Premix plaster calcium phosphate bone cement

A calcium phosphate bone cement, pre-mixing technology, applied in medical science, prosthesis and other directions, can solve problems such as wasting operation time, and achieve the effects of convenient production and operation, low raw material cost, and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

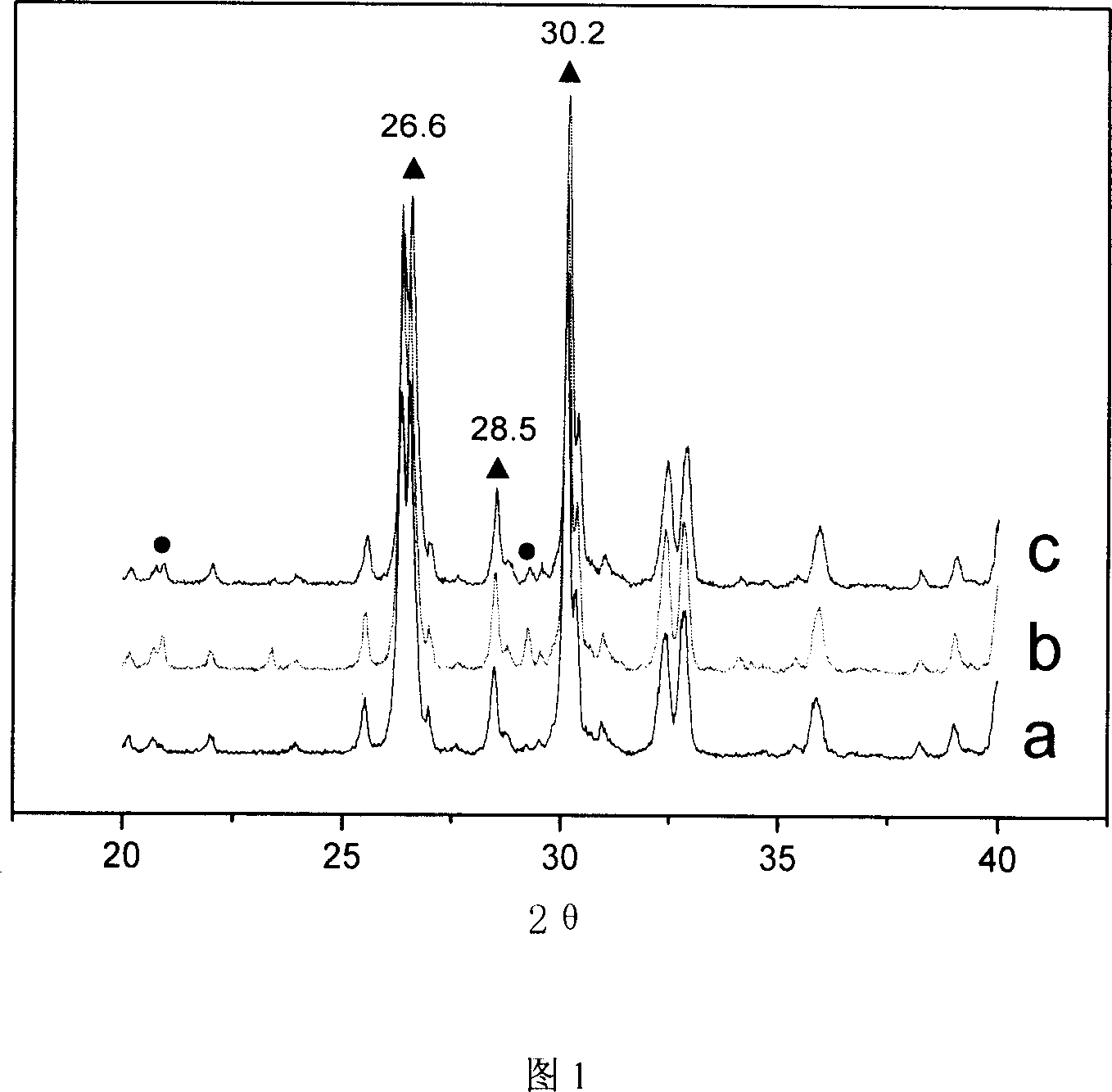

Image

Examples

Embodiment 1

[0017] Mix 0.55g of β-tricalcium phosphate and 0.45g of calcium dihydrogen phosphate monohydrate powder evenly as a premixed calcium phosphate bone cement powder, then mix the above bone cement powder with 0.37g of medical grade glycerin to make a viscous body, the viscous body was made into a Φ6mm×3mm sample through a mold and immersed in a PBS solution, placed in an environment of 37°C, and the average curing time was measured to be 18.4min. Fill the above-mentioned viscous body into a glass mold with openings at both ends of Φ10mm×8mm, and also immerse it in PBS solution and place it in an environment of 37°C and 100% humidity for 1 day and 7 days, and the average compressive strength is 7.5MPa and 7.5MPa respectively. 9.6MPa.

Embodiment 2

[0019] Except for mixing 1 g of premixed bone cement powder with 0.333 g of medical grade glycerin, the rest of the preparation methods and processes refer to Example 1. The premixed calcium phosphate bone cement samples obtained in this example had an average curing time of 15.9 minutes, and the average compressive strengths after soaking in PBS solution for 1 day and 7 days were 8.6 MPa and 10.9 MPa, respectively.

Embodiment 3

[0021] Except for mixing 1 g of premixed bone cement powder with 0.303 g of medical grade glycerin, the rest of the preparation methods and processes refer to Example 1. The premixed calcium phosphate bone cement sample obtained in this example has an average curing time of 13.0 minutes, and the average compressive strengths after soaking in PBS solution for 1 day and 7 days are 10.3 MPa and 11.1 MPa, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com