Fractal blade stirrer

A stirrer and blade technology, applied in the field of fractal blade stirrer, can solve problems such as uneven distribution of turbulent kinetic energy, non-uniform dispersion of multi-phase fluid, non-uniform mixing of fluid, etc., to improve the flow state in the kettle and strengthen the interaction , The effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

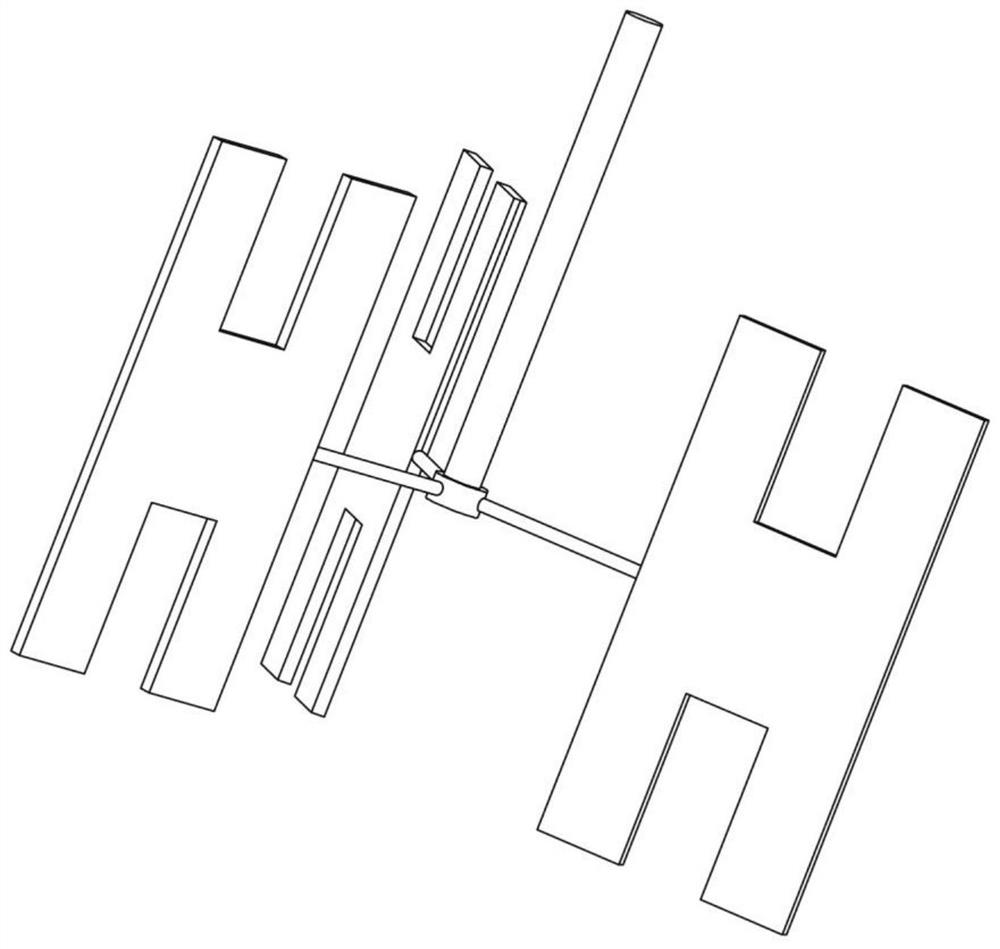

[0034] The diameter of the stirred tank is 0.4m, the height is 1m, four baffles with a width of 0.04m are evenly distributed on the wall, and the stirring volume is about 0.06m 3 , the liquid level is 0.48m high, and the blade agitator is installed on the central shaft with a diameter of 20mm through the fixed sleeve 2. Such as figure 1 As shown, the agitator has three H-shaped small blades 5 in total, each blade has a width of 75 mm, a height of 150 mm, and a thickness of 5 mm, and the height of the blades from the bottom of the kettle is 80 mm. Fixed sleeve 2 center ring array, the speed of the stirrer is 120rpm, 180rpm, 240rpm, the power of the stirrer is 115.4W, 389.5W, 923.2W, according to the evaluation results of laser-induced fluorescence, the mixing corresponding to 95% uniform mixing The times are 20.3 seconds, 14.7 seconds, 10.8 seconds.

Embodiment 2

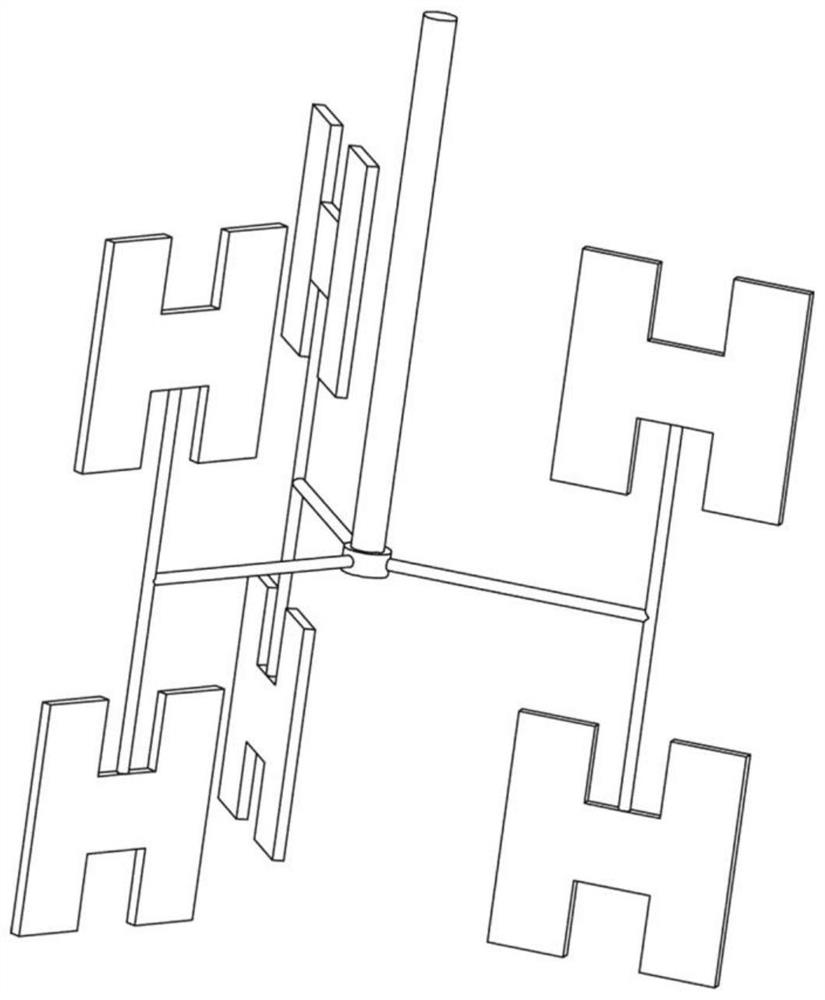

[0036] The diameter of the stirred tank is 0.6m, the height is 1.0m, four baffles with a width of 0.06m are evenly distributed on the wall, and the stirring volume is about 0.23m 3 , the liquid level is 0.8m high, and the fractal blade agitator is installed on the central shaft with a diameter of 40mm through the fixed sleeve 2. Such as figure 2 Shown, utilize the fractal blade stirrer that fractal obtains in above-mentioned example altogether 6 H-shaped small blades 5, each blade is long 80mm, wide 8mm, high 160mm, and blade is 100mm apart from the height of the bottom of the kettle, in the tank reactor The inner n-shaped blades are evenly arranged axisymmetrically along the ring direction of the fixed sleeve, and each H-shaped small blade is symmetrically distributed along the vertical connection axis. The speed of the agitator is 170rpm, 255rpm, 341rpm, and the power of the agitator is 461.8W, 1558.3W, 3695.9W, according to the evaluation results of laser-induced fluoresc...

Embodiment 3

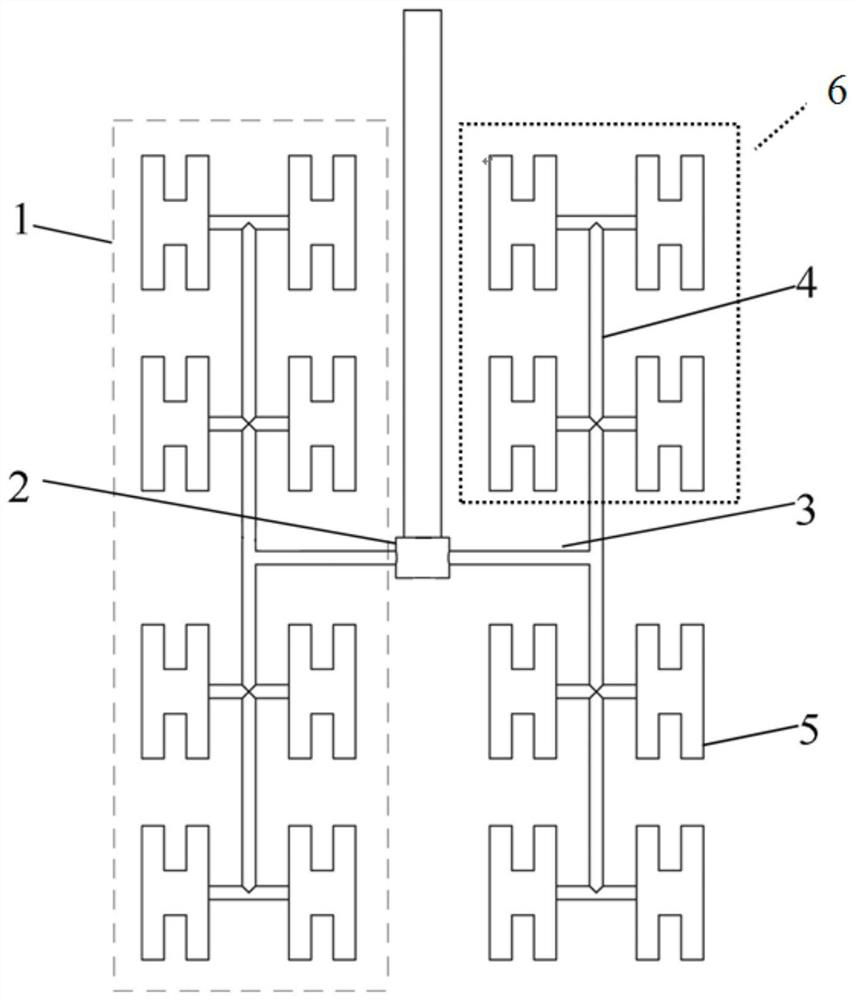

[0038] The diameter of the stirred tank is 1m, the height is 1.6m, four baffles with a width of 0.06m are evenly distributed on the wall, and the stirring volume is about 0.94m 3 , the liquid level is 1.2m high, and the fractal blade agitator is installed on the central shaft with a diameter of 200mm through a fixed sleeve. Such as image 3 As shown, using the secondary fractal in the above example, and n=2, the obtained fractal blade agitator has a total of 16 fractal blades, each H-shaped small blade is 50mm long, 8mm wide, and 100mm high, and the height of the blade from the bottom of the kettle is 200mm, in the tank reactor, the n-component shaped blades are evenly arranged axisymmetrically along the annular direction of the fixed sleeve, and each H-shaped small blade is symmetrically distributed along the vertical connection axis. The speed of the agitator is 258.6rpm, 390rpm, 517rpm, The power of the stirrer is 1847.2W, 6353.2W, and 14783.6W. According to the evaluation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com