Patents

Literature

719 results about "LED filament" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

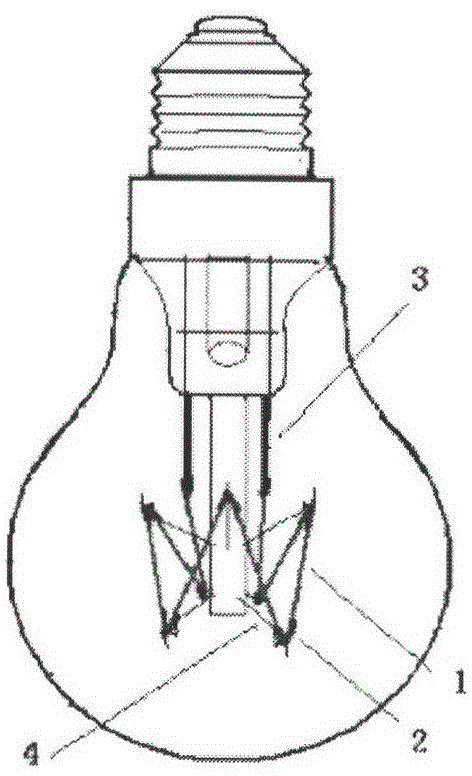

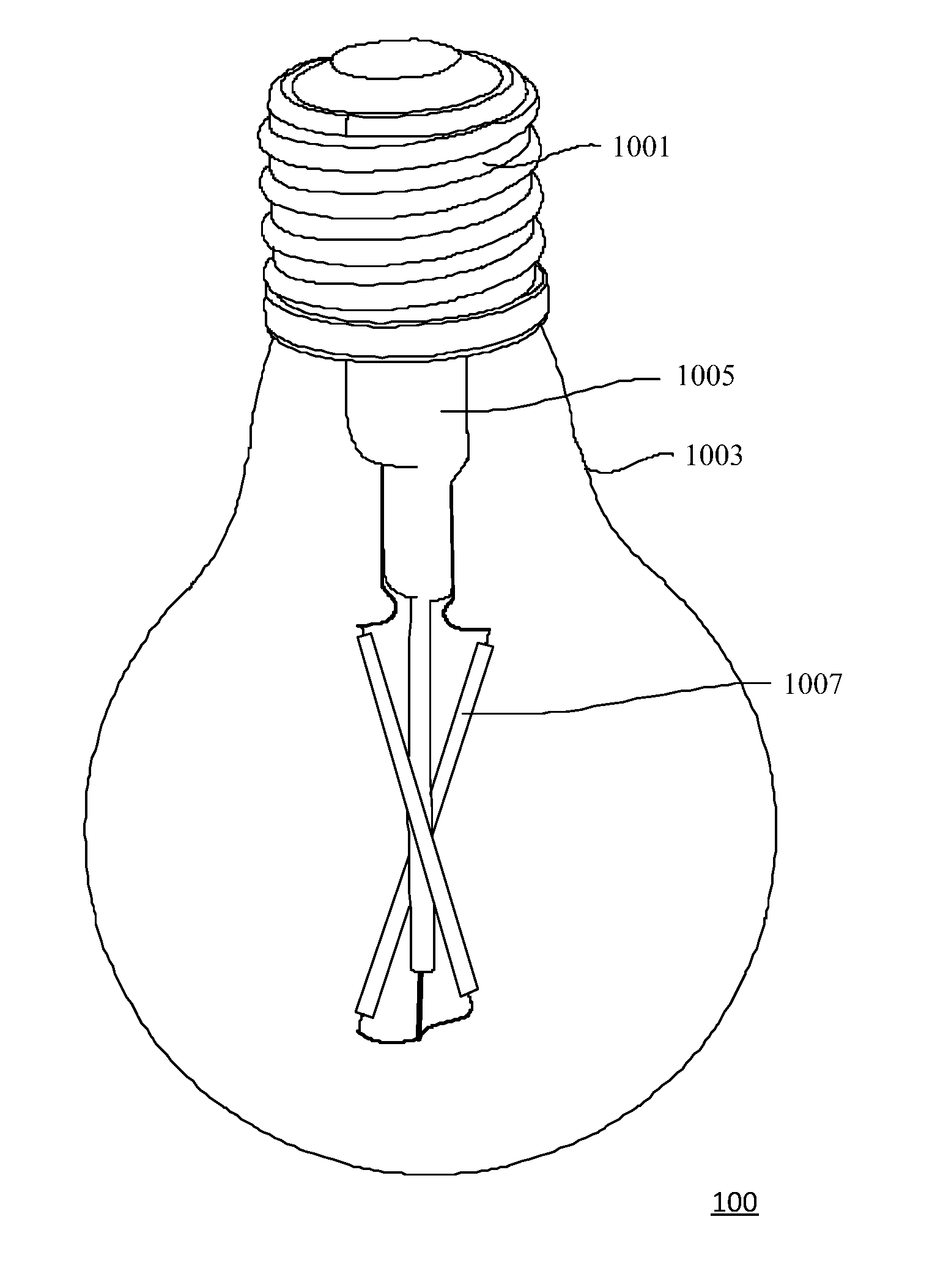

An LED filament light bulb is an LED lamp which is designed to resemble a traditional incandescent light bulb with visible filaments for aesthetic and light distribution purposes, but with the high efficiency of light emitting diodes (LEDs). It produces its light by LED filaments, series-connected strings of diodes that resemble the filament of an incandescent light bulb. They are made with the same envelope shapes, with caps to fit the same sockets, and work at the same voltage as incandescent bulbs, and are direct replacements for conventional clear incandescent bulbs. They may be used for their appearance, similar when lit to an incandescent bulb, or for their wide angle of light distribution, typically 300°. They are also more efficient than many other LED lamps.

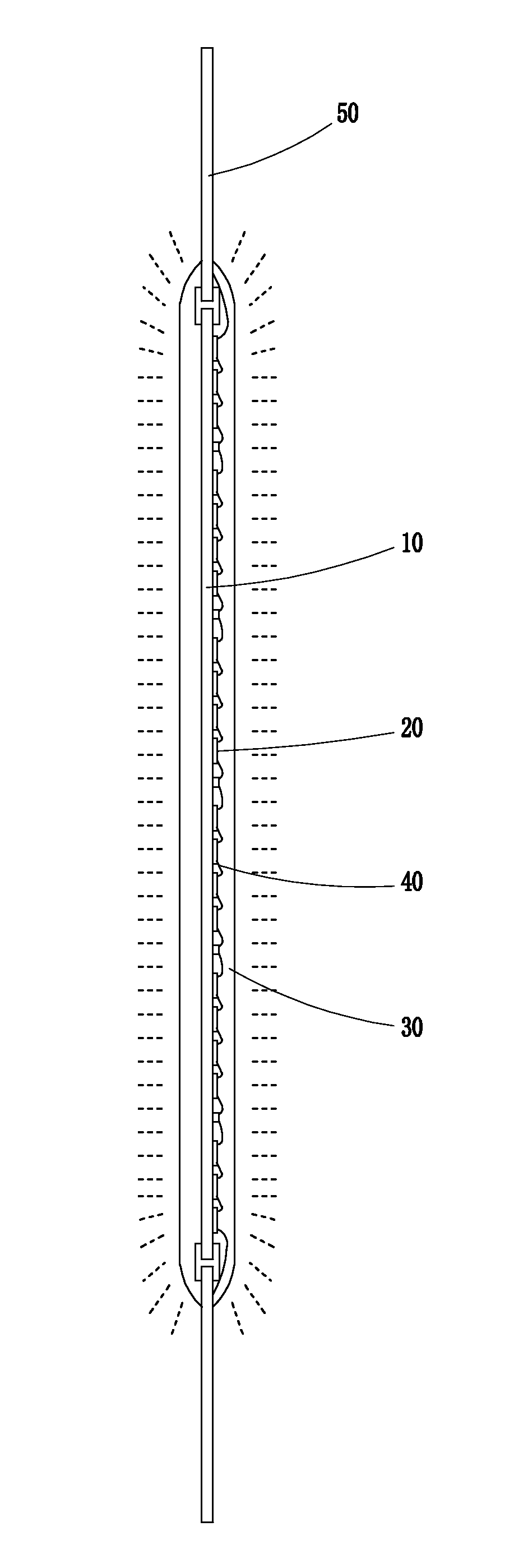

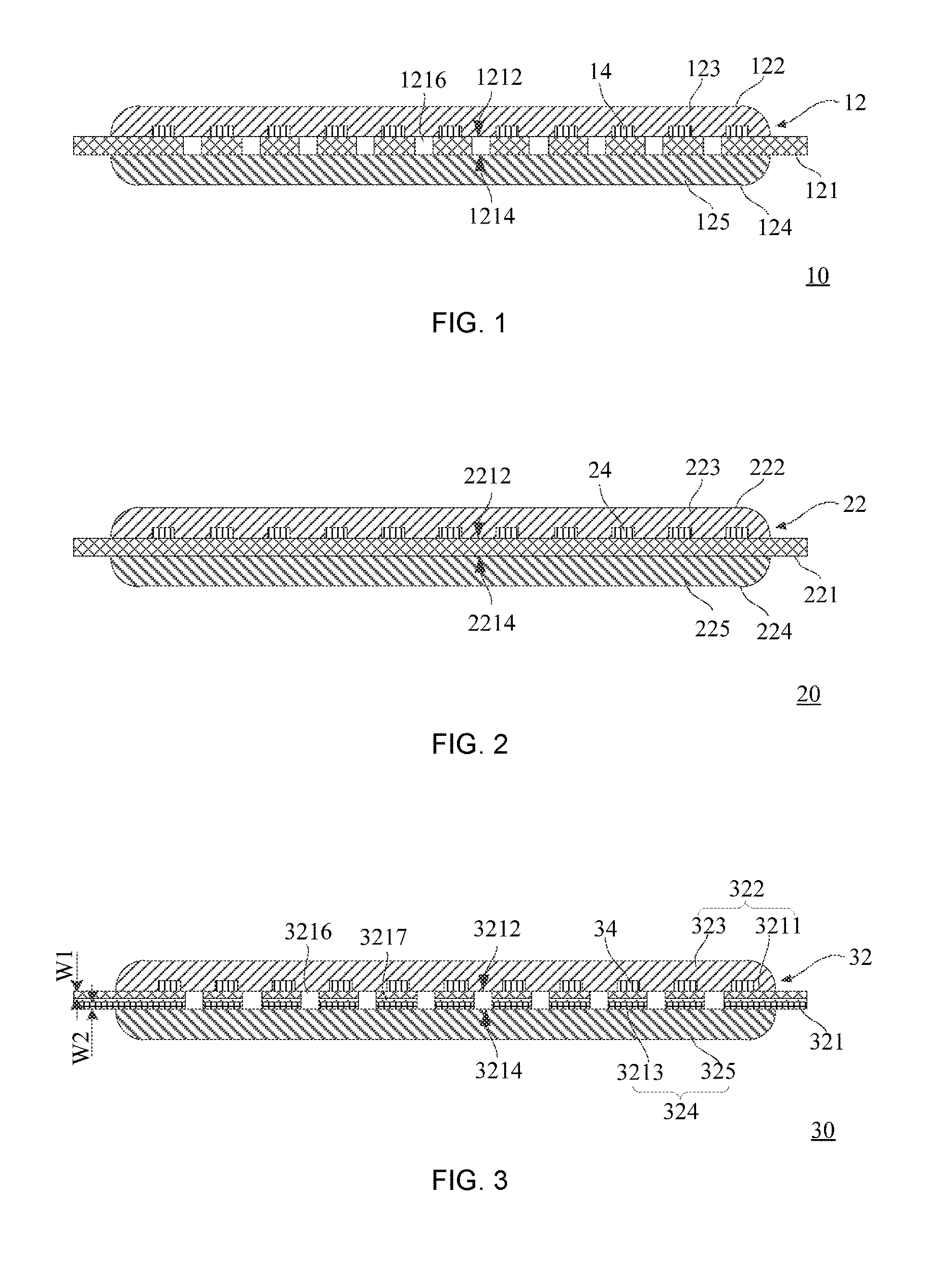

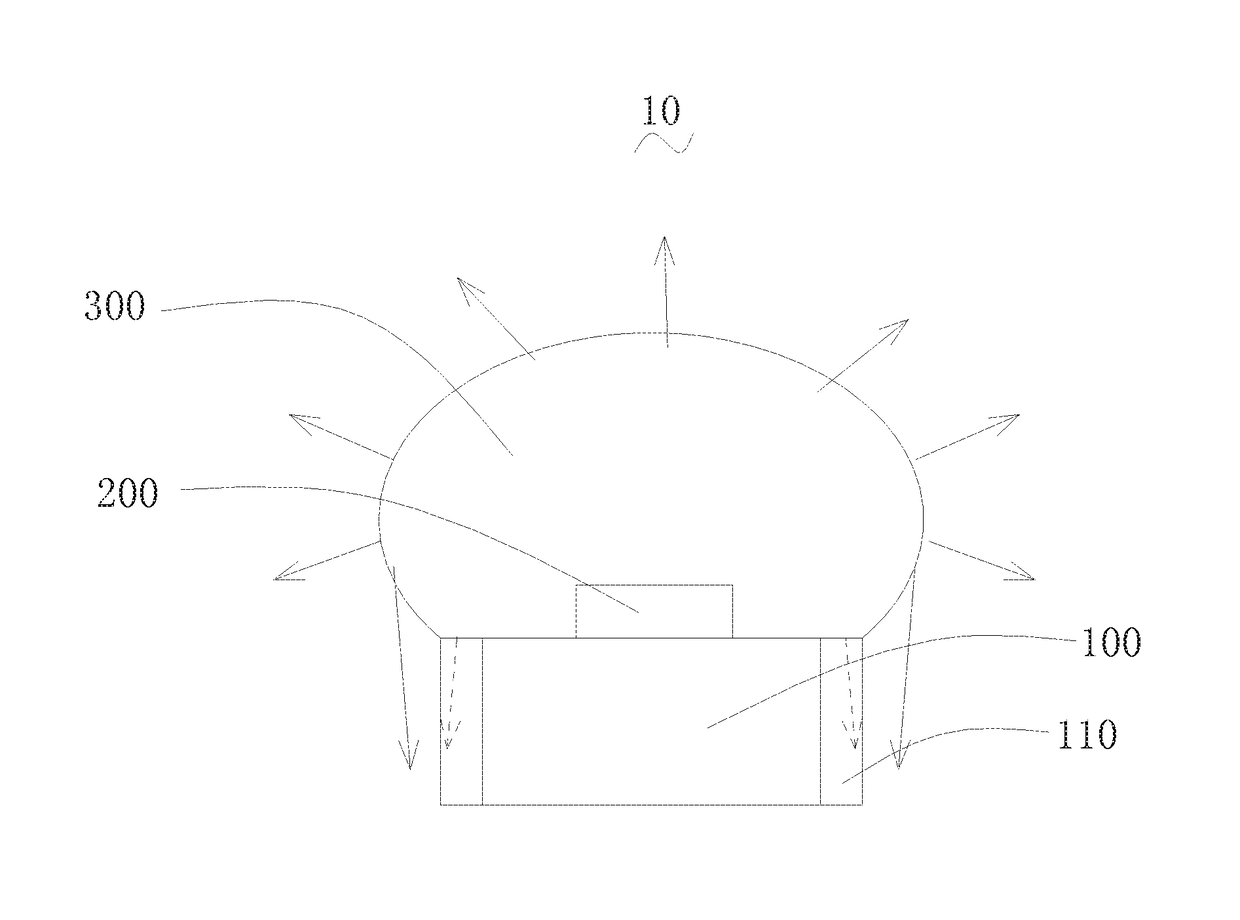

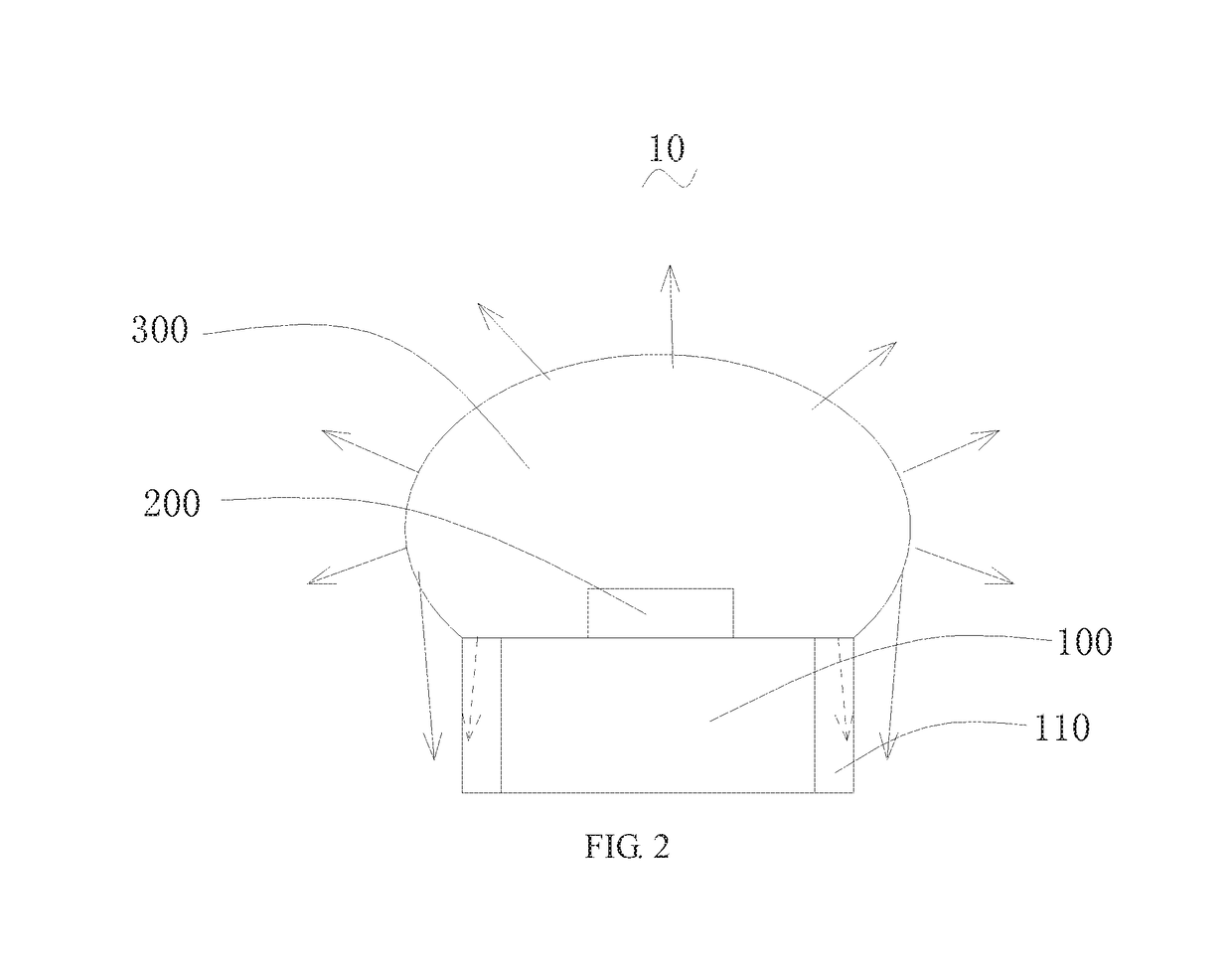

LED light and filament thereof

InactiveUS20140369036A1Light colorImprove efficiencyLight source combinationsLighting support devicesHigh colorEngineering

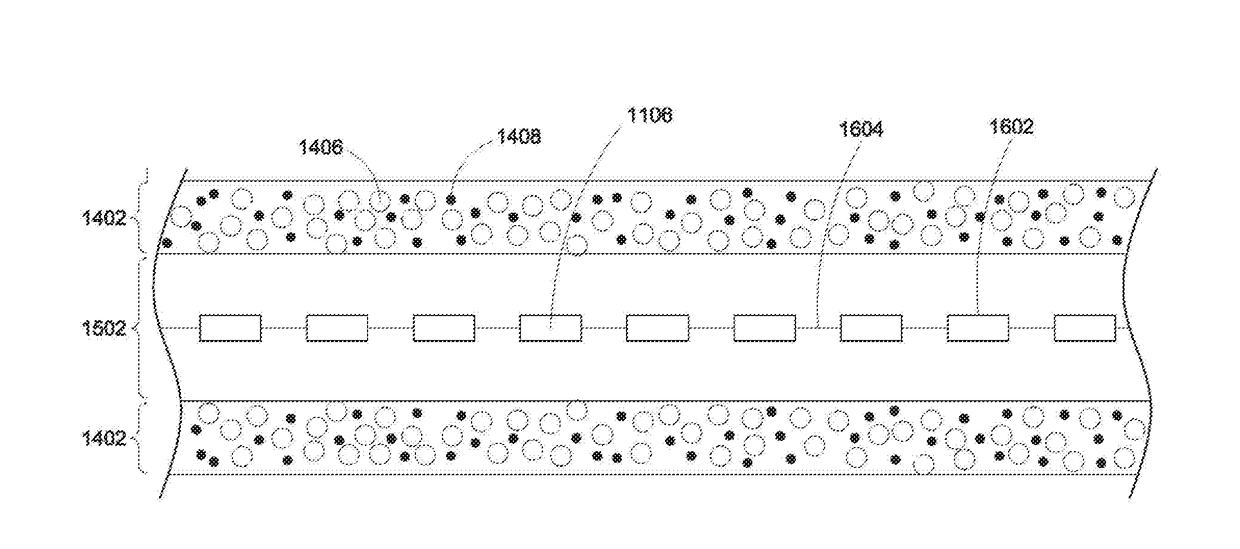

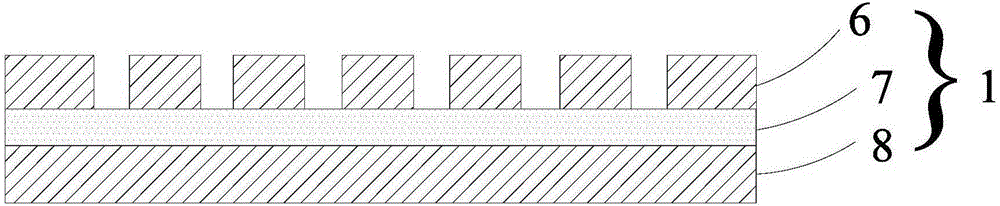

The invention discloses a LED lamp and filament thereof. The LED filament includes a substrate, a light emitting unit secured onto at least one side surface of the substrate, and a package adhesive layer surrounded on the periphery of the light emitting unit; the substrate is configured to be of an elongated bar construction; the light emitting unit comprises a plurality of blue light chips and red light chips regularly distributed on the substrate and sequentially connected to one another in series. For the LED filament of the invention, as the light emitting unit composed of blue and red light chips is disposed on the substrate, the LED filament has high color rendering and large light radiation angle.

Owner:SHENZHEN RUNLITE TECH

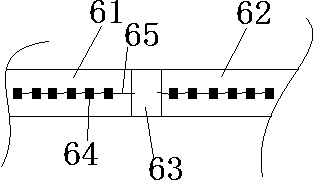

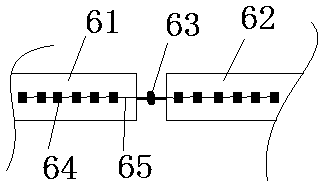

LED lamp filament illuminating strip and preparation method therefor

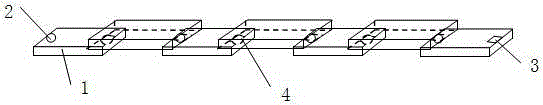

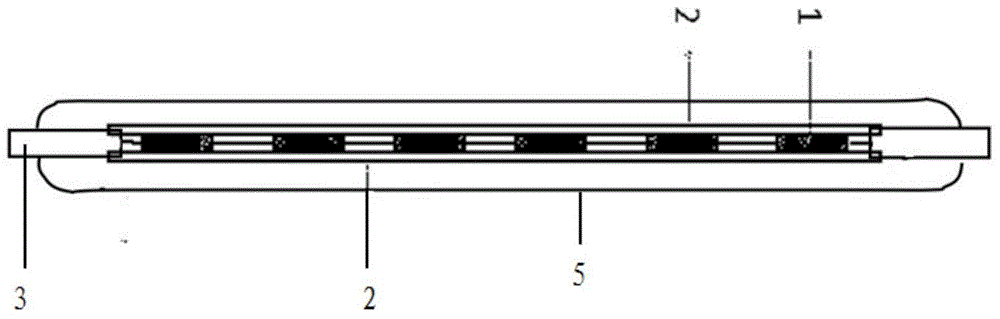

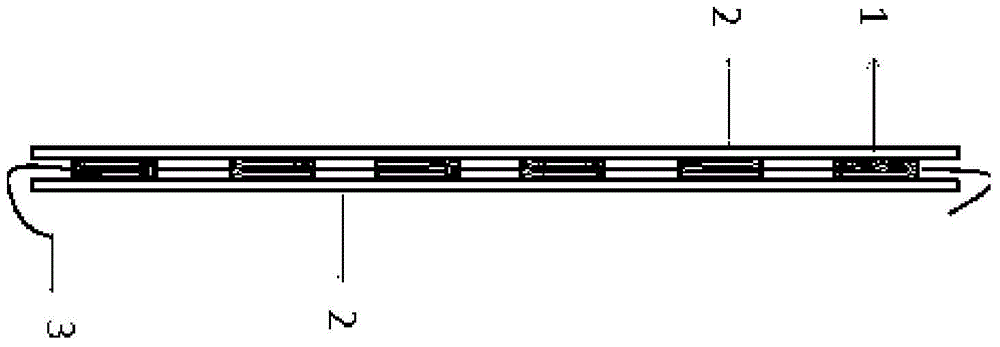

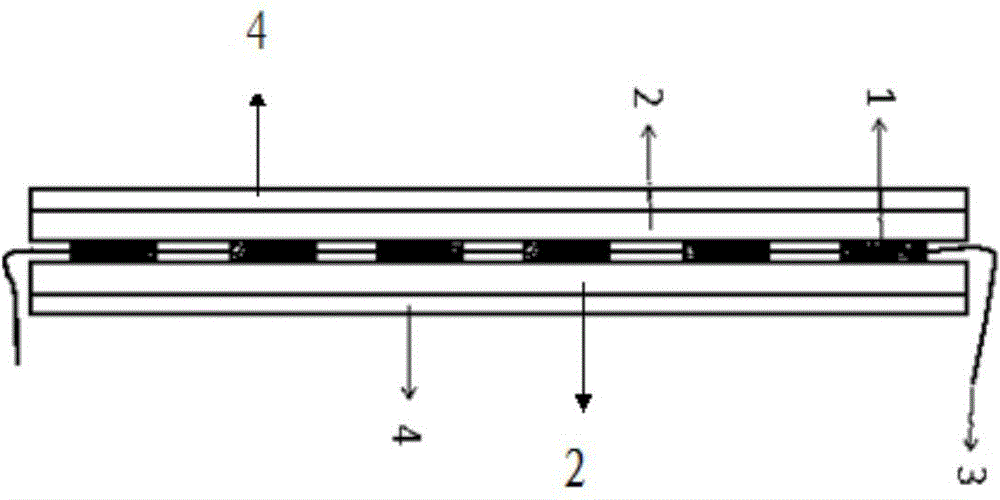

ActiveCN105161608AImprove yieldImprove uniformitySolid-state devicesSemiconductor devicesFluorescenceLap joint

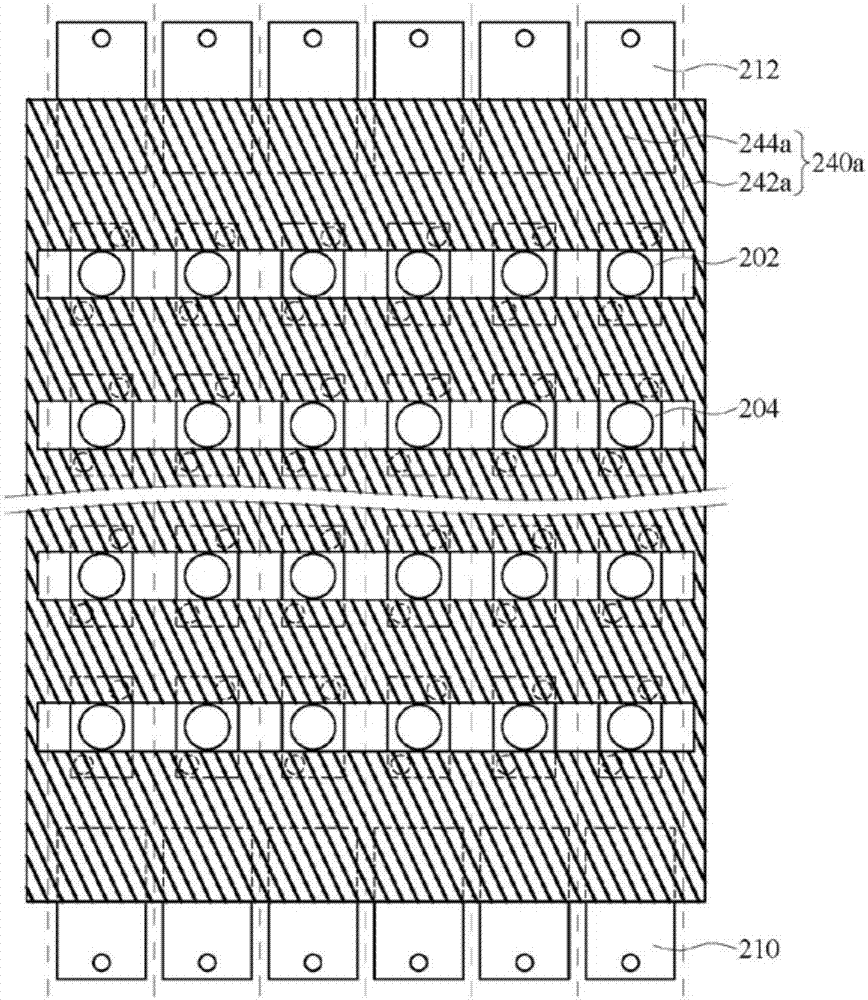

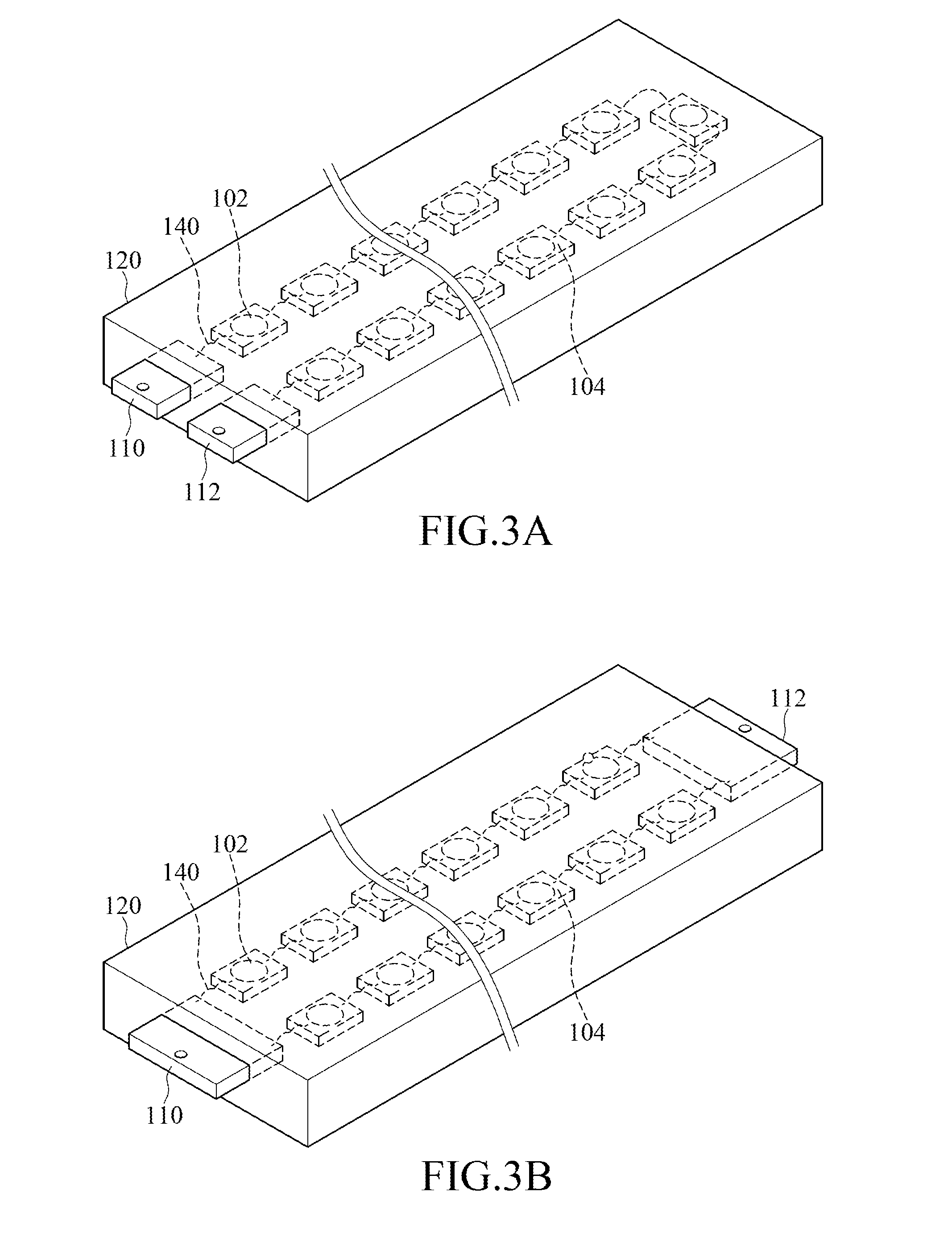

The invention discloses an LED lamp filament illuminating strip and a preparation method therefor. The illuminating strip comprises LED chips in upper and lower rows, wherein all LED chips in the lower row are distributed at intervals, and all LED chips in the upper row are respectively connected between two adjacent LED chips in the lower row in a lap joint manner. The illuminating surfaces of the LED chips in the upper and lower rows are opposite to each other. The positive and negative electrodes of all LED chips in the upper row are respectively welded with the negative and positive electrodes of two adjacent LED chips, in lap joint connection with the LED chips in the upper row, in the lower row. The preparation method comprises the steps: coating solder paste on the positive and negative electrodes of all LED chips in the lower row; heating the solder paste and enabling the solder paste to be melted, welding the corresponding electrodes, coating the front and back surfaces of chip strips in series connection with fluorescent glue, and solidifying the fluorescent glue. The illuminating strip employs the chips which are not overlapped with each other, and the illuminating surfaces of the chips are arranged oppositely, thereby improving the light-emitting uniformity and facilitating heat dissipation. The wire crossing and tandem among chips is avoided, the packaging cost is reduced, and the yield of finished products is improved.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

Packaging method of LED filament and LED filament

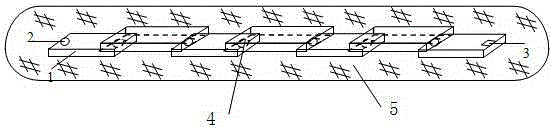

InactiveCN104319345AEnsure stabilityGuaranteed light transmittanceSemiconductor devicesLED filamentLiquid silicon

The invention discloses a packaging method of an LED filament. The packaging method of the LED filament includes the steps that a liquid silicon resin and fluorescent powder mixture is injected into a mould, and a metal conductive pin is arranged at one end of the silicon resin and fluorescent powder mixture inside the mould; the mould is removed after being heated and solidified, and silicon resin and fluorescent powder colloid with the metal conductive pin at one end is obtained; a plurality of LED chips are installed on the silicon resin and fluorescent powder colloid, and the LED chips are mutually connected through a wire and then connected to the metal conductive pin to form a conductive path; the silicon resin and fluorescent powder colloid with the LED chips is put into the mould, and a liquid silicon resin and fluorescent powder mixture is injected into the mould to cover the LED chips and the wire; the mould is removed after being heated and solidified, and the packaged LED filament finished product with a supporting frame is obtained. The LED filament is packaged without the supporting frame, and the quality problems of low yield, low light transmittance of the supporting frame and the like are resolved.

Owner:DONGGUAN INST OF OPTO ELECTRONICS PEKING UNIV +1

LED (Light Emitting Diode) lamp filament and manufacturing method thereof

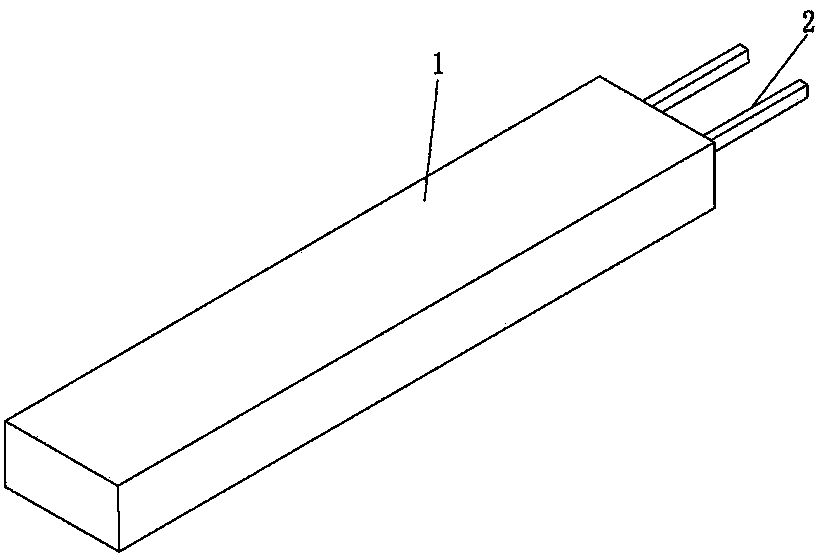

ActiveCN104600174AImprove thermal reliabilityMaximum Thermal ReliabilitySemiconductor devicesFluorescenceConductive coating

The invention provides an LED (Light Emitting Diode) lamp filament and a manufacturing method thereof. An LED chip is encapsulated on the edge top surface of a thin and long sheet metal support of the LED filament innovatively, meanwhile the sheet metal is inserted into a preformed transparent plastic model frame to produce a light source, and accordingly the automated continuous production of the LED lamp filament is implemented and the problem of the facing direction strength caused by the too thin and too long metal support is solved due to the transparent plastic model frame; meanwhile the lateral direction strength of the metal support is effectively utilized and accordingly the integral mechanical strength of the LED lamp filament is ensured; the heat dissipation characteristics of the metal is directly utilized, meanwhile the heat dissipation efficiency of the LED chip is maximized through the innovative encapsulation of thermal conductive coatings, and accordingly the problem of a heat dissipation bottleneck of the LED lamp filament is effectively solved, the LED lamp filament can work at the rated power for a long time, and the cost is reduced; the LED light extraction efficiency is improved, the light attenuation is reduced, the high lighting effect and ambient light of lamp filament light emission is implemented, and the market vacancy of the existing LED lamp filament is filled through innovative fluorescence encapsulation materials.

Owner:DONGGUAN RIWEI ELECTRONICS

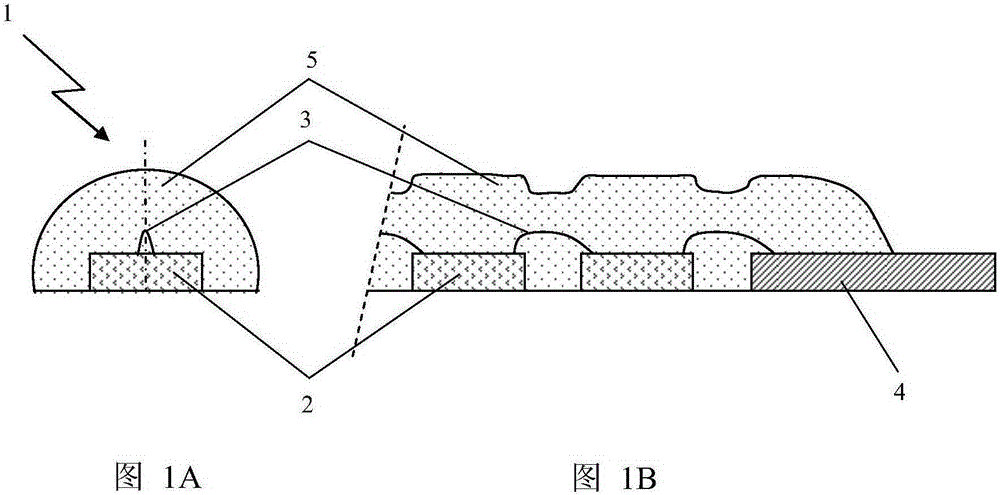

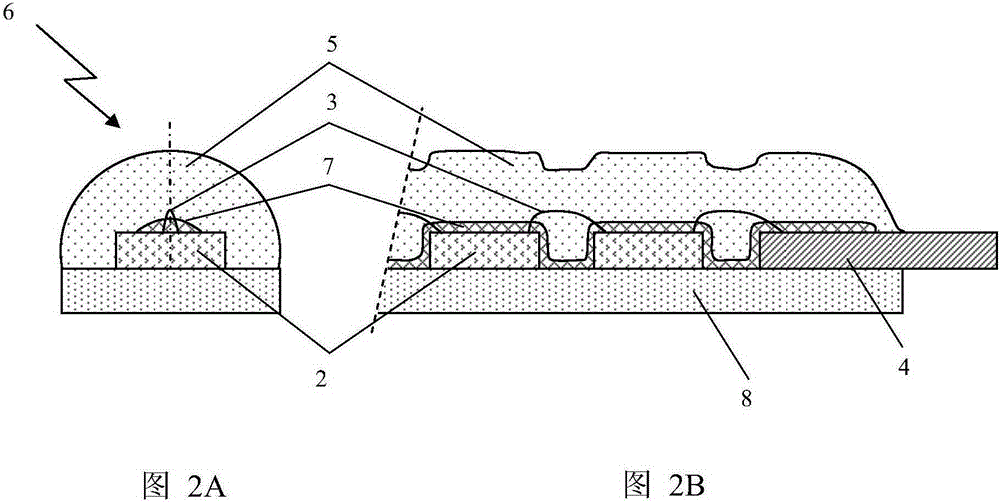

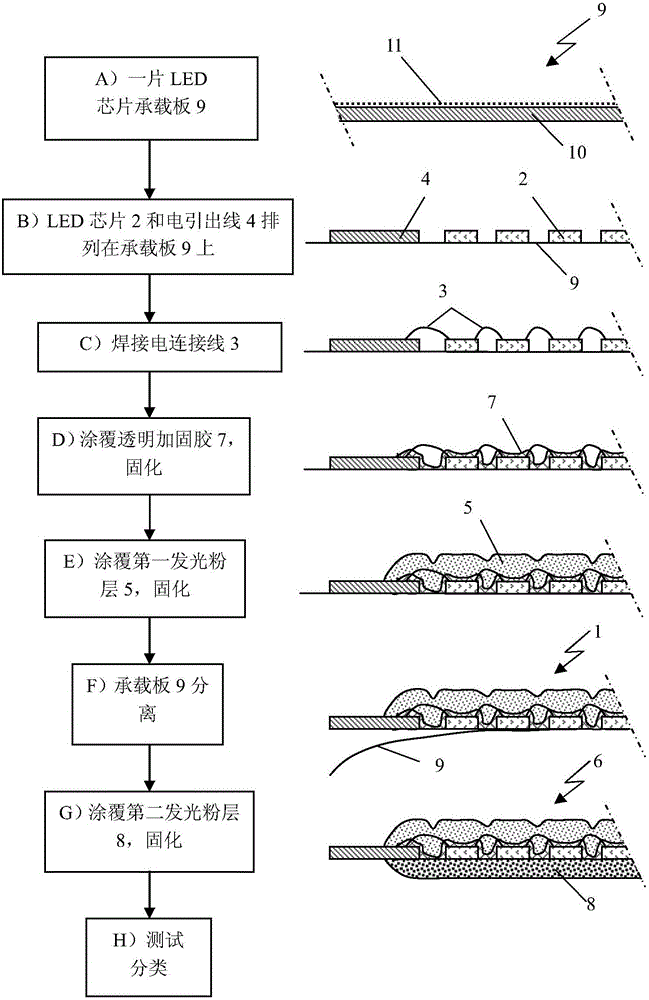

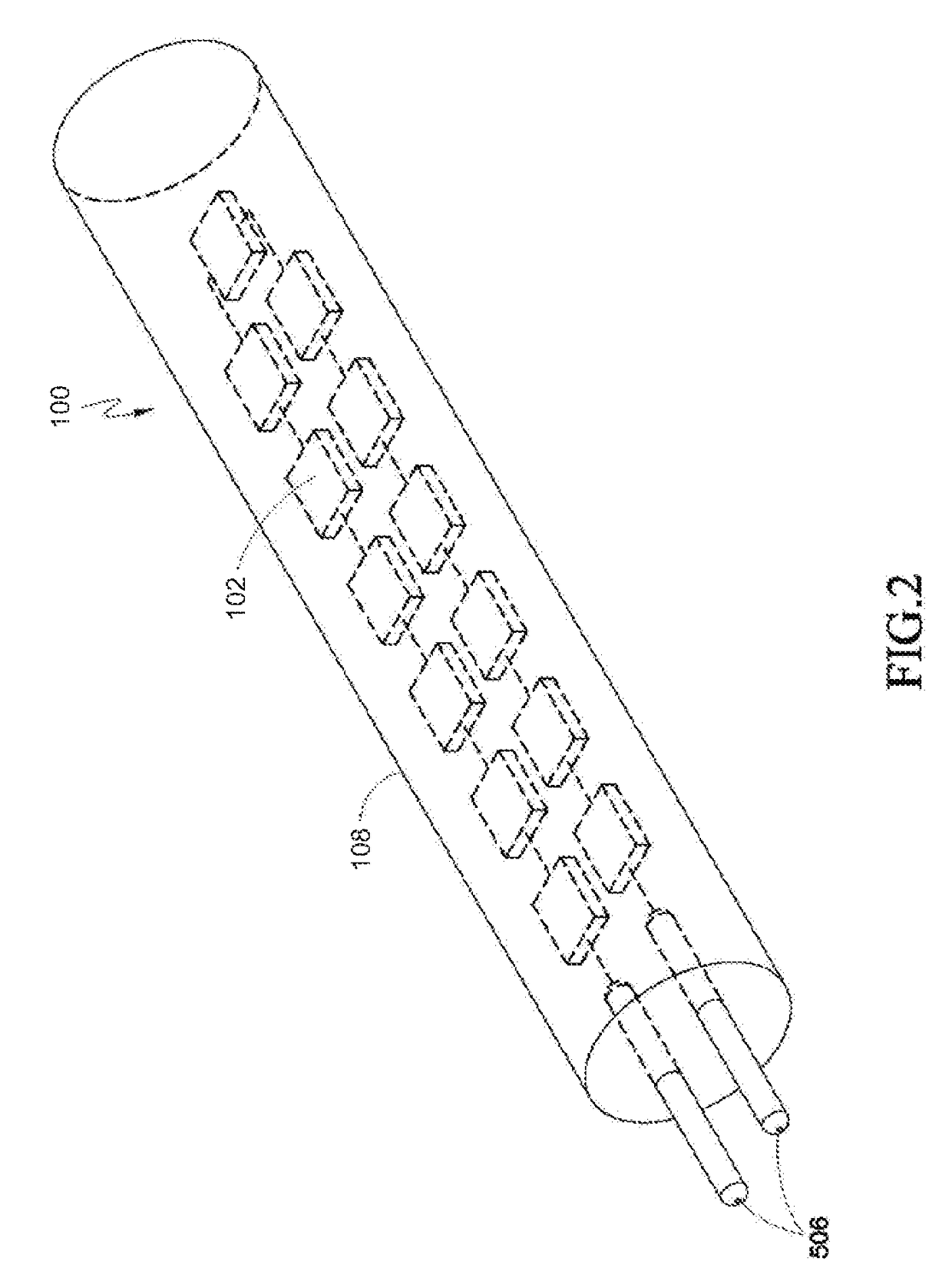

Substrate-free LED filament and manufacturing method thereof, and substrate-free LED filament lamp

ActiveCN105140381AIncrease powerIncrease luminous fluxPoint-like light sourceElectric circuit arrangementsEngineeringLED filament

The invention provides a substrate-free LED filament and a manufacturing method thereof, and a substrate-free LED filament lamp. The filament comprises at least a string of LED chips with same or different illuminant colors, electric lead-out wires, and electric connecting wires arranged between the chips and between the chips and the electric lead-out wires, welding terminals of the chips, the electric connecting wires, and the electric lead-out wires are coated by first luminescent powder layers to form an initial substrate-free LED filament, the other side of the initial substrate-free LED filament is coated by a second luminescent powder layer to form the substrate-free LED filament, and the substrate-free LED filament can be adhered on the external surface of a transparent high-heat-conductivity tube via transparent adhesive tapes or luminescent powder glue to form a cylindrical substrate-free LED filament light source used for manufacturing a high-power LED filament lamp. The substrate-free LED filament lamp comprises at least a bulb shell sealed in a vacuum manner and inflated with heat radiation protection gas, at least one substrate-free LED filament light source is arranged in each bulb shell, and the substrate-free LED filament light source comprises the initial substrate-free LED filament, the substrate-free LED filament or the cylindrical substrate-free LED filament light source; an LED drive, a drive shell, and an electric connector etc. and used for illumination.

Owner:ZHEJIANG LEDISON OPTOELECTRONICS

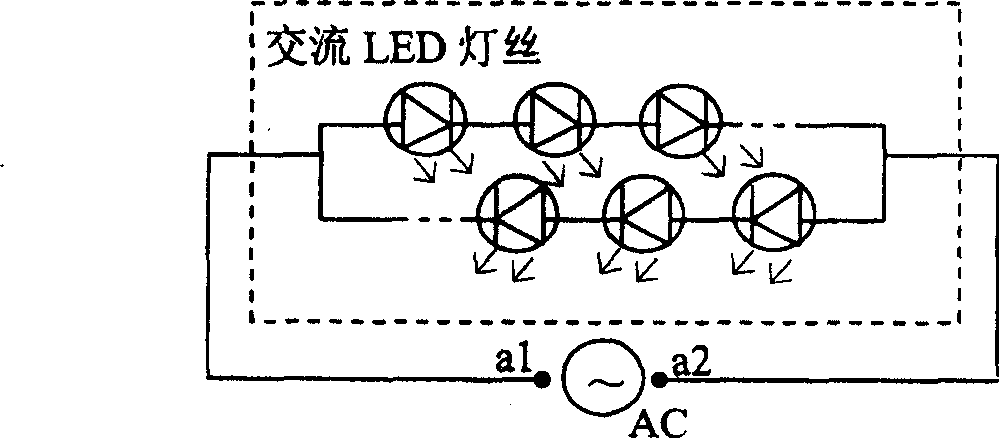

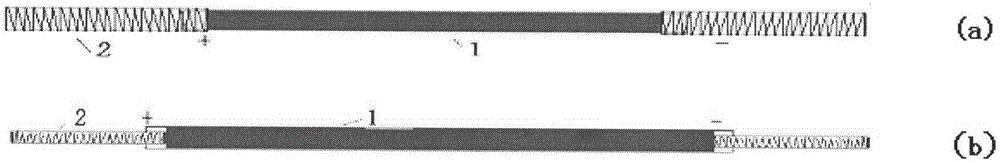

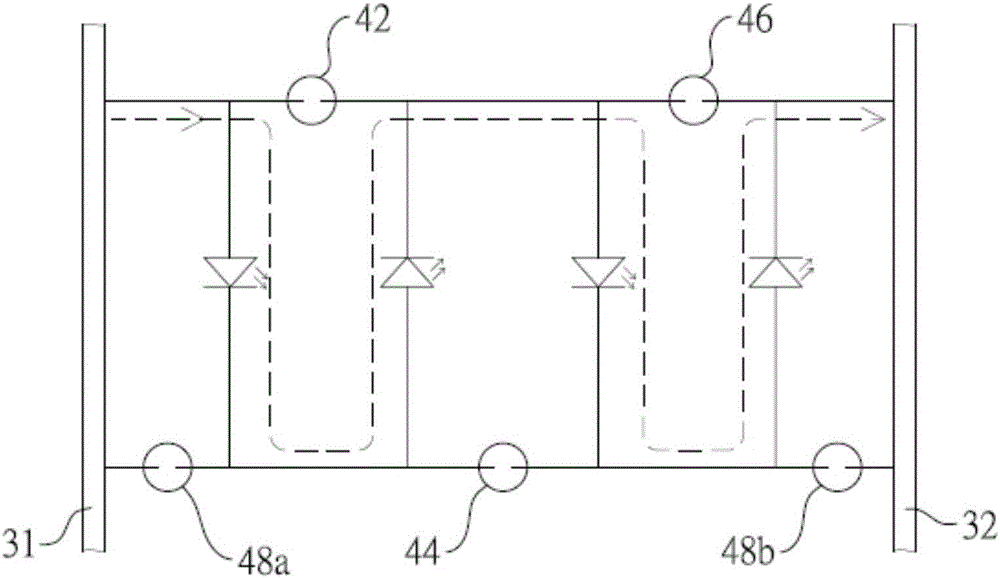

AC LED lighting lamp

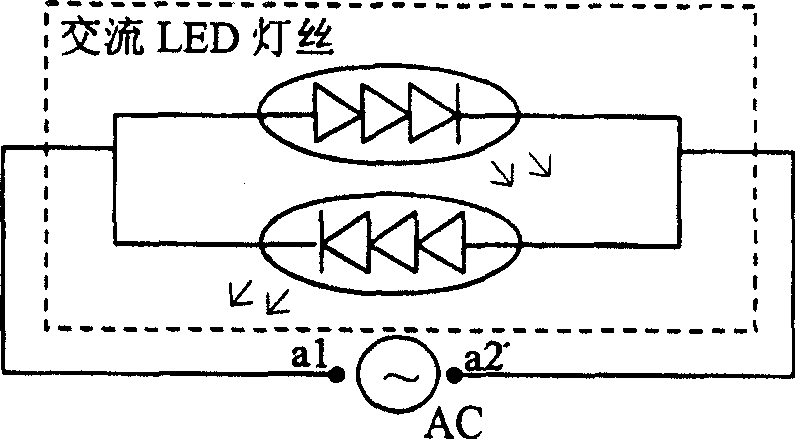

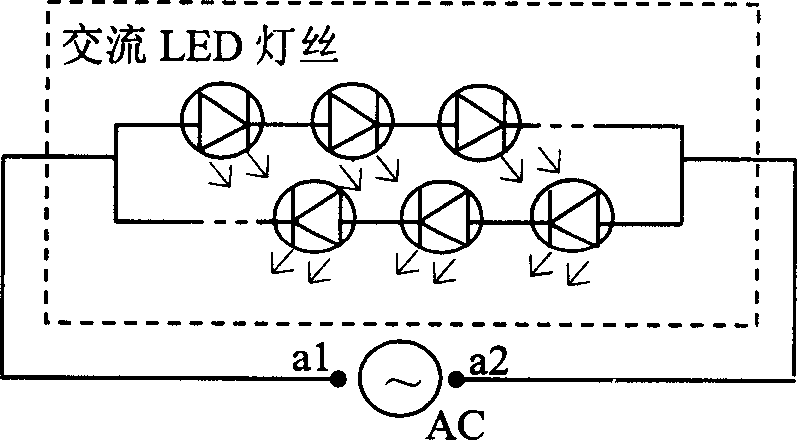

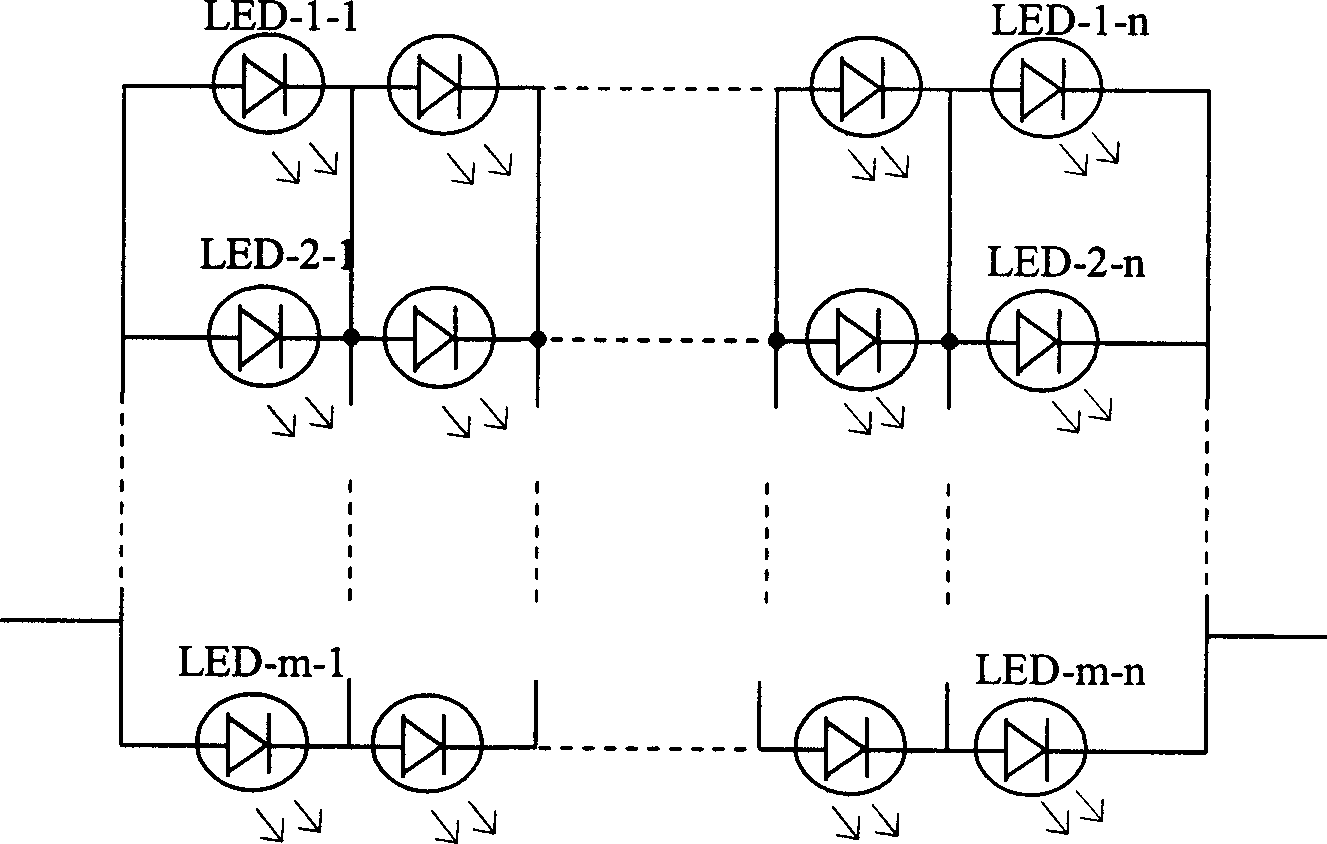

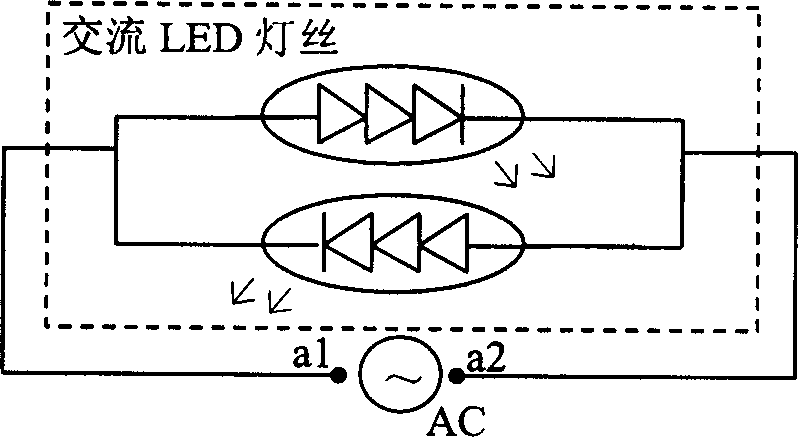

InactiveCN100464111CLow costImprove reliabilityMechanical apparatusLight source combinationsDriver circuitLed array

The AC LED lighting lamp includes AC input ends and AC LED filament, and the AC LED filament includes at least two parallelly connected LED arrays in opposite conducting directions and may be in integrated structure. The present invention has the advantages of simple structure without rectifier, voltage stabilizer, filter and switching power source, and high lighting efficiency.

Owner:厦门市清科华核供应链有限公司

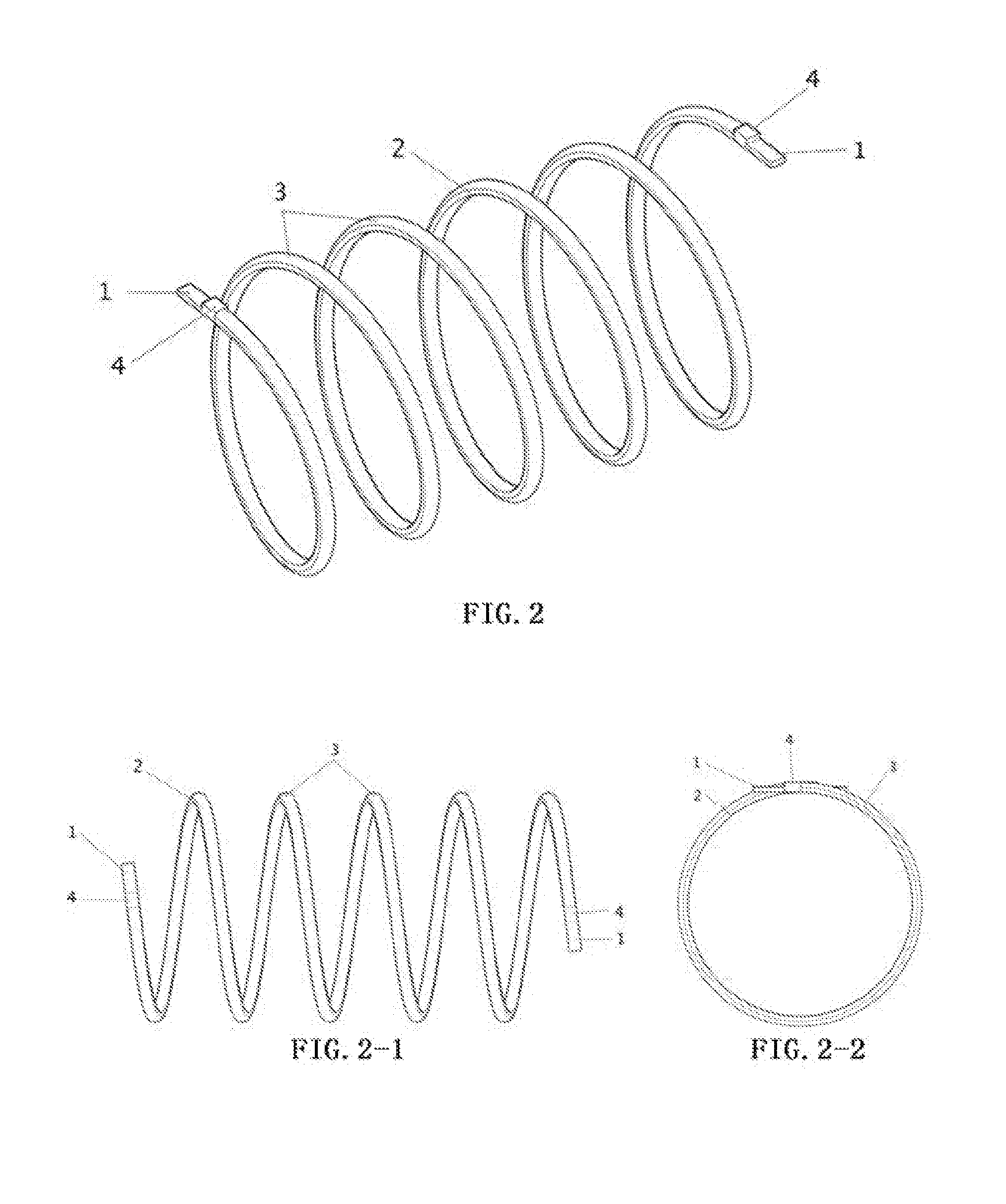

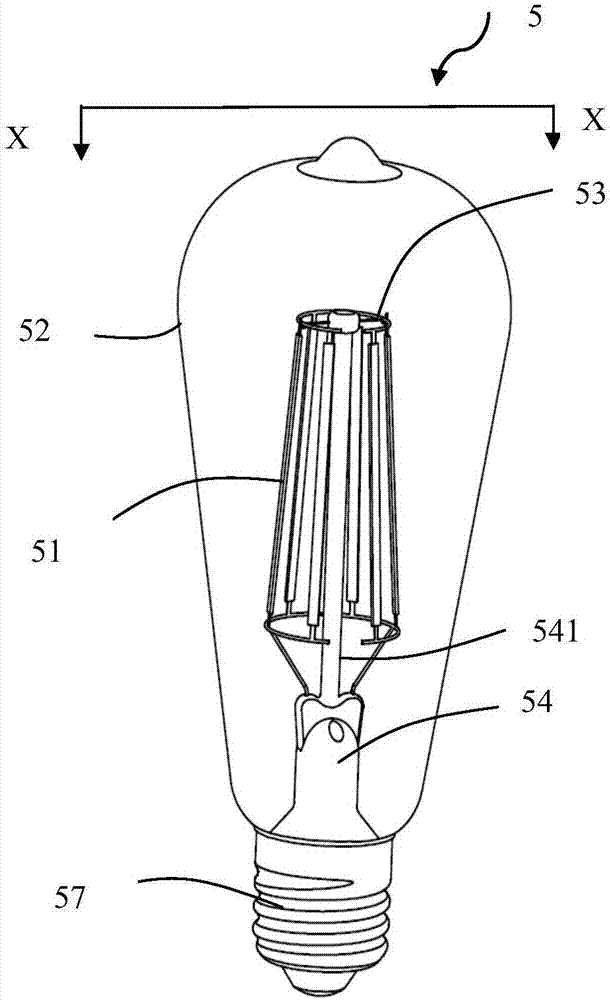

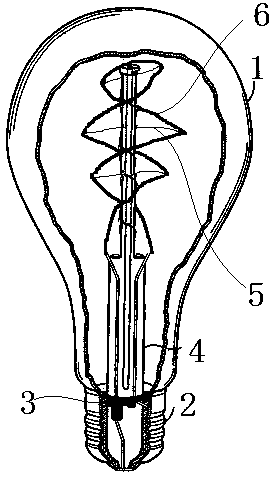

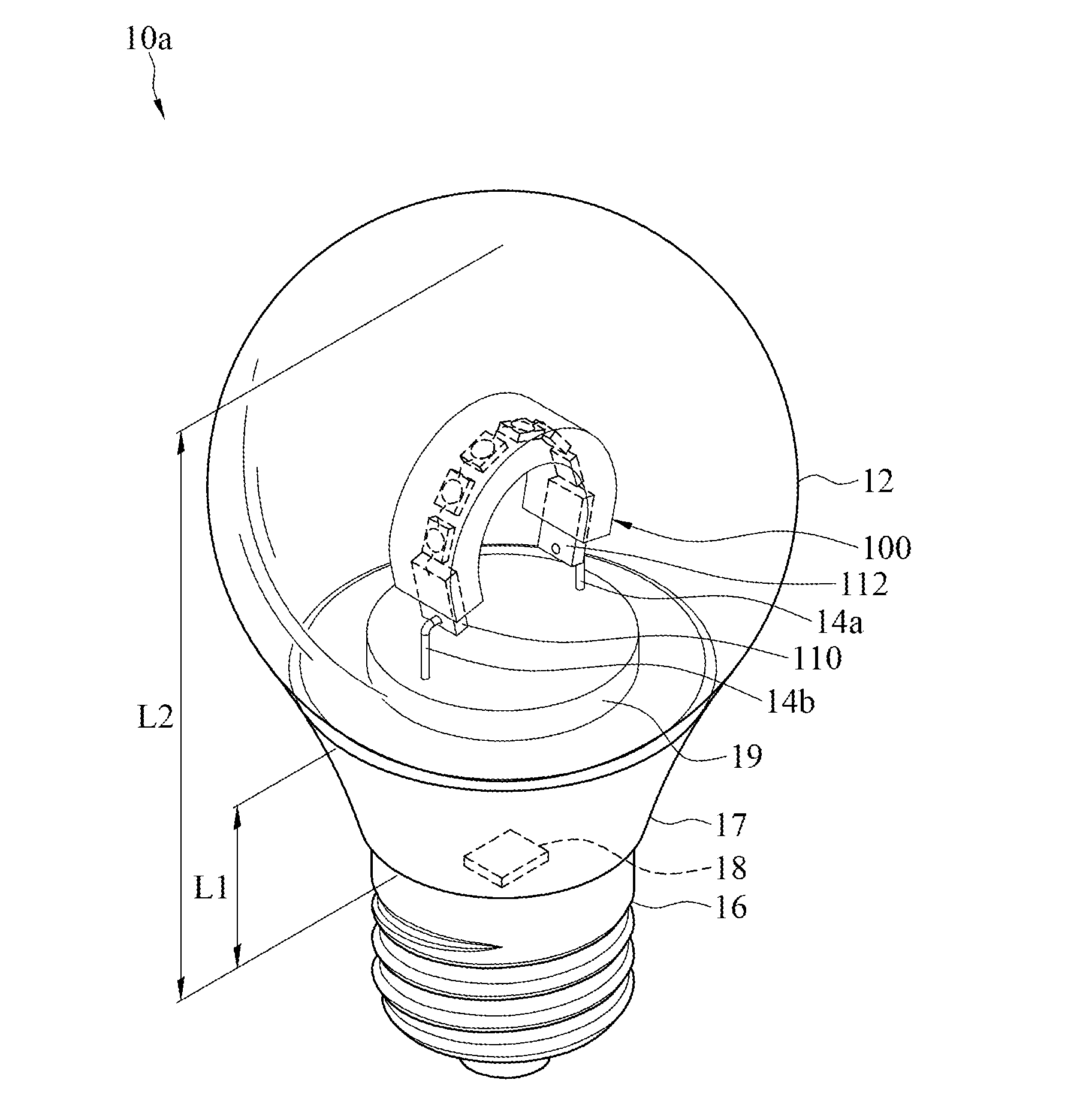

Spiral LED filament and light bulb using spiral LED filament

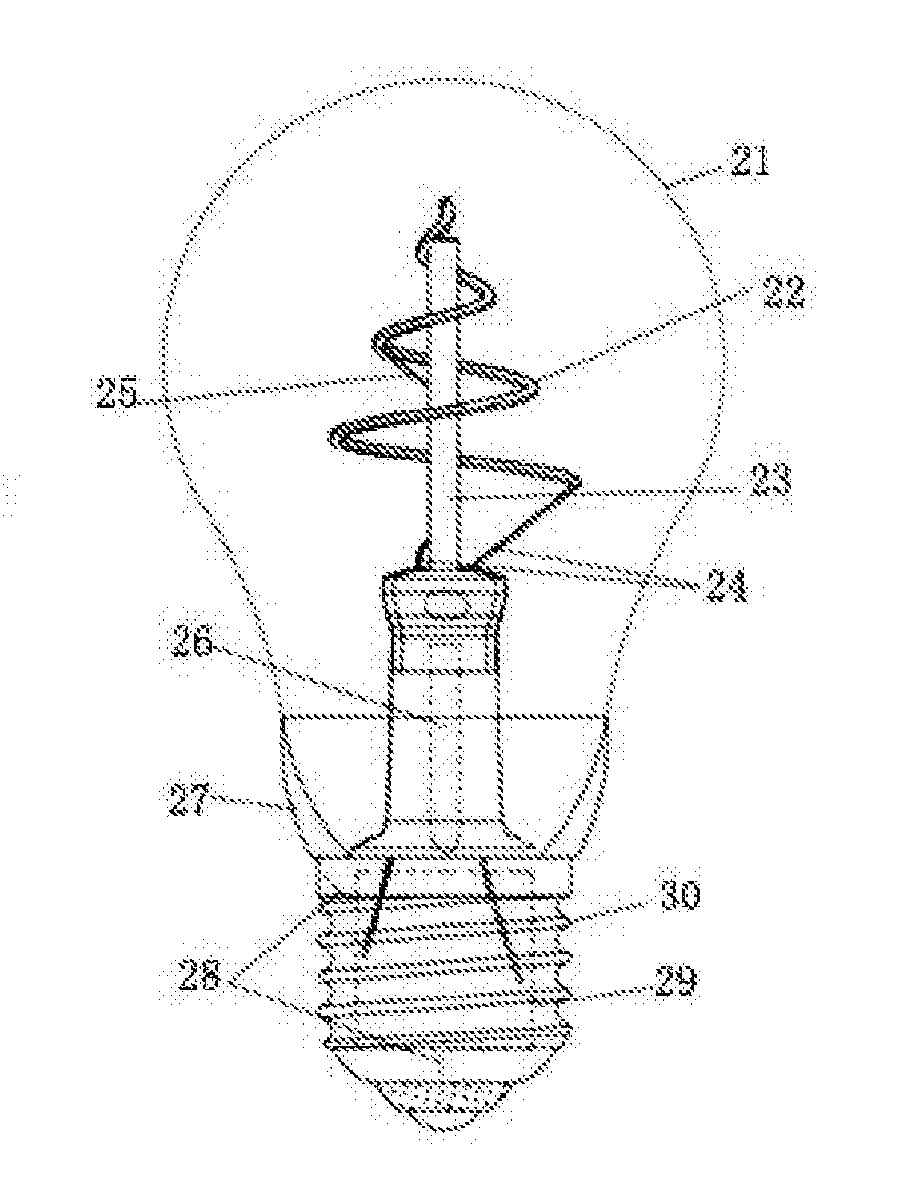

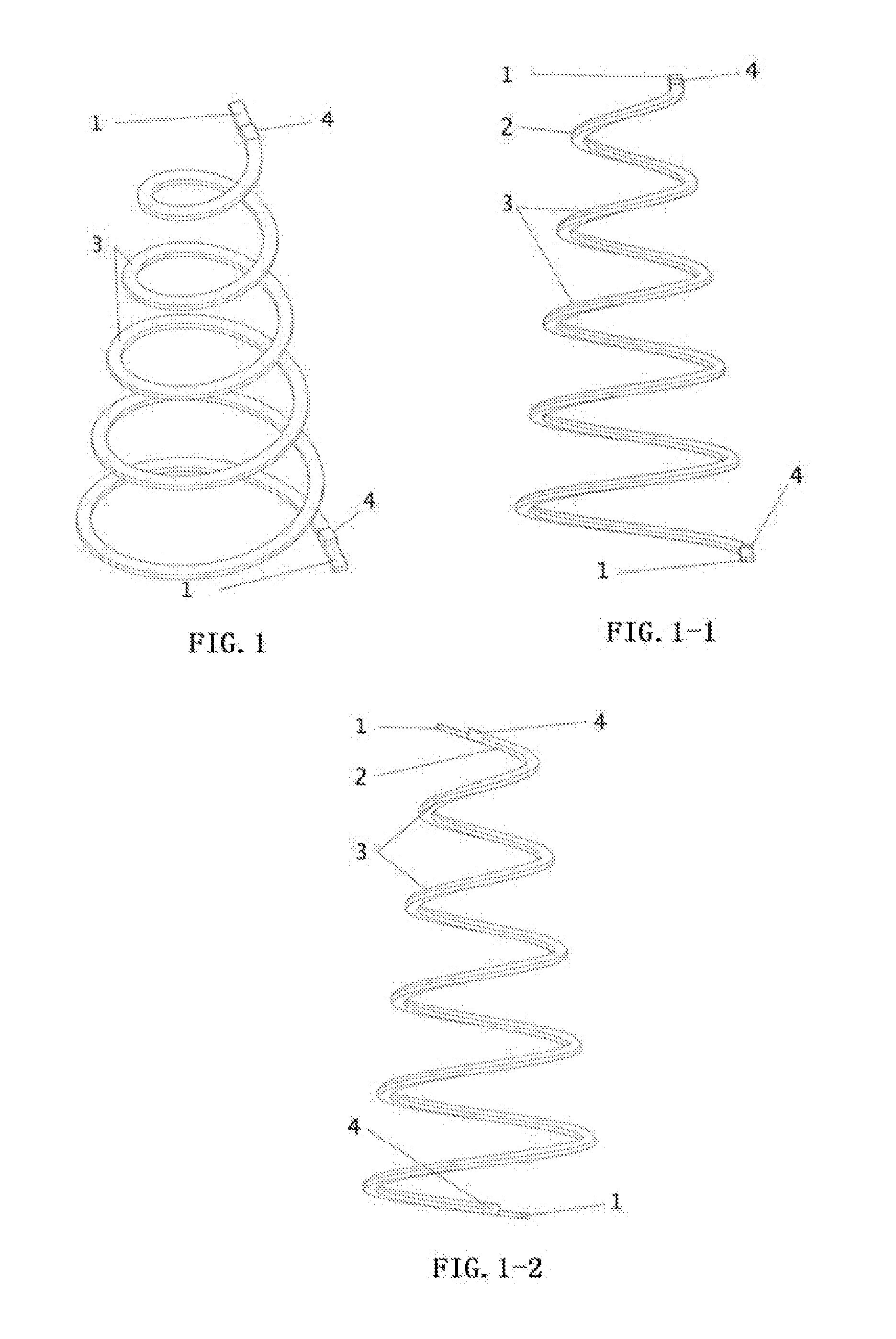

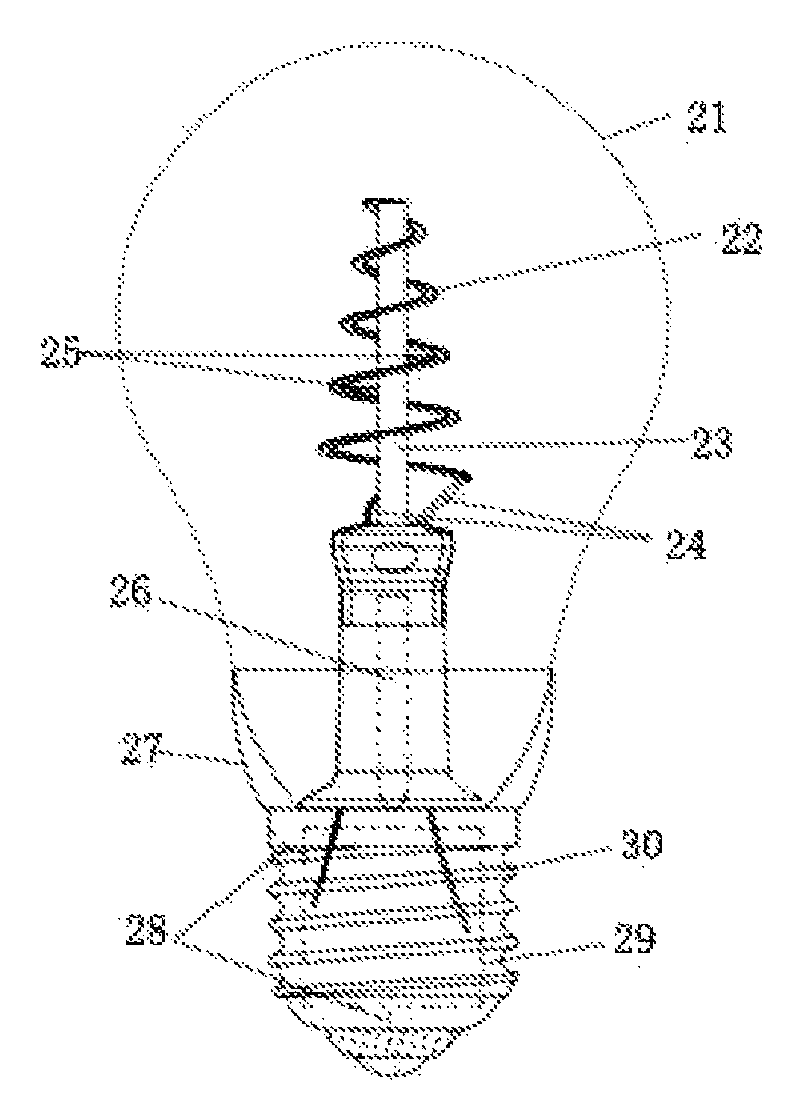

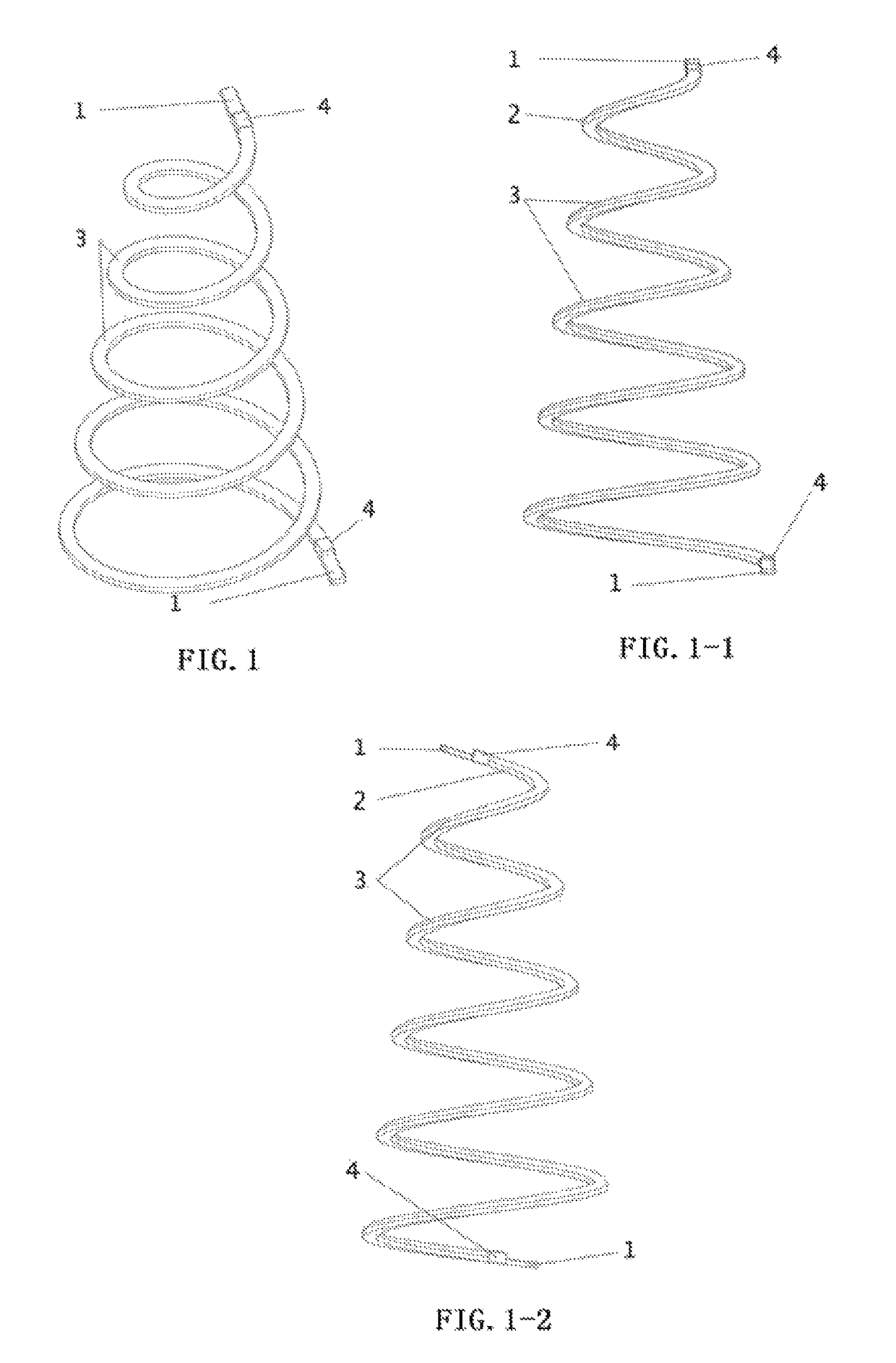

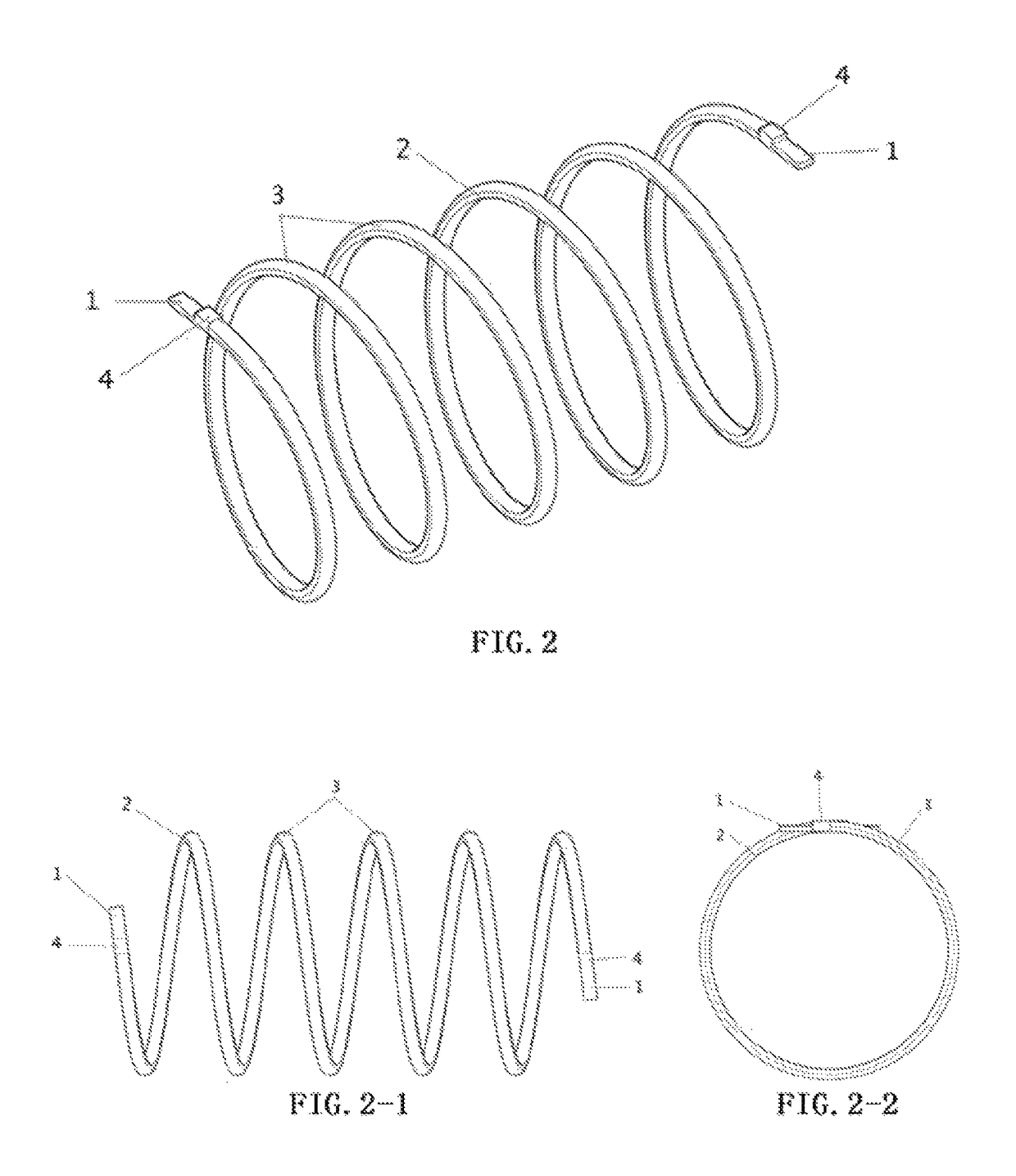

ActiveUS20160377237A1Simple manufacturing processImprove light distribution designElectric circuit arrangementsSolid-state devicesEngineeringElectrical connector

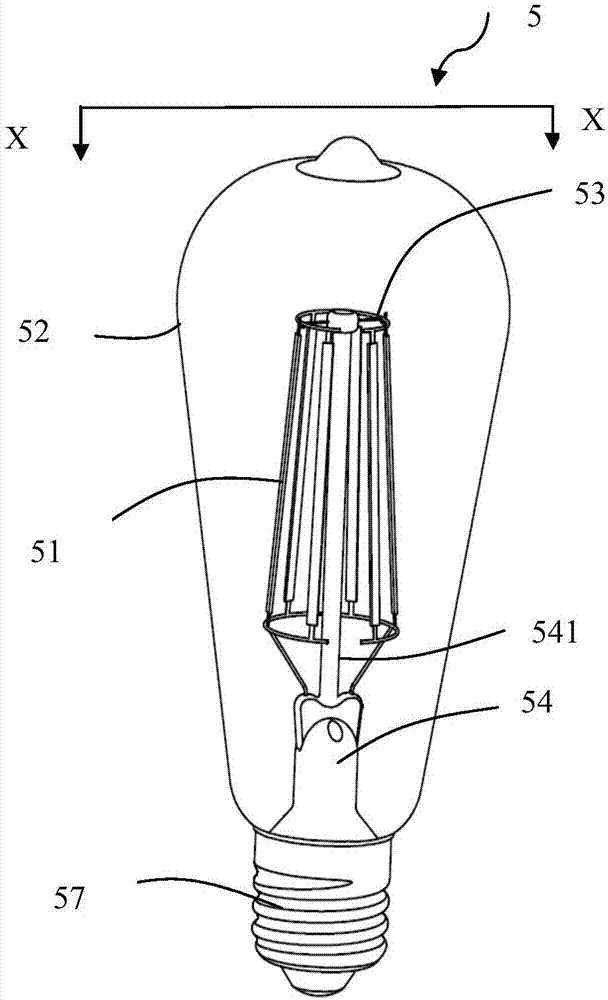

A spiral LED packaging filament comprises a substrate, a plurality of LED chips disposed on the top surface of the substrate, a medium layer sealing the plurality of LED chips and the top surfaces of the substrate into a sealed LED package; two electrode wires being electric connected to the plurality of LED chips, wherein the sealed LED package has a spiral shape. A light bulb with the spiral LED packaging filament comprises a bulb shell; a stem having a supporting pole, an electrical wire and a stem exhaust pipe, at least one spiral LED packaging filament is fixed on the stem; the electrode wire is connected to the electrical connector via the drive; and the bulb shell and the stem are respectively sealed.

Owner:GENERAL ELECTRIC SA

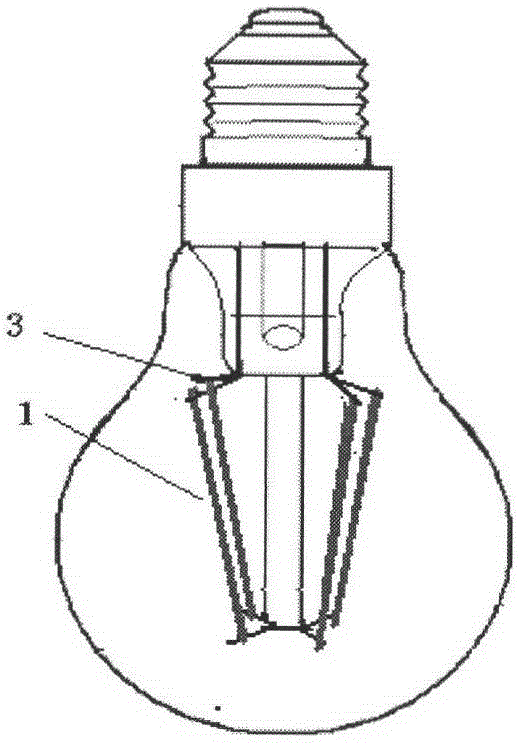

LED (light-emitting diode) lamp and filament thereof

ActiveCN103322525AGood colorIncrease the light output angleLight source combinationsPoint-like light sourceEngineeringSealant

Owner:SHENZHEN RUNLITE TECH

LED lamp based on transparent fluorescent ceramics

InactiveCN103956421AHigh thermal conductivityEfficient and stable light emissionPoint-like light sourceLighting heating/cooling arrangementsPhosphorFluorescence

Disclosed is an LED lamp based on transparent fluorescent ceramics. The LED lamp is composed of LED lamp filaments, electrode leads and a lampshade and is characterized in that the strip-shaped transparent fluorescent ceramics serve as the substrate of the LED lamp filaments, the width of the transparent fluorescent ceramics is equal to that of LED chips, then the blue LED chips (including leads) are sequentially fixed to the transparent fluorescent ceramic battens in an adhering mode, and identical transparent fluorescent ceramic strips adhere to the other sides of the LED chips or the other sides of the LED chips are coated with fluorescent optical cement. The transparent fluorescent ceramics can be Ce : YAG (including the situation when Ce ion concentration is zero), or Ce : Tb3Al5O12, or Ce, Cr : YAG, or Ce, Pr : YAG, or Ce : YAG+MgAl2O4, or Ce, Pr : YAG+MgAl2O4, or Ce, Cr : YAG +MgAl2O4. According to the LED lamp based on the transparent fluorescent ceramics, luminous decay of a fluorescent powder silica gel resin mixture phosphor can be effectively avoided, the performance of the LED lamp can be improved, and the service life of the LED lamp can be prolonged.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

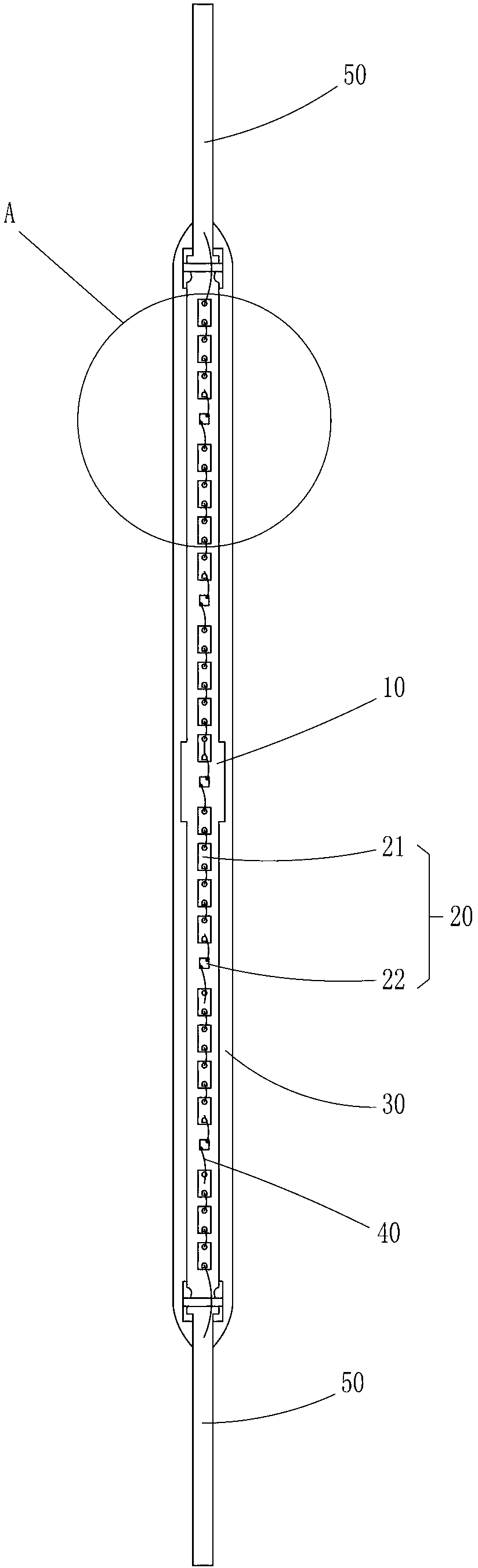

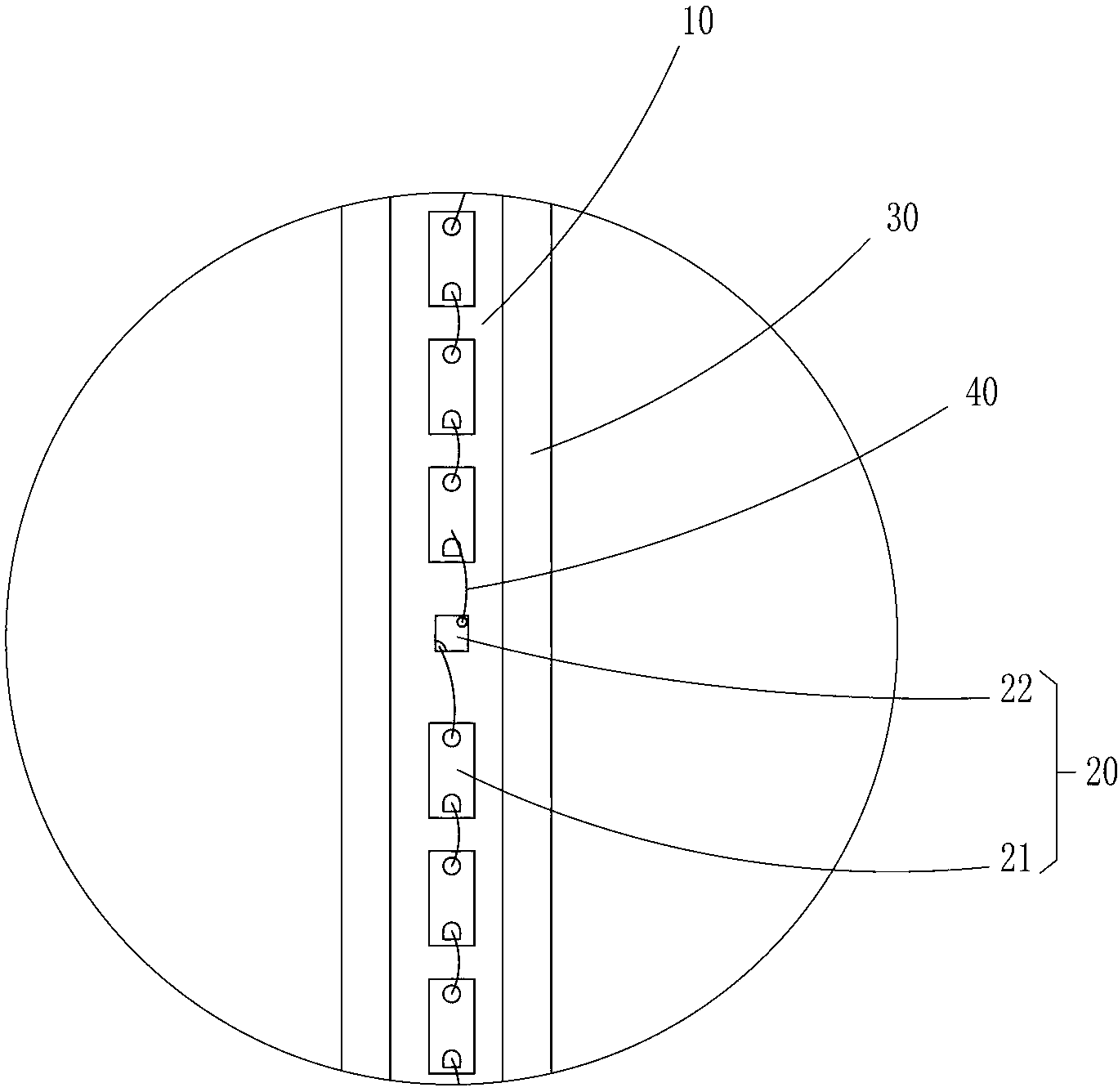

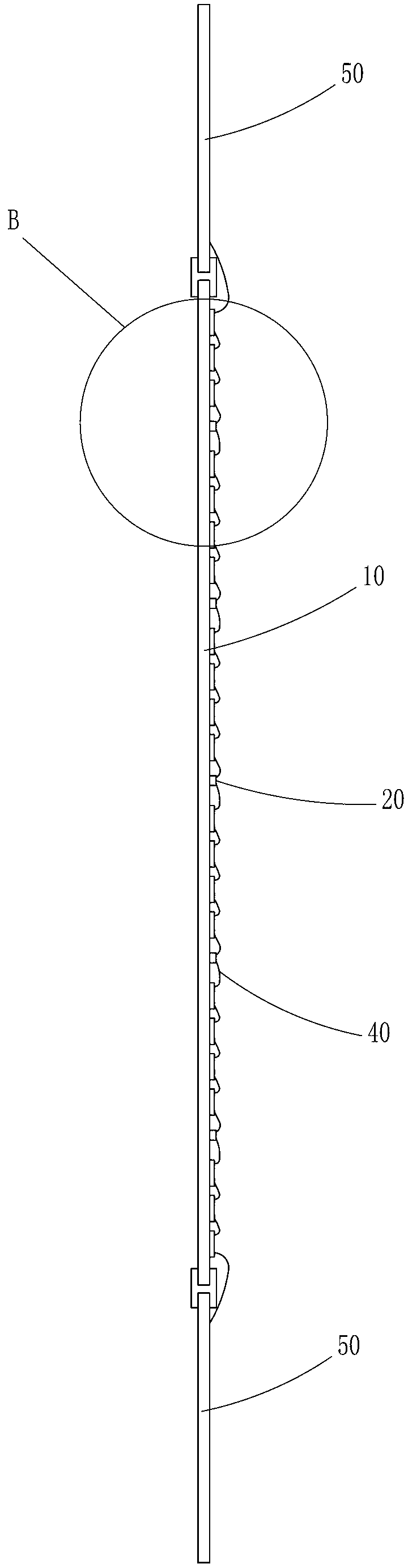

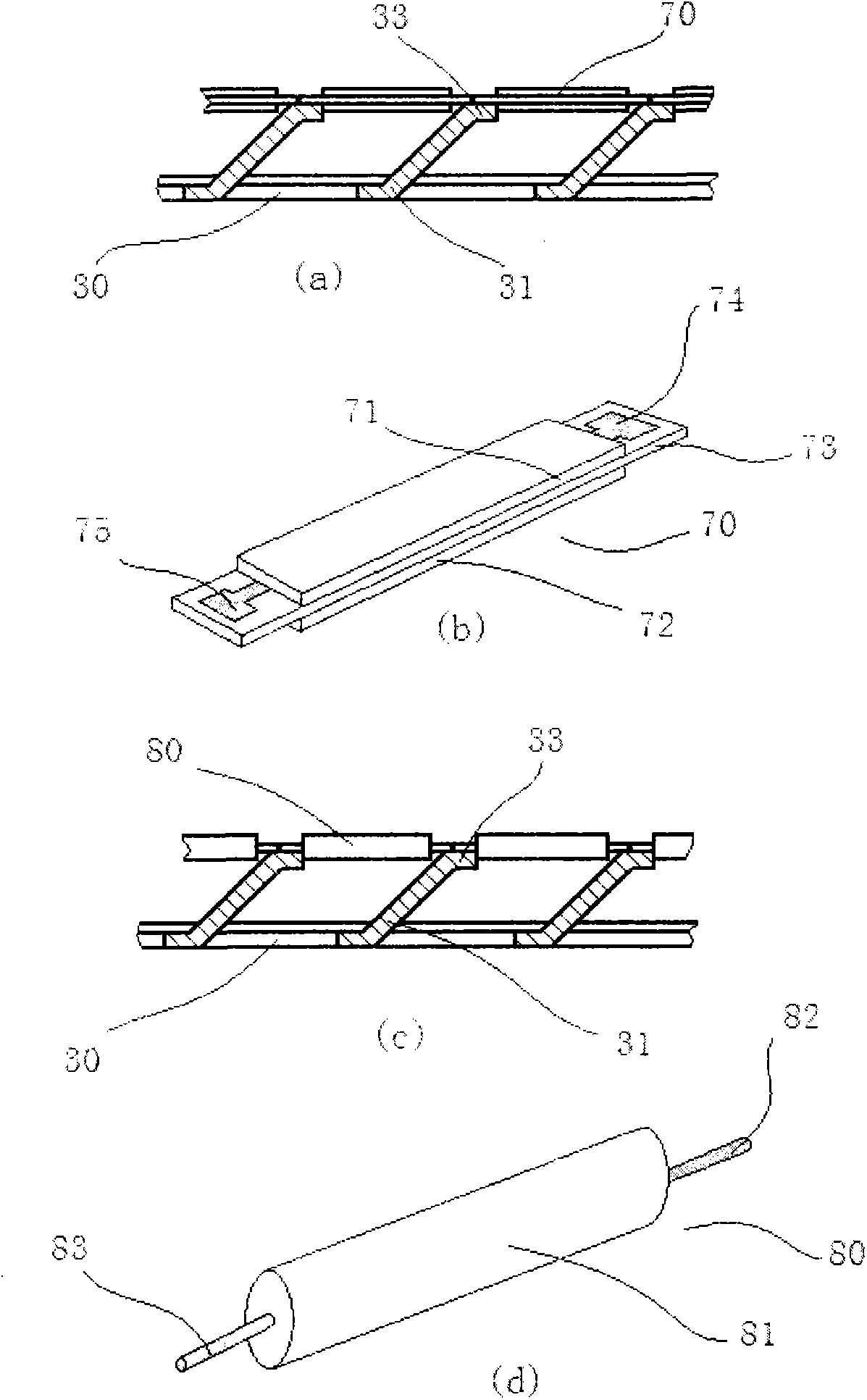

Connection and installation method for LED filaments

ActiveCN105371243AReduce damage rateReduce stressPoint-like light sourceLight fasteningsElectrical polarityEngineering

The invention provides a connection and installation method for LED filaments. The connection and installation method is used for assembling wicks in filament type LED bulbs. As the difference from the prior art of welding the lead-out ends of the LED filaments to a guide wire of a glass core column through a spot welding method, the electrode lead-out ends of the LED filaments are connected through elastic metal thin wire spiral parts, and therefore the LED filaments are connected in series one by one in an end-to-end manner according to the polarity to form a multi-joint LED filament series-connection system which can be bent. Then, the metal thin wire spiral parts at the head lead-out end and the tail lead-out end of the filament series-connection system are clamped on and fixed to corresponding core column side rod guide wires, and the metal thin wire spiral parts between the adjacent filaments are placed on corresponding filament hooks on the core column one by one so that the filaments can be arranged in order. By means of the connection and installation method, the defects that in the prior art, due to spot welding, the production efficiency is low, the finished product rate is low, and filament stress is large are overcome, and the production efficiency of filament type LED bulbs can be easily improved and the finished product rate of the filament type LED bulbs can be easily increased.

Owner:厦门银旭工贸有限公司

LED filament and manufacturing method thereof and LED bulb lamp applying filament

ActiveCN107314258AImprove luminous performanceEasy to makeElectrical apparatusElectroluminescent light sourcesHeight differenceEngineering

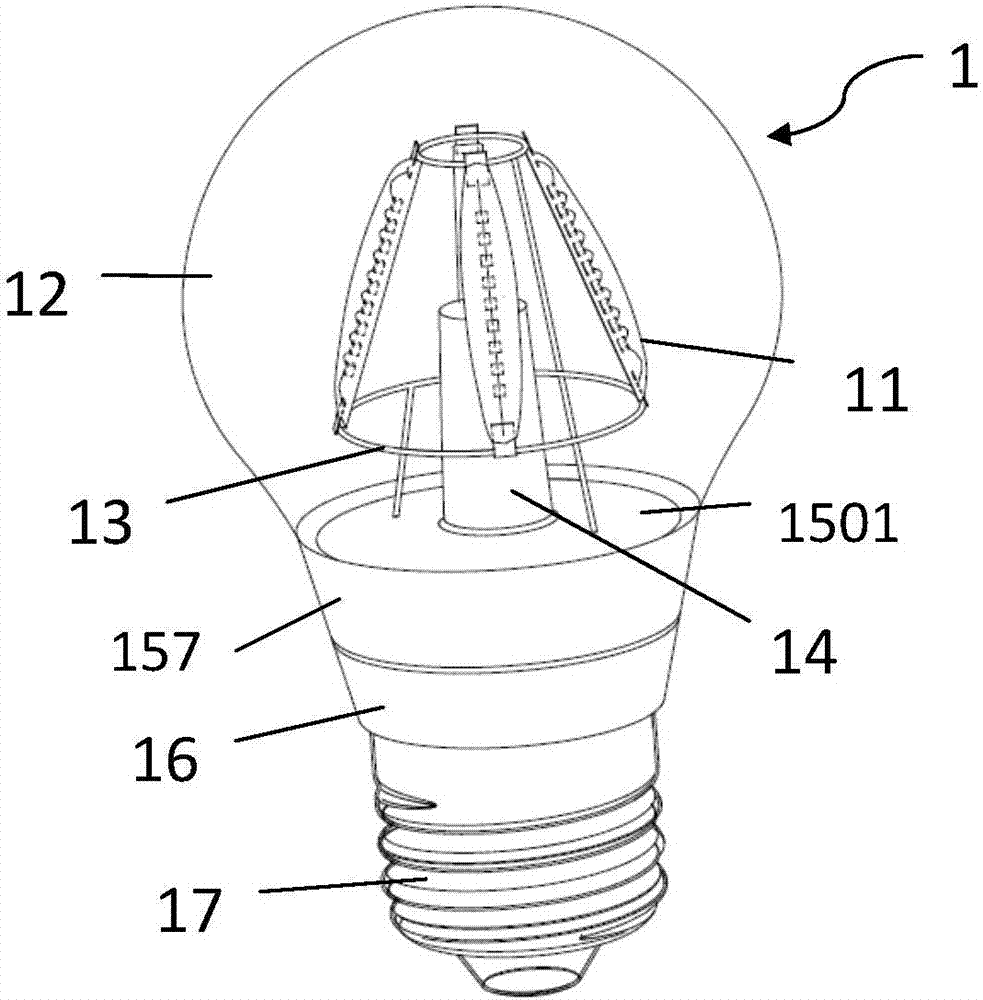

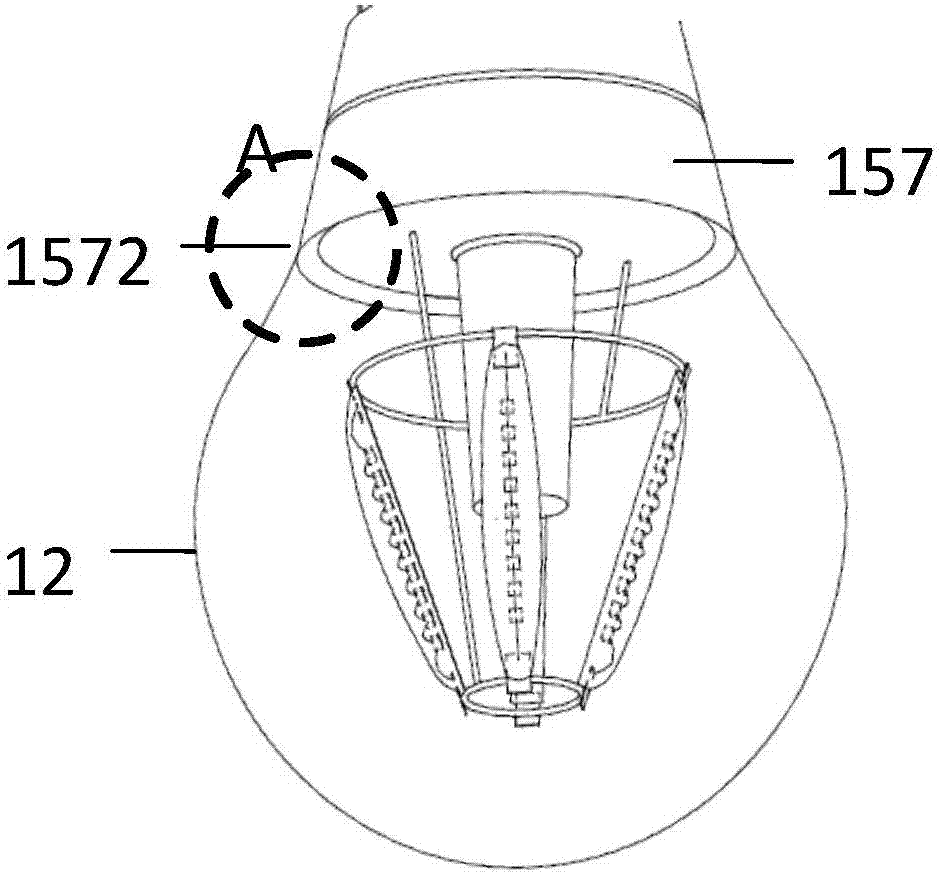

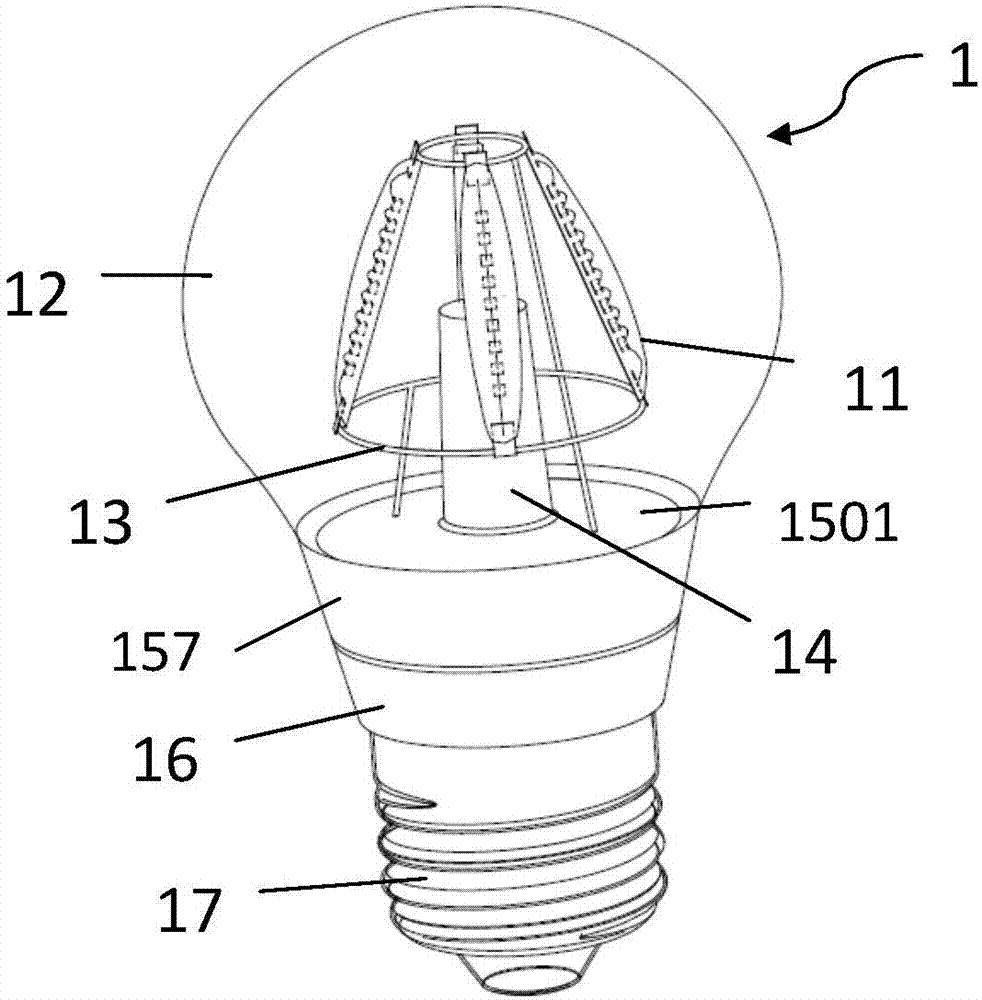

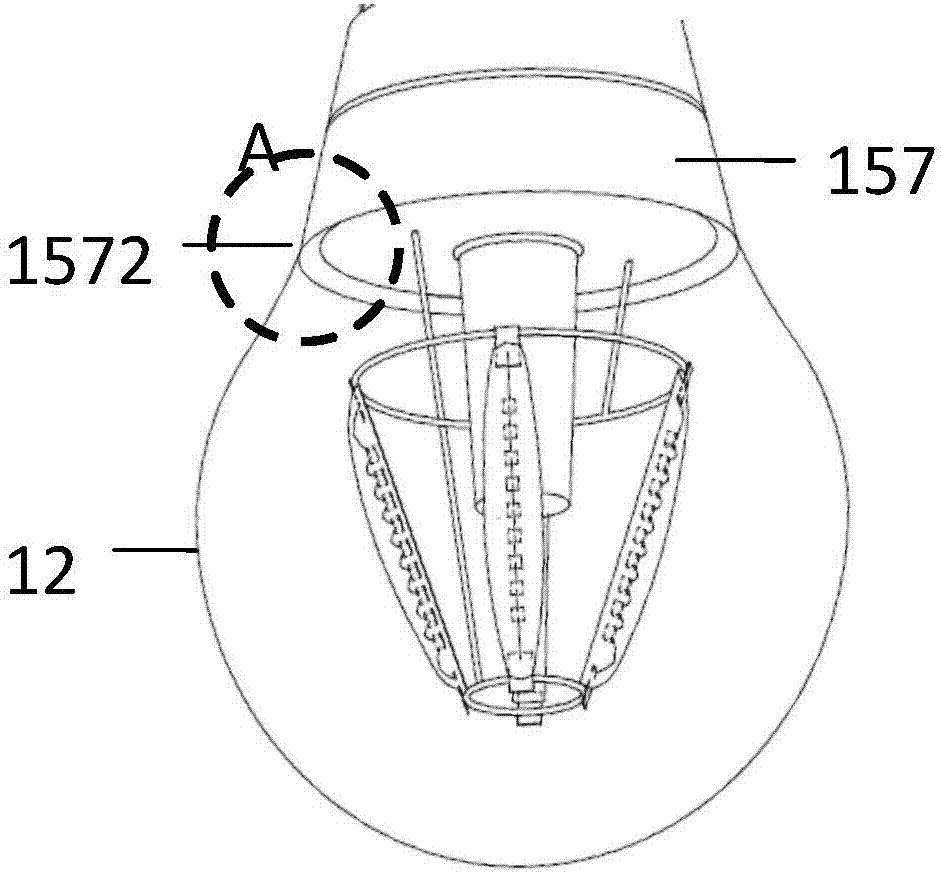

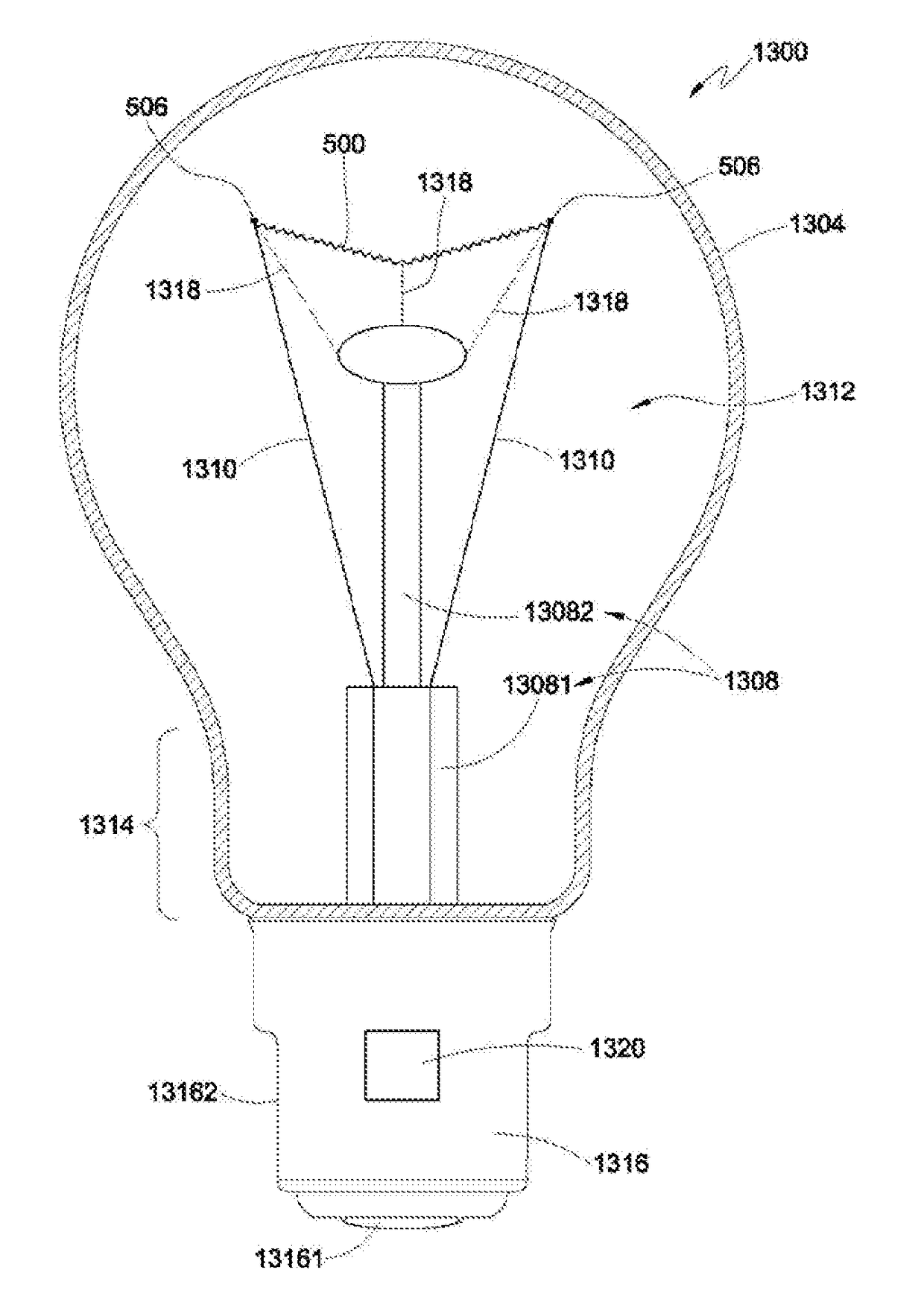

An LED bulb lamp comprises a lamp shell, a lamp head connected with the lamp shell, a core column, conductive supports, LED filaments and cantilever arms, wherein the core column comprises a core column bottom and a core column top which are opposite to each other, the core column bottom is connected with the lamp head, and the conductive supports are connected with the core column top. Each LED filament comprises a filament body and filament electrodes, wherein the filament electrodes are located at the two opposite ends of the filament body, the two filament electrodes are connected with the two conductive supports, the core column is surrounded by the filament bodies, one end of each cantilever arm is connected with the core column, and the other end of each cantilever arm is connected with the corresponding filament body. In the height direction, the distance from the bottom of the lamp shell to the top end of the lamp shell is H, a first height difference ranging from 0 to 1 / 10H exists between every two corresponding filament electrodes, each filament body is bent up and down and has a highest point and a lowest point, a second height difference exists between the highest point and the lowest point, the first height difference is smaller than the second height difference, and the second height difference ranges from 2 / 10H to 4 / 10H. The LED bulb lamp is good in glowing effect, easy to make and large in light emergent angle.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

LED filament

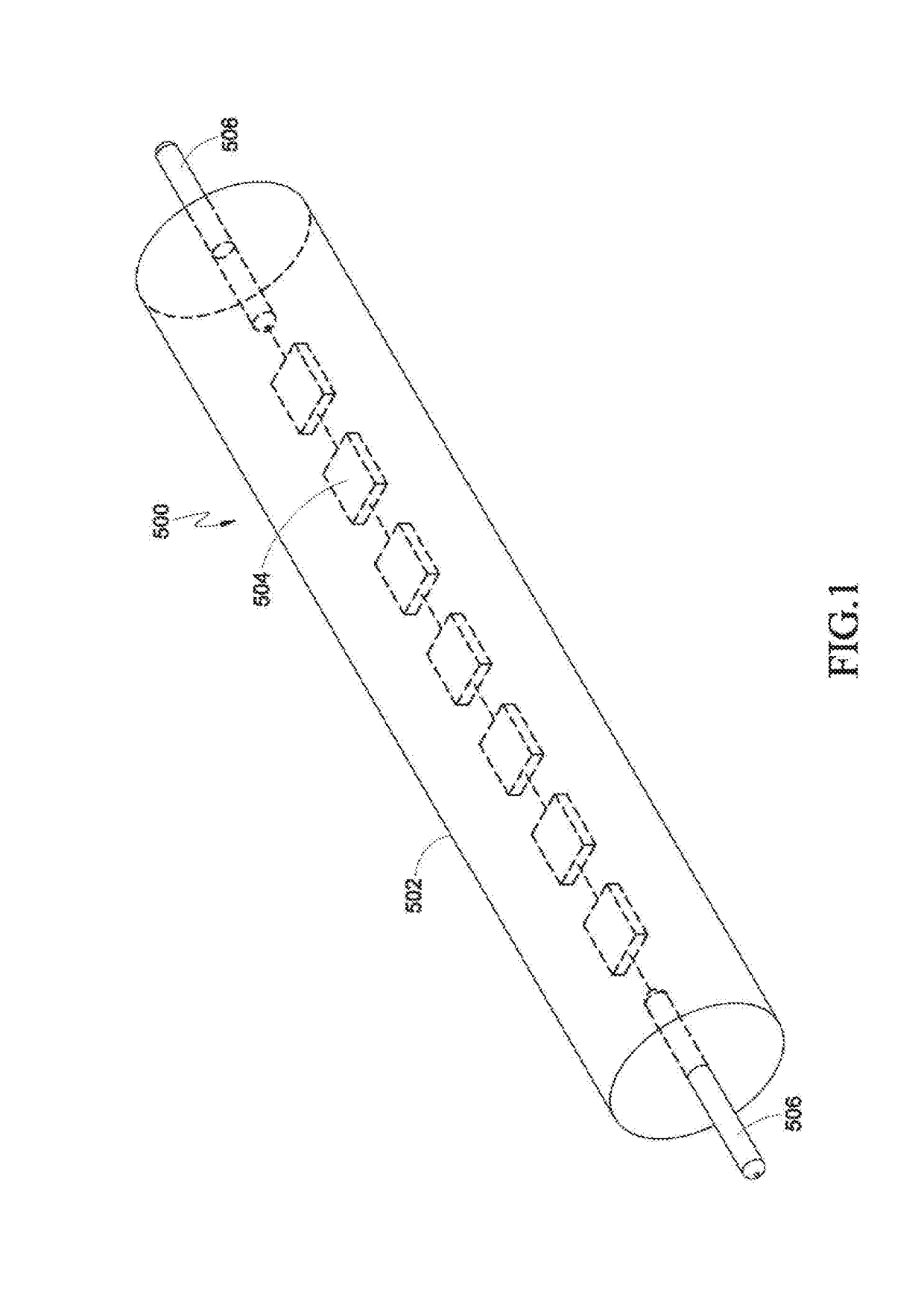

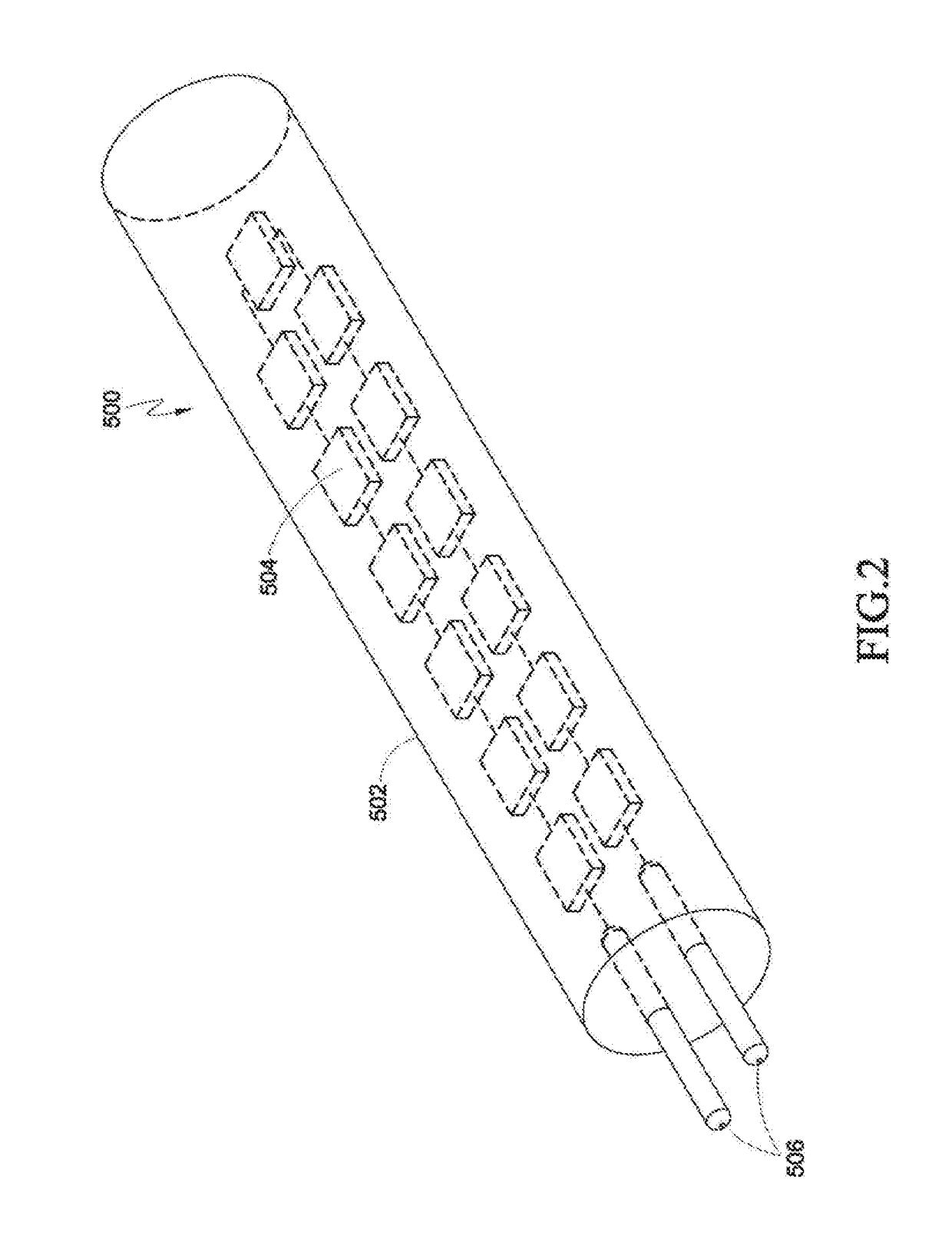

ActiveUS20170130906A1Improve energy efficiencyEasy to useElongate light sourcesElectric circuit arrangementsEngineeringLED filament

An LED filament configured to emit omnidirectional light includes a linear array of LED chips operably interconnected to emit light upon energization and a conductive electrode. The linear array of LED chips is electrically connected with the conductive electrode. A light conversion coating encloses the linear array of the LED chip and the conductive electrode. The light conversion layer includes a top layer and a base layer conformally interconnected to form a unitary enclosure. The top layer is coated on a first side of the linear array of LED chips and the conductive electrode. The base layer is coated on a second side of the linear array of LED chips and the conductive electrode.

Owner:ZHEJIANG SUPER LIGHTING ELECTRIC APPLIANCE

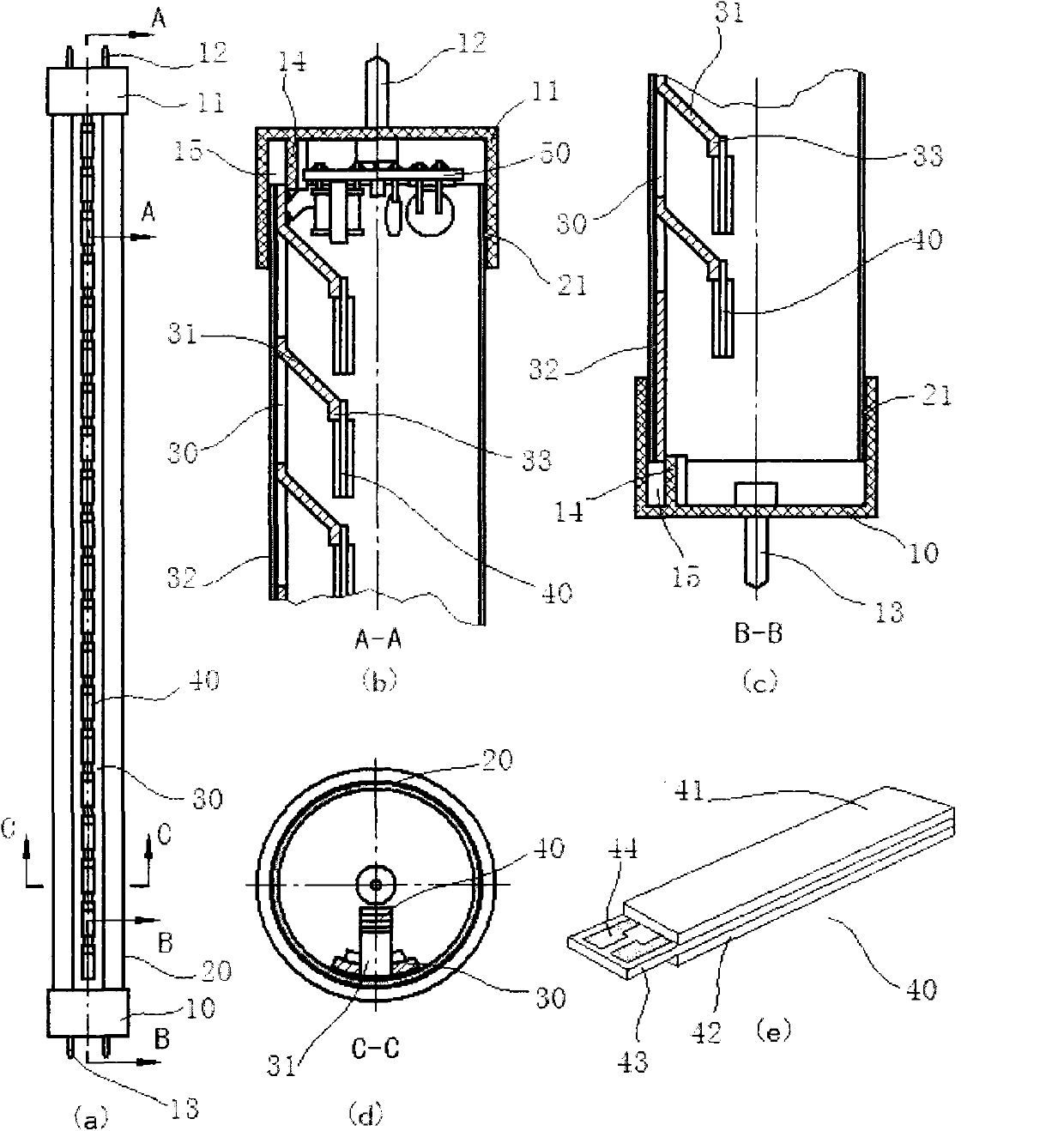

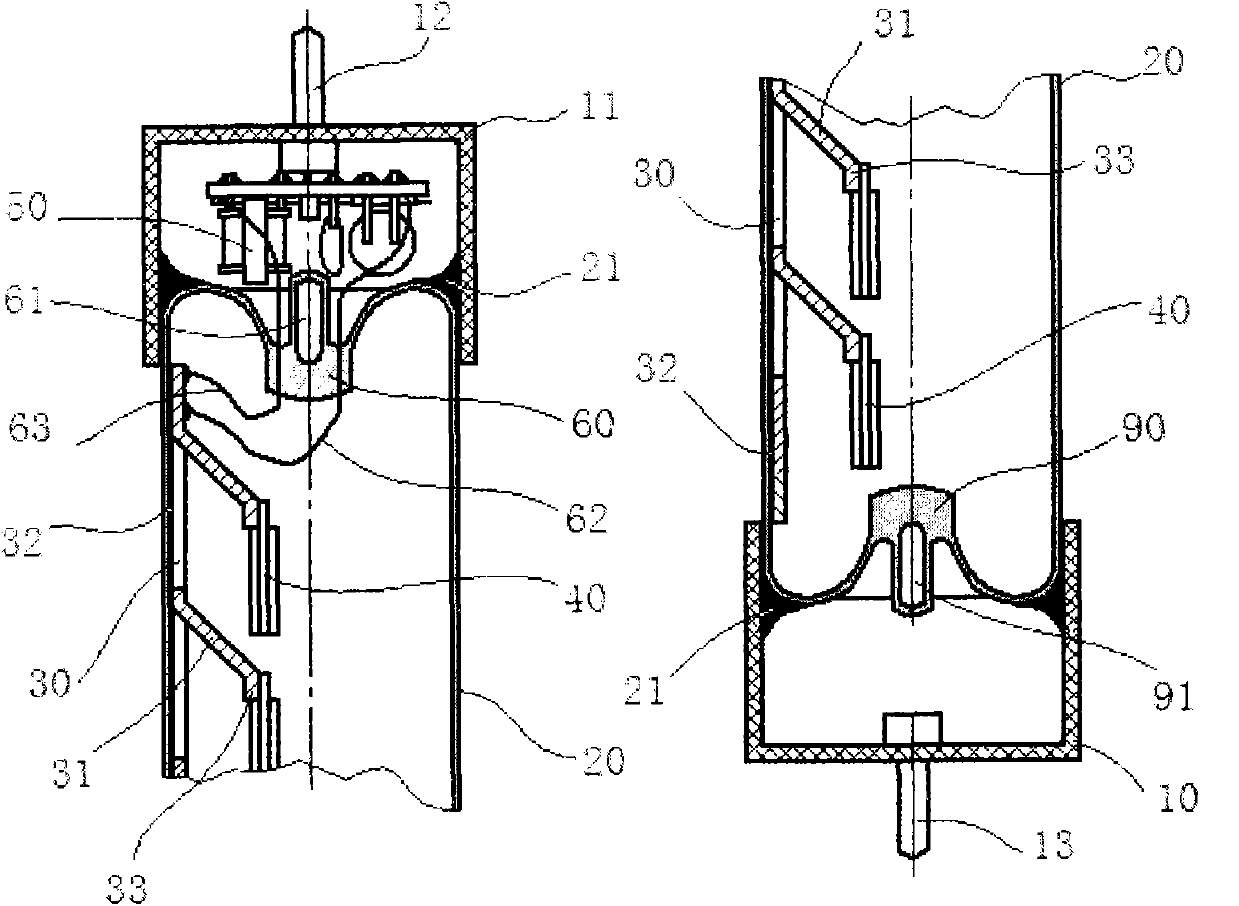

LED straight lamp made of transparent glass tube

InactiveCN103742875AReduce cooling requirementsFit tightlyPoint-like light sourceElongate light sourcesBeam angleStraight tube

The invention discloses an LED straight lamp made of a transparent glass tube. The LED straight lamp comprises a transparent glass tube body (20) and two lamp holders (10 and 11). Both the transparent glass tube body (20) and the lamp holders (10 and 11) meet the specifications of an ordinary straight tube fluorescent lamp, and the lamp holders (10 and 11) are respectively adhered to two ends of the transparent glass tube body (20). The LED straight lamp made of the transparent glass tube can also be made by the glass burn sealing technology of the ordinary straight tube fluorescent lamp. LED lamp filaments are directly welded to welding platforms (33) of LED supports (31) in the middle of an aluminum substrate (30). The outside of the bottom cross section of the aluminum substrate (30) is circular arc shaped with the curvature matching with that of the inner side of the cross section of the transparent glass tube body (20). Enough height is to be reserved between the welding platforms (33) and the aluminum substrate (30) so that light emitted from the LED lamp filaments is orthogonal to the inner wall of the transparent glass tube body (20), light consumption brought by multiple reflections is reduced, and the beam angle of the LED straight lamp made of the transparent glass tube can reach more than 300 degrees.

Owner:匡正芳

LED bulb lamp and LED filament thereof

ActiveCN107123641AAdjust the refractive indexLayered adjustment of light extraction efficiencyElongate light sourcesSolid-state devicesRefractive indexTransmittance

The invention discloses an LED filament. The LED filament comprises multiple LED chips, at least two electrodes and a light conversion layer, wherein the multiple LED chips are electrically connected with the at least two electrodes, the light conversion layer has a top layer and a base layer, the top layer and the base layer are respectively arranged at at least two sides of the multiple LED chips and the at least two electrodes, and parts of the two electrodes are exposed by the light conversion layer. The LED filament is advantaged in that the light conversion layer has a multi-layer layered structure, layered adjustment on hardness, light transmittance and a refractive index can be realized, so hardness, light transmittance and the refractive index of the LED filament can be adjusted to an optimum state, and the LED filament can be made to satisfy different demands of LED bulb lamps.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

LED filament and LED bulb with LED filament

The present disclosure relates to a LED filament and a LED bulb with the LED filament. The LED filament includes a carrier, LED chips disposed on the carrier, the carrier includes a first lateral section and a second lateral section opposite to the first lateral section, the LED chips are formed on the first lateral section, hardness of the first lateral section is less than that of the second lateral section. The disclosure further provides a LED bulb with the LED filament above. The LED filament above has benefits of improving structural strength and decreasing costs.

Owner:KAISTAR LIGHTING (XIAMEN) CO LTD +1

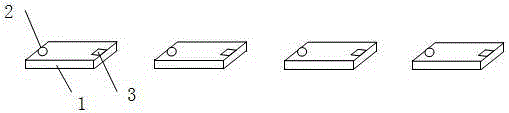

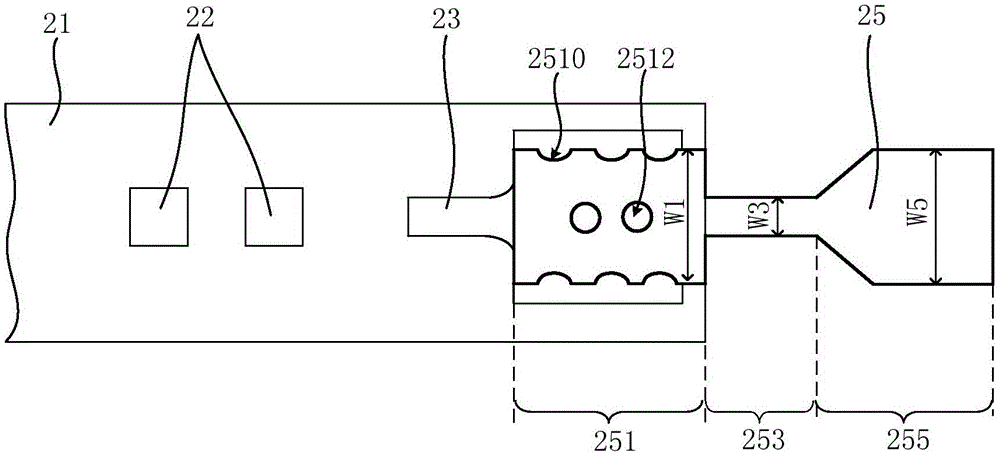

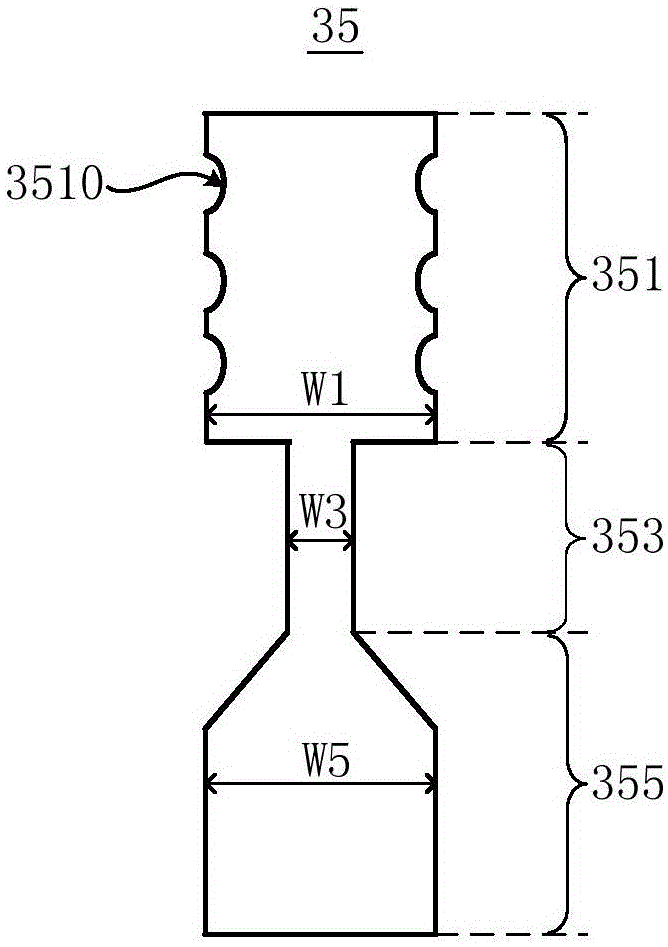

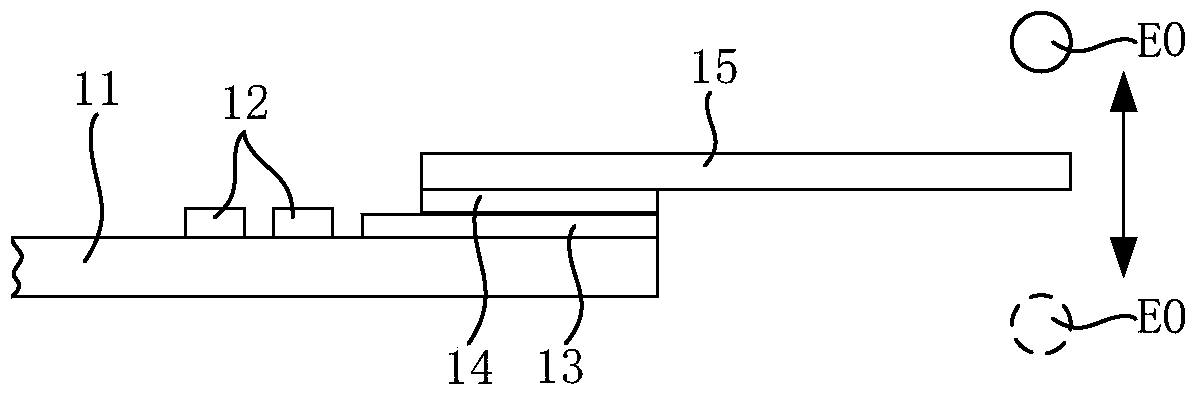

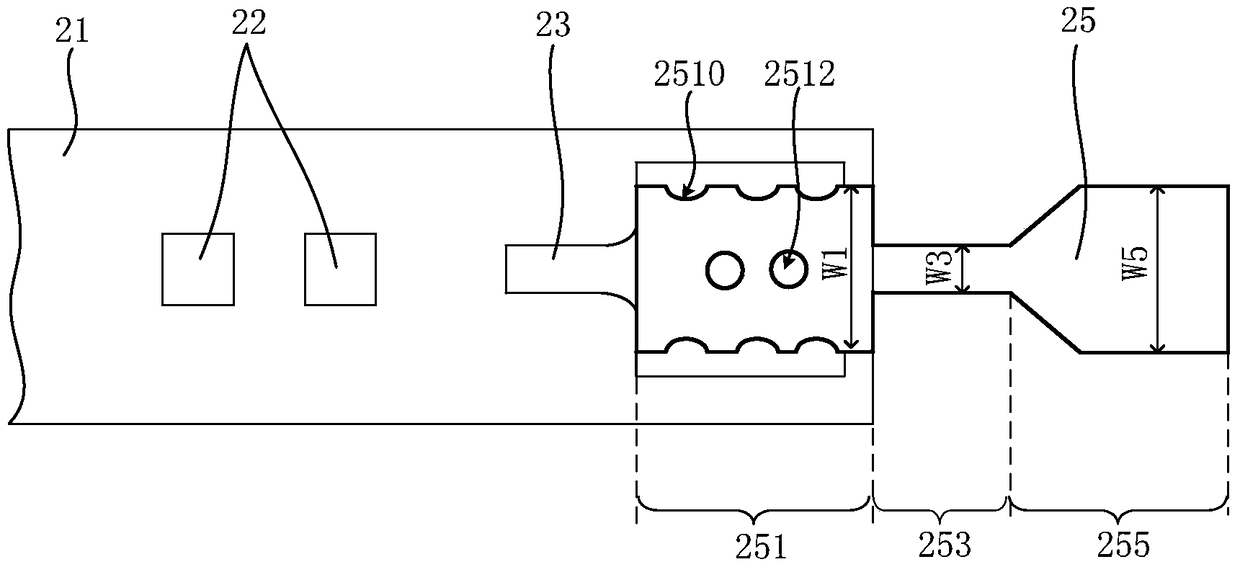

LED filament and filament type LED bulb

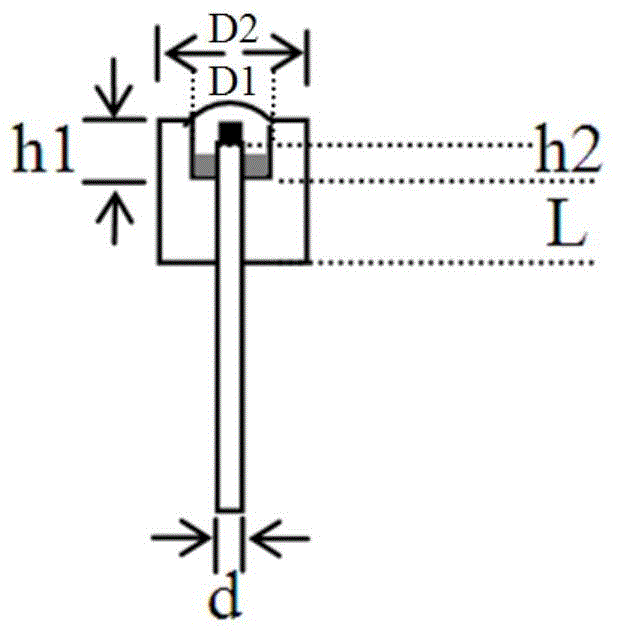

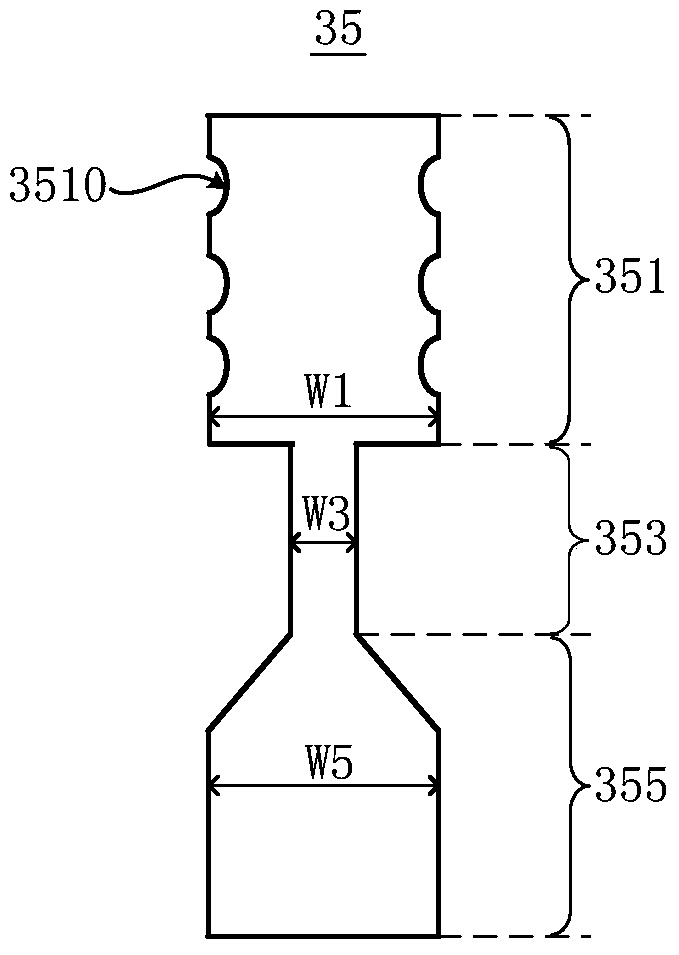

ActiveCN105090782AHigh bonding strengthIncrease joint areaPoint-like light sourceElectric circuit arrangementsNeck partsEngineering

The invention relates to an LED filament and a filament type LED bulb using the LED filament. The LED filament comprises a carrier, LED chips arranged on the carrier, and an electric conduction pin fixedly connected with the carrier. The electric conduction pin is electrically connected with the LED chips. The electric conduction pin comprises a pin head part, a pin tail part and a pin neck part used connected with the pin head part and the pin tail part. The entity width of the pin neck part is smaller than the maximum entity width of the pin head part. The pin neck part with the reduced entity width is obtained through the mode of internally reducing the width of the pin head part relative to the pin neck part or opening a through hole in the pin neck part or other modes, the pin neck part becomes a weak point of the electric conduction pin; and in this way, when stress is generated, the pin neck part acts firstly, and the joint of the pin head part and the carrier or the carrier itself can be protected.

Owner:KAISTAR LIGHTING (XIAMEN) CO LTD +1

LED filament, manufacturing method of LED filament, and LED bulb equipped with filament

ActiveCN106898681ASimple processReduce processing timeElongate light sourcesSolid-state devicesPhosphorEngineering

The invention discloses an LED filament, a manufacturing method of the LED filament, and an LED bulb equipped with the filament. The LED filament comprises multiple LED chips, at least two poles, an auxiliary strip and a light conversion layer. Wherein the poles and the LED chips are electrically connected, the LED chips and the poles are covered by the light conversion layer, the light conversion layer comprises silica gel silica gel and phosphor, the auxiliary strip is arranged on the light conversion layer along an axis direction of the LED filament. The LED filament can give out light in all directions, and all-direction illumination requirements of the bulb equipped with the LED filament can be further satisfied.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

AC LED lighting lamp

InactiveCN1683820ALow costImprove reliabilityLight source combinationsElectric lightingDriver circuitLed array

The AC LED lighting lamp includes AC input ends and AC LED filament, and the AC LED filament includes at least two parallelly connected LED arrays in opposite conducting directions and may be in integrated structure. The present invention has the advantages of simple structure without rectifier, voltage stabilizer, filter and switching power source, and high lighting efficiency.

Owner:厦门市清科华核供应链有限公司

LED bulb structure

InactiveCN105090789AStable structureSimple structurePoint-like light sourceElectric circuit arrangementsComputer moduleEngineering

The invention relates to an LED bulb structure. The LED bulb structure comprises a glass core column, a first power supply wire, a second power supply wire, a first electric conducting column, a second electric conducting column, a first light emitting module, a second or multiple light emitting modules and multiple fixed balls. The first light emitting module and the second or multiple light emitting modules respectively comprise an upper bracket set and a lower bracket set; one ends of the upper and lower bracket sets are joined with the first electric conducting column, and the other ends of the upper and lower bracket sets are joined with the second electric conducting column; and multiple lamp filaments are arranged between the upper and lower bracket sets at intervals. As LED modular lamp filament structures are serially connected, the multiple LED lamp filaments can be modularized, the LED modules are stacked and joined in a parallel connecting manner, the lumen number can be effectively increased, and the brightness is promoted.

Owner:LIQUIDLEDS LIGHTING

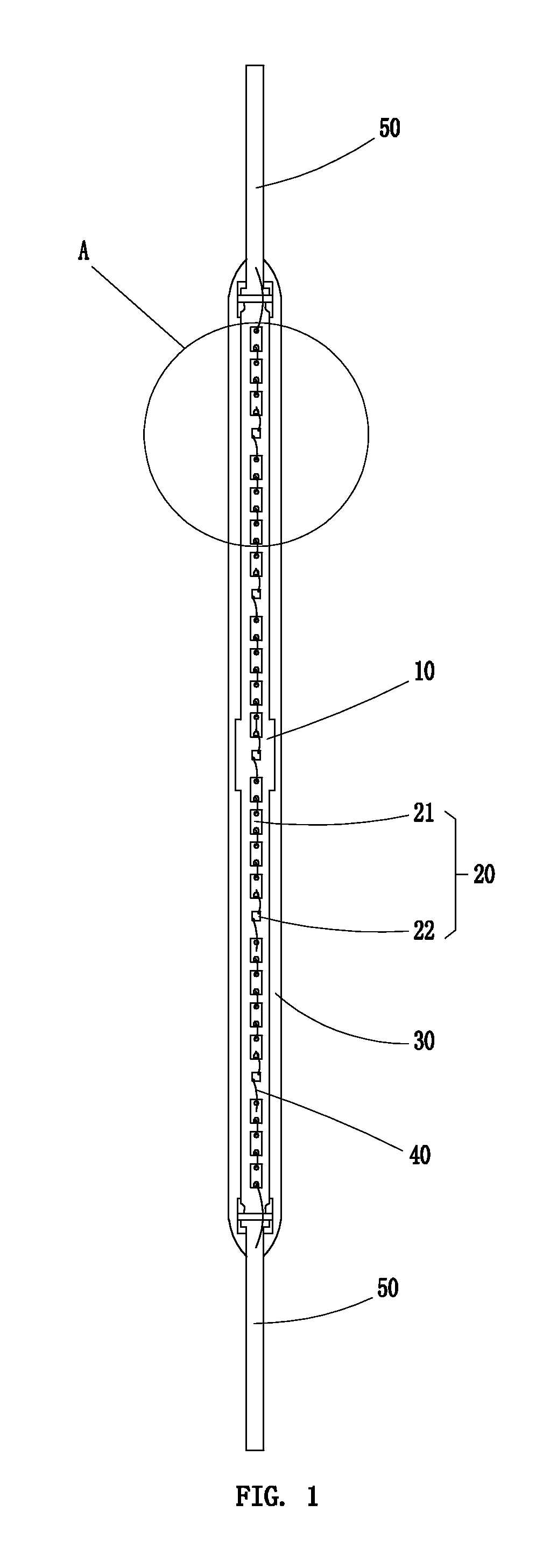

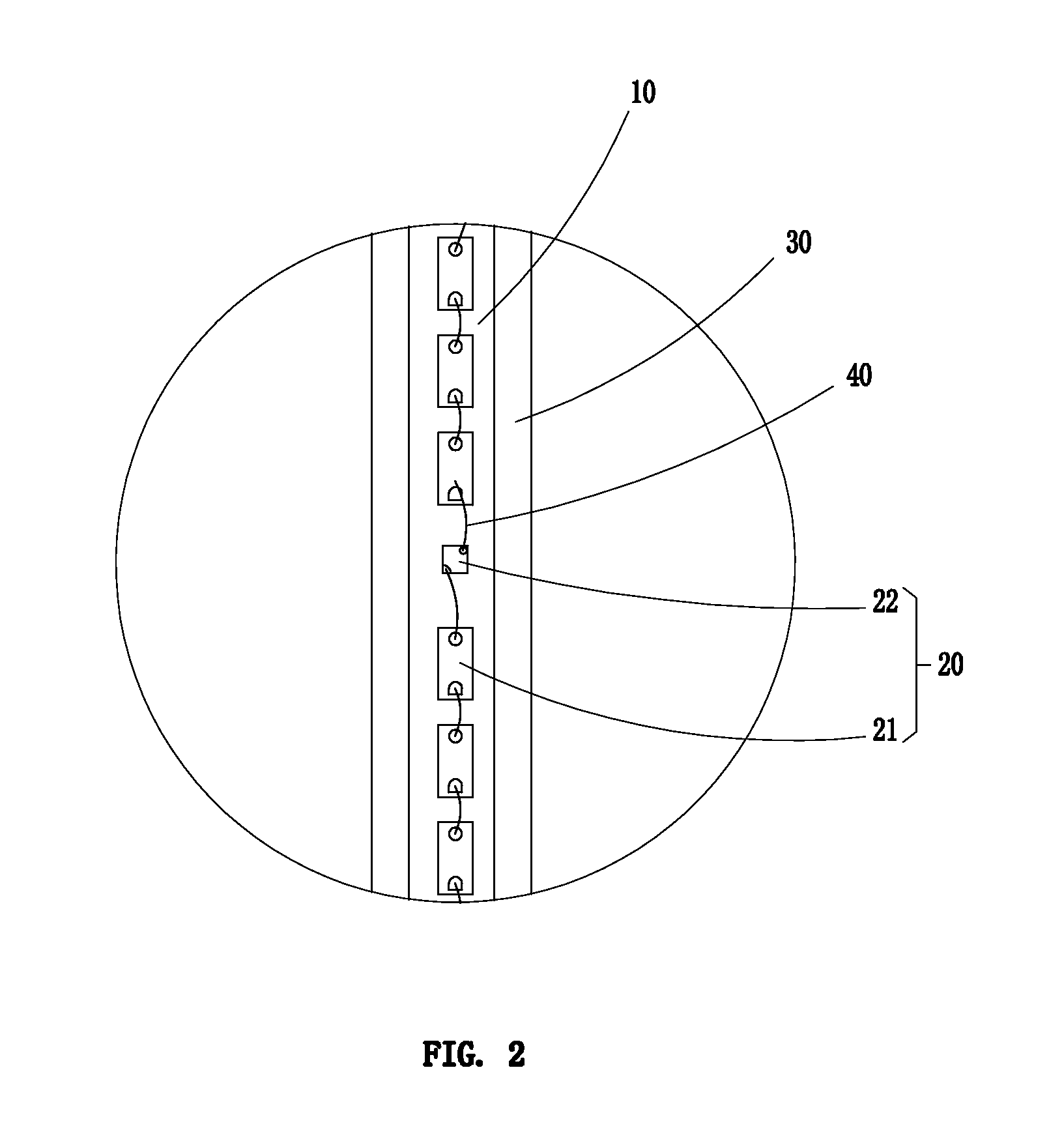

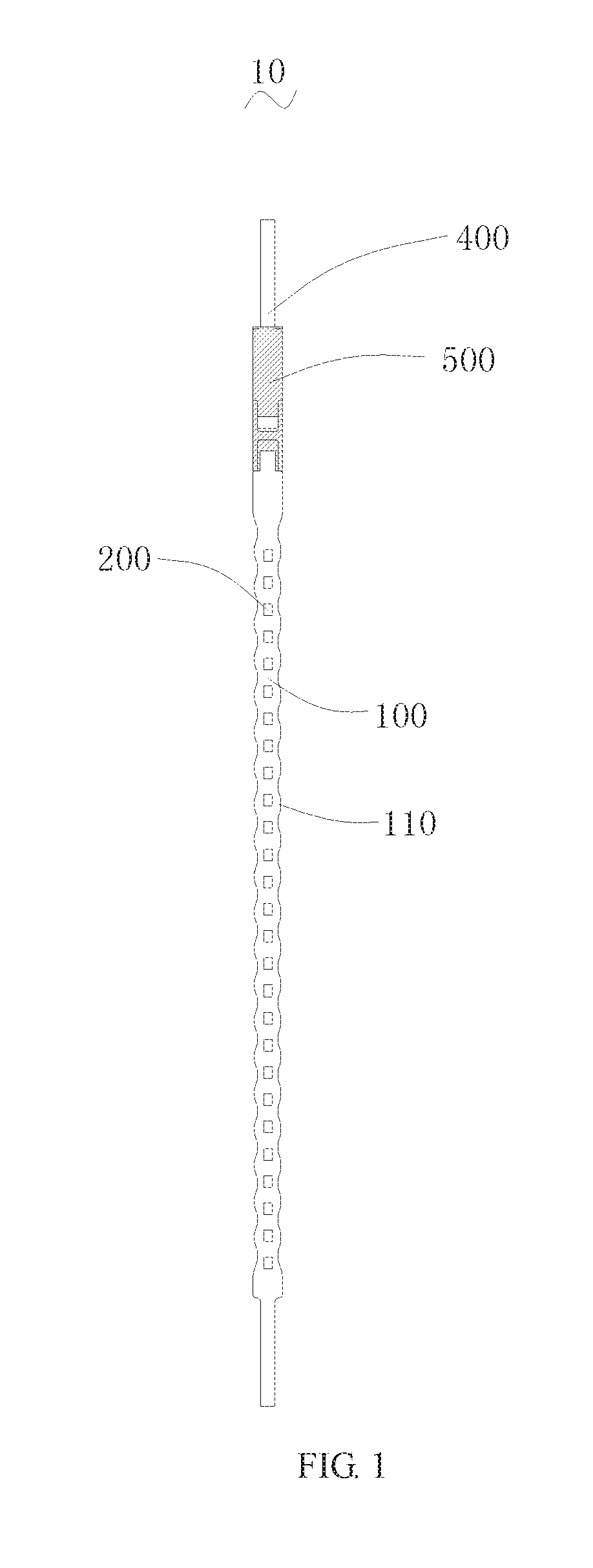

LED lamp filament

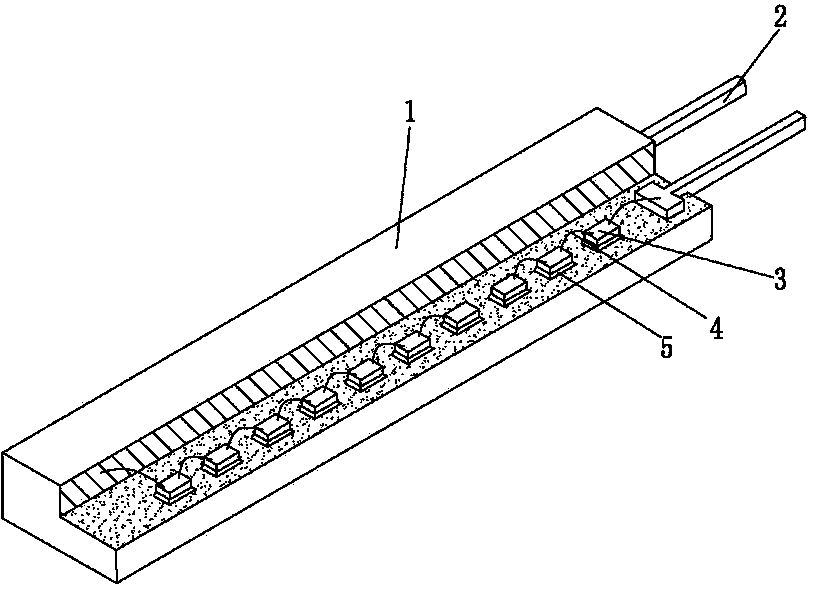

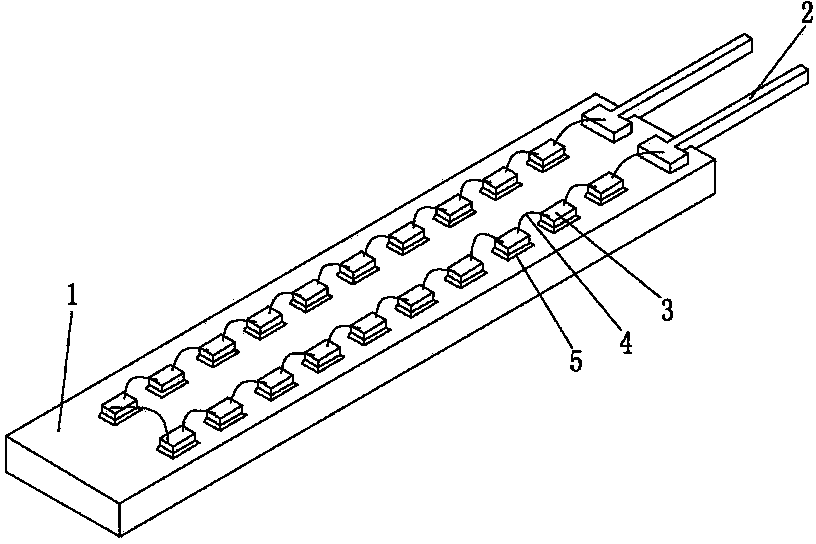

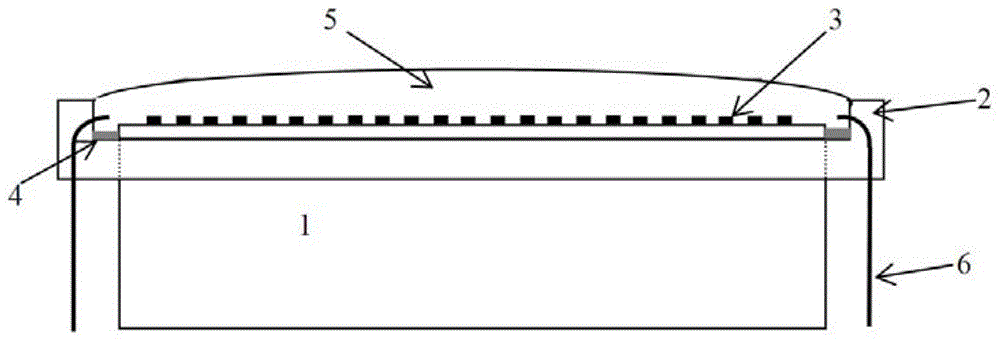

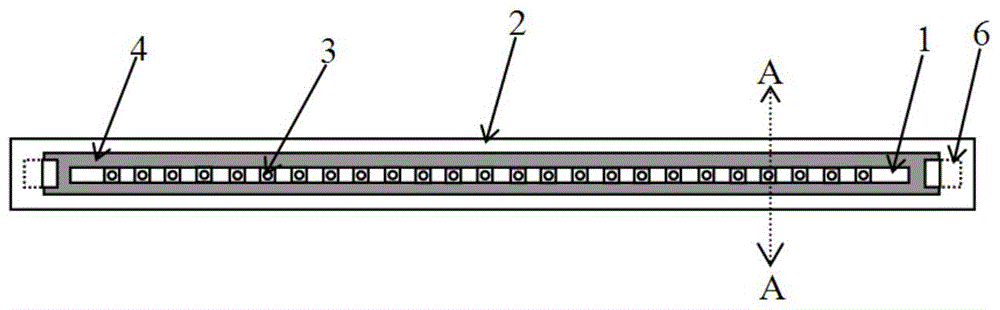

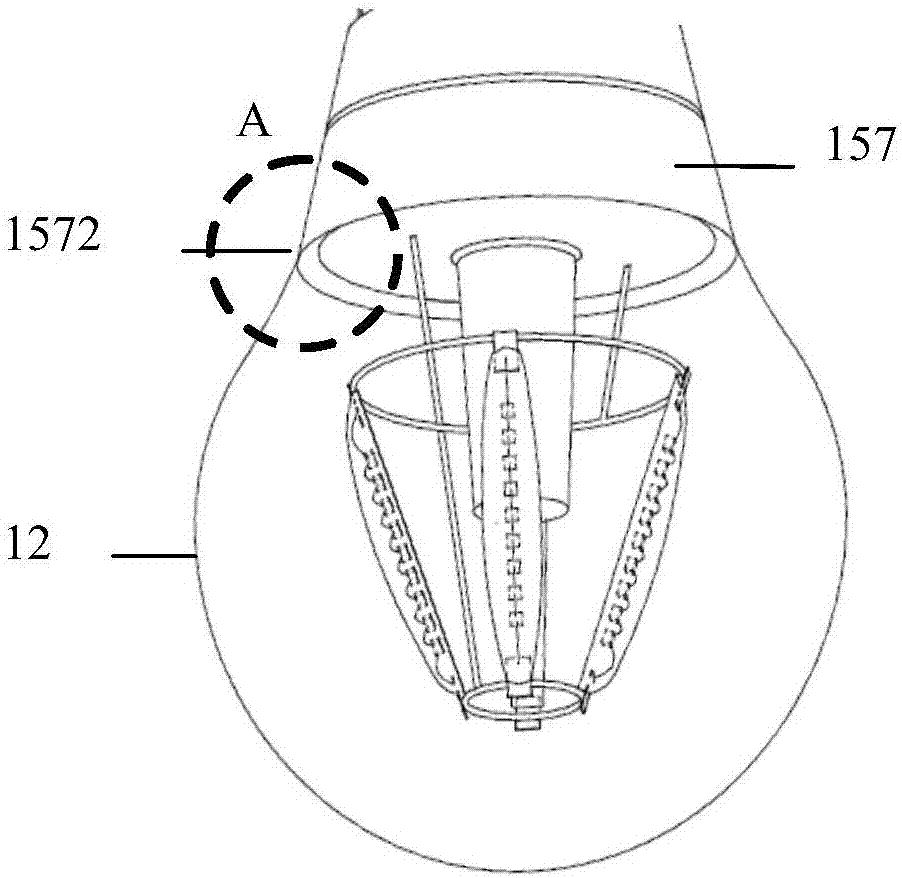

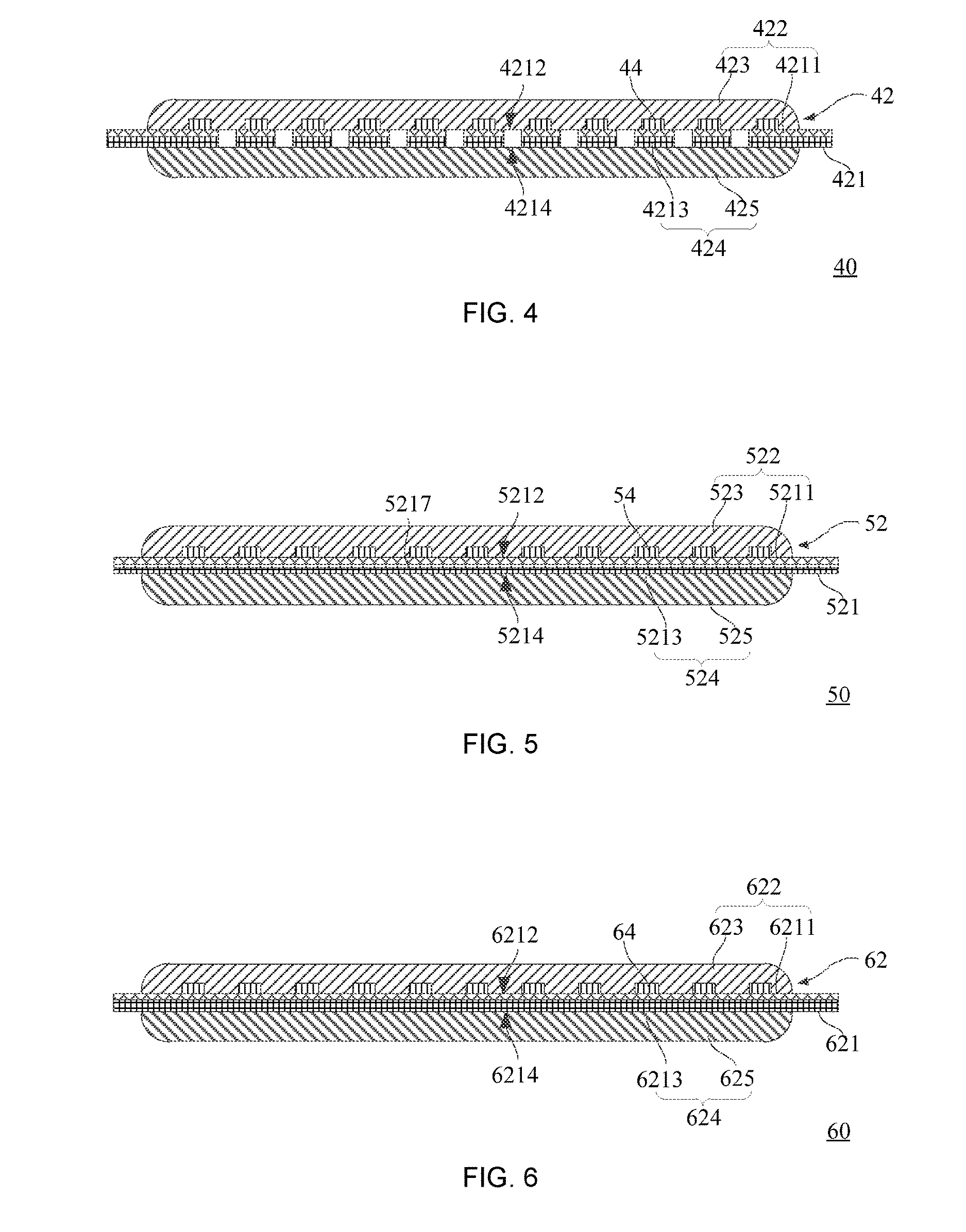

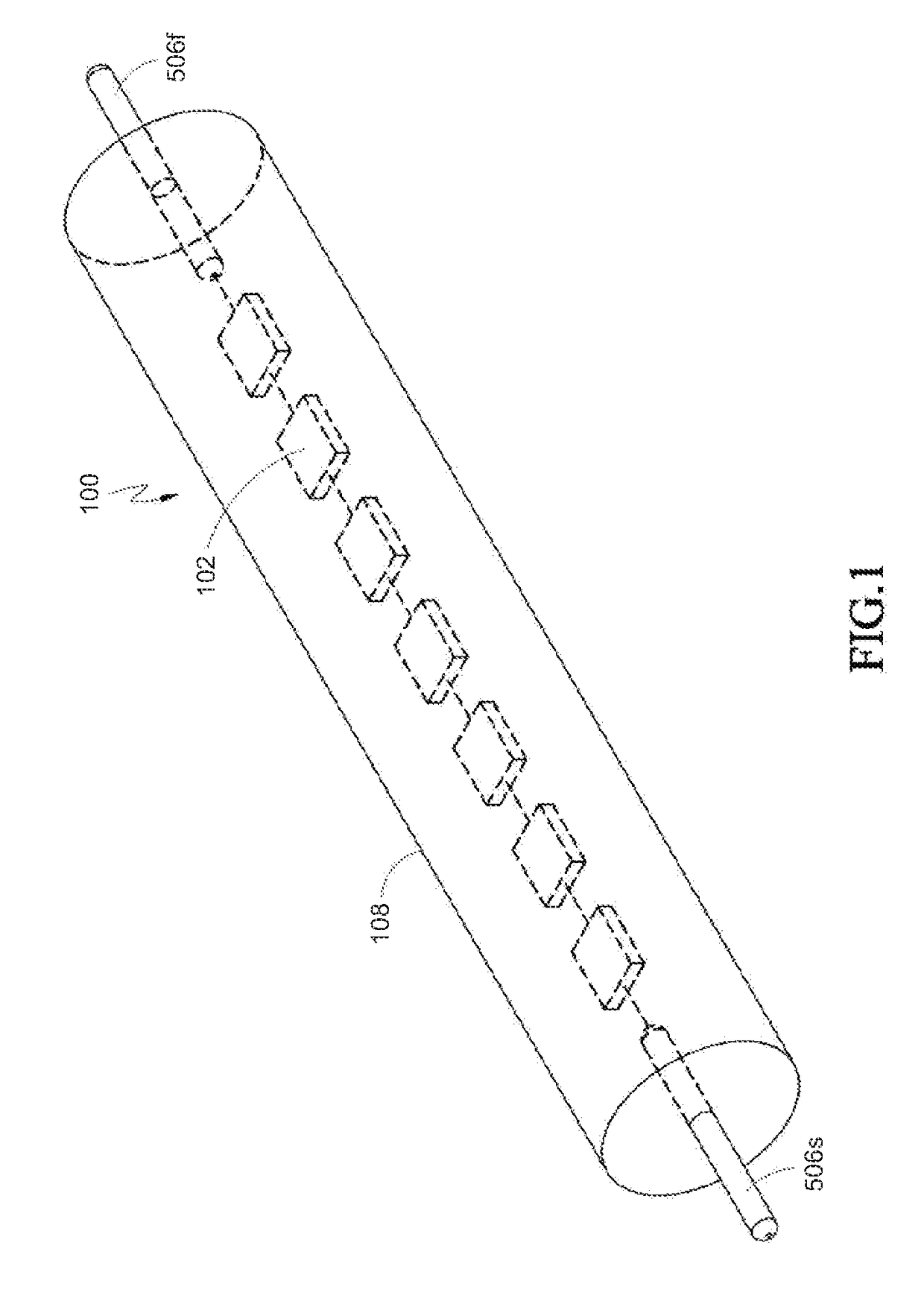

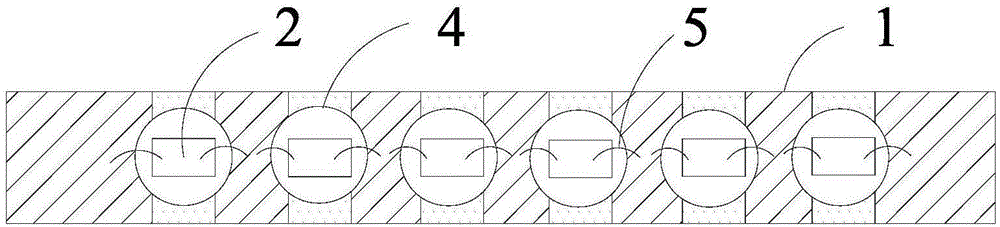

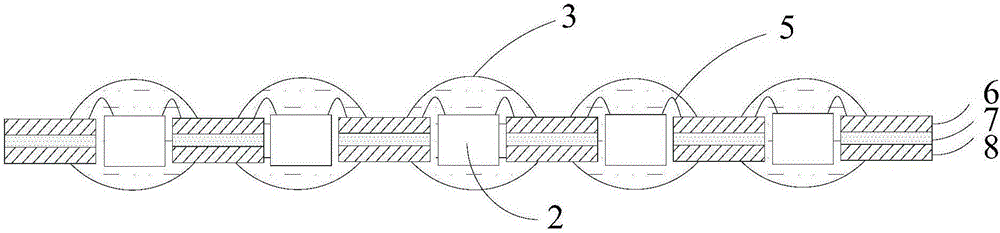

ActiveUS9982854B2Increasing an emitting angle of the LED lamp filamentLighting support devicesElongate light sourcesFluorescenceEngineering

A LED lamp filament, comprising: a long strip-shaped substrate, a plurality of light-emitting units arranged on a first surface of the substrate and distributed along the extending direction of the substrate, and a light-transmittable fluorescent glue layer covering the first surface and the plurality of light-emitting units. A plurality of bulges are provided on at least one side of the substrate, and the bulges are distributed along the extending direction of the substrate; one part of light excited by the fluorescent glue layer and emitted from the light-emitting units emits out in a direction towards a second surface, opposite to the first surface, of the substrate from a space between adjacent bulges.

Owner:TCL VERY LIGHTING TECH HUIZHOU CO LTD +1

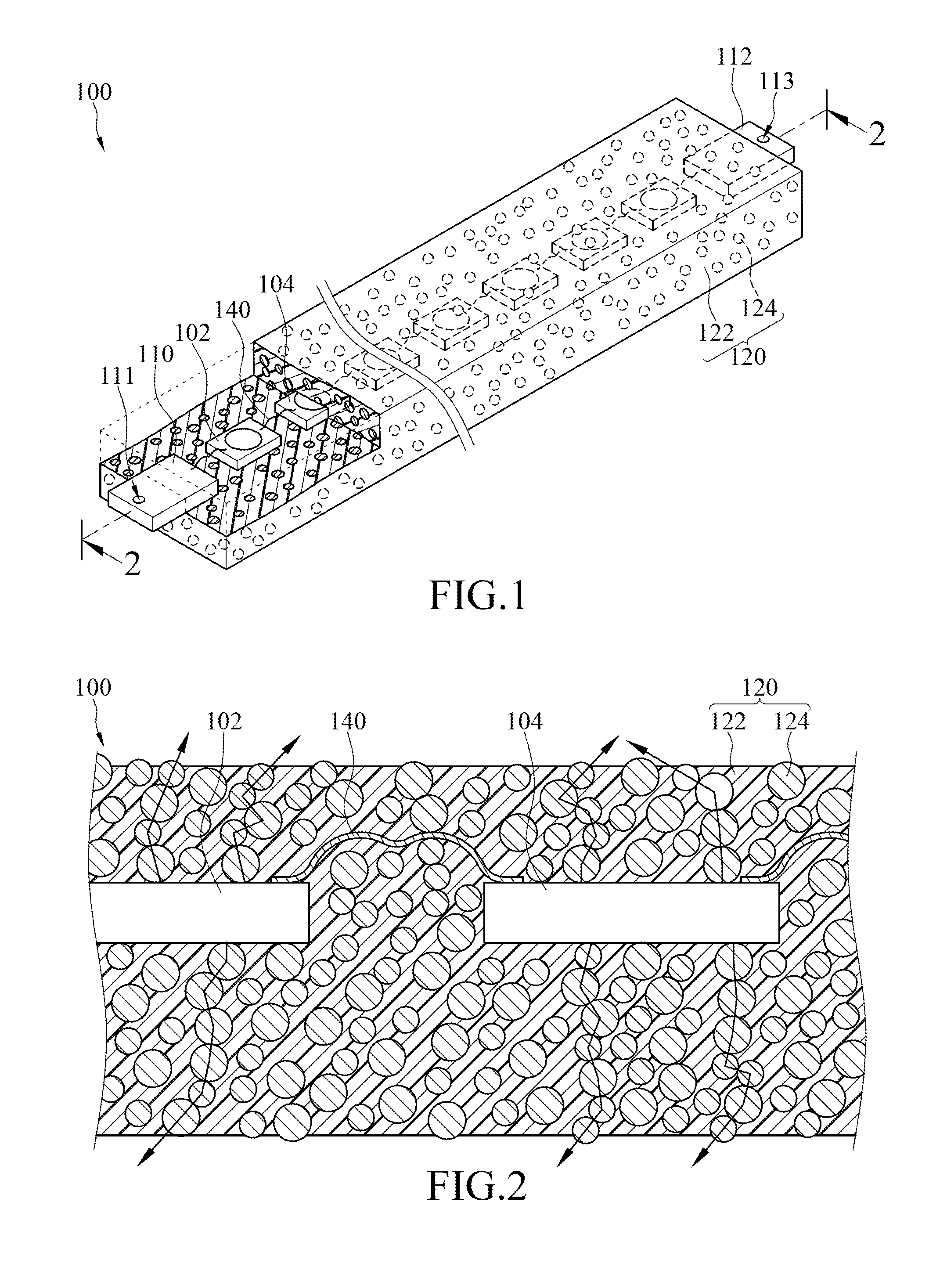

LED filament substrate, LED package structure and LED lamp

ActiveCN108039402AUnlimited spacingUnrestricted wayElectric circuit arrangementsSolid-state devicesEngineeringLight-emitting diode

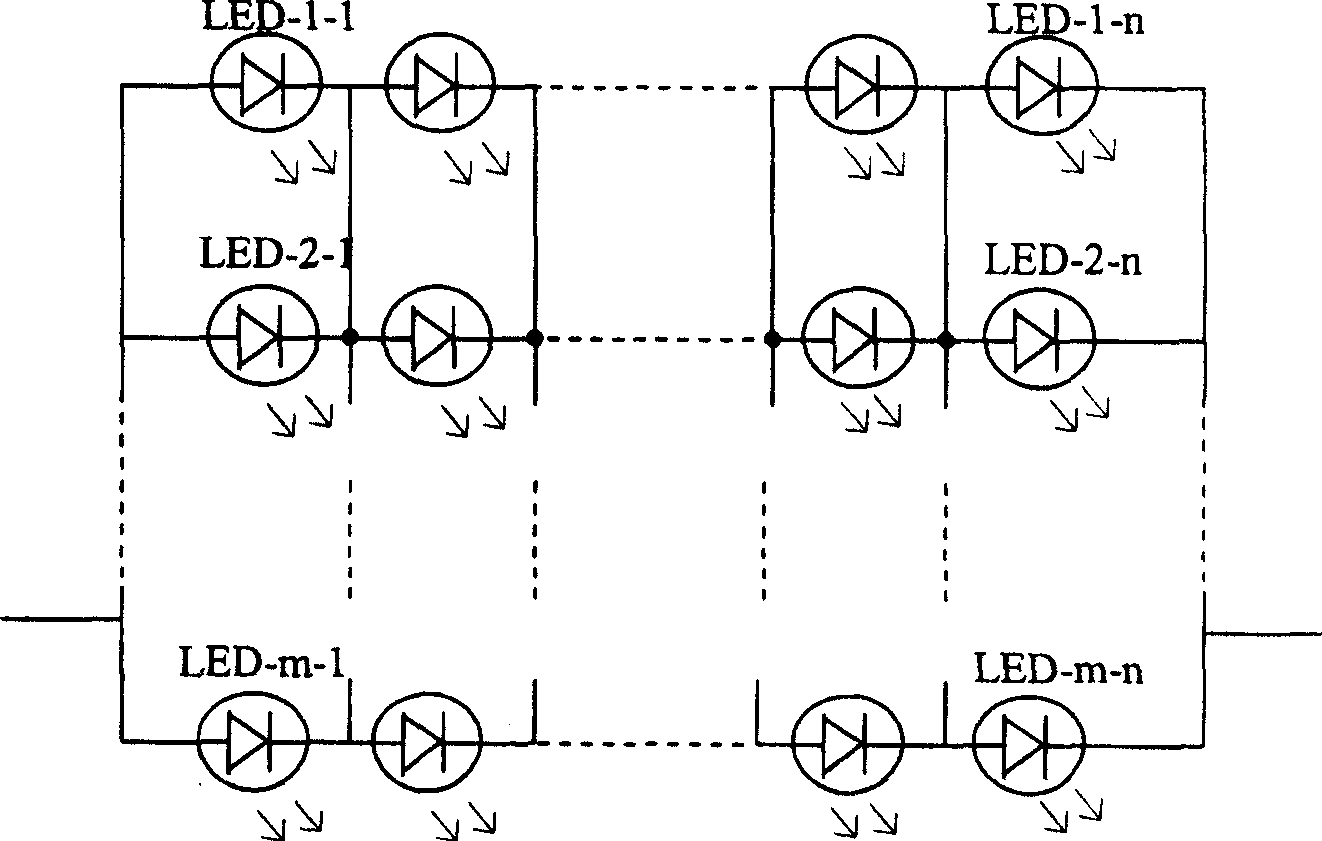

The invention is applicable to the technical field of light emitting diode applications, and provides an LED filament substrate, an LED package structure and an LED lamp. The LED filament substrate comprises an insulating substrate, conductive layers, and pins connected with an external power supply circuit. The conductive layers are arranged on the surface of the insulating substrate. The conductive layers are connected with external LED chips. The shape of the conductive layers is determined according to the type and connection mode of the external LED chips. The number of the conductive layers is determined according to the type and number of the external LED chips and the spacing between the external LED chips. The pins are arranged on the insulating substrate. According to the LED filament substrate, the LED package structure and the LED lamp, the conductive layers are arranged on the LED filament substrate; various types of LED chips can be selected; the spacing and series-parallel connection mode of the LED chips are not limited; and the arrangement of LED chips on the LED filament substrate is diversified.

Owner:SHENZHEN REFOND OPTOELECTRONICS

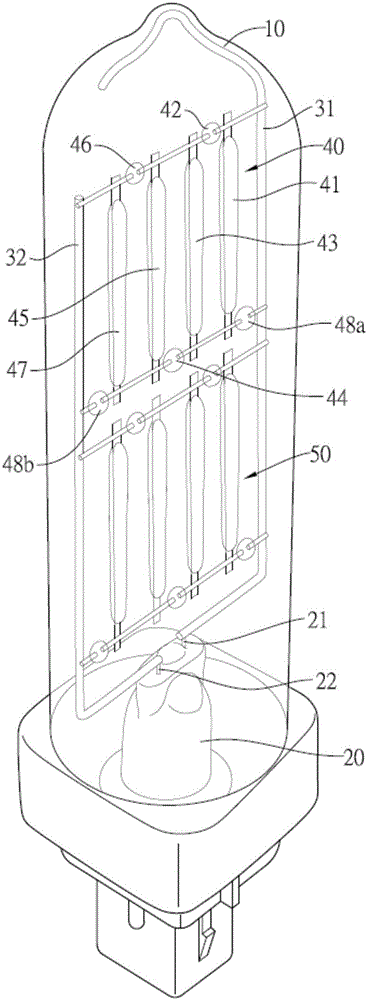

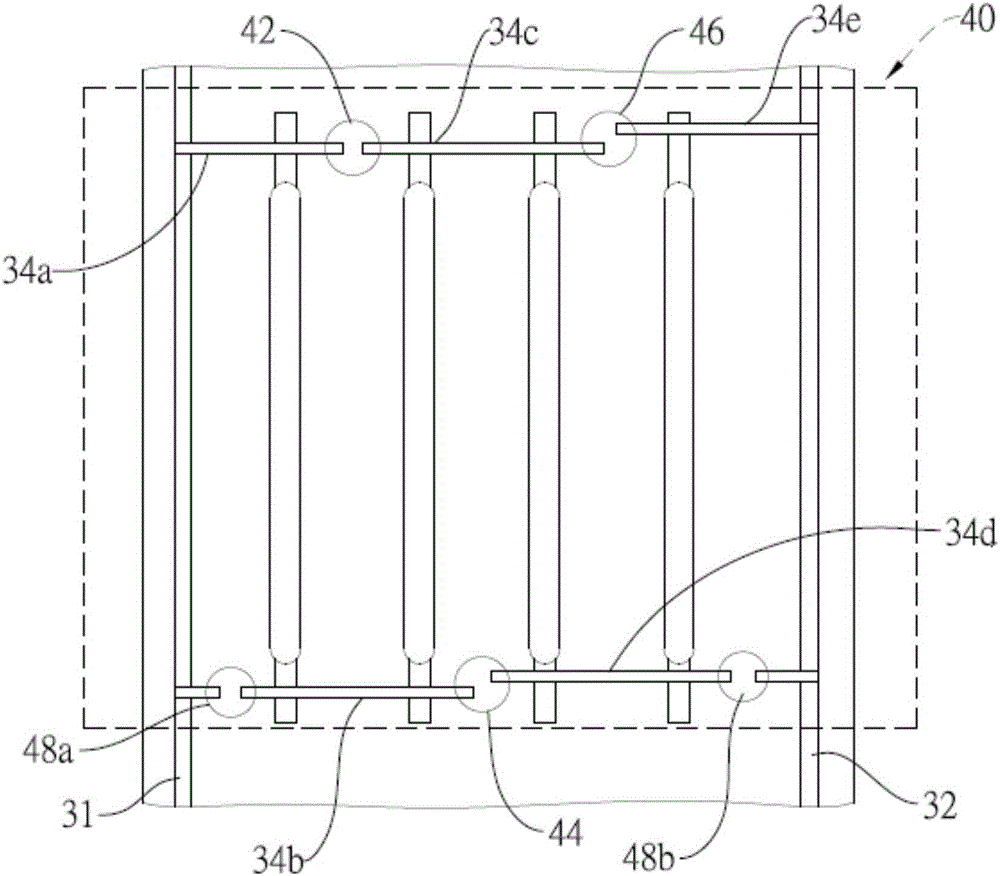

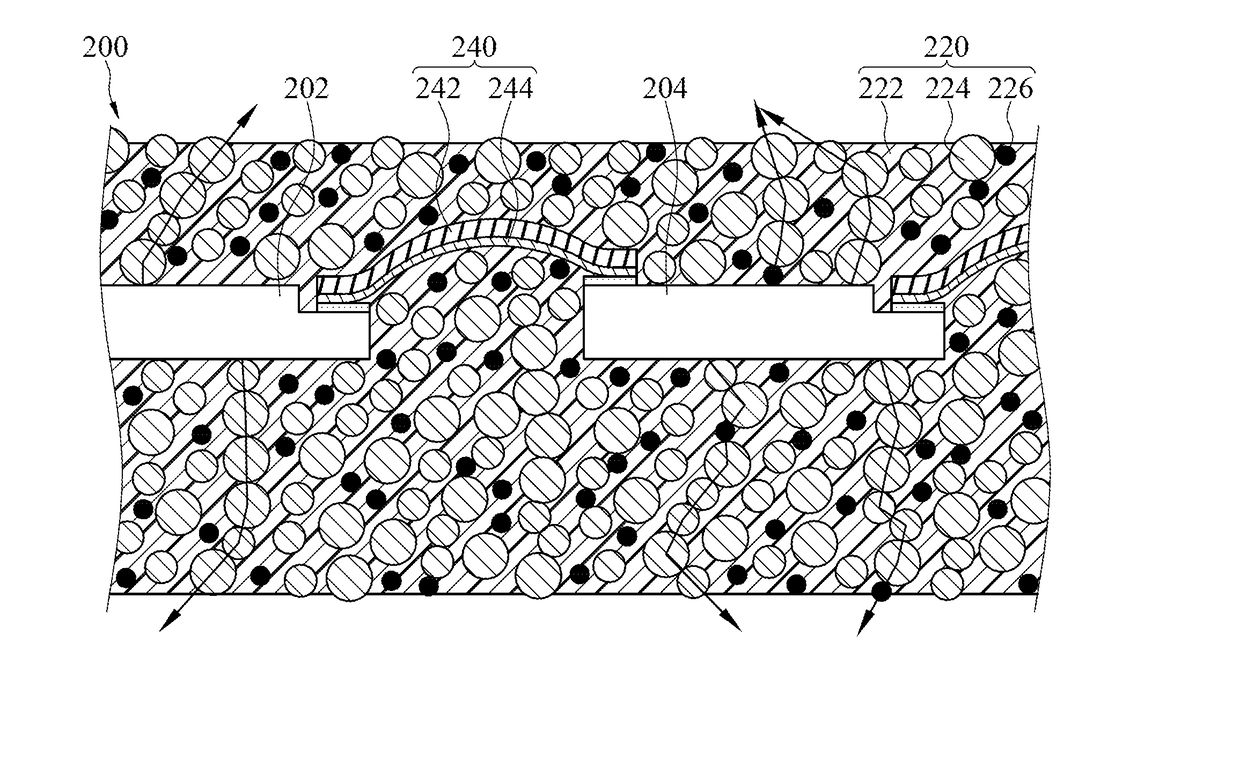

LED filament module and LED light bulb

ActiveUS20170084809A1Easy to manufactureEasy to weldElongate light sourcesLighting heating/cooling arrangementsEngineeringLED filament

An LED filament module and an LED light bulb are disclosed. The LED filament module includes one or more LED filaments, a first connecting portion, and a second connecting portion. The LED filaments are spaced from each other. Each of the LED filaments includes a first conductive electrode and a second conductive electrode opposite to the first conductive electrode. The first connecting portion is connected with the first conductive electrodes. The second connecting portion is connected with the second conductive electrodes. The LED filament module has a first type. The LED filaments, the first connecting portion, and the second connecting portion of the first type are in a three dimensional form. One or two between the first connecting portion and the second connecting portion of the first type has a torus shape.

Owner:ZHEJIANG SUPER LIGHTING ELECTRIC APPLIANCE

All-angle bendable LED (Light Emitting Diode) filament strip and antique LED bulb comprising same

The invention provides an all-angle bendable LED (Light Emitting Diode) filament strip. The all-angle bendable LED filament strip comprises a plurality of LED filament strip units which are connected end to end in turn; the two adjacent LED filament strip units are connected with each other through a rotating part in a rotating mode; every LED filament strip unit comprises a plurality of LED chips which are fixed on a quartz substrate; the LED chips which are located on the LED filament strip units achieve circuit communication through the rotating parts. The invention also provides an antique LED bulb. The antique LED bulb comprises a capsule, a lamp holder, a power circuit, the LED filament strip and a supporting part; the LED filament strip units which are arranged in the LED filament strip bend into the preset angle at the positions of the flexible electrical connection plates and accordingly the preset shape of the LED filament strip can be formed integrally; the supporting part comprises a plurality of antennas which are supported at the positions of the flexible electrical connection plates of the LED filament strip units so as to maintain the preset bending angle; the power circuit is fixedly arranged at the bottom of the capsule integrally after being arranged inside the lamp holder.

Owner:江苏华英光宝科技有限公司

LED filament

ActiveUS20170227169A1Improve energy efficiencyProlong lifeElongate light sourcesLighting heating/cooling arrangementsEngineeringLED filament

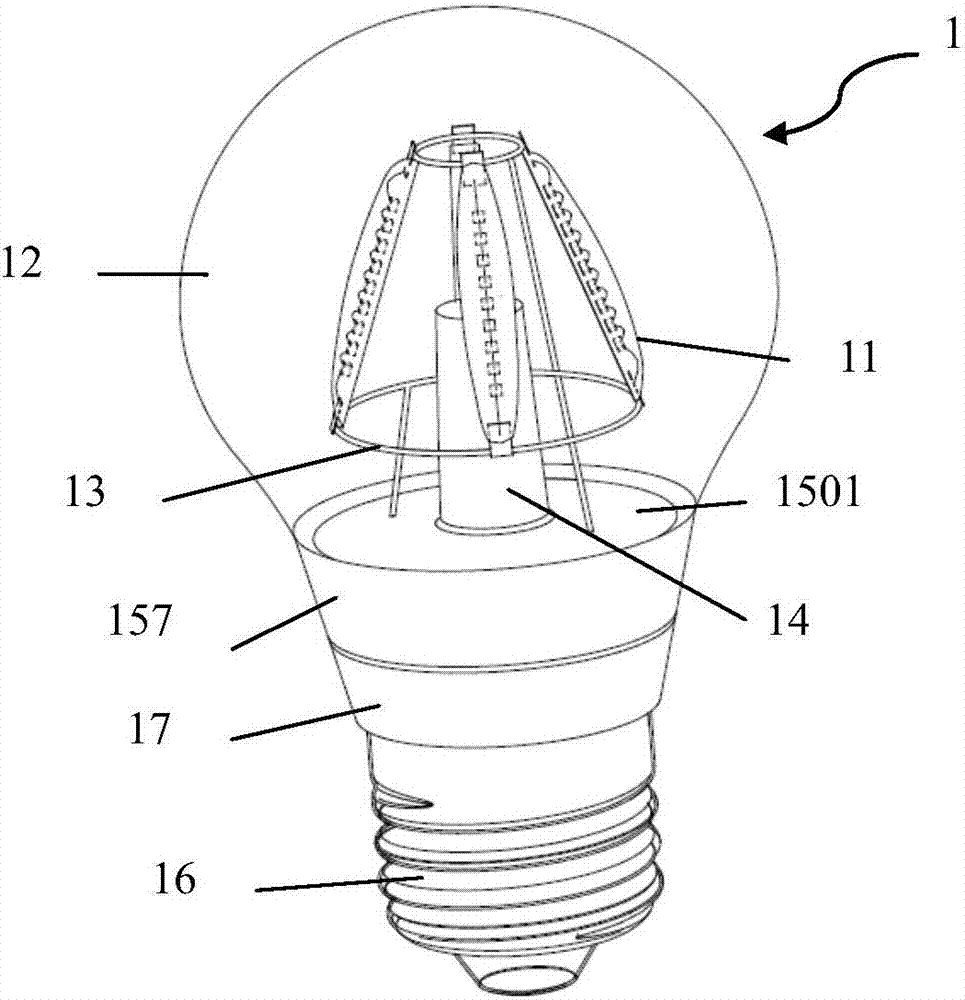

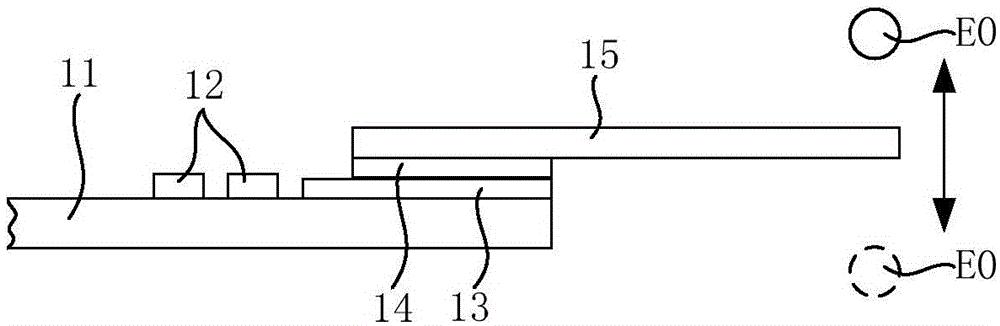

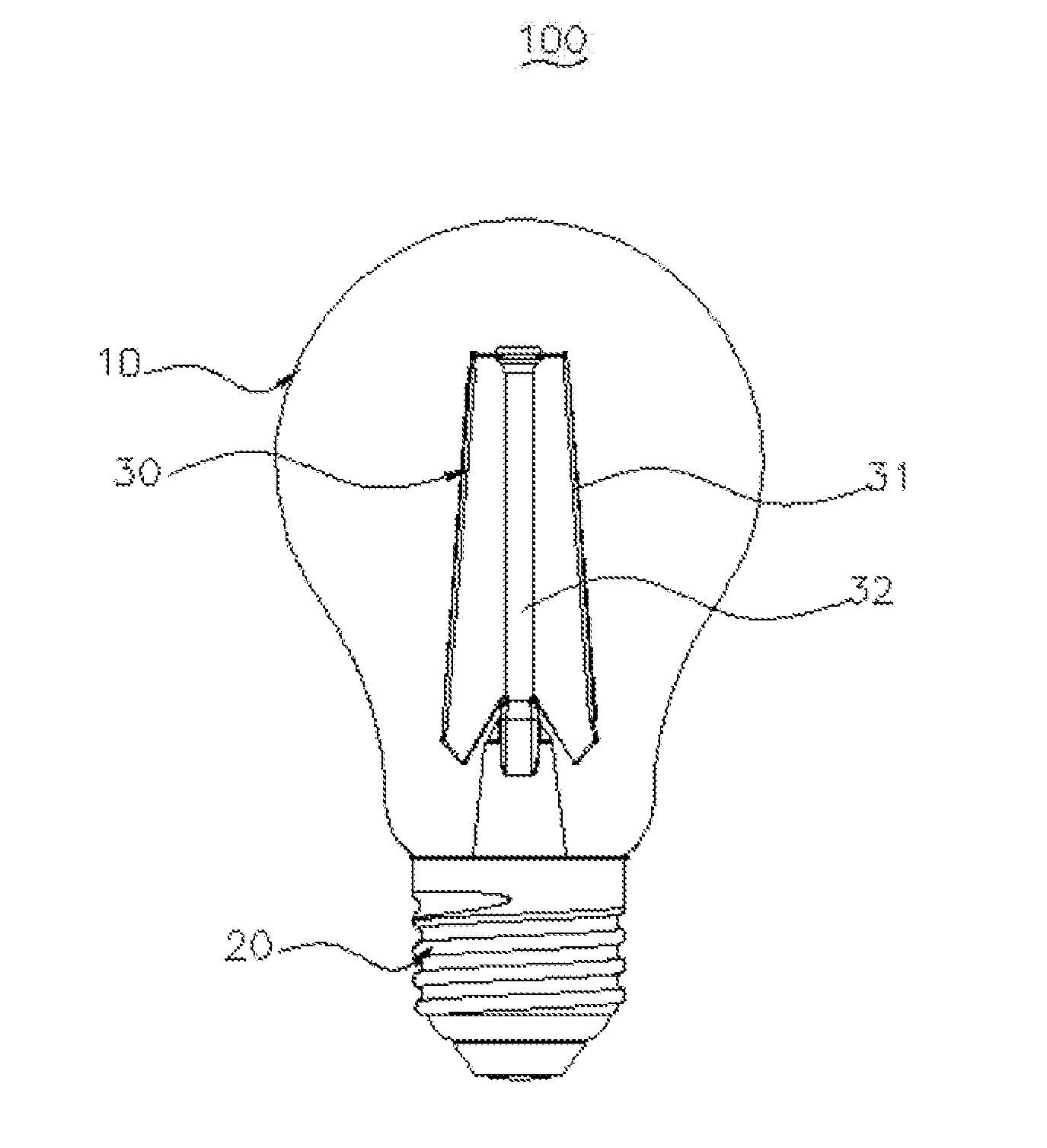

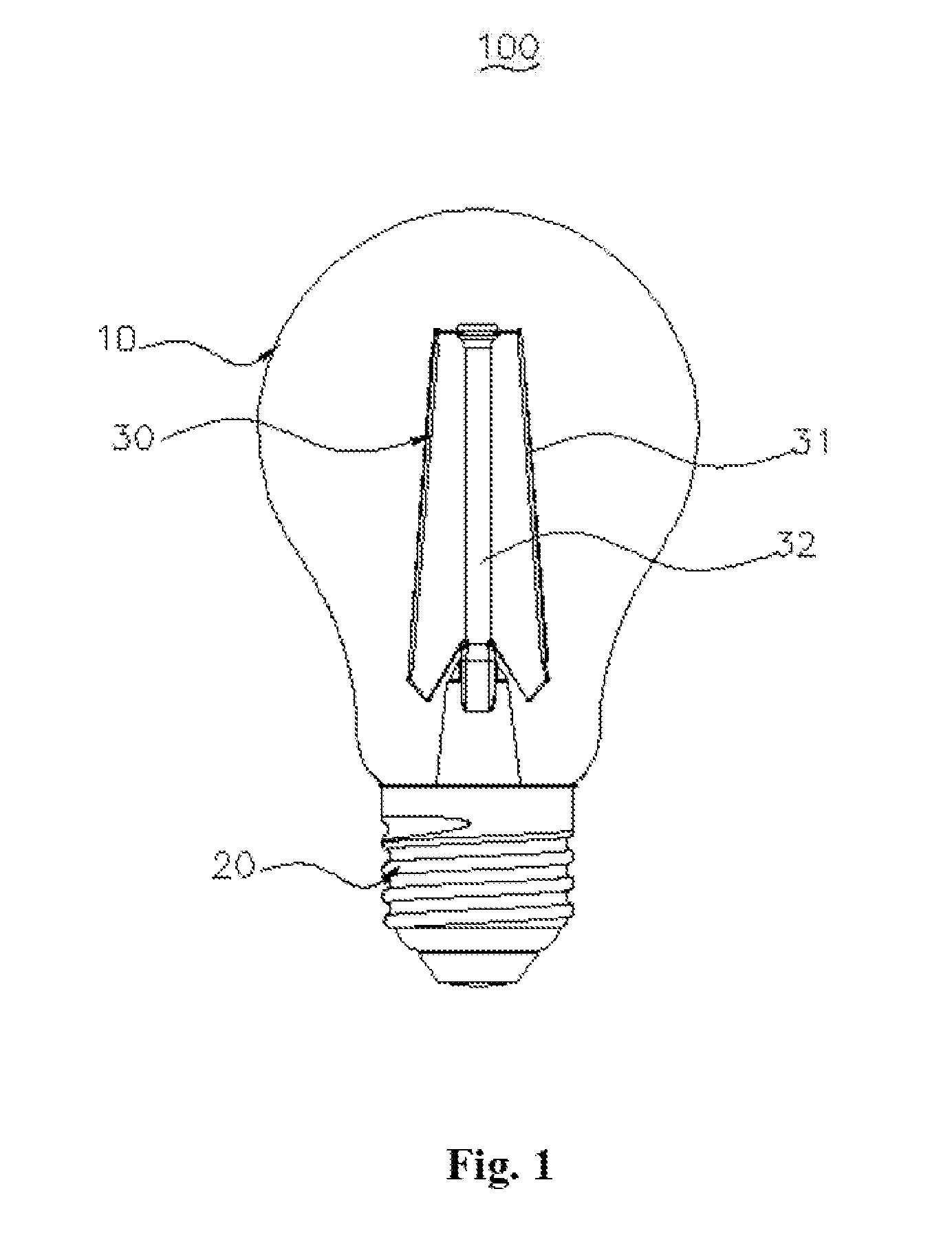

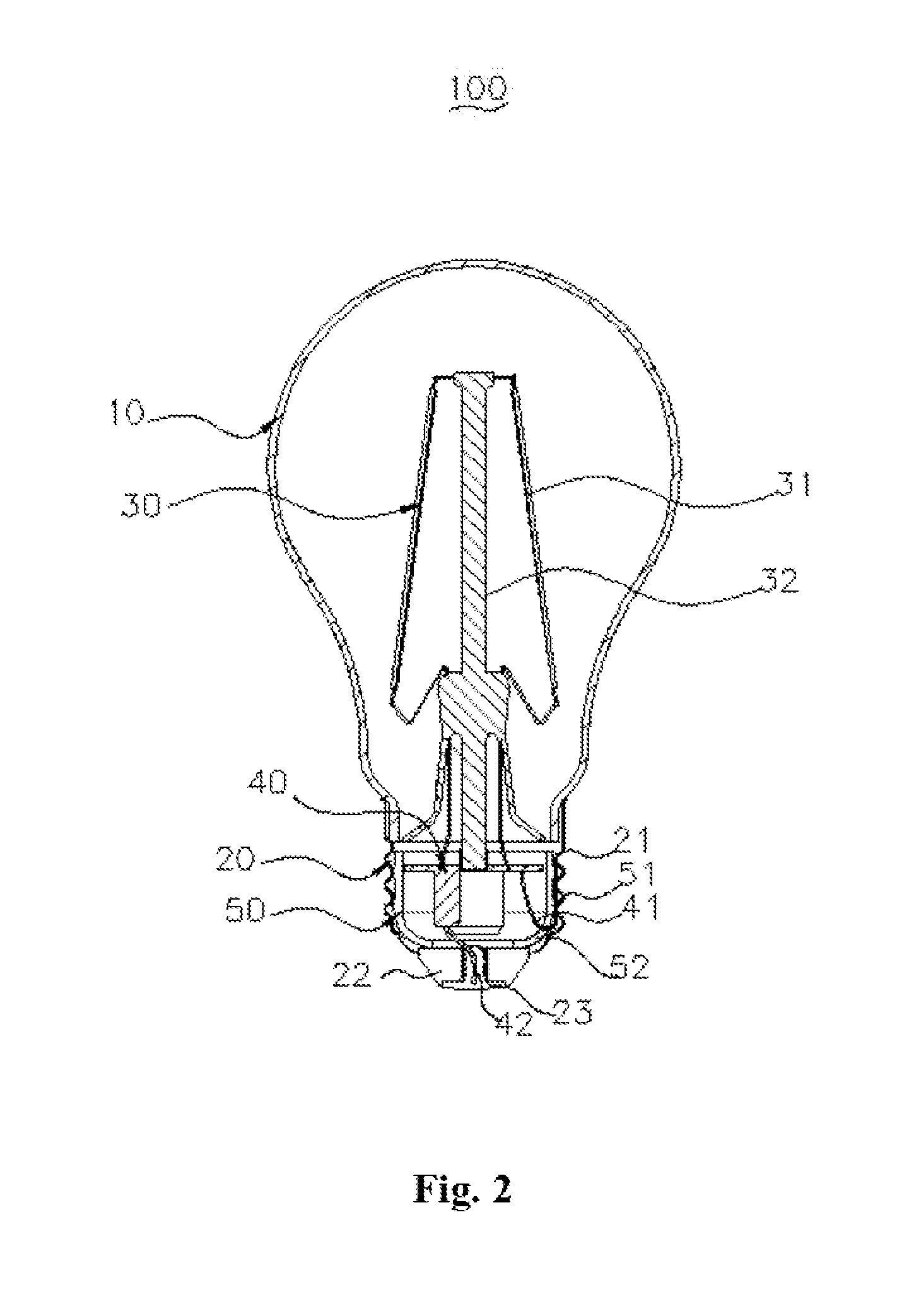

An LED light bulb includes a bulb shell, a bulb base, a stem, conductive supports, an LED filament, and a supporting arm. The bulb base is connected to the bulb shell. The stem is connected to the bulb base. The conductive supports are connected to the stem. The LED filament includes a filament body and two conductive electrodes. The conductive electrodes are at two ends of the filament body and connected to the conductive supports. The filament body is around the stem. The supporting arm is connected to the stem and the filament body. In a height direction of the LED light bulb, H is a distance from a bottom to a top of the bulb shell. A first height difference is defined between the two conductive electrodes and is from 0 to 1 / 10H. The filament body is curved to form a highest point and a lowest point. A second height difference is defined between the highest point and the lowest point. The first height difference is less than the second height difference.

Owner:ZHEJIANG SUPER LIGHTING ELECTRIC APPLIANCE

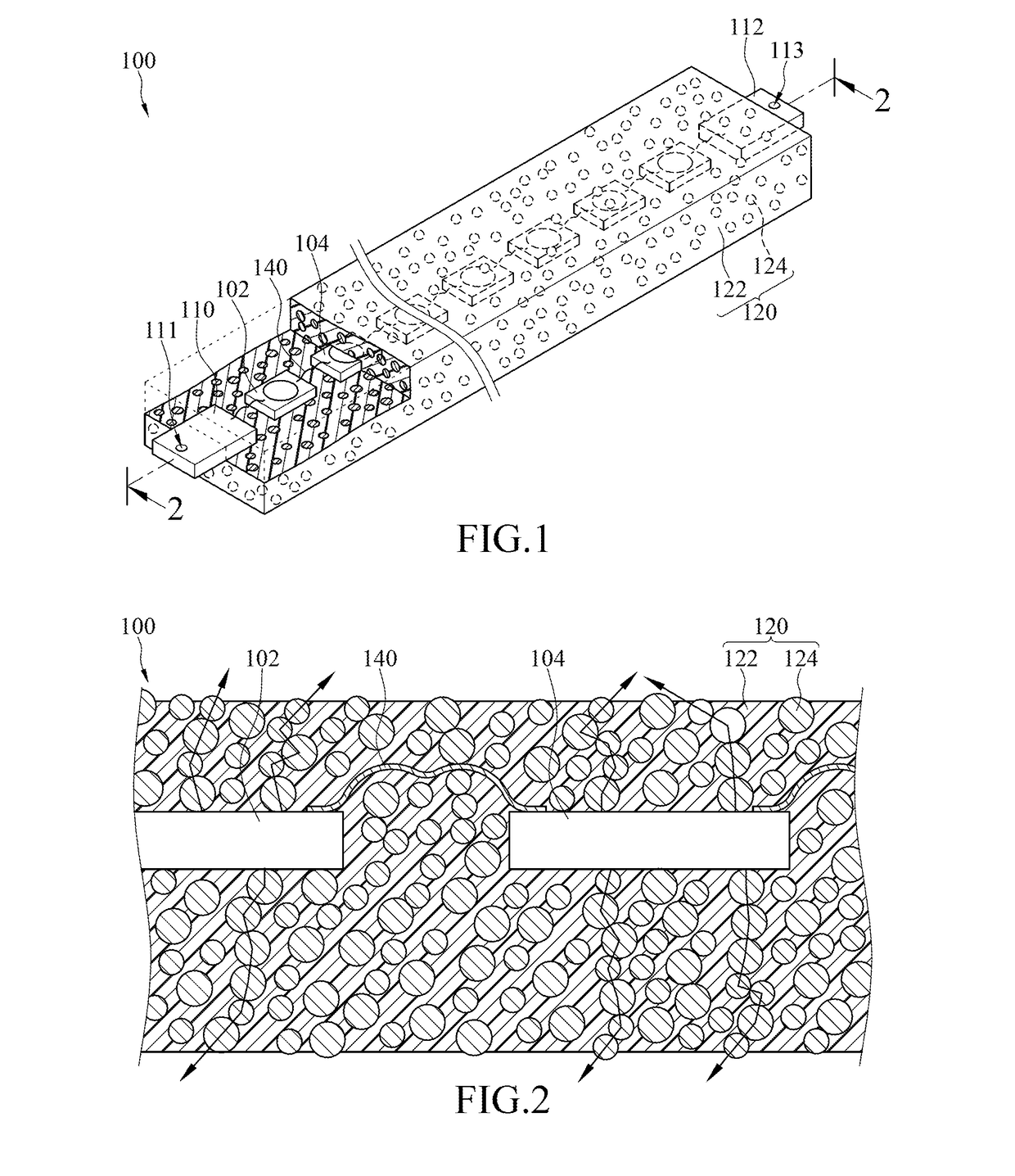

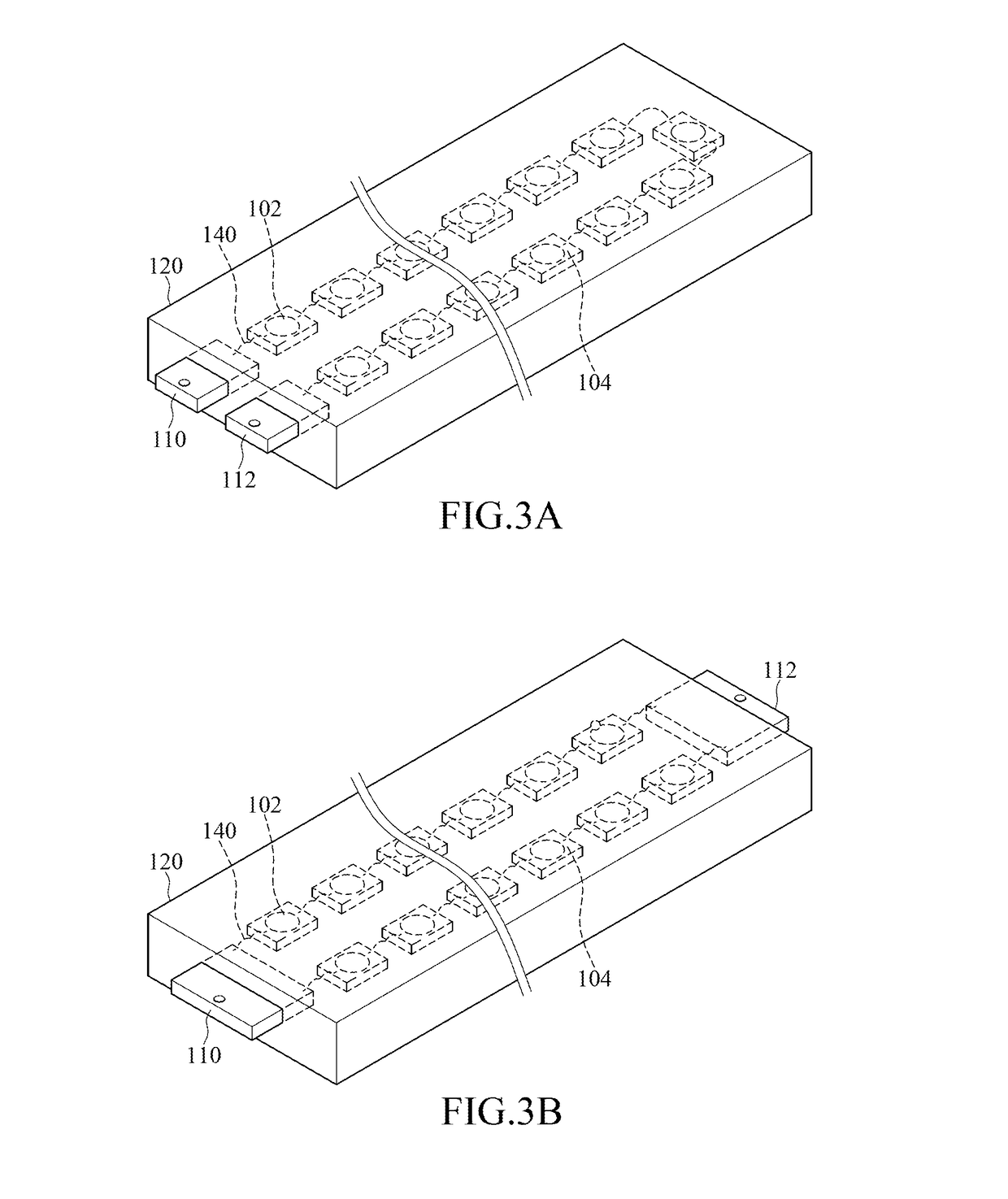

LED light bulb and LED filament thereof

ActiveUS20170051878A1Rigid enoughLong wavelengthElongate light sourcesElectric circuit arrangementsAdhesivePhosphor

An LED filament and an LED light bulb applying the same are disclosed. The LED filament includes LED chips, conductive electrodes disposed corresponding to the LED chips, and a light conversion coating. The LED chips are electrically connected together and the conductive electrodes are electrically connected with the LED chips. The light conversion coating includes an adhesive and a plurality of phosphors. The light conversion coating coats on at least two sides of the LED chips and the conductive electrodes. The light conversion coating exposes a portion of two of the conductive electrodes. Accordingly, the LED filament is capable of emitting light similar to that a point light source does and the LED light bulb may emit omnidirectional light.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

LED Filament Lamp

ActiveUS20160369949A1Simple structureEasy to assembleElectrical apparatusPoint-like light sourceEngineeringLED filament

An LED filament lamp comprises a bulb shell and an LED filament component located inside the bulb shell. The LED filament lamp further comprises a driving board, a lamp holder bulb shell and an inside liner. The inside liner is a bulb shell structure made of insulating material and installed inside the lamp holder bulb shell. At least a part of the driving board is located inside the inside liner to make the driving board and the lamp holder bulb shell separate from each other. The LED filament component is electrically connected to the driving board and the lamp holder bulb shell is electrically connected to the driving board. The LED filament lamp has characteristic of simple structure.

Owner:XIAMEN ECO LIGHTING CO LTD

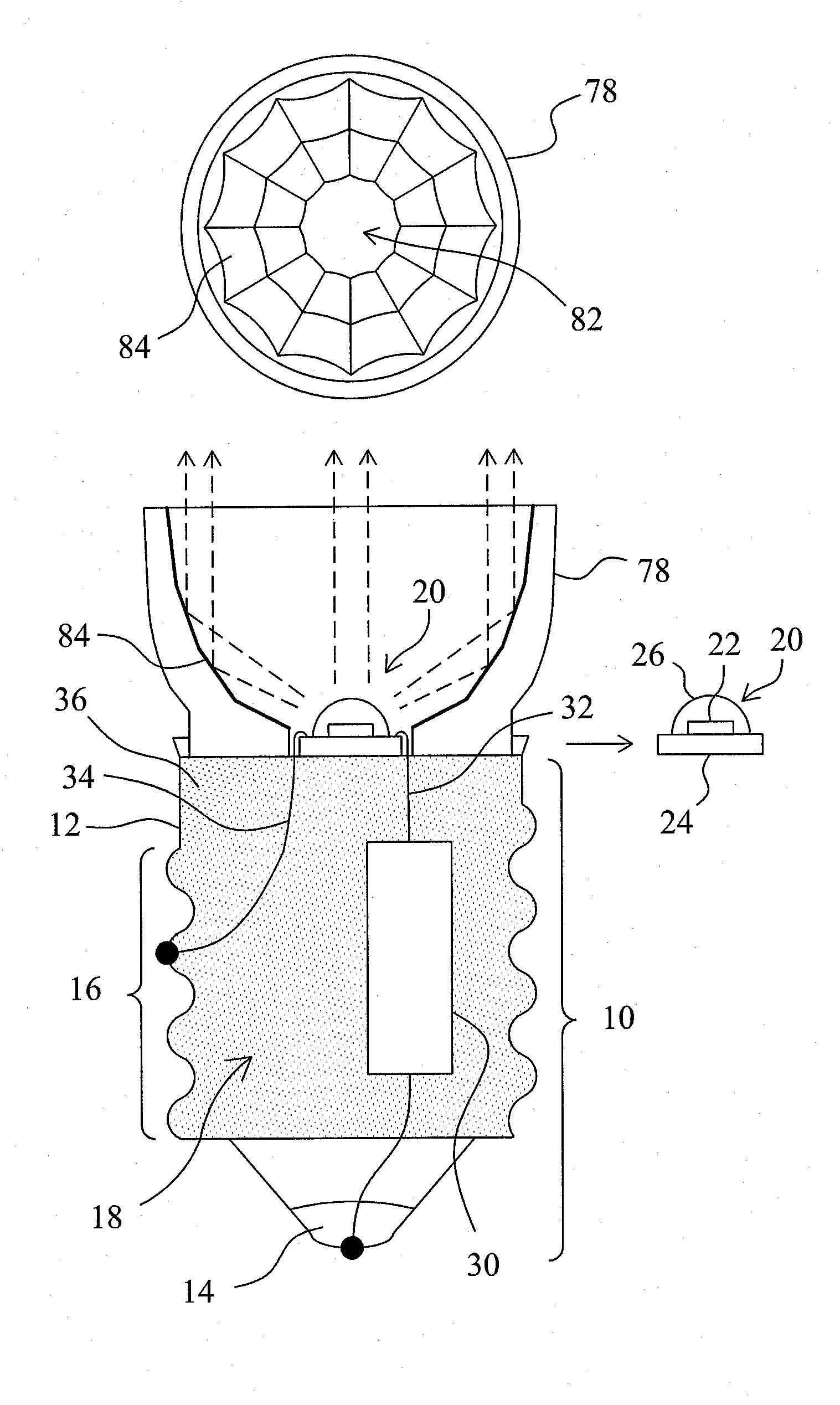

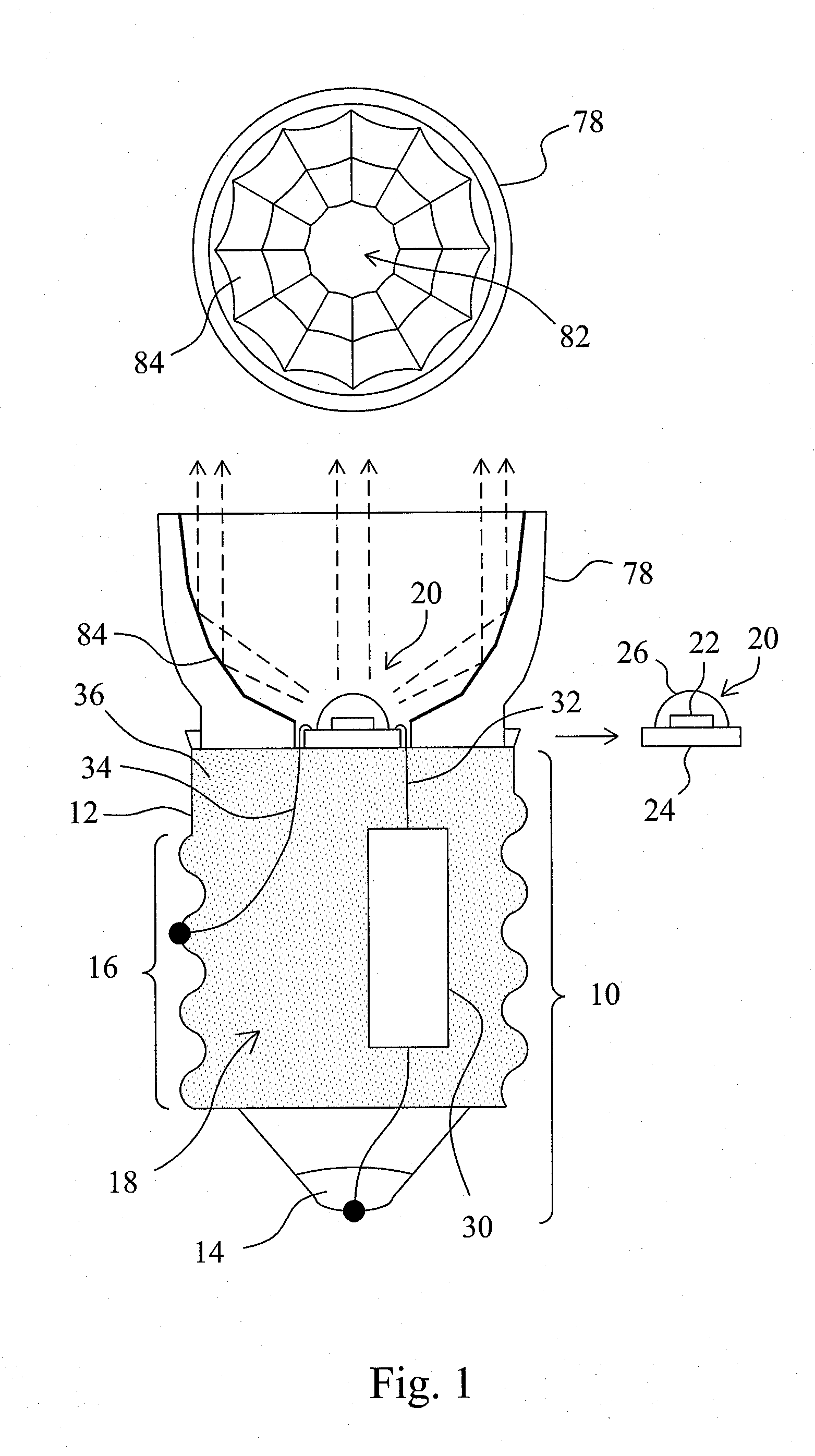

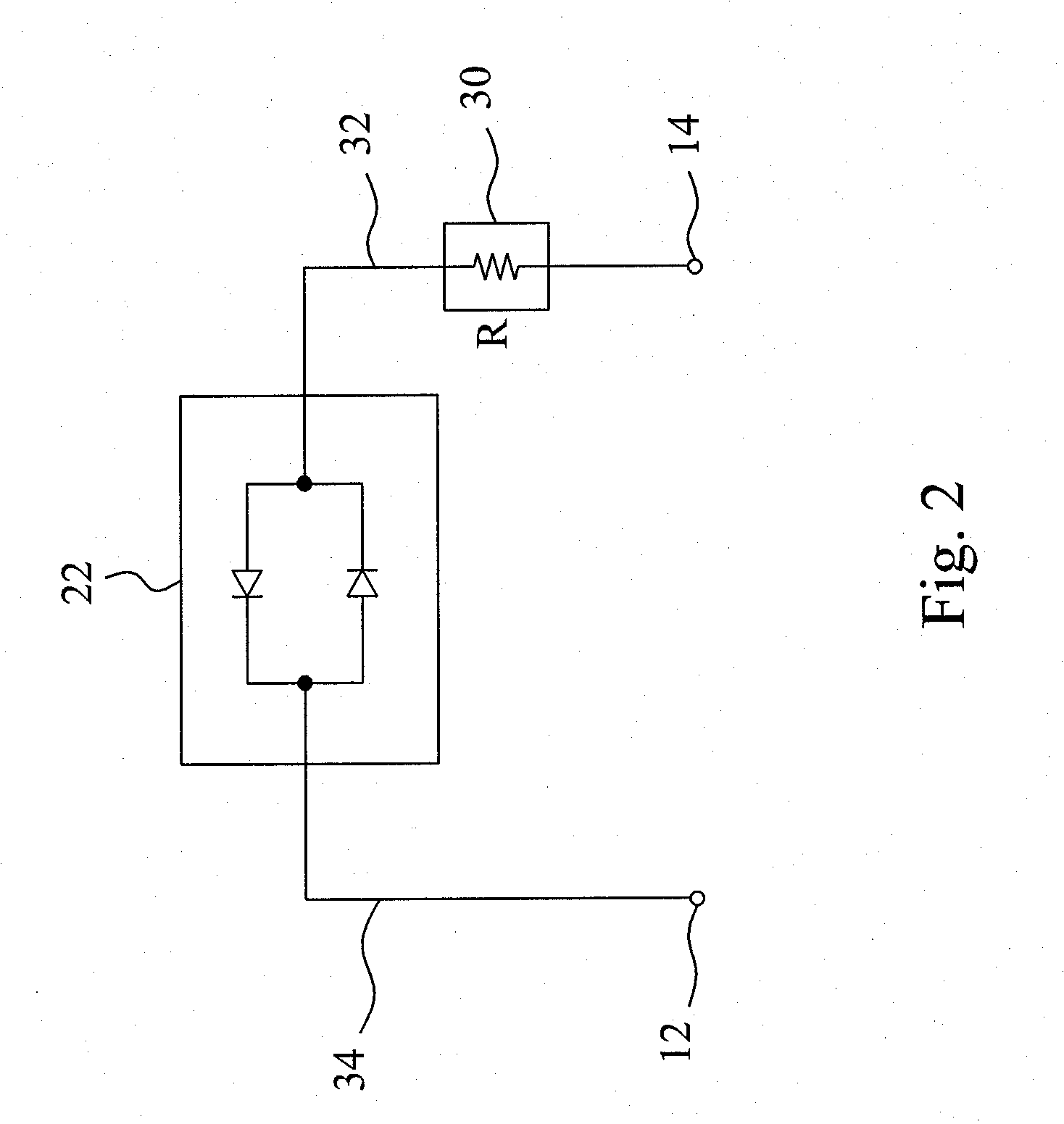

Heat dissipation enhanced LED lamp for spotlight

In a LED lamp, a thermally conductive electric insulator is filled in a cavity of a lamp base, a LED filament includes an AC LED device, a resistor is connected with the AC LED device in series between two electrodes of the lamp base to form an electric loop, and a reflective cup has a hole at a bottom thereof to expose the AC LED device and a reflective surface to reflect light of the AC LED device for providing a spotlight. The thermally conductive electric insulator mechanically contacts the LED filament and the first one of the two electrodes, and thereby establishes a heat dissipation channel from the AC LED device to the first electrode therethrough.

Owner:YU CHIH MING

Omnidirectional luminescence flexible LED filament and manufacturing method thereof

ActiveCN105226167AOvercome heat yellowingOvercome heat dissipationPoint-like light sourceSolid-state devicesFluorescenceCopper foil

The present invention discloses an omnidirectional luminescence flexible LED filament and a manufacturing method thereof. The flexible LED filament comprises a flexible substrate, an LED luminescence module and a fluorescence packaging layer. The flexible substrate is formed by laminating three layers of materials of a first copper foil layer, a polyimide base layer and a second copper foil layer, and a plurality of through holes having the equal intervals are arranged on the substrate. A line layer is formed on the first copper foil layer, and a positive electrode and a negative electrode are formed at the two sides of the substrate respectively and are connected with a driving power supply. The second copper foil layer is used for the heat radiation of the LED luminescence module, the LED luminescence module comprises a or a plurality of LED chip sets which are connected in parallel together, and each LED chip set is formed by connecting a plurality of LED chips in series. An LED chip is arranged in each through hole, and the LED chips are electrically connected with the line layer. According to the present invention, the 360-degreee omnidirectional luminescence is realized, and the flexible LED filament can be shaped into different shapes to combine into an LED bulb lamp having a high luminous efficiency.

Owner:HANGZHOU DIANZI UNIV

led filament and filament led bulbs

ActiveCN105090782BHigh bonding strengthIncrease joint areaElectric circuit arrangementsLight fasteningsLED filamentEngineering

A LED filament and a LED filament bulb using the same are disclosed. The LED filament includes a carrier, a LED chip disposed on the carrier and a conductive lead connected to the carrier. The conductive lead is electrically connected to the LED chip and includes a lead head portion, a lead tail portion and a lead neck portion connecting the lead head portion with the lead tail portion. A solid body width of the lead neck portion is less than a maximum solid body width of the lead head portion. Because the lead neck portion with reduced solid body width can function as a vulnerable position of the conductive lead, when a stress is applied onto the conductive lead, the lead neck portion would first take action and therefore the bonding location between the lead head portion and the carrier or the carrier itself can be protected.

Owner:KAISTAR LIGHTING (XIAMEN) CO LTD +1

Spiral LED filament and light bulb using spiral LED filament

ActiveUS10066791B2Simple manufacturing processImprove light distribution designElectric circuit arrangementsSolid-state devicesEngineeringElectrical connector

A spiral LED packaging filament comprises a substrate, a plurality of LED chips disposed on the top surface of the substrate, a medium layer sealing the plurality of LED chips and the top surfaces of the substrate into a sealed LED package; two electrode wires being electric connected to the plurality of LED chips, wherein the sealed LED package has a spiral shape. A light bulb with the spiral LED packaging filament comprises a bulb shell; a stem having a supporting pole, an electrical wire and a stem exhaust pipe, at least one spiral LED packaging filament is fixed on the stem; the electrode wire is connected to the electrical connector via the drive; and the bulb shell and the stem are respectively sealed.

Owner:GENERAL ELECTRIC SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com