Patents

Literature

74results about How to "Full replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feed additive as well as preparation method, application and corresponding feed thereof

ActiveCN106974113AImprove disease resistanceEnhance digestionFood processingAnimal feeding stuffRadix Rehmanniae PreparataCodonopsis pilosula

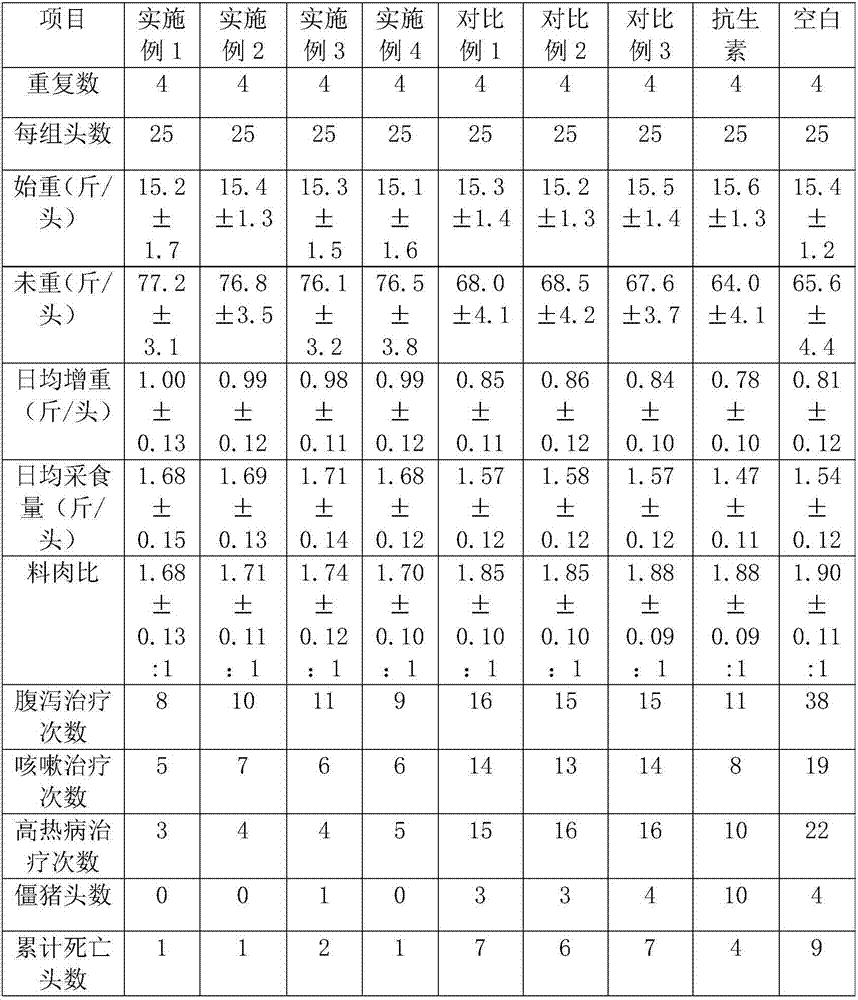

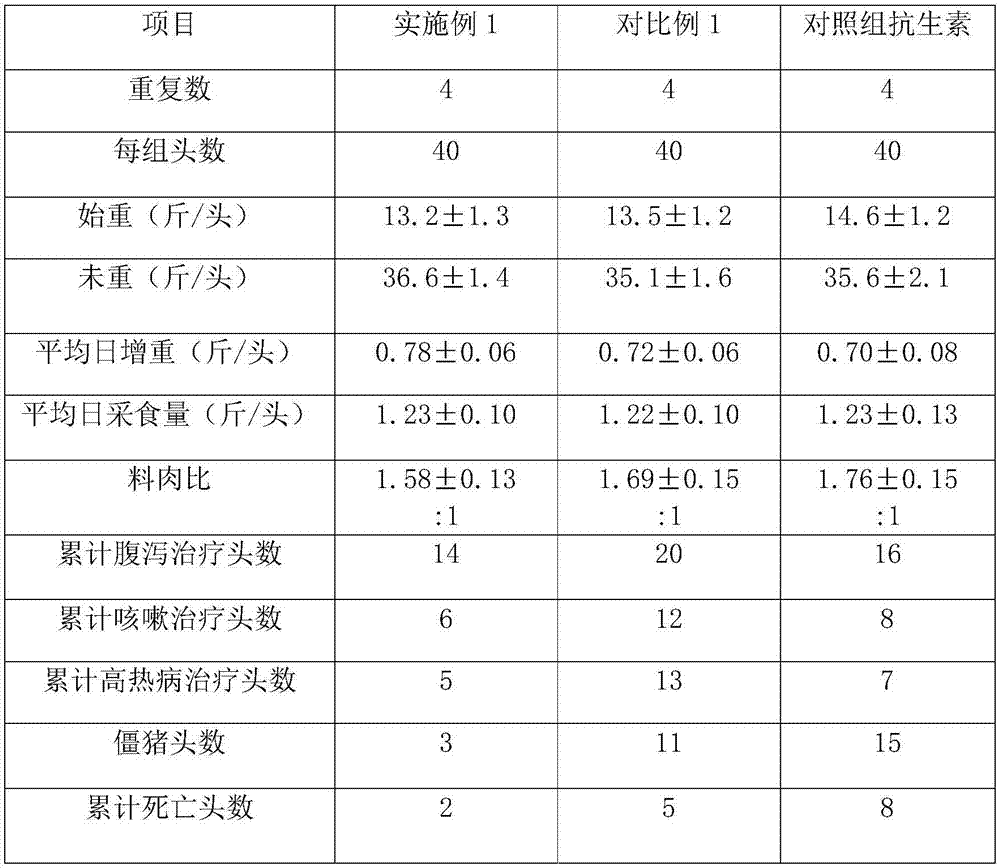

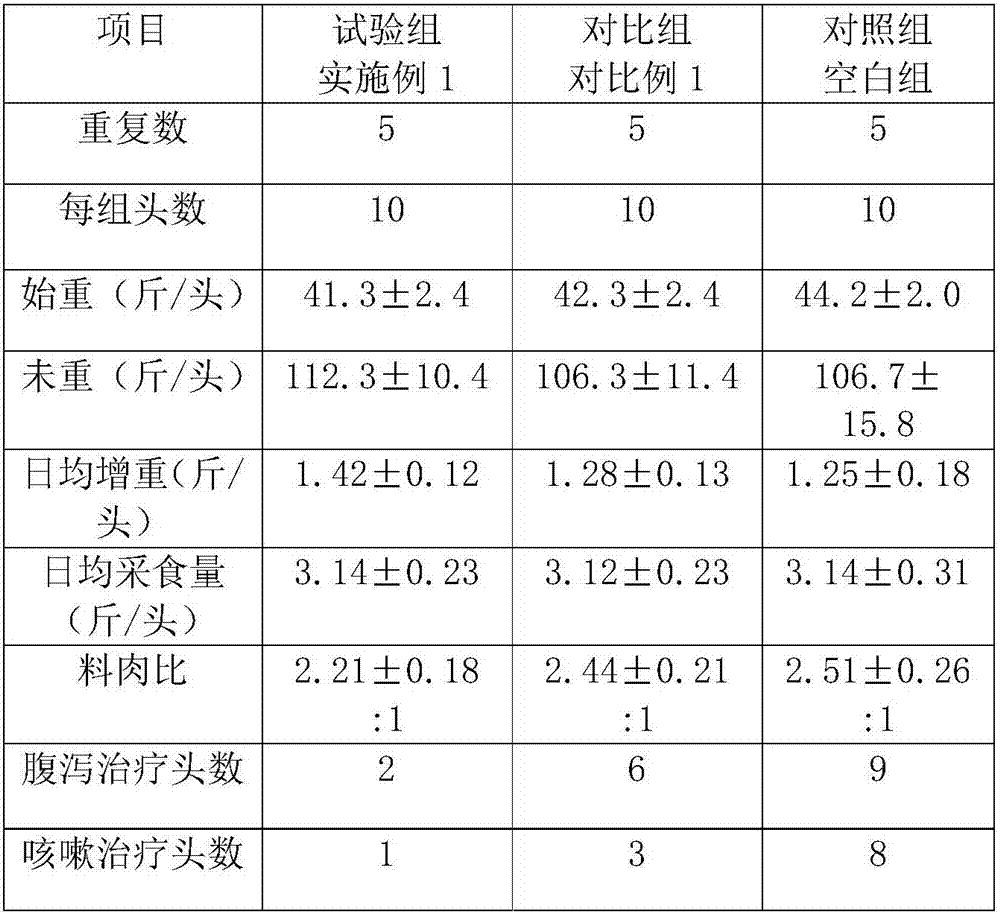

The invention provides a feed additive as well as a preparation method, an application and a corresponding feed thereof. The feed additive comprises a compound traditional Chinese medicine and other additives, wherein the compound traditional Chinese medicine comprises codonopsis pilosula, bighead atractylodes rhizome, rhizoma smilacis glabrae, liquorice, radix rehmanniae preparata, radix paeoniae alba, ligusticum wallichii, angelica sinensis, rhizoma atractylodis, mangnolia officinalis, dried tangerine or orange peel, fried endothelium corneum gigeriae galli, hawthorn, fried malt, rhizoma alismatis and carrier. The feed additive provided by the invention has the function of promoting the immunity and production performance of the pig herd in each stage, can be used for fully replacing antibiotics and also can effectively prevent and treat cad pig diseases.

Owner:谢又华

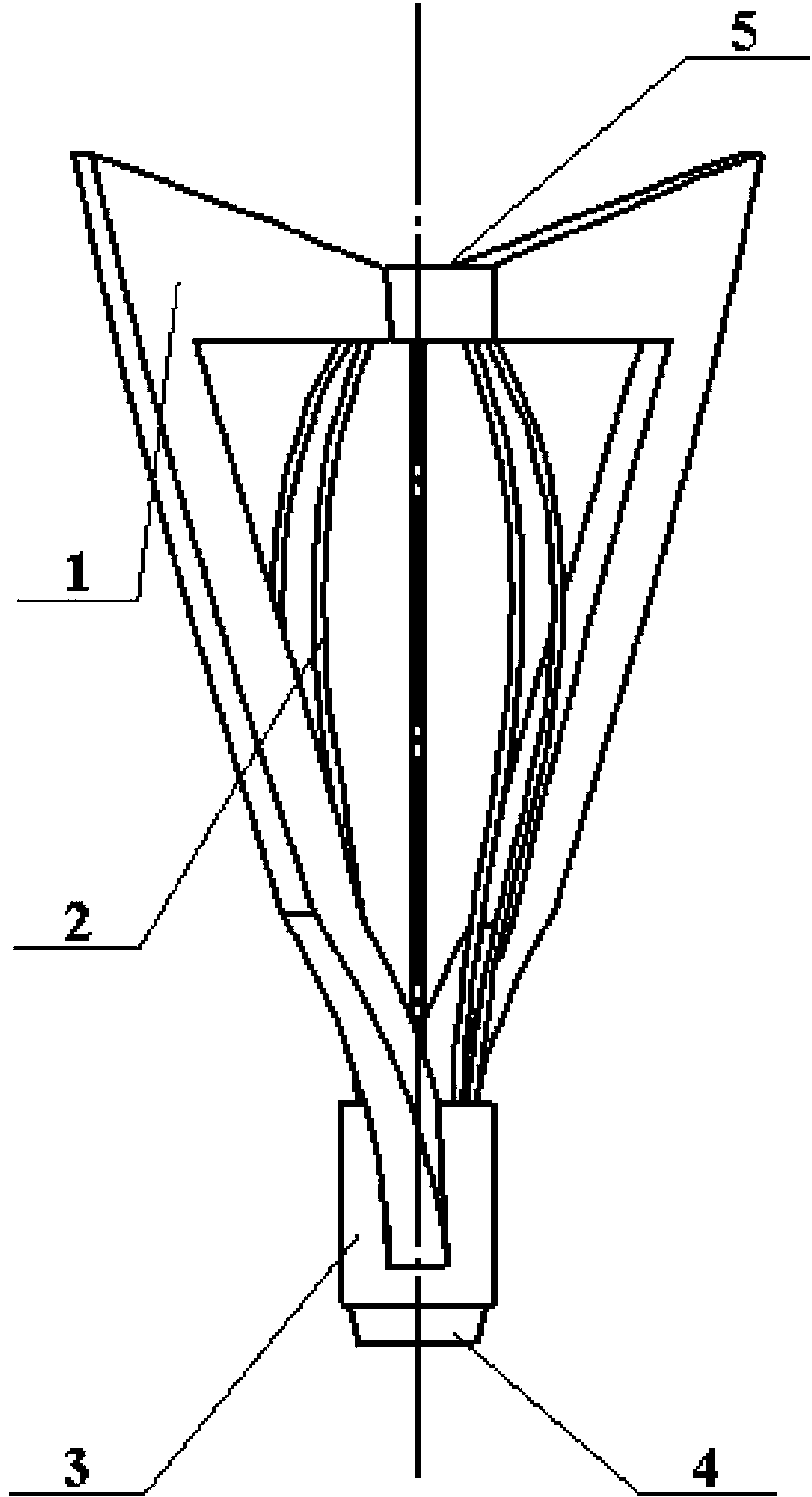

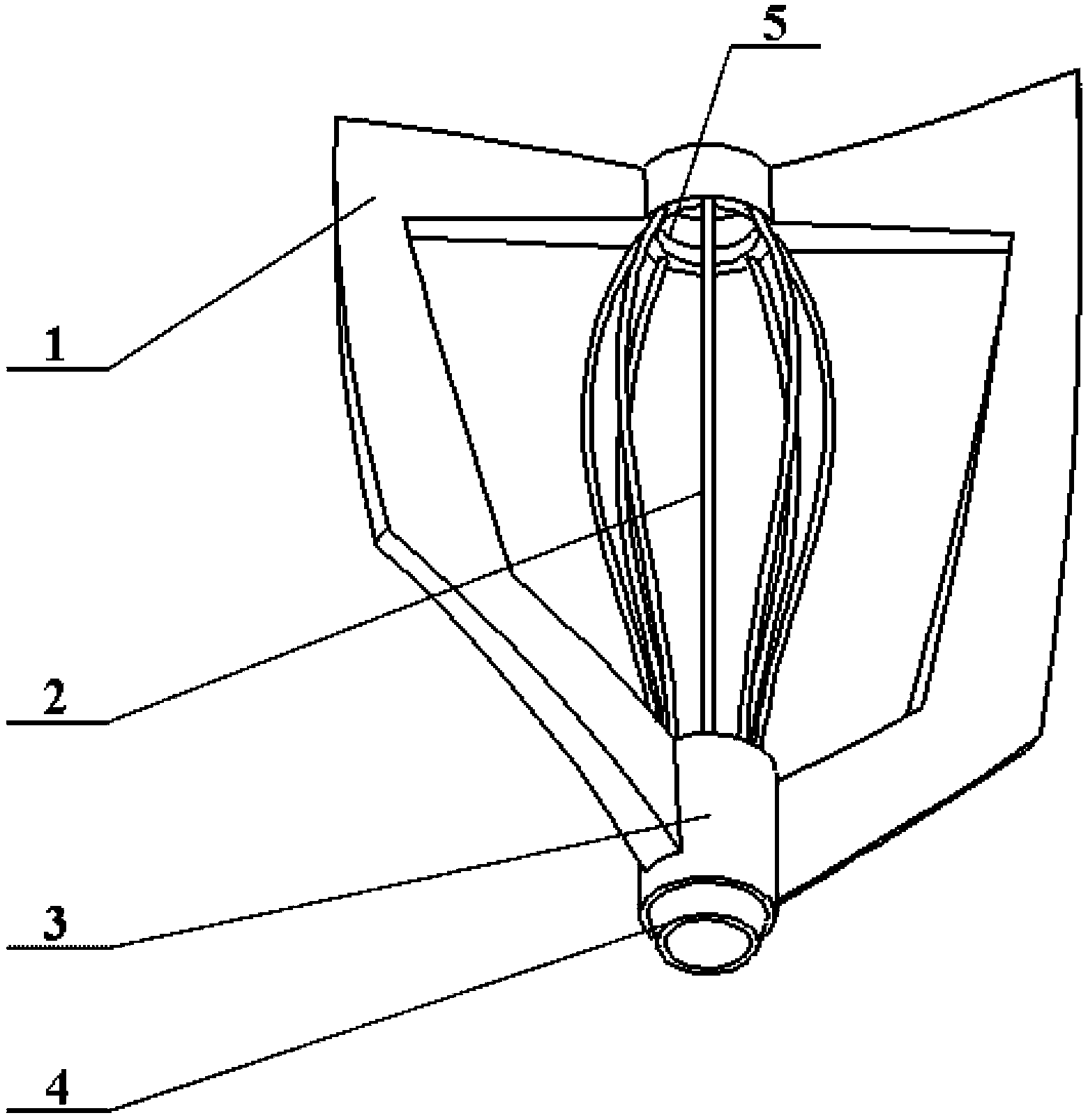

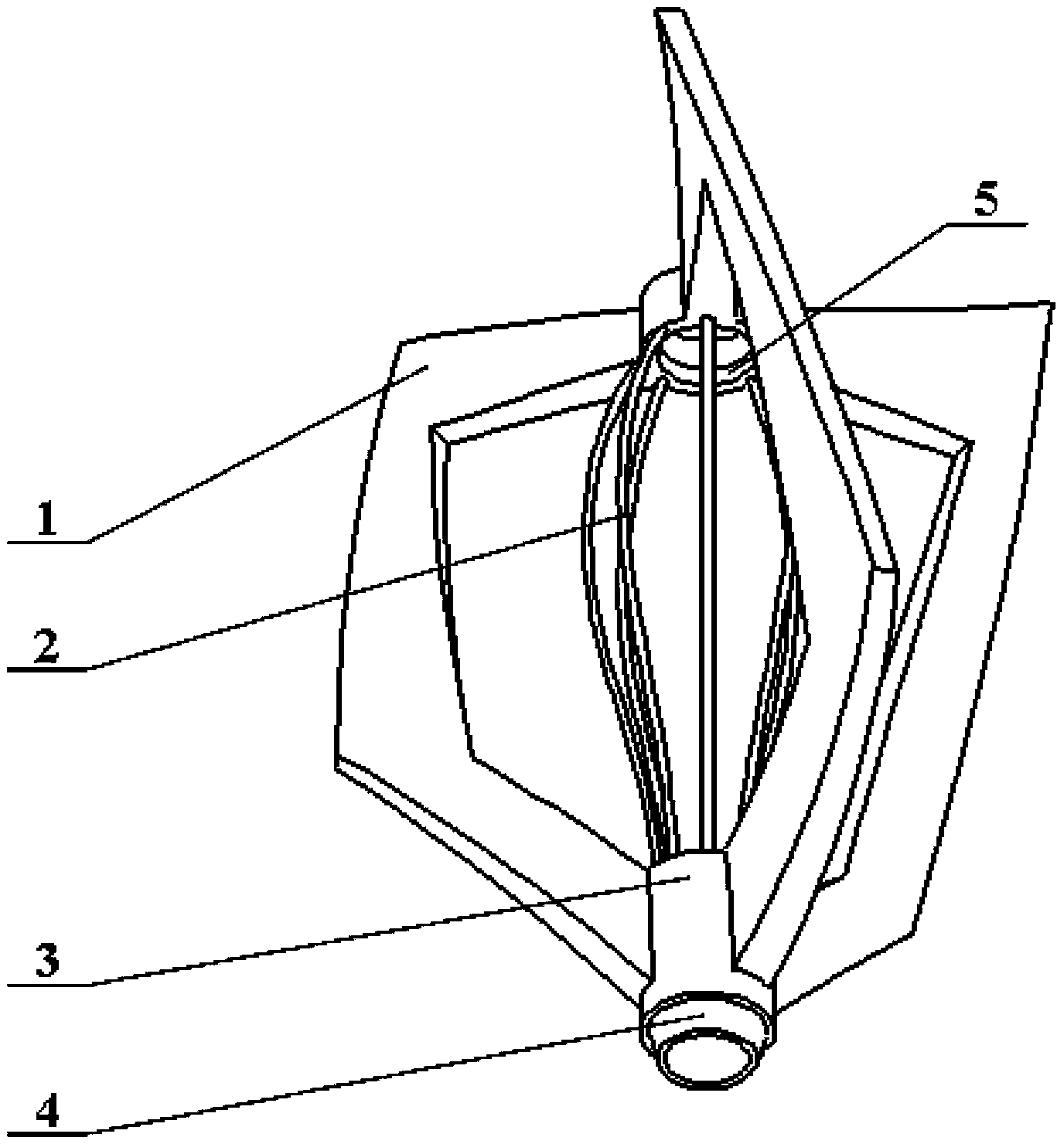

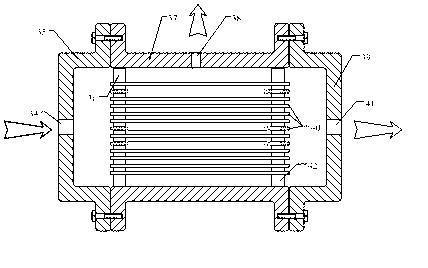

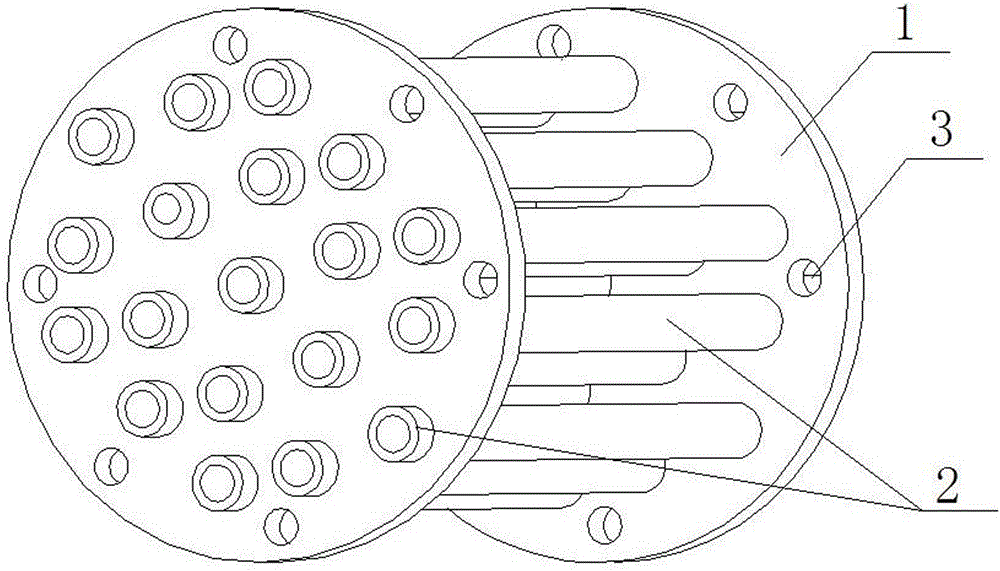

Low driving rotor with turbulence core and in heat exchange tube

ActiveCN103411467ASmall driving forceIncreased ability to remove dirtCorrosion preventionHeat transfer modificationHelical bladeWater flow

The invention relates to a low driving rotor with a turbulence core and in a heat exchange tube. The rotor is mainly composed of a hollow shaft, helical blades and the turbulence core, the outer diameter of each helical blade is smaller than the inner diameter of the heat exchange tube, the helical blades are smooth in surface, provided with hollow structures respectively and helically shaped around the hollow shaft, and the turbulence core is arranged in the hollow portions of the helical blades and consists of a plurality of turbulence strips distributed around the hollow shaft. The edge, firstly contacting with water flow, of the helical blades is chamfered or filleted; upstream faces of the blades drive the rotor to rotate under the action of fluid driving, fluid is enabled to generate centrifugal movement and is thrown to the wall of the heat exchange tube, radial flow of the heat transfer fluid is enhanced, and impacts on a laminar boundary layer of the fluid nearby the tube wall are generated to destroy the laminar boundary layer of the fluid; the turbulence core rotates with the blades, when small resistance is increased, turbulence is performed on center fluid in the tube to enable the center fluid to be replaced fully, and further effects of scale prevention, descaling and strengthened heat transfer are realized.

Owner:BEIJING UNIV OF CHEM TECH

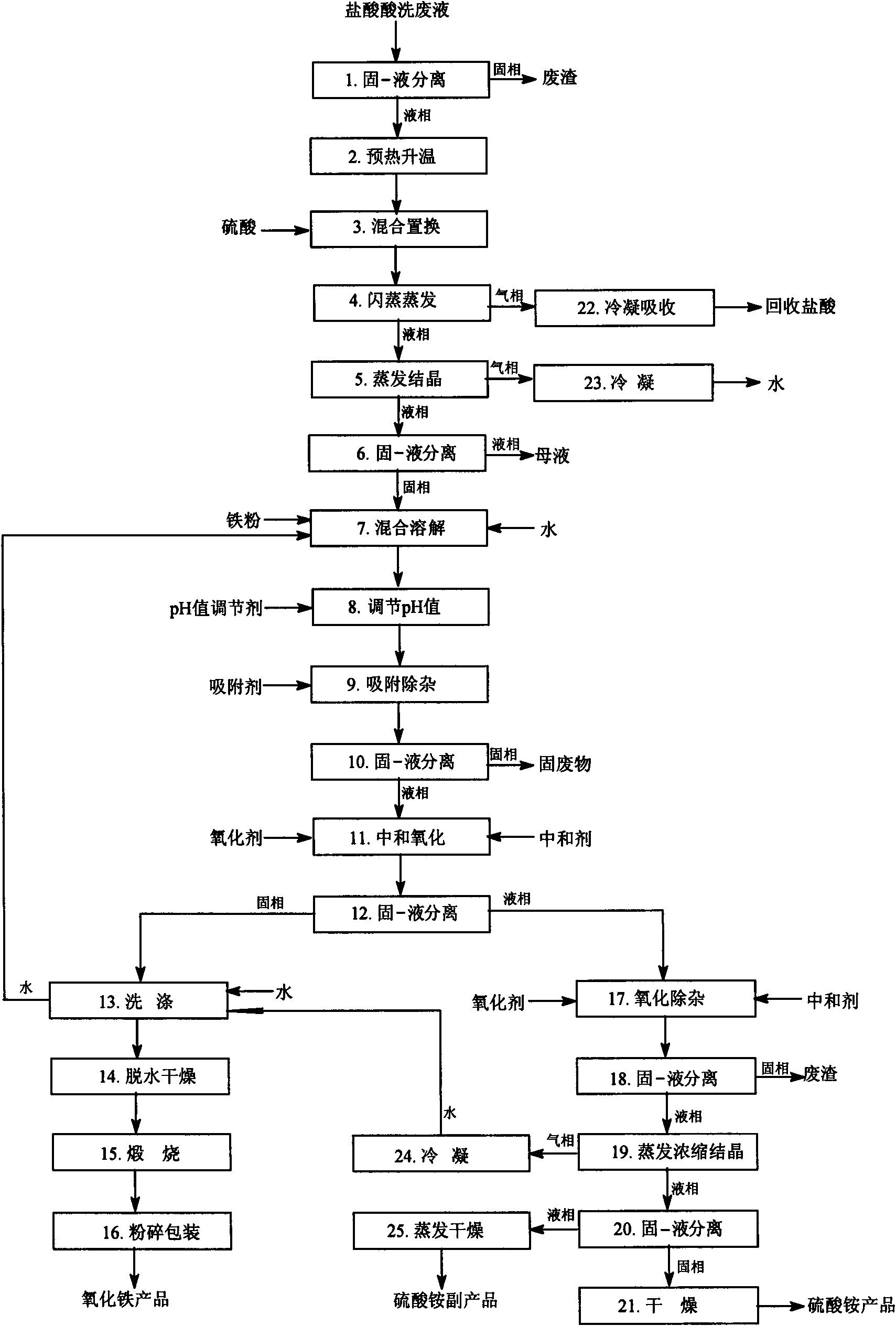

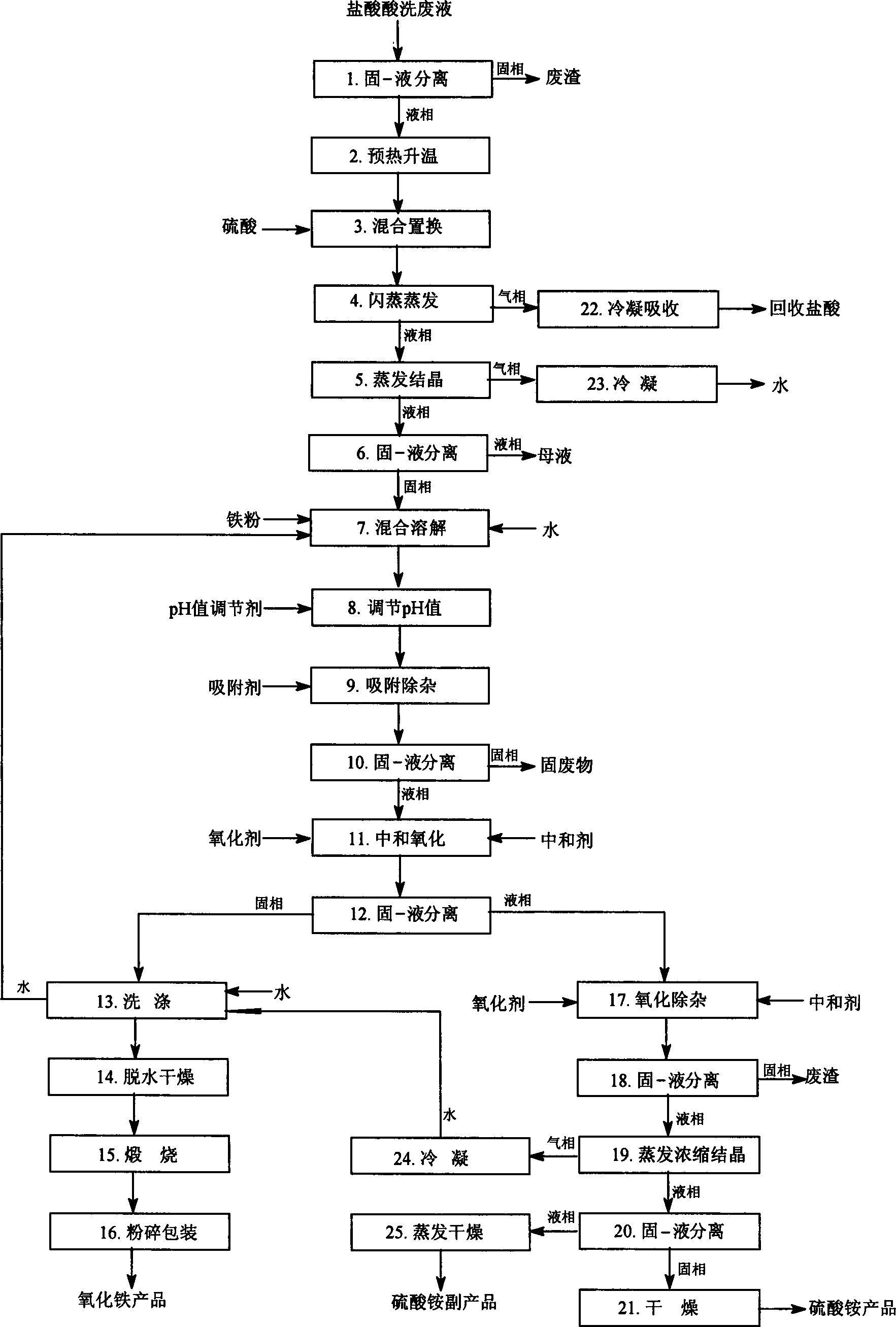

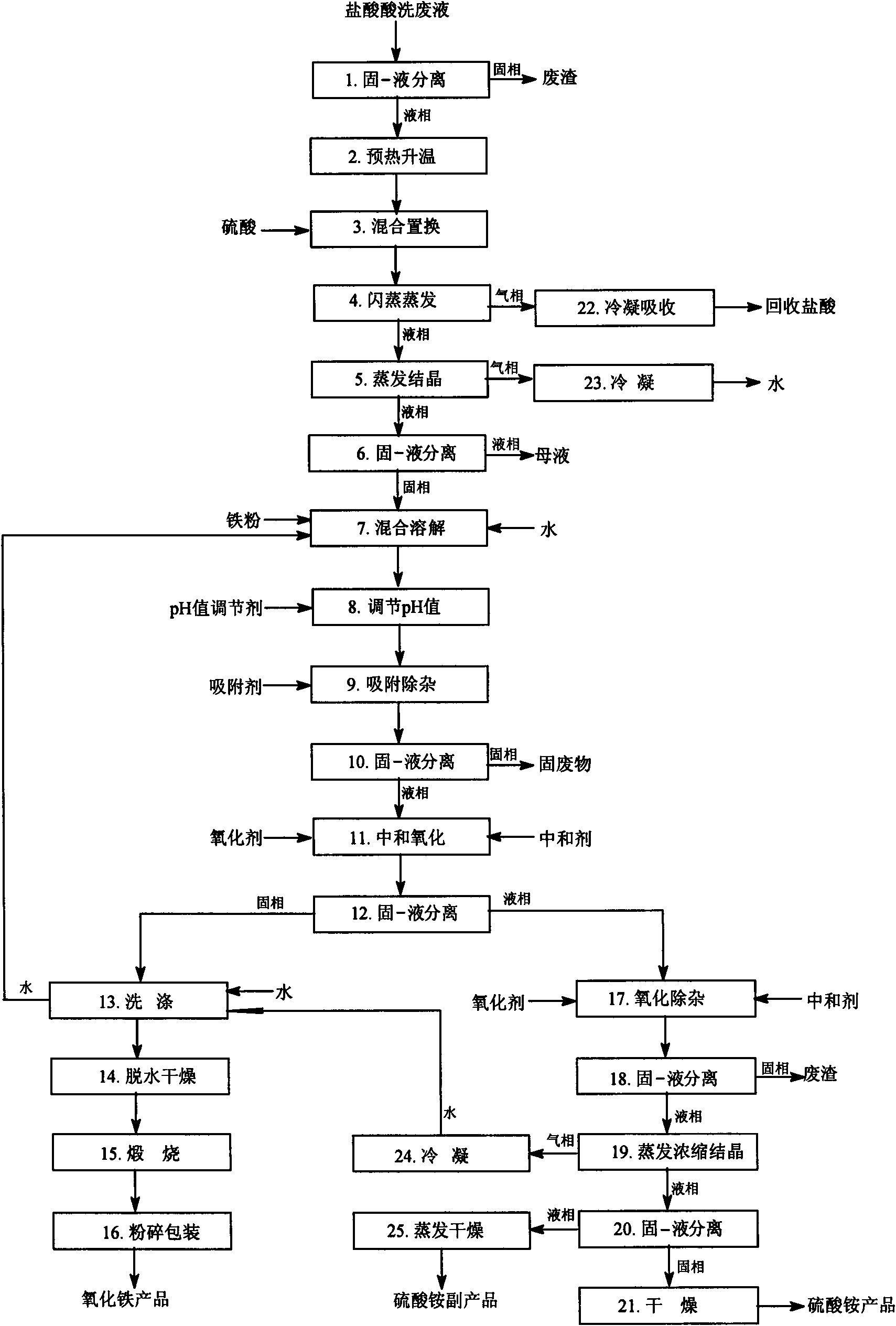

Hydrochloric acid pickling waste liquid resource integrated utilization method for preparing iron oxide and ammonium sulfate

InactiveCN102689930AFull replacementWell mixedChlorine/hydrogen-chlorideEnergy inputEvaporationImpurity

The invention relates to a hydrochloric acid pickling waste liquid resource integrated utilization method for preparing iron oxide and ammonium sulfate. Iron-containing hydrochloric acid pickling waste liquid obtained from a pickling treatment process, which uses hydrochloric acid solution as a pickle to remove surface oxides on a steel element, is used as a raw material. The method comprises the following steps of: (1) solid-liquid separation; (2) preheating and heating; (3) miscible displacement; (4) flash evaporation; (5) evaporation and crystallization; (6) solid-liquid separation; (7) mixing and dissolving; (8) pH adjusting; (9) adsorption for impurity removal; (10) solid-liquid separation; (11) neutralization and oxidation; and (12) solid-liquid separation. A liquid phase material is further used for preparation of an ammonium sulfate product, and a solid phase material is further used for preparation of an iron oxide product; besides, ammonium sulfate by-products can be prepared in further preparation of the ammonium sulfate product. The invention has advantages of reasonable technology, simple method, environment-friendliness, energy saving, low preparation cost, good product quality and high utilization rate of valuable components.

Owner:江苏江盛南节能科技有限公司

Method for extracting copper from organic silicon scrap

InactiveCN103555951AImprove solubilityFull replacementRotary drum furnacesCrucible furnacesAcid waterSlurry

The invention discloses a method for extracting copper from an organic silicon scrap, and particularly discloses a method for extracting a copper simple substance from waste contact, pulp residue hydrolysis residue and waste acid water generated in production of an organic silicon monomer. The method comprises the following steps: a, grinding the waste contact and / or pulp residue hydrolysis residue; b, adding a soluble oxidant to a solution of hydrochloric acid, and then carrying out acidizing treatment on the grinded waste contact and / or pulp residue hydrolysis residue by using the solution of hydrochloric acid containing the soluble oxidant; c, neutralizing the acidized slurry by using an alkali compound, and adjusting into subacidity; d, filtering the neutralized slurry to obtain filtrate; e, displacing copper in the filtrate with active metal, and then drying to obtain the product. By adopting the method, the solution of hydrochloric acid containing the oxidant is utilized to acidize, so that the copper in the scrap is completely converted into divalent copper; the product is high in copper purity; the copper in the scrap is lower than 0.5%; the problems of copper recovery and environmental protection in an organic silicon production process are solved.

Owner:LUZHOU NORTH CHEM IND

Double-flow-mode fuel oil ground pre-washing method and device thereof

InactiveCN102755870AIncrease mass transfer driving forceShorten washing timeInert gas productionProcess engineeringGas generator

The invention discloses a double-flow-mode fuel oil ground pre-washing method and device thereof. The double-flow-mode fuel oil ground pre-washing method comprises the following steps of: performing inertia treatment on fuel oil in an oil tank of a fuelling vehicle by using nitrogen-rich gas generated by a nitrogen-rich gas generating device, wherein the nitrogen-rich gas generating device comprises more than two nitrogen-rich gas generators, and the nitrogen-rich gas outlets of the nitrogen-rich gas generators are connected in series or in parallel or in series and parallel by switching bypass control valves respectively; and during inertia treatment on fuel oil, switching corresponding bypass control valves to make the flow and the purity of nitrogen-rich gas output by the nitrogen-rich gas generating device meet the practical requirements of inertia treatment, and arranging a suction pump at the nitrogen-rich gas outlet of each nitrogen-rich gas generator respectively. Due to the adoption of the method and the device, the contradictory relation between the flow and purity of nitrogen-rich gas generated by the nitrogen-rich gas generators in a decompressed washing process is coordinated, the separating effect of a separating film is optimized, the requirement of lower oxygen content in fuel oil at the end of washing is met, and washing time is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

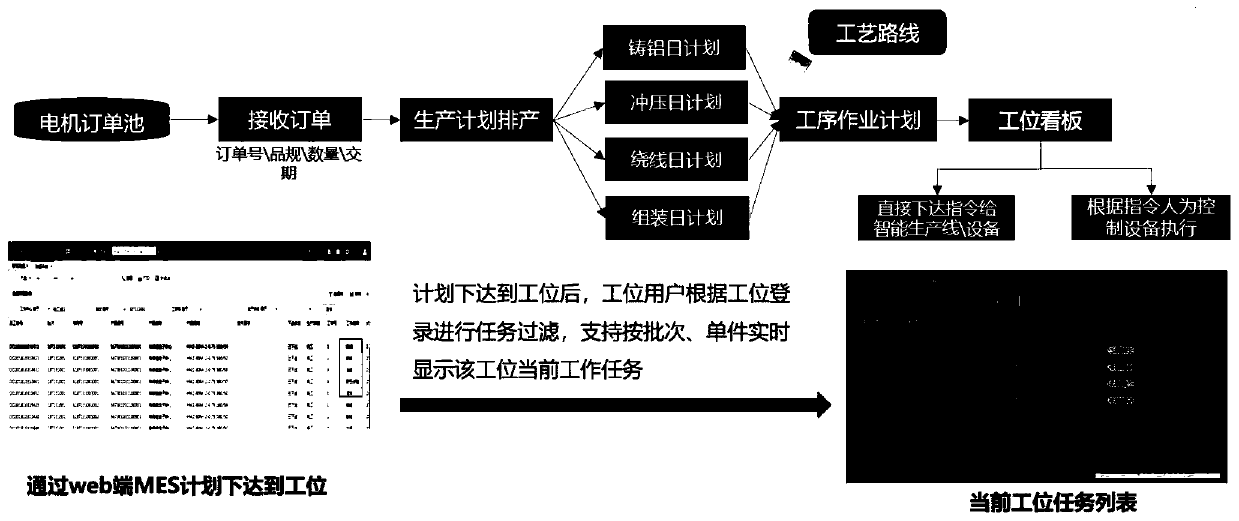

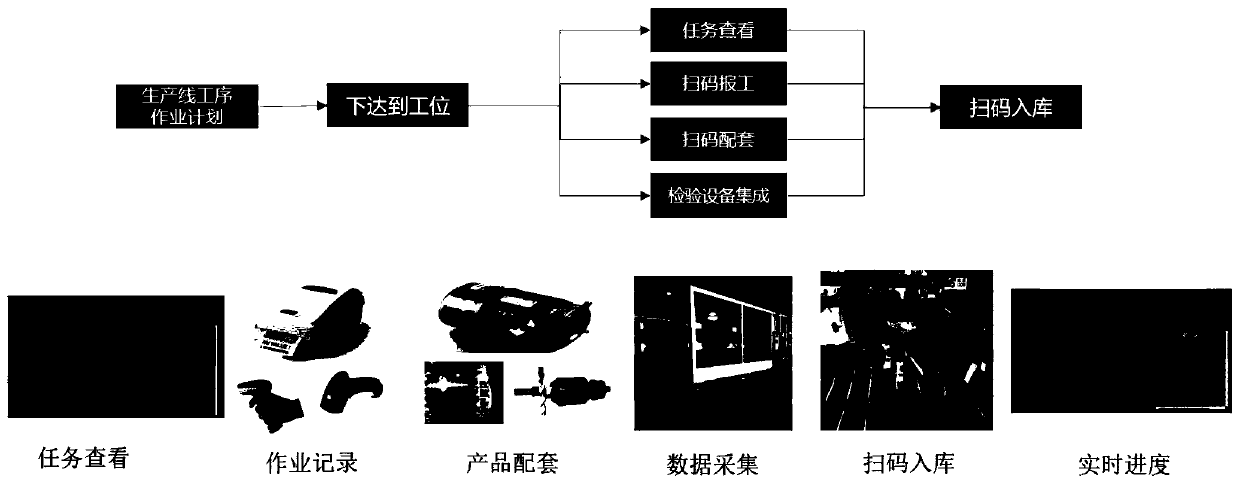

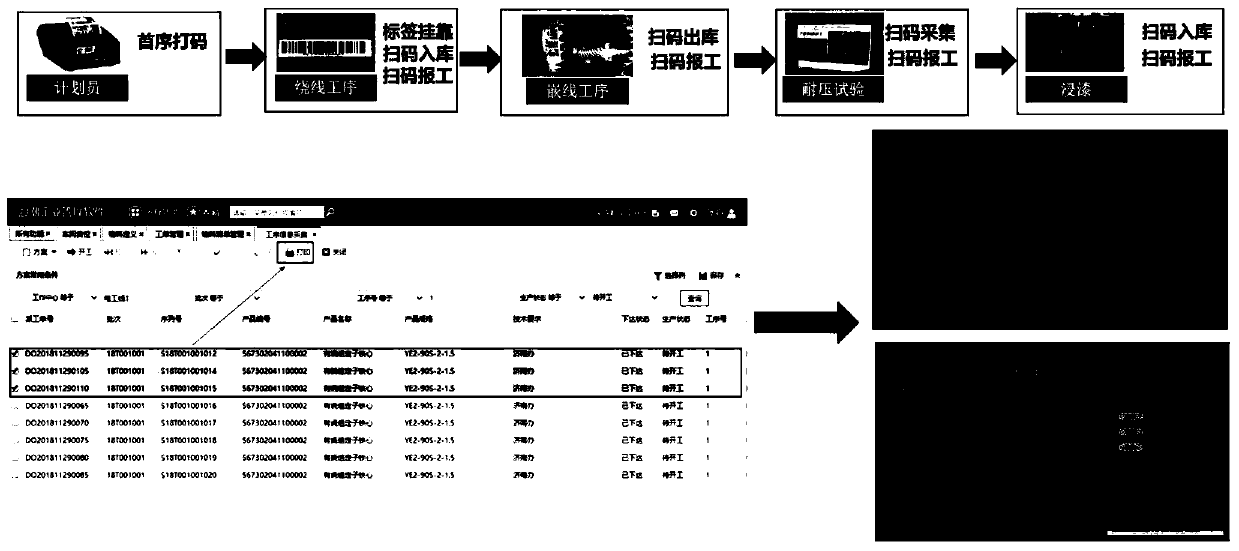

Implementation method and system suitable for motor industry workshop MES application

PendingCN111260332AFull replacementRealize electronicOffice automationManufacturing computing systemsComputer printingTouchscreen

The invention provides an implementation scheme suitable for a motor industry workshop MES application, and the method comprises the steps: automatically associating a process route through a production task, automatically dispatching to a station after the production task is issued, supporting the fine management of a workshop station task, carrying out secondary dispatching to a worker, and supporting the process operation according to the dimension of the worker; secondly, carrying out production tracking of workshop tasks with two-dimensional codes as carriers and production process management and control based on process control through cooperation of a bar code printer and a code scanning gun and a workshop station machine APP; next, based on close joint debugging of workshop networking inspection equipment and an MES database server, achieving automatic acquisition of inspection records through code scanning of a station machine APP end, and the inspection records are pushed toan ERP system quality management module in real time; finally, synchronizing the workshop execution related data collected based on the touch screen APP with the quality management module, the workshop inventory module and the like in real time. According to the implementation scheme, a workshop execution layer data upward transmission channel is broken through, and the company business managementand control capability is further optimized while the workshop production efficiency is improved.

Owner:SHANDONG INSPUR GENESOFT INFORMATION TECH CO LTD

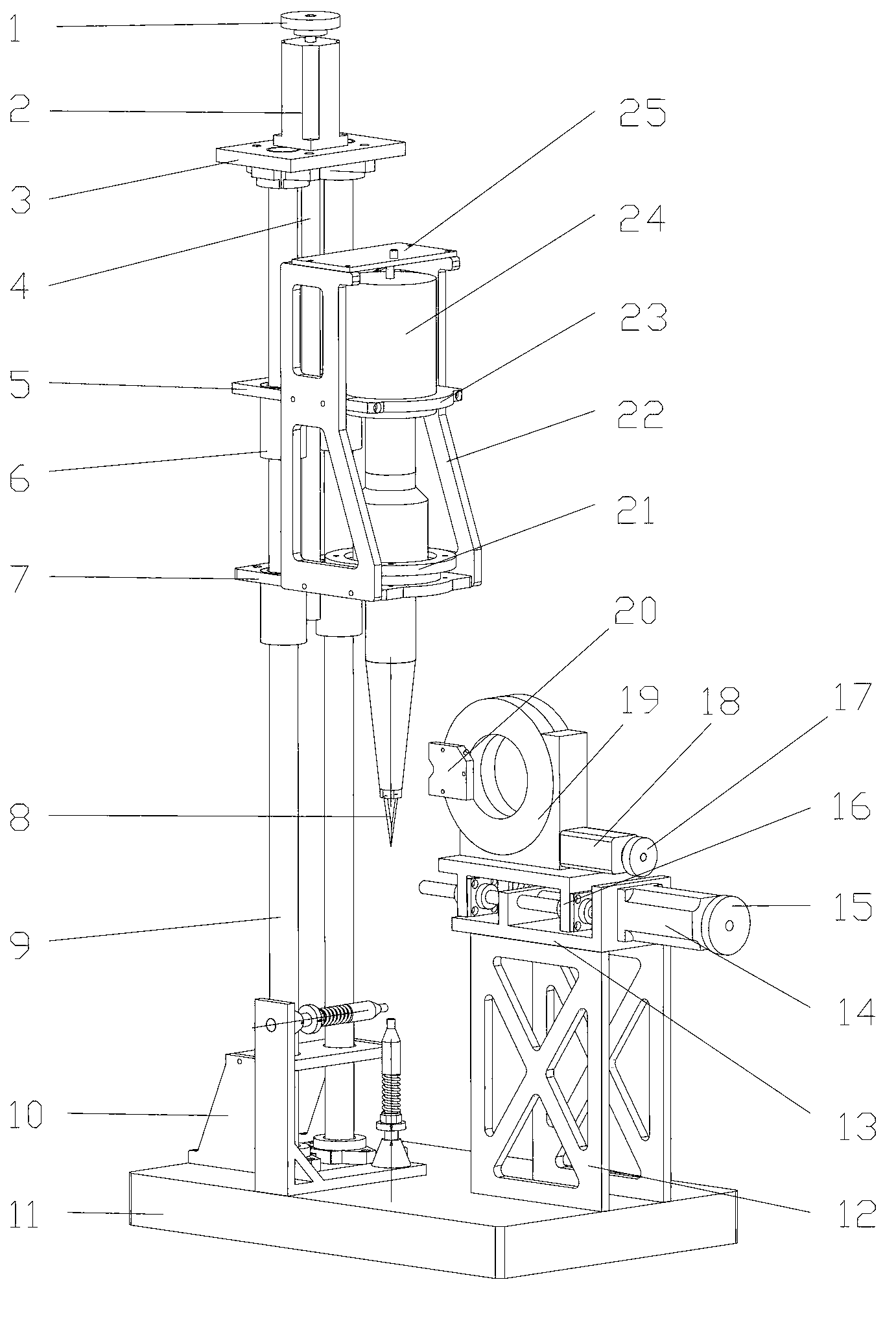

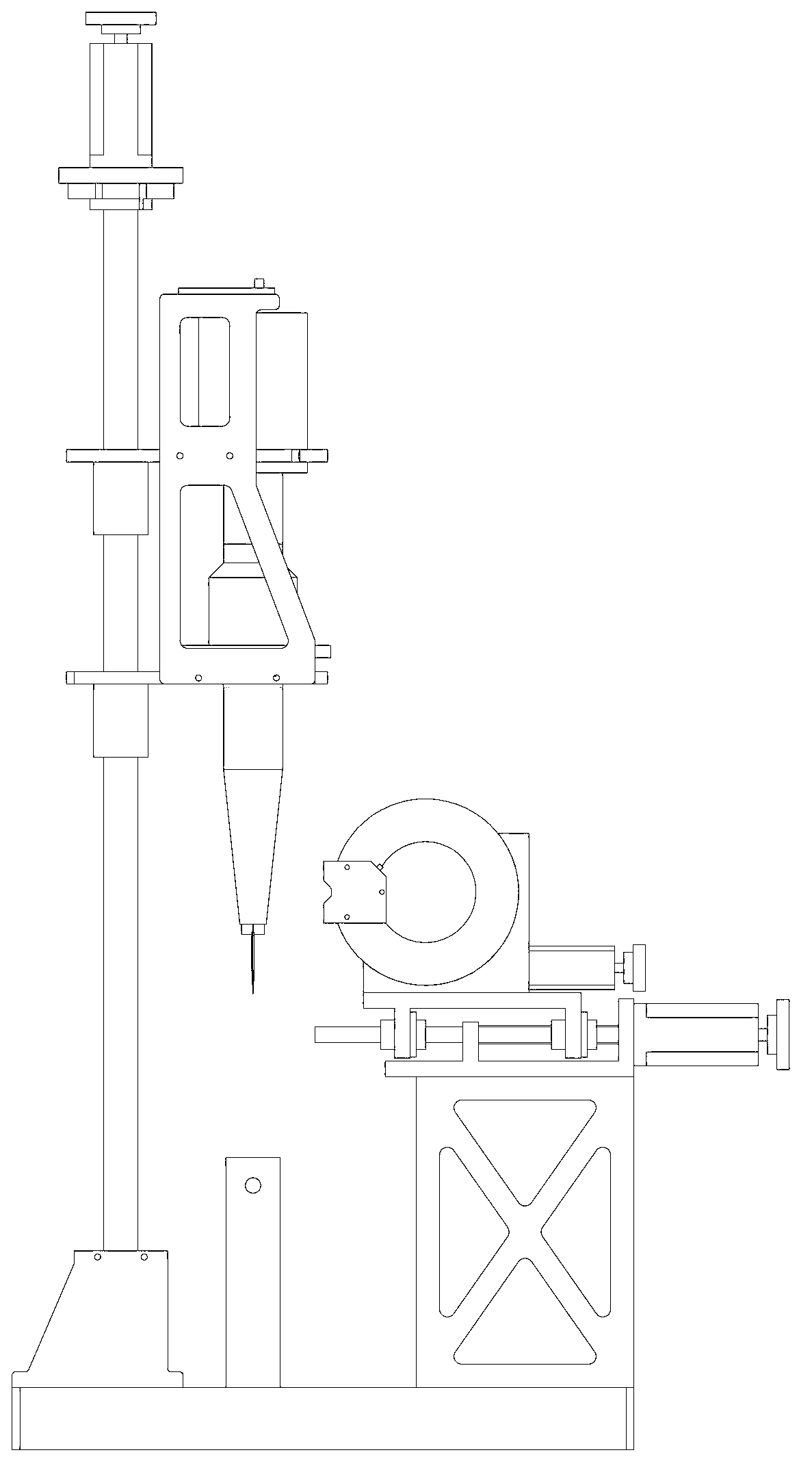

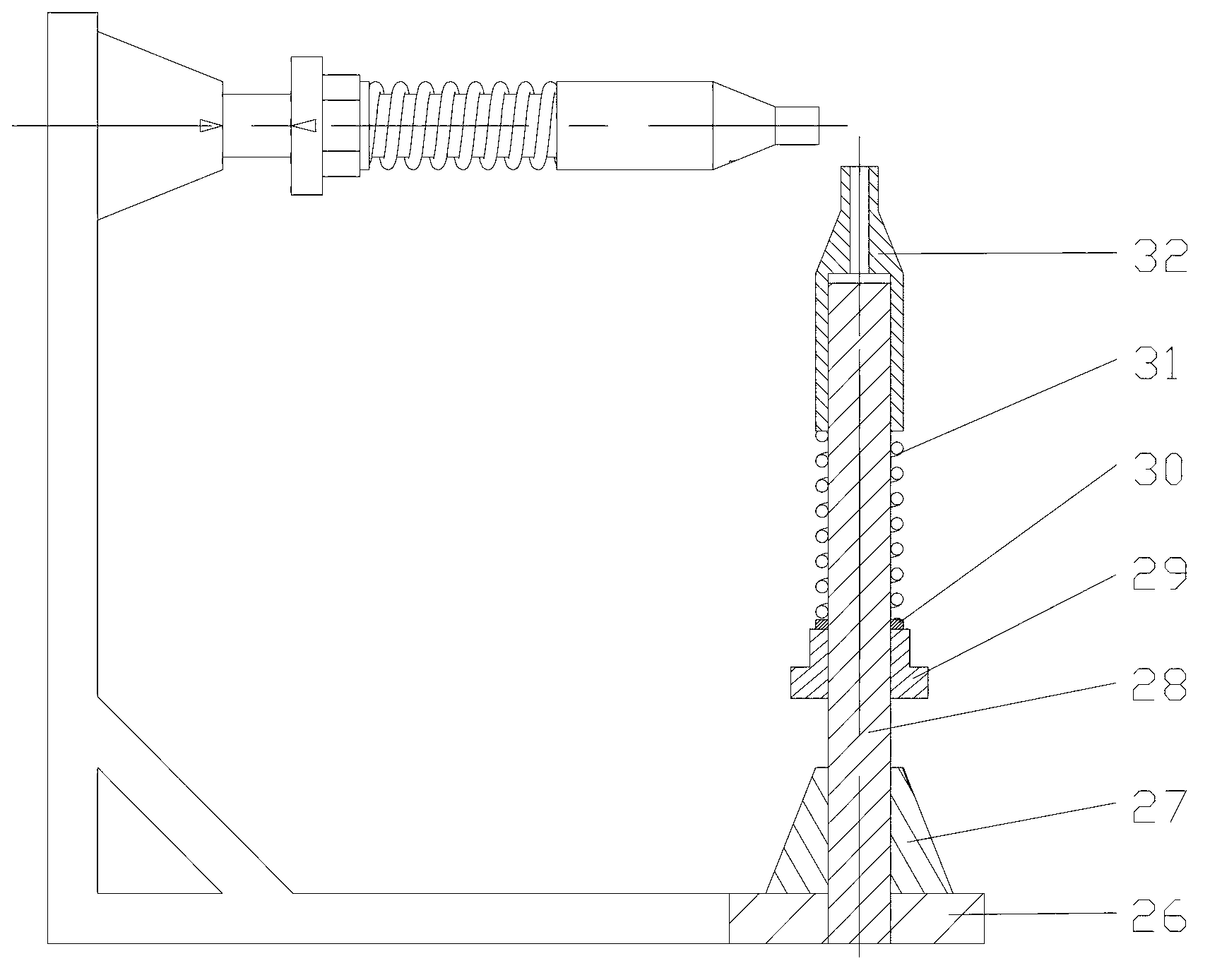

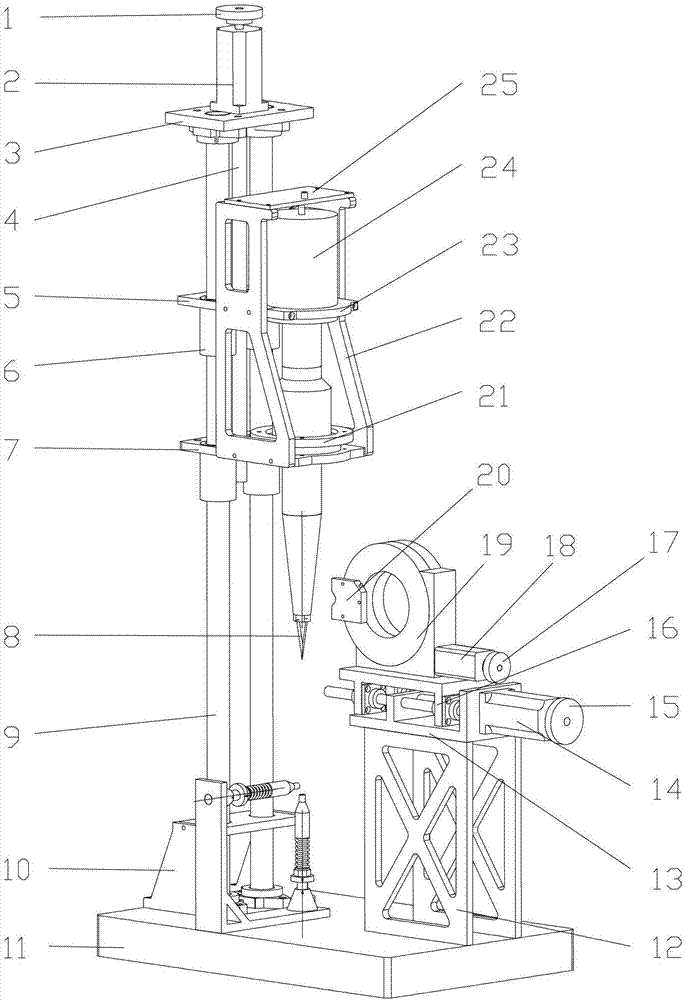

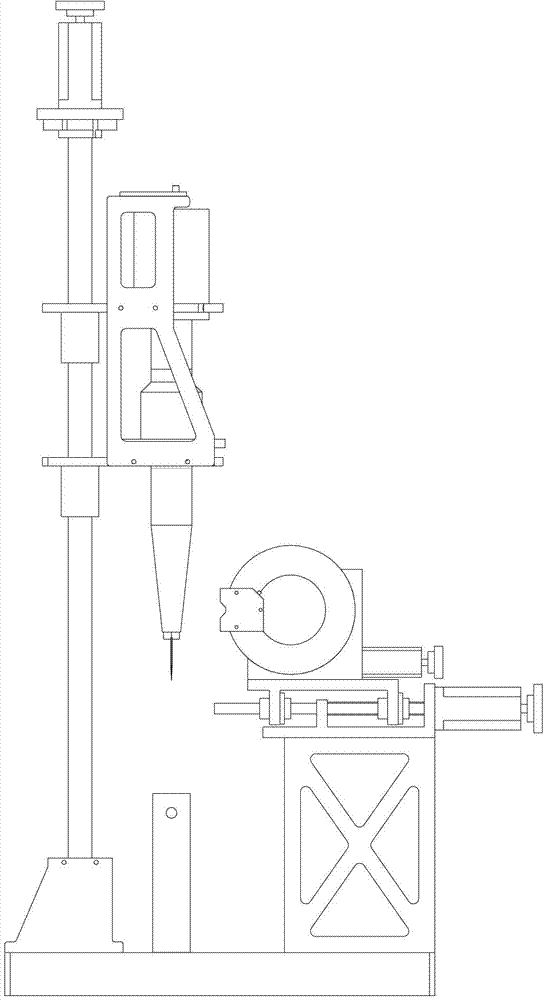

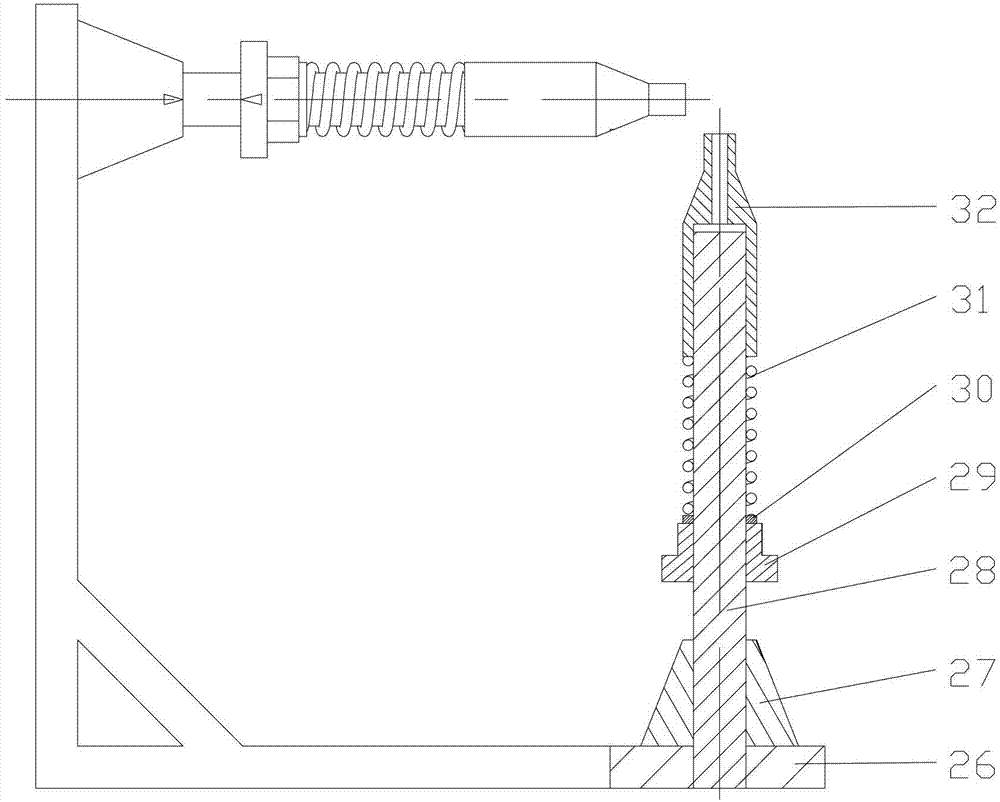

Overall performance testing rack of numerical control ultrasonic cutting sound main shaft

InactiveCN103323223AImprove performanceImprove performance testing resultsMachine part testingNumerical controlCombined test

The invention discloses an overall performance testing rack of a numerical control ultrasonic cutting sound main shaft. The overall performance testing rack comprises a base. Perpendicular linear guide rails, an artificial load device and a radial movement base are installed on the base. The perpendicular linear guide rails are in sliding fit with the ultrasonic cutting sound main shaft. The artificial load device is provided with two force application rods. The two force application rods are located at the axial position and the radial position of a cutting tool nose of the ultrasonic cutting sound main shaft respectively and used for applying artificial loads to the cutting tool nose. The radial movement base is provided with a testing probe which can move towards the ultrasonic cutting sound main shaft in a radial mode and rotate. According to the overall performance testing rack of the numerical control ultrasonic cutting sound main shaft, the testing site and various costs can be reduced, the measurement on different parameters under the same installation condition is provided, the testing errors under different installation conditions are reduced, the testing effect and the testing efficiency on the performance of the ultrasonic cutting sound main shaft are improved, and test bases are provided for the further perfection and the further improvement of the performance of the ultrasonic cutting sound main shaft.

Owner:HANGZHOU DIANZI UNIV

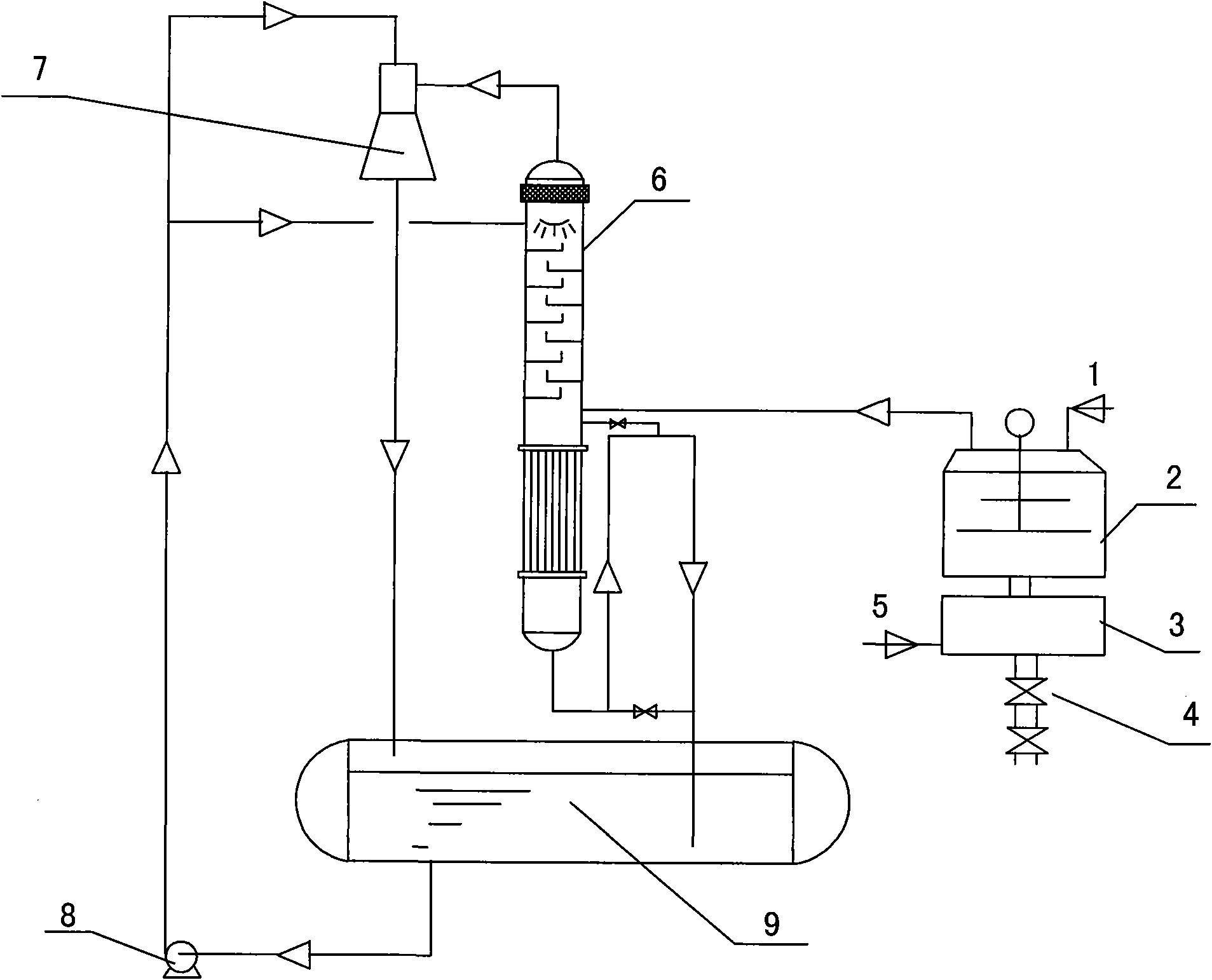

Drying process and drying system for material containing low-boiling point, inflammable and explosive organic solvent

InactiveCN101666575AImprove recovery rateWon't leakDrying using combination processesDrying solid materials with heatBenzeneOrganic solvent

The invention belongs to a drying process and a drying system for a material containing a low-boiling point, inflammable and explosive organic solvent, in particular to a drying process and a drying system for recovering solvents, such as ethanol, methanol, methylbenzene, benzene and the like. The drying process comprises the following steps: setting an airtight and explosion-proof drying system;conveying a wet material to a dryer continuously in a convey quantity of between 10 to 3000 kg; keeping the wet material for 30 to 120 minutes under protection of vacuum and inert atmosphere, and thenheating and drying the wet material at a temperature of between 100 to 300 DEG C so as to remove the solvents; cooling the material to a temperature of between 0 and 50 DEG C; and feeding the cooledmaterial to a material discharging system for discharging. The process and the system improve the solvent recovery rate, avoid potential safety hazard and environmental pollution which are caused by solvent loss, and reduce the entrainment amount of gas dust, and simultaneously reduce the probability of pipeline blockage obviously by large flow washout of a spray tower.

Owner:ZIBO MINING GRP

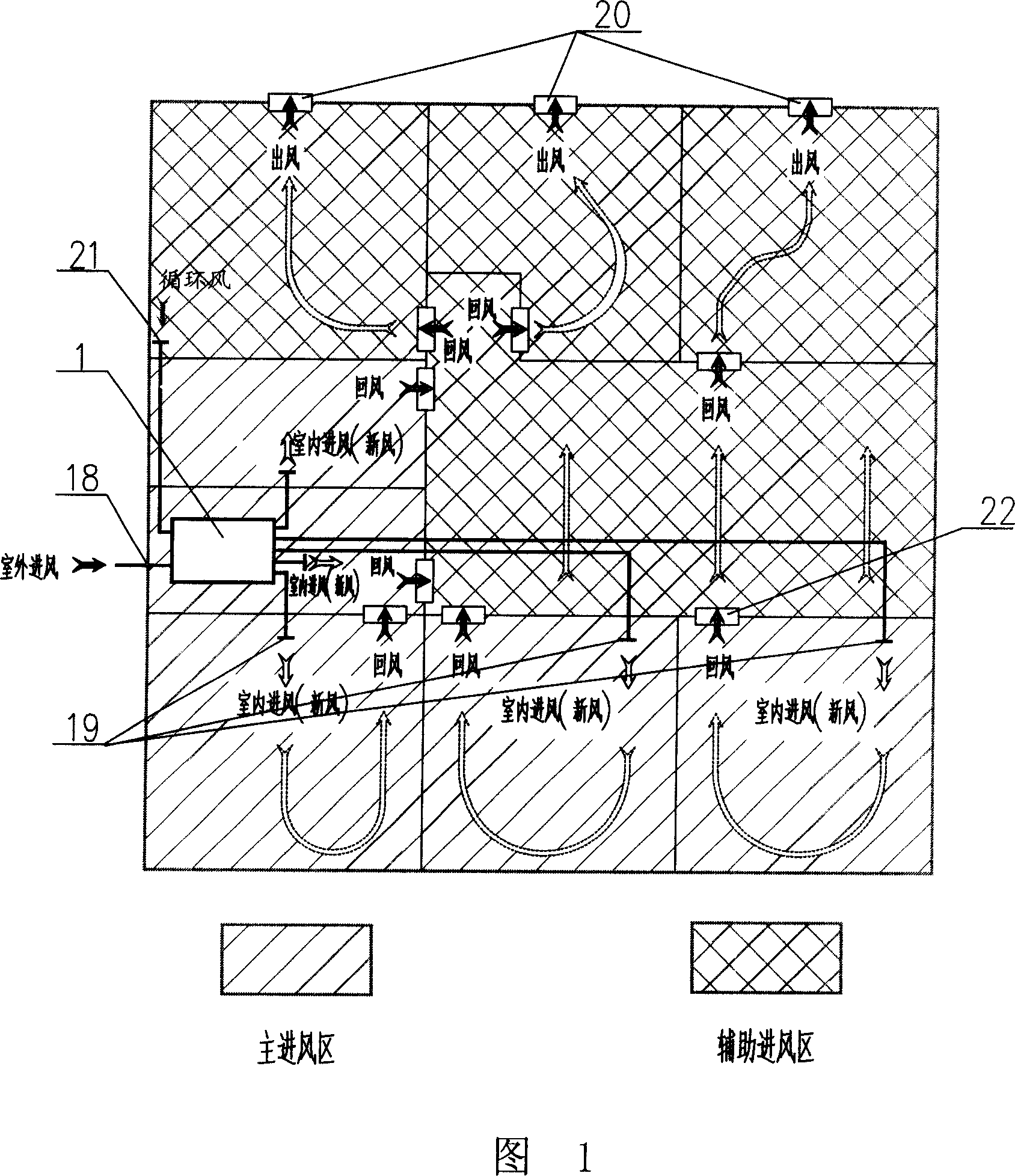

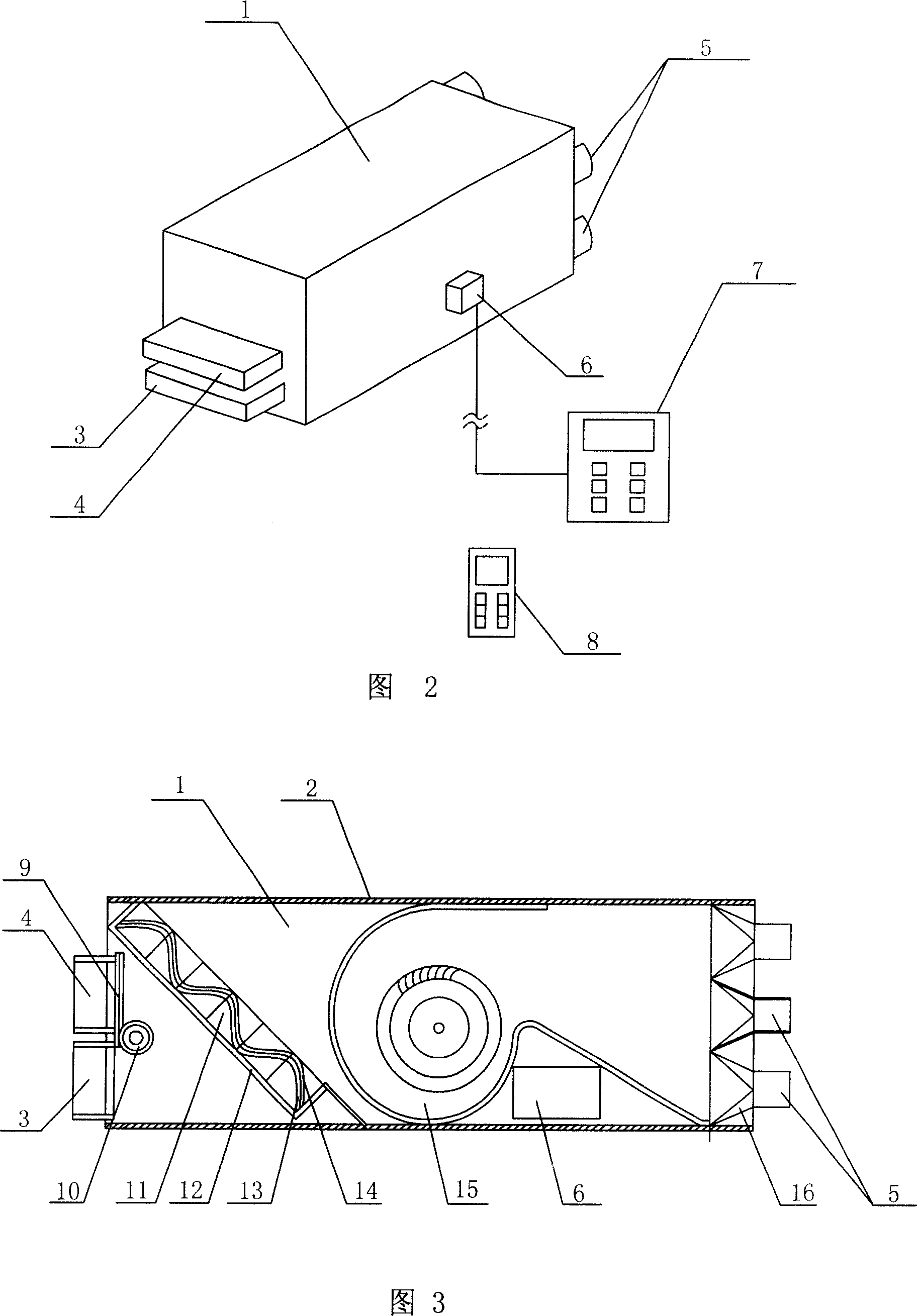

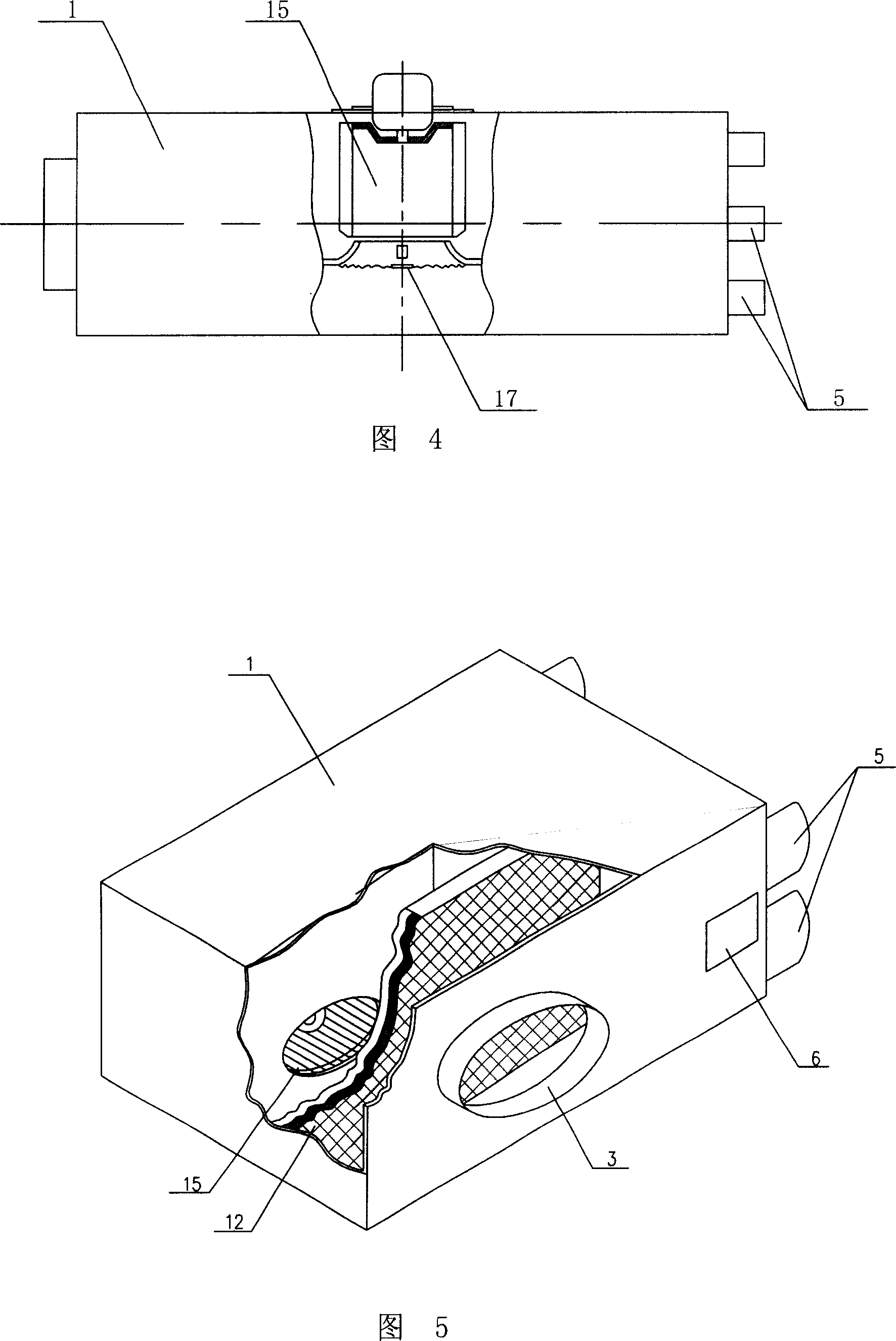

Positive-pressure air-feeding fresh-air changing system

InactiveCN1979030AImprove air qualityFull replacementLighting and heating apparatusVentilation systemsPositive pressureAir filter

The invention discloses a positive pressure air supplying air exchanging system that includes working host, control component, air sending pipeline. Air suction opening air filter, fan and air exits are set on working host. The control component includes main controller that connects to fan. Air sending pipeline includes plural indoor wind send opening and plural outdoor air exit. The invention has simple structure and has good air exchanging effect. It could be used in home or office.

Owner:刘彩君

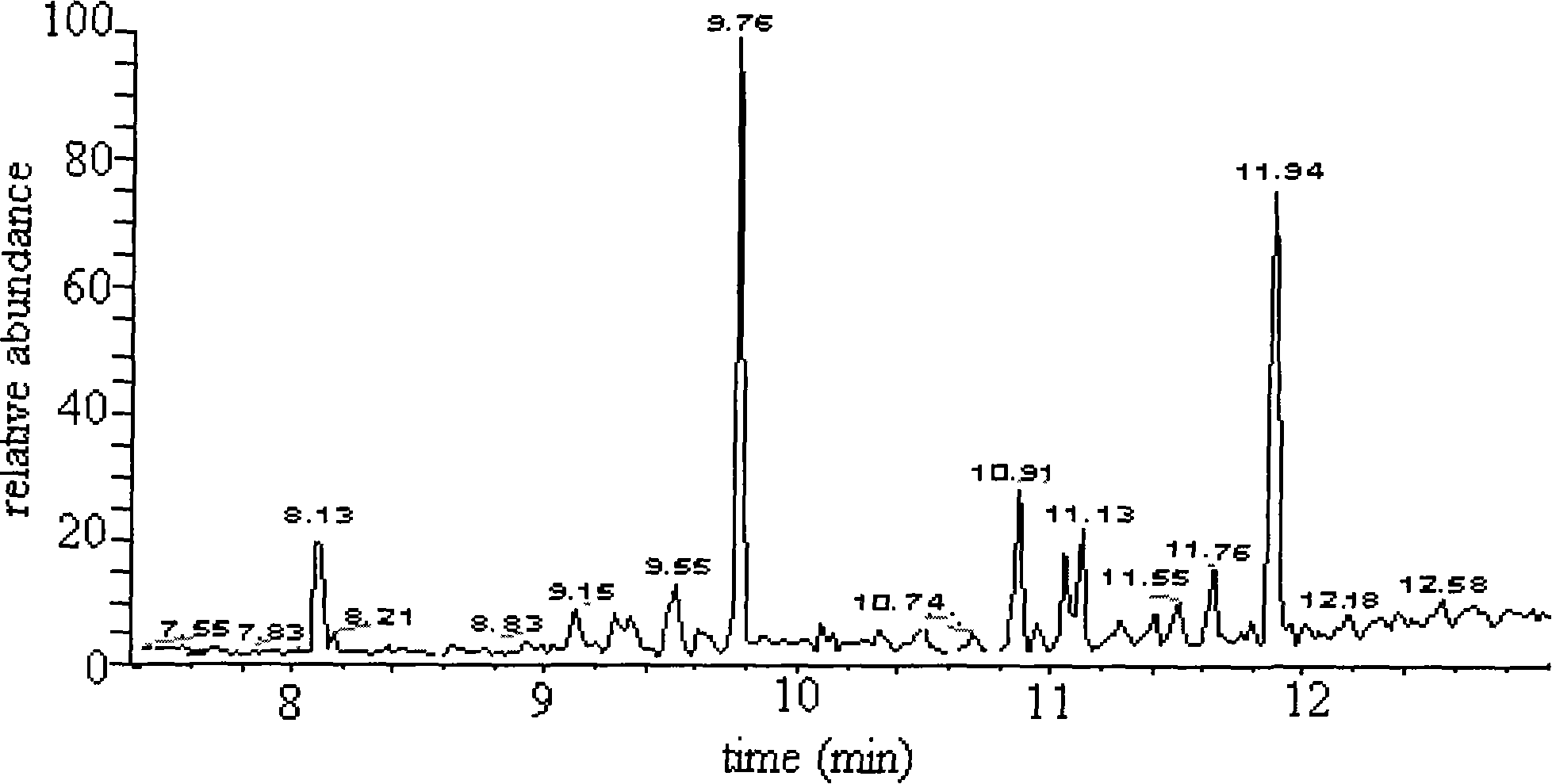

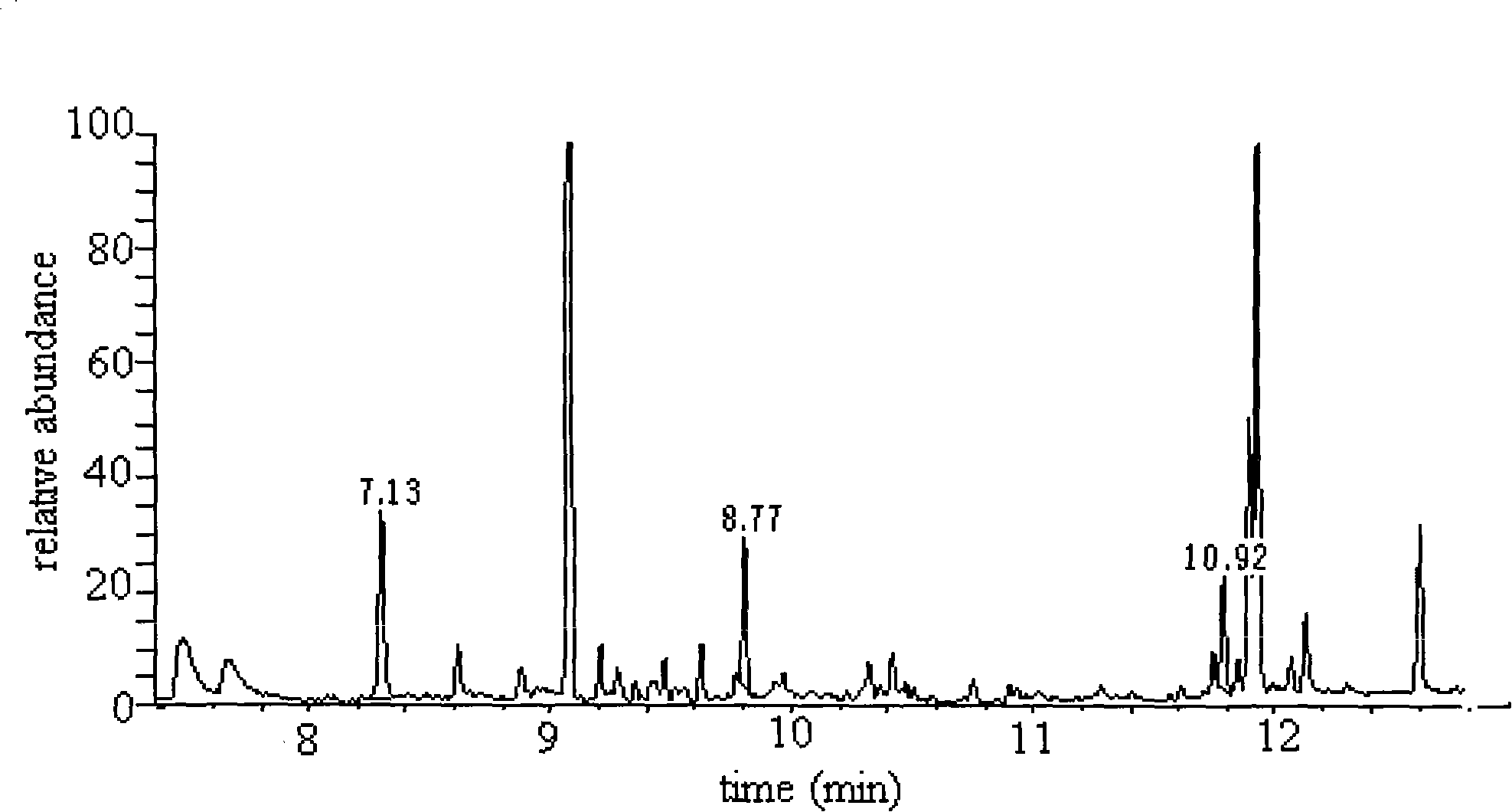

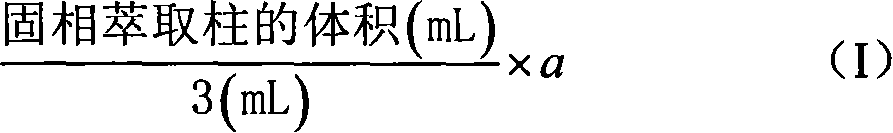

Solid phase extraction column with multi-wall carbon nano-tube matrix and preparation thereof

InactiveCN101239252ABuild as soon as possibleImprove adsorption capacityIon-exchange process apparatusOther chemical processesElectrical polarityCarbon nanotube

The present invention provides a solid phase extraction column of multi-walled carbon nantubes substrate and its preparing method, belonging to analytical instrument field. The characteristic of the solid phase extraction column of multi-walled carbon nantubes substrate is that the solid phase extraction column substrate is multi-walled carbon nantubes, the filling height of the multi-walled carbon nantubes is 0.8-1.1cm, the computing formula of the filling mass can be seen in the formula (I), wherein, numeric area of a is 0.12-0.15g. It is mainly fit for inverse extracting nonpolarity-medium polarity material, used for enriching, purifying target material in water sample or animal sample. Contrast to the traditional inverse solid phase extraction column (such as C18), the extraction column has a large loading capacity, the cost of the multi-walled carbon nantubes is lower, the material is easy to obtain, the invention employs commercial solid phase extraction column, has a simple preparation, easy to produce in batch.

Owner:BEIJING JINXIU DADI AGRI CO LTD

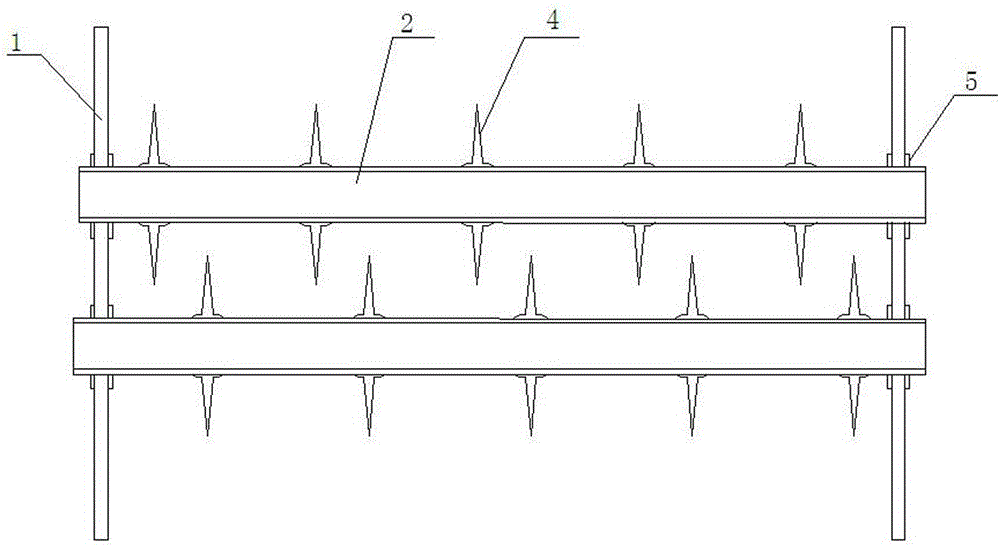

Heat exchange device capable of being applied to various places

InactiveCN106017139AEasy to replaceFull replacementStationary conduit assembliesHeat exhanger sealing arrangementThermodynamicsEngineering

The invention discloses a heat exchange device capable of being applied to various places. The heat exchange device comprises pipe plates and heat exchange pipes, and is characterized in that the two ends of each heat exchange pipe are connected with the pipe plates and extend to the outer sides of the pipe plates, and a plurality of spiral through holes are formed in the pipe plates; sealing devices are arranged at the joints of the pipe plates and the heat exchange pipes; multiple fins are arranged on the heat exchange pipes; the heat exchange pipes are arranged on the pipe plates and are arrayed on the pipe plates in a staggered manner; and the fins on the heat exchange pipes are also directly arrayed in a staggered manner. The heat exchange pipes are made of graphene. Protrusions are arranged at the joints of the two ends of each heat exchange pipe and the pipe plates. Grooves corresponding to the protrusions are formed in the joints of the interiors of the pipe plates and the heat exchange pipes. The heat exchange device has the beneficial effects that the heat exchange pipes are arrayed in a multi-layer staggered manner, thermal energy is conveniently and sufficiently exchanged, the thermal energy exchange area is enlarged, thermal energy exchange of different requirements is conveniently conducted at the same time, and the heat exchange device is suitable for various places.

Owner:HARBIN JINJING BOILER

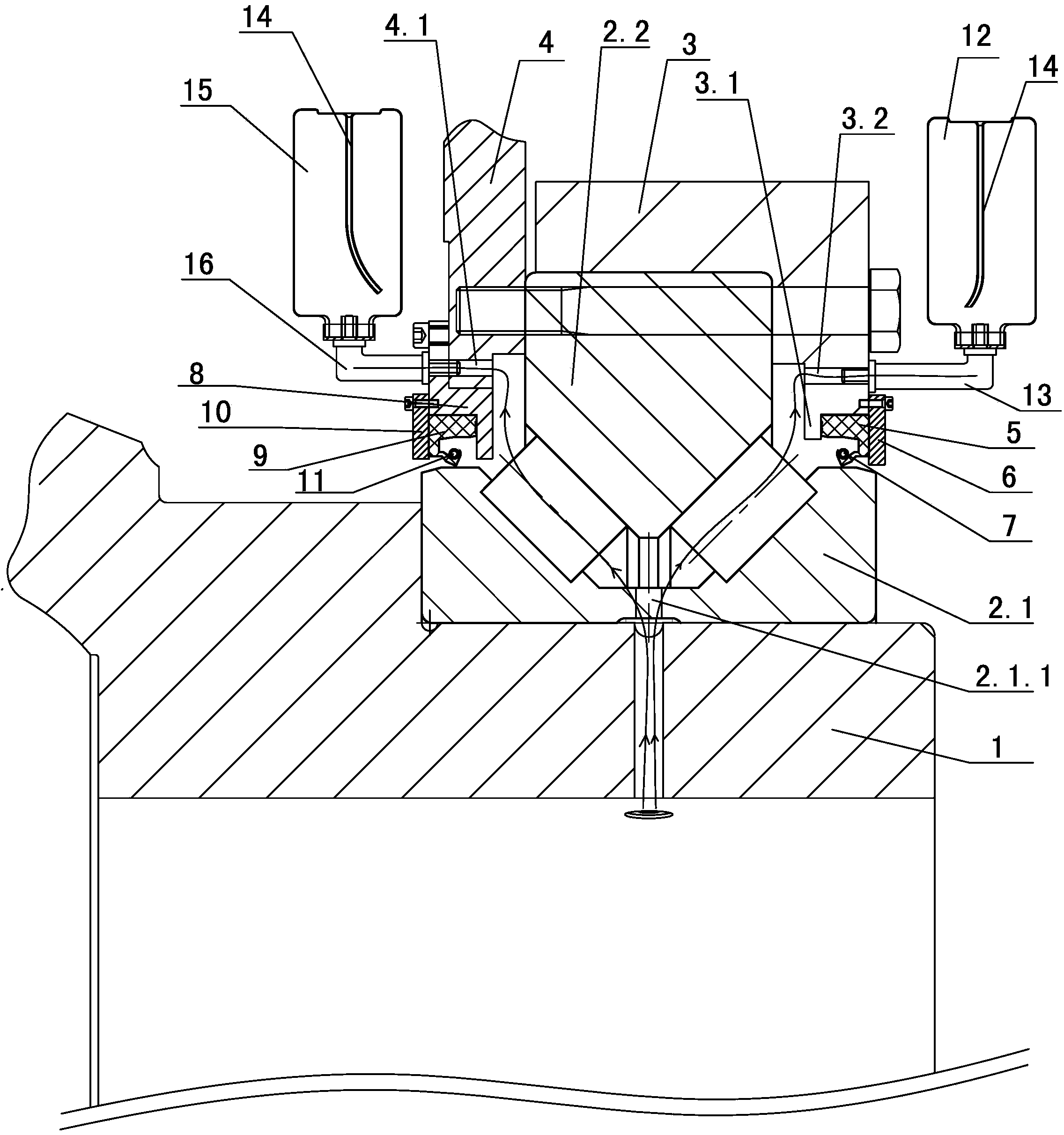

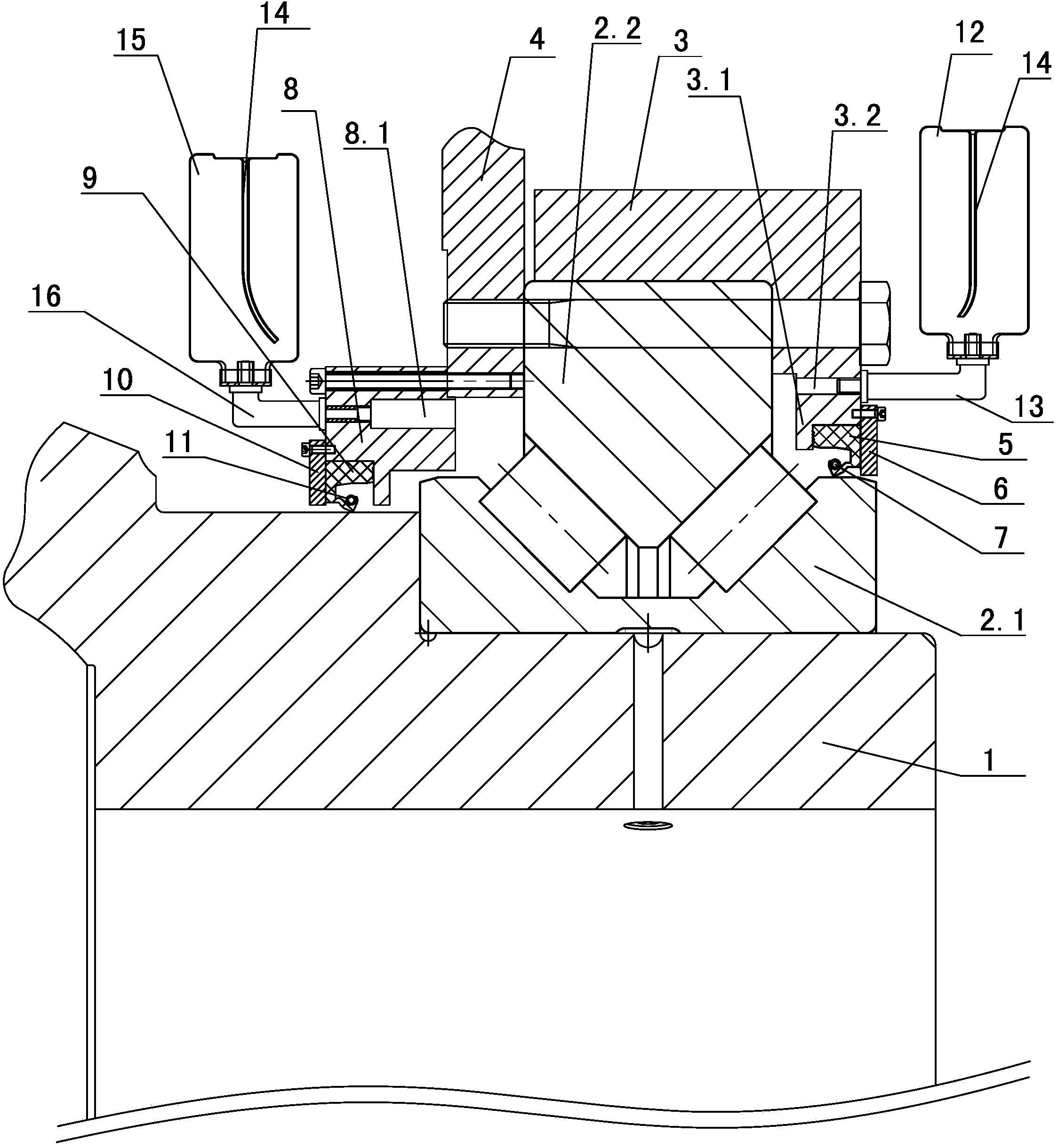

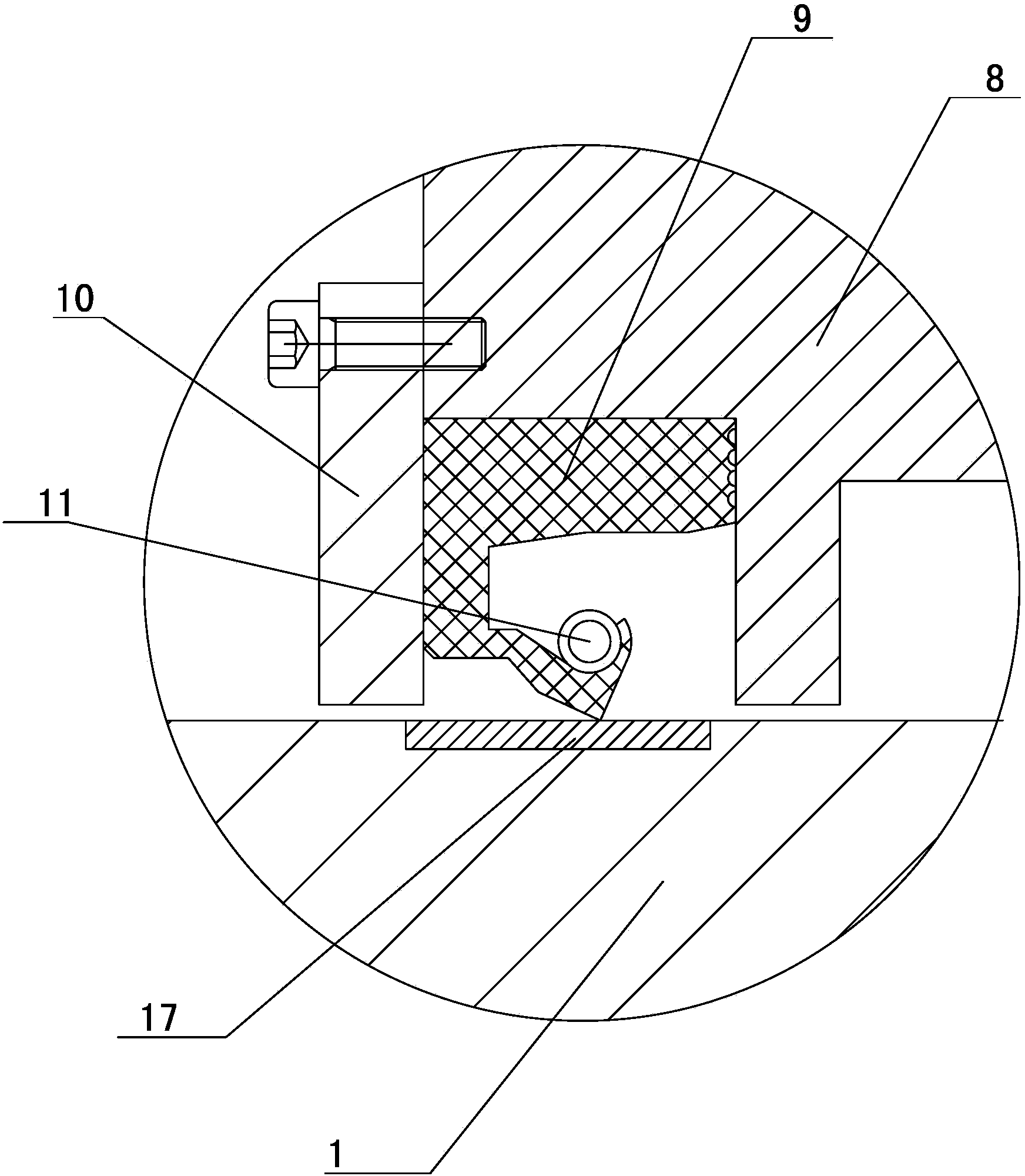

Waste lubricating grease collecting structure of wind driven generator spindle bearing

The invention discloses a waste lubricating grease collecting structure of a wind driven generator spindle bearing. The waste lubricating grease collecting structure of the wind driven generator spindle bearing has the advantages that a first grease collecting bottle is fixed to a turntable through a first grease delivery pipe and is communicated with a roller moving cavity through the first grease delivery pipe and a first grease outlet in the turntable, and a second grease collecting bottle is fixed to a rotor through a second grease delivery pipe and communicated with the roller moving cavity through the second grease delivery pipe and a second grease outlet in the rotor. A grease collecting pipeline is shortened, air in the grease collecting bottles is easily exhausted and can produce certain suction force under the effect of centrifugal force due to the fact that the first grease collecting bottle and the second grease collecting bottle are installed on the turntable and the rotor respectively, waste lubricating grease can timely flow into the grease collecting bottles, and accordingly when a grease supply device supplies new lubricating grease, the new lubricating grease can well extrude the waste lubricating grease, and the waste lubricating grease can be fully replaced by the new lubricating grease.

Owner:欣达重工股份有限公司

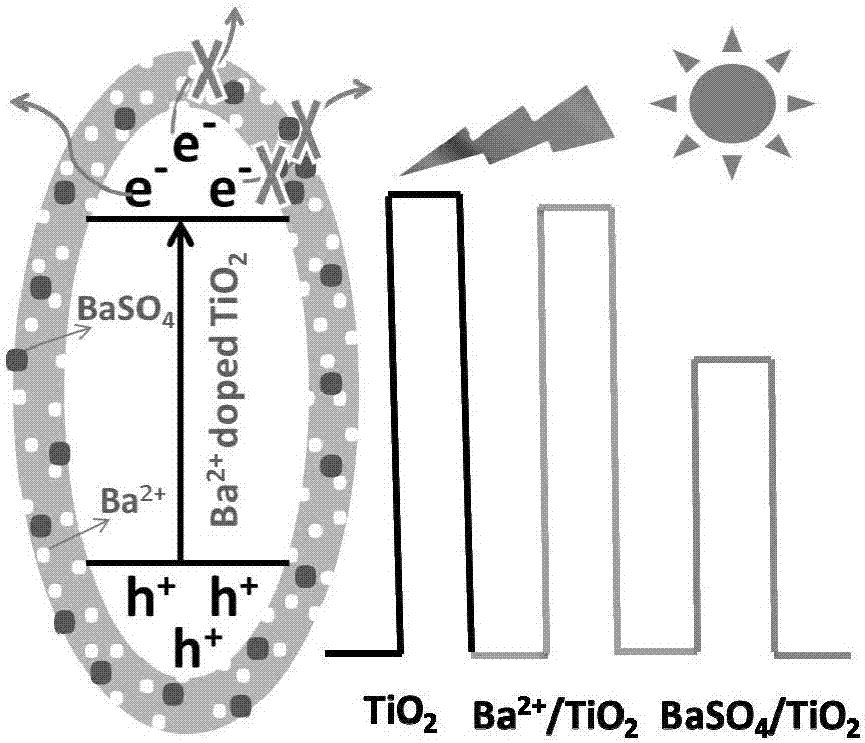

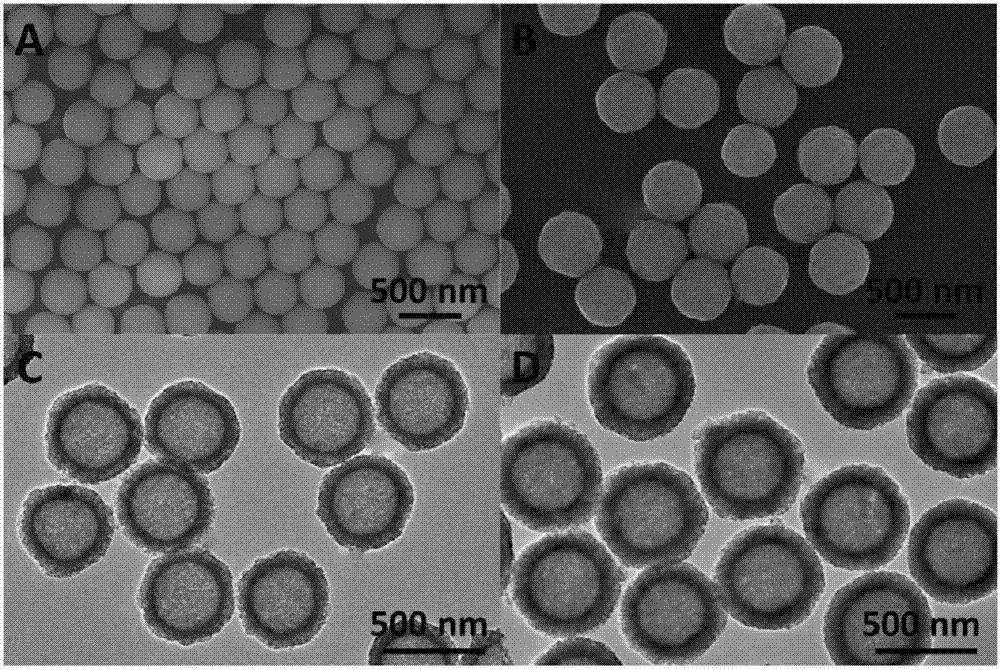

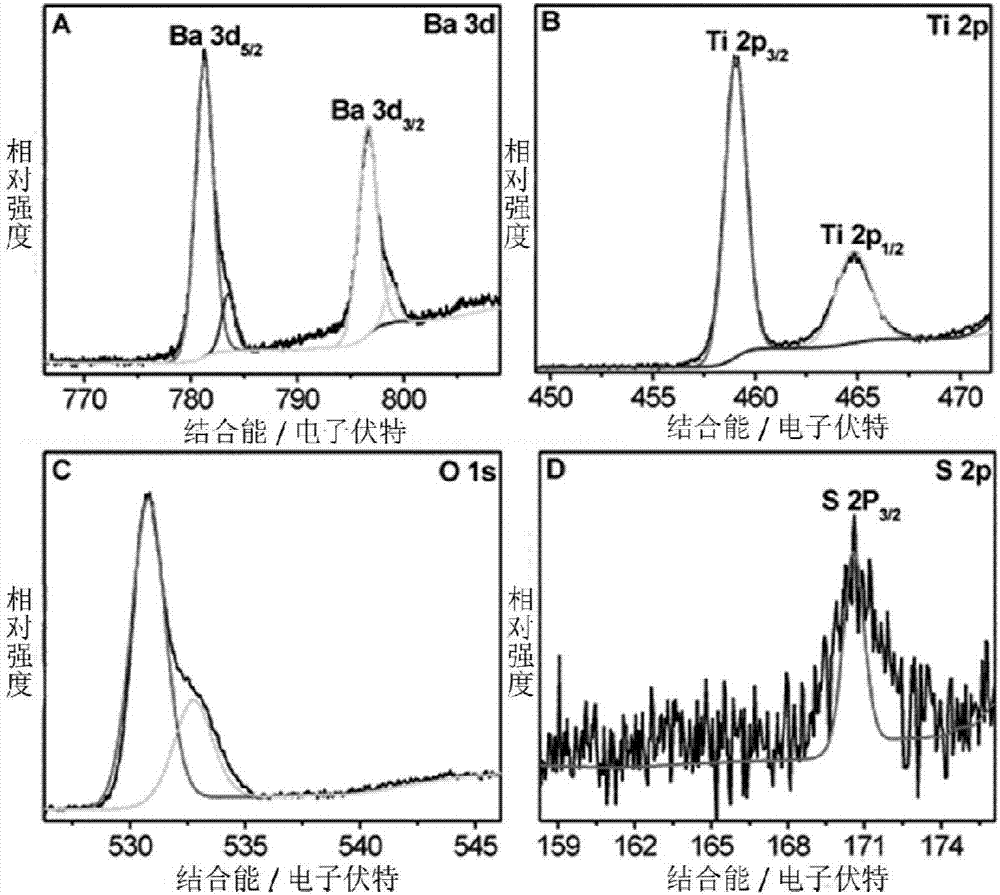

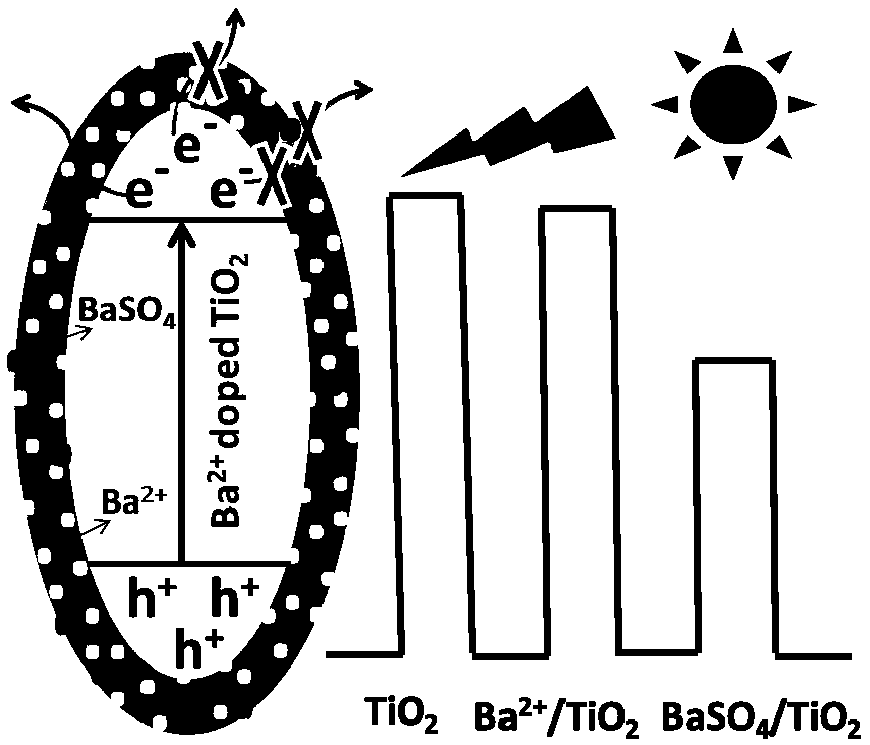

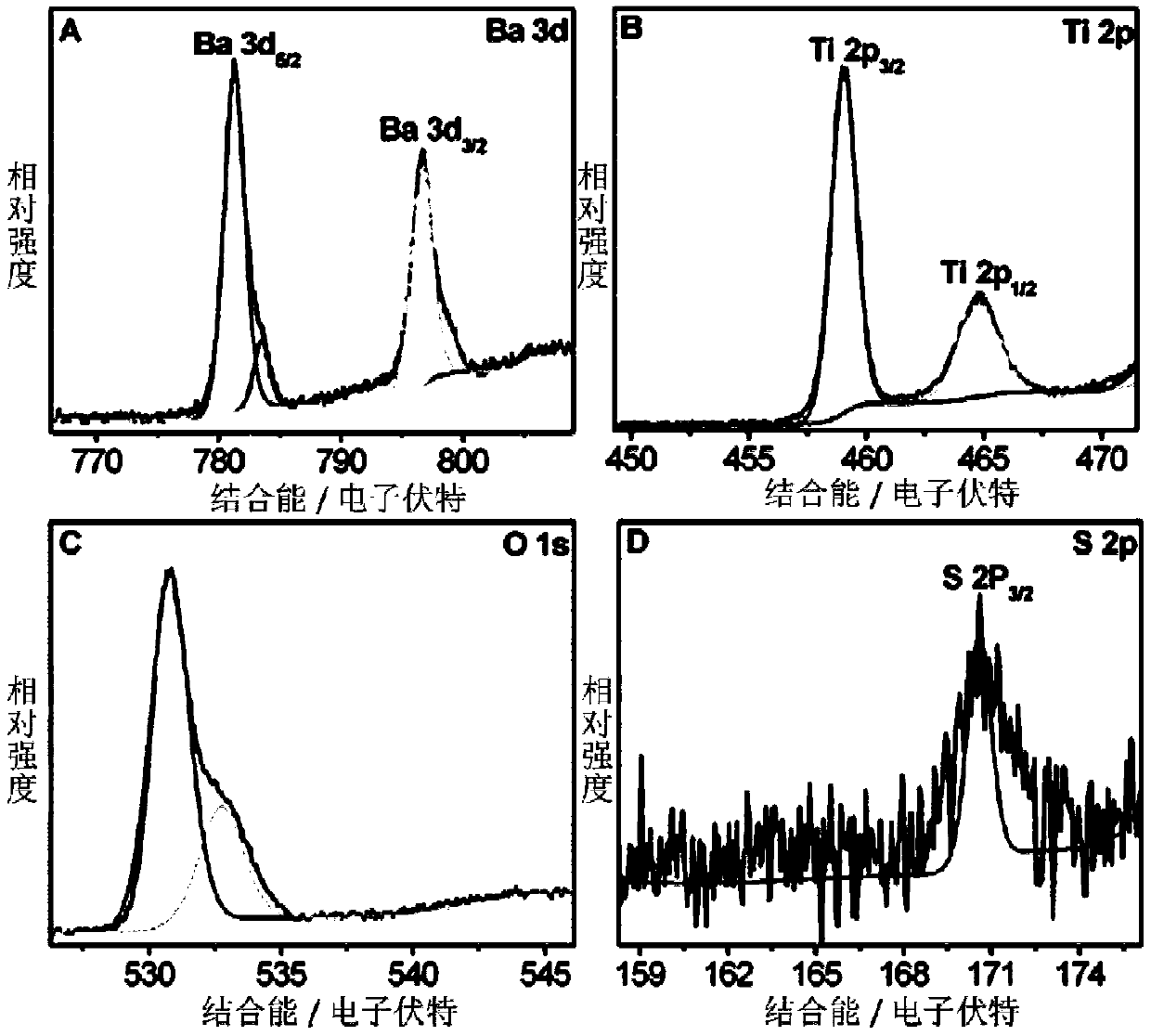

Photoelectrochemical detection method of sulfur dioxide

ActiveCN107144611AFull replacementProcess stabilityMaterial electrochemical variablesElectricityPower flow

The invention discloses a photoelectrochemical detection method of sulfur dioxide. The photoelectrochemical detection method comprises the following steps of cleanly washing a sliced ITO (Indium Tin Oxide) electrode by using alkaline liquid; preparing Ba<2+> doped TiO2 nano hollow sphere suspension liquid, then thinning the Ba<2+> doped TiO2 nano hollow sphere suspension liquid for 20 to 40 times, taking and dropwise applying 15 to 30 microliters of the thinned suspension liquid to one end of the ITO electrode, and drying the ITO electrode at a room temperature; moistening and rinsing the electrode by using water, so as to obtain a Ba<2+> doped TiO2 nano hollow sphere modified ITO electrode; making the prepared ITO electrode act with sulfate ions of different concentration values; establishing a quantitative linear equation according to the quantitative influences of the concentrations of the sulfate ions on a photoelectric current of the ITO electrode, wherein the quantitative linear equation is used for measuring the sulfur dioxide. The detection method provided by the invention has advantages of being simple, easy to operate, low in cost, high in sensitivity and good in selectivity and is operated at a room temperature, and the like.

Owner:YANCHENG INST OF TECH

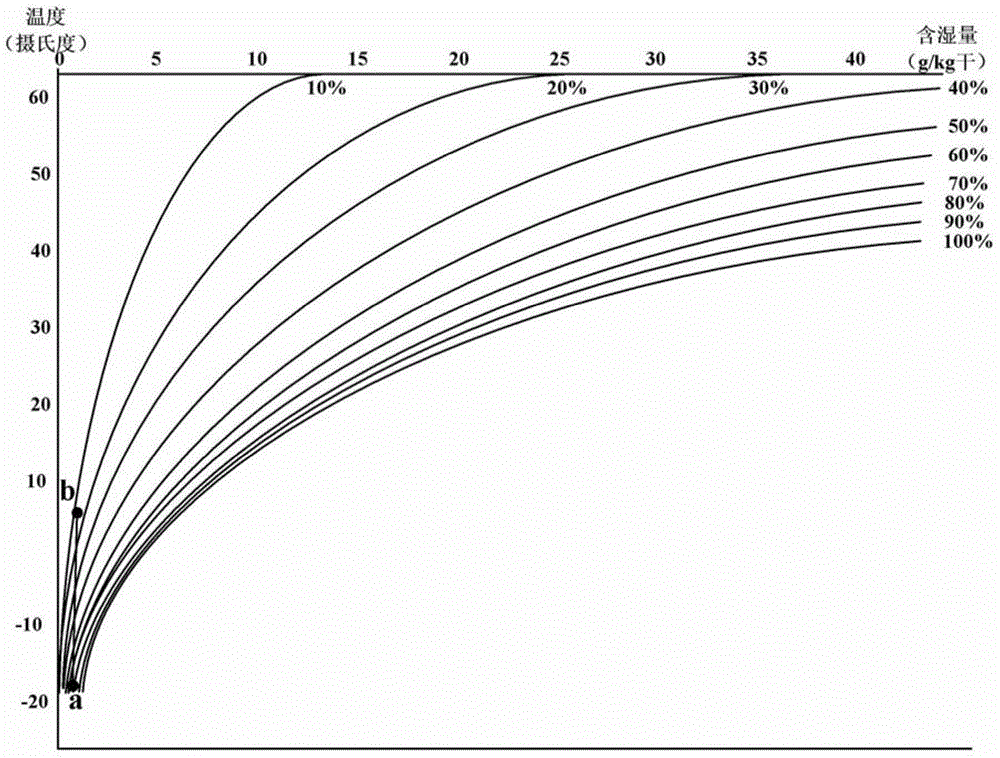

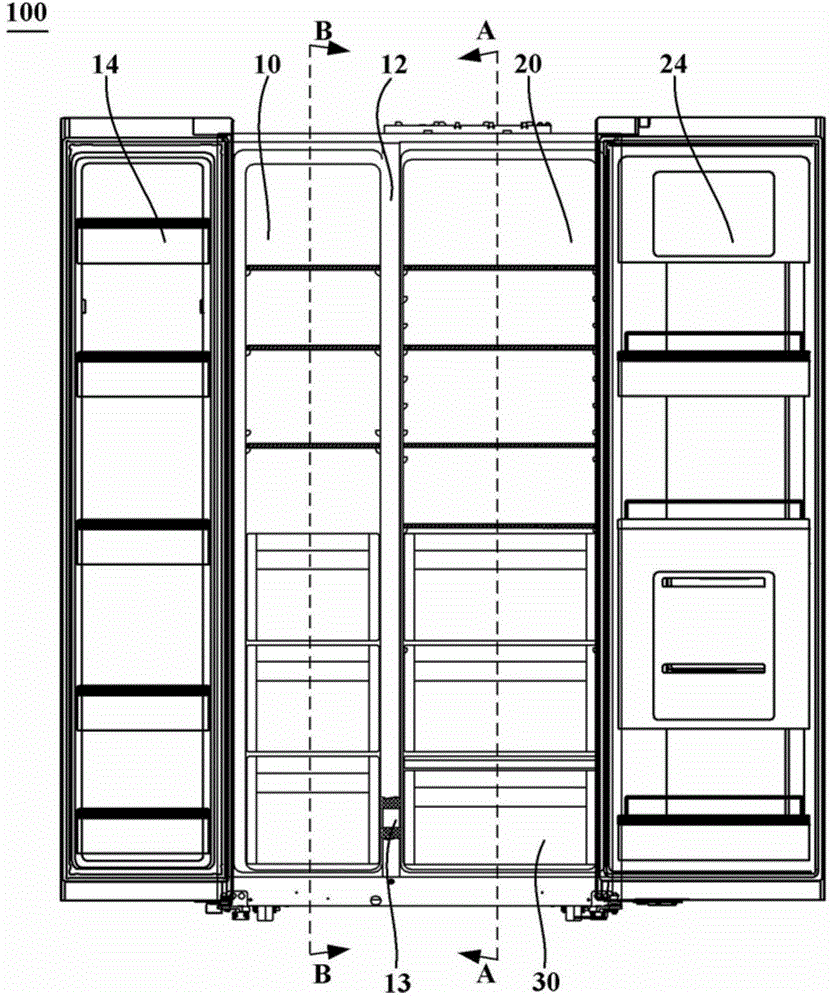

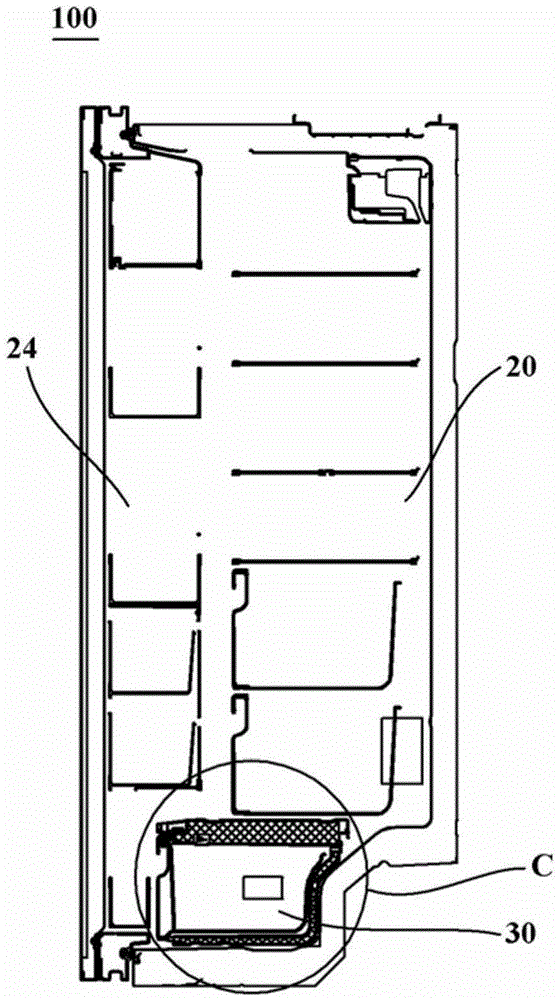

Dry storage device and ventilation method thereof

InactiveCN104567189AAvoid Mildew and ResurgenceConducive to maintainingDrying solid materials without heatDomestic refrigeratorsStart signalElectric energy

The invention provides a dry storage device and a ventilation method thereof. The dry storage device comprises a shell which defines a drying chamber, wherein the shell is provided with an air supply hole. The ventilation method of the dry storage device comprises the following steps: acquiring a starting signal for triggering the dry storage device to ventilate; opening the air supply hole according to the starting signal to provide air cooled by a cold source to the drying chamber; measuring humidity in the drying chamber, and closing the air supply hole after the humidity reaches a first preset humidity value to heat the drying chamber in a sealed state. By using the technical scheme of the invention, ventilation is started according to the starting signal, and the ending of the ventilation is controlled according to the humidity so as to guarantee that supplied low-temperature air can be used for substituting moist air in the drying chamber completely, so that the relative humidity in the drying chamber can be guaranteed to meet the requirement on long-term storage of dry cargoes after the ventilation is ended, the waste of electric energy used by refrigeration and air supply in long-term air supply can also be avoided, and foods are effectively prevented from getting mildew or becoming damp again.

Owner:HAIER SMART HOME CO LTD

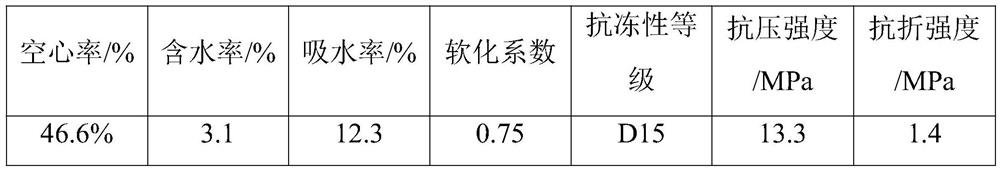

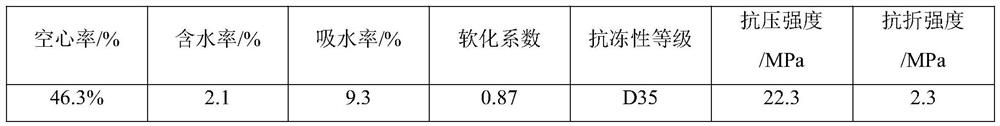

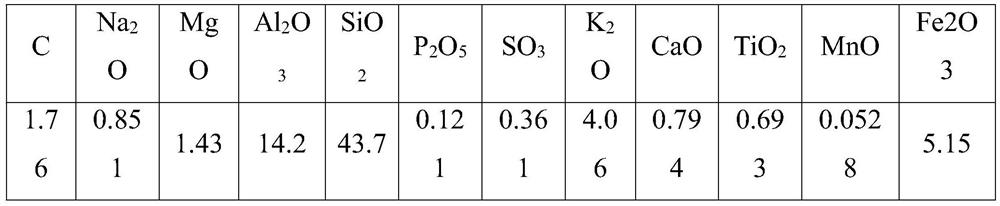

Fly ash-based geopolymer modified coal gangue concrete block and preparation method thereof

The invention relates to a fly ash based geopolymer modified coal gangue concrete block, which is prepared from 80 to 120 parts of fly ash, 40 to 65 parts of slag, 180 to 220 parts of cement, 150 to 180 parts of water, 700 to 800 parts of coal gangue coarse aggregate, 300 to 400 parts of coal gangue fine aggregate, 240 to 320 parts of coal gangue sand, 40 to 60 parts of water glass, 4 to 8 parts of sodium hydroxide and 3 to 5 parts of water reducing agent. The invention also discloses a manufacturing method of the fly ash-based geopolymer modified coal gangue concrete block; by matching the fly ash, the slag, the cement, the water, the coal gangue coarse aggregate, the coal gangue fine aggregate, the coal gangue sand, the water glass, the sodium hydroxide, the water reducing agent and the like, the existing materials such as the fly ash and the slag are fully utilized, so that the cost is reduced, and the anti-freezing performance, the compressive strength and the breaking strength are very excellent.

Owner:XIAN UNIV OF SCI & TECH

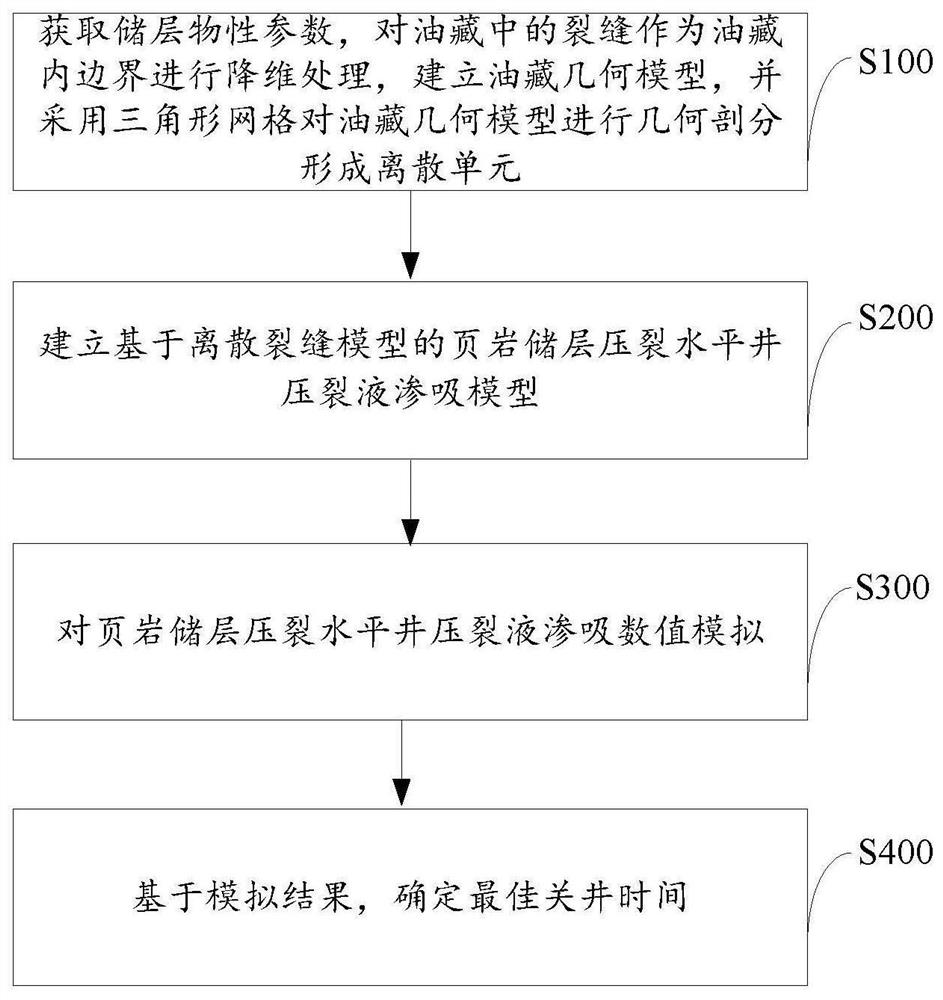

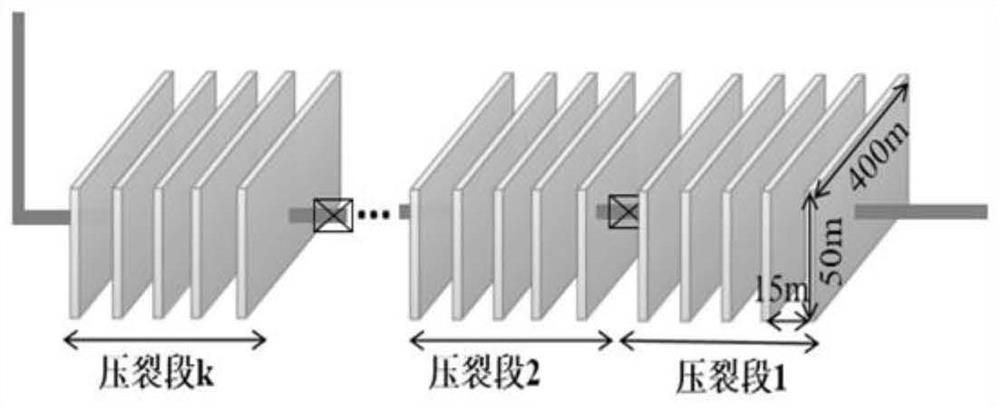

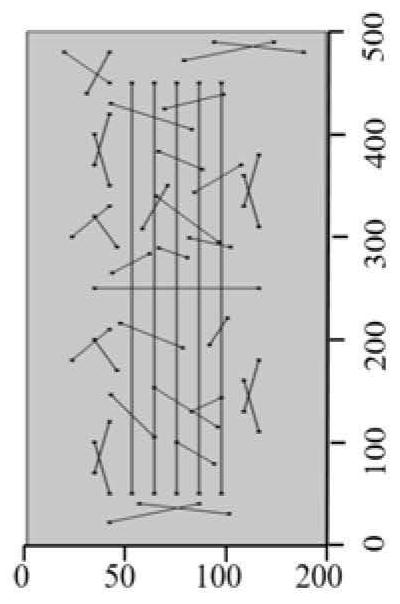

Method for optimizing well shut-in time after shale oil reservoir fracturing

PendingCN113836767AAchieve two-way couplingImprove accuracyData processing applicationsDesign optimisation/simulationHorizontal wellsFracturing fluid

The embodiment of the invention relates to a method for optimizing well shut-in time after shale oil reservoir fracturing. The optimization method comprises the steps: S100, acquiring reservoir physical property parameters, using fractures in an oil reservoir as the inner boundary of the oil reservoir to be subjected to dimension reduction processing, establishing an oil reservoir geometric model, and carrying out geometric subdivision on the oil reservoir geometric model through triangular grids to form discrete units; S200, establishing a shale reservoir fractured horizontal well fracturing fluid imbibition model based on the discrete fracture model; S300, simulating the fracturing fluid imbibition numerical value of the shale reservoir fractured horizontal well; and S400, based on the simulation result of the S300, determining the optimal well shut-in time.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

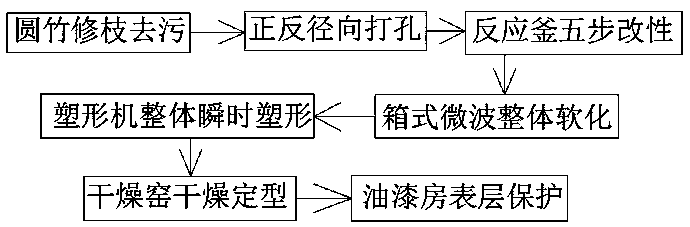

Deep processing technology of building bamboo with durability

PendingCN111055358AImprove yieldImprove flame retardant performanceRadiation/waves wood treatmentWood treatment detailsArchitectural engineeringStructural engineering

The invention discloses a deep processing technology of building bamboo with durability, relates to a deep processing technology of pure natural building materials, and in particular, relates to the deep processing technology of the building bamboo with better durability and higher fireproof level. The method comprises the steps of primary processing, deep processing, shaping and the like, primaryprocessing, pruning and decontamination are carried out, and a conical threaded drill bit is adopted to carry out radial two-way breakthrough on round bamboos through a casing pipe propelling method;deep processing is carried out on the primarily-processed bamboo. The bamboo is subjected to primary processing and deep processing treatment; it is ensured that the bamboo cannot crack in the processing and using processes; effective replacement of preservatives, flame retardants, organic matter and ash is carried out on the surface and the interior of the bamboo, the moth-proof performance, thecorrosion-proof performance, the flame-retardant performance and the like of the bamboo are essentially improved, more exquisite non-spliced integral bamboo crafts and buildings are designed on the basis, and the service life of the bamboo crafts and buildings can be as long as tens of years.

Owner:董舰泽

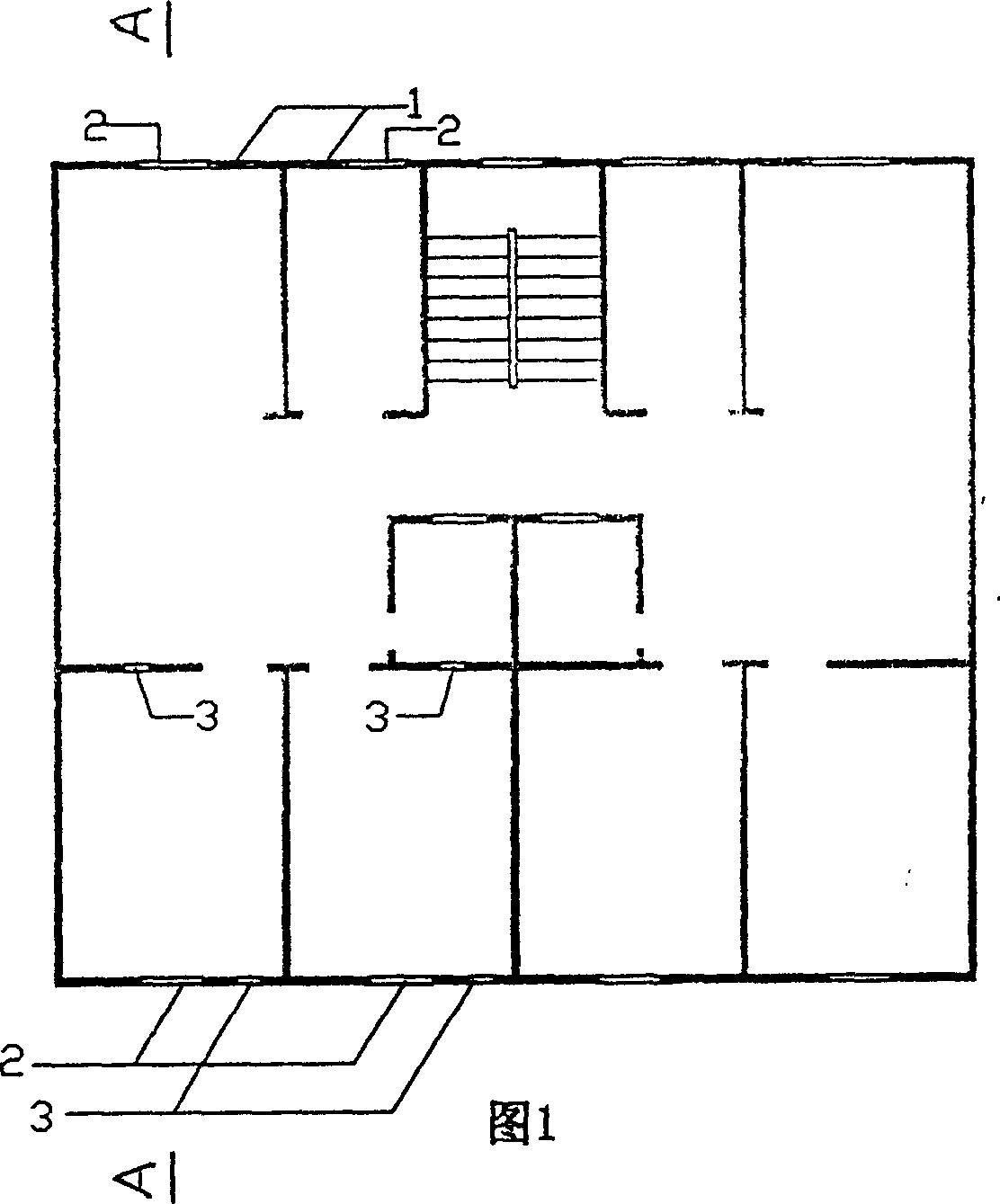

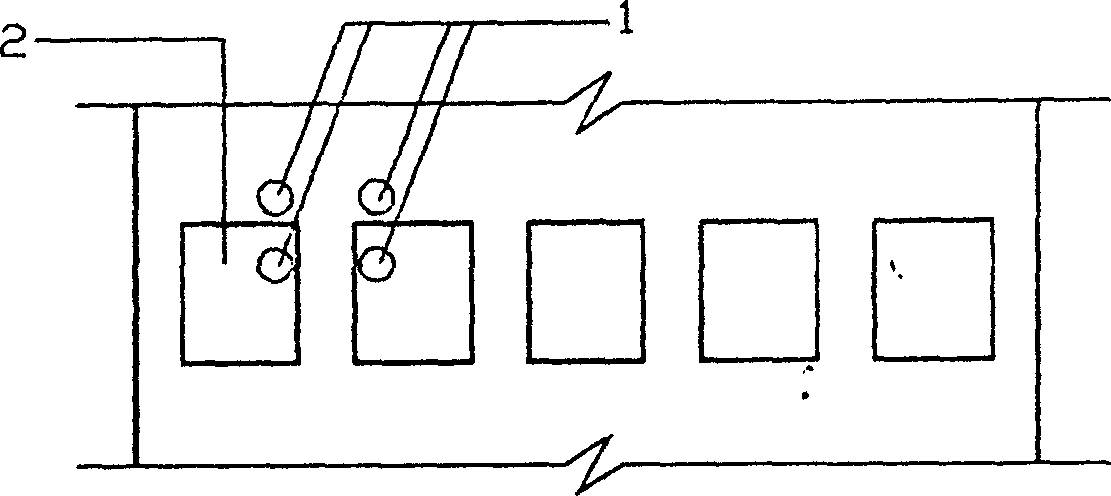

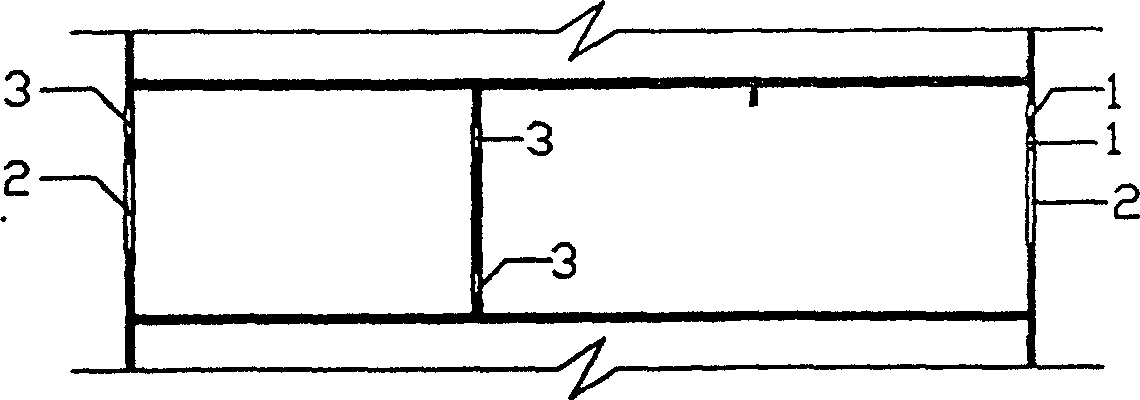

Air conditioning system in buildings

InactiveCN1228580CFull replacementFeel free to updateLighting and heating apparatusVentilation systemsAir conditioningAir door

The invention relates to an air and temperature regulating system in building, an air natural-conditioning system applied to badly facing and large enter-depth building. It installs an air exhausting fan connected with the room inside and outside on the wall of the building, installs switch on the air exhausting fan, sets air outlet hole on the wall opposite to the fan and active air door board in the air outlet hole, and it is an indoor air-conditioning system which can effectively make ventilation and temperature reduction on the building, has characters of low investment in devices, use convenience and no environmental pollution.

Owner:周瑞峰

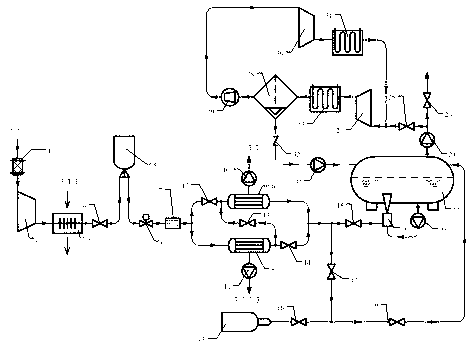

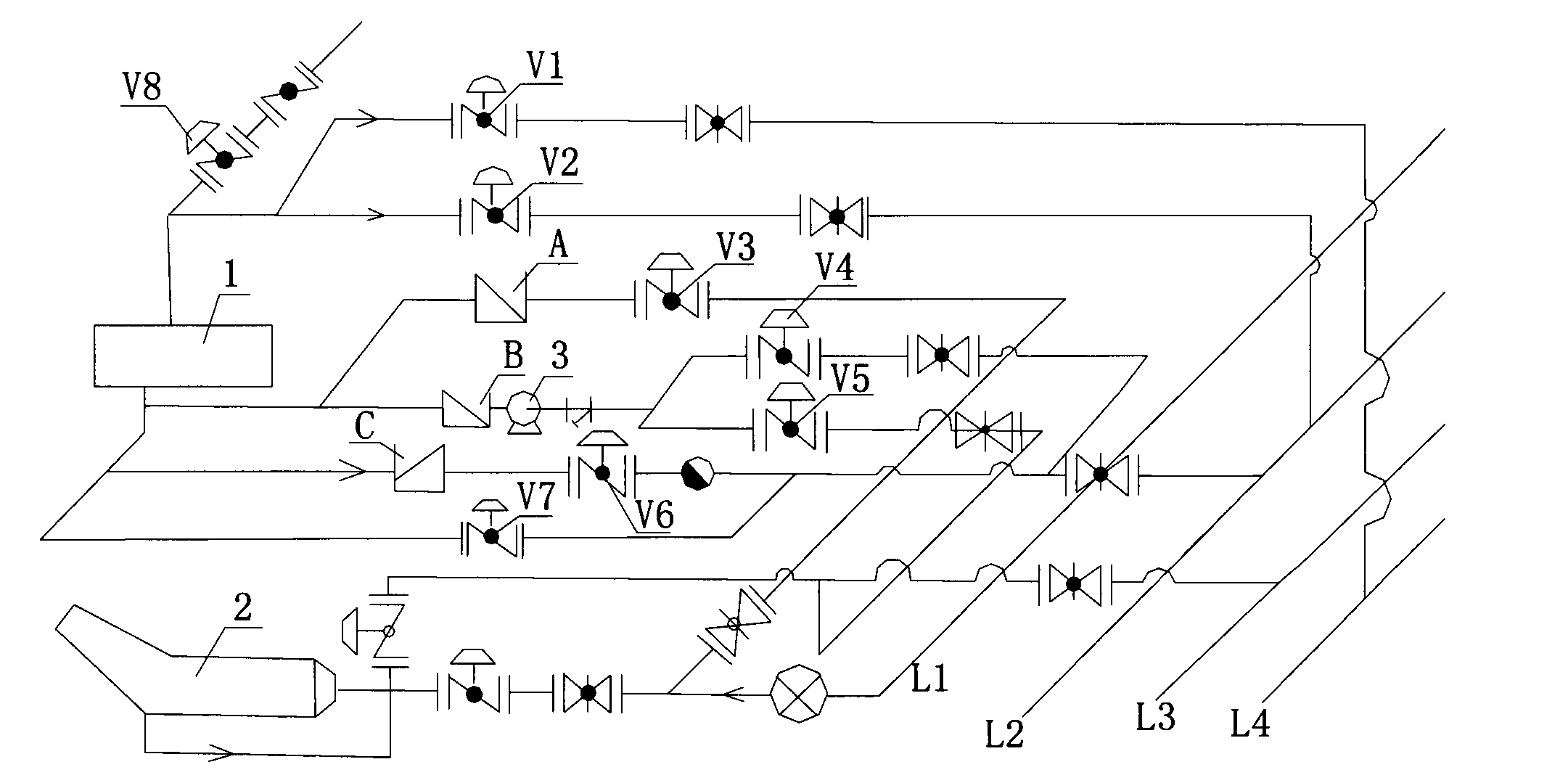

Overflow control system

ActiveCN103243503AControl flowPrecise flow controlTextile treatment machine arrangementsThermal energyWarm water

The invention discloses an overflow control system comprising an overflow machine, a heat exchanger, a thermodetector, a plurality of pneumatic valves, a plurality of check valves, a water pump, a pipeline, a high-temperature water tank, a medium-temperature water tank, a steam inlet, a tap water inlet and a control system, wherein the thermodetector is disposed on an entrance of the overflow machine; temperature changes of the heat exchanger are adjusted according to process requirements and test values; the heat exchanger is connected with the control system; and the medium-temperature water tank and the high-temperature water tank are respectively connected with the heat exchanger through the pneumatic valves and the pipeline. With the above method, the overflow control system has the advantages that utilization rate of thermal energy of the system is improved, heat pollution is reduced, service life of the device and the pipeline is prolonged during overflow process, maintenance cost is saved, production cost is reduced, and production efficiency is improved.

Owner:WUJIANG CHUANGXIN DYEING & PRINTING FACTORY

Artificial cultivation method for culter alburnus

InactiveCN106359192AConducive to healthy life and growthGood oxygen absorption functionClimate change adaptationPisciculture and aquariaBroodstockWater source

The invention relates to the technical field of fry incubation and cultivation, and particularly relates to an artificial cultivation method for culter alburnus. The method comprises the following steps: (1) performing parent fish cultivation; (2) performing parent selection; (3) performing parent temporary cultivation; (4) performing artificial inducement for spawning; (5) performing fry incubation. By virtue of restricting a parent fish cultivation pool as a flowing water source which is nearly free from pollution, and replacing whole water in the pool every two days, the external environment for parent fish cultivation is clean and sanitary and is beneficial to healthy life and growth of parent fish; by virtue of replacing with fresh water every two days, the oxygen uptake function of the parent fish is relatively good; the internal water depth of the pool is 1.0 to 1.2m, the water surface area of each pool is 2.0 to 3.0mu, the internal water temperature of the pool is kept within a range of 24 to 25 DEG C, so that the flowability of water in the pool is relatively good, the water replacement capability is relatively good, the problem that the water replacement purpose cannot be realized due to relatively static water at the bottom of the pool is avoided by virtue of suitable depth, and too large water depth hardly enables the temperature of water at the bottom to be within the required range.

Owner:湖南白泥湖高科水产养殖有限公司

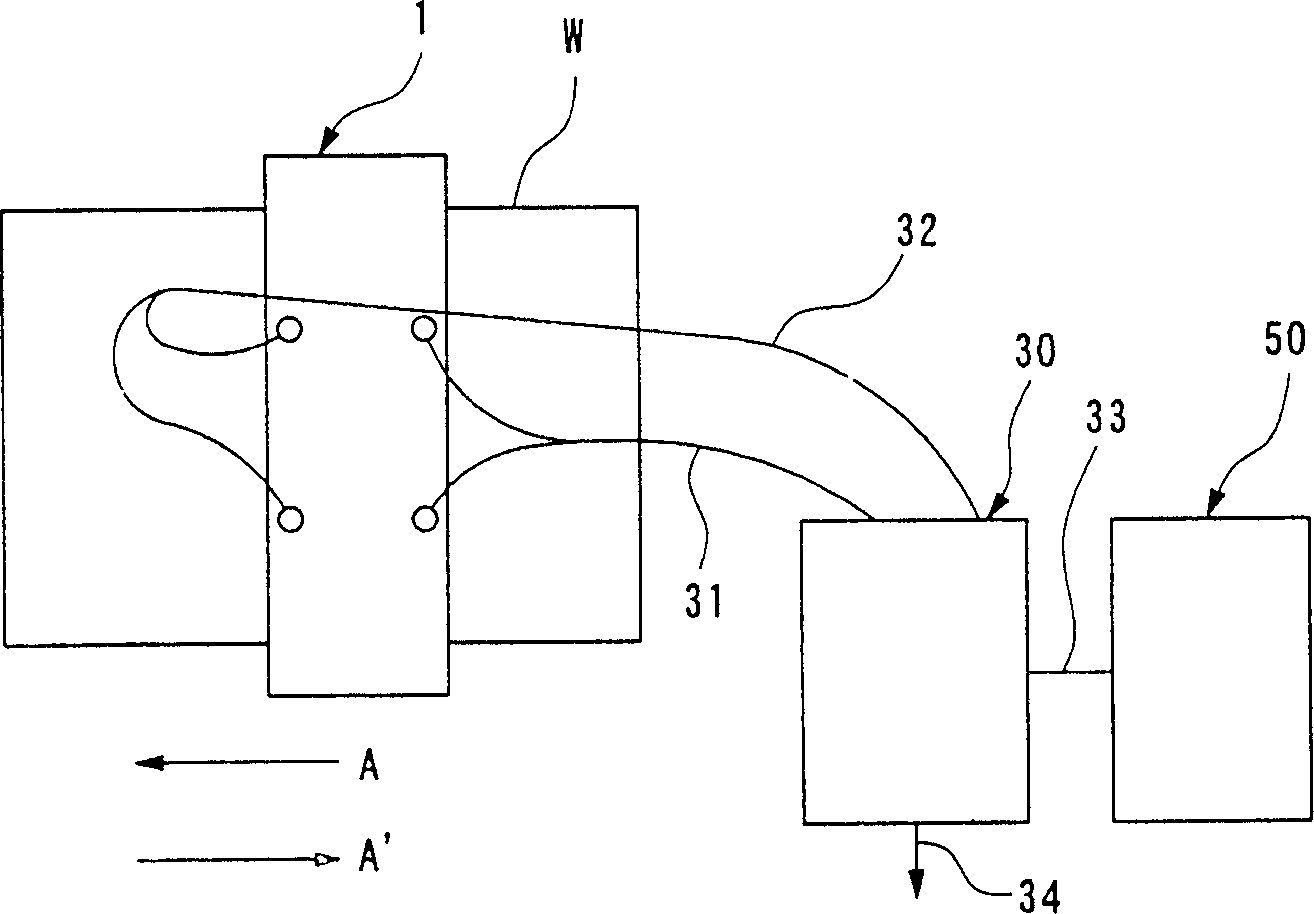

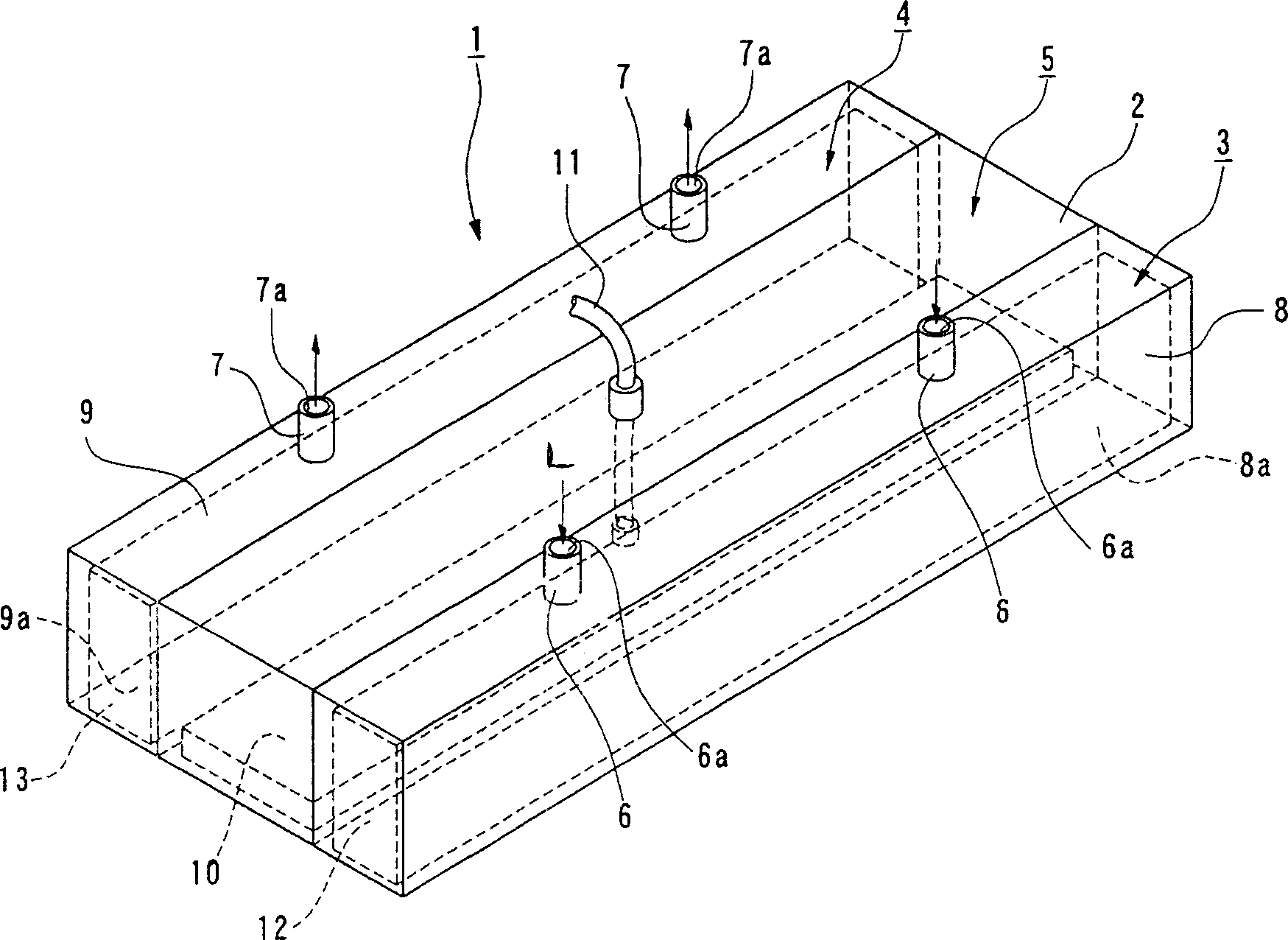

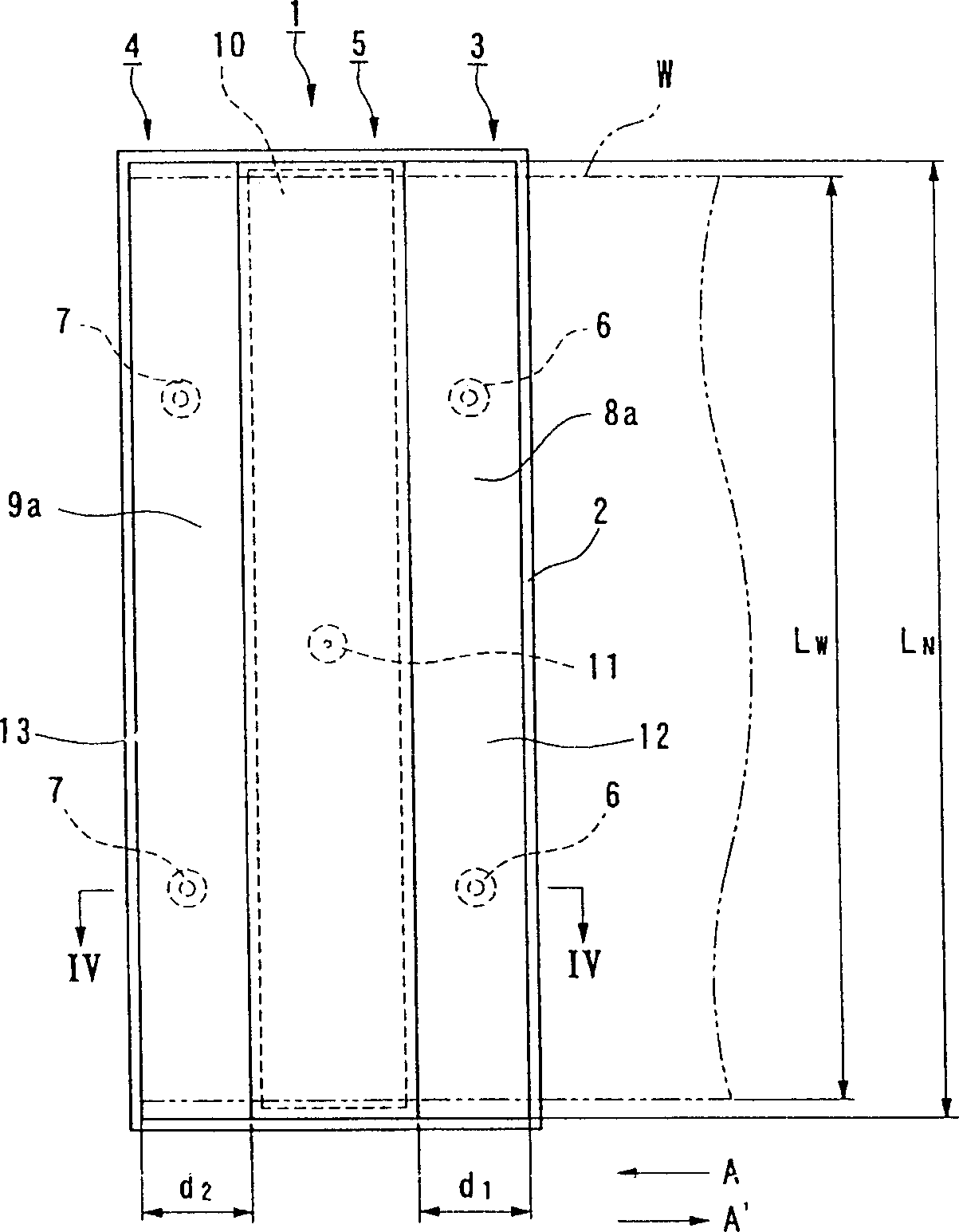

Wet type processing device

InactiveCN1340848AEffective wet processingFull replacementSemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringMechanical engineering

A wet treatment apparatus includes a nozzle having an approximately rectangular introduction opening surface (8a) which is open toward a substrate (W) to be treated and an approximately rectangular recovery opening surface (9a) which is open toward the substrate, these opening surfaces being flush with each other and disposed with the long side directions thereof in parallel with each other. A treatment liquid (L) is introduced between the introduction opening surface and the surface to be treated of the substrate and sucked and recovered from between the recovery opening surface and the surface to be treated of the substrate. At this time, the flow rate of the treatment liquid flowing from the introduction opening surface to the recovery opening surface through the surface to be treated of the substrate is controlled to 0.02 to 0.3 L / min per 1 cm in the long side direction of the introduction opening surface.

Owner:ALPS ALPINE CO LTD +1

Hydrochloric acid pickling waste liquid resource integrated utilization method for preparing iron oxide and ammonium sulfate

InactiveCN102689930BFull replacementWell mixedChlorine/hydrogen-chlorideEnergy inputLiquid wasteEvaporation

The invention relates to a hydrochloric acid pickling waste liquid resource integrated utilization method for preparing iron oxide and ammonium sulfate. Iron-containing hydrochloric acid pickling waste liquid obtained from a pickling treatment process, which uses hydrochloric acid solution as a pickle to remove surface oxides on a steel element, is used as a raw material. The method comprises the following steps of: (1) solid-liquid separation; (2) preheating and heating; (3) miscible displacement; (4) flash evaporation; (5) evaporation and crystallization; (6) solid-liquid separation; (7) mixing and dissolving; (8) pH adjusting; (9) adsorption for impurity removal; (10) solid-liquid separation; (11) neutralization and oxidation; and (12) solid-liquid separation. A liquid phase material is further used for preparation of an ammonium sulfate product, and a solid phase material is further used for preparation of an iron oxide product; besides, ammonium sulfate by-products can be prepared in further preparation of the ammonium sulfate product. The invention has advantages of reasonable technology, simple method, environment-friendliness, energy saving, low preparation cost, good product quality and high utilization rate of valuable components.

Owner:江苏江盛南节能科技有限公司

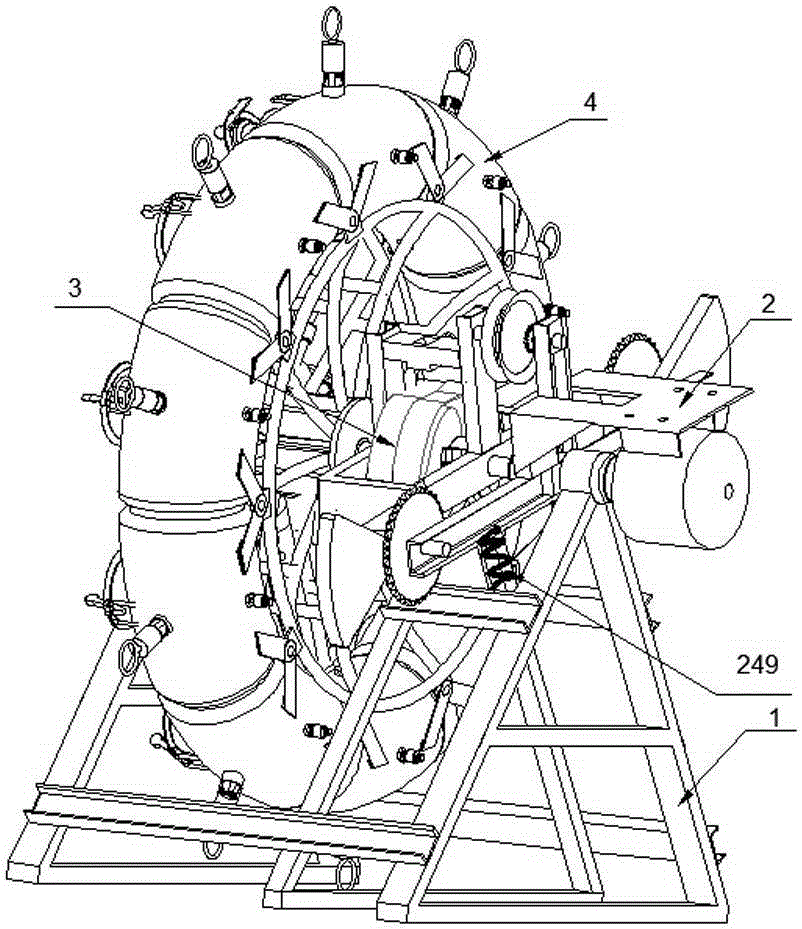

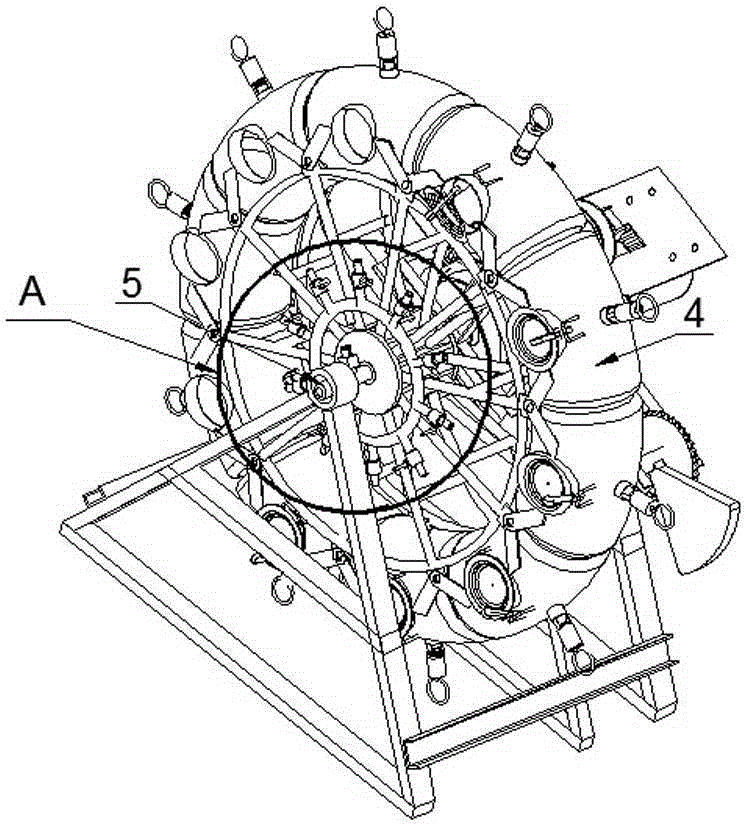

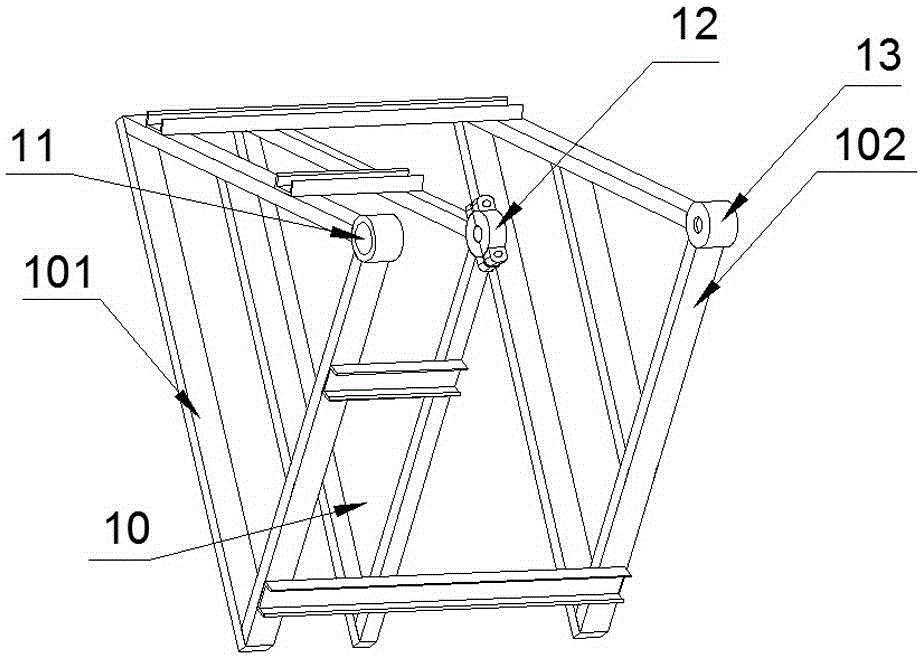

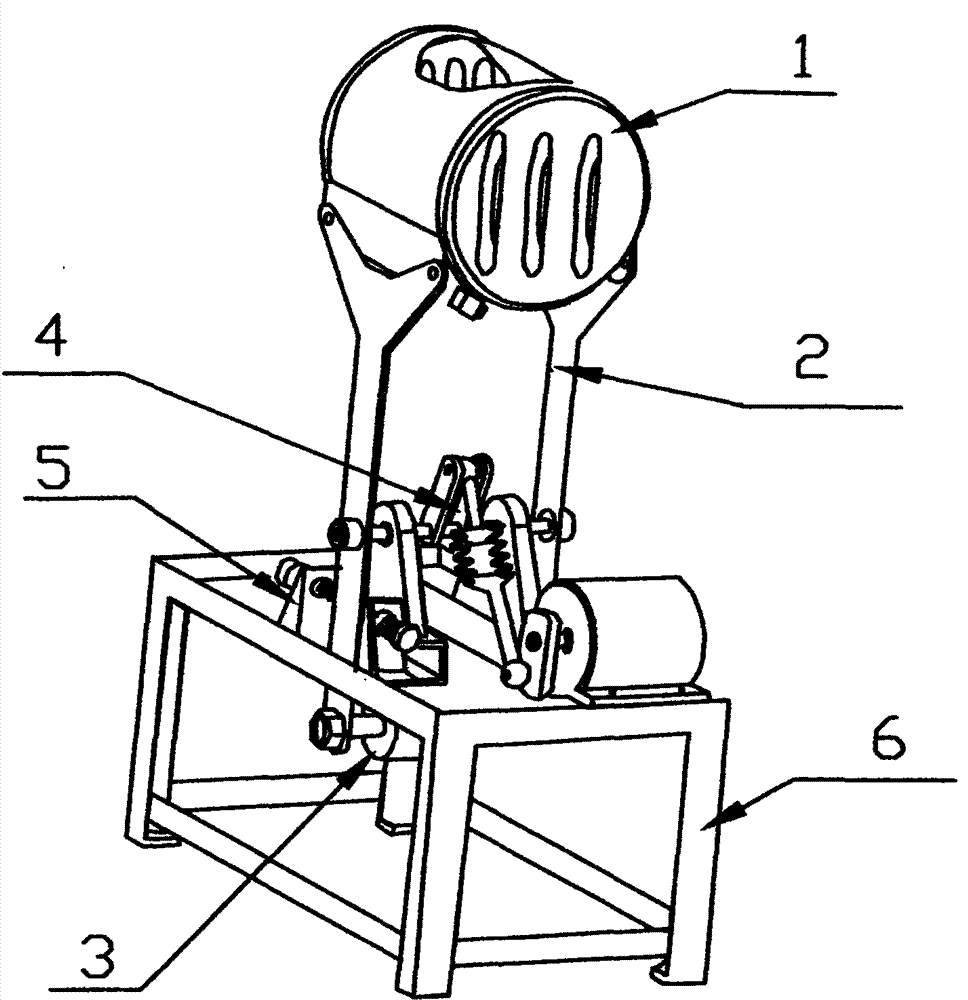

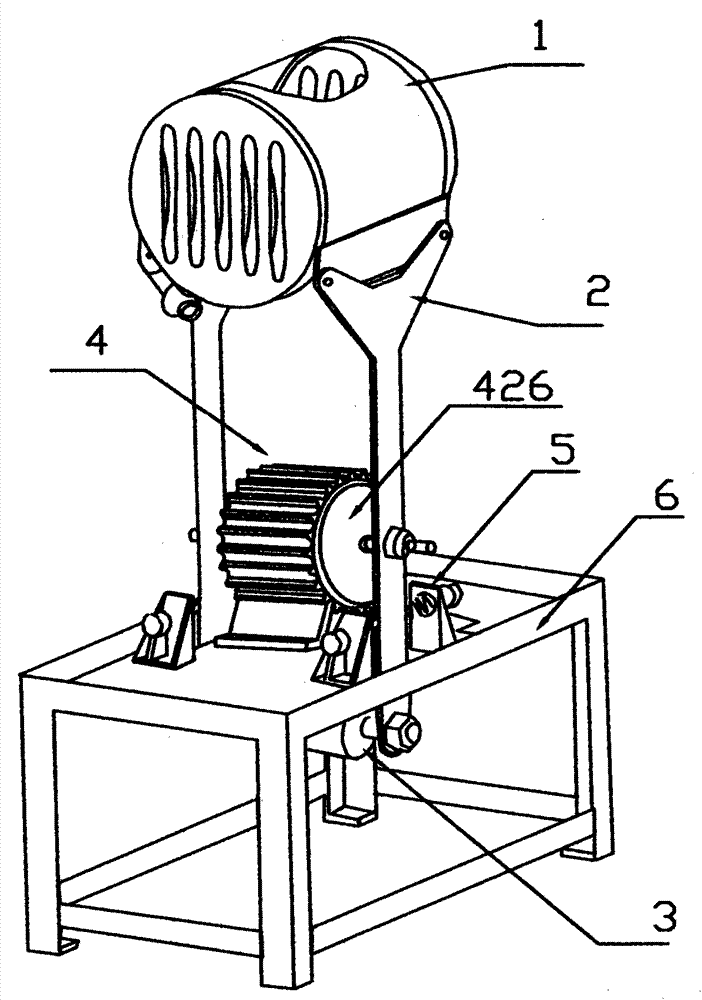

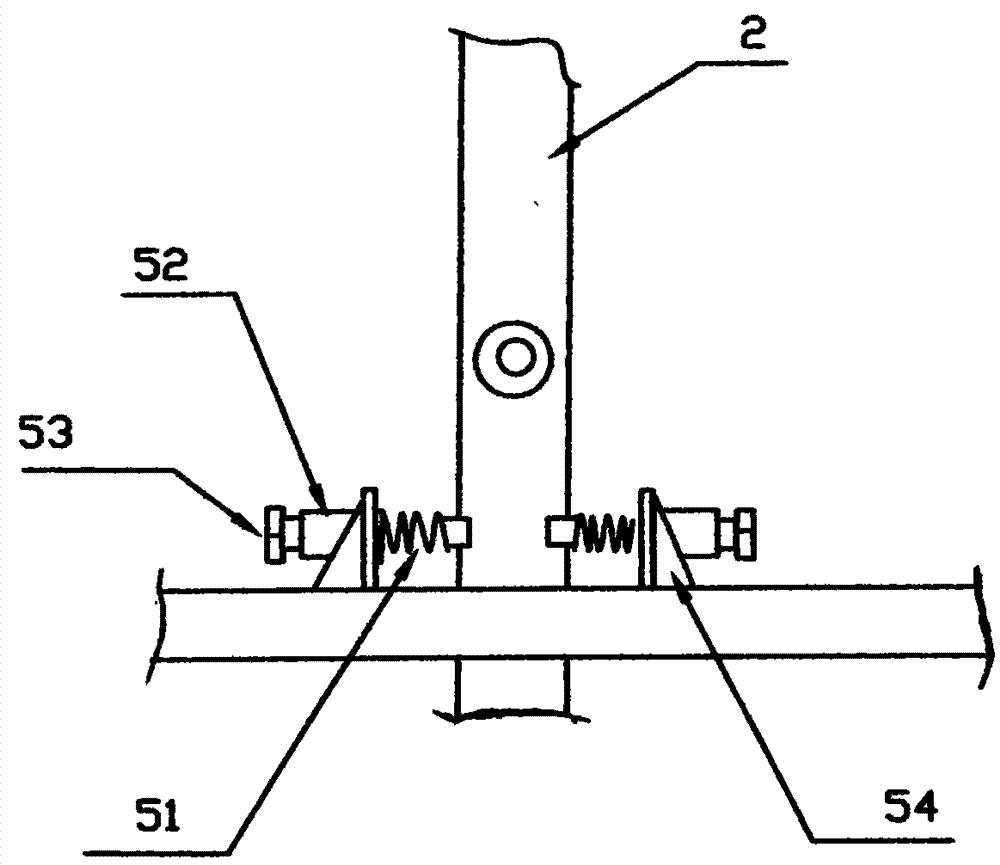

Multi-barrel rocking and impacting washing device

ActiveCN105177912ASolve the problem of insufficient beating forceRocking smoothlyOther washing machinesWashing machine with receptaclesState of artEngineering

The invention discloses a multi-barrel rocking and impacting washing device and belongs to the technical field of washing. The problems that in the prior art, water consumed for washing is large in amount, and cleaning dead corners exist in washed clothes are solved, and more importantly, the problem that in large-scale washing, the clothes cannot be separately washed, namely, cross contamination of the clothes is generated is solved. Meanwhile, a multi-barrel impacting washing method is utilized for washing the clothes more deeply. The multi-barrel rocking and impacting washing device mainly comprises a big frame, a power device, a converting mechanism, a combined washing device and the like, and washing barrels rock back and forth in a forcible mode to make the washed clothes impact back and forth and clean the washed clothes thoroughly. Through rocking washing of the multiple barrels, the clothes are separately loaded into the washing barrels to be treated, different types of clothes can be washed separately, and personal clothes are washed in a single barrel. The problem that in large-scale washing, the clothes cannot be separately washed is solved, washing and dehydrating are integrated, at each time of multi-barrel rocking and impacting washing, the barrels can work at the same time, and washing efficiency is improved.

Owner:徐州博创建设发展集团有限公司

Method for preparing iron oxide and ammonium sulfate by using hydrochloric acid washing waste liquid

InactiveCN108569722ATake advantage ofGood energy saving effectChlorine/hydrogen-chloride purificationFerric oxidesEvaporationAcid washing

The invention relates to a method for preparing iron oxide and ammonium sulfate by using a hydrochloric acid washing waste liquid, wherein an iron and steel element is subjected to acid washing treatment by using a hydrochloric acid solution as an acid washing liquid to remove surface oxides so as to obtain an iron-containing hydrochloric acid washing waste liquid, and the iron-containing hydrochloric acid washing waste liquid is used as the raw material of the method. The method comprises: (1) solid-liquid separation; (2) preheating and heating; (3) mixed displacement; (4) flash evaporation;(5) evaporation crystallization; (6) solid-liquid separation (7) mixed dissolution; (8) pH value adjustment; (9) adsorption and impurity removal; (10) solid-liquid separation; (11) neutralization oxidation; and (12) solid-liquid separation, wherein the liquid phase material is further prepared into the sulfuric acid product, the solid phase material is further prepared into the iron oxide products, and an ammonium sulfate by-product can be prepared during the preparation of an ammonium sulfate product. According to the present invention, the method has characteristics of reasonable process, simple method, environmental protection, energy saving, low preparation cost, good product quality and high utilization rate of valuable components.

Owner:XIAN YOUQING COMMERCE & TRADE CO LTD

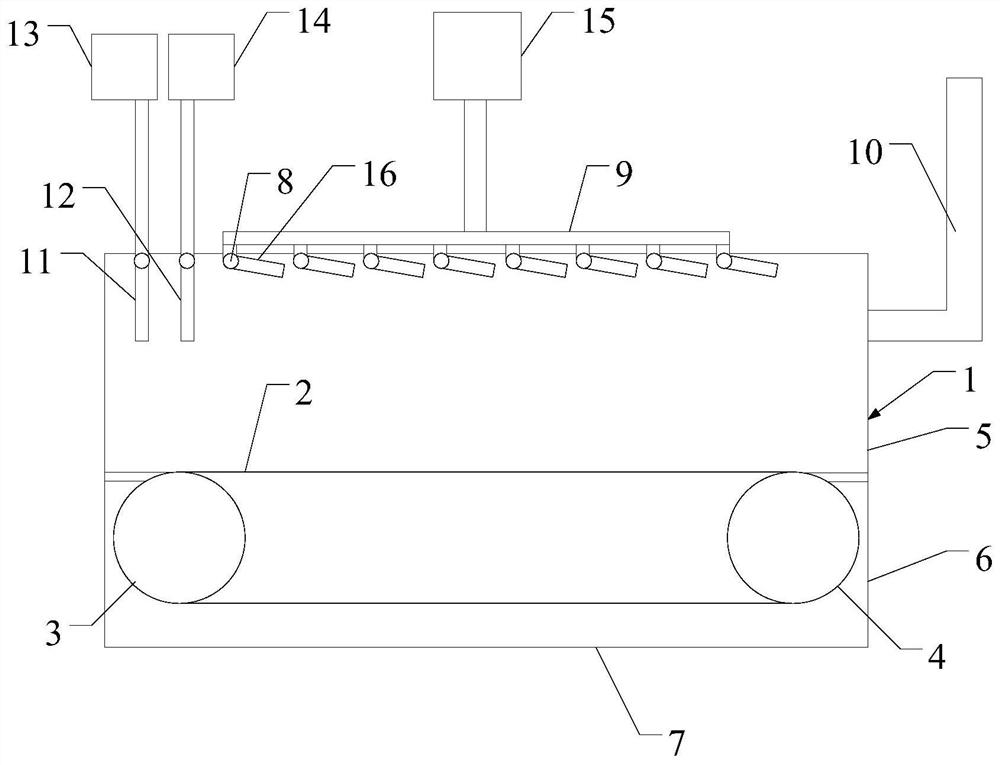

Mask conveying device

InactiveCN112623809AFull replacementAvoid pollutionDrying gas arrangementsArticle feedersRespiratorTransmission belt

The invention discloses a mask conveying device which comprises a conveying belt, a pair of conveying rollers, a drive motor, a sealing cover, a gas supply device and an air supply mechanism, wherein the sealing cover covers the outer side of the conveying belt, and the sealing cover seals the conveying belt and the pair of conveying rollers therein; the gas supply device is arranged outside the sealing cover, the gas supply device is communicated to the front end of the sealing cover through an air supply pipeline and used for supplying sterile air to the sealing cover, and an air return pipeline is communicated to the rear end of the sealing cover; and the air supply mechanism is arranged in the sealing cover and located above the conveying belt, the air supply mechanism comprises a plurality of air supply exhaust pipes which are arranged in parallel, each air supply exhaust pipe comprises a transverse pipe and a plurality of air supply nozzles arranged on the transverse pipe, the transverse pipes are communicated to the air supply pipeline, the air supply nozzles form an angle of 170-175 degrees relative to the surface of the conveying belt, and the air supply nozzles incline forwards relative to the conveying direction of the conveying belt. According to the mask conveying device, masks can be protected in the mask conveying link, and the masks are prevented from being polluted by the environment.

Owner:CHANGLE ZHIYUAN TECH DEV CO LTD

Swing impact washing device

ActiveCN104695164BFully protectedSolve the problem of insufficient beating forceOther washing machinesWashing machine with receptaclesState of artWater flow

Owner:银港北京航空地面服务有限公司

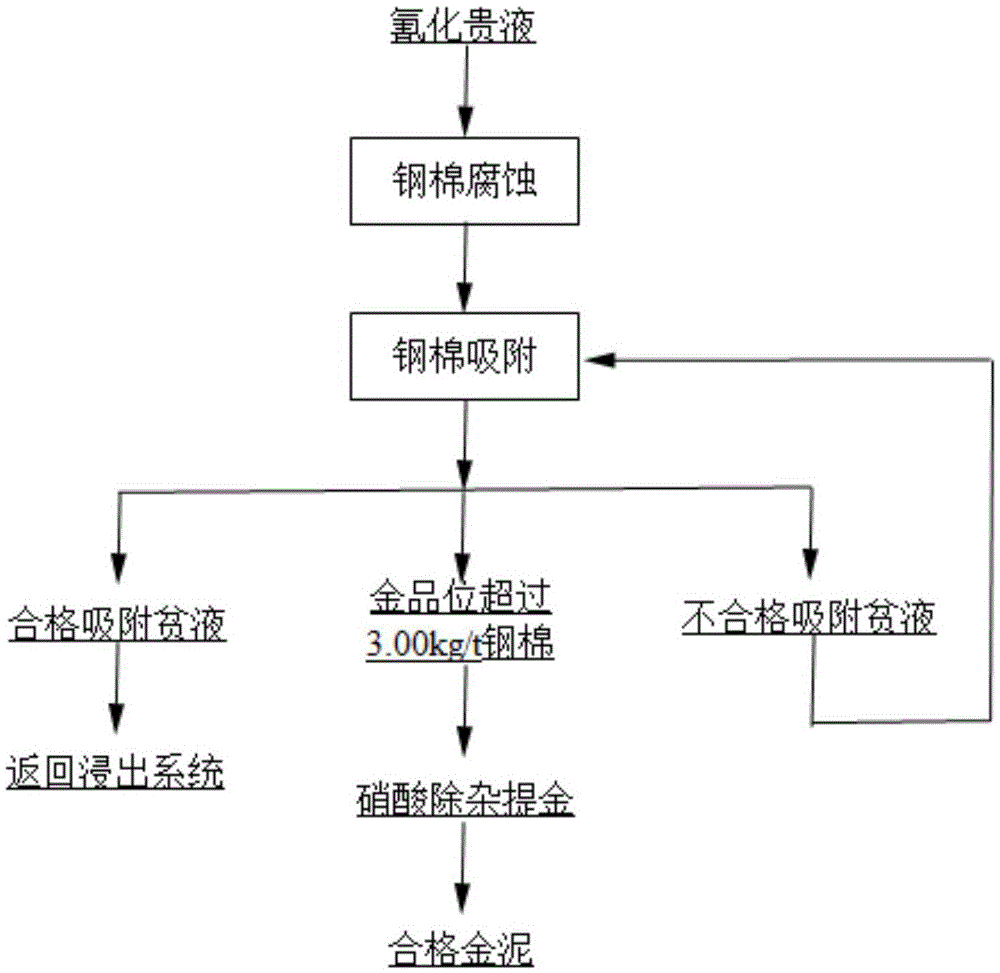

Method for recovering gold and copper from copper-containing cyanide precious liquid

ActiveCN104120265BShort processEasy to operateProcess efficiency improvementCyanideMaterials science

Owner:厦门紫金矿冶技术有限公司 +1

Overall performance testing rack of numerical control ultrasonic cutting sound main shaft

InactiveCN103323223BEasy to synthesizeFor subsequent analysisMachine part testingNumerical controlCombined test

Owner:HANGZHOU DIANZI UNIV

A photoelectrochemical detection method for sulfur dioxide

ActiveCN107144611BFull replacementProcess stabilityMaterial electrochemical variablesSulfate radicalsIndium tin oxide

The invention discloses a photoelectrochemical detection method of sulfur dioxide. The photoelectrochemical detection method comprises the following steps of cleanly washing a sliced ITO (Indium Tin Oxide) electrode by using alkaline liquid; preparing Ba<2+> doped TiO2 nano hollow sphere suspension liquid, then thinning the Ba<2+> doped TiO2 nano hollow sphere suspension liquid for 20 to 40 times, taking and dropwise applying 15 to 30 microliters of the thinned suspension liquid to one end of the ITO electrode, and drying the ITO electrode at a room temperature; moistening and rinsing the electrode by using water, so as to obtain a Ba<2+> doped TiO2 nano hollow sphere modified ITO electrode; making the prepared ITO electrode act with sulfate ions of different concentration values; establishing a quantitative linear equation according to the quantitative influences of the concentrations of the sulfate ions on a photoelectric current of the ITO electrode, wherein the quantitative linear equation is used for measuring the sulfur dioxide. The detection method provided by the invention has advantages of being simple, easy to operate, low in cost, high in sensitivity and good in selectivity and is operated at a room temperature, and the like.

Owner:YANCHENG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com