Patents

Literature

35results about How to "Eliminate concentrated stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting gas in low air permeability coal layer by pulse fracture anti-reflection

ActiveCN102155254AChange mechanical propertiesImprove breathabilityFluid removalGas removalPulse pressureDischarge rate

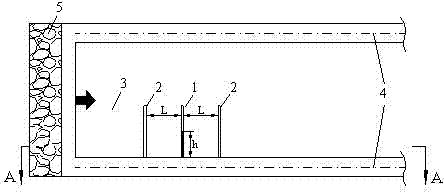

The invention relates to a method for extracting gas in low air permeability coal layer by pulse fracture anti-reflection, comprising the following steps: firstly using the blast-proof pulse-type coal layer high pressure water injector with adjustable frequency and pressure from the coal layer, high tunnel or low tunnel; using the pulse water effect generated by the periodical change of high pressure pulse water inside the drill hole of coal body, wherein the maximum pulse pressure is 35 MPa, the flow is about 300 L / min, and the pulse frequency is 0-1460 times / min; forcing the macroscopic fracture in the coal layer to be expanded and communicated; promoting the micro-pore fracture to be formed and extended; forming a new regeneration fracture net; providing a permeable channel of water inthe coal layer so as to achieve the effects of improving the mechanical property of the coal body, reducing the stress of the coal body in front of the working face and improving the discharge rate of the gas. Through the method, the pressure releasing range of the coal layer is enlarged, the whole pressure is adequately released, the radius of influence range of fracture can reach 10-40 m, and the air permeability of the coal body can be improved by 100-1000 times; and the method is simple, easy to operate and good in effect.

Owner:CHINA UNIV OF MINING & TECH

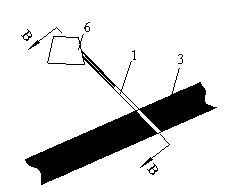

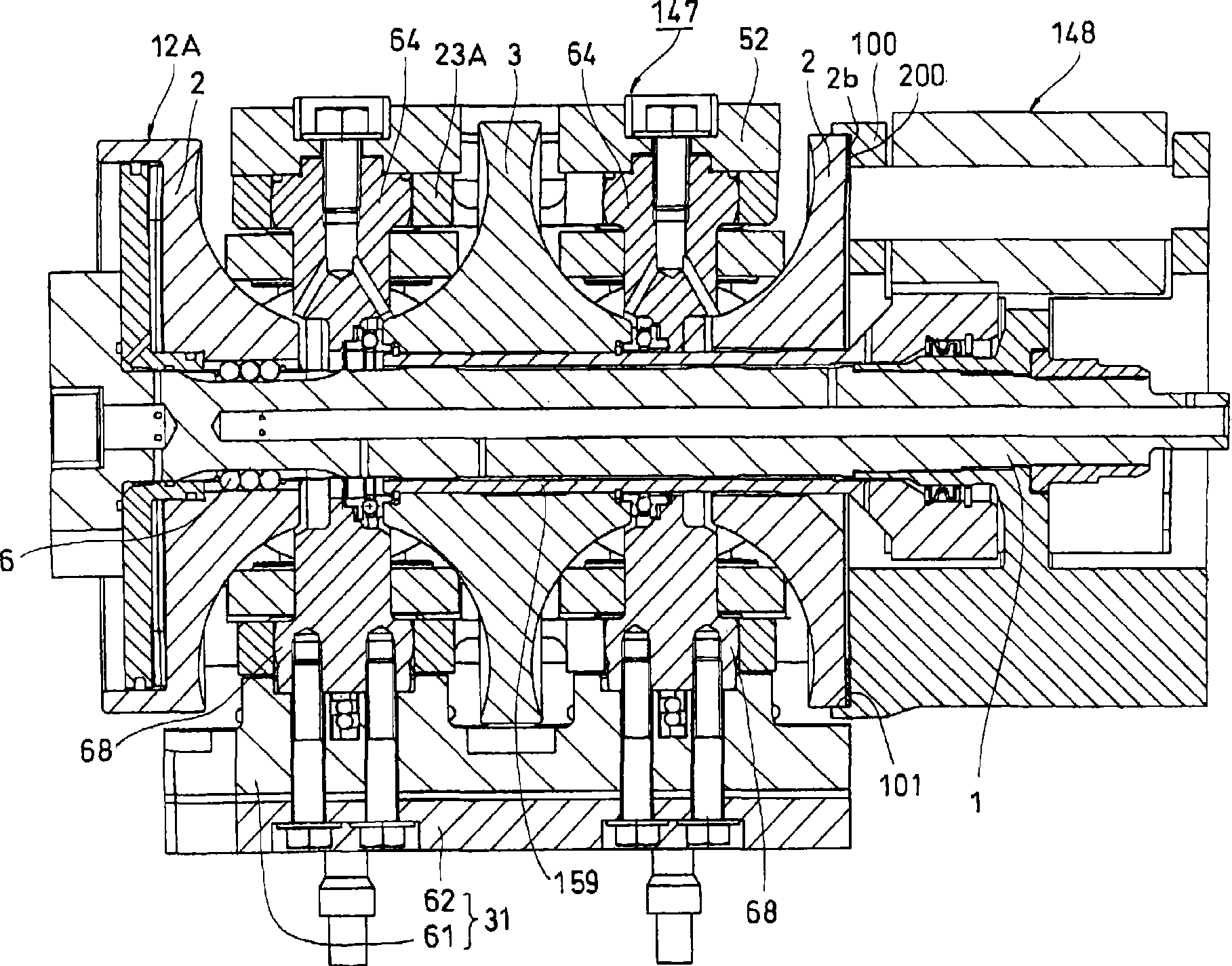

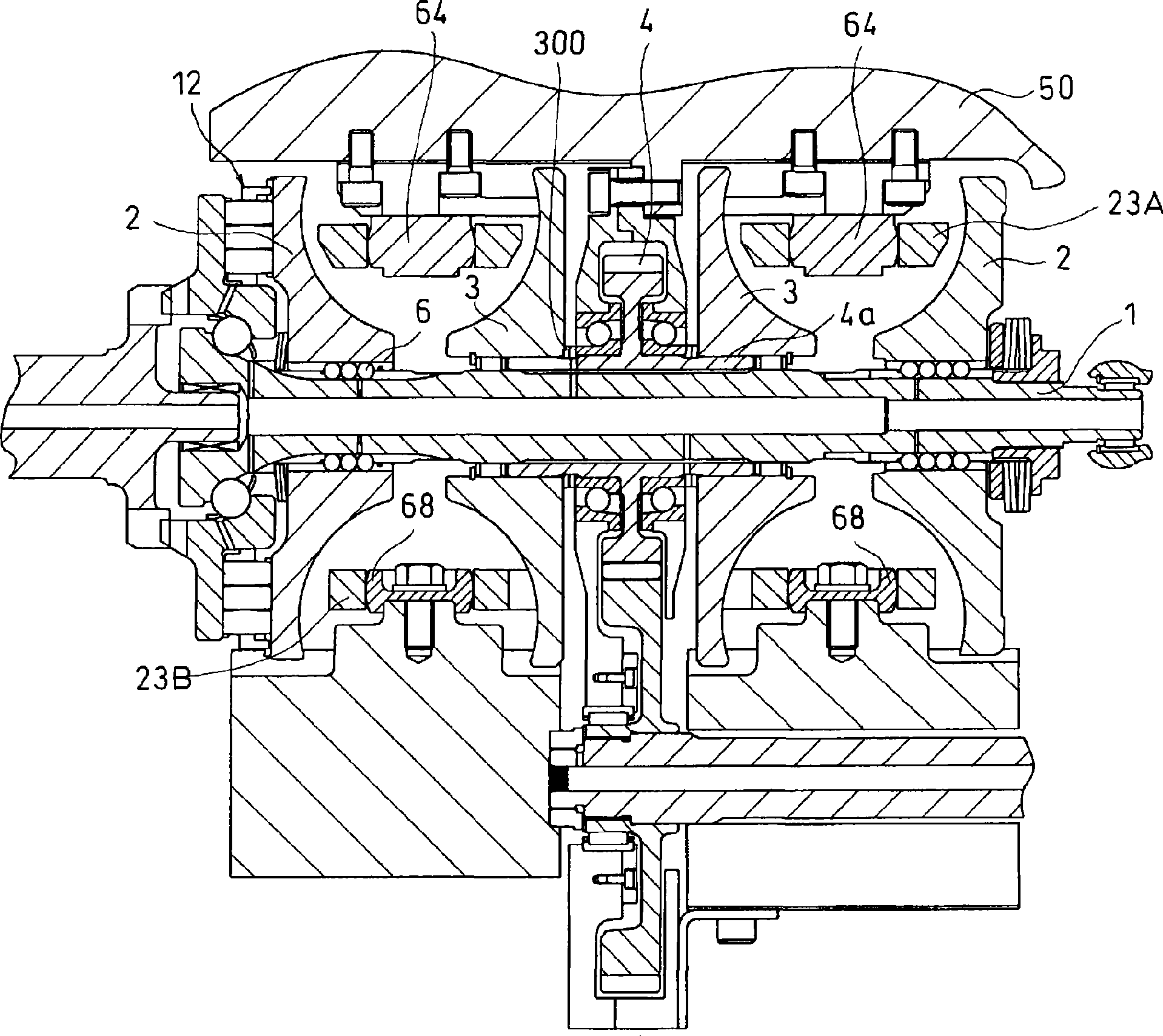

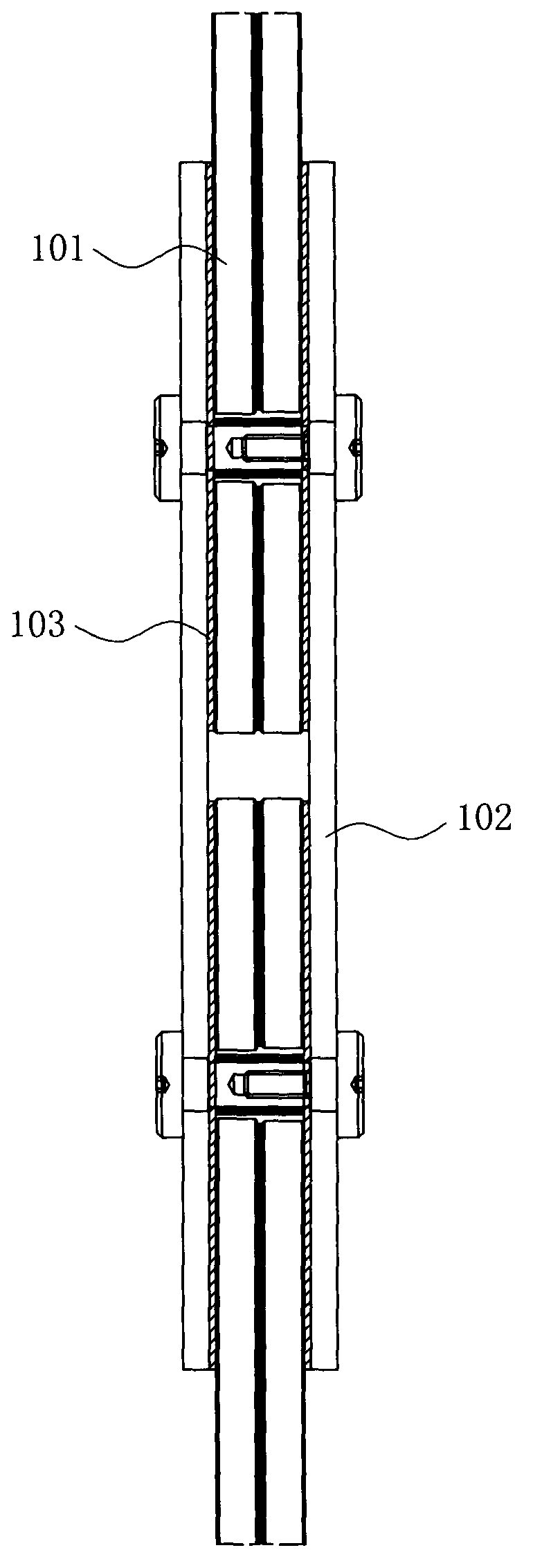

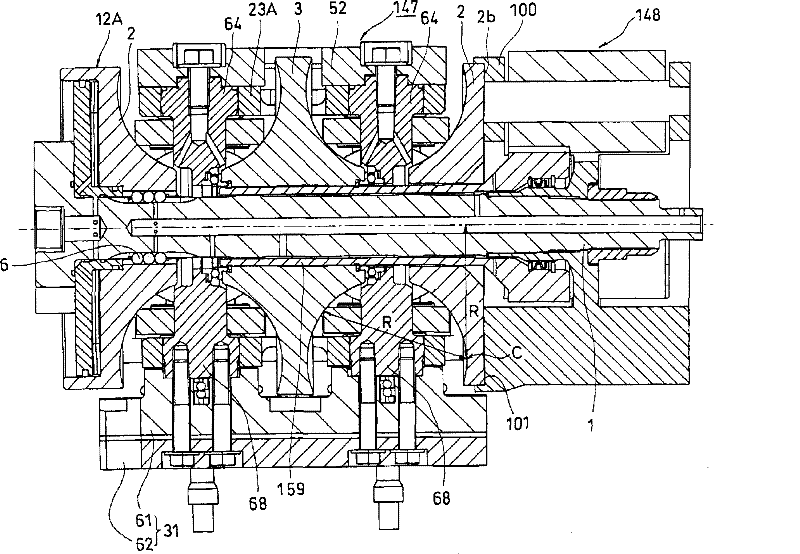

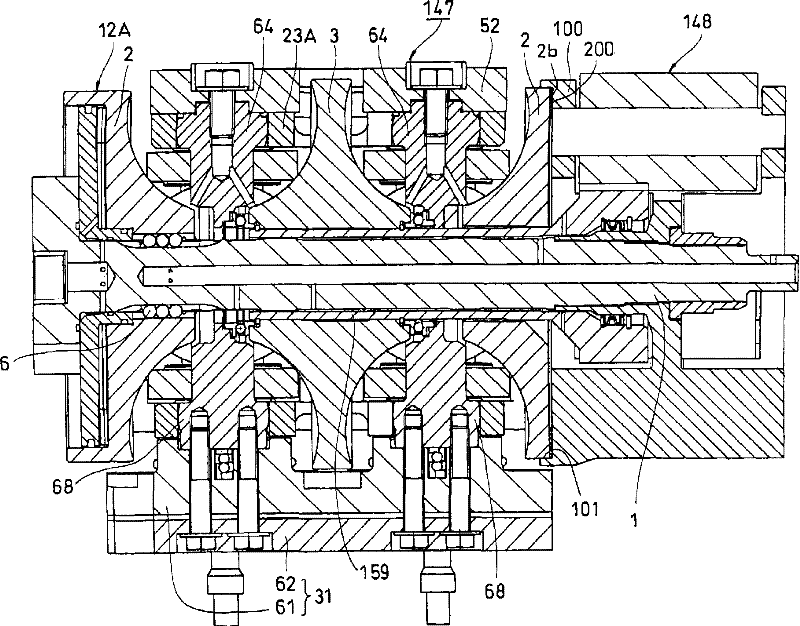

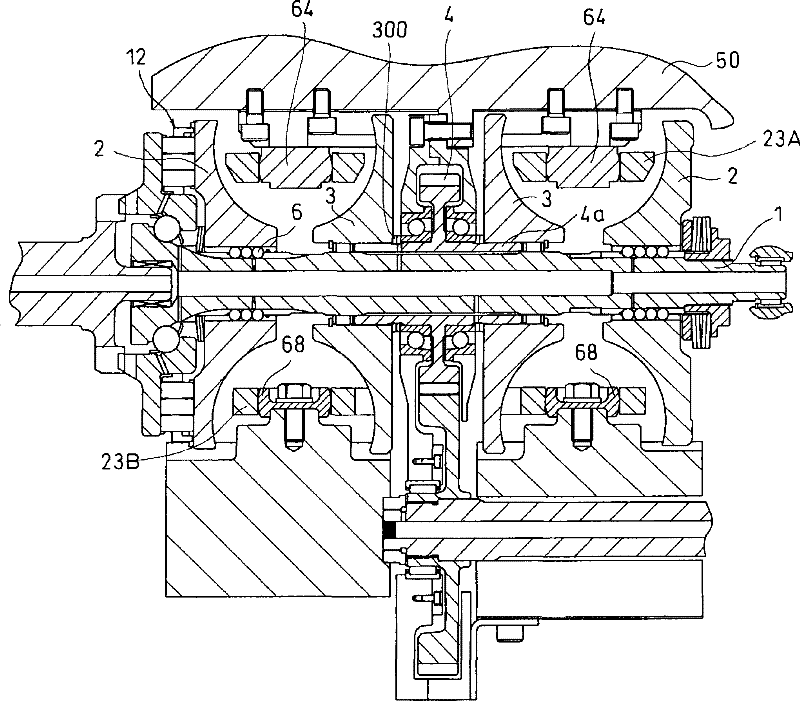

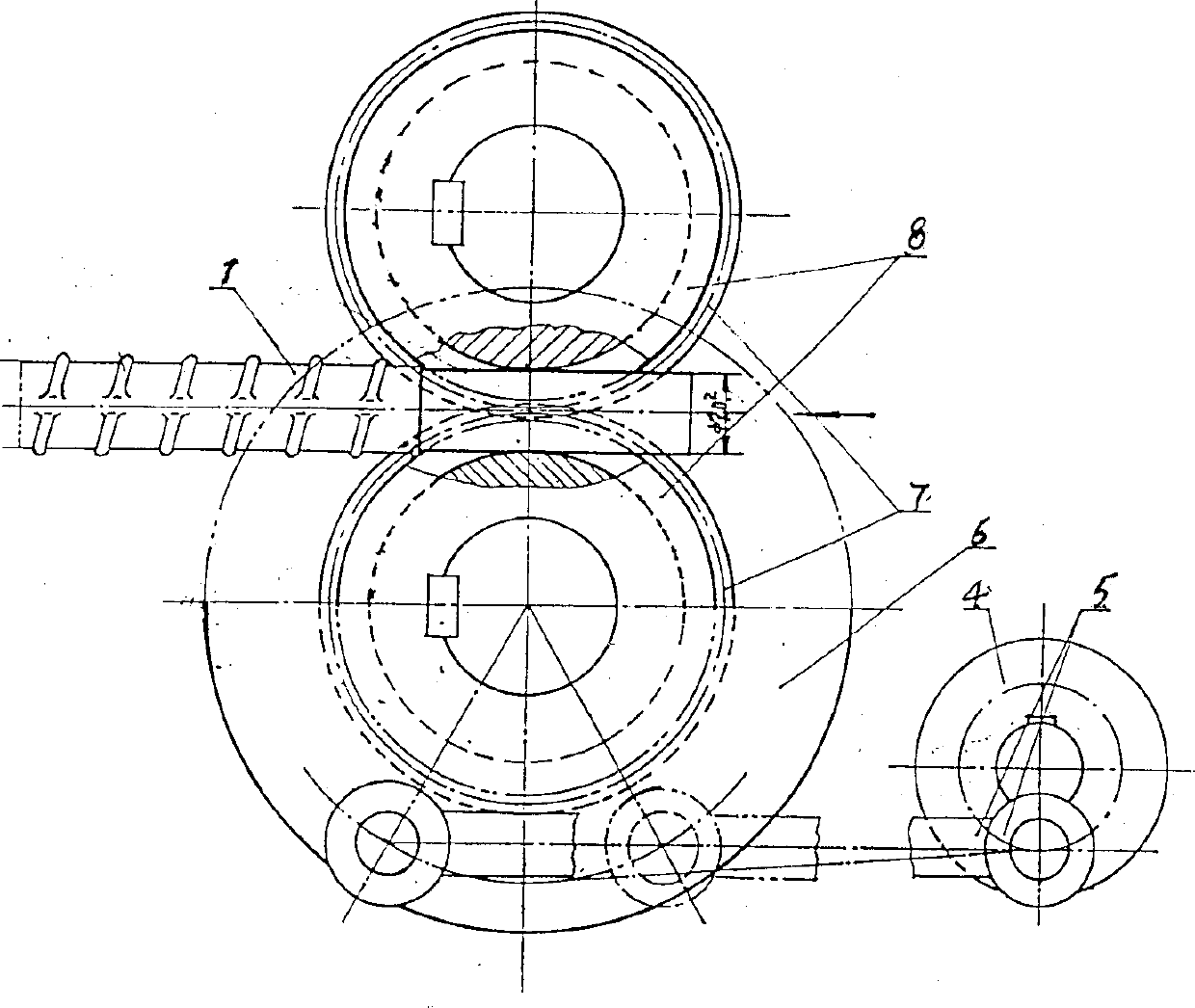

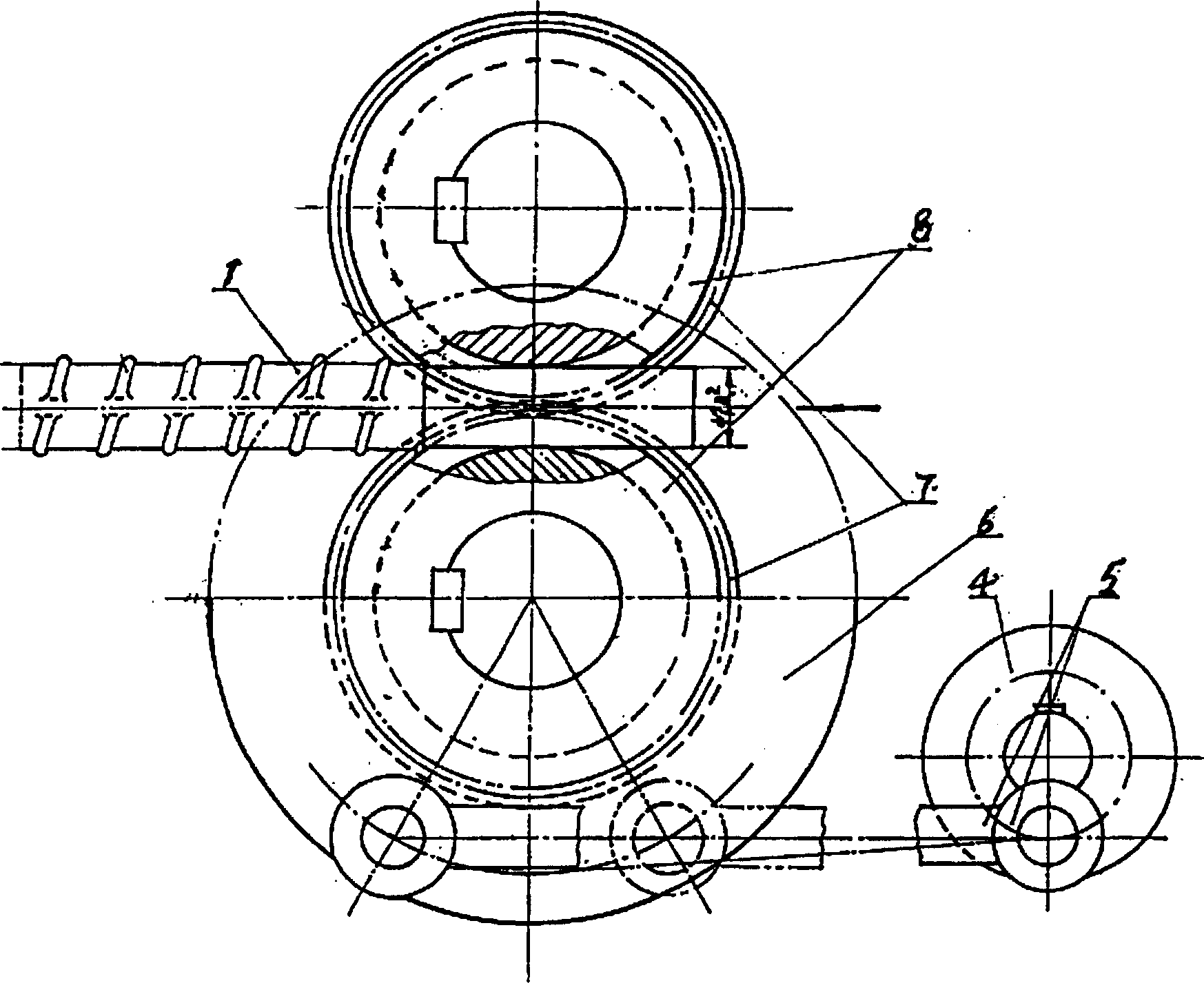

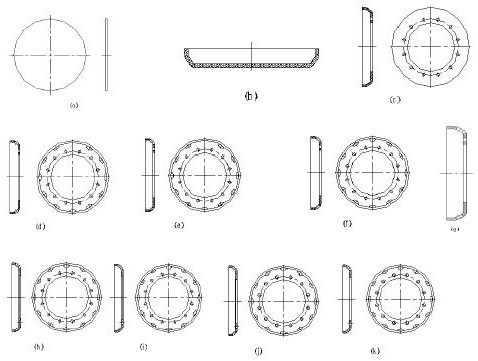

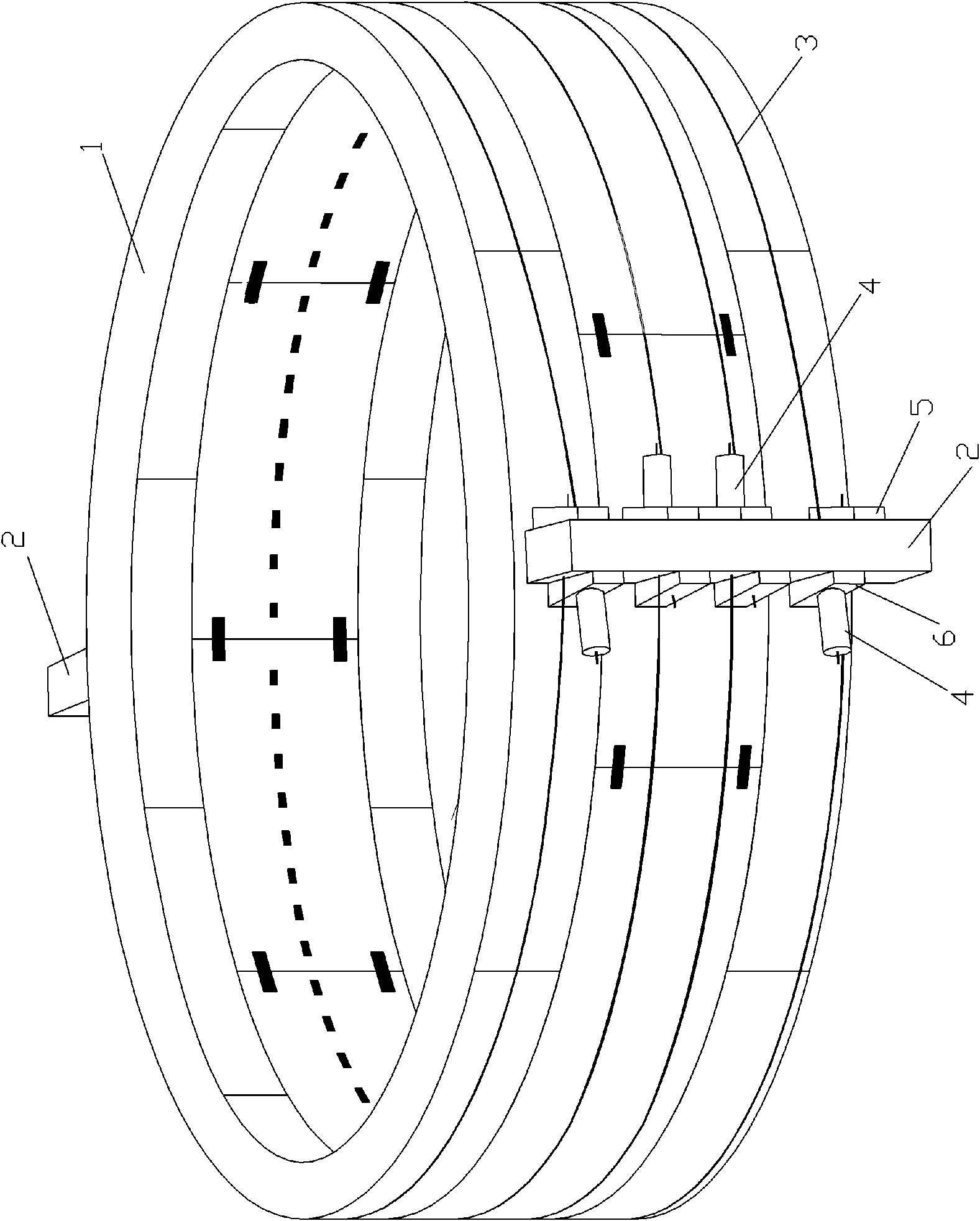

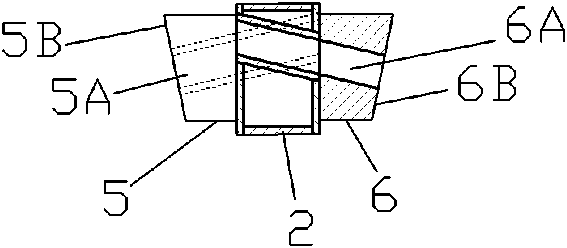

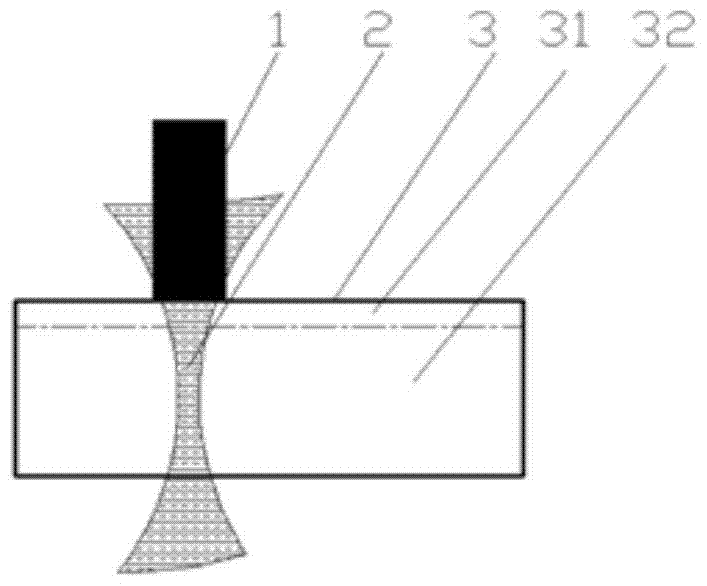

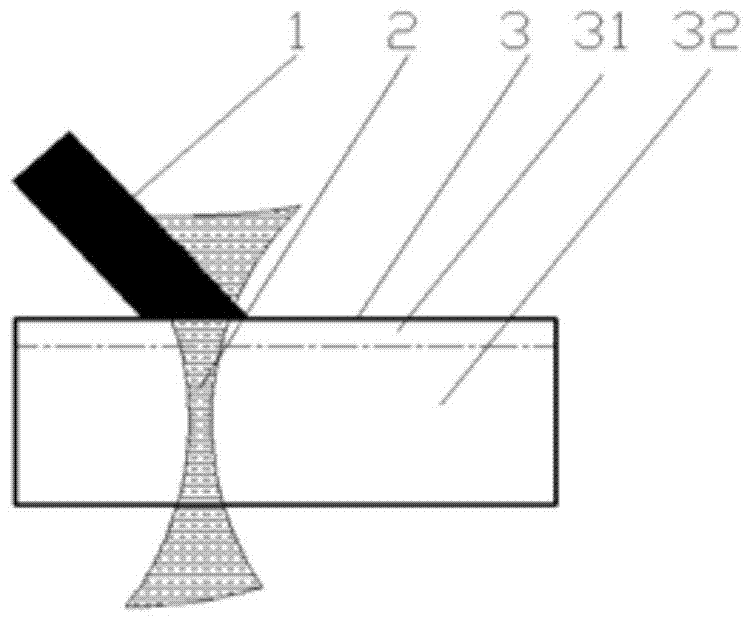

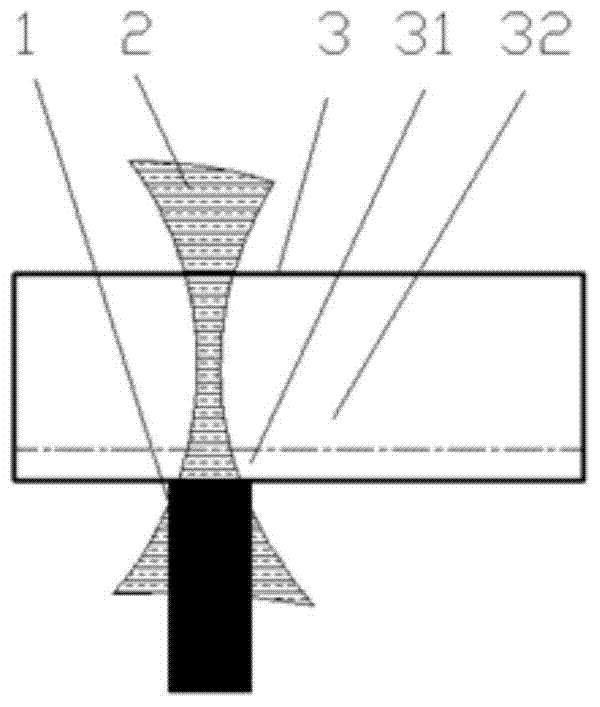

Toroidal type stepless transmission and stepless transmission

InactiveCN101479503AReduce weightAvoid getting stuckFriction gearingsElectric power transmissionGear wheel

A toroidal type stepless transmission where a carrier (100) and a disk (2) are in direct friction contact with each other to allow power transmission between the carrier (100) and the disk (2) by friction force. Accordingly, the transmission does not require processing of gears and claws on the disk or the carrier, which has been required conventionally. As a result, production processes are reduced to enable a considerable reduction in production costs.

Owner:NSK LTD

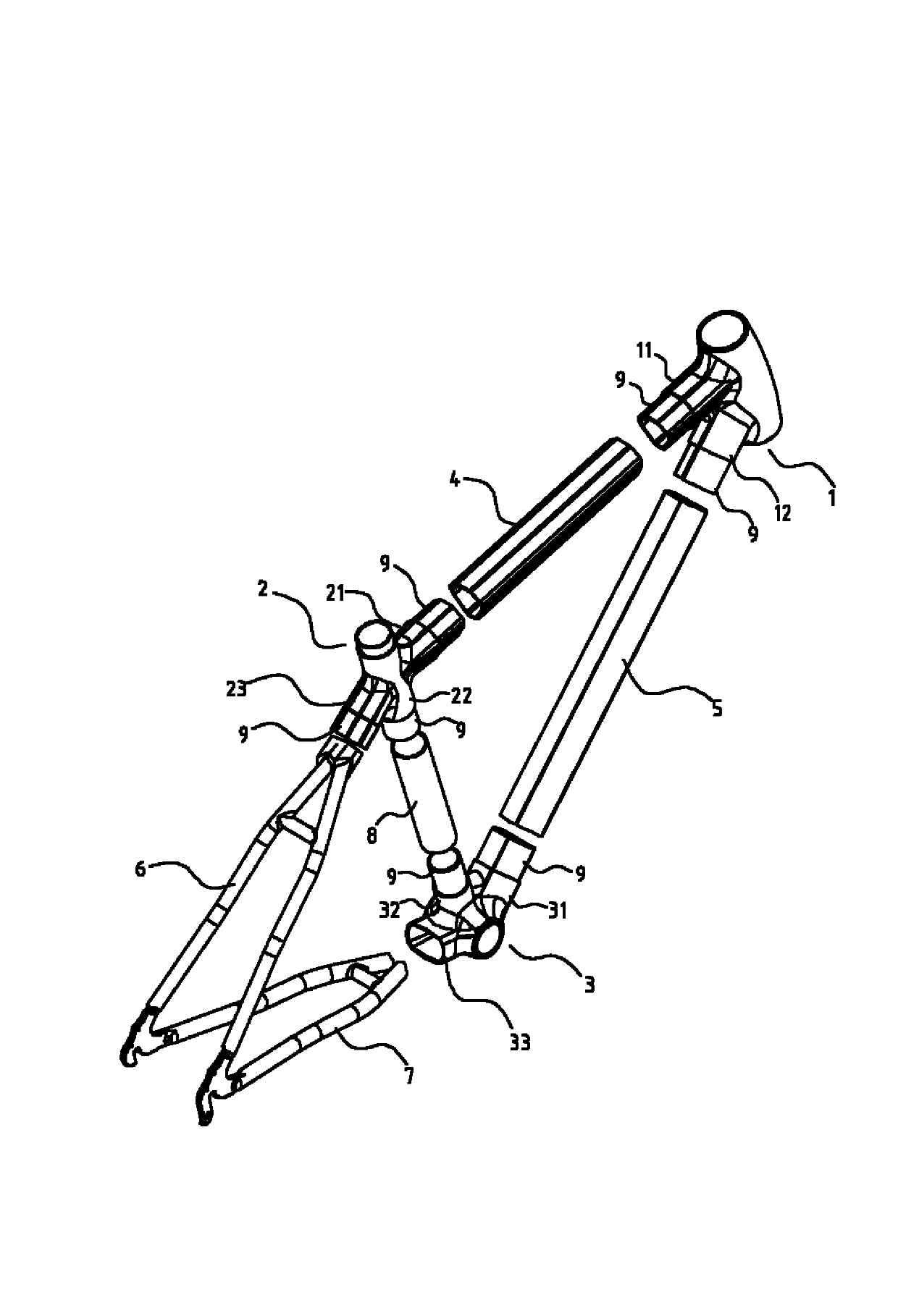

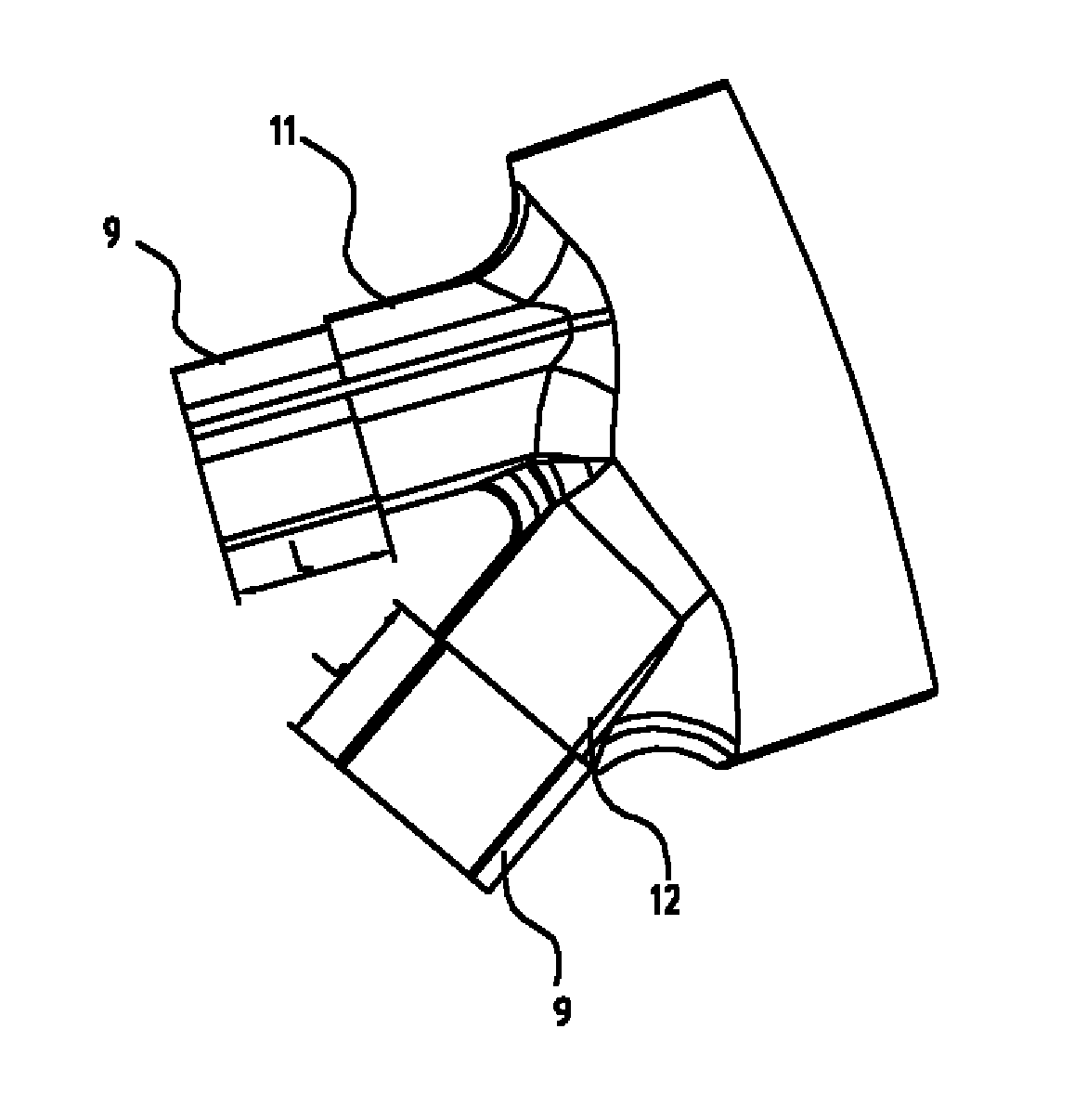

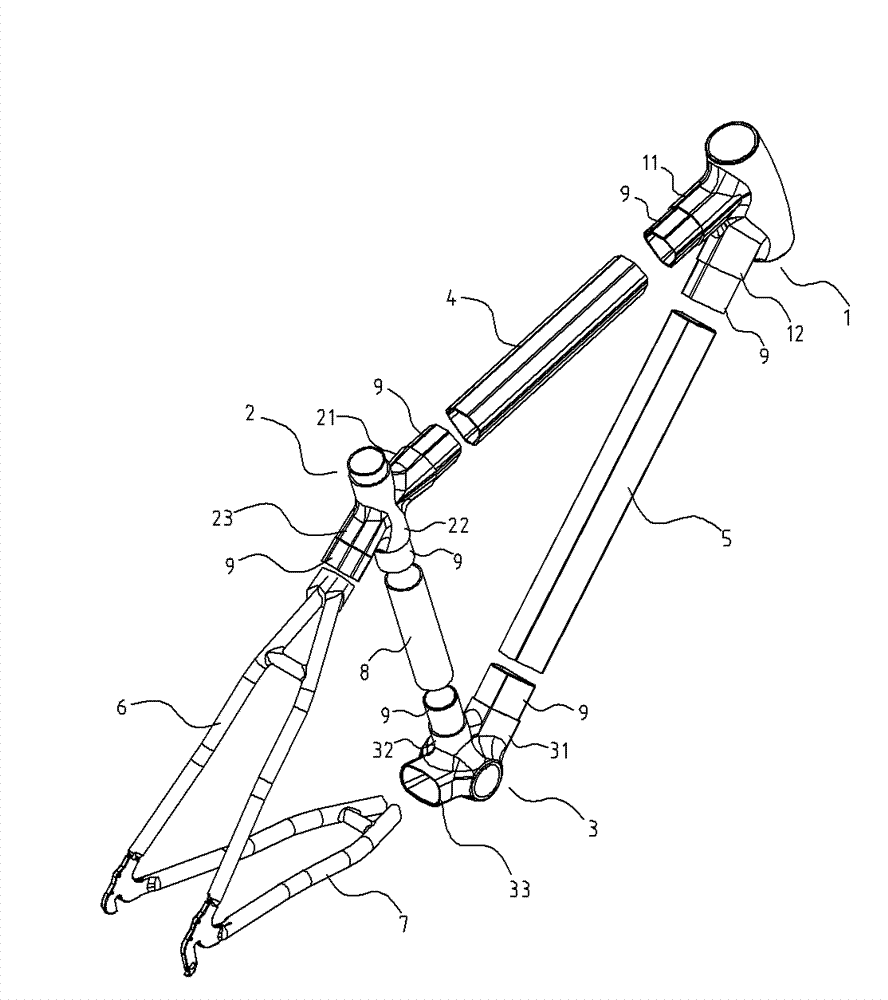

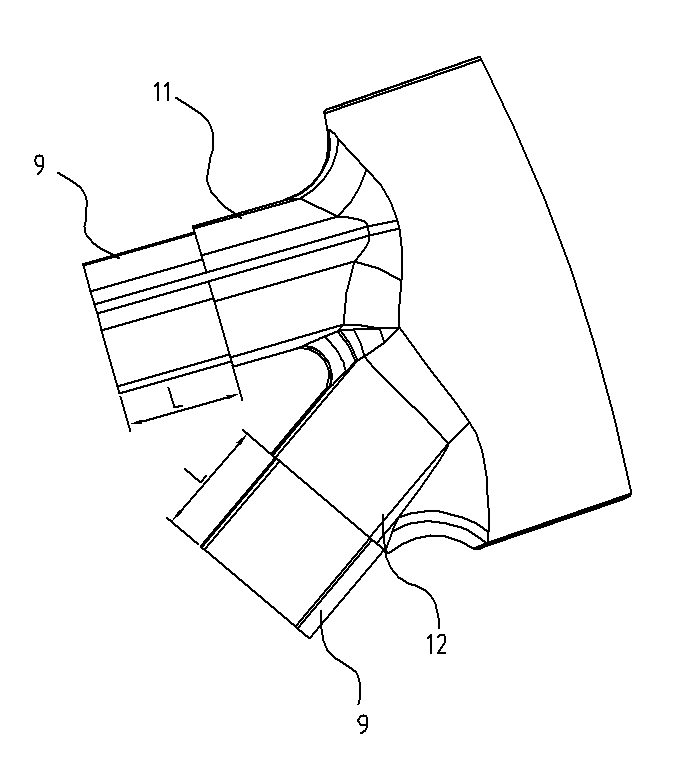

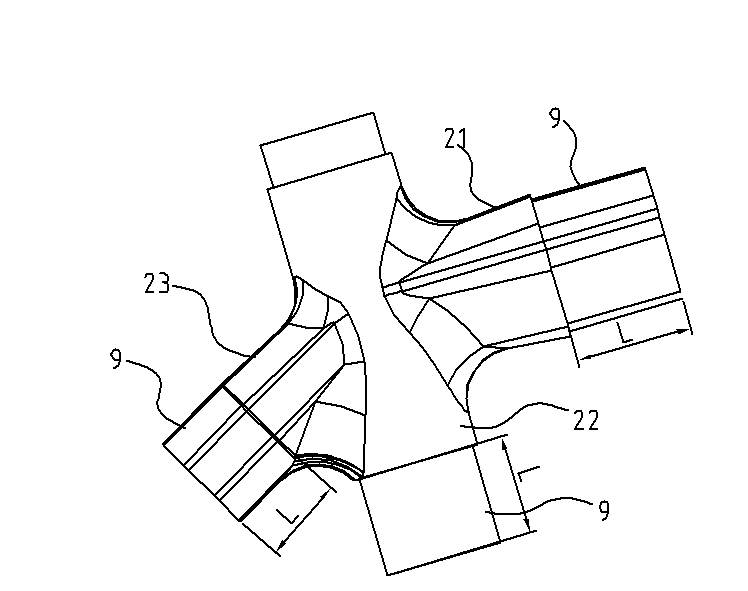

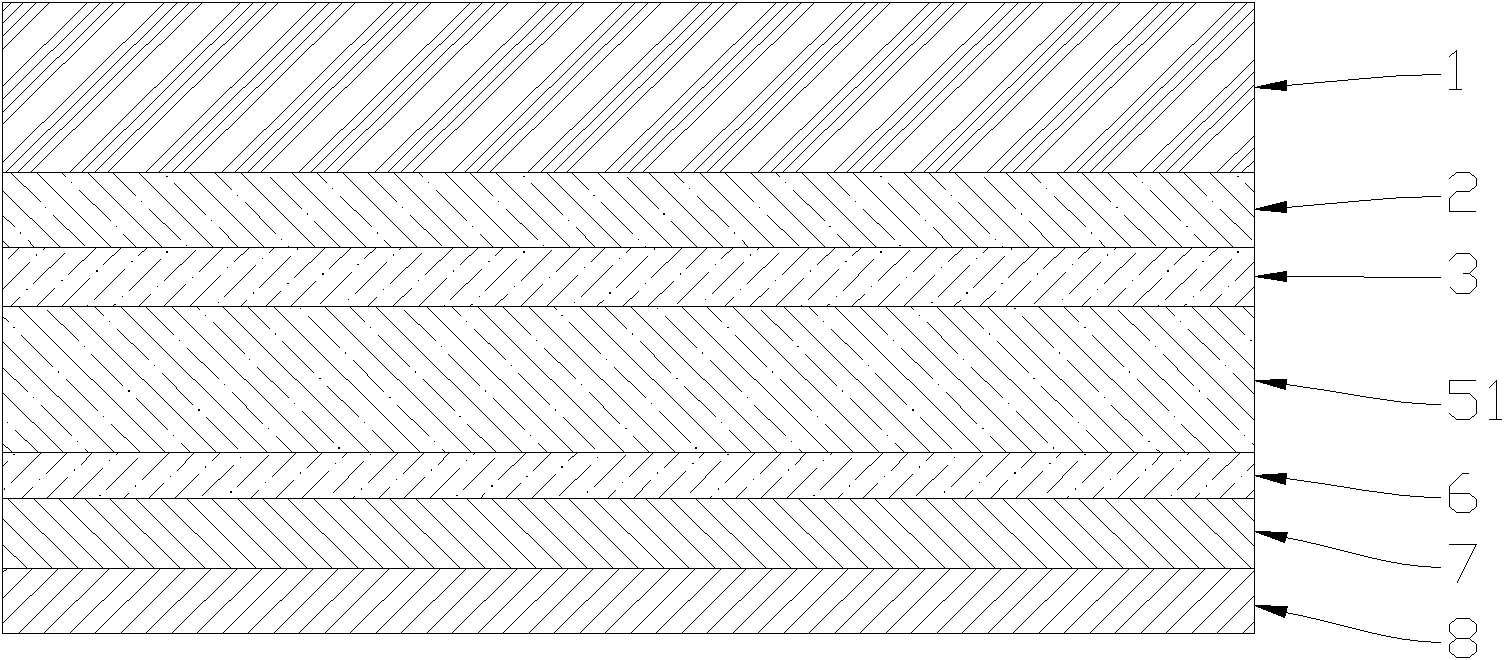

Method for manufacturing frame of combined bicycle

The invention provides a method for manufacturing a frame of a bicycle. The method comprises the following steps of: (1) manufacturing frame fittings, wherein the frame fittings comprise frame pipes and joints, the frame pipes comprise an upper pipe, a back upper fork, a back lower fork, a lower pipe and a middle pipe which are all made of aluminum alloy, and the joints comprise a head pipe joint, a middle pipe joint and a five-way joint which are all made of magnesium alloy; (2) processing surfaces of the frame fittings; (3) molding the frame pipes and the joints by gluing; (4) grinding and polishing the frame; and (5) performing baking finish on the surface of the frame. The whole frame utilizes the gluing molding technology so that the frame has beautiful appearance, better streamline form, and higher size precision; furthermore, the deformation and stress concentration caused by welding in the traditional manufacturing method are eliminated.

Owner:GUANGZHOU LEONIS MACHINERY

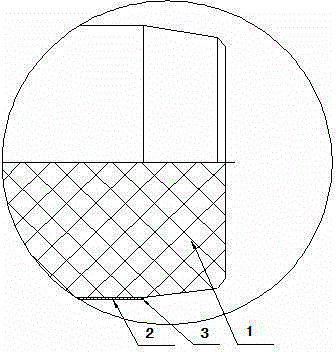

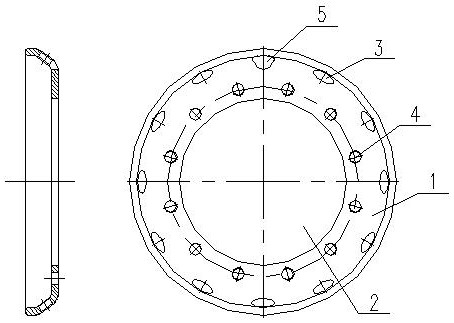

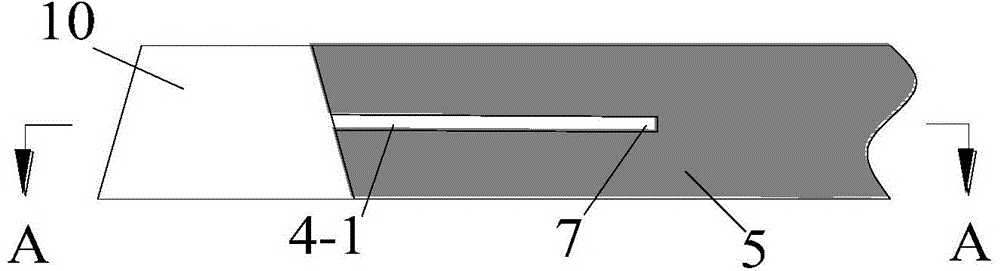

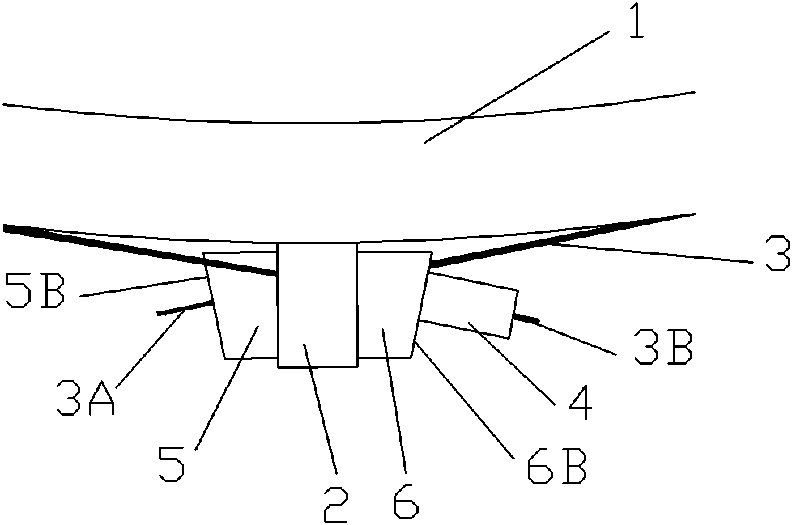

Annular combustion increasing structure on charging outer end surface of missile engine

The invention discloses a circumferential combustion-increasing structure on the outer end surface of the charge of a missile solid motor, including a charge column, a cladding sleeve and a liner. The grain is bonded to the covering sleeve through the lining layer, and the initial combustion surface of the grain can be changed by adjusting the length of the covering sleeve, so that the engine can meet the overall engine initial thrust index requirements. Compared with the prior art, the present invention adopts the hoop-increasing structure, and its advantages and beneficial effects are: the hoop-increasing structure is easy to measure and detect, and at the same time, it eliminates the stress concentration and cracks of the grain caused by the complex profile , so that the risk of engine operation is reduced; the initial burning surface of the grain can be effectively adjusted without losing the amount of medicine, so that the initial thrust of the engine can be increased, thereby ensuring the mass ratio of the engine.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

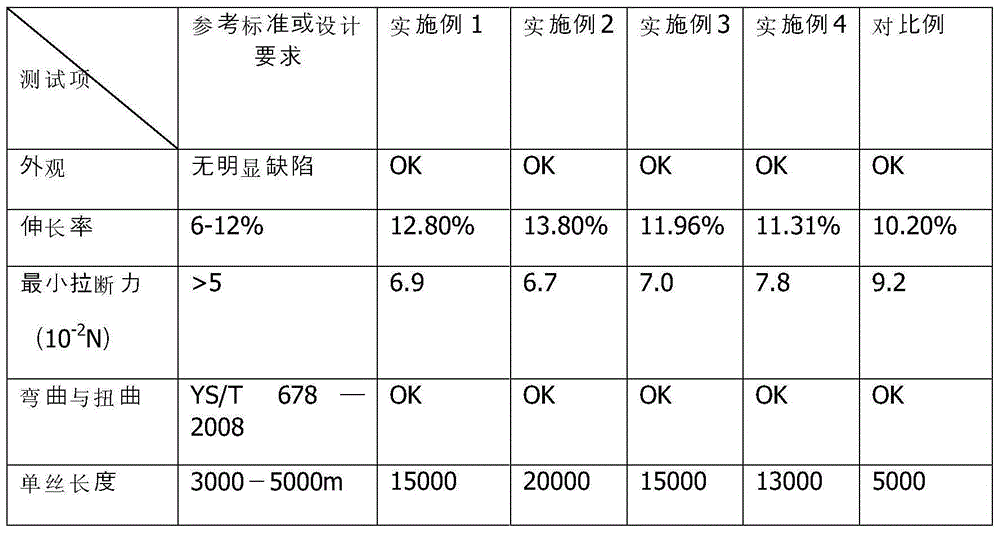

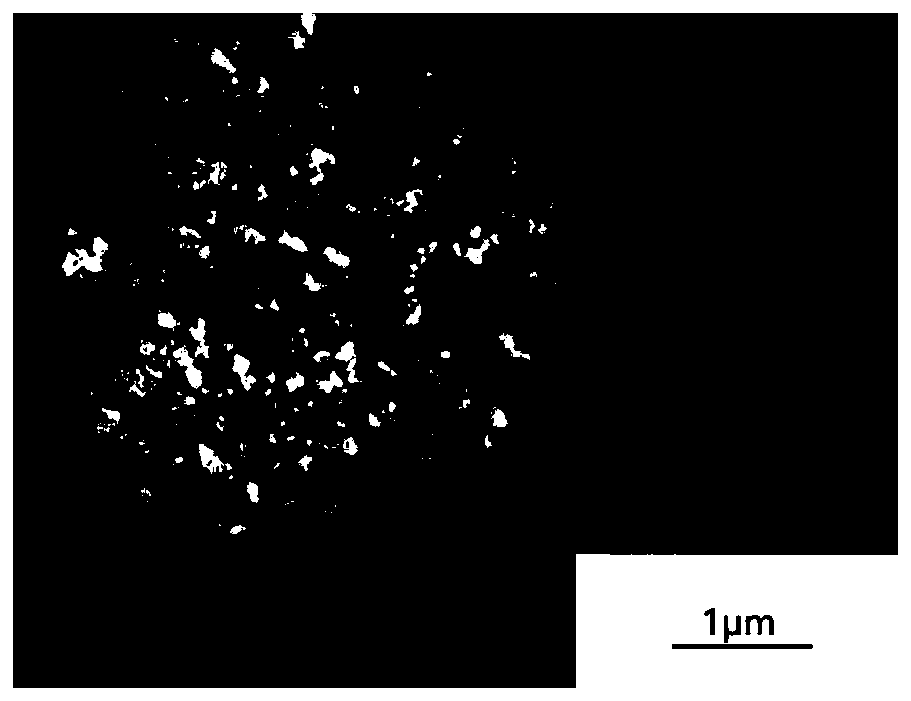

Ultra-thin copper alloy bonding wire for microelectronic packaging and preparing method of ultra-thin copper alloy bonding wire

InactiveCN105132735AImprove performanceImprove grain refinement effectSolid-state devicesSemiconductor devicesRare-earth elementImpurity

An ultra-thin copper alloy bonding wire for microelectronic packaging is characterized by being prepared from 10-50 wt.ppm of Ti, 10-50 wt.ppm of Li, 10-50 wt.ppm of Zr, 10-50 wt.ppm of Fe, 10-50 wt.ppm of Ag, 10-50 wt.ppm of B, 10-50 wt.ppm of a rare earth element and the balance copper and inevitable impurities, wherein the content of O and S in the impurities accounts for 5 wt.ppm or less in the whole copper alloy bonding wire, and the rare earth element is one of Eu, Y and Dy or a combination of Eu, Y and Dy. The invention further provides a preparing method of the ultra-thin copper alloy bonding wire for microelectronic packaging. The copper alloy bonding wire has the good oxidation resistance, good electric and heat conductivity, good weldability, large single wire length and other good performance, and the preparing method of the copper alloy bonding wire is easy and convenient to implement.

Owner:NICHE TECH KAISER SHANTOU

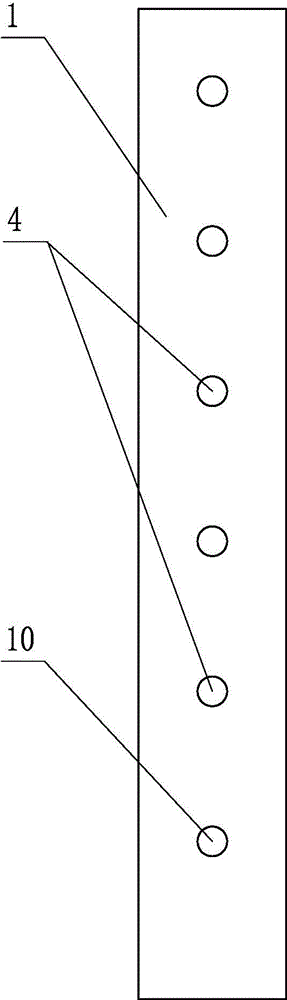

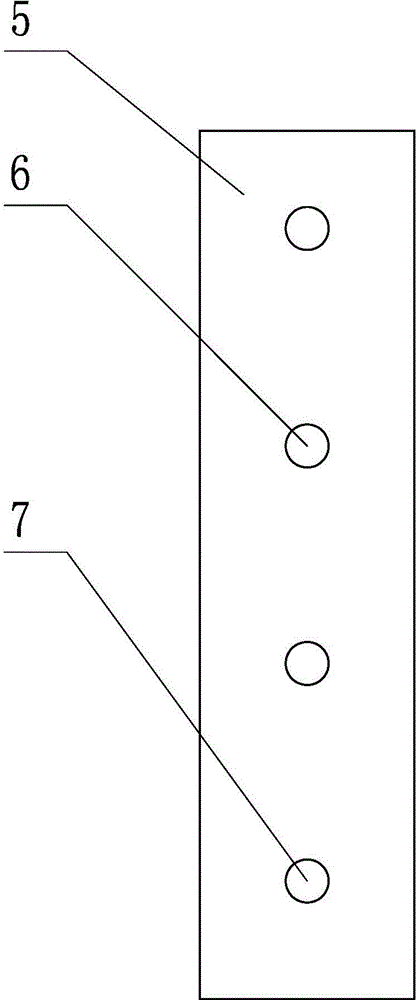

Glass rib splicing structure and construction method thereof

ActiveCN103132637AImprove stabilityReduce temperature stressWallsBuilding material handlingAdhesiveArchitectural engineering

The invention discloses a glass rib splicing structure. The glass rib splicing structure comprises outer connecting plates covered on two sides of spliced ends of adjacent glass ribs, a viscose layer and bolt pins, wherein the viscose layer is positioned between the connecting plates on two sides and a middle glass rib, and the bolt pins penetrate through the glass ribs and the outer connecting plates on two sides. The glass rib splicing structure is characterized in inner steel plates are respectively arranged between the viscose layer and the outer connecting plates and on two sides of a spliced end of every glass rib. A method for the glass rib splicing structure comprises a first step of drilling connecting holes at the spliced end of every glass rib; a second step of respectively arranging bolting holes on the small inner steel plates and the outer connecting plates corresponding to every connecting hole; a third step of adhering the inner steel plates to two sides of the spliced end of every glass rib respectively through adhesive; and a fourth step of respectively enabling the outer connecting plates to be covered on two sides of two adjacent glass ribs with the inner steel plates, and fixing the outer connecting plates by enabling the bolt pins to penetrate through the outer connecting plates, the bolting holes on the inner steel plates and the connecting holes on the glass ribs. By arranging the inner steel plates, splicing firmness of the glass ribs is improved, future maintenance is facilitated, and using cost is reduced.

Owner:苏州苏明装饰股份有限公司

Toroidal type stepless transmission and stepless transmission

InactiveCN101479503BReduce weightAvoid getting stuckFriction gearingsElectric power transmissionEngineering

Owner:NSK LTD

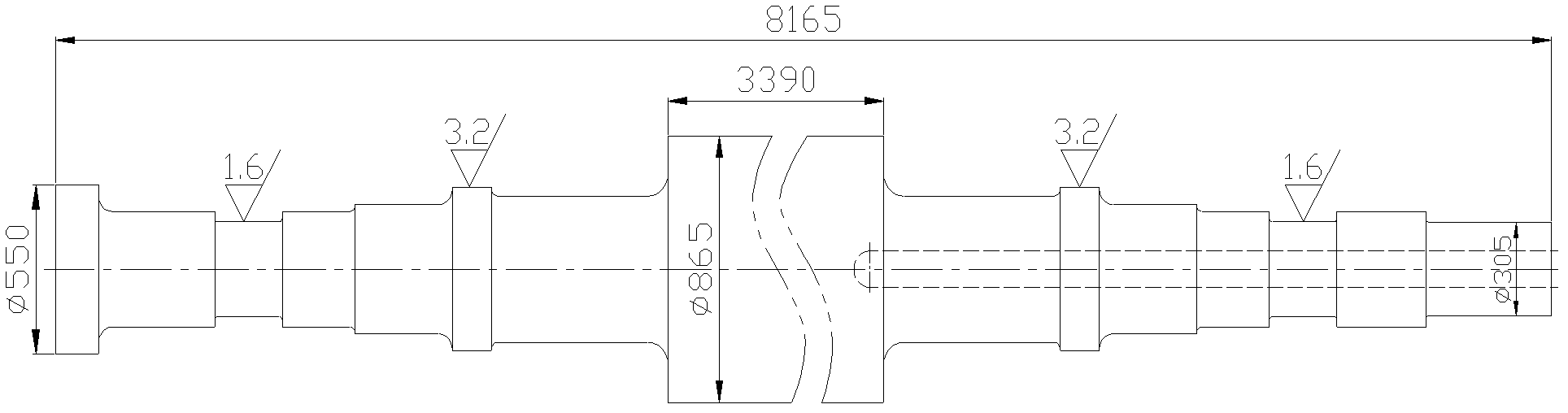

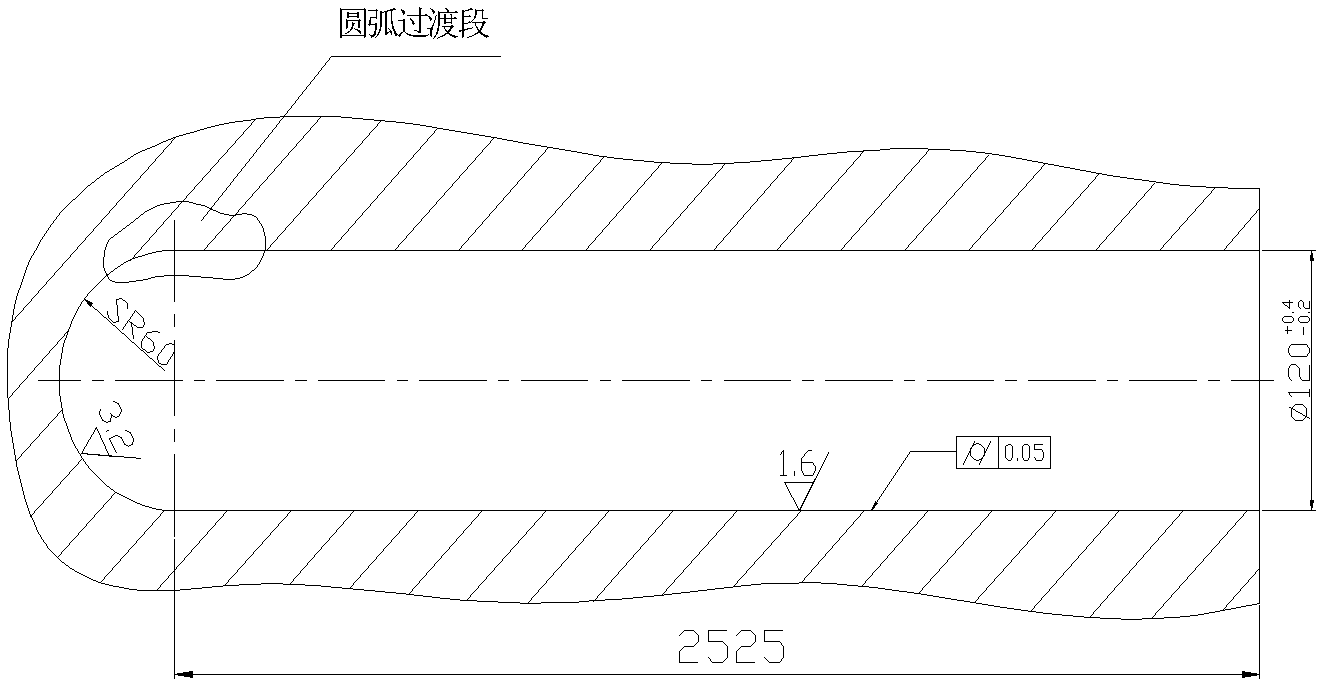

Machining method of circular transition section on bottom of central blind hole of generator rotor

InactiveCN103166382AFulfil requirementsEliminate cut marksManufacturing stator/rotor bodiesSurface roughnessEngineering

The invention discloses a machining method of a circular transition section on the bottom of a central blind hole of generator rotor. The machining method of the circular transition section on the bottom of the central blind hole of generator rotor is used for machining the central blind hole of the generator rotor, the length of the central blind hole is larger than or equal to 1800mm, the inner diameter pin of the central blind hole is 120 (adding 0.4 or diminishing 0.2) mm, and the surface roughness of the central blind hole is Ra is 1.6. The machining method of the circular transition section on the bottom of the central blind hole of generator rotor comprises the following steps: S1, the formation of a spherical-surface bottom hole, wherein the inner diameter pin of the spherical-surface bottom hole is 115-118mm, and the radius of the spherical-surface bottom hole is 57-59mm; S2, formation of a center hole, wherein the inner diameter pin of the center hole is 119.4mm, the depth of the center hole enables the center hole to be rightly connected with the spherical-surface bottom hole, the surface roughness Ra of the center hole is 3.2; S3, finish milling of the spherical surface bottom hole to enable the steradian (SR) of the spherical-surface bottom hole to reach 59.65mm and the surface roughness Ra of the spherical-surface bottom hole to reach 6.3; and S4, repeated rough polishing, fine polishing and boning of the spherical surface bottom hole and the center hole to reach drawing requirements. By means of the machining method of the circular transition section on the bottom of the central blind hole of generator rotor, lapping defects on the circular transition section on the bottom of the center hole with a 120mm inner diameter pin of the generator rotor can be eliminated, the requirements on surface roughness and performance of the circular transition section on the bottom of the central blind hole are met, and the effect of eliminating concentrated stress is achieved.

Owner:SHANGHAI HEAVY MACHINERY PLANT

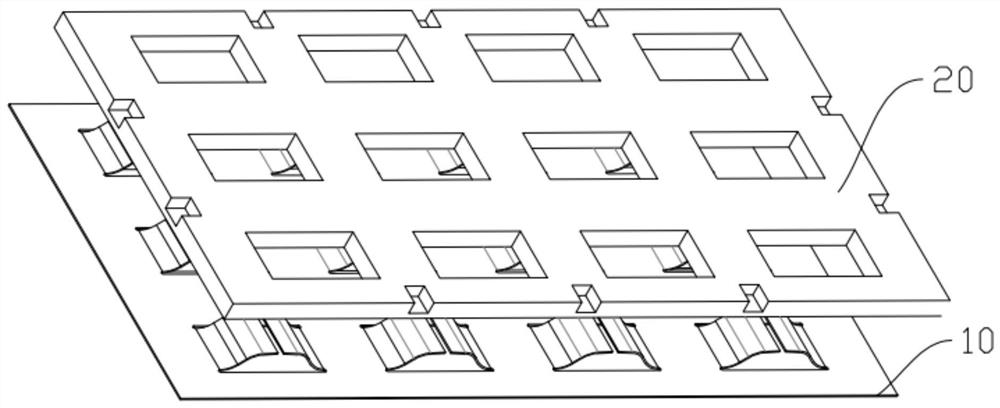

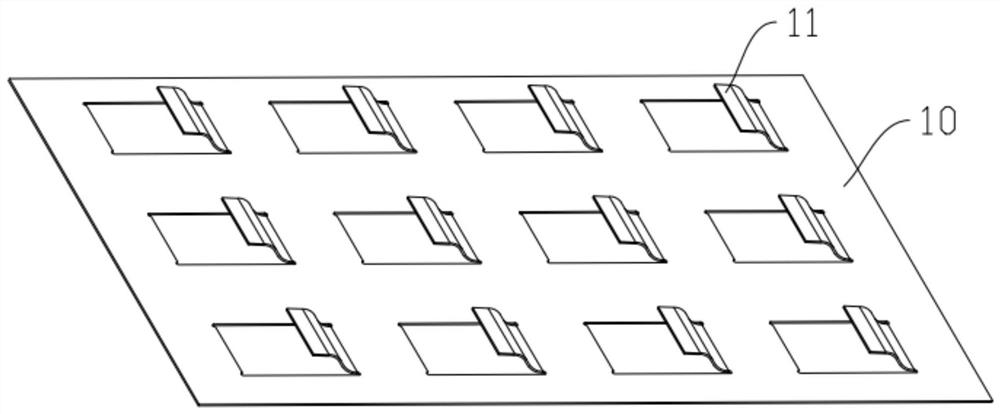

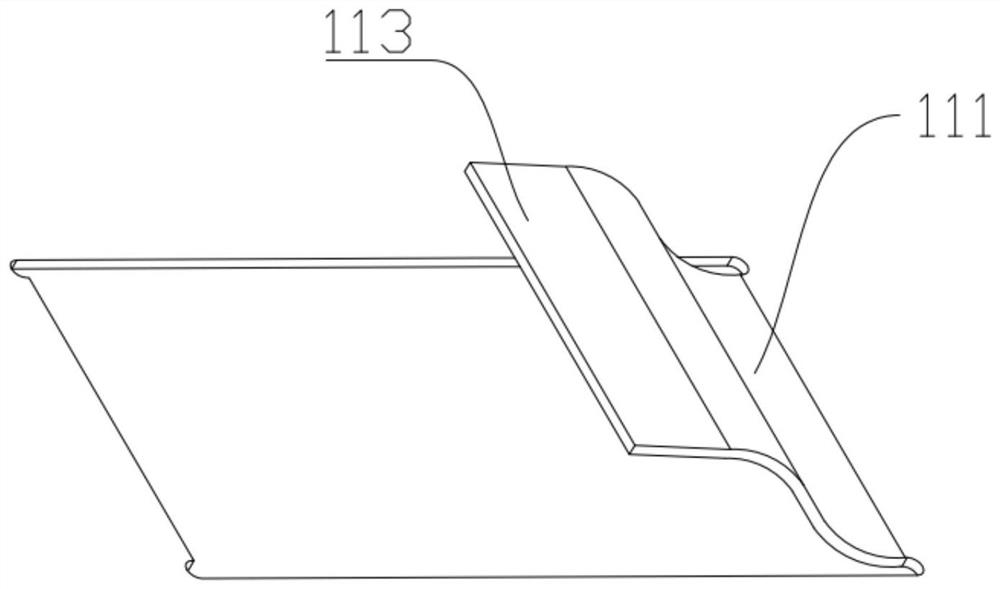

Mounting structure and mounting method for arc-shaped aluminum profile modeling

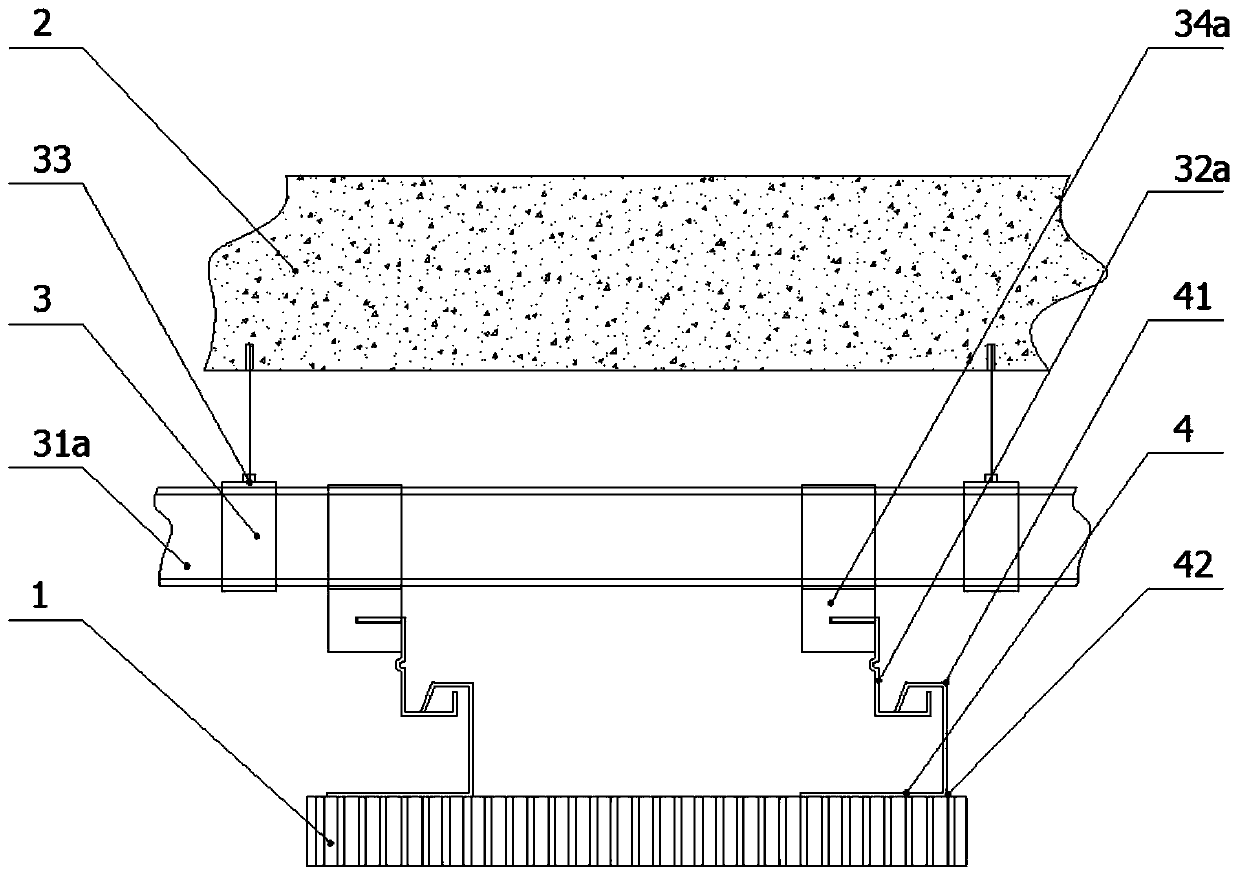

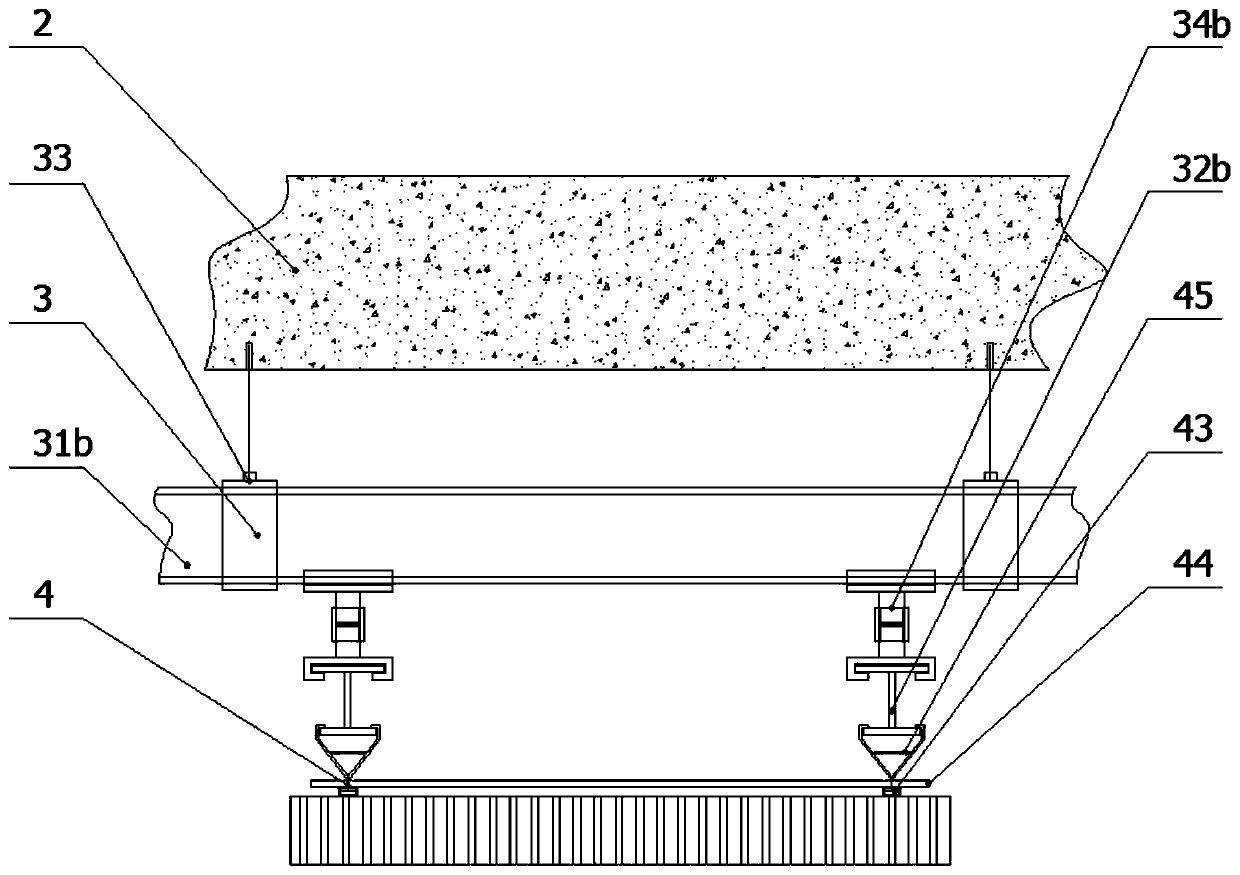

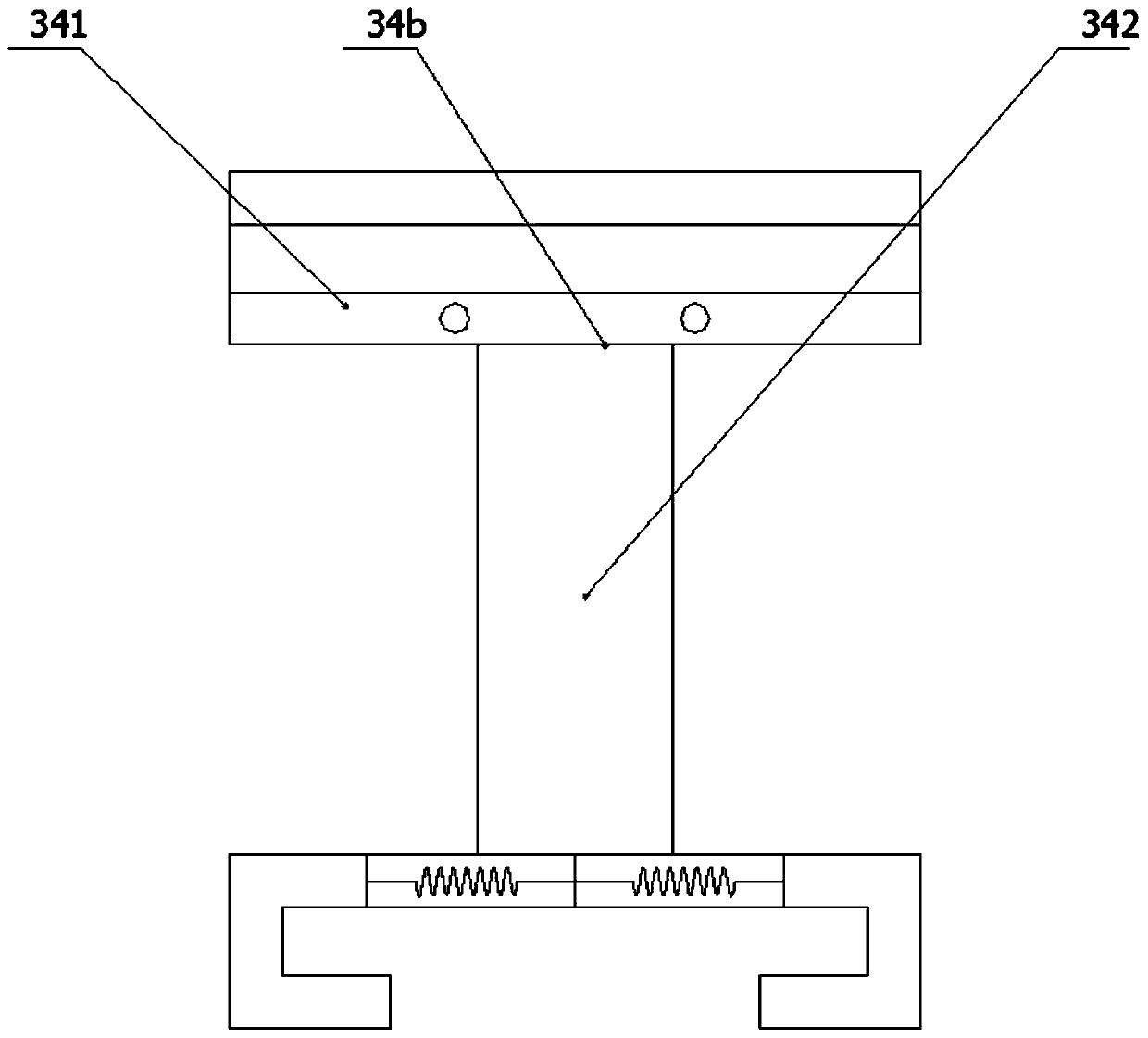

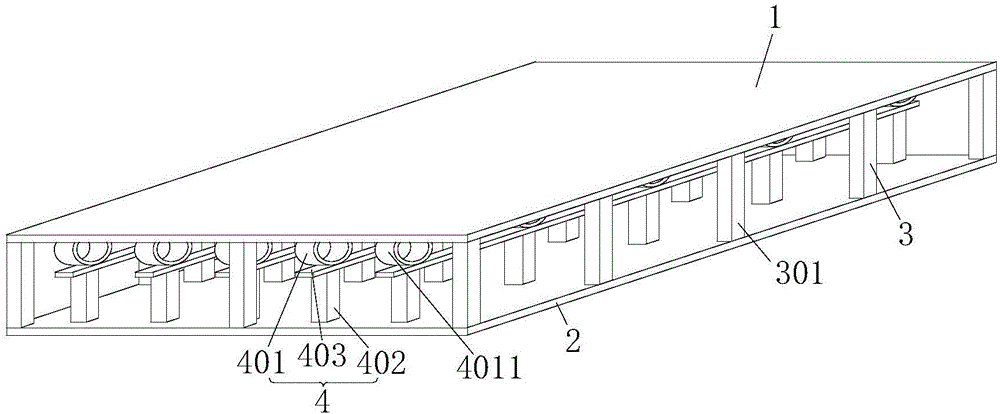

PendingCN111219009AImprove overall stiffness and strengthEliminate concentrated stressCeilingsEngineeringMechanical engineering

The invention discloses a mounting structure for an arc-shaped aluminum profile modeling. The structure comprises aluminum profiles divided into decorative surfaces and back surfaces; a roof to be decorated; a suspended ceiling framework structure, which comprises a main keel, an auxiliary keel, suspension components and keel connecting pieces, and is used for suspending and supporting aluminum profiles; veneer connecting components arranged on the back surfaces of the aluminum profiles and comprise sliding bodies and sliding body connecting pieces. The technical solution disclosed by the invention has the beneficial effects that by arranging the full-size sliding bodies on the back surfaces of the aluminum profiles, the integral rigidity and strength of the aluminum profiles are enhanced;and by arranging the sliding bodies in a more reasonable area, the stress on a forming surface is formed, the concentrated stress is eliminated, the phenomenon of downward deflection of the forming surface after the installation of the large auxiliary aluminum profile is effectively controlled, and the ceiling effect of the arc-shaped modeling formed by folding line arc splicing of the aluminum profiles is guaranteed.

Owner:GOLD MANTIS CONSTR DECORATION

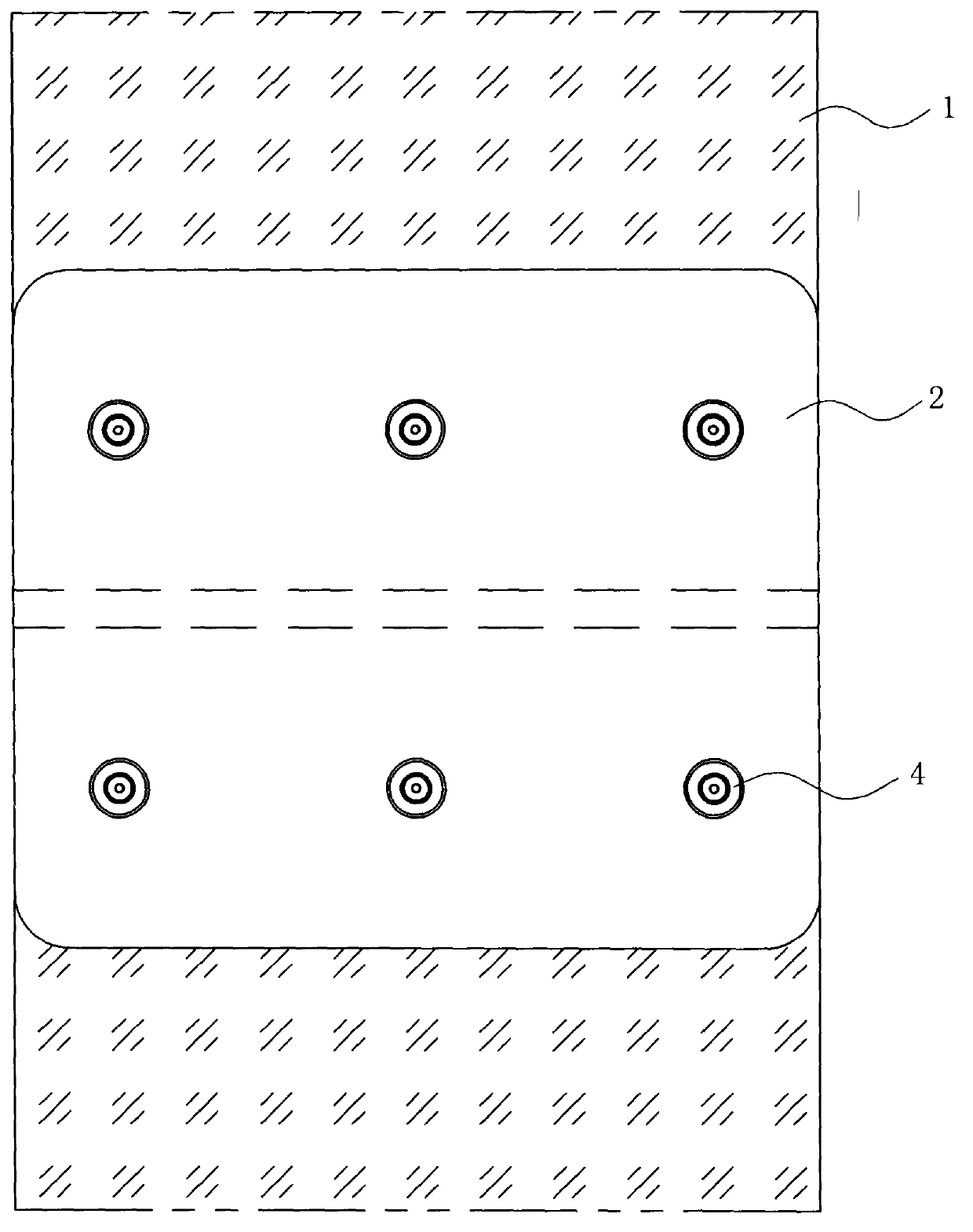

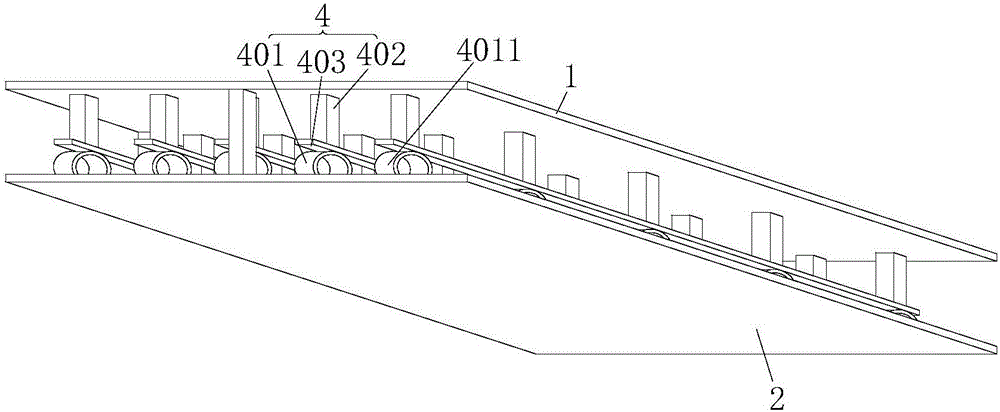

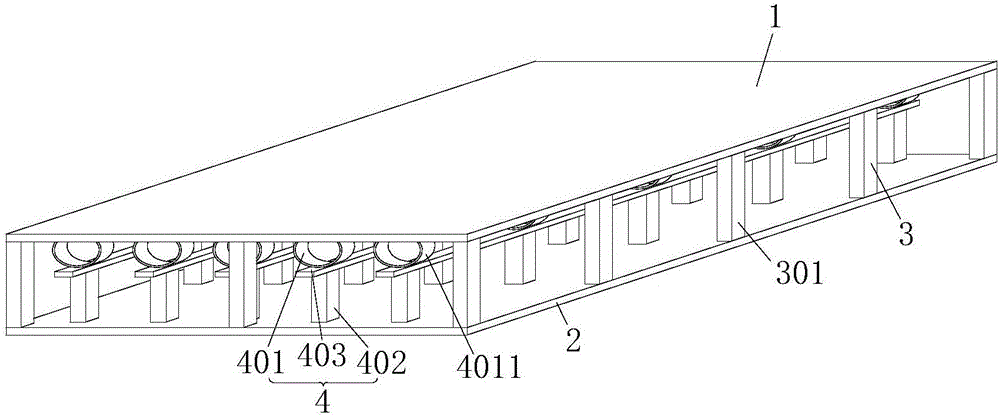

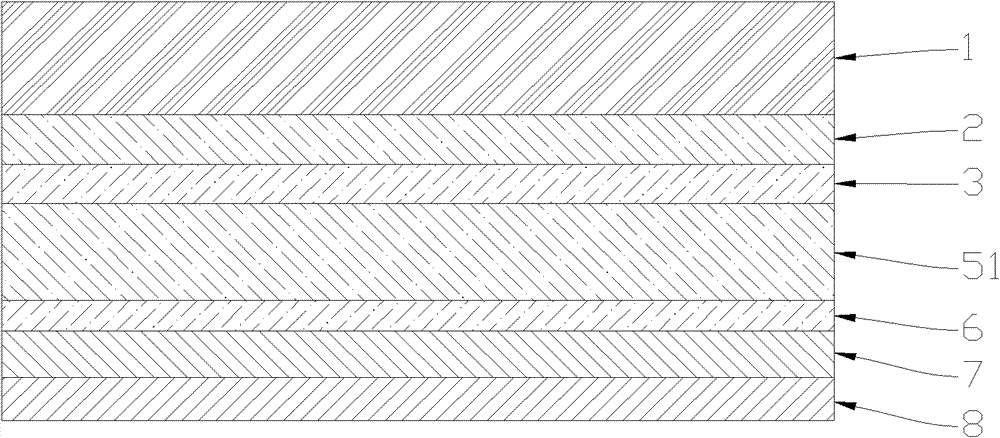

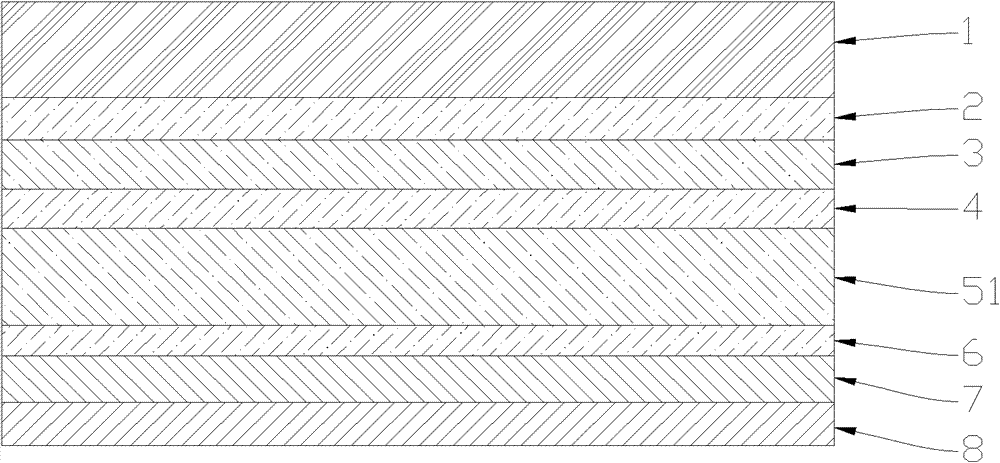

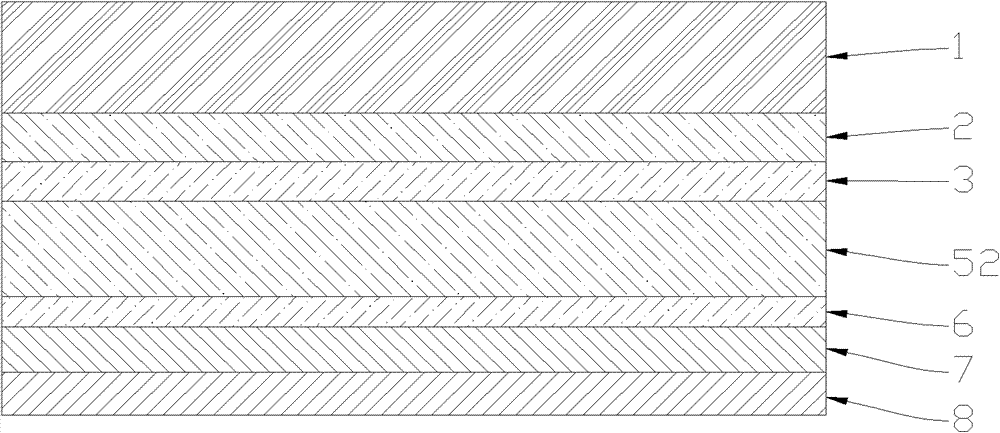

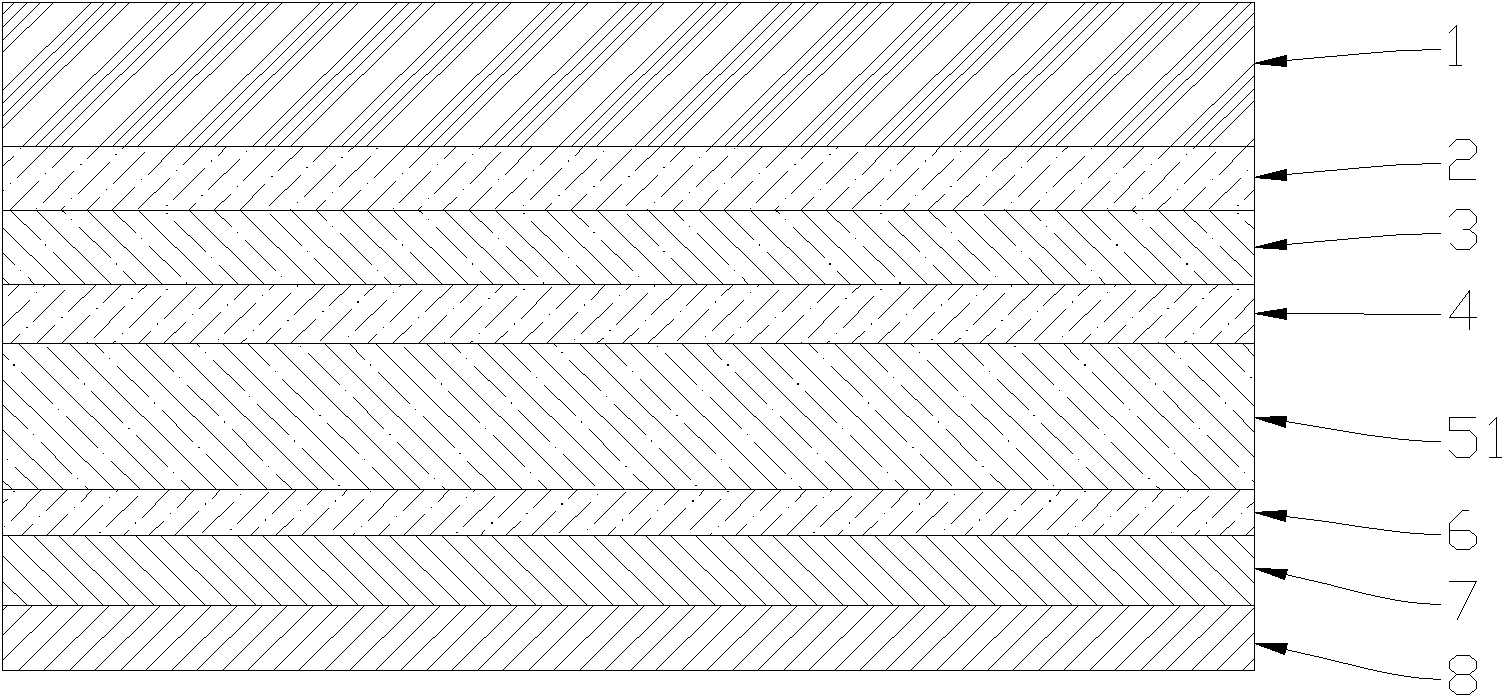

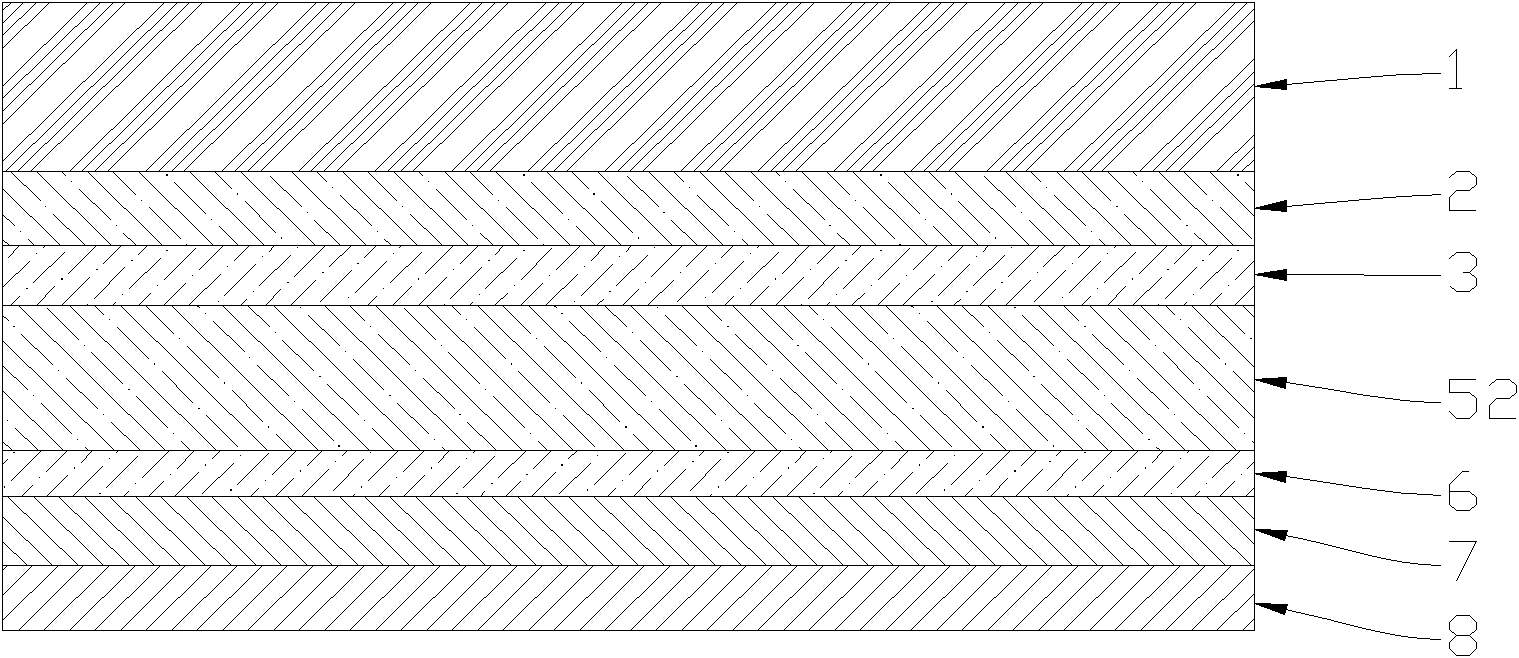

Mattress

InactiveCN106263809AImprove comfortLess discomfortStuffed mattressesSpring mattressesHuman bodyEngineering

The invention discloses a mattress, which comprises an upper panel and a lower panel, wherein the upper panel is positioned at the upper part; the lower panel is positioned at the lower part; a plurality of elastic support units used for uniformly and downwards transmitting acting force received by the upper panel and forming the elastic support on the upper panel so as to buffer the acting force of the upper part are arranged between the upper panel and the lower panel; the elastic support units are arranged in at least one direction of the longitudinal direction of the mattress, the transverse direction of the mattress and the diagonal direction of the mattress; each elastic support unit comprises a plurality of elastic elements used for forming elastic support force, a plurality of support elements used for forming rigid support and balance rods; the balance rods are arranged between the elastic elements and the support elements in the horizontal direction and are used for balancing the acting force and counterforce between the elastic elements and the support elements, and realizing the uniform transmission of the acting force and the counterforce; the elastic elements are distributed at the upper part of the balance rods; the support elements are distributed at the lower part of the balance rods; or the elastic elements are distributed at the lower part of the balance rods; the support elements are distributed at the upper part of the balance rods. The counterforce injury during human body sitting and lying is small; the mattress is suitable for various kinds of people groups to use.

Owner:CHANGSHA HUARONG ENVIRONMENTAL SCI & TECH

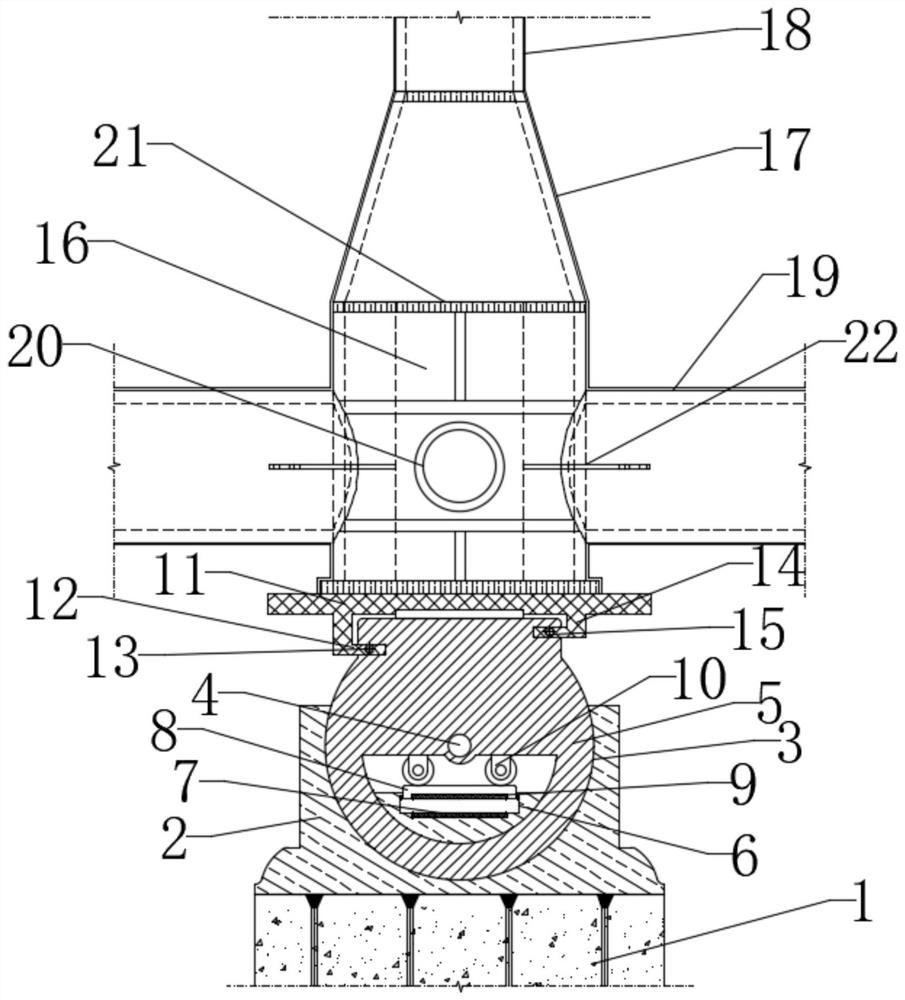

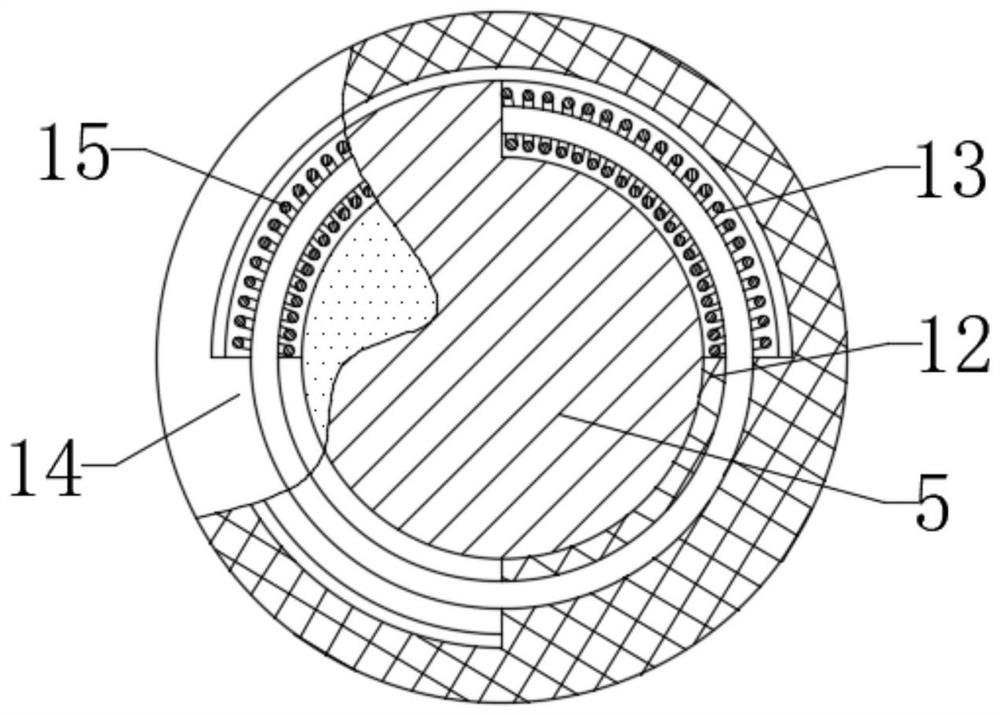

Multi-angle rotating spherical hinge support system for building steel grid structure

ActiveCN112112285AEliminate concentrated stressProtection securityBuilding constructionsBending momentArchitectural engineering

The invention relates to the technical field of building construction, in particular to a multi-angle rotating spherical hinge support system for a building steel grid structure. The multi-angle rotating spherical hinge support system for the building steel grid structure comprises an embedded part, a support is fixedly mounted on the embedded part, a rotating groove is formed in the support, a central shaft is fixedly mounted in the rotating groove, a movable seat is movably connected to the interior of the rotating groove; a sliding groove is formed in the support, a first magnetic block isfixedly mounted in the sliding groove, a limiting plate is mounted in the sliding groove in a sliding mode, a second magnetic block is fixedly mounted on the limiting plate, and a guide wheel is fixedly mounted on the movable seat. by using the embedded part and the support as structural bases, and mounting the adjustable movable seat and an adjustable rotating disc on the embedded part and the support to serve as connecting components, excessive bending moment and torque can be prevented from being generated in the structure, concentrated stress is eliminated, and the safety of the structureis protected; and meanwhile, as a magnetic reset structure is arranged in the movable seat and a spring return structure is mounted on the rotating disc, the structural stability can be guaranteed.

Owner:CHINA CONSTR EIGHTH ENG DIV

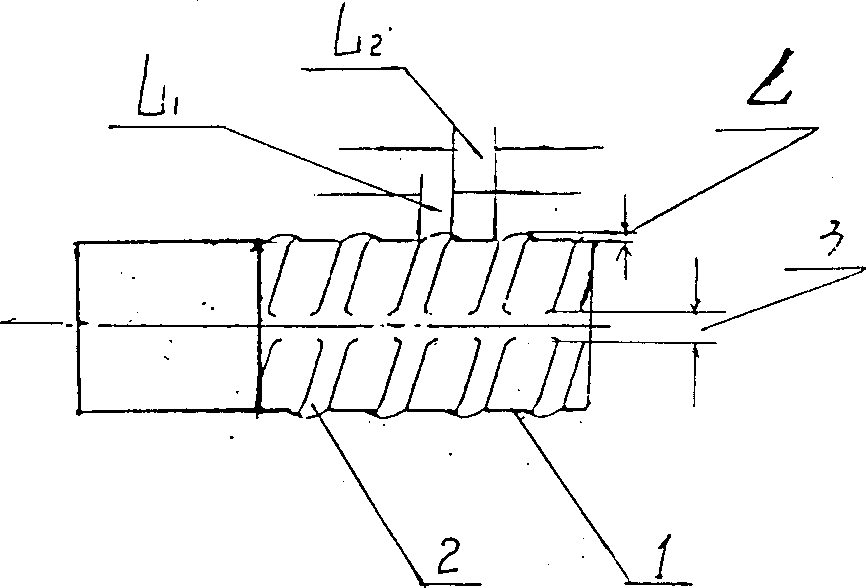

Cold-pressing technology for making equistrength archor arm and its end

A cold-pressed equistrength archor rod for supporting gallery has rod body and end part, and is made through cold (rolling) pressing the rolled rod body with axial spiral ribs to remove the ribs at head part and become a cylinder, and screwing the cylindrical head part. Its advantages are high strength, strong anchor power, and no stress concentration.

Owner:孔祥清

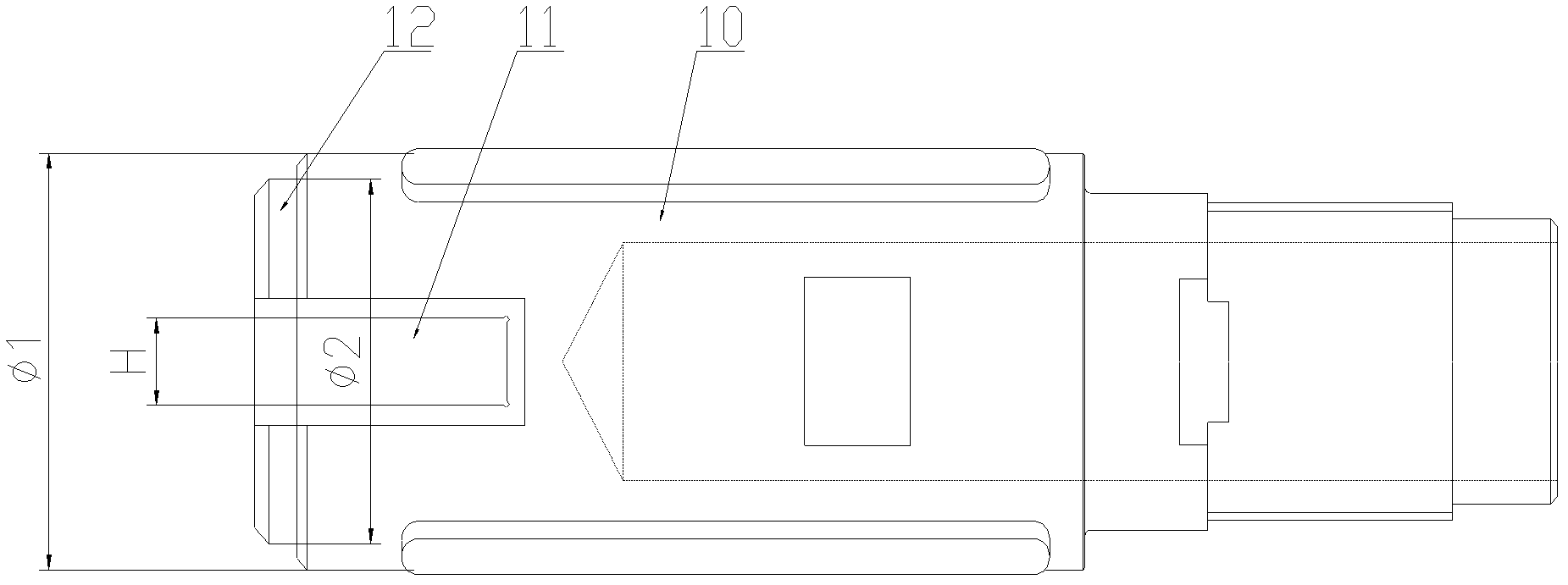

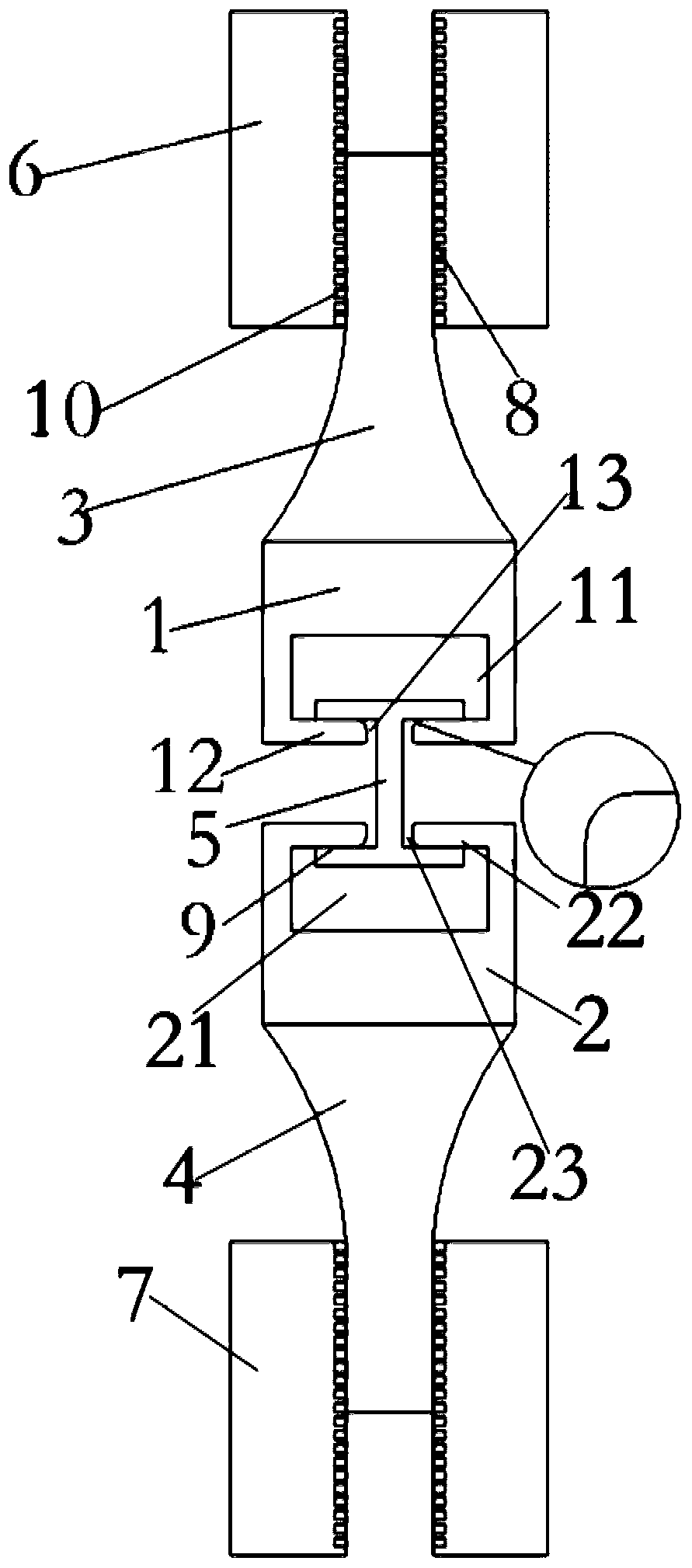

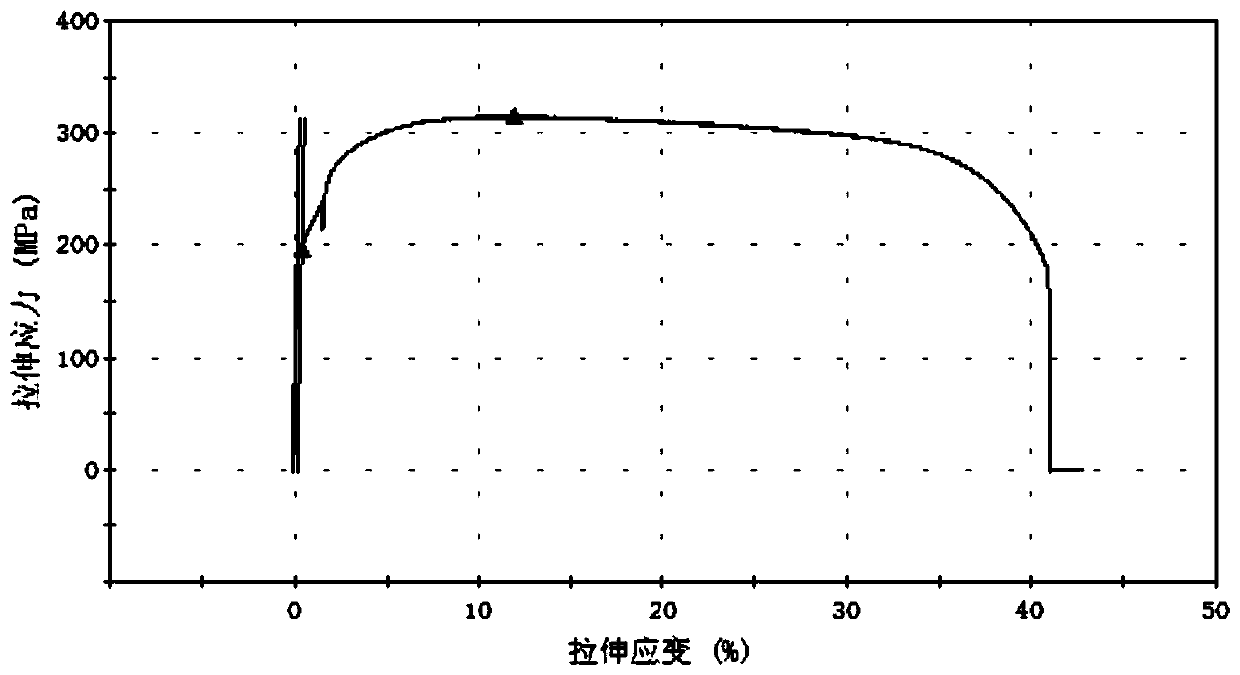

Metal plate sample stretching and clamping device and usage method thereof

PendingCN111175129AIncrease success rateImprove accuracyMaterial strength using tensile/compressive forcesEngineeringStructural engineering

The invention discloses a metal plate sample stretching and clamping device and a usage method thereof. The metal plate sample stretching and clamping device comprises a first clamping mold and a second clamping mold, the first clamping mold and the second clamping mold are installed on the testing machine upper clamping block and the testing machine lower clamping block respectively. Grooves areformed in the first clamping mold and the second clamping mold, sample steps are arranged at the ends of the grooves, and round holes are formed in the center areas of the sample steps. A sample is arranged between the first clamping module and the second clamping module, the upper clamping end and the lower clamping end are arranged in grooves of the two clamping molds respectively, and a samplebody is connected with the upper clamping end and the lower clamping end respectively after passing through the round holes. The sample clamping end is clamped through the sample step, the size of thesample clamping end is reduced, and raw materials are saved; the test failure caused by fracture of the sample clamping end due to mechanical damage in the test process of the sample is avoided, thefracture area of the sample is ensured to be a parallel section area after the test is finished, the success rate of the tensile test is effectively improved, and the test result accuracy is high.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

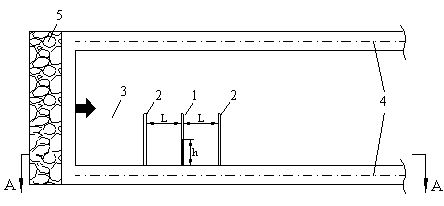

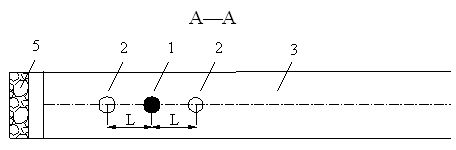

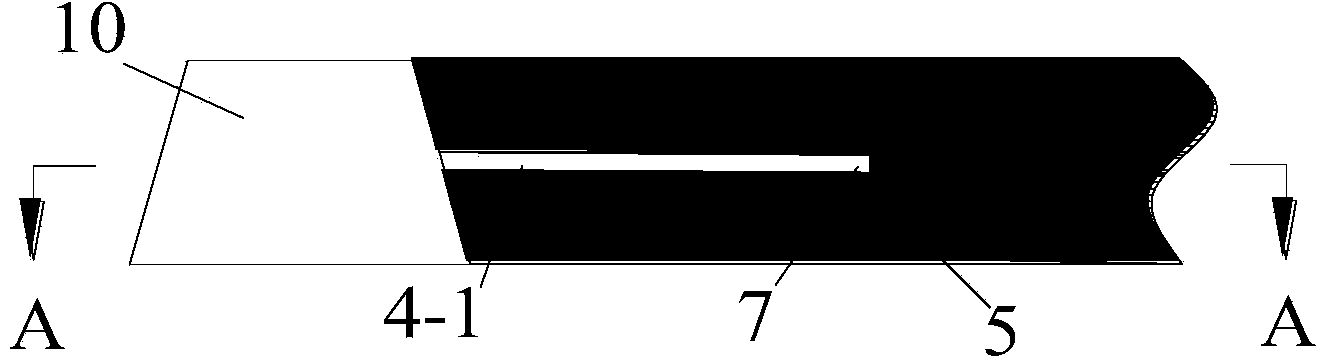

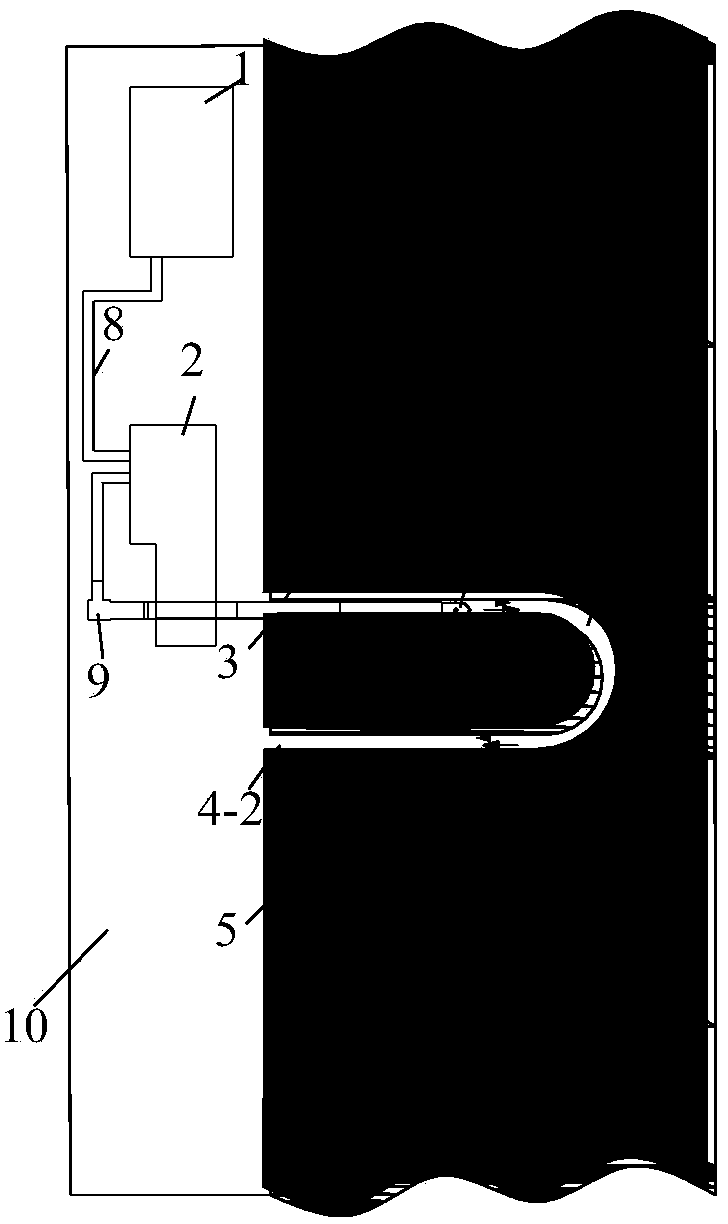

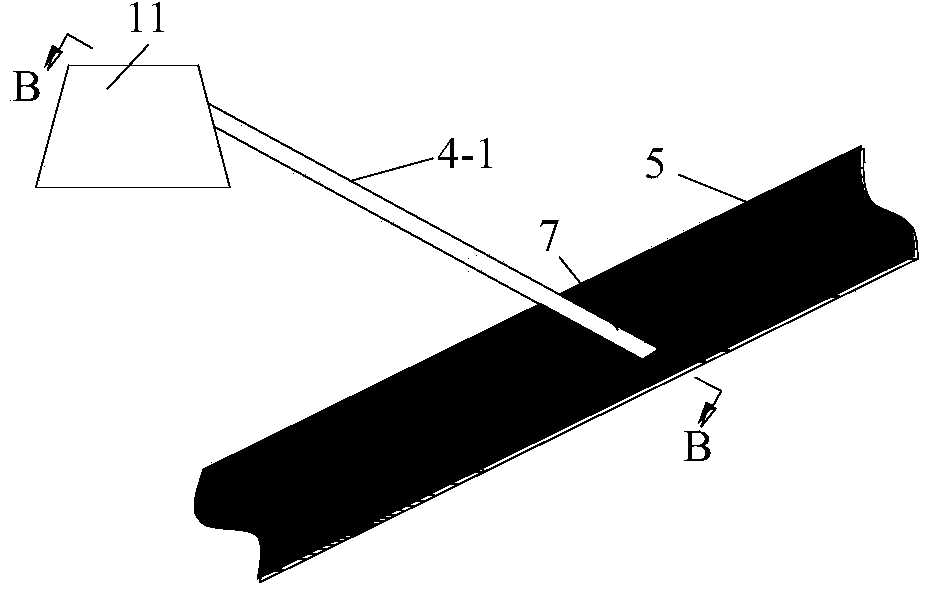

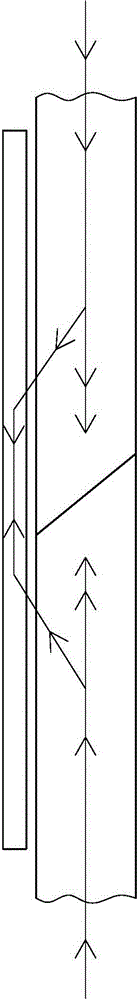

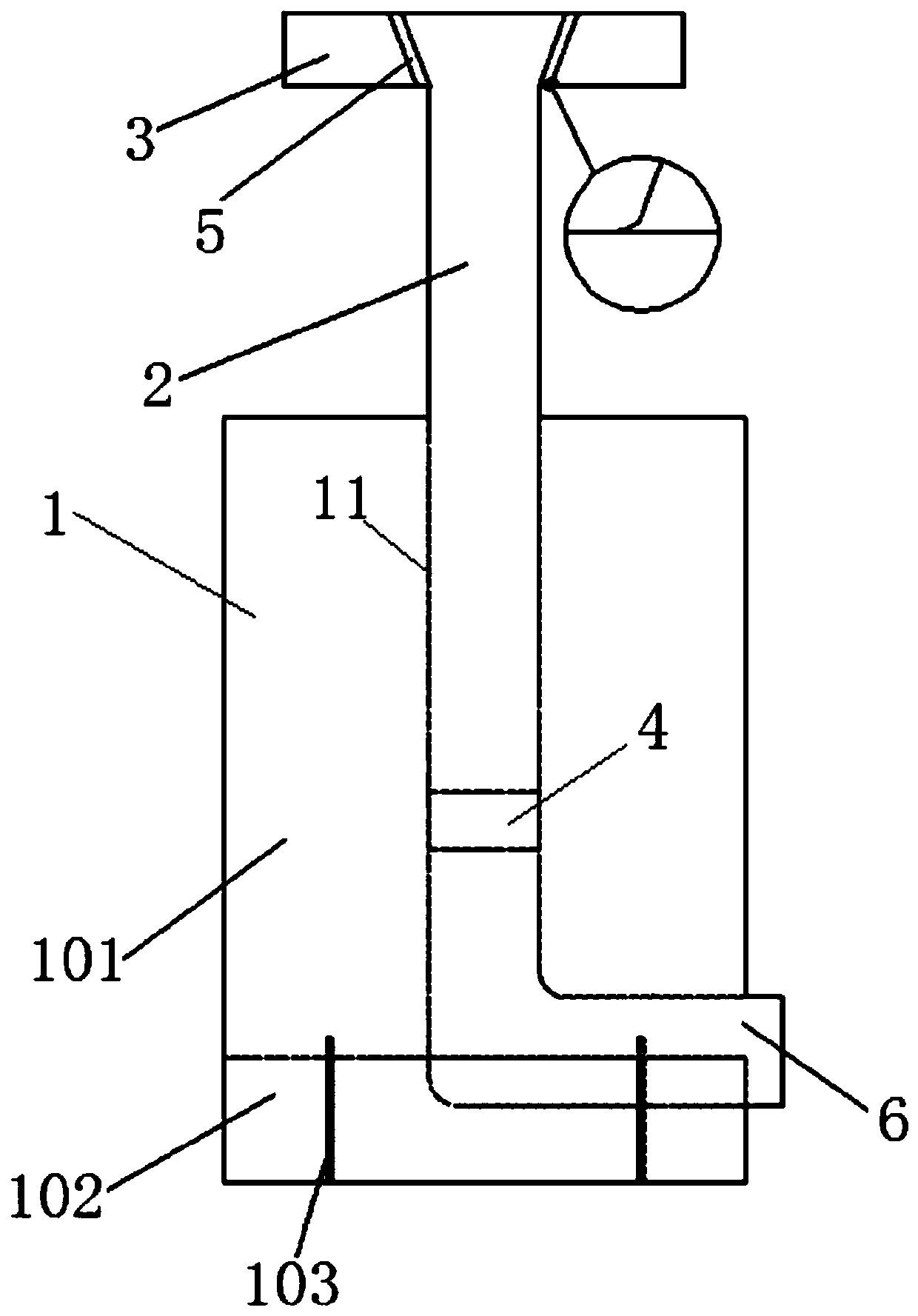

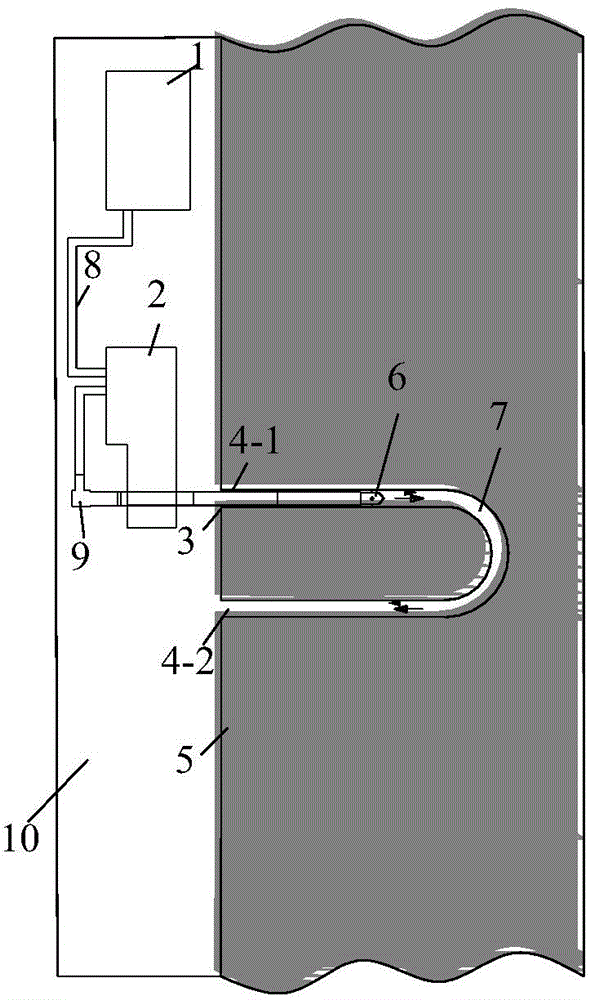

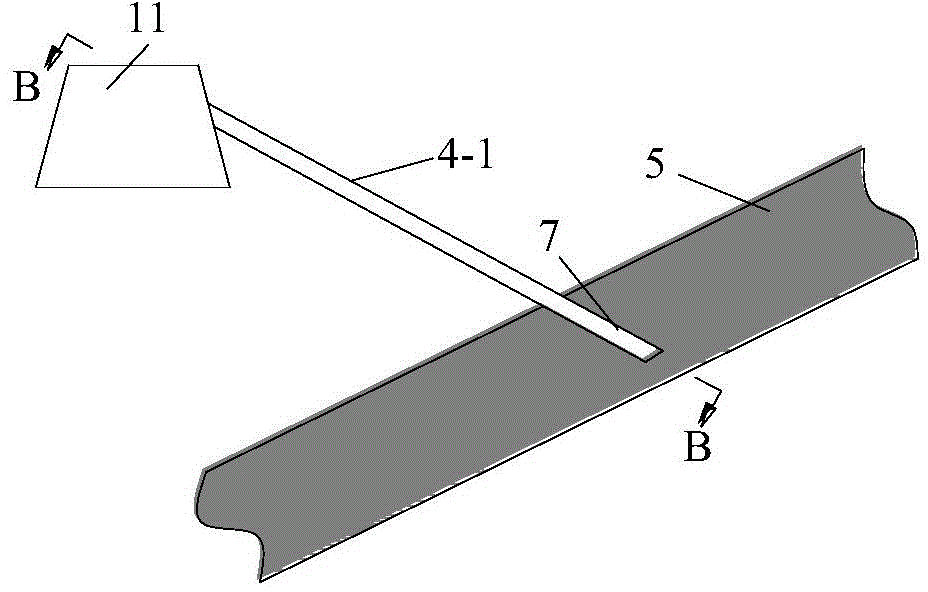

Hydraulic cutting, U-shaped hole slagging and gas treatment method

The invention provides a hydraulic cutting, U-shaped hole slagging and gas treatment method which is applicable to slagging during a process of applying a hydraulic cutting gas technology in drilling of a coal seam bedding, a high-position lane penetrating layer or a low-position lane penetrating layer. A U-shaped drilled hole is pre-constructed in a coal seam by use of a kilo directional drilling machine from the coal seam bedding, the high-position lane penetrating layer or the low-position lane penetrating layer to a target area coal body, and then a hydraulic cutting device is connected with a drill stem and is fed into one hole of the U-shaped drill hole by virtue of the drilling machine; the hydraulic cutting device is started, firstly hydraulic cutting is performed on the coal body in one hole of the U-shaped drilled hole, and draining and slagging is performed by virtue of the other drilled hole of the U-shaped drilled hole; when hydraulic cutting in one drilled hole is finished, hydraulic cutting is performedin the other drilled hole of the U-shaped drilled hole, and the previous drilled hole serves as a slagging hole. The method can be used for solving the problems of difficulty in slagging, hole blockage, hole spraying and the like in hydraulic cutting of the coal seam, further improving the air permeability of the coal seam, and eliminating the concentrated stresses of the coal body and wall rocks; great coal and gas outburst potential energy is released, so that an effective effect of preventing coal and gas outburst is achieved. The method is simple in operation, convenient in use and good in effect.

Owner:CHINA UNIV OF MINING & TECH

Locking and pressurizing bone setting device

InactiveCN105147377AAvoid breakingReduce volumeInternal osteosythesisBone platesStress concentrationShear stress

The invention discloses a locking and pressurizing bone setting device capable of eliminating stress concentration and stress shielding. The locking and pressurizing bone setting device comprises a main locking and pressurizing bone setting plate, locking screws and sleeves. Main locking screw holes corresponding to the locking screws are formed in the main locking and pressurizing bone setting plate. The locking and pressurizing bone setting device is characterized by further comprising an auxiliary locking bone setting plate and two positioning rods corresponding to the sleeves; the auxiliary locking bone setting plate and the main locking and pressurizing bone setting plate are applied at the same time, at least one auxiliary locking screw hole and at least one auxiliary screw hole are formed in the auxiliary locking bone setting plate and correspond to the main locking screw holes in position and size, and when the locking and pressurizing bone setting device is applied, the auxiliary locking screw holes and the auxiliary screw holes are distributed in the two sides of a fracture line respectively; the outer diameter of the positioning rods is the same as the inner diameter of the sleeves. The locking and pressurizing bone setting device is simple in structure and convenient to operate; a stress conduction mode is changed, shearing stress is eliminated, the bone setting plates are prevented from being broken and can be thinner and narrower, and injuries to a patient are reduced; meanwhile, as internal fixing is firmer, the patient can perform functional training in the early stage, and the limb function can be recovered as early as possible.

Owner:谢文平

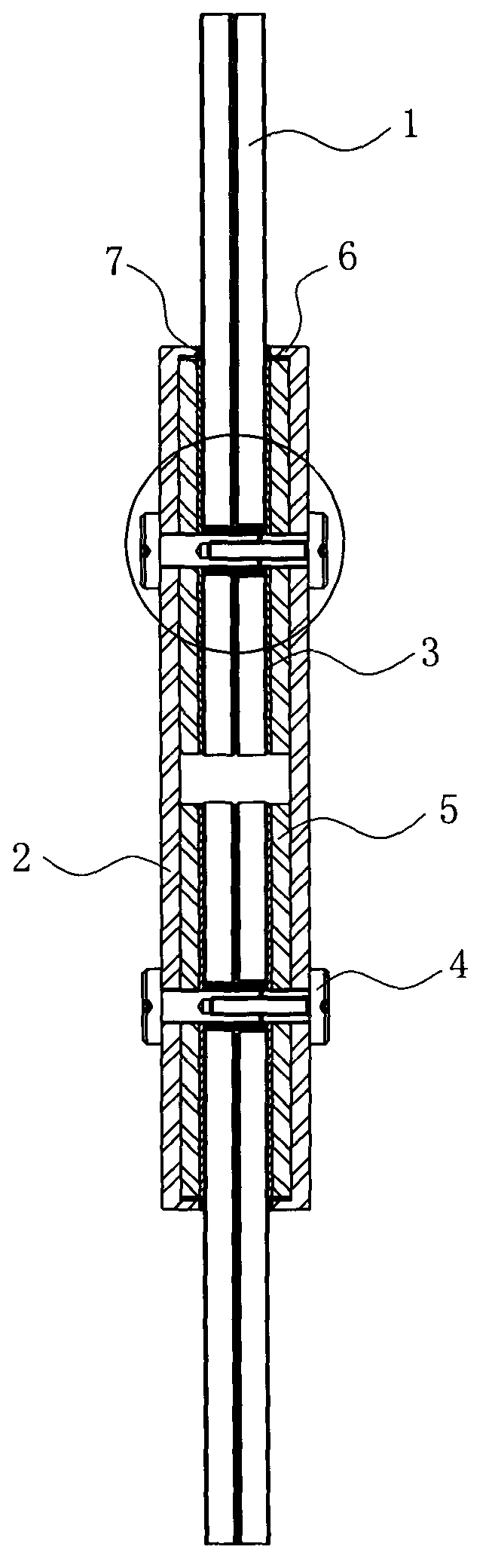

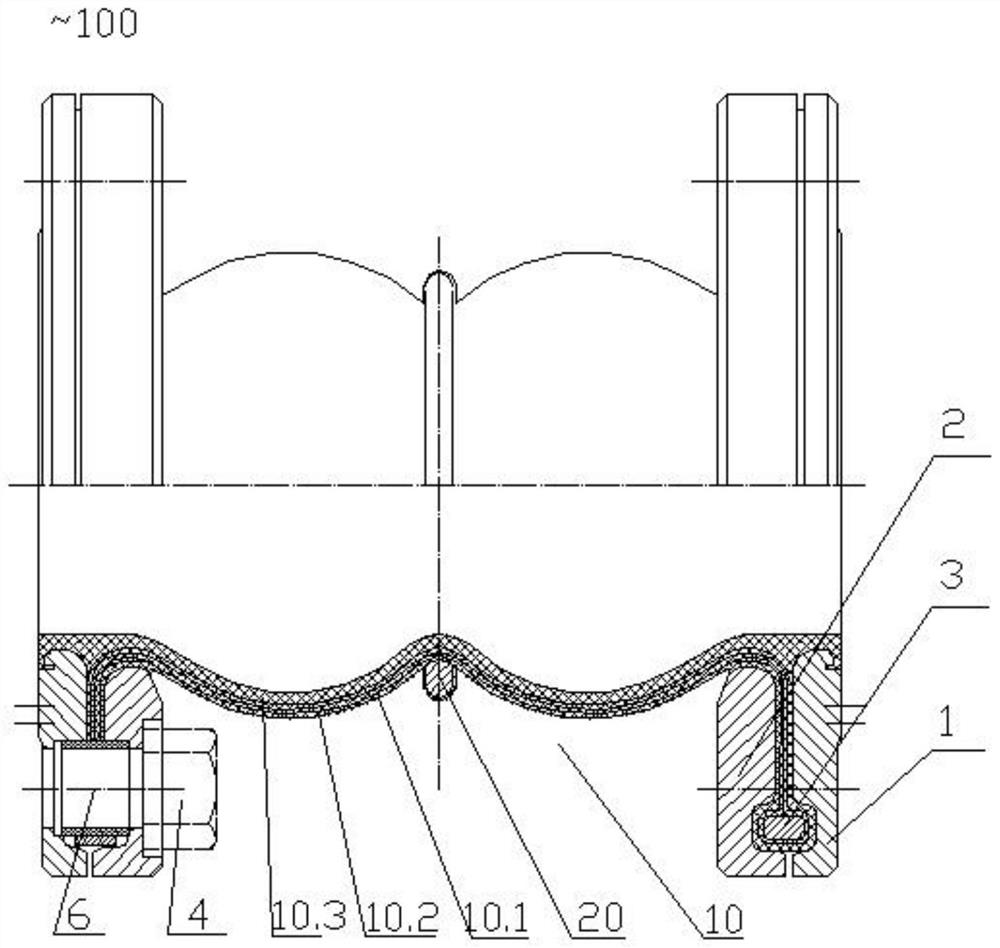

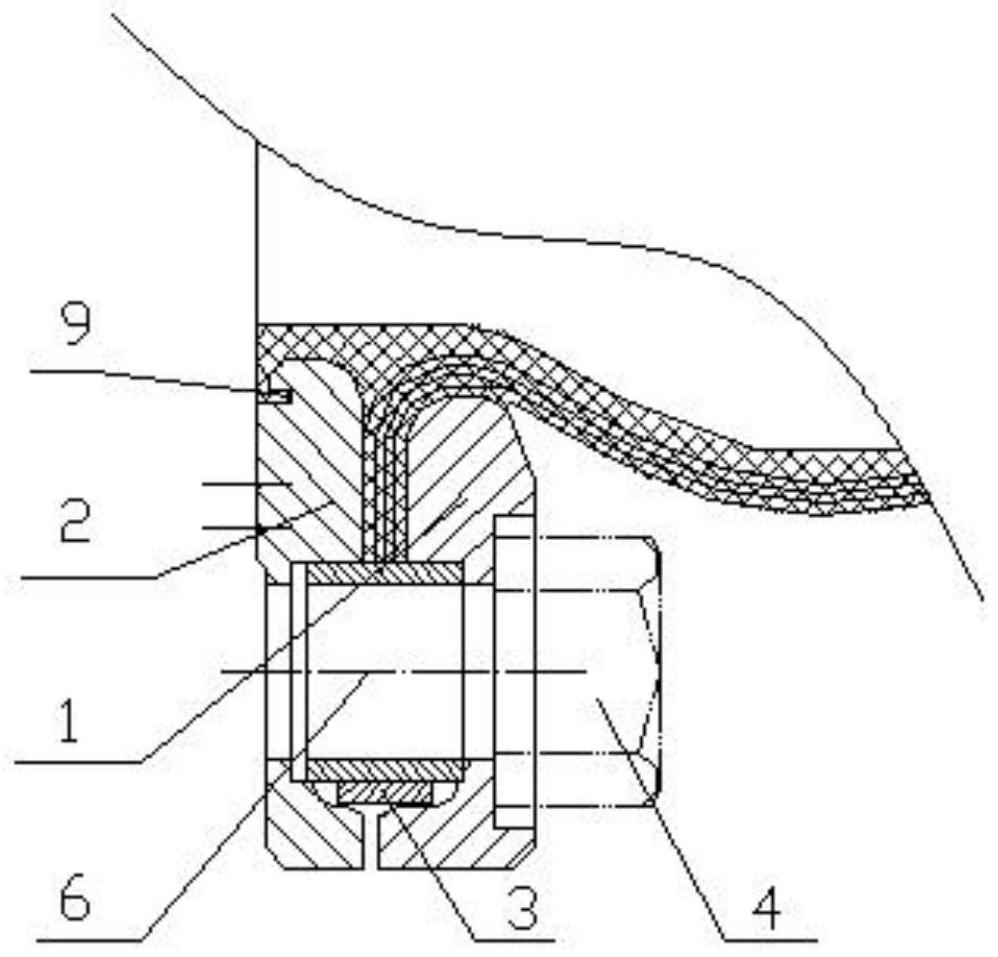

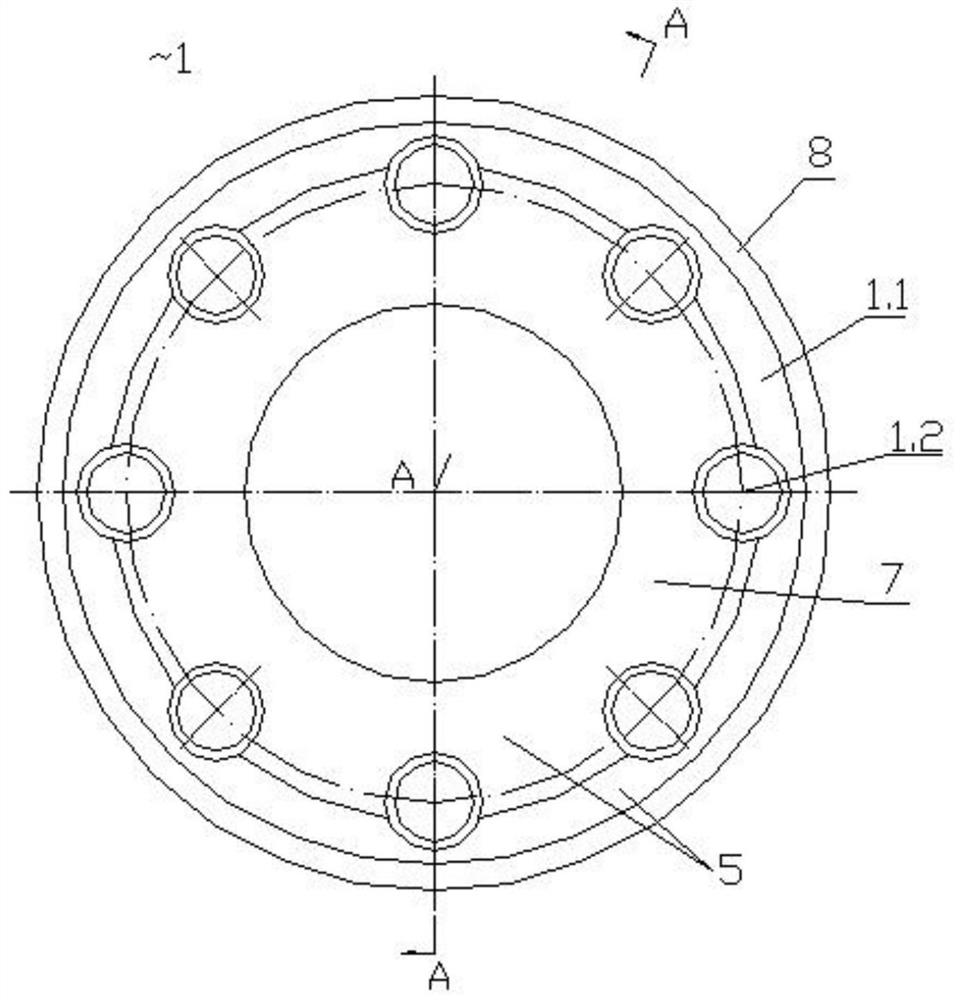

Self-locking flange pair and flexible connecting pipe

InactiveCN112238625AImprove vibration damping effectReduce rigid segmentAdjustable jointsPipe elementsEngineeringAramid

The invention discloses a self-locking type flange pair and a flexible connecting pipe. The self-locking type flange pair comprises a locking flange, a sealing flange and a fastening ring, wherein thelocking flange and the sealing flange are connected through a bolt, and a first annular groove formed in the outer side of the top surface of the locking flange is matched with a second annular groove formed in the outer side of the surface, close to the locking flange, of the sealing flange to form an annular cavity for containing the fastening ring; aramid fiber layers are arranged on the surfaces, close to each other, of the locking flange and the sealing flange respectively; and when the self-locking type flange pair is used for connecting the end of the flexible connecting pipe, the endof a framework layer of the flexible connecting pipe is turned outwards along the top surface of the locking flange and wound around the fastening ring by a circle, then the framework layer is lockedthrough the locking flange and the sealing flange corresponding to the framework layer, and the framework layer is pressed between the two aramid fiber layers. The self-locking type flange pair is simple in structure and small in size, the self-locking type flange pair is composed of the sealing flange, the fastening piece and the locking flange in a special combination mode, rigid sections can bereduced, the flexible length can be increased, and the self-locking type flange pair has excellent pull-out resistance and vibration reduction performance.

Owner:湖北维普路船舶机电科技有限公司

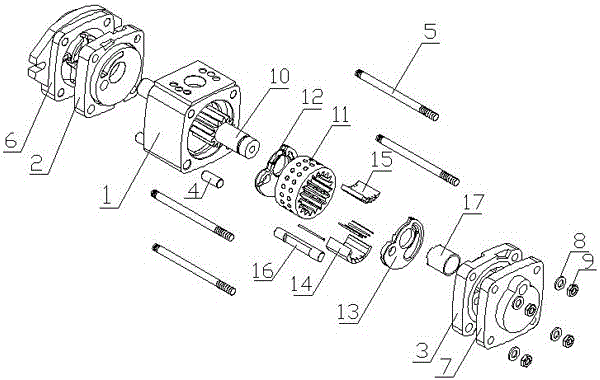

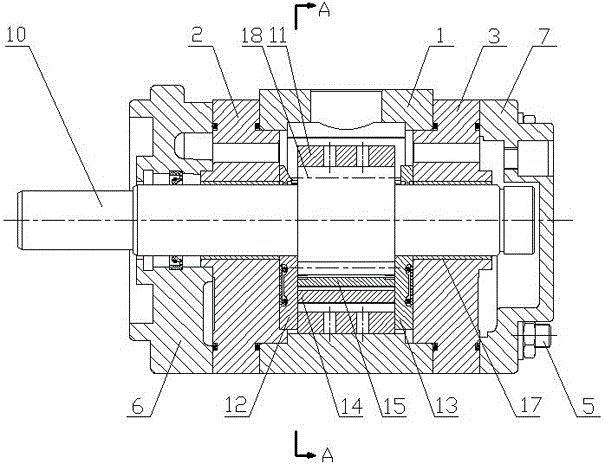

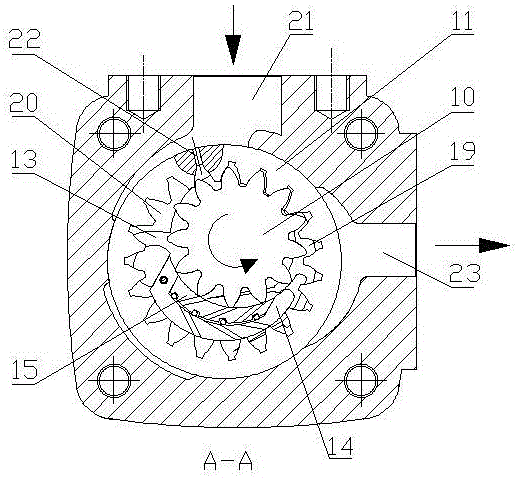

A kind of internal meshing gear pump capable of realizing partial axial compensation

InactiveCN104265623BReduce internal leakageImprove stress resistanceRotary piston pumpsRotary piston liquid enginesGear pumpEngineering

The invention relates to an internal gear pump capable of achieving partition axial compensation. The internal gear pump comprises a pump body, a gear pair and crescent blocks; a gear shaft is meshed with an internal gear ring to form the gear pair; the crescent blocks are arranged in the gear pair; a left axial compensation device and a right axial compensation device which are the same in structure are symmetrically arranged on the two end faces of the crescent blocks and the gear pair; each axial compensation device comprises a first-level side plate, a second-level side plate and a third-level side plate; a first compensation groove is formed in the outer end face of each first-level side plate; a second compensation groove is formed in the inner end face of each first-level side plate; elastic sealing rings and side plate gaskets are sequentially stacked in the first compensation grooves to form a first-level axial compensation system; springs and the second-level side plates are sequentially stacked in the second compensation grooves to form a second-level axial compensation system; sealing blocks and the third-level side plates are sequentially stacked on the second-level side plates to form a third-level axial compensation system. Partition self-adaption adjustment is carried out on abrasion positions and non-abrasion positions, internal leakage of the pump is effectively reduced, and large-area supporting of the side plates can be still achieved under the abrasion state.

Owner:FUZHOU UNIV

Manufacturing method of whisker enhancement type fiberglass full thread roof bolt

The invention discloses a manufacturing method of a whisker enhancement type fiberglass full thread roof bolt, wherein the technical process comprises the following steps: yarn supplying, resin pickup, hot briquetting, heat preservation, step cooling, dragging and cutting. The manufacturing method can overcome the defects that the traditional fiberglass full thread roof bolt has poor surface finishment, serious abrasion for equipment, poor toughness, poor fatigue resistance, poor chemical resistance, poor humidity resistance and is easy to absorb water.

Owner:HUAIBEI YUXIN NEW MATERIAL

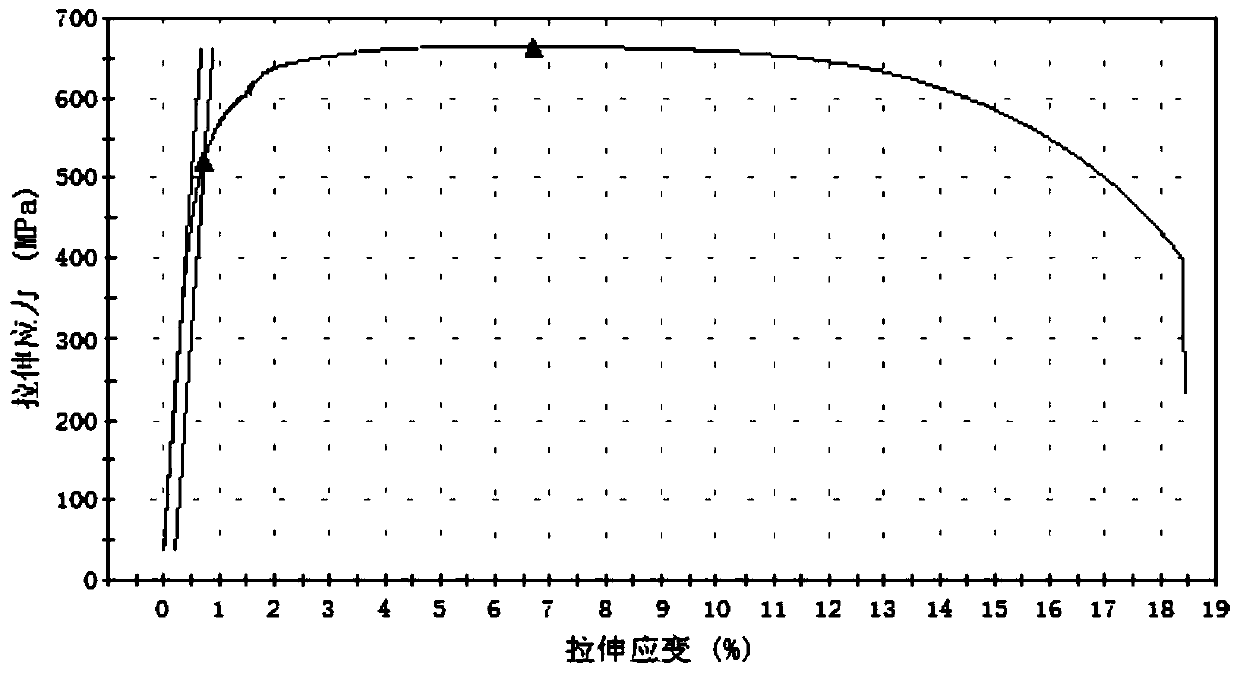

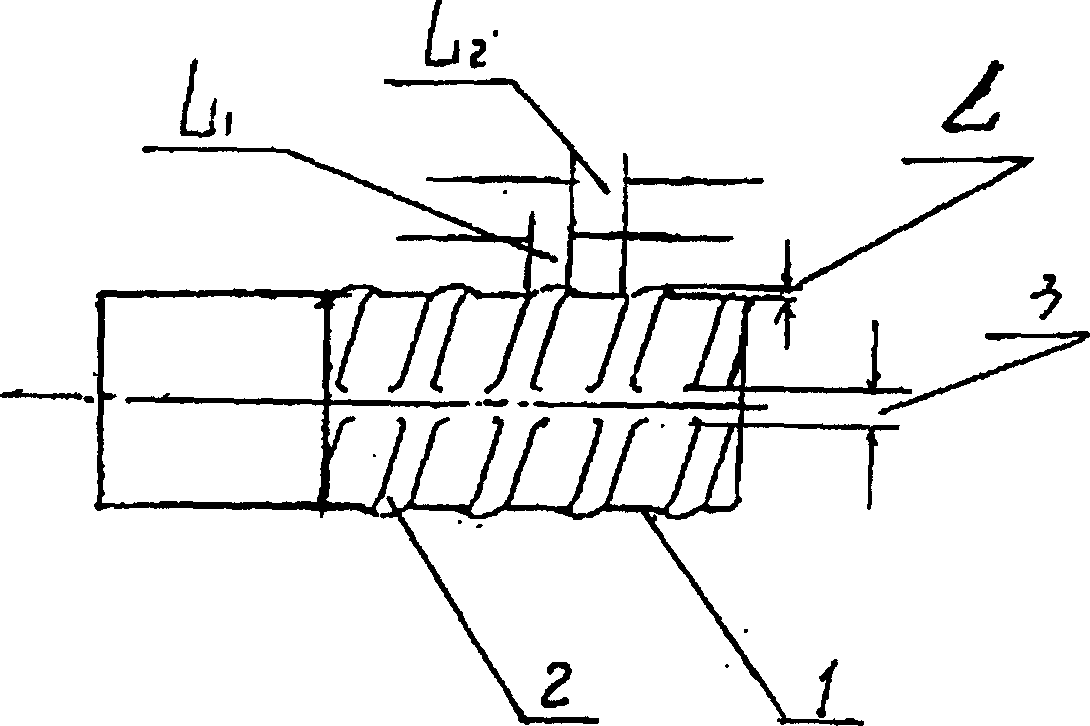

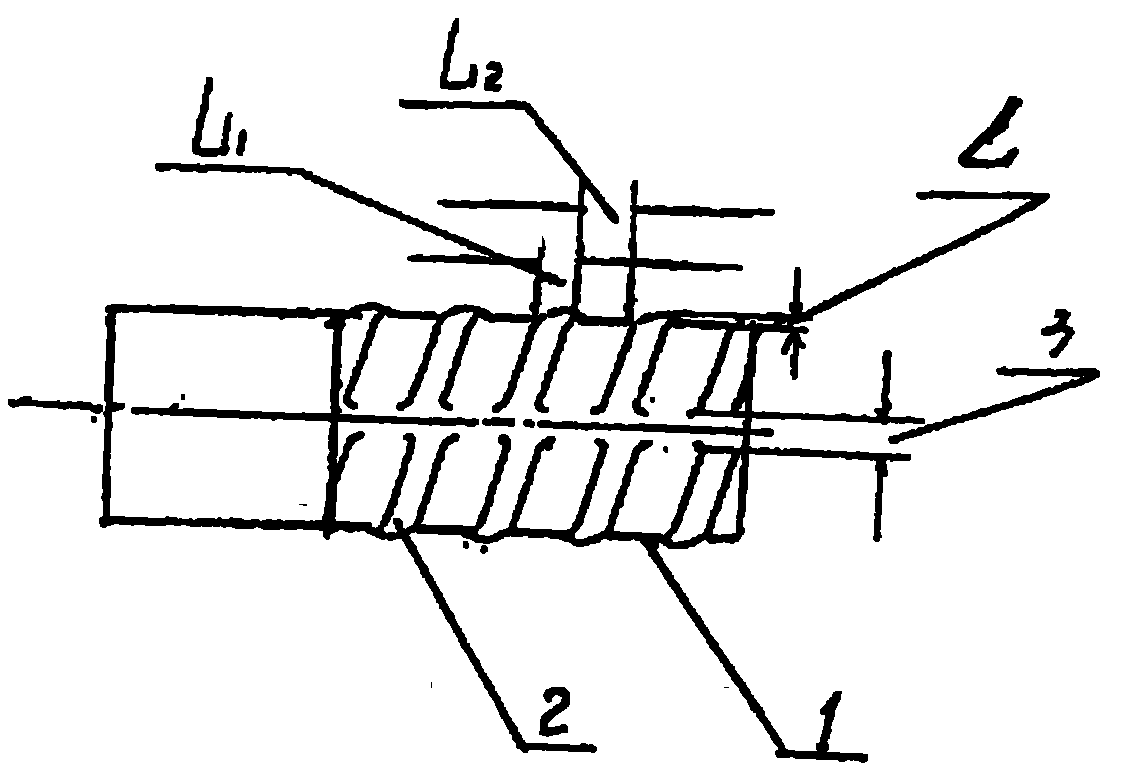

Technology for making strengthened anchor such as end cold-pressing

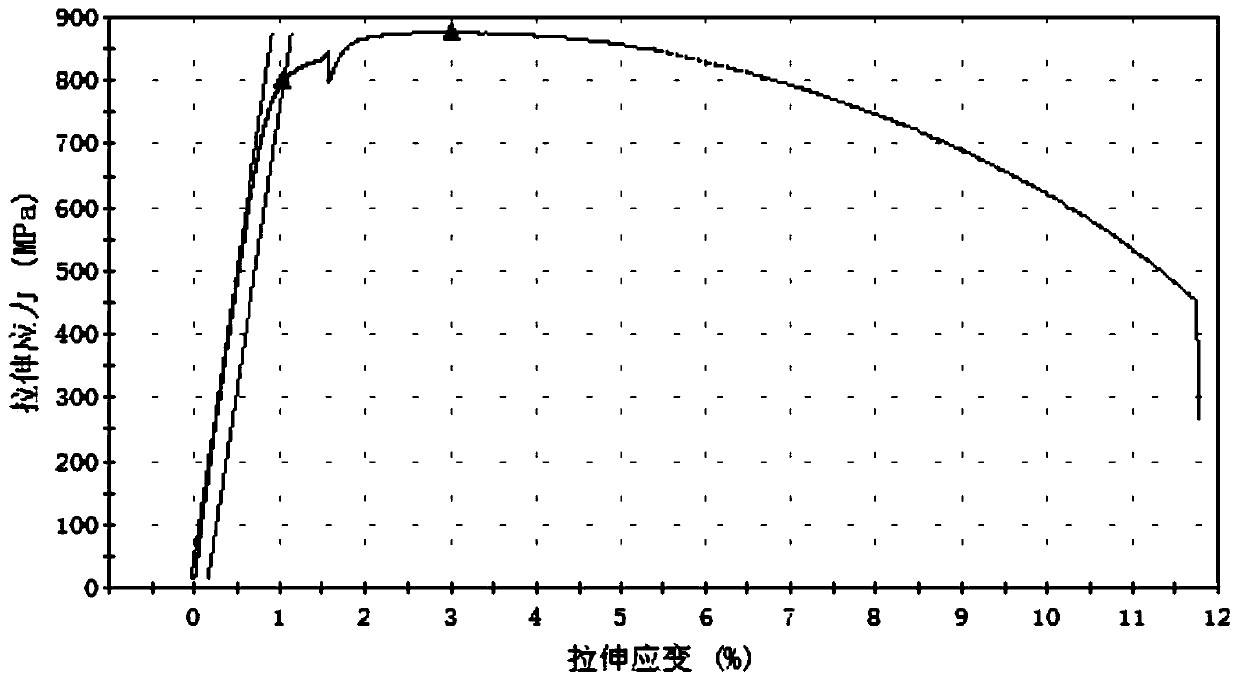

InactiveCN1284643CHigh strengthEliminate concentrated stressScrew-threads articlesStress concentrationEngineering

The invention provides a processing method of a cold-pressed head and other strong bolts. It has a rod body on which an axial spiral rib is processed. The cold-rolled and hot-rolled anchor body base material is cold-pressed by using a cold-pressed head facility. The length is about 70-150 mm. The end of the one-way spiral anchor rod without longitudinal reinforcement is cold-pressed and rounded. It is processed into a cylindrical rod body that meets the technical requirements of thread rolling, and then the standard metric thread is rolled out through the thread rolling process. During installation and construction, it can confiscate and stir the anchoring agent, the propulsion and rotation resistance is small, the rod body has good grip and wrapping force, high strength, and the transfer effect of the anchoring force and bearing capacity is improved. The force can be transmitted to the rod body to increase the bearing strength. The material of the rod body is saved, and the cost is low. The anchor rod processing method of the present invention has the following advantages: it can reduce the material loss and strength loss during the processing of the anchor rod parent rod, make the strength of the end reach about 95% of the tensile strength of the anchor rod parent material, and basically realize the anchor rod etc. Strong, eliminates stress concentration and brittle fracture, and improves the overall strength of the bolt by 15-25%.

Owner:孔祥清

Method for extracting gas in low air permeability coal layer by pulse fracture anti-reflection

ActiveCN102155254BChange mechanical propertiesImprove breathabilityFluid removalGas removalHigh pressure waterPermeable channel

The invention relates to a method for extracting gas in low air permeability coal layer by pulse fracture anti-reflection, comprising the following steps: firstly using the blast-proof pulse-type coal layer high pressure water injector with adjustable frequency and pressure from the coal layer, high tunnel or low tunnel; using the pulse water effect generated by the periodical change of high pressure pulse water inside the drill hole of coal body, wherein the maximum pulse pressure is 35 MPa, the flow is about 300 L / min, and the pulse frequency is 0-1460 times / min; forcing the macroscopic fracture in the coal layer to be expanded and communicated; promoting the micro-pore fracture to be formed and extended; forming a new regeneration fracture net; providing a permeable channel of water inthe coal layer so as to achieve the effects of improving the mechanical property of the coal body, reducing the stress of the coal body in front of the working face and improving the discharge rate of the gas. Through the method, the pressure releasing range of the coal layer is enlarged, the whole pressure is adequately released, the radius of influence range of fracture can reach 10-40 m, and the air permeability of the coal body can be improved by 100-1000 times; and the method is simple, easy to operate and good in effect.

Owner:CHINA UNIV OF MINING & TECH

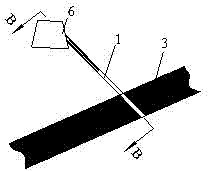

Production process of spokes for engineering machinery wheels

The invention belongs to the technical field of spokes of engineering machinery, and aims to provide a production process of spokes for engineering machinery wheels. The production process specifically comprises twelve procedures of blanking, forming, punching, air hole punching, extruding and chamfering, air hole reaming, air valve hole punching, flattening, machining, drilling, counter sinking, steel seal stamping and the like. The unique extruding and chamfering procedures are adopted, the problem of micro cracks generated by air hole punching is effectively solved, and the machining efficiency and the installation performance of bolt holes are improved through the counter sinking technology. The prepared spokes of the engineering machinery wheels have the advantages of being high in strength, free of micro cracks, accurate in size, small in installation error, stable in physical and chemical performance, high in yield (larger than or equal to 99.5%) and the like, and can be widely applied to the field of engineering machinery wheels.

Owner:杭州润德车轮制造有限公司

Metallic material acute plastic deformation extrusion die and using method of die

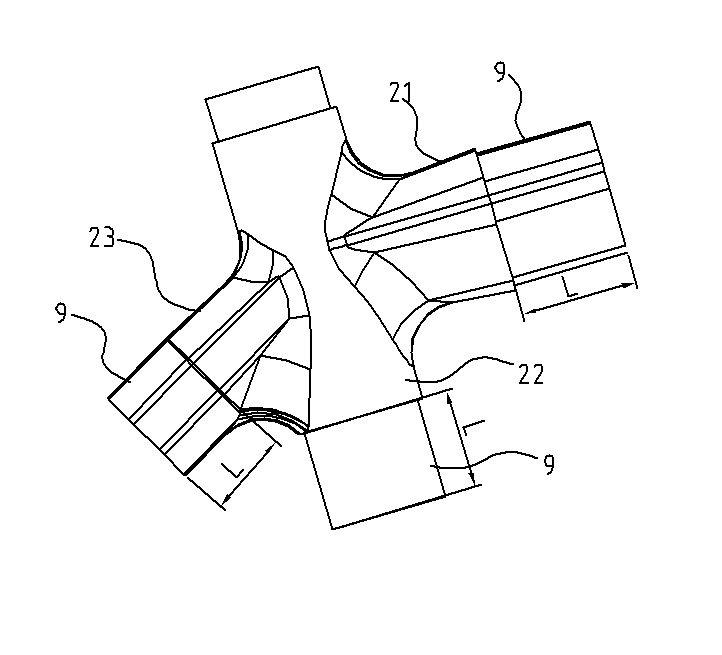

PendingCN110947786AAvoid test failuresReduce extrusion pressureExtrusion diesRams/plungersMetallic materialsLateral extrusion

The invention discloses a metallic material acute plastic deformation extrusion die and a using method of the die. The die comprises an extrusion barrel, an extrusion stem, an extrusion stem die holder and an extrusion cushion block. Extrusion channels are arranged in the extrusion barrel. An extrusion sample is arranged in the extrusion channels. The extrusion channels include the vertical extrusion channel and the transverse extrusion channel. The upper end of the vertical extrusion channel communicates with the upper surface of the extrusion barrel. The lower end of the vertical extrusion channel communicates with one end of the transverse extrusion channel. The other end of the transverse extrusion channel communicates with the surface of the side wall of the extrusion barrel. The extrusion stem penetrates through the vertical extrusion channel. The upper end of the extrusion stem is fixedly connected with the extrusion stem die holder. The lower end of the extrusion stem makes contact with the extrusion sample. The extrusion cushion block is arranged between the extrusion stem and the extrusion sample. According to the metallic material acute plastic deformation extrusion dieand the using method of the die, because the extrusion cushion block is arranged between the extrusion stem and the extrusion sample, during testing, it is avoided that a test fails because an extrusion sample is reversely extruded in the extrusion process, extrusion force is reduced, the test success rate is increased, and a test result is accurate.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for improving weak light response of amorphous silicon film battery

InactiveCN102185038BEliminate concentrated stressImproved low light responseFinal product manufactureSemiconductor devicesEngineeringLight responsive

The invention discloses a method for improving weak light response of an amorphous silicon film battery, belonging to the field of semiconductors. In the prior art, the heterojunction of a-SiC of a P layer and a-Si of an I layer causes stress concentration and defect density of a P / I interface. In the method, when raw materials containing gaseous H2 and gaseous SiH4 are used for depositing the P layer and the I layer on the basis of the decomposition reaction of the gaseous SiH4 to perform carbon element doping. The carbon element doping is to dope gaseous CH4 in the deposited raw materials. An a-Si layer of the I layer is converted into an a-SiC layer in a carbon doping mode, and the heterojunction of the a-SiC of the P layer and the a-Si of the I layer is further converted into a homojunction of the a-SiC of the P layer and the a-SiC of the I layer, thereby eliminating the heterojunction, and eliminating the stress concentration and defect density of the interface greatly, and finally improving the weak light response of the amorphous silicon film battery remarkably.

Owner:HANGZHOU AMPLESUN SOLAR TECH

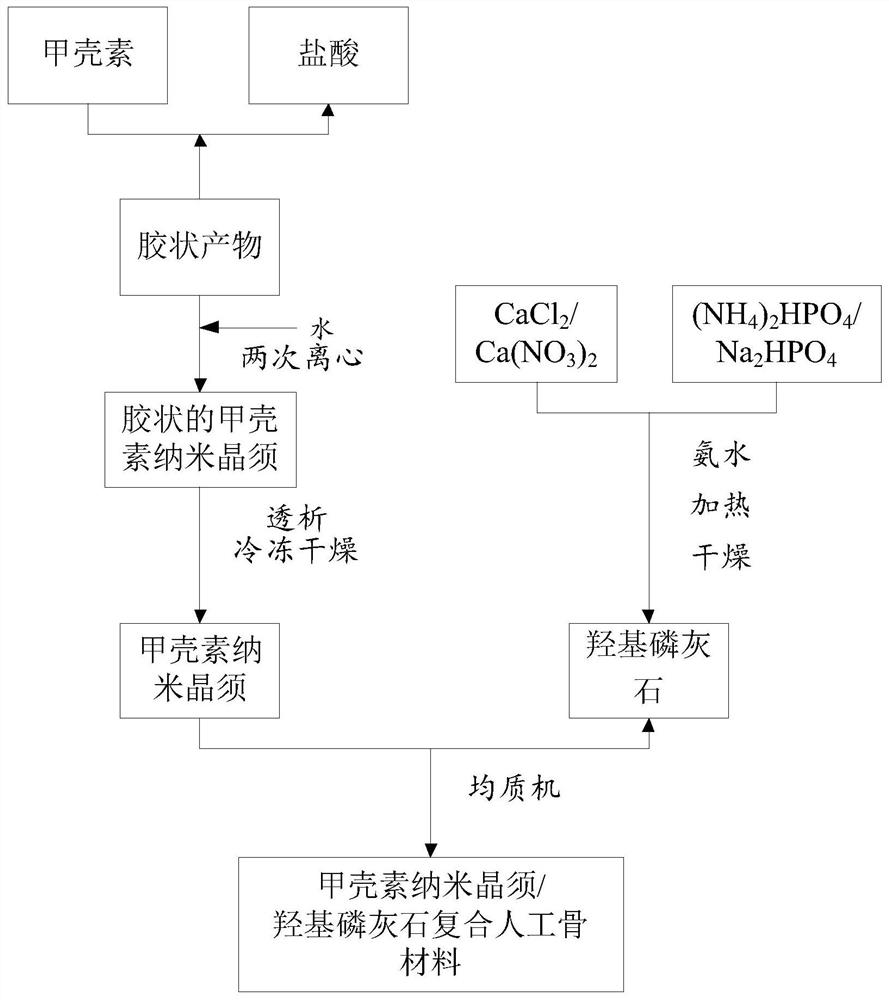

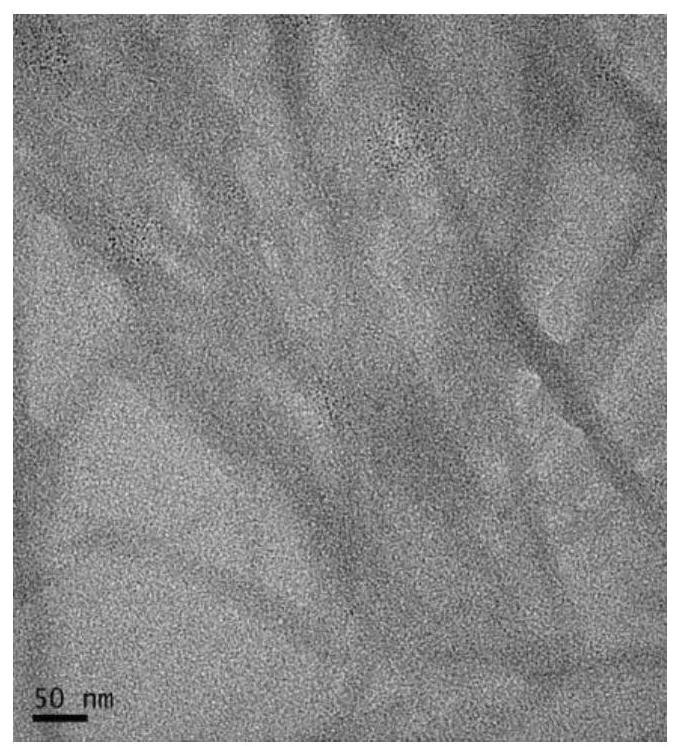

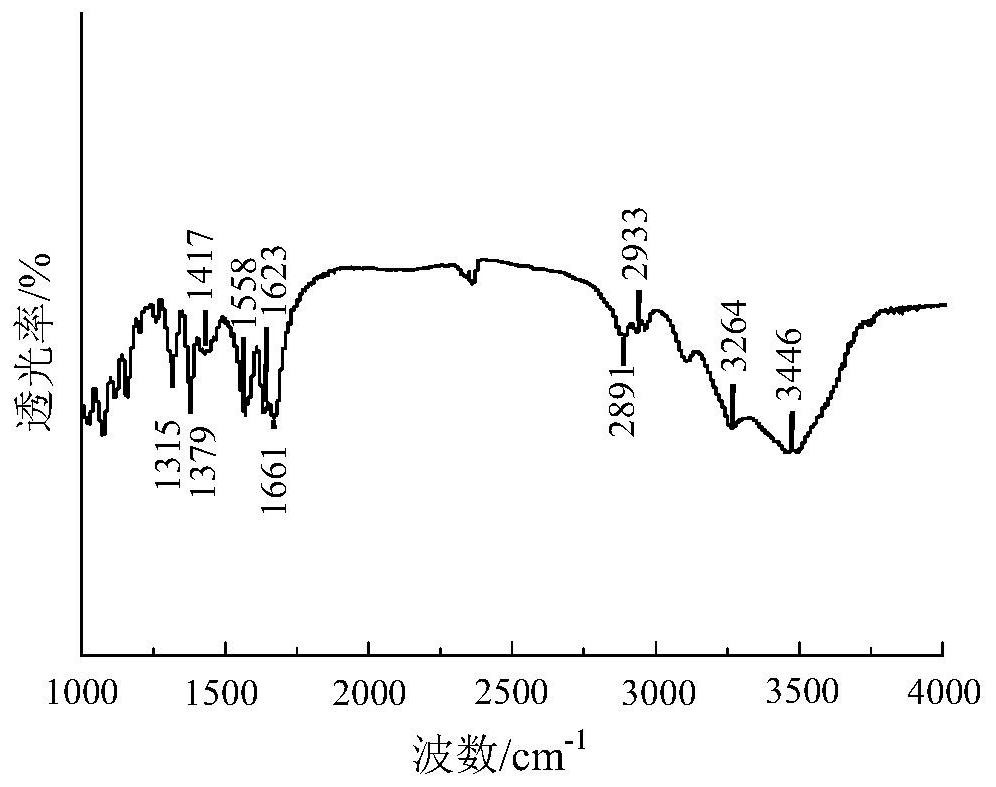

A chitin nano whisker/hydroxyapatite composite artificial bone material and its preparation method and application in 3D printing

ActiveCN109432497BHigh strengthGood bone conductionAdditive manufacturing apparatusPharmaceutical delivery mechanismArtificial boneBiocompatibility

The invention discloses a chitin nano whisker / hydroxyapatite composite artificial bone material, a preparation method thereof and an application in 3D printing. The preparation method combines chitin nano-whiskers and hydroxyapatite through a solid-state reaction method; when the prepared composite material has the characteristics of high strength of hydroxyapatite, the purpose of using whiskers to enhance the toughness of biological materials At the same time, chitin makes the material not only have good osteoconduction, osteoinduction and biocompatibility, but also has anti-inflammatory, analgesic, anticoagulant and wound healing effects; the chitin nano whiskers / When the hydroxyapatite composite artificial bone material is applied to the preparation of artificial bone, it is found that the compressive strength of the artificial bone prepared by pure hydroxyapatite material is increased by 32.6%, and the elastic modulus is decreased by 18.4%.

Owner:西安点云生物科技有限公司

A hydraulic slit U-shaped hole slag discharge gas treatment method

Owner:CHINA UNIV OF MINING & TECH

Test water pressure applying device for shield tunnel structural model

ActiveCN102095594BIncrease distanceUnrestricted installationStructural/machines measurementPore water pressureEngineering

The invention discloses a test water pressure applying device for a shield tunnel structural model. An anchoring base plate is arranged between an anchoring end and an anchoring hole of an anchor cable; anchoring through holes on the anchoring hole and the anchoring base plate are inclined, and the inclined angles ensure that no inflection points are formed at hole edges when the anchor cable passes through the anchoring hole and the anchoring through holes; the outer side of the anchoring base plate is vertical to the anchoring hole; a jack base plate is arranged between the top of a jack and a jack hole; jack through holes on the jack hole and the jack base plate are inclined, and the inclined angles ensure that no inflection points are formed at hole edges when the cable passes through the jack hole and the jack through holes; and the outer side of the jack base plate is vertical to the jack hole. A tensioning angle and a tensioning gas of the anchor cable of the device are small, and additional concentrated force at a hoop beam is small so that the influence of environmental water pressure on a model tunnel structure can be actually simulated; therefore, more accurate and reliable basis can be provided for the design and construction of the shield tunnel structure, tunnel construction and operation safety can be guaranteed, and the reliability and the safety of the device are high.

Owner:SOUTHWEST JIAOTONG UNIV

Conductive force transmission assembly and fuel cell stack

PendingCN114464860AImproved current distributionAvoiding Significant Performance DegradationCollectors/separatorsEnergy technologyFuel cells

The invention relates to the technical field of new energy, in particular to a conductive force transfer assembly and a fuel cell stack. The conductive force transmission assembly comprises an electric conductor, and a plurality of protruding parts are evenly distributed on the surface of the electric conductor. According to the invention, the electric conductor with the uniformly distributed convex parts is arranged between the short reactor assemblies, and the uniformly distributed convex parts of the electric conductor uniformly transmit the pressure applied by the previous short reactor assembly to the next short reactor assembly, so that the pressure between the short reactor assemblies is uniformly distributed again; and the phenomena of stress concentration and non-uniform distribution in the fuel cell stack are eliminated, so that the current distribution in the fuel cell is improved, and the phenomenon that the performance of the fuel cell is greatly reduced due to local water logging or local hydrogen deficiency is avoided.

Owner:FUXIN DARE AUTOMOTIVE PARTS

Method for manufacturing frame of combined bicycle

The invention provides a method for manufacturing a frame of a bicycle. The method comprises the following steps of: (1) manufacturing frame fittings, wherein the frame fittings comprise frame pipes and joints, the frame pipes comprise an upper pipe, a back upper fork, a back lower fork, a lower pipe and a middle pipe which are all made of aluminum alloy, and the joints comprise a head pipe joint, a middle pipe joint and a five-way joint which are all made of magnesium alloy; (2) processing surfaces of the frame fittings; (3) molding the frame pipes and the joints by gluing; (4) grinding and polishing the frame; and (5) performing baking finish on the surface of the frame. The whole frame utilizes the gluing molding technology so that the frame has beautiful appearance, better streamline form, and higher size precision; furthermore, the deformation and stress concentration caused by welding in the traditional manufacturing method are eliminated.

Owner:GUANGZHOU LEONIS MACHINERY

Method for improving weak light response of amorphous silicon film battery

InactiveCN102185038AElimination of heterojunctionElimination of stress concentrations and defect densitiesFinal product manufactureSemiconductor devicesChemistryHomojunction

The invention discloses a method for improving weak light response of an amorphous silicon film battery, belonging to the field of semiconductors. In the prior art, the heterojunction of a-SiC of a P layer and a-Si of an I layer causes stress concentration and defect density of a P / I interface. In the method, when raw materials containing gaseous H2 and gaseous SiH4 are used for depositing the P layer and the I layer on the basis of the decomposition reaction of the gaseous SiH4 to perform carbon element doping. The carbon element doping is to dope gaseous CH4 in the deposited raw materials. An a-Si layer of the I layer is converted into an a-SiC layer in a carbon doping mode, and the heterojunction of the a-SiC of the P layer and the a-Si of the I layer is further converted into a homojunction of the a-SiC of the P layer and the a-SiC of the I layer, thereby eliminating the heterojunction, and eliminating the stress concentration and defect density of the interface greatly, and finally improving the weak light response of the amorphous silicon film battery remarkably.

Owner:HANGZHOU AMPLESUN SOLAR TECH

Method and system for brittle fracturing of brittle semiconductor materials

ActiveCN105436712BGuaranteed flexural strengthImprove Fragmentation EfficiencyLaser beam welding apparatusSemiconductor materialsBrittle fracture

The invention discloses a method and system for brittle fracturing of brittle semiconductor materials. The method includes: using a heating laser beam to rapidly heat the inside of the brittle semiconductor material to be cleaved, so that the inside of the brittle semiconductor material to be cleaved expands to form a pressure At the same time, the surface of the brittle semiconductor material to be split is rapidly cooled, so that the surface of the brittle semiconductor material to be split shrinks to form tensile stress, so that the brittle semiconductor material undergoes brittle fracture and forms a smooth incision. Through the present invention, the brittle semiconductor material can be processed perfectly, and compared with the traditional brittle semiconductor material processing method, it can obtain extremely high incision quality, maintain the bending strength of the brittle semiconductor material, and improve the brittle semiconductor material. Fragmentation efficiency.

Owner:WUHAN EXCEL SCI & TECH LTD EST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com