Patents

Literature

2201 results about "Polarised light" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polarizing element, optical element, and liquid crystal display

InactiveUS6661482B2Reduce contrastImprove the display effectStatic indicating devicesNon-linear opticsLiquid-crystal displayPolarizer

Owner:NITTO DENKO CORP

Non-glare film, polarizing device and display device

InactiveUS6343865B1Small particle sizeImprove display qualityMirrorsDiffusing elementsRefractive indexDisplay device

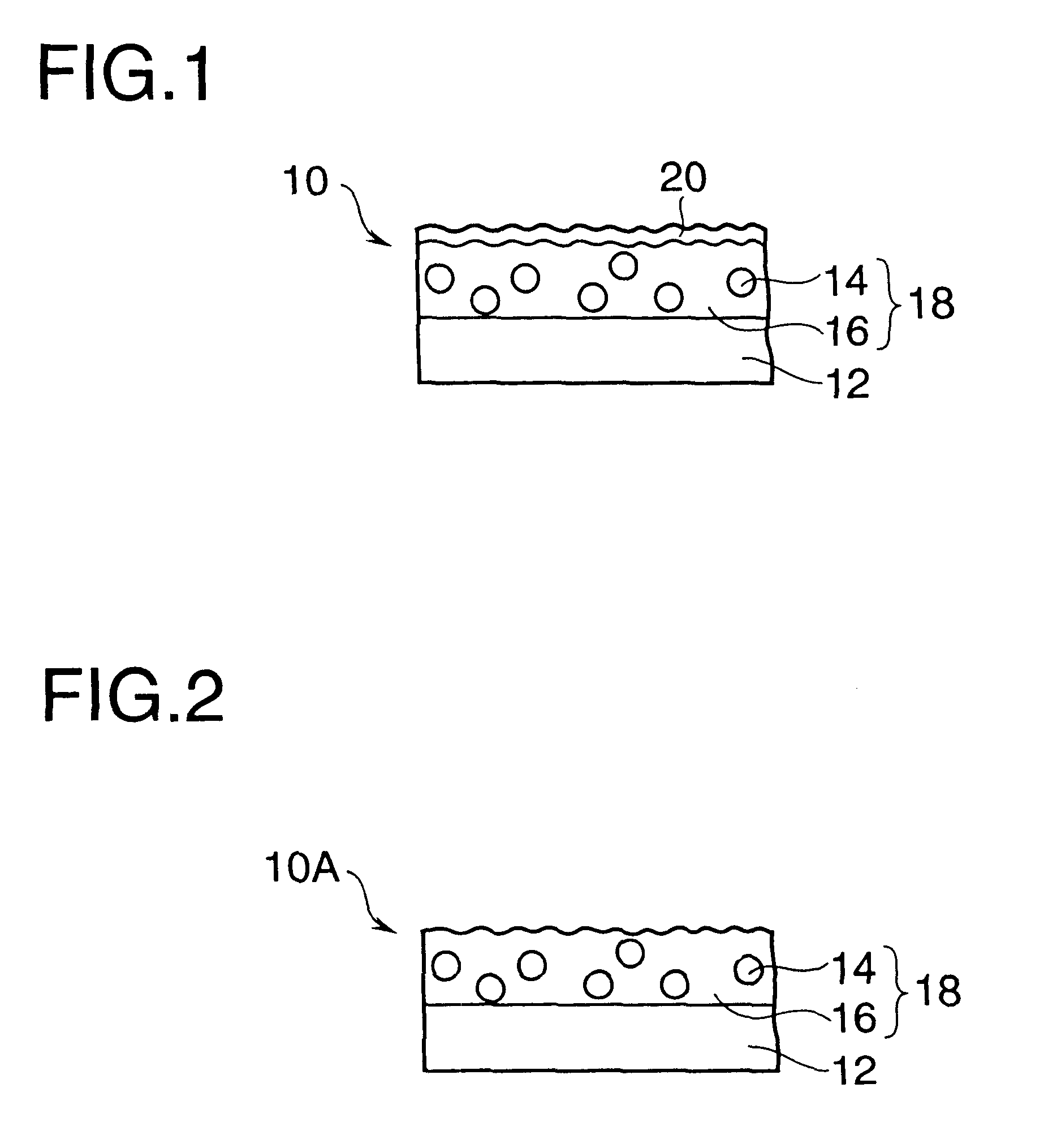

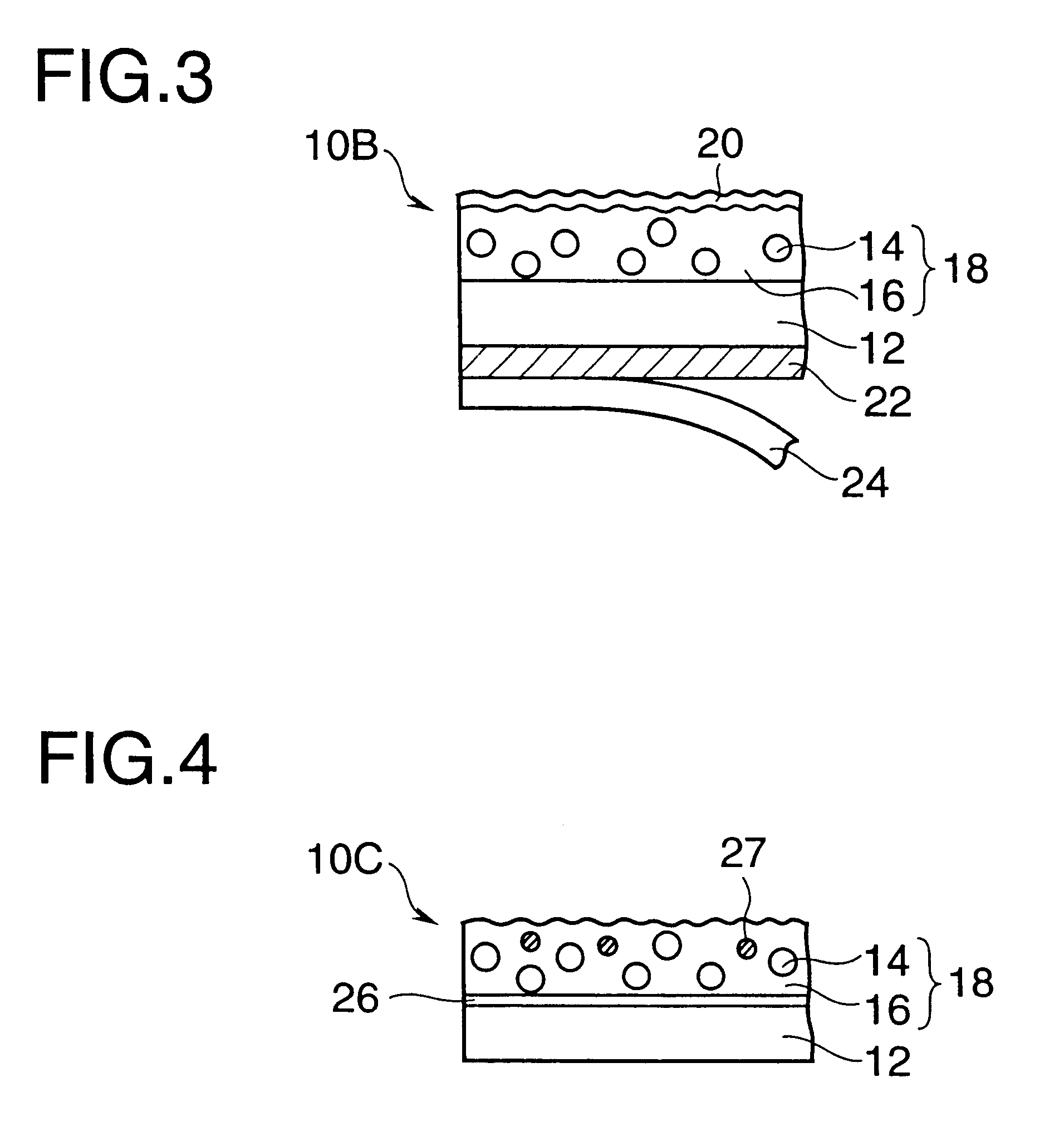

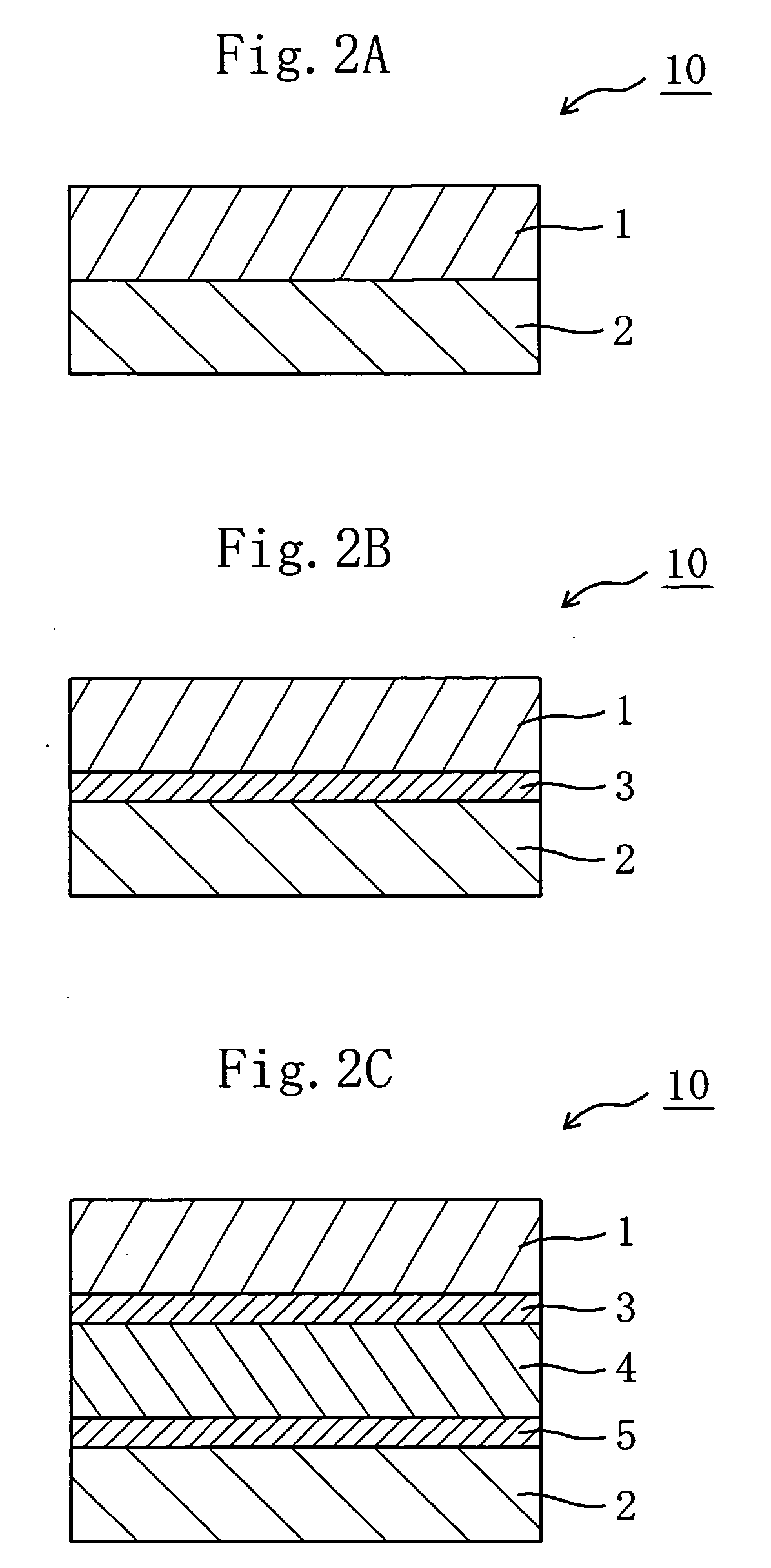

A non-glare film 10 is composed of a non-glare layer 18 formed by coating a transparent base film 12 of TAC or the like with a coating material obtained by mixing a light transmissive diffusing material 14 of resin beads and the like in a light transmissive resin 16, and a low refractive index layer 20 composed of a silicon-containing vinylidene fluoride copolymer, said low refractive index layer 20 being laminated onto the surface of the non-glare layer, in which the haze value on the surface of the non-glare layer 18 is 7 to 30 and the haze value inside the non-glare layer 18 is 1 to 15, and when the non-glare film is attached onto the surface of a display panel, it suppresses degradation in contrast and furthermore prevents face-glare, reflecting-in and whitening.

Owner:DAI NIPPON PRINTING CO LTD

Antireflection material and polarizing film using the same

InactiveUS6777070B1Improve anti-reflection effectReduce image contrastSynthetic resin layered productsCoatingsRefractive indexDisplay device

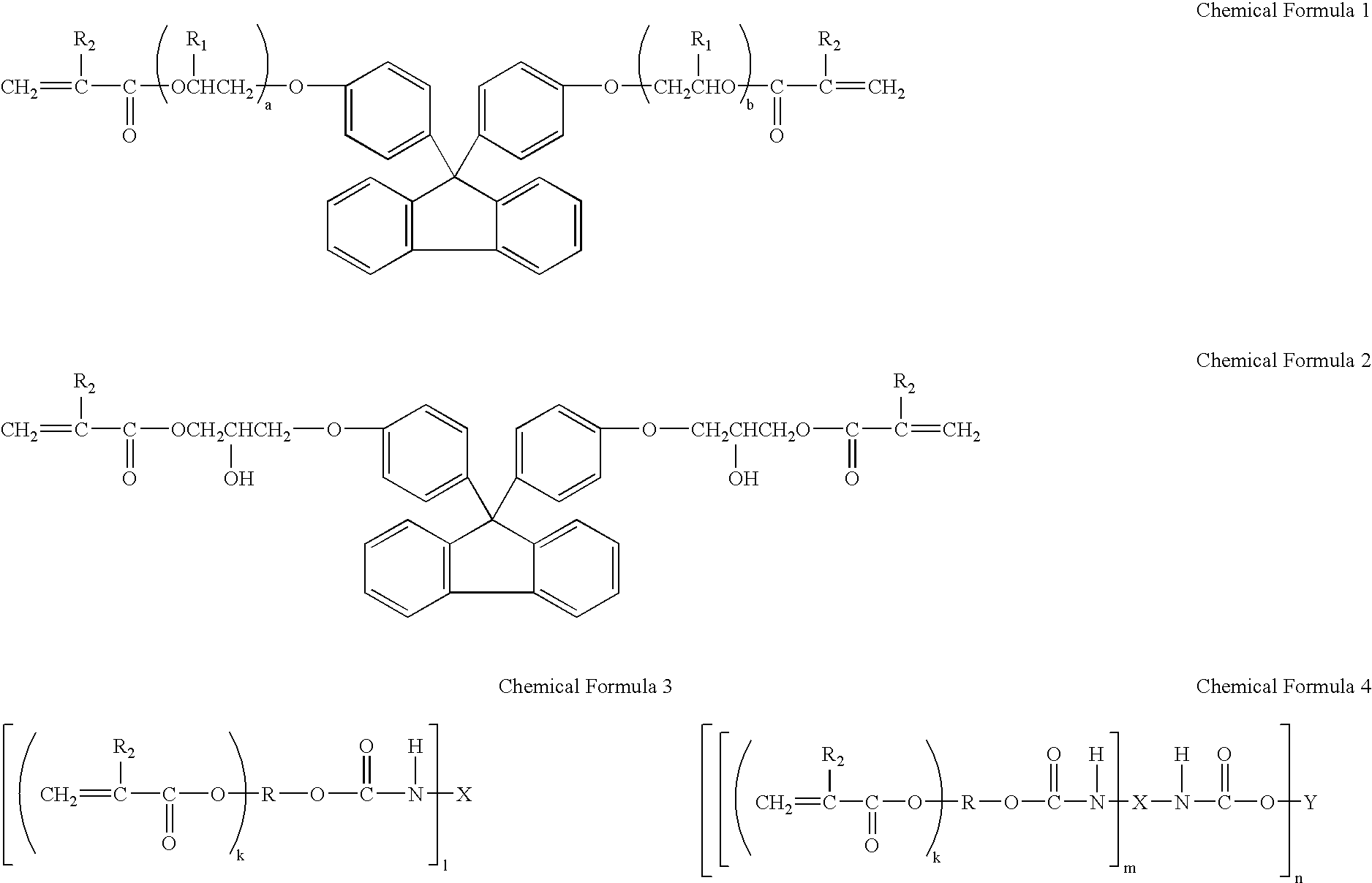

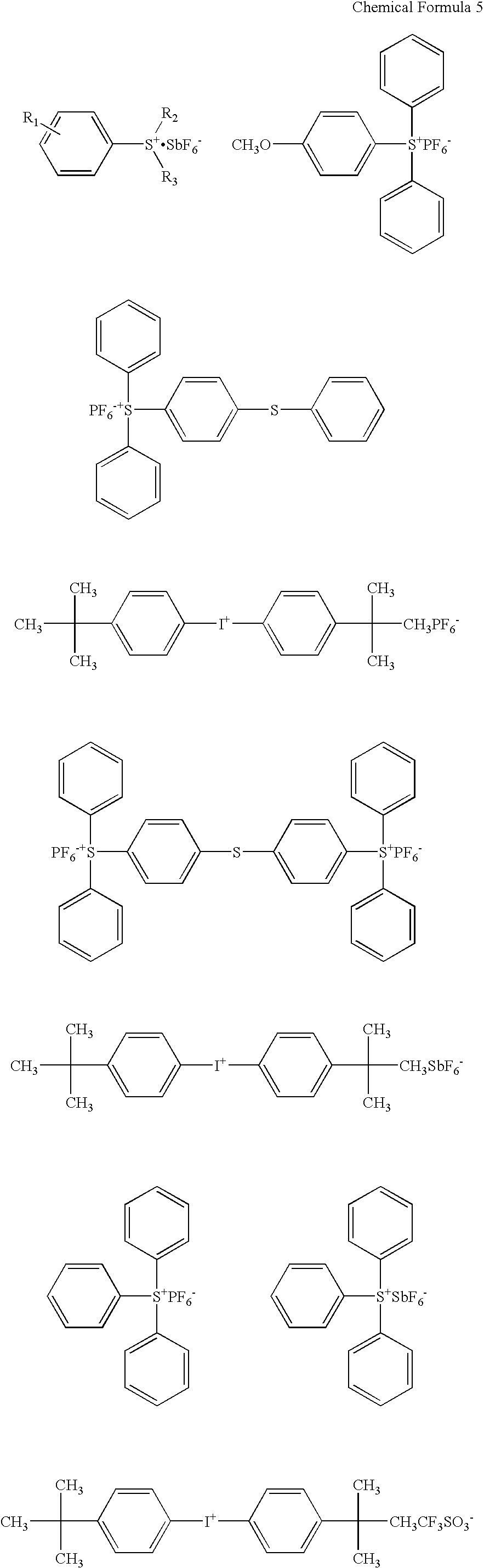

An anti-reflection material and a polarization film which exhibit superior anti-reflection properties by preventing external light such as sunlight, fluorescent light, etc., from being reflected on a display, which yield a clear image without sparkling and reduces image contrast, and which exhibit superior wear resistance, chemical resistance, and contamination resistance, as well as exhibit optical stability. A hard coat layer is provided on one surface or two surfaces of a transparent substrate directly or via another layer, and an anti-reflection film having a lower refraction index than the hard coat layer is further provide on the hard coat layer. The hard coat layer consists of at least {circle around (1 a polymer polymerizing (metha)acrylate compound having a fluorene structure; {circle around (2 a polymer polymerizing urethane (metha)acrylate compound and ultrafine particles having a high refraction index; and {circle around (3 radiation and / or thermosetting resin and surface-treated titanium oxide ultrafine particles.

Owner:TOMOEGAWA PAPER CO LTD

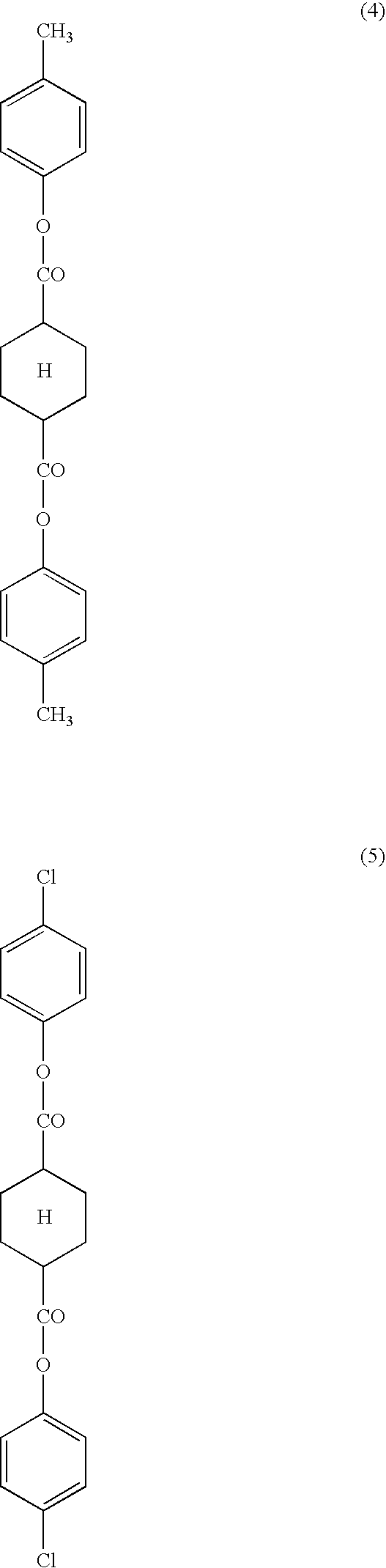

Polarized head-mounted projection display

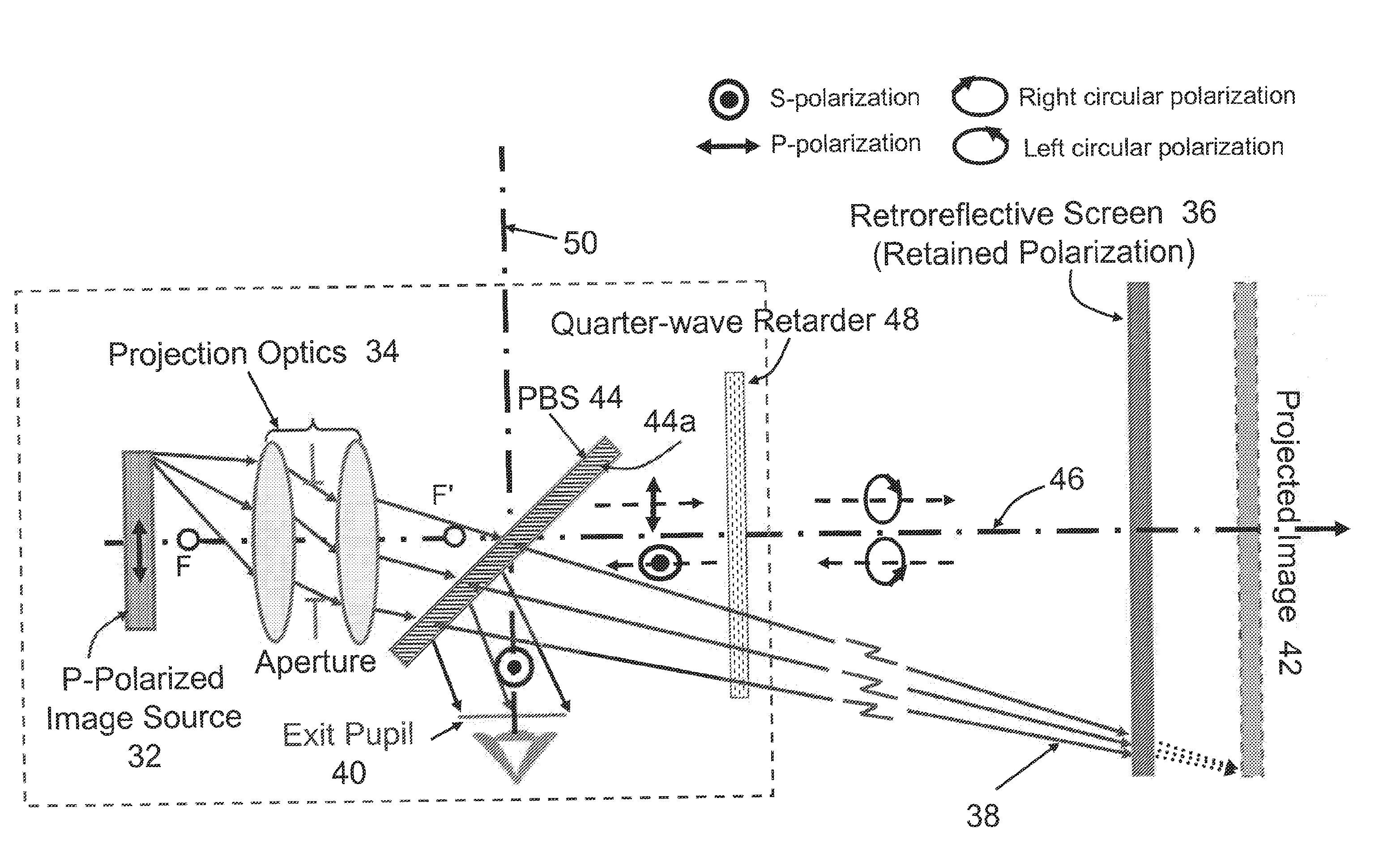

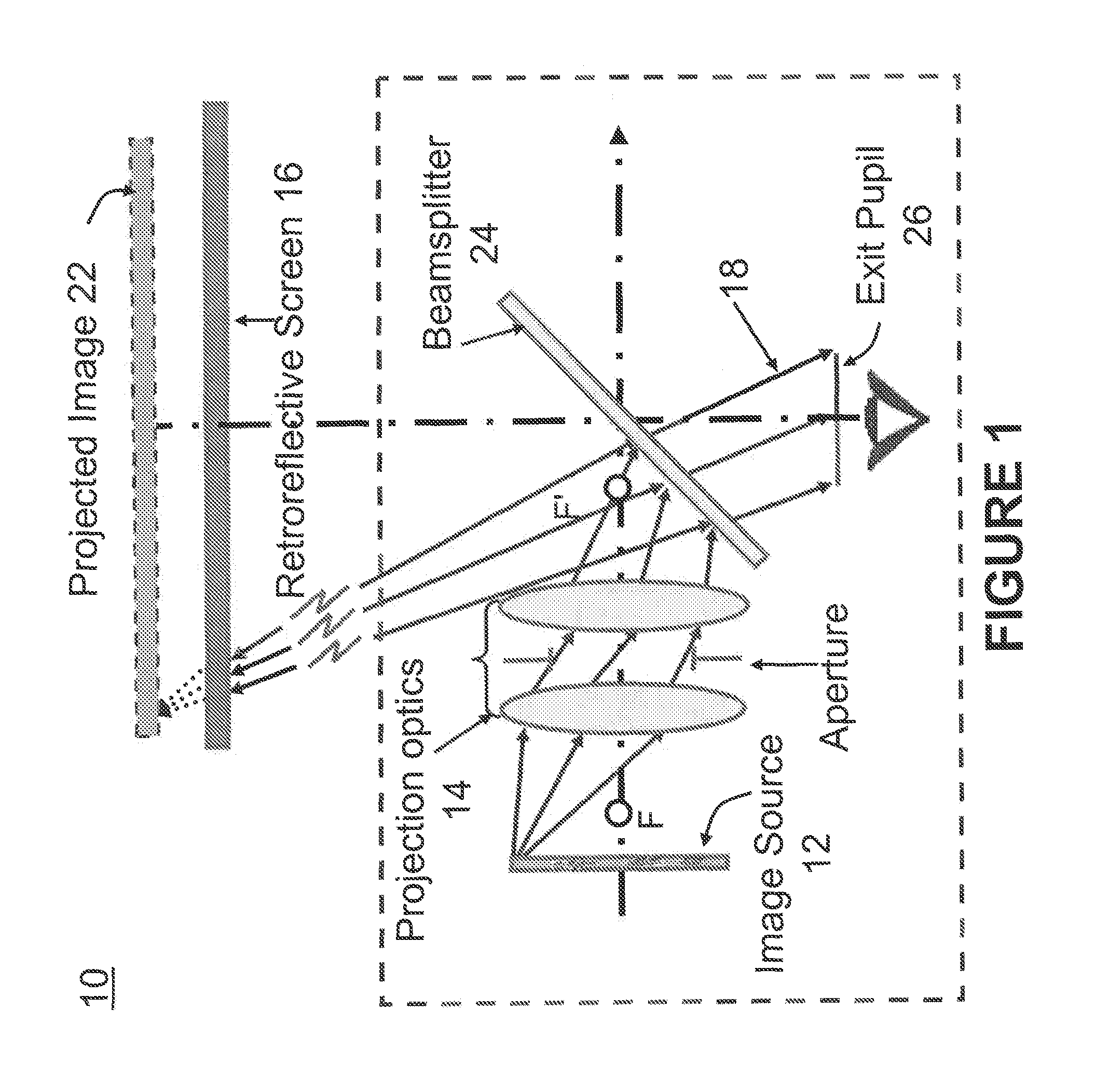

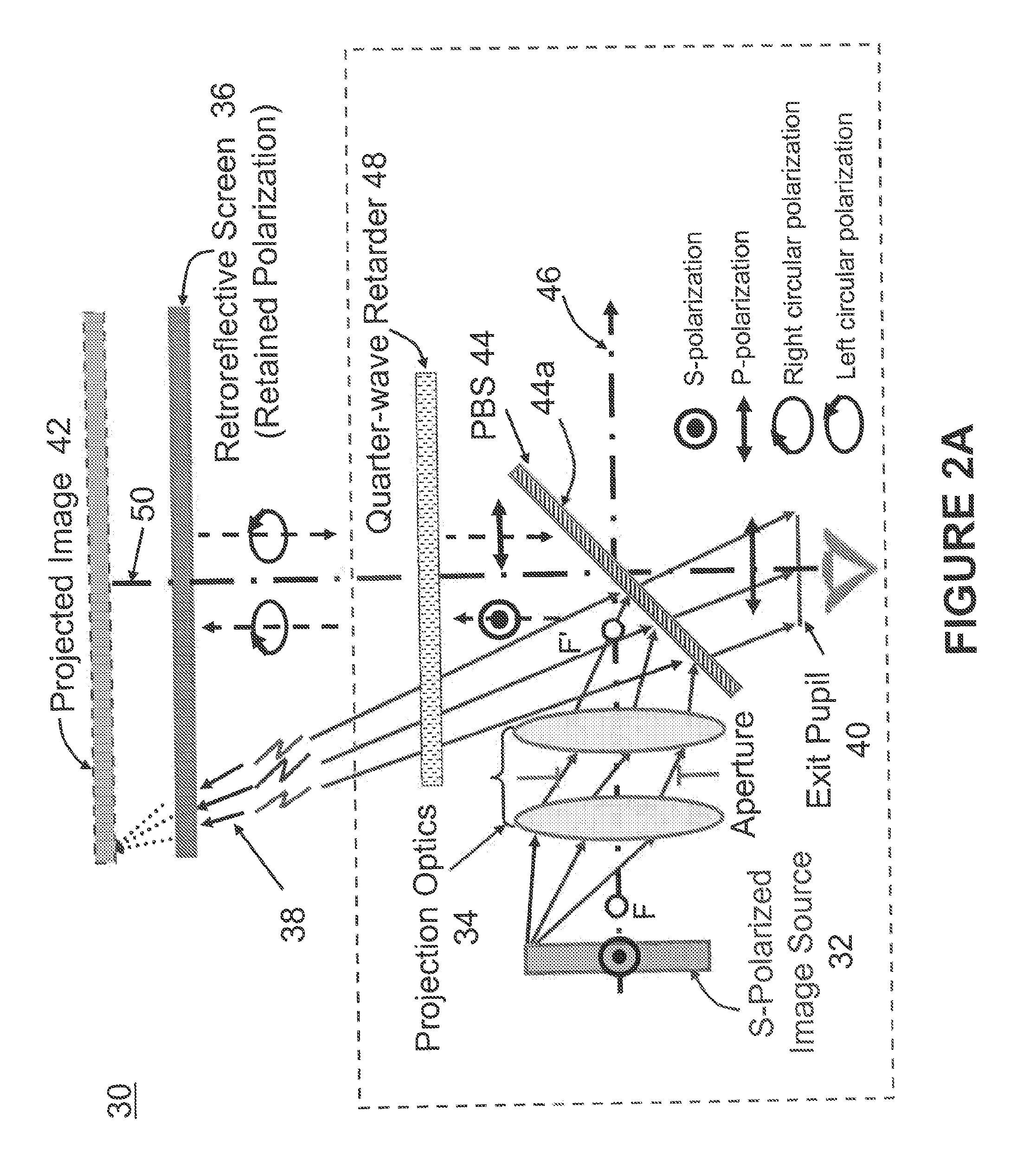

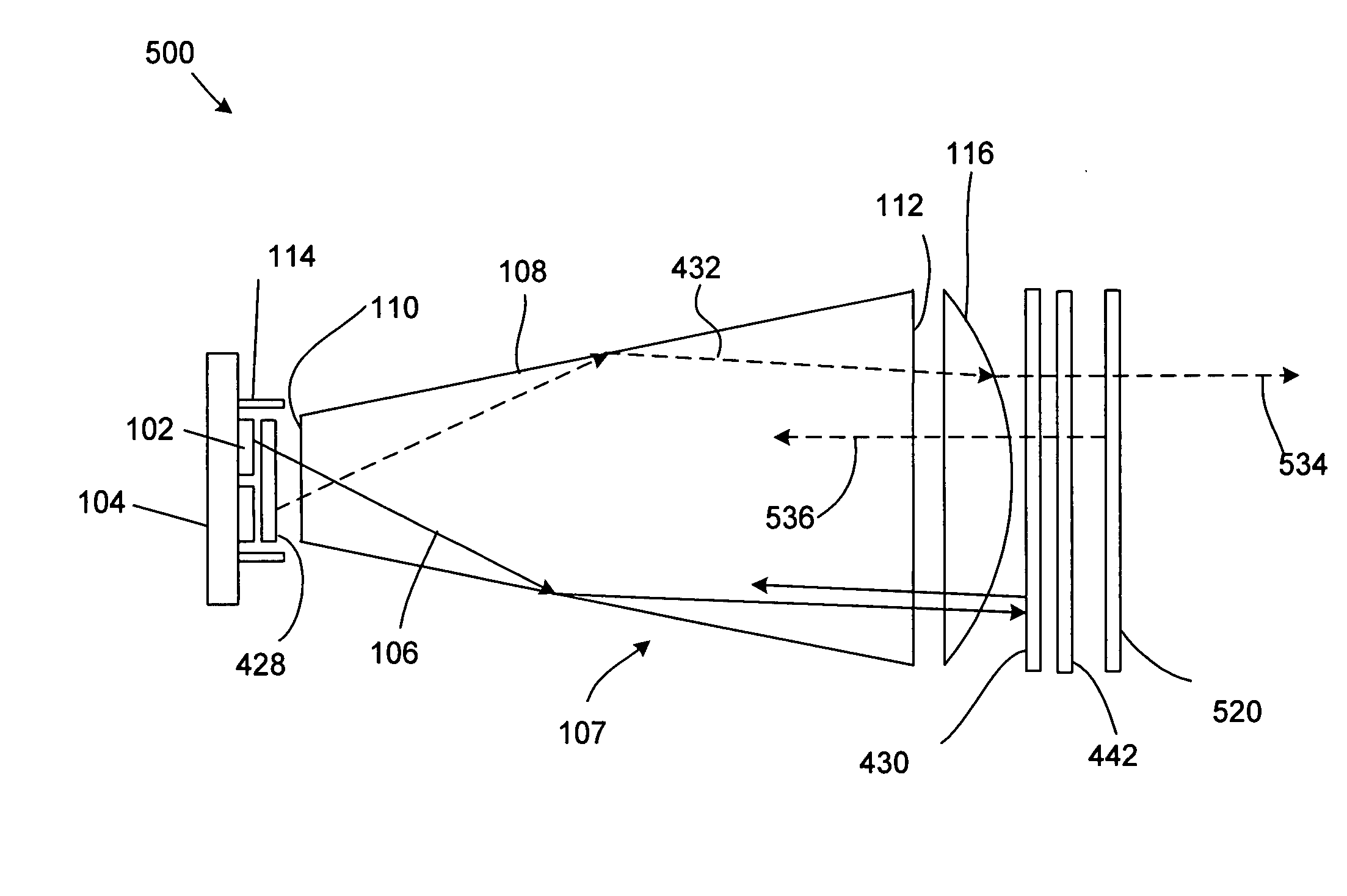

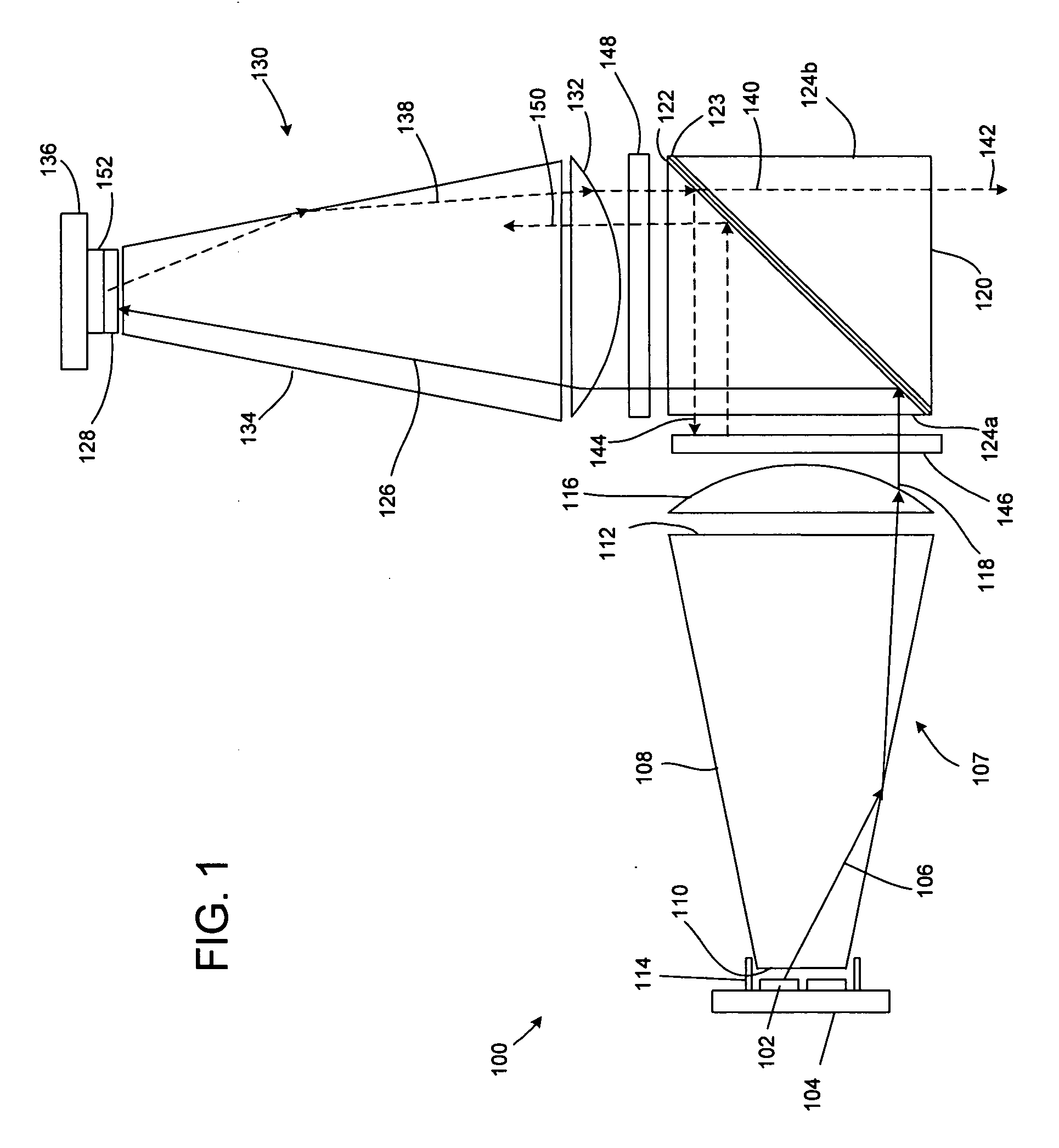

An image display system and associated method for image displaying The system includes an image source configured to generate image light, projection optics configured to project the image light, and a polarizing beam splitter optically coupled to the projection optics and configured to propagate into a first optical path first polarized light having a first polarization and to propagate into a second optical path second polarized light having a second polarization The system includes a quarter wave converter disposed in the first optical path and configured to rotate the first polarization by a quarter phase as the first polarized light first passes through the quarter wave converter, and includes a reflective screen disposed in the first optical path and configured to reflect rotated first polarized light from the quarter wave converter back through the quarter wave converter for further quarter phase rotation.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

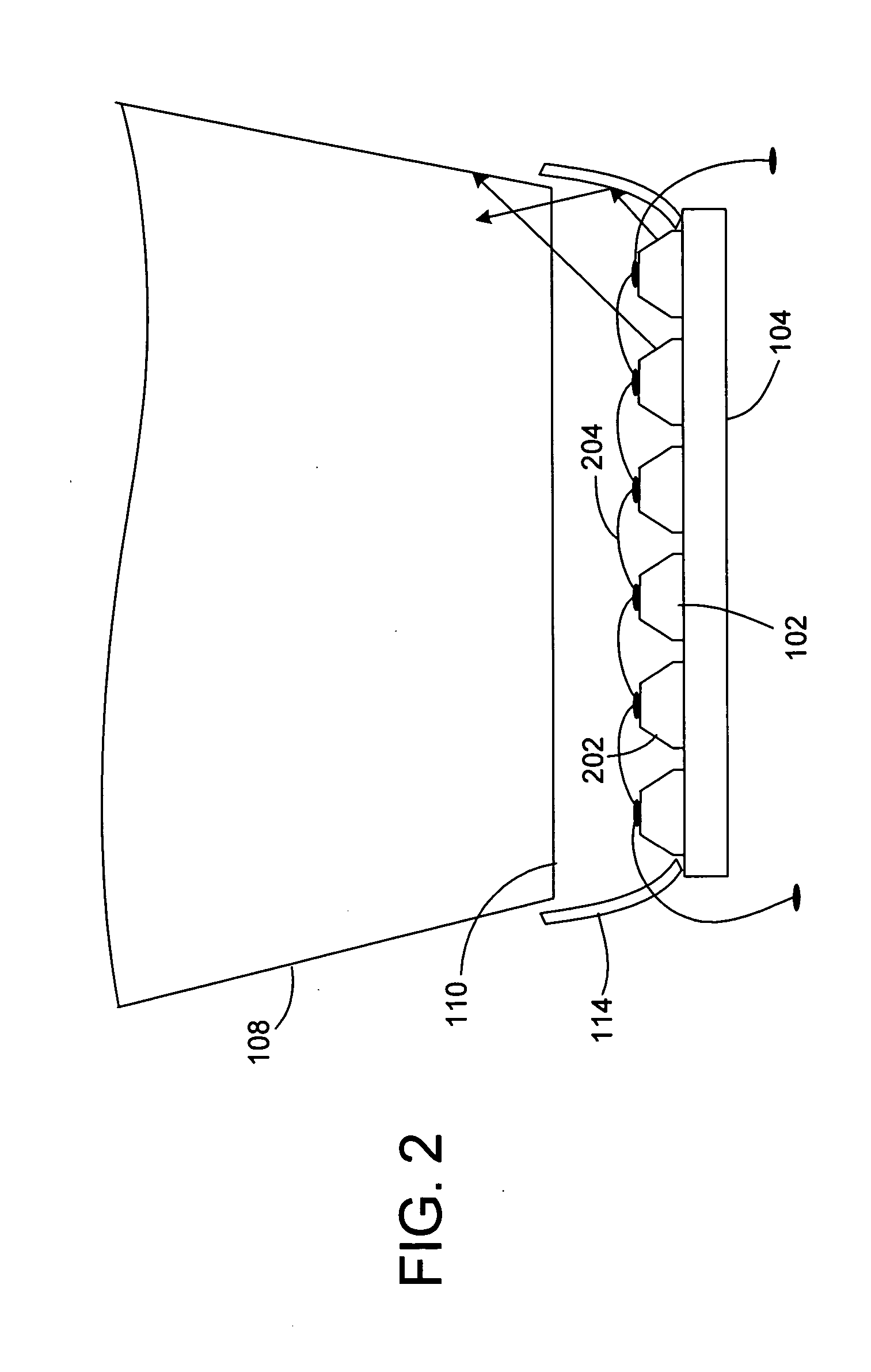

Polarized, multicolor LED-based illumination source

Light emitting diodes (LEDs) emit light at a first wavelength. A phosphor material close to LEDs converts at least some of the light to a second wavelength. The light at both wavelengths passes through a light collecting unit. A reflecting polarizer transmits both wavelengths in a first polarization state and reflects light at both wavelengths in a second, orthogonal, polarization state. Light reflected by the reflective polarizer is directed back towards the phosphor material without any substantial increase in angular range. The resulting output light beam contains polarized light at the first and second wavelengths. In some embodiments, an array of LEDs includes LEDs that emit light at a first wavelength and others that emit light at a second wavelength. The phosphor material is disposed on the LEDs emitting the light at the first wavelength.

Owner:3M INNOVATIVE PROPERTIES CO

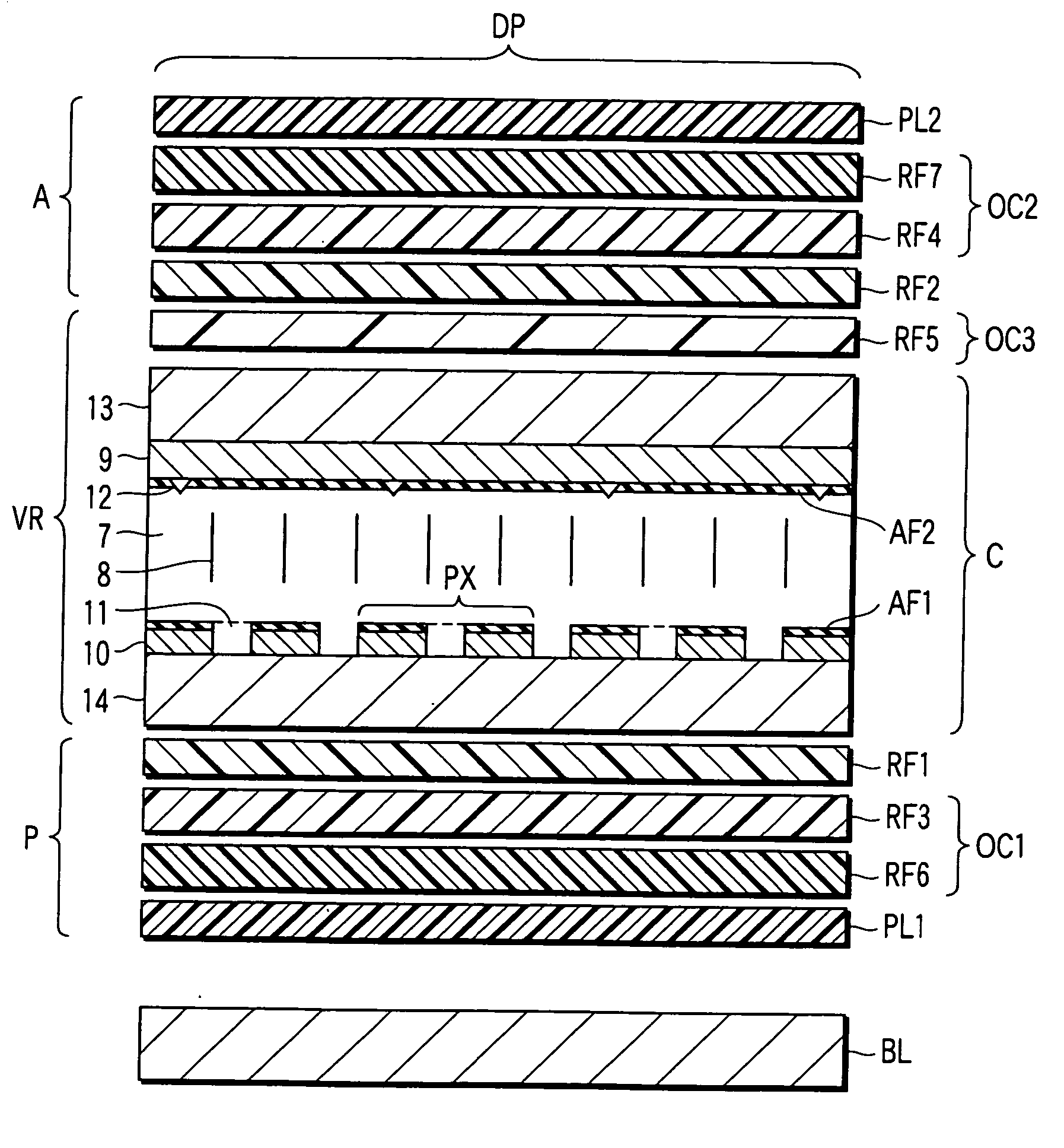

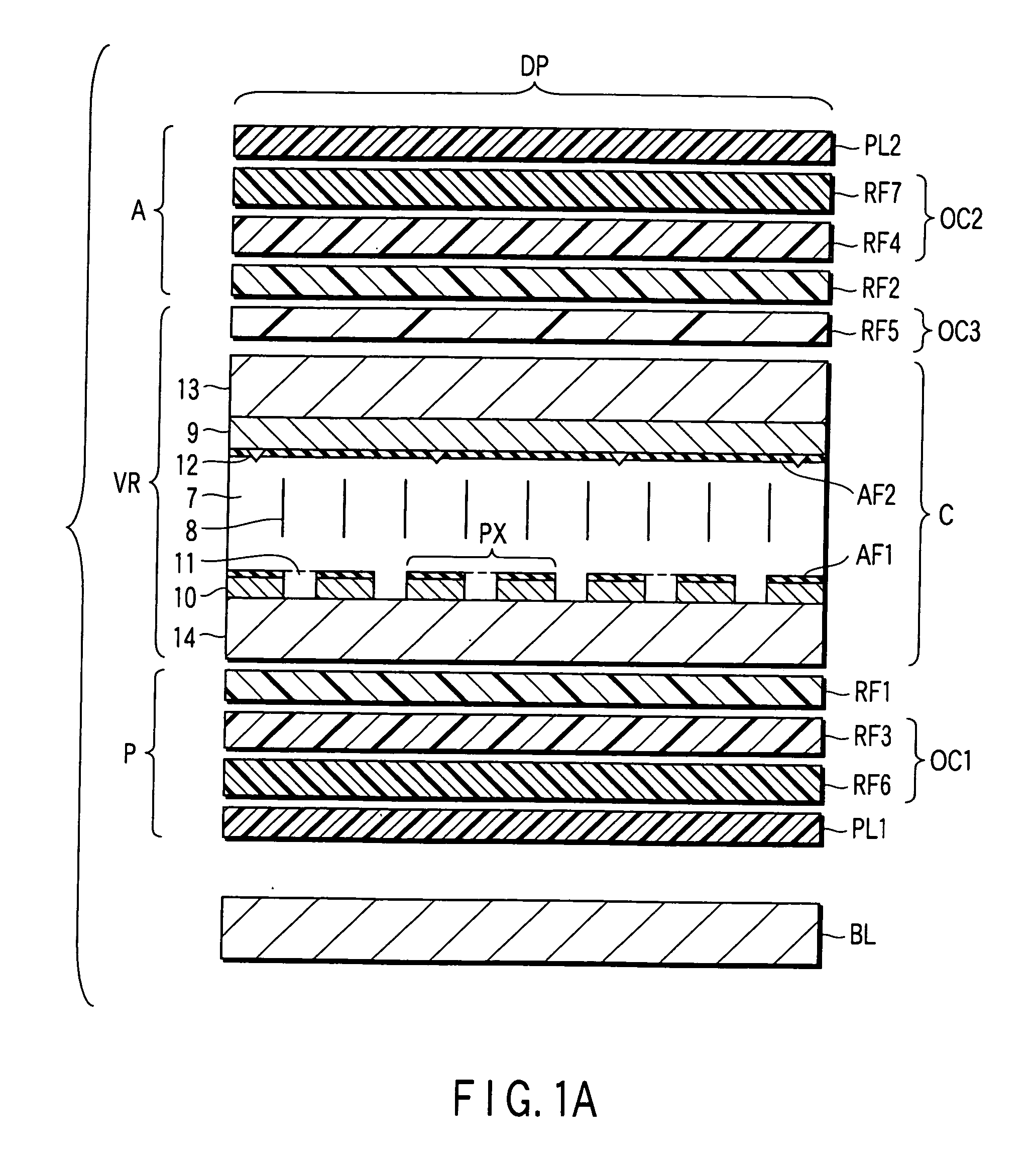

Liquid crystal display device

A circular-polarization-based vertical alignment mode liquid crystal display device includes a circular polarizer structure, a variable retarder structure and a circular analyzer structure. The circular polarizer structure includes a first optical compensation layer for optical compensation thereof, the first optical compensation layer including a uniaxial retardation plate with a refractive index anisotropy of nx≈ny<nz. The circular analyzer structure includes a second optical compensation layer for optical compensation thereof, the second optical compensation layer including a uniaxial retardation plate with a refractive index anisotropy of nx≈ny<nz. The variable retarder structure includes a third optical compensation layer for optical compensation thereof, the third optical compensation layer including a uniaxial retardation plate with a refractive index anisotropy of nx≈ny>nz.

Owner:TOSHIBA MATSUSHITA DISPLAY TECH

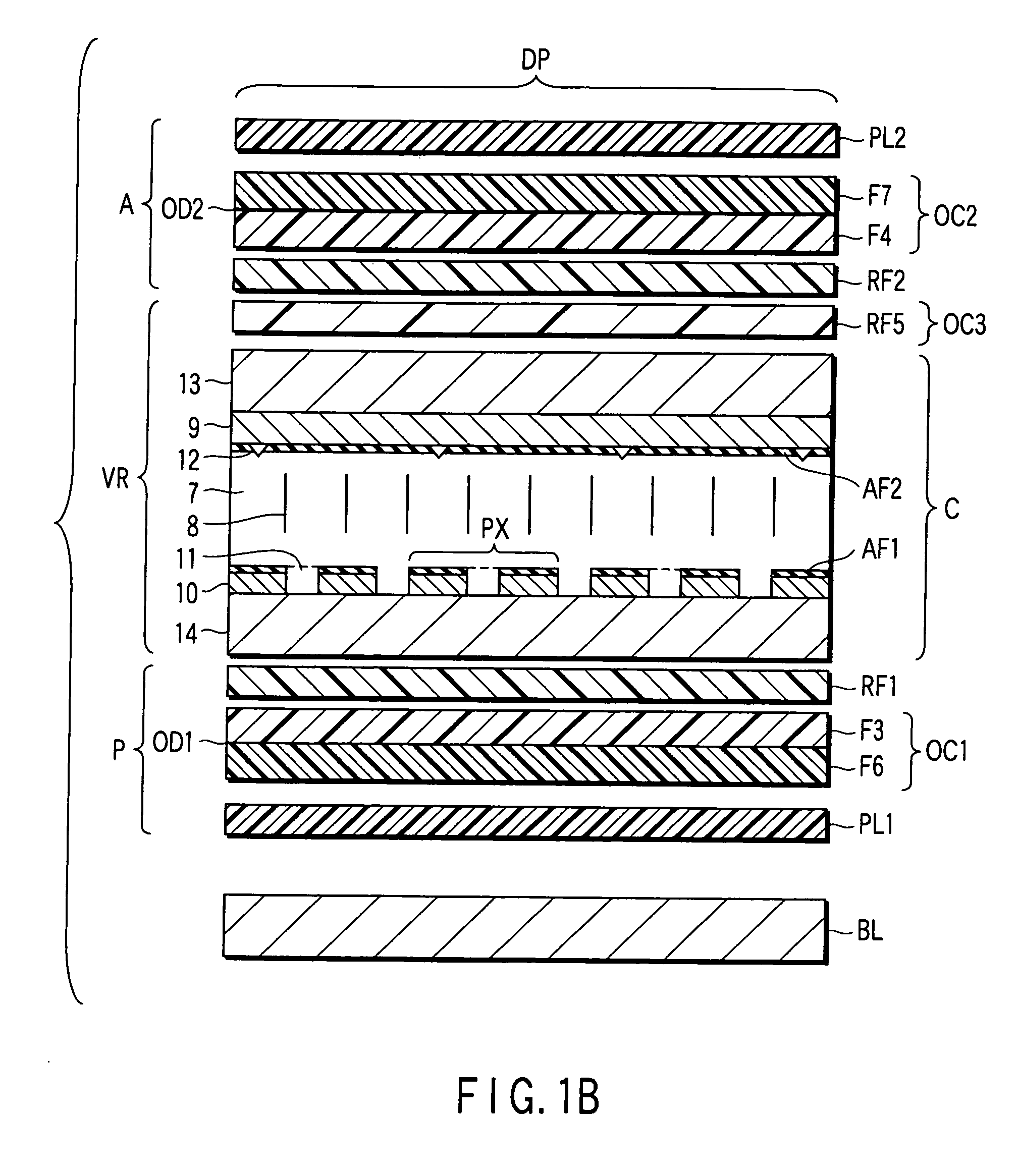

Apparatus for light intensity adjustment

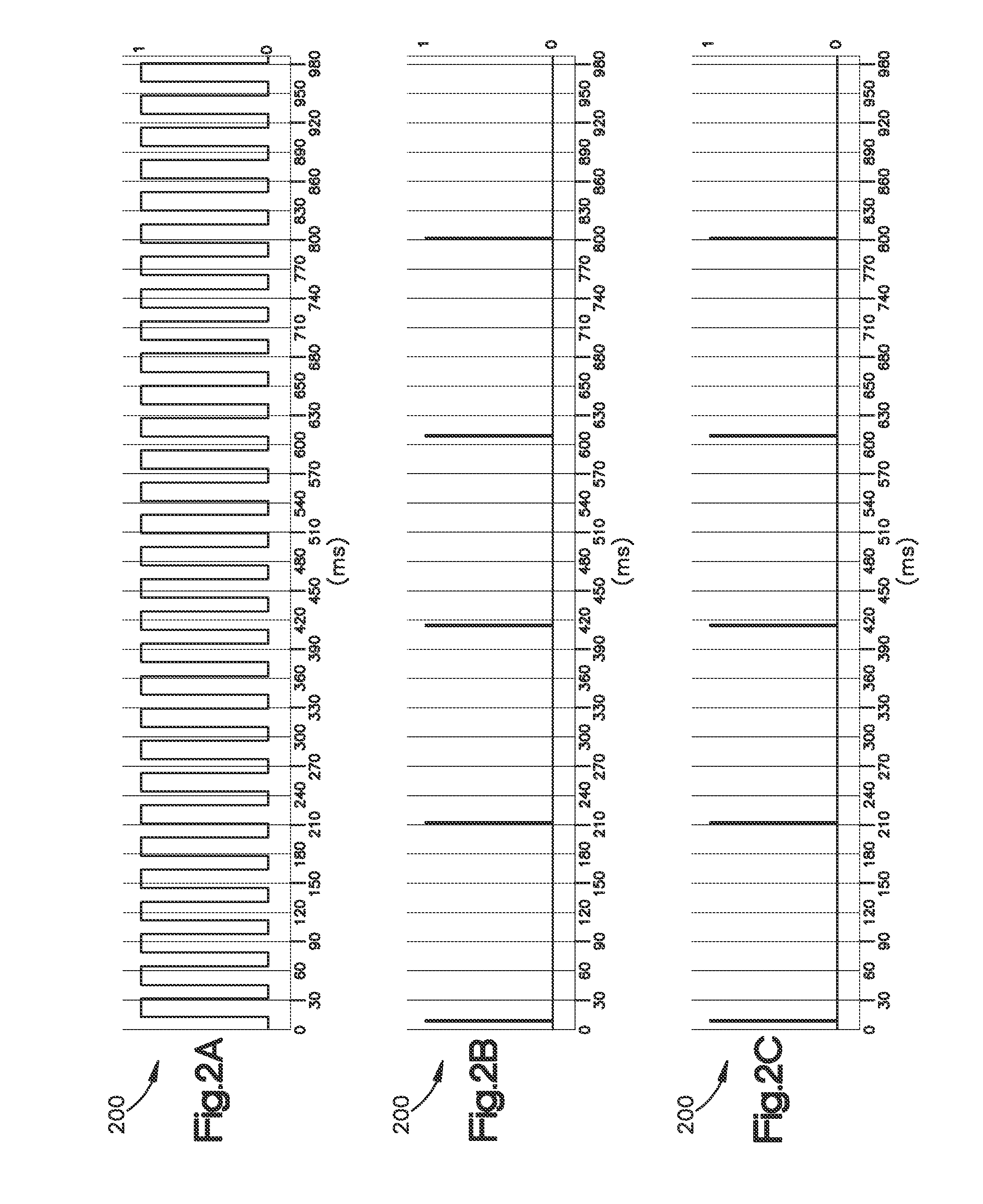

ActiveUS20160096487A1Reduce integration timeReduce light intensityTelevision system detailsColor television detailsActuatorOptical polarization

An apparatus for light intensity adjustment mountable on an automotive camera includes at least one first linear polarizing filter, at least one second linear polarizing filter, the first linear polarizing filter and the second polarizing filter are arrangeable in front of a lens unit of an automotive camera such that incident light passes through the at least one first linear polarizing filter and the at least one second linear polarizing filter before entering the lens unit of the automotive camera, and at least one actuator for moving the at least one first linear polarizing filter and / or the at least one second linear polarizing filter with respect to each other such that the intensity of the emergent light is adjustable. The apparatus is characterized in enabling adjustment of the emergent light intensity by moving the first linear polarizing filter and / or the second linear polarizing filter with respect to each other.

Owner:SMR PATENTS S A R L

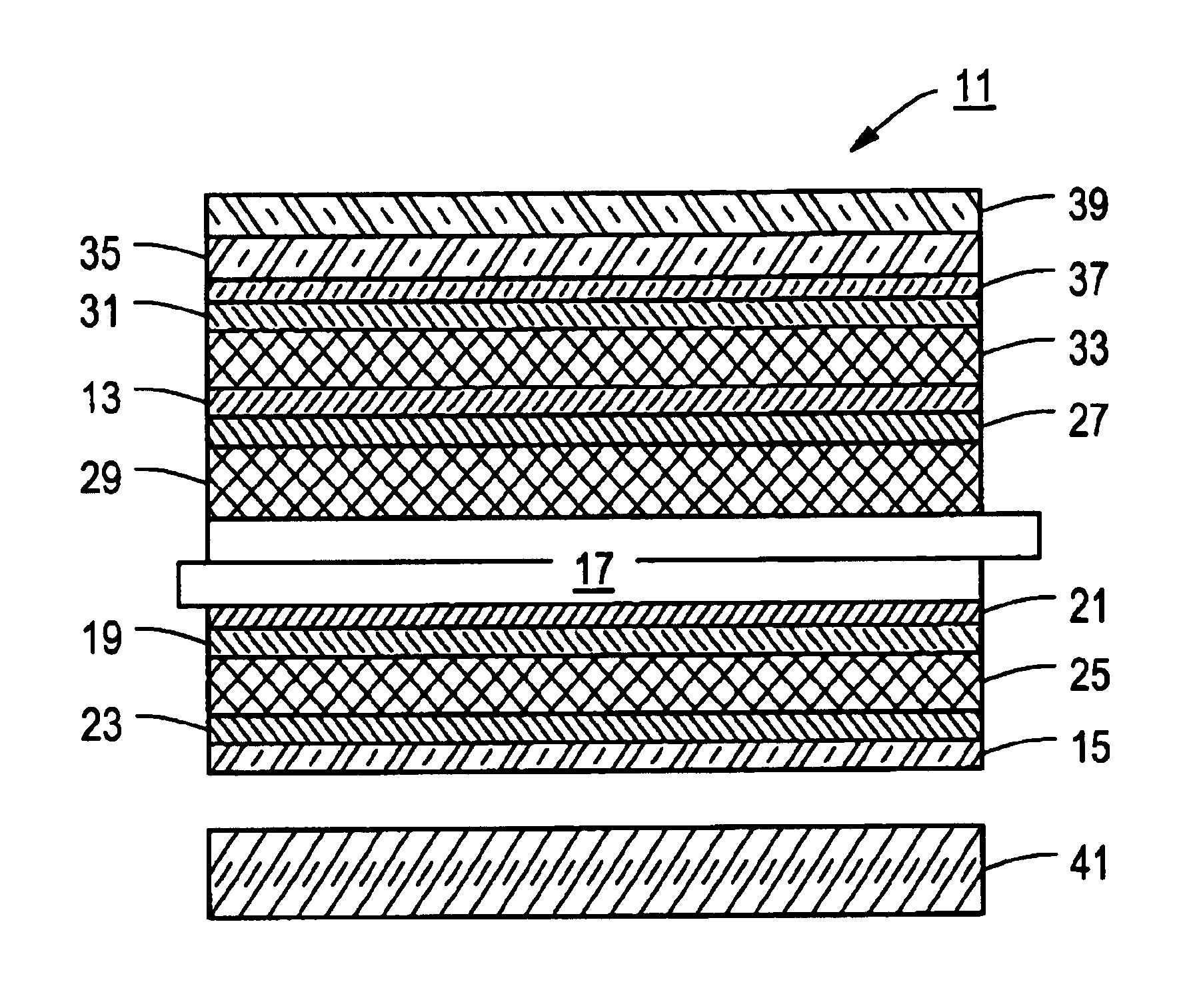

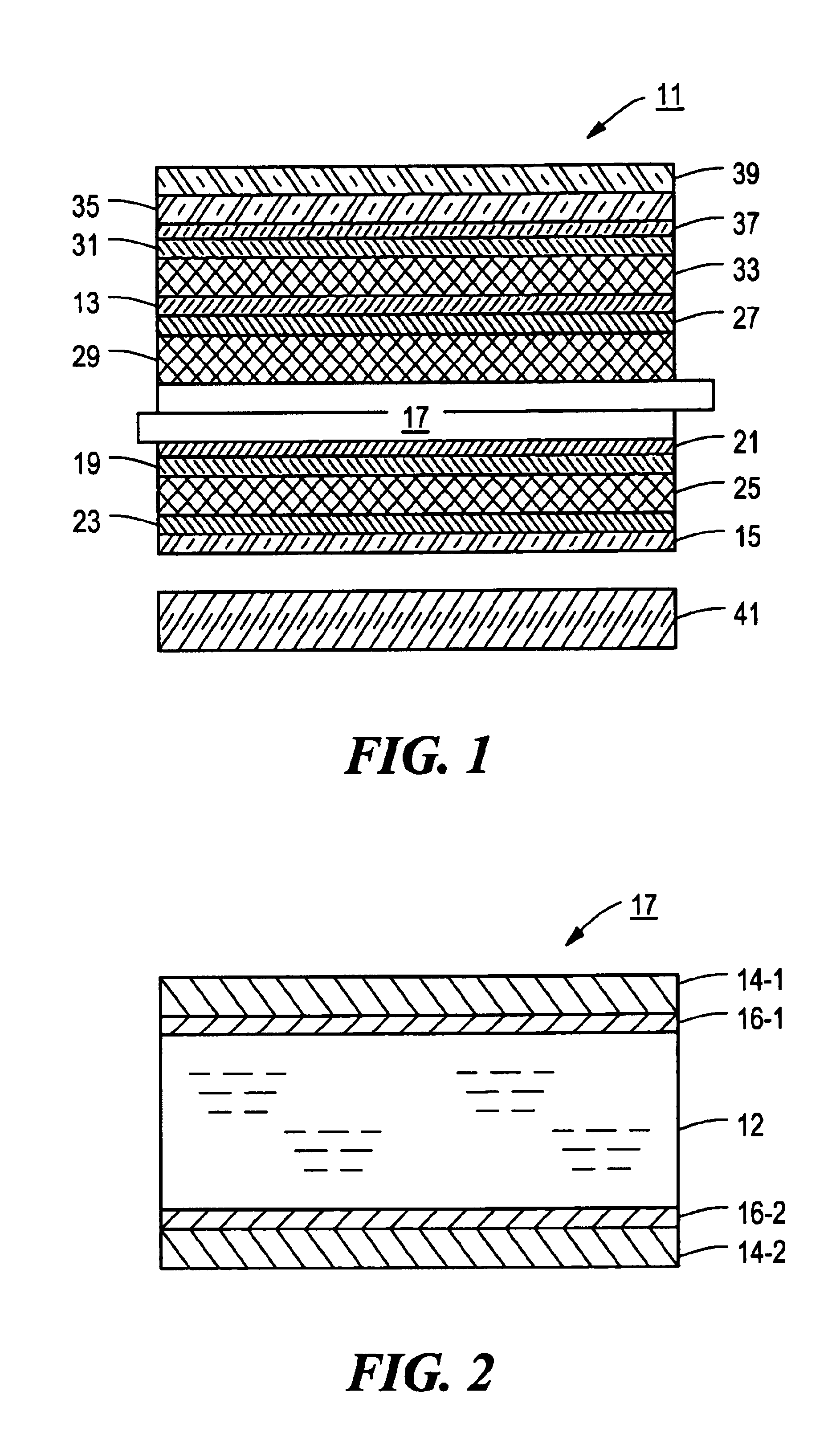

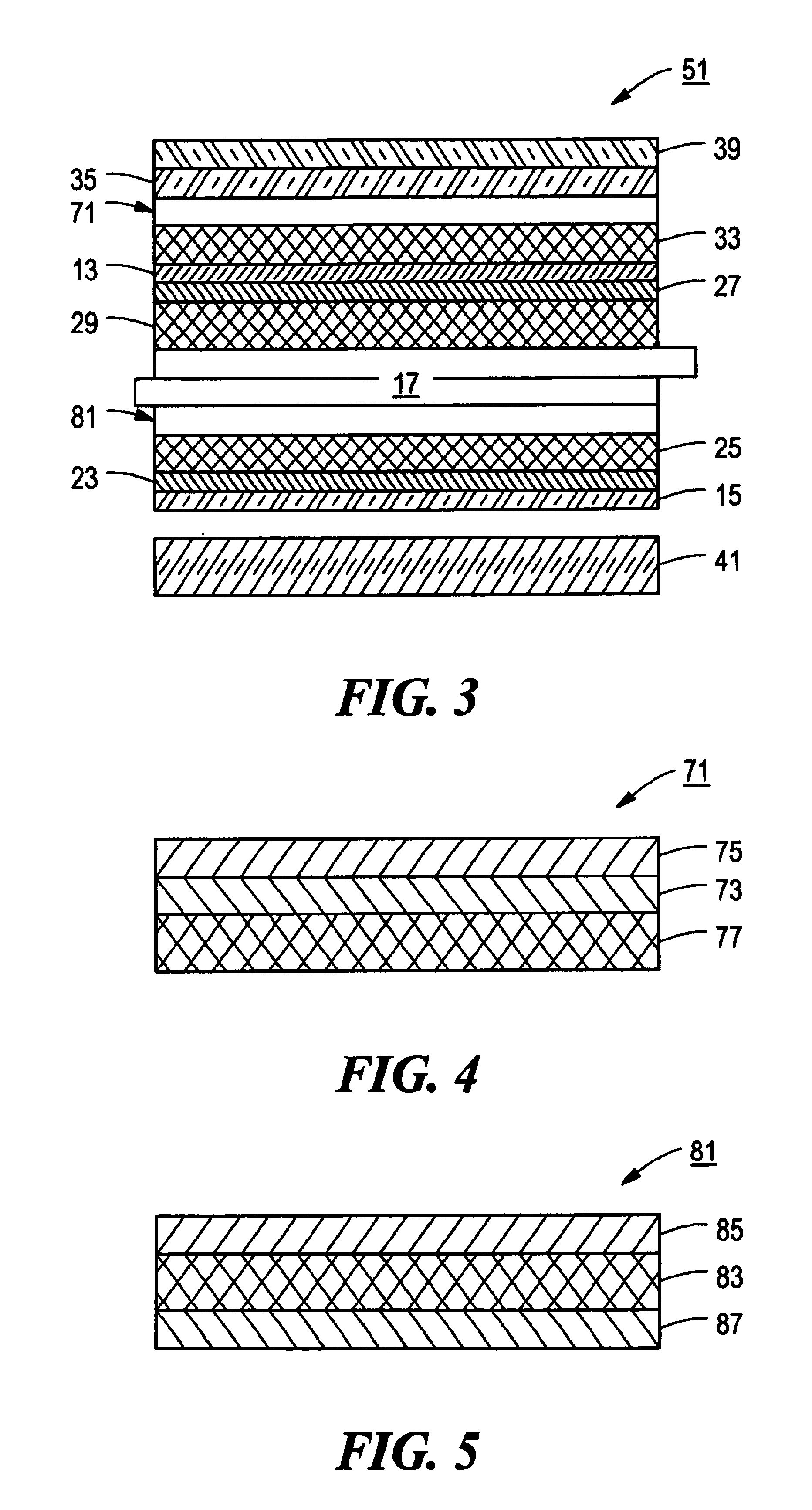

Super bright low reflectance liquid crystal display

InactiveUS6933991B2Reduce the amount requiredImprove viewing characteristicsStatic indicating devicesPolarising elementsOptical bondingPolarizer

A liquid crystal display (LCD) exhibiting enhanced optical viewing performance. In a preferred embodiment, the LCD comprises a liquid crystal display panel, the liquid crystal display panel comprising a pair of transparent substrates, liquid crystal material sandwiched between the transparent substrates and transparent electrodes positioned between the liquid crystal material and the transparent substrates. The LCD also comprises a rear polarizer assembly comprising a compensation film, a polarizer mounted on the rear surface of the compensation film, and a first index-matched, pressure sensitive adhesive (PSA) mounted on the front surface of the compensation film, the PSA being adhered to the rear surface of the LCD panel. The LCD also comprises a front polarizer assembly, the front polarizer assembly comprising a front polarizer, a compensation film mounted on the rear surface of the front polarizer and an index-matched PSA mounted on the front surface of the front polarizer. The front polarizer is crossed relative to the rear polarizer. The front polarizer assembly may be adhered to the front of the LCD panel with a second index-matched, optical bonding material or may be spaced therefrom by an air gap. A transparent cover is mounted on the second index-matched PSA. The transparent cover is preferably a plastic plate. The plastic plate may be textured to reduce glare or may have an anti-reflection coating or an anti-reflection film applied to the front surface thereof. Instead of a plastic plate, the transparent cover may be a glass plate or a touch panel.

Owner:VIA OPTRONICS

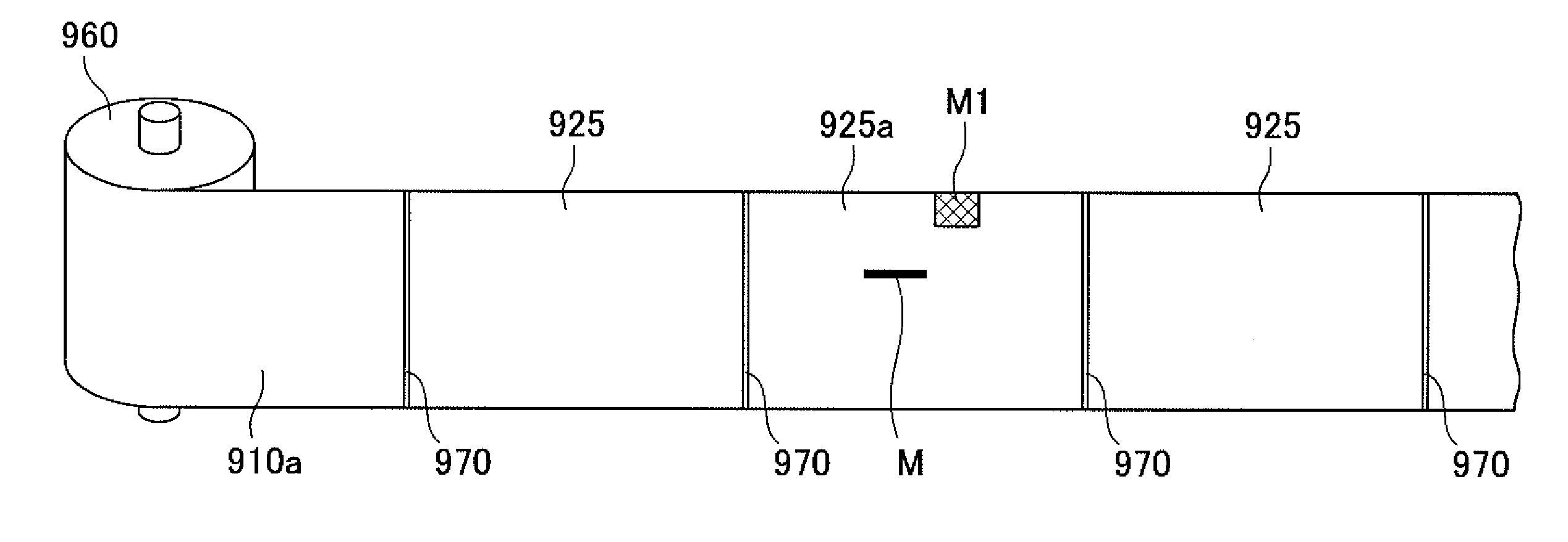

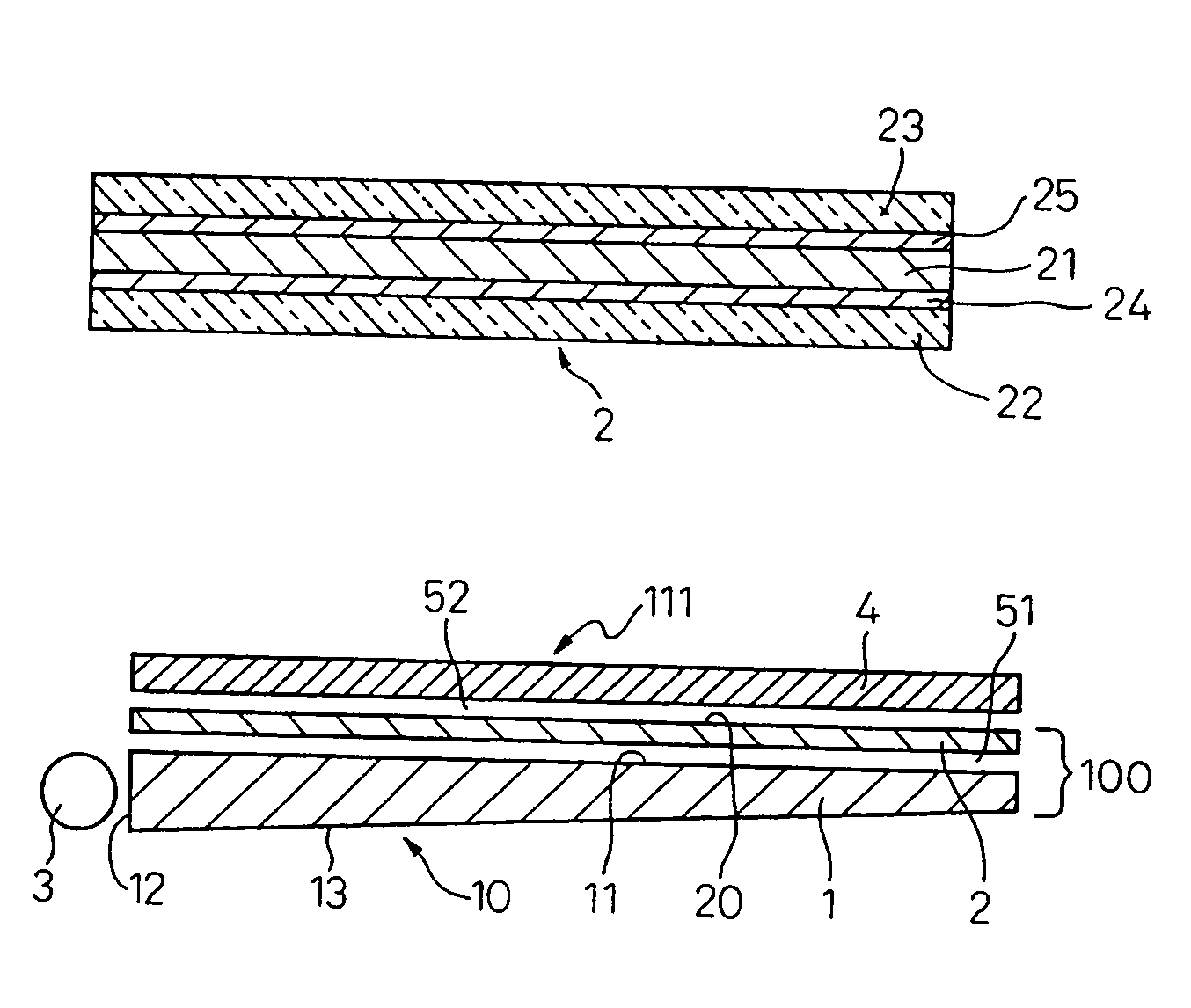

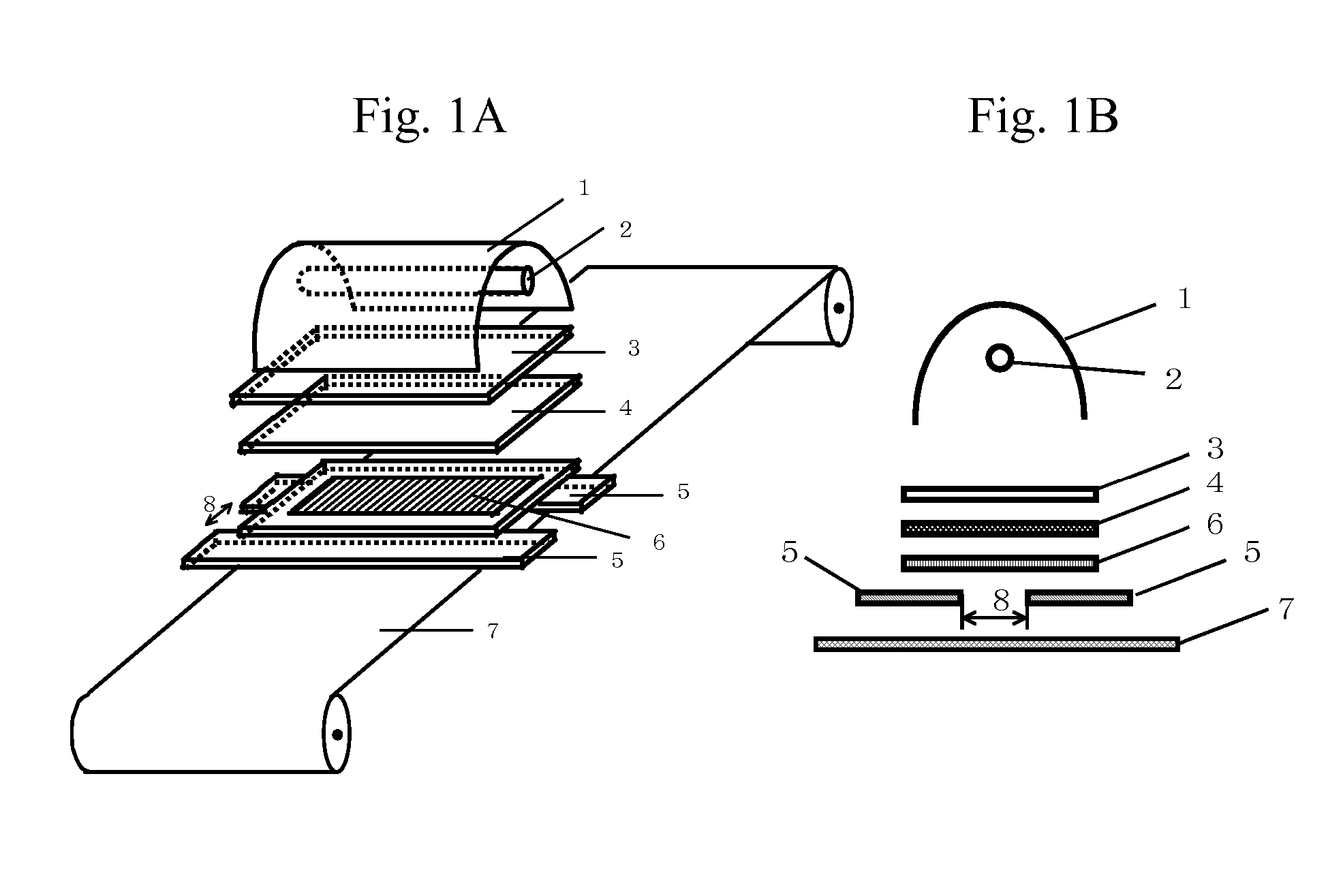

Roll of continuous web of optical film laminate and production method therefor

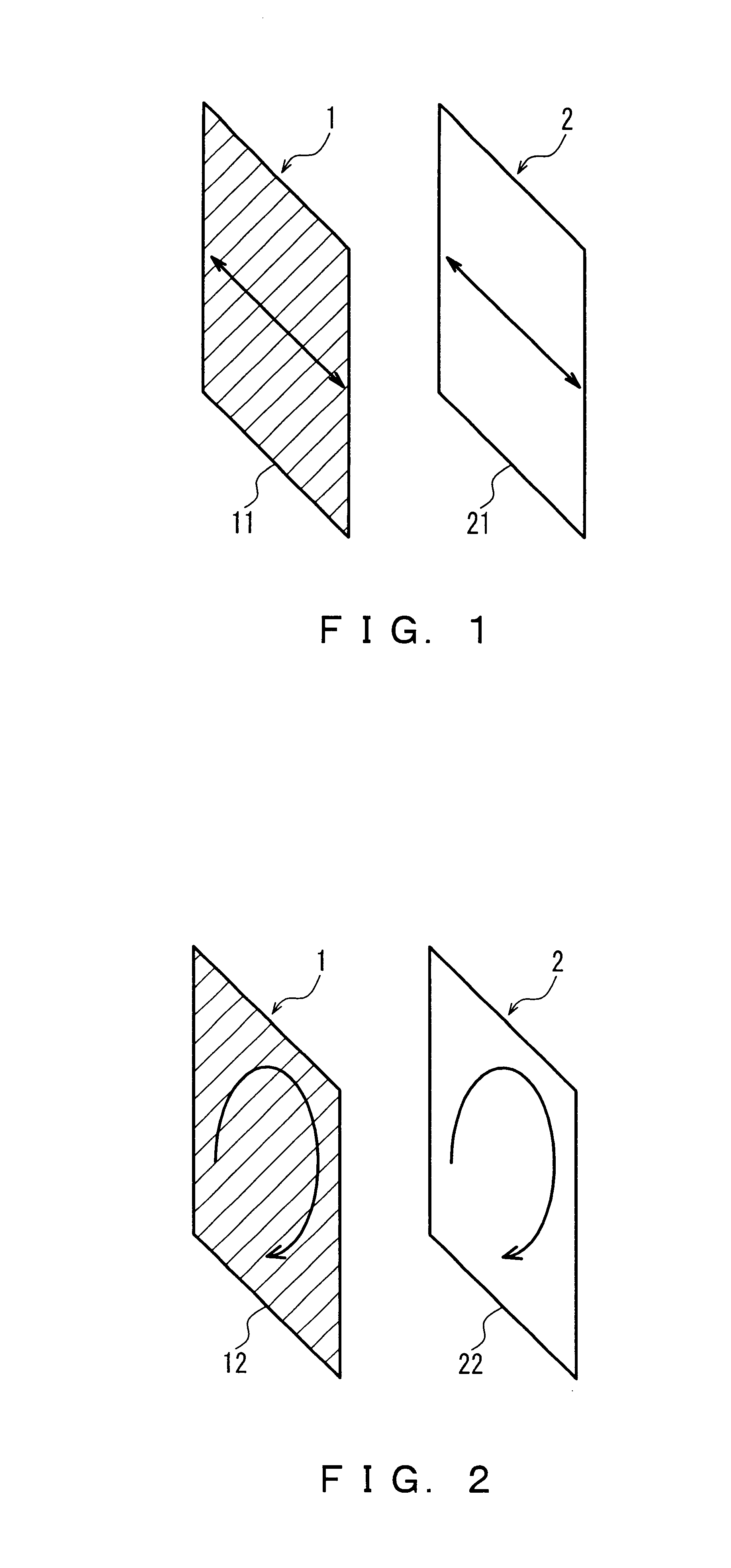

InactiveUS20120058291A1Thickness minimizationIncreasing the thicknessStampsFlexible coversEngineeringMethods of production

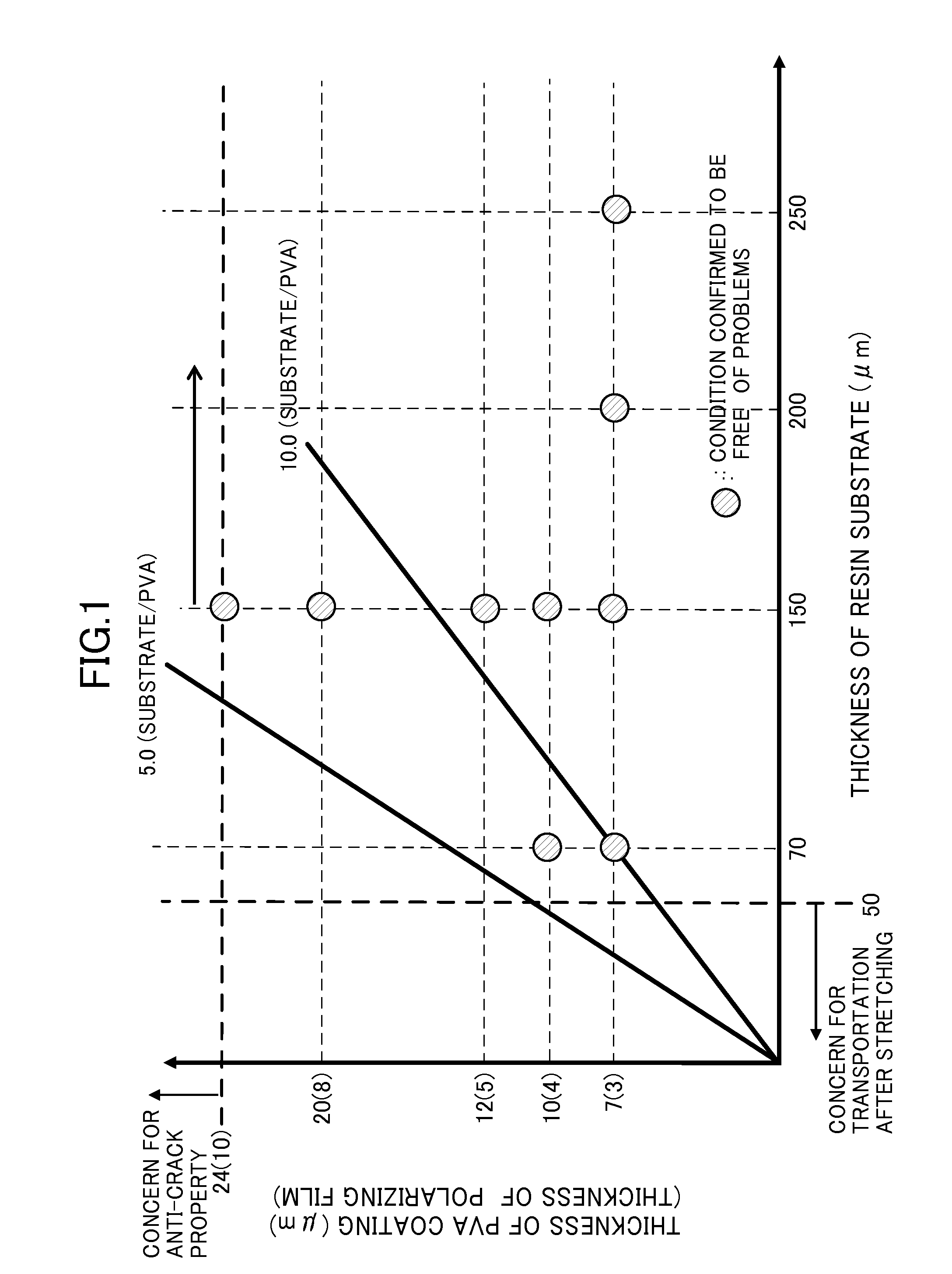

A method of producing a roll of a continuous web of an optical film laminate, usable in a process of laminating an optical film sheet including a polarizing film and formed to a size corresponding to that an optical panel to a surface of the optical panel being fed to a lamination position, is disclosed. The polarizing film is prepared by subjecting a laminate including a thermoplastic resin substrate and a PVA type resin layer formed on the substrate, to uniaxial 2-stage stretching to reduce a thickness of the PVA type resin layer to 10 μm or less, and causing a dichroic material to be absorbed in the PVA type resin layer. A carrier film is releasably attached to the continuous web of optical film laminate including the polarizing film, through an adhesive layer. A defect inspection is performed for the optical film laminate and the adhesive layer.

Owner:NITTO DENKO CORP

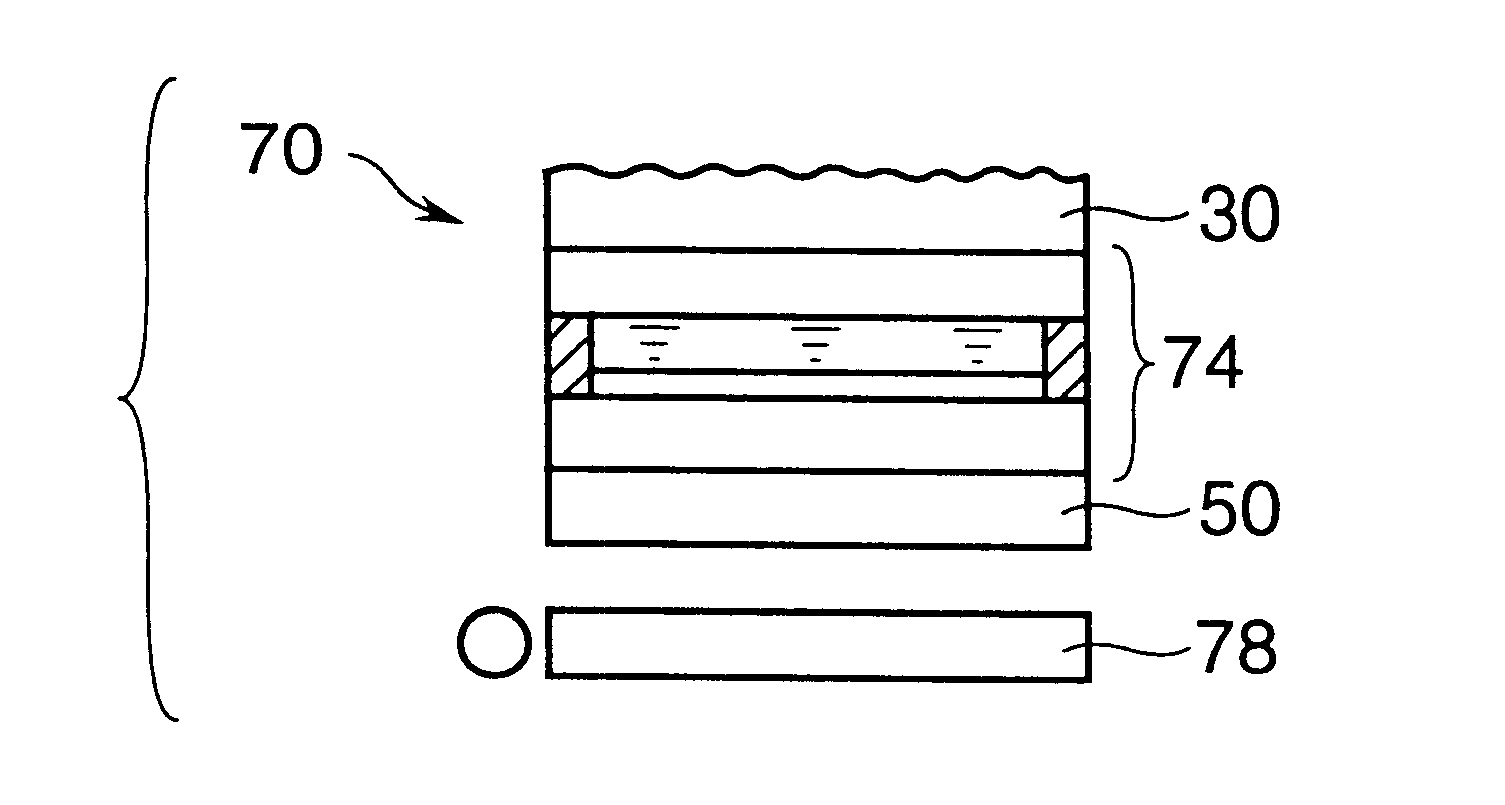

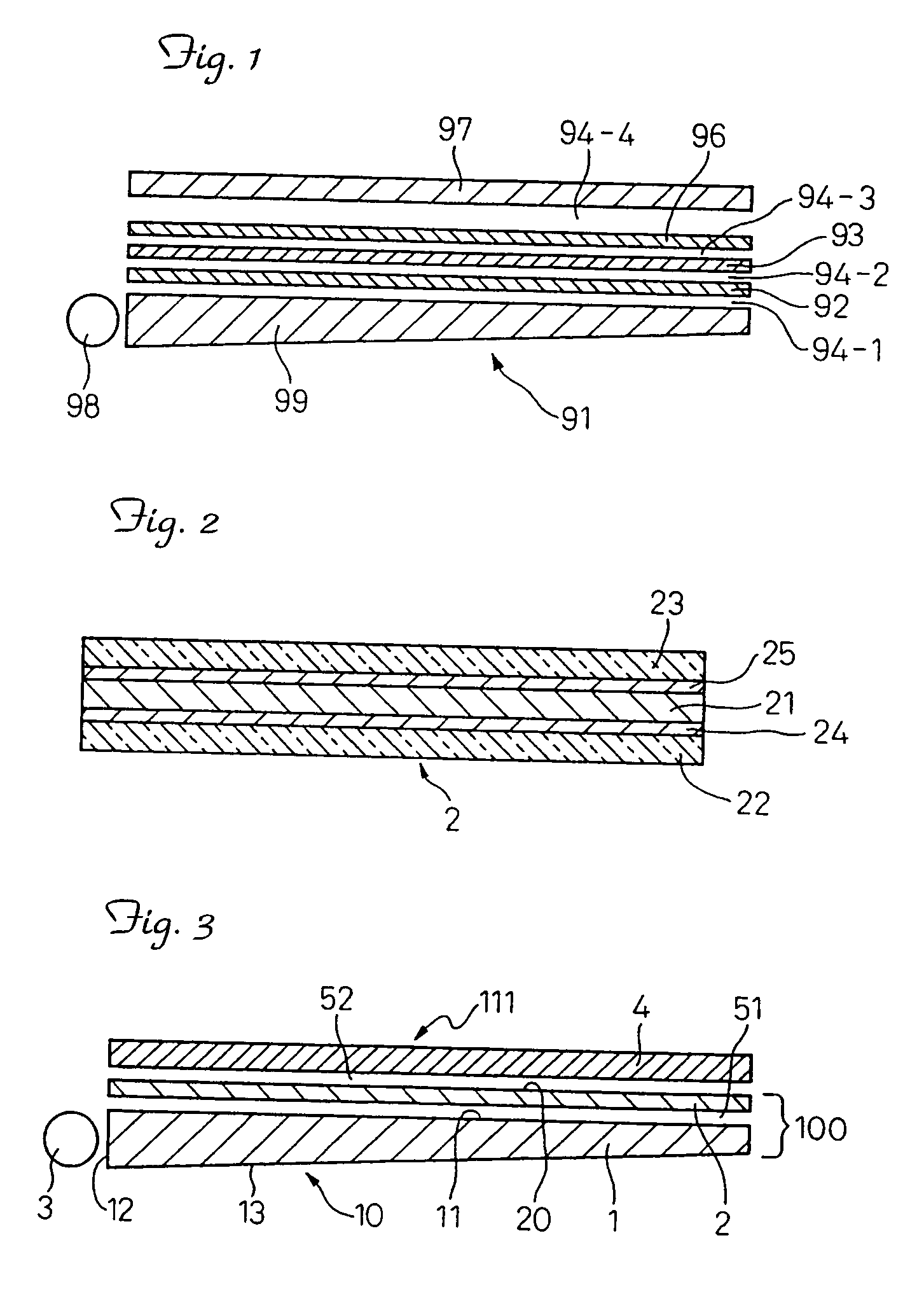

Optical laminated bodies, lighting equipment and area luminescence equipment

InactiveUS6972813B1Increase brightnessReduce the number of partsMechanical apparatusLight guides for lighting systemsLight equipmentEffect light

Lighting devices are disclosed that include optical laminated bodies. An exemplary optical laminated body includes a polarizing layer, a first transparent film disposed closely to a front surface of the polarizing layer and a second transparent film disposed closely to a back surface of the polarizing layer. The polarizing layer includes a reflective polarizing film, and both of the first transparent film and the second transparent film are diffusive films. The lighting devices further include a light source supplying light to the optical laminated body through a light entry surface of the first transparent film of the optical laminated body and a lens film disposed between the light source and the optical laminated body. The lighting device provides diffused-polarized light emitted from a light emitting surface of the second transparent film of the laminated body.

Owner:3M INNOVATIVE PROPERTIES CO

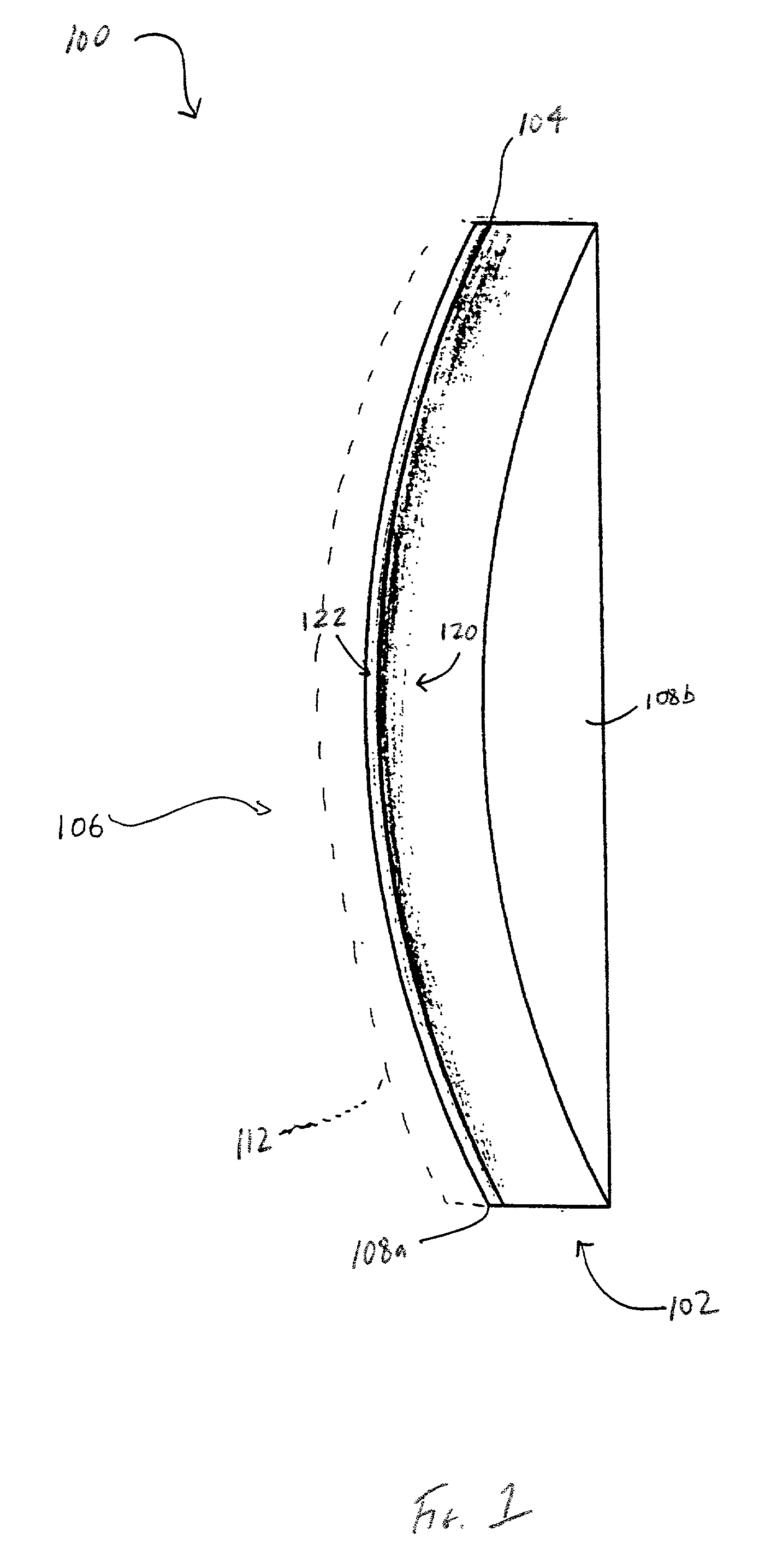

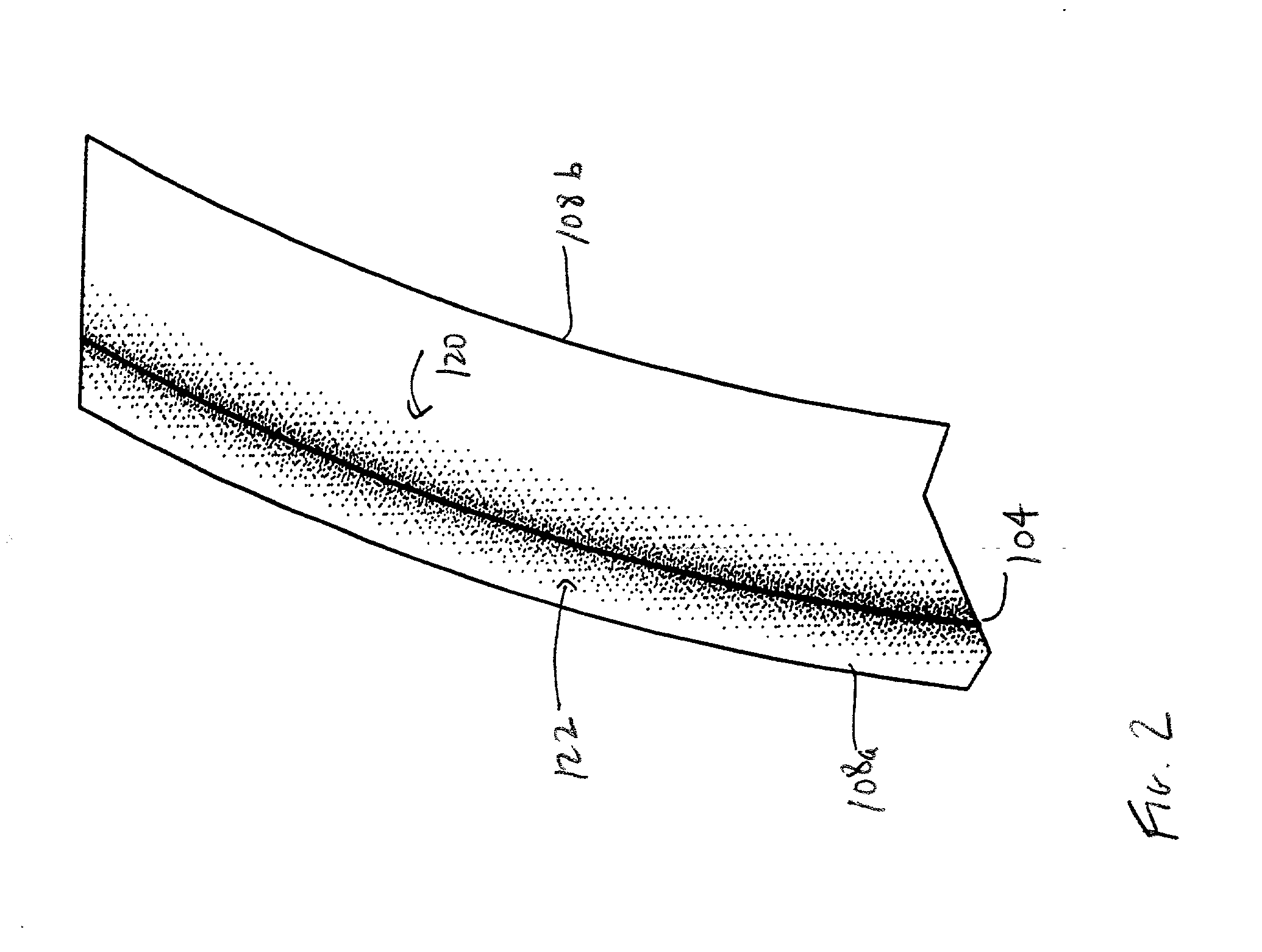

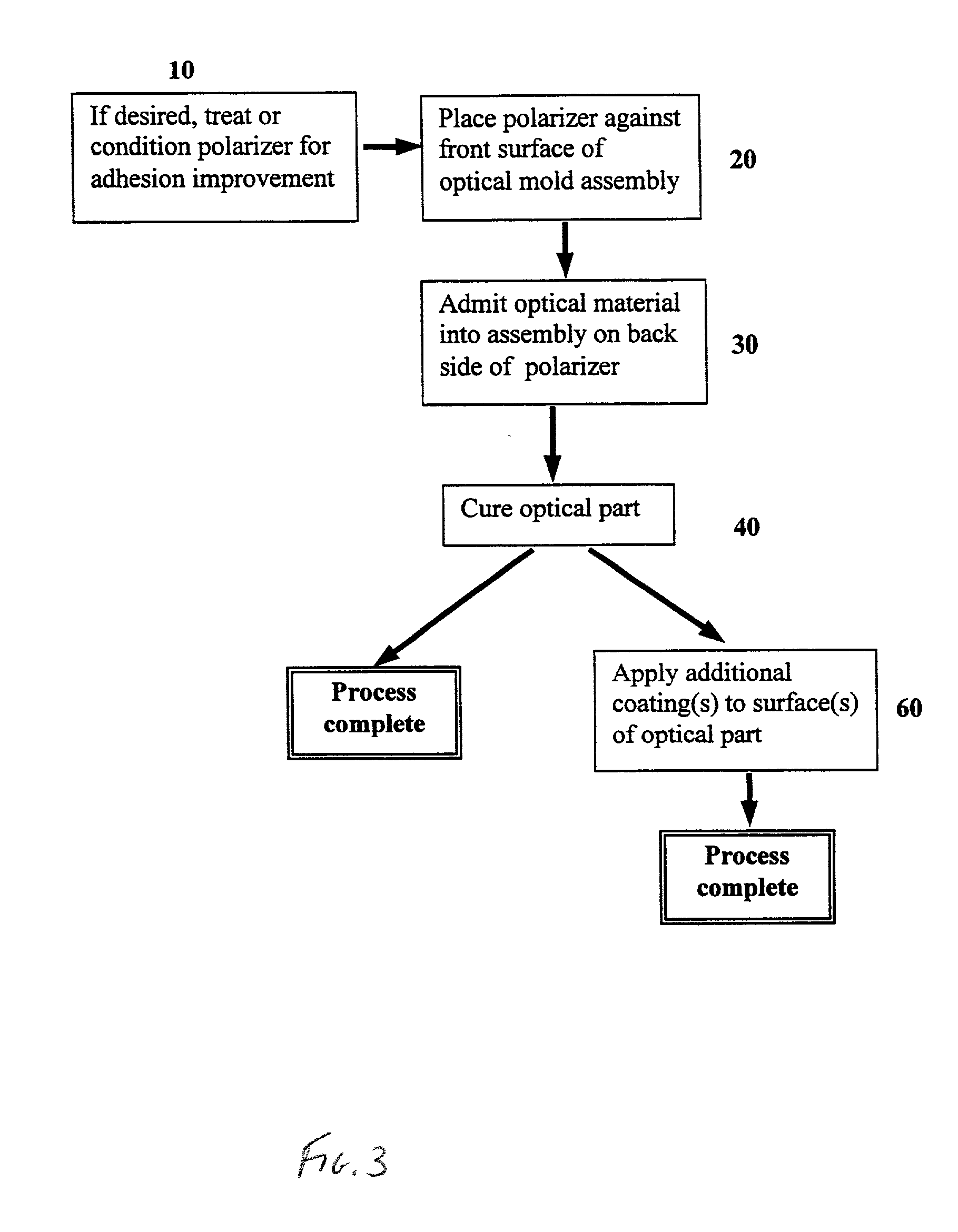

Polarized eyewear using high impact, high optical-quality polymeric material

InactiveUS20010028435A1Improve impact performanceImprove impact resistanceSpectales/gogglesSynthetic resin layered productsPolyvinyl alcoholPolarizer

Optical-quality polarized parts and methods for manufacturing the optical parts are disclosed. The optical-quality polarized parts comprise a high impact, lightweight, high optical quality polyurethane construct and a polarizer bonded to the construct. The construct may be a lens substrate wherein the polarizer is integrally bonded at or near the front surface of the lens substrate. A sidefill gasket may be used to support and position the polarizer within a mold cavity for reproducibly forming the optical part. The polarizer may comprise a polyethylene terephthalate film or a laminated polyvinyl alcohol film or wafer. The polarized optical part has improved impact resistance over conventional thermoset resin parts, as well as better optical properties than similarly impact-resistant polycarbonate constructs.

Owner:YOUNGER MFG

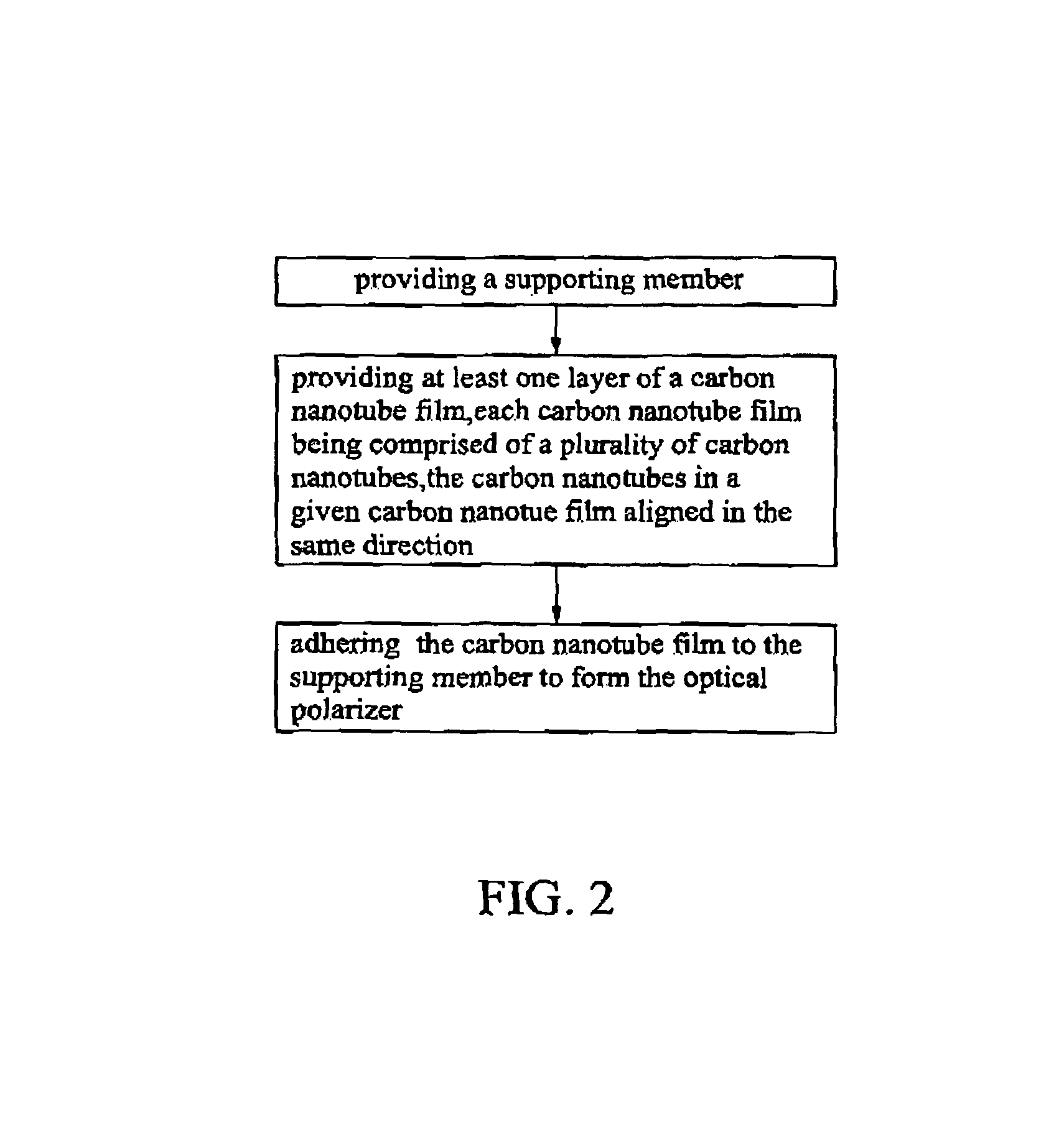

Optical polarizer and method for fabricating the same

An optical polarizer includes a supporting member and a polarizing film supported by the supporting member. The polarizing film includes at least one layer of a carbon nanotube film, and the carbon nanotubes in a given carbon nanotube film are aligned in the same direction therein. A method for fabricating the optical polarizer includes the steps of: (a) providing a supporting member; (b) providing at least one layer of a carbon nanotube film, the carbon nanotubes in a given carbon nanotube film aligned along the same direction; and (c) adhering a given carbon nanotube film to the supporting member to form the optical polarizer.

Owner:TSINGHUA UNIV +1

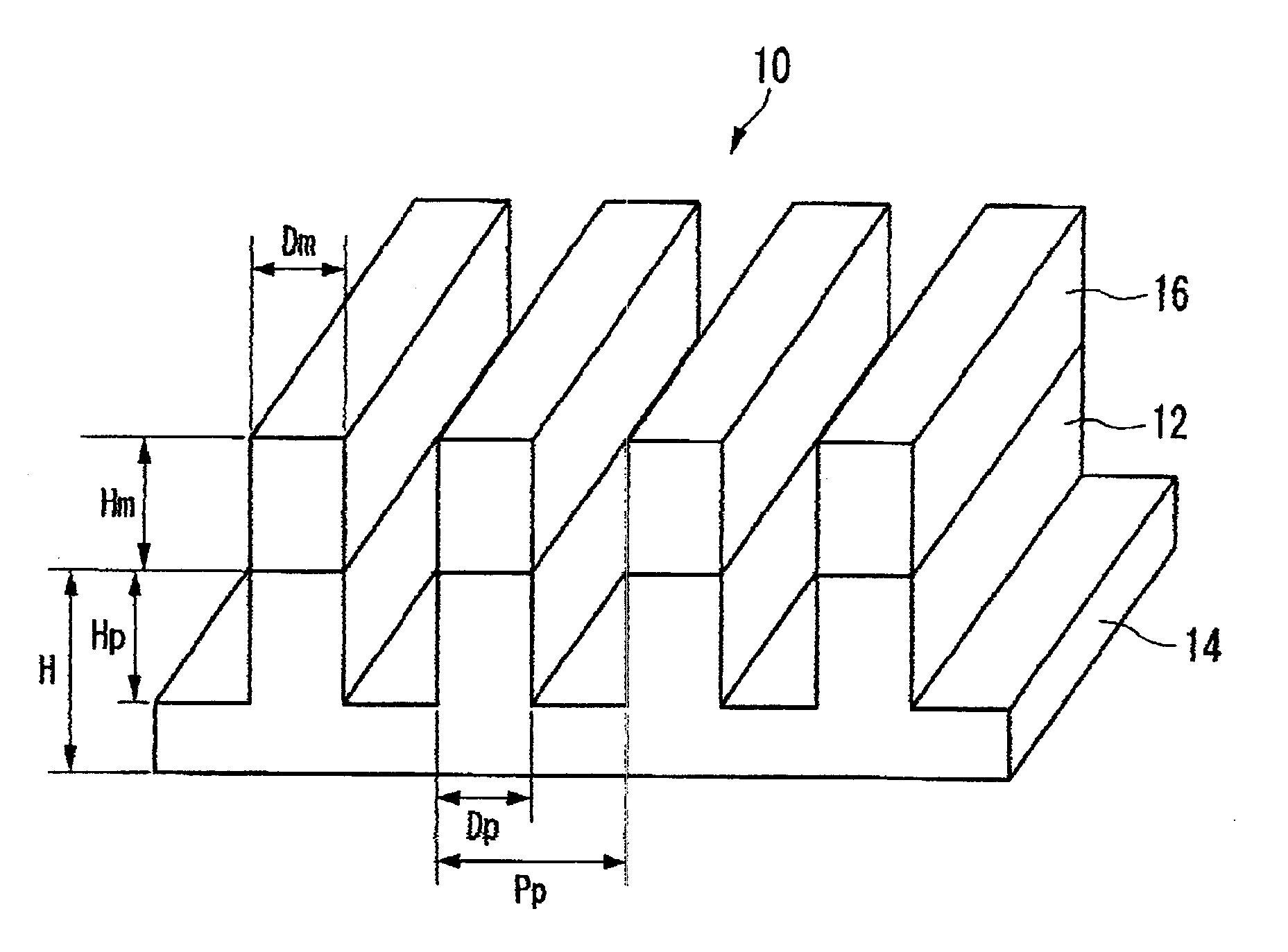

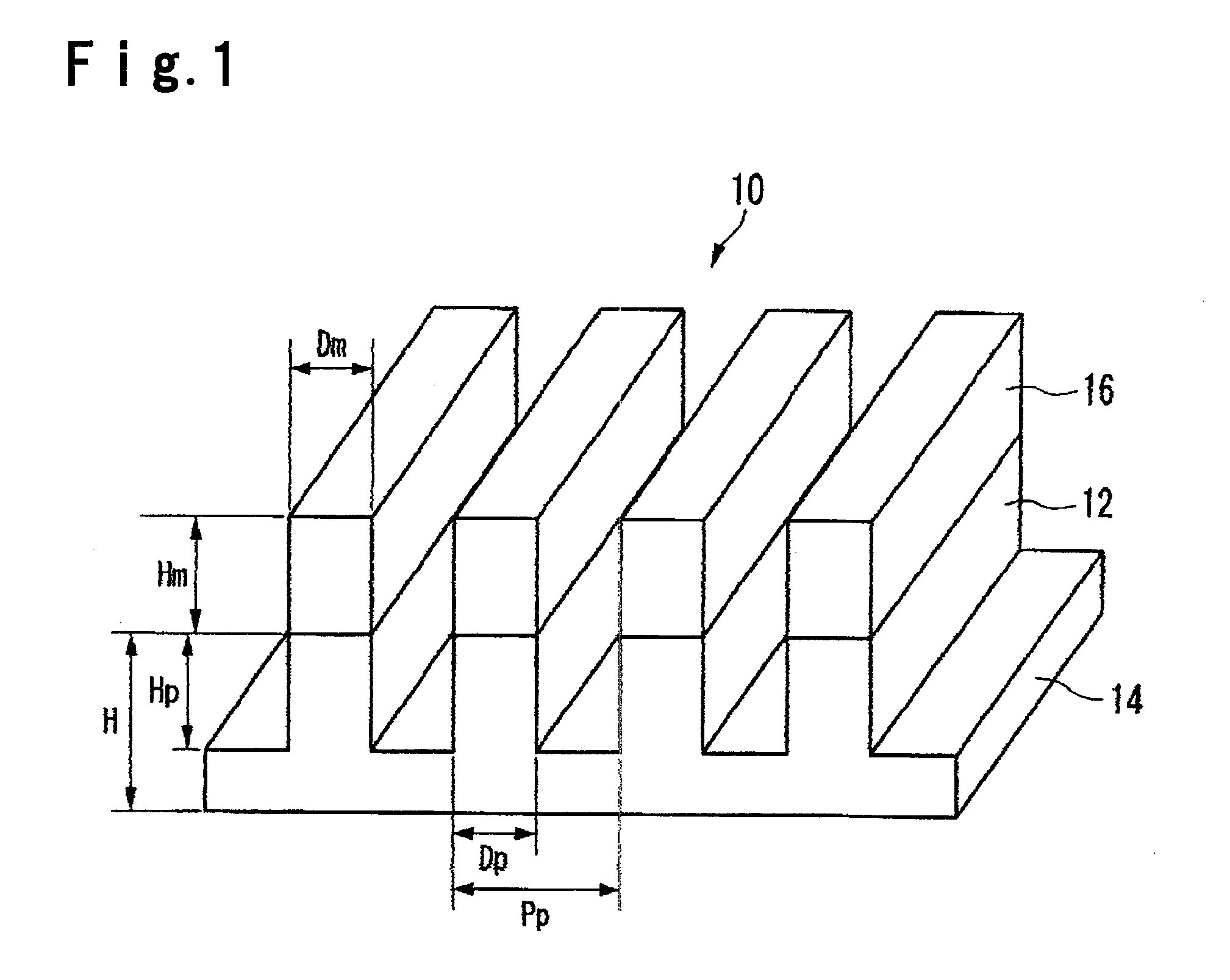

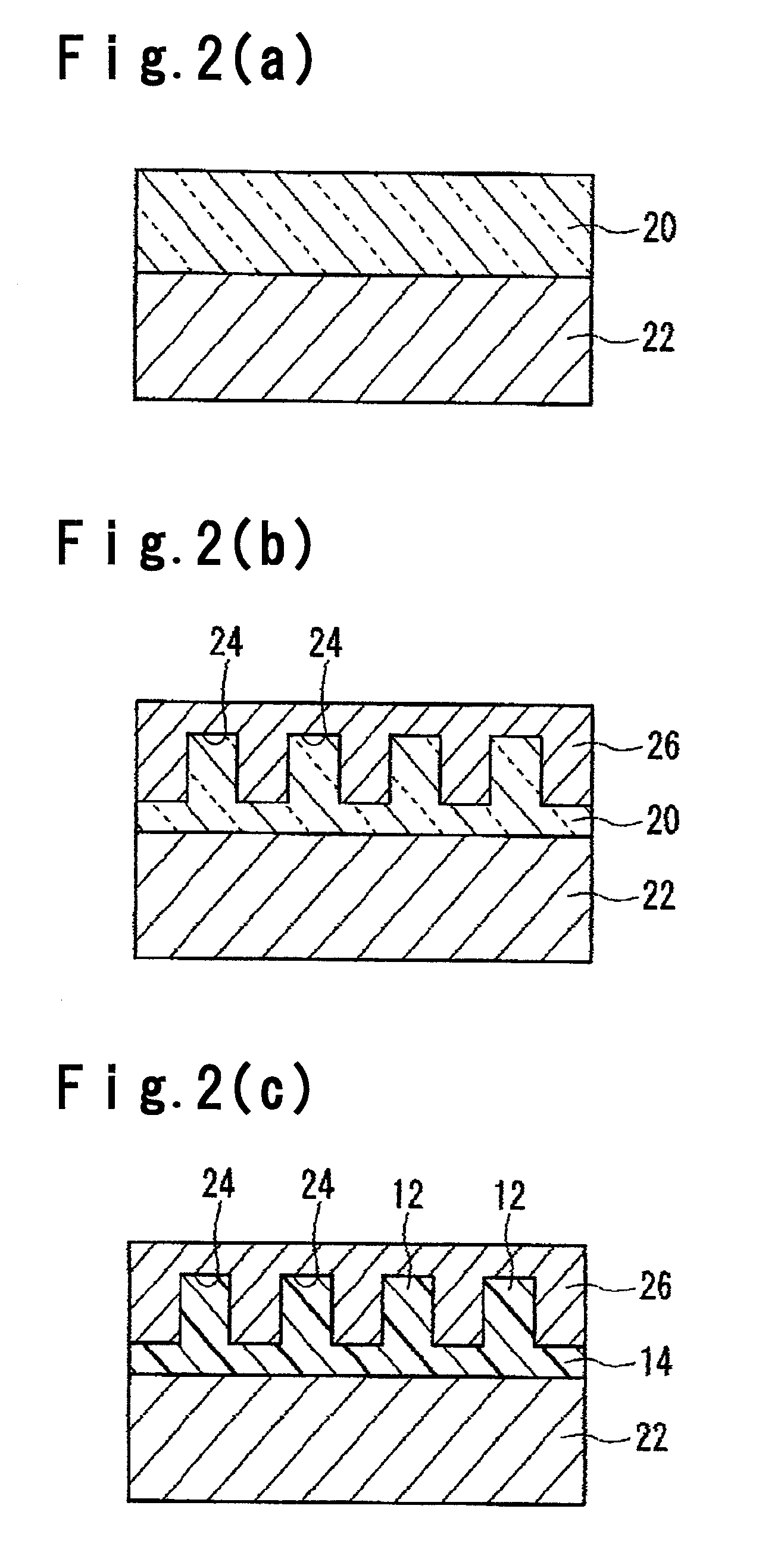

Wire-grid polarizer and process for producing the same

InactiveUS20090052030A1High polarization separation abilityIncreased durabilityNanoinformaticsPhotomechanical apparatusProduction rateWire grid

The present invention provides a wire-grid polarizer showing high polarization separation ability in the visible light region and is excellent in heat resistance and durability; and a process for producing such a wire-grid polarizer with high productivity, which enables to produce a polarizer of large area.A process for producing a wire-grid polarizer, comprising a step of coating a supporting substrate with a photocurable composition, a step of pressing a mold having a plurality of parallel grooves at a constant pitch against the photocurable composition so that the grooves contact with the photocurable composition, a step of curing the photocurable composition in a state that the mold is pressed against the photocurable composition, to form a light-transmitting substrate having a plurality of ridges corresponding to the grooves of the mold, a step of separating the mold from the light-transmitting substrate, and a step of forming fine metalic wires on the ridges of the light-transmitting substrate.

Owner:ASAHI GLASS CO LTD

Retardation film, polarizing element, liquid crystal panel, and liquid crystal apparatus

InactiveUS20060177607A1Good molding effectImproved display property displayLiquid crystal compositionsThin material handlingIn planeLength wave

There is provided a retardation film including a stretched film of a polymer film having an absolute value of photoelastic coefficient (m2 / N) of 50×10−12 or less measured by using light of a wavelength of 550 nm at 23° C., which satisfies the following expressions (1) and (2):Re[450]<Re[550]<Re[650] (1)Rth[550]<Re[550] (2).In the expressions (1) and (2): Re[450], Re[550], and Re[650] respectively represent in-plane retardation values measured by using light of wavelengths of 450 nm, 550 nm, and 650 nm at 23° C.; and Rth[550] represents a thickness direction retardation value measured by using light of a wavelength of 550 nm at 23° C.

Owner:NITTO DENKO CORP

Lighting module for a vehicle headlight

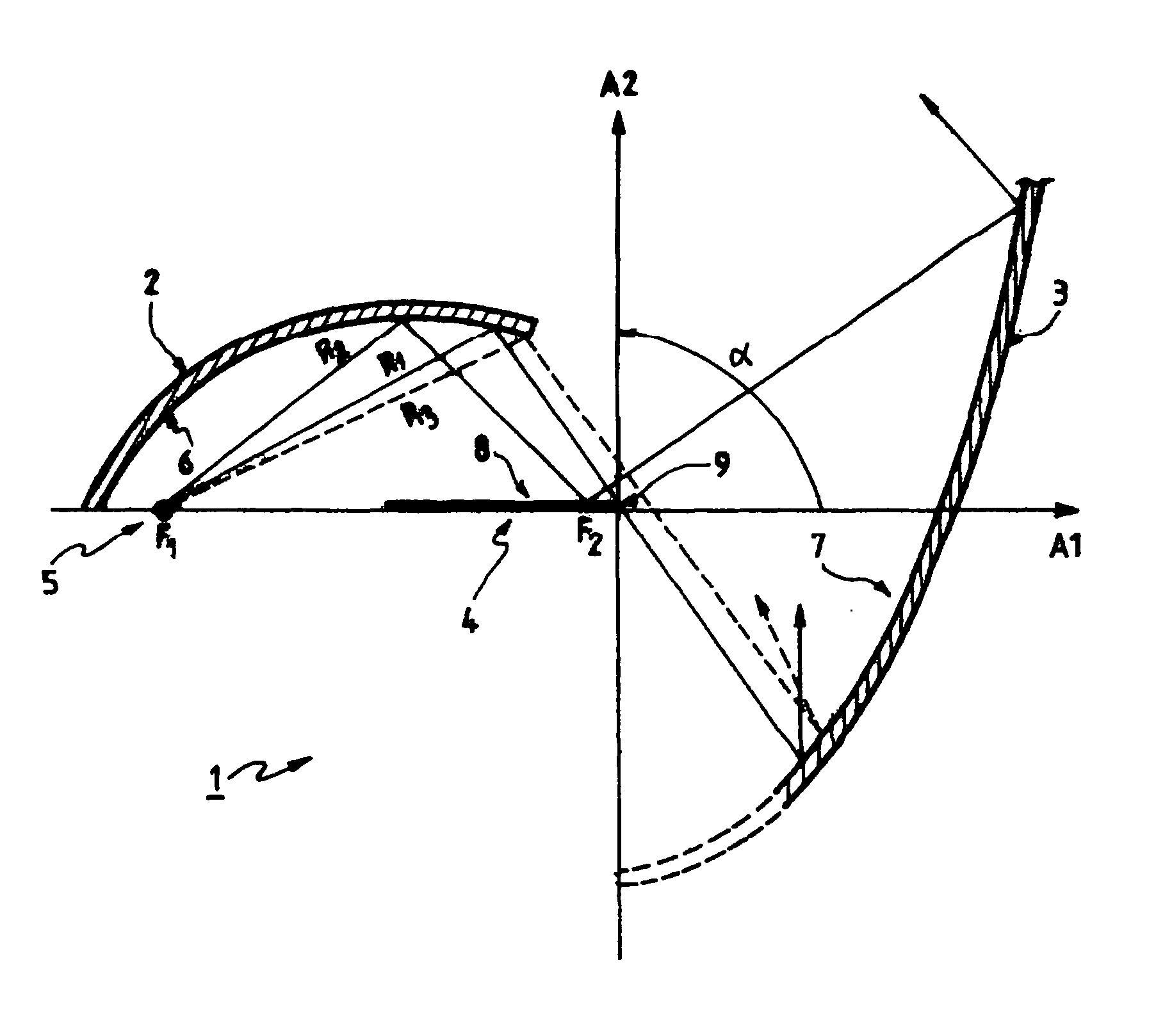

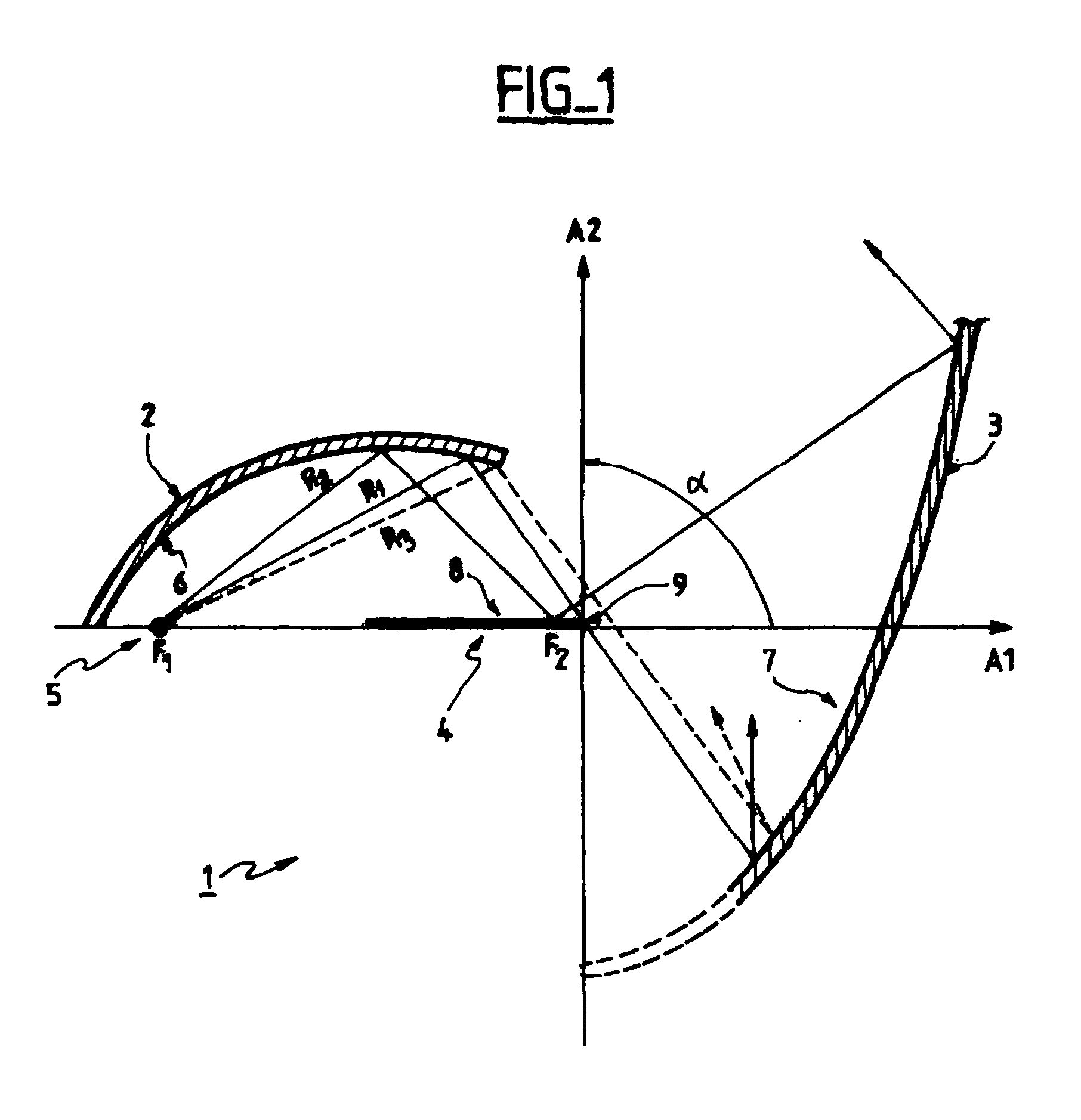

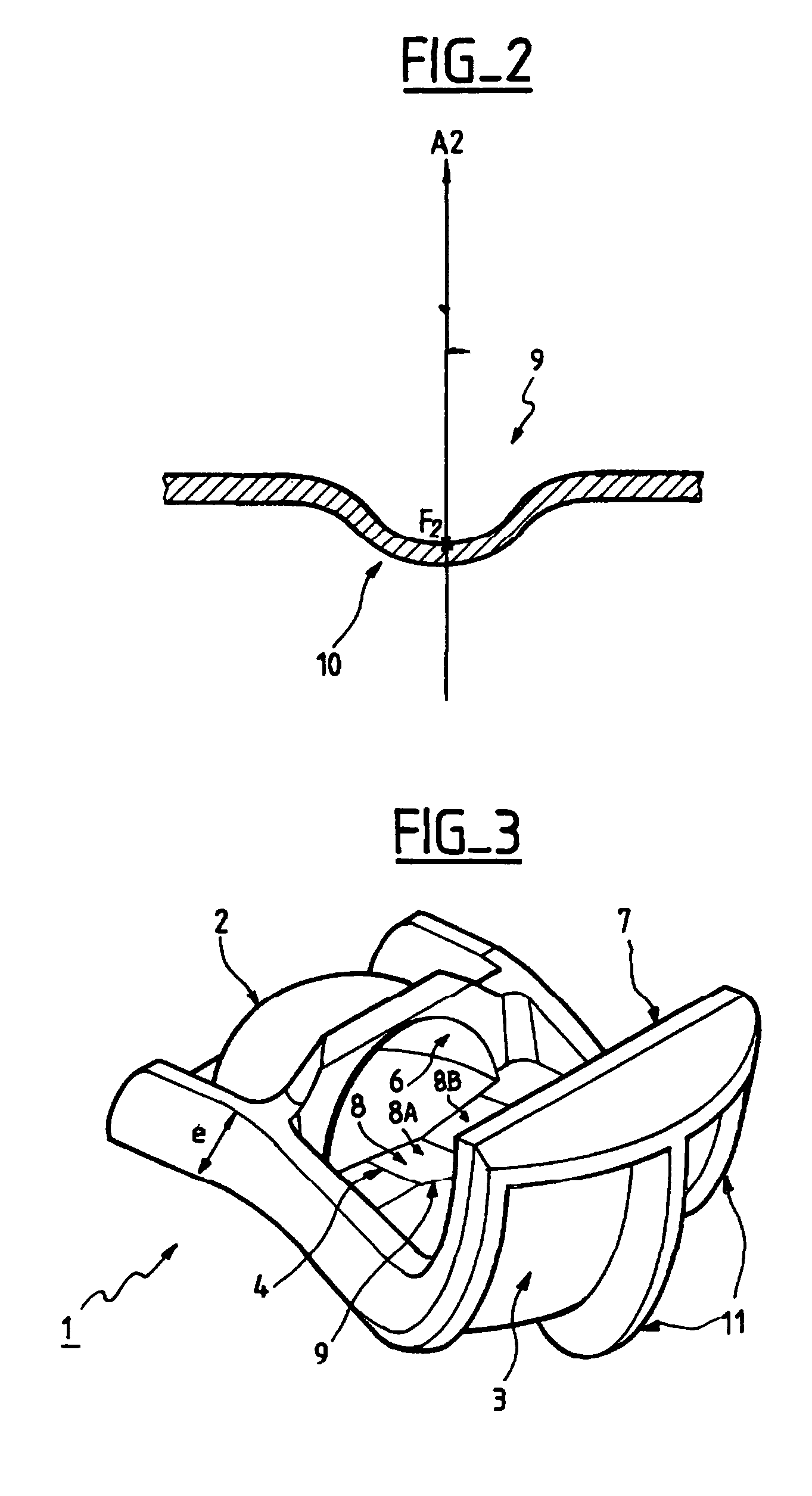

ActiveUS20040130907A1Reduce cleaningReduce lossesVehicle headlampsPoint-like light sourceEffect lightLight beam

The present invention is concerned with a lighting module for a vehicle headlight for giving a light beam of the cut-off type, particularly one which is adapted to use with light-emitting diodes. The module has a second reflector having a substantially elliptical surface for reflecting light rays and at least one light source arranged close to the first focus of the first reflector. The module also includes a second reflector for producing the cut-off or dipped output beam, the focus of this reflector being arranged close to the second focus of the first reflector. The module further includes a third reflector or bender, having a reflective top face and being situated between the first and second reflectors. This third reflector has a cut-off edge arranged close to the second focus of the first reflector, whereby to form the cut-off within the light beam. The light source is a light-emitting diode.

Owner:VALEO VISION SA

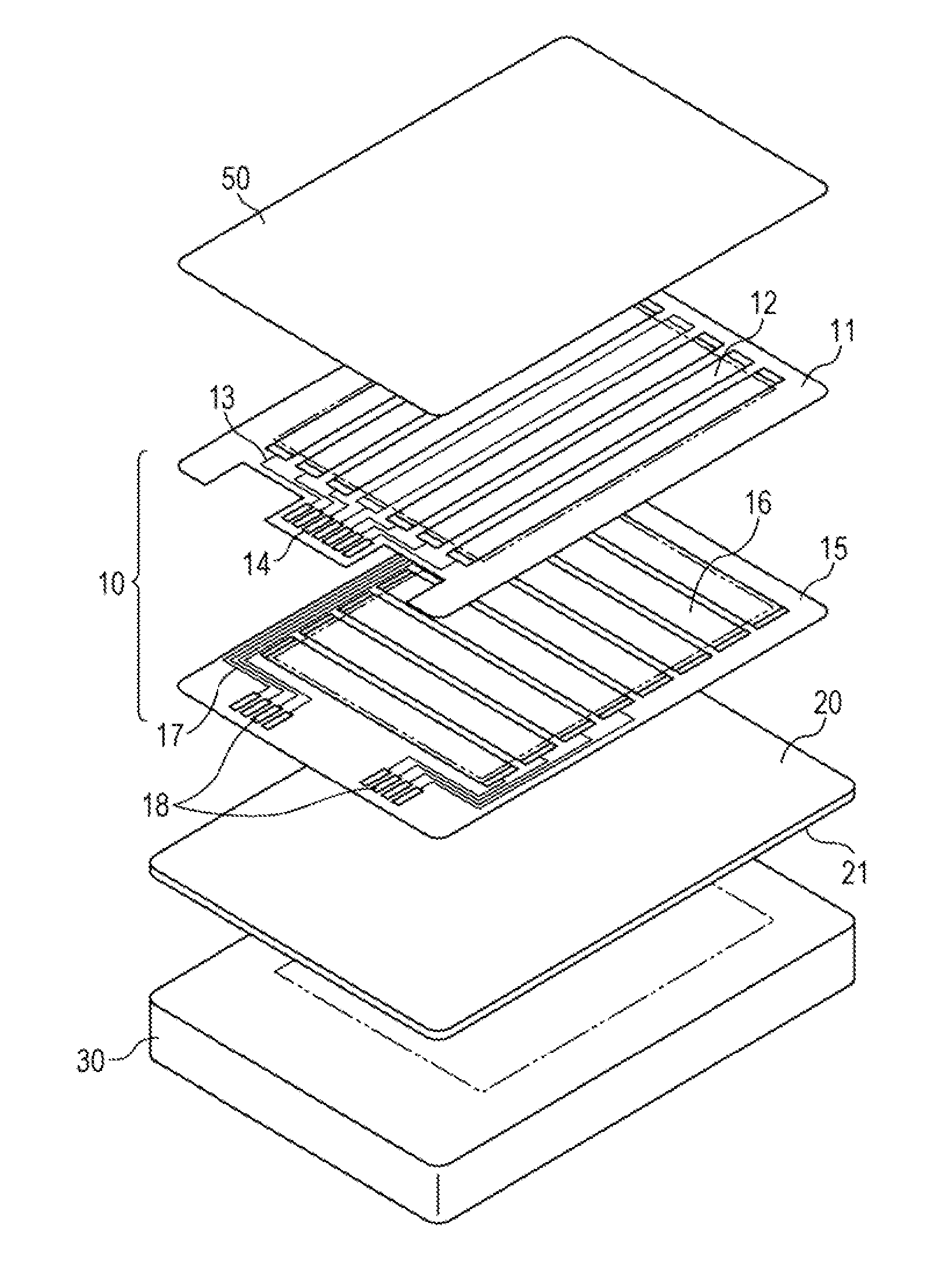

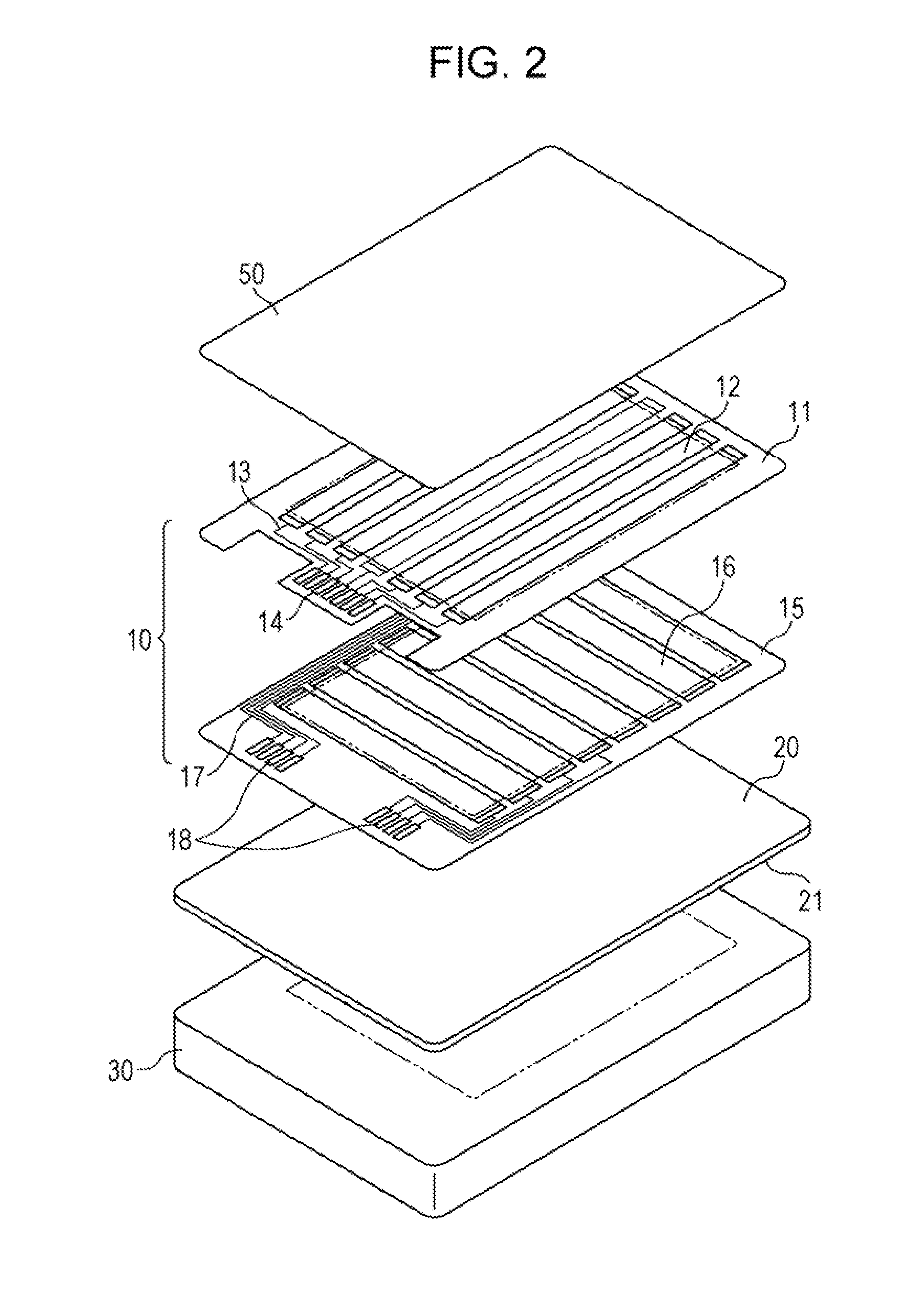

Touch panel integrated display device and method for manufacturing the same

InactiveUS20130016047A1Short timeReduce manufacturing costLaminationLamination apparatusDisplay deviceEngineering

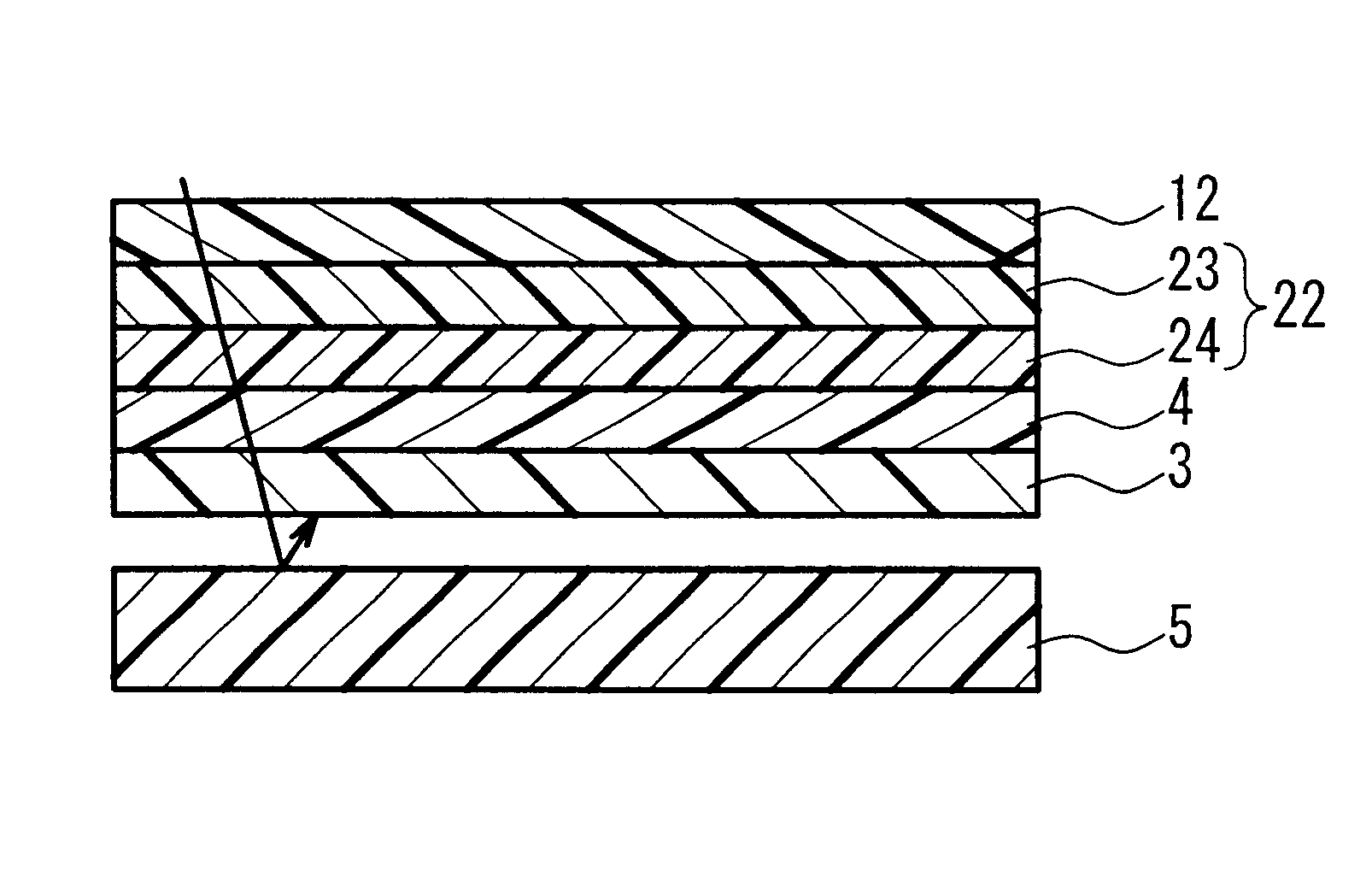

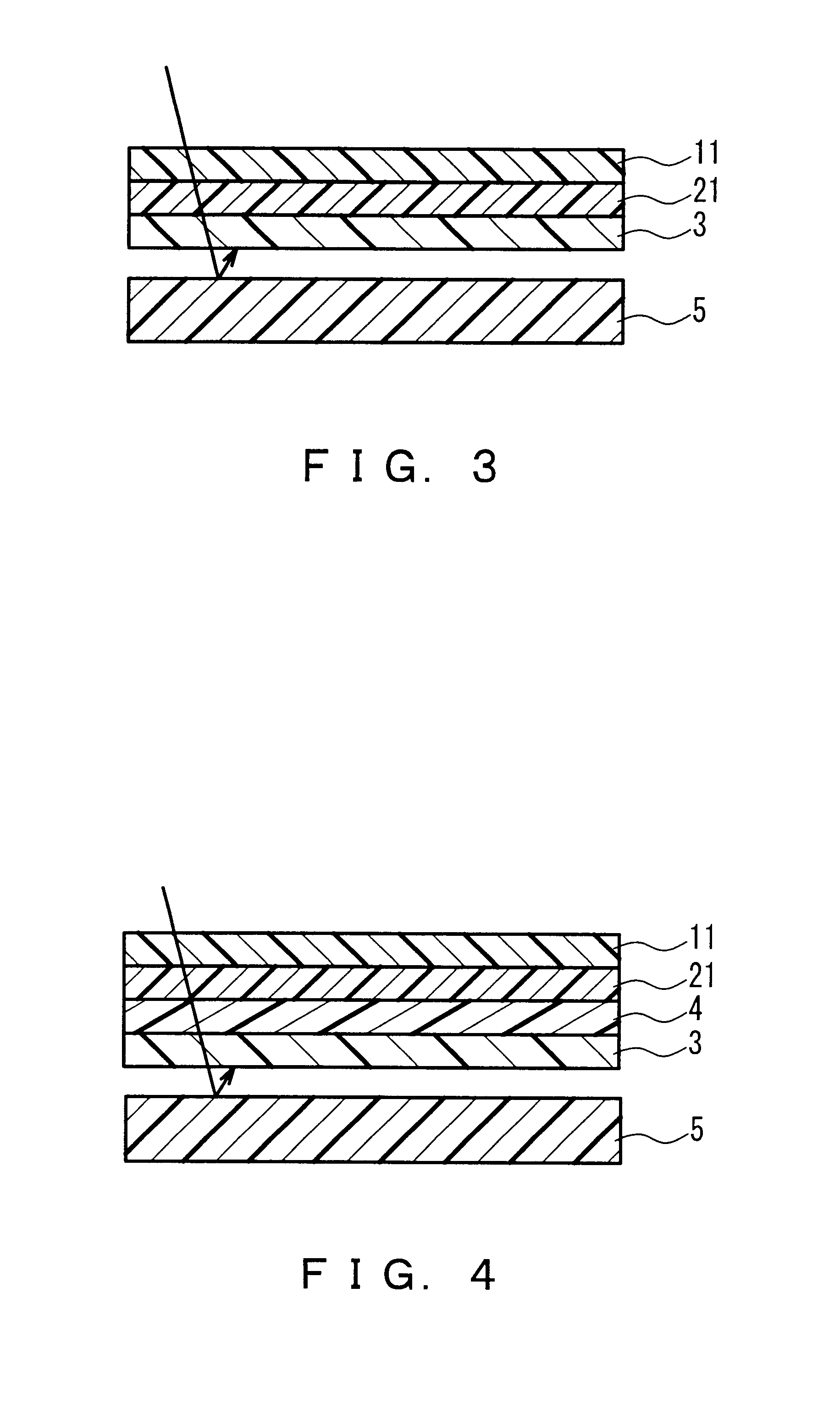

A method for manufacturing a touch panel integrated display device including a touch panel and a display panel that are integrally stacked, with a light-transmissive sticky layer interposed therebetween, includes the steps of (a) forming a transparent conductive layer by transfer onto a display surface of the display panel, with an adhesive layer interposed therebetween, by using a transferable film having the adhesive layer and the transparent conductive layer; (b) stacking a polarizing layer on one surface of the touch panel, the one surface being an input surface of the touch panel; and (c) bonding the transparent conductive layer formed on the display surface of the display panel to the other surface of the touch panel, with the sticky layer interposed therebetween.

Owner:ALPS ALPINE CO LTD

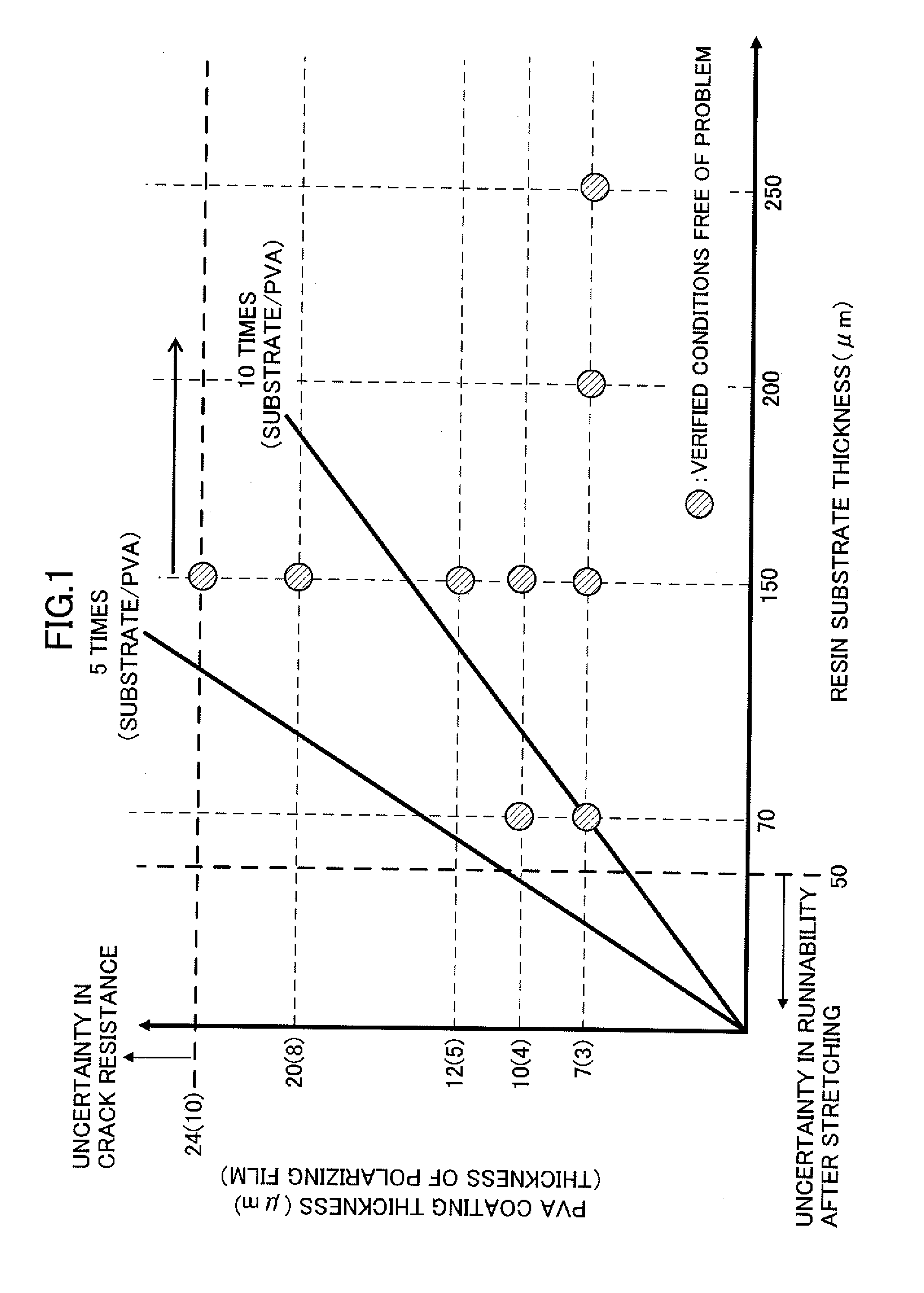

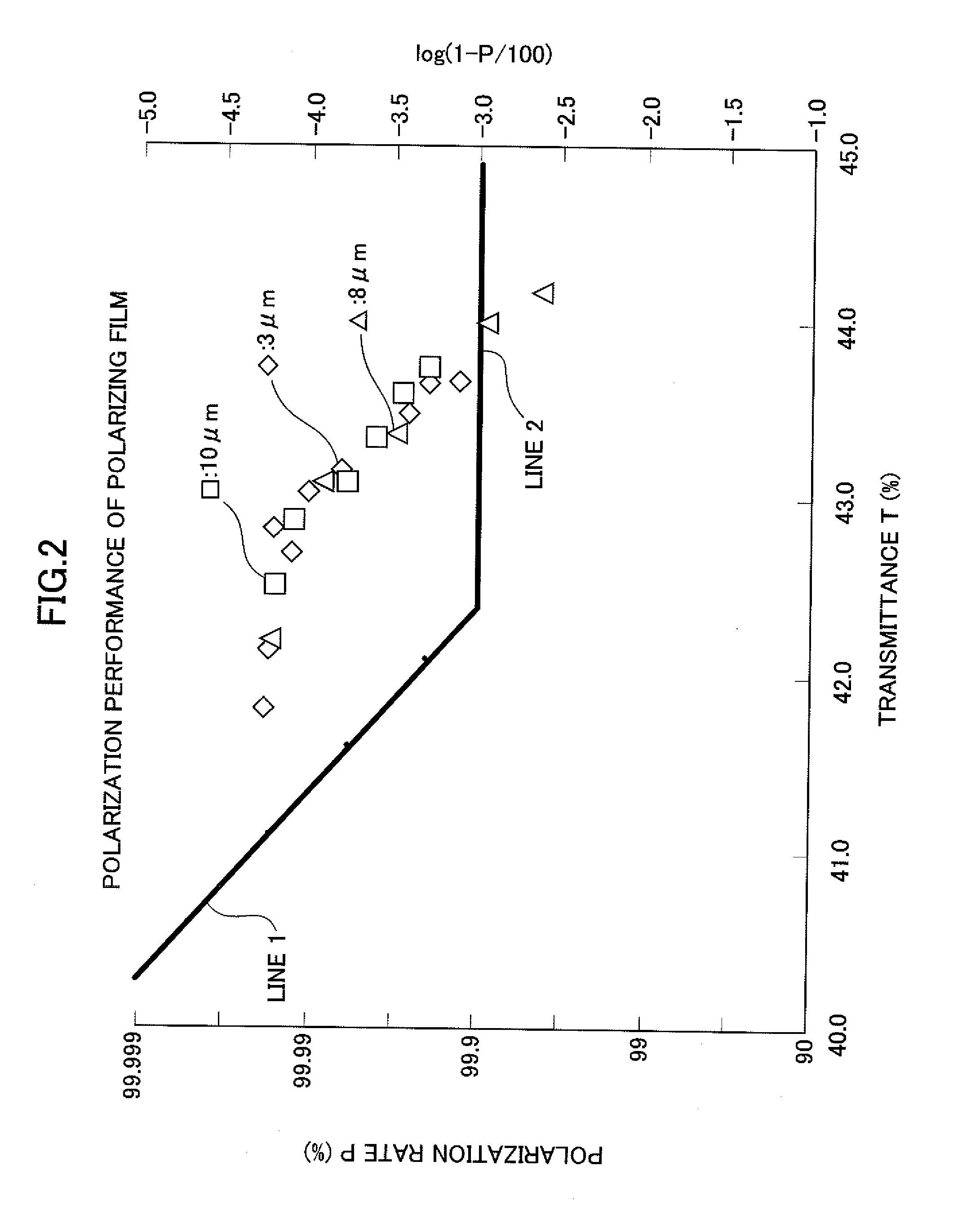

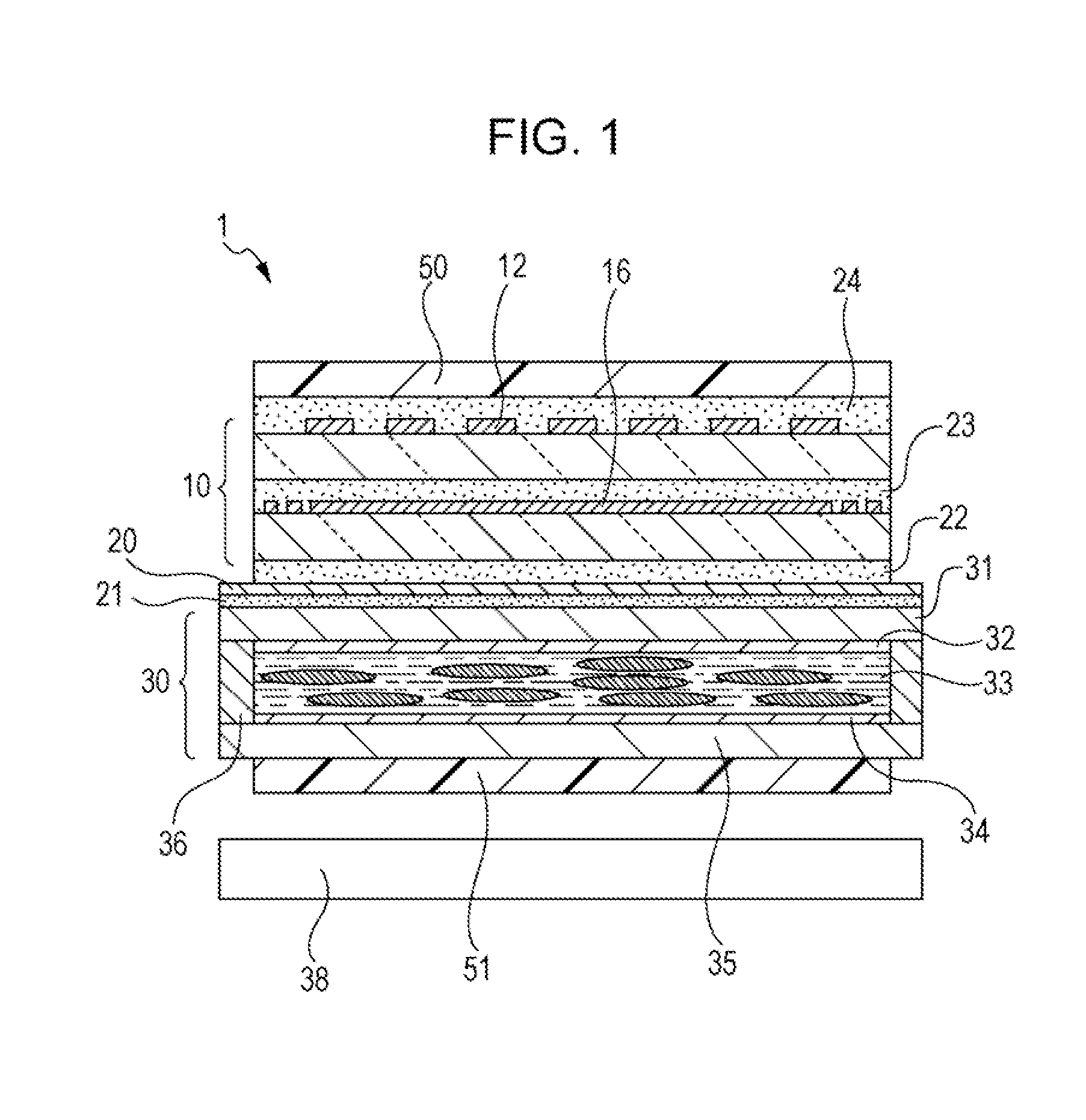

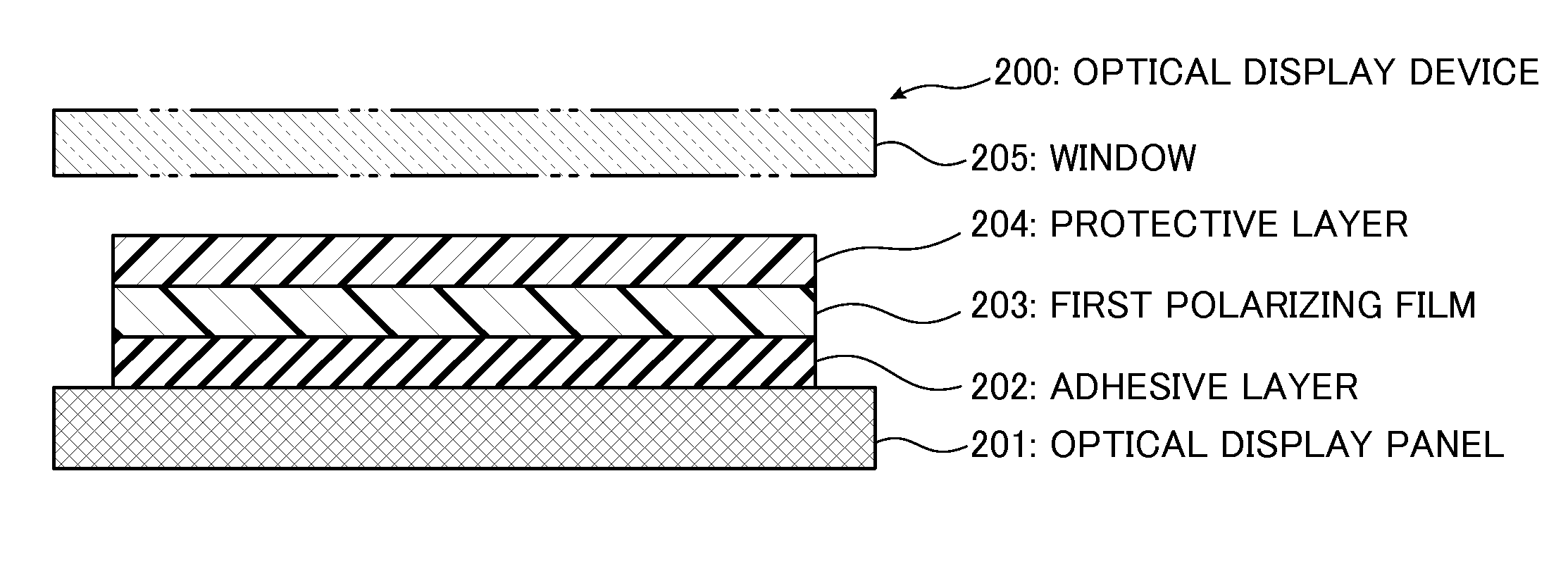

Optical display device having polarizing film

ActiveUS20120057107A1Reduce thicknessCharacterisation is requiredElectroluminescent light sourcesSolid-state devicesTransmittancePolyvinyl alcohol

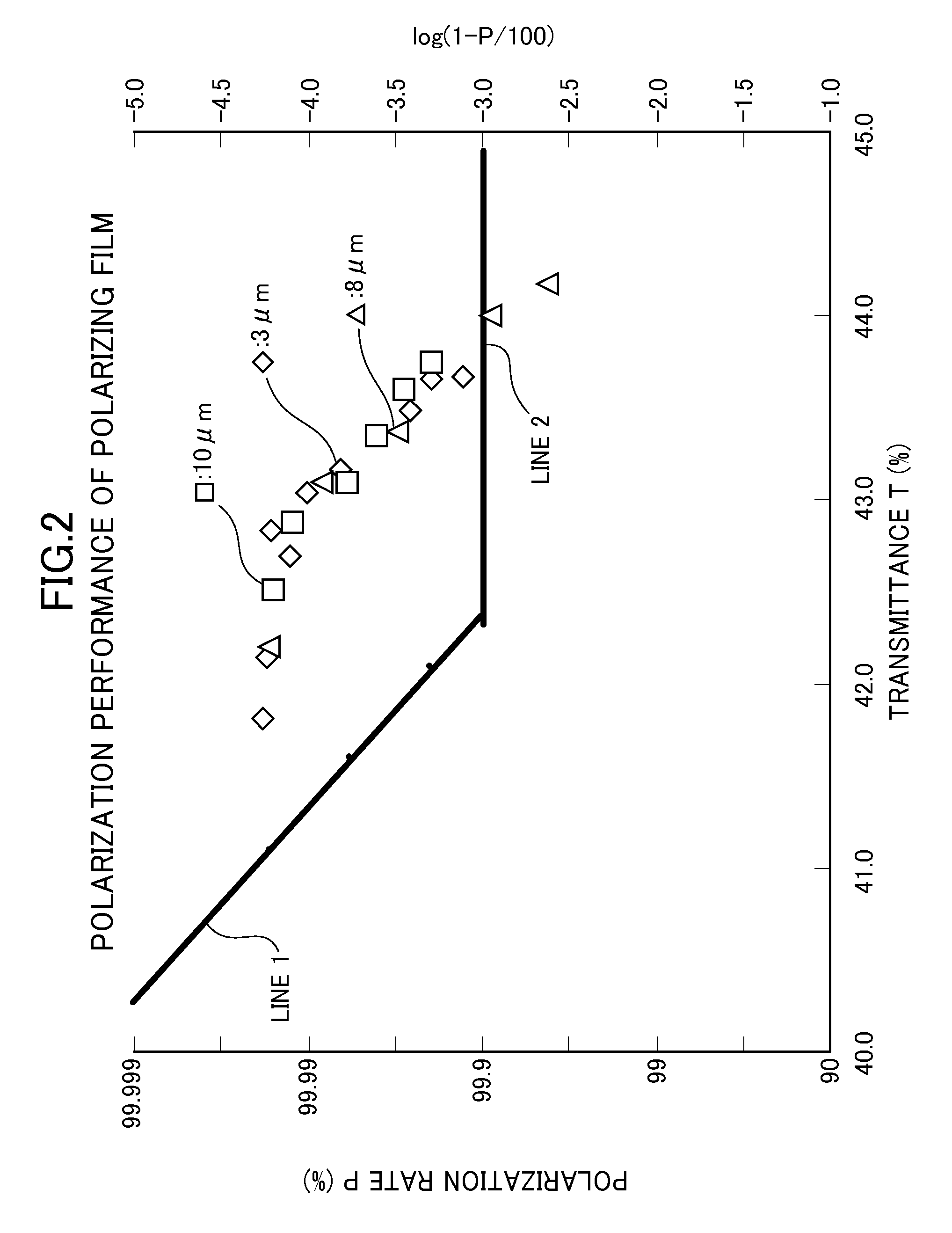

Provided is an optical display device using a polarizing film which has a thickness of 10 μm or less and exhibits high optical characteristics. The optical display device comprises a continuous web of polarizing film which is made of a polyvinyl alcohol type resin having a molecularly oriented dichroic material, and formed through stretching to have a thickness of 10 μm or less and satisfy conditions expressed by the following formulas: P>−(100.929T−42.4−1)×100 (where T<42.3); and P≧99.9 (where T≧42.3), wherein T is a single layer transmittance, and P is a polarization rate. The polarizing film may be prepared by subjecting a laminate comprising a non-crystallizable ester type thermoplastic resin substrate and a polyvinyl alcohol type resin layer formed on the substrate to by 2-stage stretching consisting of preliminary in-air stretching and in-boric-acid-solution stretching.

Owner:NITTO DENKO CORP

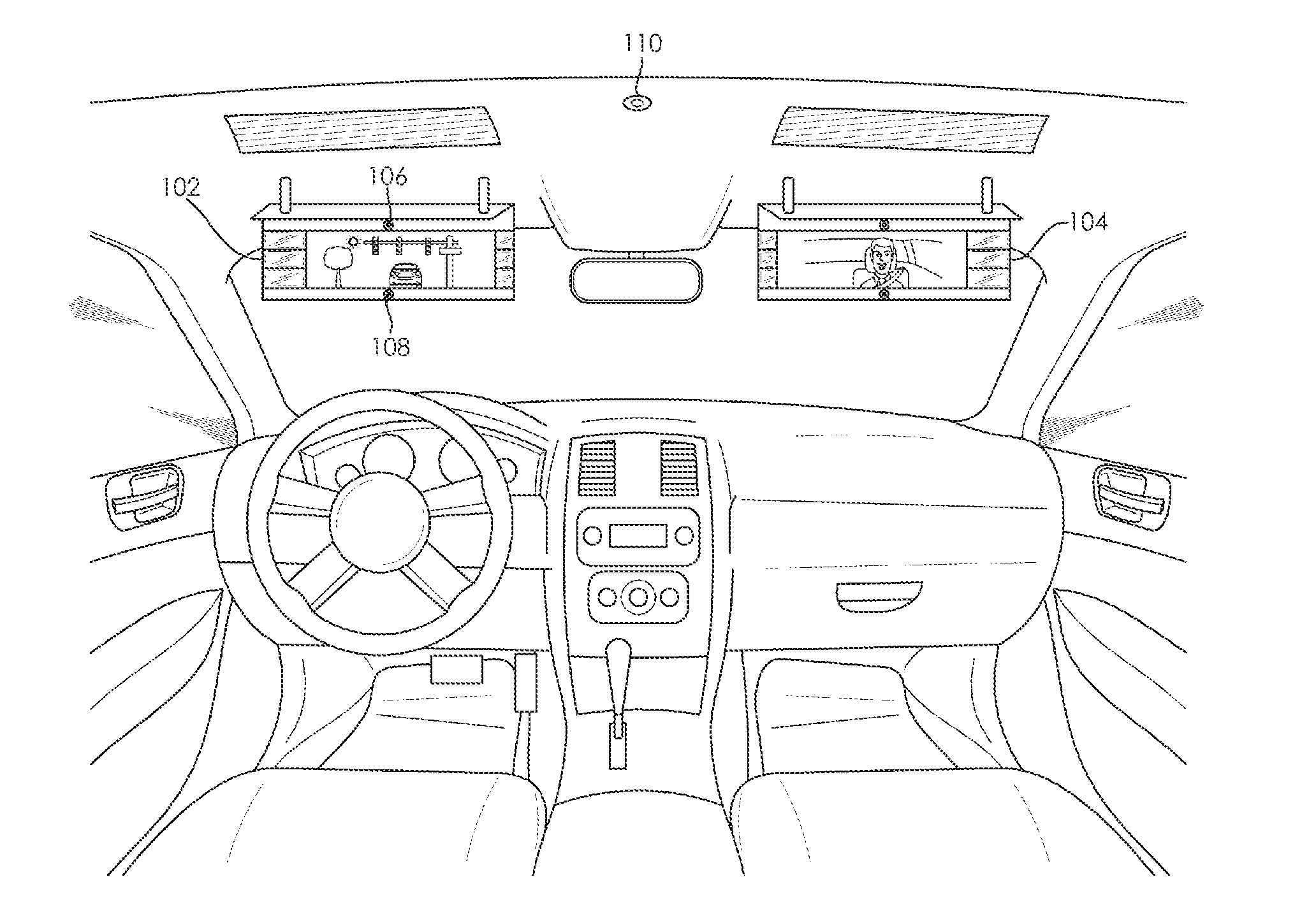

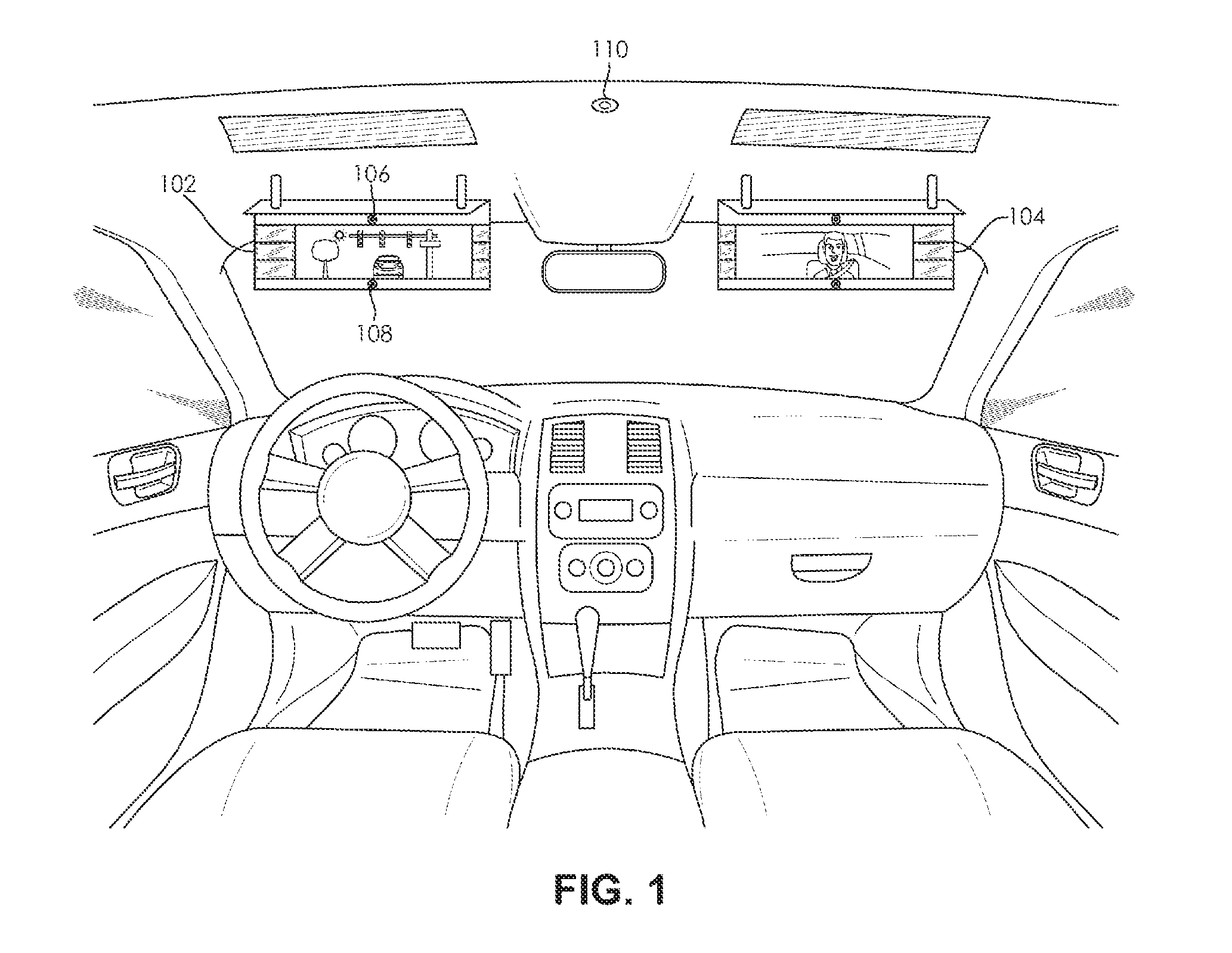

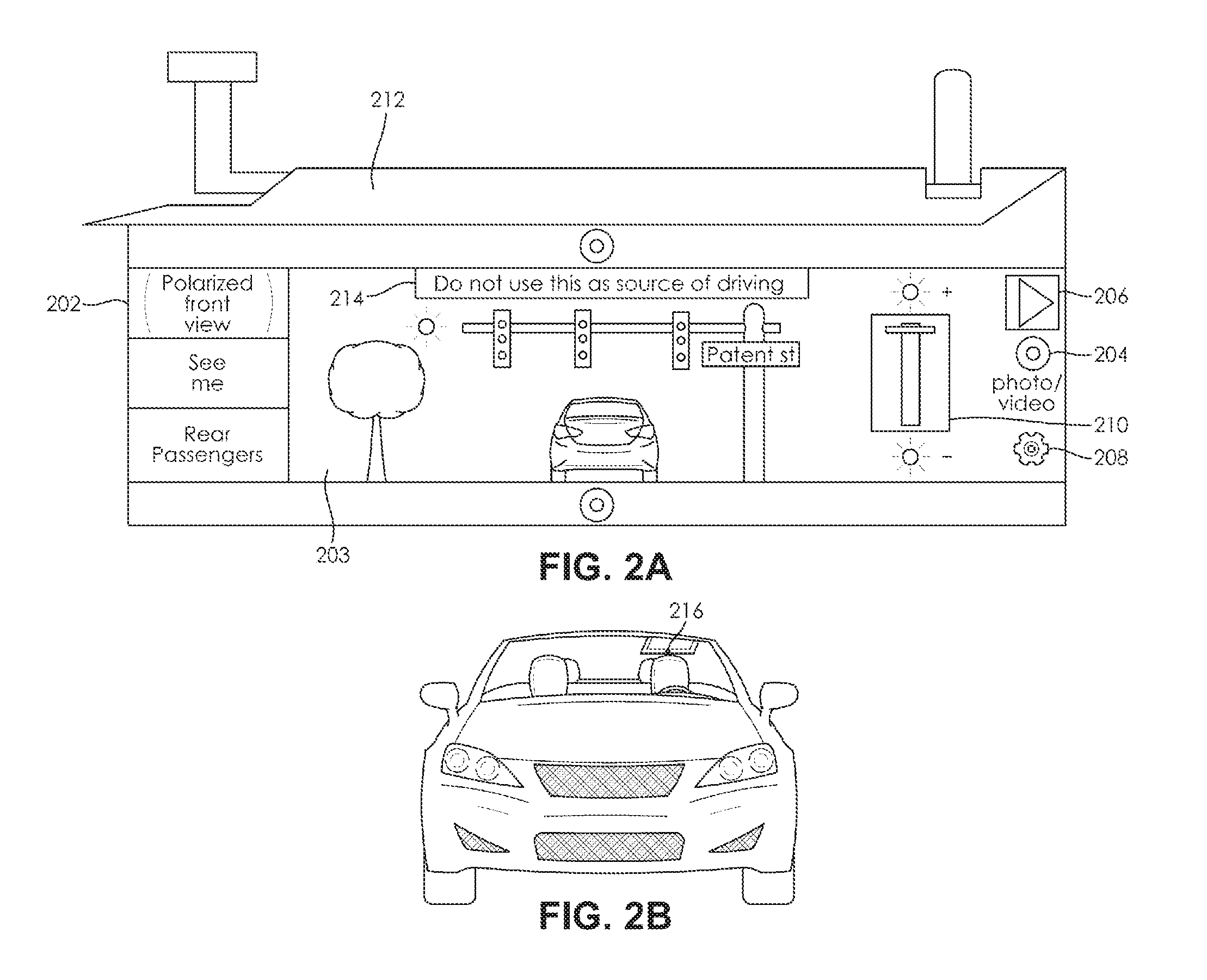

Vehicle sun visor with a multi-functional touch screen with multiple camera views and photo video capability

ActiveUS20160082888A1Reduce glareEliminate glareAntiglare equipmentColor television detailsDistractionView camera

A vehicle sun visor system with a touch screen display is configured to display video feed from one or more cameras. A front facing polarized and / or photochromic camera shows the area of view which is normally blocked by the deployed sun visor, allowing the user to view traffic lights, road signs, etc. without the distraction of glare. Software image processing may also be used to reduce glare and improve visibility. In addition the sun visor system also has a “see-me” camera which allows the user to use the screen as a mirror, and one or more rear-view cameras which can be used to see the passenger area of a vehicle through the touch-screen display. Any of the cameras may be used to take photos or videos, which may be viewed on the display and transmitted wirelessly to other electronic devices or cloud storage.

Owner:BE TOPNOTCH LLC

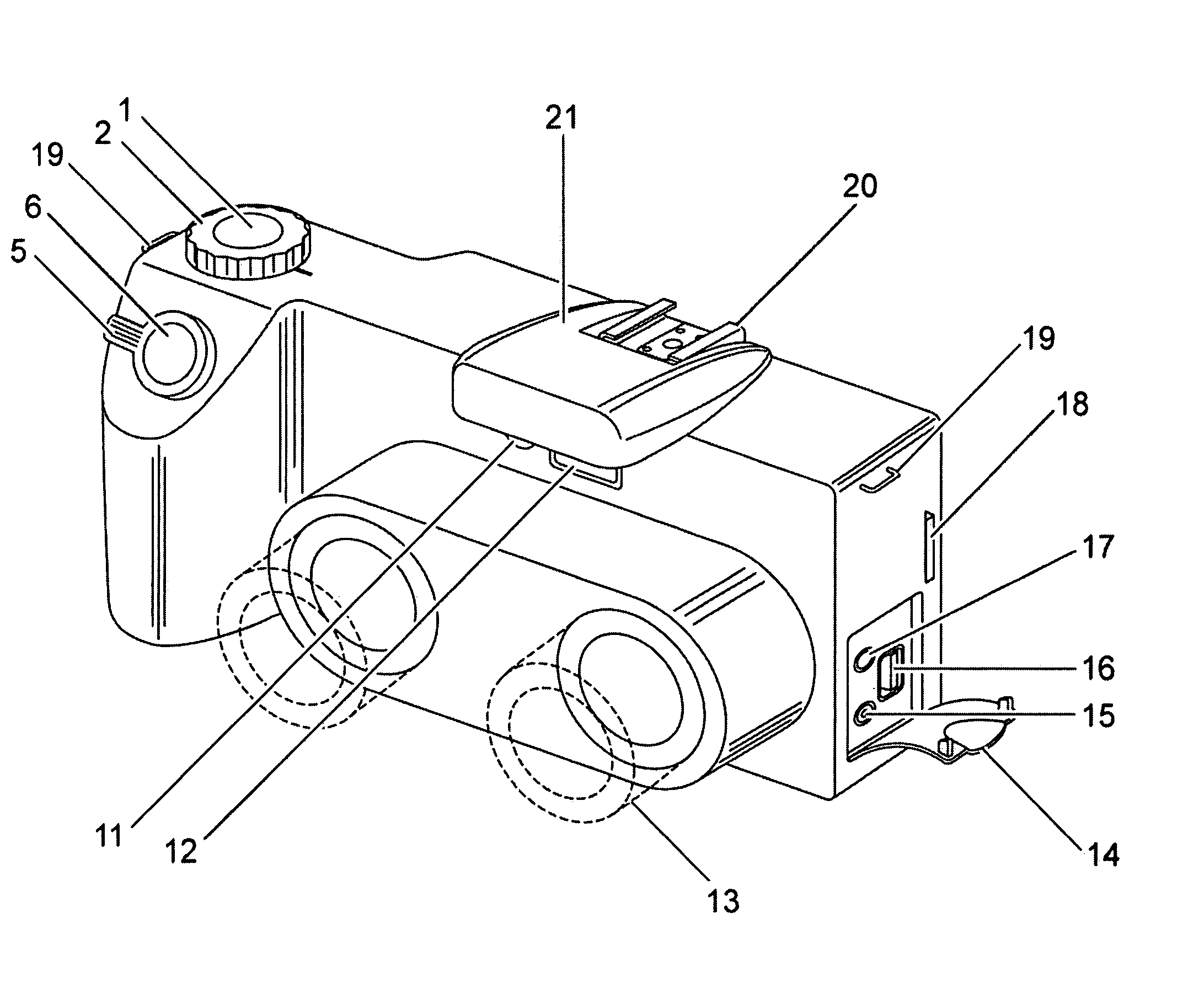

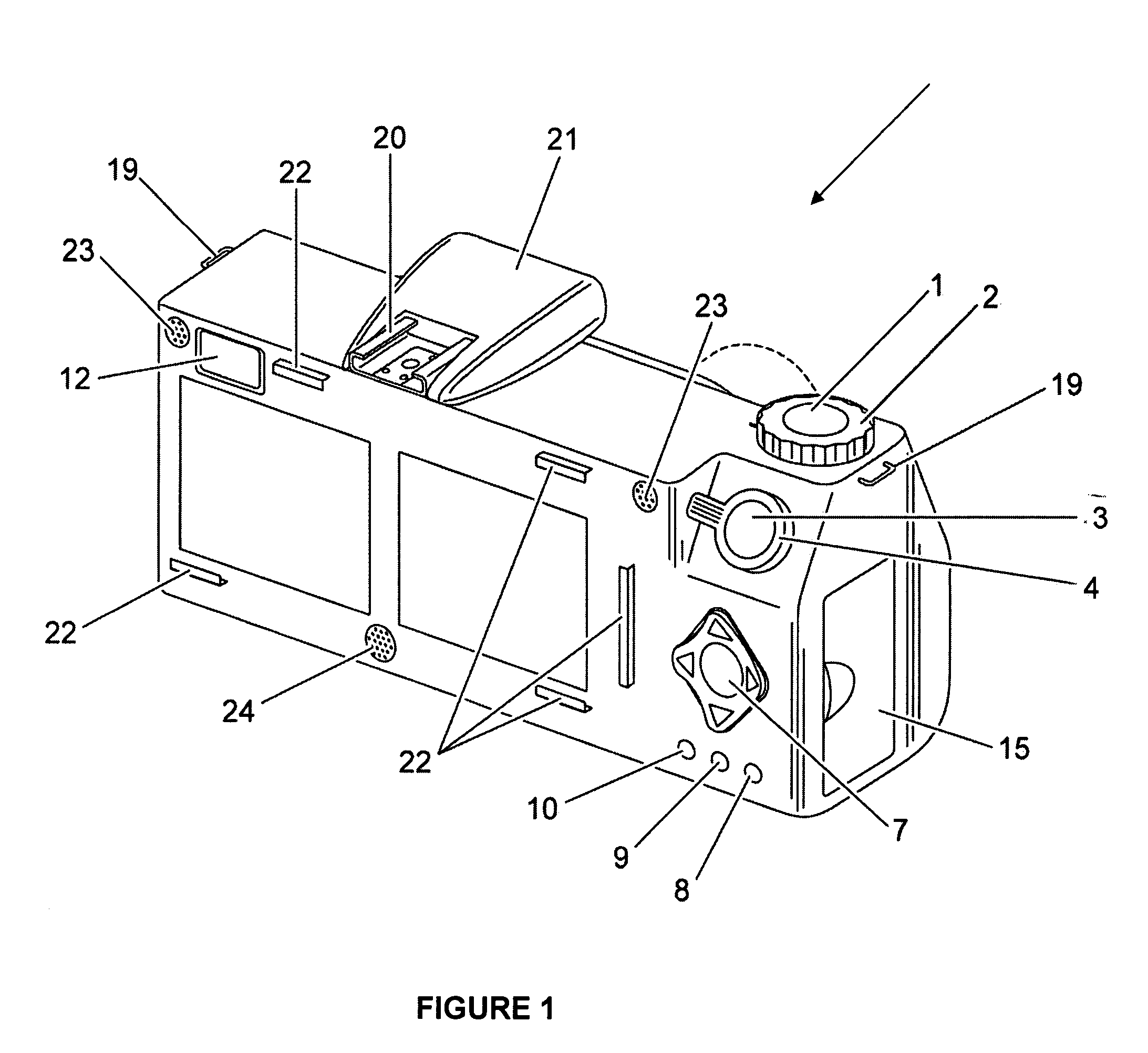

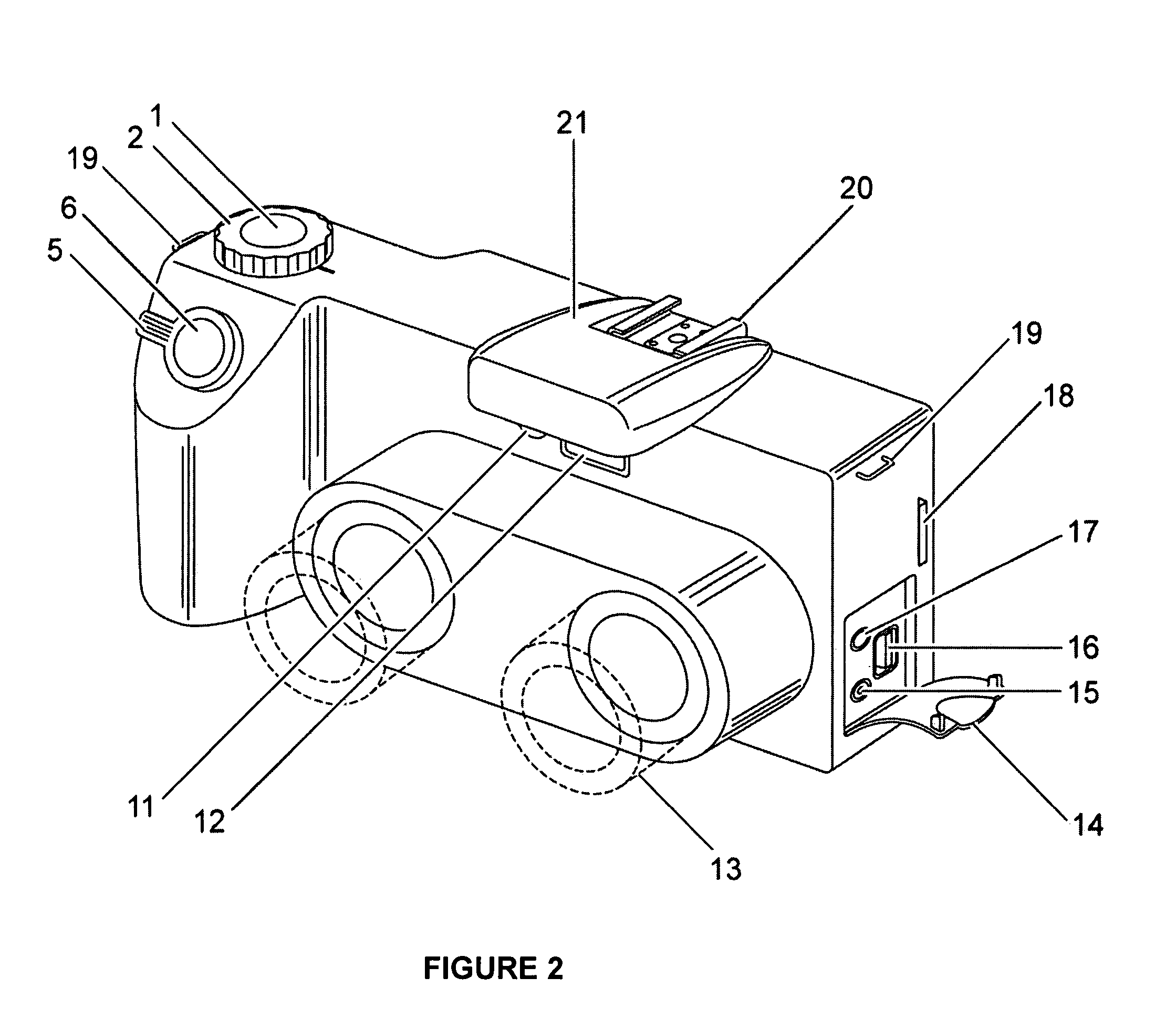

Digital stereo photographic system

The invention provides a complete system for three-dimensional (3D) (stereo) still photography in a digital format. This includes capturing the image or photo, viewing, printing and projecting it. Intermediate steps would include downloading images to a computer, editing, enhancing or modifying, saving, recording photo images to other storage medium, and the printing of still photos. This invention is a significant advancement of the traditional analog film stereo slides, in that the digital format will allow viewing of the image in the camera in 3D, prior to, during, immediately after exposure and at any other time after exposure. With significant computer processing capability after exposure in editing, enhancing, color correcting, adding text and art, the images are further improved. The system includes the ability to view images, in 3D (stereo), in the camera, in a hand held viewer, on a computer screen on a standard television set as well as printed pairs or in anaglyph formats. The images can also be viewed with conventional digital projectors using conventional polarized glasses. The camera is also a significant advancement over the standard digital still cameras because it provides the three-dimensional image capture in a digital format. It also retains the full 2-dimensional capability of digital photography.

Owner:NEWBERY REVOCABLE TRUST INDENTURE

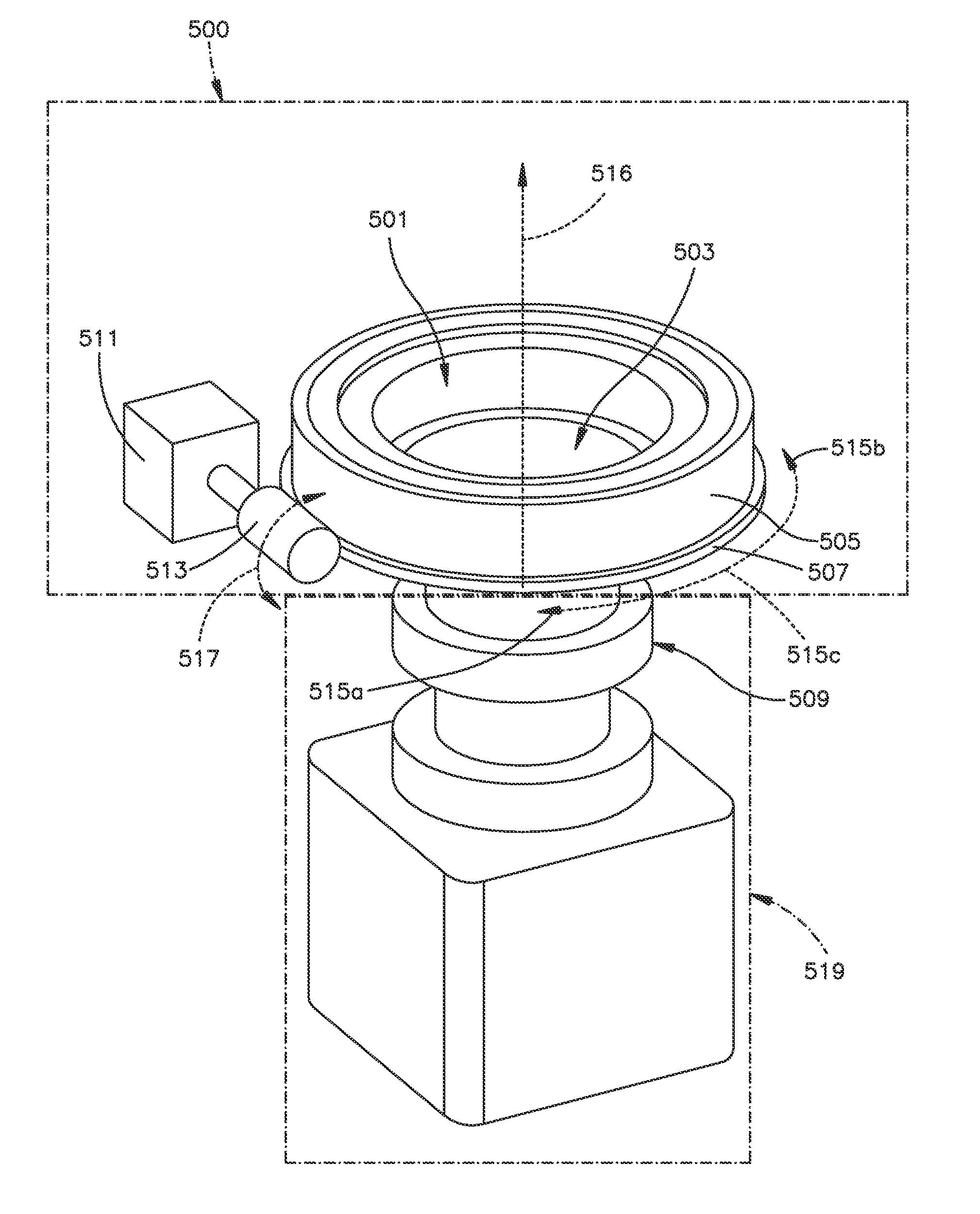

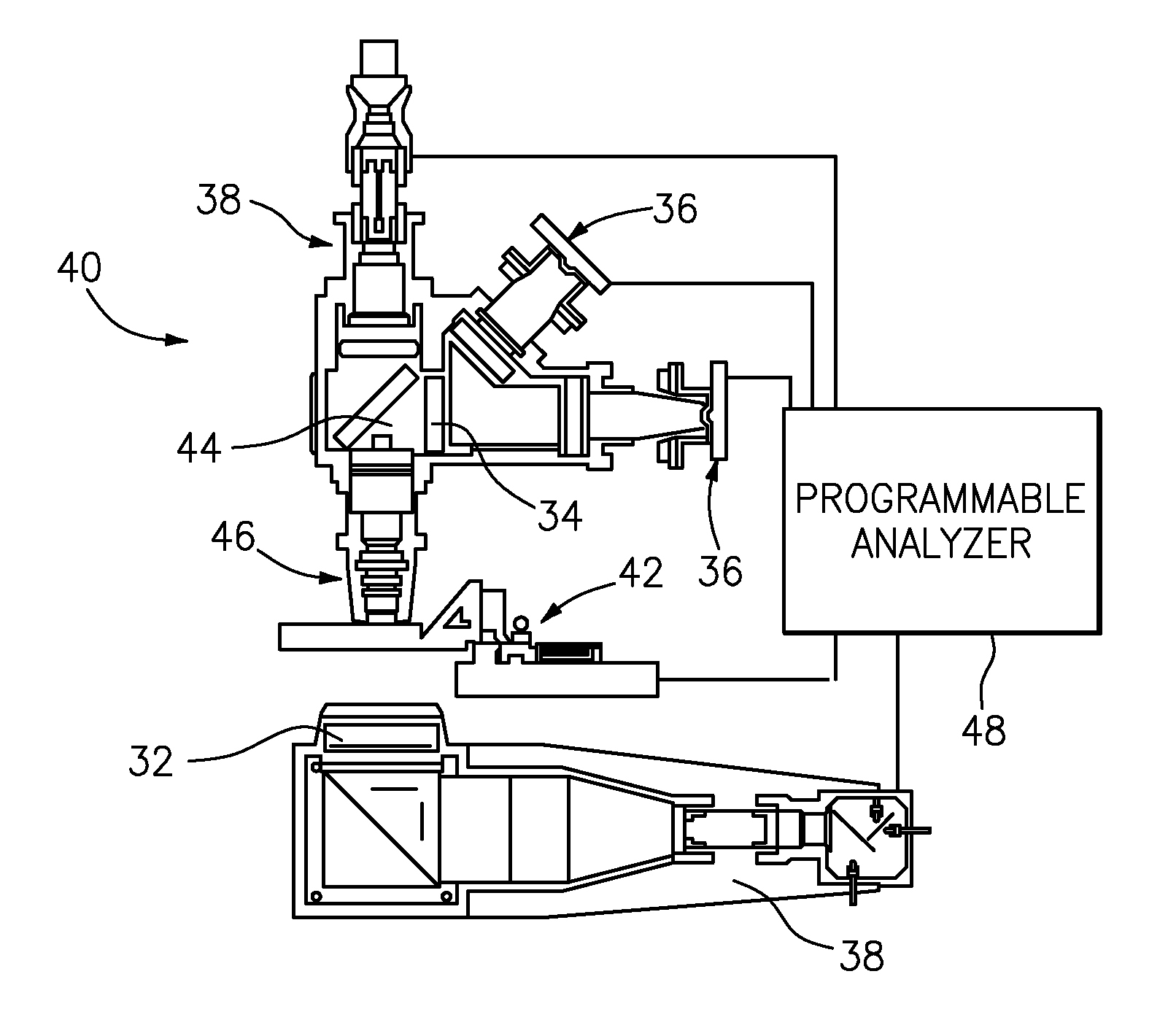

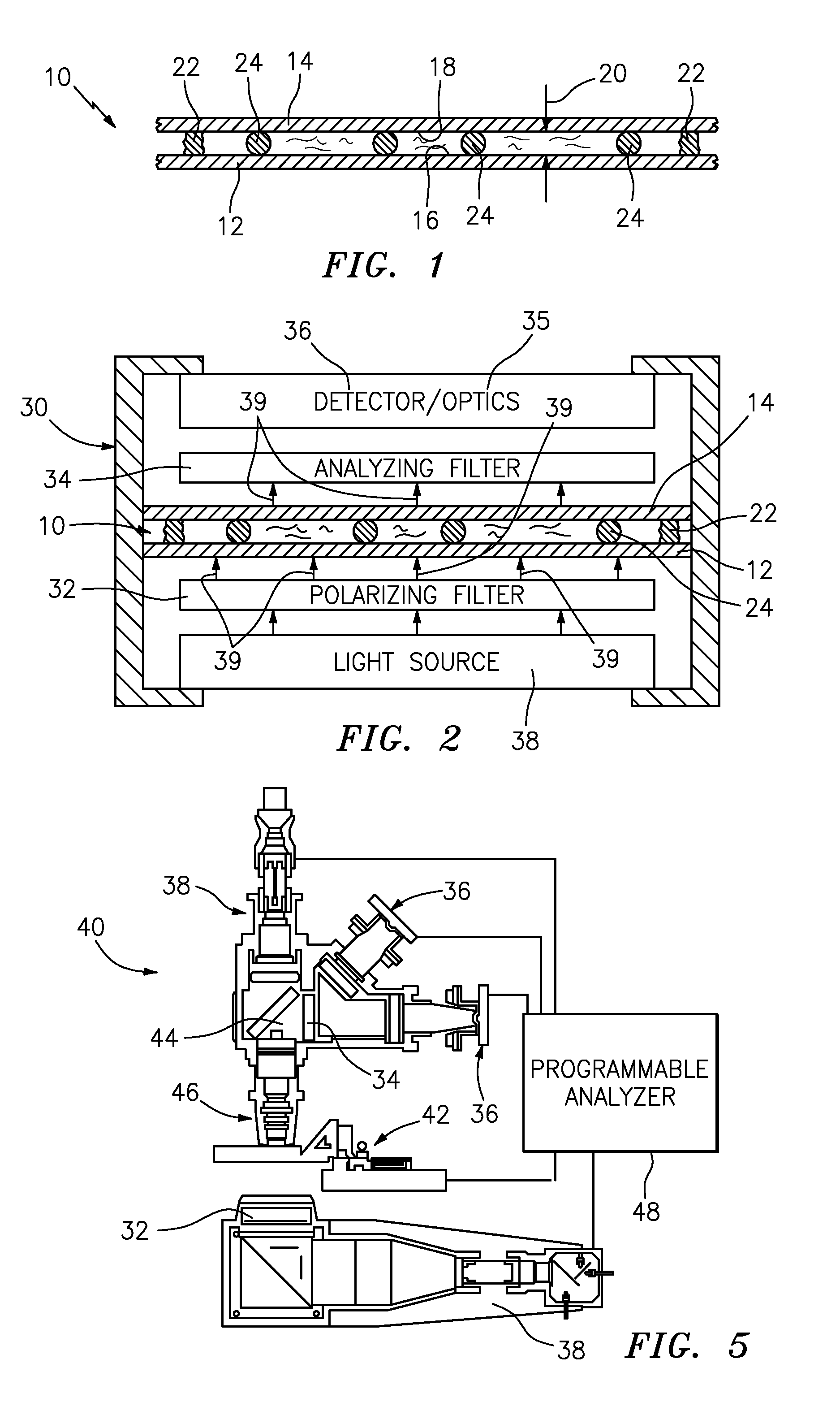

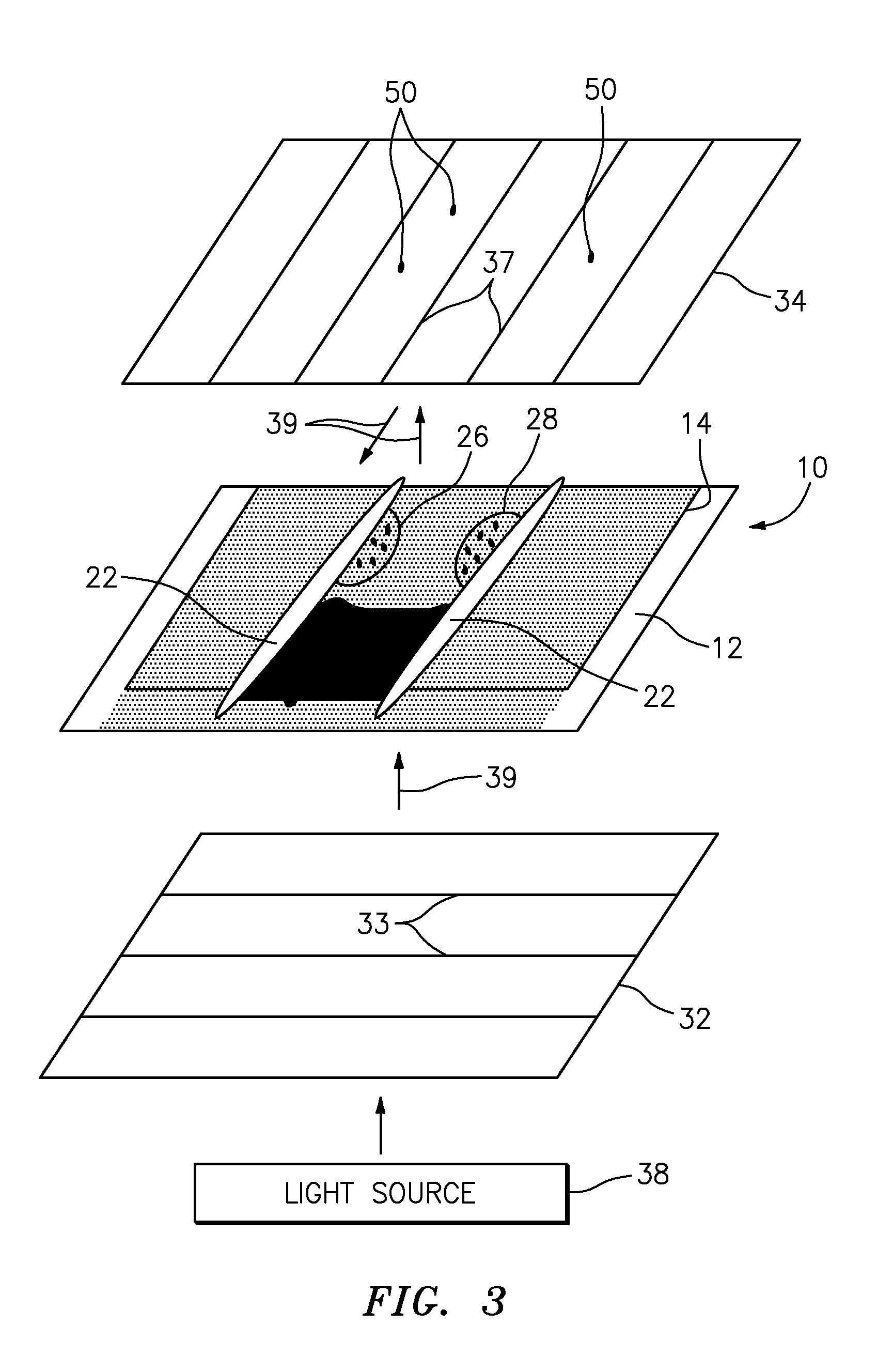

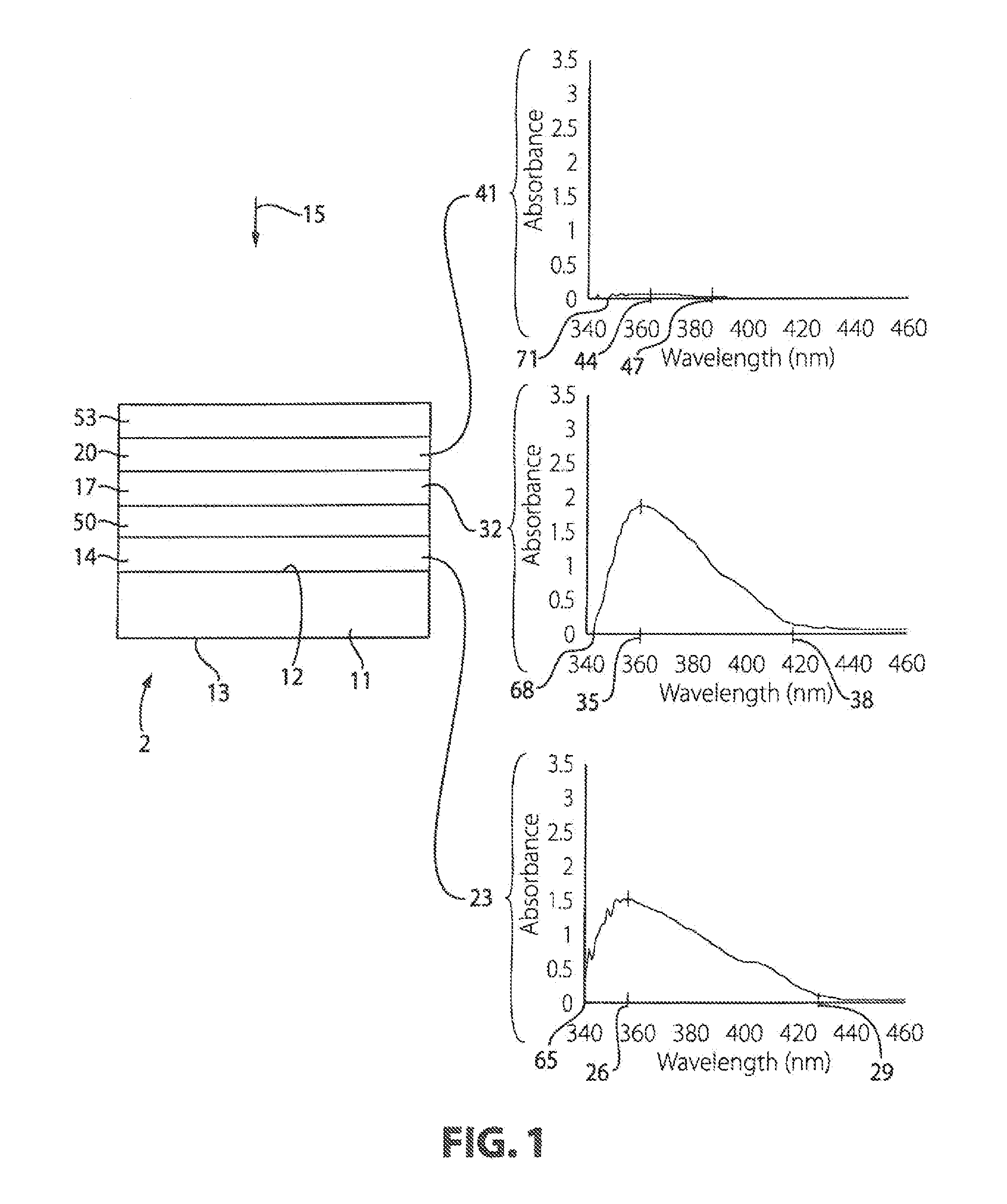

Method and apparatus for detecting the presence of anisotropic crystals and hemozoin producing parasites in liquid blood

InactiveUS20120021456A1Efficient detectionNo impact with respect to affecting the polarizationMicrobiological testing/measurementPolarisation-affecting propertiesLight filterOptical polarization

An apparatus and method for detecting the presence of anisotropic crystals within a biologic fluid sample is provided. The method includes the steps of: a) disposing the sample within a sample chamber in a sample layer having a height riot greater than about fifteen microns (15μ); b) disposing the sample layer within the sample chamber between a polarizing filter and an analyzing filter; a) disposing the polarizing filter, sample chamber, and analyzing filter in a configuration relative to a light source such that polarized light passes through the sample, and subsequently impinges on the analyzing filter; and d) wherein polar orientations of the polarizing filter and the analyzing filter are such that the polarized light will not pass through the analyzing filter, and light passing through an anisotropic crystal disposed within the sample will pass through the analyzing filter and appear as a point of light.

Owner:ABBOTT POINT CARE

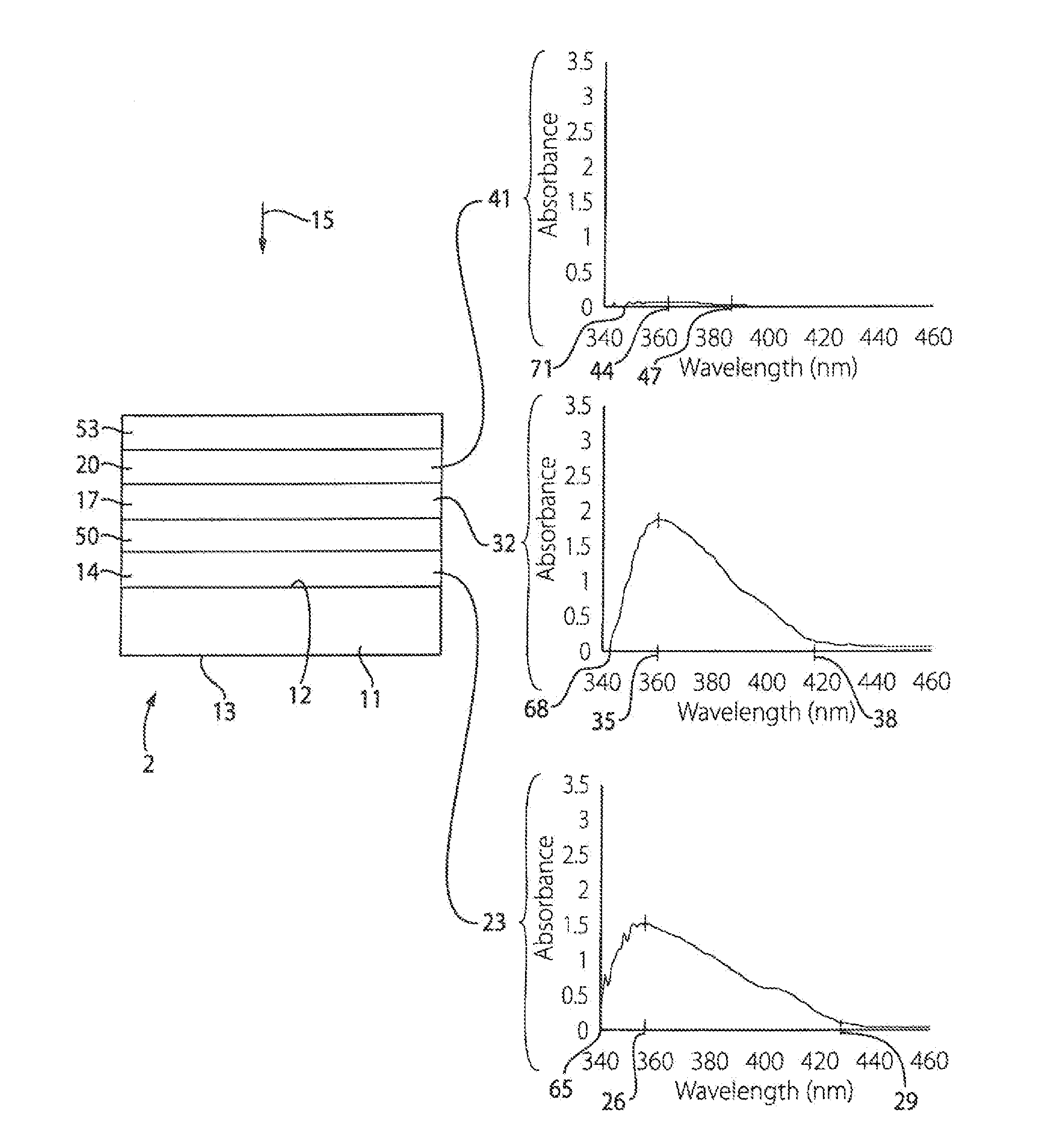

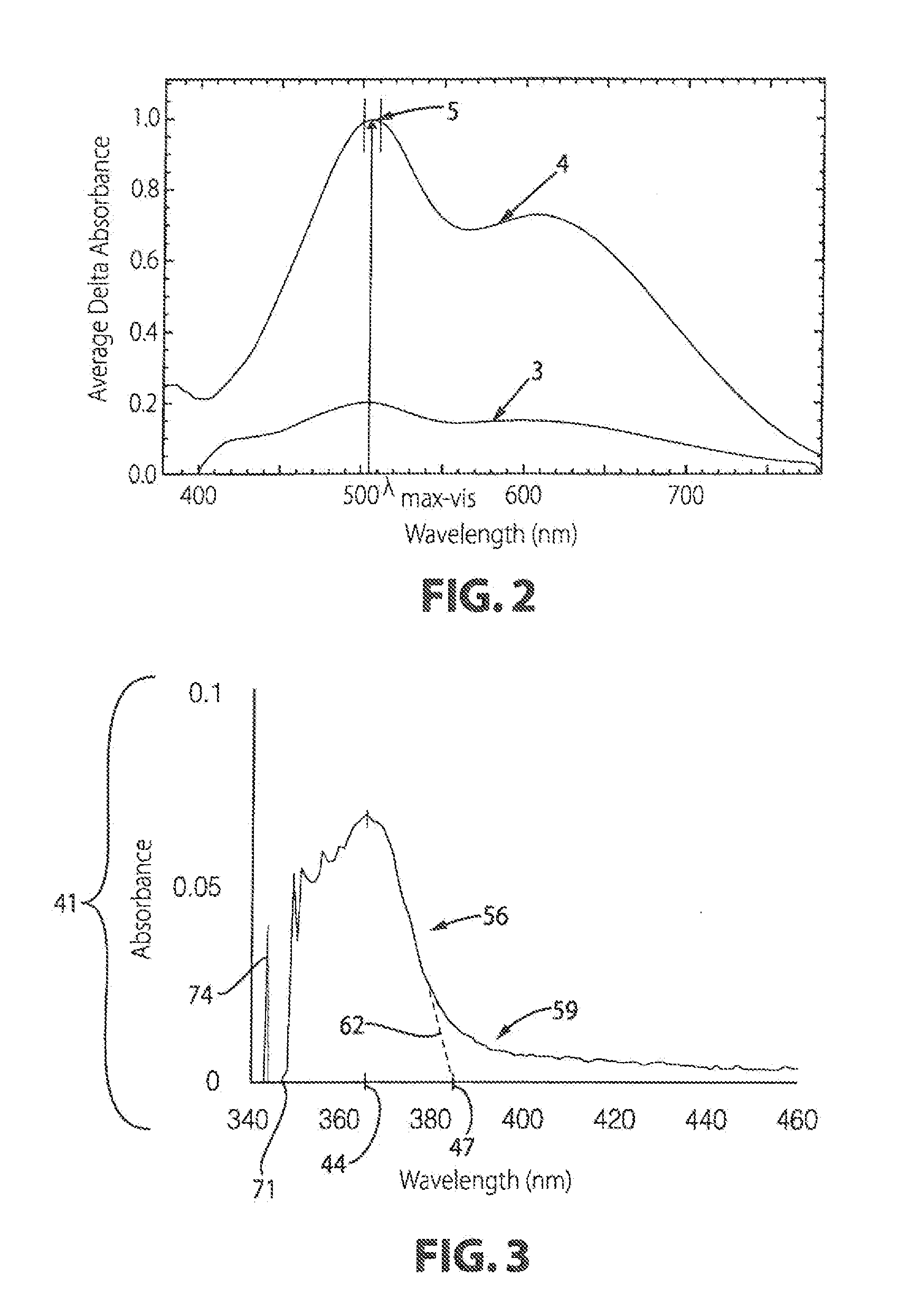

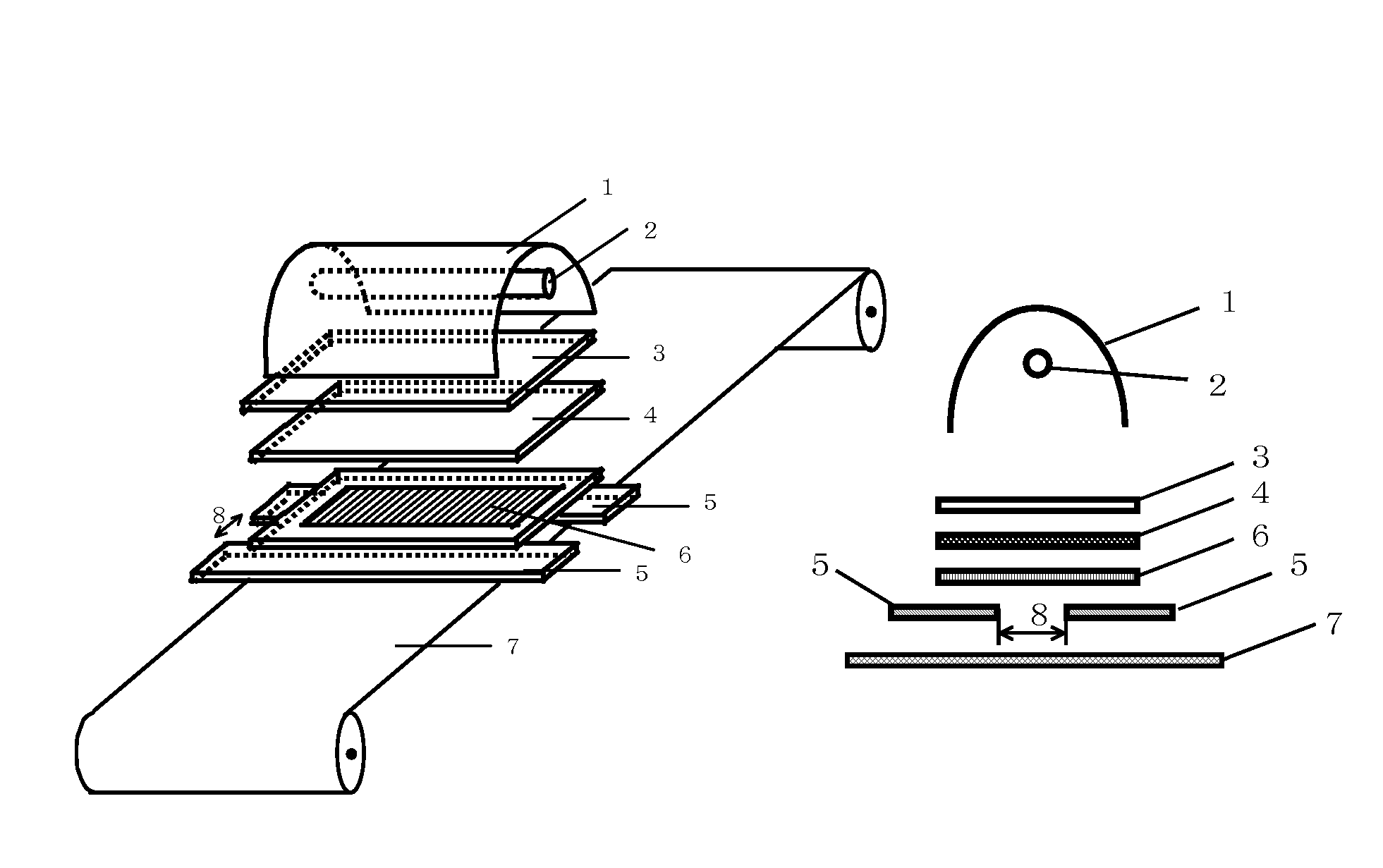

Polarizing photochromic articles

Provided are photochromic articles including a substrate, a primer layer that includes a first photochromic compound, and a photochromic-dichroic layer over the primer layer that includes a photochromic-dichroic compound. The first photochromic compound and the photochromic-dichroic compound each are selected such that the photochromic-dichroic compound has an unactivated state terminal minimum absorbance wavelength that is less than or equal to the unactivated state terminal minimum absorbance of the underlying first photochromic compound. The present invention also relates to such photochromic articles that further include a topcoat layer over the photochromic-dichroic layer, the topcoat layer including a second photochromic compound that has an unactivated state terminal minimum absorbance wavelength that is less than the unactivated state terminal minimum absorbance wavelength of the underlying photochromic-dichroic compound.

Owner:TRANSITIONS OPTICAL INC

Method of producing optical film, optical film, polarizer plate, transfer material, liquid crystal display device, and polarized ultraviolet exposure apparatus

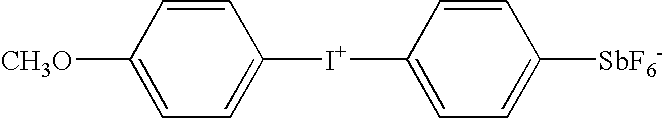

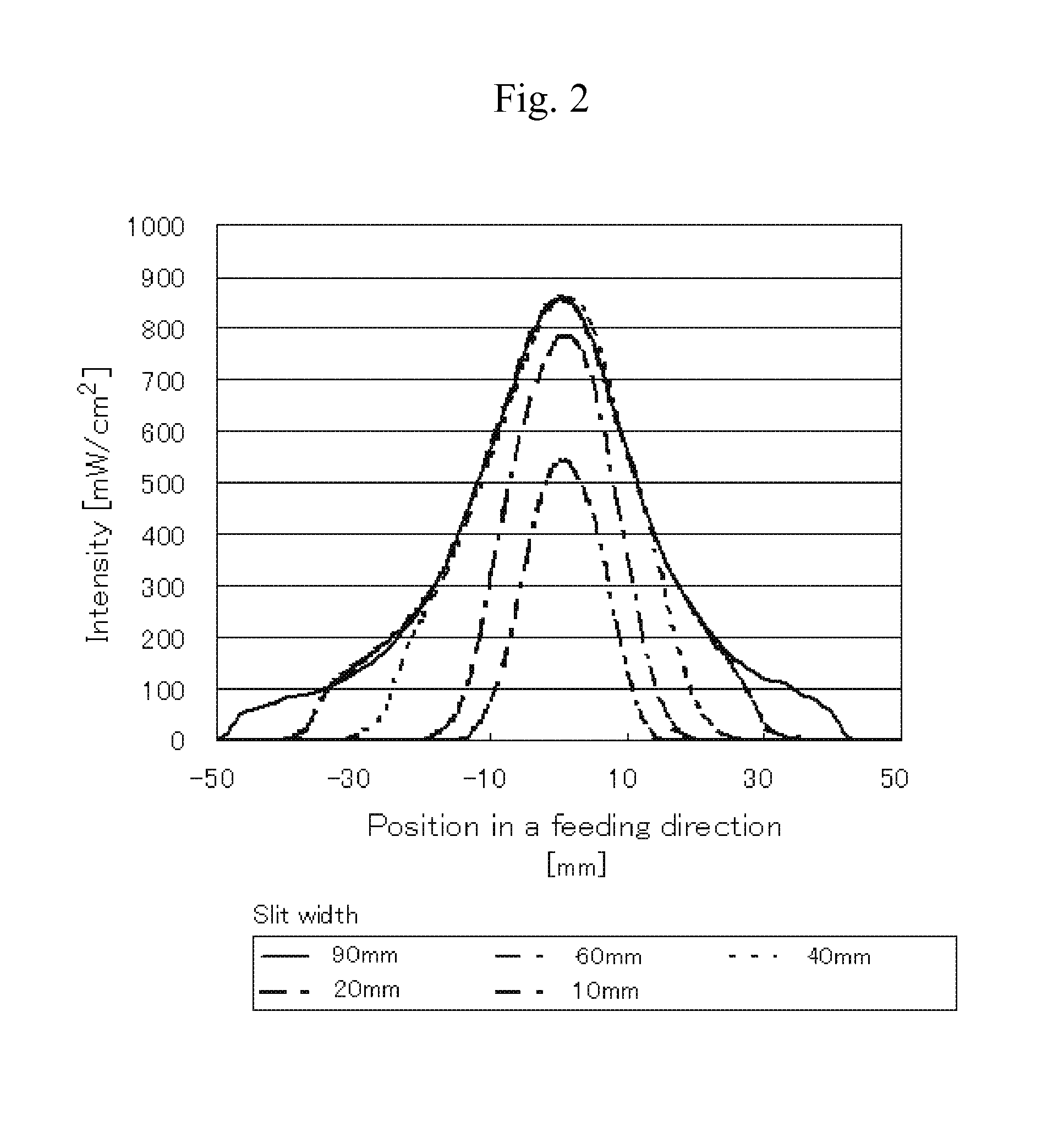

InactiveUS20080055521A1High productivityExcellent in optical characteristic and strength of filmPolarising elementsRadiation therapyPolarizerChemistry

A novel method of producing an optical film is disclosed. The method comprises steps (1) to (3) in this order: (1) preparing, on a surface of an alignment film, a layer of a polymerizable composition comprising a polymerizable liquid crystal compound and a dichroic polymerization initiator; (2) aligning molecules of said polymerizable liquid crystal compound in said layer in a first alignment state; and (3) irradiating said layer with polarized ultraviolet light to carry out polymerization of said polymerizable liquid crystal compound and fix molecules of said polymerizable liquid crystal compound in a second alignment state thereby to form an optically anisotropic layer, wherein a percentage of polarized ultraviolet light having an extinction ratio ranging from 1 to 8 is not greater than 15% with respect to an energy density of polarized ultraviolet light per unit area (J / cm2).

Owner:FUJIFILM CORP

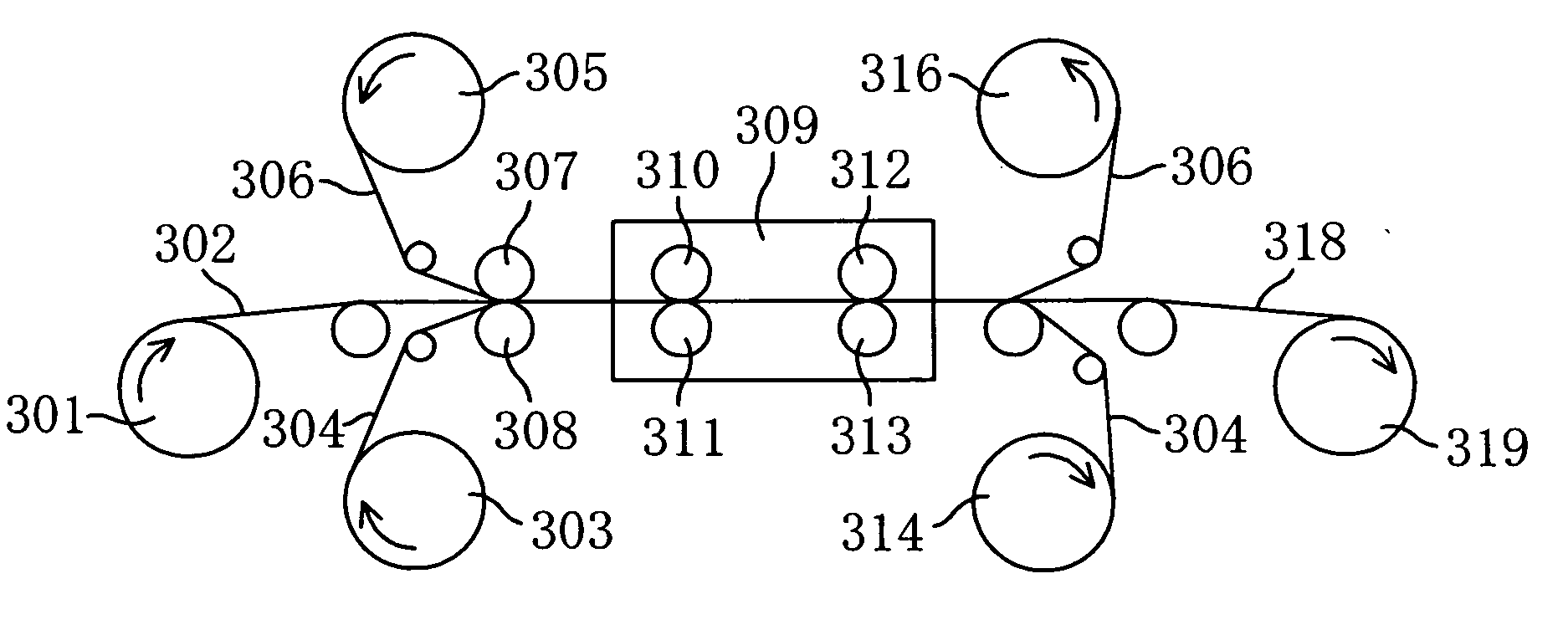

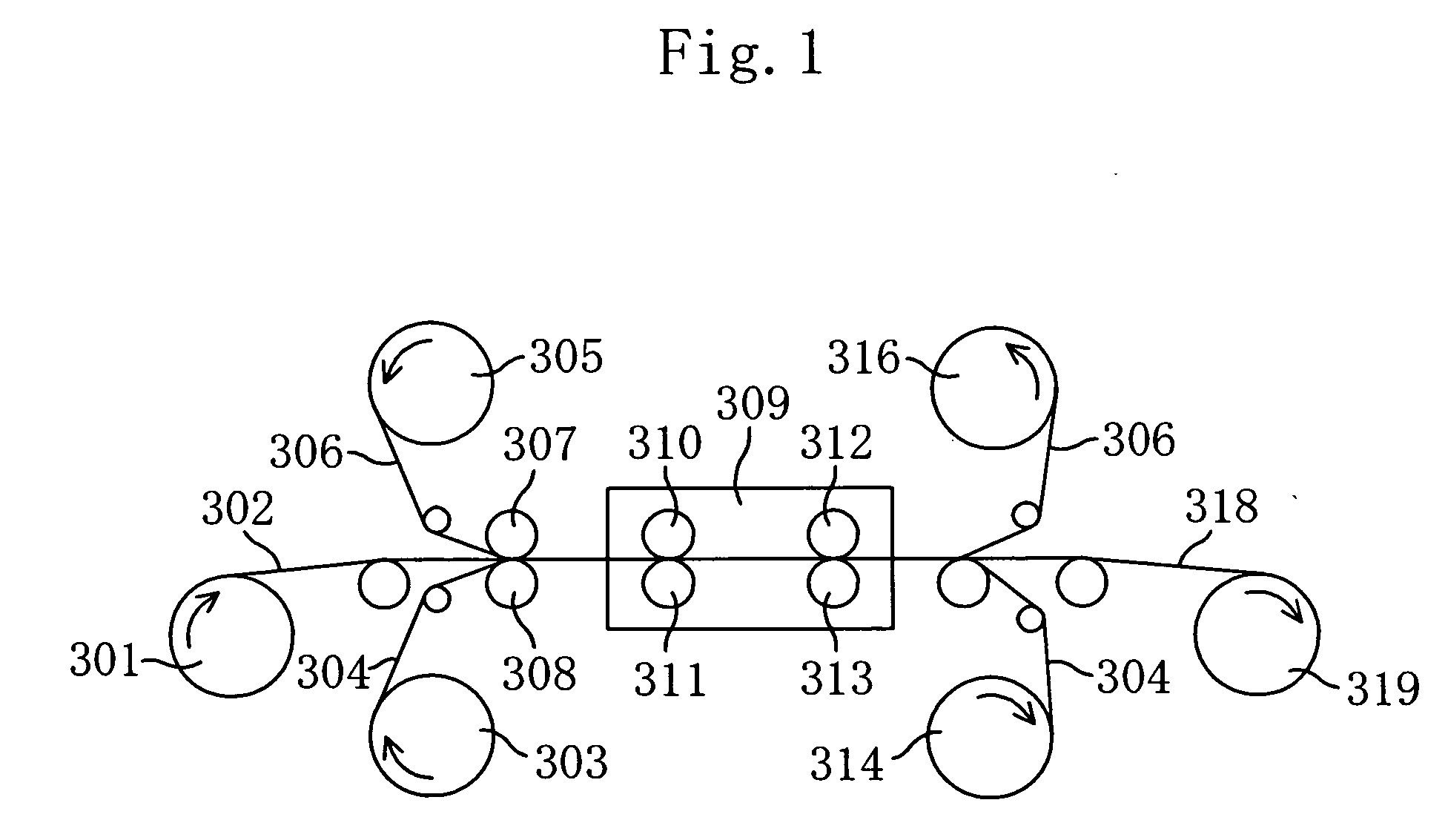

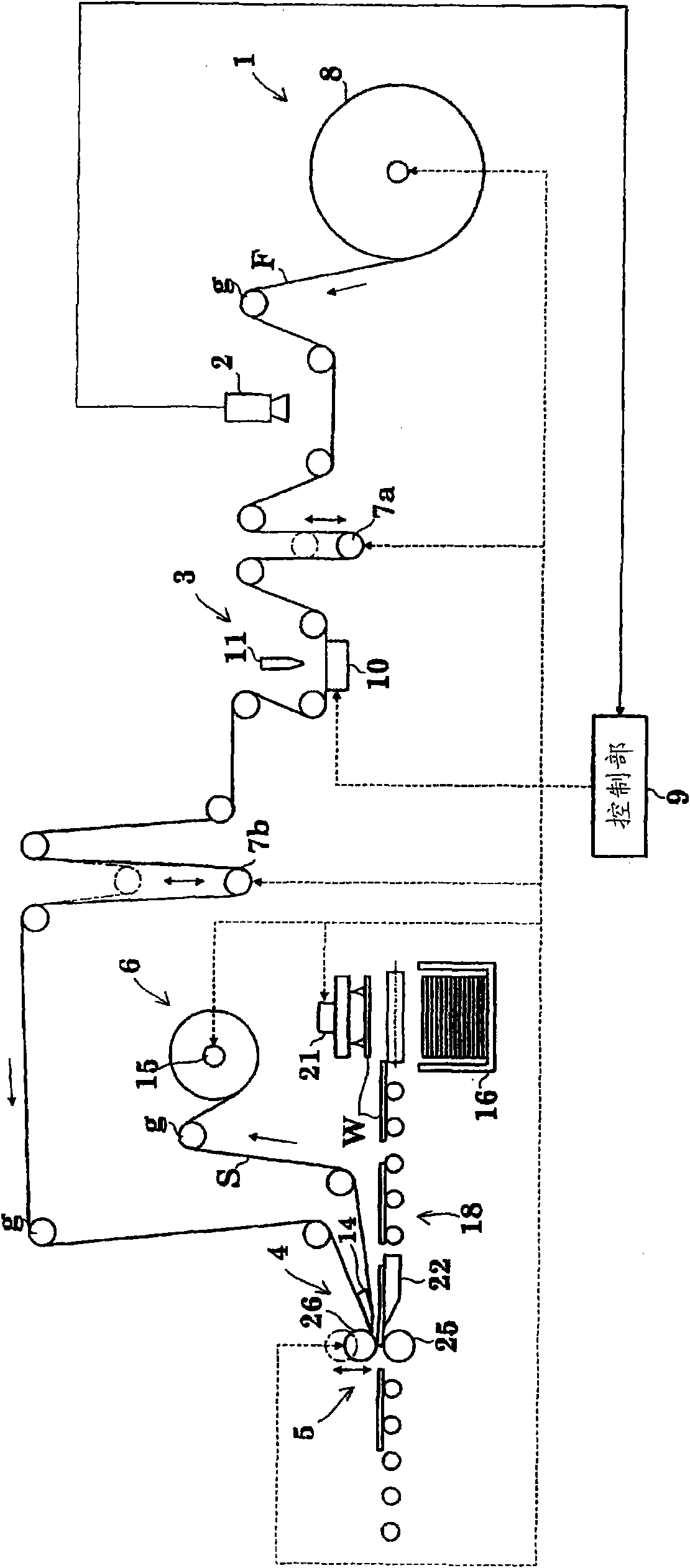

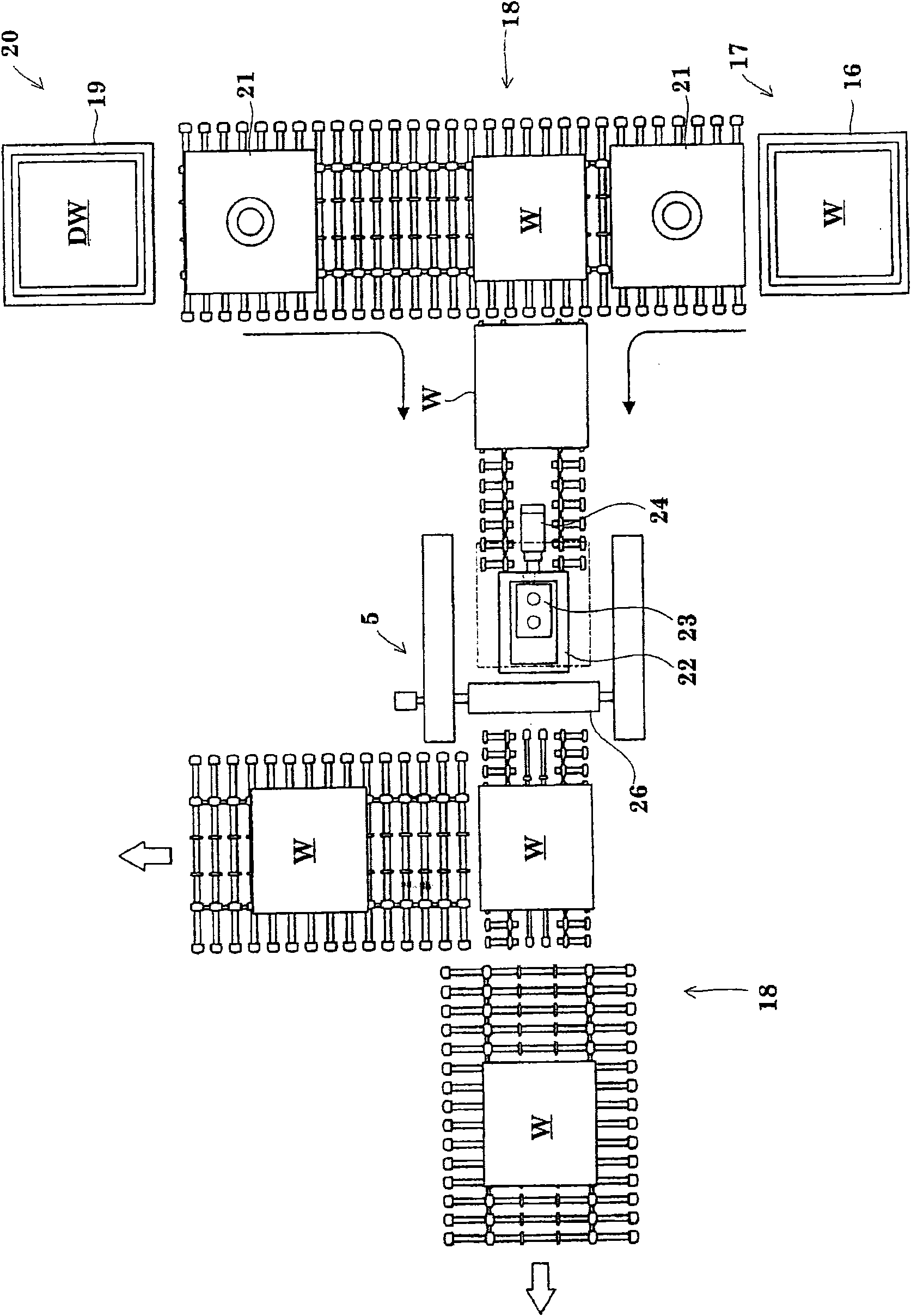

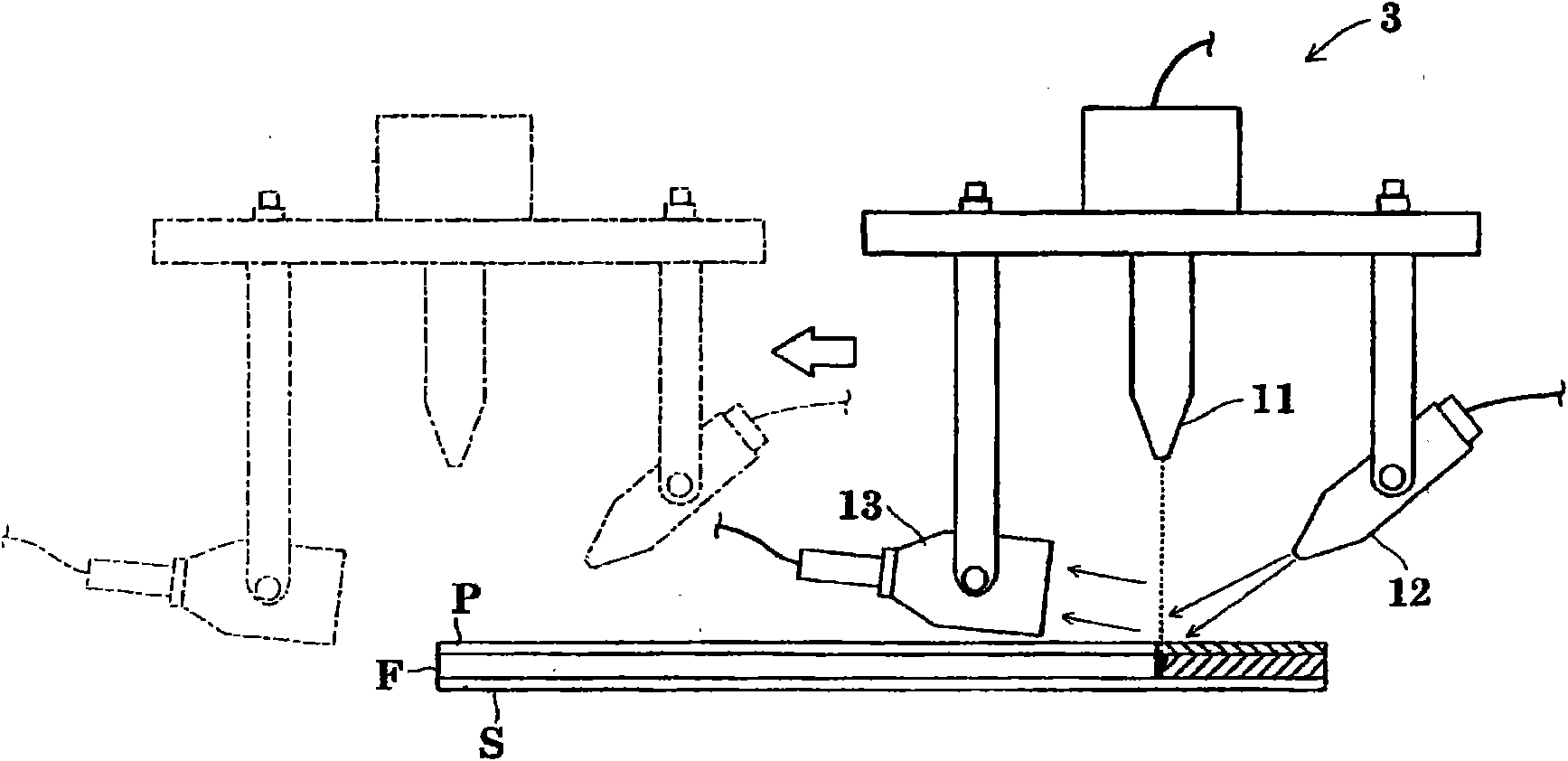

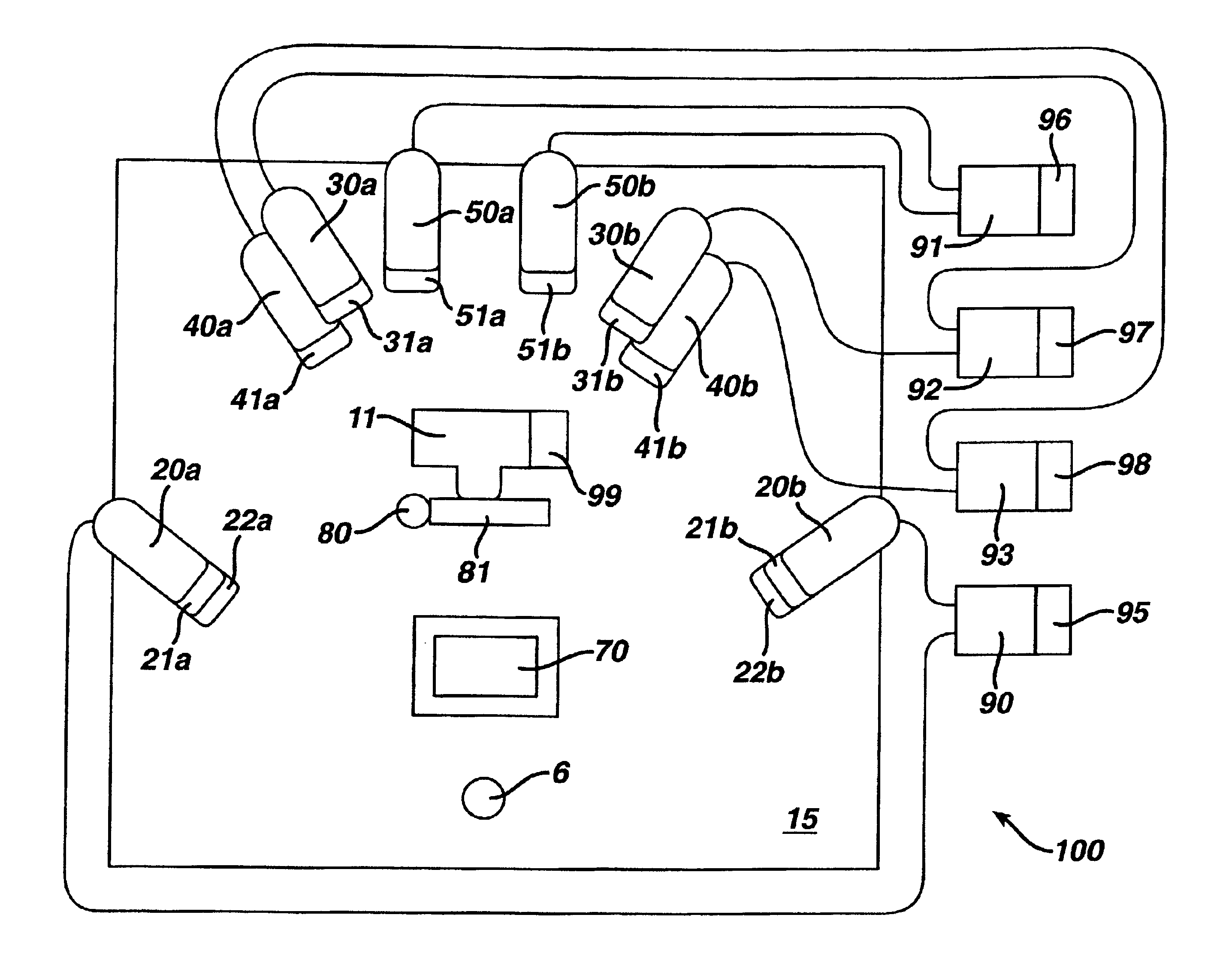

Optical member adhering method, and apparatus using the method

ActiveCN101528445AReduce foulingImprove qualityMaterial analysis by optical meansOptical articlesSynchronismLiquid crystal

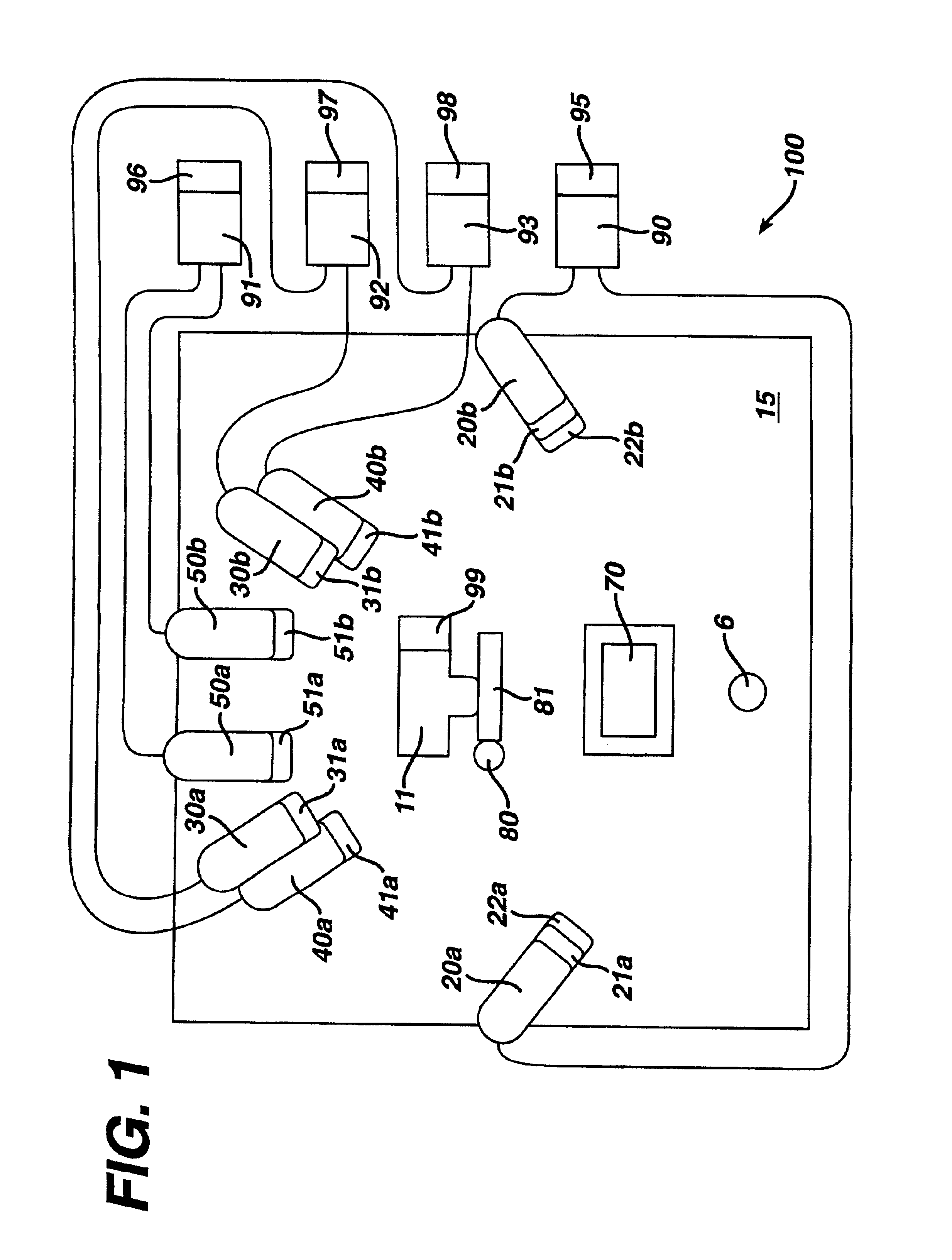

A band-shaped polarization film (F), which has a protection film extended on one face and a separator extended on the other face, is let off and fed from a film feeding unit (1), and is subjected to a visual inspection. The protection film and the polarization film (F) are then half-cut by a laser device (11) while leaving the separator. After this, the films are transferred and guided to a peeling mechanism (4) so that the polarization film (F) is fed, while the separator being peeled by a knife edge, into an adhering mechanism (5). In synchronism with this feeding action of the polarization film (F), a liquid crystal panel (W) fed from a panel transfer device (18) is transferred and guided to the adhering mechanism (5), and the polarization film (F) is adhered to the liquid crystal panel (W).

Owner:NITTO DENKO CORP

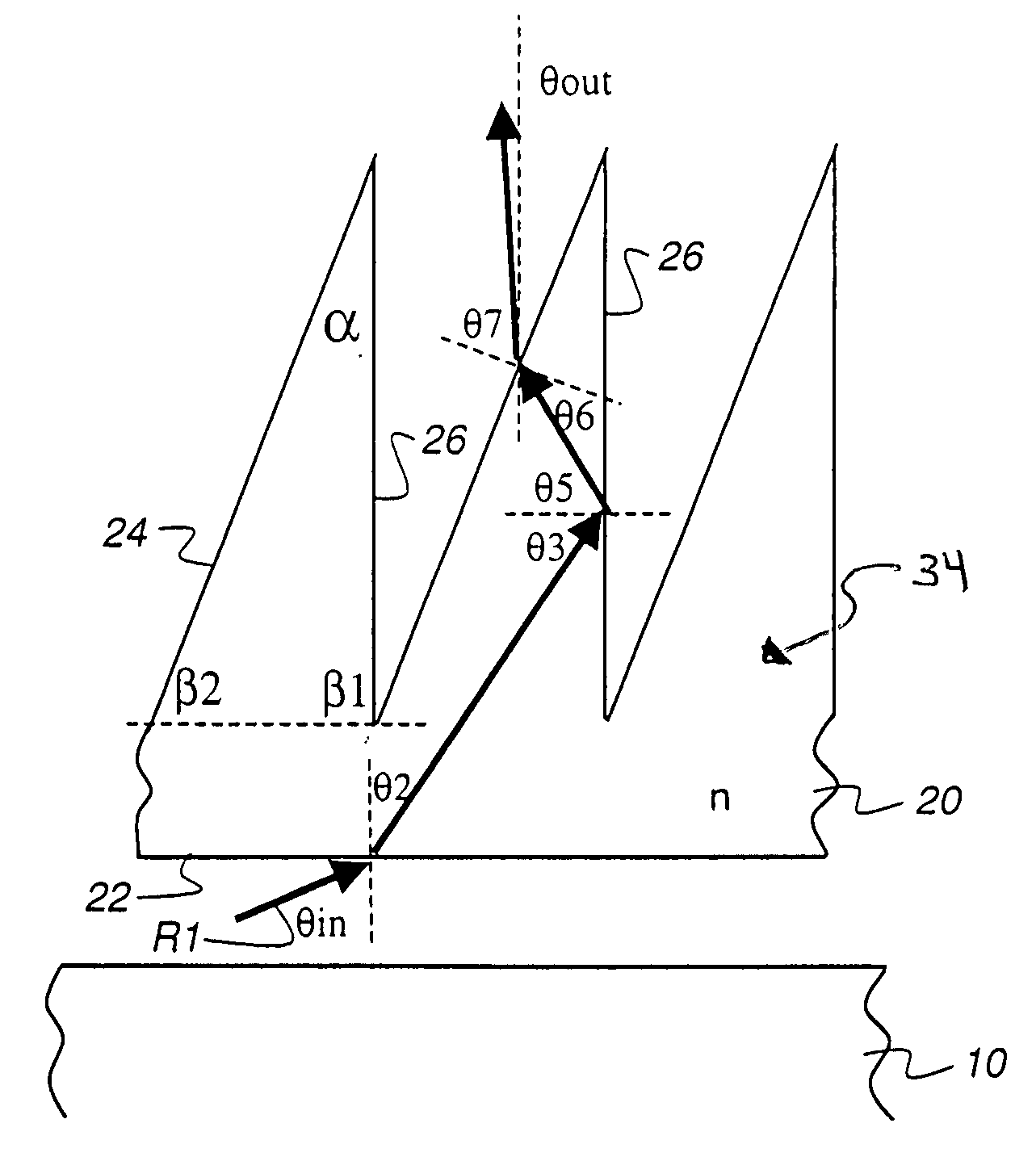

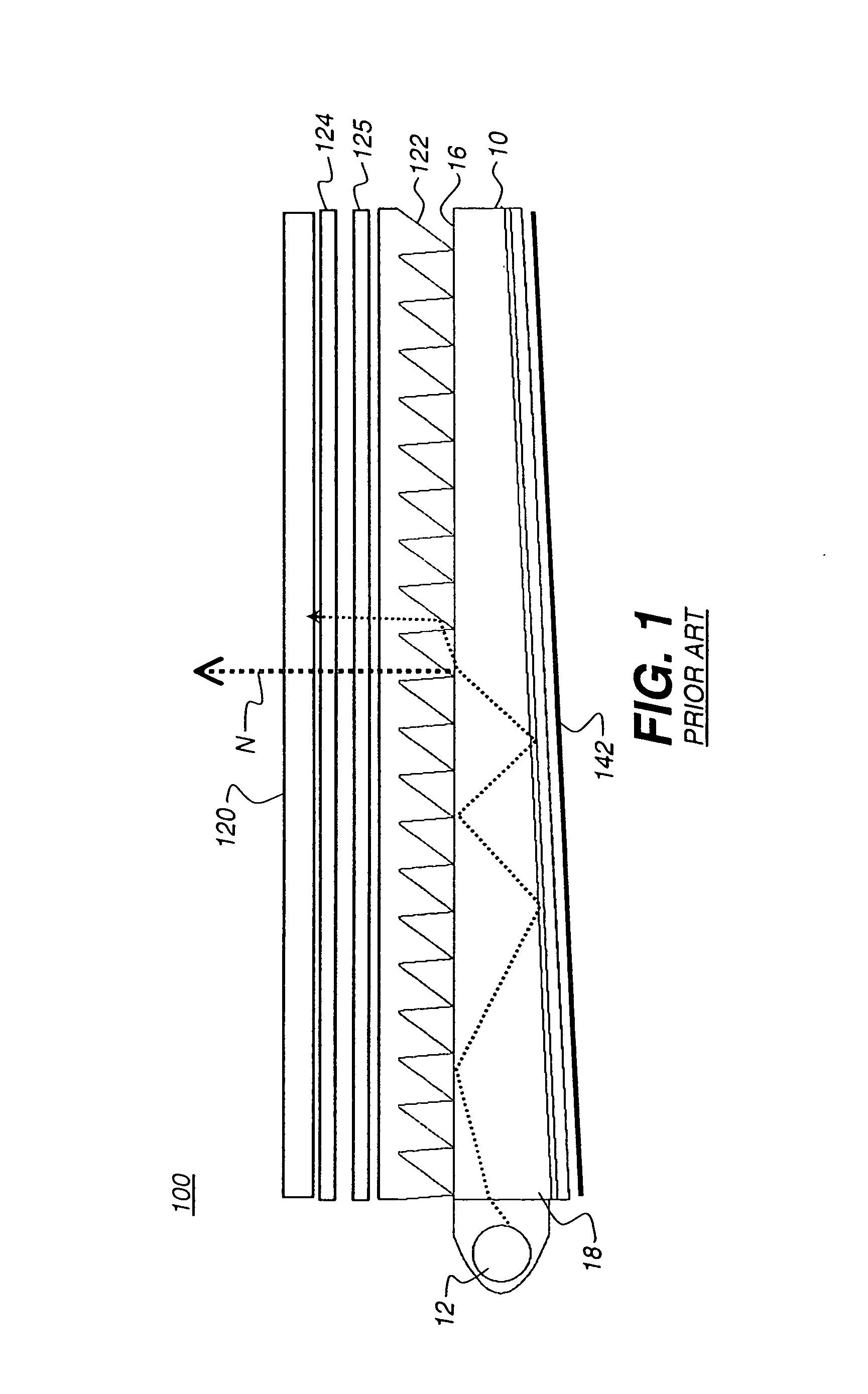

Polarizing turning film using total internal reflection

A light redirecting article redirects light toward a target angle. The light redirecting article has an input surface for accepting incident illumination over a range of incident angles and an output surface with a plurality of light redirecting structures, each light redirecting structure having an internal reflection surface oriented at a first angle with respect to the plane of the input surface and an exit surface for emitting an output light at an emitted light angle, wherein the exit surface is oriented at a second angle relative the plane of the input surface. For incident illumination at a principal angle greater than 60 degrees from normal, light is reflected from the internal reflection surface and emitted from the exit surface at an emitted light angle that is within 5 degrees of the target angle.

Owner:SK MICROWORKS SOLUTIONS CO LTD

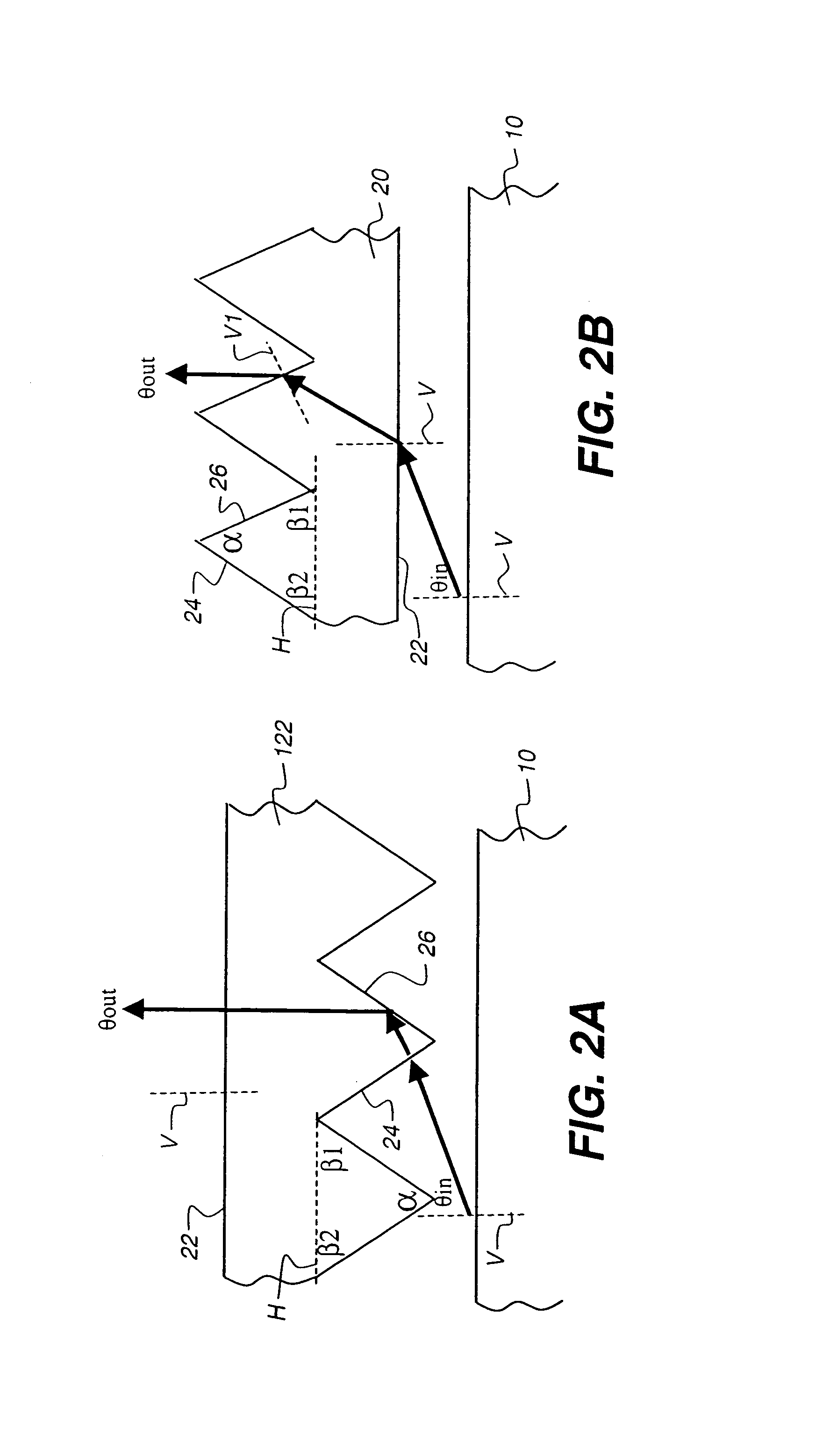

Optical cellulose acylate film, polarizing plate and liquid crystal display

ActiveUS20050142304A1Favorable retardation valueLittle changeLiquid crystal compositionsPolarising elementsCelluloseMixed fatty acid

To provide an optical film which exhibits excellent retardation values both in the film plane and along the direction perpendicular to the film plane and shows little change in retardation values depending on environmental factors such as humidity, a liquid crystal display showing little change in viewing angle characteristics due to an environmental (humidity) change, and a polarizing plate to be used in the liquid crystal display, the cellulose acylate contains a cellulose acylate which is a mixed fatty acid ester of a cellulose and satisfies formulae specified in the specification, and a polarizing plate and a liquid crystal display using this cellulose acylate film.

Owner:FUJIFILM CORP

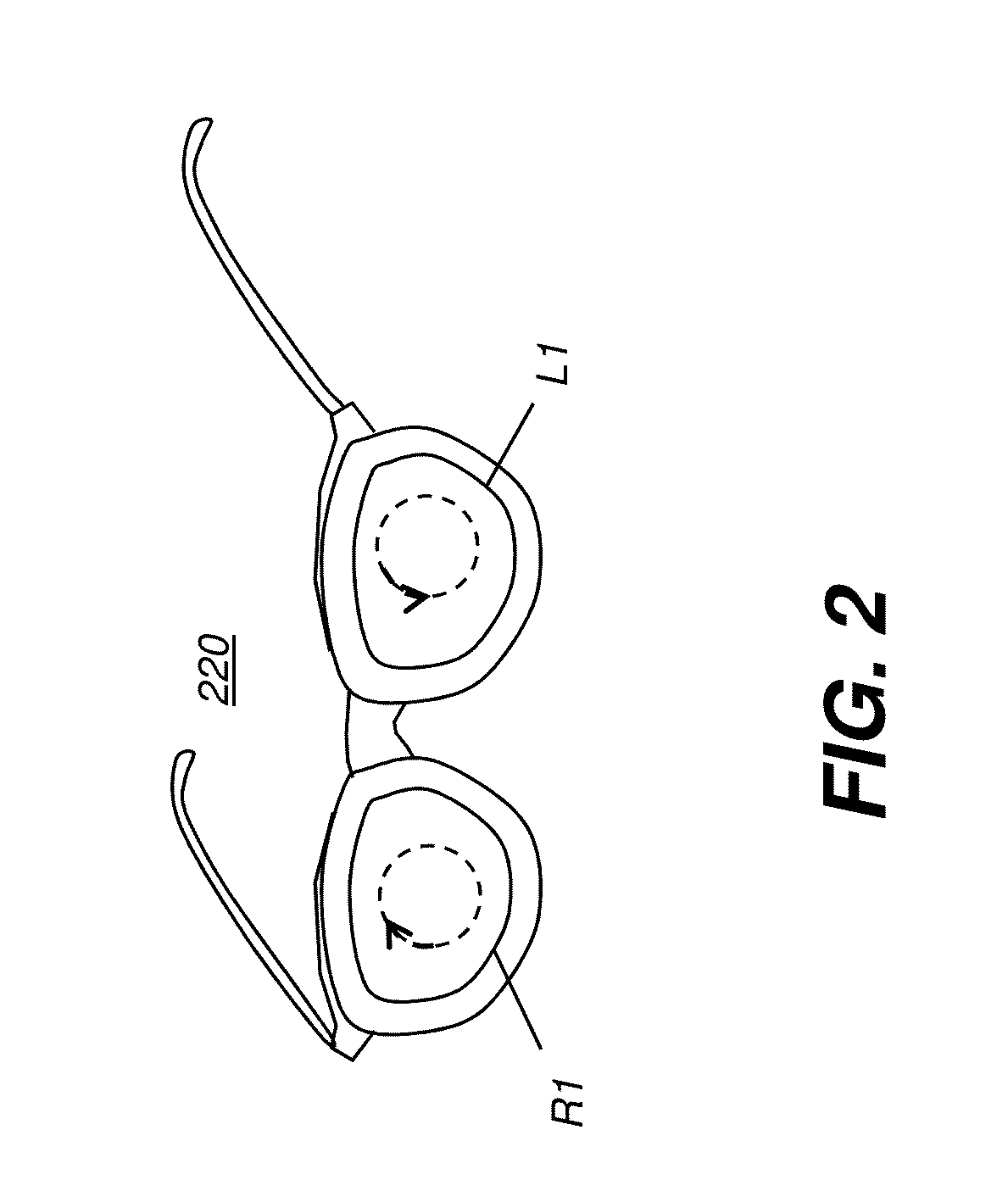

3D Polarized Eyewear

An article of eyewear for viewing a 3D display has at least one lens, wherein the at least one lens has a substrate lens material that is transparent to visible light and has a curved surface. A circular polarizer is formed on the substrate lens material and has a linear polarizer with a polarization axis and a quarter wave plate with a retardation axis that is inclined at substantially 45 degrees from the polarization axis along the curved surface. Either or both of the linear polarizer and the quarter wave plate are formed as sub-wavelength elongated structure devices.

Owner:SOL GRID

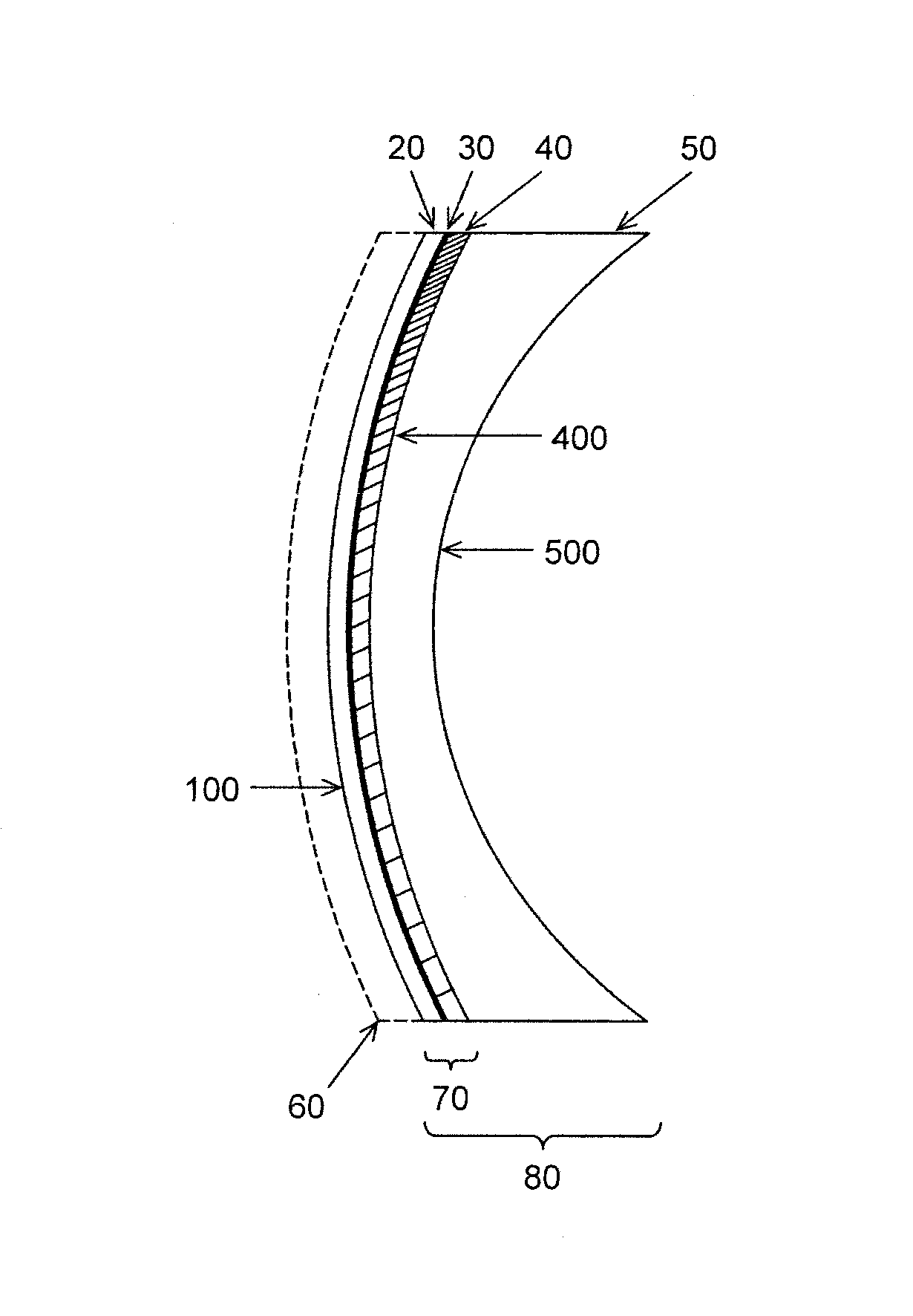

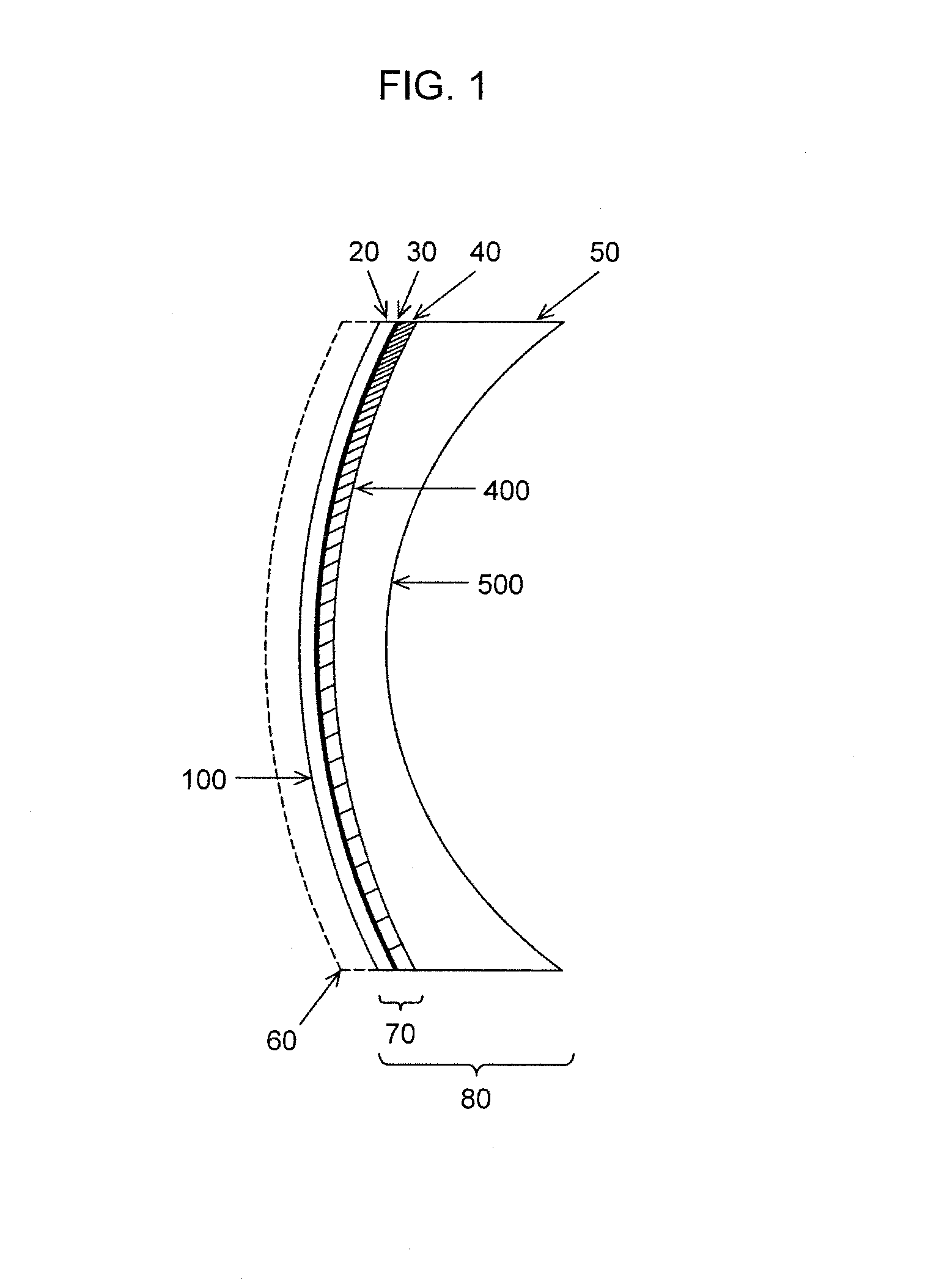

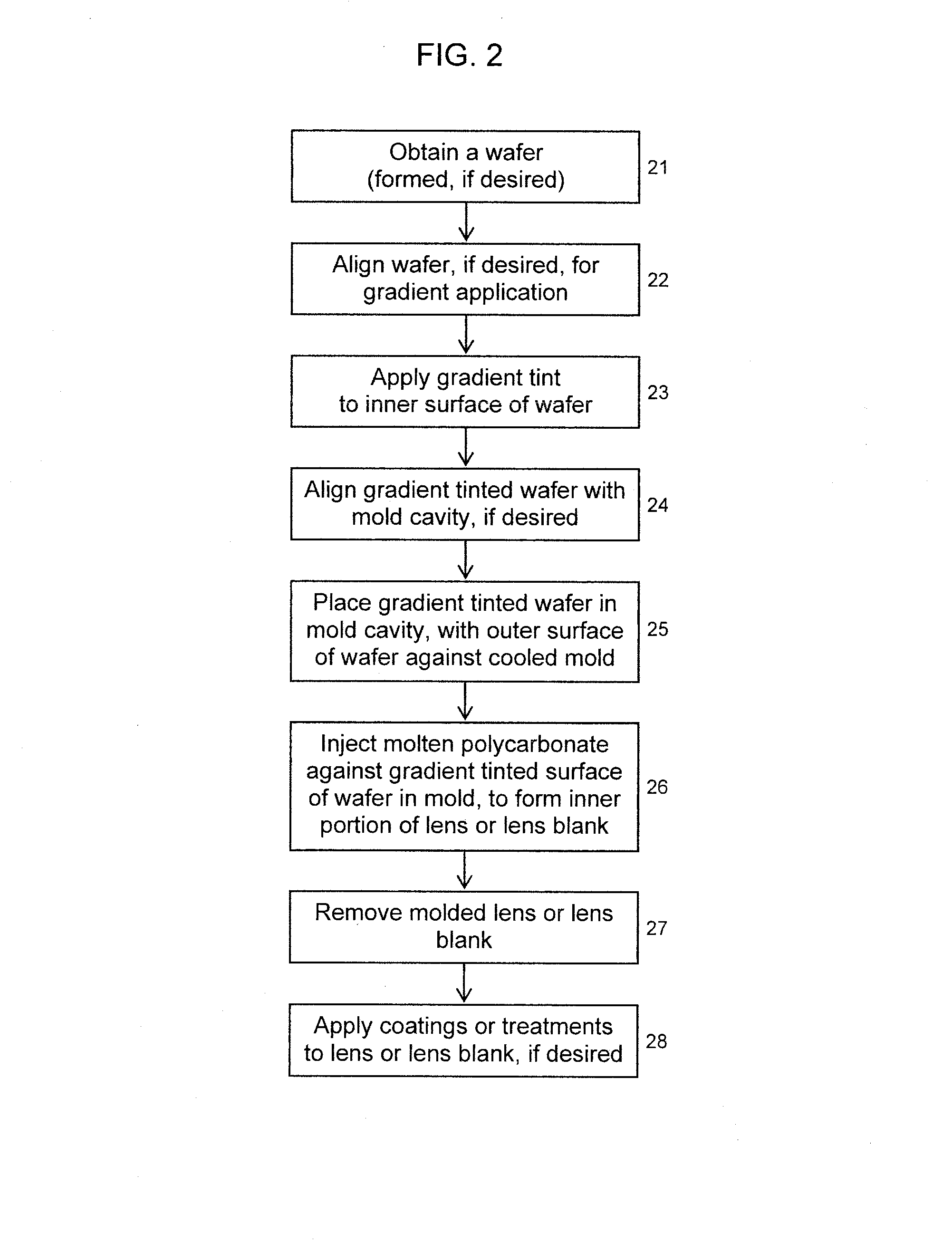

Tinted polycarbonate ophthalmic lens product and method of manufacture

The present invention describes ophthalmic lens products comprising a multilayer wafer and an injection-molded polycarbonate inner portion. The multilayer wafer includes a dyed, photochromic or polarized layer between a tinted inner layer and an outer polymeric layer. The inner layer may be solid or gradient-tinted. The polycarbonate inner portion of the lens product is directly fused to the tinted inner layer of the multilayer wafer during injection molding. The invention further describes a method to produce a gradient-tinted polarized polycarbonate eyewear lens product by obtaining a multilayer wafer having an outer layer, an inner polycarbonate layer, and a polarized layer between the inner and outer layers, applying a gradient tint to the wafer's inner layer, placing the gradient tinted wafer within an injection-molding cavity, and injecting molten polycarbonate directly against the wafer's gradient-tinted layer to form the inner portion of the lens product and to fuse it to the wafer.

Owner:YOUNGER MFG

Optical device

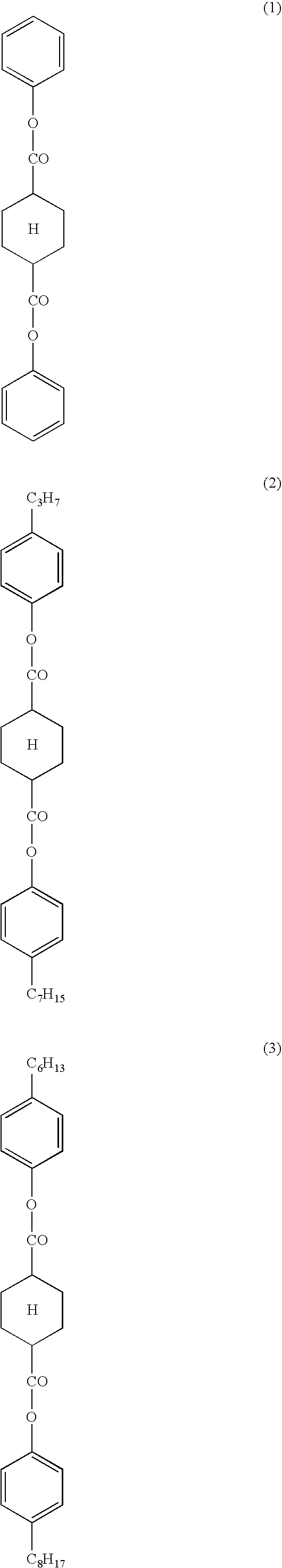

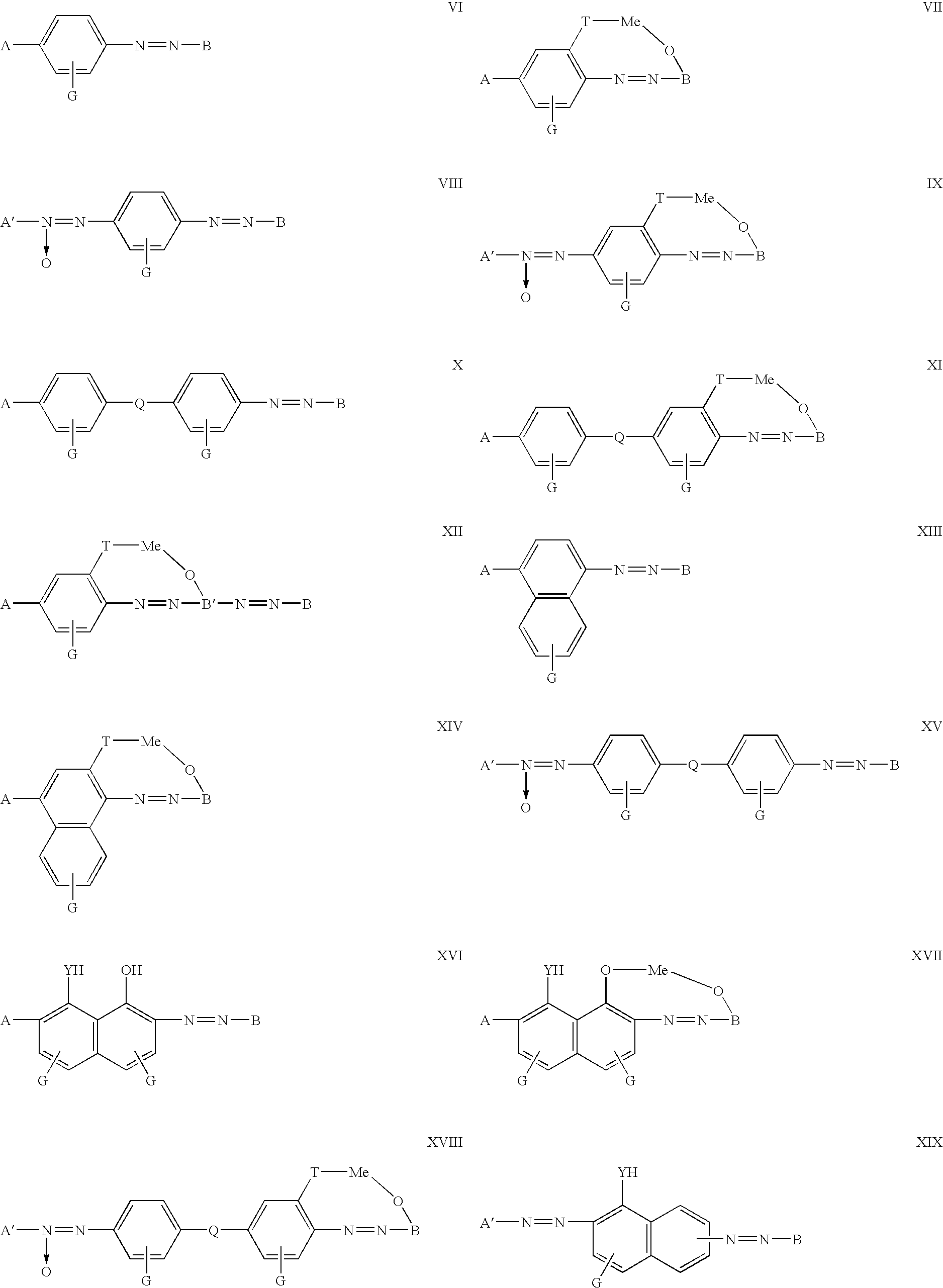

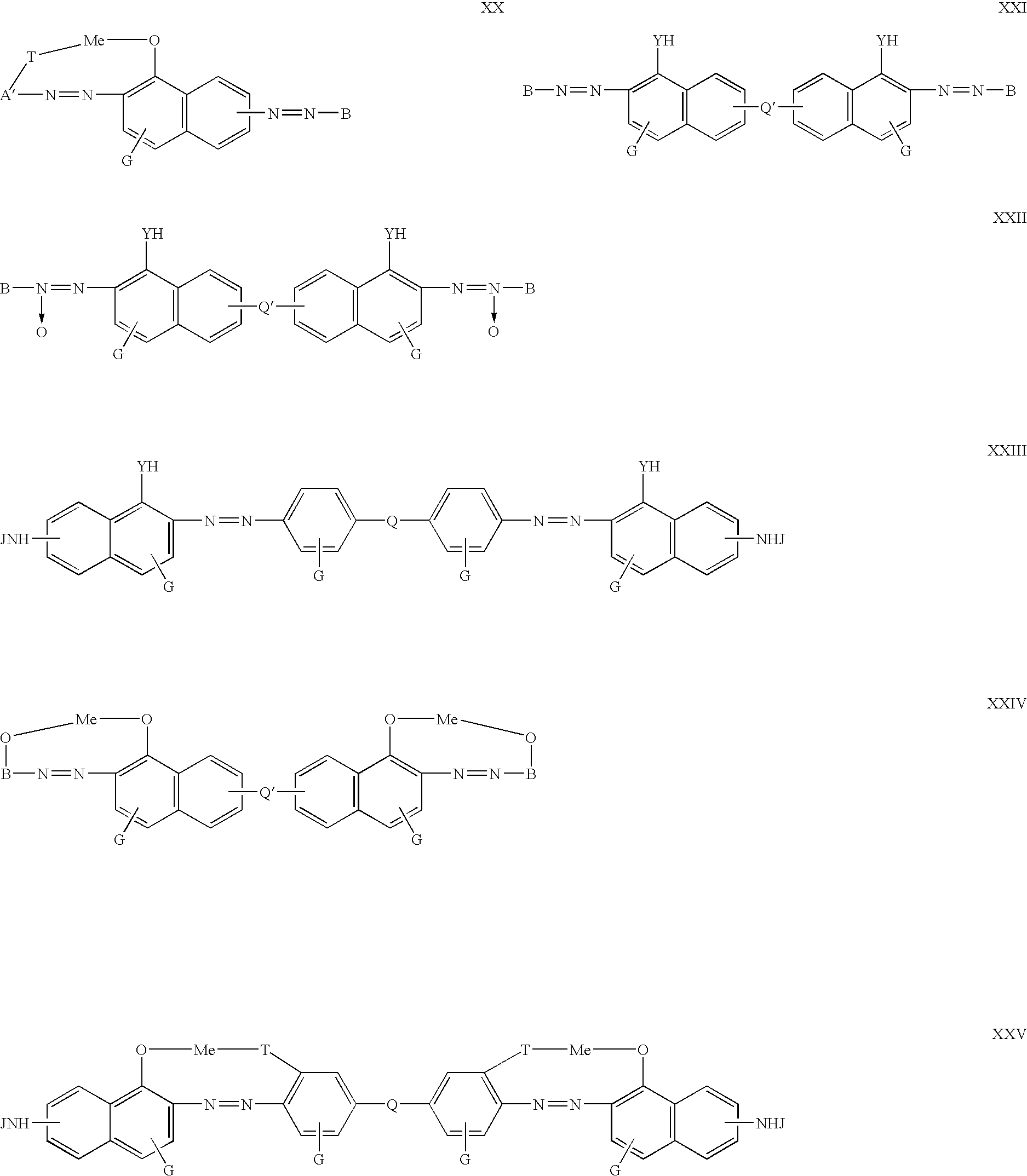

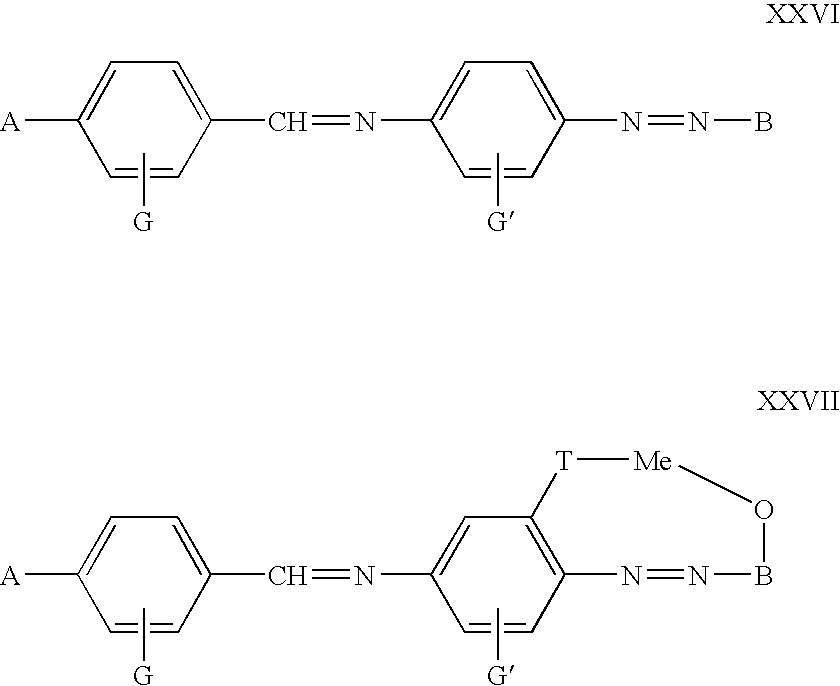

InactiveUS20040232394A1Liquid crystal compositionsMethine/polymethine dyesPolarizerElectromagnetic radiation

The invention relates to optical devices for producing and / or transforming polarised electromagnetic emission by means of anisotropic absorption and / or optical rotation effects and / or birefringence and can be used as different polarizers (dichroic, reflecting), lagging layers (retarders), liquid-crystal displays and indicators and also for producing polarising glass for building construction and for sun and antiglare glasses, masks, aprons and faceplates. The inventive optical device is based on at least one molecularly oriented layer of a low-molecular or oligomeric dichroic material which can form a stable lyotropic liquid crystal structure. The projection of at least one anisotropically absorbing fragment of a molecule of the dichroic material on the surface of the molecularly oriented layer of a dipole moment of optical transition is disposed in a parallel position to the optical axis of the molecularly oriented layer at least within several ranges of wavelength of the electromagnetic emission.

Owner:IR GVON KHAN

Method of taking polarized images of the skin and the use thereof

The present invention relates to a method of photographing the skin of a person comprising the steps of: (i) illuminating the skin with at least one light source, where the light emitted from the light source is filtered using a polarizing filter; and (ii) capturing the image of the illuminated skin with a camera; wherein the angle formed by the light source, the skin, and the camera is from about 35 degrees to about 55 degrees.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Transparent polarizing optical products and fabrication thereof

Disclosed is a polarizing, transparent optical product, the structure of which comprises a basic transparent substrate of an inorganic or organic material and, on at least one part of the external surface of said basic substrate, a polarizing coating. Said polarizing coating is fixed, in a stable manner, to said substrate and has a stratified structure which includes: a polymer layer, which is fixed to the external surface of said substrate, directly or via a coupling under-layer; a film of colorant(s) having polarizing properties, on said polymer layer; and a protective layer on said film of colorant(s). Also disclosed is a method of manufacturing such a polarizing, transparent optical product. The invention may be used for any type of substrate material, inorganic or organic, thermoplastic or thermoset.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com