Additive for strengthening wet flue gas desulfurization technology

A technology of wet flue gas desulfurization and additives, applied in the direction of chemical instruments and methods, separation methods, calcium/strontium/barium sulfate, etc., can solve the problems of poor crystallization of desulfurized gypsum, desulfurization efficiency, system fouling, overflow, and Single and other problems, to achieve the effect of inhibiting system scaling, improving gypsum quality, and convenient dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of additives for enhanced wet flue gas desulfurization process:

[0035] Formula: Mixed organic acid 45%, sodium citrate 10%, surfactant 7%, manganese sulfate 3%, sodium hydroxymethyl cellulose carboxylate 35%.

[0036] The mixed organic acid consists of pure adipic acid and nylon acid; among them, the nylon acid contains the following components by mass percentage: succinic acid 26.19%, glutaric acid 59.62%, adipic acid 10.76%, water 1.57%, Impurity margin. The amount of pure adipic acid added should ensure that the mass percentage of adipic acid in the mixed organic acid is ≥50%.

[0037] The surfactant is composed of a fast penetrating agent and sodium dodecylbenzene sulfonate, and the mass ratio of the two is 1:1.

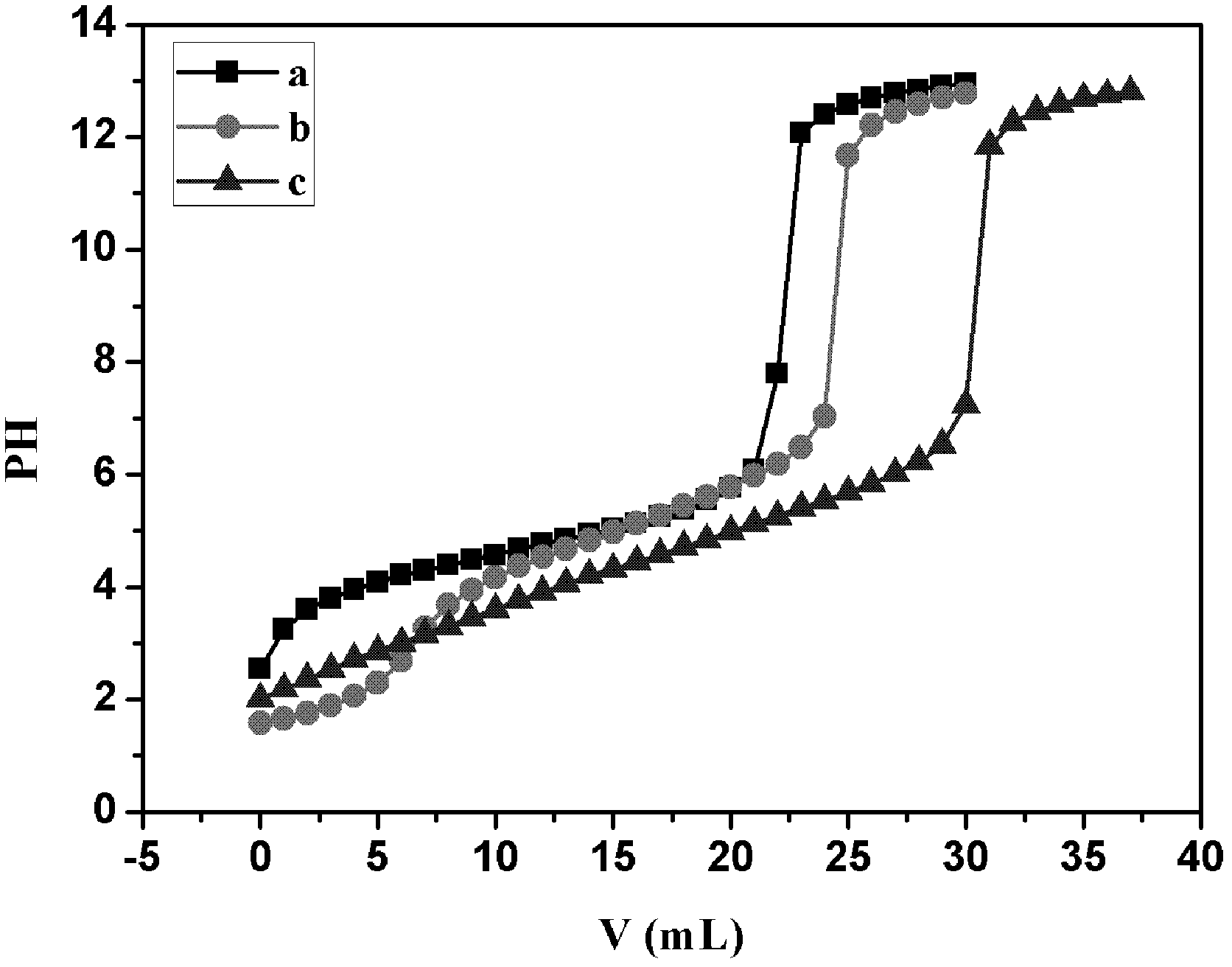

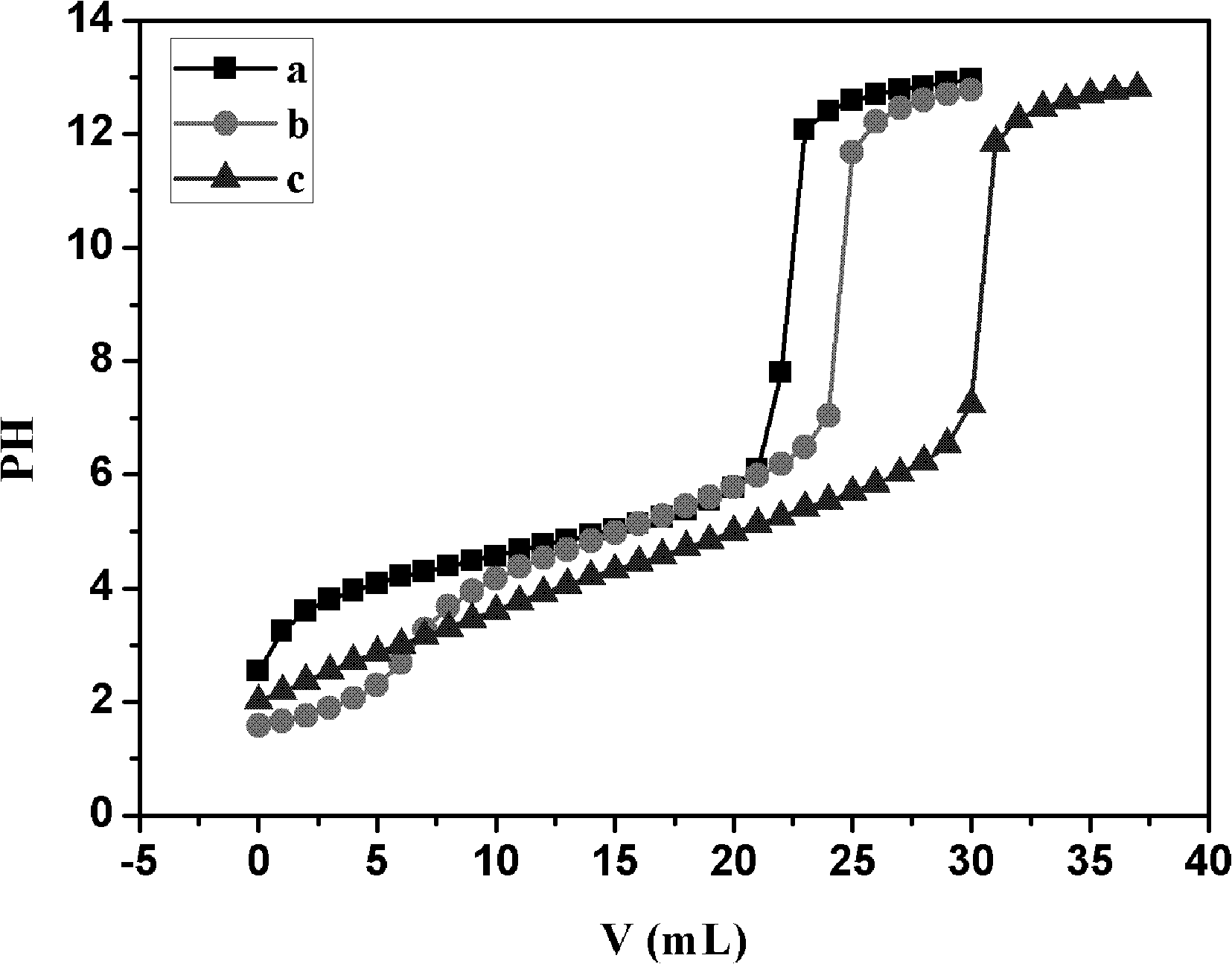

[0038] Buffer performance test: prepare adipic acid (a) with a concentration of 0.1mol / L (mass concentration of 14.6g / L), take the above-prepared additives and adjust them to weak acidity, and their mass concentration is 14.6g / L (b ), select the co...

Embodiment 2

[0042] Preparation of additives for enhanced wet flue gas desulfurization process:

[0043] Formula: Mixed organic acid 35%, sodium citrate 10%, surfactant 7%, manganese sulfate 3%, sodium hydroxymethyl cellulose carboxylate 45%.

[0044] The mixed organic acid consists of pure adipic acid and nylon acid; among them, the nylon acid contains the following components by mass percentage: succinic acid 26.19%, glutaric acid 59.62%, adipic acid 10.76%, water 1.57%, Impurity margin. The amount of pure adipic acid added should ensure that the mass percentage of adipic acid in the mixed organic acid is ≥50%.

[0045] The surfactant is composed of a fast penetrating agent and sodium dodecylbenzene sulfonate, and the mass ratio of the two is 1:1.

[0046] In a power plant desulfurization system that is using a certain brand of wet desulfurization additive, the additive prepared in Example 2 is used, 1000 ppm is added, and after a period of operation, the desulfurization efficiency reaches 93.5...

Embodiment 3

[0048] Preparation of additives for enhanced wet flue gas desulfurization process:

[0049] Formula: Mixed organic acid 40%, sodium citrate 10%, surfactant 7%, manganese sulfate 3%, sodium hydroxymethyl cellulose carboxylate 40%.

[0050] The mixed organic acid consists of pure adipic acid and nylon acid; among them, the nylon acid contains the following components by mass percentage: succinic acid 26.19%, glutaric acid 59.62%, adipic acid 10.76%, water 1.57%, Impurity margin. The amount of pure adipic acid added should ensure that the mass percentage of adipic acid in the mixed organic acid is ≥50%.

[0051] The surfactant is composed of a fast penetrating agent and sodium dodecylbenzene sulfonate, and the mass ratio of the two is 1:1.

[0052] In a power plant desulfurization system that is using a certain brand of wet desulfurization additive, the additive prepared in Example 3 was switched to 1000 ppm. After running for a period of time, the desulfurization efficiency reached 94%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com