Patents

Literature

61 results about "Interconnected porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

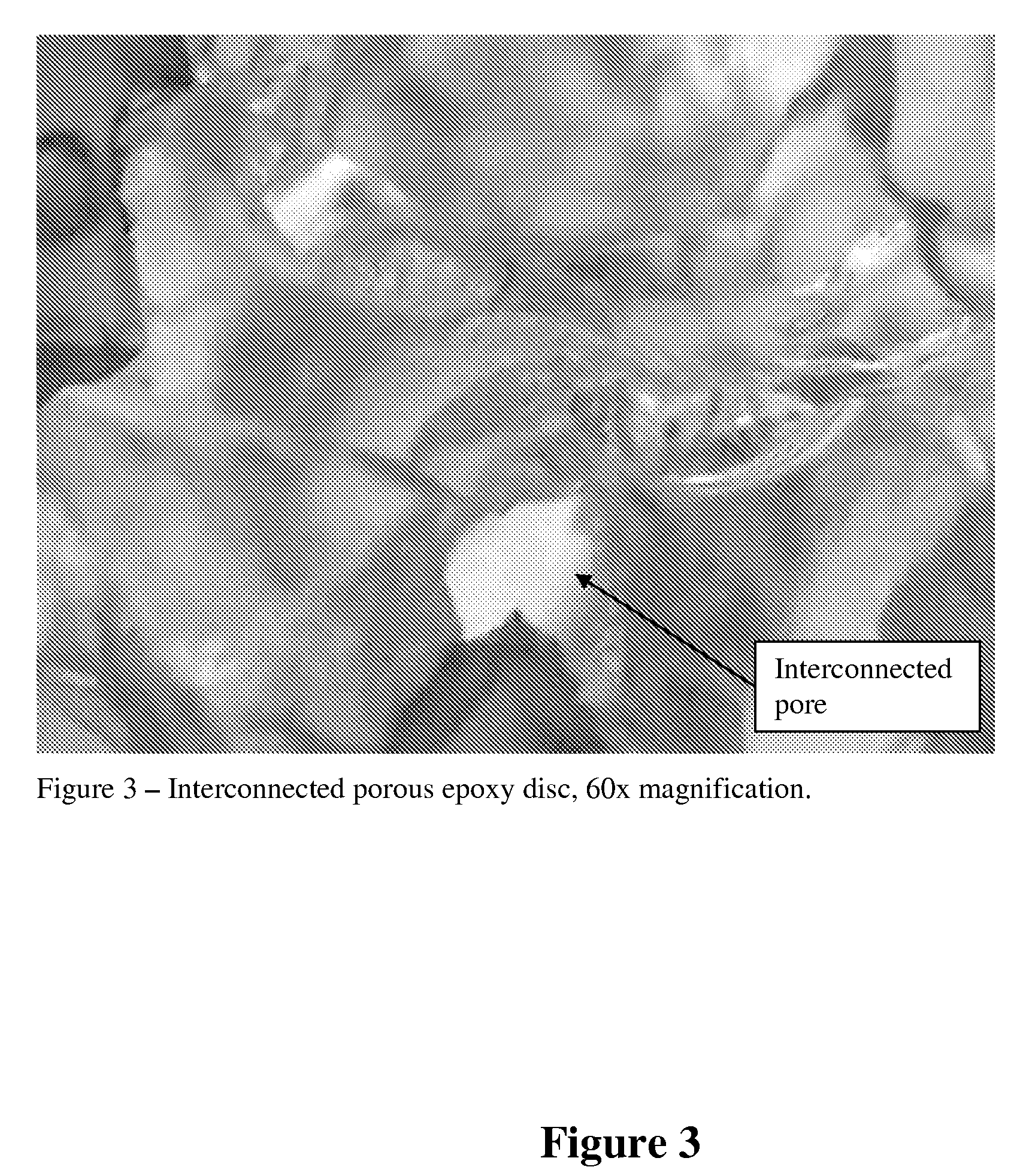

Interconnected porosity is a network of pores on a coating surface. There are two kinds of porosity - open and closed: Open porosity, also known as interconnected porosity, is the ratio of the volume of void space within the material that is accessible from the exterior to...

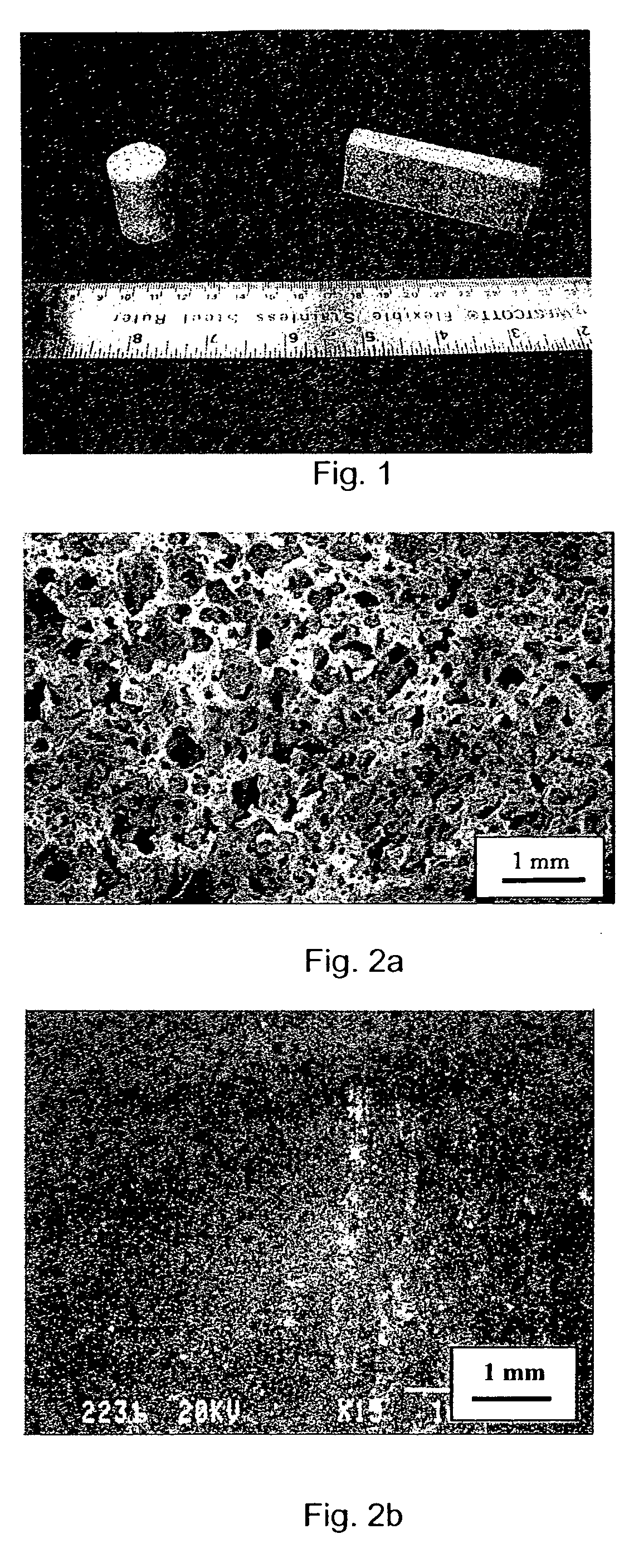

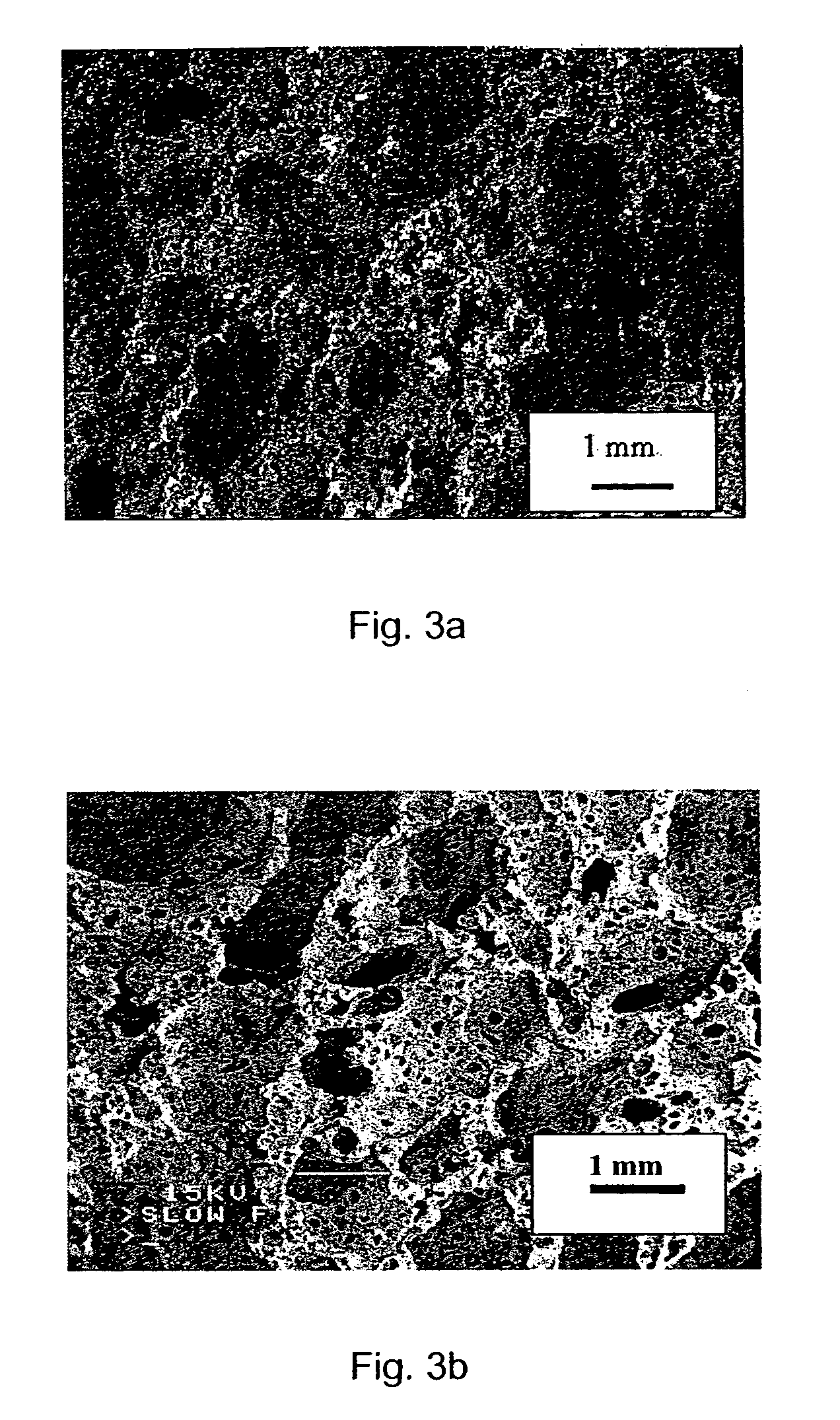

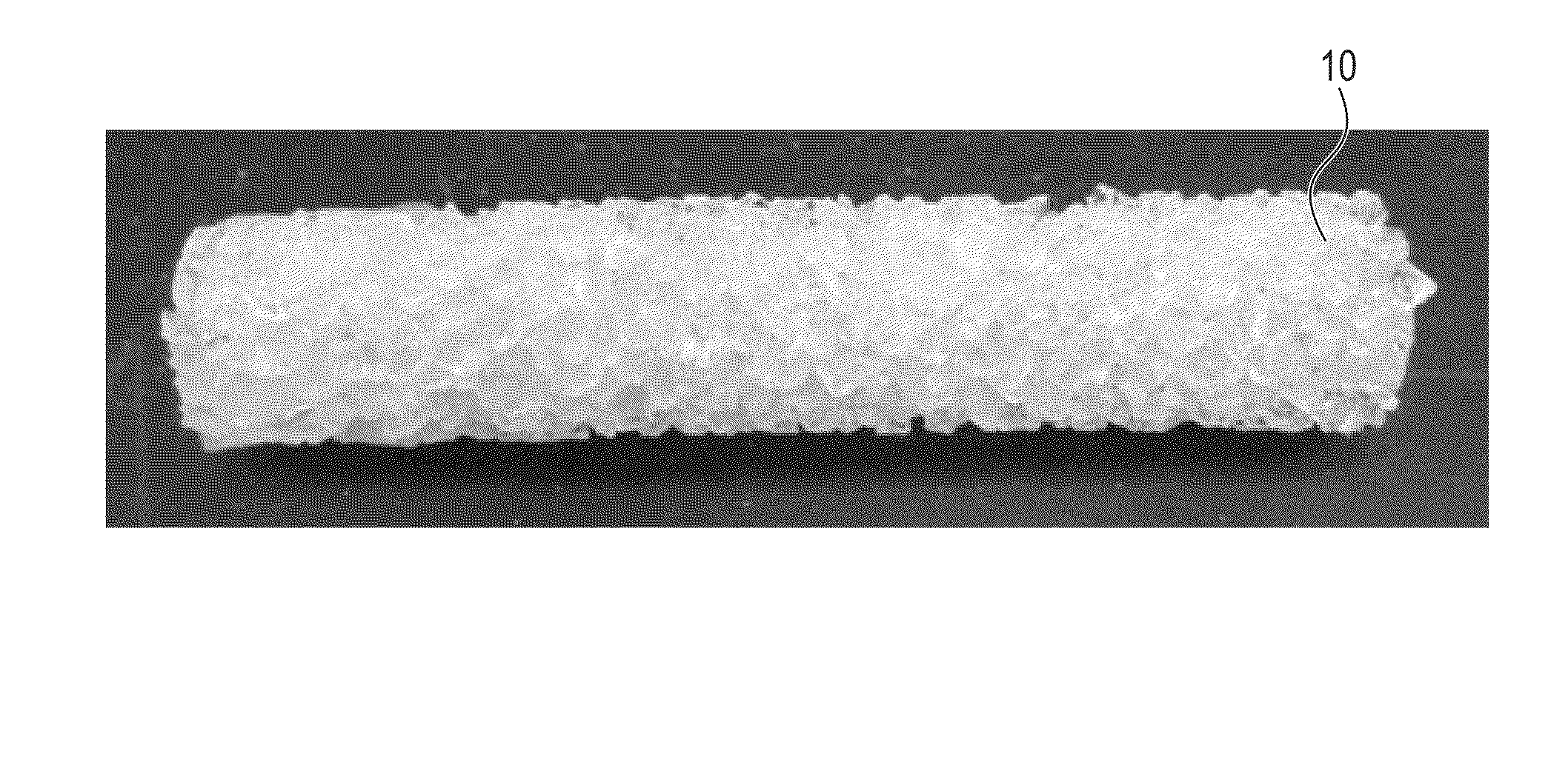

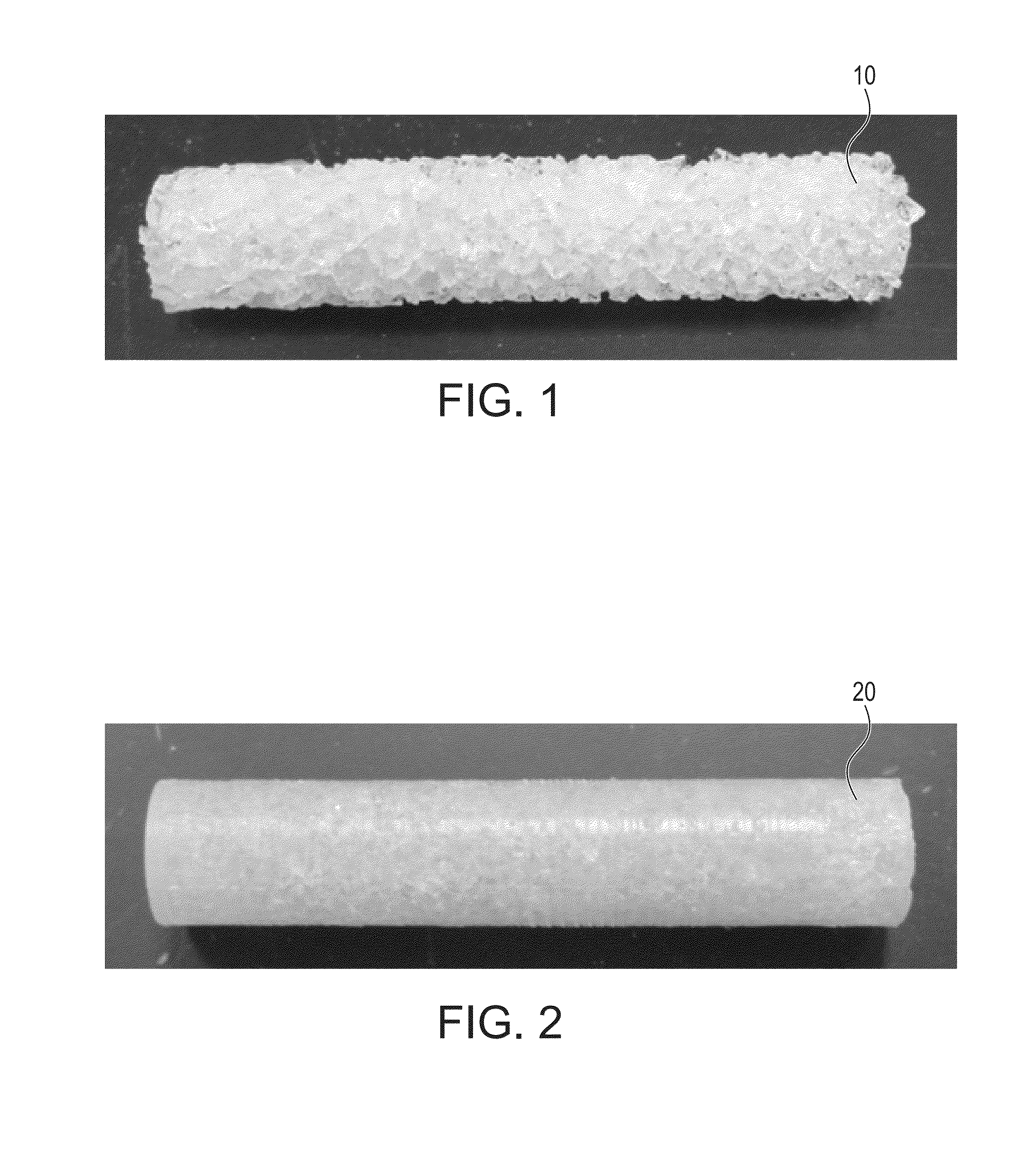

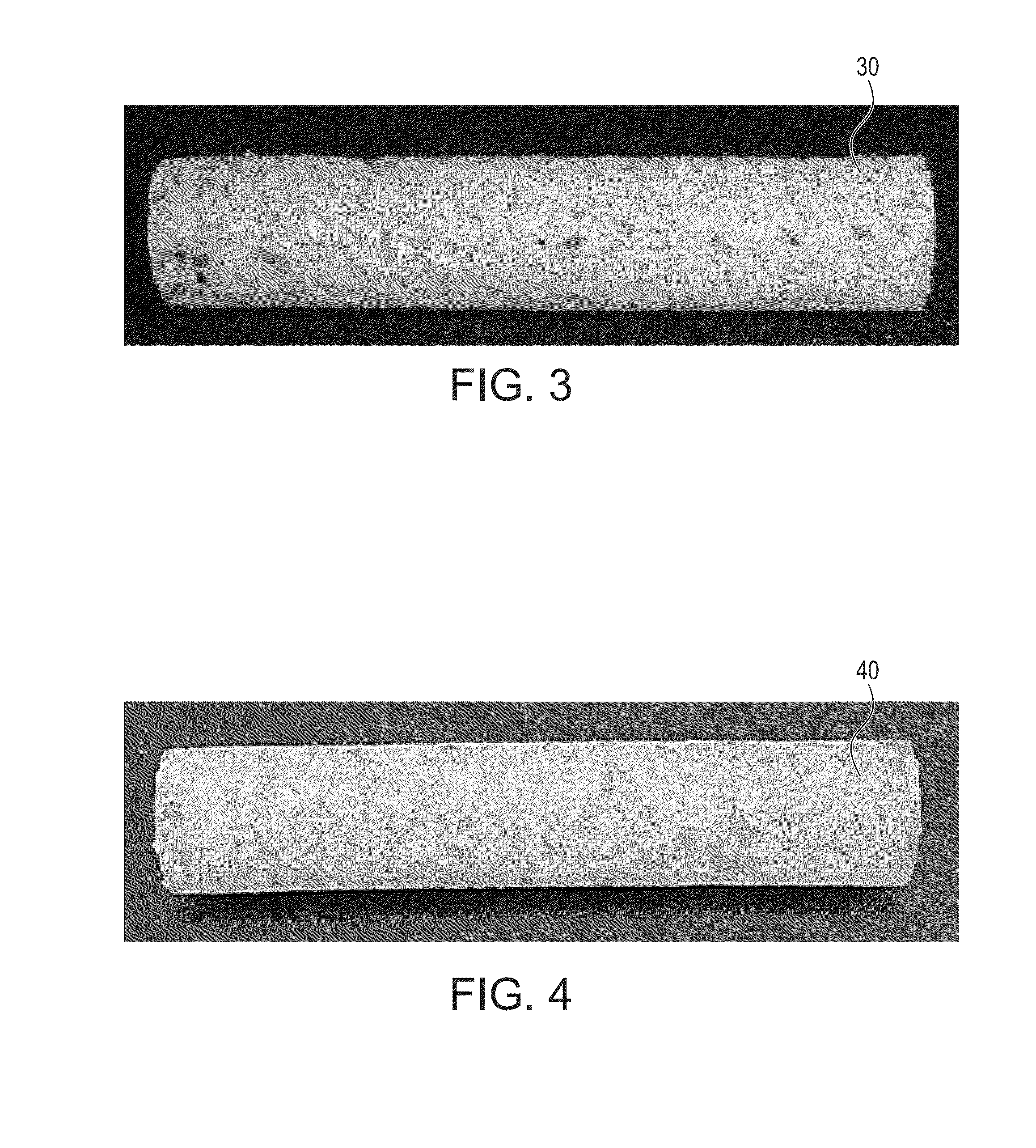

Methods for making and using composites, polymer scaffolds, and composite scaffolds

InactiveUS20070187857A1Promote safe productionTime-consumeDomestic articlesProsthesisOrganic solventTissue repair

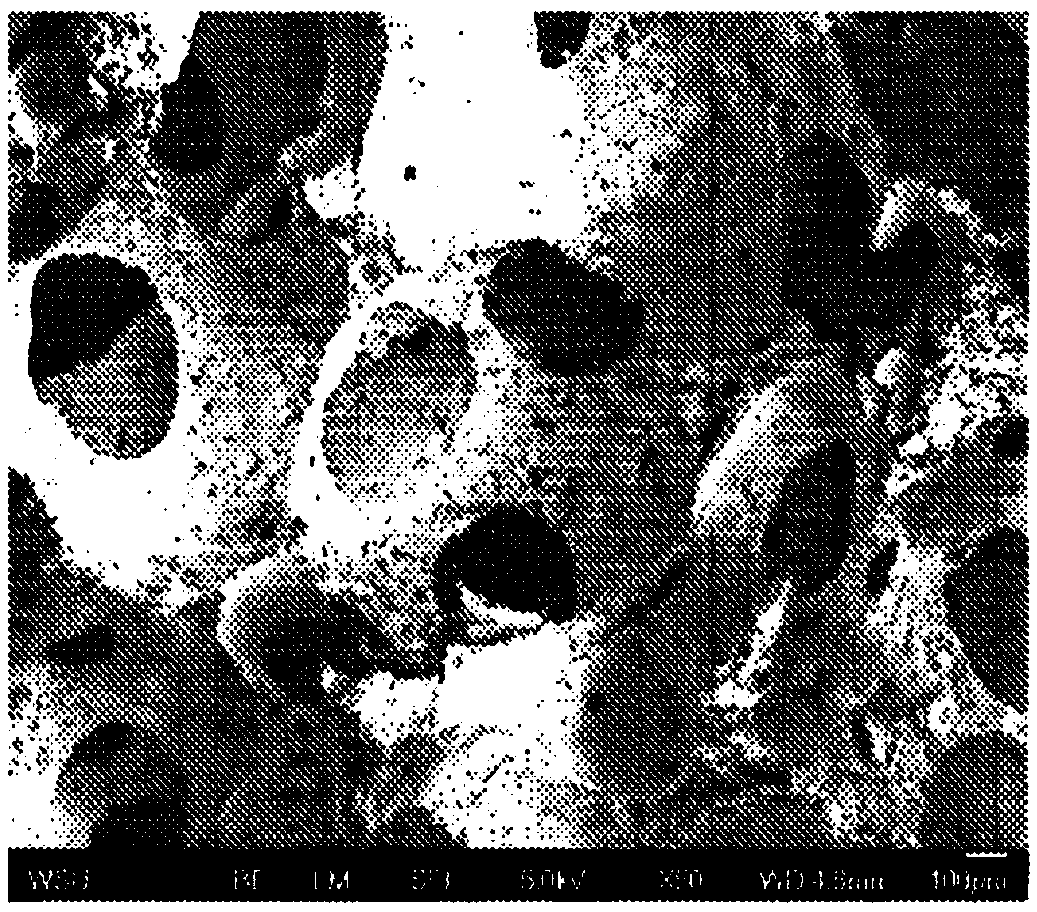

The present invention relates to methods of making and using composites and scaffolds as implantable devices useful for tissue repair, guided tissue regeneration, and tissue engineering. In particular, the present invention relates to methods of making and using compression molded resorbable thermoplastic polymer composites which can be subsequently processed with non-organic solvents to create porous, resorbable thermoplastic polymer scaffolds or composite scaffold with interconnected porosity. Furthermore, these composites or scaffolds can be coated with an organic and / or inorganic material.

Owner:LOREM VASCULAR PTE LTD

Methods for using polishing pads

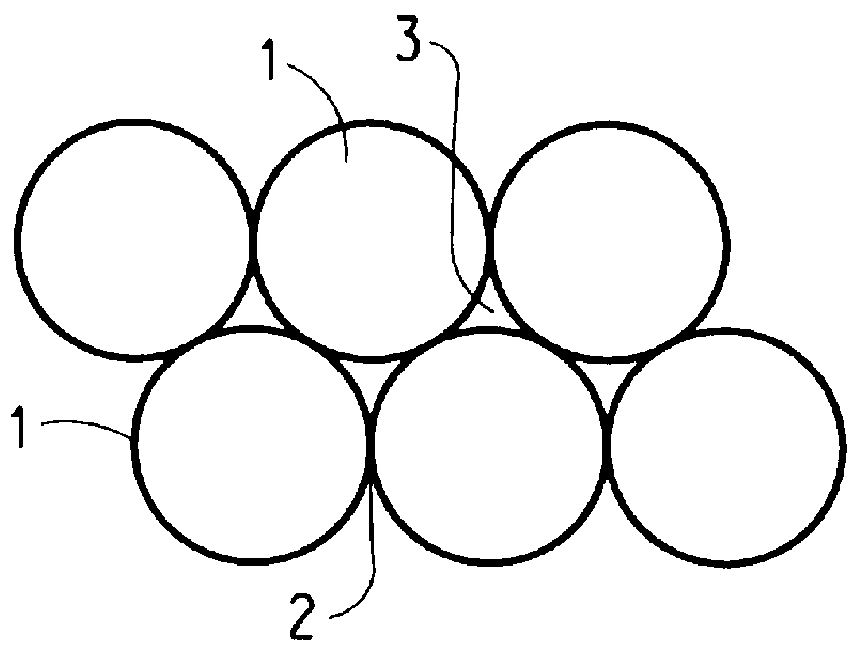

Polymer-based pads useful for polishing objects, particularly integrated circuits, having interconnected porosity which is uniform in all directions, and where the solid portion of said pad consists of a uniform continuously interconnected polymer material of greater than 50% of the gross volume of the article, are produced directly to final shape and dimension by pressure sintering powder compacts of thermoplastic polymer at a temperature above the glass transition temperature but not exceeding the melting point of the polymer and at a pressure in excess of 100 psi in a mold having the desired final pad dimensions. In a preferred version, a mixture of two polymer powders is used, where one polymer has a lower melting point than the other. When pressure sintered at a temperature not to exceed the melting point of the lower melting powder, the increased stiffness afforded by incorporation of the higher melting polymer component gives improved mechanical strength to the sintered product. Conditions for producing the pads of this invention are such that the polymer powder particles from which the pads are produced essentially retain their original shape and are point bonded to form the pad.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

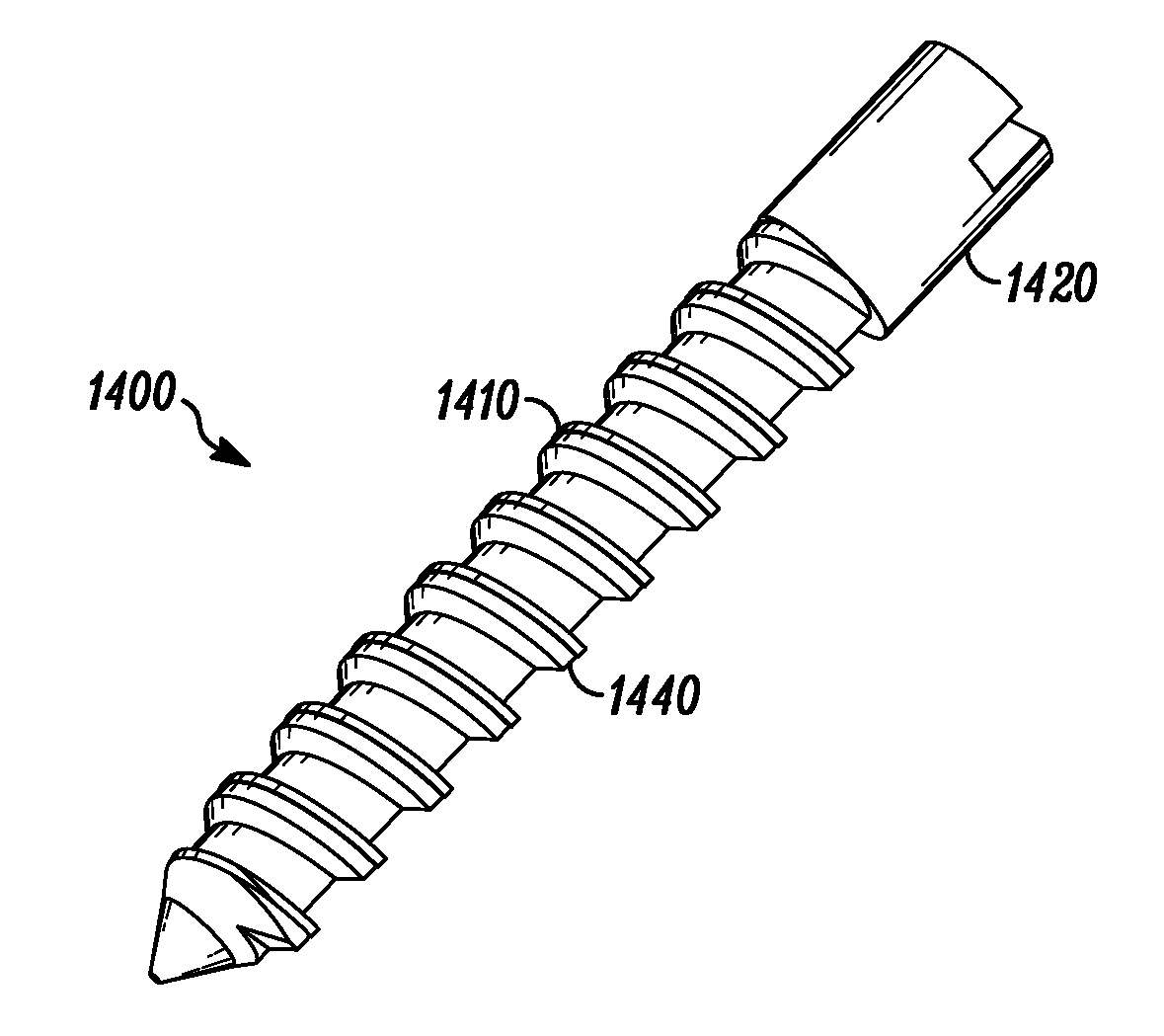

Porous Bone Fixation Device

A porous bone fixation device has a body including non-porous areas that provide superior long term fixation and osteointegration performance. The porous areas provide an in-growth surface in strategic sections such as the threaded section of the fixation device that allow substantially more contact area between in-growth surface and bone. The in-growth material is a network of interconnected porosity in a matrix of bio compatible, preferably titanium. Examples of bone fixation devices include bone screws, bone anchors, dental implants, and similar devices used to provide a fixation point in bone.

Owner:PRAXIS POWDER TECH

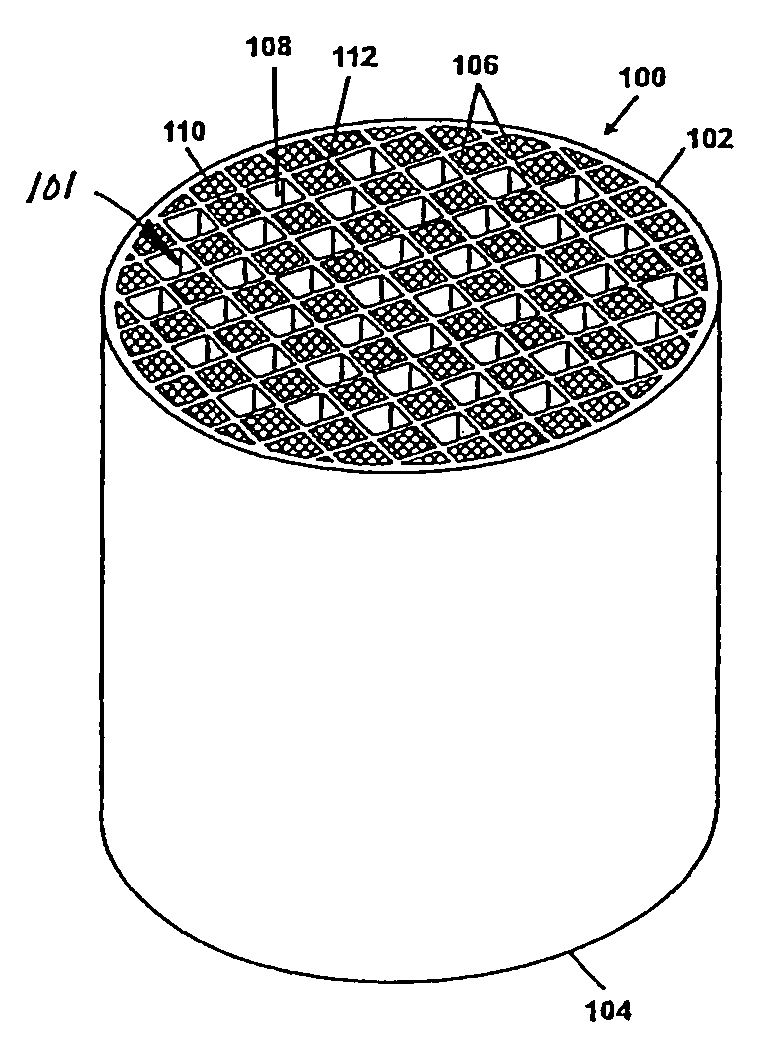

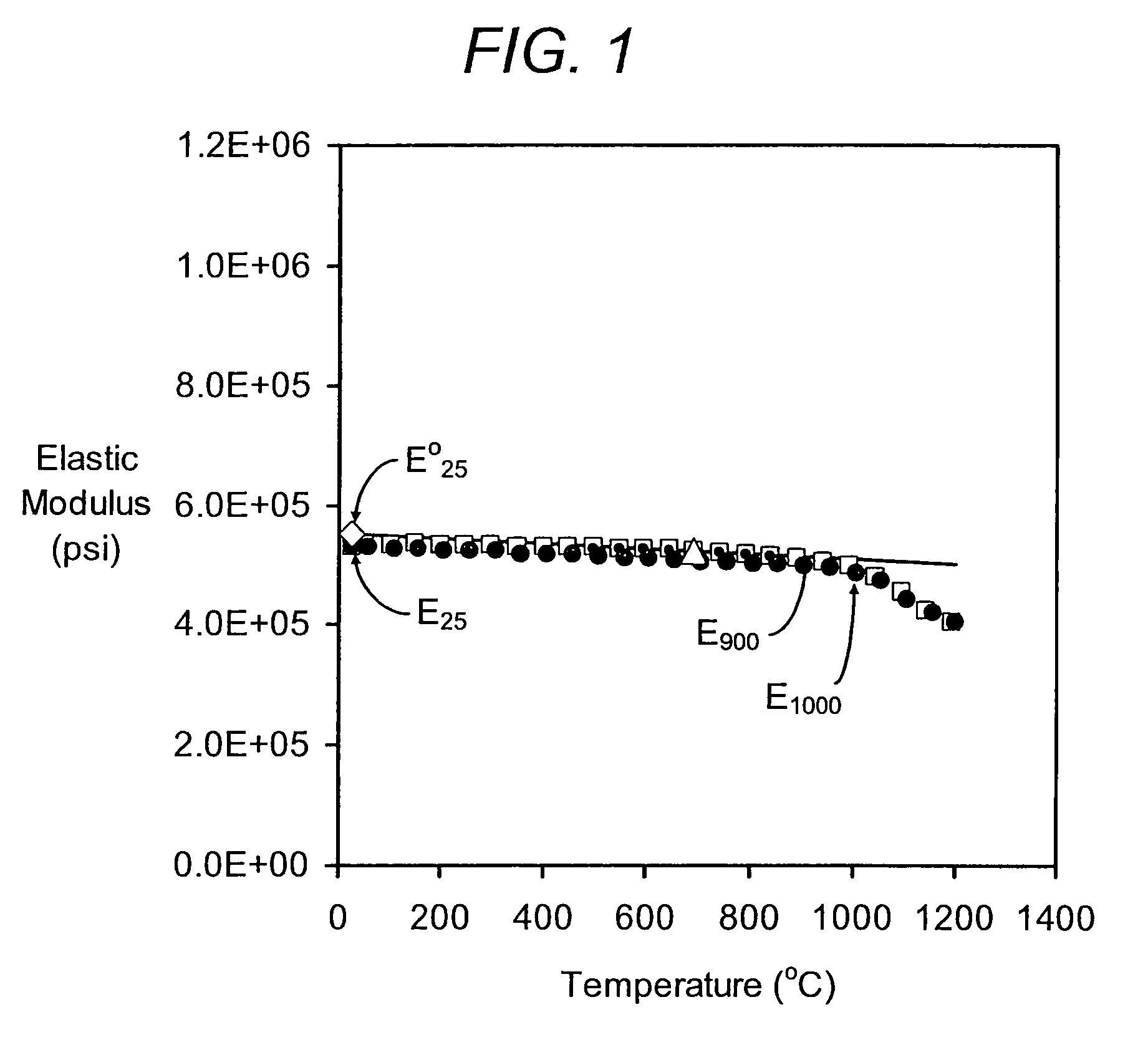

Low-microcracked, porous ceramic honeycombs and methods of manufacturing same

ActiveUS20080032090A1Improve efficiencyHigh strengthLayered productsCeramic shaping apparatusThermal expansionInterconnected porosity

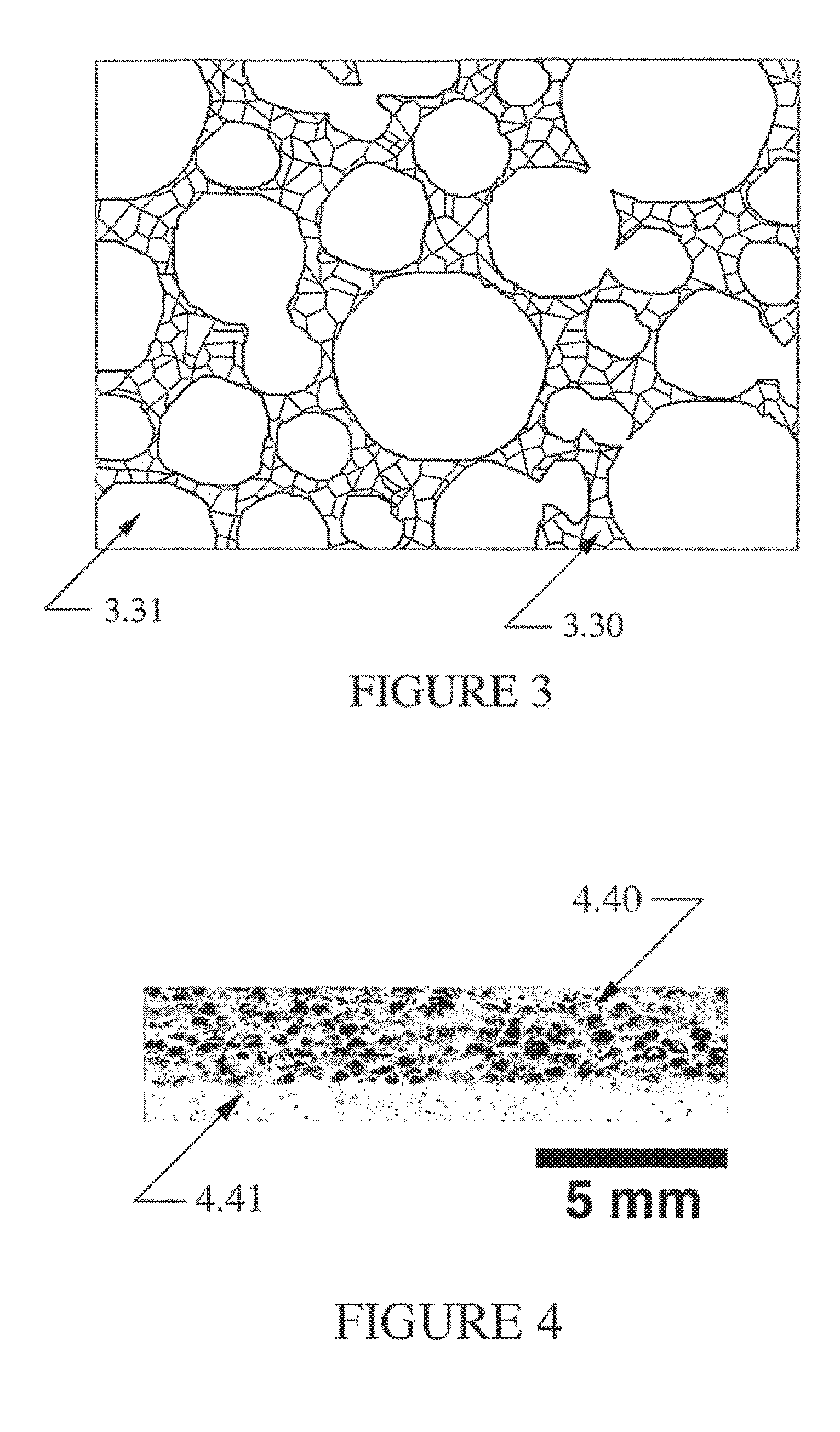

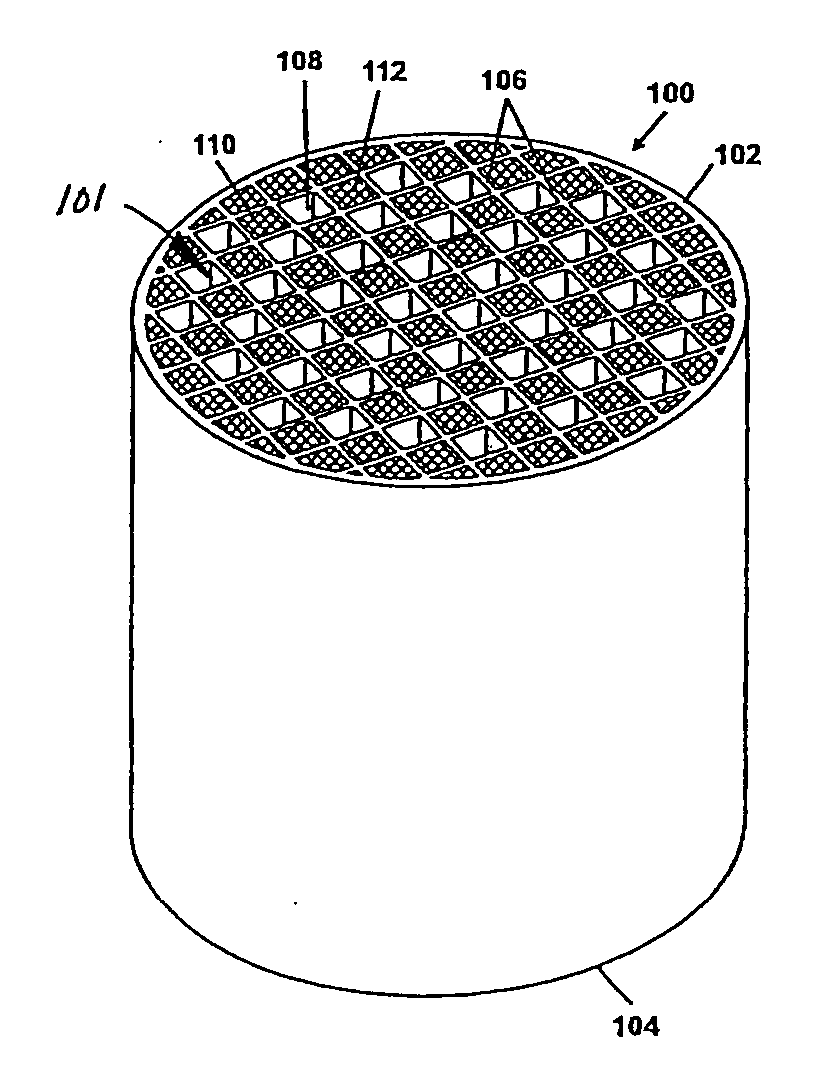

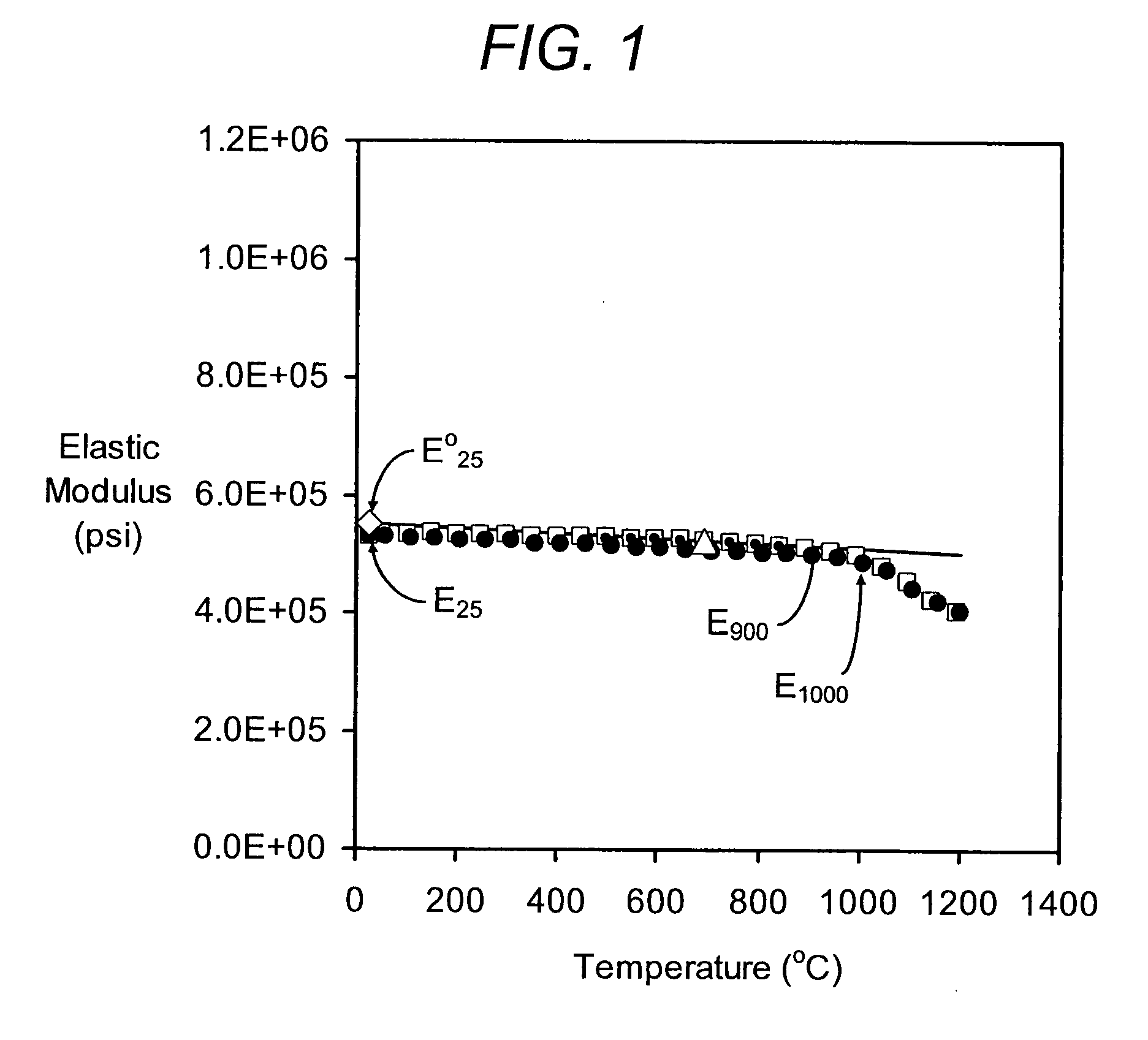

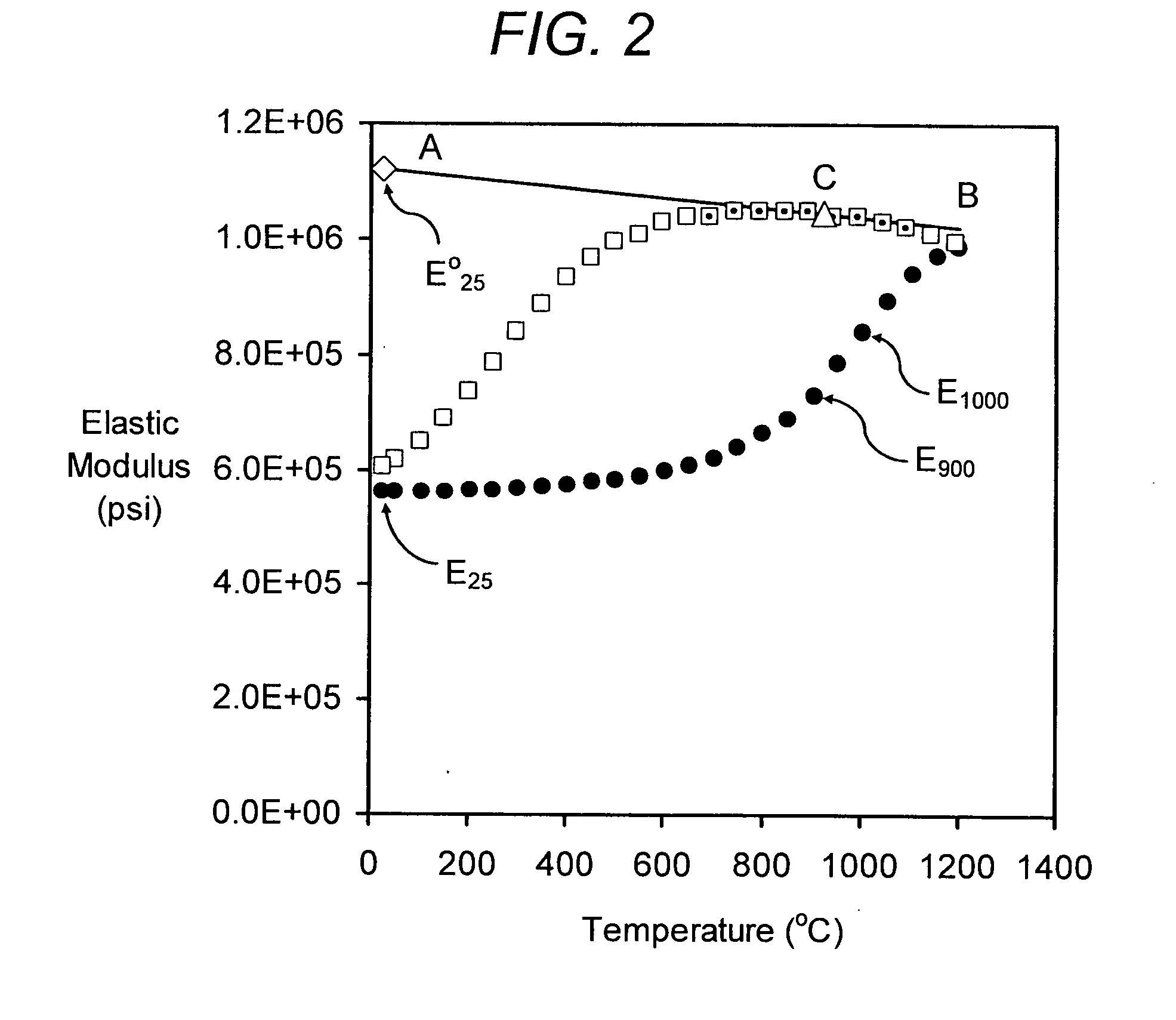

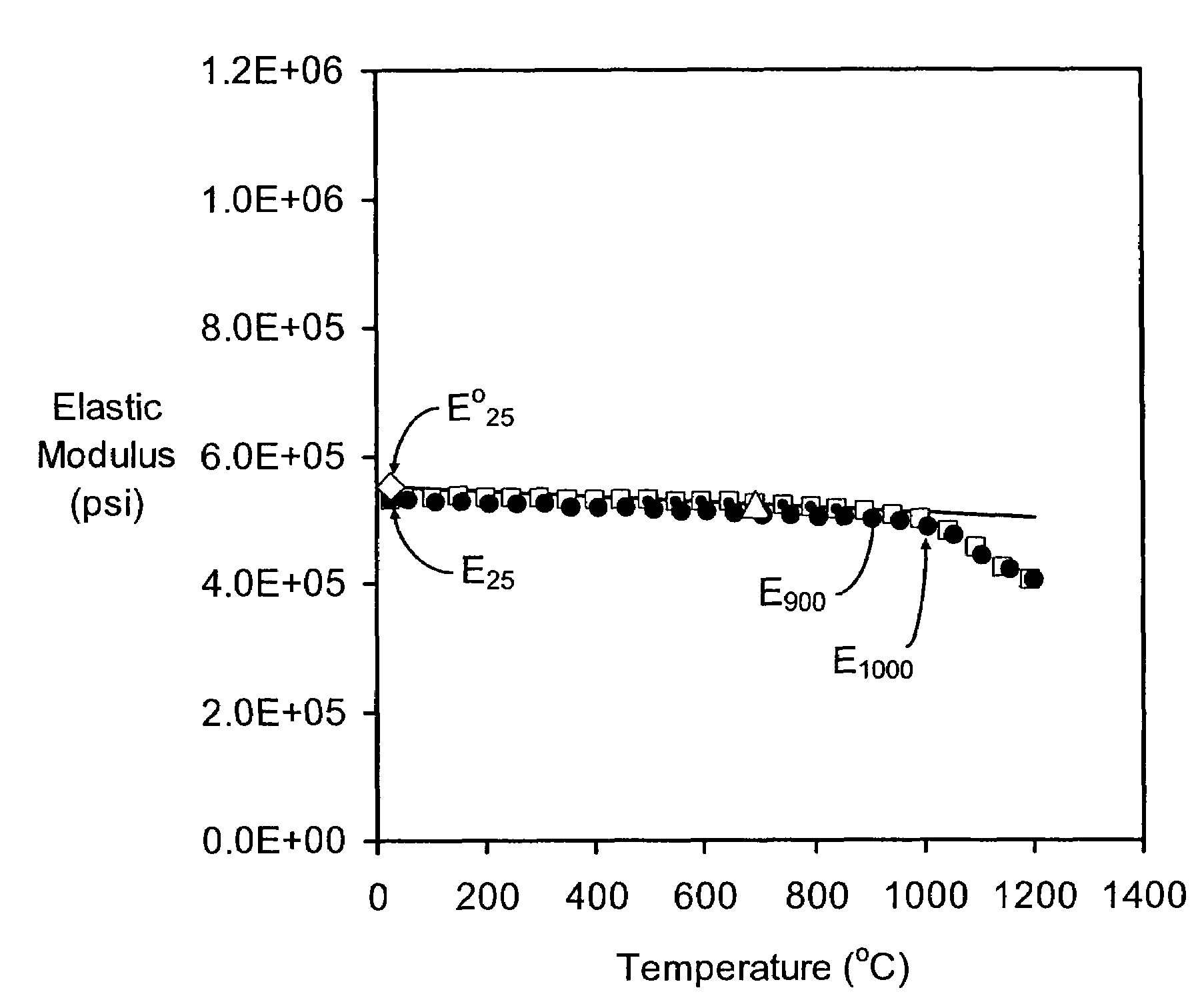

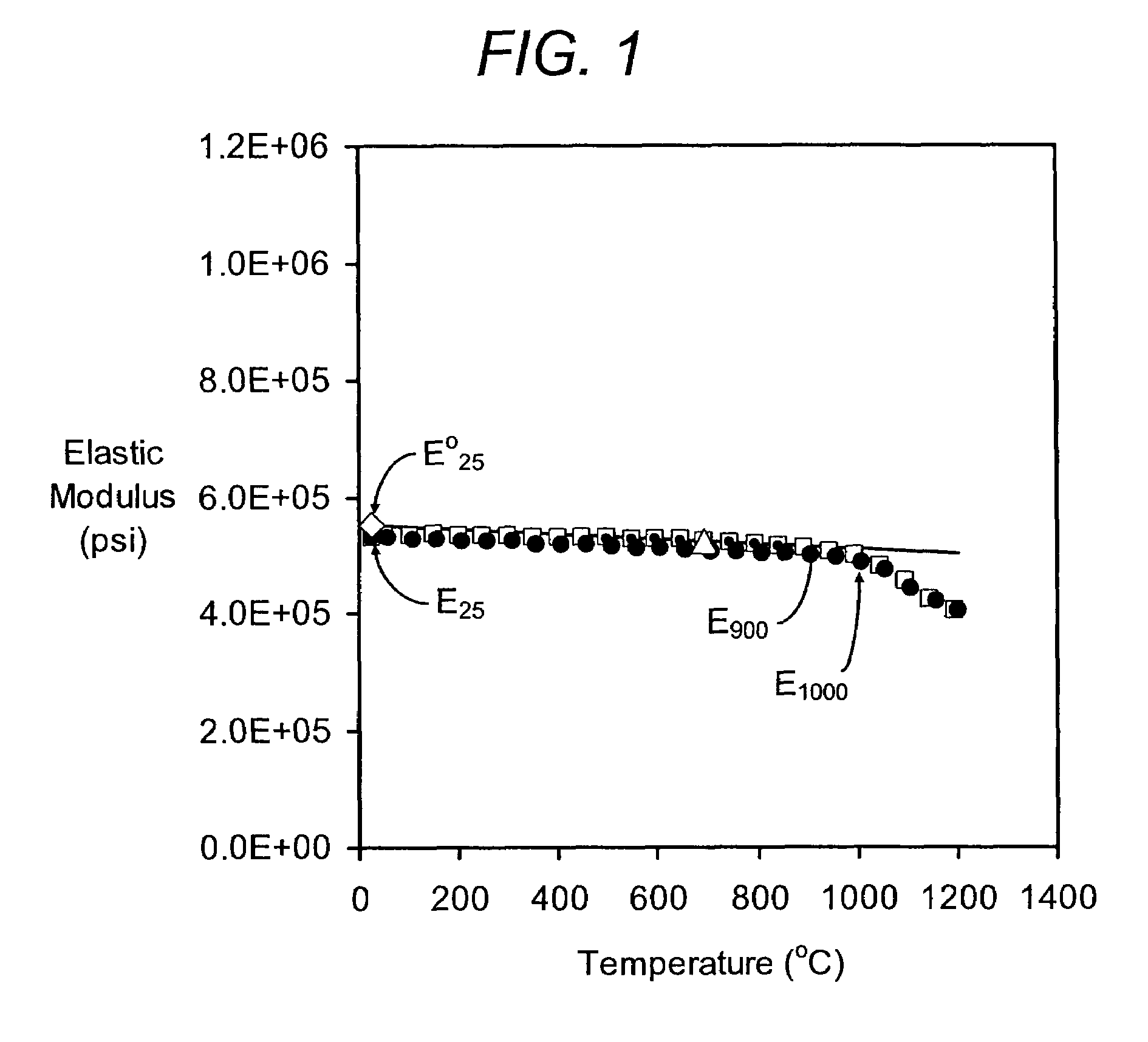

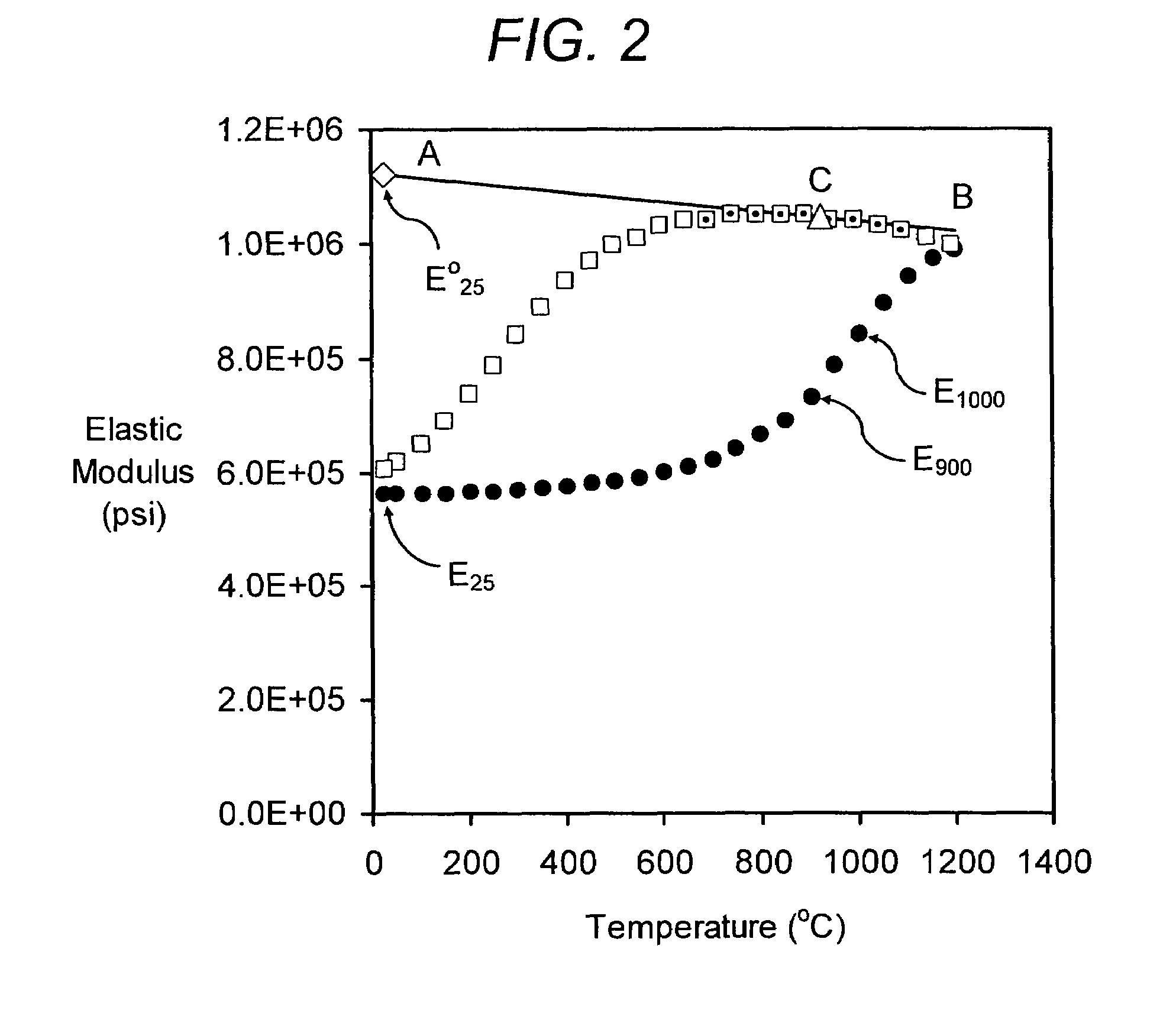

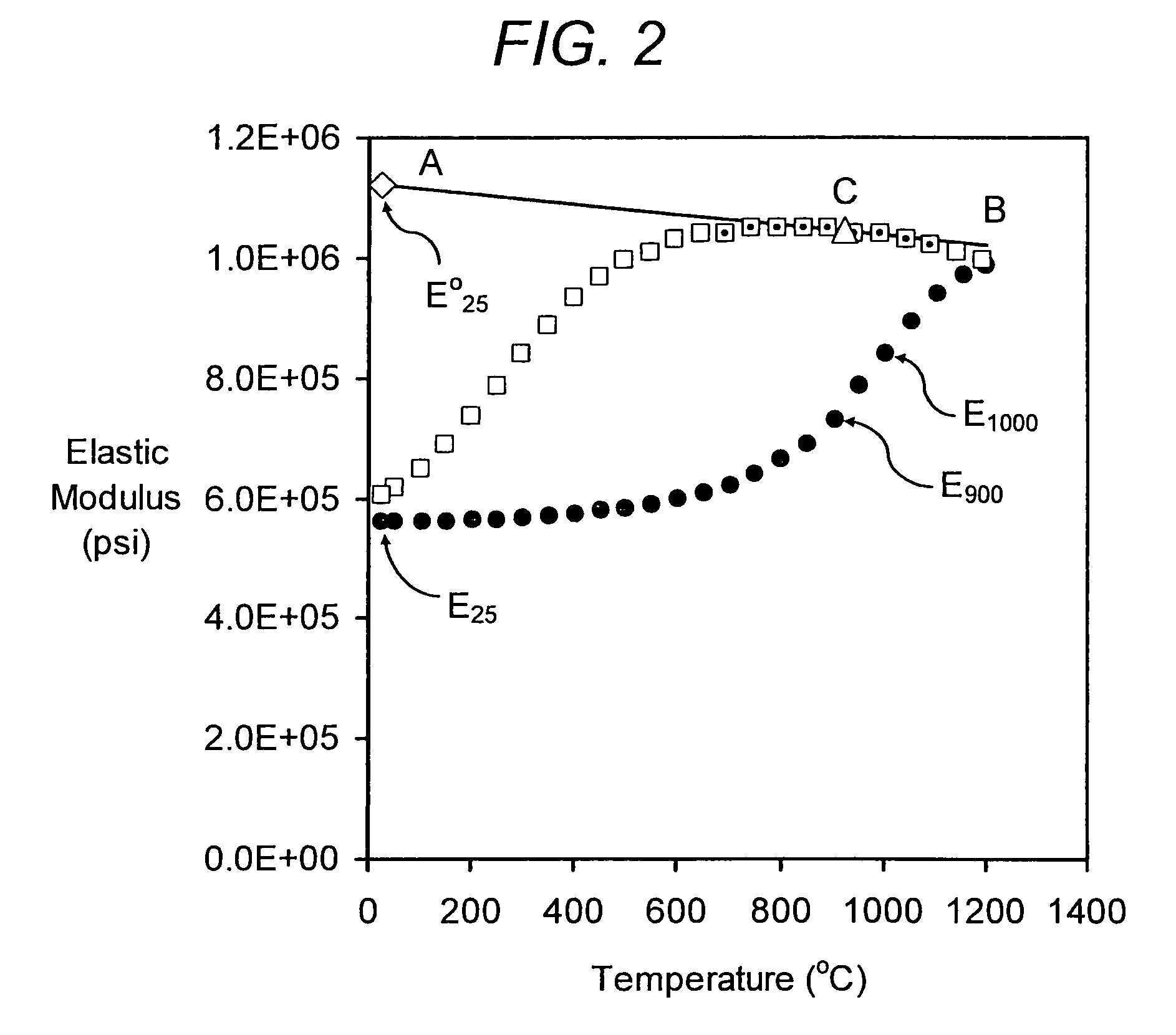

Substantially non-microcracked, porous, cordierite ceramic honeycomb bodies are provided. Although exhibiting moderately high thermal expansion (CTE) between 7×10−7 to 16×10−7 / ° C. (25-800° C.), the honeycomb bodies exhibit relatively high thermal shock parameter (TSP), such as TSR≧525° C. by virtue of a high MOR / E ratio, and / or low Eratio=ERT / E1000° C. and well interconnected porosity, as witnessed by a relatively high pore connectivity factor (PCF). A method of manufacturing the honeycomb ceramic structure is also provided.

Owner:CORNING INC

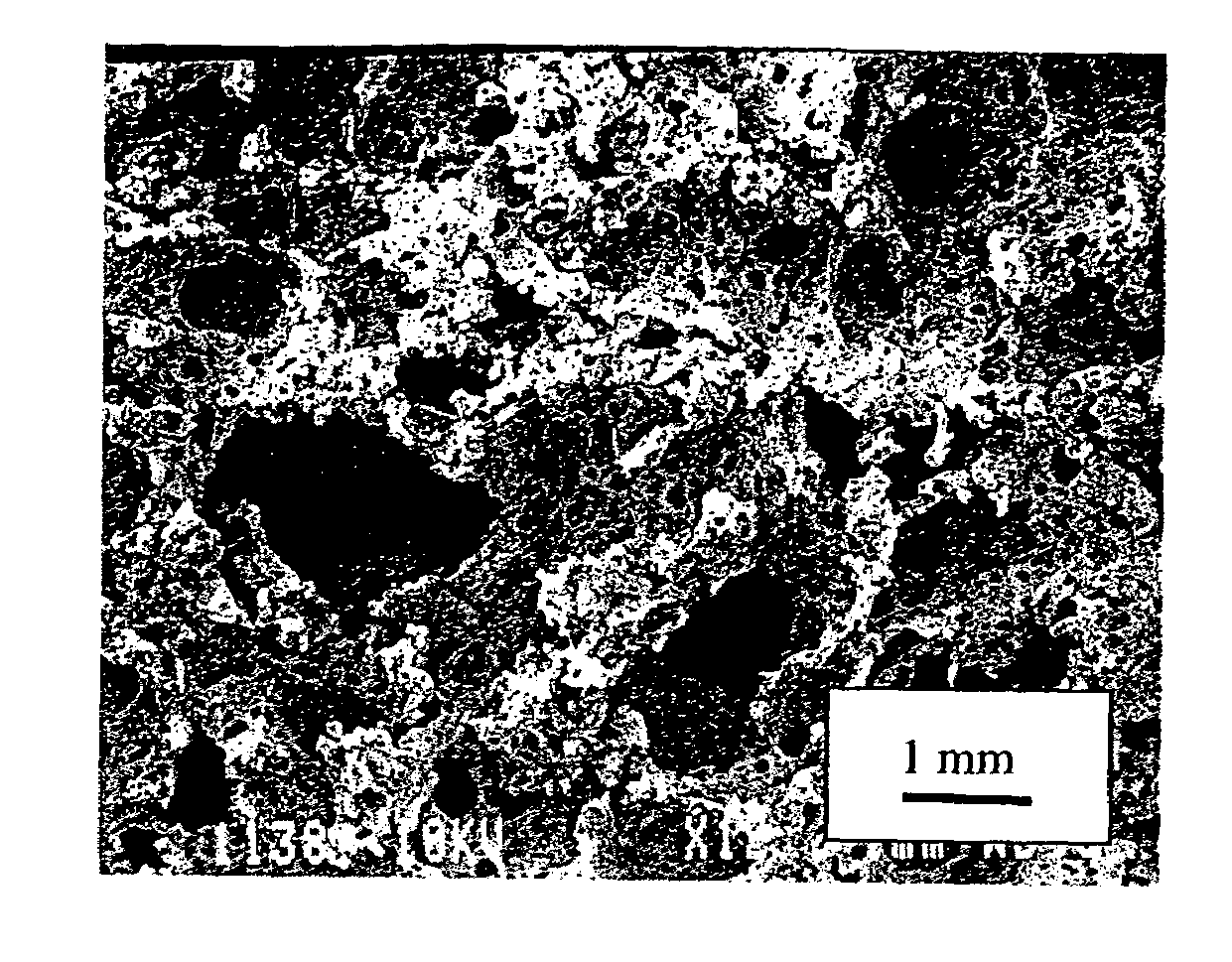

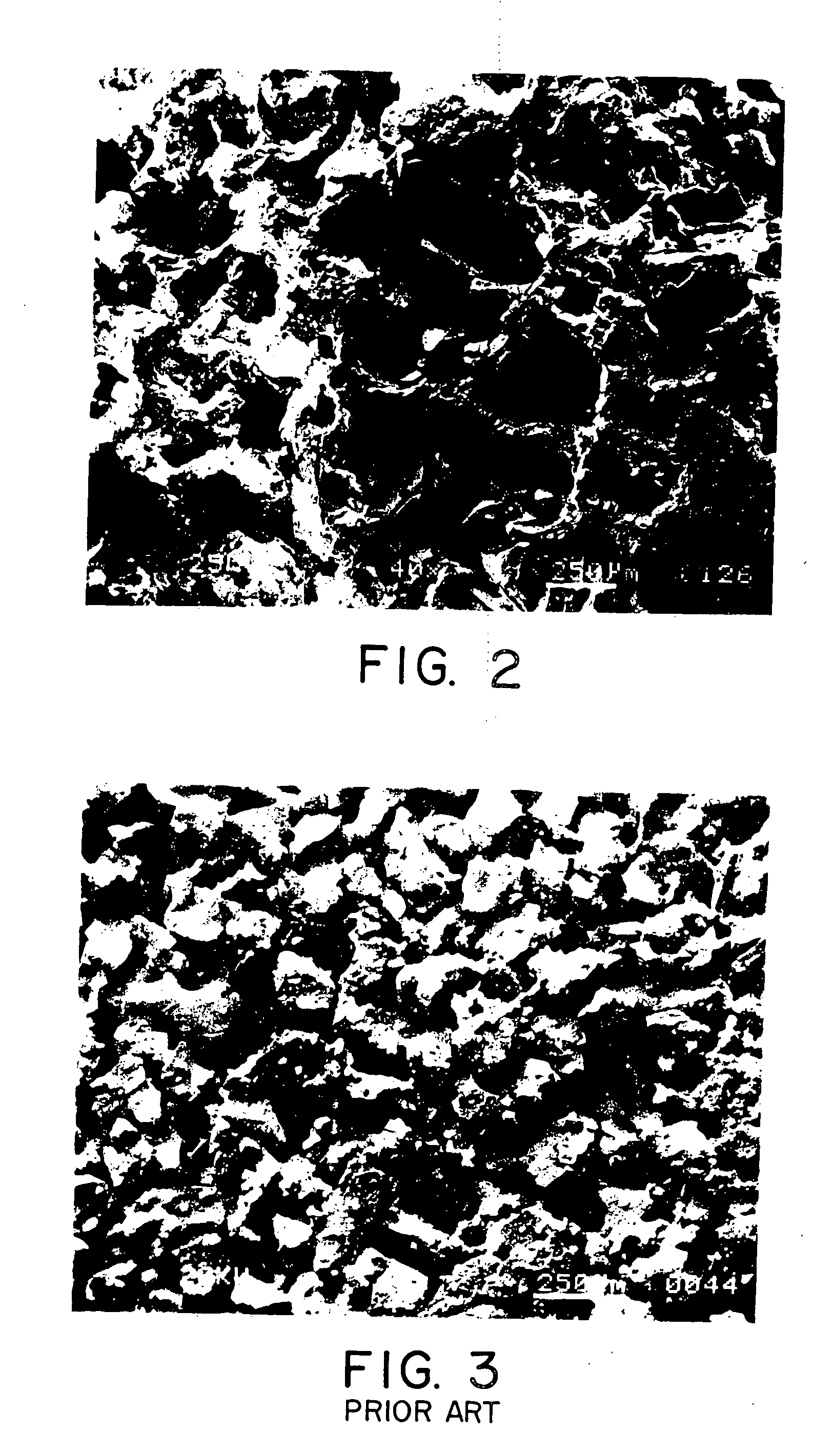

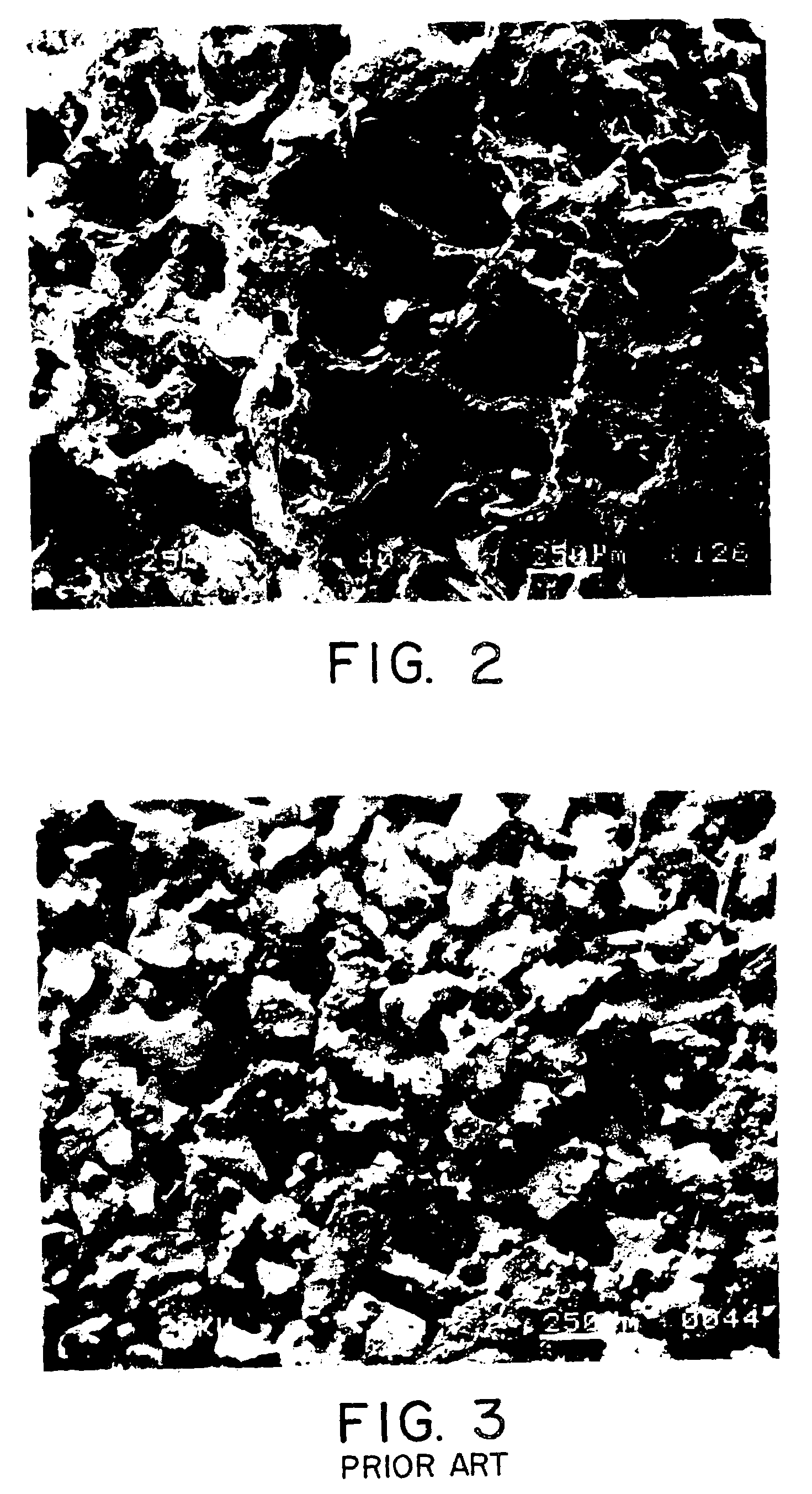

Abrasive processing of hard and /or brittle materials

ActiveUS20090084042A1Slow feed ratePigmenting treatmentOther chemical processesManufacturing technologyTitanium carbide

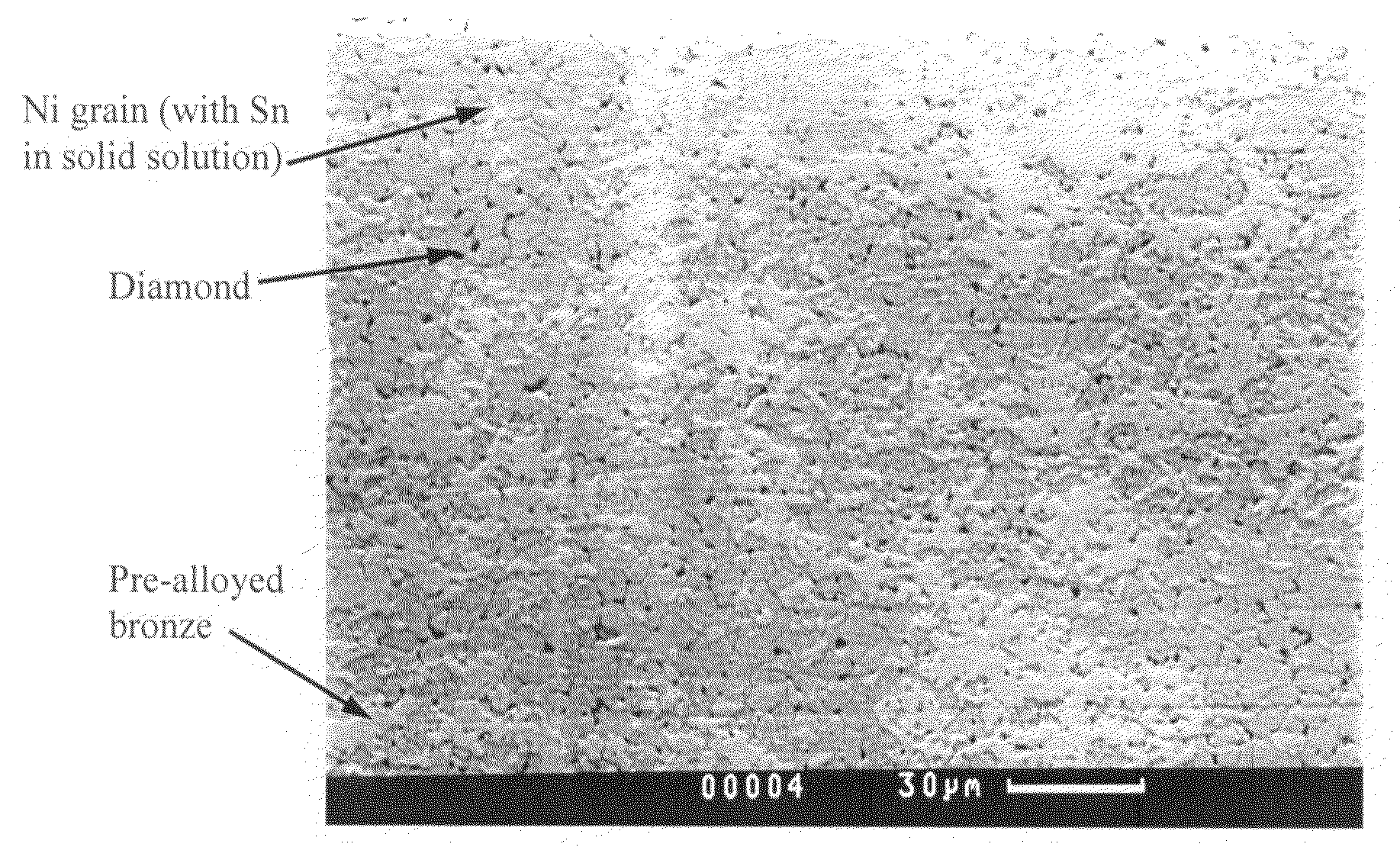

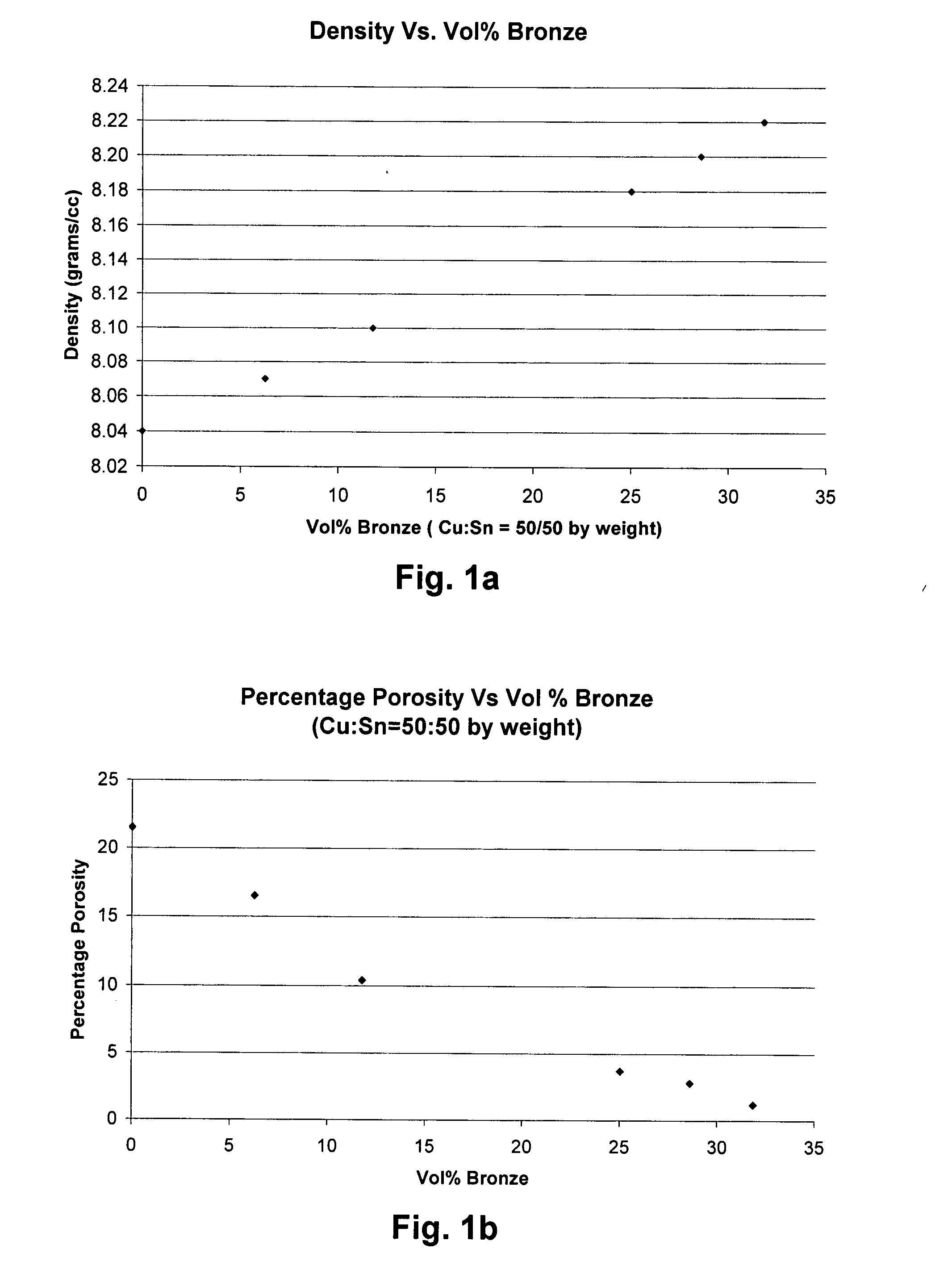

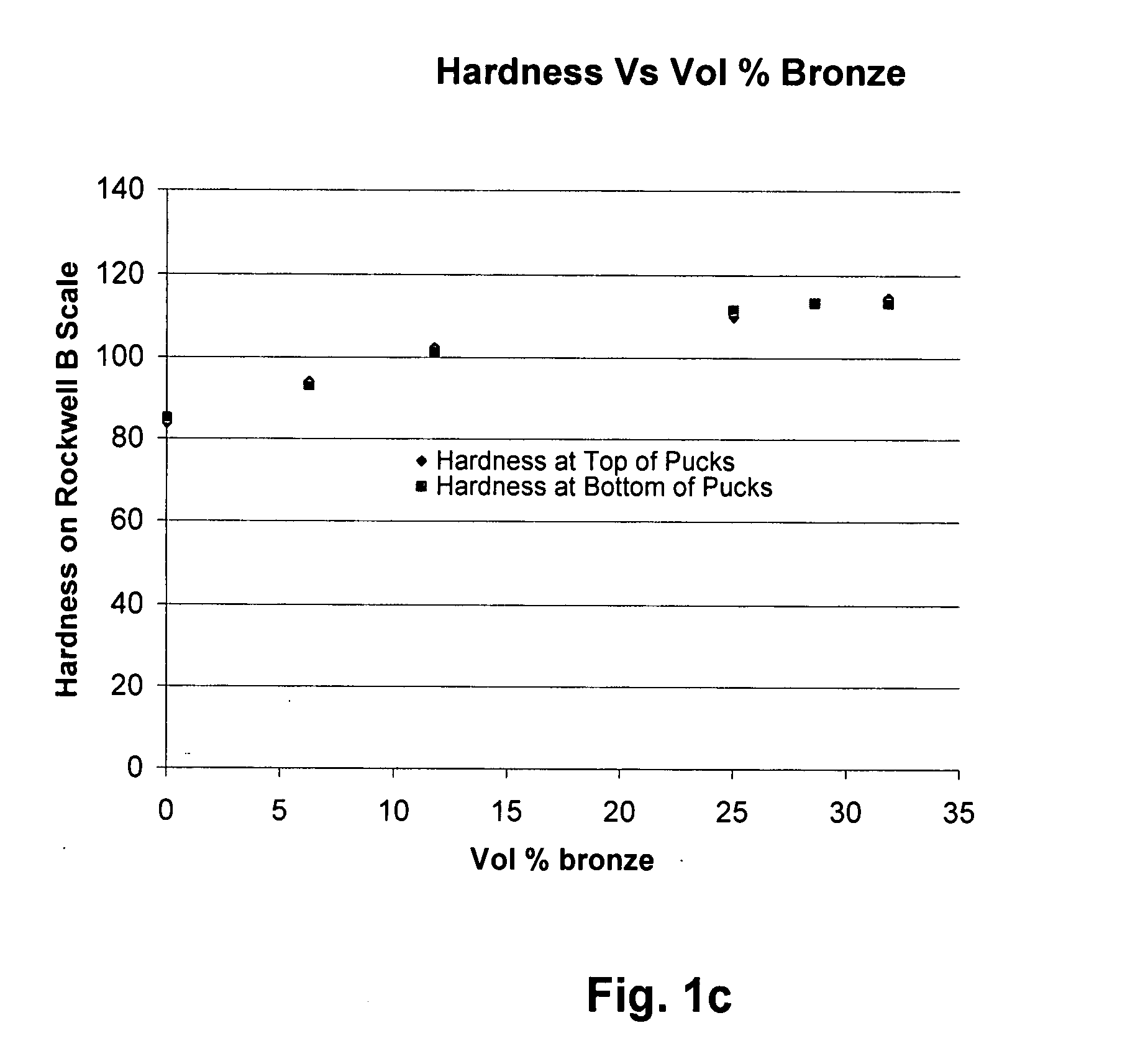

Abrasive articles possessing a highly open (porous) structure and uniform abrasive grit distribution are disclosed. The abrasive articles are fabricated using a metal matrix (e.g., fine nickel, tin, bronze and abrasives). The open structure is controlled with a porosity scheme, including interconnected porosity (e.g., formed by leaching of dispersoid), closed porosity (e.g., induced by adding a hollow micro-spheres and / or sacrificial pore-forming additives), and / or intrinsic porosity (e.g., controlled via matrix component selection to provide desired densification). In some cases, manufacturing process temperatures for achieving near full density of metal bond with fillers and abrasives, are below the melting point of the filler used, although sacrificial fillers may be used as well. The resulting abrasive articles are useful in high performance cutting and grinding operations, such as back-grinding silicon, alumina titanium carbide, and silicon carbide wafers to very fine surface finish values. Techniques of use and manufacture are also disclosed.

Owner:SAINT GOBAIN ABRASIVES INC +1

Method of making open cell material

InactiveUS20050100470A1Easily flowableHigh mechanical strengthCeramicwareFoaming agentInorganic particle

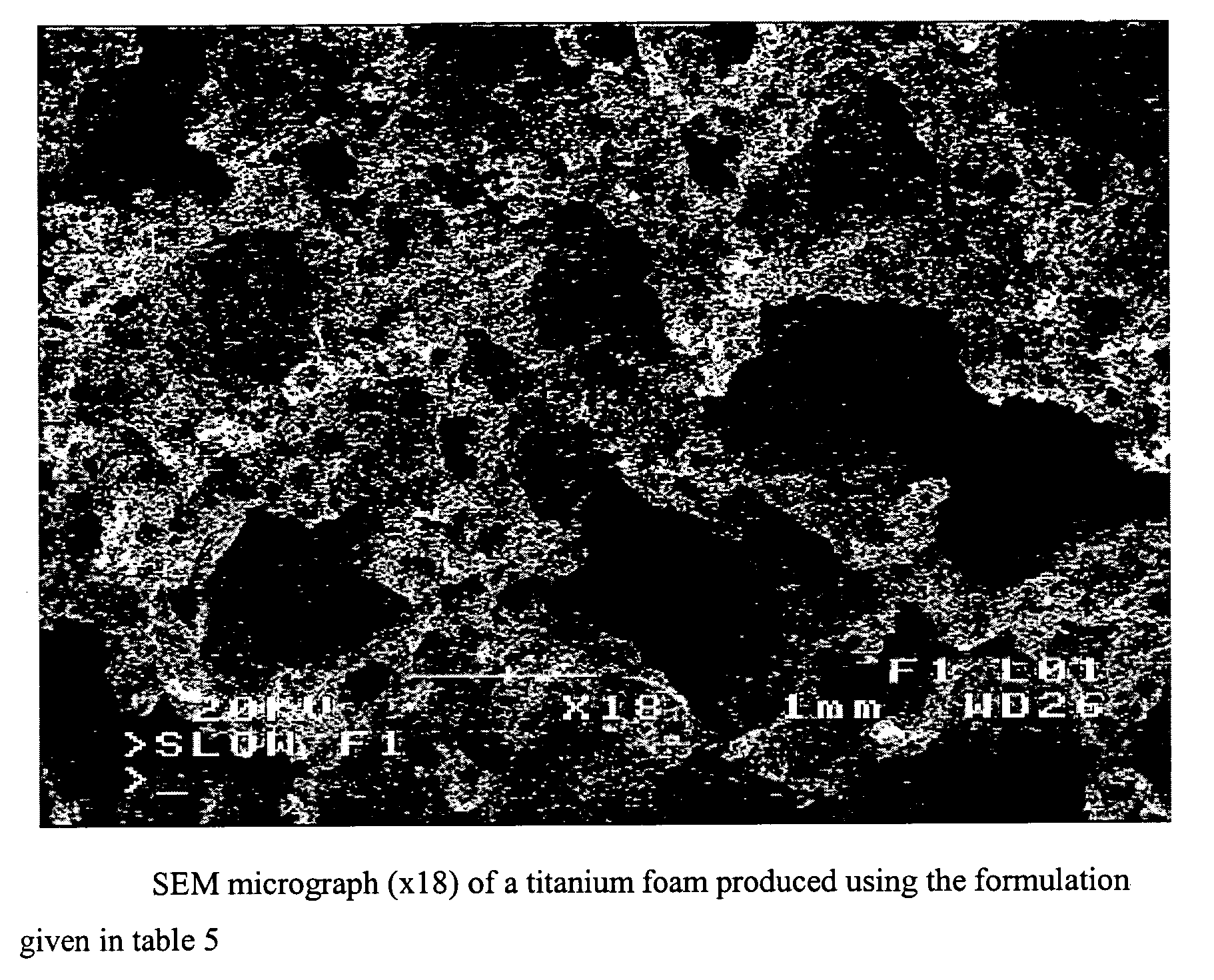

The porous material of the present invention is produced by heating a dry powder mixture, containing mainly an organic solid binder and inorganic particles. The mixture is foamed while the organic binder is melted. Foaming comes from a foaming agent in the powder mixture. The solid foamed structure comprising inorganic particles embedded in an organic binder is then heated to eliminate the organic binder and finally to sinter the remaining inorganic tri-dimensional network into a rigid structure having interconnected porosity.

Owner:NAT RES COUNCIL OF CANADA +1

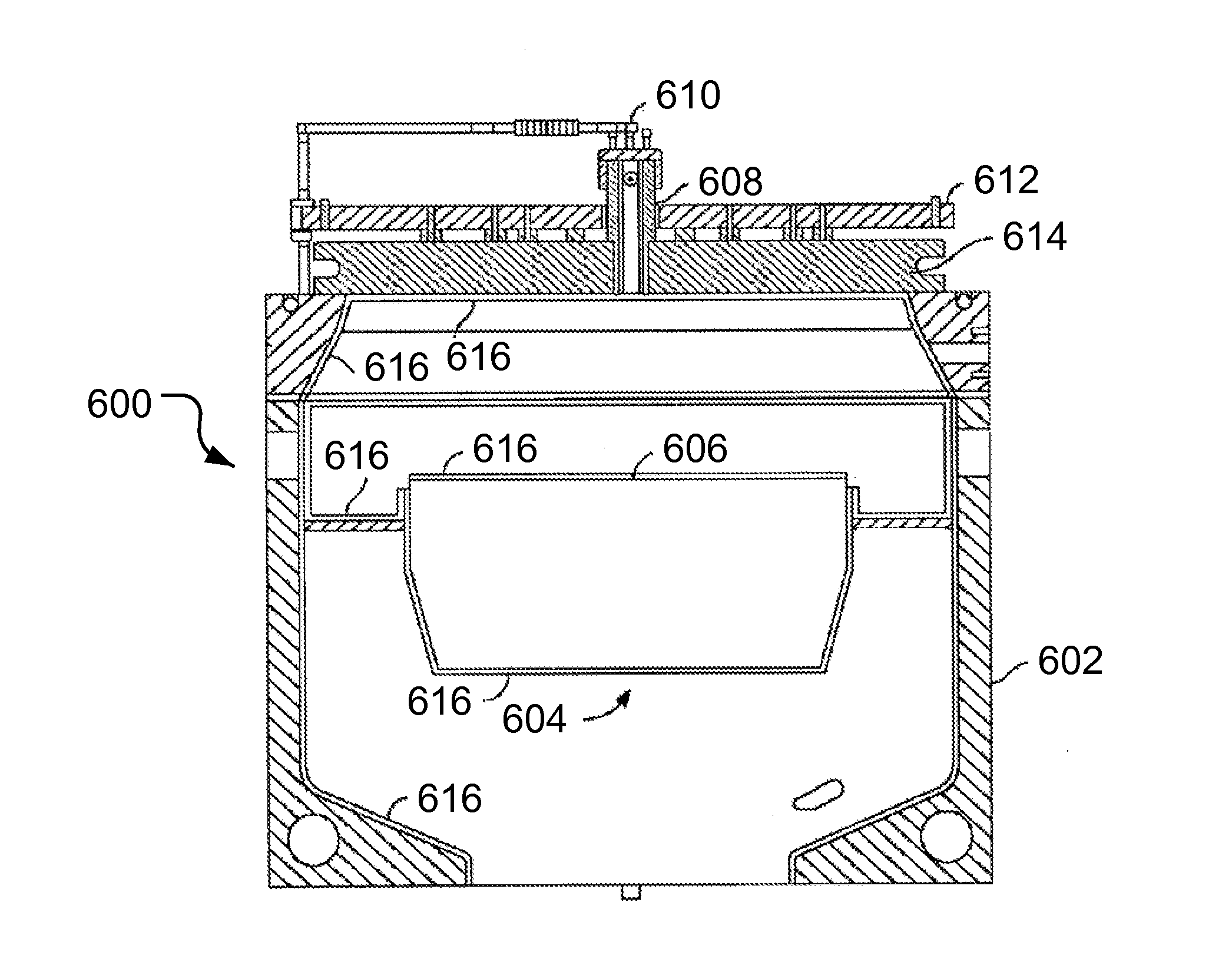

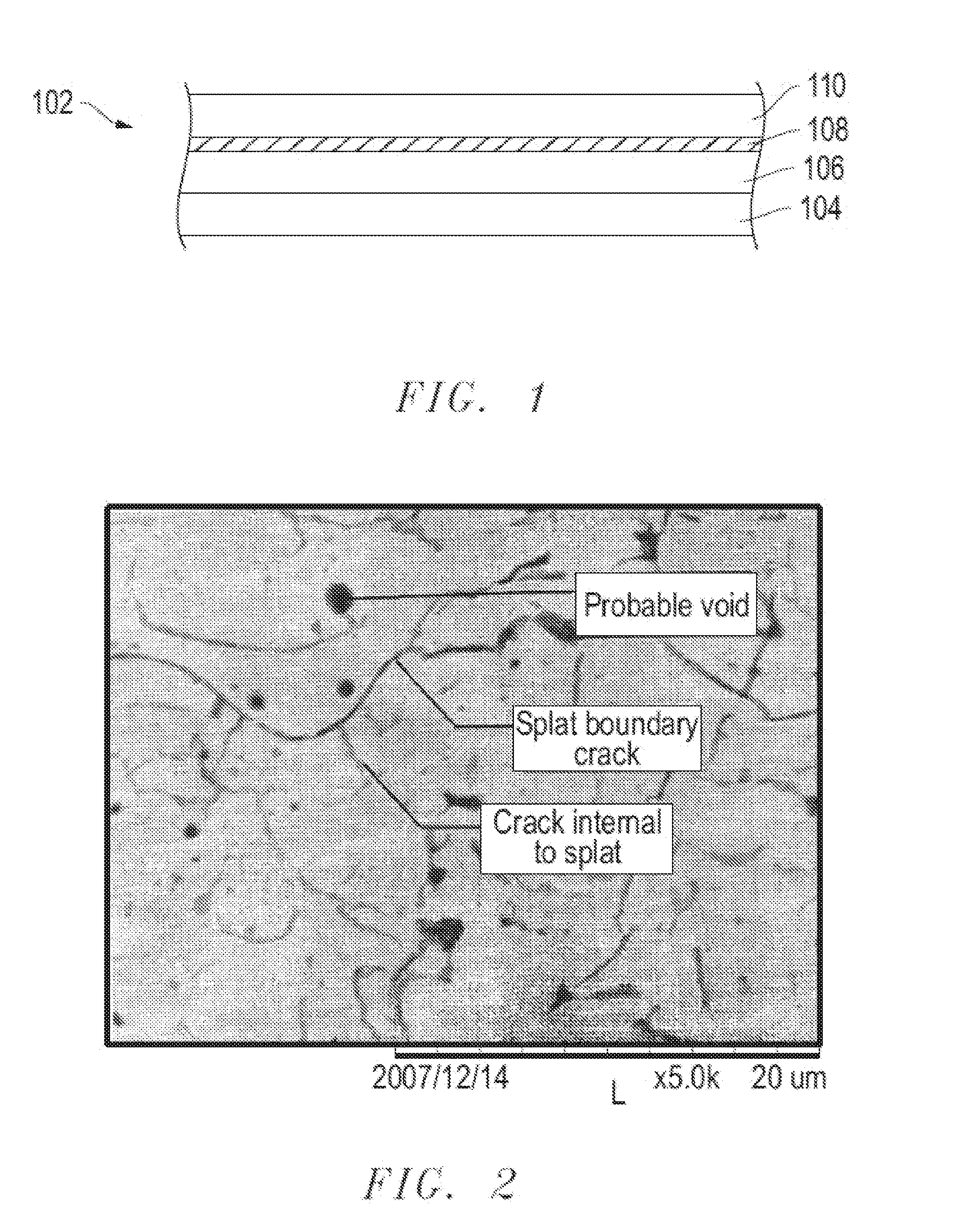

Sealed plasma coatings

InactiveUS20100323124A1Low shrinkageMolten spray coatingElectric discharge tubesInterior spacePolymer science

A processing device includes a plurality of walls defining an interior space configured to be exposed to plasma and a surface coating on the interior surface of at least one of the plurality of walls. The surface coating includes pores forming interconnected porosity. The processing device further includes a sealant residing in at least a portion of the pores of the surface coating. In an embodiment, the sealant can be a thermally cured sealant having a cure temperature not greater than about 100° C. In another embodiment, the sealant can be an epoxy sealant having a viscosity of not greater than 500 cP in liquid precursor form. In yet another embodiment, the sealant can be a low shrinkage sealant characterized by a solidification shrinkage of not greater than 8%.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

Method of making open cell material

InactiveUS7108828B2Easily flowableHigh mechanical strengthCeramicwarePowder mixtureInorganic particle

The porous material of the present invention is produced by heating a dry powder mixture, containing mainly an organic solid binder and inorganic particles. The mixture is foamed while the organic binder is melted. Foaming comes from a foaming agent in the powder mixture. The solid foamed structure comprising inorganic particles embedded in an organic binder is then heated to eliminate the organic binder and finally to sinter the remaining inorganic tri-dimensional network into a rigid structure having interconnected porosity.

Owner:NAT RES COUNCIL OF CANADA +1

Porous abrasive articles with agglomerated abrasives and method for making the agglomerated abrasives

InactiveUS20050101225A1Pigmenting treatmentRevolution surface grinding machinesThree dimensional shapeInterconnected porosity

Owner:SAINT GOBAIN ABRASIVES TECH CO

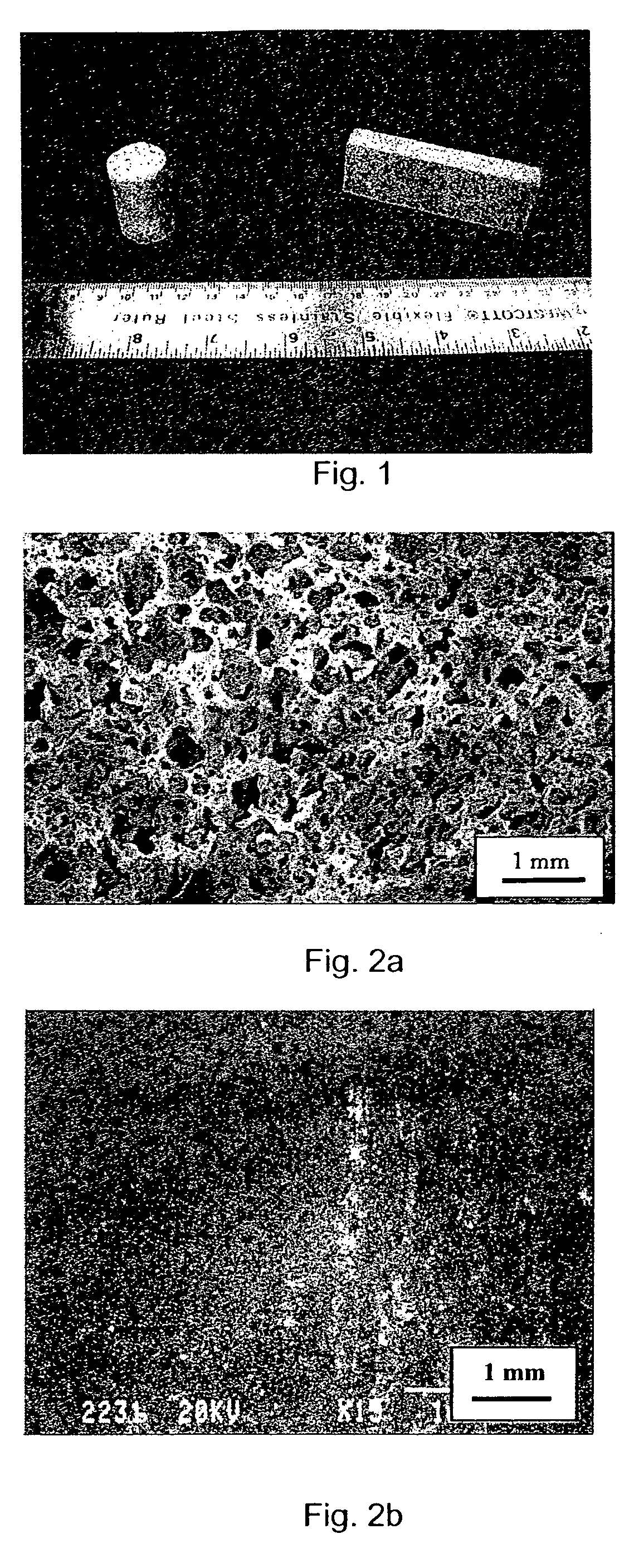

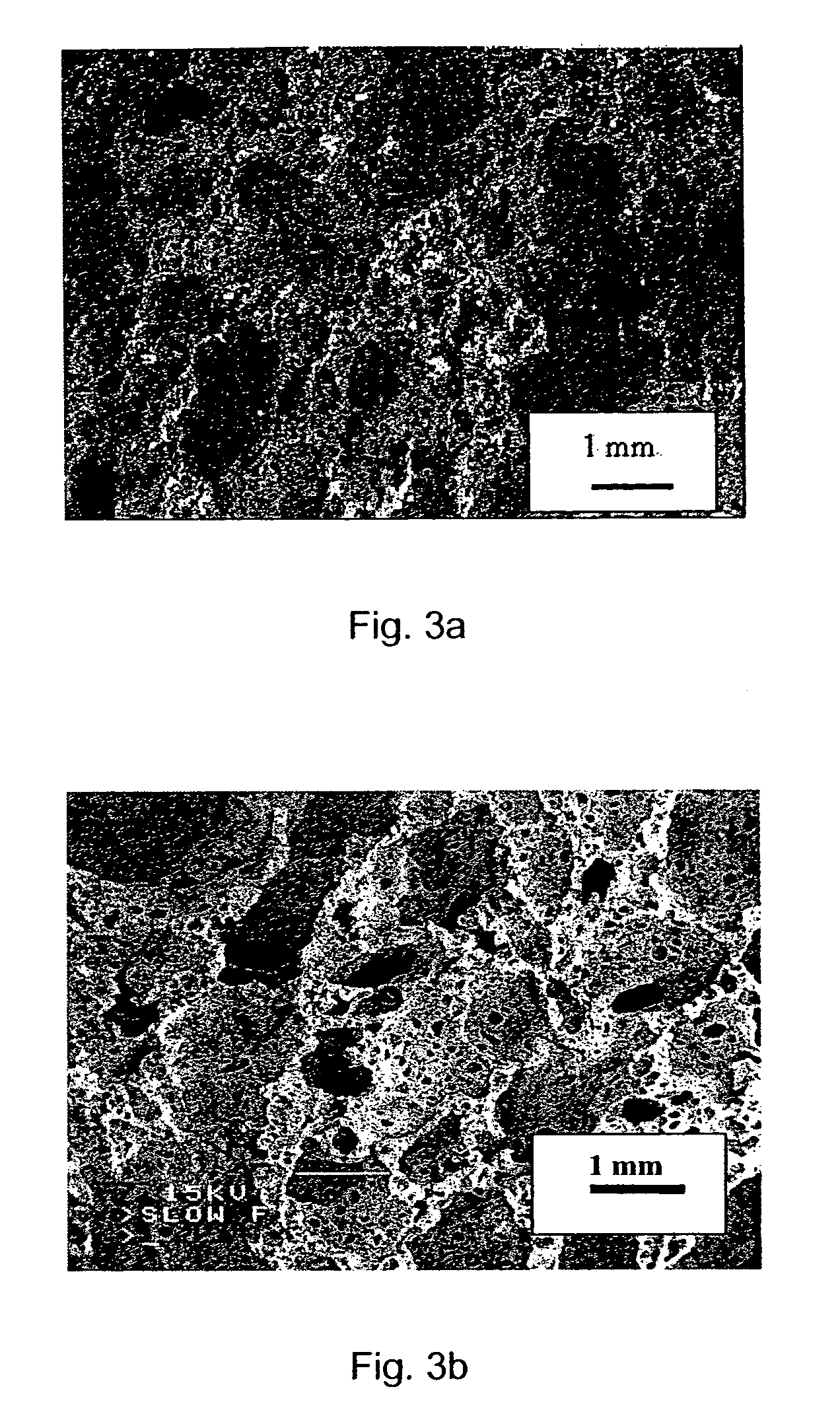

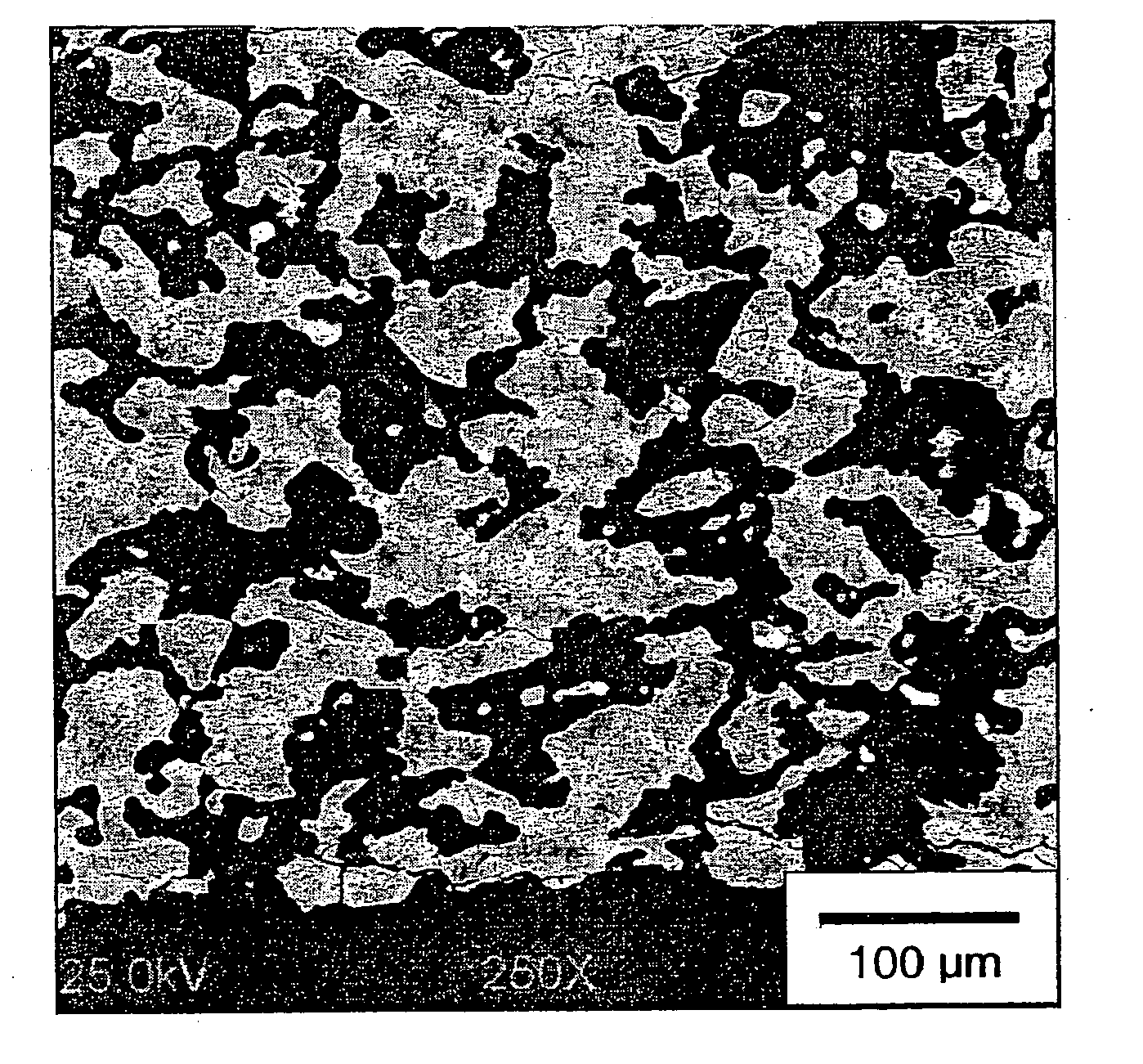

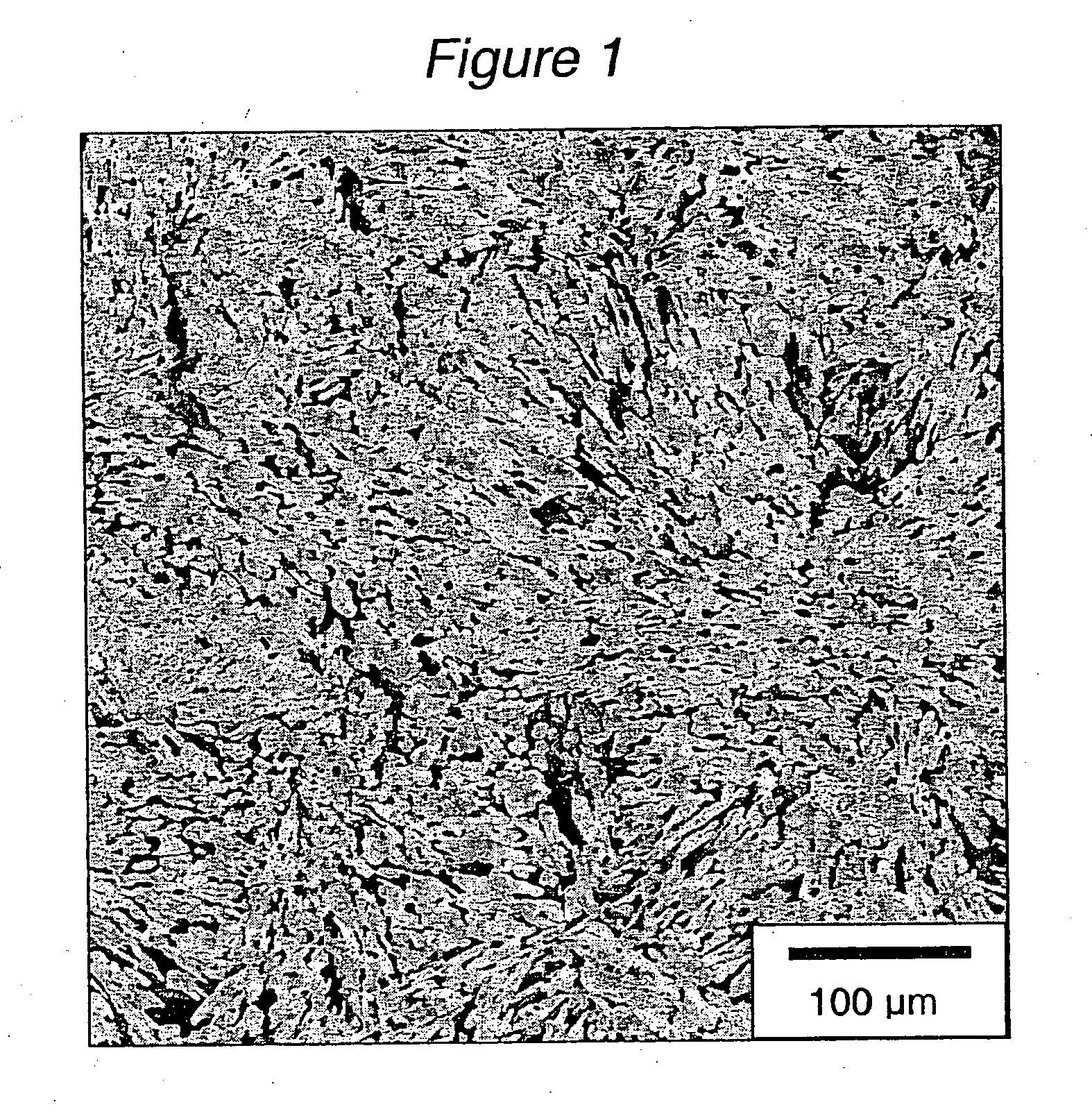

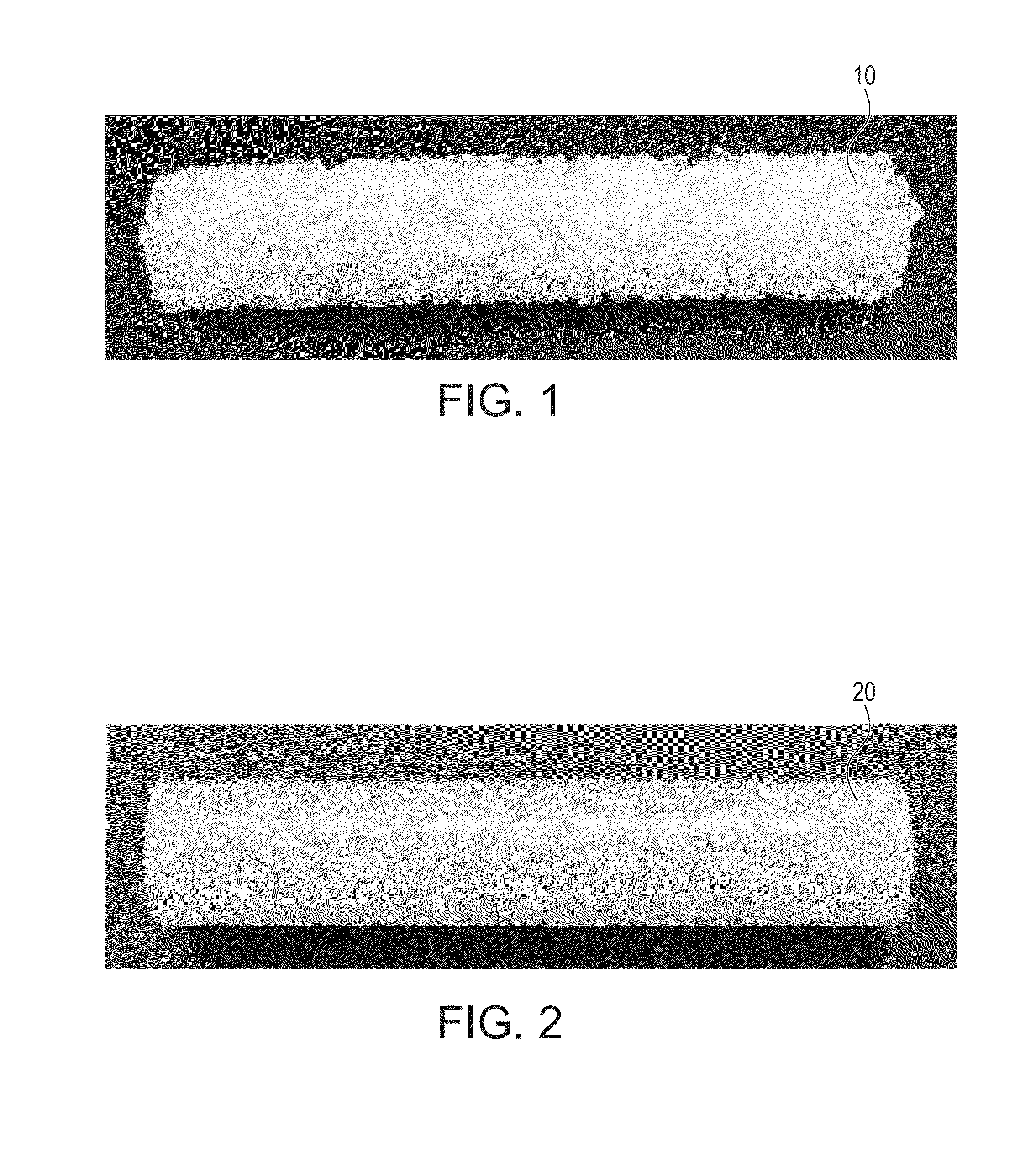

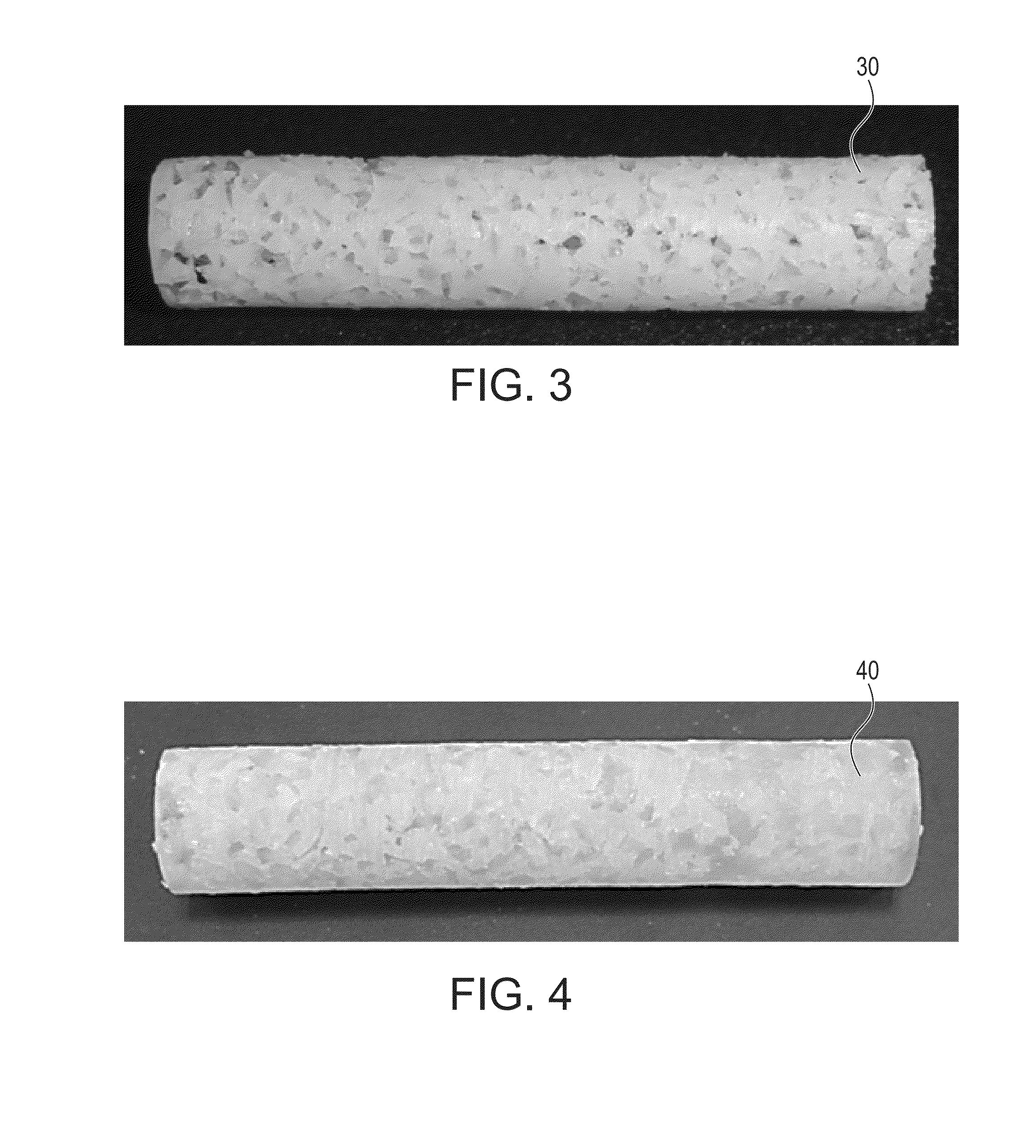

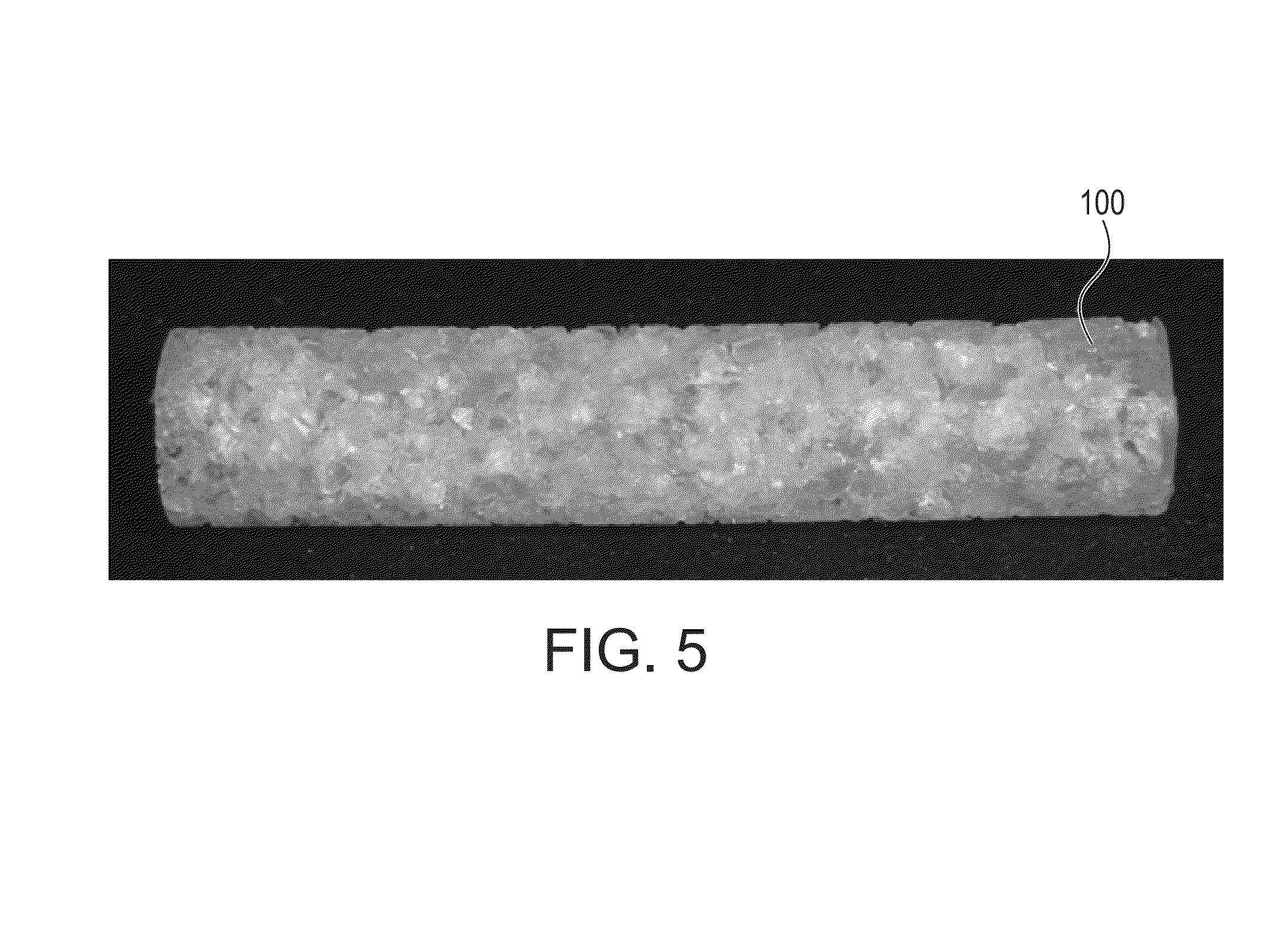

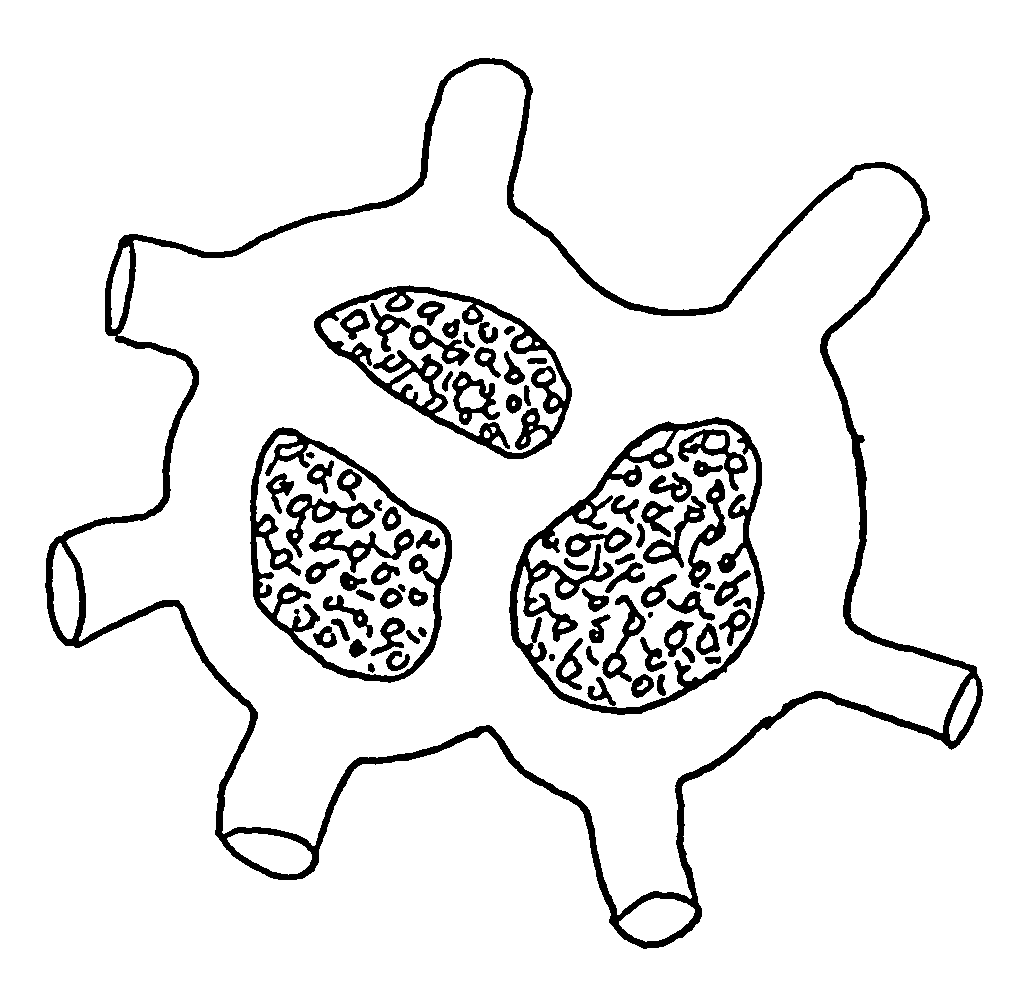

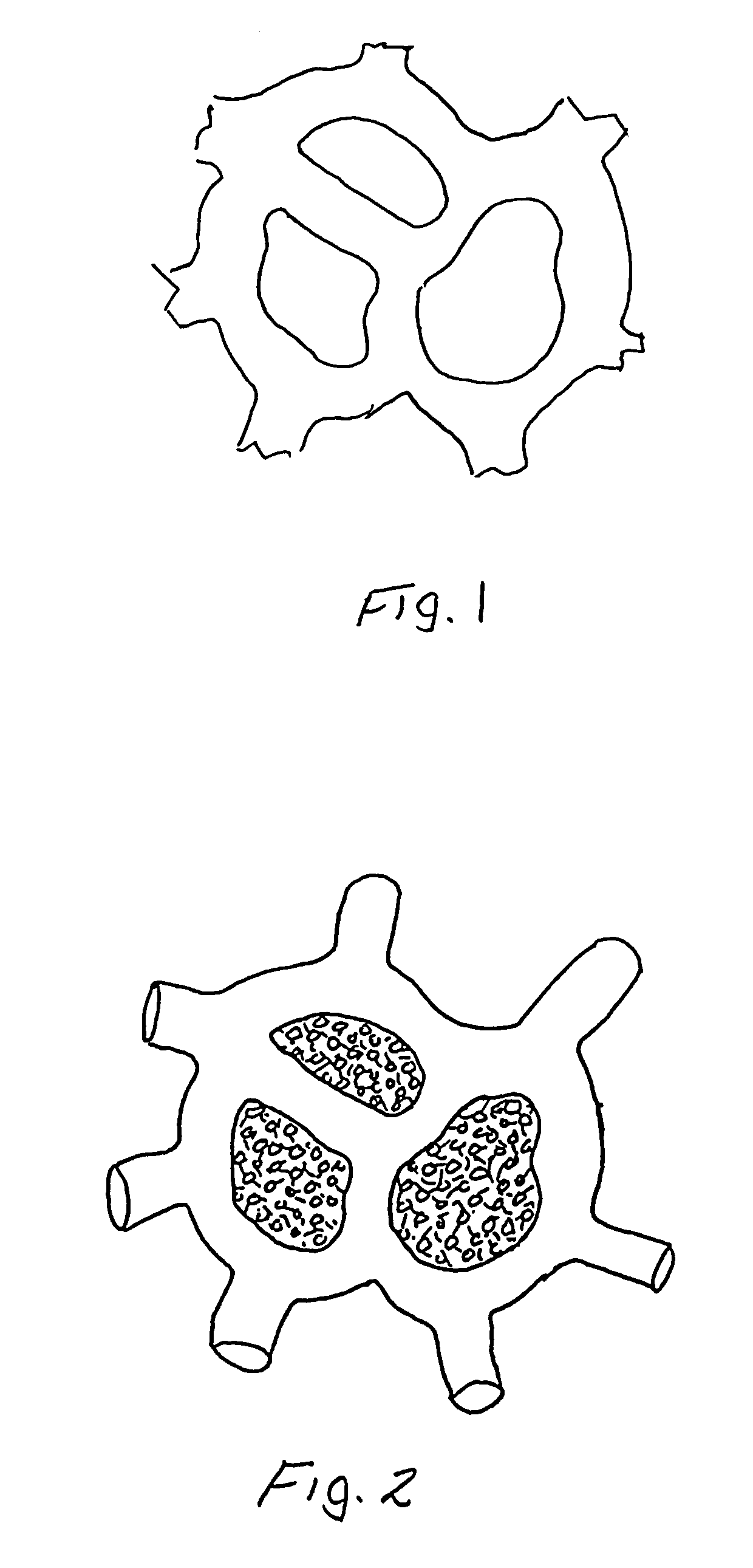

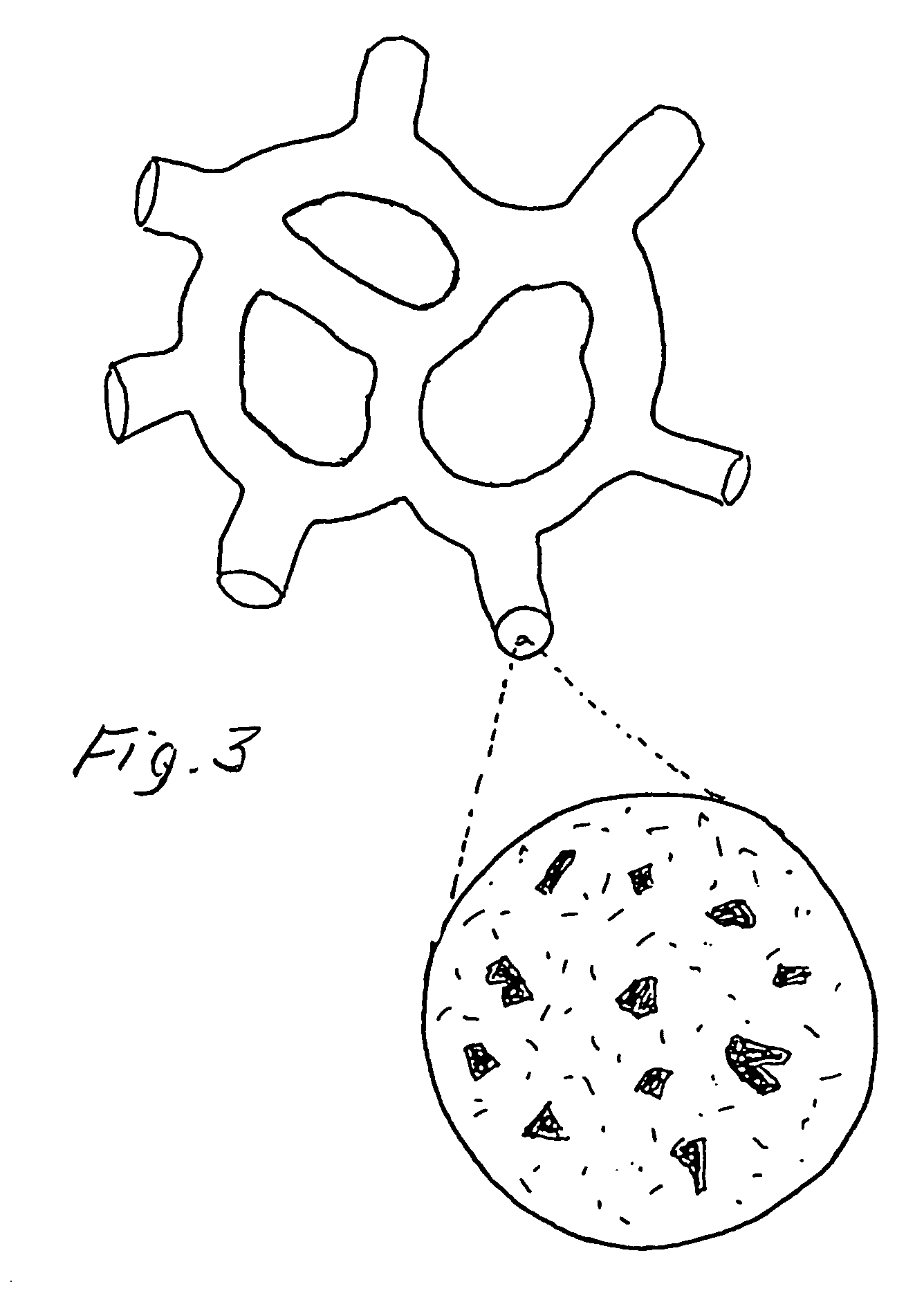

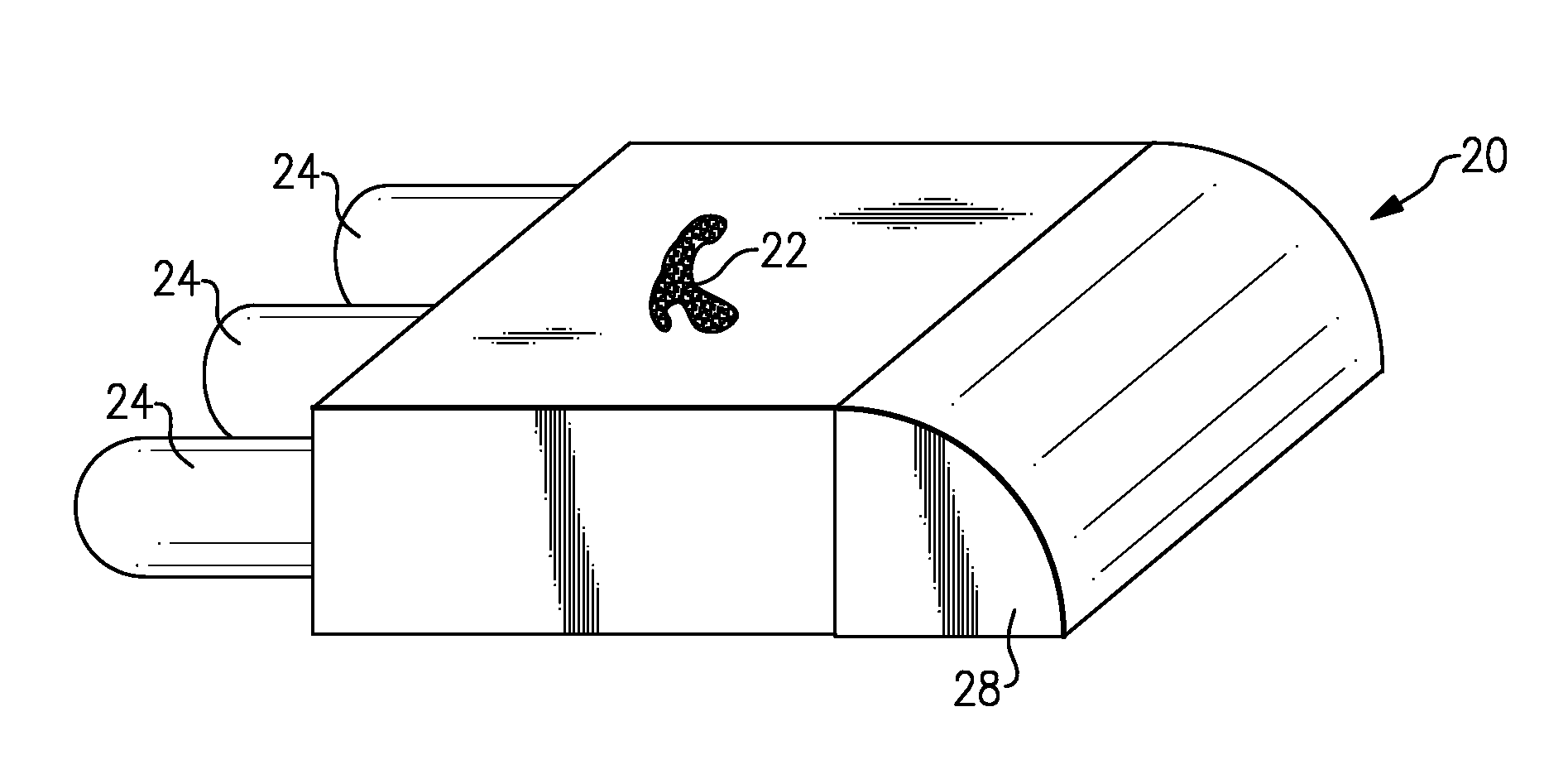

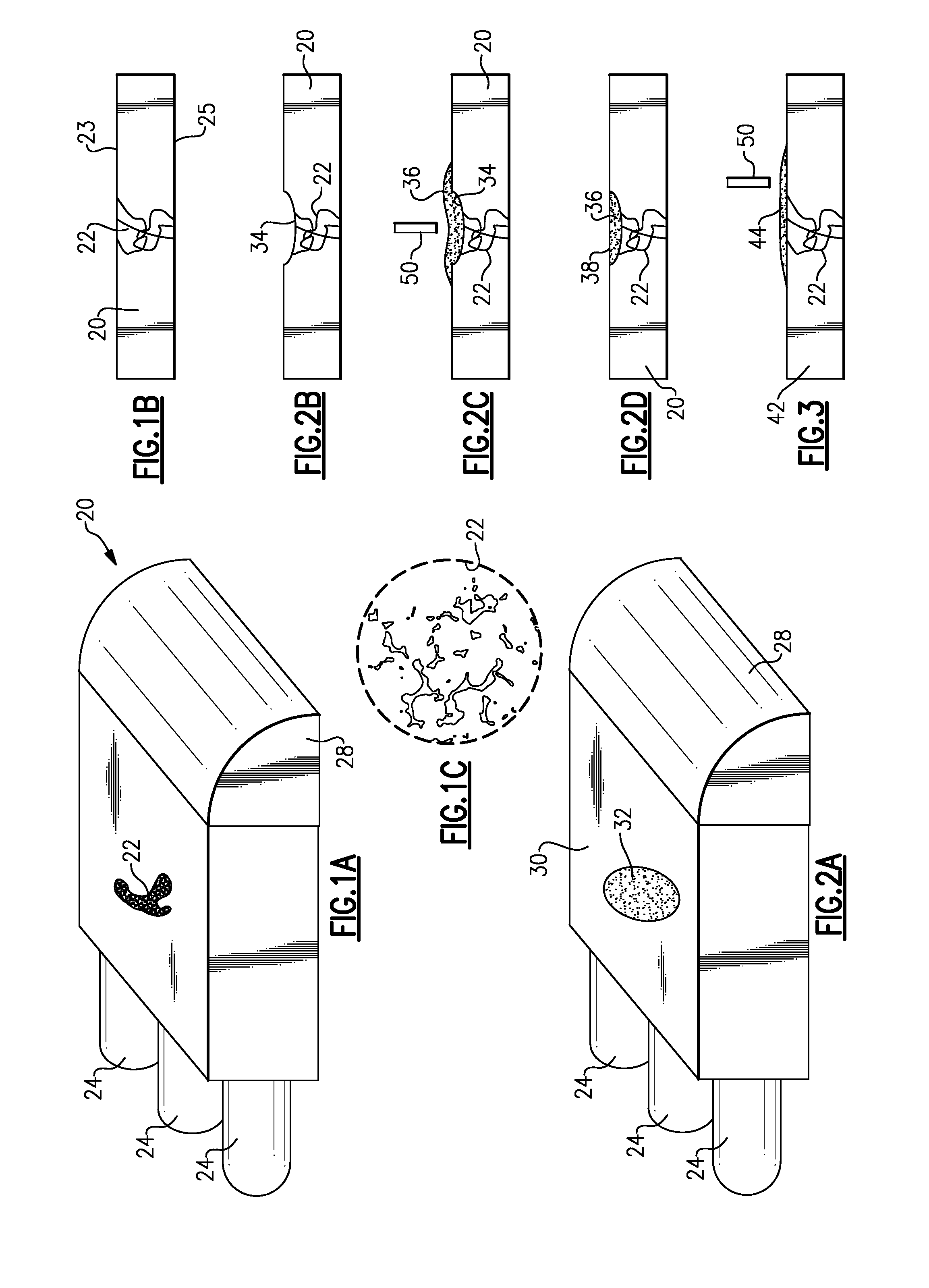

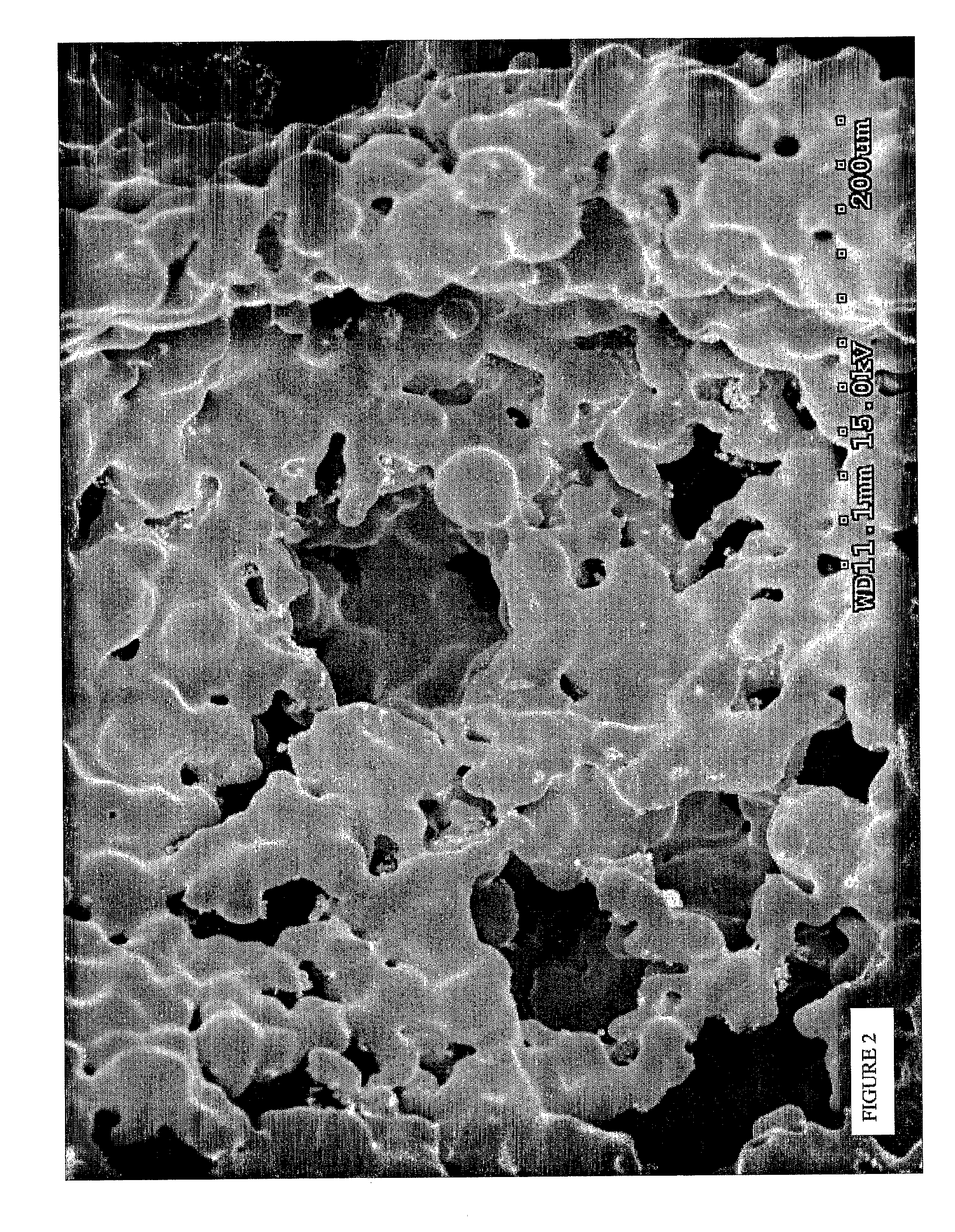

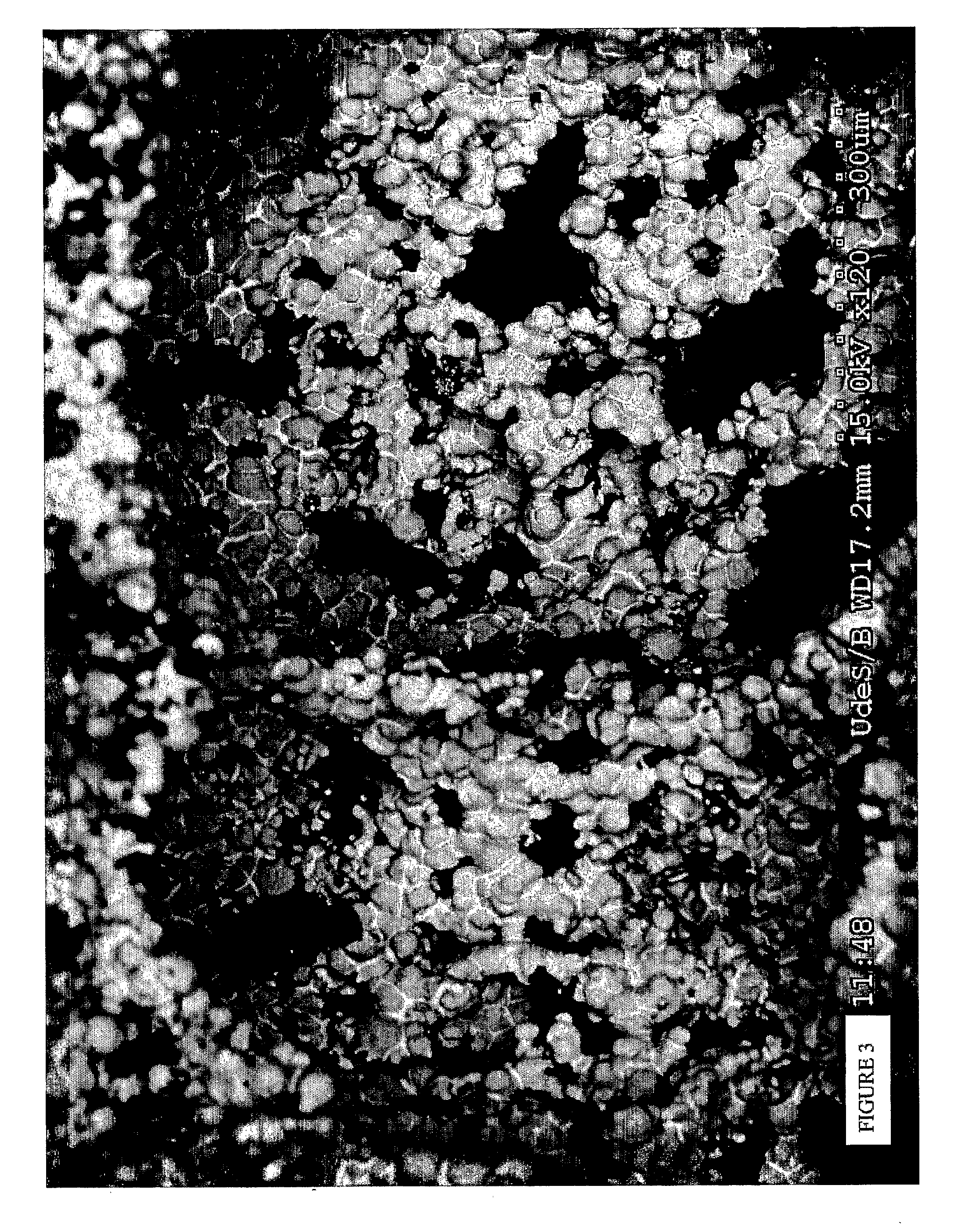

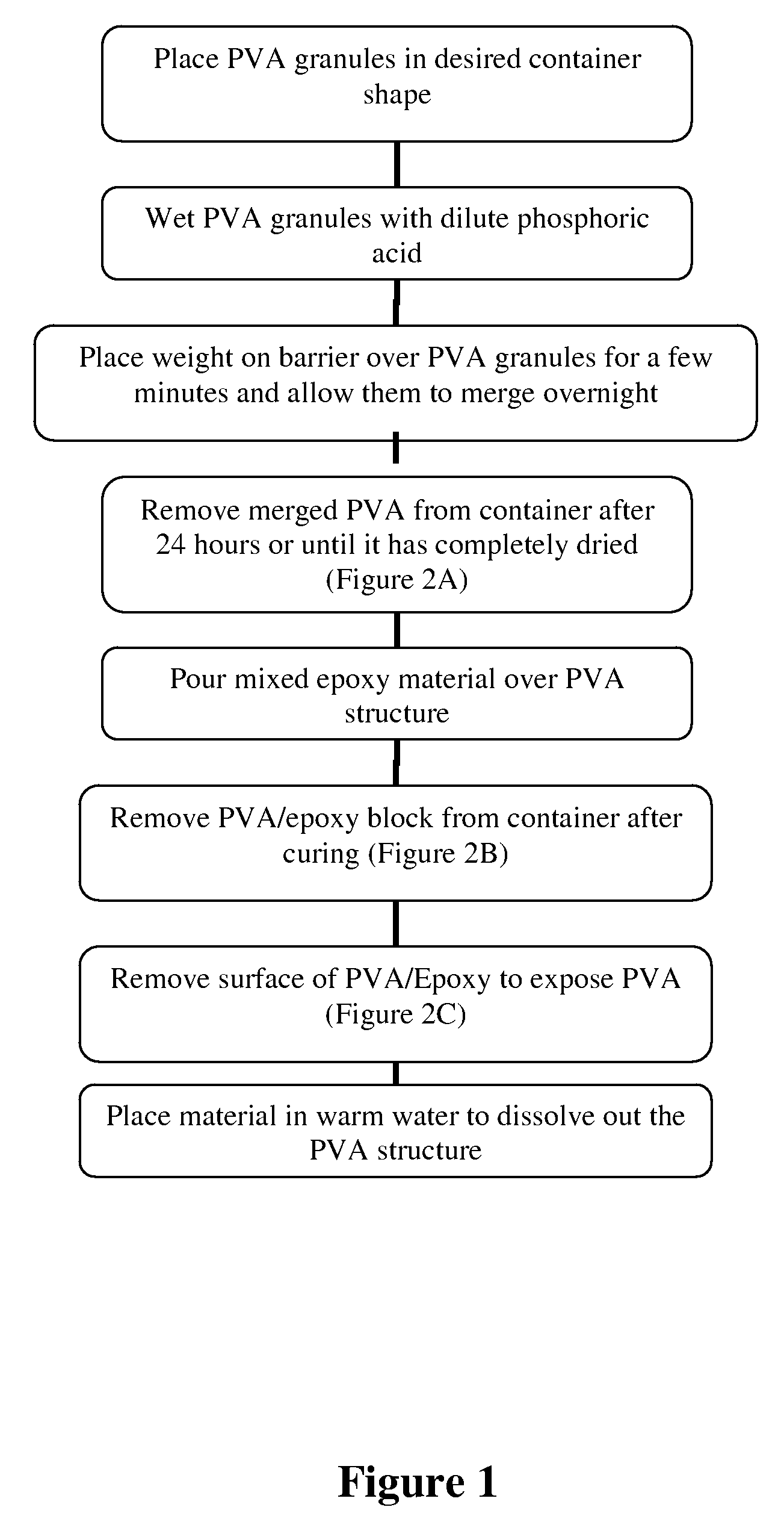

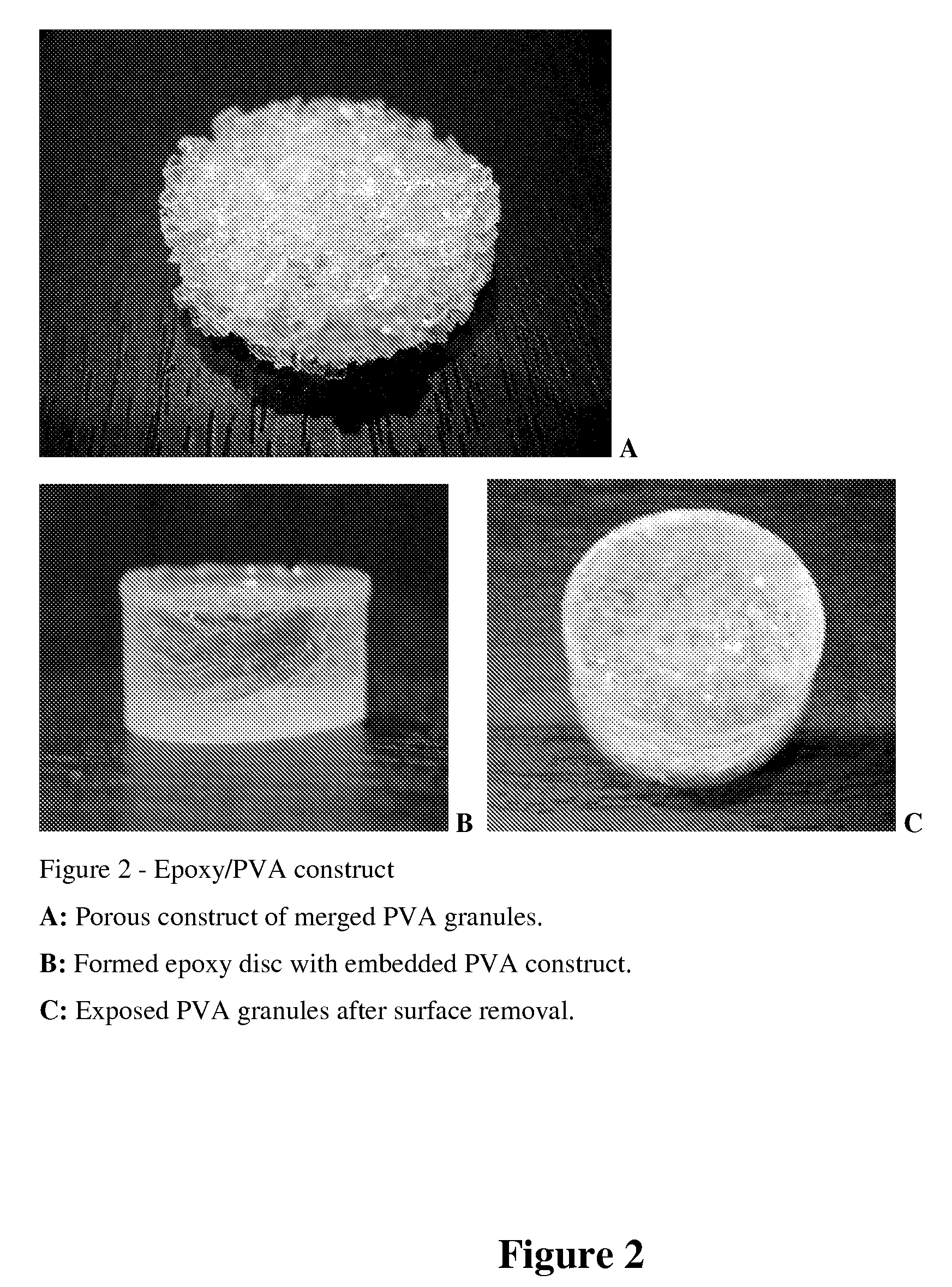

Modified porous materials and methods of creating interconnected porosity in materials

ActiveUS20140243439A1Solve Porosity InsufficiencyHigh mechanical strengthSurgeryAbsorbent padsSuture anchorsInterference screws

Techniques, mixtures and improved porous materials (interconnected porous constructs) that are capable of maintaining a sufficient porosity while conferring improved mechanical and physical strength to the final construct. A sacrificial construct (for example, a sacrificial material such as polymethyl methacrylate (PMMA)) is used to obtain an inverse porosity of the construct it was molded into. The process provides a less porous end material that may be used as an arthroplasty device or surgical implant (for example, an interference screw of suture anchor) among many other applications. The process employs a sacrificial material to reduce the porosity of the final construct to about 35%.

Owner:ARTHREX

Narrow pore size distribution aluminum titanate body and method for making same

InactiveUS20070214759A1Internal combustion piston enginesDispersed particle filtrationLanthanideThermal expansion

This invention relates to an aluminum titanate body having a narrow pore size distribution as characterized by the relation (d50−d10) / d50 being less than 0.50 corresponding to a high degree of interconnected porosity. The body also preferably exhibits a low coefficient of thermal expansion of less than 15×10−7 C−1, high porosity of at least 38% by volume, and at least 0.10% by weight metal oxide, the metal being either yttrium, calcium, bismuth, a lanthanide metal or combinations of thereof. MOR is preferably at least 450 psi. Median pore diameter is preferably at least 8 microns. The inventive ceramic body is particularly useful as a wall-flow filter for a diesel exhaust. A method of fabrication is provided where the sintering temperature is preferably between 1375°-1550° C.

Owner:MERKEL GREGORY A

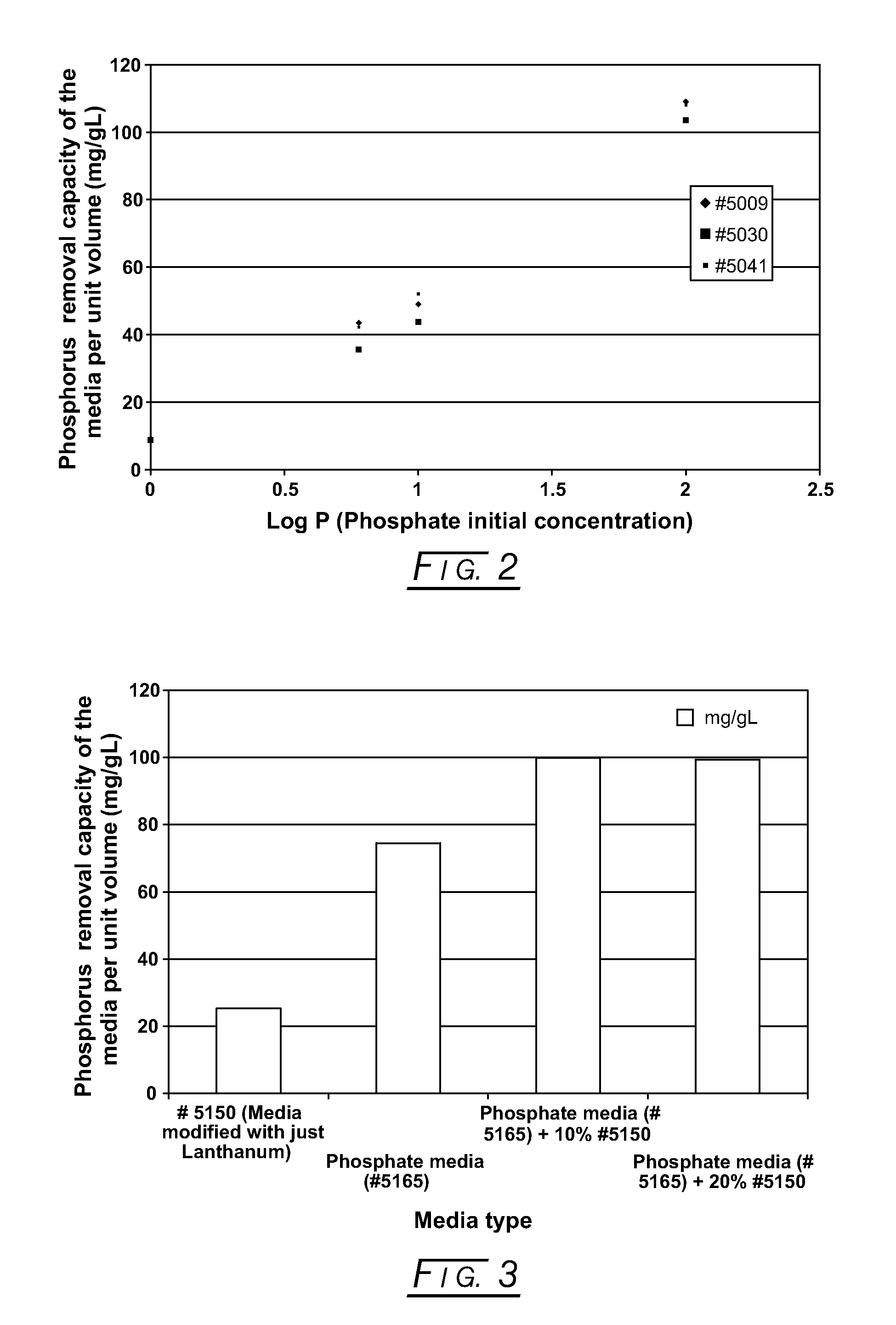

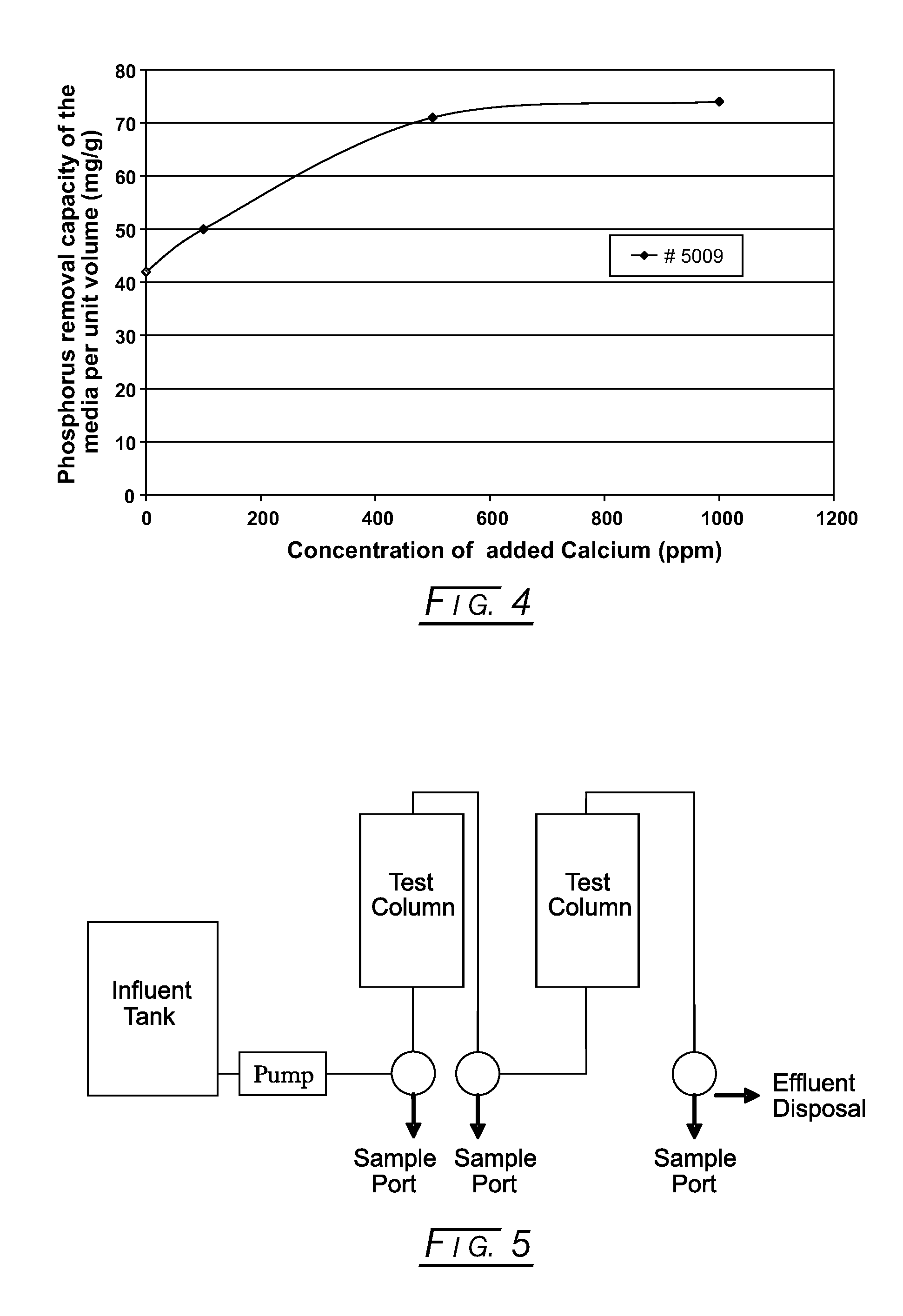

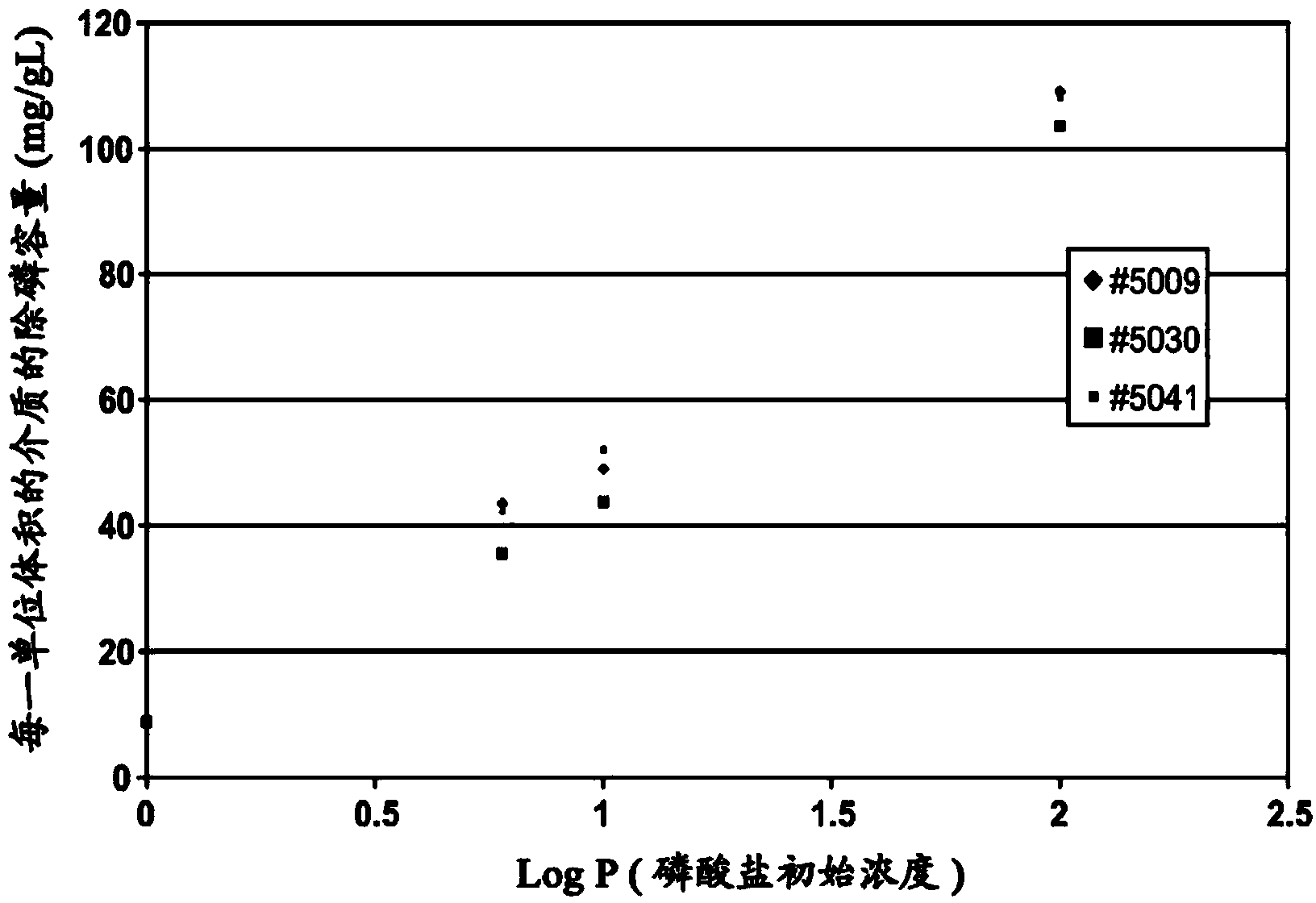

Porous Composite Media for Removing Phosphorus from Water

InactiveUS20130098840A1Strong phosphorus adsorption capacityReduce capacityMaterial nanotechnologyAluminium silicatesFiltrationPorous ceramics

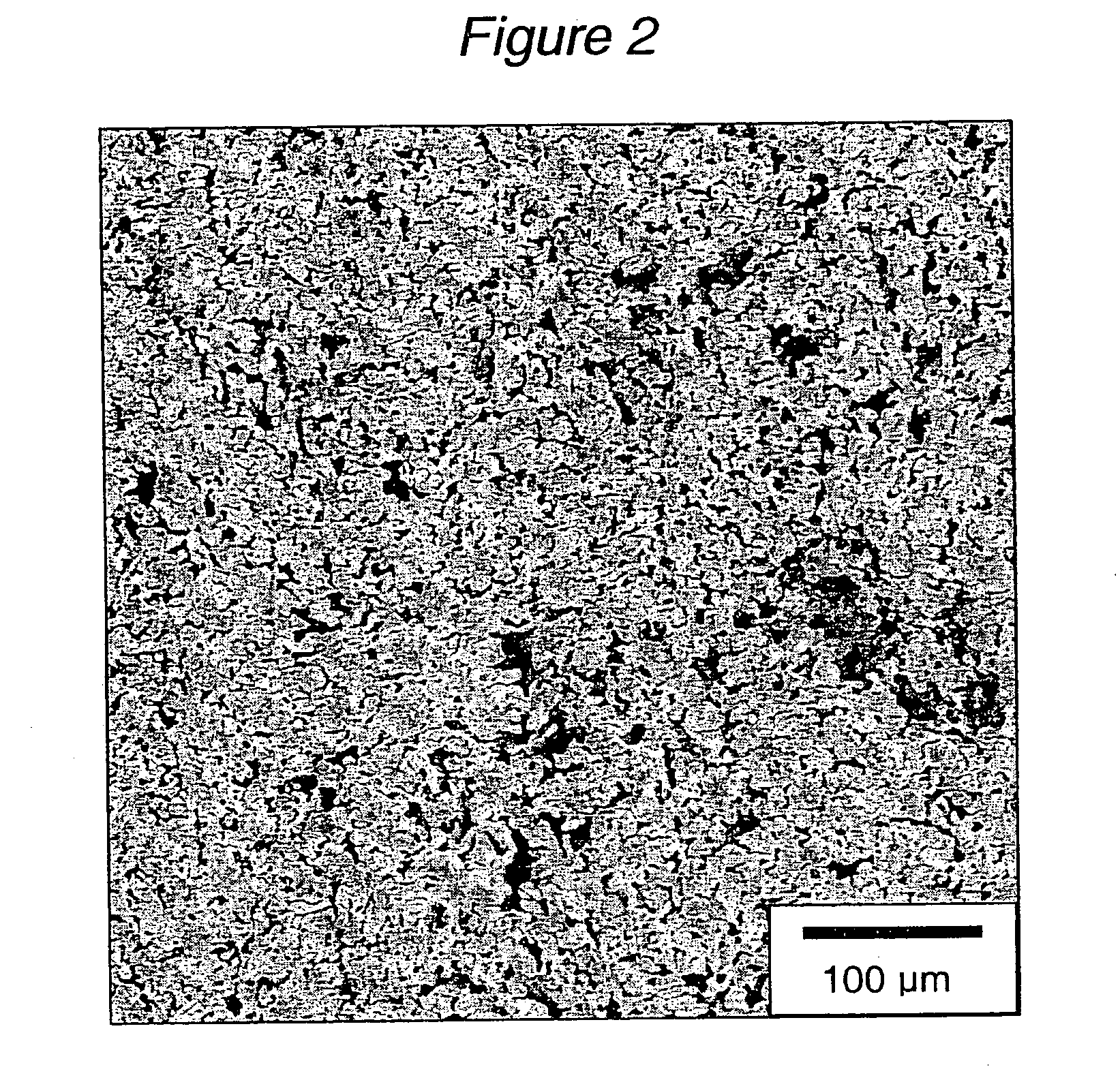

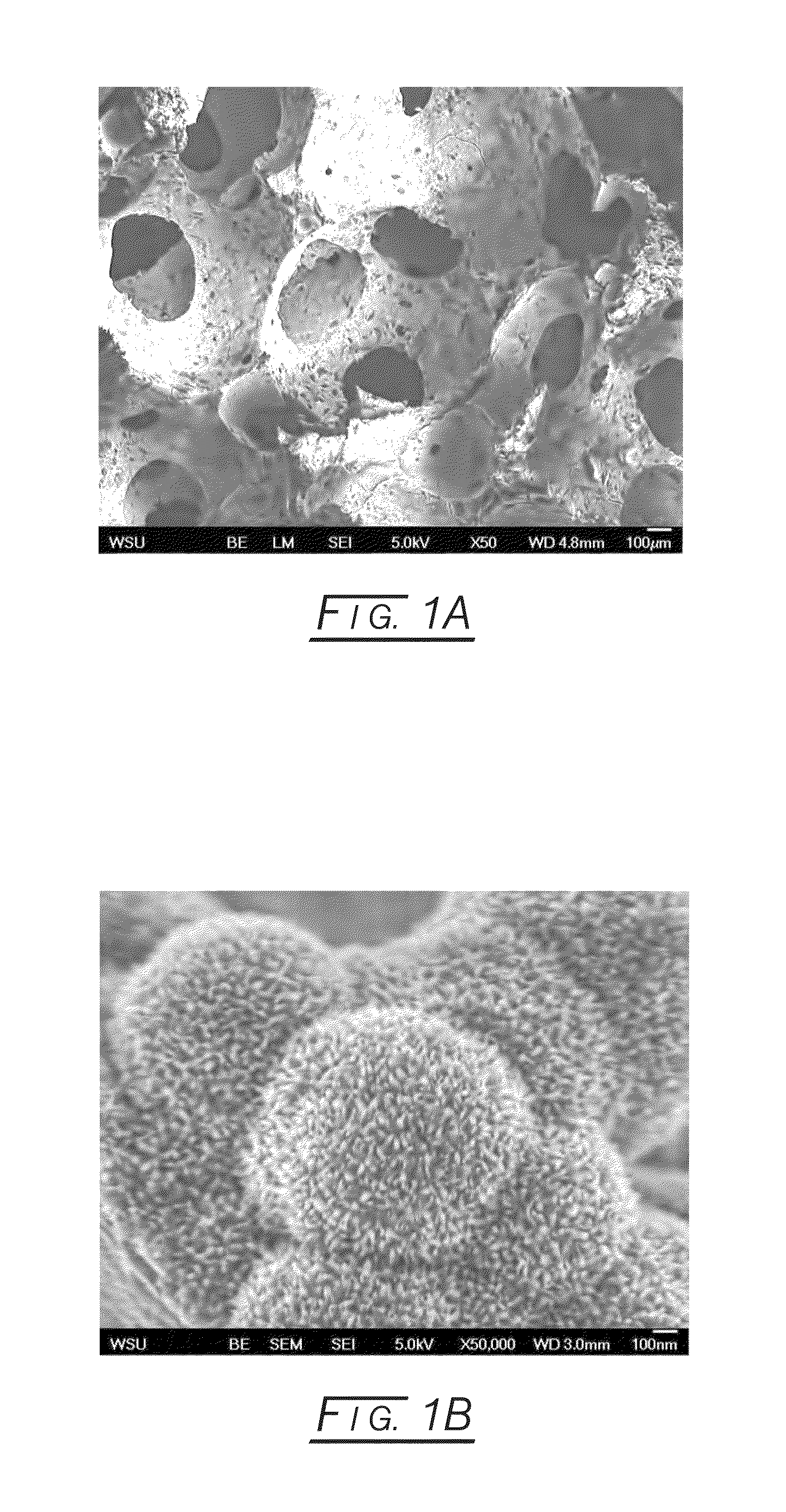

Disclosed are nano-engineered porous ceramic composite filtration media for removal of phosphorous contaminates from wastewater and other water or liquid sources. Such porous ceramic media has high surface area and an interconnecting hierarchical pore structure containing nano-iron oxide / oxyhydroxide compounds, as well as other nano materials, surfactants, ligands or other compounds appropriate for removing higher amounts of phosphorous or phosphorous compounds. The composite media can be modified with nano-phased materials grown on the high surface area and addition of other compounds, contains hierarchical, interconnected porosity ranging from nanometer to millimeter in size that provides high permeability substrate especially suited for removal of contaminants at the interface of the water or other fluids and the nanomaterial or surfactants residing on the surfaces of the porous structure.

Owner:METAMATERIA TECH

Porous abrasive articles with agglomerated abrasives and method for making the agglomerated abrasives

InactiveUS20060160476A1Revolution surface grinding machinesOther chemical processesInterconnected porosityThree dimensional shape

Owner:SAINT GOBAIN ABRASIVES TECH CO

Porous abrasive articles with agglomerated abrasives and method for making the agglomerated abrasives

InactiveUS7077723B2Pigmenting treatmentRevolution surface grinding machinesThree dimensional shapeVolumetric Mass Density

A bonded abrasive tool, having a structure permeable to fluid flow, comprises sintered agglomerates of a plurality of abrasive grains and a binding material, the binding material being characterized by a melting temperature between 500 and 1400° C., and the sintered agglomerates having a loose packing density of ≦1.6 g / cc and three-dimensional shape; a bond material; and about 35–80 volume % total porosity, including at least 30 volume % interconnected porosity. Methods for making the sintered agglomerates and abrasive tools containing the sintered agglomerates are described.

Owner:SAINT GOBAIN ABRASIVES TECH CO

Modified porous materials and methods of creating interconnected porosity in materials

ActiveUS9345817B2Solve Porosity InsufficiencyHigh physical and mechanical strengthSurgeryProsthesisSuture anchorsInterference screws

Owner:ARTHREX

Process for producing rigid reticulated articles

A process for producing a rigid reticulated article involves coating a reticulated substrate which has open, interconnected porosity with a first dispersion comprising a ceramic or metal powder to form a first coating thereon; drying the coated reticulated substrate; contacting the coated reticulated substrate with one or more additional dispersions in succession to form one or more additional coatings thereon; drying the additional coatings between the steps of contacting; heating the coated reticulated substrate to pyrolyze organic components; and sintering the coated reticulated substrate to form a reticulated article, wherein each dispersion has a viscosity less than that of all preceding dispersions. A rigid reticulated article includes inner, intermediate and outer sintered layers of material in which the inner and outer layers are of different composition and the intermediate layer is a composite of the inner and outer layers.

Owner:WRIGHT MEDICAL TECH

Low-microcracked, porous ceramic honeycombs and methods of manufacturing same

ActiveUS7618699B2Improve efficiencyHigh strengthLayered productsCeramic shaping apparatusThermal expansionInterconnected porosity

Owner:CORNING INC

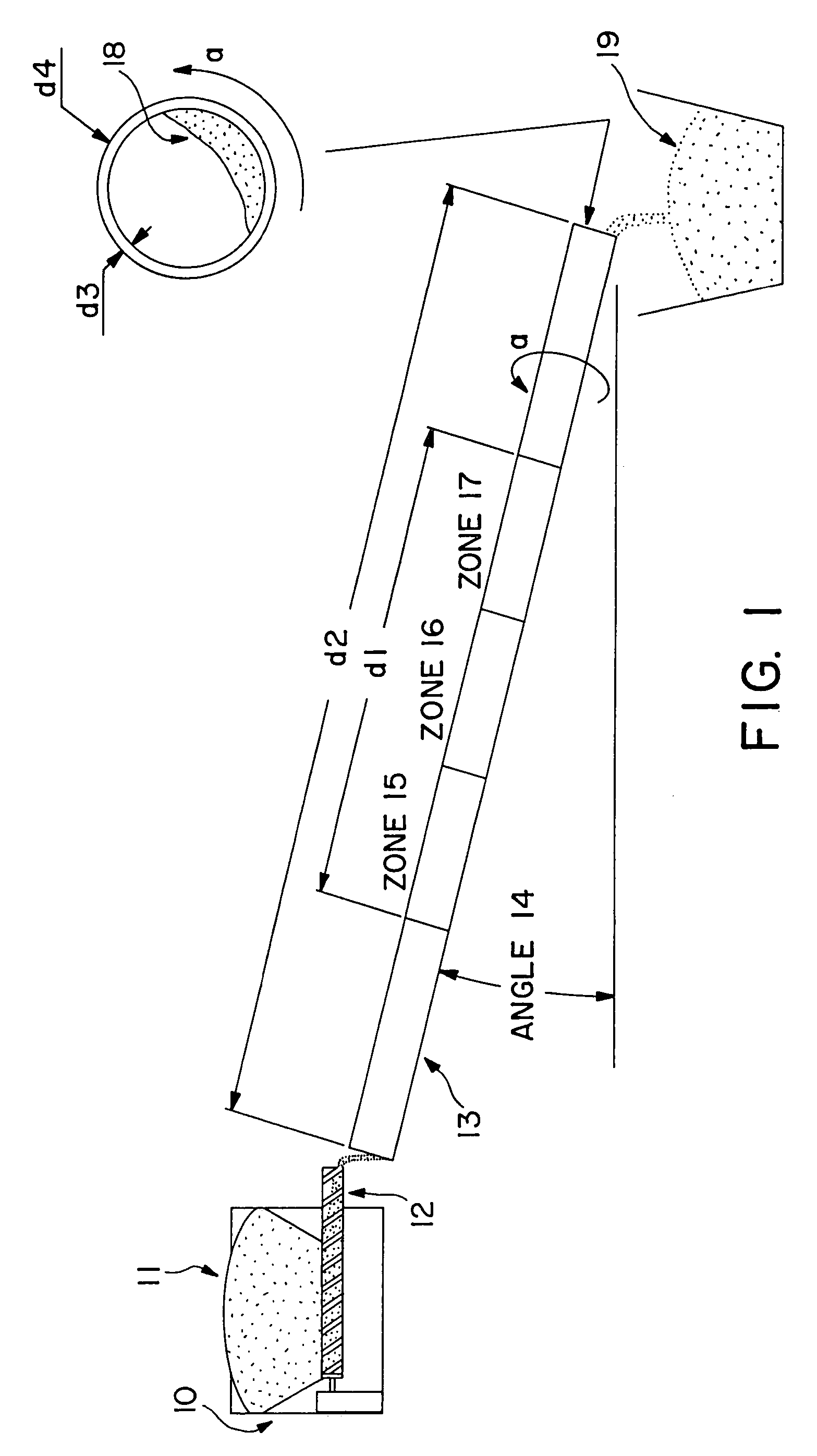

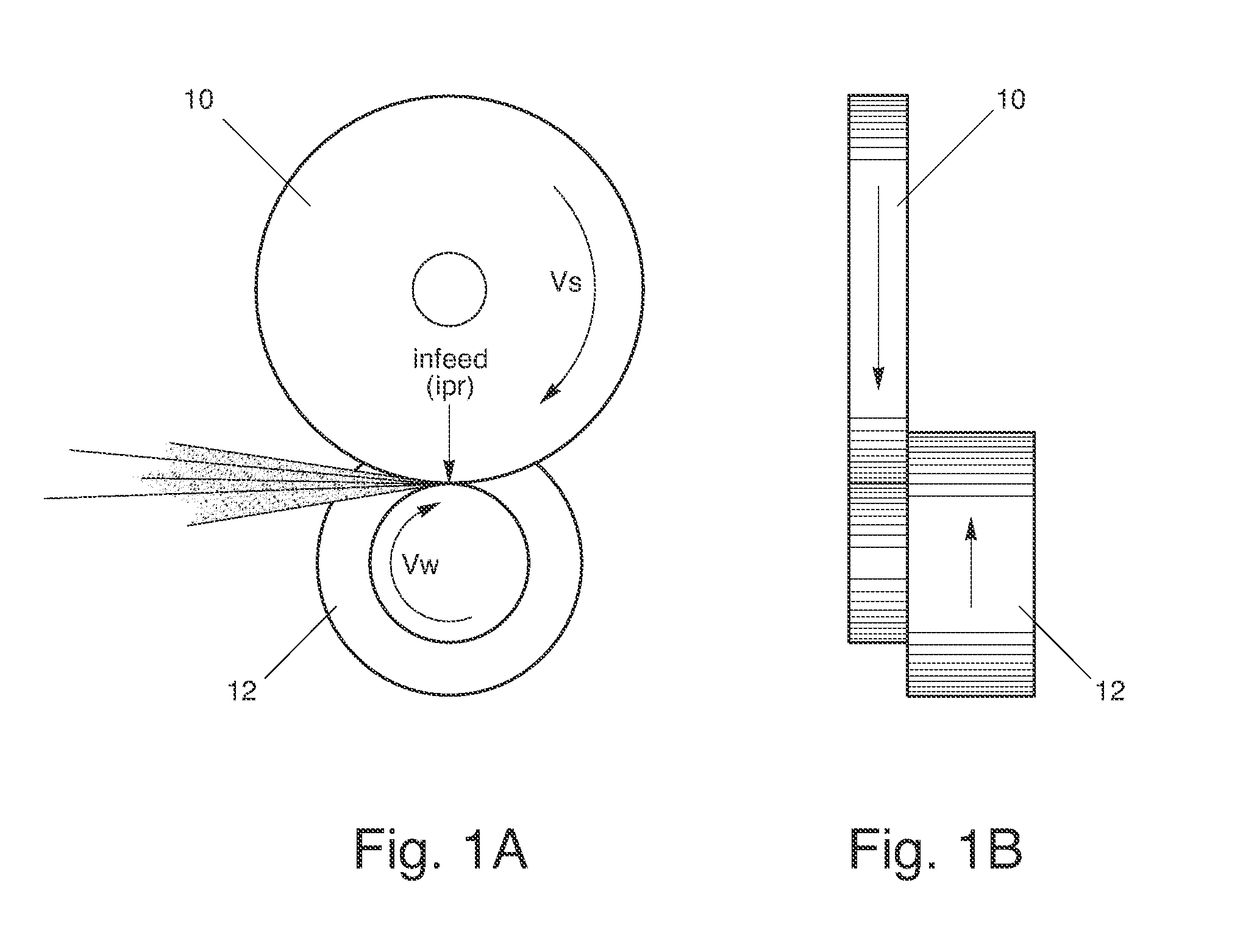

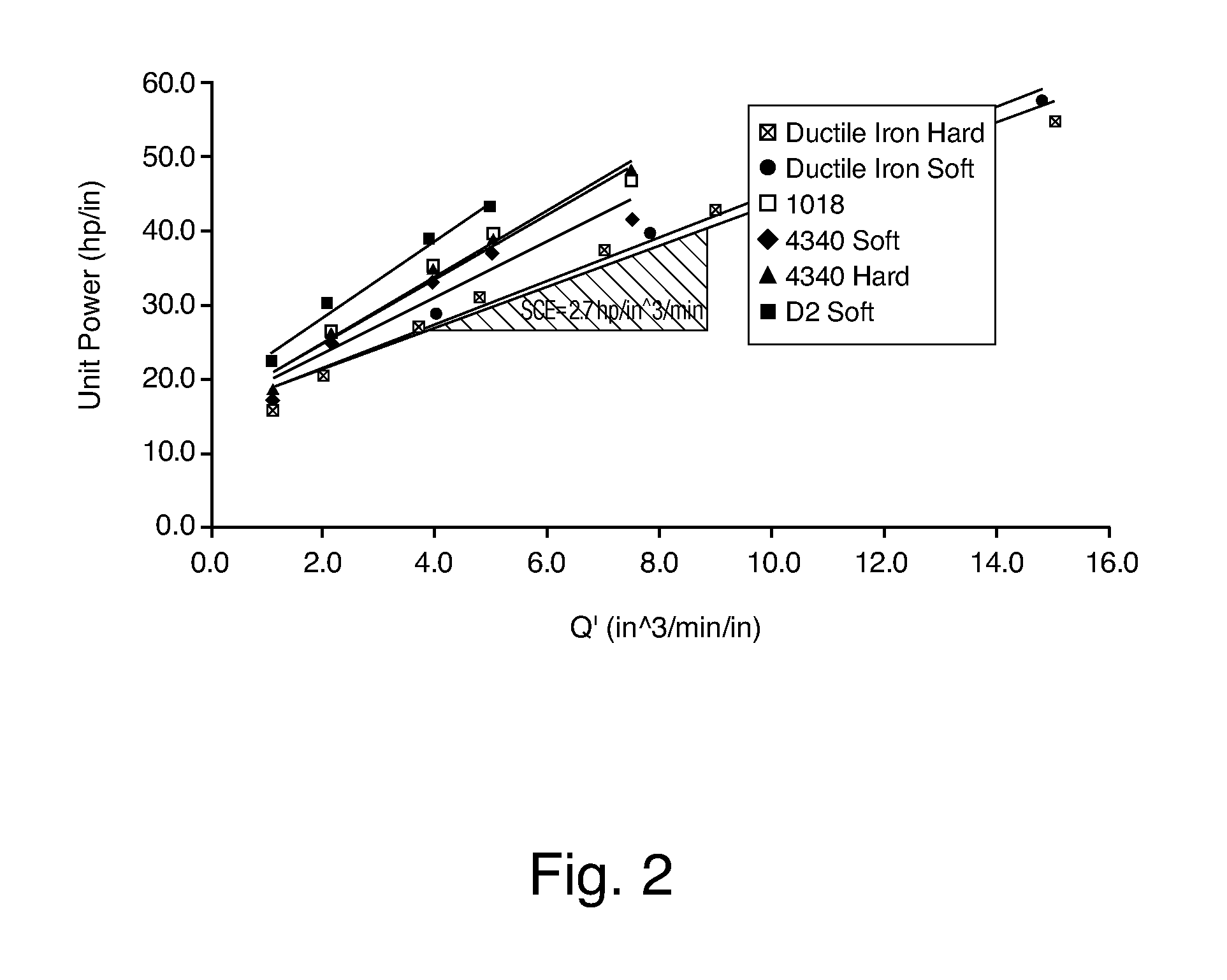

Techniques for cylindrical grinding

ActiveUS20090093198A1High surface finishShort processing timeRevolution surface grinding machinesAbrasion apparatusMaterial removalMetallurgy

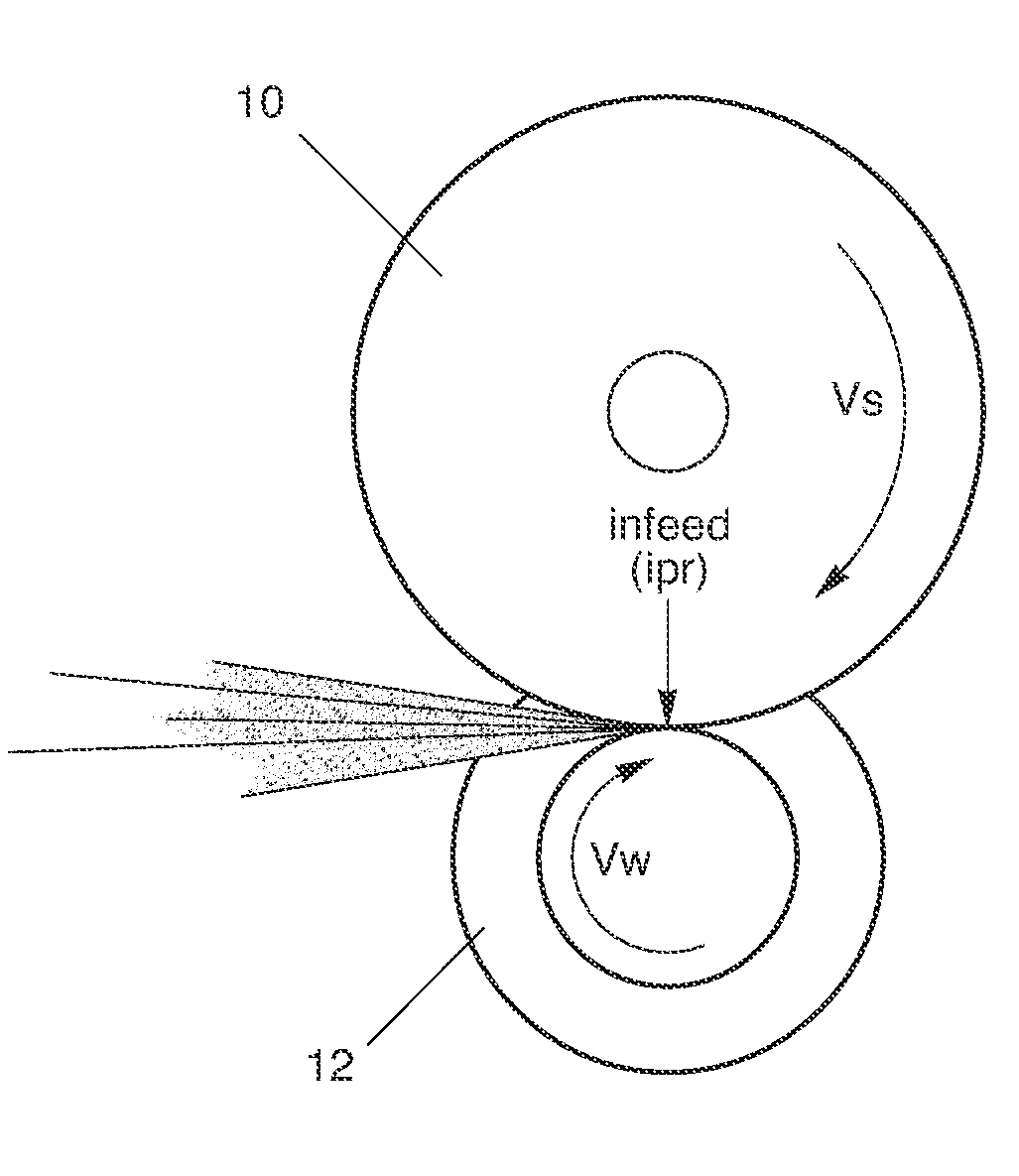

Methods for cylindrical grinding a workpiece are disclosed. The method includes cylindrical grinding, with a bonded abrasive wheel having a permeable structure that includes interconnected porosity, a workpiece at a specific cutting energy of less than about 12 Hp / in3·min (29.7 J / mm3), and a material removal rate of at least about 1 in3 / min·in (10.8 mm3 / sec / mm)grinding. The bonded abrasive wheel may include at least about 3 volume percent of a filamentary sol-gel alpha-alumina abrasive grain having an average length-to-cross-sectional-width ratio of greater than about 4:1, or agglomerates thereof. In one embodiment, the workpiece is ground in the presence of a water soluble oil.

Owner:SAINT GOBAIN ABRASIVES INC +1

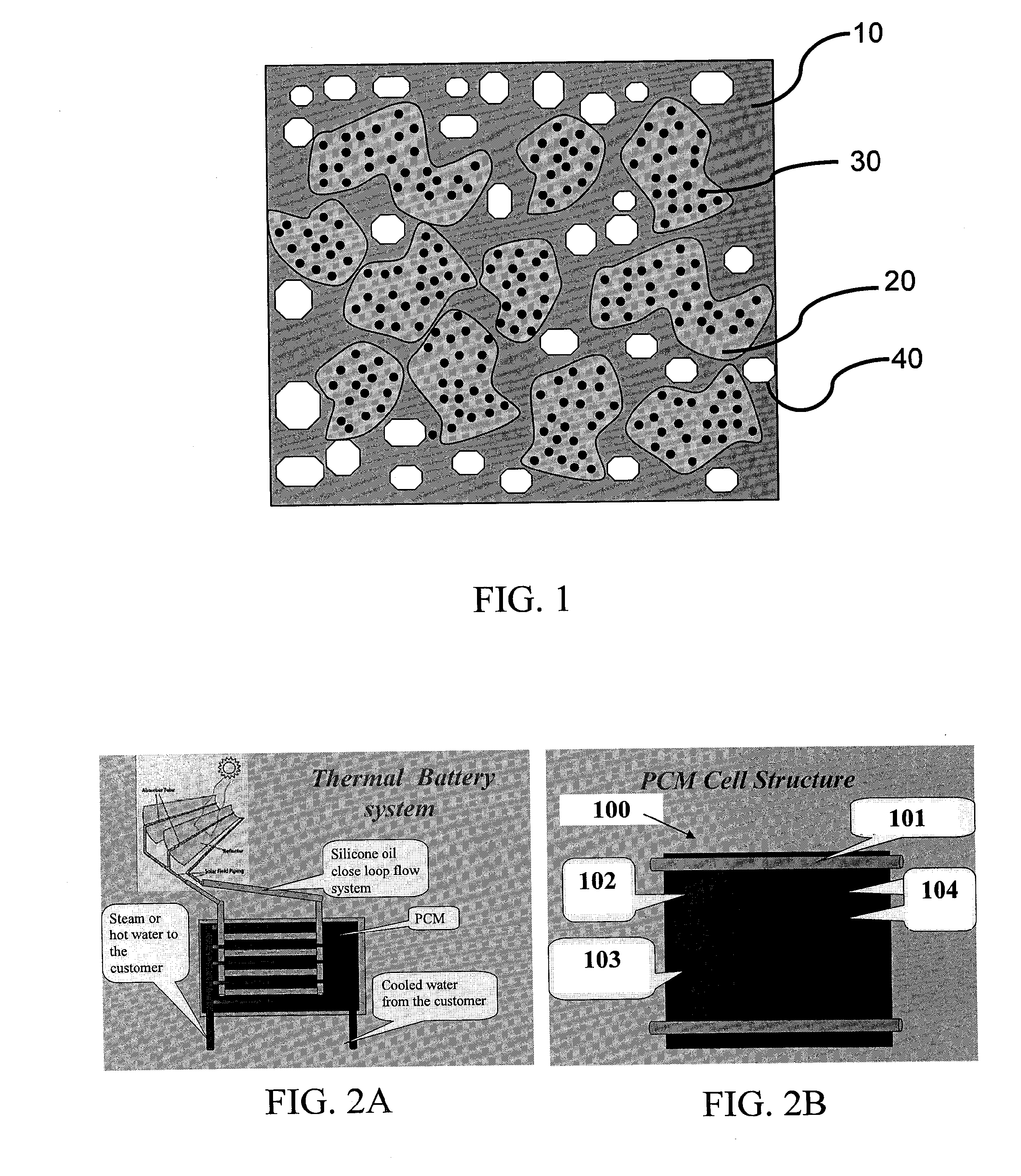

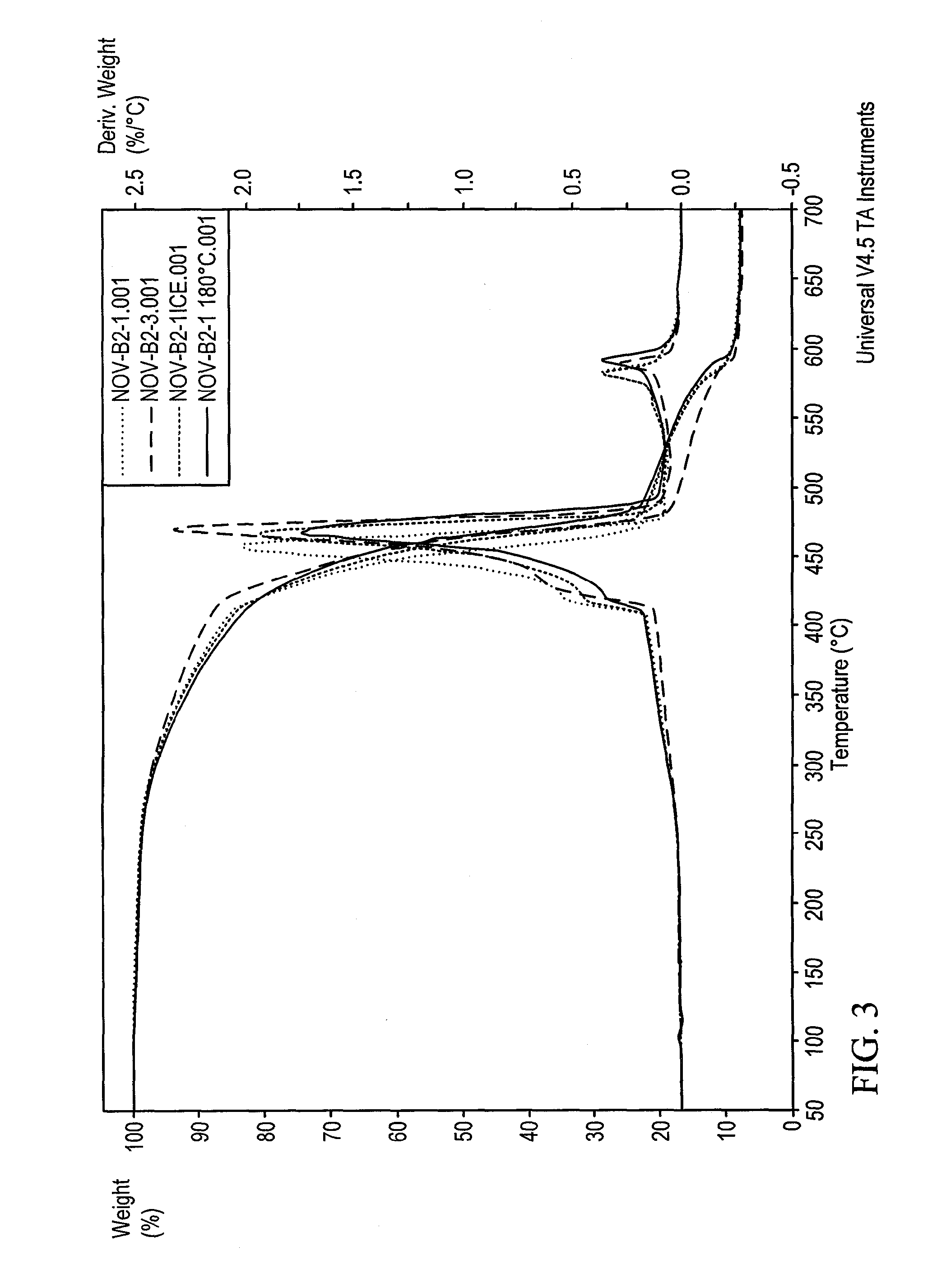

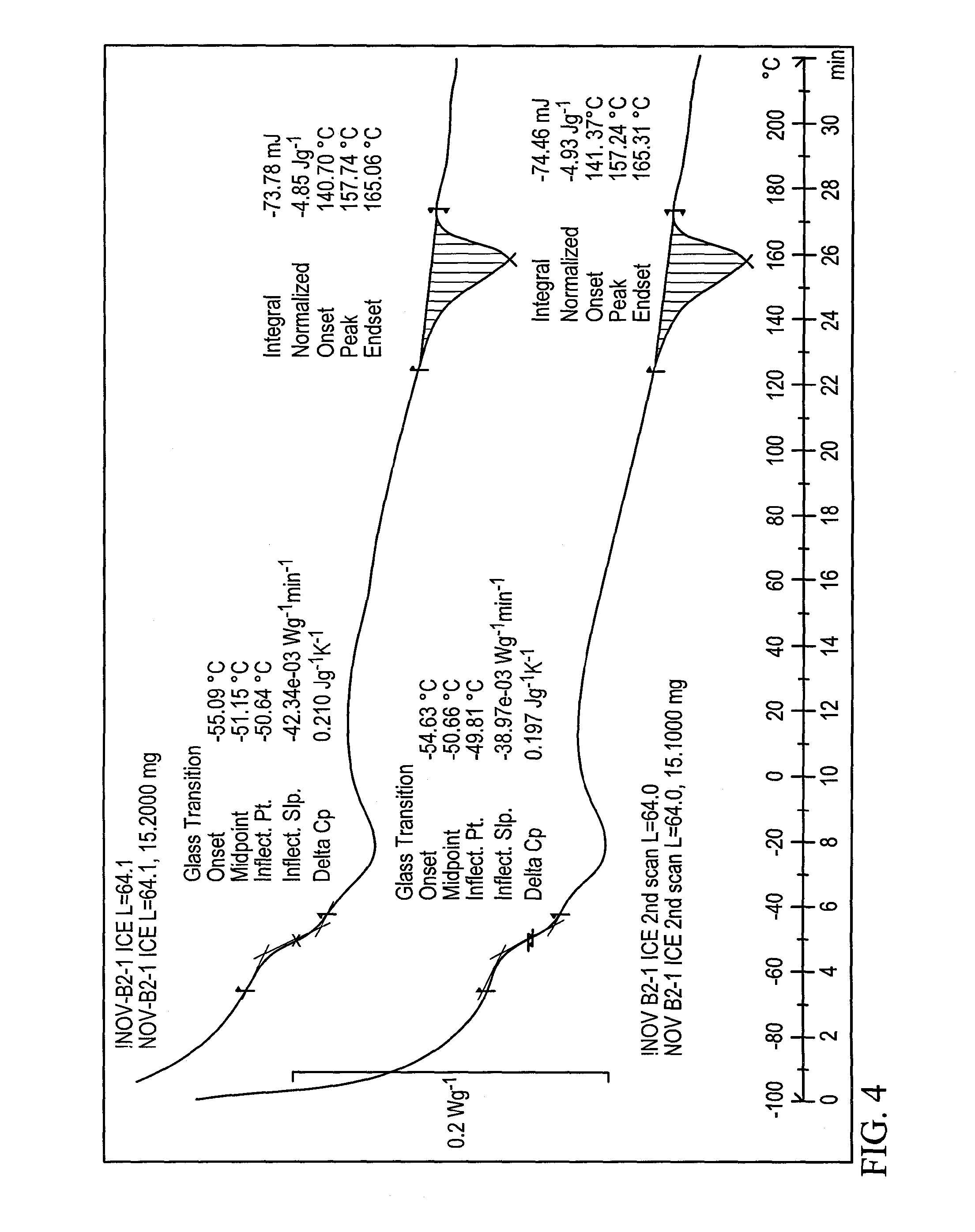

Elastomer and/or composite based material for thermal energy storage

A composite material for storing thermal energy at various temperatures (30° C. to 450° C.) formed by an elastomer matrix into which a phase change material such as an inorganic salt is encapsulated. The material is characterized by a high volumetric thermal conductivity, a low density, a highly interconnected porosity and a relatively high modulus of elasticity. The significant properties of the matrices are: a large amount of energy involved in full melting / crystallization, a fairly low relative volume expansion upon melting and fairly low sub-cooling. The main advantages of the resulting composites are a very high energy density, a relatively low volume expansion, highly enhanced heat transfer, thermo adaptability, stability and insignificant hysteresis.

Owner:ENRAD

Cold deposition repair of casting porosity

InactiveUS20090249603A1Turbine/propulsion fuel flow conduitsExhaust apparatusInterconnected porosityDeposition process

A method of repairing a component having interconnected porosity applies a material to the area of the porosity through a cold deposition process. Components repaired by this method are also claimed.

Owner:UNITED TECH CORP

Porous composite media for removing phosphorus from water

InactiveCN104136113AIncrease capacityImprove abilitiesMaterial nanotechnologyOther chemical processesComposite mediaFiltration

Disclosed are nano-engineered porous ceramic composite filtration media for removal of phosphorous contaminates from wastewater and other water or liquid sources. Such porous ceramic media has high surface area and an interconnecting hierarchical pore structure containing nano-iron oxide / oxyhydroxide compounds, as well as other nano materials, surfactants, ligands or other compounds appropriate for removing higher amounts of phosphorous or phosphorous compounds. The composite media can be modified with nano-phased materials grown on the high surface area and addition of other compounds, contains hierarchical, interconnected porosity ranging from nanometer to millimeter in size that provides high permeability substrate especially suited for removal of contaminants at the interface of the water or other fluids and the nanomaterial or surfactants residing on the surfaces of the porous structure.

Owner:METAMATERIA TECH

Low-microcracked, porous ceramic honeycombs and methods of manufacturing same

ActiveUS7927682B2Improve efficiencyHigh strengthLaminationLamination apparatusThermal expansionInterconnected porosity

Substantially non-microcracked, porous, cordierite ceramic honeycomb bodies are provided. Although exhibiting moderately high thermal expansion (CTE) between 7×10−7 to 16×10−7 / ° C. (25-800° C.), the honeycomb bodies exhibit relatively high thermal shock parameter (TSP), such as TSR≧525° C. by virtue of a high MOR / E ratio, and / or low Eratio=ERT / E1000° C. and well interconnected porosity, as witnessed by a relatively high pore connectivity factor (PCF). A method of manufacturing the honeycomb ceramic structure is also provided.

Owner:CORNING INC

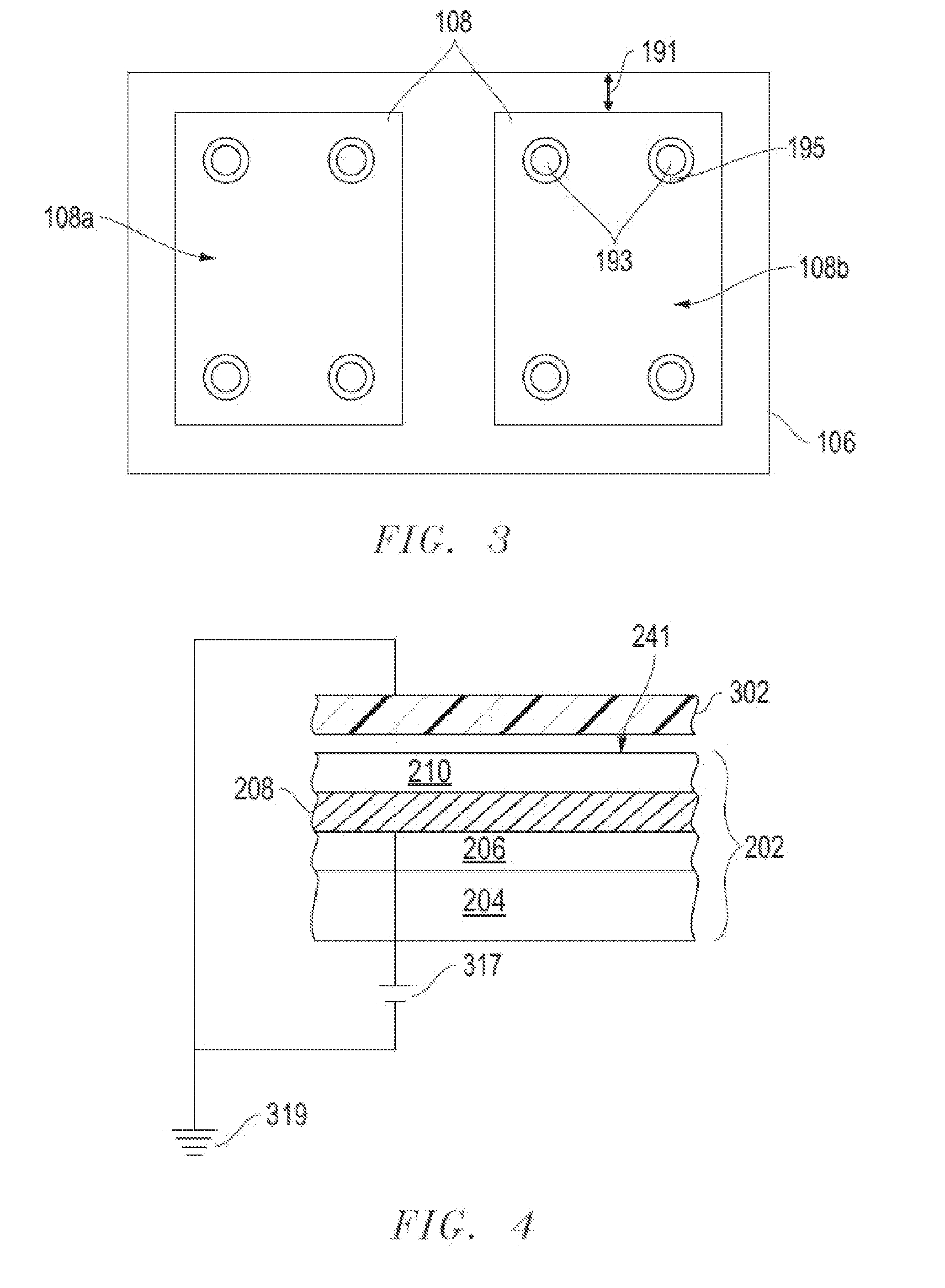

Electrostatic chuck and method of forming

InactiveUS20090161285A1Pretreated surfacesSemiconductor/solid-state device manufacturingInterconnected porosityOptoelectronics

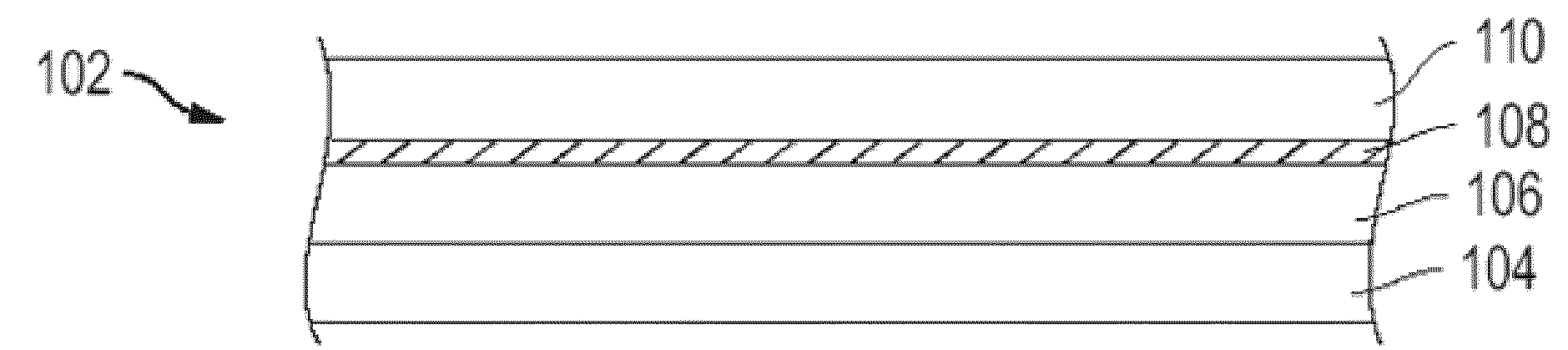

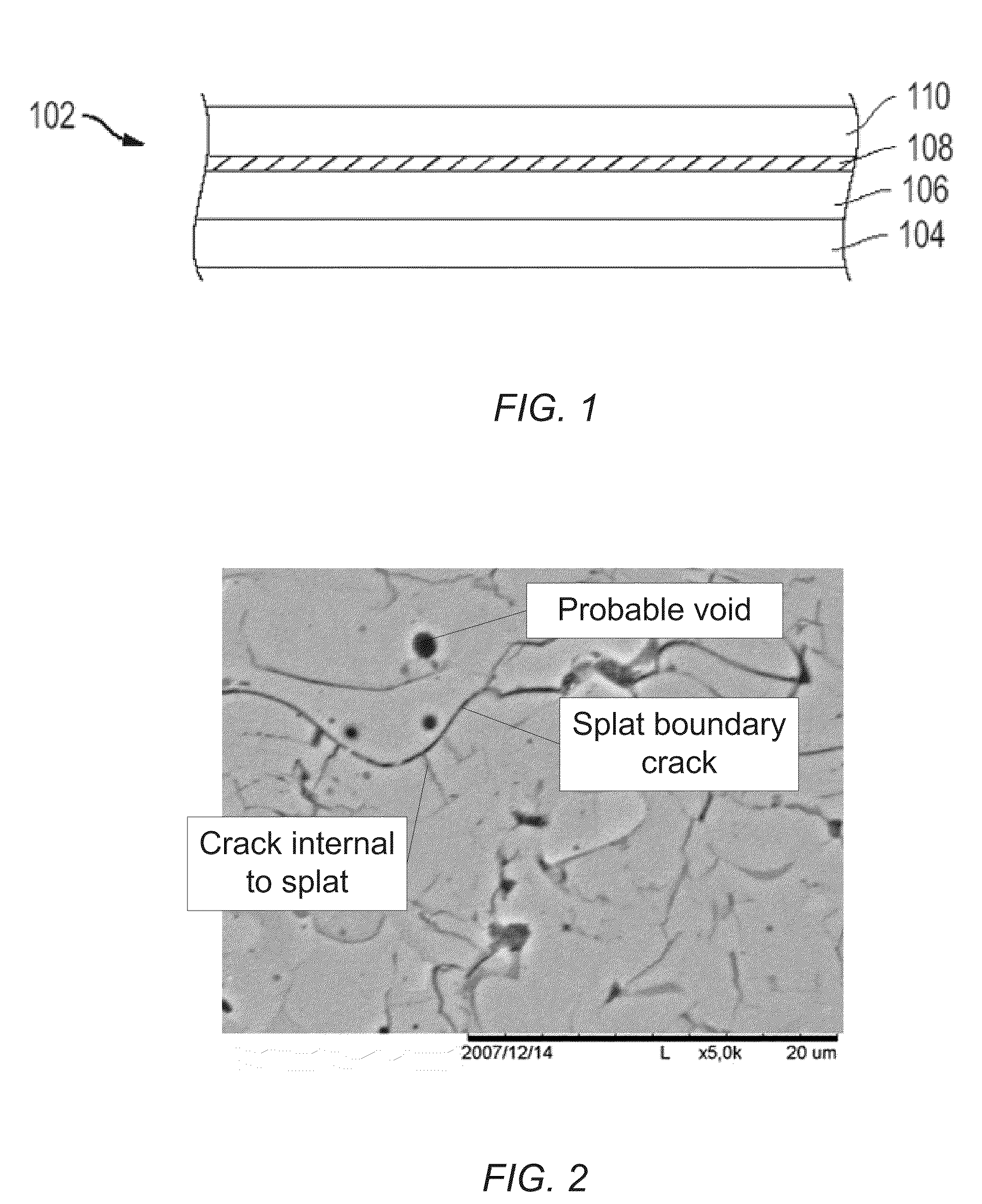

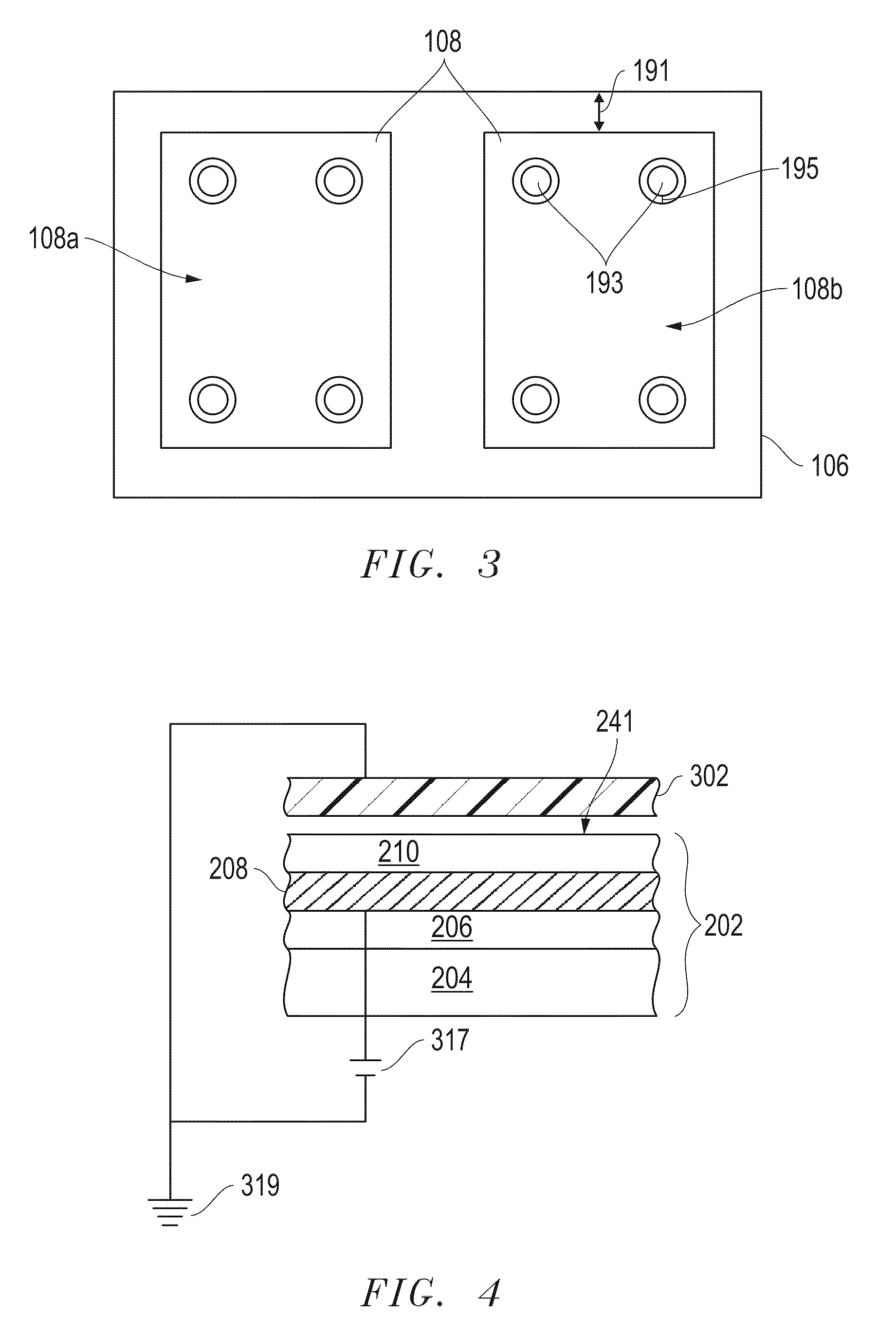

An electrostatic chuck includes an insulating layer, a conductive layer overlying the insulating layer, a dielectric layer overlying the conductive layer, the dielectric layer having pores forming interconnected porosity, and a cured polymer infiltrant residing in the pores of the dielectric layer.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

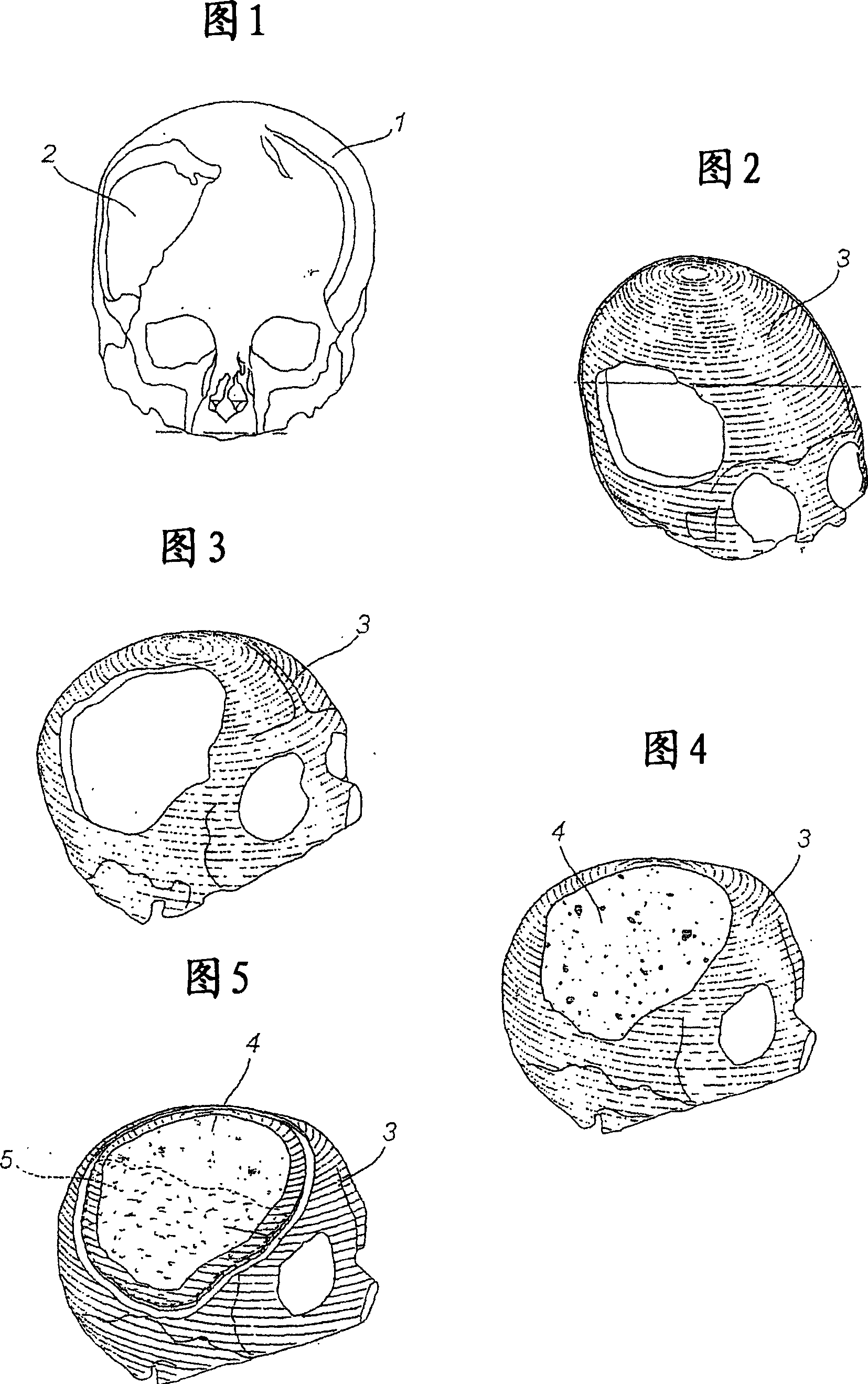

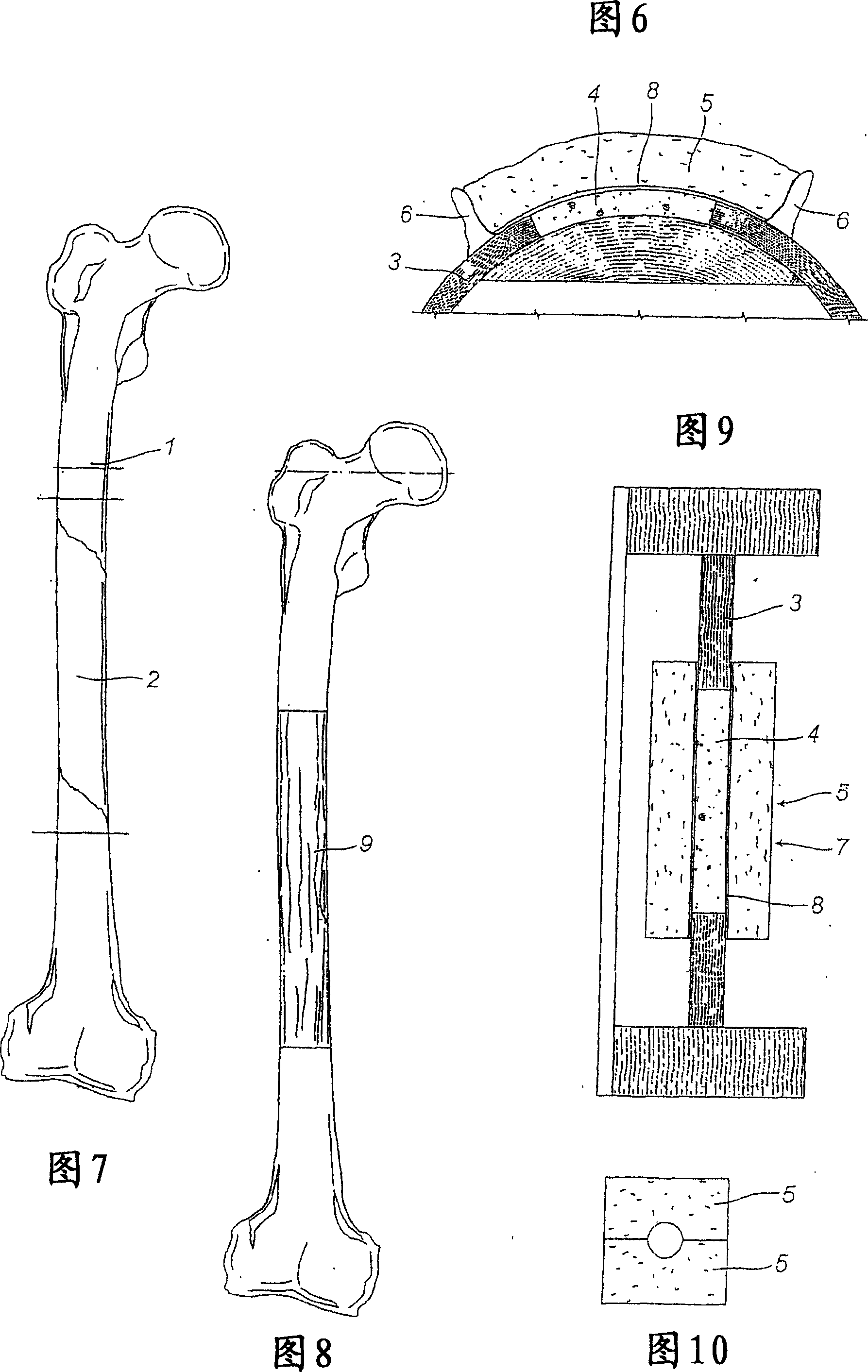

A method for the production of a biologically active prosthetic device for the reconstruction of bone tissue and the prosthetic device itself

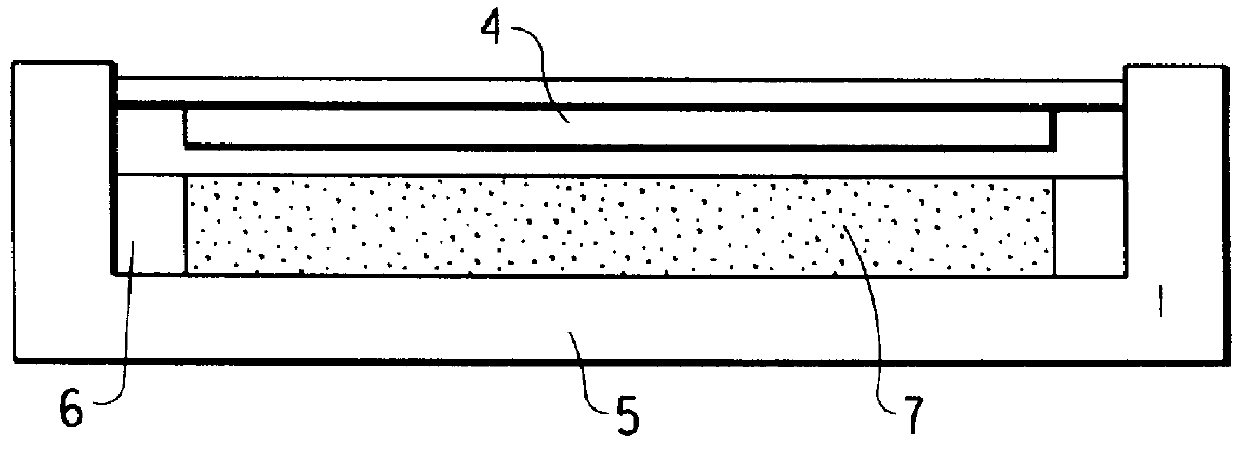

The invention relates to a method for the production of a biologically active prosthetic device for the reconstruction of bone tissue, comprising the steps of: a CAT (Computerised Axial Tomography) scan of the patient and obtaining a three-dimensional electronic model (1) of the part of the bone and of a bone defect (2) to be reconstructed; production by prototyping of a prototype resin model (3) of the area of the patient's bone involved; forming of a model (4), of the patient's bone defect (2) to be reconstructed; construction of a negative mould (5); production of a ready sintered ceramic semi-finished product with controlled and interconnected porosity, said semi-finished product being made with dimensions and shape slightly larger than the bone defect (2); mechanical processing and manual finishing of the sintered semi-finished product, to obtain the precise dimensions and shape of the bone defect (2); the invention also relating to the prosthetic device obtained. <IMAGE>

Owner:FIN CERAMICA FAENZA

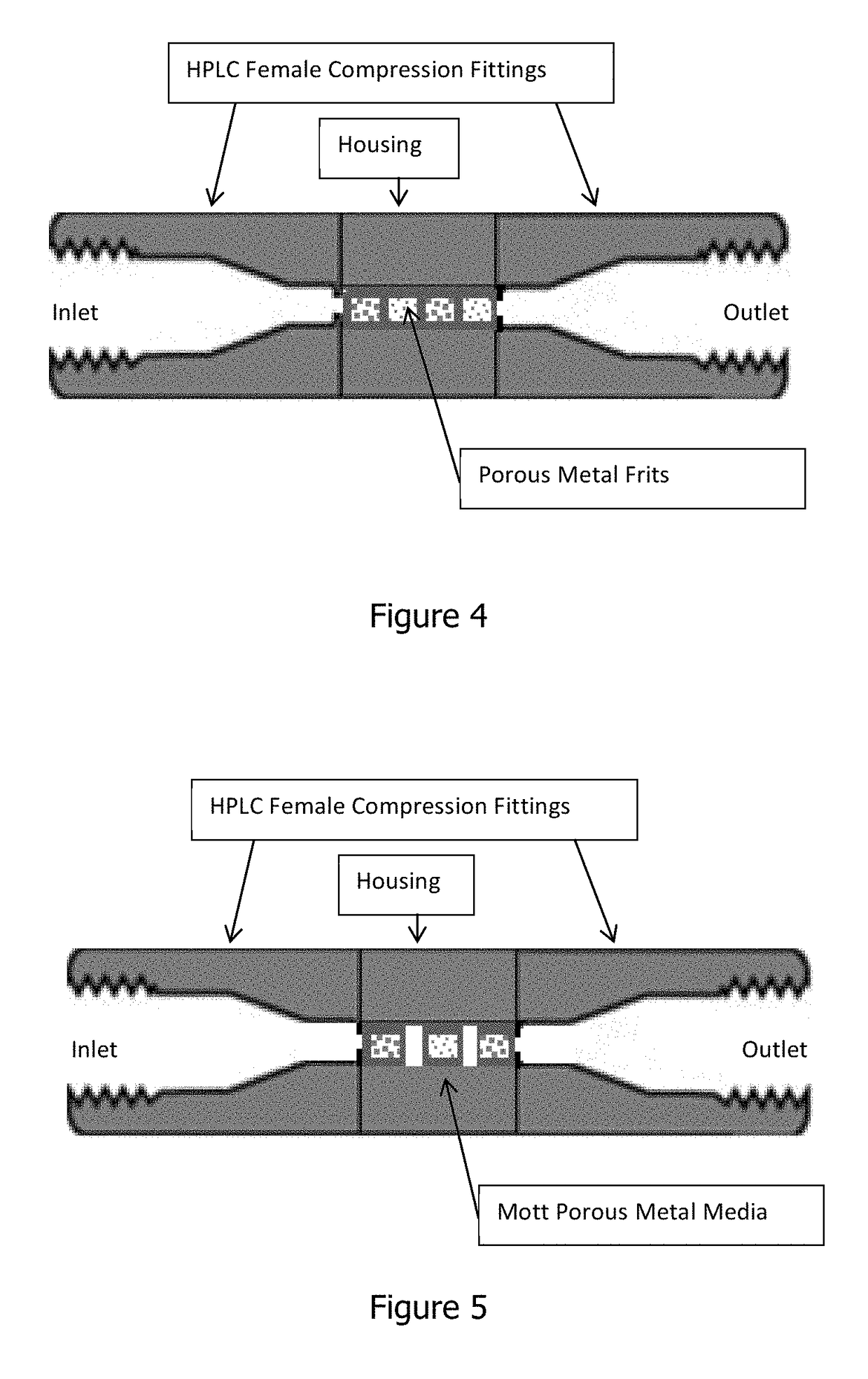

High performance static mixer

ActiveUS20180056252A1Well mixedEasy to manufactureAdditive manufacturing apparatusFlow mixersFritEngineering

A static mixer device comprising a housing having a proximal end, a distal end, and an opening extending between the proximal and distal ends. In certain embodiments, a plurality of metal frits is positioned within the opening of the housing, each of the metal frits extending across a cross-sectional dimension of the opening and having interconnected porosity. In other embodiments, one or more mixer elements fabricated using laser additive manufacturing technology and having novel configurations are positioned within the opening of the housing. In yet other embodiments, the housing comprises multiple openings having different diameters from each other, with each opening either extending through the housing with a constant diameter or with one or more of the openings having a varying diameter.

Owner:MOTT CORP

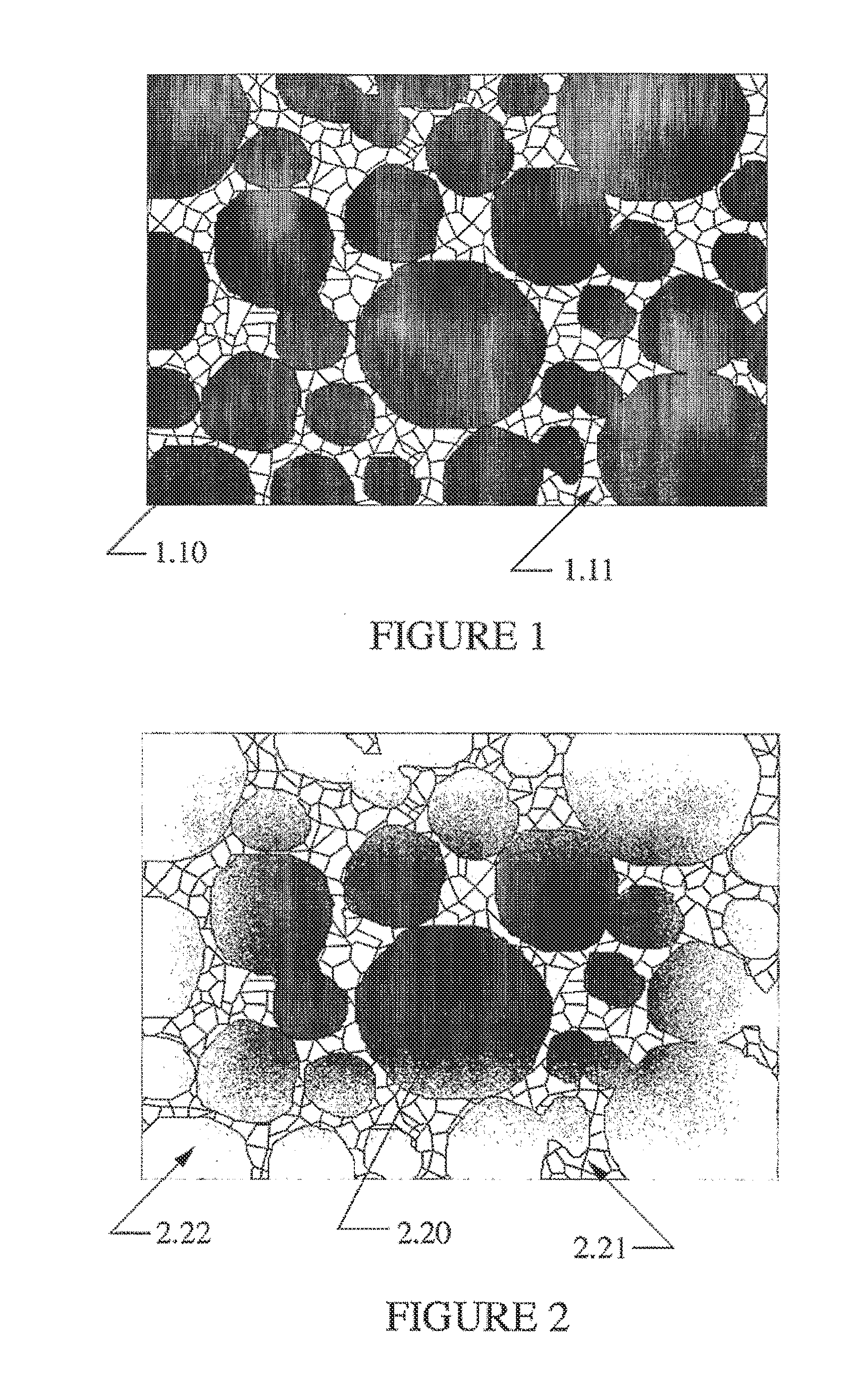

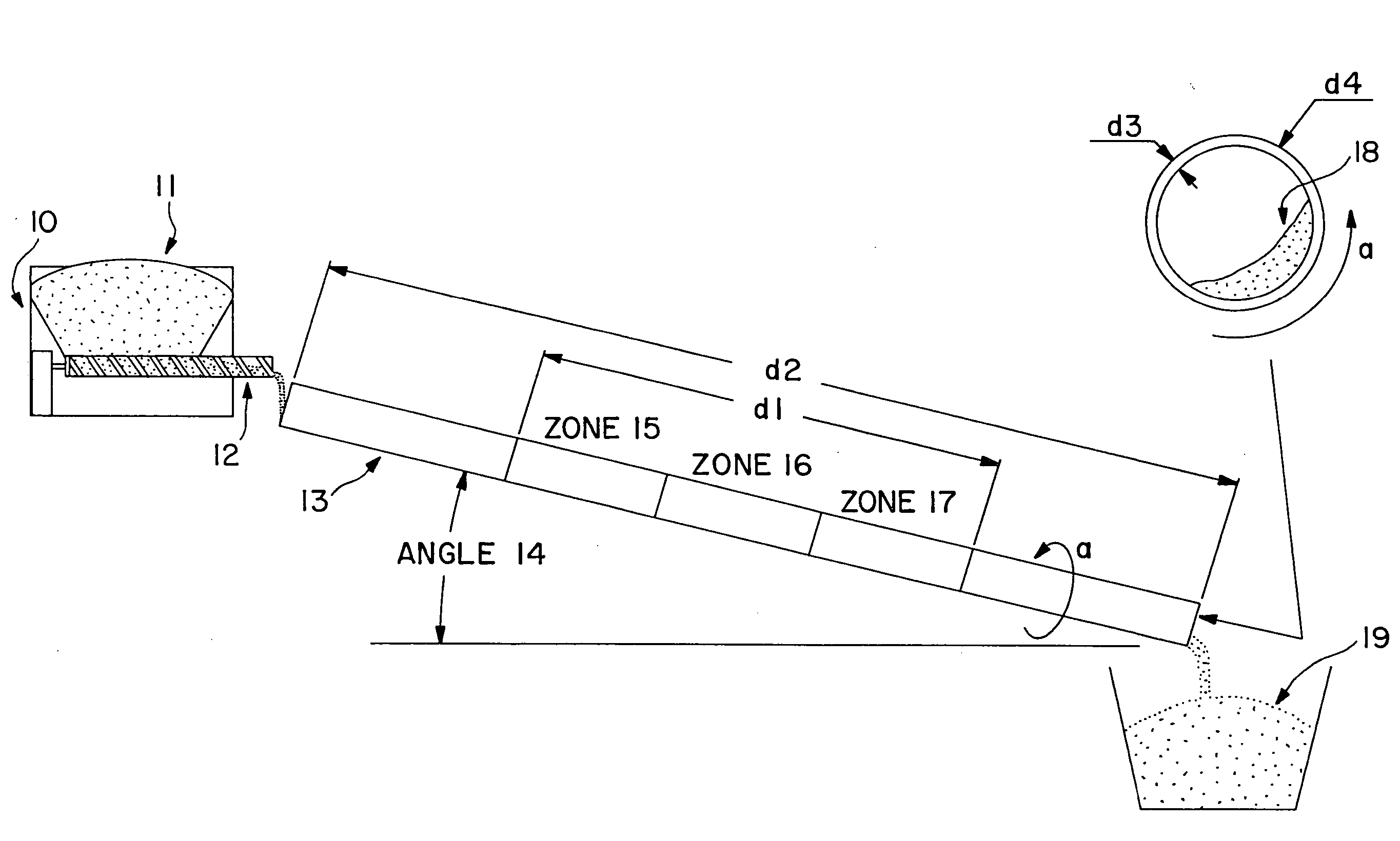

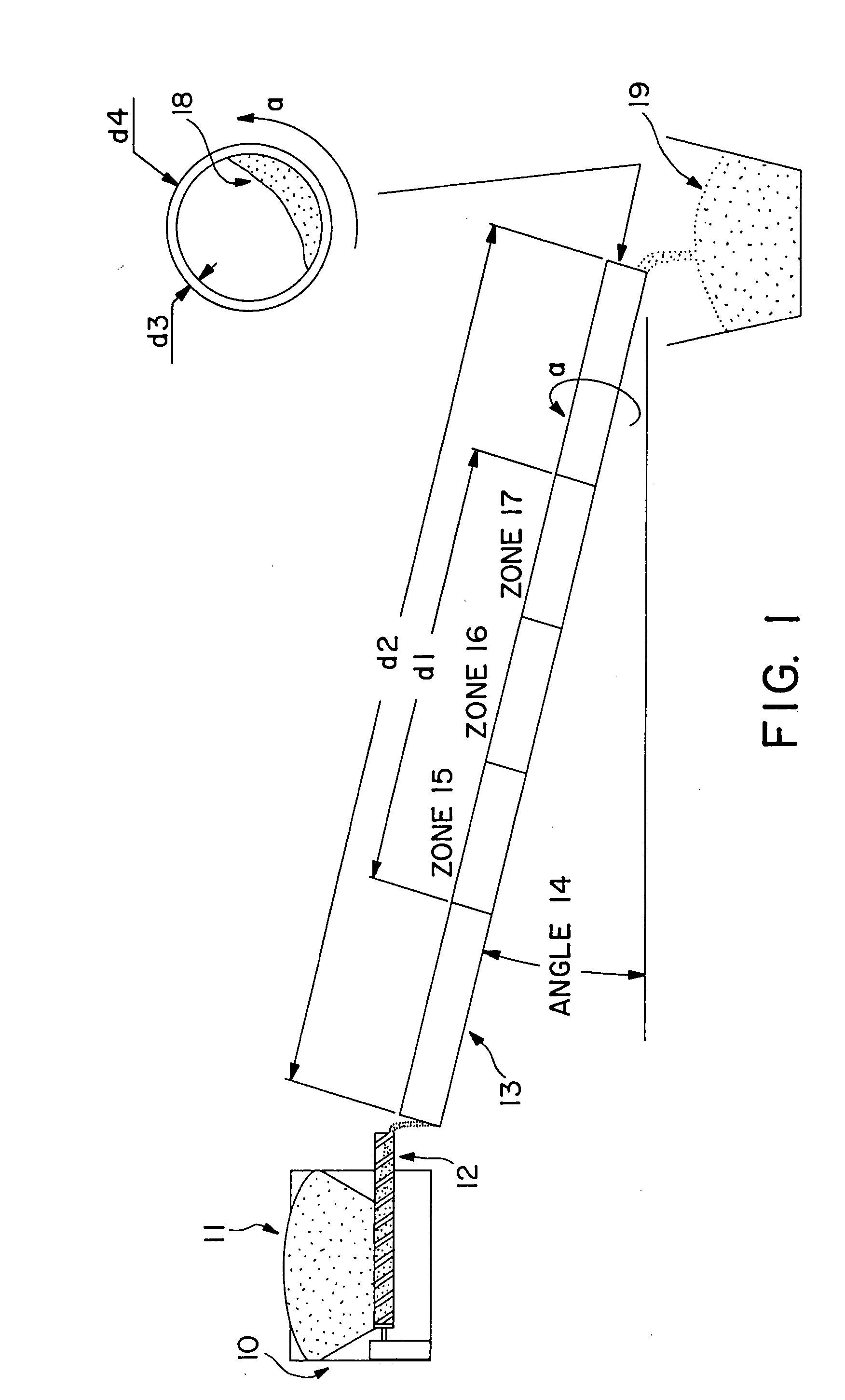

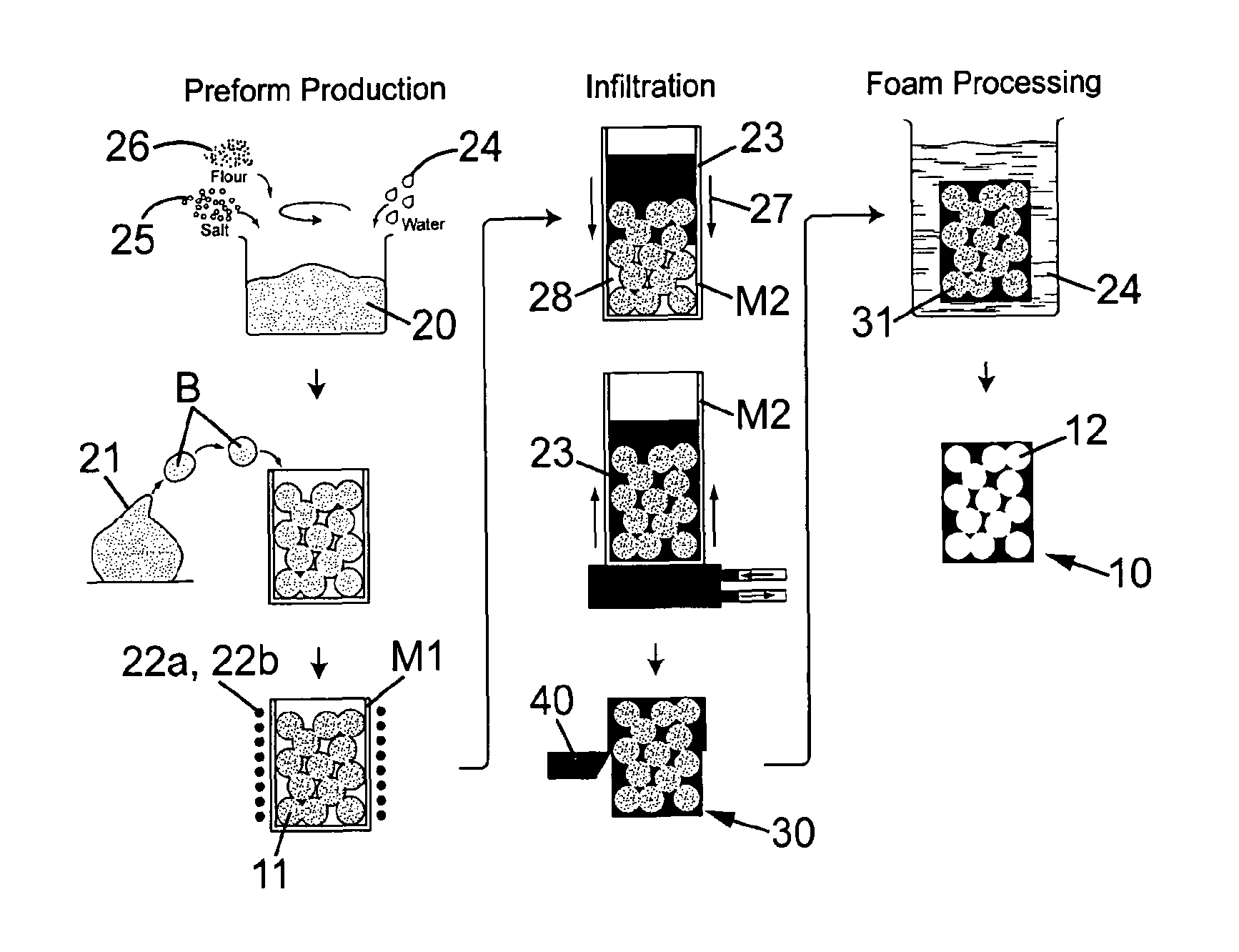

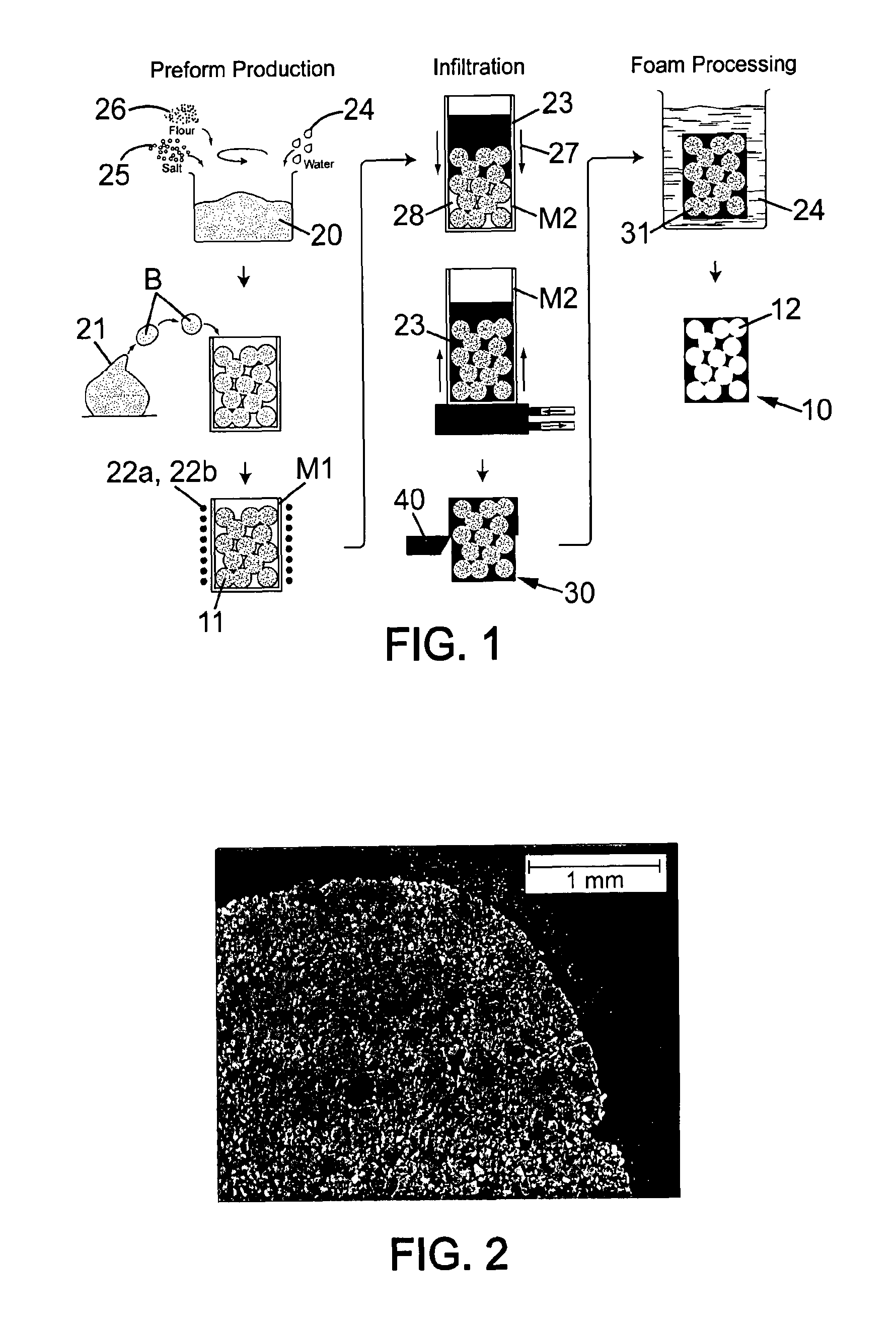

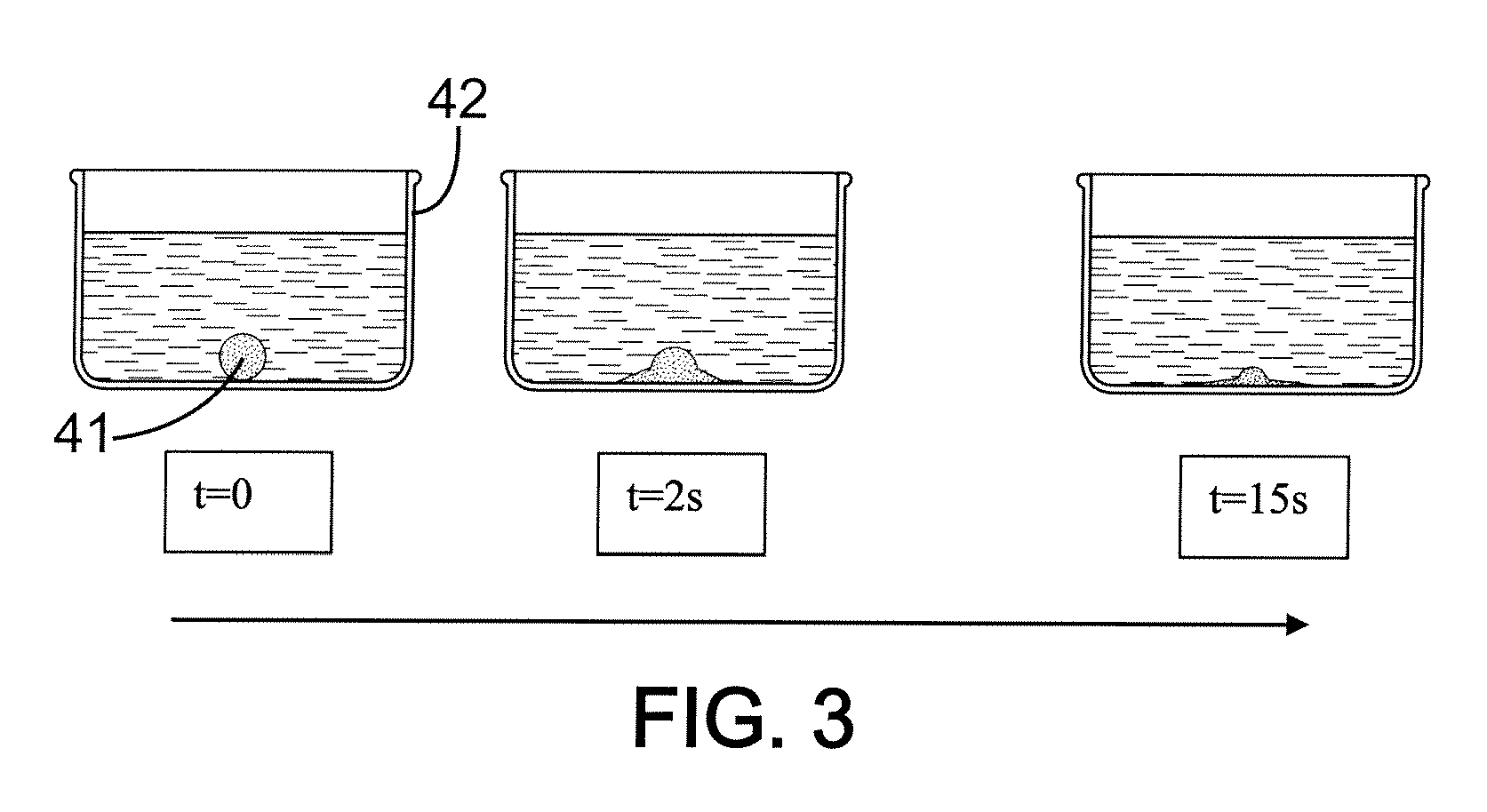

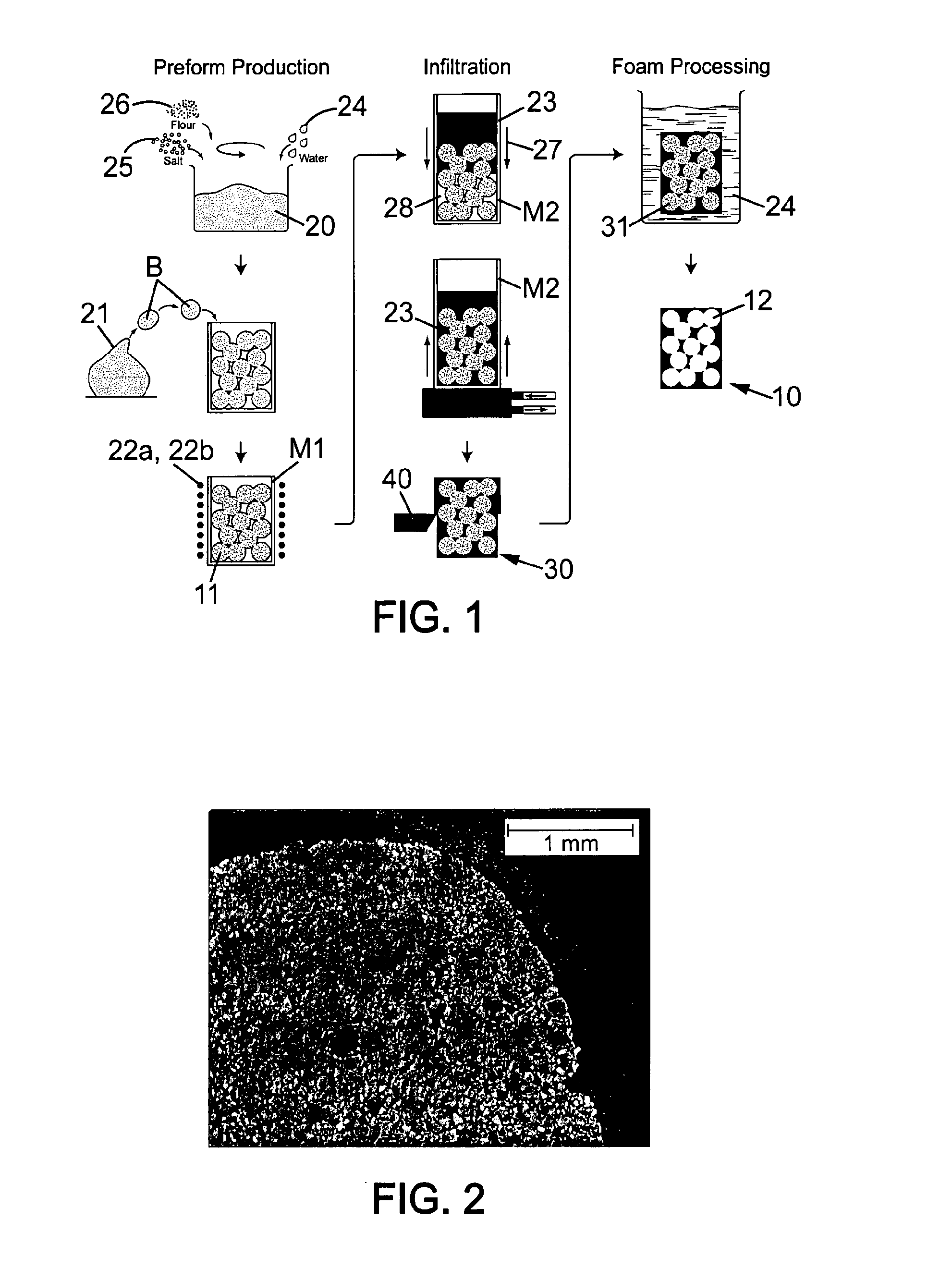

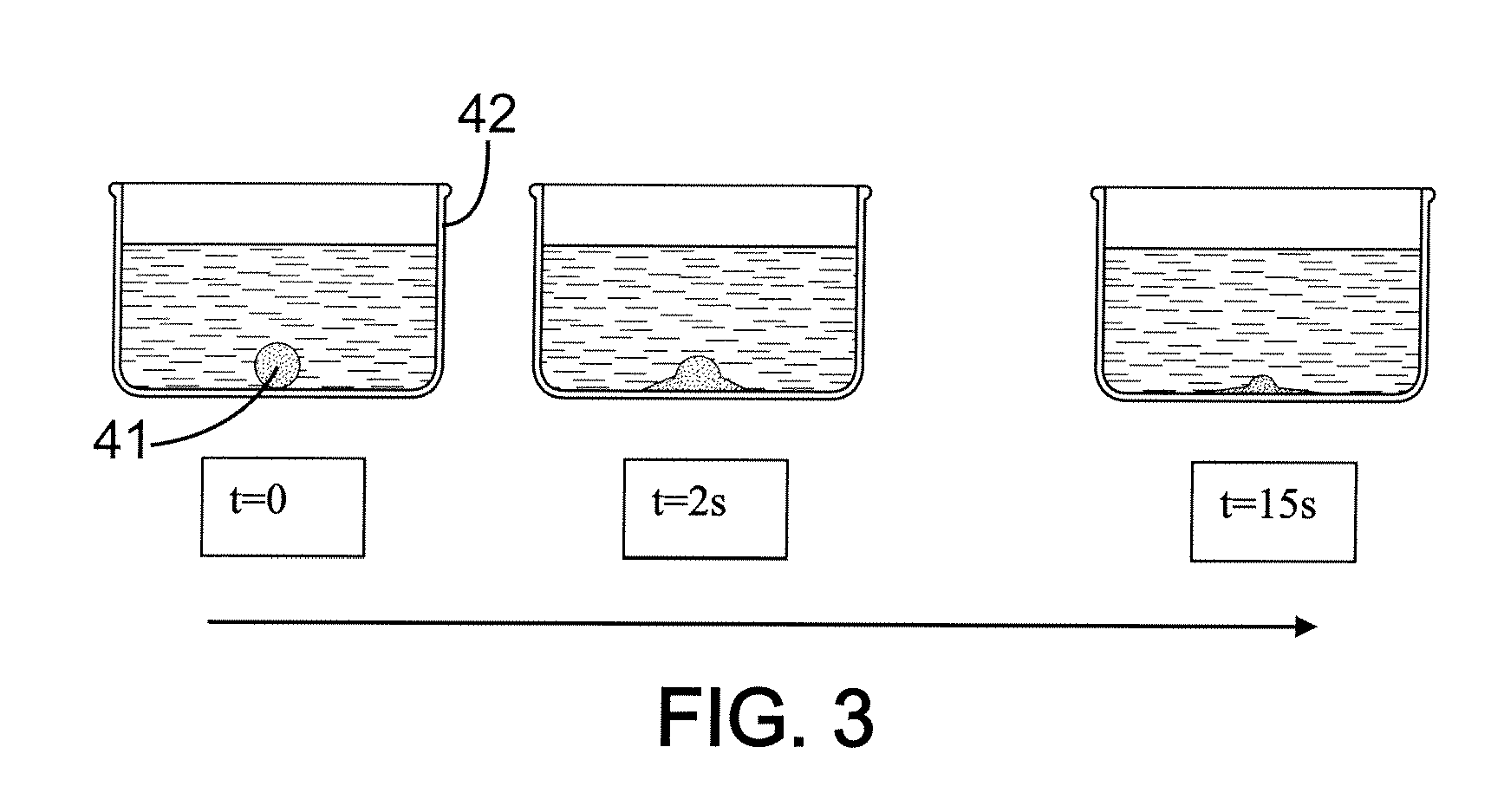

Porous metal article and method of producing a porous metallic article

InactiveUS8151860B2High porosityHelp shapeFoundry mouldsFoundry coresLiquid metalInterconnected porosity

A metal article containing at least 10% interconnected porosity is produced by using a preform.To make the preform, an organic binder, a wetting agent and a granular material are mixed to obtain a mouldable paste that combines 10 vol. pct. or more of the granular material, this material dissolving easily in a liquid solvent. The paste is shaped into an aerated preform, thus creating an open pore space to be infiltrated by the metal or alloy.The wetting agent is evaporated and the preform is baked to a temperature sufficient to degrade the binder and create a network of interconnected open porosity in the preform. Then, the open pore space is filled with the liquid metal or alloy.All or part of the baked preform can be easily leached by a liquid solvent through the network of fine pores.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

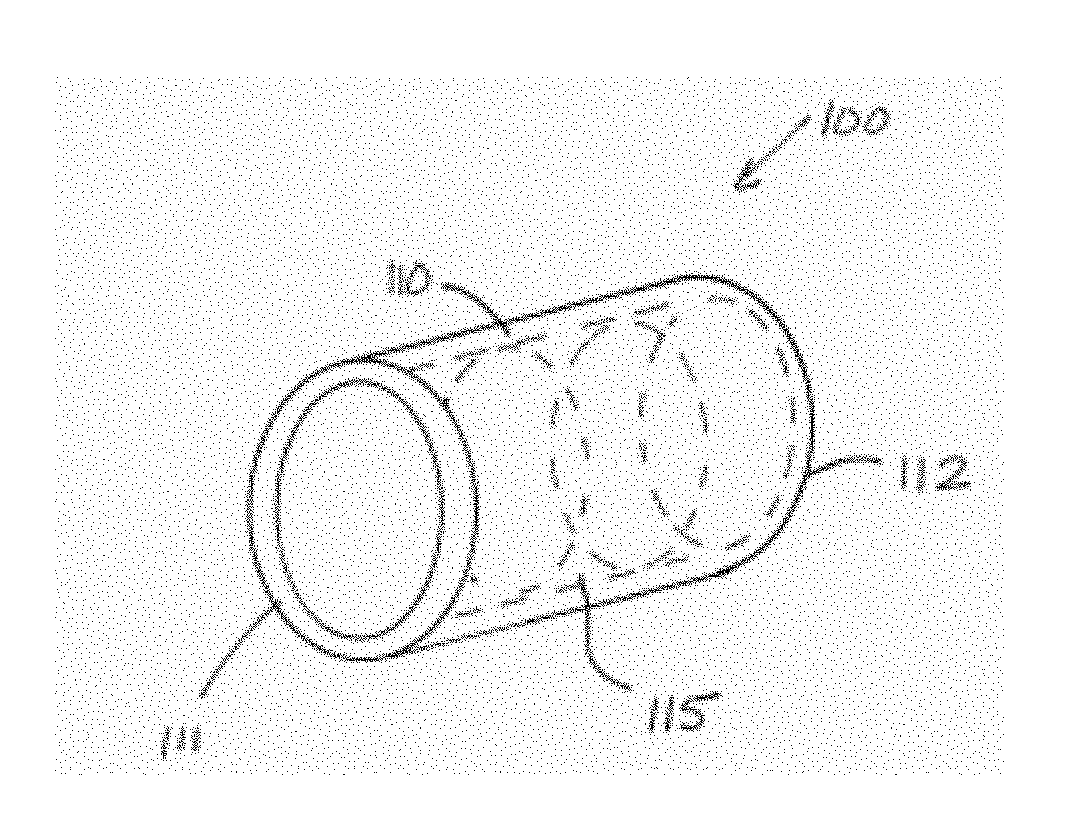

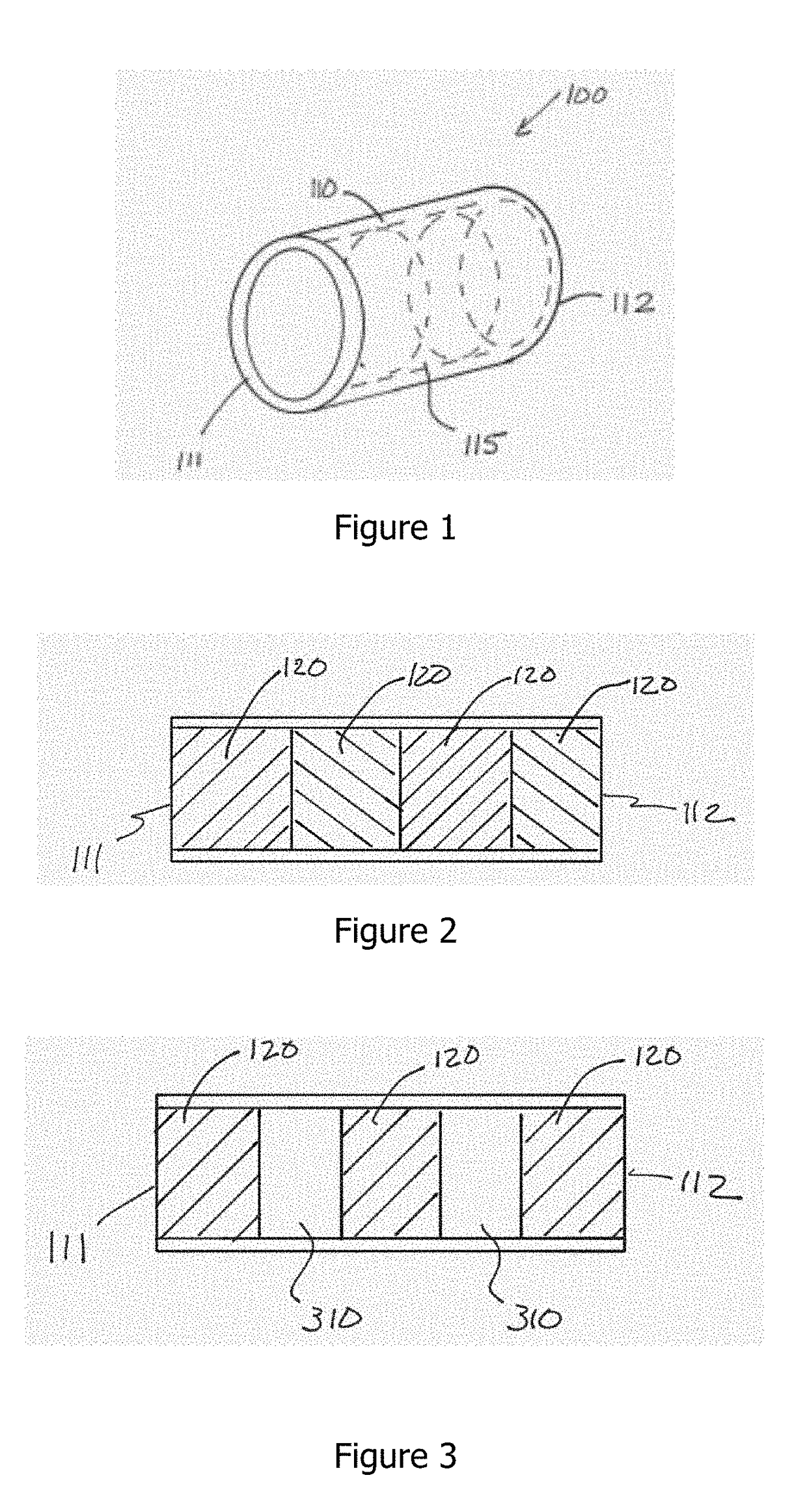

Porous metal article and method of producing a porous metallic article

InactiveUS20100021758A1High porosityShort dissolution timeLayered productsFoundry mouldsAlloyInterconnected porosity

A process for producing a metal article containing at least 10% interconnected porosity, using a preform (11), comprising:mixing an organic binder, a wetting agent and a granular material, to obtain a mouldable paste that combines 10 vol. pct. or more of said granular material, said material dissolving easily in a liquid solvent;shaping the paste into an aerated preform and providing an open pore space to be infiltrated by the metal or alloy;evaporating said wetting agent and baking said preform to a temperature sufficient to degrade the binder and create a network of interconnected open porosity in the preform;filling said open pore space with the liquid metal or alloy.All or part of the baked preform can be easily leached by a liquid solvent through the network of fine pores.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

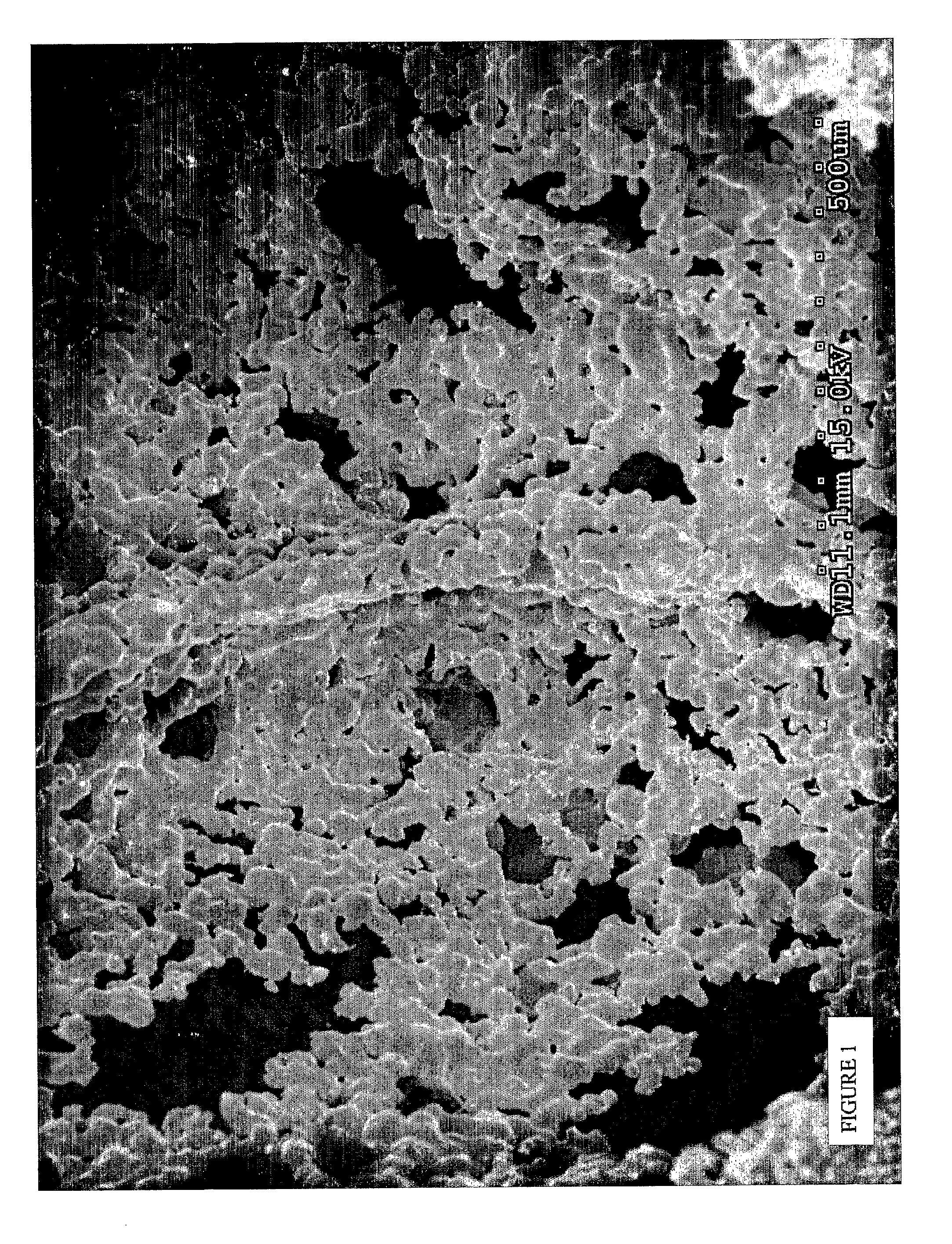

Open cell porous material and method for producing same

InactiveUS20100028710A1High mechanical strengthMinimize segregationLayered productsThin material handlingFoaming agentInorganic particle

An open cell porous material and a method for producing it is provided. The porous material of the present invention is generally composed of particles of at least one inorganic material bonded together by a brazing agent, generally provided as inorganic brazing alloy particles. The porous material is produced by heating a mixture comprising inorganic brazing alloy particles having a first melting temperature, inorganic particles having a second melting temperature higher than the first melting temperature, a binding agent having a decomposition temperature lower than the first melting temperature and preferably a foaming agent. In practice, the mixture is heated to induce foaming thereof via the foaming agent. The solid foamed structure is then heated at the decomposition temperature to substantially eliminate the binder. The resulting foamed structure is then heated again at about the first melting temperature to melt the inorganic brazing alloy particles in order to bond together the remaining three-dimensional network of inorganic particles into a rigid structure having interconnected porosity.

Owner:METAFOAM TECH INC

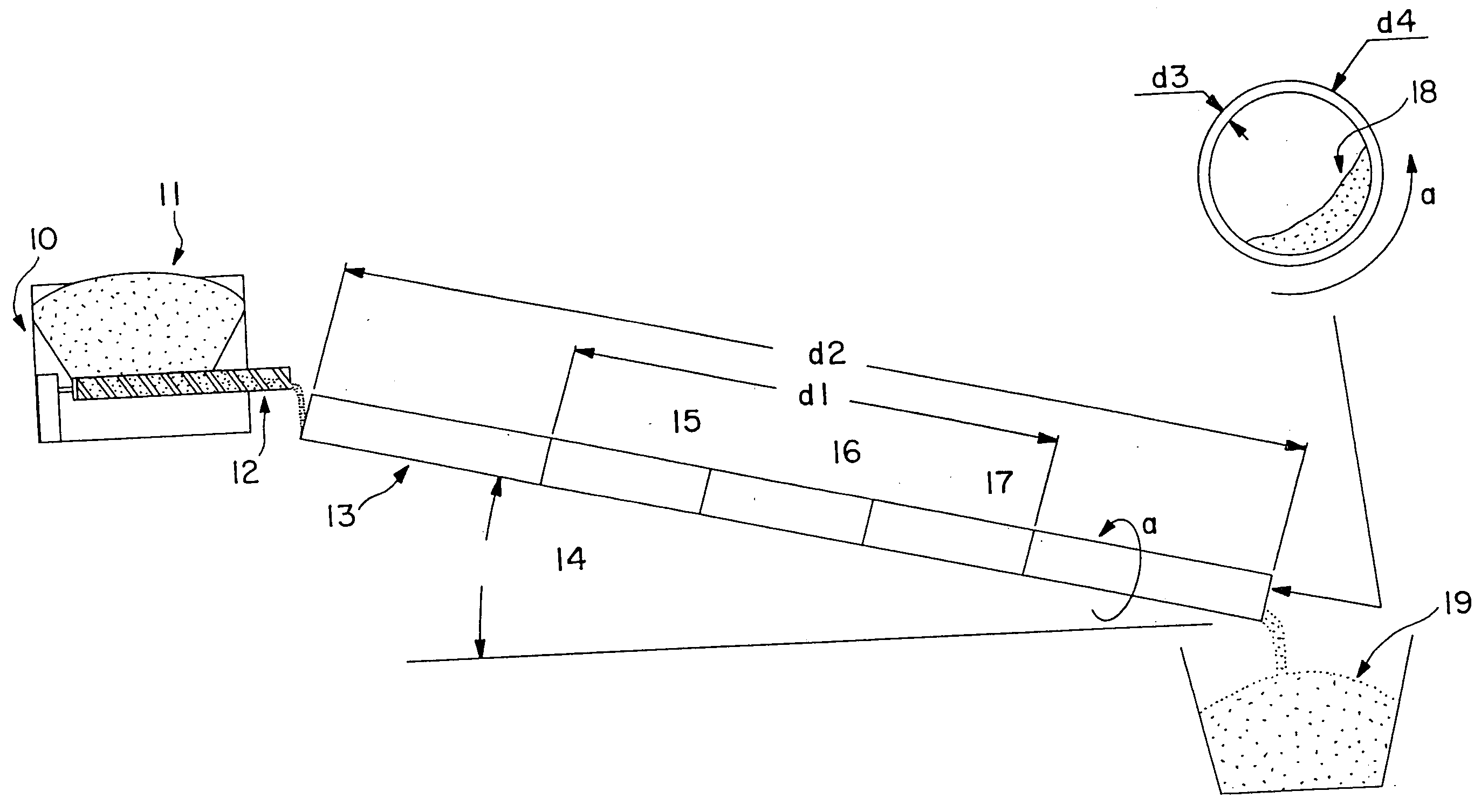

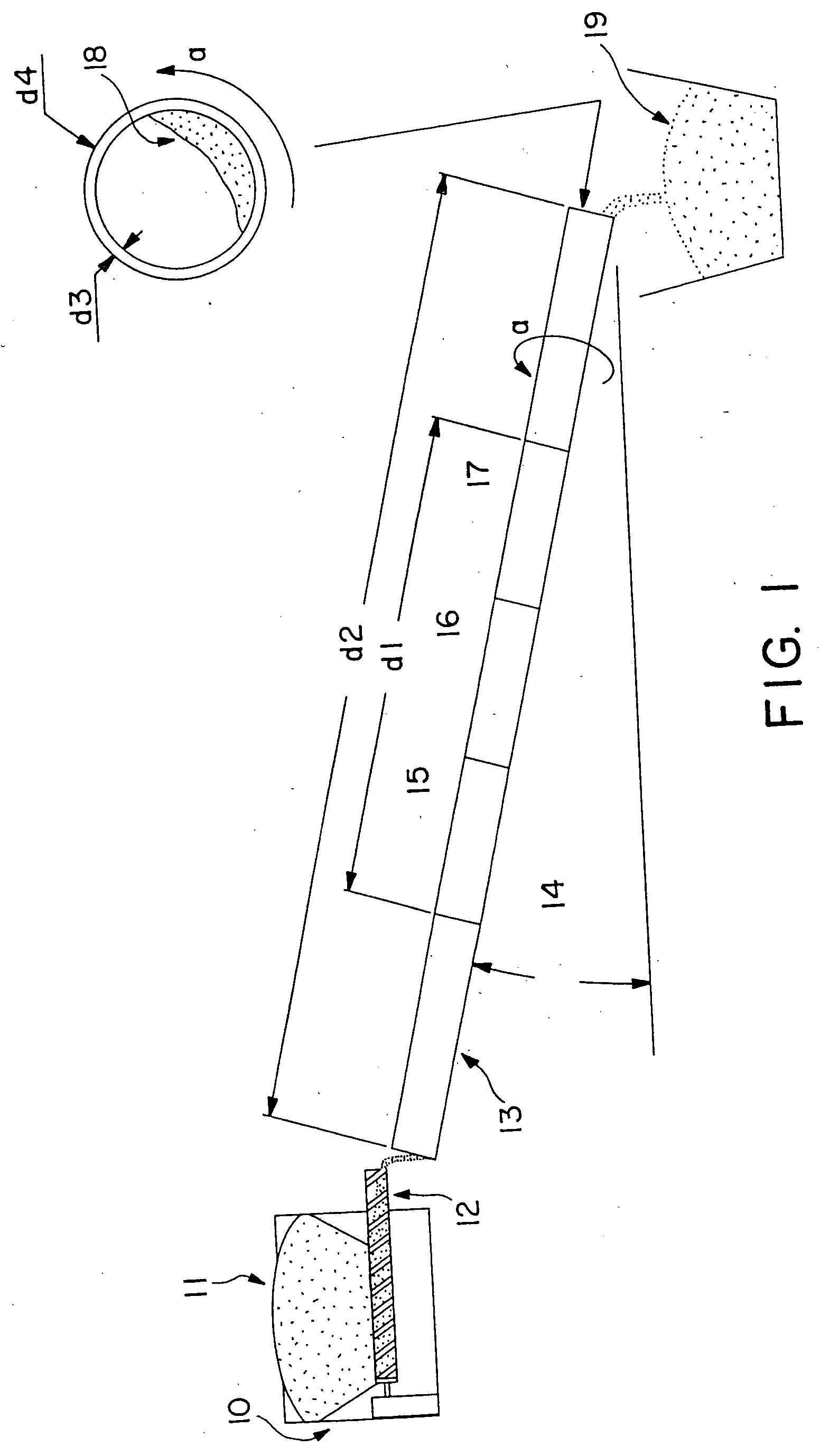

Method of producing interconnected volumetric porosity in materials

Owner:UNIV OF SOUTH FLORIDA

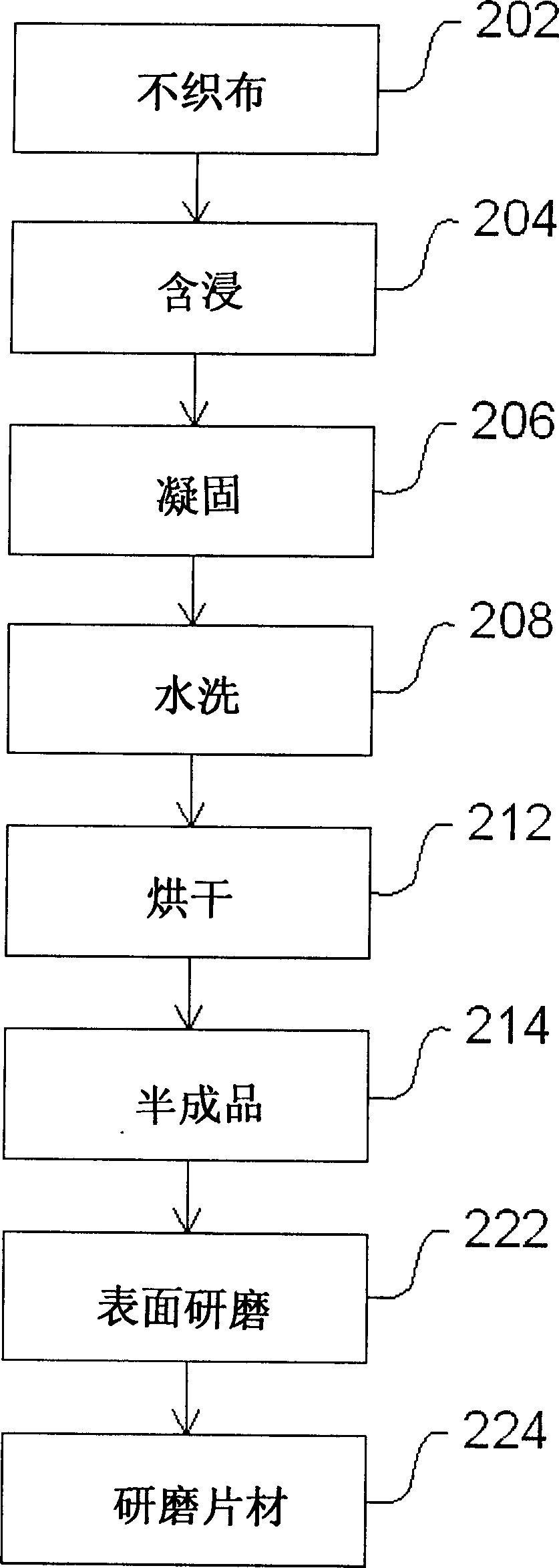

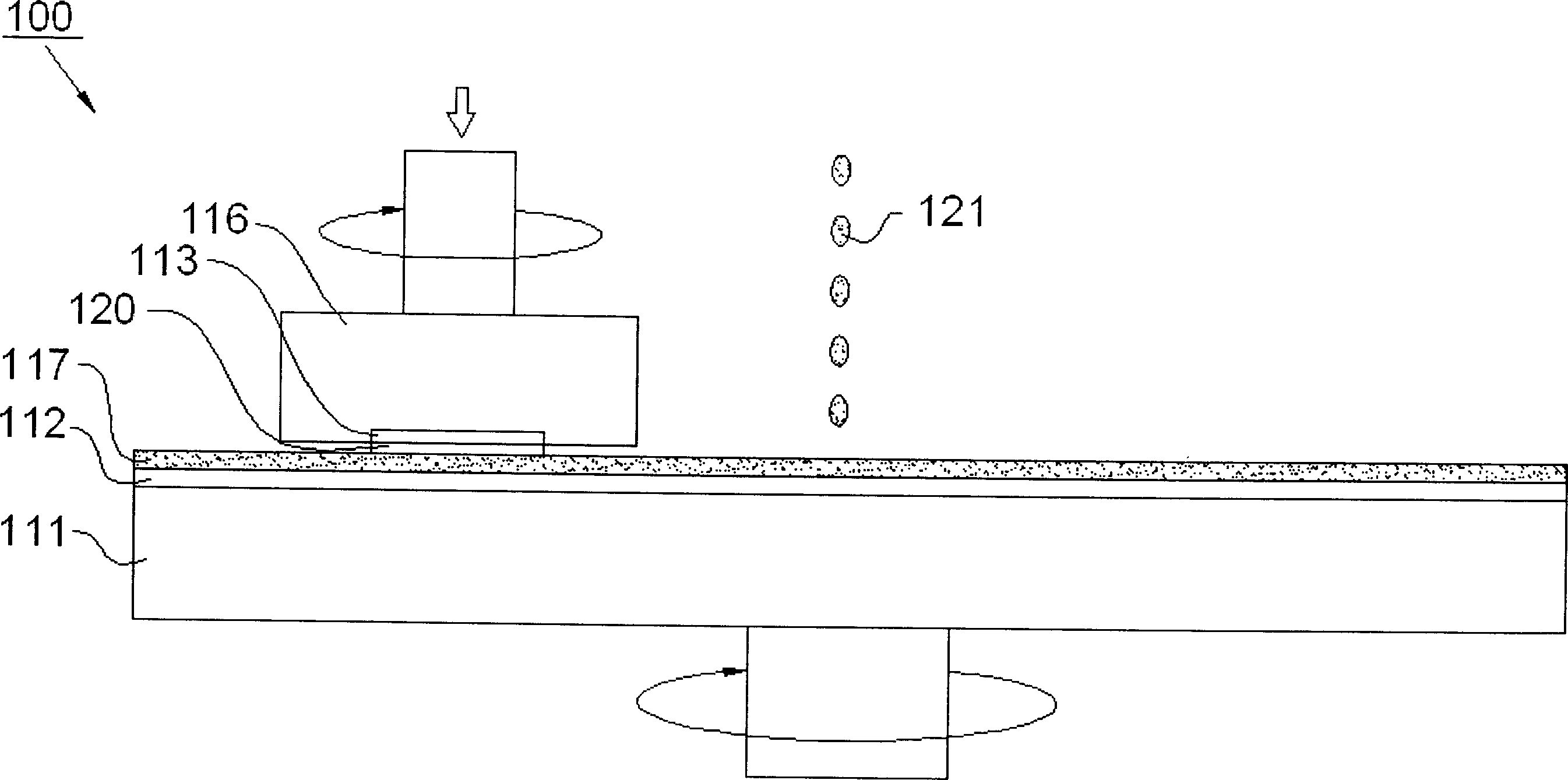

Lapping sheet and its manufacturing method and polishing device

InactiveCN1814410AImprove liquidityNot easy to scratchSemiconductor/solid-state device manufacturingLapping machinesElastomerInterconnected porosity

The invention relates to a grinding sheet material that contains a nonwoven fabric and an interconnected porosity macromolecule elastic body. The surface of the grinding sheet material is the fiber of nonwoven fabric and the macromolecule elastic body.

Owner:SAN FANG CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com