Porous inflow hedging energy dissipation structure of hydraulic structure

A technology for hydraulic structures and energy dissipation, applied in construction, water conservancy engineering, marine engineering and other directions, can solve the problems of low energy dissipation rate of stilling pool, cavitation damage, low energy dissipation rate of stilling pool, etc. Input cost, the effect of reducing the height and width of the tail sill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

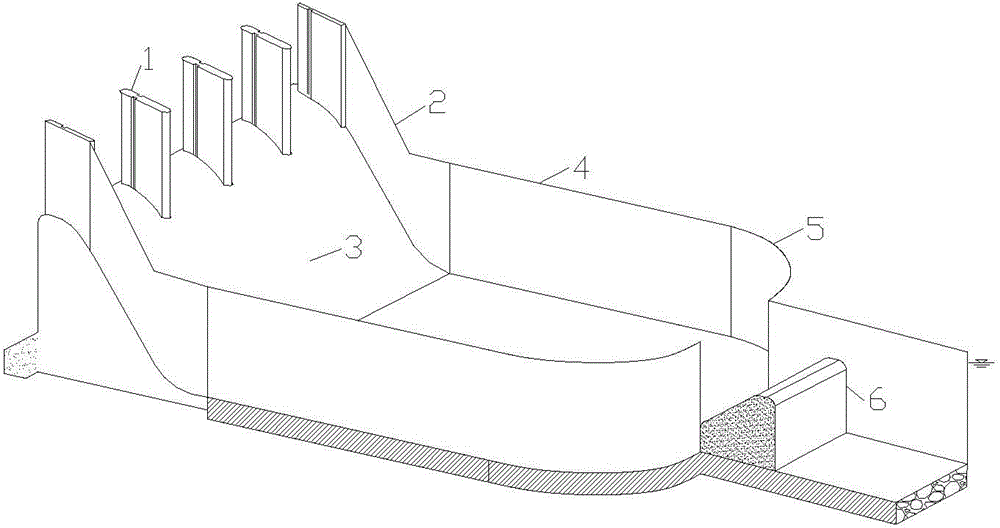

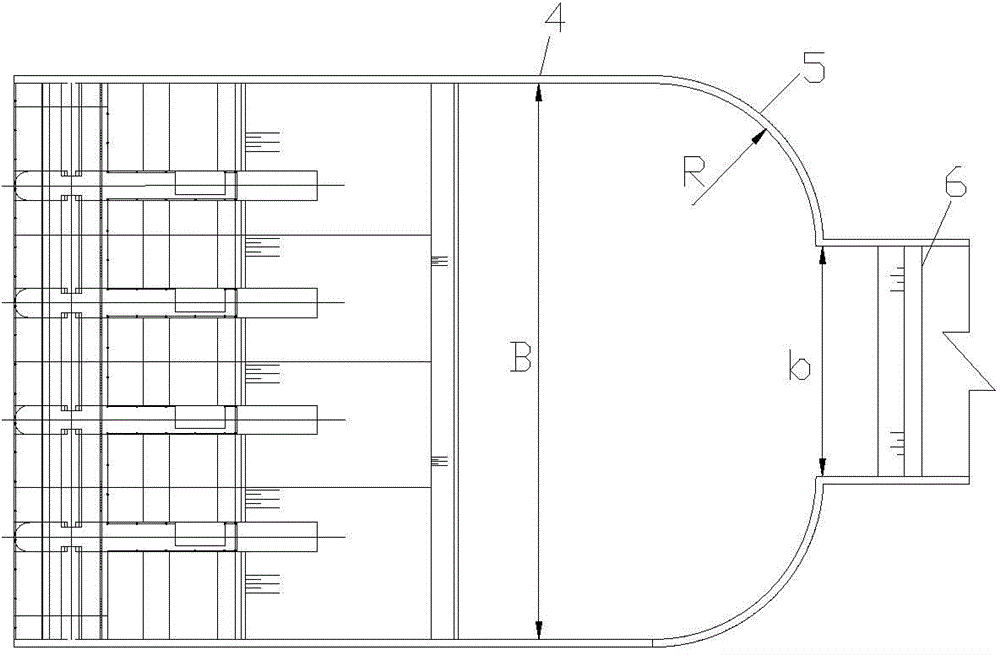

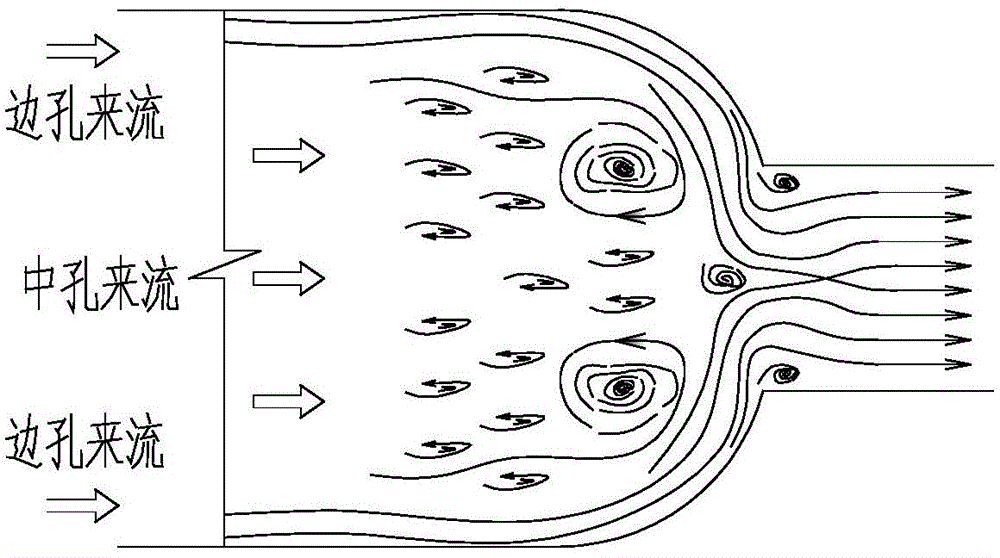

[0025] The porous inflow counter energy dissipation structure of the hydraulic structure of this embodiment has a structure as attached figure 1 And attached figure 2 As shown, it includes an overflow dam where the water body flows from its top, a stilling basin located behind the overflow dam, and a tail sill 6 located at the outlet of the stilling basin. The crest of the overflow dam is an arc surface, and the overflow The surface 3 is a plane, and the crest of the dam is designed with a number of gate piers 1 that divide the water body flow area into several openings, so that the water body can leak into the stilling pool from the multi-holes. The dam is 50 meters high and 80 meters wide; The pool has an inlet width of 75 meters, the bottom of the pool is connected to the overflow surface 3 of the overflow dam, and the protective side wall 4 of the stilling pool is connected to the side wall 2 of the overflow surface of the overflow dam. 50m downstream of the water jump ...

Embodiment 2

[0027] The porous inflow counter energy dissipation structure of the hydraulic structure of this embodiment has a structure as attached figure 1 And attached figure 2 As shown, it includes an overflow dam where the water body flows from its top, a stilling basin located behind the overflow dam, and a tail sill 6 located at the outlet of the stilling basin. The crest of the overflow dam is an arc surface, and the overflow The surface 3 is a plane, and the crest of the dam is designed with a number of gate piers 1 that divide the water body flow area into several orifices, so that the water body can be discharged into the stilling pool from the porous, the dam is 80 meters high, and the dam is 60 meters wide; the stilling pool , its inlet width dam is 55 meters wide, the bottom of the pool is connected with the overflow surface 3 of the overflow dam, the protective side wall 4 of the stilling pool is connected with the side wall 2 of the overflow surface of the overflow dam, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com