Packaging method of LED filament and LED filament

A technology of LED filament and packaging method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low yield rate and low light transmittance of brackets, and achieve improved yield rate, light output efficiency and uniformity of light output, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

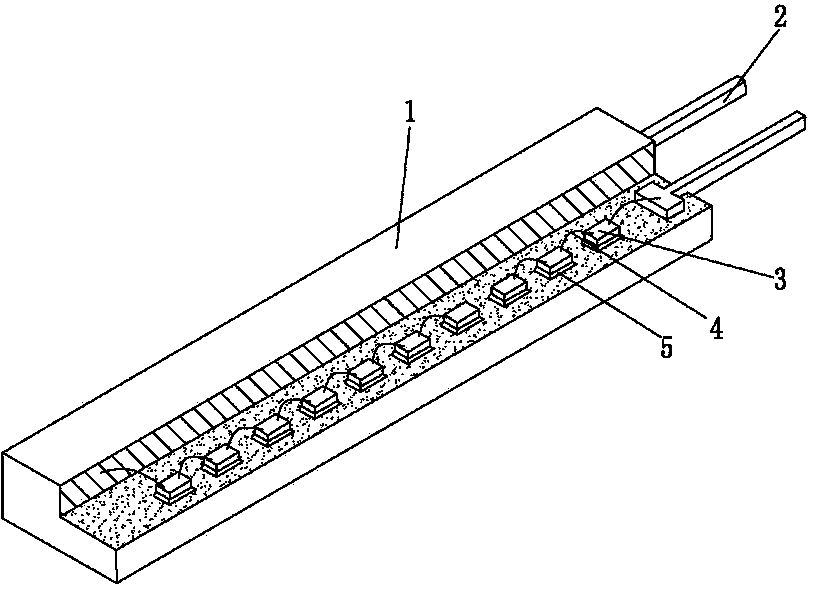

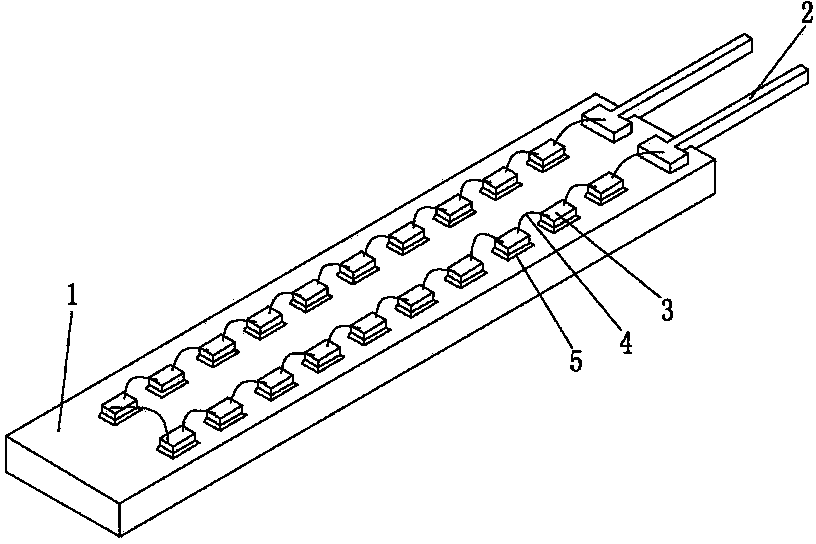

[0022] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

[0023] The invention discloses a method for packaging LED filaments. The method realizes packaging without a bracket, and does not need to use a bracket during the entire packaging process. Include the following steps:

[0024] Step 1: inject liquid silicone resin and phosphor powder mixture into the mold, and place metal conductive pins at one end of the silicone resin and phosphor powder mixture in the mold. Mixing and stirring the silicone resin and the fluorescent powder evenly and performing degassing treatment, so as to obtain the required liquid mixture of the silicone resin and the fluorescent powder. Air bubbles in the mixture are removed by defoaming treatment. There are two metal conductive pins to realize the current loop.

[0025] Step 2, removing the mold after heating and curing the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com