Patents

Literature

363 results about "Composite media" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

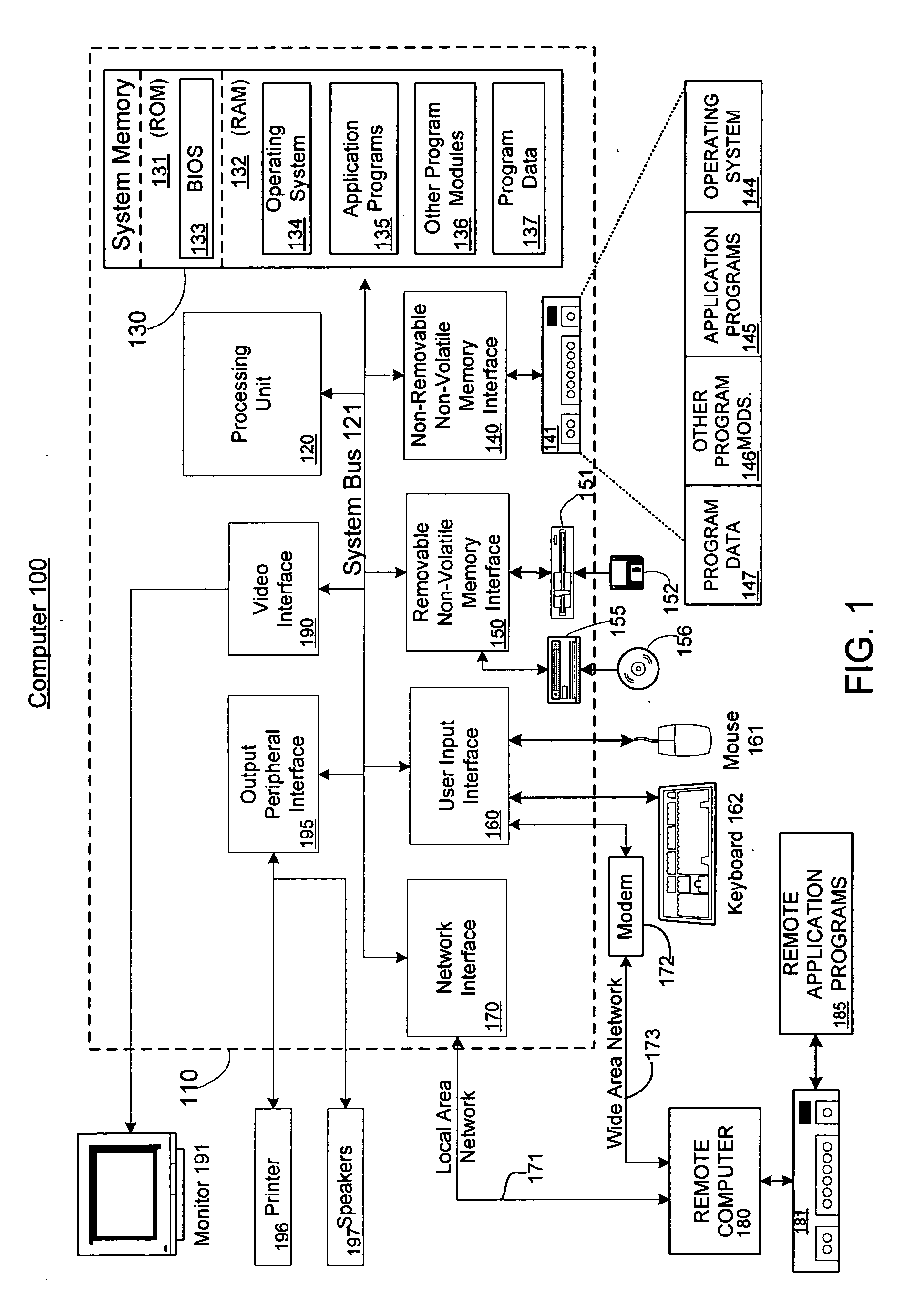

Media Processing Engine and Ad-Per-View

InactiveUS20100145794A1Input/output for user-computer interactionDigital data processing detailsComposite mediaComputer graphics (images)

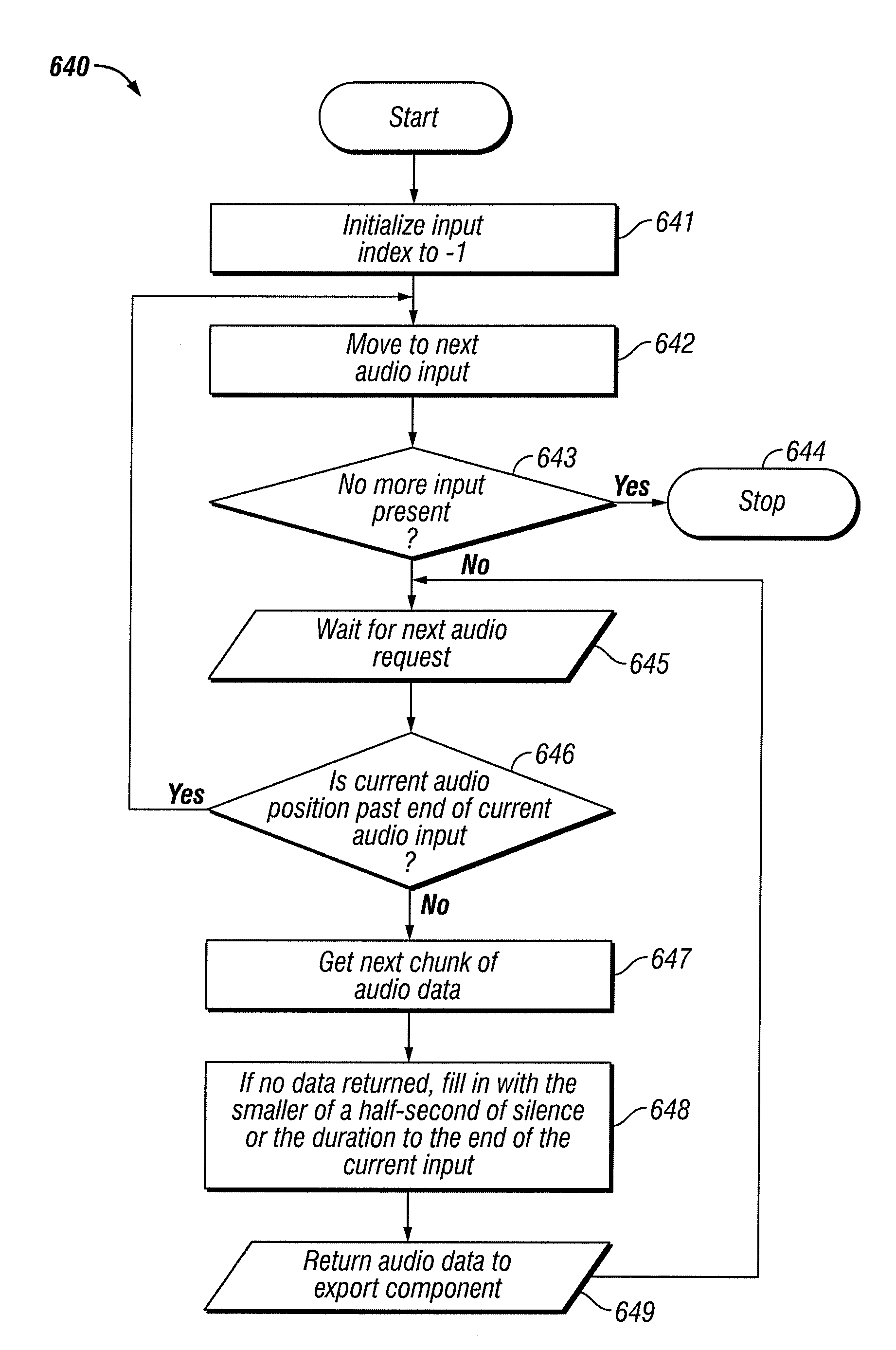

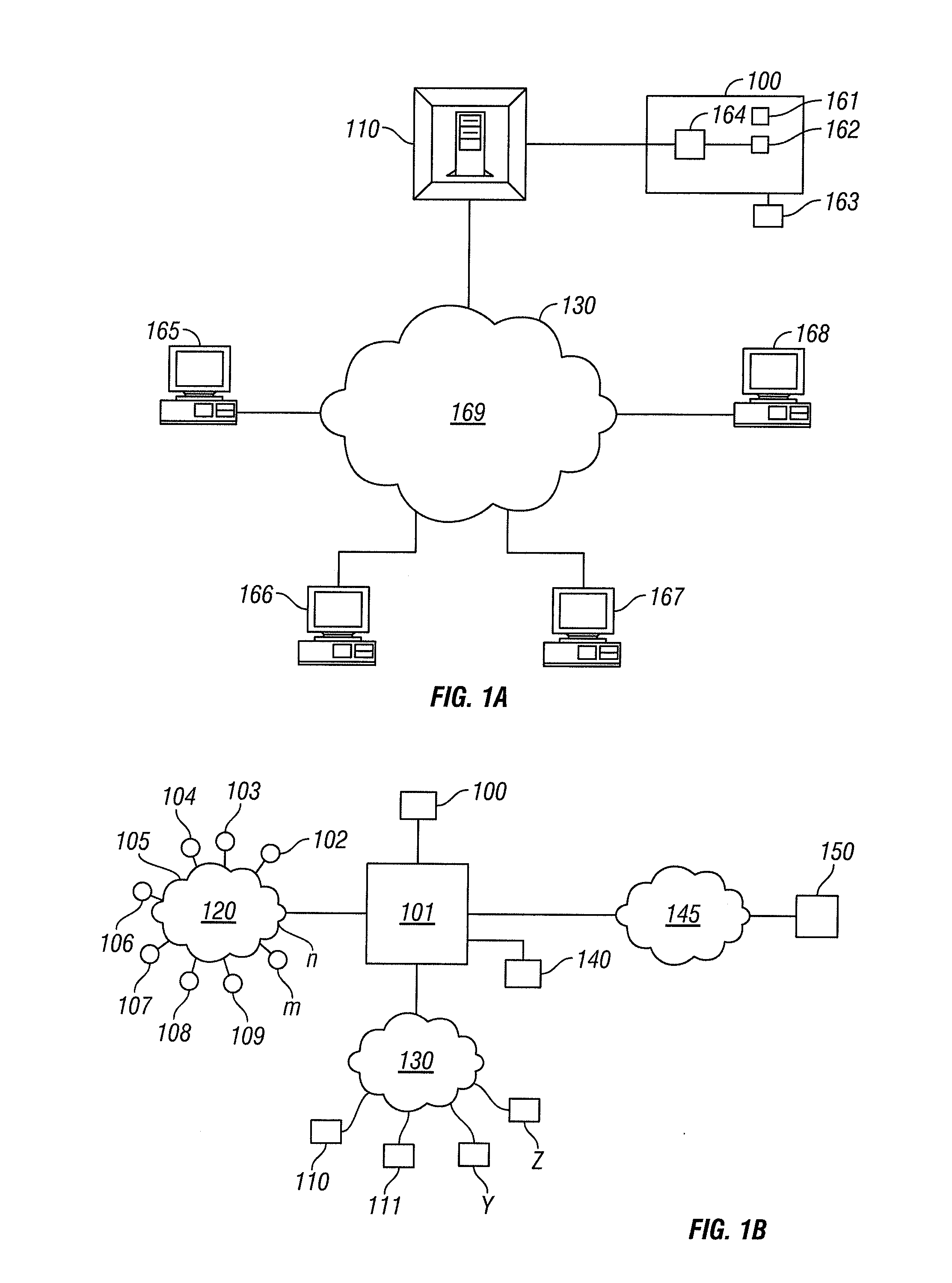

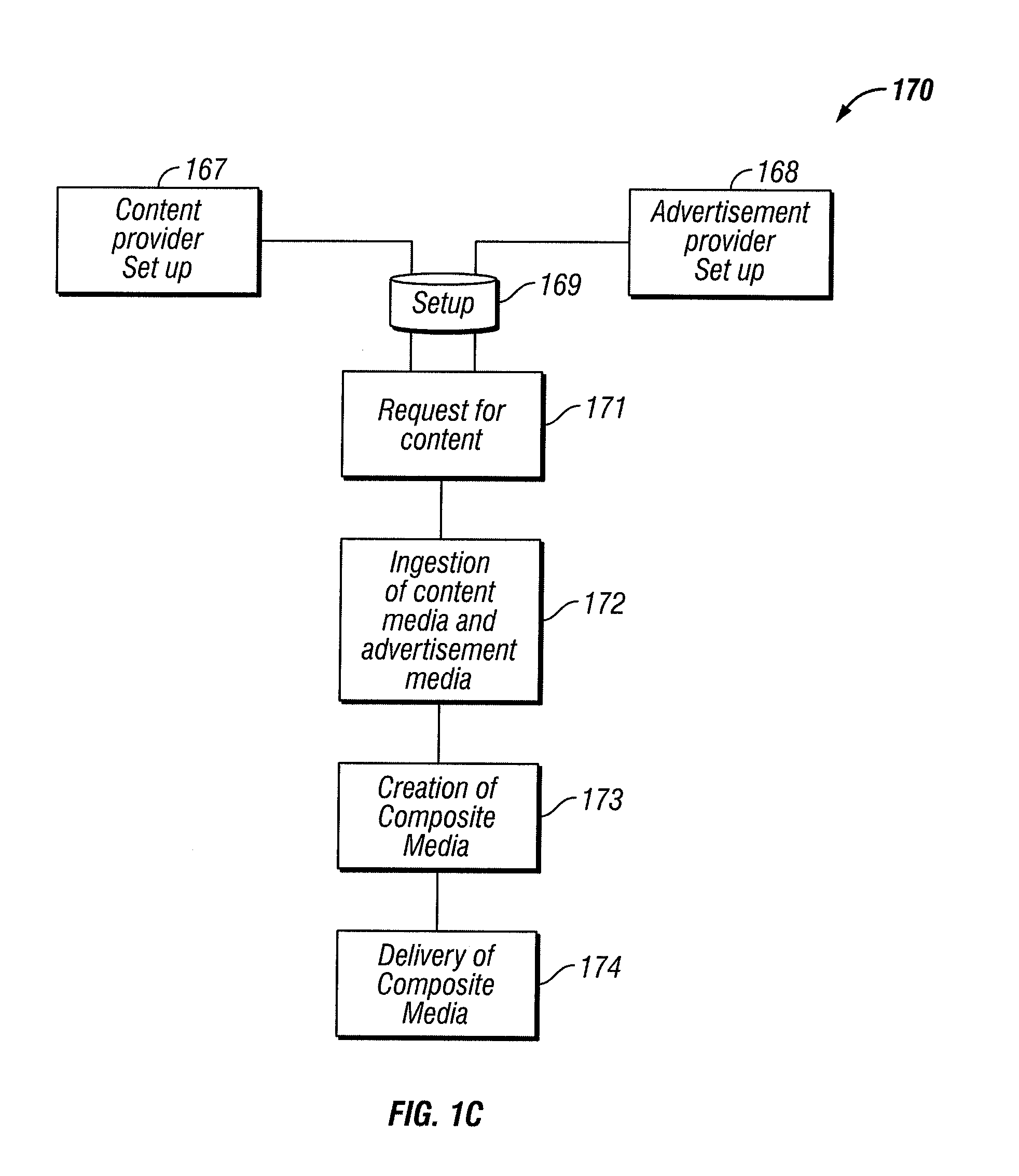

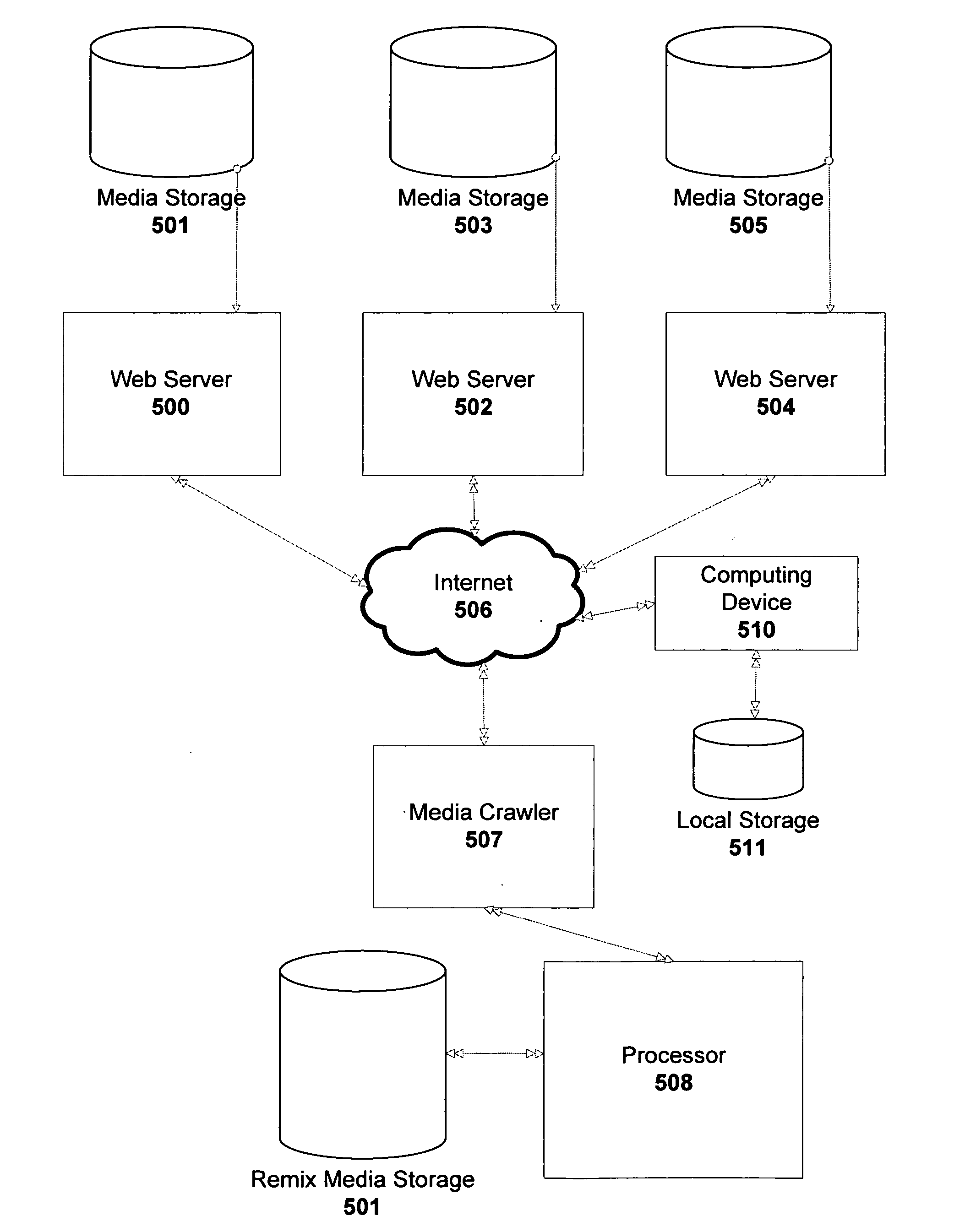

A scaleable server-based, on-demand media processing engine automates the production and delivery of media. A digital processing engine automatically transcodes a plurality of media files having different formats into a composite media file.

Owner:EQUILIBRIUM INC

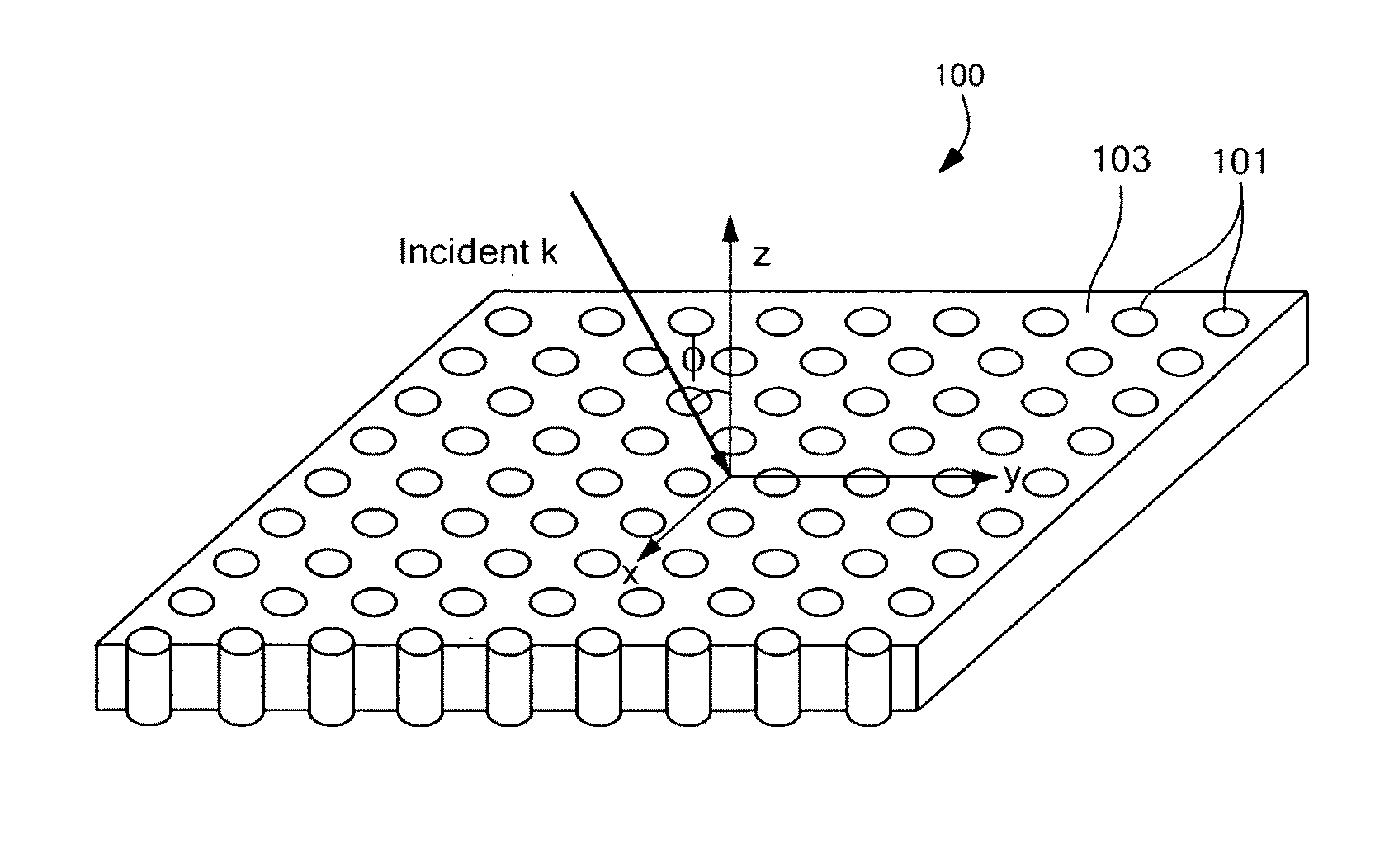

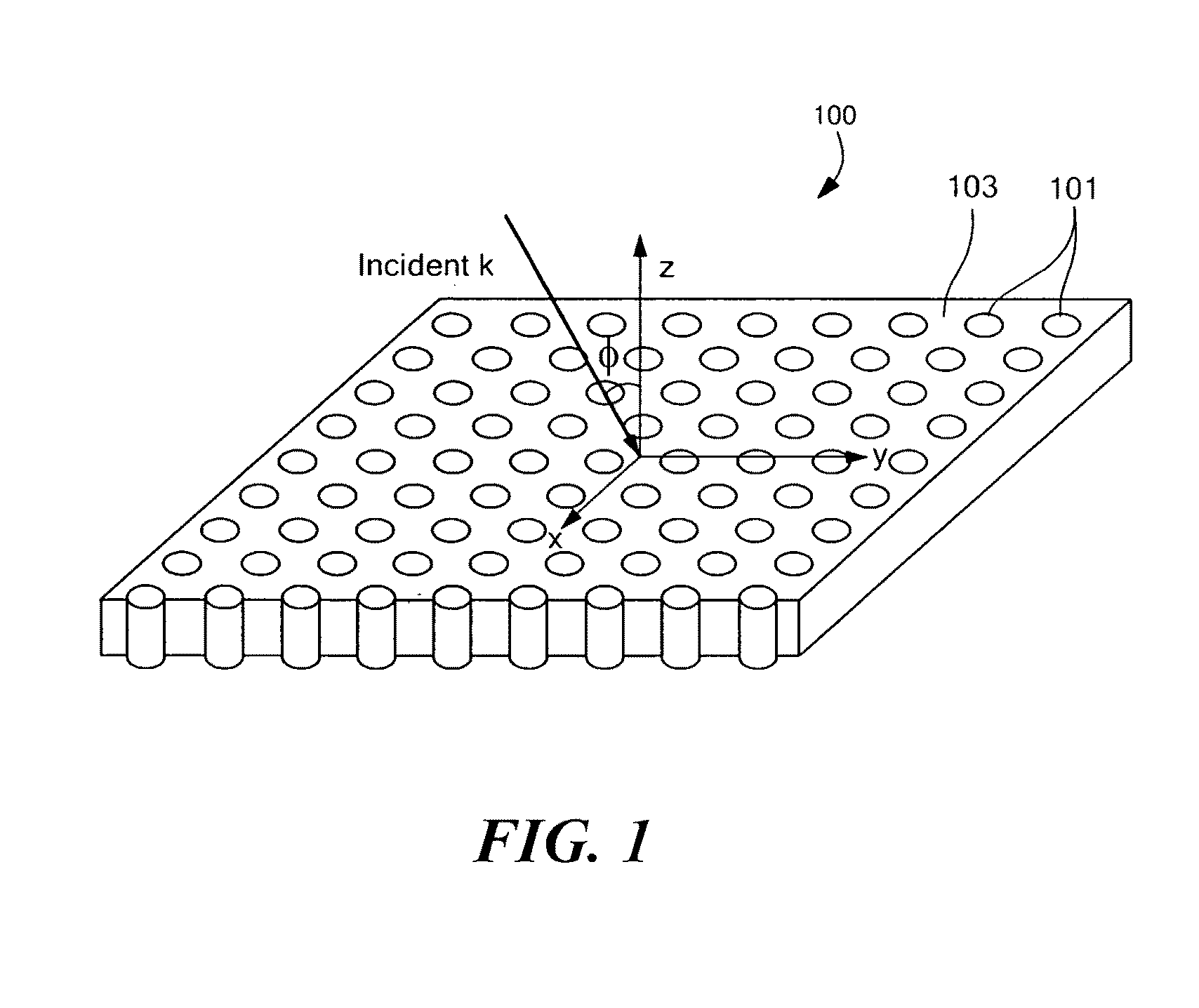

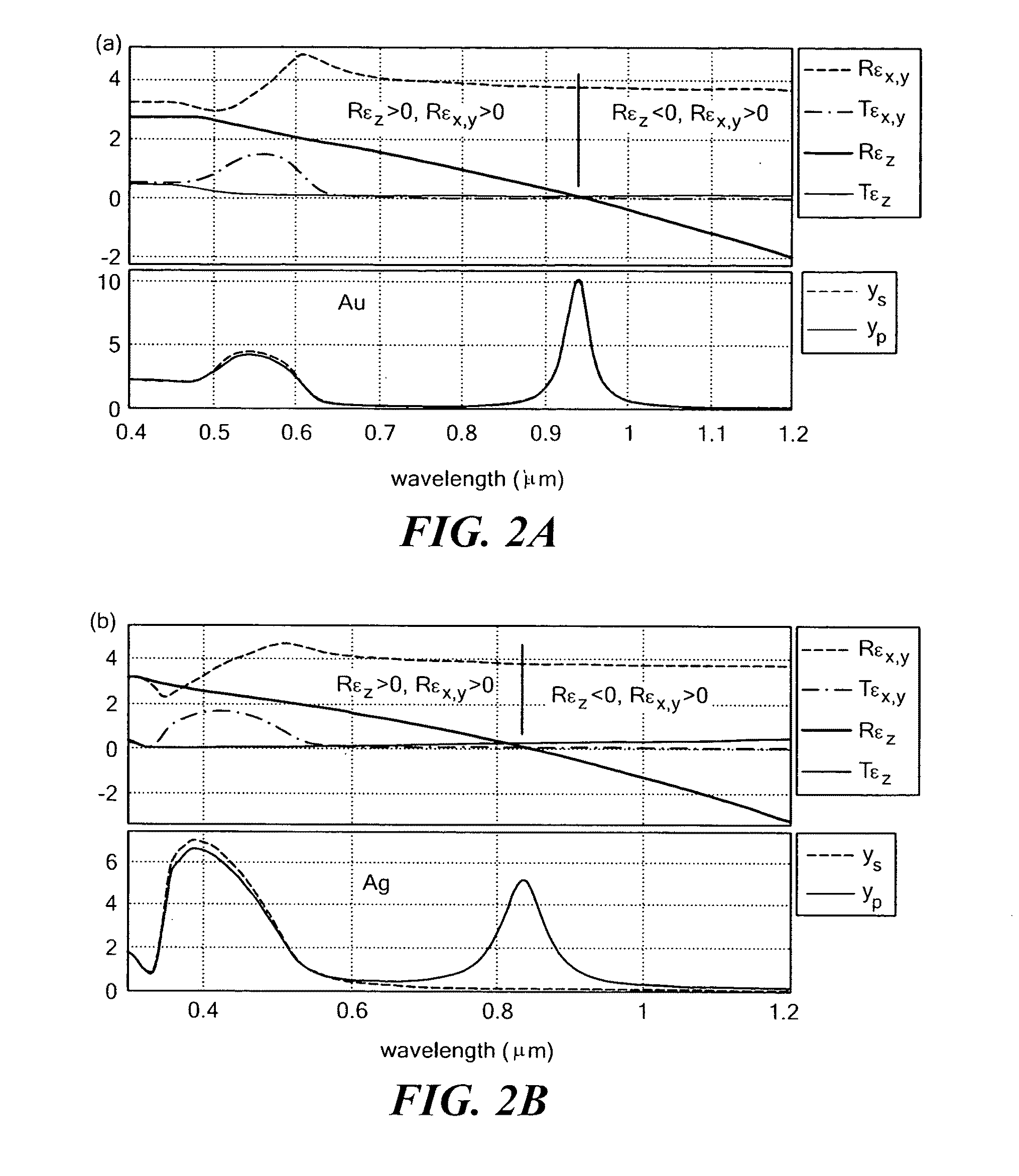

Anisotropic metal-dielectric metamaterials for broadband all-angle negative refraction and superlens imaging

InactiveUS20090040132A1Easy to makeEasy to customizeLiquid surface applicatorsCoatingsNegative refractionDielectric matrix

A metamaterial comprises a plurality of metallic nanowires embedded in a dielectric matrix. The metamaterial composite media provide broadband all-angle negative refraction and flat lens, superlens and curved hyperlens imaging in specific spectral regions over a wide range of frequencies including, for example, from deep infrared to ultraviolet frequencies.

Owner:NORTHEASTERN UNIV

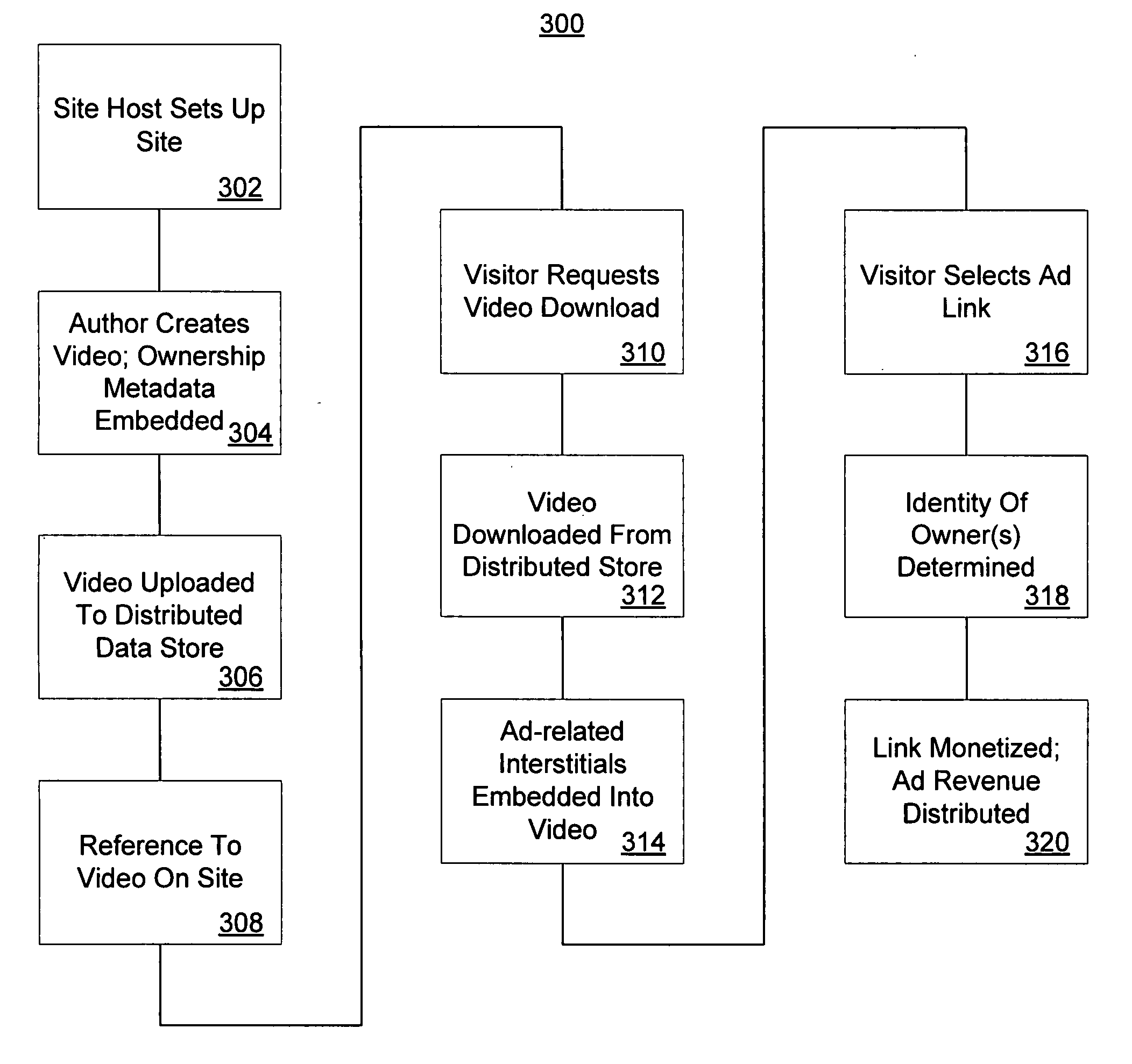

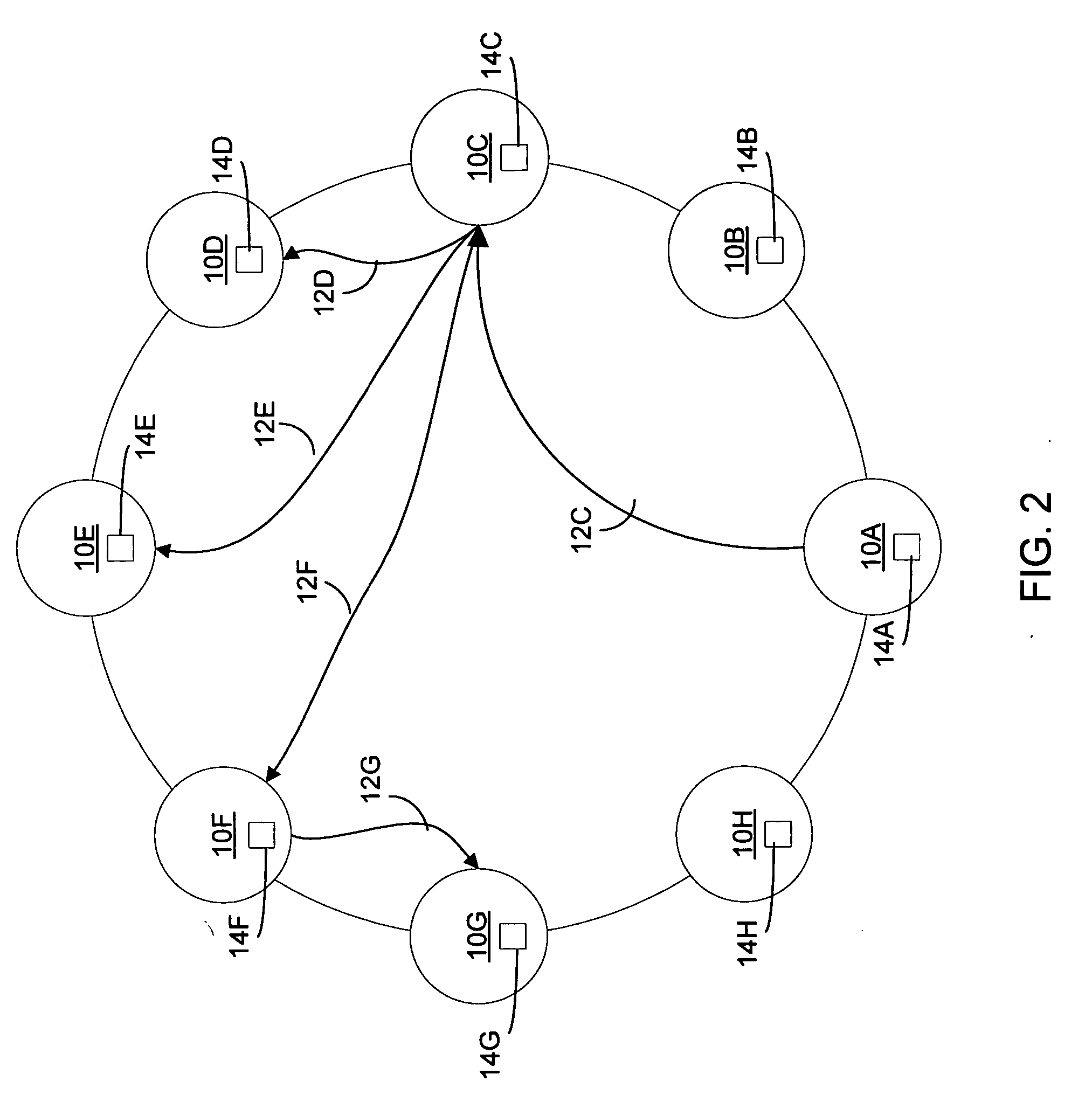

Collaborative video via distributed storage and blogging

InactiveUS20060294571A1Television system detailsAnalogue secracy/subscription systemsComposite mediaSubject matter

Systems and methods for sharing video or media content on a distributed network are disclosed. End users may be induced through a variety of ways to allocate some amount of unused disk space and otherwise idle bandwidth for storing media produced in a blogging or web-publishing context. For example, when a user creates a blog, the user may link certain video or media files to it. Such video may be kept in a distributed store across a variety of peer machines. If a visitor visits the blog, the visitor may see contextual ads based upon the subject matter associated with the blog, and the blog owner may receive a share of the advertising revenue generated. A visitor may download the video and combine it with new content. Thus, composite media files may be created from sections taken from any number of previously created video clips, each of which may be associated with a different owner. The composite media files may include pointers to any or all of the original owners, as well as the respective length of each included section. The composite video may then be added to a different blog. Anyone visiting the new blog may also see contextual ads, with pro-rated portions of the generated ad revenue flowing proportionally to each of the original media owners.

Owner:MICROSOFT TECH LICENSING LLC

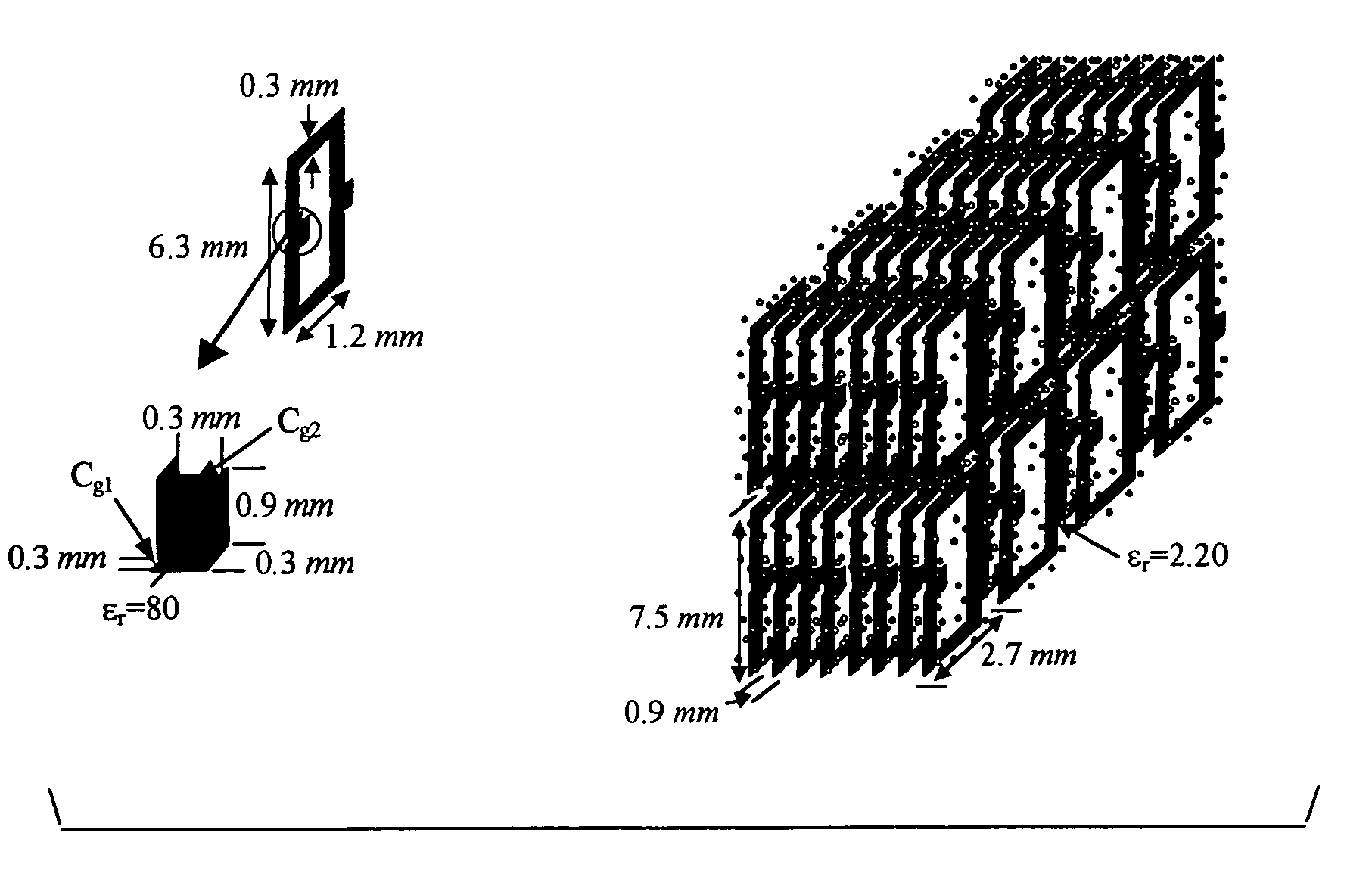

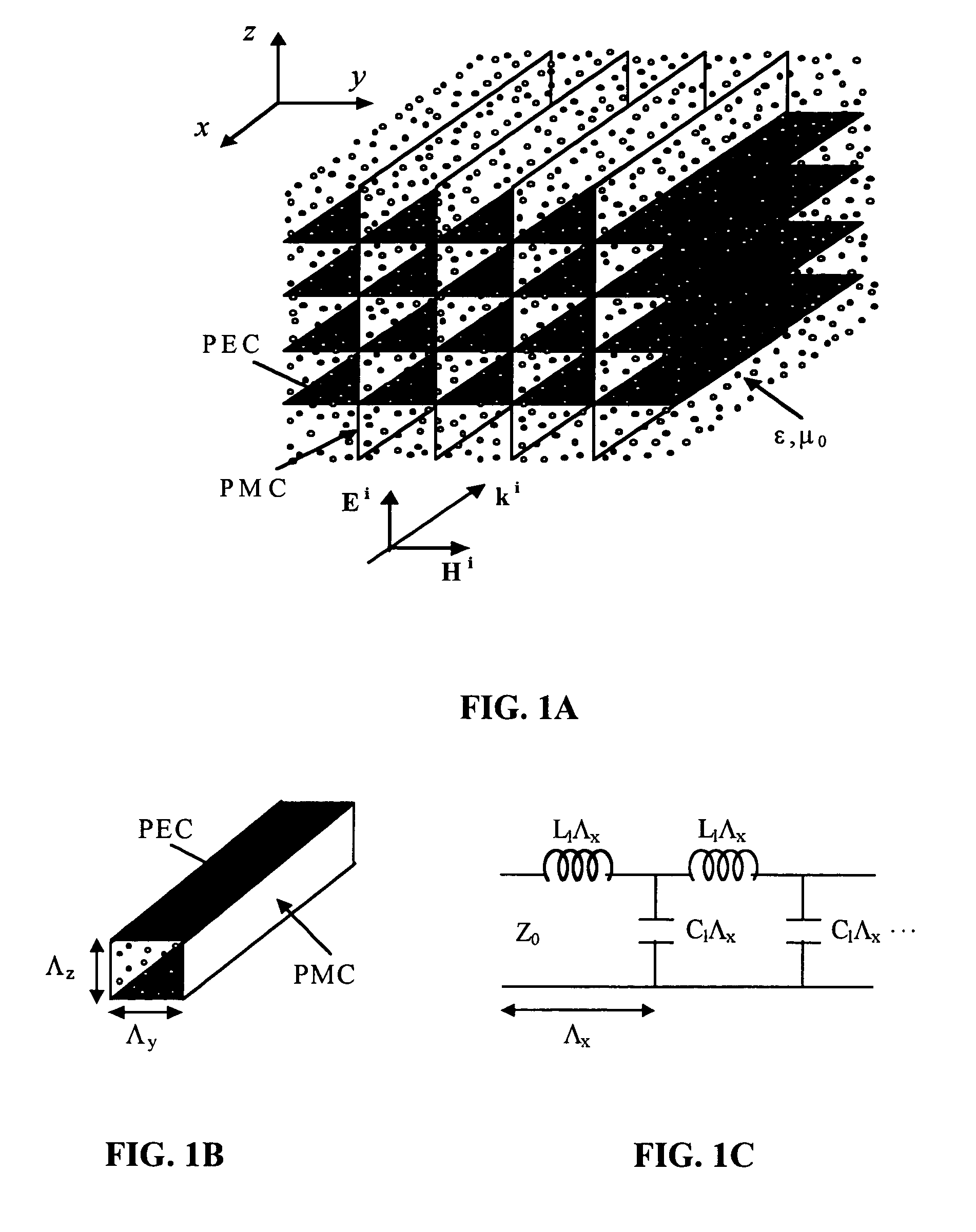

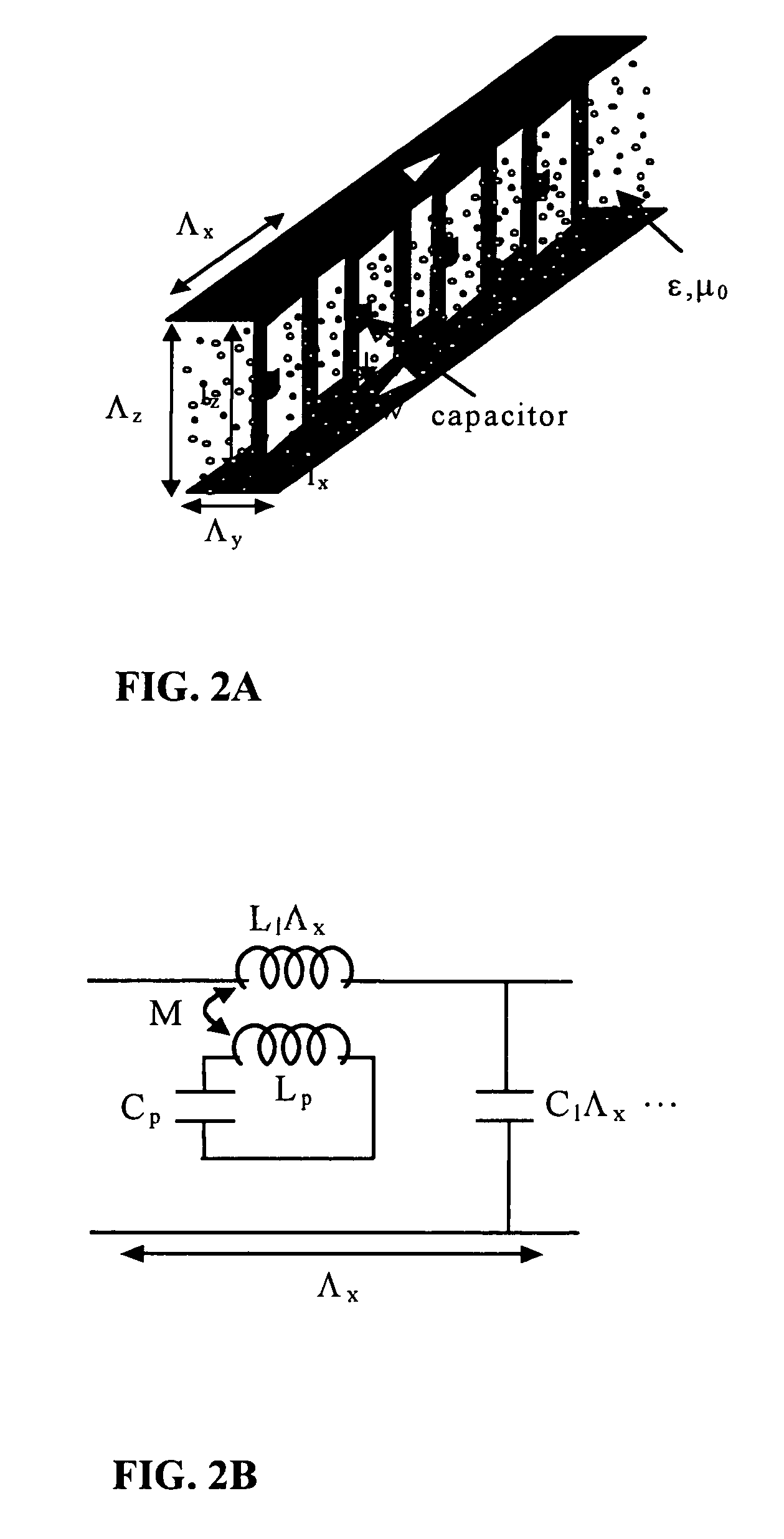

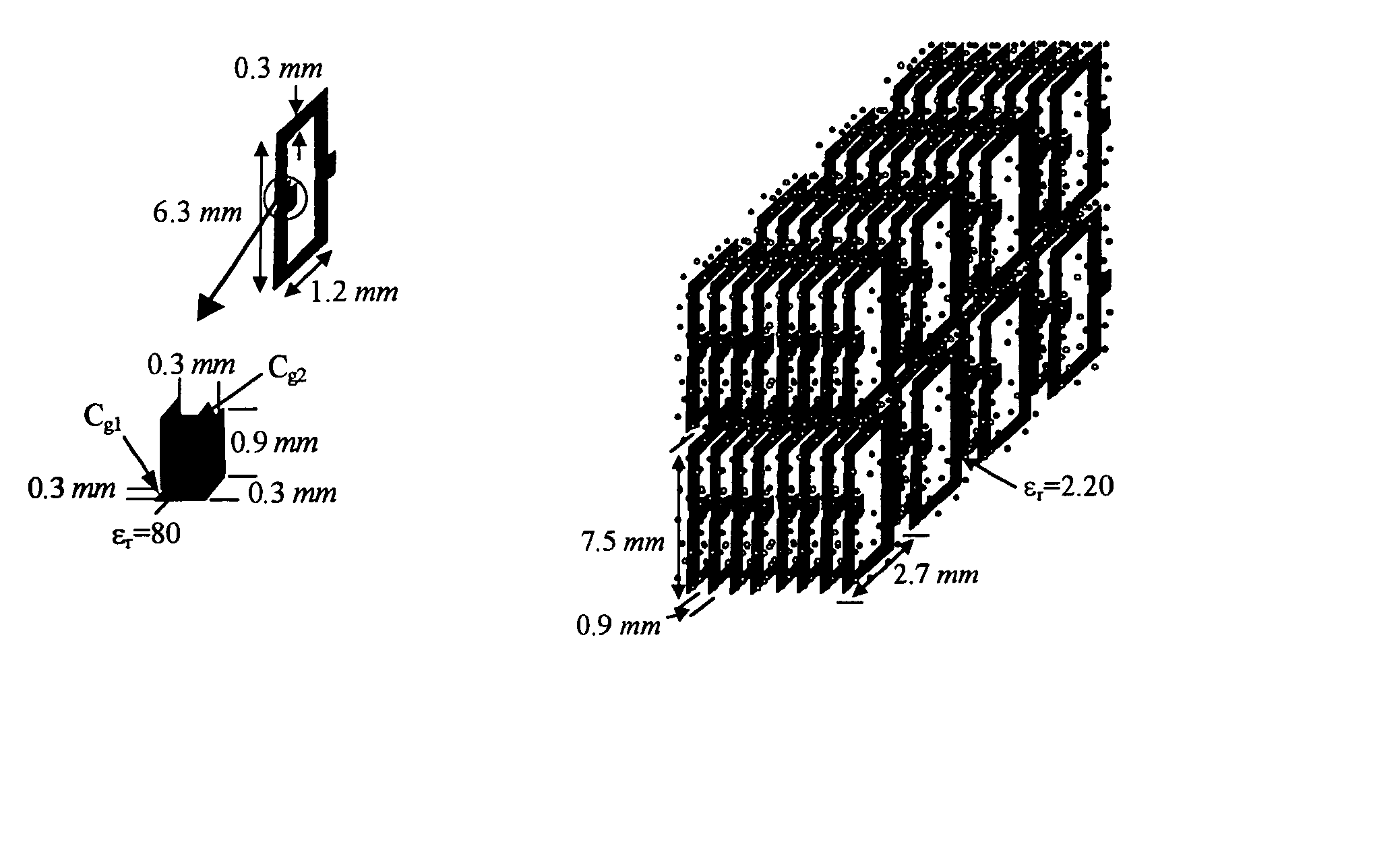

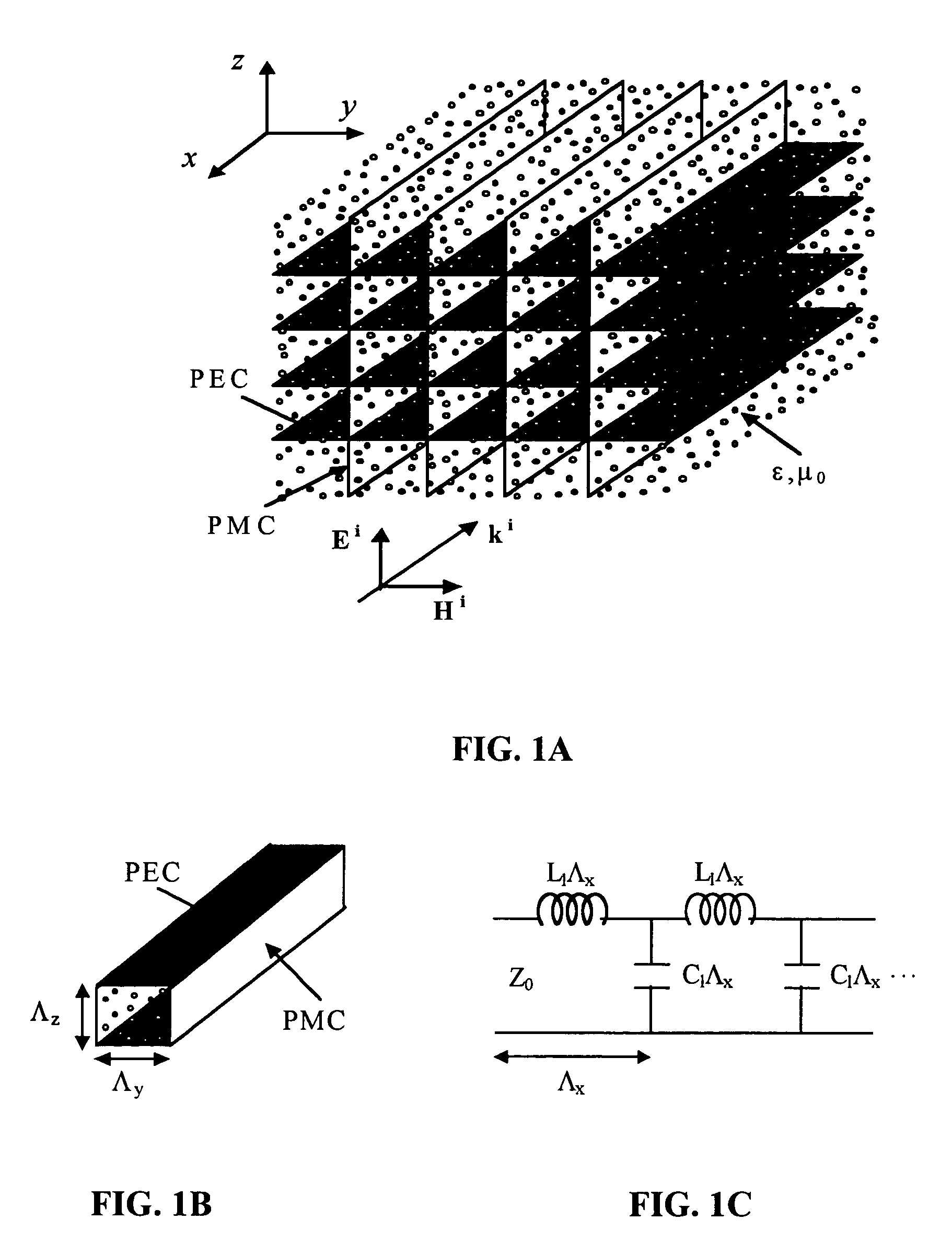

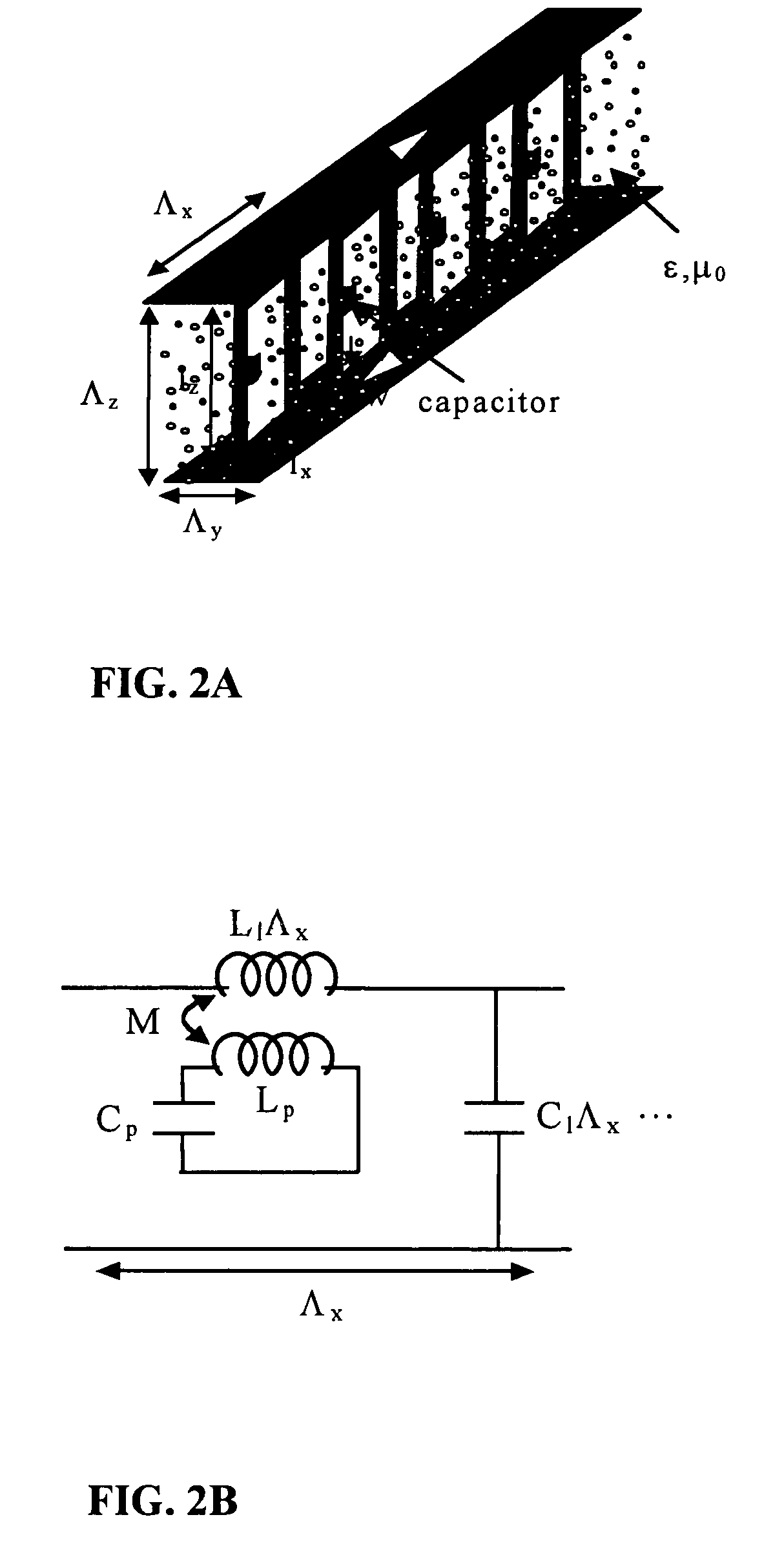

Electro-ferromagnetic, tunable electromagnetic band-gap, and bi-anisotropic composite media using wire configurations

InactiveUS6933812B2High bandwidthImprove the effective dielectric constantRadiating elements structural formsResonatorsDielectricElectricity

An artificial electro-ferromagnetic meta-material demonstrates the design of tunable band-gap and tunable bi-anisotropic materials. The medium is obtained using a composite mixture of dielectric, ferro-electric, and metallic materials arranged in a periodic fashion. By changing the intensity of an applied DC field the permeability of the artificial electro-ferromagnetic can be properly varied over a particular range of frequency. The structure shows excellent Electromagnetic Band-Gap (EBG) behavior with a band-gap frequency that can be tuned by changing the applied DC field intensity. The building block of the electro-ferromagnetic material is composed of miniaturized high Q resonant circuits embedded in a low-loss dielectric background. The resonant circuits are constructed from metallic loops terminated with a printed capacitor loaded with a ferro-electric material. Modifying the topology of the embedded-circuit, a bi-anisotropic material (tunable) is examined. The embedded-circuit meta-material is treated theoretically using a transmission line analogy of a medium supporting TEM waves.

Owner:RGT UNIV OF MICHIGAN

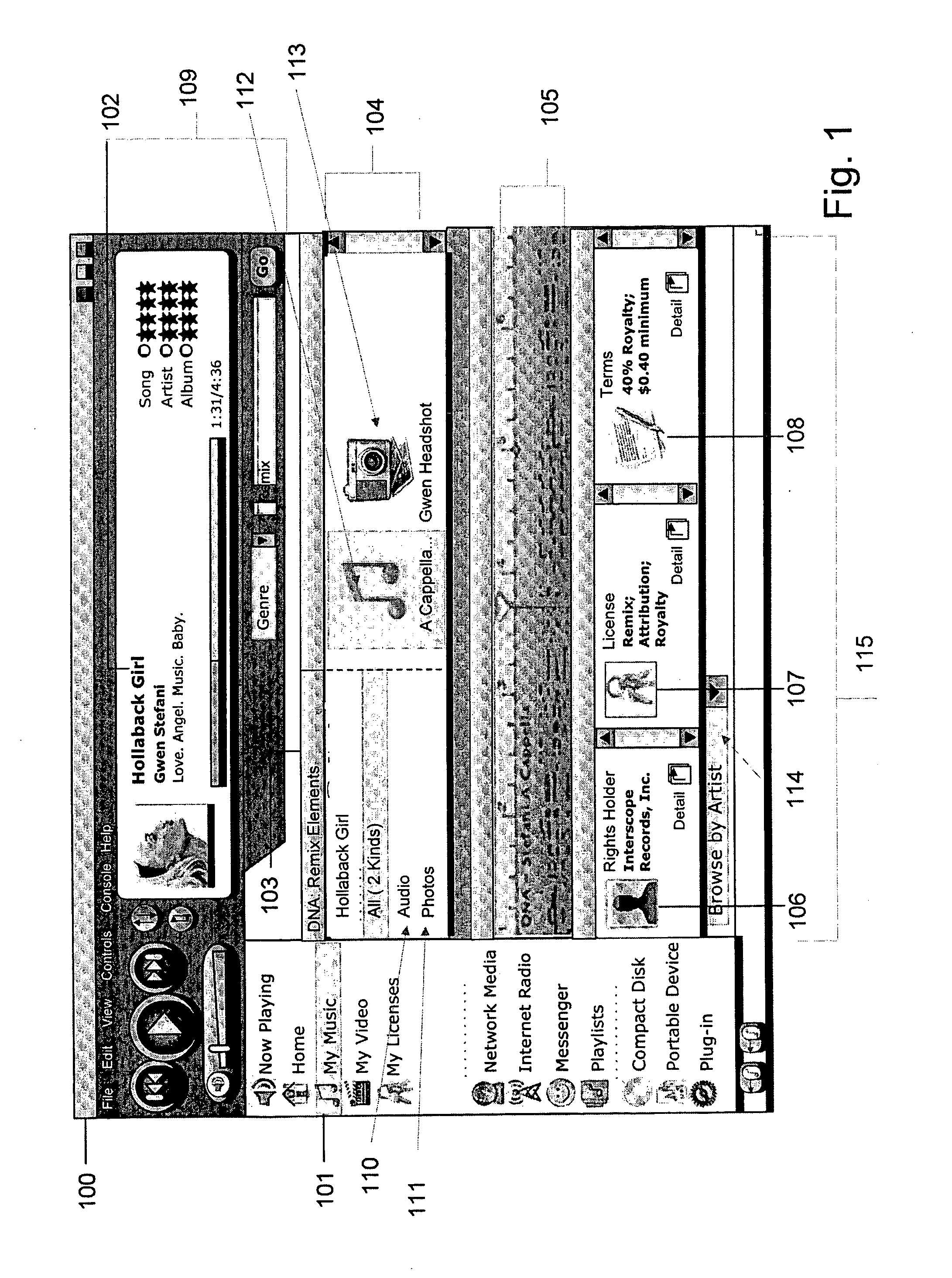

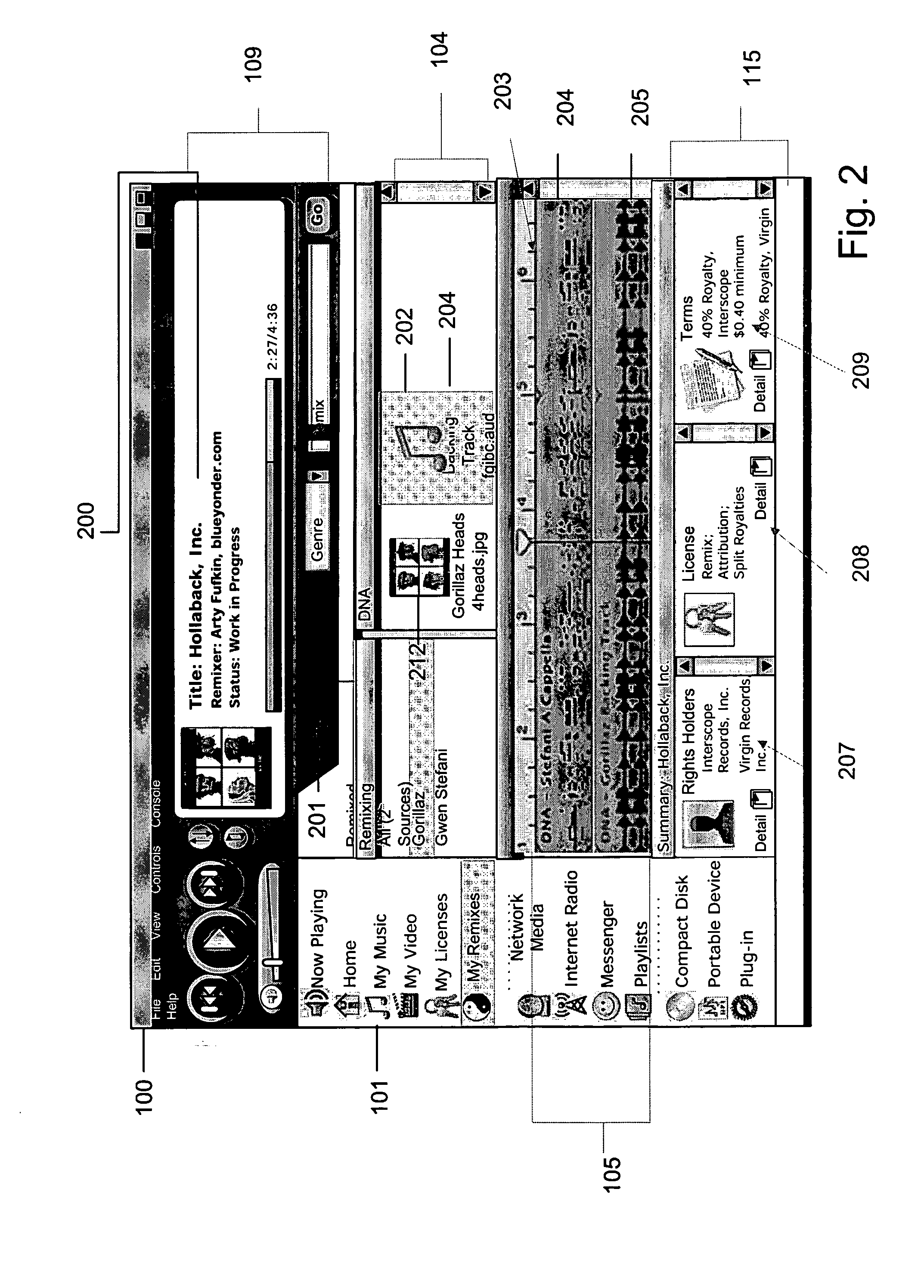

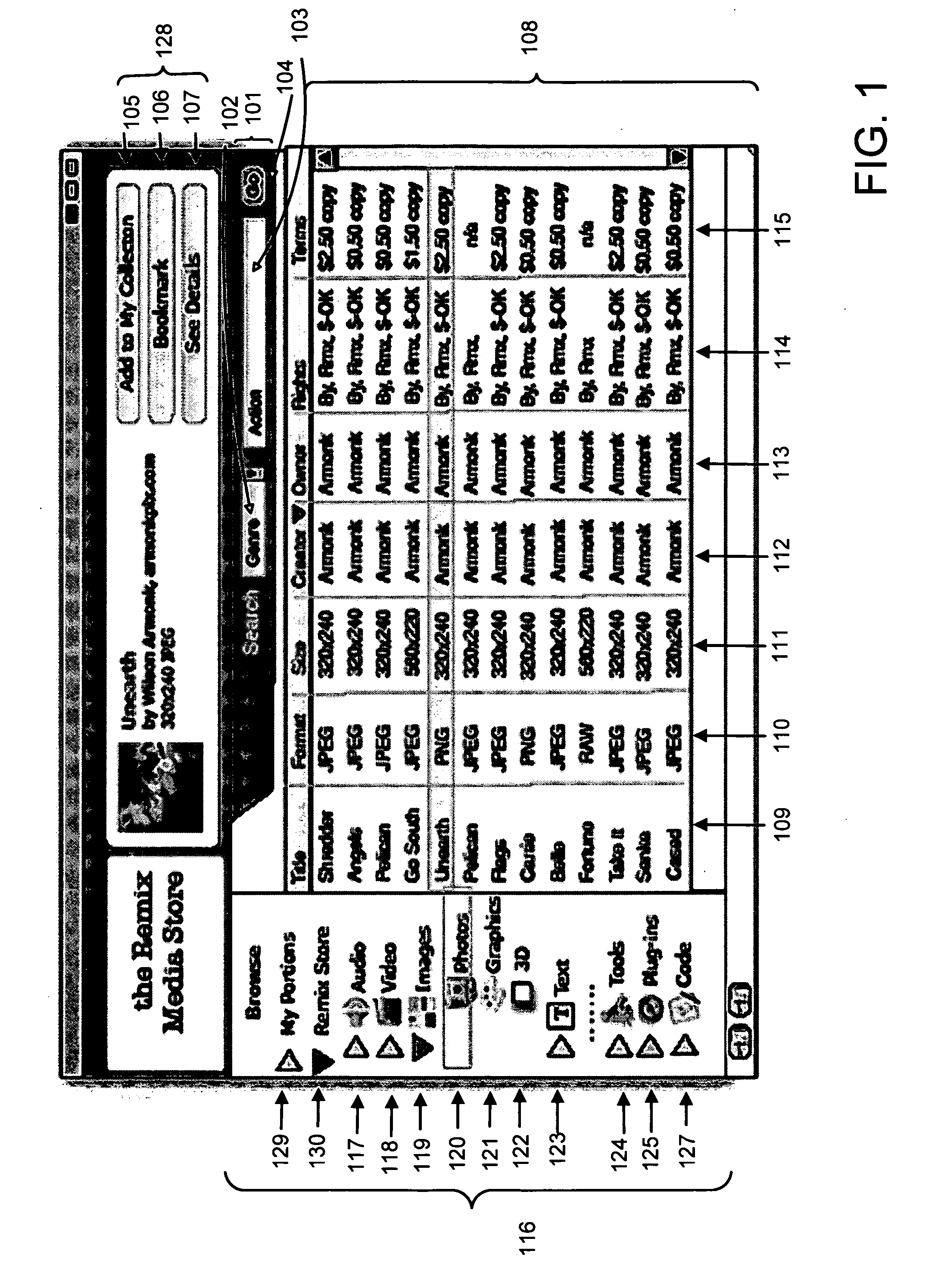

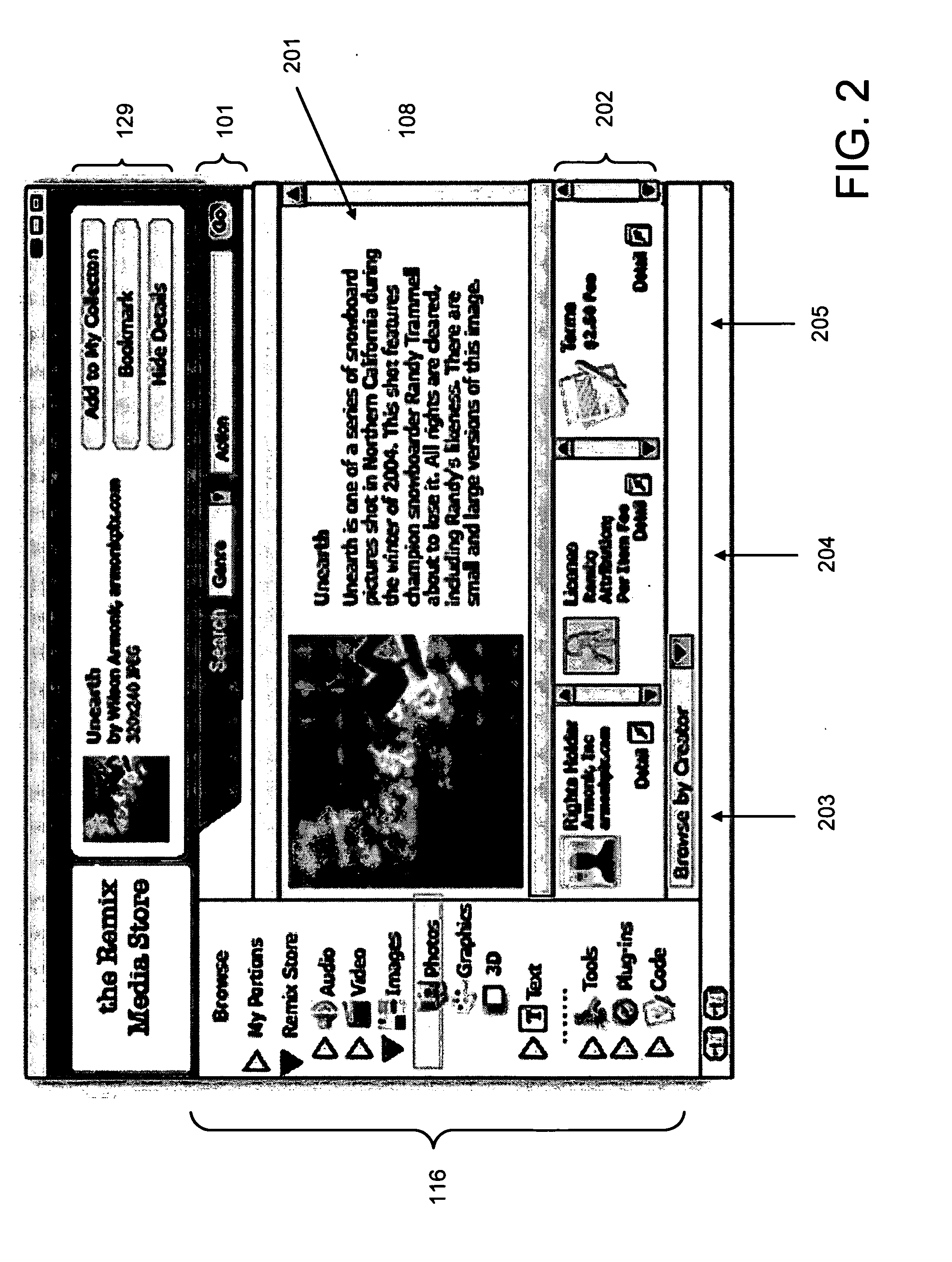

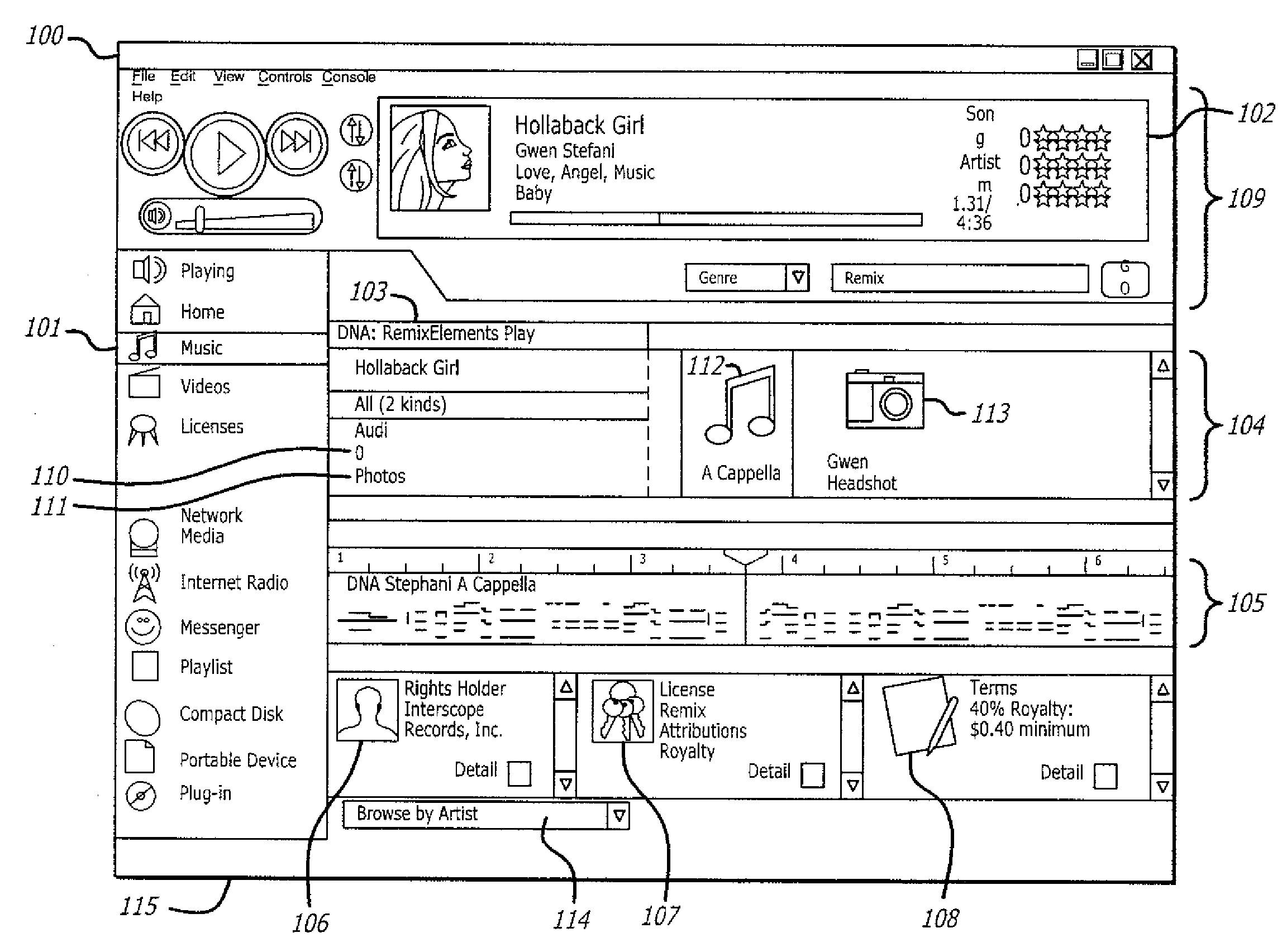

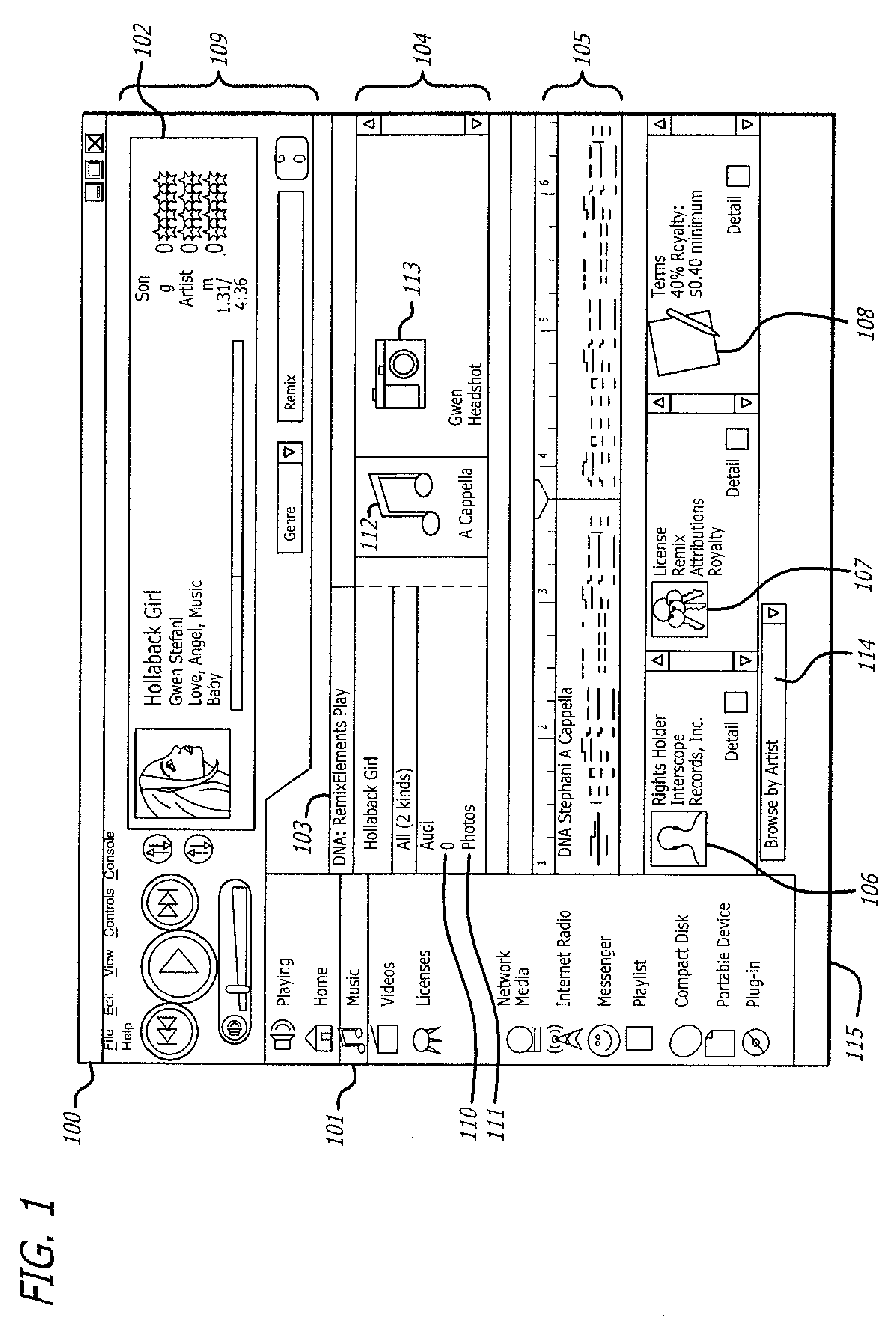

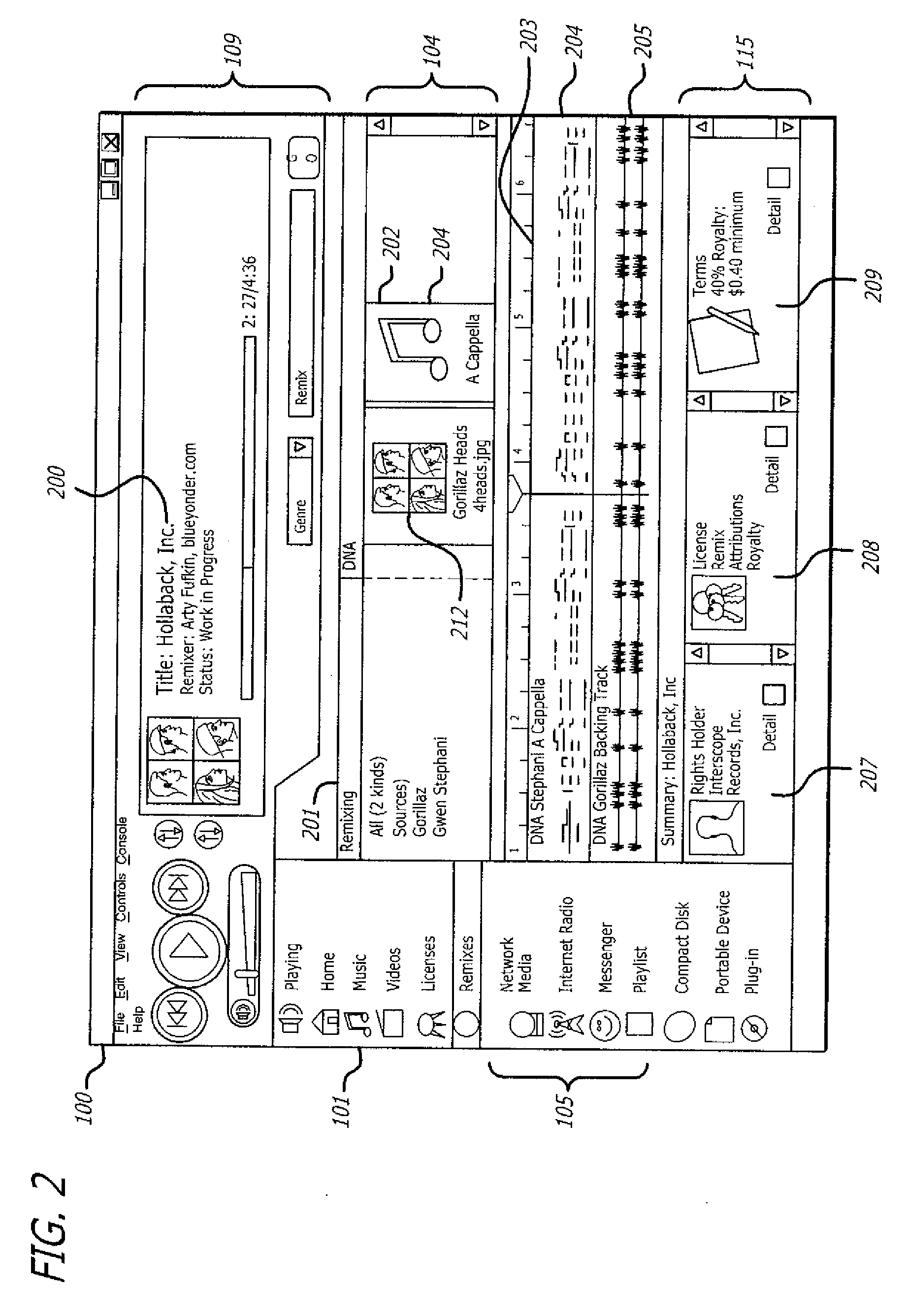

Set of metadata for association with a composite media item and tool for creating such set of metadata

ActiveUS20070083762A1User identity/authority verificationMetadata multimedia retrievalComposite mediaData set

A set of metadata for association with the composite media item and a tool for creating a composite media item with an associated set metadata. In one embodiment, the tool comprises a component for extracting a portion of a first media item having first metadata and for extracting a portion of a second media item having second metadata, a component for combining the first portion and the second portion to form a composite media item, and a component for analyzing the first metadata and the second metadata to extract portions of the first and second metadata to form a new set of metadata for association with the composite media item. In one embodiment, the new metadata is a data container.

Owner:HUAWEI TECH CO LTD

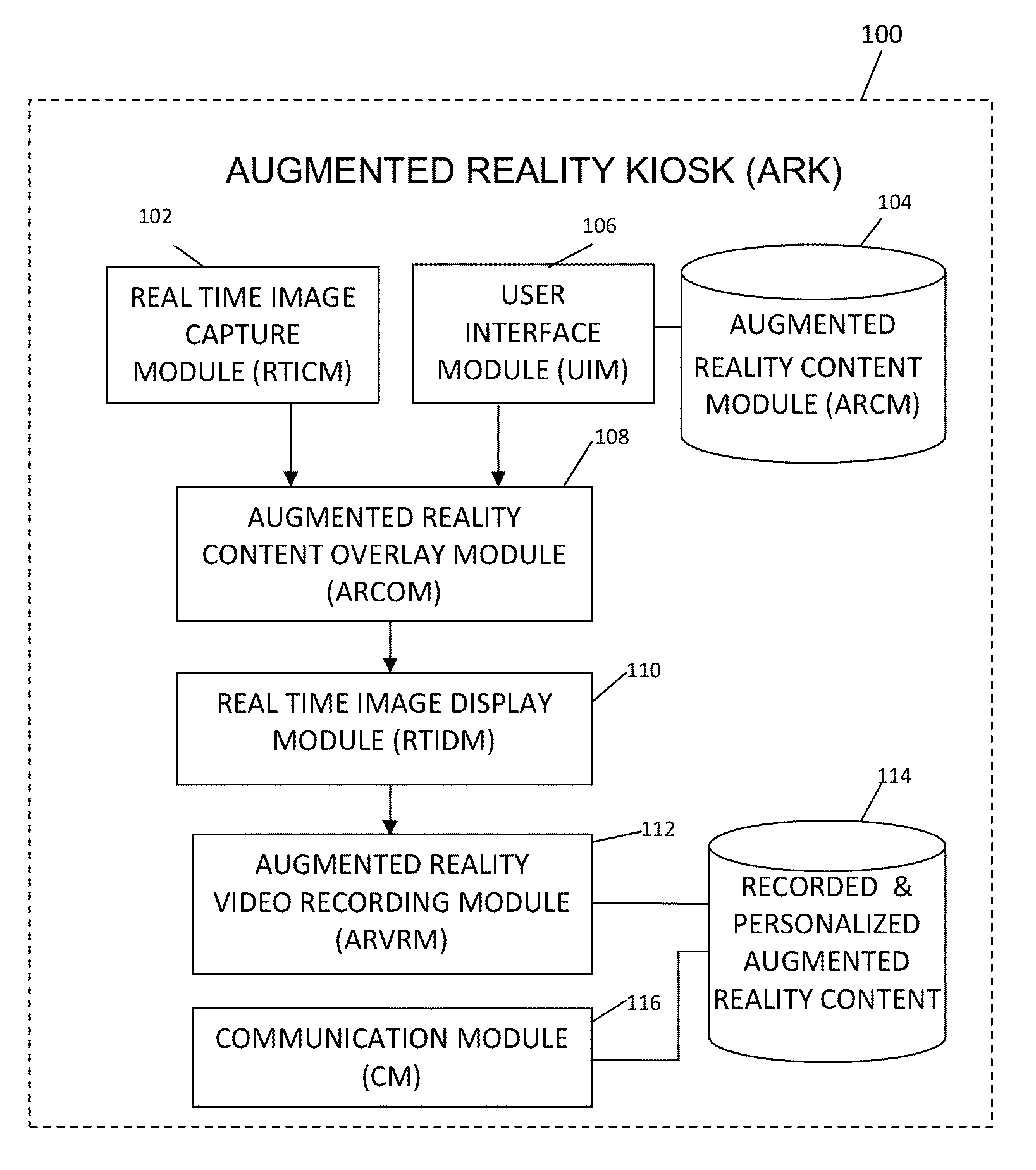

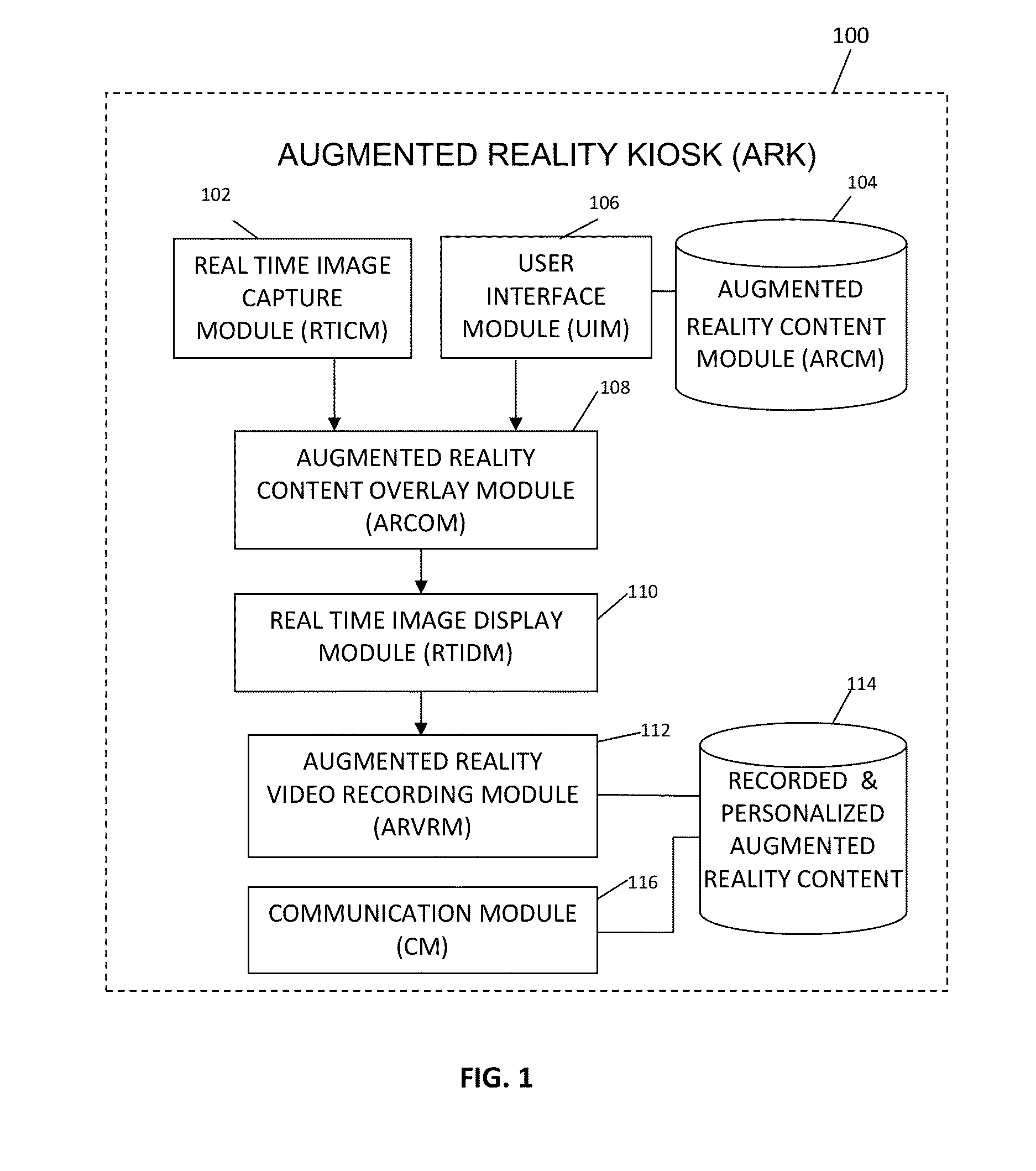

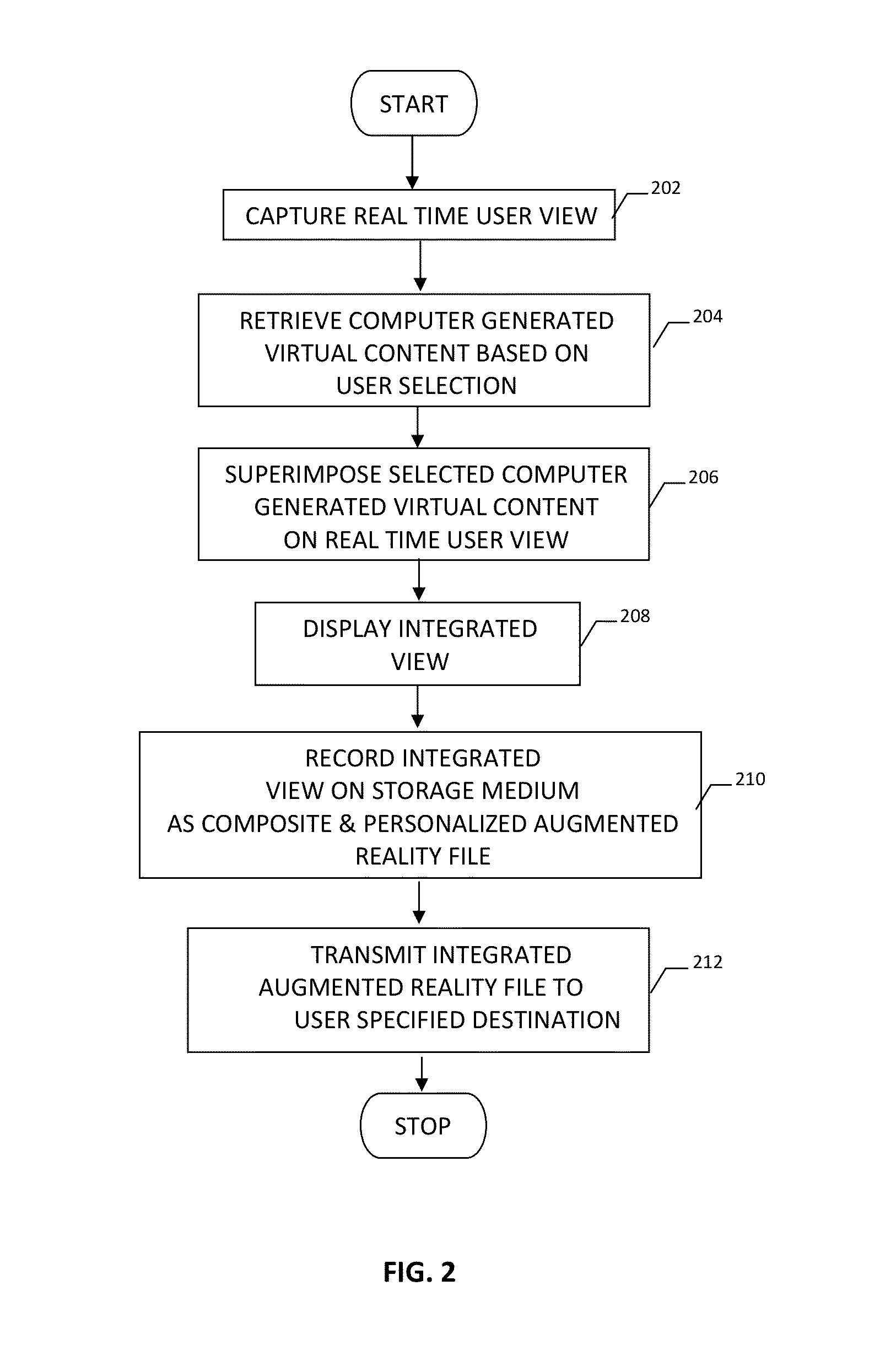

Novel Augmented Reality Kiosks

InactiveUS20140178029A1Improve viewing effectTelevision system detailsColor television detailsPersonalizationNon real time

The invention discloses an apparatus and system for establishing an Augmented Reality (AR) Kiosk (ARK) in public places or social venues such as, shopping mall, public transportation terminal, hotel, trade show, conference, convention center, expo, museum, library, college / university campus, amusement park, etc. Categories of ARKs disclosed include, Public and Private ARK, Web and Mobile Ark and their variants. ARK deploys a camera to capture, in real time, user's physical world environment, augments camera view by overlaying one or more layers of contextual computer-generated virtual content, and allows user / users to interact with the virtual content by positioning at a predefined spot in front of a digital display and the camera. Such interaction is recorded in real time, requiring zero post-production time, as composite media file, personalized with recipient's credentials, and instantly sent via Internet to one or more user specified destinations for future use and sharing with friends and family.

Owner:RAHEMAN ALI FAZAL +1

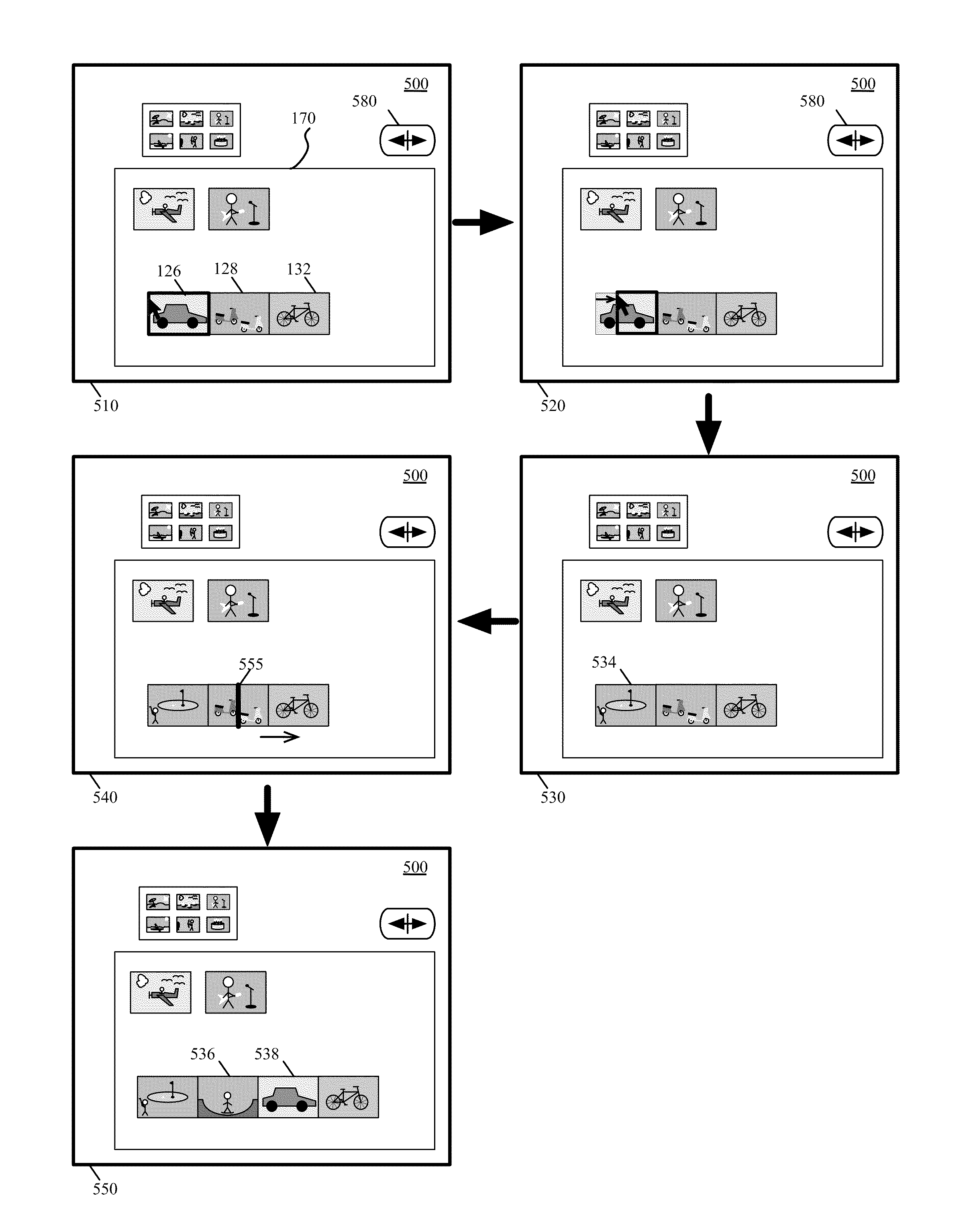

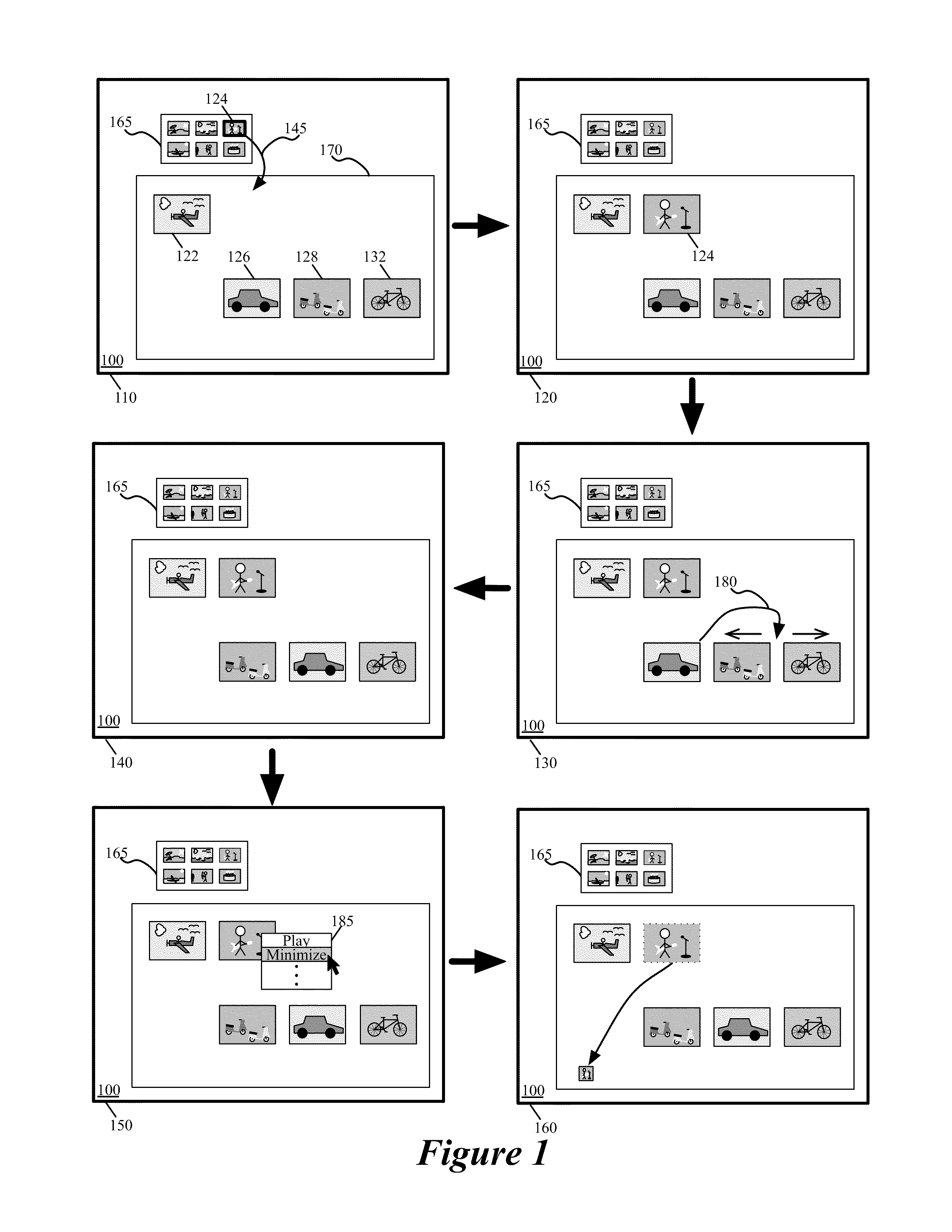

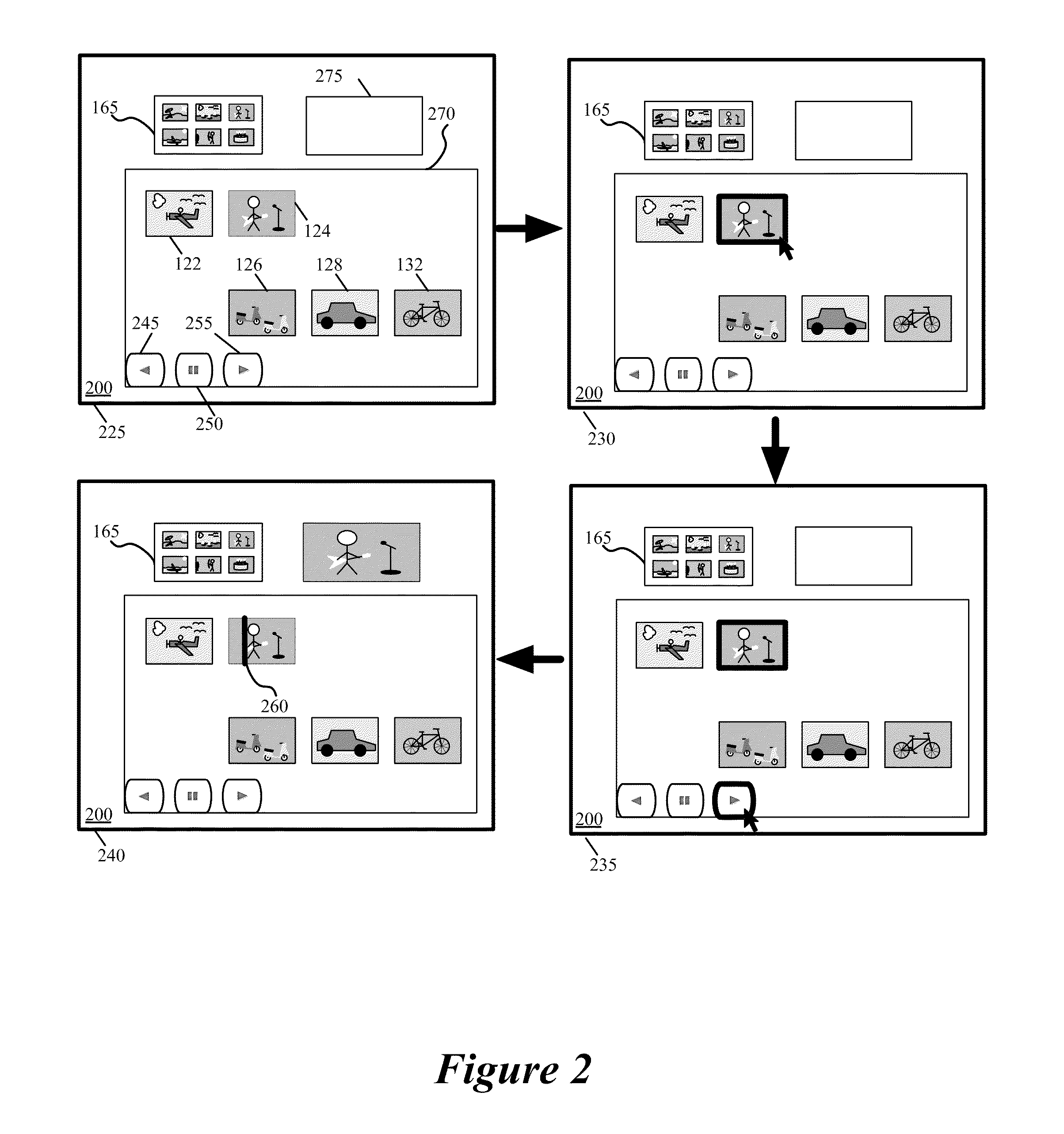

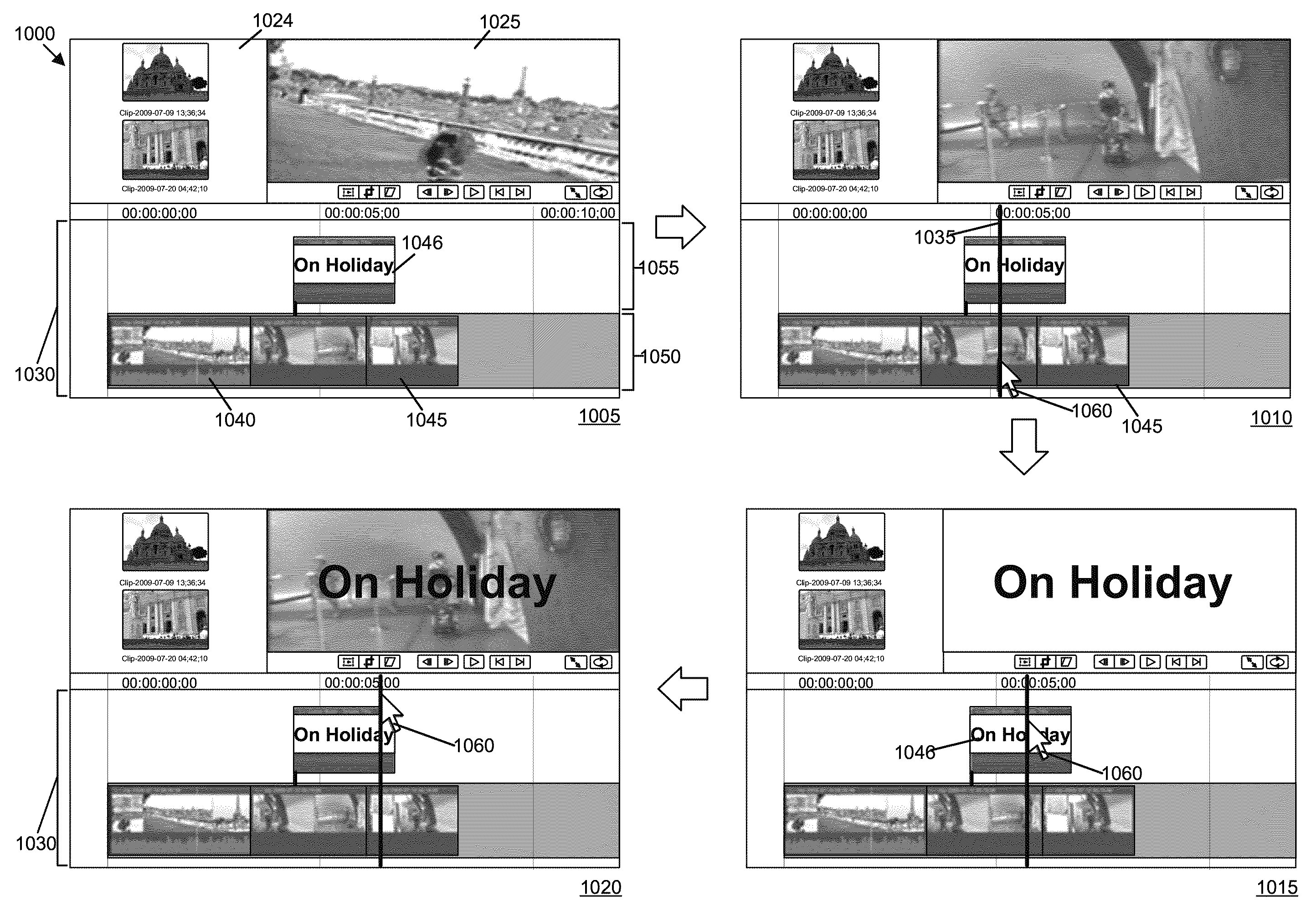

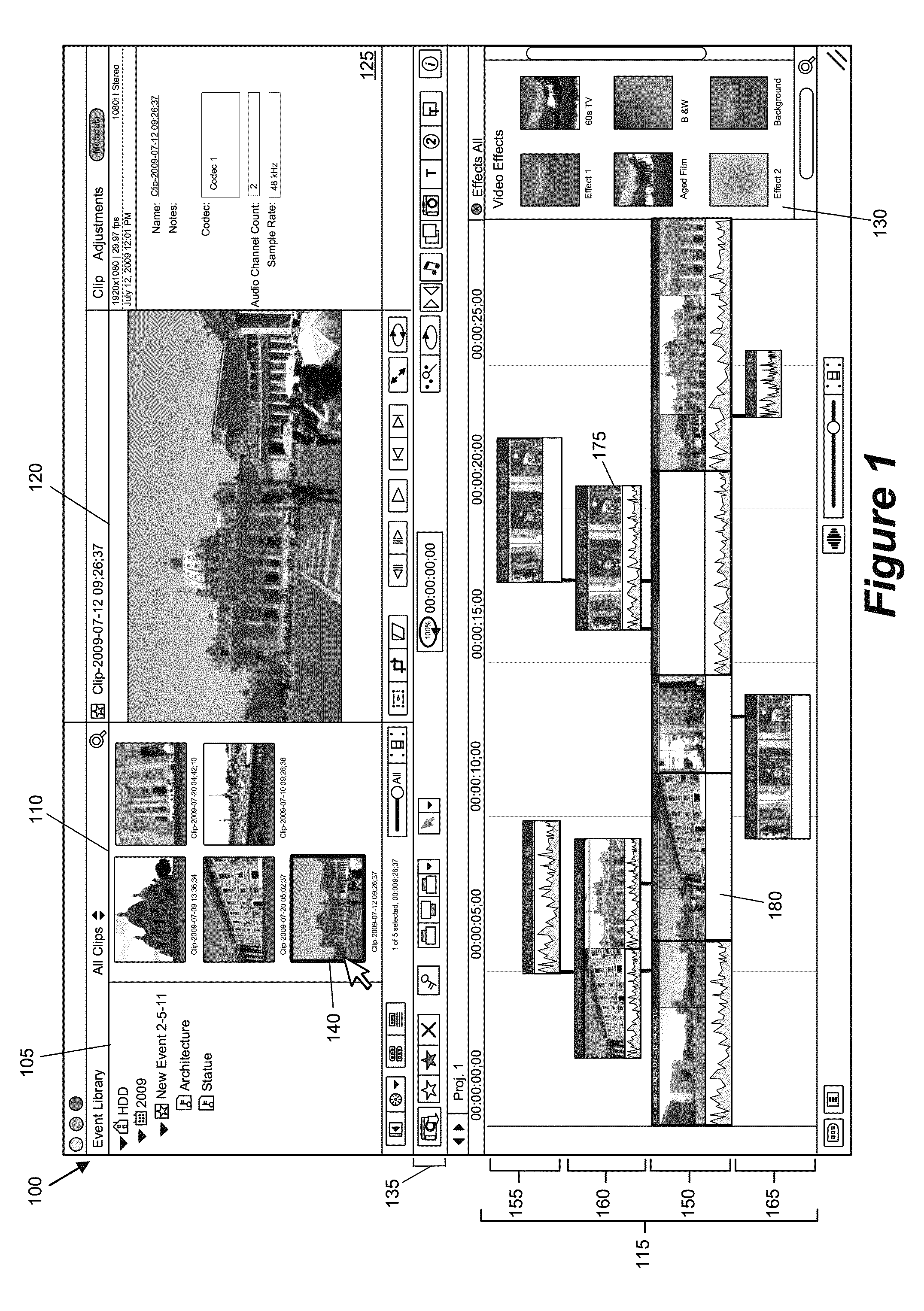

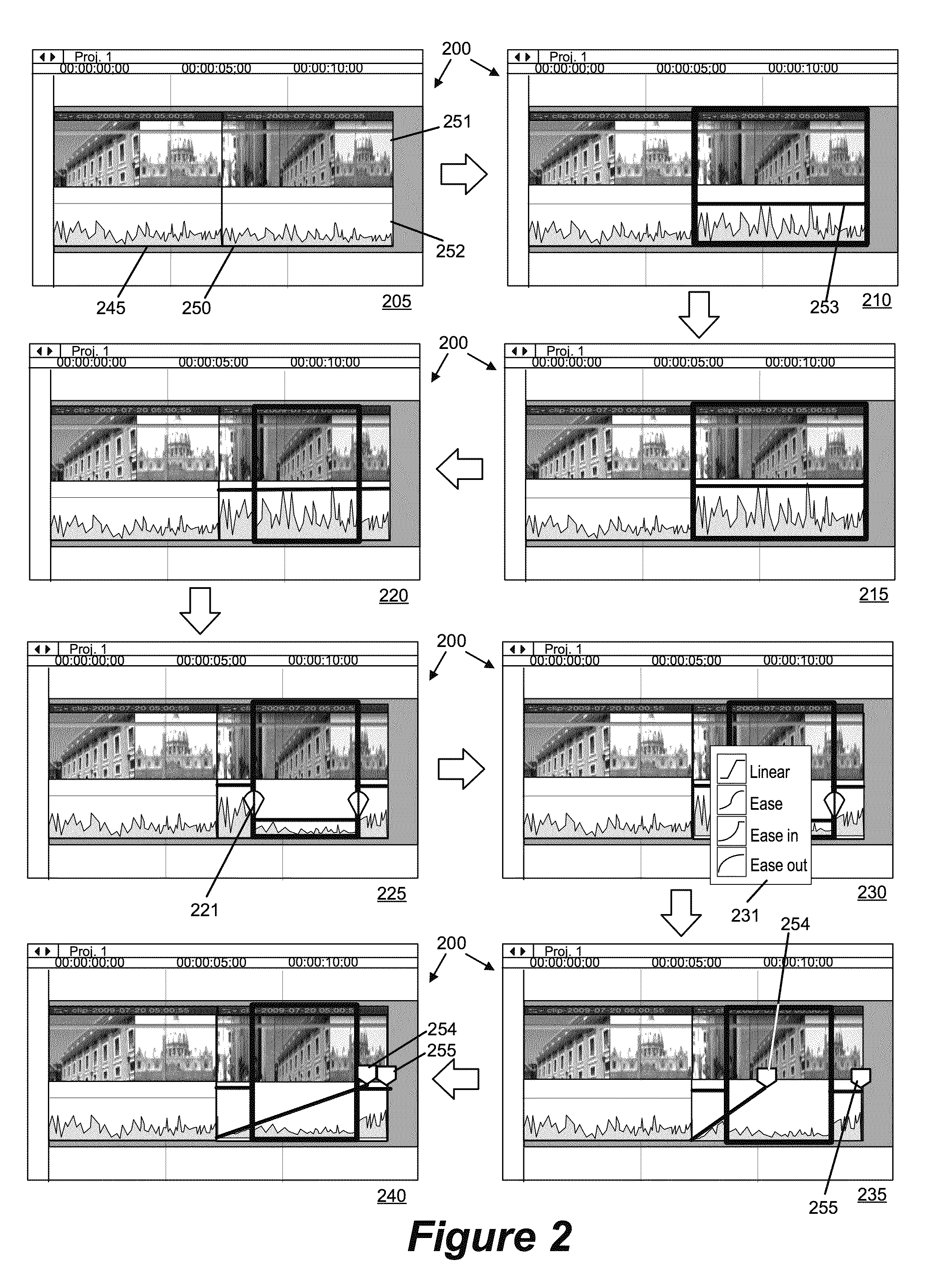

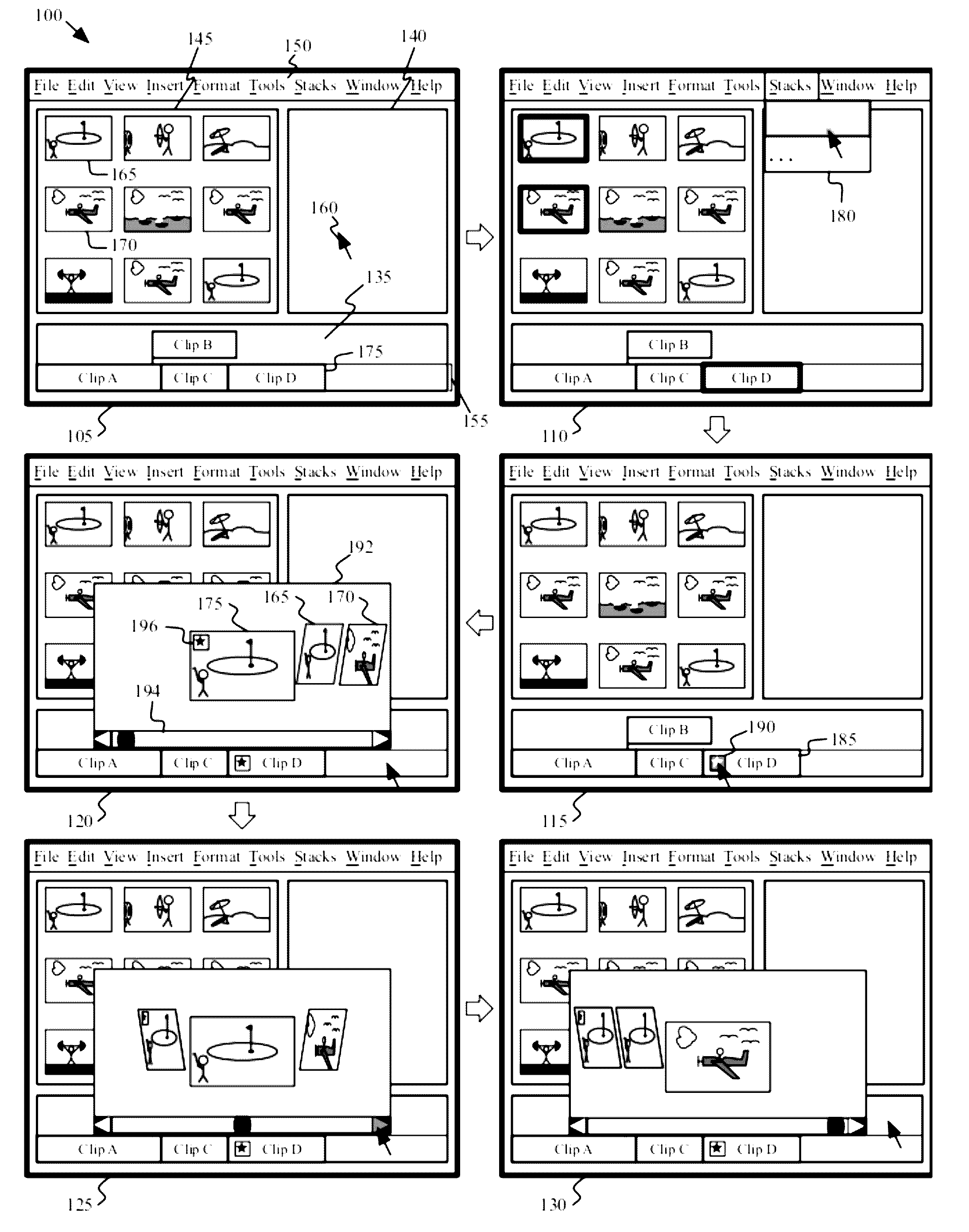

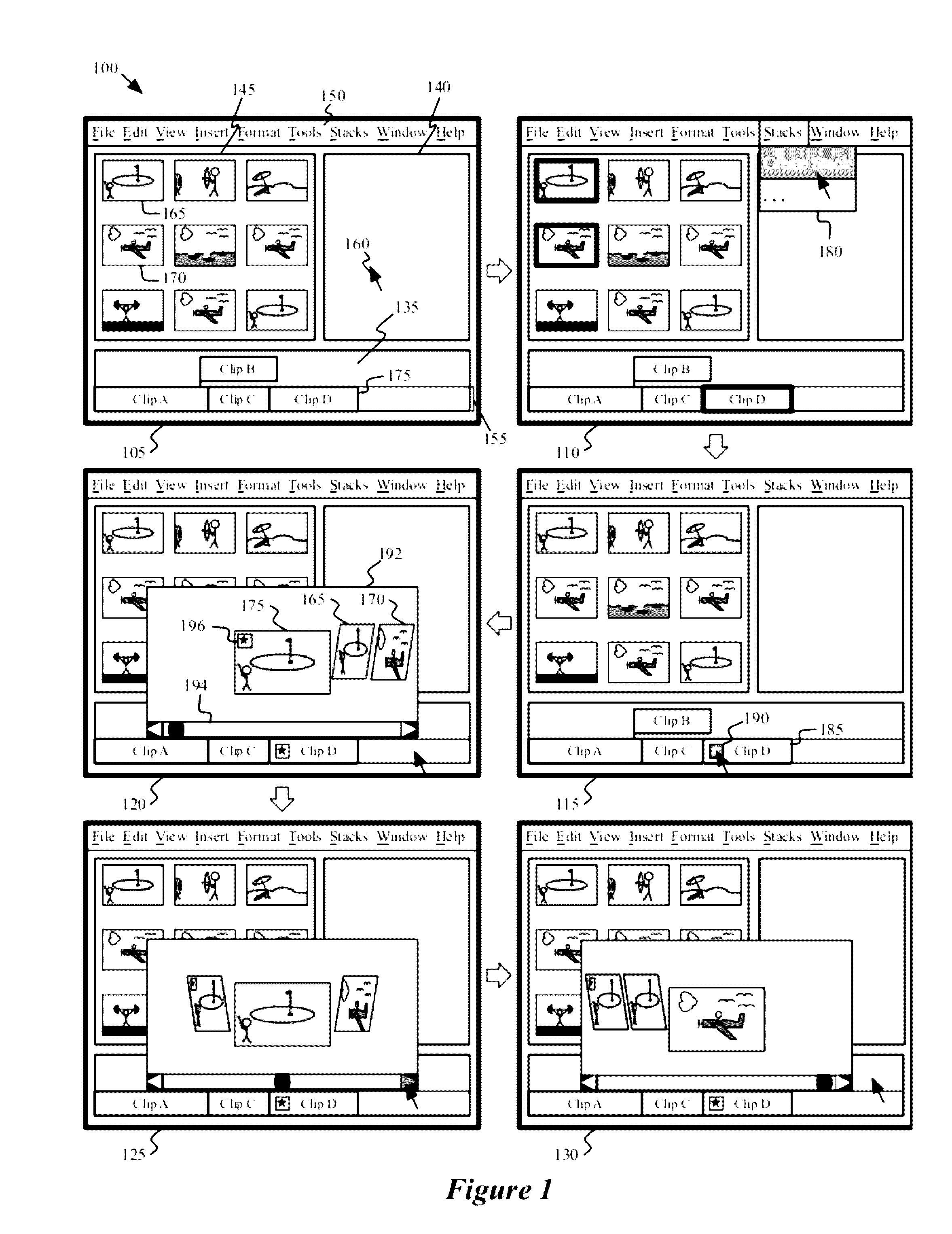

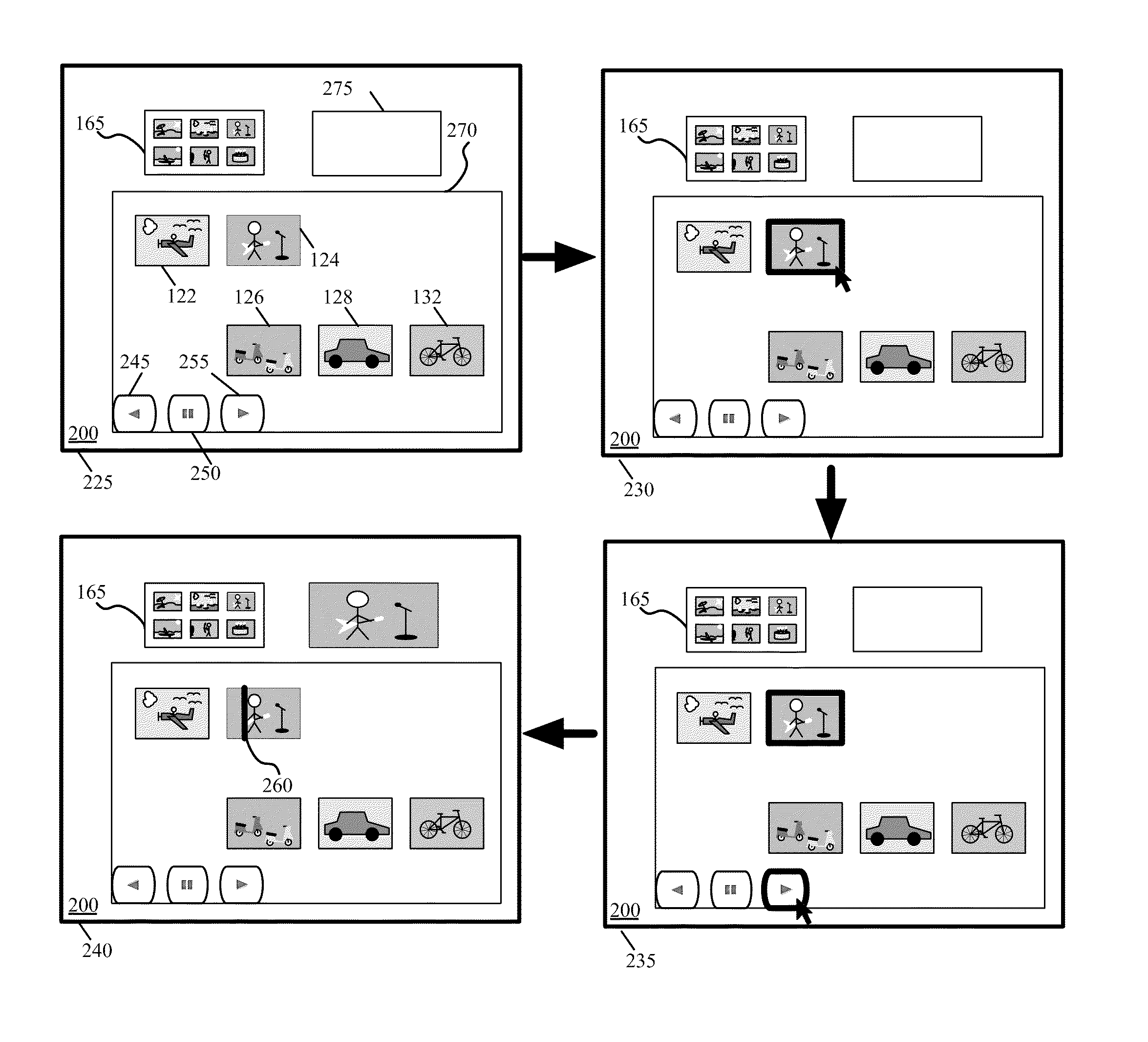

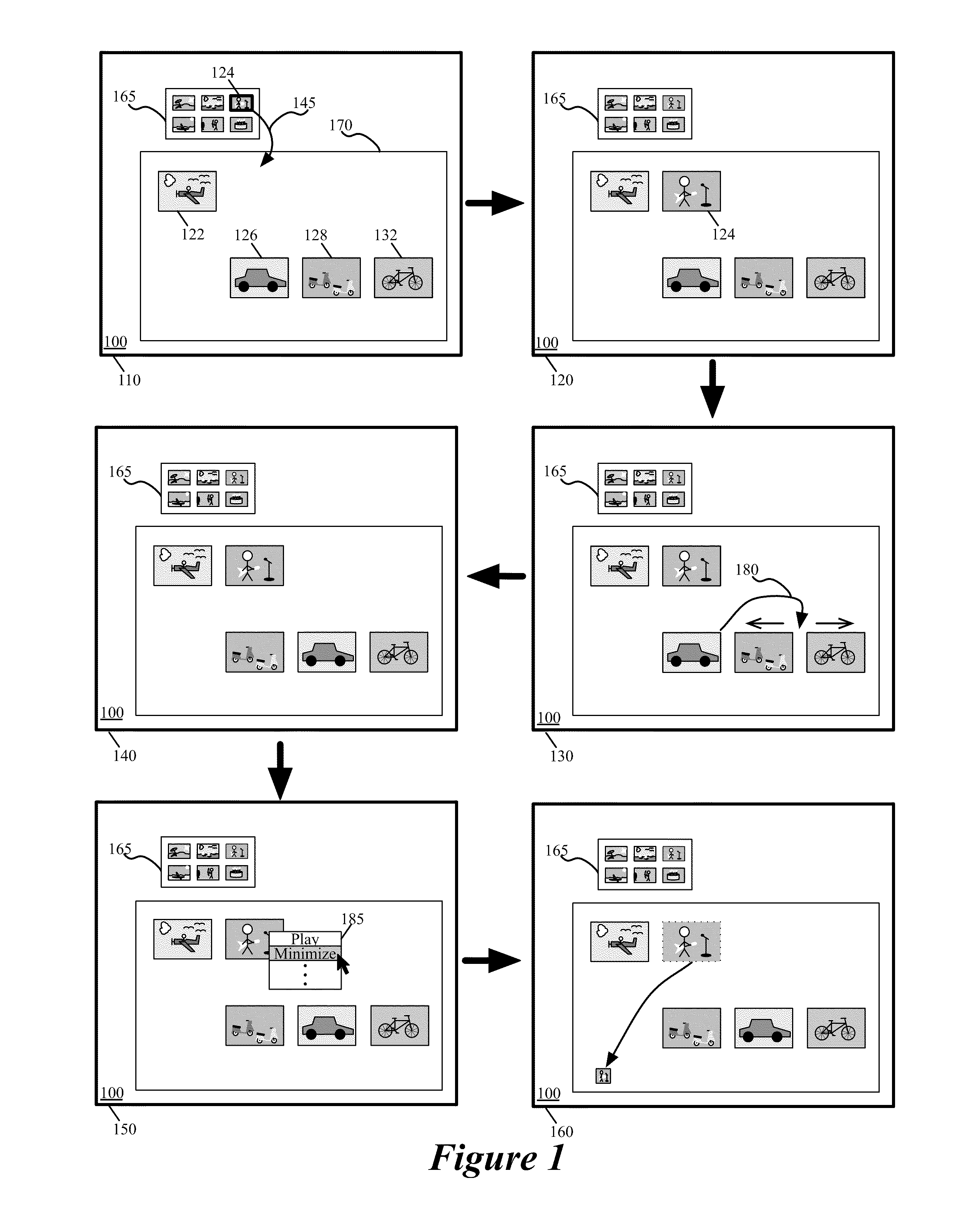

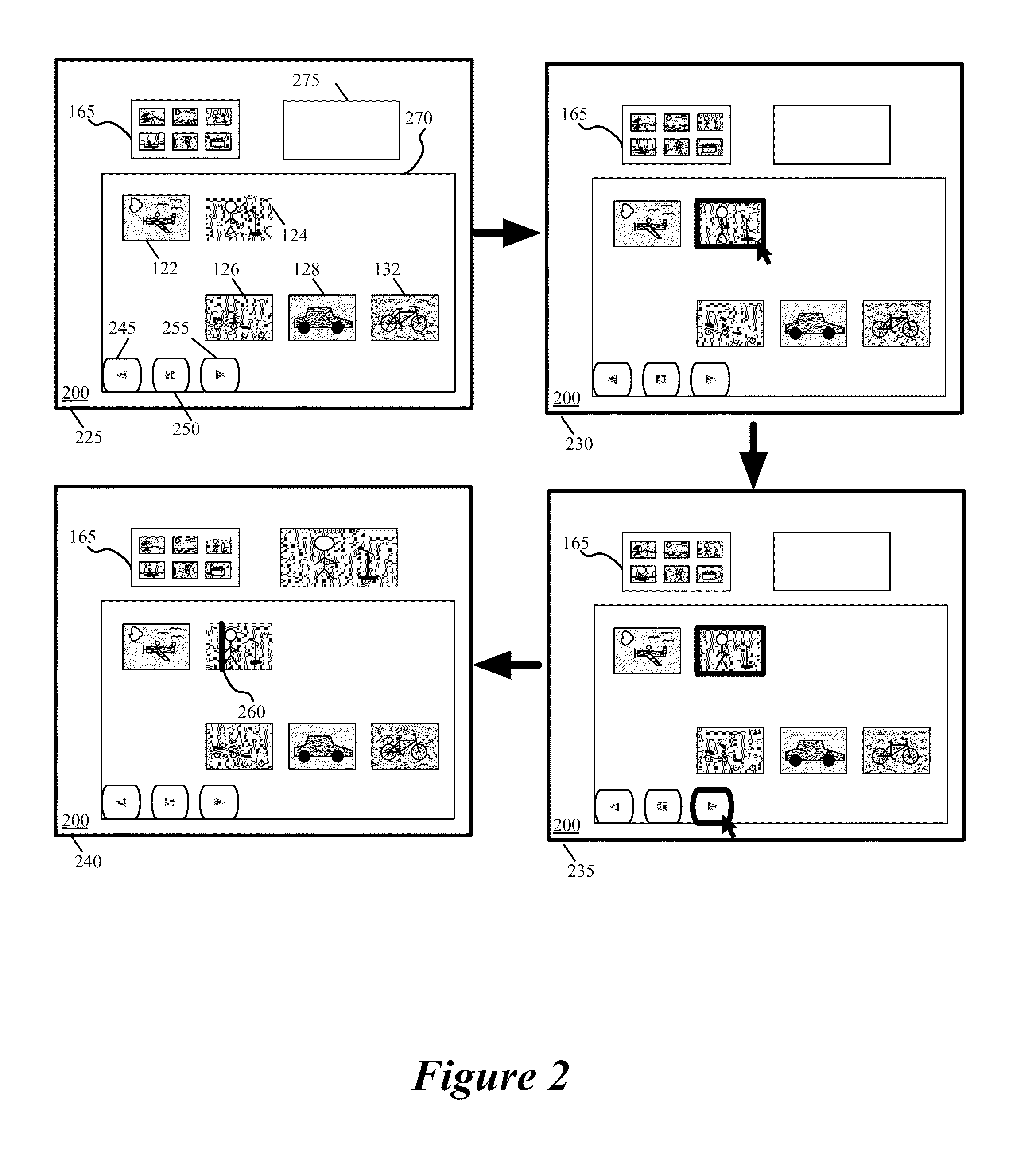

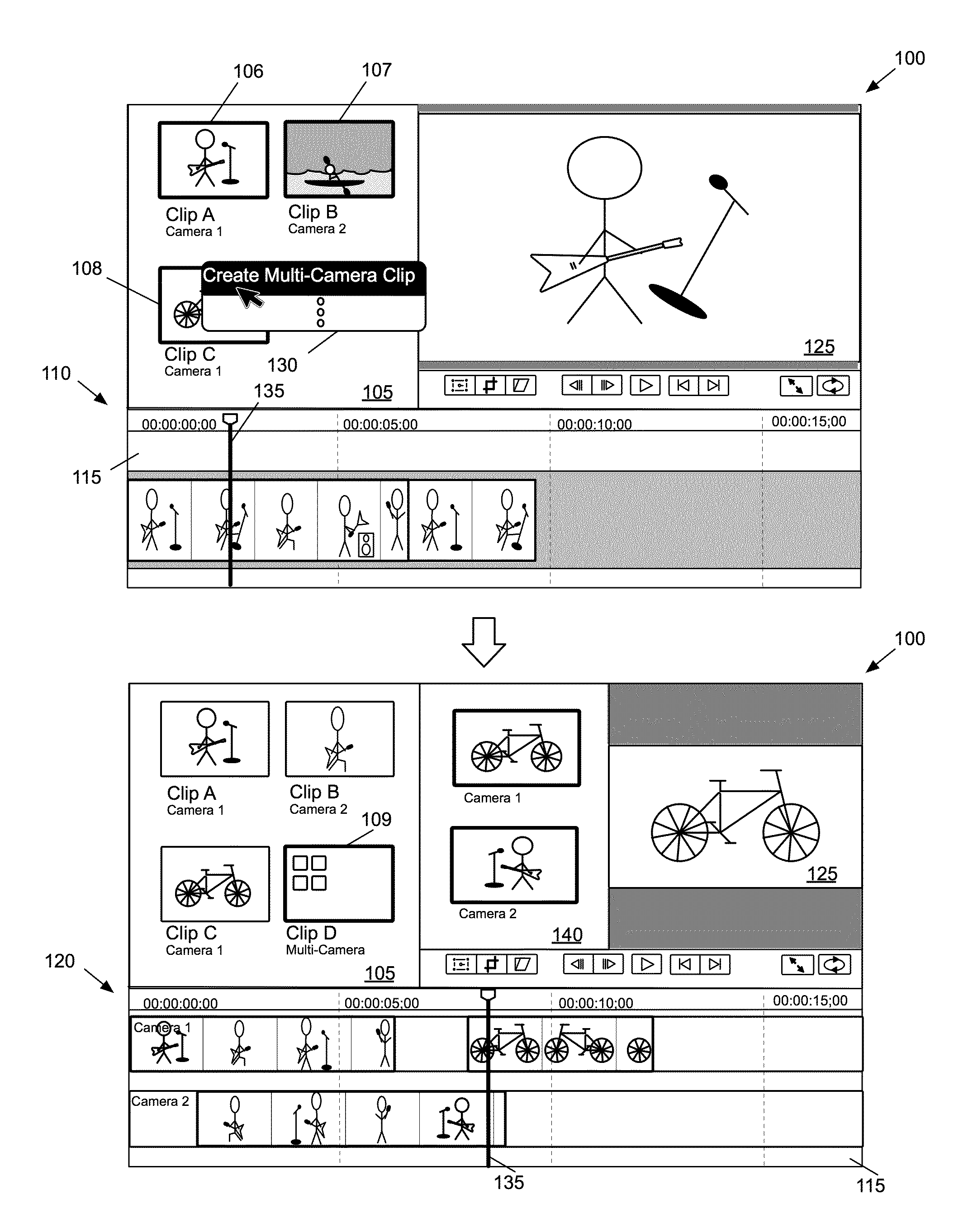

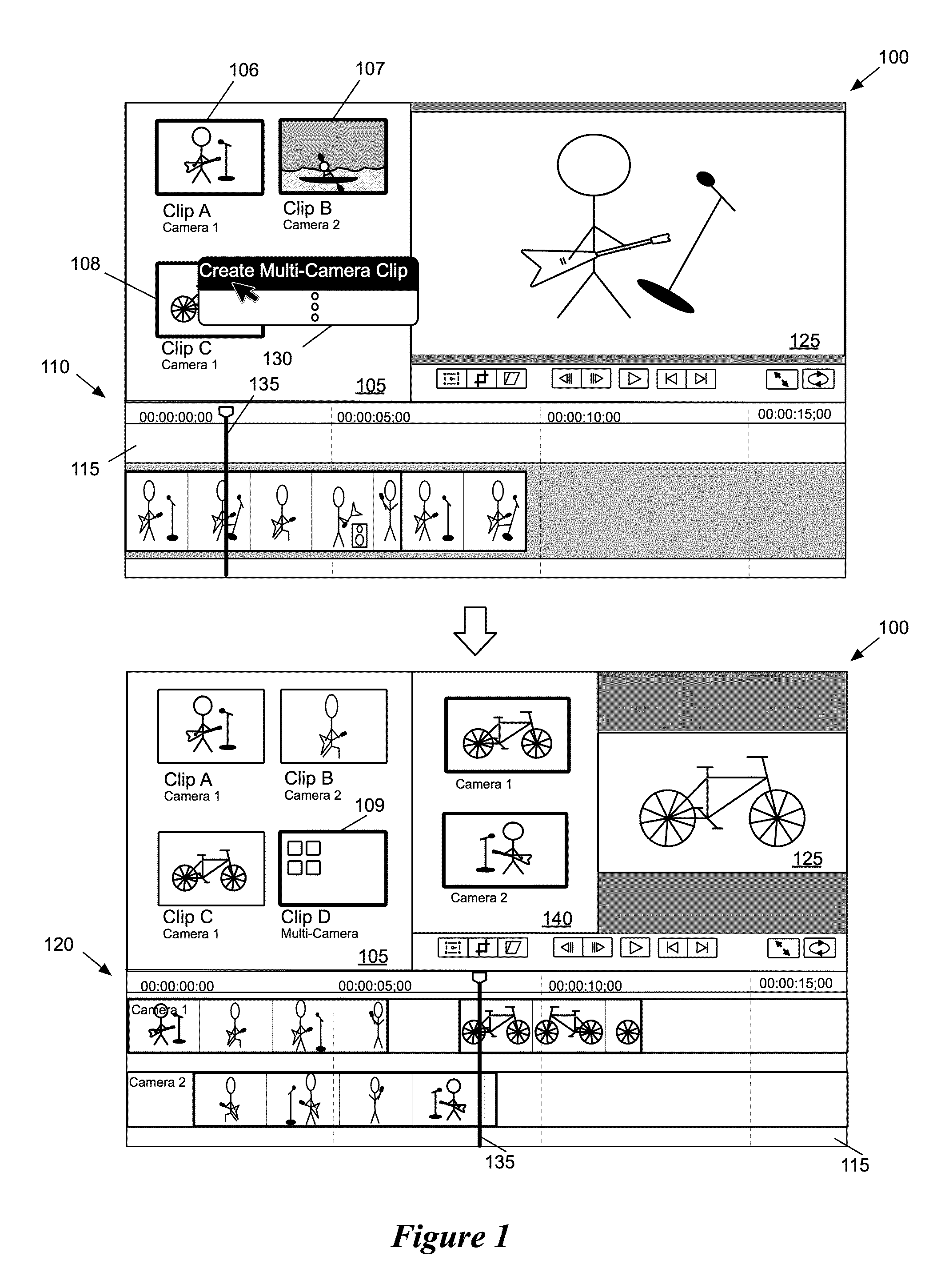

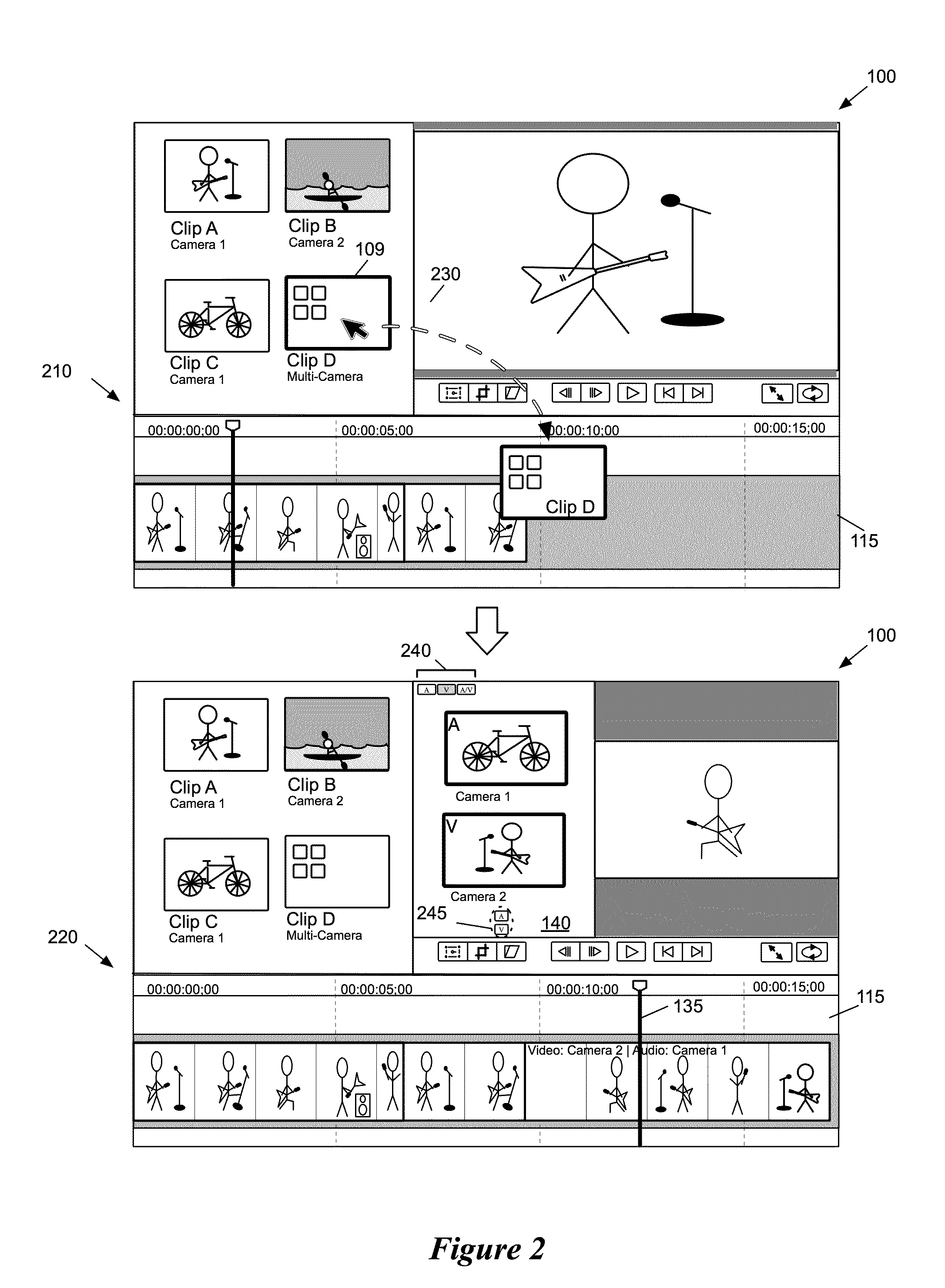

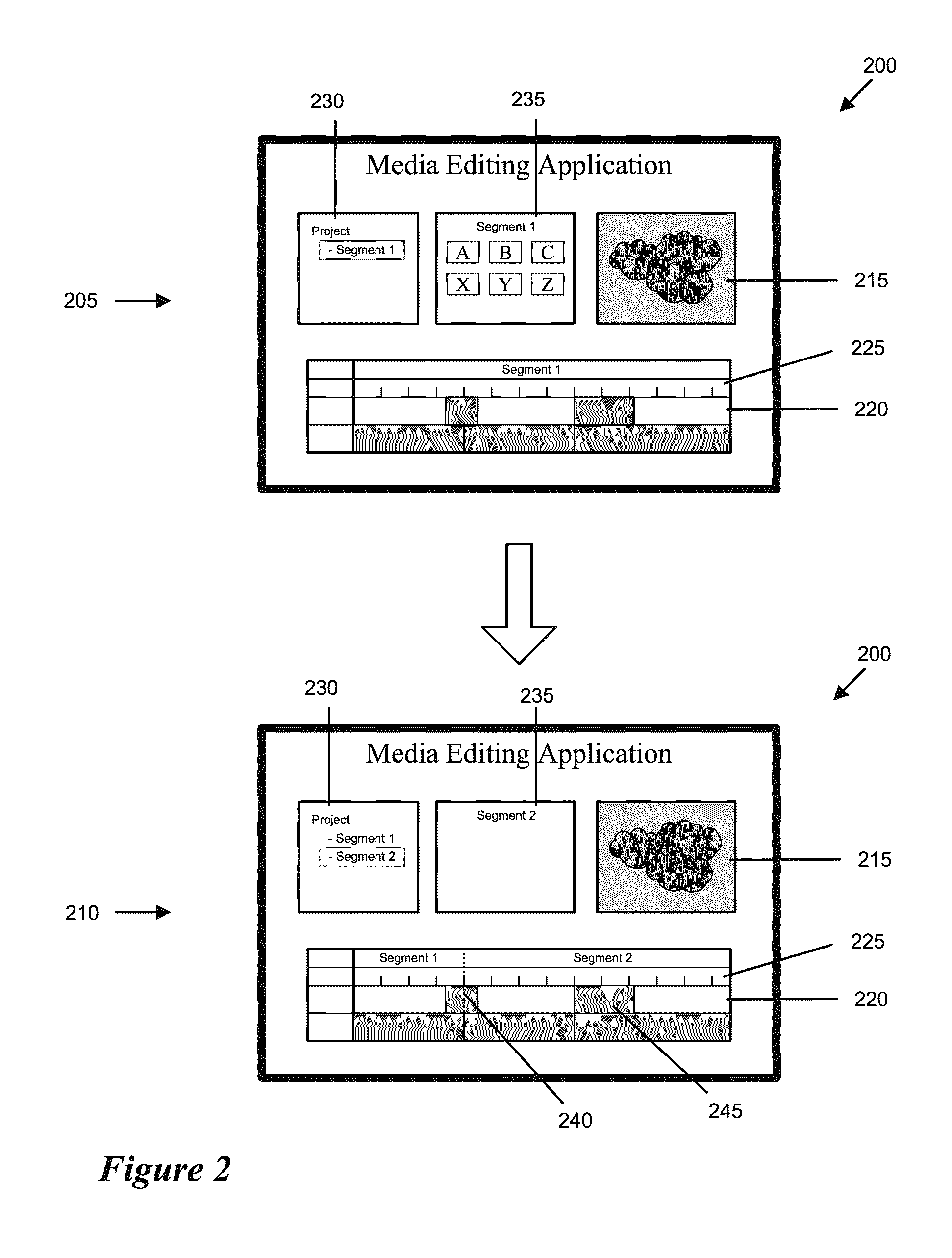

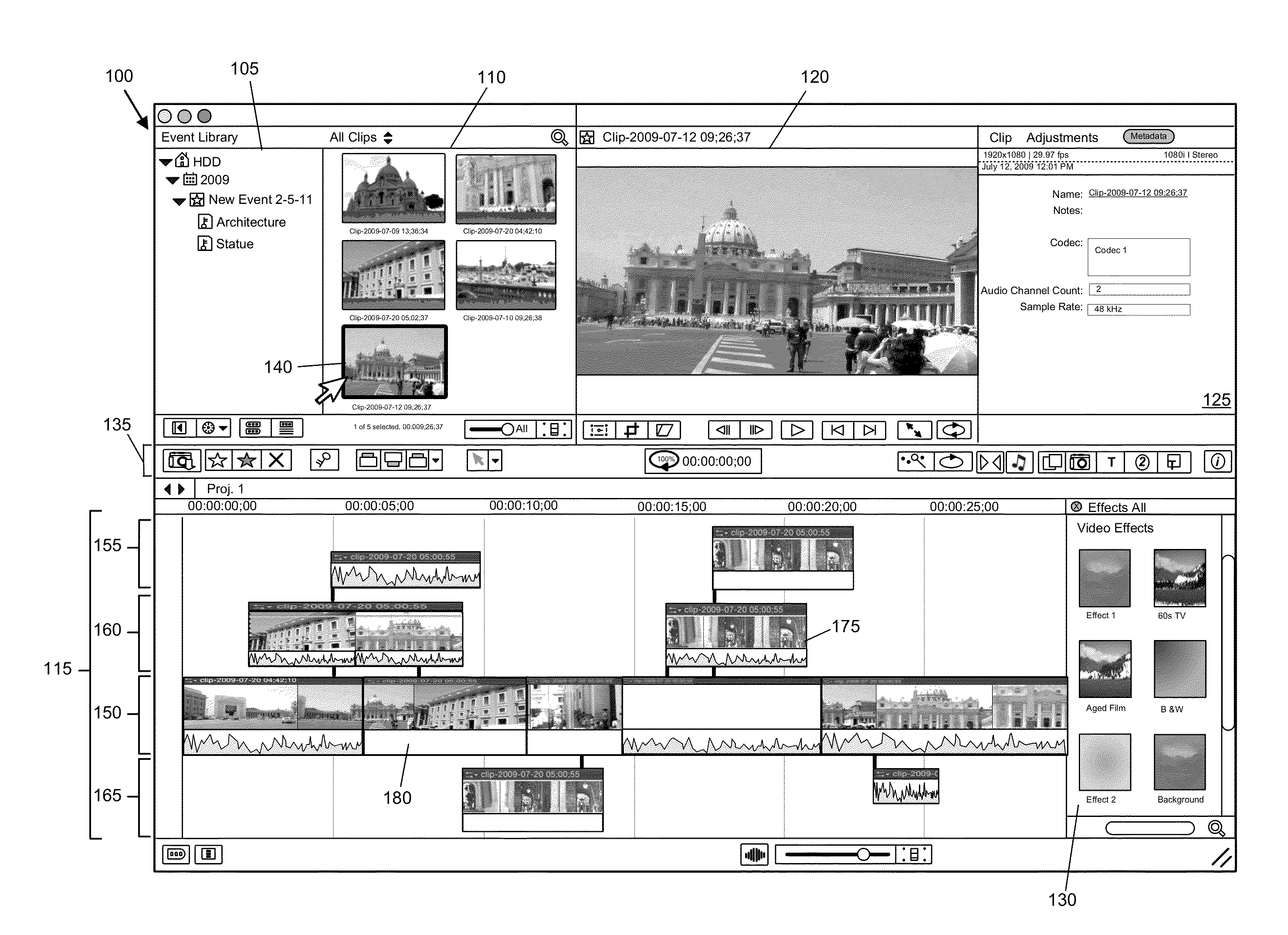

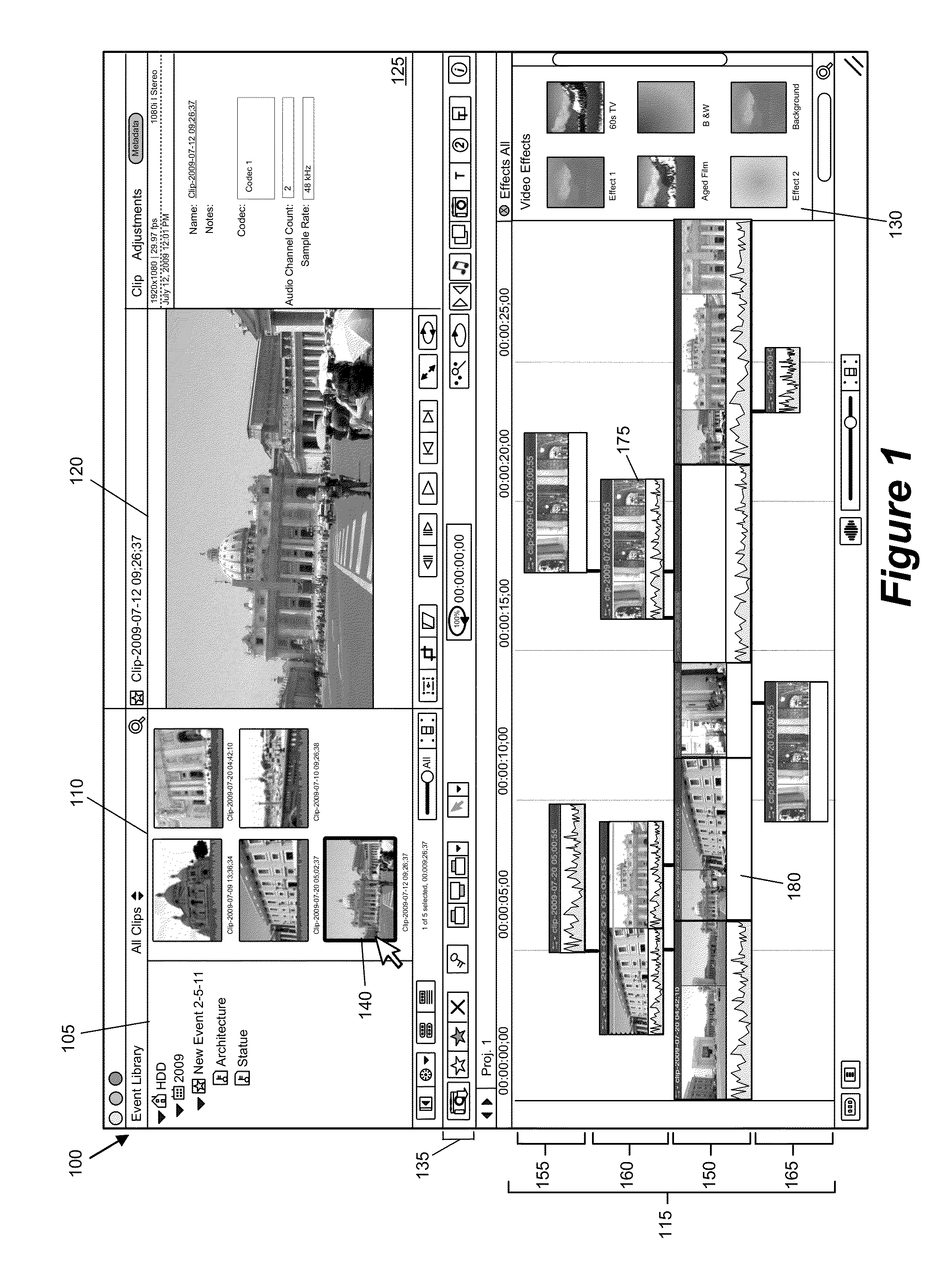

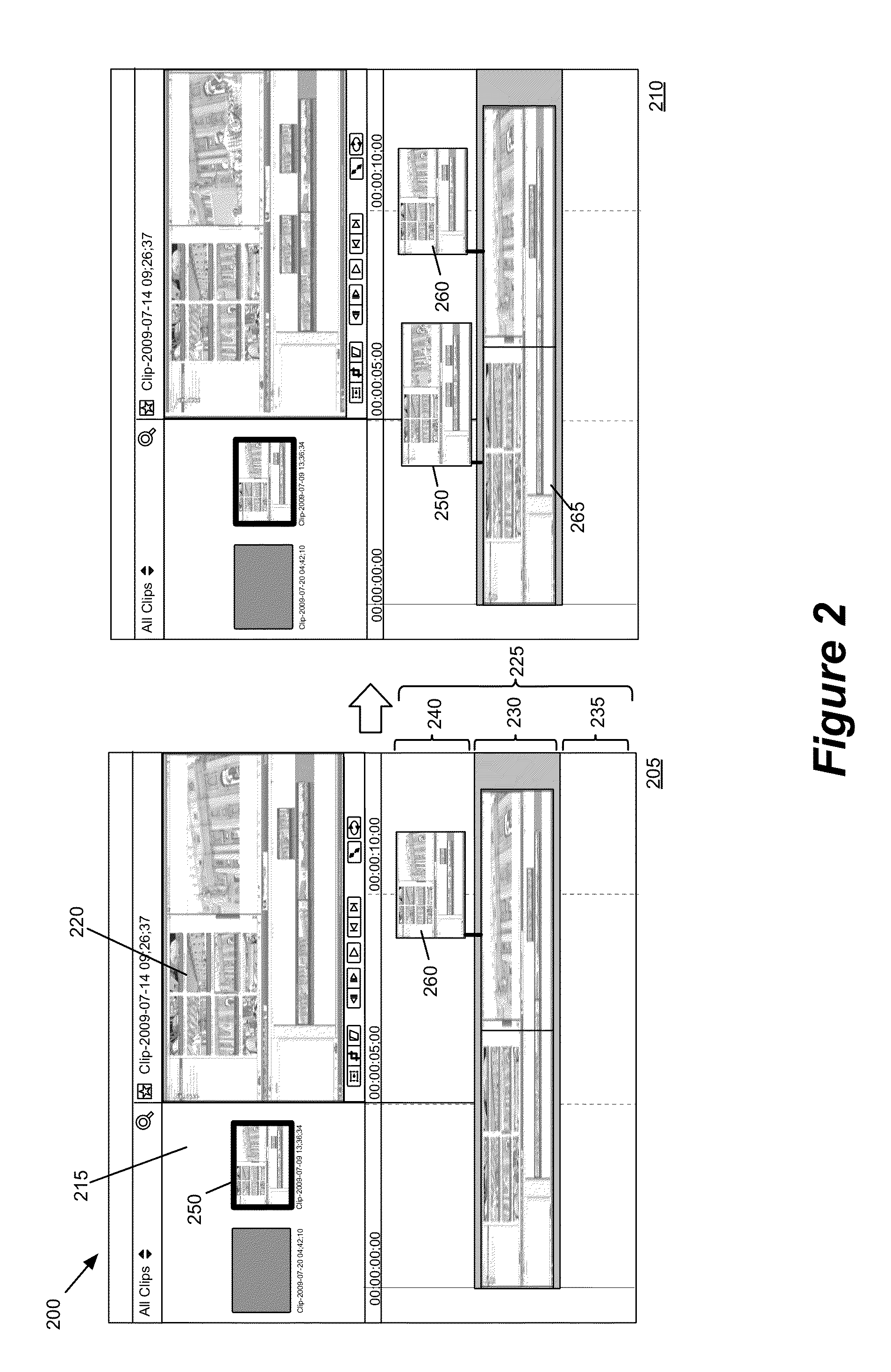

Dynamic video editing

InactiveUS20120017153A1Minimize the media clipsInput/output for user-computer interactionElectronic editing digitised analogue information signalsComposite mediaVideo editing

For a media-editing application, some embodiments provide tools for editing media clips, such as dynamic editing and playback of media clips. In some embodiments, dynamic editing allows a user of the media-editing application to perform operations on a media clip while the media clip is being played back. Examples of dynamic editing operations include tagging instances in time of the media clip, splitting the media clip into multiple media clips, trimming the ends of the media clip, and extending a trimmed media clip, among other operations. In addition, to composite media clips, some embodiments also allow the user to create sequences of media clips, reorder the media clips within sequences, stack sequences, and add or remove media clips from sequences. Some such embodiments allow the user to composite media clips while some or all of the media clips are being played back.

Owner:APPLE INC

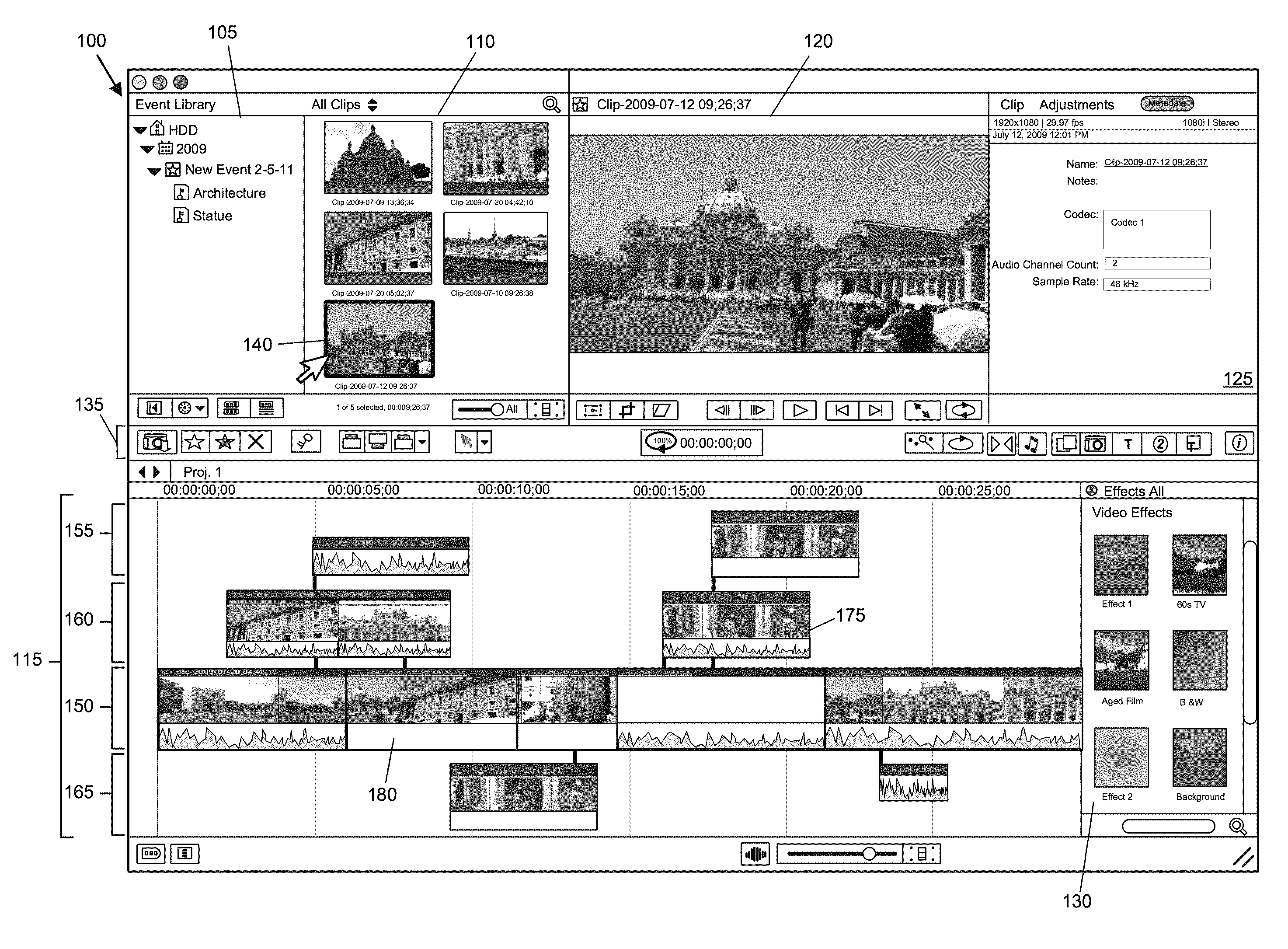

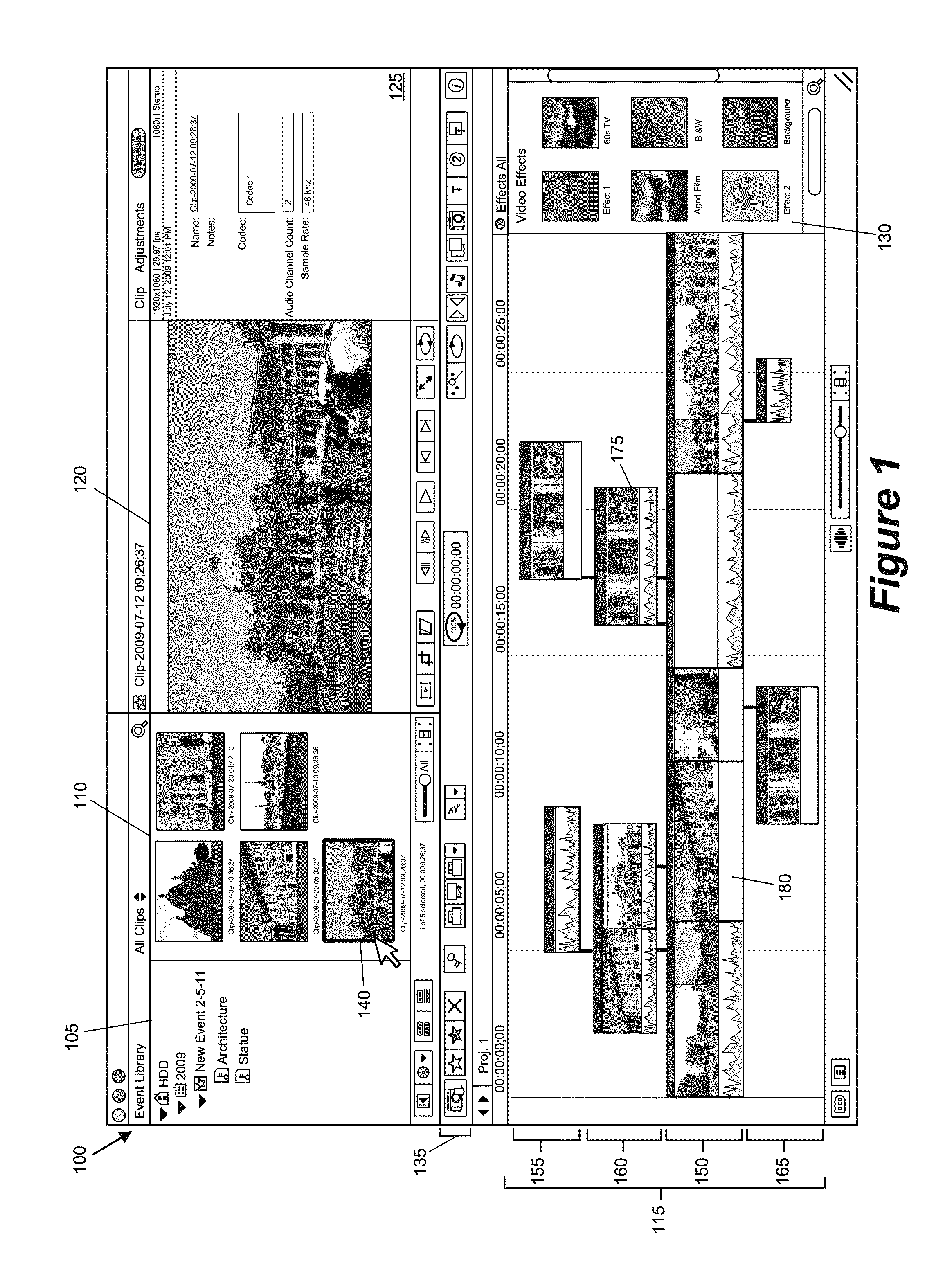

Media-Editing Application with Anchored Timeline

ActiveUS20120210230A1Direct accessDown playback speedTelevision system detailsElectronic editing digitised analogue information signalsComposite mediaComputer graphics (images)

Owner:APPLE INC

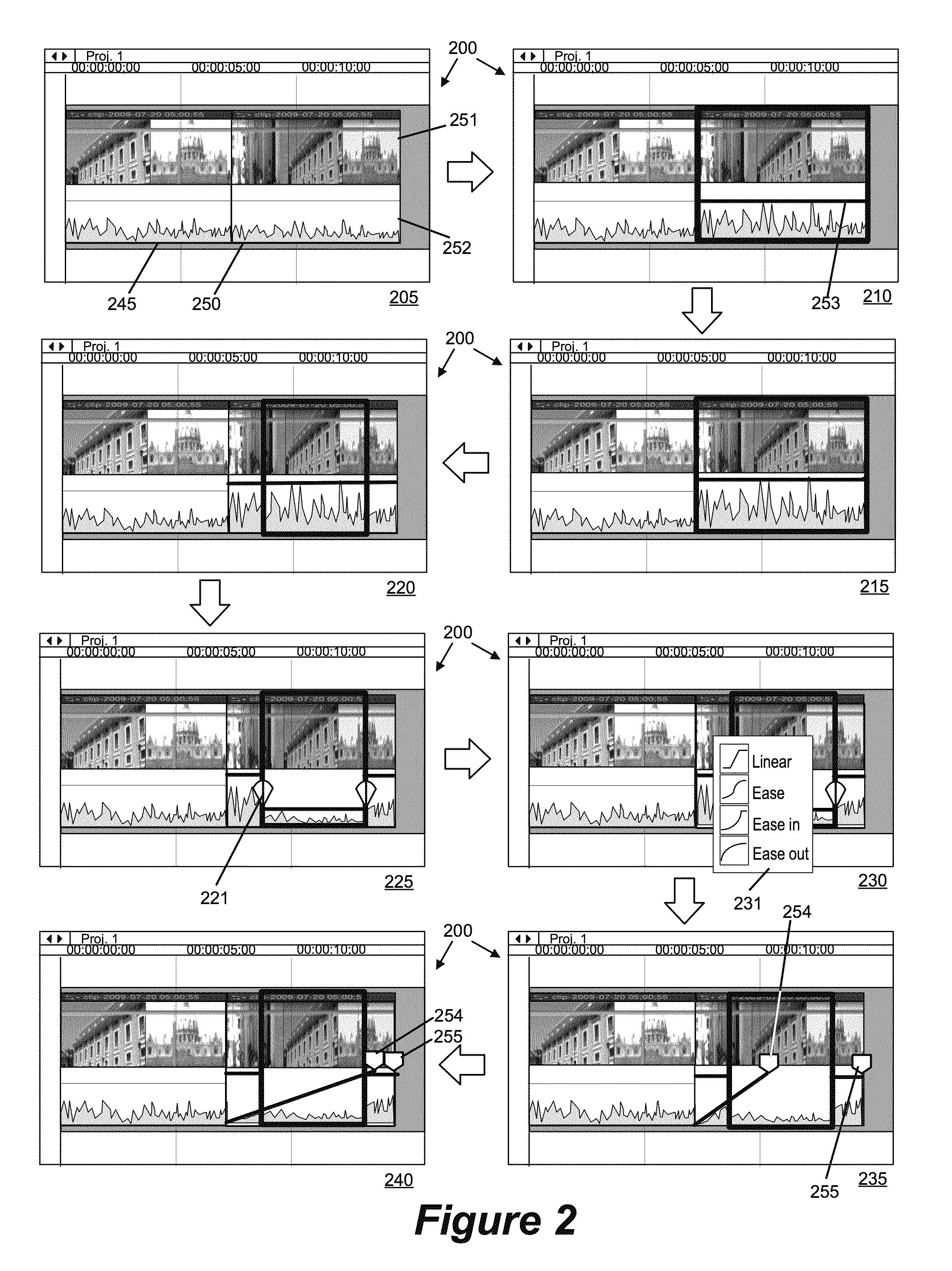

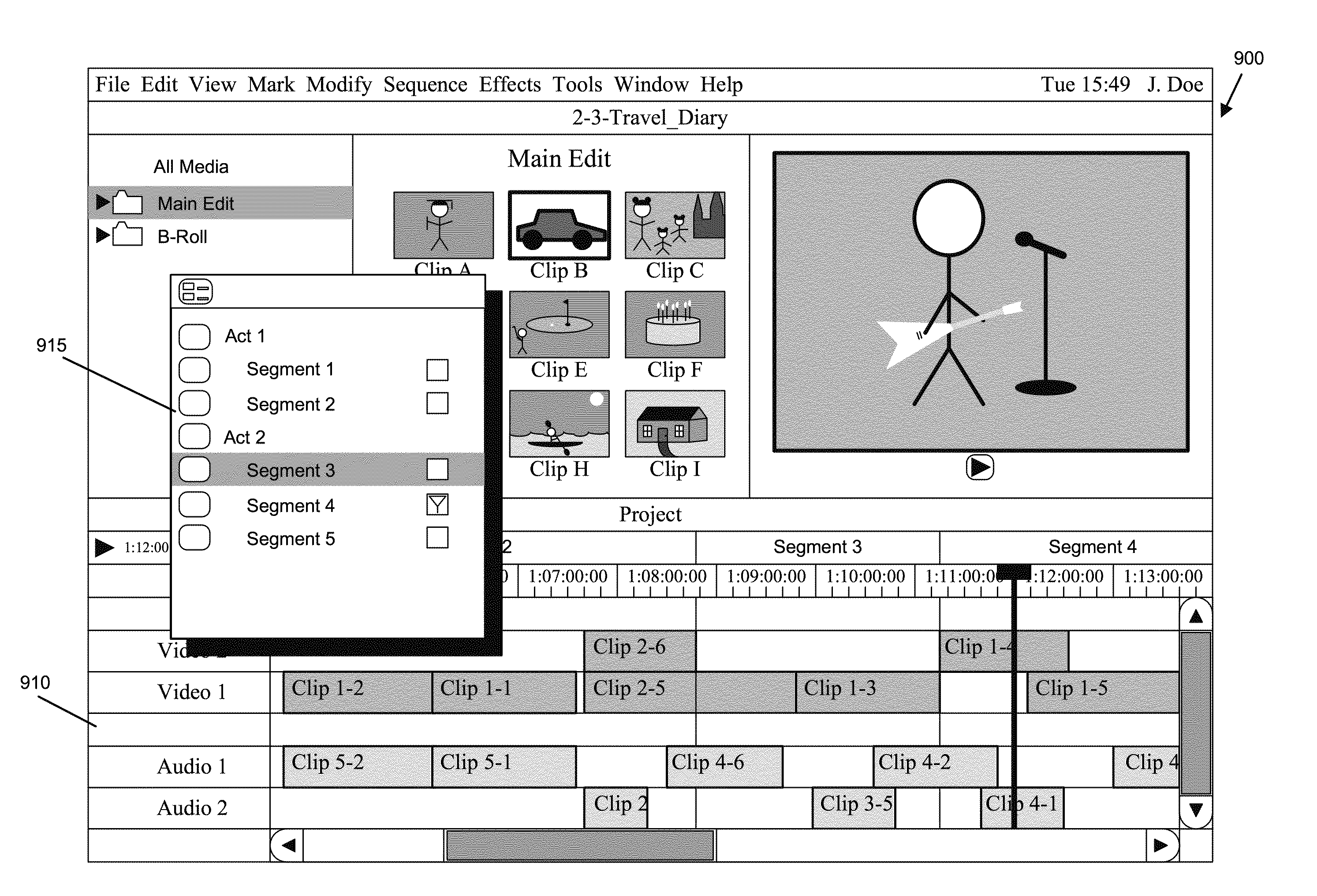

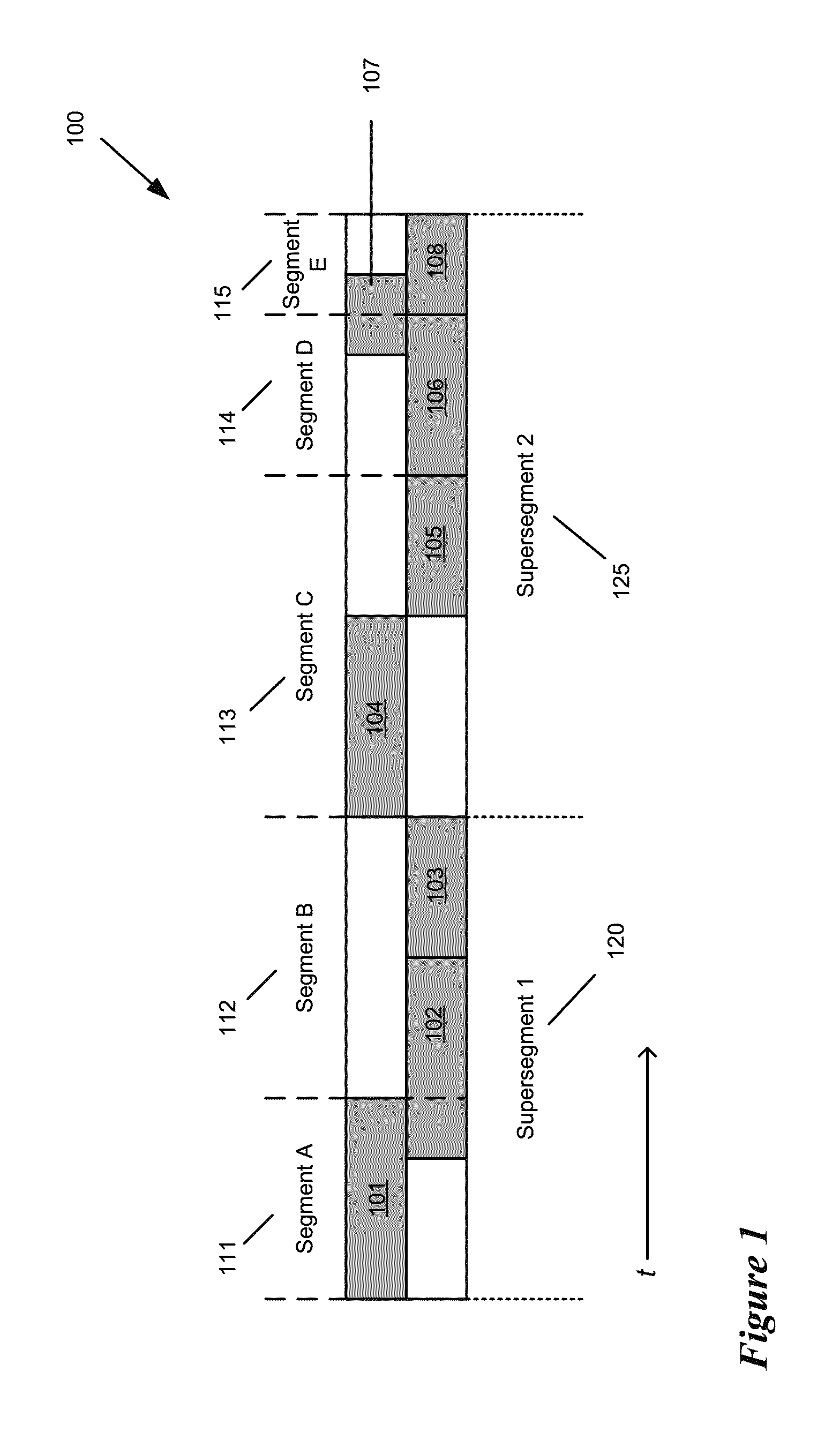

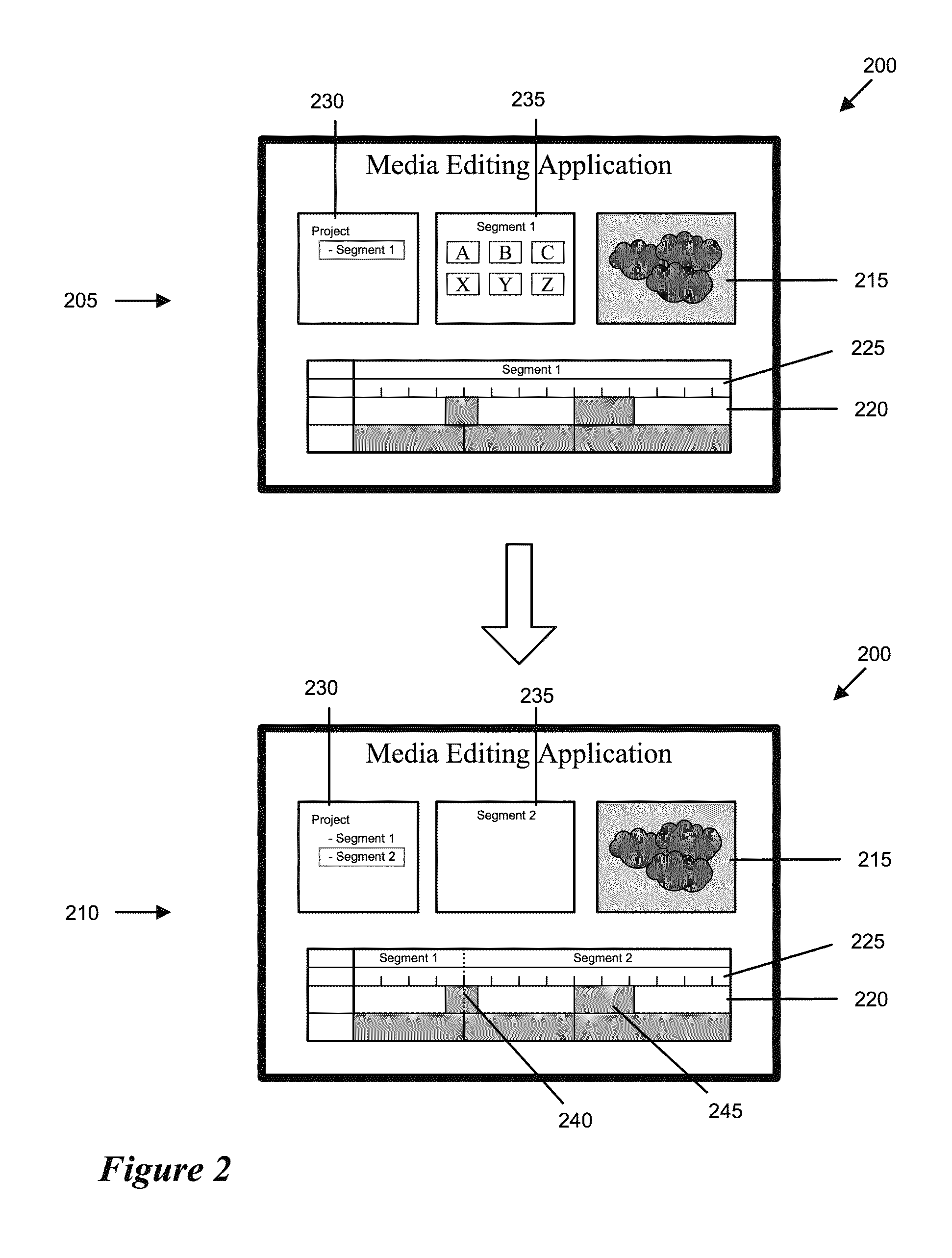

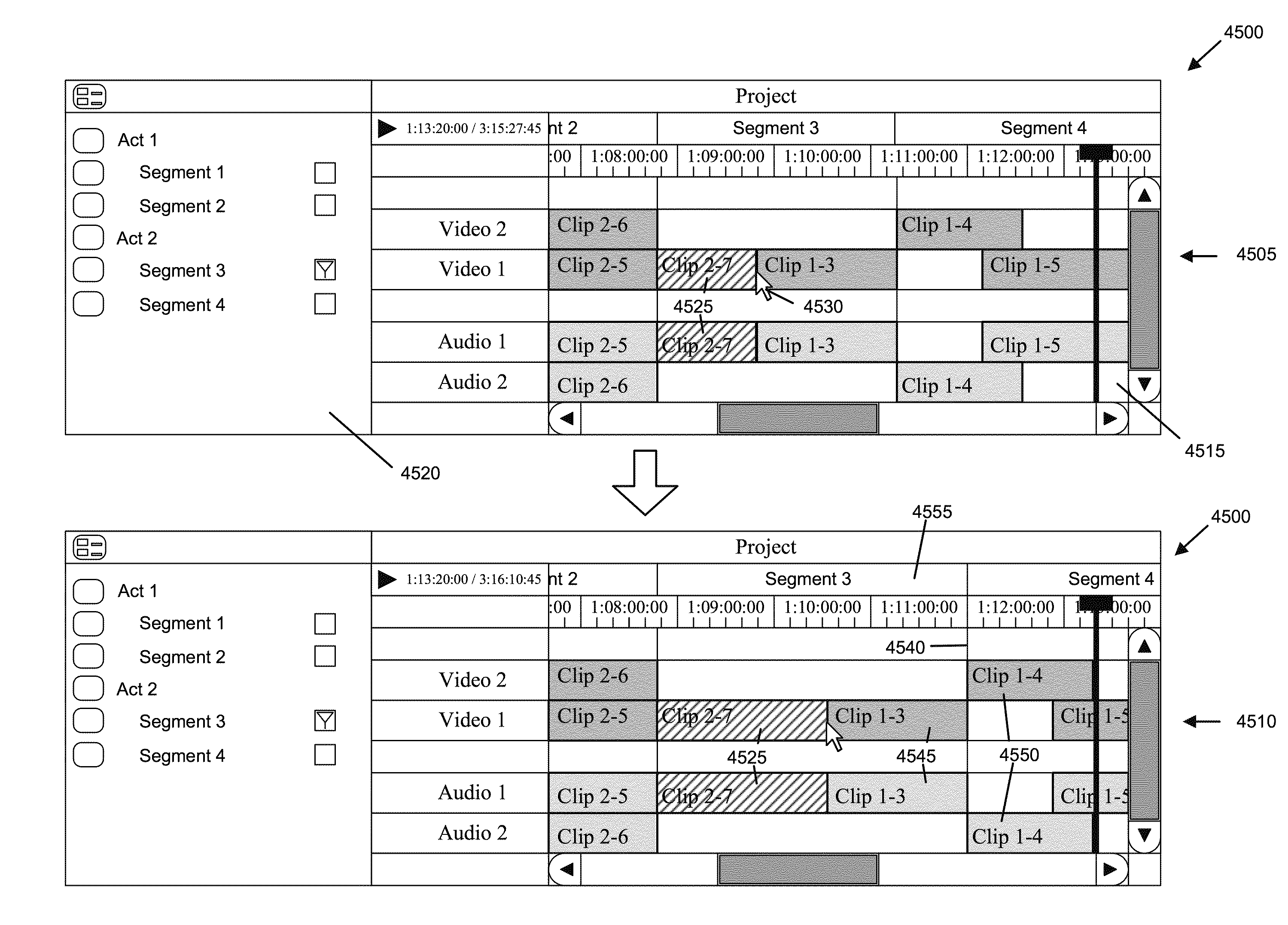

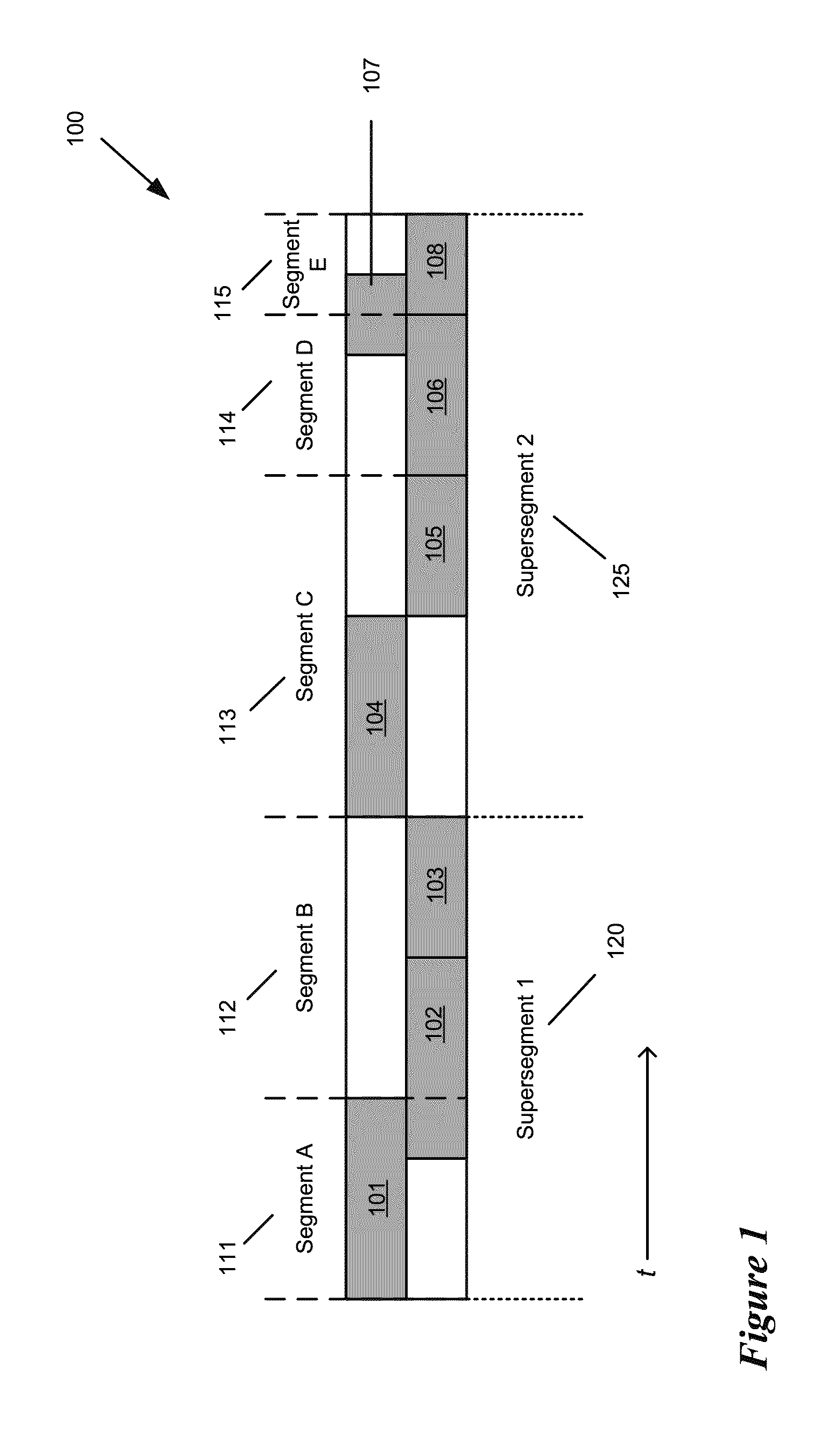

Media Editing With a Segmented Timeline

ActiveUS20100281382A1Input/output for user-computer interactionElectronic editing digitised analogue information signalsGraphicsComposite media

Some embodiments provide a computer readable medium storing a media editing application for creating multimedia presentations. The application includes a graphical user interface (GUI). The GUI includes a composite display area for displaying a portion of a timeline to which multimedia clips are assigned to create a composite media presentation. The GUI includes a user interface tool for dividing the timeline into segments. The GUI includes an editing tool for applying an effect to each of a plurality of clips in a particular segment of the timeline. The GUI includes a user interface tool for modifying a duration of at least one segment. Different versions of the segments may be created.

Owner:APPLE INC

Media-editing application with anchored timeline

ActiveUS8910046B2Television system detailsElectronic editing digitised analogue information signalsComposite mediaComputer graphics (images)

A media application of some embodiments includes a timeline, which is a composite display area for displaying media clips that are part of the composite media presentation. The timeline of some embodiments includes a primary lane called a spine as well as one or more anchor lanes. The spine represents a primary sequence of media, which, in some embodiments, does not have any gaps. When a clip is deleted or removed from the timeline, the media-editing applications automatically closes the gap created in place of the clip. The clips in the anchor lanes are anchored to a particular position along the spine. Anchor lanes may be used for compositing (e.g., removing portions of one video and showing a different video in those portions), B-roll cuts (i.e., cutting away from the primary video to a different video whose clip is in the anchor lane), audio clips, or other composite presentation techniques.

Owner:APPLE INC

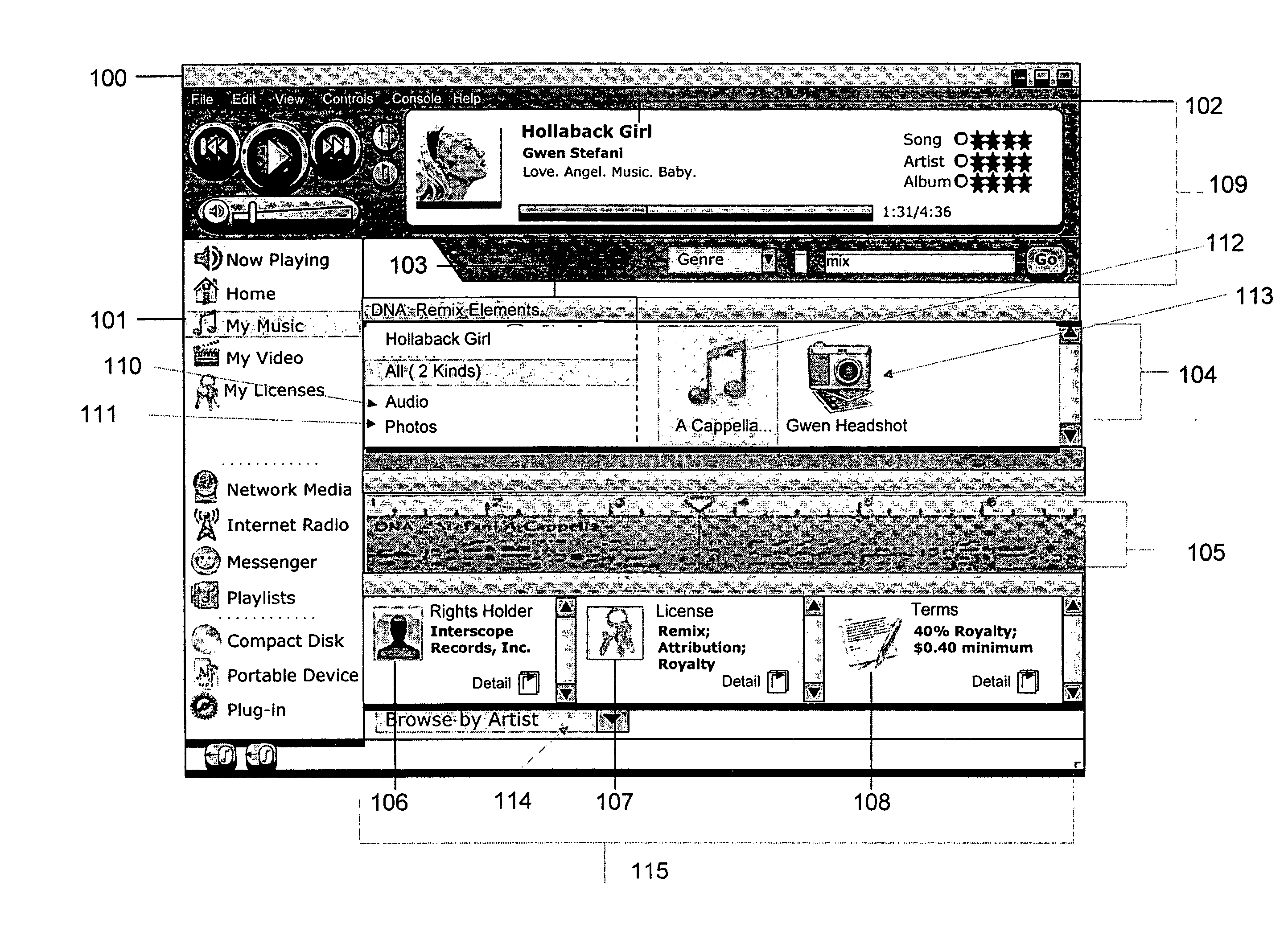

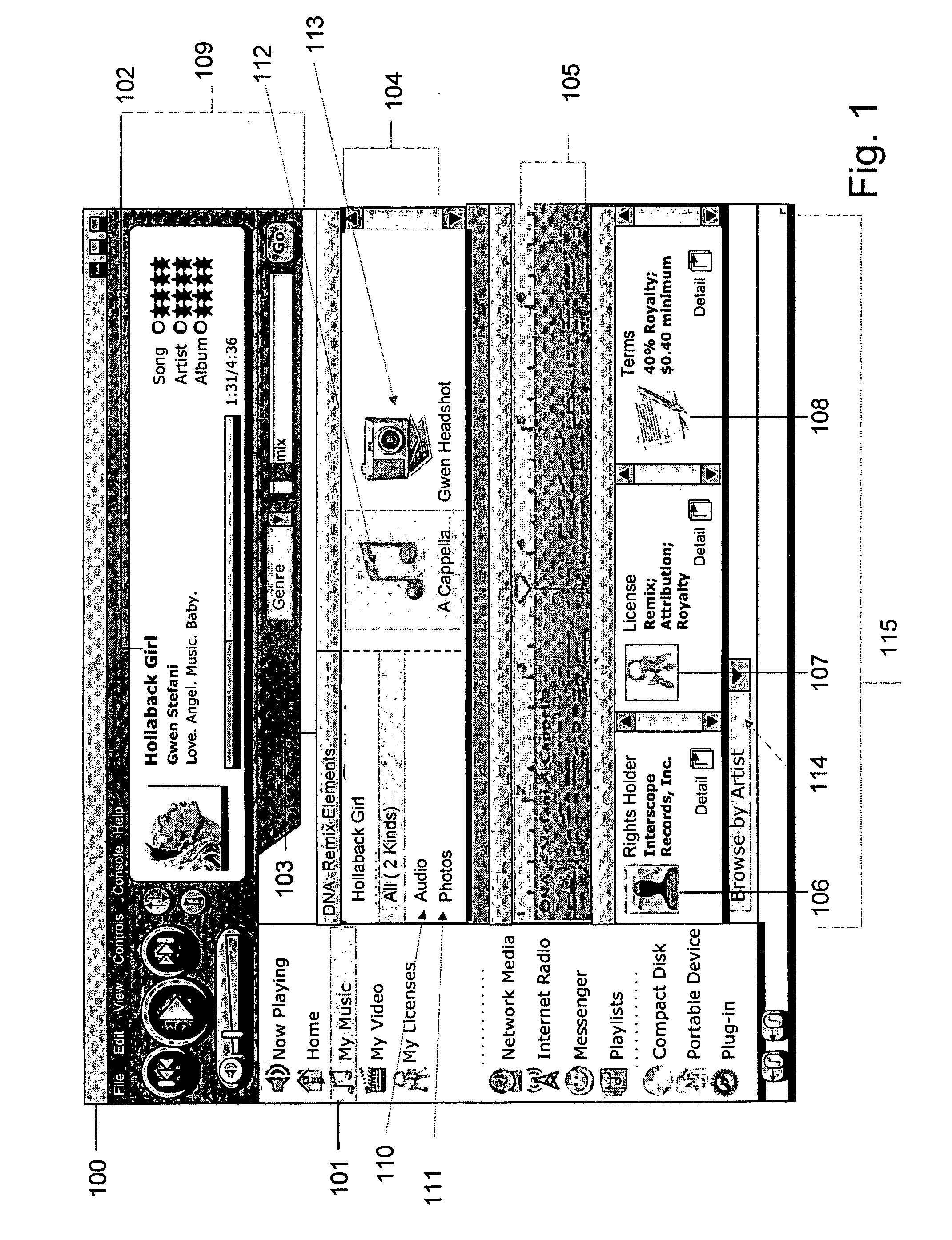

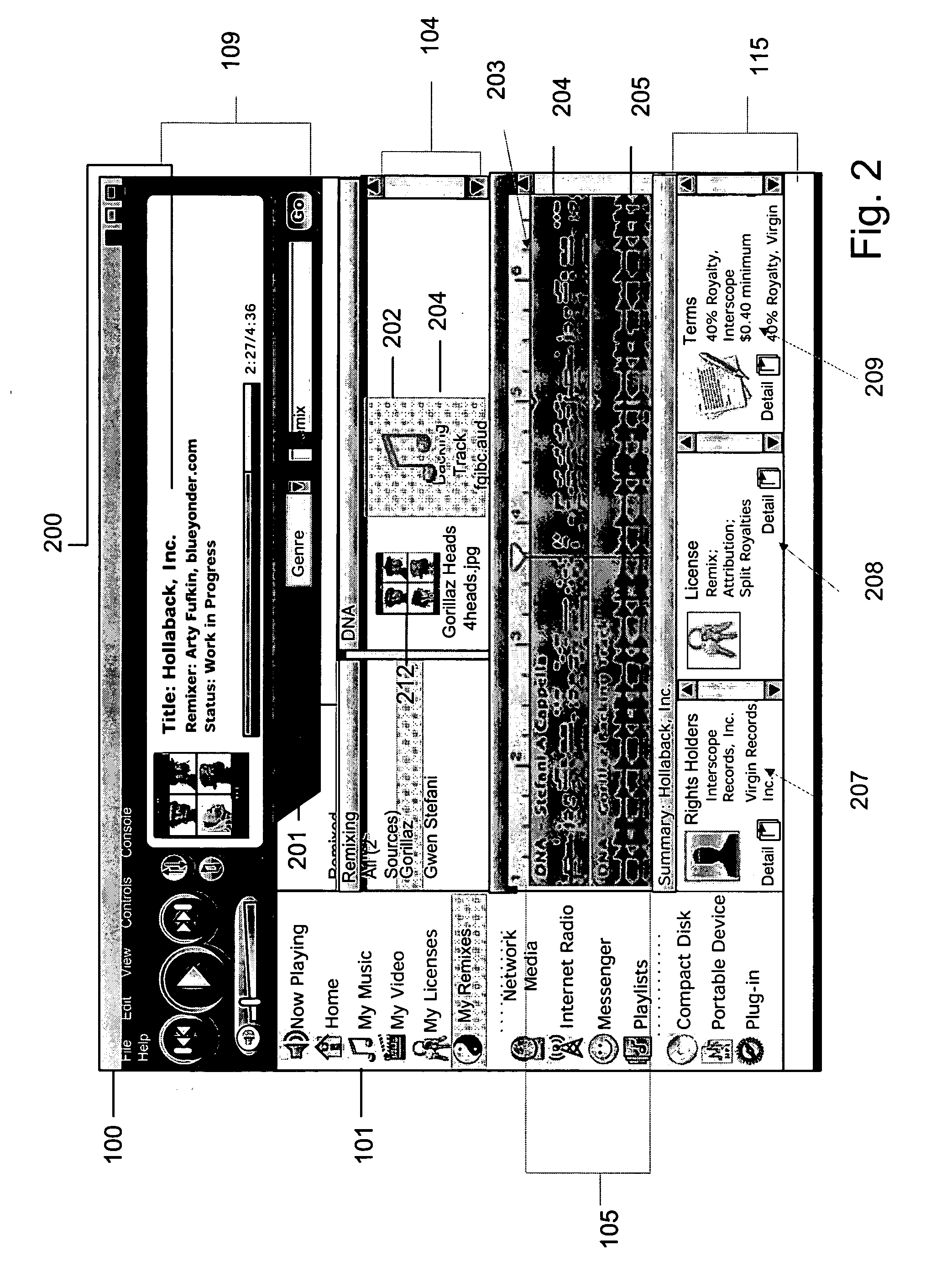

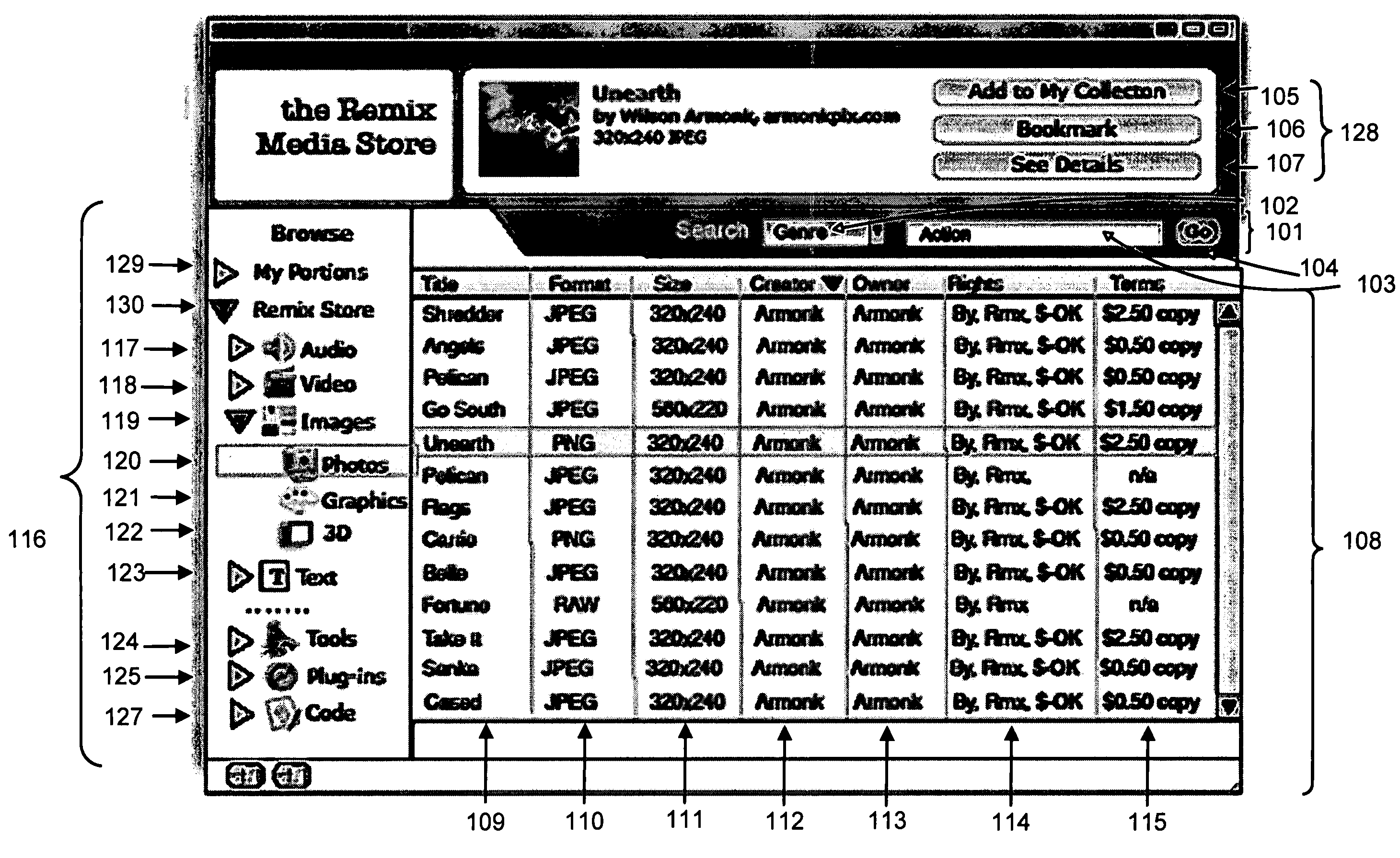

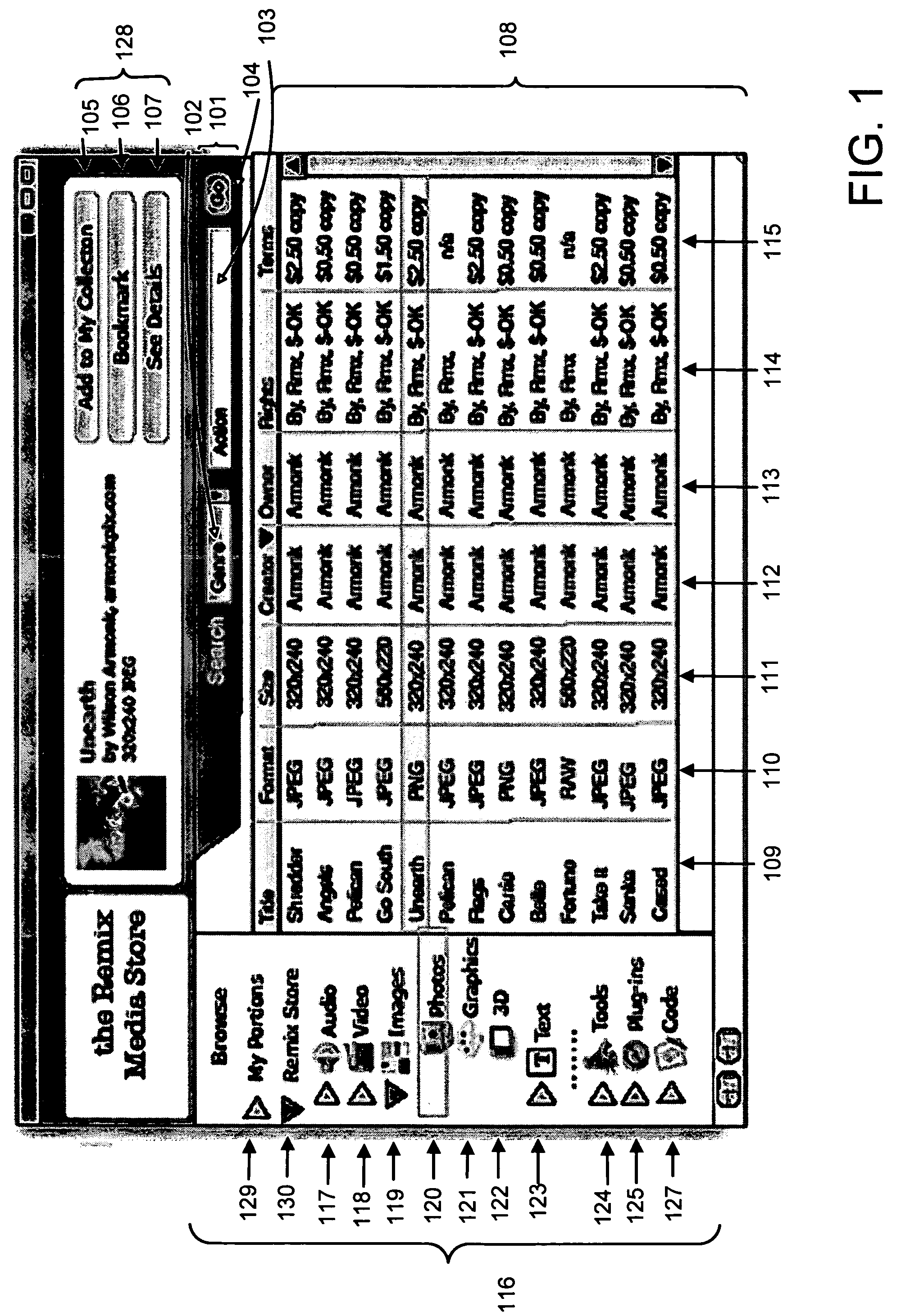

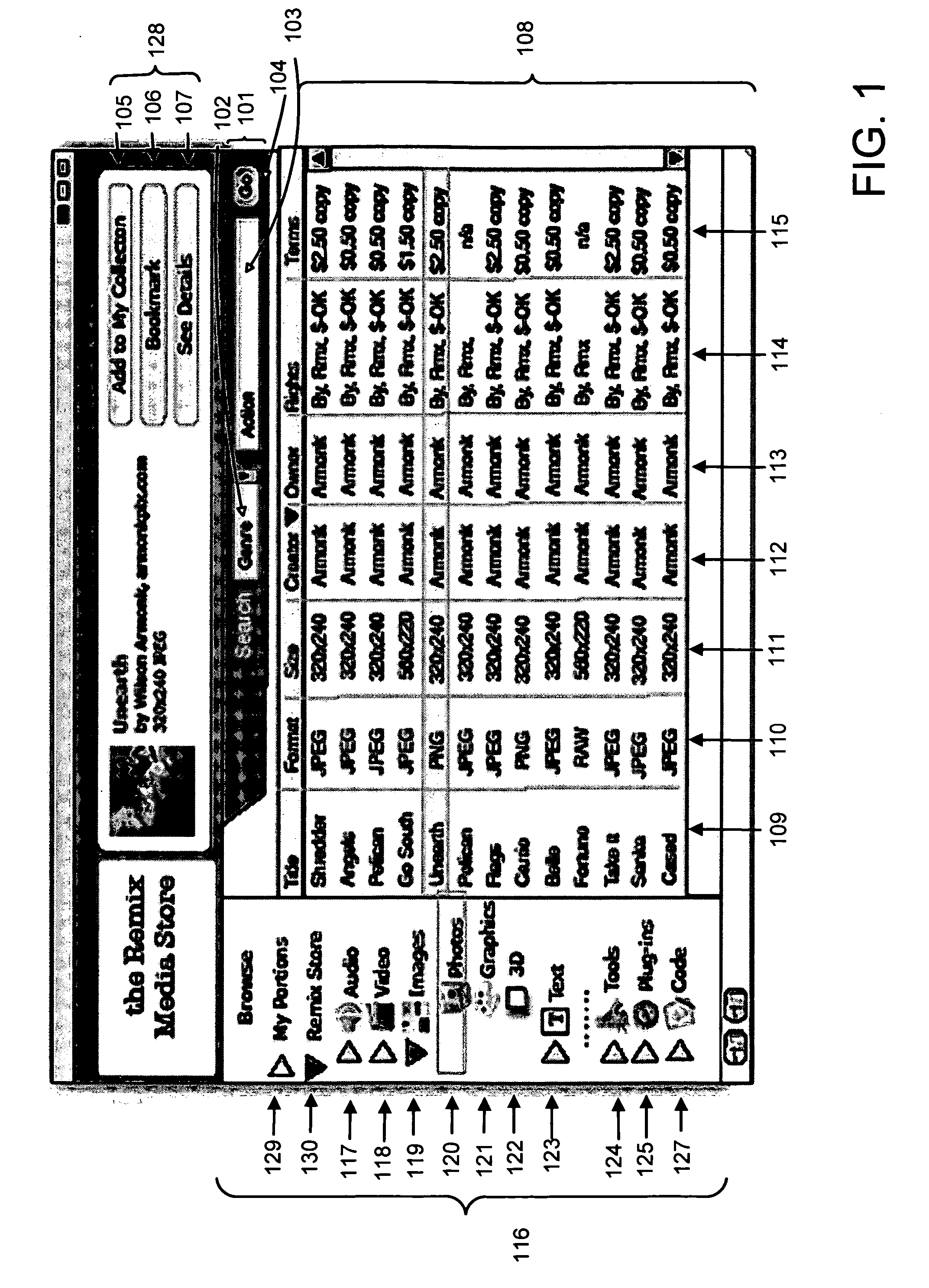

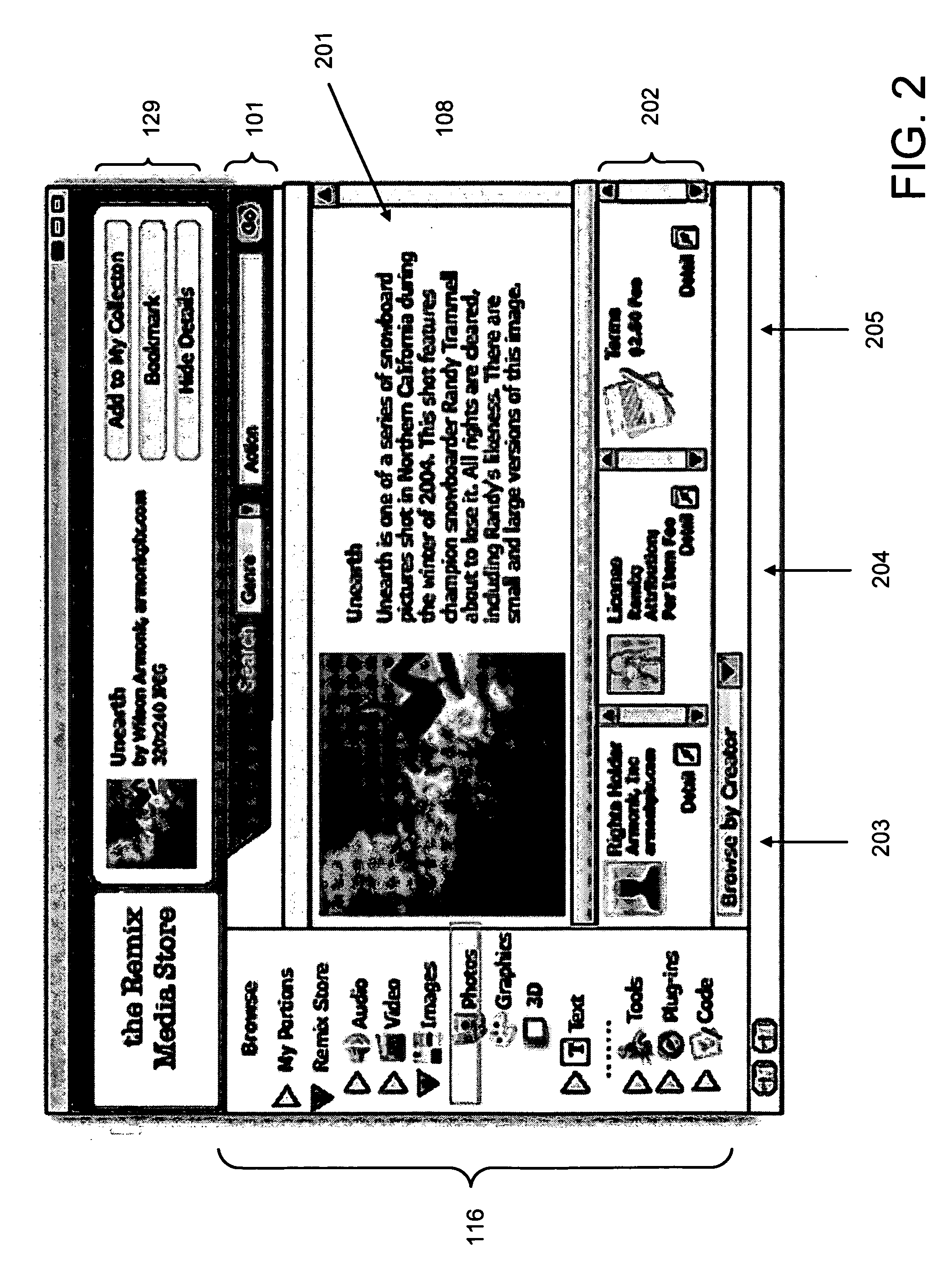

User interface for media item portion search tool

Owner:HUAWEI TECH CO LTD

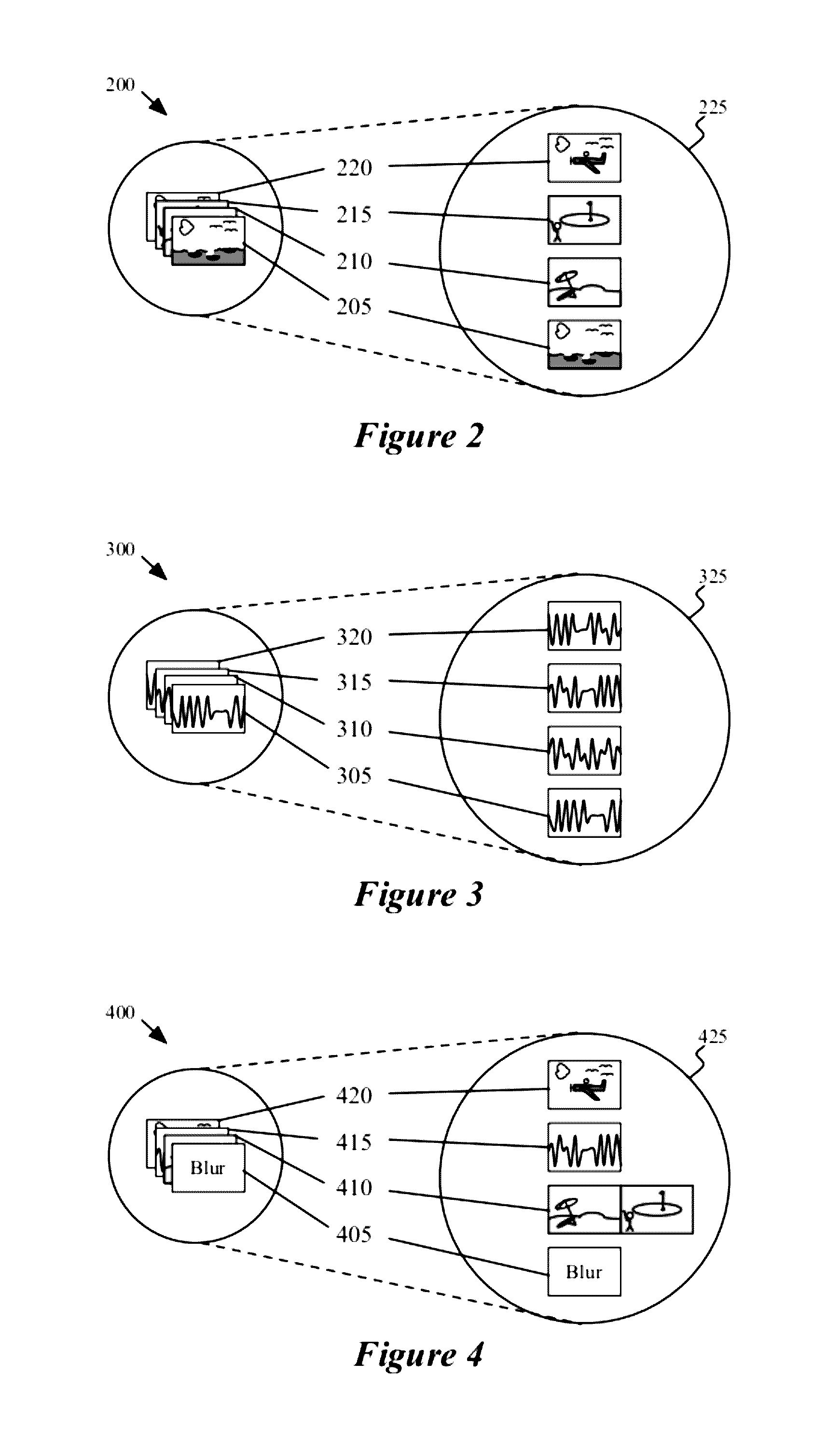

Media editing application for auditioning different types of media clips

ActiveUS9564173B2Electronic editing digitised analogue information signalsCarrier indicating arrangementsComposite mediaComputer graphics (images)

Some embodiments provide a program that creates a composite media presentation from several media clips. The program creates an audition set for a particular location in a composite display area for placing media clips to specify a description of the composite media presentation. The program adds to the audition set several different types of media clips that are candidates for placement in the composite display area at the particular location. The program iteratively selects a different media clip in the audition set as the only committed media clip in the audition set to include in the composite media presentation.

Owner:APPLE INC

Electro-ferromagnetic, tunable electromagnetic band-gap, and bi-anisotropic composite media using wire configurations

InactiveUS20050146402A1High bandwidthSmall sizeRadiating elements structural formsResonatorsDielectricElectricity

An artificial electro-ferromagnetic meta-material demonstrates the design of tunable band-gap and tunable bi-anisotropic materials. The medium is obtained using a composite mixture of dielectric, ferro-electric, and metallic materials arranged in a periodic fashion. By changing the intensity of an applied DC field the permeability of the artificial electro-ferromagnetic can be properly varied over a particular range of frequency. The structure shows excellent Electromagnetic Band-Gap (EBG) behavior with a band-gap frequency that can be tuned by changing the applied DC field intensity. The building block of the electro-ferromagnetic material is composed of miniaturized high Q resonant circuits embedded in a low-loss dielectric background. The resonant circuits are constructed from metallic loops terminated with a printed capacitor loaded with a ferro-electric material. Modifying the topology of the embedded-circuit, a bi-anisotropic material (tunable) is examined. The embedded-circuit meta-material is treated theoretically using a transmission line analogy of a medium supporting TEM waves.

Owner:RGT UNIV OF MICHIGAN

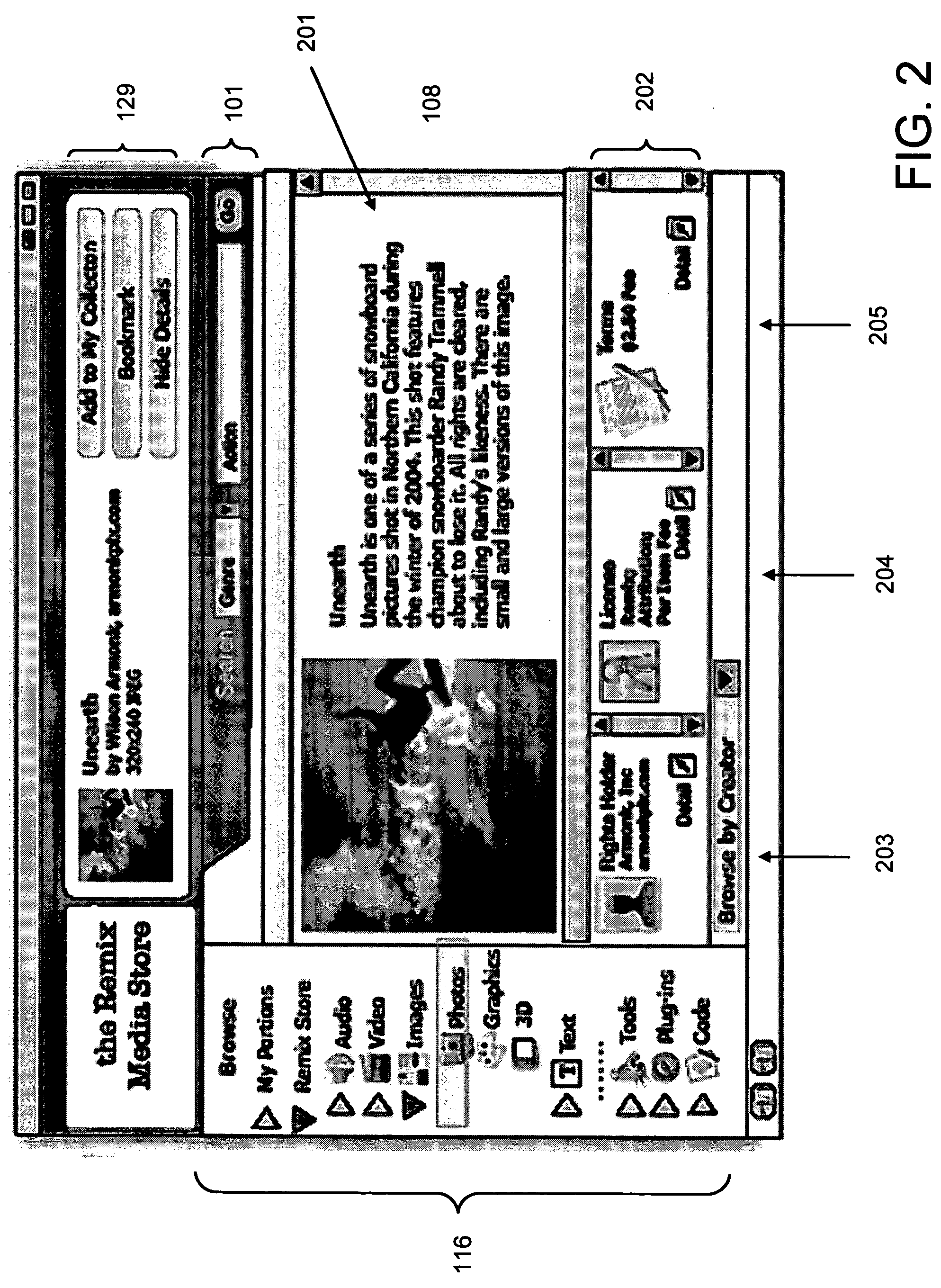

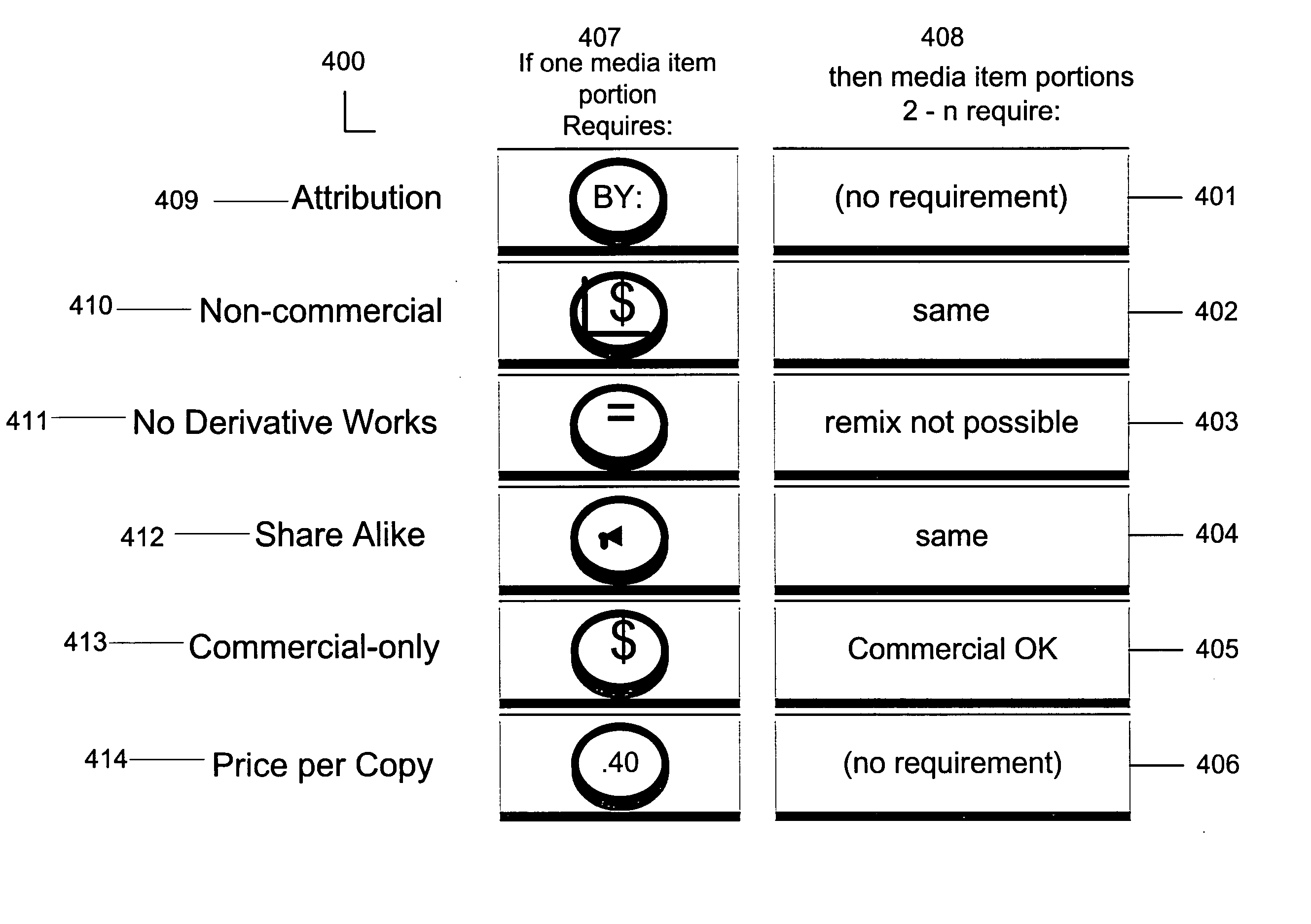

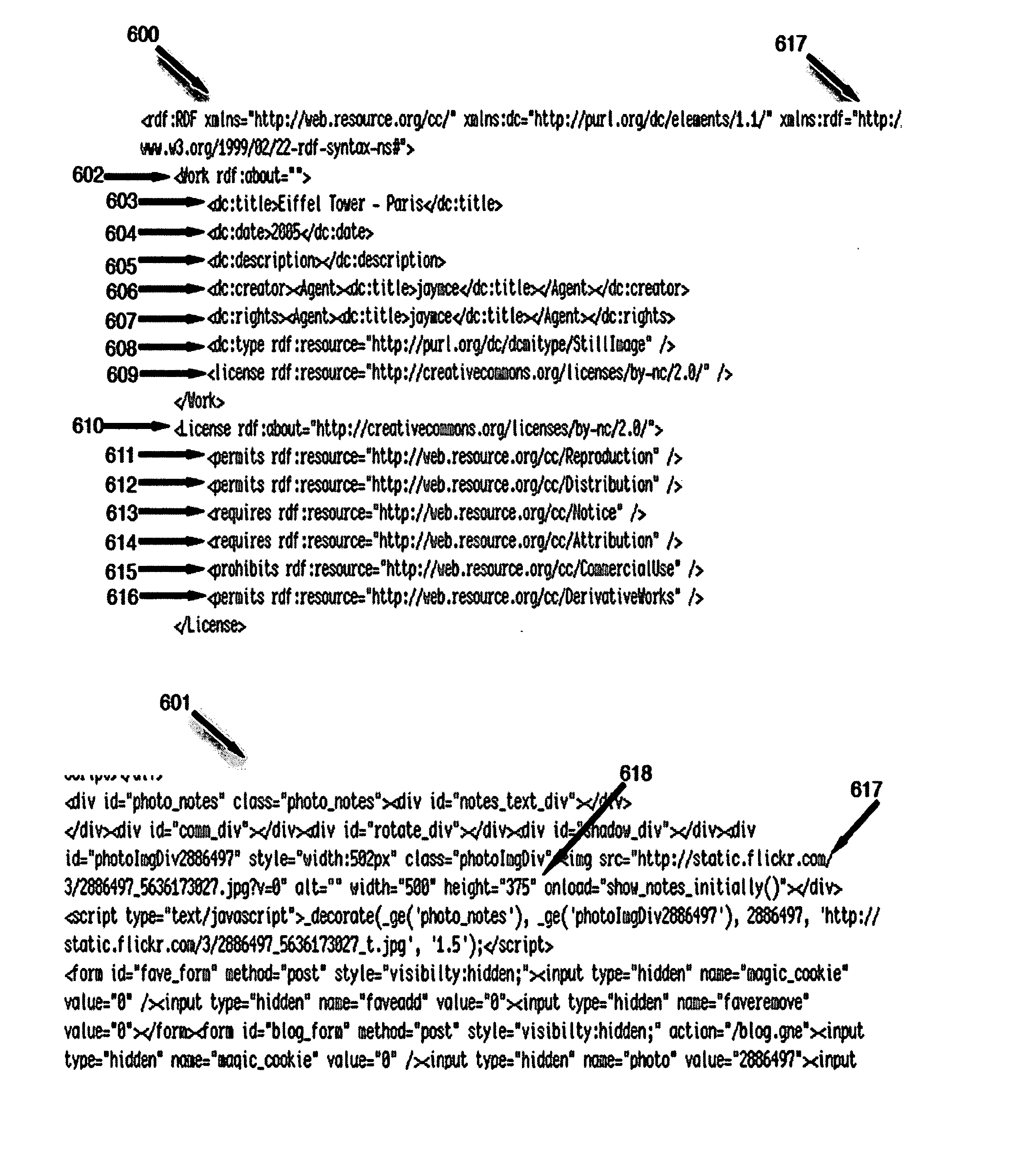

Data container and set of metadata for association with a media item and composite media items

InactiveUS20070083380A1Buying/selling/leasing transactionsProgram/content distribution protectionComposite mediaMetadata

Various types of metadata and data containers associated with a media item and media item portions. In one aspect, a data container associated a media item, a rights-preserving metadata subset associated with a media item portion, and a set of metadata associated with a composite media item. In another aspect, the data container may contain commerce-enabling information.

Owner:HUAWEI TECH CO LTD +1

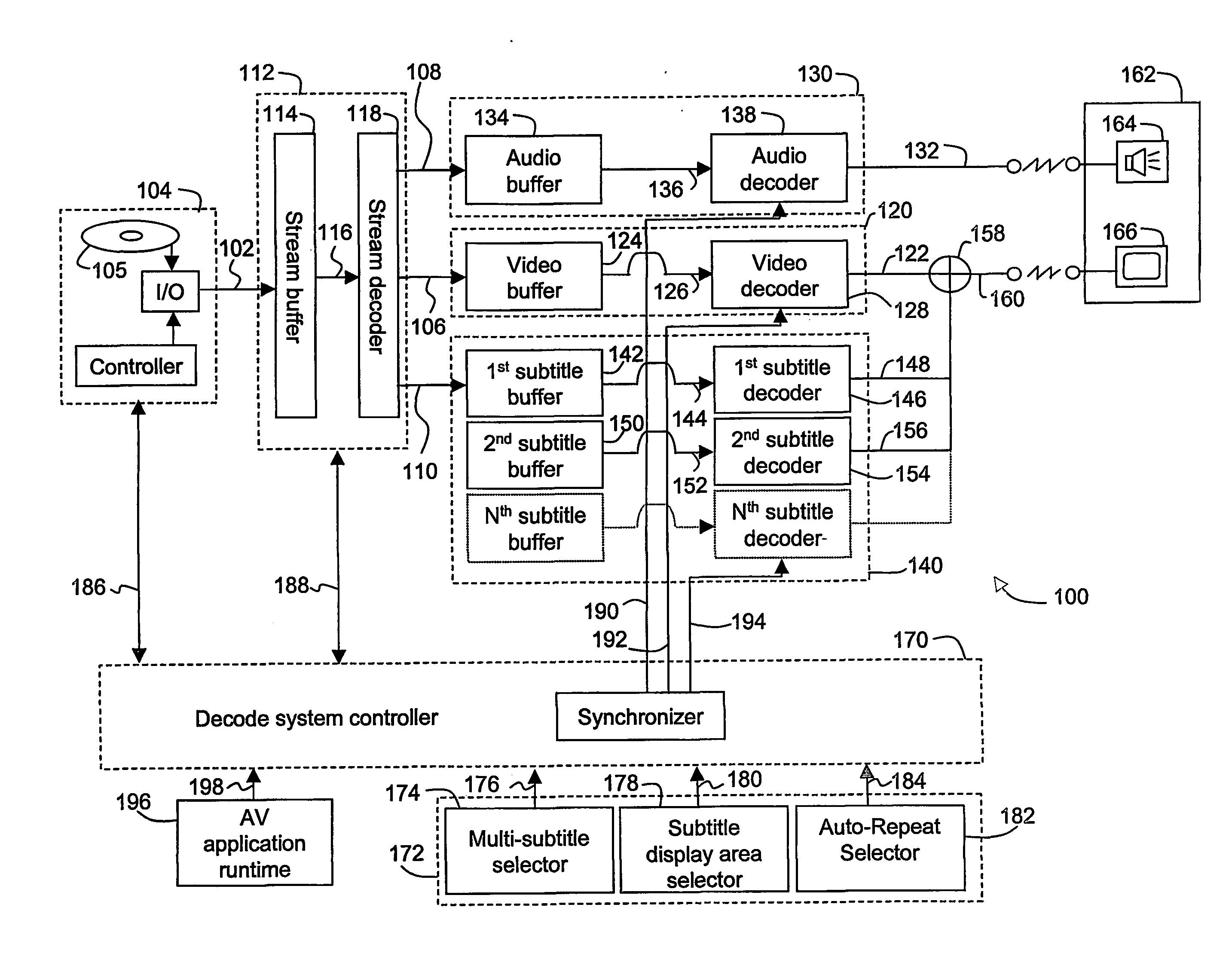

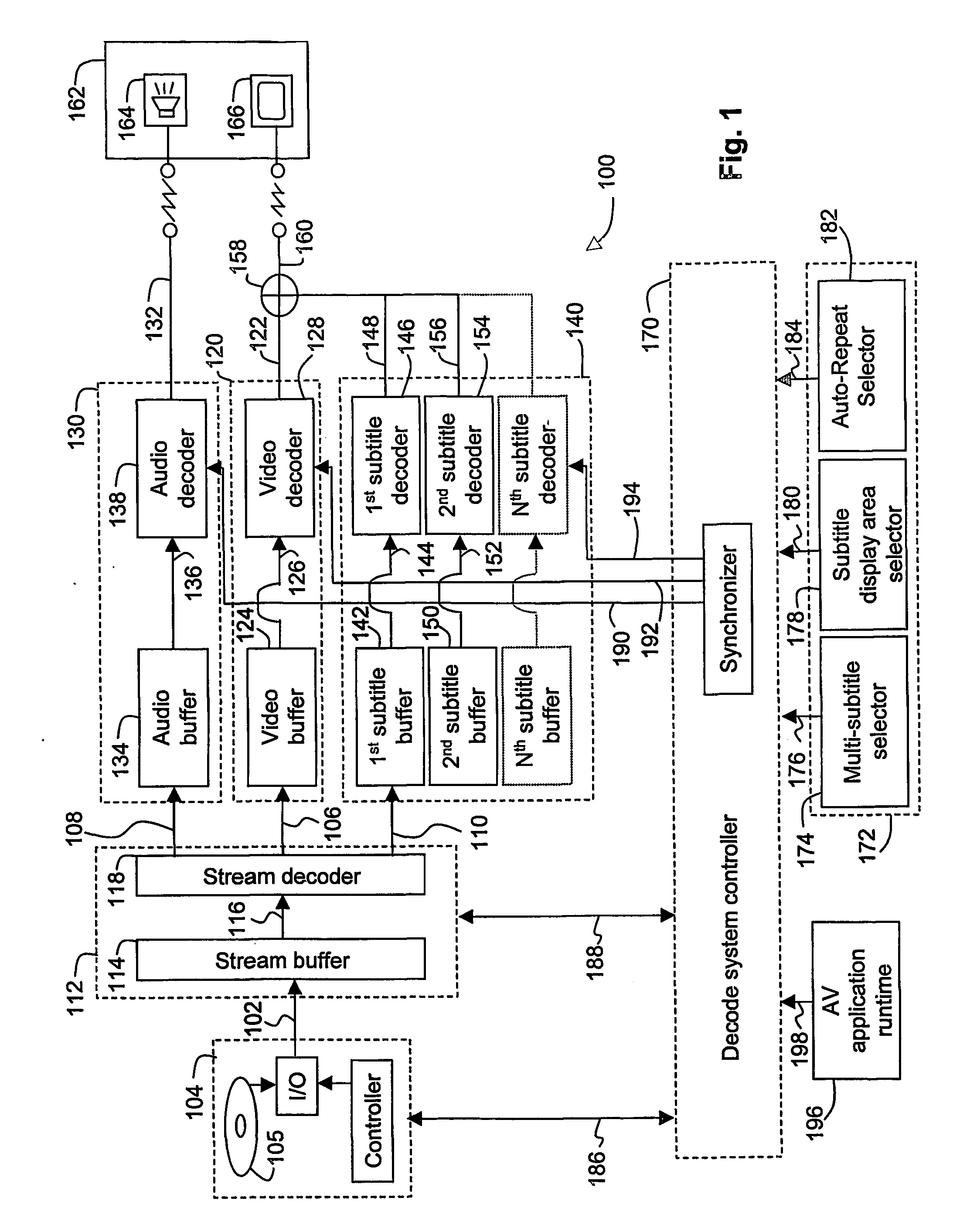

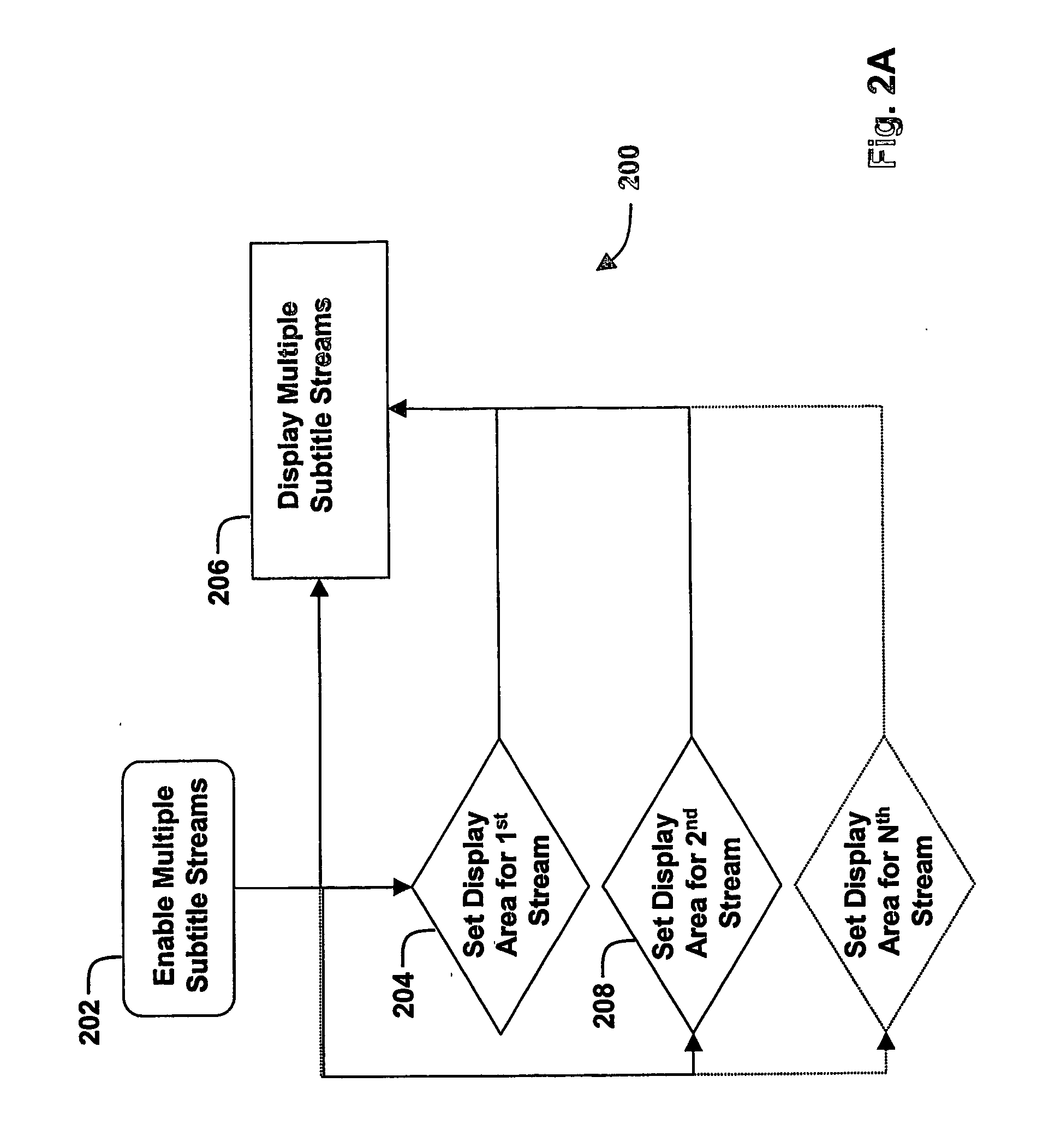

Apparatus and method for simultaneously utilizing audio visual data

InactiveUS20060210245A1Television system detailsColor television signals processingComputer hardwareComposite media

An Audio Visual reproduction system for reproducing data from a composite media stream with various stream types including video, audio, and subtitle stream. The audio stream may include a plurality of interchangeable audio substreams and the subtitle stream may include a plurality of interchangeable subtitle substreams. Selected substreams may be simultaneously reproduced under user control. The reproduction includes a composite media stream separator unit, a video decoder unit, an audio decoder unit, and a subtitle decoder unit. The audio decoder unit can simultaneously decode a plurality of audio substreams to produce a plurality of audio outputs. The subtitle decoding unit can simultaneously decode a plurality of subtitle substreams to produce a plurality of subtitle outputs. A player and user model for simultaneously utilizing multiple substreams of a stream type contained within an application that conforms to a standard wherein only one substream of each stream type is used.

Owner:PANASONIC CORP

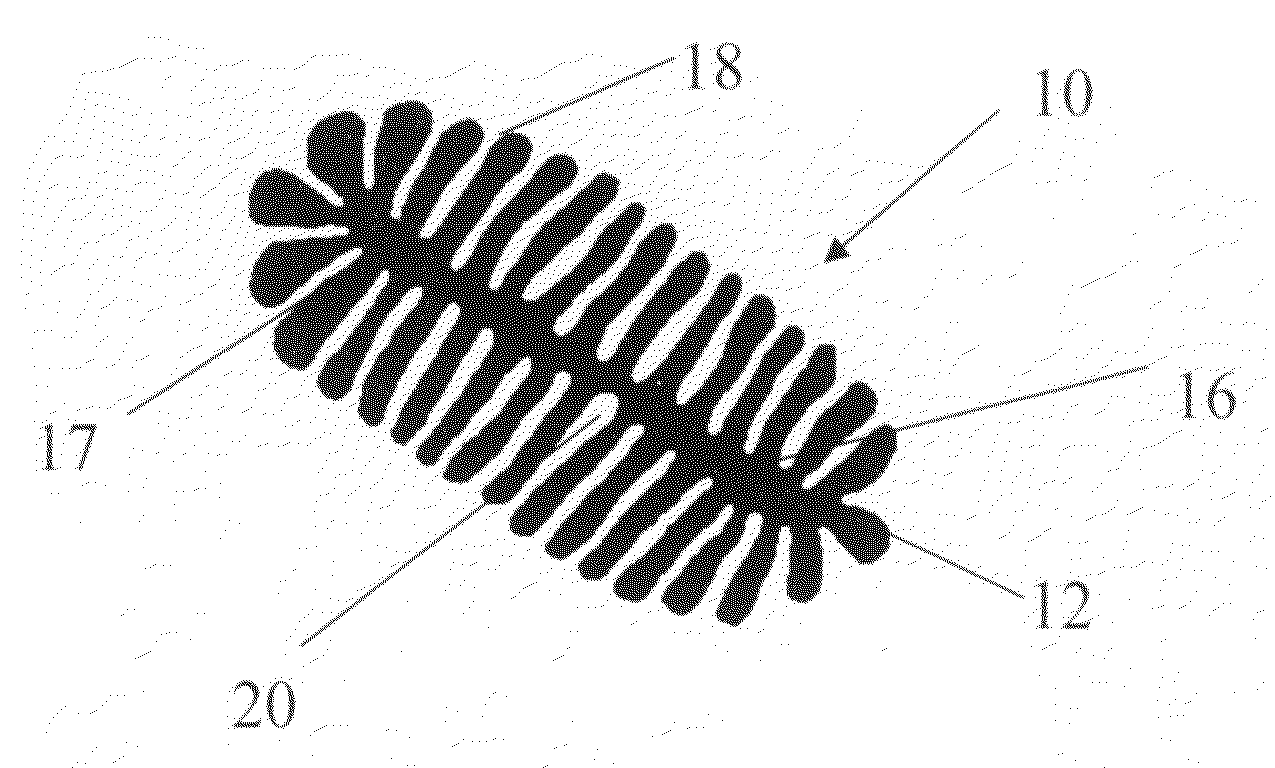

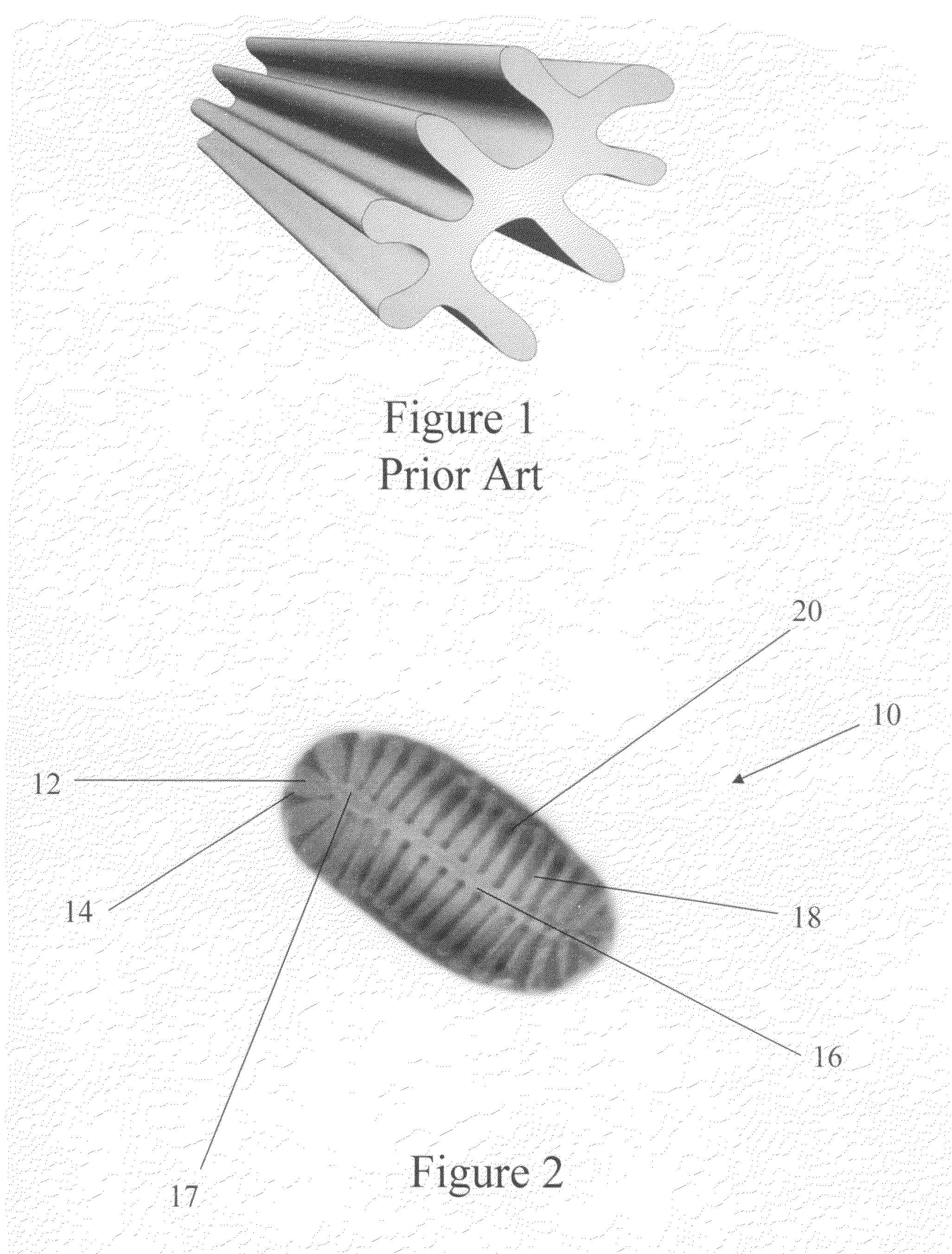

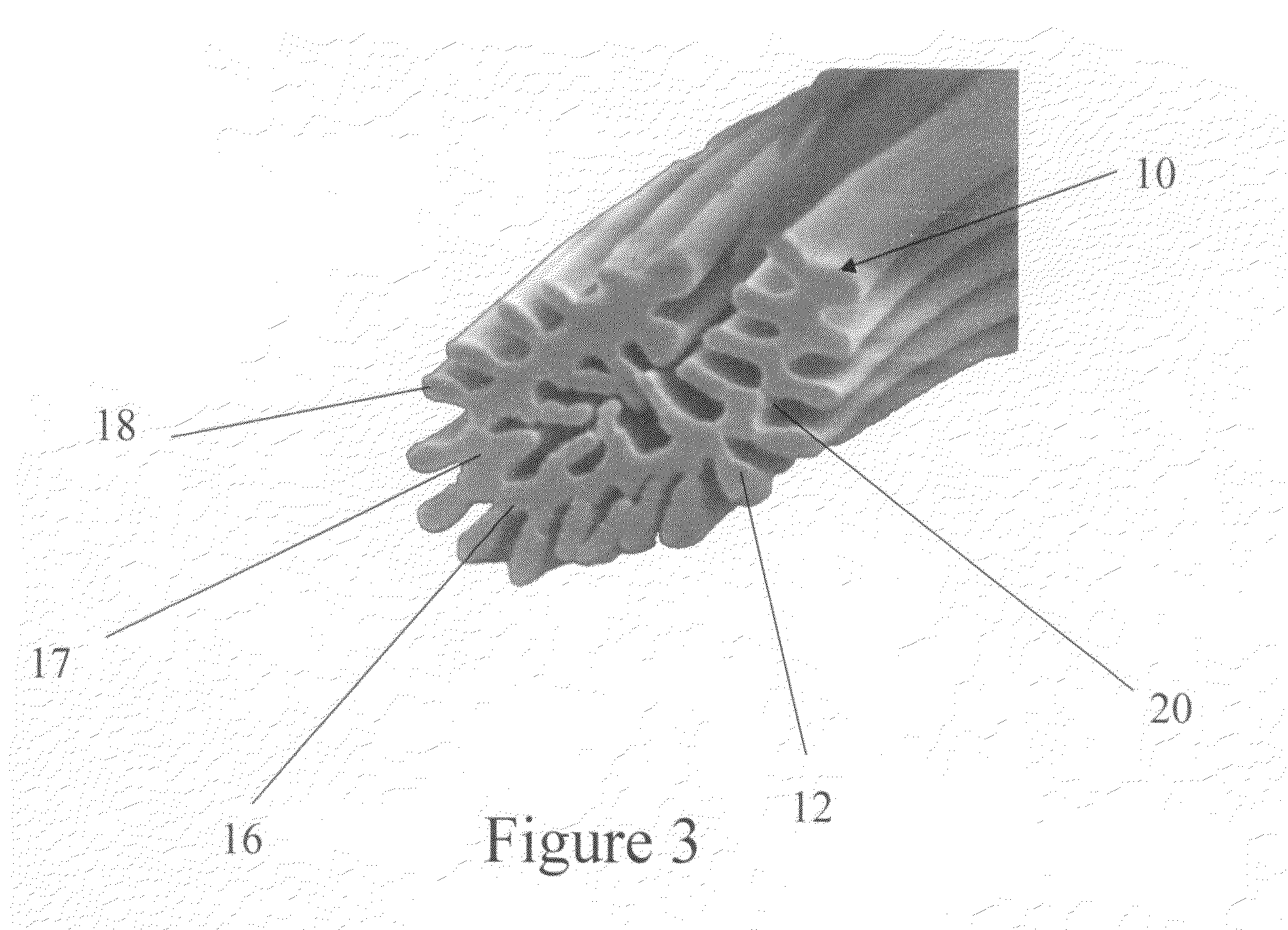

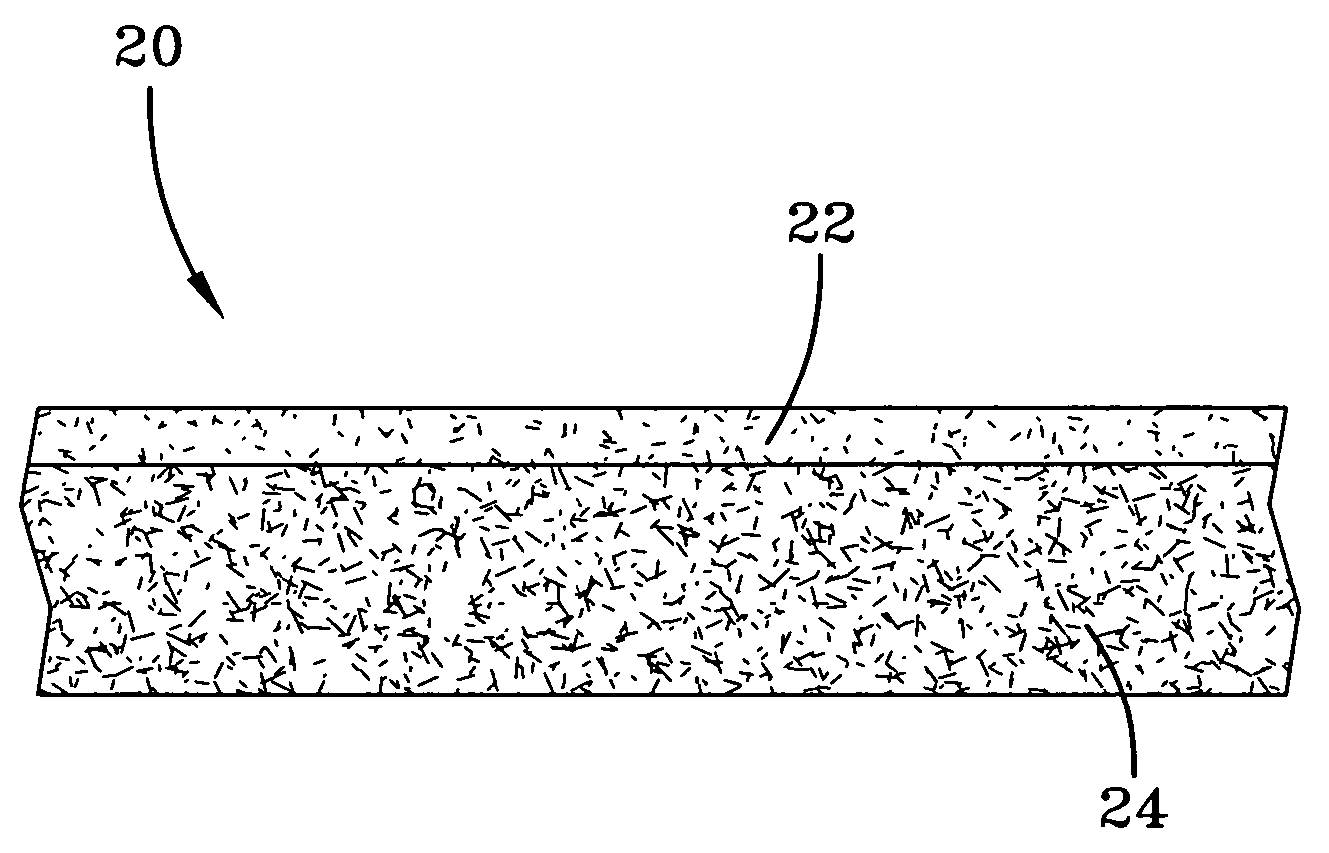

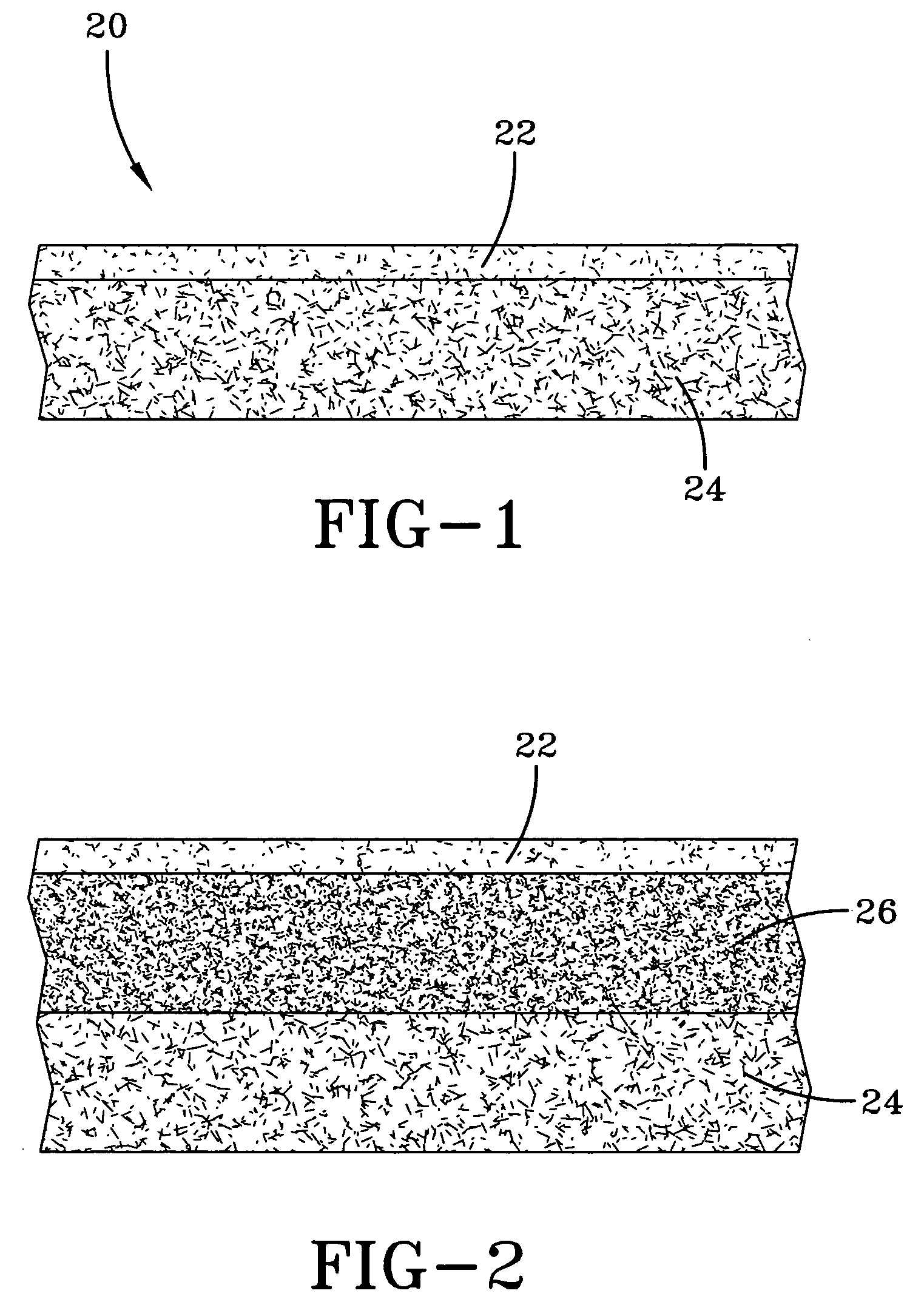

Composite filter media with high surface area fibers

ActiveUS20080105612A1Increased durabilityPromote absorptionOrnamental textile articlesFilament/thread formingComposite mediaPolymer science

The present invention is directed to a high surface area fibers and an improved filter composite media made from the same. More specifically, the composite media preferably comprises a winged-fiber layer having high surface area fibers for increased absorption and strength and a meltblown layer for additional filtration. In one preferred embodiment the high surface area fibers have a middle region with a plurality of projections that define a plurality of channels, which increases the surface area of the fiber. In one preferred embodiment, the high surface area fiber has a specific surface area of about 140,000 cm2 / g or higher and a denier of about 1.0 to about 2.0. The high surface area fiber of the present invention is made using a bicomponent extrusion process using a thermoplastic polymer and a dissolvable sheath.

Owner:ALLASSO IND +1

Media-Editing Application with a Free-Form Space for Organizing or Compositing Media Clips

ActiveUS20120017152A1Minimize the media clipsInput/output for user-computer interactionCarrier indicating arrangementsComposite mediaComputer graphics (images)

For a media-editing application, some embodiments of the invention provide a novel two-dimensional free-form space that allows a user to both visually organize media clips and composite media clips in order to create composite presentations. To visually organize media clips in the space, some embodiments allow the user to add, remove, visually arrange and rearrange, and minimize the media clips. Also, the media clips in the space can be placed at any location within the entire space when the user is visually organizing the media clips. To composite media clips in the free-form space, some embodiments also allow the user to create sequences of media clips, reorder the media clips within sequences, stack sequences, and add or remove media clips from sequences. In some embodiments, the media clips or created sequences can be placed at any location within the entire space when the user is organizing and compositing media clips.

Owner:APPLE INC

Liquid filtration media

A liquid filter with a composite medium that has a nanoweb adjacent to and optionally bonded to a microporous membrane. The membrane is characterized by an LRV value of 3.7 at a rated particle size, and the nanoweb has a fractional filtration efficiency of greater than 0.95 at the rated particle size of the membrane. The nanoweb also has a thickness efficiency ratio of greater than 0.01 at that efficiency. The nanoweb acts to provide depth filtration to the membrane, prefilters particles and extends the lifetime of the membrane.

Owner:DUPONT SAFETY & CONSTR INC

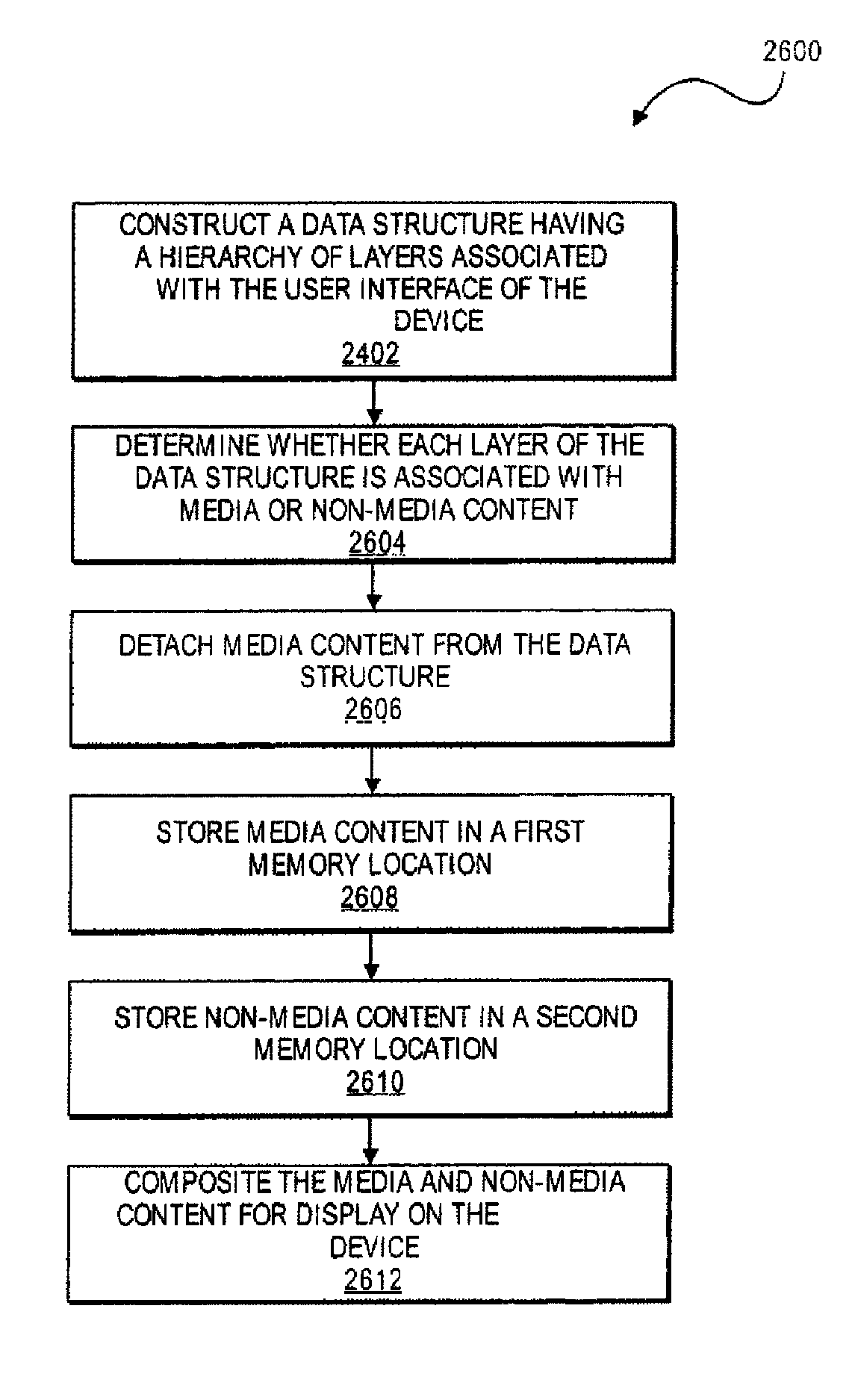

Method and apparatus for compositing various types of content

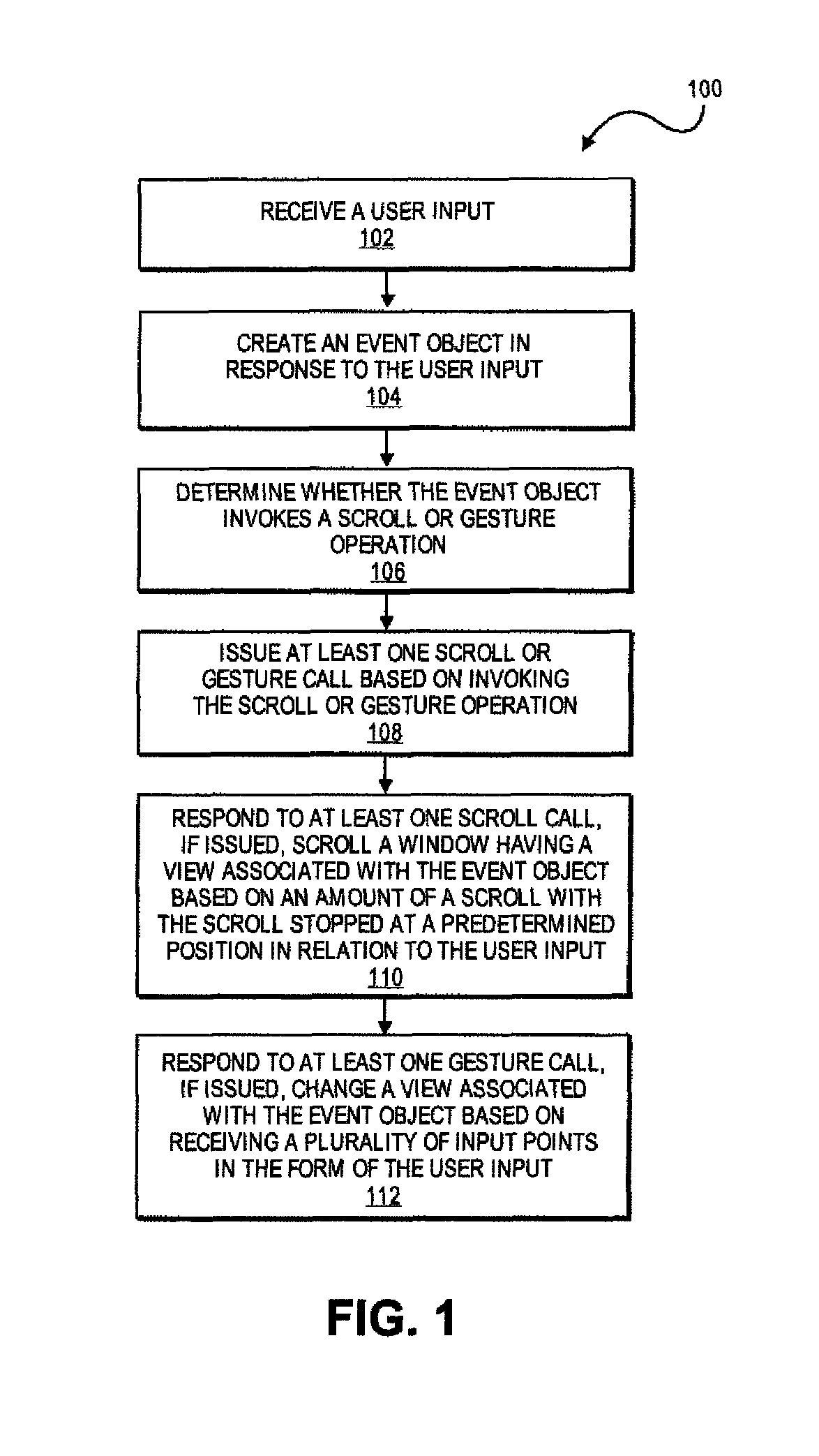

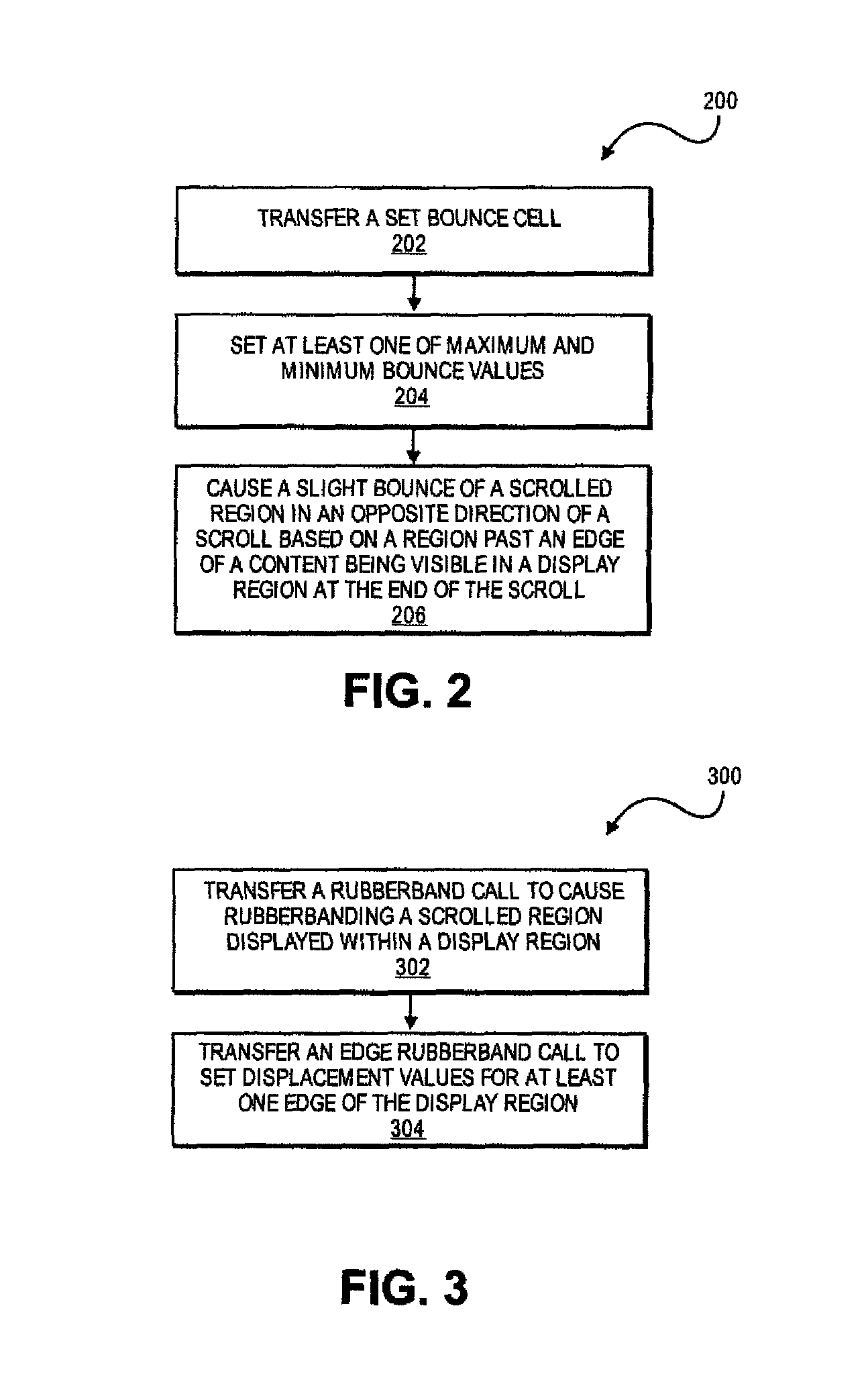

ActiveUS8656311B1Cathode-ray tube indicatorsSpecial data processing applicationsComposite mediaWorld Wide Web

At least some embodiments of the present disclosure include a method for compositing media and non-media content of user interface for display on a device. The method includes constructing a data structure having a hierarchy of layers associated with the user interface of the device. The method further includes determining whether each layer of the data structure is associated with media or non-media content. The data structure or layer tree is traversed in order to determine whether each of the layers of the data structure is associated with media or non-media content. The method further includes detaching a layer associated with media content from the data structure. The method further includes storing media content in a first memory location. The method further includes storing non-media content in a second memory location. The method further includes compositing the media and non-media content for display on the device.

Owner:APPLE INC

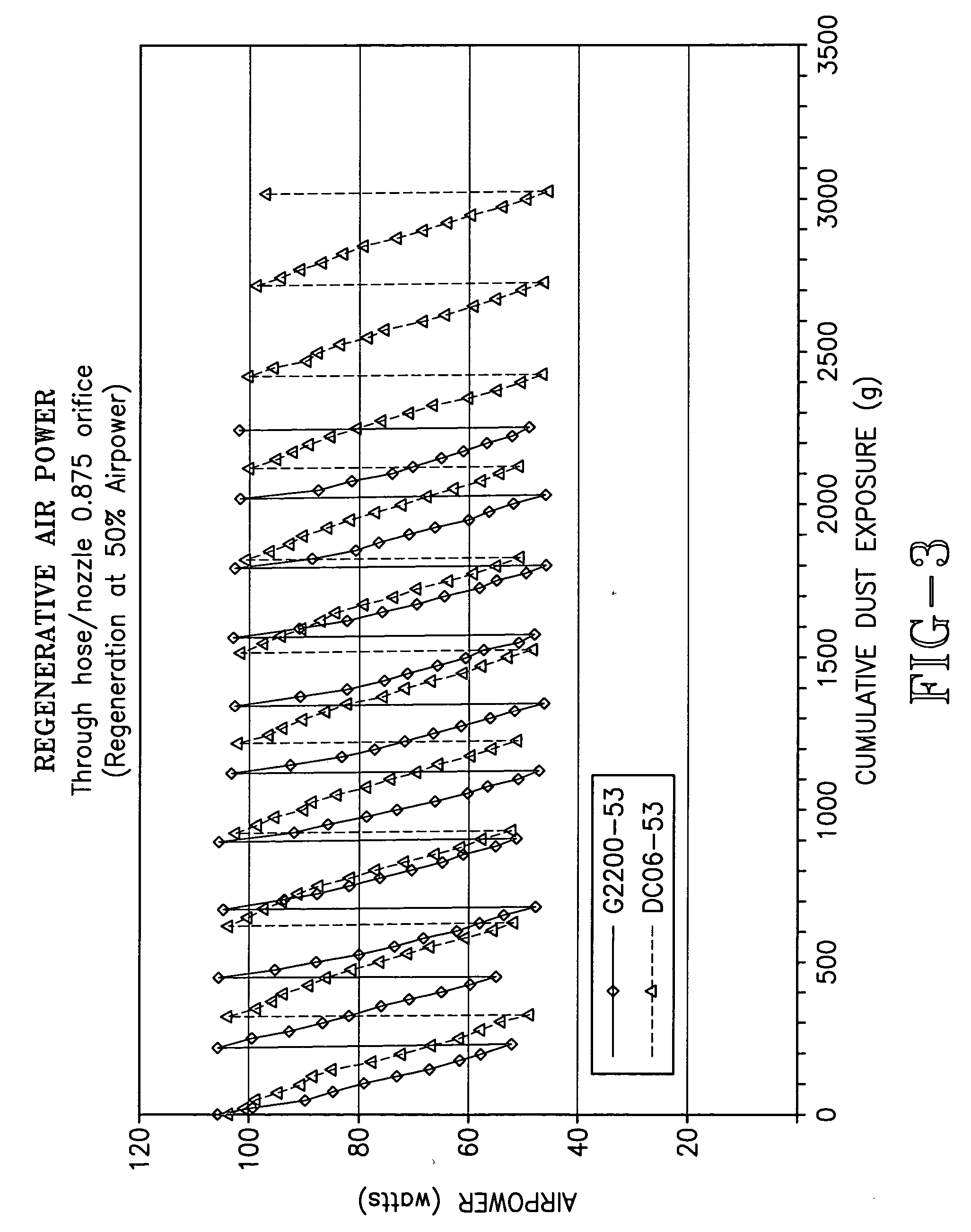

Composite filter media

InactiveUS20060060085A1Enhance dust releasing propertyImprove regenerative abilityCombination devicesDispersed particle filtrationComposite mediaFilter media

A composite filter media having excellent dust-releasing properties provided with a first layer of non-woven synthetic fibers having one outer surface hot calendered to increase smoothness and carrying a coating of a hydrophobic material which lowers surface tension and at least a second layer of non-woven synthetic fibers laminated to the downstream side of said first layer. A backing layer may be included to provide additional support to the first and second layer if desired. The second layer may include an electrostatic charge to increase filter efficiency at a reduced pressure drop across the composite media.

Owner:COLUMBUS INDS

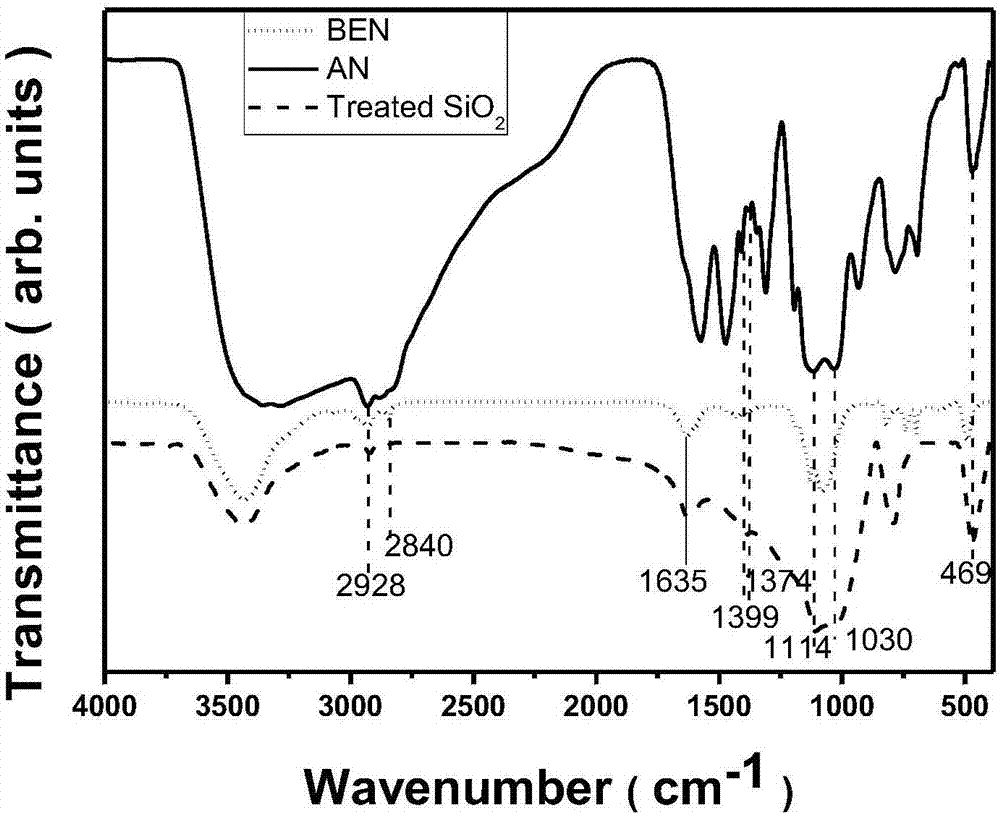

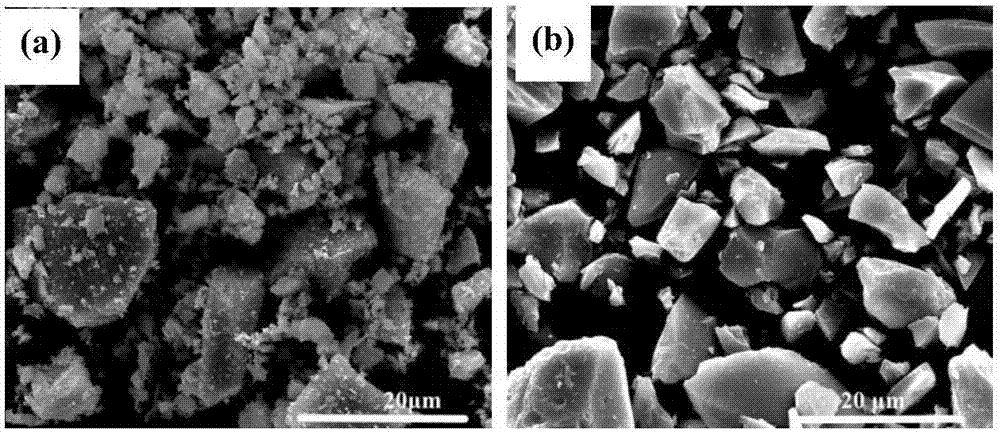

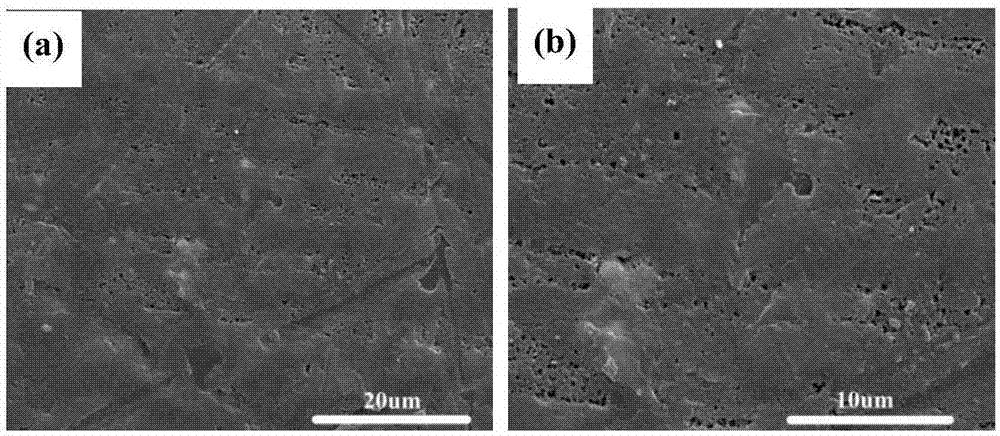

A preparing method of a ceramic-filled polytetrafluoroethylene microwave composite-medium substrate

A preparing method of a ceramic-filled polytetrafluoroethylene microwave composite-medium substrate is disclosed. The method includes 1) adding silicon dioxide ceramic powder into a liquid mixture of hydrogen peroxide and concentrated hydrochloric acid after the silicon dioxide ceramic powder is dried, and heating the mixture to 50-70 DEG C to obtain a suspension; 2) subjecting the suspension to suction filtration and drying a product in a vacuum environment; 3) adding the silicon dioxide ceramic powder obtained in the step 2) into a solution mixture of deionized water and absolute alcohol, adjusting the pH value to be 3-5, weighing a coupling agent the weight of which is 1.0-2.5% of the weight of the silicon dioxide ceramic powder, performing ball milling, and fully mixing the mixture to obtain a material mixture; 4) filtering and drying the material mixture to obtain modified silicon dioxide ceramic powder; 5) ball-milling and mixing the modified silicon dioxide powder, chopped glass fibers and polytetrafluoroethylene, and then performing demulsification to obtain dough; and 6) subjecting the dough to molding and hot-pressed sintering. The ceramic-filled material prepared by the method has a low dielectric constant (with epsilon being equal to 2.94), ultralow dielectric loss (with tg[delta] being less than 0.0008, 10 GHz), low water absorption (less than 0.02%) and a small thermal expansion coefficient (less than 20 ppm / DEG C).

Owner:汕头超声覆铜板科技有限公司

Reference clips in a media-editing application

InactiveUS20130124999A1Input/output for user-computer interactionTelevision system detailsComposite mediaMediaFLO

Some embodiments provide a media-editing application. The application defines a reference clip data structure for a media clip that represents one or more media files imported into the media-editing application. The application receives a command to add the media clip into a composite media presentation. The application defines a clip instance data structure as part of the composite media presentation. The clip instance data structure inherits properties of the reference clip data structure and subsequent modifications to the reference clip data structure affect the clip instance data structure.

Owner:APPLE INC

Media editing with a segmented timeline

ActiveUS8533598B2Electronic editing digitised analogue information signalsCarrier indicating arrangementsGraphicsGraphical user interface

Some embodiments provide a computer readable medium storing a media editing application for creating multimedia presentations. The application includes a graphical user interface (GUI). The GUI includes a composite display area for displaying a portion of a timeline to which multimedia clips are assigned to create a composite media presentation. The GUI includes a user interface tool for dividing the timeline into segments. The GUI includes an editing tool for applying an effect to each of a plurality of clips in a particular segment of the timeline. The GUI includes a user interface tool for modifying a duration of at least one segment. Different versions of the segments may be created.

Owner:APPLE INC

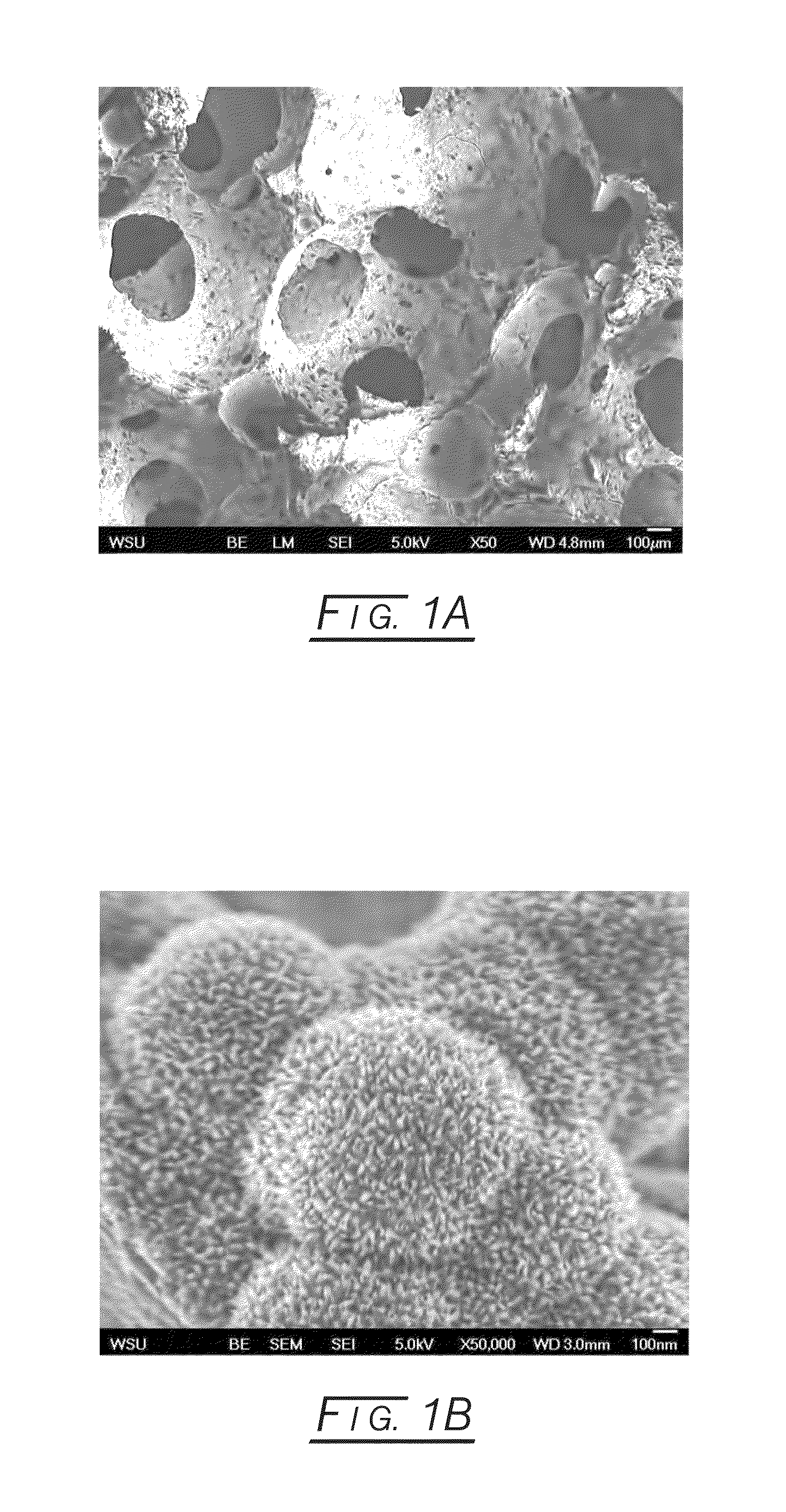

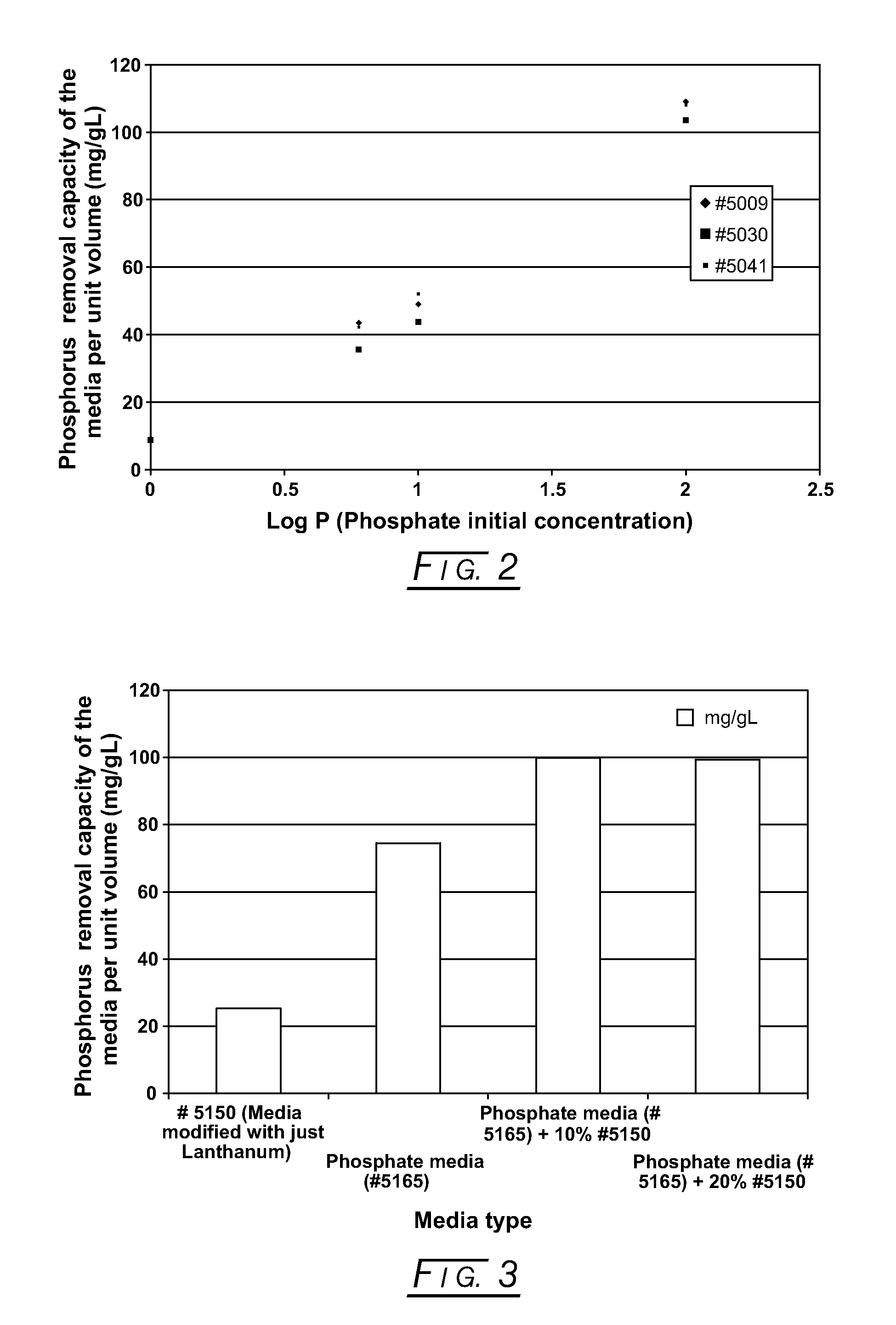

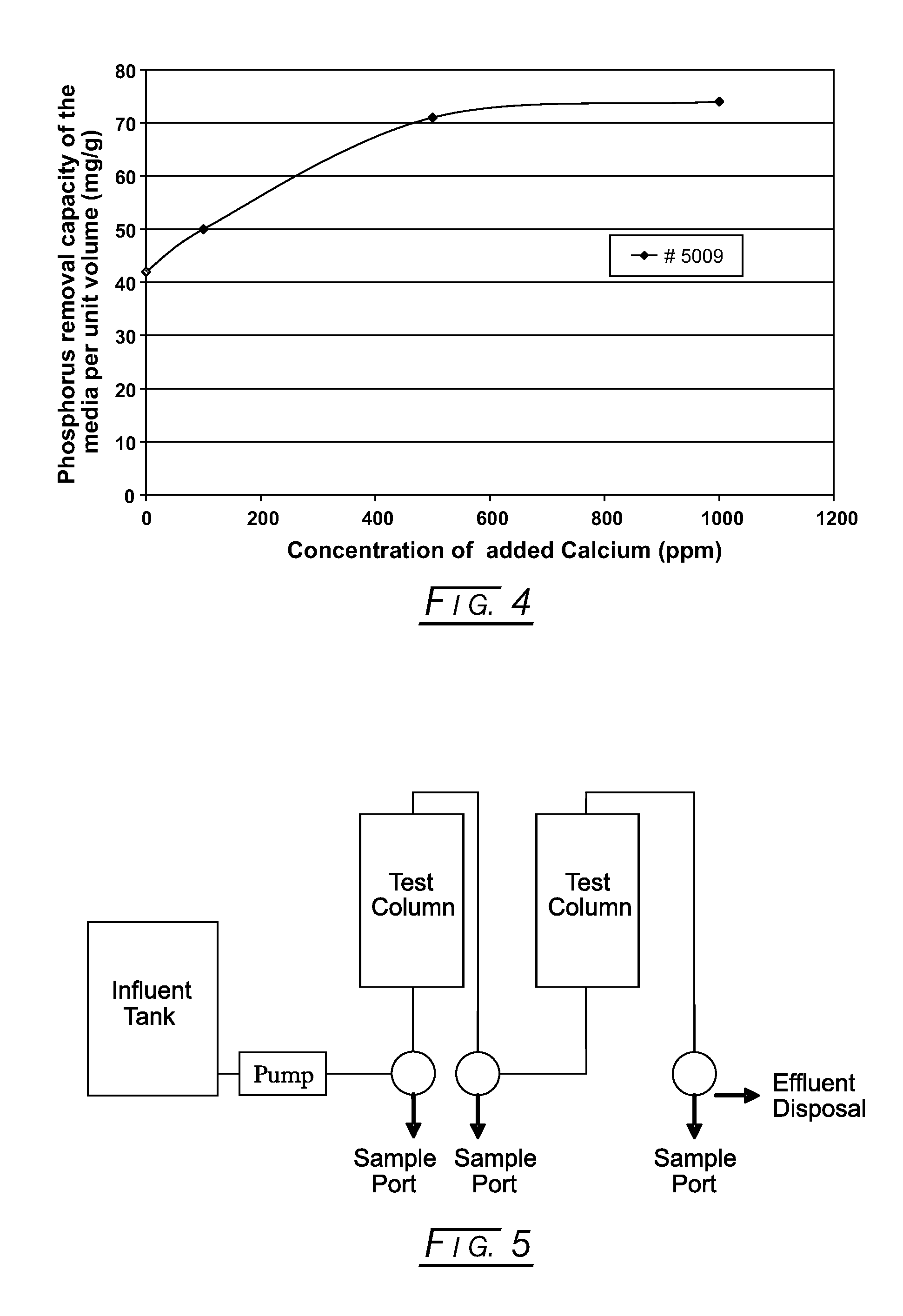

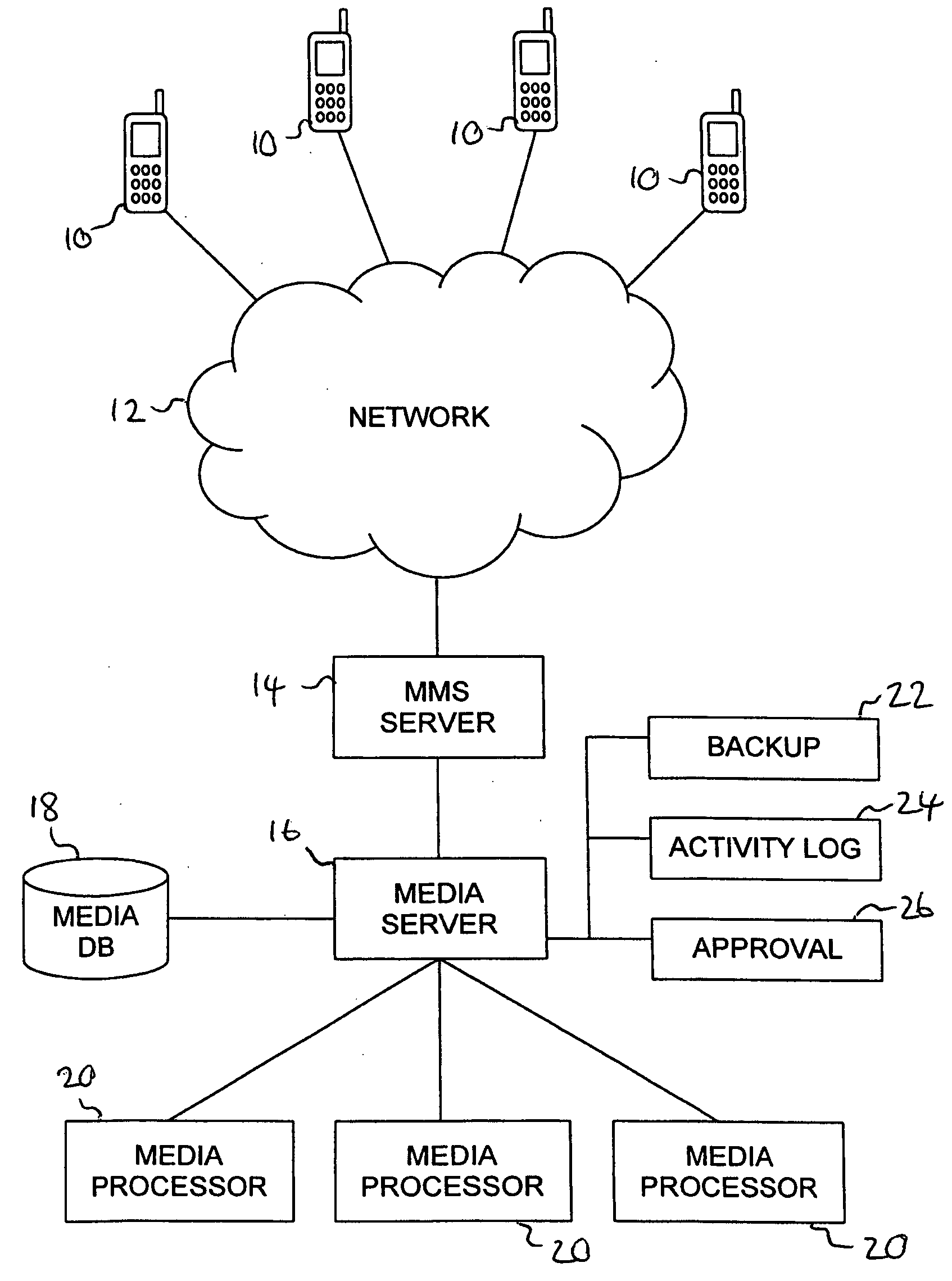

Porous Composite Media for Removing Phosphorus from Water

InactiveUS20130098840A1Strong phosphorus adsorption capacityReduce capacityMaterial nanotechnologyAluminium silicatesFiltrationPorous ceramics

Disclosed are nano-engineered porous ceramic composite filtration media for removal of phosphorous contaminates from wastewater and other water or liquid sources. Such porous ceramic media has high surface area and an interconnecting hierarchical pore structure containing nano-iron oxide / oxyhydroxide compounds, as well as other nano materials, surfactants, ligands or other compounds appropriate for removing higher amounts of phosphorous or phosphorous compounds. The composite media can be modified with nano-phased materials grown on the high surface area and addition of other compounds, contains hierarchical, interconnected porosity ranging from nanometer to millimeter in size that provides high permeability substrate especially suited for removal of contaminants at the interface of the water or other fluids and the nanomaterial or surfactants residing on the surfaces of the porous structure.

Owner:METAMATERIA TECH

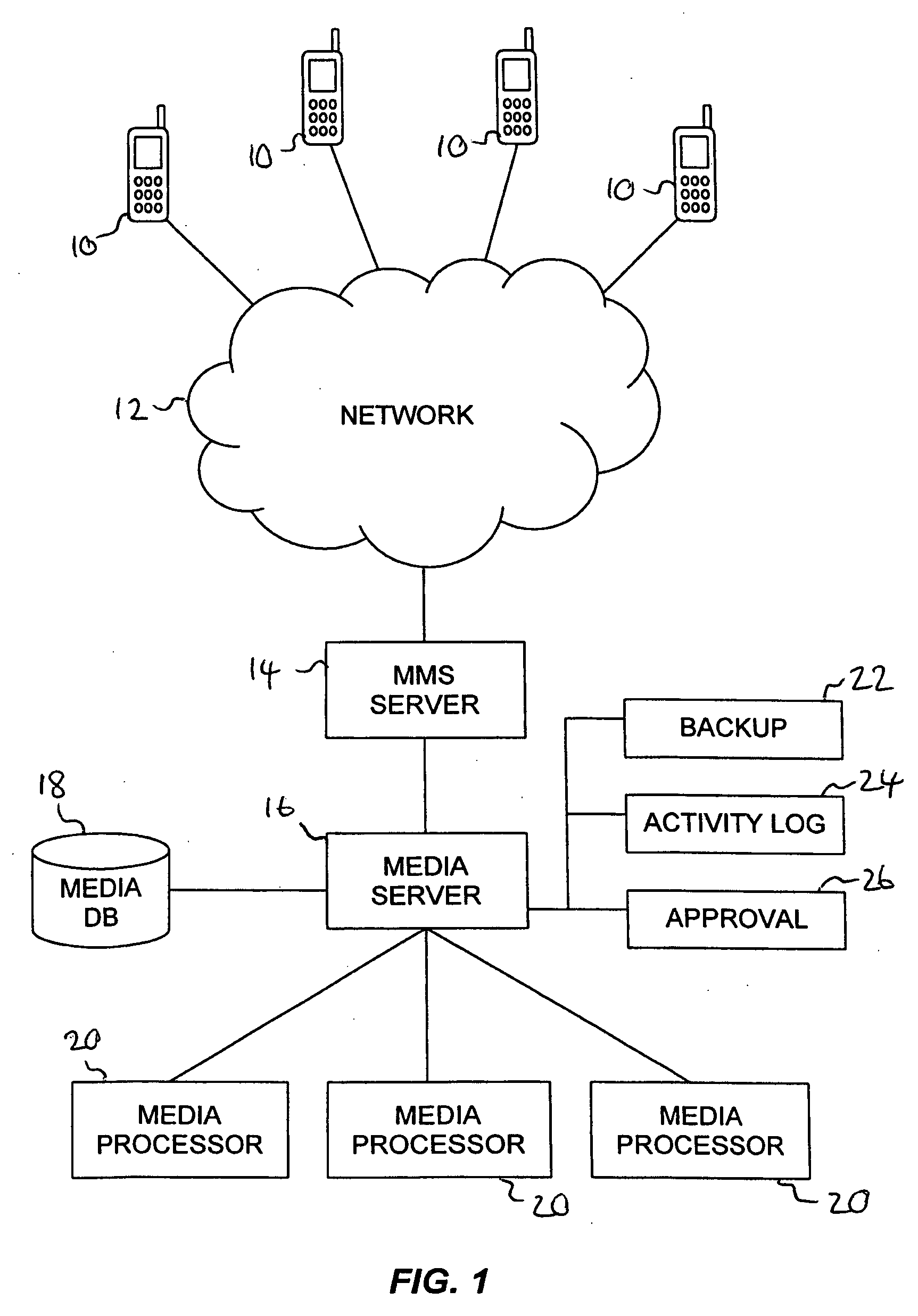

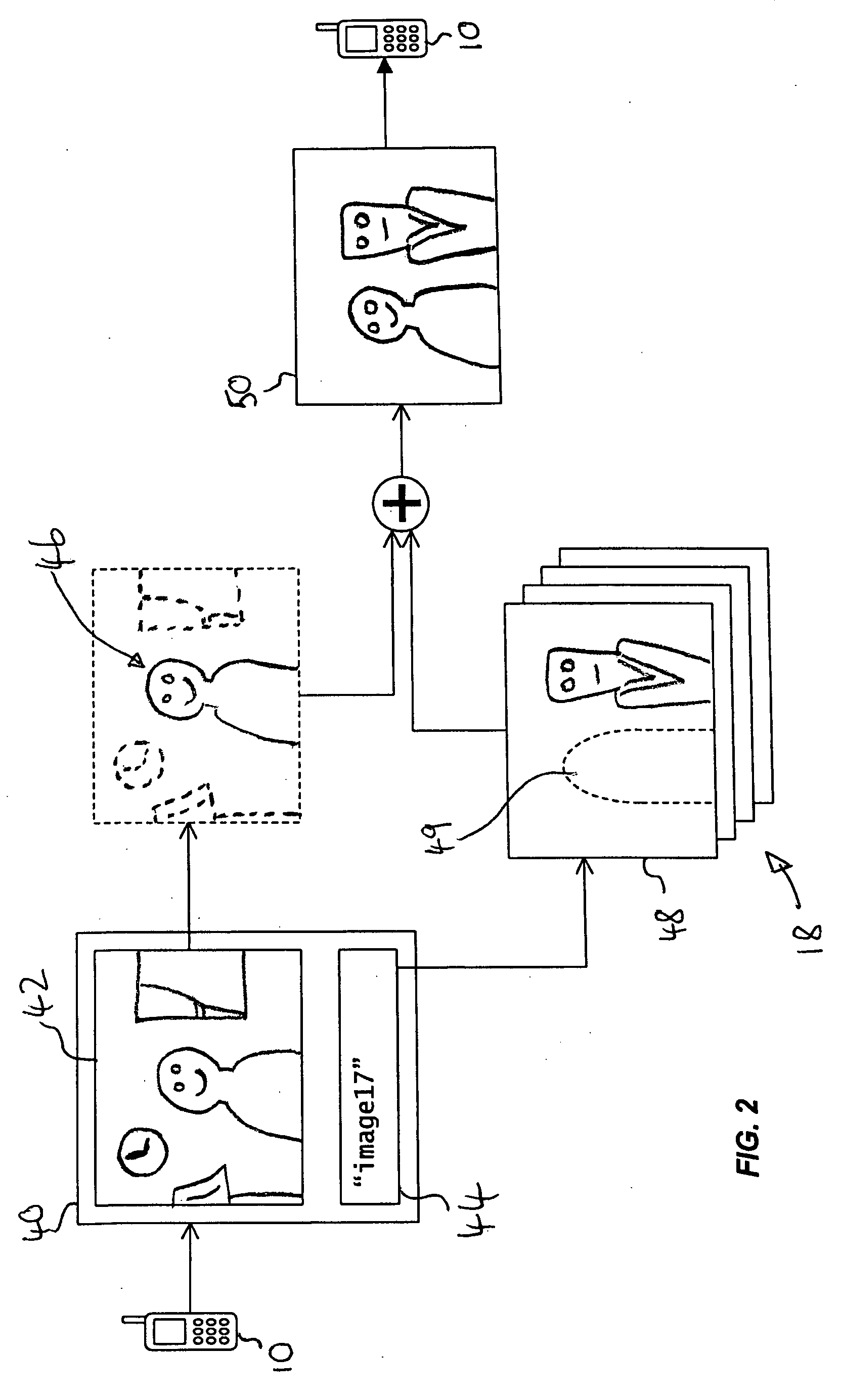

Image processing system

InactiveUS20070121146A1Improve efficiencyData switching networksDigital output to print unitsComposite mediaTelecommunications network

A method of providing media data to devices connected to a communications network is disclosed. The method comprises storing a plurality of media objects, each media object comprising image data. The media objects may be images or video clips. A request is received from a device connected to the network, the request comprising input image data and specifying one of the plurality of stored media objects. At least a portion of the input image data is composited with image data of the specified media object to produce a composite media object, and the composite media object is transmitted to the device. The method may be used with mobile telecommunications networks or over the Internet. An image processing system is also disclosed.

Owner:PRODN TLMH

Method of creating a media item portion database

InactiveUS20070083537A1Digital data processing detailsMetadata multimedia retrievalComposite mediaDatabase

A method for creating a media item portion database. In one aspect, the database entry comprises a data container. In another aspect, the media item portion entries may be used to identify media item portions used in creating composite media items.

Owner:OATH INC +1

Set of metadata for association with a composite media item and tool for creating such set of metadata

ActiveUS20080269931A1Digital data processing detailsUser identity/authority verificationComposite mediaComputer science

Owner:HUAWEI TECH CO LTD

Anchor Override for a Media-Editing Application with an Anchored Timeline

ActiveUS20130104042A1Electronic editing digitised analogue information signalsCarrier indicating arrangementsGraphical user interfaceComposite media

Some embodiments provide a non-transitory machine readable medium that stores a media-editing application which when executed by at least one processing unit provides a graphical user interface (GUI) for creating a composite media presentation from several media clips. The GUI includes a composite display area for placing media clips to specify the composite media presentation. The composite display area includes (1) a primary lane for placing a primary sequence of media clips and (2) several secondary lanes for placing media clips that are anchored to media clips in the primary lane. The GUI includes an editing tool that includes a first mode for performing an edit operation to a particular media clip and a set of media clips anchored to the particular media clip and a second mode for performing the edit operation to the particular media clip without performing the edit operation to the set of media clips anchored to the particular media clip.

Owner:APPLE INC

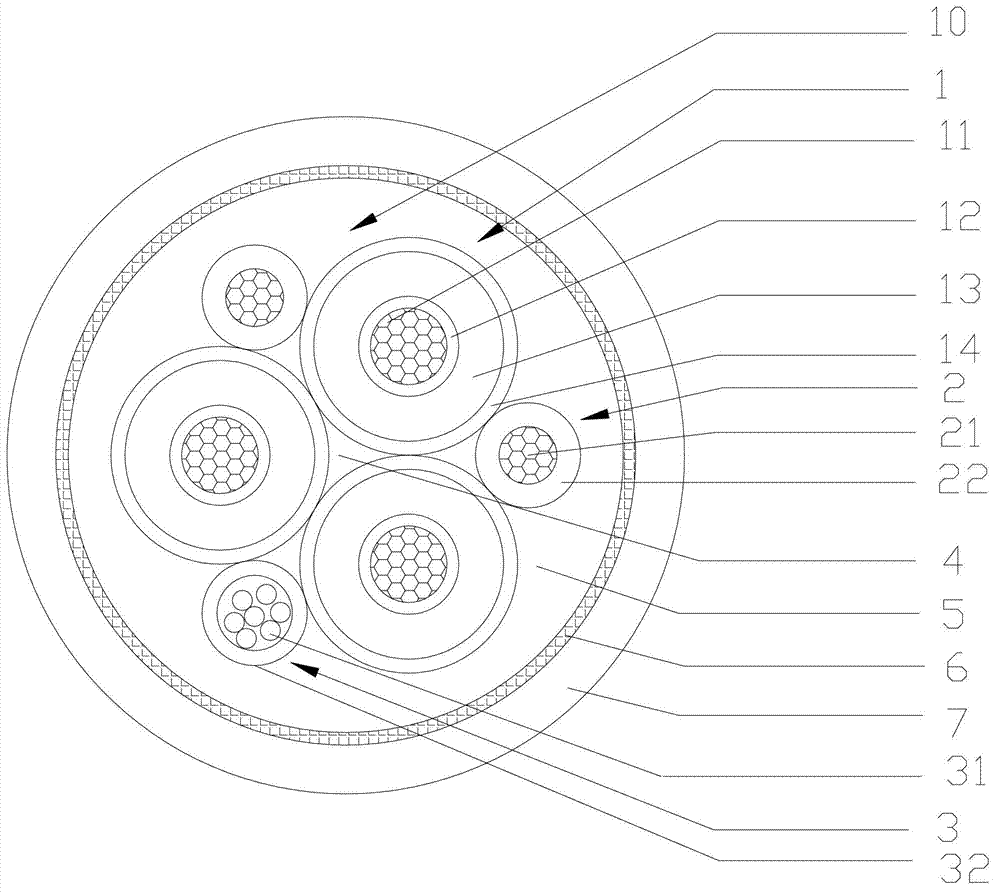

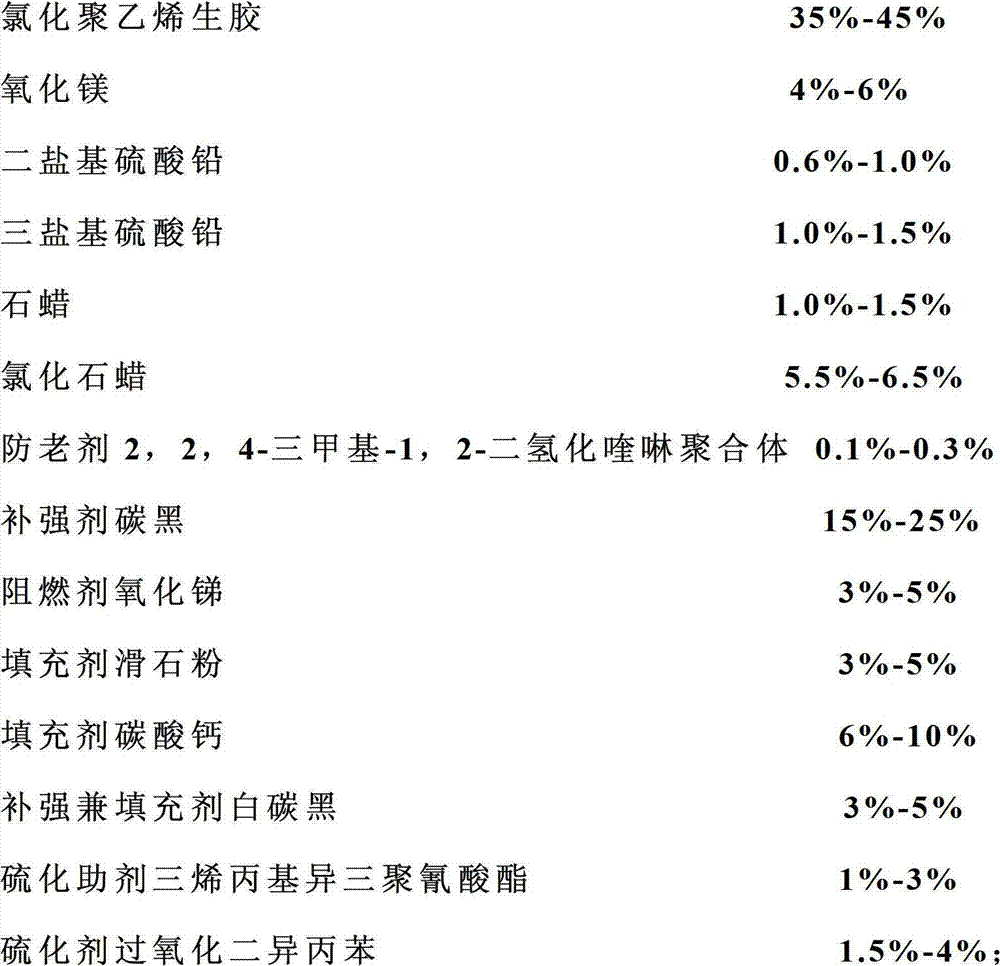

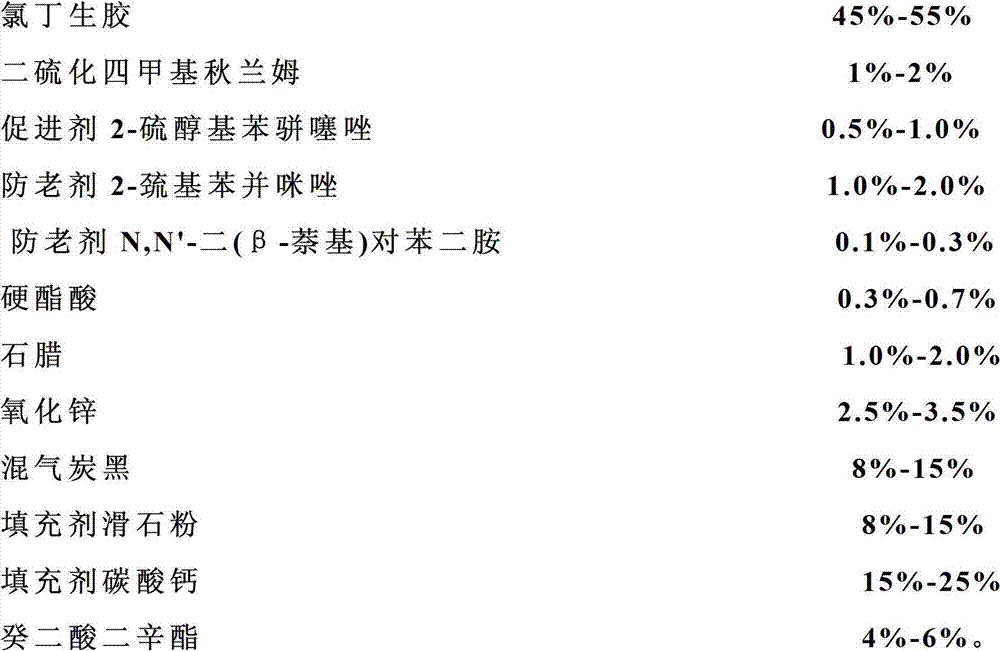

Photoelectric composite medium-voltage drum cable with rated voltage of 3.6/6kV-12/20kV and processing technology thereof

ActiveCN102760519AImprove performanceExtended service lifePower cables with screens/conductive layersCable/conductor manufactureRubber materialComposite media

The invention discloses a photoelectric composite medium-voltage drum cable with the rated voltage of 3.6 / 6kV-12 / 20kV and a processing technology thereof. An optical unit sheath is made from a chlorinated polyethylene rubber material capable of being quickly sulphuretted, so that the optical fiber performance is ensured in the rubber extruding process, and accordingly, all properties of the photoelectric composite medium-voltage drum cable are improved and the service life is prolonged. Besides, owing to the reasonably-designed cable structure and the reasonably-customized processing technology, for example, the stranding direction, the layer-stranding direction and the lay ratio of conductor braided wires, as well as the cabling layer ratio control, are controlled, one frame is changed into an active wire releasing design by cabling equipment, and the design of a weaving reinforced layer and the sulfidization degree of both an inner sheath and an outer sheath are controlled, so that the bendability, the tensile performance and the twisting resistance of the cable are ensured and the service life of the cable is prolonged. In addition, owing to the special neoprene sheath material, the cable is endowed with such favorable properties as ultraviolet resistance, oil resistance, low-temperature resistance, abrasion resistance and the like, thereby having improved service performance and prolonged service life.

Owner:JIANGSU HENGTONG POWER CABLE

Method of searching for media item portions

ActiveUS20070083497A1Metadata multimedia retrievalBuying/selling/leasing transactionsComposite mediaComputer science

A method for searching for a media item portion and utilizing a database of media item portion entries. In one aspect, the database entry comprises a data container. In another aspect, the media item portion entries may be used to identify media item portions used in creating composite media items.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com