Flue gas dust removal desulphurization system of double-circulation Venturi rod tower

A desulfurization system, dual-circulation technology, applied in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separators, etc., can solve the problem of increasing the abrasion and blockage of circulating pumps, pipelines, nozzles, and affecting the efficiency of dust removal and desulfurization. The advantages of Venturi tower , Affect the recovery and reuse of desulfurization products, and achieve the effect of reducing slurry circulation and system energy consumption, reducing scaling, wear and corrosion, and reducing land occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

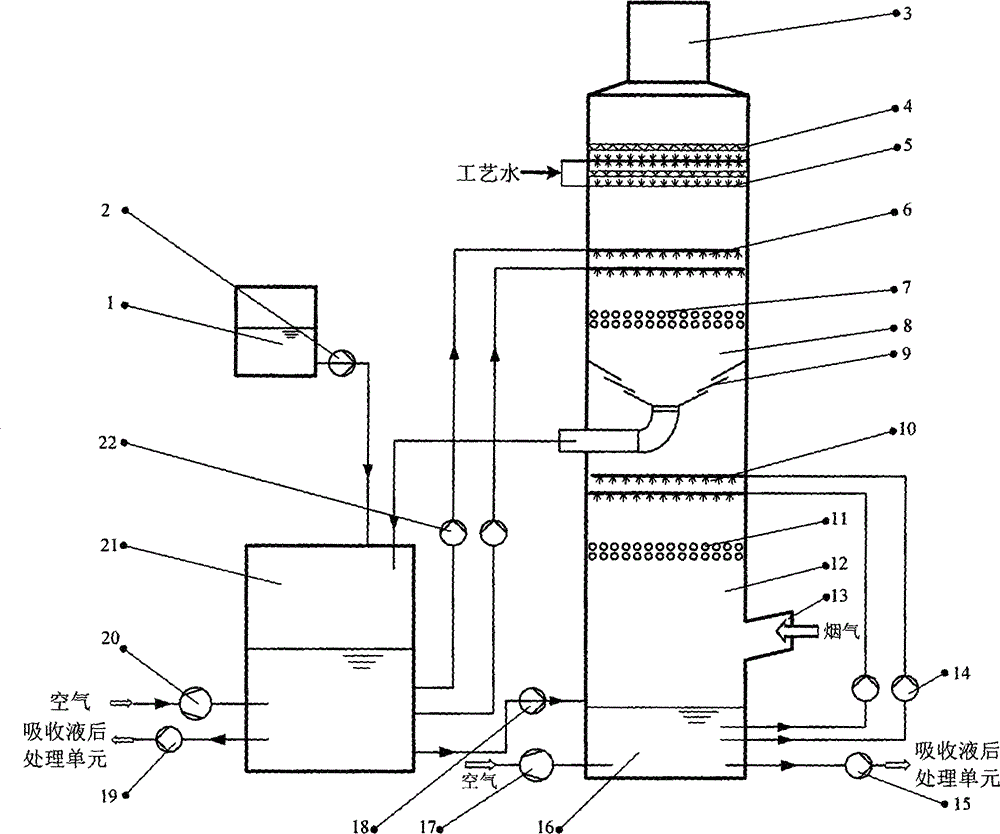

[0025] as attached figure 1 As shown, the double-cycle Venturi rod flue gas dedusting and desulfurization system of the present invention mainly includes three units: an absorption liquid supply unit, a flue gas purification unit and an absorption liquid post-treatment unit. The flue gas purification unit includes the upper Wenshi rod tower section 8, the lower Wenshi rod tower section 12, the upper and lower tower section dividers 9 (louvered partition cones in the figure), the lower circulating liquid pool, the lower circulating washing liquid pump, the upper circulating liquid Pool, upper circulation absorption liquid pump and mist eliminator located at the flue gas outlet; slag discharge pump, absorption liquid post-processing unit (not shown in the figure).

[0026]The hot flue gas enters the absorption tower through the flue gas inlet 13, and first meets the lower tower section Venturi rod layer 11 in the lower tower section 12, and after being modulated by the Venturi r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com