Patents

Literature

247results about How to "Improve flow status" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting gas in low air permeability coal layer by pulse fracture anti-reflection

ActiveCN102155254AChange mechanical propertiesImprove breathabilityFluid removalGas removalPulse pressureDischarge rate

The invention relates to a method for extracting gas in low air permeability coal layer by pulse fracture anti-reflection, comprising the following steps: firstly using the blast-proof pulse-type coal layer high pressure water injector with adjustable frequency and pressure from the coal layer, high tunnel or low tunnel; using the pulse water effect generated by the periodical change of high pressure pulse water inside the drill hole of coal body, wherein the maximum pulse pressure is 35 MPa, the flow is about 300 L / min, and the pulse frequency is 0-1460 times / min; forcing the macroscopic fracture in the coal layer to be expanded and communicated; promoting the micro-pore fracture to be formed and extended; forming a new regeneration fracture net; providing a permeable channel of water inthe coal layer so as to achieve the effects of improving the mechanical property of the coal body, reducing the stress of the coal body in front of the working face and improving the discharge rate of the gas. Through the method, the pressure releasing range of the coal layer is enlarged, the whole pressure is adequately released, the radius of influence range of fracture can reach 10-40 m, and the air permeability of the coal body can be improved by 100-1000 times; and the method is simple, easy to operate and good in effect.

Owner:CHINA UNIV OF MINING & TECH

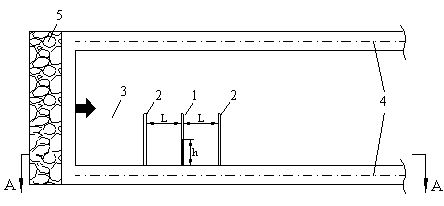

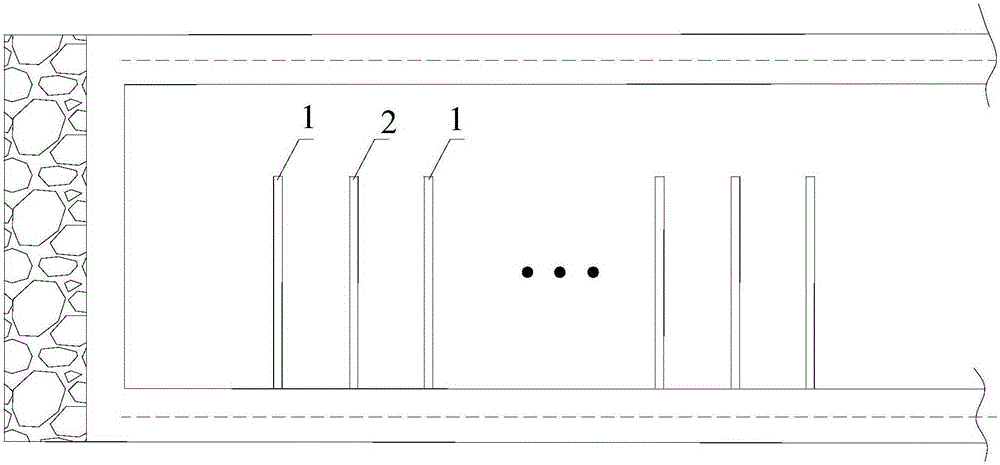

Method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing, and permeability increasing

InactiveCN101644166AImprove flow statusEasy to extractUnderground miningSurface miningHigh pressure waterHigh pressure

The invention discloses a method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing and permeability increasing, comprising the following steps: whena drill is drilled into a predetermined position of the coal seam, coal bodies at both sides of a drill hole are cut in the drill hole by high pressure water jet with a certain pressure and flow; a flat slot is formed at both sides of the drill hole; the cut coal bodies is led out the hole by the high pressure water jet. The exposed area of the coal body at the slotted part in the drill hole aregreatly increased, namely that an extremely thin protective layer is exploited with local scope of the flat slot, which enlarges effective influential range of pressure releasing, permeability increasing and gas discharging of the coal bodies in the drill hole, thus the air permeability of the coal bodies is increased about 200-300 times, the average amount of single-hole gas extraction reaches 0.3m<3> / min, the concentration of the gas extraction is 30-60%, gas drainage rate of working face of coal extraction is more than 50%, the number of drill holes for gas drainage is reduced by 10-20% after slotting, pressure releasing and permeability increasing. The method realizes the safety, high efficiency and uniform extraction of the gas from the high gas low permeability outburst coal seam, and changes high gas coal seam with outburst danger into low gas coal seam without outburst danger.

Owner:CHINA UNIV OF MINING & TECH

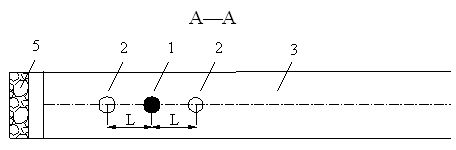

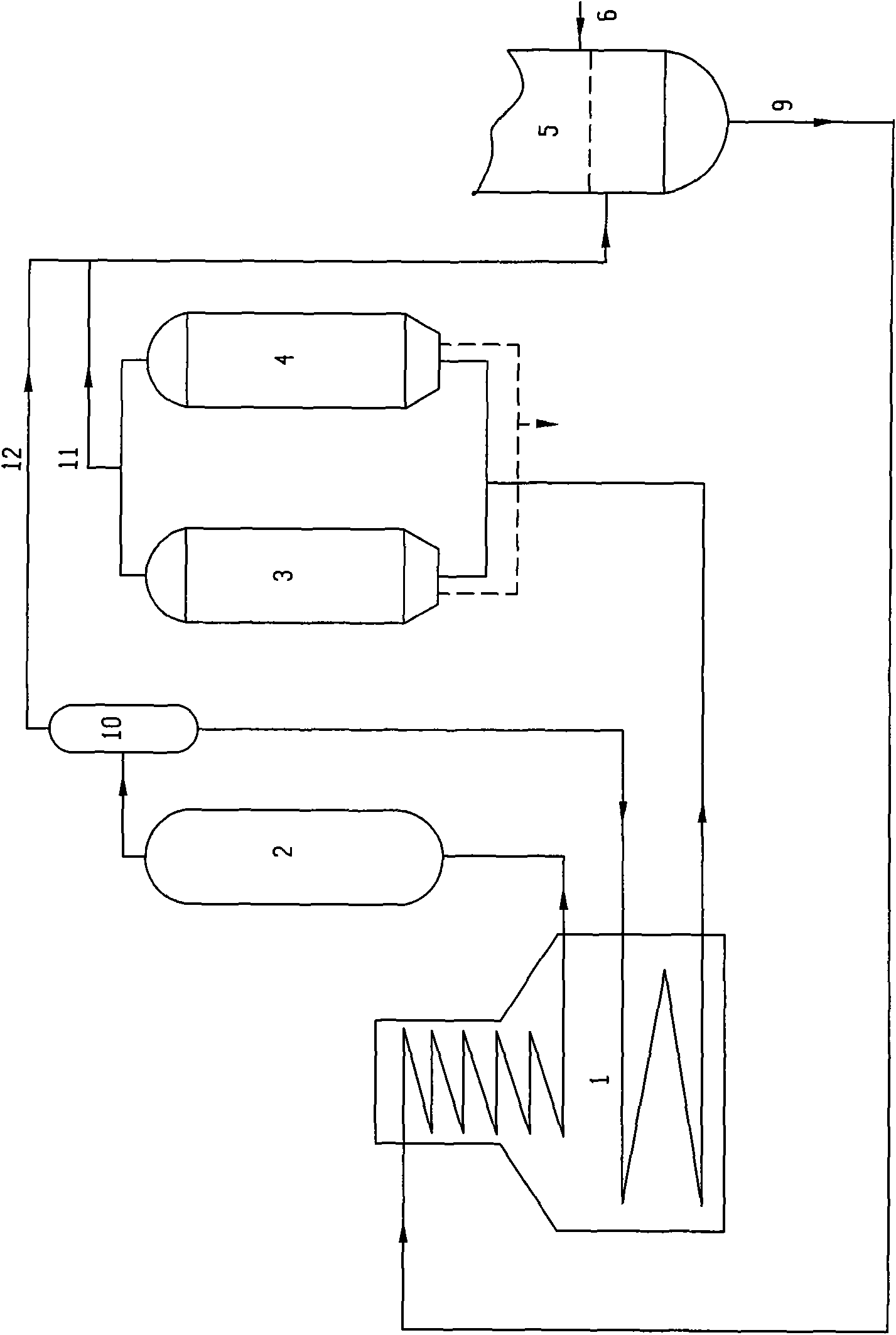

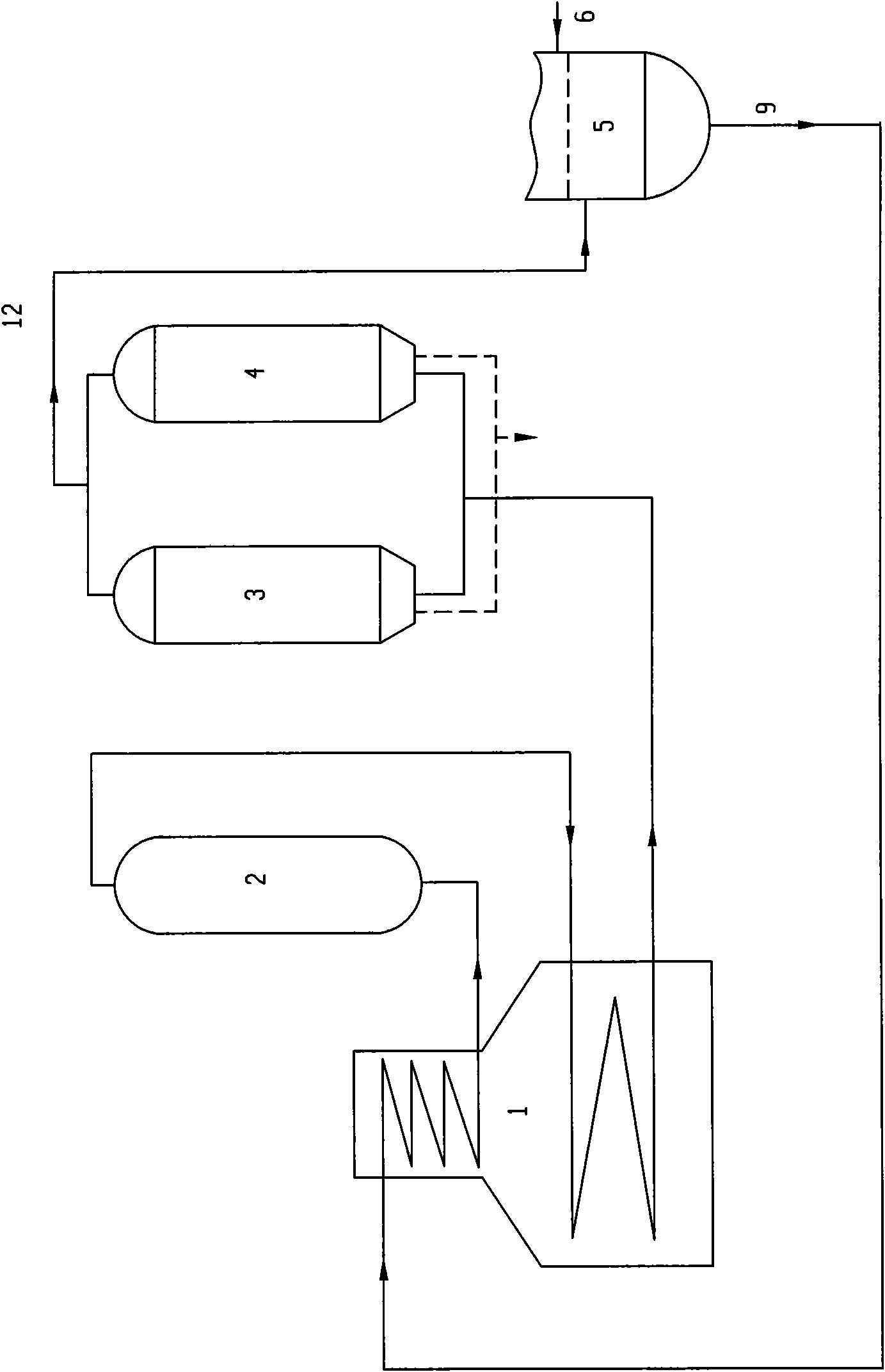

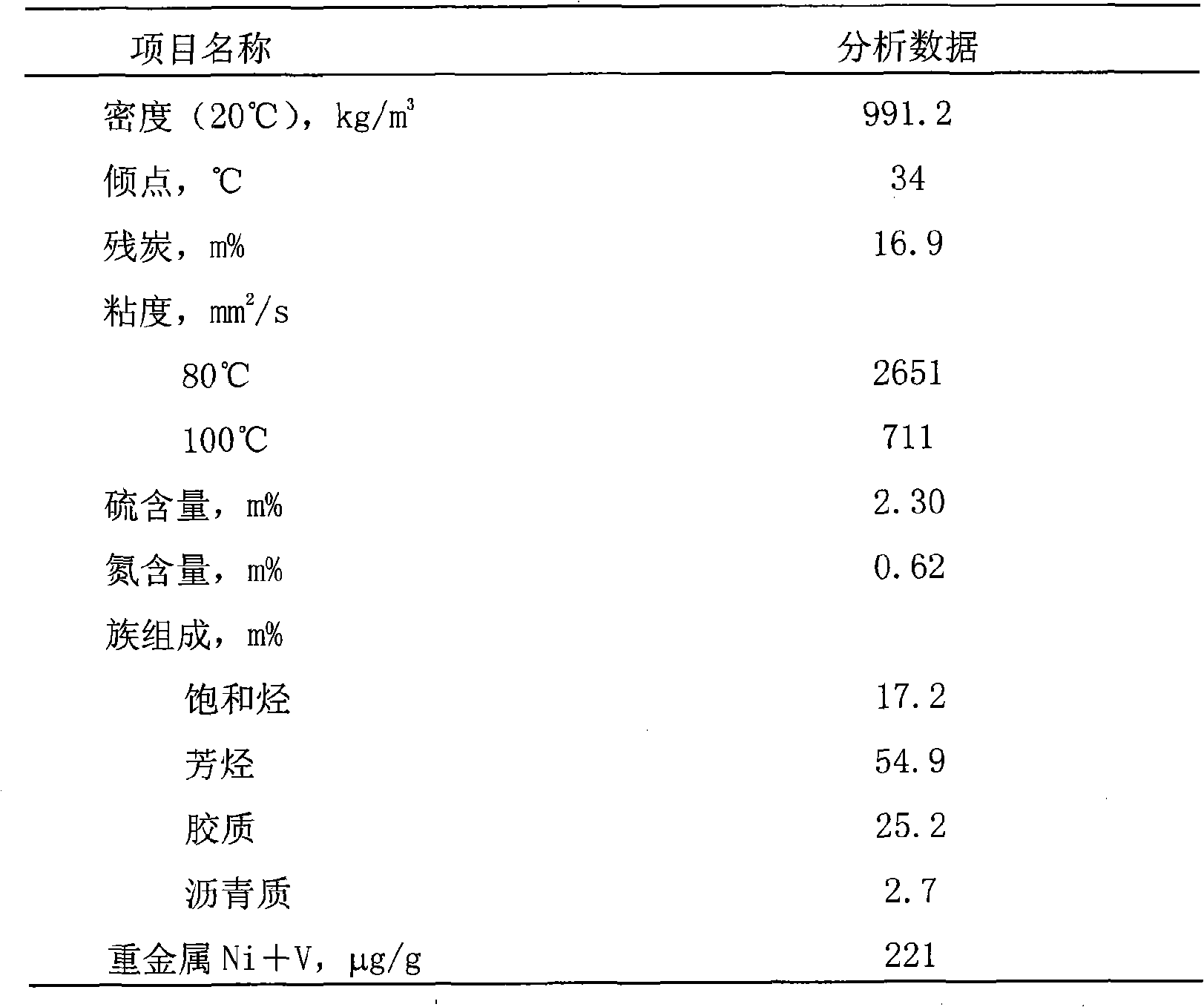

Improved delayed coking process

ActiveCN101597518AHigh yieldReduce yieldCoking carbonaceous materialsHydrocarbon oils treatmentLiquid productFractionation

The invention discloses an improved delayed coking process, aiming at solving the defects of serious heating furnace coking, low liquid product yield and the like in the current delayed coking processes. The process is characterized in that feeds are heated to 360-460 DEG C in a convection chamber or a convection chamber and a radiation chamber of the heating furnace, and then enter a visbreakingreactor for cracking reaction; heavy oil separated from the reaction product enters the radiation chamber of the heating furnace to be heated to 480-515 DEG C and then enters a coke tower; oil gas out of the coke tower singly enters or enters a fractionating tower after being mixed with the gas in the visbreaking reactor for fractionation. By adopting the process of the invention, the delayed coking liquid product yield can be improved, the coke yield reduced, the operation cycle of the delayed coking unit lengthened and the equipment investment lowered at the same time.

Owner:CHINA PETROCHEMICAL CORP +1

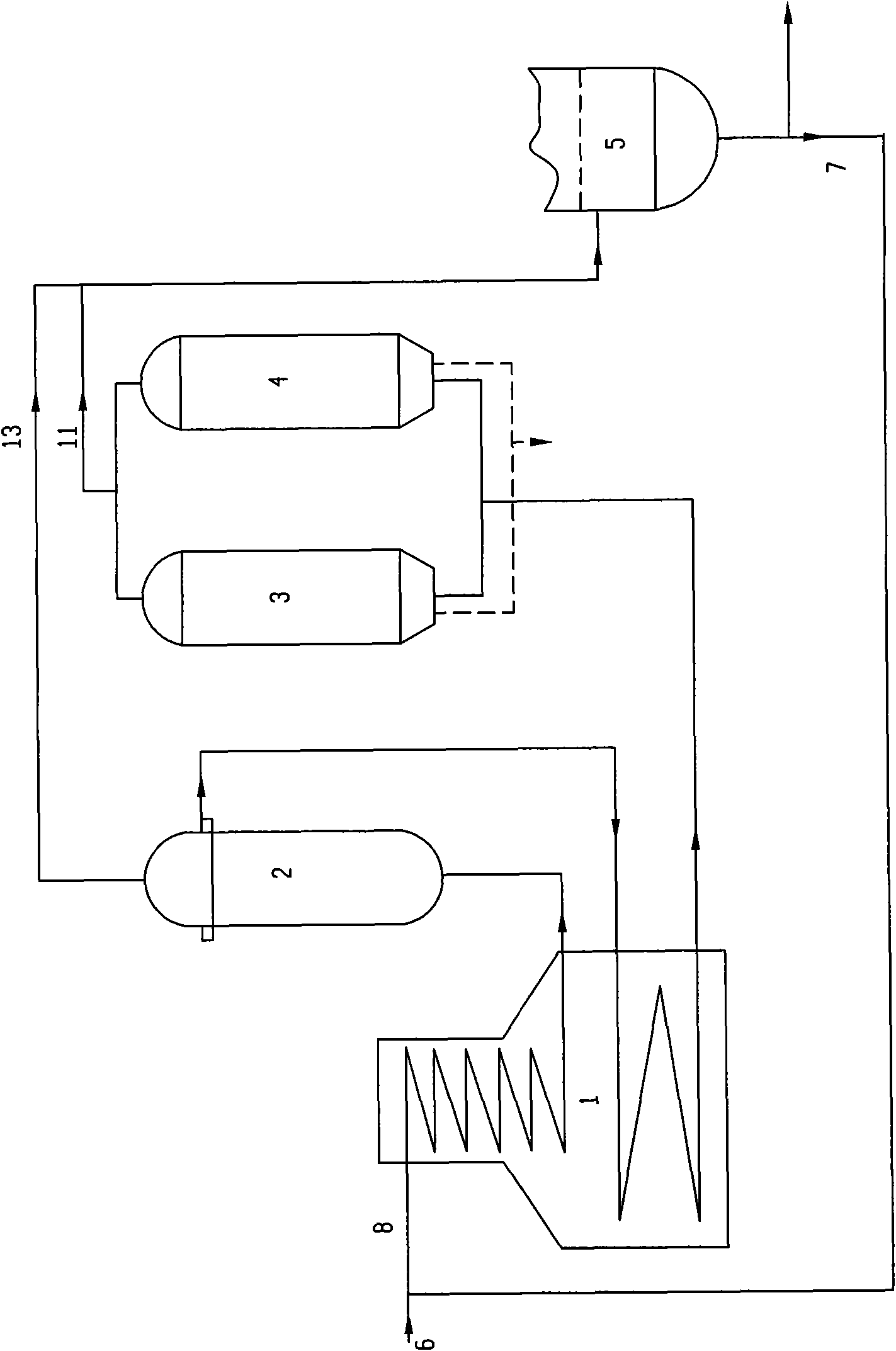

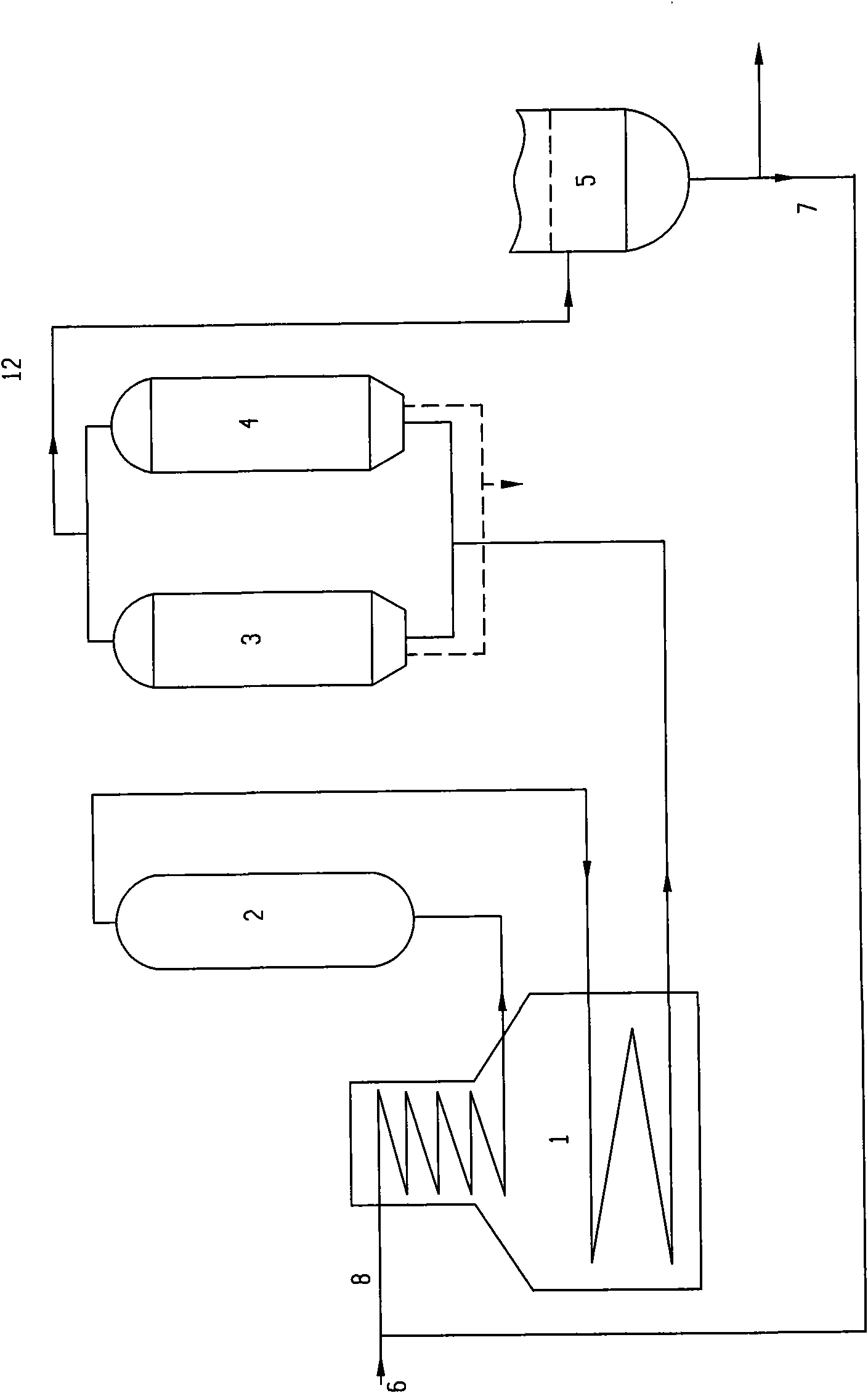

Delayed coking process

ActiveCN101591561AHigh yieldReduce yieldThermal non-catalytic crackingTreatment with plural serial stages onlyLiquid productWork period

The invention discloses a delayed coking process, which aims to overcome the defects of serious furnace coking and low liquid product yield and the like for a heating furnace in the prior delayed coking process. The delayed coking process is characterized by comprising the following steps: heating input materials to a temperature of between 360 and 460 DEG C in a convection chamber or the convection chamber and an irradiation chamber of the heating furnace, then putting the input materials into a visbreaking reactor to perform cracking reaction; putting reaction products into the irradiation chamber of the heating furnace, heating the reaction products to a temperature of between 480 and 515 DEG C, and then putting the reaction products into a coking tower; and putting oil gas from the coking tower into a coking fractionating tower to perform fractionating. The delayed coking process can improve the delayed coking liquid product yield, reduce the coke yield, prolong the start working period of delayed coking devices, and simultaneously reduce the equipment investment.

Owner:CHINA PETROCHEMICAL CORP +1

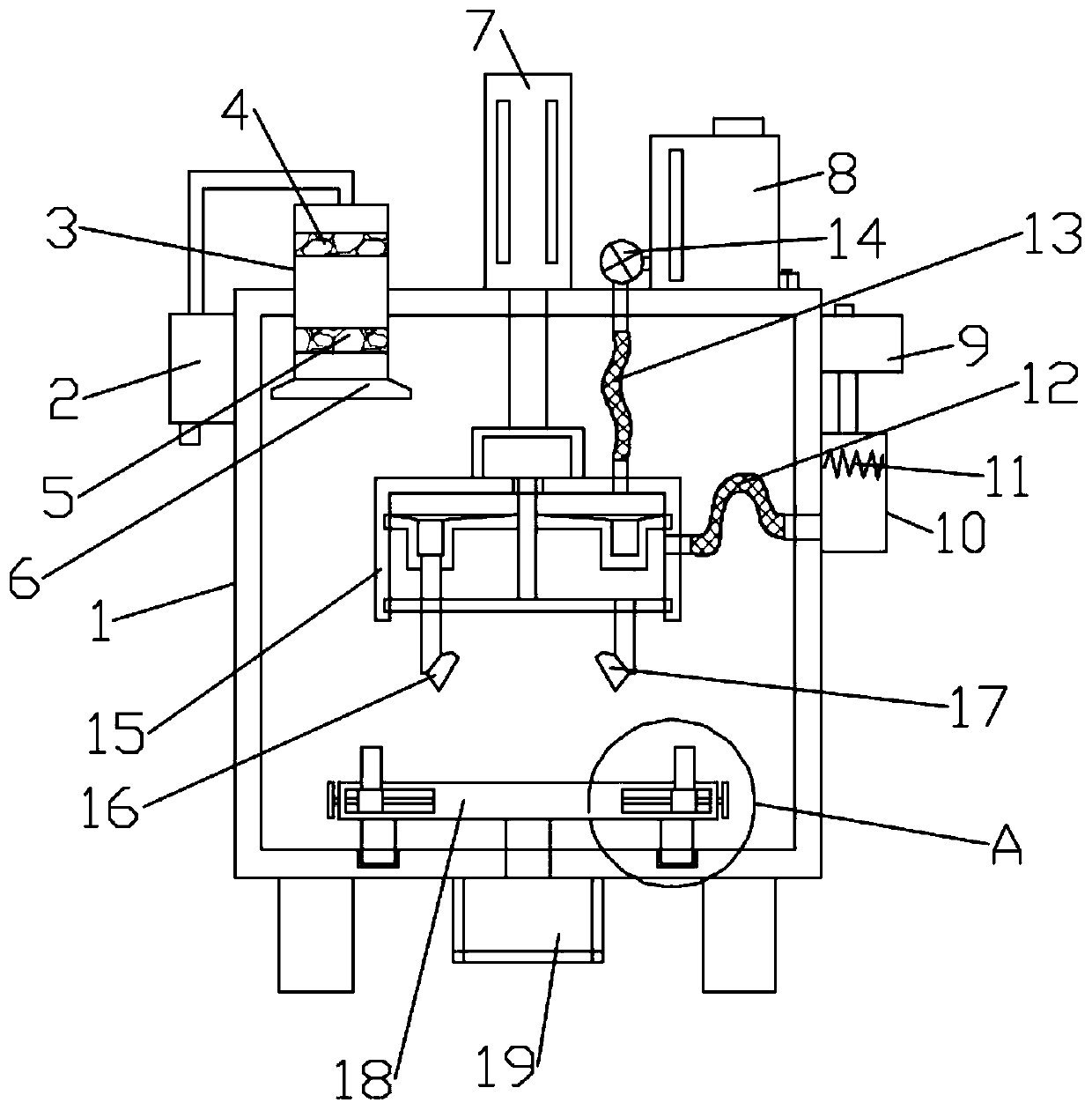

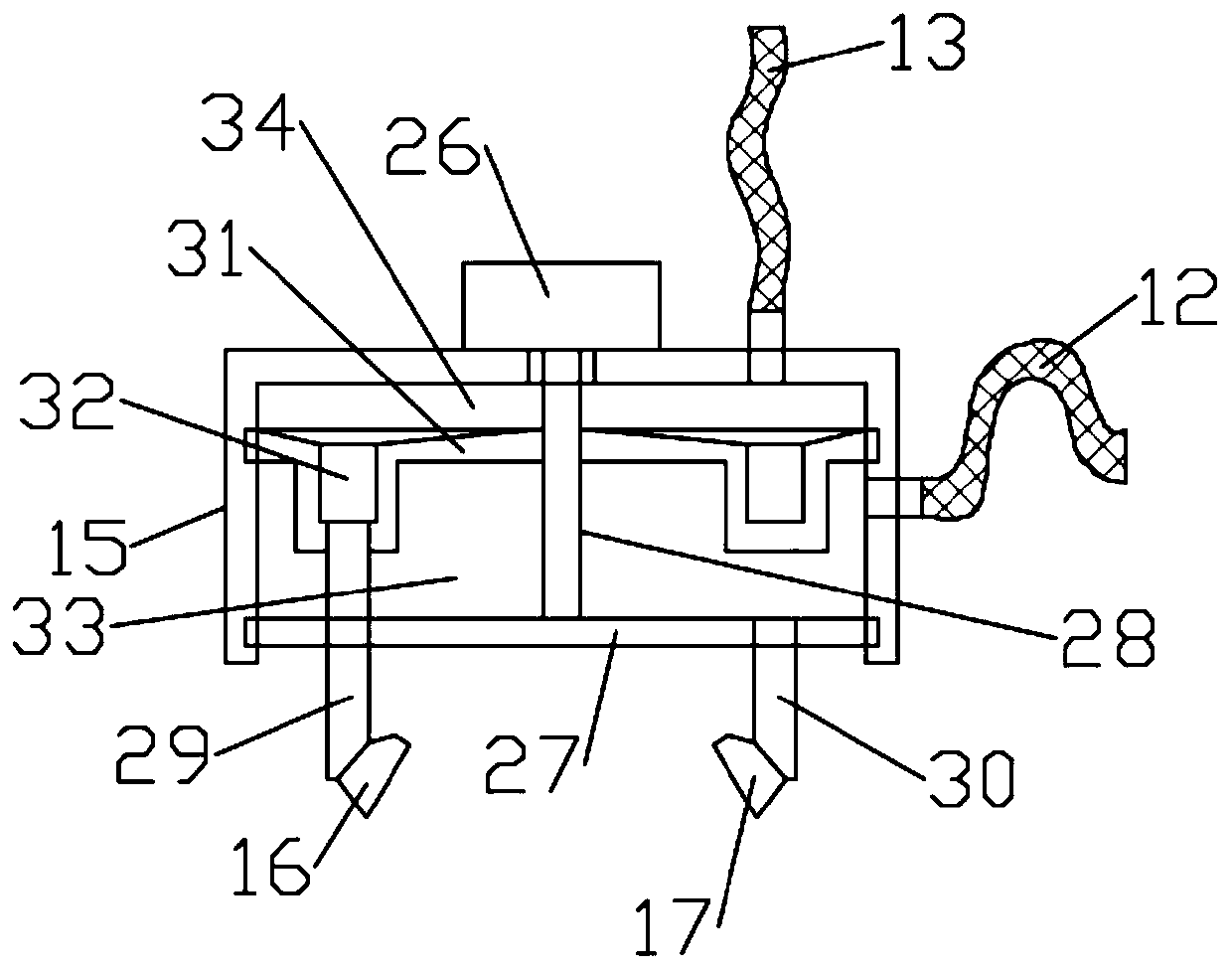

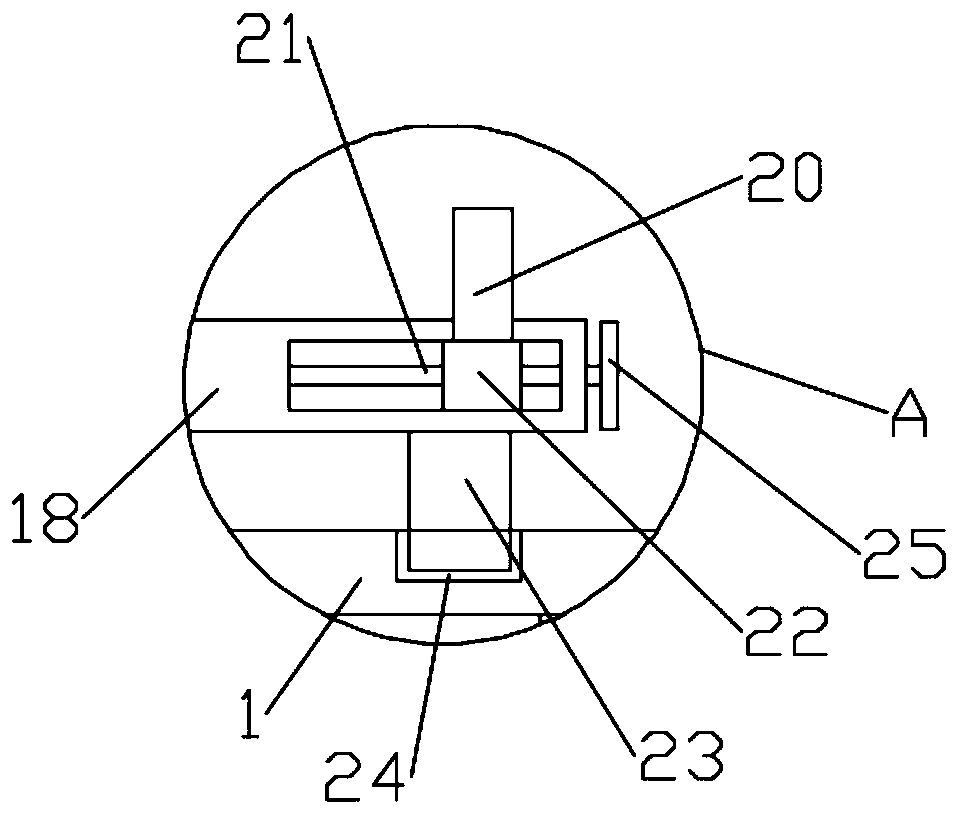

Multi-angle automatic paint spray equipment for machining mechanical part

ActiveCN110773365ADry evenlyGood effectPretreated surfacesLiquid spraying apparatusHot blastTelescopic cylinder

The invention relates to the field of automatic machining equipment and particularly discloses multi-angle automatic paint spray equipment for machining a mechanical part. The multi-angle automatic paint spray equipment comprises a box body; a supporting cylinder realizing height adjustment by virtue of a telescopic cylinder is arranged inside the box body; a rotating partition plate and a rotating plate are arranged in a synchronous rotation manner inside the supporting cylinder; an inner chamber of the supporting cylinder is divided into an upper chamber and a lower chamber, namely a paint liquid chamber and a hot air chamber by virtue of the rotating partition plate and the rotating plate; an air pipe used for exhausting hot air out of the hot air chamber is fixedly installed at one side of the rotating plate; a hot air nozzle is arranged at the bottom end of the air pipe; a paint liquid pipe used for discharging paint liquid inside the paint liquid chamber is fixedly installed at the other side of the rotating partition plate; and a paint mist sprayer used for atomizing the paint liquid is arranged at the bottom end of the paint liquid pipe which extends to a position below therotating plate. The multi-angle automatic paint spray equipment provided by the embodiment of the invention can effectively widen the paint spraying range, guarantees the uniformity of paint spraying, can also guarantee timely drying of the paint liquid at the surface of the part, and also realizes uniform drying and a good effect.

Owner:SUZHOU ODIHUA ELECTRONIC CO LTD

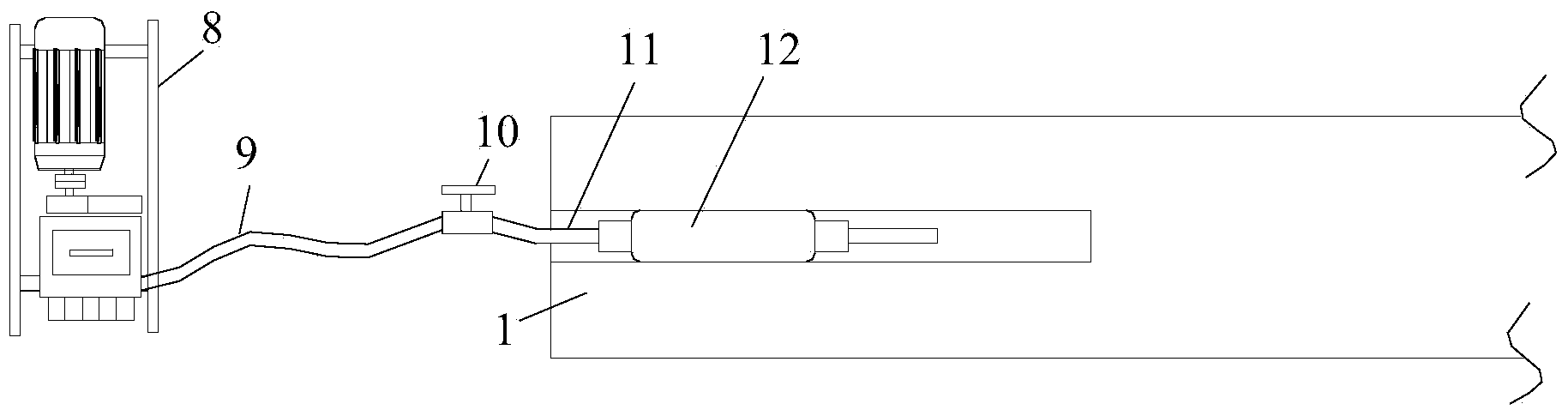

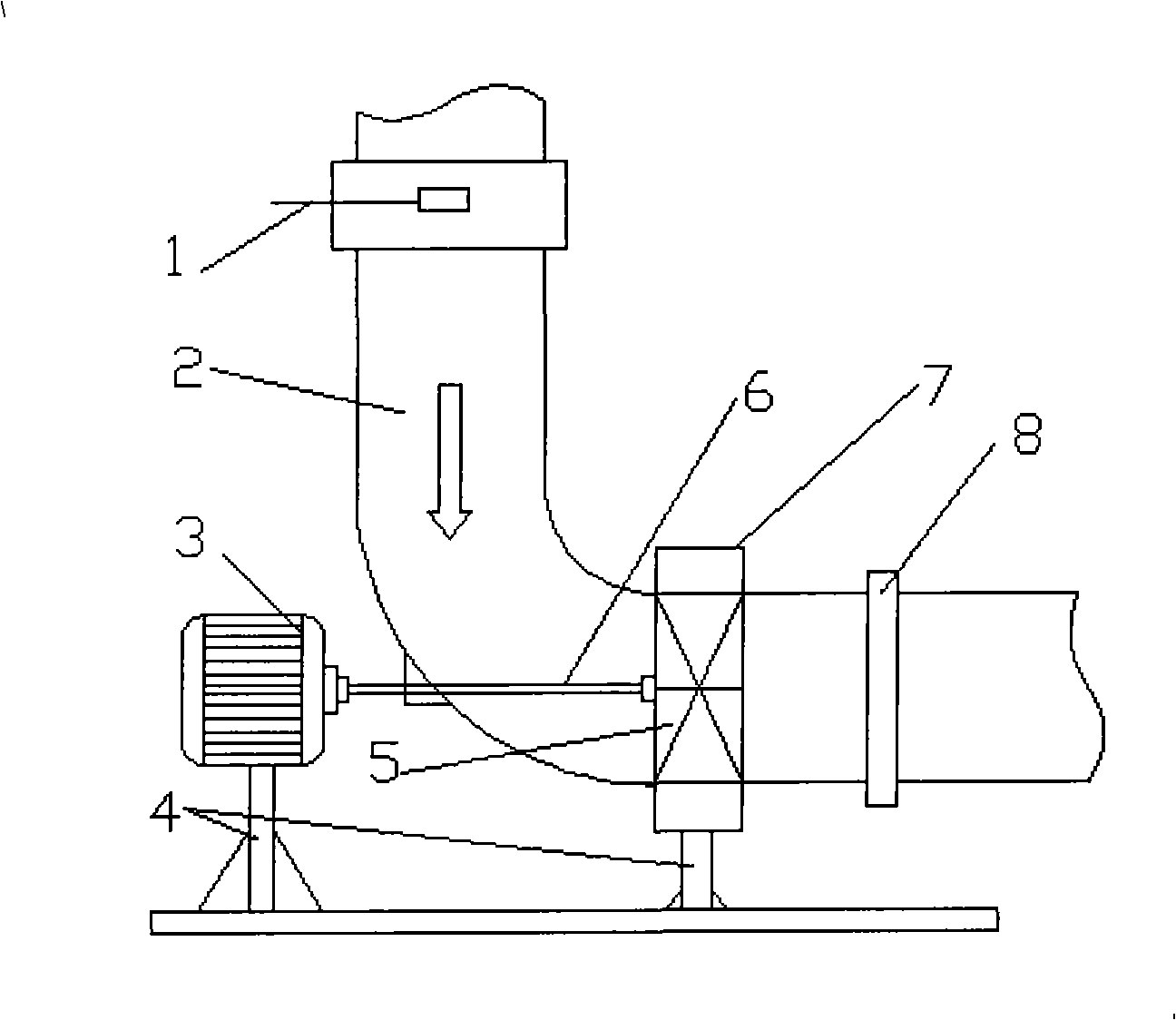

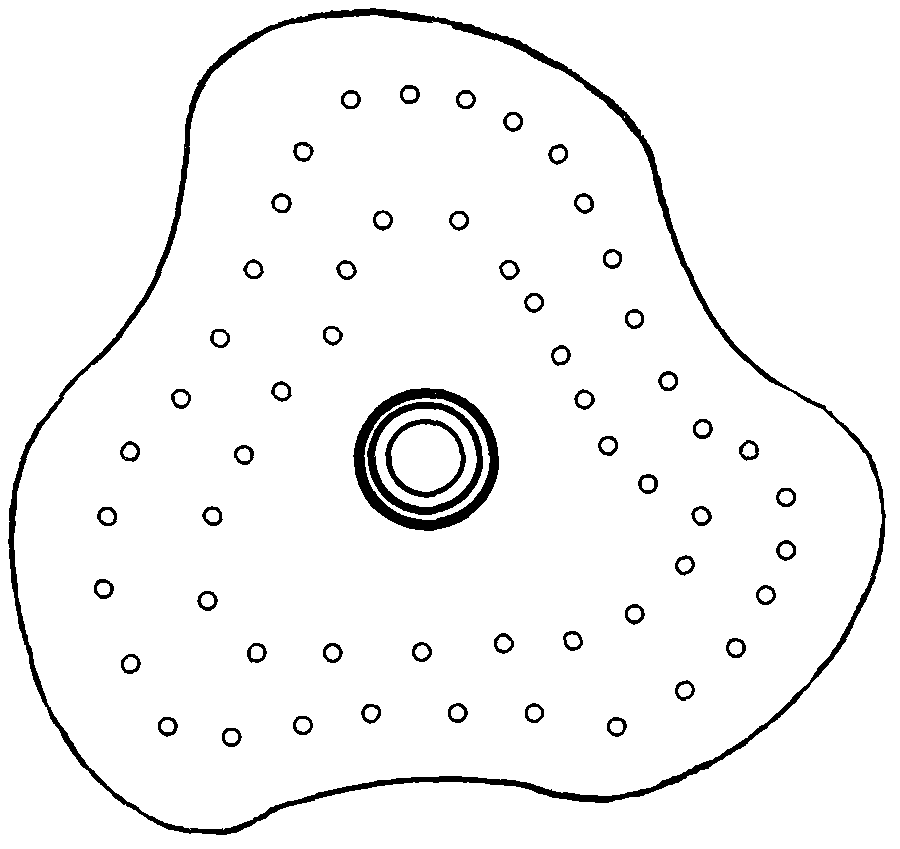

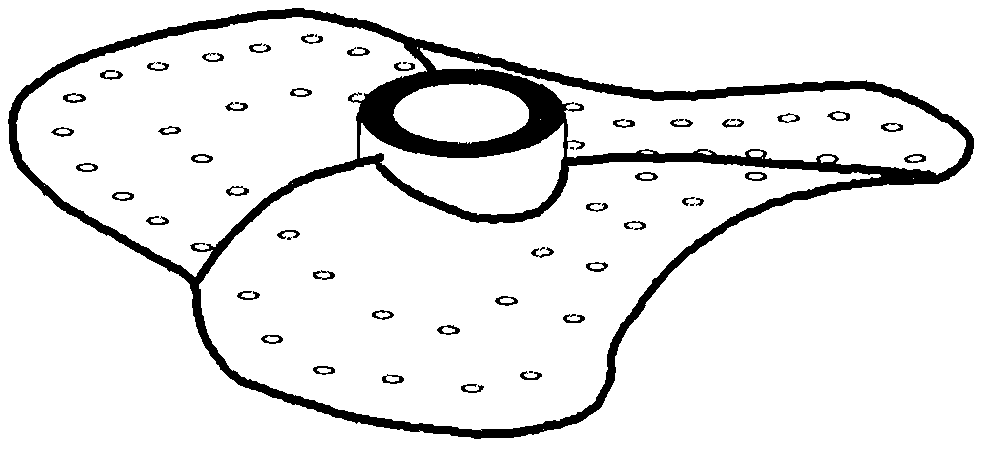

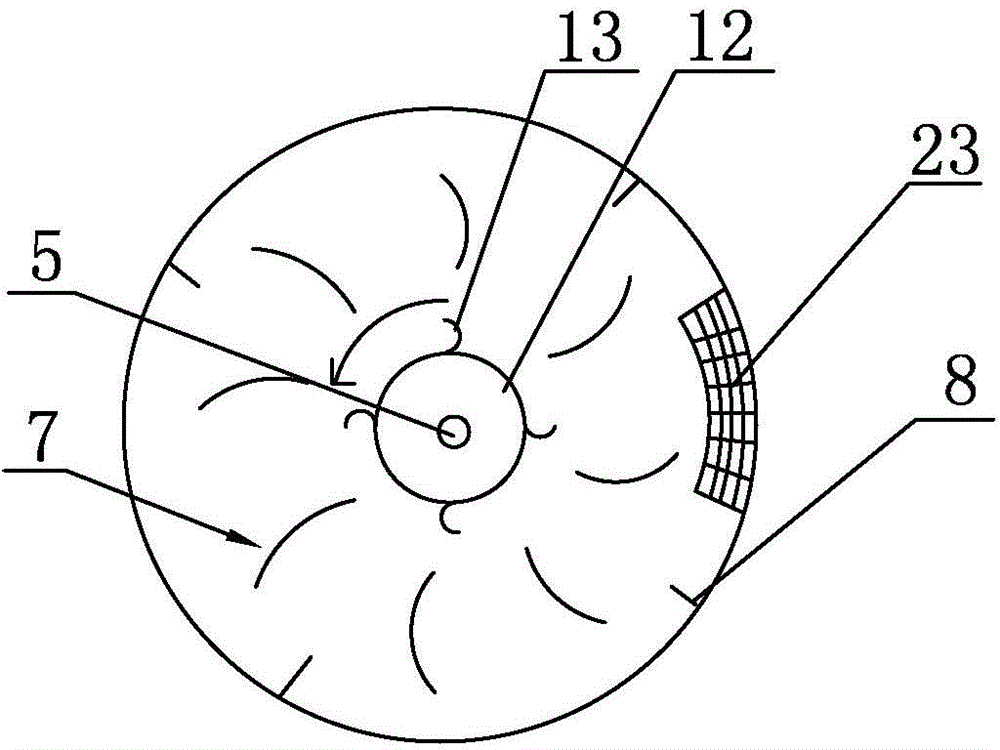

Self-suction gas-liquid mixing impeller

ActiveCN101172216AImprove flow statusIncrease the amount of introductionTreatment using aerobic processesFlow mixersChemical industryImpeller

The invention relates to a self-suction gas-liquid mixing impeller, which mainly consists of a shaft joint, a hollow disk, and guide vanes. Both the top plate and the bottom plate of the hollow disk can be provided with guide vanes; Structures with varying thickness. The impeller of the present invention can inhale gas through the negative pressure generated during the rotation process, and disperse the gas into the liquid in the form of micro-bubbles. It has the characteristics of large suction volume, good gas-liquid mixing effect, low energy consumption, and no clogging of the impeller, and is widely used. It is used in the fields of gas-liquid mixing and reaction, and phase separation, and forms a variety of special equipment, such as wastewater biochemical treatment equipment, air flotation equipment, waste gas purification equipment, and gas purification equipment in the fields of chemical industry, pharmaceuticals, metallurgy, food, papermaking, etc. Liquid contact and reaction equipment, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

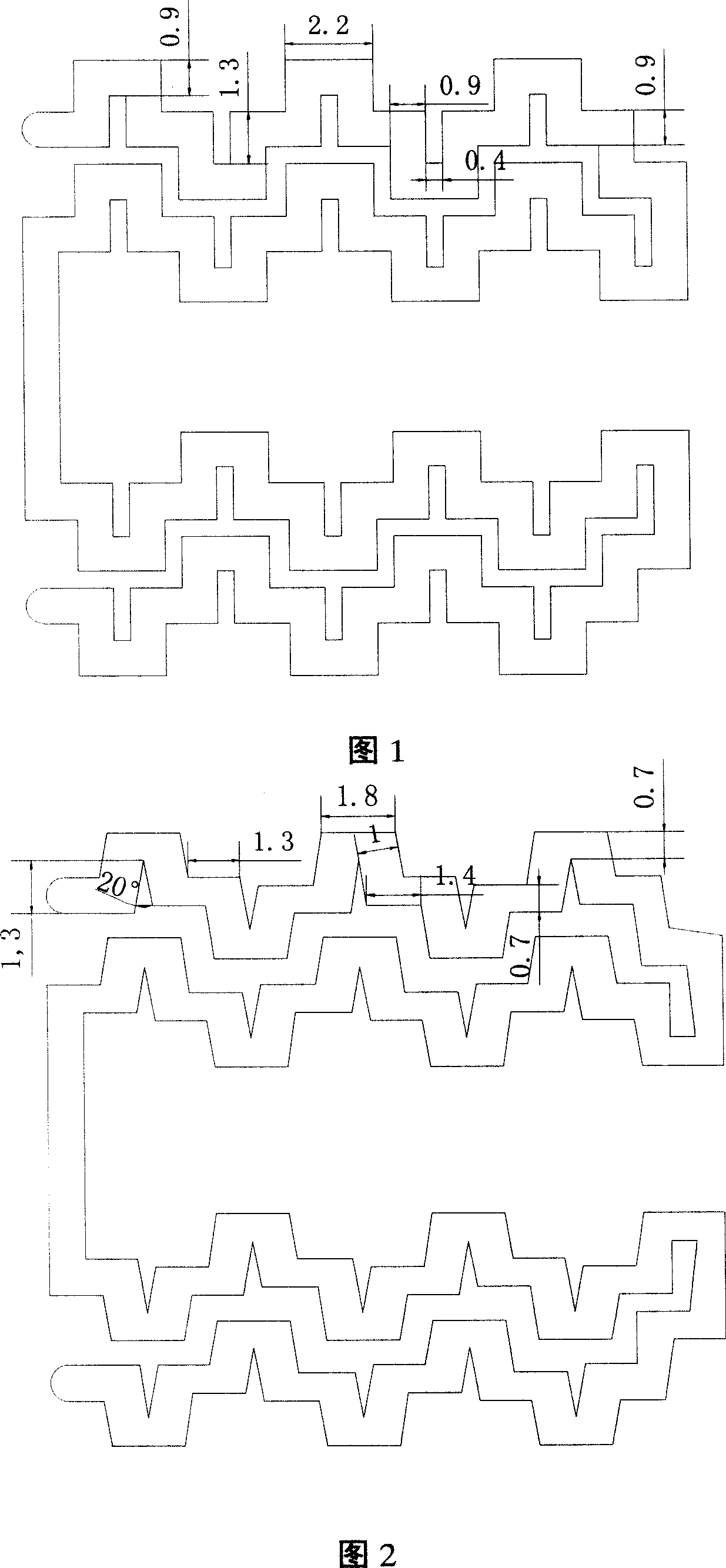

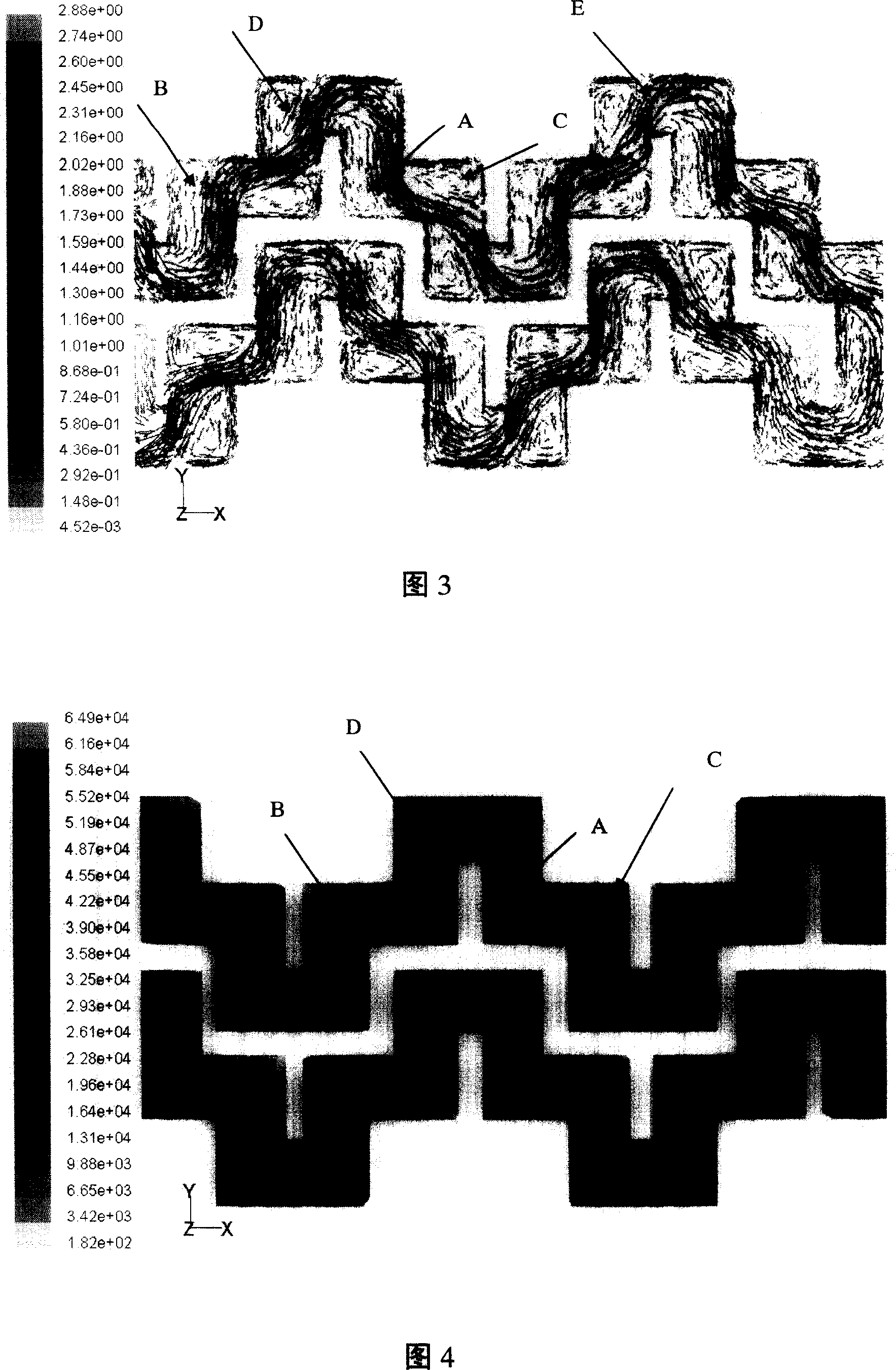

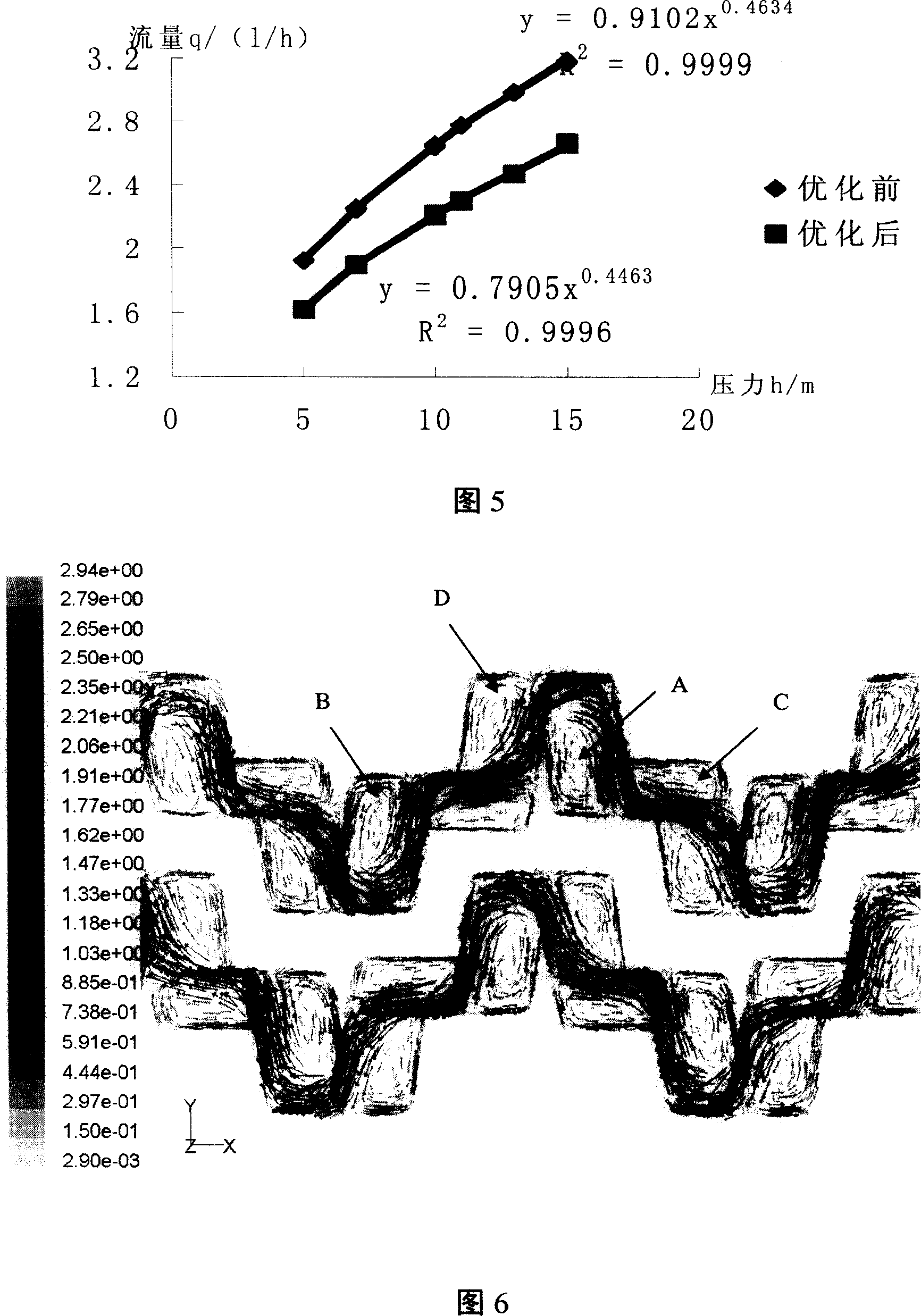

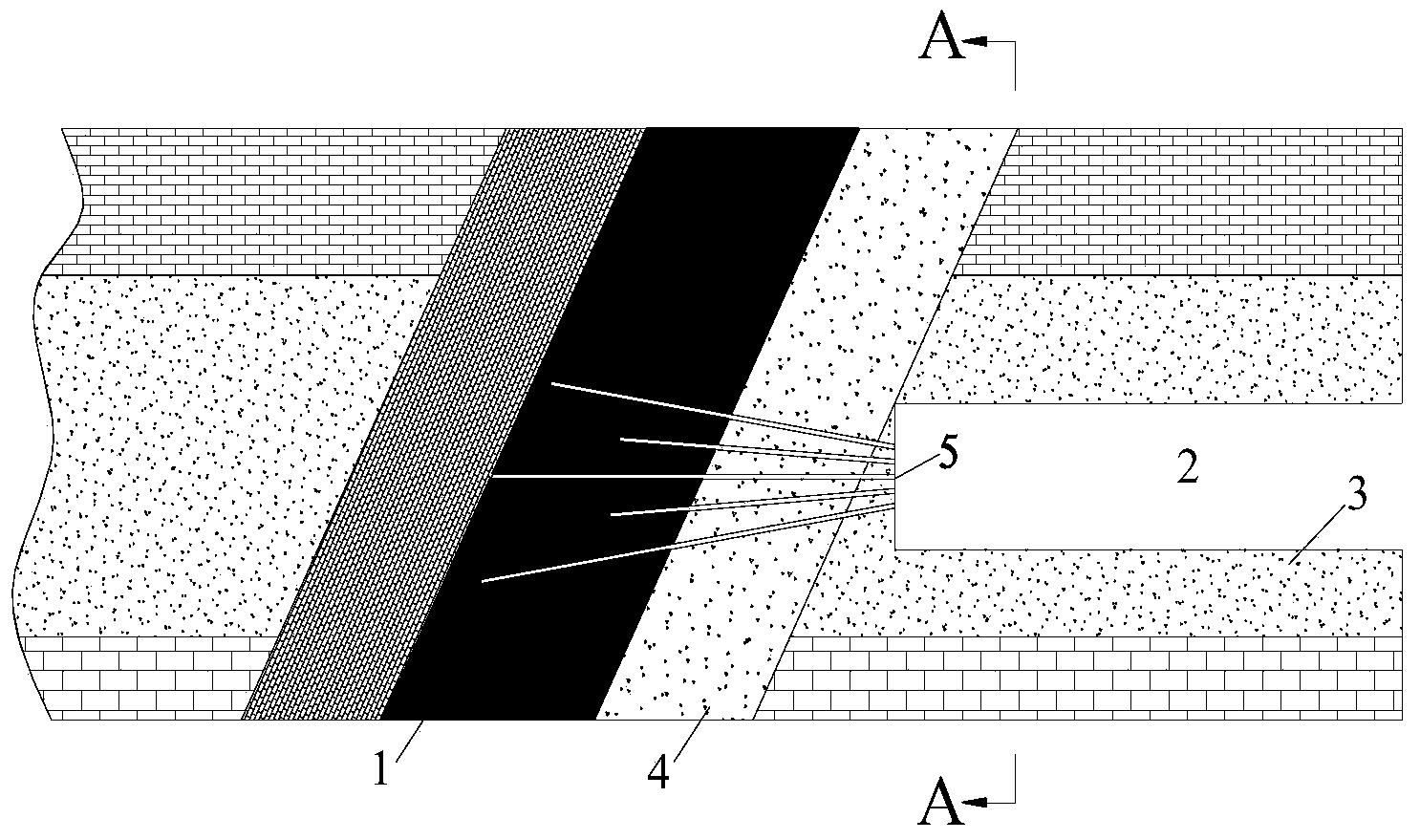

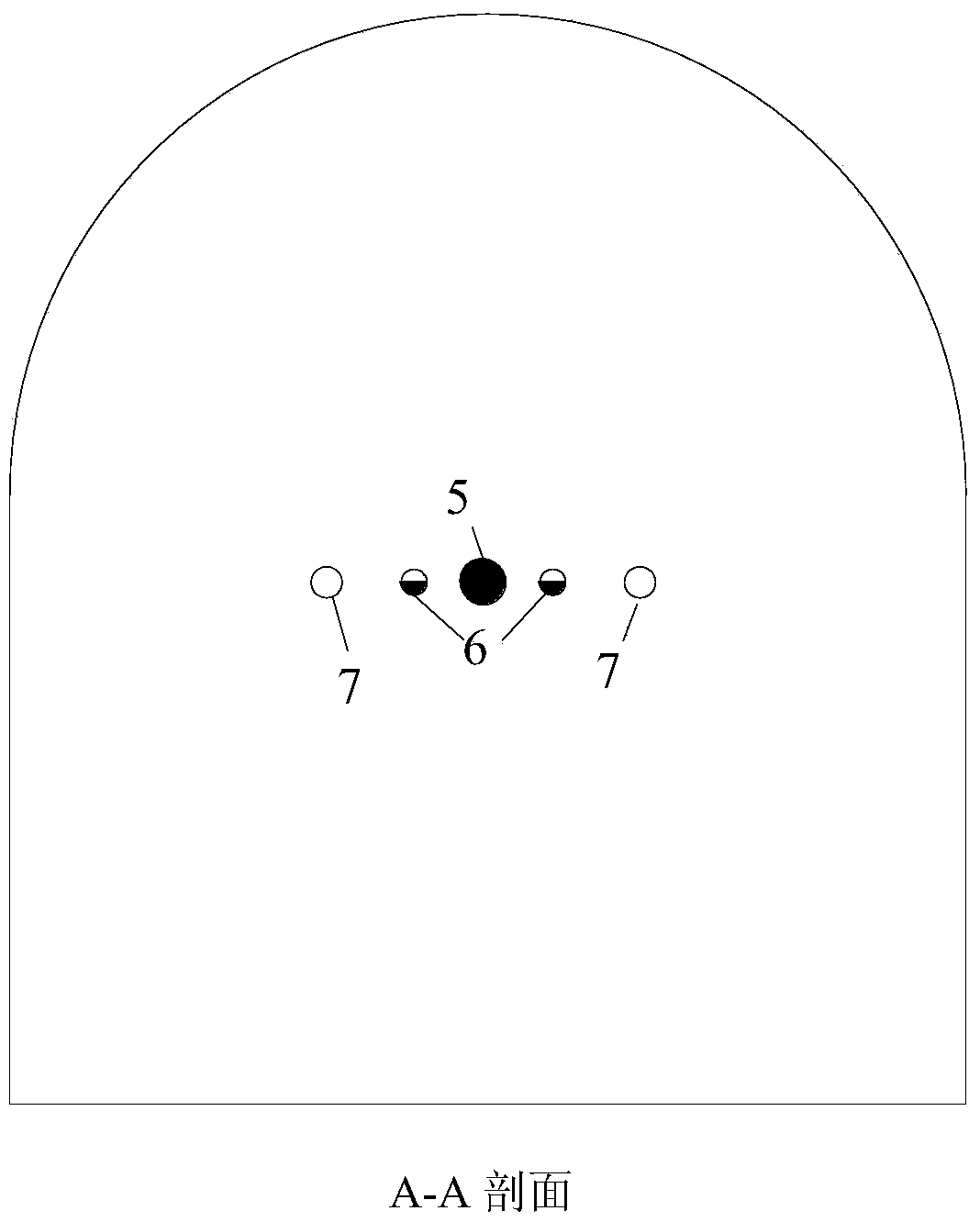

Antiplugging drip irrigation irrigator design method

InactiveCN101021881AReduce fluidity indexEnhanced flushingClimate change adaptationWatering devicesJet flowDrip irrigation

This invention provides a designing method for anti-jam drop-fill douches including: 1, setting up a structure model of the runner of a douche to divide it into lattices and design the border condition of the computed regions, 2, applying CFD evaluator to compute the runner of the drop head, 3, getting the velocity of flow field and eddy distribution parameter and determining the position of low flow rate regions in the head runner and the decision factor for pressure energy dissipation, 4, finishing borders of the runner structure and changing the tooth structure to reduce brush of the tooth tine place and the back surface to the runner borders to strengthen the eddy structure of the flow field, 5, computing repeatedly and balancing flow field parameters in the front and back runners to decide the anti-jam ability of the douche and testing the flow-pressure relation of the douche to guarantee its water power performance.

Owner:内蒙古兆通管道系统有限公司

Outburst coal bed hydraulic phase change cracking cross-cut coal uncovering method

ActiveCN104213932AChange mechanical propertiesImprove breathabilityUnderground miningSurface miningLiquid stateFreezing thawing

The invention provides an outburst coal bed hydraulic phase change cracking cross-cut coal uncovering method, which is applicable to high-gas-outburst coal bed cross-cut coal uncovering operation. The minimum normal distance from the cross-cut coal uncovering working face to the coal bed is greater than or equal to 7m position, a plurality of holes are respectively drilled in the coal uncovering region, a conventional capsule hole sealing coal bed water injection technology is adopted for injecting water into the coal bed through the drilled holes, after the water injection completion, a conventional refrigeration freezing technology is adopted for freezing the coal bed around the water injection hole, in the freezing process, free water in the coal bed is gradually converted from the liquid state into the solid state, and the volume of the water expands for 9.1 percent in the phase change process; after the freezing completion, the freezing coal bed absorbs the underground environment head and gradually thaws. After the freezing thawing completion, the water injection hole and a gas extraction pipeline are connected for gas extraction, or the gas extraction drilling is implemented on the coal bed in the phase change cracking region for gas extraction. When the coal bed gas content is less than 8m<3> / t, the gas extraction is stopped, the water is injected into the water injection hole again, the secondary freezing of the coal bed is completed, and then, the coal bed is uncovered according to a conventional coal uncovering method.

Owner:CHINA UNIV OF MINING & TECH

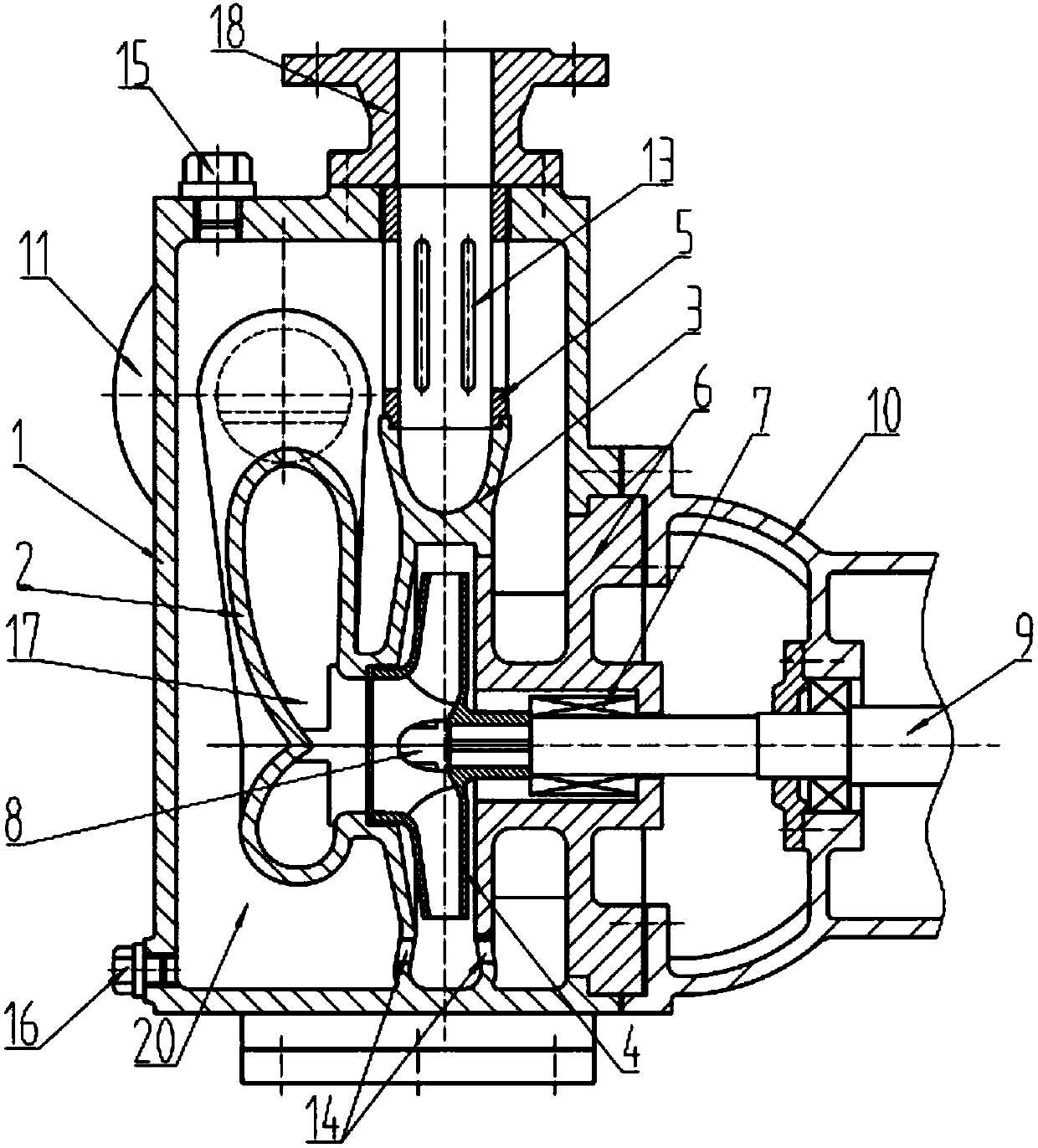

Vibration and noise reduction centrifugal pump provided with bionic structures

ActiveCN104929953AReduce the amplitudeHigh liftPump componentsPump installationsInternal pressureEngineering

A vibration and noise reduction centrifugal pump provided with bionic structures comprises a volute, a connecting shaft, a motor and an impeller. The motor is fixed to the exterior of a shell. The connecting shaft is supported on the volute and extends into the volute. The impeller comprises blades, a front cover plate and a rear cover plate. The blades are installed at the position, between the front cover plate and the rear cover plate, of the connecting shaft and are located inside the volute. The motor is in shaft connection with the impeller through the connecting shaft. A first bionic segment is arranged below a volute diffusion segment, and the contour shape of the longitudinal section of the first bionic segment is an arc toothed structure simulating the outer contour of bird wings. A starting point of the first bionic segment is located at the starting part of an isolation tongue, and an ending point of the first bionic segment extends to the position between a first section and a second section of a volute pumping chamber. The arc part of the head of the isolation tongue is provided with at least one column of raised bionic surface structures. The centrifugal pump has the advantages that the amplitude of the most intense part of internal pressure pulsation of the centrifugal pump is reduced; the flow and lift of the centrifugal pump can be conveniently, accurately and effectively enhanced, and meanwhile the hump of a centrifugal pump performance curve can be improved.

Owner:ZHEJIANG UNIV OF TECH

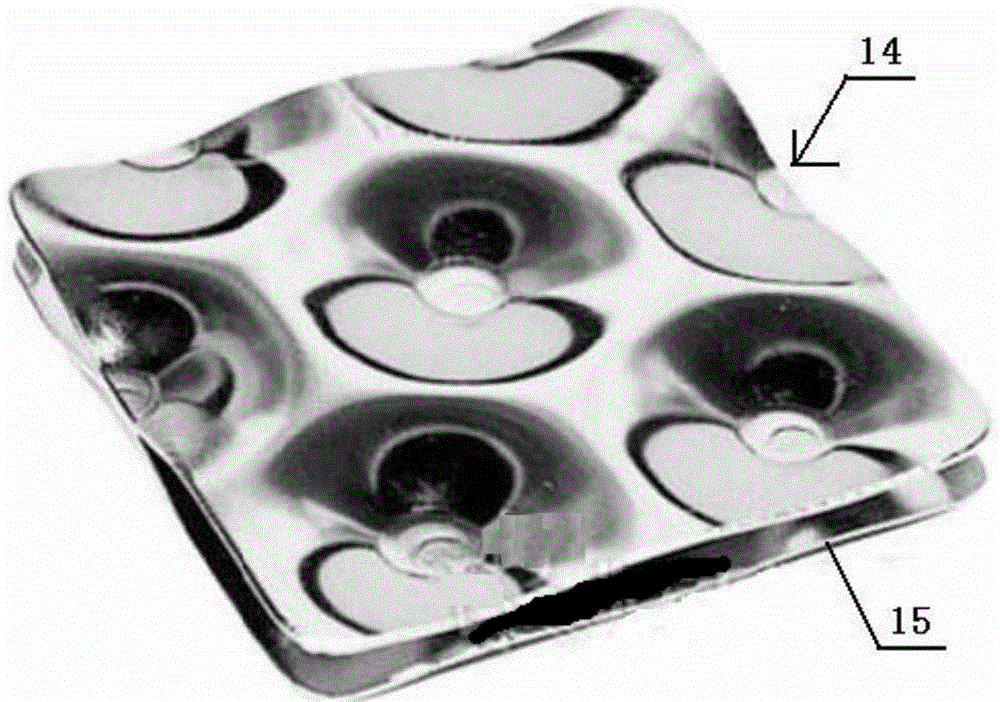

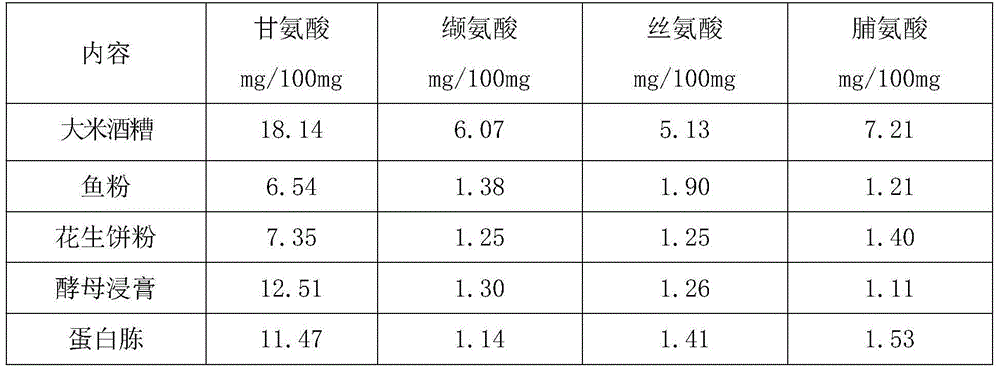

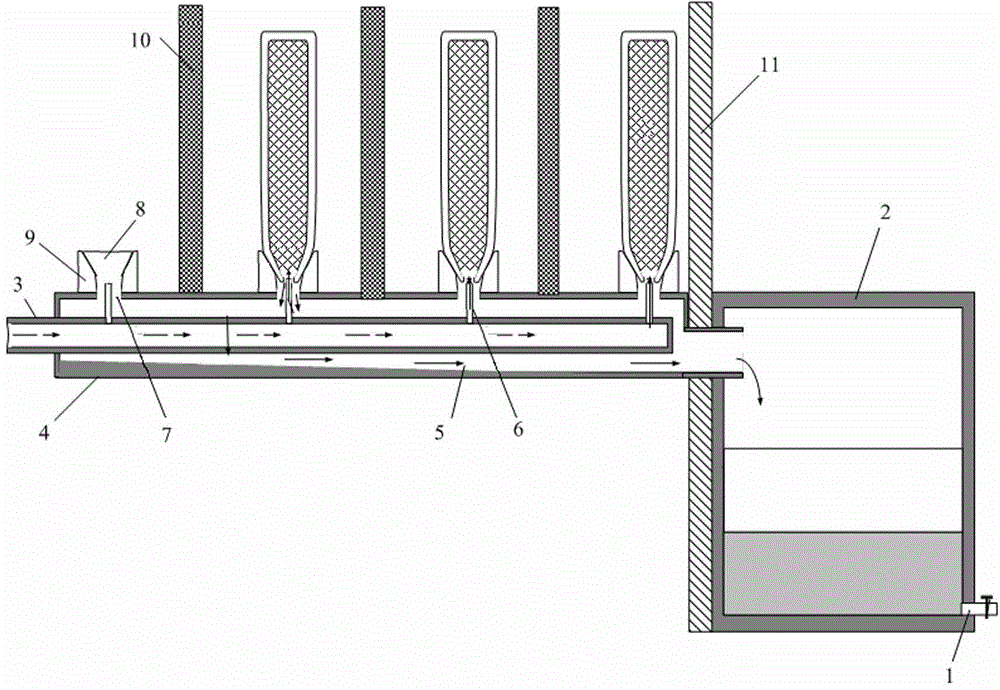

Culture mediums for producing doramectin through fermentation of mutant streptomyces avermitilis and material supplement method

ActiveCN104561180ALow market priceIncrease productionMicroorganism based processesFermentationBiotechnologyPolystyrene

The invention relates to culture mediums for producing doramectin through fermentation of mutant streptomyces avermitilis and a material supplement method. The culture mediums comprise a seed culture medium and a fermentation culture medium, and are characterized in that the seed culture medium comprises corn lees and low-temperature pressing soya bean cake powder; the fermentation culture medium comprises corn lees, low-temperature pressing soya bean cake powder, polystyrene non-polar adsorbent resins and nonionic surfactants. The cost problem of raw materials and auxiliary materials are solved, the environment influence on sources of the raw materials and the auxiliary materials is reduced to the hilt, the supplying of the raw materials and the auxiliary materials is sufficient, the stable and efficient production of the doramectin is realized, and at the same time, the fermentation unit can be improved by using the culture mediums and the material supplement method.

Owner:宁夏泰瑞制药股份有限公司

Low-gas permeability coal seam weakening and permeability increasing method combining presplitting and high-pressure water injection

ActiveCN105239983AImprove breathabilityImprove water injection effectFluid removalStress concentrationWater flow

The invention discloses a low-gas permeability coal seam weakening and permeability increasing method combining presplitting and high-pressure water injection. The method includes: using a drilling machine to construct a plurality of coal seam weakening and permeability increasing units to a working face gateway pre-exploiting coal seam side, presetting a corresponding presplitting device in one coal seam weakening and permeability increasing unit which comprises three drilled holes, detonating the presplitting device and then injecting high-pressure water into the coal seam weakening and permeability increasing unit, and stopping the water injection when water injection pressure drops suddenly, the corresponding dropped pressure is kept unchanged and stable pressure water flows out of the coal seam weakening and permeability increasing unit so as to complete the weakening and permeability increasing of the coal seam weakening and permeability increasing unit; performing weakening and permeability increasing on the next coal seam weakening and permeability increasing unit until the weakening and permeability increasing of a whole to-be-exploited coal seam are completed. The method has the advantages that presplitting is performed on deep coal surrounding high-pressure water injection holes, so that water injection influence radius is increased evidently, high-pressure water injection weakening speed is increased, and local coal stress concentration is avoided.

Owner:SHANDONG UNIV OF SCI & TECH

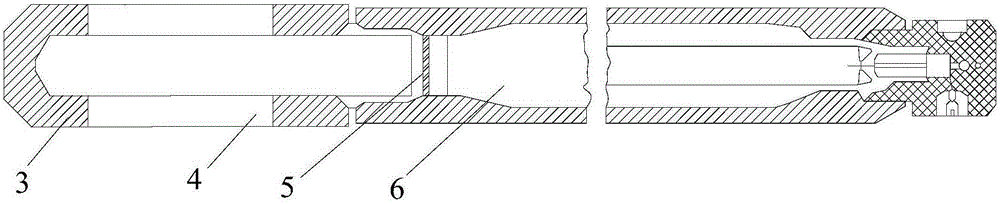

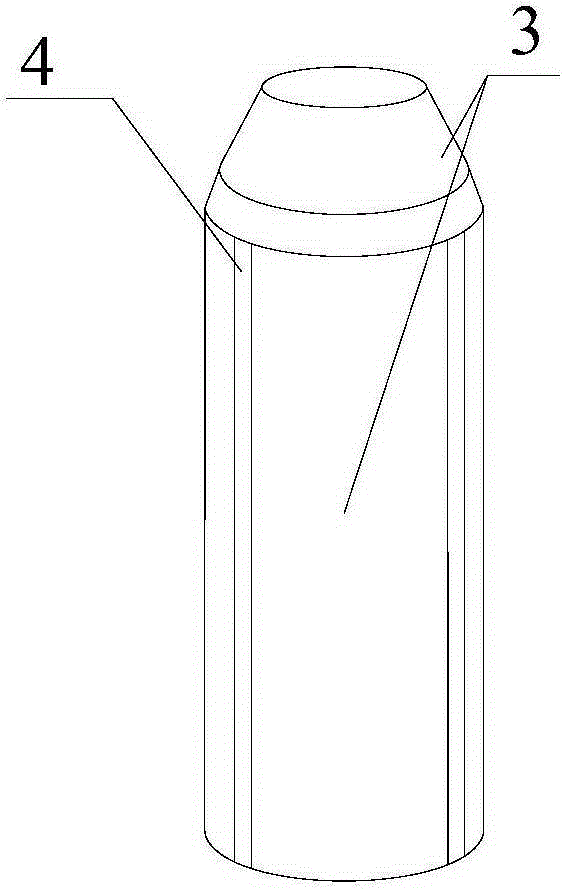

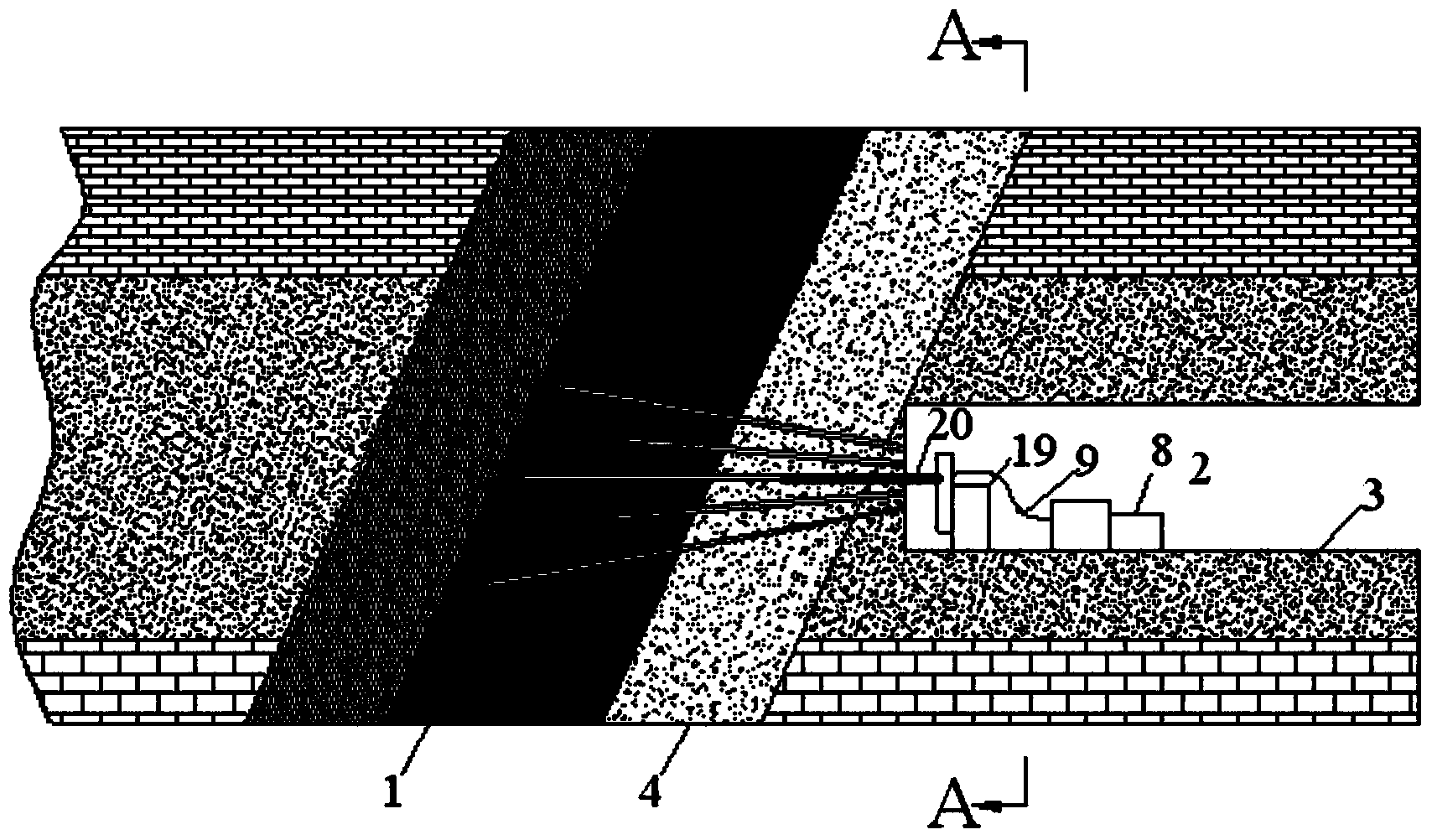

Freezing-type stone door cross-measure coal uncovering method based on hydraulic seam cutting

ActiveCN104213921AImprove flow statusImprove breathabilityUnderground miningSurface miningUltimate tensile strengthCoal

A freezing-type rock cross-measure coal uncovering method based on hydraulic seam cutting is suitable for a rock cross-measure coal uncovering operation in a high-gas outburst coal seam. The method includes following steps: (1) constructing a plurality of water injection holes into a coal uncovering operation surface at a position of the coal uncovering operation surface, wherein a minimum normal distance from the coal seam to the position is not less than 7 m; (2) performing hydraulic seam cutting to the water injection holes through a conventional hydraulic seam cutting technology; (3) when the hydraulic seam cutting is finished, connecting the water injection holes to a gas extraction pipe network to perform gas extraction; (4) when the content of gas in the coal seam is less than 8 m<3> / t, stopping the gas extraction; (5) constructing a freezing holes and a temperature measuring hole respectively at the two sides of the water injection holes; (6) sealing the holes through a capsule hole-sealing device; (7) injecting water into the coal seam through the water injection holes and closing valves when the water injection process is finished to enable the water injected into the coal seam to gradually seep into micro cracks in coal; (8) freezing the coal seam around the water injection holes through a conventional freezing technology to enable free water in the micro cracks in the coal seams to gradually convert from liquid phase into solid phase during the freezing process, so that a strength and an anti-impact performance of the coal are increased and an effect of solidification of the coal seam is achieved; and (9) uncovering the coal seam through a conventional coal uncovering method.

Owner:CHINA UNIV OF MINING & TECH

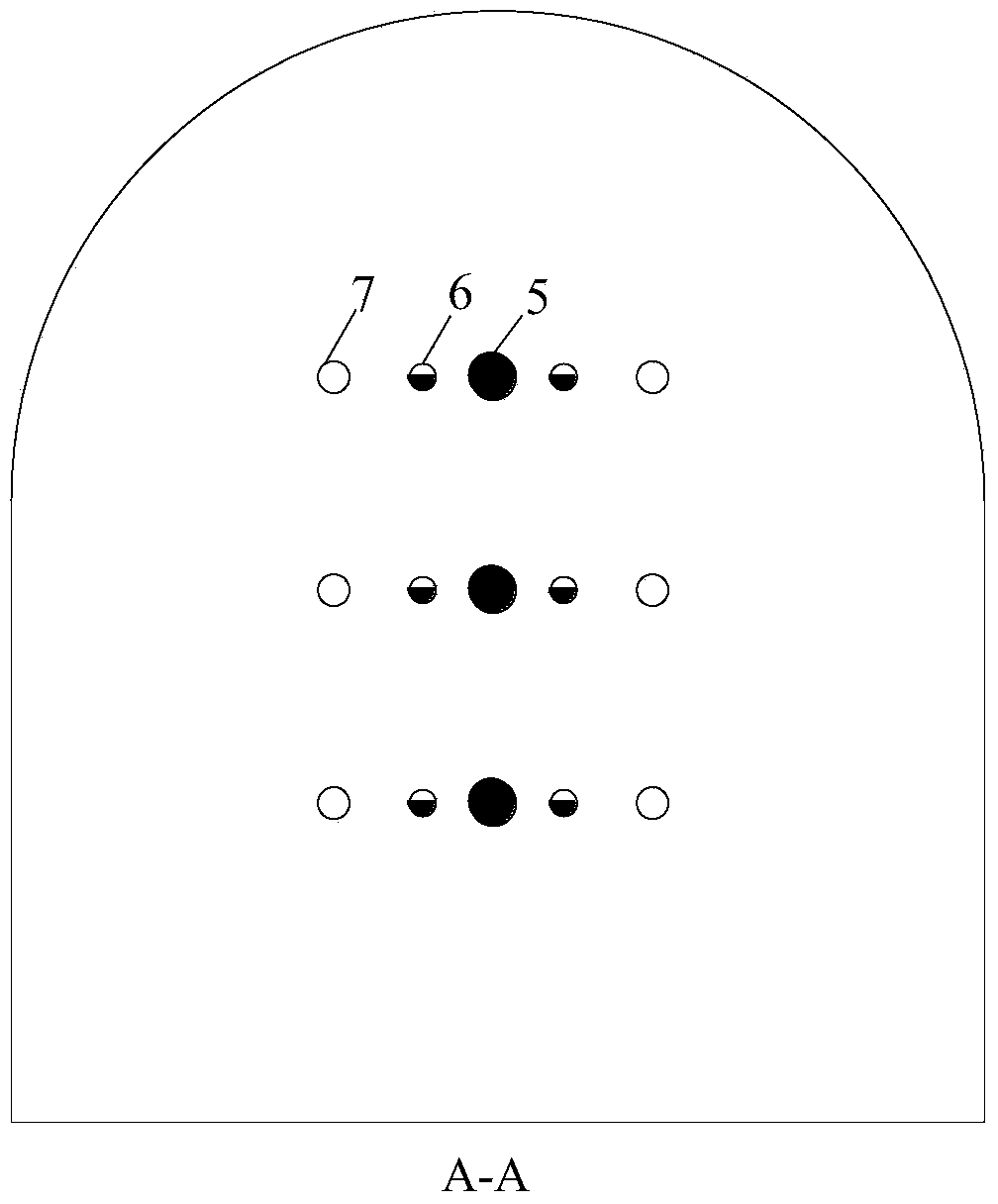

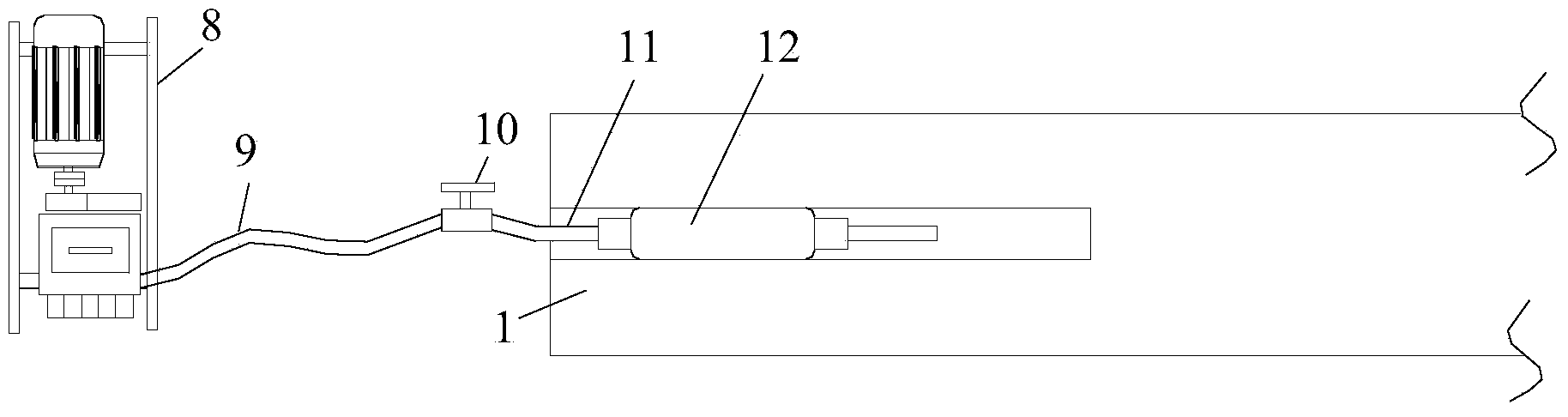

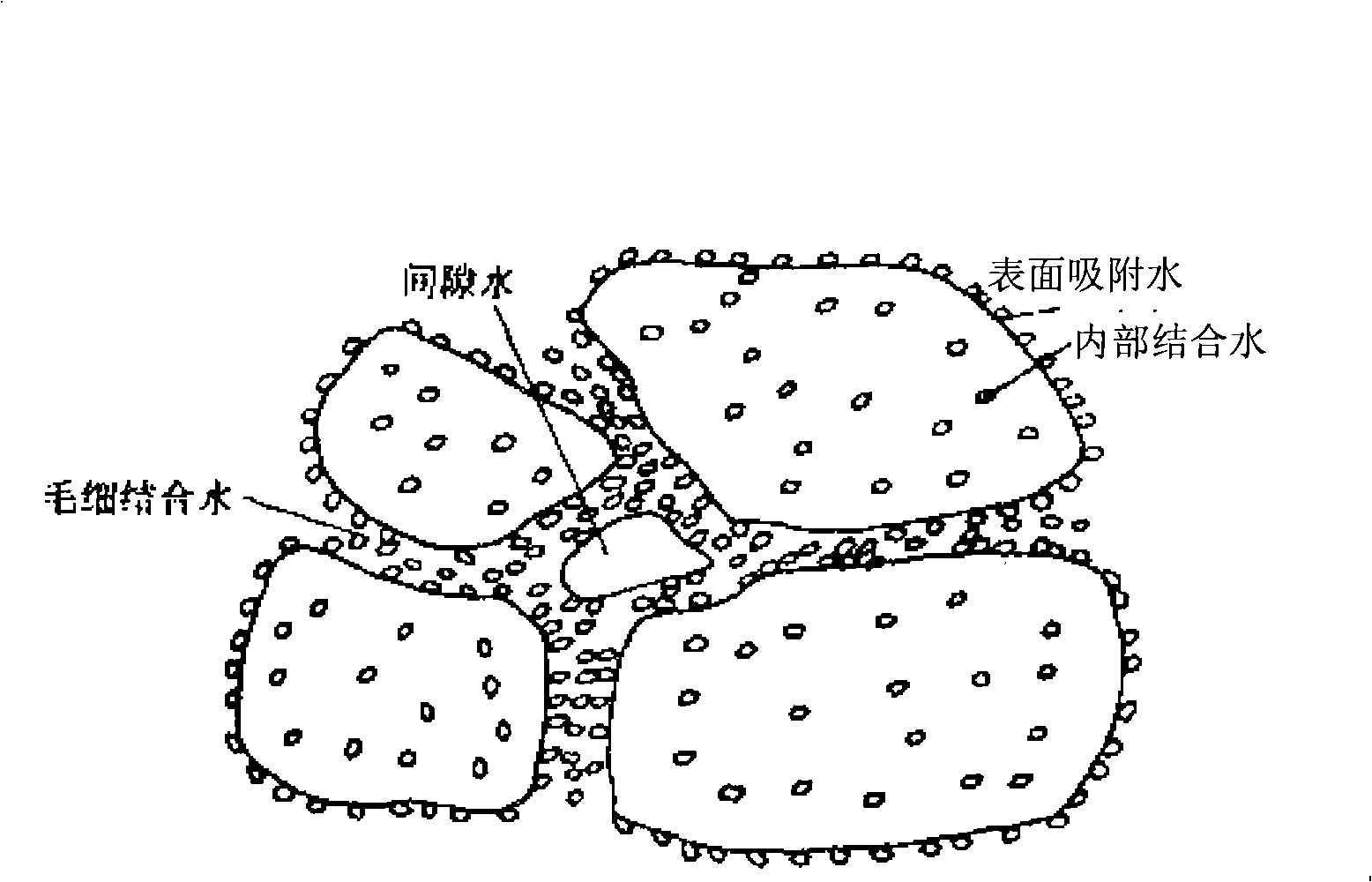

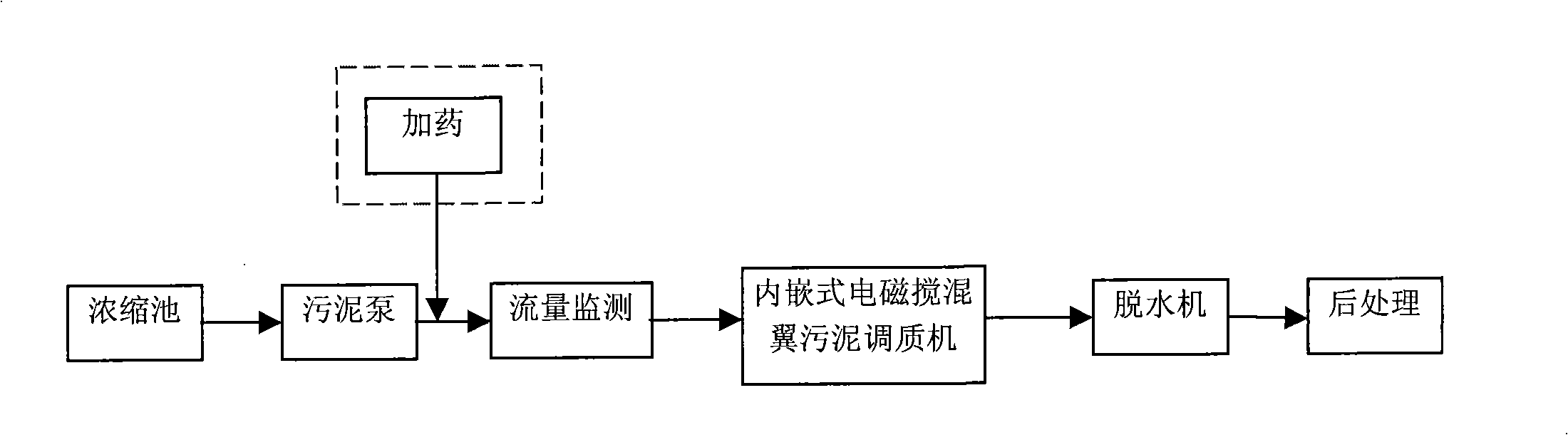

Method and apparatus for improving sludge dehydration

InactiveCN101328002APrecise temperingLower specific resistanceSludge treatment by de-watering/drying/thickeningEnergy expenditureDewatered sludge

The invention discloses a method for improving the dehydrating property of the sludge and equipment thereof. The method is to adopt an inner embedded type electromagnetic swirling wing sludge conditioner arranged in the sludge pipe or an external magnet-rotary sludge conditioner arranged on the sludge pipe to quench and temper the sludge, so as to achieve the purpose of sludge specific resistance reduction and sludge dehydrating property improvement. After the method and the equipment are implemented, the water content of the final dewatered sludge (mud cake) can reach 70-80% which reduces by 2-15% comparing to the technology without conditioner treatment. The work efficiency of the dewaterer is greatly improved, the energy consumption of the dewaterer is reduced by 5-40% and the reagent dosing is reduced by 5-100%. The method and equipment of the invention are not only suitable for the transformation of the old equipment in the prior sludge treatment, but also suitable for the establishment of the new equipment.

Owner:上海滨浦水处理设备有限公司

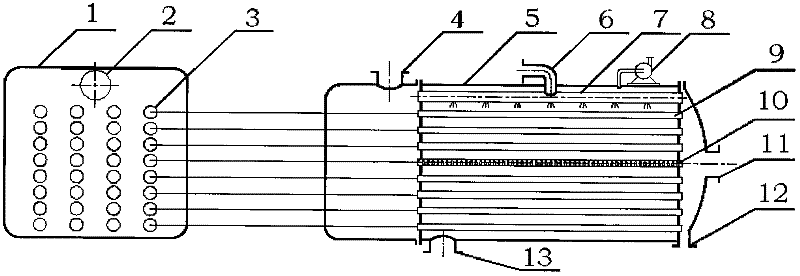

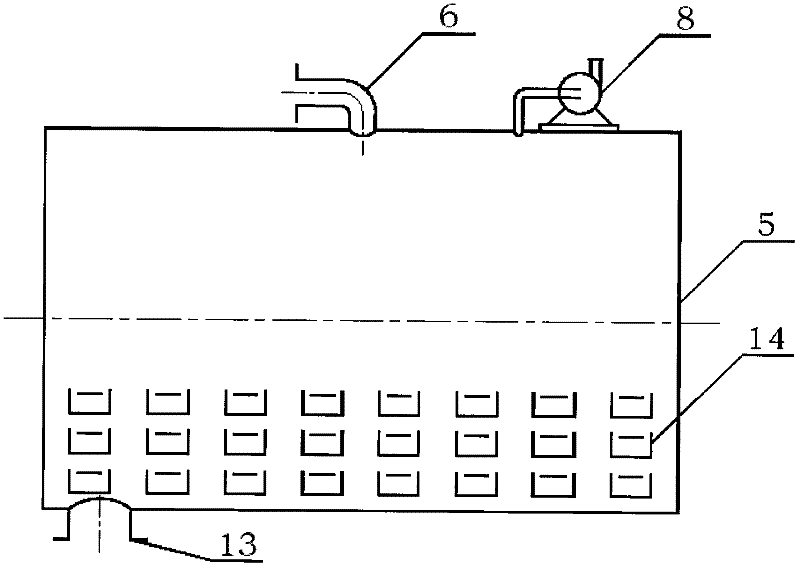

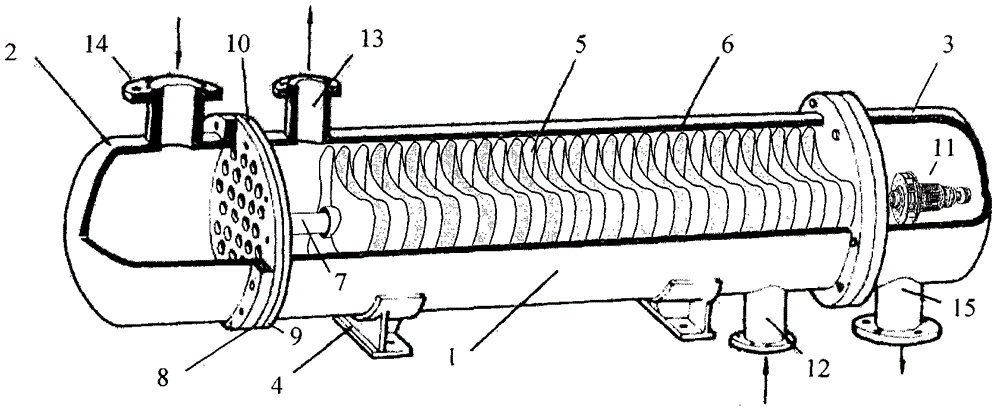

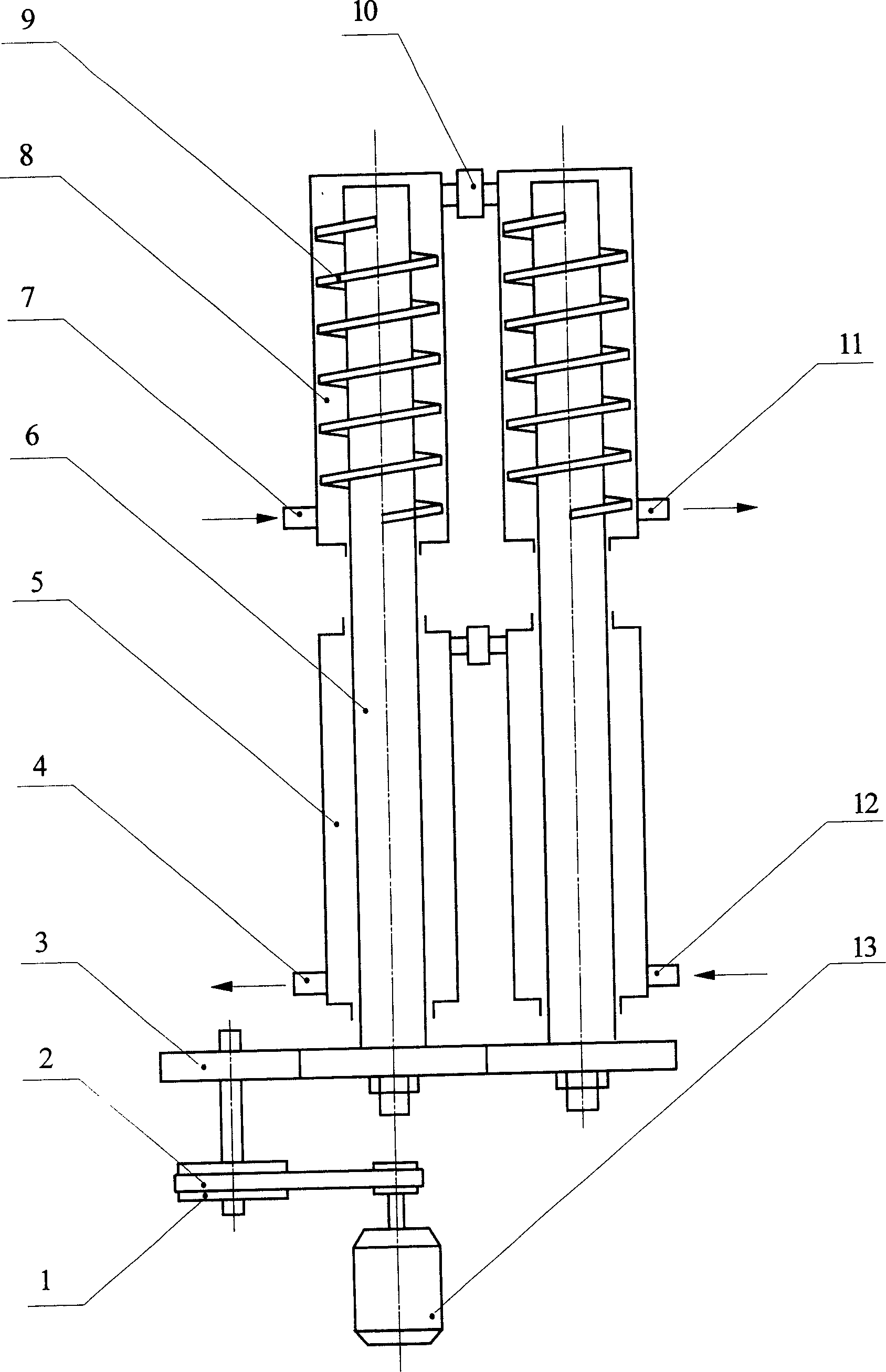

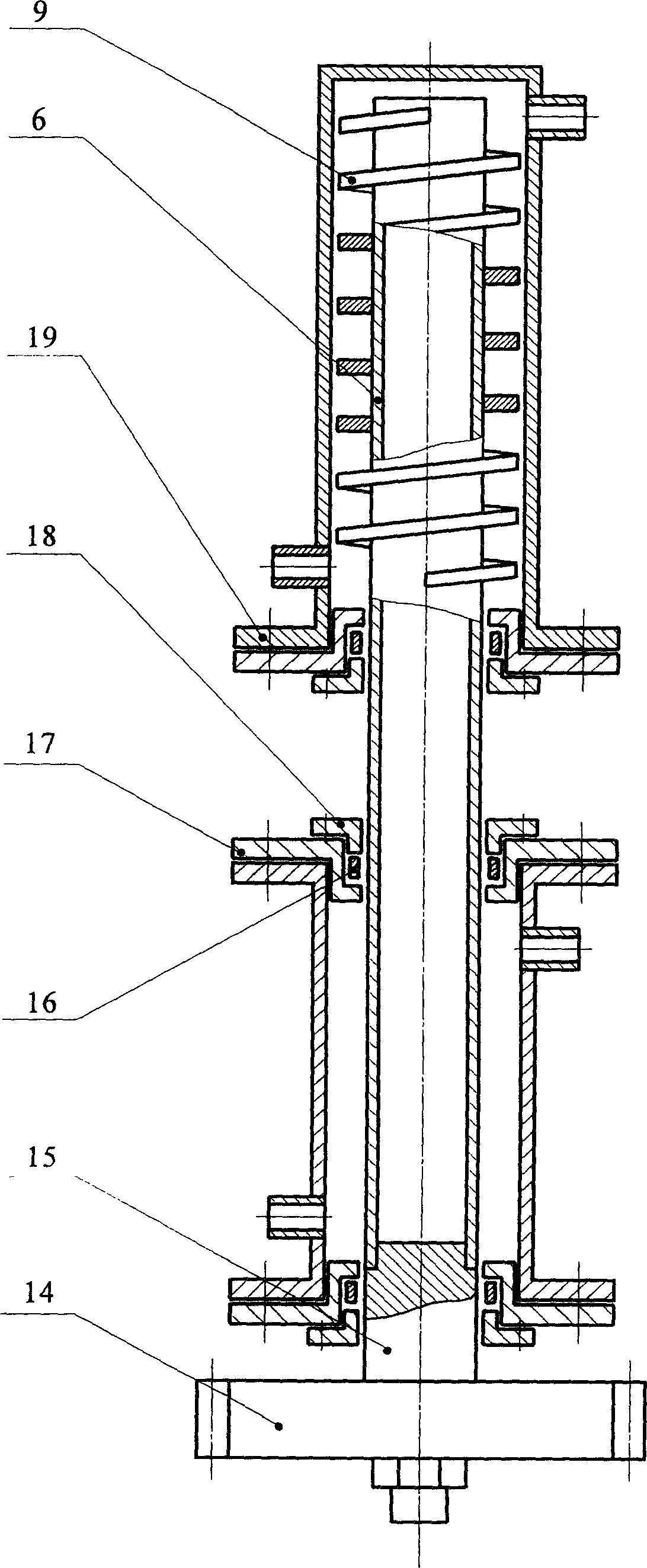

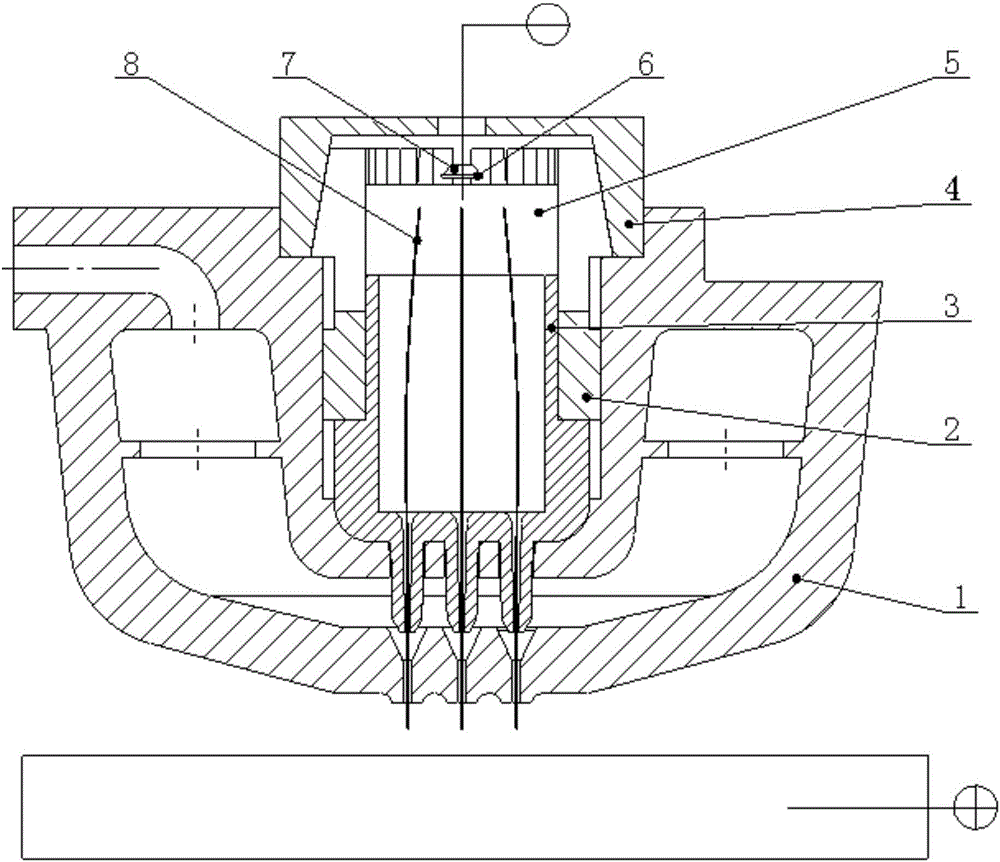

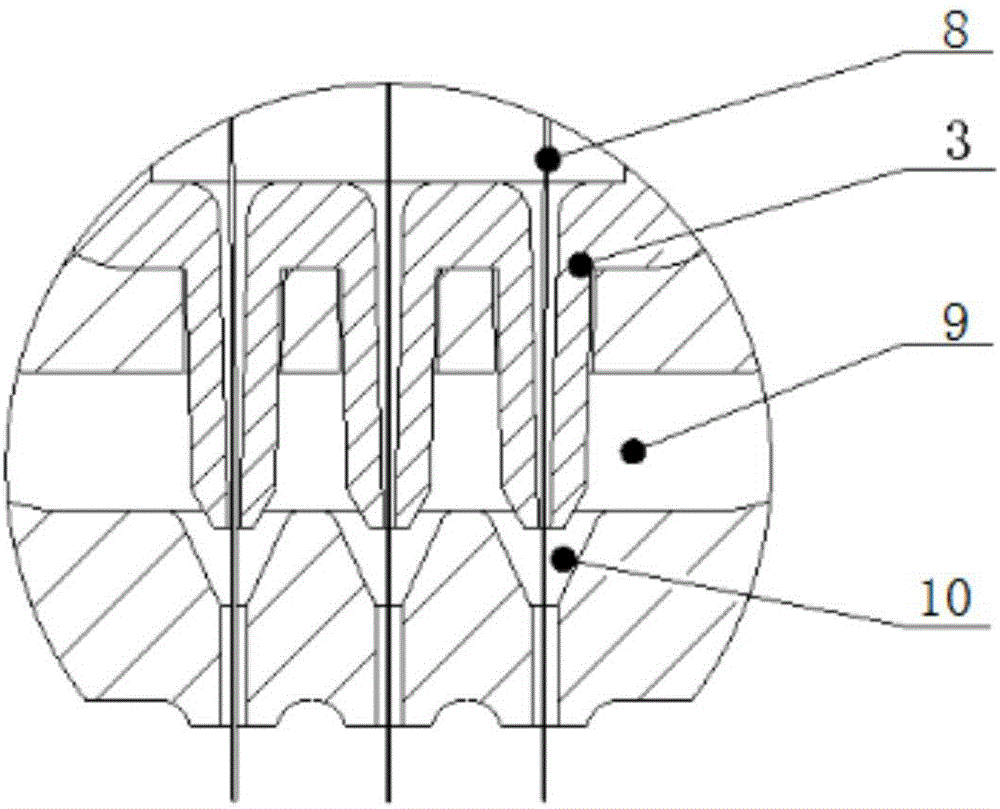

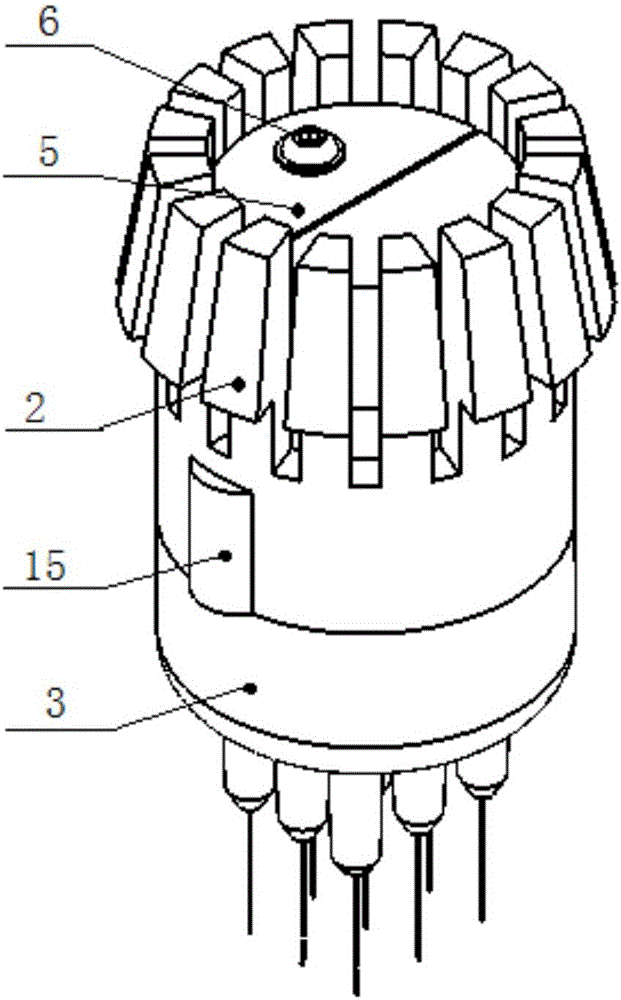

Shell-and-tube heat exchanger with stock pusher

ActiveCN102305559AImprove heat transfer efficiencyImprove heat transfer performanceStationary tubular conduit assembliesRotary device cleaningChemical industryPlate heat exchanger

The invention discloses a shell-and-tube heat exchanger with a stock pusher, relates to heat transfer equipment in industrial production, and belongs to the field of gas-liquid heat transfer devices. The shell-and-tube heat exchanger with the stock pusher mainly comprises a rotation mechanism (1), a tube box (5) and a heat exchange tube (9), wherein the rotation mechanism (1) drives the stock pusher (10) in the heat exchange tube (9) to rotate so as to push out liquid and solid, which are condensed on a tube wall, so blocking is avoided. The shell-and-tube heat exchanger with the stock pushercan be applied to heat transfer process in chemical industry, petrochemical industry, light industry, metallurgical industry and the like and has the characteristics of good blocking resistance, remarkable economic benefit and the like.

Owner:北京先锋创新科技发展有限公司

Cartridge receiver processing system

InactiveCN103133391ASimple structureWill not affect the overall working statusPump componentsFluid dynamicsPlasma actuatorGas compressor

The invention discloses a cartridge receiver processing system which comprises a plasma actuator. The plasma actuator is arranged on the periphery of a cartridge receiver of a gas compressor and above movable vanes of the inner side of the cartridge receiver of the gas compressor in a non-axial-symmetry mode. The plasma actuator is used for generating plasma and accelerating air nearby the plasma actuator. Due to the fact that plasma incentive with proper strength and frequency is exerted on the fixed position of the cartridge receiver of the gas compressor, on the one hand, the cartridge receiver processing system has the effect of broadening a stable operation area of the gas compressor, on the other hand, the cartridge receiver processing system can improve a flow state of a leaf apex area, has the effect of reducing flow loss, and enables leakage flow loss and mixing loss of the leaf apex area to be in a lower level all the time.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Merged propeller blade type electro-catalytic reactor for high-viscosity wastewater treatment

ActiveCN104925917AEvenly distributedGuaranteed reduction reactionWater/sewage treatment using germicide/oligodynamic-processElectrochemistryWater treatment

The invention relates to the technical field of electro-chemical water treatment, particularly to a merged propeller blade type electro-catalytic reactor for high-viscosity wastewater treatment. The structure of the electro-catalytic reactor comprises a casing, an upper floating head, a lower floating head, a base, propeller blade anodes, propeller blade cathodes, a conducting shaft, anode guide plates, cathode guide plates, insulation guide plates, an axial flow motor, and auxiliary components, wherein the casing, the upper floating head, the lower floating head and the base are used for protecting and supporting the reactor; the propeller blade anodes, the propeller blade cathodes, the conducting shaft, the anode guide plates, the cathode guide plates and the insulation guide plates are used for providing a reaction field for electrocatalysis; the axial flow motor is used for providing driving force for the flow of water bodies; the auxiliary components comprise a water inlet pipe, a water outlet pipe, a cleaning pipe, a residue discharge pipe and the like. After high-viscosity waste water enters a system through the water inlet pipe, and the high-viscosity waste water is uniformly distributed and violently disturbed under the stirring action of the propeller blades, so that the short pass of water flows is avoided, the mass transfer effect is also enhanced, waste water generates an oxidation reaction in the propeller blade anodes and generates a reduction reaction on the propeller blade cathodes alternately, and the effective degradation of different organic pollutants is smoothly realized.

Owner:BEIJING NORMAL UNIVERSITY

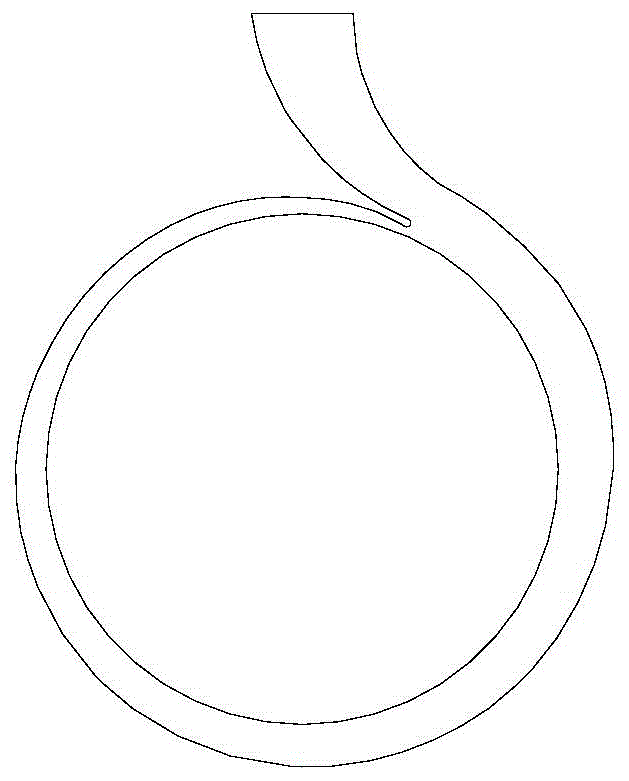

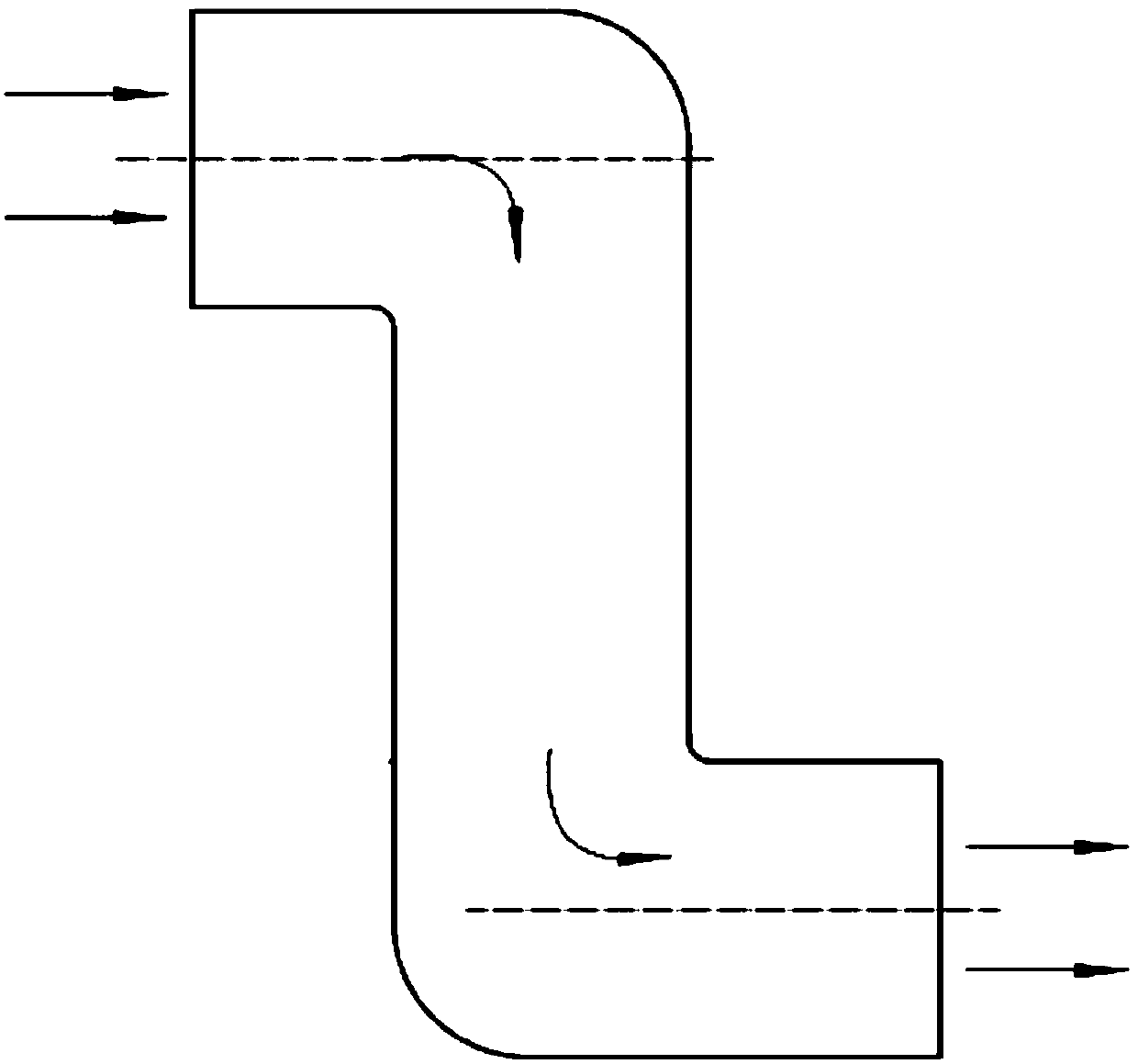

Jet pump with volute type flume

InactiveCN106224302AImprove flow statusJet pump efficiency improvementJet pumpsMachines/enginesStraight tubeWater flow

The invention provides a jet pump with a volute type flume. The jet pump comprises a fluid pipeline B, a fluid pipeline A arranged outside the fluid pipeline B in a sleeving mode, a constricted tube, a throat tube and an expansion tube, wherein the constricted tube, the throat tube and the expansion tube are sequentially connected with the water outlet end of the fluid pipeline A. The volute type flume arranged outside the fluid pipeline B in a sleeving mode is arranged at the inlet end of the fluid pipeline A. The diameter of the water outlet end of the fluid pipeline A is decreased gradually in the water flowing direction. The constricted tube is a round tube with the diameter being decreased gradually. The throat tube is a straight tube. The expansion tube is a round tube with the diameter being increased gradually. The jet pump is easy to manufacture and install, the symmetry of internal flow of the jet pump is good, flowing is more stable, and hydraulic performance is improved; the flow losses are reduced, mixing of two fluids is promoted, and the efficiency is improved advantageously; the frictional hydraulic losses are reduced; and the jet pump is suitable for an annular jet pump as well as a central jet pump.

Owner:WUHAN UNIV

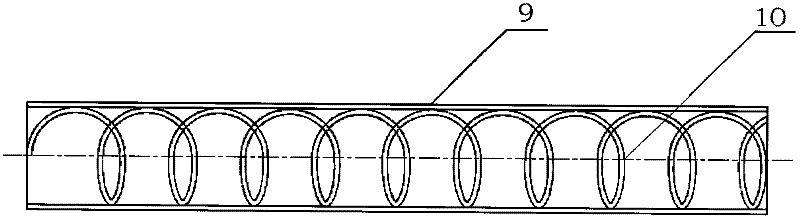

Helical propelling rotation heat pipe heat exchager

InactiveCN1657856AReduce formationUniform and stable cooling effectMoving conduit heat exchangersEngineeringHeat sensitive

The invention is a spiral boosting rotate heat tube exchanger which consists of gravity heat tube, spiral fin, transmission component (such as gear, belt wheel, chain wheel, abrasion wheel), outer sleeve tube and the sealing components. The out driving force is transmitted by the gears to the heat tube spinning the tube. The spiral fins drives the high mucosity liquor flowing outside the heat tube in the spiral channels so to exchange heat with the heat tube. The heat exchanger is able to provide the heated or cooled materials with a uniform temperature field while driving them flowing in the heat exchanger which facilitates the flow condition in the heat exchanger and prevents the jamming and delays the accumulating of the dirt layer. The invention is capable of high mucosity heat sensitive flow heating and cooling techniques.

Owner:郑小平

Realizing method for improving exhaust capacity of air inlet and exhaust valves

InactiveCN109163101AImprove intake and exhaust performanceExtended service lifeValve members for absorbing fluid energyDesign optimisation/simulationPipe burstingViewpoints

The invention discloses a realizing method for improving the exhaust capacity of air inlet and exhaust valves. On the basis of establishment of streamline mathematical models of the air inlet and exhaust valves, as for a water supplying system, the theoretical exhaust quantity is calculated, the types and specifications of the conventional air inlet and exhaust valves are determined, and the exhaust flow coefficients are calculated; and the same specification of the section-variable air inlet and exhaust valves with exhaust flow channels being in a streamline shape are designed, the actual exhaust quantity and the actual exhaust flow coefficients are tested, recorded and calculated on an exhaust performance test platform. Experiments prove that the exhaust capacity of the section-variableair inlet and exhaust valves is obviously improved, thus under the premise of meeting the exhaust requirements, the diameter and the number of the air inlet and exhaust valves can be decreased, investment is lowered, the anti-cavitation performance of inner components is improved, the service life is prolonged, and the pipe-bursting accident caused by improper type selection of the air inlet and exhaust valves is avoided; and the viewpoint that the internal and external pressure differences of the air inlet and exhaust valves are different, and thus the exhaust flow coefficients of the air inlet and exhaust valves are also different is put forward and verified for the first time, the basis is provided for improvement of type selection standards and formulation of production technical standards in the water supply industry in China, and the realizing method is of great significance to ensure safe operation of pipelines.

Owner:TAIYUAN UNIV OF TECH

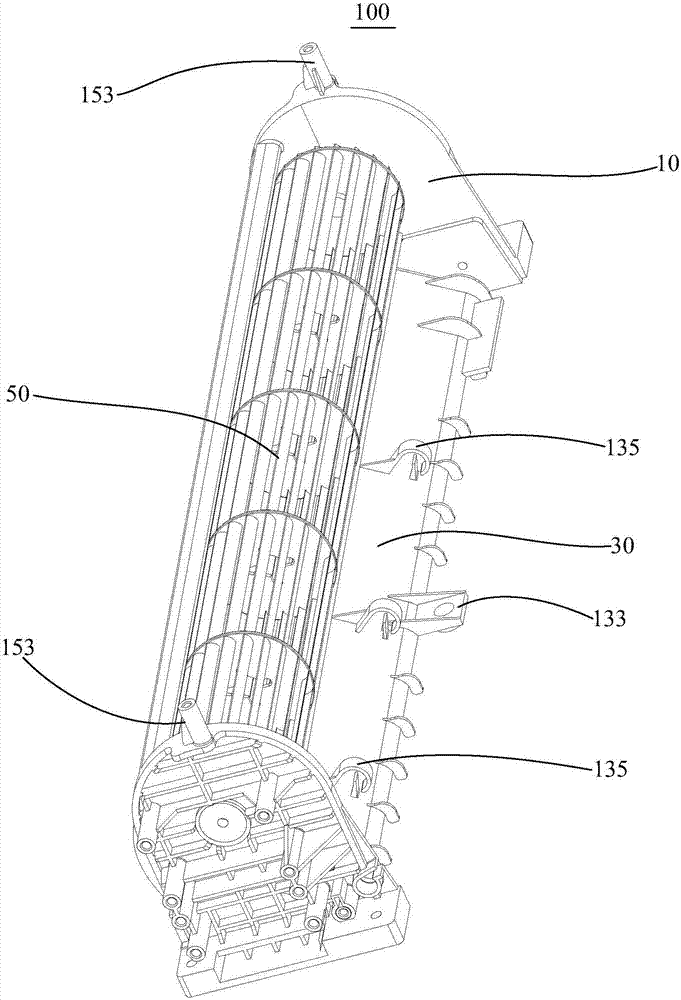

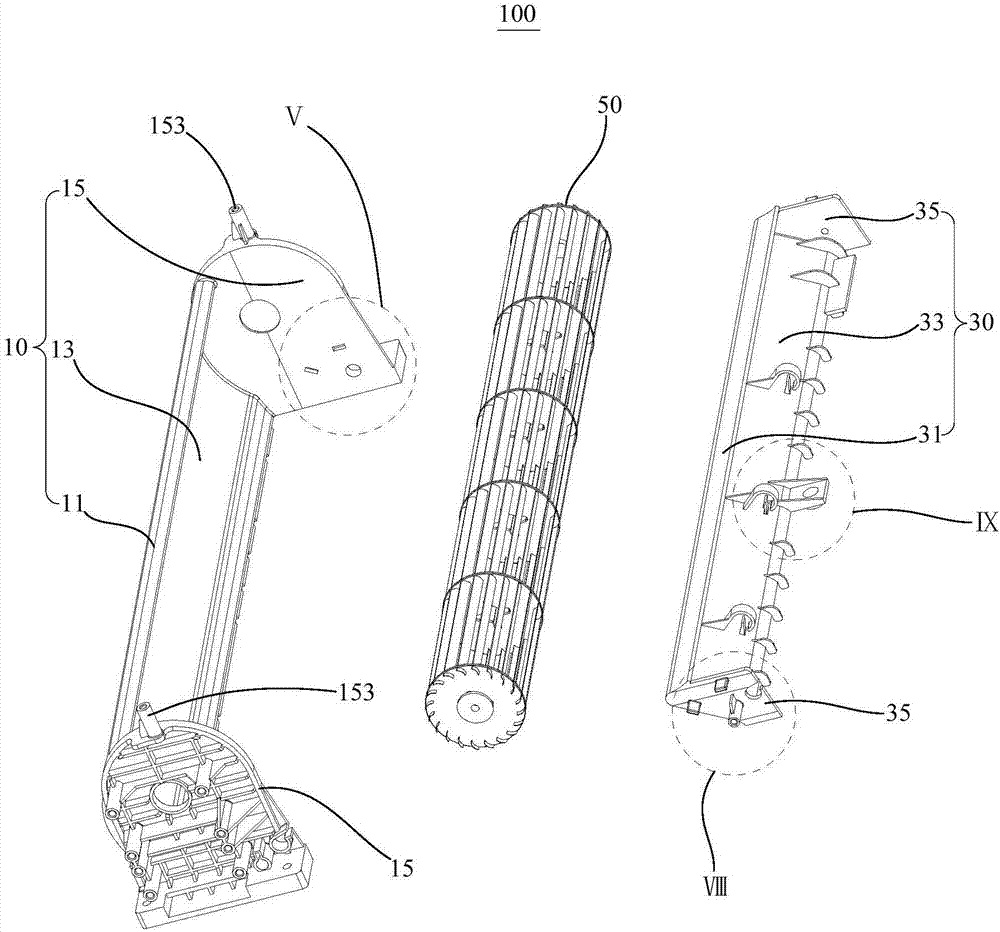

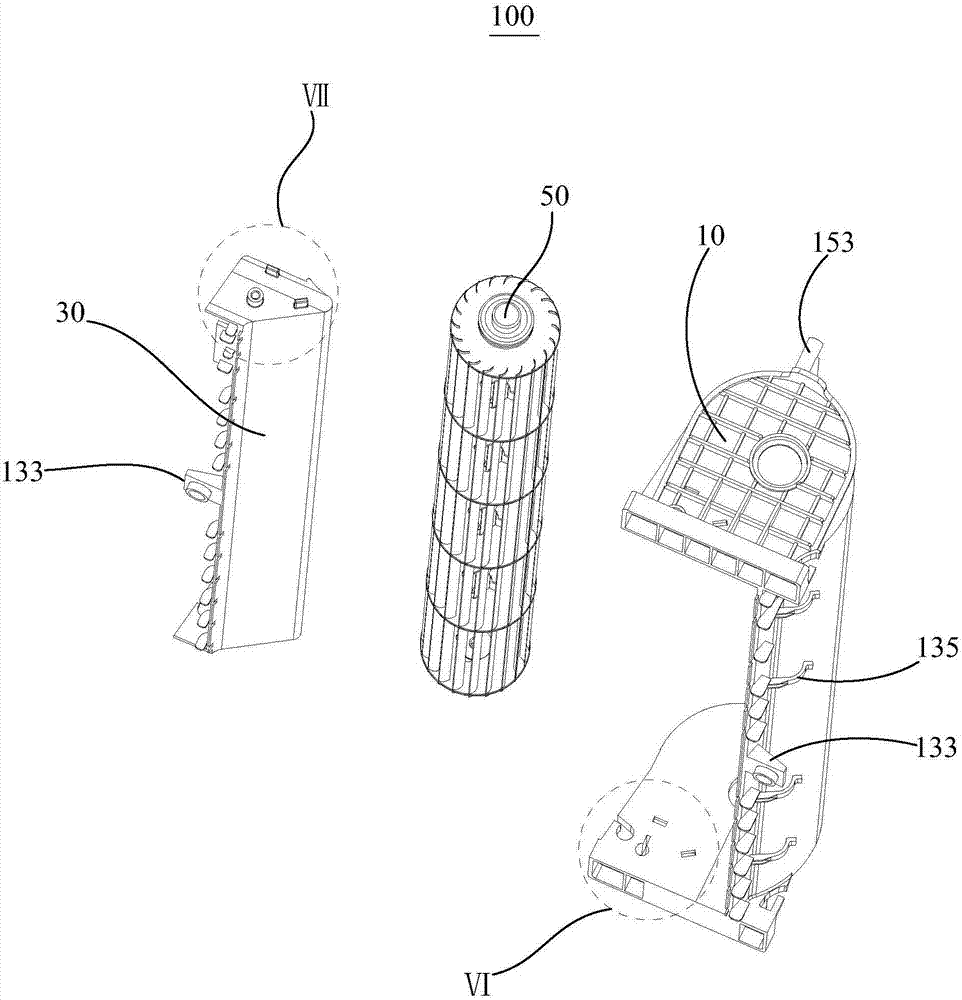

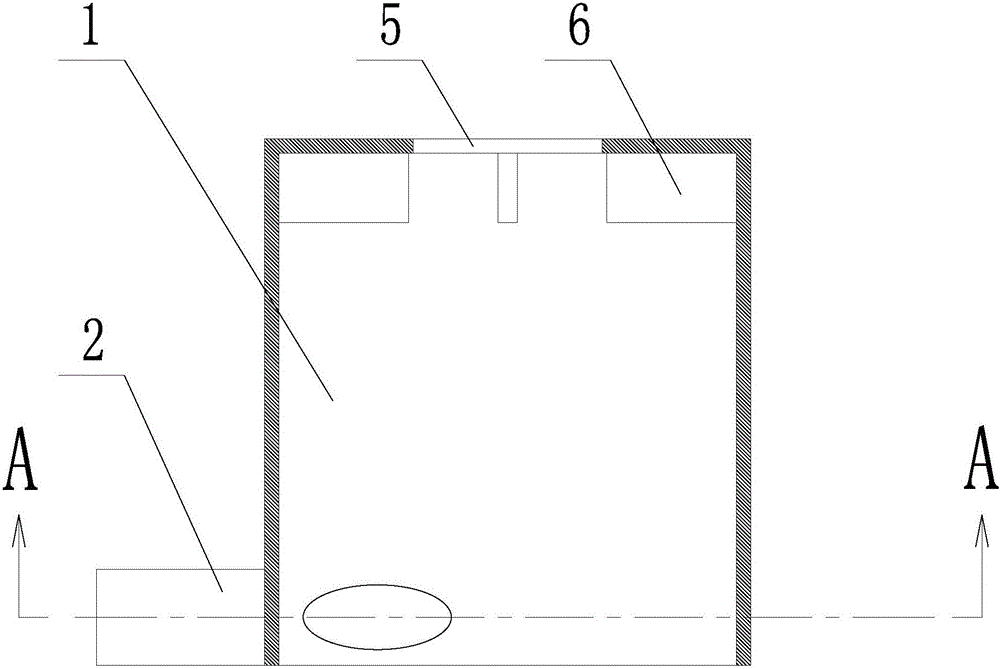

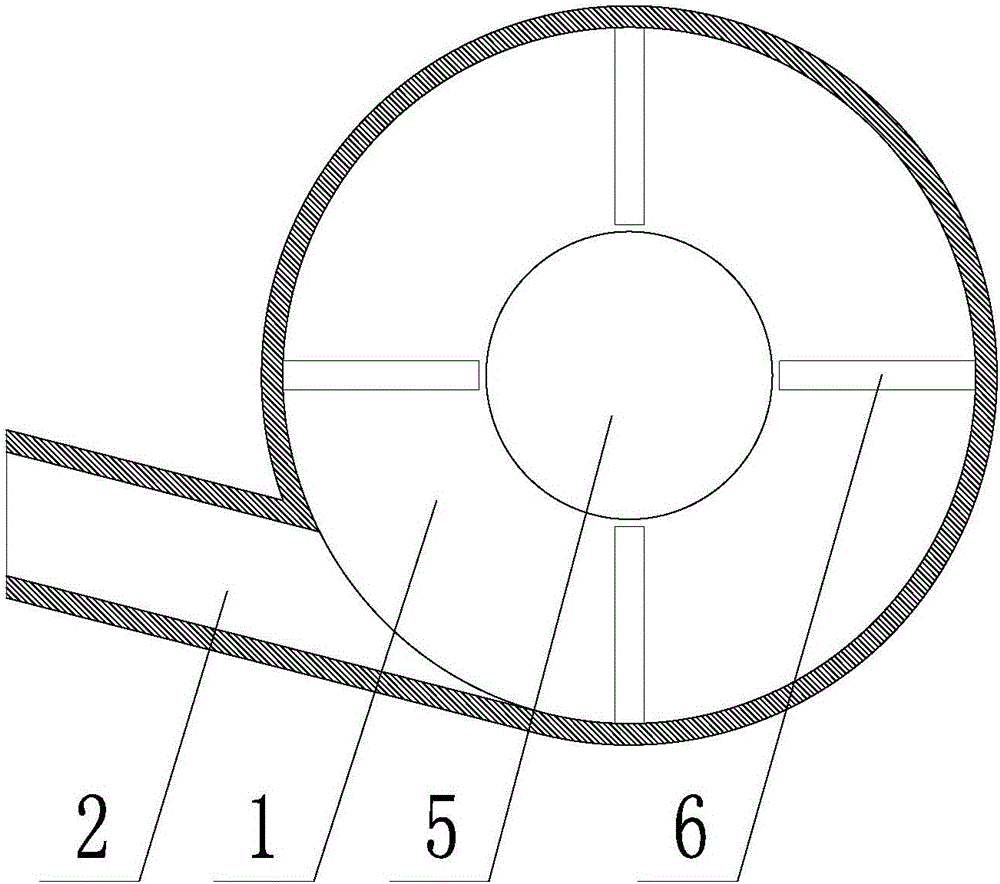

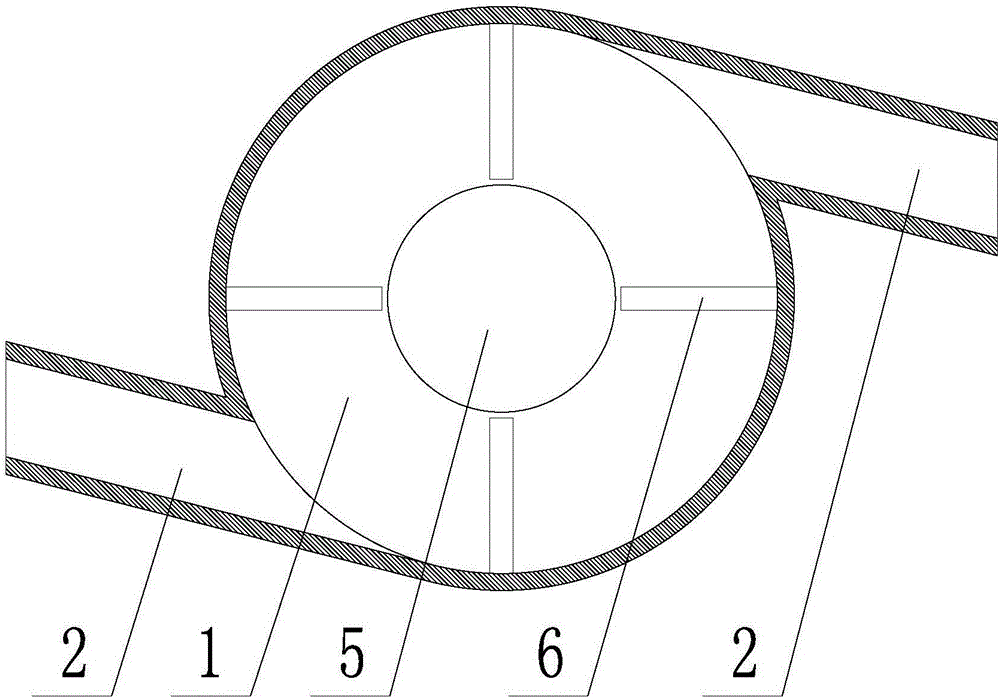

Air channel assembly and fan heater

InactiveCN107166496AReduce shockImprove air intake conditionsDucting arrangementsPump componentsAir volumeTongue part

The invention discloses an air channel assembly and a fan heater which uses the air channel assembly. The air channel assembly comprises a volute, a volute tongue and a throughflow wind wheel, wherein the volute tongue is arranged on the volute and forms an air channel together with the volute, and an air inlet and an air outlet are formed in the air channel; the throughflow wind wheel is arranged in the air channel so as to lead airflow to the air channel from the air inlet and blow the airflow in the air channel out of the air outlet; the volute comprises a first volute tongue part, the volute tongue comprises a second volute tongue part, and the first volute tongue part and the second volute tongue part are respectively located on both sides of the air inlet; and on the same cross section, an included angle A of a connecting line from the root M of the first volute tongue part to the axis O of the throughflow wind wheel and a connecting line from the root N of the second volute tongue part to the axis O of the throughflow wind wheel is 110 degrees to 170 degrees. According to the technical scheme of the air channel assembly, the air volume of the fan heater can be increased.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

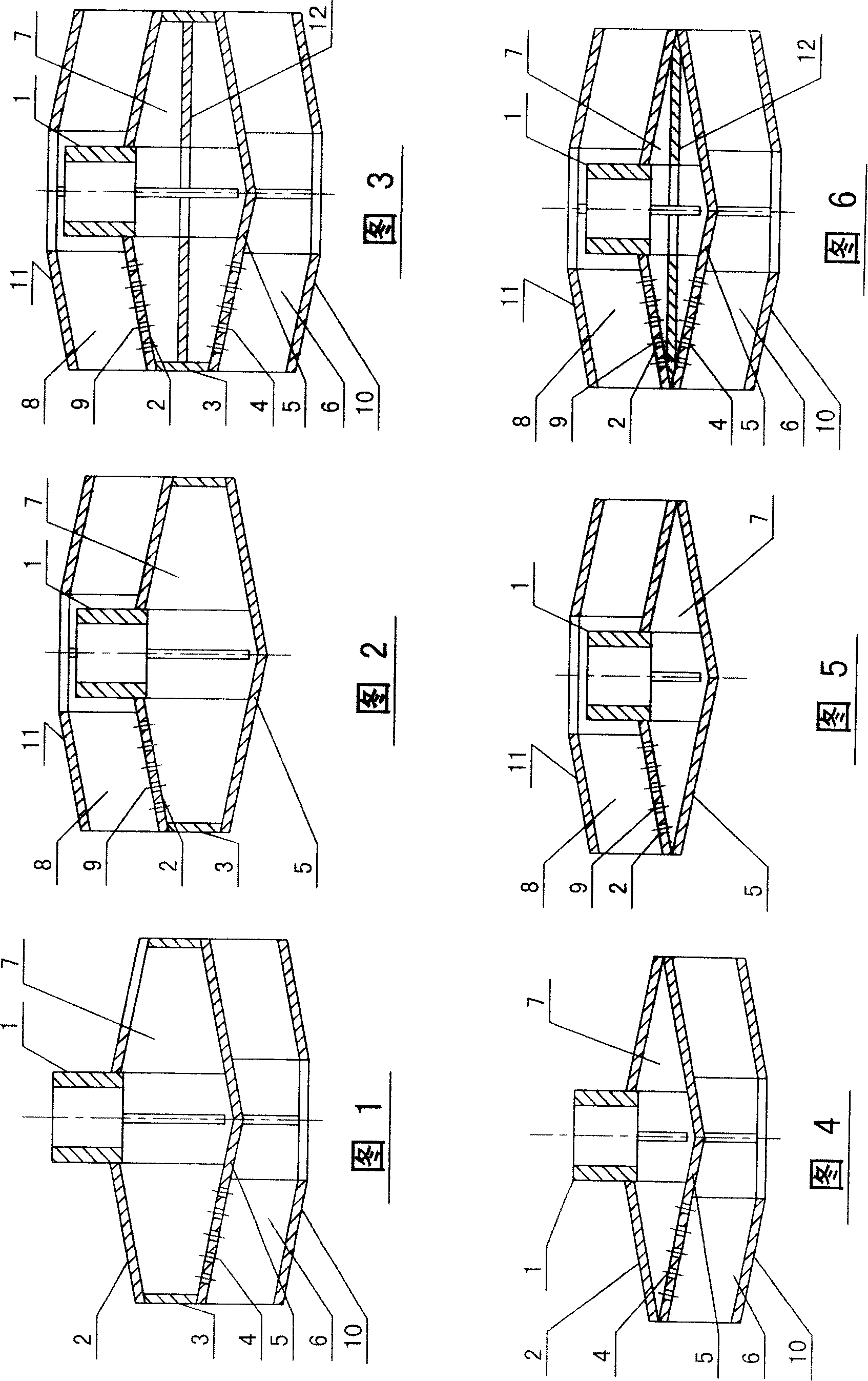

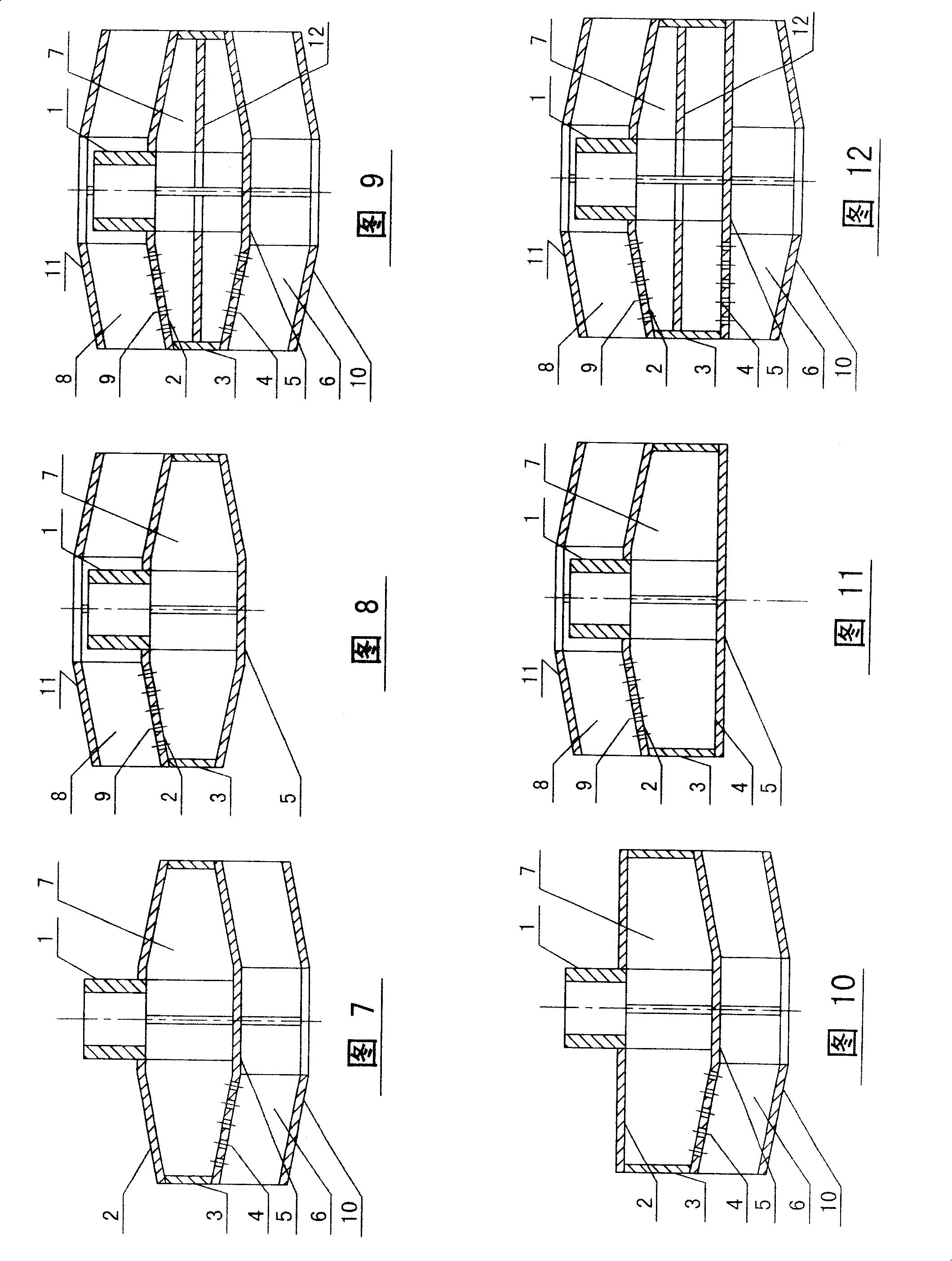

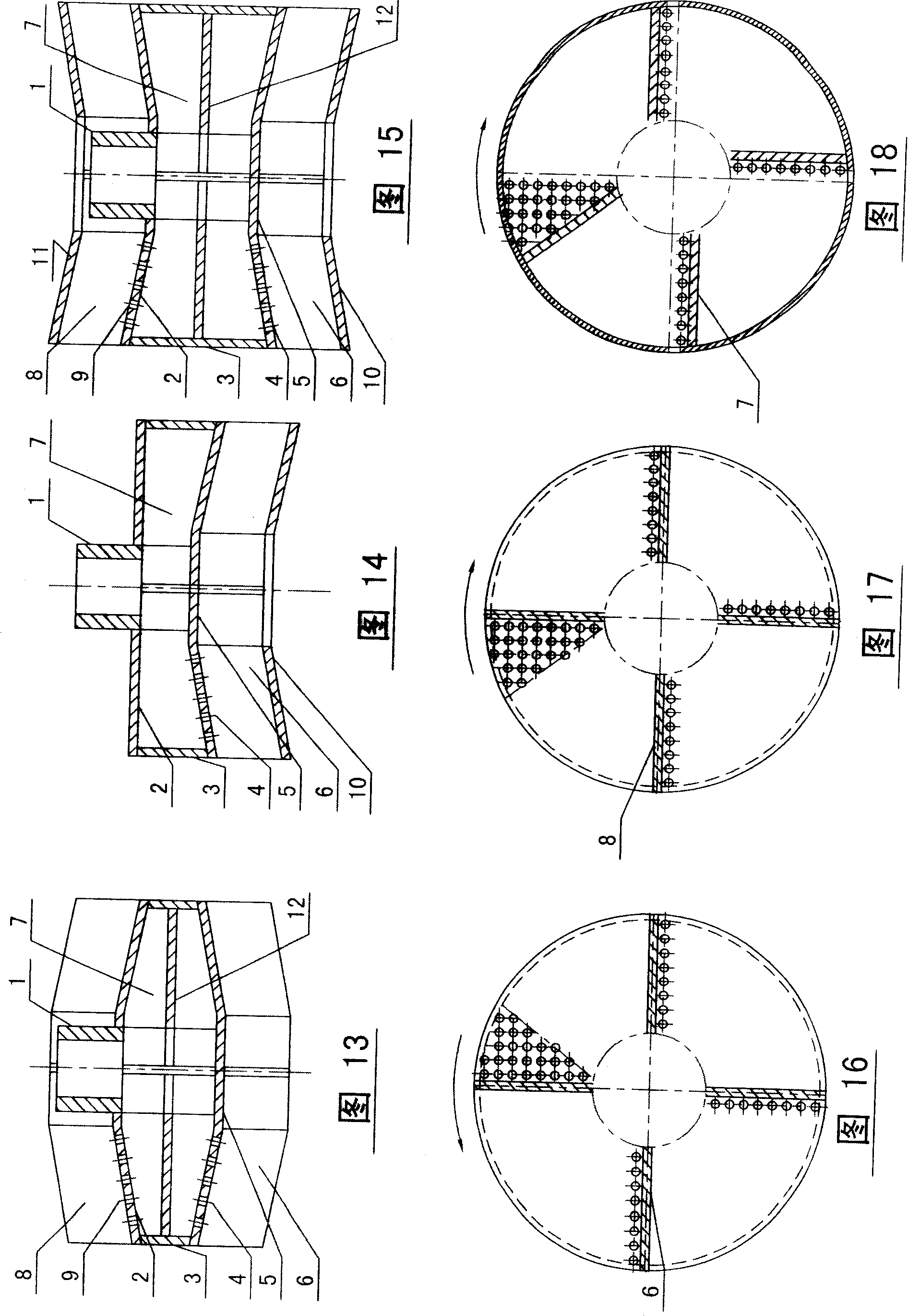

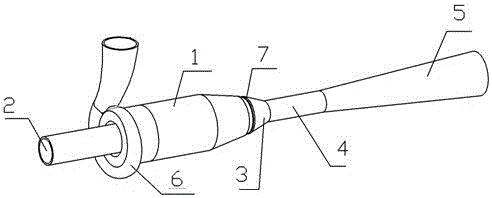

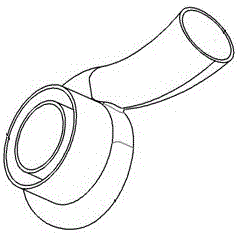

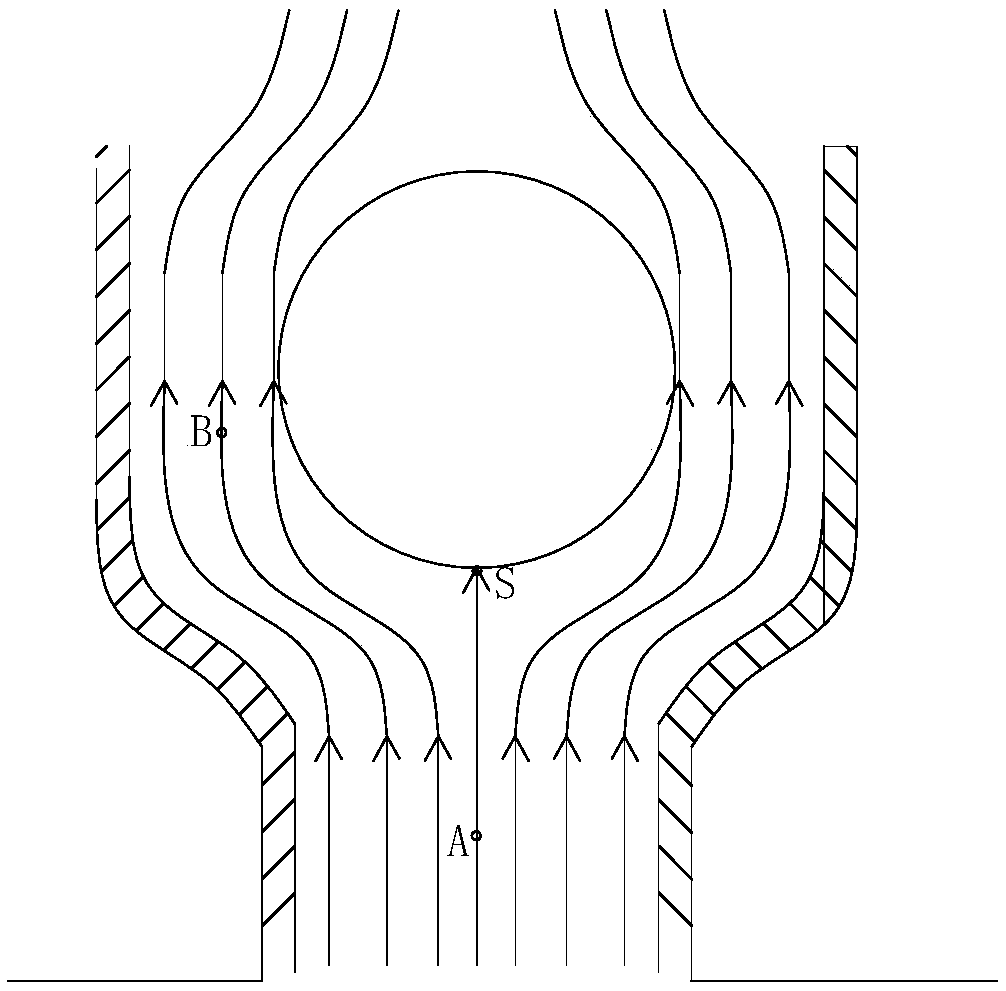

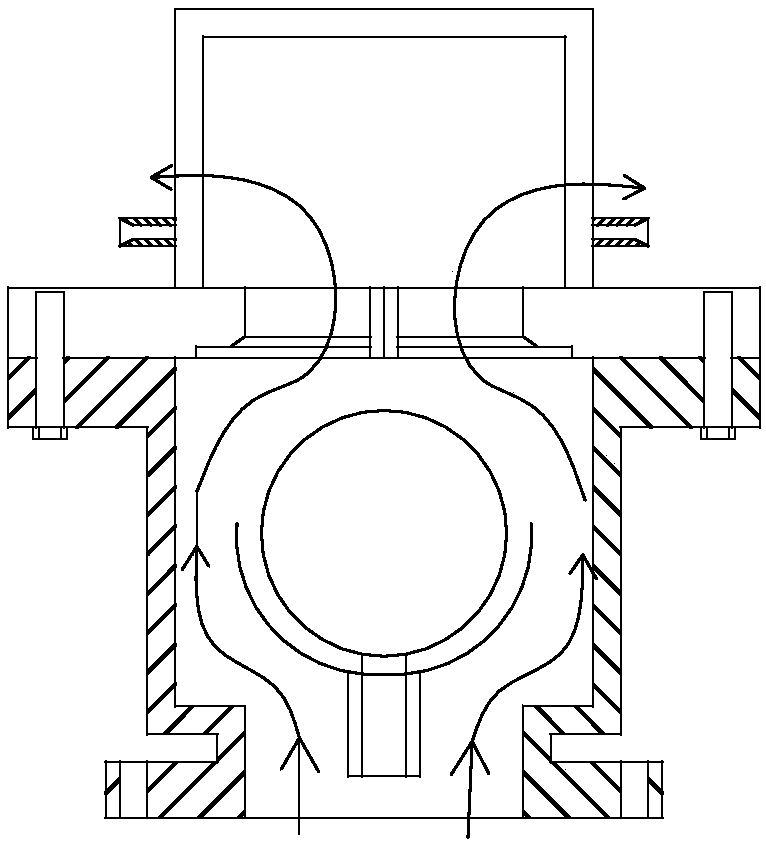

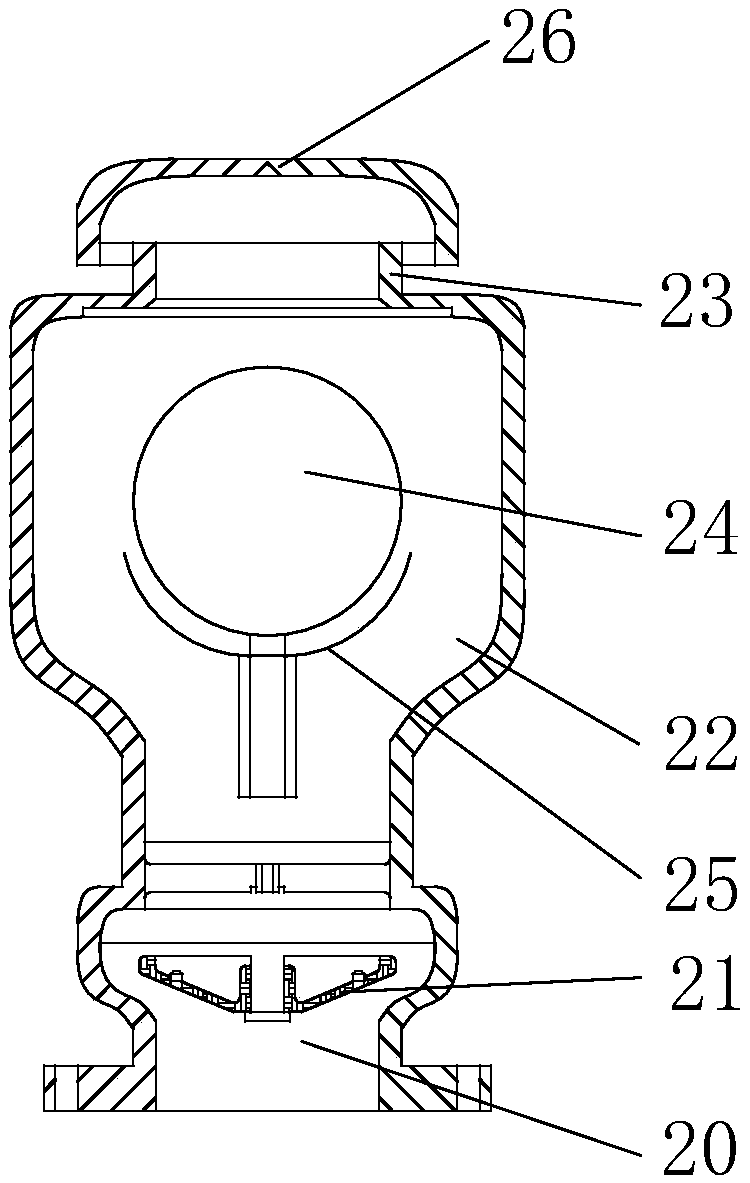

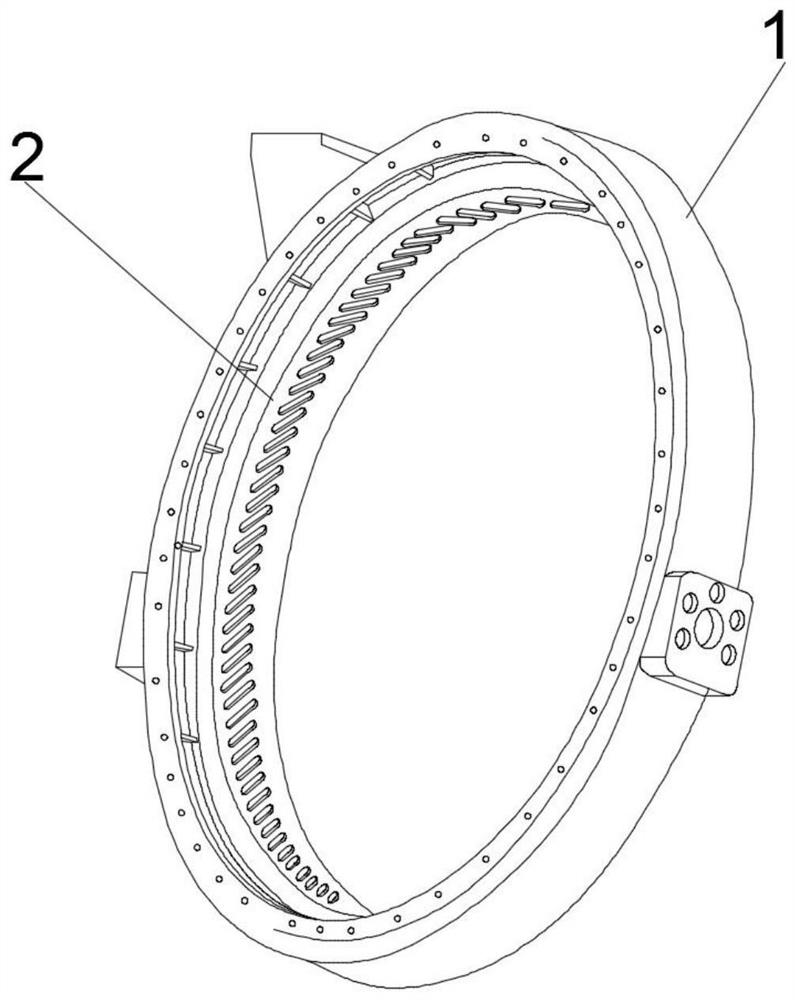

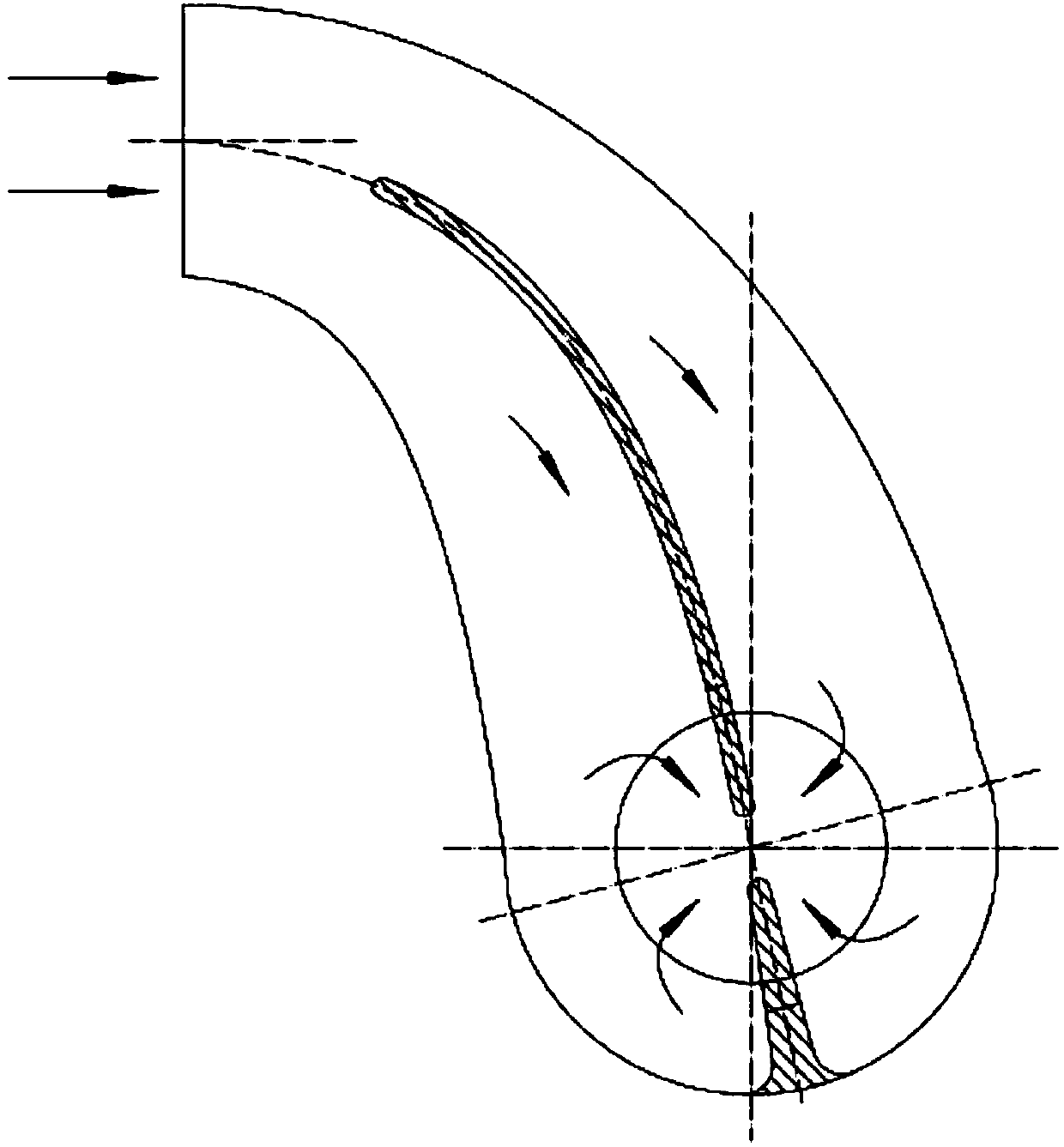

Nozzle flow rotating generation device and nozzle flow rotating continuous casting method

The invention discloses a nozzle flow rotating generation device and a nozzle flow rotating continuous casting method. The device comprises a cylinder type flow rotating generator and a cylinder type flow rotating tundish; the cylinder type flow rotating generator is mounted in a traditional continuous casting tundish, and an inner cavity of the traditional continuous casting tundish is communicated with an immersion type nozzle through the cylinder type flow rotating generator; the cylinder type flow rotating tundish has two mounting modes; according to the first mode, the cylinder type flow rotating tundish and the traditional continuous casting tundish are used in a cooperated manner, the cylinder type flow rotating tundish is mounted on the outer portion of the traditional continuous casting tundish, and the traditional continuous casting tundish is communicated with the immersion type nozzle through the cylinder type flow rotating tundish; and according to the second mode, the cylinder type flow rotating tundish is independently used, and a nozzle of a steel ladle is communicated with the immersion type nozzle directly through the cylinder type flow rotating tundish. The method comprises the steps that before continuous casting, according to the continuous casting technology, the nozzle flow rotating generation device is selected, then, the device and the traditional continuous casting tundish are assembled, during continuous casting, under the effects of molten steel gravity and tangent line entrances, molten steel generates rotating flowing, and molten steel in the immersing type nozzle generates rotary flowing.

Owner:NORTHEASTERN UNIV

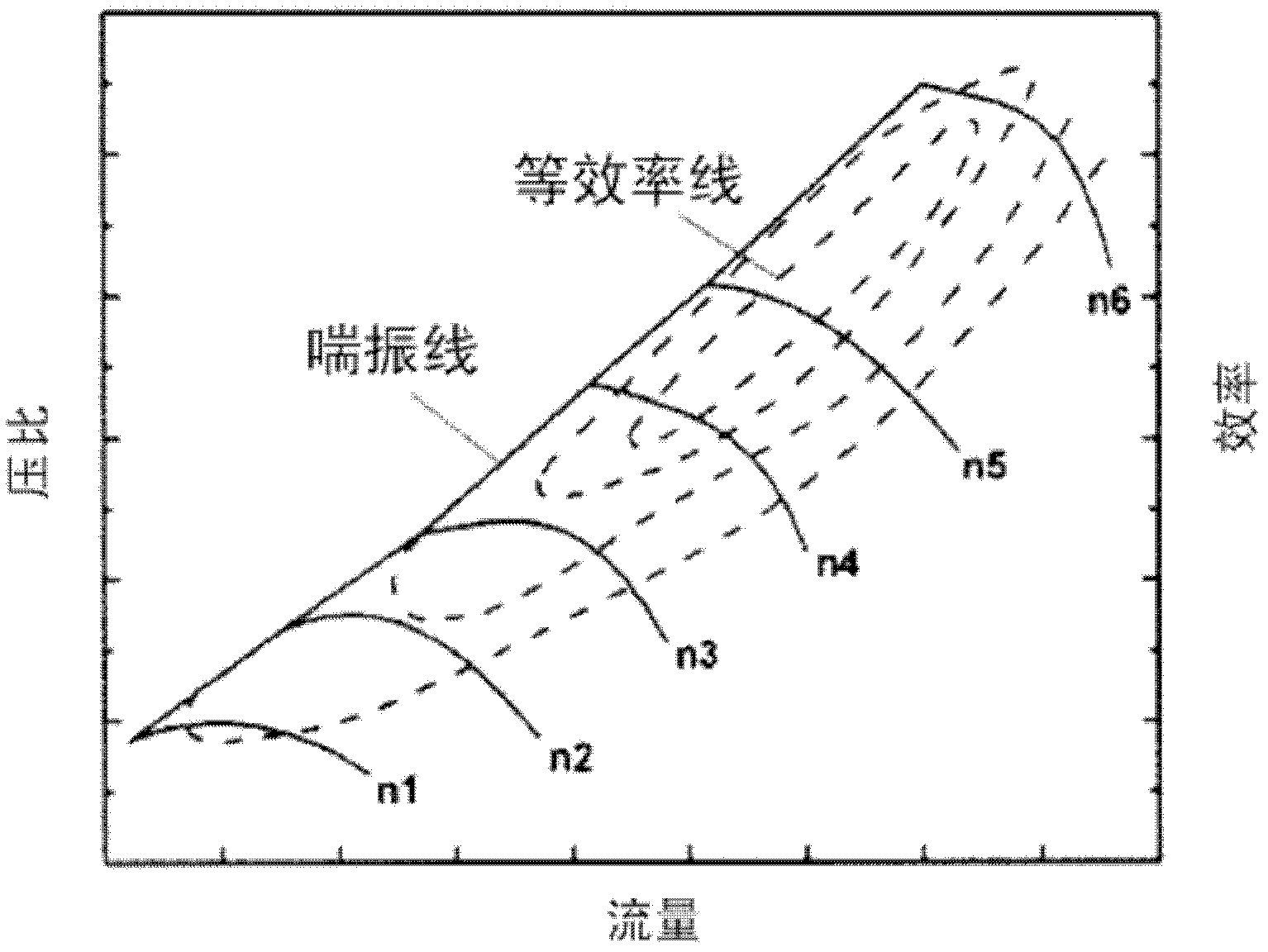

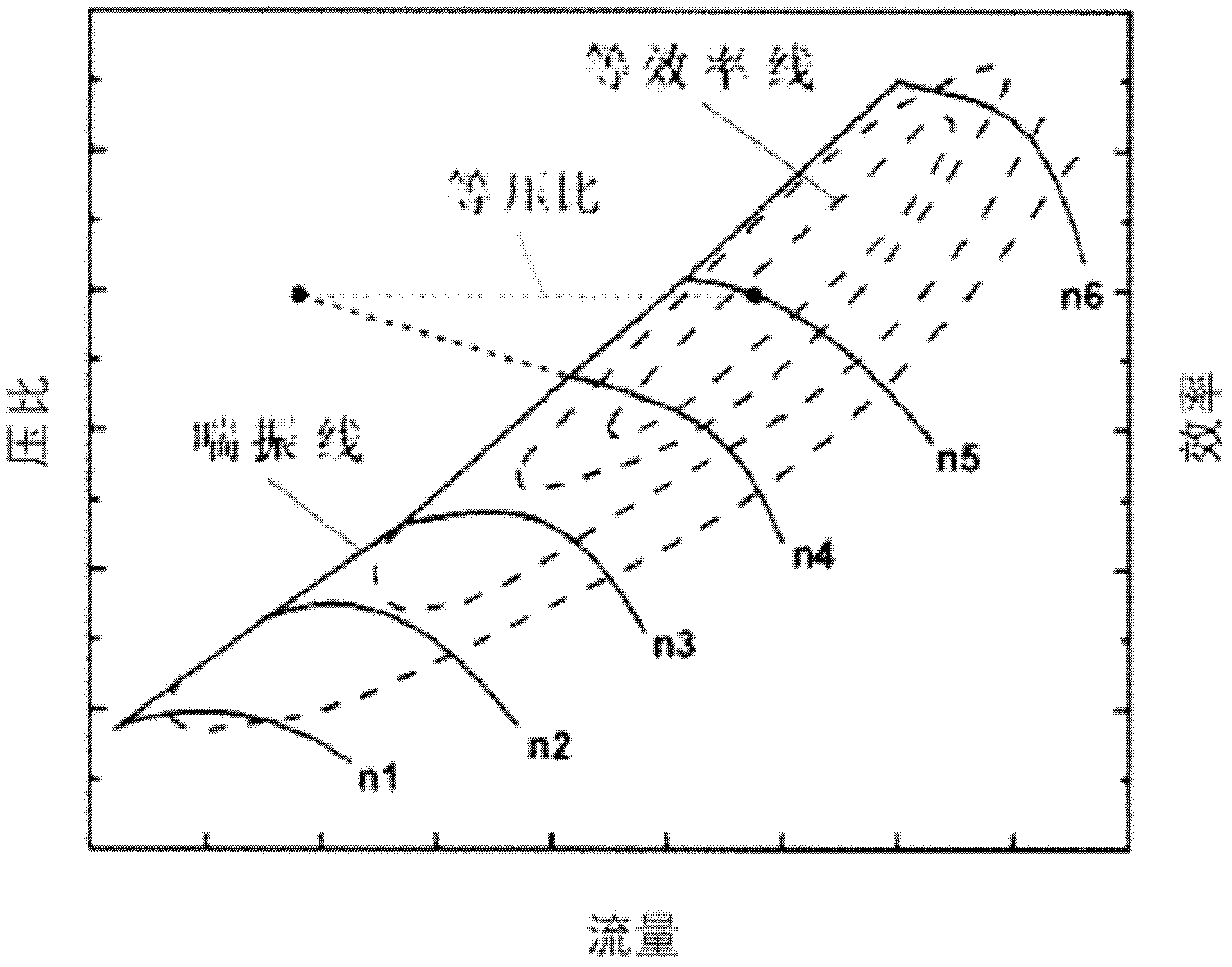

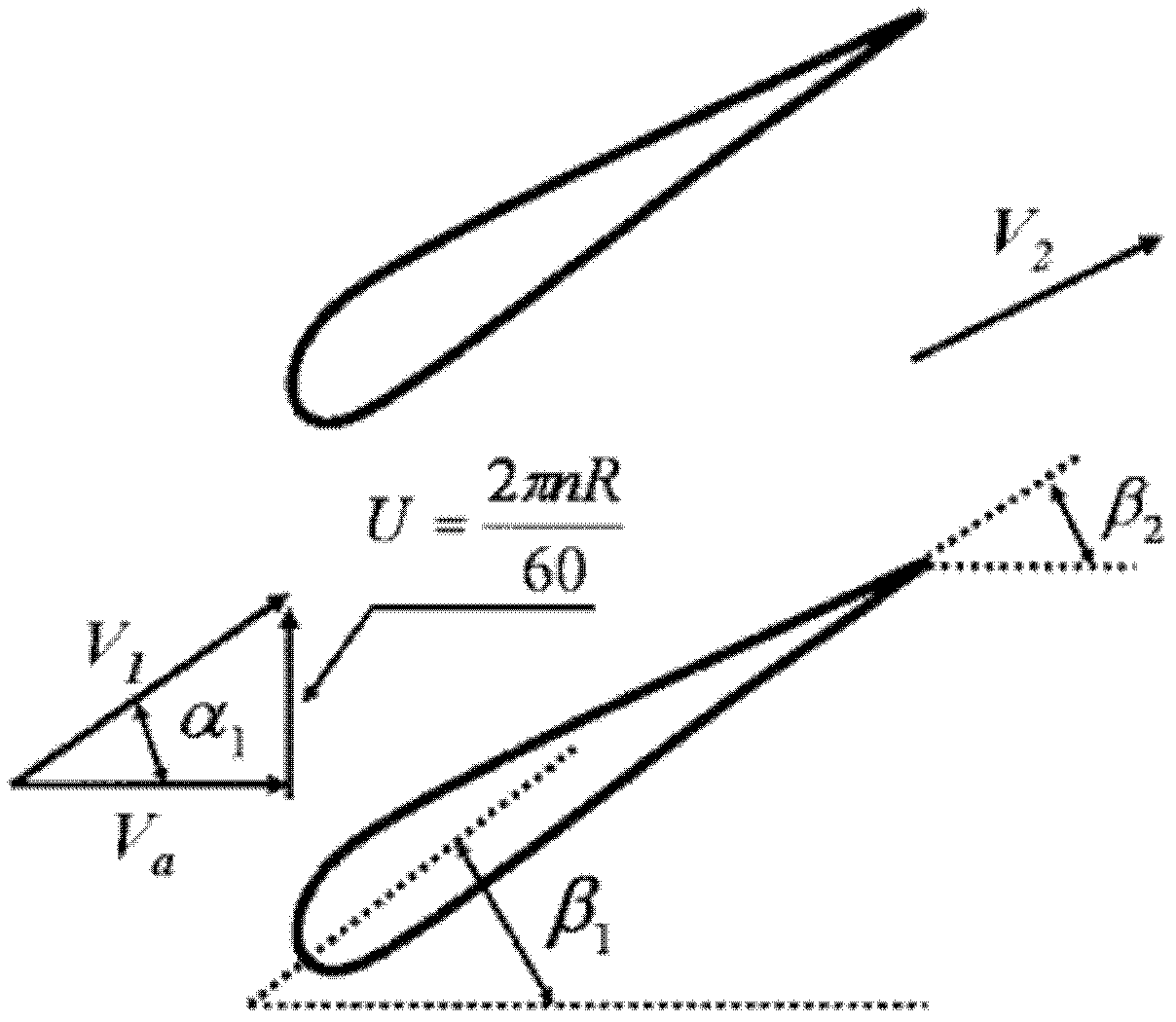

Gas turbine compressor casing anti-surge structure and surge margin evaluation method thereof

InactiveCN112160943AImprove flow statusReduce angle of attackPump componentsDesign optimisation/simulationEngineeringInlet flow

The invention discloses a gas turbine compressor casing anti-surge structure and a surge margin evaluation method thereof. The gas turbine compressor casing anti-surge structure comprises a compressorcasing, wherein a casing treatment section is arranged on the front portion of the compressor casing, the casing treatment section comprises an anti-flow-loss section inner cavity, an anti-flow-losssection inner ring is arranged on the inner side of the anti-flow-loss section inner cavity, an axial chute is formed in the anti-flow-loss section inner ring and communicates with a backflow cavity in the anti-flow-loss section inner cavity, and a radial baffle is arranged in the anti-flow-loss section inner cavity; the axial chute rotates by 90 degrees along the radius line of the circle where the axial chute is located, is parallel to the blade chord line of a rotor blade, and rotates by 45 degrees along the axis of the circle where the axial chute is located; by changing the structure of the axial chute, the air inlet amount and the air inlet flowing condition are changed; and meanwhile, an exhaust section is optimized, the axial speed is increased, the flow coefficient is increased, the flowing state with the too large top attack angle is improved, stability expansion is effectively carried out, and the beneficial effects of effectively reducing the increased air amount, reducingthe attack angle at the blade tip of a movable blade and reducing the flow of a stall point are achieved.

Owner:NAVAL UNIV OF ENG PLA

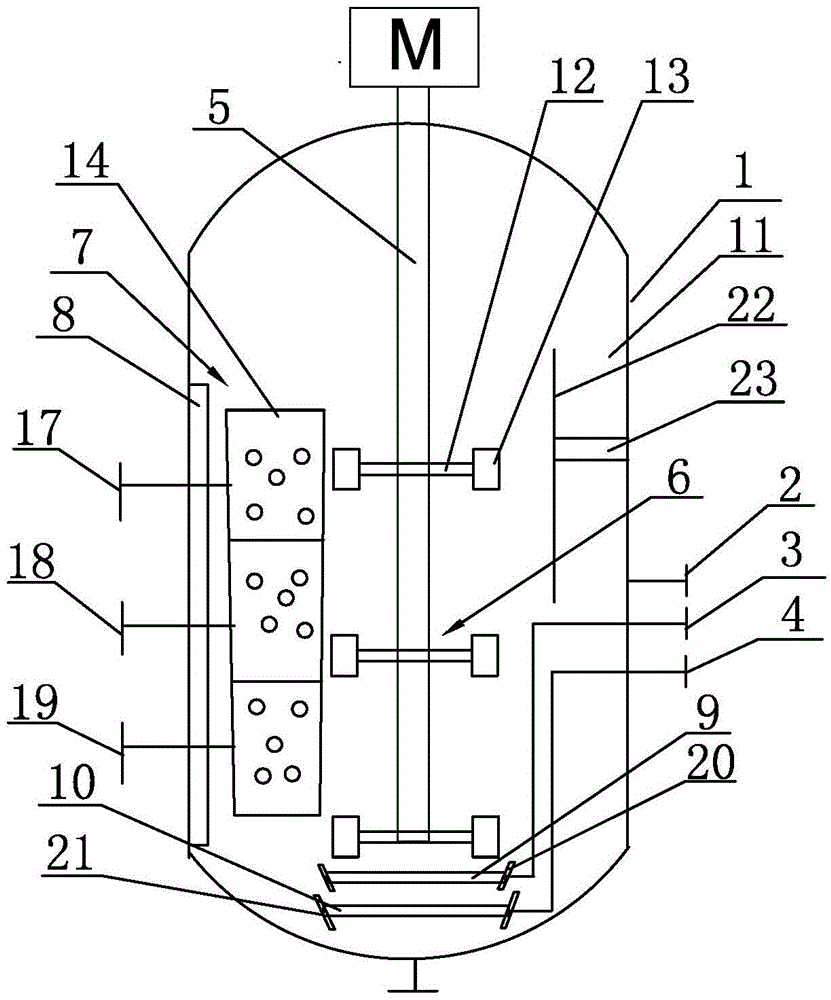

Swept-back high-efficiency hot-plate diversion rectification multiphase reaction kettle

ActiveCN104128133AIncrease contact timeIncrease contact areaHydrocarbon by hydrogenationChemical industryLiquid jetTemperature control

The invention discloses a swept-back high-efficiency hot-plate diversion rectification multiphase reaction kettle. The reaction kettle comprises a cylindrical kettle body which is arranged vertically. A discharge port, a liquid feeding port, and a gas feeding port are sequentially arranged from top to bottom on the side wall of the kettle body. A central shaft connected with an outside motor is arranged vertically in the kettle body. The reaction kettle is characterized in that three layers of vertically arranged swept-back half-pipe turbo agitators are arranged on the central shaft. 6-10 high-efficiency heat-exchange diversion rectification devices are horizontally uniformly distributed between the outer end of the swept-back half-pipe turbo agitators and the inner wall of the kettle body. 4-6 sheets of side wall diversion full baffles are uniformly distributed on the inner wall of the kettle body. A liquid jet distributor connected with the liquid feeding port and a gas jet distributor connected with the gas feeding port are arranged on the bottom of the kettle body. An overflow zone is arranged in the kettle body. Reaction products pass through the overflow zone and is collected from the discharge port. The swept-back high-efficiency hot-plate diversion rectification multiphase reaction kettle has the advantages of good multiphase system mixing effect, large heat-exchange area, and precise temperature control.

Owner:SEDIN NINGBO ENG

Culture medium for producing virginiamycin through streptomyces virginiae fermentation and feeding method of culture medium

ActiveCN104480174ALow market priceIncrease productionMicroorganism based processesFermentationMicrobiologyVinasse

The invention relates to a culture medium for producing virginiamycin through streptomyces virginiae fermentation and a feeding method of the culture medium. A seed culture medium comprises rice vinasse and low-temperature pressed soybean cake powder; a fermentation culture medium comprises rice vinasse, low-temperature pressed soybean cake powder, Dow macroporous ion exchange resin and a nonionic surfactant. Through the adoption of the culture medium and the feeding method, the cost problem of raw and supplemental materials is solved, the environment influence on the sources of the raw and supplemental materials is reduced to the greatest degree, the sources of the raw and supplemental materials are guaranteed to be fed sufficiently, the stable and efficient production of the virginiamycin is achieved, and meanwhile, the fermentation unit can be increased by using the culture medium and a culturing method.

Owner:宁夏泰瑞制药股份有限公司

Emptying device and emptying method for bullet explosives

The invention relates to an emptying device and an emptying method for bullet explosives. The emptying device comprises an explosive-emptying sleeve which is arranged horizontally, a recycle pool with an explosive discharge pipe arranged at the bottom and explosion suppression devices. The explosive-emptying sleeve includes an inner pipe and an outer pipe, and an explosive-collecting cavity is positioned between the inner pipe and the outer pipe. Nozzles are uniformly arranged on the top face pipe wall of the inner pipe at intervals. Explosive-emptying holes are formed in the positions, corresponding to the nozzles, of the top face pipe wall of the outer pipe. A bullet supporting seat with a through hole is arranged on the outer edge of each explosive-emptying hole. One end of the inner pipe is connected with a fluid control system and a supply system through pipes. Washing and heating operations are simultaneously carried on the explosives through hot water or steam to make the explosives be stripped and fused, the explosives then flow into the explosive-collecting cavity with water and finally flow into the recycle pool. The emptying device for the bullet explosives solves the problems that an existing explosive-emptying device is bad in applicability and pollutes the environment. The emptying method is both efficient and safe, and is suitable for emptying TNT explosives, TNT nitronaphthalene composite explosives and RDX composite explosives.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

Double-outlet multipurpose external mixing type self-priming pump with quasi-spiral suction chamber

PendingCN107588008AImprove self-priming performanceImprove hydraulic performancePump componentsPriming pumpAgricultural irrigationPetrochemical

The invention provides a double-outlet multipurpose external mixing type self-priming pump with a quasi-spiral suction chamber. The double-outlet multipurpose external mixing type self-priming pump mainly comprises an inlet flange, a pump body, an impeller, an air-liquid separating pipe, a rear cover, a suspension body part, an outlet flange and a flange cover, wherein the pump body is formed by the quasi-spiral suction chamber, a spiral compression chamber and a liquid storage chamber through integral casting and is provided with double outlets and the like. The hydraulic performance of the pump is effectively improved while the self-priming performance of the self-priming pump is improved, the flow losses of fluid media in a suction chamber and a water compressing chamber are remarkablyreduced, and the double-outlet multipurpose external mixing type self-priming pump has the advantages of being high in efficiency and reliability, compact in structure, convenient to install and maintain and multipurpose, serving as a pipeline self-priming pump accessed horizontally only by slightly adjusting an installing mode and the like, is suitable for the fields of agricultural irrigation and drainage, river and pond breeding, municipal drainage, petrochemical metallurgy and the like and can be installed on a movable pump truck for fire-fighting operation and the like.

Owner:JIANGSU GUOQUAN PUMP MFG CO LTD

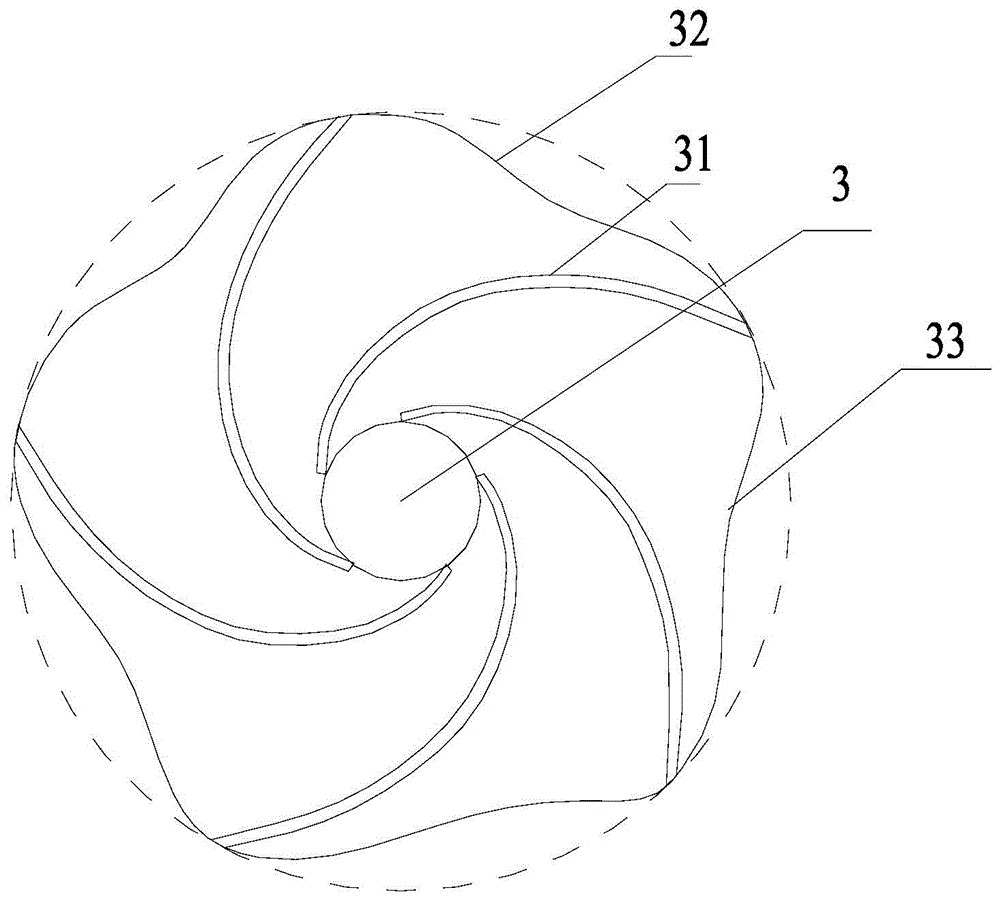

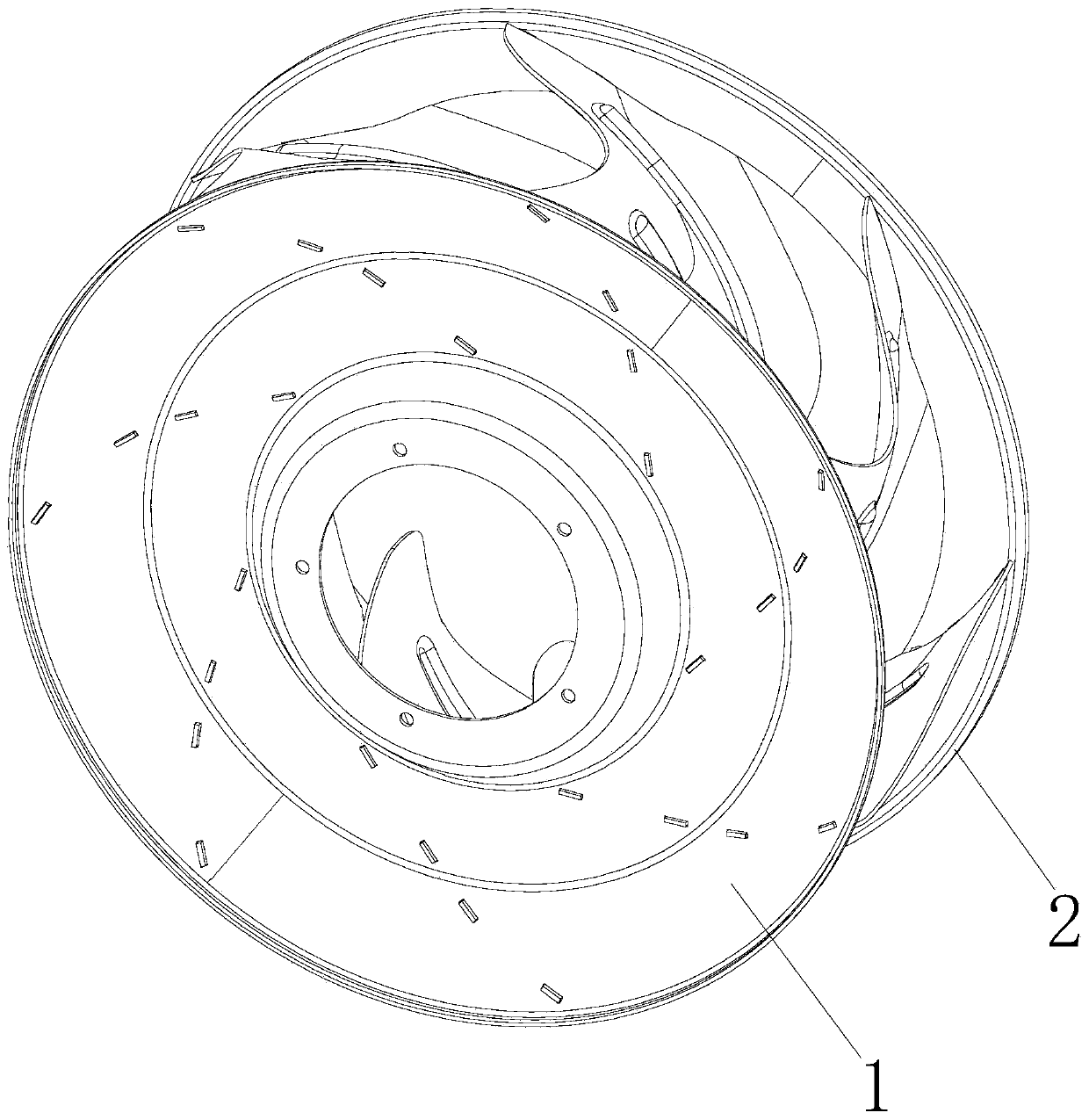

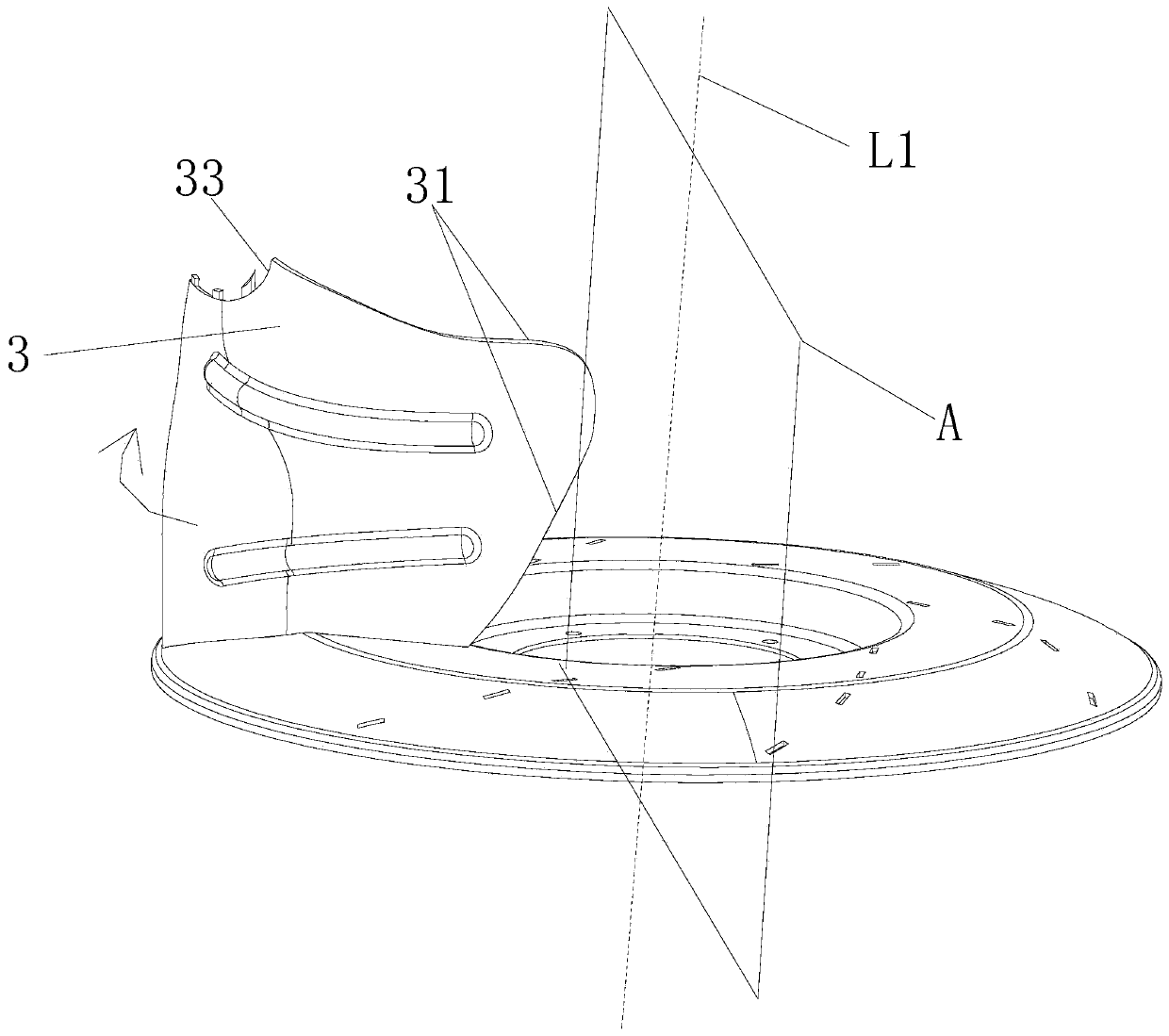

Backward centrifugal wind wheel

PendingCN109899319AImprove aerodynamic performanceReduce aerodynamic noisePump componentsPumpsLeading edgeImpeller

The invention discloses a backward centrifugal wind wheel. A three-element twisted blade(3) is adopted, a leading edge(31) is rotated along the axis L1 of the wind wheel is intersected with the meridian plane A to form a curve L2, the distance between each point on the curve L2 and the axis L1 of the wind wheel is gradually reduced from the diameter D0 to the axis L1 of the wind wheel, and then the distance is gradually increased from small to small; and the trailing edge (32) and the projection re-plane formed on the cylindrical surface B is unfolded to form a curve L3, the coordinates of thefive curvature inflection points a, b, c, d and e in the curve L3 are coordinates (xa, ya), (xb, yb), (xc,yc), (xd,yd), (xe,ye) wherein the total length of the projection is y, the total width is x.The flow in the whole flow channel is optimized, the pneumatic performance of the impeller is greatly improved, the pneumatic noise of the impeller is reduced, and the noise quality of the impeller isimproved.

Owner:ZHONGSHAN EBS TECH CO LTD

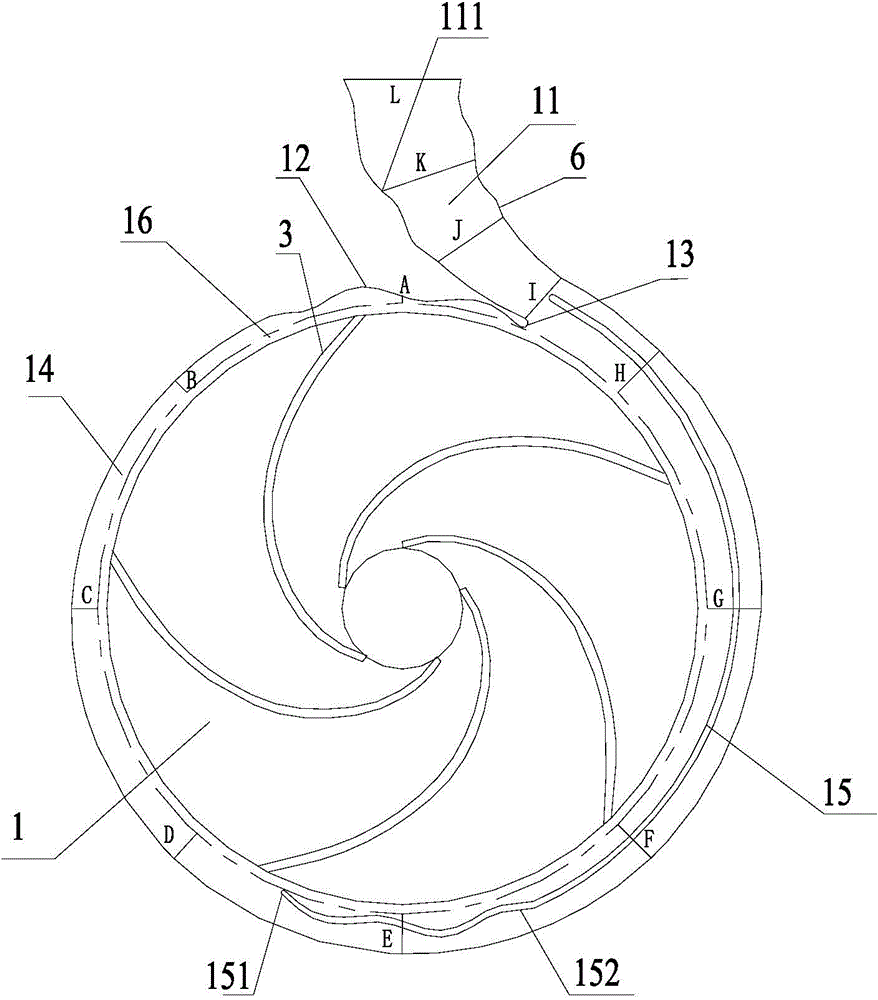

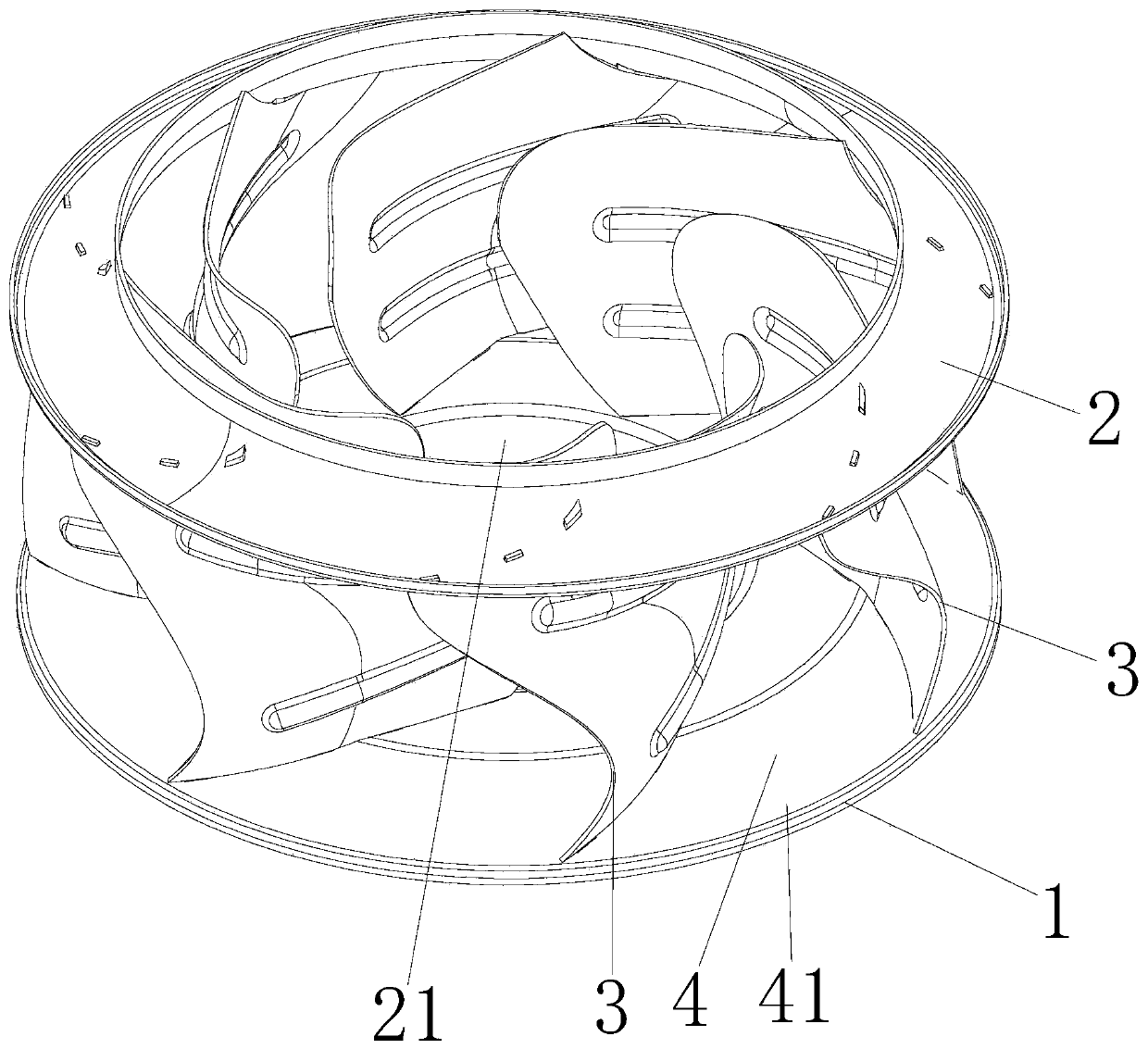

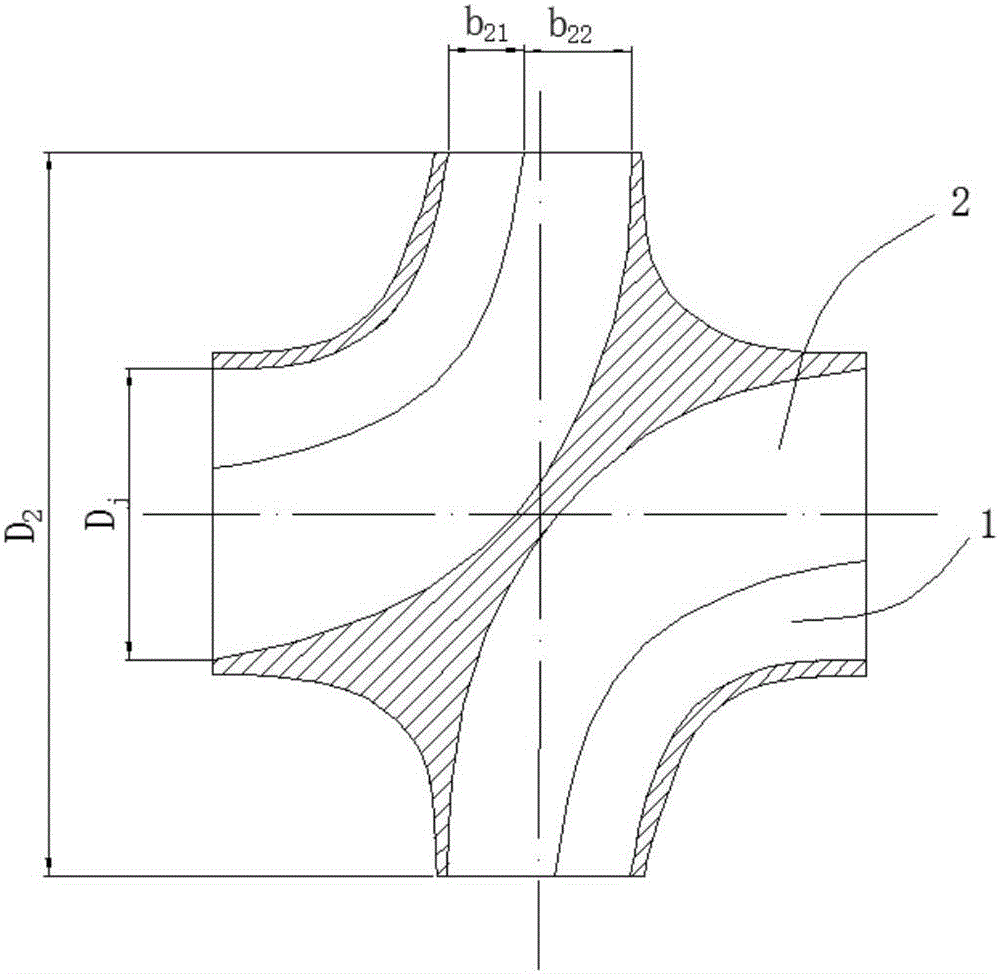

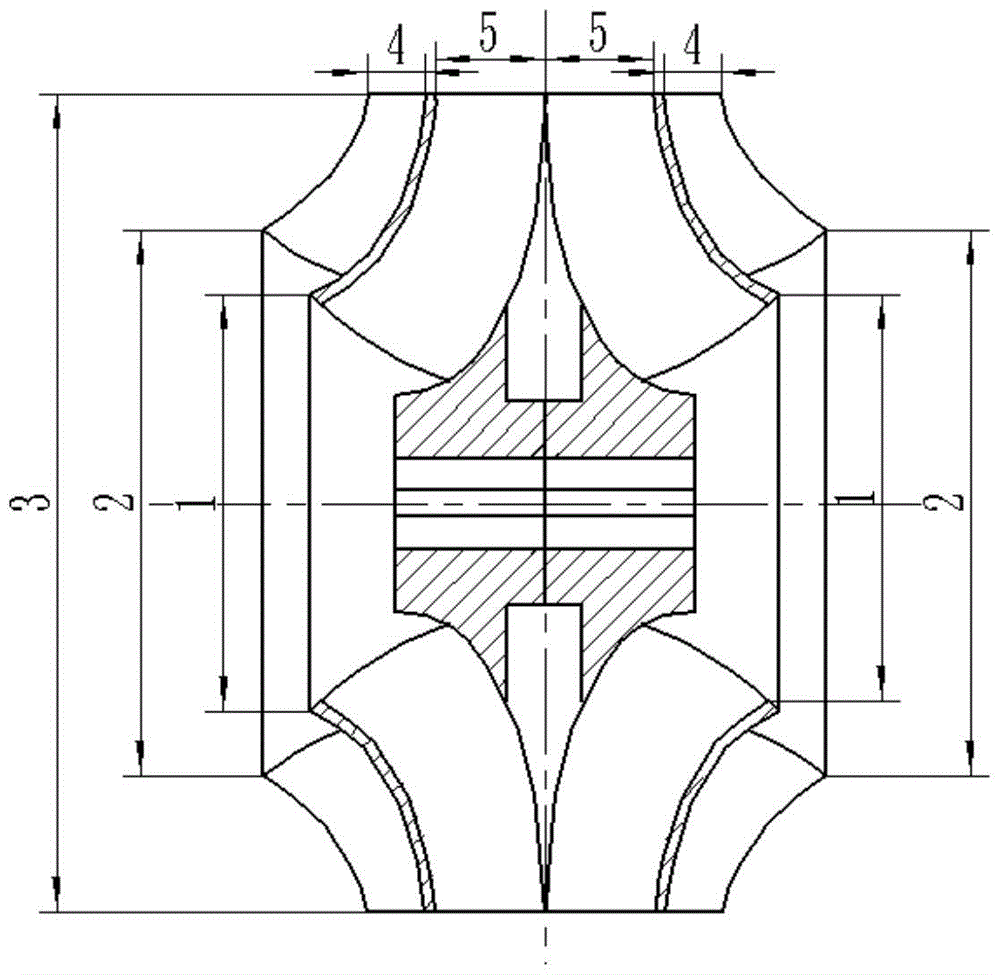

Double-suction double-layer double-channel impeller and design method thereof

ActiveCN106837855AImprove flow statusReduce problems such as excessive axial forcePump componentsPumpsImpellerOff design

The invention provides a double-suction double-layer double-channel impeller. The double-suction double-layer double-channel impeller is characterized in that the double-channel impeller is of an asymmetric double-suction structure, a left channel and a right channel are distributed in a 180-degree mirror image manner, and each channel is a double-layer impeller body; each channel of the double-channel impeller corresponds to a suction inlet, and the suction inlets are symmetrically arranged on to two sides of the double-suction double-layer double-channel impeller; each channel of the double-channel impeller comprises an upper layer and a lower layer, the layer close to a channel suction inlet cover plate is a first layer of channel, and the layer away from the channel suction inlet cover plate is a second layer of channel, the first layer of channel and the second layer of channel are different in axial width, the circumferential width of the first layer of channel is larger than that of the second layer of channel, and outer channels of the two layers of channels are different in streamline equation and inlet angles. Efficiency and non-blocking performance can be improved greatly, the problem that the conventional double-channel pump is overlarge in axial force is solved, and efficiency of the double-suction double-layer double-channel impeller at off-design condition points is increased greatly.

Owner:JIANGSU UNIV

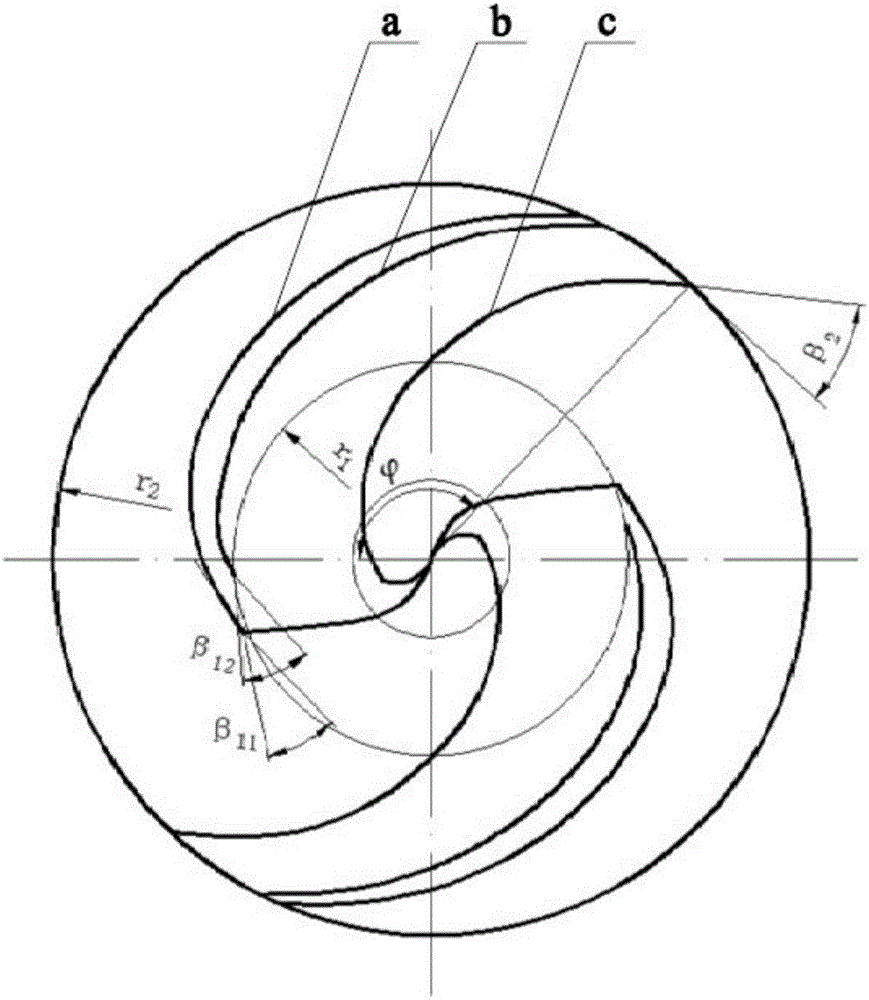

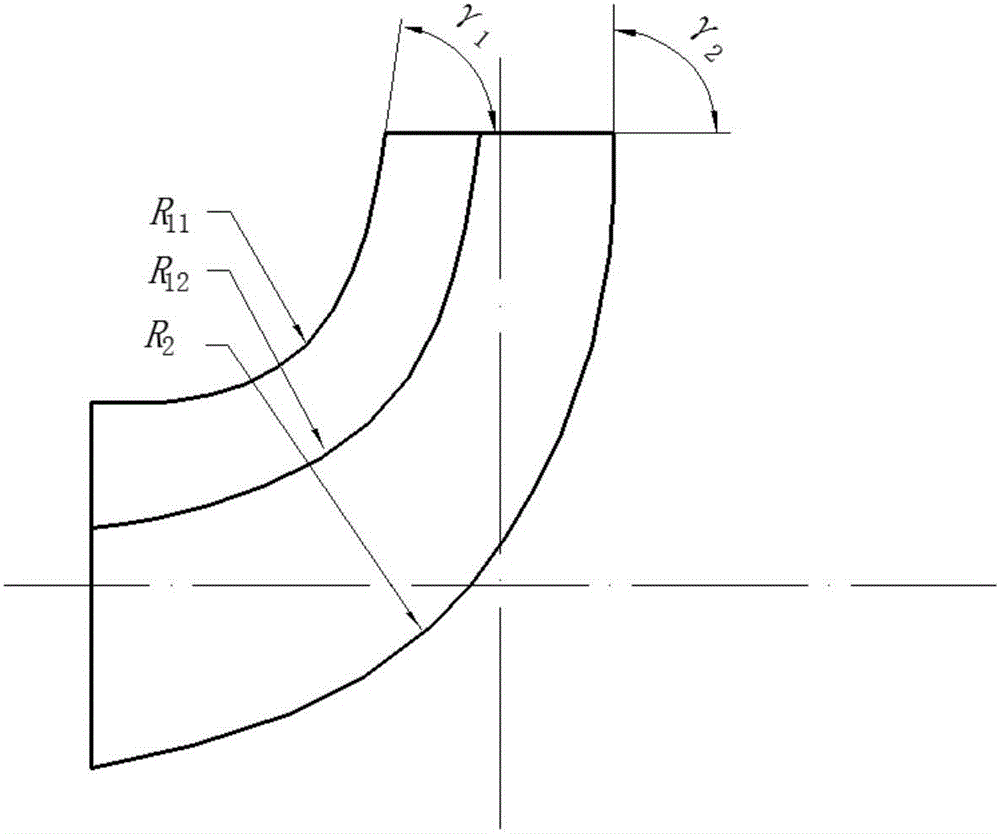

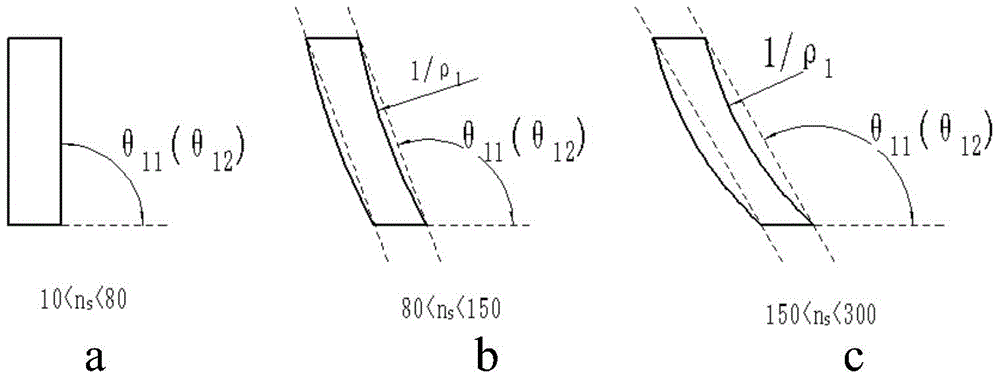

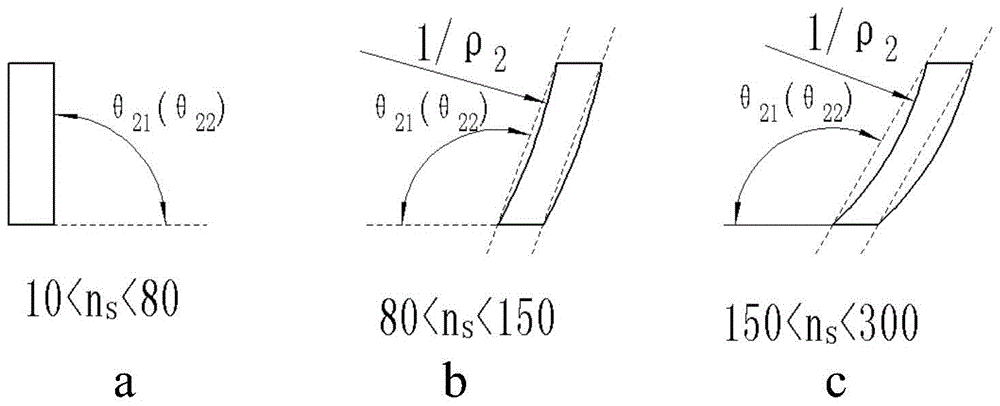

Double-suction multi-flow-channel impeller and design method thereof

ActiveCN105756991AImprove flow statusImprove efficiencyPump componentsRadial flow pumpsImpellerEconomic benefits

The invention relates to a double-suction multi-flow-channel impeller and a design method thereof, in particular to a hydraulic design method of a centrifugal double-suction multi-flow-channel impeller.Important impeller design parameters such as the inlet diameter Dj1 of an inner impeller body, the inlet diameter Dj2 of an outer impeller body, the blade length L1 of the inner impeller body, the blade length L2 of the outer impeller body, the inlet blade deflection angle theta 11 of the inner impeller body, the inlet blade deflection angle theta 2 of the outer impeller body, the outlet blade deflection angle theta 12 of the inner impeller body, the outlet blade deflection angle theta 22 of the outer impeller body, impeller inlet edge curvature rho1 and impeller outlet edge curvature rho2, of the impeller are determined through formulas.By means of check of production practice that the design efficiency and design level of a double-suction multi-flow-channel pump are improved greatly, design cost and risks are reduced, and the double-suction multi-flow-channel pump produced according to the design has good use performance and high economic benefits.

Owner:JIANGSU UNIV

Flexible bunching cluster electrode jet flow electrolytic machining method and device

ActiveCN105921832APlay a role in drainageImprove localizationMachining electrodesElectrical-based machining electrodesElectrochemical responseElectrolysis

The invention discloses a flexible bunching cluster electrode jet flow electrolytic machining method. The method comprises the steps that a tool electrode is connected with a negative pole of a power source, a workpiece is connected with a positive pole of the power source, and flexible electrode wires of the tool electrode extend out of an electric jet flow nozzle; low-voltage high speed electrolyte enters an upper portion electrolyte cavity inside the electric jet flow nozzle through an electrolyte supplying pipe, then flows through a splitter plate in the electric jet flow nozzle, is distributed to electrolyte outlets in all the flexible electrode wires, flows out of the electrolyte outlets at the high speed and is involved in an electrochemical reaction occurring between the tool electrode and the workpiece, and the flexible electrode wires are straightened under the action of the friction force of the low-voltage electrolyte flowing out at the high speed; and a machine tool spindle drives the electric jet flow nozzle and the flexible electrode wires to feed toward the workpiece, certain machining clearance is maintained between the workpiece and the flexible electrode wires on the tool electrode, and the low-voltage electrolyte flowing out at the high speed is jetted to the workpiece, so that the required machining morphology is obtained. By means of the flexible bunching cluster electrode jet flow electrolytic machining method and device, locality, stability, precision and efficiency of jet flow electrolytic machining are improved.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com