Antibacterial processing method for wool fiber

A wool fiber and treatment method technology, applied in fiber treatment, physical treatment, animal fiber, etc., can solve problems such as inability to inhibit bacterial growth, complex antibacterial treatment process, and large environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103] The present invention will be further described below in conjunction with accompanying drawing:

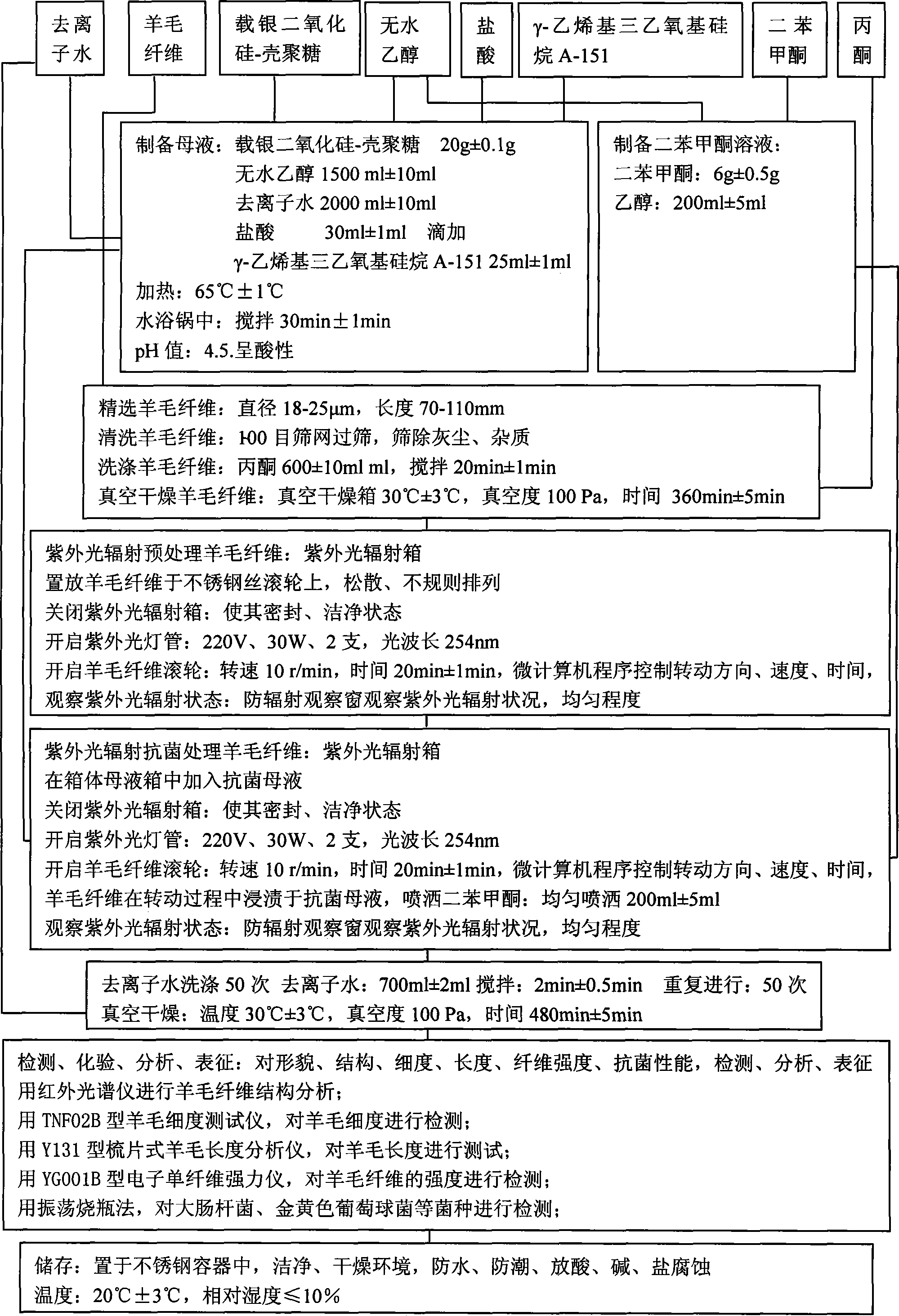

[0104] figure 1 As shown, it is the flow chart of wool fiber antibacterial treatment process, which must be strictly operated and carried out in sequence.

[0105] The elements of the chemical substances required for the preparation are determined according to the pre-set value range, with grams and milliliters as measurement units.

[0106] The antibacterial mother liquid is based on silver-loaded silica-chitosan composite antibacterial agent, mixed with absolute ethanol, deionized water, γ-vinyltriethoxysilane A-151, and dilute hydrochloric acid to make a five-component mixture The solution has a pH value of 4.5 and is acidic. The antibacterial mother solution is an inorganic-organic composite antibacterial mother solution, which is prepared under heating at 65°C.

[0107] For wool fiber, its luster, fineness and length should be selected and cleaned.

[0108] Ultravio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com