Patents

Literature

1098results about How to "Improve light uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

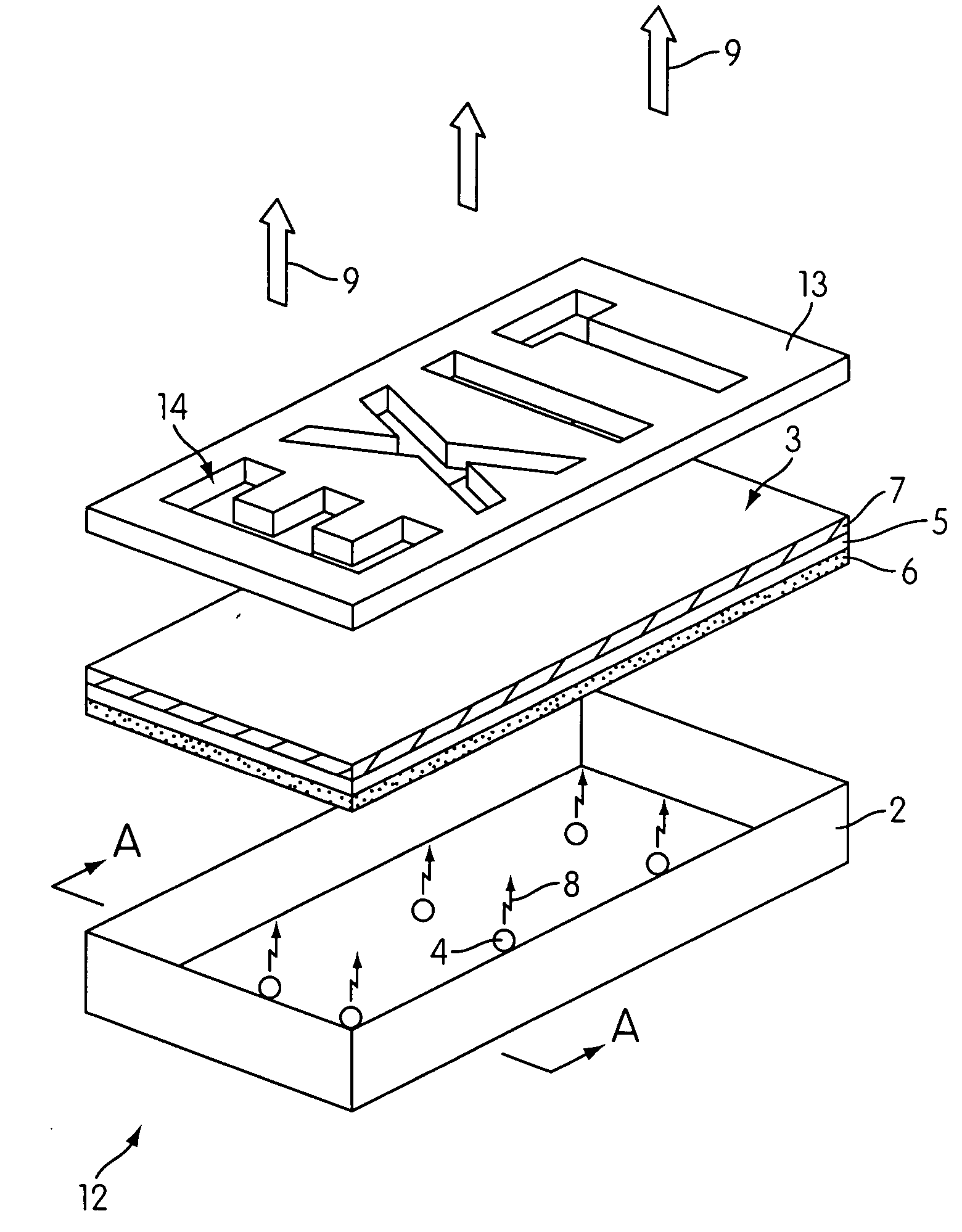

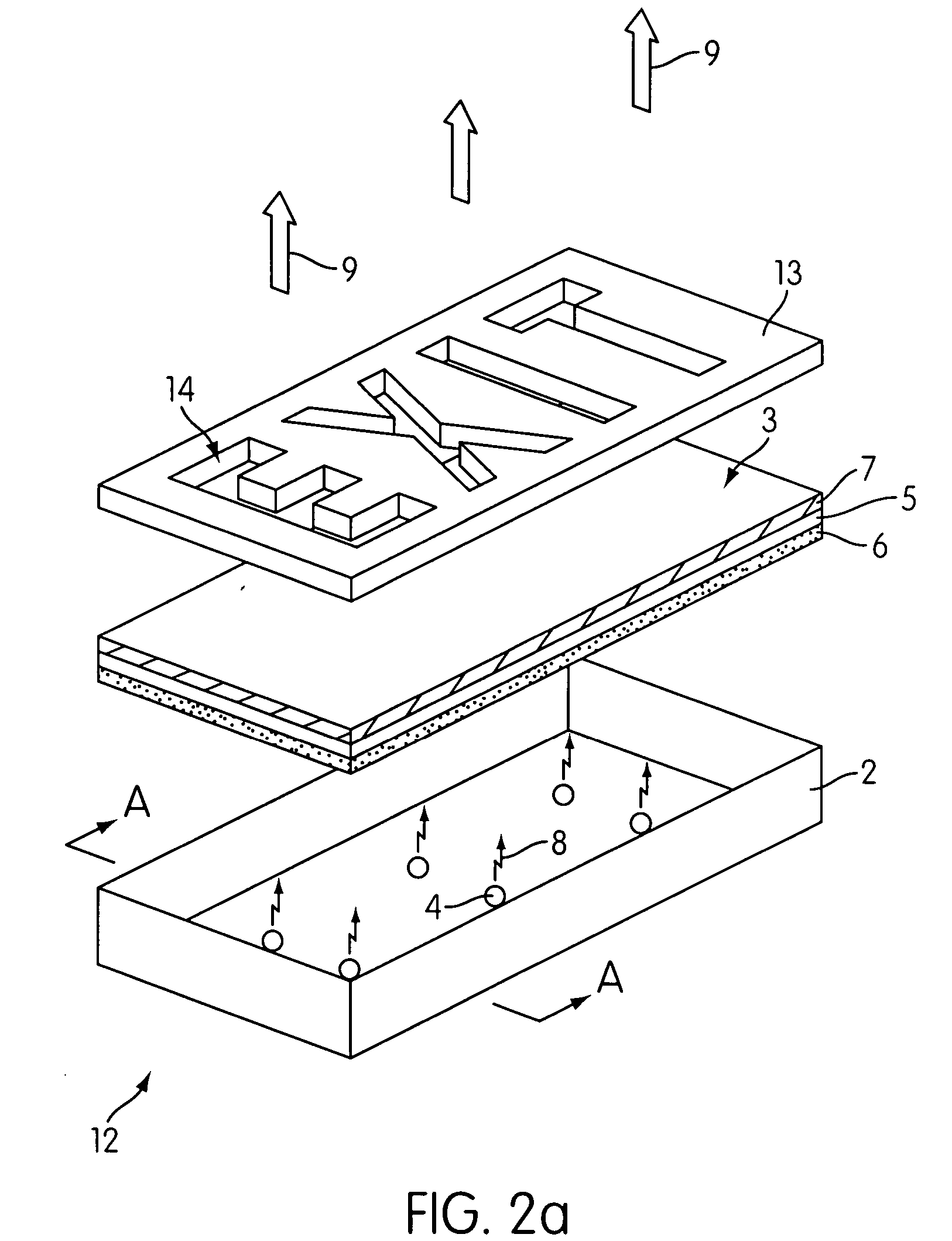

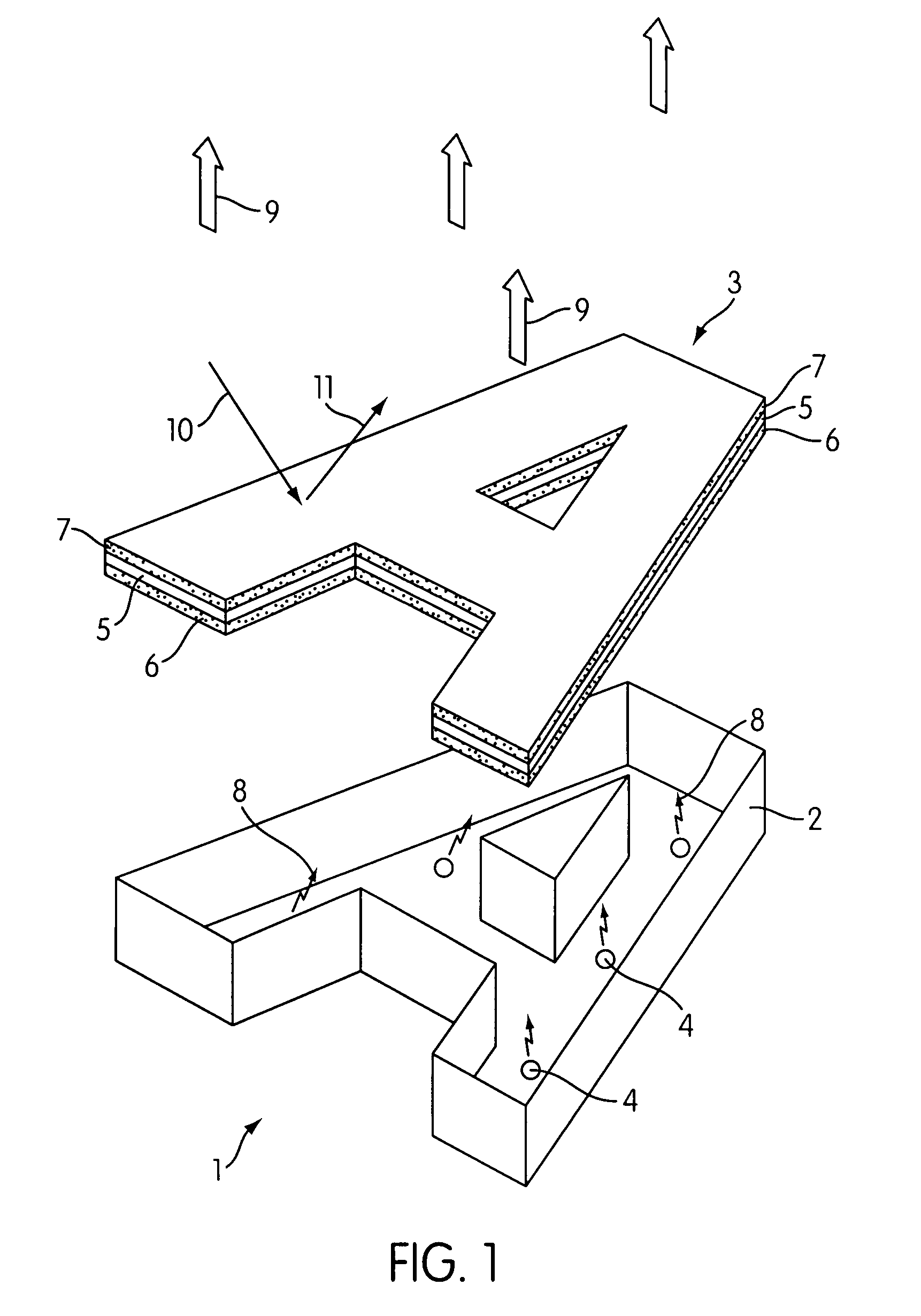

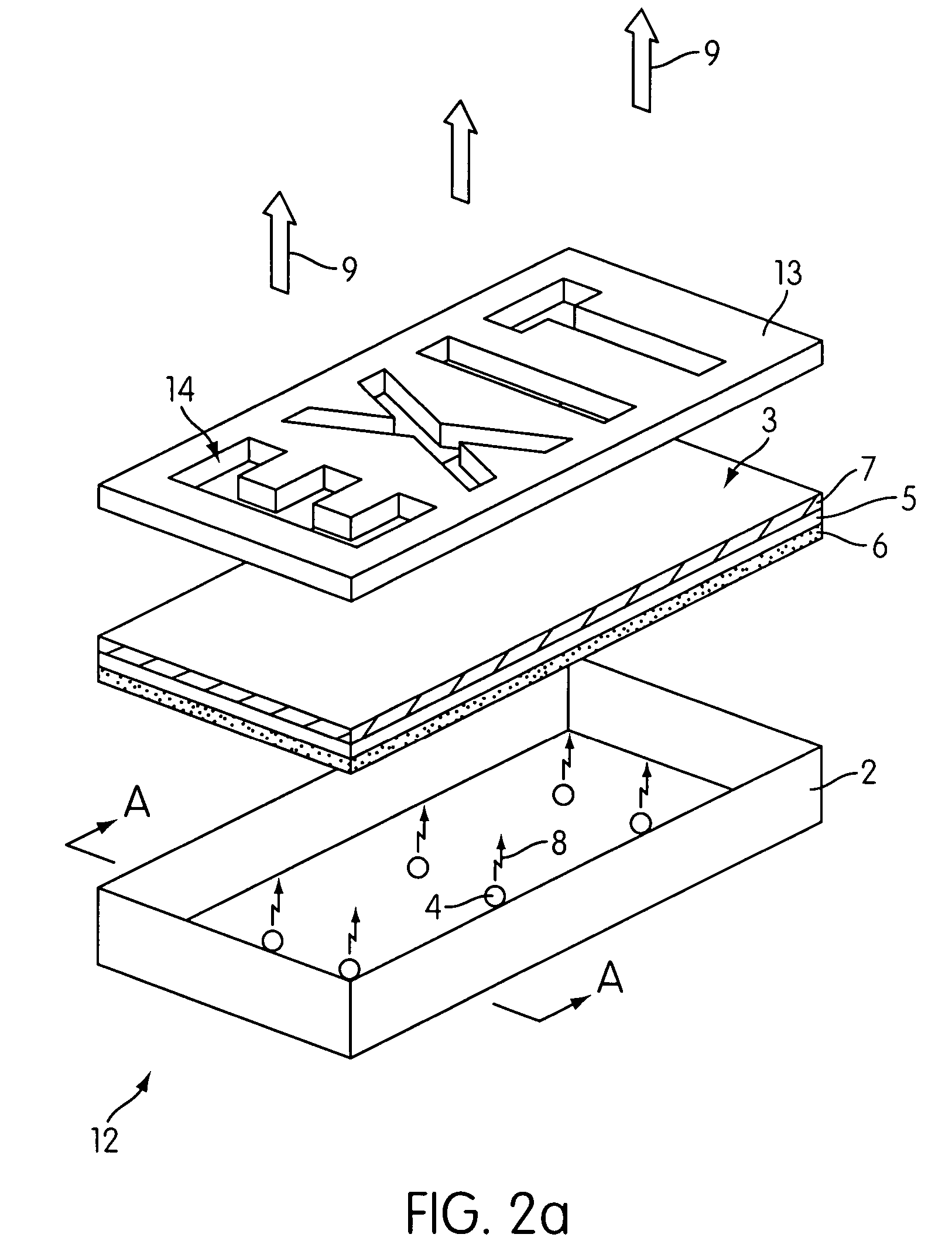

Light emitting sign and display surface therefor

InactiveUS20070240346A1Cost reductionWell light uniformityIlluminated signsSpectral modifiersPhysicsLight filter

A light emitting sign comprising a light emitting display surface including at least one phosphor, and at least one radiation source configured to irradiate the display surface with excitation energy such that the phosphor emits light of a selected color. The sign further comprises a filter which is substantially transparent to light emitted by the display surface, filtering other colors of light. The display surface may be configured into a shape of a character, a symbol, or a device. Alternatively, a mask having at least one window substantially transparent to the emitted light and / or at least one light blocking region may be provided in which the window and / or light blocking region define a character, a symbol, or a device.

Owner:INTEMATIX

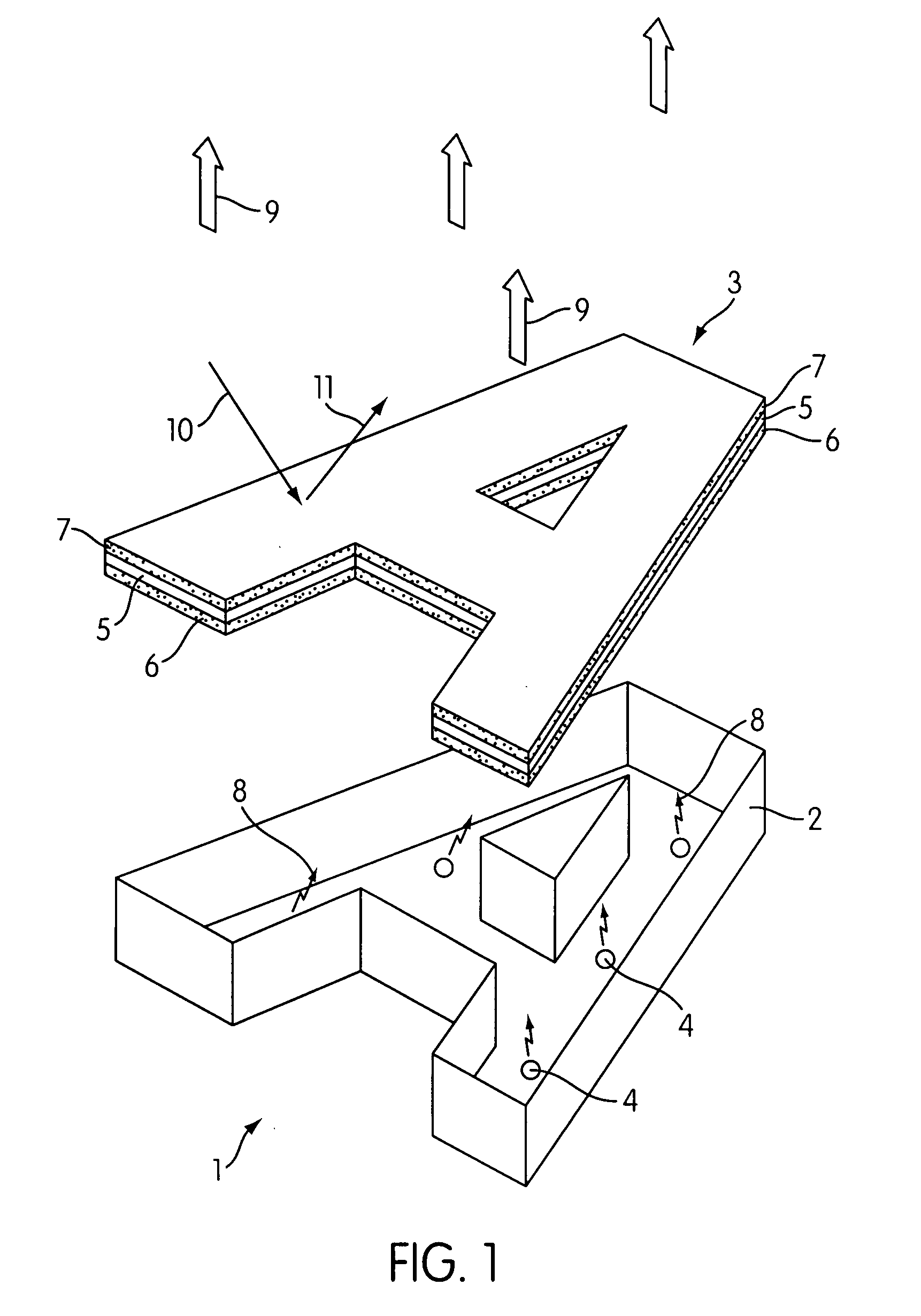

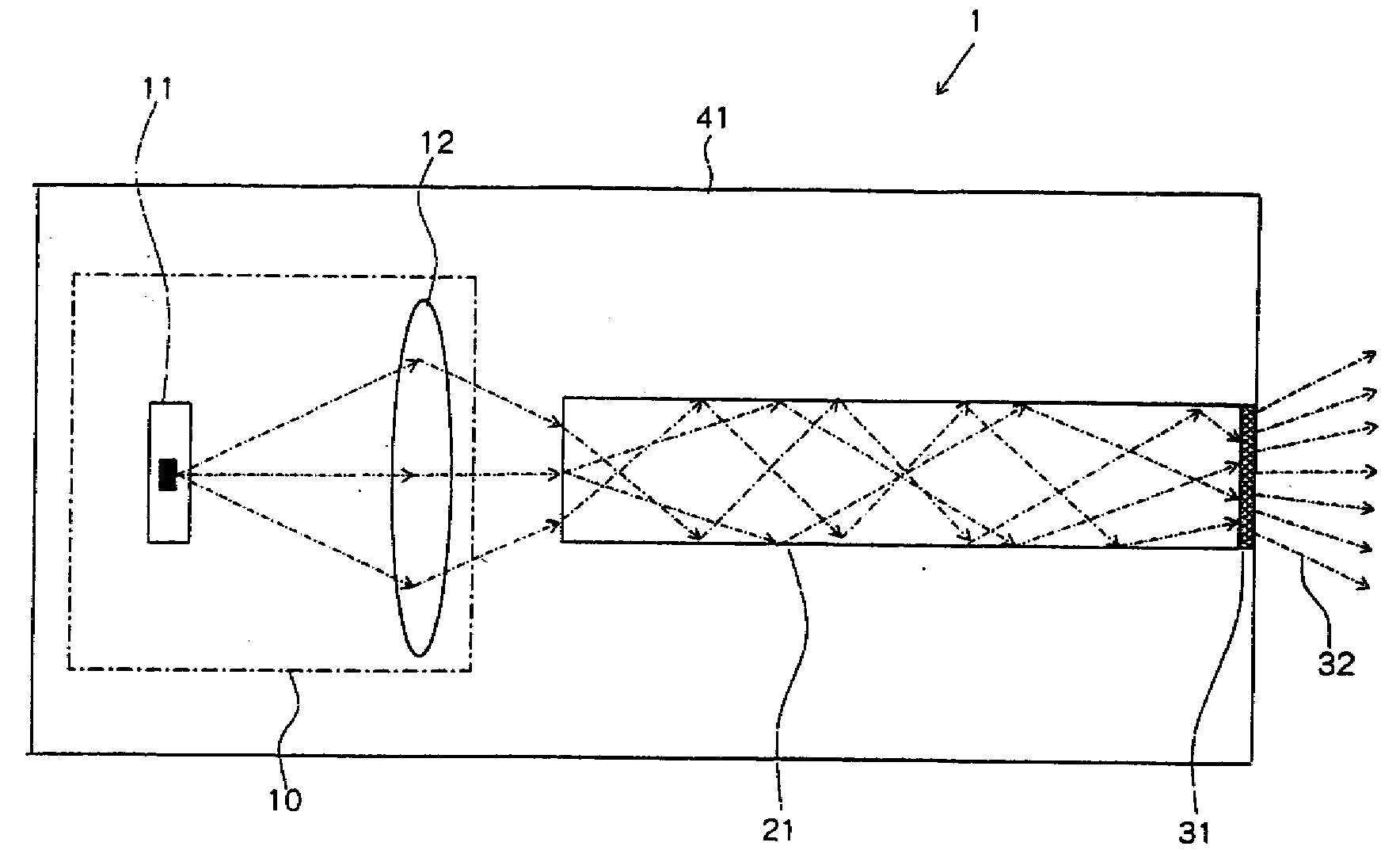

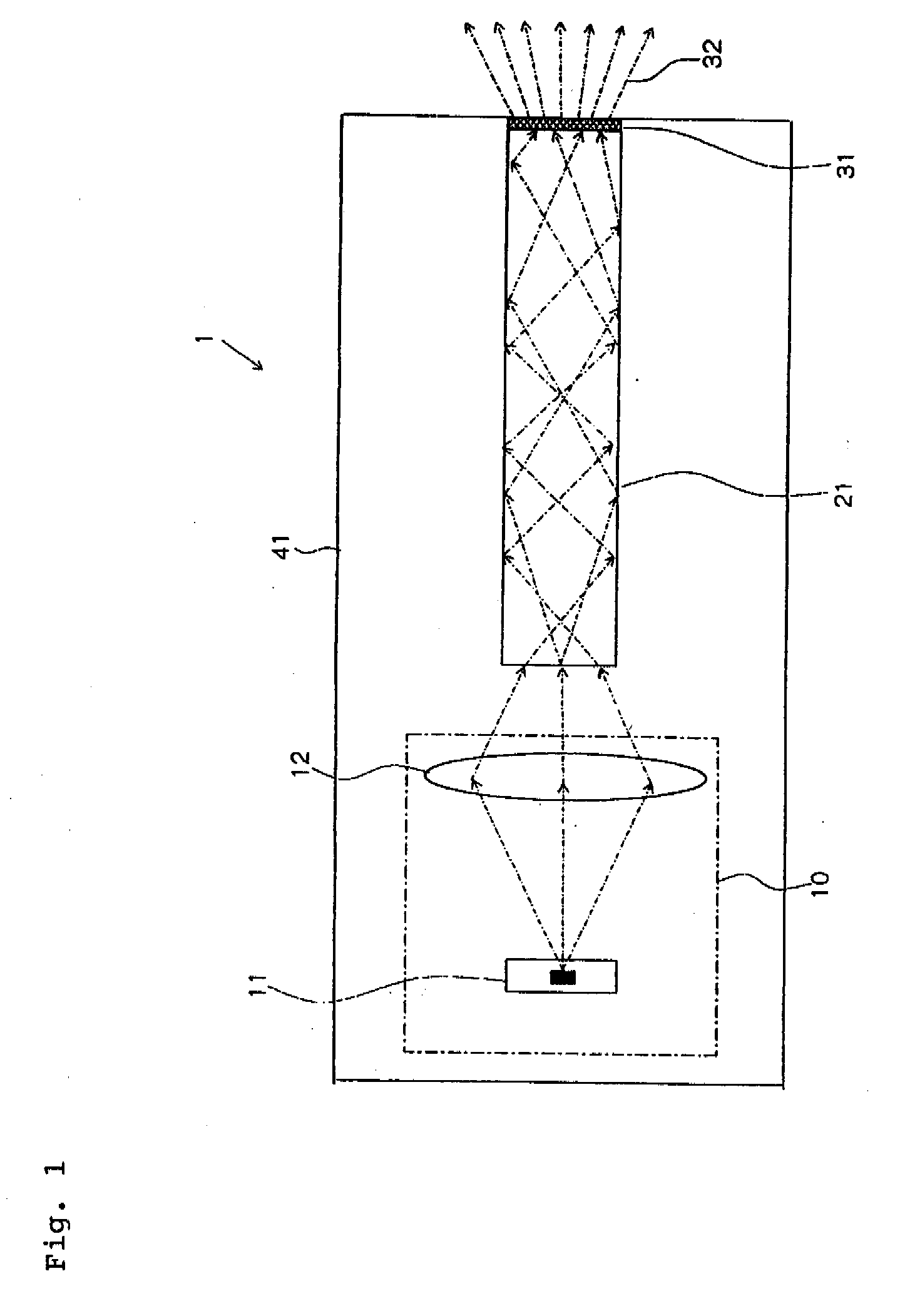

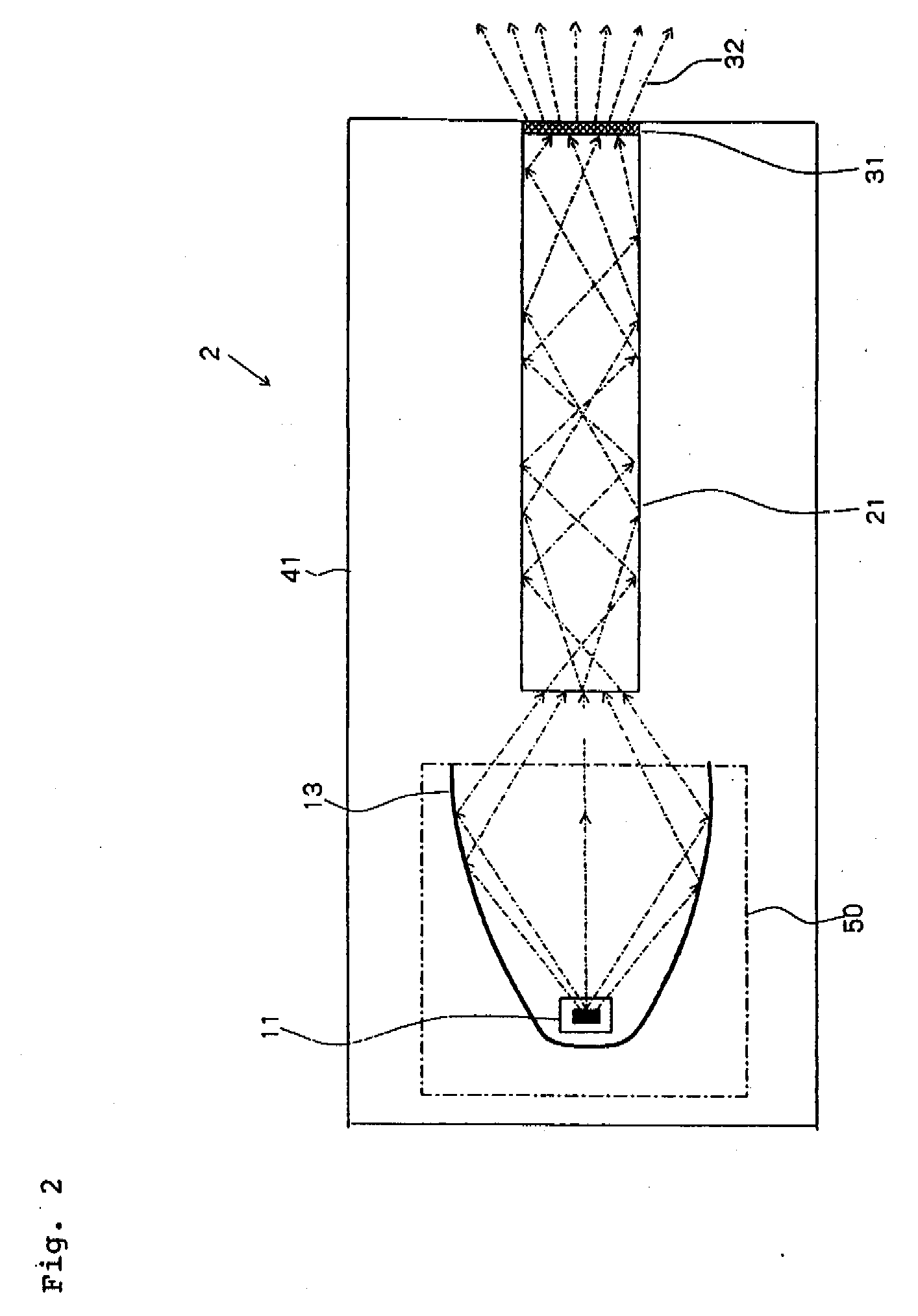

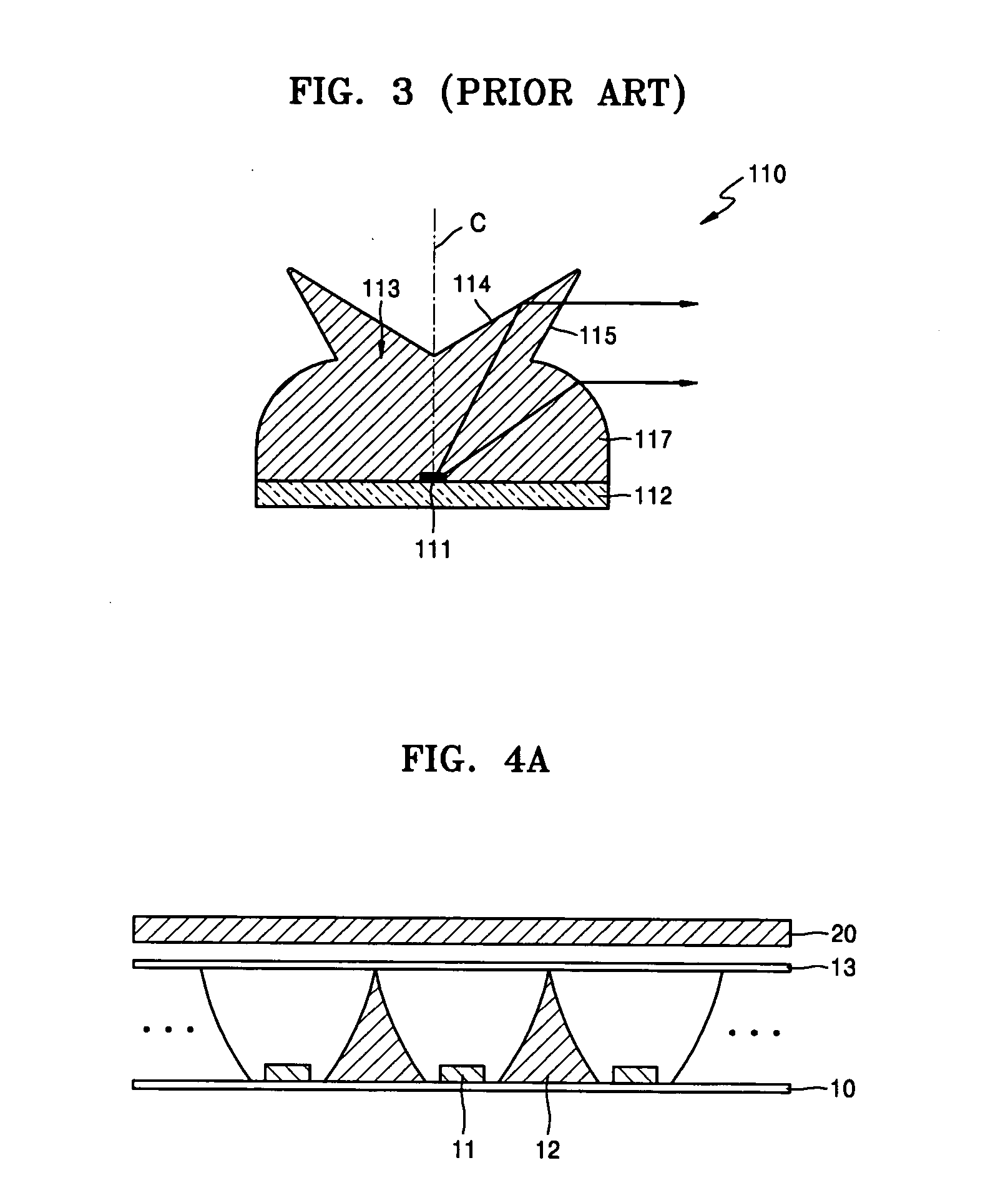

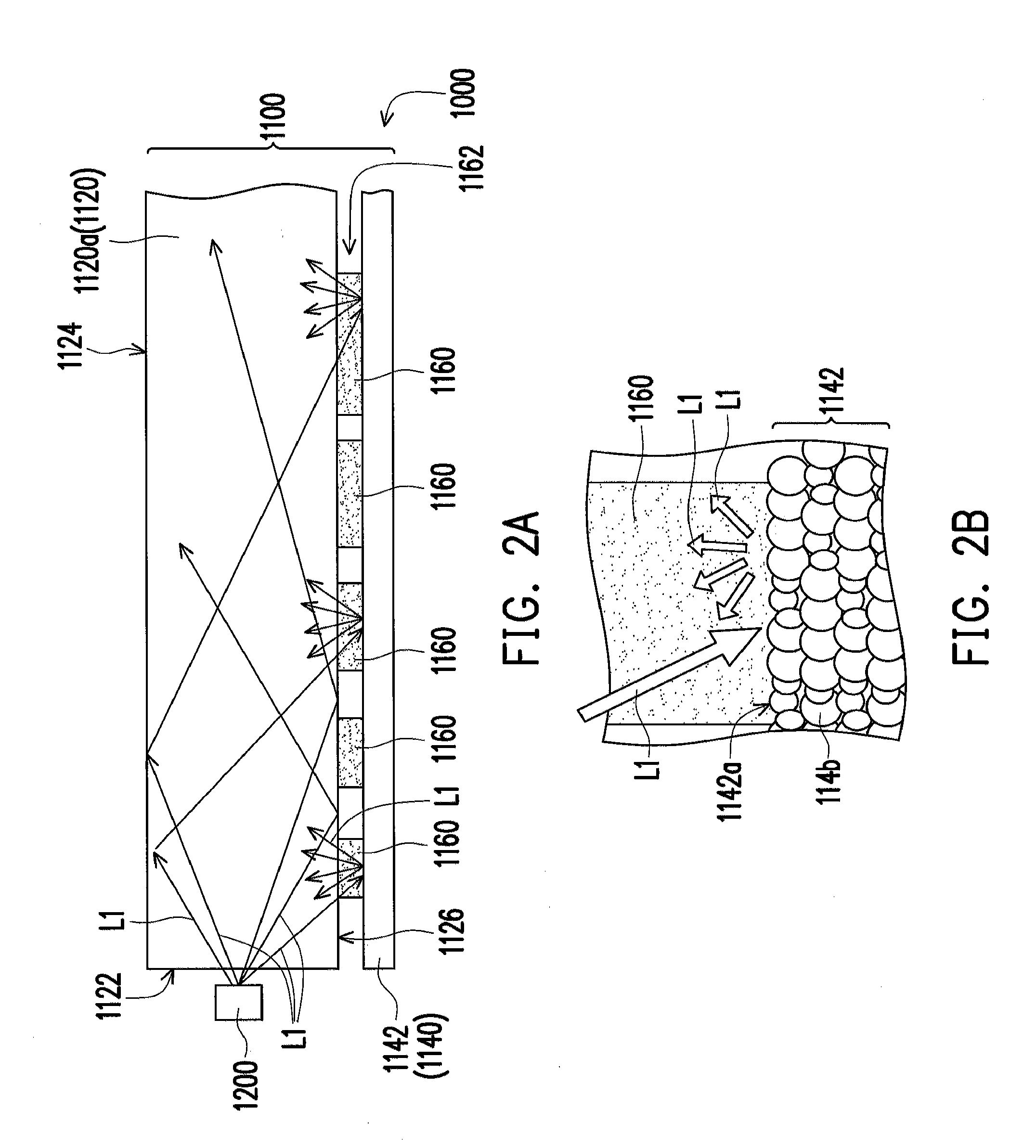

White light source device

InactiveUS20080232084A1Reduce color unevennessImprove light uniformityPoint-like light sourceLight guides with fluorescent dopantsIlluminanceLight beam

Light beams emitted from a blue LED light source of a light source unit are condensed by a condenser lens to enter an entrance end face of a rod lens, and the light beams progress through while being repeatedly reflected several times inside the rod lens. Accordingly, the unevenness of brightness is reduced, and the light enters an fluorescent material sheet bonded to an exit end of the rod lens from the exit end as blue light which is uniformed in illuminance, and white light whose color is seen as the same color viewed in any direction of the fluorescent material sheet is emitted from the fluorescent material sheet.

Owner:NEC LIGHTING

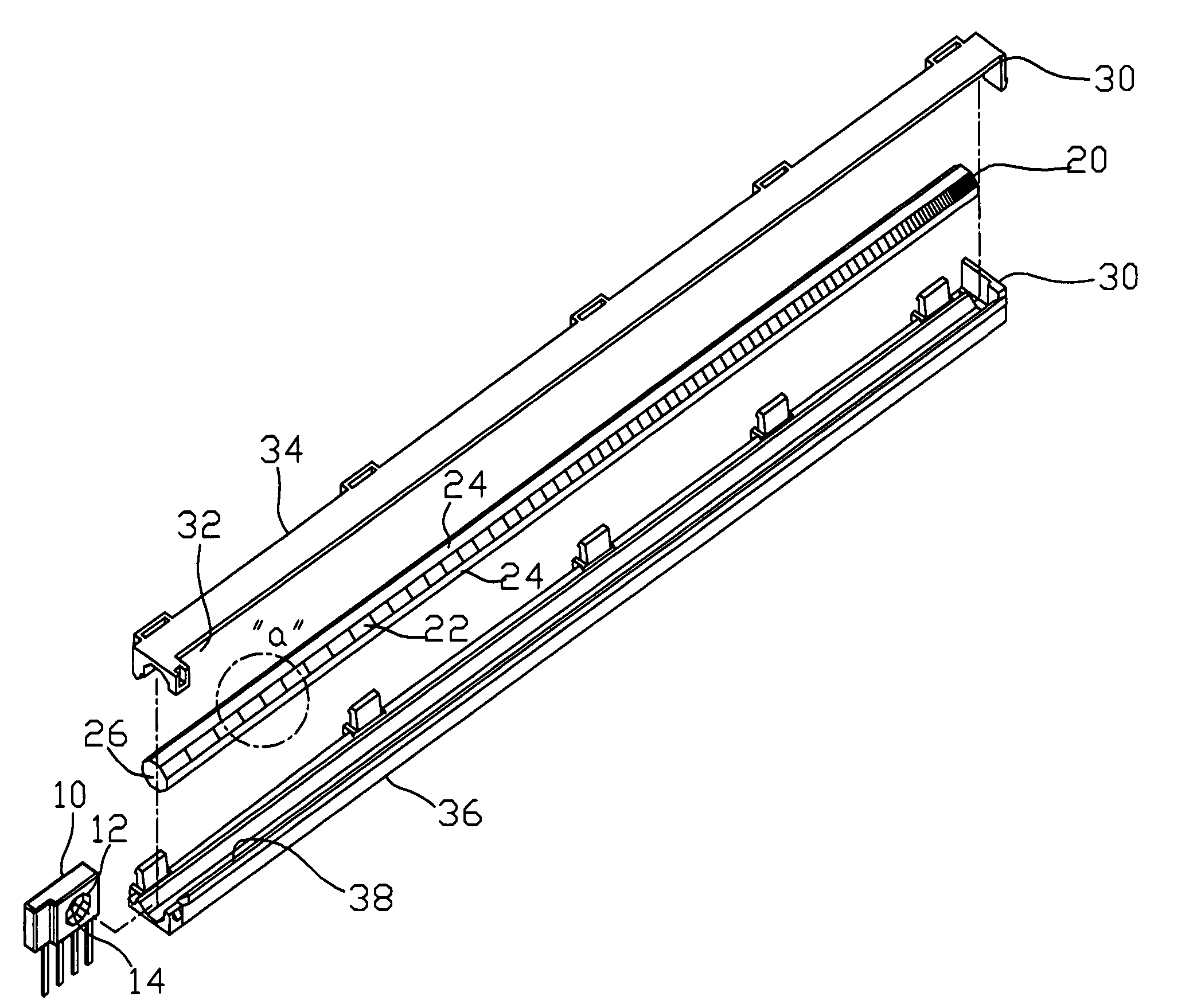

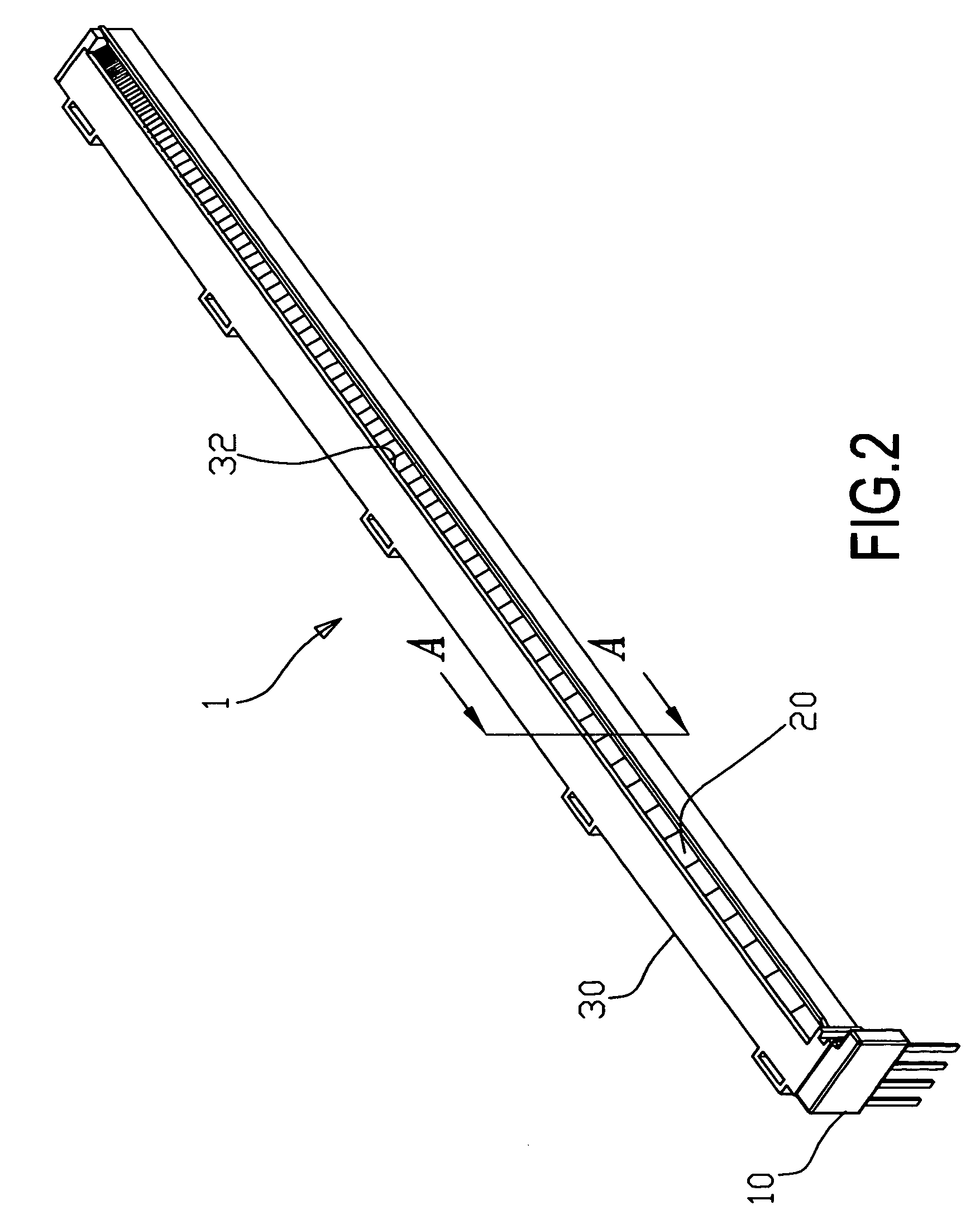

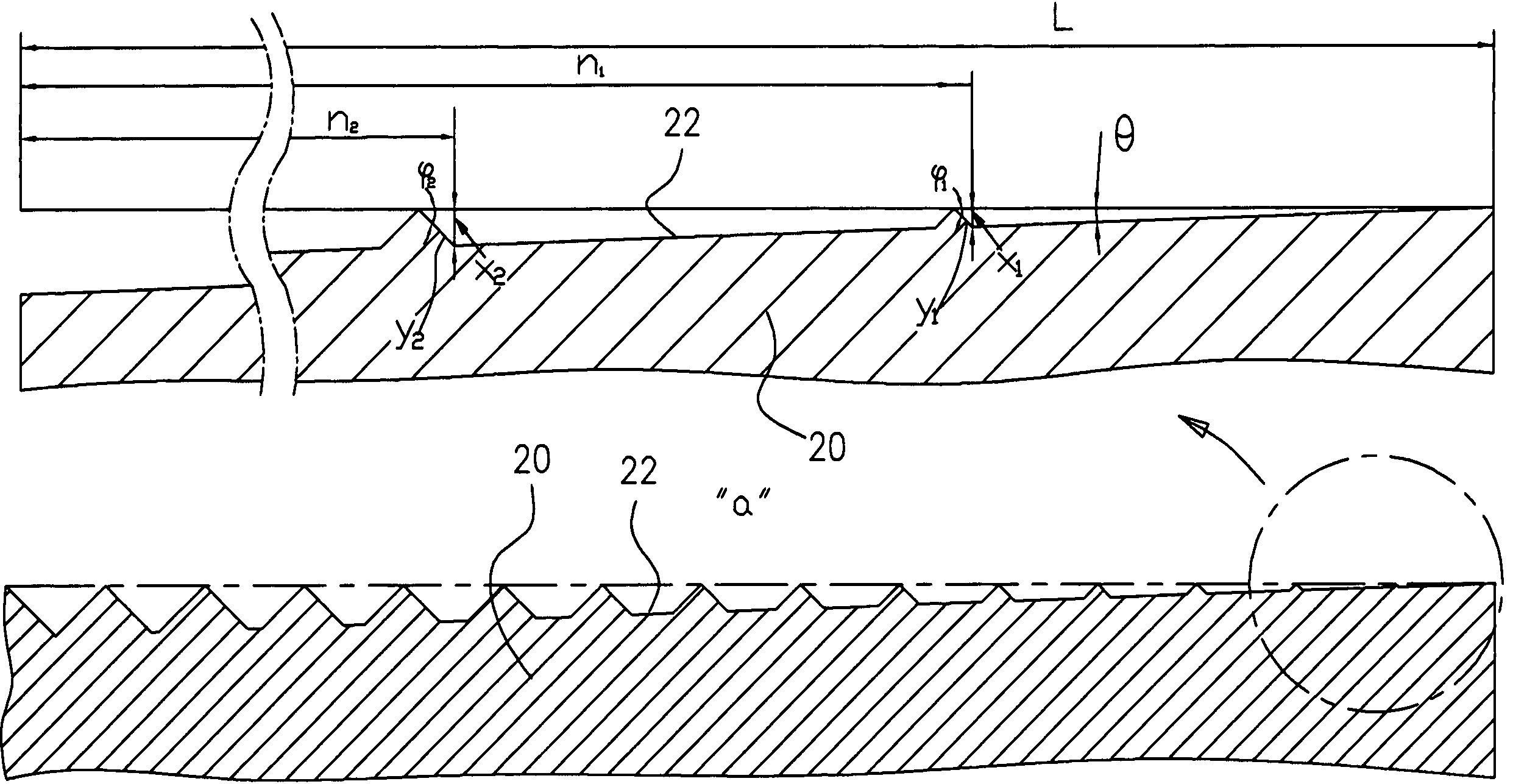

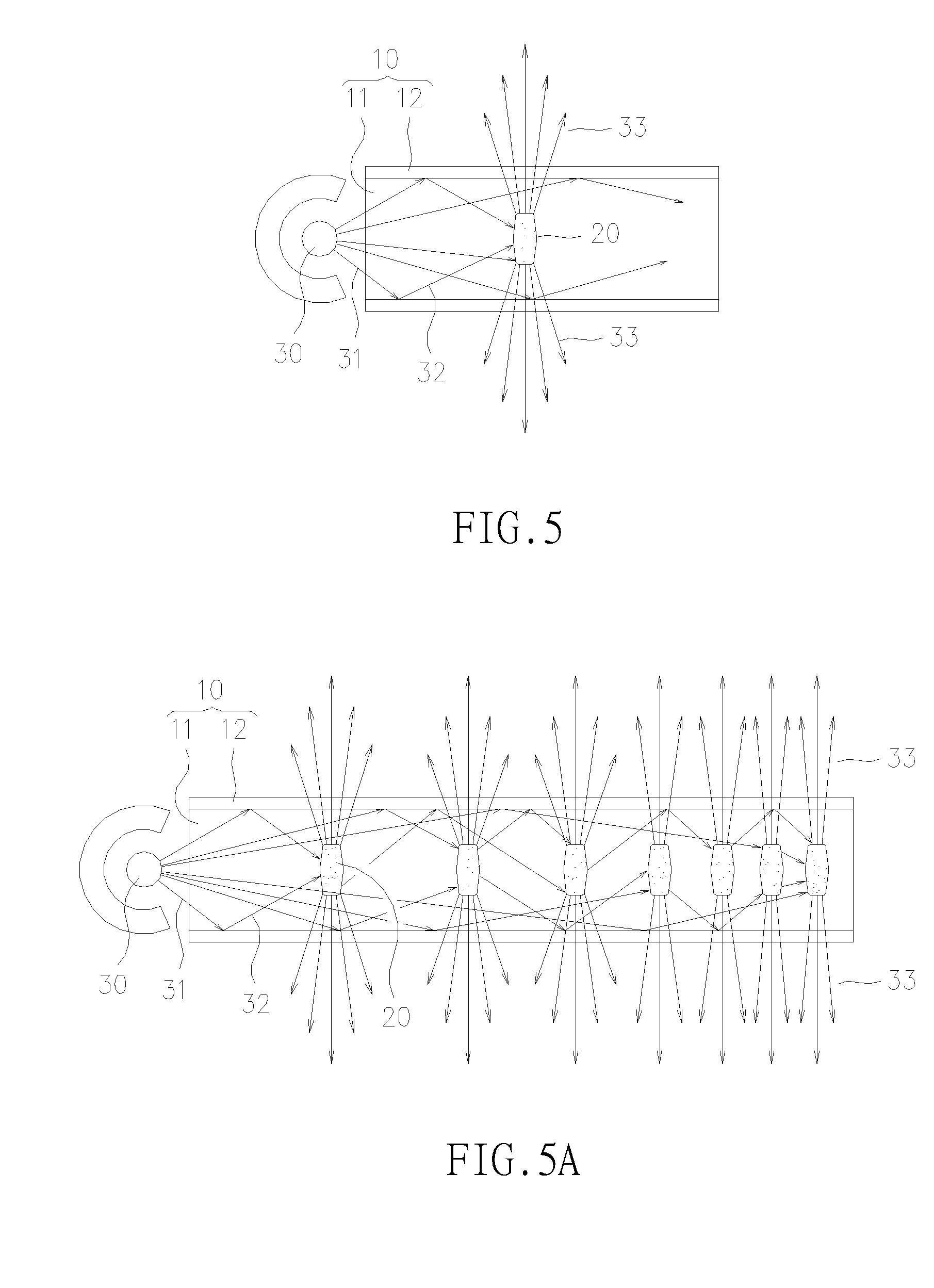

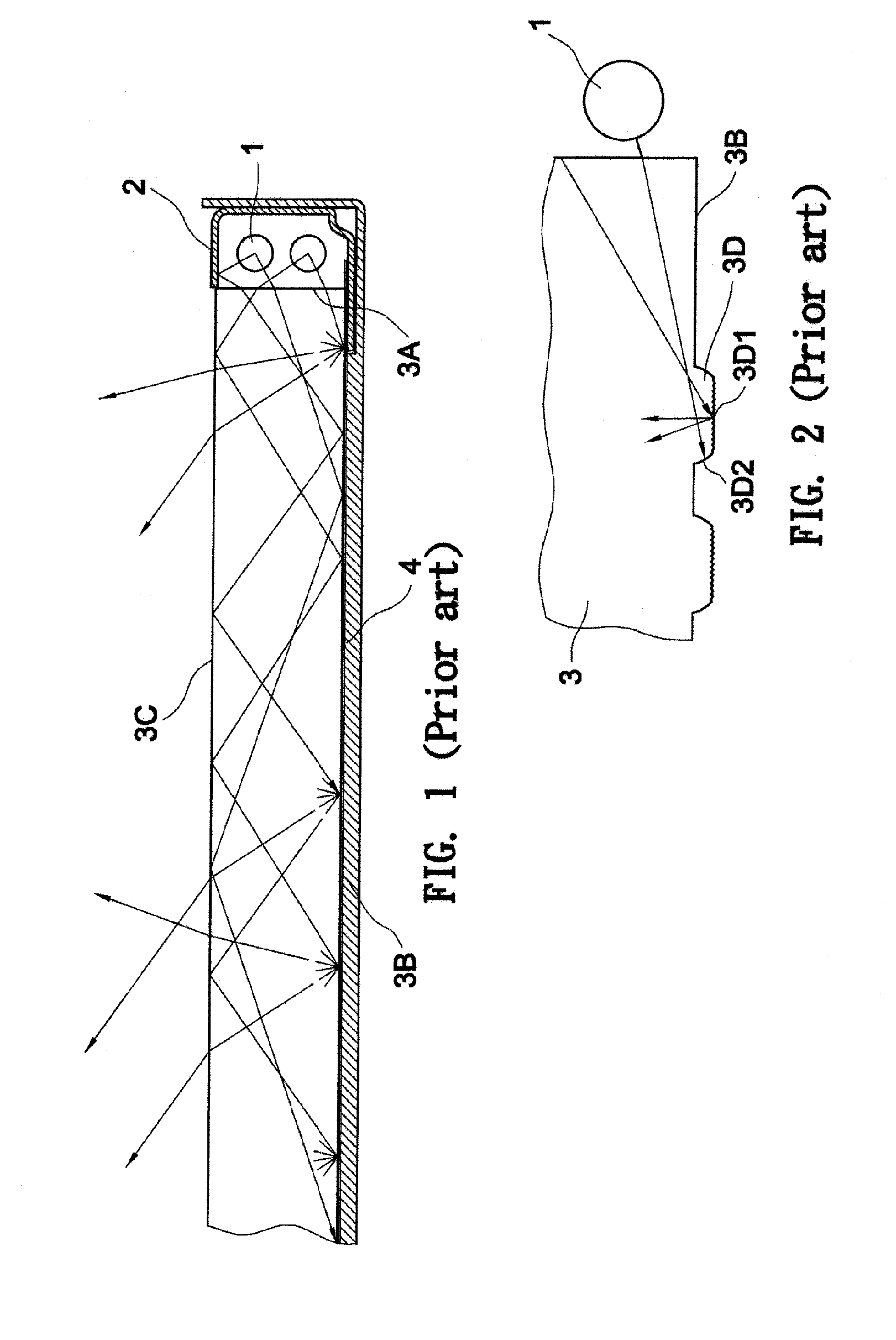

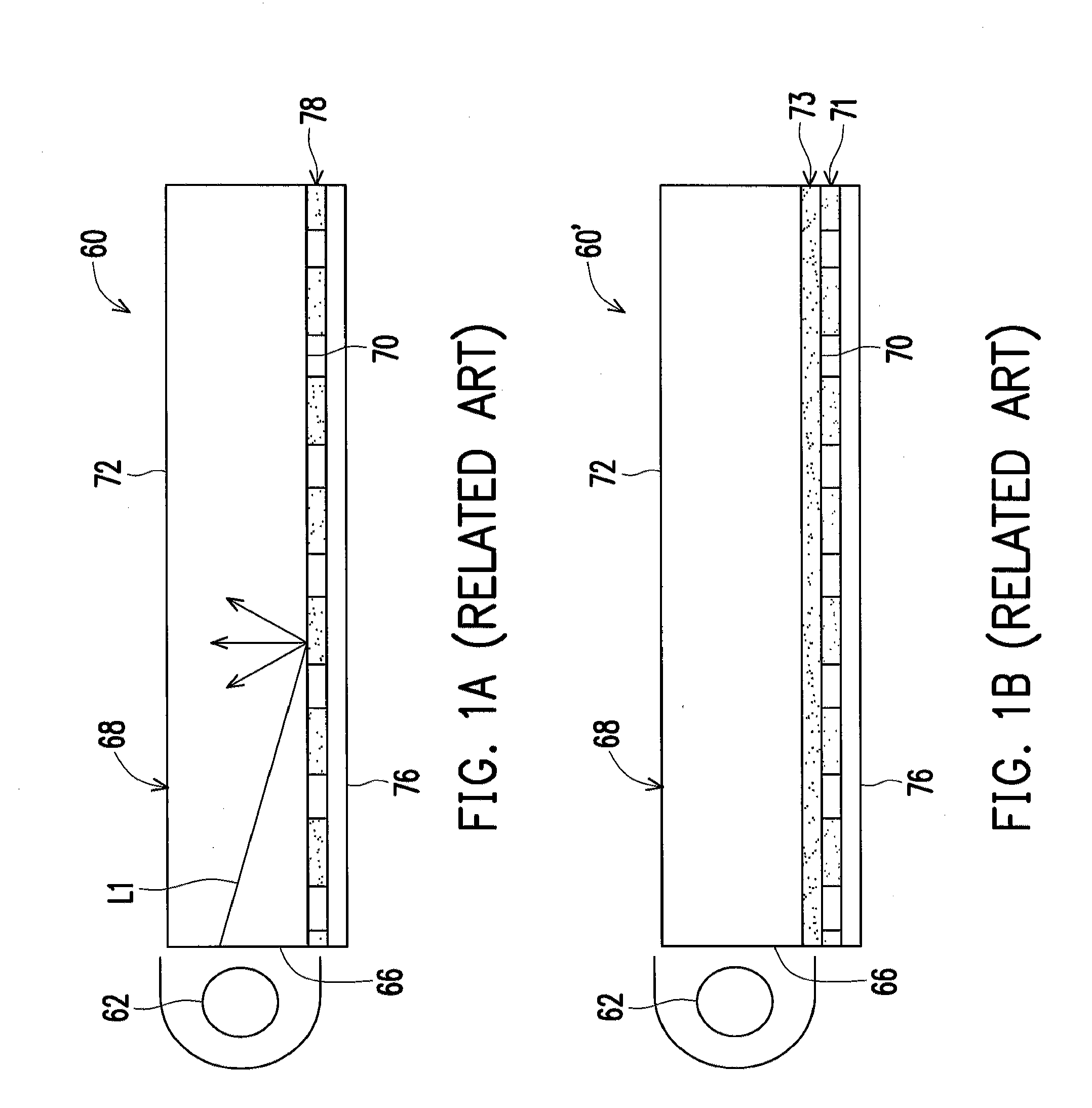

Linear light source for enhancing uniformity of beaming light within the beaming light's effective focal range

ActiveUS20050276064A1Improve definitionImprove accuracyMeasurement apparatus componentsDiffusing elementsLight guideRefractive index

A light guide assembly, as a linear light source, includes a light guide bar connected to a light source assembly and a reflective housing encasing the light guide bar. One surface of the light guide bar is a light-scattering / light-emission surface, and other surfaces are all reflective. The emission plane has gradually changing indentations for adjusting the light refractive and reflecting indexes to ensure the light uniformity. The reflective housing covering the light guide bar is used for enhancing the light reflection and intensity. An opening is formed in the reflective housing corresponding to the emission plane of the light guide bar, and a reflecting flange is formed at one side of the opening. Combined with the sloping and notched emission plane, light with high intensity and uniformity can be obtained, and the uniformity of beaming light within the beaming light's effective focal range can also be improved.

Owner:PIXON TECH CORP

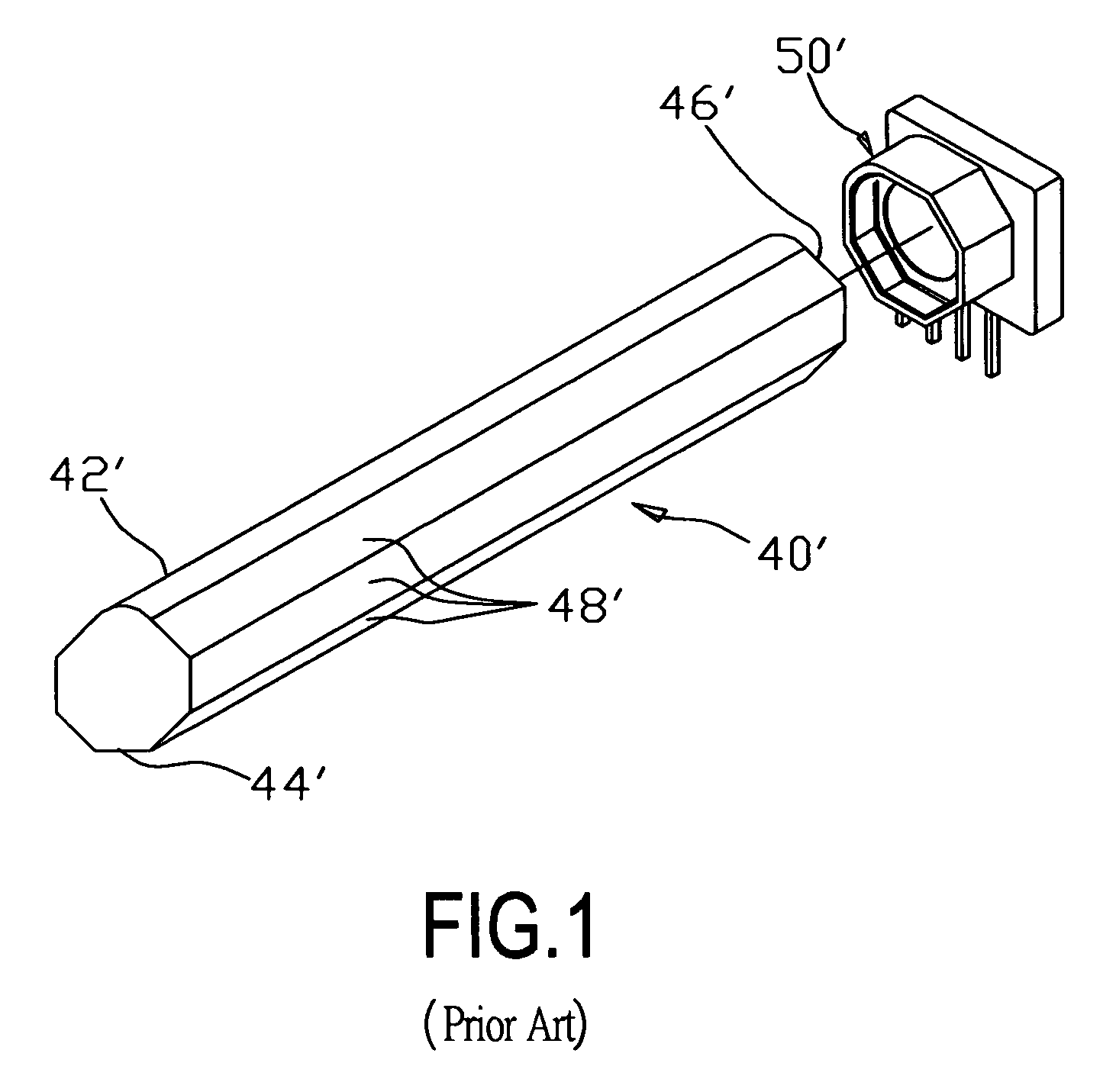

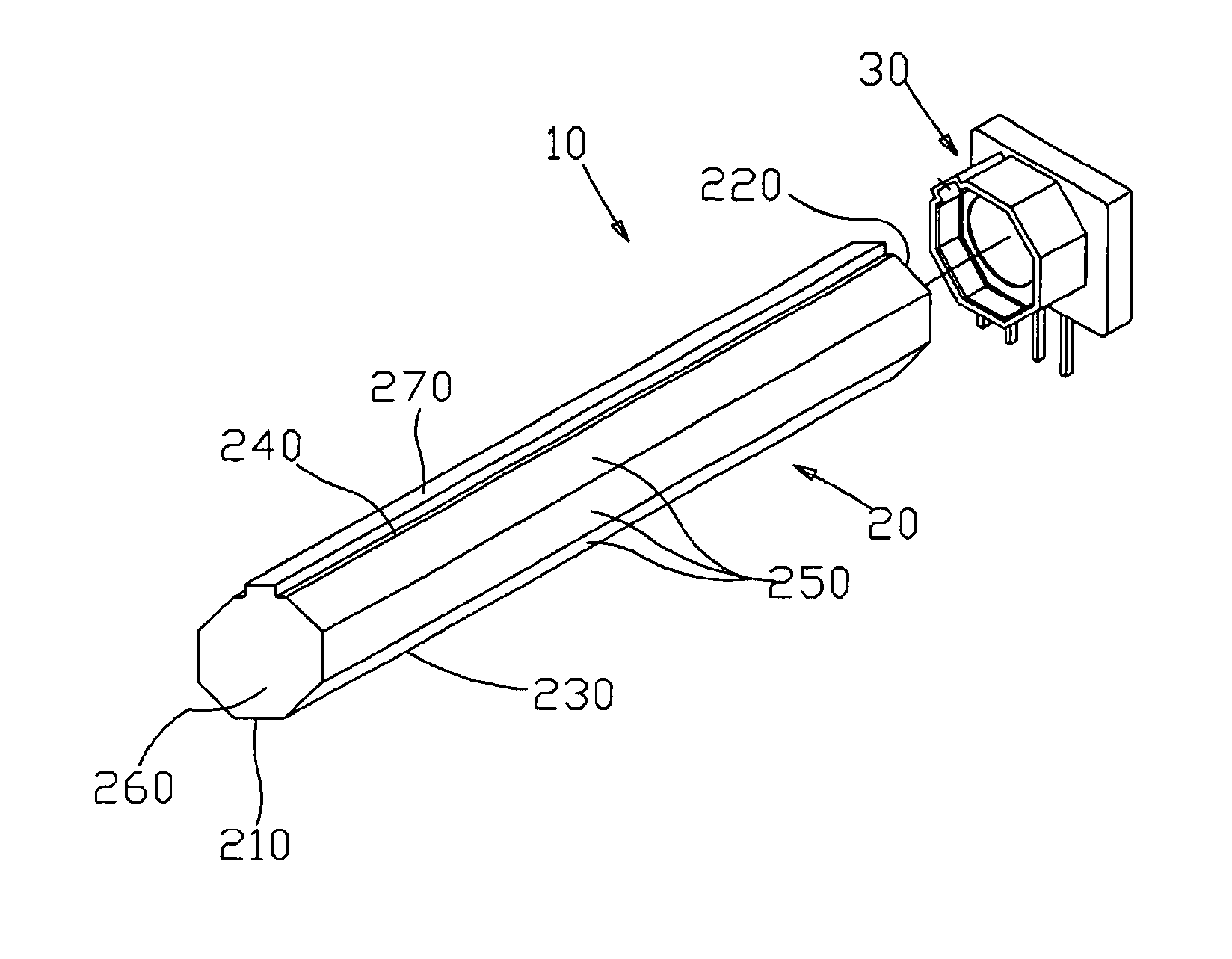

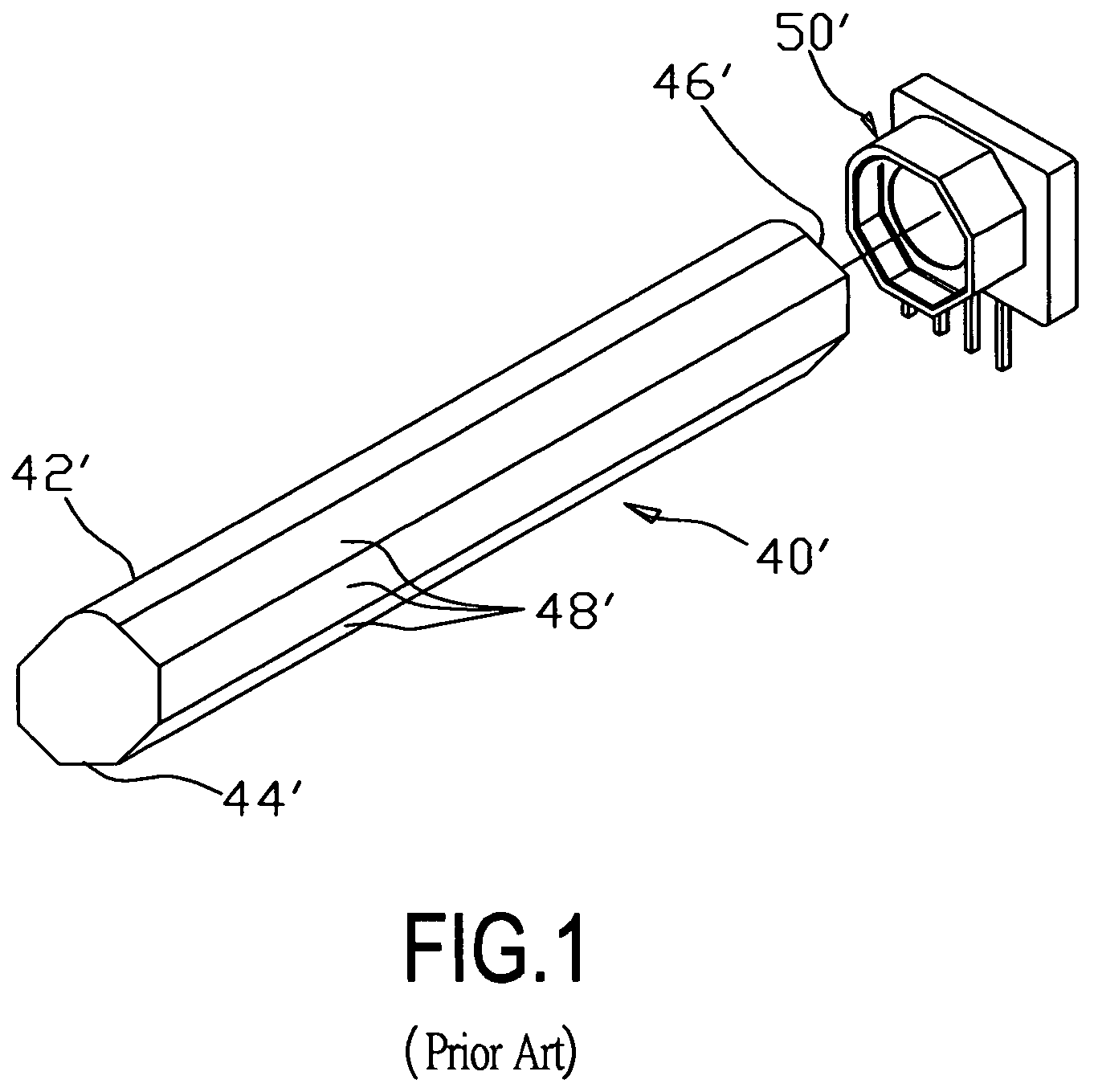

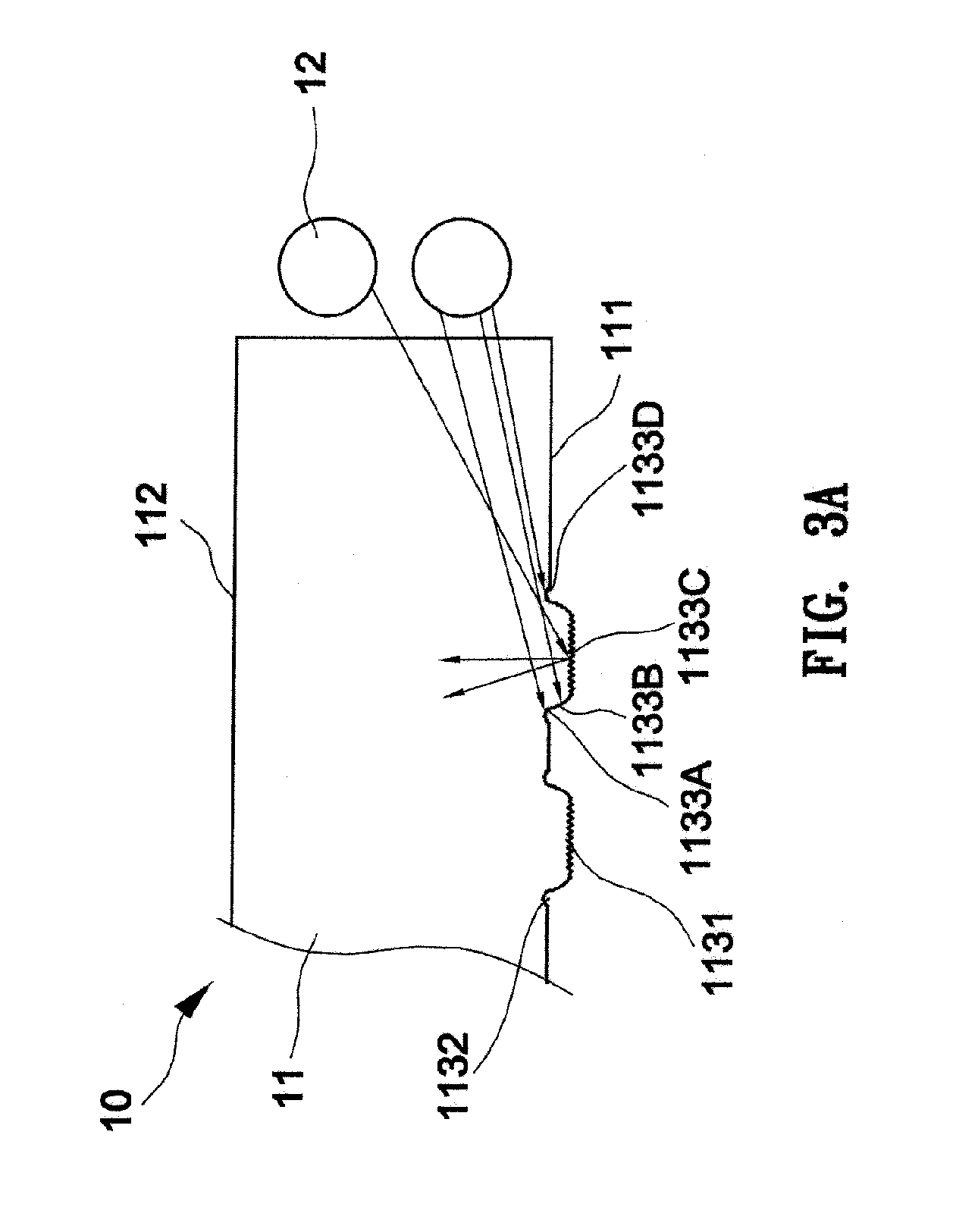

Linear light source device for image reading

InactiveUS6851816B2Simple configurationSimple structureLighting support devicesDiffusing elementsExit planeHigh rate

A linear light source device for image reading. The main body of the linear light source device includes at least a light-guide bar and a light source assembly. The light-guide bar is a polygonal column with one surface having stripes thereon, acting as a reflective plane with a reflective function. The opposite plane to the reflective plane is a light-exiting plane, and all the remaining planes are reflective layers. At least one of the ends of the polygonal column is an incident plane for a light beam to enter. Light is transmitted through both of the two ends of the polygonal column (or one end with the other end acting as a reflective plane) and uniformly transmits through the light-exiting plane. The light-guided bar has a simple structure and configuration, a compact volume, a high rate of utilization in light energy, is flexibly changed in length, and is easy to manufacture with high product yield and low manufacturing cost. In addition, it can provide uniform monochromatic and colored light, with high luminance, and at a low cost.

Owner:PIXON TECH CORP

Linear light source for enhancing uniformity of beaming light within the beaming light's effective focal range

ActiveUS7267467B2Improve definitionImprove accuracyMeasurement apparatus componentsDiffusing elementsLight guideLight reflection

A light guide assembly as a linear light source for enhancing the uniformity of beaming light within the beaming light's effective focal range comprising a light guide bar connected to a light source assembly and a reflective housing encasing the light guide bar. One surface of the light guide bar is a light-scattering / light-emission surface, and other surfaces are all reflective. The emission plane has gradually changing indentations for adjusting the light refractive and reflecting indexes to ensure the light uniformity. The reflective housing covering the light guide bar is used for enhancing the light reflection and intensity. An opening is formed in the reflective housing corresponding to the emission plane of the light guide bar, and a reflecting flange is formed at one side of the opening. Combined with the sloping and notched emission plane, light with high intensity and uniformity can be obtained, and the uniformity of beaming light within the beaming light's effective focal range can also be improved.

Owner:PIXON TECH CORP

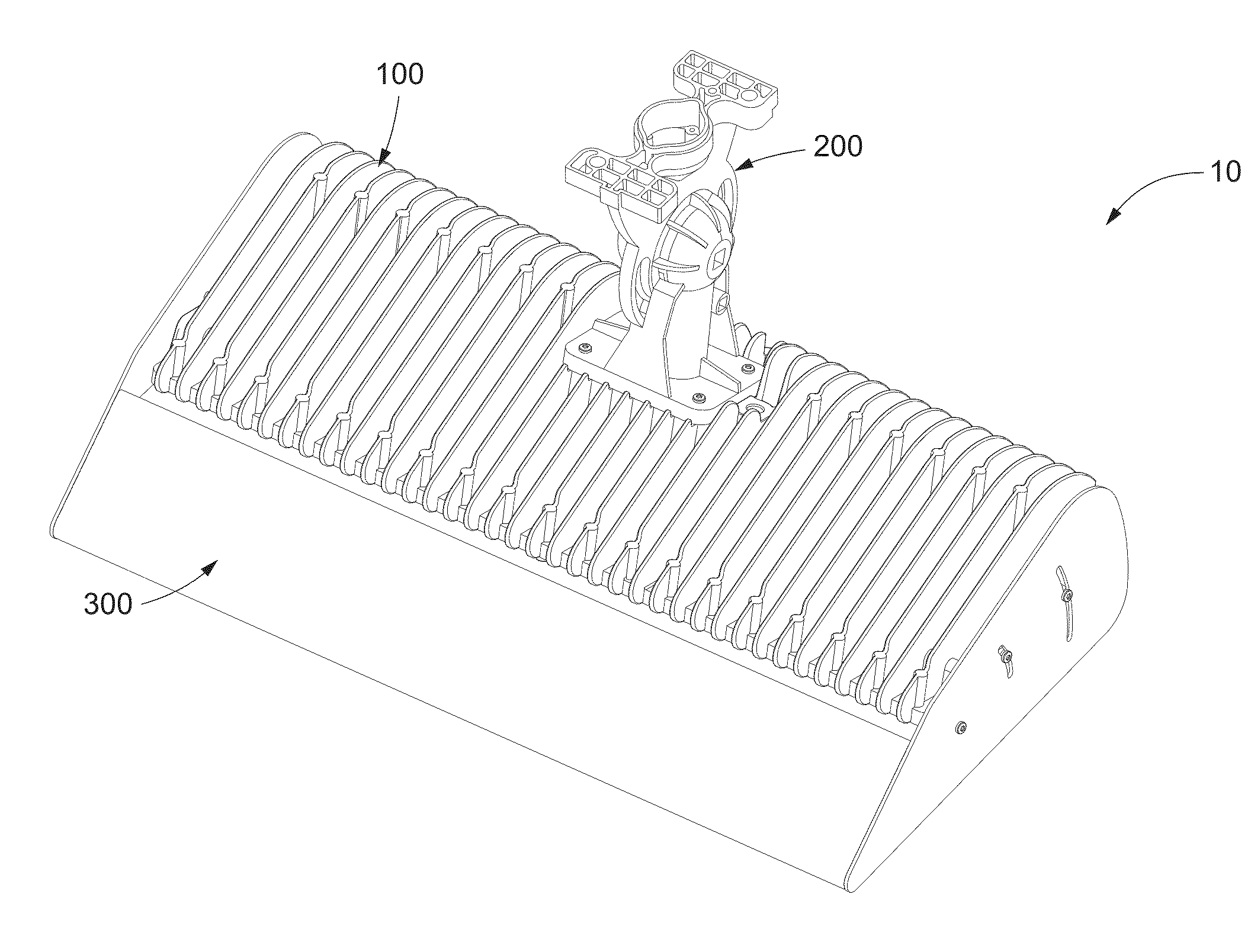

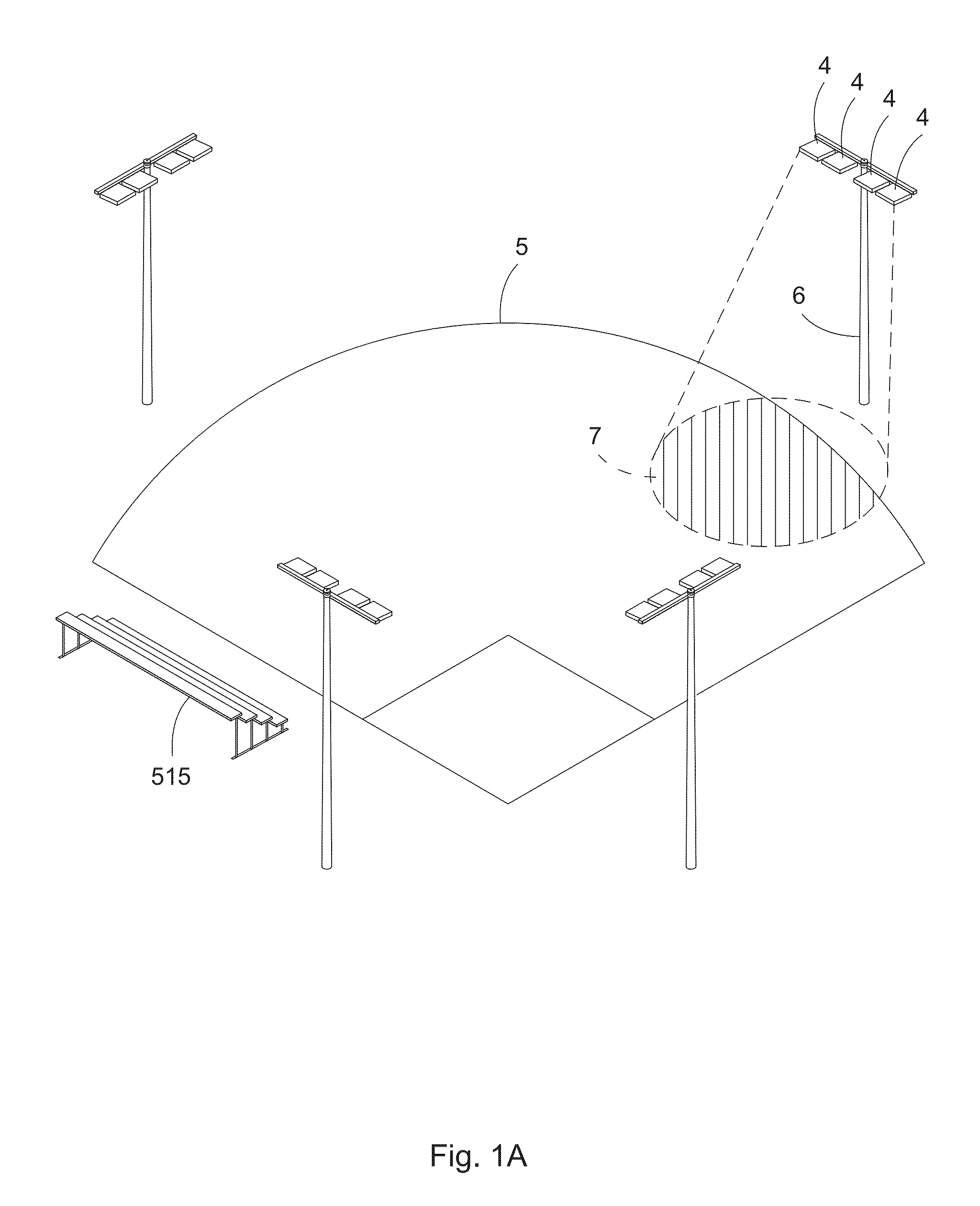

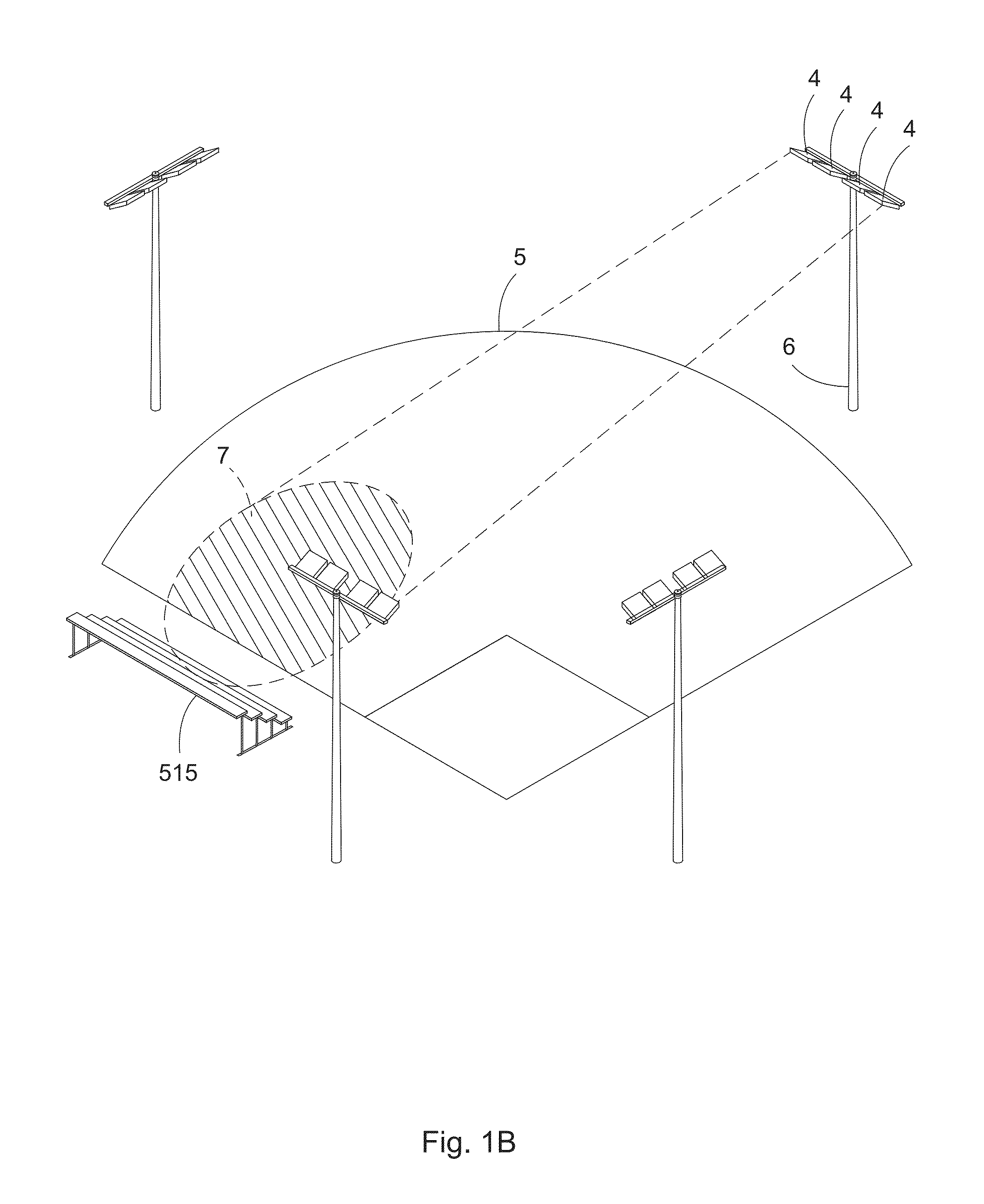

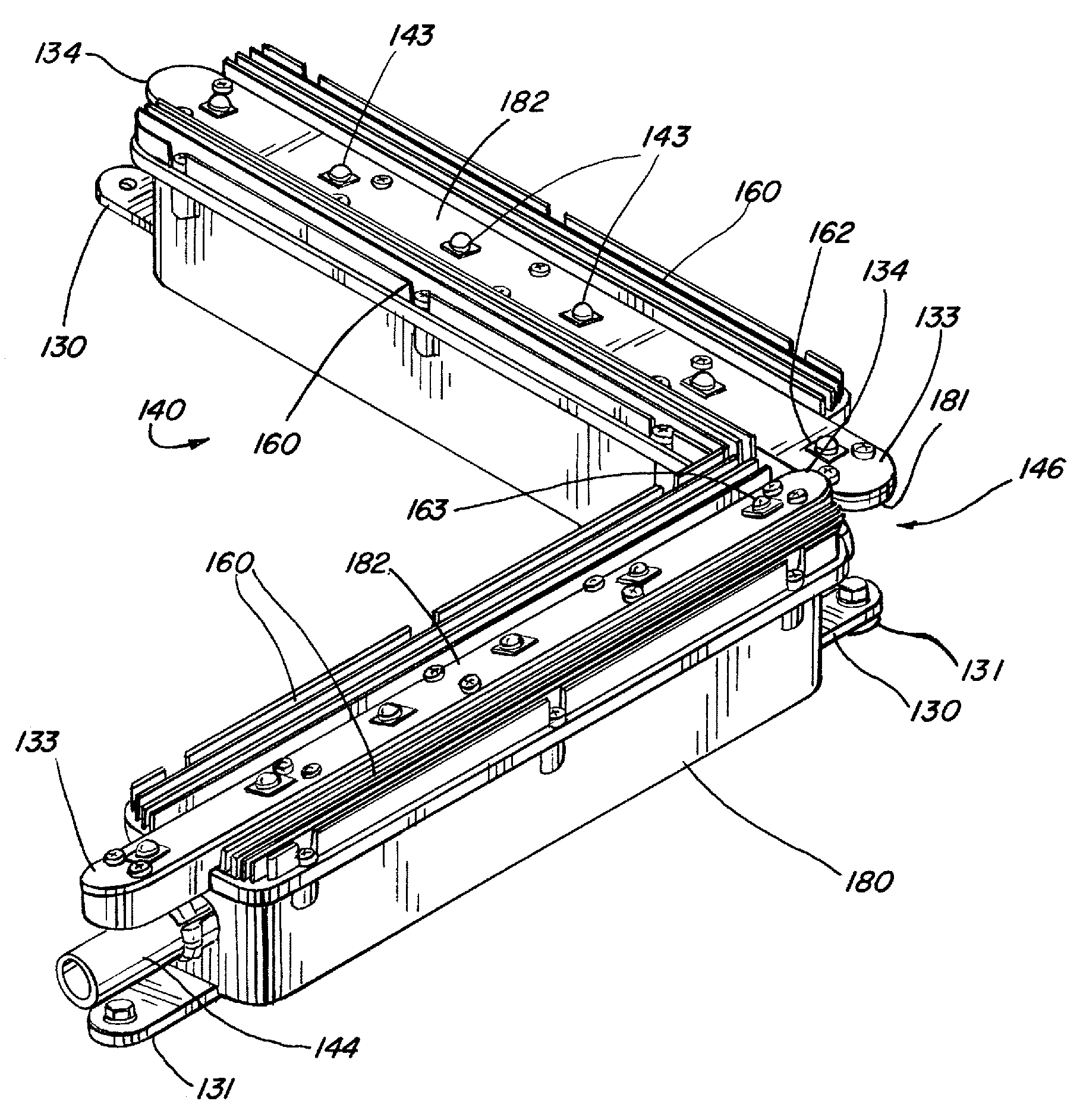

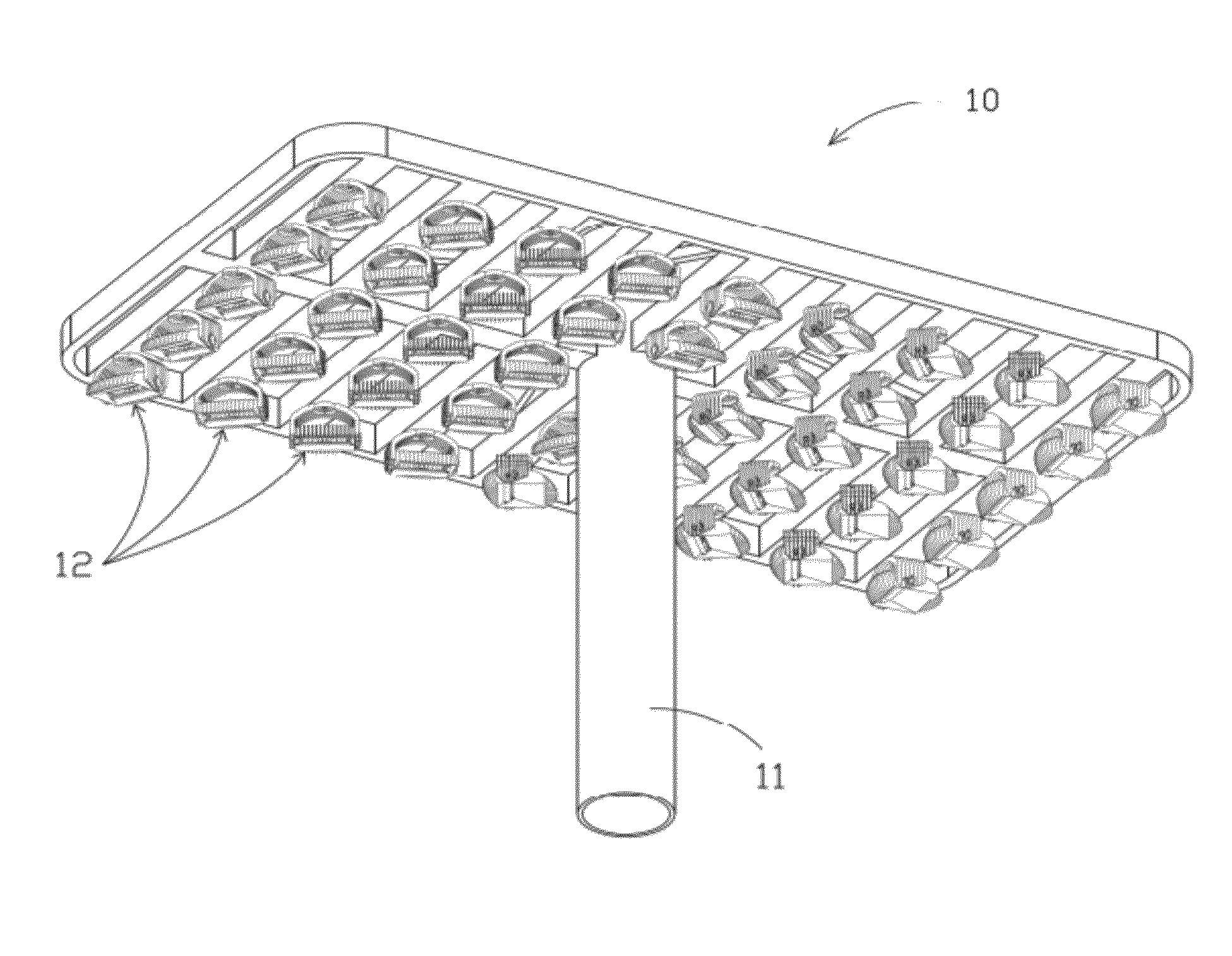

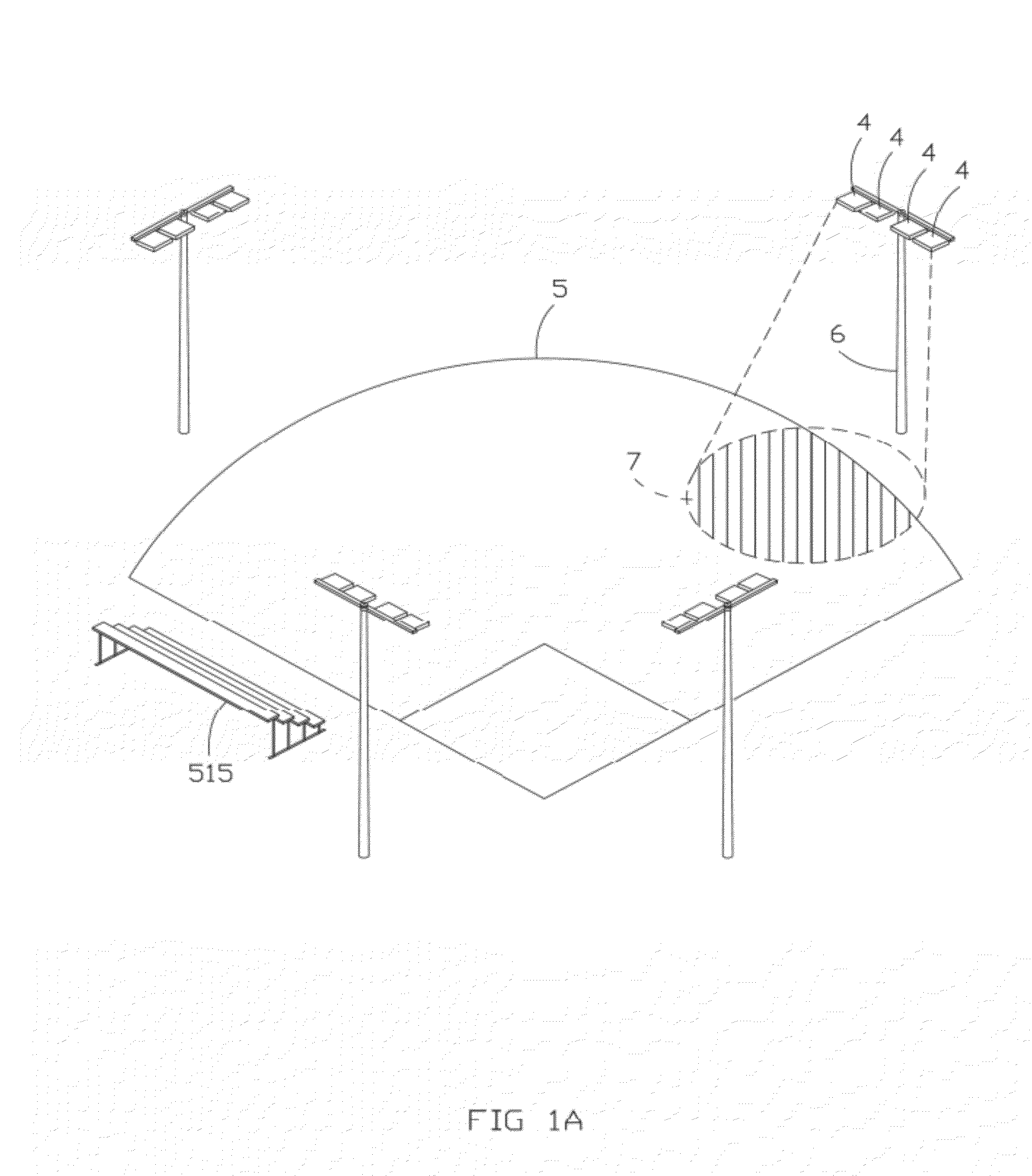

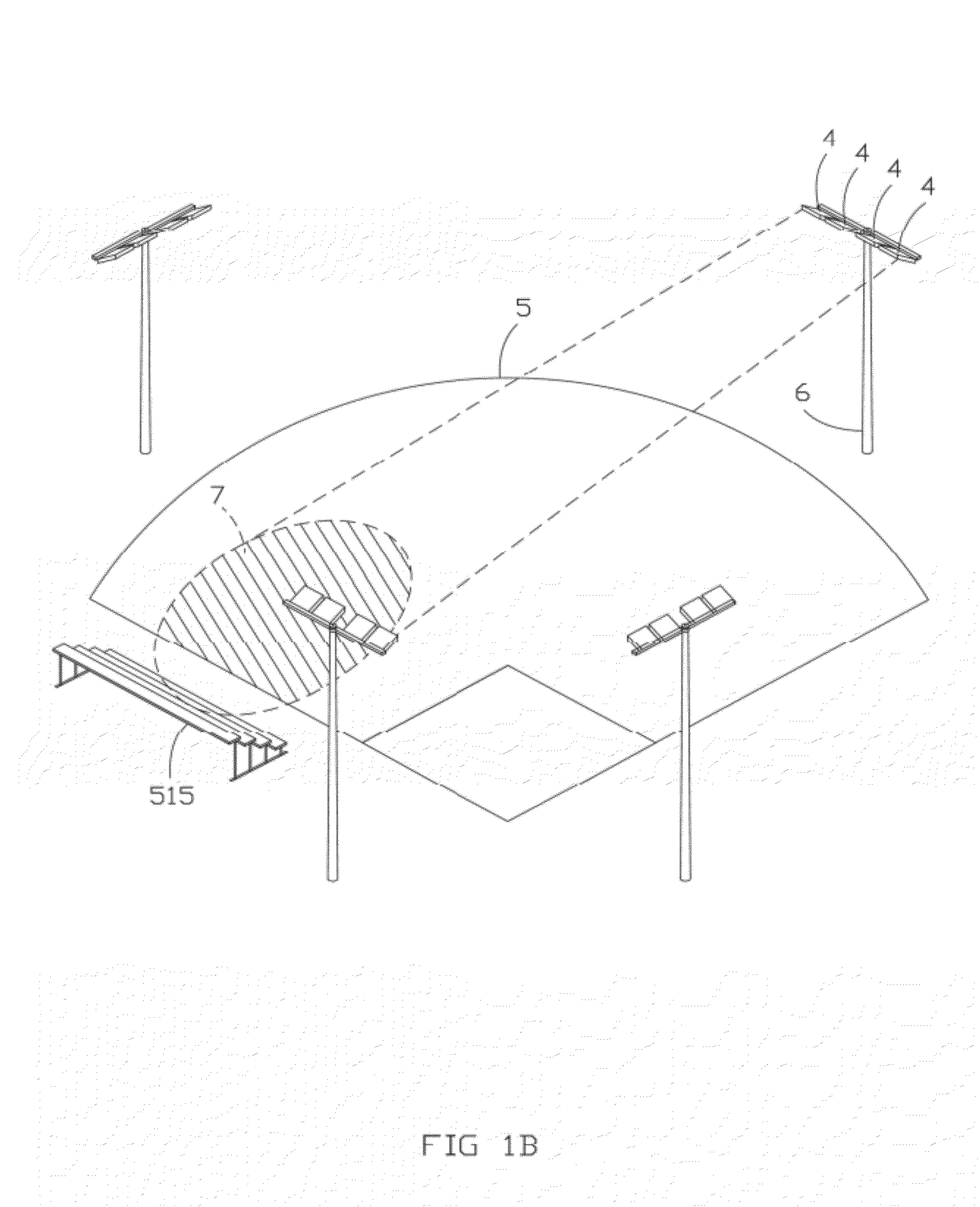

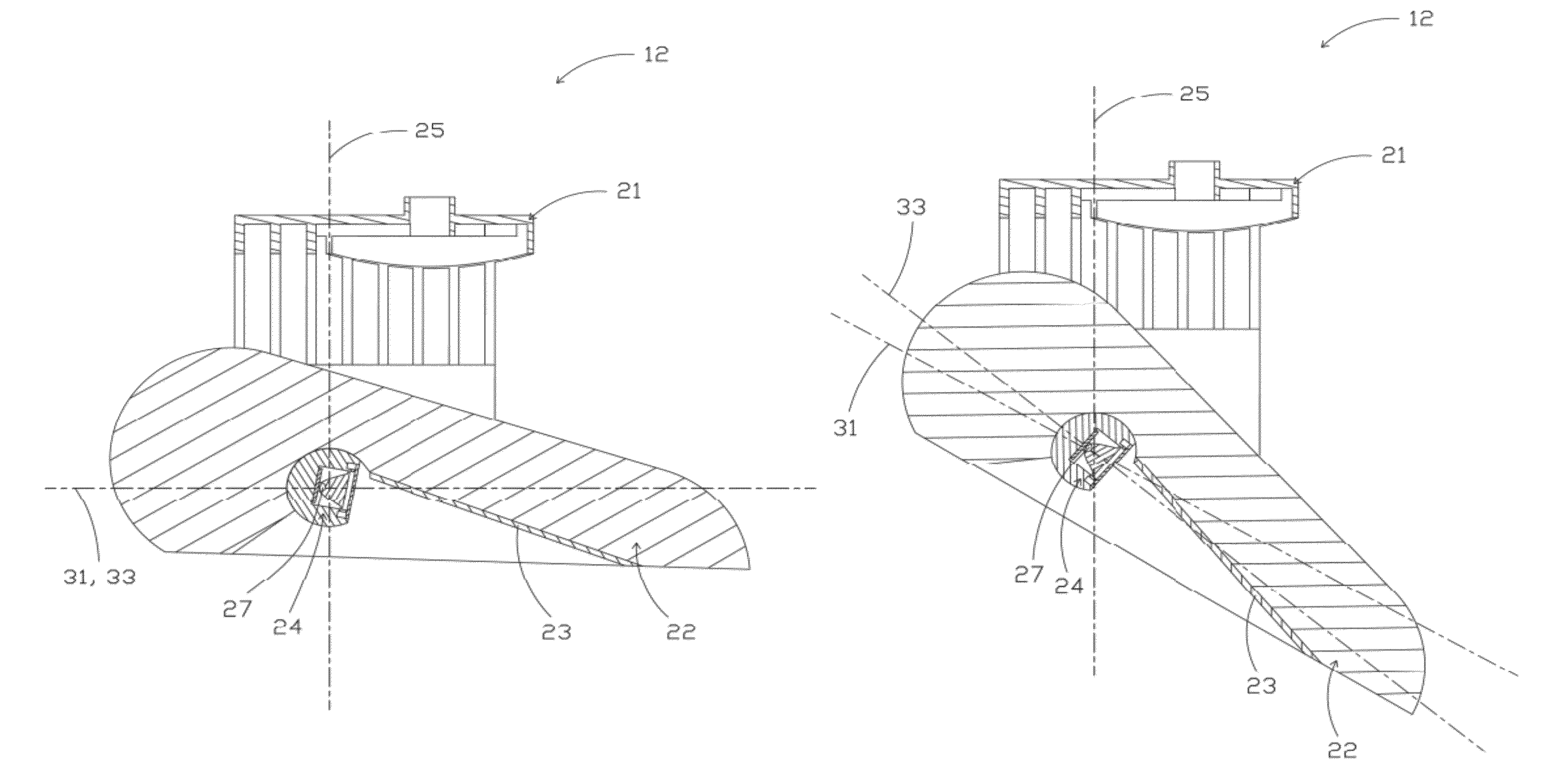

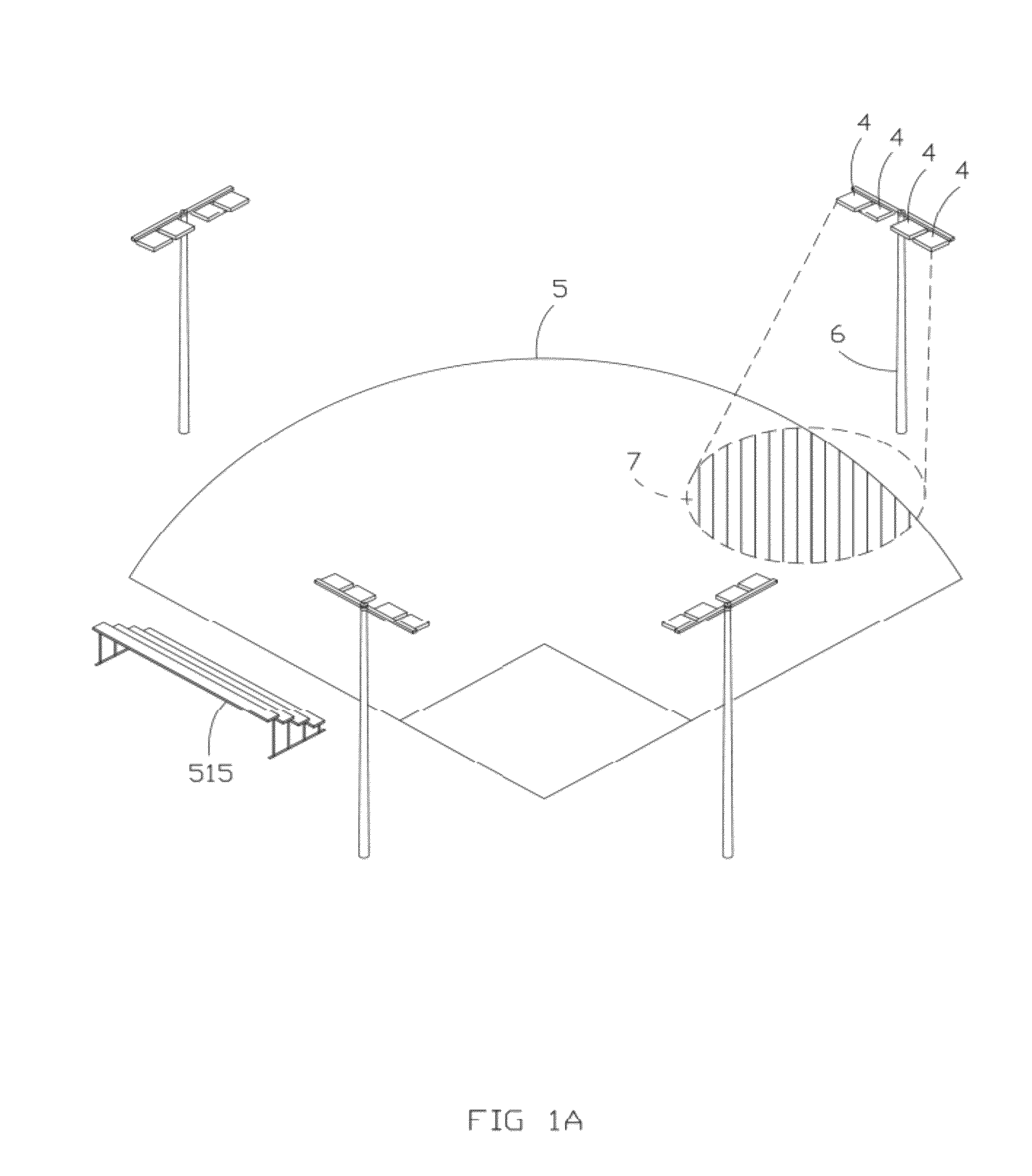

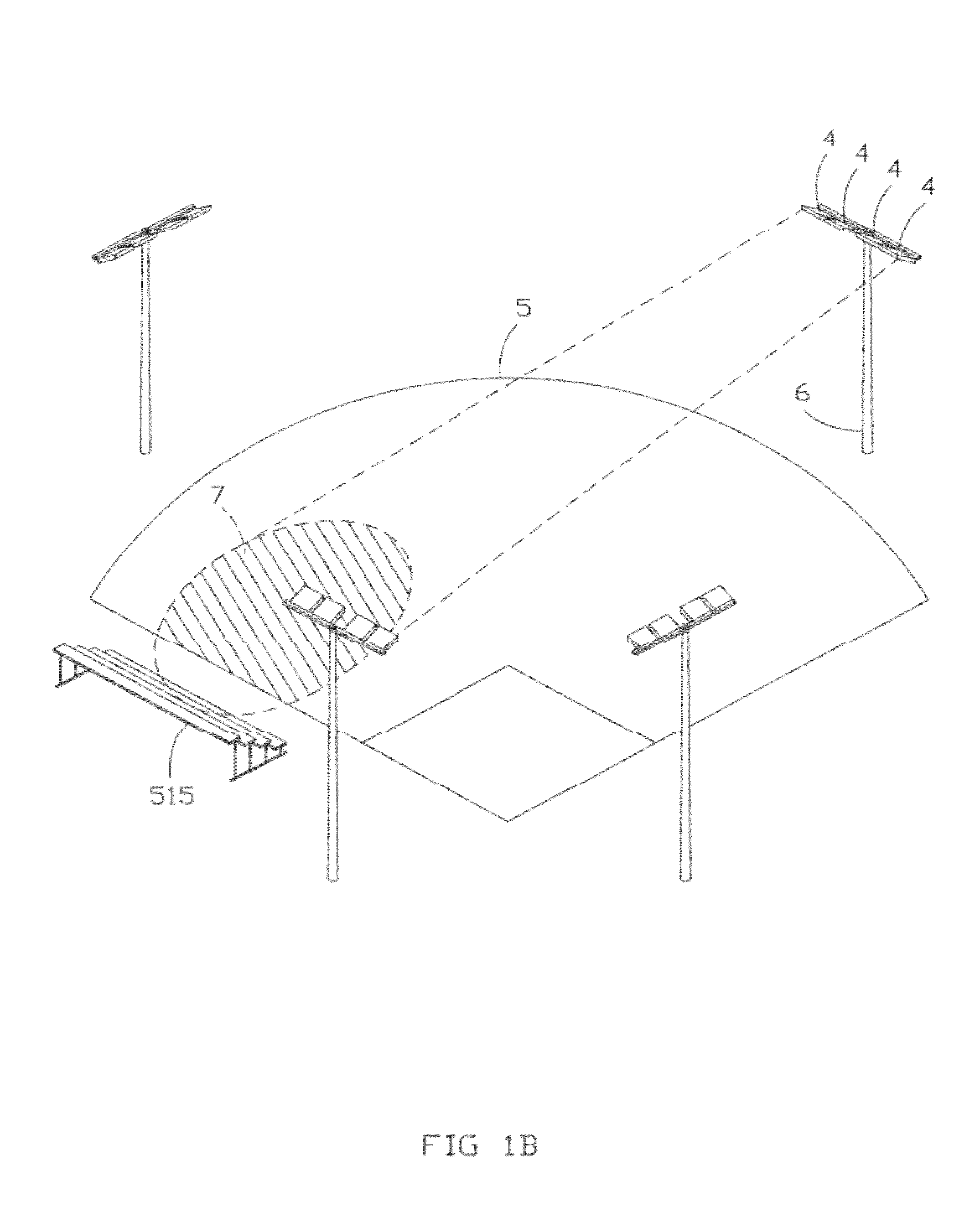

Apparatus, method, and system for independent aiming and cutoff steps in illuminating a target area

ActiveUS20130250556A1Easy to controlReduced EPAMechanical apparatusLighting support devicesProject areaEffect light

Presented is a design of modular LED lighting fixture whereby the steps of light directing and light redirecting are independent, but cooperative, so to promote a compact fixture design with low effective projected area (EPA), good thermal properties, and a selectable degree of glare control. A lighting system employing a plurality of said fixtures is highly customizable yet has the potential to be pre-aimed and pre-assembled prior to shipping, which reduces the potential for installation error while preserving the customized nature of the fixtures.

Owner:MUSCO

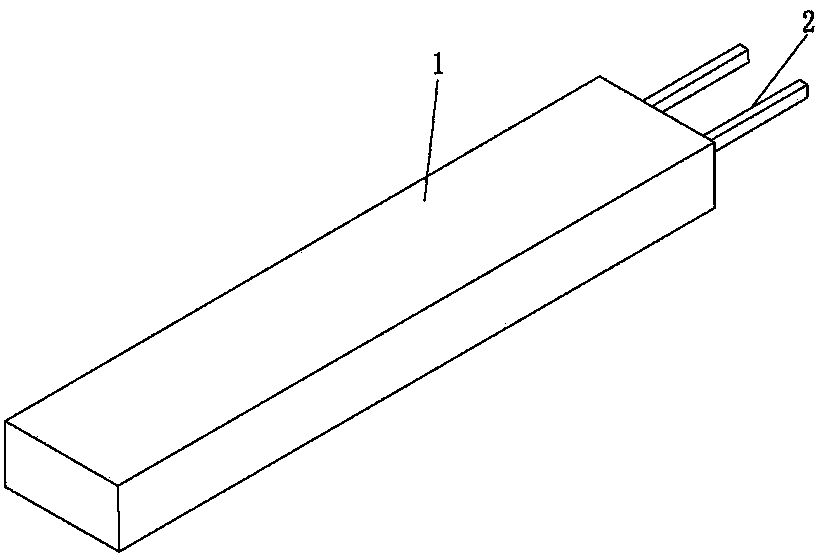

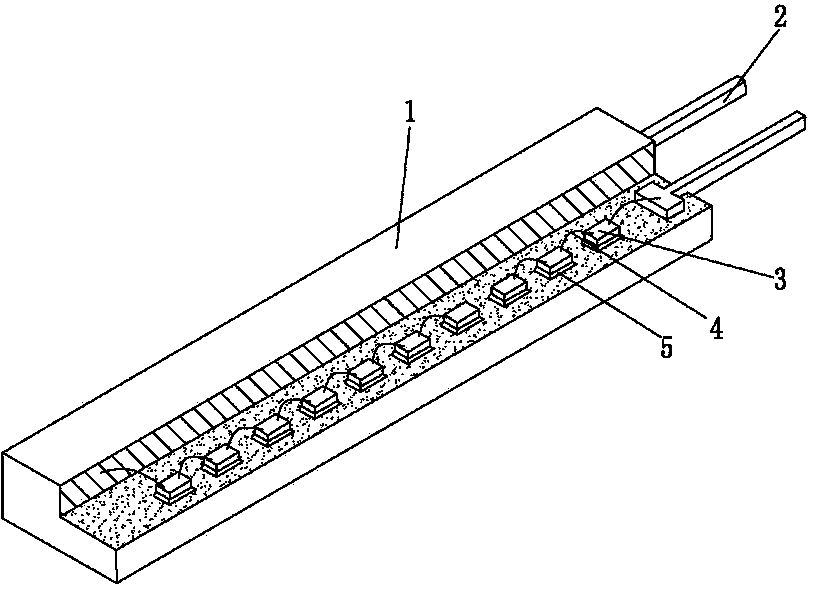

Packaging method of LED filament and LED filament

InactiveCN104319345AEnsure stabilityGuaranteed light transmittanceSemiconductor devicesLED filamentLiquid silicon

The invention discloses a packaging method of an LED filament. The packaging method of the LED filament includes the steps that a liquid silicon resin and fluorescent powder mixture is injected into a mould, and a metal conductive pin is arranged at one end of the silicon resin and fluorescent powder mixture inside the mould; the mould is removed after being heated and solidified, and silicon resin and fluorescent powder colloid with the metal conductive pin at one end is obtained; a plurality of LED chips are installed on the silicon resin and fluorescent powder colloid, and the LED chips are mutually connected through a wire and then connected to the metal conductive pin to form a conductive path; the silicon resin and fluorescent powder colloid with the LED chips is put into the mould, and a liquid silicon resin and fluorescent powder mixture is injected into the mould to cover the LED chips and the wire; the mould is removed after being heated and solidified, and the packaged LED filament finished product with a supporting frame is obtained. The LED filament is packaged without the supporting frame, and the quality problems of low yield, low light transmittance of the supporting frame and the like are resolved.

Owner:DONGGUAN INST OF OPTO ELECTRONICS PEKING UNIV +1

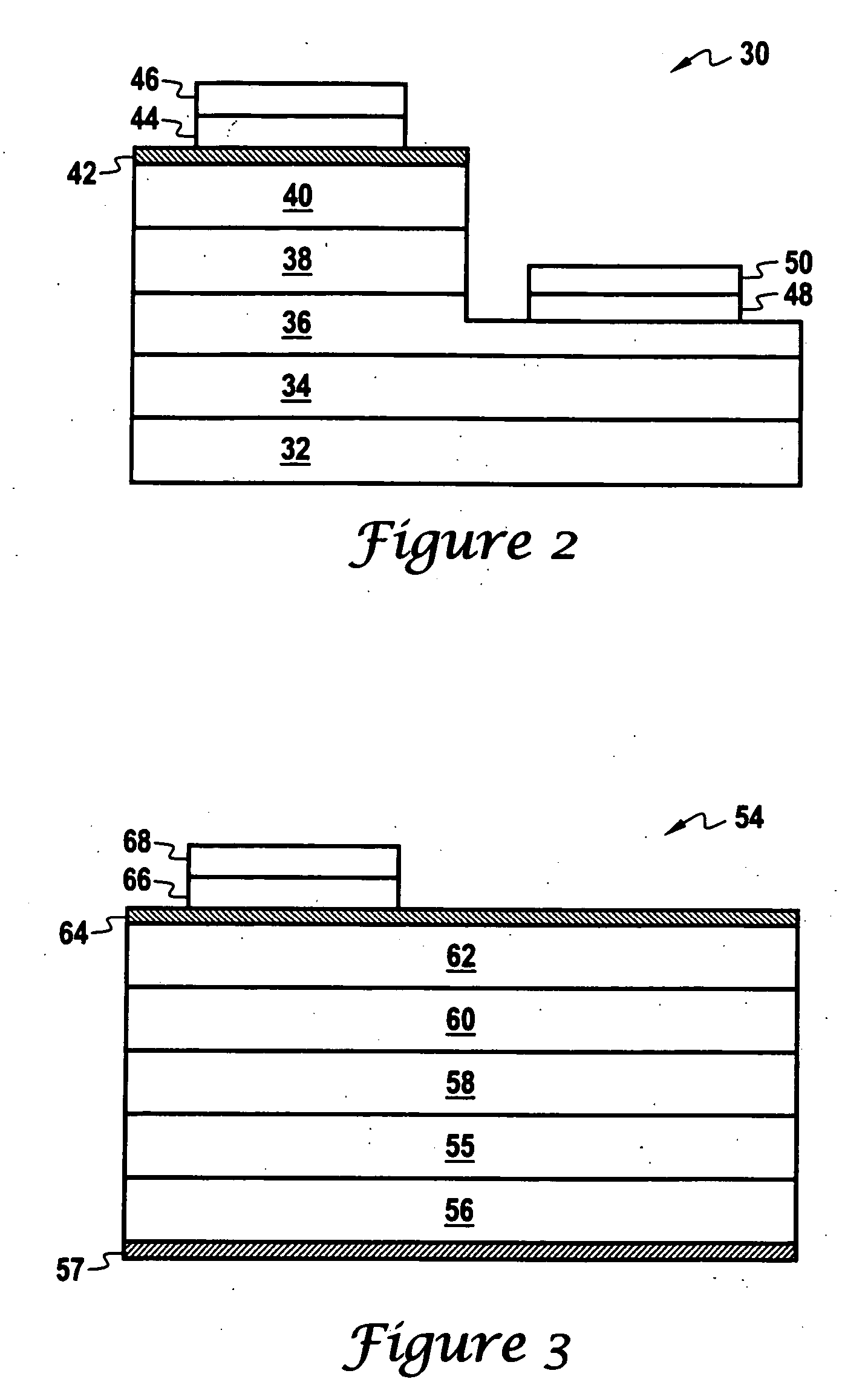

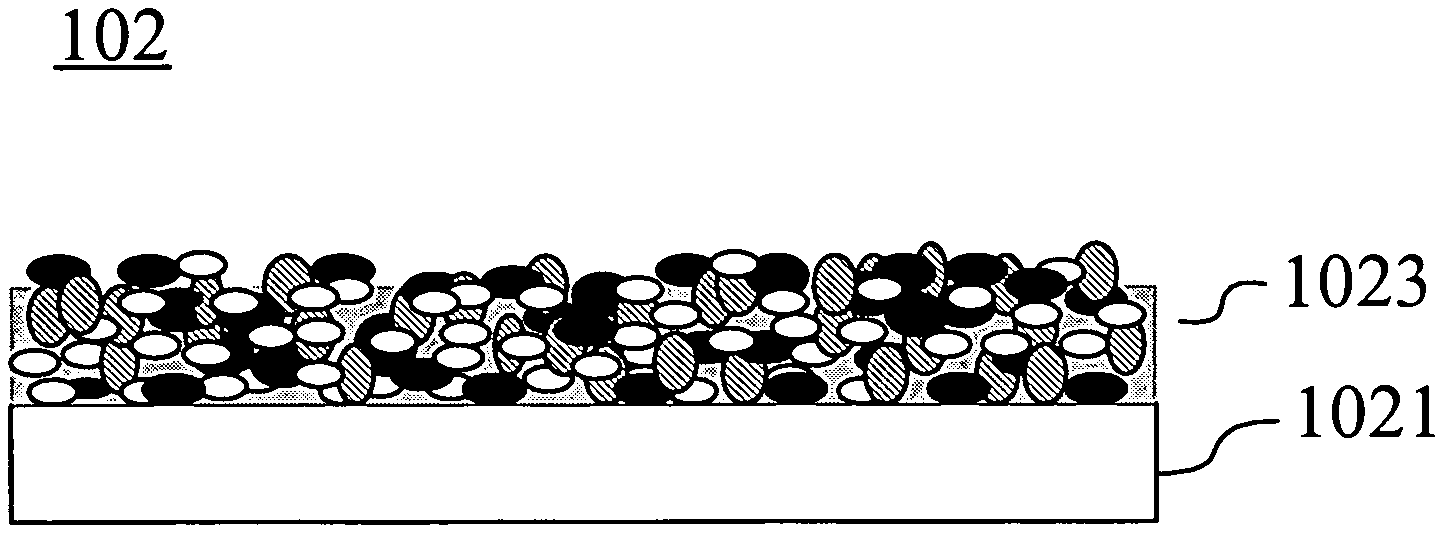

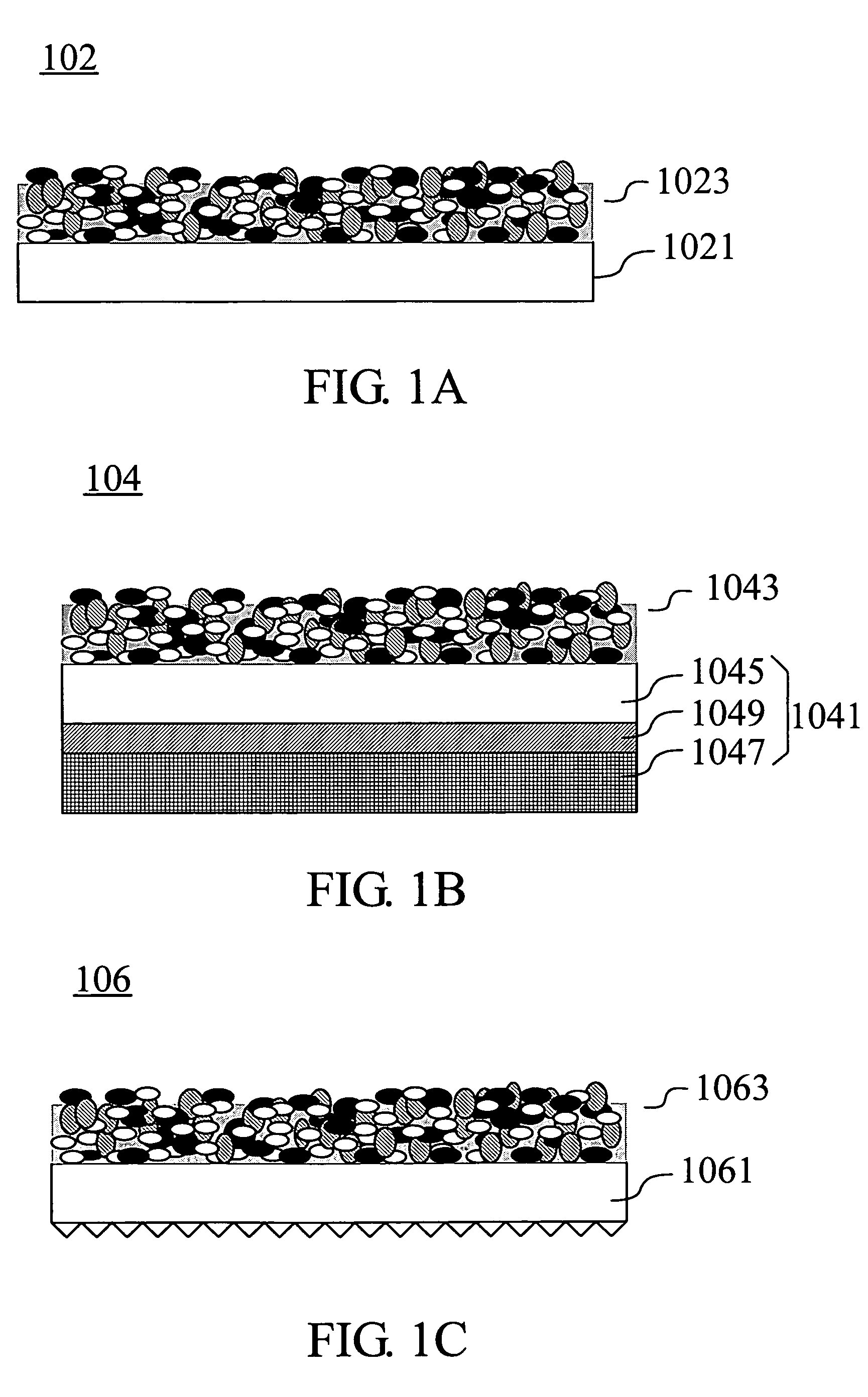

Thin film led

InactiveUS20070048885A1Improve light uniformityDischarge tube luminescnet screensElectroluminescent light sourcesLength waveLight-emitting diode

A method of fabricating a light emitting diode (LED) includes providing an LED chip that emits light having a first wavelength where the LED chip includes a first electrical contact and a second electrical contact. The method further includes forming a tinted thin film layer over the LED chip where the tinted thin film layer interacts with the first wavelength light to produce a light having a second wavelength.

Owner:SUZHOU LEKIN SEMICON CO LTD

Light source module and optical member

InactiveUS20120218752A1Good shading effectSufficiently blockNon-electric lightingMirrorsEffect lightReflective layer

A light source module includes: a light source; a lighting curtain that partially blocks light from the light source; and a reflective layer that is provided on the lighting curtain and that has a planar shape smaller than the lighting curtain.

Owner:SHARP KK

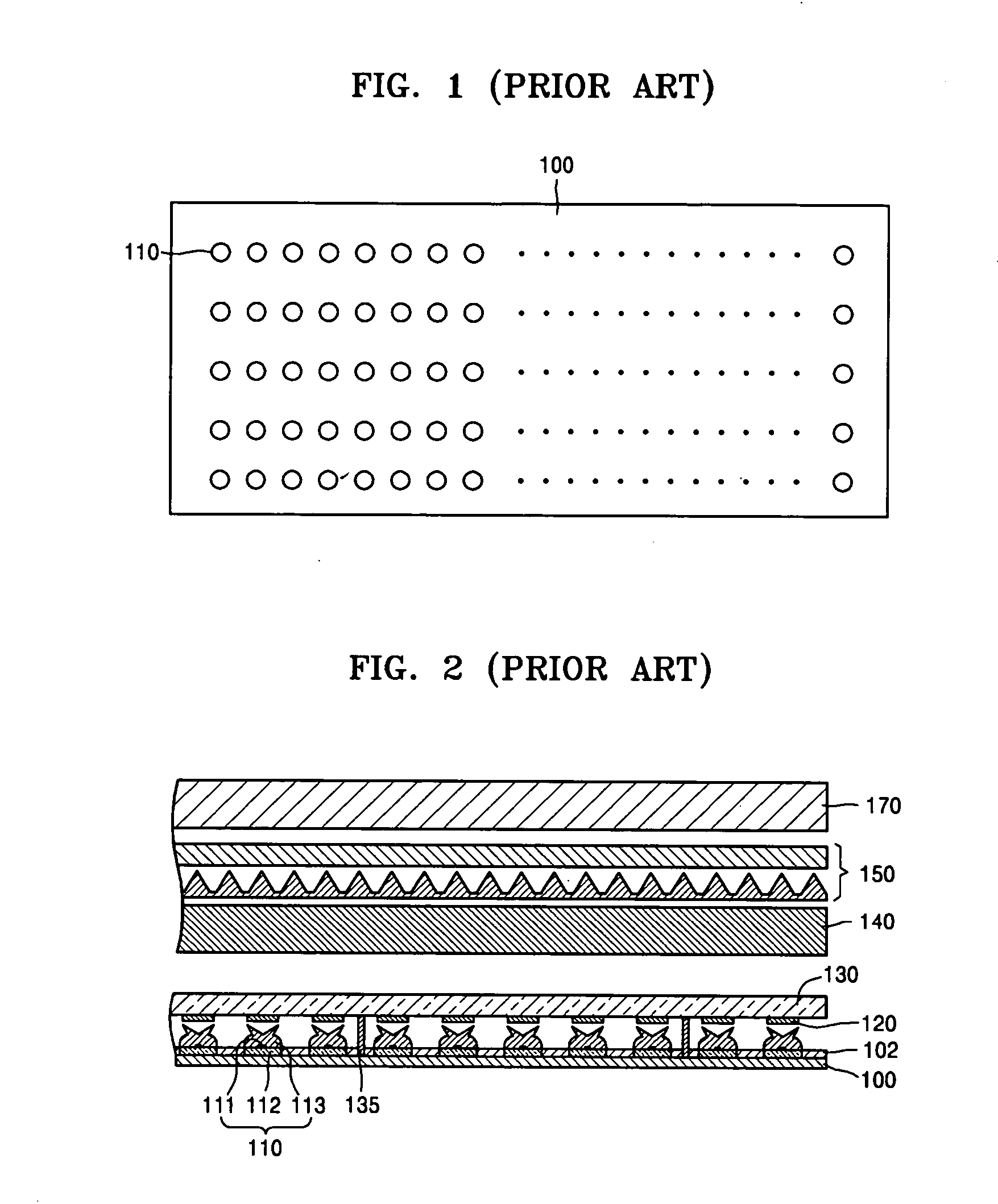

Back light unit and liquid crystal display employing the same

InactiveUS20060221611A1Improve light uniformityCarpet cleanersStatic indicating devicesLiquid-crystal displayDiffusion

A direct type backlight unit for improving high uniformity through a reflection barrier wall having a curved surface and a liquid crystal display employing the same are provided. The backlight unit includes: a base plate; a plurality of point light sources arranged in a plurality of lines on the base plate; a diffusion plate which diffuses light emitted from the plural of point light sources and generates a uniform light; and a reflection barrier wall, having a curved reflection surface, which reflects the light emitted from the point light source to the diffusion plate.

Owner:SAMSUNG ELECTRONICS CO LTD

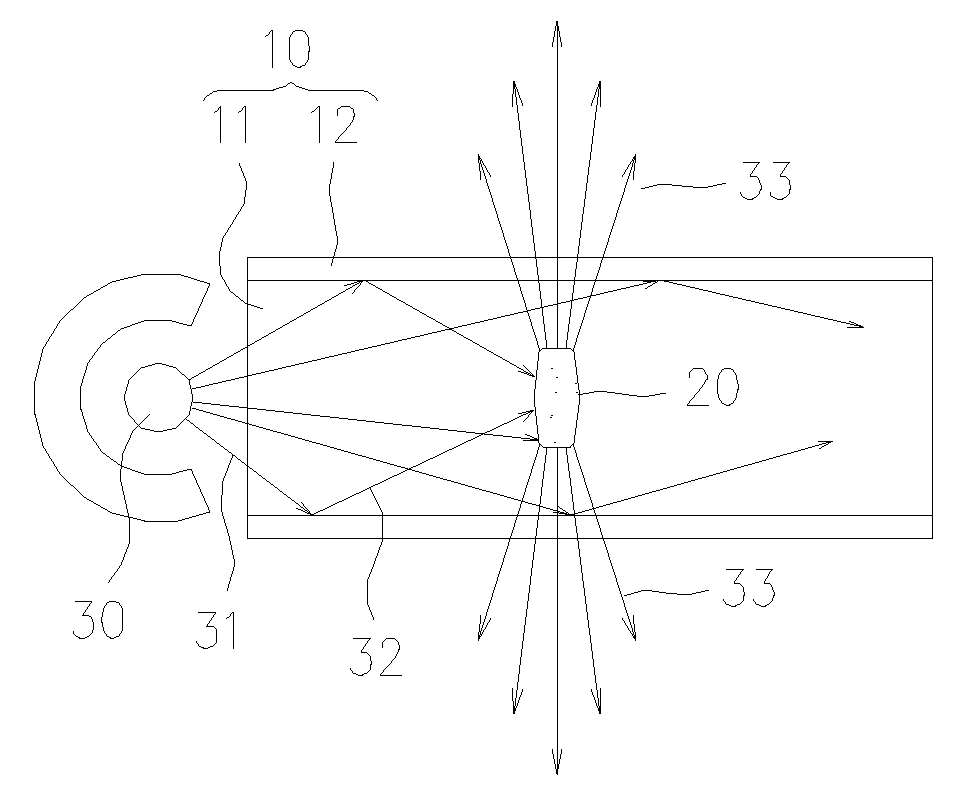

Optical fiber and the manufacturing method thereof

InactiveUS20080158905A1Reduce riskLight efficiencyGlass making apparatusMechanical apparatusAdhesiveVolumetric Mass Density

An optical fiber is disclosed, which is comprised of: a core, having a plurality of microstructures formed thereon; and a cladding layer, surrounding the core. In a preferred embodiment, as light is transmitting along the axis of the aforesaid optical fiber and strikes on the plural microstructures, it is scattered and reflected out of the optical fiber through a side wall thereof so as to achieve a side-emitting effect. As the microstructures are formed inside the core of the aforesaid optical fiber, not only they are prevented from being damaged by normal usage, contacting to adhesive directly, but also they can lower the risk of the optical fiber being snapped / deformed while the optical fiber is subjecting to an external force and bended. In addition, by controlling the shape, quantity, size, distribution density and location of the microstructure, the brightness of the side-emitting optical fiber can be adjusted correspondingly.

Owner:IND TECH RES INST

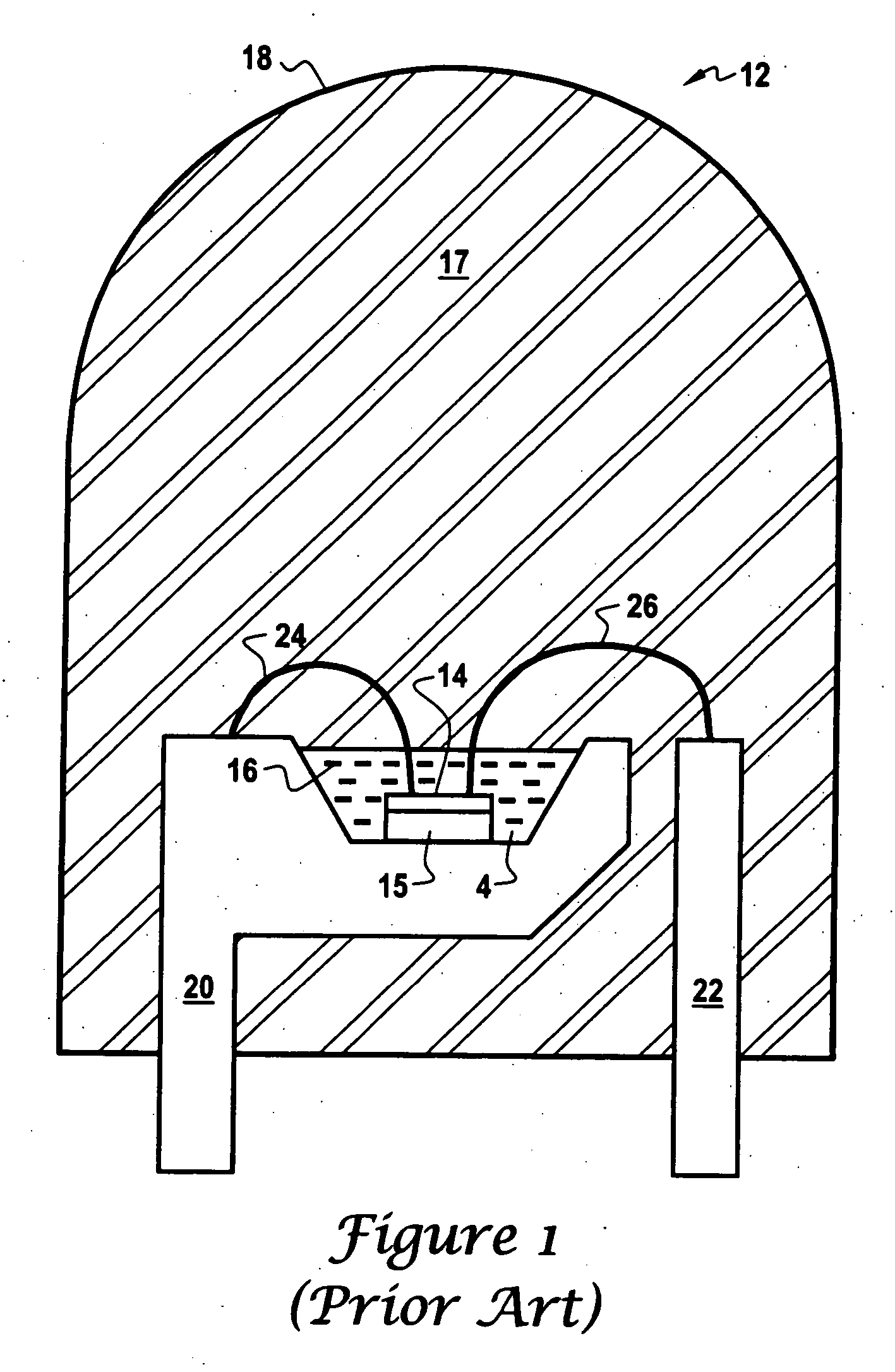

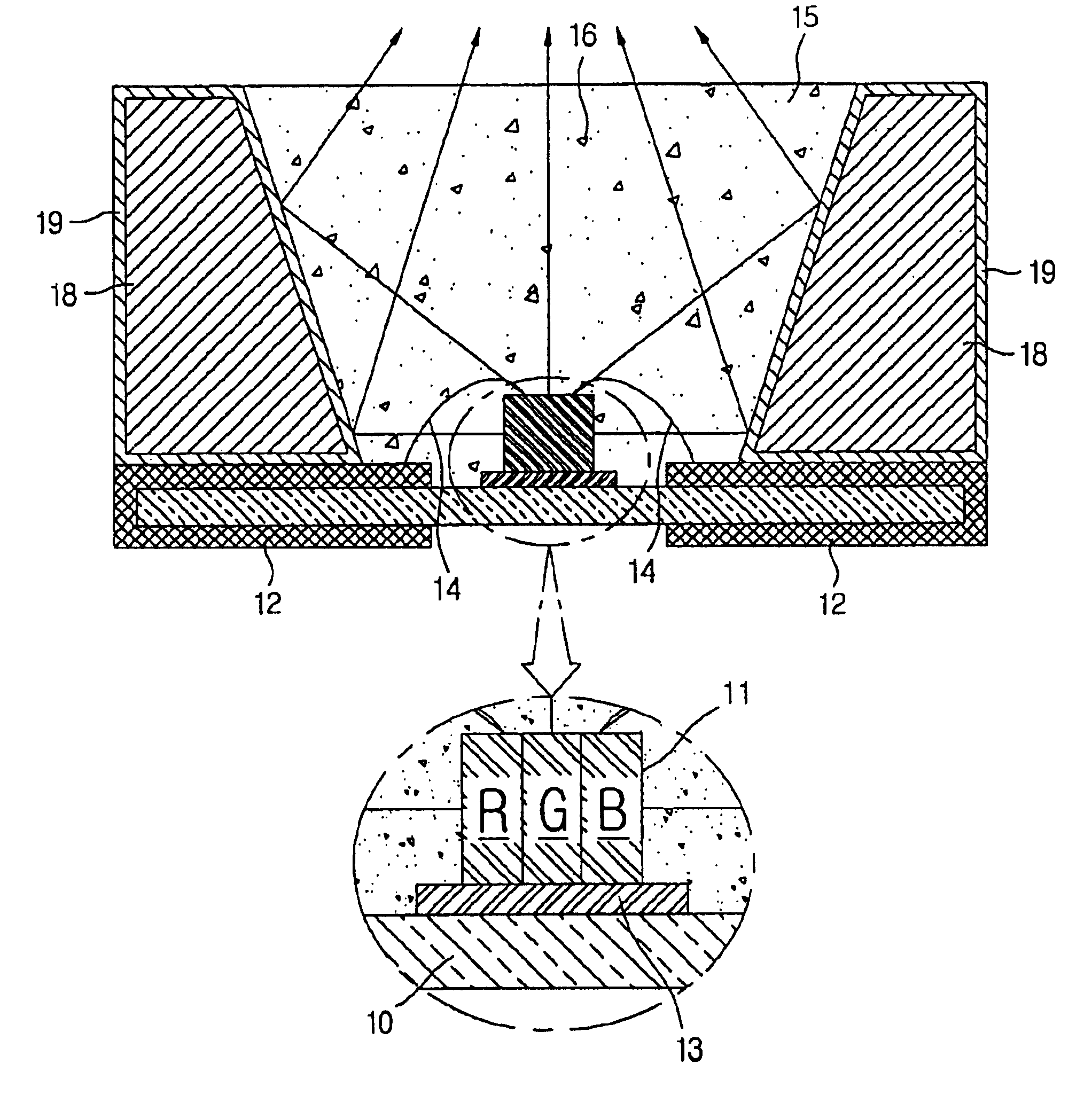

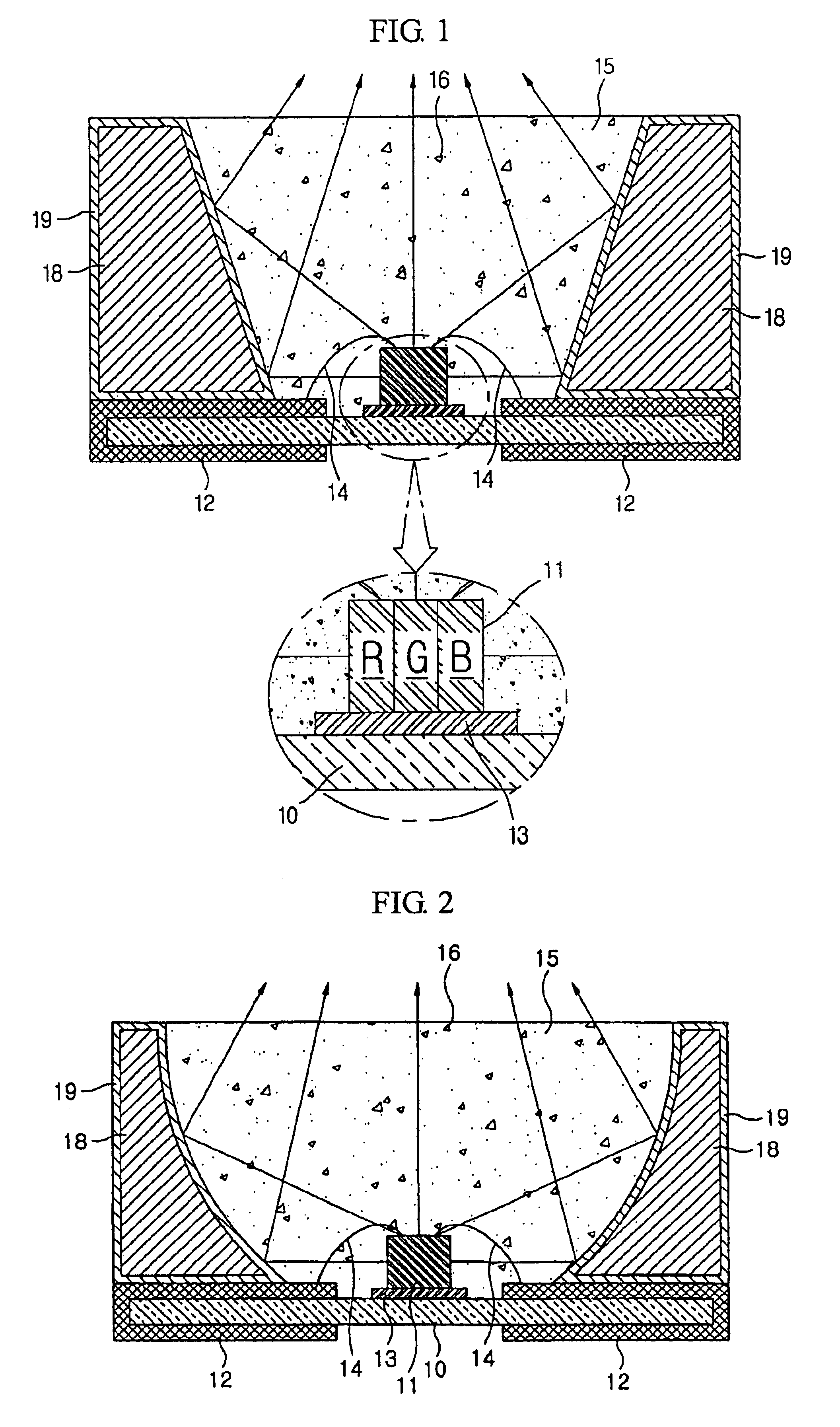

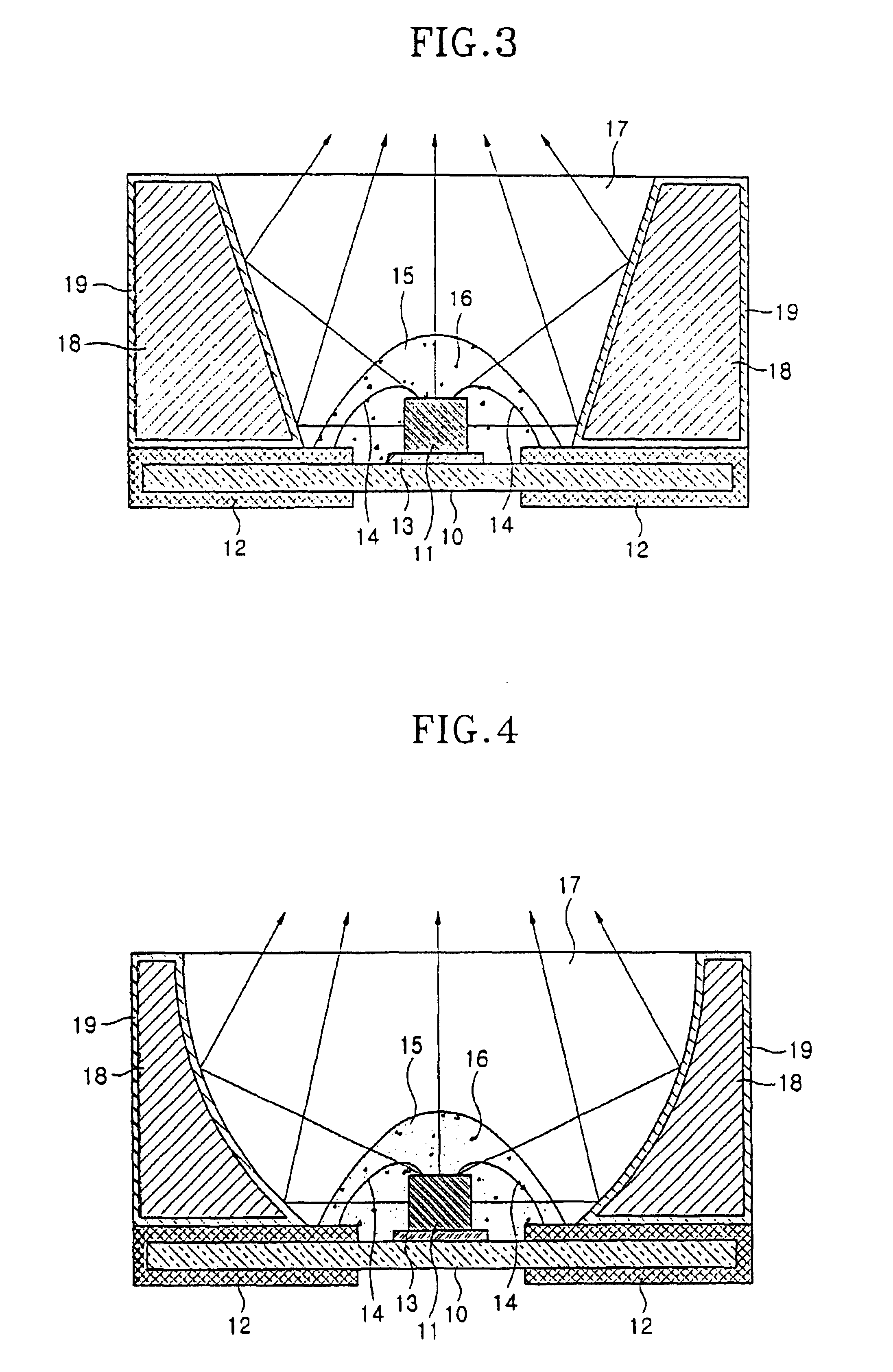

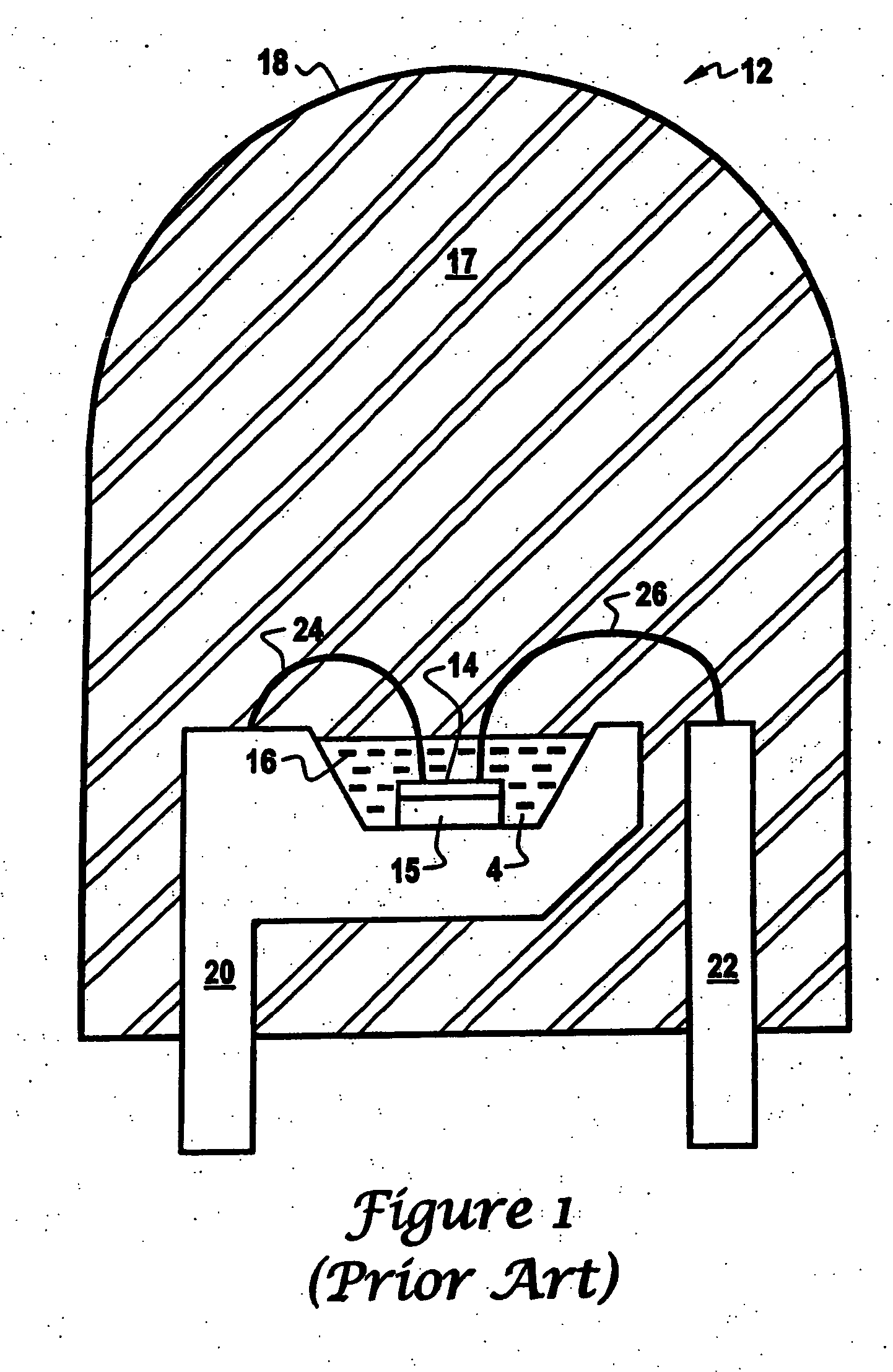

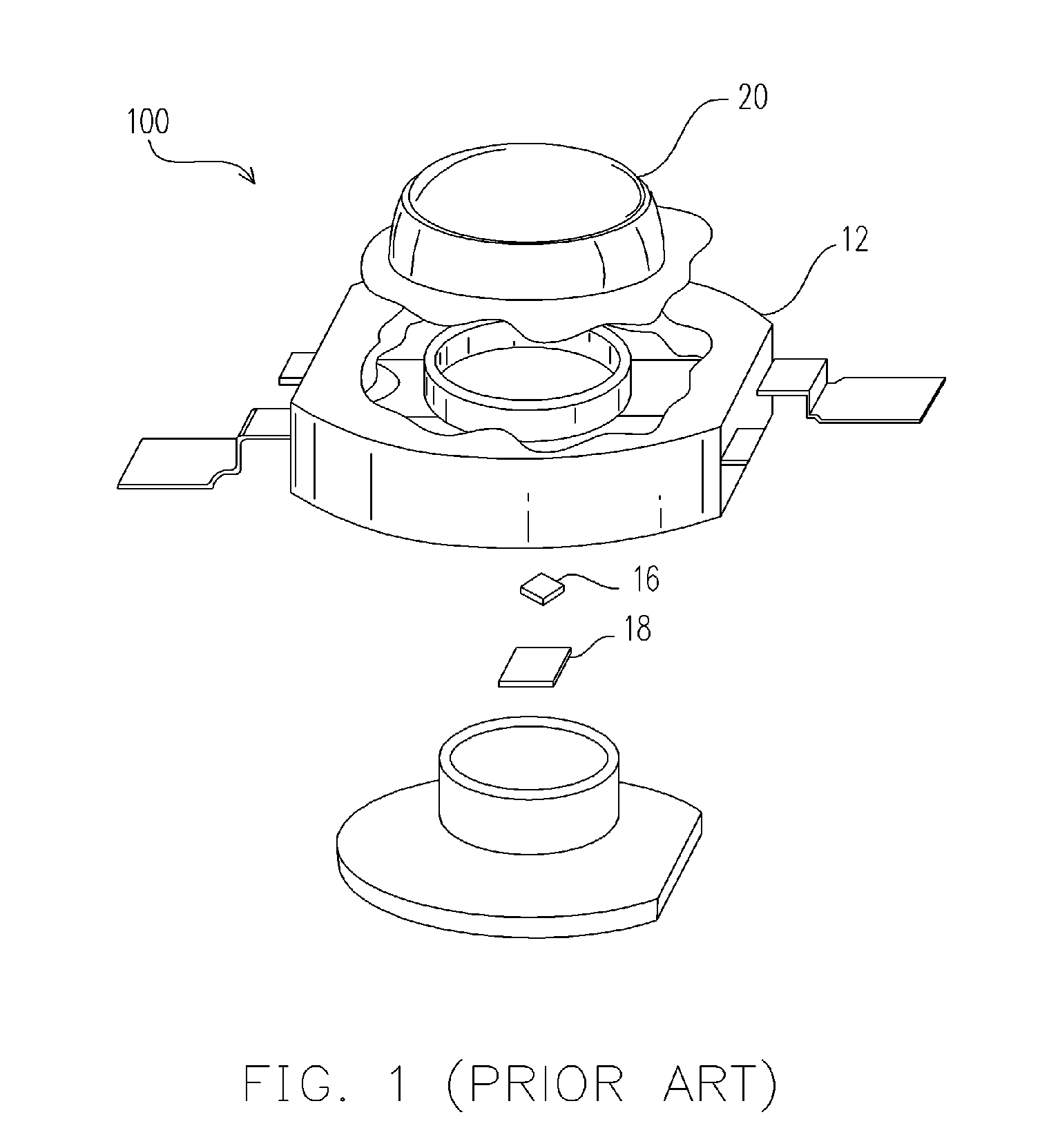

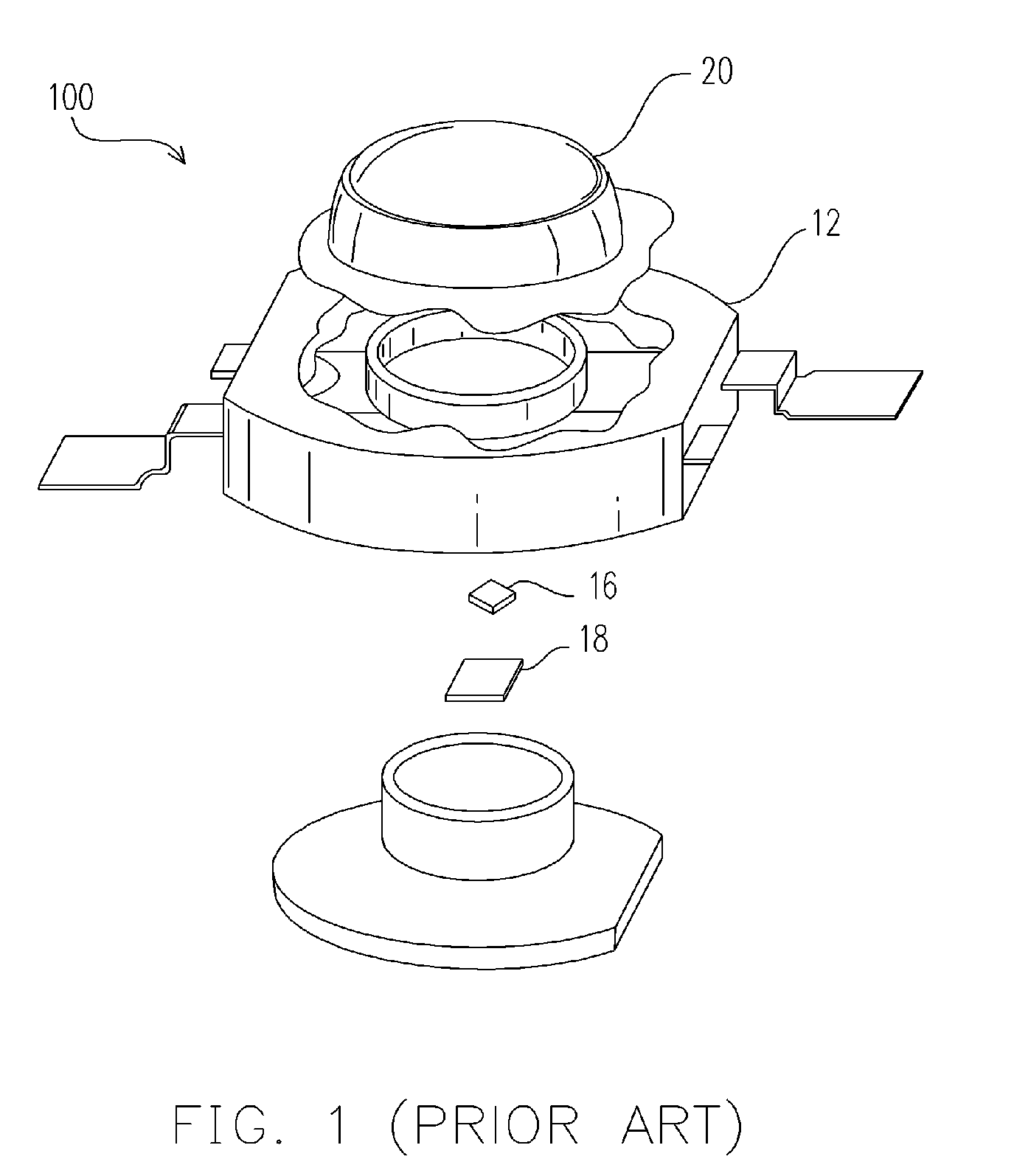

Semiconductor light emitting device with reflectors having cooling function

InactiveUS6909123B2Improve thermal conductivityImprove reflectivitySolid-state devicesSemiconductor/solid-state device manufacturingLength waveLight emitting device

A semiconductor light emitting device includes a base substrate, lead electrodes provided on the base substrate, at least one semiconductor light emitting element loaded on the base substrate so as to be spaced apart from the lead electrodes and radiating blue light, a connection member for electrically interconnecting the electrodes and the semiconductor light emitting element, a reflector extended from a bottom of the base substrate to a predetermined height for surrounding the semiconductor light emitting element, and a translucent cover layer formed in the receiving space for housing the light emitting element, the translucent cover layer containing a color-shifting substance for absorbing at least a part of blue light radiated from the light emitting element to radiate a light having a different wavelength. The reflector is made of a material having high translucency and high thermal conductivity on a surface thereof so as to reflect the light radiated from the light emitting element and form a uniform planar light, and the reflector radiates the heat radiated from the light emitting element to outside so as to cool an inside of a receiving space for receiving the light emitting element. Thus, the device emits white light outside by combination of the blue light radiated from the light emitting element and the light having a different wavelength.

Owner:HIGH POWER LIGHTING CORP

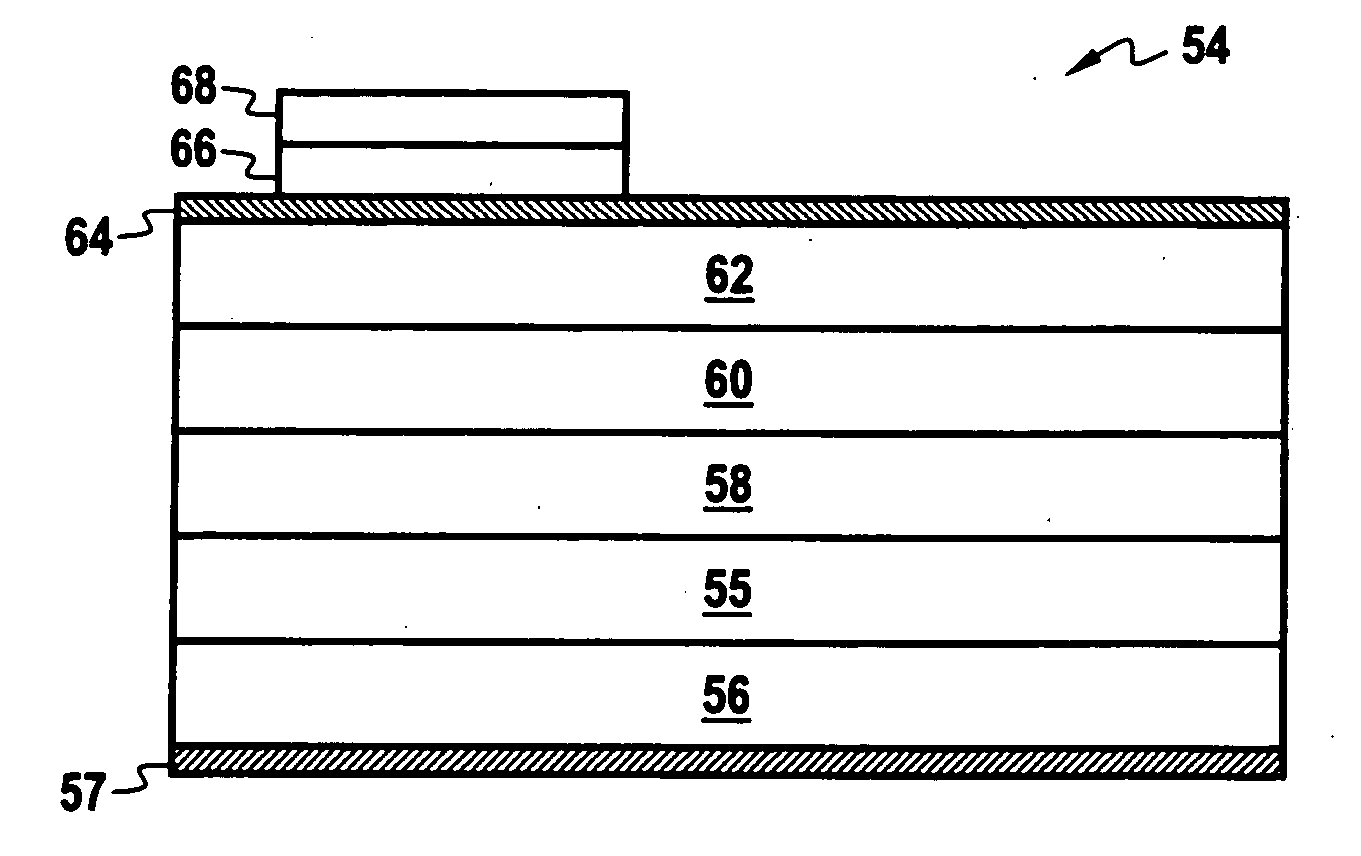

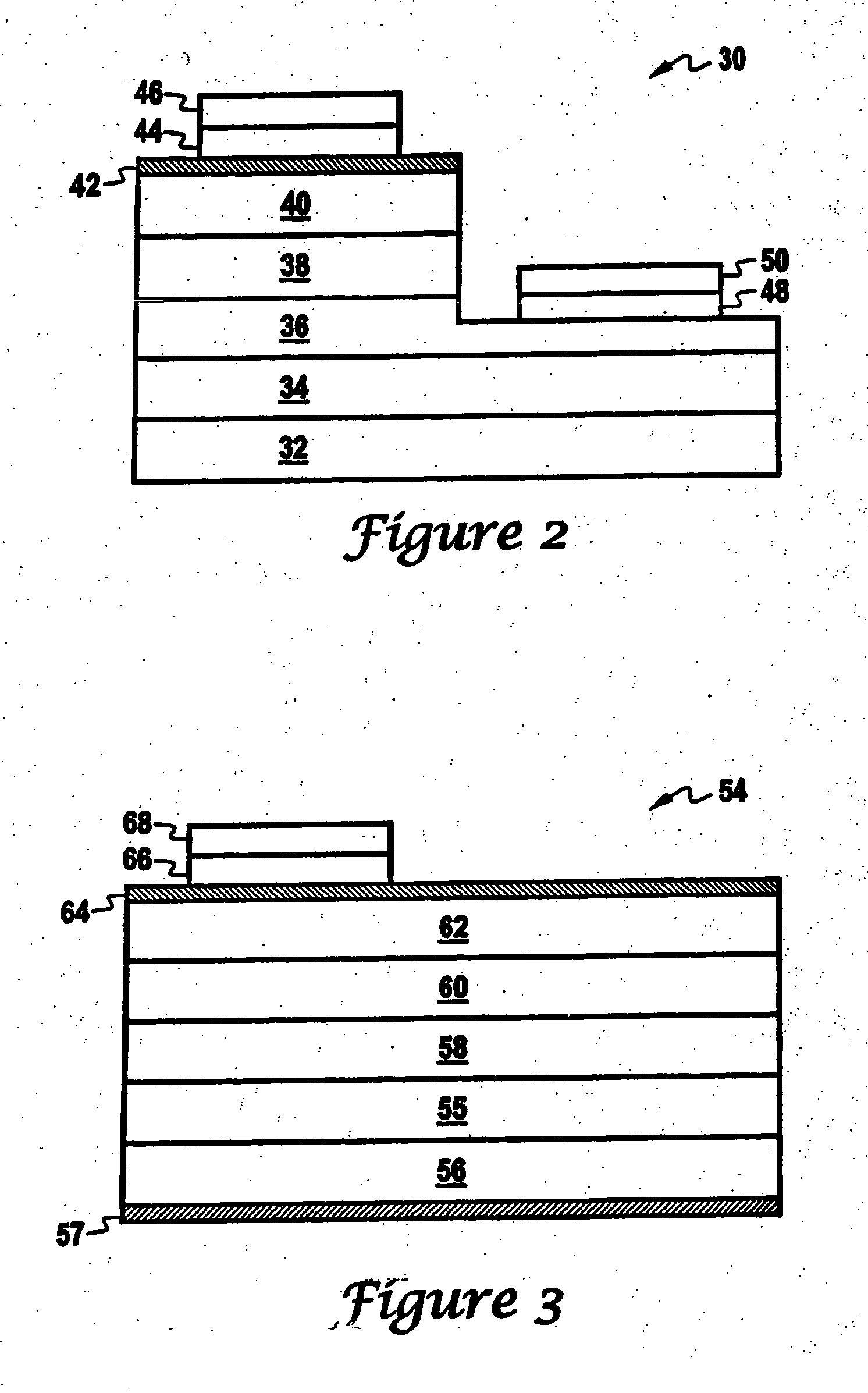

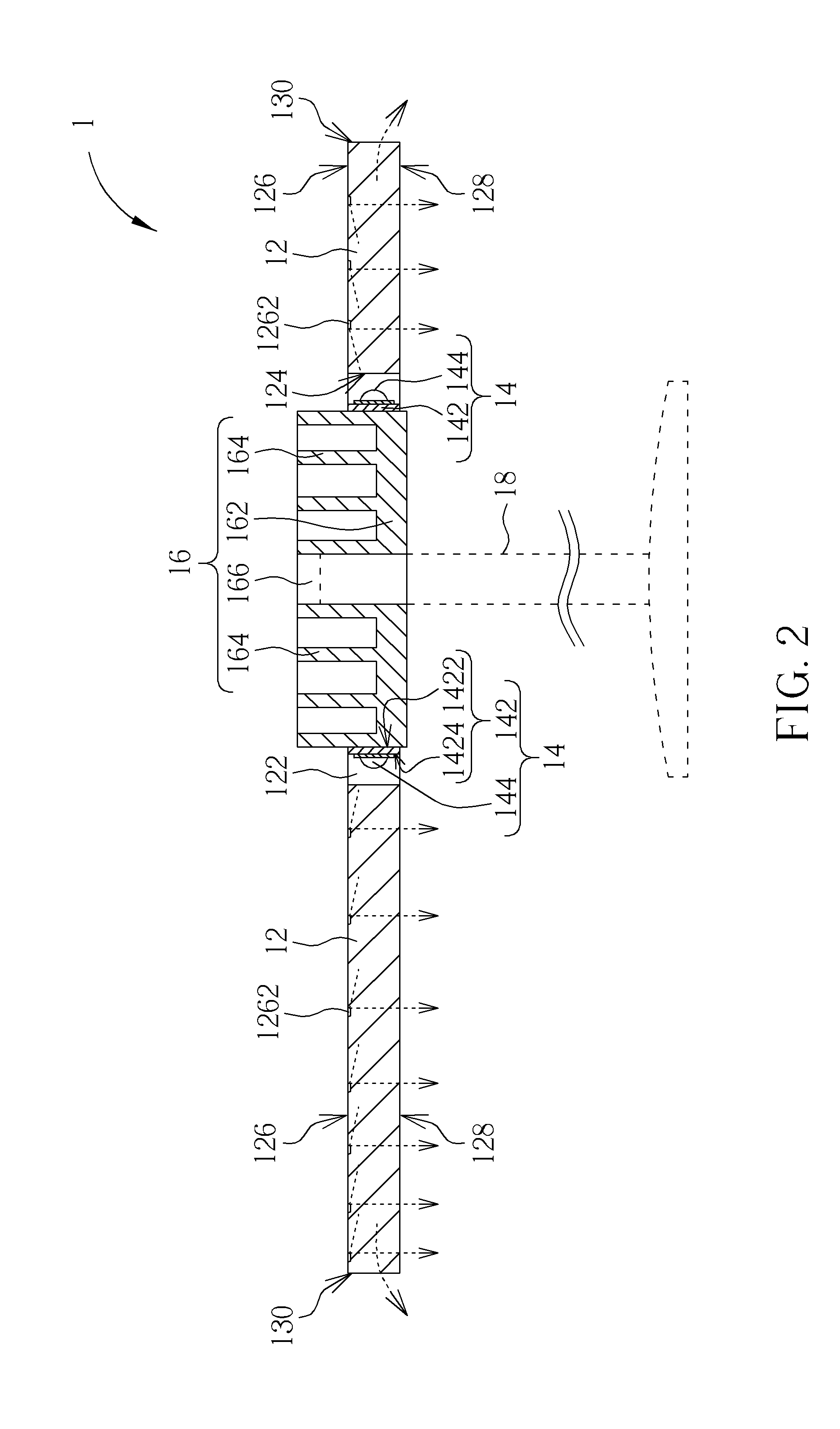

Light source module with wavelength converting structure and the method of forming the same

InactiveUS20090194774A1Reduce impactImprove light uniformitySolid-state devicesNon-linear opticsLength waveWavelength conversion

A light source package module with a wavelength converting structure is provided. The light source package module comprises a frame having a substrate and sidewalls formed on the substrate. A plurality of LED dice is disposed on the substrate, and there is a space between each of the LED dice. A wavelength converting structure is disposed on above the plurality of LED dice and the sidewalls. The light source package can provide a flat light source with a large emitting area can be made in simply as well. Additionally, the present invention further relates to the application of a backlight module.

Owner:KISMART

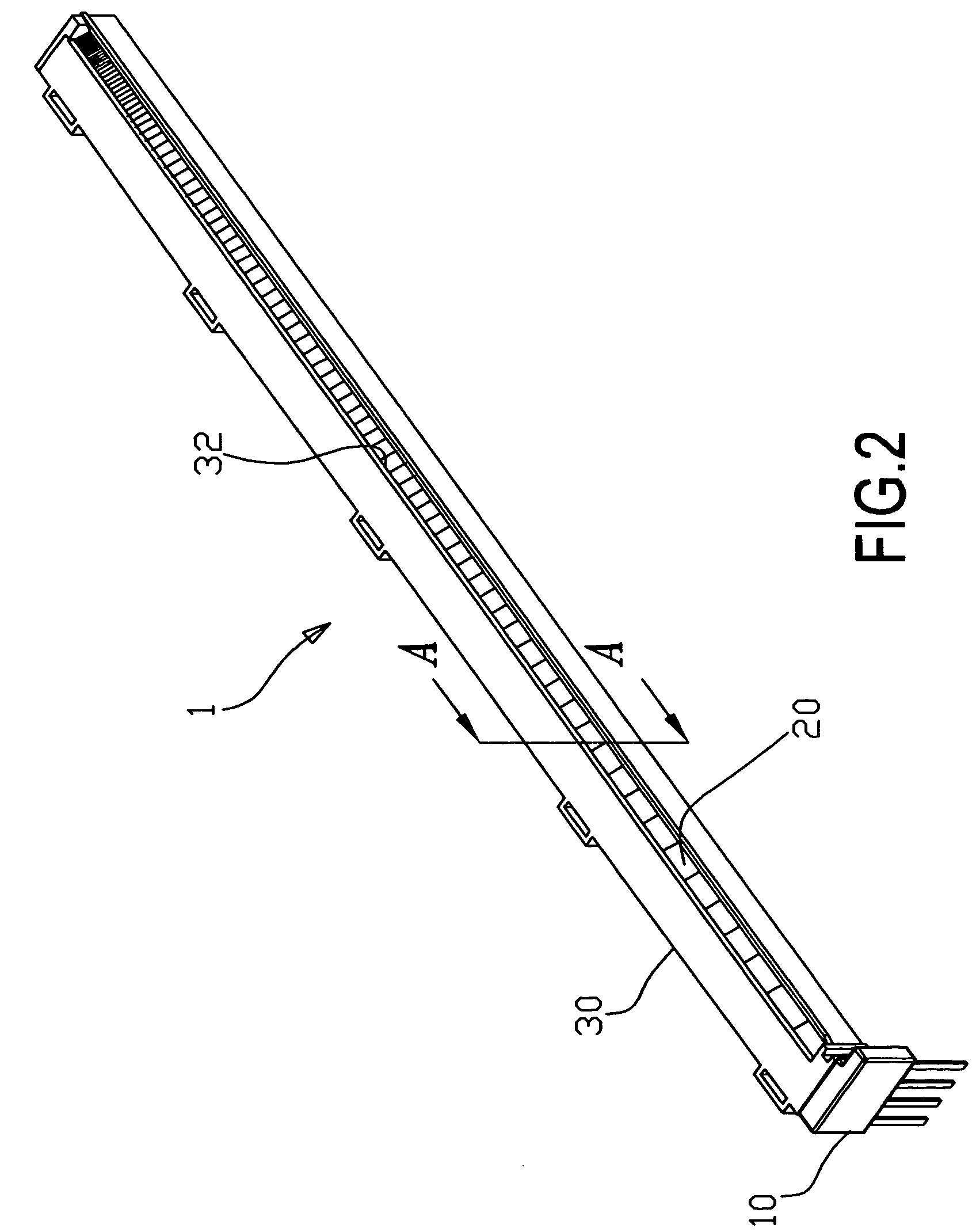

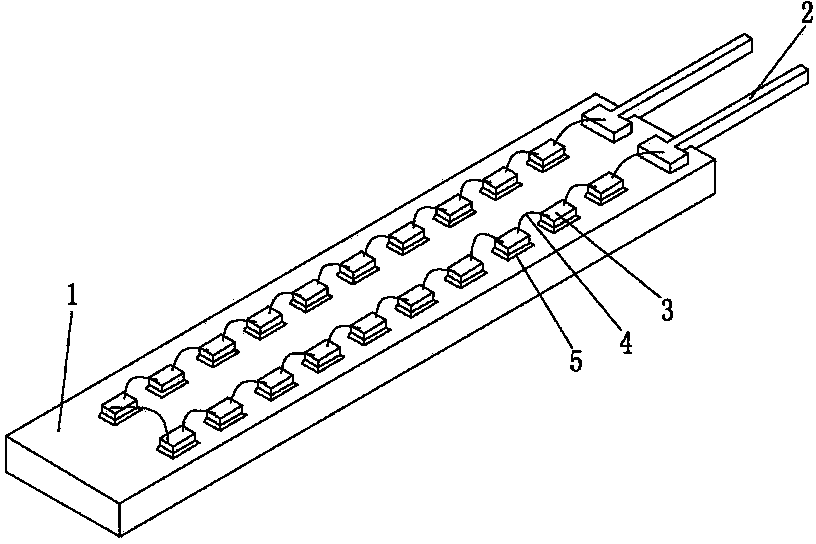

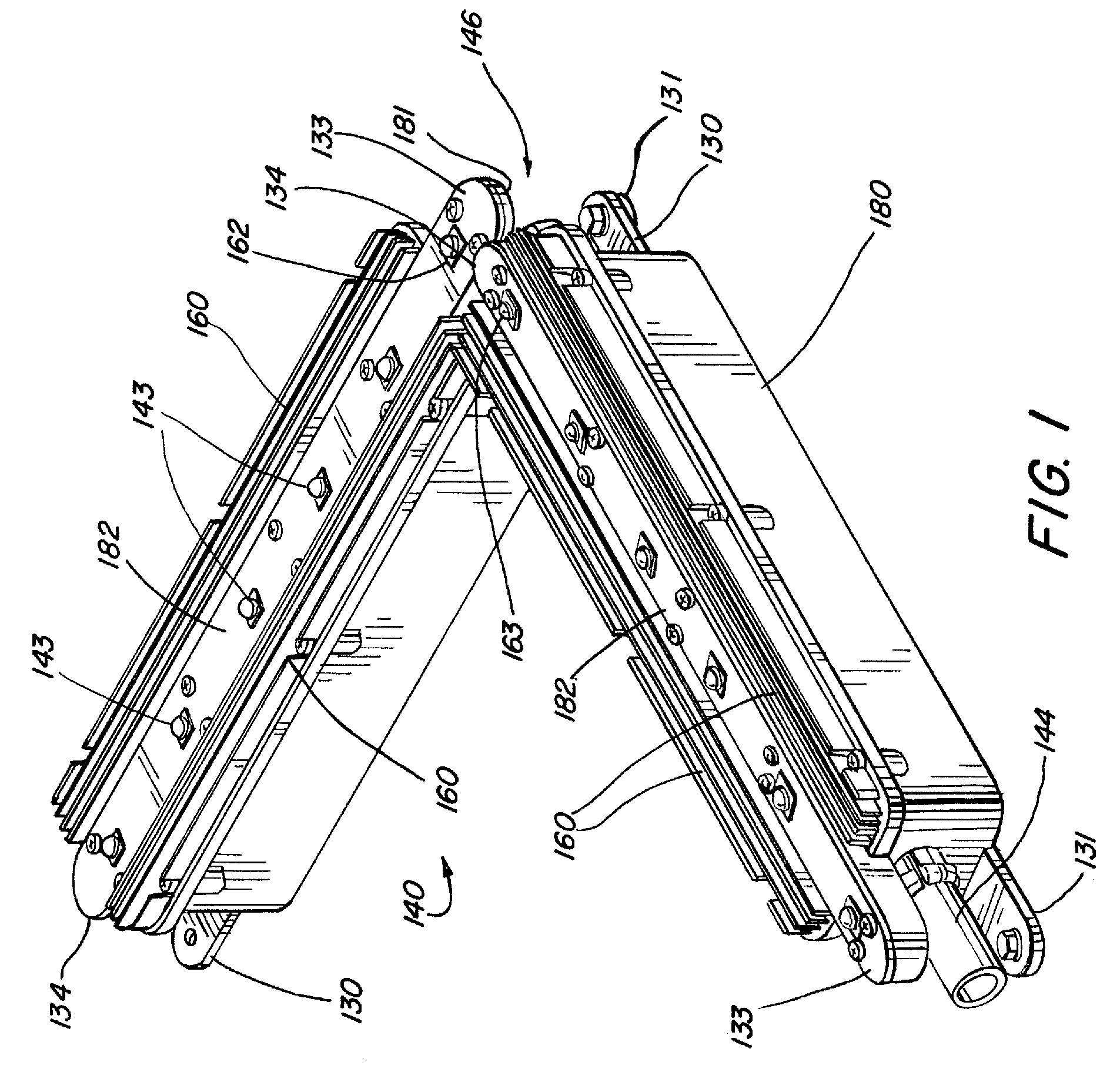

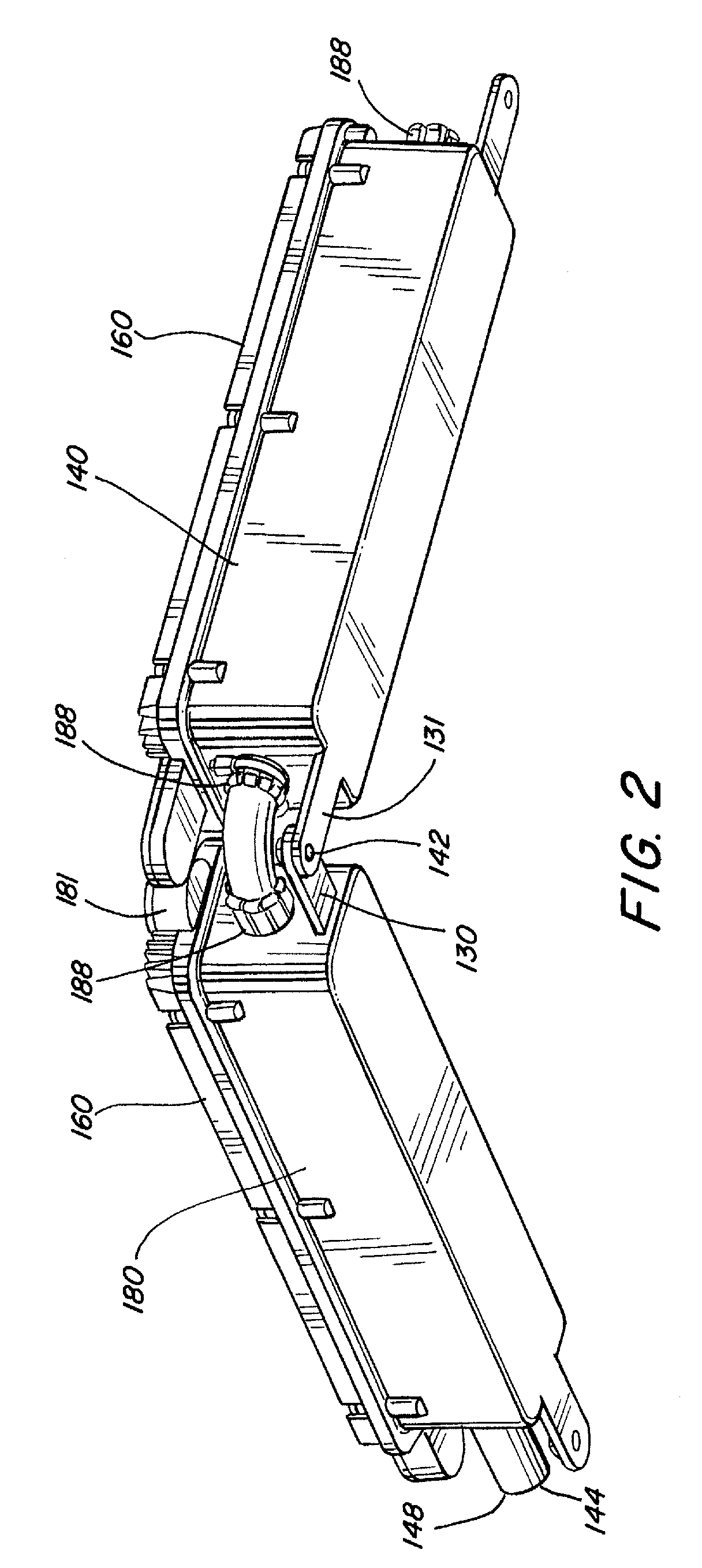

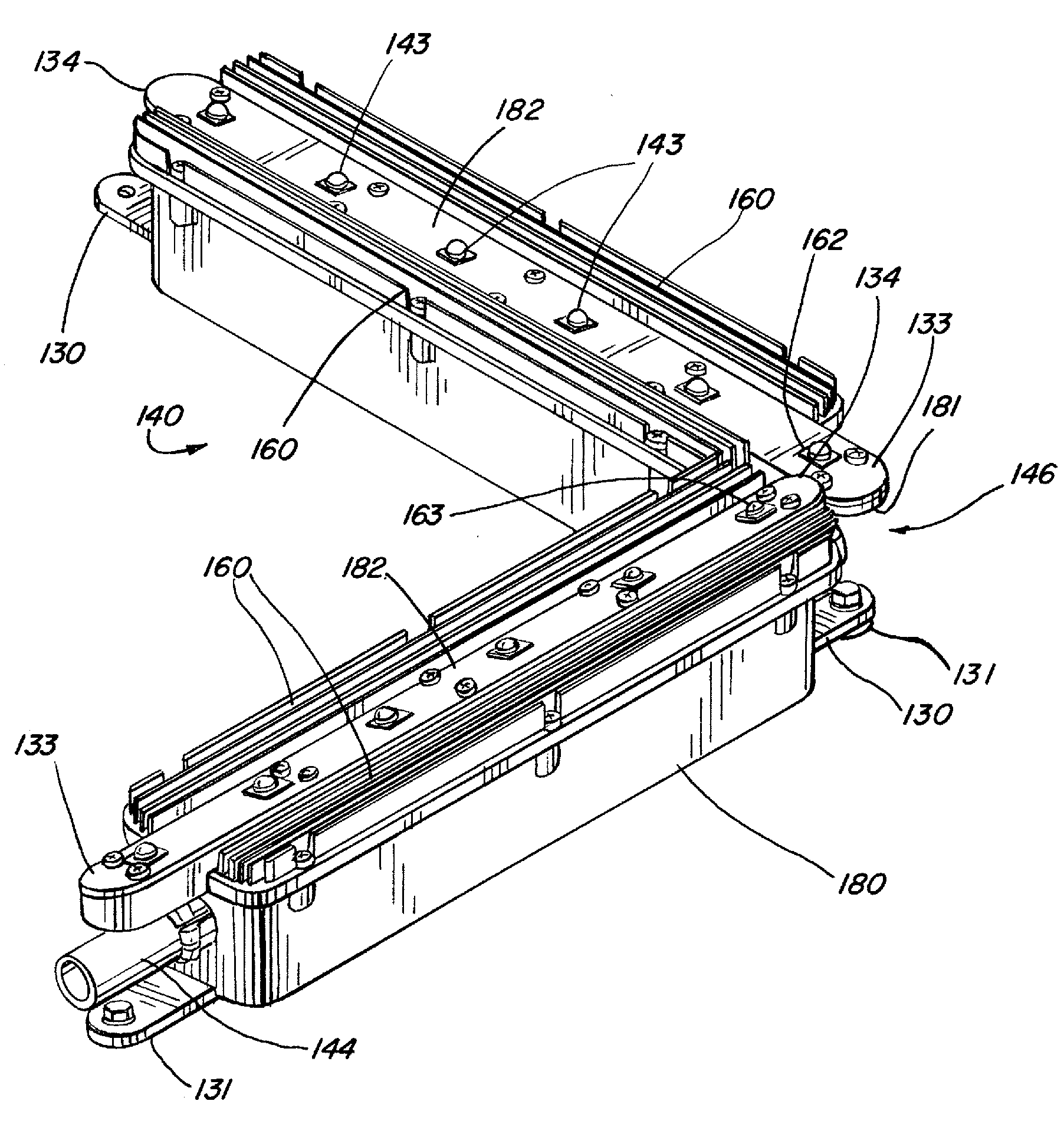

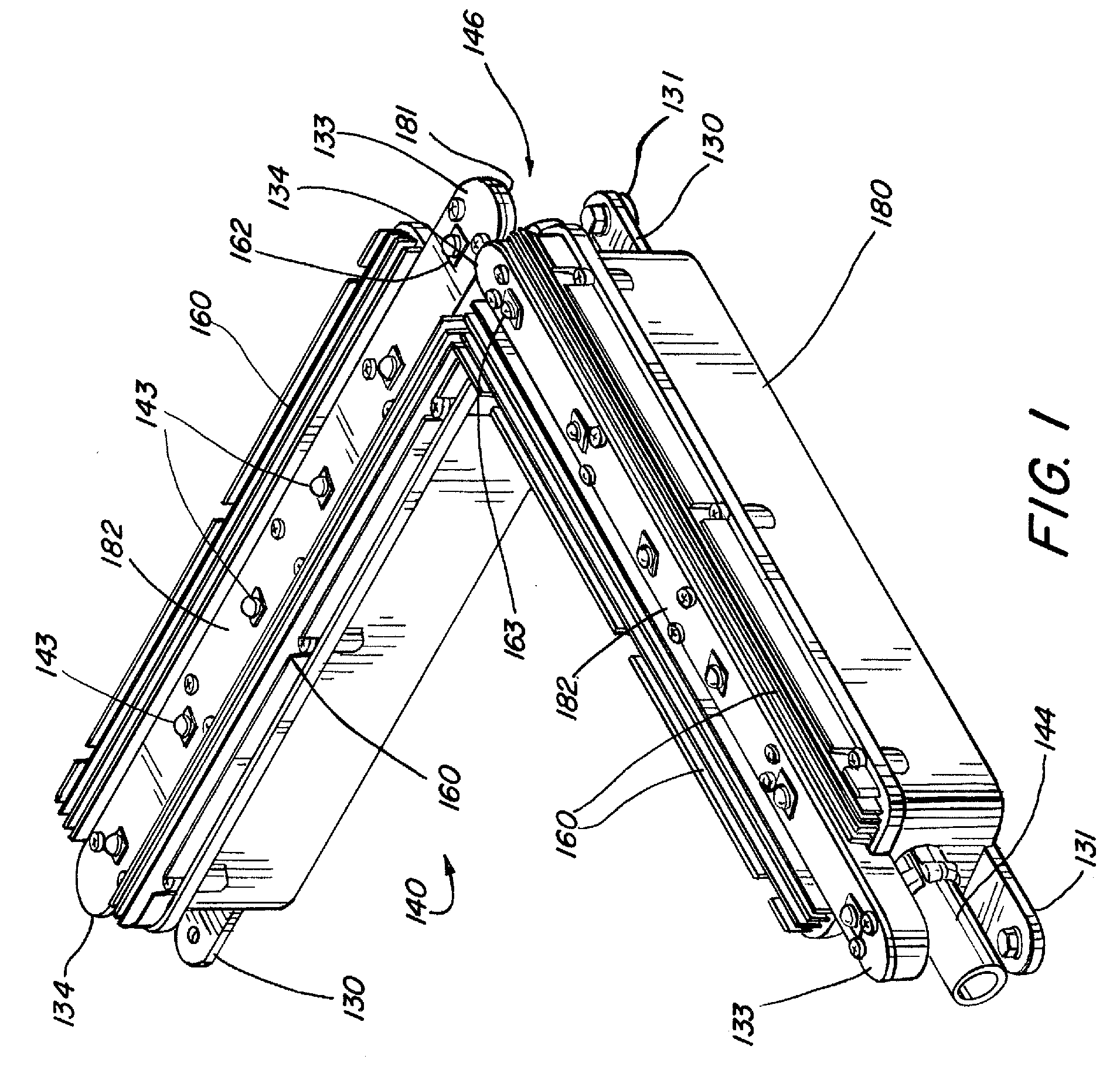

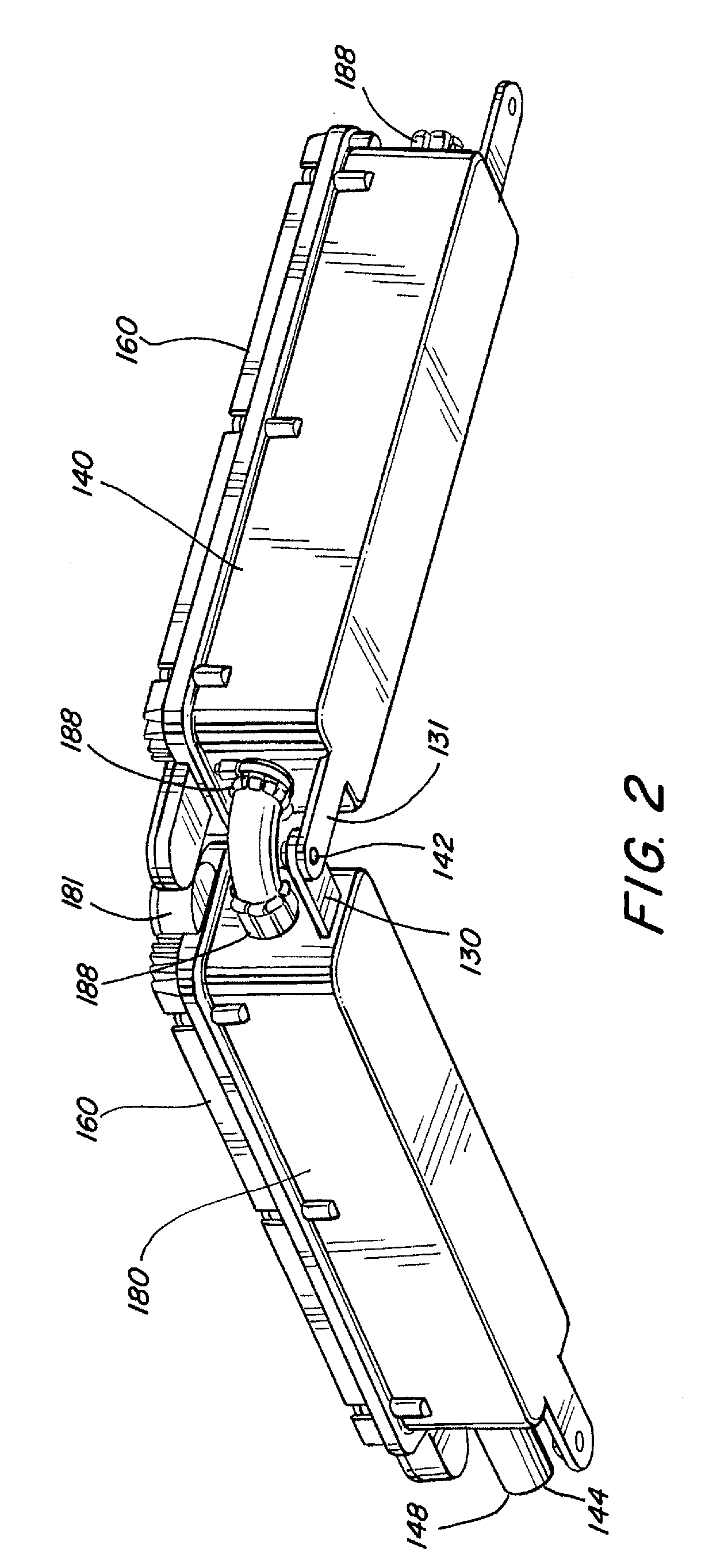

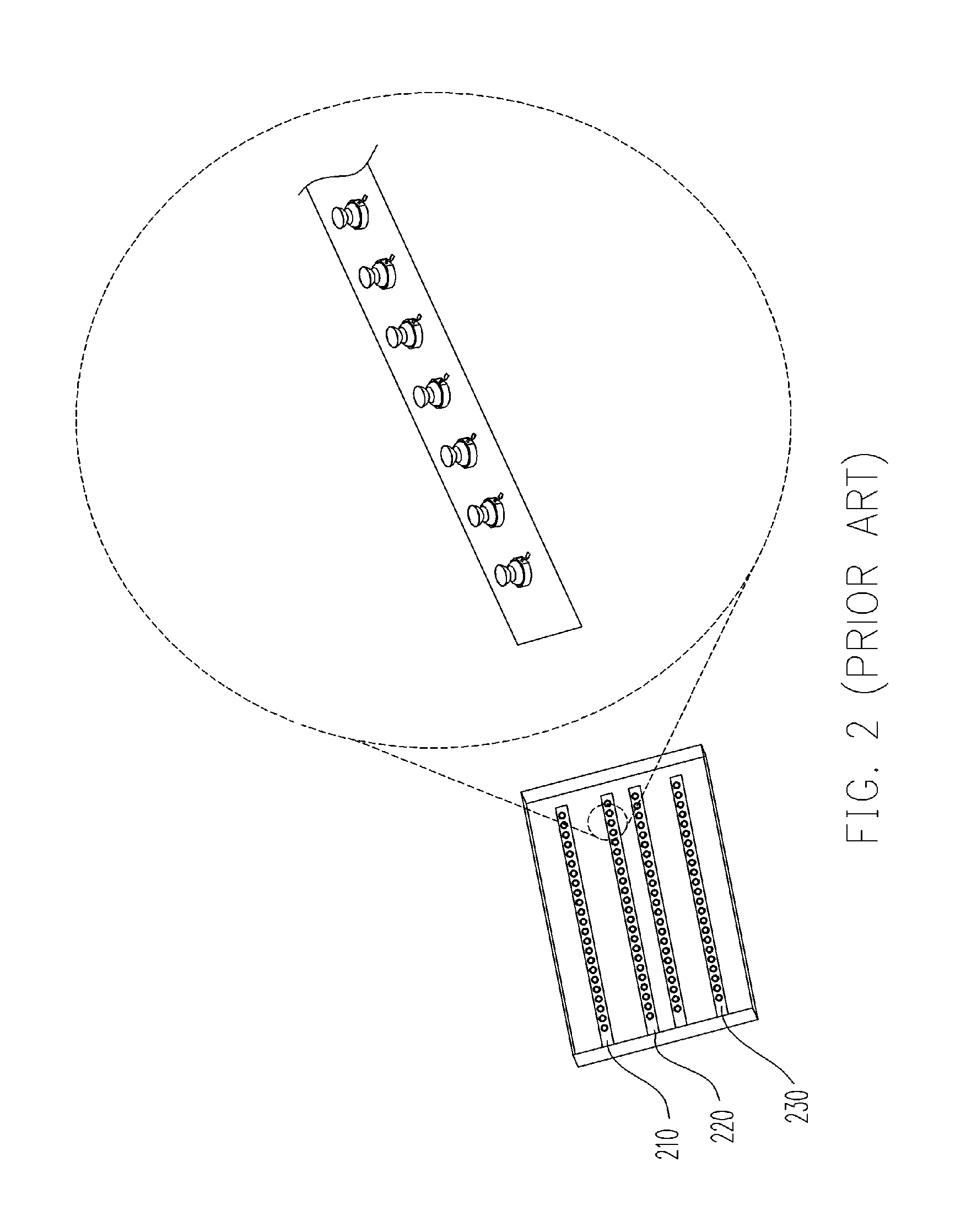

Modular LED lighting fixtures

ActiveUS7726840B2Easy to installEasy to useLighting support devicesPoint-like light sourceElectrical conductorDark spot

Concatenatable lighting fixtures, each comprising a unitary cover member having a circuit board mounting platform integrally formed with suitable heat sinking and which mounts onto a cooperating base chassis. In one embodiment, the circuit board mounting platform extends farther from one end of the cover member than the other so as to facilitate placement of LEDs in a fashion which enhances lighting uniformity and minimizes dark spots. In one embodiment, first and second guide members may be positioned in respective opposite ends of adjacent fixtures, each guide member having a plurality of extending fingers with a flexible electrical conductor-carrying conduit disposed between the respective opposite ends and retained in position by the fingers.

Owner:KORRUS INC

Apparatus, method, and system for independent aiming and cutoff steps in illuminating a target area

ActiveUS20120307486A1Easy to controlReduced EPAMechanical apparatusLighting support devicesProject areaEffect light

A lighting fixture is presented comprising a plurality of modular apparatuses wherein each modular apparatus comprises one or more light sources and one or more light directing or light redirecting devices. Methods of adjusting one or more components of said lighting fixture about one, two, or three axes are presented whereby the lighting needs of a target area—even one of complex shape—may be addressed and in a manner that promotes compact fixture design with low effective projected area (EPA) without sacrificing transmission efficiency of the light sources.

Owner:MUSCO

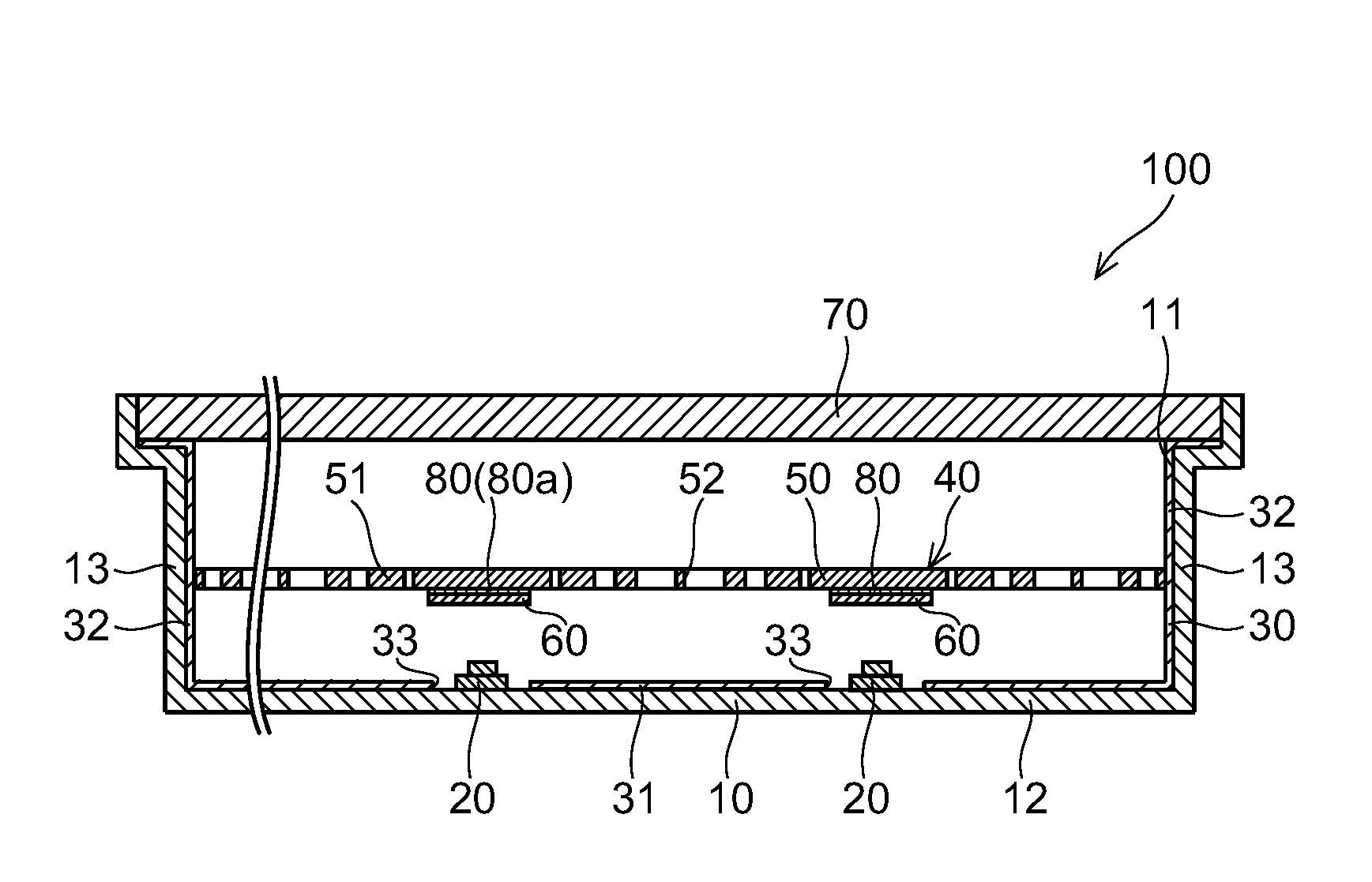

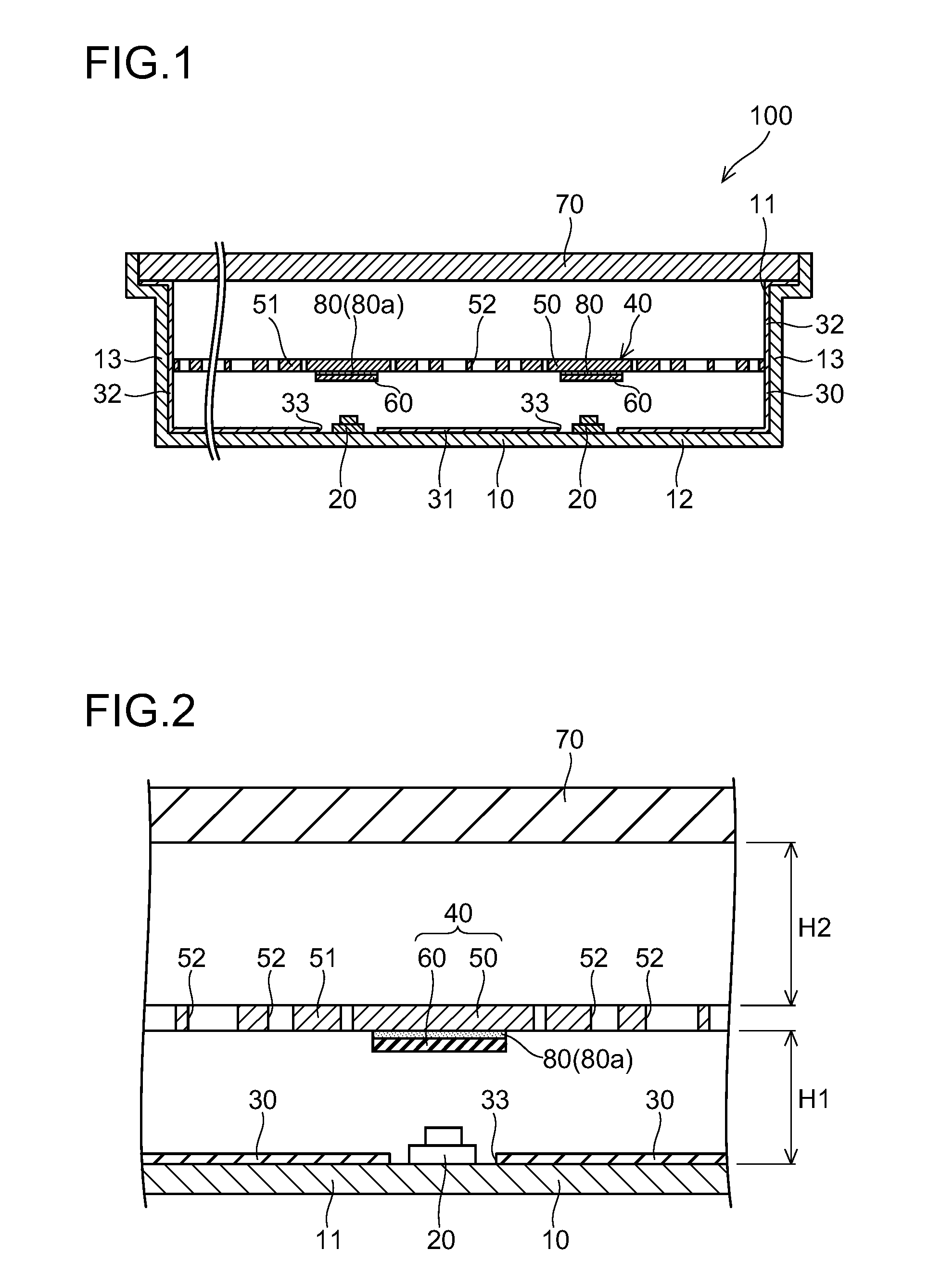

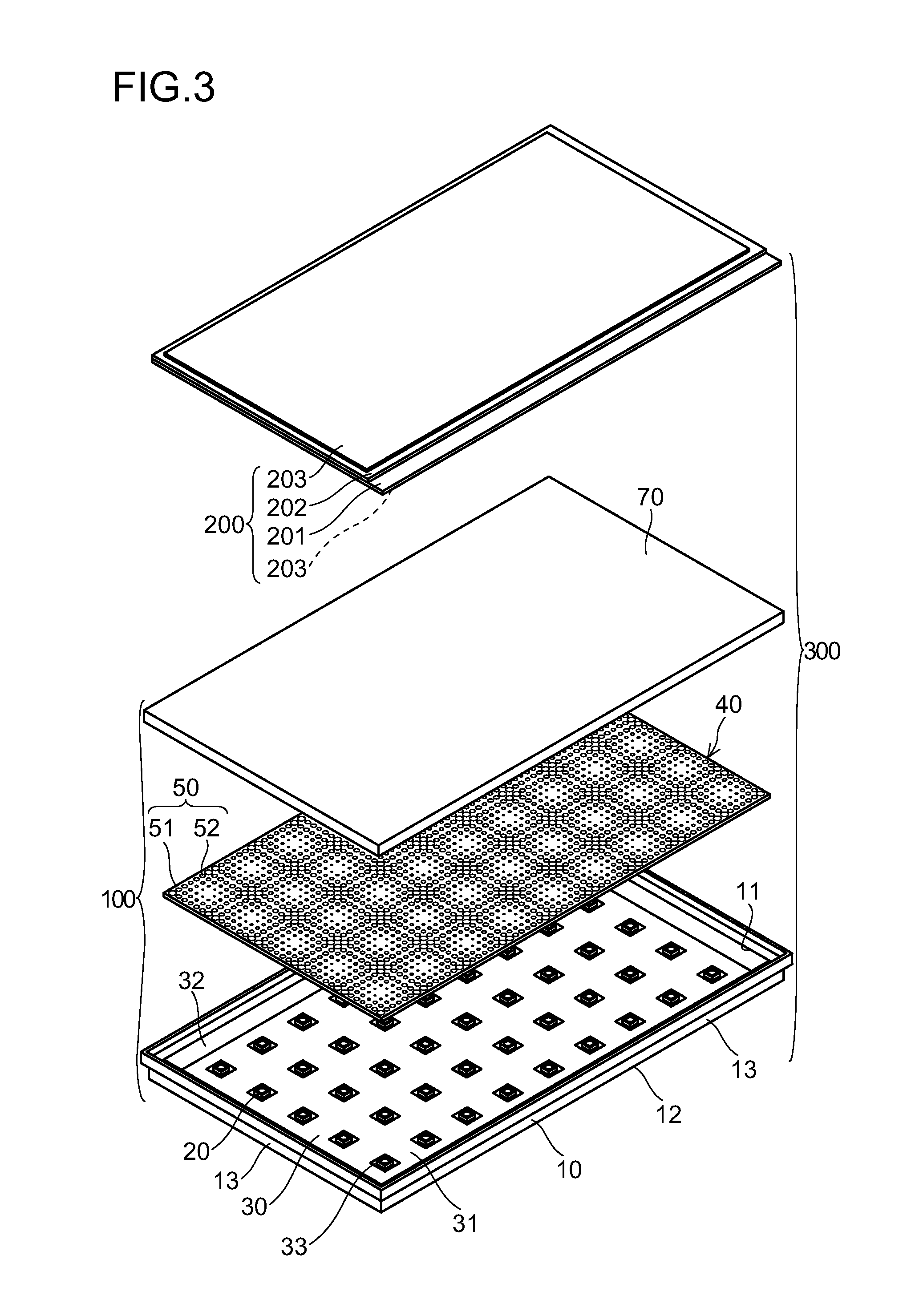

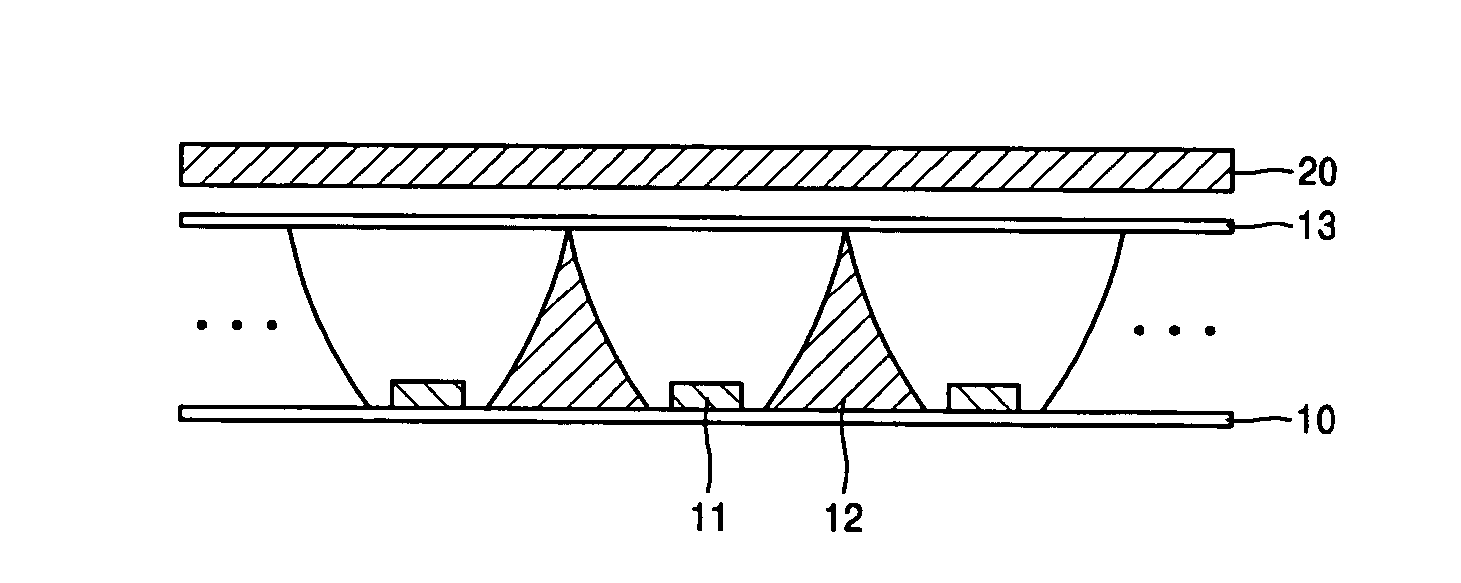

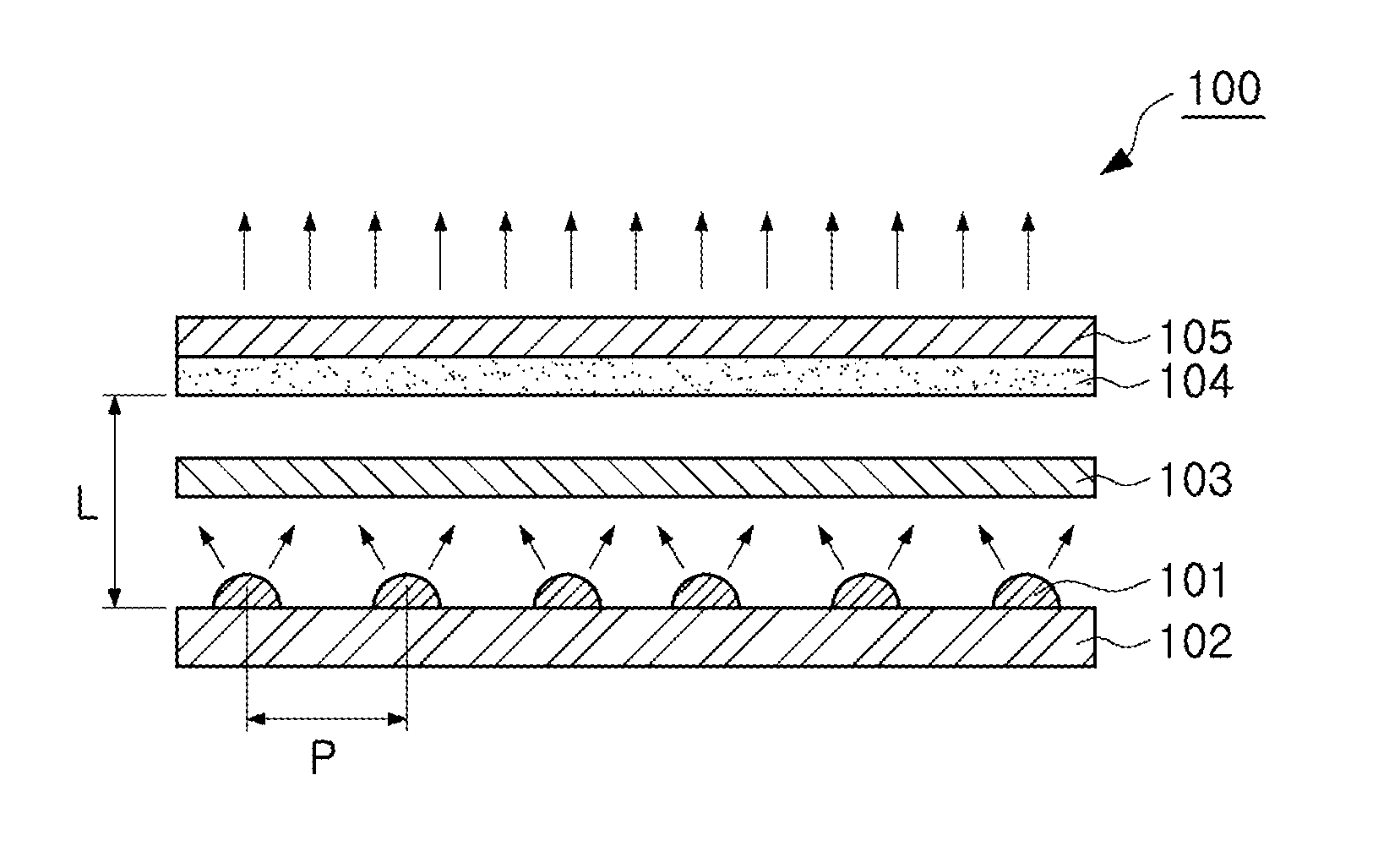

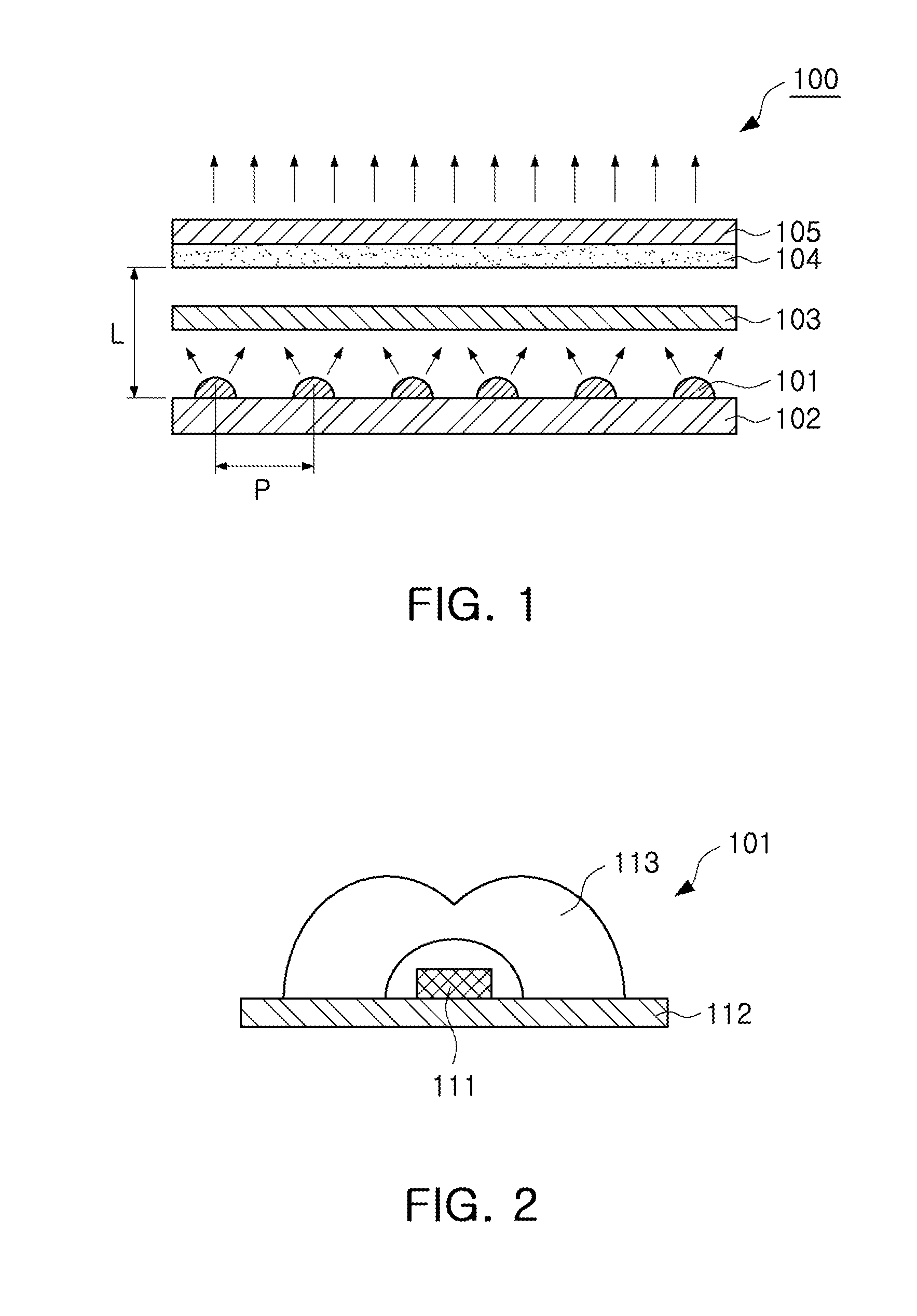

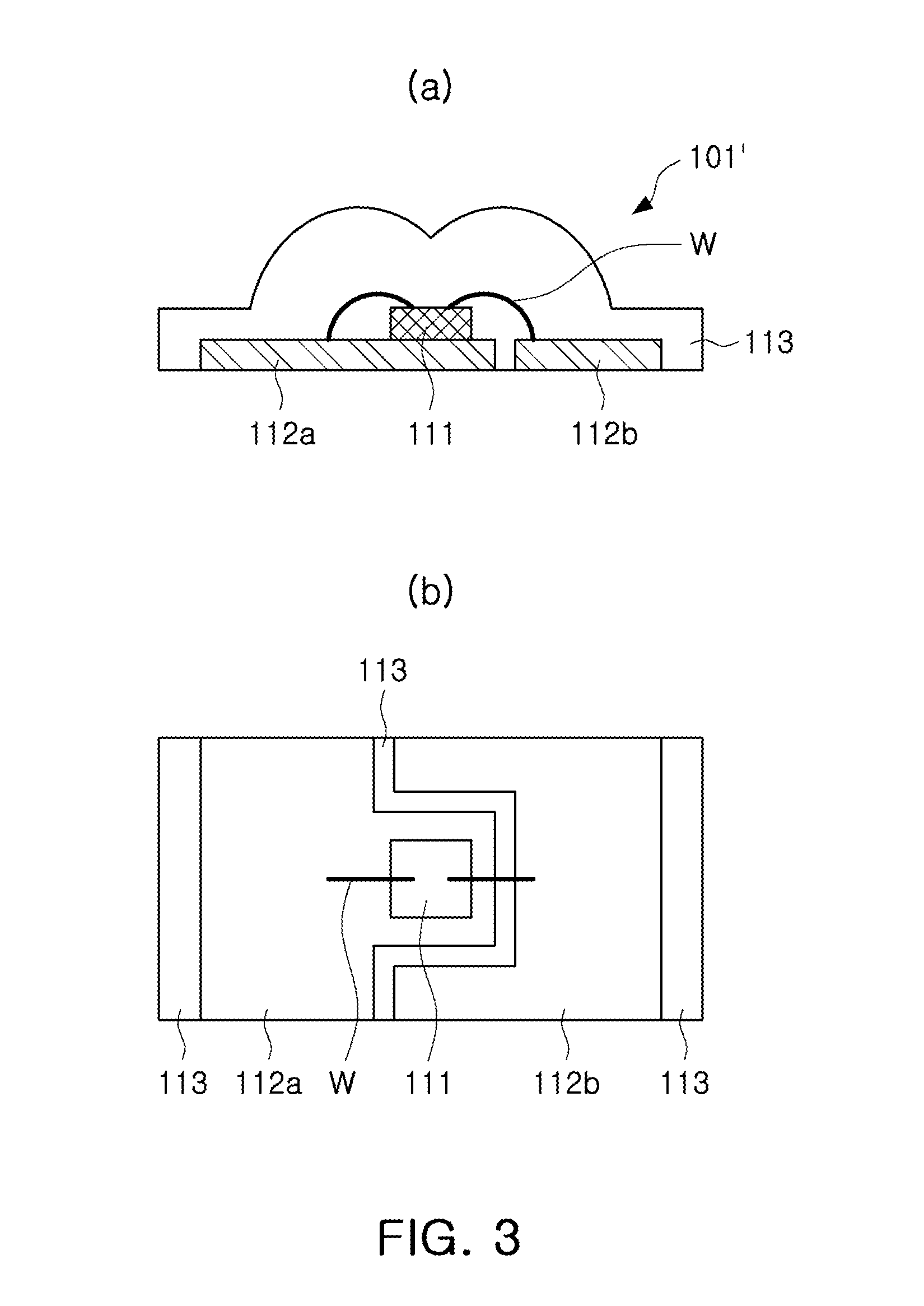

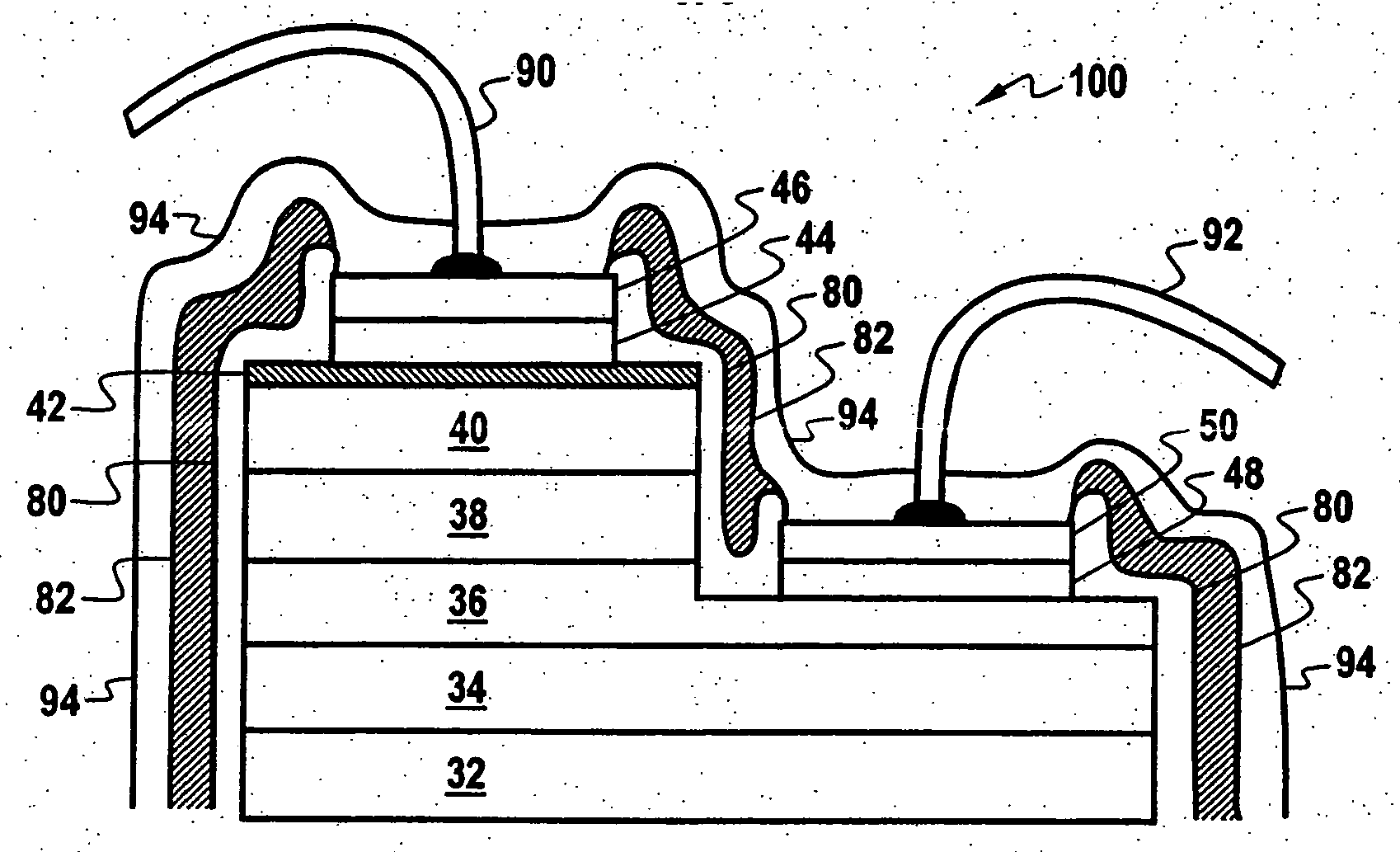

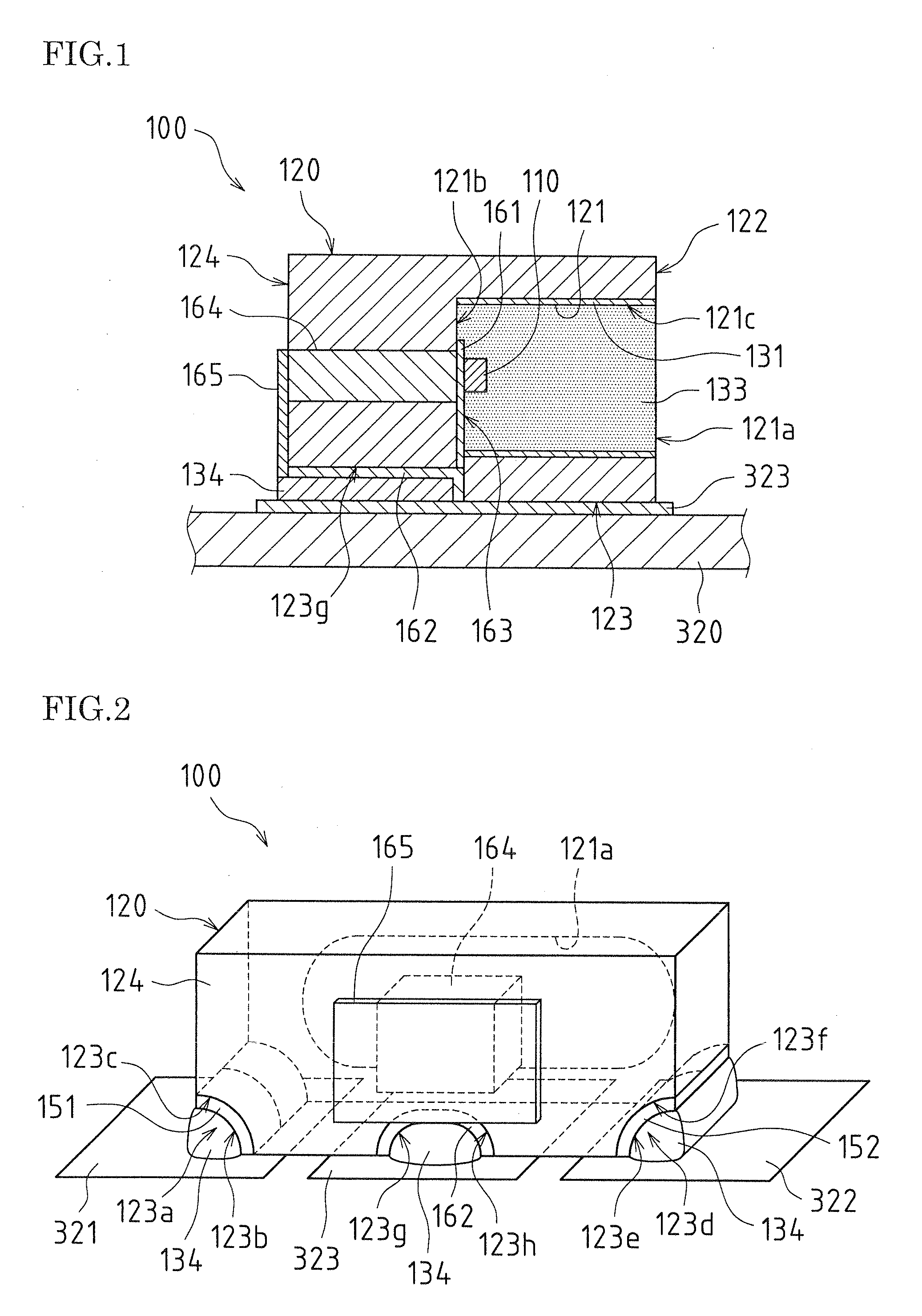

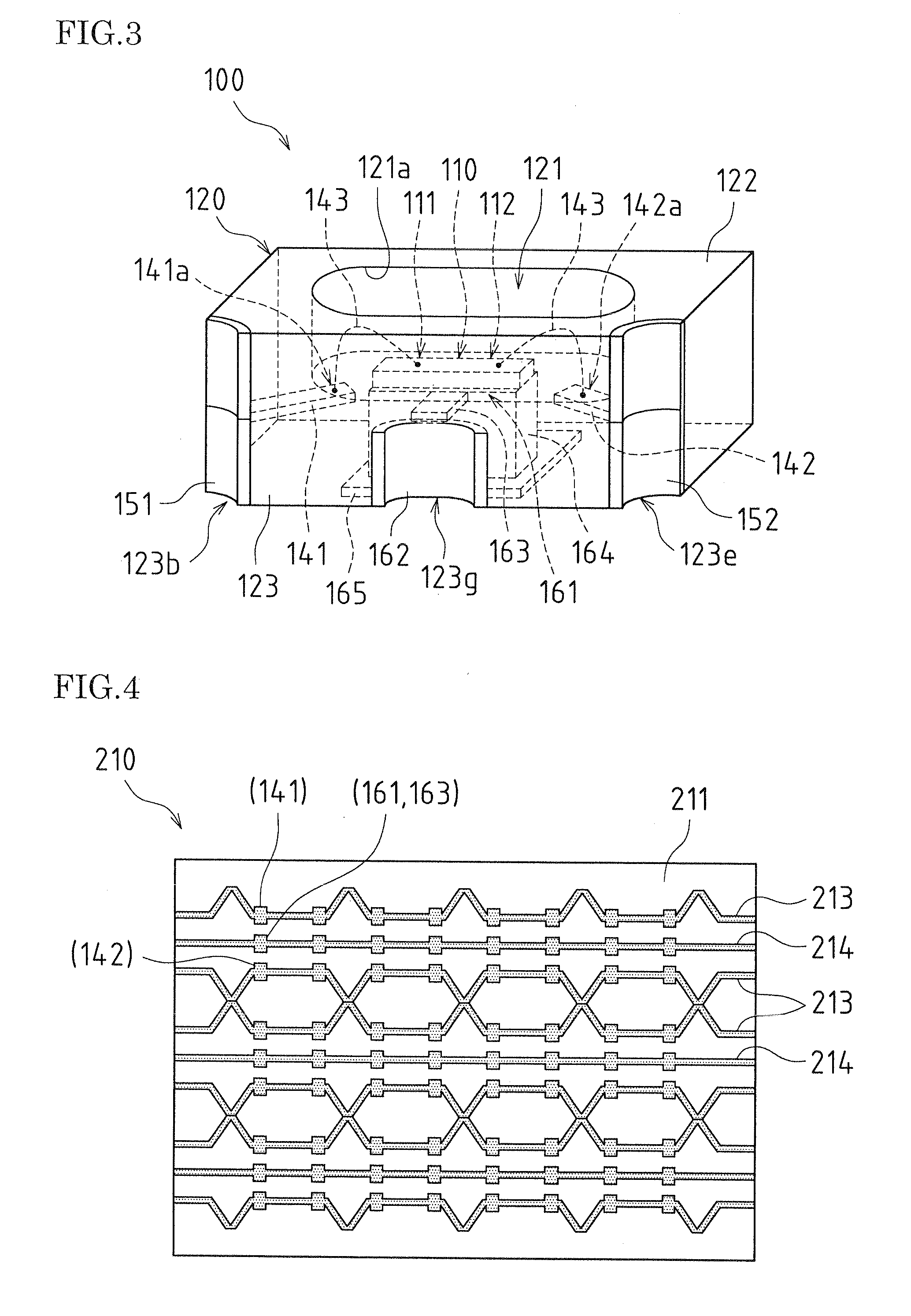

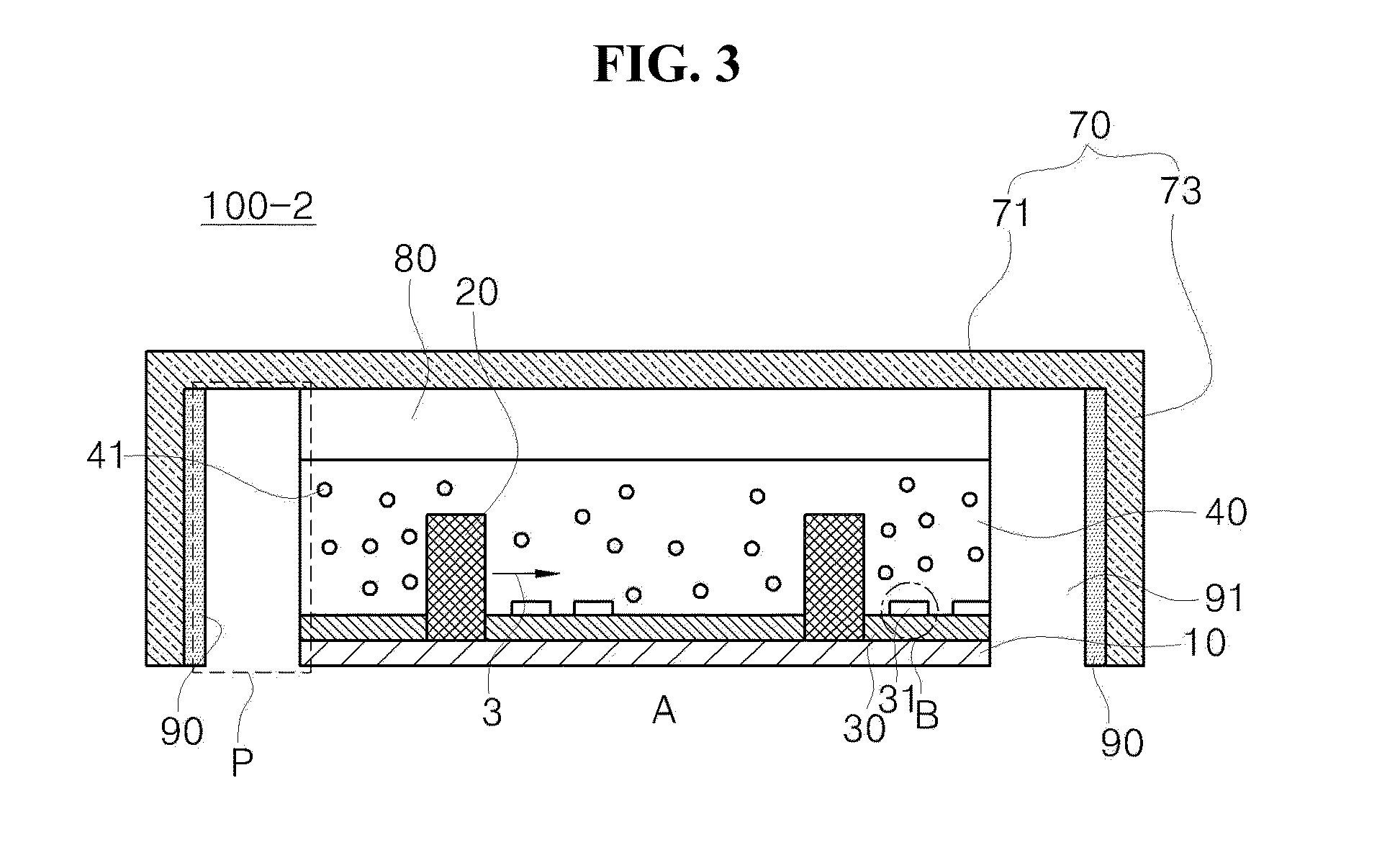

Light emitting device package, light source module, backlight unit, display apparatus, television set, and illumination apparatus

ActiveUS20110292302A1Reducing optical distanceReduce in quantityTelevision system detailsPoint-like light sourceElectricityTransmittance

A light source module, a backlight unit, a display apparatus, a television set, and an illumination apparatus are provided. The light source module includes: one or more light source units including a light emitting element emitting light when electricity is applied thereto; and an optical sheet disposed above the light source units and exhibiting bidirectional transmittance distribution function characteristics having first and second peaks at radiation angles less than 0° and greater than 0°.

Owner:SAMSUNG ELECTRONICS CO LTD

Thin film light emitting diode

InactiveUS20050093004A1Improve light uniformitySemiconductor/solid-state device detailsSolid-state devicesPhosphorGas phase

Owner:SUZHOU LEKIN SEMICON CO LTD

Light emitting sign and display surface therefor

InactiveUS7937865B2Improve light uniformityLow costIlluminated signsSpectral modifiersPhosphorDisplay device

Owner:INTEMATIX

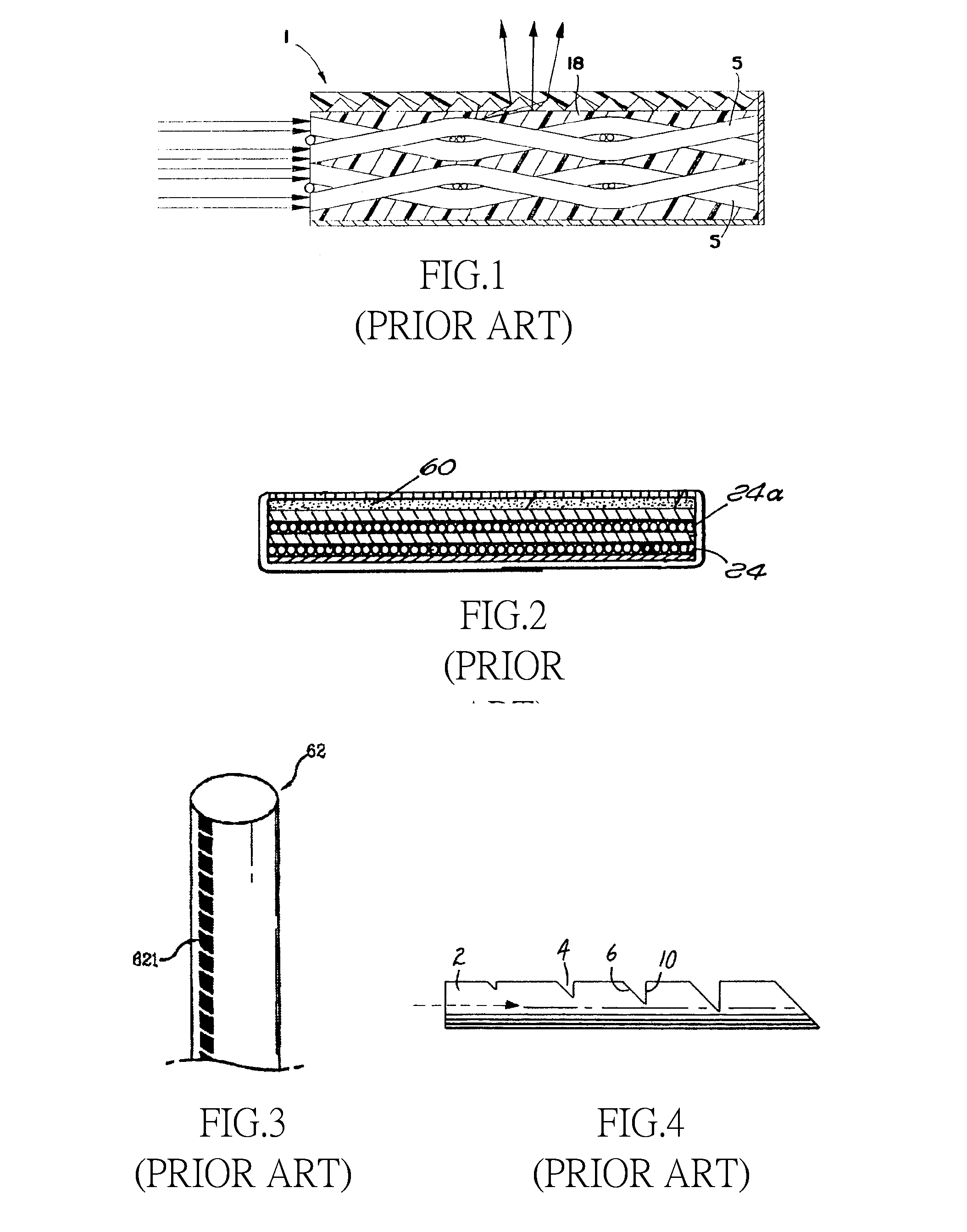

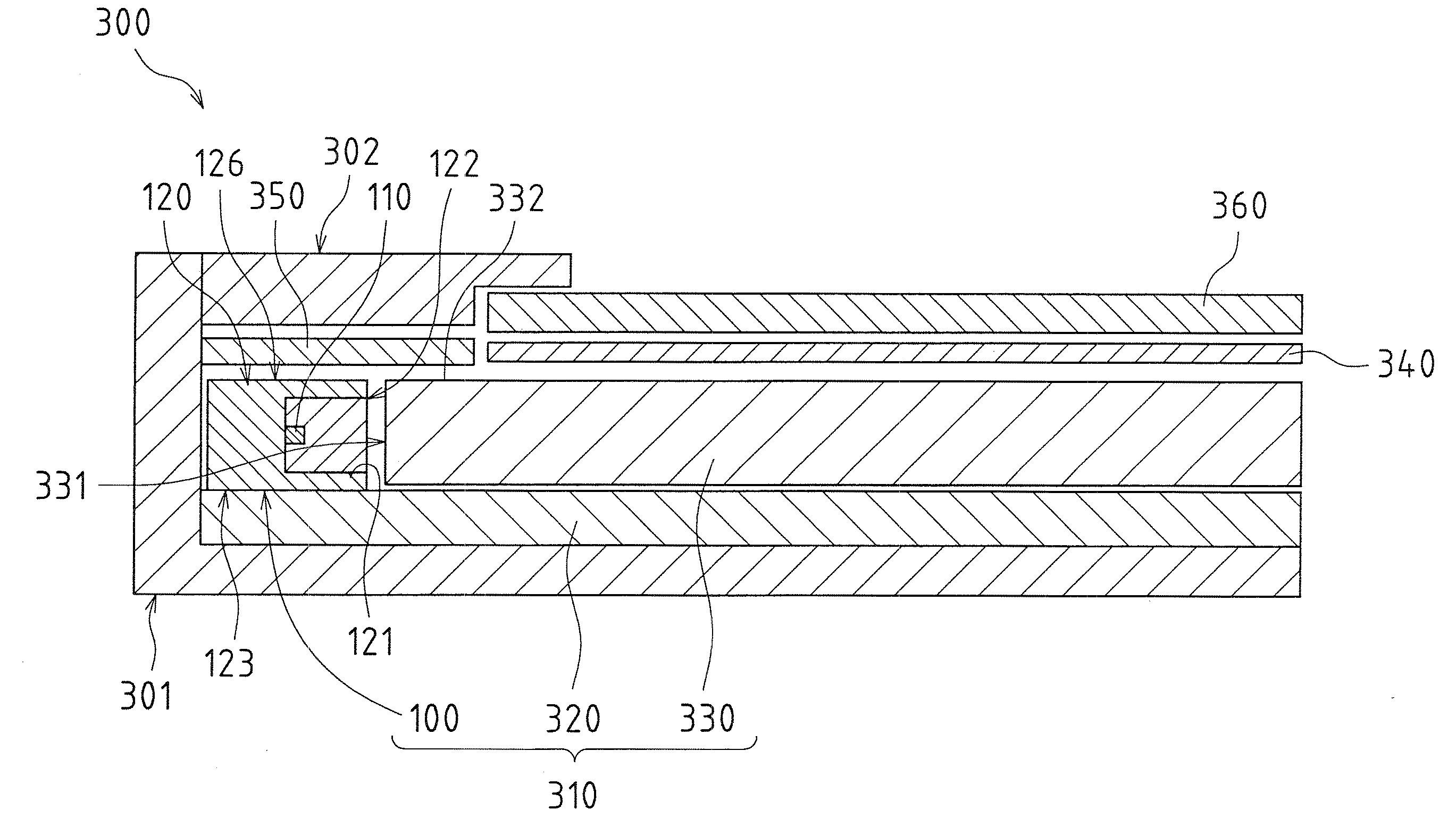

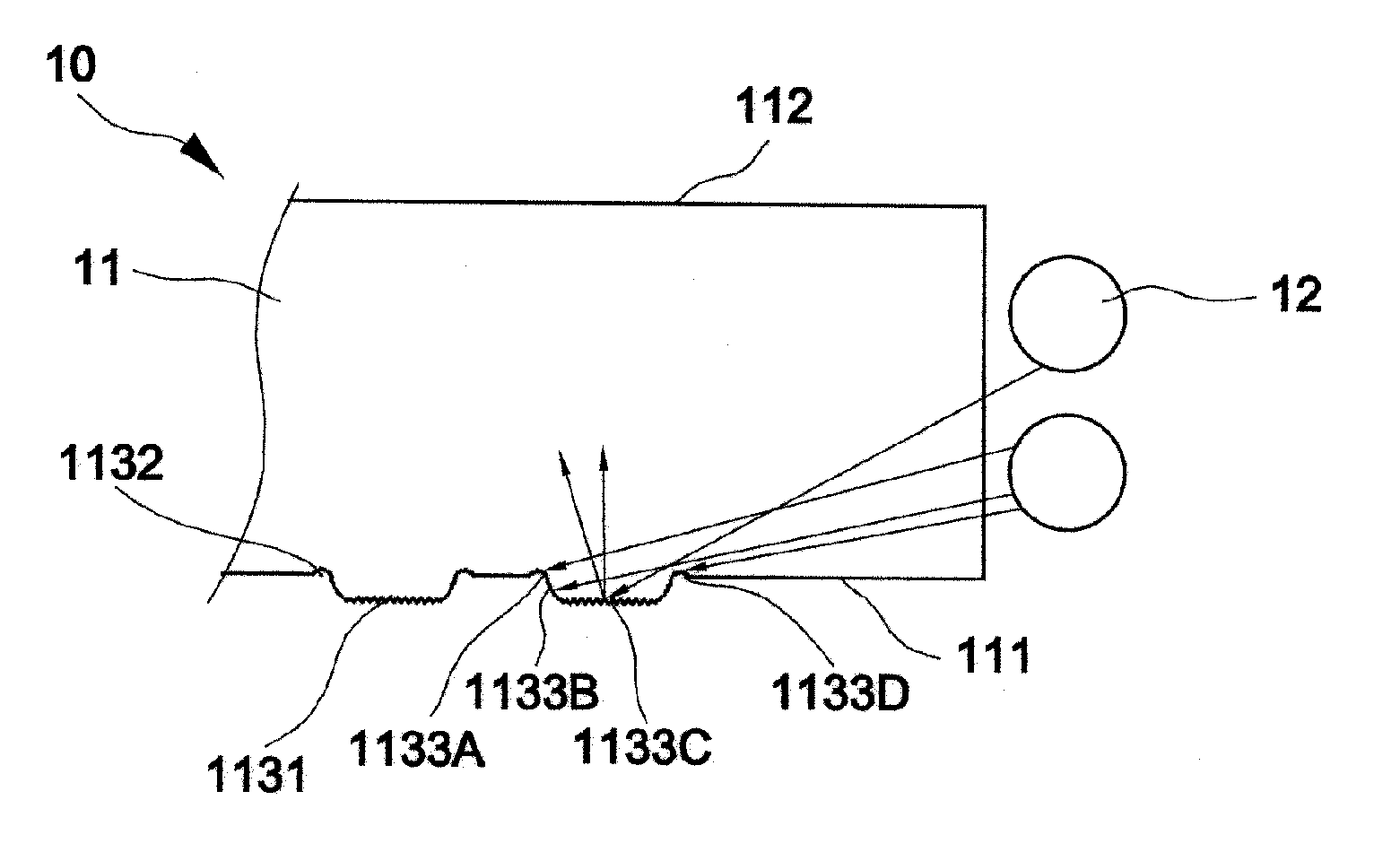

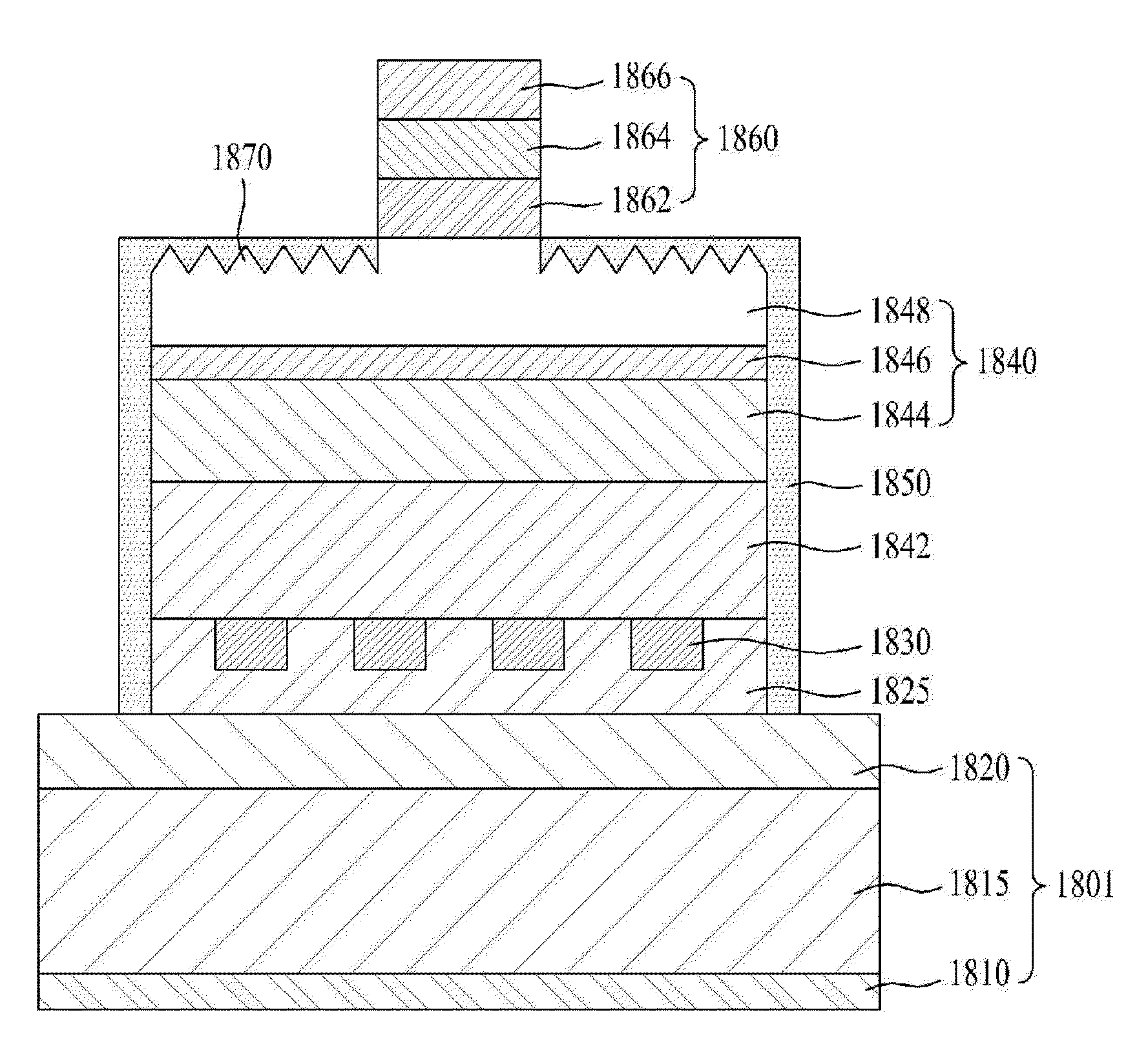

Light-emitting device, planar light source including the light-emitting device, and liquid crystal display device including the planar light source

ActiveUS20110051039A1Improve cooling effectImprove light uniformitySolid-state devicesOptical light guidesLiquid-crystal displayEngineering

A light-emitting device according to an embodiment of the present invention includes a light-emitting element, and a package substrate on which this light-emitting element is placed. This package substrate includes a placement face on which the light-emitting element is placed, a back face that is opposed to the placement face, and a mounting face that is opposed, between the placement face and the back face, to a mounting substrate when the light-emitting device is mounted, and includes a first recess portion that extends, on the mounting face, from the back face toward the placement face and that has a first heat conduction member formed on the surface thereof, and an intermediate heat conduction member for conducting heat between the light-emitting element and the first heat conduction member.

Owner:SHARP KK

Backlight apparatus

ActiveUS20050270802A1Increase reflective areaIncrease brightnessMechanical apparatusLight guides for lighting systemsOptoelectronicsBrightness perception

A backlight apparatus includes a guiding element and a light source disposed at one side of the guiding element. There is a plurality of reflective patterns at the bottom surface of the guiding element. Each reflective pattern is composed of at least one concavity and at least one convexity. The concavity is disposed at the rim around the convexity. As the light source emits light to the guiding element, the reflective area is increased by the concavity of the reflective pattern for increasing the reflecting effect and for distributing the brightness more uniformly, and thereby higher brightness and uniformity can be achieved.

Owner:NANO PRECISION TAIWAN LTD

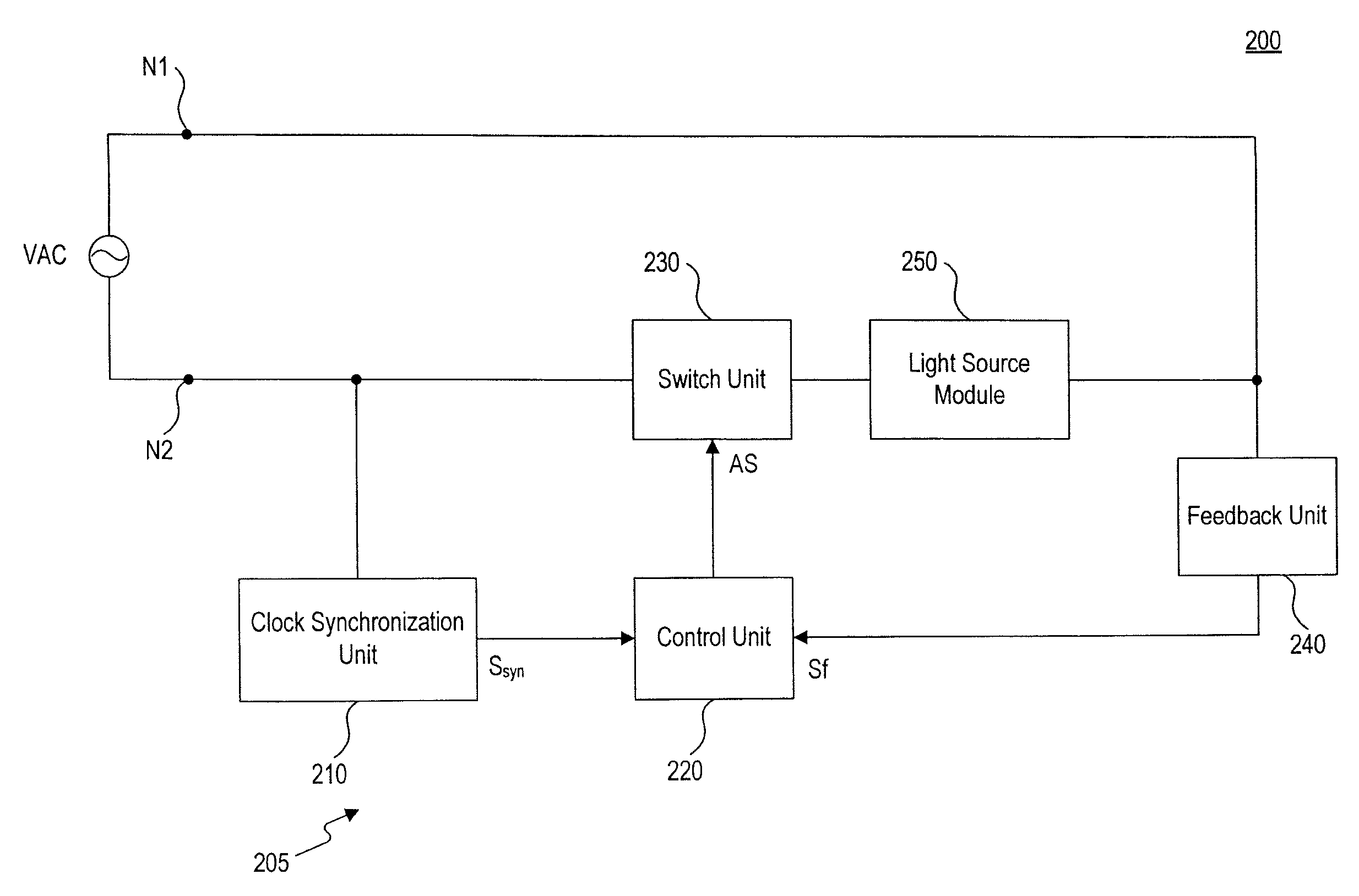

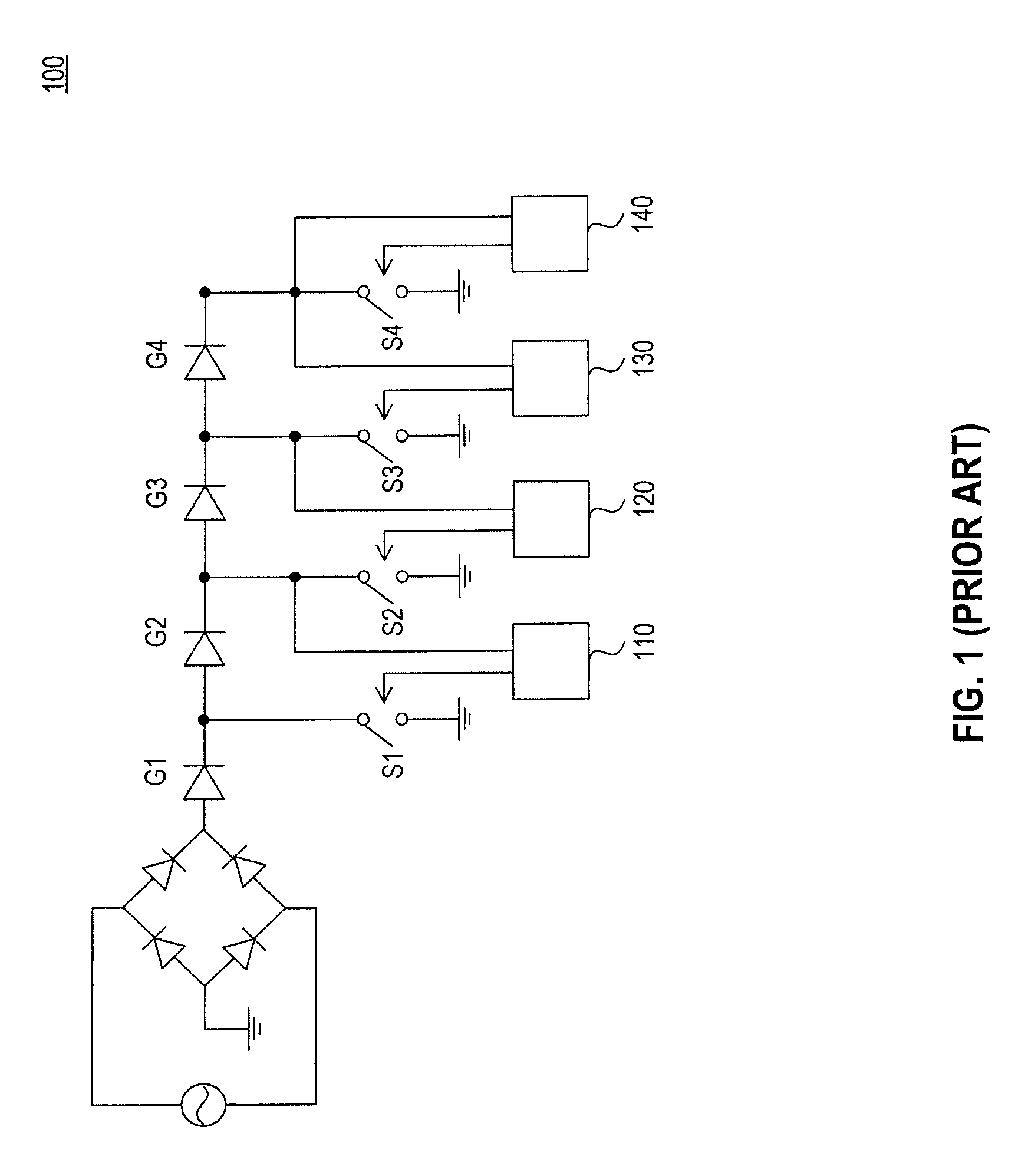

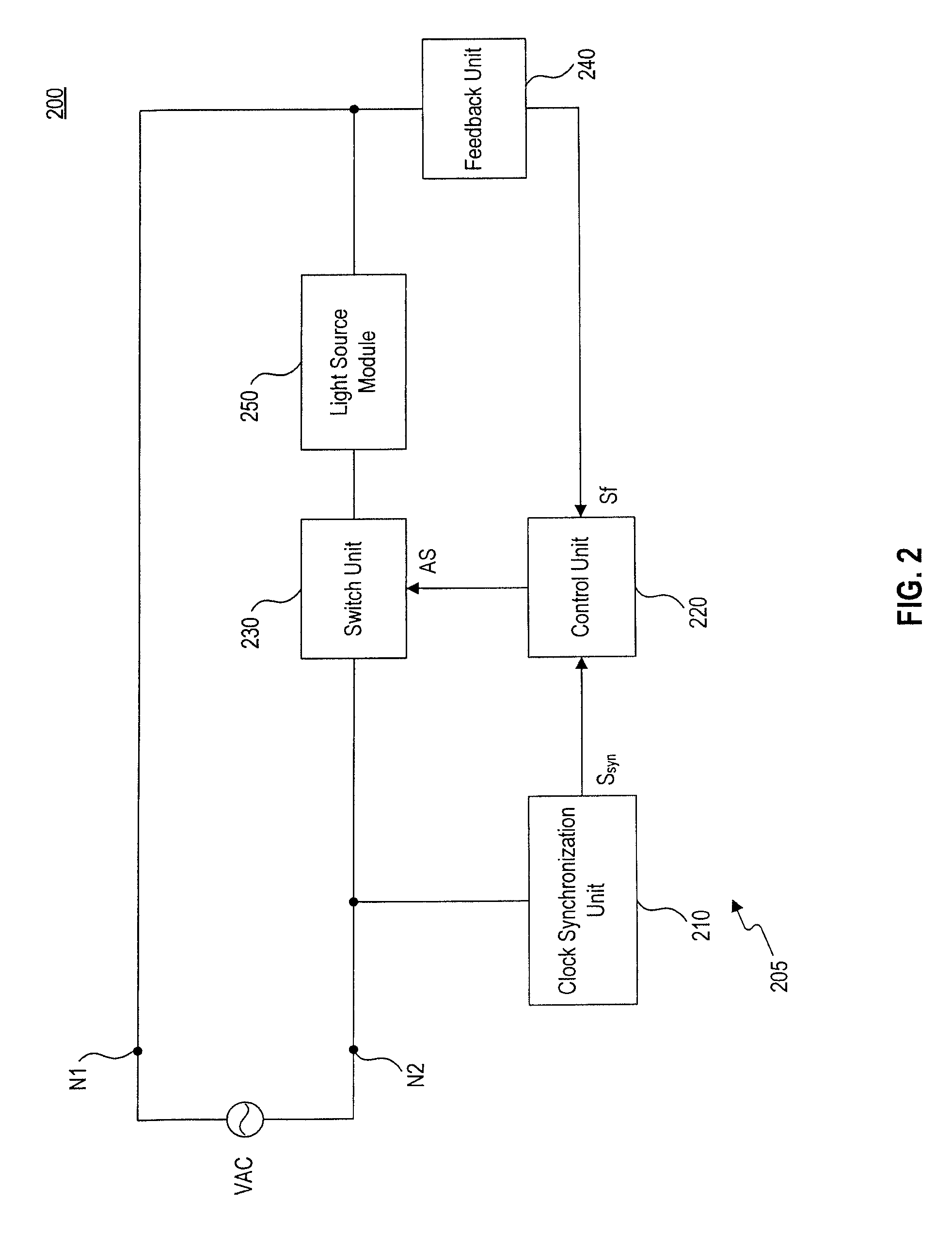

Light source apparatus and driving apparatus thereof

ActiveUS20090015172A1Improve light uniformityEfficient light sourceElectroluminescent light sourcesSemiconductor lamp usageSignal onAC power

A light source driving apparatus to drive at least one light source module includes a switch unit for coupling in series with an AC power source and the light source module; a clock synchronization unit for coupling to the AC power source and to provide a clock synchronization signal in accordance with an AC voltage of the AC power source; a control unit coupled to receive the clock synchronization signal and to provide to the switch unit an adjusting signal according to a timing of the clock synchronization signal; and a feedback unit coupled to the control unit and to detect a load state of the light source module, the feedback unit configured to provide to the control unit a feedback signal having a value representative of the detected load state of the light source module. The control unit is configured to modulate a pulse width of the adjusting signal according to the feedback signal and a preset brightness value of the light source module, the switch unit responsive to the adjusting signal to open and close to apply the AC voltage to the light source module in accordance with the modulated pulse width.

Owner:IND TECH RES INST

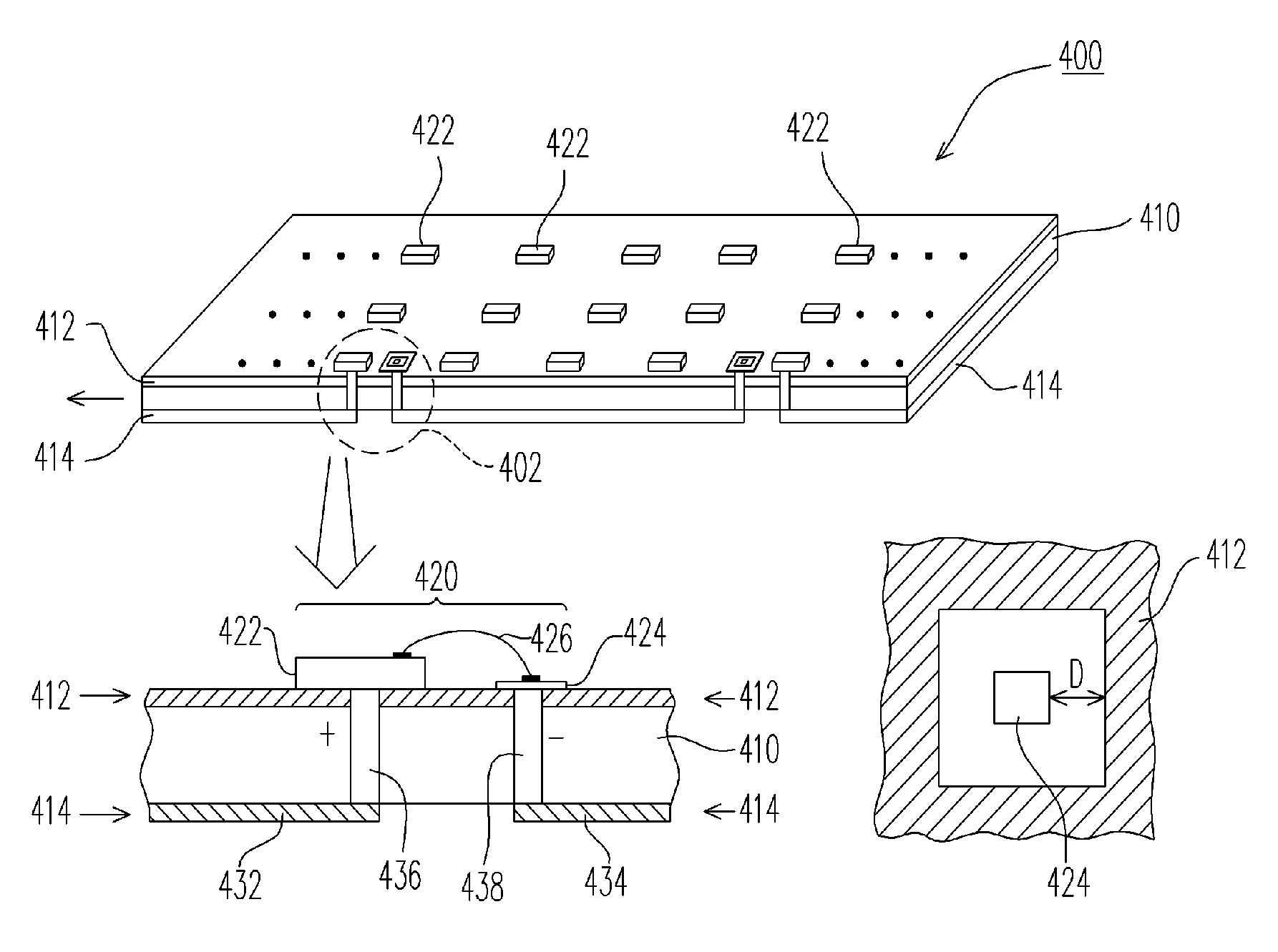

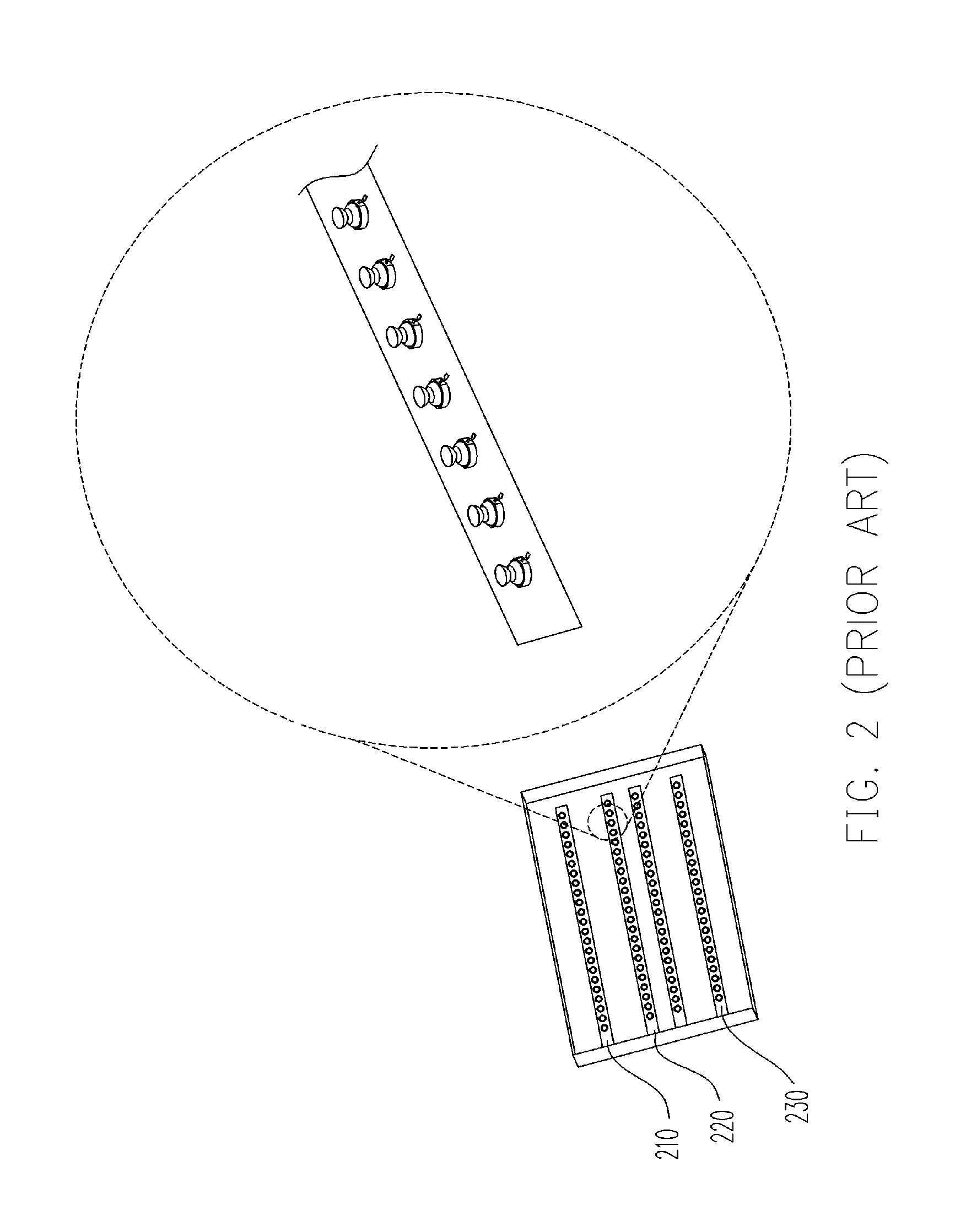

Modular LED Lighting Fixtures

ActiveUS20090225546A1Low costImprove light uniformityPoint-like light sourceLighting support devicesElectrical conductorEffect light

Concatenatable lighting fixtures, each comprising a unitary cover member having a circuit board mounting platform integrally formed with suitable heat sinking and which cover member mounts onto a cooperating base chassis. In one embodiment, the circuit board mounting platform extends farther from one end of the cover member than the other so as to facilitate placement of LEDs in a fashion which enhances lighting uniformity and minimizes dark spots. First and second guide members may be positioned in respective opposite ends of adjacent fixtures, each guide member having a plurality of extending fingers with a flexible electrical conductor-carrying conduit disposed between the respective opposite ends and retained in position by said fingers.

Owner:KORRUS INC

Apparatus, method, and system for independent aiming and cutoff steps in illuminating a target area

ActiveUS8789967B2Easy to controlReduced EPAMechanical apparatusLighting support devicesProject areaModularity

A lighting fixture is presented comprising a plurality of modular apparatuses wherein each modular apparatus comprises one or more light sources and one or more light directing or light redirecting devices. Methods of adjusting one or more components of said lighting fixture about one, two, or three axes are presented whereby the lighting needs of a target area—even one of complex shape—may be addressed and in a manner that promotes compact fixture design with low effective projected area (EPA) without sacrificing transmission efficiency of the light sources.

Owner:MUSCO

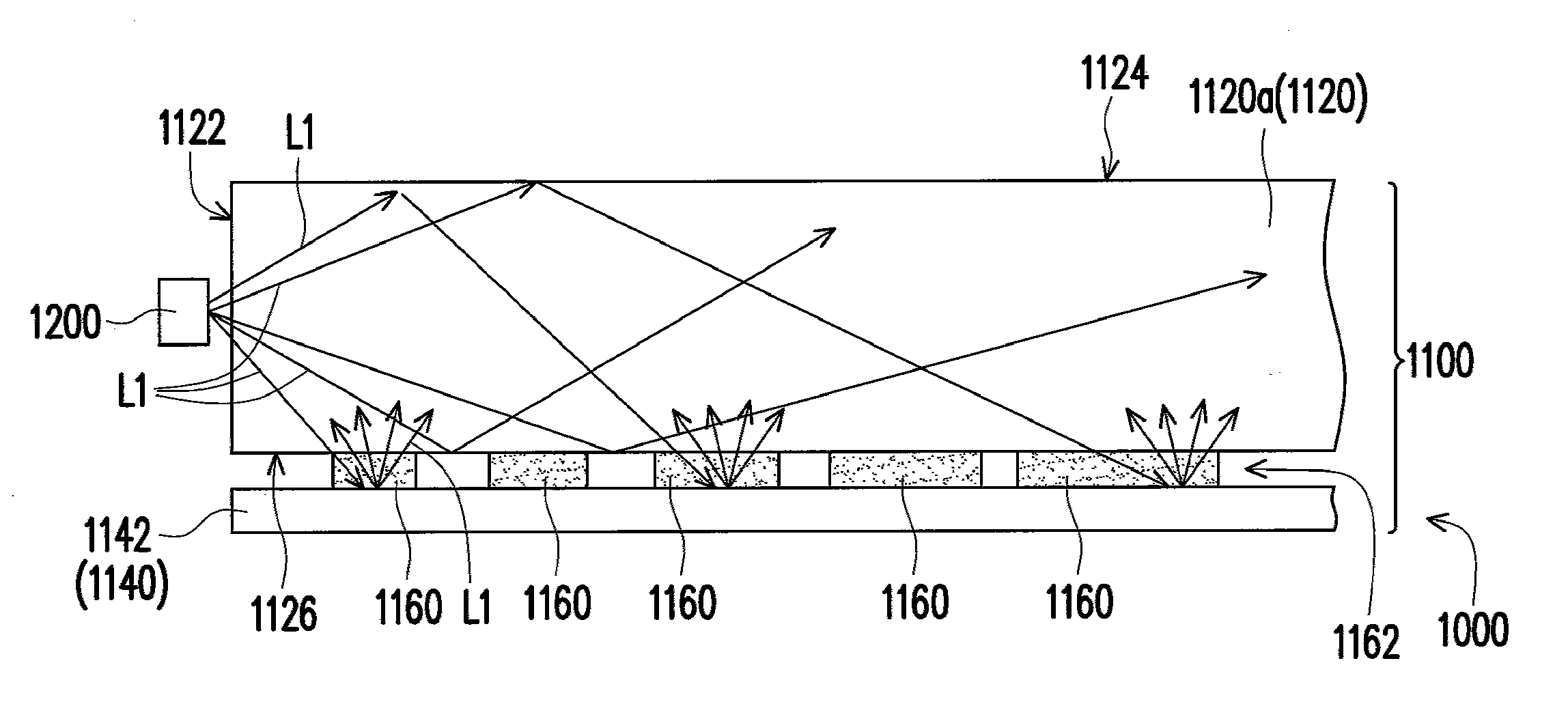

Light guide module, backlight module and fabrication method of light guide module

InactiveUS20120147627A1Improve light uniformityMechanical apparatusLamination ancillary operationsLight guideExit surface

A light guide module includes a light guide plate and a diffuse reflector. The light guide plate has a light incidence surface, a light exiting surface, and a bottom surface, wherein the light exiting surface is opposite to the bottom surface, and the light incidence surface is connected with the light exiting surface and the bottom surface. The diffuse reflector is secured to the bottom surface of the light guide plate by an adhesive pattern layer, wherein the adhesive pattern layer is formed by a plurality of light-transmissive adhesive gels, and these light-transmissive adhesive gels do not contain any diffusive particles. A backlight module using the light guide module mentioned above and a fabricating method for the light guide module are also provided.

Owner:YOUNG LIGHTING TECHNOLOGY INC

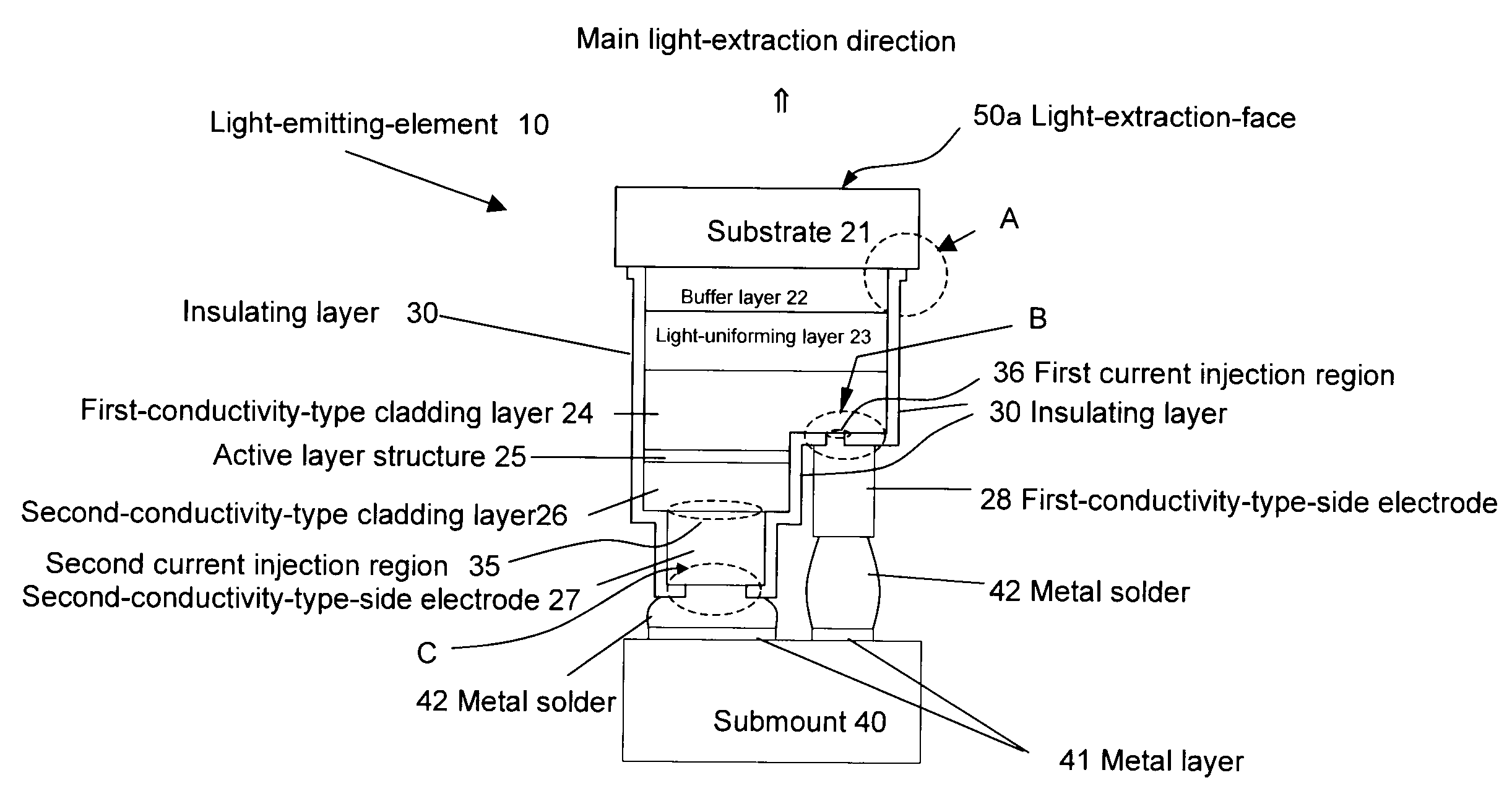

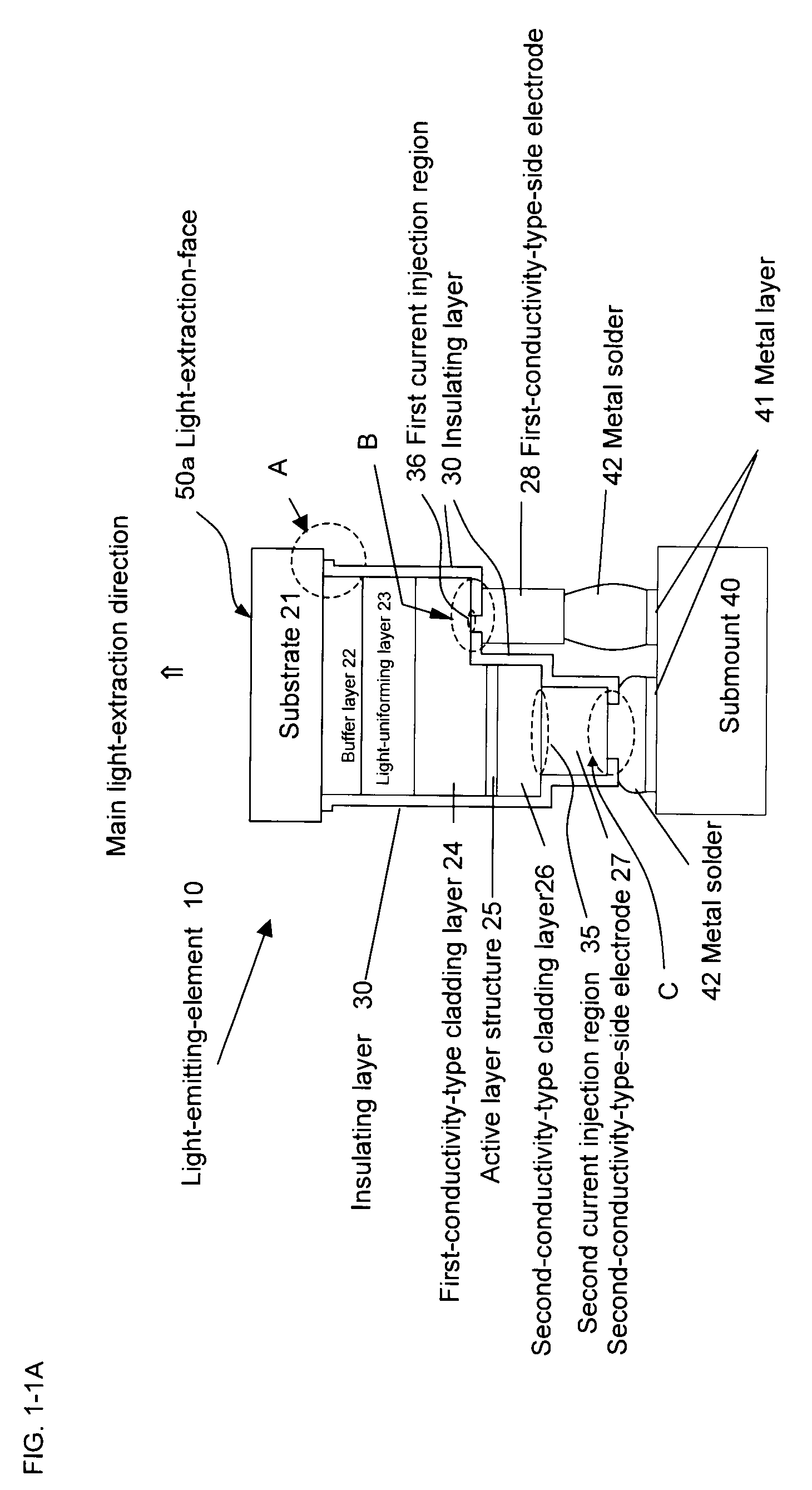

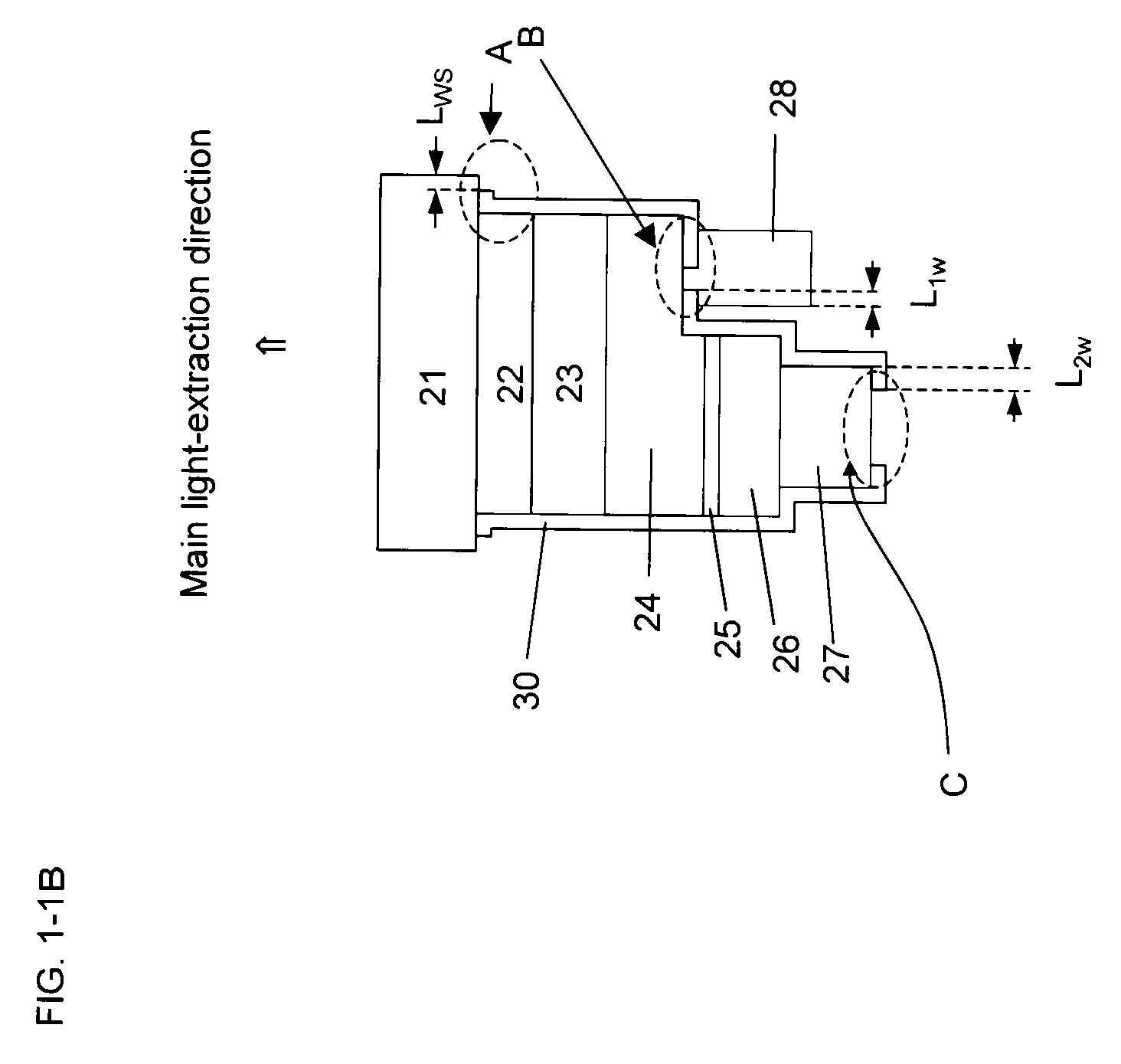

Semiconductor light-emitting device

InactiveUS20090200568A1Large power inputHigh outputSolid-state devicesSemiconductor/solid-state device manufacturingFluorideLight emitting device

An etching process includes forming a metal-fluoride layer at least as a part of an etching mask formed over a semiconductor layer at a temperature of 150° C. or higher; patterning the metal-fluoride layer; and etching the semiconductor layer using the patterned metal-fluoride layer as a mask. Using this etching method, even an etching-resistant semiconductor layer such as a Group III-V nitride semiconductor can be easily etched by a relatively simpler process.

Owner:DIEBOLD NIXDORF +1

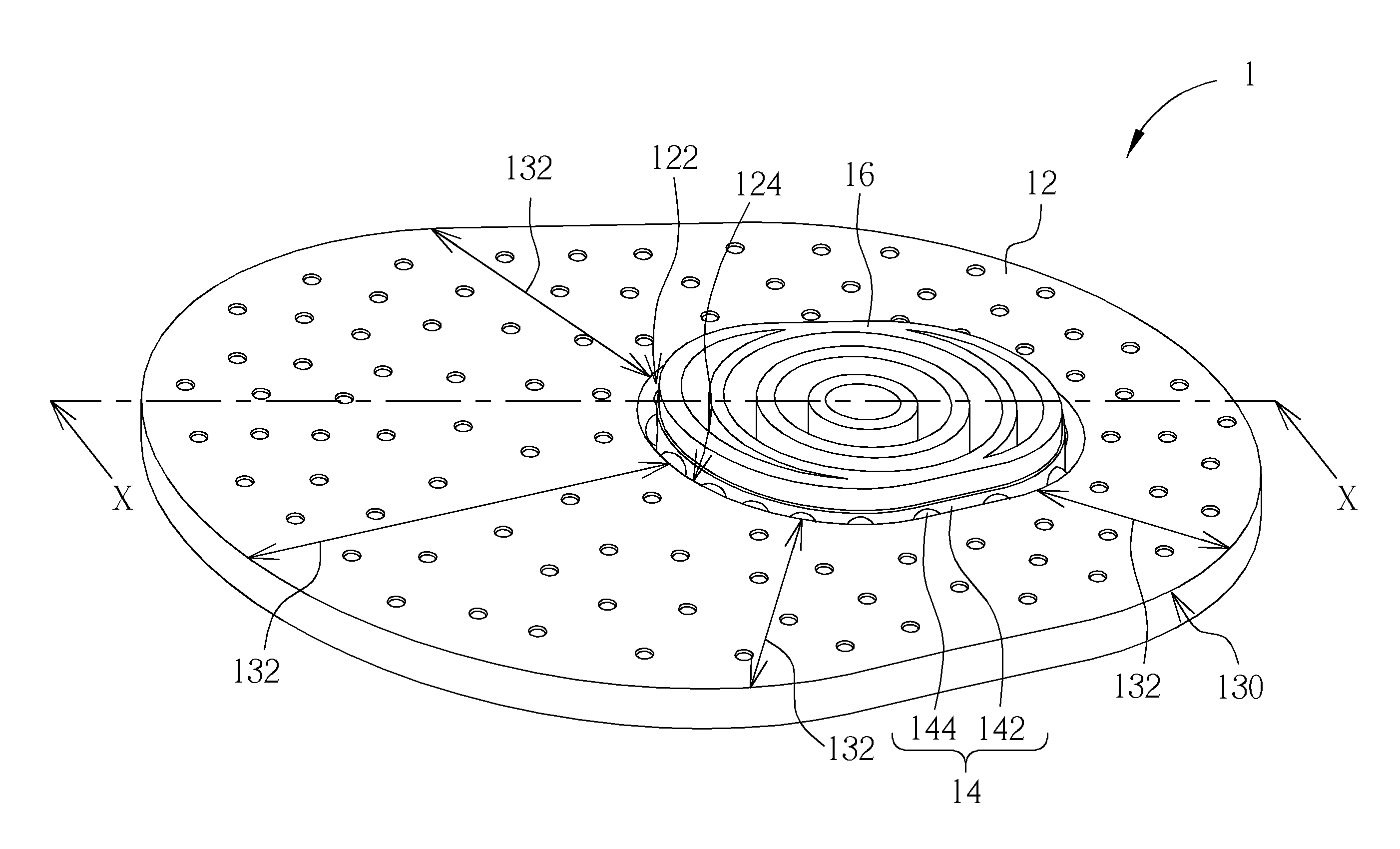

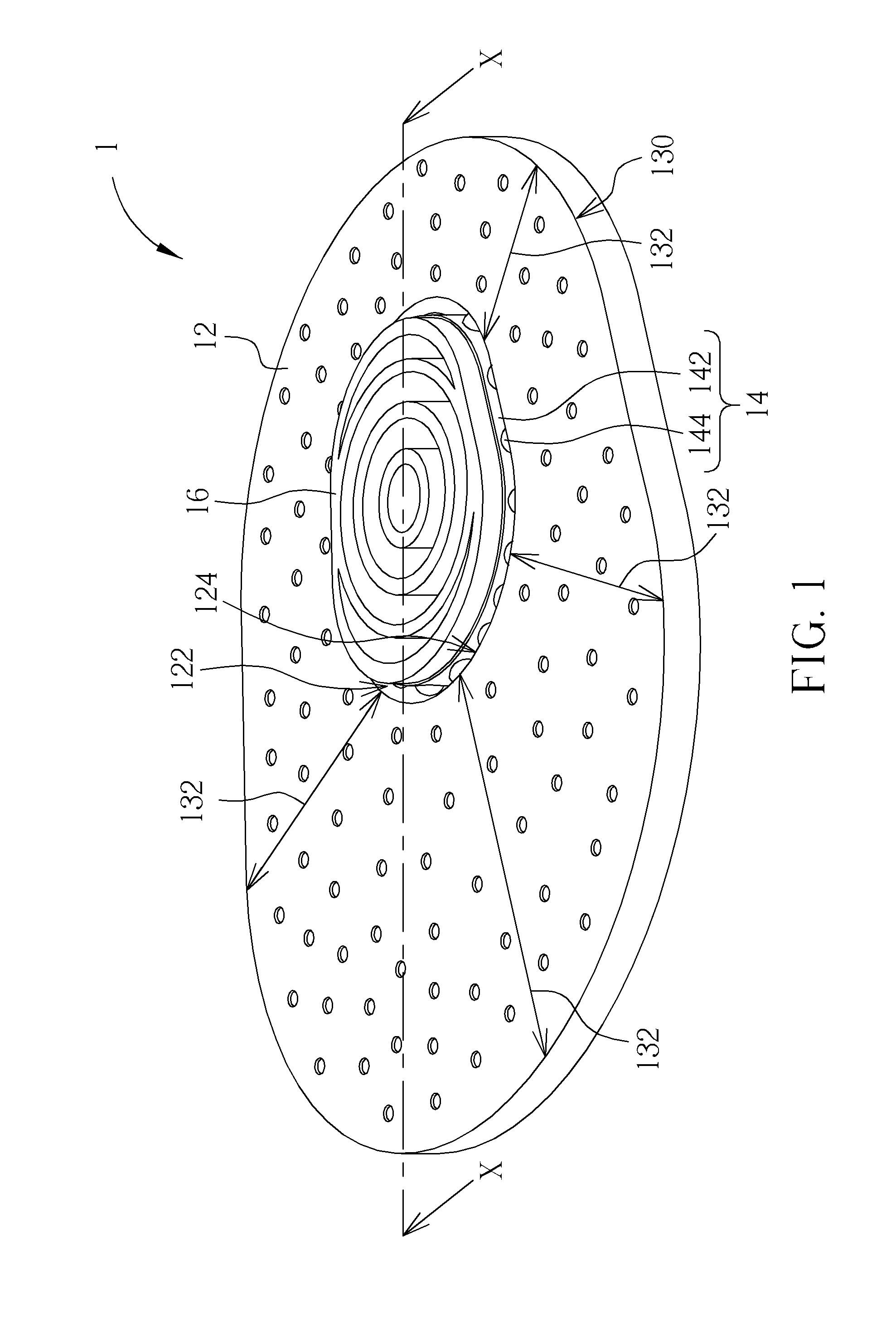

Illumination apparatus

InactiveUS20120014128A1Improve light uniformityEasy to getPoint-like light sourceElongate light sourcesLight guideEngineering

An illumination apparatus is disclosed and includes a light-guiding module and a light source module. The light-guiding module has a light-in surface, which is annular surface inside the light-guiding module. The light source module includes a plurality of light-emitting devices. Each light-emitting device is disposed toward the light-in surface and can emit light through the light-in surface into the light-guiding module. The light-guiding module can be a light-guiding plate with a through hole, a sidewall of which is treated as the light-in surface. The light source module can use an annular circuit board disposed in the through hole. The light-emitting devices are disposed on an outer annular surface of the annular circuit board toward the sidewall. Thereby, the invention can provide illumination of radially guiding light.

Owner:QISDA CORP

Lighting device

ActiveUS20130335975A1Stable brightnessImprove heat resistancePlanar light sourcesVehicle headlampsLight reflectionEffect light

Provided is a lighting device, comprising: a light source module comprising: at least one light source disposed on a printed circuit board; and a resin layer disposed on the printed circuit board so that the light source is embedded; a light reflection member formed on at least any one of one side surface and another side surface of the resin layer; and a diffusion plate having an upper surface formed on the light source module, and a side wall which is integrally formed with the upper surface and formed to extend in a lower side direction and which is adhered onto the light reflection member, wherein a first separated space is formed between the light source module and the upper surface of the diffusion plate, whereby flexibility of the product itself can be secured, and durability and reliability of the product can be also improved.

Owner:LG INNOTEK CO LTD

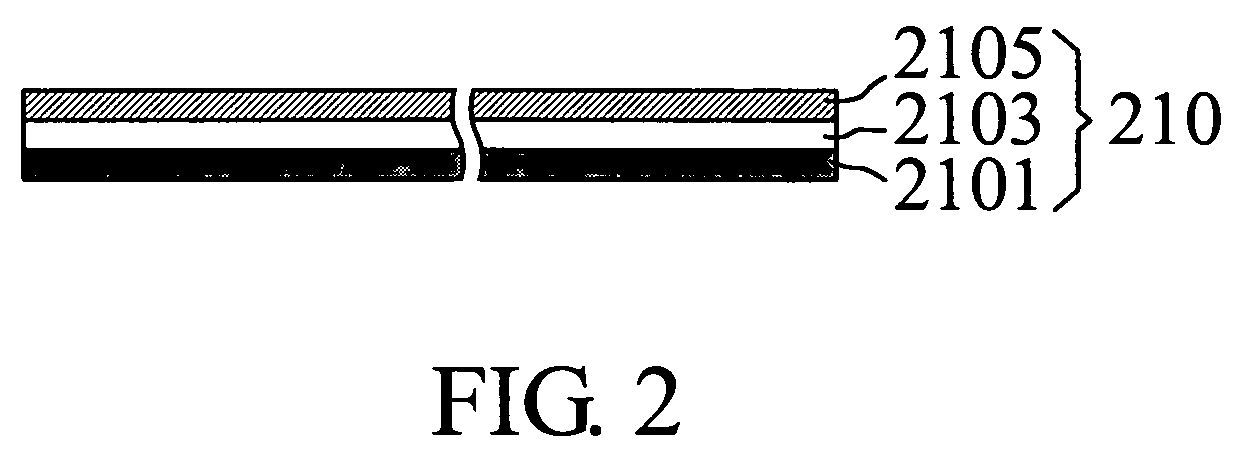

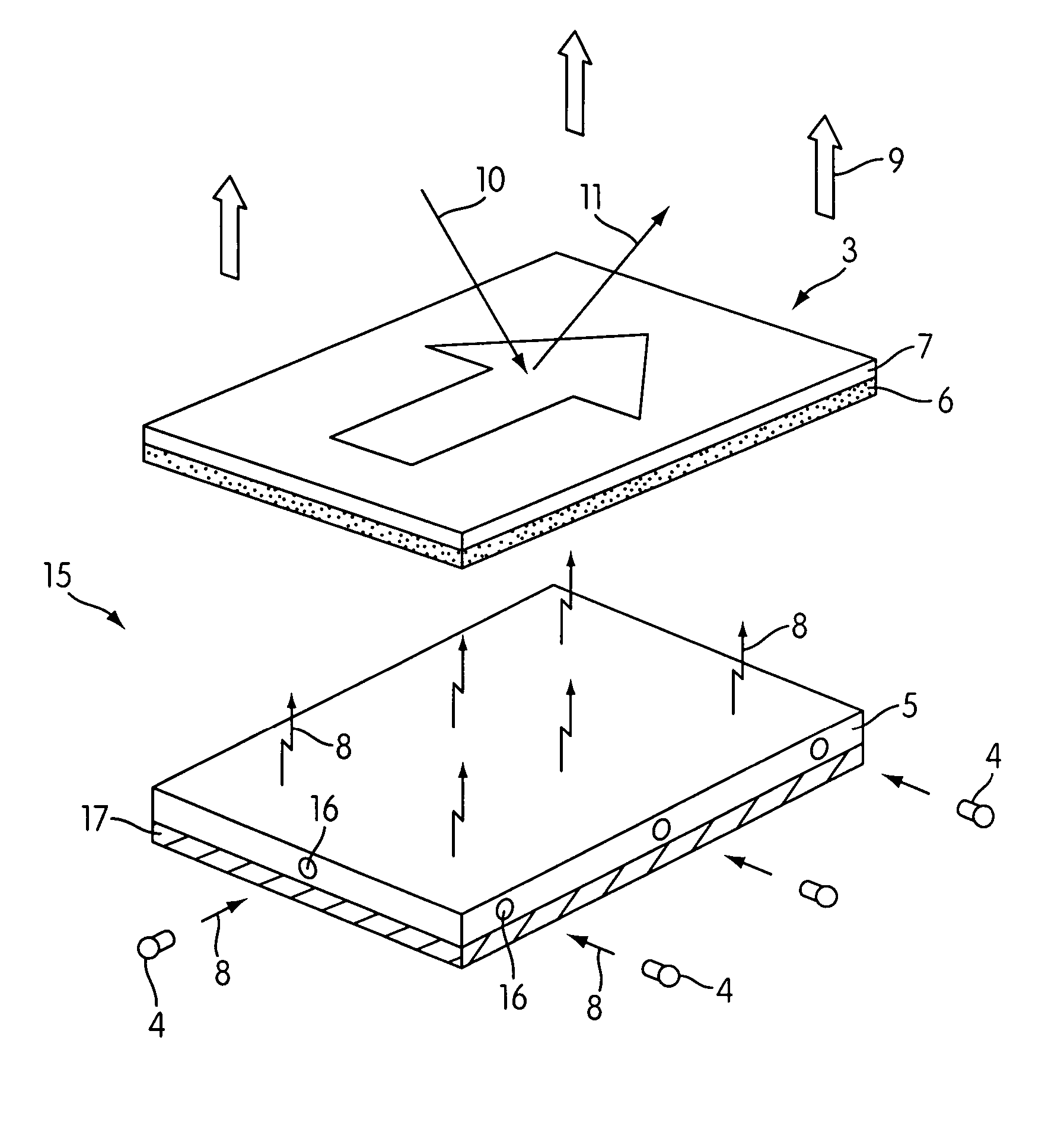

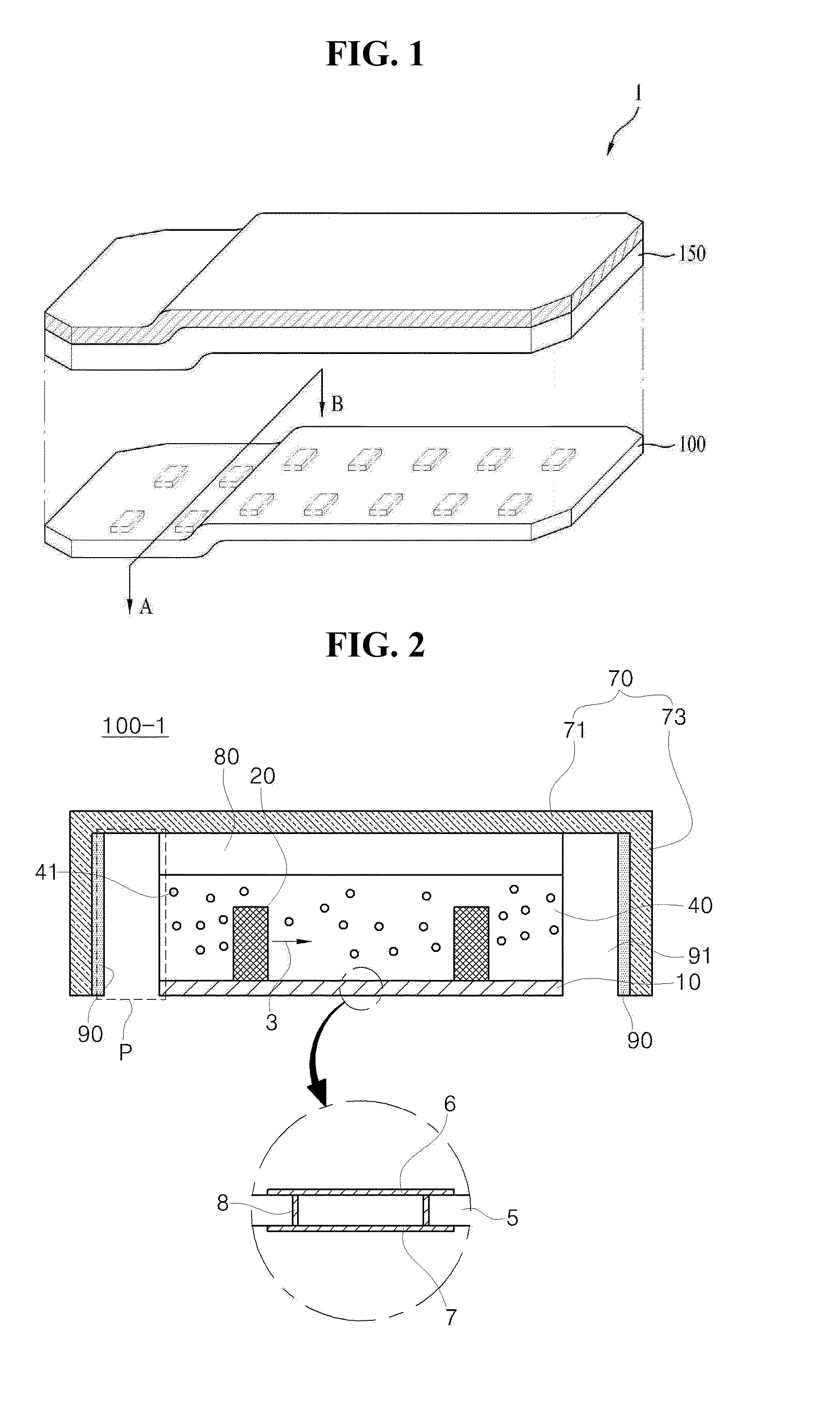

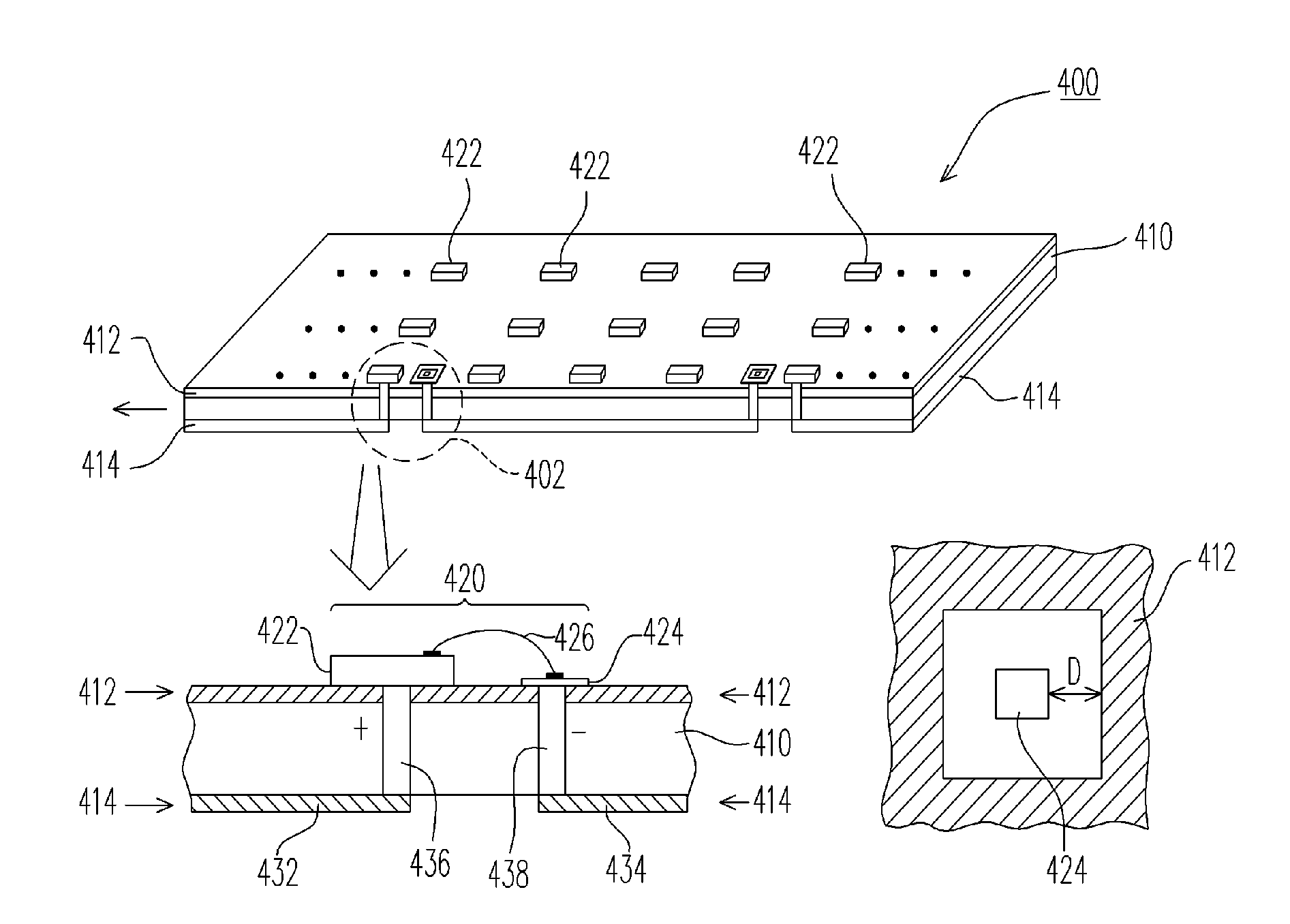

Bendable solid state planar light source structure, flexible substrate therefor, and manufacturing method thereof

ActiveUS20070217200A1Desirable effectPreferred photoelectric characteristicPlanar light sourcesLighting elementsMetal coatingEngineering

A bendable LED planar light source structure, a flexible substrate therefore, and a manufacturing method thereof are provided. The flexible substrate has metal layers on both sides, where the metal layer on one side has a circuit layout, and the metal layer on the other side has a pattern structure or a whole metal coating with reflecting and scattering characteristics. Meanwhile, bonding pads are provided on the same side or opposite side as the metal layer with the circuit layout, and an array of LED dies is bonded with the bonding pads through wire bonding or flip chip bonding, such that the LED dies are conducted with current through the circuit layout on the flexible substrate, so as to form a planar light source.

Owner:IND TECH RES INST

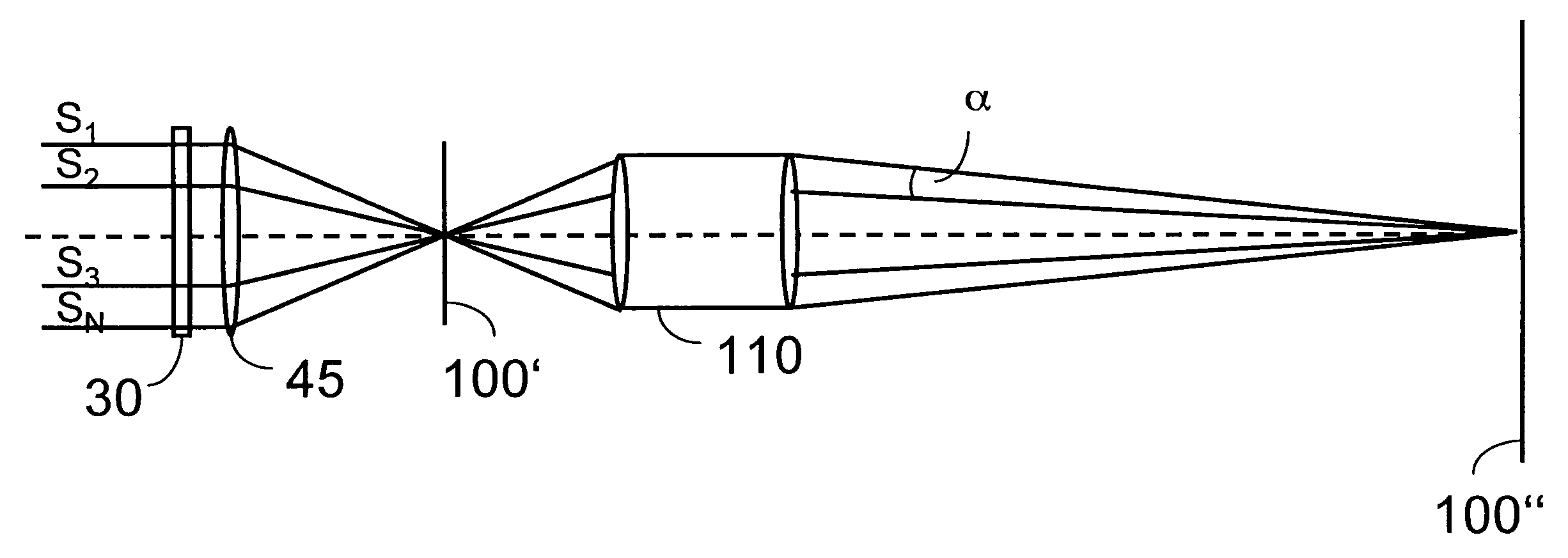

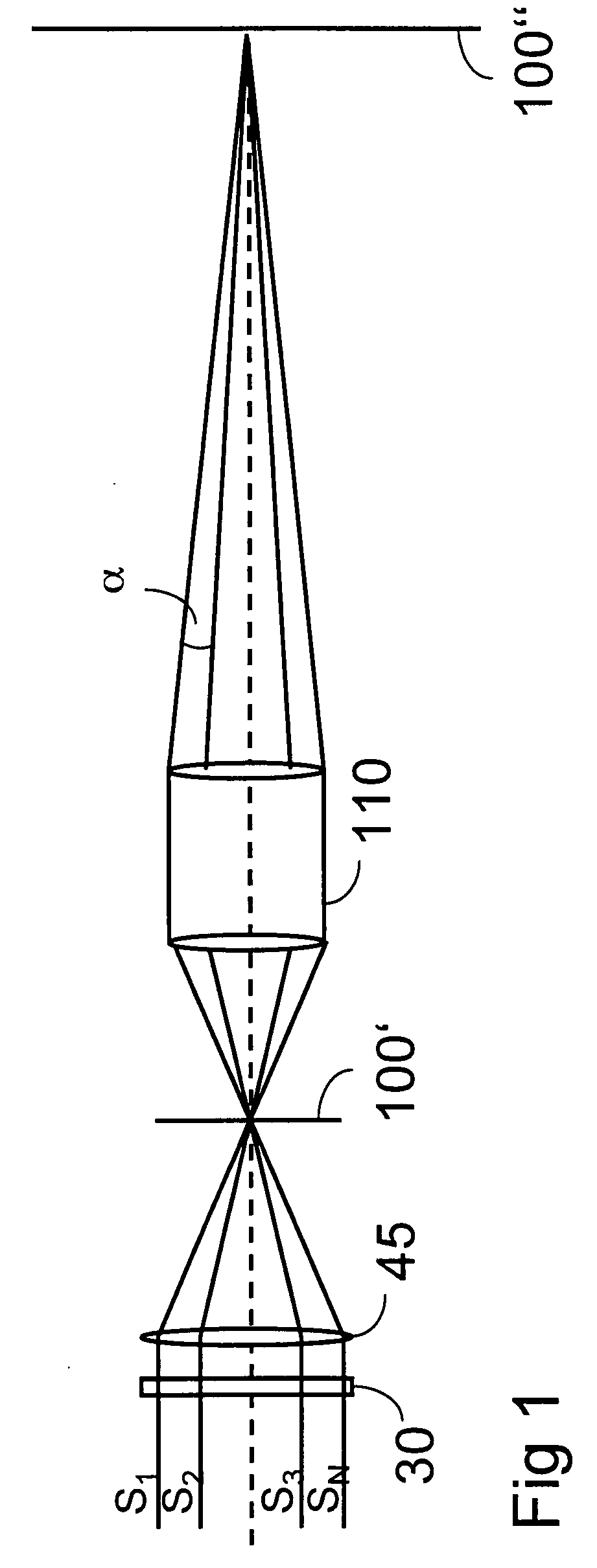

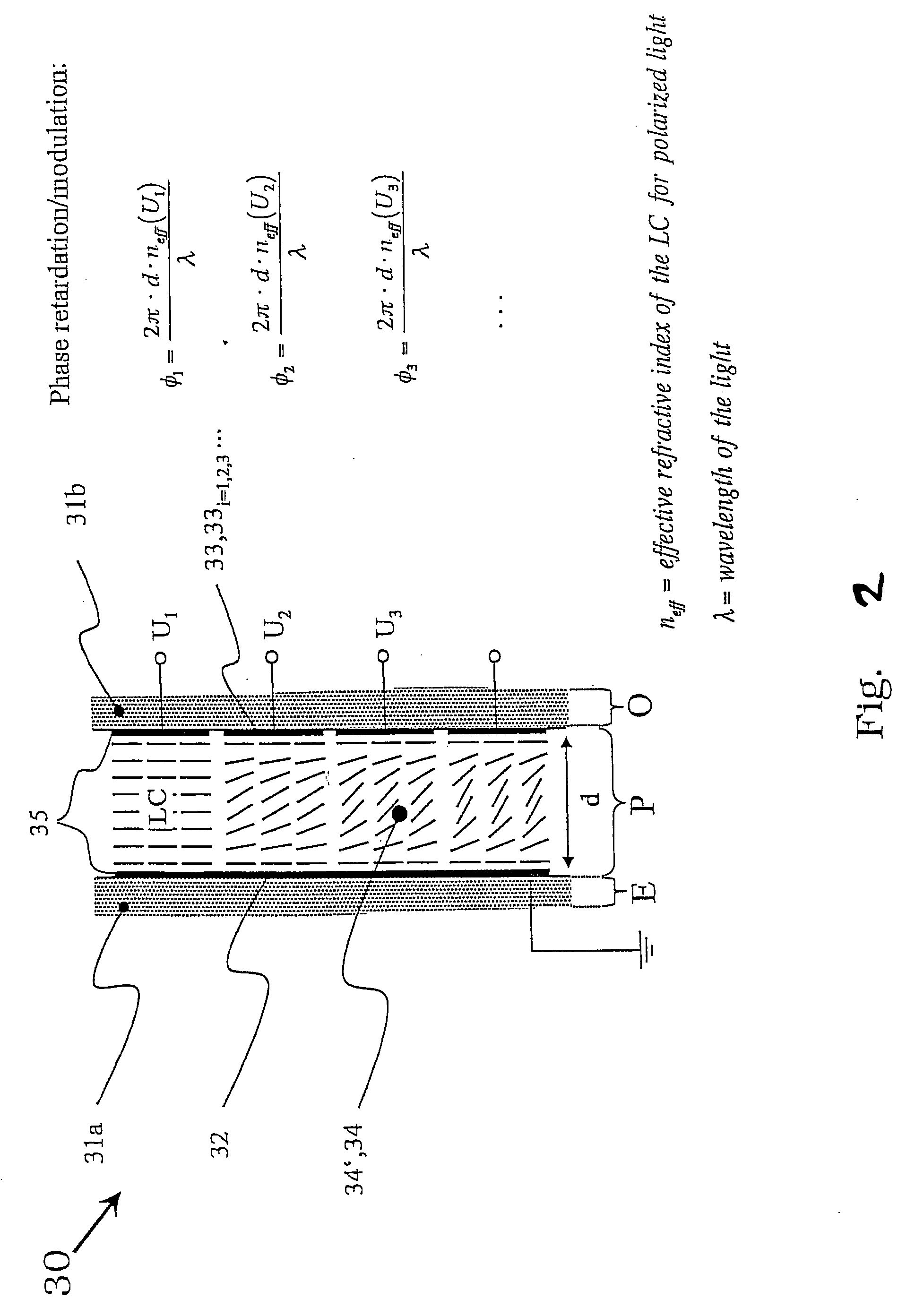

Image Generation Unit and Method to Use an Image Generation Unit

InactiveUS20080204847A1Simpler production feasibilityGood compactnessColor television detailsNon-linear opticsPhase modulationLight beam

An image generation unit with an illumination unit for generating a plurality of coherent sub-beams and for illuminating an image modulator, including a light source, and a projection lens for superimposing each of the coherent sub-beams onto a projection screen plane. An optical set-up introduces angles between each two of the sub-beams, which are chosen to produce uncorrelated speckle patterns in the projection screen plane, resulting in an interference speckle pattern. A phase modulator including a liquid crystal cell changes its directory profile in a lateral manner, thereby being able to change the phase of light of each sub-beam individually.

Owner:SONY DEUT GMBH

Bendable solid state planar light source structure

ActiveUS7626208B2Desirable effectPreferred photoelectric characteristicPlanar light sourcesLighting elementsMetal coatingEngineering

A bendable LED planar light source structure, a flexible substrate therefore, and a manufacturing method thereof are provided. The flexible substrate has metal layers on both sides, where the metal layer on one side has a circuit layout, and the metal layer on the other side has a pattern structure or a whole metal coating with reflecting and scattering characteristics. Meanwhile, bonding pads are provided on the same side or opposite side as the metal layer with the circuit layout, and an array of LED dies is bonded with the bonding pads through wire bonding or flip chip bonding, such that the LED dies are conducted with current through the circuit layout on the flexible substrate, so as to form a planar light source.

Owner:IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com