Patents

Literature

2222 results about "Diiron Trioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional composite absorbing material for purifying water and preparation method thereof

ActiveCN102350298AReduce wasteEfficient removalOther chemical processesWater/sewage treatment bu osmosis/dialysisAcrylic resinCerium

The invention provides a multifunctional composite absorbing material for purifying water and a preparation method thereof, relating to an absorbing material. The invention provides the multifunctional composite absorbing material for purifying water, which can be used for effectively removing a plurality of harmful substances in the water and has higher removal efficiency and lower production cost, and the preparation method thereof. The absorbing material is selected from at least one of absorbing materials A, B and C; the absorbing material A takes a mesoporous adsorption ceramic material as a carrier to load nano metals including nano silver, nano zinc, nano iron and nano cerium; the absorbing material B takes the mesoporous adsorption ceramic material as the carrier to load nano metal oxides including nano titanium dioxide, nano zinc oxide, nano ferric oxide and nano cerium dioxide; and the absorbing material C is prepared from the following raw materials according to the mass ratio: 100-200 parts of active carbon powder, 20-30 parts of polyethylene powder, 10-30 parts of calcium sulfite powder, 10-30 parts of natural zeolite powder, 20-40 parts of macroporous acrylic resin and 10-20 parts of attapulgite powder.

Owner:XIAMEN BAILIN WATER PURIFICATION TECH CO LTD

Formaldehyde gas oxidation catalyst under room temperature

ActiveCN1714930ARaw materials are readily availableSimple conditions of useDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationSilicon dioxide

The present invention provides a kind of formaldehyde gas oxidizing catalyst for room temperature use. Metal oxide is first obtained with soluble metal nitrate, carbonate or other inorganic salt and through oxidation and precipitation; and then loaded with small amount of metal to form the catalyst with room temperature formaldehyde oxidizing activity. The catalyst has metal oxide as main body and supported noble metal as active component, and features that the metal oxide may be oxide of Al, Ni, Mn, Si or Fe, and the noble may be Pt, Ru, Au, Rh or Pd. The catalyst of the present invention has high catalytic activity, and long sustaining time. The catalyst has formaldehyde converting rate up to 100 %, and results in low power consumption.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Process for producing carbon coated iron lithium phosphate

InactiveCN101172599AElectrode manufacturing processesPhosphorus compoundsShortest distancePhosphate ion

The invention relates to a preparation method of lithium iron phosphate for the carbon cladding of a lithium ion battery. The prior lithium iron phosphate preparation technical art is complex, and has high cost. The invention has the synthetic process that: ferric oxide, phosphoric acid, simple organics and doped element compound are mixed and dried, the mol ratio of phosphate radical ion, ferric ion and doped element ion is 1:y:z, wherein, y is larger than or equal to 0.95 and smaller than or equal to 1, and y plus z is equal to 1; the mixture is added with lithium source compound, added with water to be mixed and dried, the mol ratio of lithium ion and phosphate radical ion is x:1, and x is larger than or equal to 0.95 and smaller than or equal to 1.05; the mixture which reacts for 2 to 20 hours under 500 to 800 DEG C is cooled in a furnace. The invention finally produces the precursor uniformly mixed with superfine crystal grain, and during the subsequent high temperature solid phase reaction, the end product lithium iron phosphate can be produced through shorter distance diffuseness of atoms. The end product has high purity, the crystallisation is good, the capacity is high, and the cycle stability is good.

Owner:HANGZHOU DIANZI UNIV

Extinguishing agent

InactiveCN102058951AReduce pollutionRestricted free movementFire extinguisherSesquioxideAluminium hydroxide

The invention discloses an extinguishing agent. The extinguishing agent is formed by mixing and stirring strong hydrophobic solid particles and aqueous solution at high speed, wherein the strong hydrophobic solid particles are one type or more of magnesium hydroxide particles, silicon dioxide particles, calcium carbonate particles, talcum particles, aluminium oxide particles, aluminium hydroxide particles, zinc borate particles, zinc oxide particles, iron sesquioxide particles, titanium dioxide particles, montmorillonite particles, hydrotalcite particles, coal ash particles, diatomite particles, mica particle, attapulgite particles and zeolite particles after hydrophobic modification. The extinguishing agent disclosed by the invention is nontoxic, environmental pollution is less, and secondary loss caused by strong flowability of water can be avoided while playing the advantages of the water as the extinguishing agent and reducing the using amount.

Owner:XIAN UNIV OF SCI & TECH

Preparation method of ceramic granules

InactiveCN102060562ALow water absorptionHigh compressive strengthCeramicwareSpherical granuleDiiron Trioxide

The invention relates to a preparation method of ceramic granules, which comprises the following steps: drying and crushing coal ash, kaolin, ferric oxide and basic magnesium carbonate into powder after wet grinding; carrying out the biscuit firing treatment on the powder to prepare biscuit-firing granules after spherical granules are prepared; preparing microcrystal glass powder by utilizing an Li-Al-Si system; pouring the prepared microcrystal glass powder into a granulator to be stirred; preparing the biscuit-firing granules packaged by the microcrystal glass powder after the surface of the biscuit-firing granules is completely packaged by the microcrystal glass powder; placing the biscuit-firing granules packaged by the microcrystal glass powder into the granulator; adding the powder;preparing the ceramic granules to be treated through the biscuit firing after the biscuit-firing granules packaged by the microcrystal glass powder are completely packaged by the powder; and preparing the ceramic granules after the ceramic granules to be treated through the biscuit firing are placed into a muffle furnace to be sintered and crushed. In the invention, a packaging method is adopted to prepare the ceramic granules, the inner layer of the prepared ceramic granules is completely packaged by the glass powder, and the gas of the inner layer is prevented from discharging in the sintering course so that the inner layer is in a loose porous structure, thereby greatly reducing the water absorption rate of the ceramic granules and decreasing the specific gravity.

Owner:SHAANXI UNIV OF SCI & TECH +1

Boiler coal combustion-improving desulfurizing and denitrifying agent composition and preparation method thereof

The invention provides a boiler coal combustion-improving desulfurizing and denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-7 parts of sodium carbonate, 1-3 parts of alumina, 2-8 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 2-6 parts of ferric oxide, 3-10 parts of potassium permanganate, 3-10 parts of potassium chlorate, 10-35 parts of activated attapulgite clay, 15-30 parts of urea, 2-4 parts of ammonium formate, 2-4 parts of ammonium chloride, 6-23 parts of ammonium acetate, 3-9 parts of manganese oxide, 9-12 parts of copper chloride, 1-3 parts of copper oxide, 2-4 parts of zinc sulfate, 1-3 parts of zinc nitrate, 7-18 parts of potassium dichromate, 1.0-1.5 parts of titanium dioxide, 0.5-1.0 part of barium molybdate, 0.5-1.5 parts of cobalt sulfate, 0.5-1.5 parts of vanadium pentoxide, 0.3-0.7 part of cerium oxide, 0.1-0.2 part of sodium dodecyl benzene sulfonate and 0.1-0.2 part of alkyl glyceryl ether. The composition is convenient to use, has stable properties, plays roles of combustion improving, desulfurization and denitrification, has coal saving rate of 8-25% and can remove fixed sulfur by 50-70%.

Owner:兰州熙瑞化工科技有限公司

Biomass curing-forming fuel and preparation method thereof

The invention discloses a biomass curing-forming fuel. The biomass curing-forming fuel consists of straws, saw dust, coal dust, a combustion improver, a sulfur-fixing agent and a dust-falling agent according to parts by weight, wherein the straw is one or combination of the straw of crops such as rice, wheat, soybean, corn, sorghum, cotton, rape and tobacco, a branch and a bark of trees and shrubs, rice hull, chaff and peanut coat; the combustion improver is one or more of table salt, sodium nitrate, potassium permanganate, potassium oxide, sodium nitrite and sodium hypochlorite and capable of realizing decomposition and combustion supporting at different temperatures; the sulfur-fixing agent is in a manner that sodium carbonate, calcium hydroxide and alkyl alcohol amine compounds are synergistically used and is capable of reducing discharging of sulfur dioxide; and the dust-falling agent is selected from iron sesquioxide and capable of lowering a melting point of ash and reducing dust volume. The biomass curing-forming fuel has the advantages that the combustion efficiency is high, the slag bonding and the soot formation are not generated, the black smoke is little, the fire power strong, the combustion is sufficient, the ash does not fly, the biomass curing-forming fuel is clean and sanitary and the like. The invention further discloses a preparation method of the biomass curing-forming fuel.

Owner:JINAN SANNONG ENERGY TECH

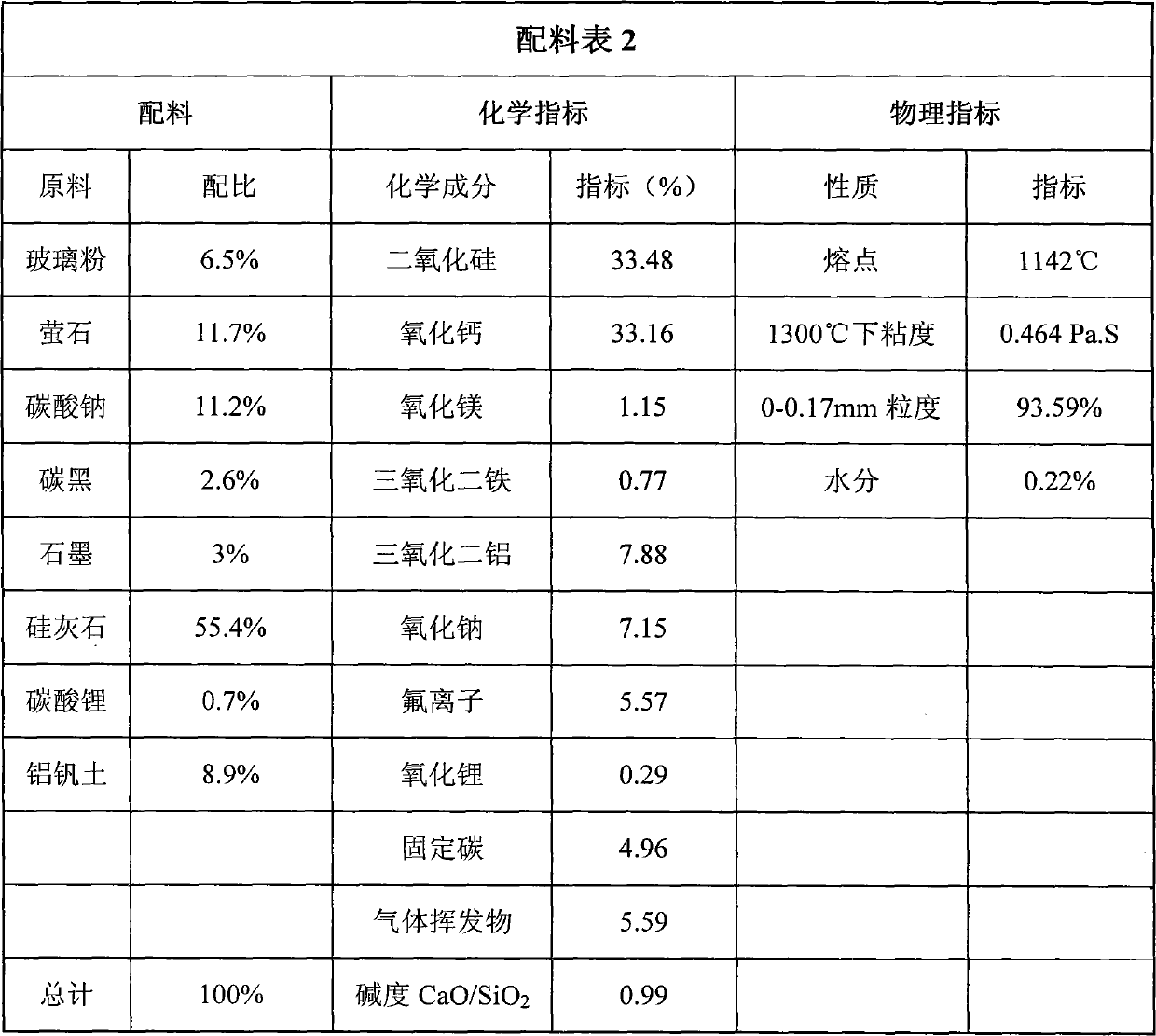

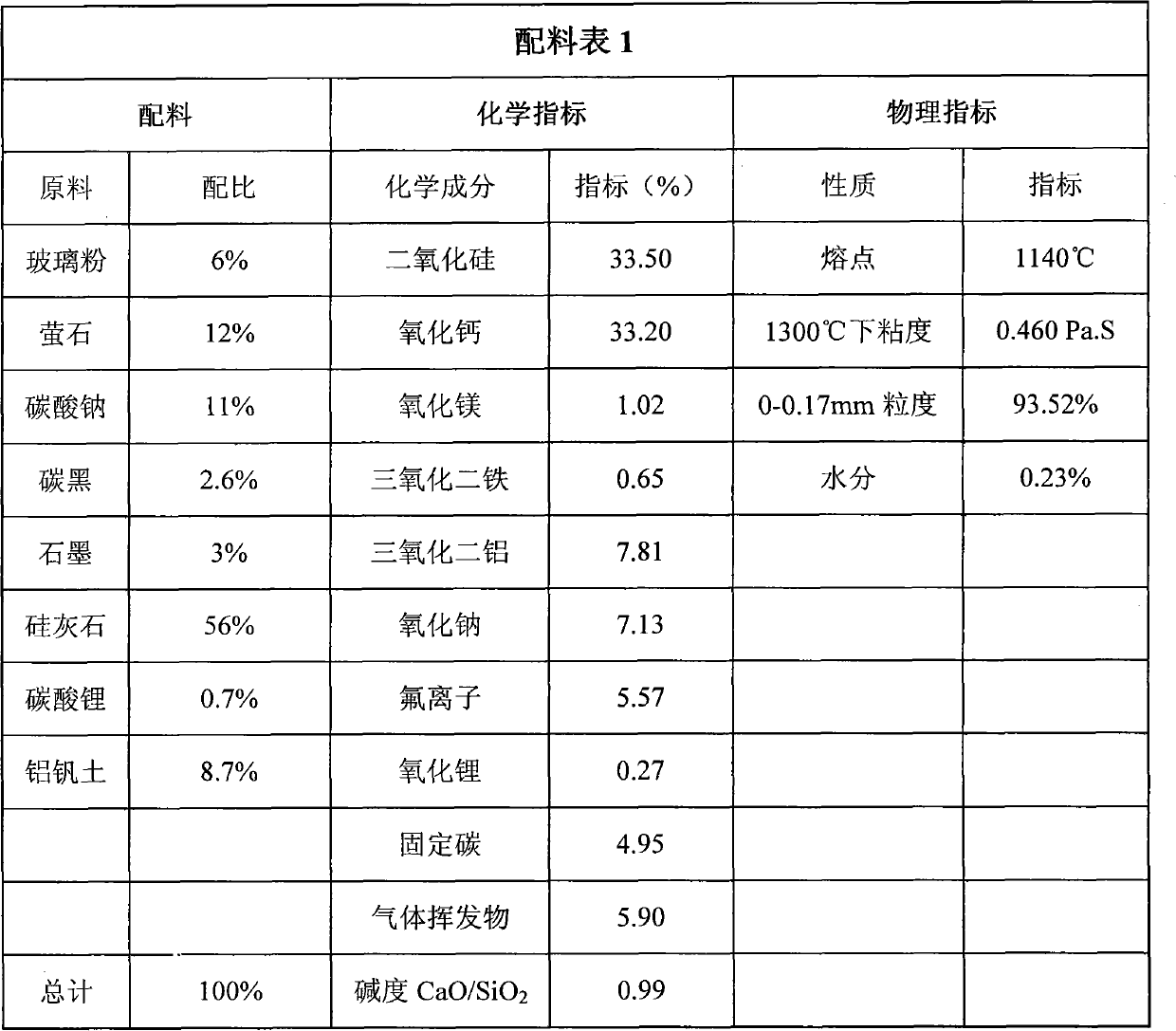

High-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag and preparation method thereof

The invention discloses high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag which comprises the following components in percentage by weight: 54-57% of wollastonite, 9-13% of fluorite, 9-13% of sodium carbonate, 0-1% of lithium carbonate, 5-7% of glass dust, 8-12% of vanadine soil, 2.5-2.7% of soot carbon and 3-3.5% of graphite, and comprises the chemical components in percentage by weight: 31.9-34.9% of calcium oxide, 32.1-35.1% of silicon dioxide, 7.3-8.3% of aluminium oxide, 0.5-1.5% of magnesium oxide, 0.5-1.4% of iron sesquioxide, 4.4-6.4% of fluorion, 6.5-7.5% of sodium oxide, 0-0.39% of lithium oxide, 4.5-6.0% of fixed carbon and 4-7% of gas volatile matters. The alkalinity of the covering slag, namely the ratio of CaO to SiO2, is 0.91 to 1.00, the melting point of the covering slag is 1100 DEG C to 1160 DEG C, and the viscosity of the covering slag is 0.3 to 0.6 Pa.s at 1300 DEG C. The invention can solve the problems of easy crusting, slag entrainment, slag inclusion, slag sticking on casting blank surfaces, bubbles under skins, cracks, deep chatter mark, felting, bleed-out, and the like of the covering slag in the crystallizer during high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting, and has the advantages of uniform and stable slagging in the crystallizer, good casting blank quality, difficult felting and bleed-out, and the like.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Porous ceramicite and preparation method and application thereof

InactiveCN101693631AHigh activityTo promote metabolismWater/sewage treatment by irradiationWater/sewage treatment using germicide/oligodynamic-processRare earthBiological activation

A porous ceramicite and a preparation method and an application thereof in the field of water purifying and filtering technologies, the porous ceramicite comprises the following components in percentage by weight: 2.5%-4.5% of titanium dioxide nanometer grade micro powder, 2%-4.5% of silicon dioxde nanometer grade micro powder, 2.5%-5.5% of zinc oxide nanometer micro powder, 12%-29% of polarity mineral tourmaline powder, 0.5%-1.5% of rare-earth activating agent, 1.5%-3% of ferric oxide red, 3%-10% of feldspar ores, 5%-8% of bergmeal ores, 15%-47% of light clay ores, and the other is water. The method ionizes water into negative ions through realizing infrared, cuts off hydrogen keys through resonance and splits the hydrogen keys into small water molecules (five-six), improves the activation, enables the small molecules into a body, can activate cells, prompts metabolism and acid-base balance, reduces the function of the oxidation-reduction potential ORP value of a water body, and the method can be used for processing water in cups and containers, such as tanks, tower pools, grooves and the like.

Owner:SHANGHAI JIAO TONG UNIV

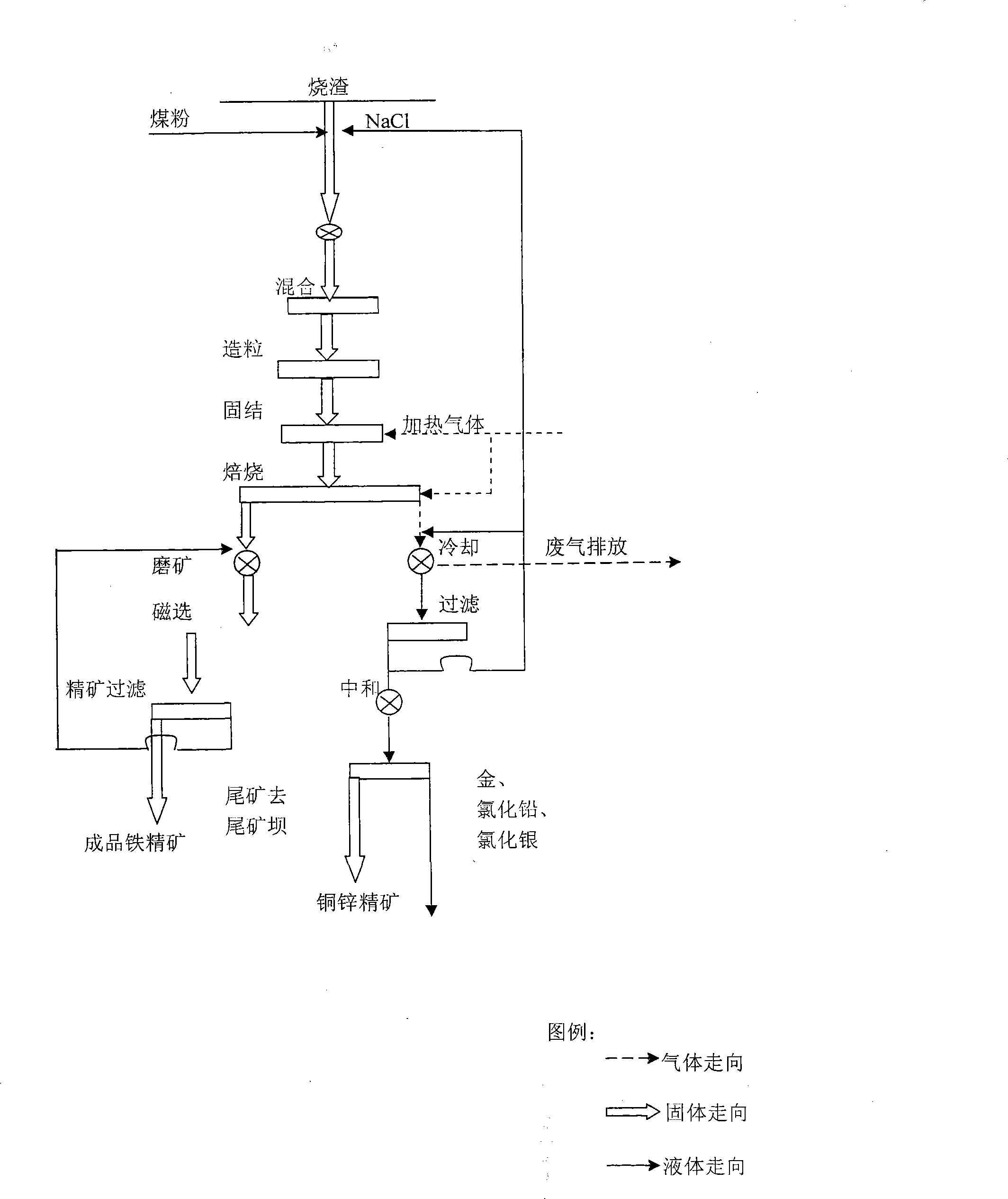

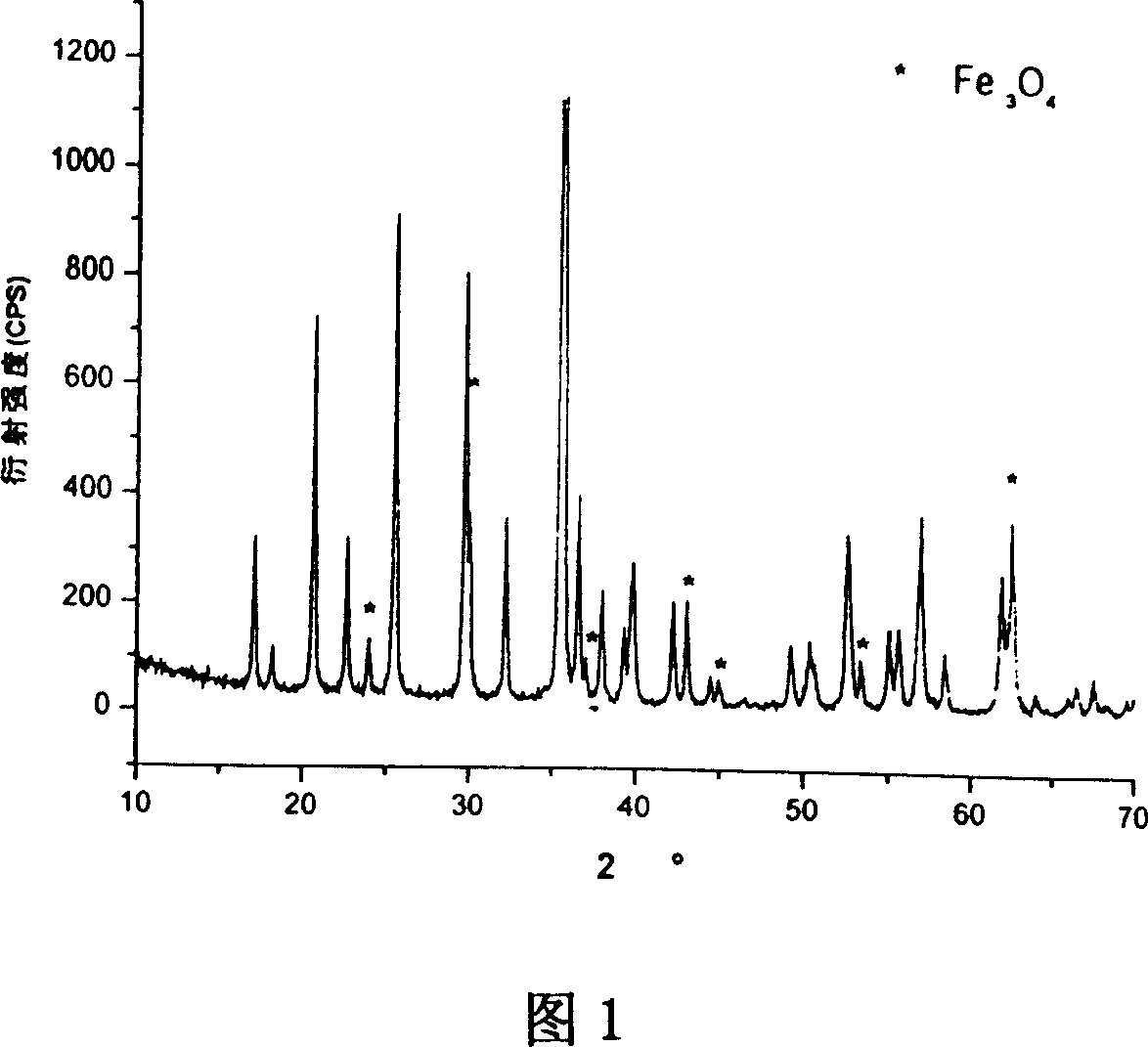

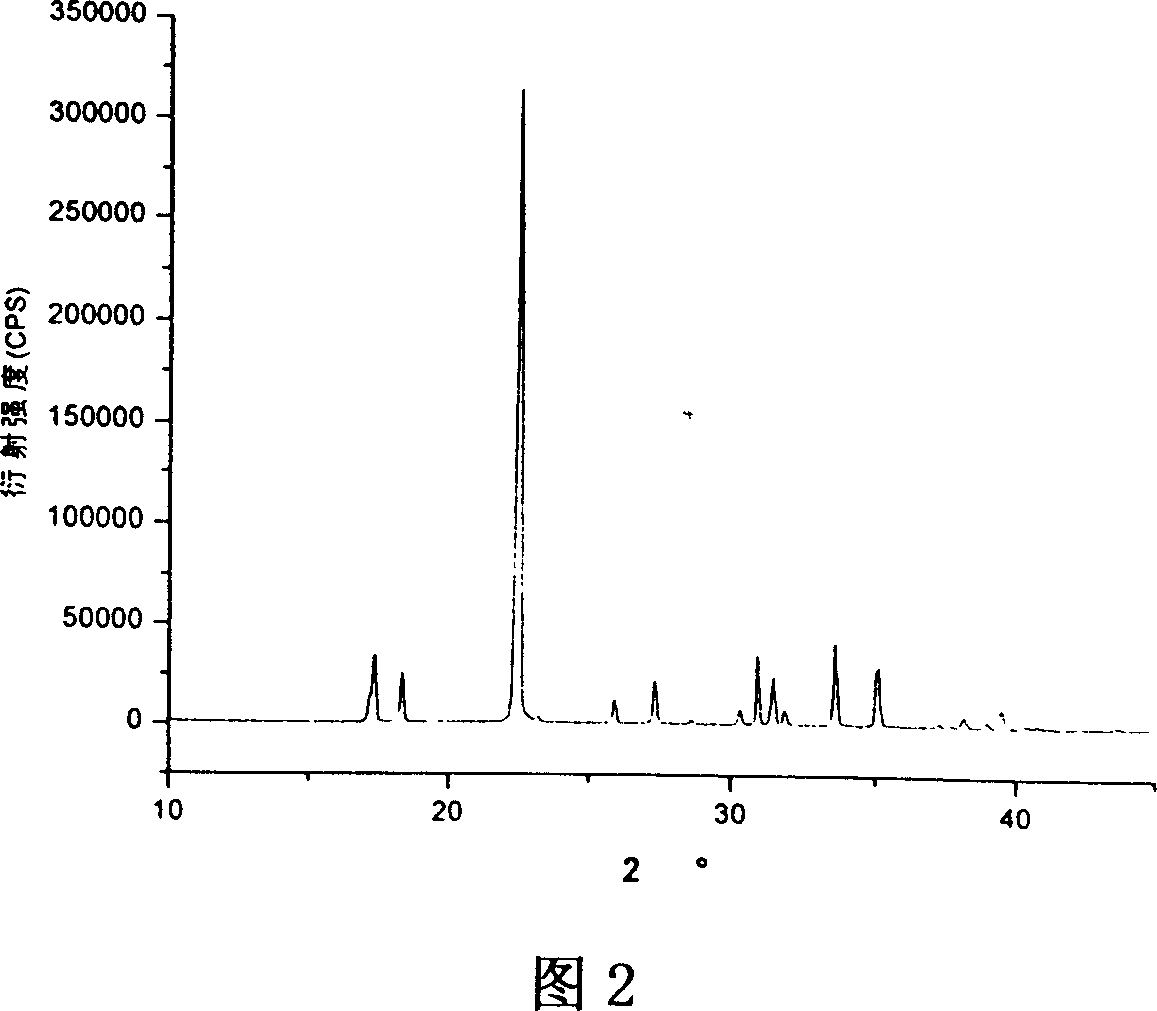

Method for recovering gold, silver, iron and lead from acid calcination slag by magnetization chlorination process

InactiveCN101225468AEliminate pollutionReduce wasteProcess efficiency improvementLimited resourcesSlag

The invention discloses a method to recover the gold, silver, iron and lead from the acidiation roasted cinder by a magnetic chlorination method, which is characterized in that the method comprises two sections, one is that the gold, silver, lead, and copper in the cinder are volatilized as a chloride gas through the high temperature chlorination roasting, and the gold, silver, copper and lead are recovered through the condensed gas; the other is that the iron is recovered by the process that the coal dust is filled during the granulation of the cinder, the magnetic reduction roasting is done with the chlorination roasting, the ferric oxide is reduced to the ferroferric oxide, and the processed cinder is ground and selected magnetically. Thanks to the recovering method, the recovery rate of the gold and silver is above 95%, the iron recovery rate is above 85%, and the lead recovery rate is above 90%, the production cost is about 300 RMB per ton, the profit is over 700 RMB per ton, so that a multiple billion RMB profit is harvested, and the waste of the limited resource is reduced. The method to recover the gold, silver, iron and lead from the acidiation roasted cinder by a magnetic chlorination method has the advantages of simple process, high efficiency, low smelting cost, comprehensive utilization of the ore resources, elimination of the environment pollution, and economic benefit growth of enterprise.

Owner:张伟晓

Universal rock and soil curing agent and preparation method thereof

ActiveCN102503328ASolidified rock and soil quality is goodLow costOrganic fertilisersSoil conditioning compositionsPowder mixtureFirming agent

The invention relates to a universal rock and soil curing agent and a preparation method of the universal rock and soil curing agent and aims at solving the problem of poor curing quality of the existing curing agent. The universal rock and soil curing agent comprises a powdery mixture formed by mixing the following raw materials: calcium oxide, silicon dioxide, aluminium oxide, sulfur trioxide, magnesium oxide and ferric oxide. The universal rock and soil curing agent is characterized in that raw materials also comprise viscous polymers and materials with cinerite activity or powdery materials with viscosity after sintering and water meeting, wherein the viscous polymers account for 2 to 8 percent of the total weight of the powdery mixture, the materials with cinerite activity or the powdery materials with viscosity after sintering and water meeting account for 5 to 20 percent of the total weight of the powder mixture, the raw materials also comprise compound body additional adding agents, the compound body additional adding agents account for 1 to 3 percent of the total weight of the powdery mixture and are formed by mixing the following raw materials in percentage by weight or are the following raw materials in percentage by weight: 0 to 100 percent of NaOH and 100 to 0 percent of water reducers. The preparation method comprises the following steps that: the raw materials according to the weight mixing ratio are put into a powder body mixing machine, the pre-mixing is firstly carried out, then, the major mixing is carried out, and the materials are sufficiently and uniformly mixed. The universal rock and soil curing agent and the preparation method have the advantages that the rock and soil curing quality is good, the cost is low, the application range is wide, various inorganic solid waste materials can be cured, waste materials are changed into useful materials, the cost performance is high, economic benefits and environment benefits are obvious, and popularization and application prospects are wide.

Owner:北京旷世达资源环境工程发展中心

Method of synthesizing iron lithium phosphate by vacuum carbon heating reduction

ActiveCN1948134AImprove protectionAvoid timePhosphorus compoundsVacuum pumpingLithium iron phosphate

The present invention relates to a method for synthesizing lithium ion battery positive electrode material lithium iron phosphate by utilizing vacuum carbonthermic reduction process. Said method includes the following steps; uniformly mixing self-made lithium dihydrogen orthophosphate containing doped element, tri-iron tetroxide or ferric oxide and electric conducting agent or precursor of said electric conducting agent, placing the mixture into a vacuum smelting furnace, vacuum-pumping, heating to make reaction for a period of time, finally cooling to room temperature so as to obtain the invented lithium ion battery positive electrode material lithium iron phosphate.

Owner:HUNAN RESHINE NEW MATERIAL

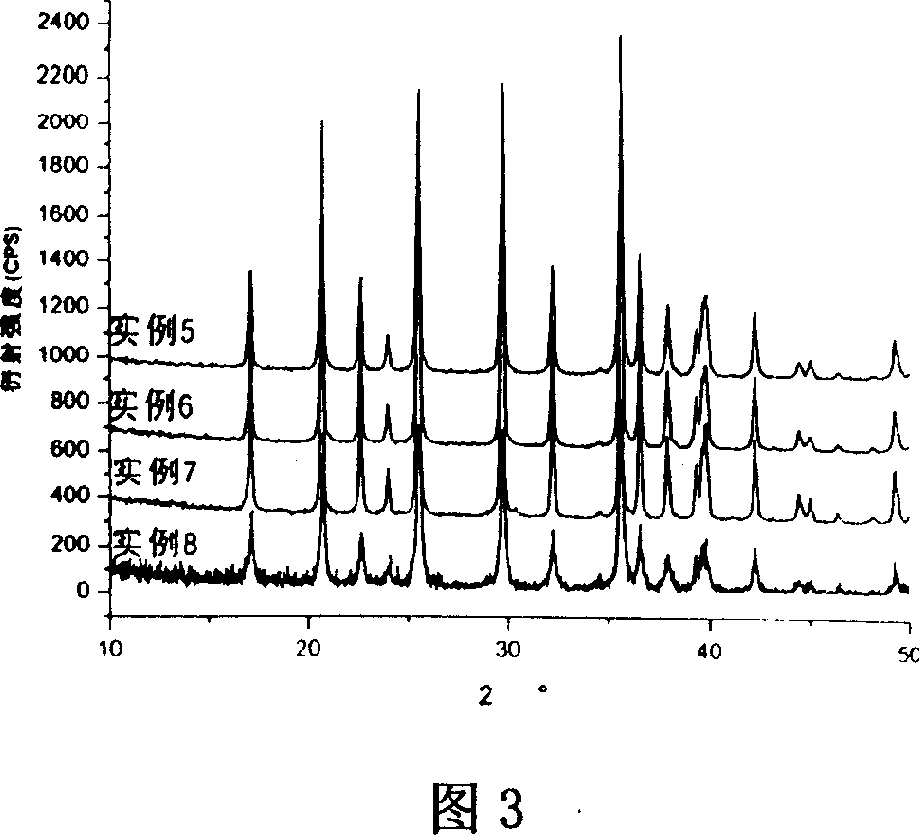

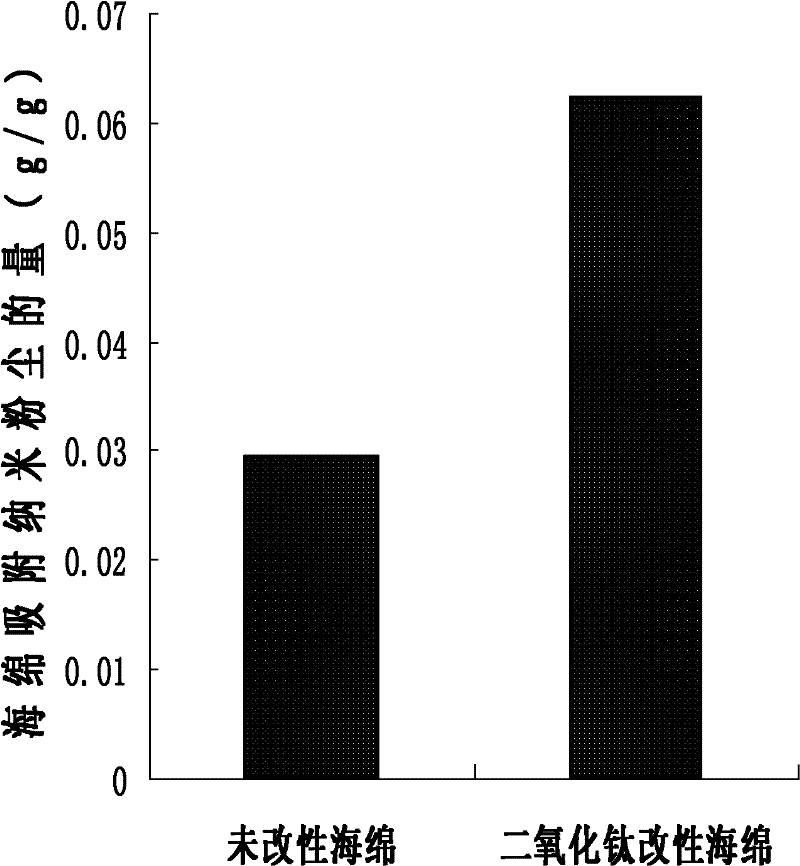

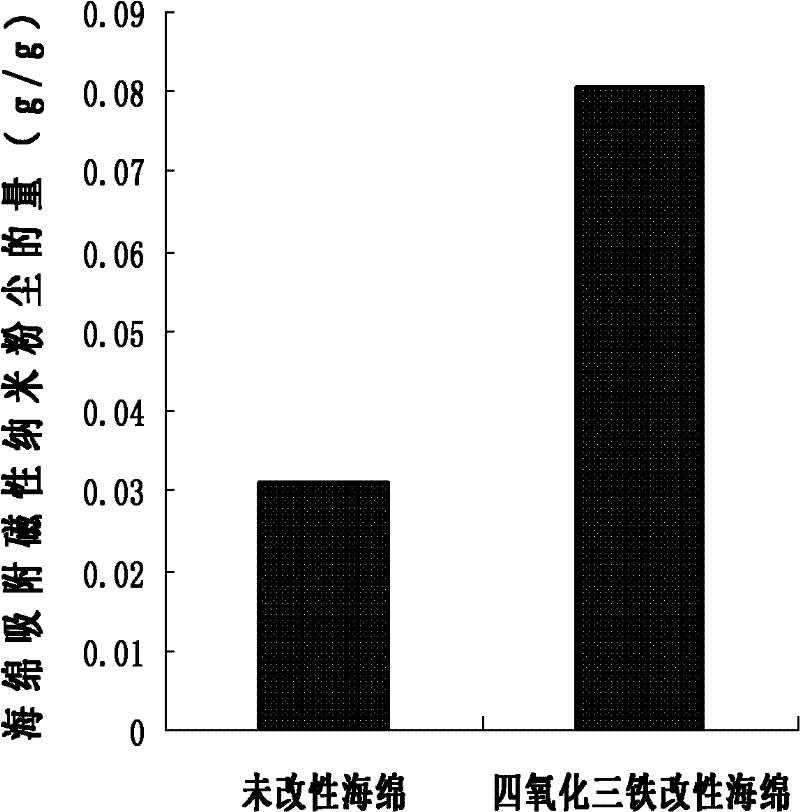

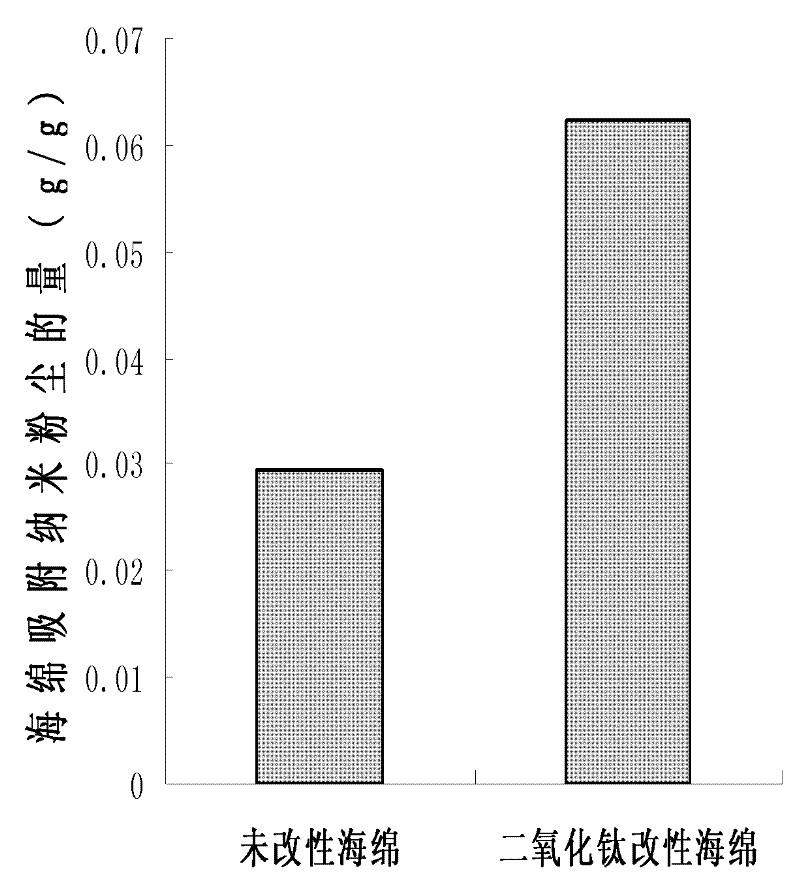

Inorganic nanoparticles-modified polyurethane sponge mask material, and preparation method and application thereof

InactiveCN102190882ARegular 3D network structureRegular three-dimensional network structure, poresProtective garmentFiberCarbon fibers

The invention provides an inorganic nanoparticles-modified polyurethane sponge mask material and a preparation method thereof, and also provides application of the inorganic nanoparticles-modified polyurethane sponge mask material in manufacturing a mask. In the invention, the inorganic nanoparticles used for modifying sponge comprise magnetic Fe3O4 nanoparticles, magnetic Fe2O3 nanoparticles, TiO2 nanoparticles, ZnO nanoparticles, mesoporous SiO2, carbon nanotubes and carbon fibers. The inorganic nanoparticles have the advantages of small particle size, large specific surface area, strong adsorption performance and like and contain charges on the surfaces, and a plurality of the nanoparticles have strong ultraviolet absorption capability, photocatalytic activity, and antibacterial and antiviral actions. The inorganic nanoparticles-modified polyurethane sponge mask material provided by the invention has high efficiency and capability in filtering out sub-micron dust, viruses and bacteria, has the function of adsorbing poisonous and harmful gases, has the characteristics of small gas absorption resistance, simple preparation method, low cost and broad application future, and can be recycled through water washing.

Owner:HUAZHONG UNIV OF SCI & TECH

Sintering-strippable red cast iron coating and preparation method thereof

InactiveCN102601300APrevent sticky sandAvoid sand inclusionsFoundry mouldsFoundry coresCrack resistancePreservative

The invention relates to a sintering-strippable low-cost red water-based cast iron coating, which is prepared by the following raw materials in percent by mass: 20-45 percent of bauxite powder or powder quartz, 0-25 percent of mullite powder, 1-6 percent of talcum powder, 1-5 percent of iron trioxide powder, 1-3 percent of suspending agent, 1.5-4.5 percent of organic binding agent, 1.5-6 percent of inorganic binding agent, 0.01-0.05 percent of wetting agent, 0.02-0.05 percent of preservative, 0.02-0.1 percent of defoaming agent, 0-0.5 percent of water reducing agent and 30-42 percent of tap water. The sintering-strippable low-cost red water-based cast iron coating has the characteristics that the raw materials are cheap and the source is wide; the product is low-cost, safe, environmental-friendly and convenient to transport; the brushing property, the flowing resistance and the leveling property of the product are good, the suspension percentage, the coating strength and the crack resistance are high and the gas evolution is low; and the sintering-stripping performance is excellent, the most part of the coating can be vastly stripped after castings are taken out of a casting box and are cooled, the defects of sand sticking, sand inclusion, sand drop, voids and the like existing the castings can be effectively avoided, and the castings with excellent surface quality can be obtained.

Owner:湖北省机电研究设计院股份公司

A kind of copper red glaze and its production method and the method for making ceramic product with it

The invention discloses copper red glaze and a production method thereof, and a method for preparing a ceramic product therefrom. The copper red glaze is prepared from parent glaze, a coloring agent and a stabilizing agent, wherein the parent glaze is prepared from the following components in parts by weight: 26 to 32 parts of quartz, 24 to 30 parts of feldspar, 10 to 14 parts of limestone, 12 to16 parts of barium carbonate, 4 to 8 parts of clay, 0 to 4 parts of zinc oxide and 0 to 4 parts of sodium borate; the coloring agent is one or a mixture of a plurality of copper oxide, cuprous oxide and copper carbonate, and the adding amount of the coloring agent is 1 to 4 parts by weight; the stabilizing agent is one or a mixture of a plurality of stannic oxide, ferric oxide, lead oxide and silicon carbide, and the adding amount of the stabilizing agent is 3 to 6 parts by weight. According to the invention, the copper red glaze is bright crimson red, the ceramic product produced from the copper red glaze has high yield and low cost, and can be used for producing domestic ceramic and display art ceramic products.

Owner:广东文化长城集团股份有限公司

Functional wallpaper material capable of purifying air

InactiveCN101333788AAvoid pollutionImprove indoor air qualityNon-fibrous pulp additionSpecial paperIndoor air qualityPolyvinyl chloride

Disclosed is a functional type wallpaper material having the air purification function, belonging to the interior decoration material technique field, and containing the components, in weight percentage: 1.5 percent to 2.5 percent of titanium dioxide nano-sized powder, 1 percent to 2.5 percent of silicon dioxide nano-sized powder, 0.5 percent to 1.5 percent of zinc oxide powder, 2 percent to 3.5 percent of negative ion powder, 0.5 percent to 1.5 percent of inorganic antibacterial powder, 0.5 percent to 1 percent of iron trioxide, 4 percent to 6 percent of conductive powder, 2.5 percent to 5 percent of polyaniline, 25 percent to 31 percent of polyvinyl chloride, 5 percent to 5.5 percent of titanium pigment, 15 percent to 18.5 percent of di-n-octyl phthalate dioctyl phthalate, 12.5 percent to 18 percent of calcium carbonate, and 3 percent to 30 percent of auxiliary agent. The wallpaper prepared by the materials can remove formaldehyde and peculiar smell, and is antibacterial and mildew-proof, and can release negative ions and resist electromagnetic radiation, as well as greatly improving the indoor air quality for people and solving the indoor air pollution.

Owner:SHANGHAI JIAO TONG UNIV +1

Water purification ceramic material and preparation method thereof

InactiveCN102219498ATo promote metabolismEfficient dischargeWater/sewage treatment by irradiationWater/sewage treatment by substance additionCalciteRare earth

The invention discloses a water purification ceramic material and a preparation method thereof, relating to a ceramic material. The invention provides a water purification ceramic material capable of releasing negative ions, radiating far infrared rays, resisting bacteria, removing residual chlorine, removing heavy metal and purifying water, and a preparation method thereof. Main components of the water purification ceramic material are tourmaline, copper oxide and iron trioxide. Auxiliary components of the water purification ceramic material are at least one of quartz, calcite, kaolin, feldspar, talc, zirconium oxide, titanium oxide, manganese dioxide, cobalt trioxide and the like. The preparation method comprises the following steps of: mixing the main components; then, mixing the mixedmain components with at least one of the auxiliary components; crushing; screening; ball-milling to obtain a mixture; then sintering to synthesize a spinel type copper oxygen body substrate material;crushing and ball-milling the spinel type copper oxygen body substrate material to form a substrate material; with at least one of copper salt, zinc salt, inorganic silver salt and rare earth metal as a metal source, dissolving the metal source in water to prepare a solution; adding the copper oxygen body substrate material to the solution and adsorbing to form a combination body; after sintering, introducing reducing gas; and forming to obtain the water purification ceramic material.

Owner:XIAMEN BAILIN WATER PURIFICATION TECH CO LTD

Basic glaze for ink jet printing, preparation method of basic glaze, and ceramic tile

The invention discloses a basic glaze for ink jet printing, a preparation method of the basic glaze, and a ceramic tile. The basic glaze for the ink jet printing comprises the following chemical components by weight percentage: 2.0-3.0% of igloss, 13.0-17.0% of aluminium oxide, 64.0-69.0% of silicon dioxide, 0.05-0.2% of ferric oxide, 0.3-0.9% of calcium oxide, 3.0-6.0% of magnesium oxide, 1.4-2.0% of potassium oxide, 1.4-2.0% of sodium oxide, 0.03-0.10% of titanium oxide, 5.0-10.0% of zirconium dioxide and hafnium oxide, 0.01-0.2% of lithium oxide, and 0.1-2.0% of zinc oxide. The basic glaze for the ink jet printing is free from such defects as deformation, bubbles, pin holes, sewage suction and poor color when an ink jet printing technique is used, and a fabricated product has good color, the surface of a glazed tile is fine and smooth, and the product quality and effect can be improved.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD

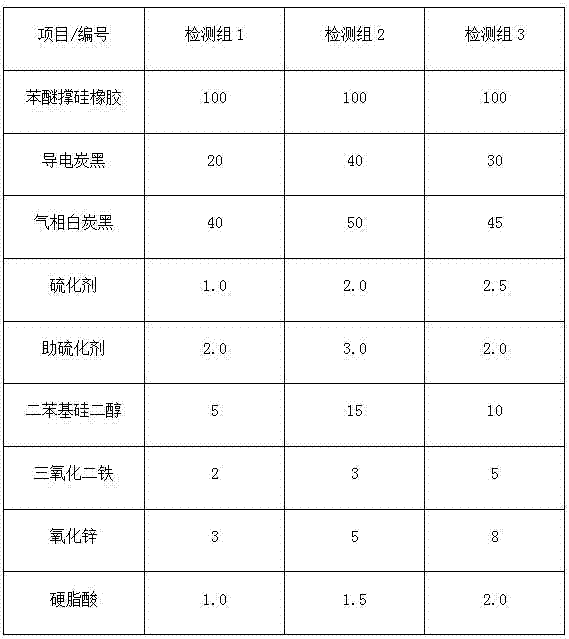

Semiconductive silicon rubber shielding material for radiation-resistant cable, and preparation method thereof

InactiveCN102964841AImprove radiation resistanceImprove plasticityInsulated cablesInsulated conductorsPolymer sciencePhenyl Ethers

The invention relates to a semiconductive silicon rubber shielding material for a radiation-resistant cable, and a preparation method of the material, belonging to the technical field of cable shielding material. The semiconductive silicon rubber shielding material comprises the raw material components in parts by weight: 100 parts of silicon rubber, 20-40 parts of conductive carbon black, 40-50 parts of white carbon black, 1.0-2.5 parts of dicumyl peroxide, 2.0-3.0 parts of auxiliary vulcanizing agent, 5-15 parts of diphenyl silanediol, 1.0-2.0 parts of stearic acid, 4-6 parts of zinc oxide and 2-5 parts of ferric oxide, wherein the silicon rubber is phenyl ether supporting silicone rubber or phenylene silicone rubber; and the auxiliary vulcanizing agent is triene propyl cyanurate. The silicon rubber shielding material is good in radiation-resistant performance, and can give play to the specified function for a long time on radiation occasion when being used as a shielding layer of an electric wire and the cable.

Owner:SICHUAN MINGXING CABLE

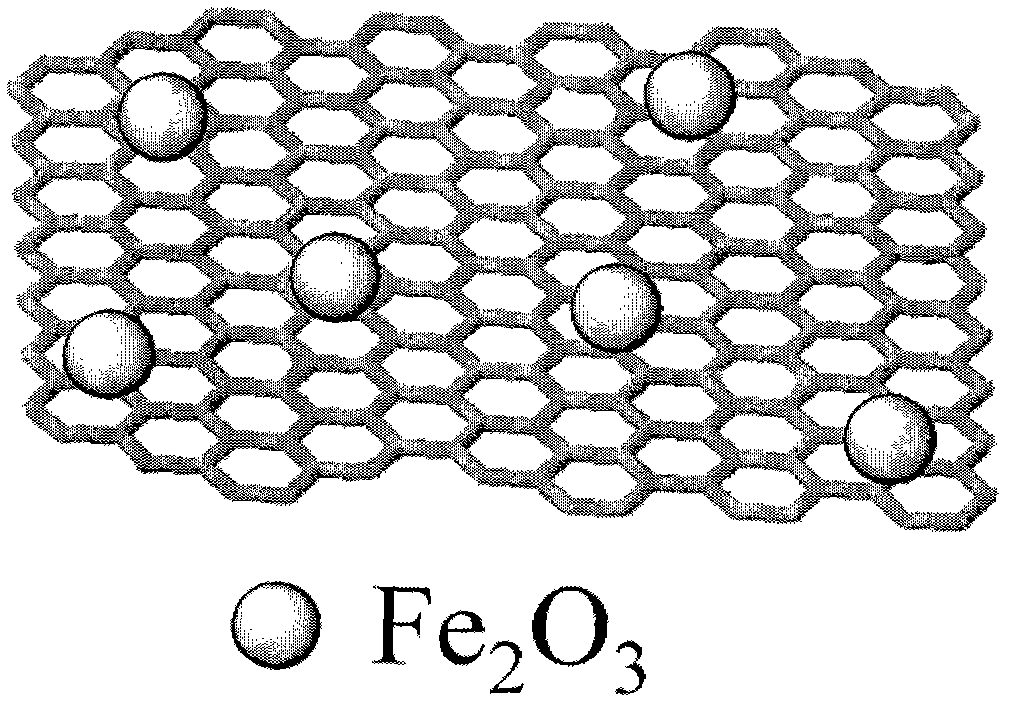

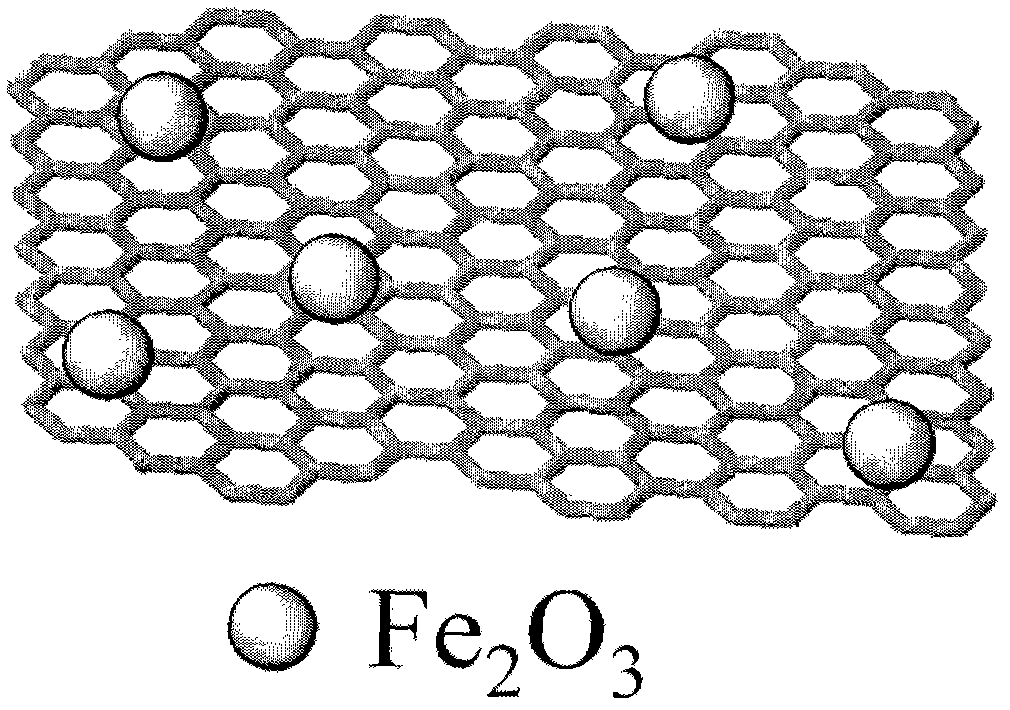

Environment-friendly and efficient method for preparing iron sesquioxide/graphene composite material

The invention relates to an environment-friendly and efficient method for preparing an iron sesquioxide / graphene composite material. In the method, cheap and abundant soluble ferrous salt serves as an iron source and reducing agent, graphene oxide is quickly reduced into the graphene by the characteristics of microwave heating, and ferrous is oxidized and converted into iron sesquioxide so as to obtain a sesquioxide / graphene composite material. The environment-friendly and efficient method fully utilizes the characteristics of ferrite, has the advantages of simple and efficient preparation technology, no industrial three-waste pollution and stable product performance and is favorable for producing on a large scale, and a product has a wide application prospect in the cathode material of a lithium-ion secondary battery.

Owner:BEIJING ZHONGKE MICRO NANO NETWORKING SCI TECH

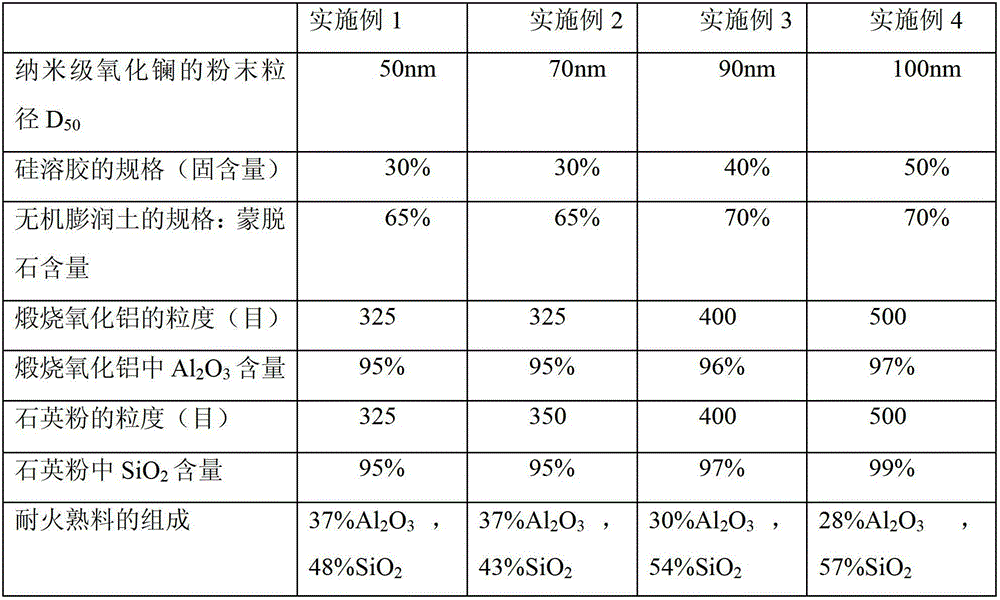

Infrared energy-saving coating of high-temperature kiln and preparation method thereof

Owner:CHINA SILICON ZIBOCERAMIC TECH

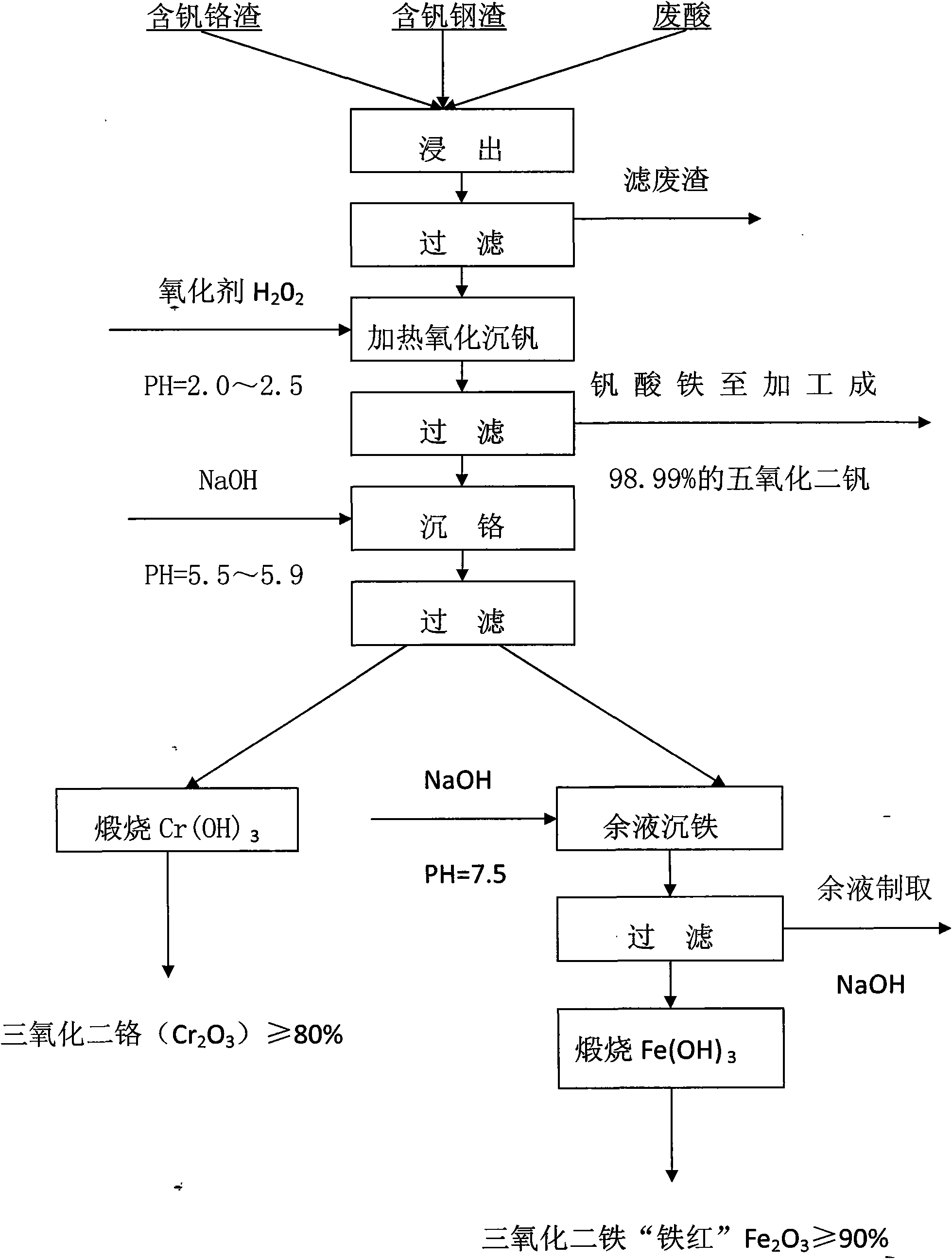

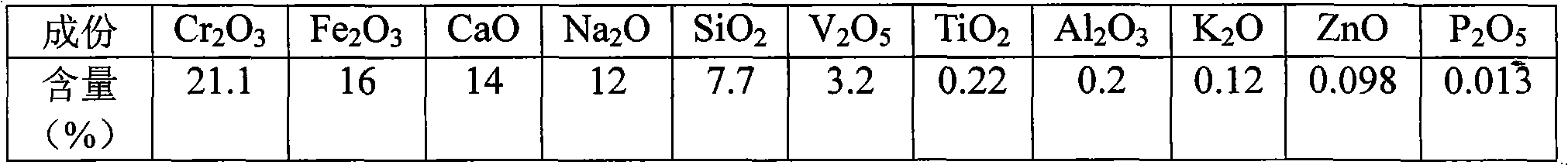

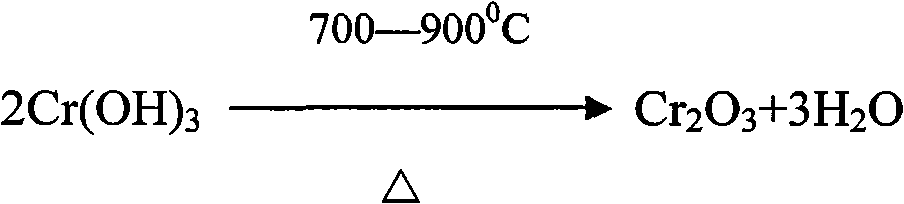

Process for extracting vanadium and chromium from chromic slag by using waste acid of titanium powder plant

InactiveCN101979683AFiltration process goes wellAchieve the purpose of separationProcess efficiency improvementChromium(III) hydroxideSlag

The invention discloses a method for separating and extracting vanadium and chromium. The method comprises the following steps of: (1) producing chromium fine sand (Cr2O3) of which the content is over 80 percent and ferric vandate of which the content is over 20 percent from two waste materials by taking waste acid of a titanium powder plant as a leaching agent and vanadium-chromium slag (containing 2.5 to 4.5 percent of vanadium and 14 to 25 percent of chromium) as a raw material; (2) putting the vanadium-chromium slag into the waste acid to allow the chromium and the vanadium in the slag to form chromium sulfate and vanadyl sulfate which can be dissolved in water very easily, wherein the leaching time is about 6 hours; (3) adding a certain amount of steel making steel slag during leaching to fulfill the aim of generating a great deal of calcium sulfate when a great deal of calcium oxide meets the acid during filtration, and wrapping, adsorbing or and stopping 'silica gel' formed by silicon dioxide in the chromium slag by the calcium sulfate which is used as a filter medium to ensure that the filtration is performed smoothly; (4) adjusting the pH value of the filtrate to be 2.5 by using sodium hydroxide, and then adding an oxidant and oxydol to ensure that the chromium in the solution is oxidized to be hexavalent, the iron is oxidized to be trivalent, and the vanadium is oxidized to be pentavalent; (5) heating the leaching solution to the temperature of between 70 and 90 DEG C to ensure that the vanadium and the iron is combined together to generate water-fast 'ferric vandate', wherein the time for thermal precipitation is about one hour, and the vanadium residual in the solution is not more than 0.4 g / L; (6) adding sodium hydroxide into the solution of which the ferric vandate is filtered out, and fully stirring the mixture until the pH value of the solution is between 5.5 and 5.9 to ensure that the chromium in the solution is completely converted into chromium.

Owner:PANZHIHUA SHUOSHENG IND & TRADING

Iron-removing concentrating process of potash feldspar

InactiveCN101028610ARich varietyNo flappy problemsSievingScreeningResource utilizationDiiron Trioxide

An iron-removing ore dressing technology for potash feldspar includes such steps as washing, breaking, sorting, concentrating, purifying, washing with sulfuric acid and sieving. It has high output (more than 90%), low content of Fe (less than 0.24%) and more by-products (silt, Fe, mica, Fe2O3 and Fe3O4).

Owner:王连民

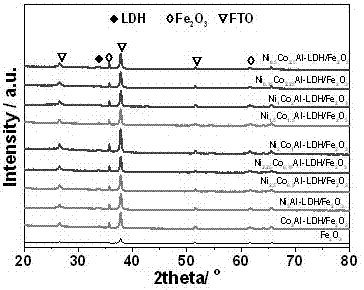

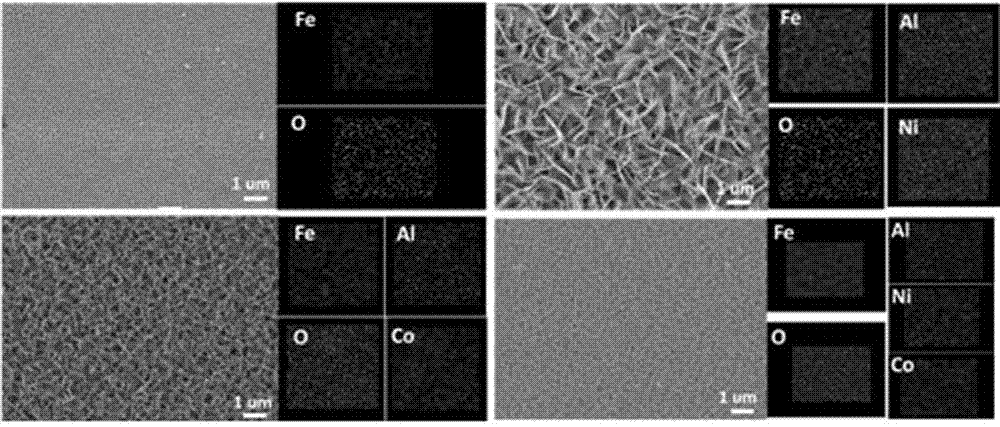

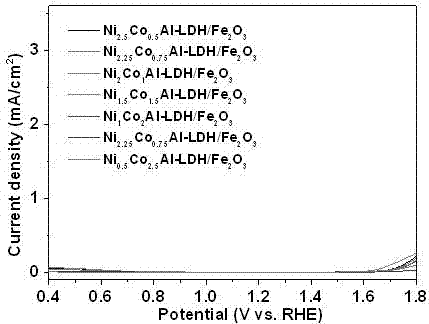

NiCoAl-LDH-modified ferric oxide composite photoanode material and preparation method and application thereof

ActiveCN107268021AEasy to buyEasy to manufactureCell electrodesHeterogenous catalyst chemical elementsOxide compositeHydrolysis

The invention relates to a preparation method of a NiCoAl-LDH-modified ferric oxide composite photoanode material. The preparation method comprises the specific steps that 1), Ni(NO3)2, Co(NO3)2 and Al(NO3)3 are dissolved into deionized water and prepared into a mixed salt solution, and the total molar concentration of the mixed salt solution ranges from 0.010 mol / L to 0.200 mol / L; 2), urea and NH4F are added to the mixed salt solution, wherein the molar concentration of the urea ranges from 0.025 mol / L to 0.500 mol / L, and the concentration of NH4F ranges from 0.010 mol / L to 0.200 mol / L; 3), the mixed solution obtained in second step is transferred into a hydrothermal kettle, and a Fe2O3 electrode plate is put into the hydrothermal kettle, a constant-temperature reaction is conducted in a drying oven at the temperature of 80-150 DEG C for 1-6 hours, taking-out is conducted after the reaction is completed, washing and drying are conducted, and then the NiCoAl-LDH-modified ferric oxide composite photoanode material is obtained. According to the preparation method, FTO loaded with Fe2O3 serves as a substrate, the in-situ growth of the NiCoAl-LDH activity protection layer is conducted through a hydrothermal method, the conductivity of a catalyst is improved, and the separation and migration of a photon-generated carrier are promoted; meanwhile active sites are provided for oxidation of water or biomass, and the reaction overpotential is lowered effectively; and migration from H+ to the solution can be promoted as well, the Fe2O3 hydrolysis is inhibited, and the stability of the NiCoAl-LDH-modified ferric oxide composite photoanode material is improved.

Owner:HENAN UNIVERSITY

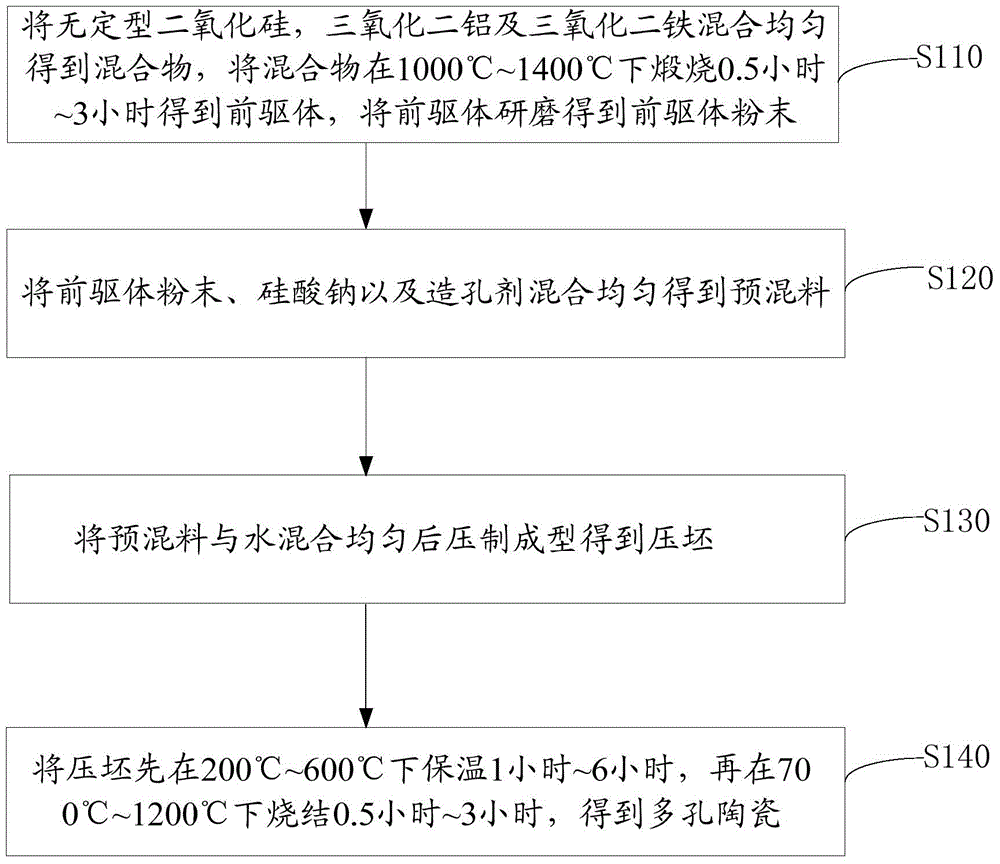

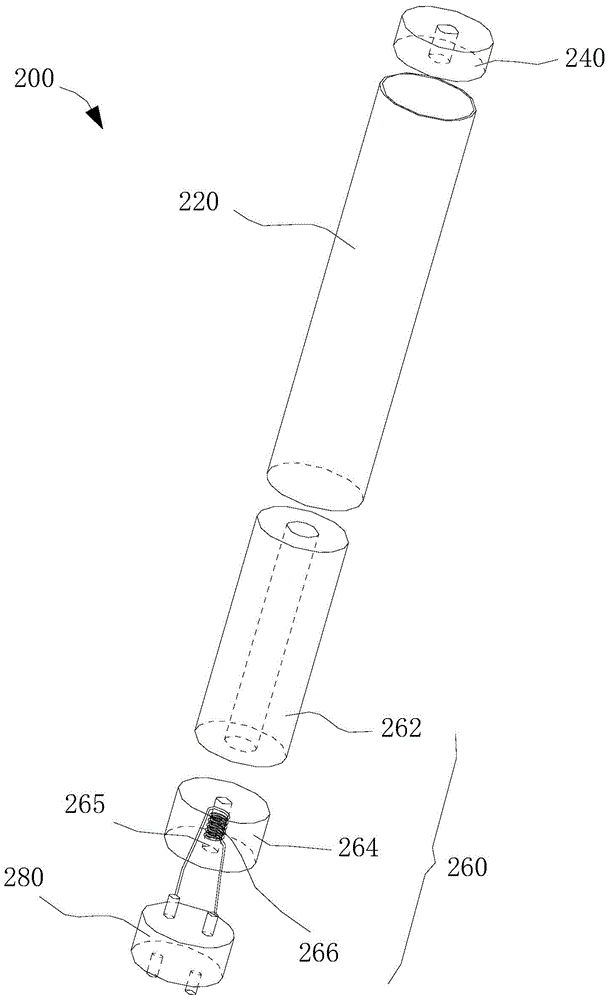

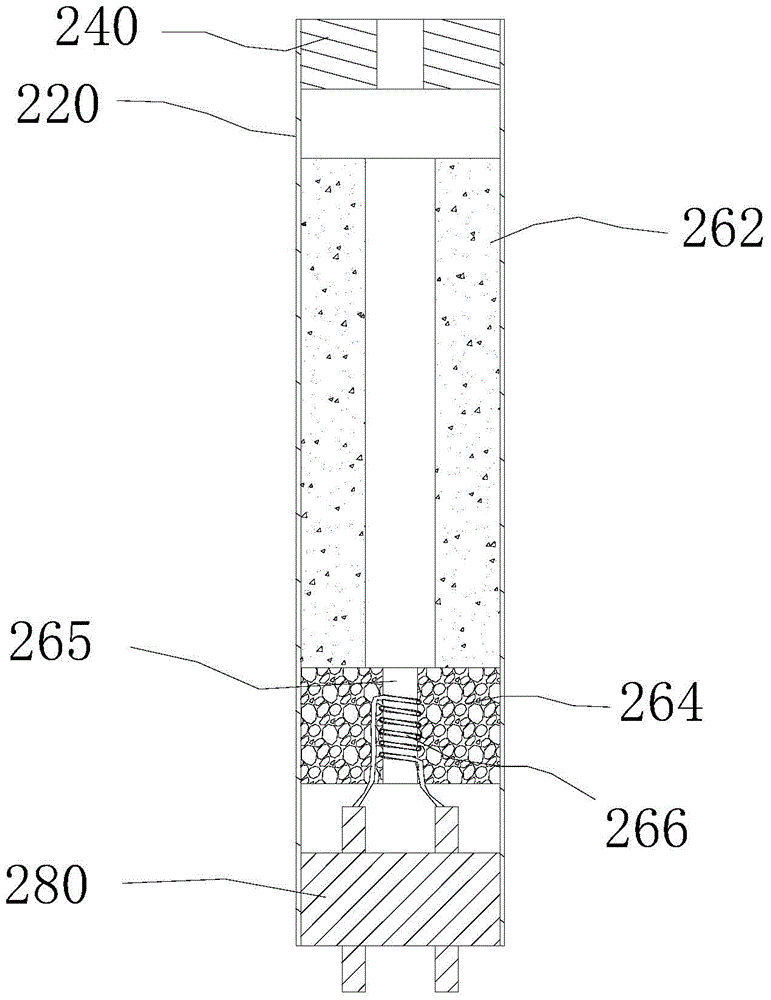

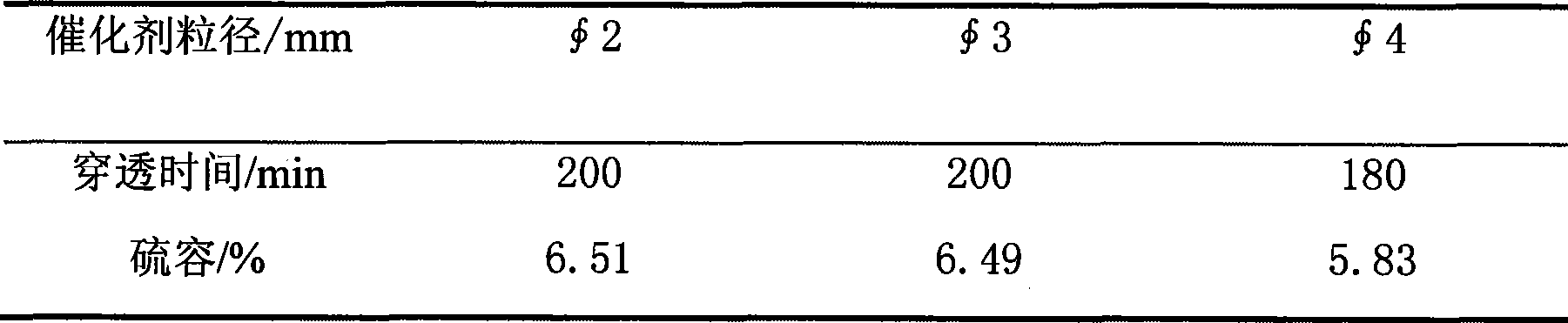

Porous ceramics preparation method, porous ceramics and application thereof

ActiveCN105294140AGuaranteed porosityHigh strengthTobacco devicesCeramicwareCompression moldingElectronic cigarette

The present invention relates to a porous ceramics preparation method, porous ceramics and application of the porous ceramics in electronic cigarettes. The porous ceramics preparation method comprises the following steps: uniformly mixing amorphous silica, alumina and ferric oxide to obtain a mixture; calcining the mixture at a temperature of 1000 C DEG-1400 C DEG for 0.5-3 hours to obtain a precursor; grinding the precursor to obtain precursor powder, wherein the mixture comprises, by mass percentage, 80%-98% of the amorphous silica, 1%-10% of the aluminum oxide, and 1%-10% of the ferric oxide; uniformly mixing the precursor powder, sodium silicate, and a pore-forming agent to obtain a premix; uniformly mixing the premix and water for compression molding to obtain a green compact; keeping the green compact at a temperature of 200 C DEG-600 C DEG for 1-6 hours; and then sintering the kept green compact at a temperature of 700 C DEG-1200 C DEG for 0.5-3 hours to obtain the porous ceramic.

Owner:SHENZHEN SMOORE TECH LTD +1

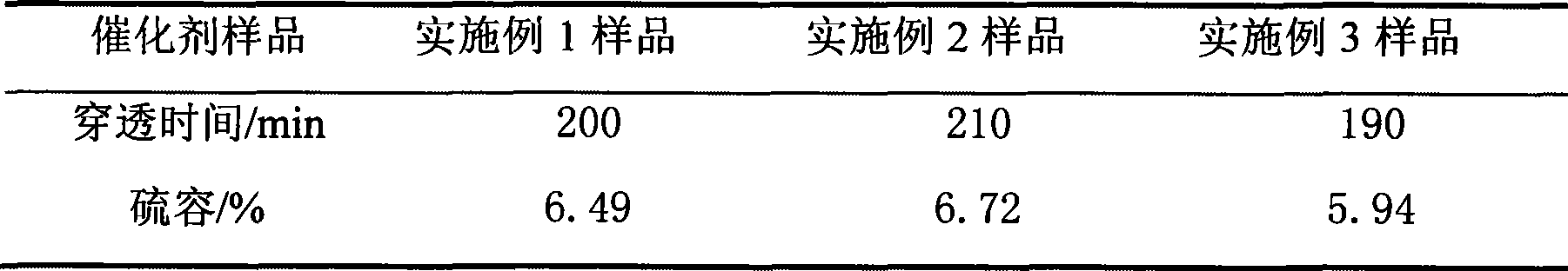

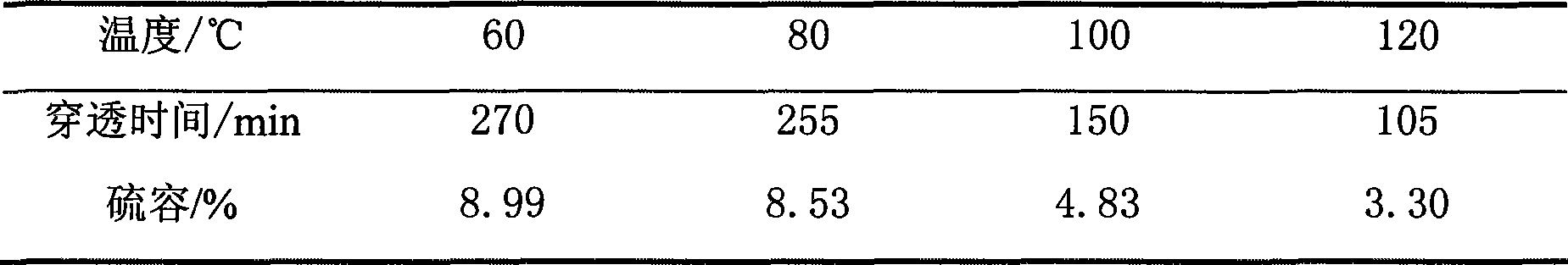

Semi-coke forming SO2and NO adsorptive catalyst and preparation method thereof

InactiveCN101362101AWide range of semi-focus sourcesRelieve pressureOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsSodium BentoniteAdhesive

The invention discloses a shaped semi-coke SO2 and NO adsorption catalyst and a preparation method thereof. The catalyst comprises 70wt percent to 80wt percent of active semi-coke, 10wt percent to 20wt percent of adhesive, 0.5wt percent to 4.0wt percent of pore-forming agent, 1.5wt percent to 4.5wt percent of kaoline and / or bentonite, 1.0wt percent to 2.0wt percent of vanadium pentoxide and / or ferric oxide, 1.0wt percent of polyethylene glycol and 0.2wt percent to 0.5wt percent of graphite (all are according to the weight percentage). The preparation method comprises the steps that the semi-coke is firstly treated with nitric acid pre-treatment, then added with the adhesive and other catalyst promoters to be extruded and shaped and then dried and activated with high-temperature vapor under oxygen to obtain the shaped semi-coke adsorption catalyst. The catalyst can remove not only sulfur dioxide from flue, but also NO, thus having good prospect of application.

Owner:OCEAN UNIV OF CHINA

MnZn ferrite material with high magnetic conductivity and manufacturing method thereof

ActiveCN101859621AImprove permeabilityOvercoming featureInorganic material magnetismCurie temperatureDiiron Trioxide

The invention provides an MnZn ferrite material with high magnetic conductivity, which comprises the following main components: 50 to 54mol% of ferric oxide calculated by Fe2O3, 22 to 30mol% of trimanganese tetroxide calculated by MnO, 20 to 24mol% of zinc oxide calculated by ZnO and auxiliary components selected from at least four of TiO2, Co2O3, V2O5, Bi2O3, MoO3, SiO2 and CaCO3. In the MnZn ferrite material with high magnetic conductivity, which is provided by the invention, the initial magnetic conductivity is greater than 15000, the Curie temperature is greater than 120 DEG C, and the normal-temperature saturation magnetic induction strength is greater than 410mT. The invention also provides a manufacturing method of the MnZn ferrite material with high magnetic conductivity, which comprises the steps of mixing, drying, pre-sintering, ball milling, granulating, pressing, forming and sintering. The method provided by the invention has the advantages of simple process and low cost.

Owner:江门江益磁材有限公司

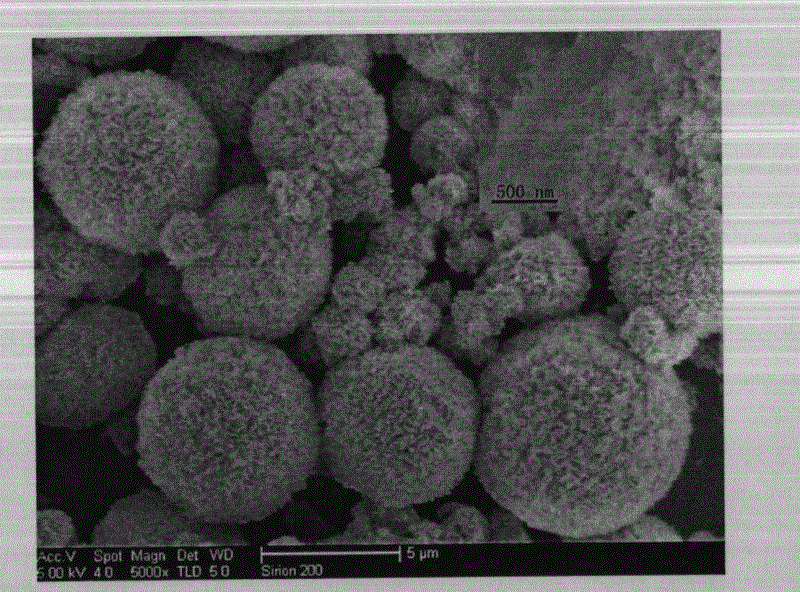

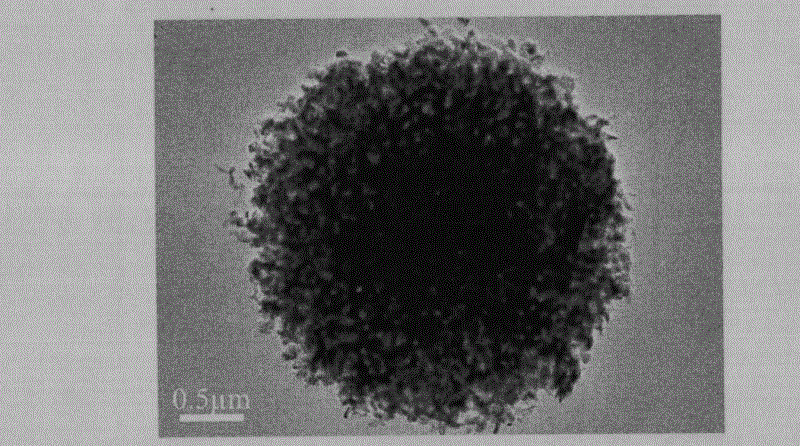

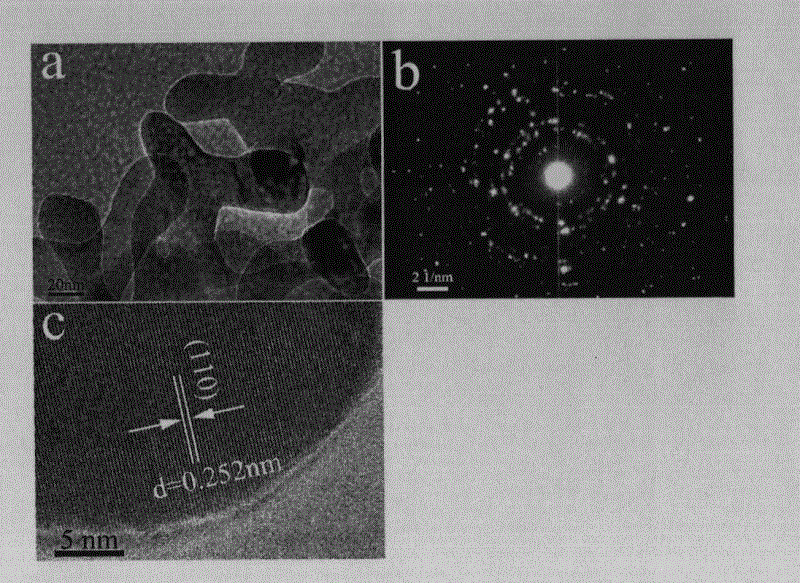

Fe2O3 micro-nano porous sphere, preparation method thereof and uses thereof

InactiveCN102616861ALarge specific surface areaImprove thermal stabilityWater/sewage treatment by irradiationOther chemical processesMicro nanoOrganic dye

The invention discloses a Fe2O3 micro-nano porous sphere, a preparation method thereof and uses thereof. The porous sphere is formed by Fe2O3 nanoparticles having a nanometer mesoporous alpha-Fe2O3 phase structure therebetween, wherein the diameter of the sphere is 500-5000nm, the specific surface area of the sphere is 15-25m<2> / g, particle sizes of the particles are 20-60nm, and pore diameters of mesopores are 2-50nm. The method comprises the following steps: mixing ferric chloride hexahydrate, ascorbic acid, urea and water, and uniformly stirring them to obtain a mixed liquid; reacting the mixed liquid under conditions that the temperature is 140-180DEG C and the pressure is a self-generated pressure for at least 4h to obtain an intermediate product; separating, washing and drying the intermediate product to obtain porous iron carbonate; and annealing the porous iron carbonate at 450-550DEG C for at least 4h, and naturally cooling the porous iron carbonate to room temperature to prepare the Fe2O3 micro-nano porous sphere. The Fe2O3 micro-nano porous sphere can be placed in water polluted by organic dyes to photocatalytically degrade under visible light, or in water polluted by potassium dichromate to adsorb.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

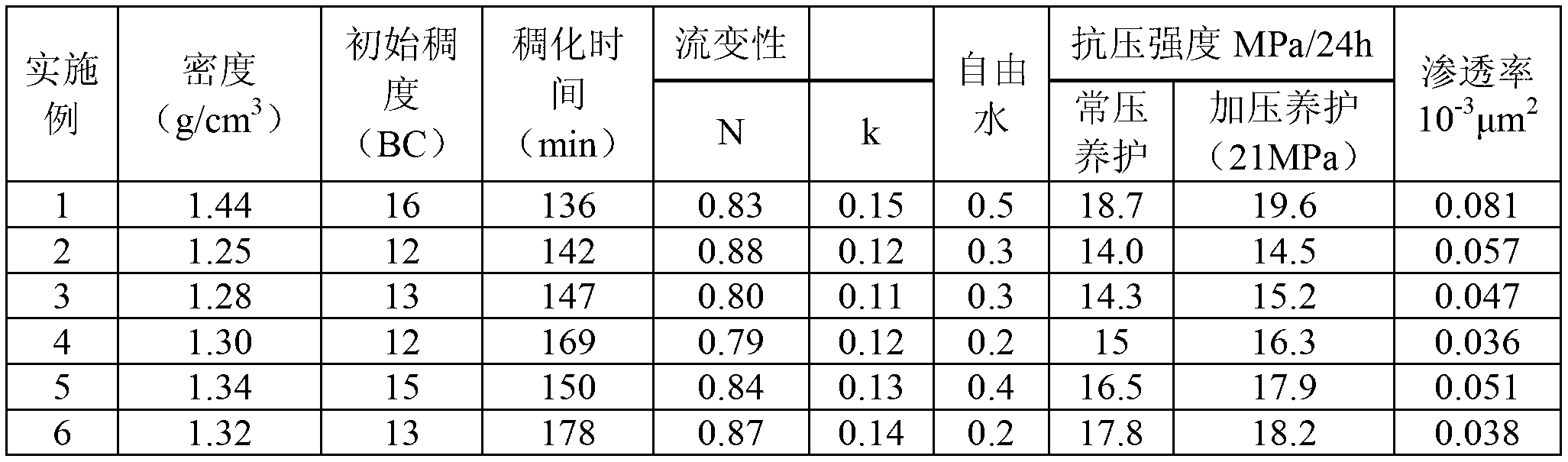

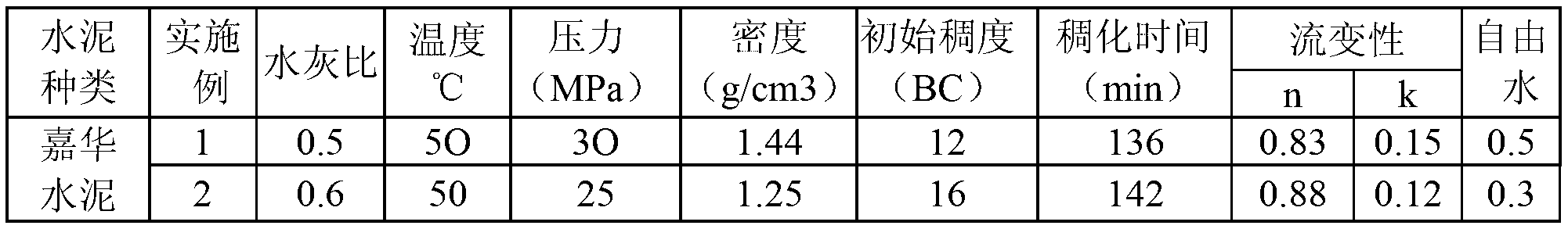

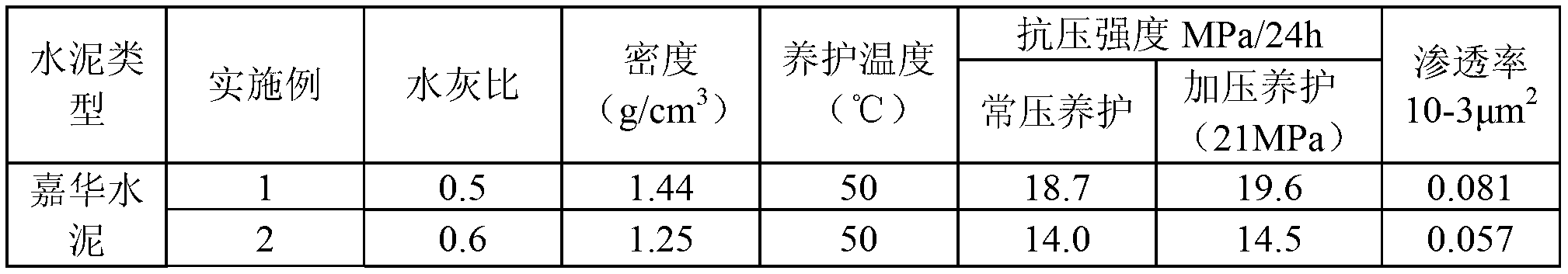

Cement slurry and preparation method and application thereof

ActiveCN103224772AReduce penetrationImprove compactnessDrilling compositionSealing/packingMicrosphereDiiron Trioxide

The present invention relates to a cement slurry and a preparation method and application thereof, wherein the cement slurry includes the following components in parts by weight of 65 to 75 parts of cement, 20 to 30 parts of reducing agent, 3 to 6 parts of reinforcing agent, 0.3 to 1 parts of filtrate reducer, 2 to 4 parts of early strength agent, 0.6 to 1.0 parts of retarder, 60 to 80 parts of water, wherein the reducing agent is the hollow microsphere containing main components of silicon dioxide, aluminum oxide, lime, magnesium oxide and ferric oxide, with particle size of between 56 and 360Mum and density of 0.80g / cm3; the reinforcing agent powder has specific surface area of between 15 and 20m2 / g and particle size range of between 0.1 and 200 Mum with particle size distribution of 0.1 Mum: 15%; 0.1-0.5 Mum: 45-50%; 0.5-1.0 Mum: 10-20%; 1.0-3.0 Mum: 5-10%; 3.0-10.0 Mum: 5%; 10.0-200 Mum: 7-12%. The cement slurry can adequate return the slurry to the top position and improve the cementing quality of low-pressure leaky well section. The cement slurry has small initial consistency, which is beneficial for on-the-site mixing, flow resistance reducing, and the high-temperature performance is table and the thickening time is adjustable.

Owner:PETROCHINA CO LTD

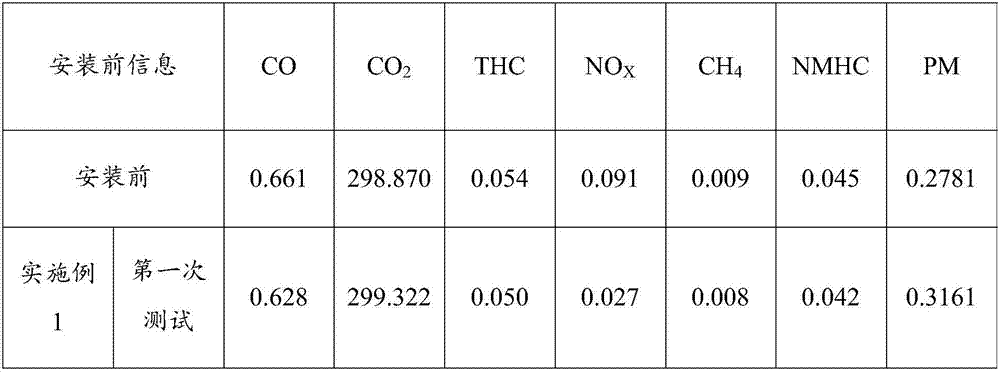

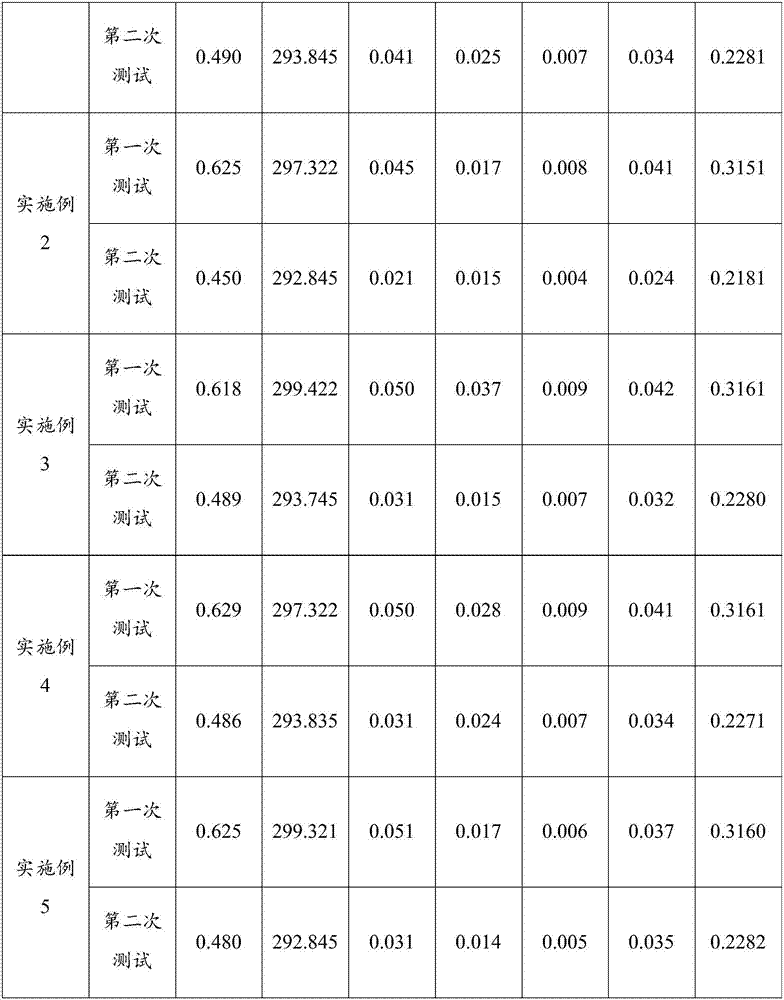

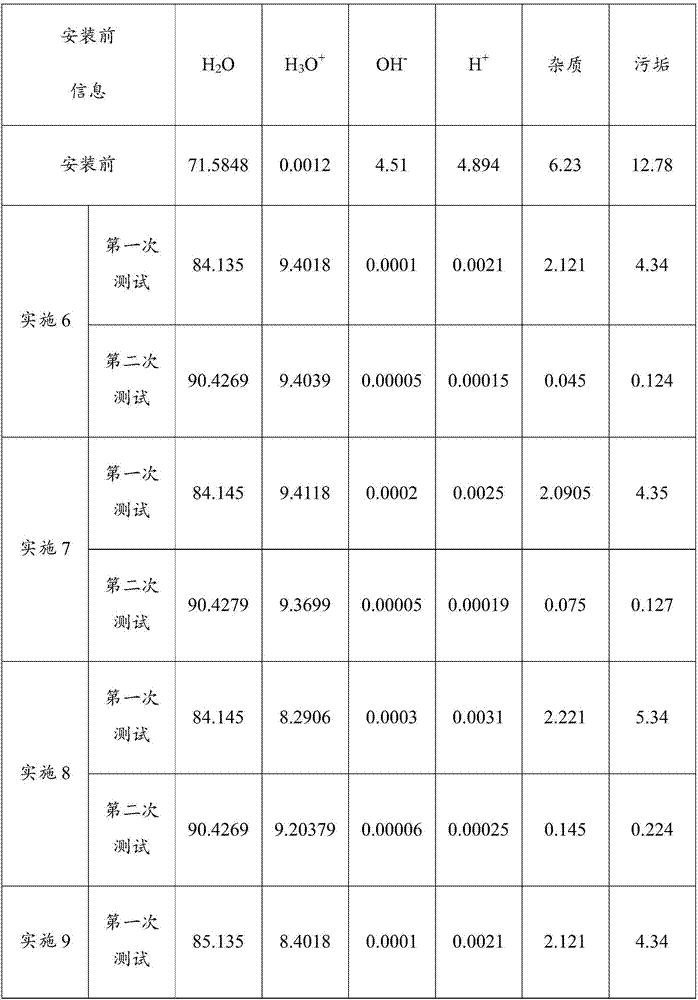

Terahertz radiating material and preparation method and application thereof

InactiveCN106883896ALower activation energyLow viscosityLiquid carbonaceous fuelsCombustionSesquioxide

The invention relates to the field of energy source and environment and particularly discloses a terahertz radiating material and a preparation method and application thereof. The terahertz radiating material is prepared from various raw materials which comprise the following components in parts by weight: 30-85 parts of silicon dioxide powder, 5-30 parts of aluminum oxide aluminum powder, 1-20 parts of iron sesquioxide powder, 1-15 parts of zirconium compound powder, 1-10 parts of potassium oxide powder and 0.01-0.1 part of a rare earth oxide. The preparation method comprises the specific steps of: mixing the various raw materials; and sintering the raw materials at 500-1800 DEG C. The radiating material has high terahertz radiating property, can emit terahertz waves to induce molecular resonance of oil molecules or water molecules, reduce the activating energy and promote reaction. The terahertz radiating material is applied to fuel oil to improve the combustion efficiency, and is applied to tape water to purity the water.

Owner:SICHUAN FULI ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com