A photoelectrochemical detection method for sulfur dioxide

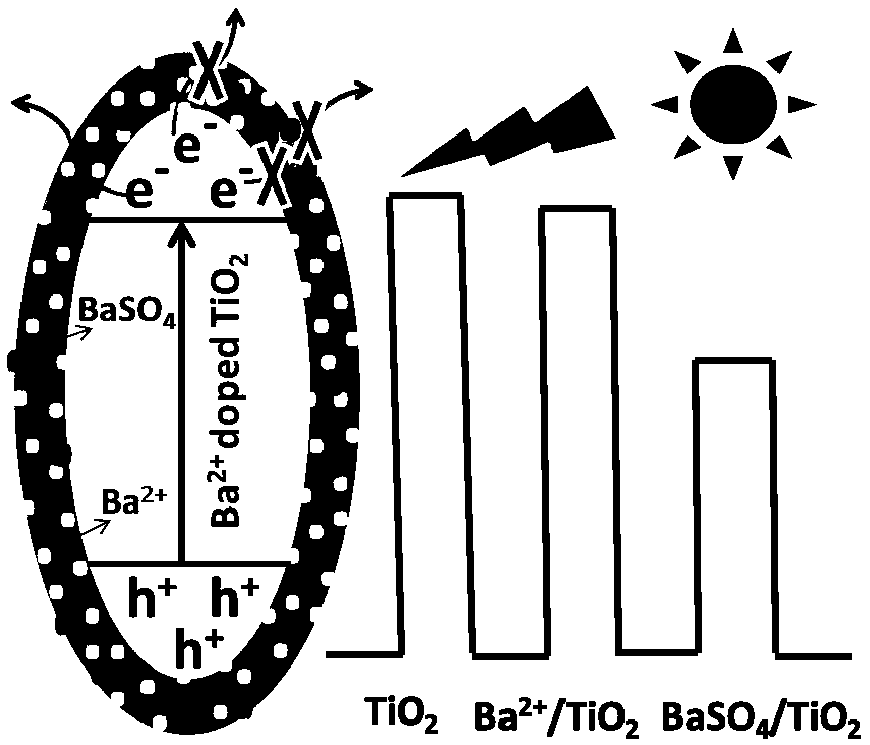

A photoelectrochemical and sulfur dioxide technology, applied in the field of analysis and testing, can solve the problems of electrochemical sensor devices such as changes in the morphology and stability of metal oxides, sensors that cannot withstand high temperatures, instability and easy degradation, etc., to promote effective separation and low cost , The effect of improving the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

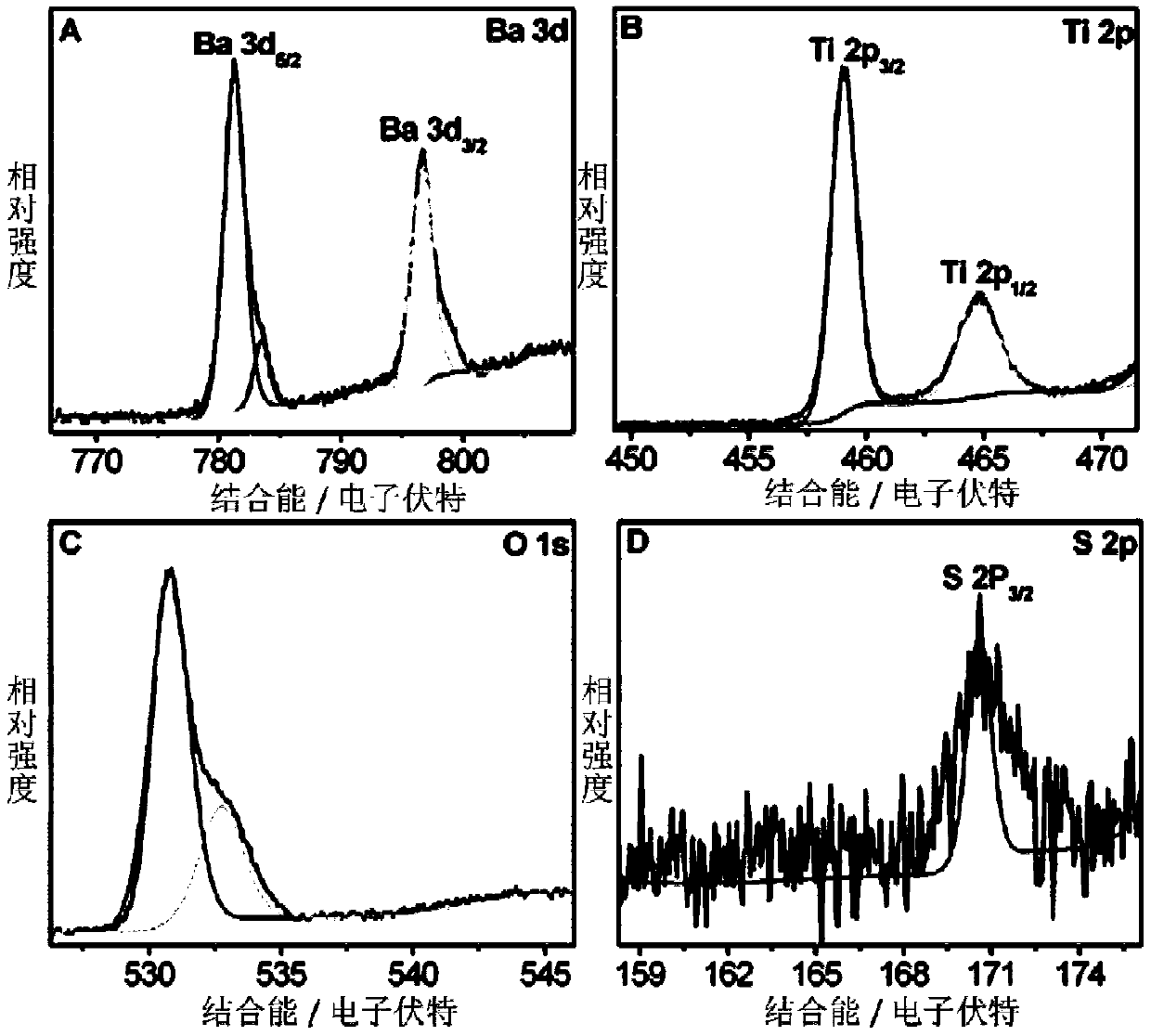

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: a kind of photoelectrochemical detection method of sulfur dioxide, comprises the steps:

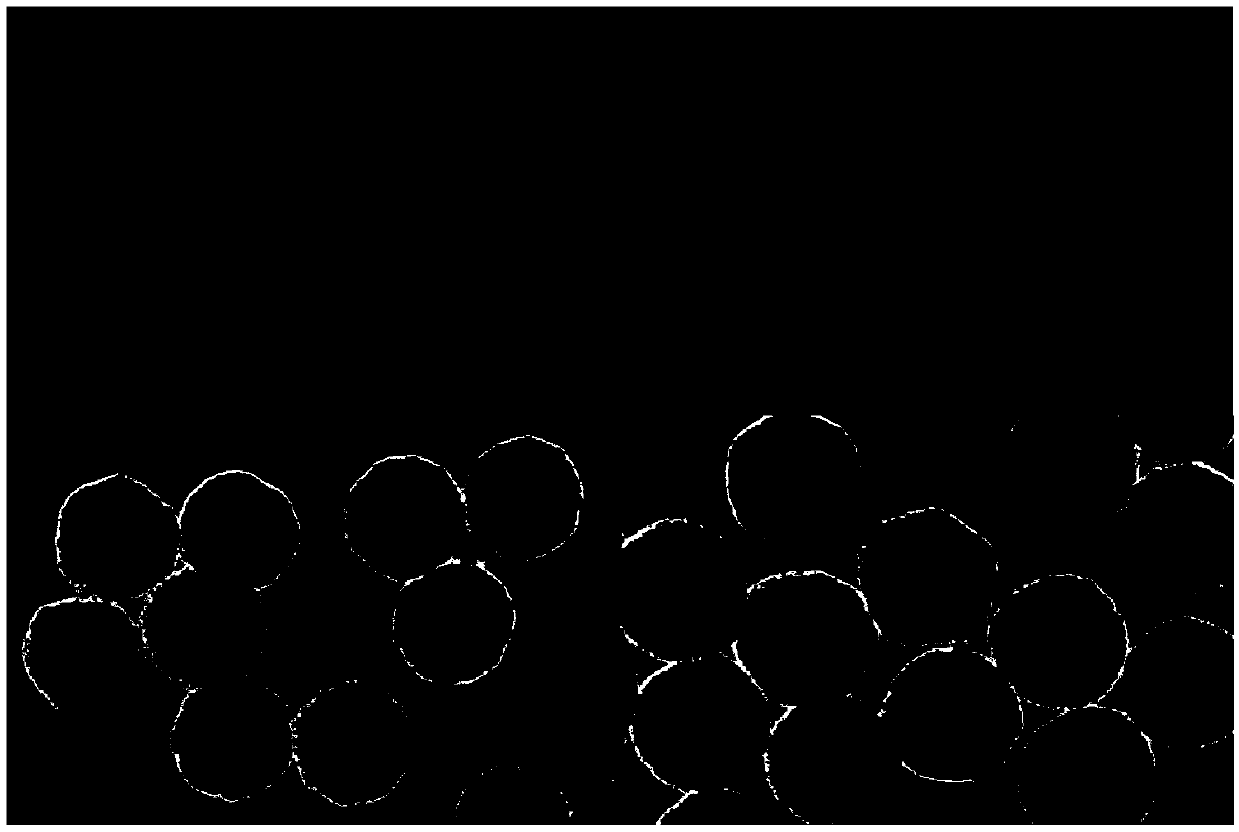

[0051] (1) Synthesis of SiO 2 Microspheres: Add 3.2 ml of 99% tetraethyl orthosilicate to 105 ml of absolute ethanol, 8.5 ml of water and 2.68 ml of 26% ammonia, and stir magnetically at room temperature for 4 hours, then use anhydrous Ethanol was centrifuged and washed three times and stored in 20 ml of absolute ethanol;

[0052] (2) Preparation of SiO 2 @TiO 2 Core-shell microspheres: the prepared 4 ml SiO 2 Disperse the microspheres in a mixed solution consisting of 50 mg of 10 ml of absolute ethanol, 8 ml of acetonitrile and 0.1 ml of 26% ammonia water and stir for 8 minutes; then add tetrabutyl titanate that has been dispersed with 4 ml of absolute ethanol ester, and stirred for 1.5 hours, and then were dispersed in 15 ml of water after washing with ethanol and water respectively twice;

[0053] (3) Preparation of hollow spherical nano-TiO 2 : 15 ml of SiO ...

Embodiment 2

[0058] Embodiment 2: a kind of photoelectrochemical detection method of sulfur dioxide, comprises the steps:

[0059] (1) Synthesis of SiO 2 Microspheres: Add 4.2 ml of 99% tetraethyl orthosilicate to 115 ml of absolute ethanol, 9.5 ml of water and 3.68 ml of 26% ammonia, stir magnetically at room temperature for 5 hours, then use anhydrous Ethanol was centrifuged and washed three times and stored in 30 ml of absolute ethanol;

[0060] (2) Preparation of SiO 2 @TiO 2 Core-shell microspheres: 5 ml of prepared SiO 2 Disperse the microspheres in a mixed solution consisting of 60 mg of 15 ml of absolute ethanol, 10 ml of acetonitrile and 0.2 ml of 26% ammonia water and stir for 10 minutes; then add tetrabutyl titanate that has been dispersed with 5 ml of absolute ethanol ester, and stirred for 2 hours, and then were dispersed in 20 ml of water after washing with ethanol and water respectively for 3 times;

[0061] (3) Preparation of hollow spherical nano-TiO 2 : 20 ml of SiO...

Embodiment 3

[0066] Embodiment 3: a kind of photoelectrochemical detection method of sulfur dioxide, comprises the steps:

[0067] (1) Synthesis of SiO 2 Microspheres: Add 5.2 ml of 99% tetraethylorthosilicate to 135 ml of absolute ethanol, 10.5 ml of water and 4.68 ml of 26% ammonia, stir magnetically at room temperature for 6 hours, then use anhydrous Ethanol was centrifuged and washed three times and stored in 40 ml of absolute ethanol;

[0068] (2) Preparation of SiO 2 @TiO 2 Core-shell microspheres: Prepare 6 ml of SiO 2 Disperse the microspheres in a mixed solution consisting of 70 mg of 20 ml of absolute ethanol, 15 ml of acetonitrile and 0.3 ml of 26% ammonia water and stir for 15 minutes; then add tetrabutyl titanate that has been dispersed with 6 ml of absolute ethanol ester, and stirred for 3 hours, and then were dispersed in 30 ml of water after washing with ethanol and water for 3 times;

[0069] (3) Preparation of hollow spherical nano-TiO 2 : 30 ml of SiO 2 @TiO 2 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com