Patents

Literature

1758 results about "Wool fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

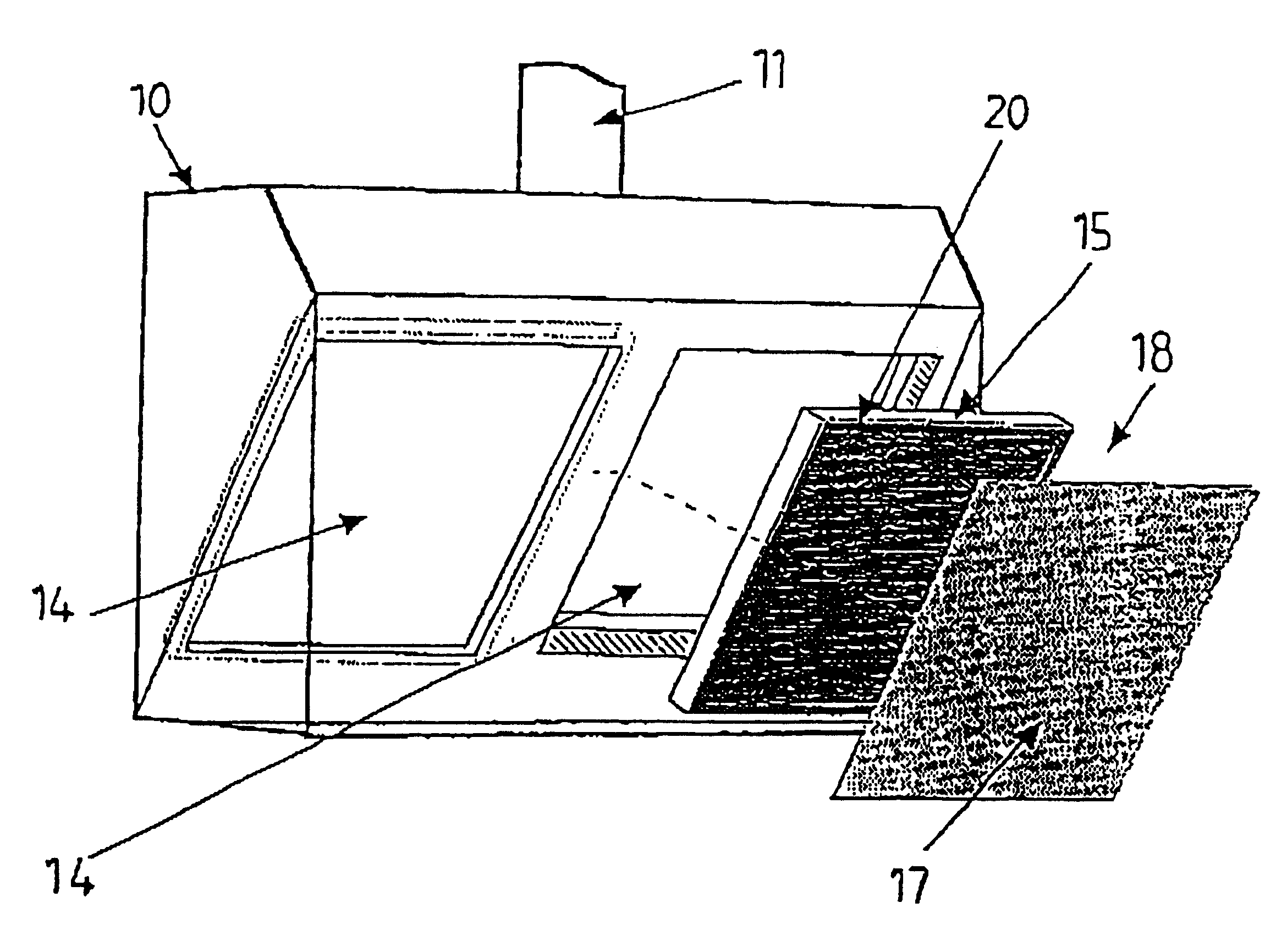

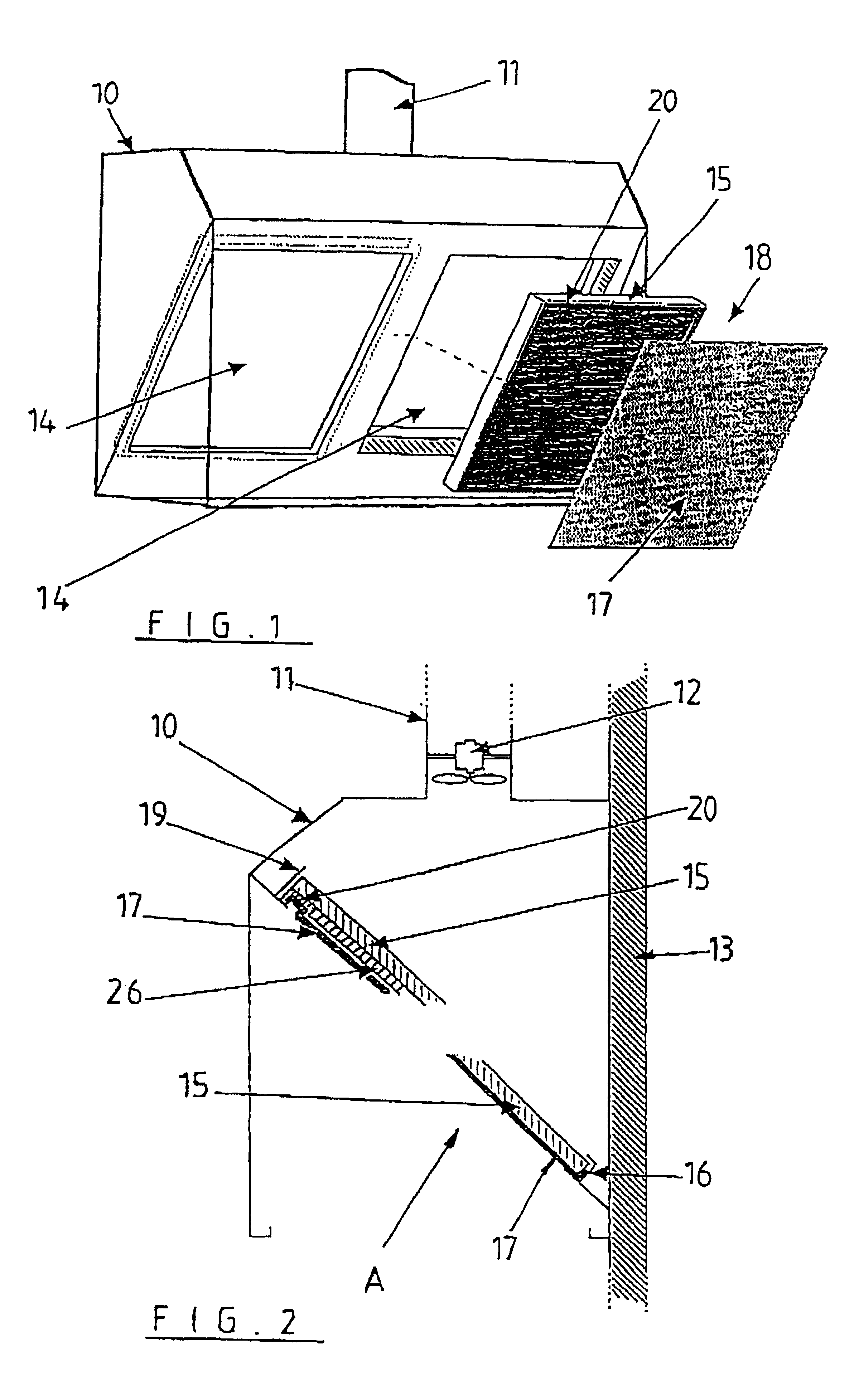

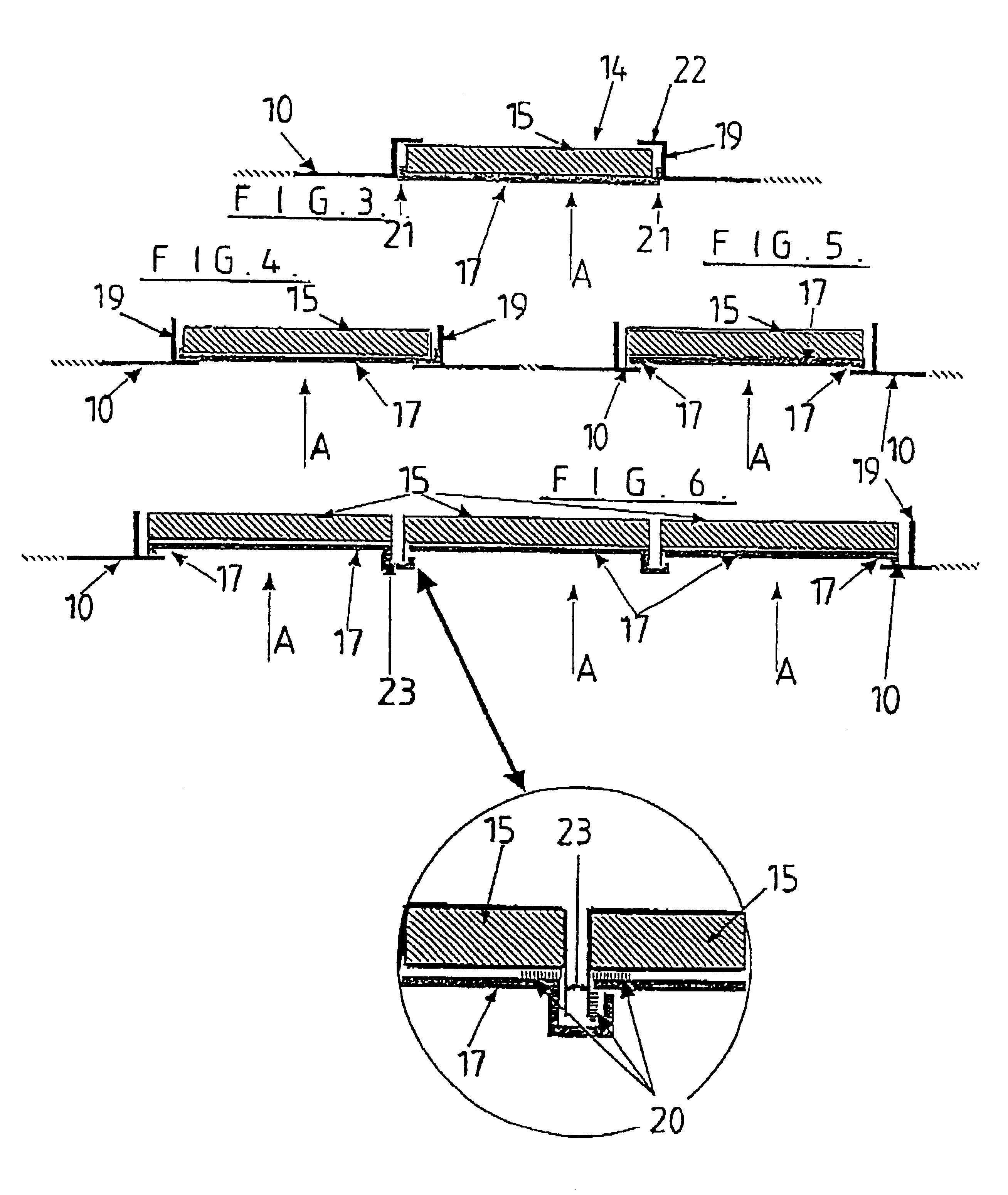

Filter assembly having a disposable pre-filter

A filter assembly for use in an air filtration unit, particularly for filtering cooking vapors. The assembly includes a filter disposed across an air flow and a grease pre-filter located upstream of the filter. The grease pre-filter is formed principally from wool fiber having an approximate density of 150-200 g / m2 and a loft of substantially 15-20 mm. The use of such a pre-filter substantially prolongs the service life of the filter before cleaning is required.

Owner:MITSUBISHI INT PATENT PROTECTION GRP +1

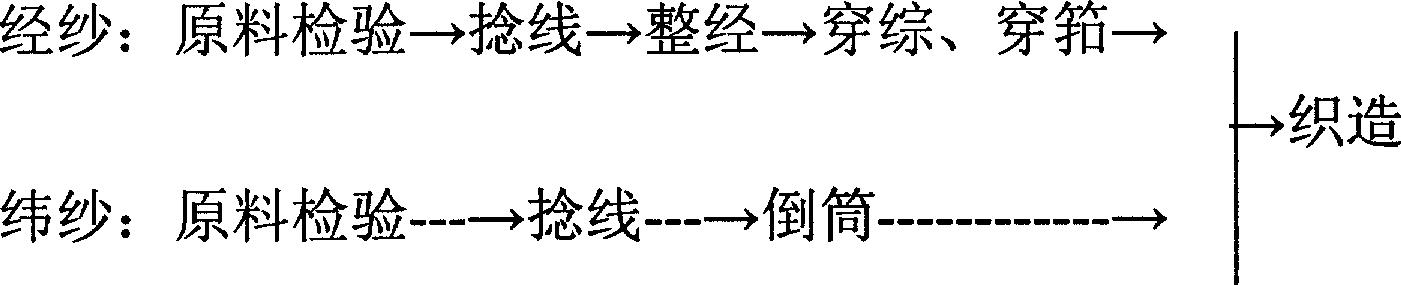

High-count single-warp single-abb worsted plus single thread and processing method thereof

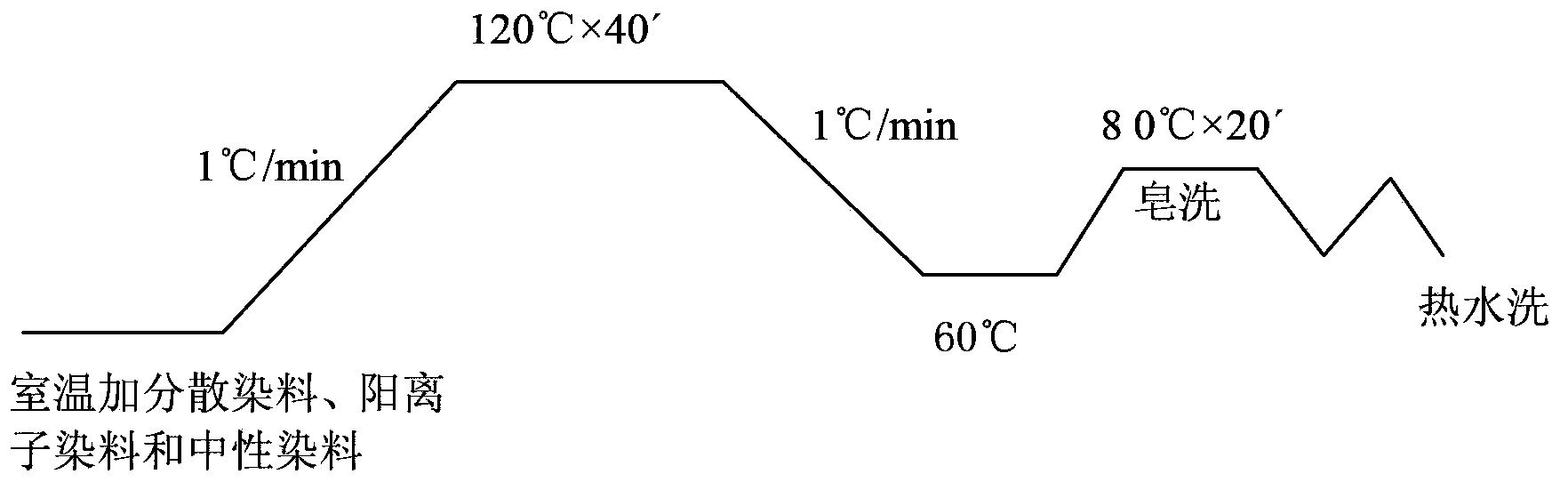

The invention discloses a high denier single spinning single yarn and the processing method. The yarn general branch is 35-60S / 1. The material is pure wool or the mixing yarn by wool and terylene, mucilage glue, nylon, the cashmere and floret. It selects the proper material and the using mass in process; also in strip dye and combing process, the animal fiber such as wool, cashmere and floret is dying in low temperature, but for terylene, it uses the dye water in 130deg.C to add the assistant agent in dye or back treat process. In spinning process, it uses the compact spinning or multi spinning to protect the wool fiber and improve the dye quality. So the single yarn has little feather and big strength, good elasticity and good abrasion resistance.

Owner:JIANGSU DANMAO TEXTILE

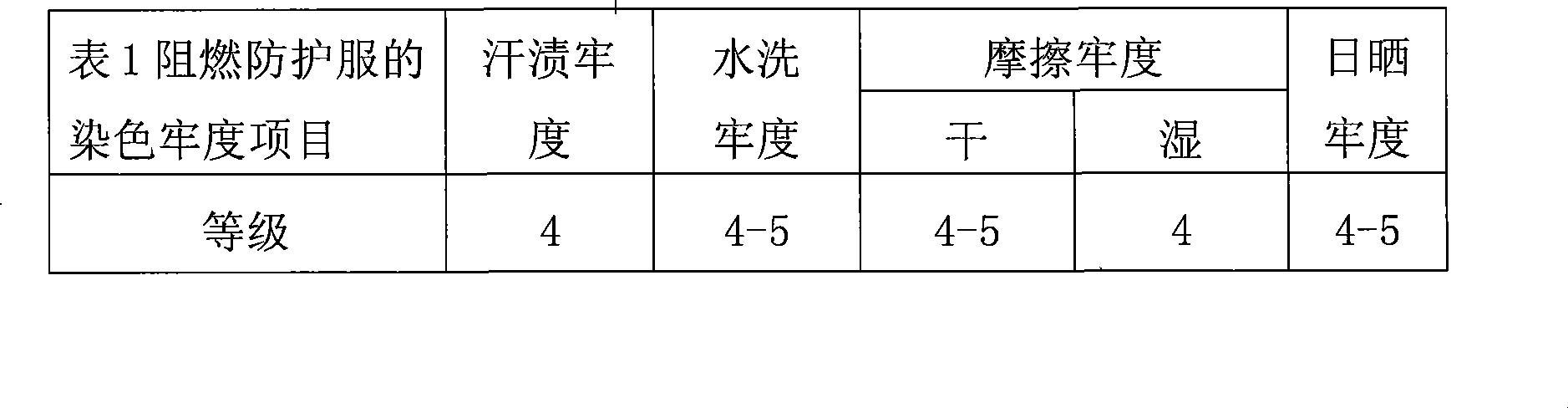

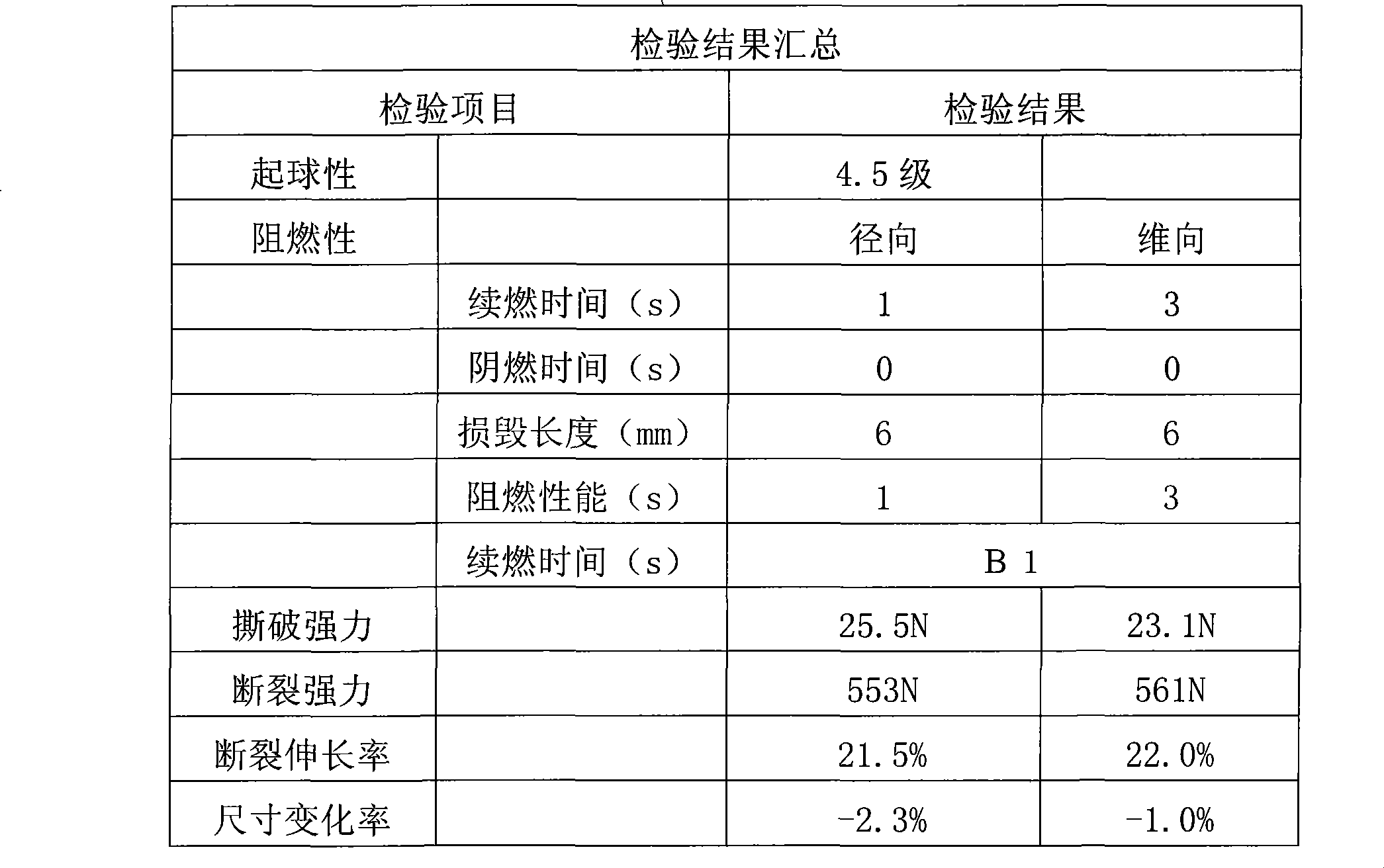

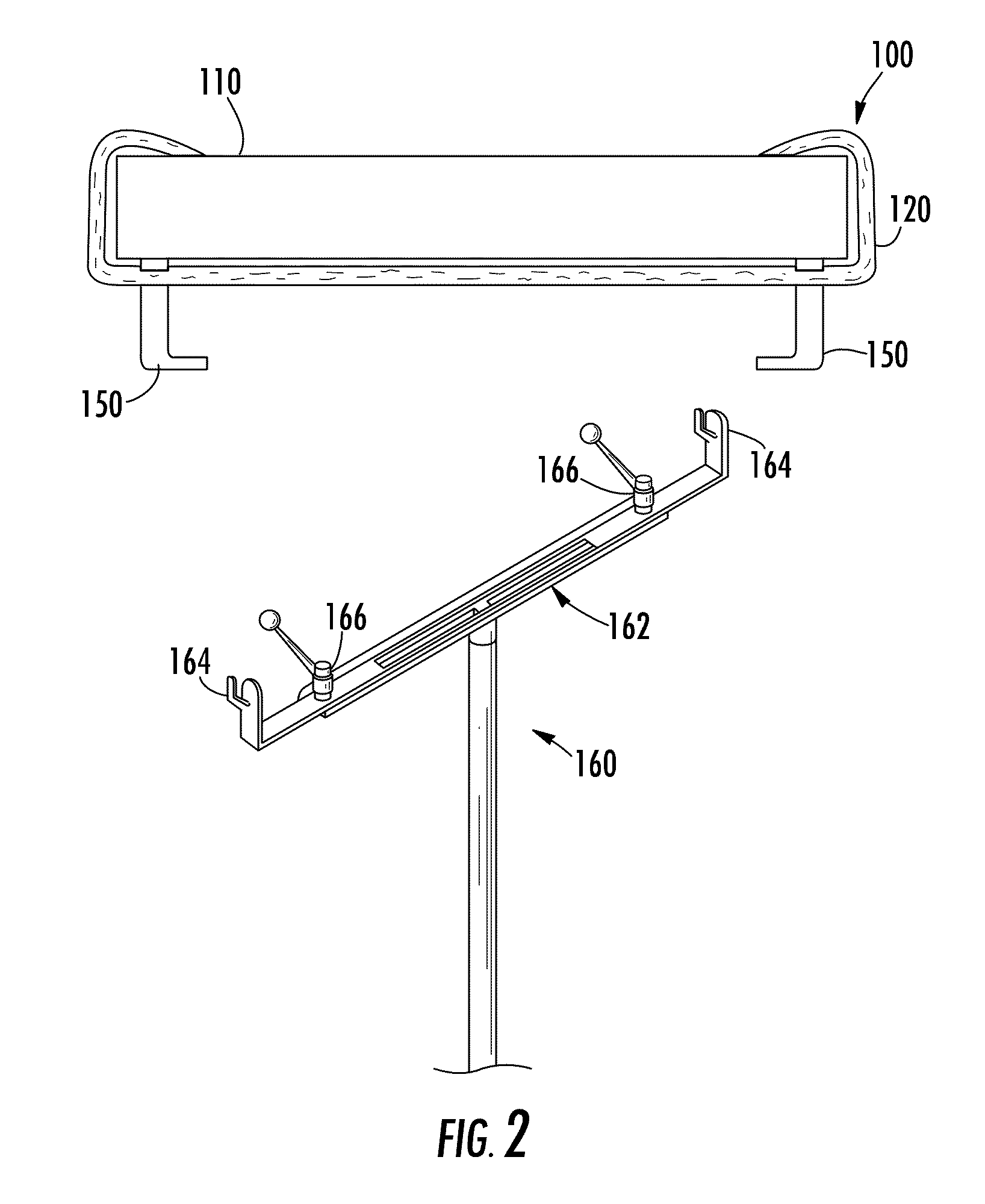

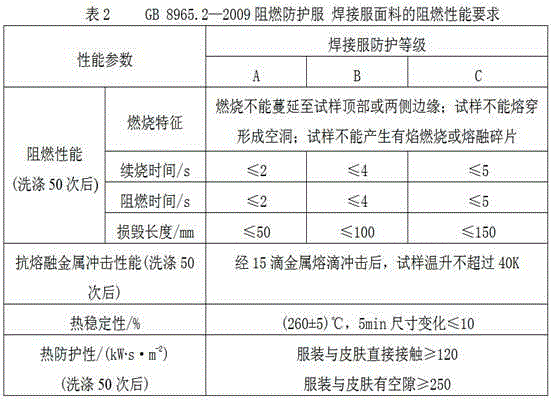

Industrial flame-retardant protection suit fabric, production method thereof and flame-retardant protection suit thereof

The invention relates to an industrial anti-flaming exposure suit fabric and a manufacturing method and an exposure suit thereof. Yarns used in the industrial anti-flaming exposure suit fabric are formed by the blending of anti-flaming viscose, wool fibers and nylon fibers. The blending proportions (weight percentage) of the anti-flaming viscose, the wool fibers and the nylon fibers are respectively 45 percent to 55 percent, 35 percent to 45 percent and 5 percent to 15 percent. The industrial anti-flaming exposure suit fabric used in front of electric welding and metallurgy smelting furnaces has the functions of permanent anti-flaming performance, high temperature resistance, heat convection resistance, molten metal splashing resistance, and the like. The fabric is not only suitable for firefighter uniforms, flying protective clothing, and the like, realizes permanent anti-flaming performance and high temperature resistance, but also meets the requirements of the anti-flaming exposure suit fabric used in front of the electric welding and metallurgy smelting furnaces for the functions of heat convection resistance, molten metal splashing resistance, and the like.

Owner:SHANGHAI IBENA TEXTILE PROD

High-count smooth double-faced wool and production process thereof

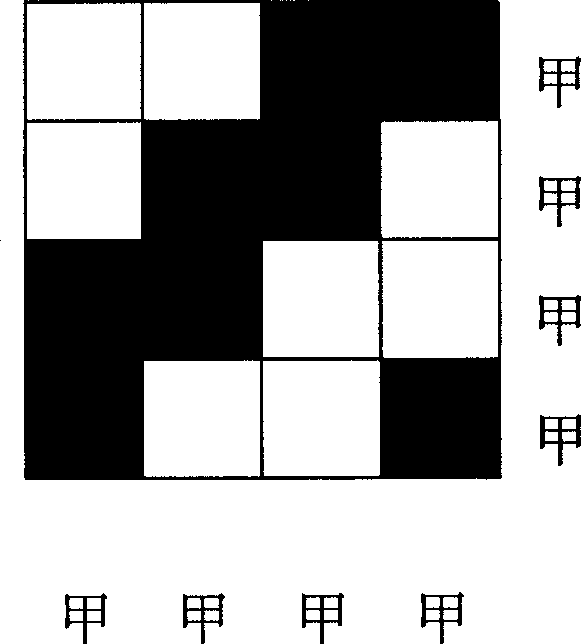

The invention discloses high-count smooth double-faced wool which is double-layer texture structure cloth with upper portion and lower portion connected. The front texture of the high-count smooth double-faced wool is 2 / 2 twill, and the back texture of the cloth is 2 / 2 herringbone. A production process of the high-count smooth double-faced wool includes: respectively performing loose fiber dying on wool fibers, dacron fibers and modal fibers, then performing full sliver mixing, and spinning the mixed fibers into 20 / 1 and 24 / 1 yarns with an open-end spinning mode; weaving the high-count smooth double-faced wool cloth on a rapier loom through yarns; and performing blank checking, mending, reviewing, hemming, wool washing, dehydration, milling, wool jigging, dehydration, rotary width drying, wool steaming, fluffing, shearing, squeezing, burring galling, rolling, drying, polishing, polishing shearing, wool steaming and finish inspection on the weaved cloth to manufacture finished products. The high-count smooth double-faced wool is full in hand feeling, elastic, natural and gentle in gloss, and smooth and ordered in villus, cannot cause bottom explosion and depilation, and is rich and smooth in hand feeling and suitable for manufacturing high-grade clothing.

Owner:苏州优布纺织科技有限公司

Ultraviolet-preventing antibacterial fabric and preparation technology thereof

ActiveCN103255538AImproves UV protectionImprove breathabilityFibre treatmentWoven fabricsCarbon fibersAnti bacterial

Ultraviolet-preventing antibacterial fabric comprises, by weight percentage, 10-15% of adhesive anion functional fibers, 10-15% of soybean protein fibers, 20-30% of bast fibers, 5-10% of wool fibers, 5-10% of nanometer bamboo carbon fibers, 10-15% of chitin fibers, 2-5% of nano-silver-ion fibers, 4-6% of ultraviolet-preventing finishing agents, and 2-4% of mosquito-repellent finishing agents. The ultraviolet prevention performance and air permeability of the fabric are improved, and meanwhile the fabric has effects of preventing bacteria and repelling mosquitoes. The fabric is good in application effect in home textiles, sanitary products, sports goods, health care, bacteria prevention and mosquito repellent.

Owner:广州市缔造亿百儿童用品有限公司

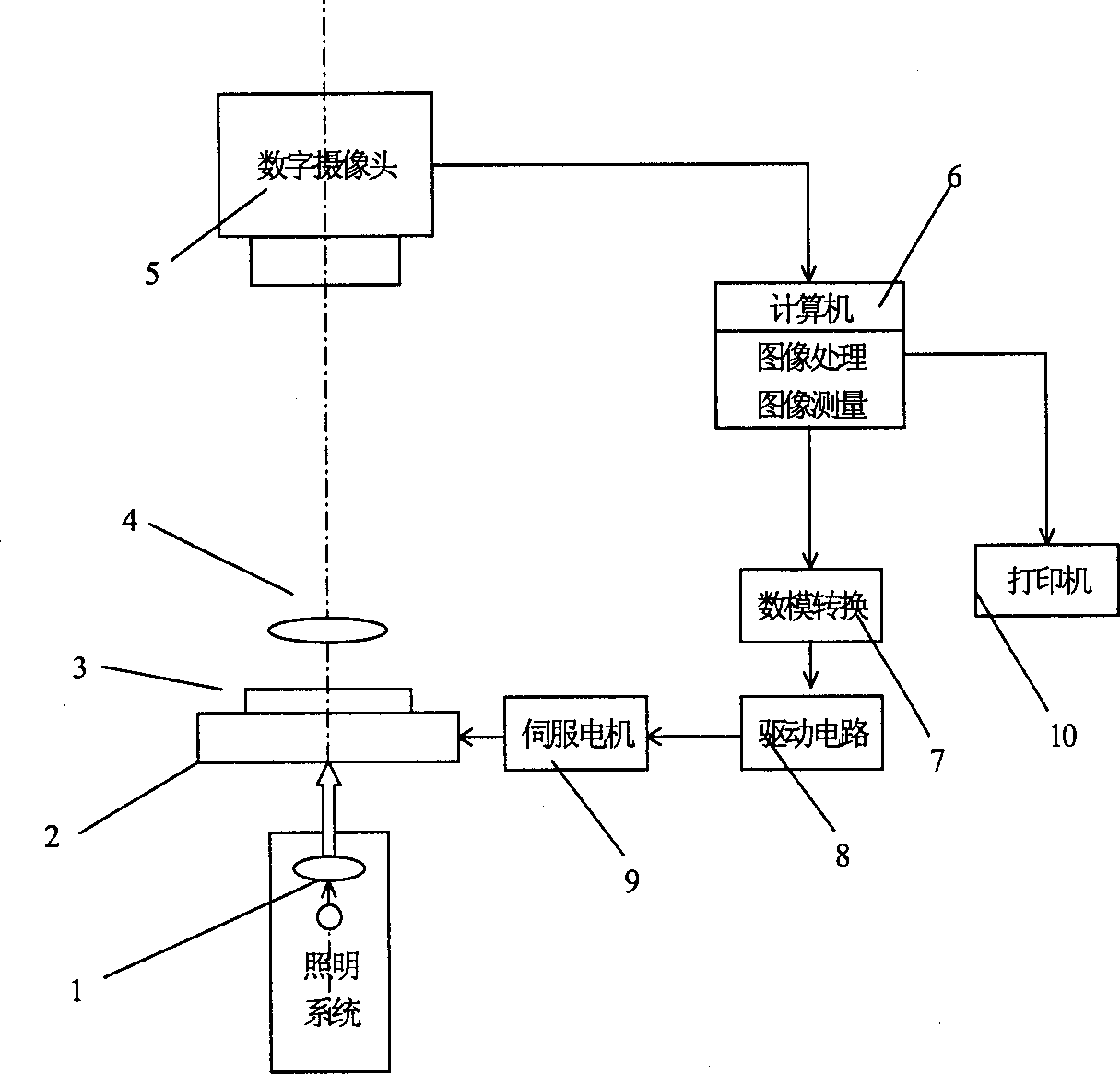

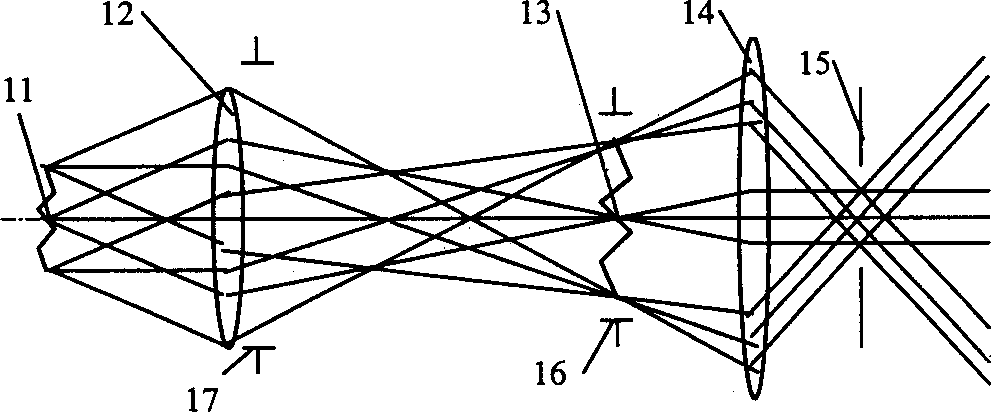

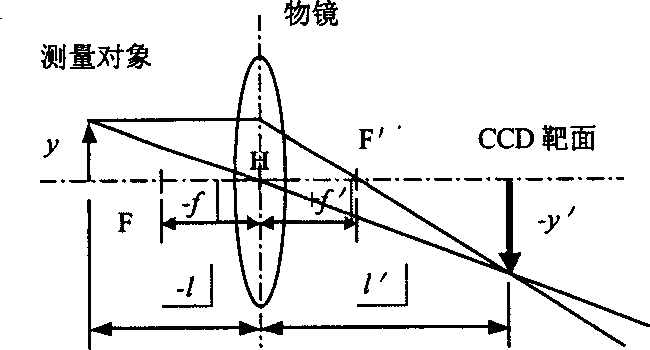

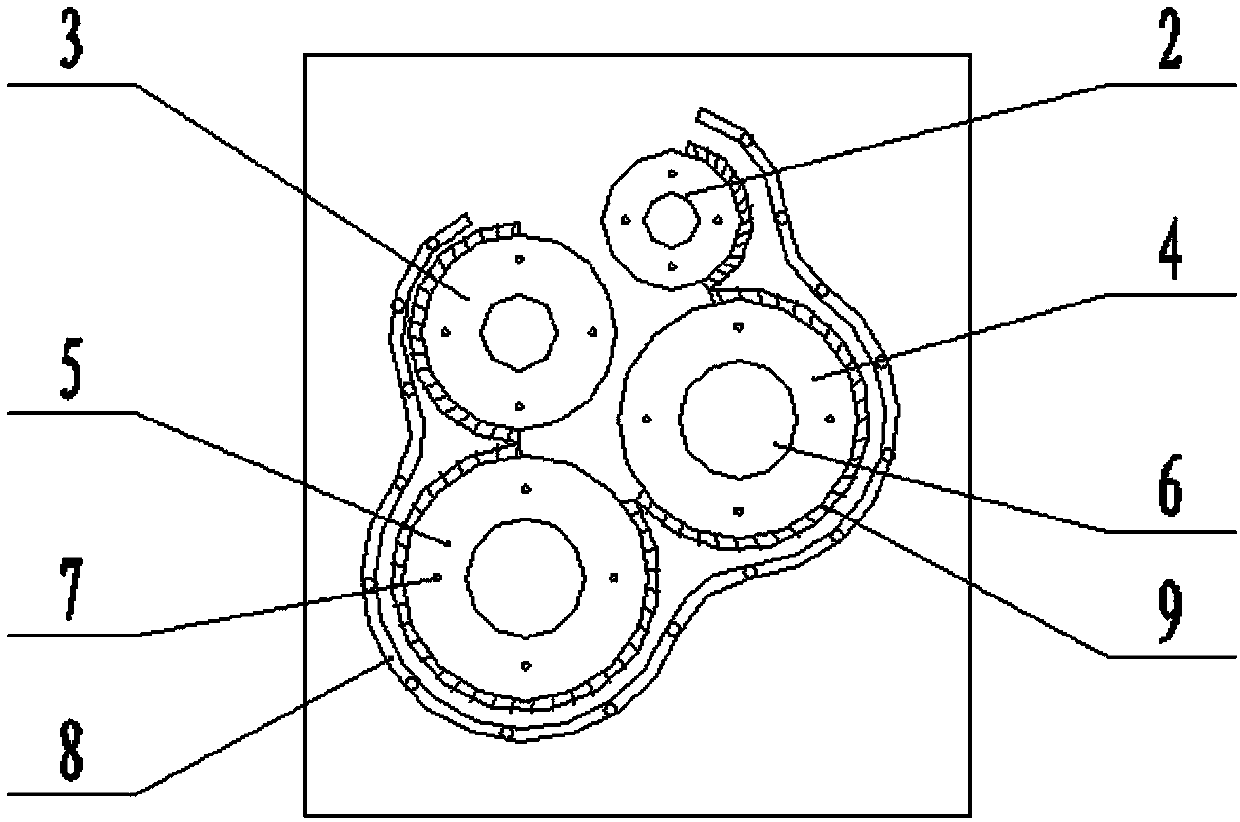

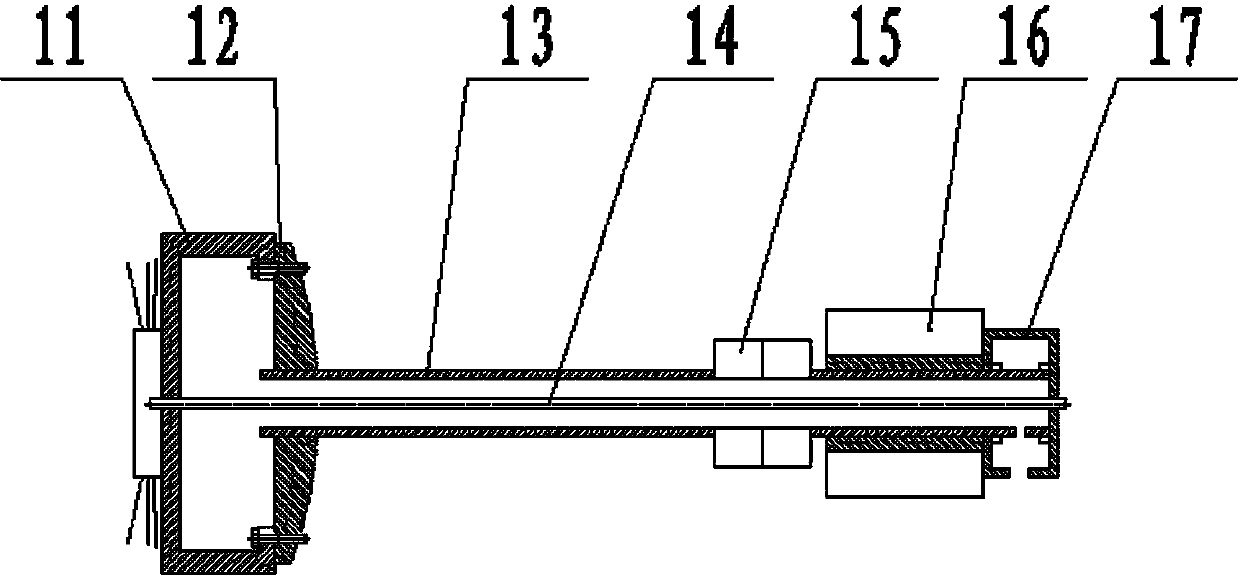

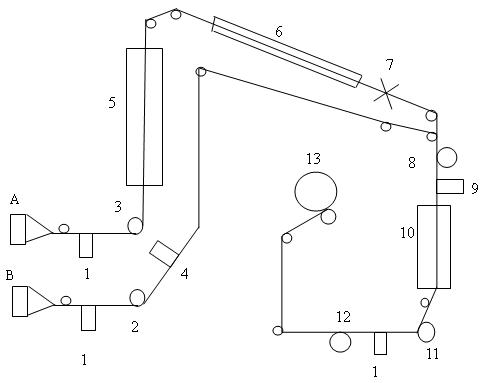

Method and system for measuring wool fiber fineness measurement

InactiveCN1359006AMany measurement parametersReliable resultsMaterial analysis by optical meansContinuous measurementSingle fibre

The present invention relates to a method for measuring wool fibre fineness and its system. Digital camera head (CCD) is adopted to convert the amplified fibre image into digital image, and transfer it into computer to mare real time processing to obtain fibre outline and calculate single fibre fineness, then it counts up the data of average fineness and fineness distribution of all the measured fibres. In said ivnention, general light source is used and the proper alogirhtm and software are designed with can measure animal fibre with the measurement range of 4-300 micrometers, and its measurement speed is 140 fibre / sec.

Owner:TSINGHUA UNIV

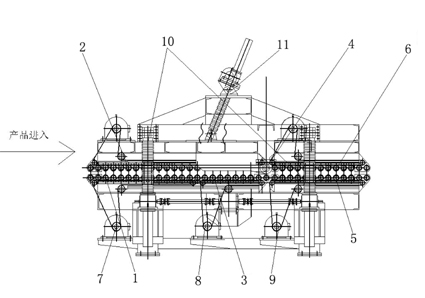

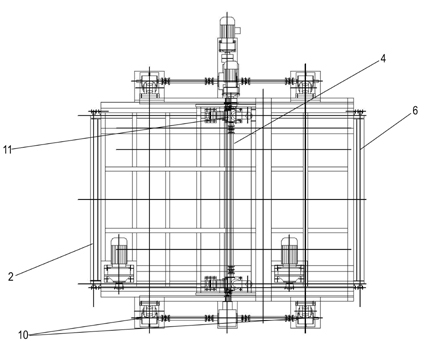

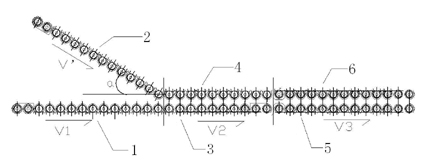

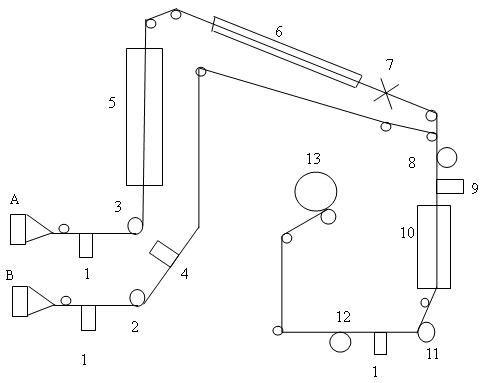

Rock wool pleating machine and pleating method thereof

The invention relates to a rock wool pleating machine and a pleating method thereof. The pleating machine comprises three groups of upper and lower compression rollers, driving devices of the compression rollers, a device for adjusting intervals between the upper compression rollers and the lower compression rollers, and a first group of upper compression roller tensioning device, wherein the first group, the second group and the third group of compression rollers are connected in sequence and independently driven. The pleating method comprises the following steps of: spreading rock wool fibers, the surface of which are sprayed with adhesives, into multilayer rock wool which is evenly distributed in density through a pendulum bob machine, feeding the multilayer rock wool into the pleating machine, and adjusting the angle of an dip angle of the first group of upper compression roller of the pleating machine and the difference value of the transmission speeds of the first group of upper compression roller and the second group of lower compression roller of the pleating machine to form a forming fold; subsequently feeding the rock wool subjected to first pleating to the third group, and enabling the rock wool to generate a second differential folding structure by adjusting the transmission speed difference of the third group and the second group of compression rollers; feeding pleated rock wool into a curing furnace, carrying out high-temperature curing and pressing into a rock wool product. In the invention, the high-temperature rock wool product with the pleating coefficient not less than 1: 3 is made, the compression strength of the rock wool product in the 10% deformation amount can reach 40-100KPa, and the perpendicular tensile strength thereof can reach 10-20KPa.

Owner:NANCHANG UNIV +1

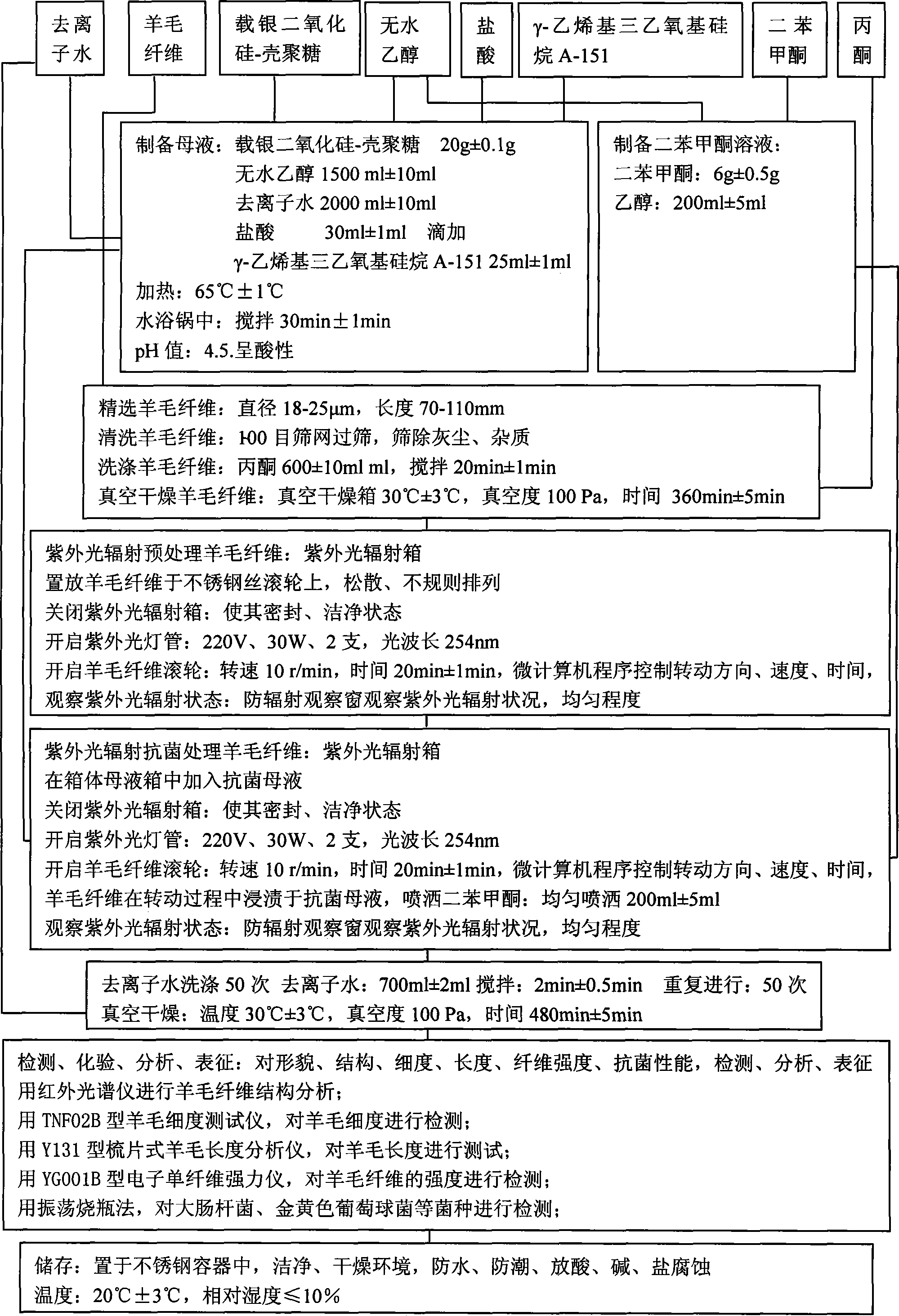

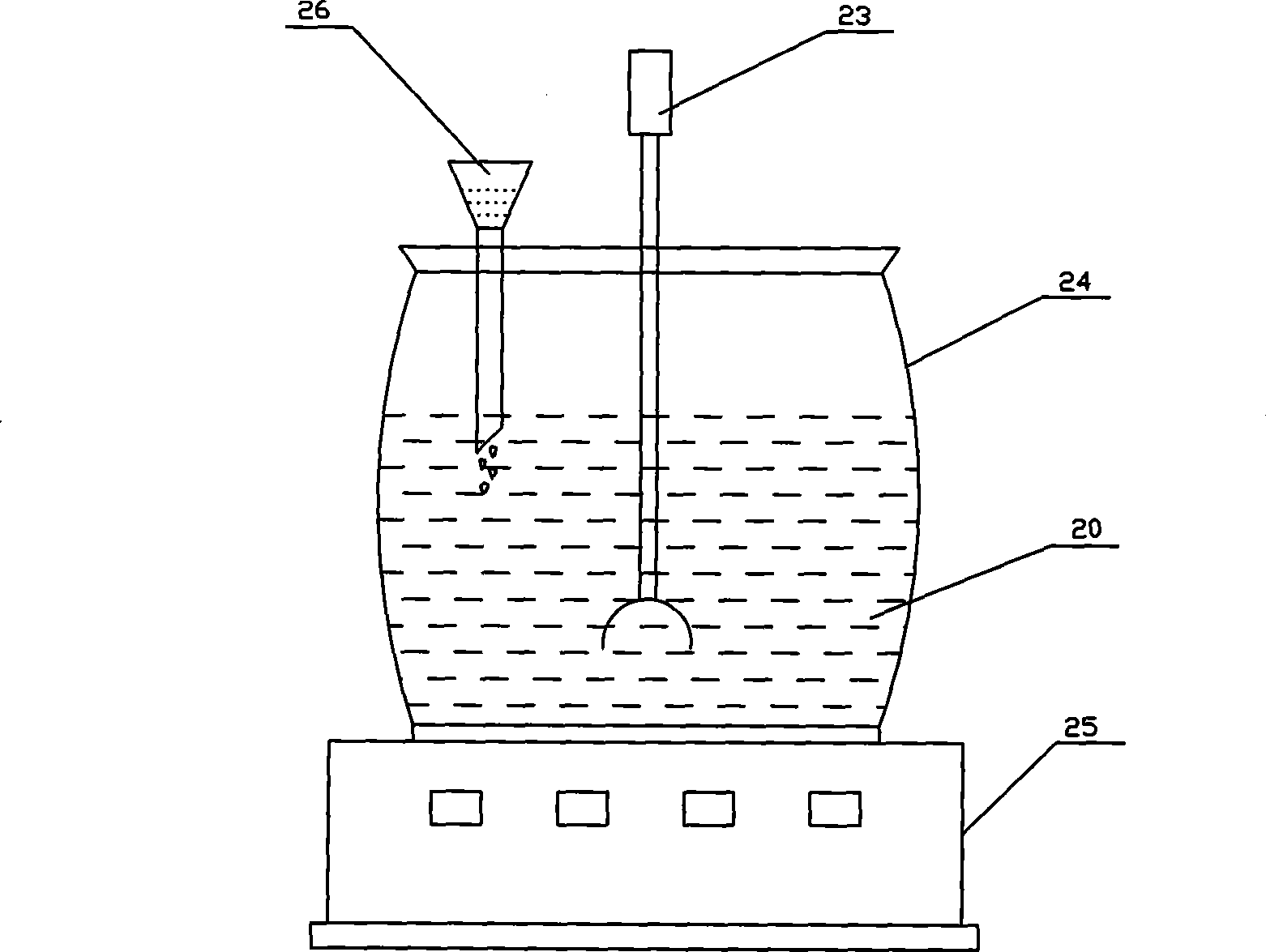

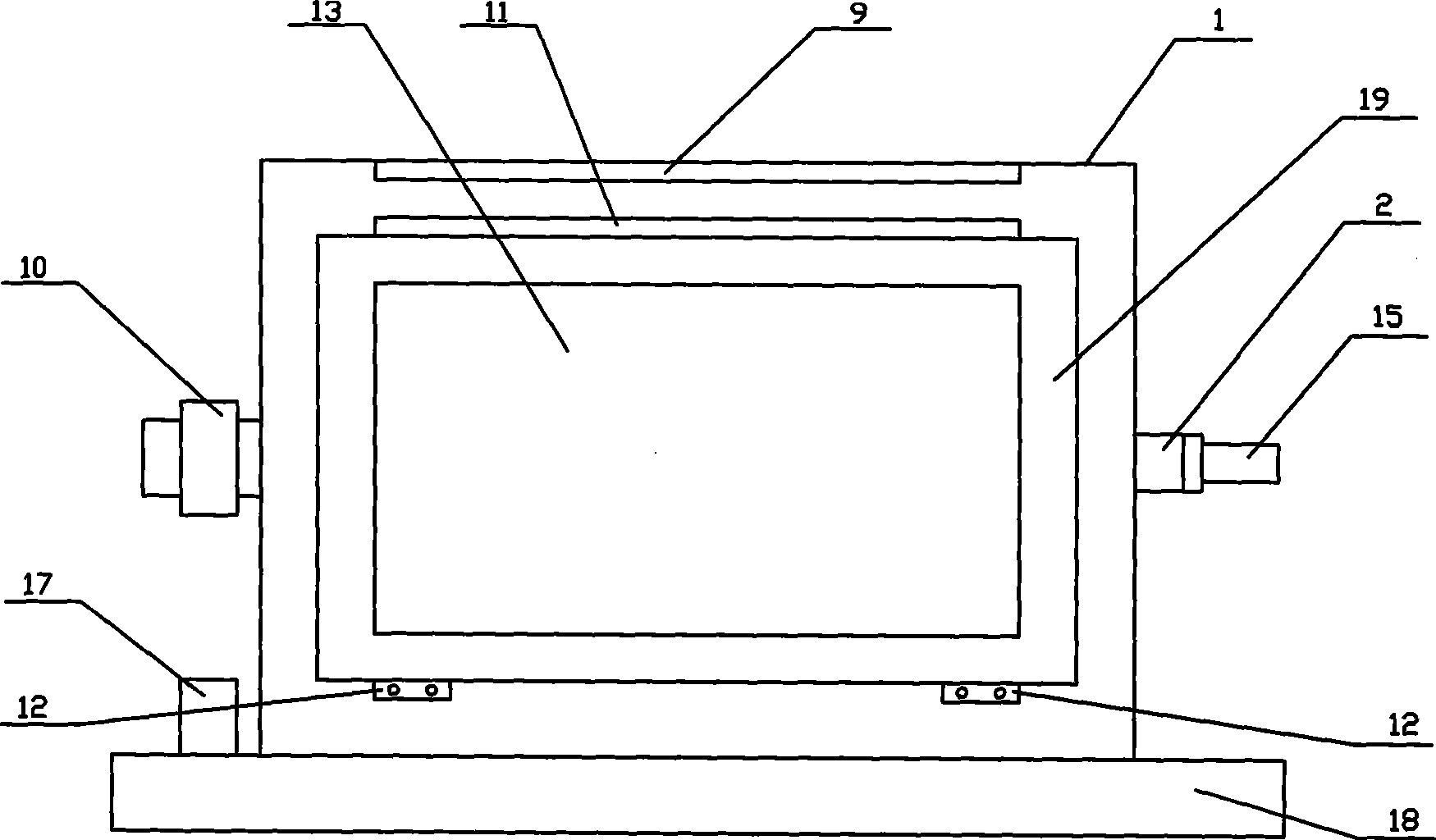

Antibacterial processing method for wool fiber

InactiveCN101413208AImprove durabilityEasy to manufacturePhysical treatmentAnimal fibresPre irradiationChemical reaction

The invention relates to an antibacterial treatment method for wool fiber, which comprises the following steps: an organic-inorganic composite antibacterial agent, namely silver-bearing silicon dioxide-chitosan is taken as an antibacterial agent and prepared into a pentabasic antibacterial mother liquor with anhydrous alcohol, deionized water, a diluted hydrochloric acid, a dispering / coupling agent and gamma-vinyltriethoxysilane A-151; the wool fiber is subjected to pre-irradiation of the ultraviolet light, and then immersed into the antibacterial mother liquor for secondary irradiation; and the wool fiber and the silver-bearing silicon dioxide-chitosan composite antibacterial agent generate chemical reaction under the action of a light trigger benzophenone and are combined by means of valence linkage to form an antibacterial film with the thickness of 200 nanometers. The antibacterial treatment method improves the persistence of antibacterial functions of the wool fiber, and the antibacterial rate of the wool fiber is still 98.6 percent after being washed for 50 times. Moreover, the antibacterial treatment method has short process flow, small number of equipment used, quick antibacterial speed, high efficiency and good effect, is easy to prepare the mother liquor, is particularly suitable for performing antibacterial treatment on the wool fiber and pashm fiber, and improves the efficiency by 90 percent compared with the prior antibacterial technology.

Owner:TAIYUAN UNIV OF TECH

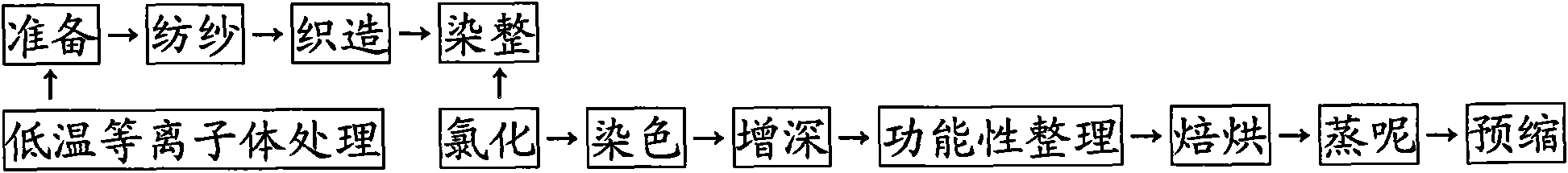

Piecedyed jet black fine-spun facing and preparation method thereof

InactiveCN101671950AImprove hydrophilicityImprove dye uptakePhysical treatmentDyeing processTextile technologyNatural fiber

The invention discloses a piecedyed jet black fine-spun facing and a preparation method thereof, and relates to the technical field of wool spinning. Raw fiber used comprises natural wool fiber. The preparation method comprises steps of preparation, spinning, weaving, dyeing, finishing and the like. The method is characterized in that the raw fiber used further comprises wool natural fiber, and non-wool natural fiber or / and chemical fiber blended spinning material. The preparation method comprises a step of wool top chlorination treatment in the preparation step, or fabric chlorination treatment in the step of dyeing and finishing, further comprises steps of low-temperature plasma treatment in the steps of preparation, spinning or dyeing and finishing to generate obvious dyed color to enhance effect, so even jet black wool and blended-spun and fine-spun facing without dyeing defect can be obtained. Detection by a computer color photometer shows that blackness of the facing is deep, L value is up to 3.5-9.5, chromatic aberration between pieces is small, and delta E is equal to or less than 0.5. No expensive piece goods treating machine is needed, and the method has the advantages oflow cost, simple process and stable quality.

Owner:JIANGSU DANMAO TEXTILE

Method for protease-method wool felt-proofing treatment by using ultrasonic technology

InactiveCN103924439AHelps catalyze hydrolysisReduce processing timeBiochemical fibre treatmentUltrasonic/sonic fibre treatmentEngineeringUltrasonic technology

The invention discloses a method for protease-method wool felt-proofing treatment by using an ultrasonic technology, belongs to the application technical filed of wool fabric dyeing and finishing in the wool manufacturing industry and aims at solving the problems that the treating time is long, the felt-proofing rate is high and the fiber damage is large in a single protease method so as to realize the effect of optimizing wool fiber / wool top / wool fabric biological enzyme-method felt-proofing finishing. The felt proofing can be performed on wool under an ultrasonic condition, the protease catalytic hydrolysis speed is increased, the shedding off of a wool scale layer is accelerated, the protease method treating time is shortened, and the degradation of the protease to the inferiors of fibers is reduced. The synergistic effect of ultrasonic waves and the protease can replace a conventional chlorination method or single protease method felt-proofing method, so that the felt-proofing performance of wool fabrics is improved.

Owner:JIANGNAN UNIV

Multifunctional thermal underwear fabric and processing method thereof

InactiveCN102312342AFunction increaseGood warmth retentionWeft knittingFibre treatmentPolyesterTextile technology

The invention relates to a multifunctional thermal underwear fabric and a processing method thereof, belonging to the field of textile technology. The multifunctional thermal underwear fabric comprises a face weave and a bottom weave, wherein the face weave consists of cotton fibers, polyester fibers, spandex fibers, bamboo charcoal fibers, viscose fibers, wool fibers and plant protein fibers; and the bottom weave consists of polyester fibers. The content of the cotton fibers accounts for 34-60 percent of the total components, the content of the polyester fibers accounts for 26-39 percent of the total components, the content of the spandex fibers accounts for 5-6 percent of the total components, the content of the bamboo charcoal fibers accounts for 0.5-6 percent of the total components, the content of the viscose fibers accounts for 1-17 percent of the total components, the content of the wool fibers accounts for 1-5 percent of the total components, and the content of the plant protein fibers accounts for 0.5-7 percent of the total components. The multifunctional thermal underwear fabric has the advantages that the functions of the fabric are expanded by guaranteeing an excellent warmth keeping performance through the cotton fibers, by guaranteeing ideal elasticity through the spandex fibers, by reflecting a good moisture absorbing performance and air permeability through the polyester fibers and by reflecting a good antibiotic property through the bamboo charcoal fibers; and since function processing, baking and secondary ironing processes are increased, the fabric has an aromatic long-lasting effect.

Owner:CHANGSHU MENGXI FURNISHINGS

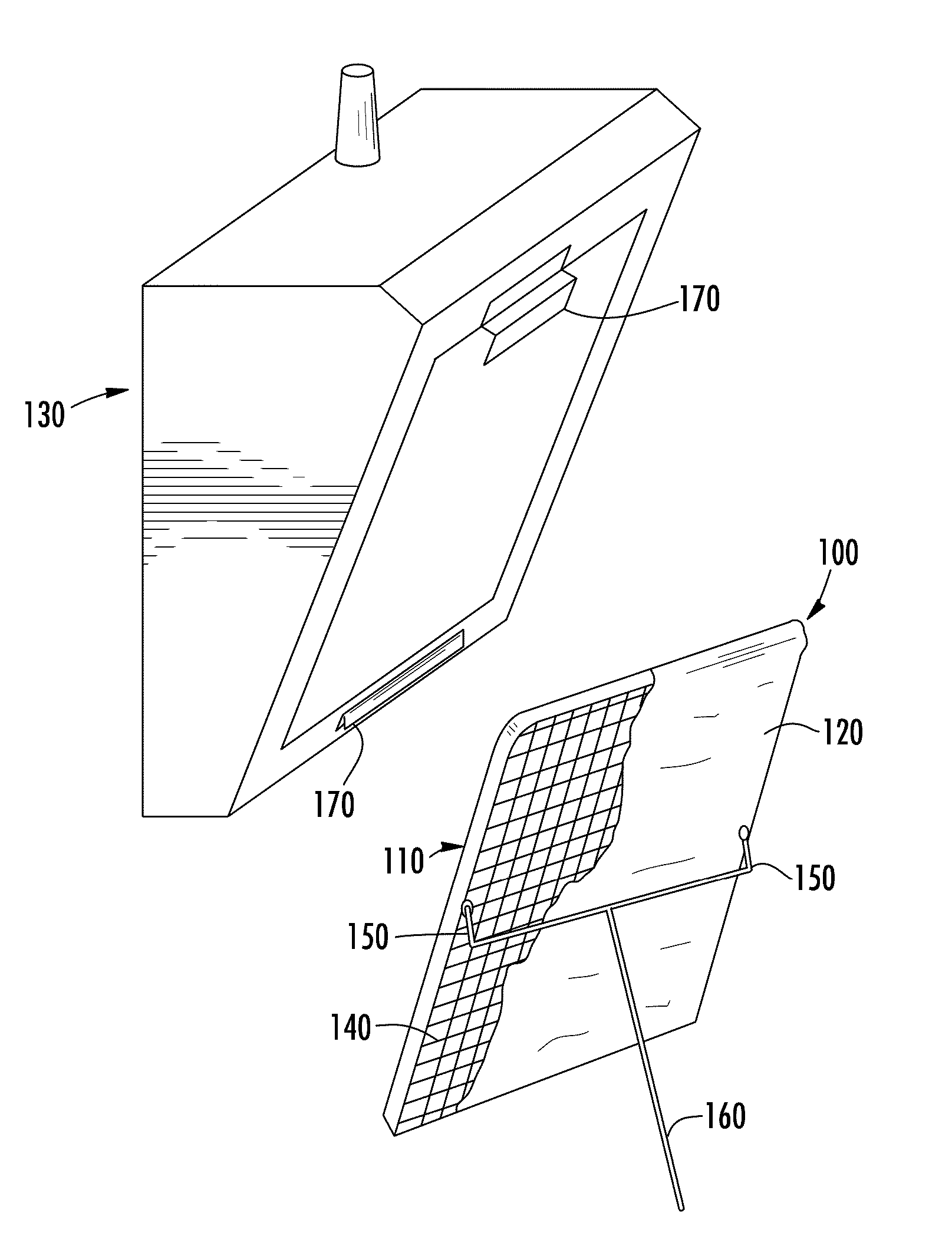

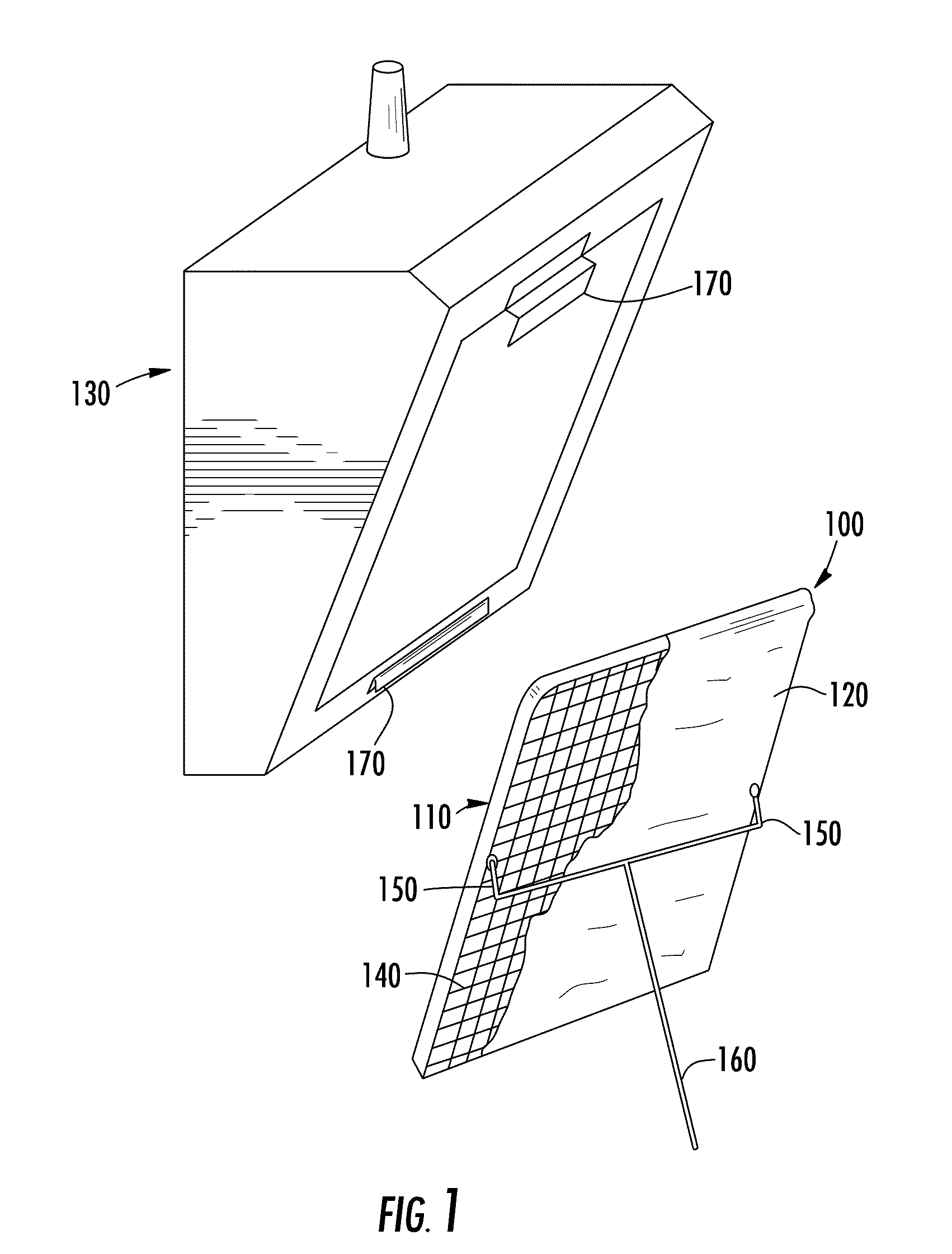

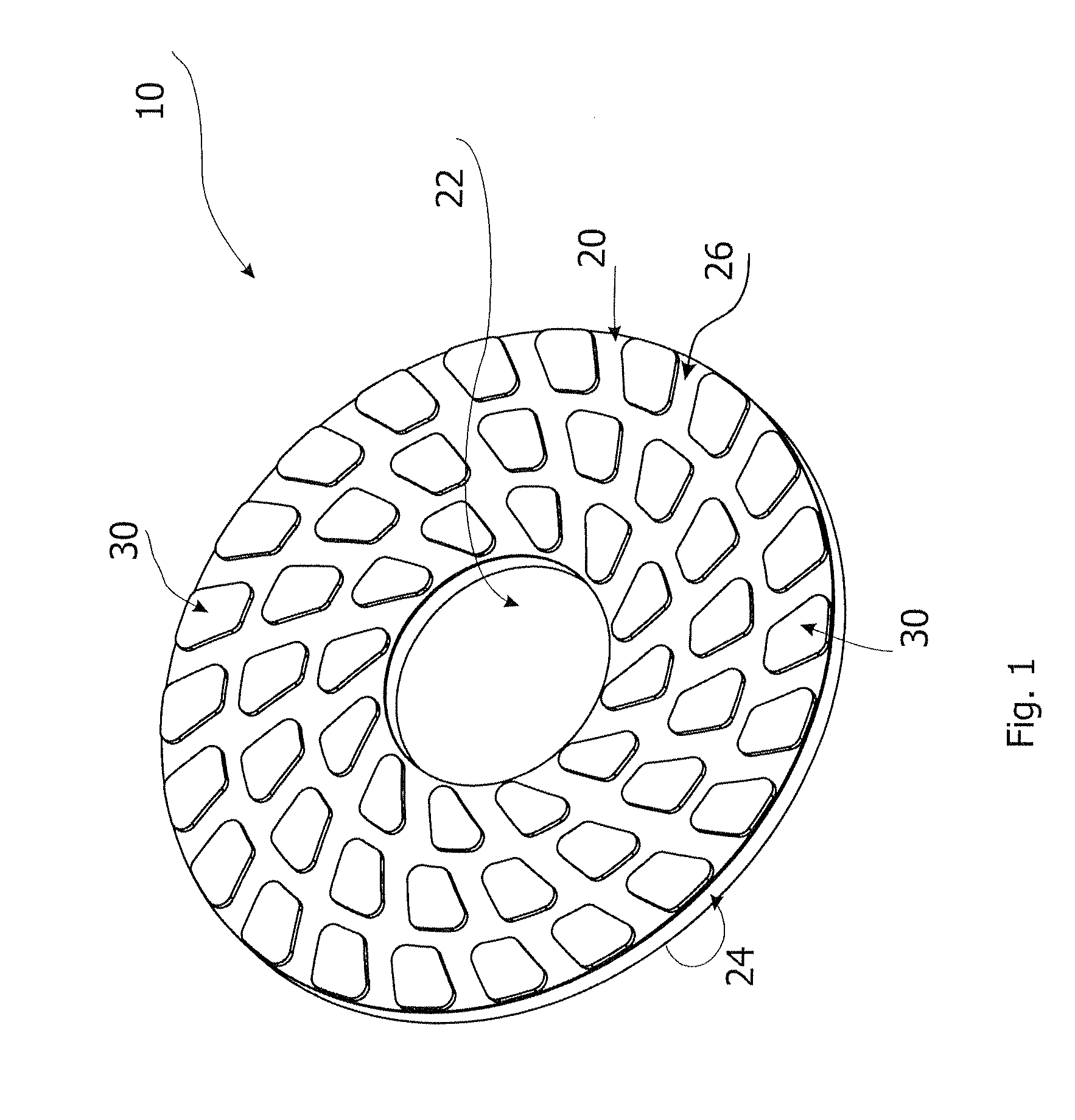

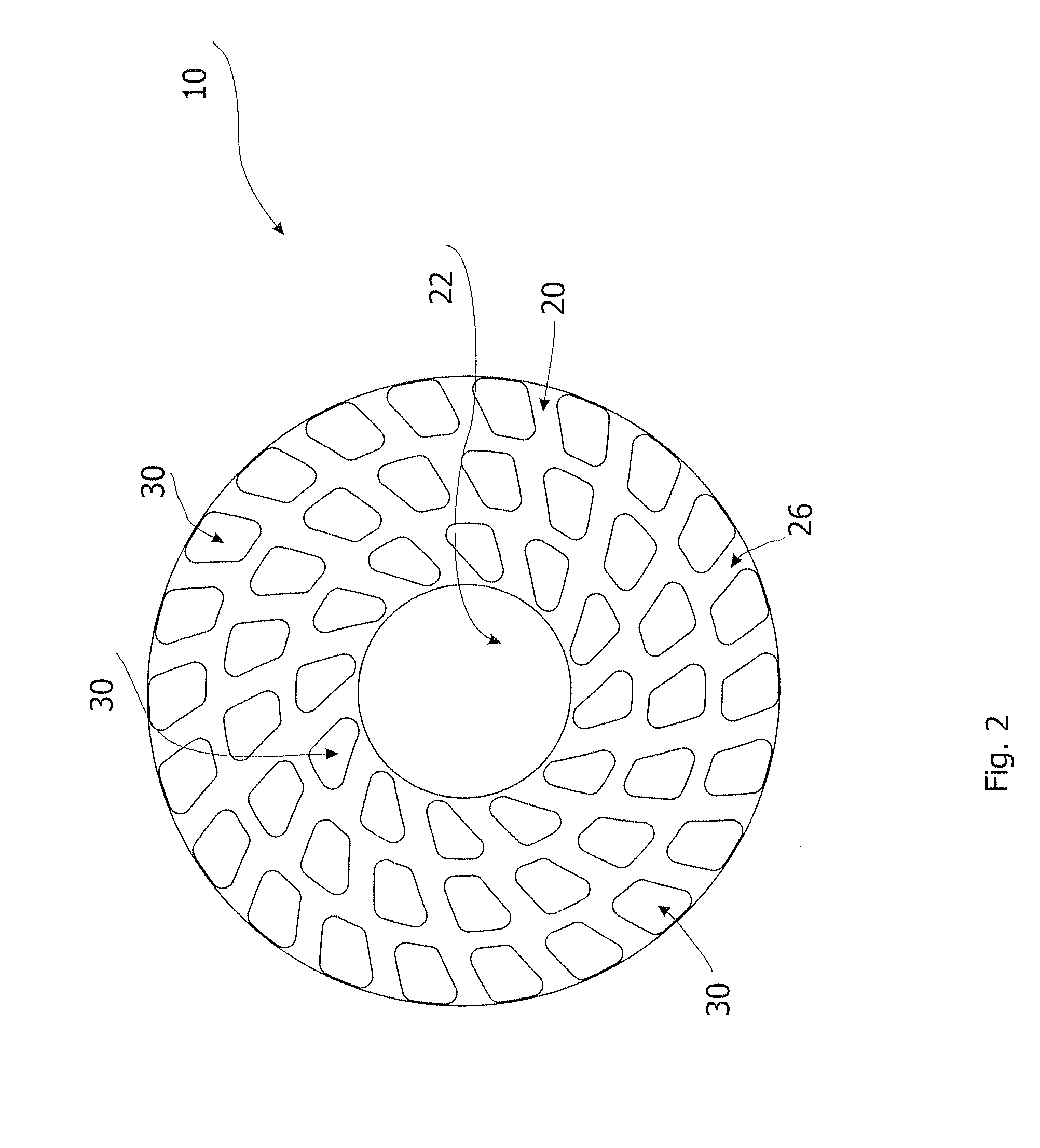

Disposable grease filter for air filtration system and method of manufacturing same

ActiveUS20070245703A1Prevent grease buildCombination devicesDomestic stoves or rangesAir filtrationGram

An all natural filter assembly without toxic materials for use in an air filtration unit is provided. The filter assembly for use in an air filtration unit includes a support frame and a disposable grease filter disposed across said support frame. The disposable grease filter is formed of wool fiber coated with a bonding agent comprising a natural soy, whey and / or linseed solution. Also provided is a disposable grease filter blanket, which includes a wool fiber woven, non-woven or needle punched blanket coated with a bonding agent of a natural soy, whey and / or linseed solution. The filter blanket can be coated with approximately 0.3 grams to 2.0 grams of bonding agent per square meter of wool fiber.

Owner:GEMCHAR

Biological protein hair fiber preparation method by dissolving animal hair and cellulose material mixture

InactiveCN1884642AReduce lossesReduce direct lossesConjugated cellulose/protein artificial filamentsCelluloseAdjuvant

The invention discloses a biological protein wool fiber preparing method, which comprises the following steps: blending animal fur and fiber to produce soluble liquid in the ion liquid with positive and negative ion of fusing condition at 100 deg.c and positive ion to form salt; solidifying in the water, carbinol, alcohol, cyanoethyl or (NH4)2SO4 solution; adding adjuvant in the soluble liquid; solidifying in the water, carbinol, alcohol, cyanoethyl or 30 percent (NH4)2SO4 solution; evolving biological protein fur fiber.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Flame-retardant protective clothing fabric

The invention provides flame-retardant protective clothing fabric, and relates to textiles, in particular to the flame-retardant protective clothing fabric. The flame-retardant protective clothing fabric is formed by weaving flame-retardant yarn comprising the following fibers by total weight: 50 to 60 percent of wool fiber, 15 to 30 percent of polyphenyl thioether fiber and 10 to 35 percent of flame-retardant viscose fiber. The flame-retardant protective clothing fabric is light, safe, and favorable in mechanical property, chemical stability and temperature resistance; and the working safety of a person wearing the flame-retardant protective clothing fabric is improved. The flame-retardant protective clothing fabric is high in strength, tearing resistance, stretching resistance and friction resistance, not only has permanent flame retardancy, but also can effectively prevent splashing of molten metal liquid drops, is high-temperature resistant, and can keep the integrity, the wearing comfort and the like of clothes.

Owner:JIANGSU TANGWEAR IND

Direct linkage type four-roller centrifuging machine for producing rock wool

ActiveCN103787574AAchieve direct connectionReasonable structureGlass making apparatusCouplingEvaporation

The invention relates to rock wool fiber forming equipment and particularly relates to a direct linkage type four-roller centrifuging machine for producing rock wool. The direct linkage type four-roller centrifuging machine comprises four roller bodies, motors and glue spraying devices, wherein each roller body comprises a roller head, a rotary shaft and an evaporation opening; the rotary shafts are connected with the motors by virtue of couplers; the rotary shafts are hollow shafts and are sleeved at the outer sides of cooling water pipes; the cooling water pipes are sleeved at the outer sides of glue spraying pipes; the front ends of the cooling water pipes are communicated with the roller heads; the front parts of the glue spraying pipes are stretched out of the front ends from the centers of the roller heads so as to be provided with glue spraying discs; the rear ends of the glue spraying pipes are stretched out of the cooling water pipes so as to be connected with a resin hose; the couplers and the motors are hollow; the couplers and the motors are sleeved at the outer sides of the rear parts of the cooling water pipes; air rings are arranged on the outer sides of the four roller bodies; edge spraying devices are arranged on the outer sides of the air rings; the edge spraying devices are in an integral structure. The direct linkage type four-roller centrifuging machine for producing the rock wool has the characteristics of capability of directly driving the roller bodies to rotate by virtue of the motors, small volume, high yield and stability in transmission.

Owner:TAISHI ROCK WOOL

Method for manufacturing micro-hollow and micro-bubble rock wool by using basalt as a main ingredient and product of the method

InactiveCN102757178AImprove toughnessImprove thermal insulationGlass making apparatusCentrifugationHigh pressure

The invention relates to a method for manufacturing a micro-hollow and micro-bubble rock wool by using basalt as a main ingredient and a product of the method. The method comprises the following steps of: 1, firing; 2, preparation of materials: pulverizing basalt, dolomite or limestone (which serves as a fluxing agent) to be a lump material with the diameter being 3-10CM, pulverizing fluorite andsilica (which serve as regulators) to be a lump material with the diameter being 0.5-2CM, processing combustion-supporting carbon to be a lump material with the grain diameter being 5-15Cm, and preparing the materials according to the weight proportion of 60-85 percent of basalt, 10-28 percent of dolomite or 10-28 percent of limestone, 5-15 percent of fluorite and 0-10 percent of silica and according to the volume ratio that aggregated rocks to combustion-supporting carbon is 4.5-6 to 3-4; 3, charging: charging the prepared combustion-supporting carbon and the prepared aggregated rocks in sequence into a smelting furnace according to a laminated circular charging way until the furnace is filled up; 4, smelting: smelting the basalt, the regulator and the aggregated rocks serving as combustion-supporting agents to form smelted streams; and 5, fiber-making: performing high speed centrifugation on the smelted streams, continuously air-blowing the smelted streams at high pressure and cooling to prepare a rock wool fiber having a micro-hollow and micro-bubble structure. By the method, the defect of technology prejudice is overcome, the method is simple in process and low in cost, and the product has high quality.

Owner:牡丹江超越新材料科技有限公司

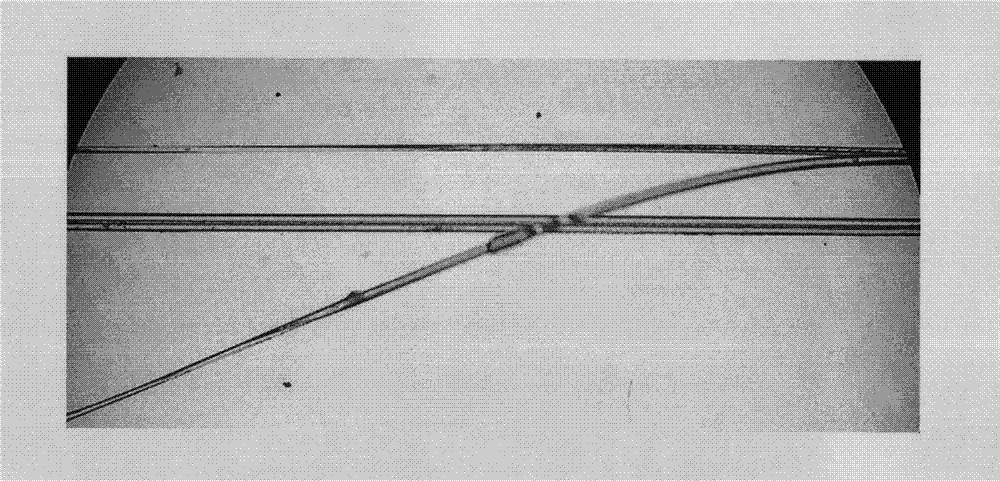

Fibrous pad for cleaning/polishing floors

InactiveUS20090053982A1Easy to placeEconomical to useFlexible-parts wheelsPlane surface grinding machinesMechanical engineeringWool fiber

A cleaning / polishing pad for cleaning or polishing stone, terrazzo or concrete floors comprises a flexible, disk-shaped pad body having an upper mounting surface and a lower working surface, the pad body comprising natural wool fibers. A plurality of resin segments spaced apart from one another and affixed adjacent the lower working surface of the disk-shaped pad body, the resin segments including diamond particles embedded therein, wherein each of the plurality of resin segments is affixed to the pad body in such a way that the majority of the resin segment stands proud of the pad body.

Owner:POPOV GEORGI M

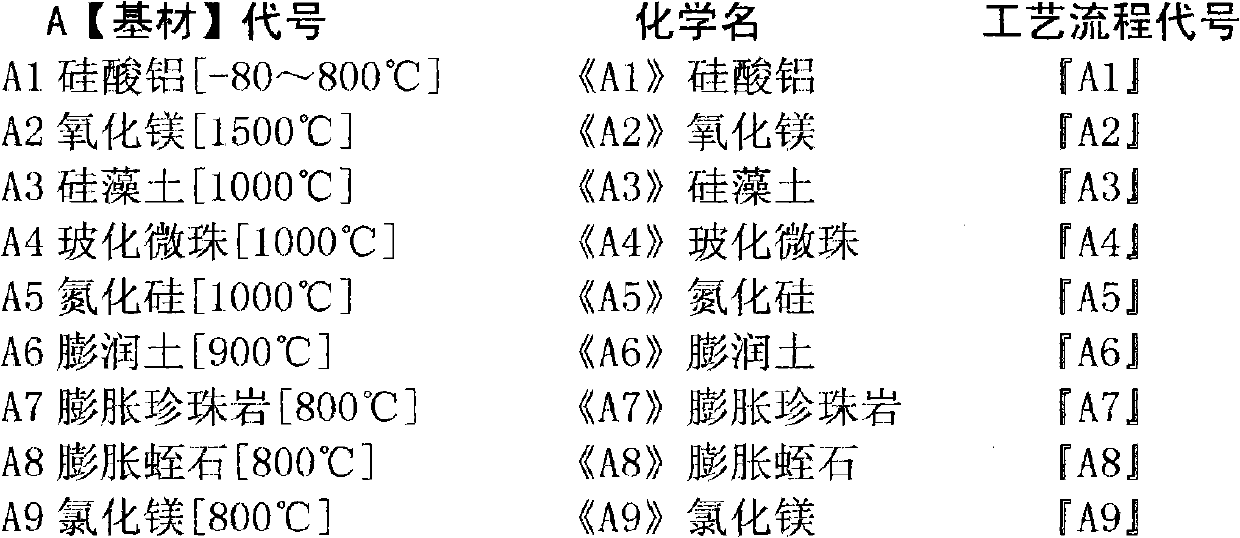

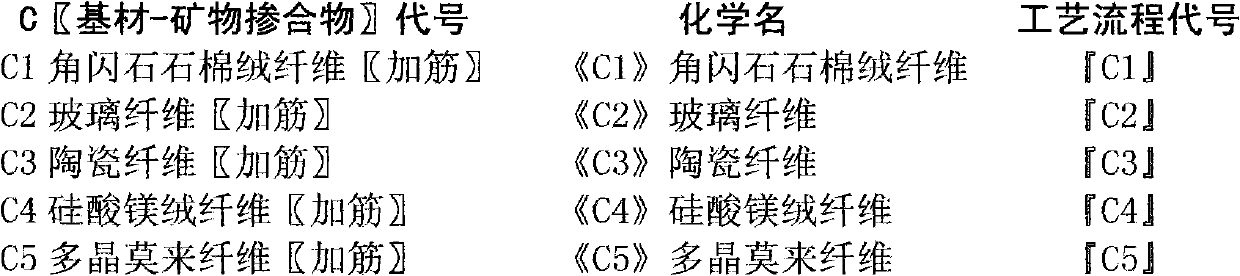

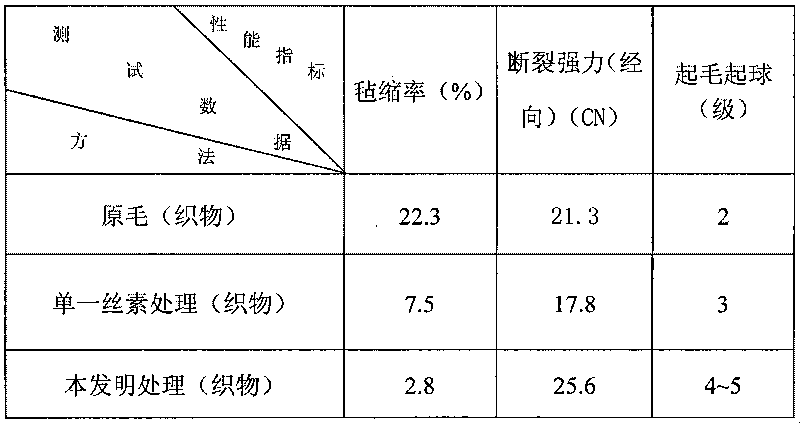

Innovative flame-retardant, water-proof, mildew-proof and radiation-proof insulating mortar and product

The invention discloses innovative flame-retardant, water-proof, mildew-proof and radiation-proof insulating mortar and products, which comprise nine base materials resisting the temperature of 80 DEG C below zero to 1,000 DEG C, i.e., aluminum silicate, magnesium oxide [1,500 DEG C], diatomite [1,000 DEG C], vitrified micro bubbles [1,000 DEG C], silicon nitride [1,000 DEG C], bentonite [900 DEG C], expanded perlite [800 DEG C], expanded vermiculite [800 DEG C] and magnesium chloride [800 DEG C], two mineral admixtures, five reinforcements, i.e., amphibole asbestos wool fiber, glass fiber, ceramic fiber, magnesium silicate wool fiber and polycrystalline mullite fiber and 14 base material-additives of different functions, i.e., a fire-proof material, a water-proof agent, an anti-radiation agent, an anti-mildew agent, an adhesive, an anti-freezing agent, a thixotropic agent, a curing agent, a brightening agent, an early strength agent, a foaming agent, an expanding agent and a masking agent, wherein nine kinds of low-carbon fire-proof insulating mortar which are used in different environments are developed through an innovative technical formula and are used for coating interior and exterior walls and manufacturing an insulating material for various plates, pipes and irregularly-shaped products; and the innovative flame-retardant, water-proof, mildew-proof and radiation-proof insulating mortar and product are national initiative environment-friendly low-carbon and fire-proof insulating mortar and product.

Owner:于斌 +2

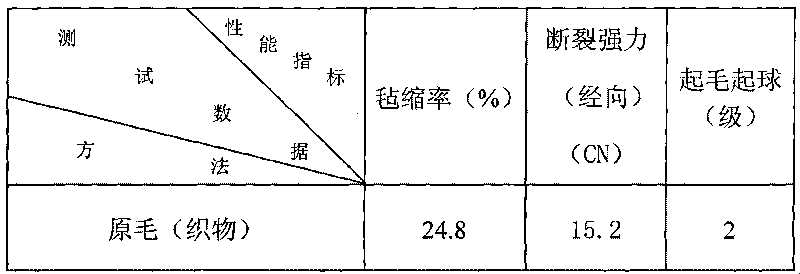

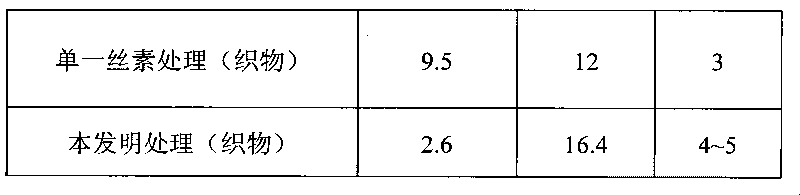

Ecological anti-felting finishing method for wools

InactiveCN101725045AImproves felting resistanceNo residueAnimal fibresHazardous substanceEngineering

The invention discloses an ecological anti-felting finishing method for wools. The pretreatment adopts hydrogen peroxide pretreatment; and by padding the wools into mixed finishing solution of fibroin finishing agent SP1 and chitosan with certain concentration, the anti-felting rate of the treated wool fabrics is less than 3 percent, the strength is increased by about 6 percent, the whiteness is changed little, the air permeability of the wool fabrics is superior to that of the primary fabrics, the elongation at break is reduced, the water absorption is increased, the handfeel is soft, the anti-pilling property of the wool fibers is improved by 2 to 3 levels, and the wool fabrics can fully meet the requirement of machine wash. The method comprehensively adopts the environment-friendly finishing agent to perform anti-felting finishing for the wools, has no residues of harmful substances, does not cause environment pollution, simplifies the treatment process, shortens the process flow, has shorter period, and improves the feasibility of industrialized operation.

Owner:SHAANXI UNIV OF SCI & TECH

High elastic wool-like fabric and production method thereof

The invention discloses a high-elasticity wool-like fabric and a method for producing the same. The method comprises the following steps: selecting two yarns with different fiber components and different blending ratios; using a folded yarn of a yarn A interlacing with a yarn B as a First warp to form a warp yarn arrangement First; using the folded yarn of the yarn A interlacing with the yarn B as a Fist weft to form a weft yarn arrangement First, wherein the fabric comprises two upper twill structures and two lower twill structures. A drafting method adopts pathwise penetration of four pieces or pathwise penetration of eight pieces, wherein the portie is between No.10 and No.11, the penetration is 2 heddles per reed, and the width of the fabric on a machine is 205 centimeters. Through dyeing the same color on an anode dyeable terylene and a viscose staple fiber, the elastic property of wool fiber and PTT fiber can be embodied sufficiently. Through the selection of a yarn combination with different fiber components, and according to selecting the prior product process flow, the produced bamboo joint color wool-like fabric has the advantages of abundant colors, gentle color and luster, and strong woolly handfeel.

Owner:富丽达集团控股有限公司

Preparation method of novel wool-like differential fibers

The invention discloses a preparation method of novel wool-like differential fibers, which is characterized by comprising the following steps of: 1) adopting polytrimethylene terephthalate (PTT) as a raw material to prepare a pre-oriented yarn (a); 2) adopting modified high-shrinkage polyester as a raw material to prepare fully-drawn high boiling water shrinkage fibers (b); and 3) on a DTY machine, passing the pre-oriented yarn (a) through a roller, a hot box and a cooling plate, performing drawing false twisting on the pre-oriented yarn on a false twister, converging the pre-oriented yarn with the high boiling water shrinkage fibers (b) in front of two rollers, and performing network compounding on the pre-oriented yarn and the high boiling water shrinkage fibers, and then passing the pre-oriented yarn and the high boiling water shrinkage fibers through two hot boxes to obtain a composite yarn product. The preparation method develops the novel wool-like differential fibers, the PTT fibers floating on the surface layer are much closer to wool fibers in performance and are superior to common wool-like products in the performance of elastic recovery, handfeel, antistatic property, dyeing and the like, and simultaneously, the treatment of forming different sections of the two raw materials ensures that the products have significant improvements on luster and fibrillation resistance.

Owner:嘉兴逸鹏化纤有限公司

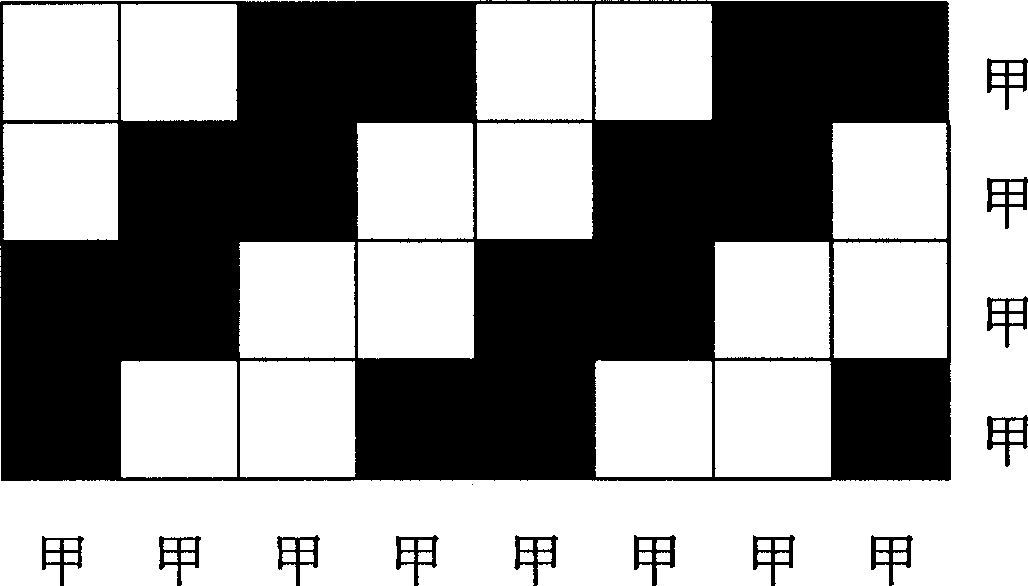

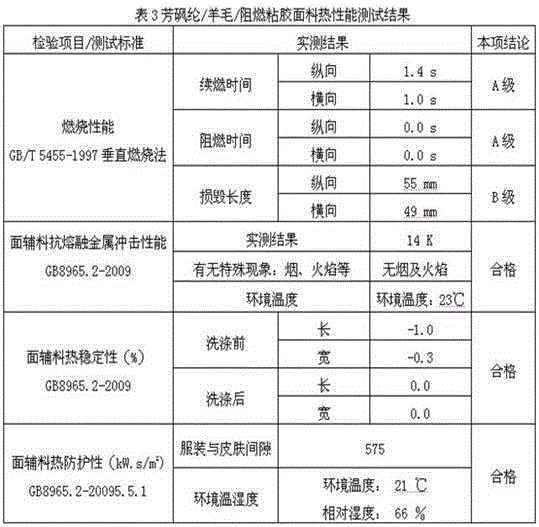

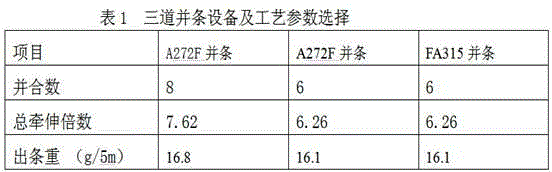

Fabrics for electric welding protective clothing and processing method thereof

InactiveCN102747504AImprove wearing comfortReduce riskWoven fabricsProtective garmentYarnPolymer science

The invention provides polysulfonamide fiber / wool fiber / flame-retarding viscose blended fabric for electric welding protective clothing and a processing method thereof. Blended yarn is designed and developed according to a semi-fine-spinning route. The processing method comprises the steps of wool blending, cotton carding, drawing, roving, spinning, stranding, weaving, cleaning, drying, brushing, shearing, softening and decating. The linear density of the yarn is 50Nm / 2, theblending ratio among the polysulfonamide fiber / wool fiber / flame-retarding viscose is 50 / 30 / 20, and spinnability of the blended yarn is improved by means of high moisture absorption and good crimpiness of the wool fiber. 2 / 1 twill weave is adopted in the fabric, warp density of a finished product is 330 per 10cm, the weft density is 278 per 10cm, and the area density is 260g per square meters. Combustion performance of the final product can reach the level B of the welding clothing national standard, and the resistance to impact of molten metal, thermal stability and thermal protection can reach the level A of the welding clothing national standard. The blended fabric achieves a flame-retarding function, simultaneously has style characteristics of wool fabrics and comfort in wearing and is soft in touch.

Owner:INST OF WOOL & HEMP TEXTILE SCI SHANGHAI

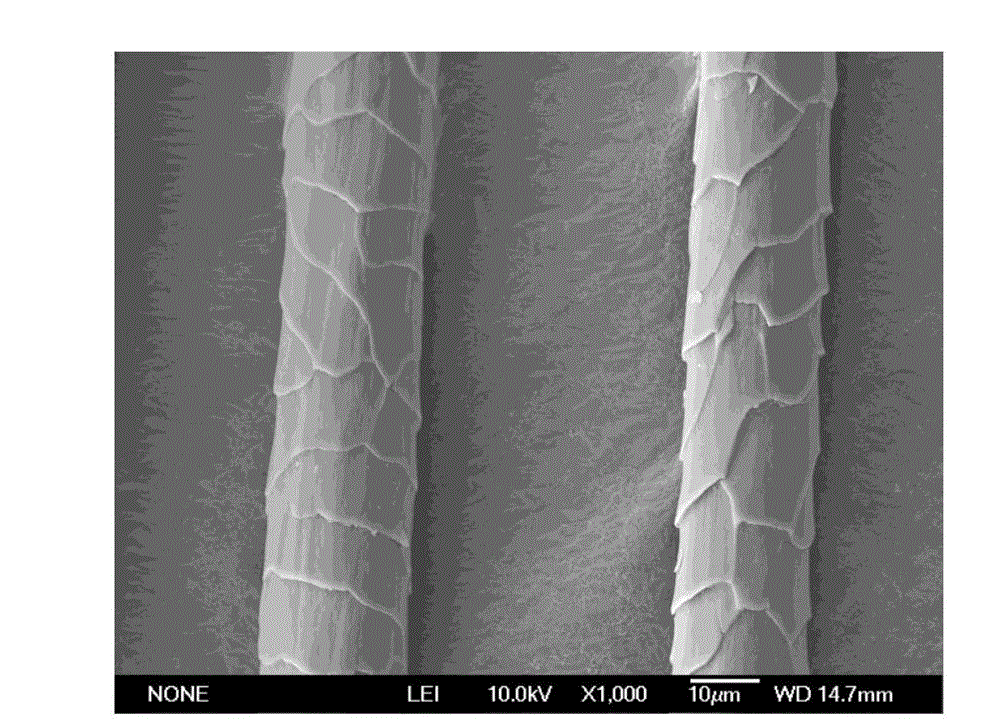

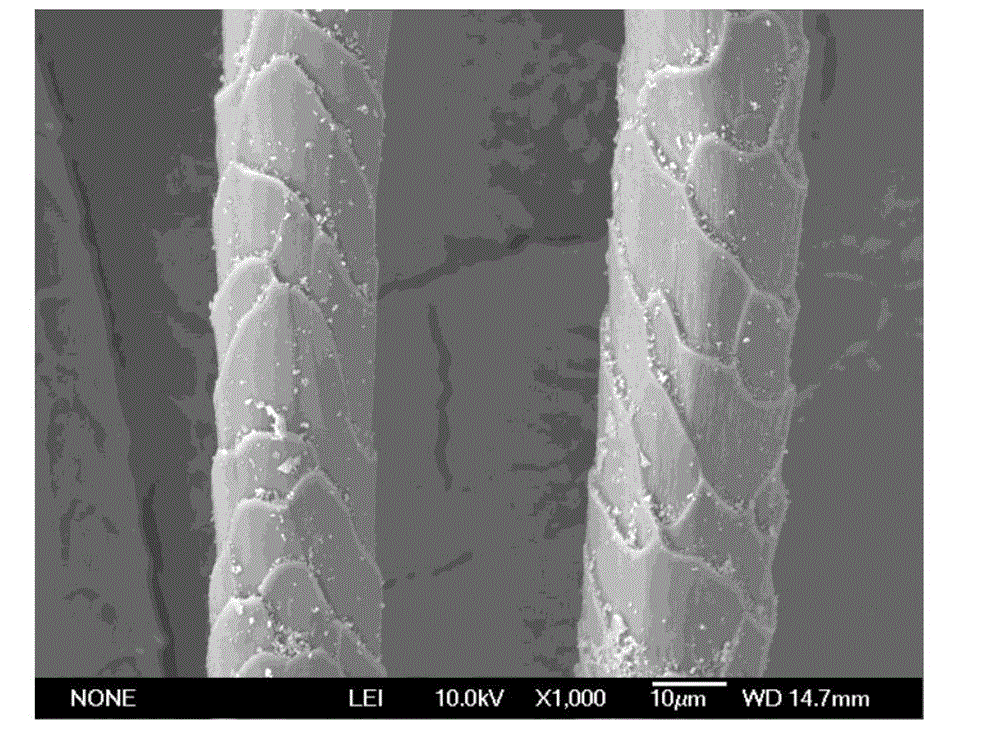

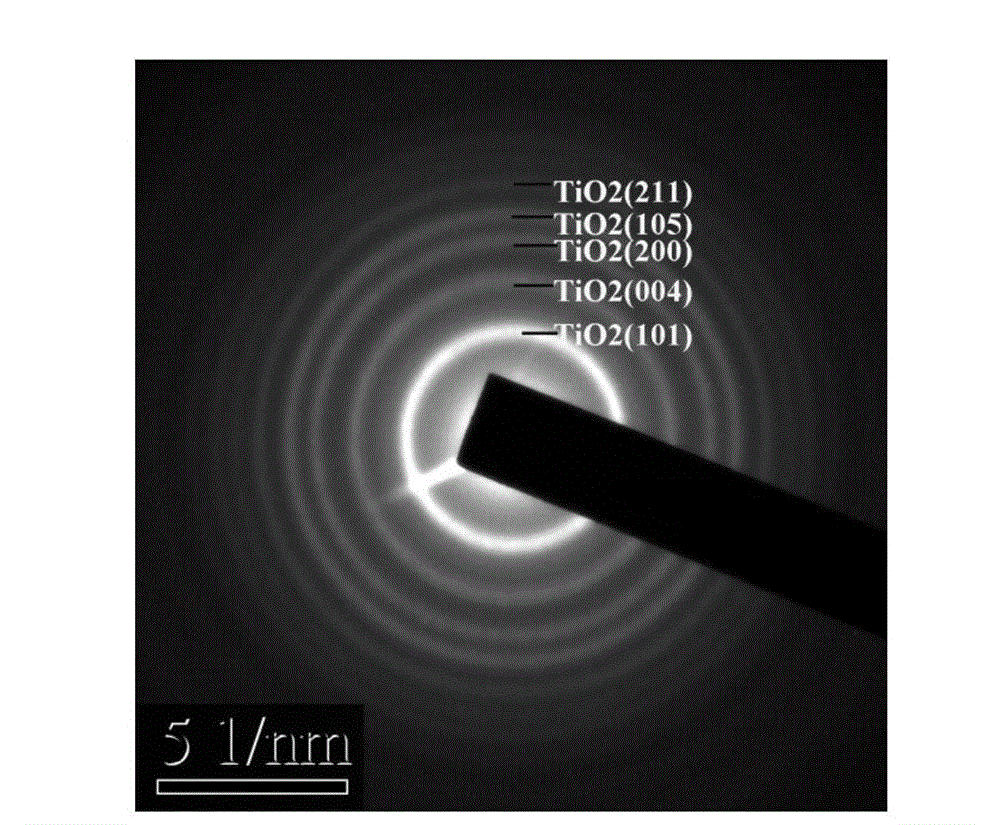

Method for modifying surfaces of wool fibers by using tetrabutyl titanate and chitosan

InactiveCN102912634ALittle strength damageSolve the problem of dyeingAnimal fibresPre treatmentWool fiber

The invention discloses a method for modifying surfaces of wool fibers by using tetrabutyl titanate and chitosan; and the method is implemented in the following steps of: (1) soaking wool fibers in a sodium carbonate solution; pretreating the wool fibers in the sodium carbonate solution; and washing and drying the pretreated wool fibers; (2) preparing a chitosan mixed solution with low molecular weight; (3) preparing a precursor solution; (4) adding the chitosan mixed solution with low molecular weight to the precursor solution, so as to prepare a modifying solution; and (5) carrying out aftertreatment on the modified wool fibers, so as to finish the modification of the wool fibers by using the tetrabutyl titanate and the chitosan. Nanometer titanium dioxide and chitosan films are directly loaded on the surfaces of the wool fibers; and problems of difficulty in heavy-shade dyeing, poorer antibacterial property, low color fastness to sunlight and easiness for felting shrinkage in the wool fibers obtained by the traditional modifying method are solved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Wool fiber modification treatment method

InactiveCN101424040AImprove shrinkageGood dimensional stabilityBiochemical fibre treatmentAnimal fibresYarnReduction treatment

The invention relates to a method for the modification treatment of wool fibre and belongs to the field of dyeing and finishing technology. The method adopts pre-oxidation treatment, oxidation treatment, reduction treatment, enzyme hydrolysis treatment, softening treatment and other modification procedures, can effectively improve the felting property of loose wool fibre, wool yarn, wool strips, wool flower type strips so as to prepare a worsted wool product, so as to achieve the effects of felting prevention and machine washablility, improve the dimension stability of the worsted wool product and simultaneously obtain soft and smooth hand feeling and excellent lustrousness. The standard washing shrinkage rate of the wool clothing product produced through the method is lower than 3 percent.

Owner:SUZHOU UNIV

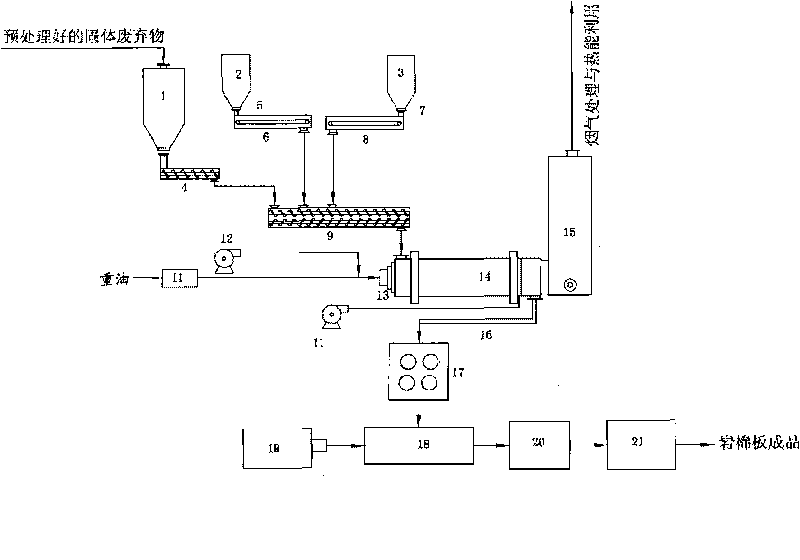

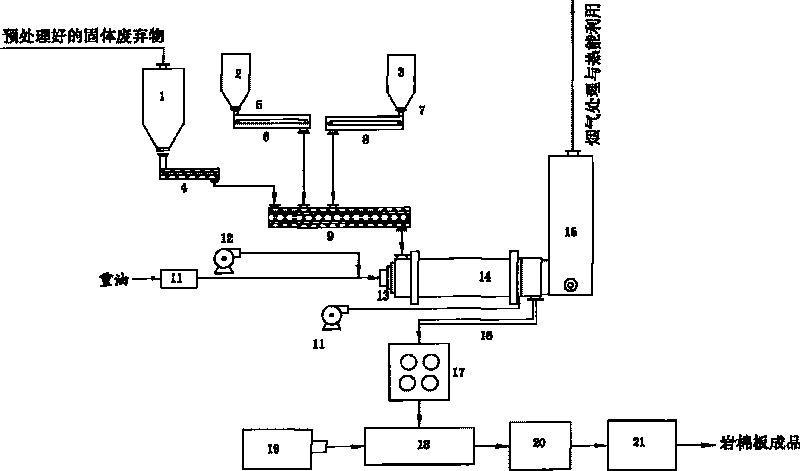

Method for preparing rock wool panel by melting solid waste

The invention relates to a method for preparing a rock wool panel by melting solid waste, comprising: by adding No.1 additive and No.2 additive, adjusting the acidity coefficient of solid waste melting material to be 1.4-1.8; under the condition of meeting the formulation of the rock wool panel, fully melting and evenly mixing the solid waste in a rotary kiln at the temperature of 1450-1530 DEG C and under the condition of rotating oxygen; and then, forming rock wool fiber by treating a melted body by thread throwing through a four-roller centrifugal machine, and preparing the qualified rock wool panel product. By adopting the method, the production power consumption and the cost of the rock wool panel product can be greatly reduced, and reclamation, reduction and hazard-free treatment of the solid waste are realized to the utmost extent.

Owner:深圳德润环保投资有限公司

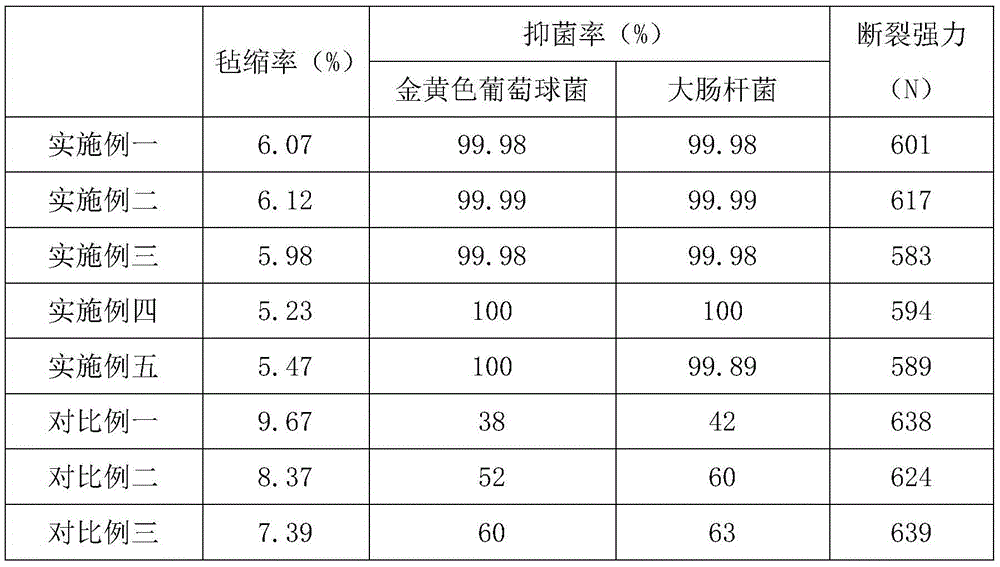

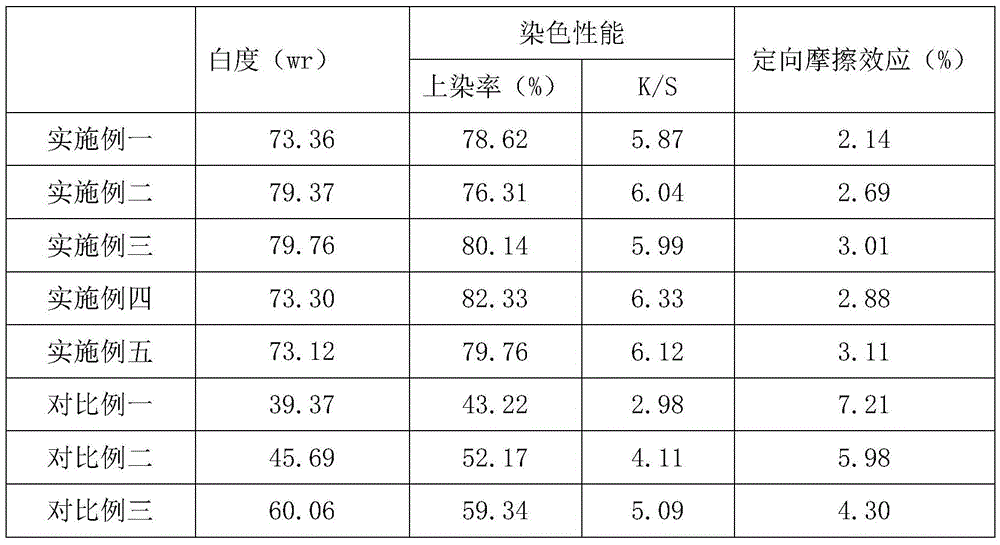

Antibacterial and anti-felting wool fabric finishing method

InactiveCN105544198AImprove antibacterial propertiesPrevent intrusionBiochemical treatment with enzymes/microorganismsShrinking resistant fibresTextile technologyFriction effect

Owner:海阳英伦纺织有限公司

Low-wool-content multi-component chemical fiber blended fabric and preparing method thereof

ActiveCN103835048AImprove perceptionEasy to takeSucessive textile treatmentsWoven fabricsPolyesterPolymer science

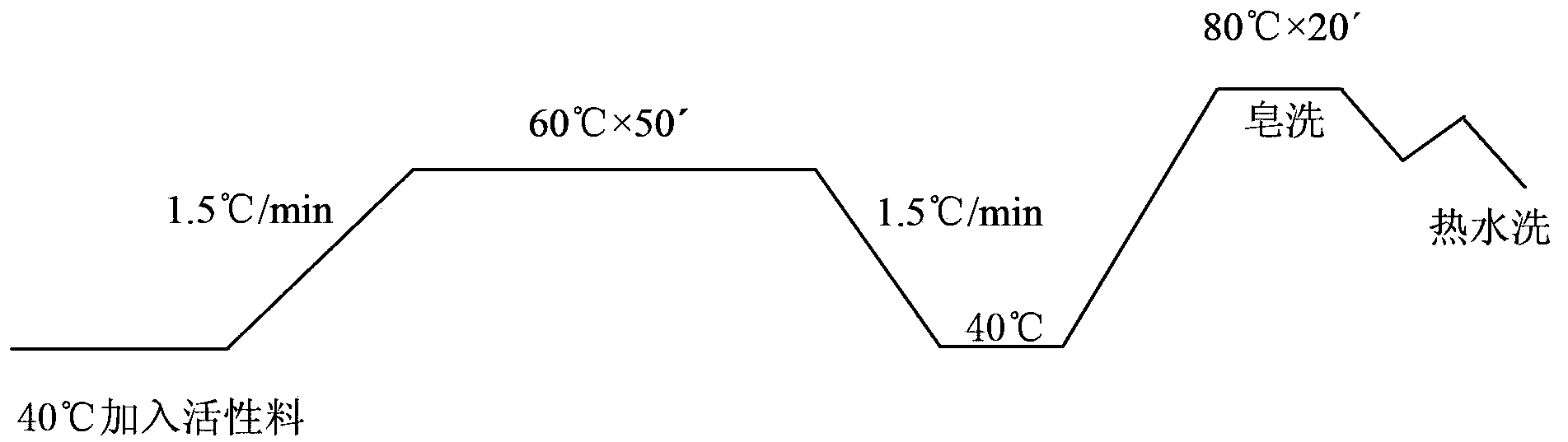

The invention provides a low-wool-content multi-component chemical fiber blended fabric and a preparing method of the low-wool-content multi-component chemical fiber blended fabric and belongs to the field of spinning dyeing and finishing. Wool is added to multi-component chemical fibers and the low-wool-content multi-component chemical fiber blended fabric comprises, by weight, 30% to 40% of polyester staple fibers, 20% to 30% of modified polyester fibers, 10% to 20% of mucilage glue, 5% to 15% of Tencel, 8% to 30% of the wool and 0.1% to 0.6% of conductive fibers. The wool content of a traditional product is changed, wool fibers with the content smaller than 30% are blended with the polyester staple fibers, the modified polyester fibers, the mucilage glue, the Tencel and the conductive fibers in the chemical fibers in a combined mode, so that mutual advantage complement of the various fibers is achieved, and multiple colors, the high comfort degree and the easy-maintenance performance of the fabric are achieved with the low wool content. The technology is reasonable, the technical purpose of one bath dyeing of the wool and the multi-component chemical fibers is effectively achieved, and a new path is created for upgrading orientation and the comfort of chemical fiber fabric.

Owner:SHANDONG WOYUAN NEWFASHIONED FABRIC

Cashmere card

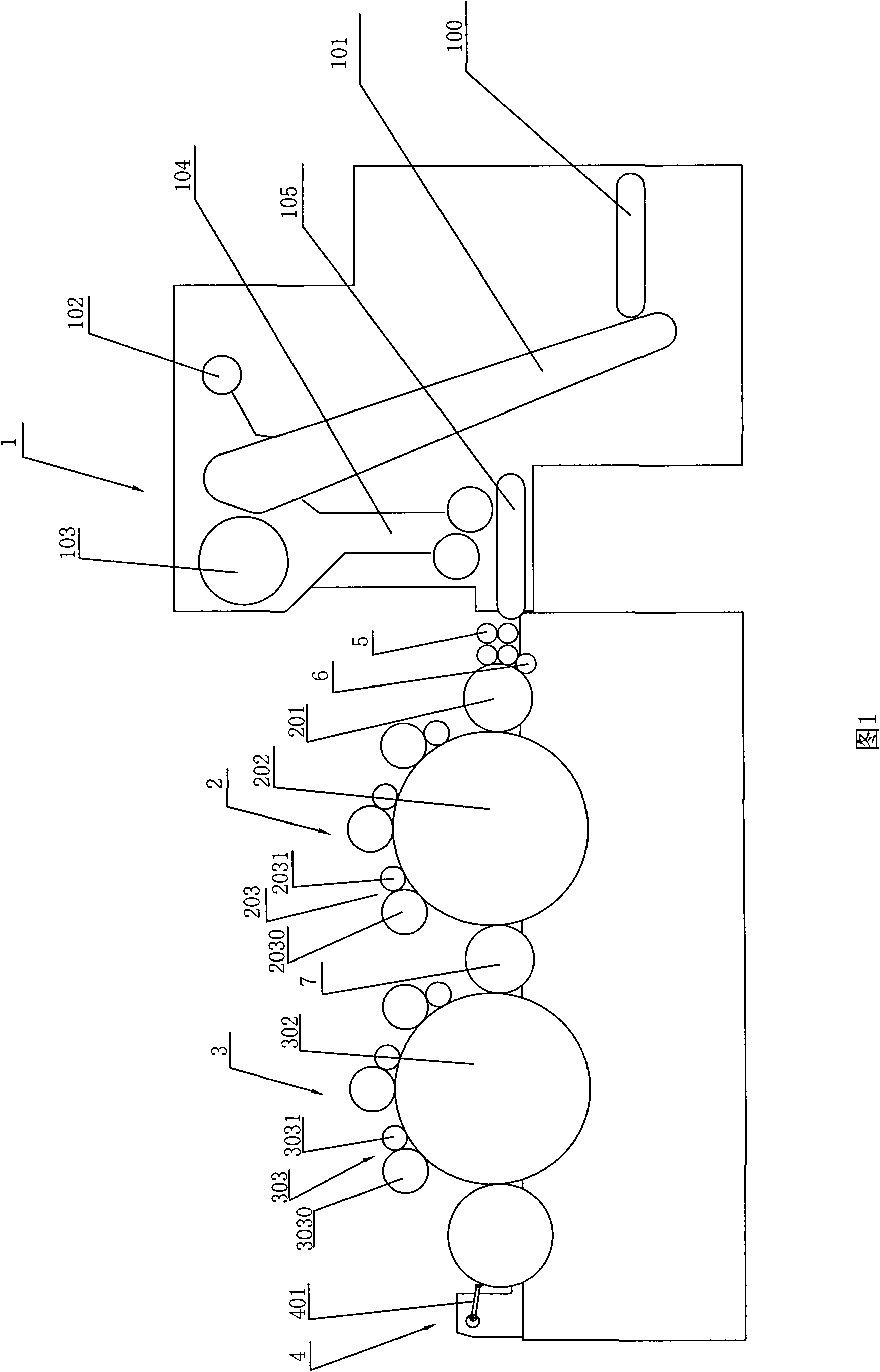

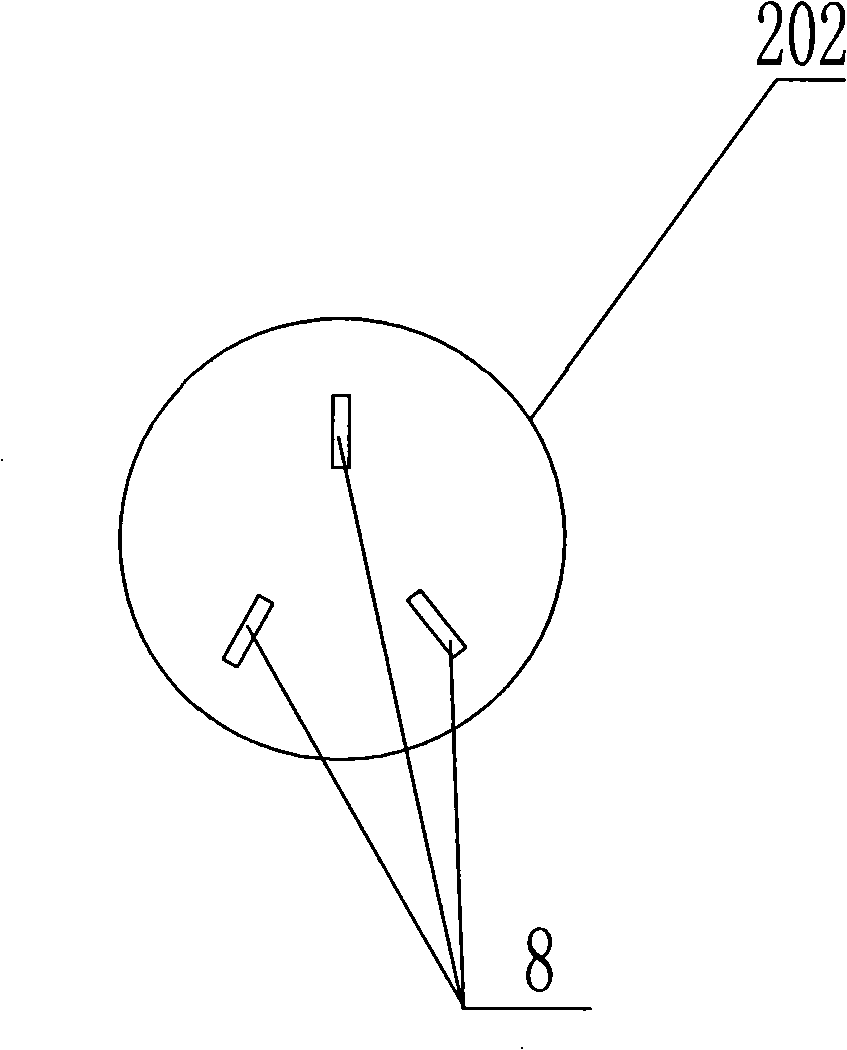

The invention discloses a cashmere carding machine. A feeding mechanism, an opening mechanism, a carding mechanism and a peeling mechanism are arranged on the cashmere carding machine; a pricker roller, a first cylinder and a working and striping roller group are arranged in the opening mechanism, a second cylinder, a working and striping roller group and a doffer are arranged in the carding mechanism, and a transferring roller is arranged between the opening mechanism and the carding mechanism; air flow generating parts are respectively arranged on both ends of each cylinder, and each air flow generating part adopts a fan blade type structure; the peeling mechanism comprises a peeling roller at the rear position and a pair of upper rollers and lower rollers at the front position, the diameter of each lower roller is larger than that of each upper roller, and the position of the lower roller is backward moved relative to the upper roller. The invention is a new machine type and is particularly suitable for carding the wool fiber material containing a low doping amount, and is of higher performance.

Owner:青岛东佳纺机(集团)有限公司

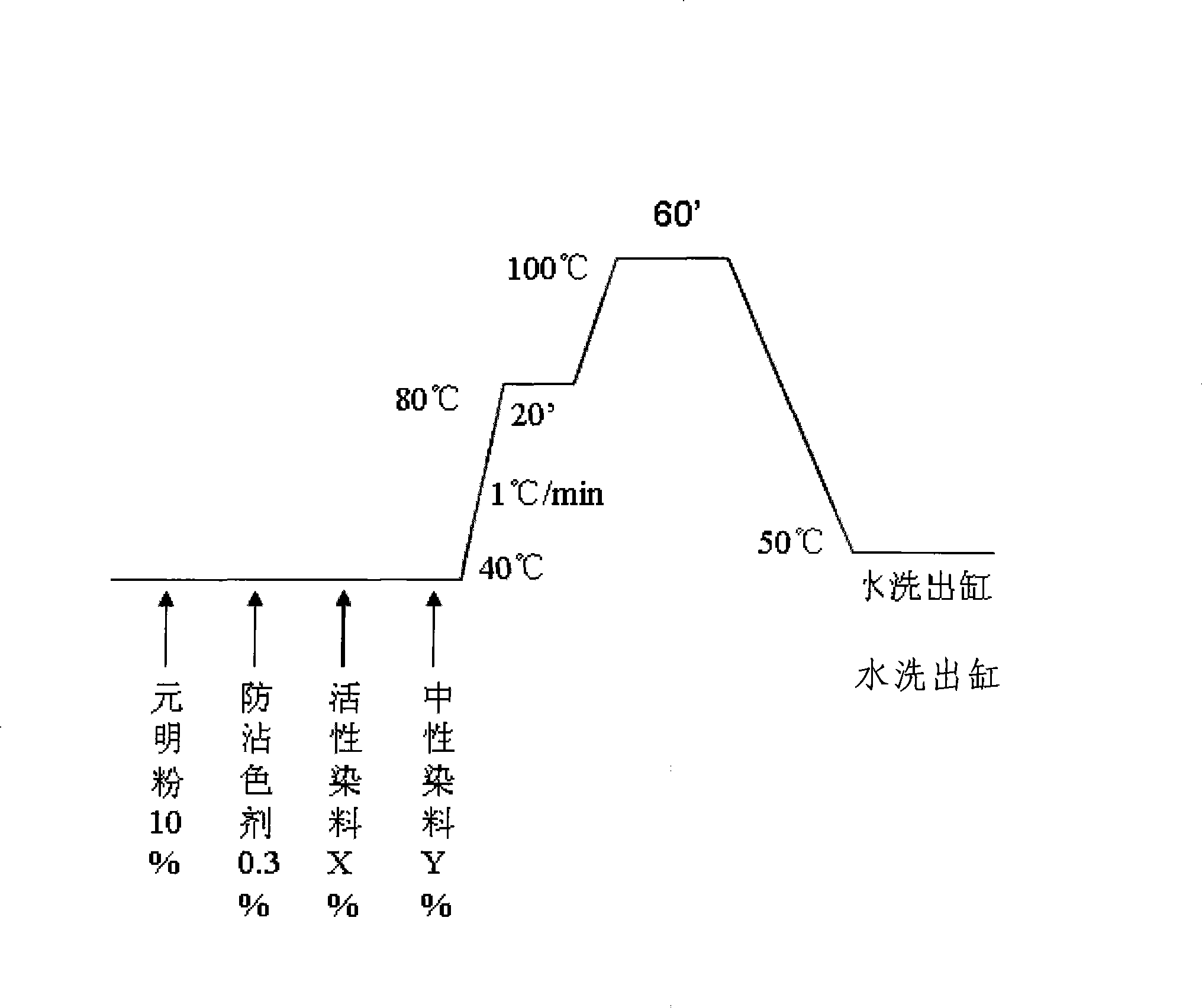

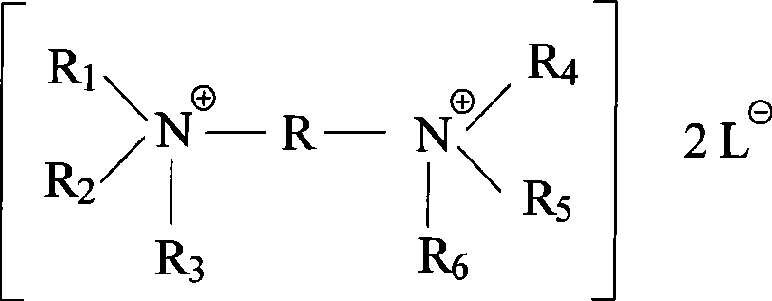

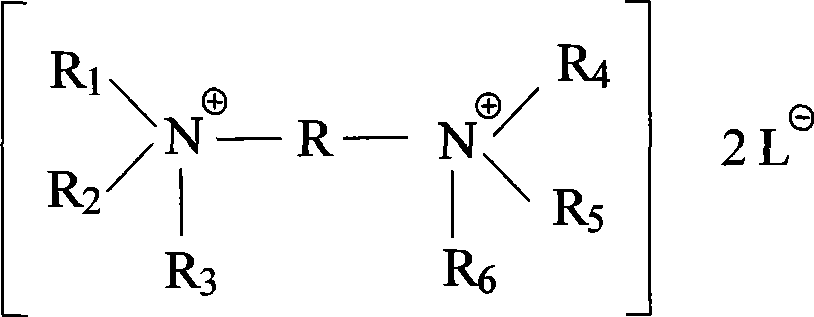

Low temperature dyeing method for wool fibre

The invention discloses a method for dyeing wool fibers at low temperature, which is characterized by comprising the following steps: increasing one or more than one Gemini cationic surfactant in the process of the prior wool acid dye dyeing or wool active dye dyeing, and then dyeing at specified temperature, wherein usually, the added weight of the Gemini cationic surfactant is 0.1 to 1.0 percent of that of the wool fibers, and the dyeing time is 40 to 90 minutes at a temperature of between 75 and 85 DEG C. The method can improve dyeing quality of the wool fibers and simultaneously reduce energy consumption in the dying process.

Owner:ZHANGJIAGANG CHENCHEN TEXTILE

Manufacture method of core material of vacuum heat insulation plate

ActiveCN101775850AFlame retardantSatisfied flame retardantClimate change adaptationInsulation improvementHigh volume manufacturingFire resistance

The invention provides a manufacture method of a core material of a vacuum heat insulation plate through aiming at the problem of high cost of the core material of the vacuum heat insulation plate in the prior art. The method comprises the following steps: rock wool fiber pulping and net covering; shaping and rolling; vacuum dehumidifying; and cooling and material forming. The invention adopts the rock wool fiber, and the produced core material of the vacuum heat insulation plate can satisfy performance required by the core material of the vacuum heat insulation plate , and also has the obvious advantages of fire resistance, sound absorption and the like. More importantly, the production process is simple, and the invention can meet the requirement of fast mass production of building industry.

Owner:ANHUI KERUIKE INSULATION MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com