Composite phosphates sugar juice decoloring agent and preparation thereof

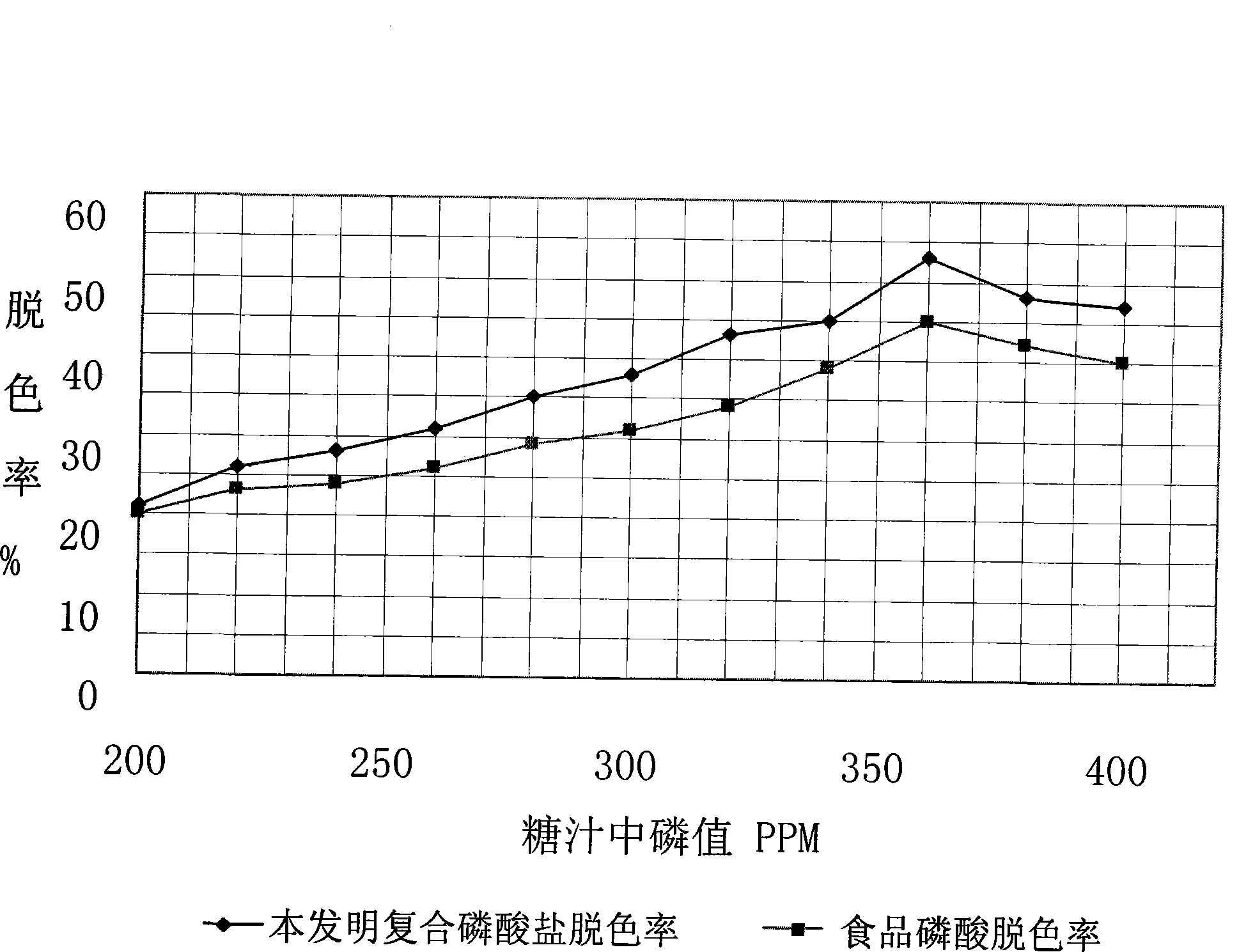

A technology of phosphate sugar and decolorizing agent, applied in the chemical field, can solve the problems of easy corrosion and high production cost, and achieve the effect of good decolorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Because the sugar juice decolorizer of the present invention relates to food production safety. Carrying out the method of the present invention requires careful selection of starting materials. Phosphoric acid chooses food grade phosphoric acid. In addition to meeting relevant industrial standards, talcum powder and heavy calcium carbonate powder should also have low content of arsenic, lead, and heavy metals, so that the final product can meet the relevant food-grade requirements, and no new Toxic and harmful substances are in line with the food hygiene and safety of sugar factories.

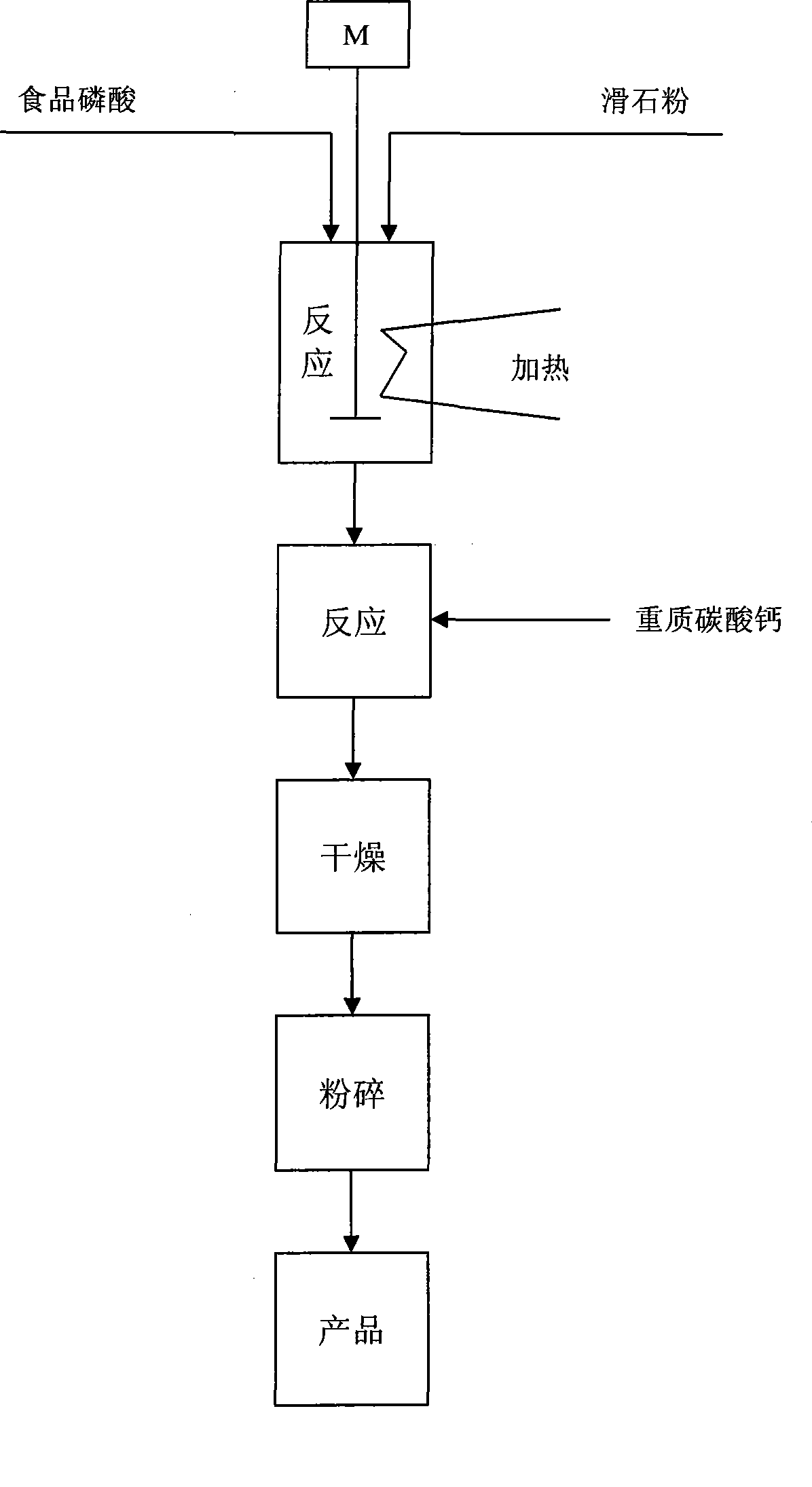

[0037] A preparation method of compound phosphate sugar juice decolorizer:

[0038] 1. Stone powder reaction

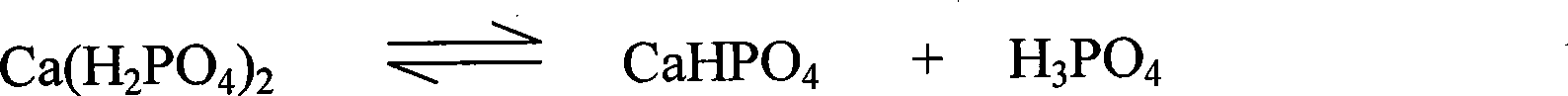

[0039] Weigh a certain amount of food phosphoric acid in a 1-liter glass beaker, gradually add the required talcum powder under heating and stirring, keep the temperature at 95°C to 110°C, continue stirring and reacting for about 40 minutes, keep warm for later use.

[0040...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com