Red powder for retouching and preparation method thereof

A technology for red powder and plate repairing, which is applied to the field of plate repairing red powder and its preparation, can solve the problems that the repairing pen cannot meet the requirements of precise line repairing plate, the original red powder has poor adhesion, and the cost of repairing images is high, and the price is low. , Easy to operate, good repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

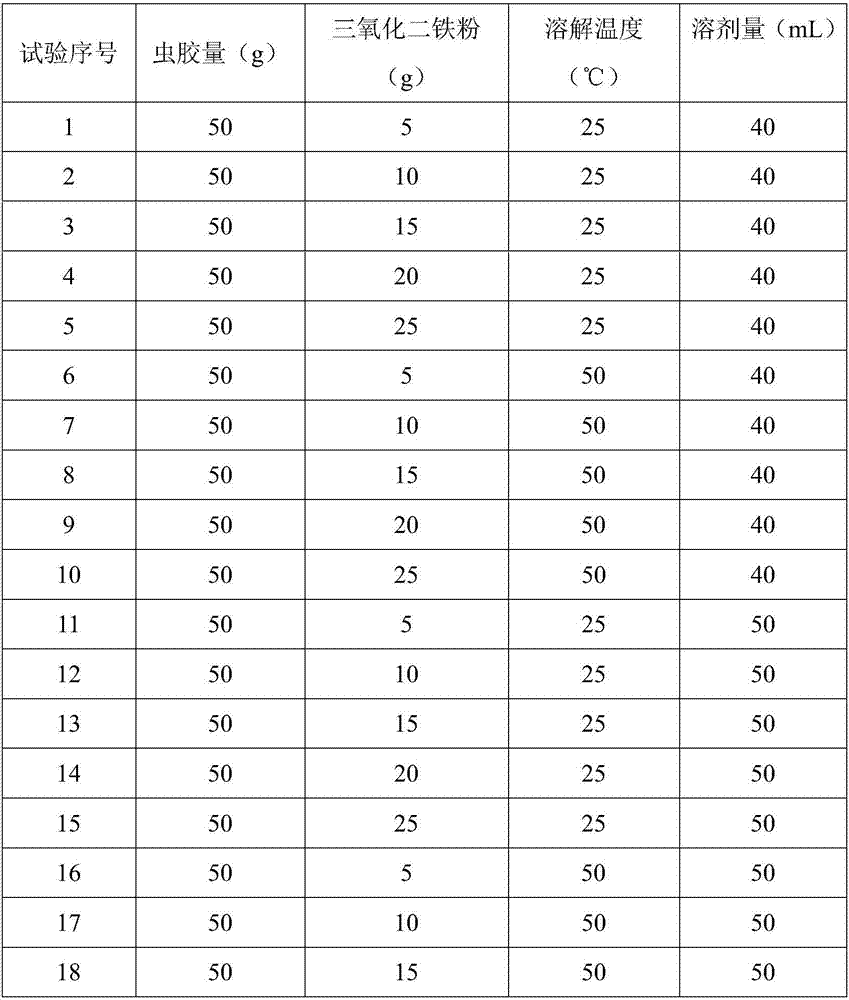

[0026] Determine the raw material ratio and dissolution temperature

[0027] Test shellac and ferric oxide powder under different weight ratios, and the influence of dissolution temperature on the state of the debugged red powder, and determine the weight ratio and dissolution temperature of raw materials.

[0028] Experimental design: Quantitative treatment of shellac, by continuously adjusting the weight and dissolution temperature of ferric oxide powder, and dissolving it in an appropriate amount of absolute ethanol, observing and analyzing the state of the debugged red powder, so as to determine the weight distribution of raw materials compared to the melting temperature.

[0029] Operation method: Add shellac to absolute ethanol and soak for 2-3 minutes, stir again to dissolve it, add ferric oxide powder several times in small amounts, stir evenly, and get ready.

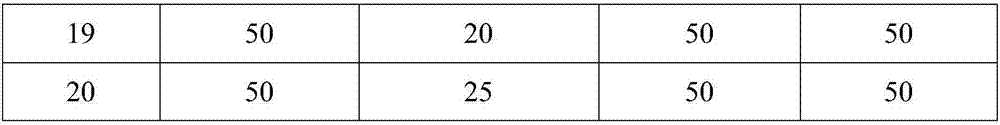

[0030] Table 1 raw material ratio and dissolution temperature table

[0031]

[0032]

[0033] test ...

Embodiment 2

[0038] Strong acid resistance test verification: simulated electroplating process test

[0039] Preparation of red powder: Add 50g of shellac to 50mL of absolute ethanol at 25°C to soak for 2-3 minutes, then stir to dissolve it, then add 15g of ferric oxide powder in small amounts for several times, and stir evenly to obtain.

[0040] Write "Small Achievement" on the Hall cell test piece with red powder, take the pattern electroplating bath as the Hall tank solution, and electroplate the Hall cell test piece coated with "Small Achievement" with the electroplating parameter of 2A for 75 minutes. After taking it out, carefully observe the words "small achievements" on the board. The result shows that neither red powder falls off nor honeycomb red powder appears on the three characters of "small results", which shows that the present invention has good adhesion and strong acid resistance.

Embodiment 3

[0042] Equipment: Guangzhou Julong vacuum etching film removal line, model JL-1601ES.

[0043] Strong acid resistance test verification: over-etching section test

[0044] With the Hall cell test piece after the simulation electroplating process test among the embodiment 2 with 1.5m / min speed, press 1.5-2.0kg / cm 2 , Press down 2.0-2.5kg / cm 2 The pressure passes through the acid etching section. From the Hall cell test piece of the acid-etched section, it can be seen that the place not coated with red powder is completely etched, and the place coated with red powder shows "small results" intact, and there is no honeycomb, indicating that the present invention has good Acid-resistant properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com