Patents

Literature

157results about How to "Production cost advantage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Battery

InactiveUS20050175890A1Production cost advantageIncrease capacityPrimary cell to battery groupingMoving electrode arrangementsEngineeringIon

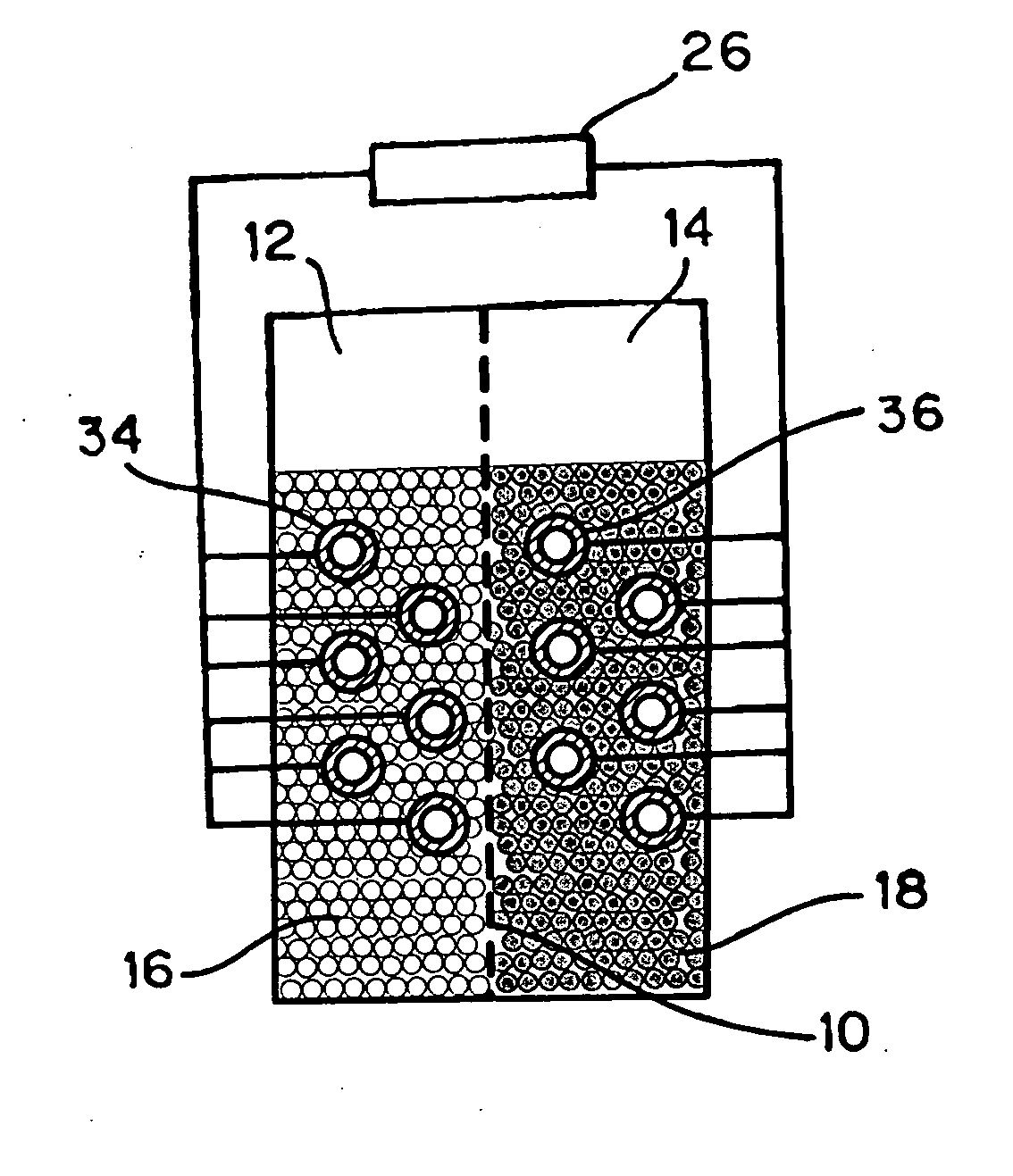

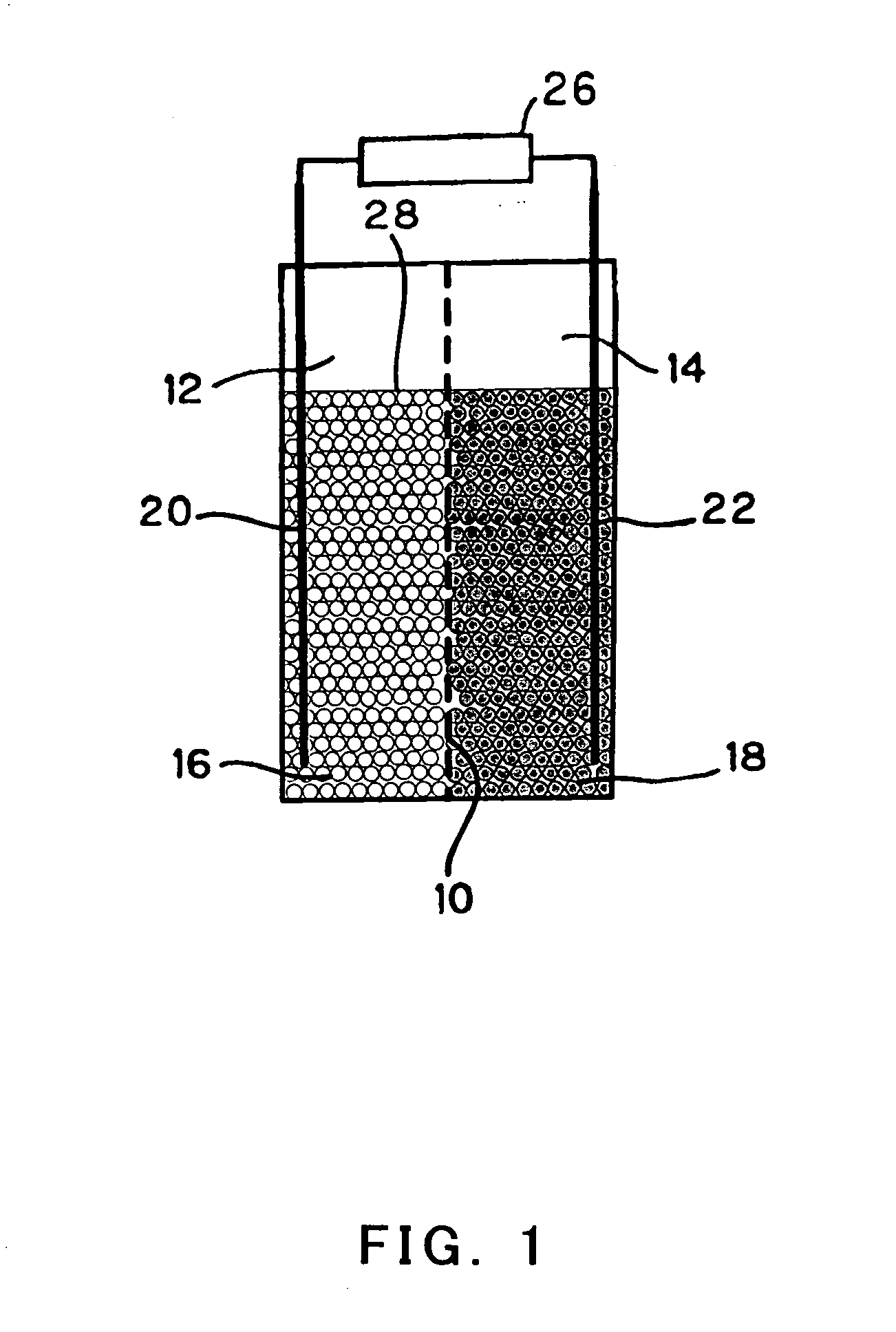

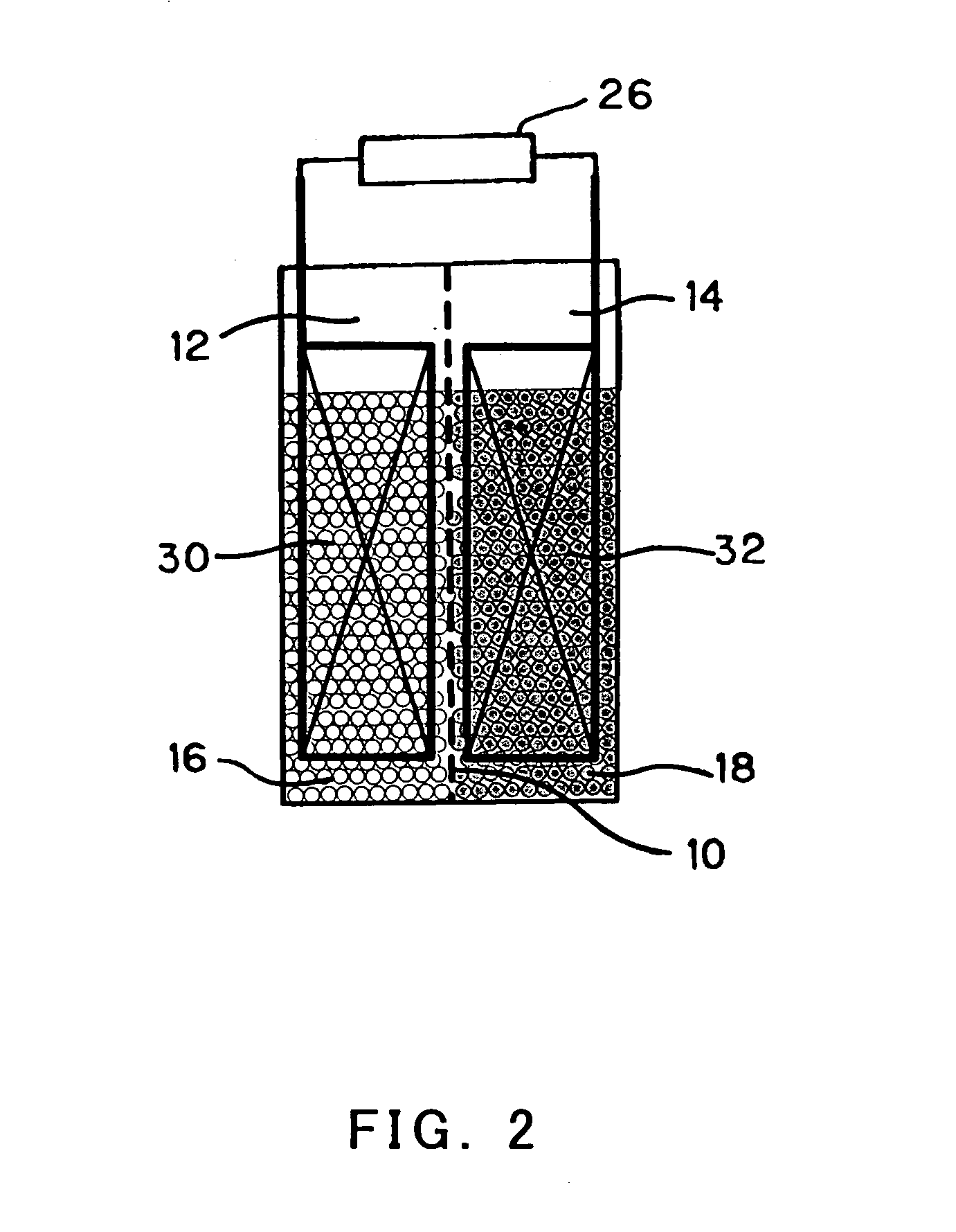

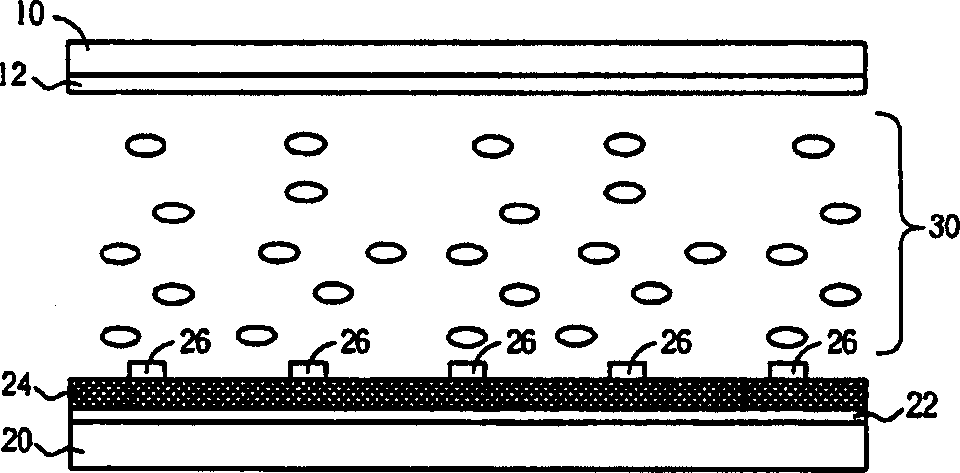

Anode active material particles and an electrolytic solution 16 are filled in an anode cell 12 as one of two vessels connected to each other with an ion-permeable separator 10 interposed therebetween, and cathode active material particles and an electrolytic solution 18 are filled in a cathode cell 14 as the other vessel. Electrically conductive current collectors 20 and 22 are provided in contact with the active material particles within the two vessels. The active material particles form fixed layers.

Owner:KAWASAKI HEAVY IND LTD

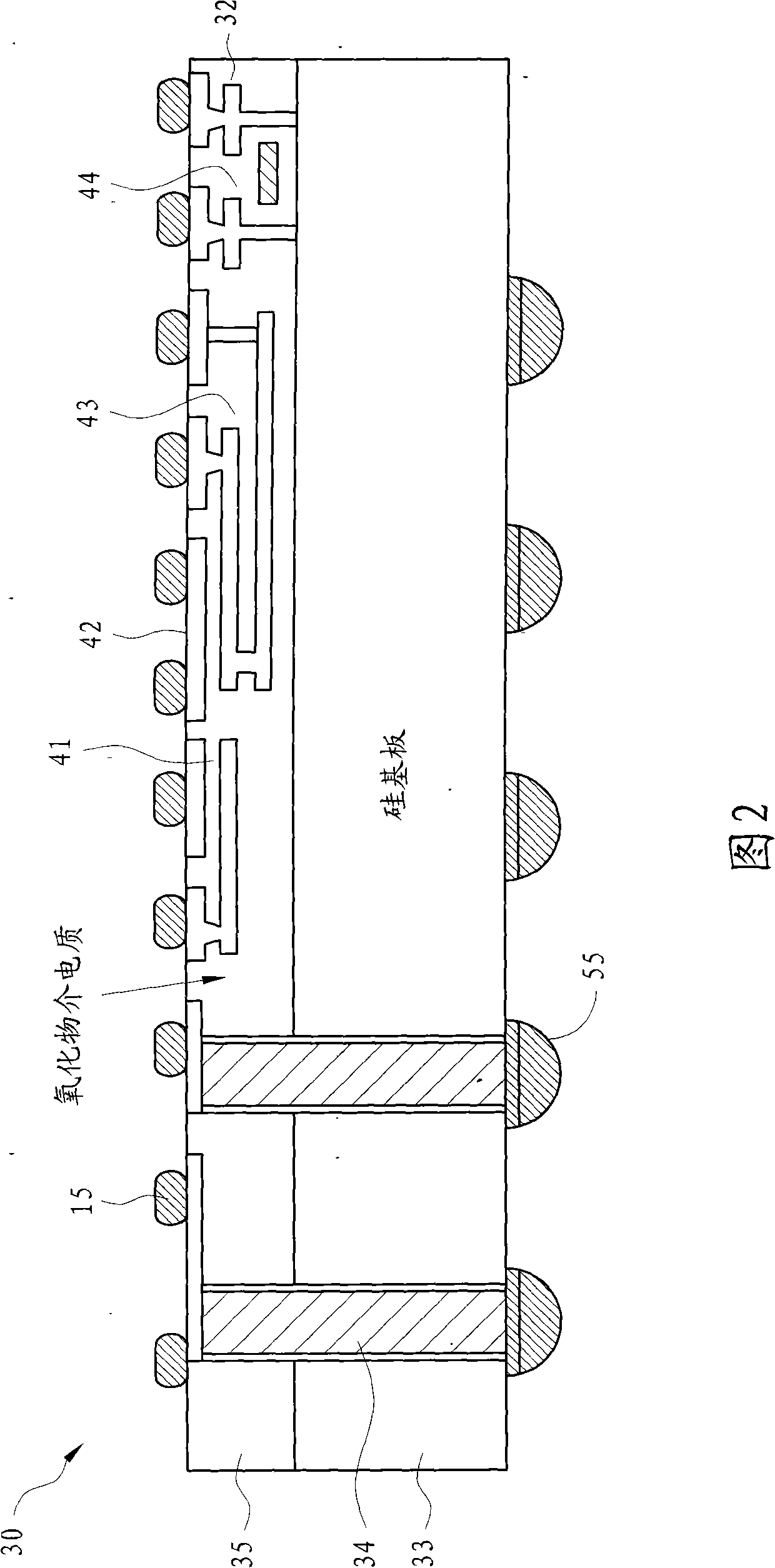

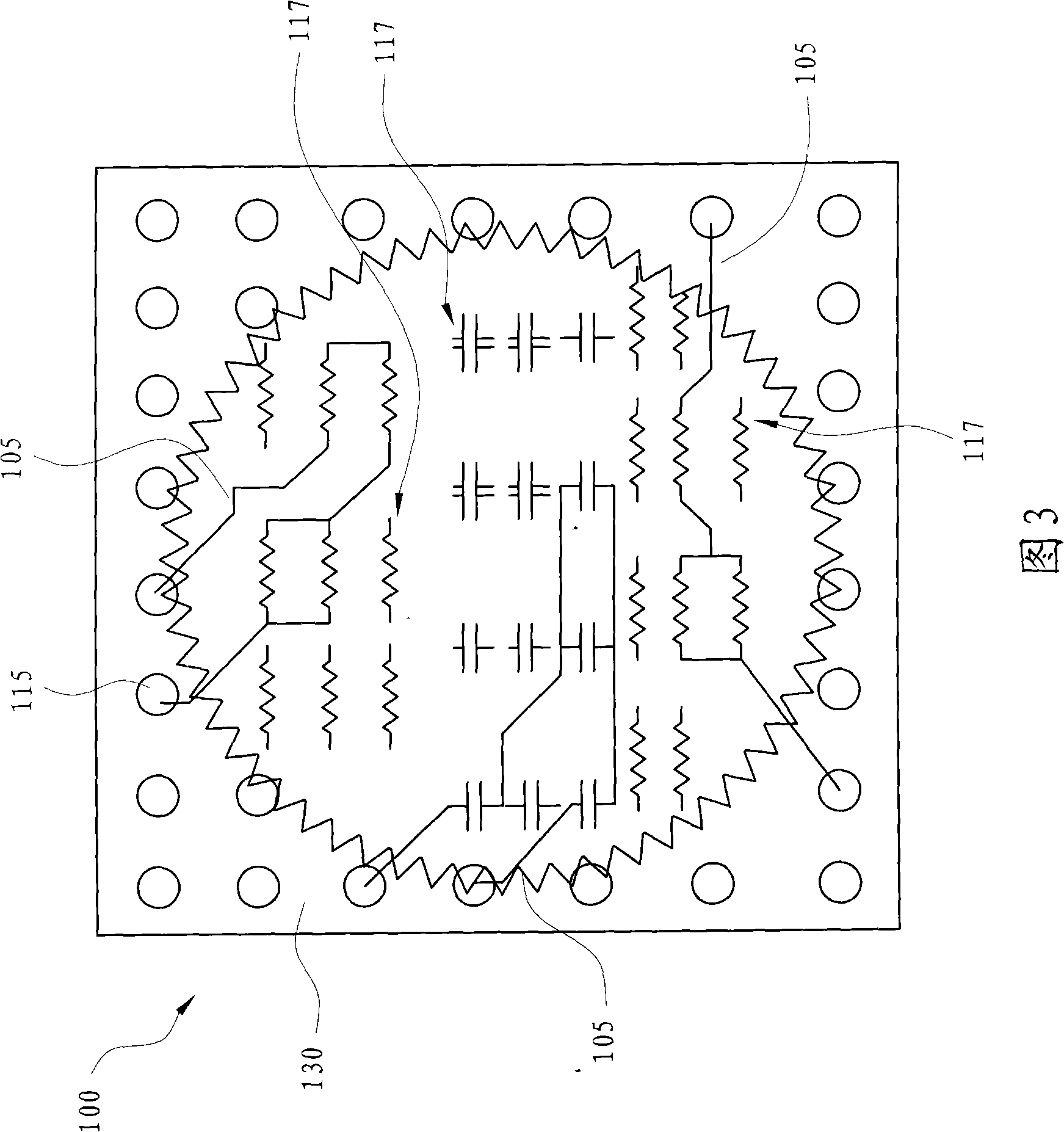

Semiconductor interposer and its application in electronic package

ActiveCN101315914ALow costShorten cycle timeSemiconductor/solid-state device detailsSolid-state devicesContact padInterposer

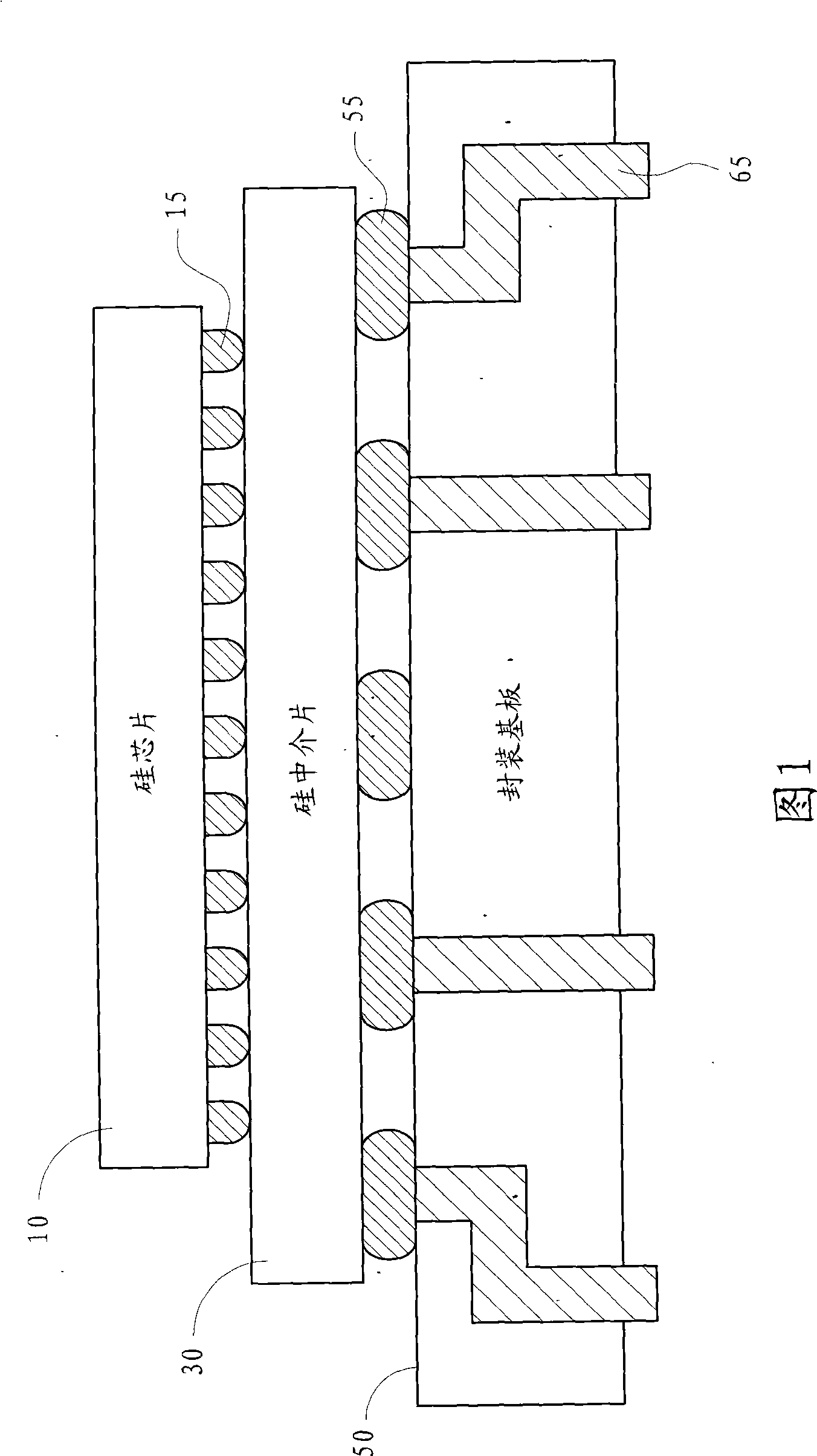

Various structures of a programmable semiconductor interposer for electronic packaging are described. An array of semiconductor devices having various values is formed in said interposer. A user can program said interposer and form a ''virtual'' device having a desired value by selectively connecting various one of the array of devices to contact pads formed on the surface of said interposer. An inventive electronic package structure includes a standard interposer having an array of unconnected devices of various values and a device selection unit, which selectively connects various one of the array of devices in said standard interposer to an integrated circuit die encapsulated in said electronic package. Methods of forming said programmable semiconductor interposer and said electronic package are also illustrated.

Owner:TAIWAN SEMICON MFG CO LTD

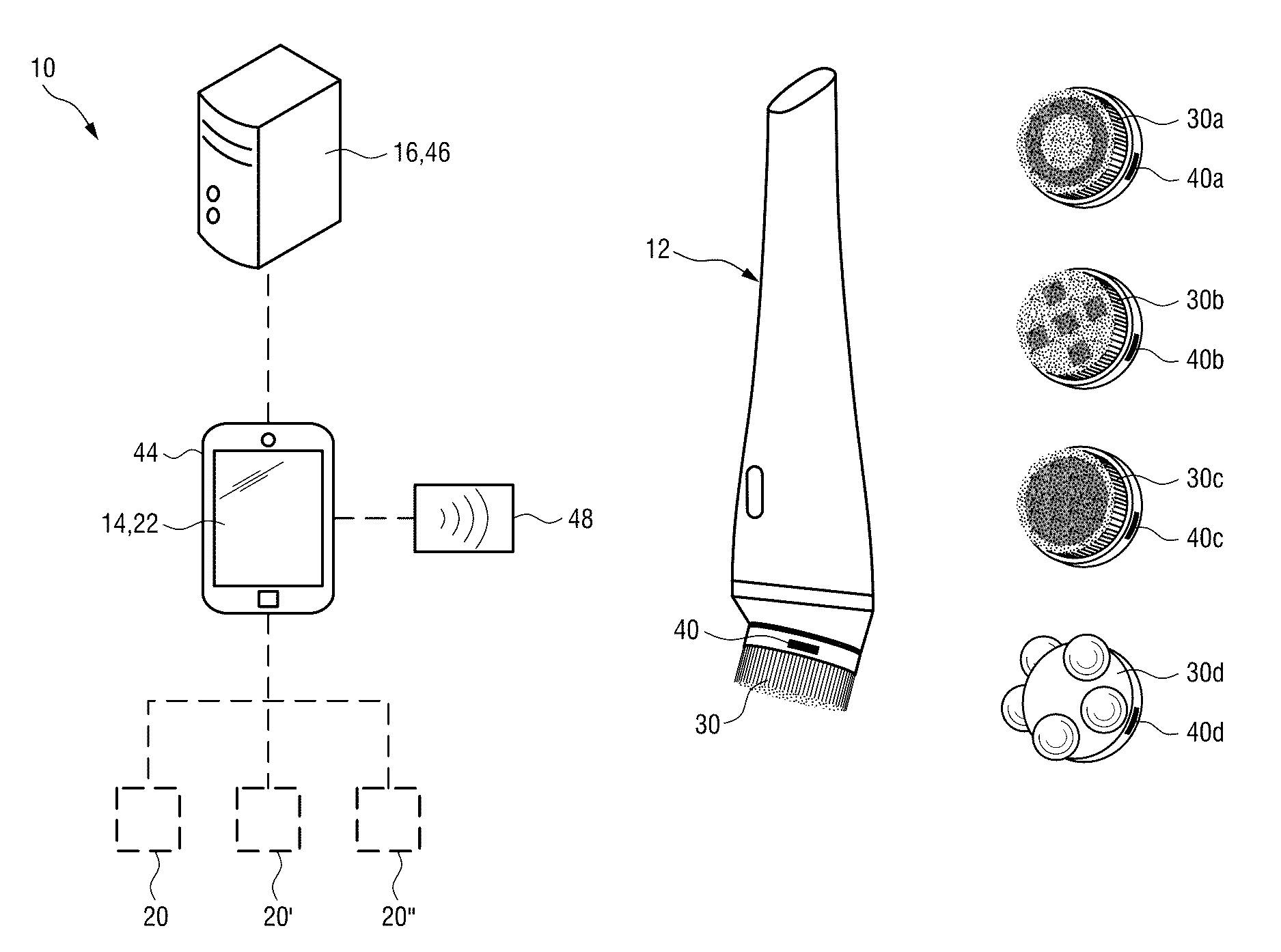

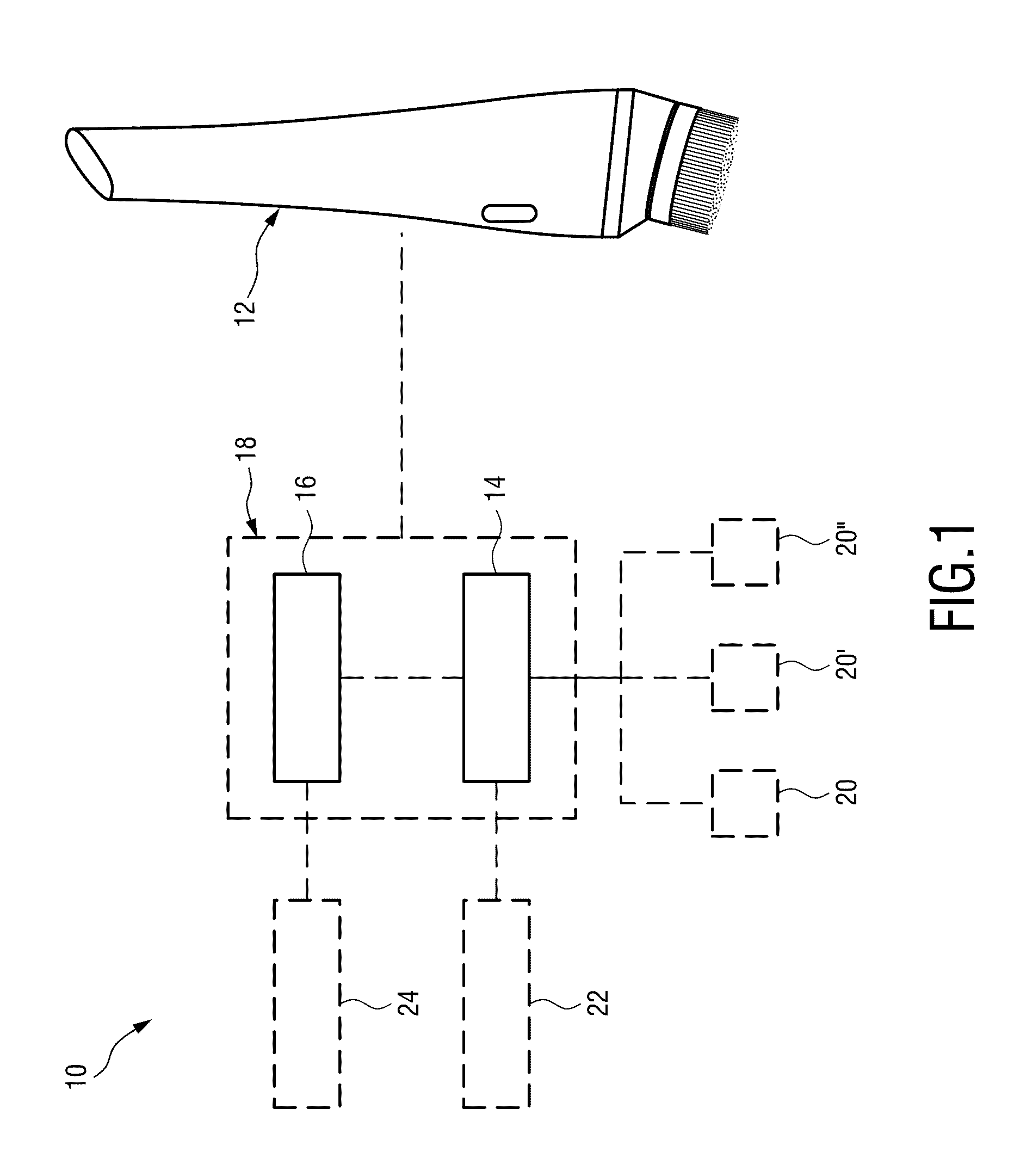

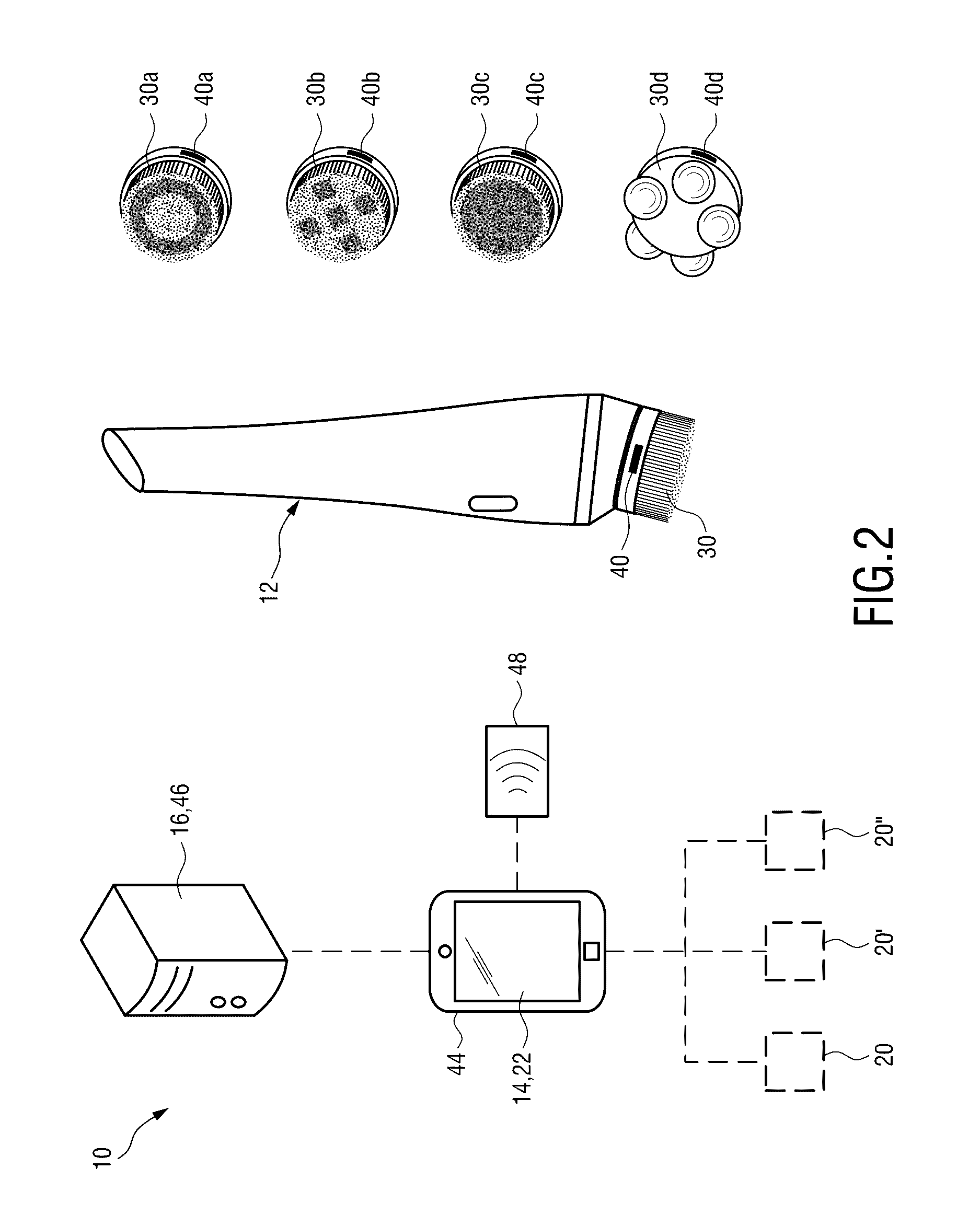

Skin care system, device and method

InactiveUS20170056685A1Improve consumer satisfactionSkin stimulationPhysical therapies and activitiesMechanical/radiation/invasive therapiesSkin treatmentsControl cell

The present invention relates to a skin care system (10), comprising: (i) a skin treatment device (12) for treating a skin of a user; (ii) a receiving unit (14) for receiving information on the skin of the user; and (iii) an evaluation unit (16) which is configured to evaluate the received information on the skin of the user and to determine based on said evaluation one or more personalized device settings for operating the skin treatment device (12). The skin treatment device (12) comprises a control unit (36) which is configured to operate the skin treatment device (12) upon initiation based on the determined one or more personalized device settings.

Owner:KONINKLJIJKE PHILIPS NV

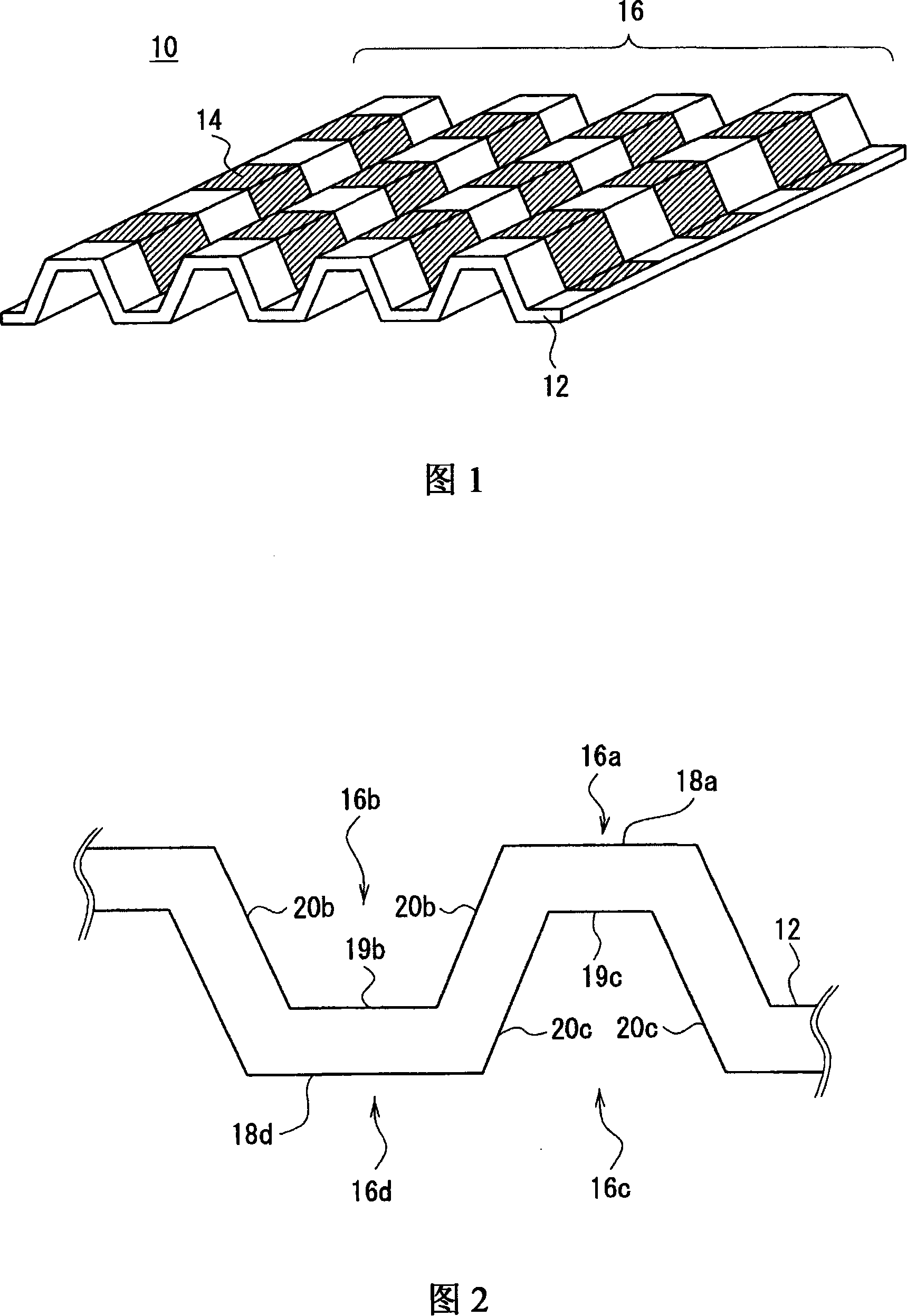

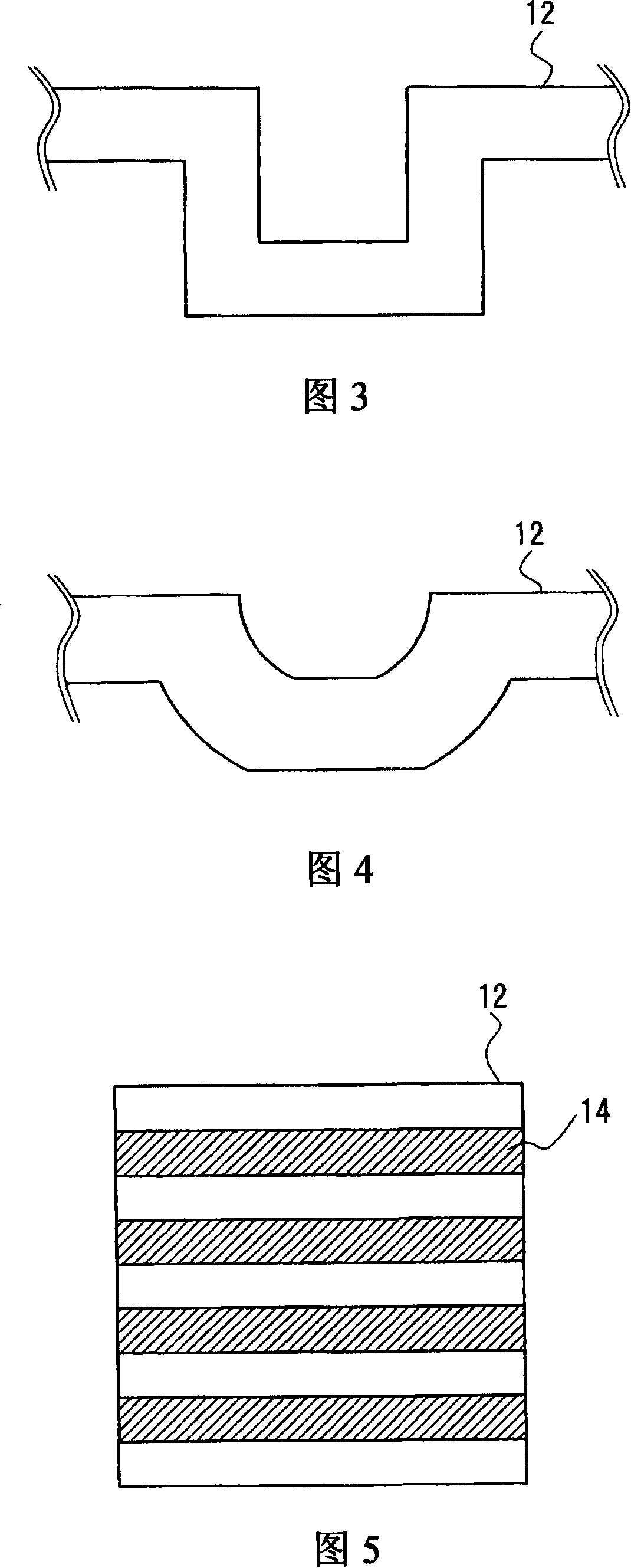

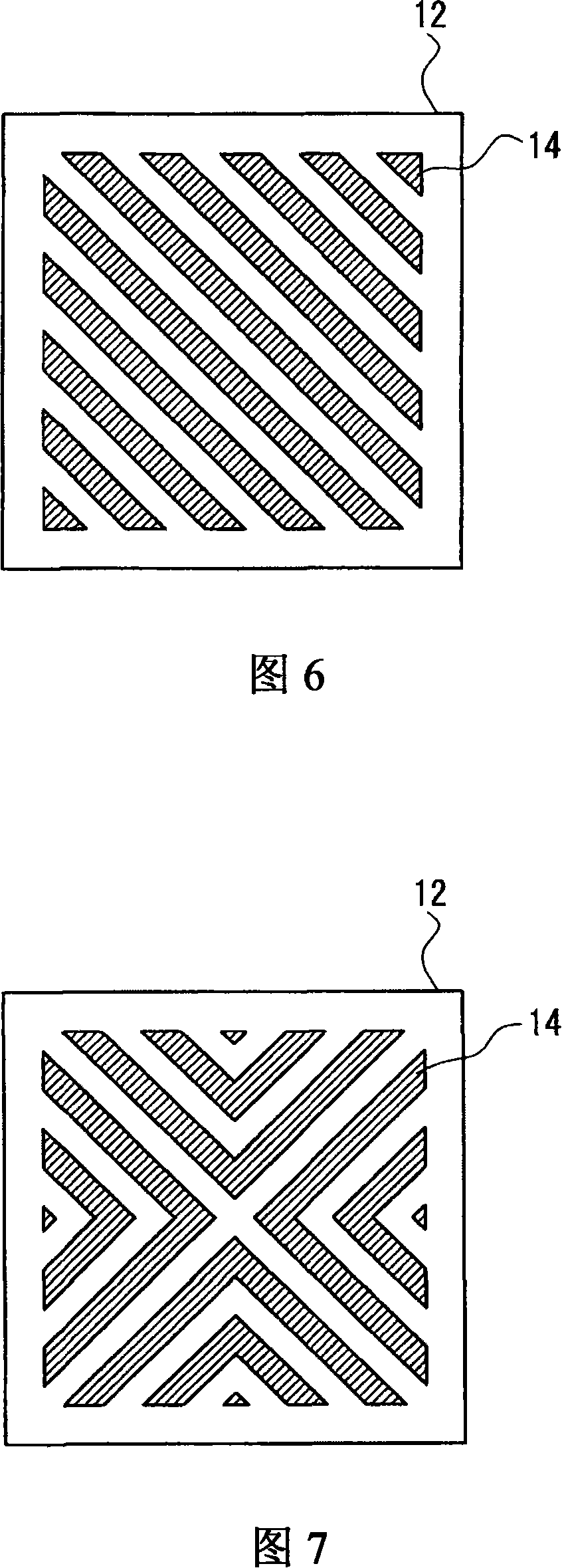

Metallic bipolar plate for fuel cells, and fuel cell comprising the same

InactiveCN101123313AReduce contact resistanceImprove corrosion resistanceCell electrodesCollectors/separatorsFuel cellsMetallic substrate

The present invention relates to a metallic bipolar plate for fuel cells, including: a plate-like metallic substrate containing a metal capable of being passivated; and a noble-metal layer disposed partially on both surfaces of the metallic substrate to coat the metallic substrate, the metallic bipolar plate having a concave-convex portion formed at least in a region facing an electrode of a membrane electrode assembly, in which both surfaces of the metallic bipolar plate respectively have a contact surface which contacts with the electrode and a non-contact surface which does not contact with the electrode, and in which both surfaces of the metallic bipolar plate respectively have a coating area ratio of the noble-metal layer to the contact surface within a range of from 20% to 100%, and a coating area ratio of the noble-metal layer to the non-contact surface within a range of from 5% or more but less than 100%.

Owner:DAIDO STEEL CO LTD

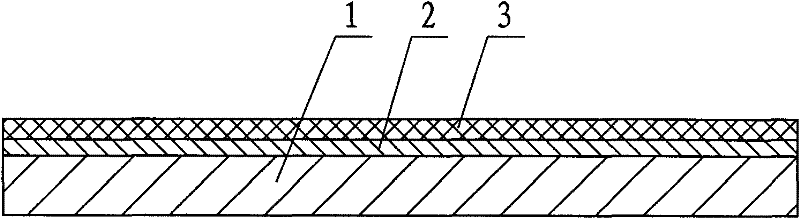

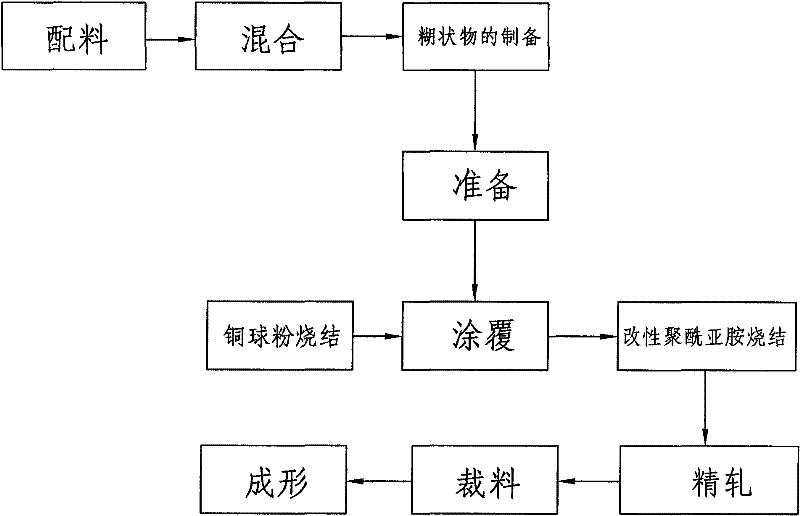

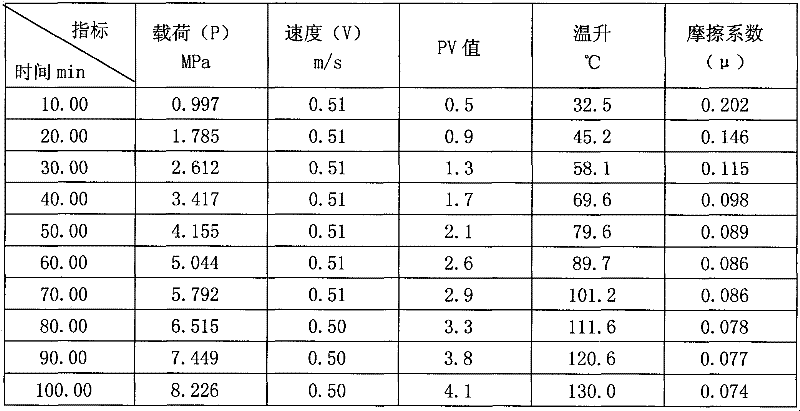

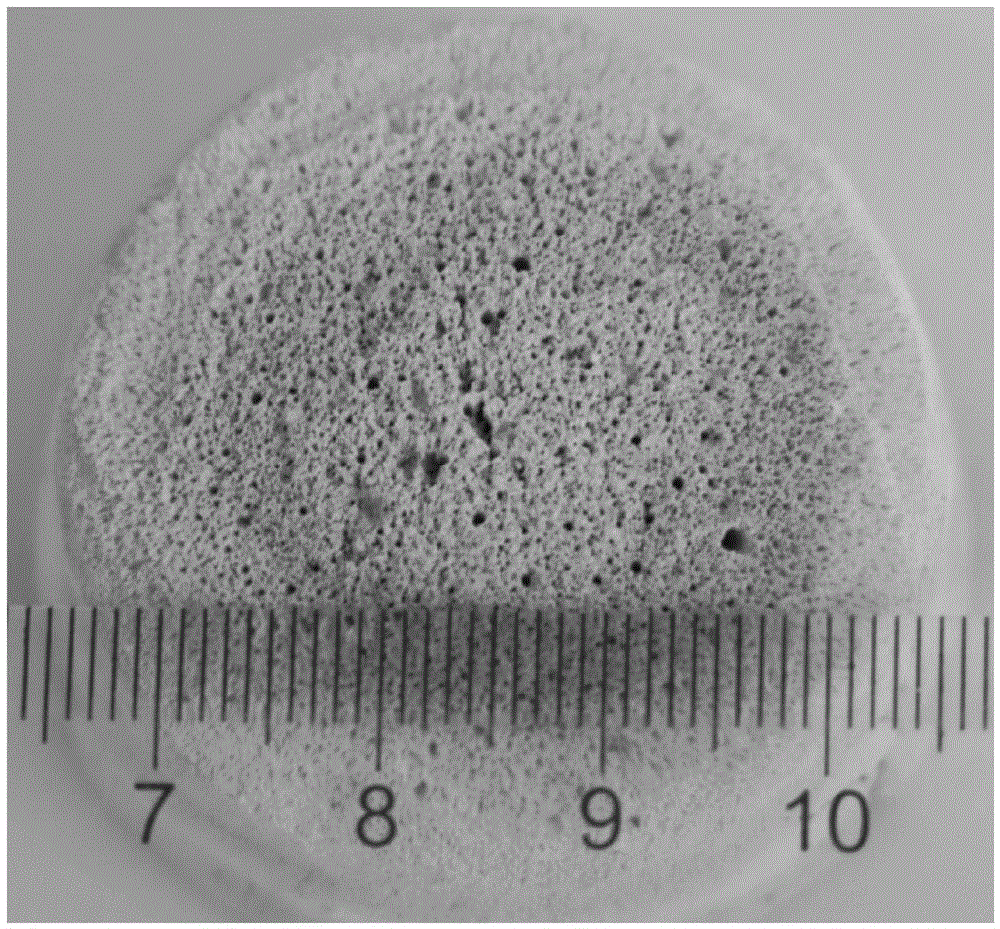

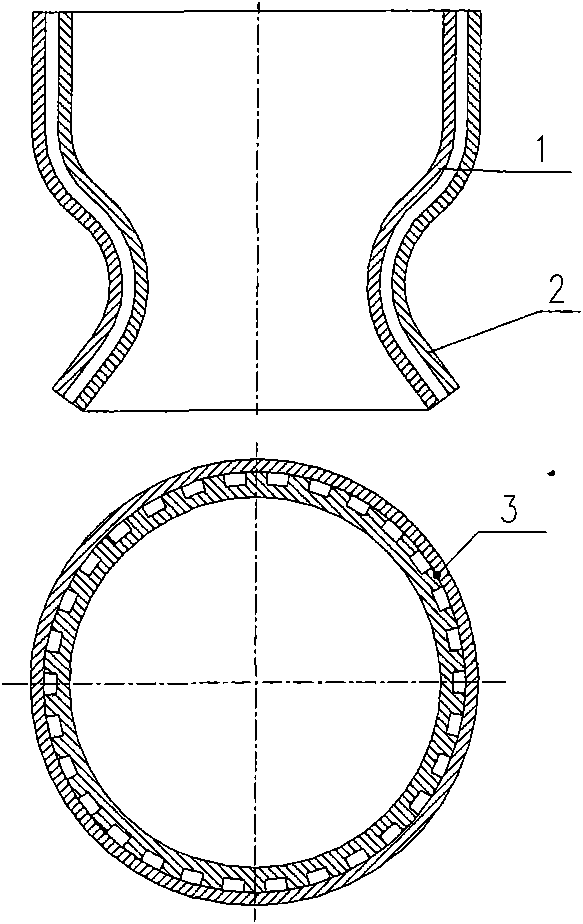

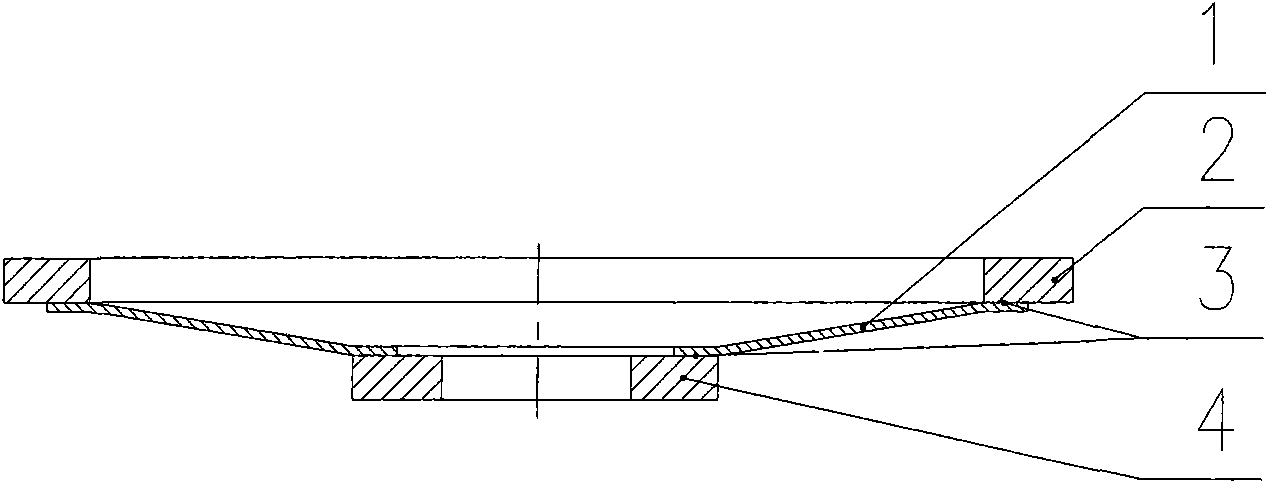

Three layer composite self-lubricating sliding bearing with modified polyimide wear layer and preparation method thereof

The invention discloses a three layer composite self-lubricating sliding bearing with a modified polyimide wear layer and a preparation method thereof. A layer of porous spherical bronze powder is sintered on a layer of a steel plate; a layer of modified polyimide wear resistant material is covered on the porous spherical bronze powder layer to prepare a sheet material of the self-lubricating sliding bearing; and the sheet material of the self-lubricating sliding bearing is prepared into products of a sliding bearing in a spindle sleeve shape or a thrust washer or a slide plate or a friction disc sheet or ball seat structural member. A production technology comprises steps of: preparing modified polyimide mash, sintering the spherical bronze powder, preparing, coating, sintering the modified polyimide, finishing rolling, cutting material and forming. The three layer composite self-lubricating sliding bearing with the modified polyimide wear layer of the invention has excellent performances of good rigidity, high strength, high temperature resistance, friction resistance and no lead, and is especially suitable for heavy load, variable load and high PV value sliding bearing.

Owner:ZHEJIANG CHANGSHENG SLIDING BEARINGS

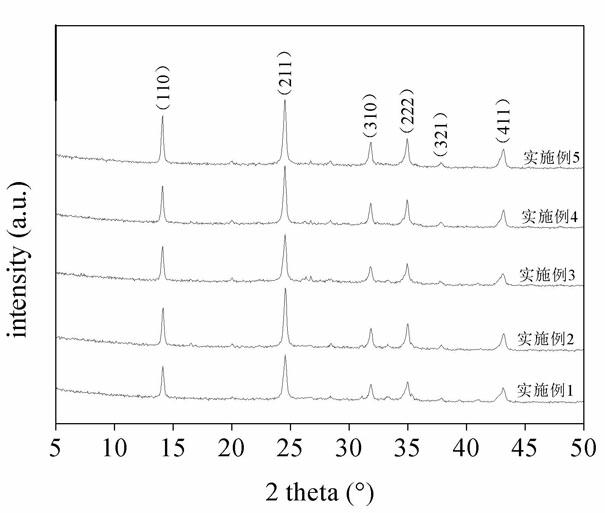

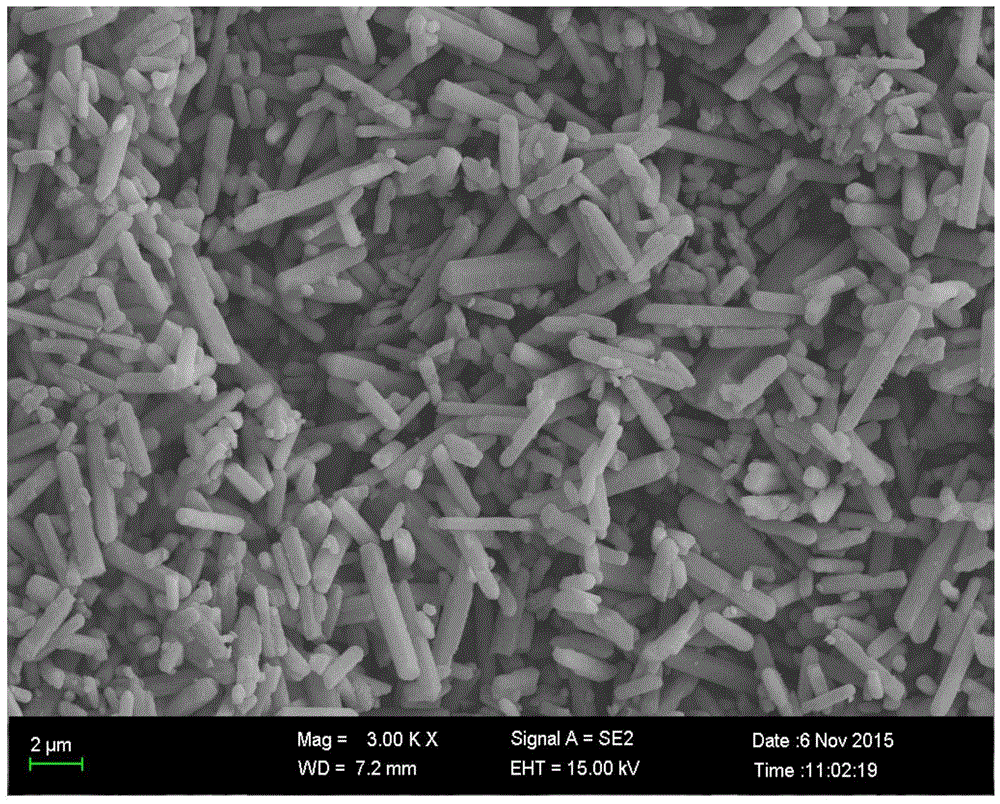

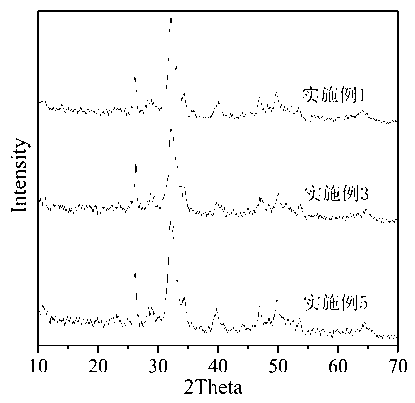

Process for synthesizing single-phase sodalite from fly ash

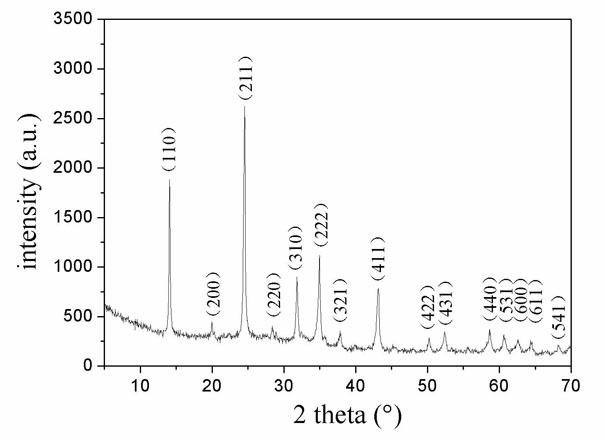

ActiveCN102173433ASolve the reuse problemExpand sourceSolid waste disposalCrystalline aluminosilicate zeolitesPre treatmentFly ash

The invention belongs to the field of production and preparation of inorganic functional materials, and particularly relates to a process for preparing single-phase sodalite from fly ash, which comprises the following steps: pretreating fly ash by an alkaline fusion method; proportionally adding the activated fly ash, aluminum hydroxide and sodium hydroxide solution into a polytetrafluoroethyleneinner container, evenly mixing, and carrying out hydrothermal crystallization in a sealed constant-temperature drying oven; and finally, filtering the product, washing until the product becomes neutral, and drying to obtain the single-phase sodalite material. The invention successfully synthesizes the low-cost single-phase sodalite zeolitization material by using solid waste-fly ash as the raw material for production. The process has the advantages of low cost, abundant sources of raw material, controllable product performance, no secondary pollution and the like, is simple and easy to operate, and thus, has great industrial application potential.

Owner:NANJING UNIV OF SCI & TECH

Method of preparing high-performance diamond semiconductor based on low-cost single crystal diamond

ActiveCN107275192AImprove performanceReduce technical difficultySemiconductor/solid-state device manufacturingSelf-healingHydrogen atmosphere

The invention discloses a method for preparing a high-performance diamond semiconductor based on low-cost single crystal diamond, and belongs to the technical field of novel semiconductor preparation. The process steps include a, a commercially available cheap high temperature and pressure Ib-type single crystal diamond substrate is subjected to acid pickling to remove surface inclusions and form a passivated oxygen termination surface; b, the activated diamond surface is subjected to short time treatment by microwave hydrogen plasmas to expose a fresh C-C dangling bond; c, a high-quality single crystal diamond thin film is epitaxially grown on the fresh diamond surface by microwave plasma chemical vapor deposition to achieve the diamond thin film epitaxy with low dislocation density and impurity content mainly through the introduction of oxygen atoms with a self-healing function; and d, a carbon source and a oxygen source are turned off, the epitaxially grown diamond surface is treated by the microwave hydrogen plasmas to obtain a high hydrogen termination density, and the treated diamond surface is cooled to room temperature under a hydrogen atmosphere to obtain a diamond semiconductor with high conductivity. According to the invention, the process flow is simplified, the technical difficulty and the production cost are reduced, and the production cycle is shortened.

Owner:UNIV OF SCI & TECH BEIJING

Liquid crystal displaying device with adjustable visual angle

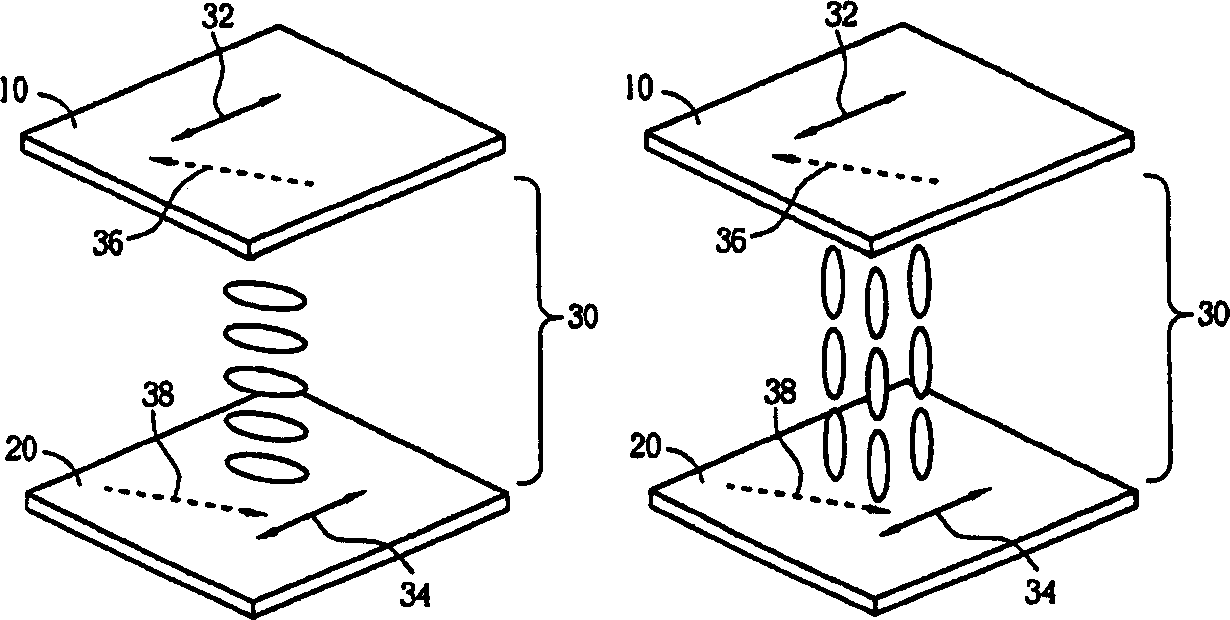

ActiveCN1645195AEasy to operateSimple structureStatic indicating devicesNon-linear opticsLiquid-crystal displayLiquid crystal

A liquid crystal display with adjustable angle consists of the first and the second base plate, liquid crystal layer, the first and the second sheared electrode, a picture element electrode, and an insulation layer between the picture element and the second sheared electrode. It is featured as providing a driving voltage at picture element by the display to have the first shear electrode earthed and the second one suspension-jointed for providing a narrow visual angle mode and applying the same way to have the second sheared electrode earthed and the first one suspension-joined for providing a wide visual angle mode.

Owner:AU OPTRONICS CORP

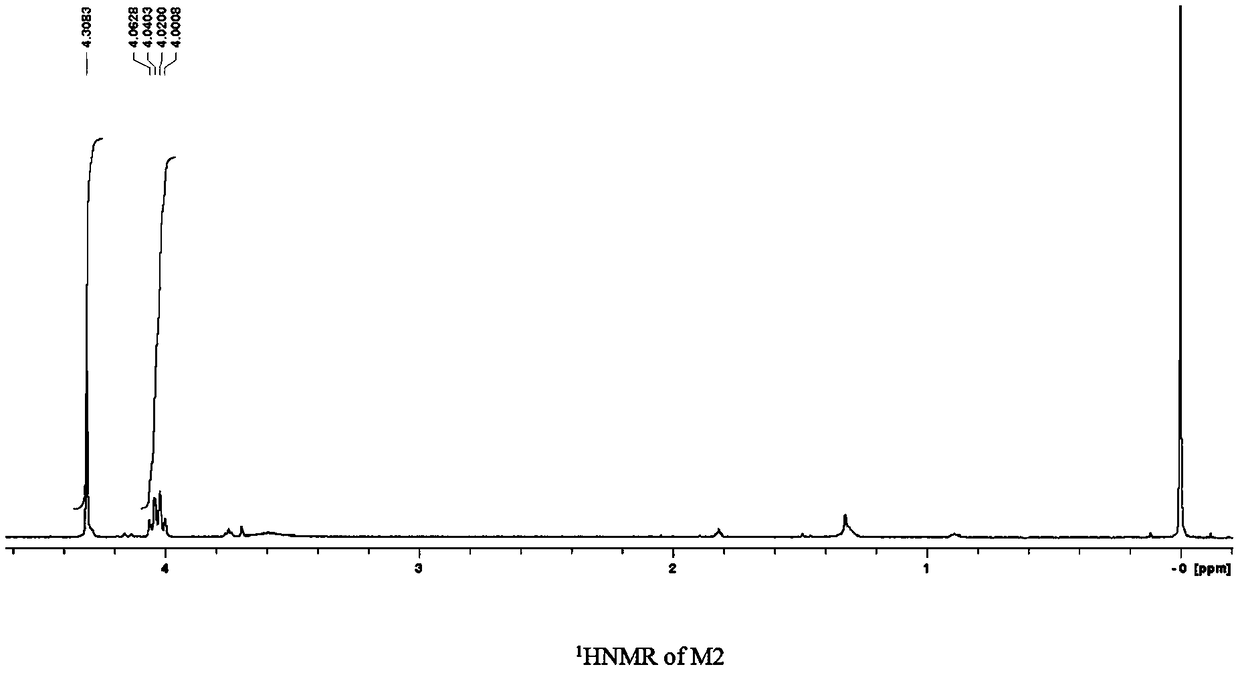

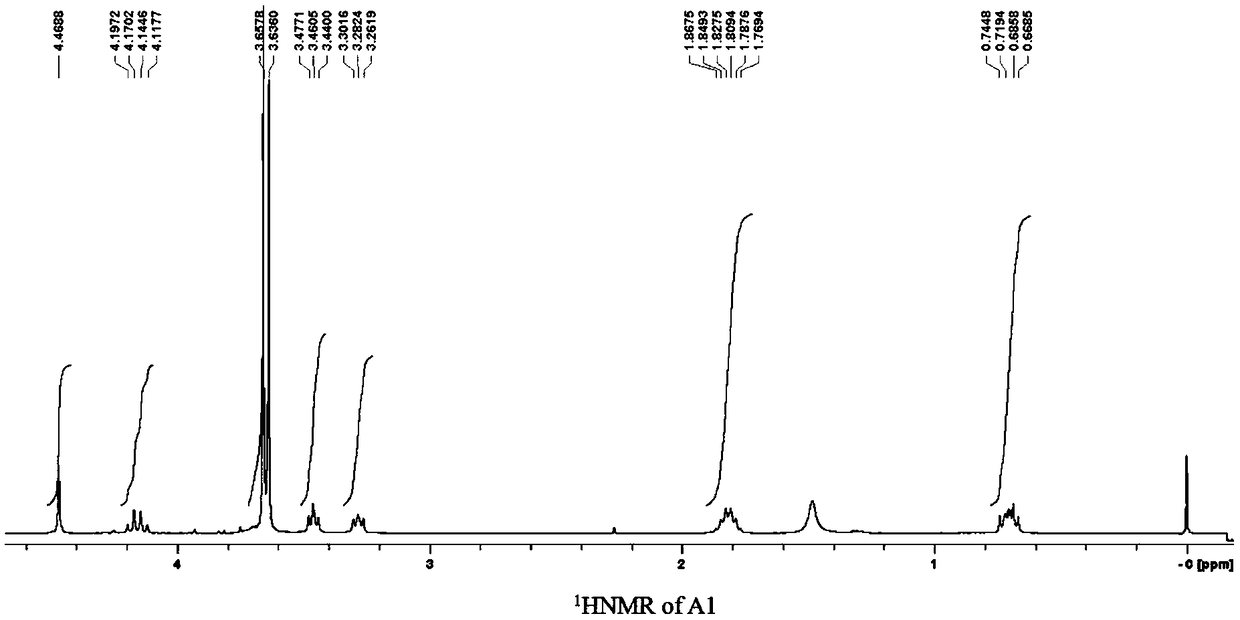

Perfluoropolyether group-containing silane compound, preparation method thereof, surface treatment agent and article

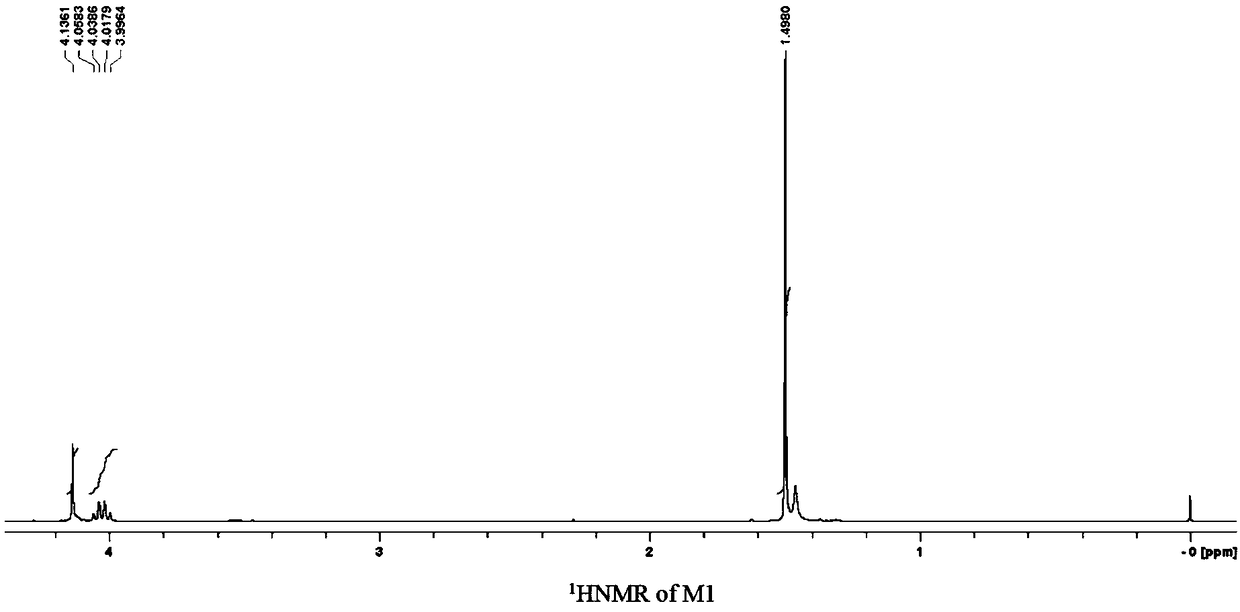

ActiveCN109071793AImprove hydrophobicityGood oleophobic effectAntifouling/underwater paintsPaints with biocidesSurface finishingWear resistant

The invention relates to a perfluoropolyether group-containing silane compound represented by a formula (1): Rf-X1-X2-NQkT2-k(1), and a preparation method therefor. The invention also relates to a perfluoropolyether group-containing silane compound shown in the description, and a preparation method therefor. The invention also relates to a perfluoropolyether group-containing silane compound represented by a formula (3) shown in the description, and a preparation method therefor. The perfluoropolyether group-containing silane compound can be used for a surface treatment agent so that the glassand other base materials processed by the surface treatment agent are excellent in anti-pollution, anti-fingerprint, scrape-resistant and wear-resistant performances, and the preparation methods for the compounds are simple in process, and are easy to operate and implement.

Owner:GUANGZHOU UR MATERIALS TECH CO LTD

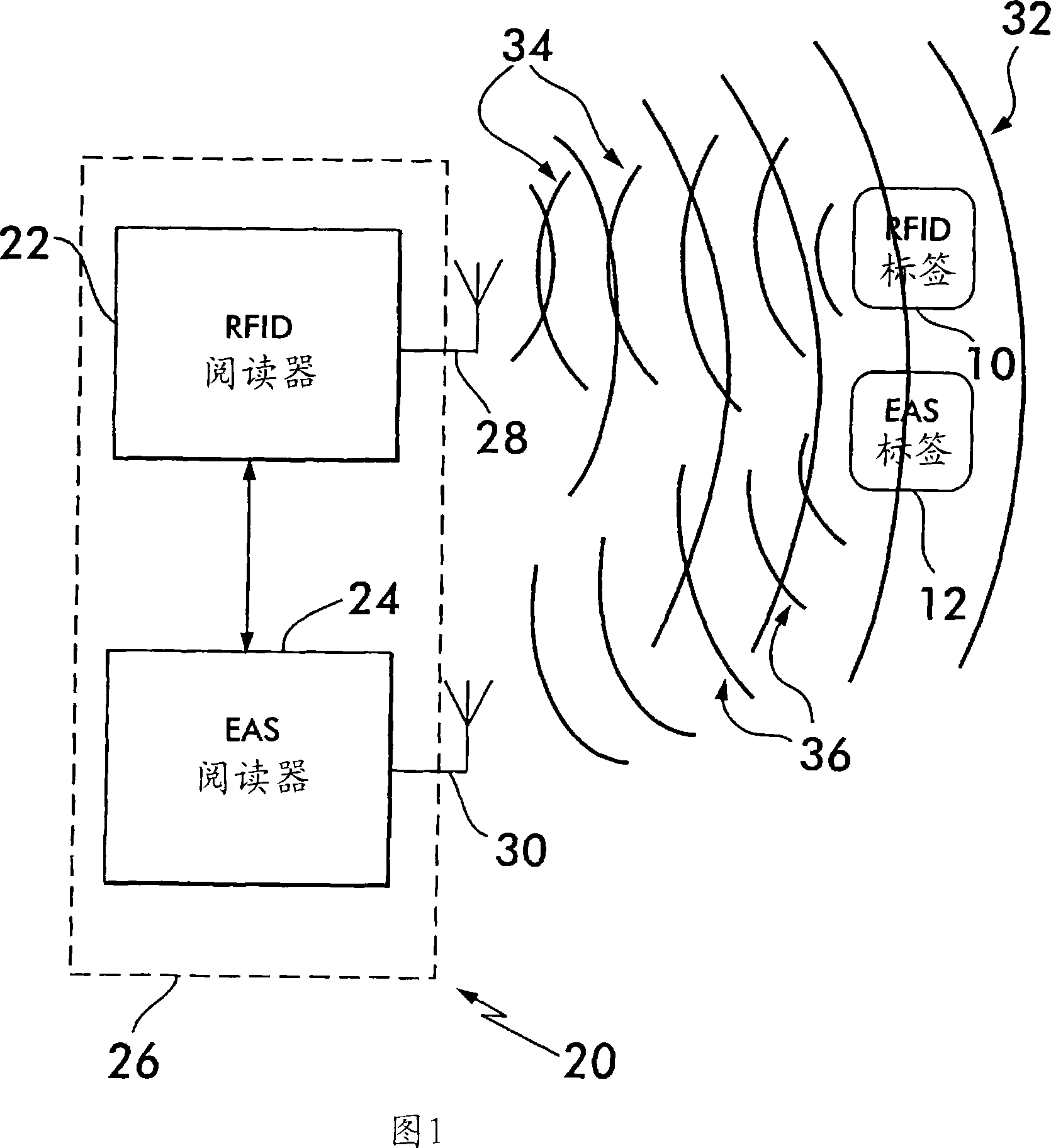

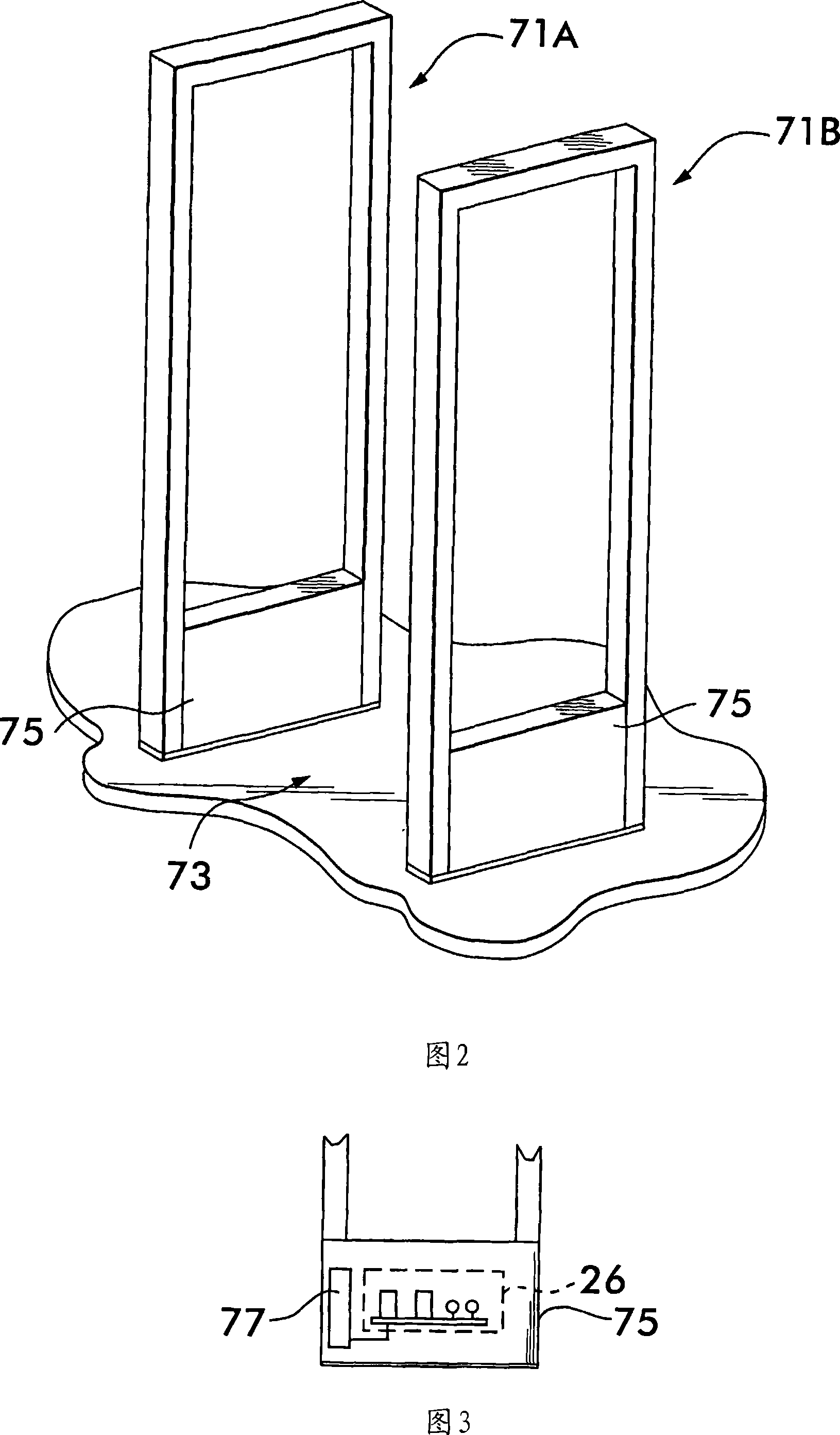

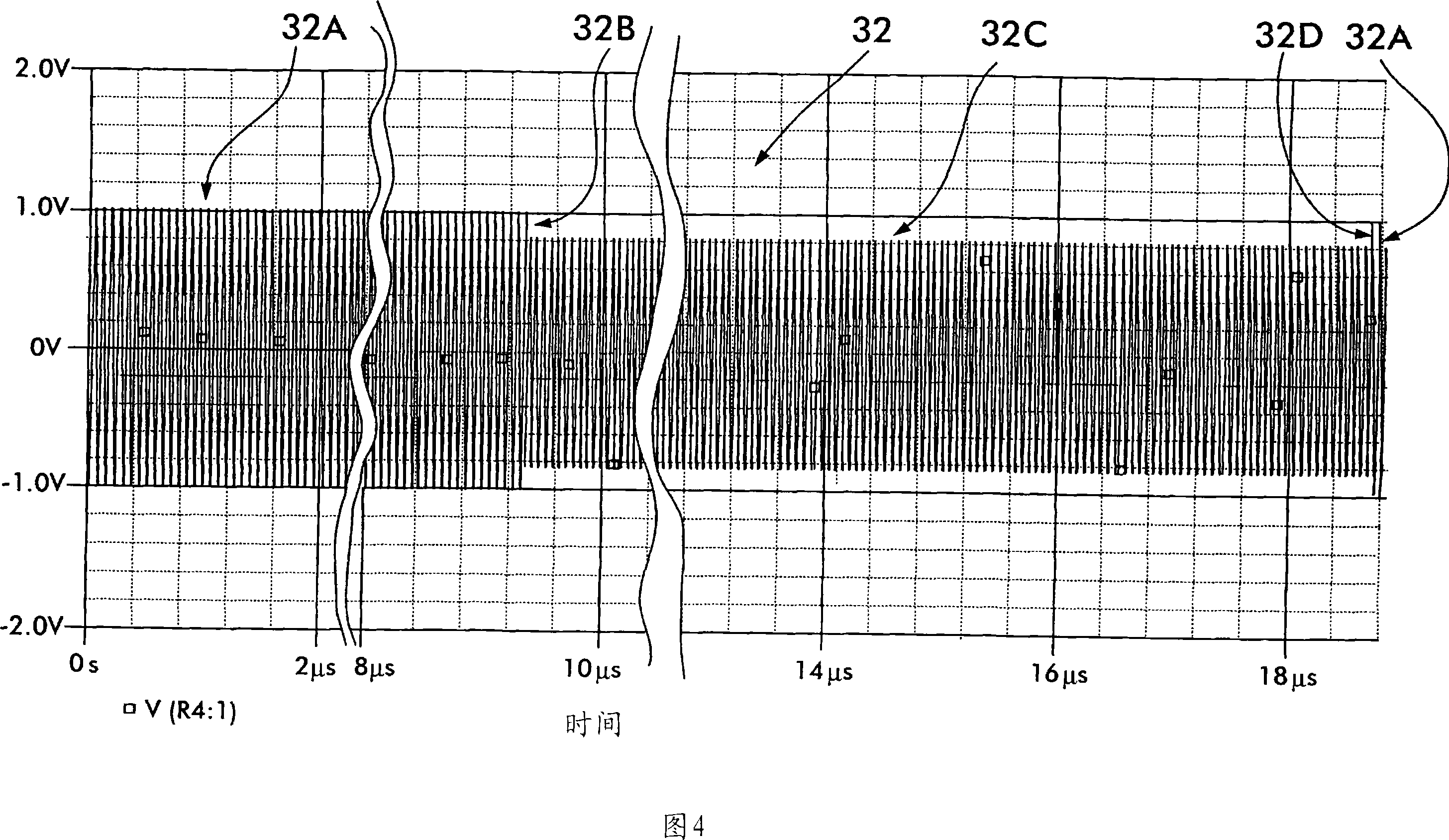

System and method for detecting eas/rfid tags using step listen

InactiveCN101099185ALabel Throughput AdvantageAdvantage detectionBurglar alarm electric actuationComputer scienceSingle stimulus

Owner:CHECKPOINT SYST INC

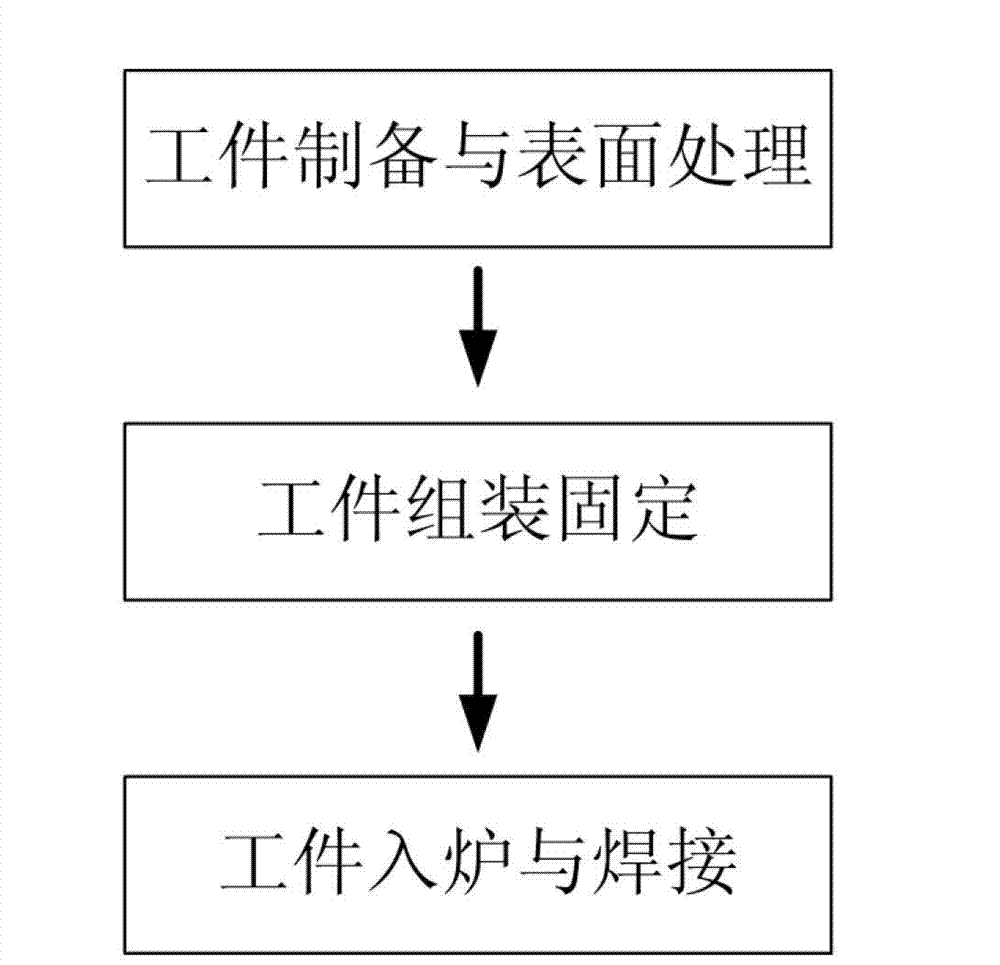

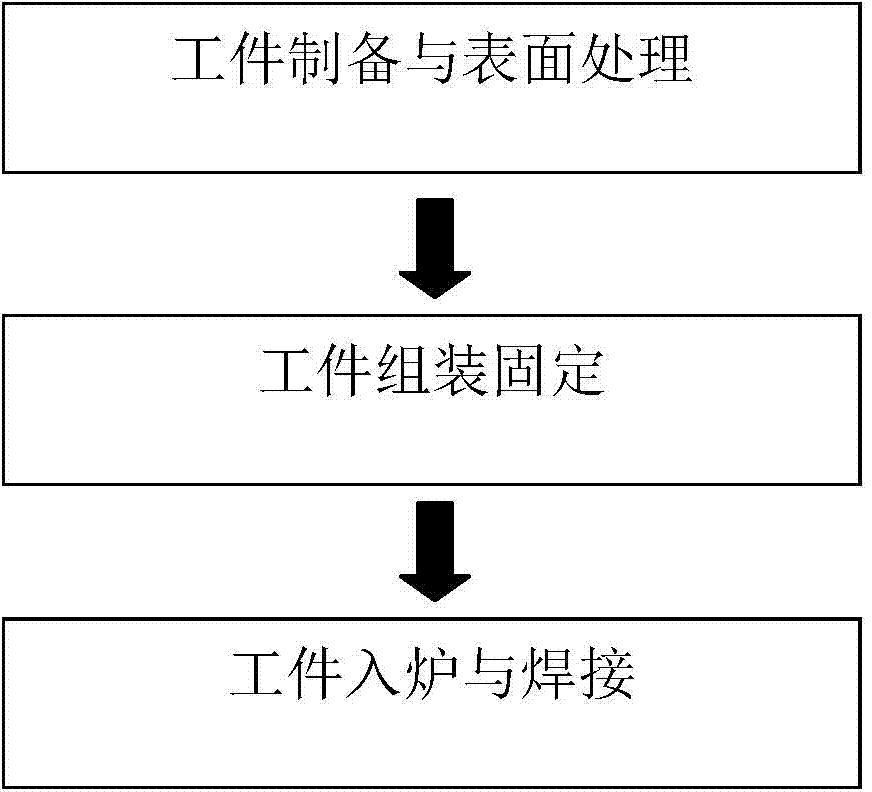

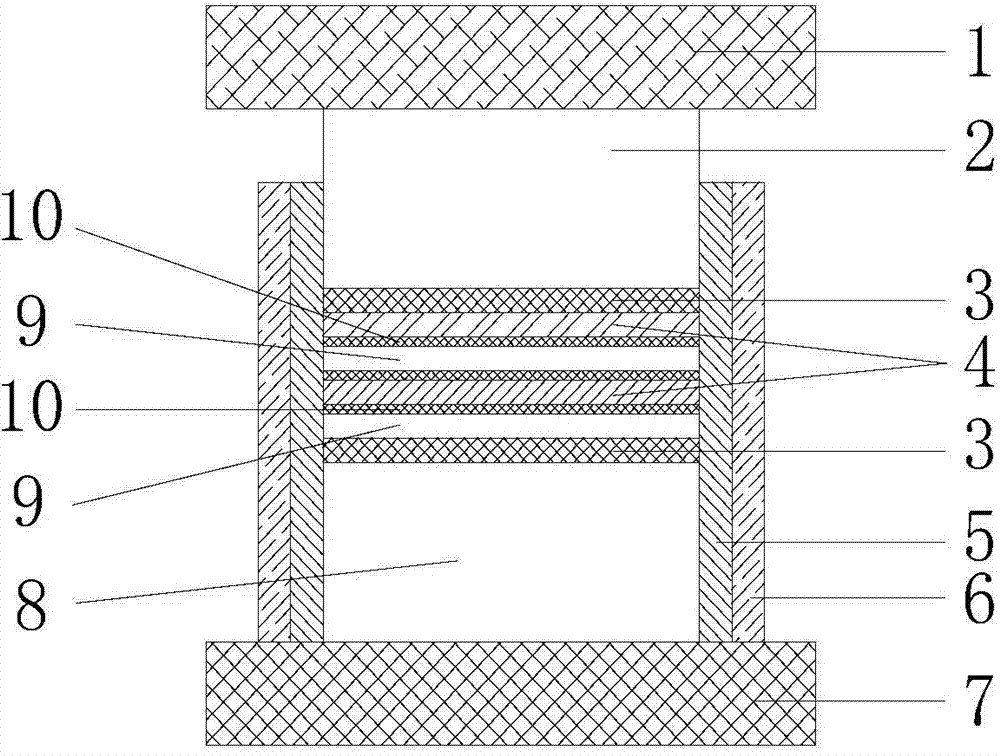

Method for manufacturing multi-layer amorphous alloy and crystal metal composite structure through diffusion welding

InactiveCN102886599AAvoid brittlenessImprove shear resistanceNon-electric welding apparatusShear capacityAlloy

The invention discloses a method for manufacturing a multi-layer amorphous alloy and crystal metal composite structure through diffusion welding. The method comprises the following steps of: cutting, grinding and cleaning an amorphous alloy sheet and a crystal metal sheet, assembling and fixing the amorphous alloy sheet and the crystal metal sheet so as to form a fixed workpiece, and welding the fixed workpiece in a vacuum diffusion furnace. According to the composite structure, extension of a shear band of an amorphous alloy material in the shearing process can be blocked, so that the problem that the pure amorphous alloy material has high brittleness is solved, and the shear resistance is improved. In addition, the welded amorphous alloy material can continuously keep the amorphous characteristics, compared with that of the pure amorphous alloy material, the shear resistance of the composite structure material is greatly improved, the toughness is improved, and the welded sheet is high in surface quality and reliable in connection.

Owner:HUAZHONG UNIV OF SCI & TECH

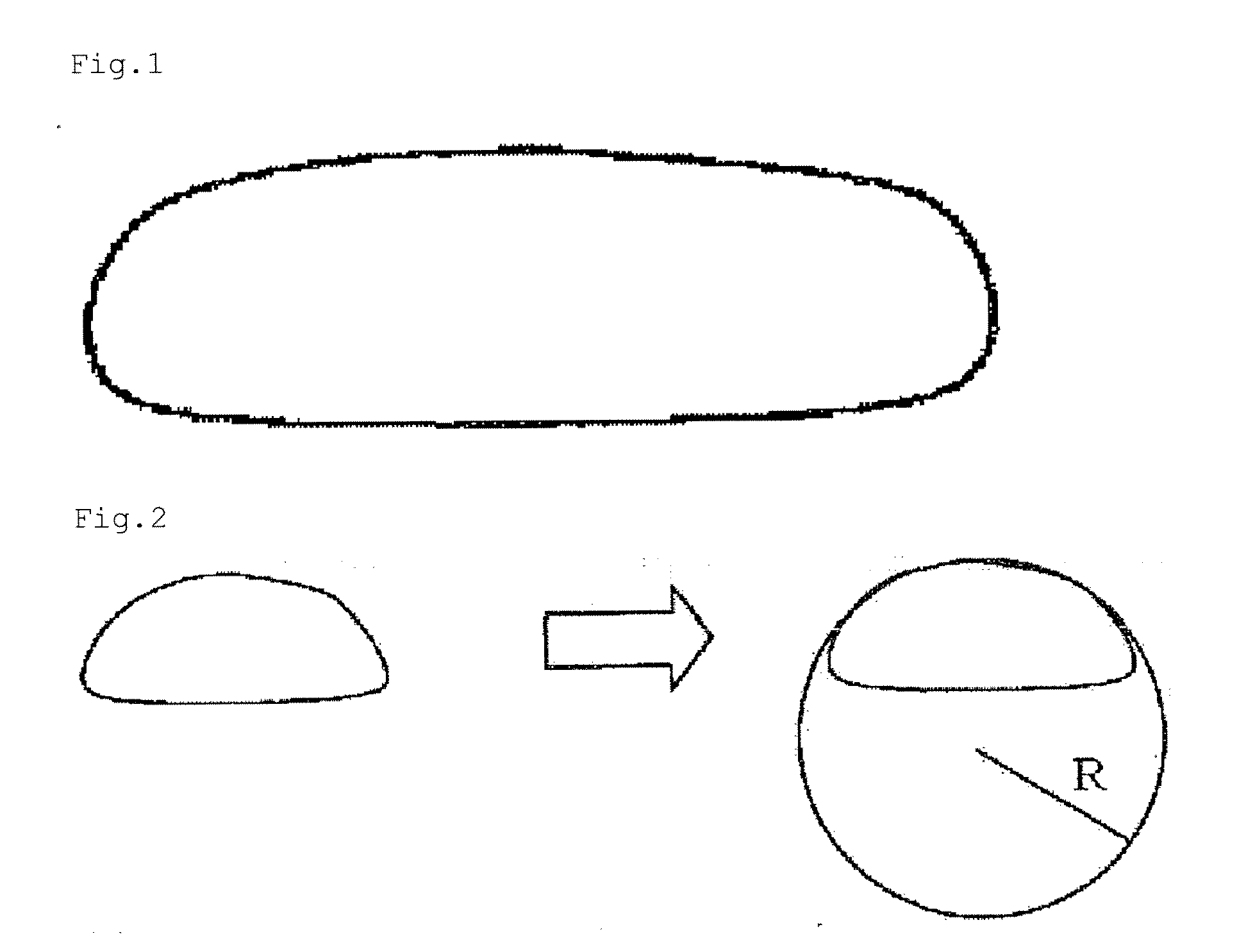

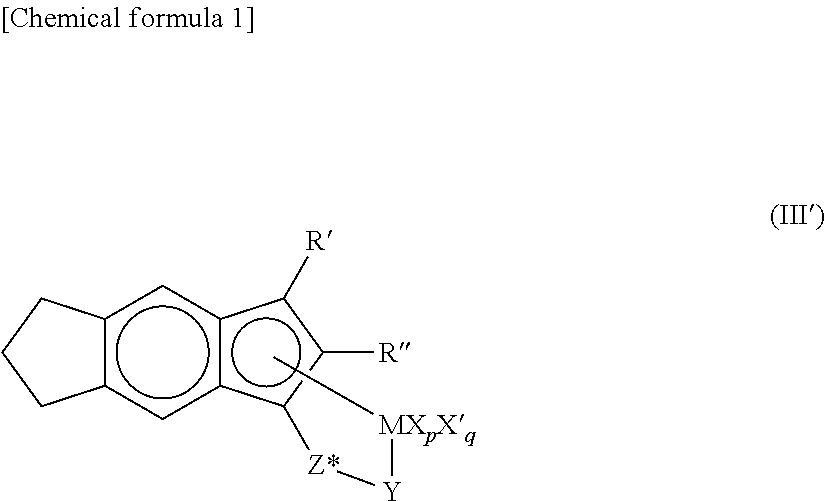

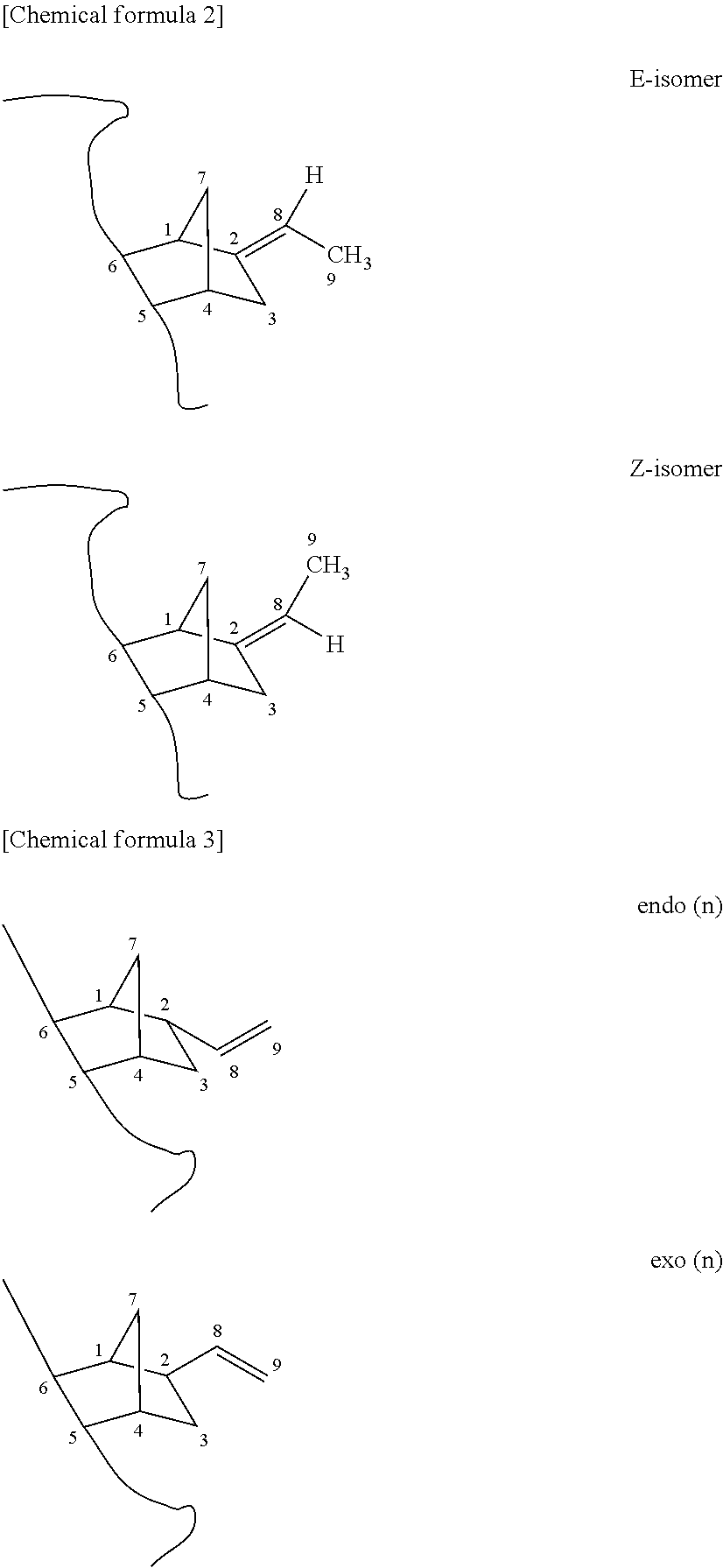

Copolymer, rubber composition, cross-linked rubber, cross-linked foam, and uses thereof

ActiveUS20110233448A1Adequate foamabilityExcellent kneading performanceBuilding constructionsPolymer sciencePtru catalyst

The present invention provides a rubber composition having adequate foamability, uses thereof, a copolymer contained in the rubber composition, a rubber composition capable of providing a cross-linked foam, which has a low specific gravity and an excellent shape-retaining property even when the usage of a nonconjugated polyene is reduced, and a cross-linked rubber and a cross-linked foam, which are produced from the rubber composition. A copolymer (A) according to the present invention is a copolymer including structural units derived from ethylene [A], an α-olefin [B], a nonconjugated polyene [C-1], in which one carbon-carbon double bond (C═C) polymerizable with a metallocene catalyst is present in one molecule, and a nonconjugated polyene [C-2], in which two bonds of C═C polymerizable with the metallocene catalyst are present in one molecule, and being synthesized with the metallocene catalyst, wherein (1) the units derived from the component [B] constitute 10 to 50 percent by mole, (2) the total of the units derived from the component [C-1] and the units derived from the component [C-2] is 1.0 to 6.0 percent by mole, (3) the molar ratio of the units derived from the component [C-1] to the units derived from the component [C-2] is 75 / 25 to 99.5 / 0.5, (4) [ML (1+4) 100° C.] is 10 to 200, and (5) 50>activation energy of fluidization (kJ / mol)>35 is satisfied.

Owner:MITSUI CHEM INC

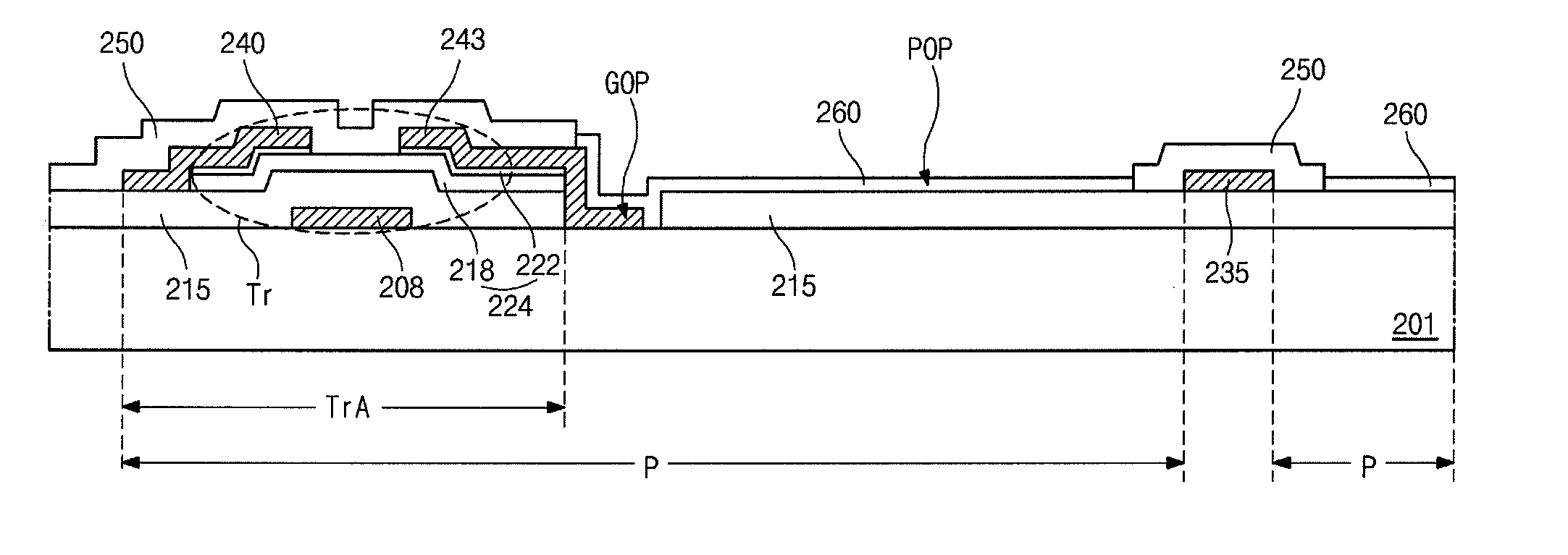

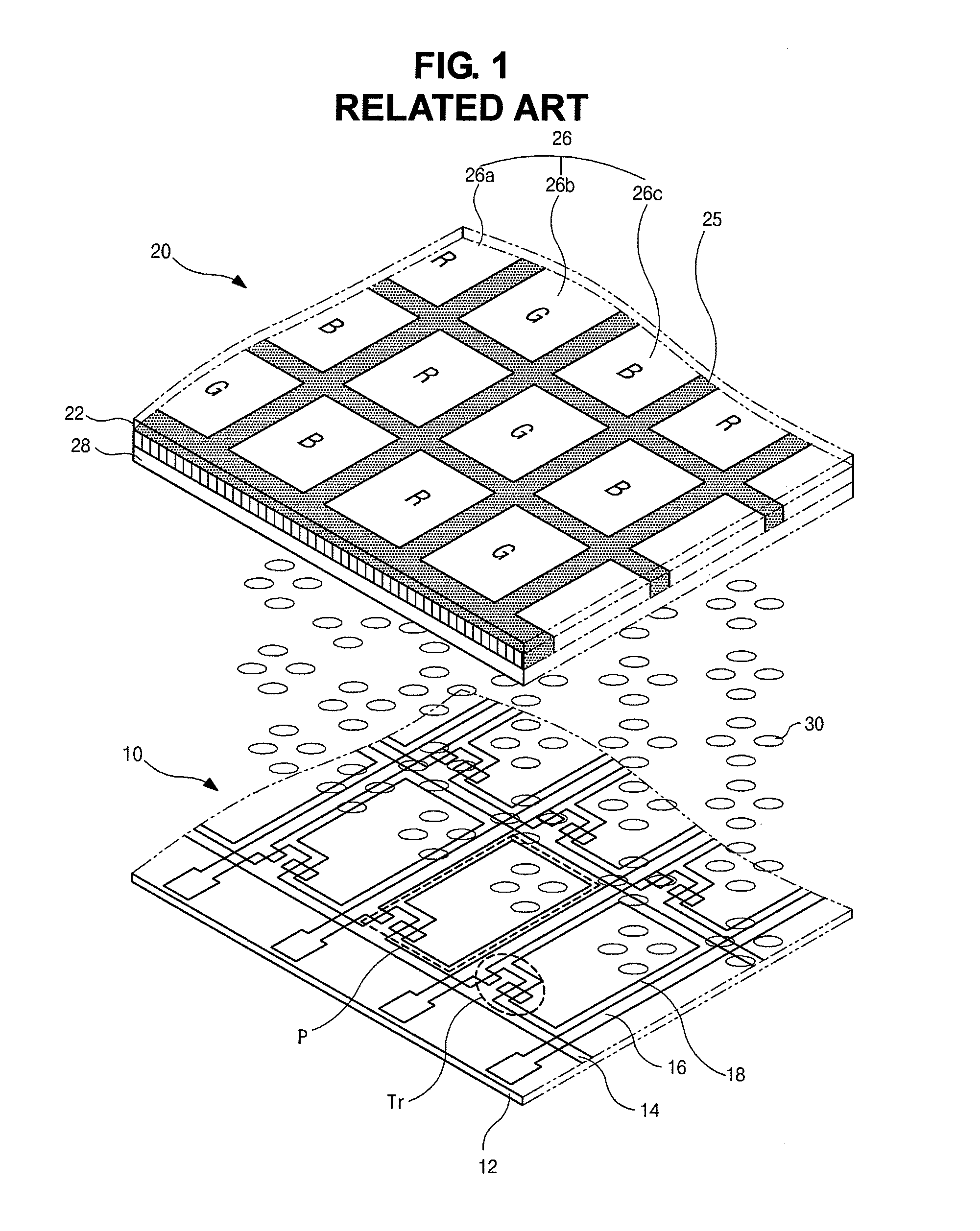

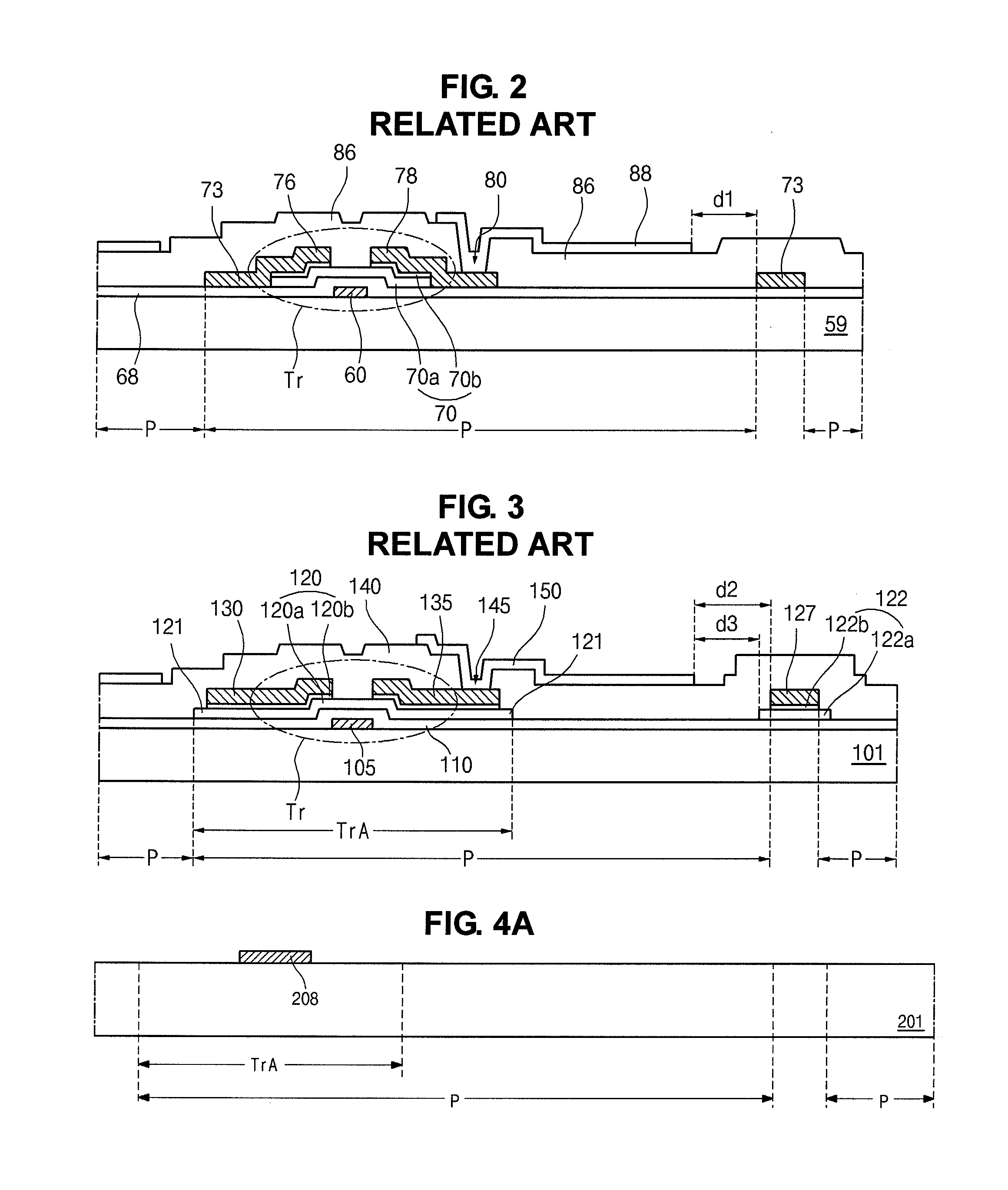

Array substrate for liquid crystal display device and method of fabricating the same

ActiveUS20110127532A1Advantage in production costPrevent problemSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsLiquid-crystal display

An array substrate for a liquid crystal display device includes a gate line on a substrate; a gate electrode connected to the gate line; a gate insulating layer on the gate line and the gate electrode and including a gate opening; an active layer on the gate insulating layer and overlapping the gate electrode; an ohmic contact layer on the active layer; a source electrode on the ohmic contact layer; a drain electrode on the ohmic contact layer and spaced apart from the source electrode, wherein one end of the drain electrode is disposed in the gate opening; a data line on the gate insulating layer and connected to the source electrode, the data line crossing the gate line; a passivation layer on the data line and the source and drain electrodes and including a pixel opening, wherein the pixel opening exposes the drain electrode in the gate opening and a portion of the gate insulating layer; and a pixel electrode on the gate insulating layer and in the pixel opening, the pixel electrode contacting the one end of the drain electrode in the gate opening.

Owner:LG DISPLAY CO LTD

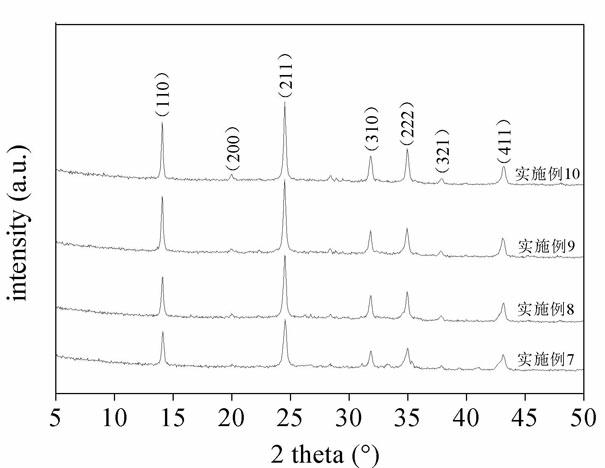

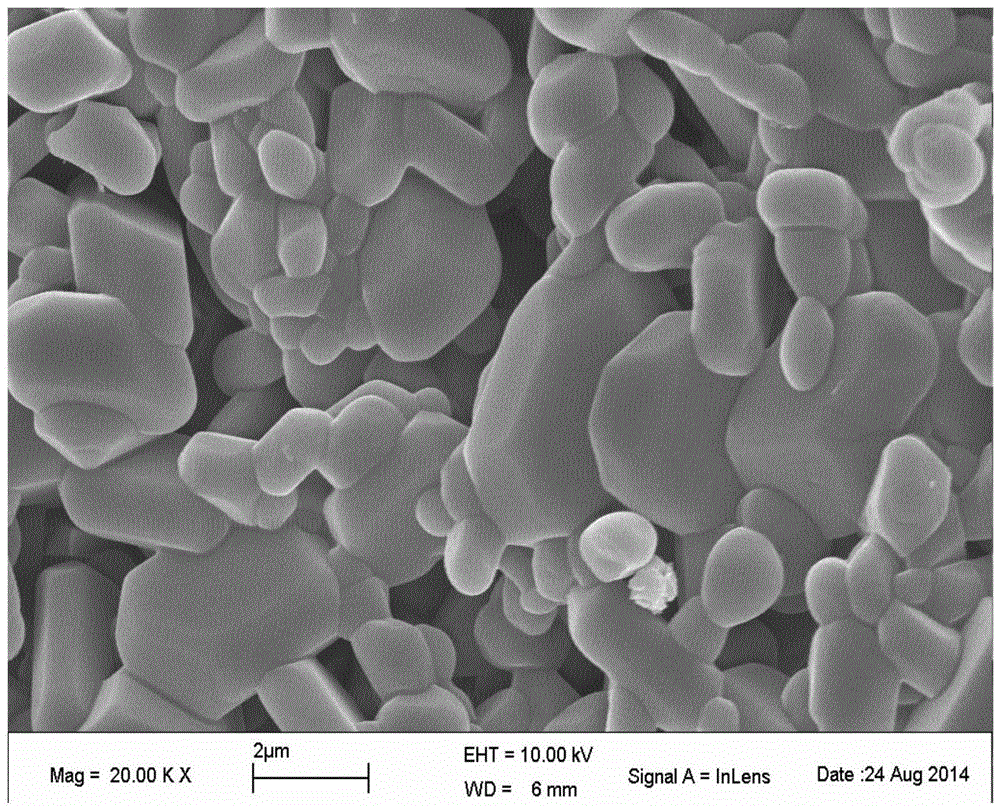

Method for preparation of silicon-aluminum nitride or oxynitride fluorescent powder

ActiveCN105778903AGuaranteed uniformityGuaranteed stabilityLuminescent compositionsFreeze-dryingSlurry

The invention belongs to the technical field of fluorescent powder preparation, particularly relates to a method for freeze drying and auxiliary combustion synthesis of silicon-aluminum nitride or oxynitride fluorescent powder, and is characterized in that the method is implemented according to the following steps: (1) weighing raw material powder and a PVB binder according to the stoichiometric proportion of a fluorescent material; (2) adding the raw material powder and the binder to a tertiary butanol solvent, and carrying out ball milling, to obtain an evenly mixed slurry; (3) freezing and curing the obtained slurry for 2 h to 6 h; (4) placing the cured blank in a freezing dryer, carrying out vacuum drying to obtain a porous blank; and (5) placing the porous blank in a combustion synthesis reaction kettle, placing a Ti powder on the upper surface of the front end of the blank to be used as an igniting agent, vacuumizing, then filling nitrogen gas, and triggering the blank to carry out combustion synthesis reaction. The prepared silicon-aluminum nitride or oxynitride fluorescent powder has the advantages of uniform particle size distribution and good crystallization, allows the product to have no sintering agglomeration phenomenon, has no need for a subsequent crushing treatment process, and has significant advantages in preparation cost.

Owner:QINGDAO CUP NEW MATERIALS CO LTD

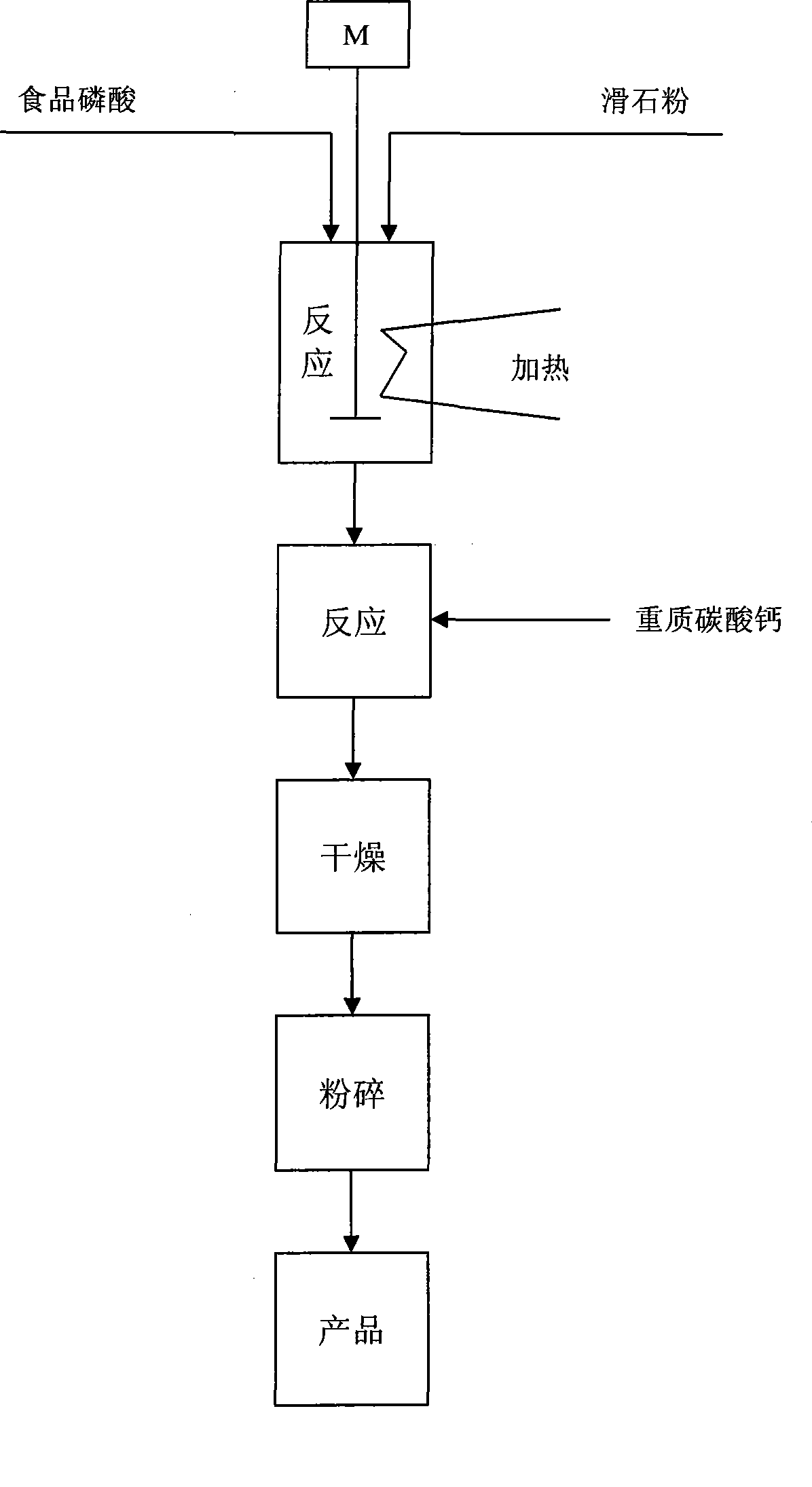

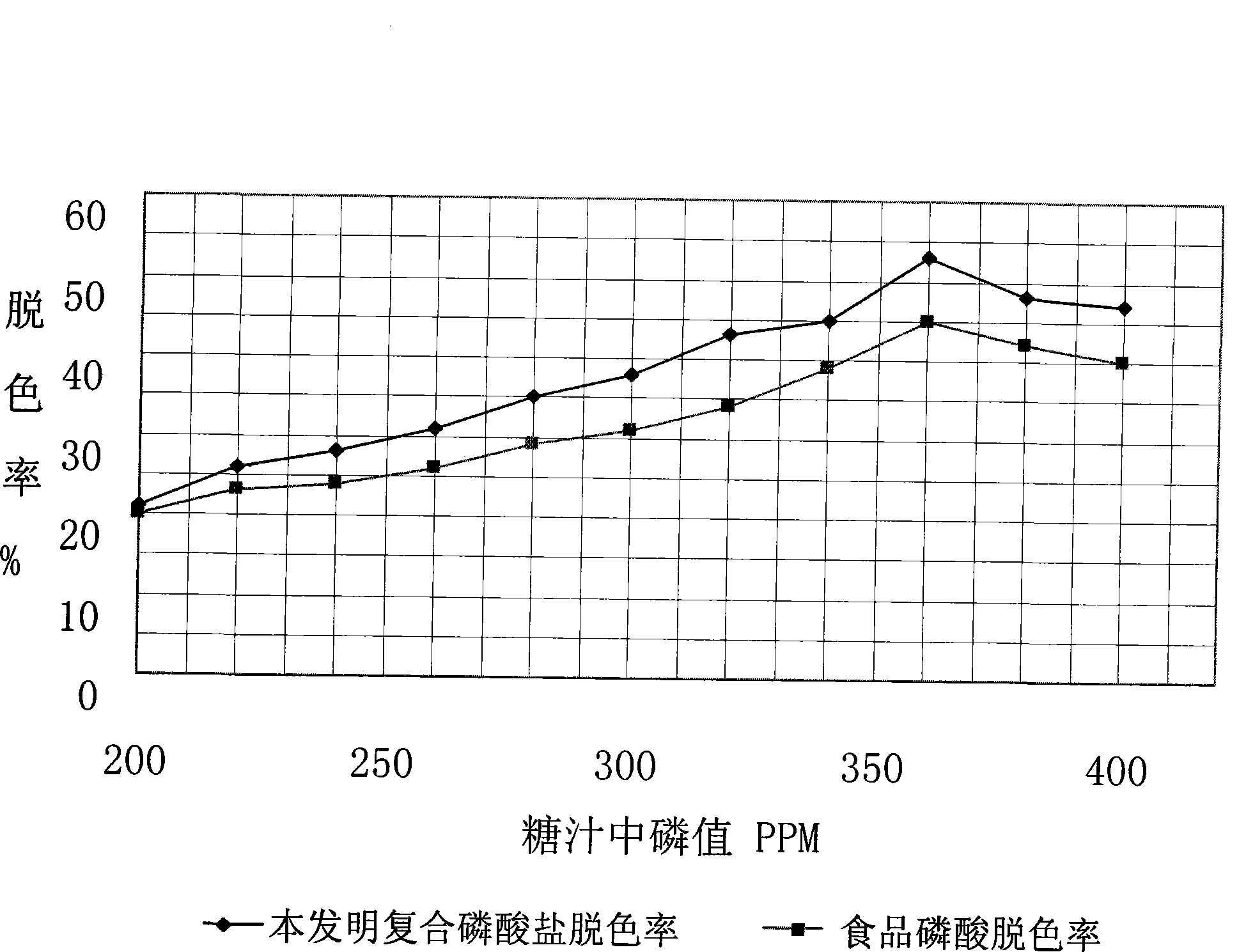

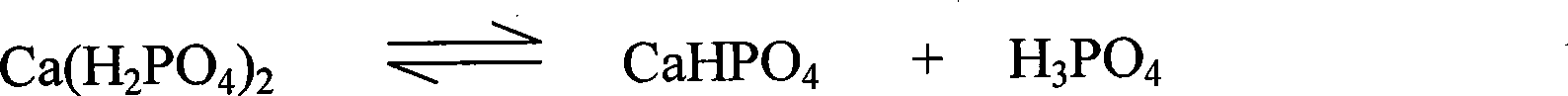

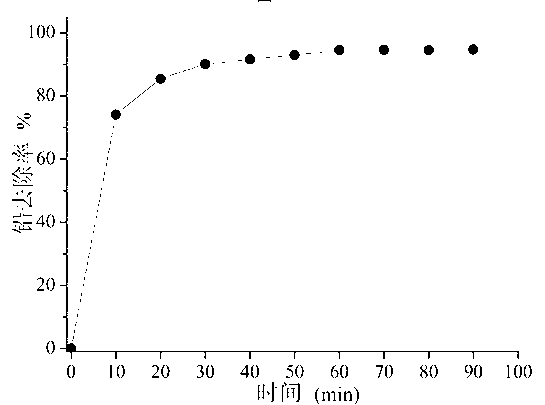

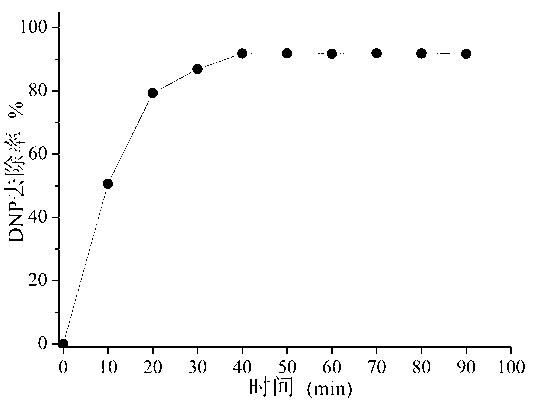

Composite phosphates sugar juice decoloring agent and preparation thereof

ActiveCN101440412AEasy to storeEasy to transportPurification by oxidation/reductionMonomagnesium phosphatePhosphate

The invention provides a composite phosphate sugar juice decoloring agent and a preparation method thereof, which belongs to the technical field of chemical engineering. The decoloring agent consists of the following four components: (1) calcium biphosphate, (2) magnesium dihydrogen phosphate, (3) precipitated silica and (4) free phosphoric acid. The preparation method for the decoloring agent comprises the following steps: (1) talc is added to food-grade phosphoric acid hydrolysate and dissolved, so as to obtain a phosphoric acid aqueous solution which dissolves magnesium dihydrogen phosphate and disperses precipitated silica; and (2) heavy calcium carbonate powder is put into a mixer and added with the phosphoric acid aqueous solution in a step (1), and reaction evaporates the moisture of materials and progressively cures the materials, so as to obtain the composite phosphate sugar juice decoloring agent containing moisture. Compared with the food-grade phosphoric acid used by the prior sugar factories, the decoloring agent has the advantages of good decoloring effect, economical efficiency, convenience, no relation to dangerous chemicals, and the like.

Owner:YUNNAN JIANGLIN GROUP

Aluminium casting alloy cylinder cap

InactiveCN101644203AImprove fatigue strengthReduce wearCylinder headsCylindersSolution treatmentChemical composition

The invention relates to an aluminium casting alloy cap, comprising the following chemical components by weight percent: 8-10% of Si, 2-3% of Cu, 0.15-0.35% of Mg, less than 0.3% of Mn, less than 0.45% of Fe, the balance Al. The hardness of the cylinder cap is 100-130HBS. The material adopted by the aluminium casting alloy cap of the invention is on the basis of aluminium-silicon alloy, micro elements of Fe, Cu, Mg and the like are added to form more Mg2Si, Al3Mg2, CuAl2 and the like, so that strengthening phase is formed in the alloy, and grain structure is refined by solution treatment, thusimproving comprehensive mechanical property of material and meeting requirement of high boost high performance.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

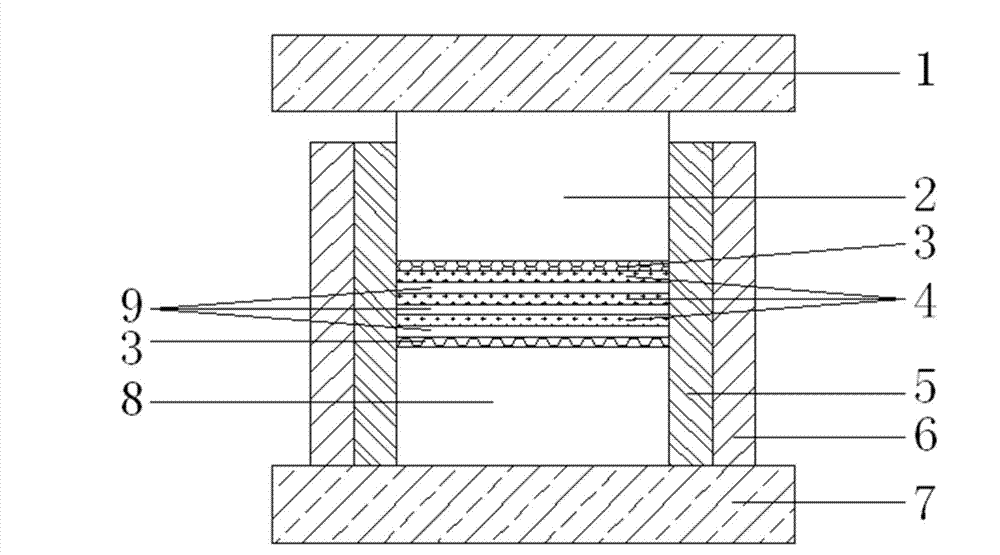

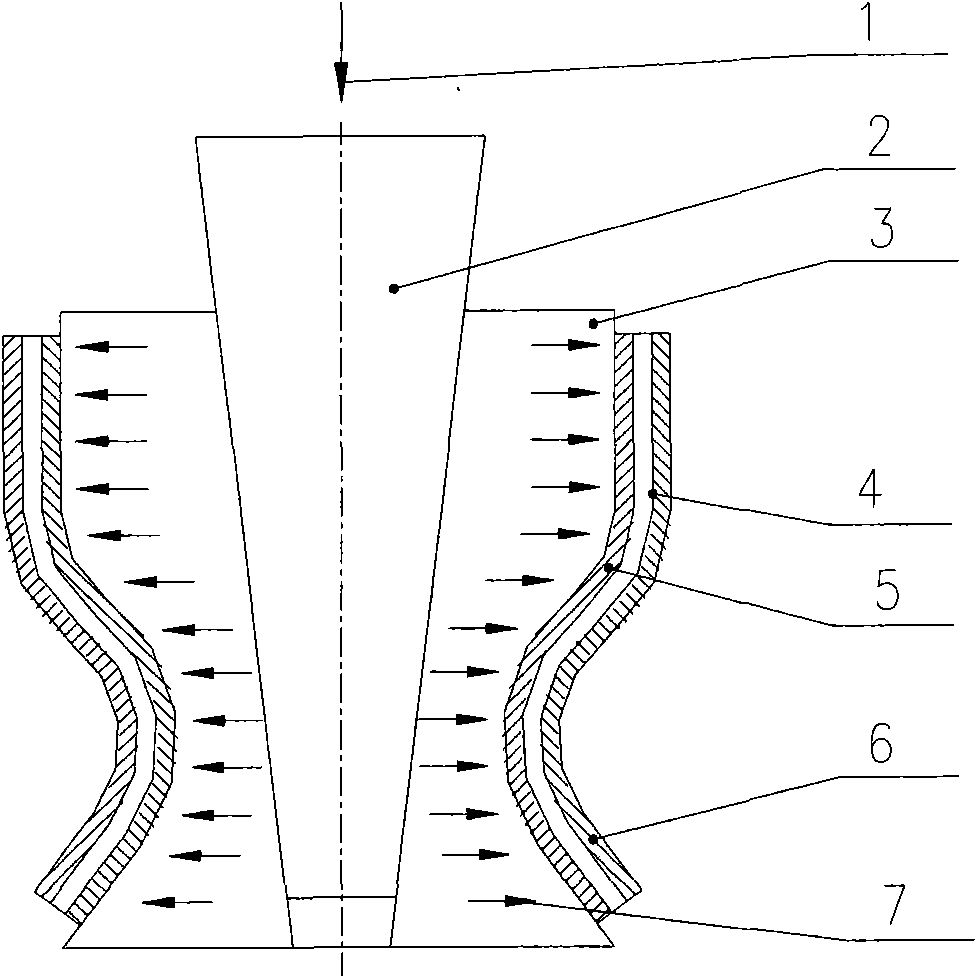

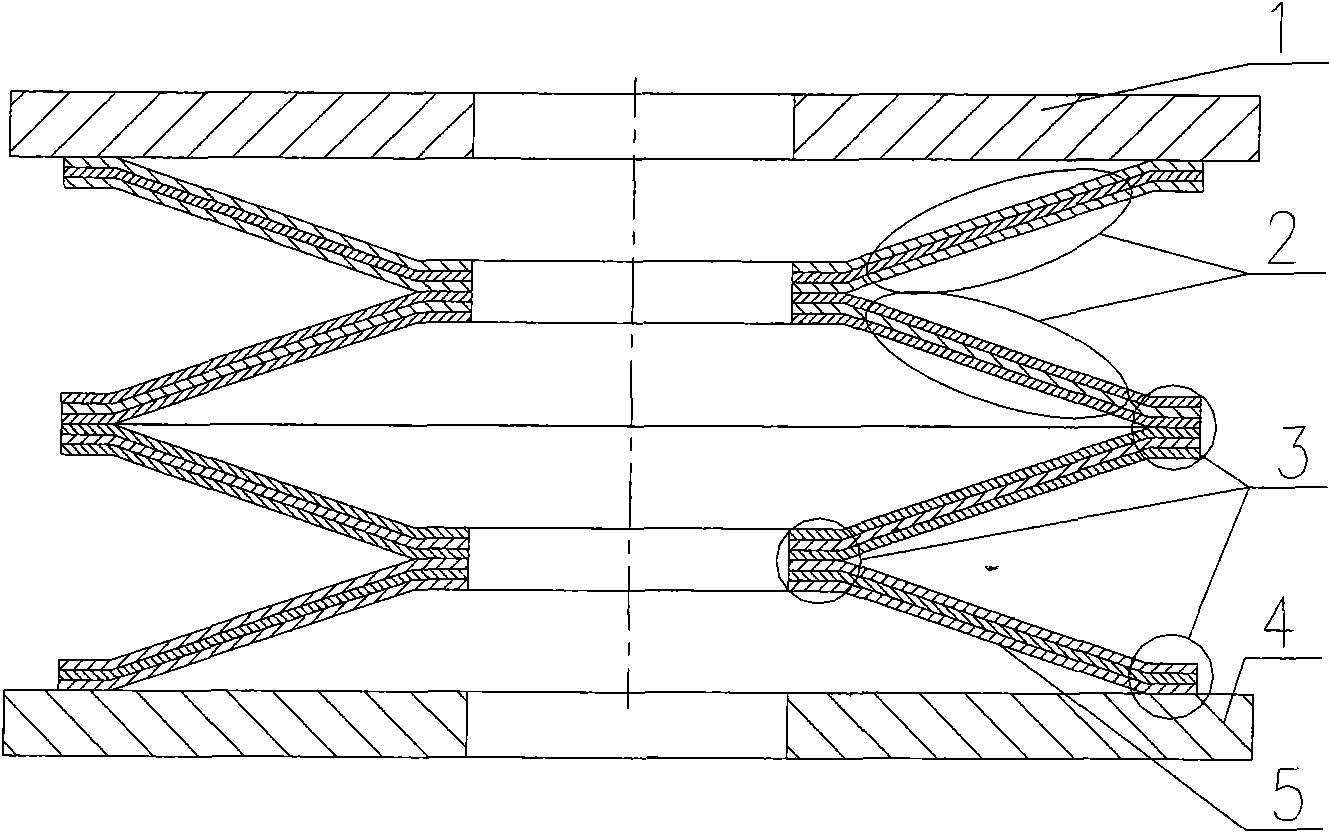

Manufacturing of composite sandwich nozzle by dynamic pressurizing transient liquid phase diffusion welding

InactiveCN101633081AAdvantages of manufacturing cycleProduction cost advantageWelding apparatusLiquid phaseDiffusion welding

The invention realizes the manufacturing of a composite sandwich structured nozzle by a dynamic pressurizing transient liquid phase diffusion welding method; the composite sandwich structured nozzle manufactured by the invention has advantages of long fatigue life, strong compression capacity, high welding rate, short manufacturing cycle, no blocking in the passageway and the like. The composite sandwich structured nozzle between materials of the same type can be manufactured by utilizing the invention, and the composite sandwich structured nozzle between materials of different types can also be manufactured, thus providing composite sandwich structured nozzle products with good performance for related industries.

Owner:北京智创联合科技股份有限公司

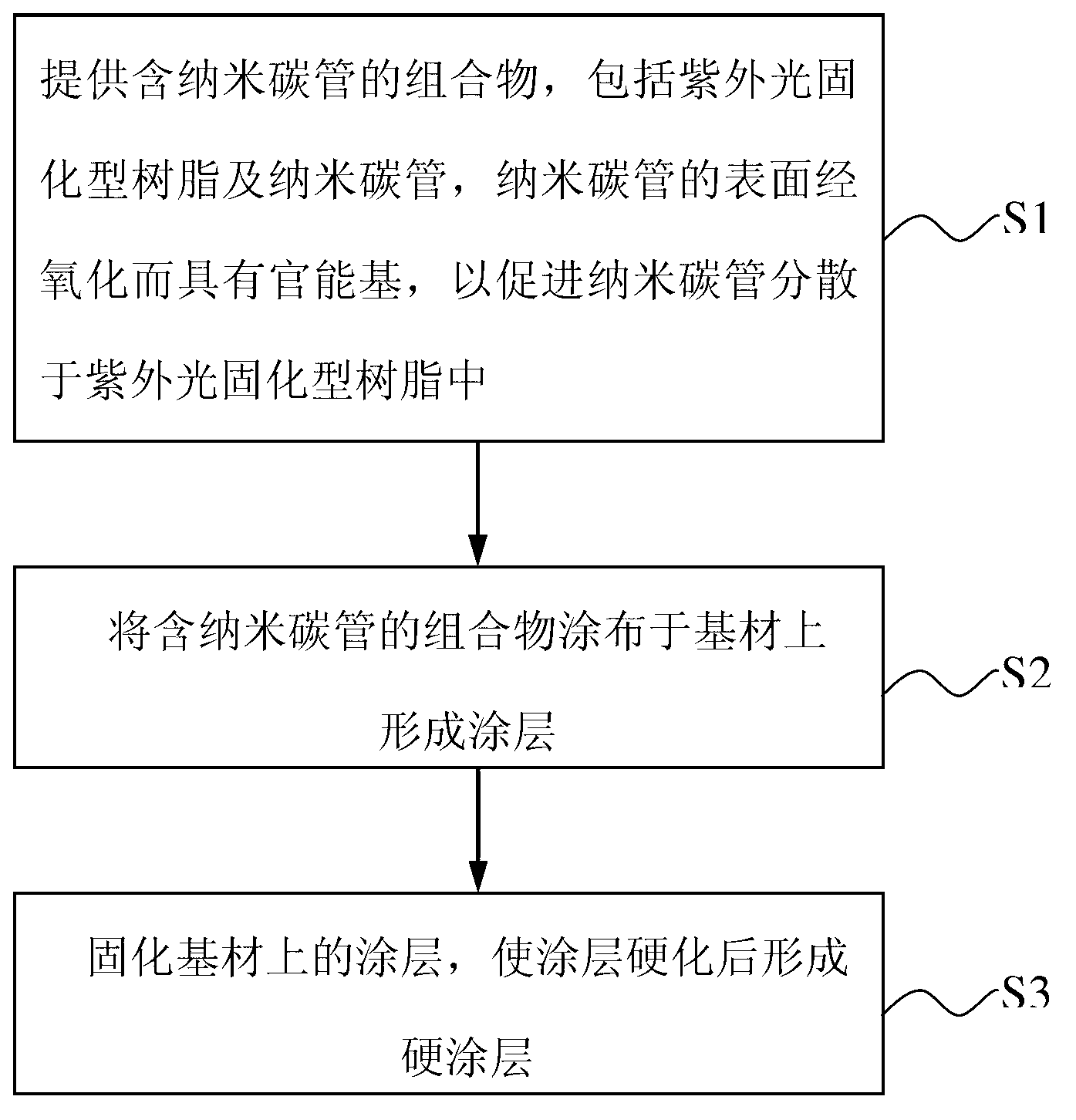

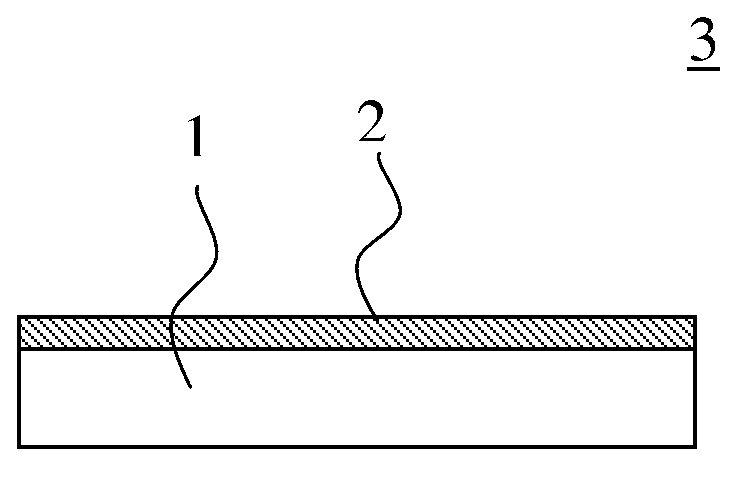

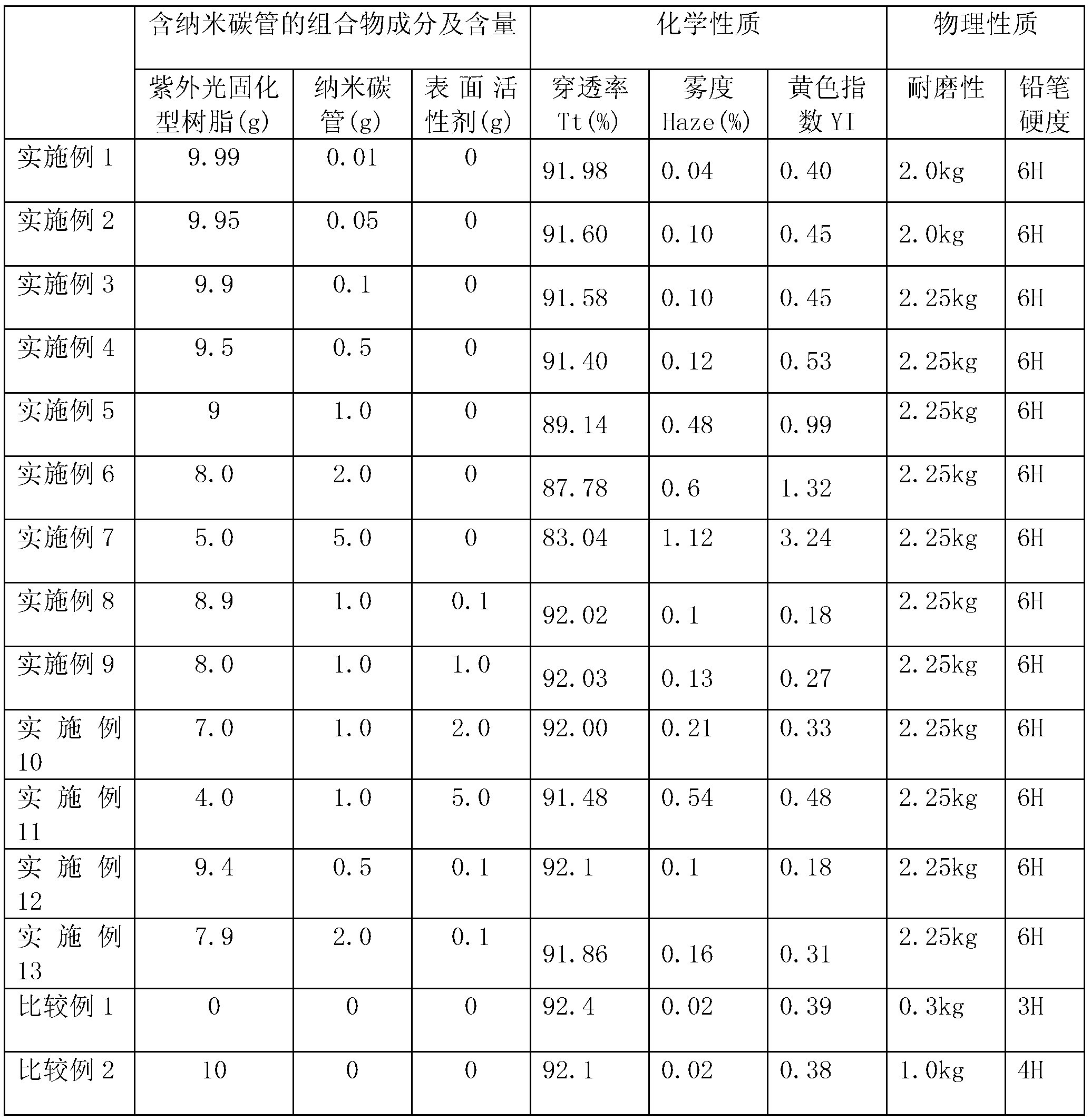

Compound containing carbon nano-tube, hard coating and forming method thereof and hard coating film

InactiveCN103214891AIncrease productionProduction cost advantageCoatingsOptical elementsHardnessWear resistance

The invention discloses a compound containing a carbon nano-tube, a hard coating and a forming method thereof and a hard coating film. The compound containing the carbon nano-tube comprises ultraviolet curing resin and the carbon nano-tube, wherein the surface of the carbon nano-tube is provided with functional groups after being oxidized to accelerate the carbon nano-tube to be dispersed in the ultraviolet curing resin. The compound containing the carbon nano-tube can be applied to various base materials, and problems of wear resistance on the surface of the base materials and surface hardness and the like are solved under the premise of not affecting the optical effect of the base materials.

Owner:辅讯光电工业(苏州)有限公司 +1

Method for manufacturing multilayer amorphous alloy and copper composite structure through intermediate layer diffusion

InactiveCN103753123AAvoid brittlenessImprove shear resistanceNon-electric welding apparatusInter layerAlloy

The invention discloses a method for manufacturing a multilayer amorphous alloy and copper composite structure through intermediate layer diffusion. The method includes the steps of cutting, grinding, polishing and cleaning an amorphous alloy sheet and a copper sheet; dividing an intermediate layer into a predetermined size with a blade; assembling and fixing the amorphous alloy sheet, the intermediate layer and the copper sheet for forming a fixed workpiece; placing the fixed workpiece in a vacuum diffusion furnace for enabling the intermediate layer to be dissolved in the amorphous alloy sheet and the copper sheet for further achieving diffusion welding. According to the method for manufacturing the multilayer amorphous alloy and copper composite structure through intermediate layer diffusion, the diffusion temperature can be reduced through the intermediate layer so as to enable the amorphous alloy sheet to maintain an amorphous state. The composite structure has the strength of the amorphous alloy and the toughness of the copper and can block the extension of a shear band in plastic deformation of the amorphous alloy, so that the problem of brittle failure easiness of pure amorphous alloy can be avoided, the anti-shear ability can be enhanced, the surface of the welded sheet is high in quality, and the connection is reliable.

Owner:HUAZHONG UNIV OF SCI & TECH

Method of manufacturing AF1410 ultrahigh strength steel airplane horizontal tail axis

InactiveCN101229585AProduction cost advantageAdvantages of manufacturing cycleIncreasing energy efficiencyStatic strengthDigital control

The invention relates to a method for producing an AF1410 ultrahigh strength steel aircraft horizontal tail shaft. Bar or forging of the AF1410 ultrahigh strength steel is mechanically processed into a fine bar and is then produced into powder; by adopting laser forming technology, the AF1410ultrahigh strength steel powder is melted and deposited layer by layer according to a three-dimensional number module of parts of the horizontal tail shaft; the whole horizontal tail shaft can be produced by carrying out digital control mechanical process only once during the process. The invention initially utilizes laser melting deposition (laser fast forming) technology in a creative way, which realizes the manufacture of the AF1410 unimach whole horizontal tail shaft, without processes of forging and welding and special requirements for the dimension of raw materials. The structure, the components and the properties of the parts are equal to the parts manufactured with the forging part; manufacturing cost is reduced by 1 / 3 and manufacturing period is reduced by more than 1 / 2; static strength is improved by 10 percent and endurance life can be prolonged by more than 3 times.

Owner:王云阁

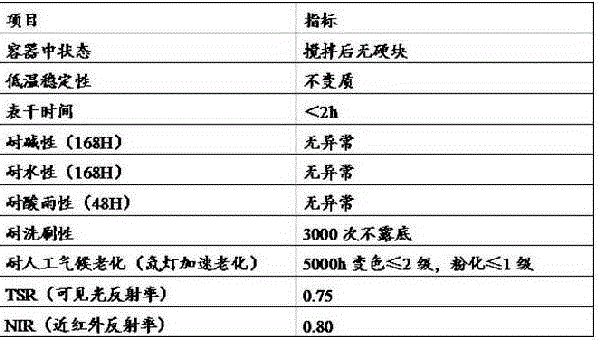

Water-based metallic paint and preparation method thereof

InactiveCN105400350AImprove reflective effectPromote environmental protectionAntifouling/underwater paintsPaints with biocidesSilver pasteEmulsion

The invention discloses a water-based metallic paint and a preparation method thereof, wherein the water-based metallic paint is prepared from the following components in parts by weight: 5-15 parts of propylene glycol, 1-3 parts of a film forming auxiliary agent, 0.1-0.5 part of a bactericide, 0.3-1.0 part of a dispersion agent, 0.1-0.5 part of a wetting agent, 8-10 parts of a modified aluminum silver paste, 20-25 parts of water, 0.1-0.5 part of a defoaming agent, 0.1-0.5 part of a pH regulator, 40-60 parts of an emulsion, 0.1-1.0 part of a mildew preventive, 1-2 parts of a thickening agent solution, and 0.5-1.0 part of a levelling agent. According to the technical scheme, the heat insulation and the reflection effect of the water-based metallic paint can be improved.

Owner:SHENZHEN JIADA HIGH TECH IND DEV

Diffusion welding multilayer structure diaphragm capsule

The invention is a diffusion welding multilayer structure diaphragm capsule, belonging to the field of diaphragm capsule manufacturing. By adopting the methods of diffusion welding, machining and shaping, the manufacturing of diaphragm capsule in the invention can be realized. The main procedures include thin wall blank preparation, surface cleaning, surface modified treatment, welding-stopping treatment, diffusion welding, machining, shaping and the like. Compared with the multilayer structure diaphragm capsule manufactured by other methods, the multilayer structure diaphragm capsule manufactured by the invention has the advantages of fine fatigue property (above 1 million times), strong pressurization performance, adjustable rigidity, high compression ratio (higher than 80%), capability of micromation of inner holes, high precision of geometric dimensions, strong destabilization resistance, precise and controllable weldingline profile, adjustable width of weldingline and the like. By using the invention, the diaphragm capsule in the shape of circle, square and other shapes can be manufactured, and can serve as a compensation element of displacement and angle in hydraulic, barometric, transferring pipeline installation, an elastic compensation element and a pore damping element as well as a measuring element for a manometer and an altimeter; besides, the diaphragm capsule can be also used as a heat transferring finned tube for air conditioning, refrigeration and other devices as well as a metal capsule of separating gas or liquid for an accumulator and a storage box. The invention can provide multilayer structure diaphragm capsule products with fine performance for related industries.

Owner:北京智创联合科技股份有限公司

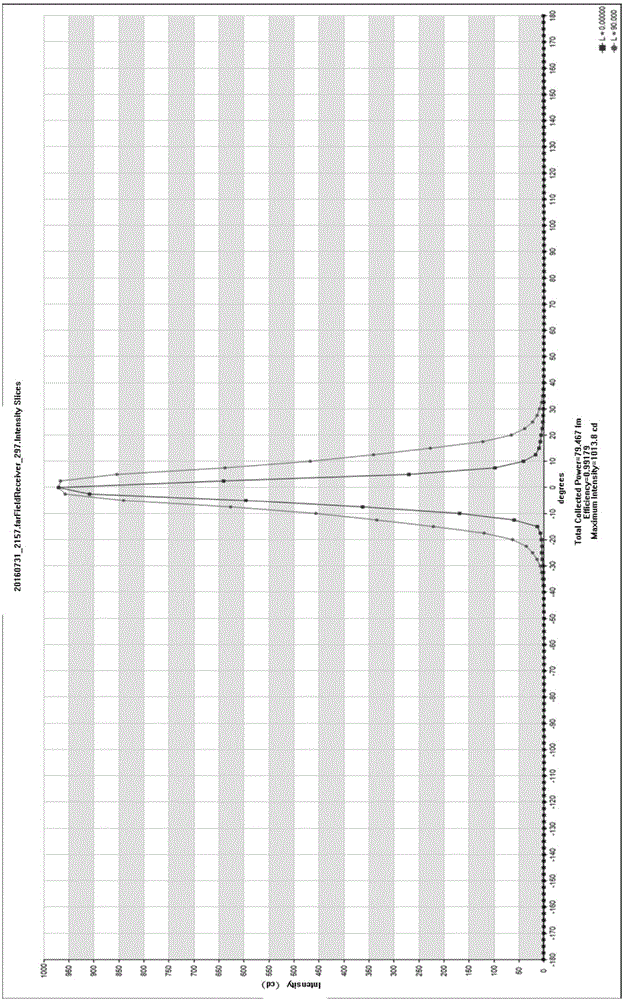

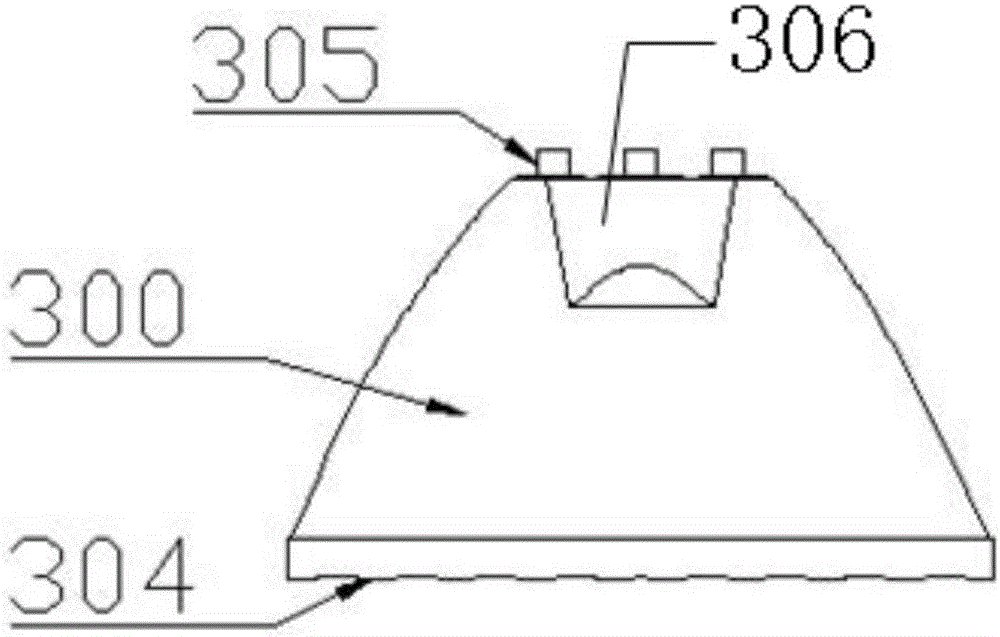

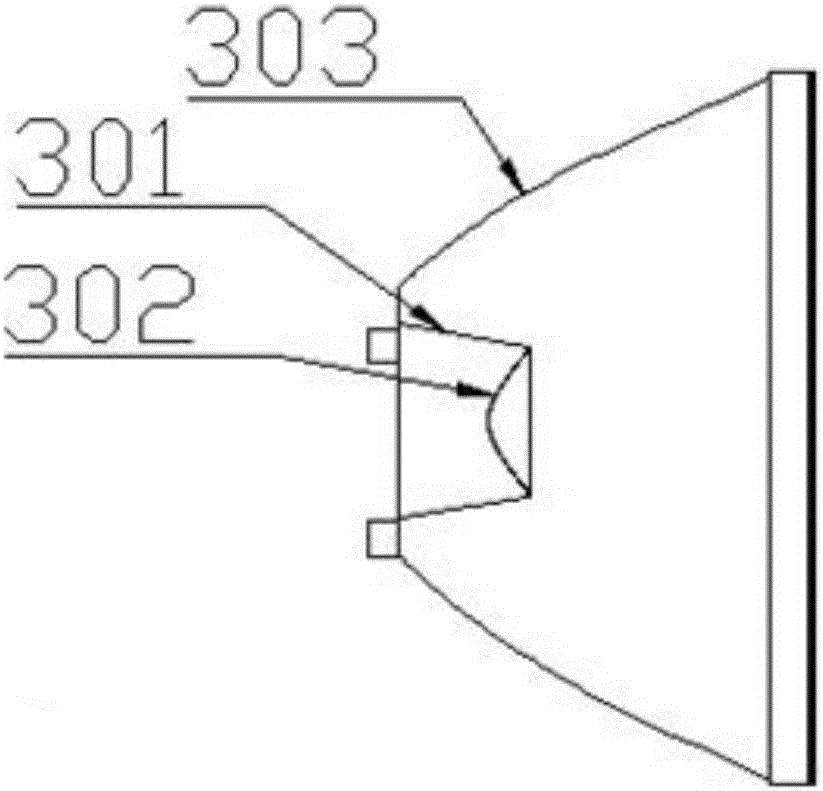

Spreadlight lens and edge-lit backlight module containing spreadlight lens

InactiveCN106647032AImprove brightness uniformityHigh light efficiencyNon-linear opticsSurface typeBrightness perception

The invention discloses a spreadlight lens comprising a lens body. The lens body comprises an incident surface, a reflecting surface and an emergent surface. The incident surface comprises an incident top surface and an incident side surface, the incident top surface is connected with the incident side surface to form a rotationally symmetric recess part, and a light source is arranged on the rotation axis of the recess part; the reflecting surface is not rotationally symmetric. The invention further discloses an edge-lit backlight module comprising a body. The body comprises a cavity, reflecting paper, a light bar, a diffuser plate and a optical film. The reflecting paper comprises attaching cavity reflecting paper which is attached to the bottom face in the cavity and light bar upper reflecting paper arranged at the top of the cavity. The light bar comprises a PCB substrate, a CSP light source and the spreadlight lens, wherein the PCB substrate, the CSP light source and the spreadlight lens are arranged on the inner side wall of the cavity. By the adoption of a special secondary light distribution spreadlight lens edge-lit mode and the arrangement of the reflecting paper with a special cambered surface type, the effects of being high in brightness uniformity, high in luminous efficiency and lightening and thinning in backlight module are achieved.

Owner:NINGBO ZHENGTE OPTICAL ELECTRIC APPLIANCE

Method for synthesizing hydroxyapatite from alkali residue

The invention discloses a method for synthesizing hydroxyapatite from alkali residue. The process of the method comprises the following steps of: (1) drying the alkali residue at 100-105 DEG C, grinding the alkali residue until the alkali residue can pass through a sieve with 80-140 meshes, so as to obtain alkali residue powder for the future use; (2) mixing the alkali residue powder with diluted hydrochloric acid in a solid-liquid ratio (g: mL) of 1: 10 to 1: 20, adequately stirring and then filtering, adjusting the pH of the filtrate to 9.5-10.5, and then removing a precipitate to obtain a supernatant, namely a calcium source; (3) slowly adding the calcium source in phosphate solution until a calcium-phosphorus molar ratio is 1.67, stirring to react for 1-2 hours, and then ageing for 12-24 hours; and (4) filtering and separating the reaction solution to obtain a white precipitate, washing the white precipitate with water and alcohol and drying the white precipitate to obtain white powder, namely hydroxyapatite. According to the method disclosed by the invention, the waste residue-alkali residue of an alkali factory is used as the calcium source, and hydroxyapatite is synthesized by a simple precipitation preparation method, thus reducing the production cost of hydroxyapatite and realizing the environmental protection conception of turning waste into wealth.

Owner:NANJING UNIV OF SCI & TECH

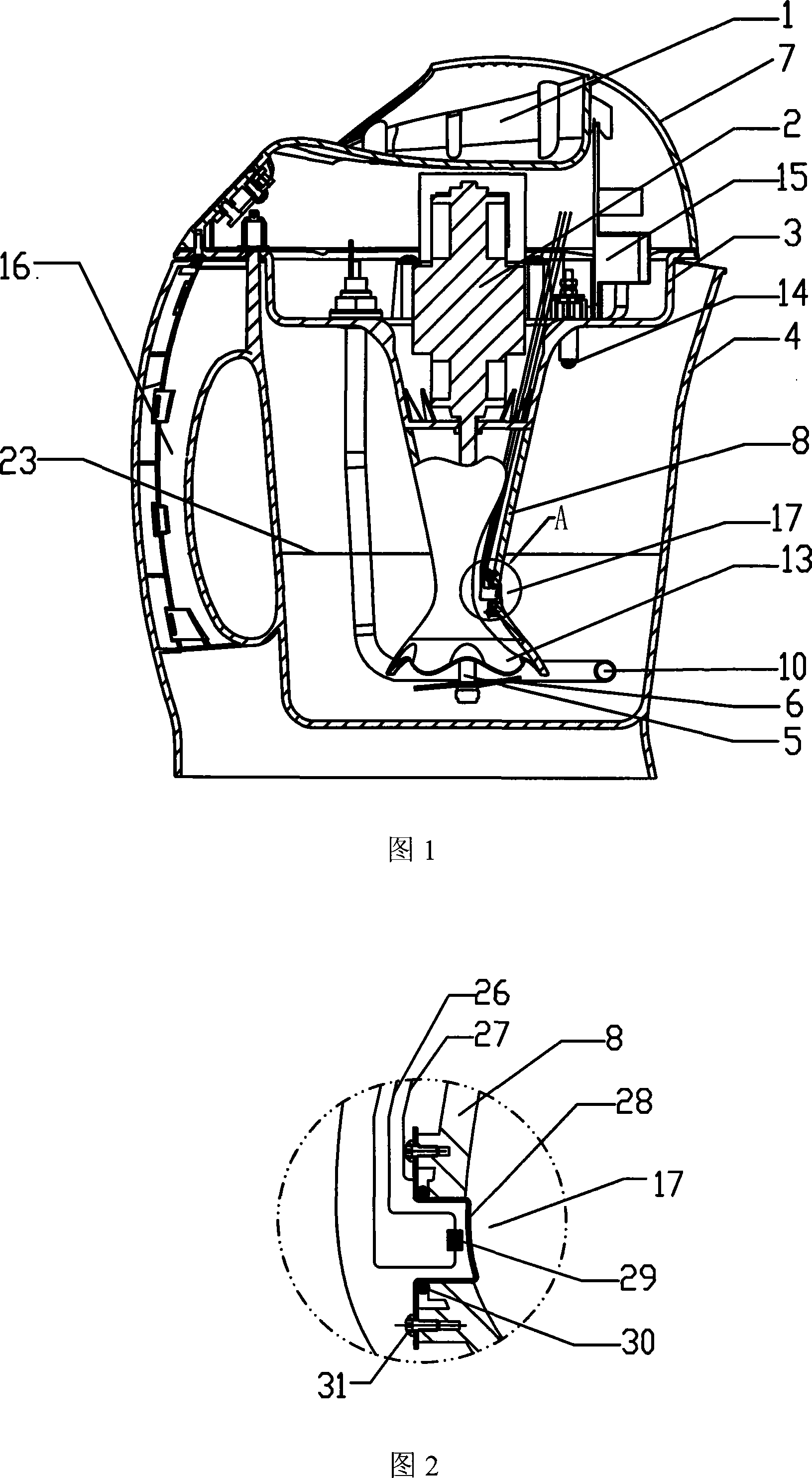

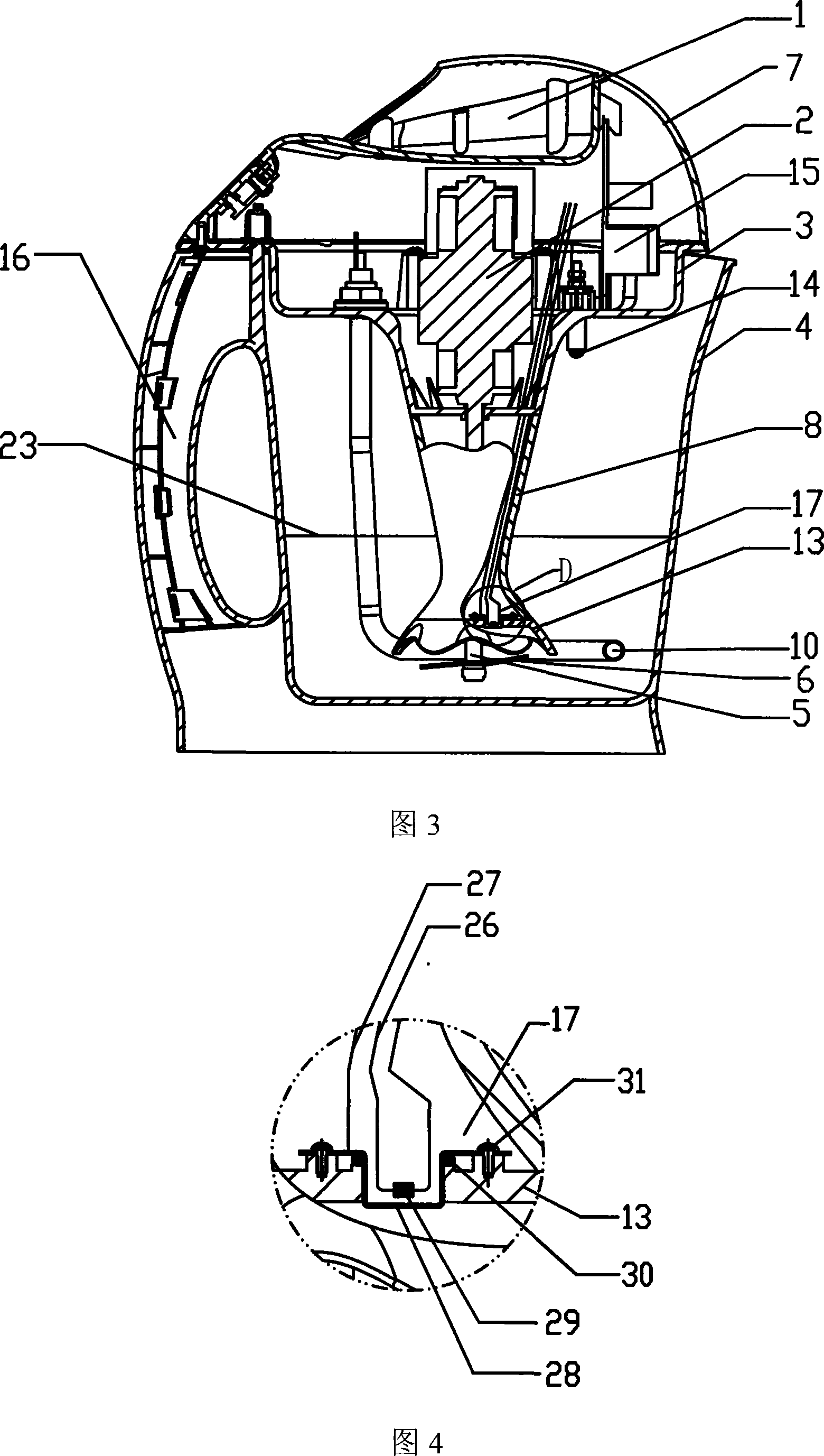

Machine for making soya-bean milk easy to clean

ActiveCN101194693AHigh precisionProduction cost advantageBeverage vesselsFood preparationFlow curveEngineering

The invention relates to a soymilk machine which is easy to clean, and comprises a head, a cup body, a motor, a knife shaft, a grinding knife, a heating device and a control circuit board, wherein the head is covered on the cup body, and the motor is fixedly arranged in the head. The end portion of the knife shaft is fixed with the grinding knife, the head comprises a head upper cover and a head lower cover, the lower end of the head lower cover is fixedly equipped with a connector, the lower end of the connector is equipped with a disturbed flow curved surface body which is arranged on the upper of the grinding knife, and the connector and the disturbed flow curved surface body form into a cavity which is separated from water. A temperature sensor which is capable of directly contacting with the water is arranged on an opening which is arranged on the cavity wall of the cavity, a temperature-sensing end of the temperature sensor is in contact with liquid in the cup body, and the temperature sensor passes through the cavity, the head lower cover and the control circuit board through temperature signals. Under the state of working, the disturbed flow curved surface body or / and the lower portion of the connector are in general stretched into the water, the temperature sensor is arranged on the opening which is arranged on a touching water cavity wall, the temperature sensor directly contacts and perceives water temperature, which is transfered to the control circuit board to achieve effective temperature control through signal lines.

Owner:JOYOUNG CO LTD

Polypropylene resin composition and production process for large-caliber wall tube with hot-state winding structure

InactiveCN103044840AGood chemical resistanceStrong impact resistanceTubular articlesMolten statePolymer science

The invention discloses a polypropylene resin composition. The polypropylene resin composition comprises the following components in parts by weight: 75 to 85 parts of block polymerization polypropylene, 15 to 25 parts of reinforced modified master batch, 1 to 2 parts of a processing modifier, 3 to 8 parts of an anti-impaction modified material, and 0 to 2 parts of color concentrate. The invention also discloses a production process for a large-caliber wall tube with a hot-state winding structure. The production process comprises the following steps of: (1) blending and mixing the materials; (2) drying and preheating: drying and preheating the polypropylene resin composition by using hot blast; (3) performing plasticization and extrusion and molding by winding: plasticizing and extruding the polypropylene resin composition which is obtained in step (2), and performing hot-state winding on the extruded molten-state plastic to form a tubular product; (4) molding by cooling; (5) leveling by cutting; and (6) demolding: demolding the tubular product from a hot-state winding forming mold. The large-caliber hot-state winding structure wall tube produced from the polypropylene resin composition has high mechanical property, chemical corrosion resistance, high temperature resistance and long service life.

Owner:重庆顾地塑胶电器有限公司 +1

Single layer structured diaphragm and diaphragm capsule by diffusion welding

InactiveCN101634363AShort process routeThe process is simple and reliableBellowsNon-electric welding apparatusSurface cleaningEngineering

In the invention, the manufacturing of a single layer structured diaphragm and diaphragm capsule by diffusion welding is realized by the method of 'diffusion welding' + 'mechanical processing' + 'shaping' with the main process as follows: foil plate blank preparation, surface cleaning, surface modification treatment, stop welding treatment, diffusion welding, mechanical processing and shaping. The single layer structured diaphragm and diaphragm capsule by diffusion welding manufactured by the invention has good fatigue property which can reach over 1 million times according to the difference between structures, materials and use environment, strong compression capacity, high precision of geometric dimension, convenient installation, good sealing property, precise and controllable welding line outline, adjustable welding line width, unconstrained size of the workpiece being welded and other advantages. The single layer diaphragm and diaphragm capsule with the outline of a round, a square and other types of shapes can be manufactured by utilizing the invention, which can be used as installation displacement and angle compensation element, elastic compensation element and air hole damp element, and can also be used as the measuring element and information acquisition element of a pressure gauge and an altimeter, thus providing single layer diaphragm and diaphragm capsule products with good performance for related industries.

Owner:北京智创联合科技股份有限公司

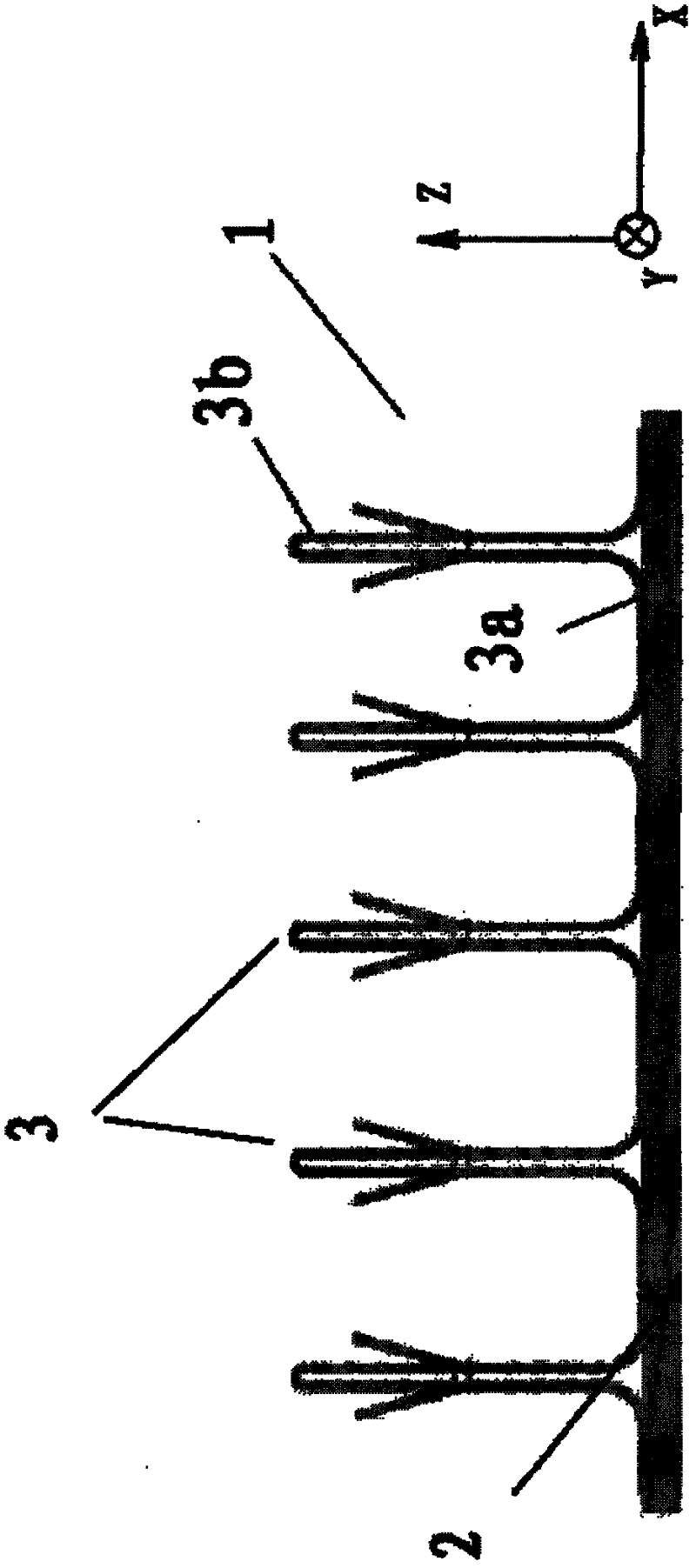

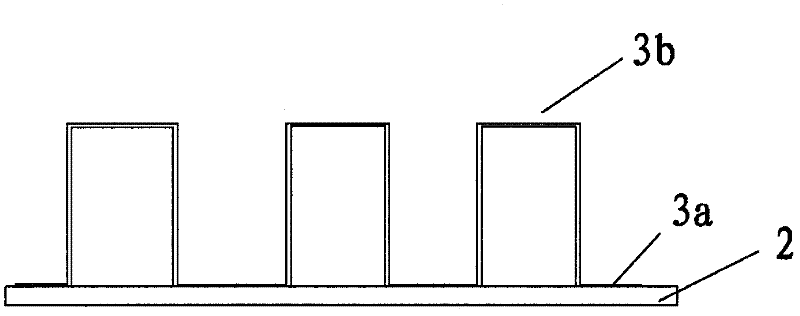

Radiator for electronic or electric products and manufacturing method thereof

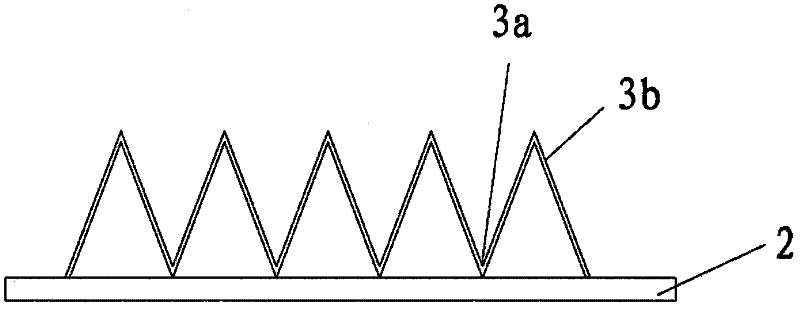

InactiveCN102510702AProduction cost advantageSemiconductor/solid-state device detailsSolid-state devicesAluminum compositesMechanical engineering

The invention relates to a radiator for electronic and electric products. The radiator comprises a baseplate and at least one fin group, wherein each fin group comprises a plurality of fins, each fin comprises a connecting part and a fin main body protruding from the connecting part, and the fins are combined with the baseplate through the connecting parts, the baseplate and a material of the fins are made of metal, and at least one of the baseplate and the material of the fins is an aluminum composite brazed plate; and the connecting parts and the main bodies of the plurality of fins are integrally formed by the single fin material, and the at least one fin group and the surface of the baseplate are connected through a brazing process.

Owner:ALUMINUM CO OF AMERICA

Catalyst for hydrogenolysis and preparation method thereof

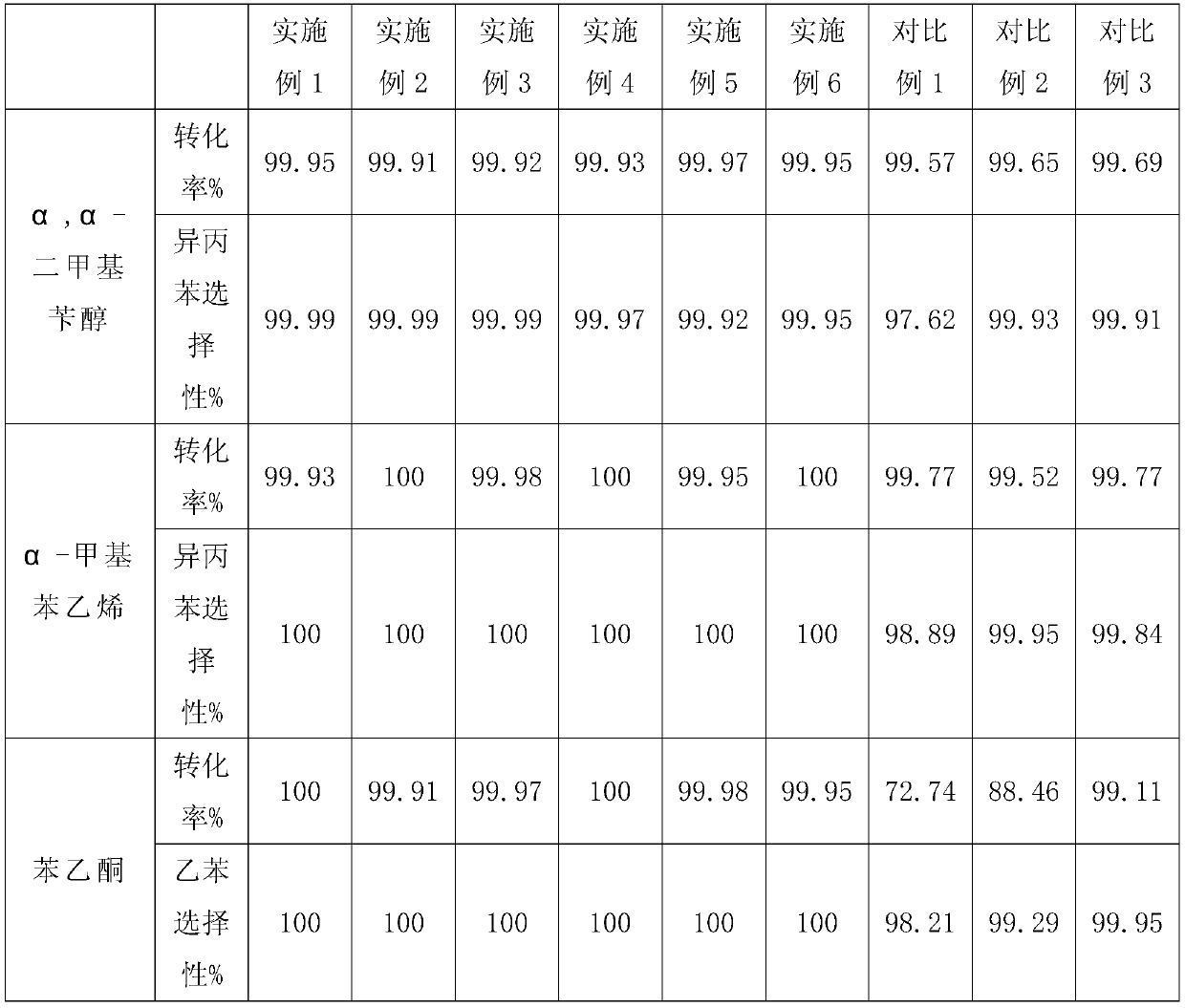

ActiveCN110813319AHigh conversion rate and target product selectivityHigh reactivityMolecular sieve catalystsHydrocarbon by hydrogenationSodium acid carbonateEngineering

The invention discloses a catalyst for hydrogenolysis, which comprises the following components in percentage by mass: (a) 40-80% of component A; (b) 0.5 to 10% of a component B; (c) 0.01 to 1% of a component C; (d) 0.1 to 5% of a component D; and (e) 10-50% of a component E; the preparation method of the catalyst comprises the following steps: (1) dropwise adding a sodium carbonate solution and afirst metal salt solution into deionized water; (2) adding a second metal salt solution and the component E; and (3) filtering, forming and calcining the solution to form a catalyst finished product.According to the catalyst, a small amount of second metal components containing elements such as zinc, magnesium, calcium and barium are added into copper, nickel and palladium as main components, sothat the dispersion effect of the main components such as copper, nickel and palladium in the catalyst can be effectively improved, and meanwhile, the reaction activity and the reaction stability ofthe catalyst are improved.

Owner:HONGBAOLI GRP CO LTD

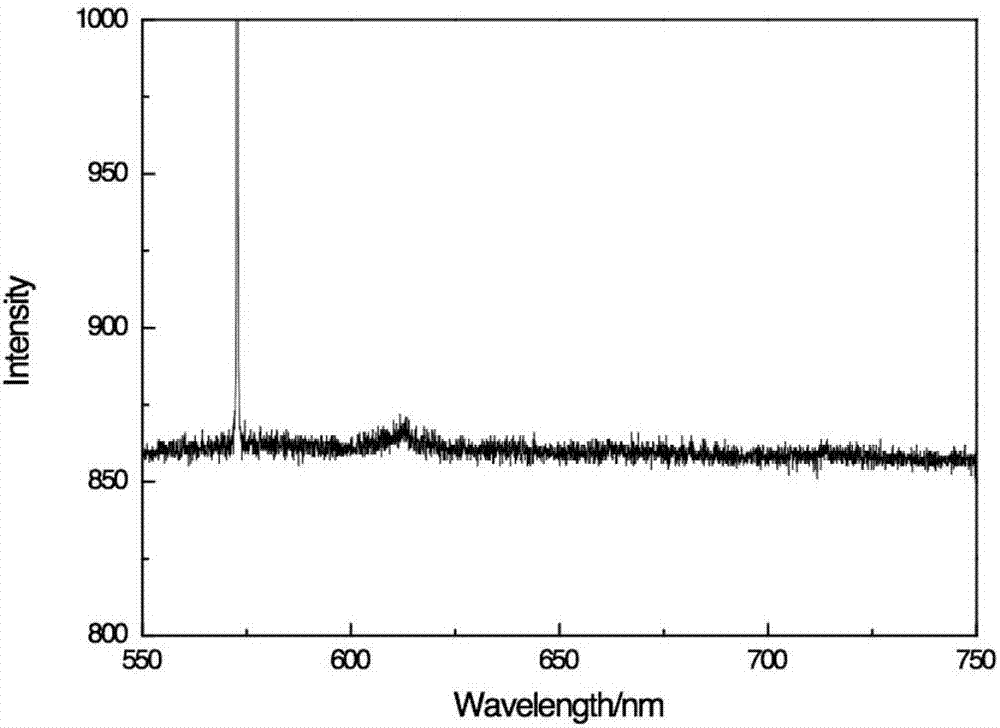

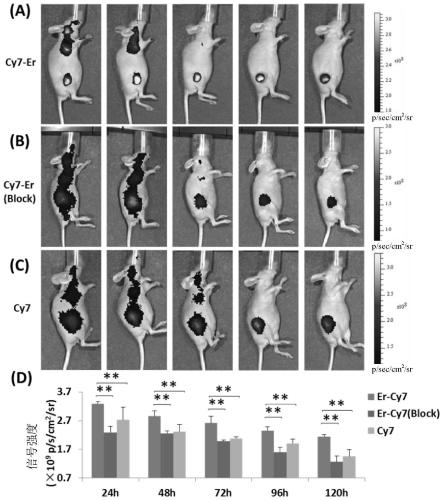

Double-targeted compound, preparation method and application thereof

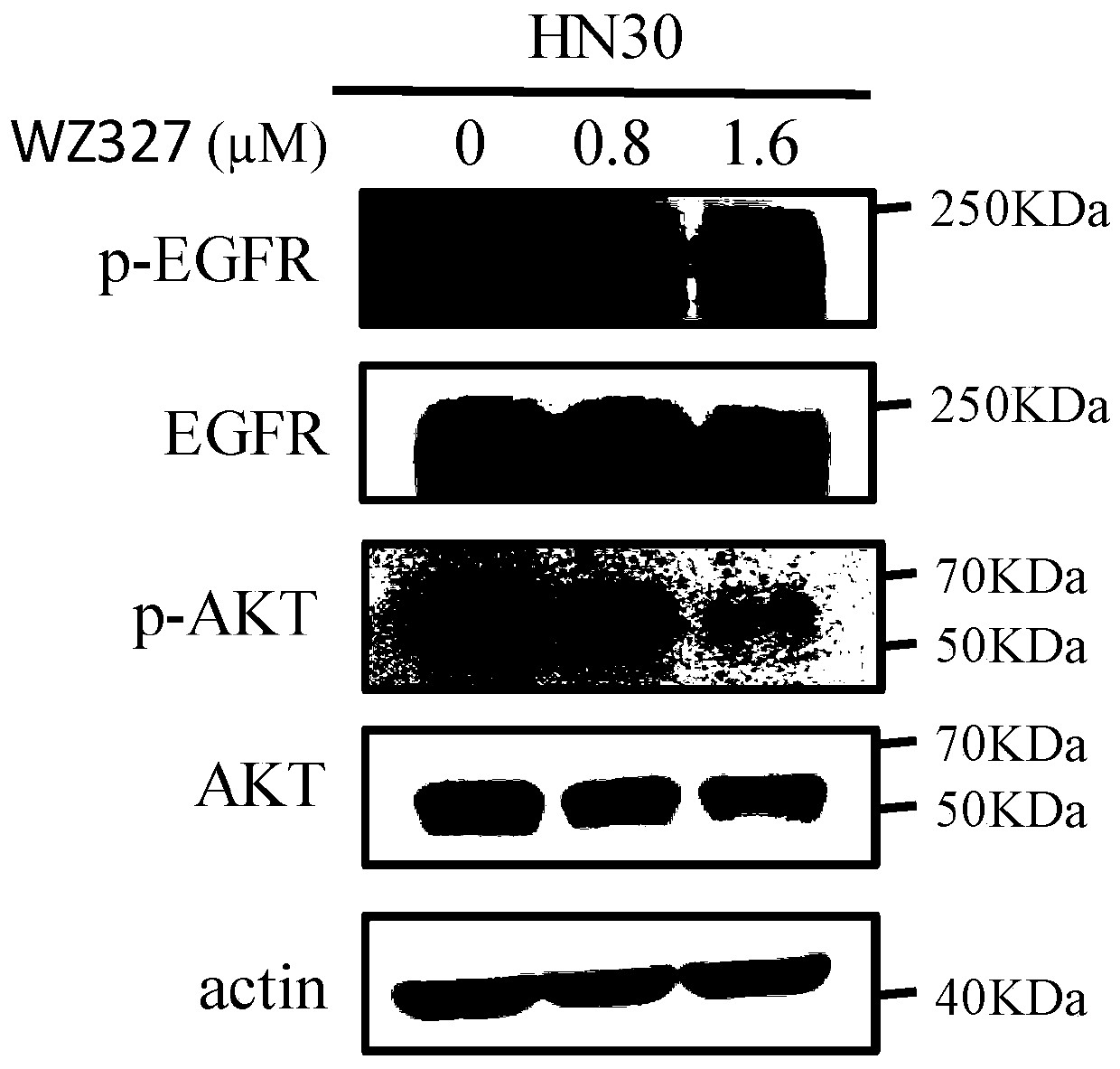

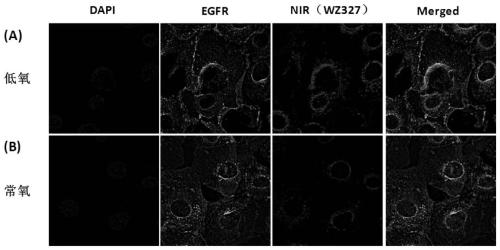

ActiveCN110075299AImprove specific recognitionImaging results are clearly identifiableOrganic chemistryPhotodynamic therapyMalignant Neoplastic DiseaseEgfr expression

The invention provides a compound, which is obtained by splicing a heptamethine cyanine structure and an epidermal growth factor receptor(EGFR) targeted drug molecular structure. The compound providedby the invention can be used as a hypoxia and EGFR double-targeted near infrared fluorescence probe, can realize the purpose of accurate imaging on malignant tumor lesions with high EGFR expression by targeting the tumor marker EGFR and the hypoxia state of tumor cells; in addition, the compound provided by the invention can be used as a photosensitizer for cancer treatment.

Owner:NINGBO HAIBO BIOTECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com