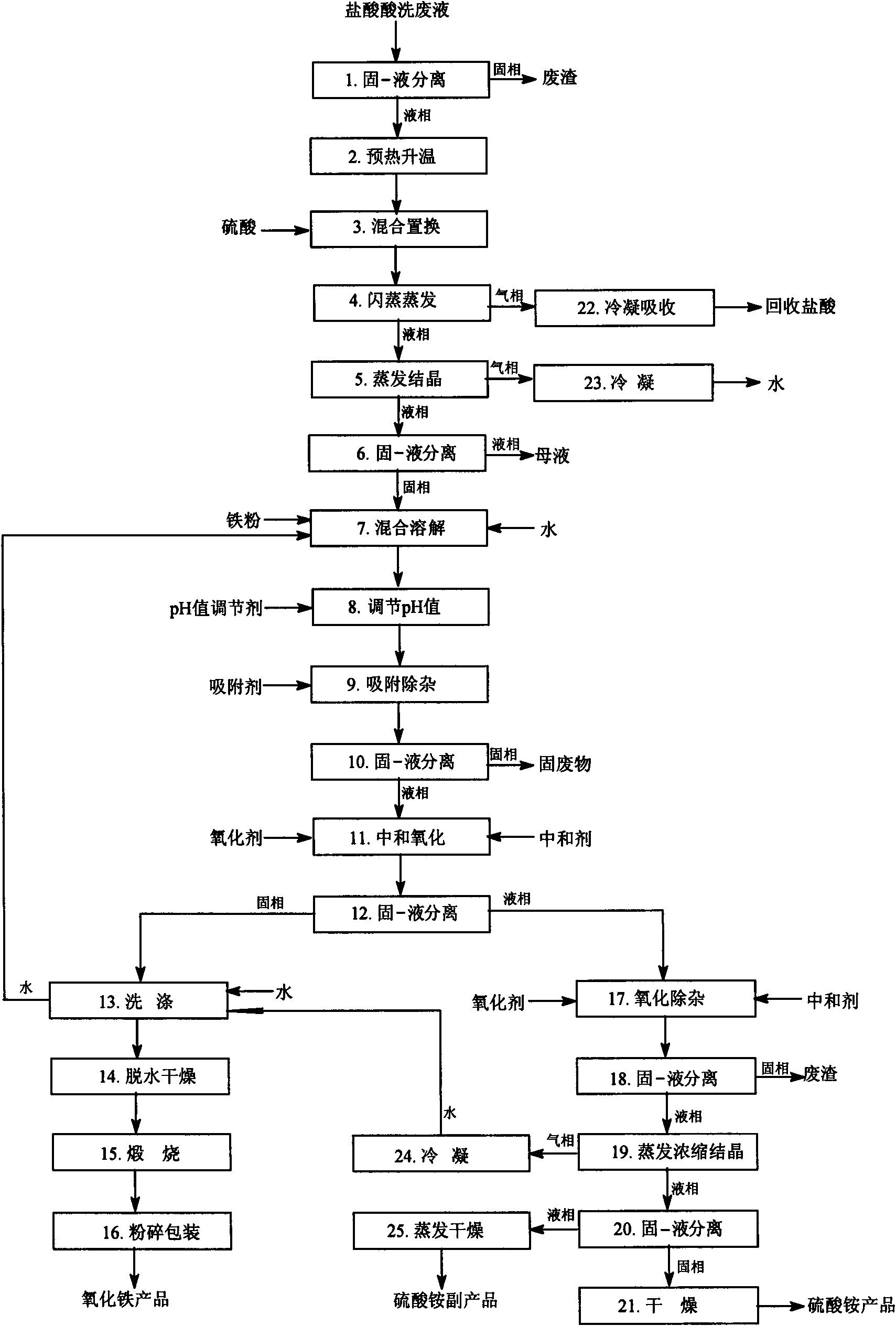

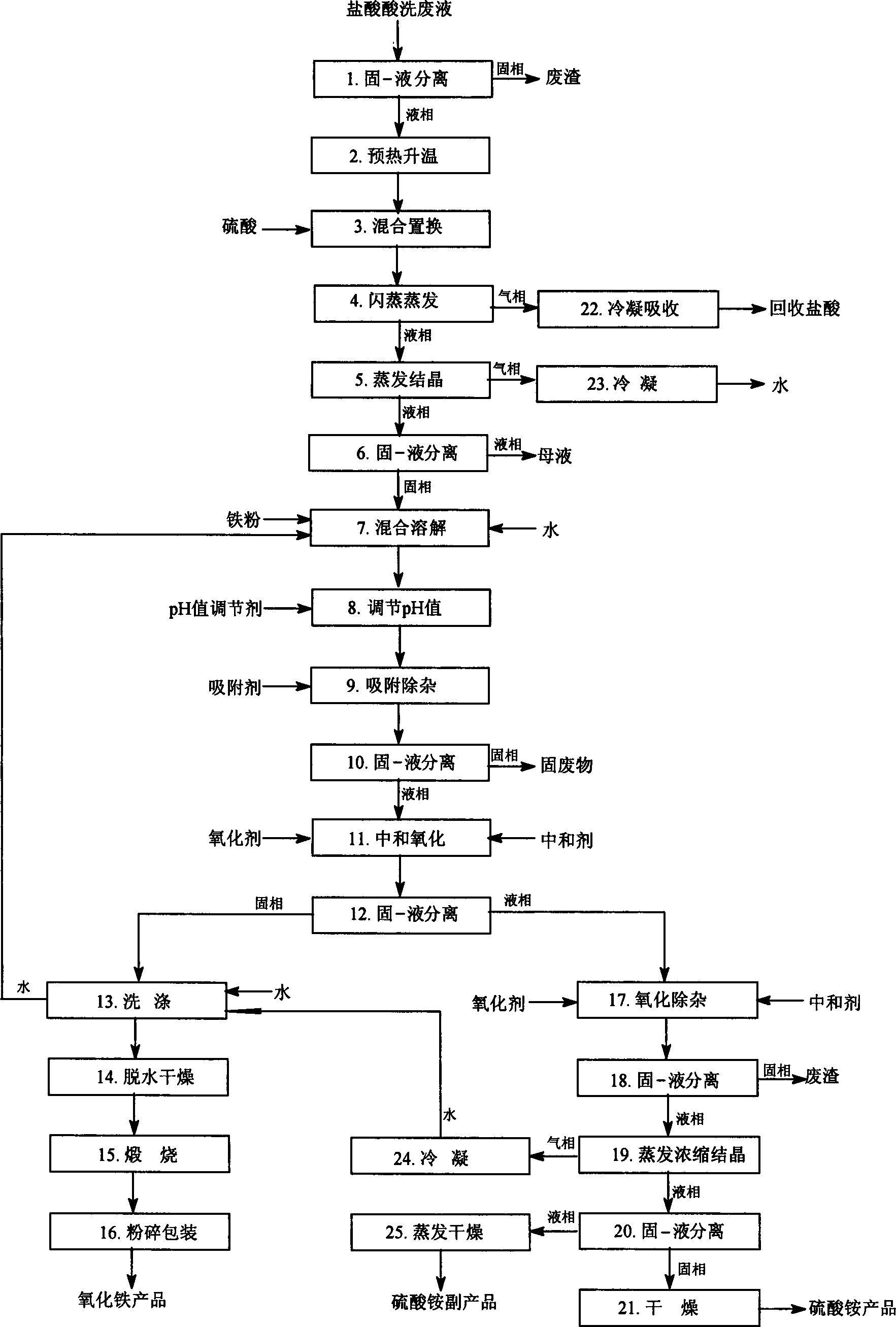

Image

Examples

Embodiment 1

[0070] The main process equipment is static mixer, indirect heat exchanger, decompression flash evaporation equipment, mixing and dissolving equipment, neutralization oxidation reaction equipment, oxidation impurity removal reaction equipment, heat pump evaporation crystallization equipment, sedimentation type solid-liquid separation device, filter type Solid-liquid separation device, dehydration drying equipment, etc.

[0071] A method for preparing ferric oxide and ammonium sulfate by utilizing hydrochloric acid pickling waste as a resource and comprehensively utilizing hydrochloric acid solution as the pickling solution to pickle iron and steel components to remove iron-containing hydrochloric acid pickling in the process of removing surface oxides Waste liquid is used as raw material, and the method for preparing ferric oxide and ammonium sulfate by comprehensive utilization of resources is carried out, and the steps of the method are as follows:

[0072] (1) Solid-liquid ...

Embodiment 2

[0094] The main process equipment is tubular mixer, indirect heat exchanger, decompression flash evaporation equipment, mixing and dissolving equipment, neutralization oxidation reaction equipment, oxidation impurity removal reaction equipment, heat pump evaporation crystallization equipment, centrifugal solid-liquid separation device, filtration Type solid-liquid separation device, dehydration drying equipment, etc.

[0095] A method for preparing ferric oxide and ammonium sulfate by utilizing hydrochloric acid pickling waste as a resource and comprehensively utilizing hydrochloric acid solution as the pickling solution to pickle iron and steel components to remove iron-containing hydrochloric acid pickling in the process of removing surface oxides Waste liquid is used as raw material, and the method for preparing ferric oxide and ammonium sulfate by comprehensive utilization of resources is carried out, and the steps of the method are as follows:

[0096] (1) Solid-liquid se...

Embodiment 3

[0118] The main process equipment is static mixer, indirect heat exchanger, decompression flash evaporation equipment, mixing and dissolving equipment, neutralization oxidation reaction equipment, oxidation impurity removal reaction equipment, heat pump evaporation crystallization equipment, filter type solid-liquid separation device, blade type Solid-liquid separation device, dehydration drying equipment, etc.

[0119] A method for preparing ferric oxide and ammonium sulfate by utilizing hydrochloric acid pickling waste as a resource and comprehensively utilizing hydrochloric acid solution as the pickling solution to pickle iron and steel components to remove iron-containing hydrochloric acid pickling in the process of removing surface oxides Waste liquid is used as raw material, and the method for preparing ferric oxide and ammonium sulfate by comprehensive utilization of resources is carried out, and the steps of the method are as follows:

[0120] (1) Solid-liquid separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com