Patents

Literature

264results about How to "Increased turbulence intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

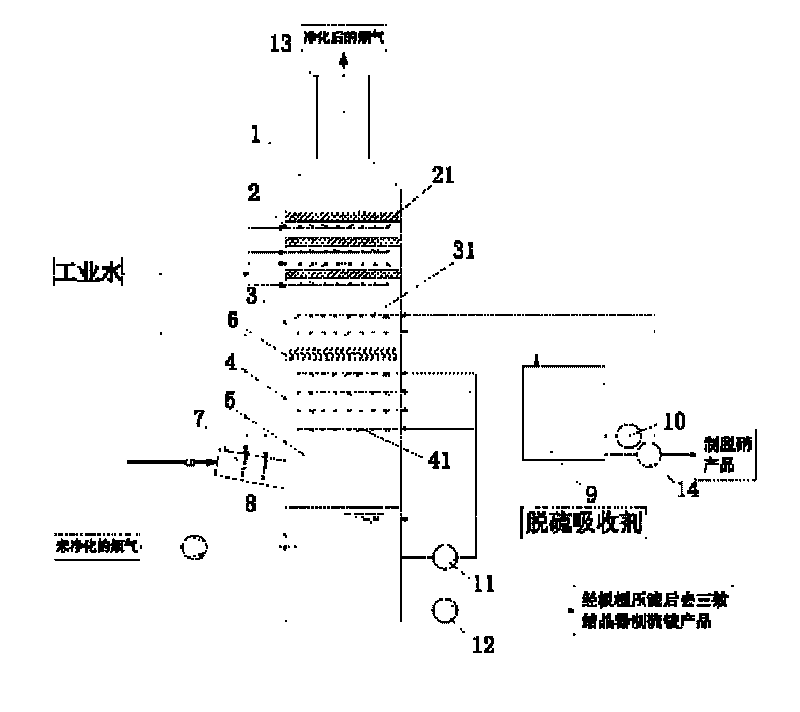

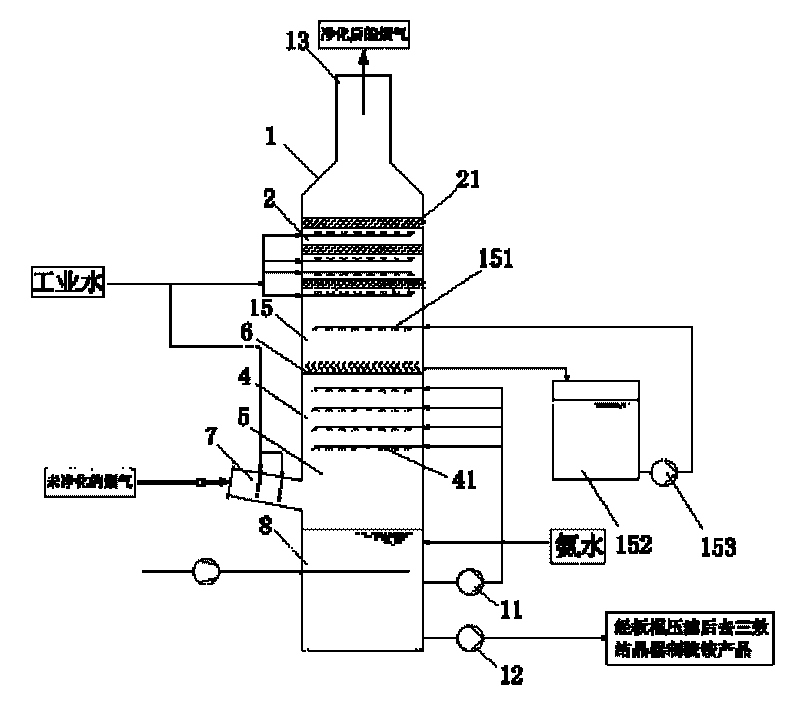

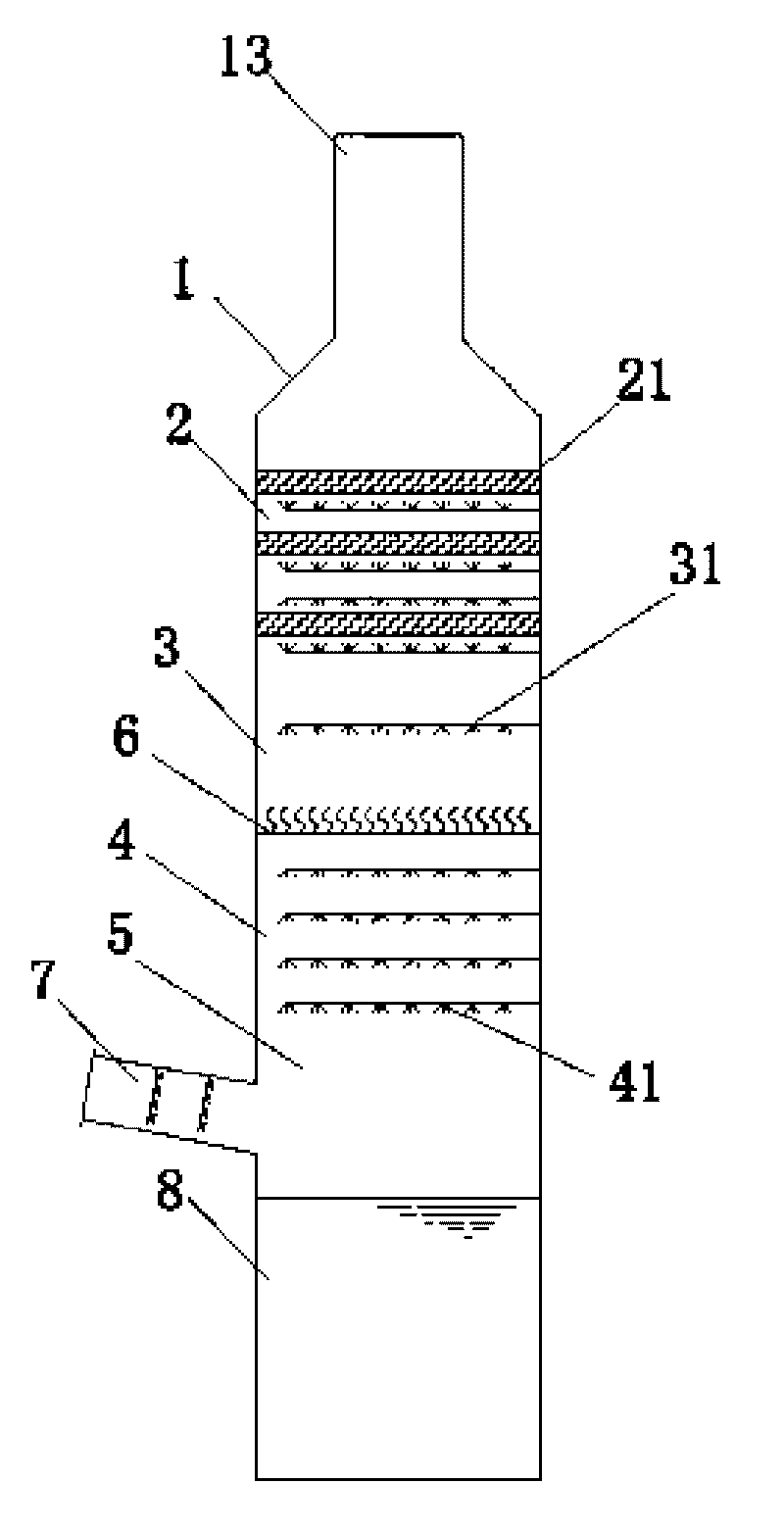

Treatment technique for pollutants in sinter fume and spraying and absorbing tower thereof

InactiveCN101708420AEasy to handleQuality improvementLighting and heating apparatusDispersed particle separationMulti pollutantEngineering

The invention discloses a treatment technique for pollutants in sinter fume and a spraying and absorbing tower thereof. After cooling and dedusting, the sinter fume is led into the spraying and absorbing tower, moves upwards to pass through at least two spraying and absorbing sections partitioned from up down in the spraying and absorbing tower, each spraying and absorbing section sprays and absorbs more than one pollutant in the sinter fume and the spraying and absorbing solution does not fall into the absorbing section of next layer, after passing through all the spraying and absorbing sections, the fume is demisted and exhausted from the top of the spraying and absorbing tower. The spraying and absorbing tower comprises a tower body, the tower body is partitioned into a demisting section, more than two spraying and absorbing sections and a fume inlet section from up down and a seriflux pool on the bottom of the tower body, and the adjacent spraying and absorbing sections are partitioned by a tower board assembly. The invention has the advantages that the loss of system resistance is small, the structure is simpler and more compact, the operation is convenient, the absorption effect is good, the treatment capacity is high and the like, and the invention can treat various pollutants in sinter fume.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

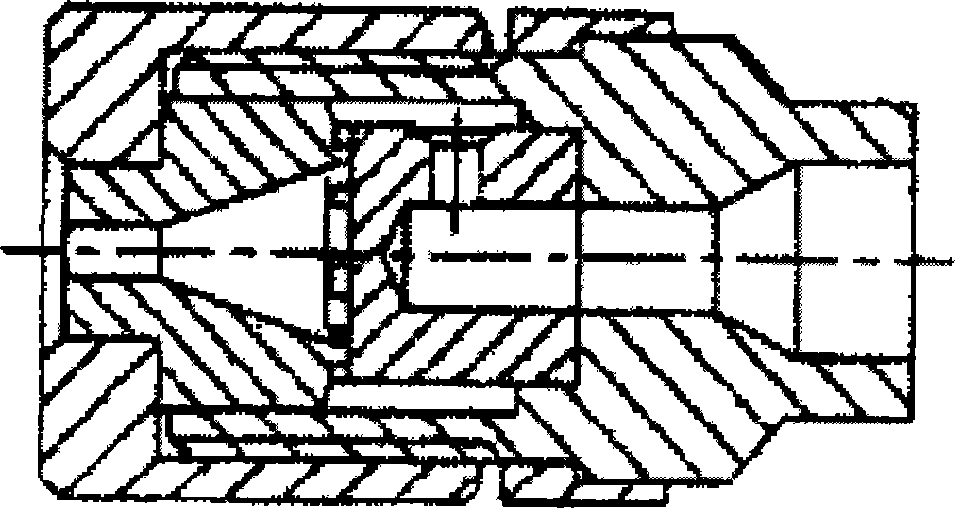

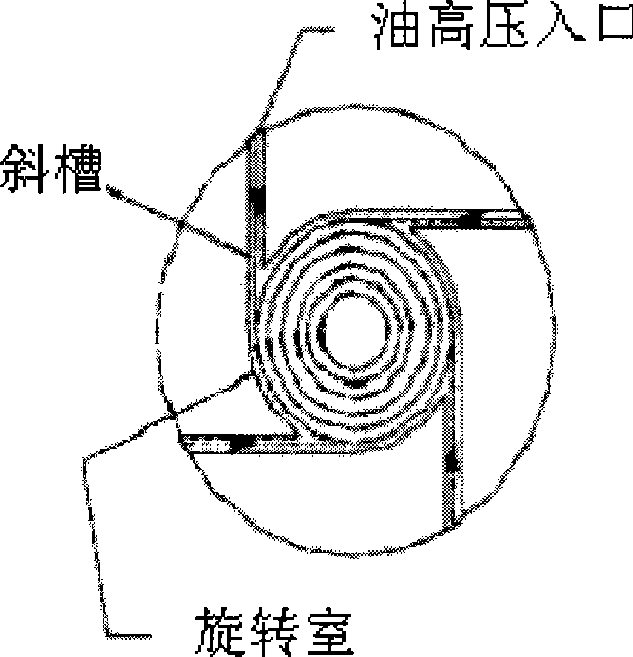

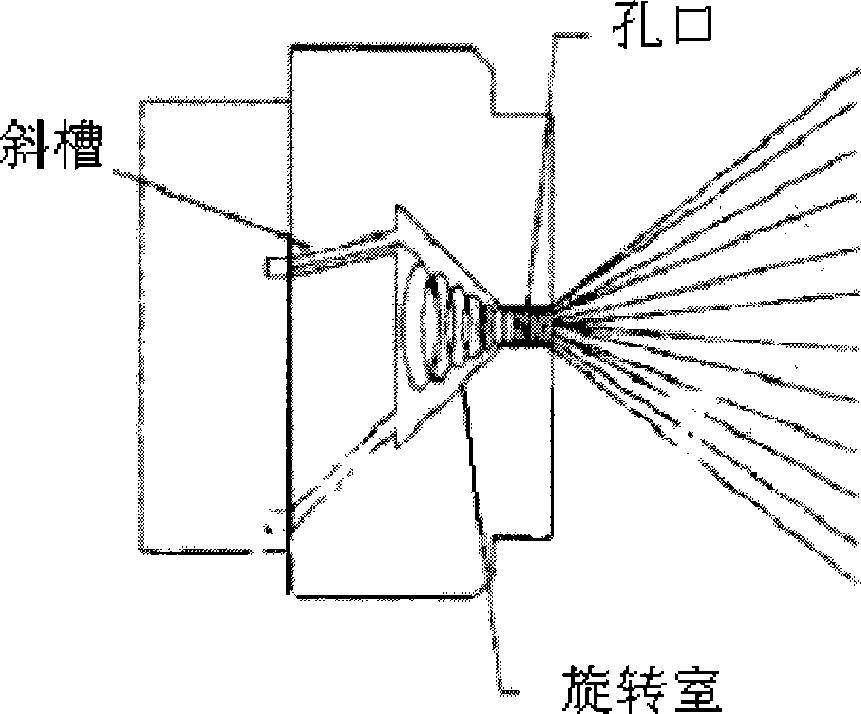

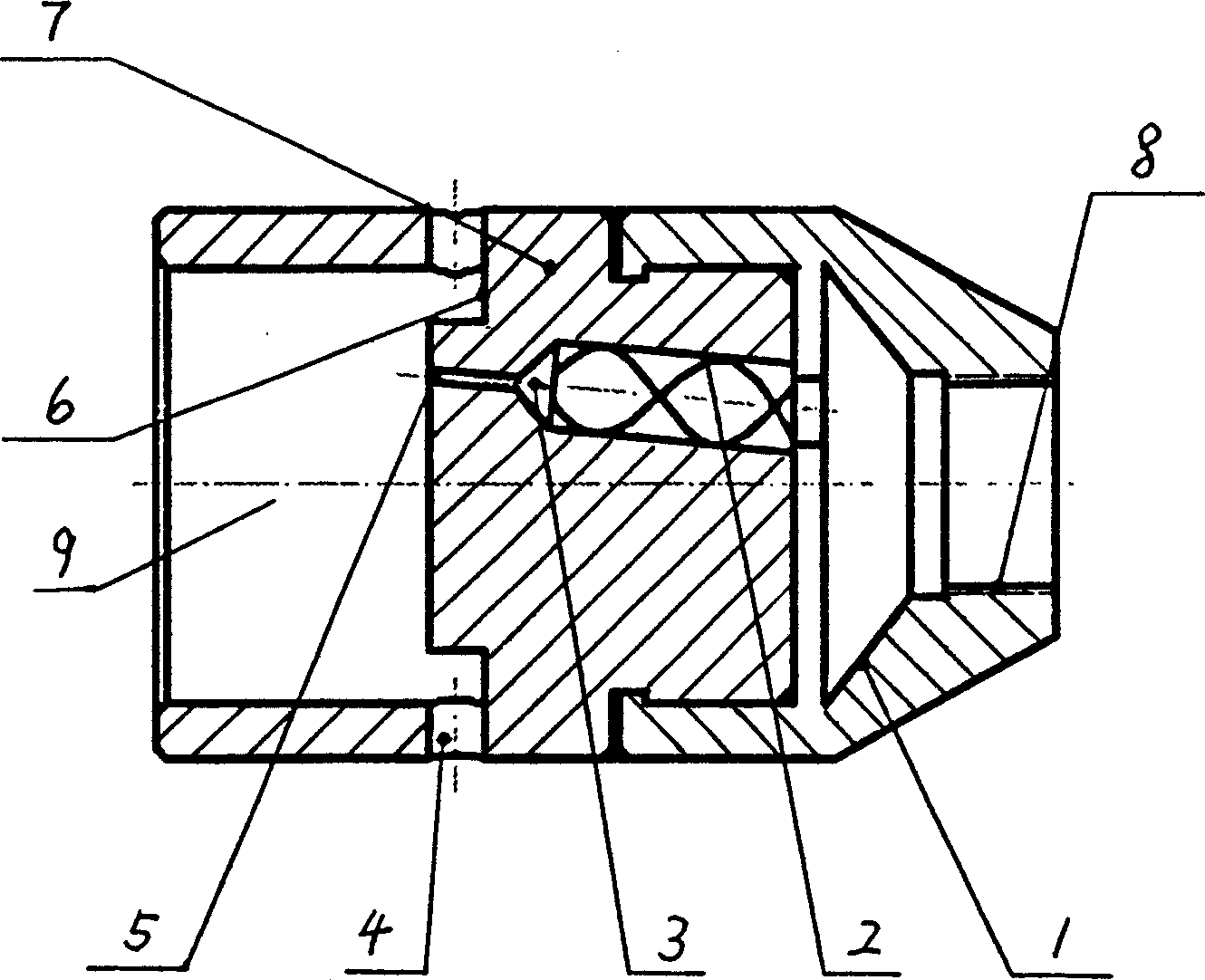

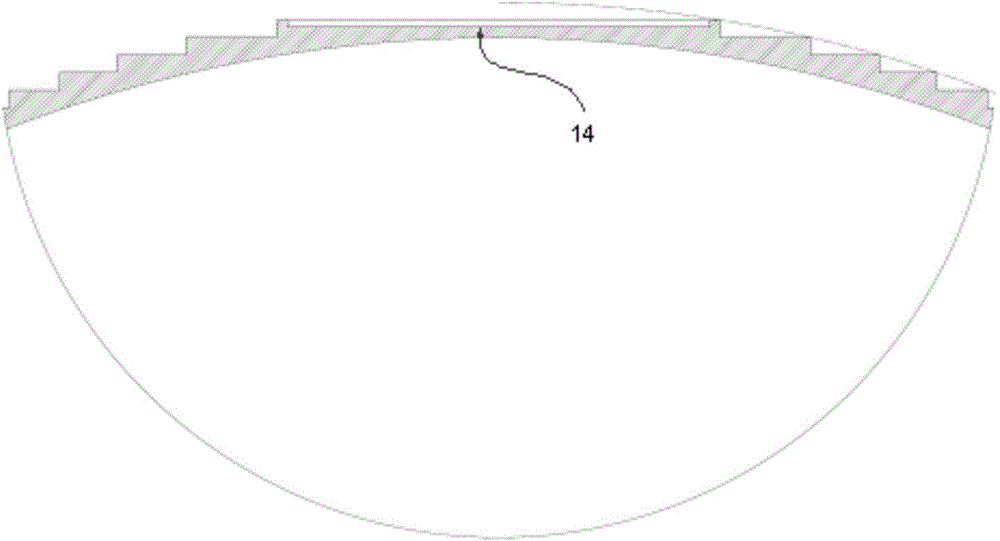

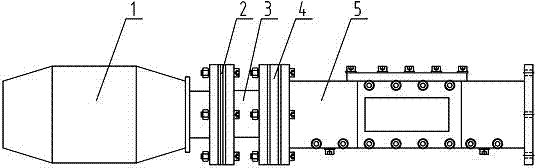

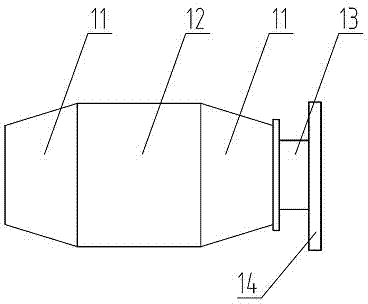

Self-absorption rotational flow pneumatic atomization nozzle device

InactiveCN101398186AGood fuel atomization qualityReasonable spatial distributionContinuous combustion chamberCombustion systemCombustion

The invention discloses a self-sucking swirl pneumatic atomizing nozzle device relating to a fuel atomizing evaporation mixing nozzle used for a full-automatic combustion engine and belongs to the field of industrial combustion systems. An atomizing sheet 2, a swirl sheet 3 and a stream guidance sheet 4 are compressed closely by a compression nut 1 and a fixing piece 5; the atomizing sheet 2 is an internal cone and the outlet of the atomizing sheet 2 is a spout 14; the swirl sheet 3 is provided with a tangential air hole 11; the outlet hole of the stream guidance sheet 4 is an oil hole 12 and the outlet of the stream guidance sheet 4 is a swirl chamber; the compression nut 1 is connected with the fixing piece 5 and a connecting piece 7; the outer surface of the upstream of the fixing piece 5 is provided with a seal ring 6; an oil inlet hole 8 is the inner hole of the connecting piece 7; an air inlet hole 9 is the connection hole of the connecting piece 7 along the radical and coaxial direction; compared with the existing centrifugal nozzle or pneumatic atomizing nozzle, the self-sucking swirl pneumatic atomizing nozzle device does not need an oil pump; has the advantages of improving the fuel atomizing evaporation mixing characteristic and the distribution uniformity of oil-gas space, improving the combustion performance, reducing contamination discharge, having no coking and plugging, and is an ideal nozzle for combusting the heavy oil and waste oil by the full-automatic combustion engine.

Owner:PEKING UNIV +1

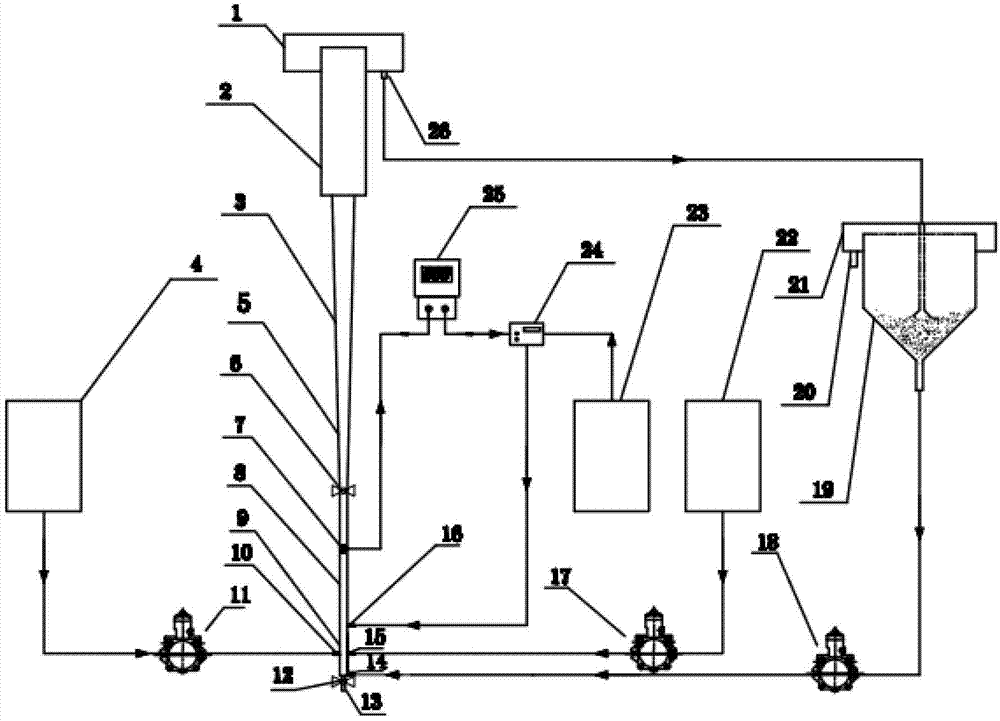

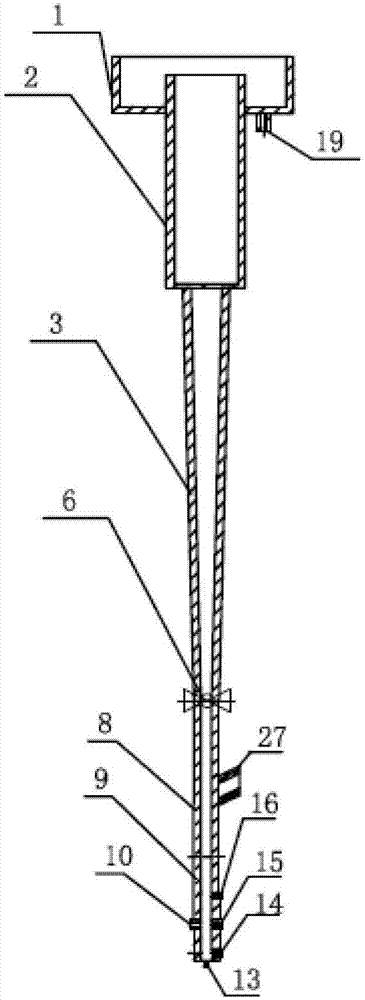

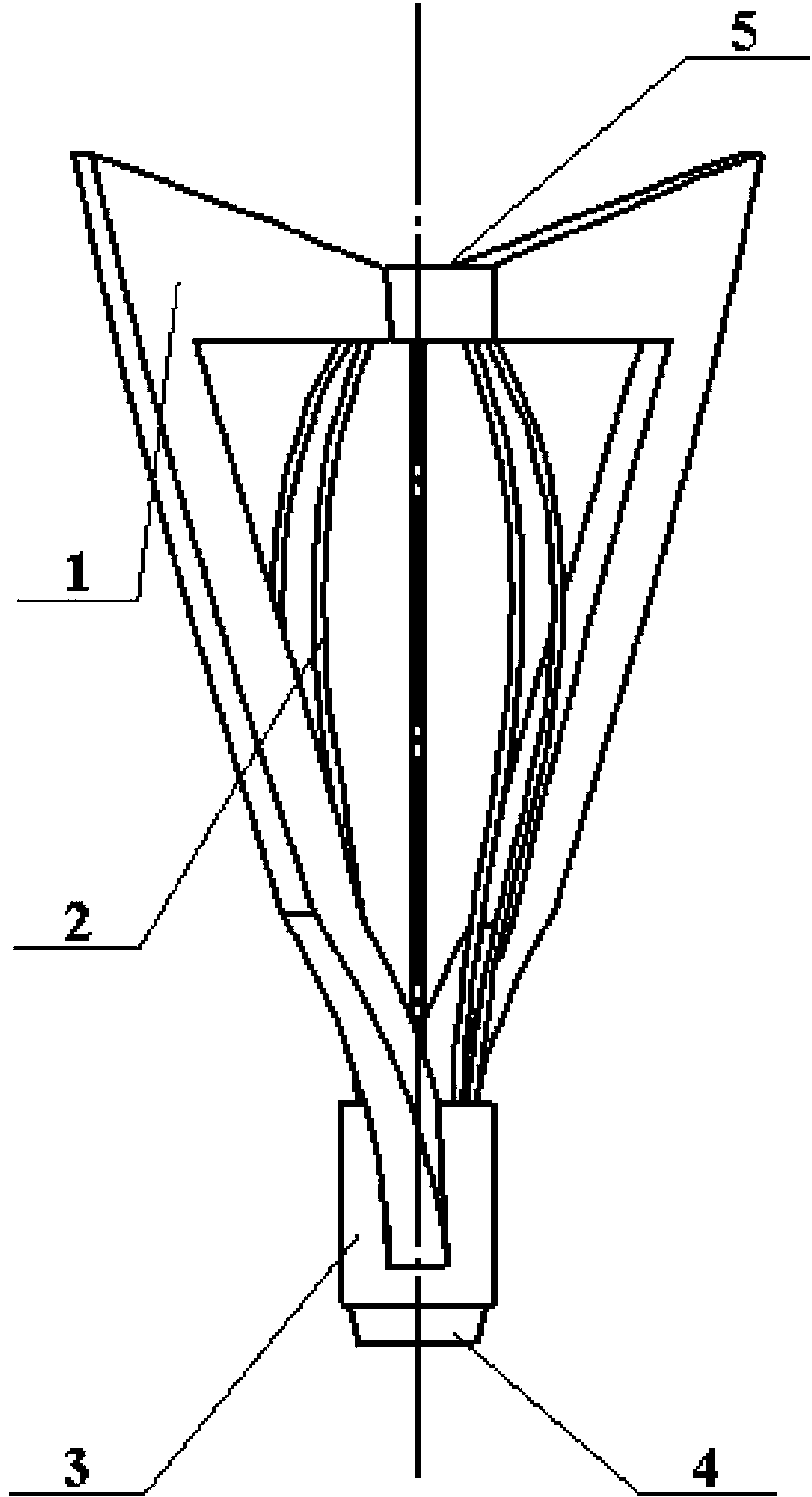

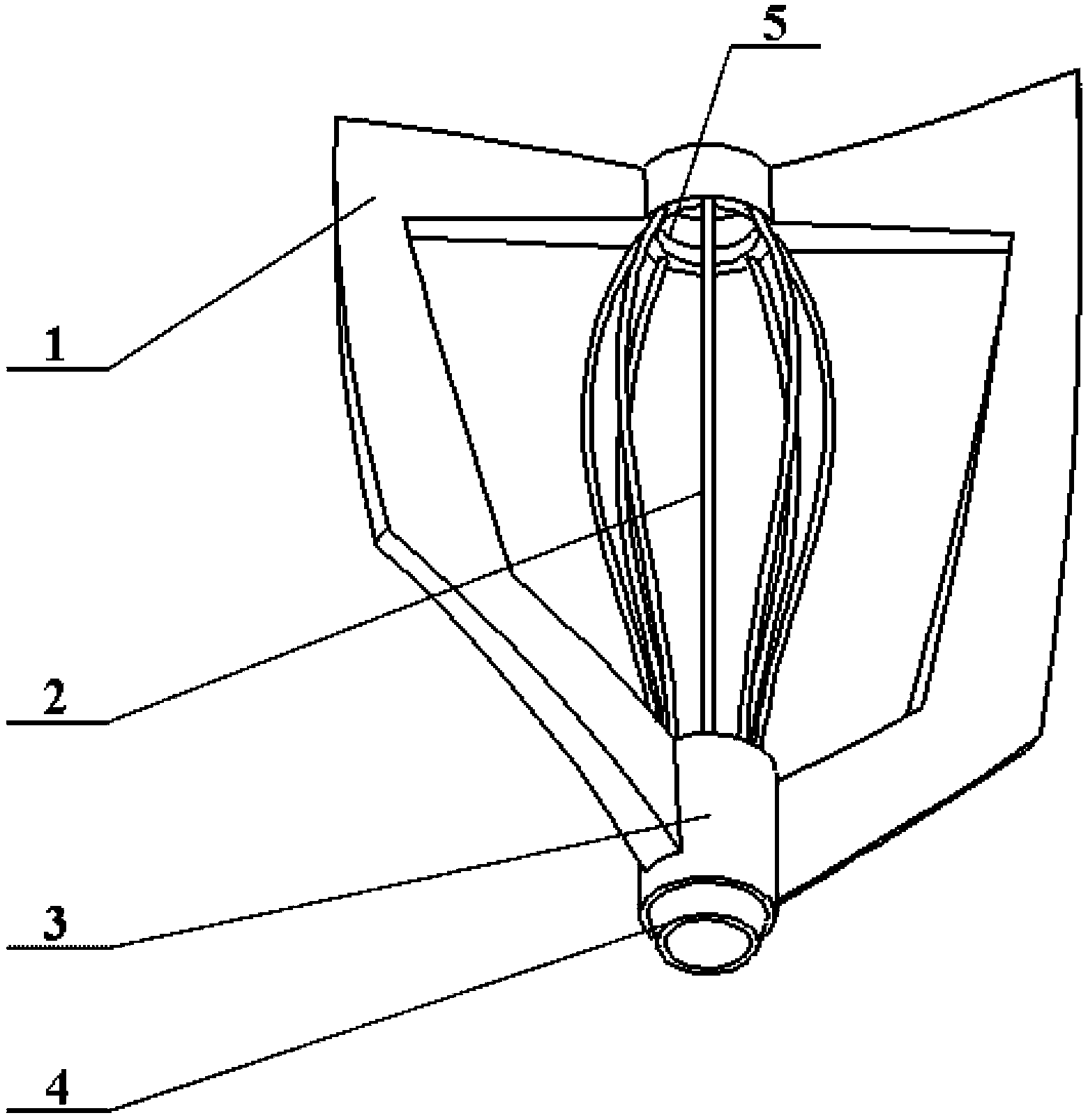

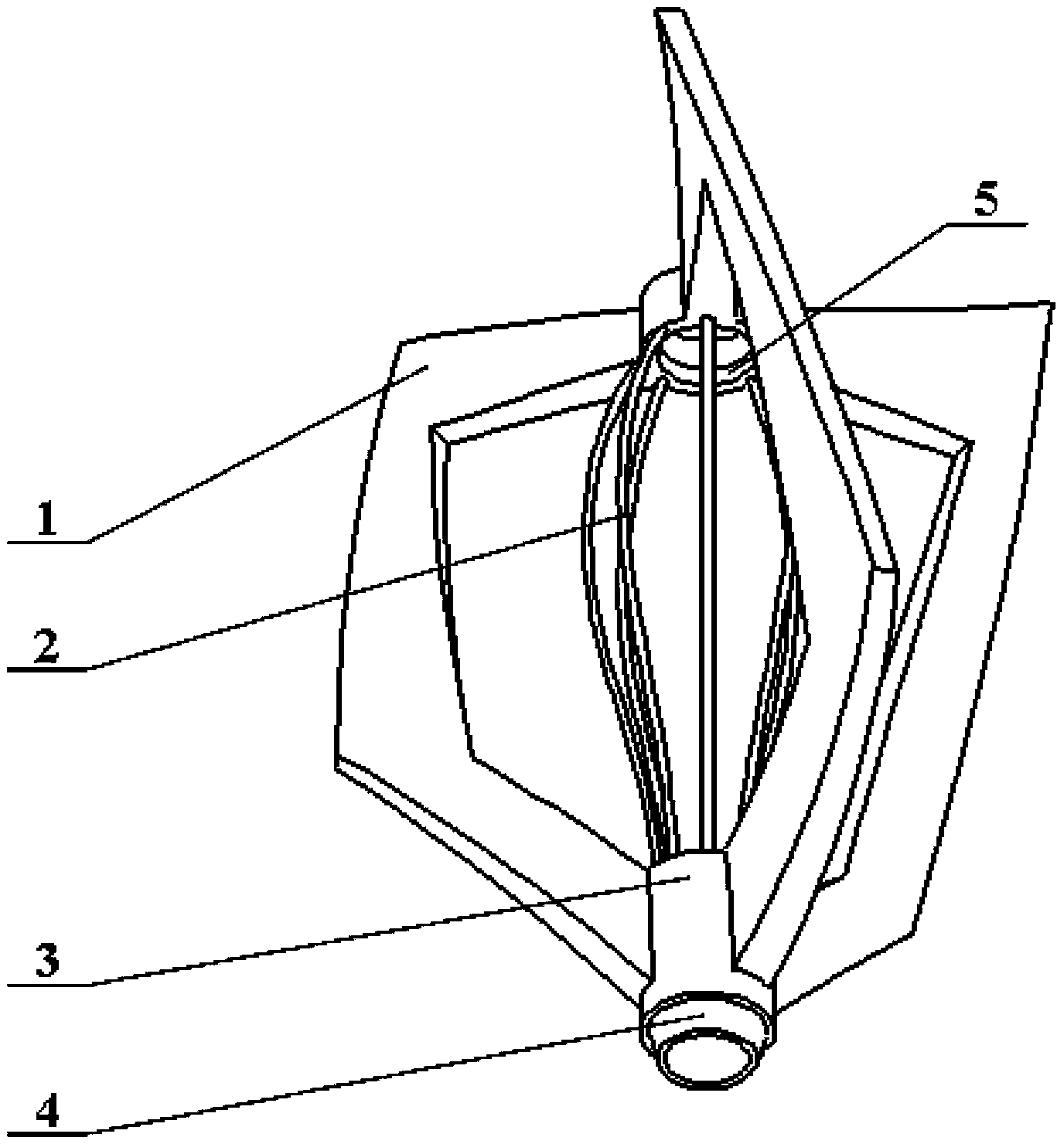

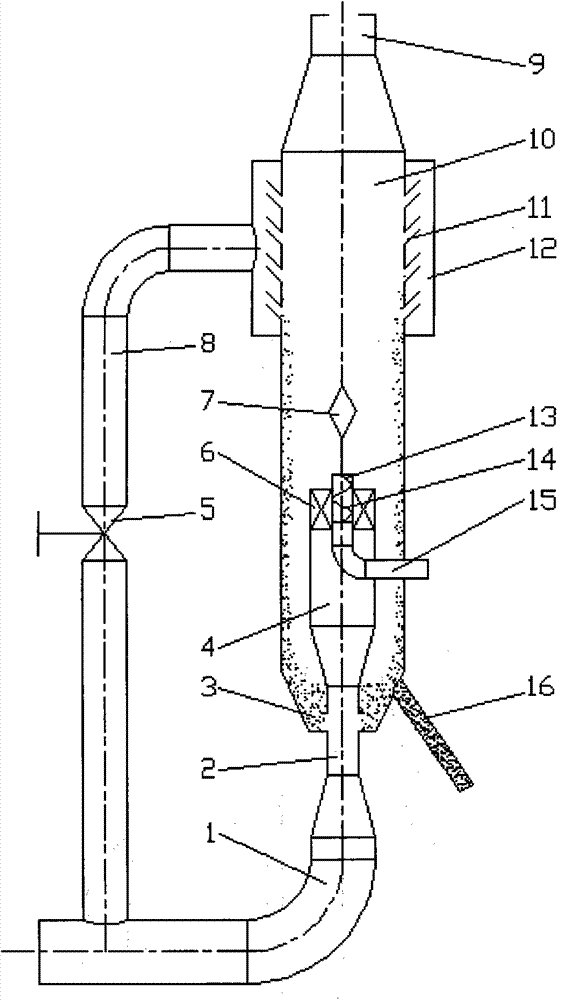

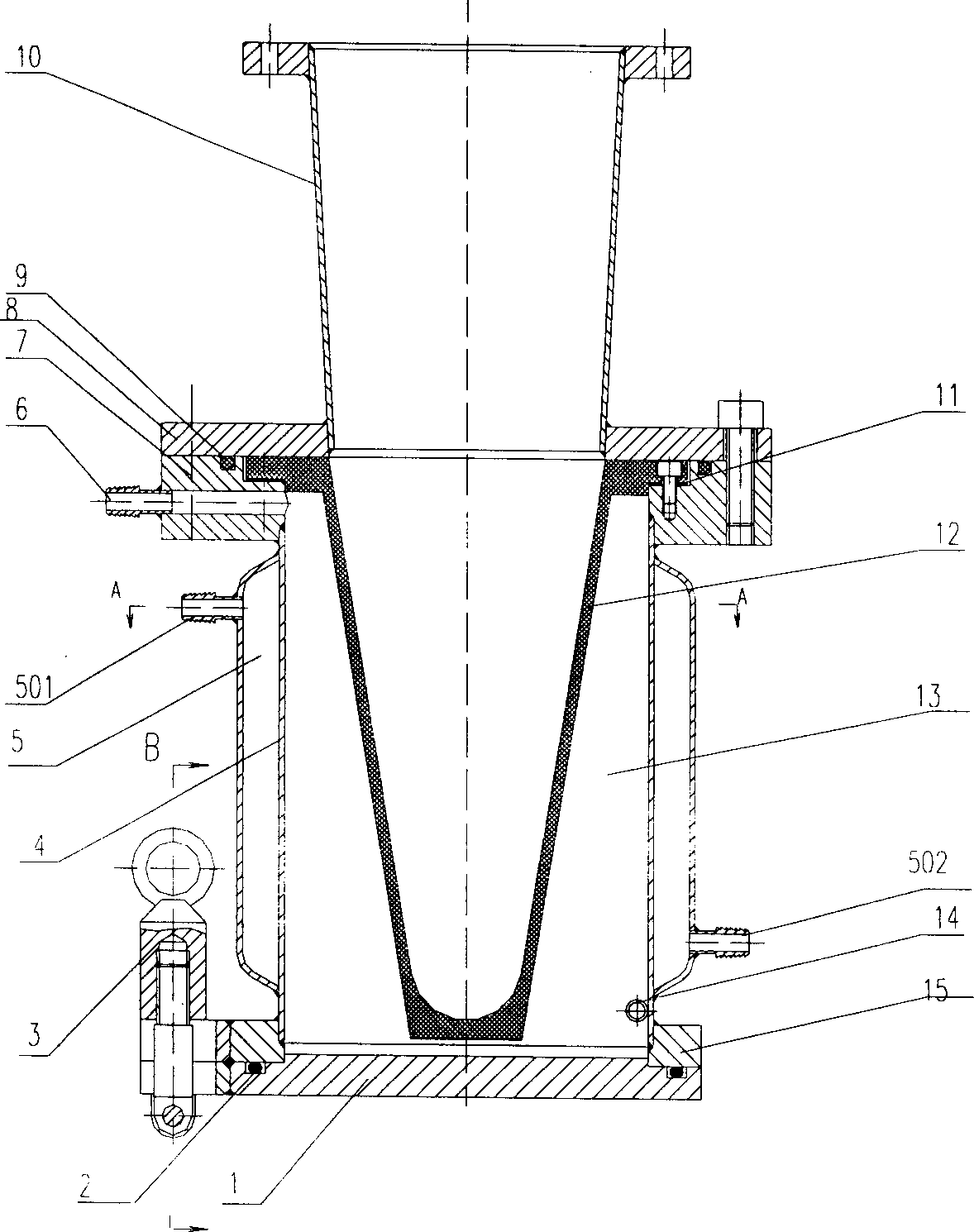

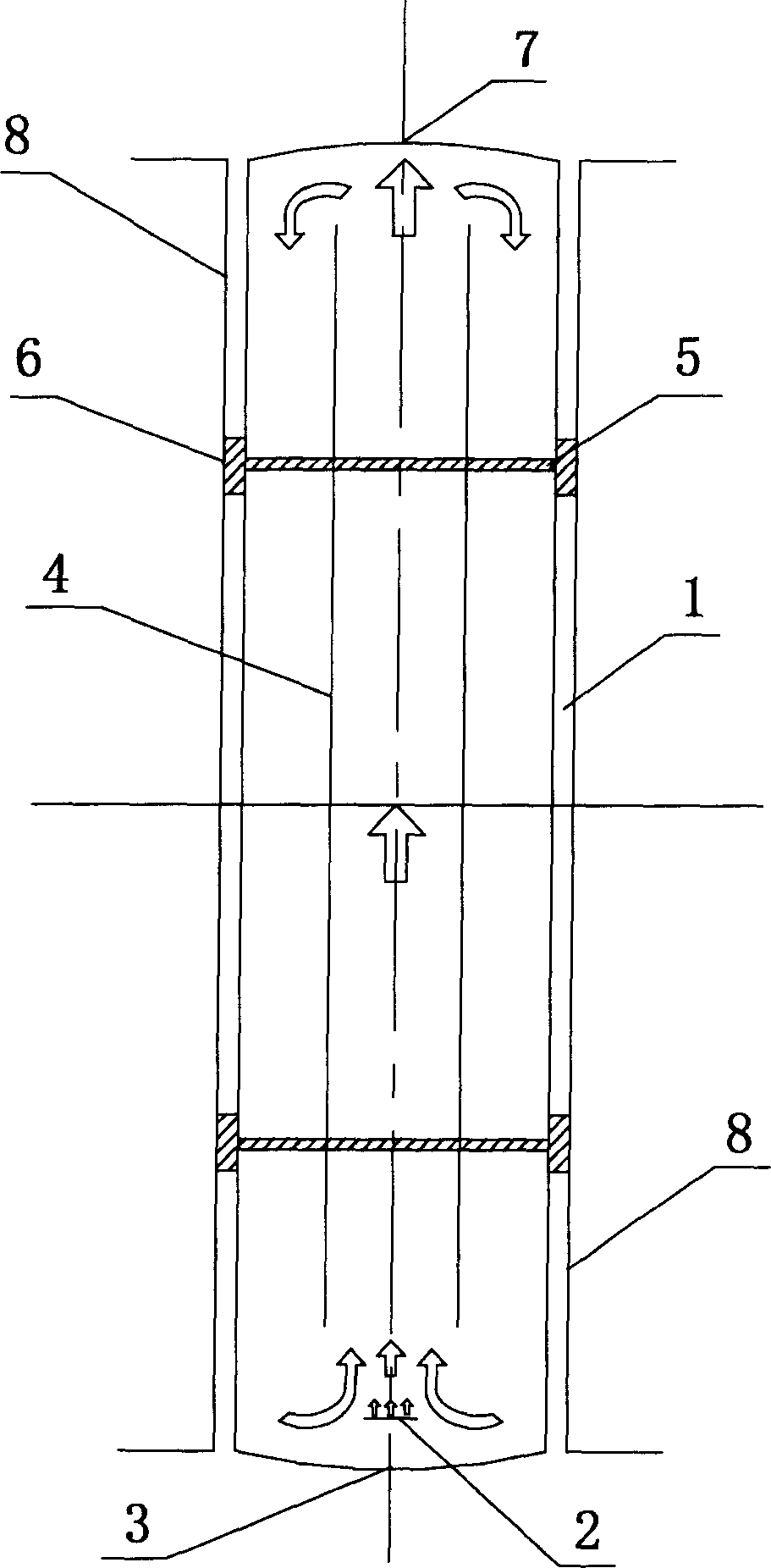

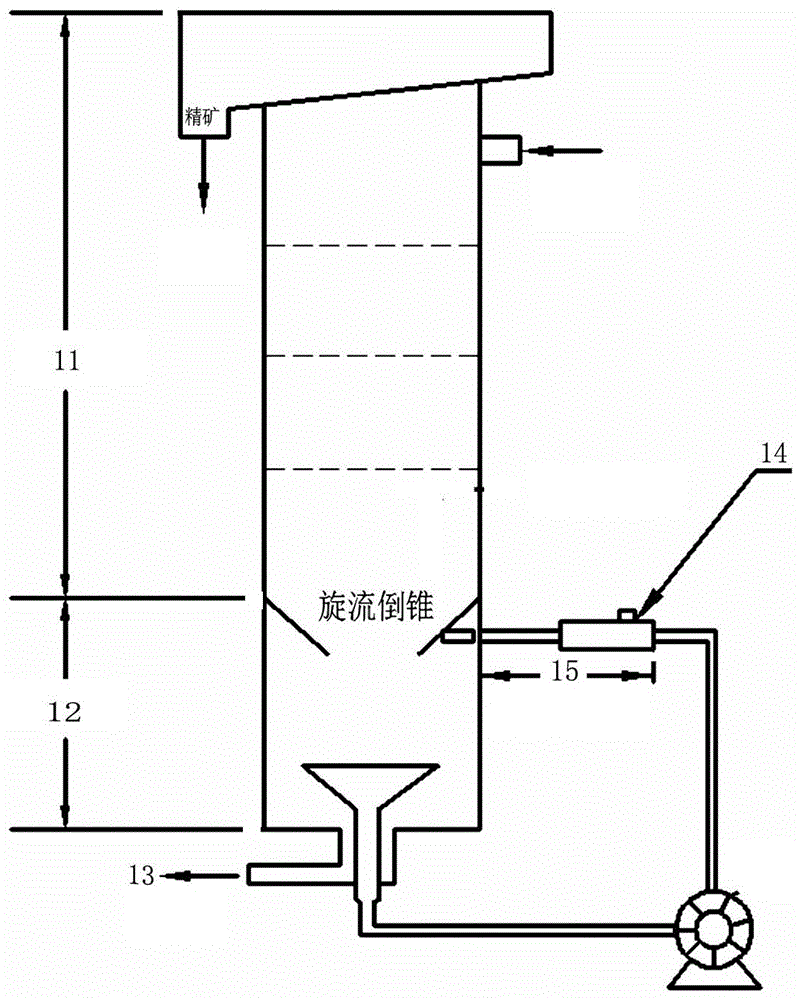

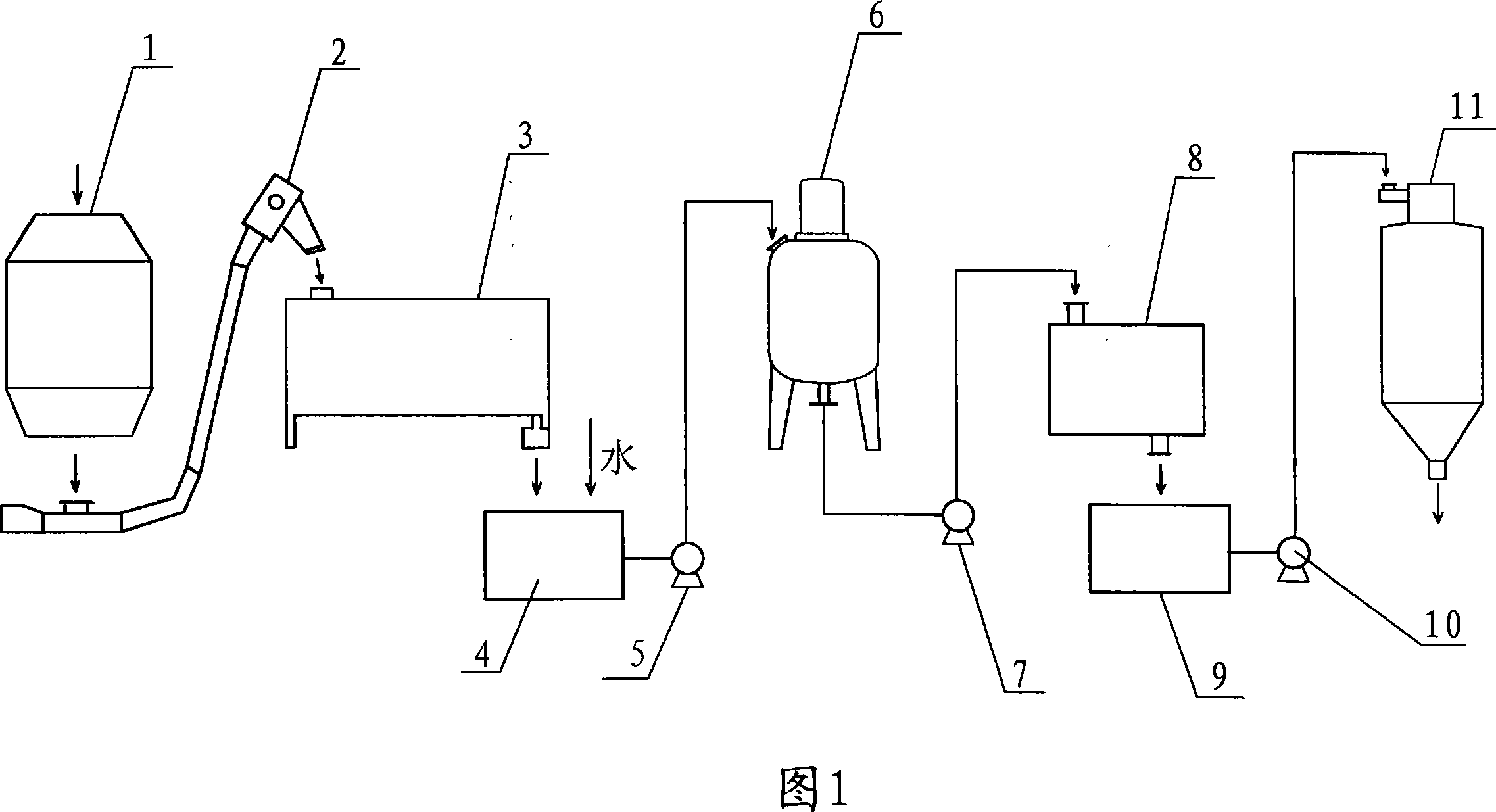

Device and process for preparing struvite crystals from nitrogen and phosphorus in sewage

InactiveCN102963970AIncreased turbulence intensityCompact structureWater/sewage treatment by flocculation/precipitationPhosphorus compoundsStruvite CrystalsSmall footprint

The invention relates to a device and a process for preparing struvite crystals from nitrogen and phosphorus in sewage. The device comprises a reactor (5), a pH (potential of Hydrogen) controller (25), a pH regulating pump (24), an alkali liquor tank (23), a nitrogen and phosphorus containing waste water tank (22) and a secondary sedimentation tank (19), wherein the reactor (5) is composed of a reactor feed pipe (9), a reactor crystal collecting pipe (8), a reactor growth tube (3) and a reactor sediment tube (2) from bottom to top. The process comprises the steps of pumping nitrogen and phosphorus containing wastewater into the reactor (5) and pumping a magnesium chloride solution into the reactor (5) to ensure that the molar ratio of NH3-N to PO43-P to Mg <2+> in the reactor (5) is (1:1:1)-(1:1:1.3); controlling the reflux ratio between 14 and 28 and the pH equal to 6.4-9.2; and forming the struvite crystals in the reactor (5) by using the nitrogen, phosphorus and magnesium containing solution. The device disclosed by the invention has the advantages of simple structure and small floor space, is simple and easy to operate and difficult to scale, can be widely applied to preparation of the struvite crystals from the nitrogen and phosphorus containing wastewater such as coking wastewater, pig manure wastewater or sludge fermentation liquor, and is capable of realizing the resource recycling of nitrogen and phosphorus.

Owner:TONGJI UNIV

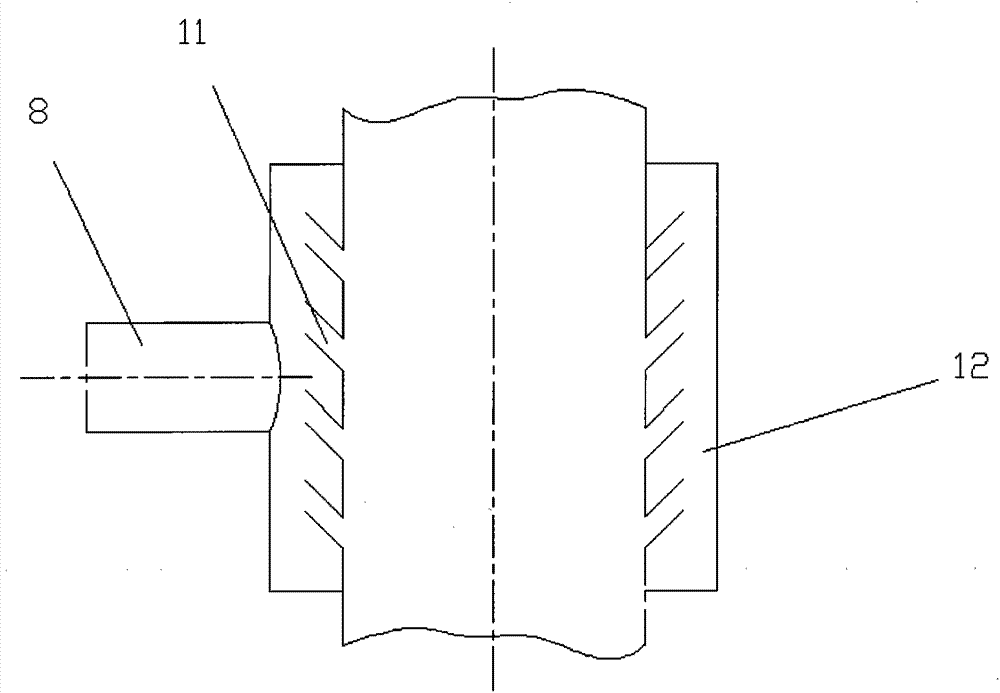

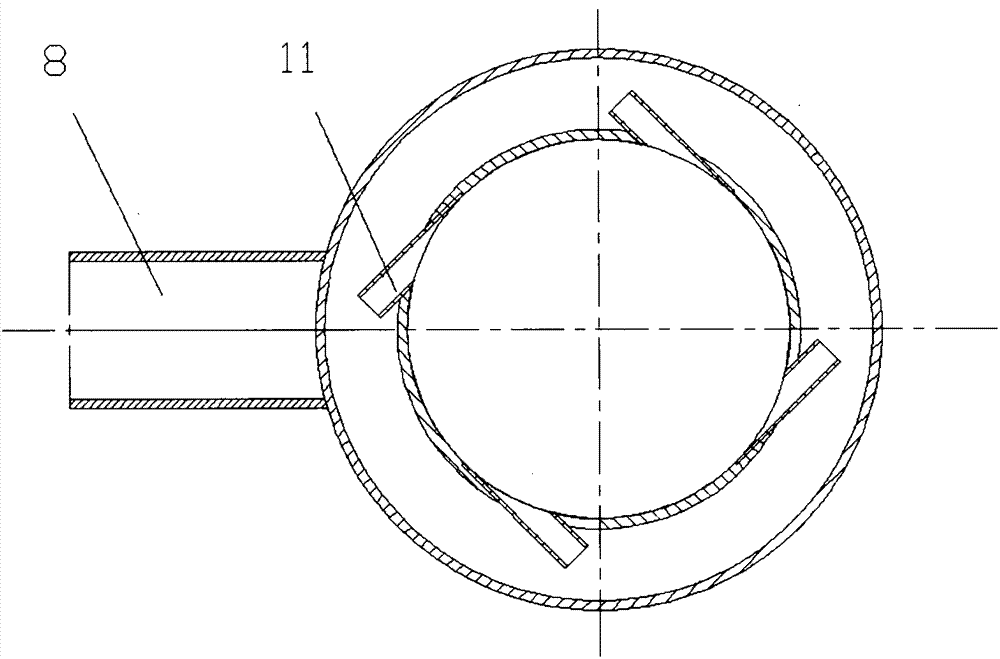

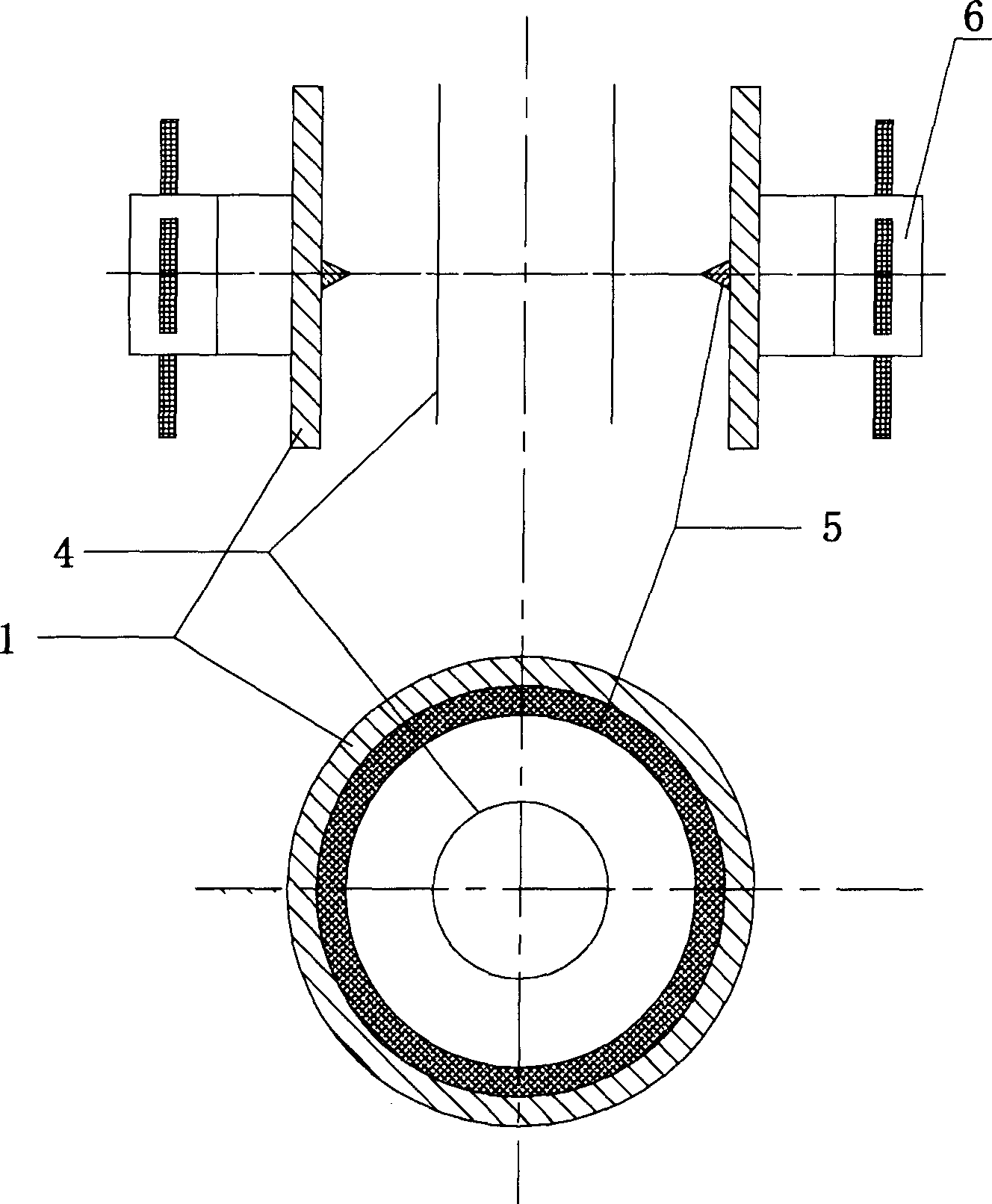

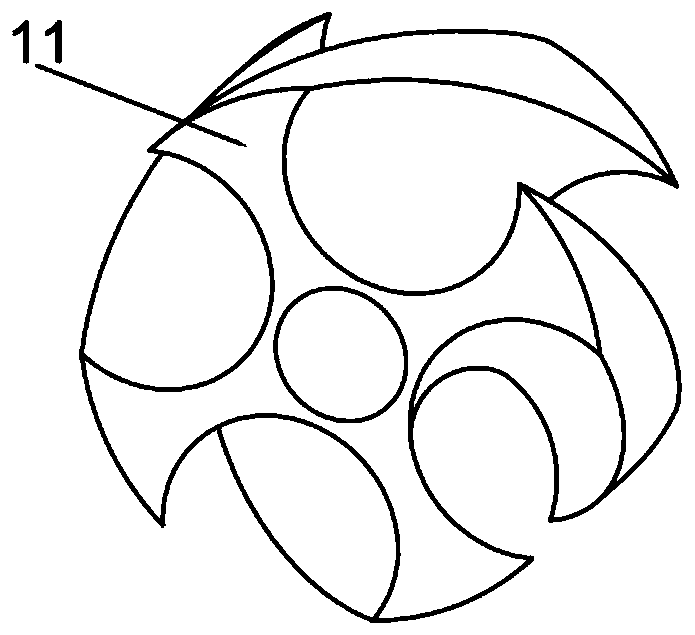

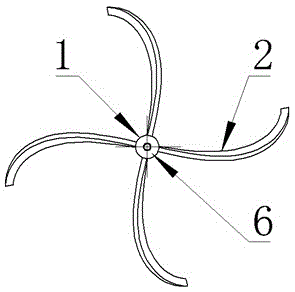

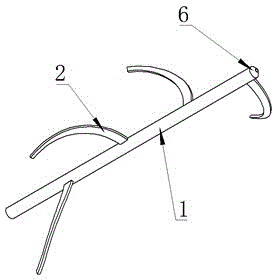

Low driving rotor with turbulence core and in heat exchange tube

ActiveCN103411467ASmall driving forceIncreased ability to remove dirtCorrosion preventionHeat transfer modificationHelical bladeWater flow

The invention relates to a low driving rotor with a turbulence core and in a heat exchange tube. The rotor is mainly composed of a hollow shaft, helical blades and the turbulence core, the outer diameter of each helical blade is smaller than the inner diameter of the heat exchange tube, the helical blades are smooth in surface, provided with hollow structures respectively and helically shaped around the hollow shaft, and the turbulence core is arranged in the hollow portions of the helical blades and consists of a plurality of turbulence strips distributed around the hollow shaft. The edge, firstly contacting with water flow, of the helical blades is chamfered or filleted; upstream faces of the blades drive the rotor to rotate under the action of fluid driving, fluid is enabled to generate centrifugal movement and is thrown to the wall of the heat exchange tube, radial flow of the heat transfer fluid is enhanced, and impacts on a laminar boundary layer of the fluid nearby the tube wall are generated to destroy the laminar boundary layer of the fluid; the turbulence core rotates with the blades, when small resistance is increased, turbulence is performed on center fluid in the tube to enable the center fluid to be replaced fully, and further effects of scale prevention, descaling and strengthened heat transfer are realized.

Owner:BEIJING UNIV OF CHEM TECH

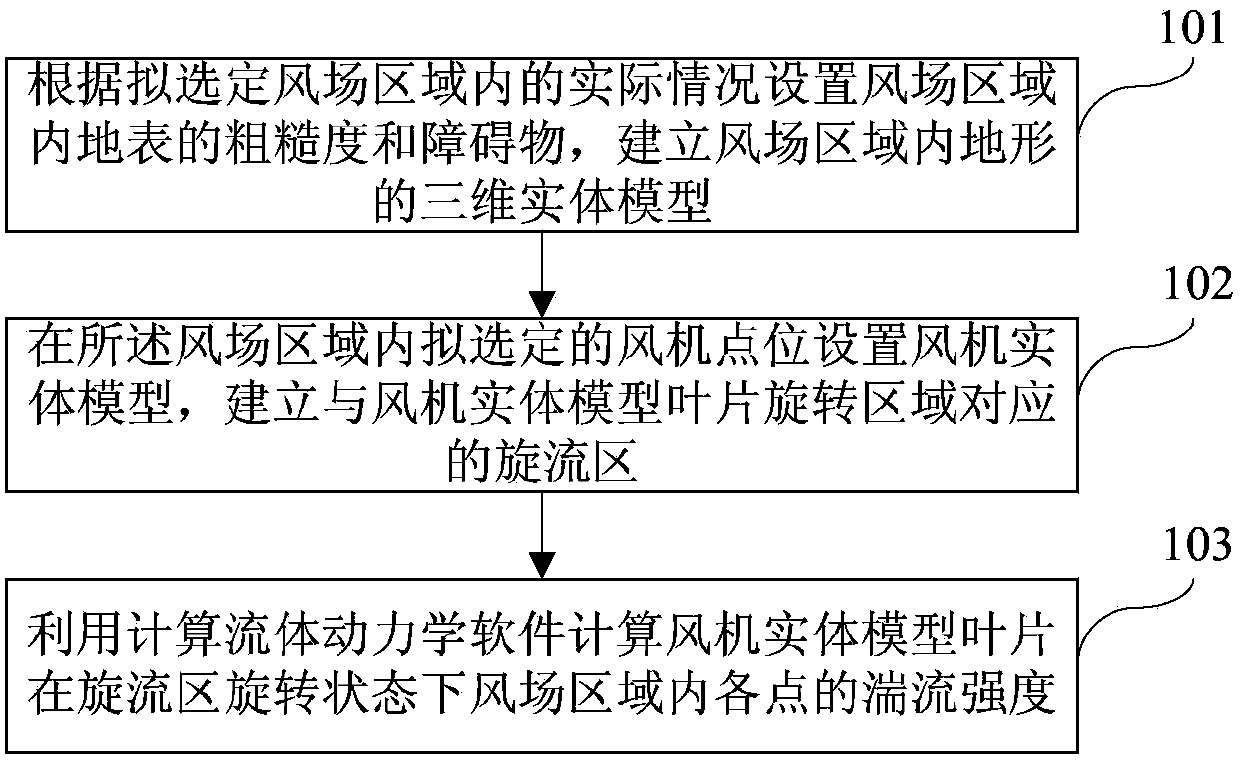

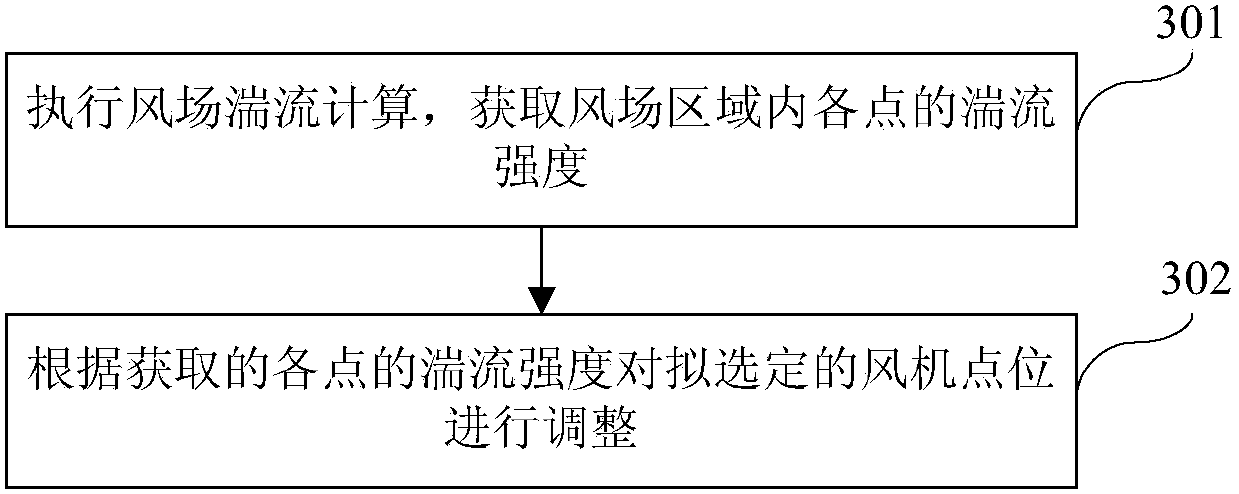

Wind-field turbulence computing method and wind farm micro-siting method and device

InactiveCN103745032AIncreased turbulence intensityImprove calculation accuracyData processing applicationsSpecial data processing applicationsTerrainWind field

The invention discloses a wind-field turbulence computing method and a wind farm micro-siting method and device. The wind-field turbulence computing method comprises the first step of setting the roughness and barriers of the earth surface in a wind field area and establishing a three dimensional solid model of the terrain in the wind field area according to the actual situation in the wind field area to be selected, the second step of setting a fan solid model at a fan point location to be selected in the wind field area and establishing a rotational flow area corresponding to a blade rotation area of the fan solid model, and the third step of computing the turbulence intensity of all points in the wind field area when blades of the fan solid model rotate in the rotational flow area by utilizing computational fluid dynamics software. According to the wind turbulence computing method and the wind field micro-siting method and device, the computational accuracy of the turbulence intensity can be improved, and therefore micro-siting of a fan in a wind farm can be conveniently and accurately performed.

Owner:SINOVEL WIND GRP

Semi-dry circulating cyclone bed desulfurizing tower

InactiveCN103480268AIncrease shear forceIncrease profitDispersed particle separationCycloneFluidized bed

The invention discloses a semi-dry circulating cyclone bed desulfurizing tower. By providing a tangential exhaust gas inlet structure of the desulfurizing tower, a rotating flow field is established inside the desulfurizing tower so as to sufficient mixing and contact of exhaust gas, so that the desulfurizing reaction process inside the desulfurizing tower is intensified, a desulfurizing agent is sufficiently utilized, the desulfurizing efficiency is improved; and secondary air is arranged to intensify the intensity of a rotating flow, so that separation of gas from solid is achieved inside the desulfurizing tower. By adopting the structure, an external cyclone separator in a conventional circulating fluidized bed desulfurizing process is omitted, so that the semi-dry circulating cyclone bed desulfurizing tower is compact in structure and easy to install and maintain.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

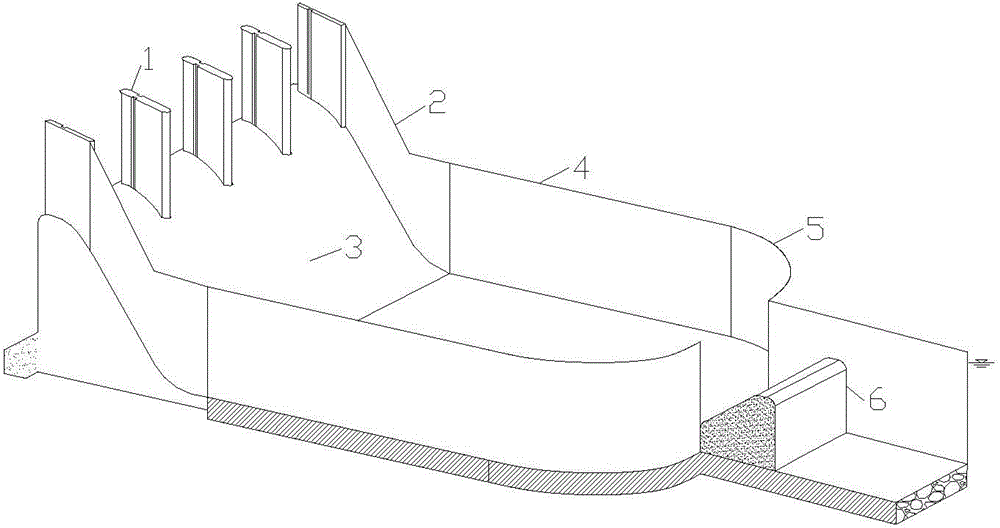

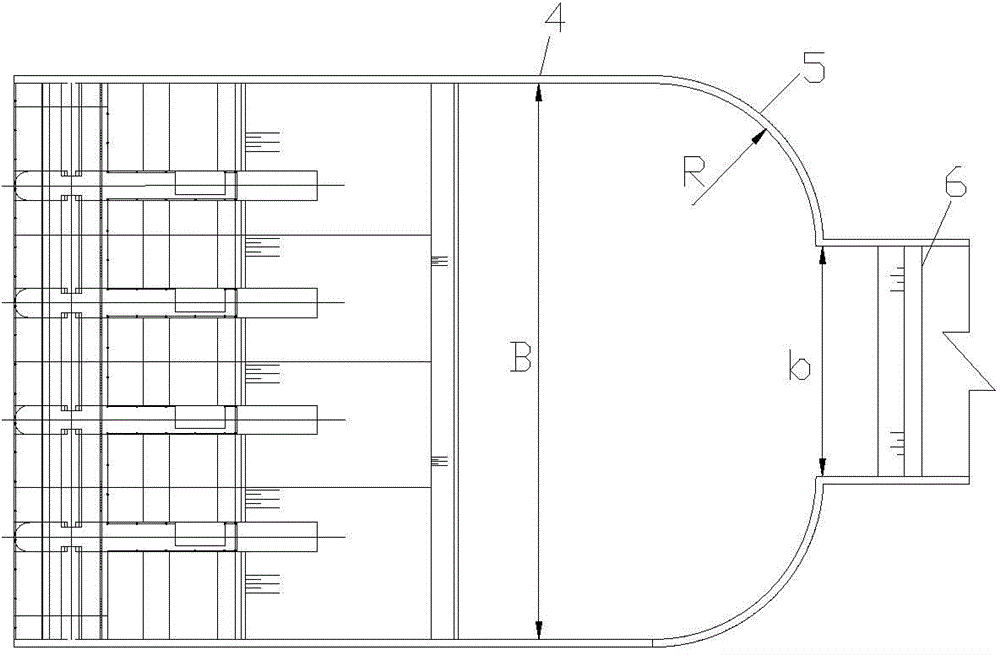

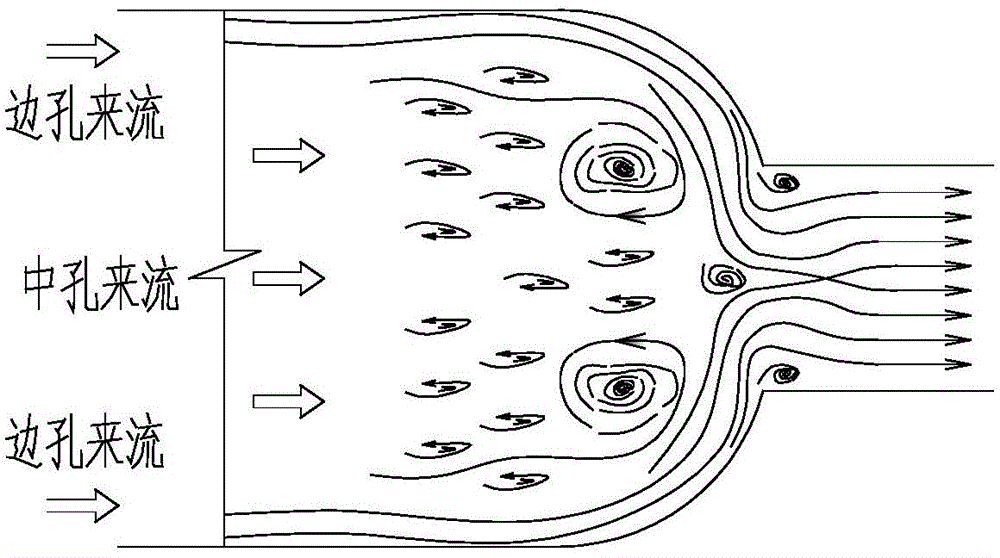

Porous inflow hedging energy dissipation structure of hydraulic structure

ActiveCN104404925AImprove energy dissipation effectShorten the lengthBarrages/weirsWater flowHydraulic structure

The invention discloses a porous inflow hedging energy dissipation structure of a hydraulic structure. The hydraulic structure comprises an overflow dam and an absorption basin, wherein a water body flows through the top of the overflow dam; the absorption basin is arranged behind the overflow dam; the bottom of the absorption basin is connected with the overflow surface of the overflow dam; protective edge walls of the absorption basin are connected with edge walls of the overflow surface of the overflow dam; the top of the overflow dam is provided with multiple gate piers for dividing a water body flowing area into multiple holes, so that the water body is discharged into the absorption basin from the multiple holes; and the protective edge walls are symmetrically provided with steering edge wall sections at the downstream of the head part of a hydraulic jump by 50-80 m for narrowing an outlet of the absorption basin, so that the water current discharged from the holes of the overflow dam flows through the narrowed outlet of the absorption basin to realize the rising of the water surface in the absorption basin so as to achieve quick transition of the flowing state of the water current from rapid current to slow current. The structure has such advantages as prominent energy dissipation effect and low construction cost of the hydraulic structure.

Owner:SICHUAN UNIV

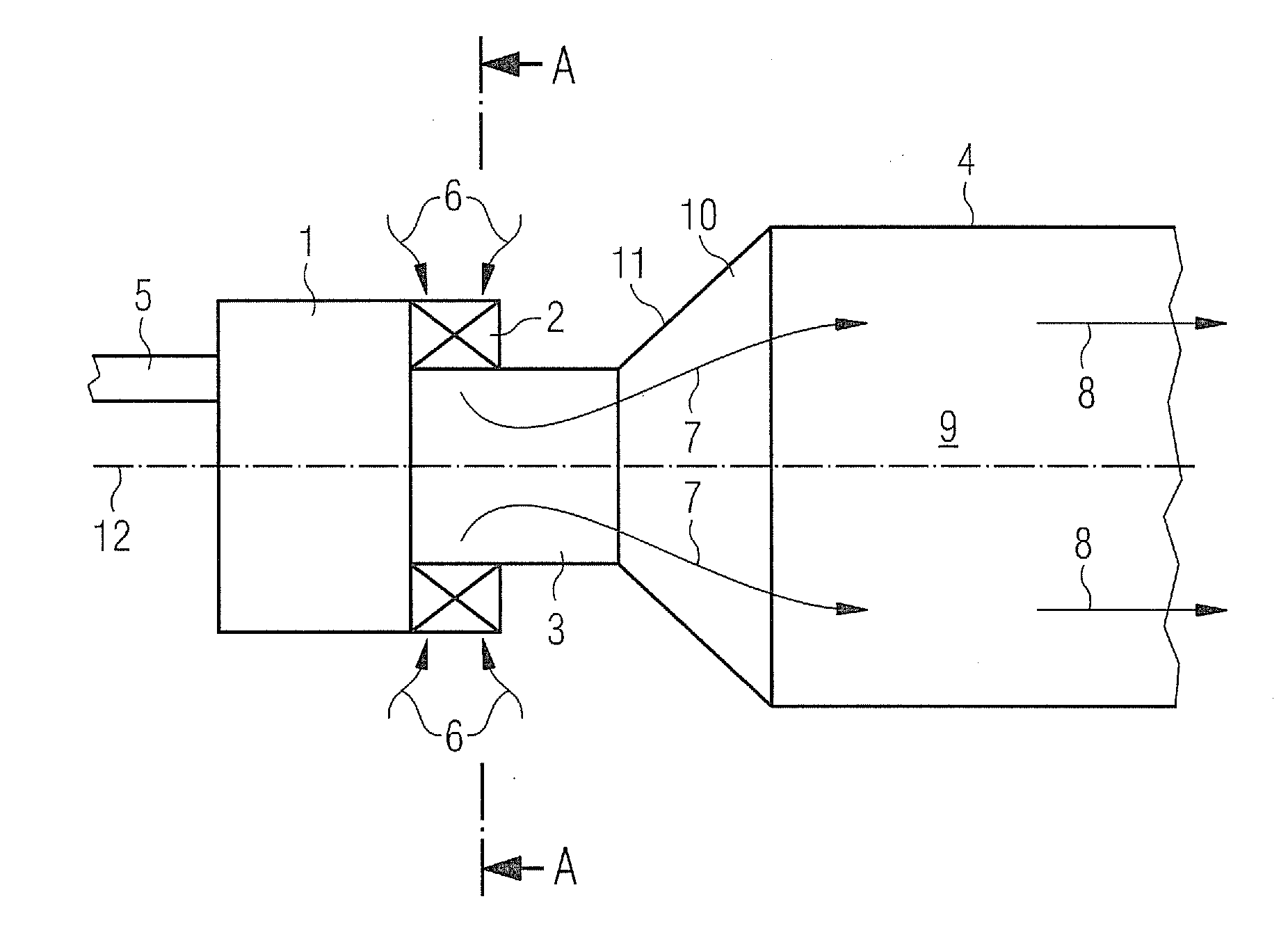

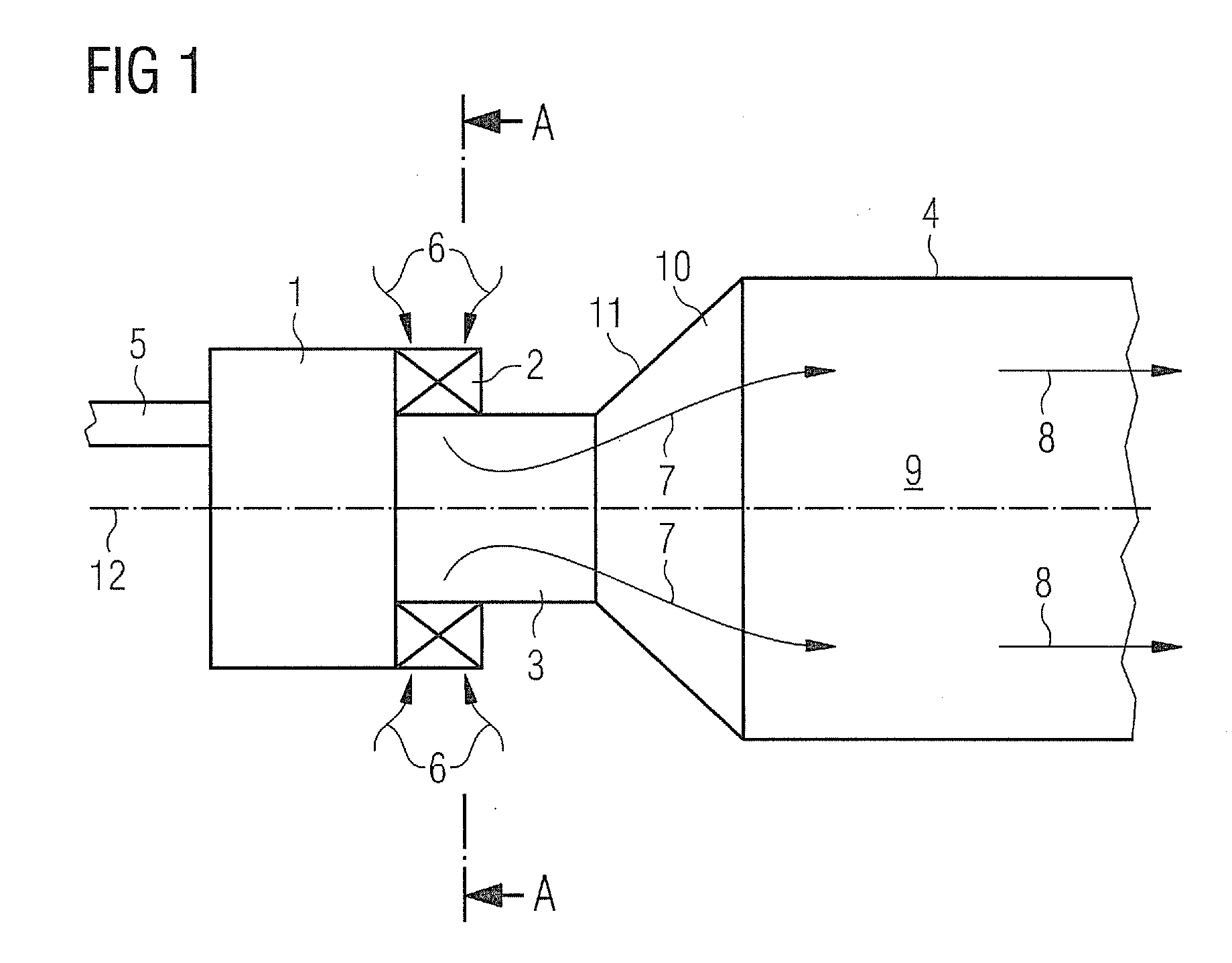

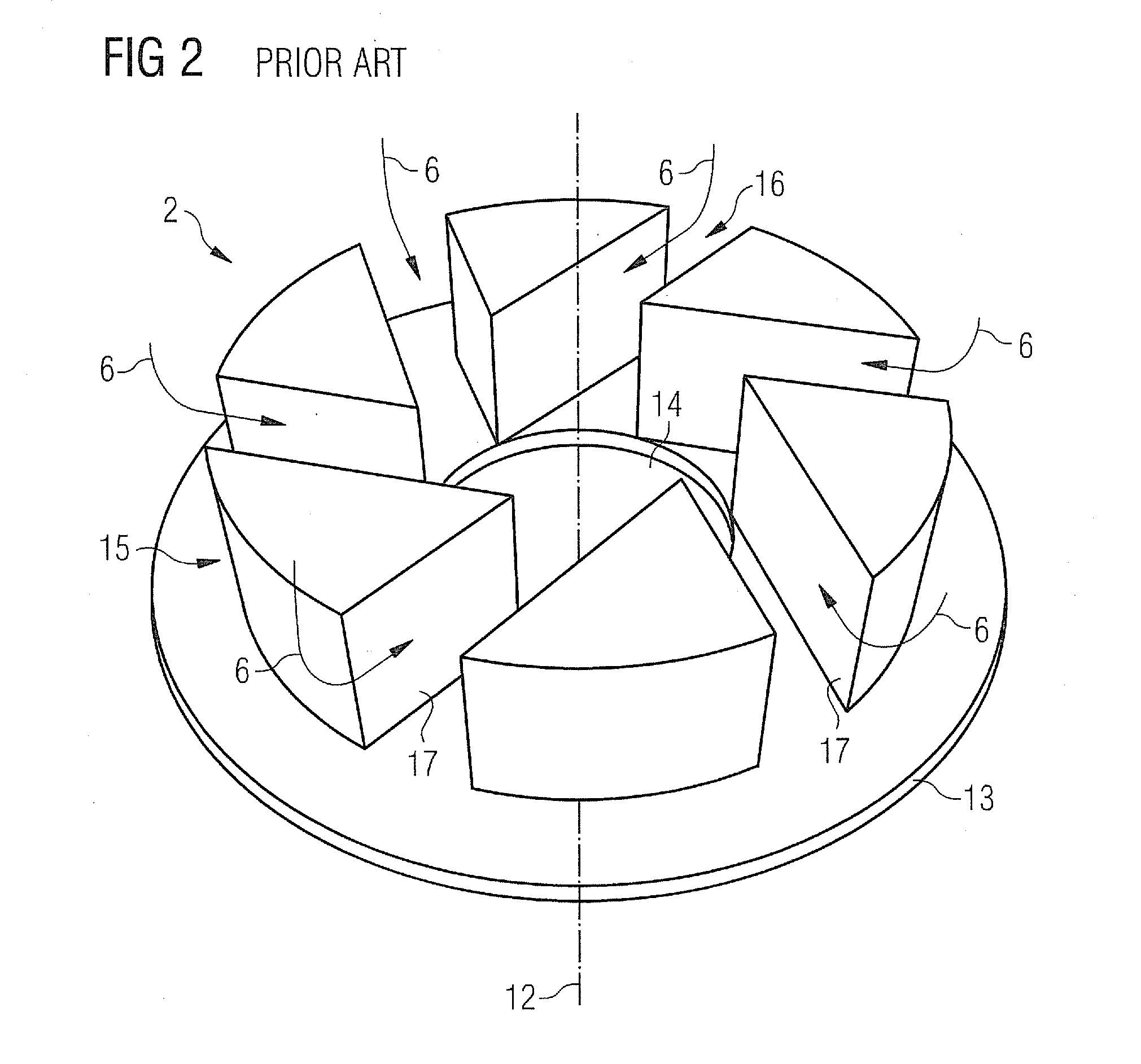

Swirler, combustion chamber, and gas turbine with improved mixing

InactiveUS20120042655A1Promote air mixingExtensive interactionContinuous combustion chamberGas turbine plantsCombustion chamberNuclear engineering

A swirler for mixing fuel and air is provided. The swirler includes a plurality of vanes positioned radially around a central axis of the swirler and a plurality of mixing channels for mixing the fuel and the air. At least one mixing channel of the plurality of mixing channels is defined by opposite walls of two adjacent vanes of the plurality of vanes and is comprising at least one fuel injection opening and is further comprising at least one dimple for generating a vortex of the air. Further, a combustion chamber incorporating such a swirler and a gas turbine incorporating such a combustion chamber are provided.

Owner:SIEMENS AG

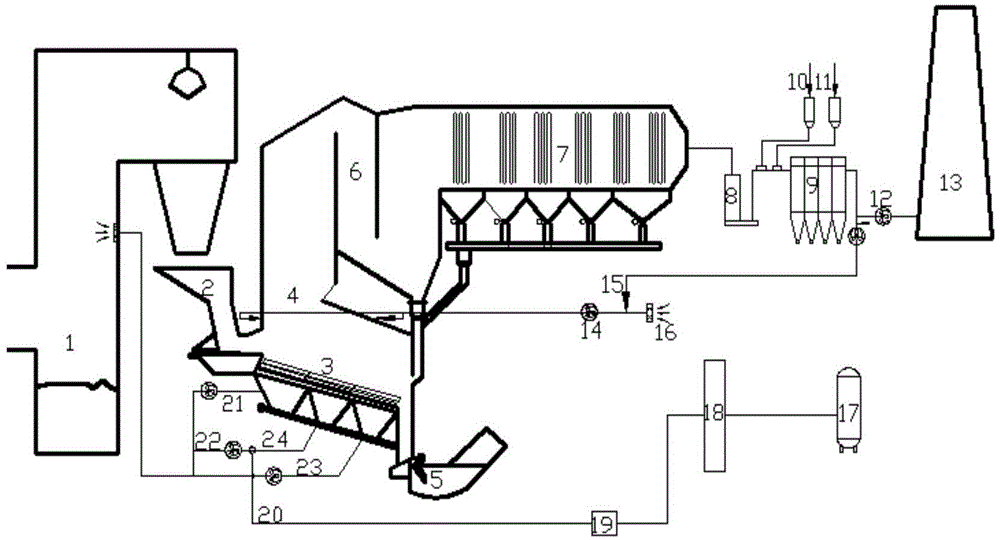

Oxygen-enriched combustion transformation method and device for garbage incineration grate furnace

InactiveCN104100979ABurn fullyAdjustable temperatureIndirect carbon-dioxide mitigationIncinerator apparatusBaghouseEngineering

The invention discloses an oxygen-enriched combustion transformation method for a garbage incineration grate furnace. The method comprises the steps that an oxygen injecting step is added before the primary air of a combustion section, namely, oxygen obtained by gasifying and pressure regulating is injected into a primary air pipeline of the combustion section, so the air is fully mixed with the normal air of the combustion section and is then injected into a hearth; injection of normal secondary air is stopped, a draught fan behind a cloth bag deduster is connected with a secondary fan by a pipeline, so circulated smoke is guided into a secondary air pipeline by the secondary draught fan, and is injected into the hearth by a secondary air opening. The invention discloses a corresponding oxygen-enriched combustion device. The excess air coefficient is reduced, the flame temperature in the furnace is improved, the combustion condition is optimized, the generation of pollutants such as dioxin is effectively inhibited, the efficient, stable and safe operation of the incineration equipment is ensured, the smoke exhaust is reduced, the smoke heat loss and output of the draught fan are reduced, the combustion efficiency is improved, and the investment and operation cost of smoke purifying equipment are favorably reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

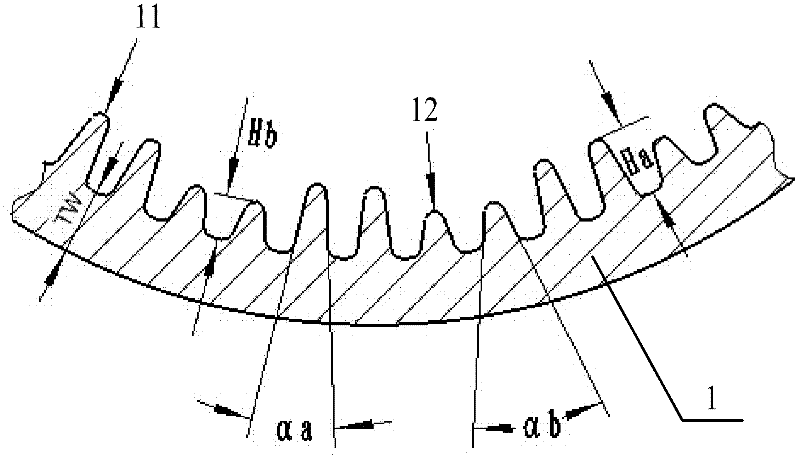

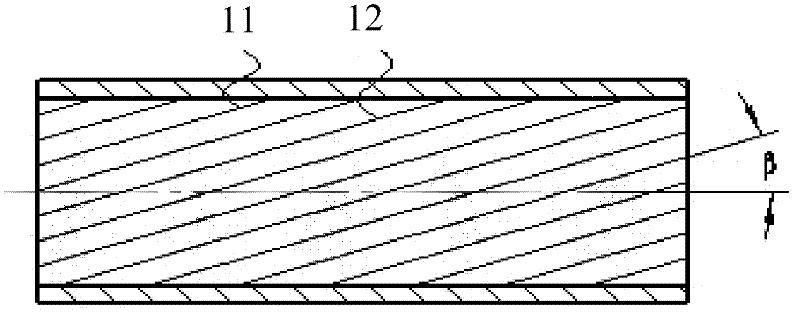

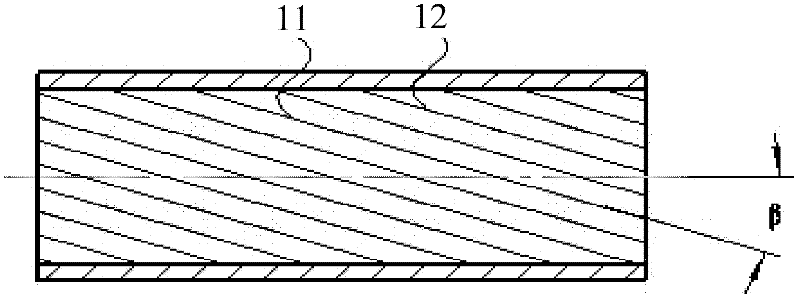

Heat exchanger and internal threaded copper tube thereof

InactiveCN102353296AEnhanced turbulence intensityIncrease disturbanceChemical industryTubular elementsChemical industryHeat transfer efficiency

The invention discloses an internal threaded copper tube. The internal threaded copper tube comprises a tube body (1), wherein internal threaded teeth with different height and various tooth shapes are formed on the inner wall of the tube body (1) and are alternately distributed. Due to the difference of the tooth shapes and the height, the turbulent flow intensity of a coolant is increased, and disturbance on the coolant and heat conduction energy efficiency are improved. In the using process, the tooth shapes of the common internal threaded copper tube are damaged while the tube is expanded, and due to the difference of the tooth shapes and the height, only a part of tooth shapes of the internal threaded copper tube are damaged after the internal threaded copper tube is expanded, and the internal threaded copper tube still has high heat transfer efficiency. By using the optimized design, the weight, production cost and using cost of the tube can be reduced. The internal threaded copper tube is suitable to be widely used in the fields of refrigeration, air conditioning, power generation, sugar making, chemical industry, solar energy and the like.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

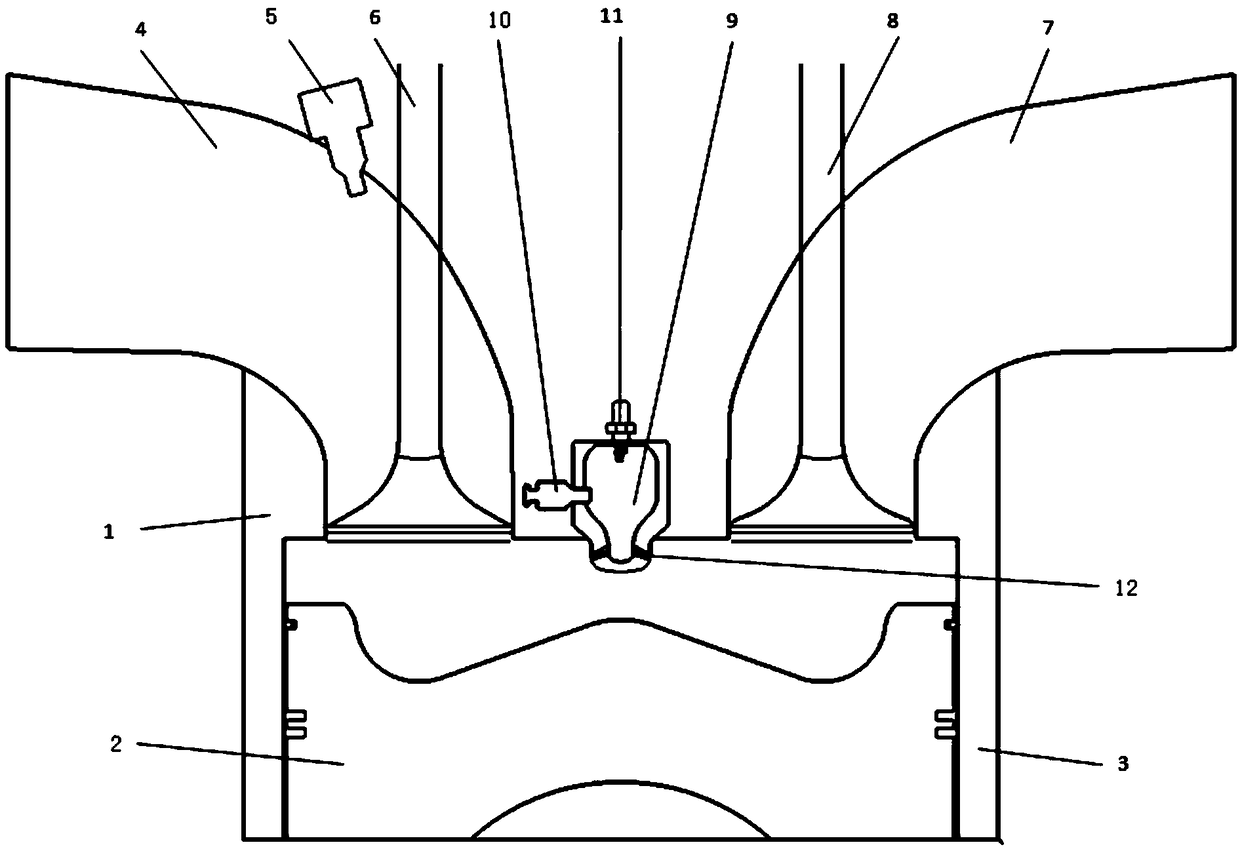

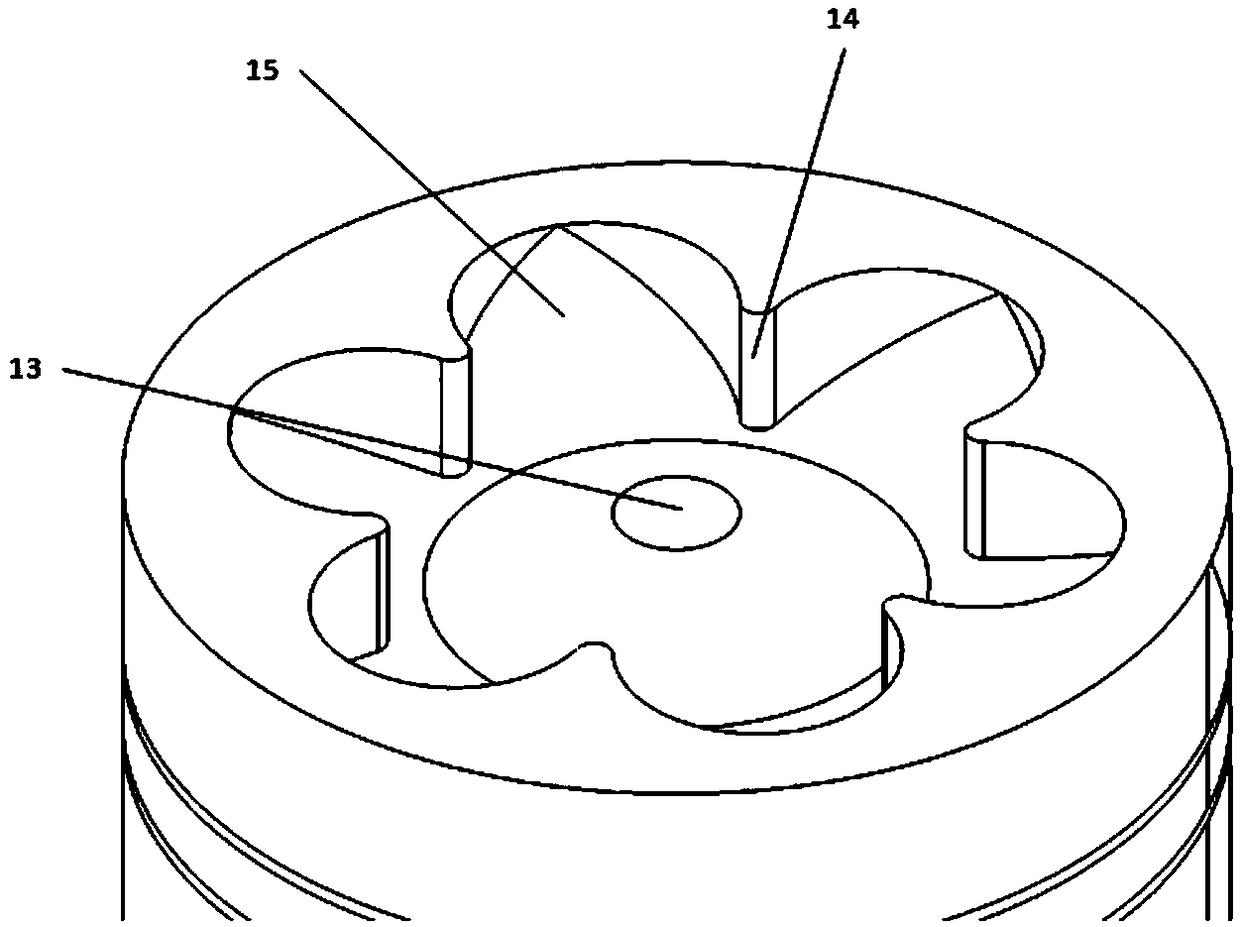

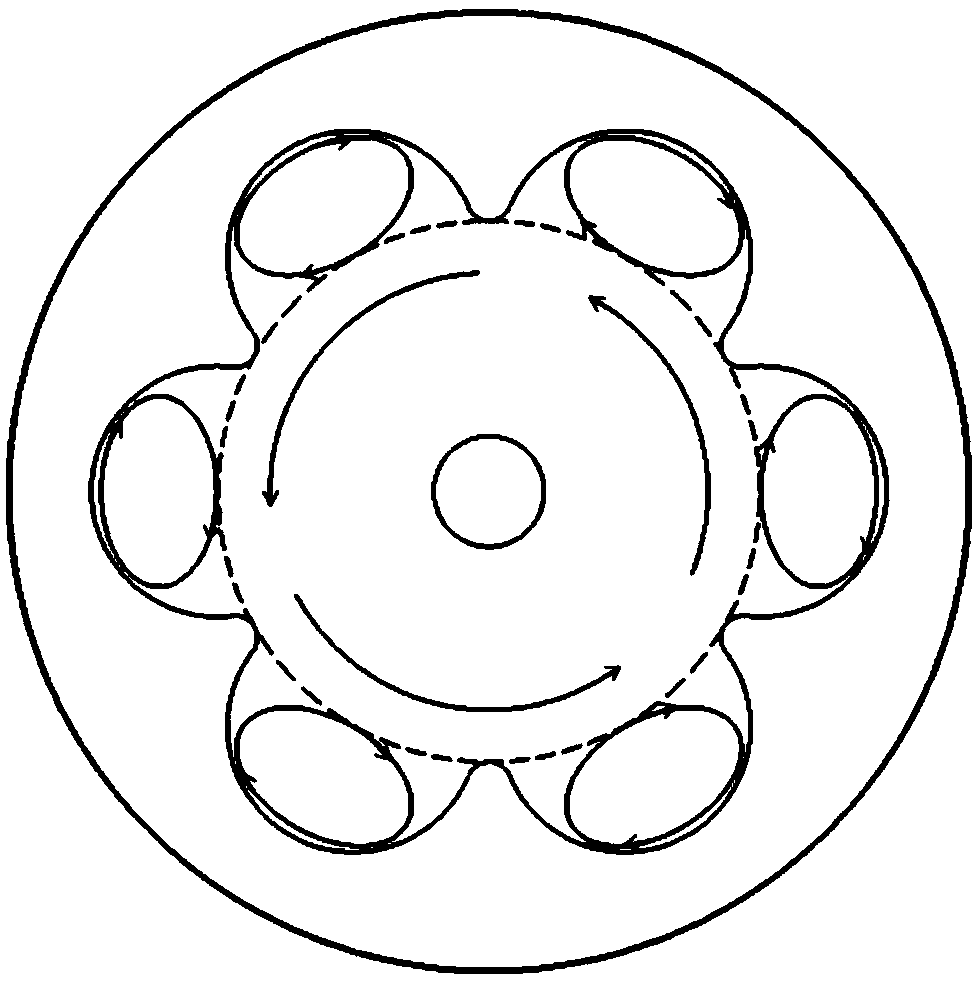

Marine large-bore natural gas engine precombustion chamber porous jet flow ignition type efficient combustion system

PendingCN109184898AImprove combustion efficiencyShorten the flame propagation distanceInternal combustion piston enginesFuel supply apparatusCombustion chamberInlet valve

The invention provides a marine large-bore natural gas engine precombustion chamber porous jet flow ignition type efficient combustion system which comprises a cylinder cover, an air cylinder sleeve,a piston, an air inlet passage and an air discharging passage, wherein the piston is positioned in the air cylinder sleeve; a combustion chamber is formed between the top of the piston and the cylinder cover; an air inlet valve is arranged in the air inlet passage; an air discharging valve is arranged in the air discharging passage; a natural gas supply device is arranged in the air inlet passageand is positioned in front of the air inlet valve; a precombustion chamber is formed in the cylinder cover; a sparking plug and a precombustion chamber natural gas jetting device are arranged in the precombustion chamber; and a jet orifice is formed in the part, stretching into the combustion chamber, of the precombustion chamber. The system utilizes high-temperature and high-pressure flue gas jetted by a porous passage to form a plurality of ignition sources and the compact structure of a main combustion chamber, so that the spreading distance of the natural gas flame is shortened, and multi-area ignition combustion of rate mixed gas in the cylinder is realized; and in addition, the high-temperature and high-pressure flue gas jet flow damages the large-scale eddy current in the cylinder,so that the turbulence intensity in the cylinder is improved and the combustion efficiency is remarkably improved.

Owner:HARBIN ENG UNIV

Microwave extracter

InactiveCN1386561ATake advantage ofIncreased turbulence intensitySolid solvent extractionMicrowaveEngineering

A microwave extractor for the flowing micron-class or mm-class particles or fixed great particles is composed of a cylindrical container made of the material impermeable to microwave and an isolator (or transition tube) made of the material permeable to microwave. An annular working gap is formed between said cylindrical container and isolator, and has a height which is the integer times of the half-wavelength of microwave field in consonant mode. Its advantages are high uniformly to absorbing microwave energy, simple structure, and low cost.

Owner:EAST CHINA UNIV OF SCI & TECH

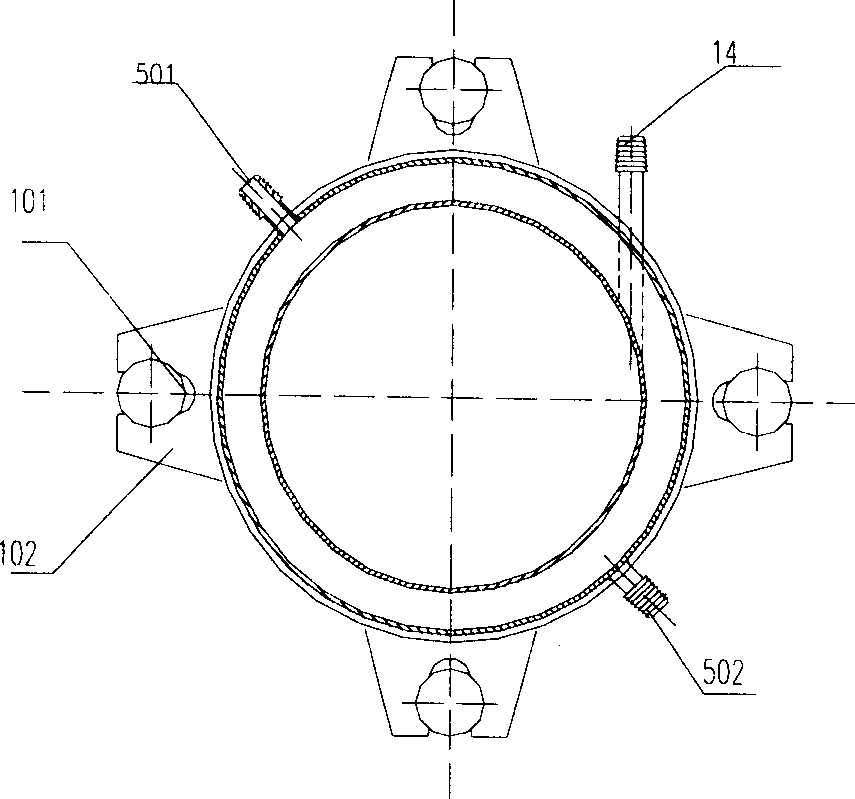

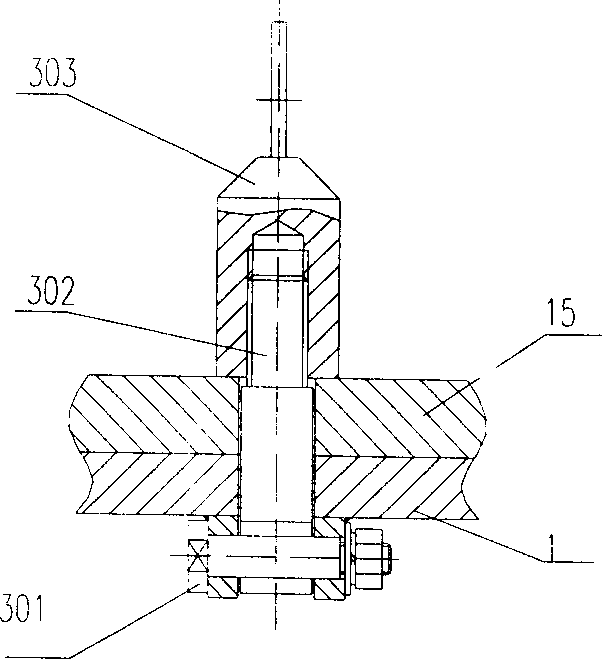

Cyclone fine mist spray head

InactiveCN1751802ALong rangeSolve the problem of remote spray fire suppressionSpray nozzlesAirflowEngineering

A cyclone nozzle able to highly atomize water for extinguishing fire is composed of main body with front blind hole, boosting airflow holes on its periphery, internal mixing cavity consisting of slender holes, internal flow guiding post, and holder of cyclone nozzle. Its advantages are long spray distance, high atomizing effect and long service life.

Owner:许智远

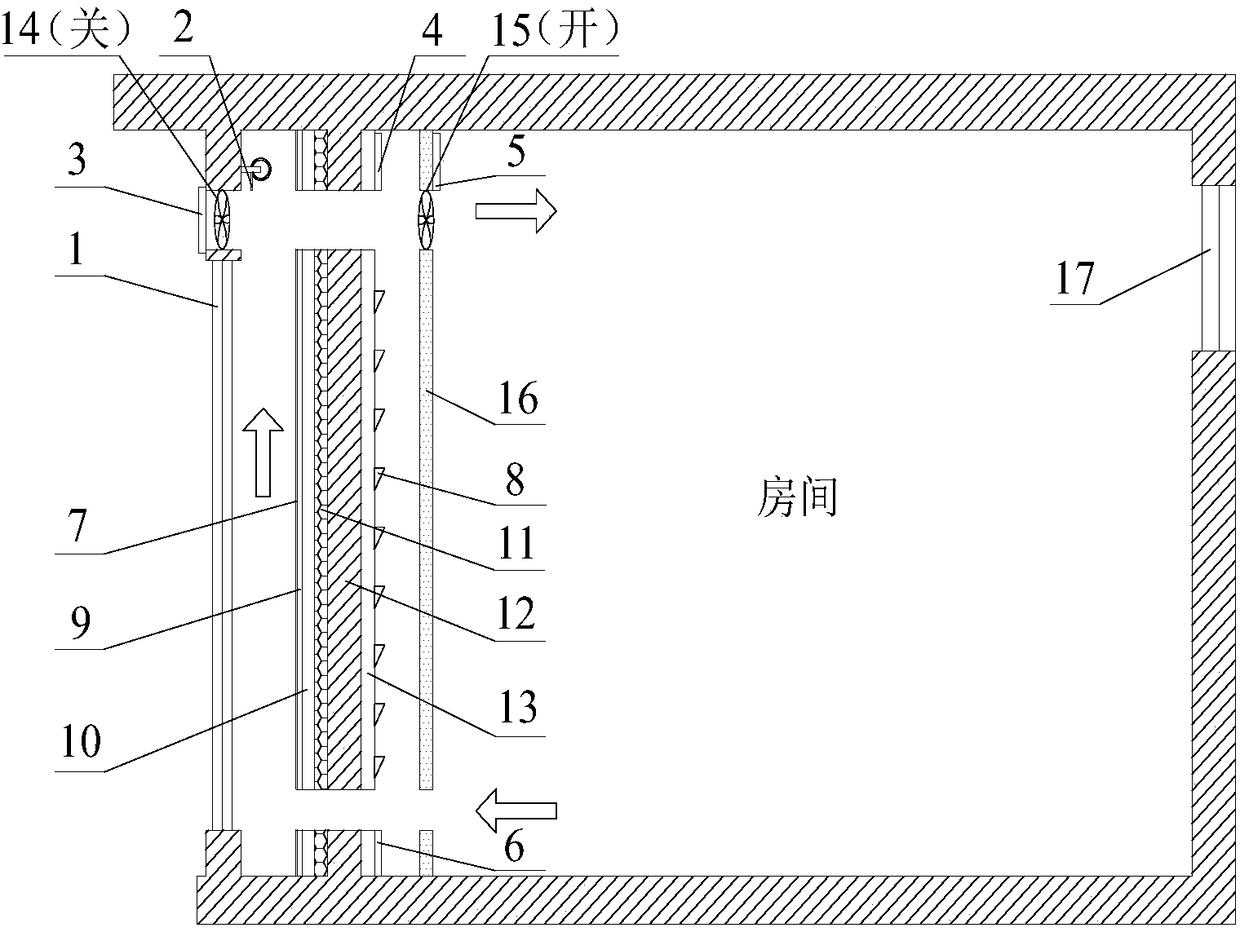

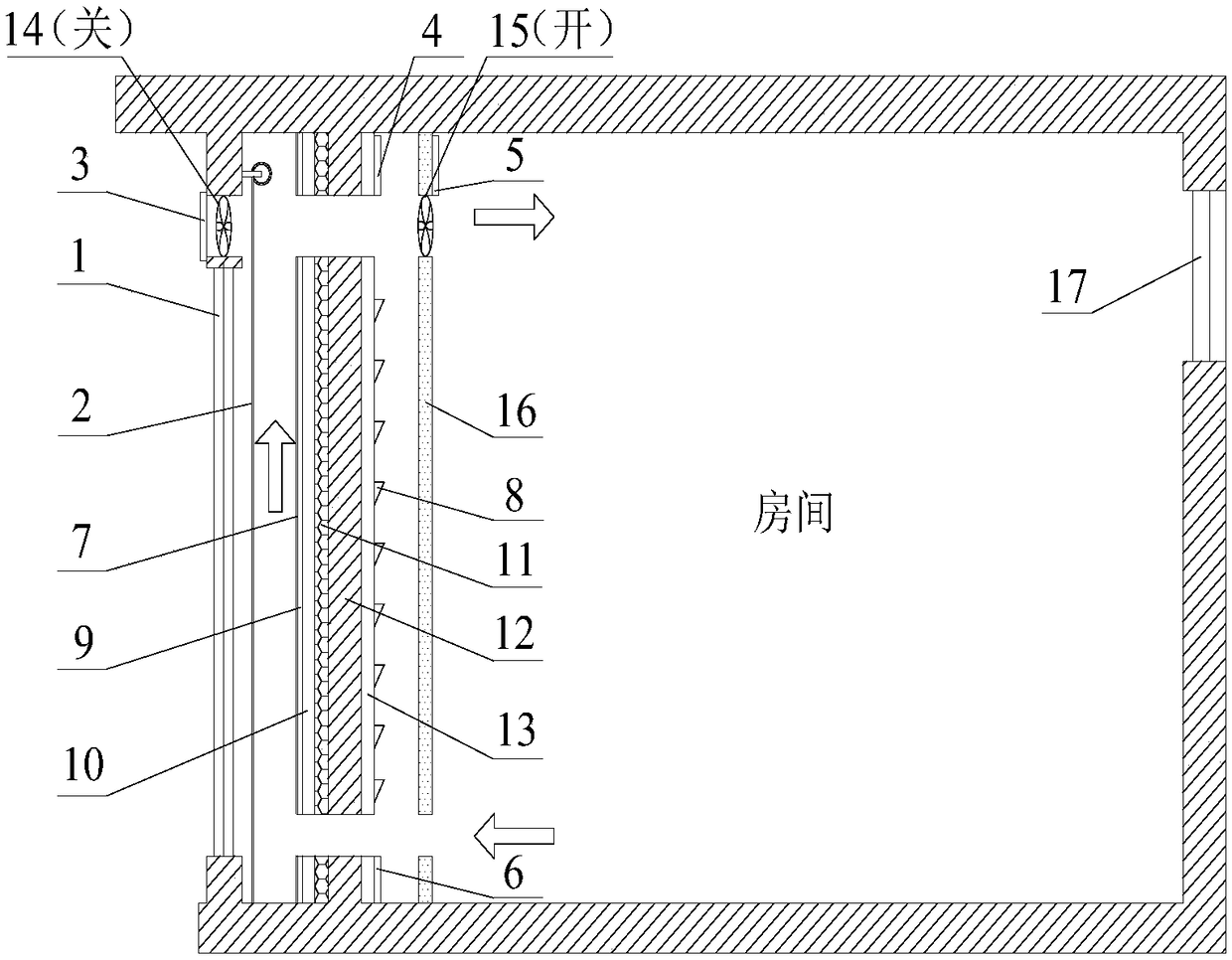

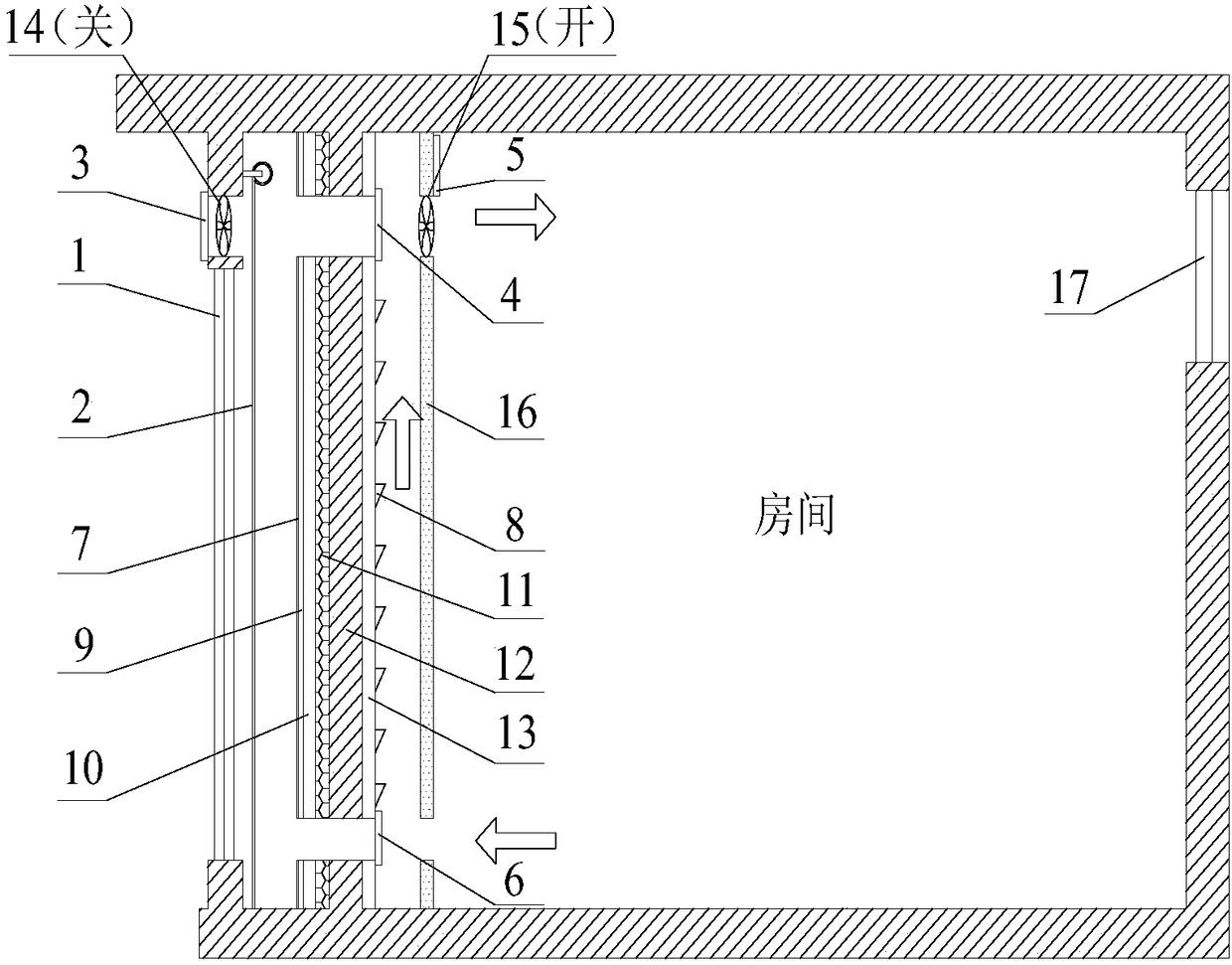

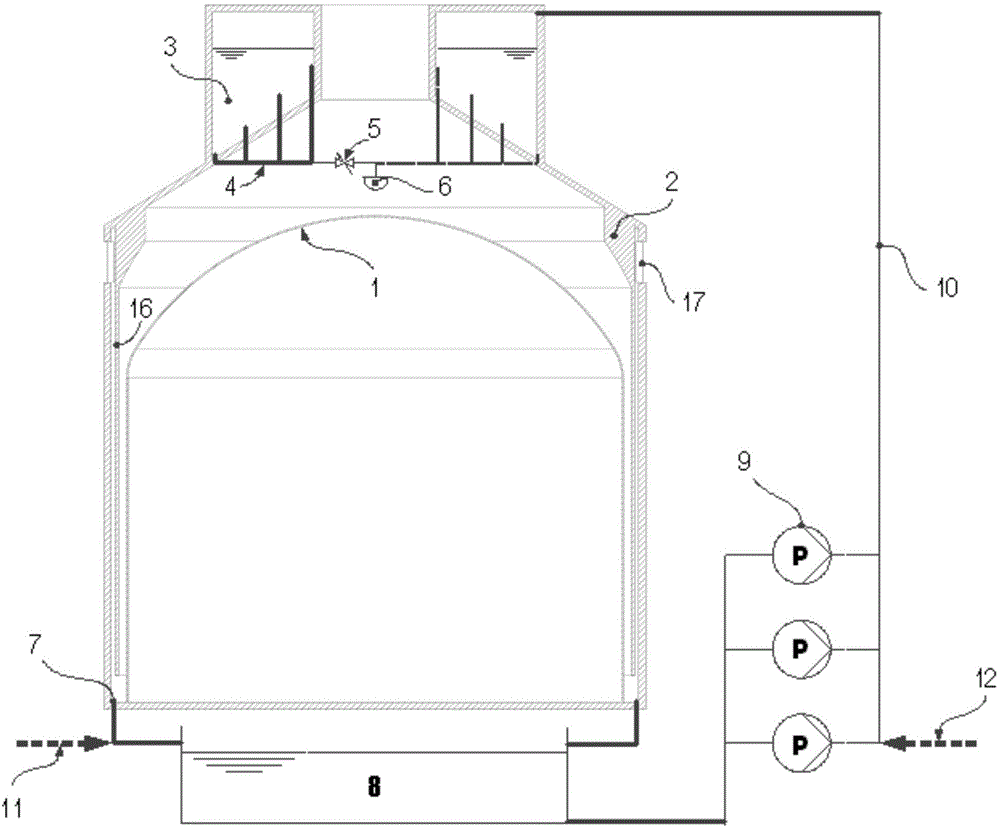

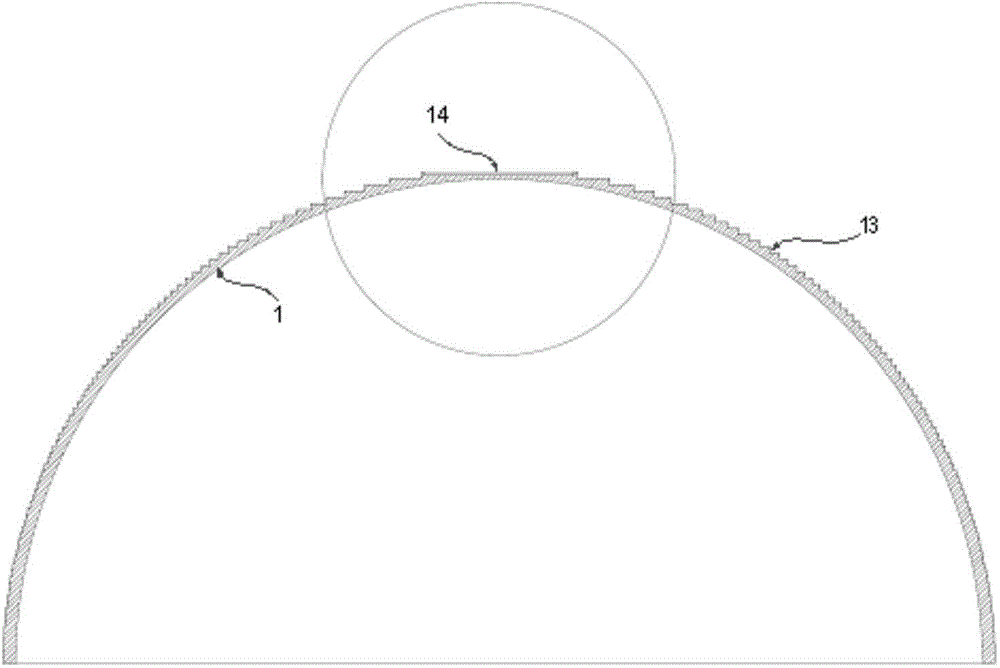

Phase change heat collecting-heat dissipation wall system operating under full working conditions

ActiveCN108589960ARealize the adjustment of indoor thermal environmentIncrease heat storage rateWallsLighting and heating apparatusGlass coverThermal insulation

The invention belongs to a phase change heat collecting-heat dissipation wall system operating under full working conditions in the technical field of building energy saving. The phase change heat collecting-heat dissipation wall system comprises a glass cover plate arranged on a room window, a heat storage wall is arranged inside the glass cover plate, and a decorative plate is arranged inside the heat storage wall. A top opening of the glass cover plate communicates with the outdoor, and a double-cavity channel is formed by opening of the top end and the bottom of the heat storage wall. Thetop end and a bottom opening of the decorative plate communicate with a room, and an outdoor exhaust suction fan and an indoor air supply suction fan are separately installed at the top opening of theglass cover and the top opening of the decorative plate. A thermal insulation roller blind is installed inside the glass cover. The heat storage wall realizes winter heating and summer cooling of a phase change material with different phase transition temperatures, an outside phase change material with a perforated aluminum plate attached to the outer side and an inside phase change material surface longitudinal vortex generator by starting different operating modes in winter and summer. The phase change heat collecting-heat dissipation wall system has broad application prospects and popularization value in areas at which solar energy resources are enriched and the temperature difference between day and night is large.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Passive containment cooling system keeping dynamic circulation of cooling water

ActiveCN104934078AIncreased turbulence intensityAvoid dry spotsNuclear energy generationCooling arrangementSystems designWater source

The invention belongs to a containment cooling system design for a nuclear power plant and particularly relates to a passive containment cooling system keeping dynamic circulation of cooling water. The system structurally comprises a steel containment which is arranged in a shield building, wherein a top water tank is arranged in the upper part of the shield building; a containment spray pipeline arranged above the steel containment is connected with the top water tank; the containment spray pipeline is connected with a generalized passive flow control unit and a shower nozzle to form a spray path; the generalized passive flow control unit is normally open, so that the spray process of a water source in the top water tank through the spray path is continuously processed, and the spray water forms a liquid membrane on the outer surface of the containment and is gathered and conveyed to the top water tank through a water return pipeline. According to the system provided by the invention, the heat exchanging capacity of the containment cooling system is relatively strong, so that start and operation of the system are of relatively high reliability.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Magnetic scraper loop reactor for coal direct liquefaction and coal direct liquefaction method thereof

InactiveCN1803985AReduce contentEasy to operateLiquid hydrocarbon mixture productionMagnetic tension forceProcess equipment

The related loop reactor for coal direct liquefaction comprises: an outside cylinder, a central tube, a gas distributor, a plurality of magnetic scrapers arranged equally between the cylinder and tube, a magnetic draw device, and a device frame. This invention improves material loop speed and turbulence strength to avoid coking and raise heat / mass transfer efficiency for wide application.

Owner:CHINA COAL RES INST +1

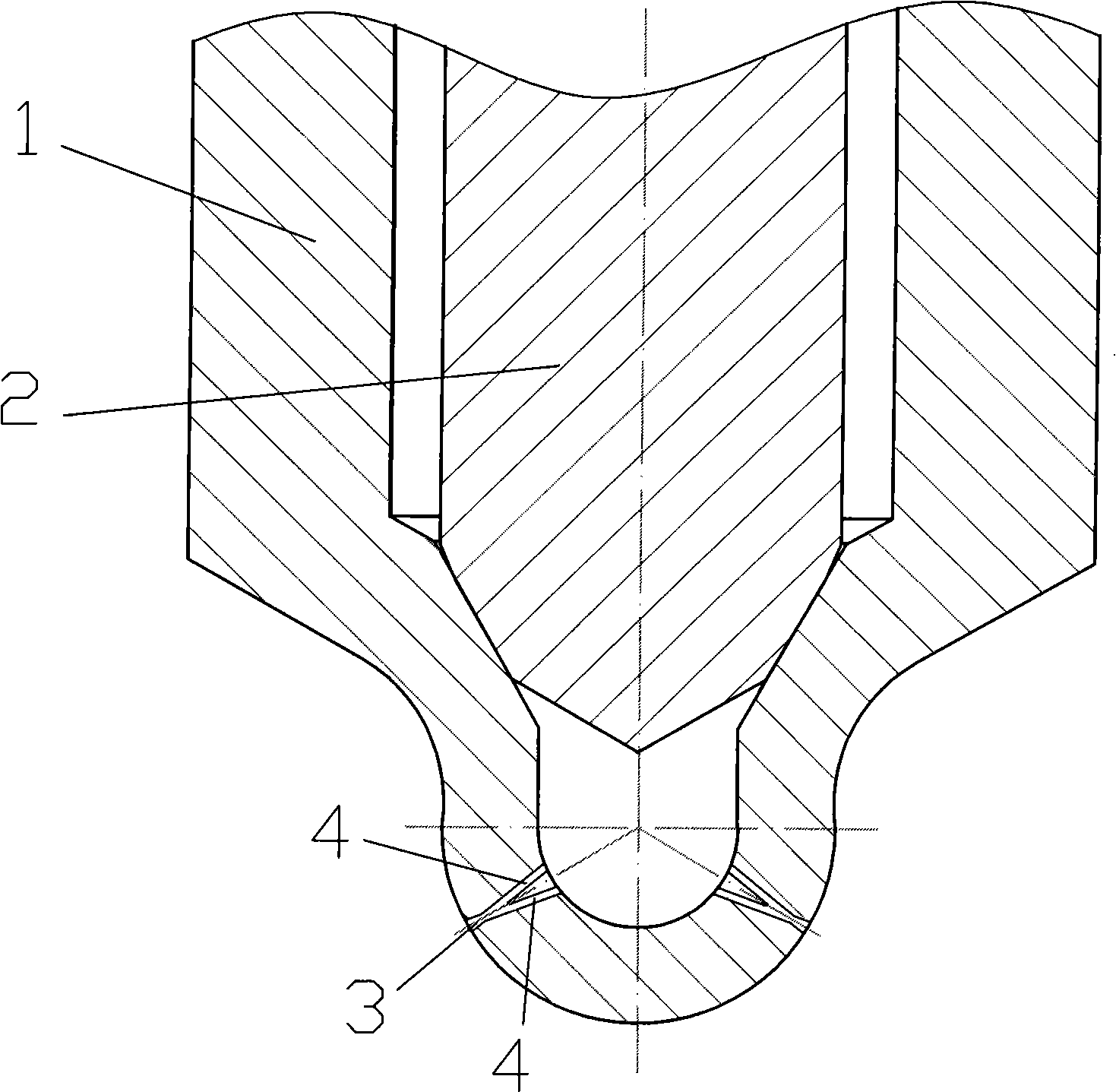

Crossing spray orifice type injection nozzle of internal combustion engine

InactiveCN101294533AIncreased turbulence intensityPromote atomizationFuel injection apparatusMachines/enginesCombustionExternal combustion engine

The invention relates to a cross orifice typed injection nozzle for an internal-combustion engine and belongs to an oil injection device of a fuel system of the internal-combustion engine. The nozzle is a precision coupling formed by an injector valve body and an injector valve. The head of the injector valve body is provided with at least one cross sub-orifice and each cross orifice is formed by crossing and collecting of at least two sub-orifices. As the collection of fuel in the sub-orifices of the cross orifice can form intense disturbance, the turbulent kinetic energy is increased and the atomization is improved; as an outlet of the cross orifice is formed by the collection of the sub-orifices, the flow area of the outlet is less than the sum of the outlet areas of all the sub-orifices, the injection nozzle is characterized by improving discharge coefficient like an analogous V-shaped gradually shrinking orifice. In brief, the crossing of the sub-orifices increases the internal flow, improves the turbulent intensity, causes the cross orifice to improve atomization, improves the quality of the mixed gas and leads to rapid, sufficient and perfect combustion, thus being beneficial to the further improvement of the economic performance, discharging performance and kinetic performance of the motor.

Owner:DALIAN UNIV OF TECH

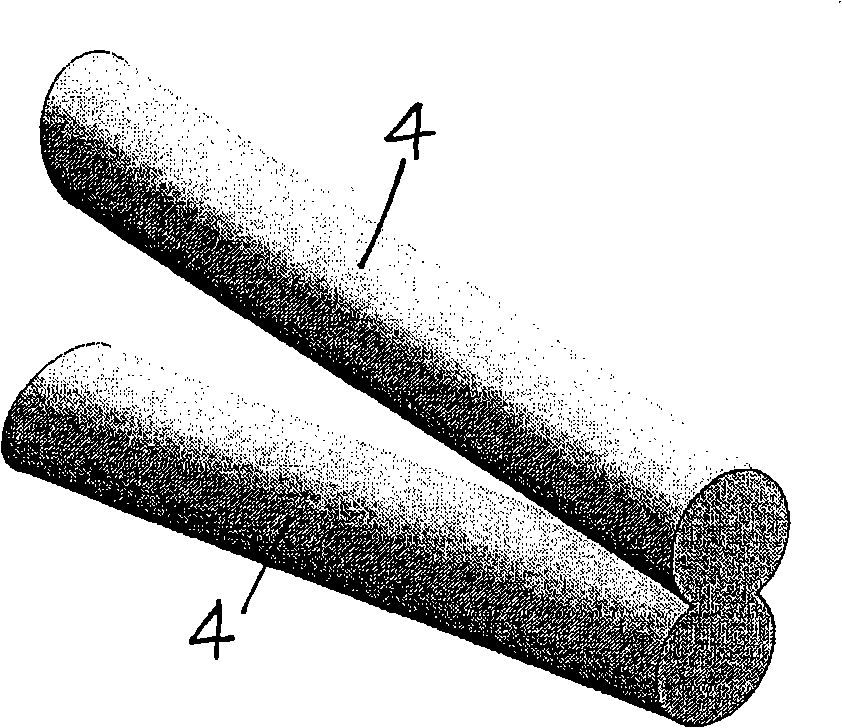

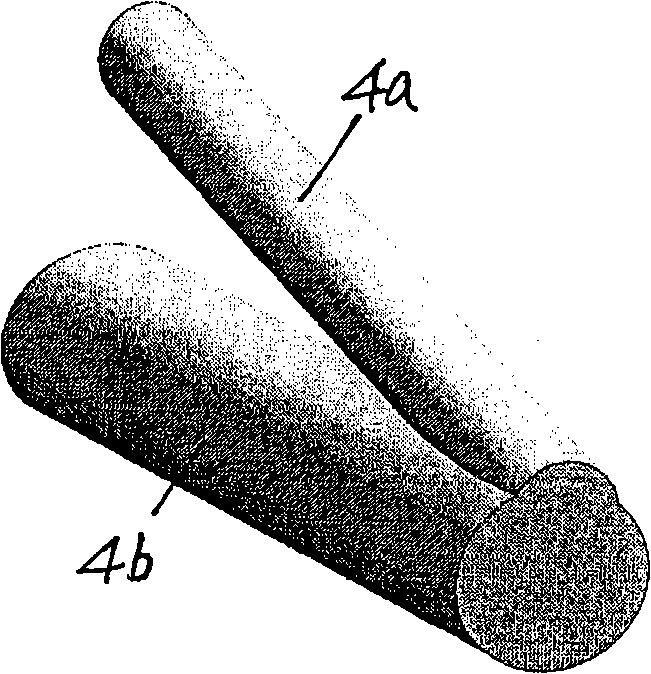

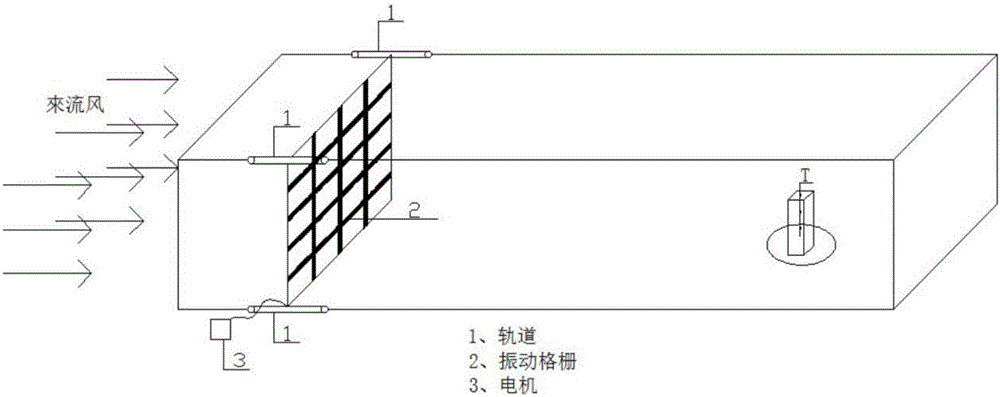

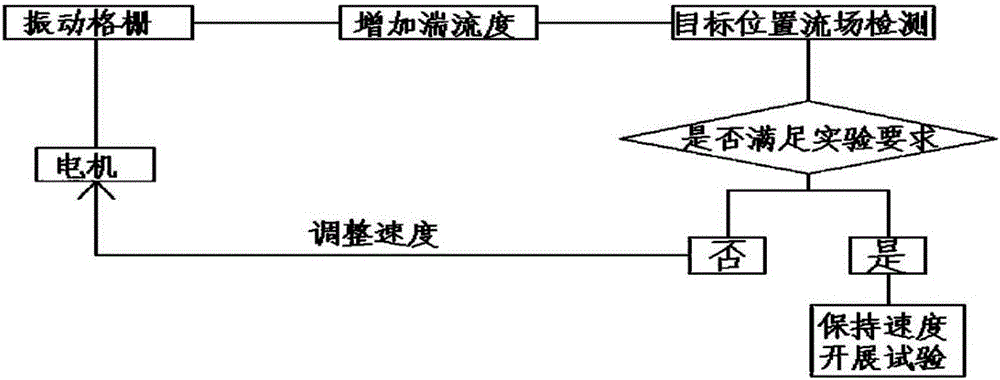

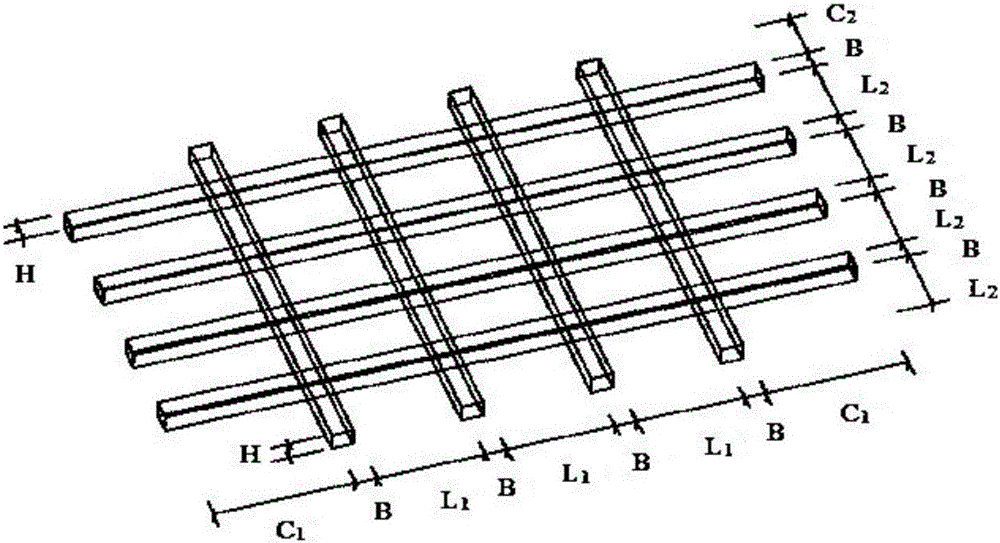

Active vibration grating capable of increasing atmosphere boundary layer wind tunnel turbulence level

InactiveCN105910793ARealize analysisRealize real-time quantitative controlAerodynamic testingGratingMotor drive

Firstly, a vibration grating method is adopted to research a uniform turbulent flow, an active vibration grating capable of increasing an atmosphere boundary layer wind tunnel turbulence level is provided, the grating is arranged in a wind tunnel box, the grating is connected with a motor, the motor drives the vibration grating to change the vibration speed, and the grating is enabled to vibrate controllably in the wind tunnel box. Inflow wind can pass through the grating, the turbulent flow intensity of a test position is enhanced by the wake of grating strips, and precise adjustment of the turbulent flow intensity is realized. The invention aims to obtain a control method of the turbulence level of a uniform turbulent flow field, and wind-induced vibration response tests of structures such as a deck slab under a specific uniform turbulent flow field are accurately carried out; and then a vibration grating, wedge and rough element combined coupling system is adopted to simulate an atmosphere boundary layer in practical engineering, and the accurate analysis of wind vibration responses of building models is realized. According to the invention, the research of structures in the uniform turbulent flow field and the atmosphere boundary layer wind field is realized, and wind vibration response analysis requirements of a plurality of kinds of structures are met.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

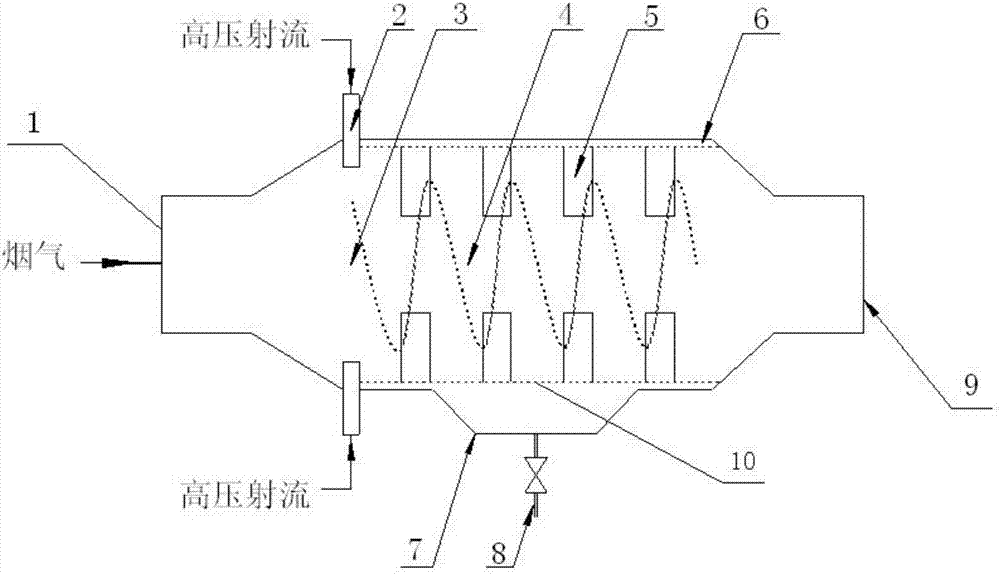

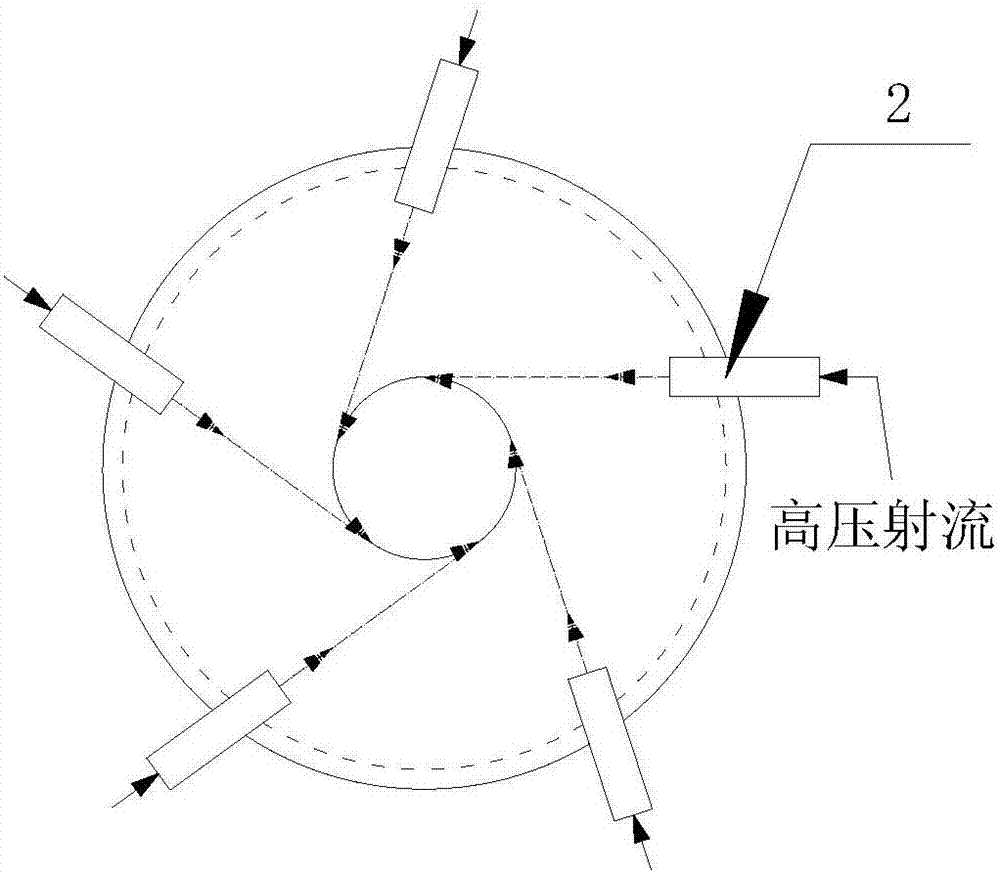

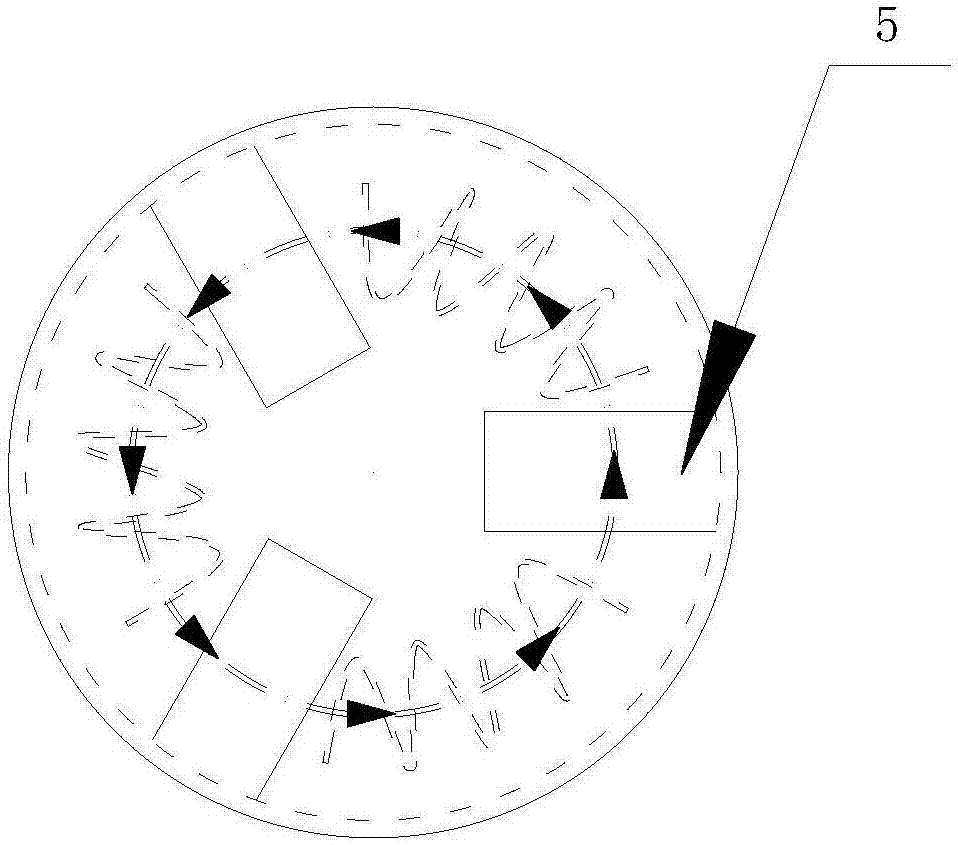

Device and method for coagulating fine particles under tangentially circular cyclone atomization and sound wave action

ActiveCN107088344AEnhanced mixing processReduce energy consumptionCombination devicesCycloneFlue gas

The invention discloses a device and a method for coagulating fine particles under tangentially circular cyclone atomization and sound wave action. The device comprises a double-layer cylinder; coagulation turbolators are distributed on the inner wall surface of the double-layer cylinder in an array manner; the coagulation turbolators distributed on the inner wall surface of the double-layer cylinder in an array manner form a cyclone coagulation area; a plurality of cyclone atomized sound wave turbulators are distributed on the inner wall surface of a flue gas inlet end of the double-layer cylinder in an array manner and tangentially circular manner; a section area formed by enclosing of the cyclone atomized sound wave turbulators form a high-pressure cyclone area; when entering the high-pressure cyclone area through a flue gas inlet, the dust-containing residual heat flue gas and wet saturated steam, generated by the cyclone atomized sound wave turbulators move and collide with each other along the tangentially circular direction under the sound wave action, and spirally move forward in a tangentially circular manner to enter a cyclone coagulation area, thus forming vortex flow after colliding with the coagulation turbolators; and the coagulation separation of the dust-containing residual heat flue gas fine particles can be realized under the mutual coupling action of sound wave, phase change and turbulence.

Owner:SOUTH CHINA UNIV OF TECH +1

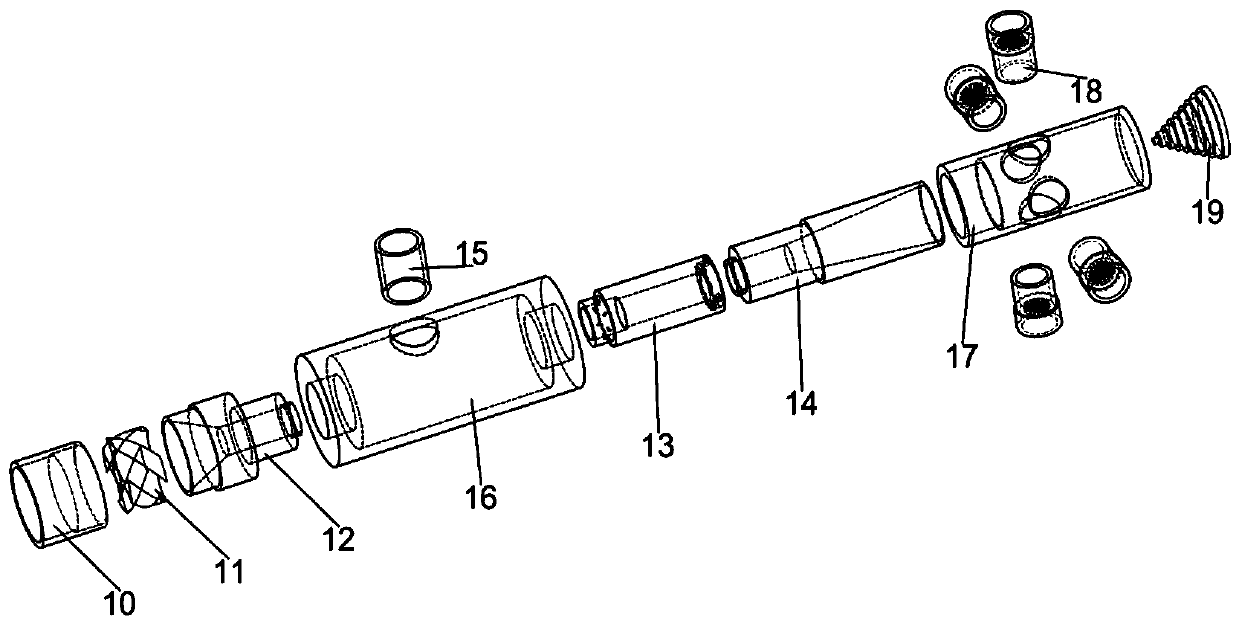

Micro-nano bubble generator

ActiveCN111298670AInflatable volumeSmall bubble diameterFlow mixersMixing methodsMicro nanoEngineering

The invention discloses a micro-nano bubble generator. The micro-nano bubble generator comprises a liquid inlet pipe, a swirl flow groove, a reducing pipe, an air inlet pipe, a shell, a throat pipe, adiffusion pipe, a mixing pipe, a breaker and release heads, wherein the reducing pipe, the throat pipe and the diffusion pipe are sequentially connected to form a Venturi-pipe-like water passing channel structure; a gap between the joints of the reducing pipe, the throat pipe and the diffusion pipe is a multi-stage air inlet; the inner walls of two ends of the shell are connected with the outer wall of the reducing pipe and the outer wall of the diffusion pipe respectively to form an air storage chamber which communicates with a throat flow channel through the multi-stage air inlet; and the breaker is arranged in the mixing pipe; and the outer side of the mixing pipe is connected with four release heads. According to the micro-nano bubble generator disclosed by the embodiments of the invention, large bubbles can be quickly broken; formed bubbles have the characteristics of small size and uniform dispersion; meanwhile, the diameters of the bubbles can be adjusted by replacement of therelease heads with different specifications.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

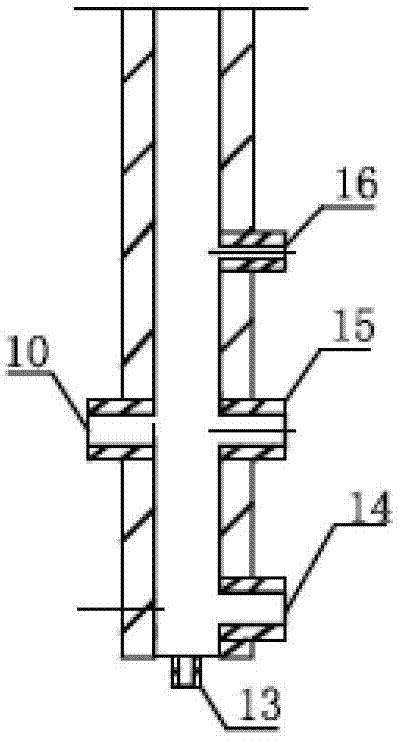

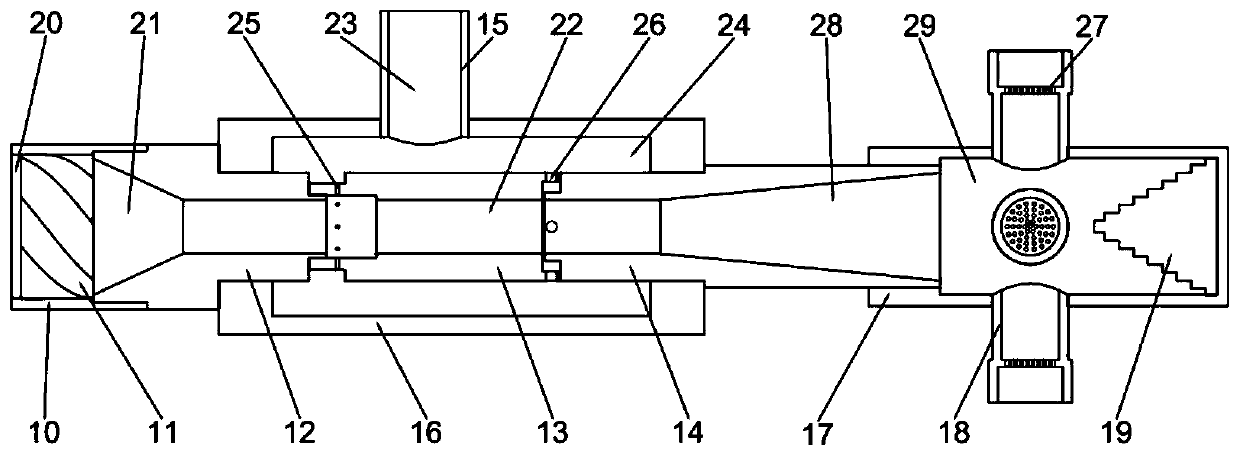

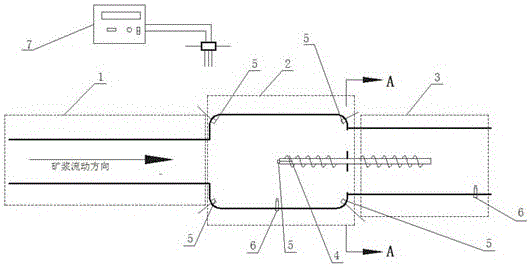

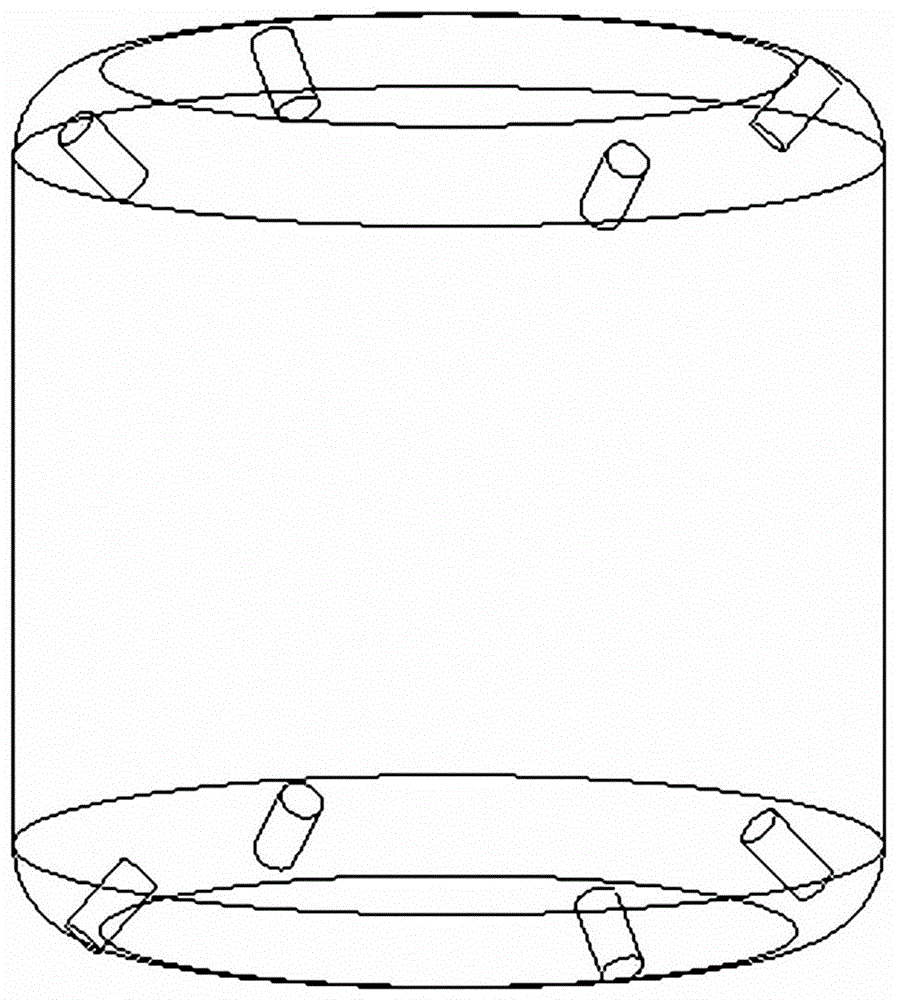

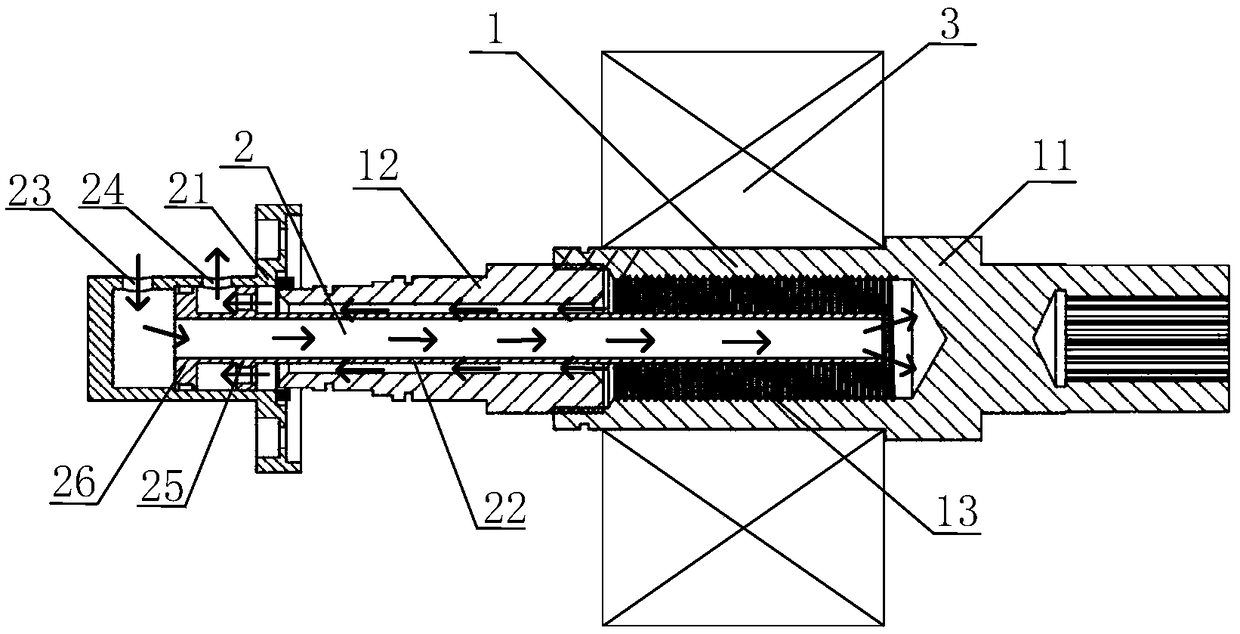

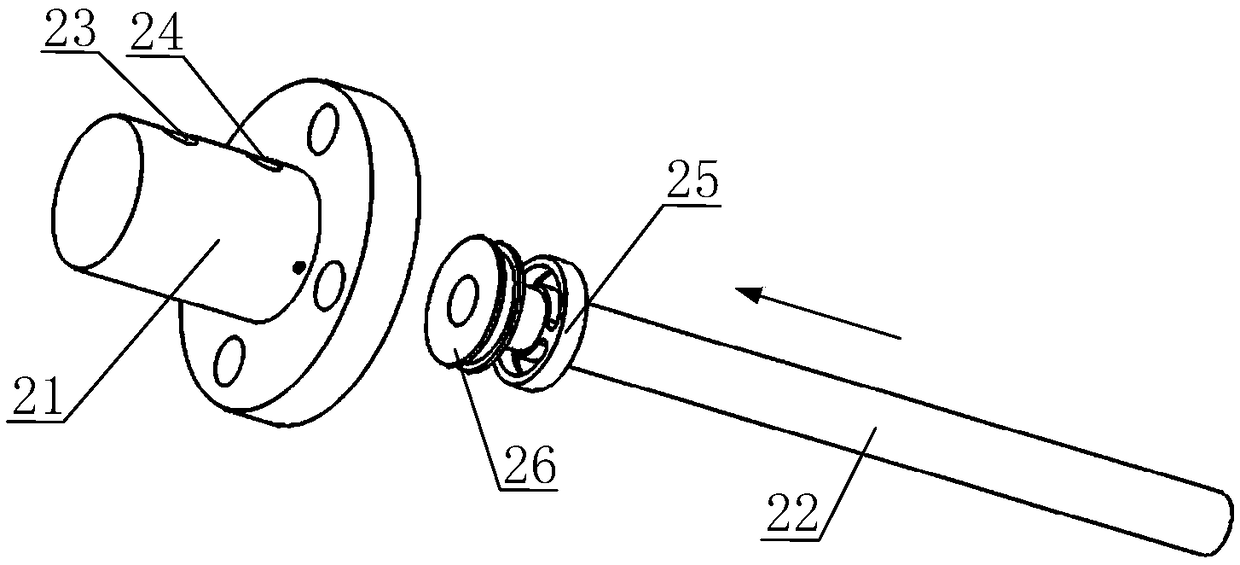

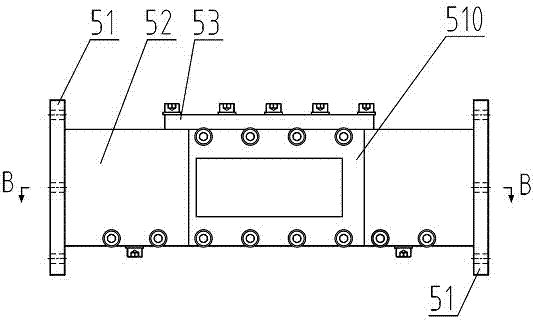

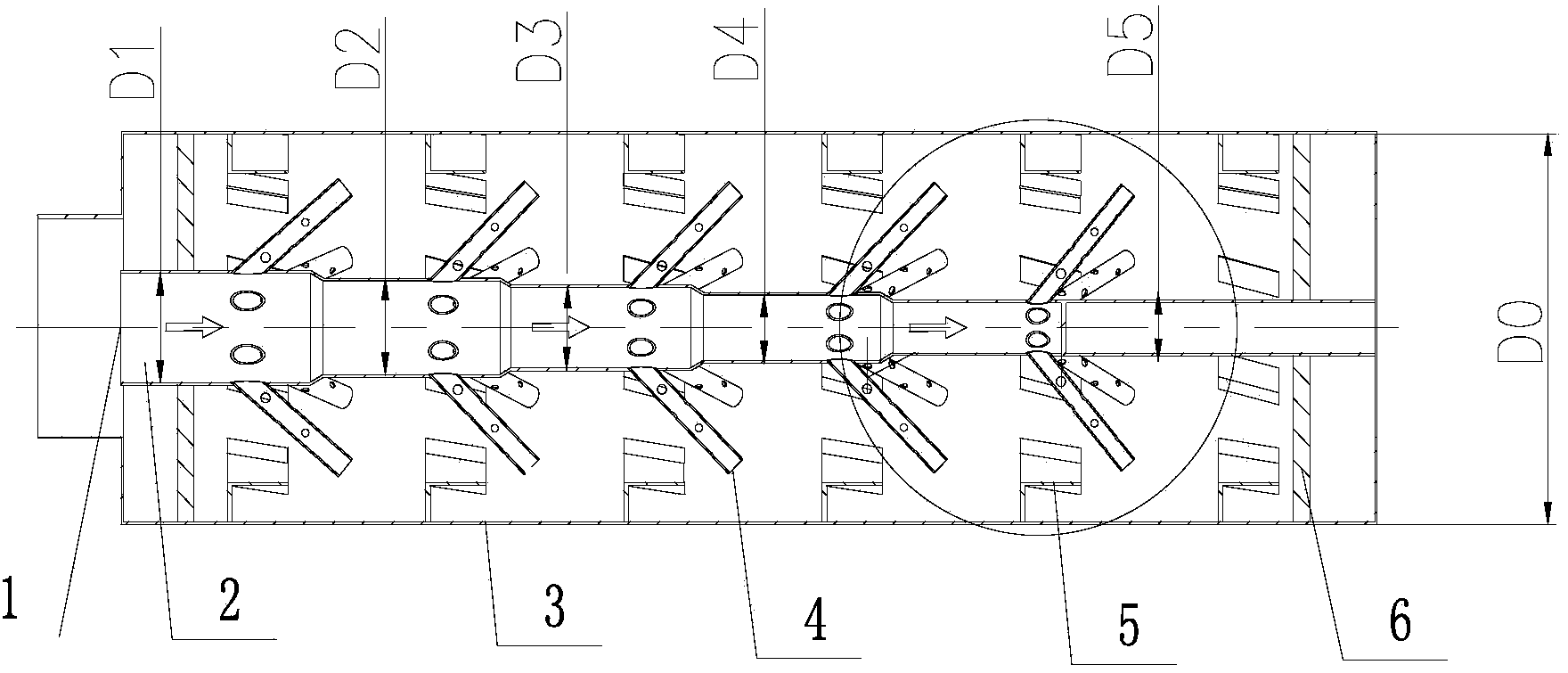

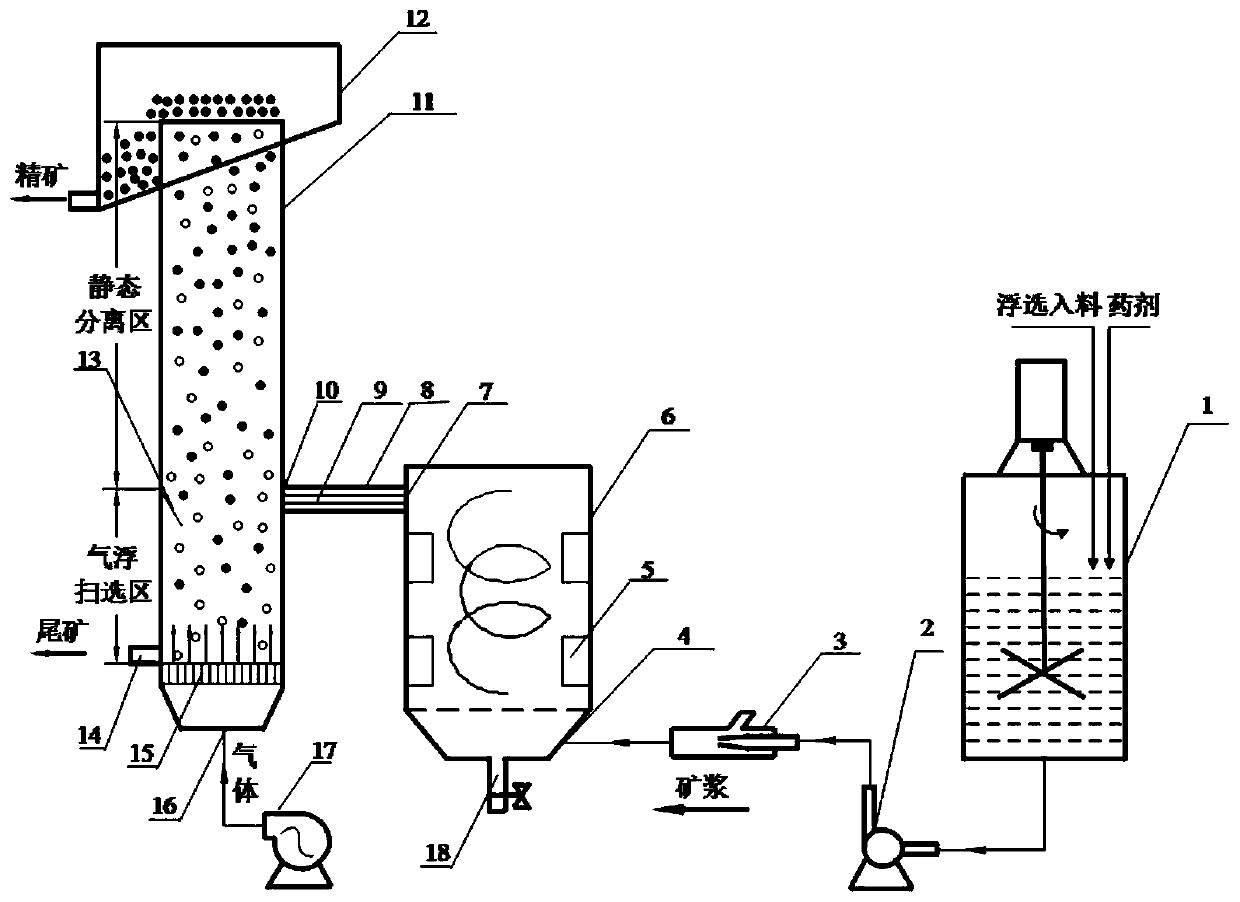

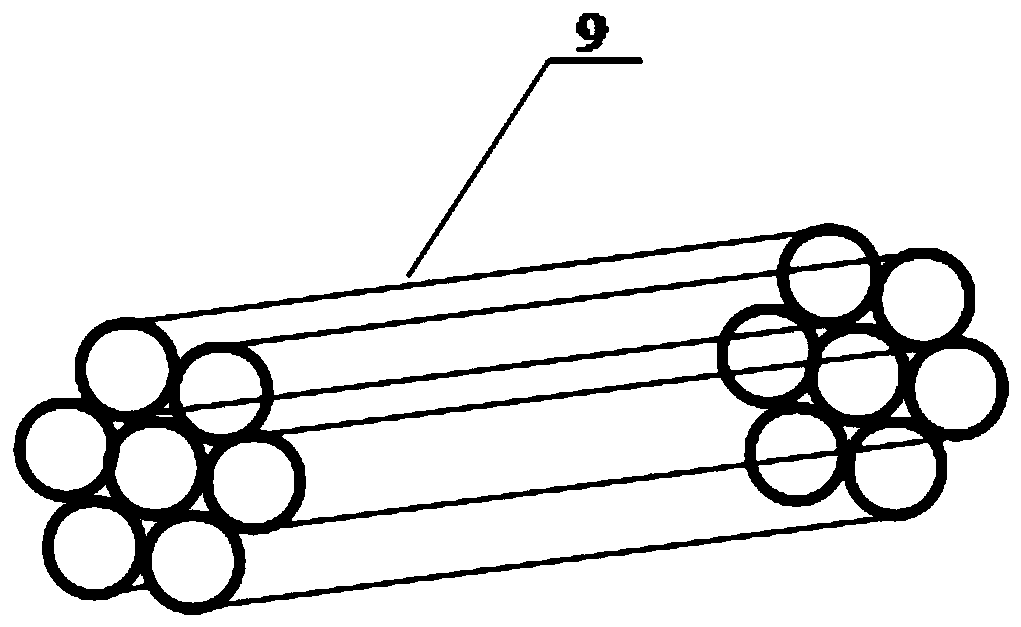

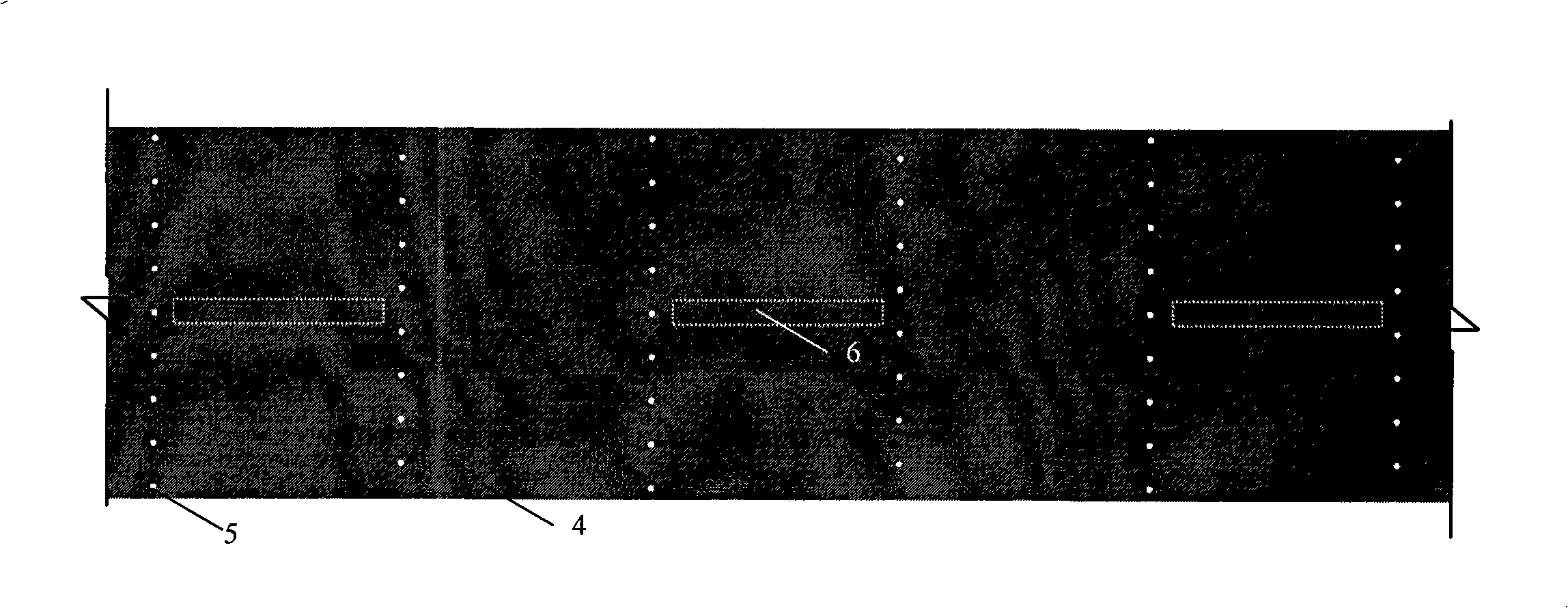

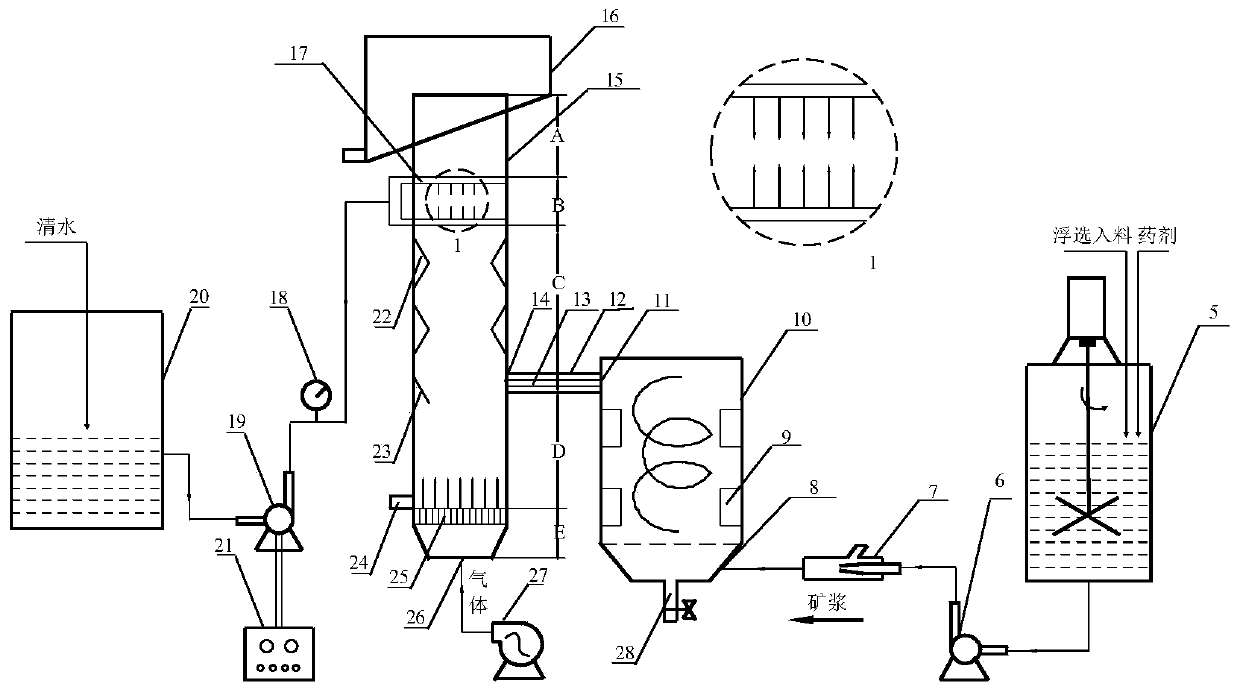

Cyclone-static micro bubble flotation column ultrasonic enhanced pipe flow section mineralization device

The invention discloses a cyclone-static micro bubble flotation column ultrasonic enhanced pipe flow section mineralization device. The cyclone-static micro bubble flotation column ultrasonic enhanced pipe flow section mineralization device comprises an upstream narrow pipe section, an ultrasonic enhanced region, a downstream wide pipe section, an ultrasonic generator, a plurality of ultrasonic oscillators, a resonance screw and a hydrophone. The ultrasonic oscillators are arranged inside the ultrasonic enhanced region, the ultrasonic generator is connected with the ultrasonic oscillators, and the resonance screw is arranged in the ultrasonic enhanced region and the downstream wide pipe section; and the hydrophone is arranged in the ultrasonic enhanced region and the downstream wide pipe section. According to the cyclone-static micro bubble flotation column ultrasonic enhanced pipe flow section mineralization device, the evenly-distributed ultrasonic oscillators are adopted, so that spreading of ultrasonic waves in the ultrasonic enhanced region is facilitated, and sound waves are spread to the upstream and the downstream at the same time with the same transmitting characteristics. The ultrasonic enhanced region is arranged so that ore pulp flowing through the region can bear the strong ultrasonic effect, vacuoles can be generated, disturbance to flow can be generated, continuous generation of the vacuoles can continuously generate pulsating flow, and accordingly the turbulence intensity is greatly improved. The resonance screw has the effects of flow disturbance and turbulence intensity improving.

Owner:CHINA UNIV OF MINING & TECH

Motor rotor cool structure

ActiveCN109067092AIncrease contact areaReduce weightMechanical energy handlingCooling/ventillation arrangementEngineeringCantilever

The invention discloses a motor rotor cooling structure, comprising: a half hollow shaft, a cooling pipe assembly and a motor rotor; The half hollow shaft has a half hollow structure and an internal cavity with a closed end enlarged; The motor rotor is sleeved on the half hollow shaft and close to the closed end of the half hollow shaft; The cooling tube assembly includes an interconnected coolingtube head and a cooling pipe; The opening end of the cooling tube head and the half hollow shaft is connected by a dynamic seal and fixed on the motor end cover, and an inlet and an outlet are also arranged on the cooling tube head and the half hollow shaft. An outer diameter of the cooling pipe is smaller than an inner diameter of an open end of the half hollow shaft and is axially inserted intoa cavity of the half hollow shaft, thereby forming a cooling passage between an outer wall of the cooling pipe and an inner wall of the semi-hollow shaft. The invention can effectively increase the heat dissipation area and effectively prevent the end of the cooling pipe from contacting the inner wall of the half hollow shaft due to the deformation of the cantilever structure.

Owner:HUAZHONG UNIV OF SCI & TECH

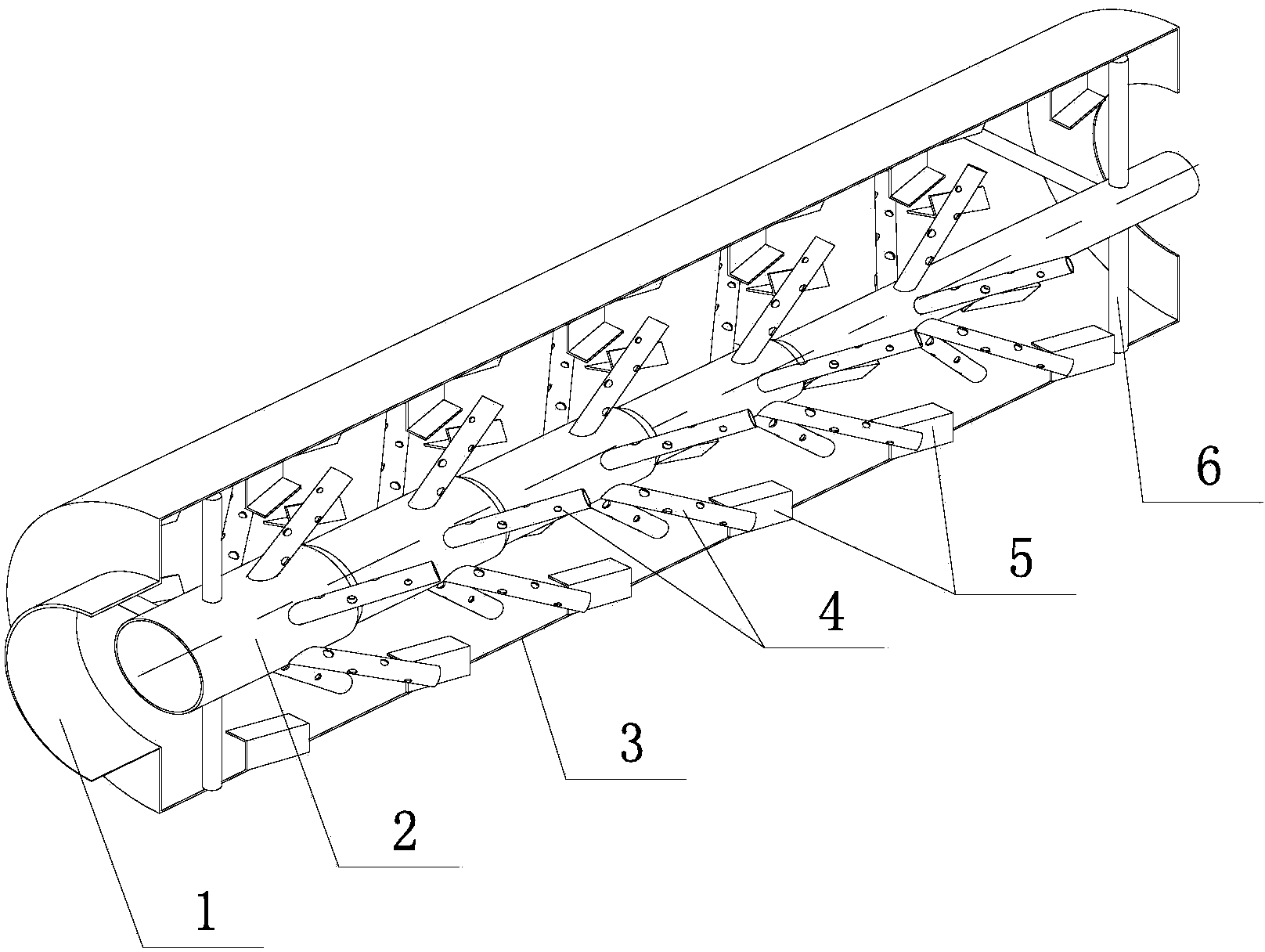

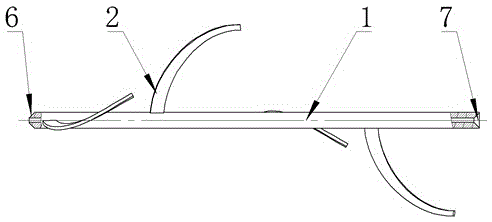

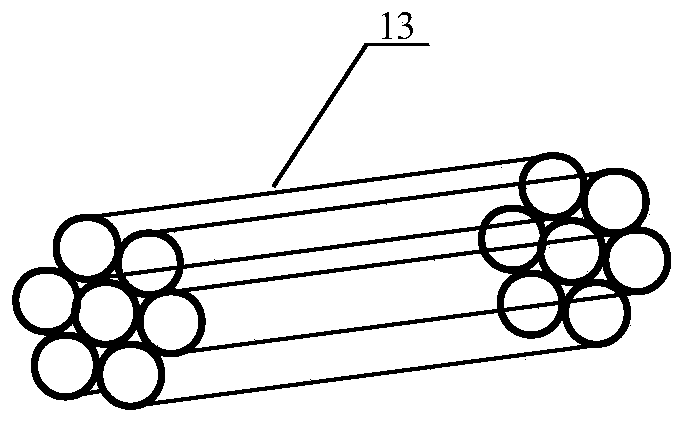

Pipe flow section device applicable to mineralized fine grain minerals

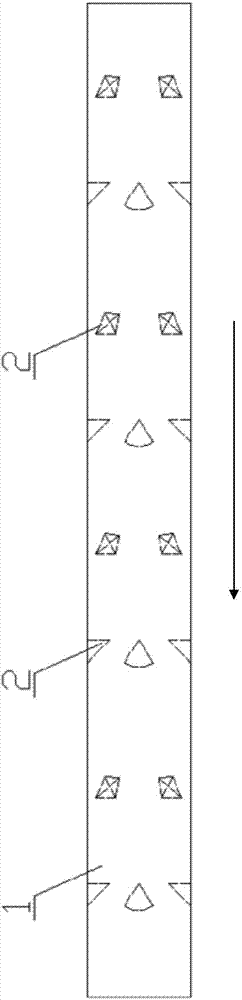

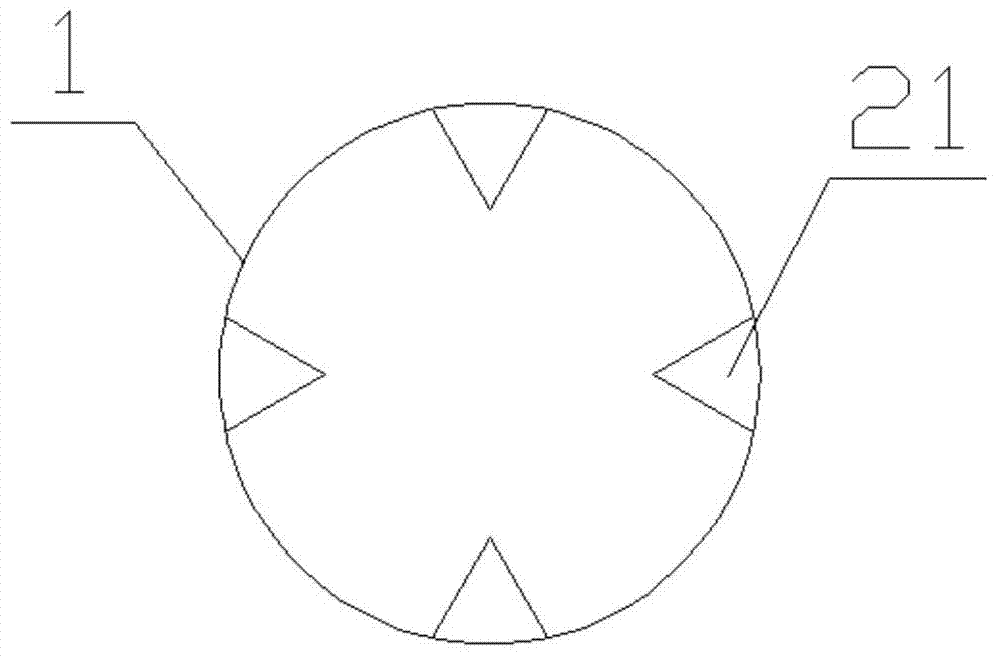

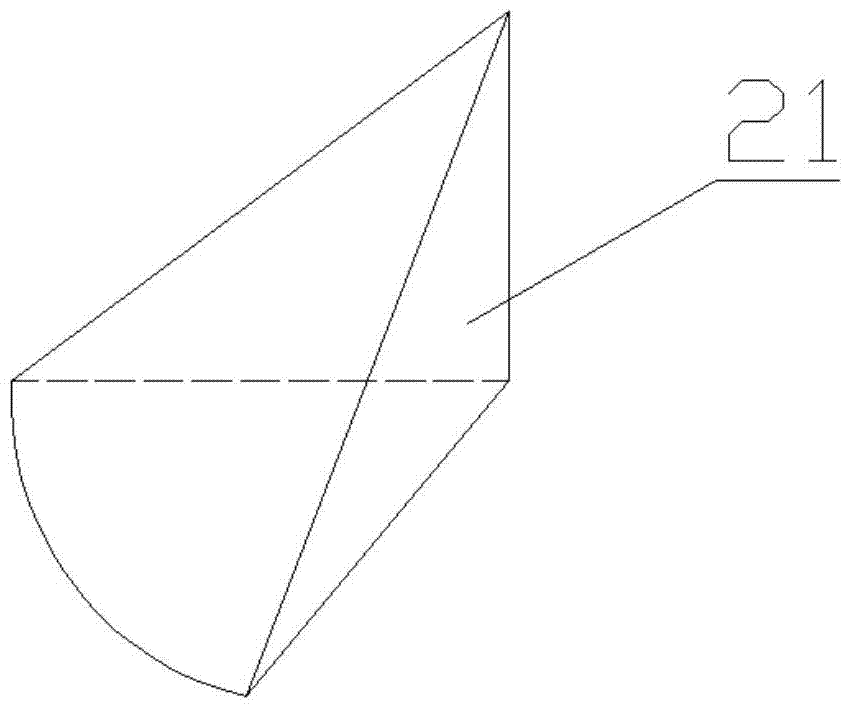

ActiveCN104511374AIncreased turbulence intensityIncrease the probability of collisionVortex flow apparatusFlotationEngineeringMaceral

The invention discloses a pipe flow section device applicable to mineralized fine grain minerals. The device comprises a pipeline (1) between the downstream of a bubble generator of a flotation column and an inlet end of a rotating flow inlet end, wherein the inner pipe wall of the pipeline (1) along the inner pipe wall of a pipeline axis is provided with at least a row of vortex generators (2), and the vortex generators are a plurality of protuberances (21) surrounding the inner pipe wall. The vortex generator in the pipe can be changed by the vortex generator set in the pipeline, therefore the collision probability between mineral grains and bubbles can be improved, the turbulence intensity in the pipe can be gradually enhanced, the mineral effect can be enhanced, and the recovery ratio of the fine minerals can be improved.

Owner:CHINA UNIV OF MINING & TECH

Hydrodynamic cavitation generating device

ActiveCN103611481AImprove stabilityGuaranteed smoothChemical/physical/physico-chemical processesSquare cross sectionCavitation

The invention provides a hydrodynamic cavitation generating device. The hydrodynamic cavitation generating device comprises a buffering body, a rectifying pore plate, a rectifying body, a rectifying grid plate and a testing body which are connected by flanges in sequence, wherein the testing body is a fluid channel which is composed of a shell and a ladder-shaped bottom plate and has a square cross section; three observation windows which are as wide as the fluid channel are opened on front, back and upper sides of the testing body; a bottom plate is split and is provided with a turbulent flow platform. A coming liquid sequentially passes through the buffering body, the rectifying pore plate, the rectifying body and the rectifying grid plate, the turbulence intensity can be reduced and the stability of water flow is enhanced effectively, so that the coming liquid can stably enter the testing body. The hydrodynamic cavitation generating device is simple in structure, convenient to detach, high in structural strength and good in impermeability; a test piece and the turbulent flow platform are convenient to replace; the distance between the test piece and the turbulent flow platform is convenient to adjust; the turbulence intensity is small and the cavitation strength can be adjusted continuously; the cavitation property can be observed directly and easily.

Owner:CHINA UNIV OF MINING & TECH

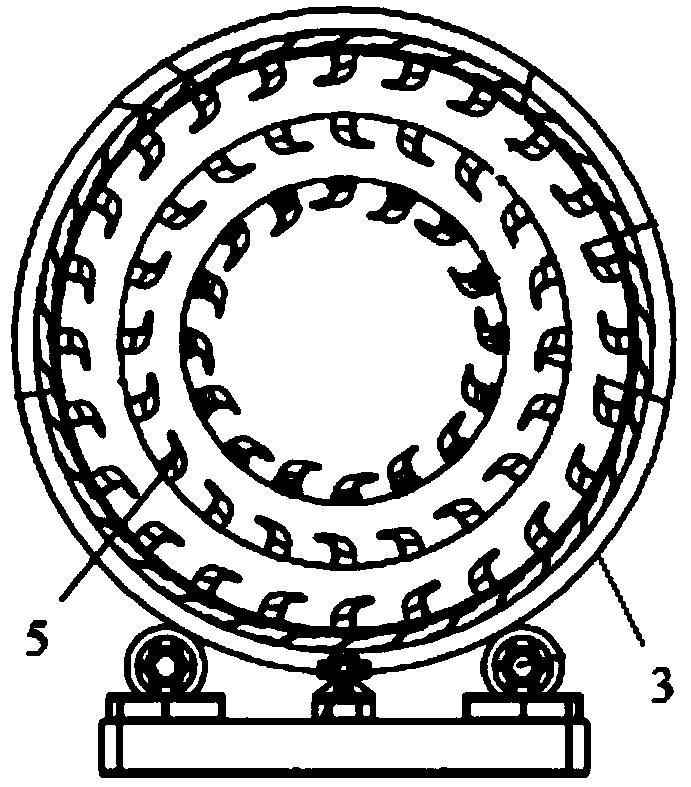

Drying drum

ActiveCN103673580AImprove heat exchange effectIncreased turbulence intensityDrying gas arrangementsDrying chambers/containersEngineeringEnergy consumption

The invention discloses a drying drum which comprises a drum body (3), a main drainage pipe (2) and branch drainage pipes (4), wherein hot airflow is input into the main drainage pipe (2) and the branch drainage pipes (4). The main drainage pipe axially extends into an inner cavity of the drum body from an inlet end (1) of the drum body, the branch drainage pipes are communicated with the main drainage pipe and used for draining hot airflow in the main drainage pipe to the inner cavity, and therefore turbulent flow is formed. When the hot airflow is input into the inlet end, a major part of the hot airflow enters the main drainage pipe, a small part of the hot airflow enters the space formed between the main drainage pipe and the inner wall of the drum body, and the hot airflow in the main drainage pipe flows everywhere in the inner cavity of the drum body through the branch drainage pipes which extend in the radial direction. The airflow which flows into the branch drainage pipes from the main drainage pipe and then is sprayed out has the higher speed, speed difference exists between the airflow and the hot airflow directly flowing into the inner cavity, a flow field in the inner cavity of the drum body generates strong disturbance due to the speed difference and the rotation of the drum, and turbulence intensity is enhanced, so that the good heat convection effect is good, and the energy consumption use ratio is improved.

Owner:ZOOMLION HEAVY IND CO LTD

Mineralization-flotation separation column sorting device and method

ActiveCN109759243AImprove recycling effectIncrease the probability of collisionFlotationFlocculationSlurry

The invention provides a mineralization-flotation separation column sorting device and method, which are applicable to ore processing. The mineralization-flotation separation column sorting device comprises a stirring barrel, a pump, a bubble generator, a mineralization chamber, a flocculation elimination pipe, a flotation column and an air compressor; after flotation ore slurry is mixed through slurry blending equipment and passes through the bubble generator, the ore slurry enters the cyclone mineralization chamber; the ore slurry which is rotated at a high speed and bubbles are subjected tohigh-strength turbulent flow collision and mineralized bubbles are formed; a large vortex of the mineralized bubbles are eliminated through the flocculation elimination pipe and then the mineralizedbubbles enter a flotation column static sorting region to finish static separation; a flotation assisting baffle plate is arranged at the bottom of the flotation column static separation region and the ore slurry is prevented from entering tailings due to short circuiting; ore grains which are not mineralized and desorbed are subjected to intensive recovery; low-ash clean coal is recycled and high-ash ores are discharged from a tailing opening. According to the mineralization-flotation separation column sorting device, the flotation and falling probability of low-ash coarse grains is effectively reduced and the equipment processing capability is great; the device has strong adaptability on different coal properties, low production and operation cost and is convenient to mount and operate;the quantity and quality of clean coal products are wholly improved.

Owner:CHINA UNIV OF MINING & TECH +2

Low-flow-resistance rotor for reinforcing heat transfer and scale removal/prevention in heat exchange tube

InactiveCN105135932AIncreased turbulence intensitySimple structureHeat transfer modificationRotary device cleaningSmooth surfaceHeat transfer efficiency

The invention relates to a low-flow-resistance rotor for reinforcing heat transfer and scale removal / prevention in a heat exchange tube, which mainly comprises a hollow shaft and helical blades, wherein the hollow shaft is provided with the two or more helical blades; the helical blades are equantly arranged along the axial and circumferential direction of the hollow shaft; the helical blades have smooth surfaces, and the external diameter is slightly smaller than the internal diameter of the heat exchange tube; and the thickness of the helical blades is kept constant, and the width gradually decreases from the hollow shaft. When the fluid in the tube enters the heat exchange tube, the acting force of the fluid perpendicular to the radial direction of the helical blades enables the rotor to rotate around the hollow shaft, and the fluid in the tube forms a three-dimensional helical flow state to reinforce the turbulent intensity of the fluid and aggravate the disturbance of the boundary layer, thereby enhancing the heat transfer efficiency, improving the on-line cleaning effect, reducing the deposition of the dirt on the internal wall of the heat exchange tube and prolonging the service life of the heat exchange tube and rotor. The rotor has the advantages of simple structure, low flow resistance and high safety and reliability, and is convenient for mounting.

Owner:ZHENGZHOU UNIV

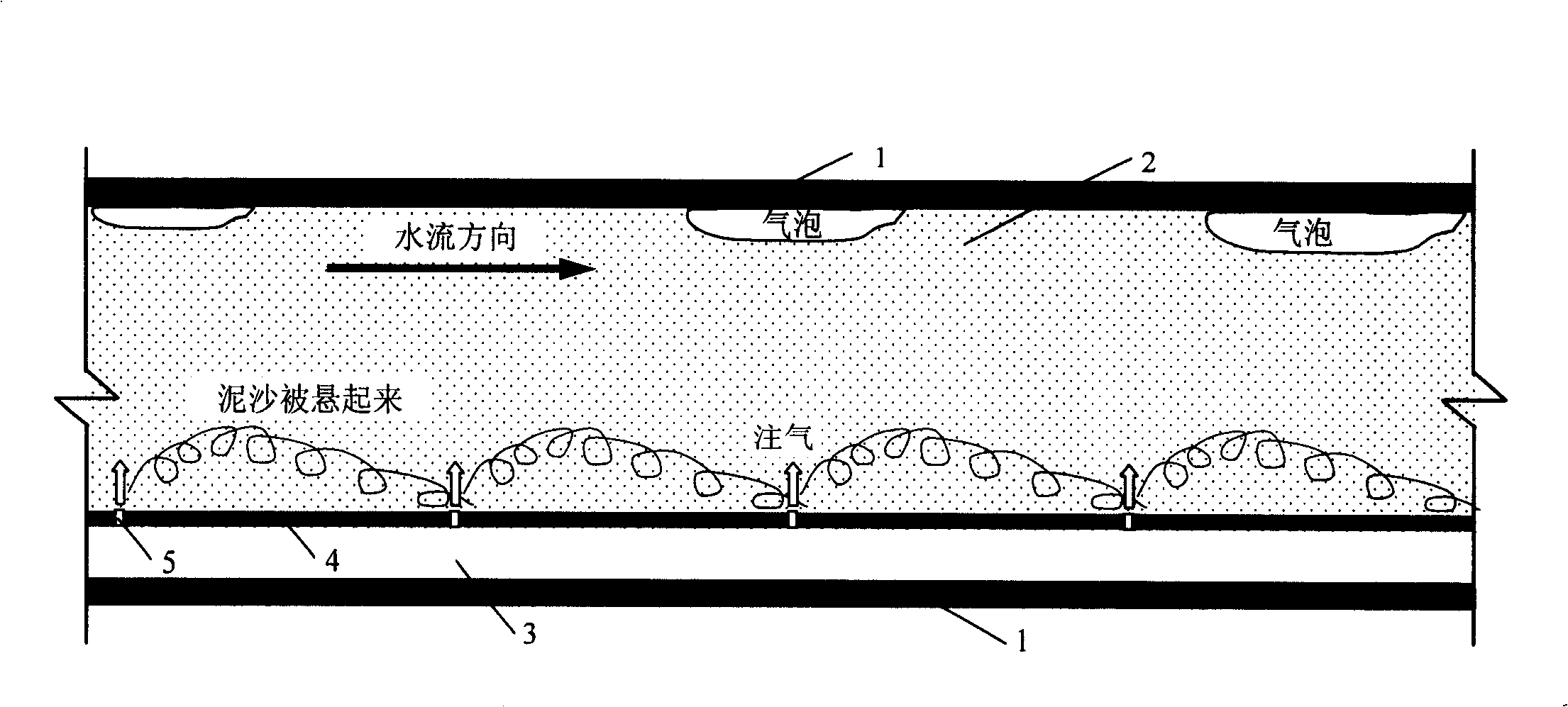

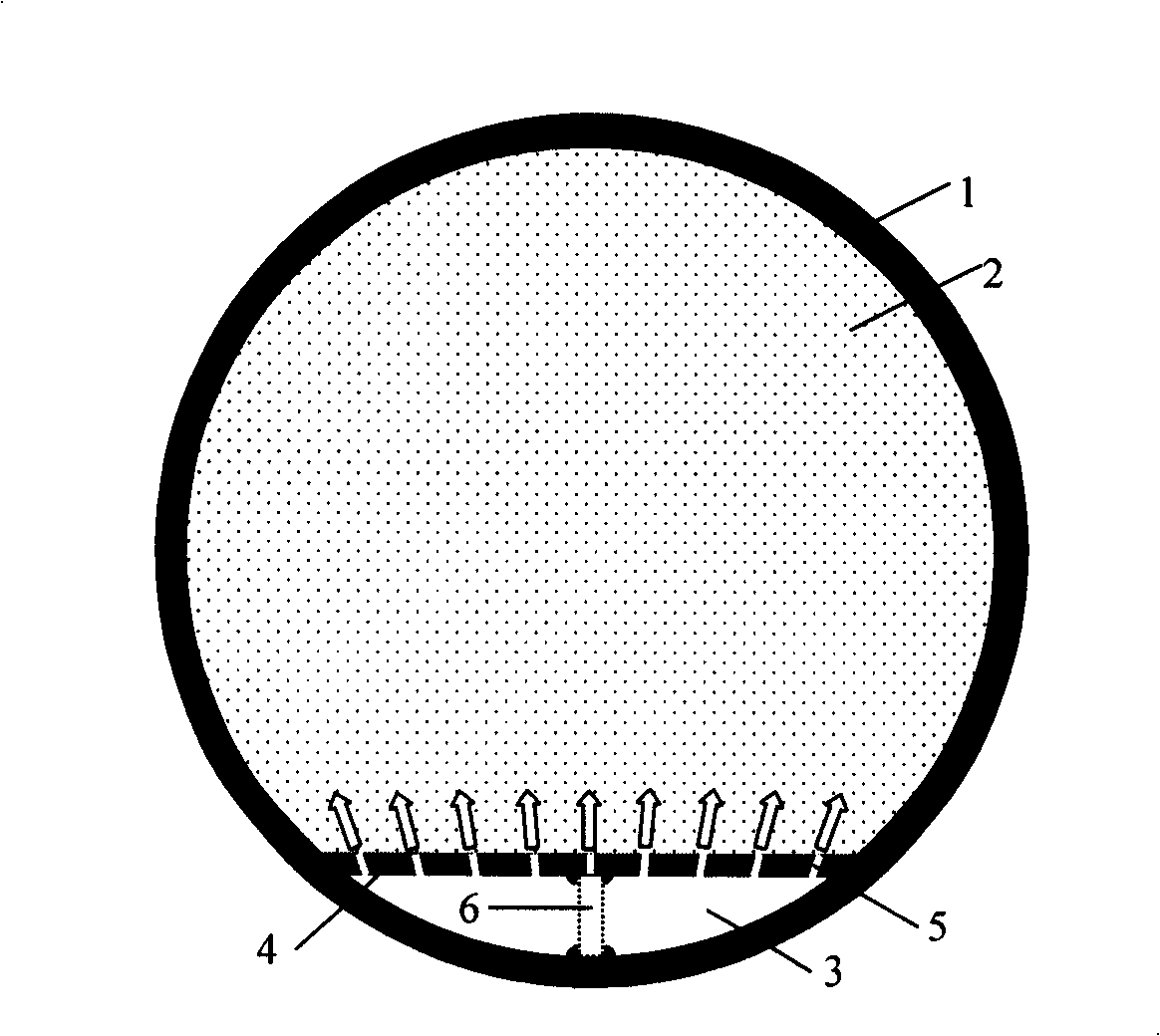

Gas injection type slurry pipe-line transportation method and device

InactiveCN101270848AReduce resistanceReduced sand carrying capacityPipeline systemsProduct gasSlurry pipeline

A gas injection type of slurry pipeline transportation method relates to a novel method which injects the gas into the sediment fluid to reduce the transportation resistance of the slurry and the sedimentation of the sediment and improve the transportation efficiency of the slurry. The transportation method comprises that the transportation pipelines which contain the gas injection channels are prepared; the gas injection type of transportation pipelines are connected according to the traditional pipeline connection method; a gas supply device is connected with the gas injection channels; during the transportation process of the slurry, the gas is injected into the sediment fluid continuously; the gas supply pressure is adjusted until the best sediment transportation efficiency is attained; after the transportation of the sediment, the gas continues to be injected into the transportation pipeline until the cleaning of the pipeline is completed. The invention has simple implementation technology and low sediment transportation cost. The invention can not only reduce the sedimentation of coarse sediment in the transportation pipeline, improve the transportation efficiency of the sediment and produce great transportation effect under the working conditions of wide sediment gradation and coarse grain size, but also improve the transportation distance and slurry concentration, reduce the post-processing dehydration working load of the dredging and reclamation and decrease the environmental pollution.

Owner:TONGJI UNIV

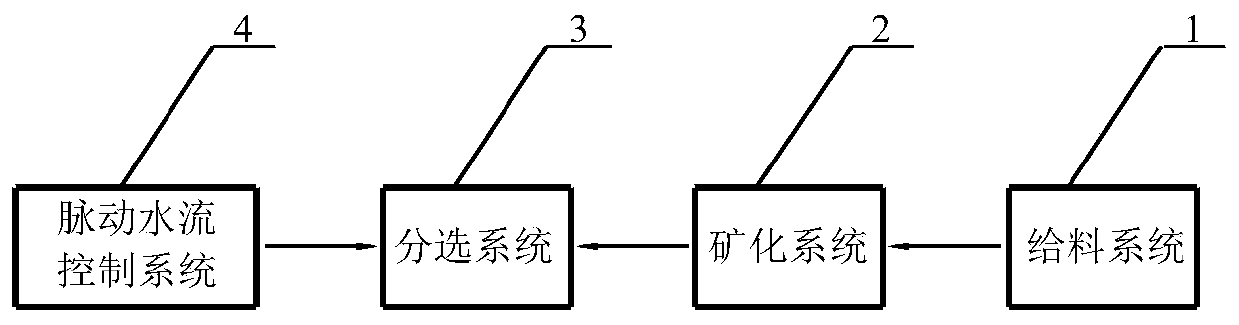

High ash fine grain coal slurry separation equipment and method

ActiveCN109759242AImprove recycling effectIncrease the probability of collisionSeparation devicesFlotationControl systemWater flow

The invention provides a high ash fine grain coal slurry separation equipment and method which areapplicable to the field of coal washing. The separation equipment comprises four parts, specifically afeeding system, a mineralization system, a separation system and a pulse water flow control system. The equipment is characterized in that a coal slurry mineralization area is separated from a separation area, and the ore separation system is internally provided with a damping block and a pulse water flow device. Flotation materials are fed into the feeding system, the size mixing operation is completed, coal slurry subjected to size mixing enters the mineralization system to be subjected to turbulent collision, mineralized bubbles are formed, the mineralized bubbles enter the separation system after passing through a disorder eliminating pipe, meanwhile the pulse water flow control system supplies the separation system with pulse water flows with certain frequency and waveform, the finecoal ash content is lowered, and the coal slurry separation selectivity is improved. Recycling of low ash coarse particles is effectively improved, high ash thin slurry carried by water flow and the thin slurry covering the surface of the particles are beneficially reduced by means of the damping block and the pulse water flow effect, and the separation selectivity is improved. The equipment has high coal slurry adaptability on different coal qualities, the separation effect is good, the separation efficiency is high, the production operation cost is low, and the economical benefit is outstanding.

Owner:CHINA UNIV OF MINING & TECH +1

Method for preparing functional protein peptide

InactiveCN101063162AHigh yieldResidue reductionFermentationProtein foodstuffs working-upNeutral proteinaseSlurry

The invention discloses a preparing method of functionality protein peptide, which comprises the following steps: pretreating cotton seed; leaching out cotton oil with 6# solvent oil; stripping gossypol with carbinol; drying the material under 100-120 deg. c; ripening for 10-30 min; getting raw material; putting into enzymolysis retort; adding into bromelain; proceeding joint hydrolysis with A. S1398 neutral proteinase; controlling stirring speed; dropping progressively; proceeding dynamic state controlling monitor for acidity of material in enzymolysis retort; stabilizing pH value of the material at 7. 5-8. 5; filtering protein slurry in centrifuger; drying in spray drying tower; packing; getting the product. This invention can further improve enzymolysis efficiency and quality of protein peptide product.

Owner:中发麦迪尔生物科技江苏有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com