A method for the production of a biologically active prosthetic device for the reconstruction of bone tissue and the prosthetic device itself

A bioactive, bone tissue technology, used in tissue regeneration, prostheses, bone implants, etc., to solve the problems of shrinkage in size, unsatisfactory results, and difficulty in obtaining parts with specified shapes and sizes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] According to the present invention, the method of manufacturing a prosthetic device for reconstructing bone tissue basically comprises the following steps:

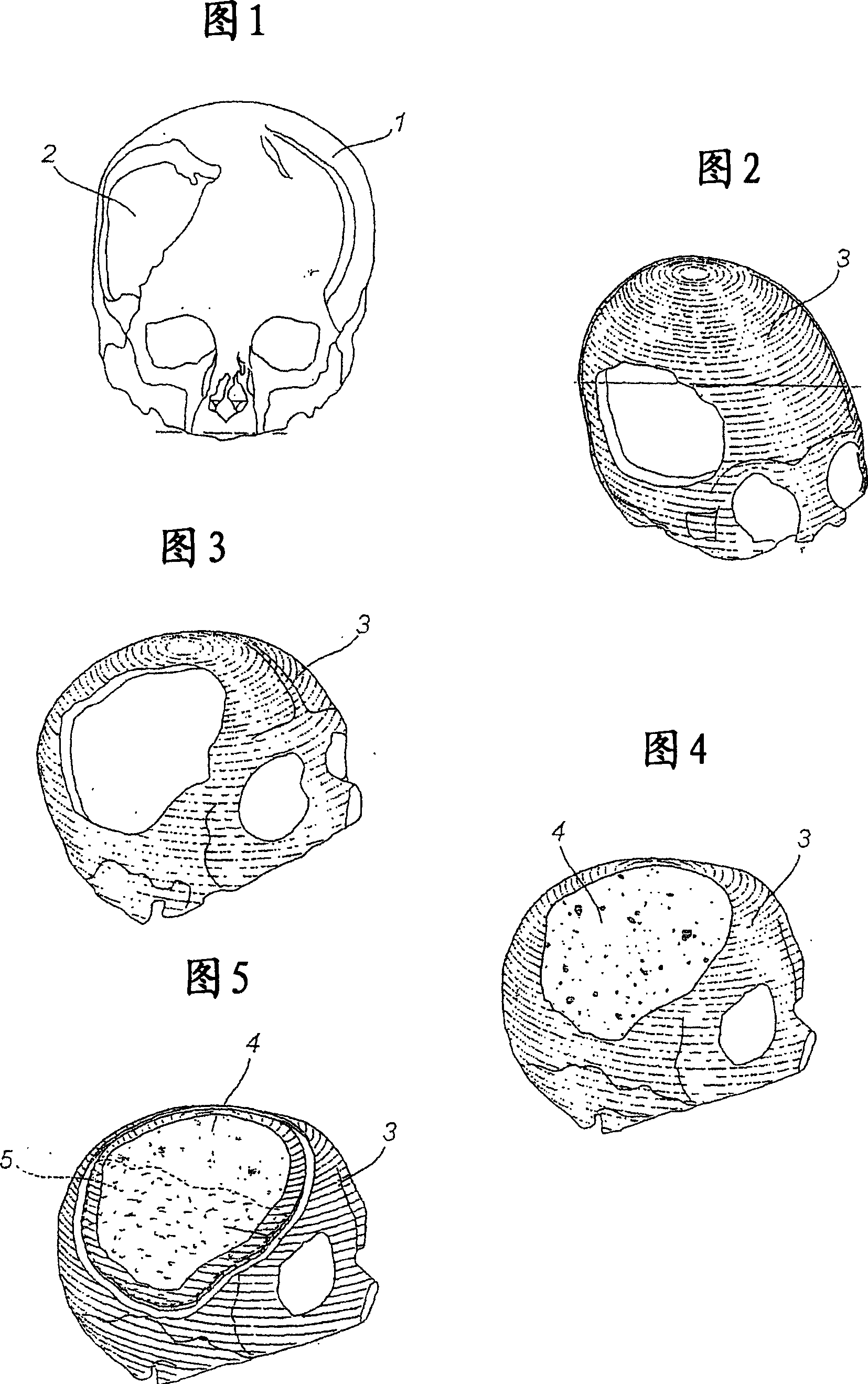

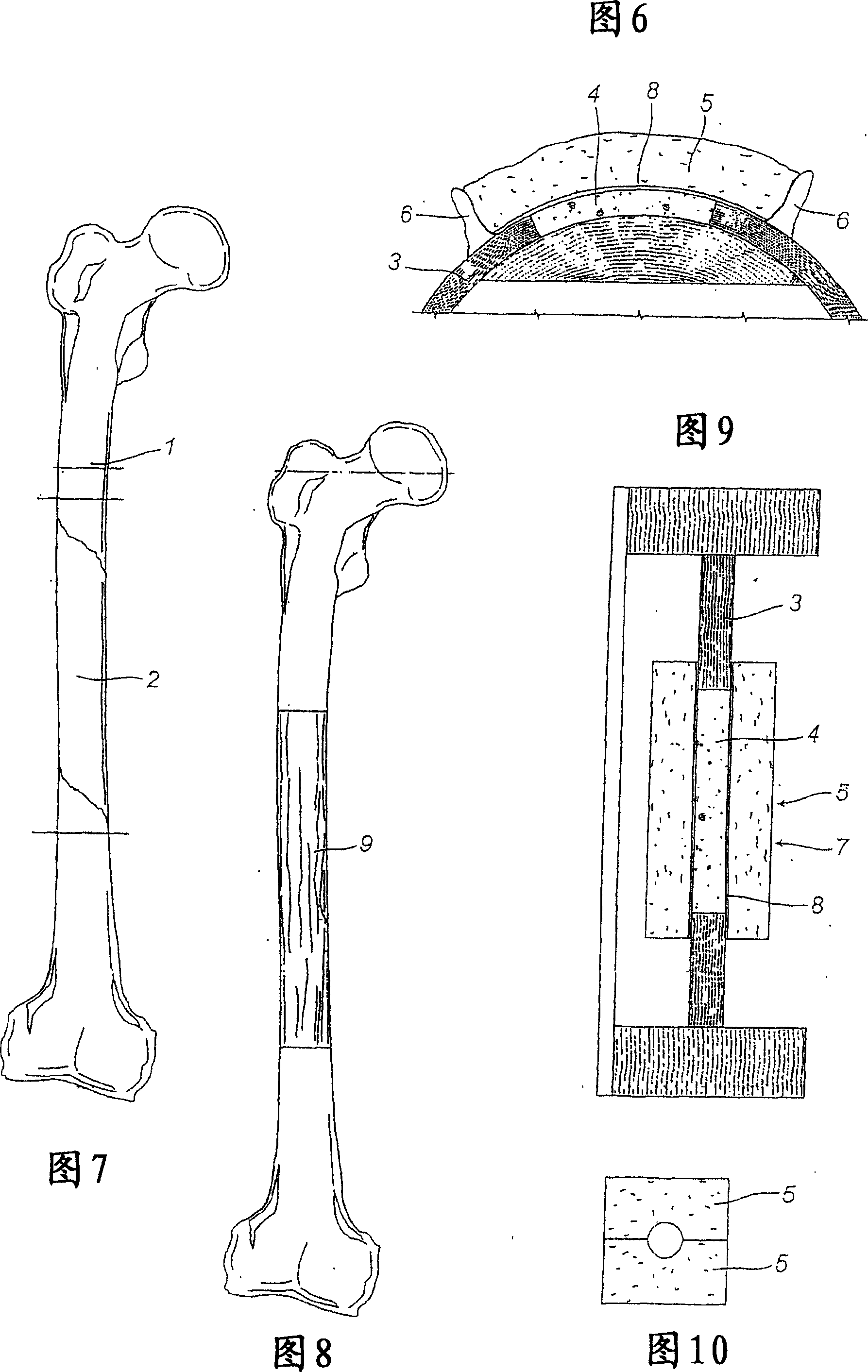

[0030] 1. Carry out CAT (computed axial tomography) scan to patient and generate CAT file, and this file has shown the three-dimensional electronic model 1 of the bone to be reconstructed and the part of bone loss 2 (Fig. 1 and 7);

[0031] 2. Based on the data obtained from the CAT (Computed Axial Tomography) scan of the patient and the CAT file, rapid main group (main) and interface software system controlled prototyping is used to generate a prototype of the patient's skeletal region involved Resin model 3 (Figures 2, 3 and 9), for example model 3 can be obtained using three-dimensional stereolithography;

[0032] 3. Use the resin prototype to make a model 4 of the patient's bone defect to be reconstructed (in calcium sulfate, resin or silicone rubber) using the slip casting technique;

[0033] 4. Use the slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com