Semi-refined spinning slivering machine

A technology of strip machine and feeding mechanism, which is applied in the field of carding machines, can solve problems such as failure to find, achieve the effect of reducing damage rate and improving carding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

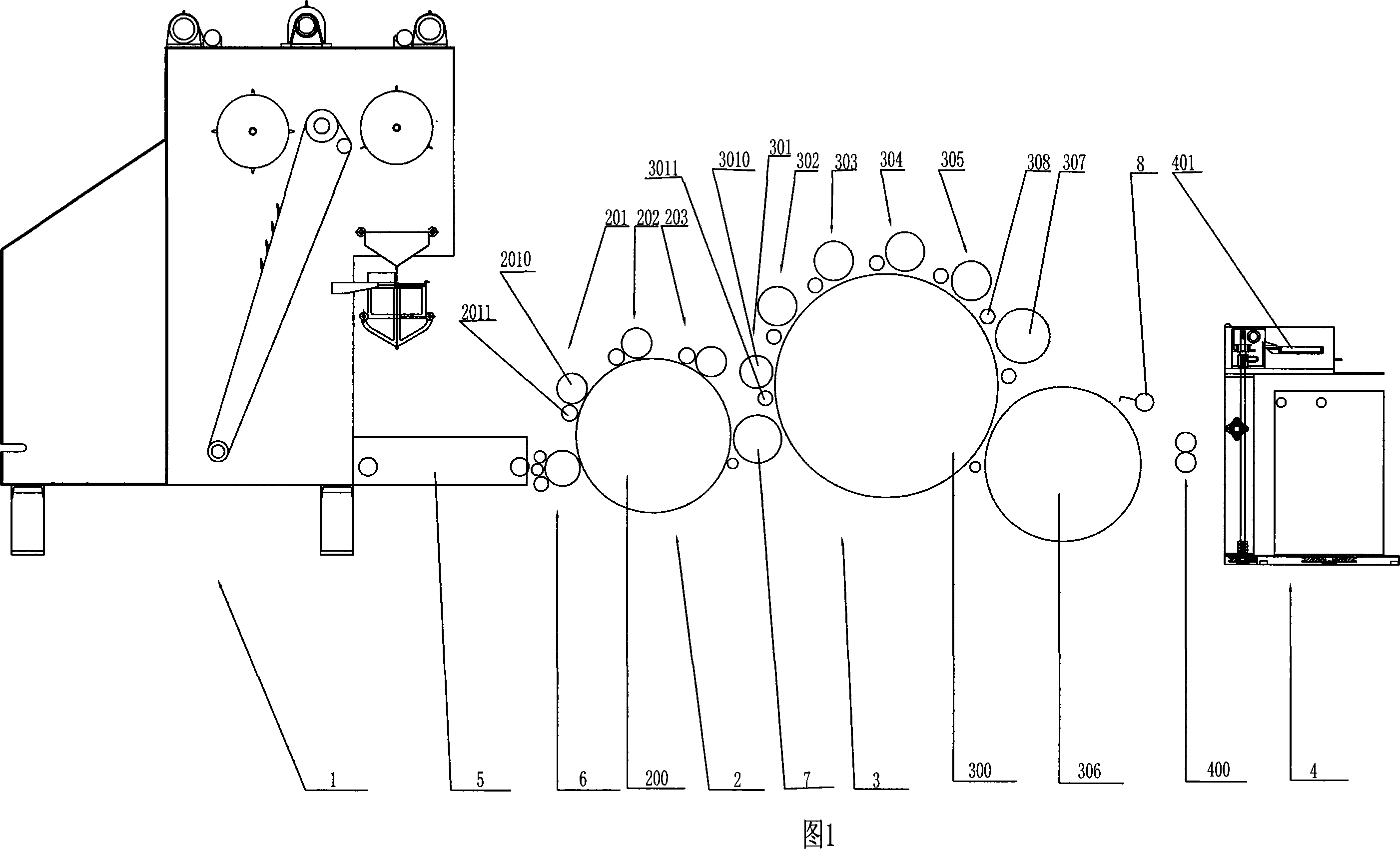

[0015] With reference to FIG. 1 , a semi-worsted sliver making machine includes a feeding mechanism 1 , a pre-carding mechanism 2 , a carding mechanism 3 and a coiling mechanism 4 . Wherein, all the technical contents of the feeding mechanism 1 and the coiling mechanism 4, and some technical contents in the pre-carding mechanism 2 and the carding mechanism 3 can be directly adopted or used for reference in the prior art. The most relevant existing technical features are combined below, and the technical features that the present invention contributes to the prior art are explained emphatically:

[0016] The feeding mechanism 1 connects the breast cylinder 200 in the pre-carding mechanism 2 through the conveying flat curtain 5 and the feeding roller group 6, and the breast cylinder 200 connects with the large cylinder 300 in the carding mechanism 3 through the transfer roller 7, and in the carding mechanism 3 After the doffer 306 in the doffer 306, a chopping knife 8 is set on ...

Embodiment 2

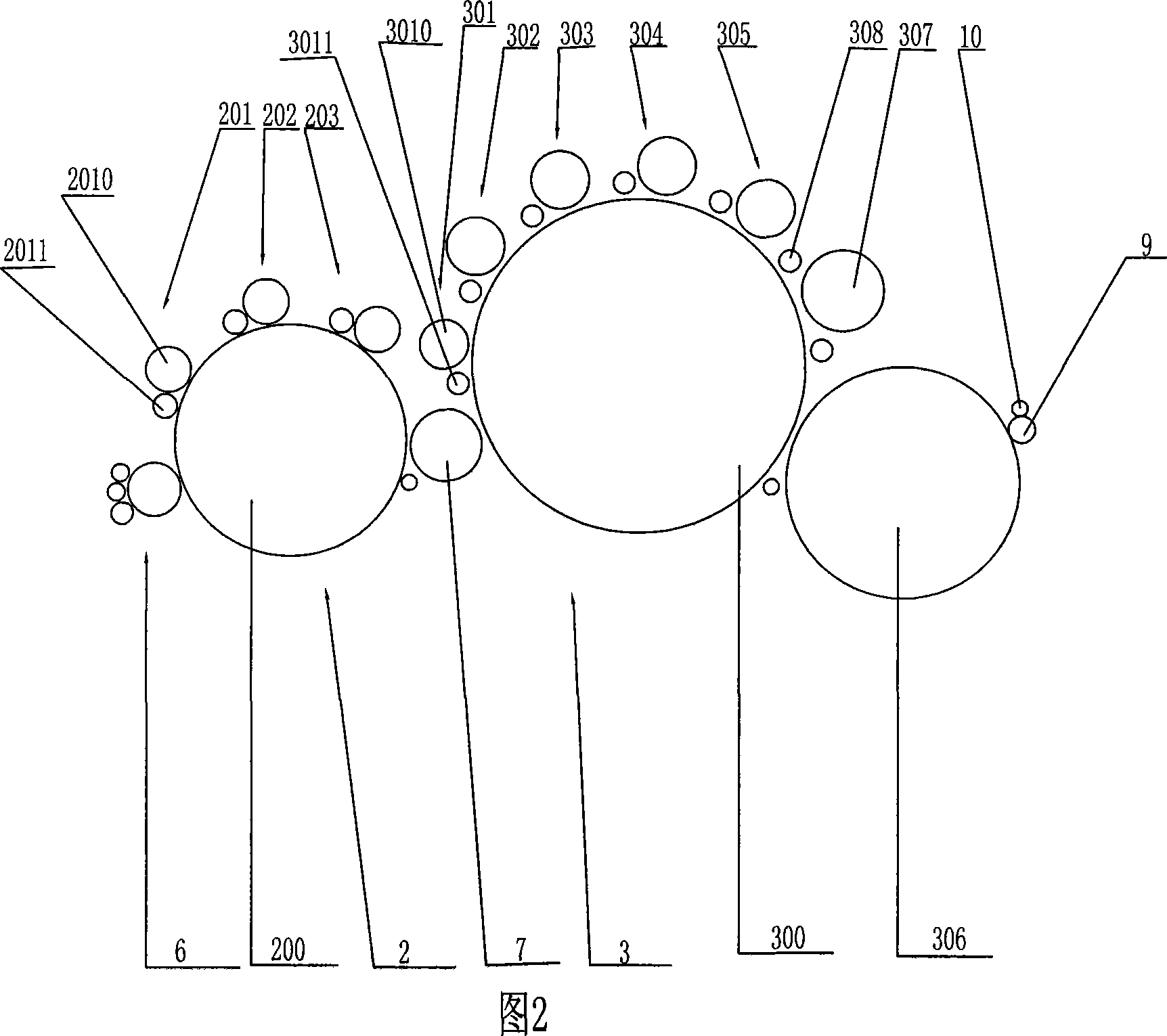

[0018] In conjunction with Figure 2, a semi-worsted sliver making machine, except for the following technical content, other parts can be the same as the technical content of the corresponding part of embodiment 1.

[0019] Pre-carding mechanism 2: configure three pairs of work roll groups 201, 202, and 203 on the chest cylinder 200, and each work roll group is provided with a work roll and a stripping roll, such as the work roll group 201 being provided with a work roll 2010 and a stripping roll. The take-up roll 2011; the working roll set 201 and the working roll set 203 are covered with metal card clothing, and the working roll set 202 is covered with elastic card clothing. Carding mechanism 3: Five pairs of work roll groups 301, 302, 303, 304, 305 are arranged on the large cylinder 300, and each work roll group is provided with a work roll and a stripping roll, such as the work roll group 301 is provided with a work roll 3010 and the stripping roller 3011; the work roll se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com