Method for manufacturing frame of combined bicycle

A bicycle and combined technology, applied in the direction of bicycle frame, bicycle accessories, transportation and packaging, can solve the problems of affecting the beauty of the frame, joint marks, and high defect rate, and achieve a good overall sense of flow and increase the degree of fit. , the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings of the description.

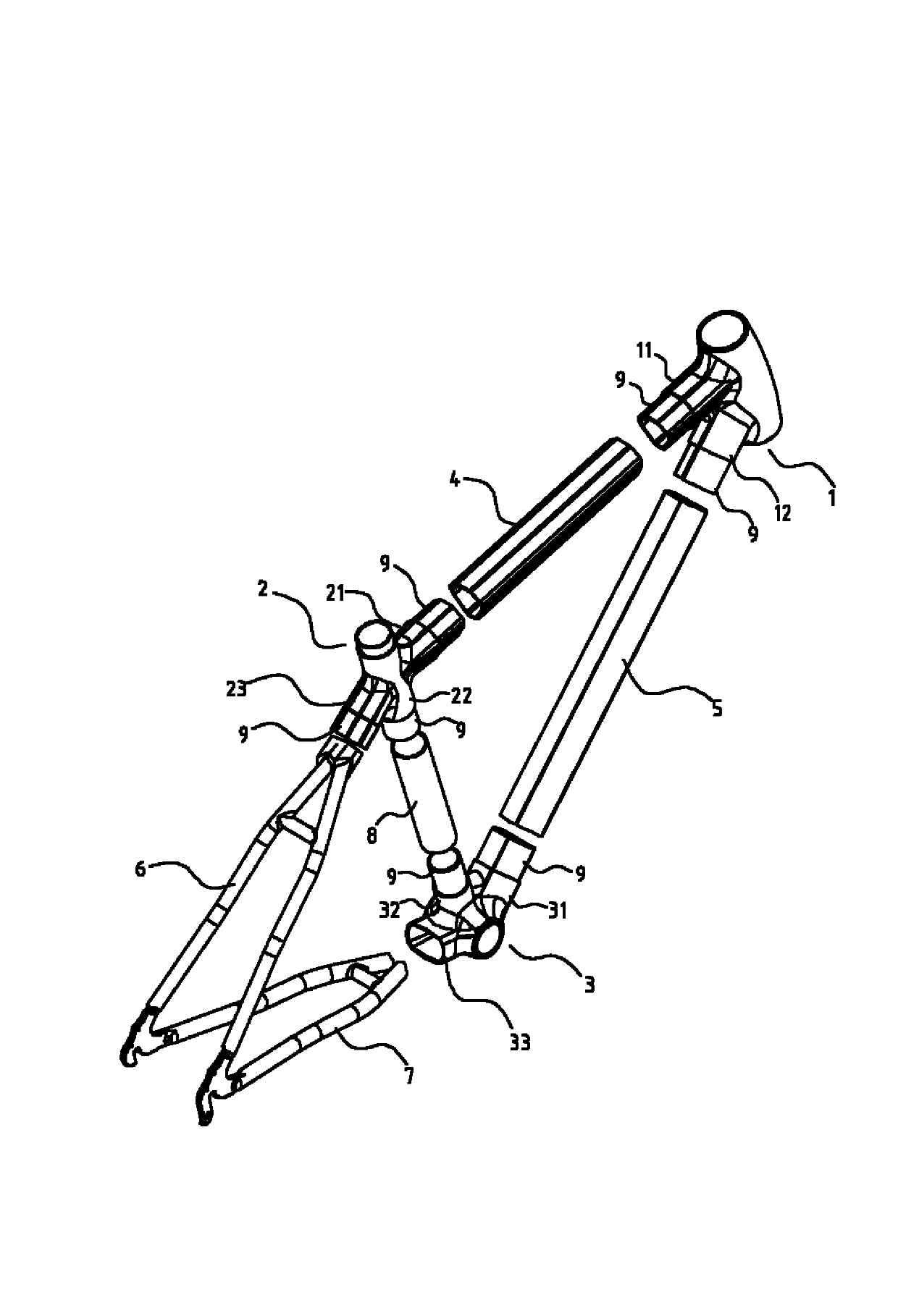

[0037] Such as figure 1 Shown, a kind of preparation method of combined bicycle frame comprises the following steps:

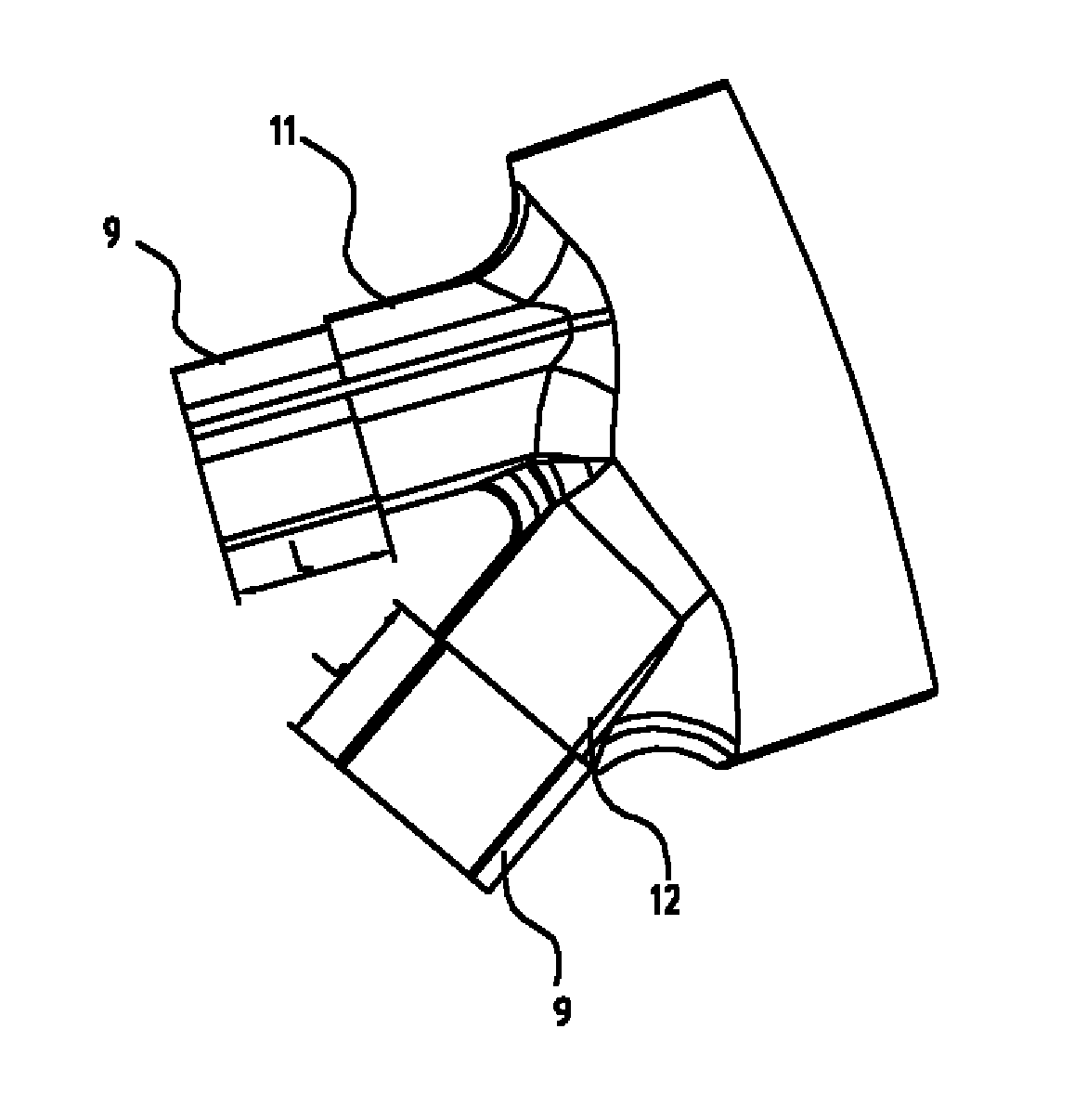

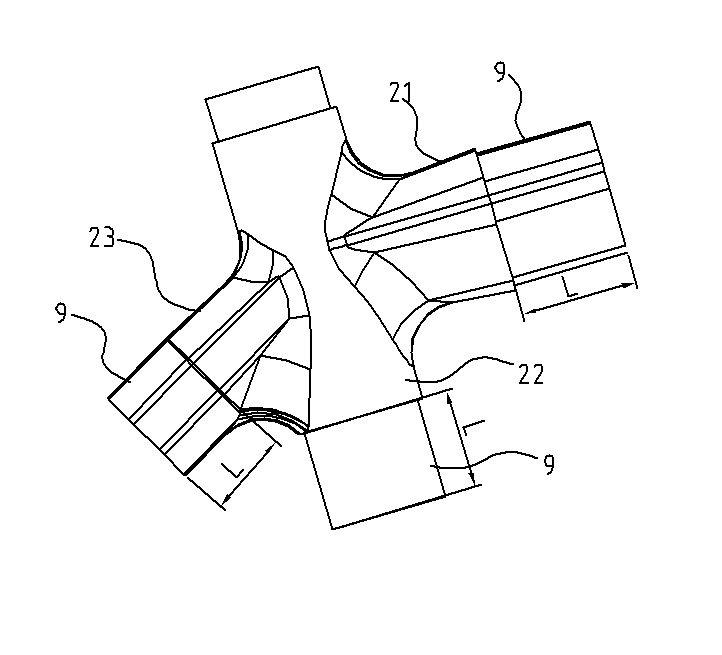

[0038] (1) Manufacture frame accessories, the frame accessories include frame pipes and joints, the frame pipes include aluminum alloy upper tube 4, seat stay 6, chain stay 7, down tube 5, middle tube 8 ;Such as Figures 2 to 4 As shown, the joint is a magnesium alloy joint integrally formed by die-casting, including a head pipe joint 1, a middle pipe joint 2, and a bottom bracket joint 3; The lower pipe connecting pipe section 12, the first upper pipe connecting pipe section 11 and the first lower pipe connecting pipe section 12 are provided with steps 9; the middle pipe joint 2 is extended with a second upper pipe connecting pipe section 21, The connecting pipe section 22 of the first middle pipe and the connecting pipe section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com