Preparation method of cement-based material having deep self-repairing function

A cement-based material and self-healing technology, applied in the fields of microbiology and civil engineering materials, can solve problems such as endangering structural safety, reducing structural service life, and small crack damage, achieving good repairing effect, stable properties, and good compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a preparation method of cement-based material with deep self-repair function, the specific operation is as follows:

[0029] (1) Sieve 2000-3000 g of carriers with a particle size of 0.3-4.75 mm, wash them with tap water for 2-3 times, and dry them for later use.

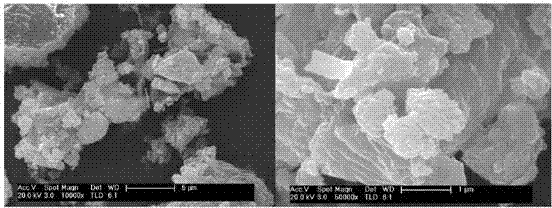

[0030] (2) Prepare 2000-3000mL liquid culture medium. Taking Bacillus colloidus as an example, each liter of medium contains 8-12g of sucrose, Na 2 HPO 4 12H 2 O 2~3g, MgSO 4 0.4~0.6g, CaCO 3 0.5~1.5g, KCl 0.1~0.2g, (NH 4 ) 2 SO 4 0.4-0.6g, yeast extract 0.2-0.4g, and adjust the pH to 7±0.5. Inoculate carbonic anhydrase-producing microorganisms into the sterilized medium, culture at 30±0.5°C for 36-48 hours, centrifuge in a high-speed refrigerated centrifuge at a speed of 4000-6000r / min, and concentrate the bacterial solution to 10 5 ~10 6 a / mL;

[0031] (3) Mix 200-240 g of concentrated solution of carbonic anhydrase-producing bacteria and 4 g of yeast powder evenly, and ...

Embodiment 1

[0036] (1) Sieve out 500 g of a certain type of natural clinoptilolite powder and 500 g of ceramsite with a particle size of 0.3 to 4.75 mm, wash them twice with tap water, and dry them for later use;

[0037] (2) Weigh 20g of sucrose, Na 2 HPO 4 12H 2 O 5g, MgSO 4 1g, CaCO 3 2g, KCl0.2g, (NH 4 ) 2 SO 4 1g, 0.5g of yeast extract, dissolved in 2000mL of deionized water, adjusted to pH 7±0.5, prepared into a liquid medium, sterilized at 120°C for 20 minutes under high temperature regulation. Inoculate the Bacillus colioids into the cooled medium, and culture it with shaking at 30±0.5°C for 48 hours, and the shaking frequency is 170r / min. The above bacterial liquid was concentrated to 10 by centrifugation in a high-speed refrigerated centrifuge for 15 minutes. 5 ~10 6 pieces / mL, the rotation speed is 6000r / min;

[0038](3) Weigh 4g of yeast powder and 200g of the above-mentioned bacterial concentrate, mix them evenly on 400g of zeolite powder, and shake and cultivate ...

Embodiment 2

[0042] (1) Sieve 1000 g of ceramsite with a particle size of 0.3 to 4.75 mm, wash it twice with tap water, and dry it for later use;

[0043] (2) Weigh 60g of sucrose, NaNO 3 6g, MgSO 4 ·7H 2 O 1g, KCl 1g, FeSO 4 4H 2 O 0.02g, K 2 HPO 4 2g, 30g of agar, dissolved in 2000mL of deionized water, adjusted to pH 6-6.5, prepared into a liquid medium, sterilized at 120°C for 20 minutes under high temperature regulation. Aspergillus niger was inoculated into the cooled medium, and cultured with shaking at 30±0.5°C for 36 hours at a shaking frequency of 170r / min. The above bacterial liquid was concentrated to 10 by centrifugation in a high-speed refrigerated centrifuge for 15 minutes. 5 ~10 6 pieces / mL, the rotation speed is 6000r / min;

[0044] (3) Weigh 4g of yeast powder and 200g of the above-mentioned bacterial concentrate, mix them evenly on 400g of ceramsite, and shake and cultivate them in a 30°C incubator for 6 hours, so that Aspergillus niger and yeast powder are ful...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com