LED bulb structure

A technology for LED bulbs and LED filaments, applied in lighting devices, light sources, electric light sources, etc., can solve the problems of LED filament swing, unstable structure, loose structure, etc., so as to improve the manufacturing yield, facilitate manufacturing and production, and increase the number of lumens. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The invention relates to an LED bulb structure, in particular to an assembly structure of LED filaments (LED filaments) in an LED filament bulb (LED filament lightbulb) that can be extended in multiple layers. Mainly through the modular setting of the LED filament bulb structure, multiple modules can be stacked and joined during use, which can effectively increase the number of lumens and increase the brightness; at the same time, the method of superimposing and combining multiple modules can effectively Designed to match bulbs of different lengths and sizes.

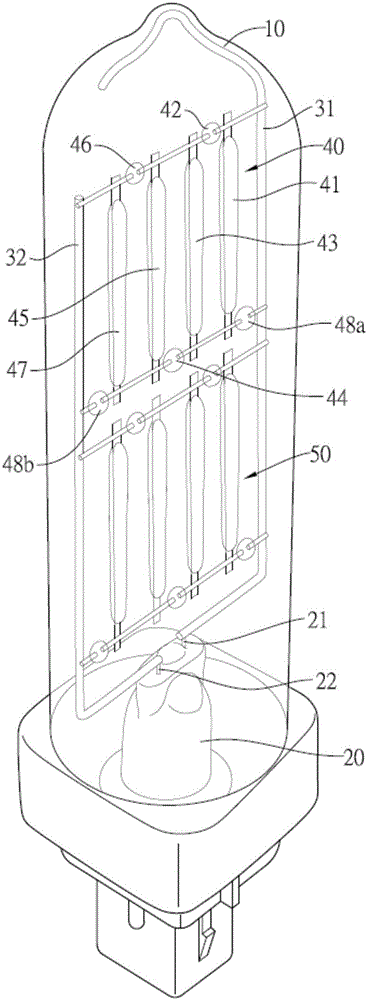

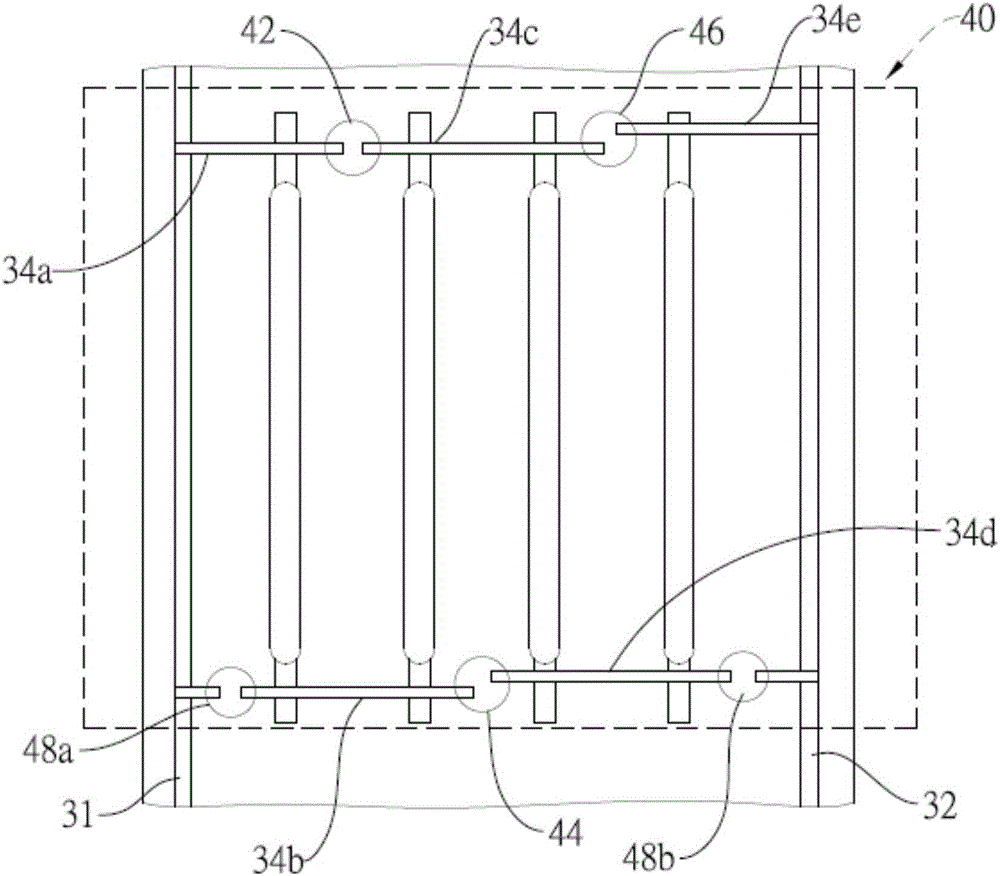

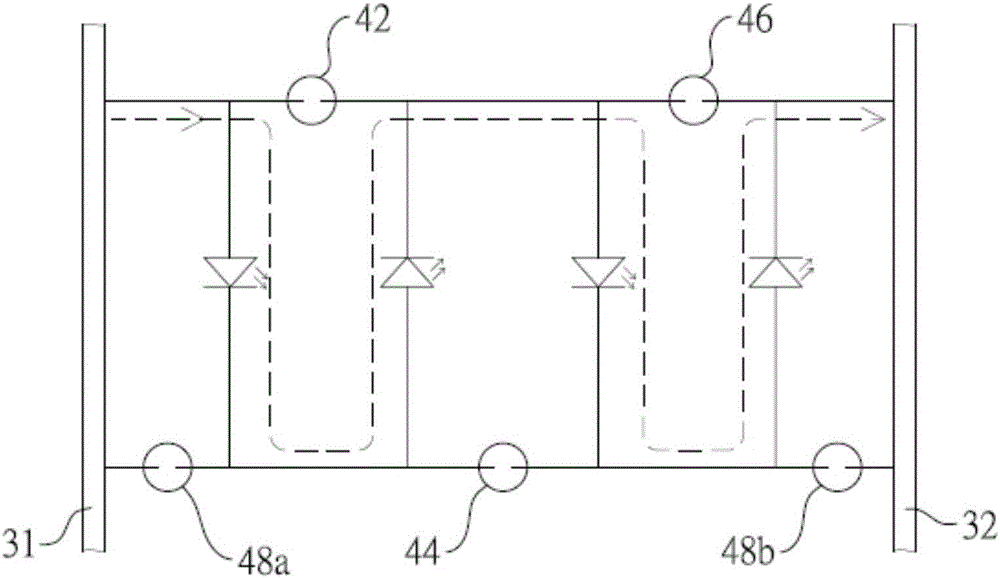

[0046] see Figure 1A and Figure 1B , the first preferred embodiment of the present invention includes: a first light-emitting module 40; and includes a glass cover 10, a glass stem 20, a first power line 21, a second power line 22, a first conductive column 31. A second conductive pillar 32.

[0047] Figure 1A As shown, the inside of the glass cover 10 is a glass sealed cavity, the inside of which is evacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com