Patents

Literature

66 results about "Monomagnesium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

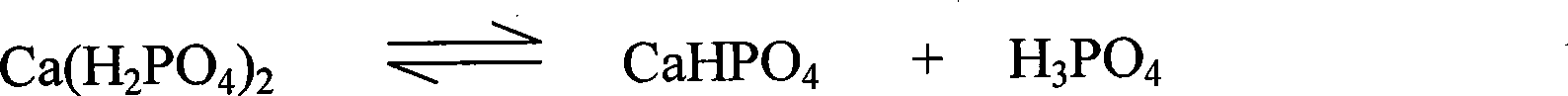

Monomagnesium phosphate is one of the forms of magnesium phosphate. It is a magnesium acid salt of phosphoric acid with the chemical formula Mg(H₂PO₄)₂. Di- and tetrahydrates are known also. It dissolves in water, forming phosphoric acid and depositing a solid precipitate of Mg(HPO₄).3H₂O, dimagnesium phosphate.

Formation of chemically bonded ceramics with magnesium dihydrogen phosphate binder

InactiveUS6776837B2Reduce solubilityLess energySludge treatmentSolid waste managementFiberSolubility

Owner:UCHICAGO ARGONNE LLC +1

Formation of chemically bonded ceramics with magnesium dihydrogen phosphate binder

InactiveUS20030092554A1Reduce solubilityLess energySludge treatmentSolid waste managementFiberSolubility

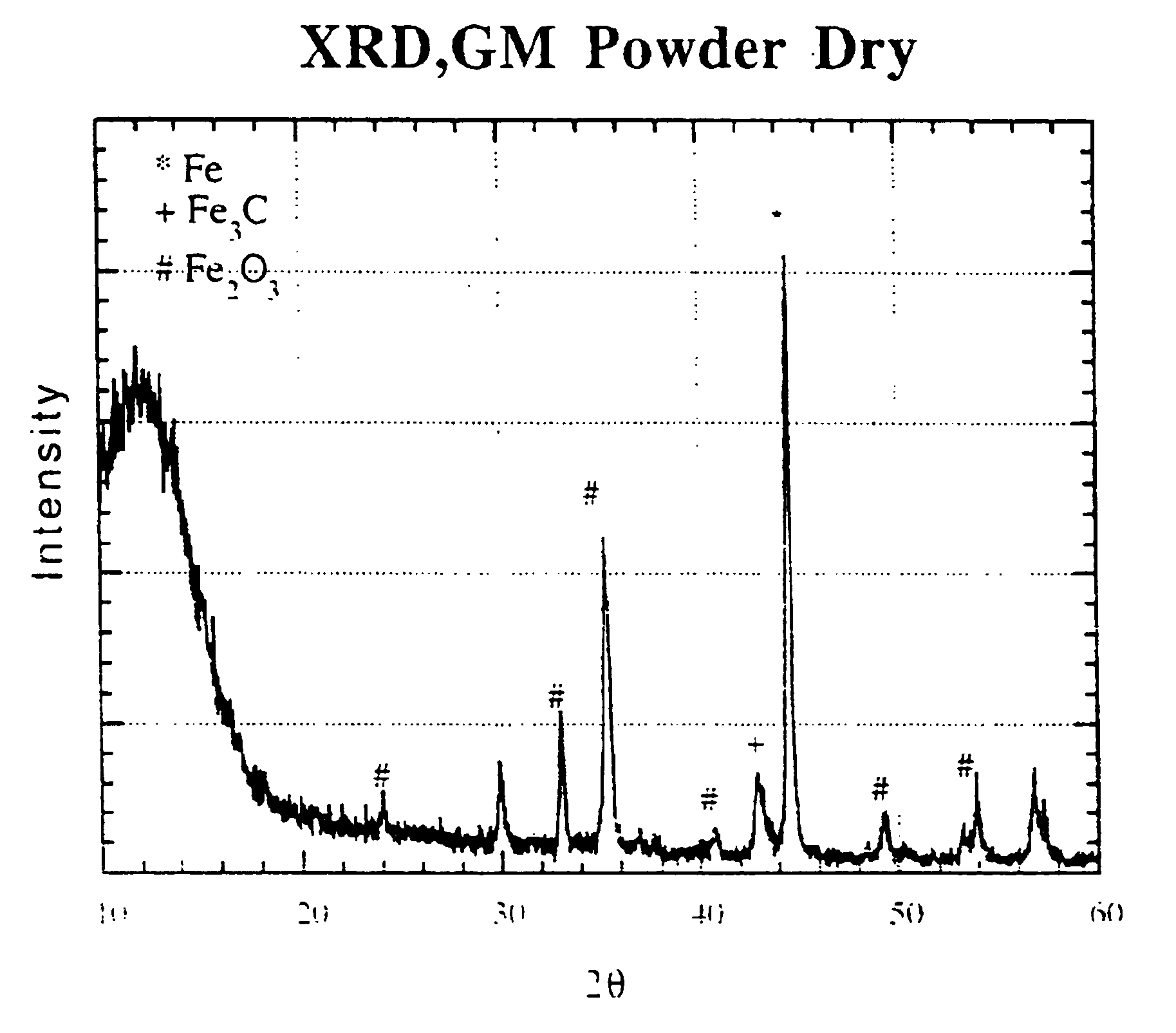

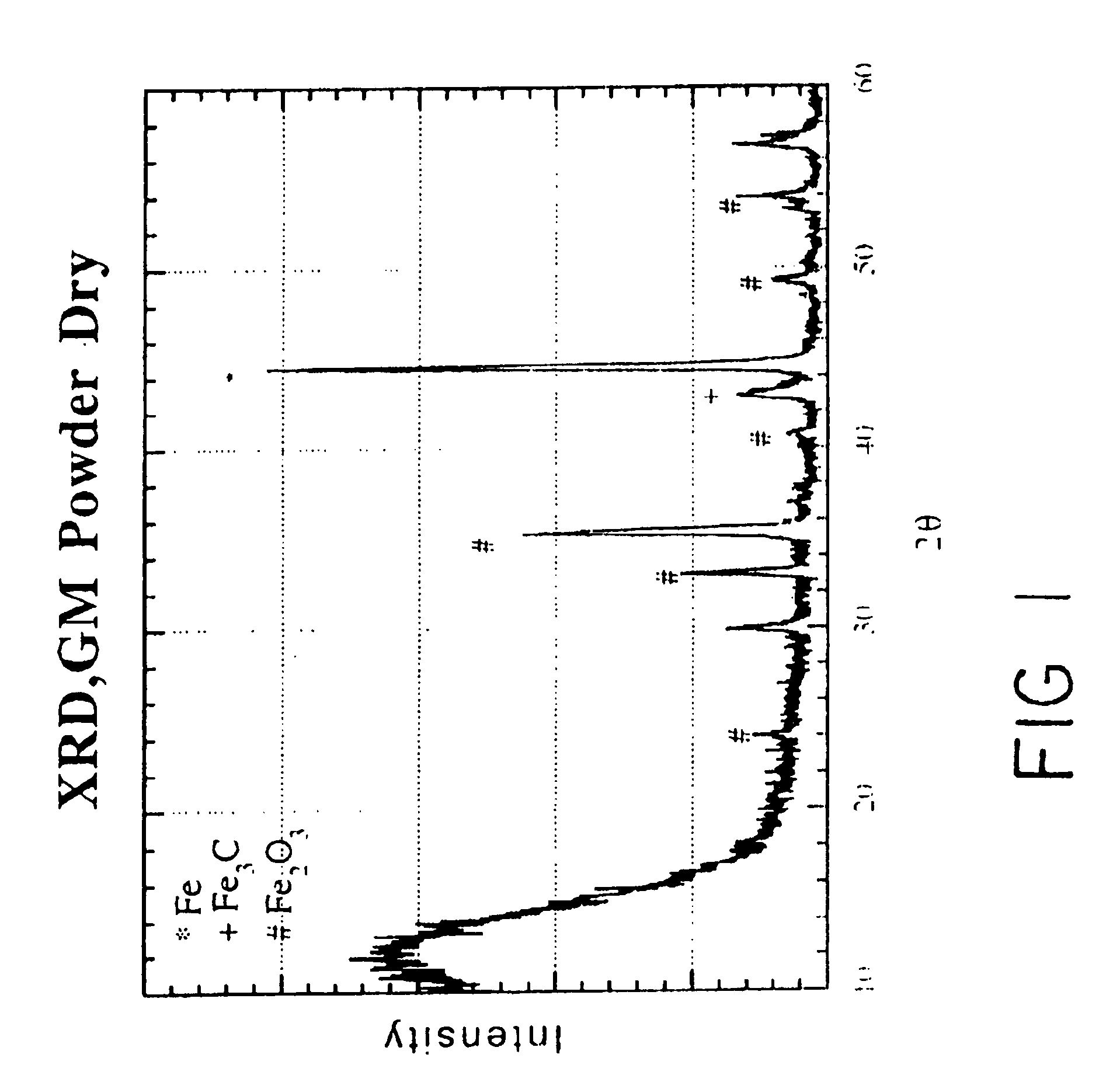

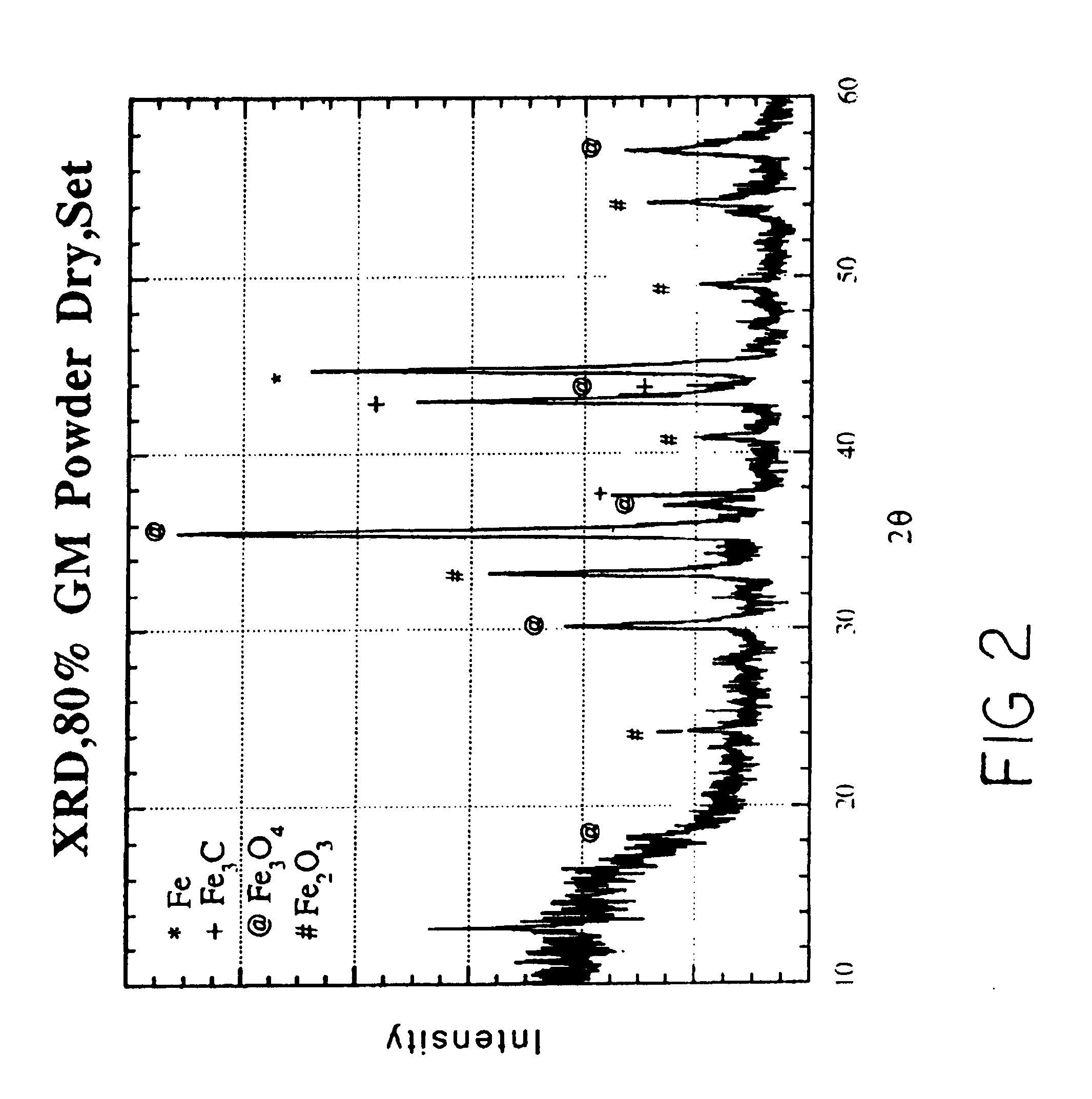

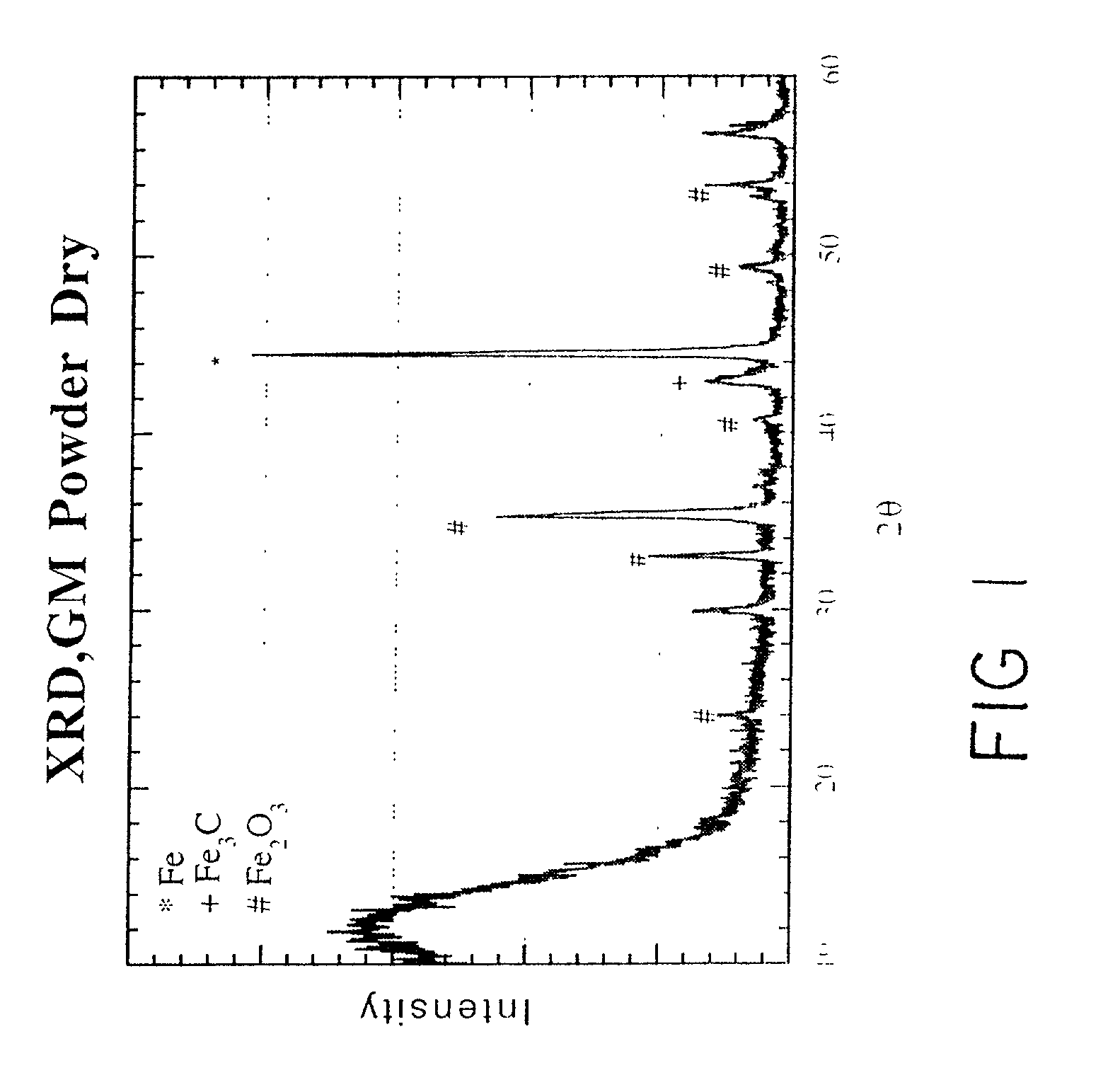

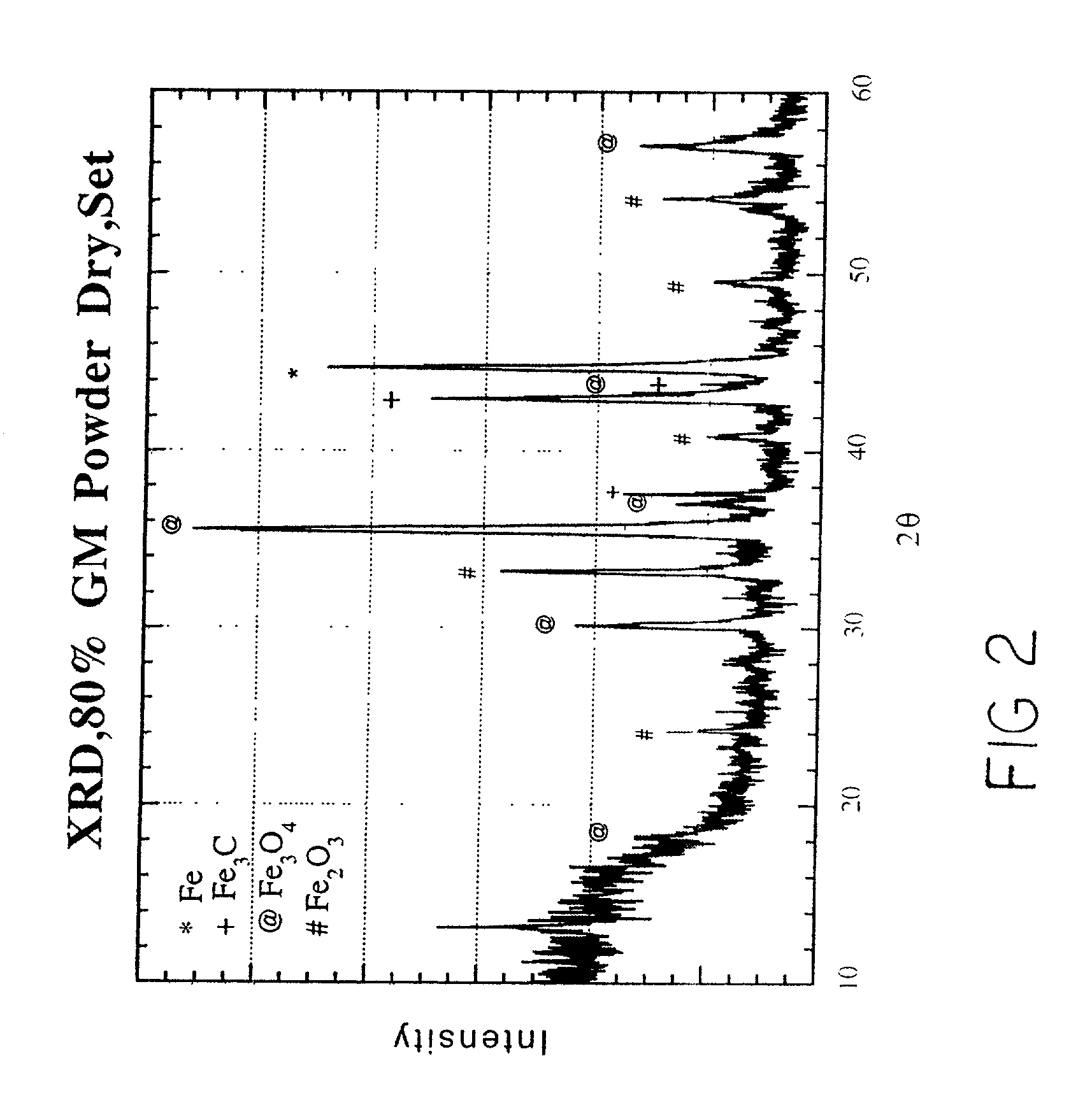

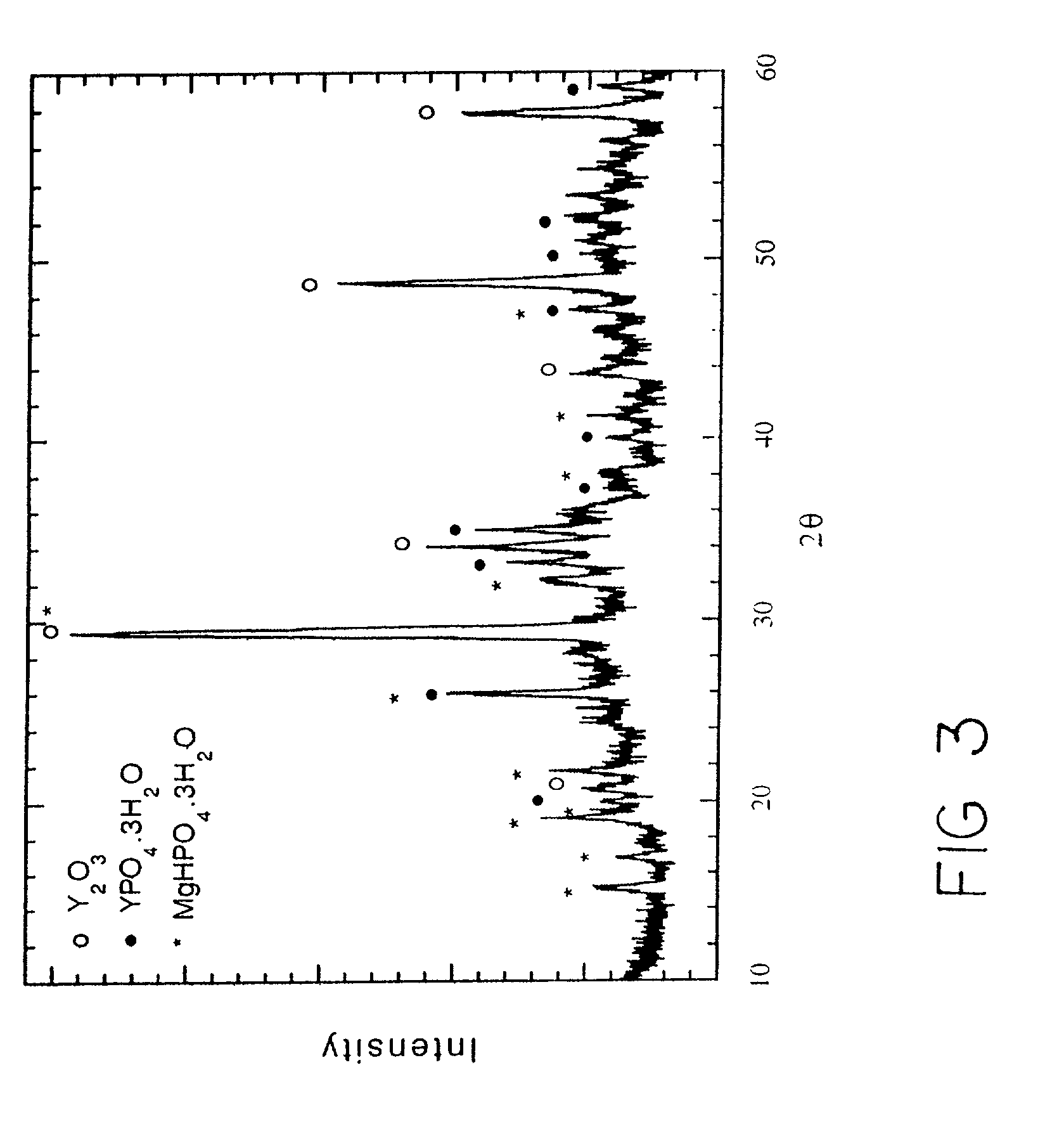

A new method for combining magnesium oxide, MgO, and magnesium dihydrogen phosphate to form an inexpensive compactible ceramic to stabilize very low solubility metal oxides, ashes, swarfs, and other iron or metal-based additives, to create products and waste forms which can be poured or dye cast, and to reinforce and strengthen the ceramics formed by the addition of fibers to the initial ceramic mixture.

Owner:UCHICAGO ARGONNE LLC +1

Method and compositions for improving performance properties of magnesium oxychloride cements

ActiveUS20130263759A1Improve water resistanceEarly water resistanceSolid waste managementMonomagnesium phosphatePhosphate

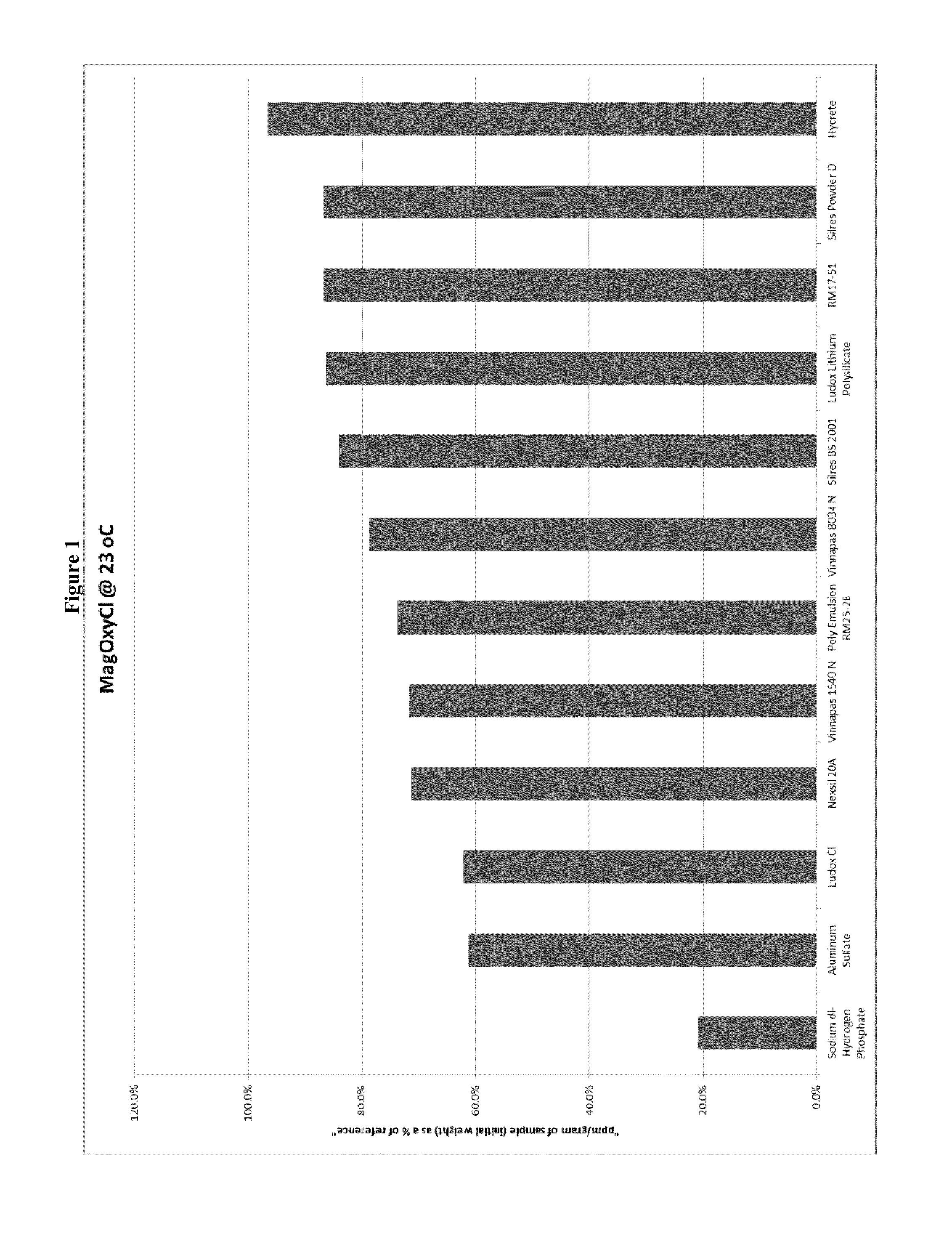

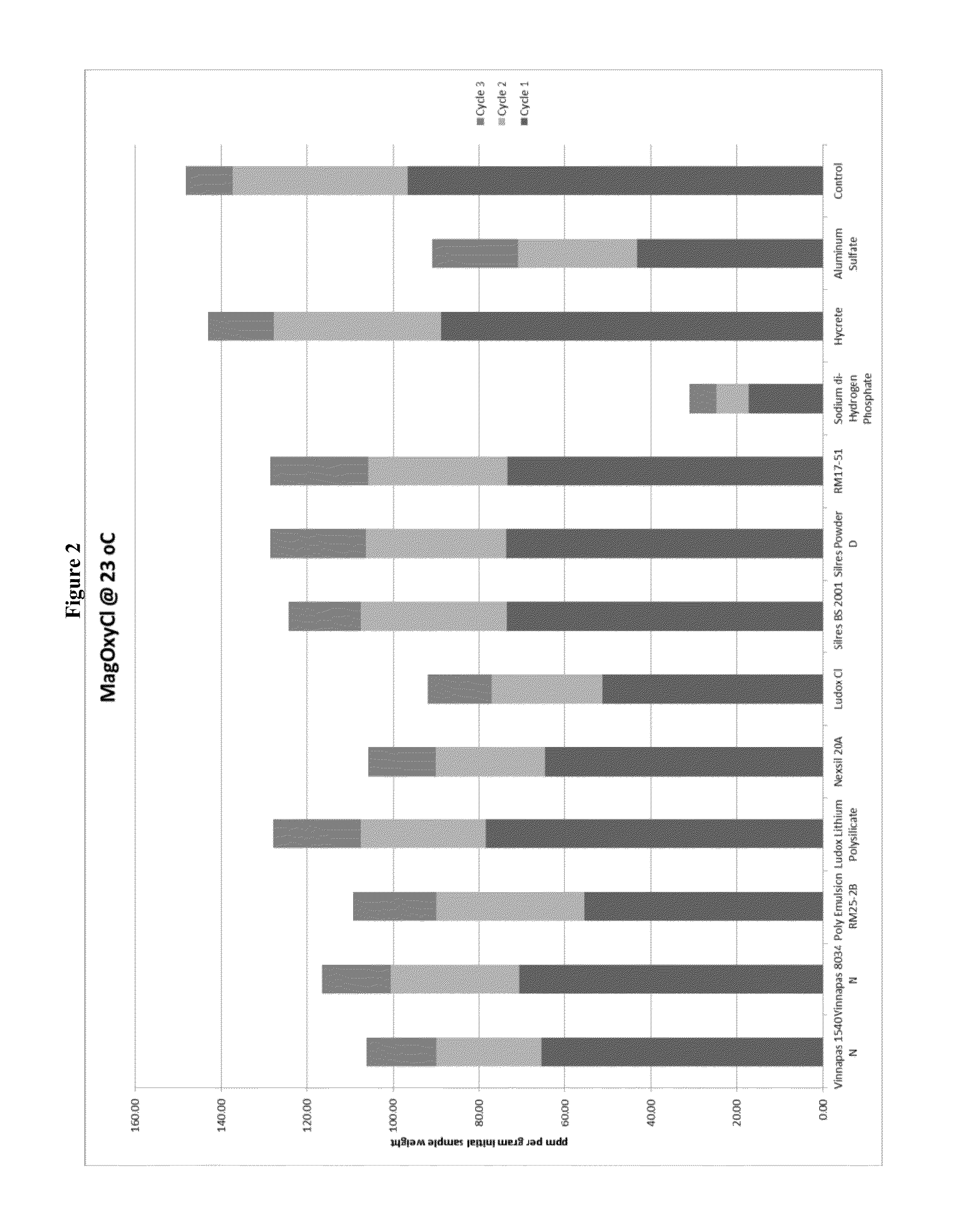

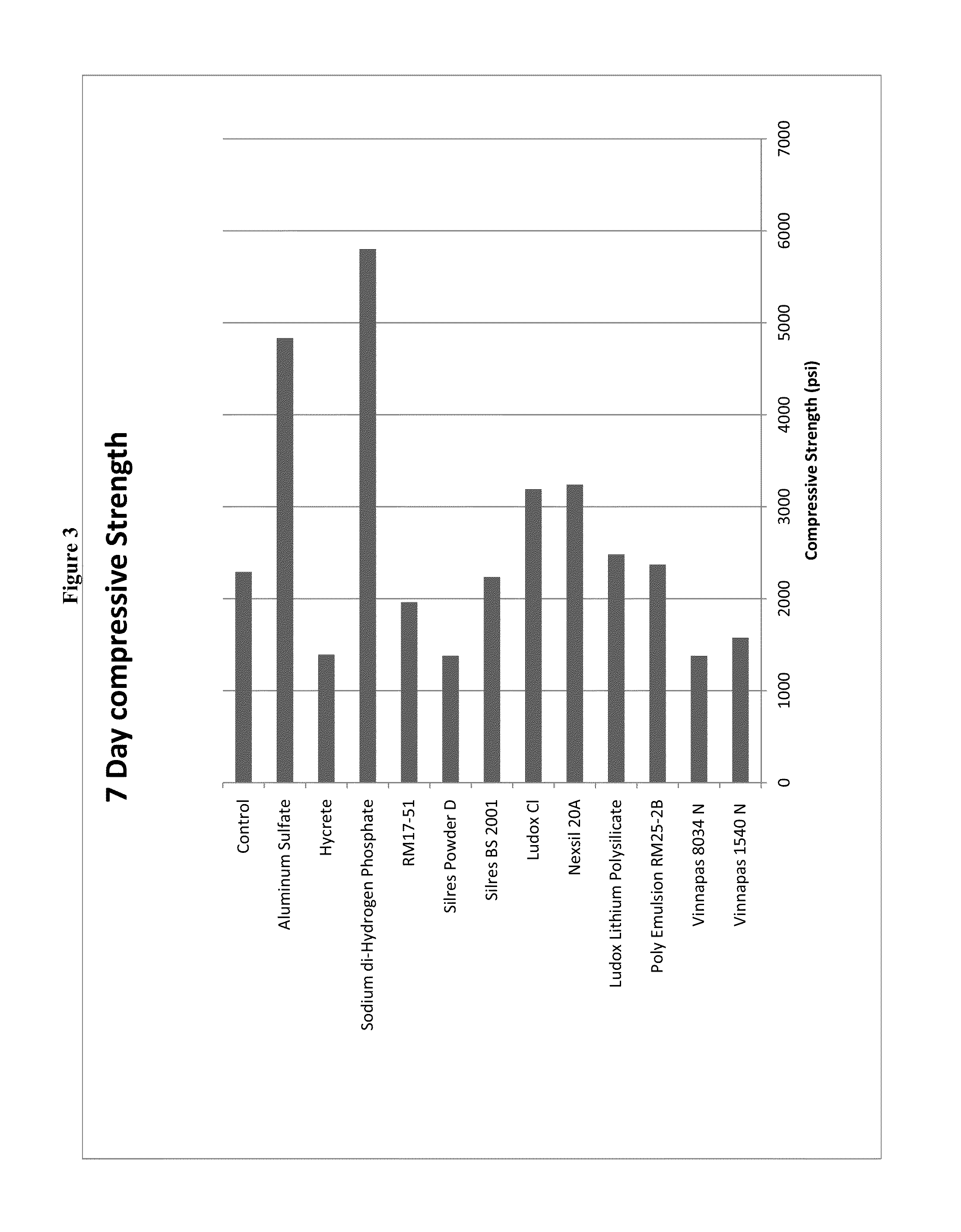

Despite the excellent properties associated with Magnesium OxyChloride (Sorel) based cements and Magnesium OxySulfate based cements, water and corrosion resistance has been limiting factors for achieving greater commercial applications. Such issues can be addressed by incorporating various alkali metal phosphates, such as Magnesium mono- or dihydrogen phosphate (MgHPO4 or MgH2PO4) with alkali metal fatty acids; such as Magnesium Stearate; and metal or alkali metal sulfates such as Aluminum Sulfate or Magnesium Sulfate. Water resistance is further enhanced by either pre-carbonating the mix water or the liquid magnesium chloride phase of the cements, or by adding a carbonate into the powder phase. Accelerated cure of this system has also been obtained by using various inorganic metal oxides. Additionally, improved corrosion resistance is achieved through the use of certain phosphates, zeolites, nitrites and other novel additives.

Owner:PREMIER MAGNESIA

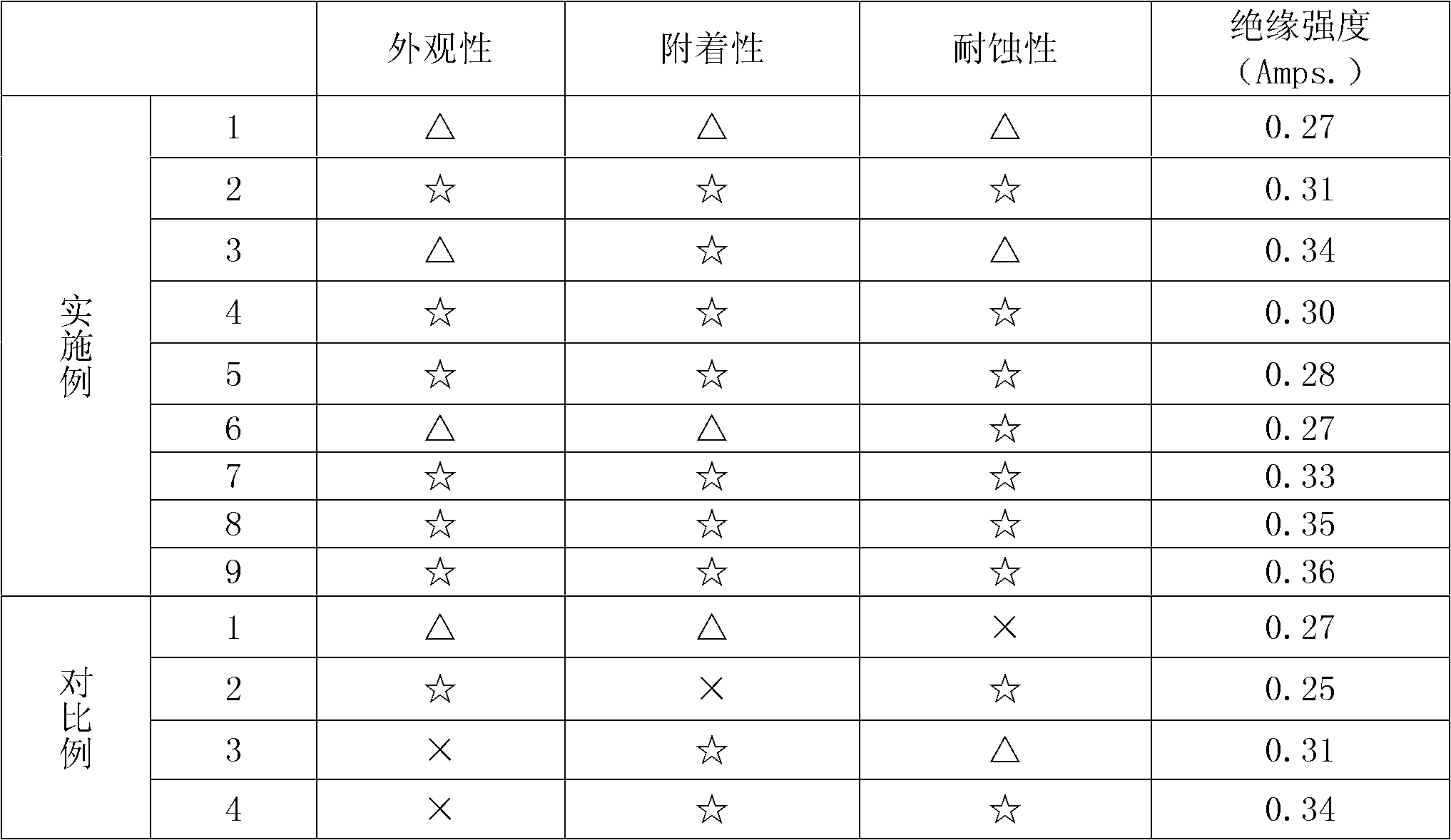

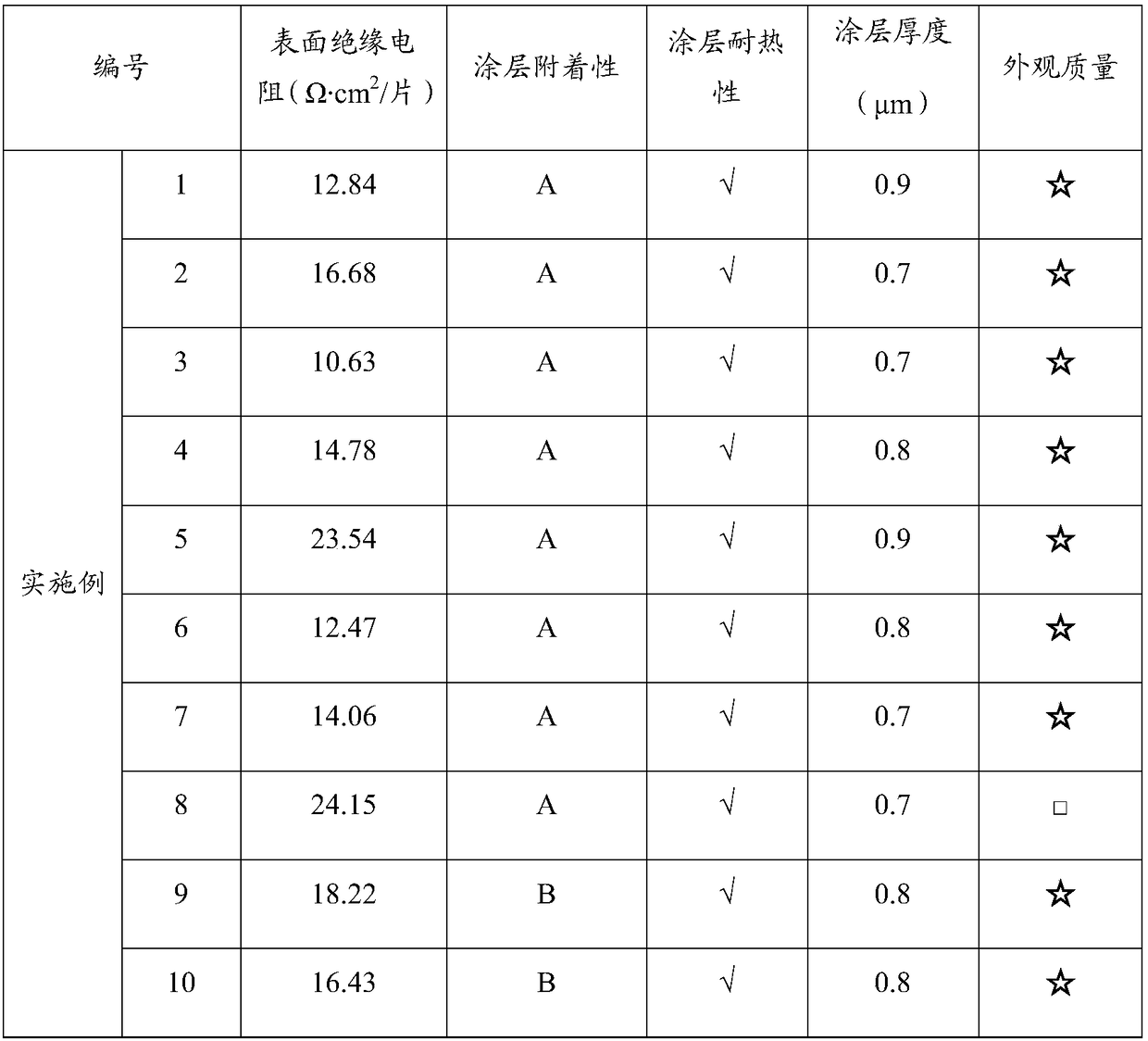

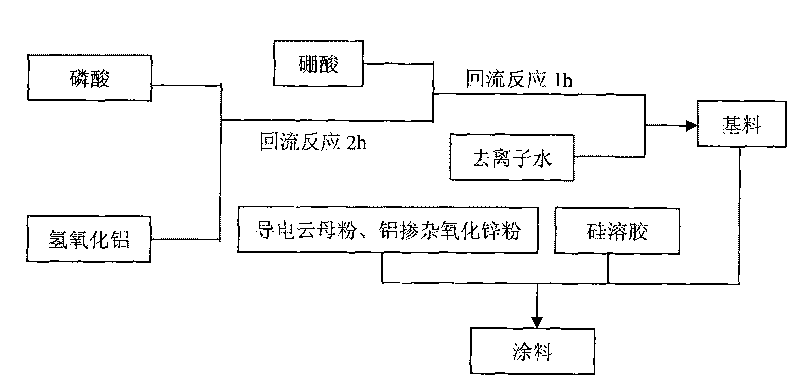

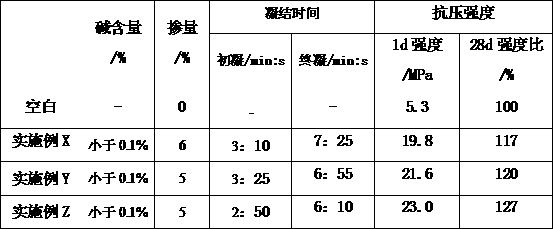

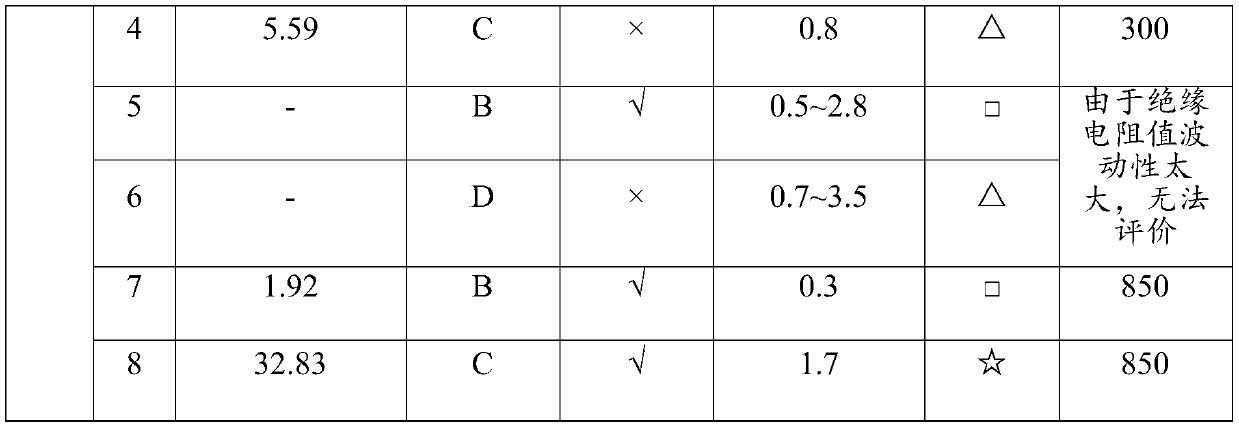

Non-oriented electrical steel chromium-free insulating environment-friendly coating and preparation method of coat thereof

ActiveCN101591495AImprove heat resistanceLow Free Phosphorus ContentLiquid surface applicatorsCoatingsMonomagnesium phosphateChromium free

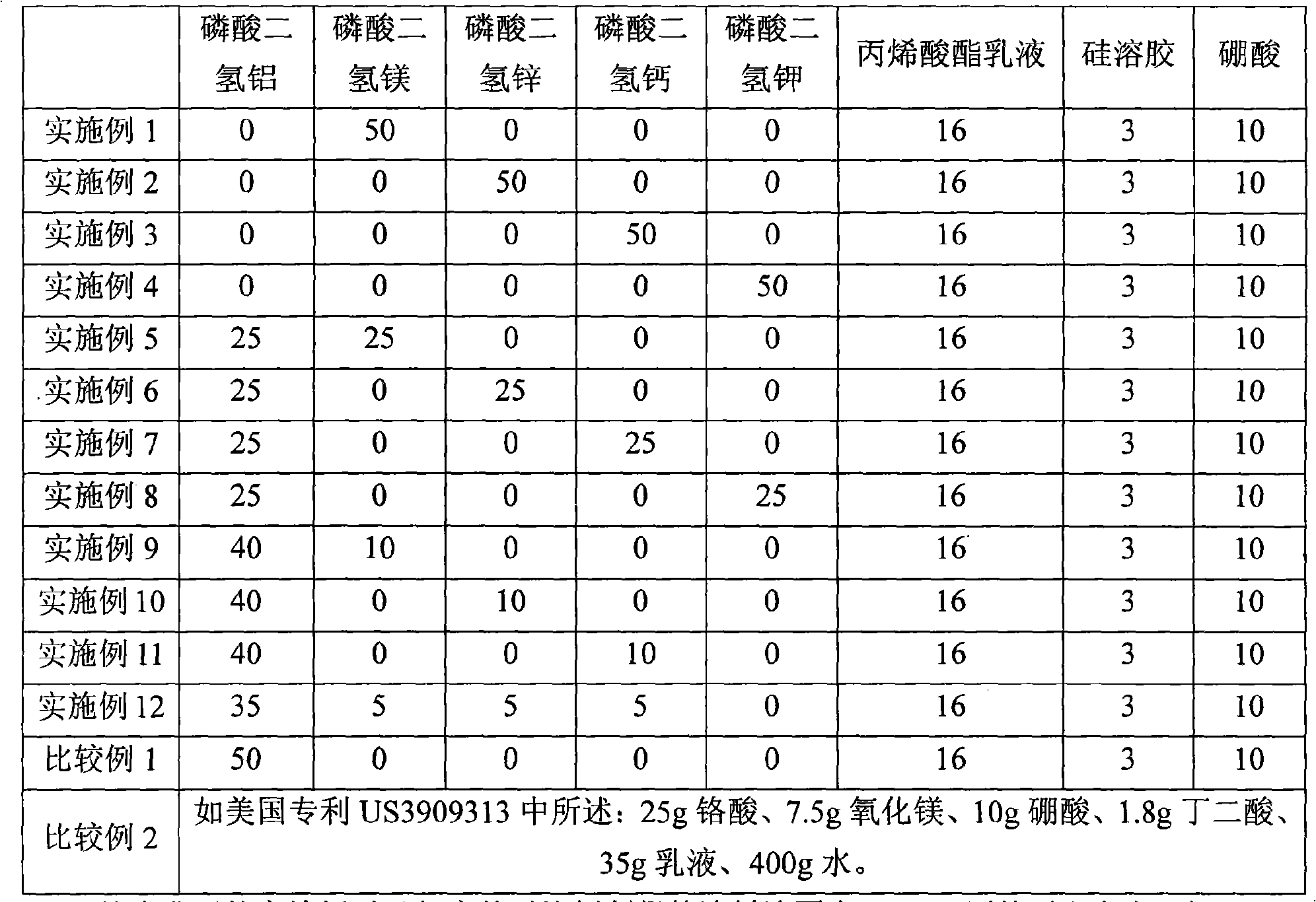

The invention relates to a non-oriented electrical steel chromium-free insulating environment-friendly coating and a preparation method of a coat thereof, and belongs to the technical field of electrical steel coatings. The non-oriented electrical steel chromium-free insulating environment-friendly coating comprises the following compositions calculated by dry weight: 0 to 70 percent of aluminium dihydrogen phosphate, 0 to 70 percent of monopotassium phosphate, 0 to 70 percent of zinc dihydric phosphate, 0 to 70 percent of monocalcium phosphate, 0 to 70 percent of magnesium dihydrogen phosphate, 5 to 30 percent of acrylate emulsion, 1 to 20 percent of boric acid and 0.5 to 6 percent of silica sol; and the percent being weight percent. The coating is an environment-friendly coating not containing chromium; and the prepared coat has bright and even surface, good insulation property, adhesiveness and heat resistance, and also has the advantages of small moisture absorption and strong rust prevention capacity.

Owner:SHOUGANG CORPORATION

Environment-friendly insulating coating solution used for non-oriented silicon steel and preparation and application thereof

ActiveCN102115881AReduce wearEliminate environmental concernsMetallic material coating processesMonomagnesium phosphatePhosphate

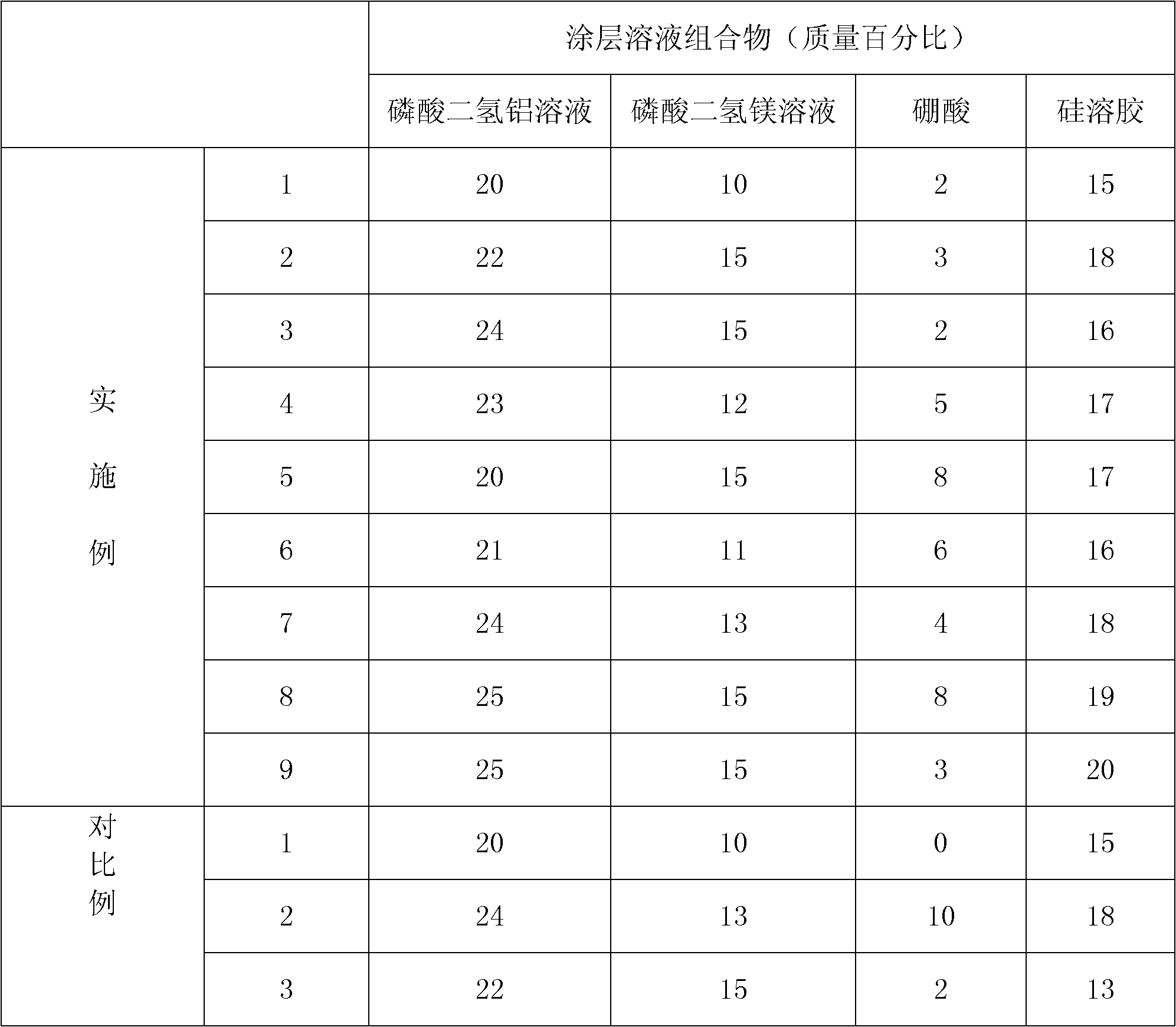

The invention relates to an environment-friendly insulating coating solution used for non-oriented silicon steel and preparation and application thereof, in particular to a phosphate coating solution and preparation and application thereof, belonging to the technical field of preparation of a silicon steel insulating coating. Based on the total mass of the coating solution, the environment-friendly insulating coating solution used for non-oriented silicon steel comprises the components by the mass percentage of: 20 to 25 percent of aluminum dihydric phosphate solution, 10 to 15 percent of magnesium dihydrogen phosphate solution, 15 to 20 percent of ludox, 2 to 8 percent of boric acid and the balance of deionized water. The insulating coating prepared by using the environment-friendly insulating coating solution used for non-oriented silicon steel not only can guarantee that all the performances such as uniformity, insulating performance, adhesiveness, corrosion resistance, heat resistance, weldability and the like are excellent, but also totally solves the problem in environment protection caused by chromium.

Owner:上海迪升防腐新材料科技有限公司

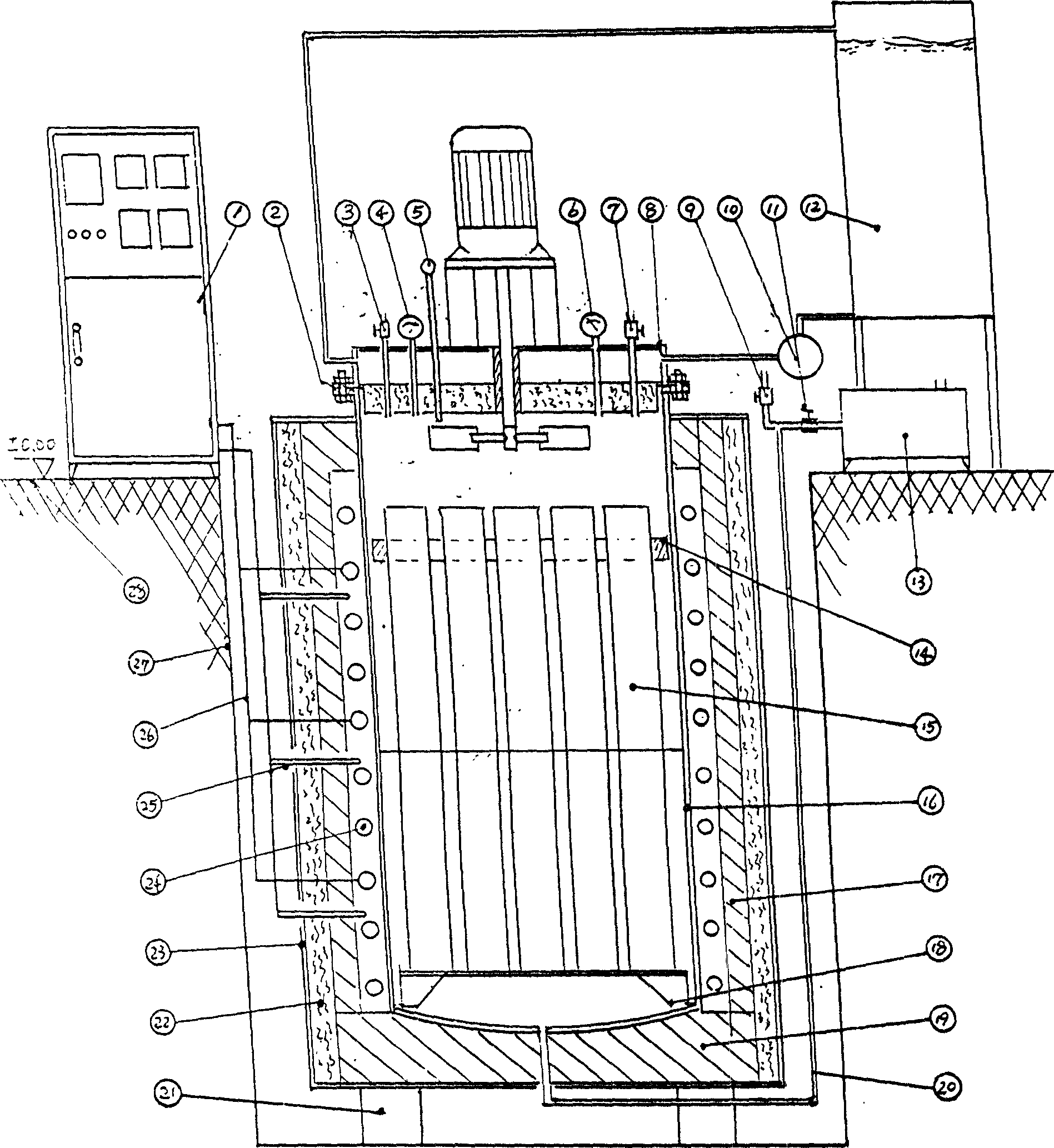

Graphite sleeves of rollers at furnace bottom and their dipping process and special apparatus thereof

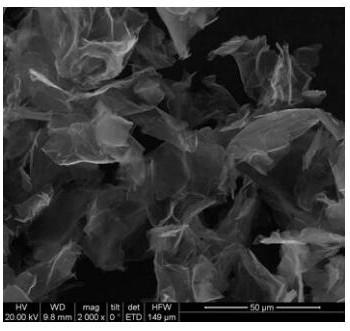

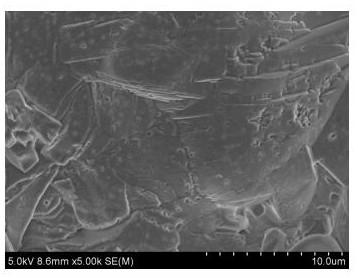

InactiveCN1583668AHigh bulk densityLow resistivityFurnace typesHeat treatment furnacesChemical treatmentGraphite carbon

A graphite carbon sleeve of the roller at furnace bearth is prepared from calcined coke powder, adhesive, and additional coke through proportional mixing, kneading, die pressing, calcining, high-pressure dipping in metallic phosphate solution, graphitizing machining for shaping, chemical treating and high-temp treating. Its dipping method and dedicated apparatus are also disclosed.

Owner:BASAN SPECIAL FIRE RETARDANT MATERIAL FACTORY SHANDONG

Shell filler assisting shell manufacture in investment casting and method filling shells by adopting filler

InactiveCN102935488AImprove liquidityEasy to fillFoundry mouldsFoundry coresMonomagnesium phosphateInvestment casting

The invention provides a shell filler assisting shell manufacture in investment casting and a method filling shells by adopting the filler. The shell filler is characterized by comprising the following components in parts by weight: ammonium dihydrogen phosphate 6-20, quartz and / or fused quartz: 58-83, magnesium oxide 5-18, monomagnesium phosphate: 0.3-8andorganic silicon defoamer: 0.002-0.3; and the method is characterized by comprising the steps of filling shells with the shell filler through operations including preparing shells to be filled, preparing size, pouring the size to fill the shells, solidifying, drying, then smearing and the like. The shell filler assisting shell manufacture in investment casting and the method filling shells by adopting the filler can resolve the problems of cast piece inner cavity shiming and shell runout during casting with low cost, and shorten shell manufacture period of silica solution shells with blind holes; and moreover, the shell filler further has the advantages of being good in mobility and filling performance and capable of self-solidification and the like.

Owner:CHONGQING JINGRUI CASTING MATERIAL

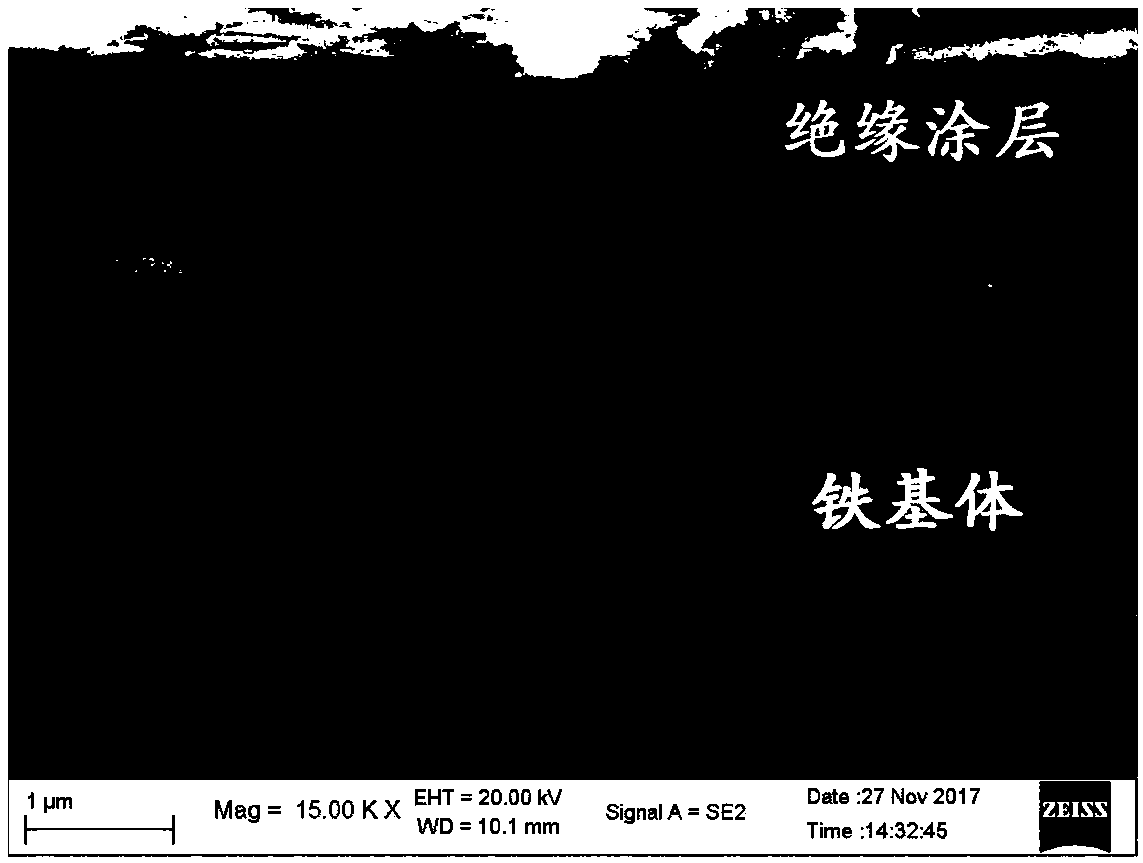

Ultra-thin silicon steel surface insulating coating and preparation method thereof

ActiveCN108659584AGood adhesionHigh insulation resistanceFireproof paintsMonomagnesium phosphatePhosphate

The invention belongs to the technical field of coating compositions, in particular to an ultra-thin silicon steel surface insulating coating and a preparation method thereof. The insulating coating provided by the invention is prepared from the following components: 65 to 85 parts of magnesium dihydrogen phosphate, 0.1 to 1.5 parts of insulating inorganic nanoparticles, 2 to 15 parts of silica sol, 2 to 4 parts of boric acid and 1 to 32.9 parts of deionized water. The coating formed by synergistic effects of all the components has excellent adhesion property to the surface of a bare steel sheet of ultra-thin silicon steel, and meanwhile, the insulation performance is ensured. The insulating coating provided by the invention is also prepared from 0.01 to 5 parts by weight of organic resin;by the addition of the organic resin, the adhesion of the ultra-thin silicon steel surface coating can be improved and subsequent high temperature sintering can be resisted, so that the ultra-thin silicon steel with the coating can be suitable for preparing a roll core of a saturation reactor, and further complex operating conditions such as strong vibration and high temperature rise of high pressure anode saturation reactors are met.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

Inorganic early-strength and quick-setting material

The invention discloses an inorganic early-strength and quick-setting material, which is characterized in that the inorganic early-strength and quick-setting material is mainly prepared from magnesium oxide, sodium hydroxide, magnesium dihydrogen phosphate, aluminum dihydrogen phosphate, retarder, short fiber, filling material and water according to a certain weight proportion; and the inorganic early-strength and quick-setting material can be formed by direct casting or mould casting, or be prepared into various products by extrusion forming. The material disclosed by the invention is simple and convenient to operate, excellent in physical performance, good in density, leakage-resistant, acid and alkali corrosion-resistance, low in manufacturing cost, and environment-friendly in material and preparation process, wide in application range, wide in application prospect and the like. The material is simple and convenient in preparationand forming process and low in cost, and is not only suitable for the small-scale manual manufacturing but applicable to the large-scale industrial production. The material is suitable for preparing the artist decoration, the section bar, the tank body, the framework, the board and the civil construction engineering, and is capable of replacing the silicate cement, the glass fiber-reinforced plastic, the ceramic, the plastic, the metal, the wood material and other materials on many aspects.

Owner:郭静萍 +1

Inorganic high-temperature resistant and antistatic coating

The present invention discloses an inorganic high-temperature resistant and antistatic coating. The coating is mainly prepared from constituents of the following contents (percentages by weight): 30 to 60% of phosphate, 5 to 25% of silicasol, 2 to 10% of boric acid, 25 to 45% of water, 2 to 5% of titanate coupling agent, 8 to 18% of conductive mica powder and 5 to 10% of aluminium powder mixed with zinc oxide. Dihydric phosphate water solution is prepared from the following substances at least, and the phosphate consists of one or several of aluminium dihydrogen phosphate, aluminium hydrogen phosphate, magnesium dihydrogen phosphate, magnesium hydrogen phosphate, zinc dihydrogen phosphate and zinc hydrogen phosphate. The ratio of P to M (M refers to metal elements) in the phosphate is from 1.2 to 2.6. The conductive mica powder and the aluminium powder mixed with zinc oxide are processed by the titanate coupling agent before being added to a base material.

Owner:中昊北方涂料工业研究设计院有限公司

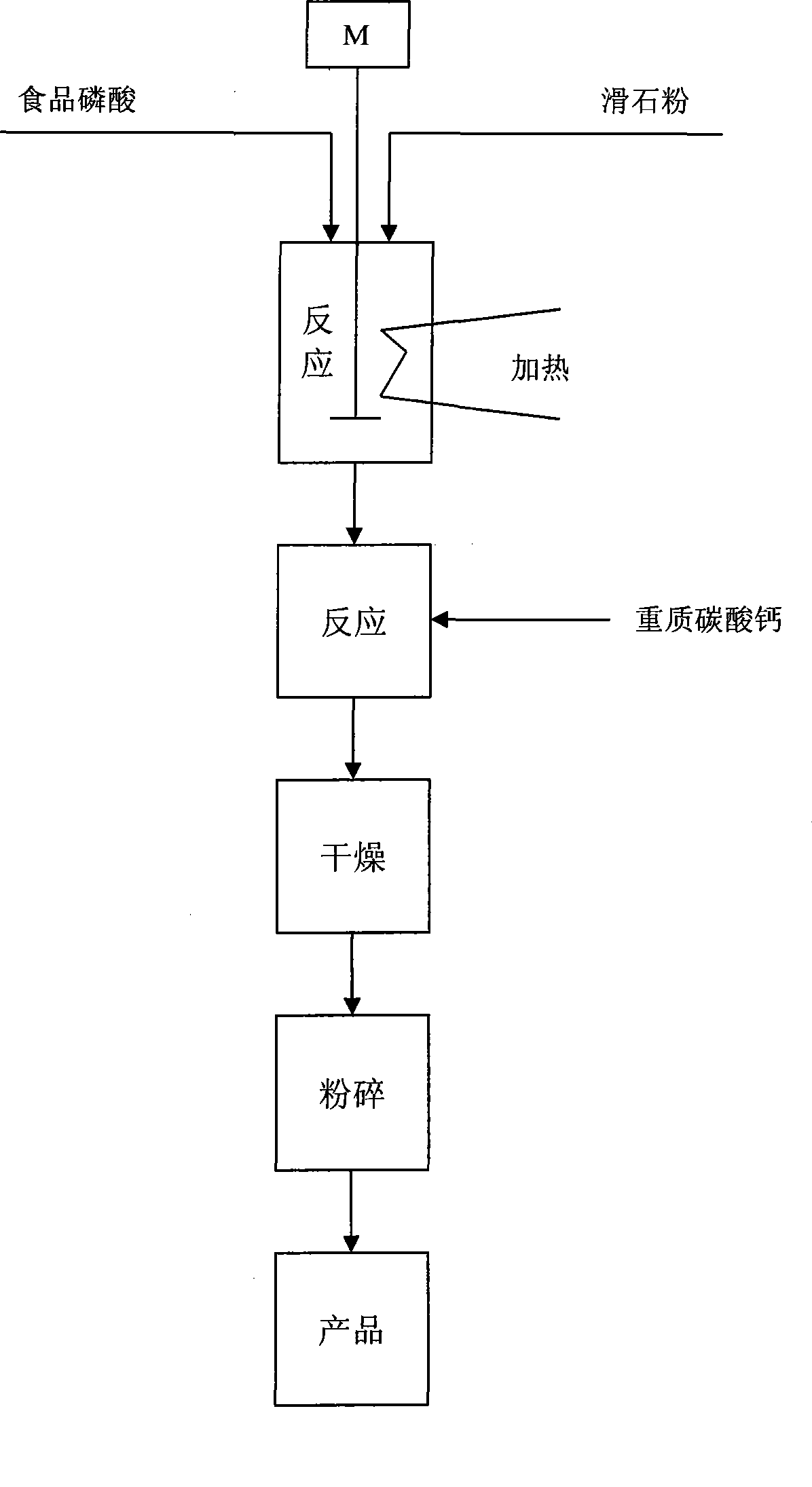

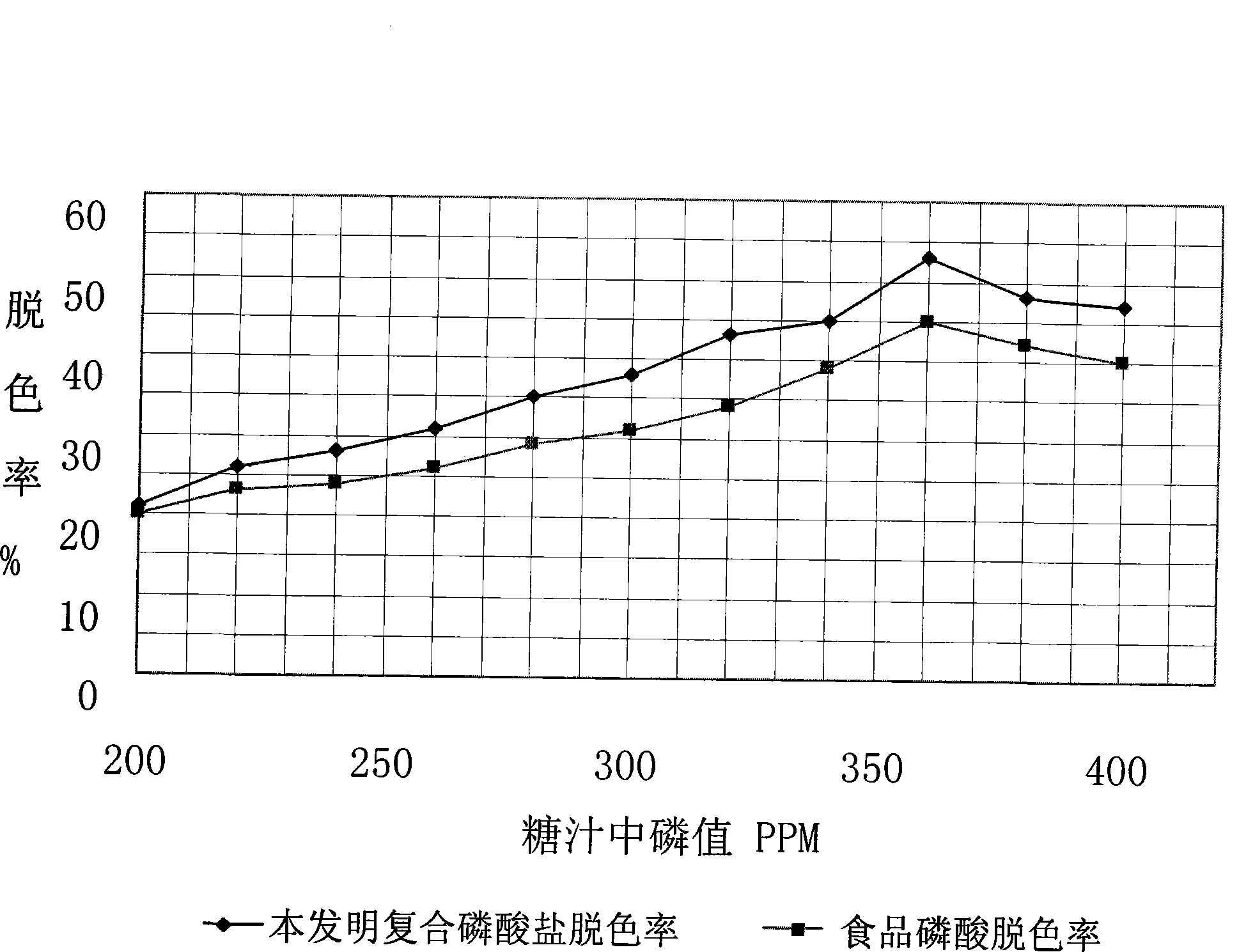

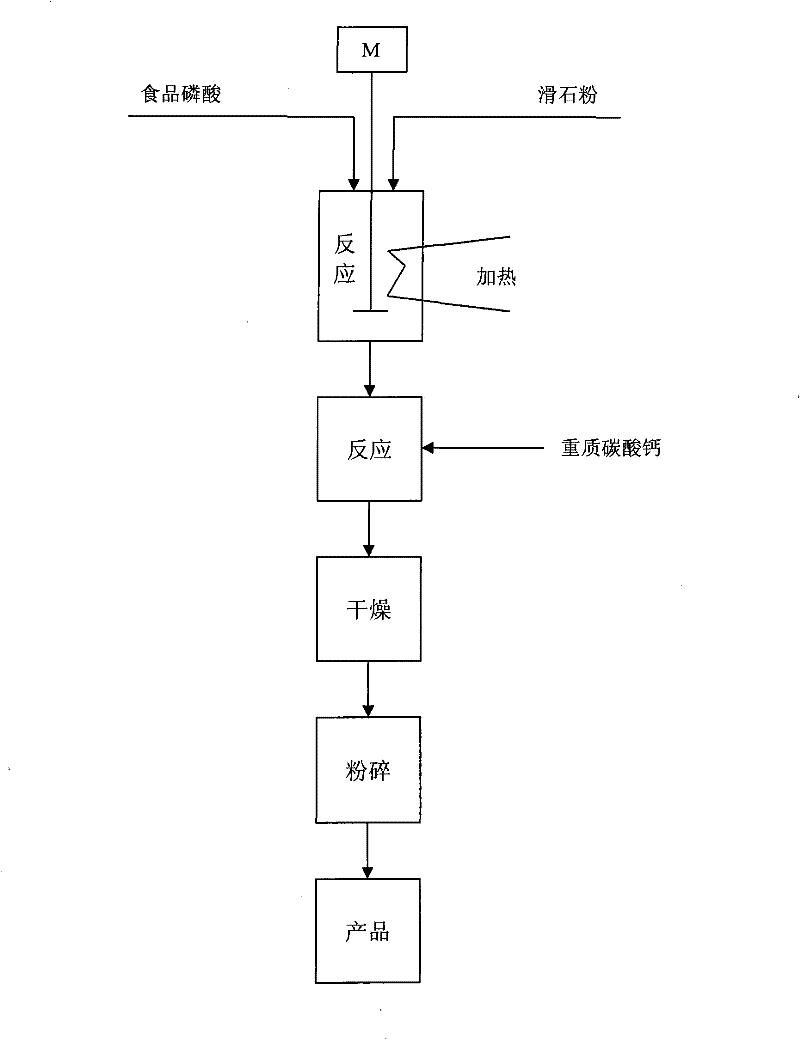

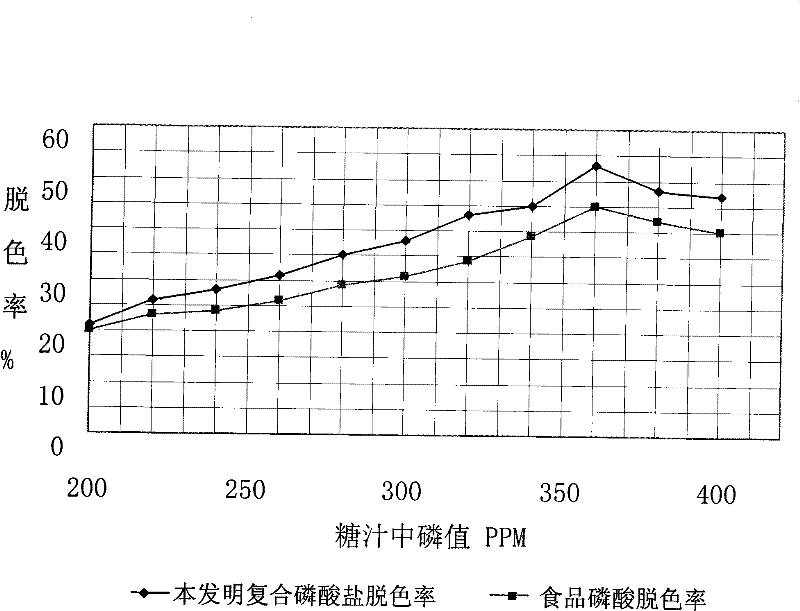

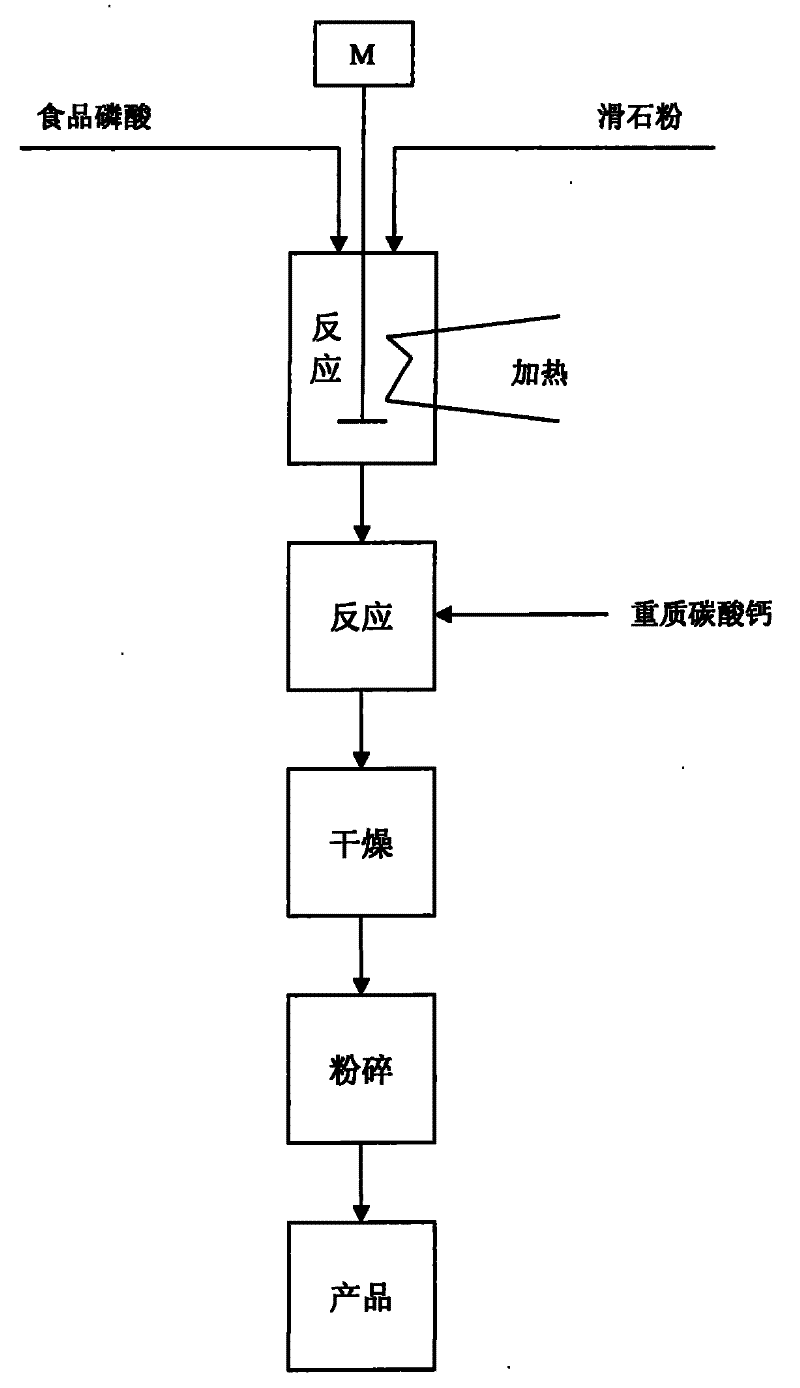

Composite phosphates sugar juice decoloring agent and preparation thereof

ActiveCN101440412AEasy to storeEasy to transportPurification by oxidation/reductionMonomagnesium phosphatePhosphate

The invention provides a composite phosphate sugar juice decoloring agent and a preparation method thereof, which belongs to the technical field of chemical engineering. The decoloring agent consists of the following four components: (1) calcium biphosphate, (2) magnesium dihydrogen phosphate, (3) precipitated silica and (4) free phosphoric acid. The preparation method for the decoloring agent comprises the following steps: (1) talc is added to food-grade phosphoric acid hydrolysate and dissolved, so as to obtain a phosphoric acid aqueous solution which dissolves magnesium dihydrogen phosphate and disperses precipitated silica; and (2) heavy calcium carbonate powder is put into a mixer and added with the phosphoric acid aqueous solution in a step (1), and reaction evaporates the moisture of materials and progressively cures the materials, so as to obtain the composite phosphate sugar juice decoloring agent containing moisture. Compared with the food-grade phosphoric acid used by the prior sugar factories, the decoloring agent has the advantages of good decoloring effect, economical efficiency, convenience, no relation to dangerous chemicals, and the like.

Owner:YUNNAN JIANGLIN GROUP

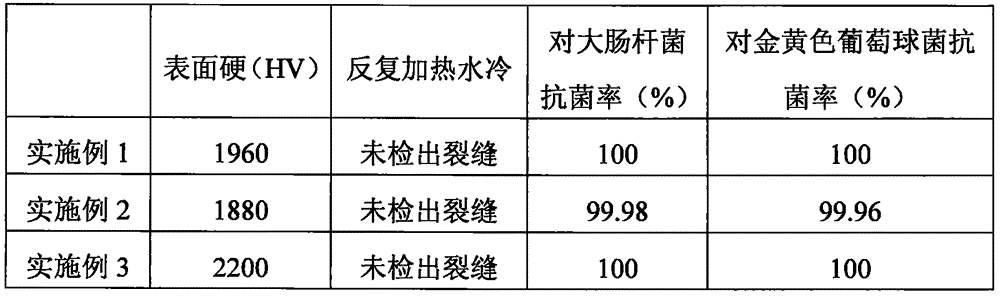

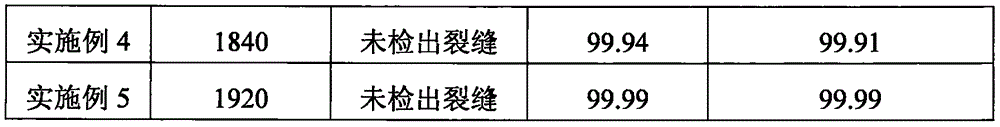

Antibacterial ceramic coating layer for non-stick pan and preparation method thereof, and non-stick pan

InactiveCN105967661AImprove toughnessHigh hardnessCooking-vessel materialsMonomagnesium phosphateBoride

The invention provides an antibacterial ceramic coating layer for a non-stick pan and a preparation method thereof, and the non-stick pan. The antibacterial ceramic coating layer adopts the following raw materials: modified alumina, silicon nitride, silicon dioxide and / or titanium dioxide, titanium nitride, zirconium boride, chromium oxide, a modified zinc oxide antibacterial agent and magnesium dihydrogen phosphate. Compared with the prior art, the modified alumina is adopted, on one hand, the toughness of the coating layer is enhanced, on the other hand, the expansion coefficient of a ceramic film is improved and is closer to a metal substrate expansion coefficient, and a chipping phenomenon is improved to a certain extent. Secondly, the modified zinc oxide antibacterial agent has synergistic effect with zinc oxide, silicon dioxide and titanium dioxide, so that the coating layer has relatively high antibacterial properties; thirdly, chromium oxide, titanium nitride, zirconium boride and other components can increase the hardness and wear resistance of the coating layer through a dispersion strengthening mechanism. Therefore, the prepared coating layer has the advantages of high-temperature resistance, wear resistance, bacteria resistance, and excellent non-stick performance and adhesion power.

Owner:NINGBO XIAYUAN TECH

Production method of compound fertilizer containing poly-magnesium phosphate

InactiveCN105481515AReduce manufacturing costImprove qualityFertilisers by pryogenic processesAmmonium nitrate fertilisersMonomagnesium phosphateMagnesium orthophosphate

The invention discloses a production method of compound fertilizer containing poly-magnesium phosphate. The method includes the following steps that firstly, wet-process phosphoric acid and magnesium oxide powder are added into a reactor in proportion, and a dilute magnesium biphosphate solution is obtained; secondly, one or more of urea, ammonium nitrate, calcium ammonium nitrate and nitric phosphate are added into the dilute magnesium biphosphate solution and placed in an evaporator to be heated and evaporated, and a sizing agent is obtained; thirdly, the sizing agent is produced to form the compound fertilizer containing poly-magnesium phosphate. According to the production method of the compound fertilizer containing poly-magnesium phosphate, conventional wet-process phosphoric acid serves as main raw materials, the magnesium oxide powder is applied to perform reaction and processing, the compound fertilizer containing poly-magnesium phosphate is produced, and production cost is low. Not only is magnesium fertilizer added, but also 10% or above ortho-dihydrogen phosphate radicals are converted into poly-phosphate radicals, and product quality is high.

Owner:王丰登

Product containing magnesium pyrophosphate and use thereof as a raising acid for the production of bakery products

ActiveUS20110111110A1Dough treatmentProtein composition from eggsMagnesium phosphateMagnesium pyrophosphate

A product which contains acid magnesium pyrophosphate (magnesium dihydrogen diphosphate) and at least magnesium orthophosphate, producible by removal of water from an aqueous solution or suspension of a magnesium phosphate compound which has a molar ratio of Mg:P of 0.4-0.6:I, wherein the product has a loss on ignition of 7.5 to 13.5% and its method of preparation and its use in a leavening agent for bakery products.

Owner:CHEM FAB BUDENHEIM AG

Fast-setting, fibrous, portland cement-based building material

InactiveUS6464775B2Solid waste managementCeramic shaping apparatusMonomagnesium phosphatePortland cement

A fast-setting, fibrous, Portland Cement-based building material is made by soaking wood chips in water to provide substantially saturated wood chips, combining the saturated wood chips with a slurry of Portland cement to provide a wood chip / cement slurry, mixing a slurry of monomagnesium phosphate ("MOP") with the wood chip / cement slurry to provide a quick-setting MOP / wood chip / cement composition, and compressing the quick-setting MOP / wood chip / cement composition to make the fast-setting, fibrous, Portland Cement-based building material. The inventive composition combines the best properties of cement and wood, yet uses recycled materials to make an environmentally-friendly building material.

Owner:HEARTSWORK LLC

Method for improved the handling heat-resistance of the ethylene-vinyl alcohol copolymer

ActiveUS20050228129A1Improve heat resistanceOrganic compound preparationOxygen compounds preparation by hydrocarbon oxidationAcetic acidMonomagnesium phosphate

The present invention relates to a method for increasing the heat-resistant of ethylene-vinyl alcohol copolymer (EVOH), the method is characterized by using a mixture of acetic acid, magnesium dihydrogen phosphate, and potassium dihydrogen phosphate at a certain ratio as an acid-treating solution in the acid-treating procedure of a process for preparing EVOH. The EVOH produced by the method of the present invention exhibits an excellent heat-resistance and does not become yellowing attributed to the elevated processing temperature. Also, the EVOH generated by the method of the present invention exhibits a uniform heat-resistance since the additives are dispersed evenly in the EVOH.

Owner:CHANG CHUN PETROCHEMICAL CO LTD

Inorganic high-temperature fused salt corrosion resistant graphene paint and preparation method thereof

The invention relates to the field of paint, and discloses inorganic high-temperature fused salt corrosion resistant graphene paint. The inorganic high-temperature fused salt corrosion resistant graphene paint comprises the following raw materials in parts by weight: 45-55 parts of a high temperature adhesive, 3-10 parts of a graphene dispersing liquid, 5-15 parts of corrosion-proof filling, 8-18parts of a lamellar material, 2-8 parts of a flexibilizer and 10-20 parts of deionized water, wherein the high temperature adhesive comprises one or a combination of aluminum dihydrogen phosphate, magnesium biphosphate, zinc dihydrogen phosphate, chromium aluminum phosphate and zircon collosol; the graphene dispersing liquid comprises the following ingredients: graphene powder, a dispersing agentand deionized water; the corrosion-proof filling comprises one or a combination of aluminum triphosphate, chromium oxide and zinc phosphate; the lamellar material comprises one or a combination of hexagonal boron nitride, flake aluminum and sericite; and the flexibilizer comprises at least one of a zirconia fiber and a silicon oxide fiber.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD +1

Preparation method for colorless glass-state electronic-grade magnesium metaphosphate

ActiveCN102311107AHigh purityReduce manufacturing costPhosphorus compoundsMonomagnesium phosphateElectric arc furnace

The present invention discloses a preparation method for colorless glass-state electronic-grade magnesium metaphosphate. The method comprises the following steps: adding phosphoric acid, water and magnesium carbonate to a reactor; heating the reactor to a temperature of 130-150 DEG C after completing the reaction, then carrying out boiling and evaporation for 3-5 hours until the crystal is generated; removing the crystal from the reactor; carrying out quenching, then carrying out treatments of dilution and settling separation; loading the prepared magnesium dihydrogen phosphate into a box prepared from a magnesium alloy, and heating the box to the temperature less than 650 DEG C; transferring the box to a sealed electric furnace after heating, carrying out the treatment of air exhaust for the electric furnace until the pressure in the electric furnace is the negative pressure, maintaining the constant temperature and carrying out sintering for 4-6 hours; removing the sintered magnesium metaphosphate from the electric furnace and cooling. According to the present invention, the specially-prepared magnesium carbonate is adopted as the raw material; the special magnesium alloy box is adopted for loading the magnesium dihydrogen phosphate; the preparation has the following characteristics that: the operation steps are simple and clear, the industrial process operation has high stability and high safety, the produced magnesium metaphosphate has high purity, the production cost is low, bulk production can be realized, and the like.

Owner:SICHUAN MINGJING PHOTOELECTRIC TECH

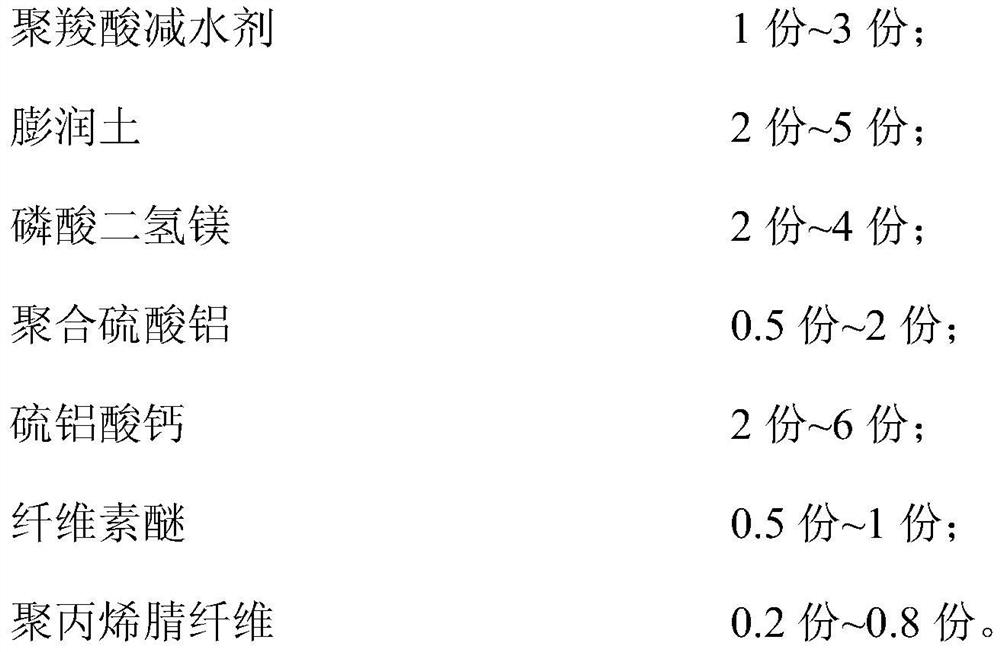

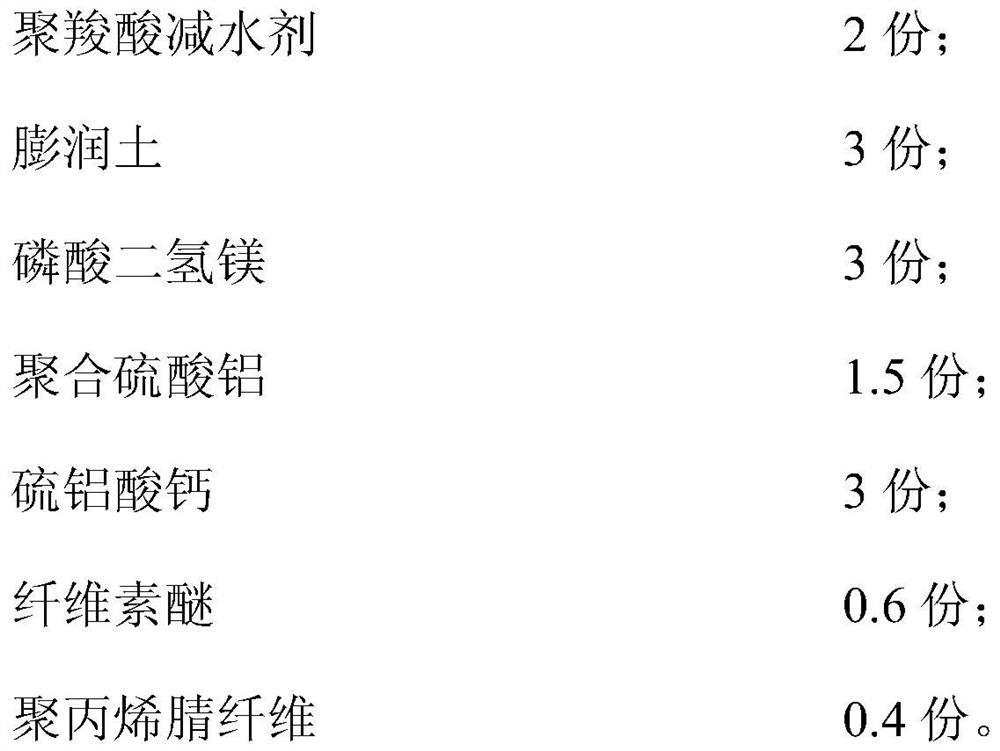

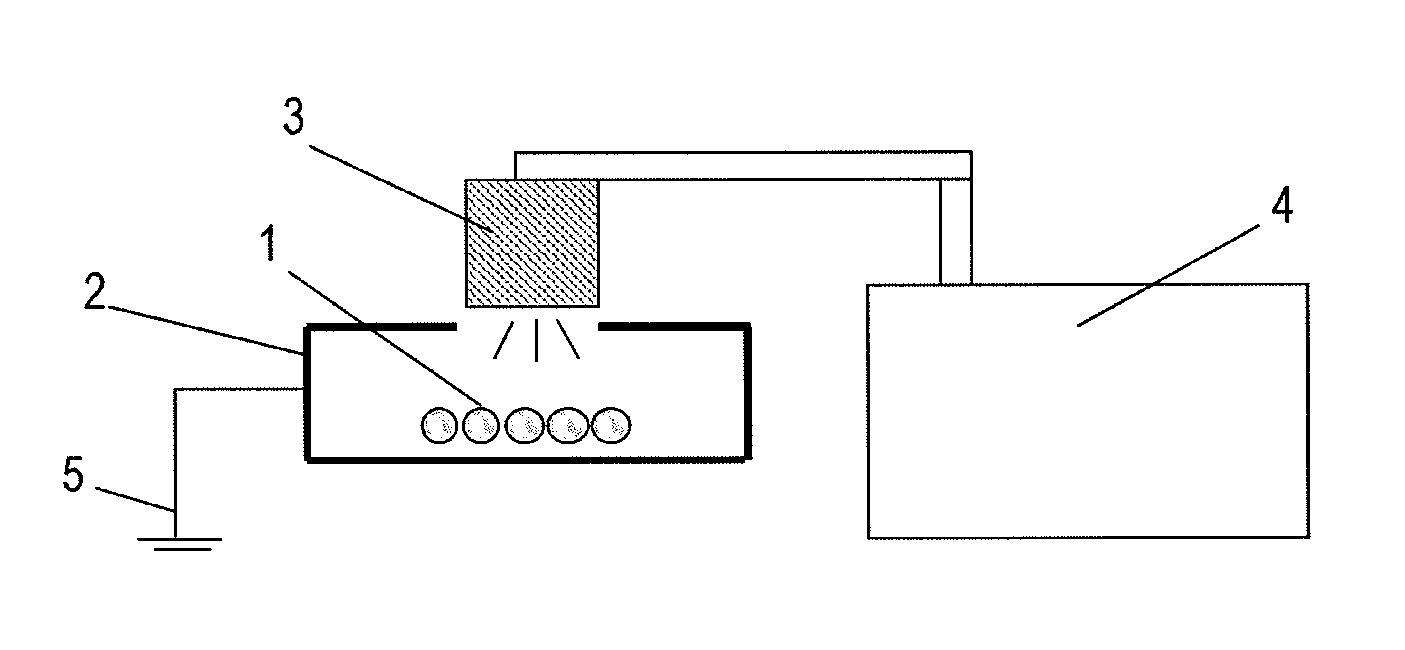

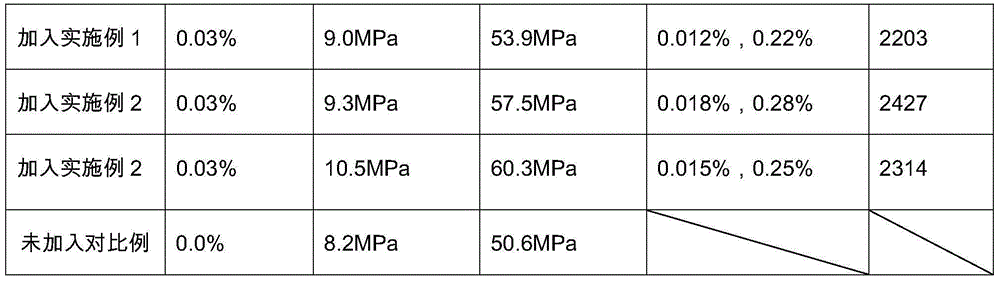

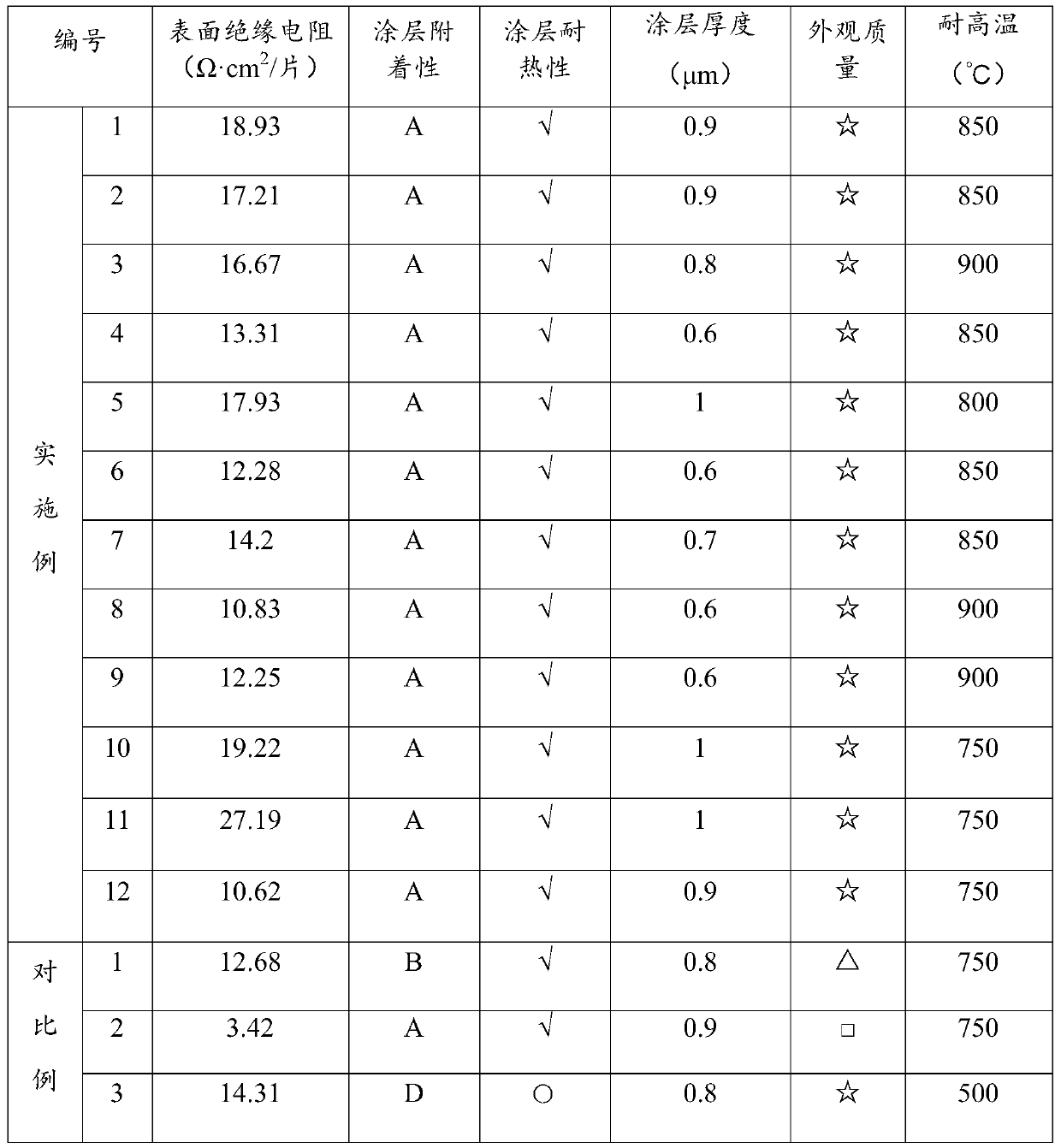

Composite additive for grouting material and grouting material

InactiveCN111792871AControl different physical and mechanical propertiesMeet different grouting needsCelluloseMonomagnesium phosphate

The invention provides a composite additive for a grouting material and a grouting material. The composite additive comprises the following components in parts by weight: 1-3 parts of a polycarboxylate water reducer, 2-5 parts of bentonite, 2-4 parts of magnesium dihydrogen phosphate, 0.5-2 parts of polymeric aluminum sulfate, 2-6 parts of calcium sulfoaluminate, 0.5-1 part of cellulose ether and0.2-0.8 part of polyacrylonitrile fibers. The composite additive is added into cement slurry (especially silicate cement), so that the physical and mechanical properties of the cement slurry can be adjusted and changed, and effects of cement slurry such as rock surrounding, reinforcing, water intercepting, leakage stopping, geologic structure processing, and the like, are obviously improved.

Owner:北京中矿时代工程技术研究院有限公司

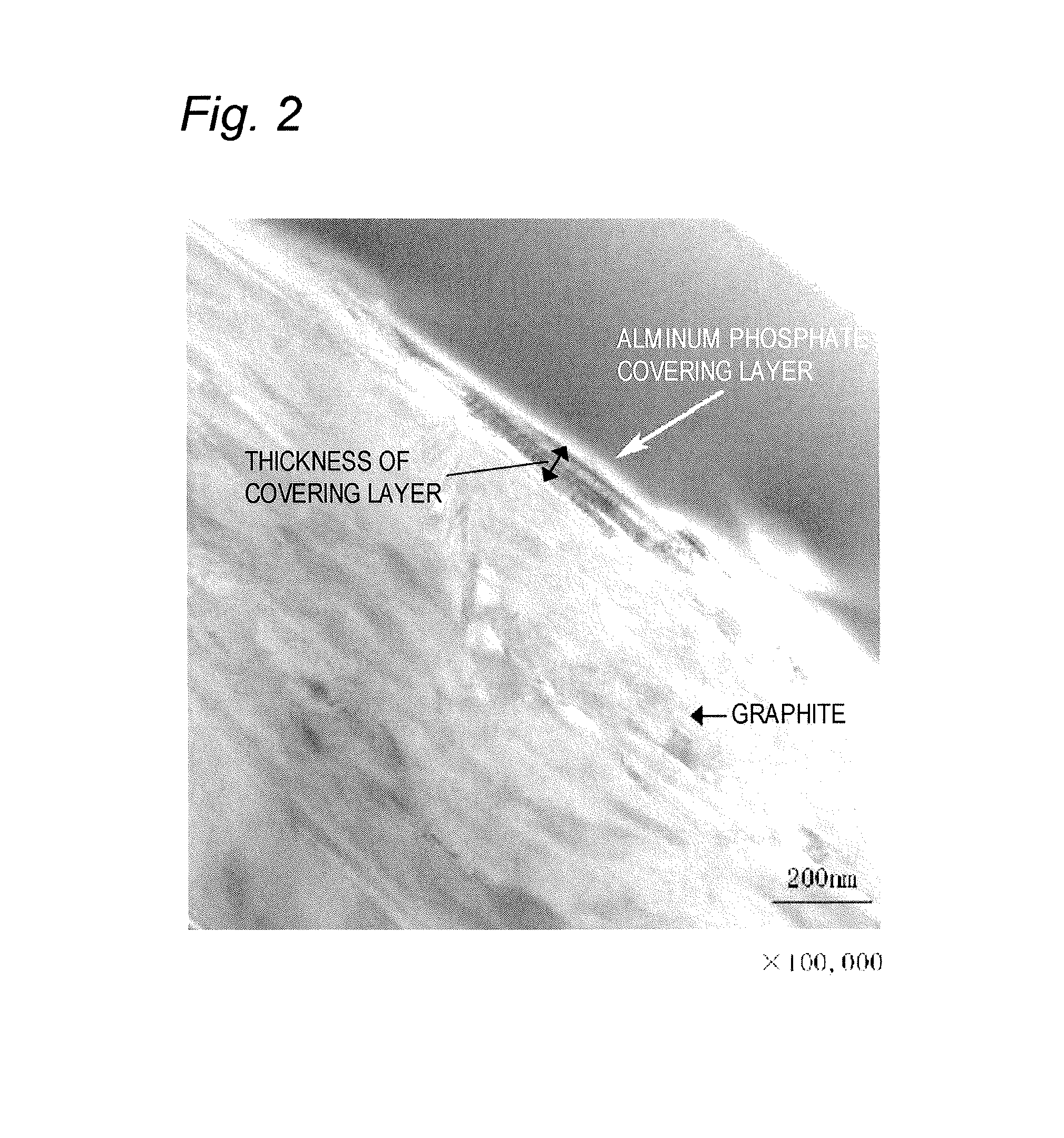

Solid lubricant and production method thereof

ActiveUS8513170B2Promote oxidationIncrease thermal resistanceBase-materialsMonomagnesium phosphatePhosphate

A method for producing a solid lubricant includes steps of preparing and coating. A phosphate aqueous solution prepared by the step of preparing is an aqueous solution containing at least one of aluminum dihydrogen phosphate and magnesium dihydrogen phosphate in an amount of 0.5 to 10% by mass. A graphite material is coated with a phosphate using the phosphate aqueous solution. The graphite material is used at a ratio of 40 to 50 parts by mass based on 100 parts by mass of the aqueous solution.

Owner:AKEBONO BRAKE IND CO LTD

Silicon carbide-based ferrite magnetic core material for transformer

InactiveCN104064311AHigh energy productMagnetically stableInorganic material magnetismMonomagnesium phosphatePorosity

The invention discloses a silicon carbide-based ferrite magnetic core material for a transformer. The material comprises major ingredients and additives, wherein the major ingredients comprise 58.7 to 65 moles of Fe2O3, 15.1 to 19 moles of manganese oxide, 10.2 to 14 moles of zinc oxide, 4 to 5.6 moles of ferroferric oxide, 0.1 to 0.2 mole of calcium sulfate, 0.1 to 0.2 mole of magnesium dihydrogen phosphate and 0.01 to 0.02 mole of rare earth composite magnetic-conducting powder according to a molar ratio; the additives comprise 80 to 100 parts per million of molybdenum oxide and 40 to 50 parts per million of zirconium oxide based on the weight of the ferrite magnetic core material. The rare earth composite magnetic-conducting powder added to the ferrite magnetic core material has a magnetic energy product and stable magnetism, a preparation method is simple, and a finished product has the characteristics of high grain boundary resistivity, low porosity and large and uniform crystal grain sizes.

Owner:ANHUI WANHONG ELECTRICAL EQUIP

Fast-setting, fibrous, portland cement-based building material

InactiveUS20010045179A1Solid waste managementCeramic shaping apparatusMonomagnesium phosphatePortland cement

A fast-setting, fibrous, Portland Cement-based building material is made by soaking wood chips in water to provide substantially saturated wood chips, combining the saturated wood chips with a slurry of Portland cement to provide a wood chip / cement slurry, mixing a slurry of monomagnesium phosphate ("MOP") with the wood chip / cement slurry to provide a quick-setting MOP / wood chip / cement composition, and compressing the quick-setting MOP / wood chip / cement composition to make the fast-setting, fibrous, Portland Cement-based building material. The inventive composition combines the best properties of cement and wood, yet uses recycled materials to make an environmentally-friendly building material.

Owner:HEARTSWORK LLC

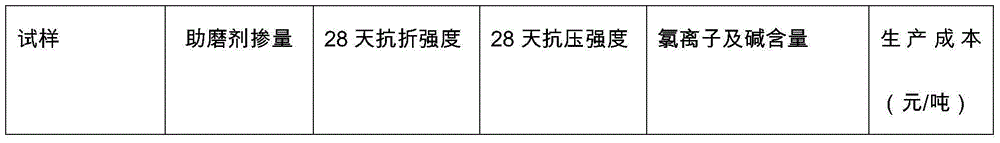

Low-chloride and low-alkali composite cement grinding aid and preparation method thereof

InactiveCN105236814AReduce manufacturing costControl concentrationMonomagnesium phosphateSodium acetate

The invention discloses a low-chloride and low-alkali composite cement grinding aid and a preparation method thereof. The low-chloride and low-alkali composite cement grinding aid is prepared from, by weight, 2-6 parts of hydroxypropyl methyl cellulose, 0.2-0.6 part of sodium chloride, 2-4 parts of sodium hexametaphosphate, 2-4 parts of magnesium dihydrogen phosphate, 2-4 parts of ammonium sulfate, 0.8-1.8 parts of sodium thiosulfate, 2-4 parts of sodium formate, 2-4 parts of sodium acetate, 2-4 parts of aluminum sulfate, 0.8-1.8 parts of sodium thiocyanate, 2-4 parts of sodium metasilicate pentahydrate, 2-6 parts of sodium lignin sulfonate, 2-4 parts of molasses, 2-4 parts of calcium lignosulphonate, 2-6 parts of triisopropanolamine, 2-4 parts of glycerin, 1.2-1.8 parts of pentaerythritol, 5-7 parts of p-aminobenzene sulfonic acid, 2-4 parts of methacrylic acid, 2-4 parts of maleic anhydride, 0.8-1.2 parts of polysorbate, 0.8-1.8 parts of active silica, 4-8 parts of kieselguhr, 2-4 parts of teflon powder, 5-12 parts of pulverized fuel ash and 70-120 parts of water.

Owner:韩功篑

Core material for hot-compacted low-temperature roasted mold cores and method for manufacturing mold cores by adopting core material

InactiveCN102935485ALow costEfficient productionFoundry mouldsFoundry coresMonomagnesium phosphateInvestment casting

The invention provides a core material for hot-compacted low-temperature roasted mold cores and a method for manufacturing mold cores by adopting the core material. The core material is characterized by comprising the following components in parts by weight: ammonium dihydrogen phosphate: 3.5-15, monomagnesium phosphate: 0.5-8, quartz and / or fused quartz: 52-71, magnesium oxide: 1.2-10 and paraffin: 13-26; and then the core material is hot-compacted, enchased, roasted and dipping-strengthened to obtain the mold cores. The core material for hot-compacted low-temperature roasted mold cores and the method for manufacturing mold cores by adopting the core material are easy to operate and control, not only investment casting mold cores which are thin, precise, smooth in surface, accurate in size and low in cost can be manufactured, but also manufacture cost of the mold cores is low, and further the mold cores can be produced by investment casting factories in self-actuated, large-batch and high-efficient mode.

Owner:CHONGQING JINGRUI CASTING MATERIAL

Environment-friendly water treatment agent capable of removing ammonia and nitrogen

ActiveCN107021562AImprove removal efficiencyLow costWater contaminantsBiological water/sewage treatmentMonomagnesium phosphatePhosphate

The invention provides an environment-friendly water treatment agent capable of removing ammonia and nitrogen. The water treatment agent is prepared from the following raw materials: nitrosomas, polyacrylamide, sodium dodecyl-benzenesulfonate, nekal, polyferric chloride, sodium hydroxide, sodium hypochlorite, zeolite, zinc hydrogen phosphate, magnesium dihydrogen phosphate, aluminum hydroxide, magnesium hydrate and phosphoric acid. A preparation method of the environment-friendly water treatment agent capable of removing ammonia and nitrogen comprises the following steps: a, weighing polyacrylamide, sodium dodecyl-benzenesulfonate, nekal, polyferric chloride and deionized water, then adding the materials into a stirrer, and uniformly stirring; b, successively adding sodium hydroxide, sodium hypochlorite, zeolite, zinc hydrogen phosphate, magnesium dihydrogen phosphate, aluminum hydroxide and magnesium hydrate into the stirrer, and uniformly stirring; c, adding nitrosomas into the stirrer, and uniformly stirring; and d, adding phosphoric acid into the stirrer, and uniformly stirring to obtain the treatment agent. The environment-friendly water treatment agent capable of removing ammonia and nitrogen is low in cost and high in removal efficiency of ammonia and nitrogen, and is suitable for extensive popularization.

Owner:江苏宜净水处理化学品有限公司

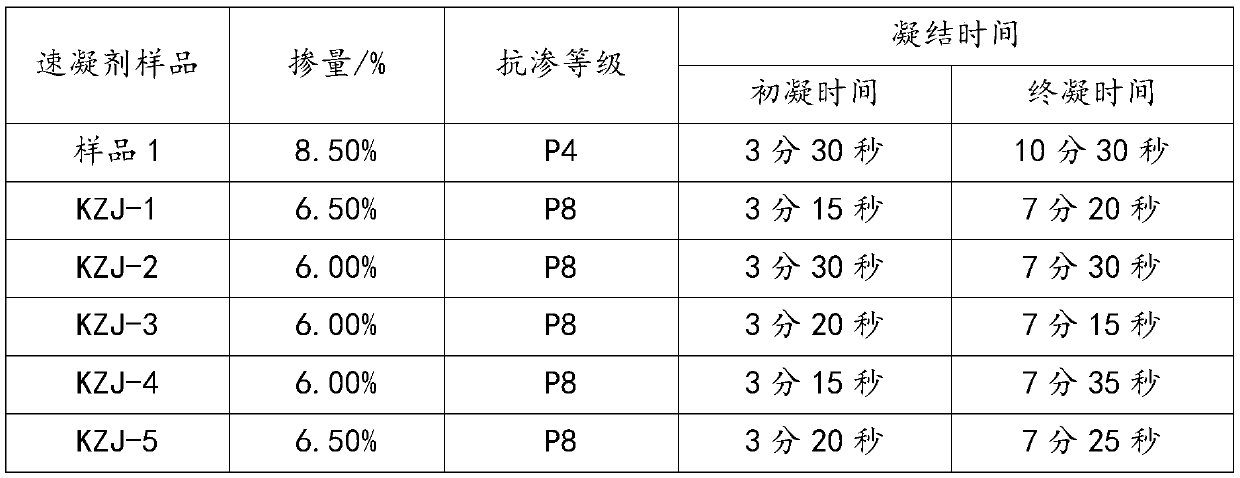

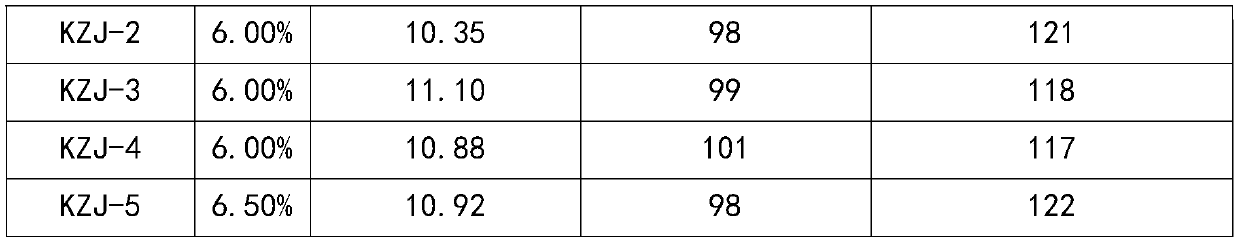

High-strength alkali-free setting accelerator used for cementing material containing cement and preparation method

The invention discloses a high-strength alkali-free setting accelerator used for a cementing material containing cement and a preparation method. The cementing material is prepared from, by weight, 15-25% of aluminium dihydrogen phosphate, 10-15% of monomagnesium phosphate, 0.01-0.1% of antifoaming agent, 20-30% of polyhydroxy dispersing enhancer; 2-5% of modified stabilizer, 3-6% of sulfonated graphene and the balance water, and the total weight is 100%. The alkali content in the alkali-free liquid setting accelerator is less than 1%, the possibility that sprayed concrete generates an alkali-aggregate reaction is greatly reduced, and the durability of concrete is improved; according to the prepared setting accelerator, no sulfate is introduced, and the sulfonated graphene is introduced inthe sulfonated graphene system, so that the setting accelerator not only can strengthen the early compression resistance strength of the concrete but also is quite beneficial for the growth of the long-term strength of the sprayed concrete.

Owner:王宇青

High-temperature-resistant insulating composition, insulating coating, and preparation method and application of insulating coating

ActiveCN110229549AImprove insulation performanceGood adhesionFireproof paintsPolyester coatingsWater basedMonomagnesium phosphate

The invention belongs to the technical field of coating composition preparation, and particularly relates to a high-temperature-resistant insulating composition, an insulating coating, and a preparation method and application of the insulating coating. Raw materials of the high-temperature-resistant insulating composition comprise one or more selected from a group consisting of magnesium dihydrogen phosphate, silica sol, chromic anhydride, ethylene bis(oxyvinyl) bis[3-(tert-butyl-4-hydroxy-m-tolyl) propionate], bis[3-(3,5-di-tert-butyl-4-hydroxy)phenyl] triethylene glycol propionate, butyloctyldiphenylamine and high-molecular phenolic ester, and comprise one or more selected from a group consisting of cyano acetoxyl ethyl methacrylate, hydroxymethyl diacetone acrylamide and a water-based alkyd resin emulsion. The coating formed by the synergistic effect among all the components can resist high-temperature heat treatment at a temperature of 750-900 DEG C for a long time, has excellent insulating performance, has excellent adhesion performance on the surface of a bare steel sheet of ultra-thin silicon steel, and can reach a grade A.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD

Waterproof reinforcing alkali-free liquid setting accelerator and preparation method thereof

ActiveCN110395939AWith waterproof functionIncreased durabilityGroup 4/14 element organic compoundsAluminateMolten state

The invention relates to the technical field of building materials and in particular to a waterproof reinforcing alkali-free liquid setting accelerator and a preparation method thereof. The setting accelerator comprises a modified aluminate solution, a stabilizer, a pH value adjusting agent, magnesium biphosphate and water, wherein the preparation method of the modified aluminate solution comprises the following steps: putting stearic acid into a reaction kettle, performing heating to 70-80 DEG C, performing heating to a molten state, powering on a stirring device, adding ammonium hydroxide toimplement a reaction, performing cooling to 35-50 DEG C, adding aluminum sulfate, aluminum isopropoxide and water into the reaction kettle, performing an ultrasonic reaction, performing cooling to anormal temperature, and further adding calcium hydroxide to implement a reaction, so as to obtain modified aluminate. The setting accelerator is applied to synthesis for preparing an alkali-free liquid setting accelerator, the prepared alkali-free liquid setting accelerator has a waterproof function, is capable of improving the durability of concrete, reducing the rebound rate of the concrete, improving the stability of a product and remarkably improving early-stage and later-stage strength of sprayed concrete, and has significant practical application values in concrete construction.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

Composite phosphates sugar juice decoloring agent and preparation thereof

ActiveCN101440412BEasy to storeEasy to transportPurification by oxidation/reductionMonomagnesium phosphateHydrolysate

Owner:YUNNAN JIANGLIN GROUP

Stephanoporate photocatalysis function composite material for venomousness liquid pollutant cleaning treatment

InactiveCN101219387AAdsorptiveBoth functionalPhysical/chemical process catalystsWater/sewage treatment by irradiationMonomagnesium phosphateAdhesive

The invention relates to a porous photo catalytic compound material used for the purification treatment of toxic liquid contaminants, in particular to a porous sodium zirconium phosphate / nano titanium dioxide photo catalytic compound material, which is provided with absorption, decomposition and purification functions, and can quickly separate, high effectively absorb and rapidly decompose such toxic organic contaminants as toluene and phenol under ultraviolet or natural light, and can purify water source through highly effective absorption even without lighting. The compound material has a porous structure, and has the weight percentages of: 50 to 80 percent of sodium zirconium phosphate, 5 to 30 percent of nano titanium dioxide, and 5 to 30 percent of phosphate adhesive; the phosphate adhesive is selected from one or more of aluminum dihydrogen phosphate, magnesium dihydrogen phosphate, potassium phosphate and sodium phosphate; the particle sizes of nano titanium dioxide range between 1nm and 500nm. The compound material can be prepared from such methods as foam immersion.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com