Patents

Literature

1308 results about "CALCIUM DIHYDROGEN PHOSPHATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

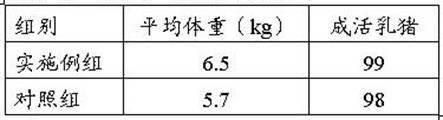

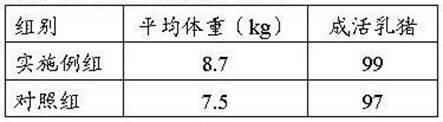

Nonreactive health powdered suckling pig creep compound feed and preparation method thereof

InactiveCN102885236AIncrease feed intakeImprove Gut HealthFood processingAnimal feeding stuffBiotechnologyPhytase

The invention discloses a nonreactive health powdered suckling pig creep compound feed and a preparation method thereof, wherein the feed is prepared from the following materials: corn, broken rice, puffed corn starch, puffed soybean meal, dehulling soybean meal, fermented soybean meal, white fish meal, flour, plasma protein flour, whey powder, fruit sugar, glucose monohydrate, bean oil, calcium formate, calcium biphosphate, salt, enveloped slow release acidulant, choline chloride, suckling pig compound premix, zinc oxide, yeast cell wall polysaccharides, sodium glutamate, arazyme, lipidase, Clostridium butyricum, essential oils, L-lysine hydrochloride, DL methionine, L-threonine, tryptophan and phytase. Based on the physiological characteristics of suckling pig and by the combination of various materials, the feed is supplementary in nutrition and high in design of amino acid and daily ration of energy without adding antibiotics, and Clostridium butyricum and various essential oils are used for protecting the health; therefore, the feed intake of suckling pig can be increased, the weight growth rate is increased, the diarrhea rate after ablactation is reduced, the intestine health of suckling pig can be improved, the immunity is improved, and the survival rate of suckling pig is increased.

Owner:HUAIAN ZHENGCHANG FEED

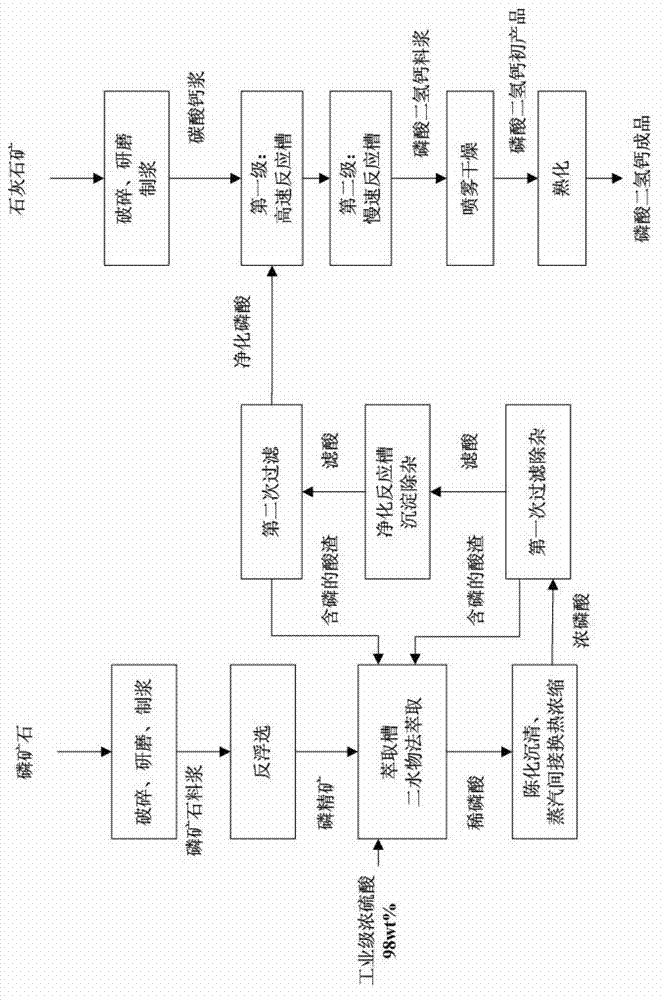

Method for producing feed-grade calcium dihydrogen phosphate from wet-process phosphoric acid

A method for producing feed-grade calcium dihydrogen phosphate from wet-process phosphoric acid comprises the following steps of: pulping by the use of natural phosphate rock and carrying out reverse flotation to obtain phosphate concentrate, extracting for desulphurization by a dihydrate process so as to obtain dilute phosphoric acid, aging, setting and condensing to obtain concentrated phosphoric acid; filtering the concentrated phosphoric acid to remove impurities, extracting acid sludge, filtering acid, setting, removing impurities, carrying out secondary filtration to obtain purified phosphoric acid, and returning filter residue to the extraction step; and grinding limestone mine to obtain a calcium carbonate powder which can pass through a Tyler sieve of -100 meshes and is greater than 95 wt%, adding water to prepare a pulp, performing two stages of high-speed and low-speed reactions between the pulp and the purified phosphoric acid so as to generate a calcium dihydrogen phosphate slurry, and drying and slaking the slurry to obtain a powdered feed-grade calcium dihydrogen phosphate finished product. The method provided by the invention has advantages of high phosphorus yield, good impurity removal effect, low cost, coarse and large crystalllization product and good fluidity. The product is not easy to cake. The method replaces a technological method for producing feed-grade calcium dihydrogen phosphate from hot-process phosphoric acid. The method provided by the invention has advantages of saving energy, reducing emission, decreasing production cost and improving caking property of the calcium dihydrogen phosphate material and material fluidity.

Owner:SINOCHEM YUNLONG

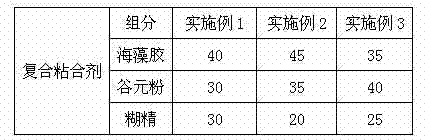

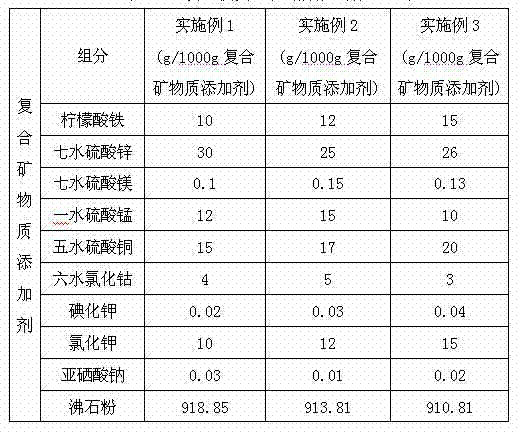

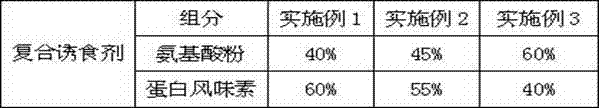

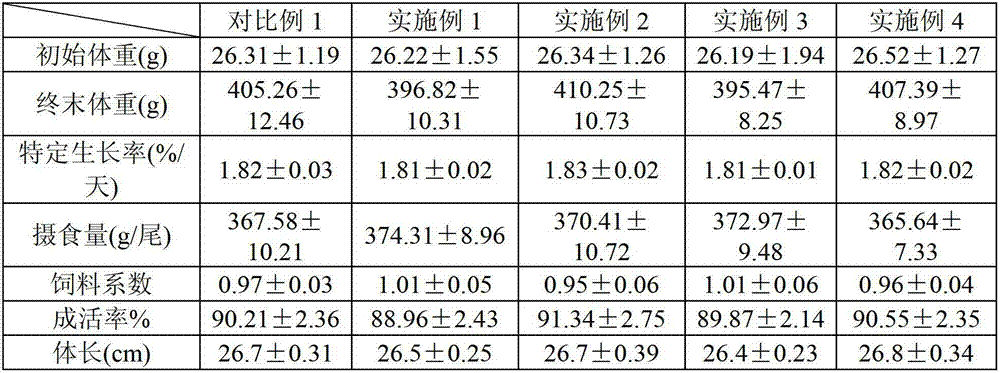

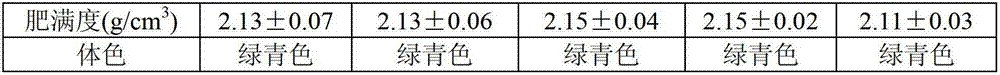

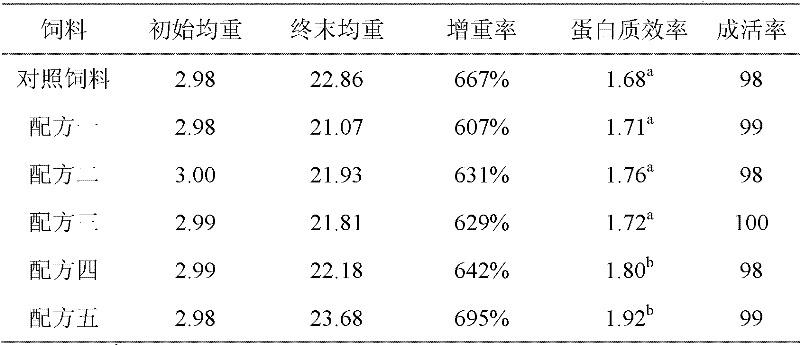

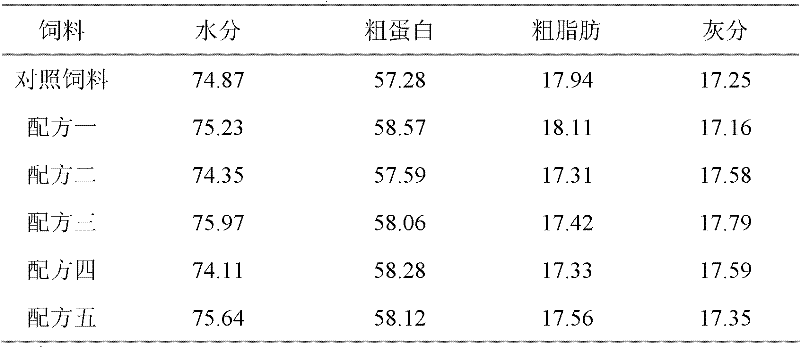

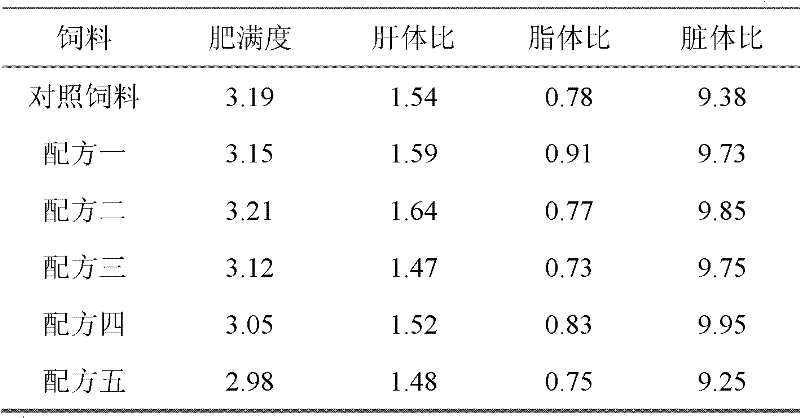

Compound feed for Scylla serrata and preparation method of same

ActiveCN102687810ALow costNutritional balanceAnimal feeding stuffBacillus licheniformisAnimal science

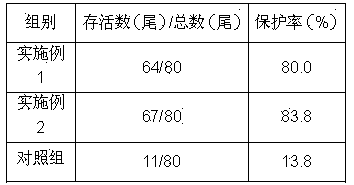

The invention discloses a compound feed for Scylla serrata, comprising fish meal, shrimp head powder, soybean meal, rapeseed meal, fish oil, soybean phosphatide powder, brewers yeast, choline chloride, molt hormone, bread flour, calcium dihydrogen phosphate, sodium dehydroacetate, butyl hydroxy anisole, astaxanthin, Schizochytrium limacinum, Bacillus licheniformis, a composite feeding promoting agent, a complex vitamin additive, a composite mineral matter additive and a composite adhesive. The feed has balanced nutrition, is resistant to spoilage, has a long storage life, not only reduces feed cost but also promotes the growth and improves the color of the Scylla serrate. In addition, the feed is friendly to environment, has good palatability and feed promoting effect, has high utilization efficiency and good stability in water, and can enhance the immunity and survival rate of scylla serrata. The invention also provides a preparation method for the compound feed for scylla serrata, which is simple in technology, with the function substance in raw material undestroyed in the preparation process.

Owner:ZHEJIANG MARINE DEV RES INST

Piglet prescription milk powder and preparation method thereof

ActiveCN101731365AGood water solubilitySolve insufficient milk intakeWhey manufactureSolubilityFully developed

The invention discloses a prescription milk powder for a piglet and a preparation method thereof. The prescription milk powder comprises the following components: whole milk powder, desalinized whey powder, whey concentrated protein, egg powder, swollen rice powder, powdered grease, glucose, lactose, lysine, methionine, threonine, trace element additive, complex vitamin, glutamine, choline chloride, vitamin C, milk flavouring agent, calcium lactate, calcium dihydrogen phosphate, antioxidant, astragalus polysaccharide and oligosaccharide. The piglet prescription milk powder has high palatability and high water solubility, is abundant in immune globulin, immune polysaccharide, functional oligosaccharide and high-cream lactoprotein, can well overcome the defect of insufficient milk absorption of the piglet, improves the immunity and disease resistance of the piglet and the raising rate and uniformity before ablactation and during the care period, and fully develops the growth potential of the piglet.

Owner:铁骑力士食品有限责任公司

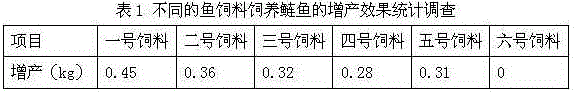

Feed stuff for common carp

InactiveCN101077132AMeet actual needsModerate proportionFood processingClimate change adaptationCommon carpFodder

The present invention discloses one kind of carp feed, which consists of soybean dregs 35-50 wt%, cotton seed dregs 15-25 wt%, DDGS 3-8 wt%, fish meal 3-8 wt%, starch 6.2-16.1 wt%, corn dregs 8-12 wt%, calcium dihydrogen phosphate 1.5-1.7 wt%, salt 0.2-0.4 wt%, Chinese medicinal stone 1.5-2.5 wt%, soybean oil 0.5-1.5 wt%, and premixed fish feed material 0.8-1.2 wt%. It has comprehensive balanced nutrients, and can promote the growth of carp and raise its disease resistance.

Owner:侯彦卫

Environmentally-friendly tilapia feed

InactiveCN102106474AIncrease contentImprove immunityFood processingClimate change adaptationBiotechnologyPhytase

The invention discloses an environmentally-friendly tilapia feed, which is mainly prepared from the following raw materials in percentage by weight: 15 to 30 percent of bean pulp, 2 to 5 percent of fish meal, 10 to 20 percent of maize alcohol lees, 10 to 17 percent of rape seed dreg, 3 to 12 percent of cotton seed meal, 5 to 12.5 percent of rice bran meal, 20 to 30 percent of wheat flour, 1 to 5 percent of fish oil and 3 to 5 percent of environmentally-friendly additive, wherein the environmentally-friendly additive is a mixture of vitamins, minerals, salt, choline chloride, calcium dihydrogen phosphate, immune polysaccharide, allicin and phytase. According to the nutrition requirement of tilapia, the balance of amino acid is regulated, the consumption of animal protein fish meal in the formula is regulated, and the content of vegetable protein is increased as a main protein source; and meanwhile, biological agents such as the allicin, immune polysaccharide, enzyme preparation phytaseand the like are added, so the coefficient of the tilapia feed is reduced, the culture period is shortened, and the ammonia nitrogen content of the culture water body is simultaneously improved.

Owner:BAIYANG INVESTMENT GRP INC

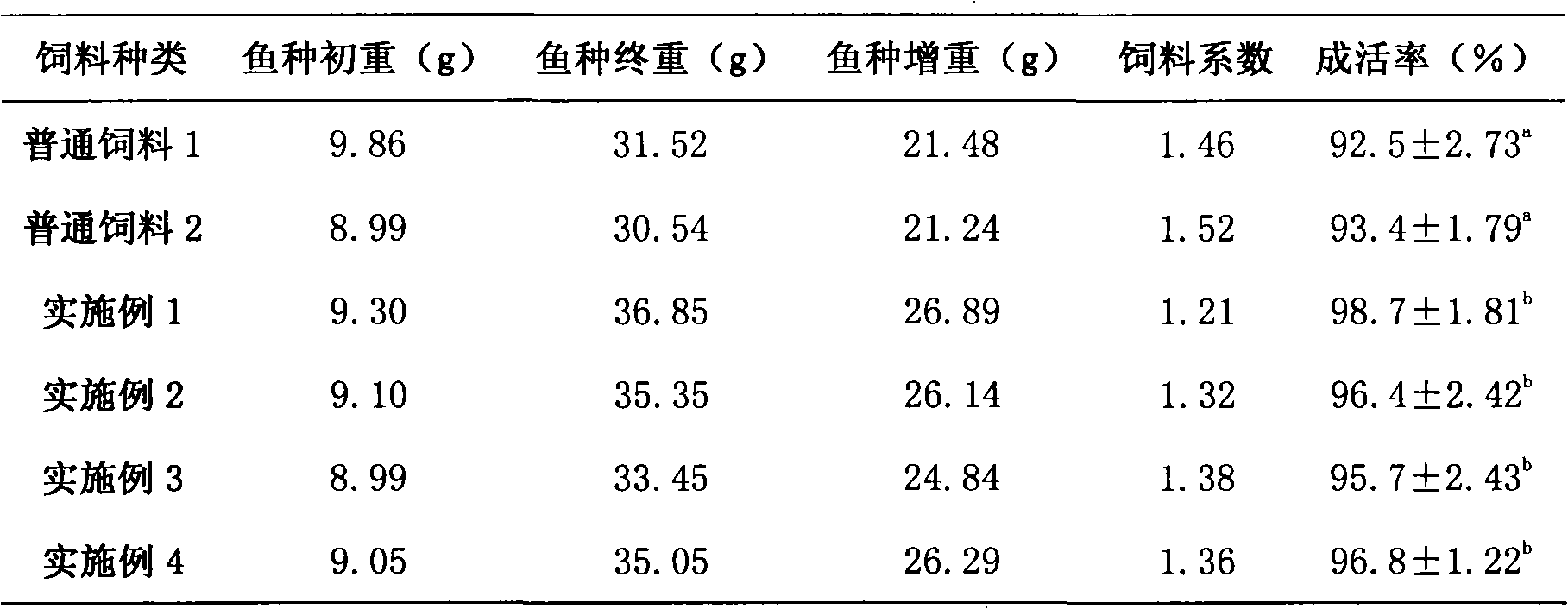

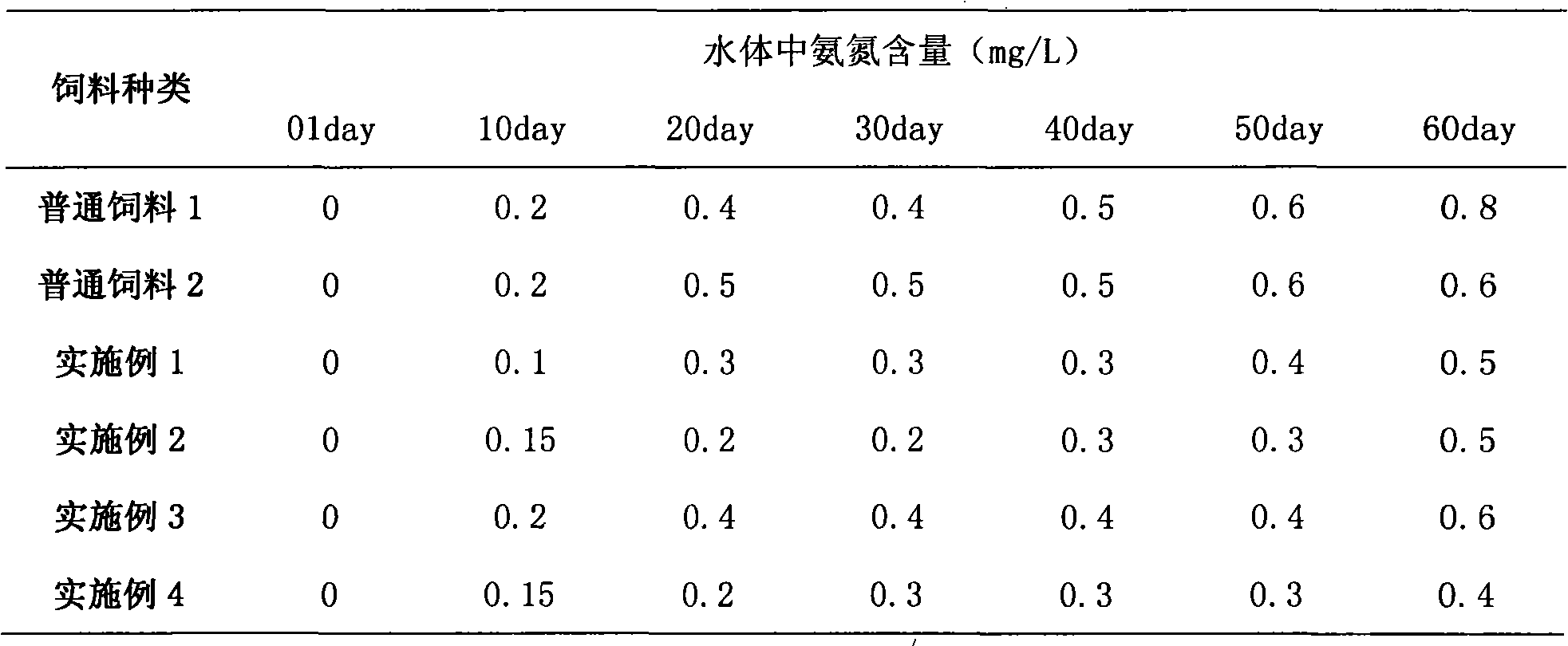

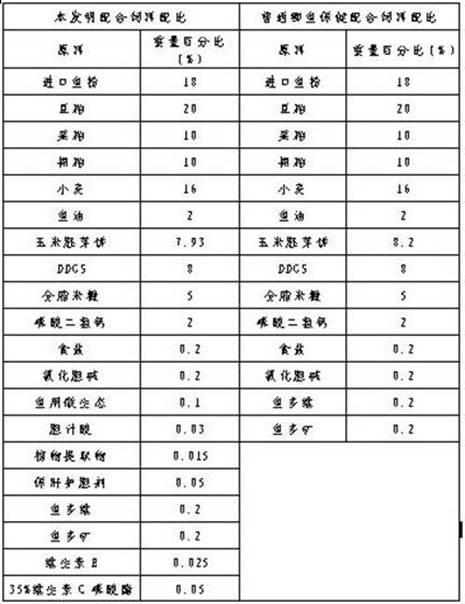

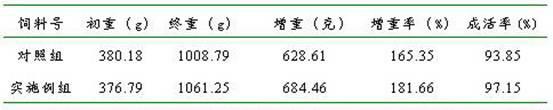

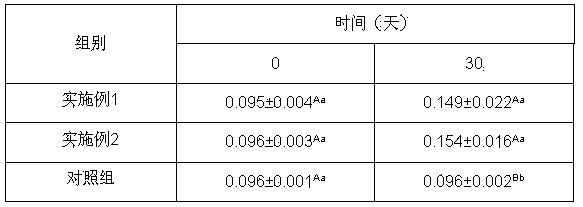

Compound crucian feed and preparation method thereof

The invention provides a compound crucian feed and a preparation method thereof. The compound crucian feed can solve a series of problems that the traditionally bred crucian grows fast in the early and middle periods, but the subsequent growth is slow, the death rate rises, the anti-stress ability is reduced and the like because hepatobiliary syndrome frequently occurs in the middle and later periods. The compound feed comprises the following formula in percentage by weight: 5-20% of imported fish meal, 10-30% of soybean meal, 10-20% of rapeseed meal, 10-15% of cottonseed meal, 10-20% of wheat, 2-3% of fish oil, 5-15% of maize germ cake, 5-15% of DDGS(distillers dried grains with soluble), 5-10% of full-fat rice bran, 1.0-2.0% of calcium biphosphate, 0.1-0.3% of salt, 0.1-0.3% of choline chloride, 0.05-0.15% of microecologics for fish, 0.01-0.02% of plant extracts, 0.02-0.04% of bile acid, 0.05-0.1% of hepatobiliary protecting agent, 0.1-0.3% of multivitamin for fish, 0.1-0.3% of multi-mineral for fish, 0.015-0.030% of vitamin E and 0.04-0.08% of 35% vitamin C phosphate. All the raw materials are finely ground, 95% of the ground raw materials pass through a 40-mesh standard sieve,the sieved raw materials are granulated at 95 DEG C, and the degree of gelatinization reaches 95%. The compound crucian feed can meet the requirements of crucian bred in the middle and later periods for nutrition, and can effectively prevent the occurrence of hepatobiliary syndrome and achieve the health protection purpose.

Owner:SHANDONG NEW HOPE LIUHE GROUP

Magnesium alloy phosphorization solution and magnesium alloy surface treatment method

ActiveCN101638780AImprove corrosion resistanceImprove bindingMetallic material coating processesSodium molybdateSalt spray test

The invention relates to a magnesium alloy phosphorization solution, which is an aqueous solution containing phosphoric acid, calcium dihydrogen phosphate, sodium silicate, sodium molybdate and ammonium metavanadate. The invention also provides a magnesium alloy surface treatment method, which comprises a step of phosphorizing the surface of magnesium alloy by using the magnesium alloy phosphorization solution. The method uses a calcium phosphorization solution to phosphorize the surface of the magnesium alloy, does not require substances containing hexavalent chrome, fluorions and the like which are harmful to the environment and human bodies in the whole phosphorizing process, and is the environment-friendly method. The magnesium alloy surface treated by the method has high corrosion resistance, good bonding force and low surface resistance, wherein the corrosion area after 60 hours of a neutral salt spray test can reach less than 5 percent, the bonding force can reach 5B level, andthe surface resistance can be lower than 0.0002 ohm.

Owner:BYD CO LTD

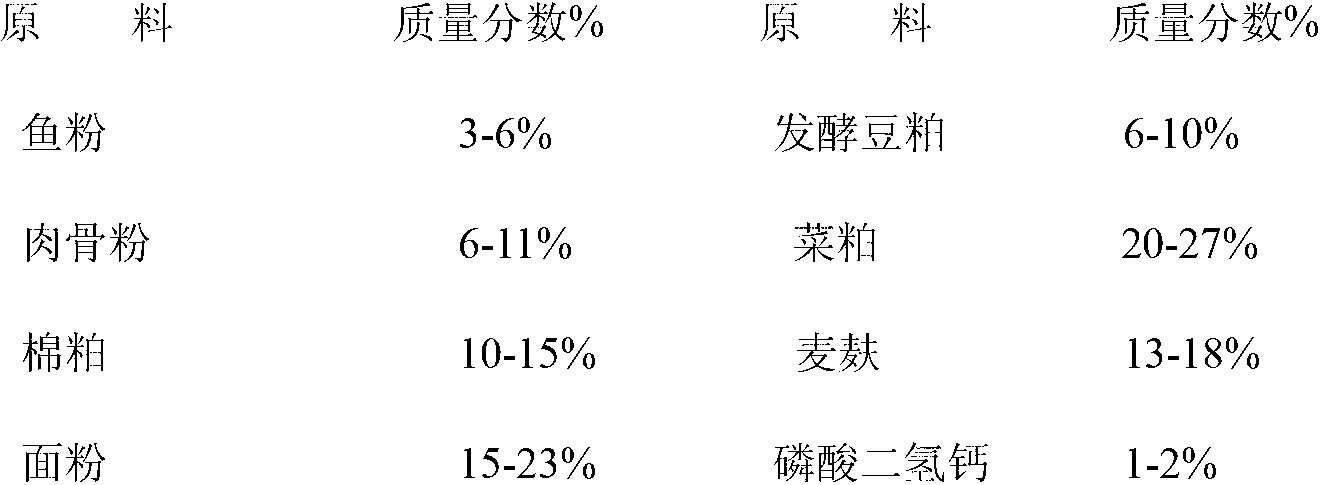

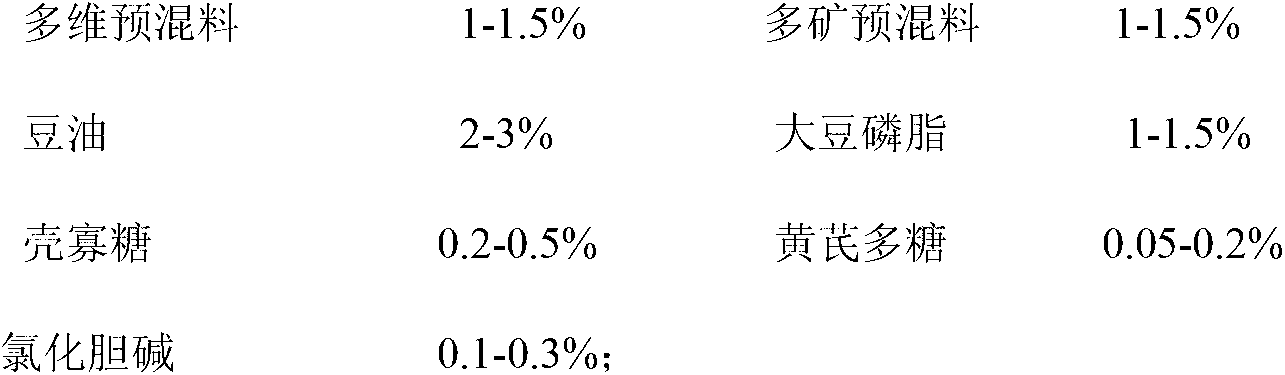

Compound feed for preventing fatty liver of tilapia and preparation method of feed

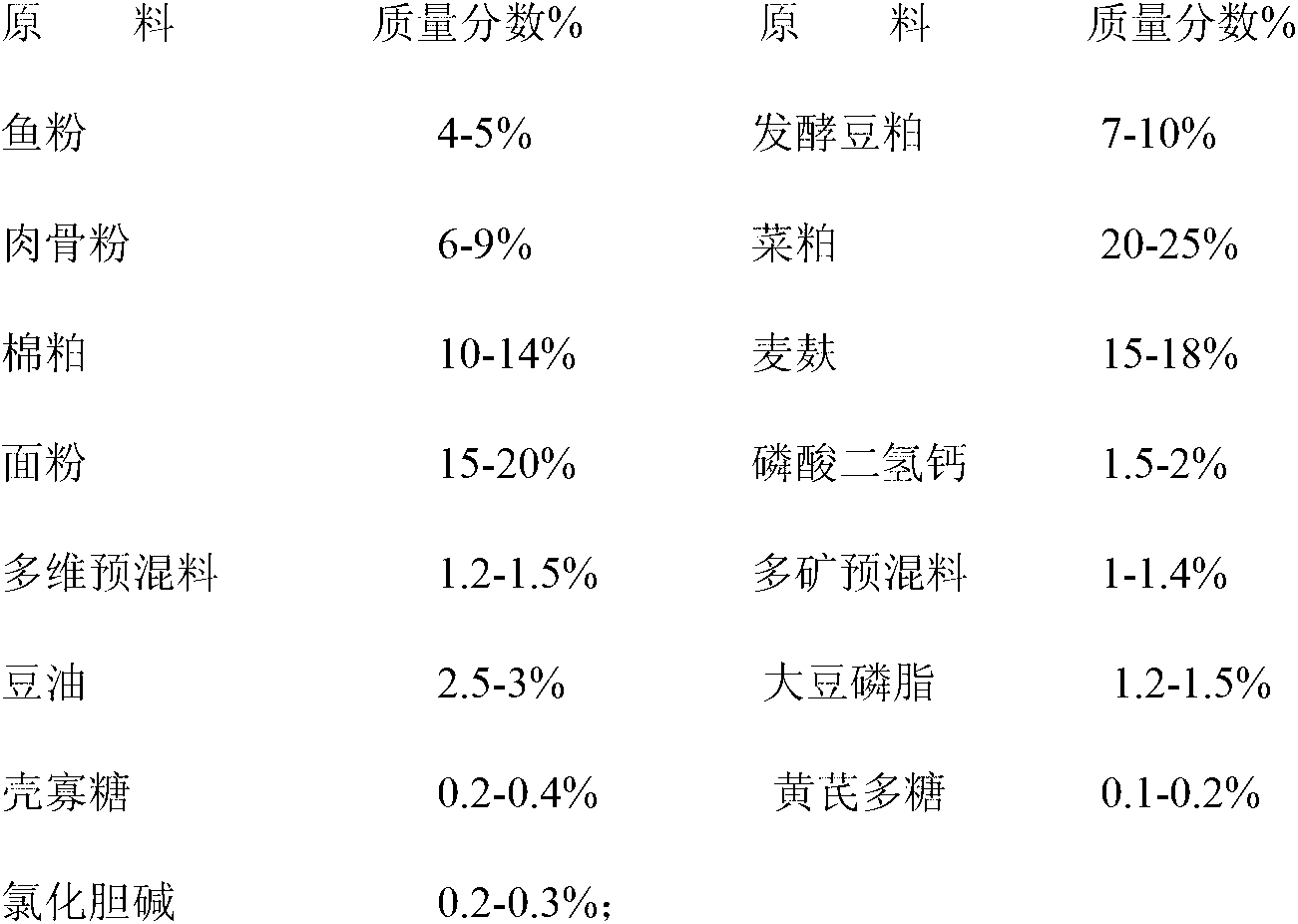

The invention discloses a compound feed for preventing fatty liver of tilapia and a preparation method of the feed. The compound feed is prepared from the following raw materials according to a certain proportion: fish meal, fermented soybean meal, meat and bone meal, rapeseed meal, cottonseed meal, wheat bran, wheat flour, calcium dihydrogen phosphate, multi-vitamin premix, multi-mineral premix, soybean oil, soybean lecithin, chitosan oligosaccharide, astragalus polysaccharide and choline chloride. The preparation comprises the following steps of: respectively crushing and screening all the raw materials (except the soybean oil) by a crushing machine, weighing the flour, the calcium dihydrogen phosphate, the multi-vitamin premix, the multi-mineral premix, the soybean lecithin, the chitosan oligosaccharide, the astragalus polysaccharide, the choline chloride and other raw materials according to the mass fraction in the formula and mixing uniformly, further weighing the remaining raw materials, uniformly stirring and mixing, fully uniformly mixing with water, performing extrusion and pelletization by a feed machine, and drying at the temperature of 55-60 DEG C to prepare the feed for the tilapia. The compound feed has balanced nutrition, is suitable for requirements of healthy growth of the tilapia and can further reduce the accumulation of fat in livers of the tilapia and improve disease resistance of the tilapia.

Owner:YANGTZE RIVER FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Porket creep feed and production method thereof

InactiveCN101617783AMeet nutritional needsImprove palatabilityFood processingAnimal feeding stuffSucroseAnimal science

The invention discloses porket creep feed and a production method thereof. The feed comprises the following components in percentage by weight: 30.0 expanded corns, 30.0 high-quality corns, 12.0 high-protein soybean meal, 4.5 whole milk powder, 4.0 fermentative soybean meal, 3.0 expanded soybeans, 3.0 Chilean white fish meal, 3.0 plasma protein powder, 3.0 acidifying agents, 2.0 sugar, 1.2 stone powder, 1.0 calcium dihydrogen phosphate, 1.0 grade-IV soyabean oil, 0.12 methionine, 0.4 lysine, 0.10 threonine, 0.18 salt, 1.0 porket additives and 0.5 medicament additives. The production method comprises the following steps: crushing the high-quality corns, the high-protein soybean meal and the Chilean white fish meal at one time, granulating at a high temperature and cooling; carrying out secondary crushing after the granulated and cooled high-quality corns, the high-protein soybean meal and the Chilean white fish meal are mixed with the expanded corns and the expanded soybeans; carrying out tertiary mixing with other components of the feed according to the weight percentage and granulating at a low temperature; and packaging and warehousing. The invention optimizes the quality of the porket creep feed, improves the stability and the palatability of the feed, strengthens the digestion and absorption and the availability of nutrition, promotes the health growth of porkets and effectively controls diarrhea, growth retardation, and the like.

Owner:江苏华威农牧发展有限公司

Piglet creep feed

InactiveCN102100315AImprove immunityReduce emergency responseFood processingAnimal feeding stuffSucroseChemistry

The invention discloses a piglet creep feed, which comprises the following components in part by weight: 15 to 25 parts of fish meal, 15 to 25 parts of cane sugar, 5 to 10 parts of lysine, 15 to 25 parts of intestine membrane protein, 30 to 45 parts of cheese powder, 25 to 35 parts of plasma protein powder, 35 to 45 parts of whey powder, 1 to 3 parts of salt, 8 to 12 parts of piglet creep feed premix, 180 to 220 parts of puffed soybean, 5 to 10 parts of milk carbon calcium, 550 to 590 parts of puffed rice meal, 2 to 4 parts of slow-release zinc oxide, 15 to 25 parts of glucose, 2 to 4 parts of acidulating agent, and 7 to 12 parts of calcium dihydrogen phosphate. The piglet creep feed can induce piglets to eat the feed early so as to improve the immunity of the piglets, reduce the emergency response after weaning and avoid growth cessation; and the components of the piglet creep feed are similar to the components of pig breast milk.

Owner:TIELING SHUGUANG AGRI DEV GROUP DANONGYOU FEED

Special penaeus orientalis functional biological feed in the thickness marking period

The present invention discloses a special penaeus orientalis functional biological feed in the thickness marking period and the functional biological feed consists of the following components: import fish meal, shrimp meal, fermented peanut meal, fermented soybean meal, yeast lysates, cuttlefish powder, high gluten flour, calcium dihydrogen phosphate, soybean lecithin, fish oil, vitamin-mineral premixes, probiotics and functional additives; wherein the probiotics consist of Bacillus subtilis subsp., Candida utilis yeast and Bifidobacterium longum; the functional additives are made of natural astaxanthin, linolenic acid, fermented chlorella and fermented spirulina. The functional biological feed aims at the physical characteristics of high density, high nutrition and fast growth of penaeus orientalis seedlings in the thickness marking period, uses high-quality animal protein, contains high levels of unsaturated fatty acids and bio-fermentation raw materials, is rich in lecithin, has a reasonable balance ratio of calcium and phosphorus, and fortified vitamin nutrition, adds immunoenhancers, living beneficial bacteria and digestive enzymes, promotes the rapid growth, enhances disease resistance and improves survival rate of penaeus orientalis seedlings which have strong body constitution and tidy specifications, and lay a solid foundation for subsequent successful breeding.

Owner:YANTAI DALE FEED CO LTD

High-immune anti-stress turtle complete feed

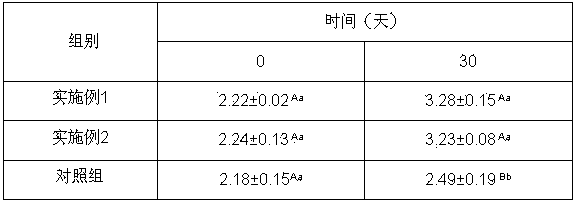

ActiveCN103039730AImprove survival rateImprove stress resistanceAnimal feeding stuffAnti stressVitamin C

The present invention relates to a high-immune anti-stress turtle complete feed, including a base material. The base material includes red fish meal, white fish meal, cod meal, skim fish meal, chicken meal, alpha-starch, fermented soybean meal, extruded soybean, vital gluten and yeast wall-broken meal; and further comprises by weight: 1.2-2% of calcium dihydrogen phosphate, 0.3-0.6% of choline chloride, 0.4-0.6% of glucose, 0.15-0.4% of compound probiotics, 0.1-0.2% of vitamin C, 0.2-0.3% of a compound hepatobiliary preparation, 0.2-0.3% of compound immunopotentiator, 2.5-3.5% of compound vitamins, and 5-6.5% of a compound mineral salt. By using the feed, the survival rate and anti-stress of the turtle can be significantly improved, the occurrence of white abdominal shell, leukoderma and enteritis of the turtle is reduced, specification and quality of the products are improved, and the economic efficiency is increased.

Owner:深圳市澳华集团股份有限公司

Sinking extruded granular feed of penaeus uannamei and preparation method thereof

InactiveCN101779723AReduce feed factorStrong changes in physical and chemical propertiesAnimal feeding stuffAnti nutrientsSteam pressure

The invention discloses sinking extruded granular feed of penaeus uannamei. The density of the sinking extruded granular feed is more than 1.03, and the curing degree is 100 percent. Brown fishmeal, squid liver paste, shrimp shell meal, flour, not-genetically-modified soybean meal, canola meal, peanut meal, cassava block, mineral gunk, vitamin gunk, calcium dihydrogen phosphate, fish oil, calcium propionate, phospholipids oil and DDGS are adopted as raw materials, the feed base stock which is proportioned by weight part is regulated for 160 to 200 seconds by a double-shaft extruding full-curing bulking machine under the conditions that the steam pressure is 0.4 to 0.5MPa, the moisture is 19 to 23 percent and the temperature is 85 to 90 DEG C, and then is cured at a curing temperature of 135 DEG C, the cavity pressure of 3MPa and the curing time of 90 to 120 seconds. The sinking extruded granular feed has fewer animal raw materials and has low feed coefficient which is less than or equal to 1.1. All anti-nutrient factors in the feed are completely destroyed, the stability in the water is more than 12 hours, and the feed is completely cured.

Owner:NINGBO TECH BANK

Lobster feed capable of purifying water and improving immunity and preparation method of lobster feed

InactiveCN104489354AImprove survival rateNutritional balanceFood processingAnimal feeding stuffBiotechnologyDisease

The invention discloses a lobster feed capable of purifying water and improving immunity. The lobster feed is prepared from the following raw materials in parts by weight: 3-5 parts of garlic, 1-3 parts of calcium dihydrogen phoshate, 2-3 parts of tender leaves of fennel, 4-6 parts of banana skin, 2-4 parts of villous amomrum fruit, 3-5 parts of cluster mallow fruit, 3-4 parts of sargassum thunbergii, 4-6 parts of dehydrated spinach, 2-4 parts of cinnamon, 6-8 parts of cuttleflsh bone, 5-8 parts of wheat middling, 20-30 parts of rapeseed dregs, 15-20 parts of meat and bone meal, 4-6 parts of stevioside and 6-10 parts of an assistant. The lobster feed disclosed by the invention is balanced in nutrient; due to addition of the rapeseed dregs, the meat and bone meal and the like, most of basic nutrients required by the lobster can be supplemented; the added stevioside is high in sweetness, and long in duration, and can play a good attractant effect; due to addition of villous amomrum fruit, the cluster mallow fruit and the like, the disease resistance of the lobster is further enhanced; and the survival rate of the lobster is increased.

Owner:全椒县赤镇龙虾经济专业合作社

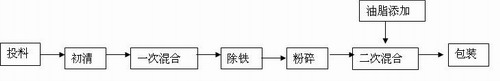

Compound feed for young soft-shelled turtles and preparation method thereof

The invention provides a compound feed for young soft-shelled turtles and a preparation method thereof. The compound feed comprises fish meal, alpha-starch, fermented soya bean meal, fish oil, yeast, methionine, lysine, milk powder, yolk powder, composite mineral premix for feed of the soft-shelled turtles, composite vitamin premix for the feed of the soft-shelled turtles, calcium dihydrogen phosphate, an enzyme preparation and a Chinese medicinal additive. The preparation process comprises the following steps of: feeding; cleaning for the first time; mixing for the first time; removing iron; pulverizing; mixing for the second time and packaging. The compound feed and the preparation method thereof have the advantages of improving disease resistance of the young soft-shelled turtles, selecting high-digestibility feed raw materials, increasing conversion rate of the feed, reducing the emission of pollutant of nitrogen, phosphorus and the like, reducing pollution of culture water, reducing disease of the young soft-shelled turtles, reducing the using amount of pesticide, meeting the requirement of ecologic cultivation at last, increasing adsorption and utilization rate, meeting the nutritional requirement of the young soft-shelled turtles, reducing cultivation cost, and reducing pollution on water, along with scientific and reasonable formula, scientific and reasonable preparation method and obvious economic benefit and environmental benefit.

Owner:FUJIAN ZHENGYUAN FEED

Low fish meal compound feed capable of improving ingestion rate of cultured weever

The invention provides a low fish meal compound feed capable of improving ingestion rate of cultured weever. The compound feed consists of the following components in part by weight: 26 to 31 parts of fish meal, 2 to 10 parts of whole shrimp powder, 12 to 16 parts of soy protein concentrate, 8 to 12 parts of fermented bean pulp, 9 to 12 parts of peanut cake, 20 to 23.5 parts of strong flour, 0.8 to 1.2 parts of calcium dihydrogen phosphate, 1.5 to 2 parts of fish oil, 1 to 2 parts of bean oil, 2 parts of vitamin and mineral salt premix, 0.2 to 0.4 part of betaine, 0.3 to 0.5 part of taurine, 0.05 to 0.1 part of citric acid, 0.3 to 0.5 part of Chinese asafetida, 0.1 to 0.2 part of glycine, 0.5 to 1 part of glutamic acid, and 0.05 to 0.12 part of alanine. The low fish meal compound feed canpromote ingestion and food digestion of fish, so that the utilization rate of the feed is improved, the coefficient of the feed is reduced, and the raising cost is reduced.

Owner:湛江粤华水产饲料有限公司

Fishmeal-free buoyant puffed feedstuff for micropterus salmoides and preparation method of feedstuff

The invention discloses fishmeal-free buoyant puffed feedstuff for micropterus salmoides and a preparation method of the feedstuff. One thousand kilograms of feedstuff comprises the following components: 41-53 kg of dephenolized cottonseed protein, 20-30 kg of spray-dried animal blood cells, 200-240 kg of soy protein concentrate, 180-220 kg of rice protein powder, 150-170 kg of fish soluble protein, 30-32 kg of calcium dihydrogen phosphate, 30kg of wheat gluten protein, 220kg of wheat flour, 20kg of lecithin oil, 30kg of fish oil, 5kg of fish trace elements, 2.5kg of betaine hydrochloride, 3kg of salt, 1.75kg of multi-vitamines for fish, 1kg of choline chloride, 1kg of L-carnitine, 1kg of a mildew inhibitor, 1.55kg of zeolite powder, and 0.2kg of ethoxyquinoline. The feedstuff use animal by-products and vegetable proteins to replace fish meal feedstuff, and the various raw materials are in synergistic combination to achieve cost minimization and benefit maximization of the feedstuff and solve the problem of high breeding cost.

Owner:SHANGHAI NONGHAO FEED

Channel catfish immunity enhancing feed

ActiveCN104187085APromote rapid growthImprove digestion and absorption rateClimate change adaptationAnimal feeding stuffAdditive ingredientSpecific immunity

The invention discloses a channel catfish immunity enhancing feed, which comprises the following components in parts by weight: 5-14 parts of meat and bone meal, 15-25 parts of rapeseed meal, 20-40 parts of de-hulled soybean meal, 0.2-0.5 part of choline chloride, 15-22 parts of wheat middling, 0.5-1 part of soybean oil, 0.2 part of vitamin premix, 0.15 part of mineral premix, 1-2 parts of calcium dihydrogen phosphate, 0.01-0.03 part of plant enzyme, 0.05-0.1 part of cholate substances, 0.03-0.06 part of a toxin adsorbent, 0.1-0.3 part of a natural plant compound and 0.1-0.3 part of a polysaccharide compound. According to the immunity enhancing feed disclosed by the invention, nonspecific immunity of the channel catfish is enhanced through various compounds, and through reasonable proportioning of various natural plants and the polysaccharide components, nonspecific immunity of the channel catfish is significantly improved and infection resistance of the fish is enhanced; and meanwhile, growth performance of the fish is improved and a food coefficient is reduced.

Owner:广州市海维饲料有限公司

A high-sugar and low-protein tilapia feed

InactiveCN102265983AIncrease dosageLow in proteinFood processingClimate change adaptationRapeseedVitamin B6 synthesis

The invention discloses a high-sugar and low-protein tilapia feed. Based on the total mass fraction of 100%, it consists of the following components: fish meal: 0-3%, soybean meal: 16-20%, rapeseed meal: 18-21%, cotton meal: 12-16%, secondary meal: 39- 42%, soybean oil: 2-3%, choline chloride: 0.2-0.5%, sodium chloride: 0.1-0.5%, calcium dihydrogen phosphate: 1-2%, vitamin B1: 0.004-0.006%, vitamin B6: 0.002-0.004%, zinc sulfate: 0.02-0.04%, chromium chloride: 0.0001-0.0003%, vitamin premix: 0.1-0.2% and mineral premix: 0.5-1%. The invention maximizes the amount of secondary powder in the feed, adds several plant protein sources to overcome the problem of amino acid imbalance of a single protein source, and at the same time significantly reduces the amount of fish meal. By optimizing and adjusting the feed formula, supplementing suitable vitamin and mineral premixes to adjust the sugar utilization ability of tilapia, so that the tilapia can make good use of the sugar compound of the present invention, avoiding the damage of fish liver caused by high sugar, Fatty liver is formed, and even the fish body becomes obese, and the symptoms of "big belly" appear.

Owner:广东省农业科学院畜牧研究所 +1

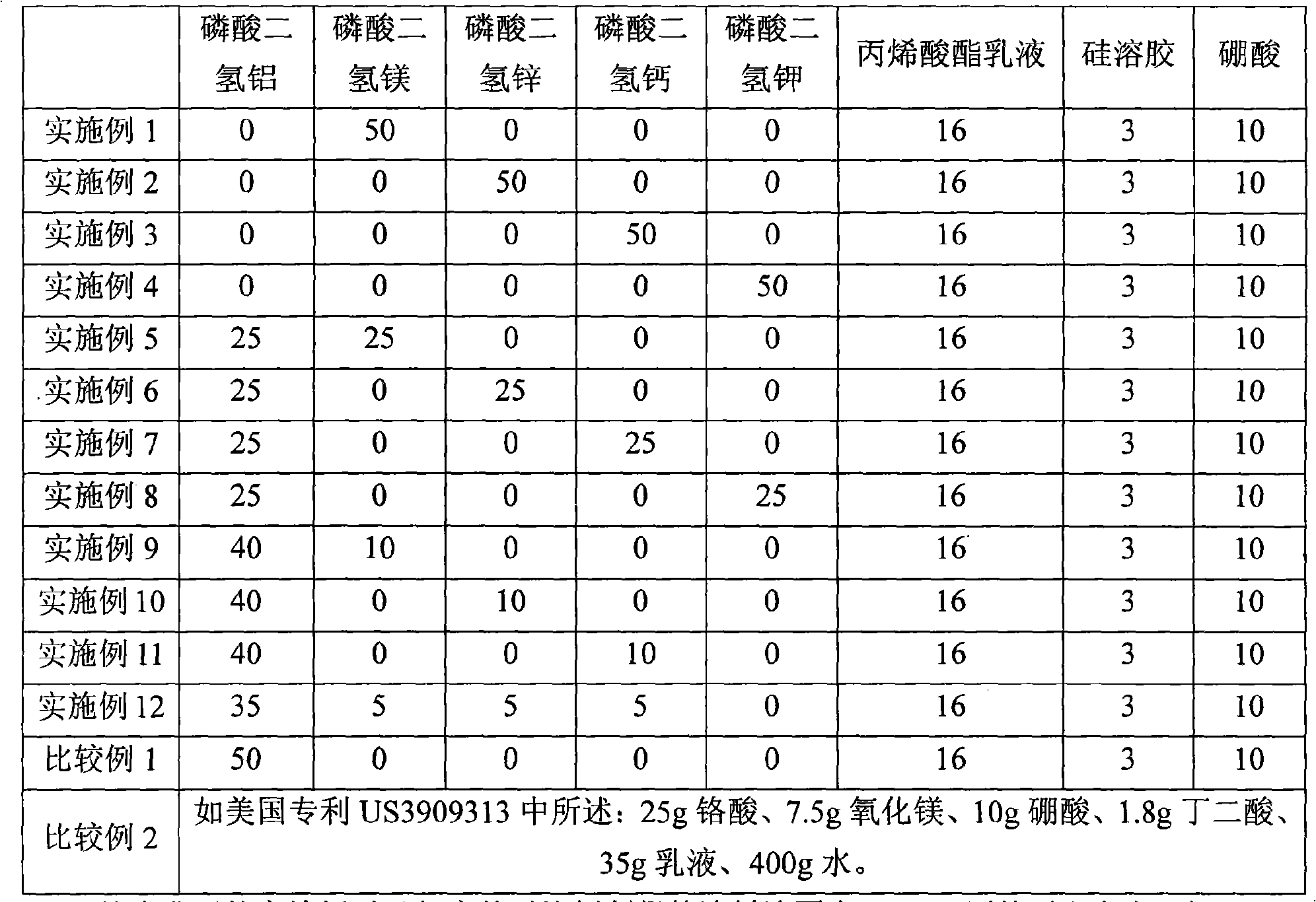

Non-oriented electrical steel chromium-free insulating environment-friendly coating and preparation method of coat thereof

ActiveCN101591495AImprove heat resistanceLow Free Phosphorus ContentLiquid surface applicatorsCoatingsMonomagnesium phosphateChromium free

The invention relates to a non-oriented electrical steel chromium-free insulating environment-friendly coating and a preparation method of a coat thereof, and belongs to the technical field of electrical steel coatings. The non-oriented electrical steel chromium-free insulating environment-friendly coating comprises the following compositions calculated by dry weight: 0 to 70 percent of aluminium dihydrogen phosphate, 0 to 70 percent of monopotassium phosphate, 0 to 70 percent of zinc dihydric phosphate, 0 to 70 percent of monocalcium phosphate, 0 to 70 percent of magnesium dihydrogen phosphate, 5 to 30 percent of acrylate emulsion, 1 to 20 percent of boric acid and 0.5 to 6 percent of silica sol; and the percent being weight percent. The coating is an environment-friendly coating not containing chromium; and the prepared coat has bright and even surface, good insulation property, adhesiveness and heat resistance, and also has the advantages of small moisture absorption and strong rust prevention capacity.

Owner:SHOUGANG CORPORATION

Health-care grass carp fingerling feed

InactiveCN104146188AImprove survival ratePromote healthy growthFood processingClimate change adaptationPeanut mealCorn meal

The invention discloses health-care grass carp fingerling feed. The health-care grass carp fingerling feed is characterized by the following components: green alfalfa whole plant powder, green soybean whole plant meal, ryegrass powder, soybean meal, peanut meal, wheat bran flour, corn meal, fish meal, pupa powder, bone and meat meal, spirulina powder, carrot powder, edible salt, calcium dihydrogen phosphate and Chinese herbal additives. The grass carp fingerling feed can increase the survival rate of grass carp fingerling in the grass carp fingerling cultivating state effectively, promote the grass carp fingerling to grow healthily, protect the grass carp fingerling from liver and gallbladder discomfort, and expel pests in an intestinal canal of the grass carp fingerling, so that adverse phenomenon caused by large-scale use of chemical drugs in the grass carp fingerling cultivating stage is avoided, the immune function of the fish body is improved and a high-quality and healthy grass carp fingerling is provided for cultivation of adult grass carps.

Owner:杨成胜

Compound feed for young grass carps

ActiveCN101869211AMeet nutritional needsImprove stabilityAnimal feeding stuffAquatic animalPea protein

The invention provides a compound feed for young grass carps, which relates to a feed for aquatic animals, in particular to a feed for fishes. The compound feed comprises the following raw materials in mass percent: 5-15% of steamed fish meal, 20-30% of strong flour, 15-25% of bean pulp, 4-8% of soybean protein concentrate, 1-4% of pea protein powder, 8-15% of peanut meal, 15-25% of rapeseed meal, 1-3% of fish oil, 1-3% of bean oil, 0.1-0.3% of choline chloride, 1-2% of calcium biphosphate, 0.1-0.2% of garlicin, 0.1-0.2% of glucan, 0.5-1.0% of zeolite powder, 1-3% of wheat shorts, 0.2-0.3% of compound vitamin and 2-4% of compound mineral. Compared with the prior art, the feed product of the invention has balanced nutrition, can meet the requirement of young grass carps for nutrition in the process of growth, has good palatability and high feed intake rate, has good stability in water, and can not pollute the water quality of aquaculture water easily.

Owner:GUANGDONG TONGWEI FEED

High-protein-content growth-promoting environment-friendly fish feed and preparation method thereof

InactiveCN105767594APromote growthPromote reproductionClimate change adaptationAnimal feeding stuffSynbioticsPhytase

The invention discloses a high-protein-content growth-promoting environment-friendly fish feed. The high-protein-content growth-promoting environment-friendly fish feed comprises the following raw materials: bean cakes, cotton meal, corns, bran, fish meal, rapeseed cakes, spirulina powder, seaweed powder, wheat middling, polygonatum sibiricum powder, fish oil, calcium lactate, calcium dihydrogen phosphate, lysine, methionine, aspartic acid, glutamic acid, a vitamin mixture, minerals, phytase, synbiotics, a traditional Chinese medicine compound additive and a food attractant. The high-protein-content growth-promoting environment-friendly fish feed is rich in nutrition, and rich in contents of proteins, amino acids, vitamins, probiotics and growth substances; thus, the high-protein-content growth-promoting environment-friendly fish feed is capable of effectively promoting growths and breeding of the fishes, and improves yields and qualities of the fishes.

Owner:LIANYUNGANG HENGTU FARMING DEV CO LTD

Compound feed for ietalurus punetaus

InactiveCN101238860AReduce wasteIncrease profitFood processingClimate change adaptationPhosphateAdditive ingredient

The invention discloses a Ictalurus punctatus compound feed, the contents of mass ratio of characteristic materials are as follows: vitamin A 0.005-0.007, vitamin D3 0.004-0.006, vitamin E 0.070-0.090, vitamin K3 0.002-0.004, vitamin B1 0.003-0.005, vitamin B2 0.005-0.007, vitamin B6 0.08-0.012, vitamin B12 0.001-0.003, nicotinamide 0.030-0.050, calcium pantothenate 0.10-0.30, folic acid 0.01-0.03, biotin 0.001-0.002, VC-phosphate 0.300-0.400, inositol 0.070-0.090, antioxidants 0.200-0.300, wheat-middlings 1.000-1.200, ferrous sulfate 0.400-0.600, copper sulfate 0.010-0.030, zinc sulfate 0.150-0.200, manganese sulfate 0.100-0.150, iodine 0.050-0.150, Se 0.050-0.070, cobalt chloride 0.010-0.030, magnesium sulfate 1.000-1.500, zeolite powder 5.0-6.0, xylo-oligosaccharide 0.008-0.012, bacillus licheniformis 0.01, weatings 90.-110., wheat-middlings 110-130, rice bran 75-85, soy bean powder 55-65, soybean meal 190-210, peanut meal 25-35, fish meal 95-105, cottonseed meal 75-85, rapeseed meal 110-130, gem meal 45-55, soybean oil 15-25, lysine 0.8-1.2, methionine 0.8-1.2, salt 2.0-2.5, betaine 3-5, allicin 0.1-0.3, choline chloride 1.0-2.0, calcium dihydrogen phosphate 15-25. Compared with other feeds, the usage rate of feed nutrient ingredients for Ictalurus punctatus is increased by 10-15%, feed coefficient is reduced by 5-10%, feed waste is reduced, nitrogen and phosphorus excretion of Ictalurus punctatus in the environment is reduced, at the same time the survival rate of Ictalurus punctatus is improved significantly.

Owner:袁珍虎

Creep compound feed for piglets and preparation method thereof

ActiveCN102450519AImprove disease resistanceFast growthAnimal feeding stuffNutritionCholine chloride

The invention discloses a creep compound feed for piglets. The compound feed is prepared from the following raw materials in percentage by weight: 13-18% of corn, 23-27% of flour, 10-13% of broken rice, 15-20% of soybean meal, 1.5-2.5% of soybean oil, 6-10% of whey powder, 5-10% of glucose, 3-5% of plasma protein powder, 2-5% of fish meal, 2-5% of dried porcine solubles, 0.4-0.8% of calcium dihydrogen phosphate, 0.08-0.15% of common salt, 0.06-0.15% of sodium butyrate, 0.2-0.5% of acidifier, 0.05-0.15% of emulsifier, 0.02-0.05% of microecological matters, 0.03-0.07% of choline chloride and 0.8-1.5% of premix, wherein the sum of the percentages by weight of all the raw materials is 100%. The preparation method comprises the following steps: weighing all the raw materials in percentage by weight, and pouring into a pulverizer for pulverization, wherein the pulverization particle size is 30 meshes; and pouring into a mixing machine and uniformly mixing. The creep compound feed for the piglets, disclosed by the invention, has the beneficial effects of meeting the nutritional needs of the piglets during the creep period, being good in palatability and high in digestibility, and effectively preventing loss of flesh due to ablactation, diarrhea and underweight of the piglets.

Owner:SHANDONG NEW HOPE LIUHE GROUP

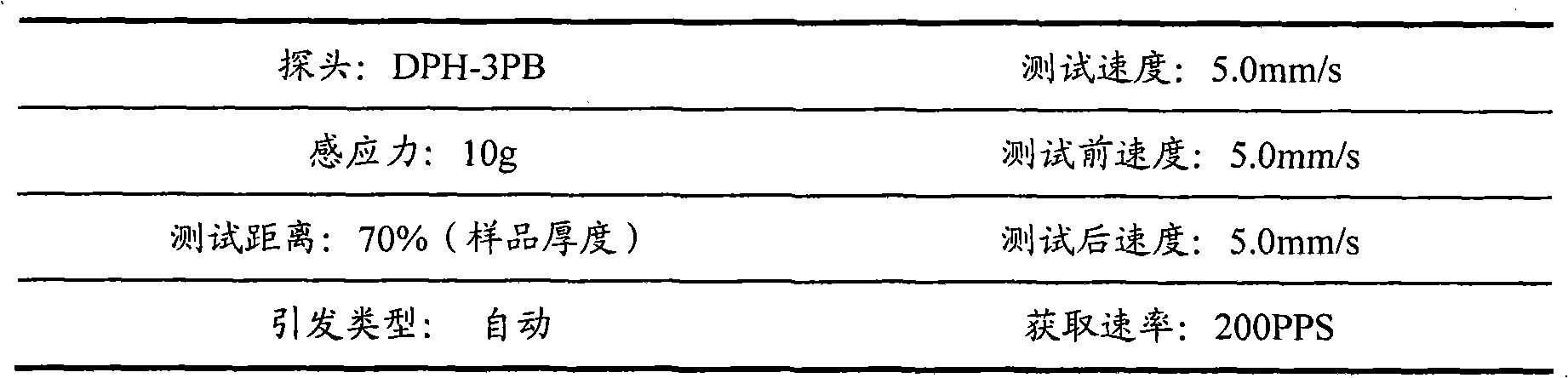

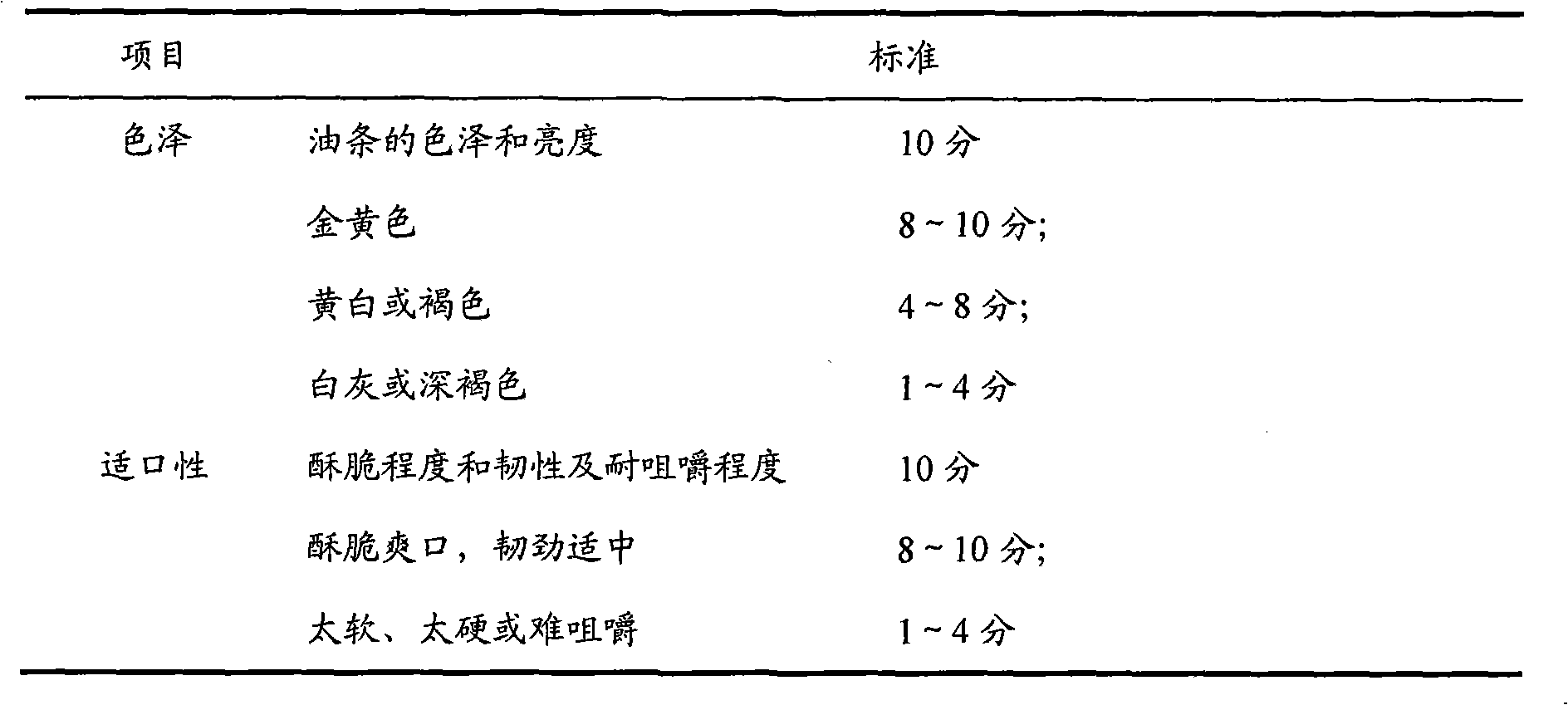

Method for preparing quick frozen deep-fried puffy dough strips

ActiveCN101816392AReduce usageImprove securityBakery productsFood preparationSodium bicarbonateAdditive ingredient

The invention relates to a method for preparing novel aluminum-free quick frozen deep-fried puffy dough strips. The method comprises the steps of: making dough by taking ingredients, such as gluconic acid-delta-lactone, calcium dihydrogen phosphate, sodium bicarbonate, glycerol monolaurate and the like, as a leavening agent and performing the processes of blanks making, frying, quick freezing and the like. Compared with the deep-fried puffy dough strips prepared by the traditional alums formula, the deep-fried puffy dough strips prepared by the method has the advantages that the evaluation result of sense organ is better, and the grease content is reduced by 9.7 percent, so that the process of the deep-fried puffy dough strips is simplified and convenient, the market is convenient to develop and the economic benefit is better.

Owner:JIANGNAN UNIV +2

Formulation and preparing method of expanded assorted feed for ophiocephalidae

InactiveCN101040668APromote rapid growthImprove digestion and absorption rateFood processingClimate change adaptationYeastWater quality

The invention relates to a formula of compound puffed feed for snakehead mullet and process for preparation, wherein the constituents in the formula comprise (by mass ratio): fish meal 35-50%, fermented soybean waste 10-20%, meat and bones meal 0-12%, silkworm chrysalis powder 0-5%, blood powder 0-5%, brewer's yeast 2-5%, shrimp grease 0-6%, fish oil 1.0-3%, high grade flour 10-20%, liquid phosphatide 1-2%, calcium dihydrogenphoshate 0.5-1.5%, composite vitamin 0.5-1%, compound minerals 0.5-1%, choline chloride 0.3-0.5%. The preparing process consists of proportioning constituents, mixing homogeneously, disintegrating, modulating, palletizing and drying.

Owner:GUANGDONG HENGXING GROUP

Environmental-protection type high performance compounding feed for perch

InactiveCN100998375APromote growthImprove bioavailabilityFood processingClimate change adaptationPhytaseFeed conversion ratio

A high-effect composite forage for perch frog is proportionally prepared from Bacillus subtitis, phytase, non-starch amylase, red fish powder, soybean dregs, peanut bran, bone powder, powdered ink fish gut, high-gluten wheat flour, soybean lecithin, soybean oil, sea fish fat, choline chloride, VC-phosphate, calcium dihydrogen phosphate, vitamin composition, and mineral salt composition.

Owner:GUANGDONG YUEHAI FEED GROUP

Special feed for loach and preparation method of same

The invention discloses a special feed for a loach. The special feed for loach is a dragon beard-shaped or granular soft feed and is prepared from the following raw materials in mass percentage: 20-30% of flour, 10-25% of soybean meal, 15-25% of rapeseed meal, 3-7% of fishmeal, 10-15% of cottonseed meal, 5-8% of soybean protein powder, 1-2% of soybean oil, 1-3% of calcium dihydrogen phosphate, 1-3% of premix, 5-8% of corn protein powder and 5-8% of corn protein feed. The invention further discloses a preparation method of the special feed for loach. The special feed for loach is reasonable in compatibility; the feed form adapts to body features and life habits of loach; the special feed for loach is lower in nutrient loss rate than expanded granular feed and softer than hard granular feed; the special feed for loach can effectively avoid a phenomenon of throat blockage caused by swallowing the hard granular feed; the loss rate of high nutrition is low and the utilization ratio of the special feed for loach is improved; the special feed for loach can effectively promote the growth rate of loach; the preparation method is more reasonable in process design and simple in process; and the obtained special feed for loach has the advantages of long service life, low nutrition loss rate and the like.

Owner:陈忆凤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com