Method for extracting gas in low air permeability coal layer by pulse fracture anti-reflection

A technology for gas extraction and gas permeability, which is applied in gas discharge, mining fluid, mining equipment, etc., can solve the problems of small effective impact range of drilling, difficult regional overall pressure relief, and inability to control fracturing direction, etc. Effect of gas flow state, improved air permeability, and wide practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

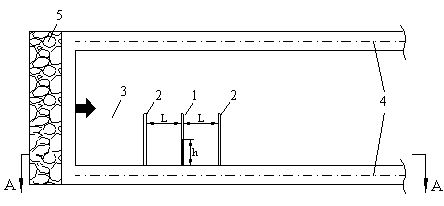

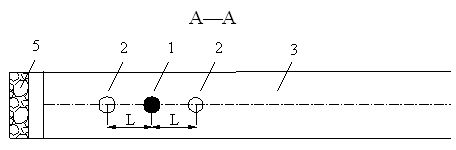

[0023] Such as figure 1 , figure 2 As shown in the figure, it is the drilling of high-pressure pulse hydraulic fracturing along the coal seam 3 to enhance the drainage of gas. Firstly, the fracturing units are implemented in groups along the coal seam 3 along the coal seam 3 in the air inlet lane or return air lane 4. 1. Then construct a pilot hole 2 on both sides of the center position L 10-20m away from the fracturing hole 1, and three drilling holes form a fracturing unit; the depth of the drilling hole in the coal seam 3 is 50-120m, Same as the prior art, the helical drill rod, circular drill rod or triangular drill rod can be selected as required. After the drilling construction is completed, insert a high-pressure resistant seamless steel pipe with several holes evenly distributed on the front pipe wall into the fracturing hole 1. The length of the front pipe wall is 0.5~1.5m. Seal the gap between the high-pressure seamless steel pipe and the fracturing hole 1 with a...

Embodiment 2

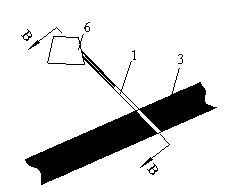

[0025] Such as image 3 , Figure 4 As shown, the high-level roadway 6 penetrates the layer and goes down the hole, and the high-pressure pulse hydraulic fracturing enhances the drainage of gas, which is basically the same as the first embodiment. The different parts are mainly to implement fracturing units sequentially in groups from the high-level roadway through the bed to the fracturing target area of the lower coal seam 3. Firstly, the fracturing hole 1 is constructed, and then the center position L of the fracturing hole 1 is located on both sides. A pilot hole 2 is constructed respectively, and three drill holes form a fracturing unit; the depth of the drill holes penetrates the coal seam 3 . The remaining parts are all the same as in Embodiment 1, and the same parts are omitted.

Embodiment 3

[0027] Such as Figure 5 , Figure 6 As shown, the low-level roadway 7 penetrates the layer and goes up the hole for high-pressure pulse hydraulic fracturing to enhance the drainage of gas, which is basically the same as that of the first embodiment. The different parts are mainly to carry out fracturing units sequentially in groups from the lower roadway 7 to the upper coal seam 3 to the fracturing target area. A pilot hole 2 is constructed on each side, and three drill holes form a fracturing unit; the depth of the drill holes should penetrate the coal seam 3 . The remaining parts are all the same as in Embodiment 1, and the same parts are omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com