Porous composite media for removing phosphorus from water

A filter medium and pore technology, applied in the direction of silicon compounds, cement production, water pollutants, etc., can solve the problems of accelerated eutrophication, toxic compound pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

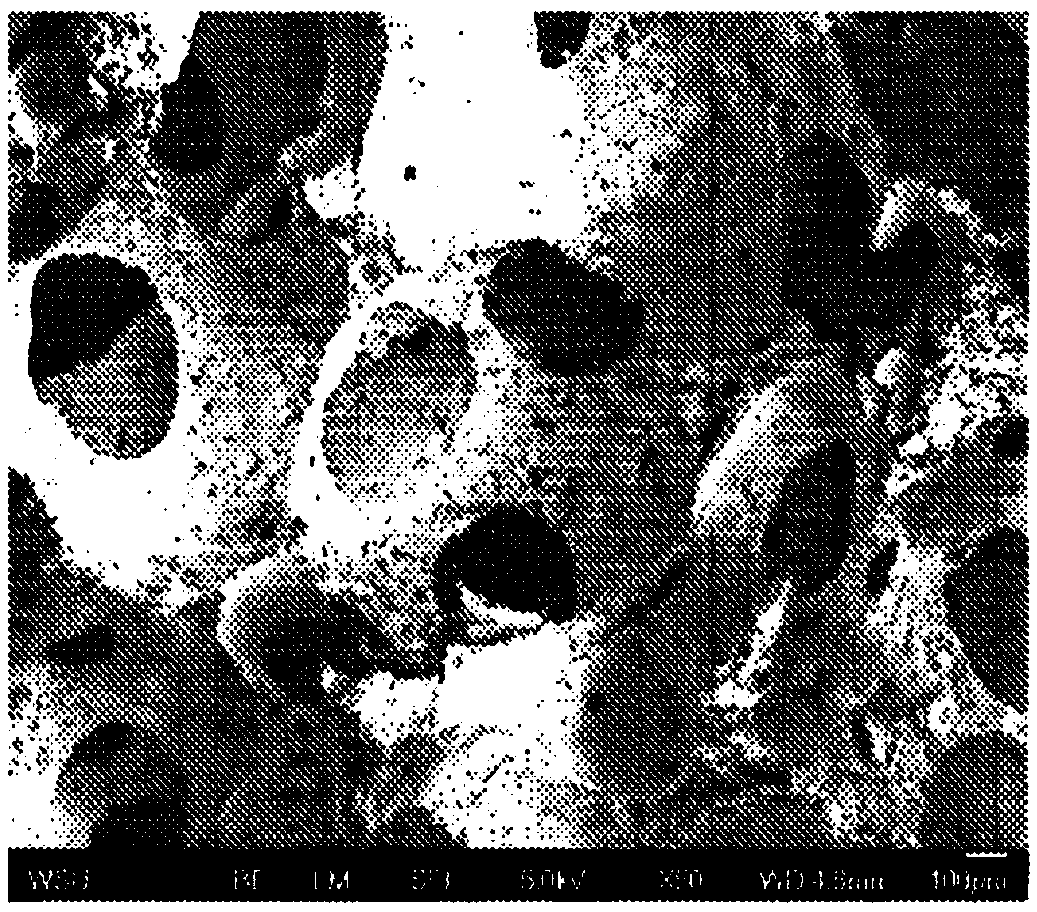

[0050] The preparation of embodiment 1-porous matrix

[0051] To prepare the porous ceramic matrix, two slurries were prepared; one containing a soluble silica source such as sodium silicate, plus an active silica compound (e.g. fumed silica, metakaolin, etc.), as aggregates Iron powder, silicone glycol copolymer surfactant and gas generating agent; while the second slurry contains a soluble alumina source such as sodium aluminate, plus an active silica compound (such as fumed silica , metakaolin, etc.), iron powder and silicone glycol surfactants as aggregates. Each of the two slurries is cooled to below room temperature (<20°C) and then the two slurries are mixed in equal amounts and formed into the desired shape using a mold or pelletizing equipment. The mixed slurry foams (expands) and cures to a hard product within 10-30 minutes. The mixture of the two slurries is molded in the presence of metallic or polymeric reinforcement such as wires or rods.

[0052] Aggregates a...

Embodiment 2

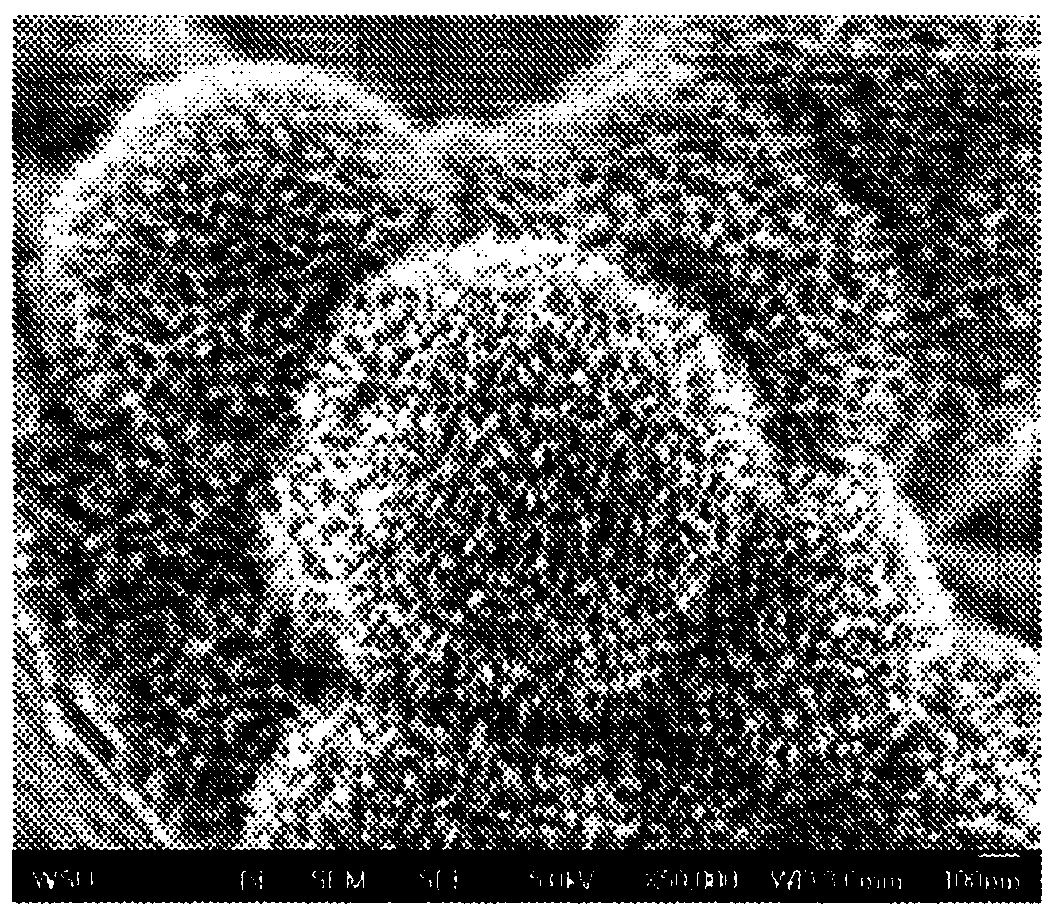

[0053] The first method of embodiment 2-nanometer modification

[0054] The media of Example 1 was modified by first immersing the media in an alkaline solution such as TMAOH (tetramethylammonium hydroxide) until saturated, then removing the media and immersing in the iron precursor solution. The method is optimized by varying different parameters such as immersion time, concentration and type of chemical reagents such as ferric nitrate or ferric sulfate. After the modification is complete, the medium is dried. The surface area of the media after nanomaterial deposition is typically in the range of 50-65 m 2 / g range. Media produced using this method had an increased phosphorus removal rate of 50-55 mg phosphorus per gram of media at a concentration of 10 mg / L phosphorus in water (using a standard 24 hour batch test).

Embodiment 3

[0055] The second method of embodiment 3-nanometer modification

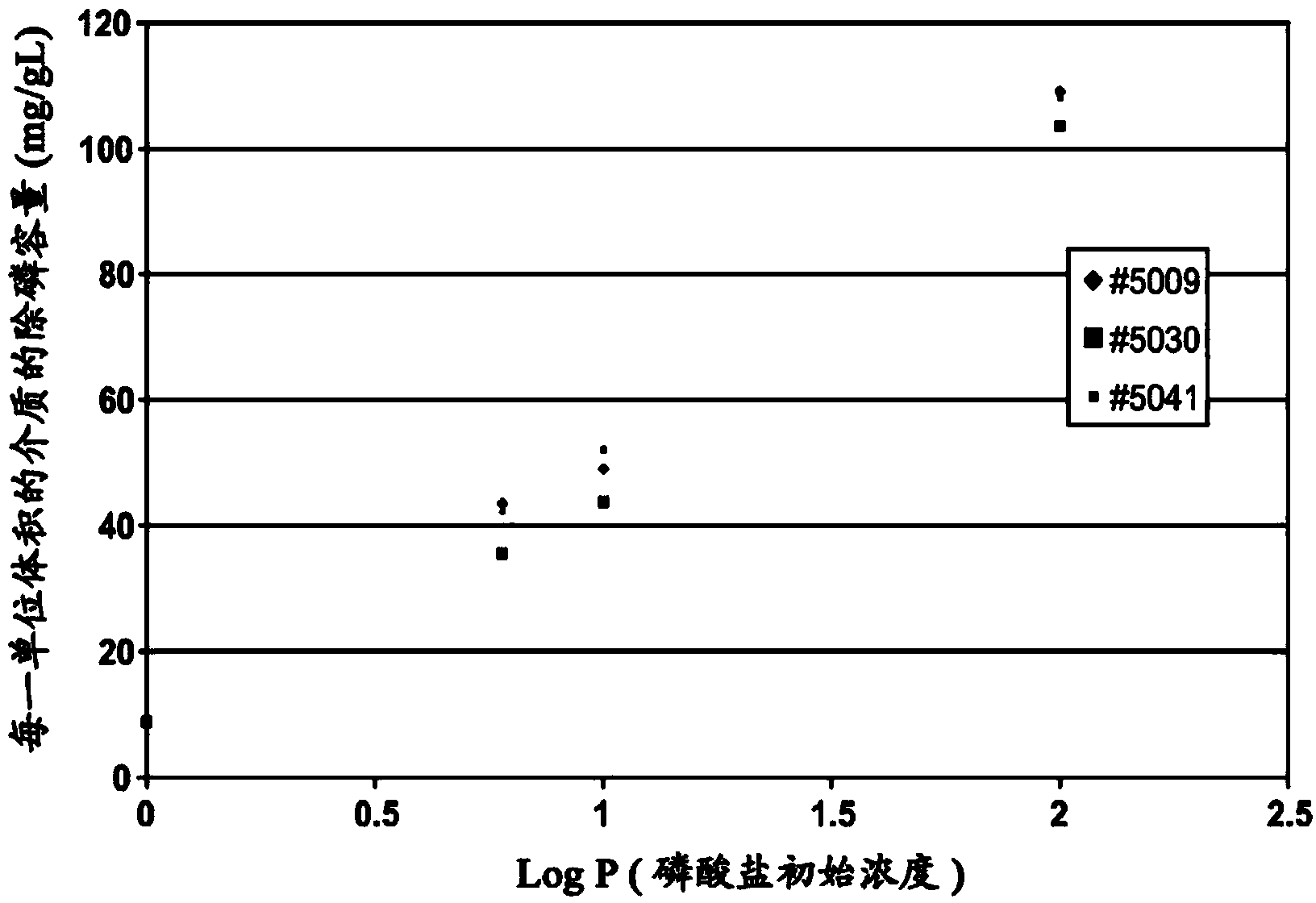

[0056] The media of Example 1 is first treated with an oxidizing agent such as potassium permanganate for 2-3 hours and then exposed to an iron precursor solution to form iron oxyhydrogen by oxidation and deposition or growth of these nanomaterials on the surface of the substrate porous media Oxygen compounds or iron oxides. After the modification is complete, the medium is dried. Adding nanomaterials using this method increases the surface area of the media by increasing the active layer for phosphorus uptake. After one treatment cycle, the surface area ranges from ~15m 2 Grams increased to 55m 2 / g (BET method), and after the second treatment cycle, the surface area increased to more than 70m 2 / g. Chemical analysis of the modified media (ICP Inductively Coupled Plasma Spectroscopy) was used to assess the amount of nano-iron added to the porous media. Multiple sampling tests showed the addition of 8 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com