Optical member adhering method, and apparatus using the method

A technology for laminating devices and optical components, applied in the direction of optical elements, optical elements, chemical instruments and methods, etc., can solve problems such as poor quality, achieve the effect of maintaining quality, high quality, and reducing dust adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

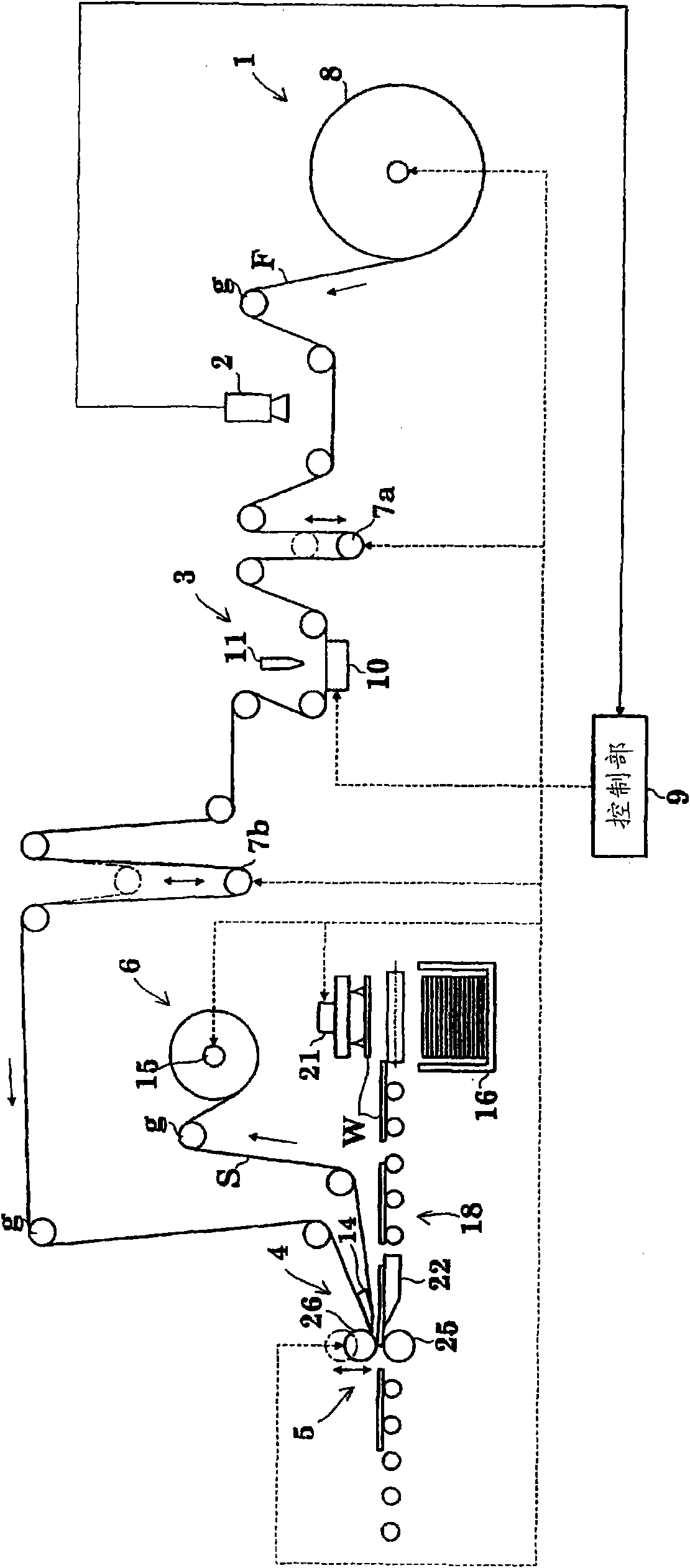

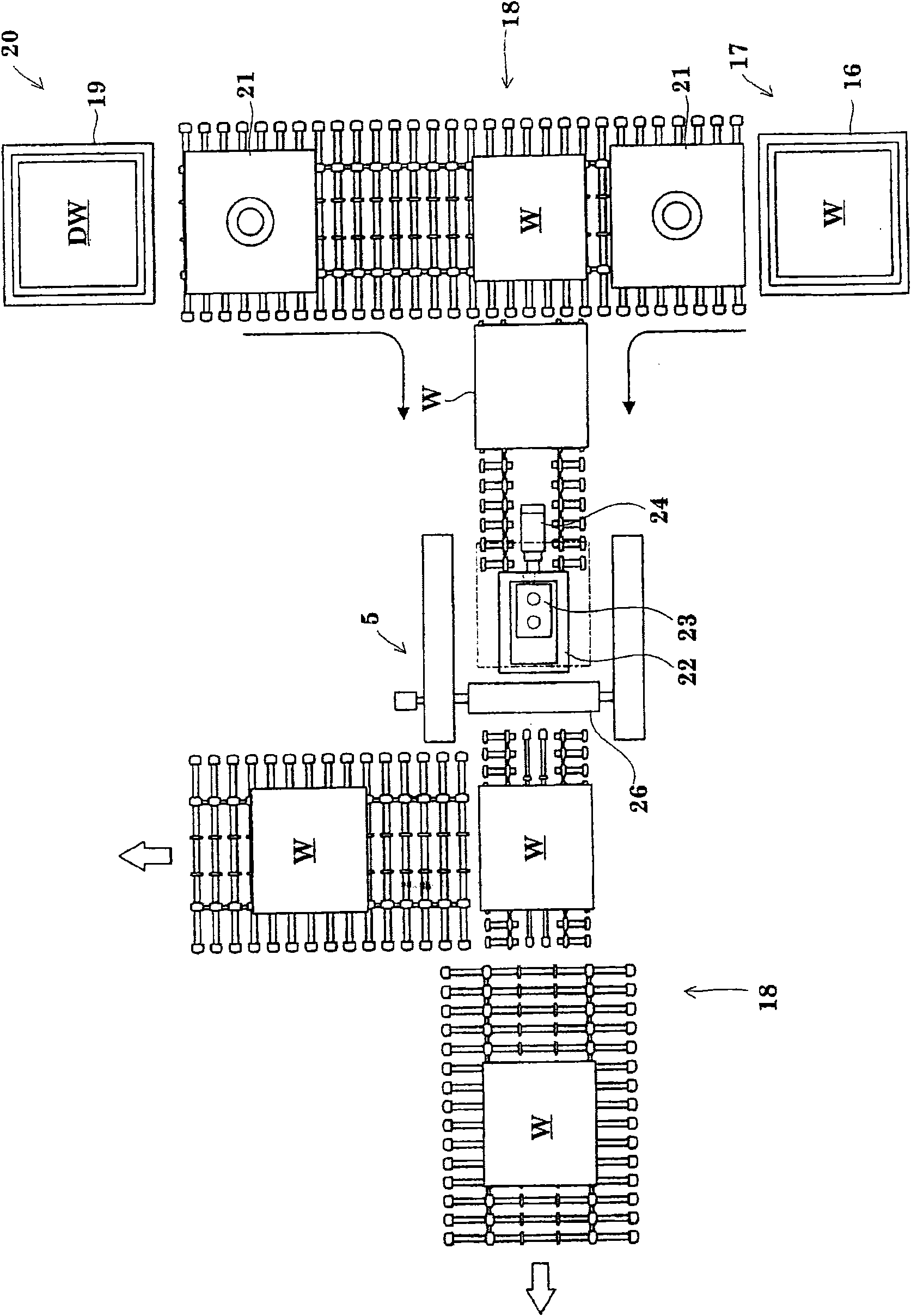

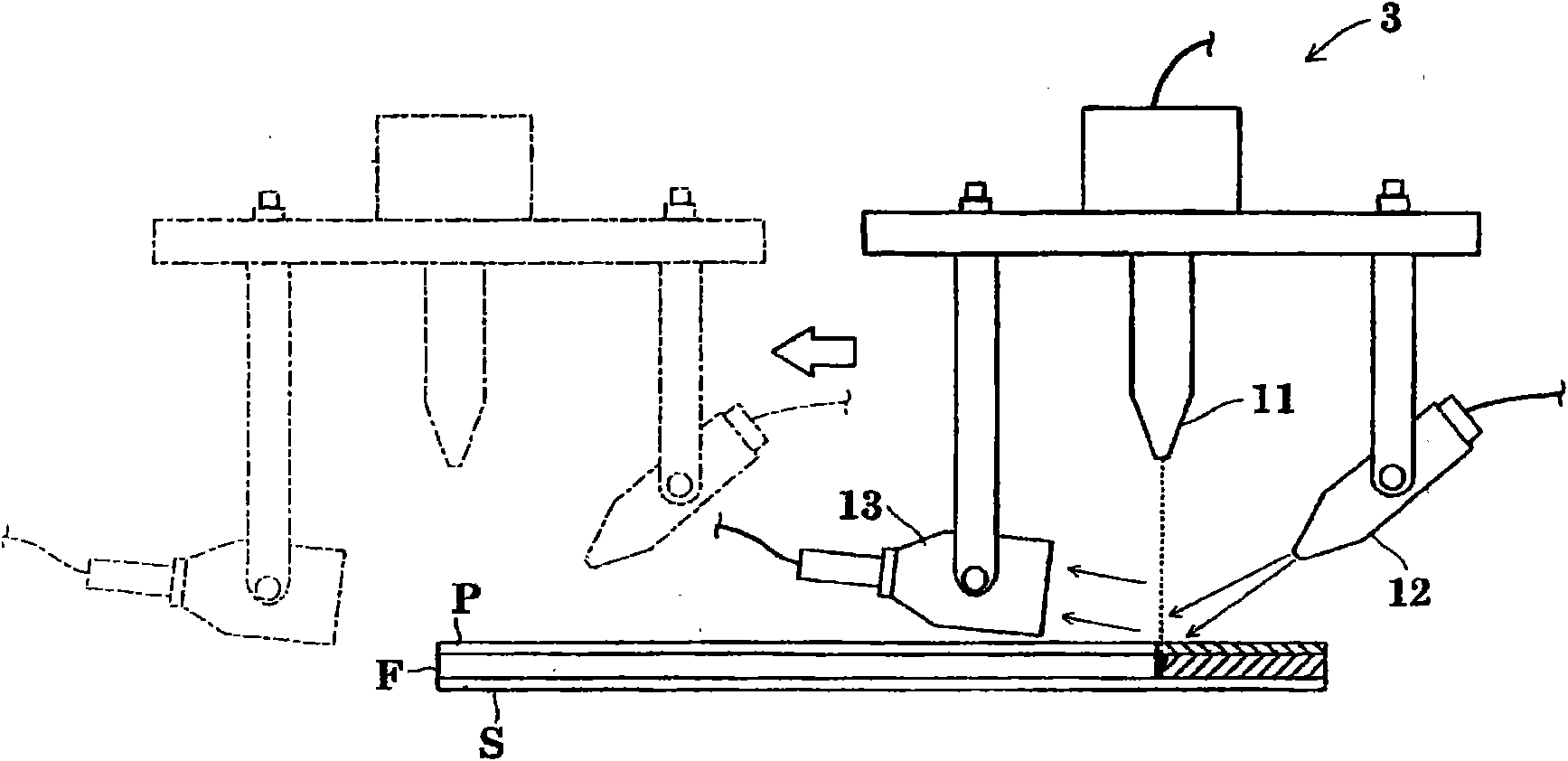

[0098] Embodiments of the present invention will be described below with reference to the drawings. In addition, in the present invention, the optical member is not particularly limited as long as it is a flexible strip-shaped functional film such as a polarizing film, a retardation film, or a brightness improvement film. In this embodiment, the case where a polarizing film is used is taken as an example and described. In addition, the monolithic body of the present invention is not particularly limited as long as it is a functional film such as a polarizing film, a retardation film, and a brightness-enhancing film, a polarizing plate, and a liquid crystal panel. In this embodiment, a liquid crystal panel is used as an example for description. .

[0099] In addition, both the separation film and the protective film of the present invention cover and protect an optical member or a polarizing film in order to prevent surface damage and the like. Here, the separation film can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com