Patents

Literature

2331results about "Screw-threads articles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

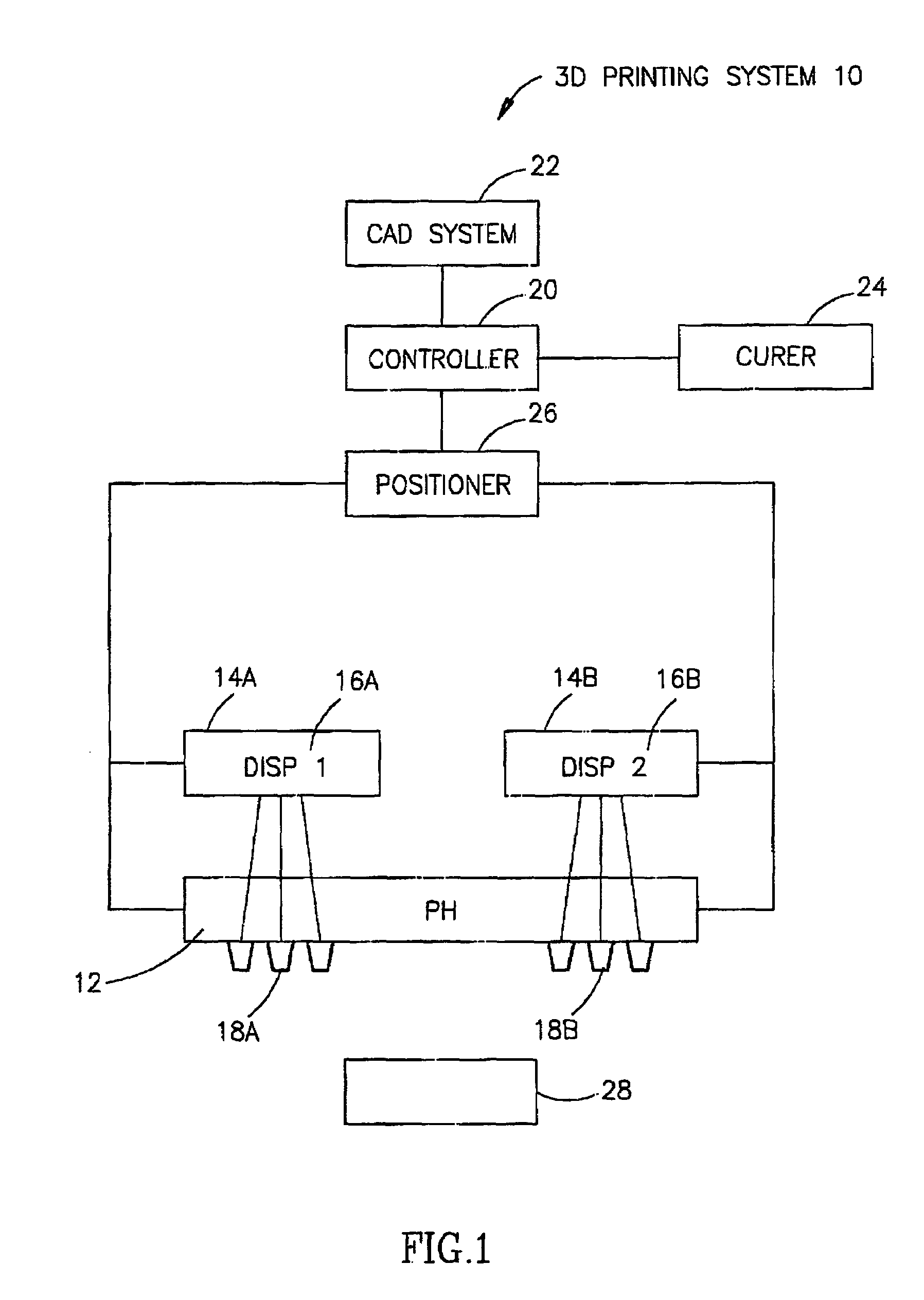

Compositions and methods for use in three dimensional model printing

InactiveUS7300619B2Similar elasticitySimilar strengthButtonsLiquid surface applicatorsOrganic compoundPolymer chemistry

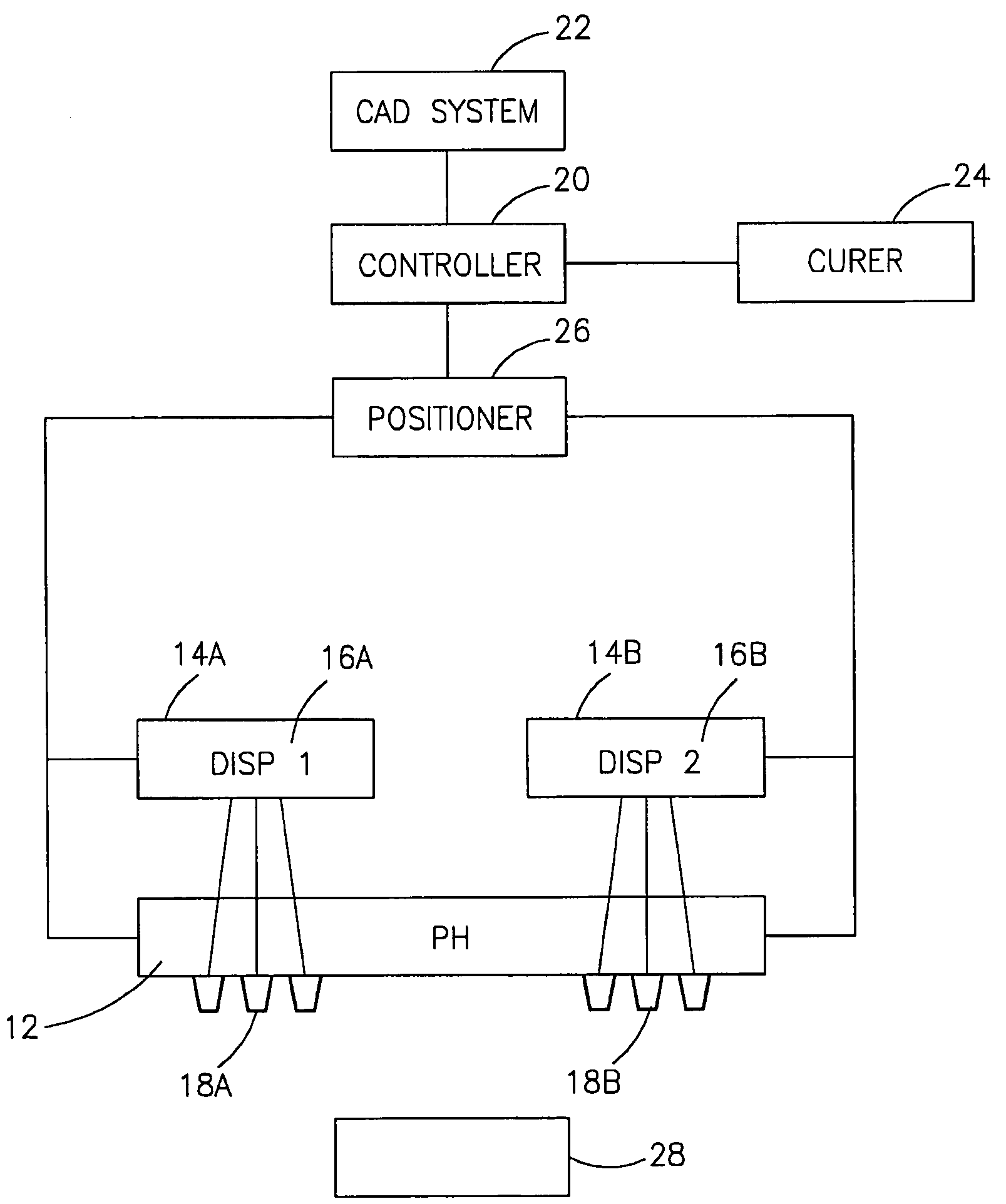

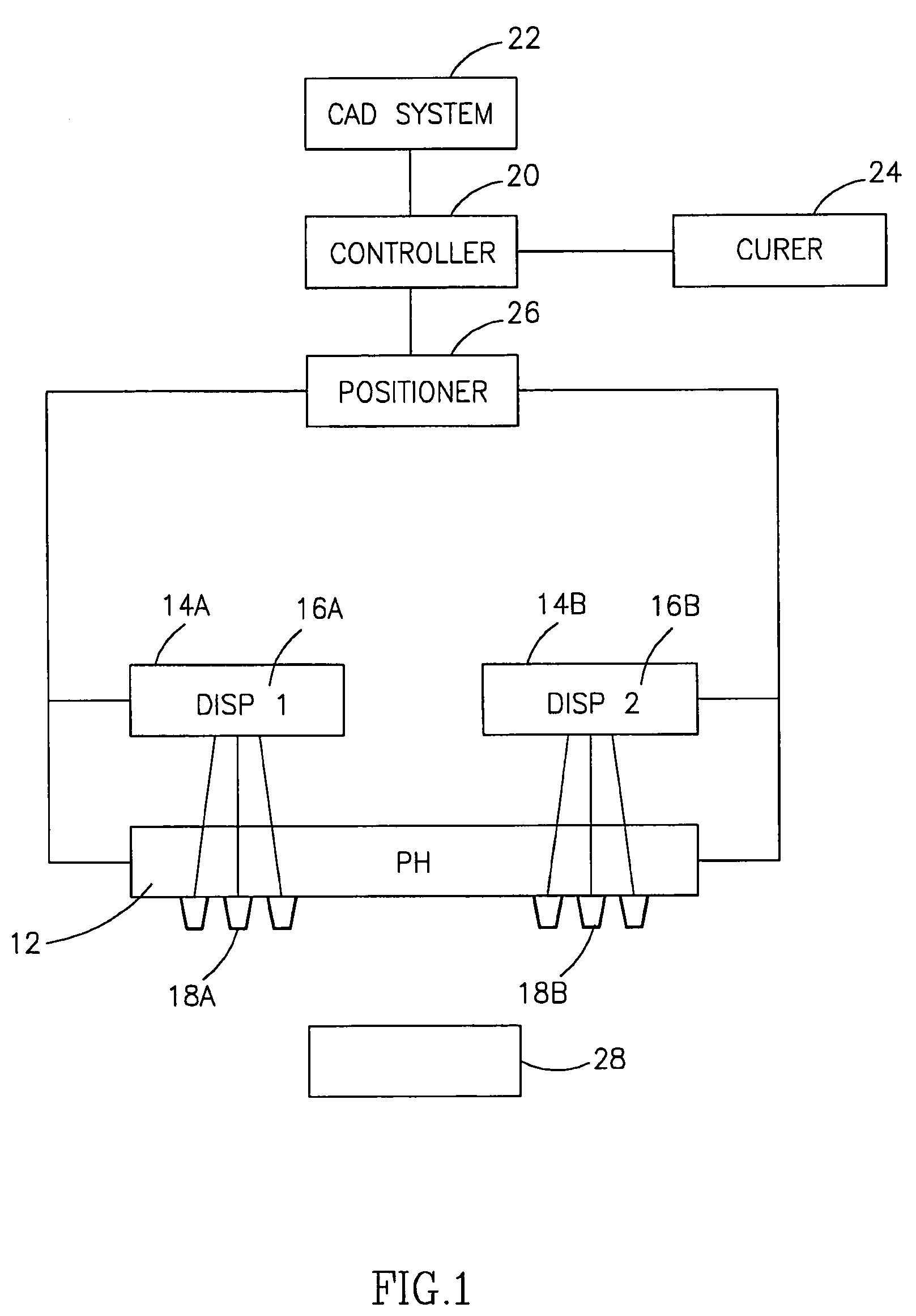

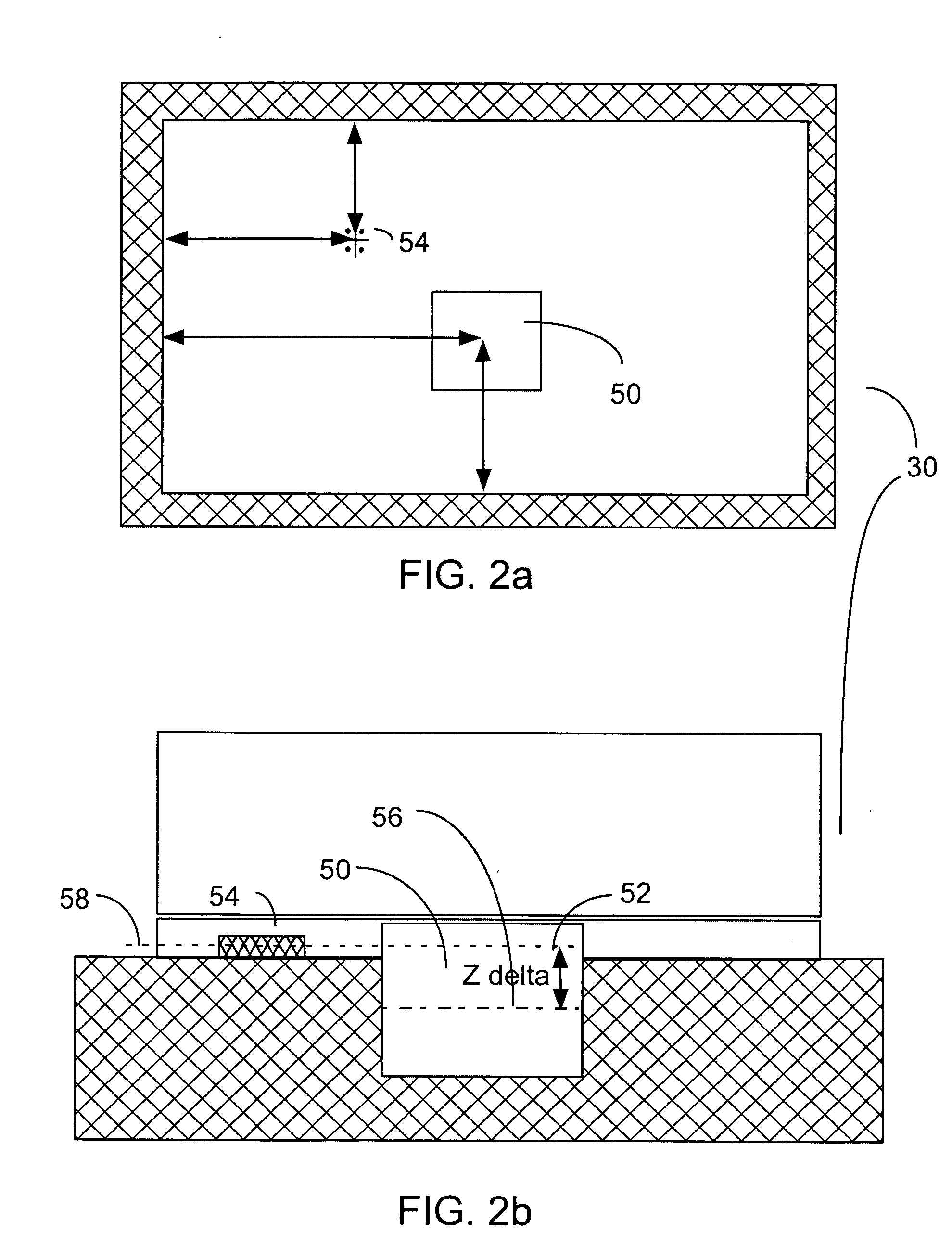

A pseudo composite material, may include, inter alia, a first phase and a second phase, wherein each phase may include, inter alia, an organic compound, wherein each phase comprising a multiplicity of construction layers, wherein the layers were deposited by ink-jet printing, wherein the pseudo composite material exhibits non-homogeneous three-dimensional structure. A method is disclosed for the preparation of a pseudo composite material. An apparatus is disclosed for printing a pseudo composite material. Furthermore, there is disclosed a method for printing a three-dimensional object using various suitable materials.

Owner:STRATASYS LTD

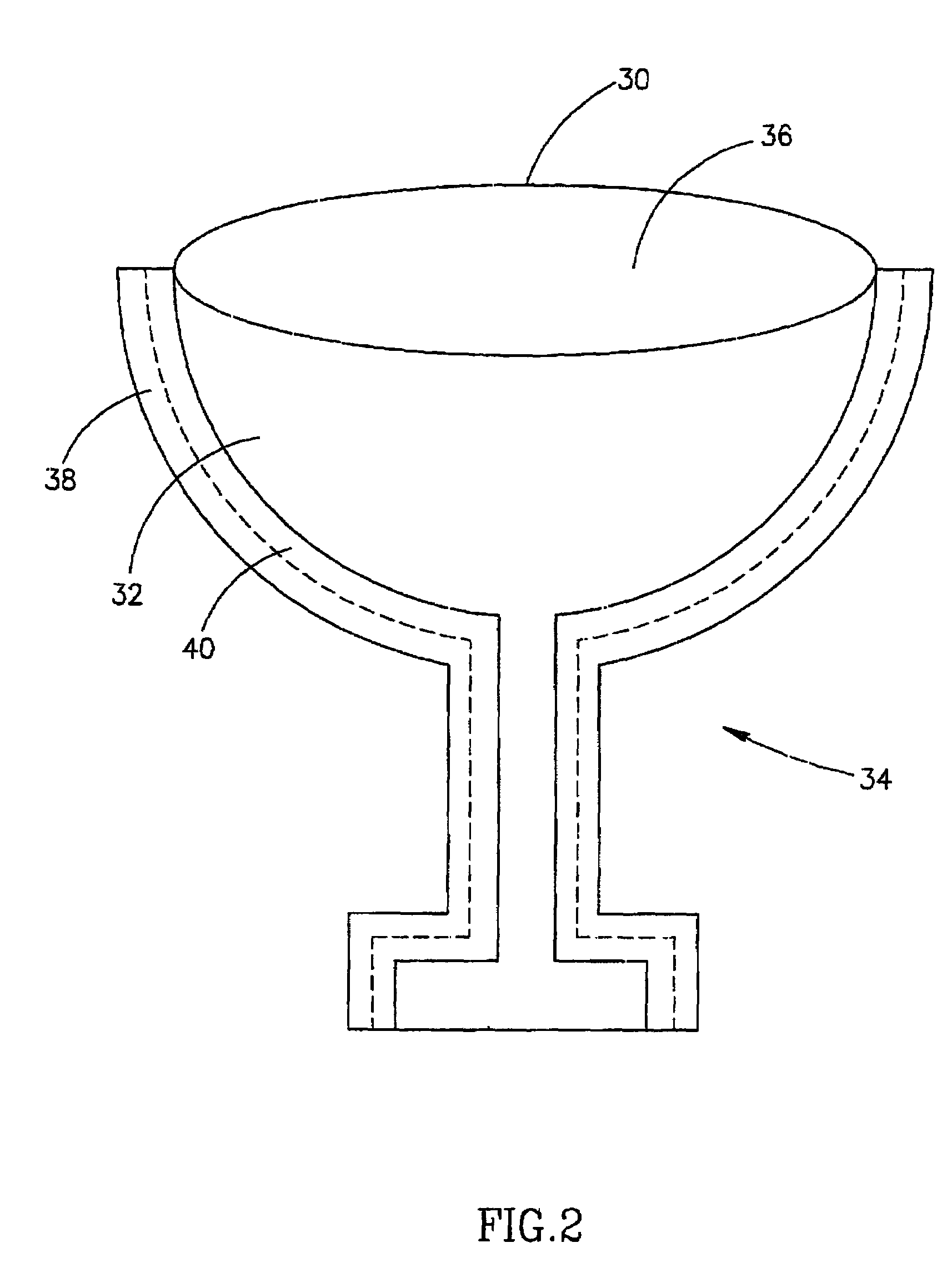

Compositions and methods for use in three dimensional model printing

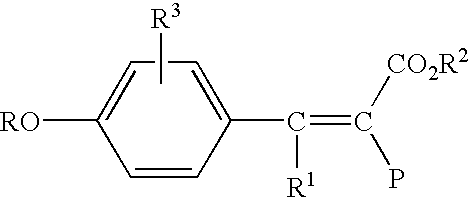

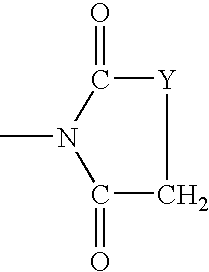

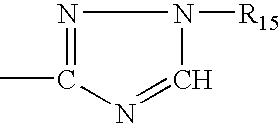

Compositions for use in the manufacture of three-dimensional objects including compositions for use as a support and / or release material in the manufacture of the three-dimensional objects are provided. There is thus provided, in accordance with an embodiment of the present invention, a composition suitable for building a three-dimensional object. The compositions may include, inter alia, a curable component, having a functional group, wherein if the functional group is a polymerizable reactive functional group, then the functional group is a (meth)acrylic functional group, a photo-initiator, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 50–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after curing, the composition results in a solid form. There is thus provided, in accordance with another embodiment of the present invention, a composition suitable for support in building a three-dimensional object. The compositions may include, inter alia: a non-curable component, a curable component, wherein the non-curable component is not reactive with said curable component, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 20–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after irradiation, the composition results in a solid, a semi-solid or liquid material. A method for the preparation of a three-dimensional object by three-dimensional printing is provided in accordance with embodiments of the present invention. Embodiments of the present invention further provide a three-dimensional object prepared according to the methods of the invention.

Owner:STRATASYS LTD

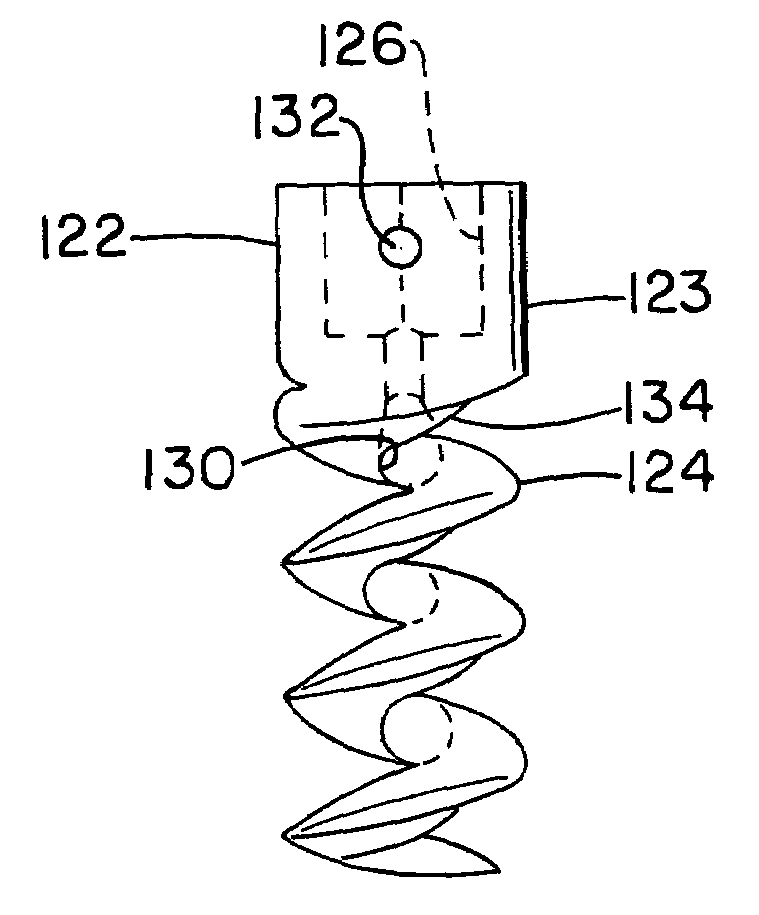

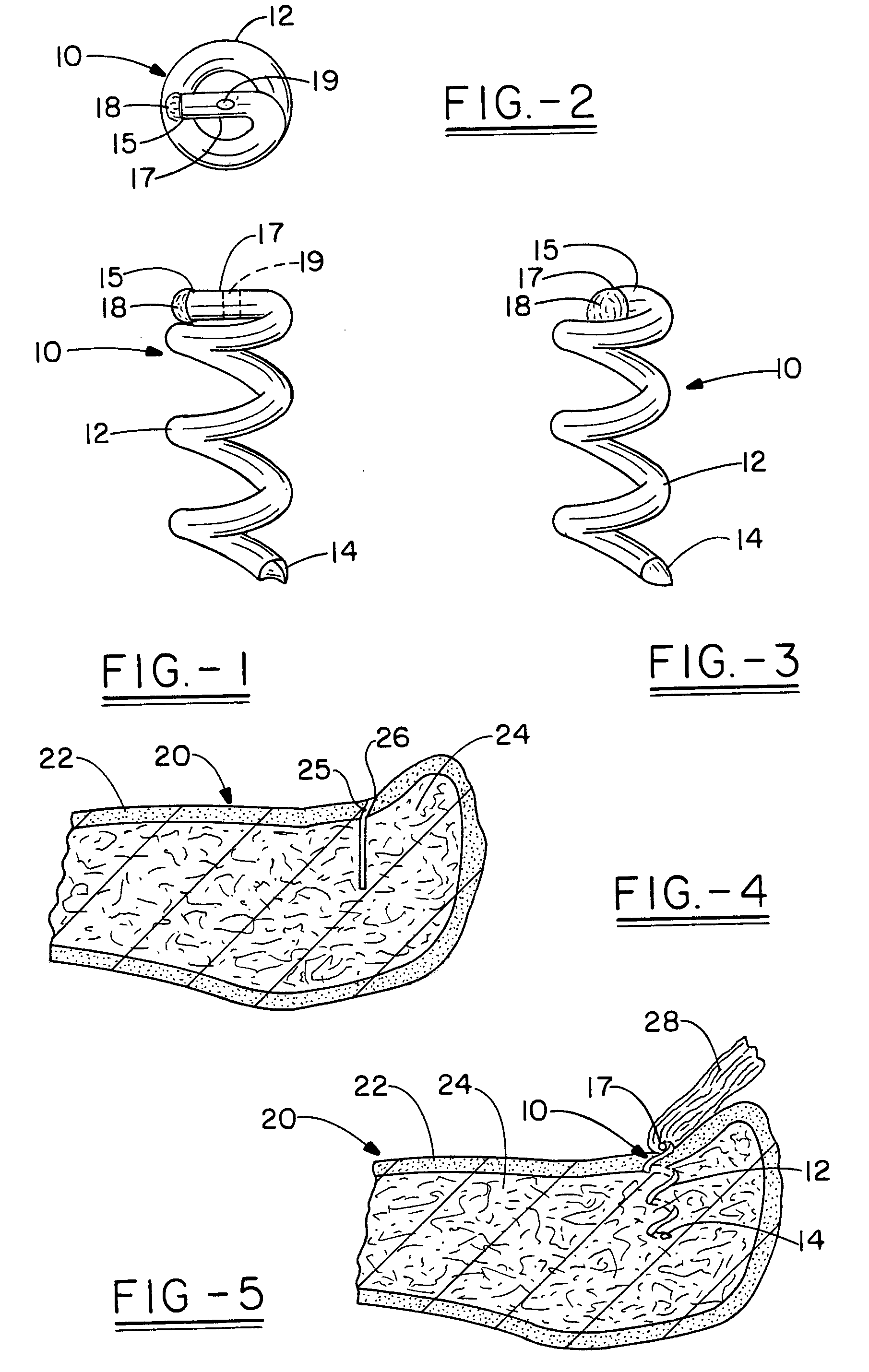

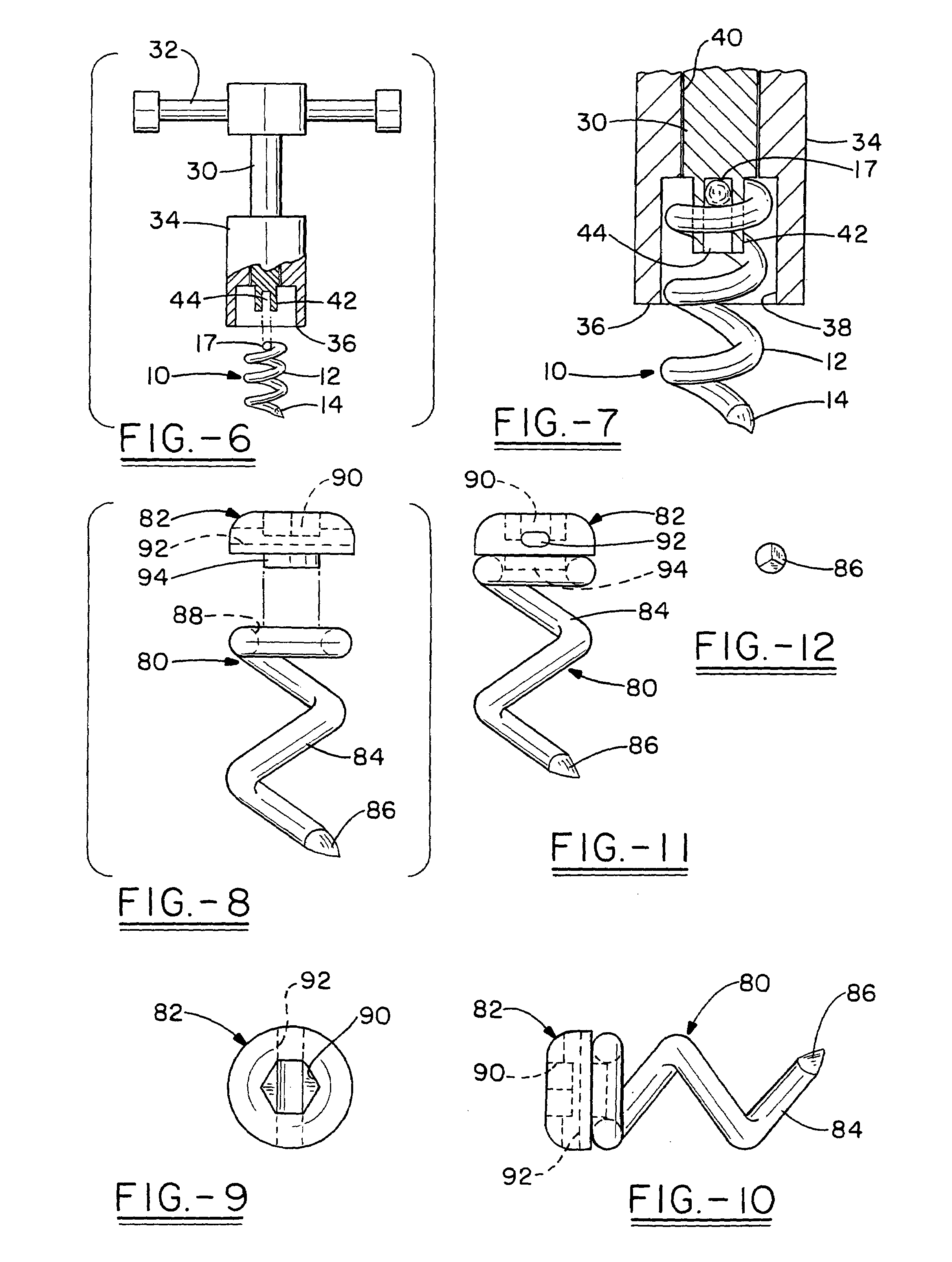

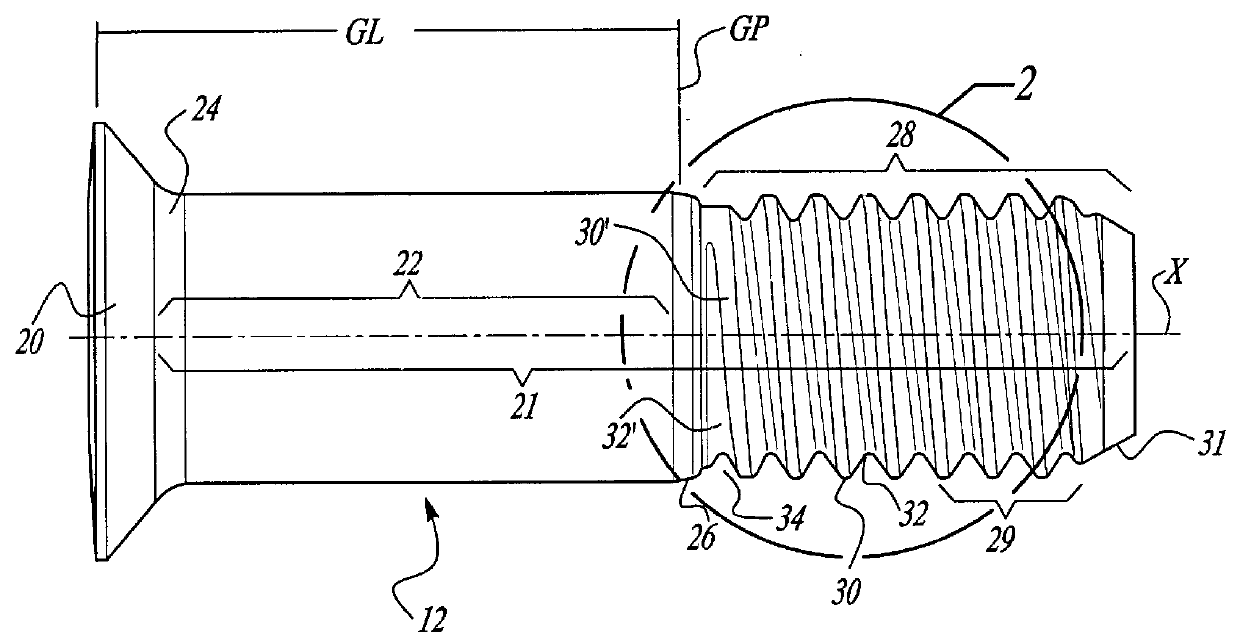

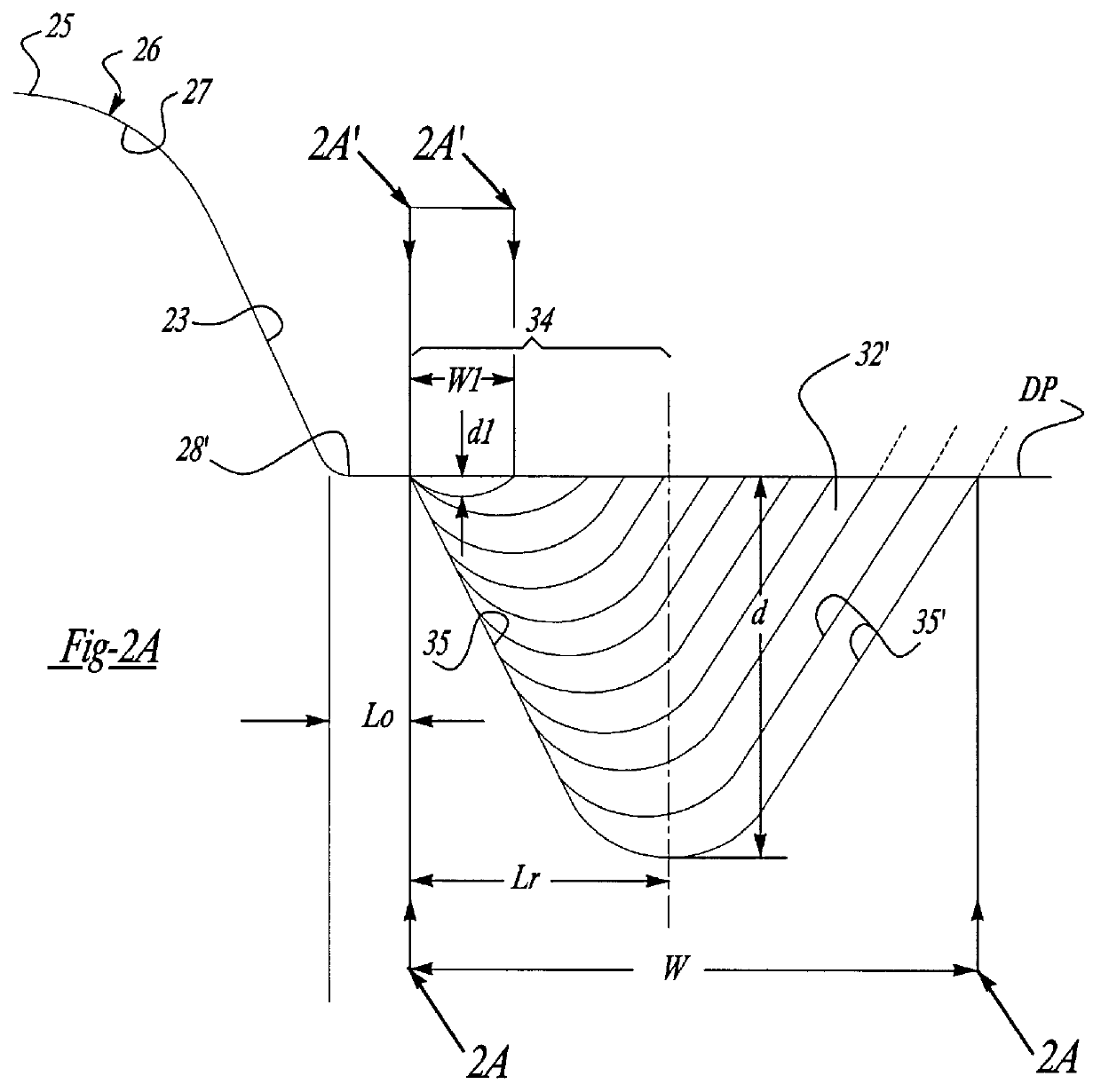

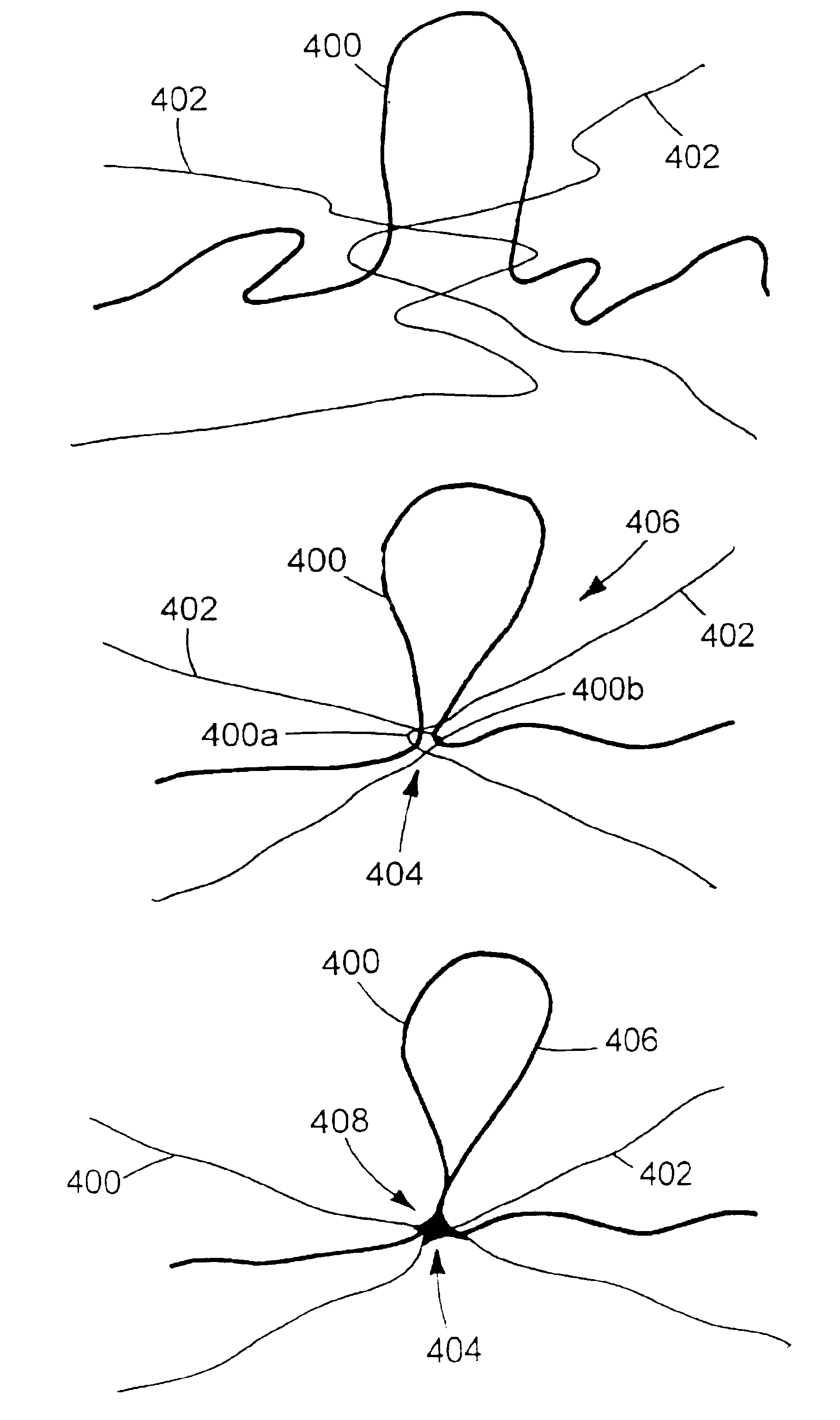

Open helical organic tissue anchor having recessible head and method of making the organic tissue anchor

InactiveUS7189251B2Easy to anchorStrengthens helixSuture equipmentsPinsSelf reinforcedLigament structure

The invention relates to a tissue anchor which is an open helix of biocompatible material having a slope of from 0.5 to 10 turns per centimeter, a length from 3 to 75 millimeters, a diameter of from 1.5 to 11 millimeters, and an aspect ratio of from about 3 to about 5 to 1. The anchor can have a head which is capable of securing or clamping tissue together, such as holding a suture to secure a ligament or tendon to bone. The anchor can also have a head which causes an inward, compressive loading for use in fastening bone to bone, orthopedic plates to bone, or cartilage to bone. The head may be an integral member and may include a self-reinforcing wedge which joins the helix to the head. Further, the elongate member, or filament that forms the helix may have a tapering diameter along its length.

Owner:ORTHOHELIX SURGICAL DESIGNS

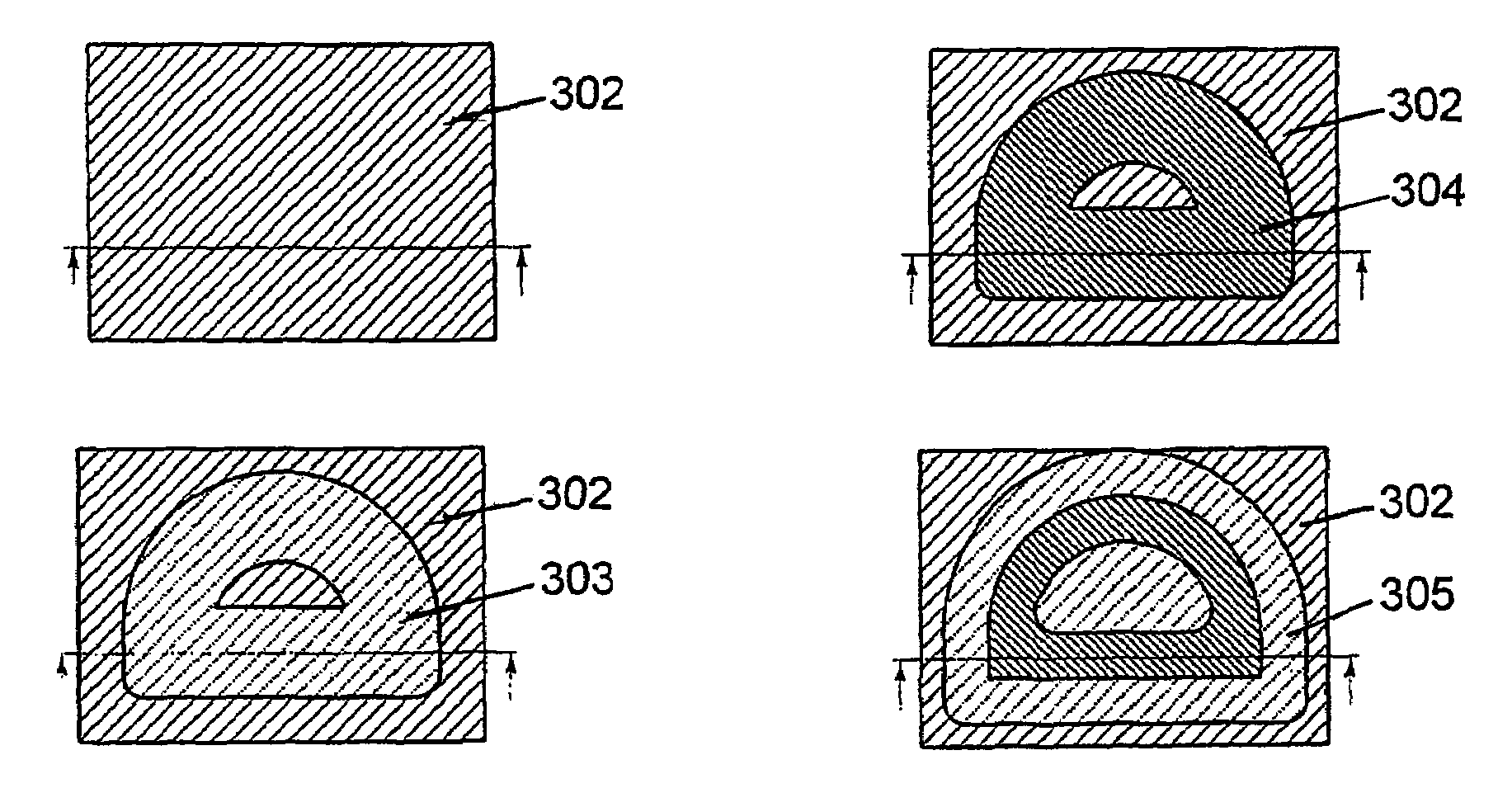

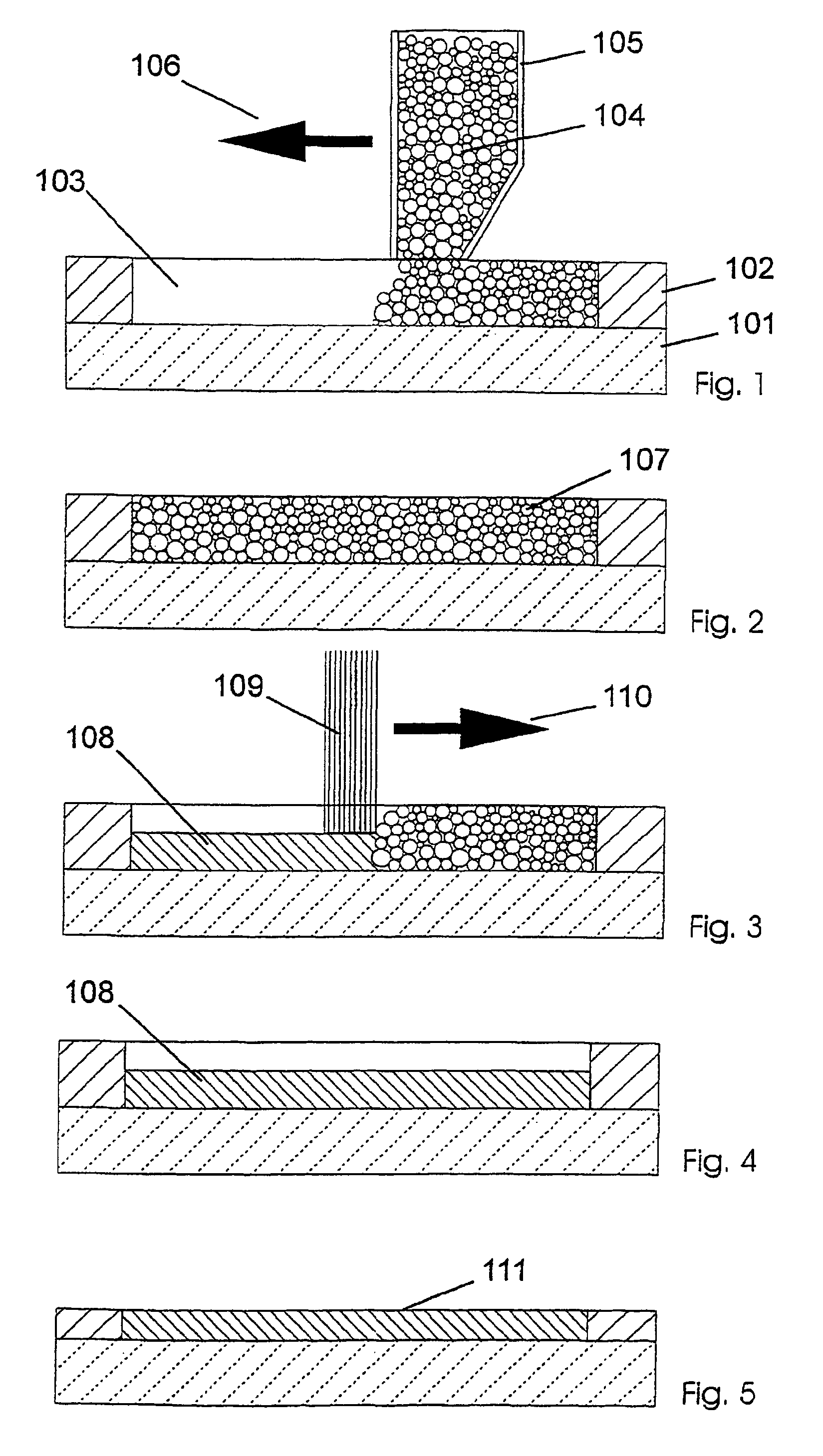

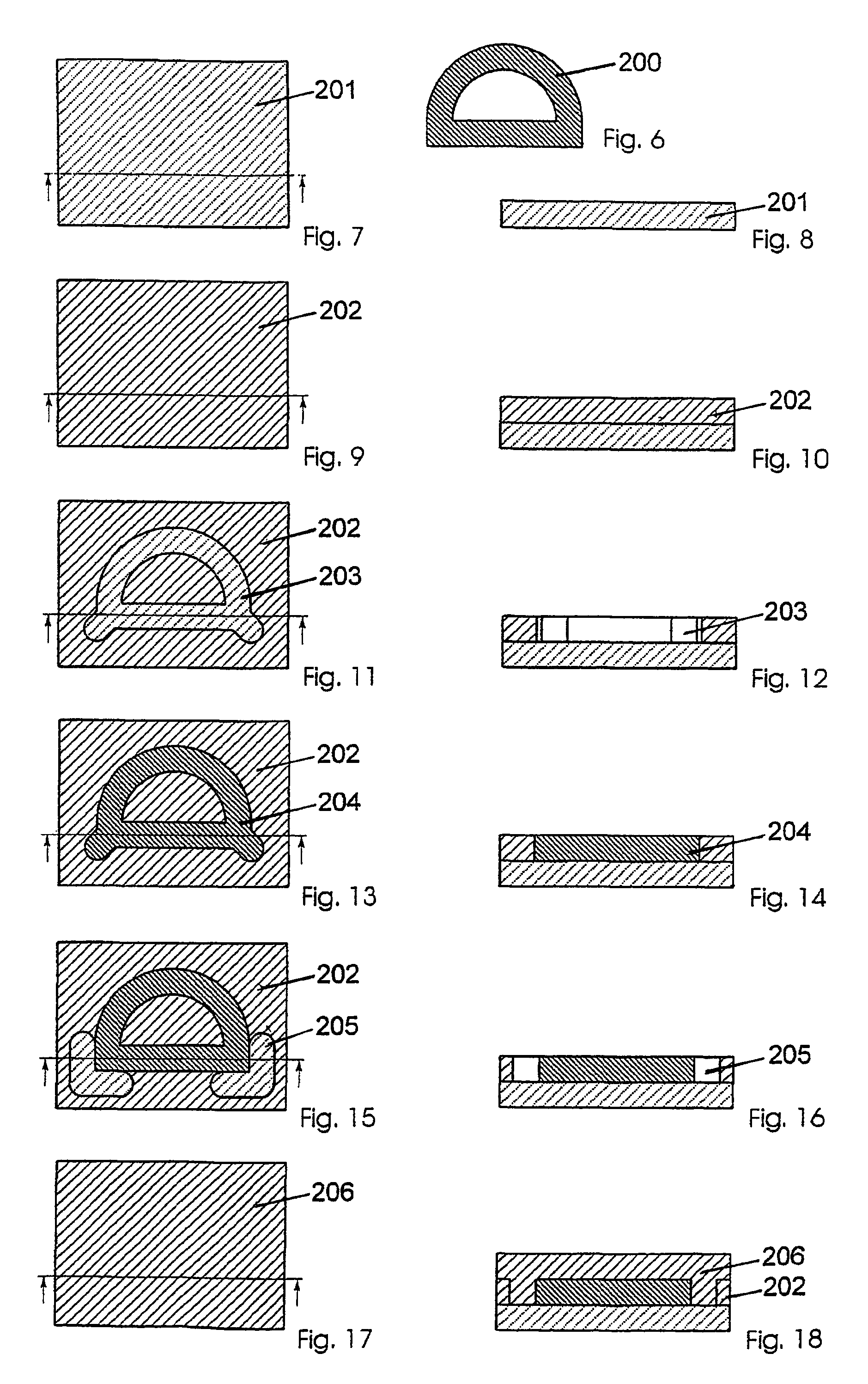

Method for producing a part and device for carrying out this method

InactiveUS7003864B2Faster machinabilityReduced tool wearMouldsWood working apparatusEngineeringRapid prototyping

The present invention relates to a method for producing a part (108, 200, 300), comprising the following steps:a) applying a first flat layer consisting of a support material (102, 202, 302), to a construction platform (101, 201, 301),b) introducing at least one recess (103, 203, 303) into the support material (102, 202, 302),c) filling the recess (103, 203, 303) with a construction material (104, 204, 304),d) applying a further layer of support material (102, 202, 302),e) repeating steps b) through d) until completion of the part (108, 200, 300), andf) removing the support material (102, 202, 302).This method is to provide a manufacturing method and a device that combine the advantages of the layerwise construction (rapid prototyping) with the advantages of machining (e.g. high-speed cutting) and particularly permit the production of sharp-edged contours.Furthermore, the present invention relates to a device for carrying out the method.

Owner:HERMLE MASCHENBAU

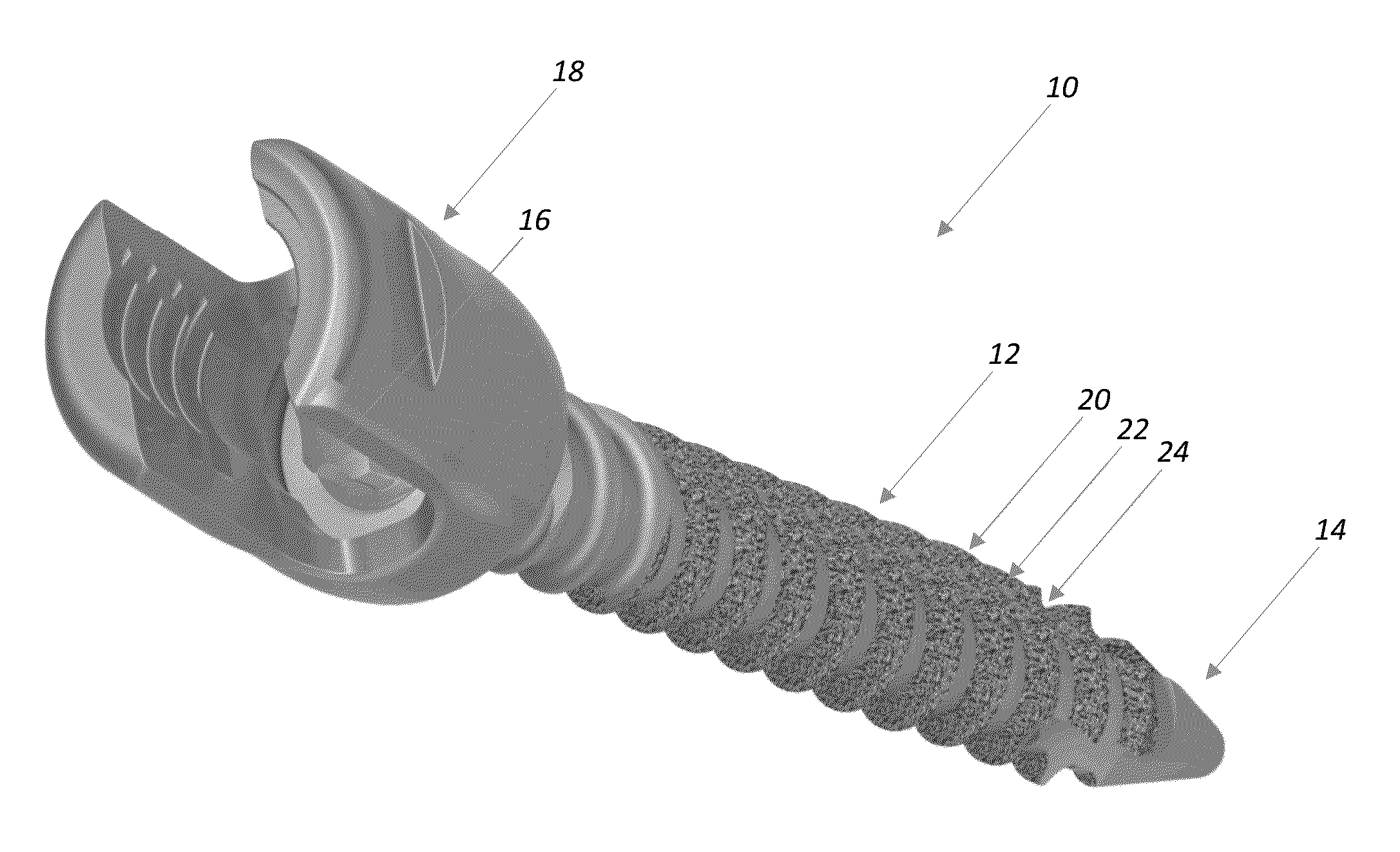

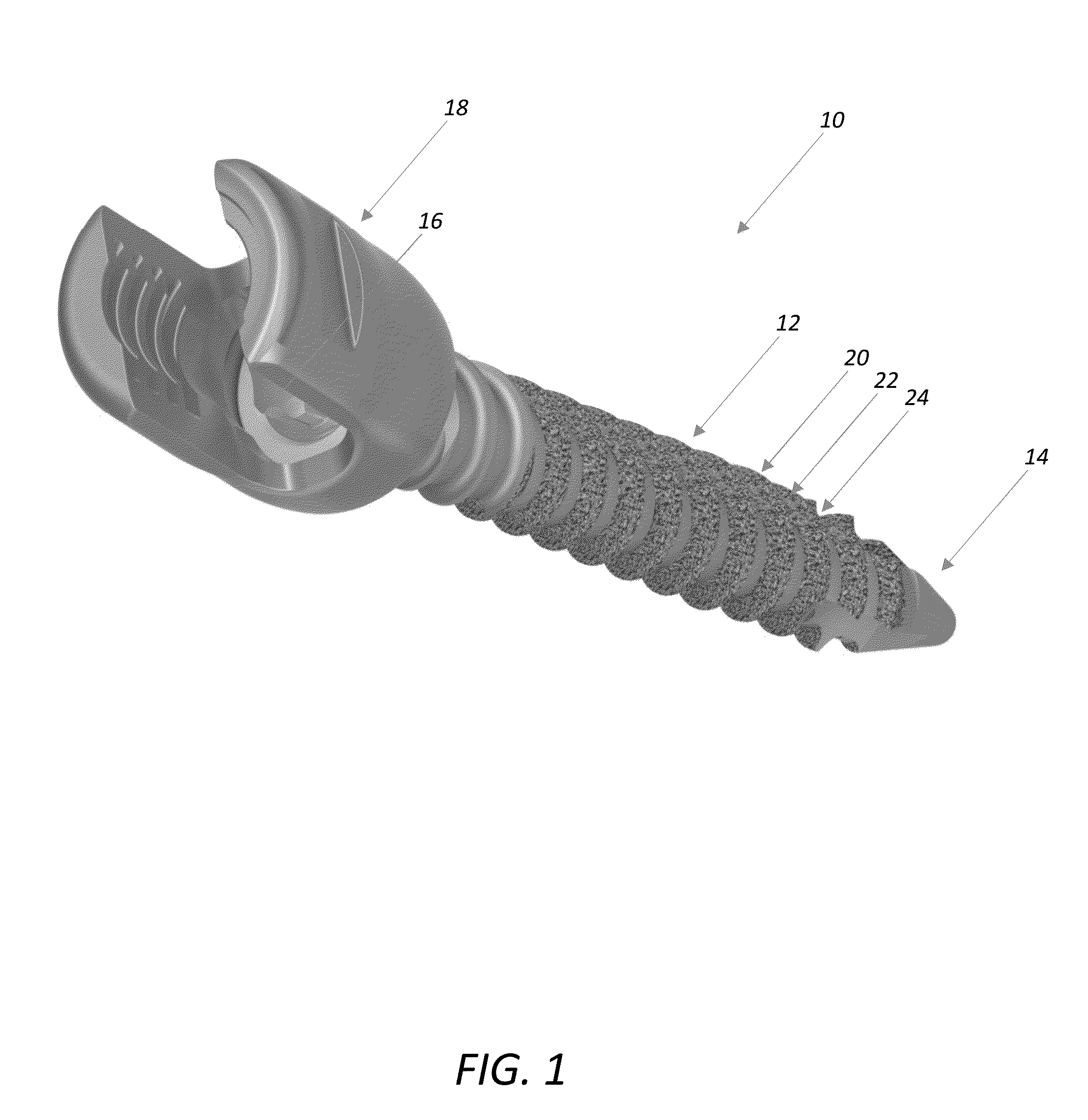

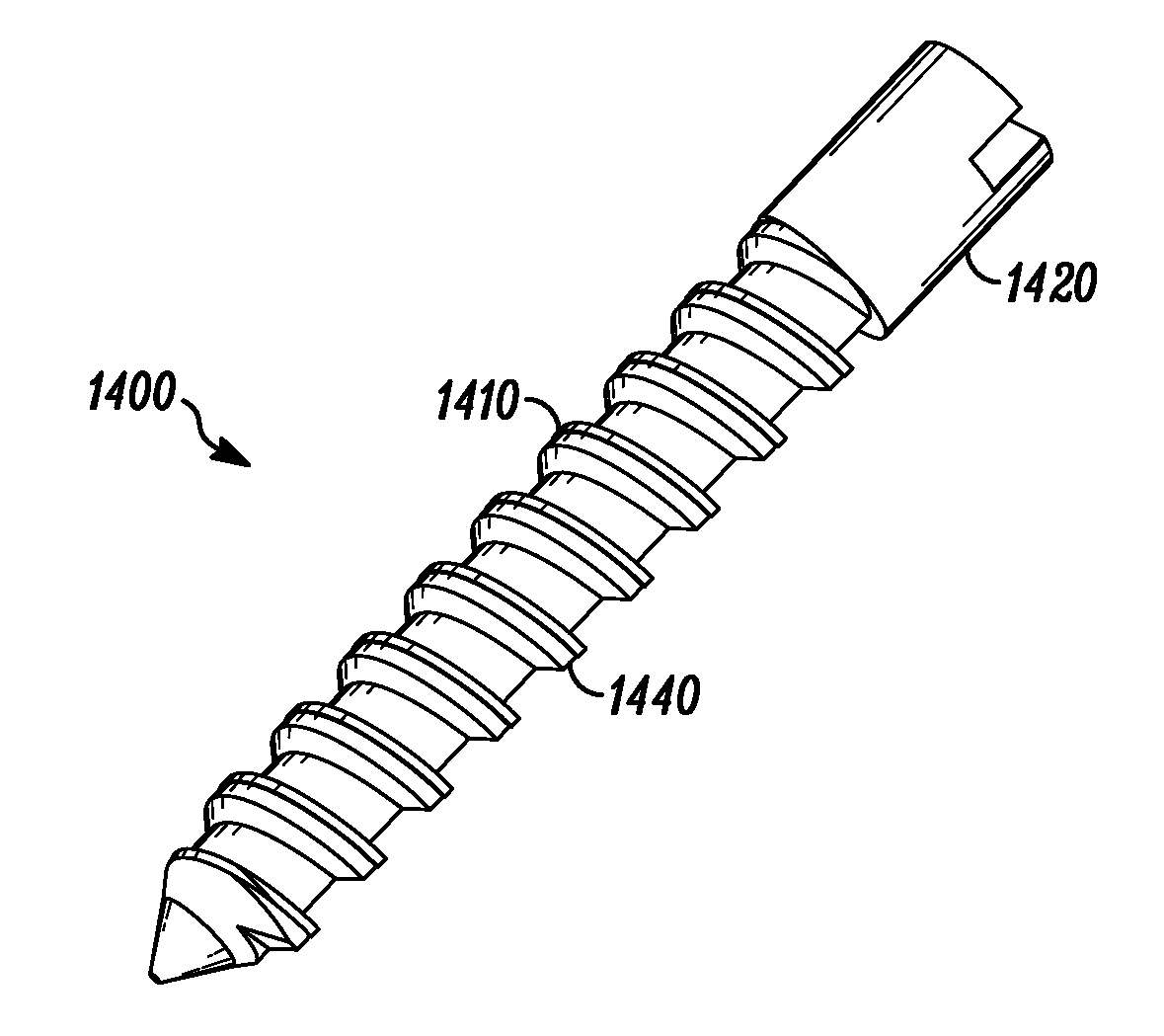

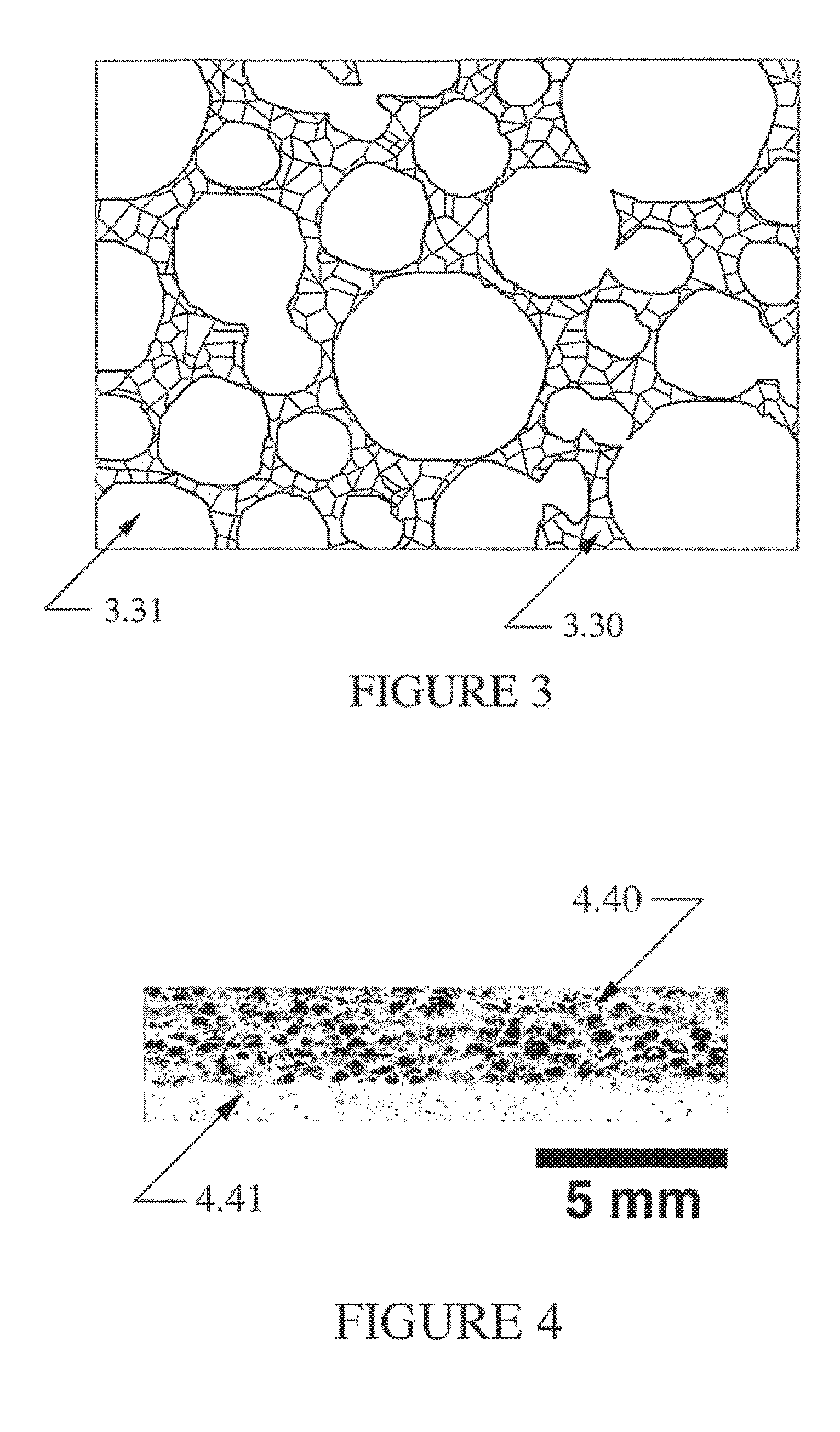

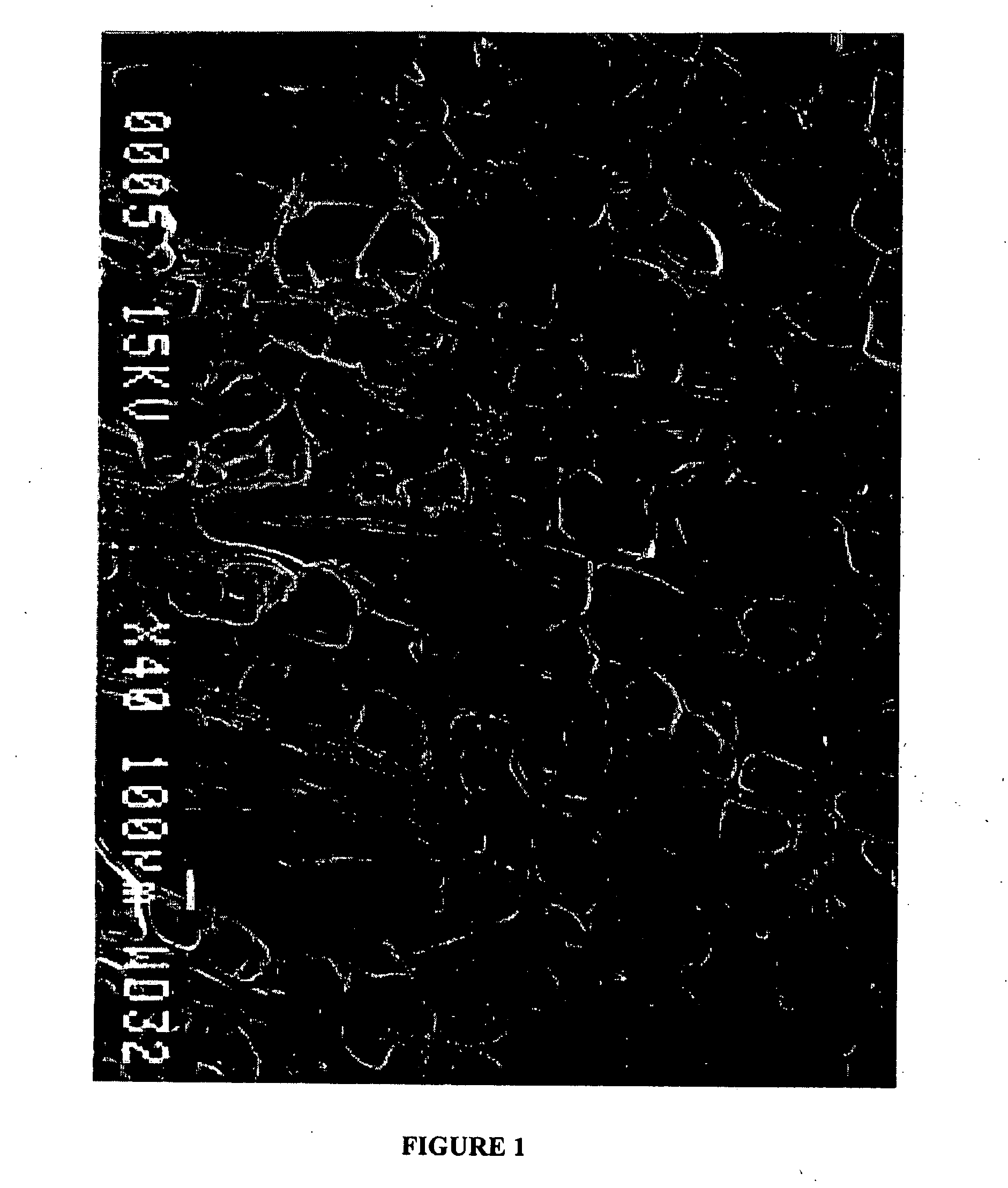

Bone screw incorporating a porous surface formed by an additive manufacturing process

ActiveUS20160157908A1Enhancing bony fixationEnhancing ingrowthSuture equipmentsAdditive manufacturing apparatusMachining processIliac screw

The present invention provides a bone screw or bone anchor, such as a threaded pedicle screw or the like, incorporating a porous surface for enhancing bony fixation, ingrowth, and purchase when implanted in bone. Preferably, this porous surface covers at least a portion of the threads of the bone screw or bone anchor. The porous surface is formed by a conventional or novel additive manufacturing process, such as three-dimensional (3D) printing or the like, optionally as well as a prior and / or subsequent machining process. The porous surface may include novel needle-like protrusions and / or lattice structures, and / or any other protruding / depressed features, whether regular or irregular.

Owner:KYOCERA MEDICAL TECH INC

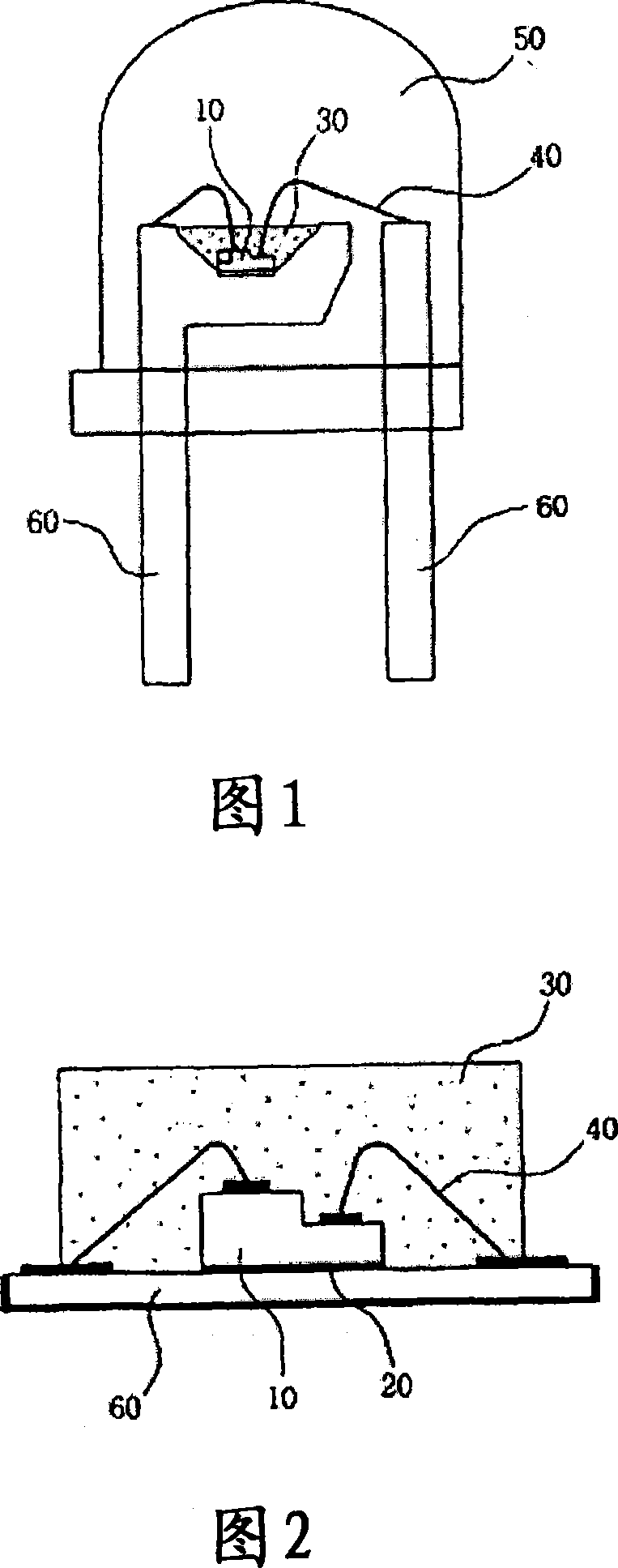

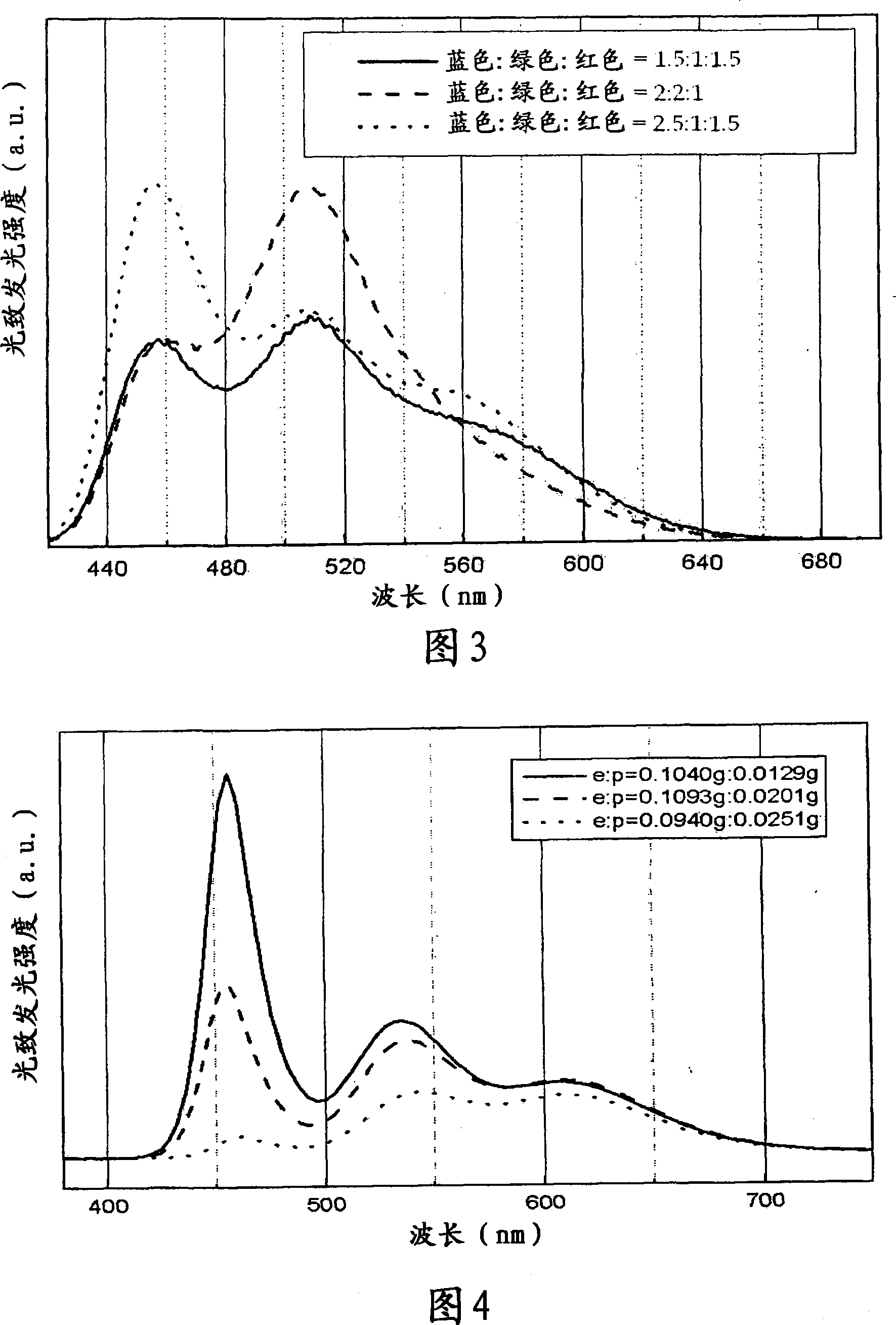

Preparation of white light emitting diode using a phosphor

The present invention relates to a method for preparing a white light emitting diode (LED) using phosphors, especially to a white light emitting diode prepared by applying a tri-color phosphor material mixture of red, blue and green on a UV LED chip made of a packaging substrate, where white light is obtained by transmitting light through the tri-color phosphor mixture since the UV LED chip emits purple light. In particular, the present invention relates to a white light emitting diode prepared by laminating green and red or yellow and red phosphor materials on a blue LED chip, where white light is obtained as light is transmitted and absorbed by the phosphors. The method in accordance with the present invention is advantageous in that a white light emitting diode having superior photoluminescence efficiency can be provided using a single chip.

Owner:KOREA RES INST OF CHEM TECH

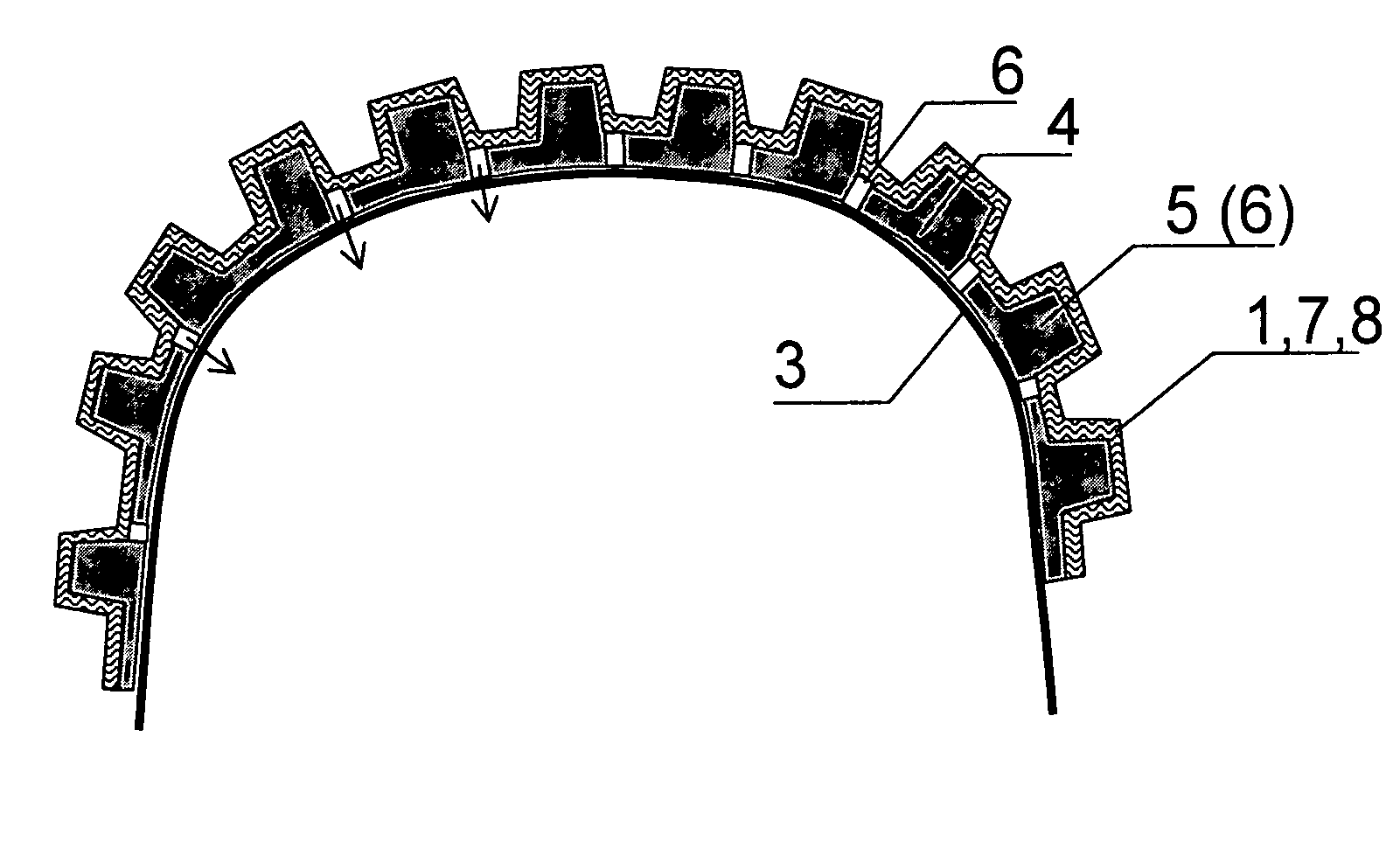

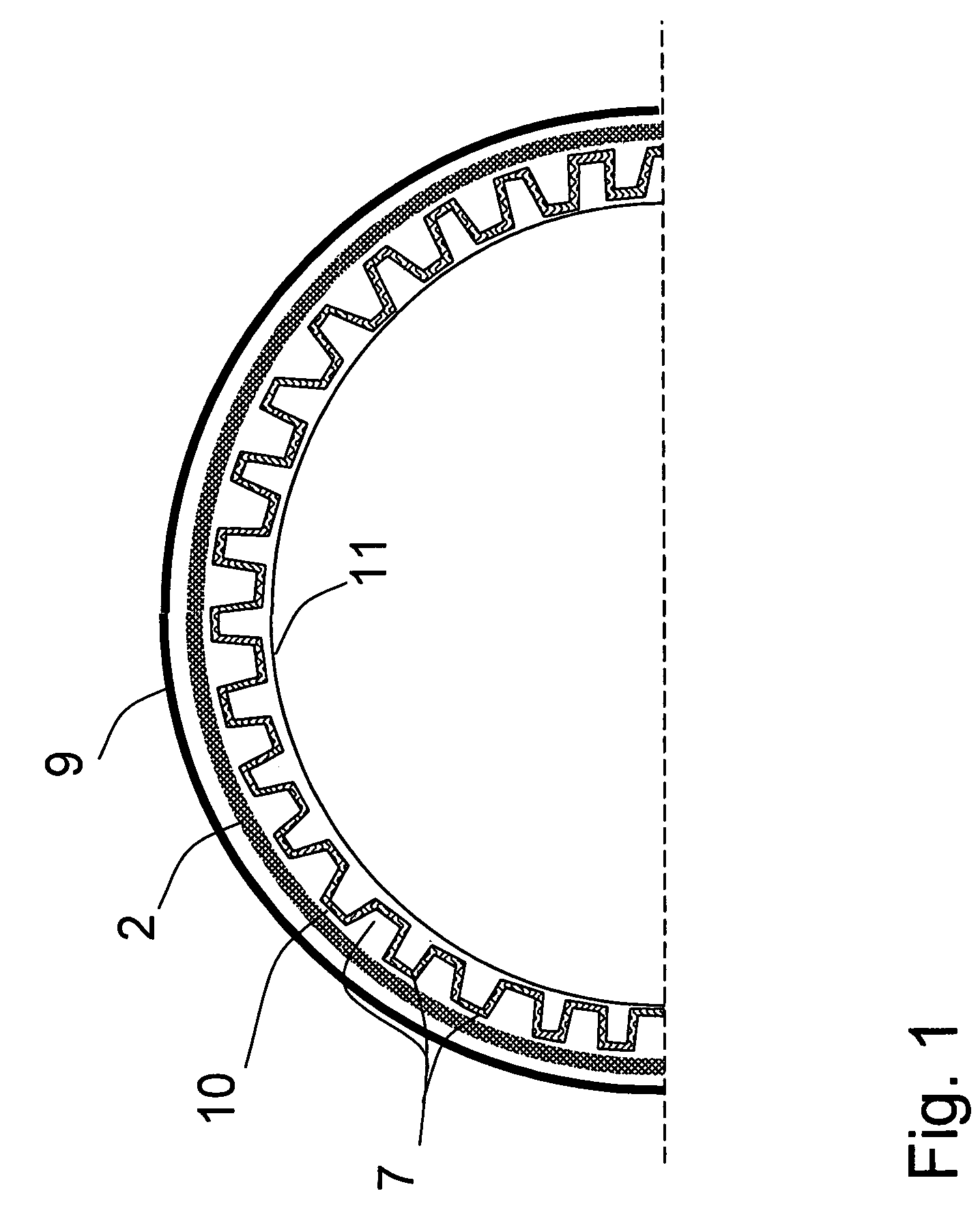

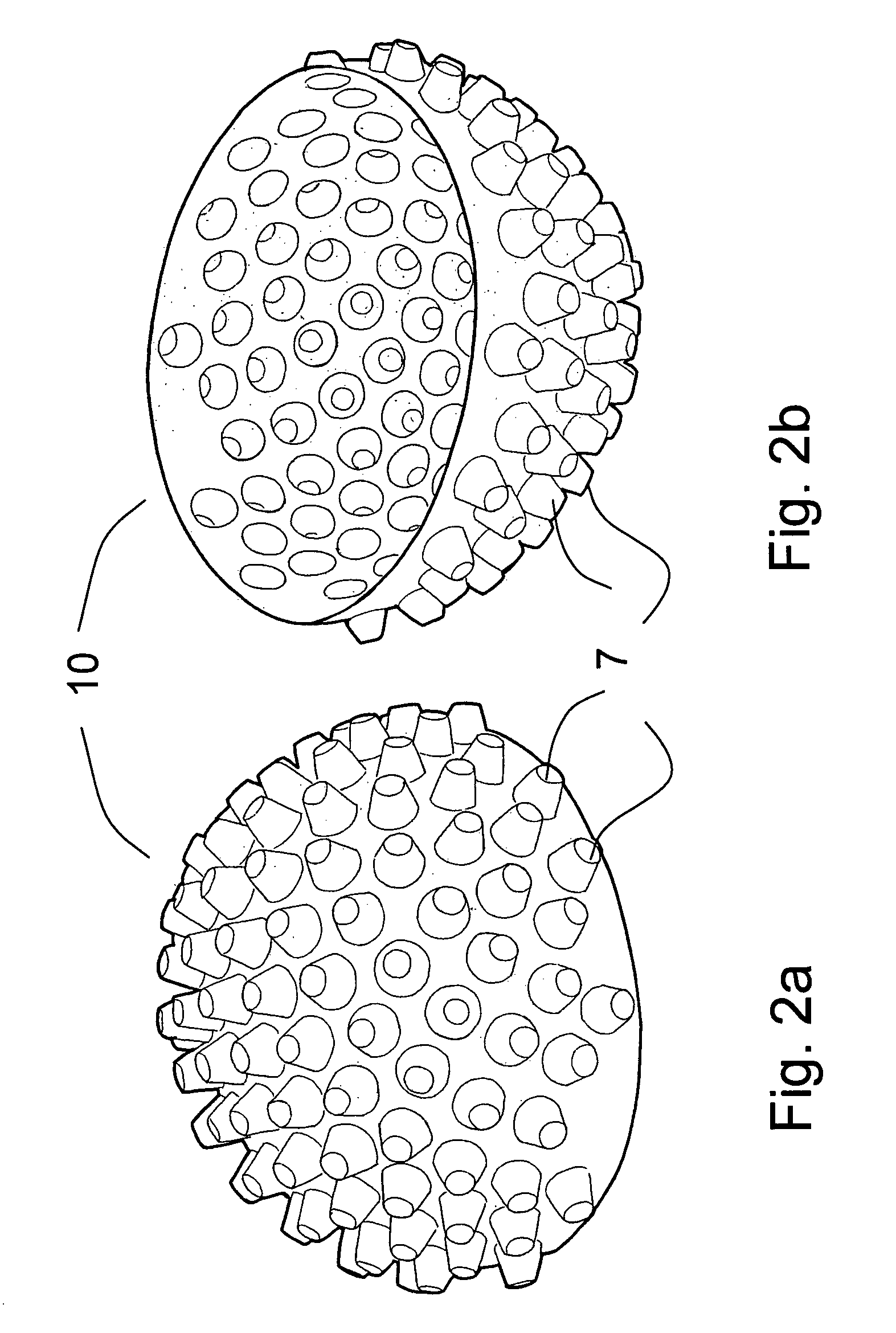

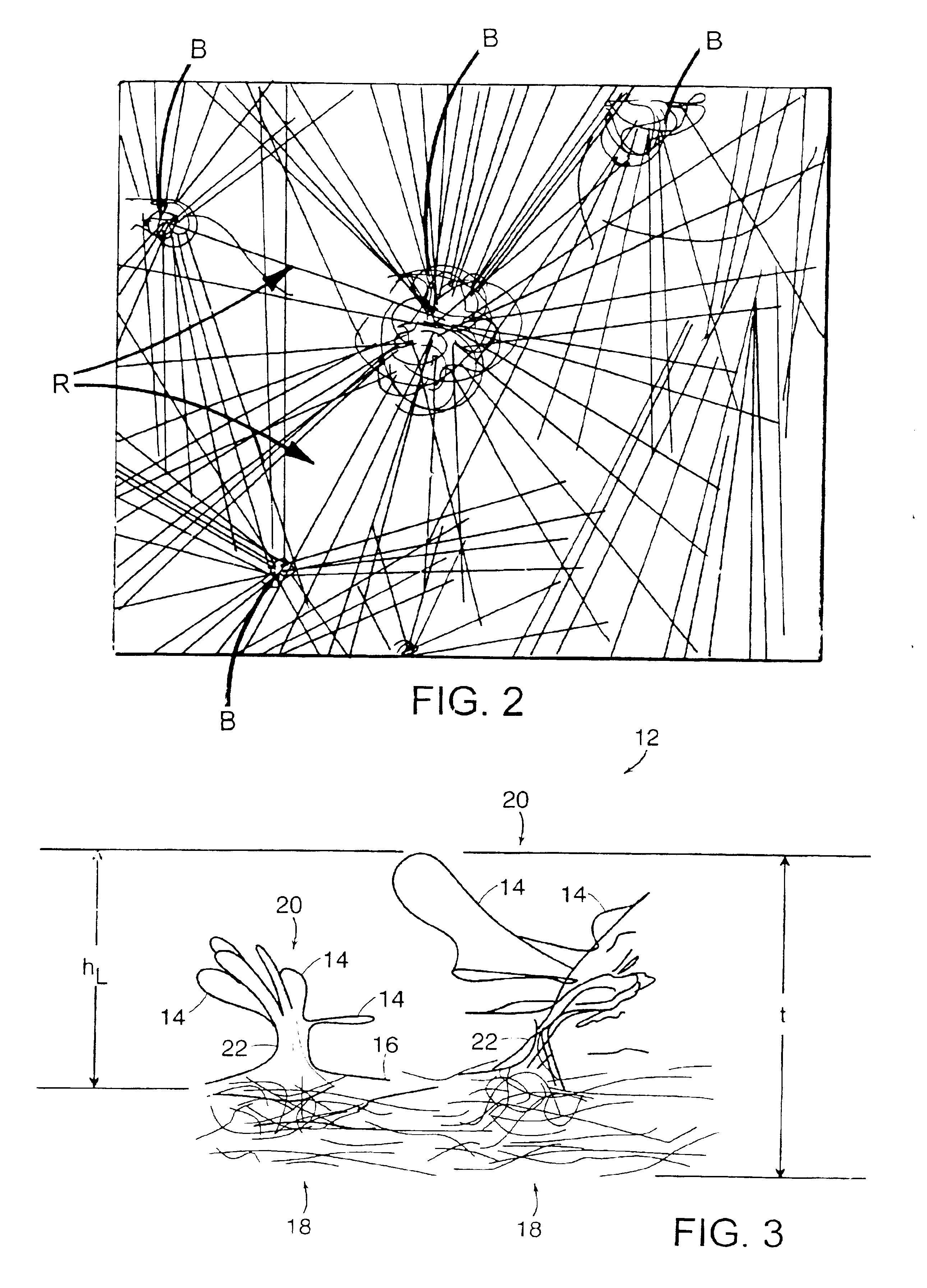

Helmet, helmet liner and method for manufacturing the same

This invention relates to a helmet, comprising an external shell (9) and an impact-absorbing helmet liner (10) in which the helmet liner comprises a layer provided with protruding, deformable and impact-absorbing hollow knobs (7) distributed on an substantial part of the surface of the helmet liner as a protective layer.The helmet is characterized in that the hollow knots (7) are arranged for deformation by crushing in case of external impact on the helmet, and that the helmet liner (10) with the hollow knots (7) exhibits undercut.The helmet may also comprise an impact-absorbing and preferably resilient layer (2) which may be arranged between the external shell (9) and an internal lining (11) being arranged to rest in contact with the head of a user.

Owner:CRESCENDO AS

Silver alginate foam compositions

The invention described herein relates to the preparation of cellulosic foam products prepared from silver alginate and derivatives thereof and the process for preparing them. The silver alginate products and related silver products are amenable for use in the preparation of medical and veterinary dressings for the treatment of burns, wounds, ulcerated lesions, and related pathological states.

Owner:B BRAUN HOSPICARE LIMITED IRELAND

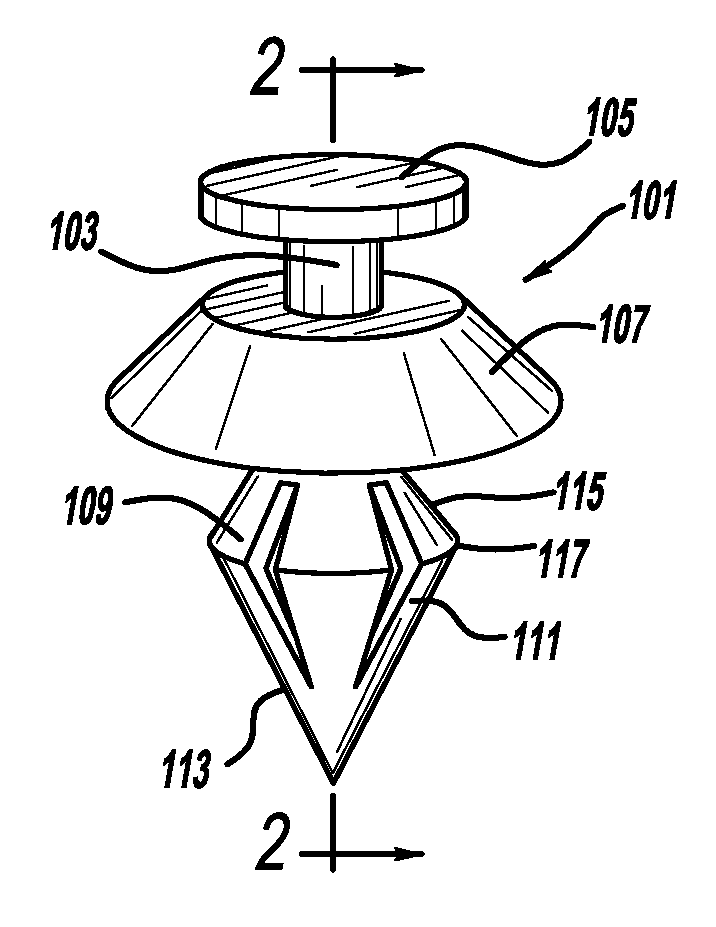

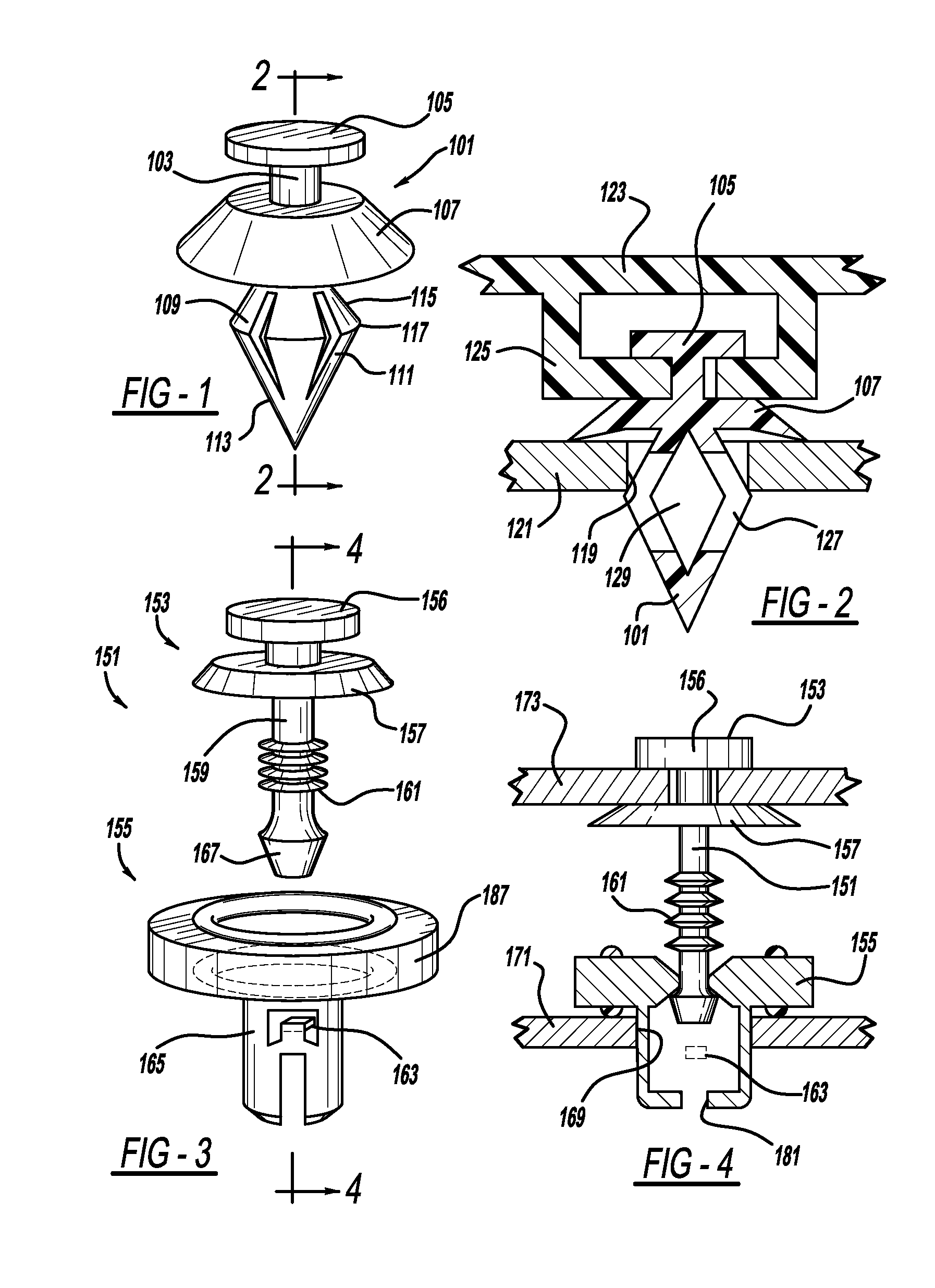

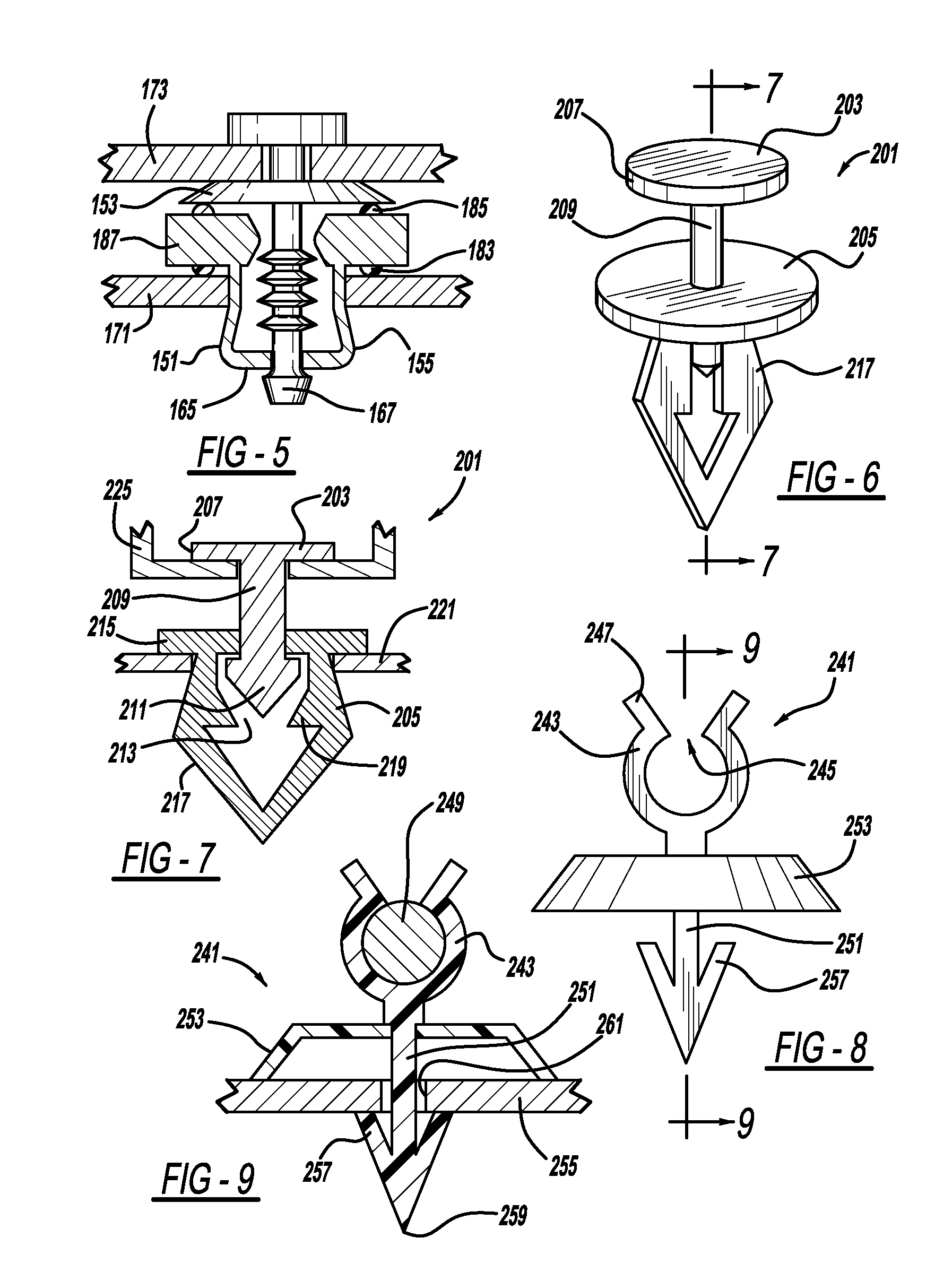

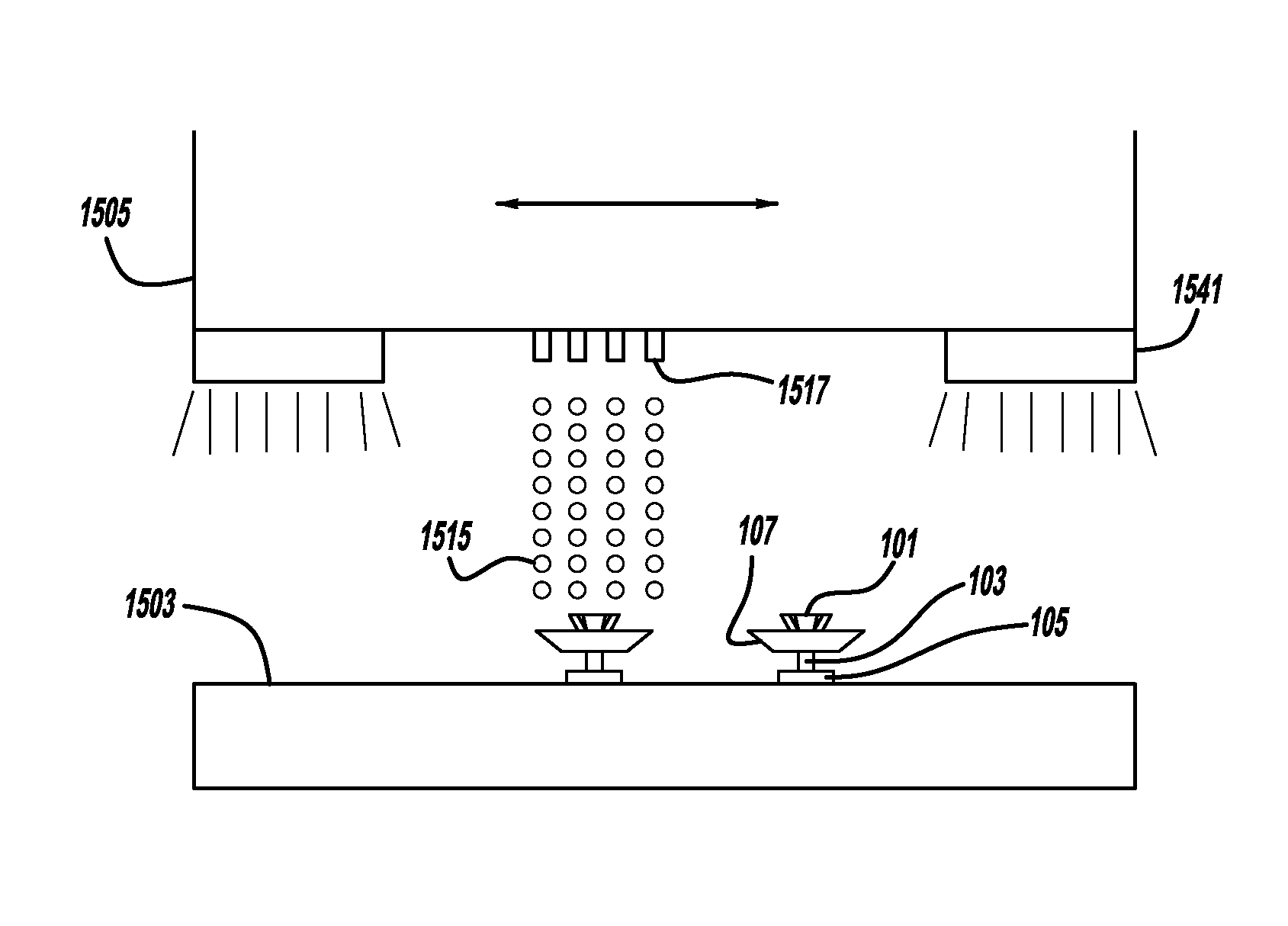

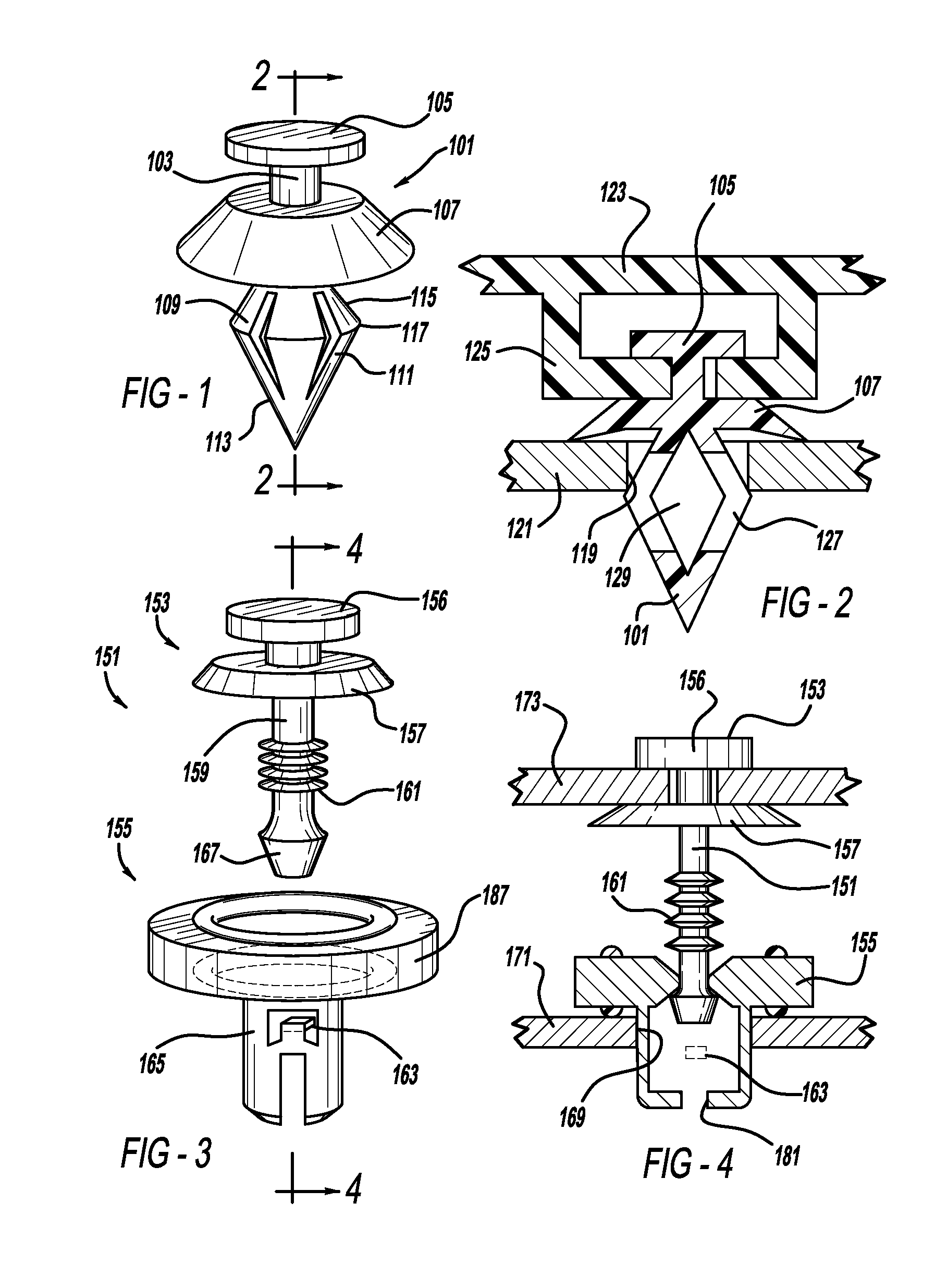

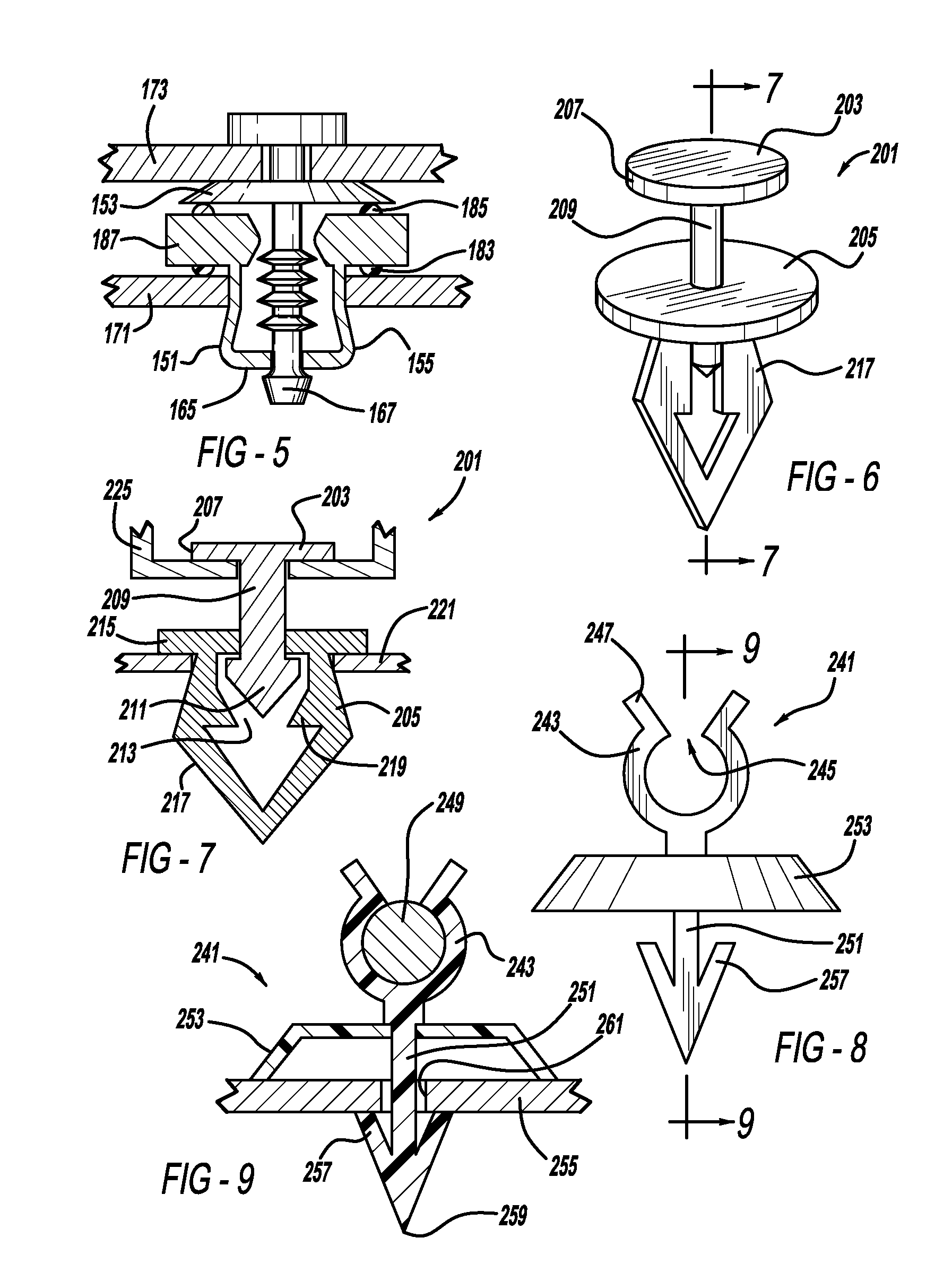

Fasteners manufactured by three-dimensional printing

InactiveUS20140086704A1Many timesQuick and inexpensive designDeformable pinsPinsEngineeringPrinting press

Owner:A RAYMOND & CO

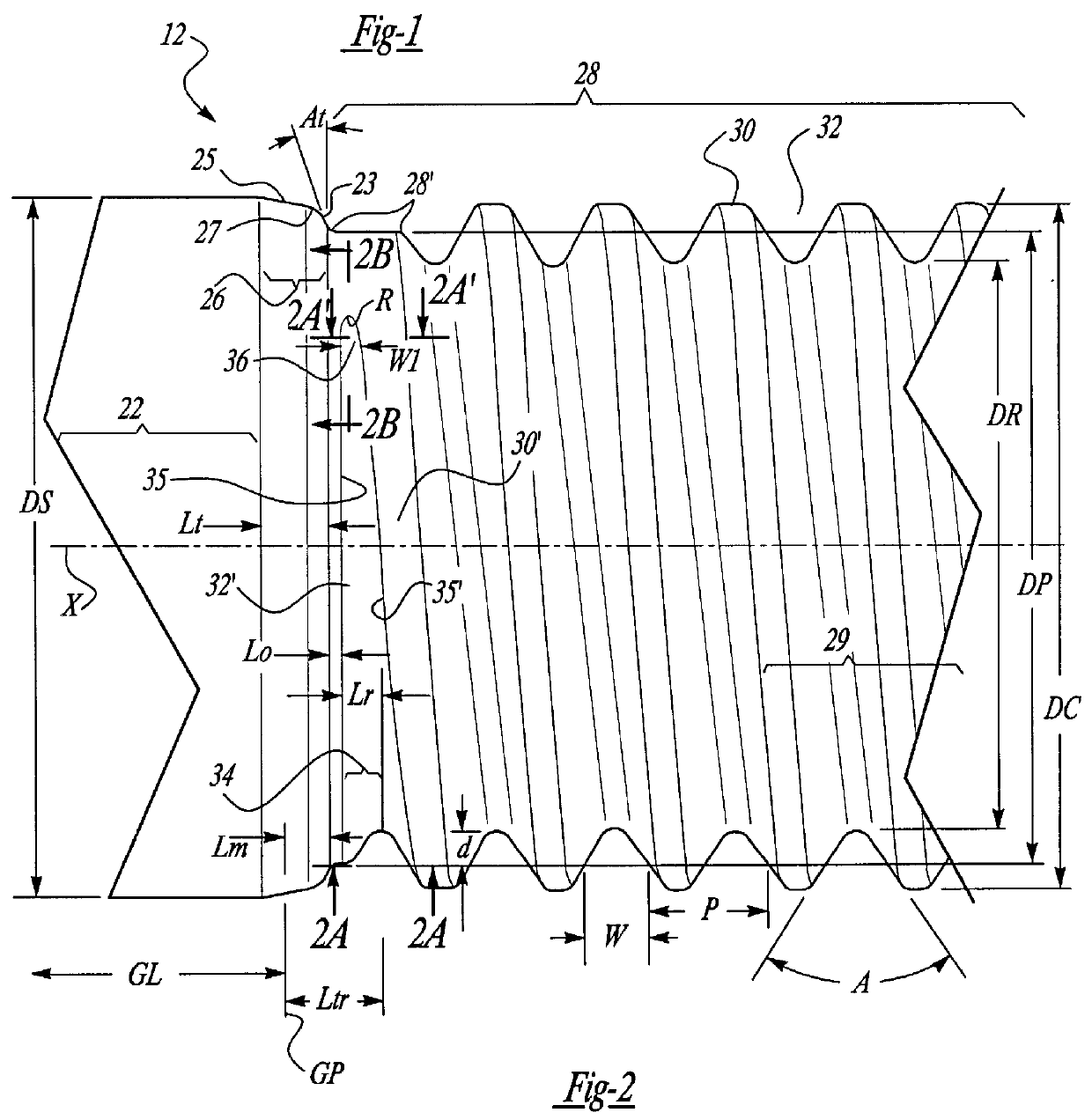

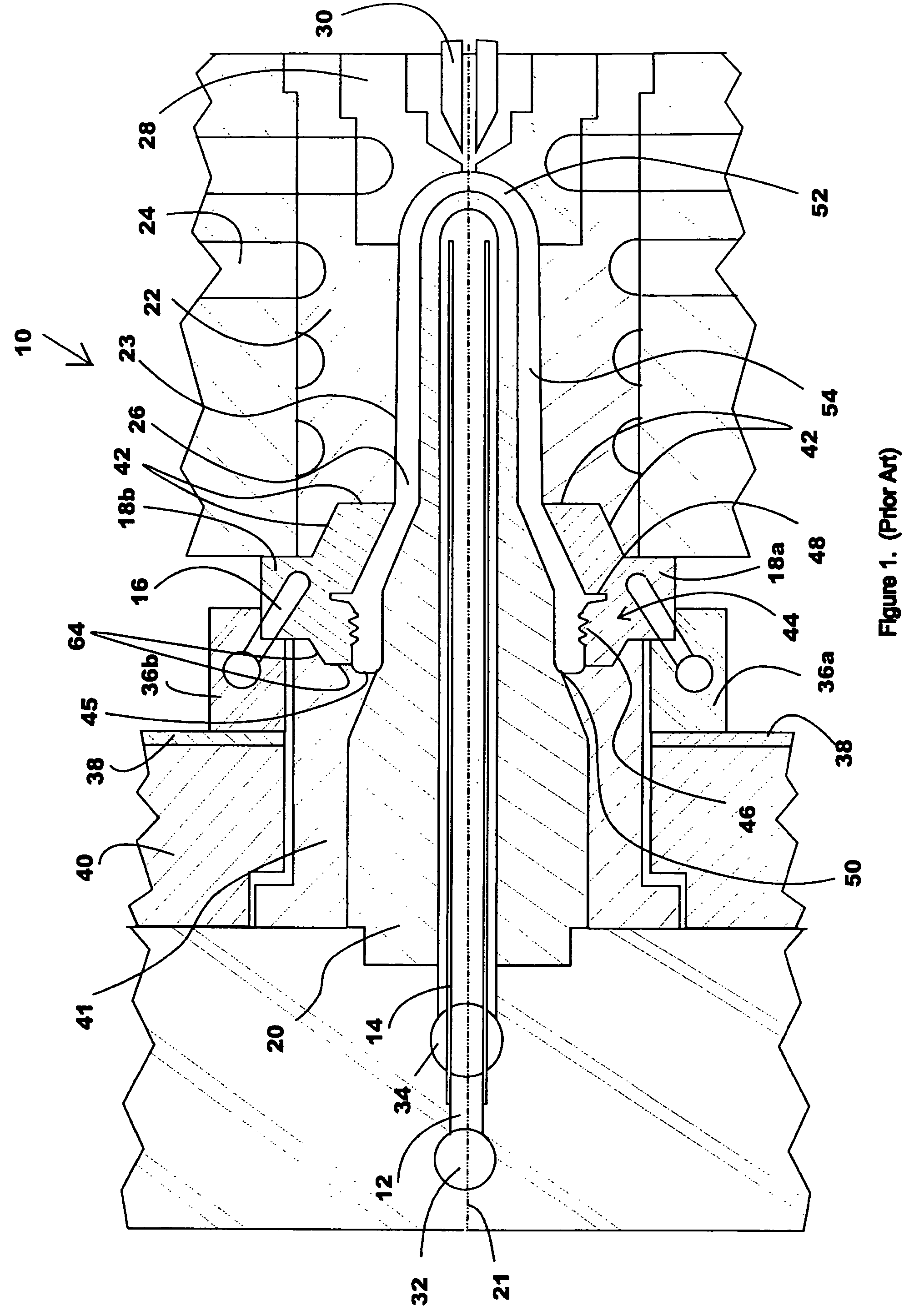

Lightweight threaded fastener and thread rolling die

InactiveUS6149363AImprove fatigue performanceImprove wear resistanceNutsBoltsEngineeringScrew thread

The present invention is to a lightweight threaded bolt type fastener having a shank with a large diameter portion and small diameter portion connected by a transition portion; a thread is roll formed on the small diameter portion and terminates in a run-out section where the thread gradually decreases in root depth and width and with the run-out section being of minimal axial length and being located closely adjacent the transition portion to produce a run-out zone of minimal axial length. A rolling die for forming the thread with minimal thread run-out having ridge segments with tapered end surfaces for providing the run-out thread with an end wall parallel to the transition portion and a method of making the bolt type fastener.

Owner:HUCK INT INC

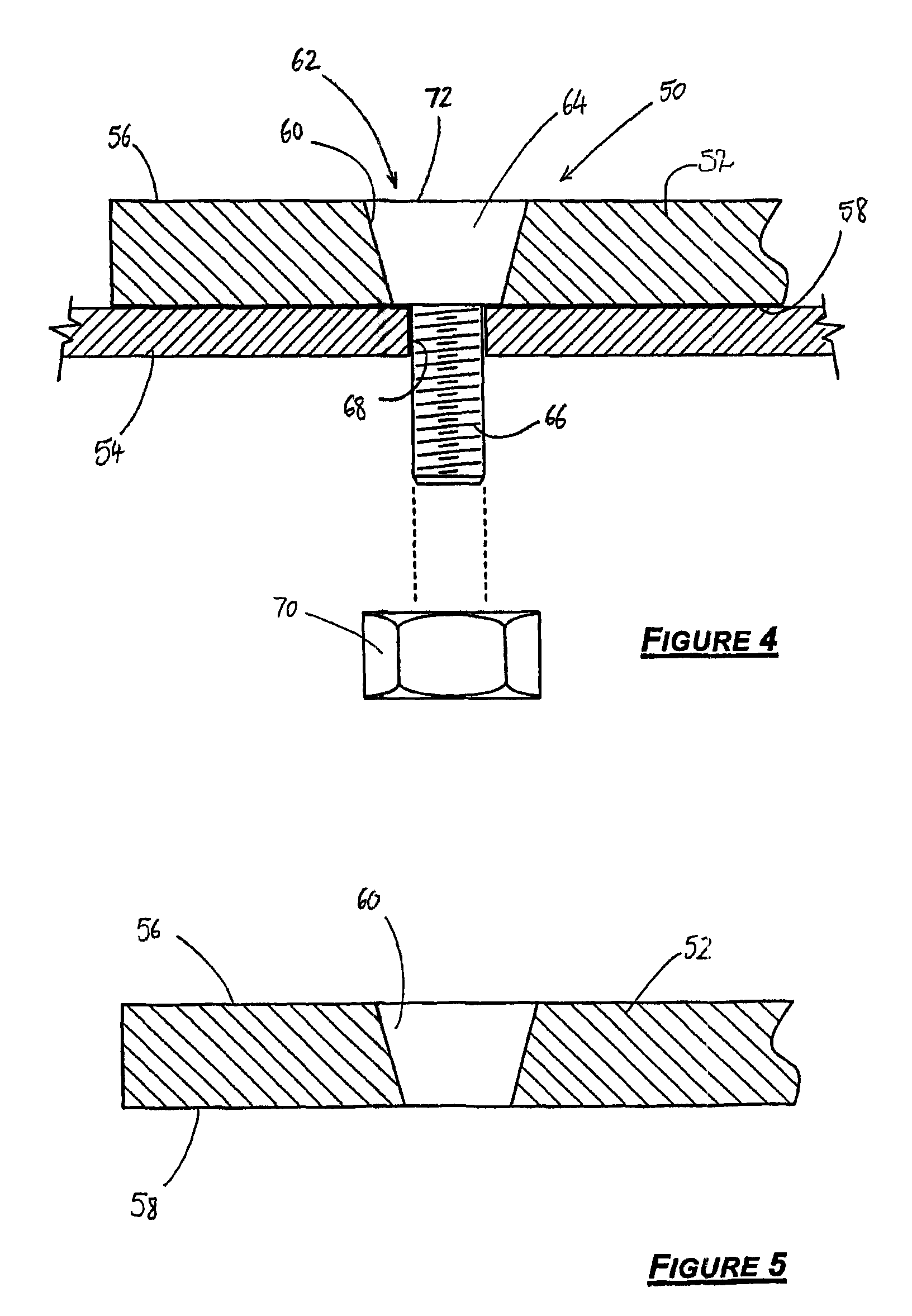

Apparatus and method for two stage ejection of a molded preform from a mold

InactiveUS7128865B2Quickly and efficiently removingDeformation MinimizationMouldsFood shapingEngineeringCycle time

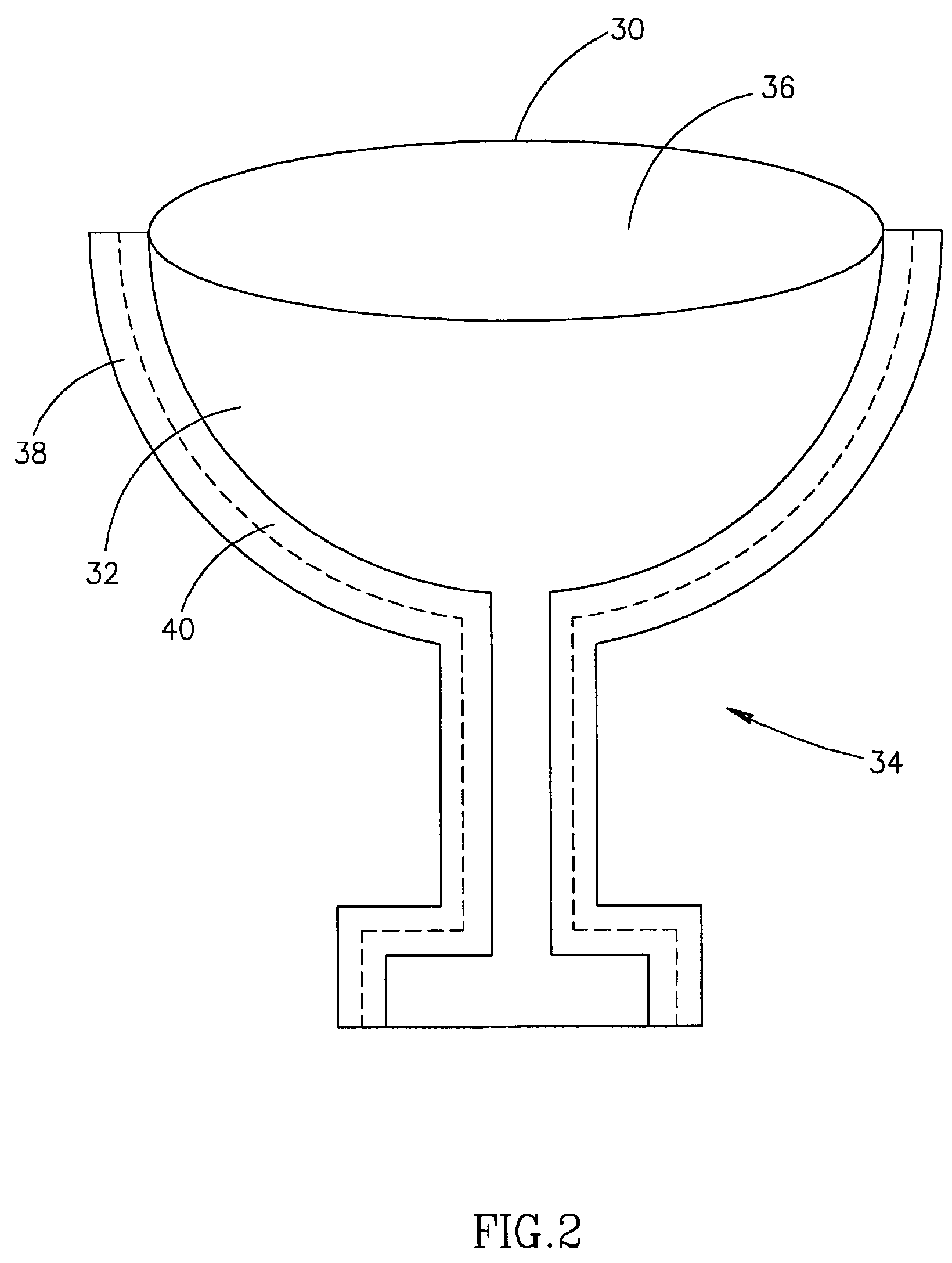

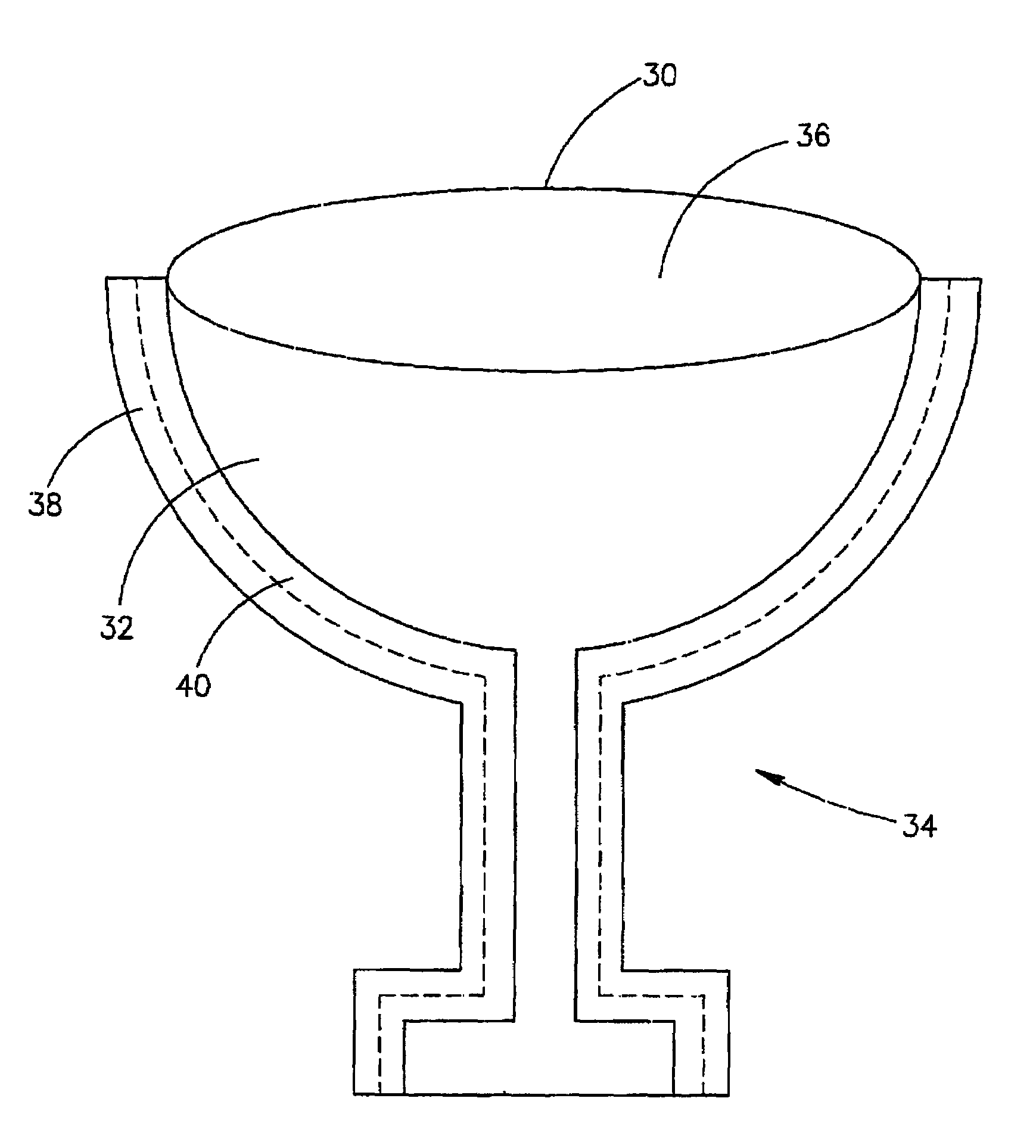

Injection molding method and apparatus for ejecting a molded plastic preform from a mold. A first lifting structure and / or step is configured to have an inner surface with an area for sealing and aligning with a complementary surface on a core, and to have an upper surface with an area for sealing and aligning with a complementary surface on a second lifting structure, said upper surface of said first lifting structure being configured to lift a molded plastic preform from the injection mold in a lifting direction for a first period of time, the lower portion of the molded plastic preform lying in a plane substantially perpendicular to the lifting direction. A second lifting structure and / or step is configured to have an inner surface configured to lift an outer surface of the molded plastic preform from the injection mold in the lifting direction for a second period of time, the outer surface of the molded plastic preform including structure lying in a plane substantially parallel with the lifting direction.Since the molded plastic preform is lifted by its end, the preform does not have to be solidified at its interior, thus allowing earlier removal of the preform from the mold, reducing cycle time.

Owner:HUSKY INJECTION MOLDING SYST LTD

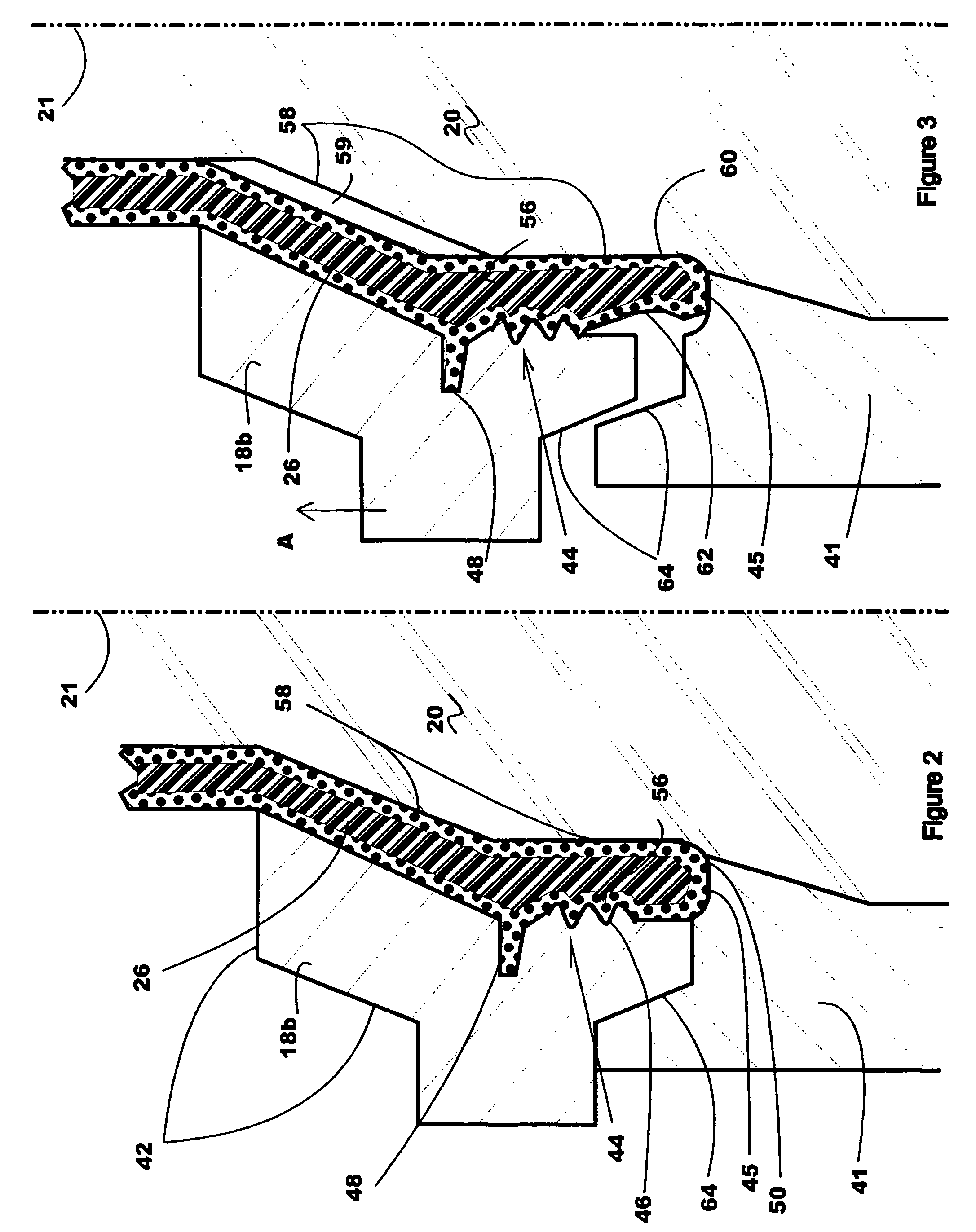

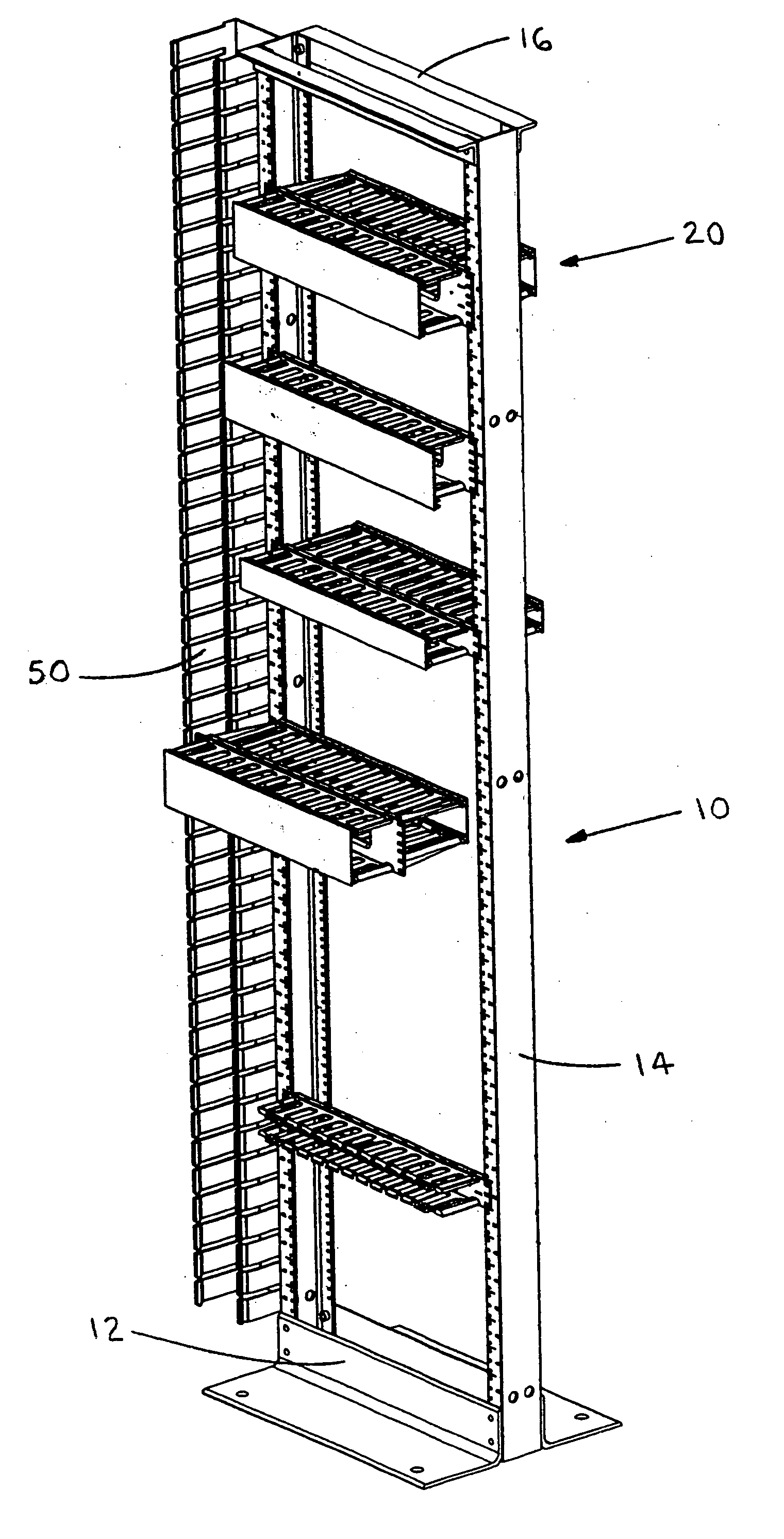

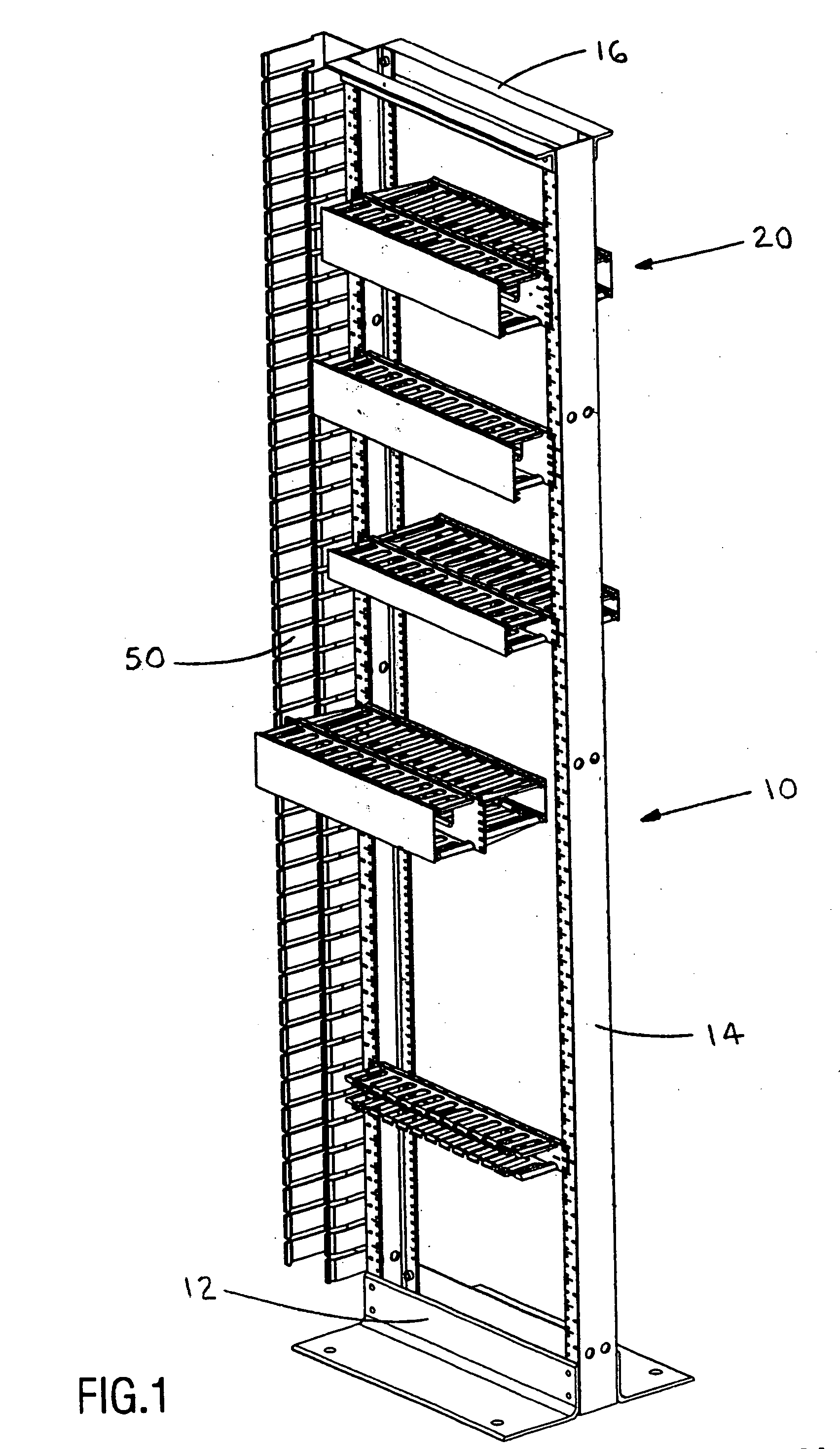

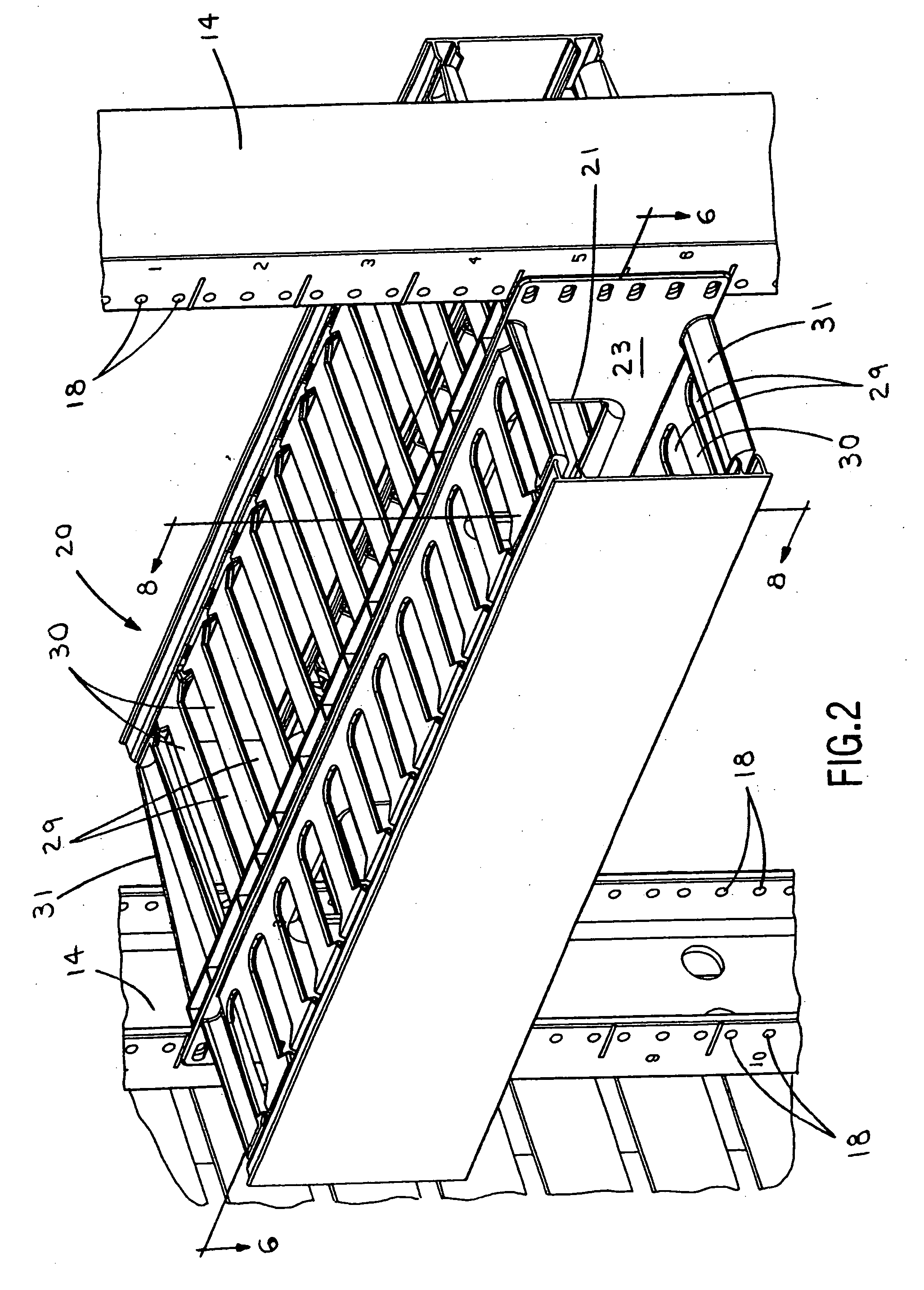

Rack-mountable cable manager

InactiveUS20060091086A1Complex structureContact safetyBus-bar/wiring layoutsMouldsEngineeringCable management

Owner:PANDUIT

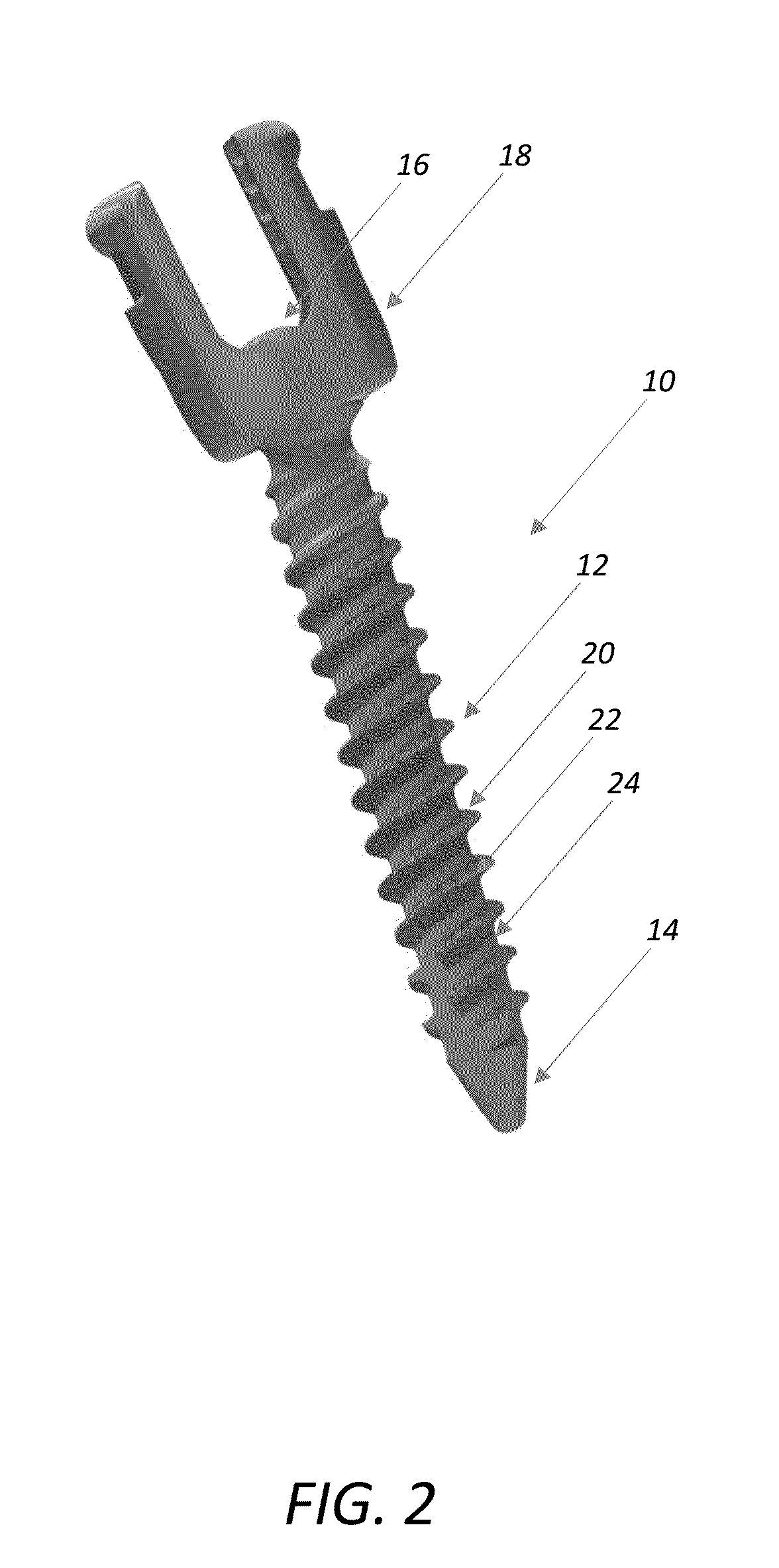

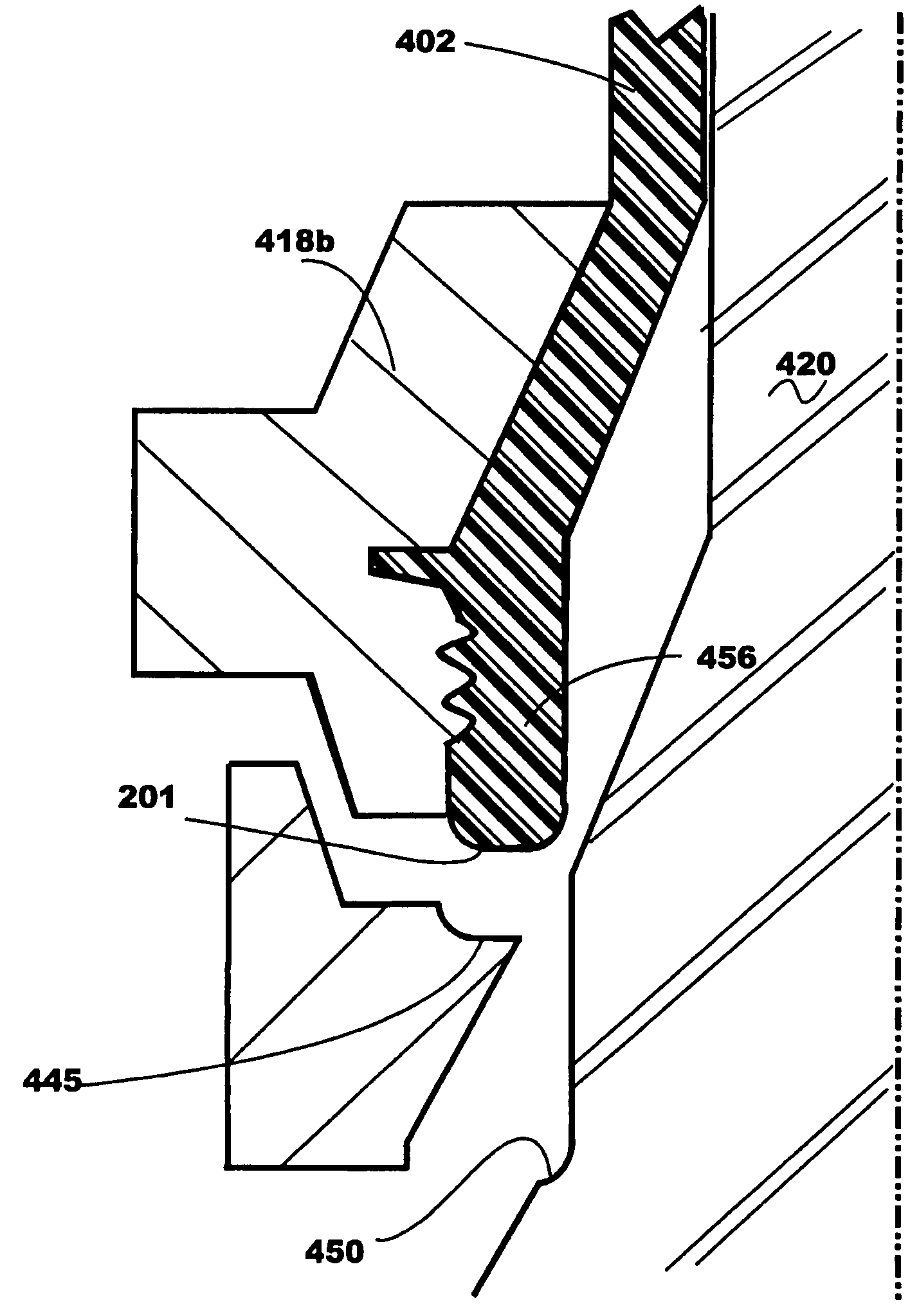

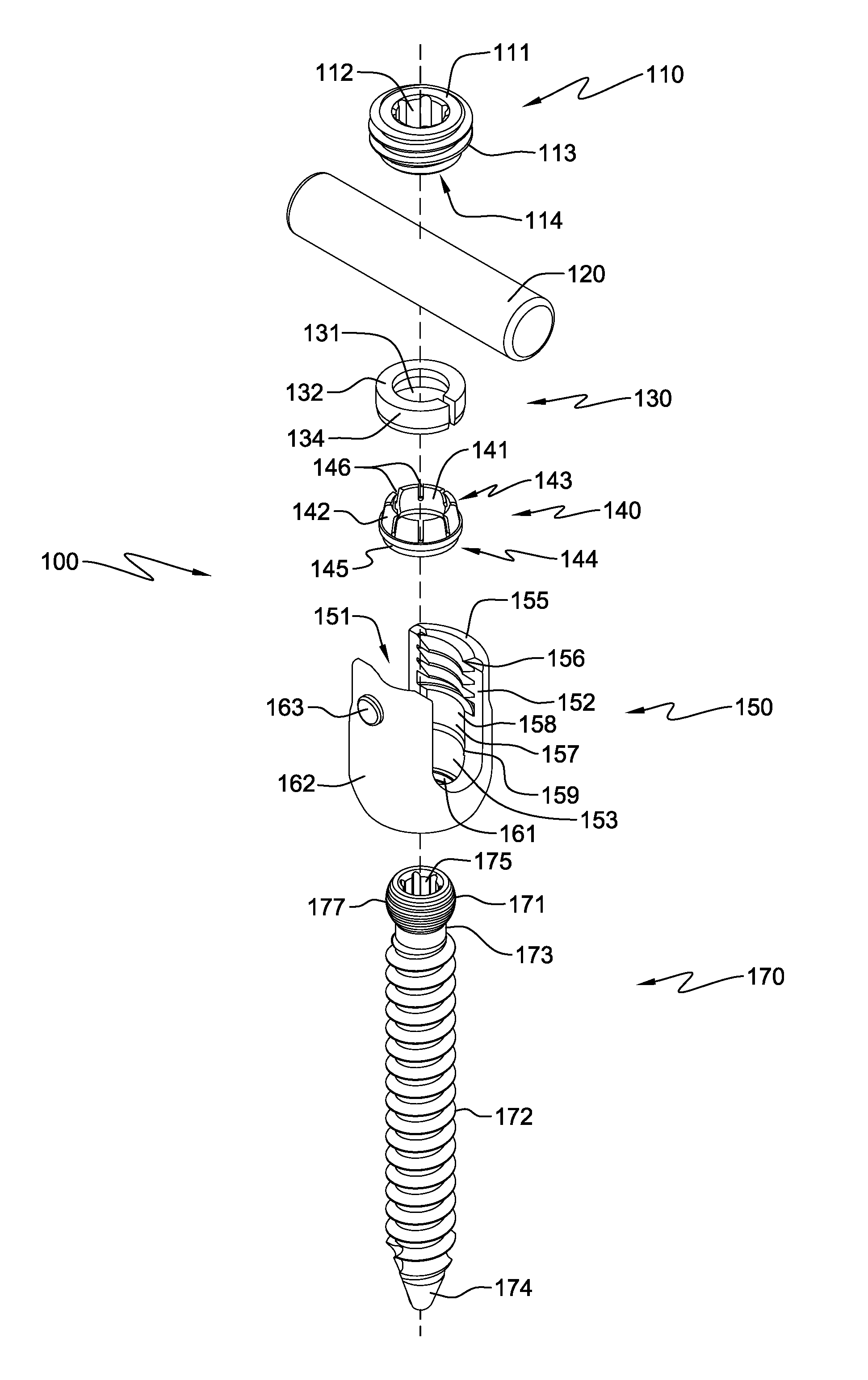

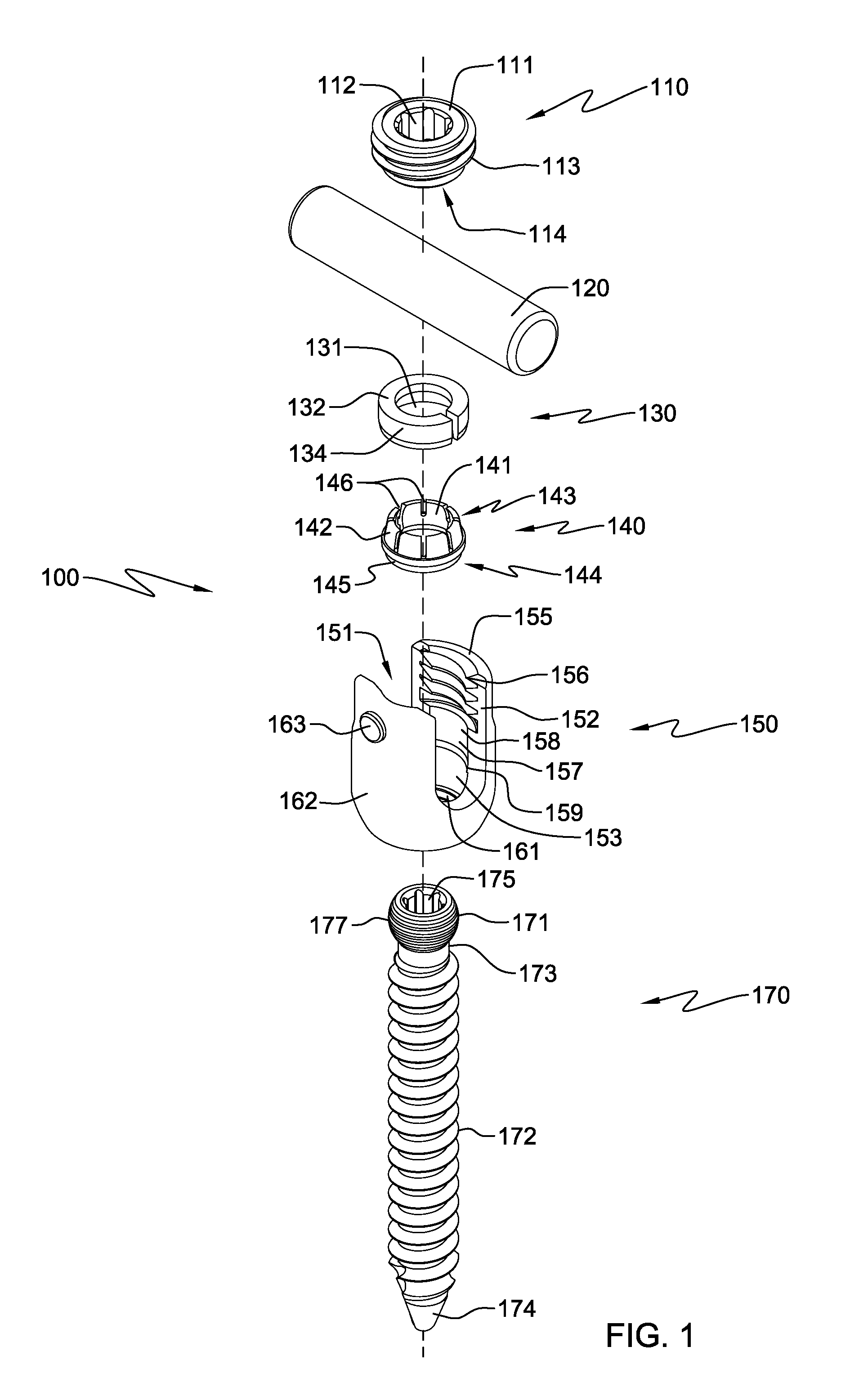

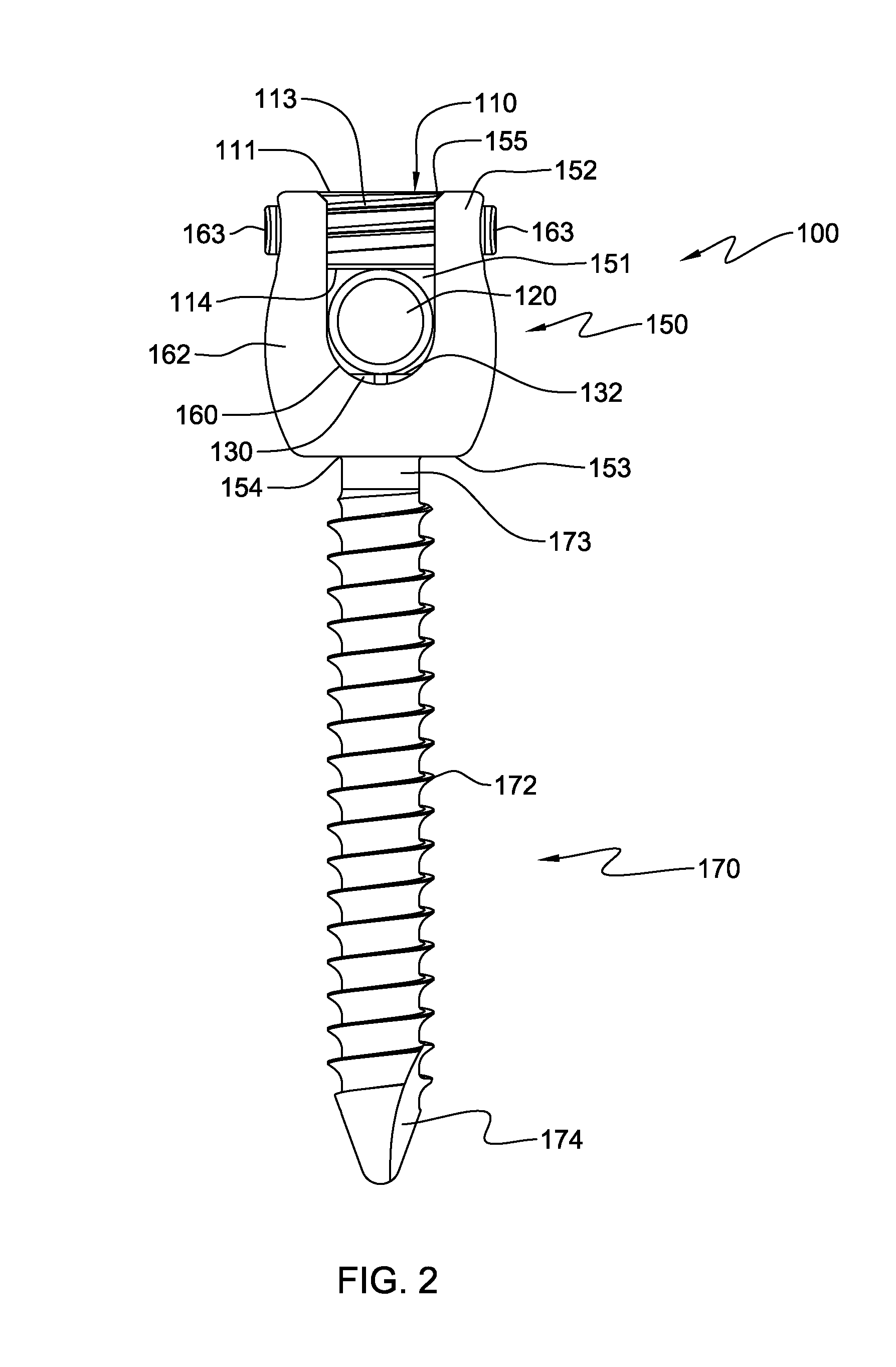

Pedicle screw assembly and method of assembly

ActiveUS20130211465A1Reduces splaying forceReduction in splaying forceSuture equipmentsInternal osteosythesisCompression memberPedicle screw

A pedicle screw assembly and method of assembly are disclosed. The pedicle screw assembly includes a bone fastener having a head at a proximal end and a threaded portion extending between the proximal end and a distal end. The assembly also includes a compression member having a conical inner surface and a locking member having an outer surface adapted to mate with the conical inner surface of the compression member. The assembly may also have an elongated member and a set screw that has a threaded portion. The assembly may also have a receiving housing having a central bore extending from a threaded proximal end to a distal end and a U-shaped cavity positioned perpendicular to the central bore and configured to receive the elongated member.

Owner:SKELETAL DESIGN PARTNERSHIP LLC

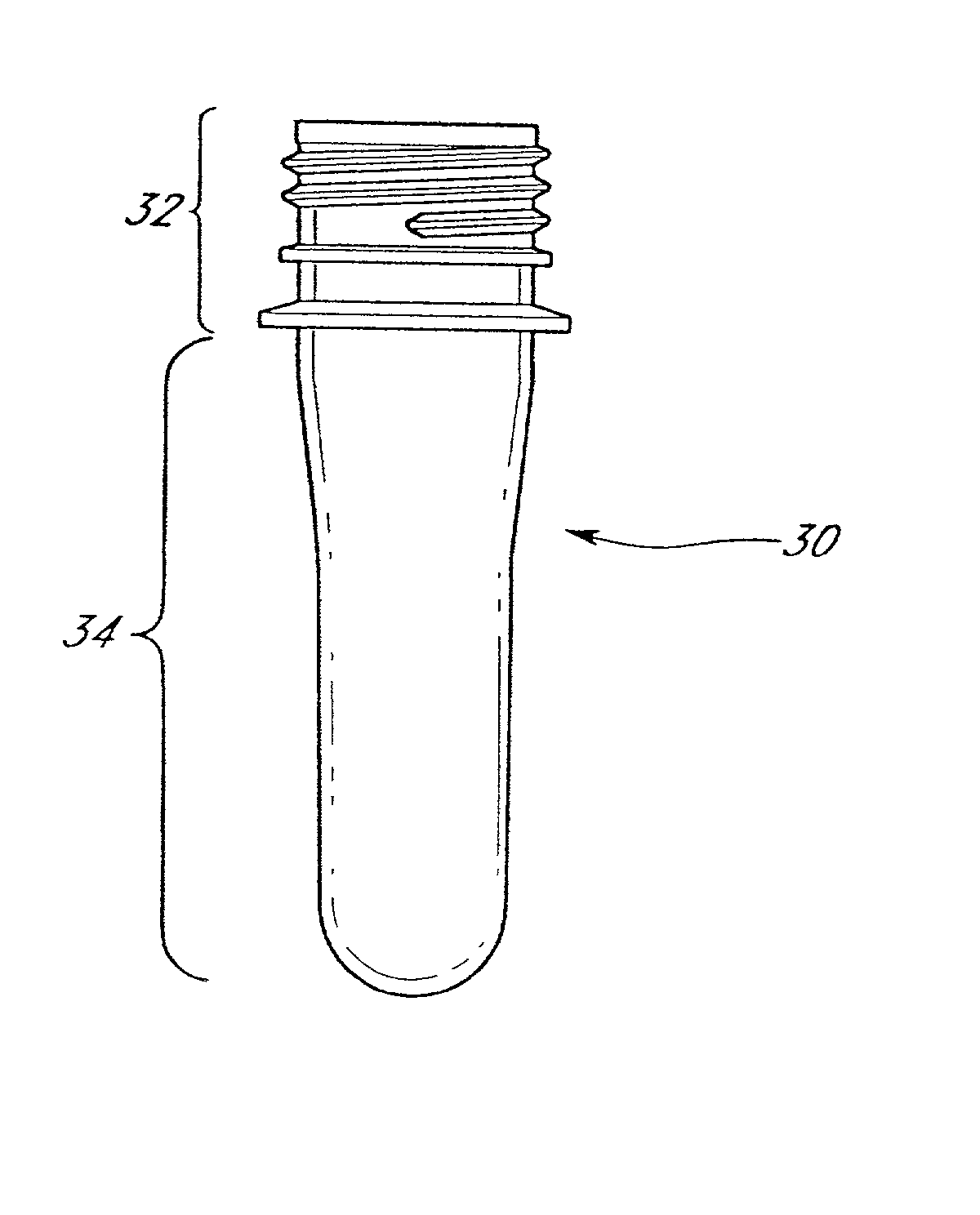

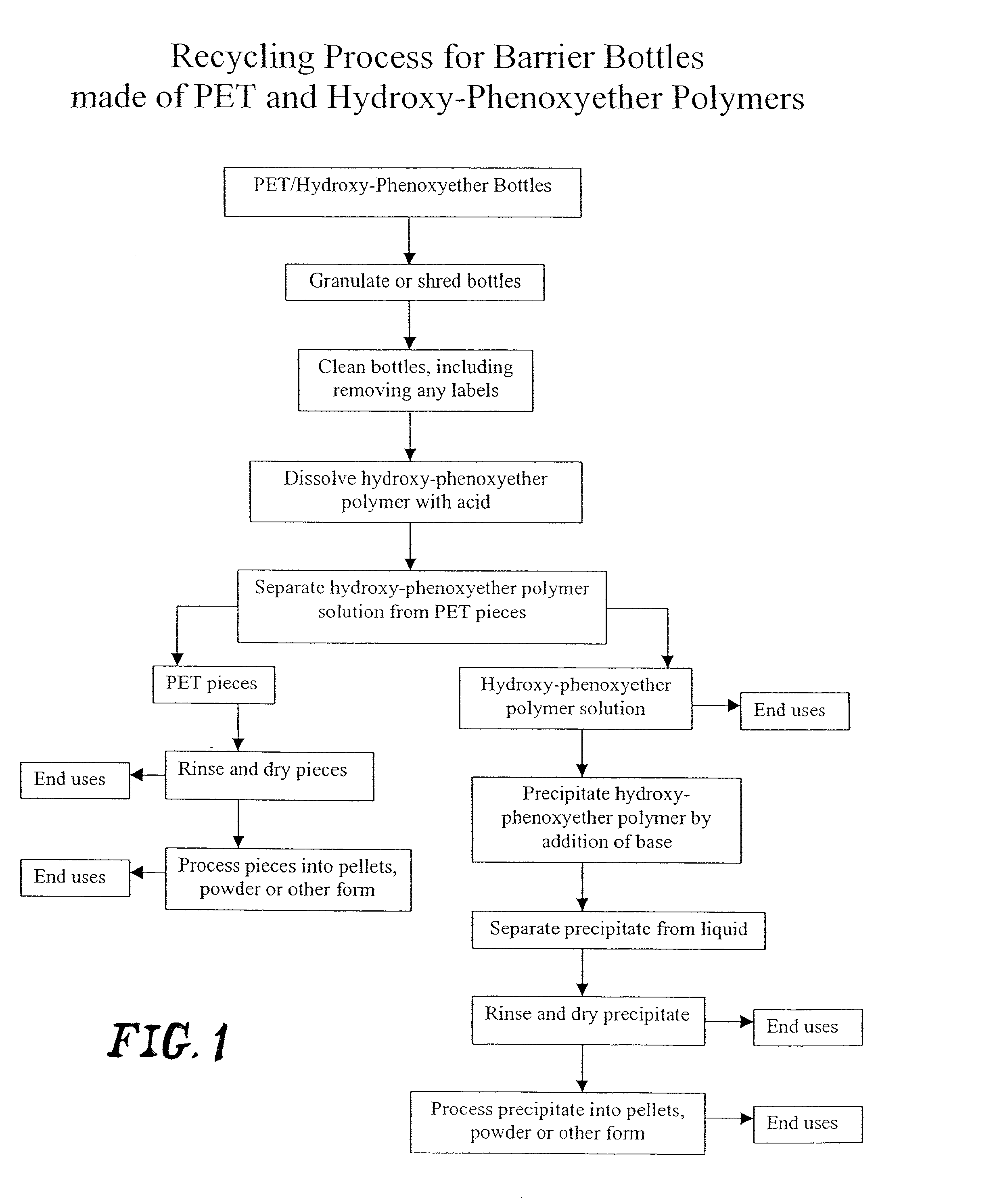

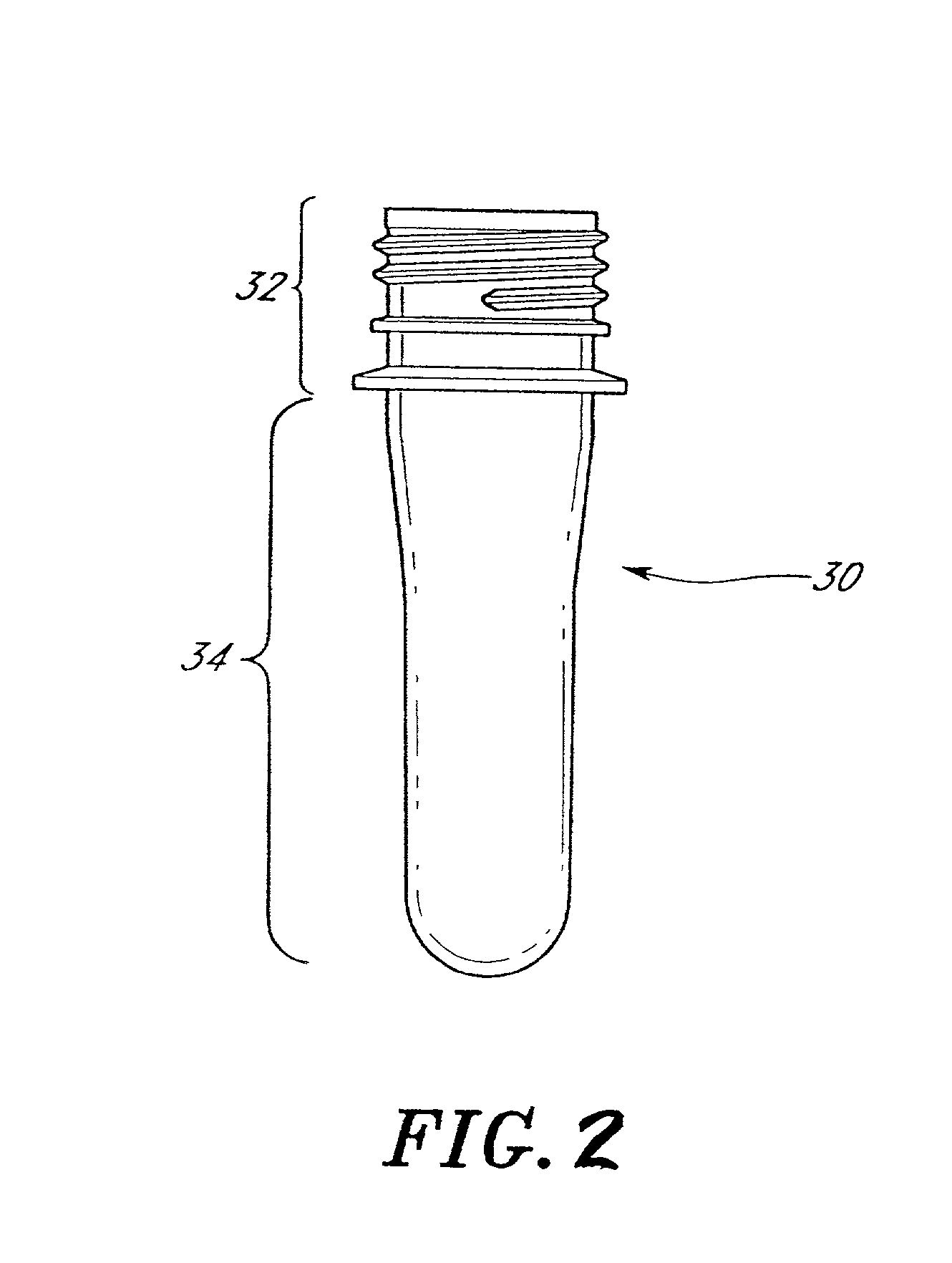

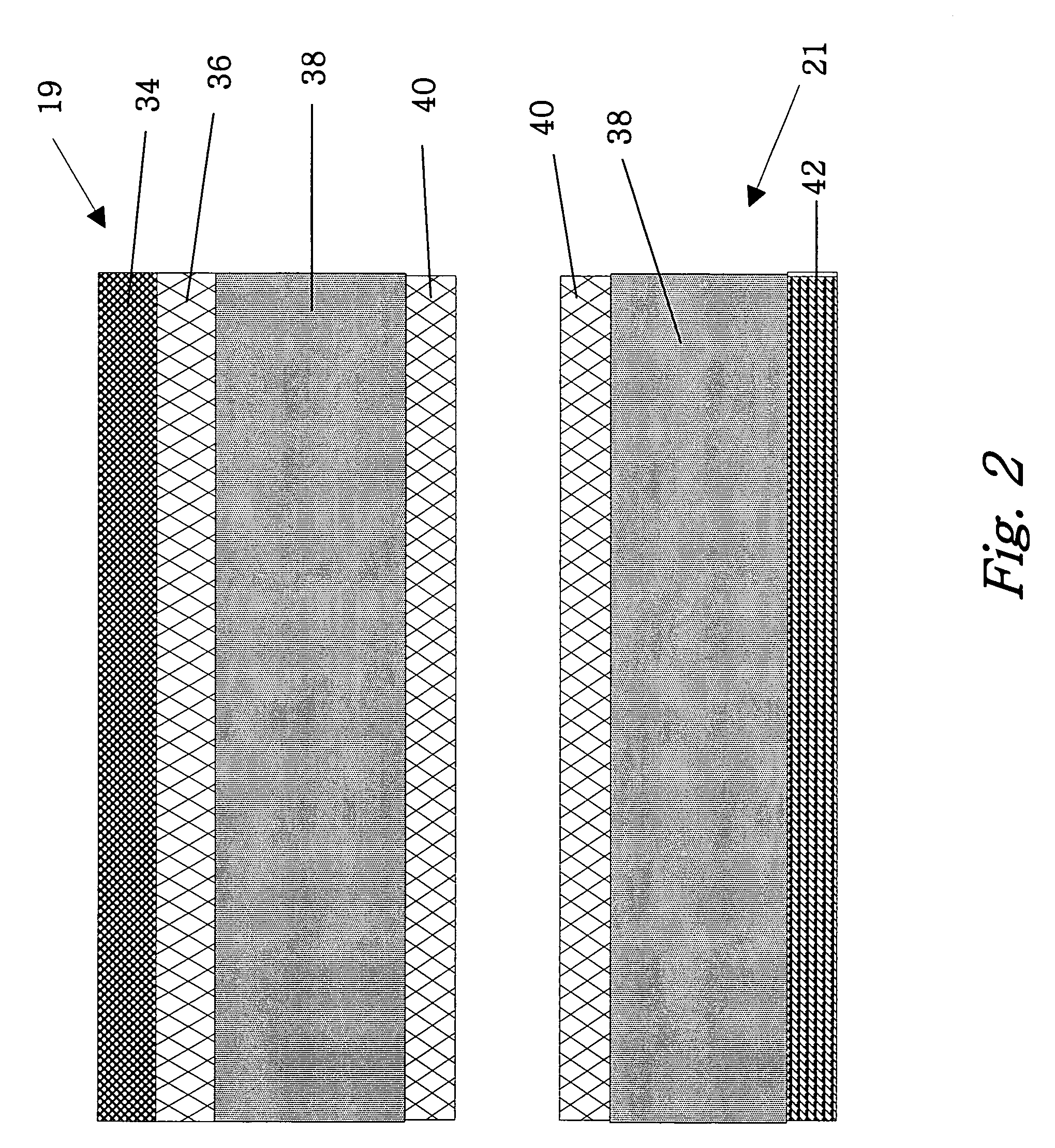

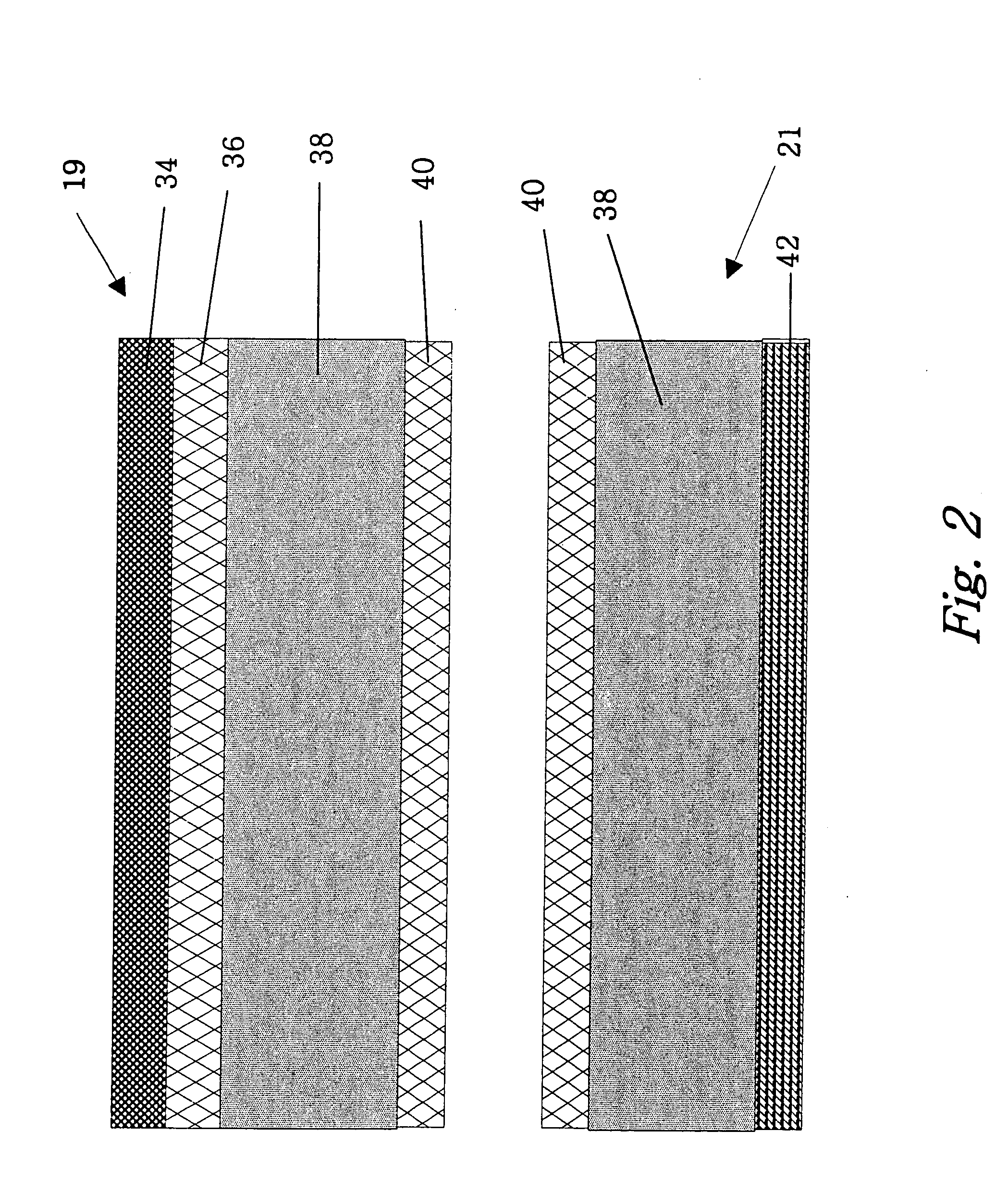

Multilayer containers and preforms having barrier properties utilizing recycled material

InactiveUS20020090473A1Reduce the amount requiredMaintain good propertiesMouldsConfectioneryPolyesterPolyethylene terephthalate glycol

Preferred embodiments relate to methods and apparatus for making articles made of polyester, preferably virgin polyethylene terephthalate (PET), having coated directly to at least one of the surfaces thereof one or more layers of recycled or post-consumer PET and one or more layers of a material with good gas-barrier characteristics, preferably silicon oxide. Preferably, the recycled PET layer comprises about 25% to about 50% of the entire material content. Preferably the articles take the form of preforms and the containers are blow-molded therefrom and the barrier layer is subsequently applied. The preferred barrier materials have a lower permeability to oxygen and carbon dioxide than PET. In addition, the neck of the preforms and bottles is at least partially in the crystalline state and the body is primarily in the amorphous or semi-crystalline state. This structure in a preform enables the preform to be easily blow molded by virtue of the amorphous material in the body, while being able to have dimensional stability in hot-fill applications.

Owner:CONCENTRATE MFG OF IRELAND

Porous Bone Fixation Device

A porous bone fixation device has a body including non-porous areas that provide superior long term fixation and osteointegration performance. The porous areas provide an in-growth surface in strategic sections such as the threaded section of the fixation device that allow substantially more contact area between in-growth surface and bone. The in-growth material is a network of interconnected porosity in a matrix of bio compatible, preferably titanium. Examples of bone fixation devices include bone screws, bone anchors, dental implants, and similar devices used to provide a fixation point in bone.

Owner:PRAXIS POWDER TECH

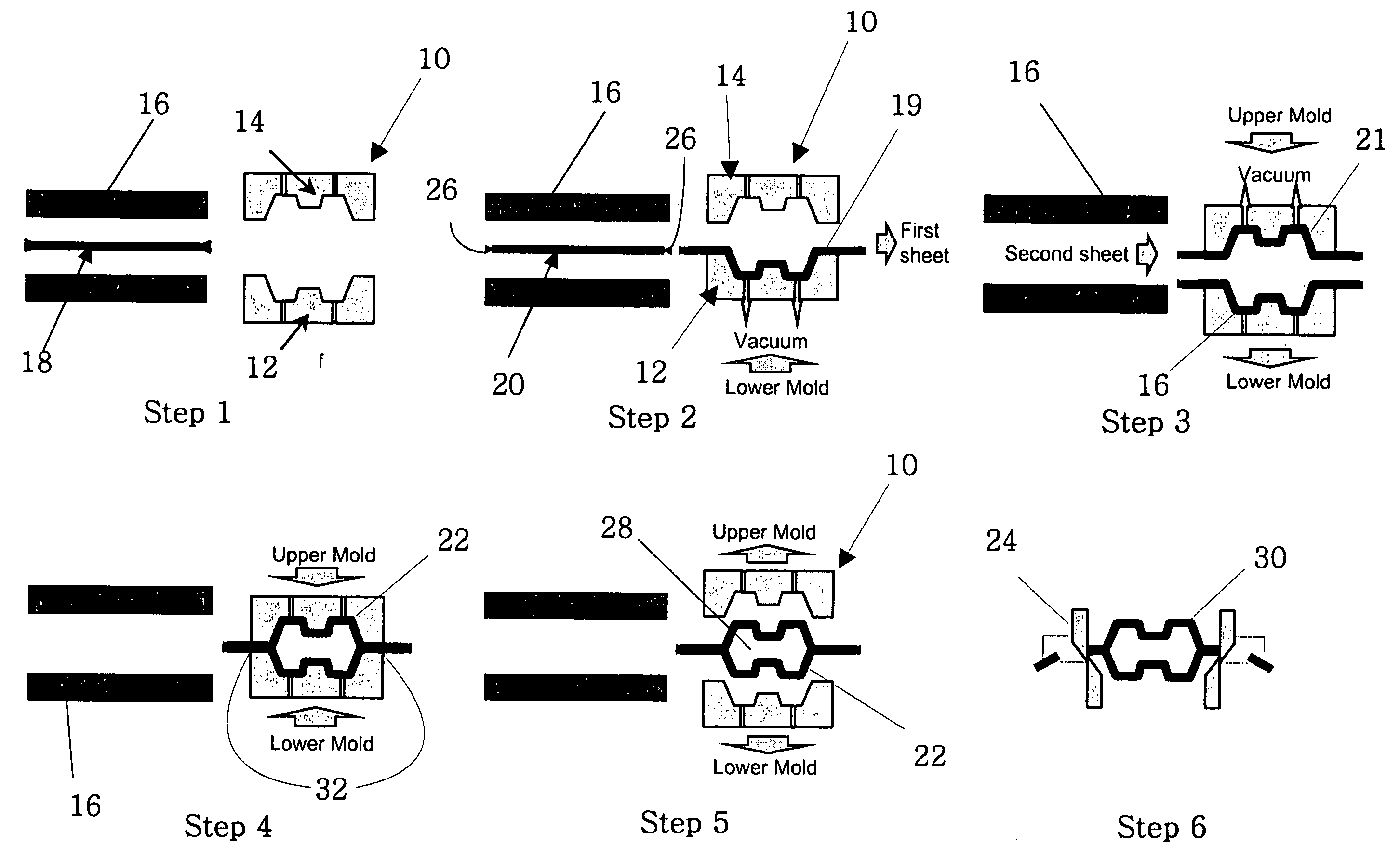

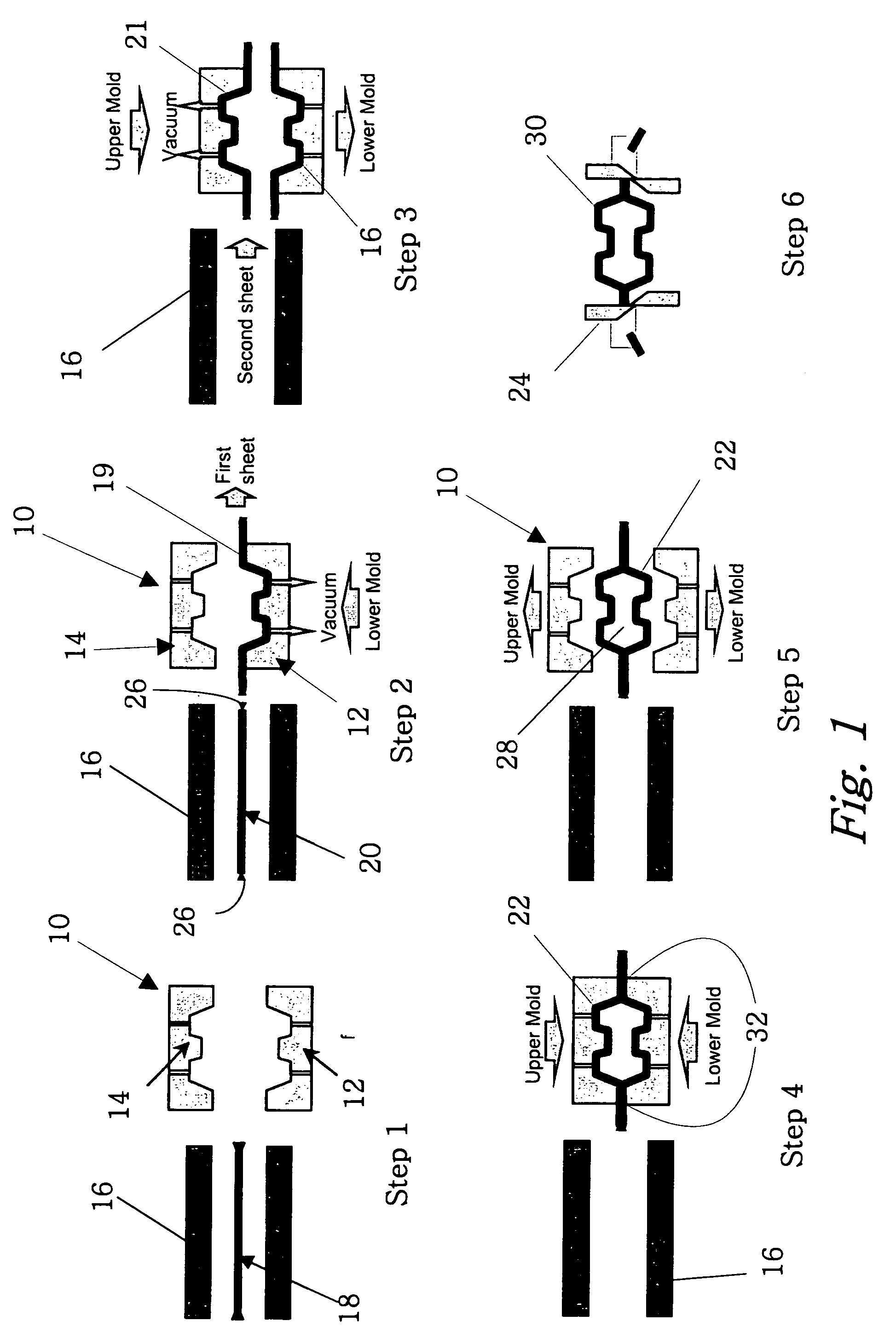

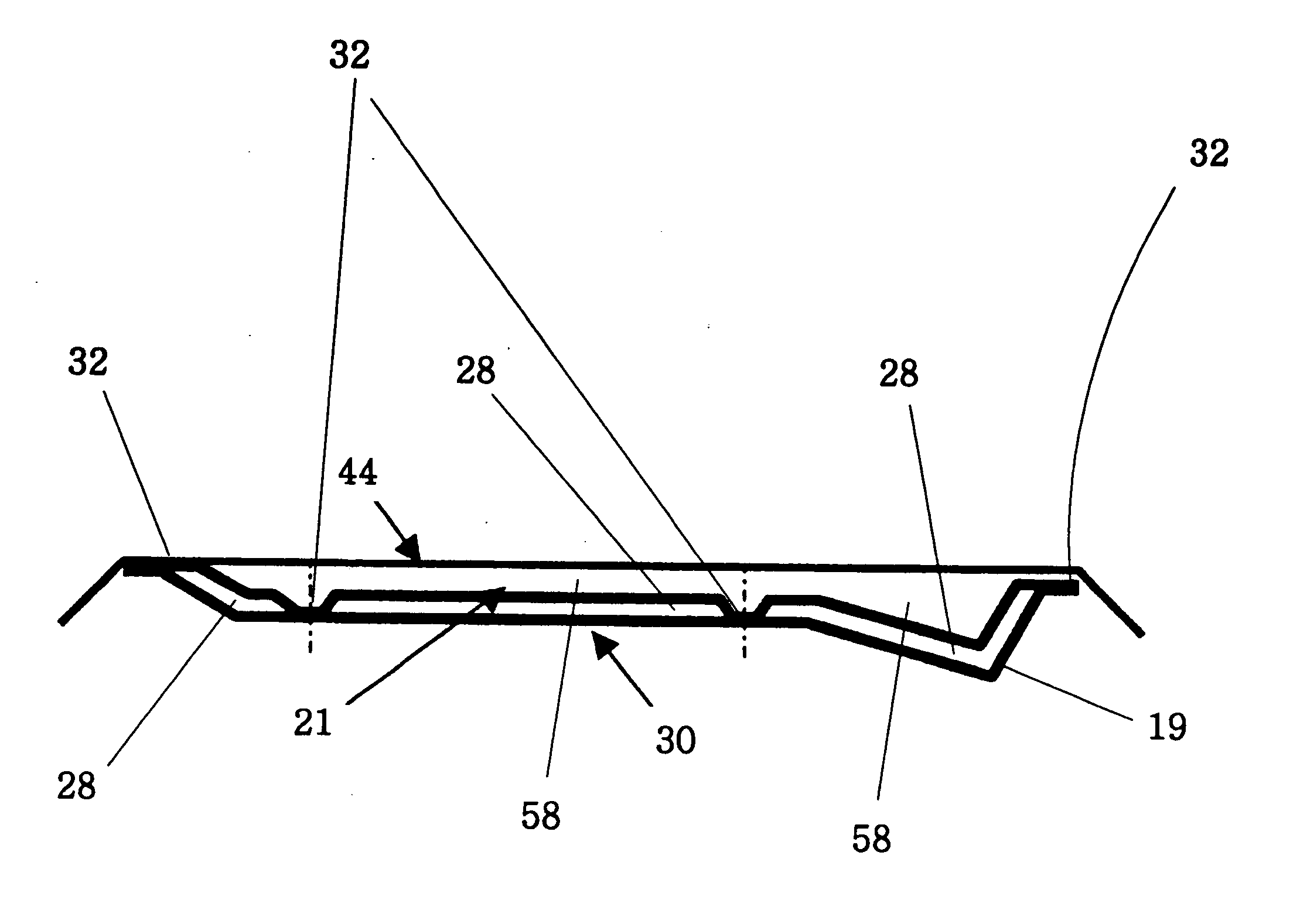

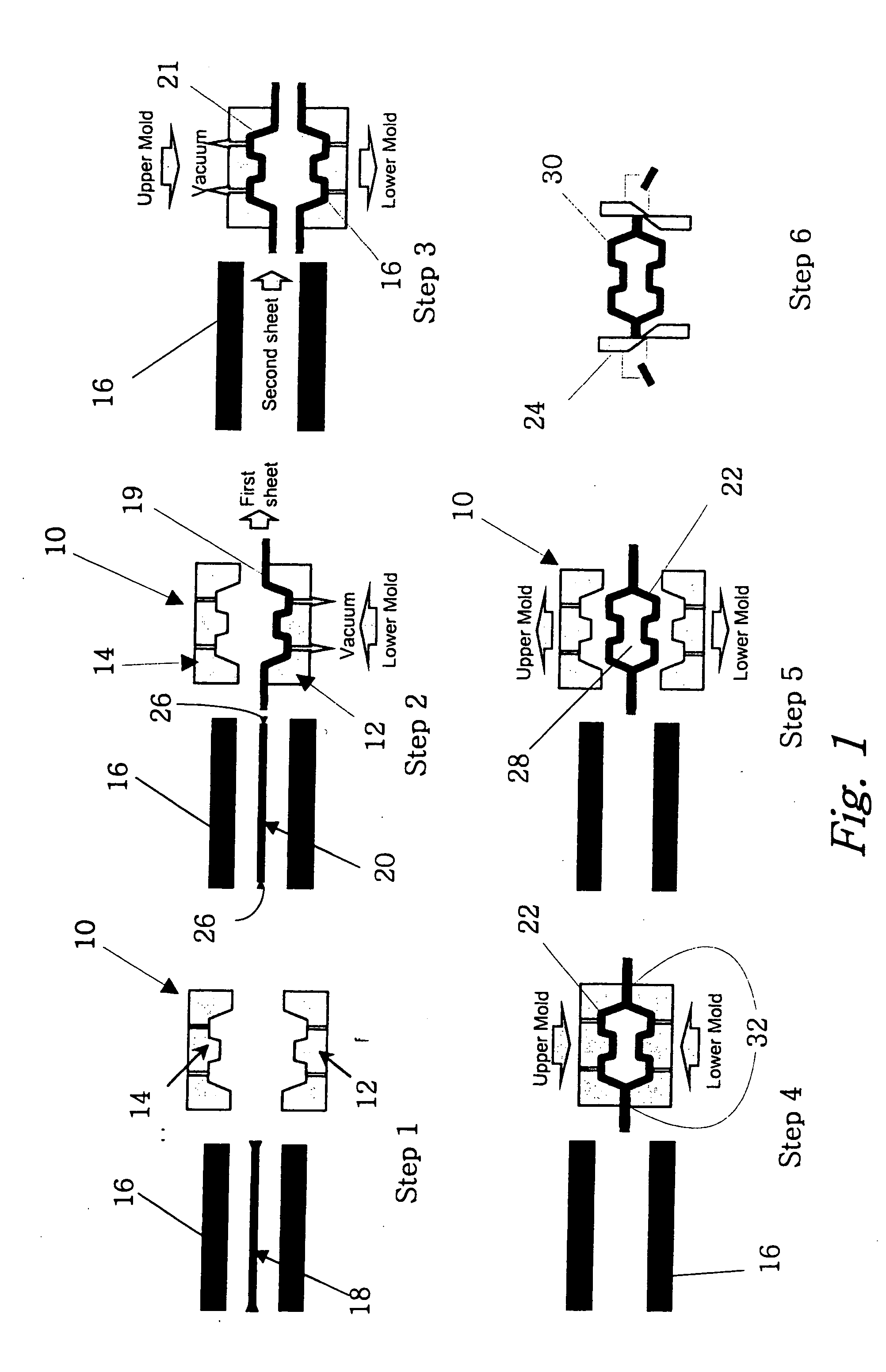

Twin-sheet thermoforming process

A twin-sheet thermoforming process for the manufacture of vehicle headliners. In the process a first sheet and second sheet of SuperLite material are mounted onto respective frames. The frames transfer the sheets into an oven, where they are heated to a desired temperature using IR. The first sheet is combined with a cover-stock material using compression molding forming a covered first headliner part. The covered first headliner part is then transferred to a second mold station. The second sheet is heated and then transferred from the oven to the second mold station where it is vacuum-formed on the upper half mold, forming a second headliner part. The upper and lower mold halves are pressed together fusing and sealing the first and second headliner parts into a unified part. The unified part is then unloaded and trimmed as necessary forming a headliner. The SuperLite material used to form the headliner is a sheet of low pressure, thermoformable, thermoplastic composite comprised of polypropylene and long chopped glass fibers.

Owner:AZDEL INC

Twin-sheet thermoformed products

A twin-sheet thermoforming process for the manufacture of vehicle headliners. In the process a first sheet and second sheet of SuperLite material are mounted onto respective frames. The frames transfer the sheets into an oven, where they are heated to a desired temperature using IR. The first sheet is combined with a cover-stock material using compression molding forming a covered first headliner part. The covered first headliner part is then transferred to a second mold station. The second sheet is heated and then transferred from the oven to the second mold station where it is vacuum-formed on the upper half mold, forming a second headliner part. The upper and lower mold halves are pressed together fusing and sealing the first and second headliner parts into a unified part. The unified part is then unloaded and trimmed as necessary forming a headliner. The SuperLite material used to form the headliner is a sheet of low pressure, thermoformable, thermoplastic composite comprised of polypropylene and long chopped glass fibers.

Owner:AZDEL INC

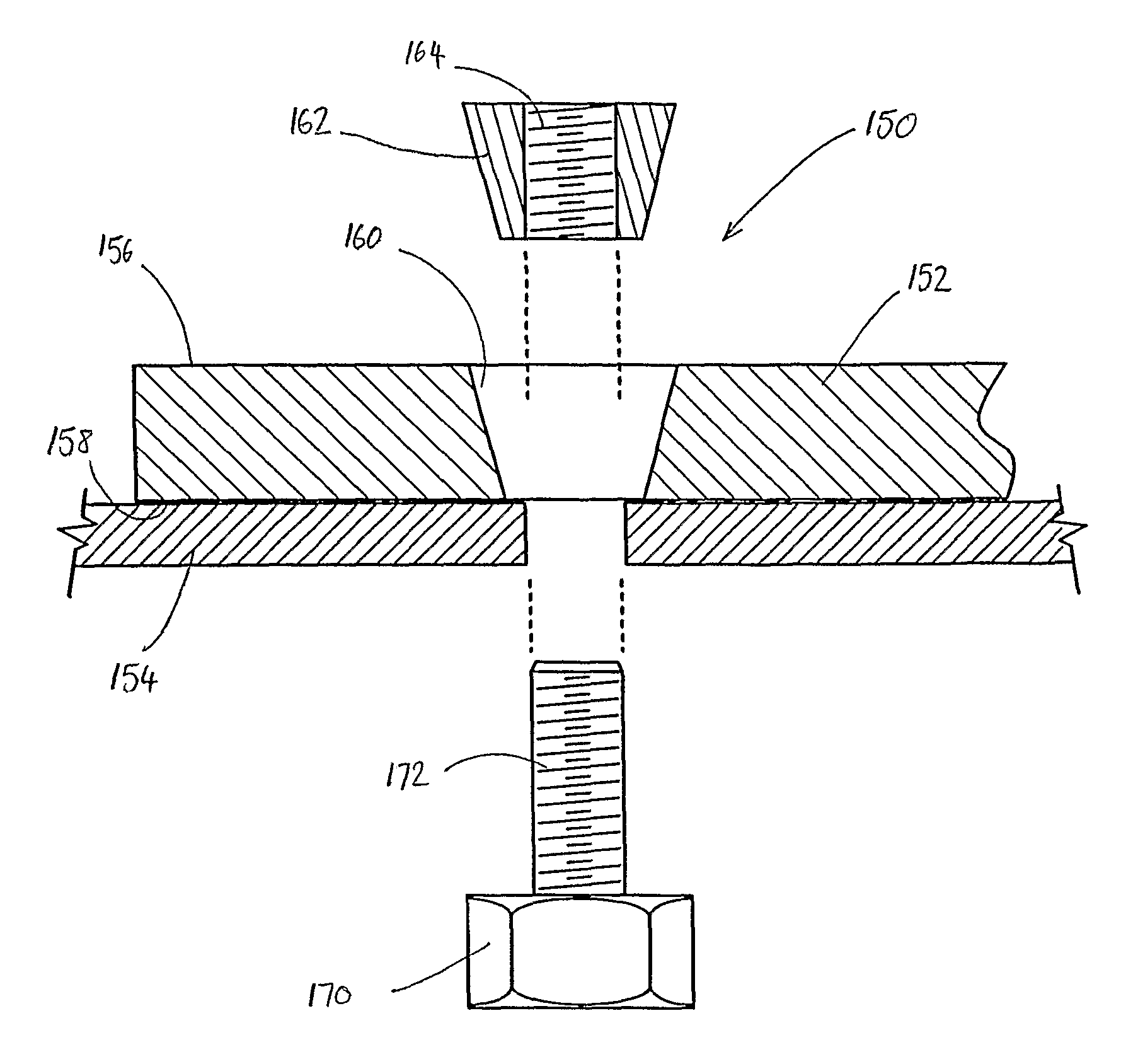

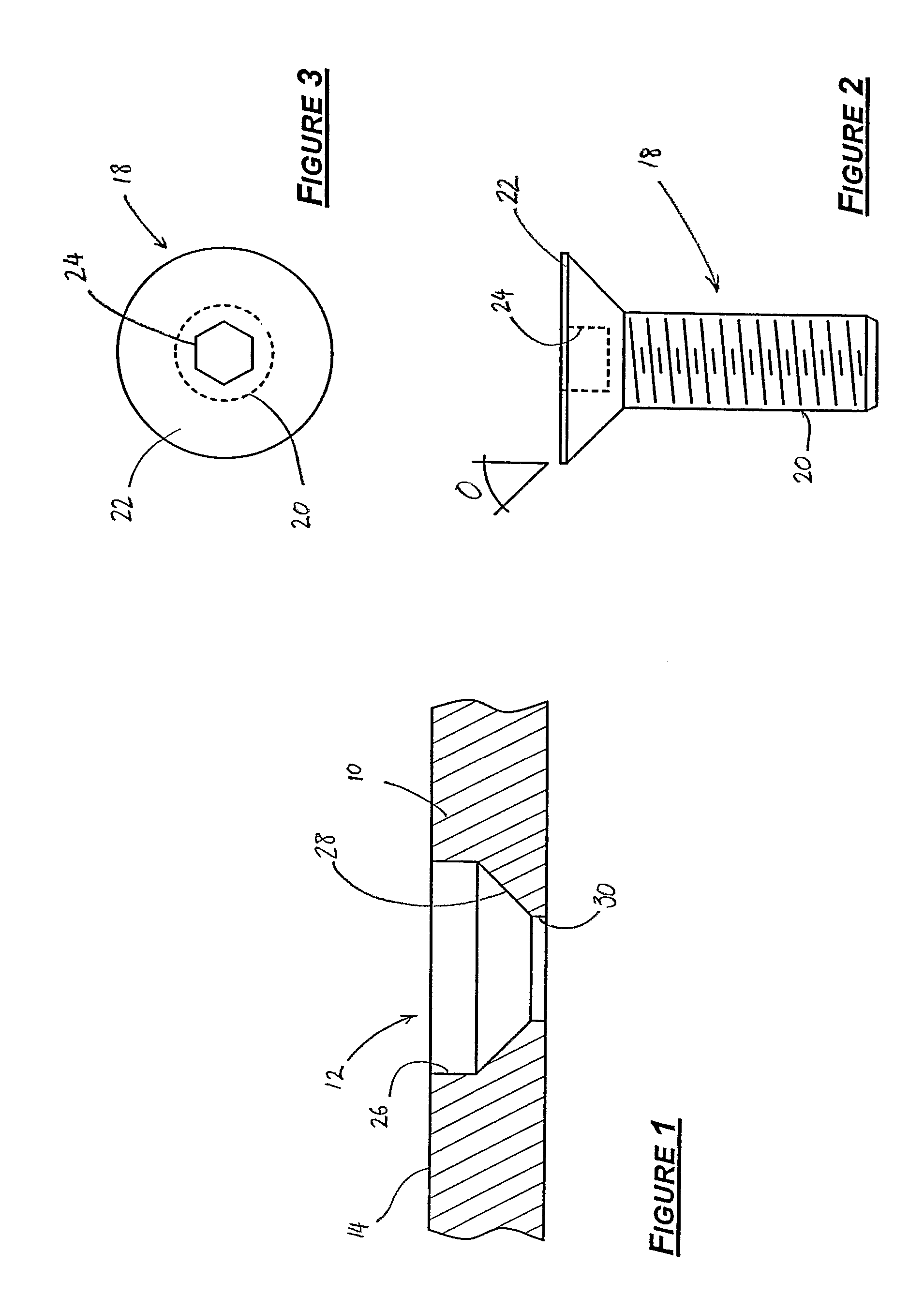

Fastener system for fixing hardened plates

A fastener system for fixing hardened plates includes a fastener element having a frusto-conical head and a threaded shaft portion, wherein a smallest outer diameter of the frusto-conical head is adjacent the threaded shaft, and a largest outer width of the shaft is smaller than a smallest diameter of the head.

Owner:METSO OUTOTEC (FINLAND) OY

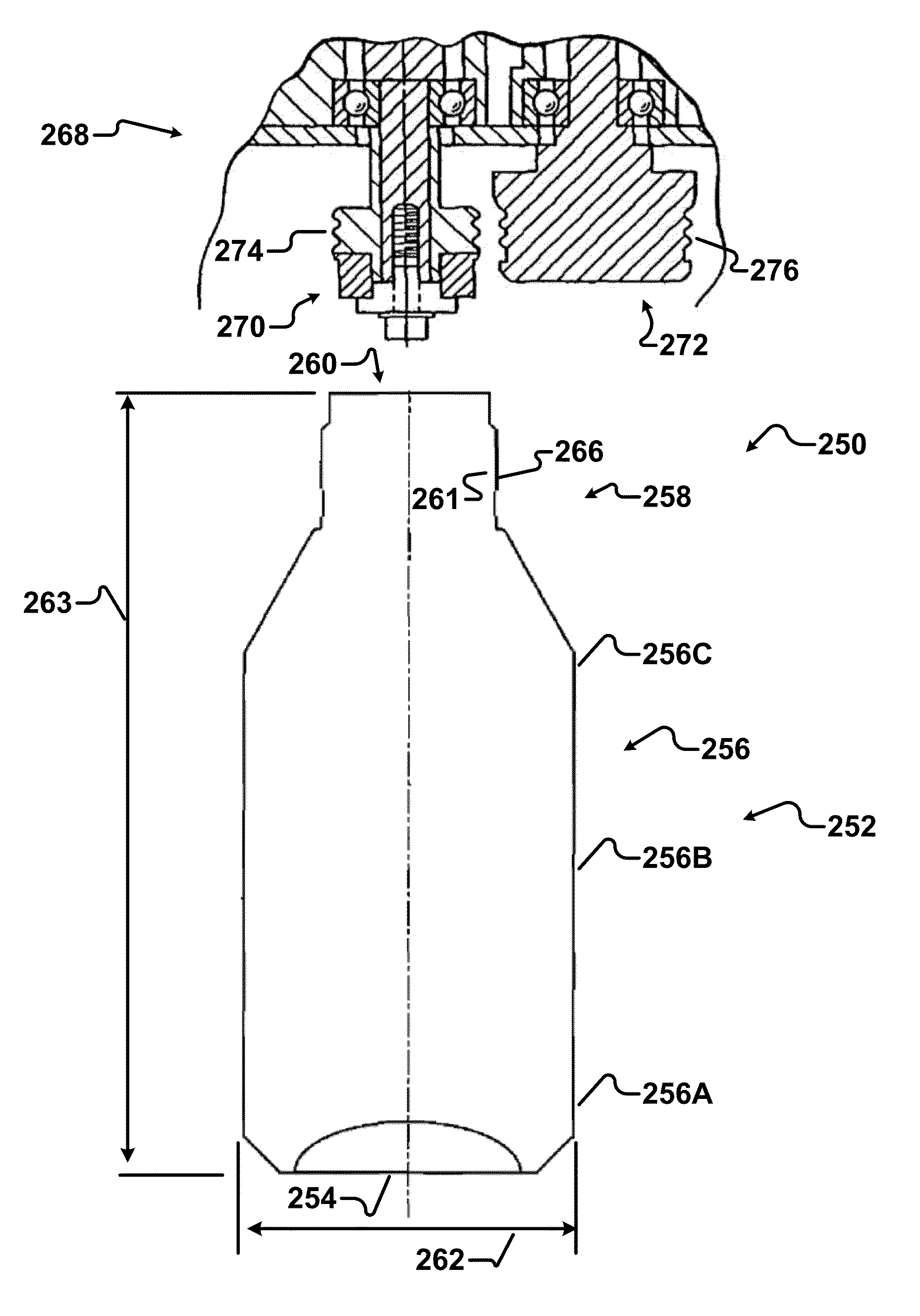

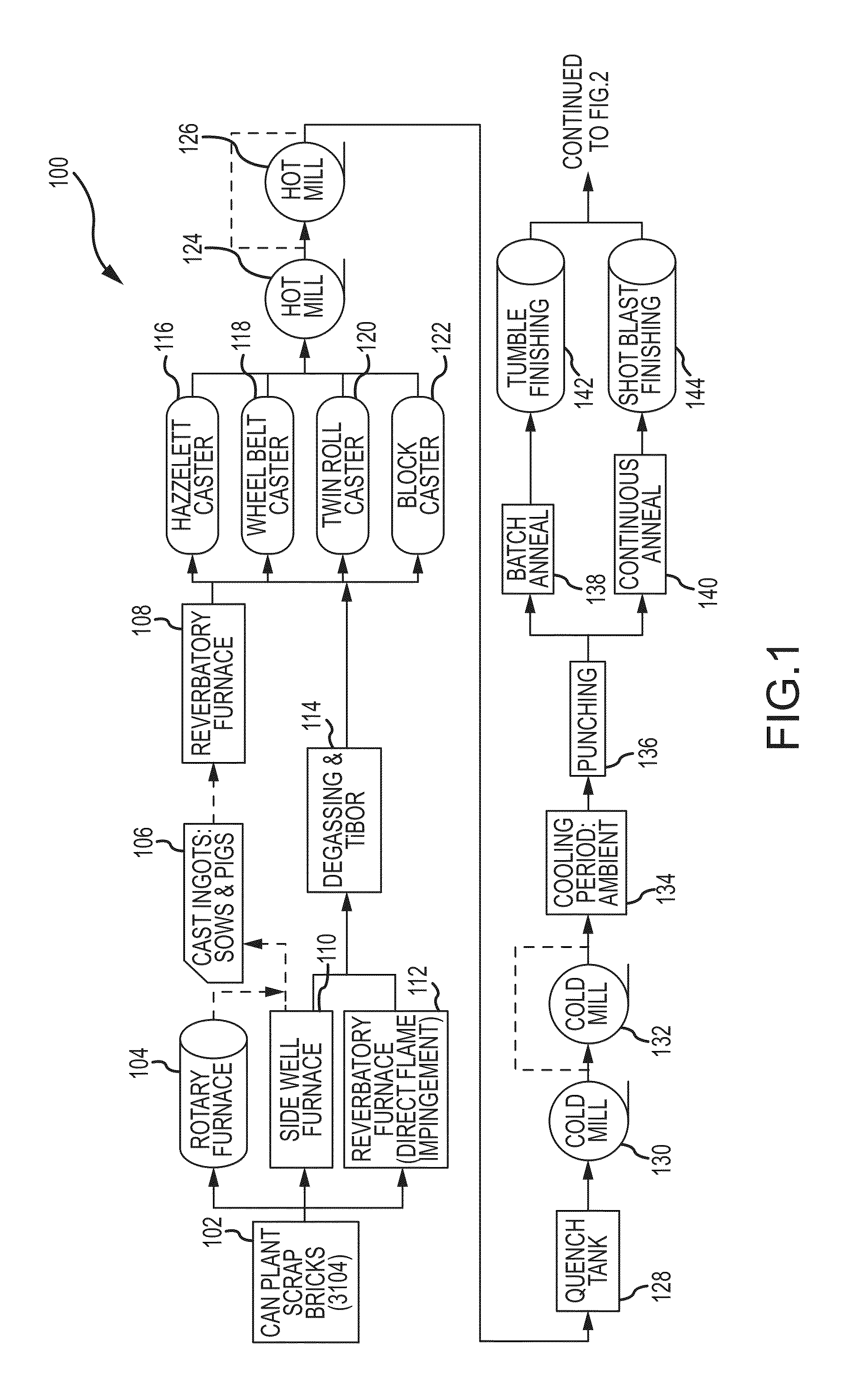

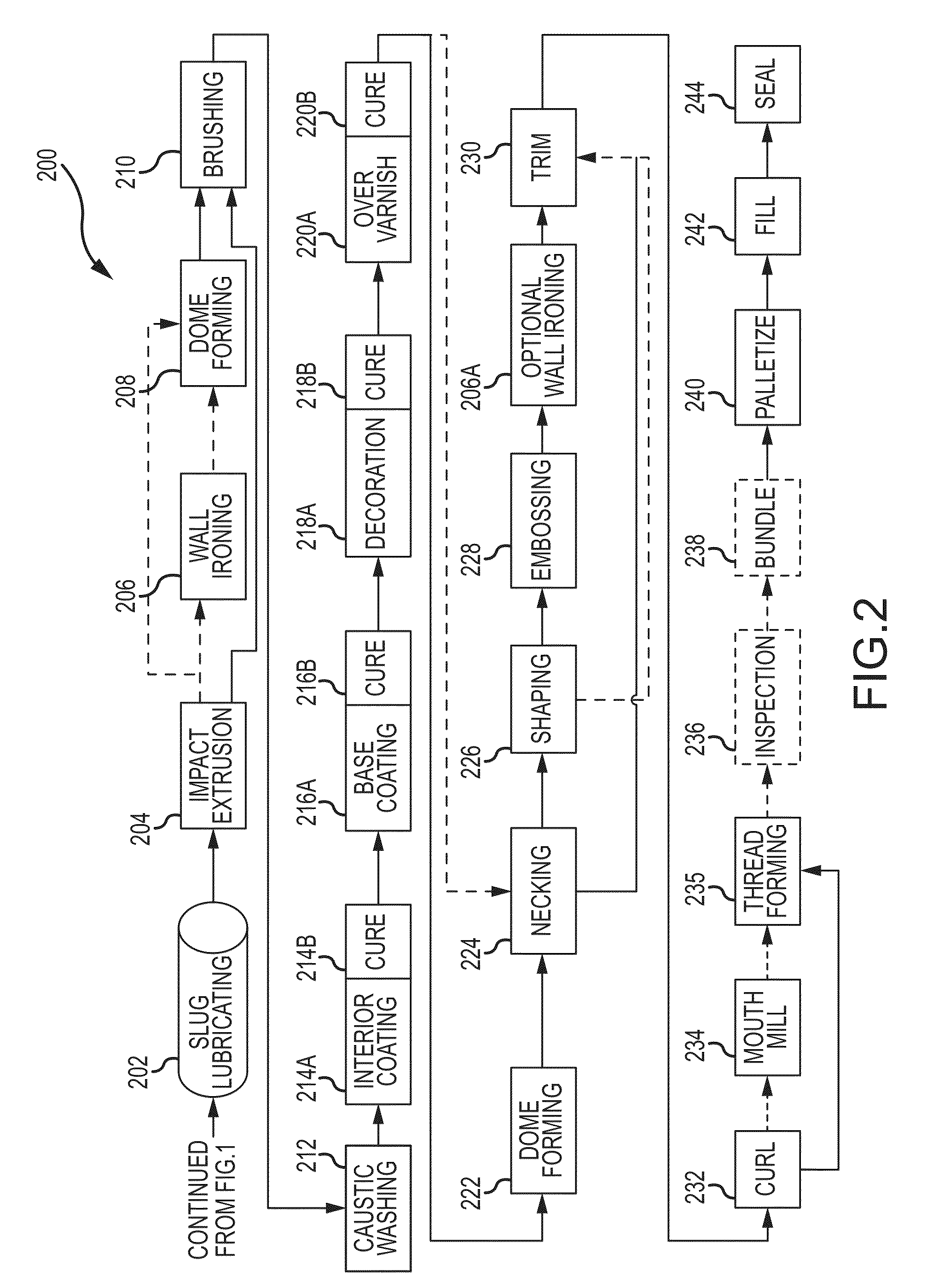

Aluminum impact extruded bottle with threaded neck made from recycled aluminum and enhanced alloys

ActiveUS20140298641A1High mechanical strengthLow costMetal rolling stand detailsClosure capsBottleUltimate tensile strength

The present invention relates generally to forming a threaded neck in a metal bottle manufactured by a process known as impact extrusion. More specifically, the present invention relates to methods, apparatus and alloy compositions used in the impact extrusion manufacturing of containers and other articles with sufficient strength characteristics to allow threading the container necks to receive a threaded closure on the threaded neck.

Owner:BALL CORP

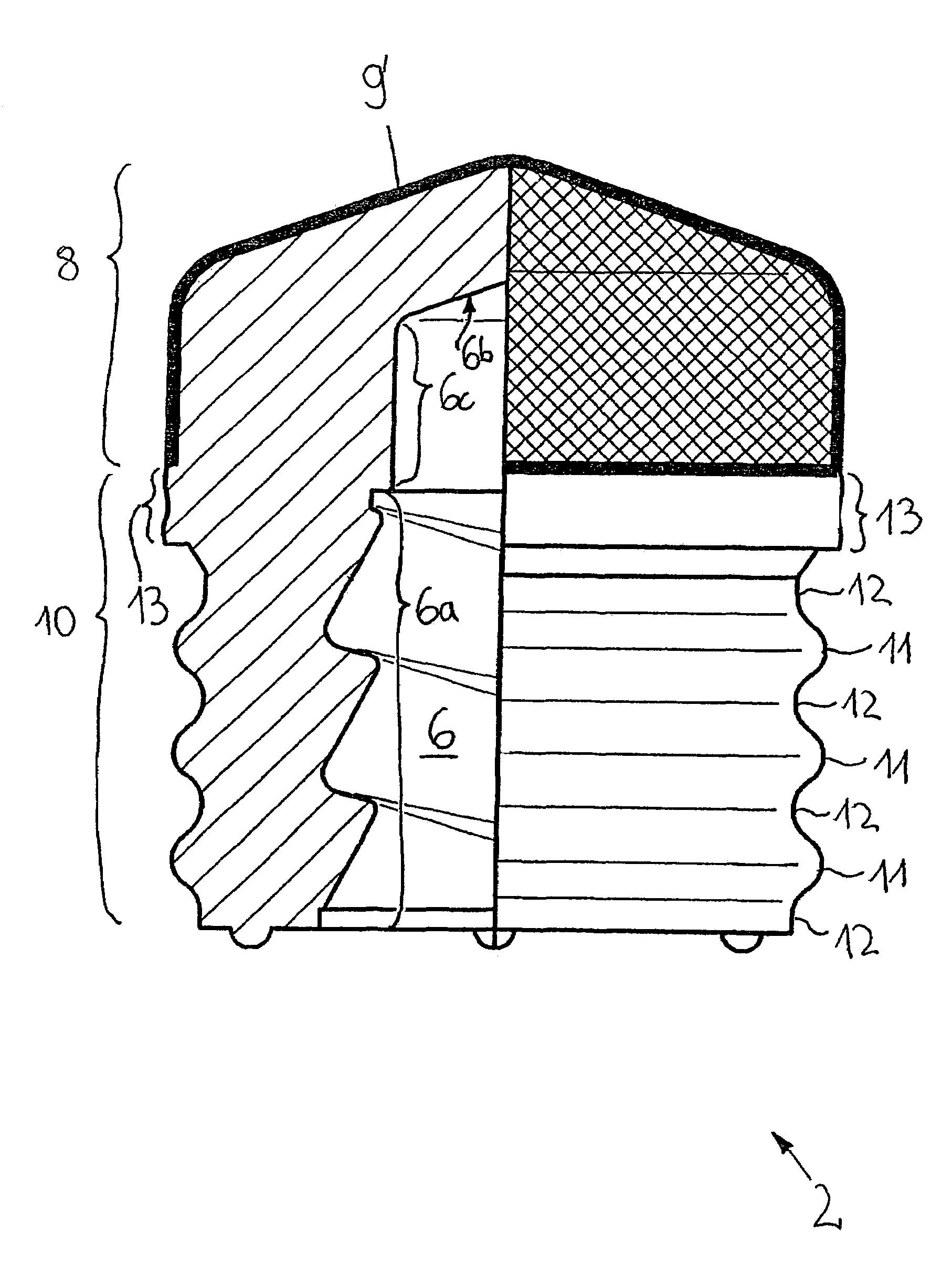

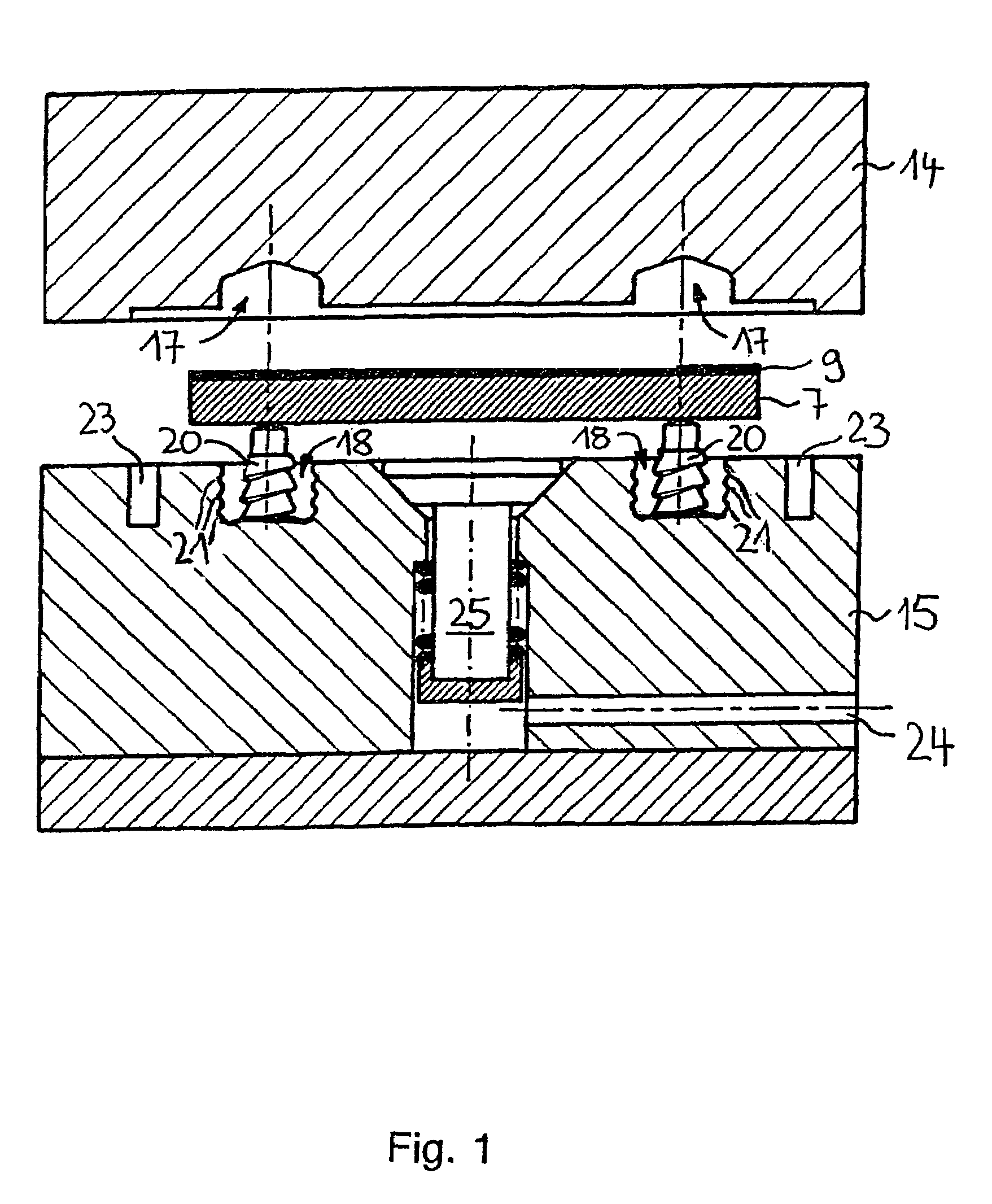

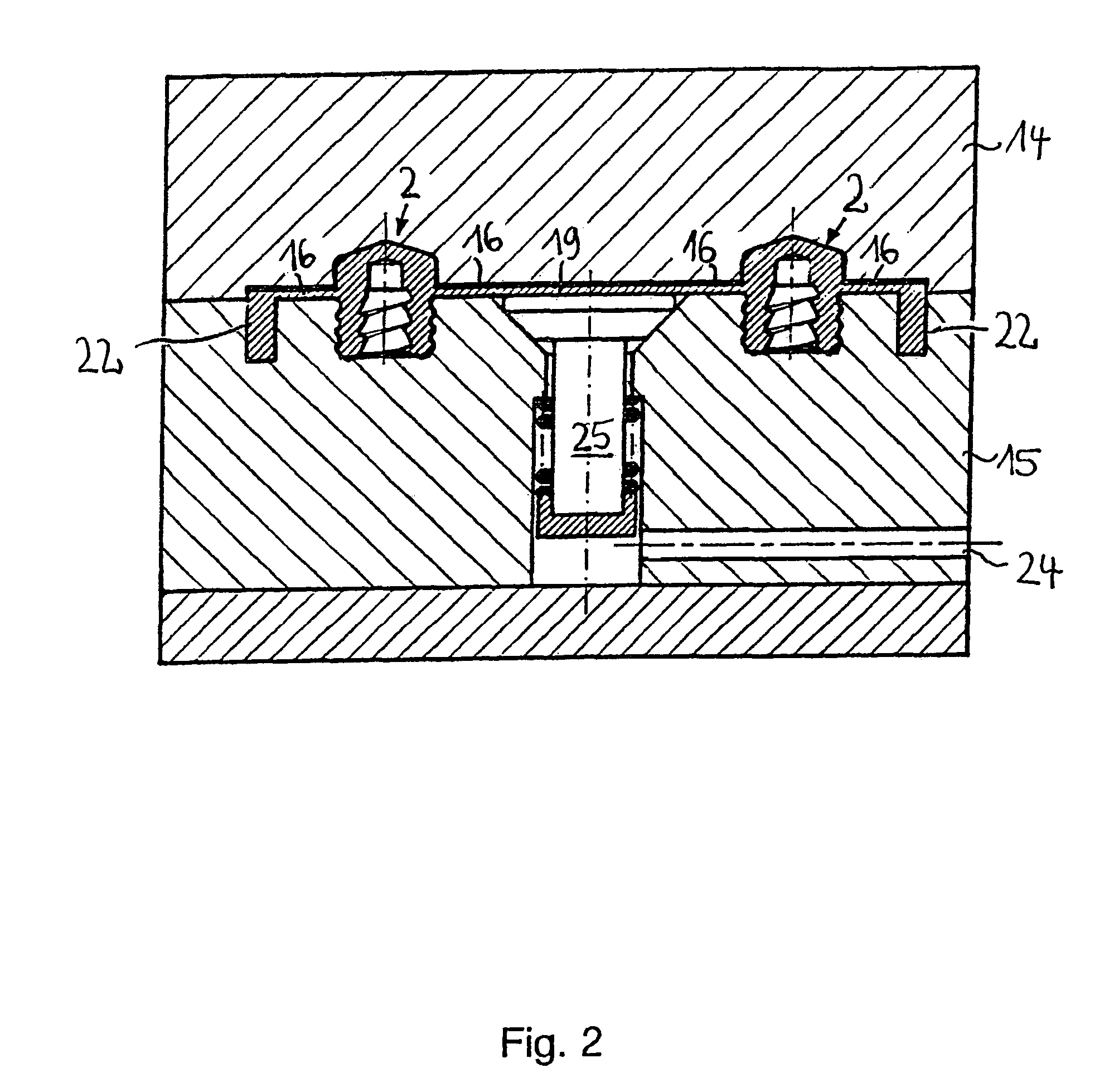

Pharmaceutical syringe piston

InactiveUS7547297B2Simply and cost-effectively producedImprove sealingMedical devicesScrew-threads articlesEngineeringRubber sheet

A piston stopper (2) made substantially of rubber has a piston section (8) enclosed in cap-like manner by an inert film (9′) facing the contents of a syringe or carpule cylinder (1), the inert film (9′) being located adjacent to the syringe or carpule cylinder (1). Adjacent to the piston section (8), the piston stopper (2) has a non-coated sealing section (10). According to a device and method for producing one such piston stopper (2), a non-vulcanized rubber sheet (7) is inserted into a form tool, together with an inert film (9). Under the effect of pressure and heat, an entire piston stopper contour is formed from the layered arrangement, extending to a flange (16) which protrudes laterally beyond the piston stopper (2) in the region of the separating plane of the form tool. A receiving cavity (6) for a piston rod is created in the piston section (8). The wall area of the sealing section (10) surrounding the receiving cavity (6) is forced into the receiving cavity (6). The piston stopper (2) is subsequently separated from the flange (16) in a blanking process, whereby a peripheral sealing area (13), directly adjacent to the edge of the inert film (9′) enclosing the piston section (8), is formed in the sealing section (10).

Owner:WEST PHARMA SERVICES DEUT GMBH & CO KG

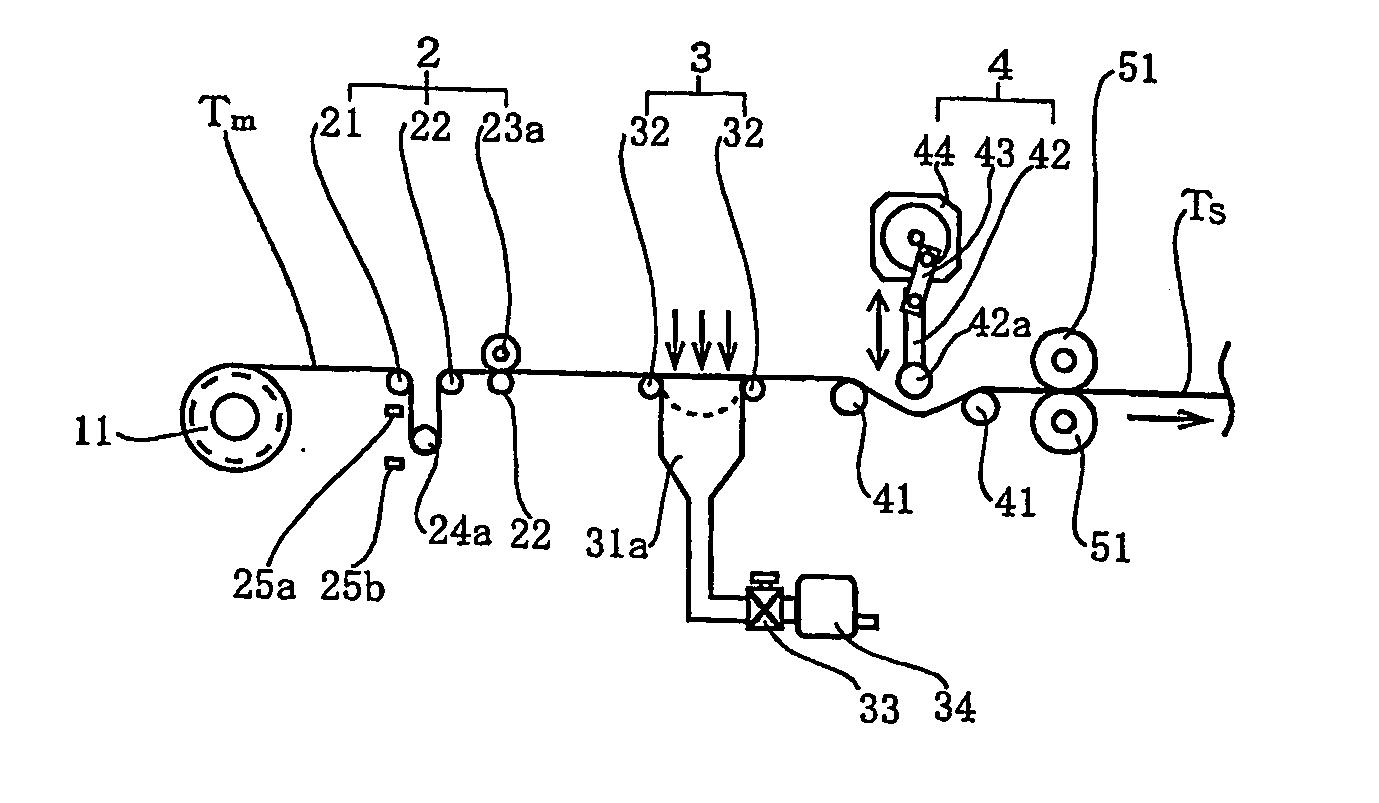

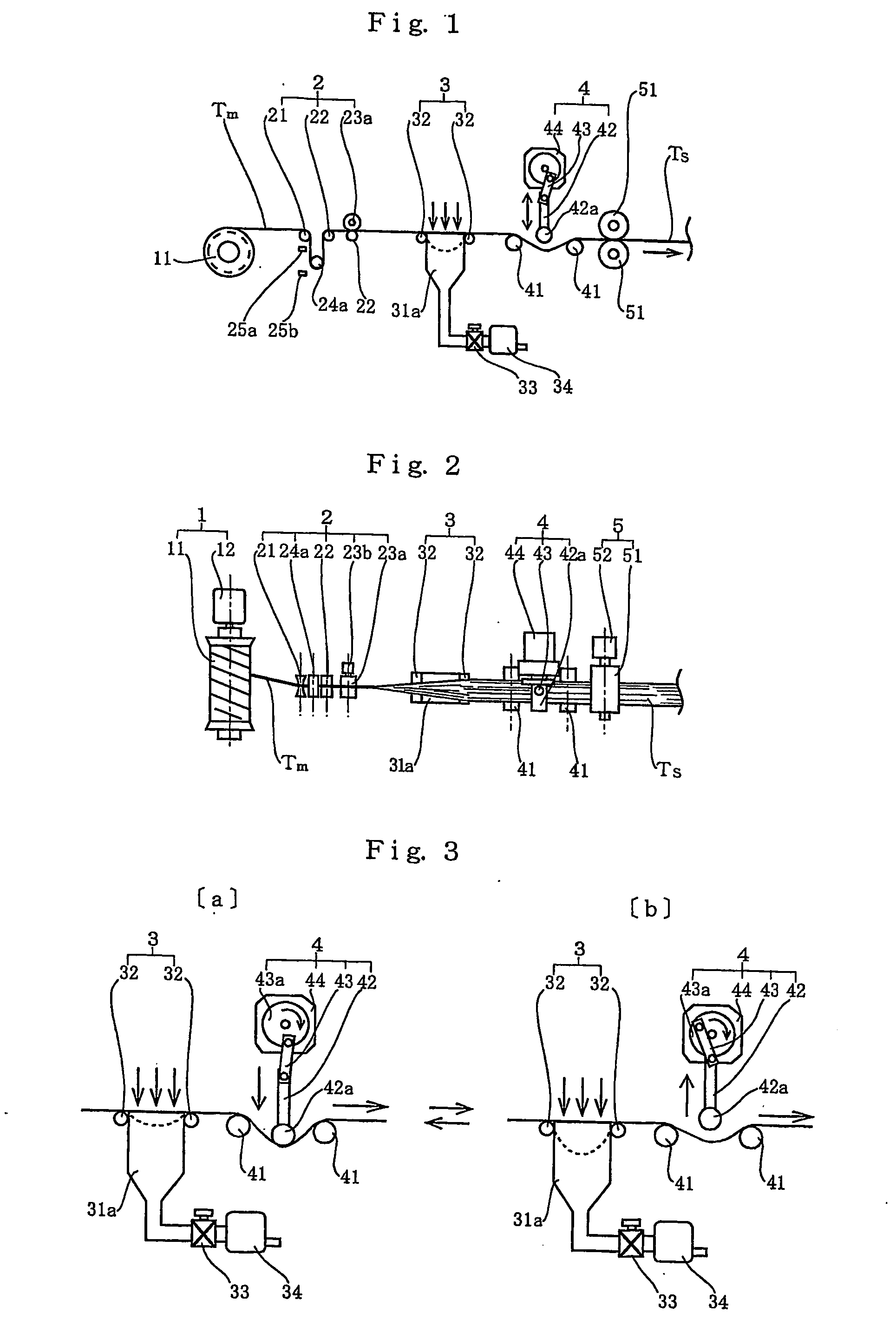

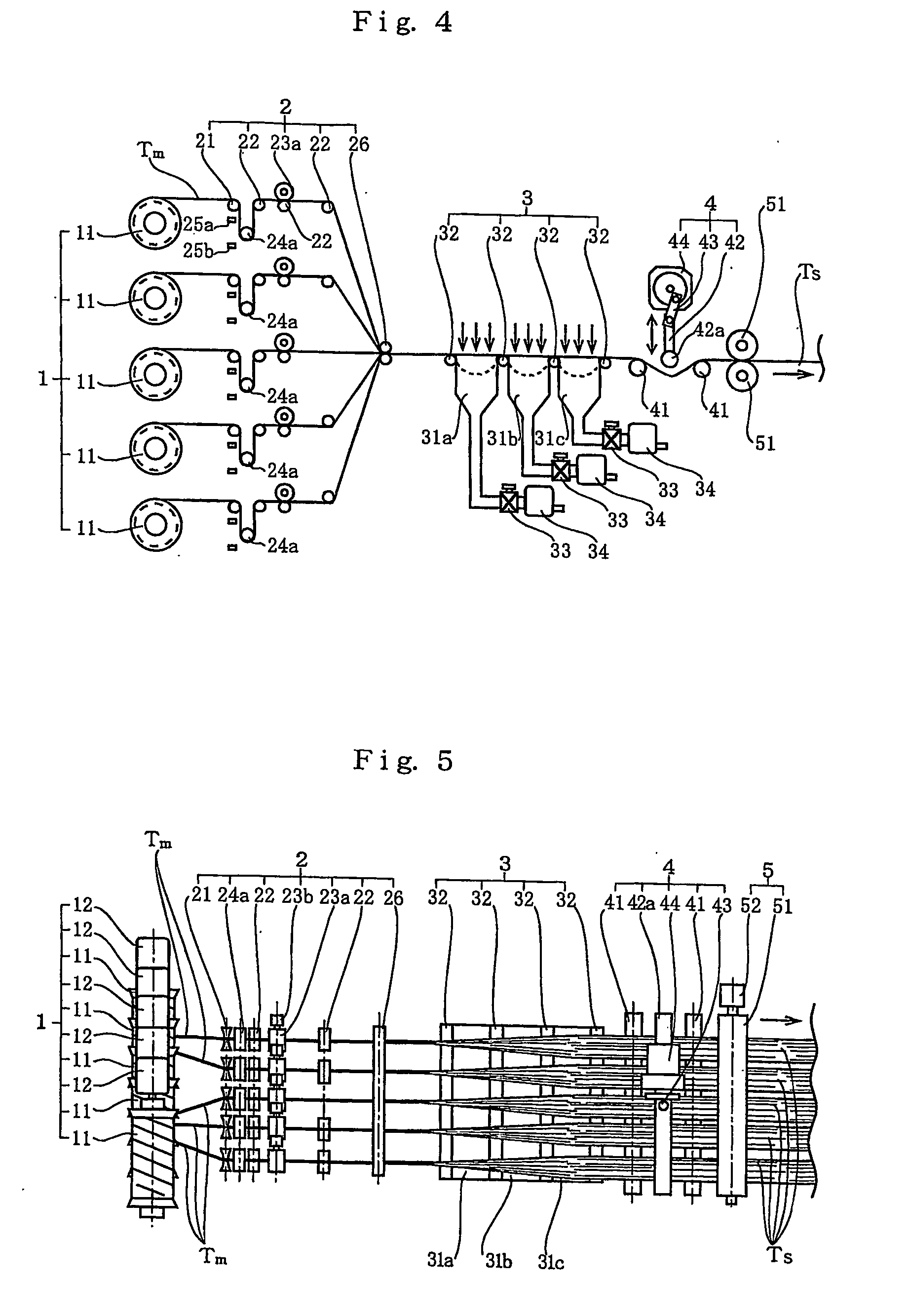

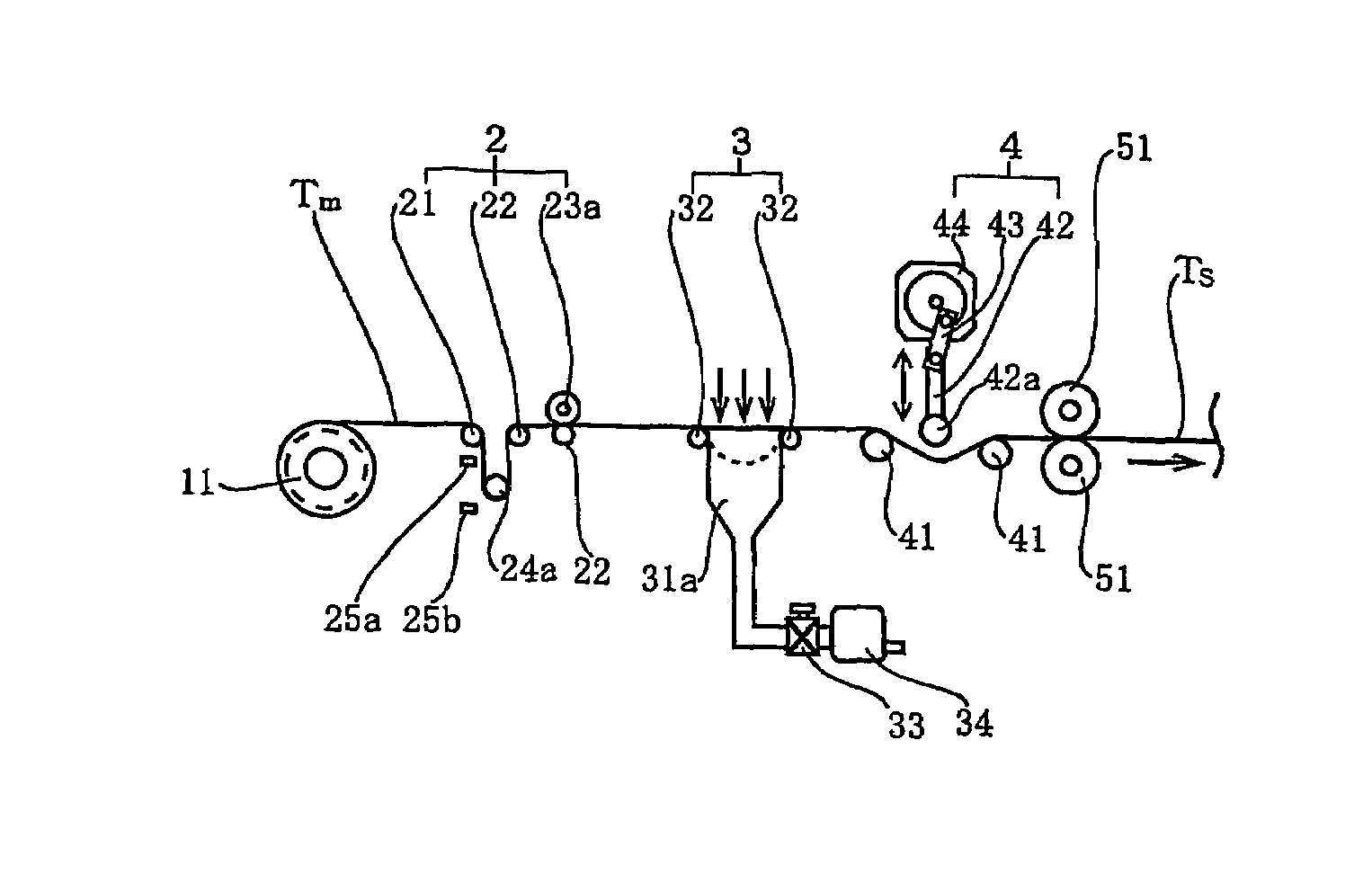

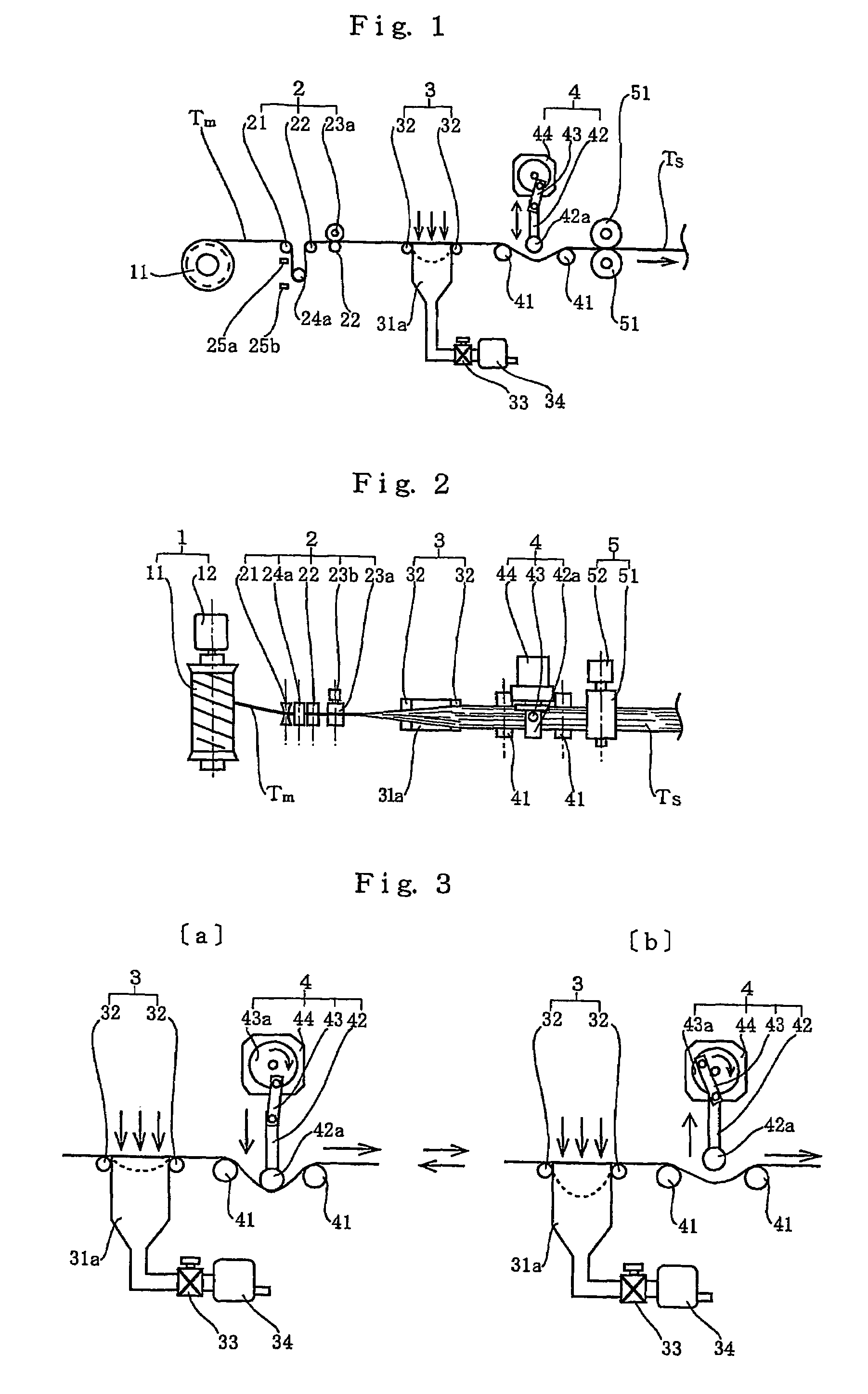

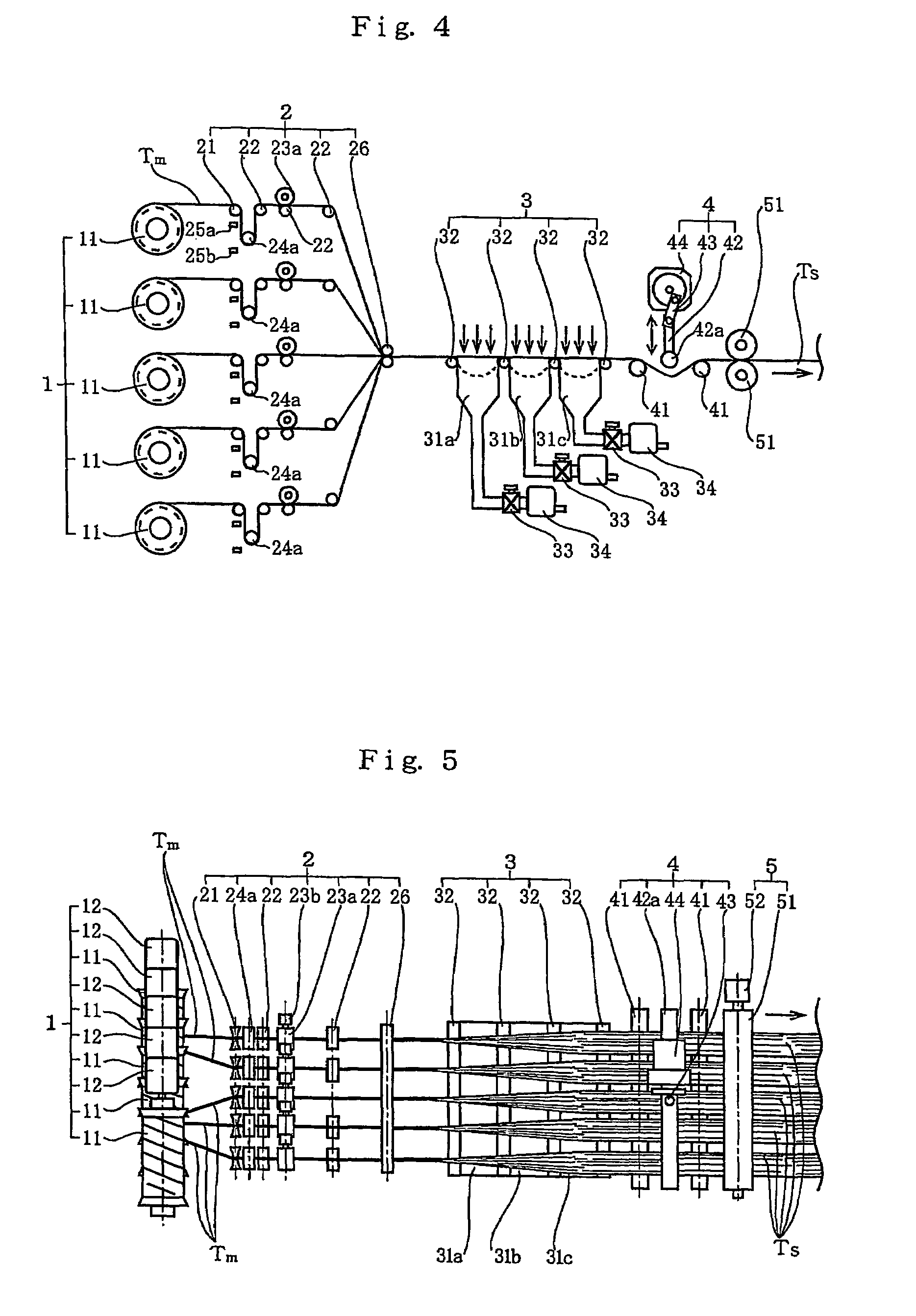

Method of producing a spread multi-filament bundle and an apparatus used in the same

ActiveUS20060137156A1Efficient mass productionImprove efficiencyButtonsRecord carriersEngineeringVolumetric Mass Density

A method of producing a spread multi-filament bundle and an apparatus is used in which an arbitrary number of multi-filament bundles of higher strength are simultaneously spread with high speed and a high-quality. A spread multi-filament bundle or sheet with the component monofilaments thereof aligned in parallel widthwise and uniformly distributed in density is produced. The respective multi-filament bundles fed from a yarn supplier or a creel are subjected to fluctuation of the tensile force applied thereto alternatively between tension and relaxation and the respective bundles as subjected to such fluctuation are passed in succession through a fluid flowing spreader.

Owner:FUKUI PREFECTURE

Fiber-reinforced, porous, biodegradable implant device

InactiveUS20050240281A1Promote regenerationProvide strengthBone implantLaminationArticular cartilagePolymer

A fiber-reinforced, polymeric implant material useful for tissue engineering, and method of making same are provided. The fibers are preferably aligned predominantly parallel to each other, but may also be aligned in a single plane. The implant material comprises a polymeric matrix, preferably a biodegradable matrix, having fibers substantially uniformly distributed therein. Inorganic particles may also be included in the implant material. In preferred embodiments, porous tissue scaffolds are provided which facilitate regeneration of load-bearing tissues such as articular cartilage and bone. Non-porous fiber-reinforced implant materials are also provided herein useful as permanent implants for load-bearing sites.

Owner:OSTEOBIOLOGICS

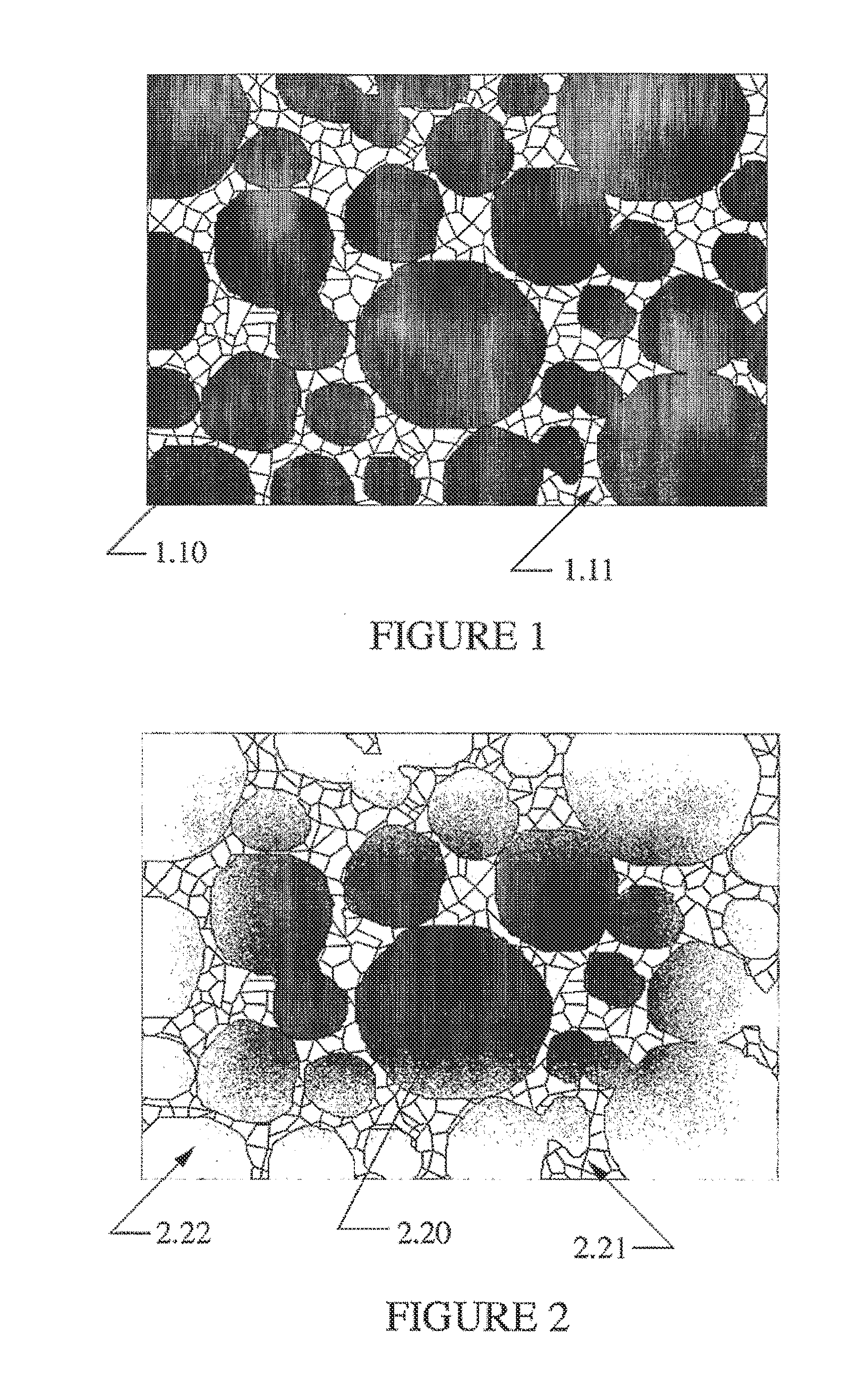

Image processing method and system for microfluidic devices

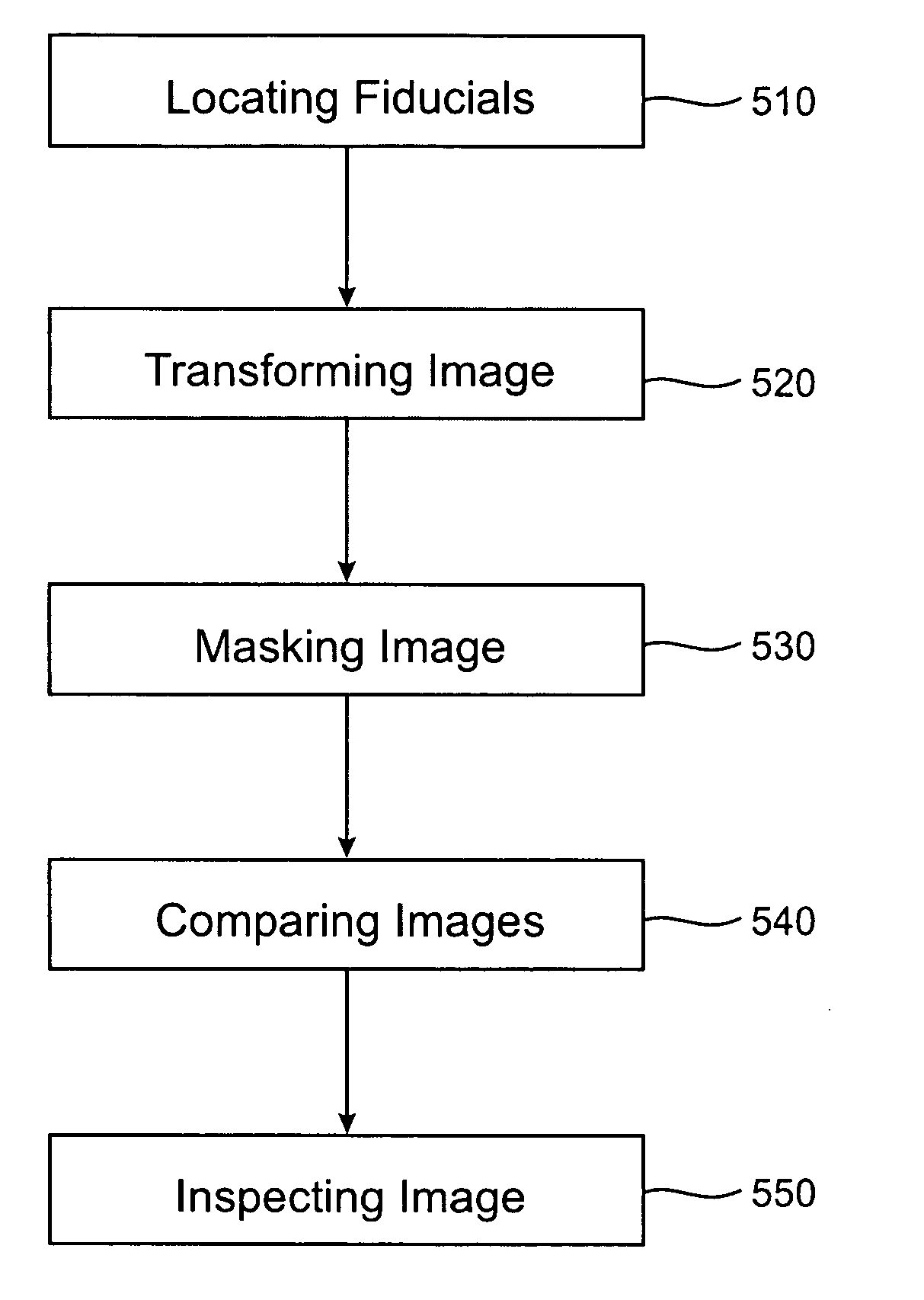

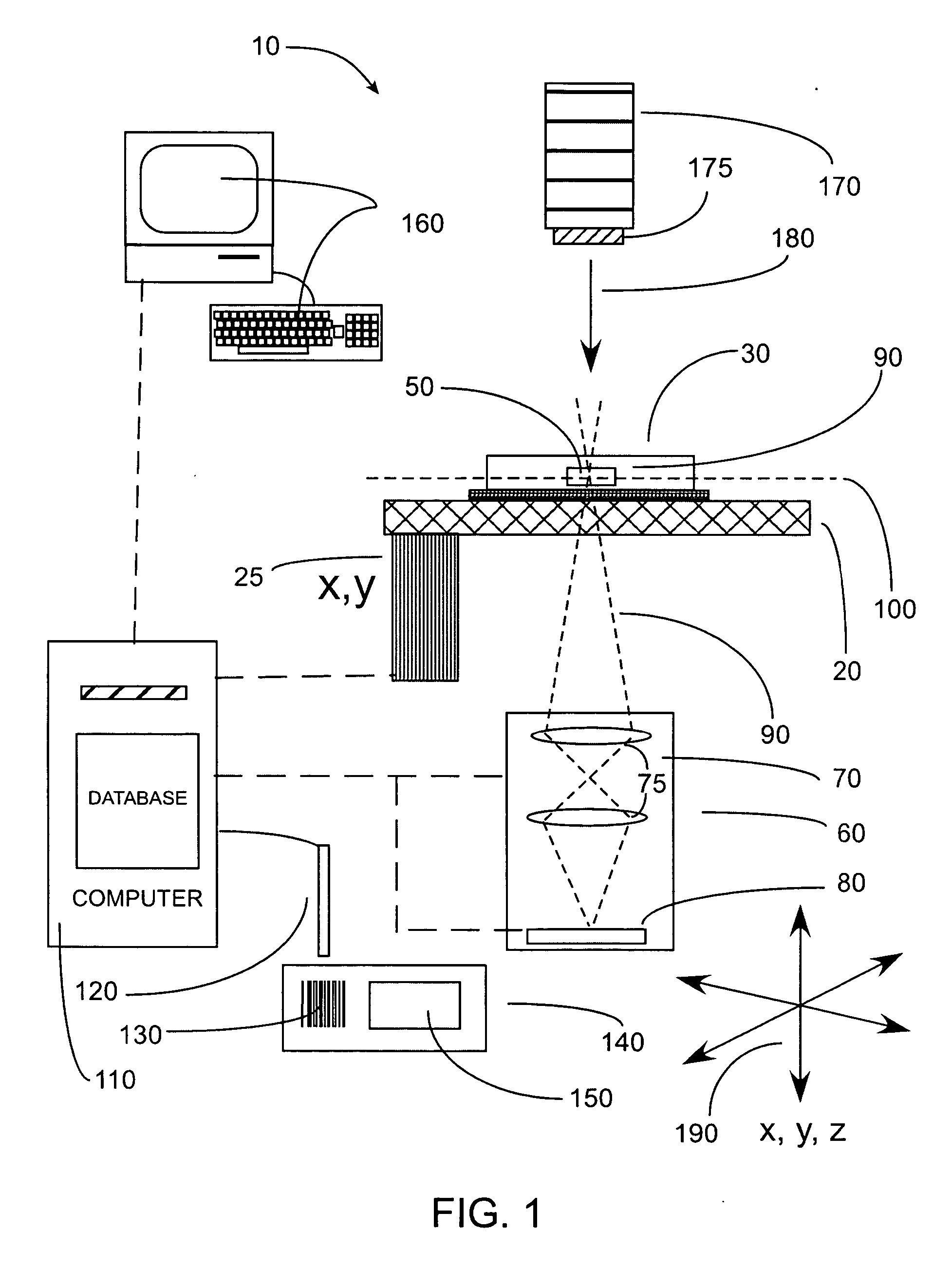

InactiveUS20050282175A1Increase speedSimple processImage enhancementButtonsImaging processingState dependent

A method for processing an image of a microfluidic device. The method includes receiving a first image of a microfluidic device. The first image corresponds to a first state. Additionally, the method includes receiving a second image of the microfluidic device. The second image corresponds to a second state. Moreover, the method includes transforming the first image and the second image into a third coordinate space. Also, the method includes obtaining a third image based on at least information associated with the transformed first image and the transformed second image, and processing the third image to obtain information associated with the first state and the second state.

Owner:FLUIDIGM CORP

Method of making fasteners by three-dimensional printing

Owner:A RAYMOND & CO

Method of producing a spread multi-filament bundle and an apparatus used in the same

ActiveUS7571524B2Efficient mass productionImprove efficiencyButtonsRecord carriersYarnVolumetric Mass Density

A method of producing a spread multi-filament bundle and an apparatus is used in which an arbitrary number of multi-filament bundles of higher strength are simultaneously spread with high speed and a high-quality. A spread multi-filament bundle or sheet with the component monofilaments thereof aligned in parallel widthwise and uniformly distributed in density is produced. The respective multi-filament bundles fed from a yarn supplier or a creel are subjected to fluctuation of the tensile force applied thereto alternatively between tension and relaxation and the respective bundles as subjected to such fluctuation are passed in succession through a fluid flowing spreader.

Owner:FUKUI PREFECTURE

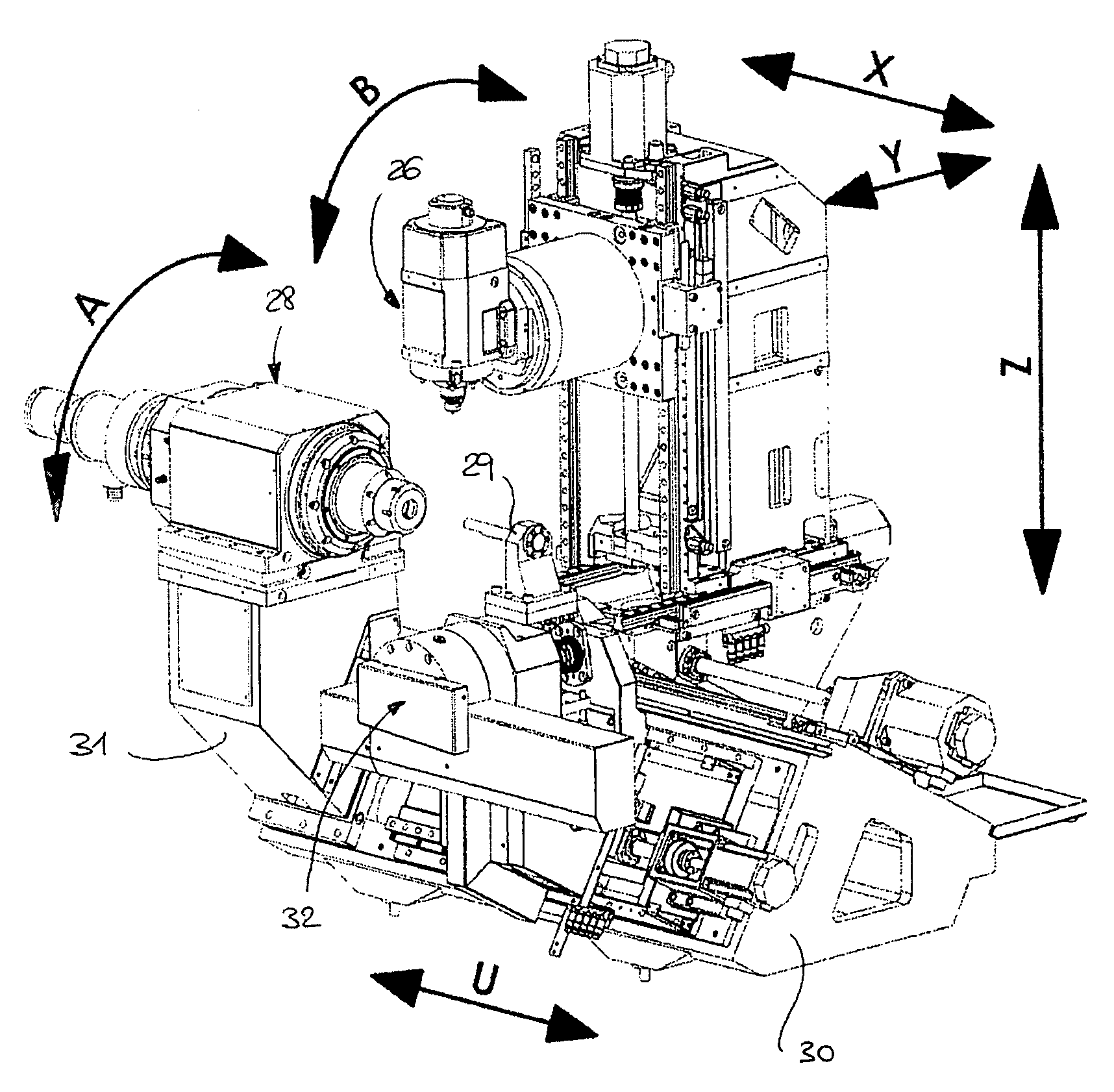

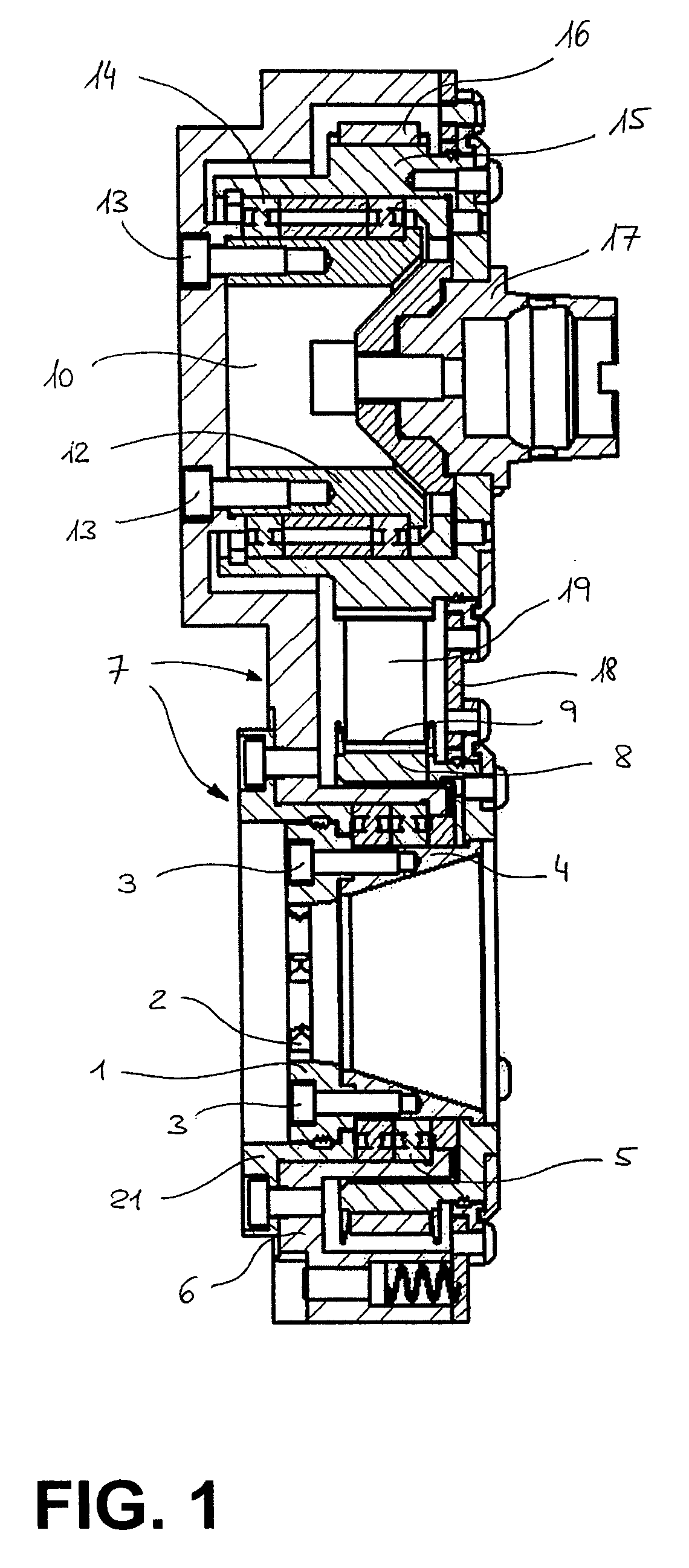

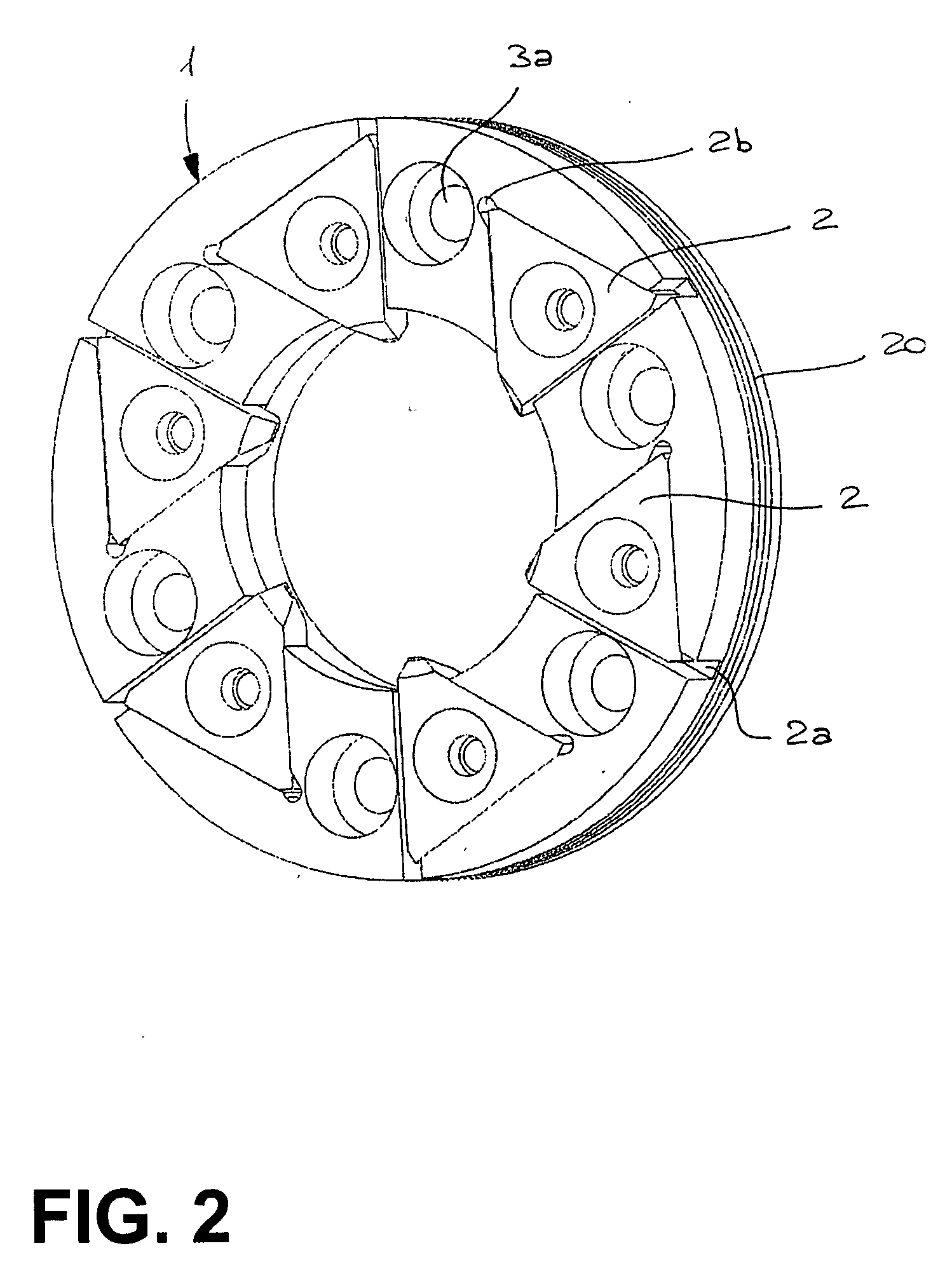

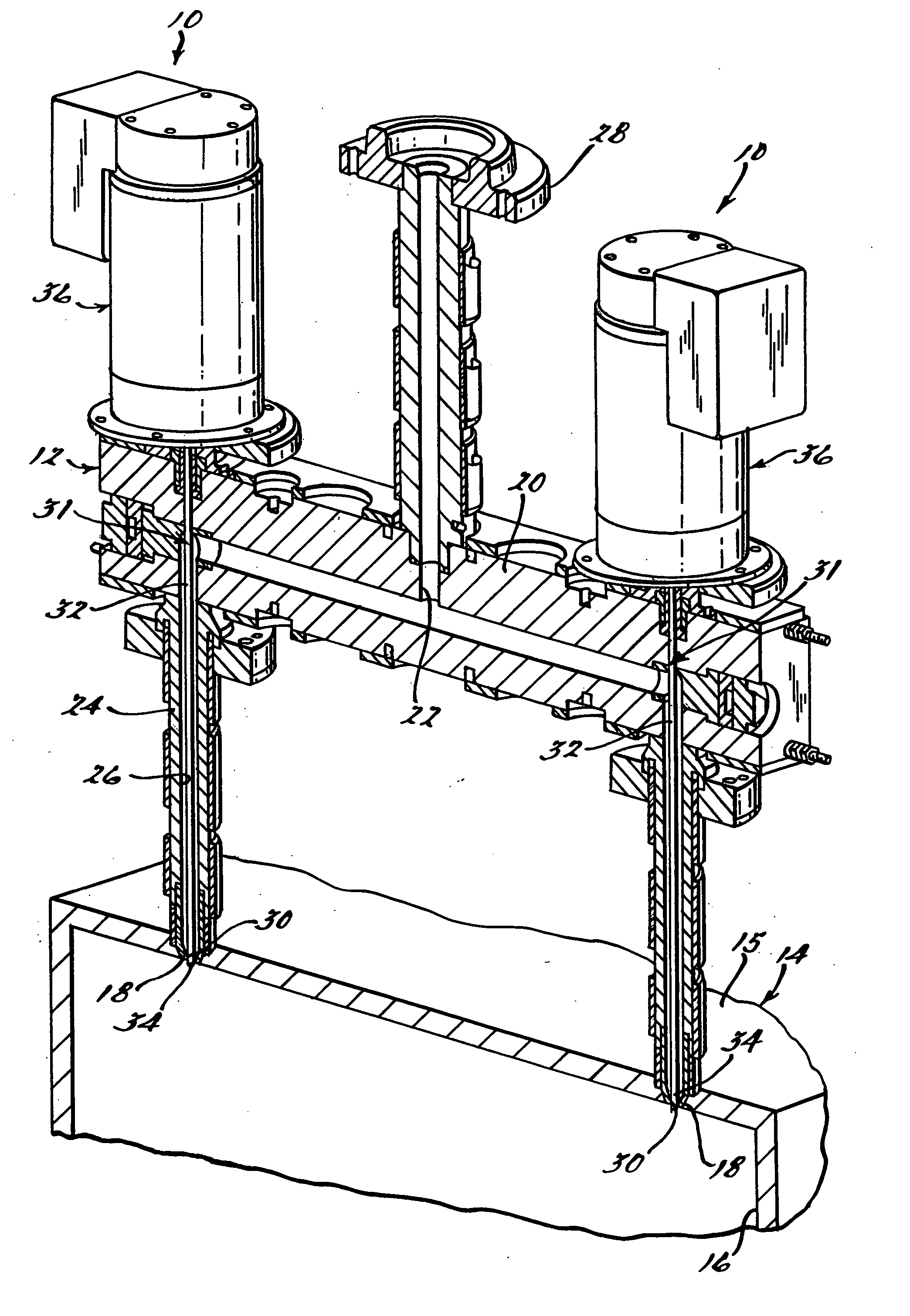

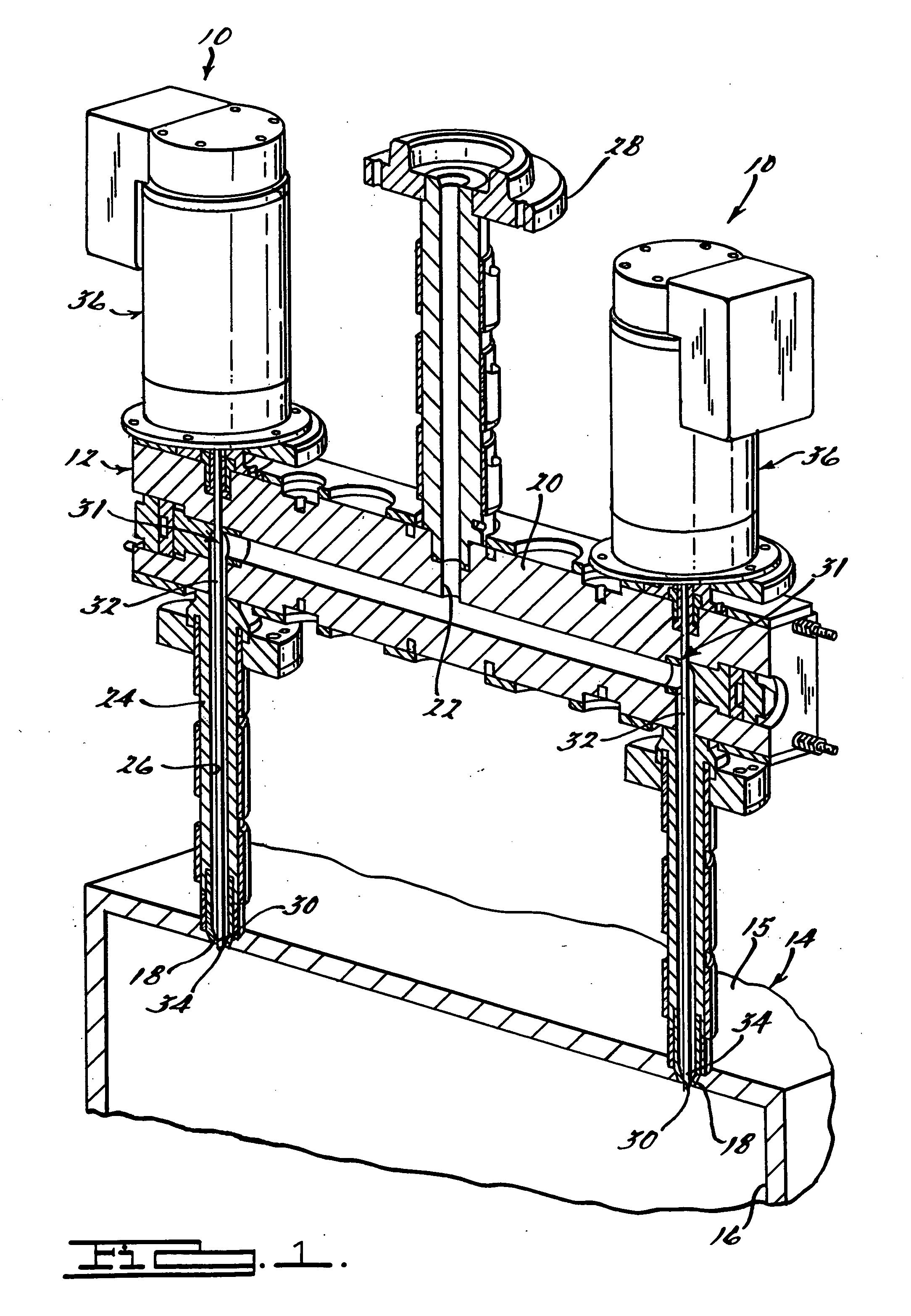

Whirling head and its use

The frame of the whirling head comprises the rigid casing (7), in which the part (10) contains the drive pulley (15) solidly attached to the coupling member (17) connected to the drive shaft of the spindle (26). By means of the belt (19), this pulley (15) drives the pulley (8) solidly attached to the connecting cone (4), which in turn comprises the internal milling cutter (1) which cuts the thread of the screw shaft (27) supported between the bar advance unit (28) and the tailstock centre (29). The latter is mounted as an exchangeable tool on the return unit (32).

Owner:WILLEMIN MACODEL

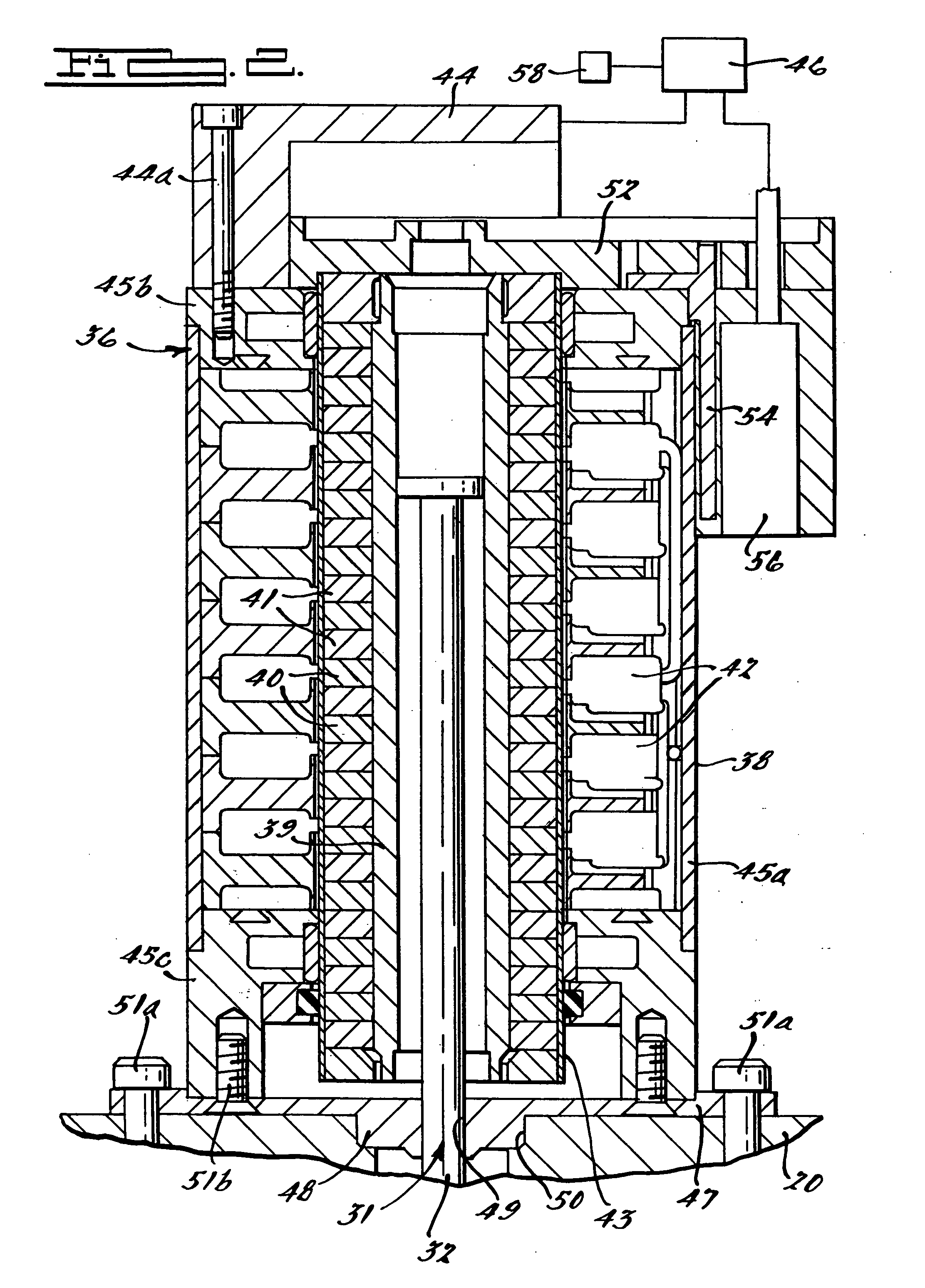

Valve gate assembly

ActiveUS20050100625A1Process controlEasy to adjustButtonsRecord carriersEngineeringMechanical engineering

A valve gate assembly for regulating a flow of molten material into a mold. The valve gate assembly includes a movable valve that can move between a fully closed position and a fully open position. The valve gate assembly further includes an actuating system operatively cooperating with the valve to move the valve and infinitely position the valve between the fully closed position and the fully open position.

Owner:PLASTIC ENG & TECHN SERVICES

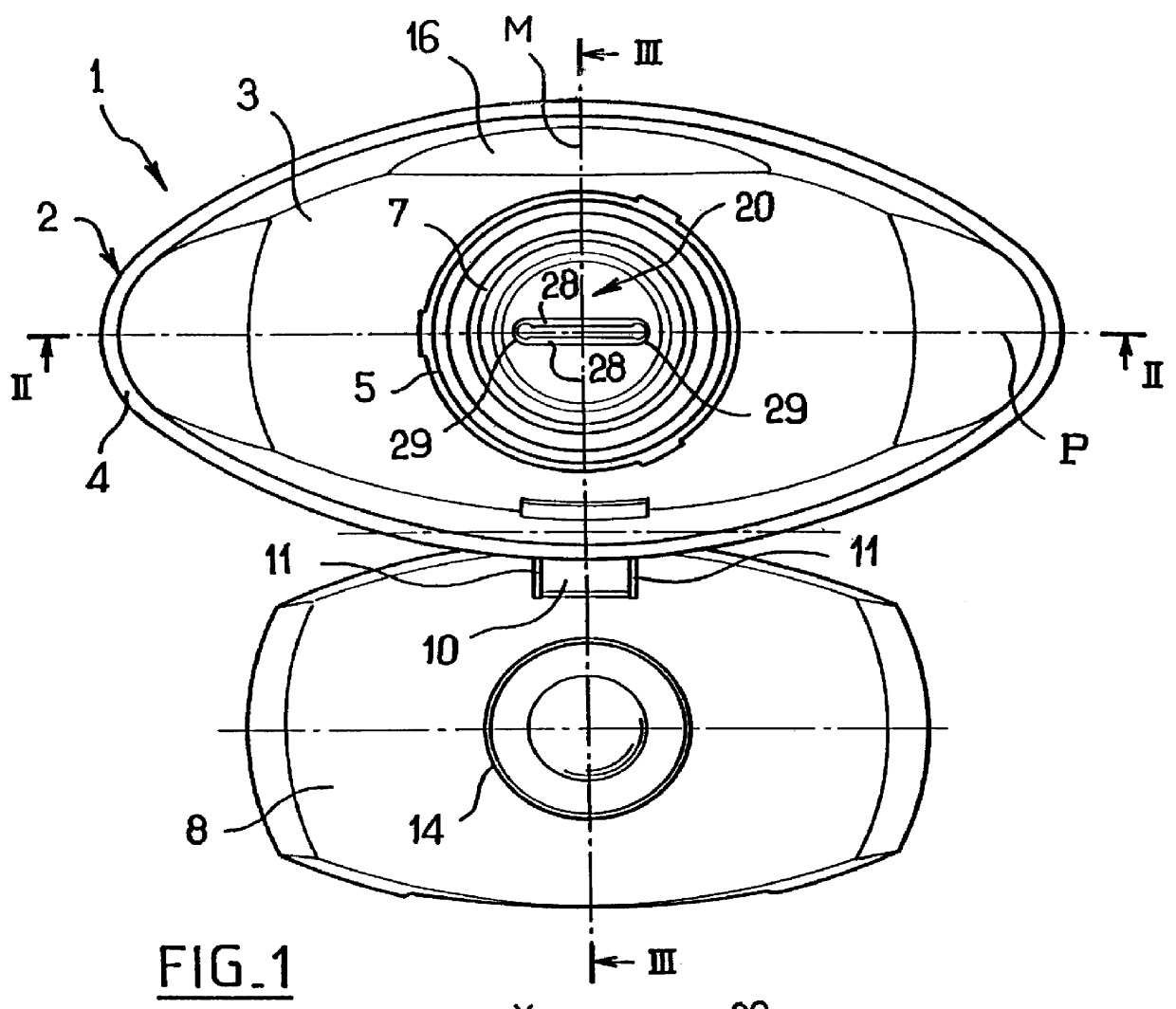

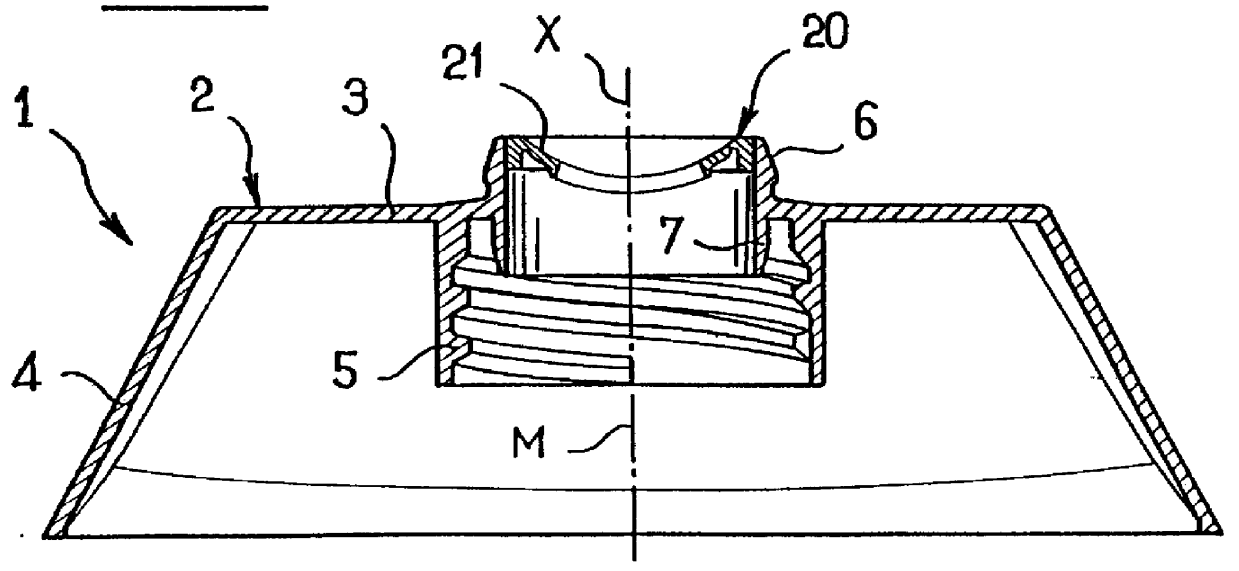

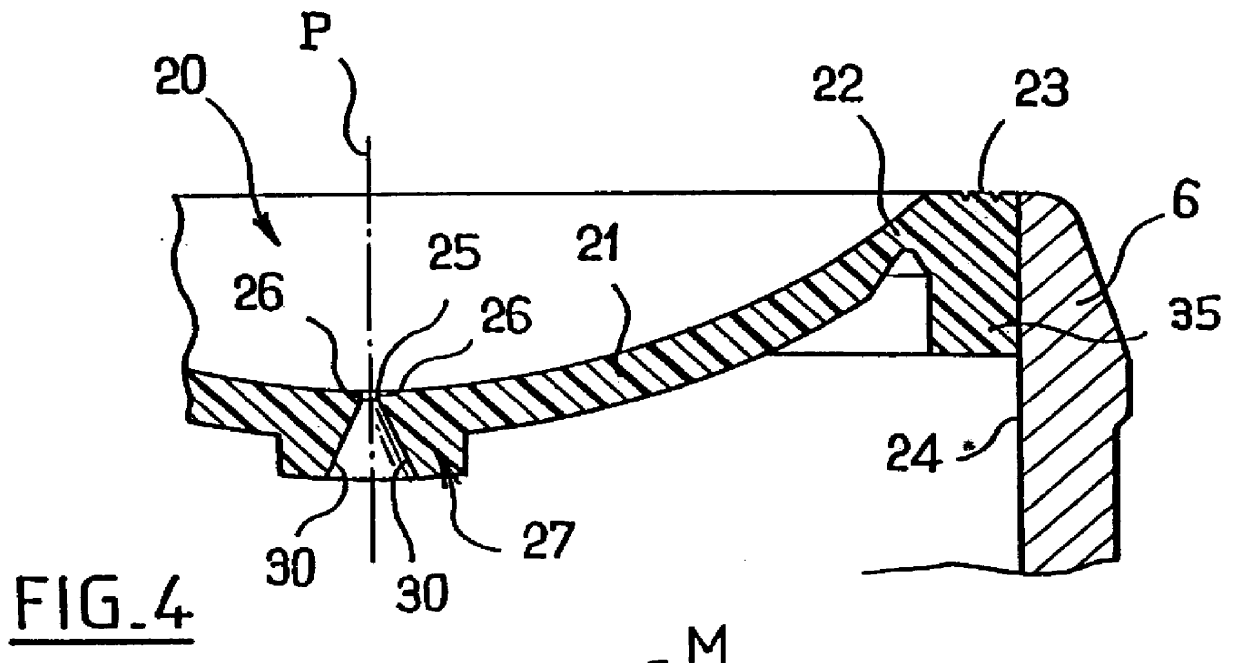

Flow reducer member, in particular for a receptacle containing a cosmetic, and a method of manufacture

InactiveUS6152324ALow costReliable manufacturingPower operated devicesMouldsInjection pointEngineering

A dispenser head for dispensing a fluid includes a dispenser endpiece of rigid or semi-rigid thermoplastic material and a flow reducer member of elastically deformable thermoplastic material secured to the endpiece. The member includes at least one slot whose edges are suitable for moving apart under the effect of thrust from the fluid while it is being dispensed. A method of making the dispenser head includes making the flow reducer member by injection molding from one or more injection points situated on one or both sides of the slot.

Owner:LOREAL SA

Compositions and method for improving reheat rate of PET using activated carbon

ActiveUS20040249113A1Improving reheat rateMinimize impactEnvelopes/bags making machineryButtonsActivated carbonPolyester

A polyester composition, a preform, and a bottle, containing a polyester such as polyethylene terephthalate or polyethylene naphthalate and activated carbon to enhance the rate for reheating the composition is provided. Activated carbon may be added in the presence of active phosphorus containing compounds, or at any stage in the melt phase after prepolymerization and after the polyester polymer is solidified. Polyester concentrates containing activated carbon may be added to bulk polyesters to make preforms suitable for blowing into bottles.

Owner:ALPEK POLYESTER SA DE CV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com