MnZn ferrite material with high magnetic conductivity and manufacturing method thereof

A technology of ferrite materials and high magnetic permeability, which is applied in the direction of magnetic properties of inorganic materials, can solve the problems of limiting the temperature range and anti-saturation performance of high magnetic permeability materials, achieve low cost, simple process, and meet market demand Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

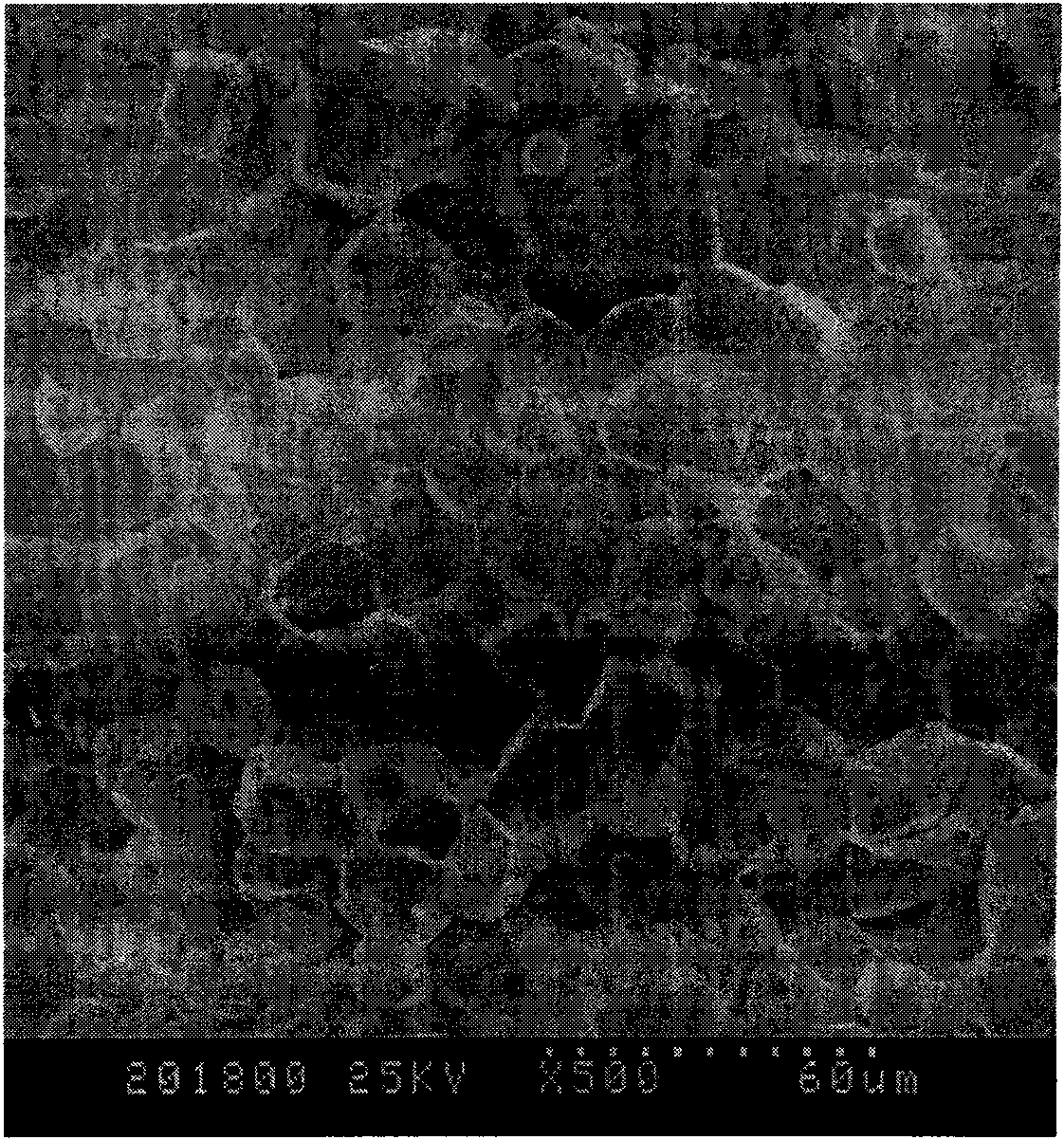

Image

Examples

example 1

[0016] Using commercially available Fe 2 o 3 , Mn 3 o 4 , ZnO as the main component, 52.0mol% Fe 2 o 3 , 25.0mol% MnO (raw material is Mn 3 o 4 ) and 23.0mol% ZnO were placed in a sand mill and mixed for 1 hour, then taken out and placed in a drying oven for drying. Use a box-type resistance furnace to pre-fire for 2 hours at 800°C-900°C. Then put the pre-fired powder into the ball mill, and add auxiliary ingredients at the same time, the auxiliary ingredients include Bi 2 o 3 、MoO 3 , CaCO 3 , SiO 2 , the addition amount is respectively 0.04wt%, 0.04wt%, 0.05wt%, 0.01wt% of the total weight of the main component, and then add 60wt% of deionized water and 1wt% of the total weight of the main component The dispersant and 1wt% defoamer are ball milled together. Ball mill the powder until the average particle size is about 1.0±0.2 μm, after drying, add 8wt% polyvinyl alcohol aqueous solution to the powder based on the total weight of the powder after ball milling, mi...

Embodiment 2

[0020] Using commercially available Fe 2 o 3 , Mn 3 o 4 , ZnO as the main component, 52.0mol% Fe 2 o 3 , 25.2mol% MnO (raw material is Mn 3 o 4 ) and 22.8mol% ZnO were placed in a sand mill and mixed for 1 hour, then taken out and placed in a drying oven for drying. Use a box-type resistance furnace to pre-fire for 2 hours at 800°C-900°C. Then put the pre-fired powder into the ball mill, and add auxiliary ingredients at the same time, the auxiliary ingredients include Bi 2 o 3 、MoO 3 , CaCO 3 、Co 2 o 3, the addition amount is respectively 0.04wt%, 0.04wt%, 0.08wt%, 0.03wt% of the total weight of the main component, and then add 60wt% of deionized water and 1wt% of the total weight of the main component The dispersant and 1wt% defoamer are ball milled together. Ball mill the powder until the average particle size is about 1.0±0.2 μm, after drying, add 8wt% polyvinyl alcohol aqueous solution to the powder based on the total weight of the powder after ball milling, ...

Embodiment 3

[0023] Using commercially available Fe 2 o 3 , Mn 3 o 4 , ZnO as the main component, 53.0mol% Fe 2 o 3 , 25.0mol% MnO (raw material is Mn 3 o 4 ), 22.0mol% ZnO was placed in a sand mill and mixed for 1 hour, then taken out and placed in a drying oven for drying. Use a box-type resistance furnace to pre-fire for 2 hours at 800°C-900°C. Then put the pre-fired powder into the ball mill, and add auxiliary ingredients at the same time, the auxiliary ingredients include Bi 2 o 3 、MoO 3 , V 2 o 5 、TiO 2 , the addition amount is respectively 0.04wt%, 0.04wt%, 0.05wt%, 0.05wt% of the total weight of the main component, and then add 60wt% of deionized water and 1wt% of the total weight of the main component The dispersant and 1wt% defoamer are ball milled together. Ball mill the powder until the average particle size is about 1.0±0.2 μm, after drying, add 6 wt% polyvinyl alcohol aqueous solution to the powder based on the total weight of the powder after ball milling, mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

| Grain | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com