LED filament, manufacturing method of LED filament, and LED bulb equipped with filament

A technology of LED bulb lamp and LED filament, which is applied in the field of lighting, can solve problems such as flexible changes in process conditions, displacement of LED chips, different silica gel, etc., and achieve the effects of improving heat conduction effect, saving processing time, and multiple heat conduction paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0210] In order to make the above objects, features and advantages of the present invention more obvious and comprehensible, the implementation of the present invention will be described in detail below with specific embodiments in conjunction with the accompanying drawings.

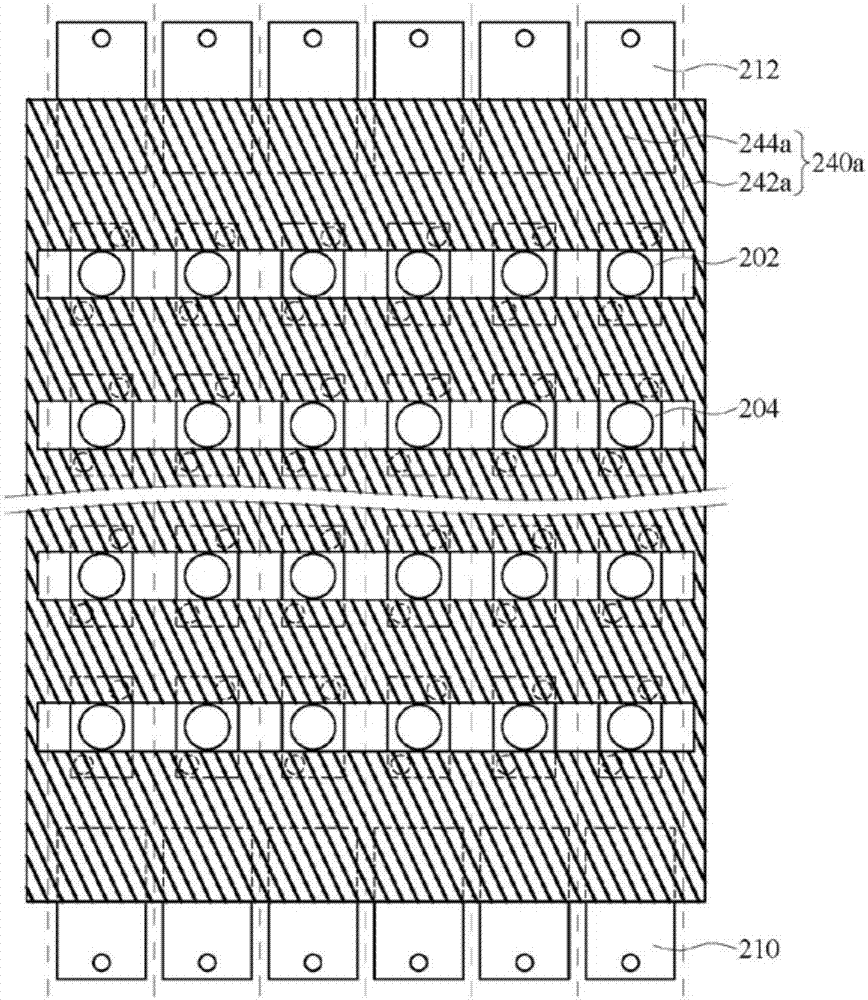

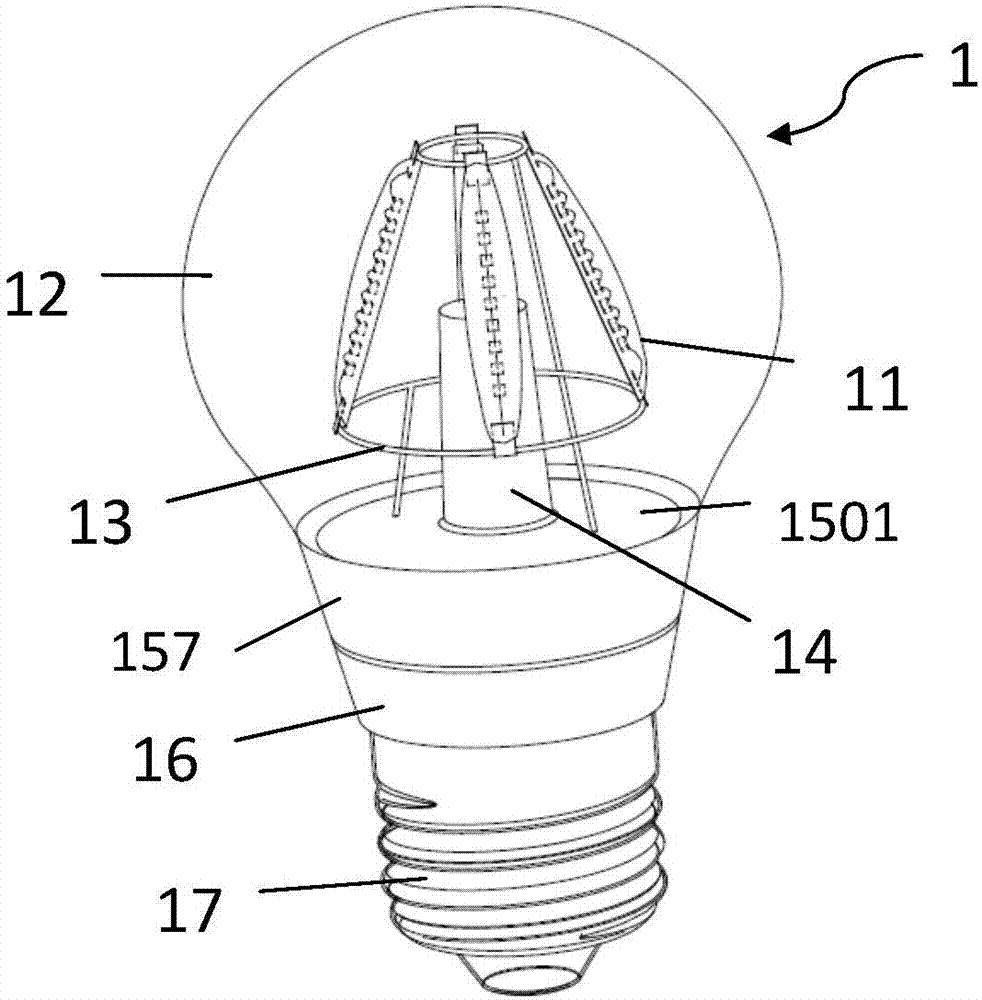

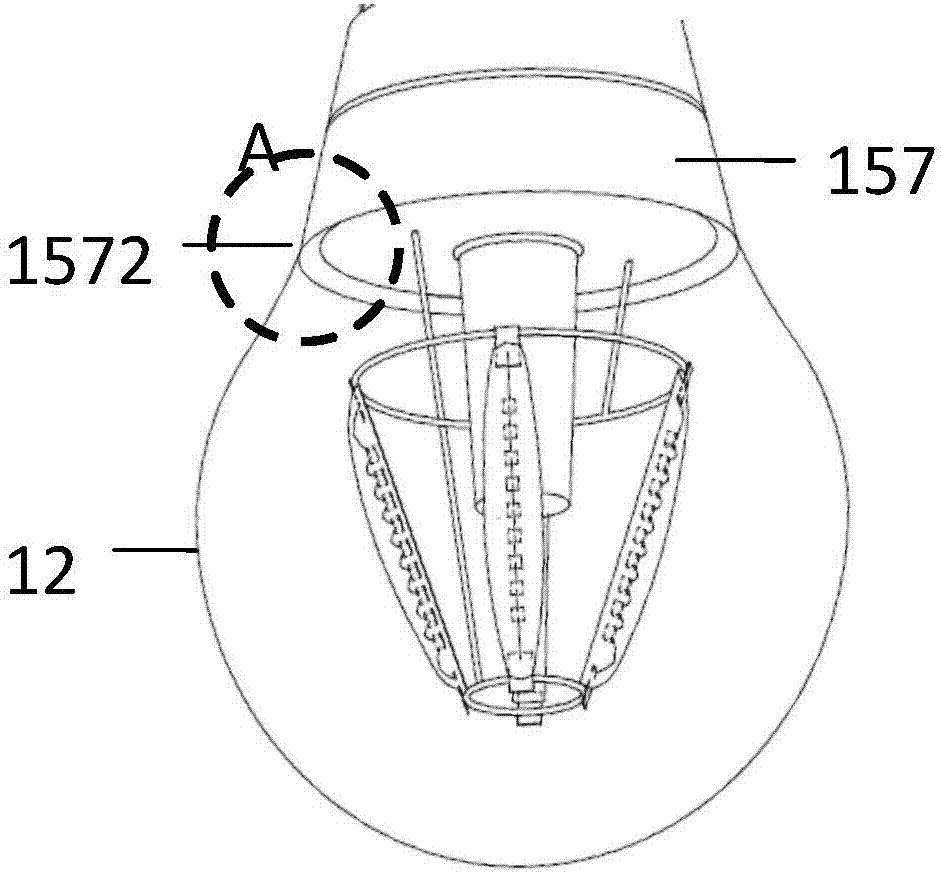

[0211] During the manufacturing process of traditional bulb lamps, in order to prevent the tungsten wire from burning in the air and causing oxidative fracture failure, a horn stem glass structure is designed to be sintered and sealed at the opening of the glass lamp housing, and then penetrated The port of the horn stem is connected to a vacuum pump to replace the air inside the lamp housing with nitrogen to prevent the tungsten wire inside the lamp housing from burning and oxidizing, and finally the port of the horn stem is sintered and sealed. In addition, the water mist scattered in the air inside the lamp housing can also be removed through the pumping of the gas. Further, please refer to Figure 1A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com