Patents

Literature

186 results about "Beta-tricalcium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

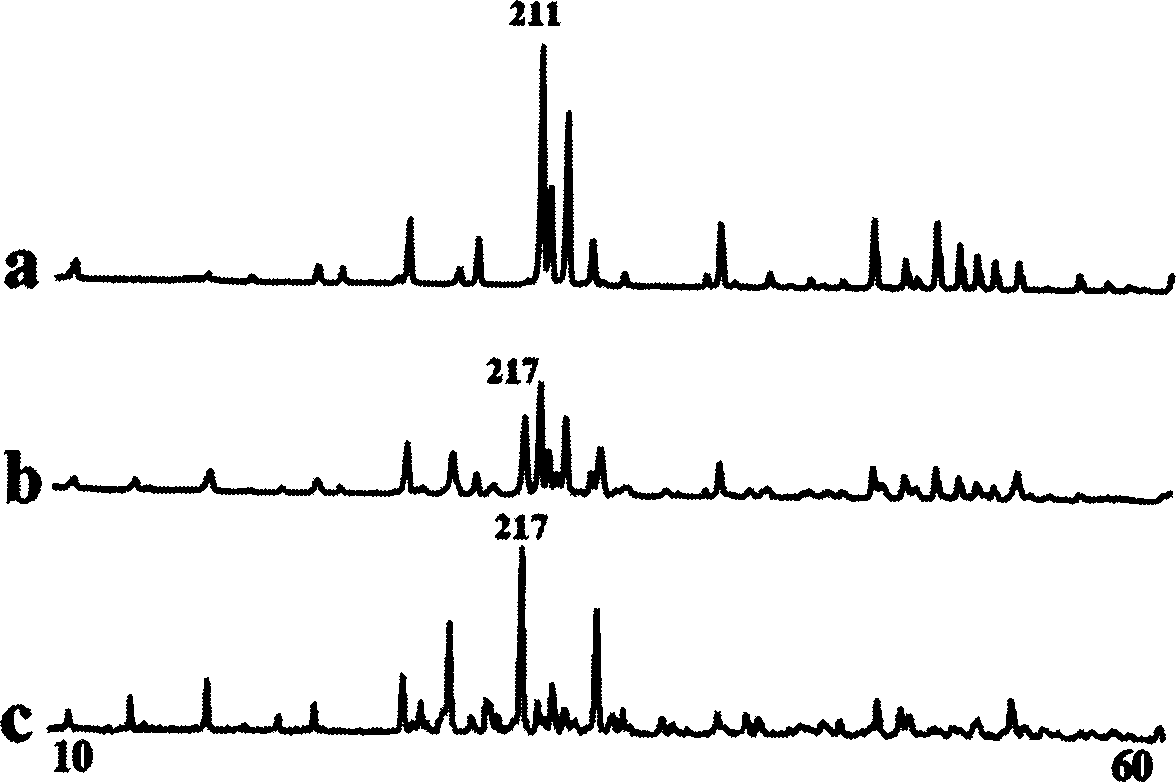

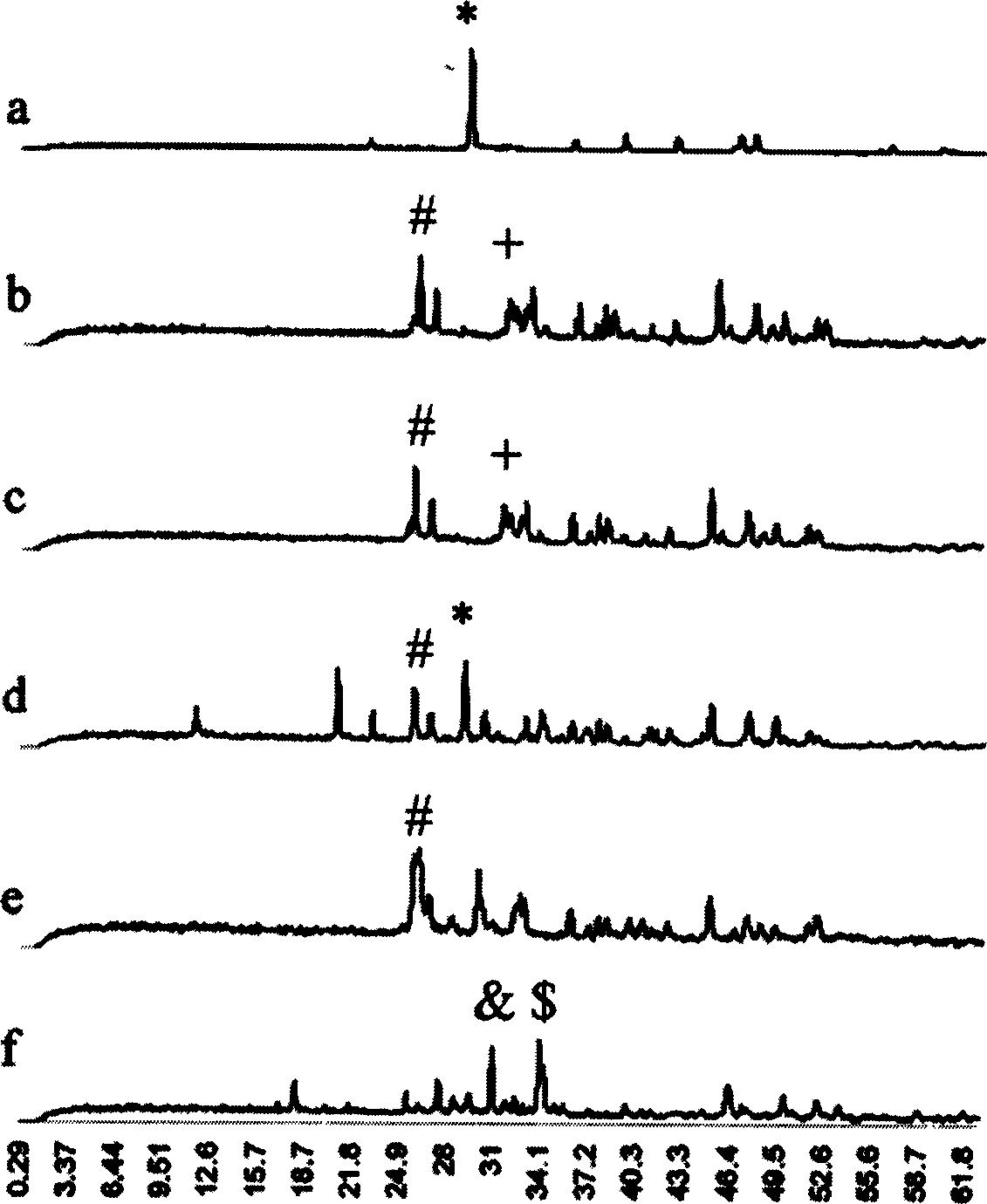

Beta tricalcium phosphate is commonly used in metaphyseal defects but its use in posterolateral spinal fusion remains controversial. There are very few published animal studies in which use of beta tricalcium phosphate has been evaluated in the posterolateral lumbar arthrodesis model.

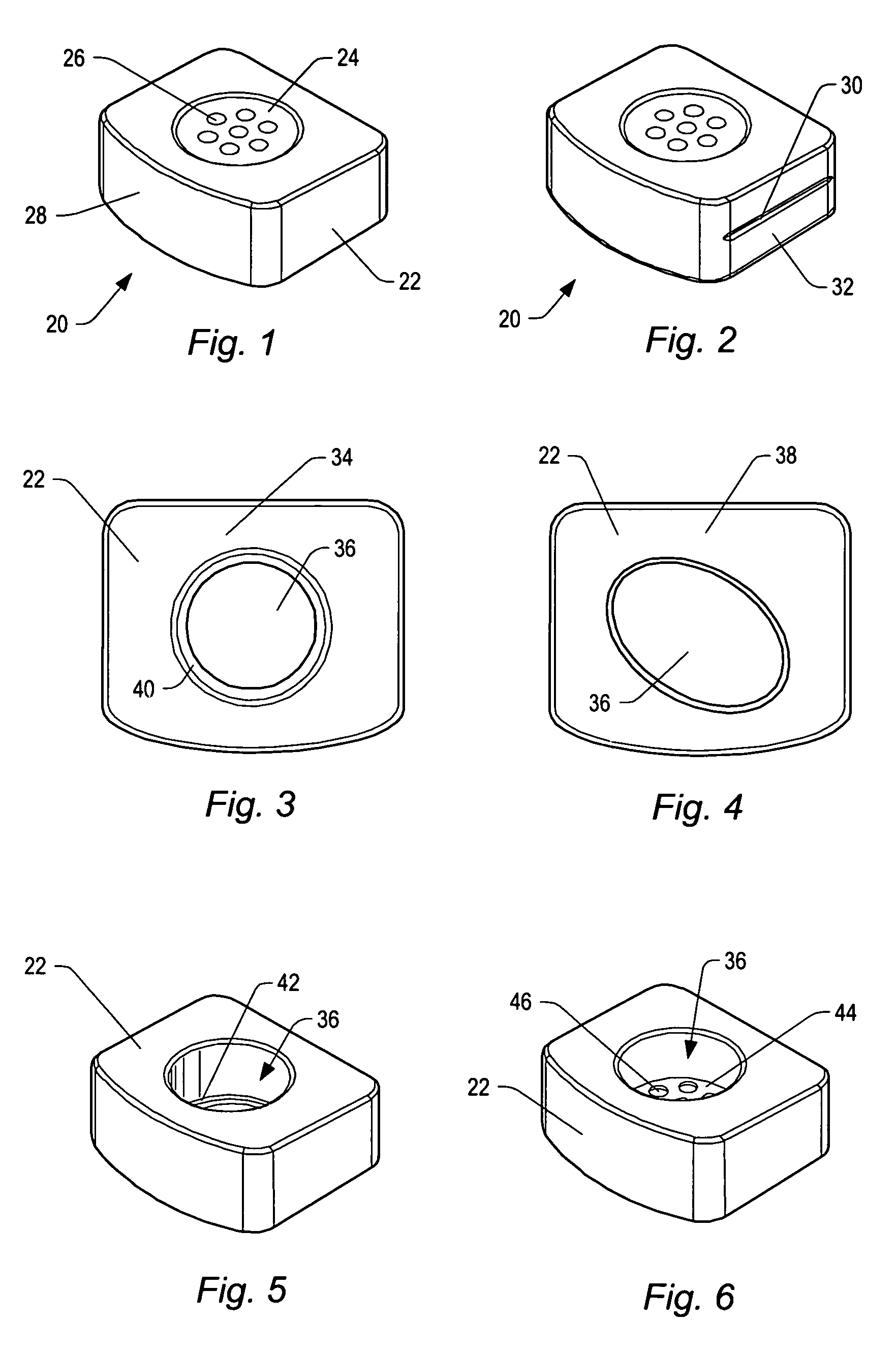

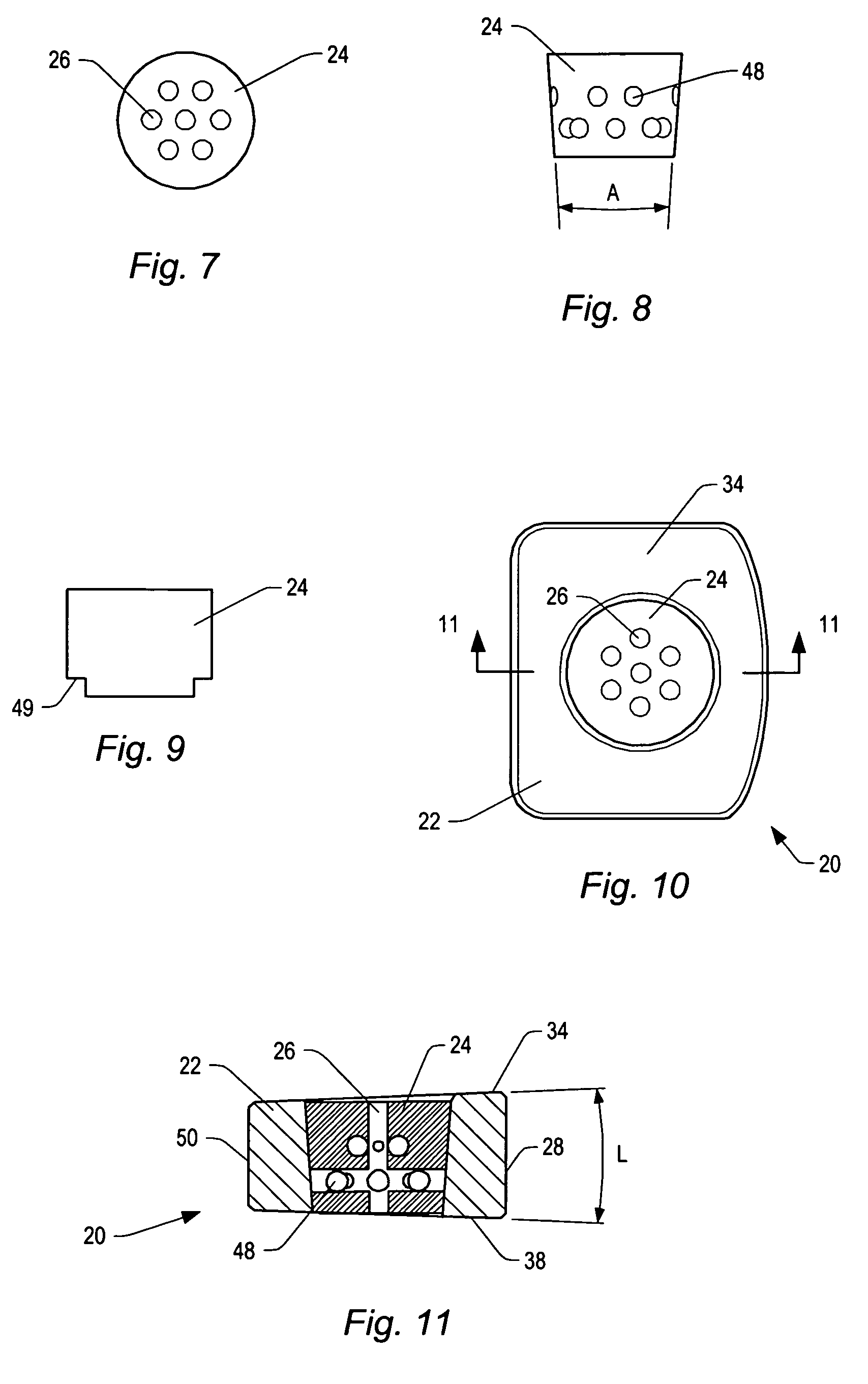

Spinal implants with body and insert

ActiveUS20050251257A1Easy to integrateAvoid passingBone implantJoint implantsBone growthSpinal implant

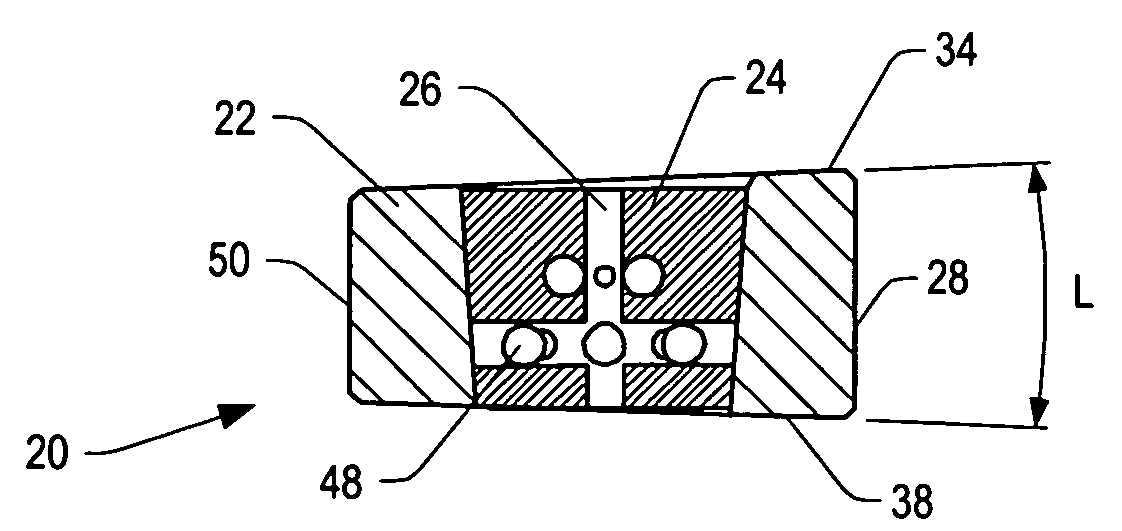

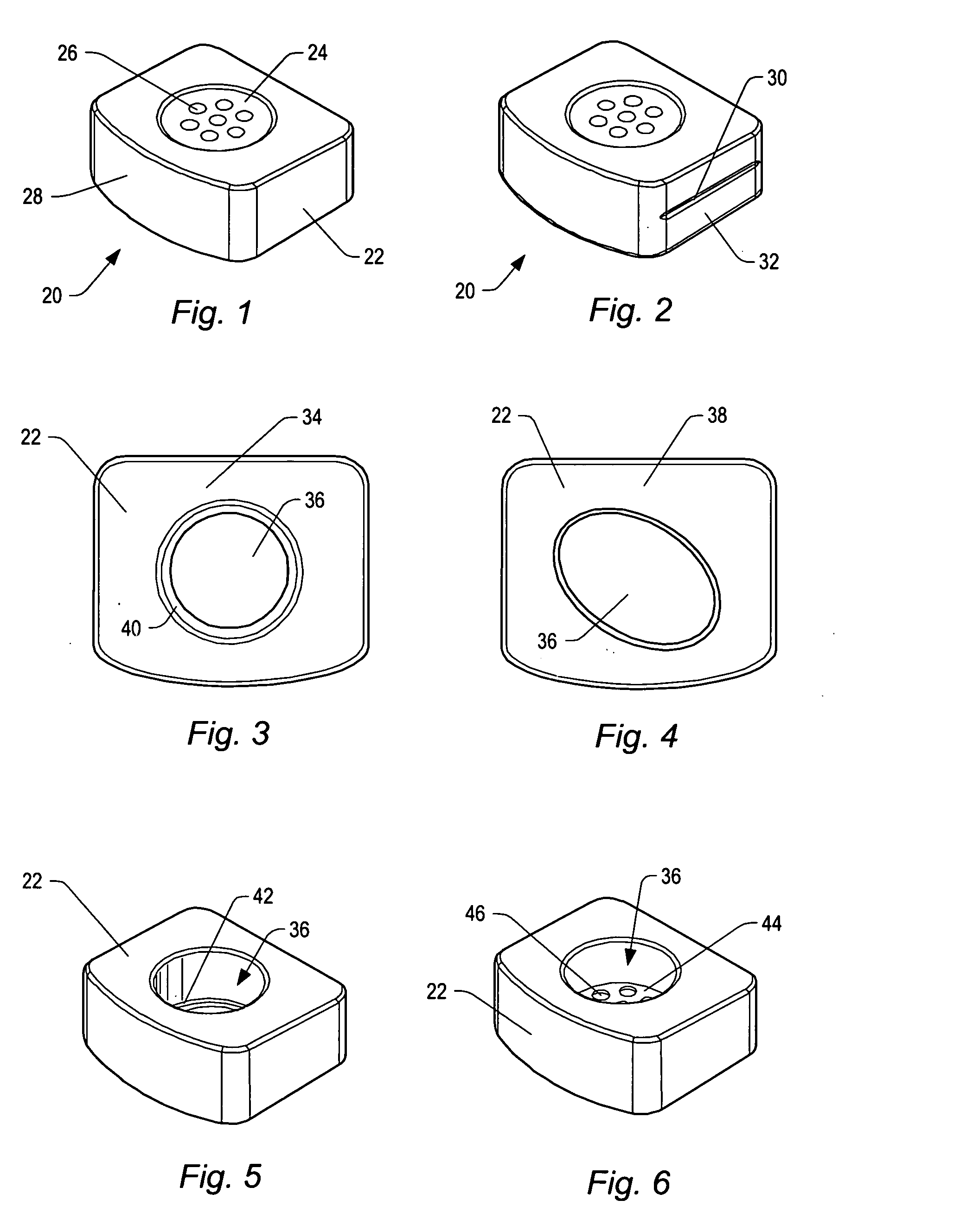

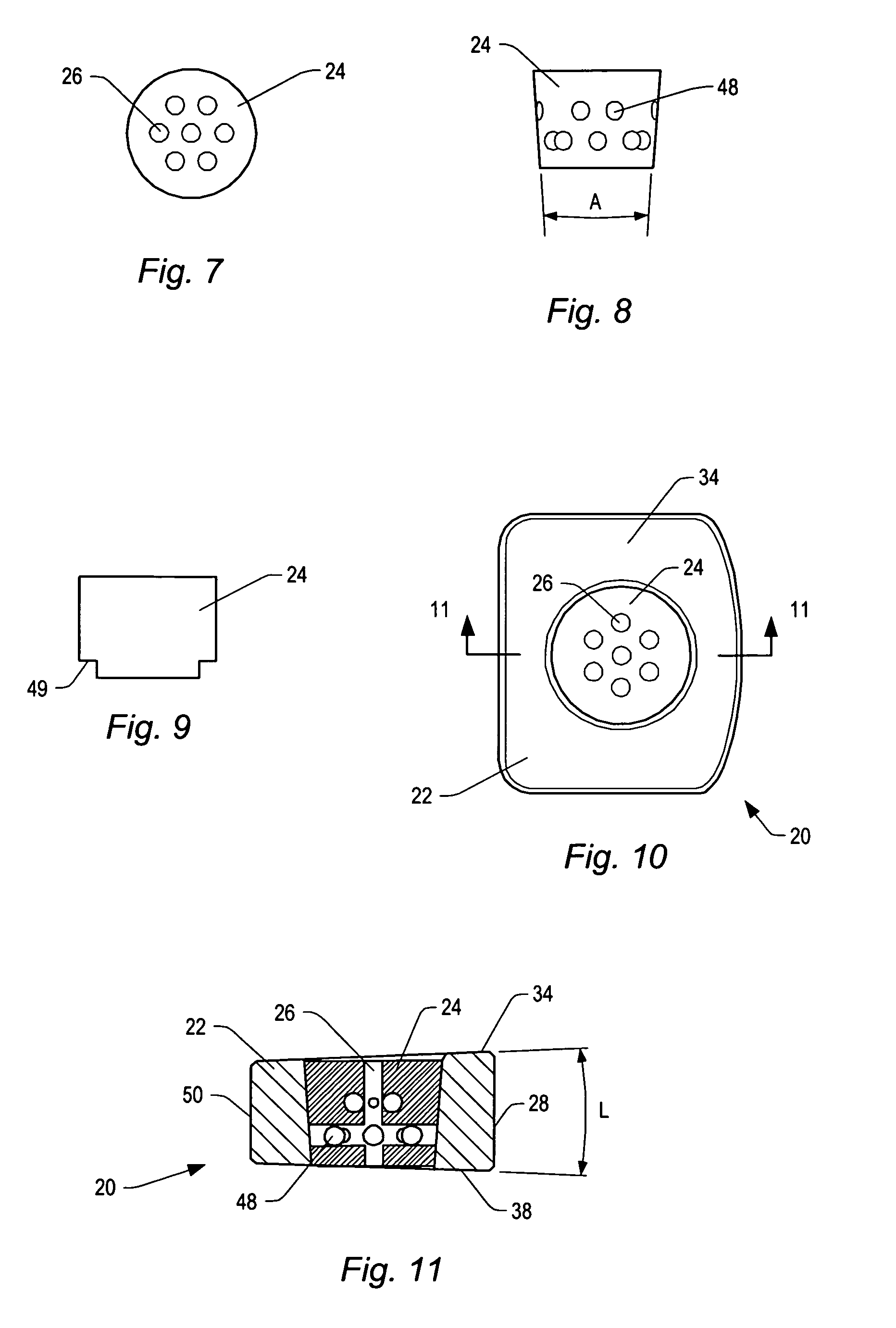

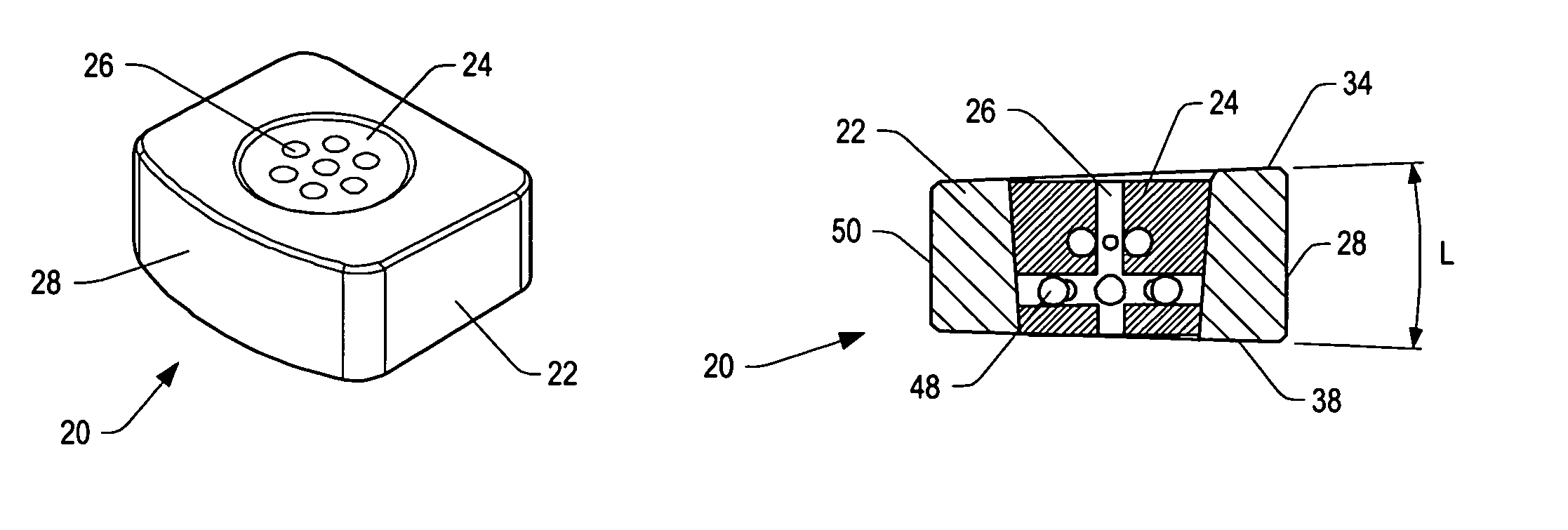

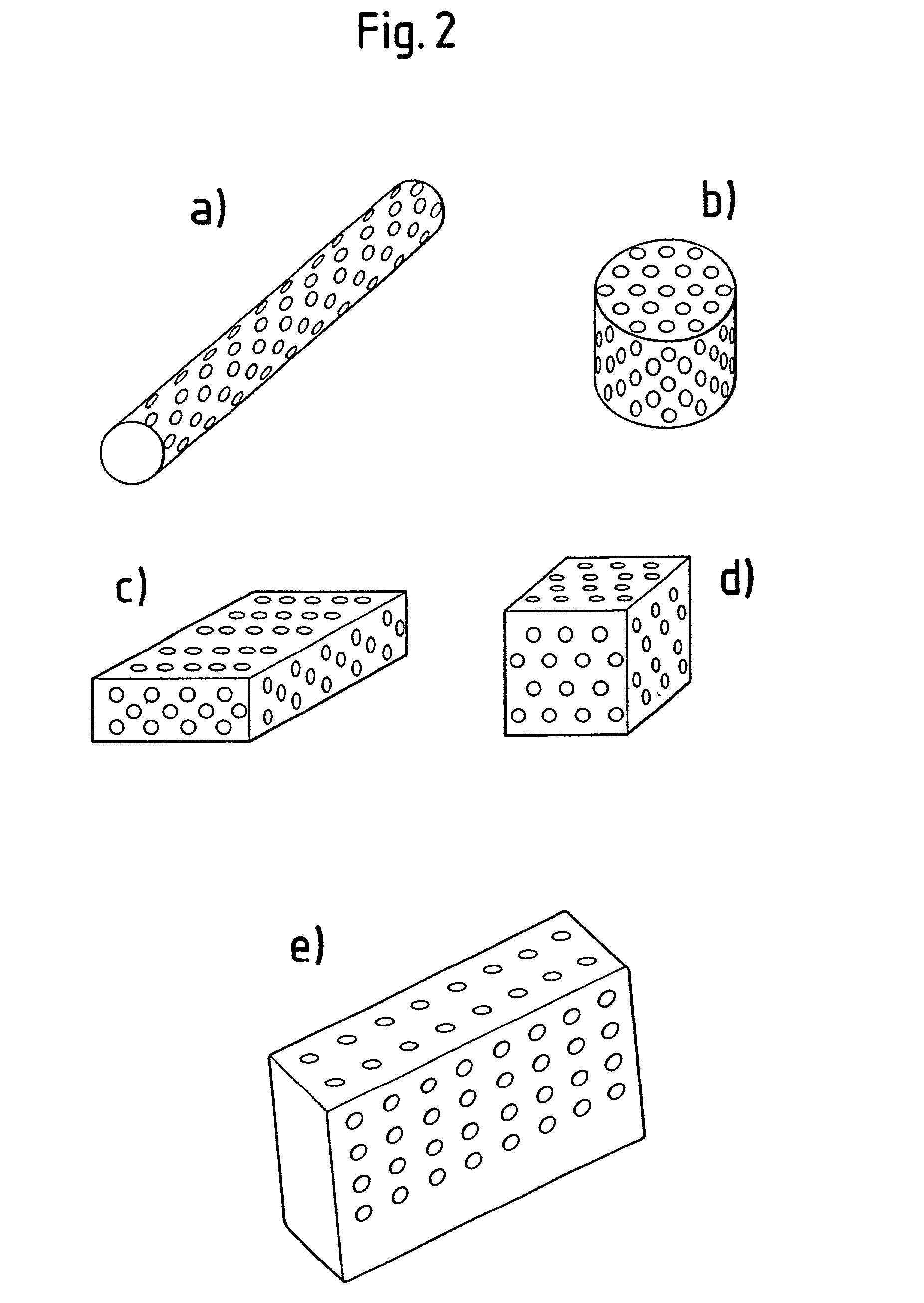

A spinal implant is provided which maintains intervertebral spacing and stability within the spine. The spinal implant may include a body and an insert. The body of the spinal implant may be formed of a ceramic material. In some embodiments, the body may be formed of beta tricalcium phosphate. The body may include an opening that is complementary to the insert. The insert may fit within the opening. The insert may include a number of passageways. Some of the passageways may intersect to form a scaffold for bone growth. Bone growth promoting material may be introduced into the insert before the insert is positioned in a body and inserted in a patient between two vertebrae.

Owner:ZIMMER BIOMET SPINE INC

Spinal implants with body and insert

A spinal implant is provided which maintains intervertebral spacing and stability within the spine. The spinal implant may include a body and an insert. The body of the spinal implant may be formed of a ceramic material. In some embodiments, the body may be formed of beta tricalcium phosphate. The body may include an opening that is complementary to the insert. The insert may fit within the opening. The insert may include a number of passageways. Some of the passageways may intersect to form a scaffold for bone growth. Bone growth promoting material may be introduced into the insert before the insert is positioned in a body and inserted in a patient between two vertebrae.

Owner:ZIMMER BIOMET SPINE INC

Composite material for porous material and gel use thereof

InactiveCN1644221AImprove stabilityGood adhesionProsthesisCalcium biphosphateAlpha-tricalcium phosphate

A composition of porous material and gel for preparing artificial bone is prepared from collagen and porous material chosen from alpha-tricalcium phosphate / hydroxy apatite, beta-tricalcium phosphate / hydroxy apatite-coral, calcium phosphate / hydroxy apatite, calcium carbonatel tricalcium phosphate, etc.

Owner:徐小良

Resorbable bone replacement and bone formation material

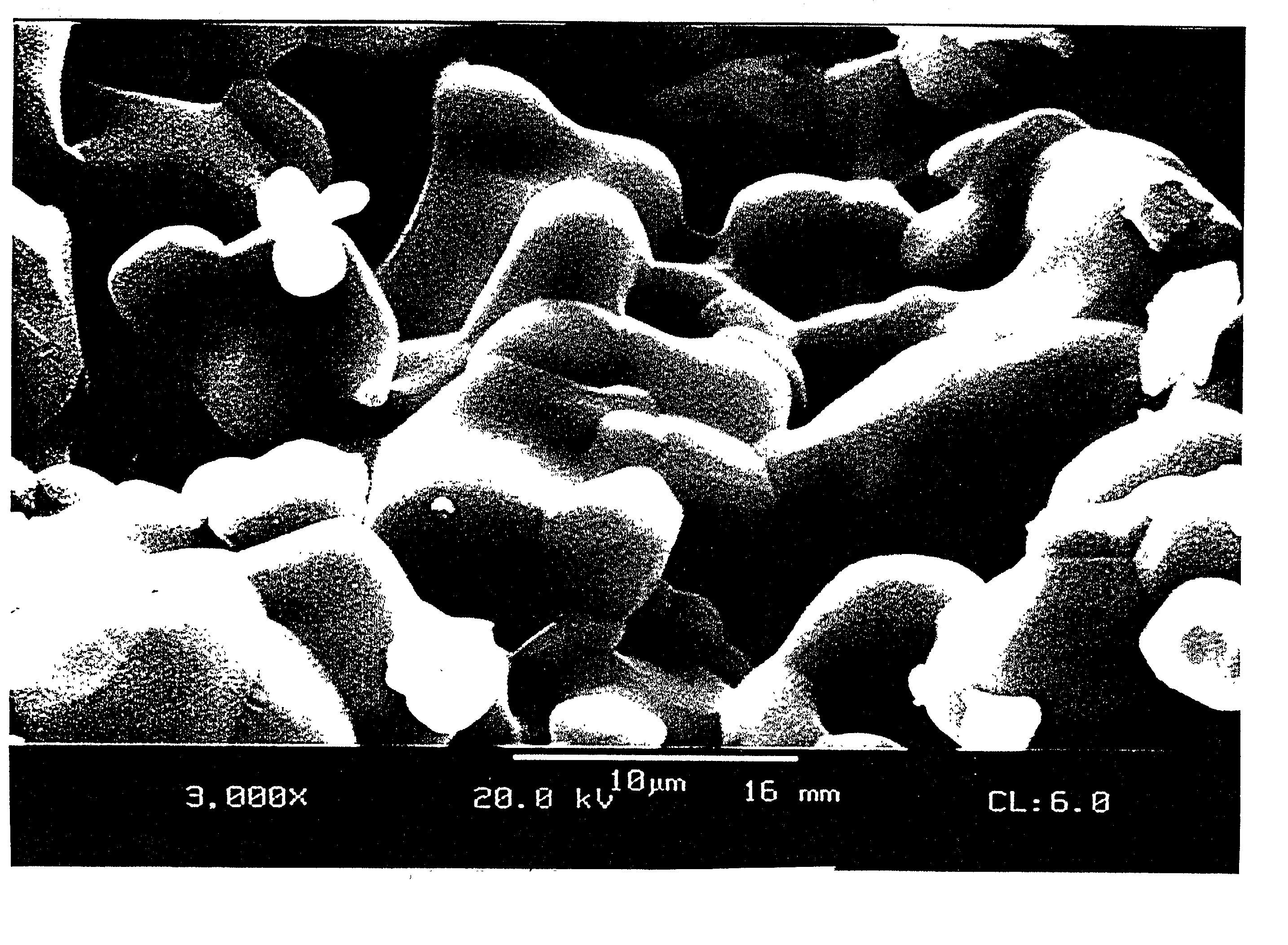

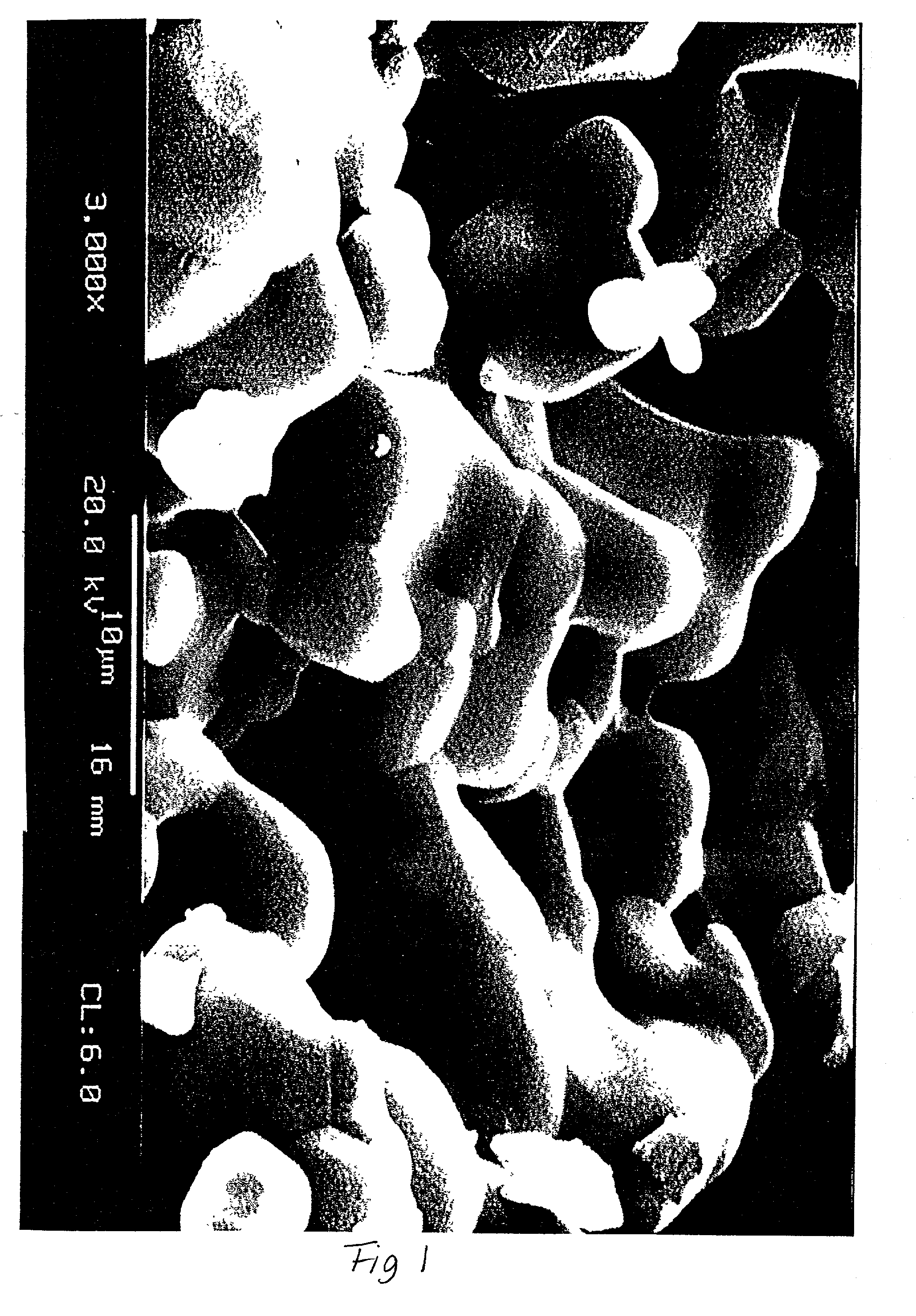

The invention relates to a resorbable bone replacement and bone formation material (augmentation material) based on porous beta-tricalcium phosphate (beta-TCP).

Owner:CURASAN

New-type of inorganic bone grafting material and its prepn and use

InactiveCN101020085AGood biocompatibilityPromote degradationProsthesisSulfateBiocompatibility Testing

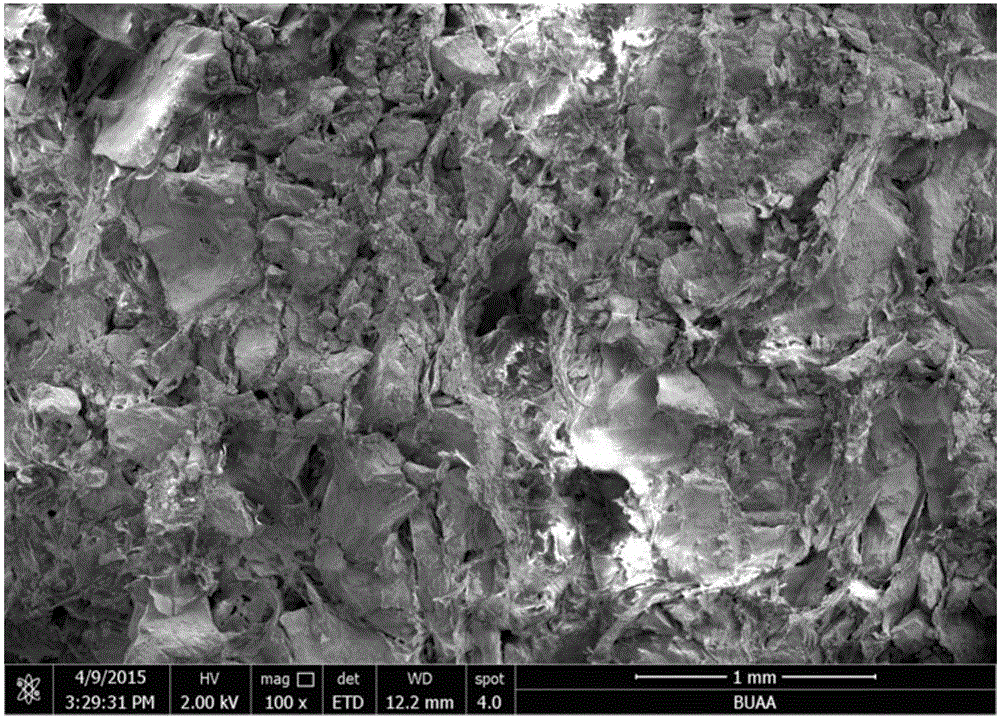

The present invention is one kind of new inorganic bone grafting material and belongs to the field of medical material. The inorganic bone grafting material consists of beta-tricalcium phosphate grain in 20-80 wt% and alpha-calcium sulfate semihydrate powder in 20-80 wt%, and the alpha-calcium sulfate semihydrate powder form layered structure in the surface and / or pores of beta-tricalcium phosphate grain. Both beta-tricalcium phosphate and alpha-calcium sulfate semihydrate have excellent biocompatibility and excellent in vivo degrading performance, and the composite artificial bone grain may be used in repairing bone defect of different shapes. The composite artificial bone grain has wide material source, convenient use, excellent performance, simple preparation process, low cost and other advantages.

Owner:GENERAL HOSPITAL OF PLA

Premix plaster calcium phosphate bone cement

InactiveCN1919357ASimple compositionGood biocompatibilityProsthesisPhosphoric acidPolyethylene glycol

The invention discloses a pre-mixing typed plaster calcium phosphate bone cement in the biological medical bone tissue material technology, which is characterized by the following: the solid powder and liquid powder with quality rate at 2.5-3.7: 1 are sealed container, the solid powder is beta-tricalcium phosphate and hydrated acid calcium phosphate with molar rate at 1:1, the liquid material is medical glycerin or polietilenglicol with molecular quantity at 400-800.

Owner:TIANJIN UNIV

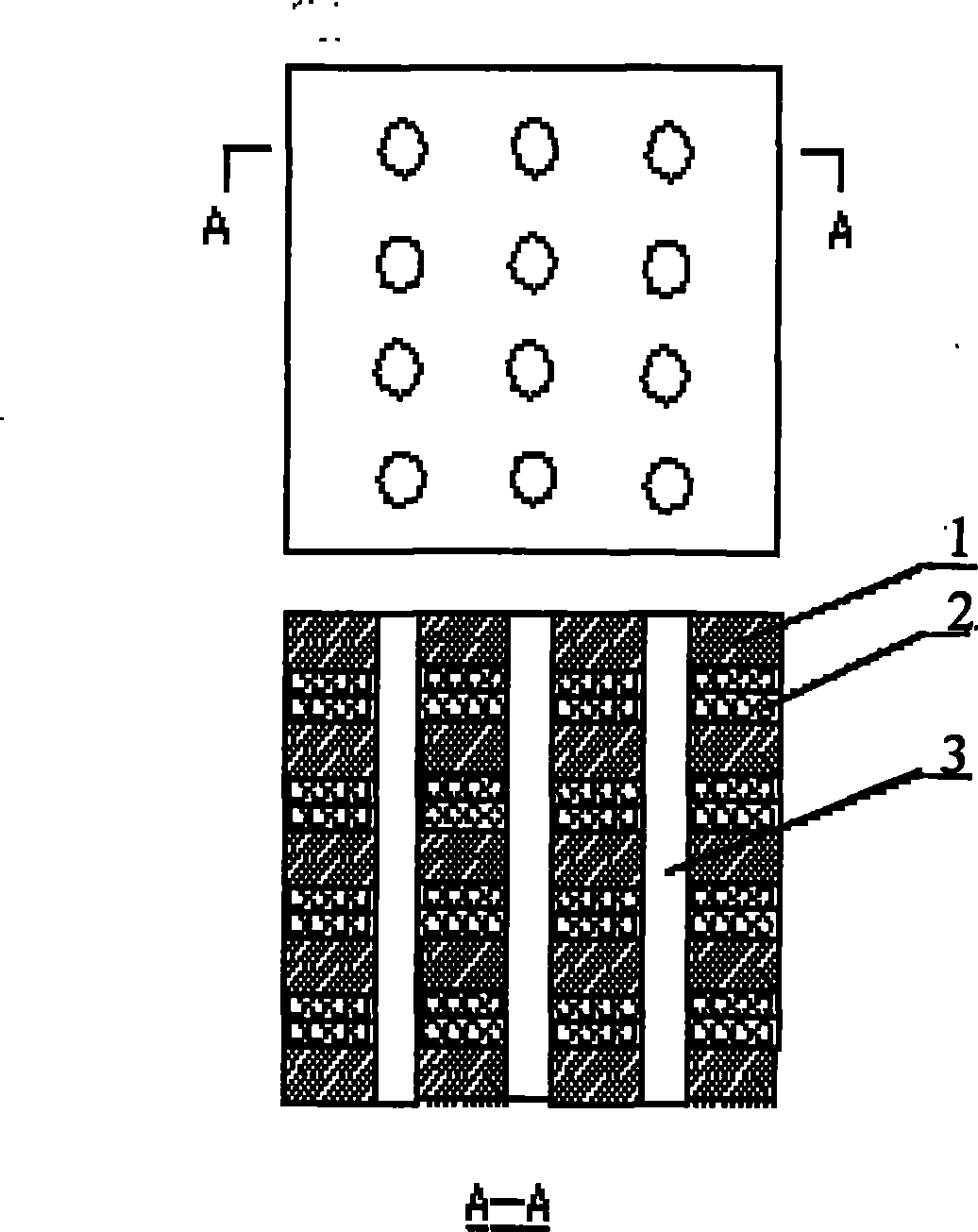

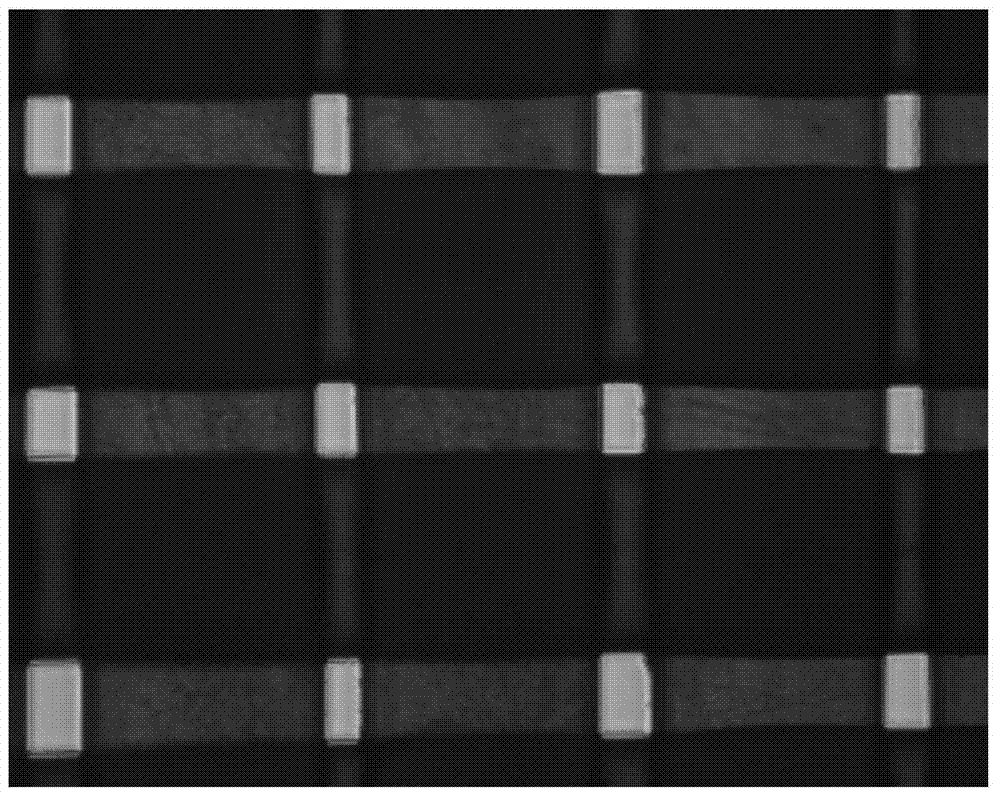

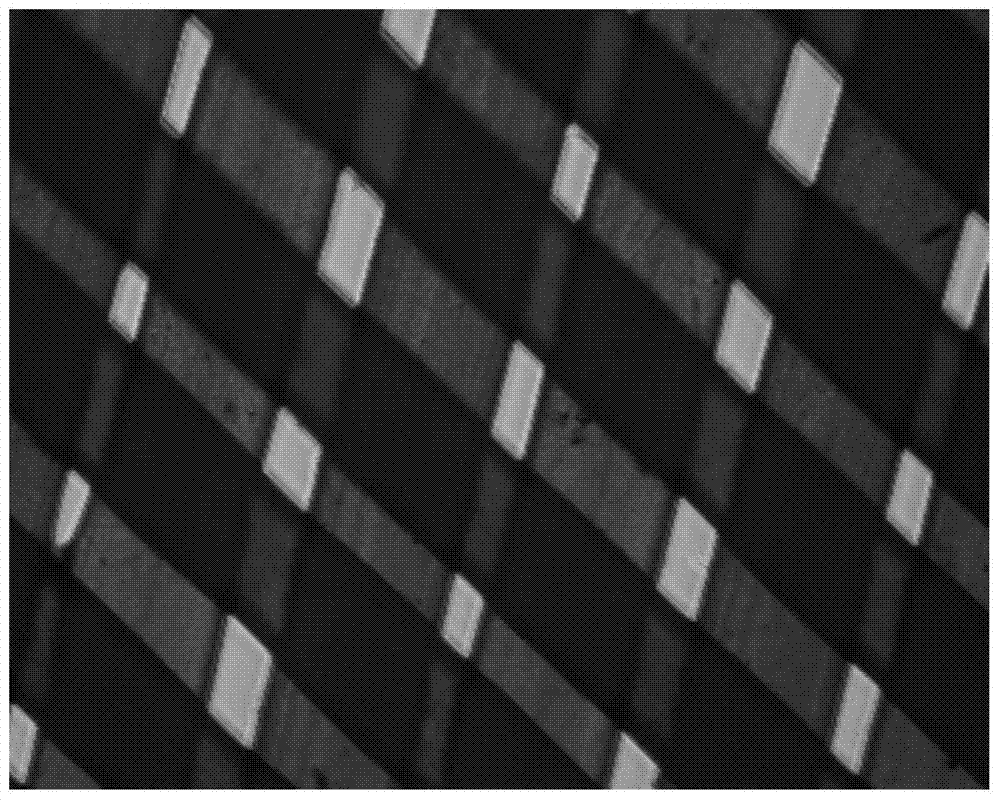

Artificial bone with porous laminated structure and passages and preparation method thereof

InactiveCN101766843AControllable degradation rateGood biocompatibilityBone implantOsteoblast adhesionOrthopedic department

The invention relates to an artificial bone with a porous laminated structure and passages, which belongs to the technical field of biomedical materials. The artificial bone is alternately laminated and formed by compact layers and porous layers which are made of calcium phosphate base biological ceramic materials, and in addition, passages for conveying cells and body fluid are arranged in the direction which forms a set angle with the laminated layers. The preparation method comprises the following step: mixing powder such as hydroxylapatite, beta-tricalcium phosphate and the like through using deionized water as medium to be prepared into pulp. A three-dimensional gel laminated forming system is adopted for preparing ceramic blanks formed by the compact layers, the porous layers and the passages, and then the ceramic blanks are sintered at a high temperature for preparing the artificial bone. The invention has the characteristics that the artificial bone has high mechanical strength, has the porous structure with the effects of osteoplast adhesion, propagation, growth and vascularization, can be used as the artificial bone, can also be used as a bone tissue engineering support frame, and has wide application prospects in clinics in the orthopedics department.

Owner:TSINGHUA UNIV

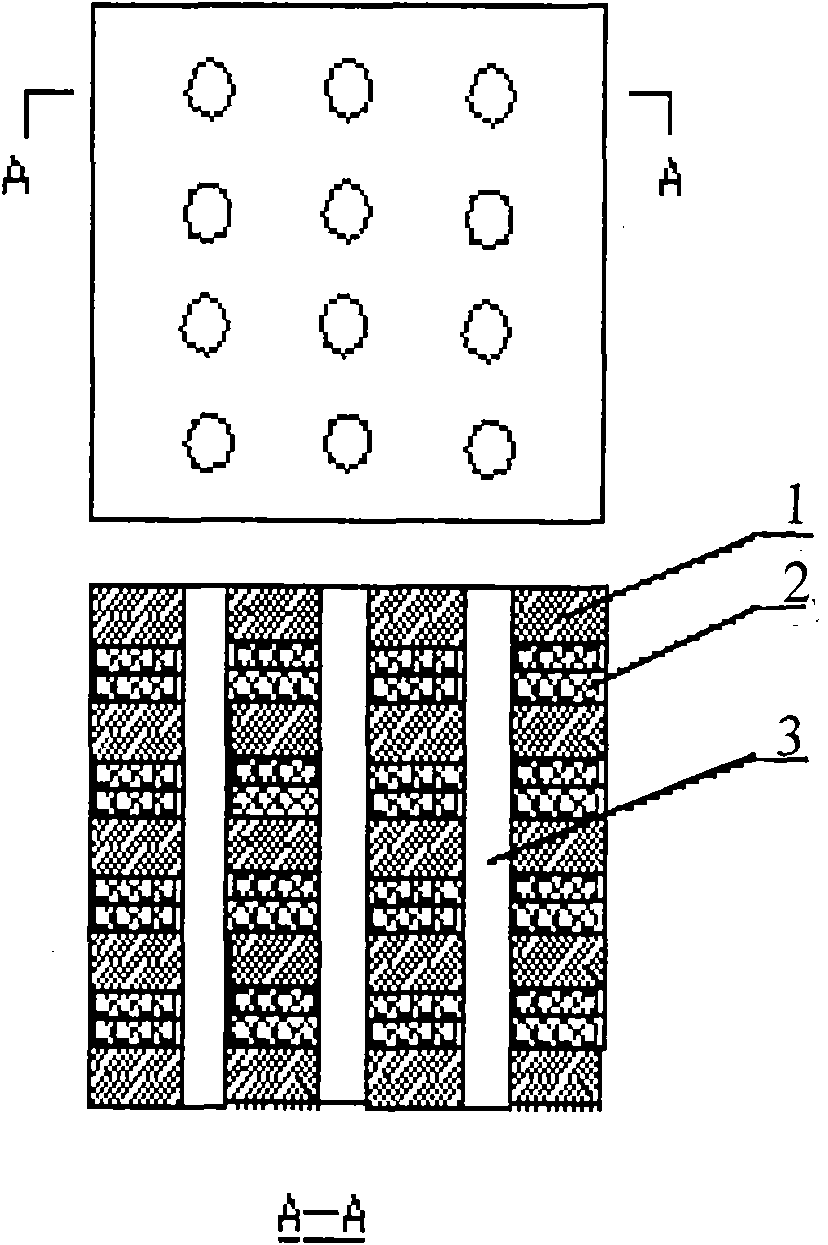

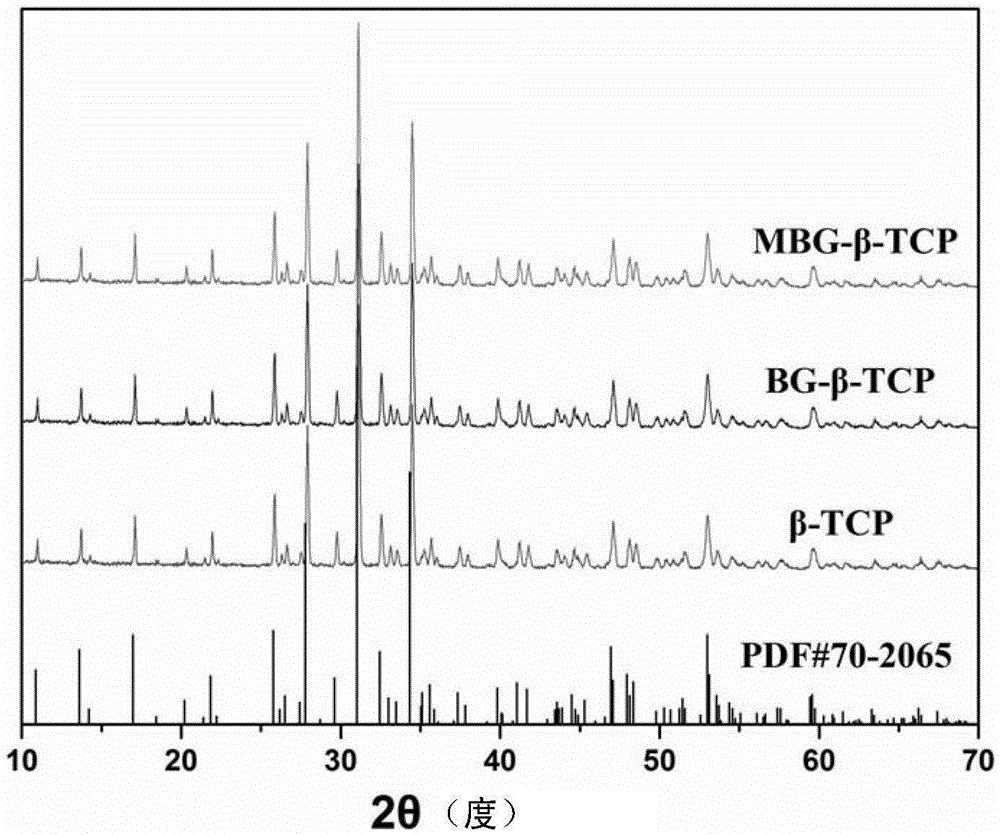

3D (three-dimensional) printing mesoporous bioactivity glass modified biological ceramic support, and preparation method and application thereof

ActiveCN105311673AGood mechanical propertiesGood mineralization effectAdditive manufacturing apparatusProsthesisBioactive glassTri calcium phosphate

The invention relates to a 3D (three-dimensional) printing mesoporous bioactivity glass modified biological ceramic support, and a preparation method and application thereof. The biological ceramic support comprises a beta-tricalcium phosphate bioactivity support prepared by using a three-dimensional printing technology and mesoporous bioactivity glass coating the surface of the support uniformly. The biological ceramic support has good mechanical property, mineralization capability and osteogenic and hematopoietic activities, is expected to serve as an effective bone repairing material, and is a potential multifunctional hard tissue bioactivity implanting material.

Owner:中科硅诺(太仓)生物材料科技有限公司

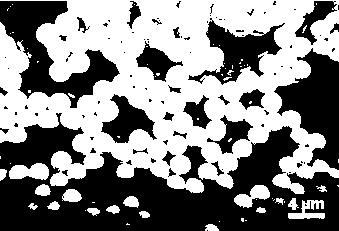

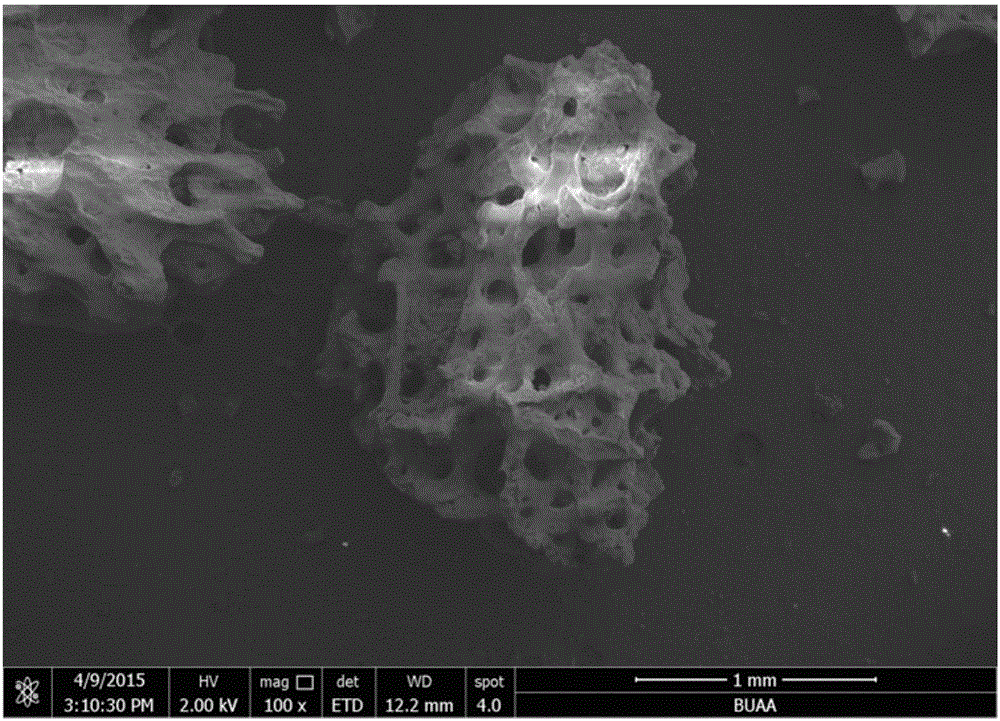

Beta-tricalcium phosphate/alginic acid composite microsphere and preparation method and application of beta-tricalcium phosphate/alginic acid composite microsphere

ActiveCN104174342AEasy to operateThe process is simple and easy to controlPharmaceutical non-active ingredientsGranular deliveryTissue repairTissue fluid

The invention discloses a beta-tricalcium phosphate / alginic acid composite microsphere and a preparation method and an application of the beta-tricalcium phosphate / alginic acid composite microsphere. The method comprises the following steps: dropwise adding a mixed solution of beta-tricalcium phosphate and sodium alginate into a calcium chloride solution of which the pH value is 4.5 to 5.0 by virtue of an electrostatic liquid dropping device, and continuing to calcify for a period of time after dropwise adding; pouring out the calcium chloride solution after reaction, then washing a calcified crosslinked microsphere with deionized water, and airing, so as to obtain the beta-tricalcium phosphate / alginic acid composite microsphere. The method is carried out at normal temperature without heating or reference to poisonous and harmful liquid and other volatile solids and gases. The beta-tricalcium phosphate / alginic acid composite microsphere prepared by using the preparation method has the advantage of wide particle size adjusting range and can be widely applied to tissue repair and drug carriers, and a plurality of micropores are formed in the surface of the beta-tricalcium phosphate / alginic acid composite microsphere, so as to be easy for cells to adhere, for tissue fluid to permeate and for loading of drugs, growth factors and cells, and therefore, the beta-tricalcium phosphate / alginic acid composite microsphere can be widely applied to tissue repair and drug carriers.

Owner:JINAN UNIVERSITY

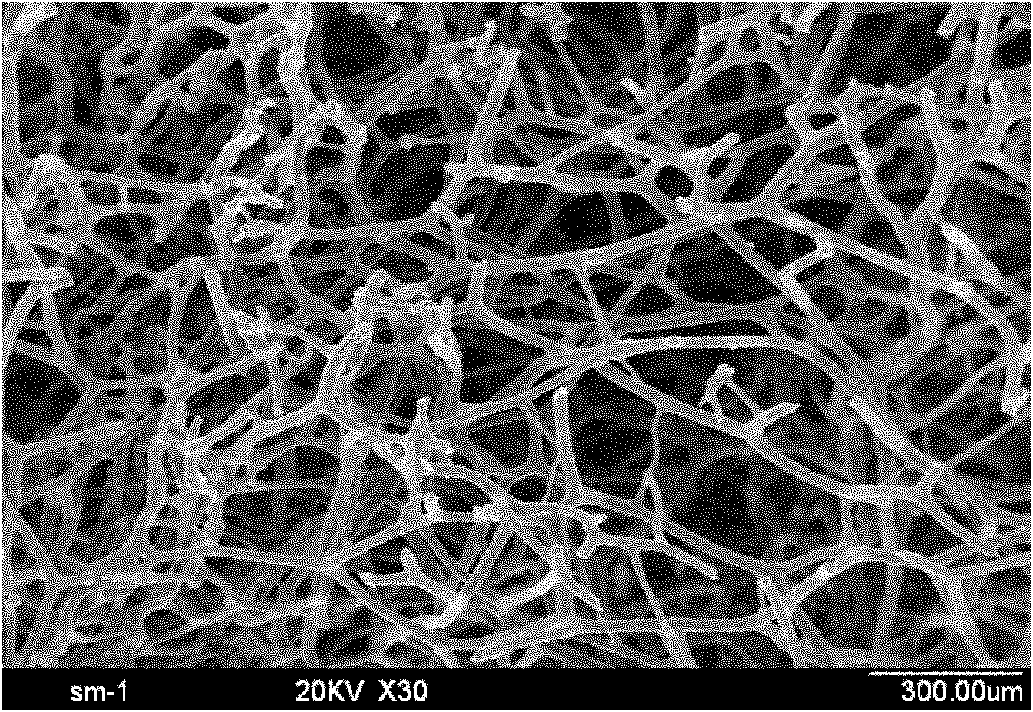

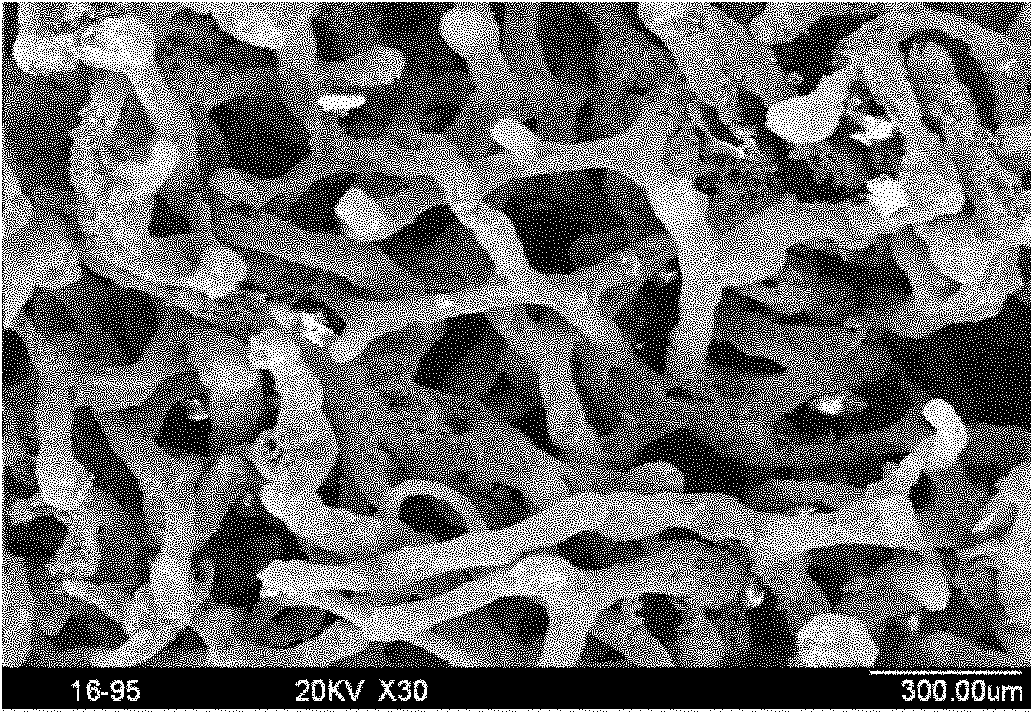

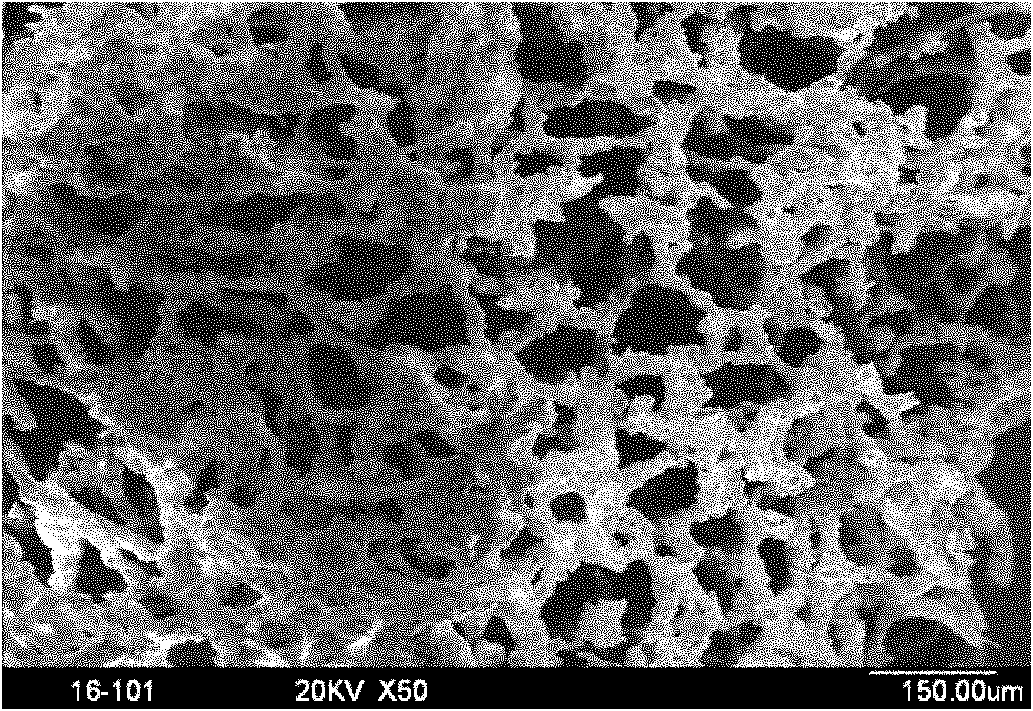

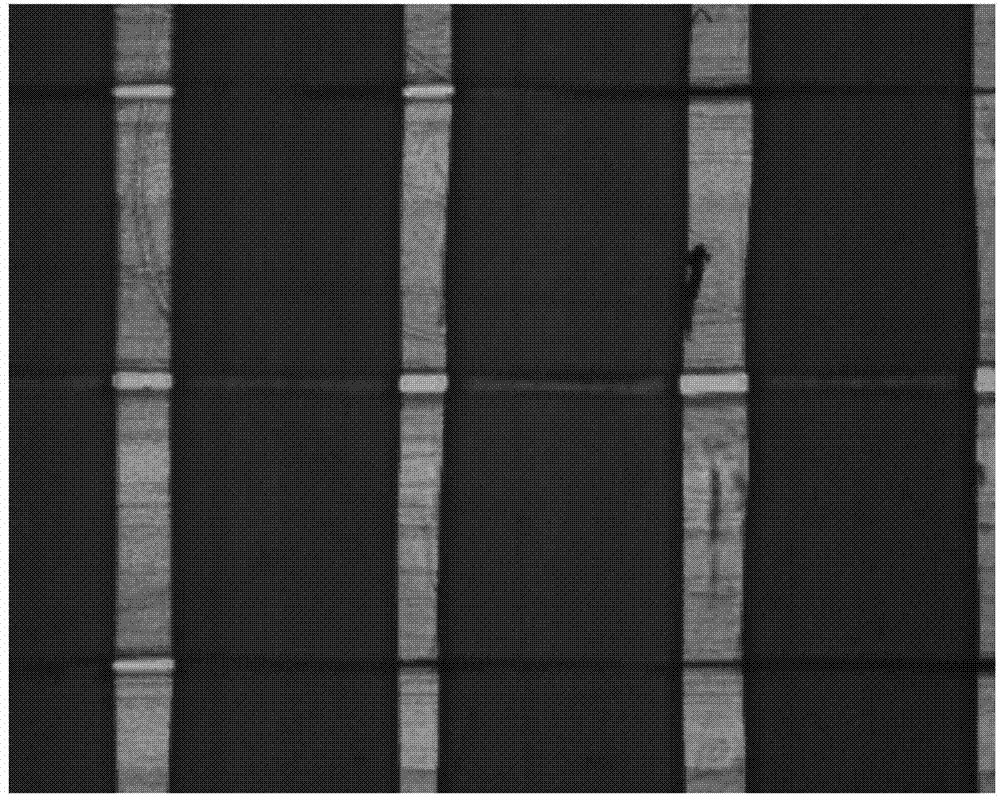

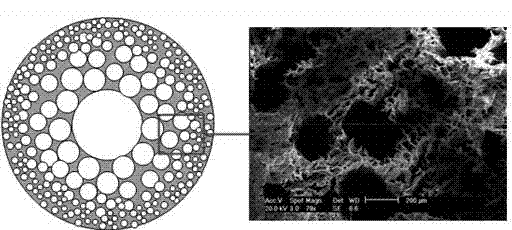

Method for preparing mesh-shaped bionic bone porous stent material

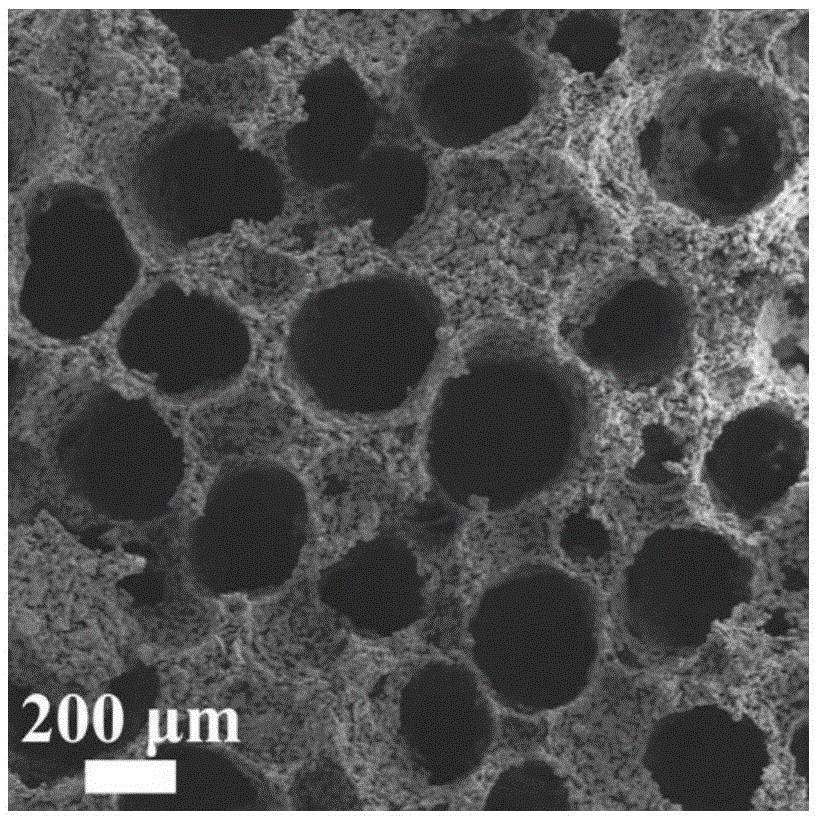

InactiveCN102058902AHigh porosityImprove connectivityImpression capsDentistry preparationsWater basedCalcium silicate

The invention relates to a method for preparing mesh-shaped bionic bone porous stent material, comprising the following steps: taking a multi-cellular marine animal natural sponge processed by organic acid and inorganic alkali solution as a template, impregnating with sol or water based slurry of hydroxylapatite, 45S5 bioactive glass, beta-tricalcium phosphate or calcium silicate, drying, oxidizing, demoulding and sintering at high temperature, thereby preparing the bone tissue engineering stent material in a mesh-shaped pore structure. The pore structural parameters and degradation performance of a porous stent are controlled by adjusting the solid content in the sol or the slurry, impregnation frequency and parameters in the process of oxidizing and demoulding as well as sintering at high temperature. Pore size of the mesh-shaped porous stent produced by adopting the invention is 100-300Mum, porosity is 68-94%, and the porous stent is highly similar to a natural cancellous bone in the shape and pore size. The product prepared by adopting the invention has the characteristics that bionic degree of the porous structure is high, adaptation to materials is high, process is simple and cost is low and the product has a great application potential in the regeneration repairing technology of hard tissue engineering, such as bone, basibranchial bone and teeth.

Owner:XI AN JIAOTONG UNIV

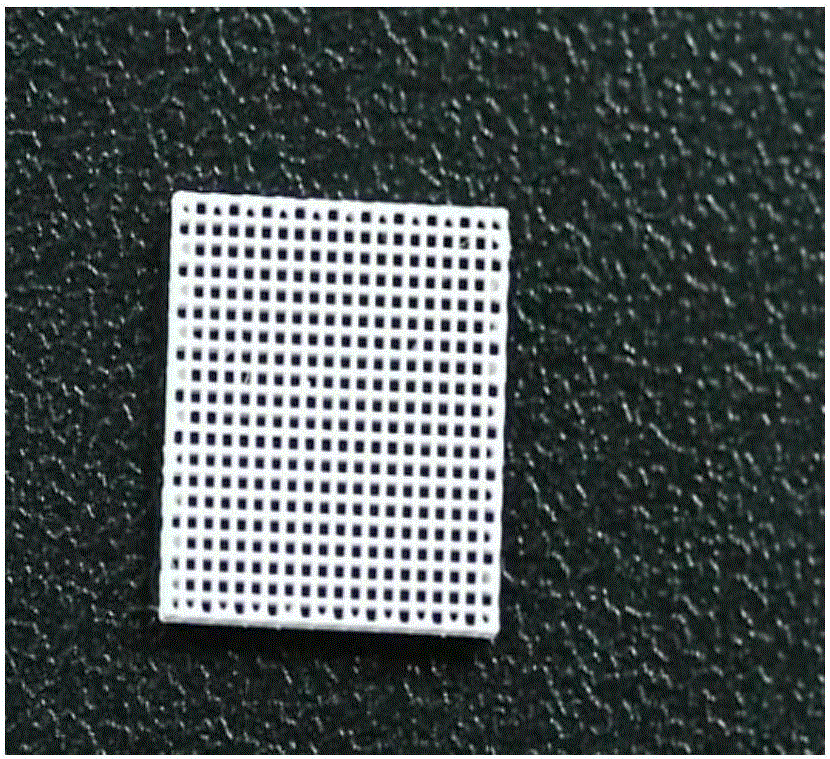

Medical polycaprolactone membrane as well as preparation method and application of medical polycaprolactone membrane

The invention relates to the technical field of medical high polymer materials and discloses a medical polycaprolactone membrane as well as a preparation method and an application of the medical polycaprolactone membrane. The constituents of the membrane include polycaprolactone; the membrane is 0.5-2mm thick; and the membrane is of a planar mesh structure and the mesh aperture of the planar mesh structure is 100-300 microns. Besides, composite additive materials, such as BETA-tricalcium phosphate, hydroxylapatite and coral, also can be added to the membrane. The invention also provides a method for preparing the medical polycaprolactone membrane by use of the 3D printing technology; the membrane is applicable to the field of bone tissue engineering; and the medical polycaprolactone membrane is used for covering a bone defect part and then repairing the bone defect, and therefore, the effects of surrounding and protecting the bone defect part, reducing stem cell loss, preventing surrounding fiber tissue ingrowth and guiding bone regeneration can be achieved.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Bioactive multilayer multiphase ceramic microsphere material and its preparation method and use

The invention discloses a bioactive multilayer multiphase ceramic microsphere material and its preparation method and use. The bioactive multilayer multiphase ceramic microsphere material comprises multilayer microspheres obtained by alternate wrapping of beta-tricalcium phosphate and calcium silicate respectively doped with foreign ions. The preparation method comprises the following steps of respectively dispersing the beta-tricalcium phosphate and calcium silicate powder respectively doped with the foreign ions into alginate hydrosol to obtain two types of paste, putting the two types of paste respectively into liquid storage tanks connected to two layers of coaxial tubular nozzles, synchronously injecting the paste in the liquid storage tanks to outlets of the two layers of coaxial tubular nozzles to obtain concentric multilayer paste liquid drops, and receiving the concentric multilayer paste liquid drops by an inorganic calcium salt aqueous solution, and carrying out drying and calcination. The bioactive multilayer multiphase ceramic microsphere material has the fast-slow alternative degradation rate characteristic in the normal liquid, and can release an inorganic ion composition with layer-by-layer degradation. Granularity, each-layer thickness and an inorganic ion release rate of the bioactive multilayer multiphase ceramic microsphere material can be controlled easily. The bioactive multilayer multiphase ceramic microsphere material can be used for bone defect repair and bone regeneration medical science.

Owner:ZHEJIANG UNIV

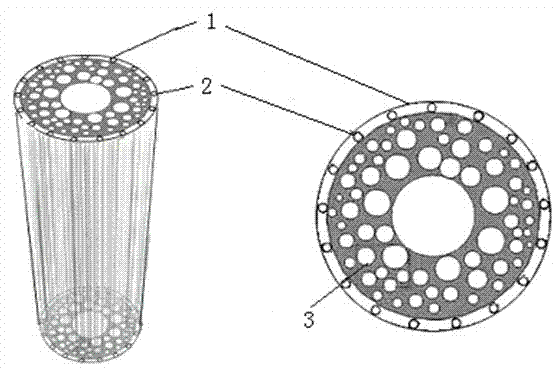

Construction and preparation of three-dimensional bionic electropolarized gradient pore nerve conduit

InactiveCN102727931ASolving Control Release IssuesGuaranteed effective current problemProsthesisPeripheral neuronPeripheral nerve

The invention provides construction and preparation of a three-dimensional bionic electropolarized gradient pore nerve conduit. The nerve conduit is an electropolarized beta-tricalcium phosphate / polylactic acid / hyaluronic acid / chitosan / nerve growth factor nerve conduit, and is prepared by the steps of: preparing a uniformly dispersed electropolarized beta-tricalcium phosphate and polylactic acid core material by using polylactic acid as a substrate material and adding the electropolarized beta-tricalcium phosphate; and preparing a three-dimensional bionic electropolarized gradient pore nerve conduit with component and pore structure double gradient by attaching the hyaluronic acid, the chitosan and the nerve growth factor to the surface of the core material by virtue of electrostatic self-assembly and coupling crosslinking, wherein the length is between 10 and 100mm, the inner diameter is between 1 and 6mm, the wall thickness is between 0.5 and 2mm, and the outer tube wall is of a three-dimensional network structure. The nerve conduit is applied to repairing of a peripheral nervous system, induction of peripheral nerve regeneration and in-vitro culture of nerve cells in tissue engineering. The three-dimensional bionic electropolarized gradient pore nerve conduit has the advantages of simple preparation method, low cost, environmental friendliness and high economical benefit, and is applicable to industrial production.

Owner:武汉渝联生物科技有限公司

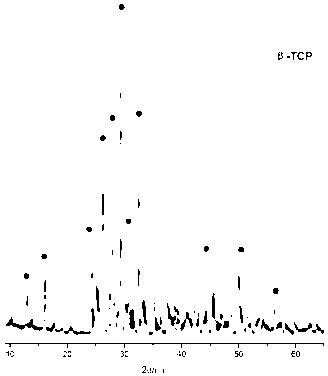

Method for preparing bioceramic in complex phase of hydroxyapatite and beta triealcium phosphate

InactiveCN1562873AGuaranteed uniformityQuality assuranceImpression capsBone implantApatiteTri calcium phosphate

In the invention, biological glass powder (weight percentage is 5-15) is added in oxhydryl kietyoite powder to be formed by dry pressing on pressure 10-30 Mpa, then to be fired in temp. 1050-1250 deg.C to produce compound biological ceramics of oxhydryl kietyoite and beta-tricalcium phosphate that content can be controlled.

Owner:TSINGHUA UNIV

Bone repairing biological ceramic material based on 3D printing and preparation method thereof

ActiveCN105770988AGood biocompatibilityImprove mechanical propertiesTissue regenerationProsthesisPorosityPolymer science

A bone repairing biological ceramic material based on 3D printing is prepared from beta-tricalcium phosphate, hydroxyapatite and polylactic acid with the molecular weight being 100,000-120,000 and the viscosity being 0.79 dL / g-0.84 dL / g, and is of a three-dimensional grid structure with the porosity being 70%-90%, and the line diameter forming a grid is 100 micrometers to 300 micrometers. A preparation method comprises the steps that polylactic acid is dissolved in chloroform to prepare a solution with the mass concentration being 15-20%; beta-tricalcium phosphate and hydroxyapatite are added into the solution, and the mixture is stirred evenly and stably so that composite pulp can be obtained; the composite pulp is added into a 3D printing device to be printed, a precursor of the printed biological ceramic material is vacuumized so that chloroform can be fully volatized, and the product is obtained. The ceramic material is adjustable in degradation rate and good in mechanical performance and biocompatibility, can adapt to osteocyte and chondrocyte co-culture and composition of growth factors or micro-molecule polypeptides and can be used for simultaneous repairing of bones and cartilages.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

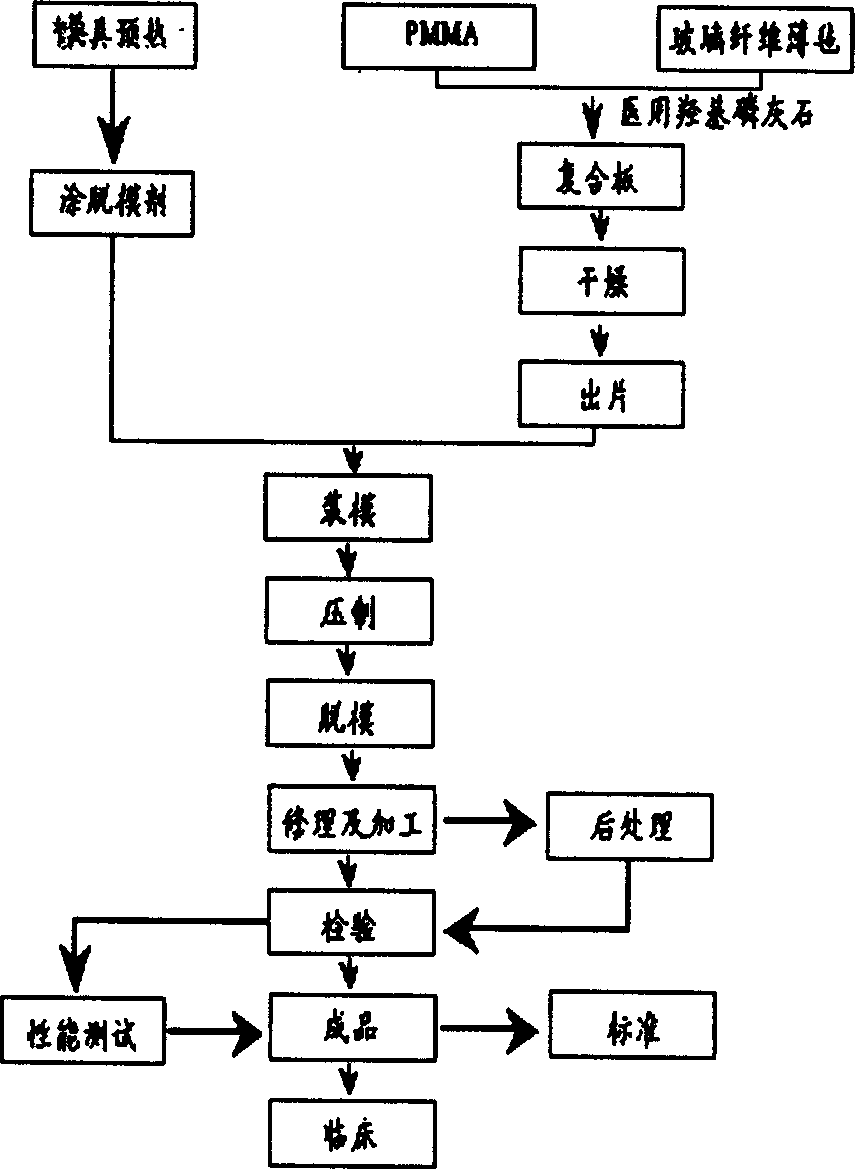

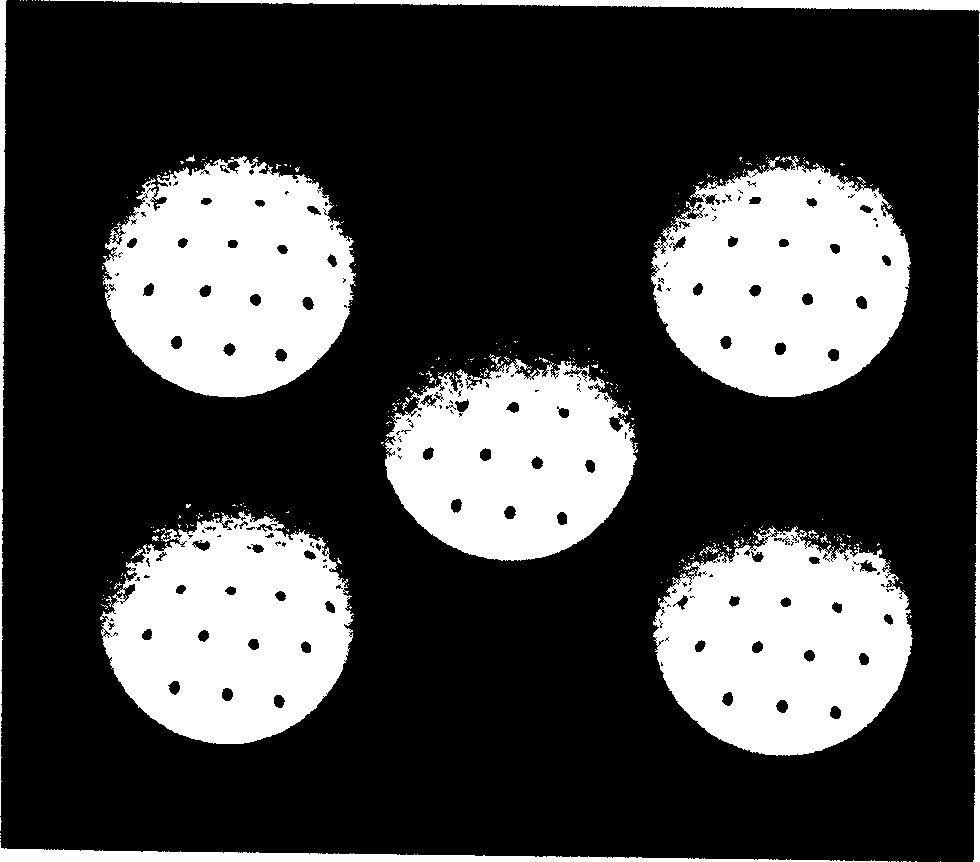

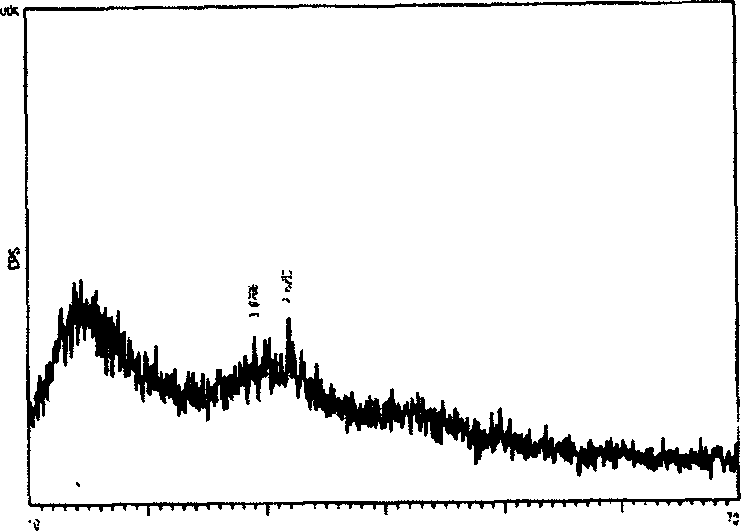

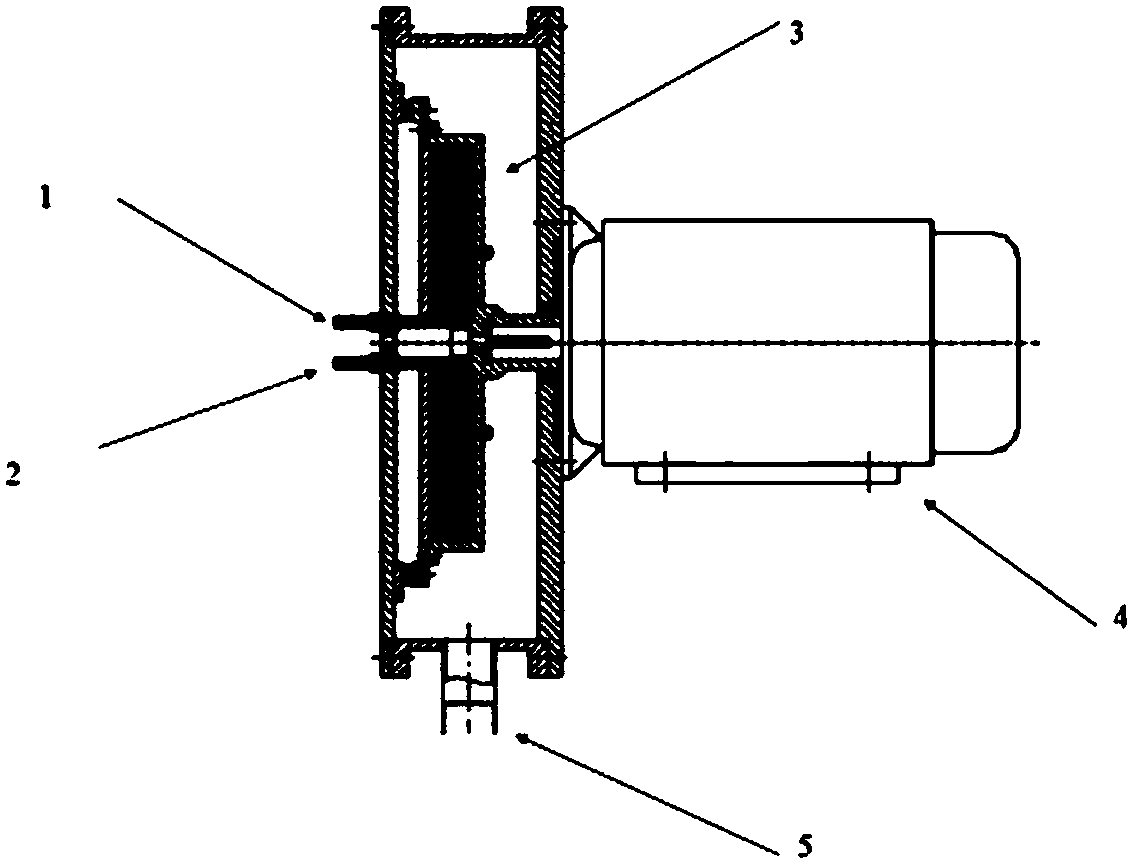

Method for preparing artificial head bones made from composite material and for modifying surface

An artificial skull with high surficial bioactivity is prepared from methyl polymethacrylate, biological carbon (or glass) fibres and hydroxy apatite (or beta-tricalcium phosphate) micropowder through laminating or hot pressing, and immersing in simulative body fluid.

Owner:WUHAN UNIV OF TECH

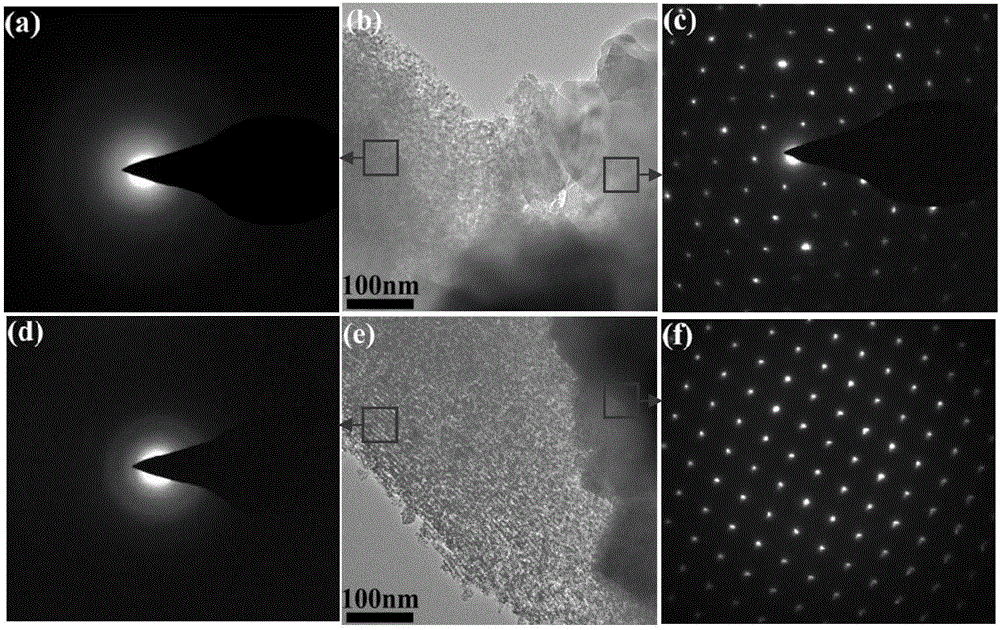

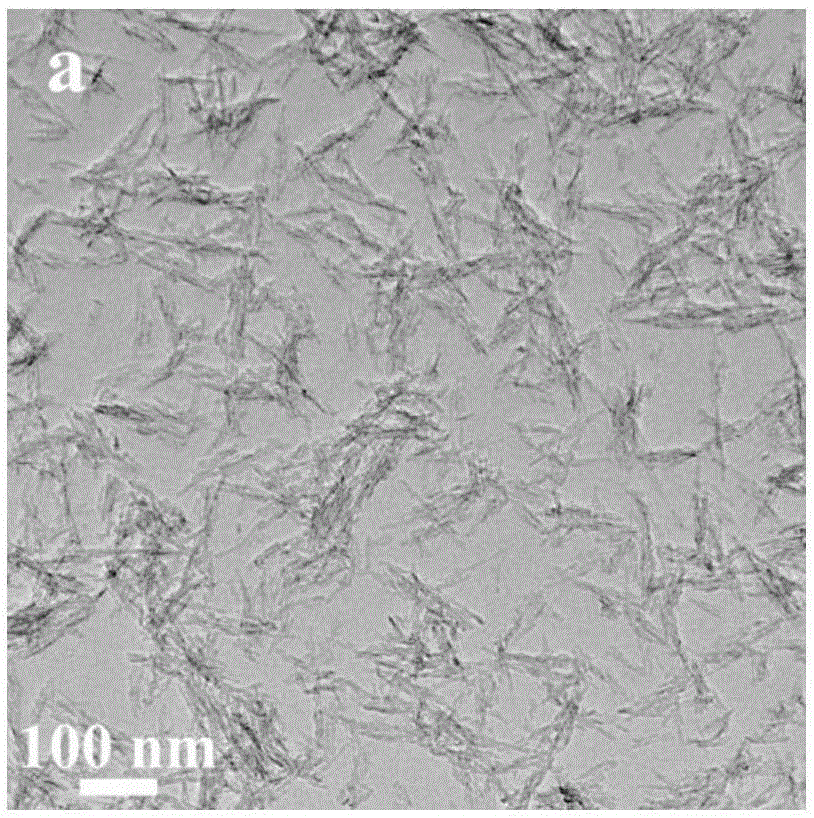

Preparation method of calcium phosphate nanopowder with controllable length-to-diameter ratio and calcium-to-phosphorus ratio

ActiveCN107555405ACalcium Phosphorus Ratio ControlSmall sizeMaterial nanotechnologyPhosphorus compoundsCalcium biphosphateApatite

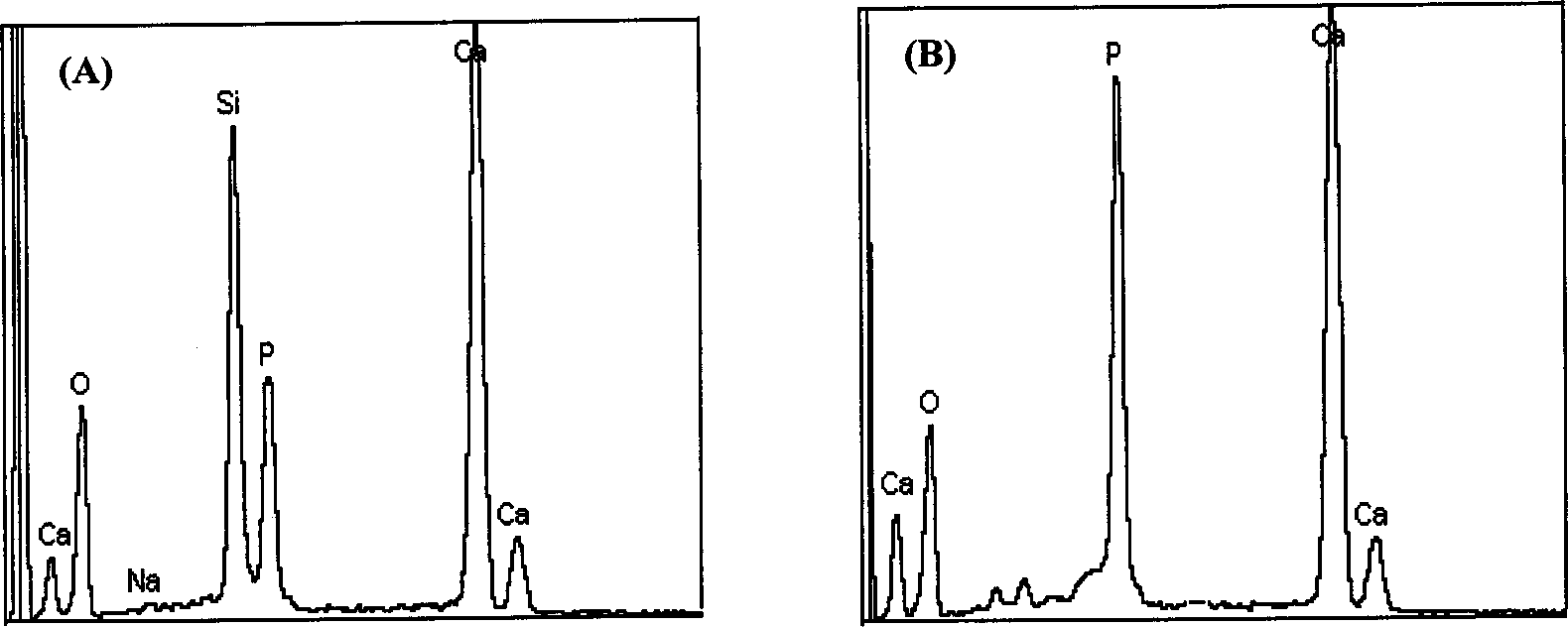

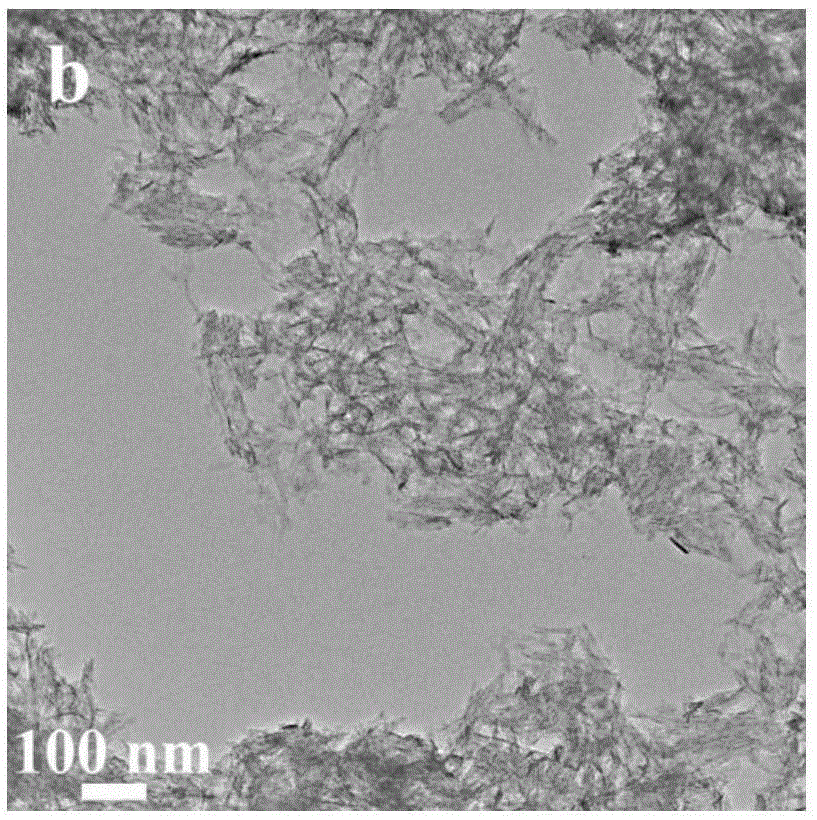

The invention discloses a preparation method of calcium phosphate nanopowder with a controllable length-to-diameter ratio and calcium-to-phosphorus ratio. The method comprises the step: carrying out areaction by mixing phosphate or phosphoric acid with a calcium salt to prepare the calcium phosphate nanopowder, wherein the one-dimensional size of a calcium phosphate nanoparticle can be regulatedto be 50nm-5mu m and the length-to-diameter ratio can be regulated to be 2-50 by adding a pH regulator into a reactant, components and proportions of the calcium phosphate nanopowder serving as a product can be regulated by controlling the feeding ratio of the phosphate or phosphoric acid to the calcium salt to be 1.5-1.67, and the calcium phosphate nanopowder is beta-tricalcium phosphate and / or hydroxyapatite. According to the method disclosed by the invention, the length-to-diameter ratio of the product is regulated by controlling the proportion of weak bases and relatively strong bases in the pH regulator; the calcium-to-phosphorus ratio of the product is controlled by changing the feeding ratio of a calcium source to a phosphorus source; a supergravity technology is combined to enhancea micromixing effect, so that the calcium phosphate nanopowder is prepared; and the preparation method is low in production cost, simple in operation, good in repeatability, better in application performance and wider in application range.

Owner:BEIJING UNIV OF CHEM TECH

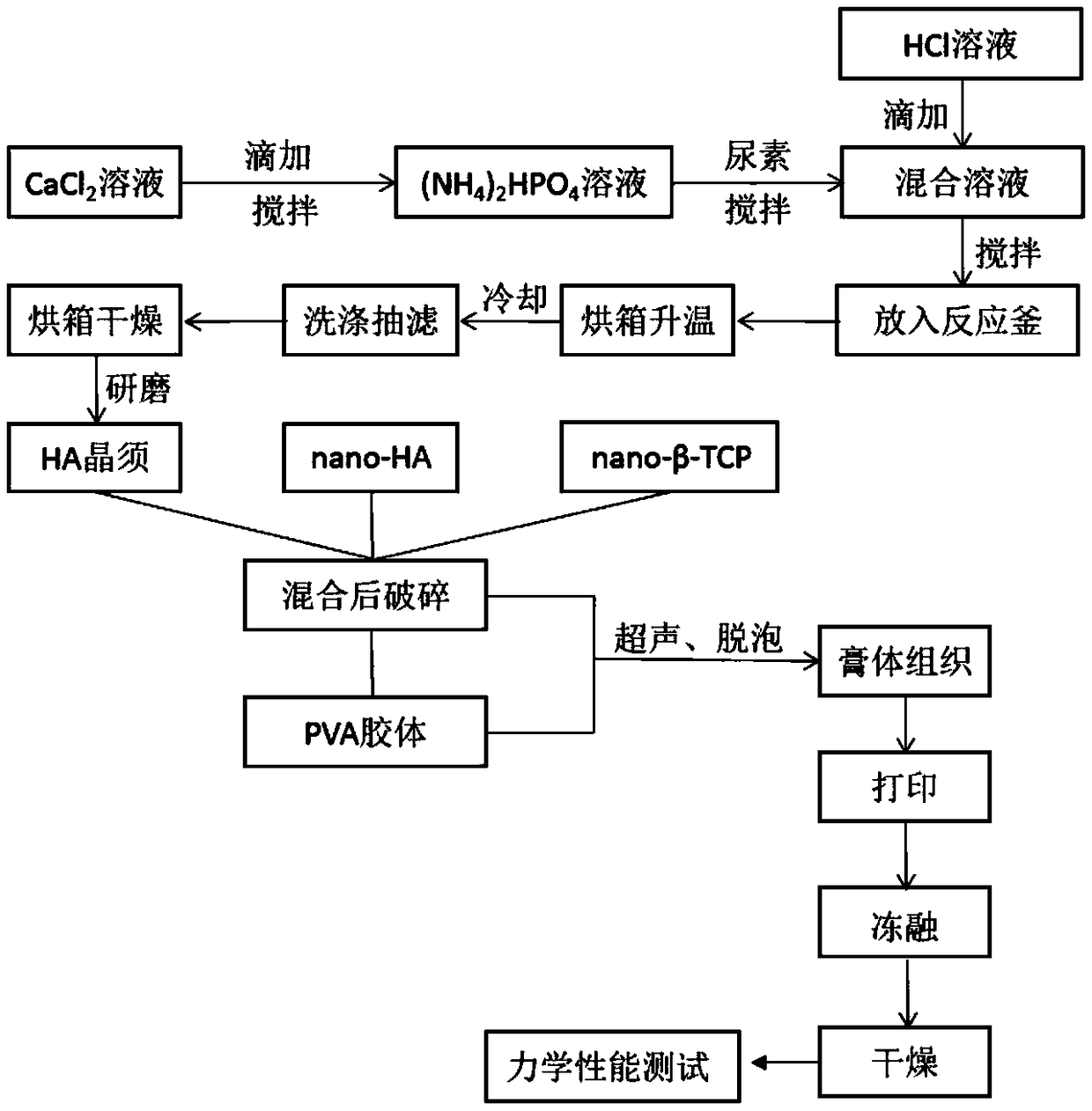

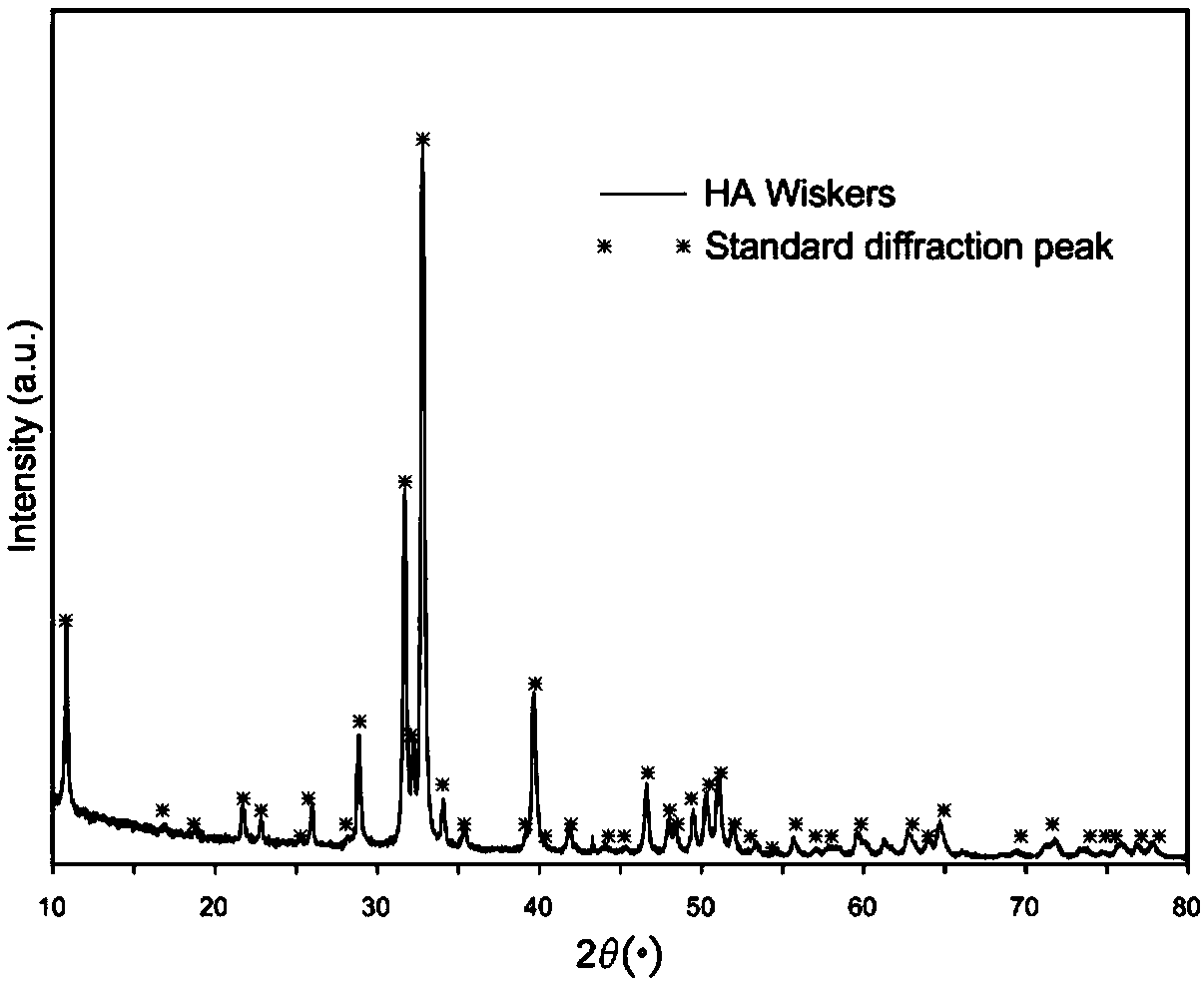

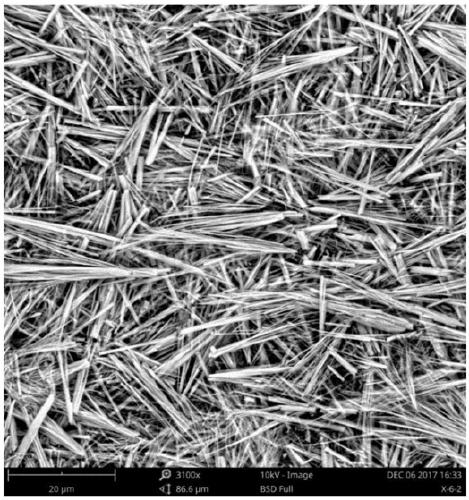

Artificial bone containing hydroxyapatite whiskers and diphasic calcium phosphate and preparation method of artificial bone

InactiveCN109133907APromote growthPromote healingPolycrystalline material growthAdditive manufacturing apparatusPorosityTri calcium phosphate

The invention discloses an artificial bone containing hydroxyapatite whiskers and diphasic calcium phosphate and a preparation method of the artificial bone. The hydroxyapatite whiskers, hydroxyapatite powder and beta-tricalcium phosphate are used as raw materials of the artificial bone, the artificial bone has an induction effect on growth of osteocytes, and growth and healing of the osteocytes are promoted; by controlling the ratio of the hydroxyapatite whiskers, the hydroxyapatite powder and the beta-tricalcium phosphate, the strength of the artificial bone is increased; the preparation method of the artificial bone is a 3D printing technology, on the one hand, the 3D printing technology can customize a stent according to the shape of a bone defect portion, and the shortcomings that bymanufacturing through a traditional mold, molding is required at first, then size is limited after molding, and the cost of the mold is high are overcome; and on the other hand, by the method, the aperture, the porosity and the connectivity of the stent can be controlled precisely, and an open porous structure and an interconnected network are of great important on cytotrophy supply, proliferationand differentiation and formation of tissues and blood vessels.

Owner:迈海新型材料科技(固安)有限公司

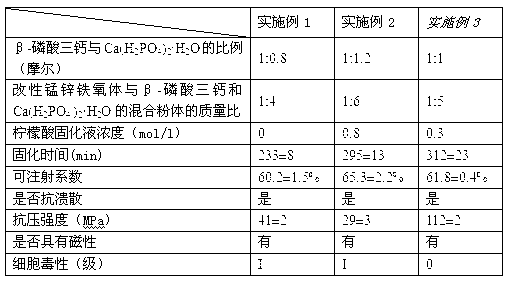

High-strength magnetic calcium-phosphate-based bone cement and preparation method thereof

InactiveCN103058645ALow preparation temperatureReduce energy consumptionProsthesisTri calcium phosphateMixed materials

The invention relates to high-strength magnetic calcium-phosphate-based bone cement which is obtained by blending a solid-phase mixed material and a liquid phase before use. The ratio of the solid-phase mixed material to the liquid phase when blending is that every 2.8-3.2g of the solid-phase mixed material requires 1mL of liquid phase. The liquid phase is a citric acid solution with a concentration of 0-0.8mol / L. The solid-phase mixed material is composed of the raw materials of beta-tricalcium phosphate, Ca(H2PO4)2.H2O, and Mn-Zn ferrite with a chemical composition of Mn0.4Zn0.6Fe2O4. The molar ratio of beta-tricalcium phosphate to Ca(H2PO4)2.H2O is 1:0.8-1.2. The weight ratio of Mn-Zn ferrite to the mixture of beta-tricalcium phosphate and Ca(H2PO4)2.H2O is 1:4-6. According to the invention, beta-tricalcium phosphate, Ca(H2PO4)2.H2O, and modified Mn-Zn ferrite with the chemical composition of Mn0.4Zn0.6Fe2O4 are adopted as solid-phase raw materials. With the three substances, preparation temperature is low, energy consumption is low, quenching is not needed, and operation is safe. The compressive strength of the bone cement can reach 112MPa, which is greatly higher than that of existing calcium-phosphate-based bone cement. The bone cement has good injectable performance, anti-collapsing performance, and low cytotoxicity.

Owner:HENAN UNIV OF SCI & TECH

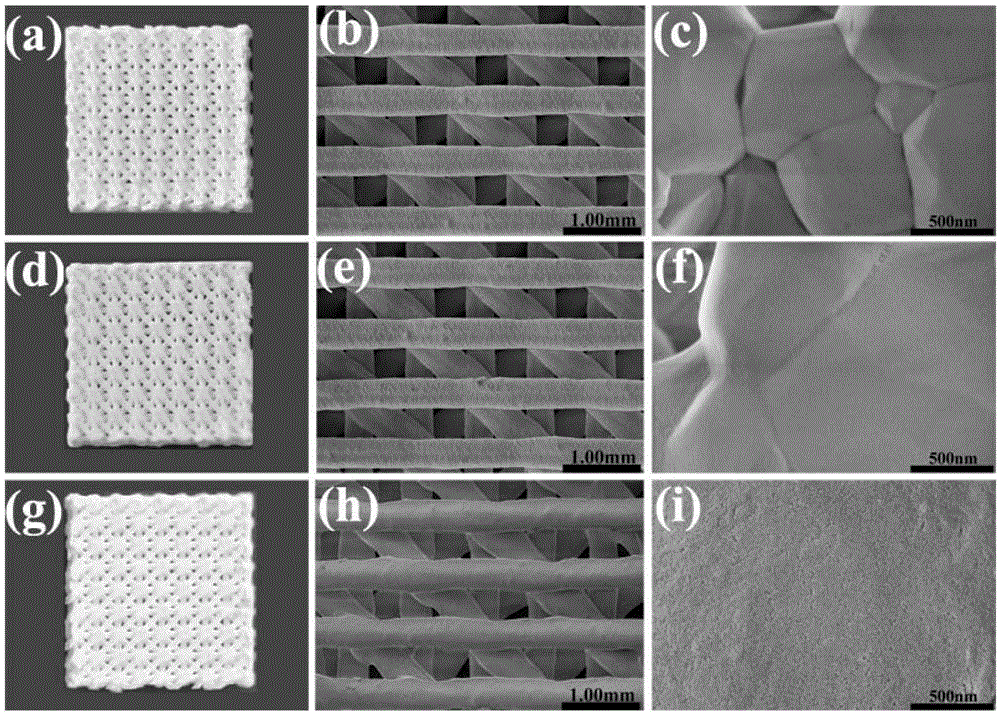

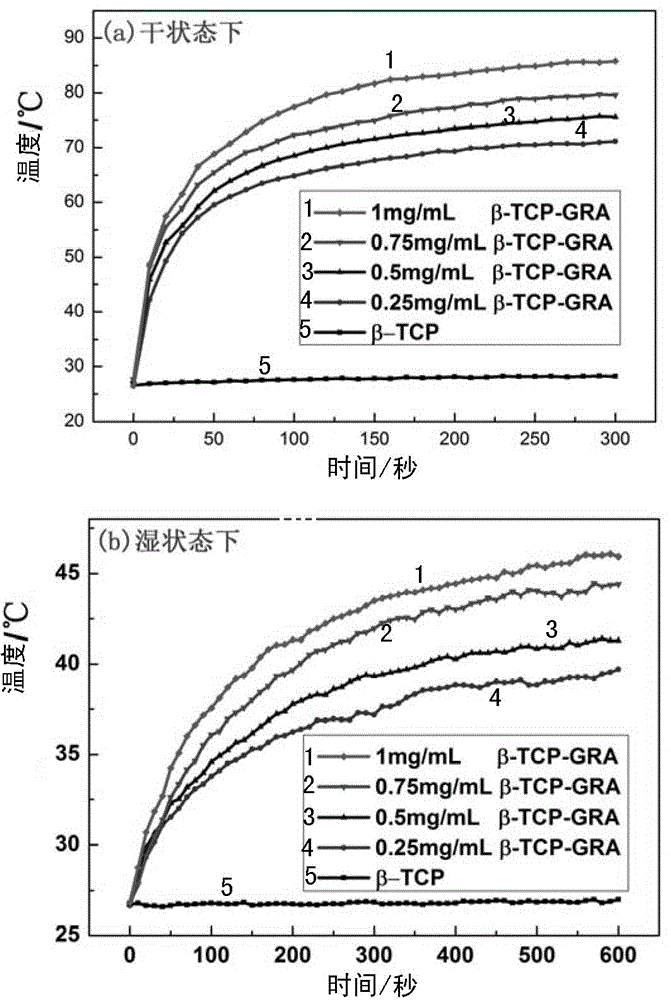

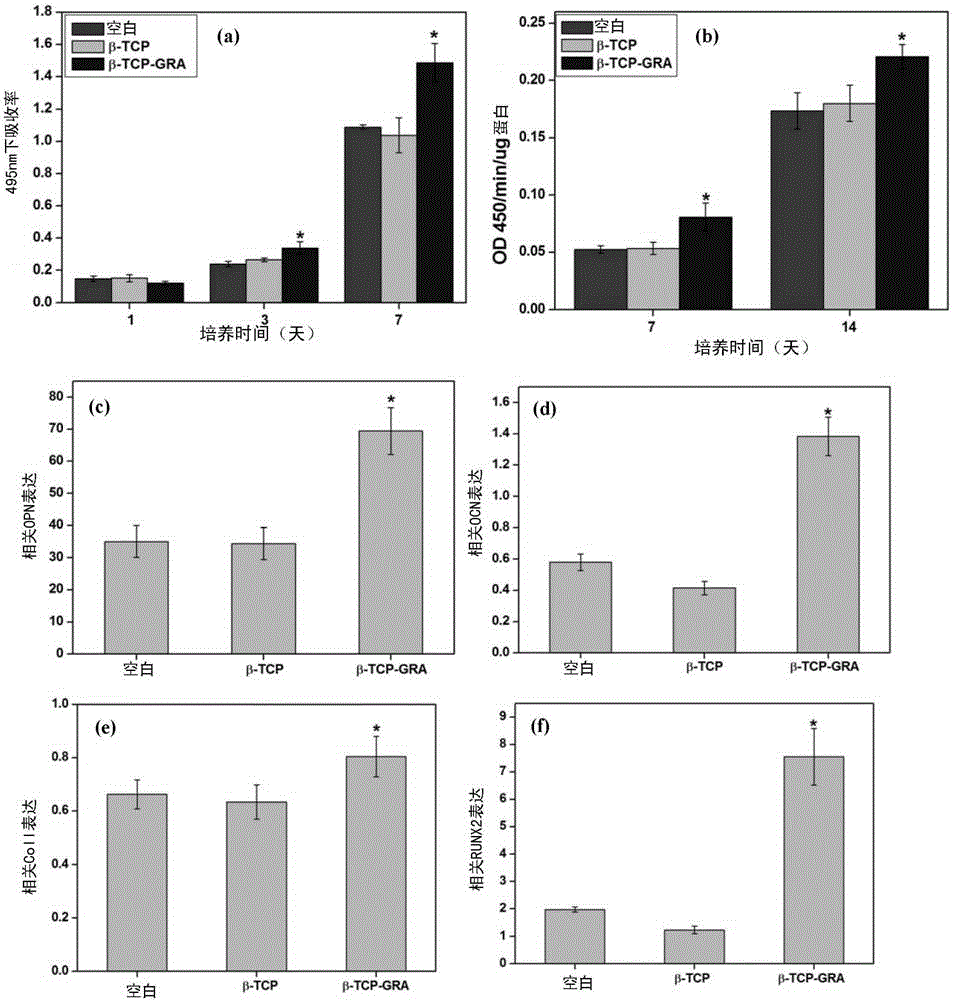

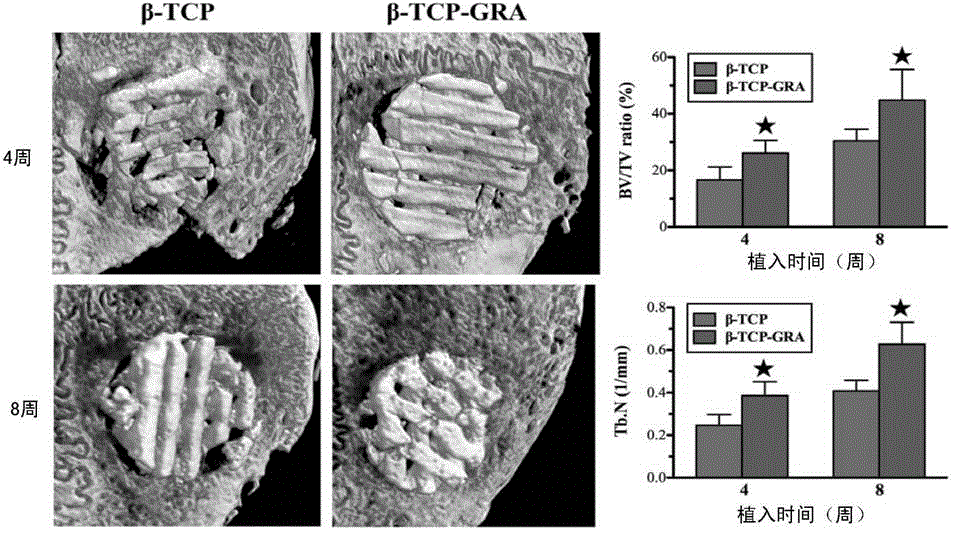

Graphene-modified biological ceramic support material and preparing method and application thereof

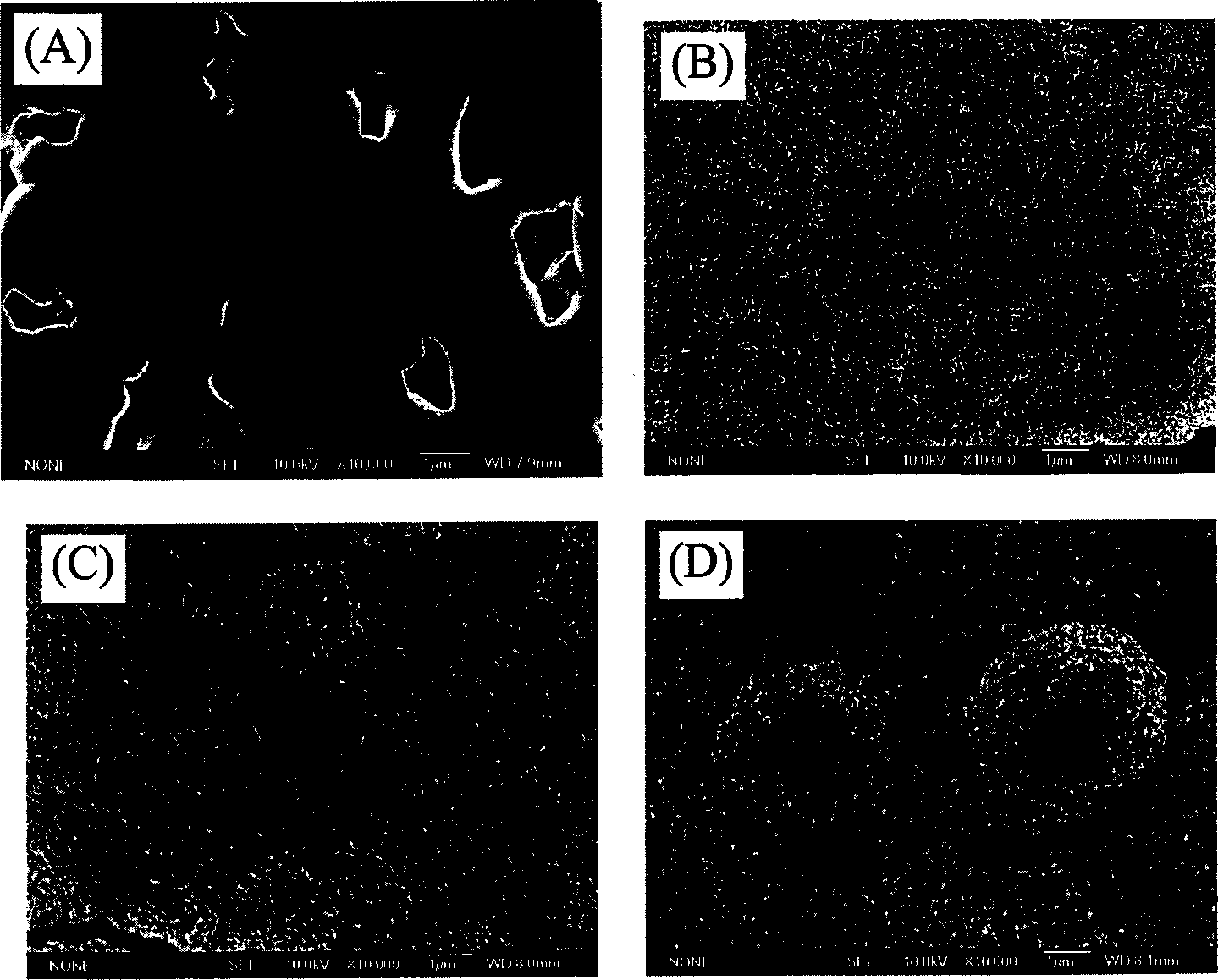

InactiveCN106139242AImprove anti-tumor effectRestoration of biological activityEnergy modified materialsAntineoplastic agentsDual effectRestorative material

The invention relates to a graphene-modified biological ceramic support material and a preparing method and application thereof. The graphene-modified biological ceramic support material comprises a beta-tricalcium phosphate support and a graphene layer with which the surface of the beta-tricalcium phosphate support is evenly covered. The graphene-modified biological ceramic support material has the quite good anti-tumor capacity and the osteogenesis promoting characteristic, and can serve as a repairing material for excising bone tumor; meanwhile, the photo-thermal performance of the graphene-modified biological ceramic support material is used, residual tumor cells are killed, and the dual effects of treating and repairing are achieved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for 3D printing of porous ceramic texture engineering workpiece

ActiveCN110028335AGood biocompatibilitySolve the shortcomings of poor resistance to external impactAdditive manufacturing apparatusCeramicwareCeramic compositeBiocompatibility Testing

The invention provides a method for 3D printing of a porous ceramic texture engineering workpiece, and belongs to the field of material preparation in additive manufacturing. The preparation method comprises the following steps: uniformly mixing two ceramic powders, namely beta-tricalcium phosphate and magnesium silicate, with an additive through rolling ball-milling, pre-sintering the mixed powder, and conducting crushing to obtain ceramic composite powder; mixing the ceramic composite powder with organic premix liquid to prepare ceramic slurry which is high in solid content, low in viscosityand suitable for printing; adopting 3D gel printing for printing forming, and conducting drying, degreasing and sintering on a printing blank to obtain a porous ceramic product sintered body; and then soaking the porous ceramic product sintered body in a polycaprolactone (PCL) solution to prepare a polycaprolactone (PCL) film layer on the surface of the product sintered body, so as to overcome the brittleness and low strength of a tricalcium phosphate ceramic scaffold, and improve the biocompatibility.

Owner:GENERAL HOSPITAL OF PLA

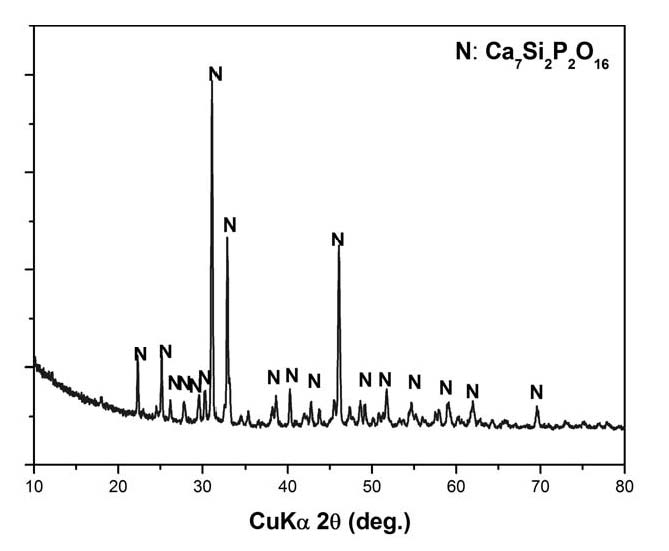

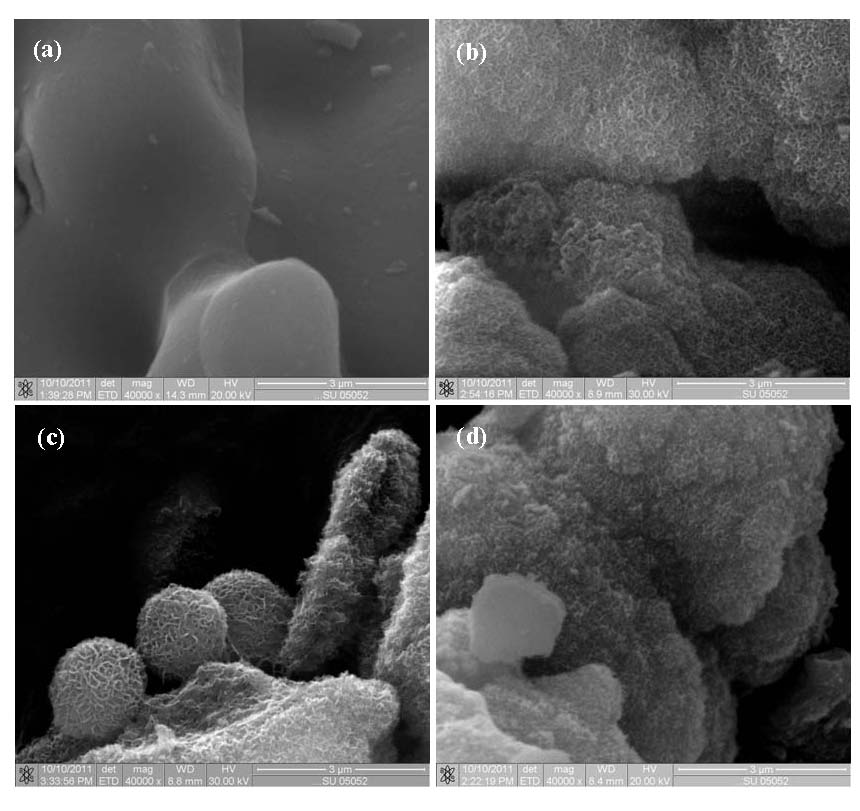

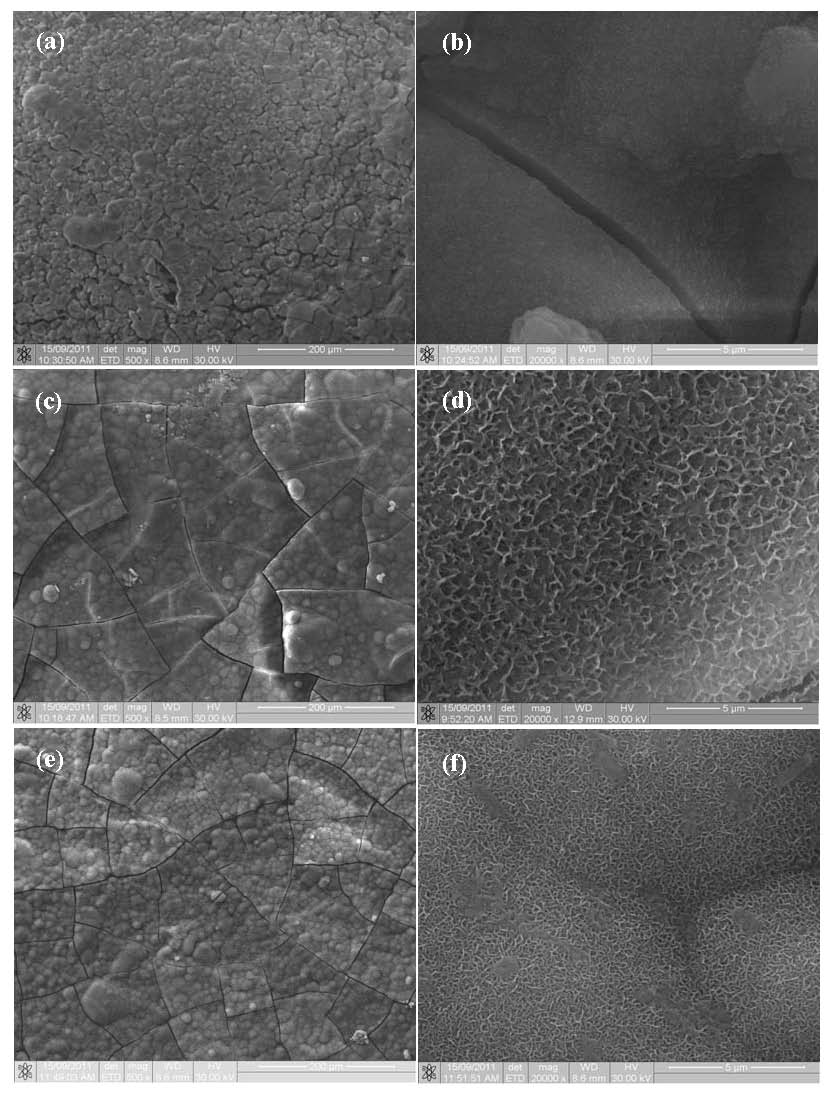

Bioactive ceramic material and preparation method thereof

InactiveCN102584203APromote osteogenic differentiationImprove biological activityProsthesisBone Marrow Stromal CellPolyvinyl alcohol

The invention discloses a bioactive ceramic material with degradability. The chemical formula of the bioactive ceramic material is Ca7Si2P2O16. A preparation method for the bioactive ceramic material comprises the following procedures: A) synthesizing pure Ca7Si2P2O16 powder by using a sol-gel method; and B) adding polyvinyl alcohol into the Ca7Si2P2O16 powder for granulation, dry pressing to obtain a blank, and calcining the blank at high temperature to obtain the Ca7Si2P2O16 bioactive ceramic material. The nagelschmidtite ceramic can support adherence and proliferation of bone marrow stromal cells. Compared with the traditional beta-tricalcium phosphate ceramics, the bioactive ceramic material can better promote osteogenic differentiation of the bone marrow stromal cells and has higher degradability.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Bone repairing material and preparation method thereof

The invention provides a bone repairing material and a preparation method thereof. The bone repairing material is of a porous structure and the bone repairing material comprises strontium, hydroxyapatite, beta-tricalcium phosphate and collagen. The porous structure is good for proliferation and differentiation of bone cells. Meanwhile, the bone repairing material comprises the hydroxyapatite and the beta-tricalcium phosphate, and the disadvantages that the hydroxyapatite is too stable and the beta-tricalcium phosphate is too rapidly degraded are overcome; and the degradation speed of the material is balanced and is matched with a human skeleton repairing speed very well. The collagen can be used for promoting cell migration, adhesion and differentiation and adjusting cell growth. The strontium can be used for enhancing the activity of osteoblasts and inhibiting the activity of osteoclasts. To sum up, the bone repairing material provided by the invention has various advantages and can be matched with the human skeleton repairing speed, and the bone repairing requirements of human bone defects are met.

Owner:BEIJING AKEC MEDICAL

Medical beta phase tricalcium phosphate/collagen cmposite material and its preparing method

InactiveCN1647826AComponent distribution is evenGood biocompatibilityProsthesisBeta phaseRestorative material

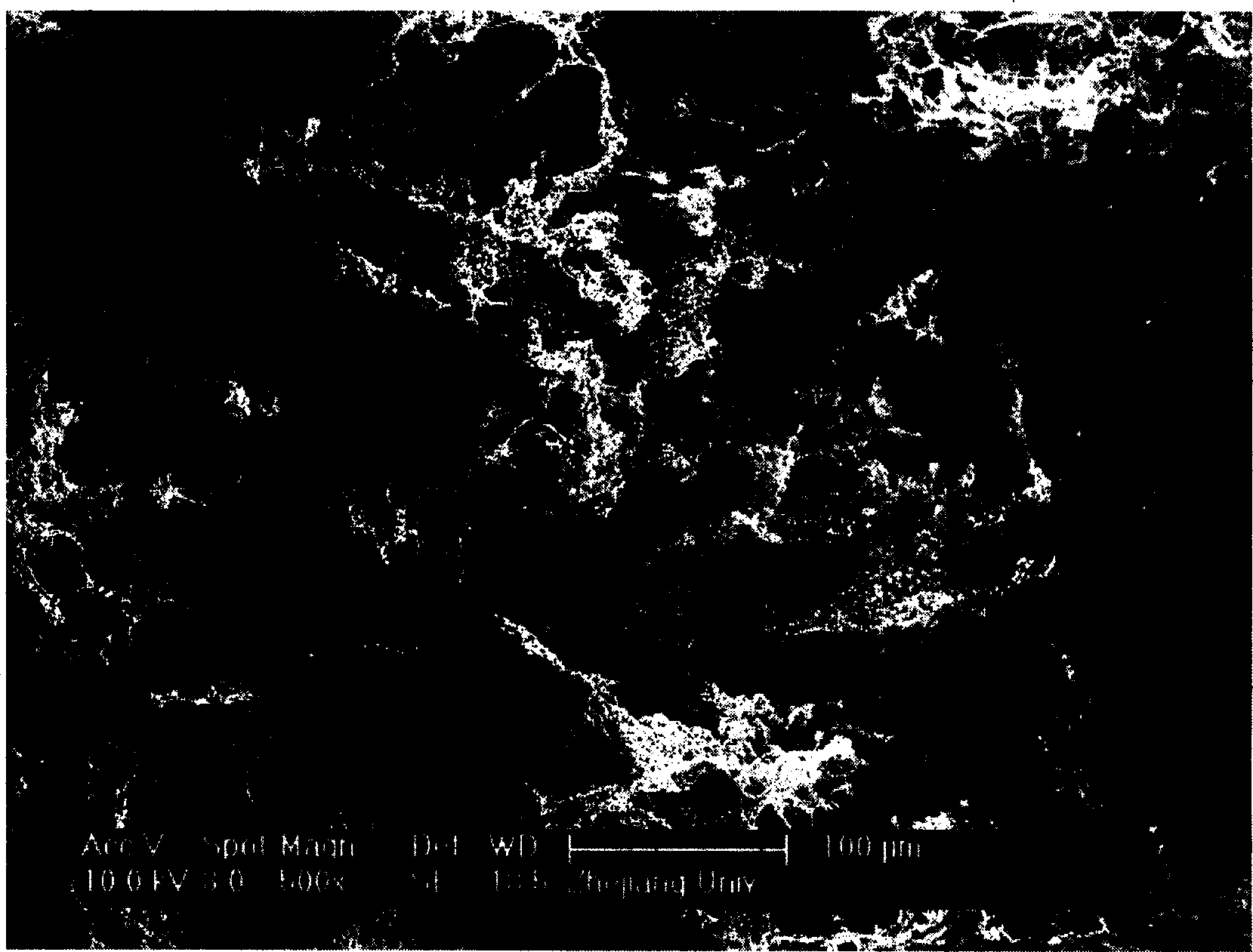

The medical composite beta-tricalcium phosphate / collagen material consists of nano level beta-tricalcium phosphate in 50-67 wt% and collagen 33-50 wt%. Through in-situ complexing of collagen and beta-tricalcium phosphate, nanometer level beta-tricalcium phosphate powder is deposited on collagen substrate, and under the action of glutaraldehyde, the composite material has raised mechanical strength. The composite beta-tricalcium phosphate / collagen material of the present invention has homogeneous components, close combination, excellent biocompatibility, proper pore size and other features, and is suitable for use as the medical bone repairing material.

Owner:翁文剑 +7

Drug-loading sustained-release support composite body for treating infectious bone defect

InactiveCN108671269AAchieve the purpose of infection controlFor the purpose of infection controlTissue regenerationProsthesisMicrosphereBone formation

The invention relates to a drug-loading sustained-release support composite body for treating infectious bone defect. The drug-loading sustained-release support composite body is prepared by the stepthat vancomycin is encapsulated by polylactic acid-glycolic acid copolymer to prepare sustained release microspheres and loaded to a beta-tricalcium phosphate support. The vancomycin, with broad-spectrum antibacterial capacity, is encapsulated by the polylactic acid-glycolic acid copolymer to prepare into sustained microspheres, and loaded to the beta-tricalcium phosphate support to prepare a novel drug-loading sustained-release anti-infection bone substitute material which can slowly release the vancomycin at a part of the infectious bone defect. When being applied to treating the infectiousbone defect, the material can release the encapsulated vancomycin in an all-dimensional mode for a long time in a partial three-dimensional space of the infectious bone defect after being embedded; thus, the purpose of controlling infection within the focus of infection is achieved; meanwhile, the effects of filling bone defect, promoting bone formation and quickening bone reconstruction are achieved.

Owner:SHANGHAI INST OF TECH +1

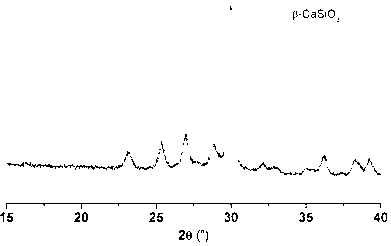

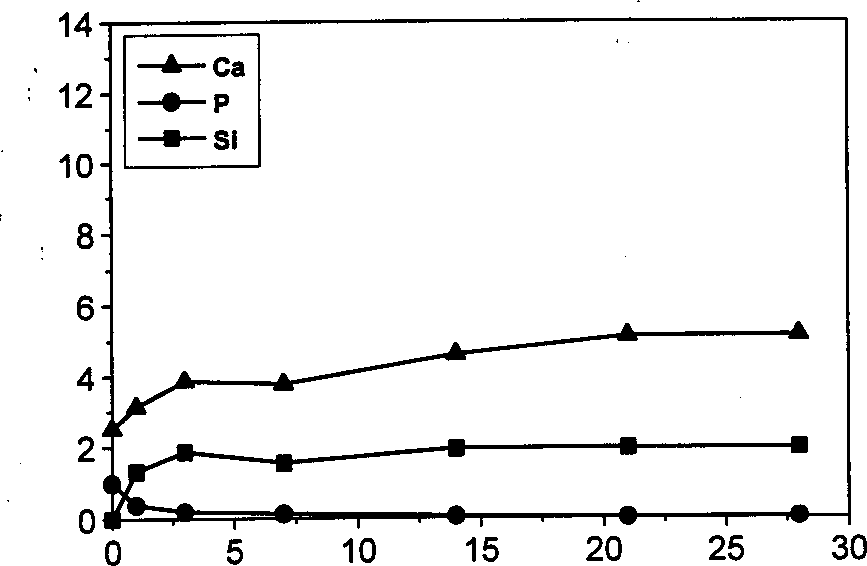

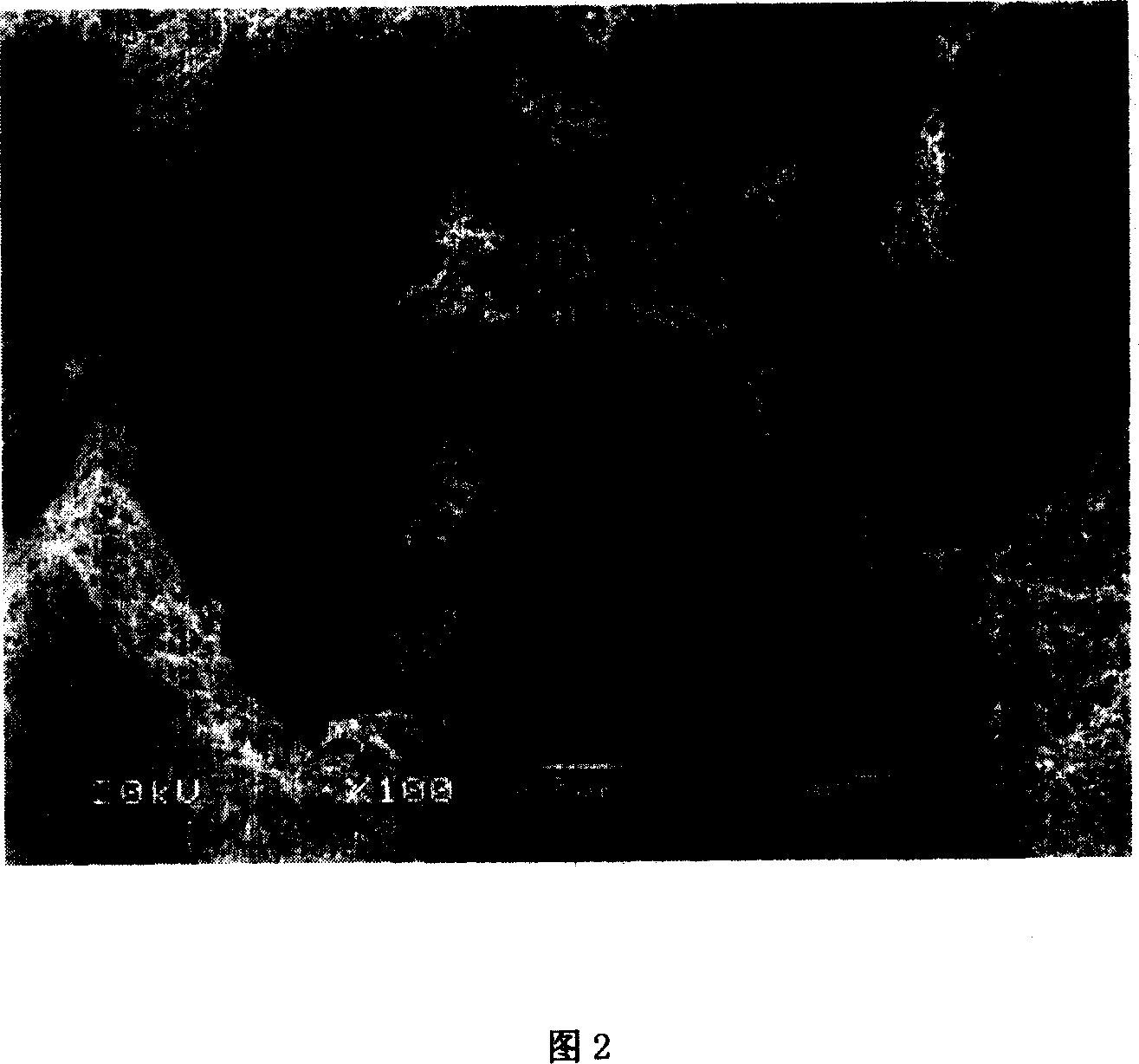

Preparation method of wollastone/tricalcium phosphate composite bio-active material

The preparation method of wollastonite / tricalcium phospate composite biological material includes the following steps: using Na2SiO3 or silicon sol as silicon source and using Ca(Na3)2 or CaCl2 and Ca(OH)2 as calcium source, respectively preparing their solutions with a certain concentration and pH value, adding proper quantity of beta-tricalcium phosphate (beta-TCP) to calcium contained solution, uniformly dispersing, then utilizing chemical coprecipitation process to prepare calcium silicate hydrate and beta-TCP powder uniformly-mixed precipitate, washing and drying, roasting at 800-900 deg.c to obtain wollastonite and beta-TCP composite powder, granulating, dry-pressing and forming, sintering for 2-5 hr. at 1300-1400 deg.C to obtain the invented wollastonite / tricalcium phosphate composite biological ceramics. According to the different requirements, the above-mentioned composition can be resulated, specially the formation of in-situ porous structure is favourable for growing of tissue and blood vessel, etc.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

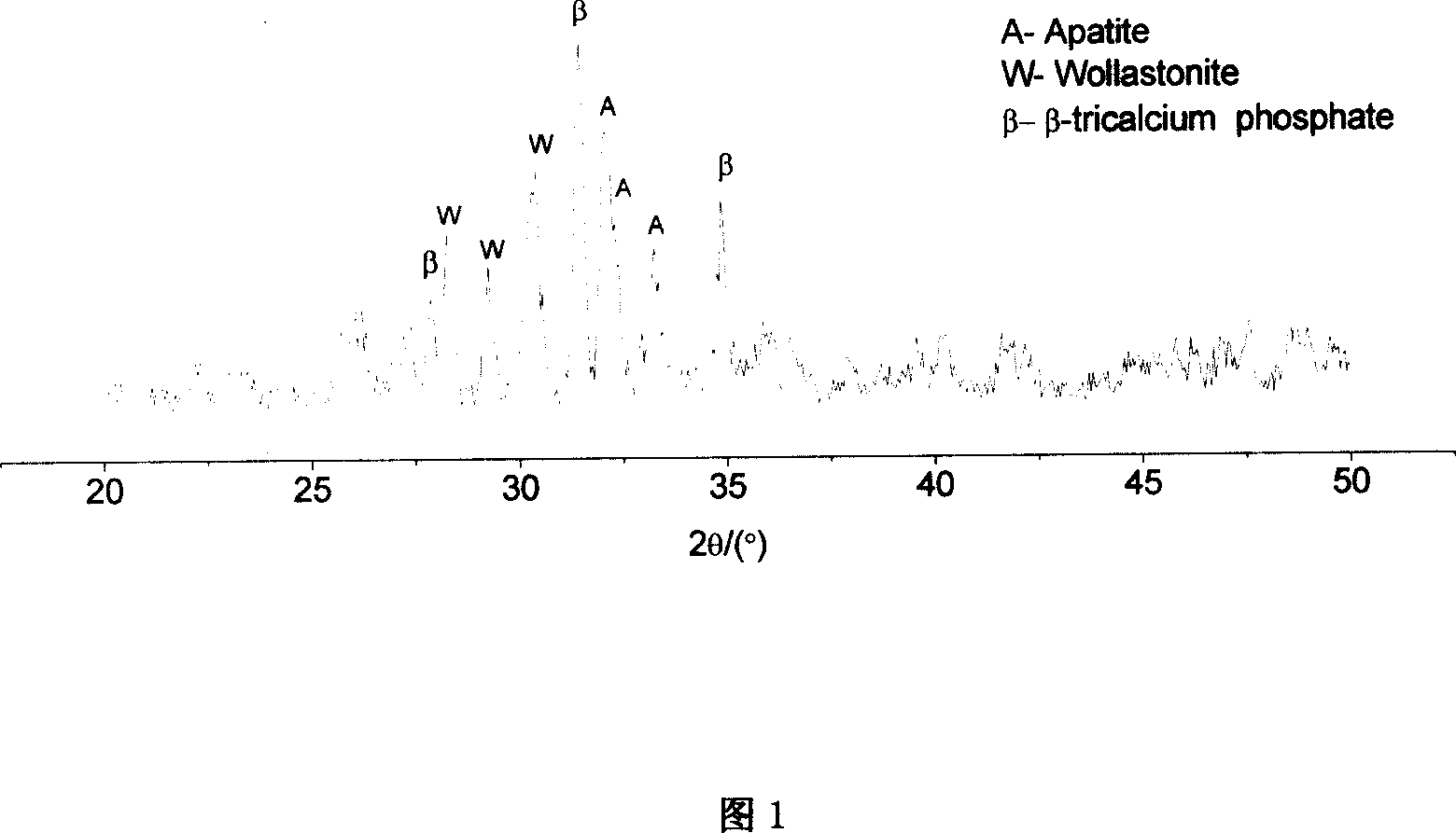

Composite organism ceramic material composed of apatite-wollastonite/beta-tricalcium phosphate

InactiveCN1923752AImprove biological activityFast adhesionCeramicwarePorosityAlpha-tricalcium phosphate

The invention discloses a composite biological active ceramic material of Apatite-Wollastonite / beta-tricalcium phosphate (AW / beta-TCP), which comprises the following steps: adopting sol-gel process to prepare AW former powder; preparing TCP former powder through chemical sediment method; sieving TCP former powder through 60-order standard sieve; putting AW former powder and TCP former particle in the material mixing machine according to different proportion; adding certain rate corresponding to powder weight geoceric acid or naphthalene particle with grain size at 20-30 order; making 5wt% polyvinyl alcohol solution as adhesive; blending completely; moulding; drying; sintering to obtain porous product.

Owner:SICHUAN UNIV

Method for preparation of controlled pore size biphasic calcium phosphate composite ceramic scaffold

InactiveCN105288740AAperture controllableEvenly distributedProsthesisBiphasic calcium phosphateFoaming agent

The present invention discloses a method for preparation of a controlled pore size biphasic calcium phosphate composite ceramic scaffold. Firstly, nano-hydroxyapatite and nano-beta-tricalcium phosphate powder are prepared, the nano powder and a surfactant and a pore-forming agent are uniformly mixed, ground and sieved, added dropwise with a foaming agent solution, stirred into stick viscous slurry, and dried in air at room temperature to obtain a ceramic blank, the ceramic blank is foamed at a certain temperature and dehydrated, and sintered at high temperature, and after removal of the surfactant, the pore-forming agent and the foaming agent, the porous biphasic calcium phosphate ceramic composite scaffold can be obtained. The method is simple in process and strongly practical, by regulating of the use amount of the surfactant, the pore-forming agent and the foaming agent, the porous biphasic calcium phosphate ceramic composite scaffold can be controlled in pore size, even in distribution, and conductive to the practical application in biological medicines.

Owner:SHANGHAI JIAO TONG UNIV

Injection type tissue engineering bone renovation material and construct method thereof

The invention relates to an injection organism repair material and relative production. Wherein, it comprises carrier support and seed cell adhered on the carrier support to form skeleton three-dimension structure and biological active composite; and it uses the injection chitose-beta-tricalcium phosphate composite as carrier support to couple seed cell; the seed cell is bone marrow substrate stem cell. The test has proved that the chitose-beta-tricalcium phosphate composite has better compatibility with BMSCs.

Owner:NAN FANG HOSPITAL

Method for manufacturing biological bone wires usable for FDM (frequency-division multiplexing) 3D (three-dimensional) printer models

ActiveCN105751472AWell mixedAvoid cloggingTissue regenerationProsthesisFrequency-division multiplexingSolvent

The invention discloses a method for manufacturing biological bone wires useable for FDM (frequency-division multiplexing) 3D (three-dimensional) printer models.The method includes weighing, by weight, 10-90% of PLA (polylactic acid) and 90-10% of hydroxyapatite and beta-tricalcium phosphate; ultrasonically dispersing artificial bone induction and repair substrates by the aid of solvents to obtain dispersion liquid A; dissolving a binder into the dispersion liquid A by the aid of mechanical stirring processes so as to obtain mixtures B; drying the mixtures B and removing redundant solvents to obtain mixtures B for blocks; extruding the mixtures B for the blocks by the aid of double-screw extruders to obtain wires with the diameters of 1.75 millimeters.The PLA is used as the binder, and the hydroxyapatite and the beta-tricalcium phosphate are used as the artificial bone induction and repair substrates.The wires with the diameters of 1.75 millimeters are the biological bone wires.The method has the advantages that the biological bone wires manufactured by the aid of the method are combined with desktop machines and can be used for directly printing absorbable bone repair models, accordingly, the biological printing ranges can be greatly expanded, and biological printing access threshold can be lowered.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com