Connection and installation method for LED filaments

A technology of LED filament and installation method, which is applied to lighting devices, lighting device parts, light sources, etc., can solve problems such as affecting the production yield, difficult to automate production, and breaking of filament substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

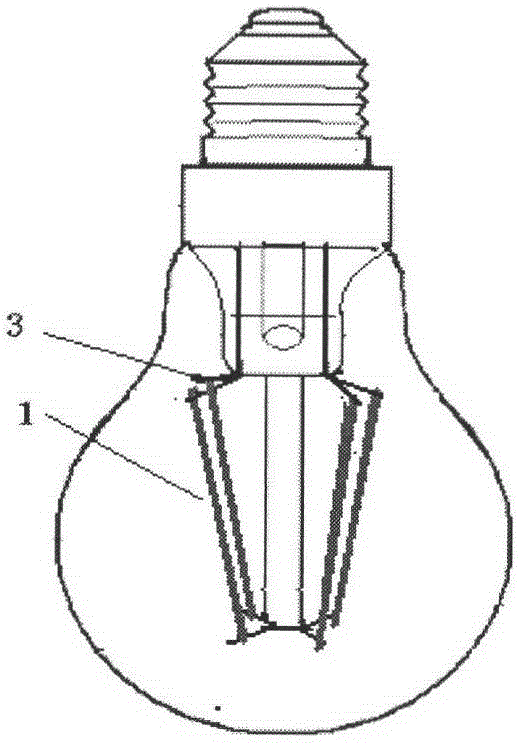

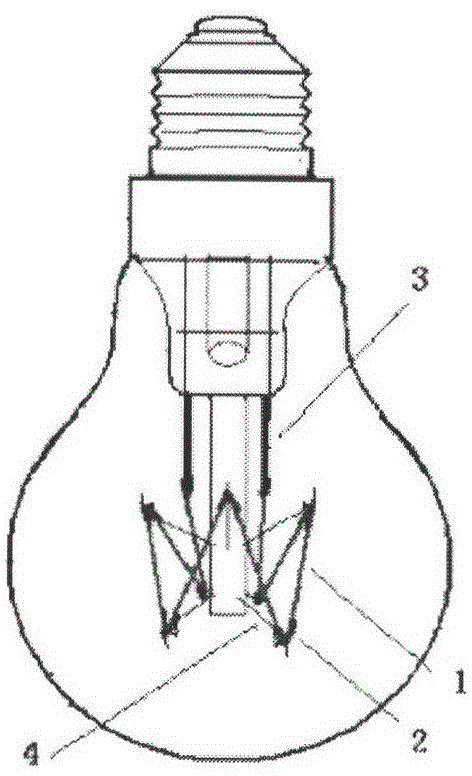

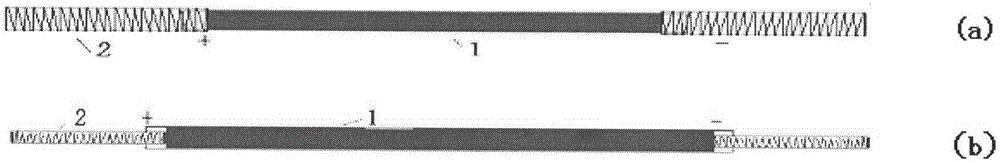

[0014] Embodiment 1 of the present invention is a method in which 8 LED filaments are connected to each other and assembled into a wick on a glass stem. The LED filament series system includes 8 LED filaments and 9 metal filament spirals, such as Figure 4 As shown; the connection method between the leading end of the LED filament and the metal filament spiral is to insert the leading end of the filament into the spiral, and firmly bite the leading end of the filament by the deformation elastic force of the spiral, as shown in image 3 As shown in a; in order to install the filament series system on the stem, 7 filament hooks made of molybdenum wire are installed on the stem glass rod, divided into upper and lower layers, 3 on the upper layer near the stem plate, and 4 on the lower layer only if Figure 5 As shown; the method of installing the LED filament series system to the glass stem is as follows. First, the metal filaments drawn from the front "+" end of the above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com