Special-shaped step energy dissipater

A technology of energy dissipators and steps, applied in water conservancy engineering, marine engineering, coastline protection and other directions, can solve the problem that the rectangular stepped spillway cannot meet the requirements of engineering operation, and achieves the avoidance of cavitation erosion, strong turbulence, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] What is the relationship between the slope of the floor and the angle of the inclined wall in the examples and the numerical values defined in the claims? All are within the scope defined by the claims.

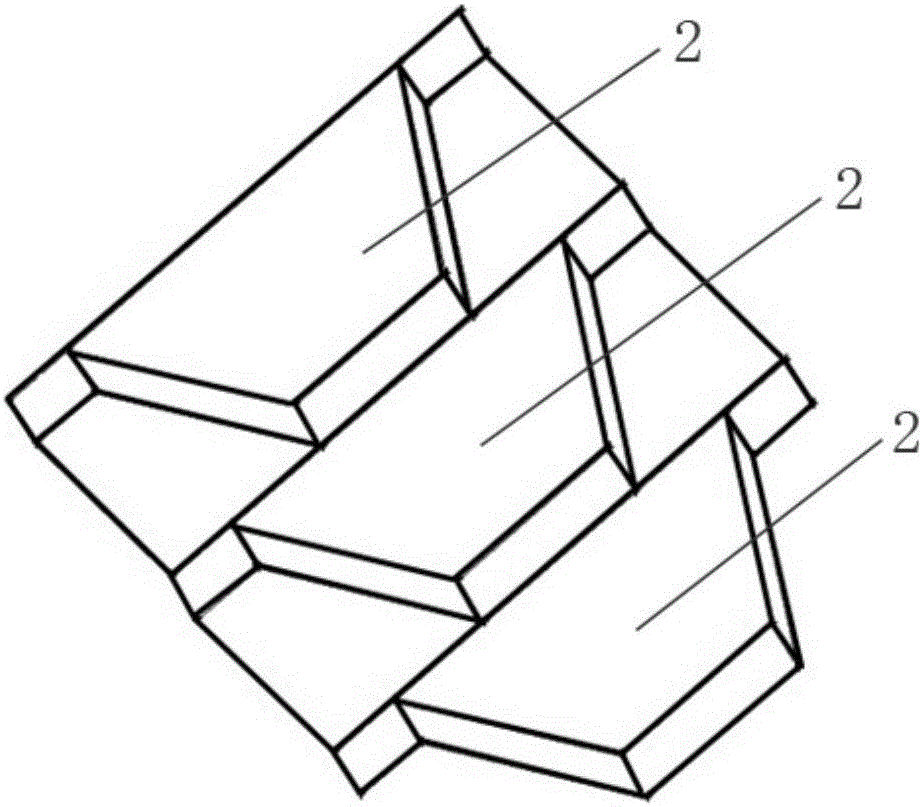

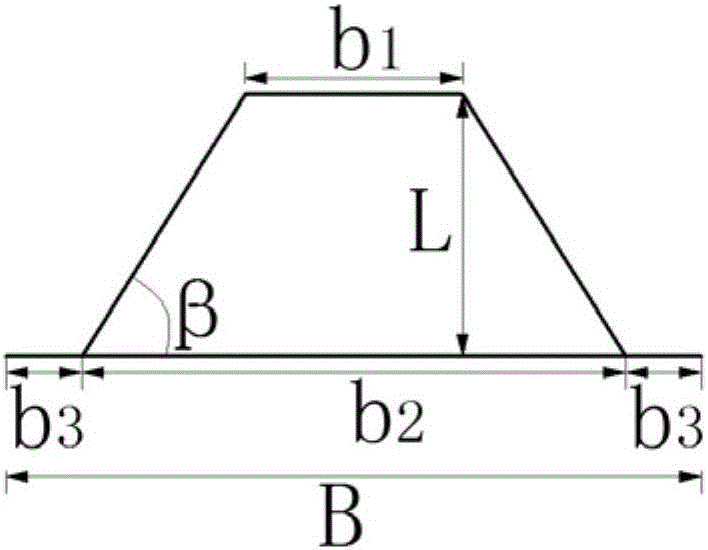

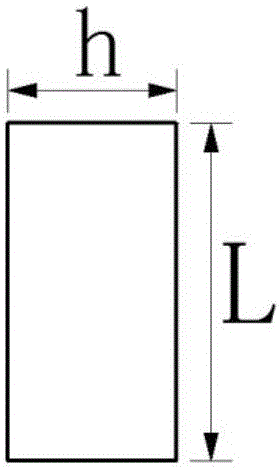

[0052] In this embodiment, the trapezoidal step energy dissipator is used for the spillway, as figure 1 , 2 , 3, 4 and 17, the maximum single-width discharge of the spillway is q=240m 3 / s.m, spillway width B=30m, floor slope θ=18°. The width of the trapezoidal step 2 set on the bottom plate of the spillway is B=30m at the end and b at the head 1 =10m, tail width b 2 = 30m, the distance between the tail of the trapezoidal step 2 and the side wall 1 of the spillway or spillway is b 3 =0m; the length of the step 2 is L=12m, the angle of the inclined wall of the trapezoidal step 2 is β=50°; the height of the trapezoidal step 2 is h=4m, and a total of 30 steps are set with a drop of 120m.

[0053] Model tests show that the flow velocity at the beginning section of ...

Embodiment 2

[0055] In this embodiment, the triangular step energy dissipator is used for the spillway, such as Figure 5 , 6 , 7, 8 and 18, the maximum single-width discharge of the spillway is q=160m 3 / s.m, spillway width B=25m, floor slope θ=27°. Width b at the end of the triangular step 3 set on the bottom plate of the spillway 2 = 15m, the distance from the tail of the triangular step 3 to the spillway or the inner side wall 1 of the spillway is b 3 = 5m; the length of the step 3 is L=12m, the angle of the inclined wall of the triangular step 3 is β=58°; the height of the step 2 is h=6m, and a total of 20 steps are set with a drop of 120m.

[0056] The model test shows that the flow velocity at the beginning section of the triangular-step spillway in this embodiment is 25m / s, the flow velocity at the end section of the step is 27m / s, and the energy dissipation rate is about 75.5%. The water flow in the spillway flows from the third step Begin to aerate strongly, the water after t...

Embodiment 3

[0058] In this embodiment, the dovetail-shaped step energy dissipator is used for the spillway, such as Figure 9 , 10 , 11, 12 and 19, the maximum single-width discharge of the spillway is q=200m 3 / s.m, spillway width B=25m, floor slope θ=22°. Width b at the end of the dovetail step 4 set on the bottom plate of the spillway 2 =20m, the middle width of the dovetail is b 4 = 5m; the length L of the dovetail-shaped steps 4 = 10m, the angle of the inclined wall of the dovetail-shaped steps 4 β = 45°; the height of the dovetail-shaped steps 4 h = 4m, a total of 25 steps are set, and the drop is 100m.

[0059] The model test shows that the flow velocity at the beginning section of the dovetail-shaped spillway in this embodiment is 20m / s, the flow velocity at the end section of the step is 25m / s, and the energy dissipation rate is about 73.5%. The steps begin to be strongly aerated, and the water flow after the second step is full of air bubbles, presenting a "white water" stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com