Spreadlight lens and edge-lit backlight module containing spreadlight lens

An edge-type backlight and polarizing lens technology, applied in the field of edge-type backlight modules, can solve the problems of development limitation, light energy loss, low brightness of the display screen, etc., to solve the problem of uneven brightness, high brightness uniformity, production The effect of cost advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

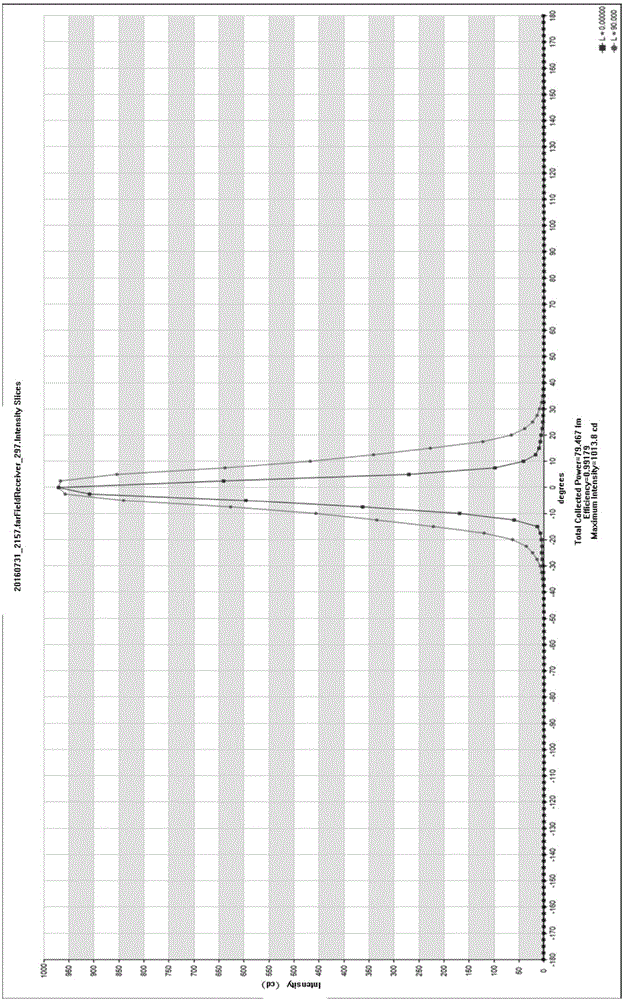

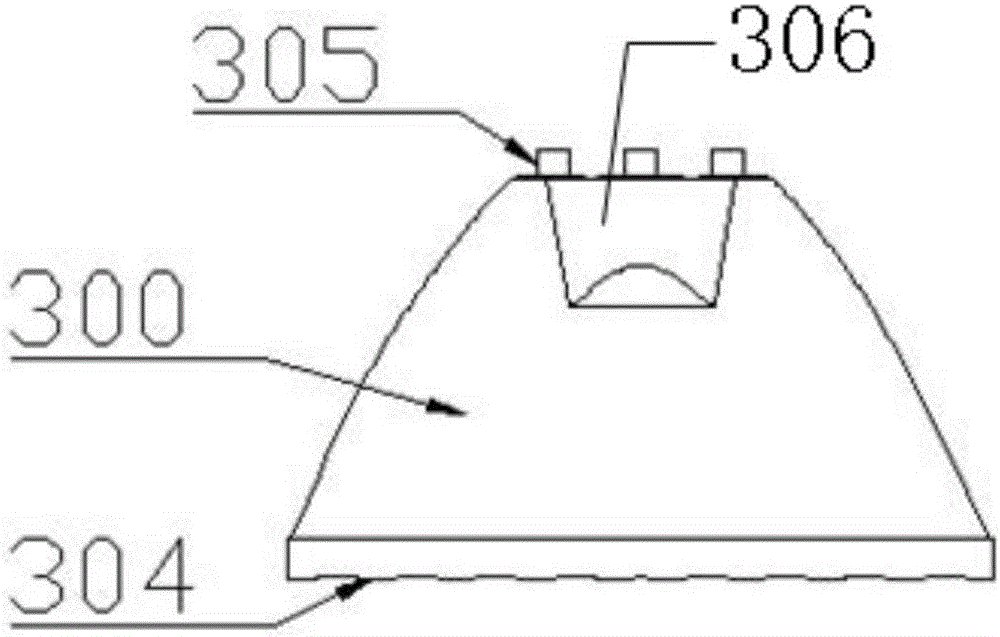

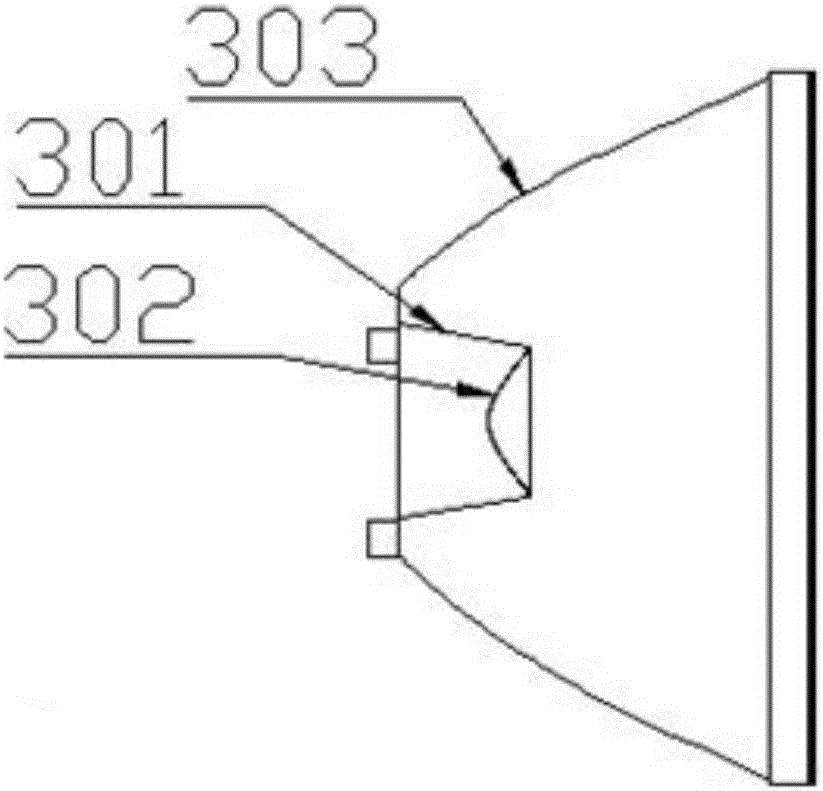

[0047] A polarizing lens such as figure 1 , figure 2 and image 3 As shown, including a mirror body, the mirror body includes an incident side surface 301, an incident top surface 302, a reflective surface 303, and an exit surface 304, and the material of the polarizing lens 300 is PMMA; the inner concave portion 306 formed by the incident side surface 301 and the incident top surface 302 is rotationally symmetrical , the light source is located on the axis of rotation of the inner concave portion 306; the reflective surface 303 is non-rotationally symmetrical, that is, the meridional axis and the sagittal axis of the polarizing lens 300 do not coincide; the incident side 301 is connected to the reflective surface 303, and the reflective surface 303 is connected to the outgoing surface 304 The exit surface 304 of the polarizing lens 300 can be a convex surface, a concave surface, a scale surface or a smooth surface, preferably a scale surface; the draft angle of the incident...

Embodiment 2

[0049] Side-entry backlight module, including body 1, such as Figure 4 as shown, Figure 4 It is a structural schematic diagram of the 32-inch backlight module provided by Embodiment 2 of the present invention. The main body includes: cavity 104, reflective paper, light bar 106, diffusion plate 102 and optical film 101; the cavity 104 is the overall shape structure of the backlight module, and the reflective paper is tightly attached to the inside of the cavity 104 by double-sided adhesive The cavity on the bottom surface is attached with reflective paper 103 and the upper part of the light bar reflective paper 105 attached to the upper part of the cavity 104, and the cavity attached reflective paper 103 and the bottom surface of the cavity 104 have the same shape, and the upper part of the light bar reflective paper 105 is located on the light bar 106 Above, the length of the reflective paper 105 on the upper part of the light bar is greater than or equal to the length of t...

Embodiment 3

[0072] Such as Figure 13 as shown, Figure 13 It is a schematic diagram of the structure of the 55-inch backlight module provided by Embodiment 3 of the present invention. The difference from Embodiment 2 is that

[0073] The 55-inch backlight mode light bar 106 of the embodiment of the present invention needs two, and each is installed on the opposite inner wall of the cavity 104 .

[0074] The mixing distance OD value of the embodiment of the present invention is 20mm, that is, the maximum distance from the bottom surface of the diffusion plate 102 to the bottom surface of the cavity 104 is 20mm, and the minimum distance is 8.2mm; the model of the CSP light source 400 is EPISTAR 1010, and the CSP light source 400 and polarizing lens on the single light bar 106 The number of 300 is 42, and the distance between the CSP light source 400 is 29mm, the outer size of the polarizing lens 300 is 20mm*20mm*11.2mm, the material of the reflective paper 103 and 105 is RA8E, and the thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com