Patents

Literature

3651results about How to "To satisfy the market's needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

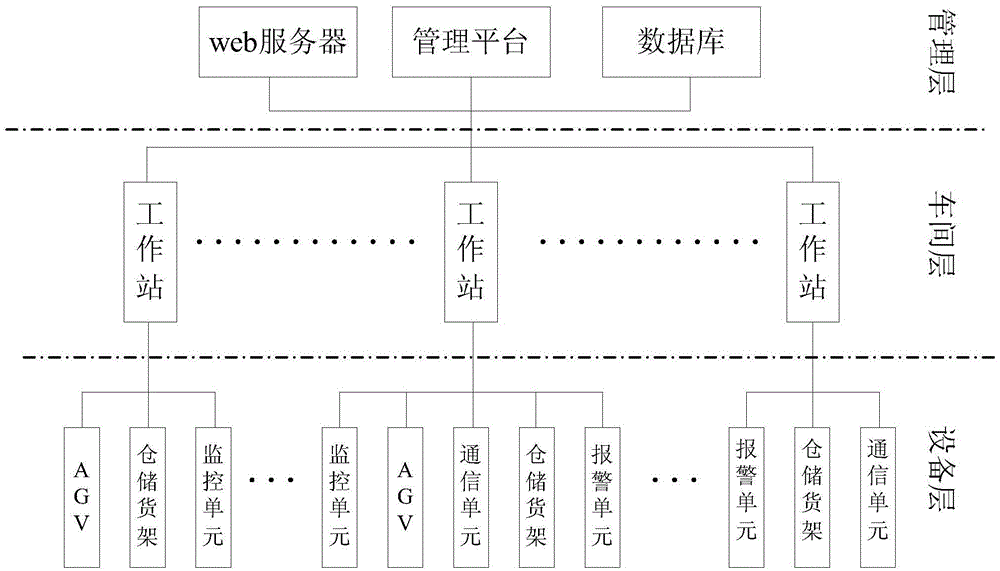

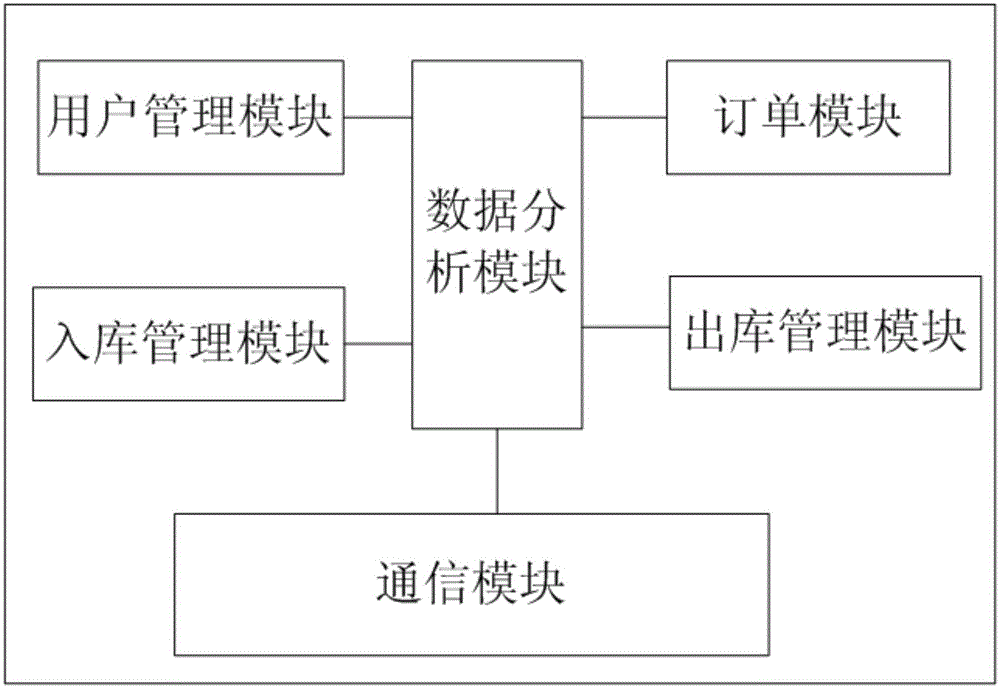

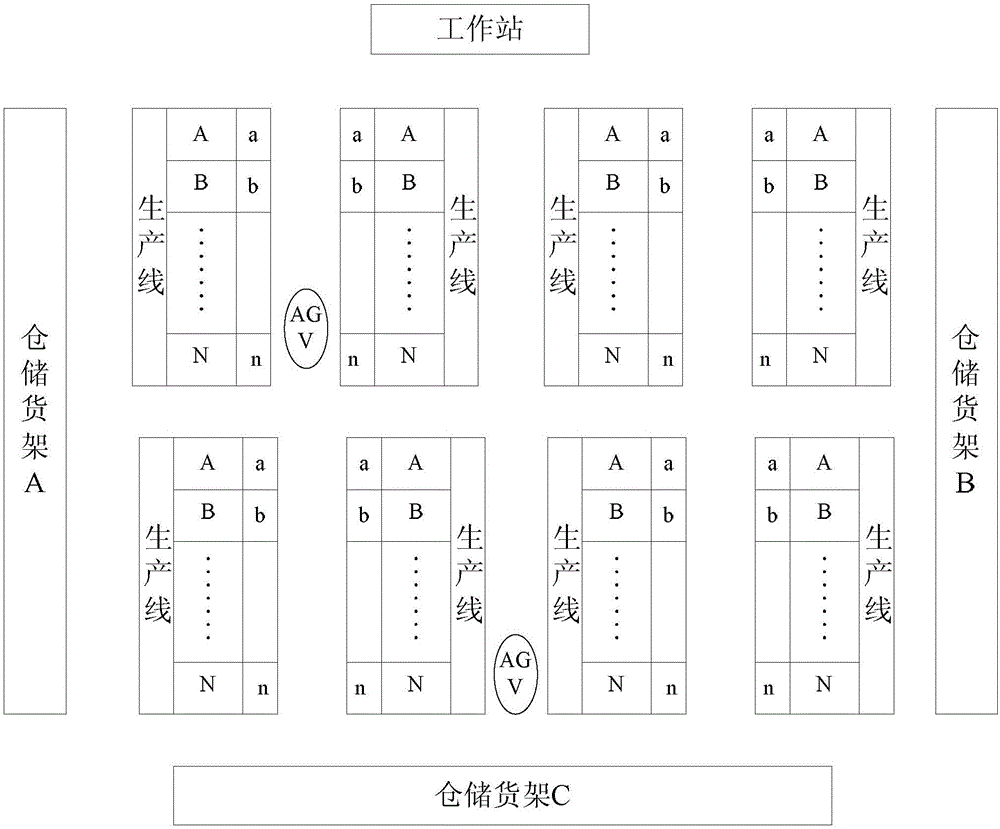

Automatic warehouse management method

Owner:GUANGDONG IND TECHN COLLEGE

Construction material produced by utilizing industrial residue

The invention discloses a construction material produced from industrial residue, aims to provide a construction material having the advantages of light weight, sound insulation, heat insulation, low cost, fire resistance, dense products, high rigidity and the like, and solves the problems with land occupation and pollute environment of phosphate slag and phosphogypsum at the same time. the invention is realized through the following technical scheme: phosphate slag and phosphogypsum are used as raw materials for producing the construction material, which comprises the following components by the weight part: 35 to 65 parts of phosphate slag, 10 to 40 parts of phosphogypsum, 5 to 15 parts of lime, 15 to 28 parts of cement, 0.1 to 0.4 part of light aggregate, 0.02 to 0.05 part of soluble glass, 0.02 to 0.05 part of water-reducing agent, 0 to 0.004 part of retarding agent, 0 to 0.005 part of early-strength admixture, and 0 to 0.008 part of foam killer; the components are weighed by the formula weight part and added to a blender; water is added to the blender with the water-to-material proportion being 4 to 10 and mixed evenly with the materials; and the solution is cast into a die and natural air dried after molding. Dies with different structures can be used according to purposes to conduct cast molding. The construction materials such as wall plates, guardrail decoration pillars, door and window sleeves, vase sleeves and the like can be produced.

Owner:张勇飞

Ultra centrifuge

InactiveCN102974474AImprove integrityGuaranteed uptimeMagnetic circuit rotating partsDynamo-electric gearsUltracentrifugeElectric machine

The invention discloses an ultra centrifuge. The ultra centrifuge solves the two major problems of development of high-speed motors and development of high-speed vacuum sealing devices, air floatation and air floatation hybrid bearing technology is adopted in the design of the high-speed motors, and bearing stiffiness and bearing stability are enhanced greatly; a large interference shrink fit method is adopted in the design of protective sleeves, and completeness of rotors is protected effectively; the rotors are of a three-section structure; a stator core is of a relatively eclectic 12-groove structure, and a winding utilizes a ring-type winding; and the cooling method is a force-air cooling method, and reliable and stable operation of an ultra centrifuge driving device is guaranteed. High-speed vacuum sealing utilizes a magnetic drive vacuum dynamic sealing connection method, and non-contact transmission of motive power is achieved through magnetic transmission between an inner magnet rotor and an outer magnet rotor. The successful development of the ultra centrifuge changes the passive situation that out country completely relies on import in an ultra centrifuge market, and the ultra centrifuge has wide market prospects and great social benefits.

Owner:HUNAN AEROSPACE ELECTROMECHANICAL EQUIP & SPECIAL MATERIAL INST

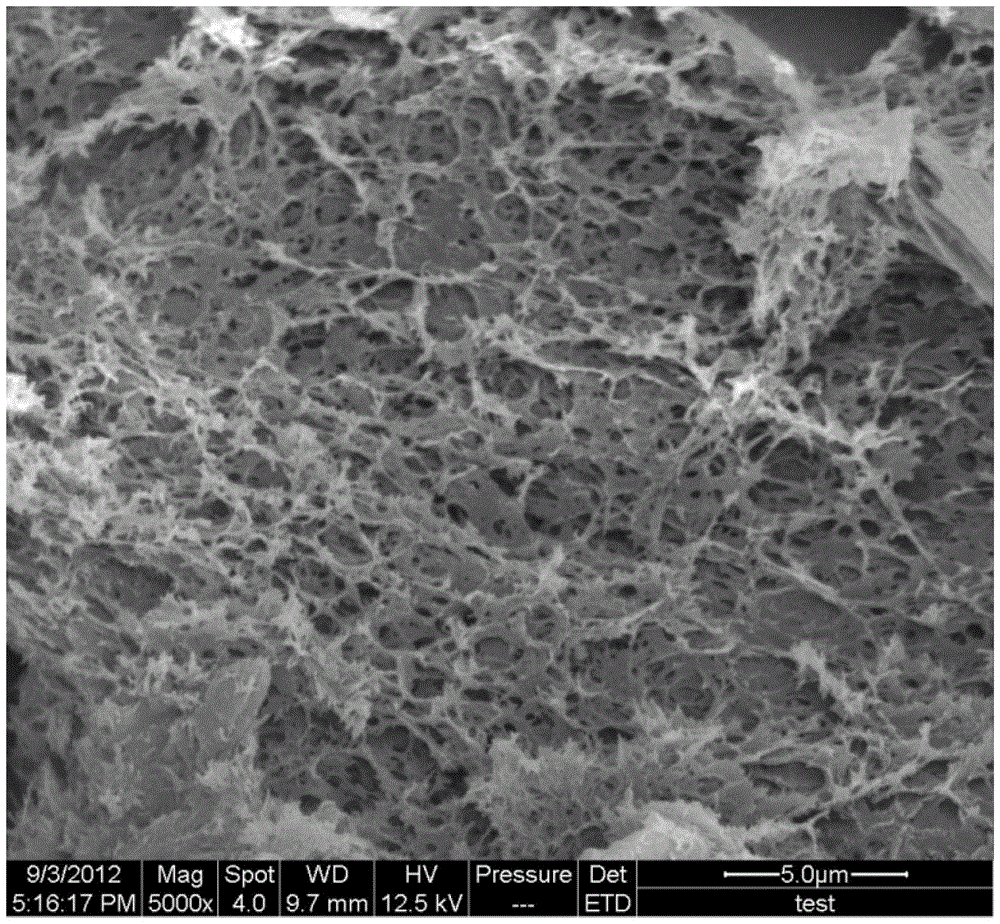

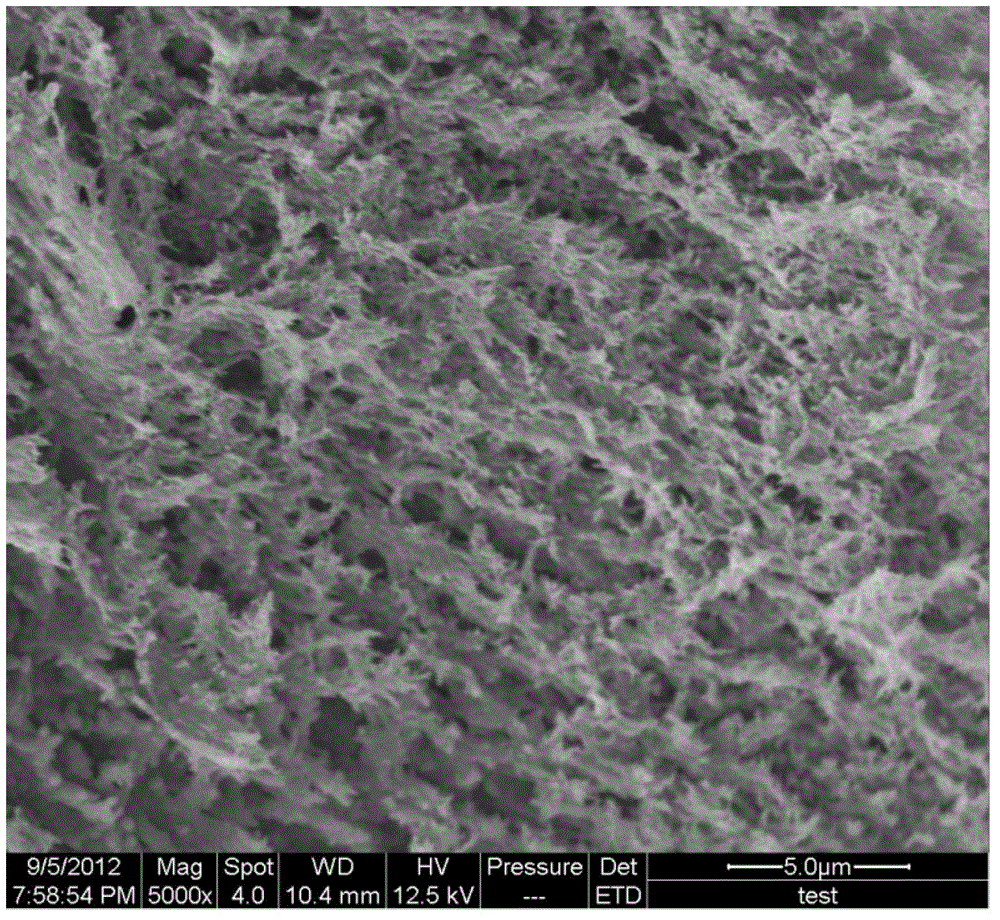

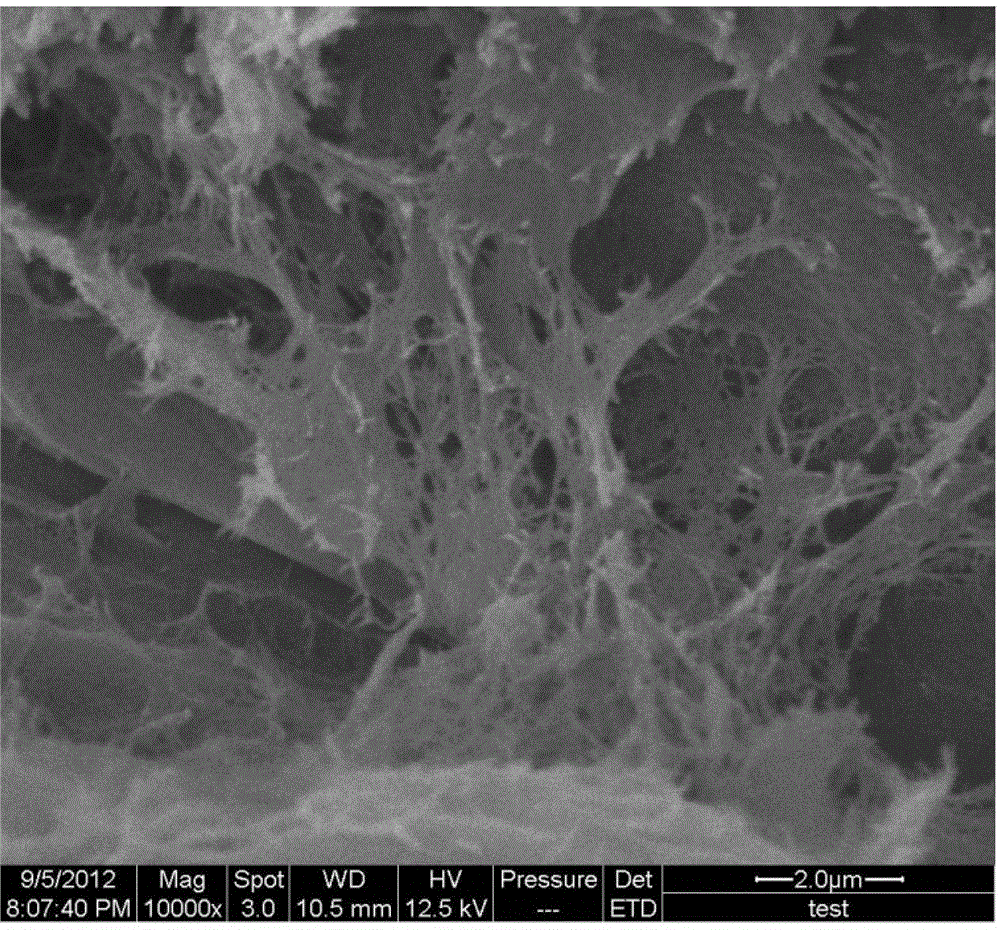

Method for preparing aerogel by quickly dissolving lignocellulose

The invention discloses a method for preparing aerogel by quickly dissolving lignocellulose, and relates to a method for preparing the aerogel. The problems that the existing lignocellulose is low in dissolution efficiency and cannot meet market demand are solved. The method comprises the following steps of: (1) using natural lignocellulose as a solute and using ion liquid as a solvent; (2) quickly dissolving lignocellulose to form a brown solution; (3) cooling the solution and pouring anti-solvent into the solution for precipitating and gelating the lignocellulose solution; (4) changing the anti-solvent for several times and totally replacing the ion liquid to form lignocellulose hydrogel; and (5) drying and processing the hydrogel to obtain an aerogel material. According to the method, the ion liquid can be recovered and recycled, and the prepared lignin aerogel has an excellent porous structure and has certain mechanical strength and is complete in form, so that the efficient utilization of low-quality wood resources is increased.

Owner:NORTHEAST FORESTRY UNIVERSITY

Method for producing high strength fine-denier polyamide fiber 6 fully drawn yarn

ActiveCN101476169AIncrease draft ratioReduce tensionSpinning head liquid feederMelt spinning methodsYarnHigh intensity

The invention provides a method for producing fine chinlon 6 fully drawn yarn with high strength which includes steps as follows: (1) chinlon 6 slice enters into a screw extruder with electrical heating function through a storage hopper that makes slice showing melt shape; (2) the melt material is pressed in a spinning subassembly through a metering pump quantificationally, and is spout by a spout plate for forming filament bundle in a spining box body; (3) the filament bundle is cooled by side wind through the spinning box body and is cooled further through a corridor; (4) the cooled filament bundle is oiled by an oil roll; (5) oil in the filament bundle is more uniform and has high amplexus degree through confounding; (6) the filament bundle passes through a first group filament guide roll and a second group filament guide roll for drafting forming, then passes through a third filament guide roll to reel. A grade product produced by the method has average more than or equal to 6.0cN / dtex rupture strength that is higher 22% than the product produced by normal method, and has better transparent sense and visual effect, the produced clothes has better flexible sense and handle sense for wearing cosily.

Owner:烟台华润锦纶有限公司

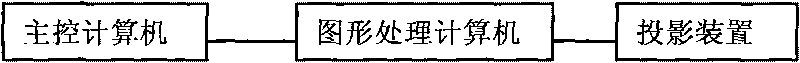

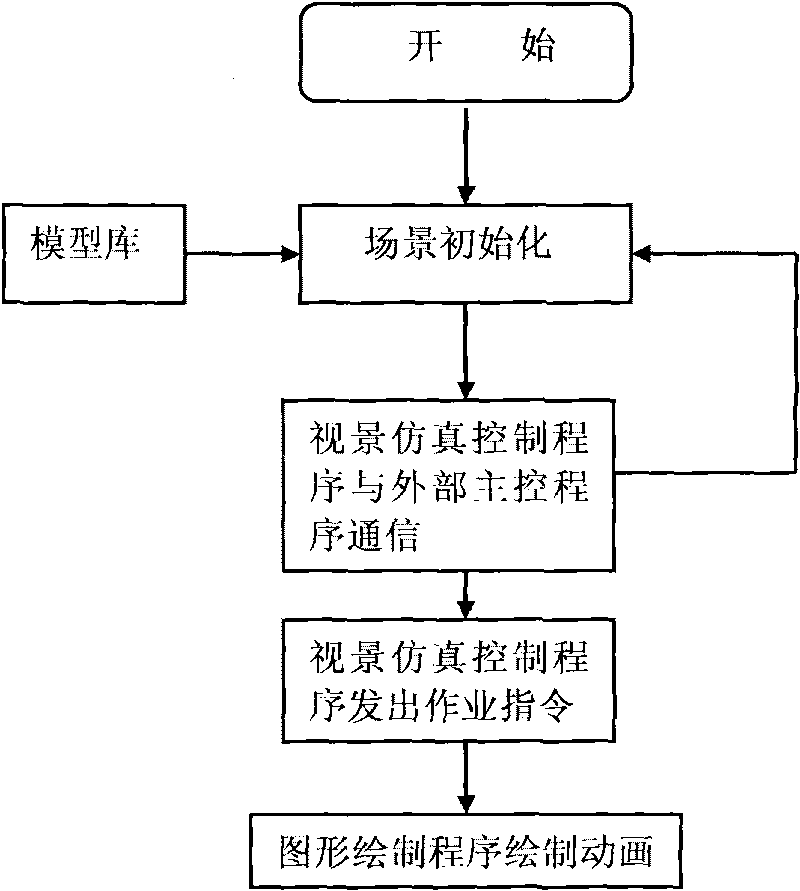

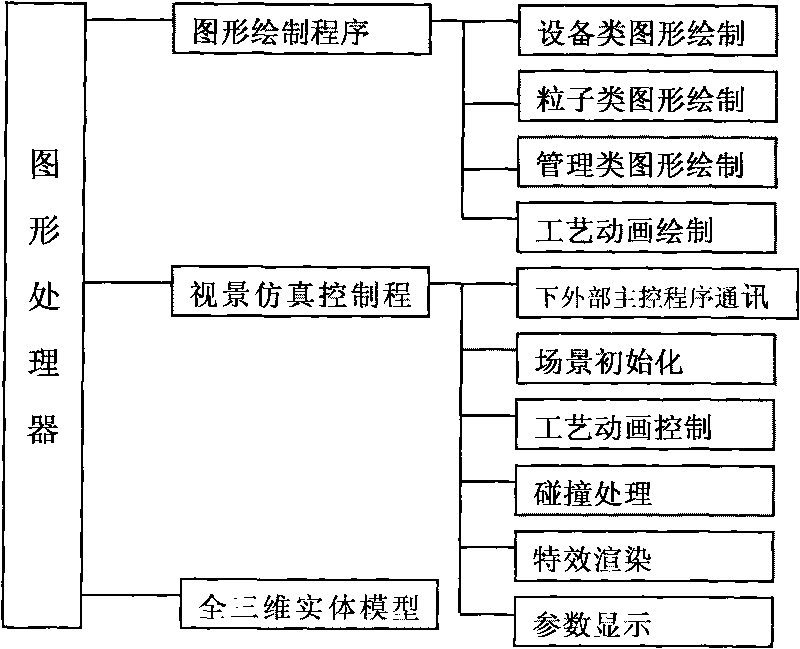

Full-three-dimensional real-time drilling simulation method

InactiveCN101719332AEnhance the ability of analysis and judgmentEasy to handleEducational modelsTraining periodGraphics

The invention discloses a full-three-dimensional real-time drilling simulation method, comprising the following steps: (1) a three-dimensional drilling solid model bank is built by adopting a three-dimensional animation modeling method; (2) a graphics processor is specially arranged, the graphics processor comprises a graphics drawing program and a scene simulation control program; (3) the scene simulation control program is communicated with an external mast control program according to given data format, so as to obtain the real-time animation commands and data; (4) scene simulation control program sends out an operational instruction to the graphics drawing program, and the graphics drawing program realizes drilling simulation animation drawing and display. In the invention, based on the computer simulation technology, by taking the practical operational flow of the drilling operation filed as reference, the drilling process and the operation method can be simulated vividly, and high-quality graphics animation is generated for the training of technical skills of operating personnel at the drilling site and students, the training effect is improved, the training period is shortened and the training cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

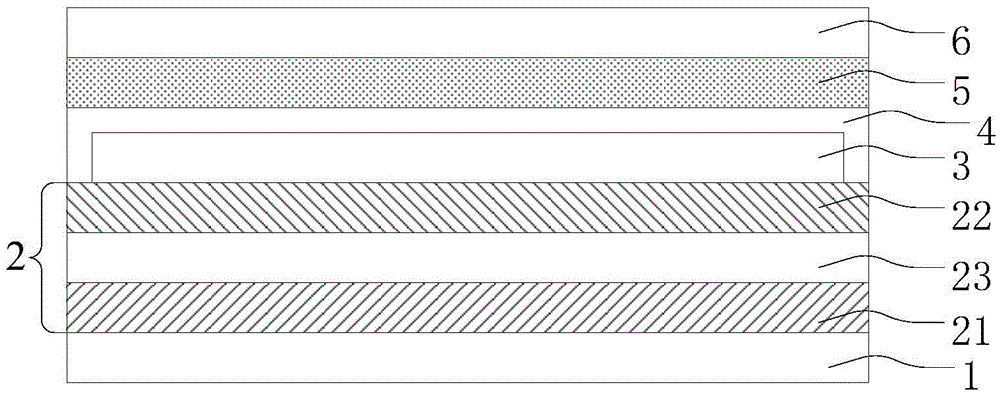

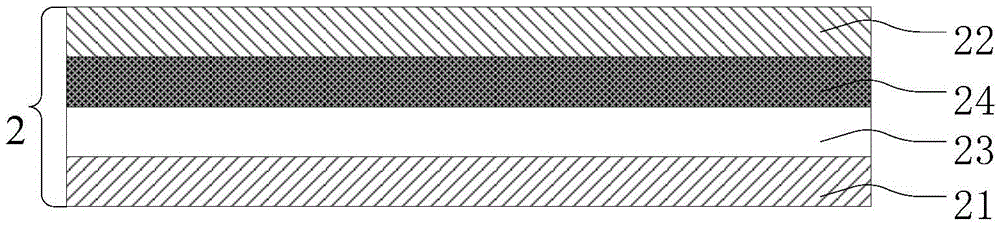

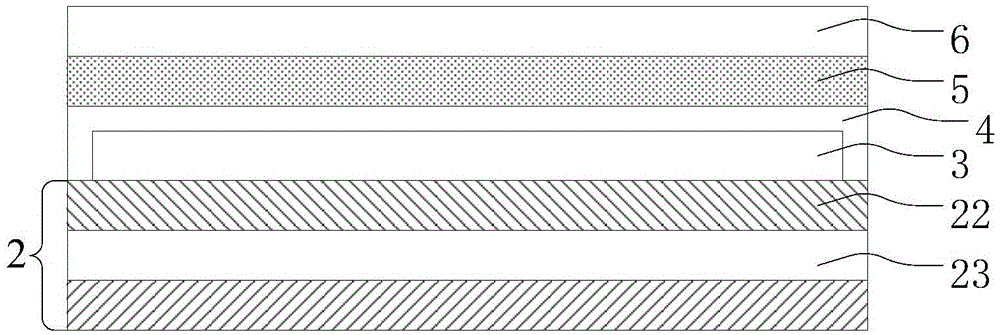

Composite substrate, flexible display device and preparation method thereof

ActiveCN105552247AImprove yieldOvercome uneven thicknessSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmComposite substrate

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

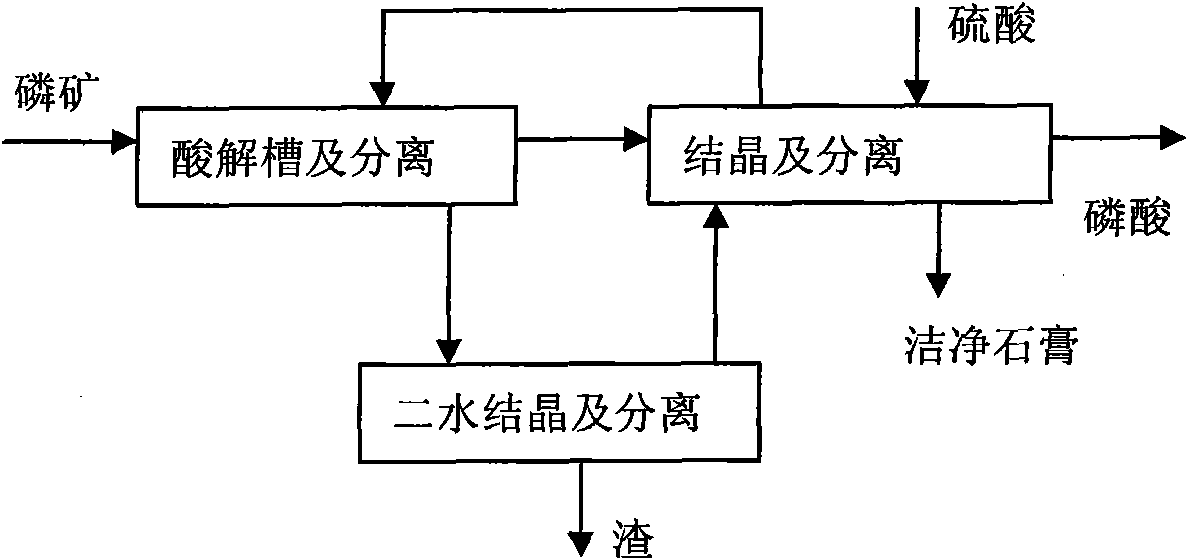

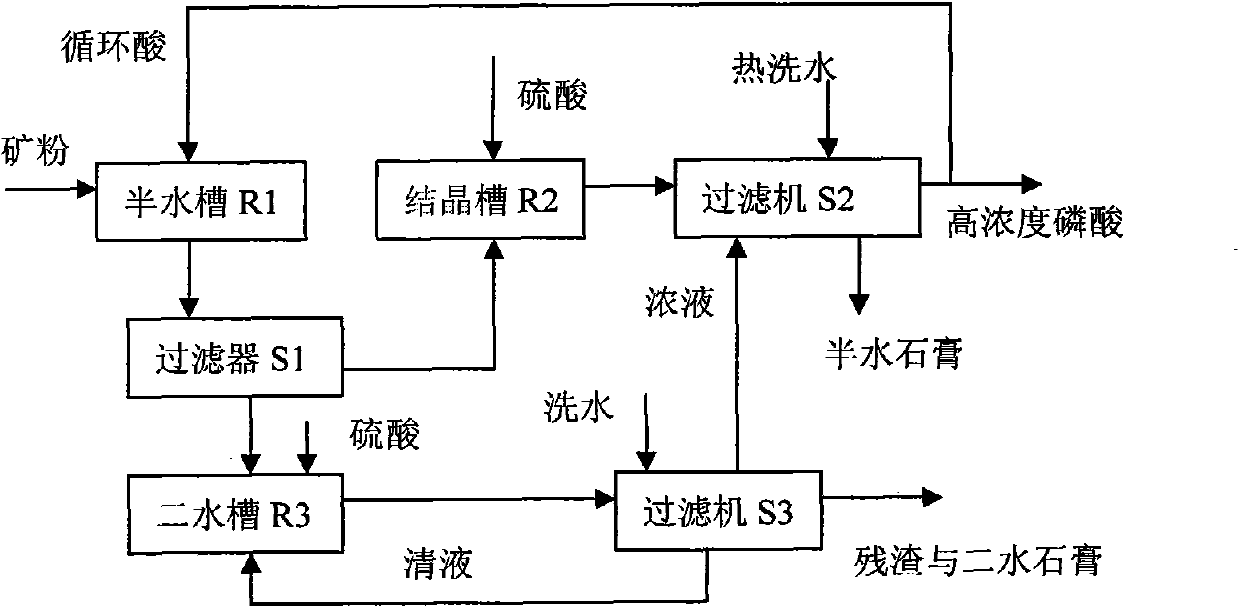

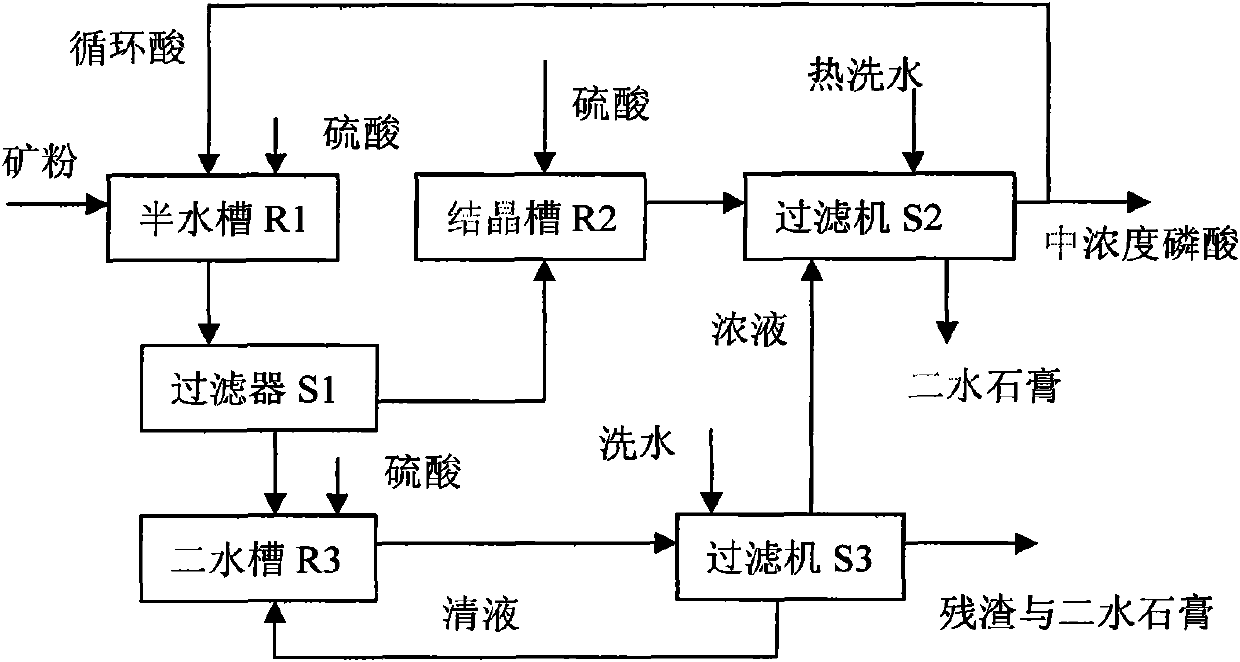

Method for producing broad-concentration phosphoric acid and clean plaster by middle-low grade phosphorus ore wet process

InactiveCN102001636AImprove phosphorus yieldOmit the beneficiation processCalcium/strontium/barium sulfatesPhosphoric acidSolid phasesLow graded

The invention discloses a method for producing broad-concentration phosphoric acid and clean plaster by a middle-low grade phosphorus ore wet process. The method comprises the following main procedures: (1) adding powder phosphorus ore and phosphoric acid to a semi-acid hydrolysis reaction tank for acid hydrolysis reaction at 95-105 DEG C, and carrying out solid-liquid separation on the slurry obtained by acid hydrolysis after full acid hydrolysis reaction; (2) transferring phosphoric acid clear liquid separated in procedure (1) into a crystallization tank, adding sulfuric acid and carrying out crystallization at 70-110 DEG C, and carrying out solid-liquid separation after full reaction, wherein, a liquid phase is the phosphoric acid to be prepared and a solid phase is the functional clean plaster to be prepared; and (3) transferring residue slurry separated in procedure (1) into a secondary acid hydrolysis reaction tank, adding water, carrying out secondary acid hydrolysis and recrystallization on the residue slurry at 65-80 DEG C, carrying out solid-liquid separation after full reaction, transferring the obtained separation liquid into procedure (2), and discharging the separated solid residues. The method of the invention has the characteristics of high production efficiency, high phosphorus resource recovery rate, strong production capacity, good economic benefit, strong operability and the like.

Owner:SICHUAN UNIV

A kind of early-maturing cultivation method of small watermelon

InactiveCN102282987AGood economic benefitsImprove yield and economic efficiencyClimate change adaptationFertilising methodsPruningElectric heating

The invention belongs to the technical field of agriculture, and discloses a cultivation method for premature small watermelon. The method comprises the following steps of: (1) grafting and raising seedlings: the sowing time of stocks is the first ten days and the middle ten days of December, and scions are sowed in 7 to 12 days later than the stocks; (2) planting grafted seedlings, and performing heat insulation and temperature rise by adopting four-layer coverage of a big shed, a medium shed, a small shed, a mulching film and an electric heating wire; (3) controlling the temperature; (4) pruning with a double-vine or three-vine pruning method; (5) performing artificial pollination and leaving fruits: performing artificial pollination when the second female flower of the main vine and the first female flower of the side vine come out; and (6) harvesting. The harvesting time of the premature small watermelon cultivated by using the method is advanced to the middle ten days and the last ten days of April and advanced by 20 to 30 days compared with the conventional greenhouse cultivated watermelon, and the harvesting time is kept away from the plum rain season of the southern district, so that high yield and stable yield are ensured. Not only the market demand is met, but also the yield and the economic benefit are greatly improved.

Owner:NANJING INST OF VEGETABLE SCI

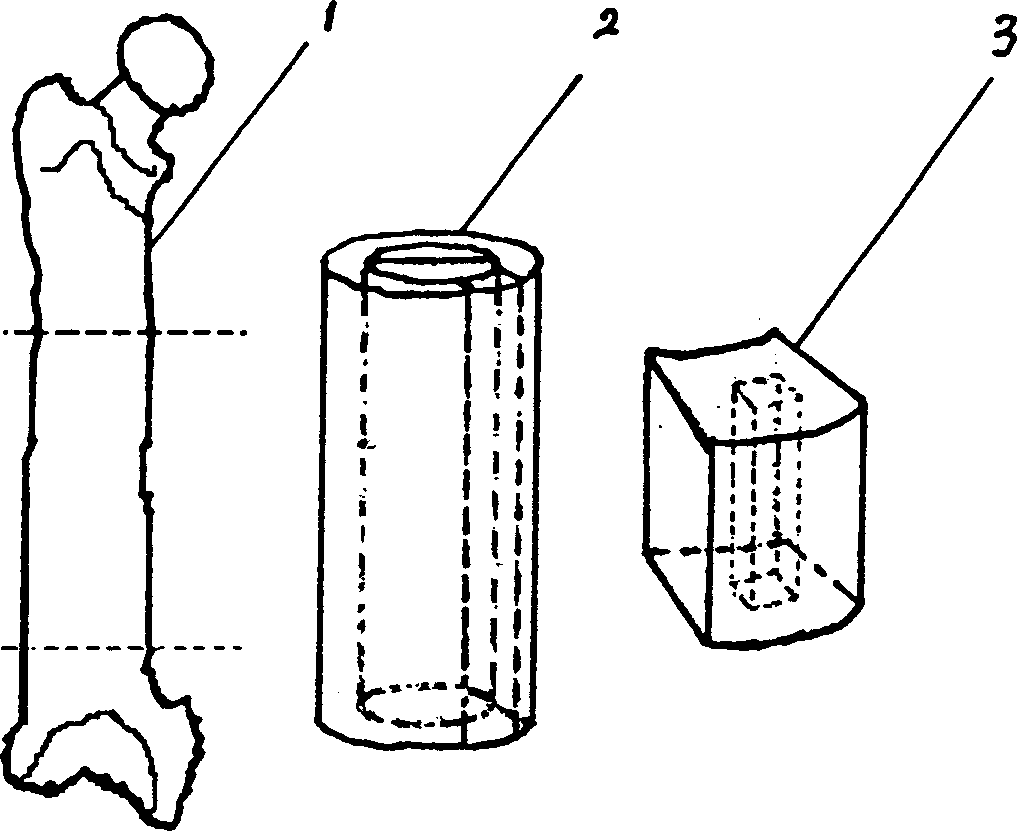

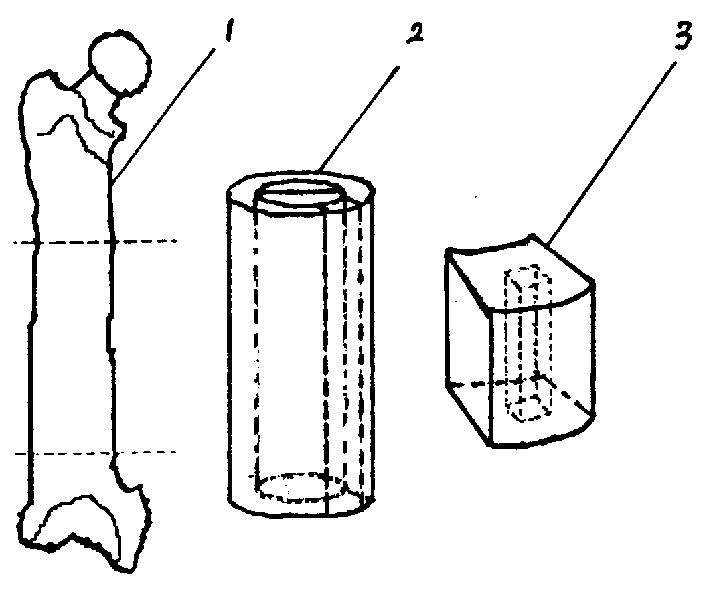

Preparing method for heteroossein base materials

A process for preparing collagen matrix with heterogeneous bone, used as the bone repairing material and the extracellular matrix of bone tissue engineering, includes such steps as treating ox bone or pig bone, defatting, partial decalcifying, removing non-collagen, proteinas digesting, disinfecting and packing. It has better porosity and pore canal structure.

Owner:CHONGQING UNIV

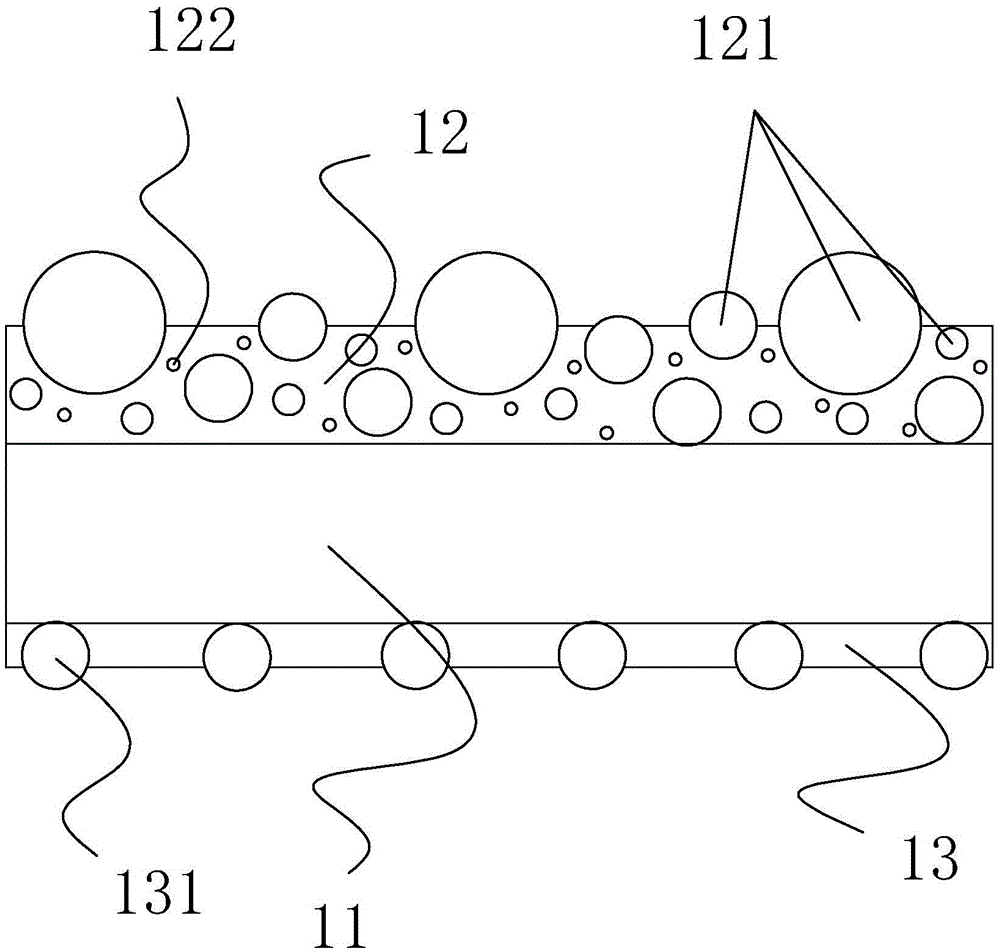

Optical diffusion barrier with covering power and light transmittance compatibility and preparation method thereof

InactiveCN105589117AGuaranteed light transmittanceImprove scratch resistanceDiffusing elementsInorganic particleOptical transmittance

The invention discloses an optical diffusion barrier with covering power and light transmittance compatibility, comprising a transparent PET base material, a diffusion layer coating the upper surface of the base material, and a back coating layer coating the lower surface of the base material. The diffusion particle of the diffusion layer comprises composite particle size organic particles composed of large particle size organic particles with a particle size range of 10-20 mu m, middle particle size organic particles with a particle size range of 5-8 mu m, and small particle size organic particles with a particle size range of 1-3 mu m, and small particle size inorganic particles with a particle size range of 20-500 nm. The arrangement format, particle size and mass percent of organic particles in the diffusion layer and the thickness of the diffusion layer are controlled, thereby realizing the covering power and light transmittance compatibility of the diffusion barrier; in addition, anti-adhesion inorganic particles are arranged in the back coating layer, so as to enhance scraping resistance performance, and to allow the diffusion barrier to possess better antistatic and anti-adhesion performance. The invention also discloses a preparation method of the optical diffusion barrier with covering power and light transmittance compatibility, which meets market demands, possesses simple processes and is easy to operate.

Owner:FSPG HI TECH

Alumina supporter containing modified gamma zeolite and its preparation method

ActiveCN1765492ALowering the freezing pointReduce crackingMolecular sieve catalystsCatalyst activation/preparationIon exchangeMetal

The invention discloses an alumina support containing Y zeolite and relative preparing method. The carrier utilizes the Y zeolite and alumina as carriers, while the property of zeolite can be changed via changing the metallic positive ions between the VIB group and / or VIII group to adjust the acid distribution, especially the proportion of B acid and L acid. The invention can be used a carrier of hydro-treating catalyst to fraction prepare the winter cleaning diesel fuel from poor diesel fuel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cultivation technique for radishes

InactiveCN102090233AImprove qualityNo blemishesSeed and root treatmentHorticultureDiseasePest control

The invention relates to a cultivation technique for vegetables, specifically to a cultivation technique for radishes, belonging to the technical field of agricultures. The technique comprises the following steps such as variety breeding, fertilization and soil preparation, seed immersion and germination accelerating, disease and insect controlling and the like so as to improve the conventional culture technique, enable the yield of the radishes to 4000-5000kg / mu and ensure that the radishes have good quality and no spots; the raw radish has crisp taste; and the cooked radish is sweet, fine and smooth in mouth feel, so that the radishes can meet the demands of the market.

Owner:李秀云

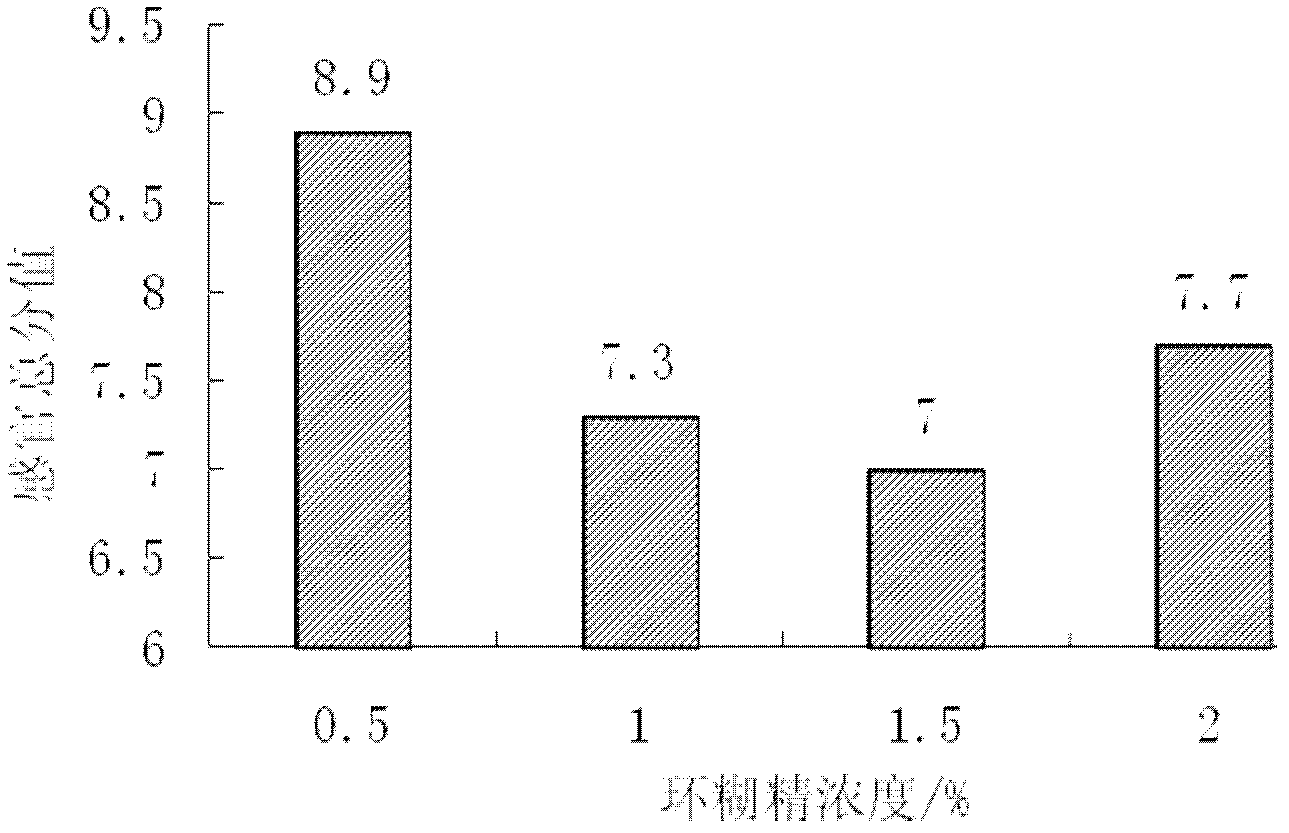

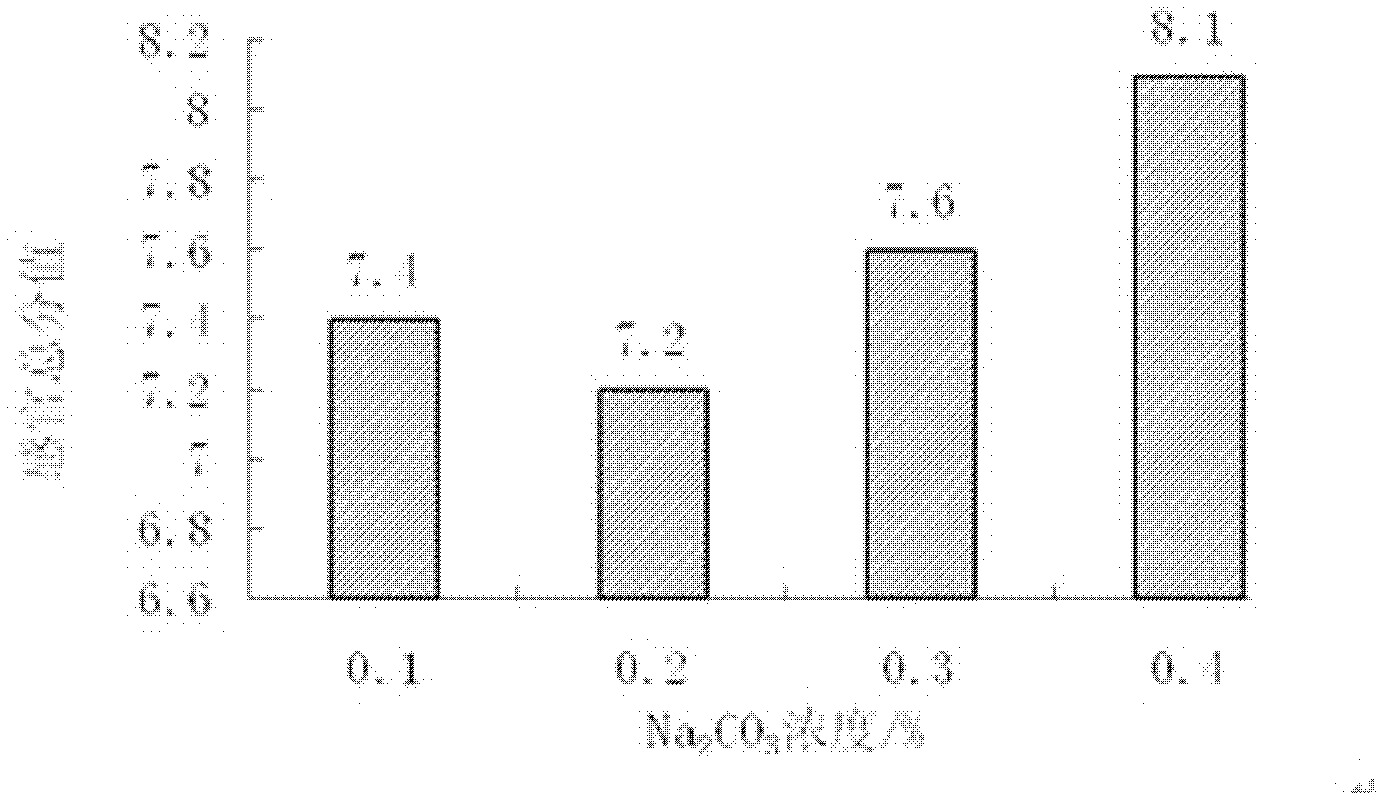

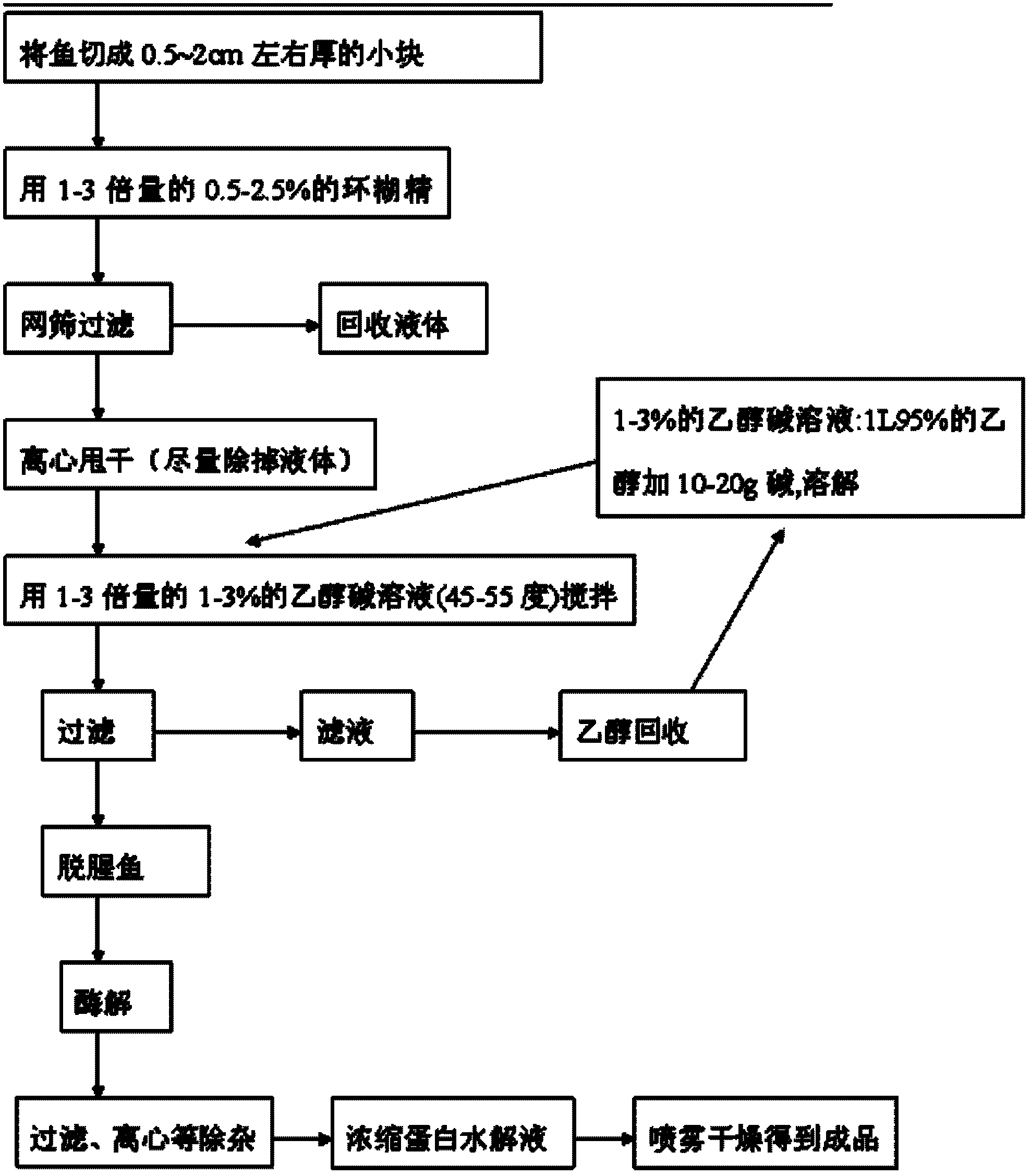

Preparation method of deodorized fish protein powder

InactiveCN102318721AImprove developmentTo satisfy the market's needsProtein composition from fishHydrolysateFresh water fish

The invention relates to a preparation method of deodorized fish protein powder. A technical process of the method comprises the following steps of: crushing low-value trash fishes; deodorizing; adding water for homogenating; performing enzymolysis on a mixed liquor by adopting a protein enzymolysis technology; blanching to obtain enzymolysis protein liquid; concentrating the enzymolysis liquid and performing spray drying; and packaging in vacuum to obtain a finished product. The protein powder is produced from low-value trash fishes and has a wide source, and a new way for high-value utilization of fresh water fishes is provided; the problem of the influence of odor substances in a hydrolysate on the utilization of the fish protein powder is solved; a biological enzymolysis technology isutilized, so that the efficiency is high and pollution is avoided; and the deodorized fish protein powder is safe and effective, is free from toxic and side effects, a rich in nutritional substances,can be developed as a food substrate, and has wide market prospect.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Artificial cultivation method of wild pinellia

ActiveCN103650855AImprove disease resistanceIncrease organic matterBiocideSeed and root treatmentPinelliaAgricultural engineering

The invention discloses an artificial cultivation method of wild pinellia. The method includes the steps of land selection, land preparation, seed selection, seed soaking, timely seeding, field management, prevention and control of plant diseases and insect pests, harvesting, treating and the like. A self-prepared plant ash soaking solution is adopted for seed soaking, a good growing environment can be provided for pinellia tubers, plant diseases and insect pests can be reduced, and survival rate can be improved. A soil conditioner is applied during land preparation and base fertilizer applying, the soil conditioner can improve soil, break soil hardening, loosen soil, increase organic matters in the soil and promote soil microorganism activity, and can decompose animal and plant residues and trace metal elements in the soil to convert the same into nutrients of plants, serve as fertilizer, improve disease resistance of pinellia and promote quick growing of the pinellia. The artificial cultivation method is simple and easy to implement, simple and convenient in management, easy for growers to operate and implement, suitable for large-scale cultivation, high in yield and good in quality and completely meets market requirements.

Owner:舒城鸿升农林科技有限公司

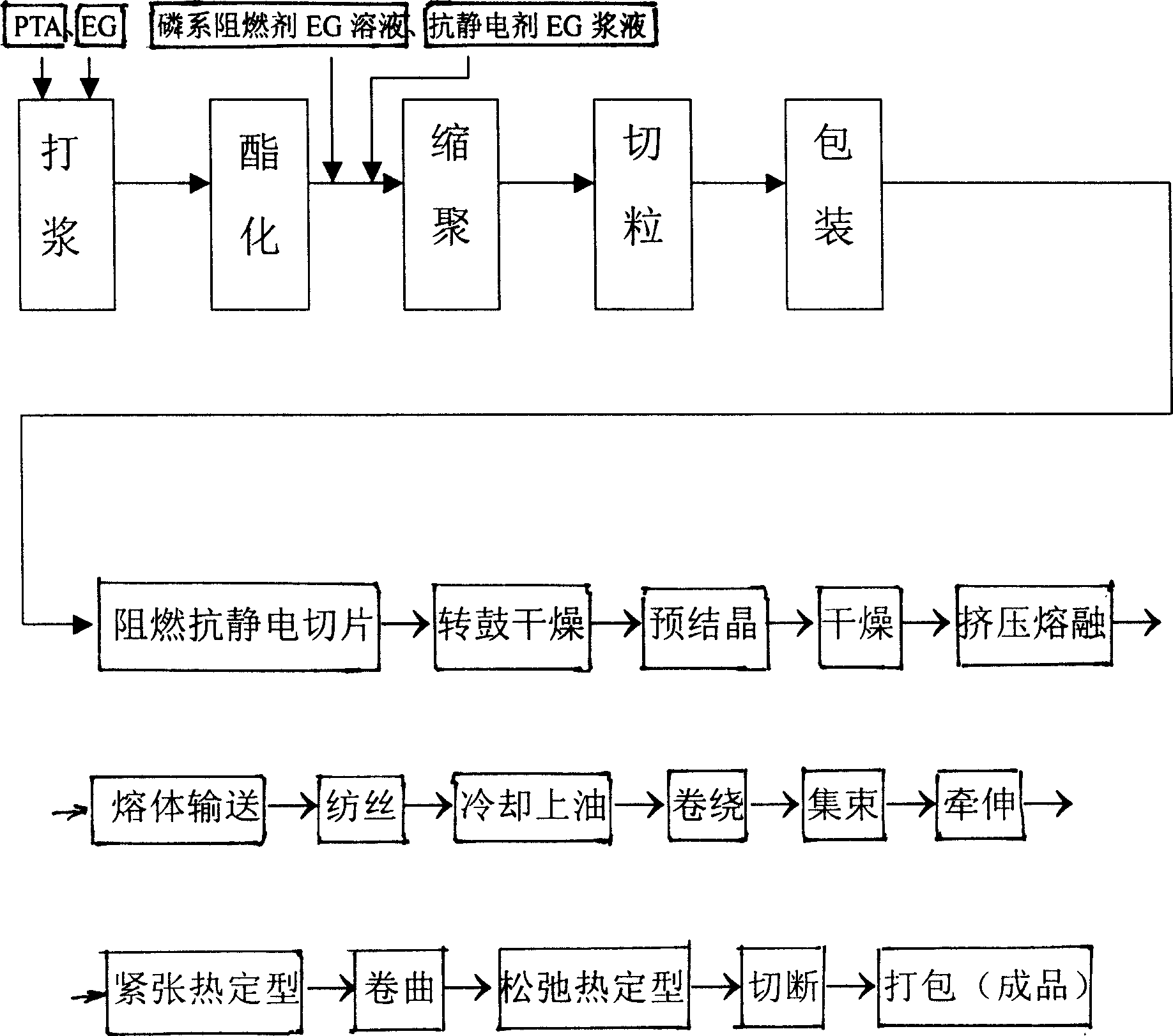

Method for manufacturing fire retardant-antistatic polyester fiber

InactiveCN1763275ATo satisfy the market's needsEvenly distributedFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberAntistatic agent

The invention relates to a making method of flame-proof-and-antistatic polyester fiber, which comprises the following steps: generating BHET terephthalic glycol ester monomer after the esterifying reaction of raw PTA terephthalic acid and EG glycol ester in the heating condition; leading the material into polyaxe; adding the preparing modulated functional additive of inorganic antistat EG glycol ester slurry in the atmospheric polycondensation reaction stage; putting the phosphorus-series flame retardant monomer of EG glycol ester solution into the polyaxe after 5 minutes; starting pressure-relief reaction after 5 minutes; generating the flame-proof-and-antistatic composite functional polyester microtome section by cooling the fondant; textiling the flame-proof-and-antistatic composite functional polyester microtome section into everlasting flame-proof-and-antistatic composite multi-functional polyester staple fiber. The technological program is reasonable and easy to operate.

Owner:天津石油化工公司化纤厂

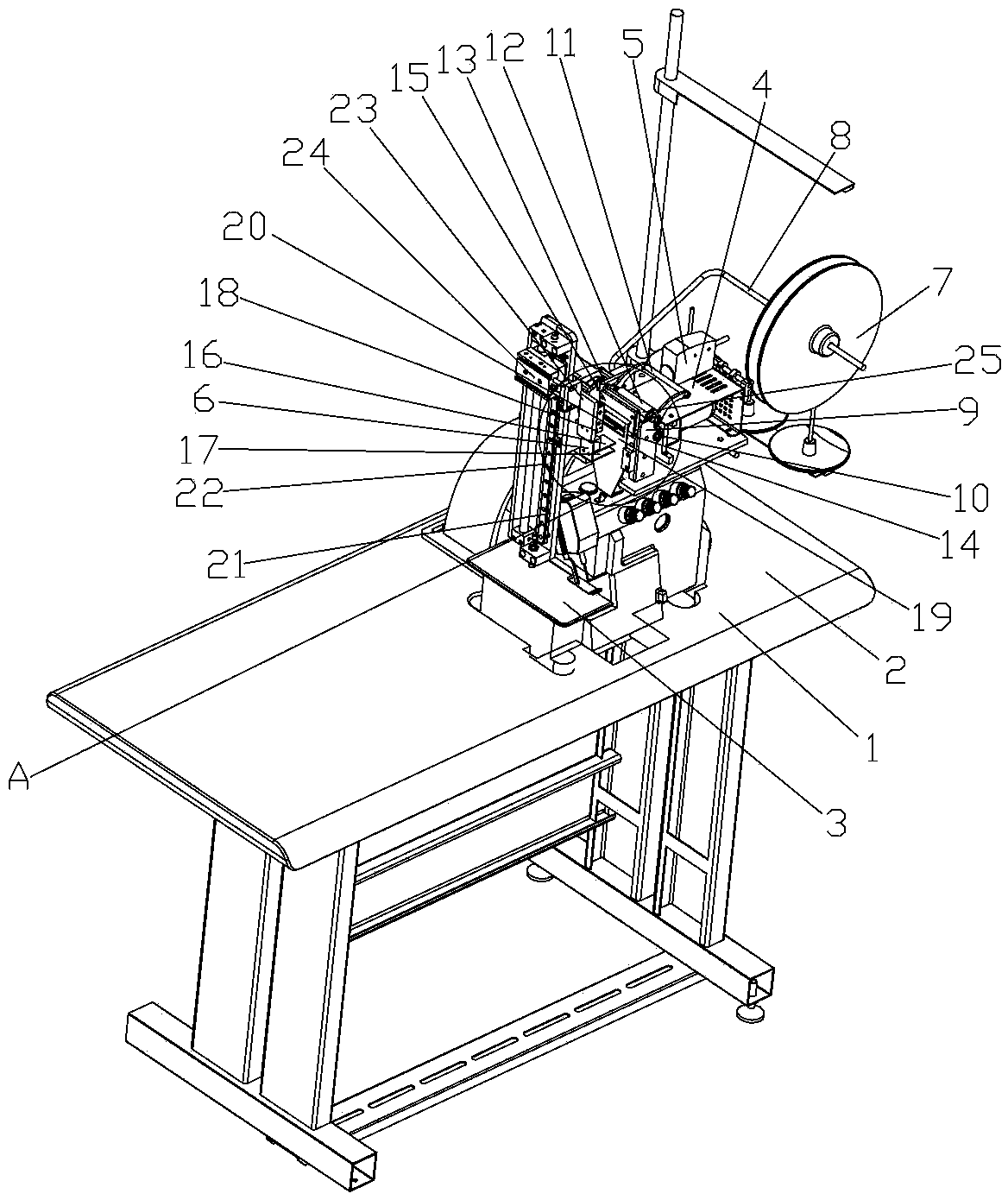

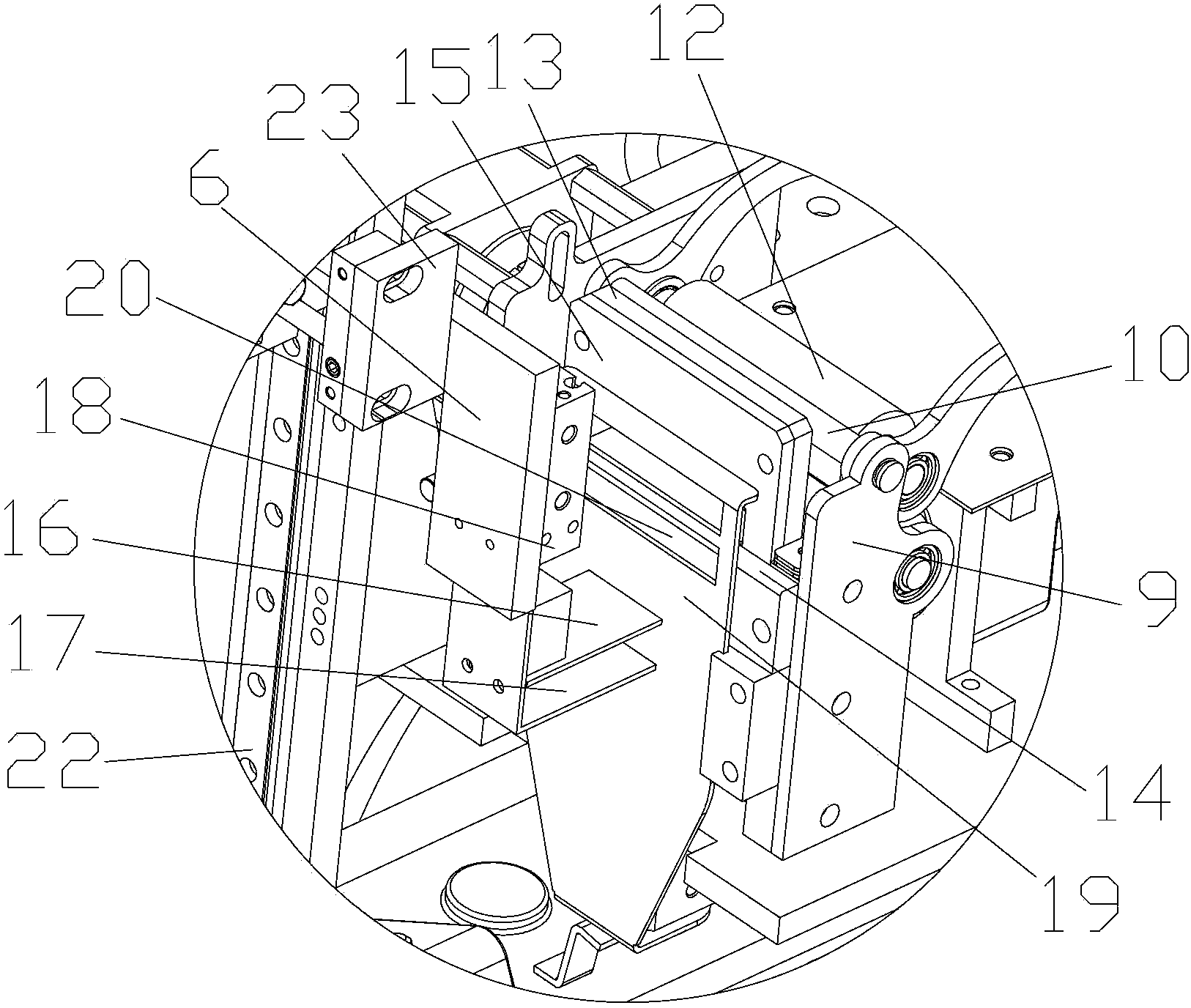

Bar tacker

The invention discloses a bar tacker. The bar tacker comprises a bar tacker body located on a machine base, an operating table face, a feeding device, an automatic detector, a pressing device, a shearing device, a folding device and a conveying device, wherein a sewing table face is arranged on the bar tacker body; the feeding device, the automatic detector, the pressing device, the shearing device, the folding device and the conveying device are fixedly arranged on the operating table face in sequence; the folding device is fixedly connected with the conveying device, shell fabric enters the operating table face through the feeding device and is conveyed into the folding device through the automatic detector, the pressing device and the shearing device; after being folded trough the folding device, the shell fabric is conveyed to the sewing table face of the bar tacker body through the conveying device to be sewn. The bar tacker is convenient to operate, manual operation is avoided, mechanical automation is achieved, production efficiency is achieved, production cost is reduced, market requirements are met, and the bar tacker is applicable to promotion and application on a large scale.

Owner:SUZHOU TRANSPARENT TECH CO LTD

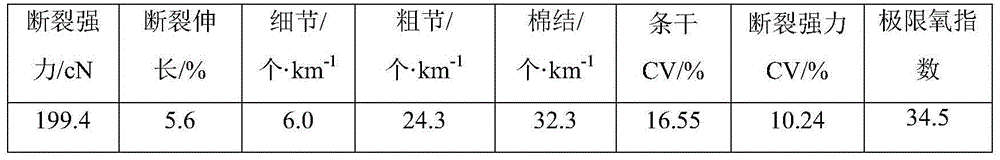

Flame retardant blended yarn and production method thereof

InactiveCN104404671AImprove flame retardant performanceIncrease added valuePhysical treatmentYarnCotton fibreSingle fiber

The invention relates to a flame retardant blended yarn and a production method thereof. According to weight percentage, the flame retardant blended yarn is formed by the following components through blending: 25-30% of flame retardant polyester filament yarns, 20-25% of flame retardant acrylic fibers, 20-30% of hemp fibers and 20-30% of cotton fibers. The production method includes: making hemp fibers and cotton fibers into card slivers respectively and tearing the card slivers into loose fibers, and making the card slivers into hemp / cotton blended combed silvers through second blowing carding in a single fiber type mixing way; making the flame retardant acrylic fibers into flame retardant acrylic card silvers; producing blended rough yarns by use of the hemp / cotton blended combed silvers and the flame retardant acrylic card silvers; producing flame retardant blended yarns by use of spun yarns in a core spun mode; producing the needed flame retardant blended yarns after plasma preprocessing and yarn flame retardant finishing. According to the flame retardant blended yarn and the production method thereof, the hemp fibers, the cotton fibers and two flame retardant fibers are selected for blending, and accordingly the produced yarns have excellent flame retardant performance as well as good antibacterial, moisture absorptive and ventilate wearing performances; the spun yarns are in the core spun mode so the tare effect is eliminated and the flame retardance is improved.

Owner:青岛博徕施纺织有限公司

Method for improving production performance of laying hens

InactiveCN105379668APromote industrial progress and developmentImprove the quality of lifeAnimal husbandryDorking chickenAgricultural science

The invention discloses a method for improving production performance of laying hens. The method for improving production performance of laying hens adopts a three-stage production mode, namely a brooding period of laying hens, a growing period, and an egg-producing period and takes a breeding mode featured by all-in-all-out for large-scale sound breeding. While breeding management is carried out in a scientific and rational way, measures for disease prevention and control are taken well and appropriate cleansing and disinfection means are used such that all indices for laying hens in all production periods are in accord with national advanced level. With promotion and application of the achieve, the method can greatly push forward the development of the laying hen industry in Guangdong and other provinces and offer fresh, safe and pollution-free eggs for consumers. As a result, the market demand is accommodated, living standards are improved, employment is ensured for people living in rural areas, and famers' income is increased.

Owner:广东省家禽科学研究所 +1

Production technology of viscose extinction monofilament

InactiveCN103215680AImprove spinnabilitySoft touchSpinnerette packsArtificial filaments from viscoseInlet channelExtinction

The invention relates to a production technology of viscose extinction monofilament. The production technology takes cellulosic fiber pulp as a raw material and obtains viscose extinction monofilament through preparation of a spinning solution, injection before spinning, spinning and aftertreatment, and specifically comprises the following steps of: (A) preparing the spinning solution from the cellulosic fiber pulp through steeping, ageing, yellowing, dissolving, defoaming and filtering; (B) adding a titanium dioxide solution into the spinning solution so that the weight ratio of titanium dioxide to alpha cellulose content in the spinning solution reaches (0.5-5.0):100; and uniformly mixing and feeding for spinning; (C) feeding the spinning solution into a spinning machine, and enabling the spinning solution to pass through a spinneret orifice of a single-hole spray head under pressure, and solidifying and molding the formed viscose trickle to form raw silk strips, wherein the spray head is stretched by +60% to +80%, and an inlet channel of the spinneret orifice is in a parabola shape; and (D) performing aftertreatment: performing desulfurization, bleaching, oiling and drying on the raw silk strips to obtain the viscose flat monofilament. According to the production technology provided by the invention, the filament number of the prepared viscose monofilament is 50-6,000D, the strength is high over 75CN, and the requirements on dyeing, weaving and finished product taking are met; and moreover, the viscose extinction monofilament has gentle color and an extinction effect.

Owner:YIBIN HIEST FIBER +2

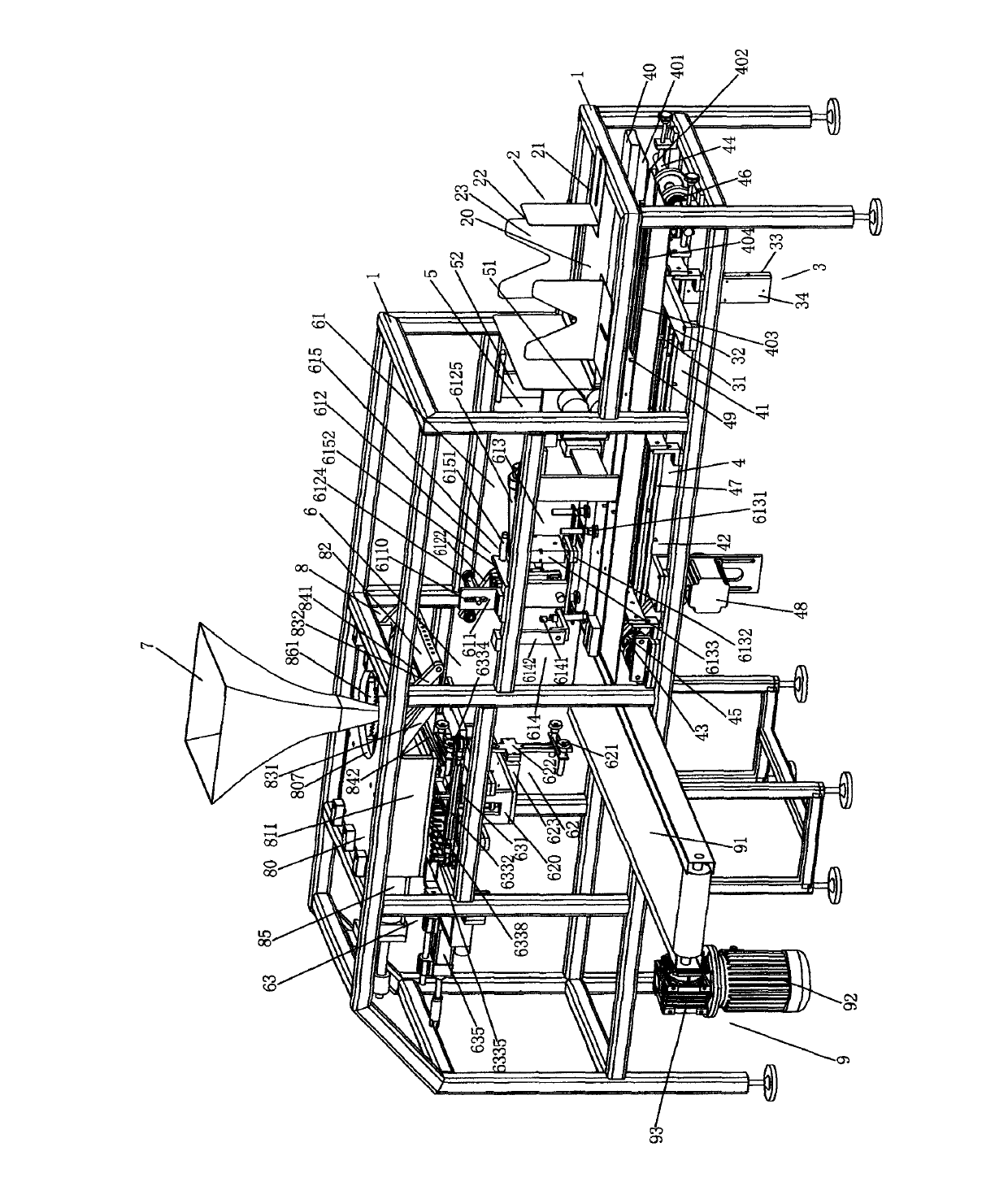

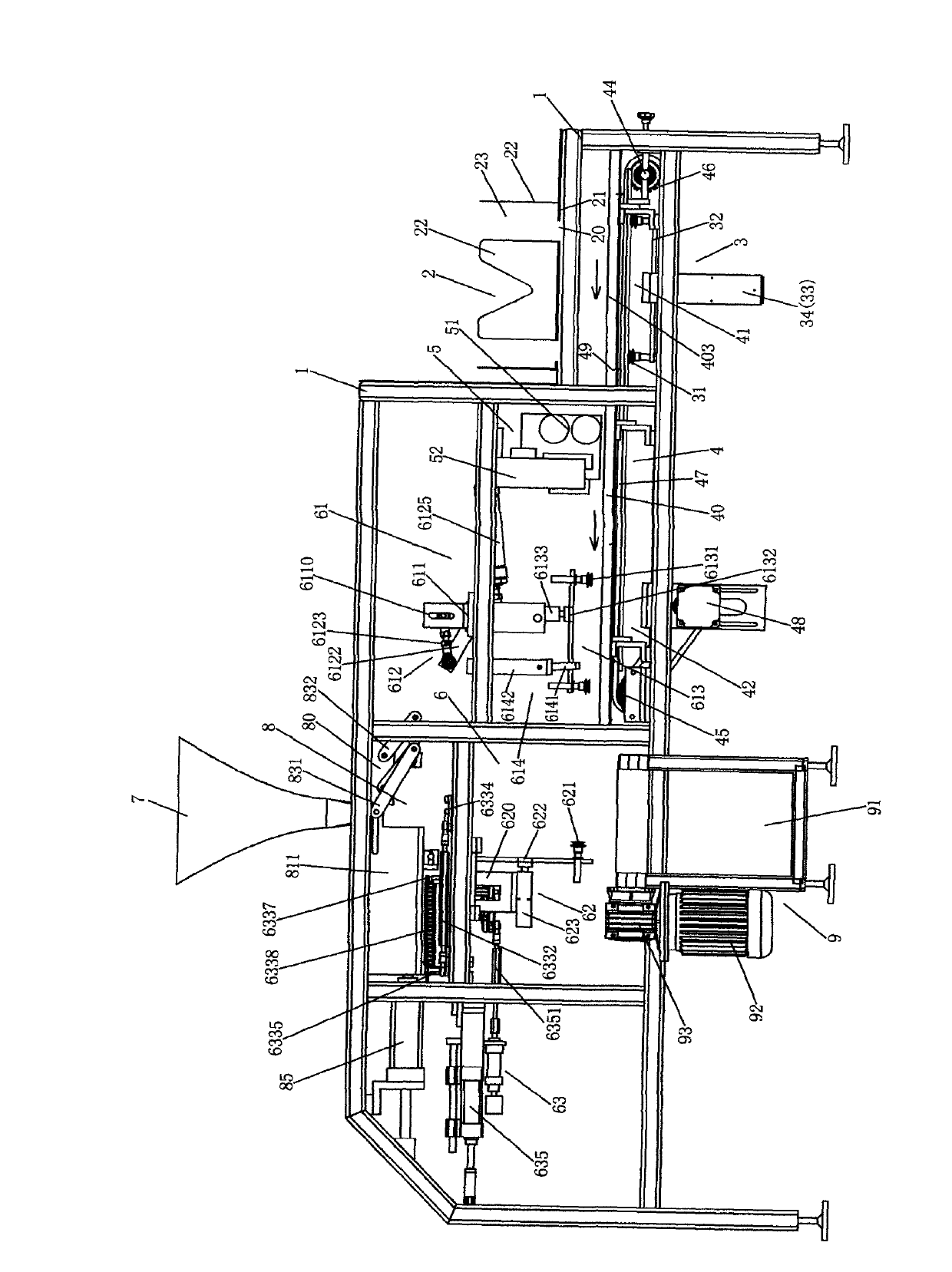

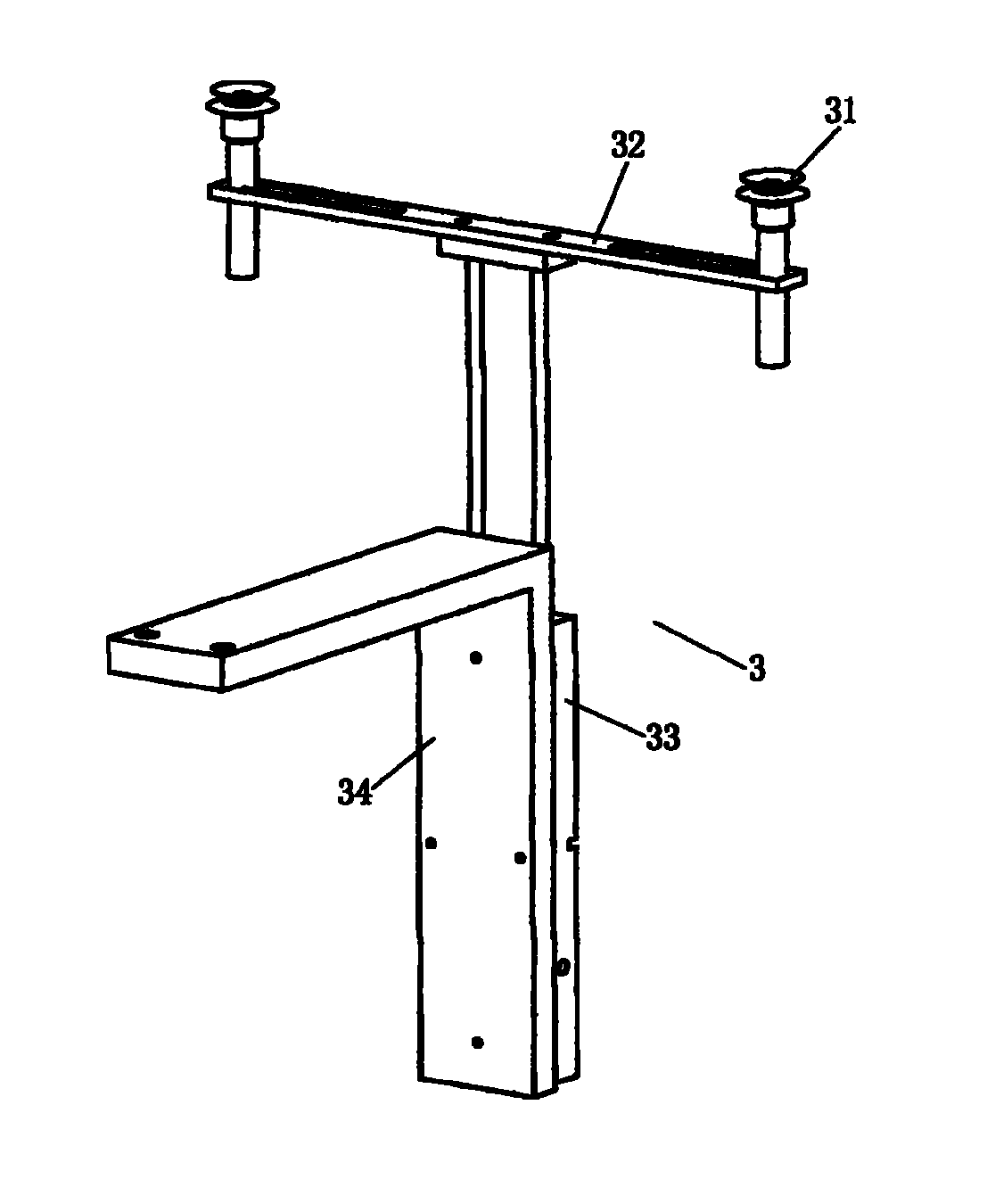

Bag-supplying type filling sealing machine

ActiveCN103129754AHigh degree of automationReduce labor intensitySolid materialEngineeringMechanical engineering

A bag-supplying type filling sealing machine is characterized by comprising a rack and a bag-arranging device, a bag-taking device, a bag-transporting device, a suction transporting bag opening device, a filling device, a sealing device and a finished product output device, wherein the bag-arranging device, the bag-taking device, the bag-transporting device, the suction transporting bag opening device, the filling device, the sealing device and the finished product output device are arranged on the rack. The suction transporting bag opening device is arranged below the filling device, the bag-transporting device is arranged between the bag-arranging device and the suction transporting bag opening device, the bag intake portion of the bag transporting device is arranged below the bag-arranging device, and the bag output portion of the bag transporting device is arranged below the suction transporting bag opening device. The bag-taking device is arranged below the bag intake portion of the bag-transporting device, and the bag-taking device stretches into the bag-arranging device. The sealing device is arranged between the suction transporting bag opening device and the filling device, and the finished product output device is arranged below the suction transporting bag opening device. And therefore, the bag-supplying type filling sealing machine is high in production efficiency, at the same time, is suitable for filling and sealing of large packaging bags.

Owner:广东中一智能科技有限公司

Cultivating method of tuckahoe

InactiveCN101578945AExpedited screeningGood yieldHorticultureFertilizer mixturesCuticleWolfiporia extensa

The invention discloses a cultivation method of tuckahoe, which comprises the steps of: (1) firstly, the epidermis of the tuckahoe is cut; the tuckahoe is superficially sterilized by 70 to 75% of ethanol and washed with sterile water; the water content of the tuckahoe is blotted up by disinfection cloth or a filter paper; in an aseptic inoculation box, an alcohol burner is lightened, the processed tuckahoe is sliced off by an abacterial knife near fire and the cross section is scraped into be cambered and successively scraped for twice; on the second scraping position, blocks like wheat size are connected on a pure strain culture medium, placed in a greenhouse, and cultured in the temperature of 25 to 30 DEG C till mycelial overgrows; the blocks which are white, are not infected by mixed bacterium, are villous, dense and craggy, vigorously and uniformly grow, secretes white milk pearl mycelium are pure strains; (2) a primary strain cultivation is carried out; (3) a second class strain cultivation is carried out; (4) a third class strain cultivation is carried out. The method is characterized by short production period of mycelium, excellent and stable tuckahoe quality and high yield.

Owner:贵州昌昊中药发展有限公司

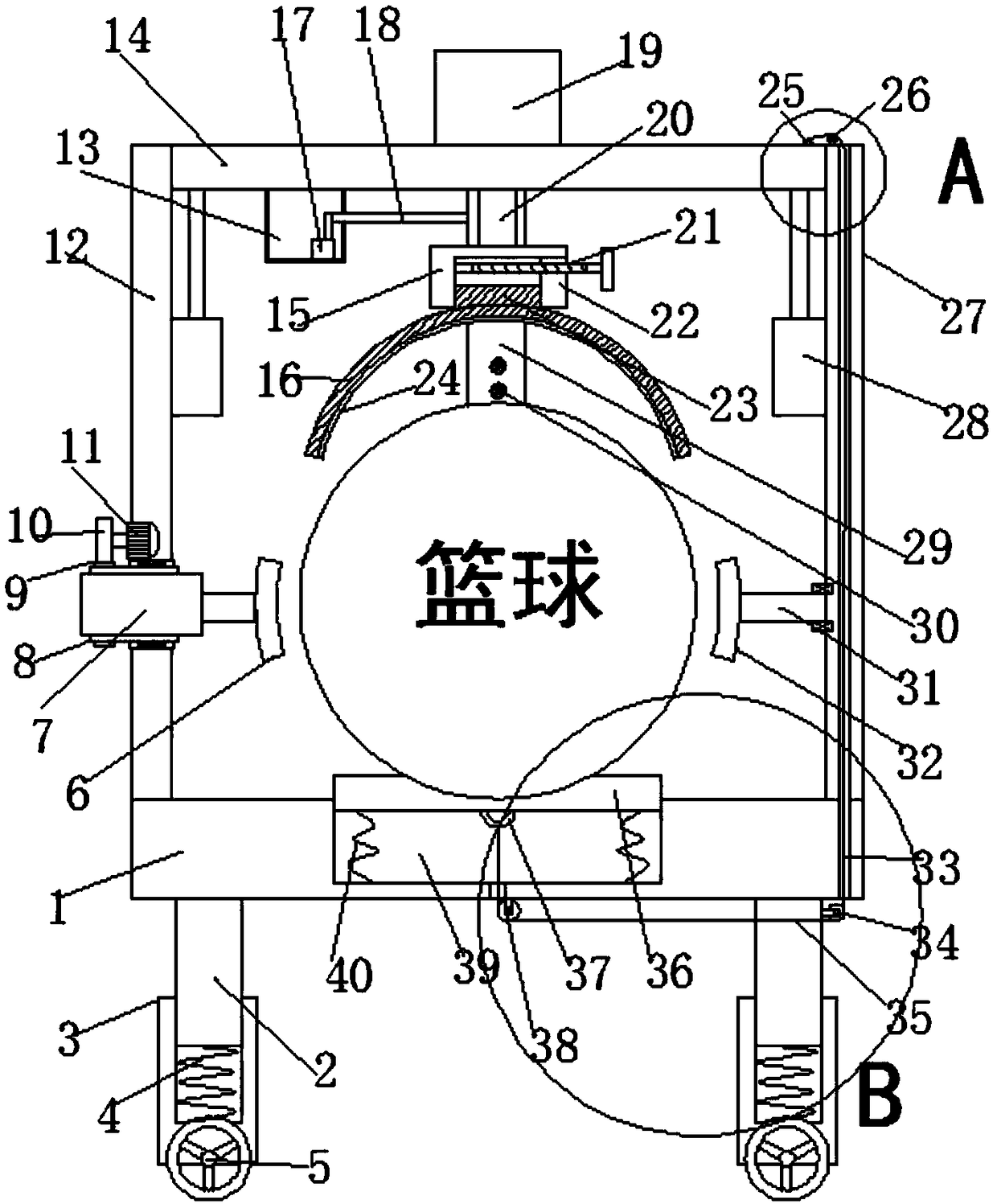

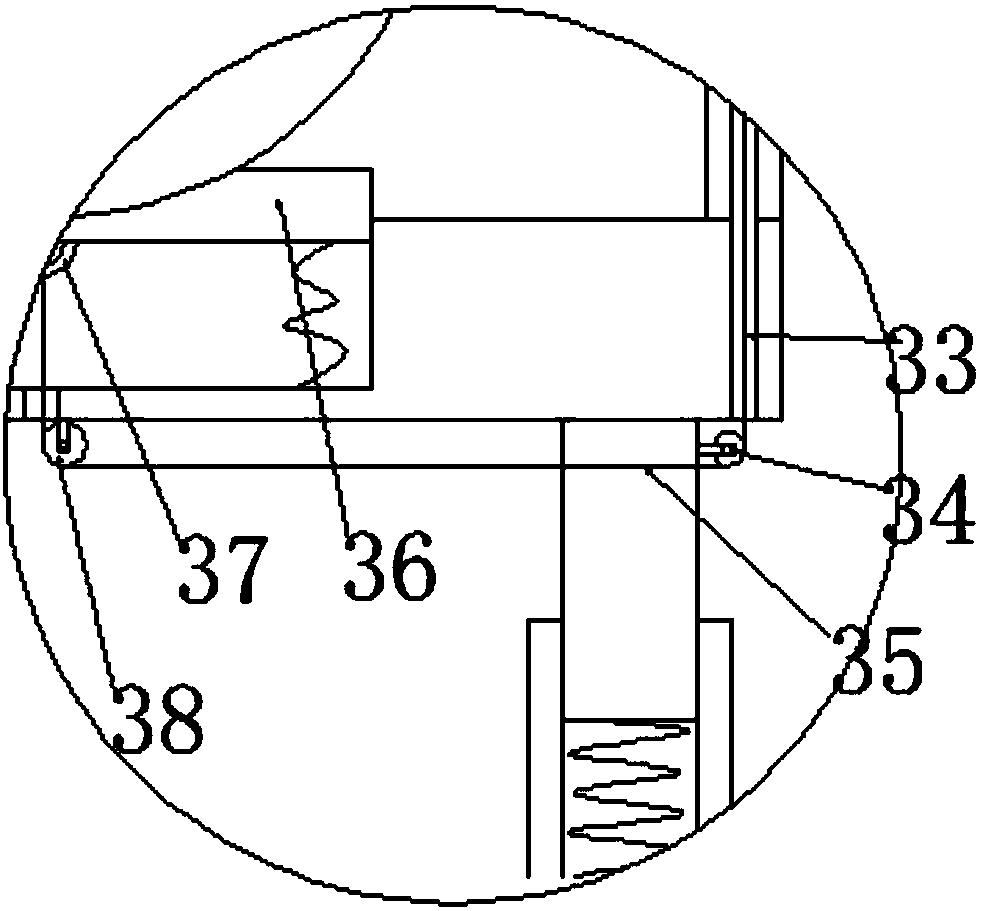

Efficient basketball washing device

InactiveCN108525235AImprove cleaning efficiencyGuaranteed service lifeBall sportsPulp and paper industryClean water

The invention discloses an efficient basketball washing device. The efficient basketball washing device comprises a fixed base. Landing legs are symmetrically arranged on the two sides of the lower end of the fixed base, the lower ends of the landing legs are slidingly sleeved with supporting sleeves, and rollers facilitating carrying of the device are arranged at the lower ends of the supportingsleeves. Buffer springs are arranged in the supporting sleeves, and the landing legs and the supporting sleeves are connected and fixed through the buffer springs. Through the arrangement of the buffer mechanisms, the anti-shake performance of the device is effectively improved. A first supporting plate is vertically fixed to the upper left end of the fixed base, a second supporting plate is vertically fixed to the upper right end of the fixed base, and a movable installing plate is slidingly arranged between the first supporting plate and the second supporting plate. Basketballs can be automatically scrubbed instead of being manually scrubbed, thus, the washing efficiency of the basketballs is greatly improved, a large batch of basketballs can be washed, and market requirements are met; besides, the washing mode differs from traditional clean water soaking and flushing modes, the service life of the basketballs is guaranteed, and high practicality is achieved.

Owner:SHANDONG WOMENS UNIV

Production method of small rice vinegar

InactiveCN101984037AHigh degree of automationKeep the scentMicroorganism based processesVinegar preparationAcetic acidSlurry

The invention belongs to the technical field of edible vinegar, in particular to a production method of small rice vinegar. The invention aims at solving the technical problems of low production efficiency, unstable process conditions, high labor intensity of workers, impacts on quality and taste of the rice vinegar and the like in manual control which is mostly adopted for making the vinegar at present. The production method of the small rice vinegar comprises the following steps: 1) taking small rice, preparing into rice flour, and adding a certain amount of water for preparing into slurry; 2) adding amylase and glucoamylase into the slurry, and preparing into serous fluid; 3) adding brewing yeast and Daqu into the serous fluid for preparing into wine mash; 4) taking a certain proportion of the wine mash, rice hull and wheat bran, placing into a fermentation tank, adding acetic bacteria, preparing into fermented material, further using water to leach acetic acid in the fermentation tank and preparing into vinegar liquor; 5) sterilizing the vinegar liquor, placing the vinegar liquor after sterilization into an aging tank for hermetical aging for at least 90 days, and preparing into mature vinegar; and 6) filtering the mature vinegar, carrying out instantaneous sterilization at 125-135 DEG C for 4-6s, and preparing into the small rice vinegar. The production method of the small rice vinegar adopts the automatic mechanical vinegar making way, has high production efficiency and stable process conditions, and can reduce the labor intensity of the workers and meet the market demand.

Owner:SHANXI SANSHENGHE BREWING

Industrialized iconological breeding method of young shrimps having high stress resistance and high disease resistance

ActiveCN104872032APromote healthy developmentImprove stress resistanceClimate change adaptationPisciculture and aquariaPrawnWater quality

The invention relates to the technical field of marine product seed breeding and in particular relates to an industrialized iconological breeding method of young shrimps having high stress resistance and high disease resistance. The industrialized iconological breeding method comprises the steps of the construction and sterilization of an isolating breeding workshop and a standard breeding pool, the integrated treatment of breeding water, the healthy cultivation and reproduction of prawn parents, the throwing-in of healthy nauplius, the preparation of a breeding bait, the biological control and management of breeding water quality, bait feeding management, control of physical factors such as temperature and light, and the like. Due to biological control on the water environment of the indoor breeding pool and effective control on water temperature, illumination, transparency, dissolved oxygen, salinity, PH value, harmful substances, pests and the like, the breeding environmental conditions are optimized, the drug use, the feeding capacity and the drainage are reduced; in addition, the stress resistance and the disease resistance of the young prawns are enhanced, the quality and the survival rate of the young prawns are increased. The industrialized iconological breeding method of young prawns having high stress resistance and high disease resistance is used for solving the key technical problems of prawn breeding; a high-efficiency environment-friendly breeding mode is provided to promote efficient sustainable development of the prawn breeding industry.

Owner:GUANGDONG JINYANG BIOTECHNOLOGY CO LTD

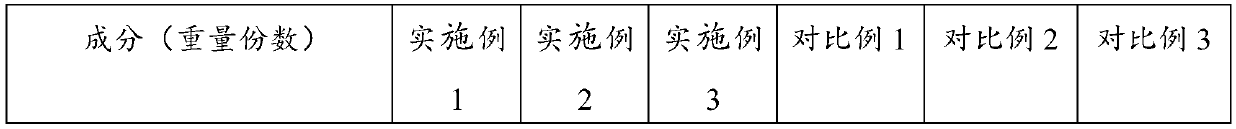

PBAT/starch full biodegradation thin film and preparation method thereof

The invention provides a PBAT / starch full biodegradation composition, which is characterized by being prepared from the following raw materials: 50 to 85 weight parts of PBAT, 10 to 40 weight parts ofmodified starch, 0.3 to 3 weight parts of lubricating agents, 5 to 15 weight parts of small molecule plasticizers and 1 to 5 weight parts of enhancing agents, wherein the modified starch is starch modified by a modifying agent; the modifying agent is a mixture of one of maleic anhydride and butanedioic anhydride, and one of titanium ester coupling agents, aluminic acid ester coupling agents and silane coupling agents. By mixing PBAT resin, the modified starch and the rest auxiliary agents, and combining the specific proportion, a thin film prepared by the finally prepared composition has theadvantages of high tensile and tear strength, good elasticity modulus, good elongation at break, high density, high degradation performance and the like.

Owner:浙江中科应化科技有限公司 +1

Mulberry leaf deodorization and astringency removal process and mulberry cold tea preparation method

InactiveCN1522582AImprove processing technologyThe processing technology is cool and sweetPre-extraction tea treatmentTea substituesChrysanthemum FlowerPeppermints

The present invention discloses a deodorization and astringency-removing process of mulberry leaf and a production method of mulberry leaf cold tea. The deodorization and astringency-removing process of mulberry leaf includes the following steps: steaming, primarily dehydrating, rolling, fully-drying and high-temp. deoiling; and the production method of mulberry leaf cold tea includes the following steps: mixing the above-mentioned prepared mulberry leaf, tea peppermint chrysanthemum flower, licorice and lonicera flower in certain ratio, pulverizing and packing them in punches so as to obtain the invented product with the health-care functions of clearing away heat and removing toxic material, clearing throat and moistening lung, etc.

Owner:JIANGXI SERICULTURE & TEA RES INST

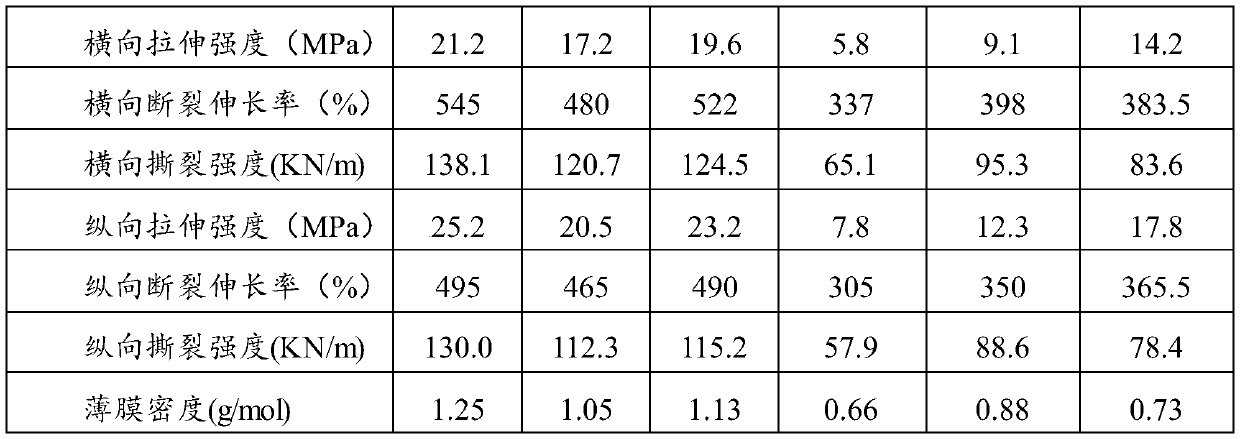

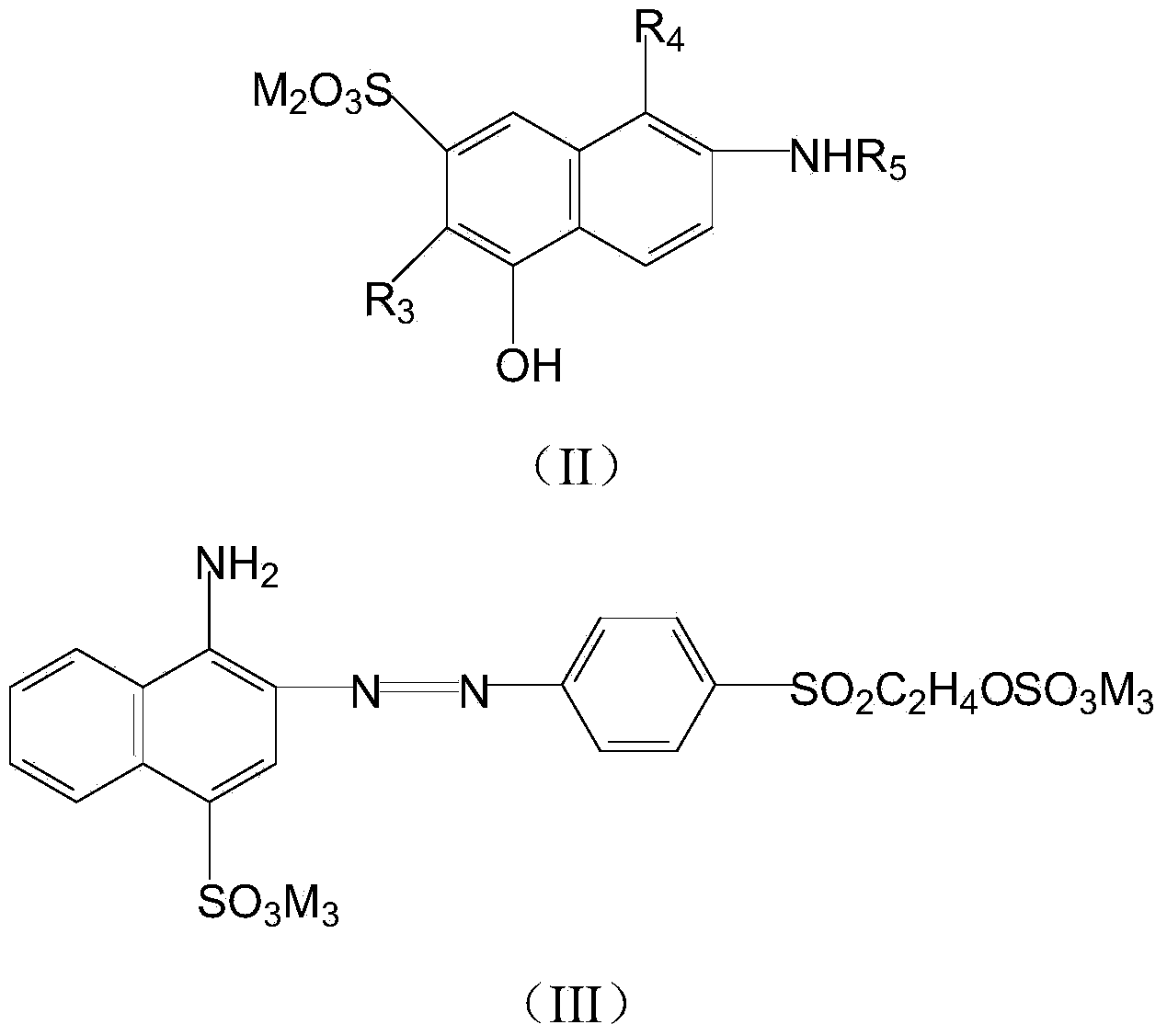

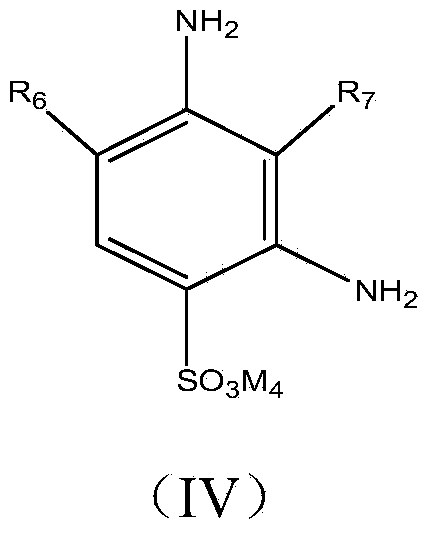

Compound black reactive dye composition, and applications thereof and fiber or fiber textile made thereby

ActiveCN104059387AImprove dyeing effectGood blacknessOrganic dyesDyeing processCellulose fiberProtein fiber

The invention relates to a compound black reactive dye composition, and applications thereof and a fiber or fiber textile made thereby, belonging to the field of reactive dyes. Particularly, the invention relates to a compound black reactive dye composition applicable to printing and dyeing cotton, rayon, hemp, regenerative fiber or textiles thereof, or to printing and dyeing polyamide fiber, cellulose fiber, protein fiber or textiles thereof. The invention further relates to applications of the compound black reactive dye composition, and fiber or fiber textile made by the compound black reactive dye composition.

Owner:ZHEJIANG RUIHUA CHEM

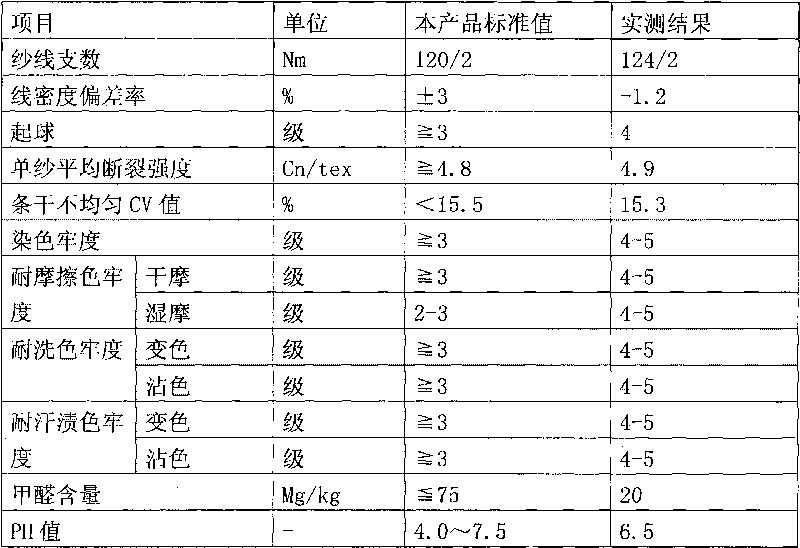

Superfine wool yarn and manufacturing method thereof

InactiveCN101709522AGood anti-pillingImprove effective controlDrafting machinesYarnInternational standardEngineering

The invention discloses a superfine wool yarn and a manufacturing method thereof. The superfine wool yarn comprises 100-120Nm / 2 of yarn counts, 1050-1200t / m of single twist with a twist direction of Z and 480-550t / m of plied twist with a twist direction of S. The manufacturing method comprises the process steps of wool top recombing, primary silver mixing, secondary silver mixing, quartic gilling, triple roving, spun yarn, spooling, doubling, two-for-one twisting, reeling silk, checking and the like. In the invention, raw materials of the superfine wool are selected, and the reasonable yarn counts and the twist are determined at the same time. By adopting some special measures on the spinning process and optimizing the technological parameters, the excellent and low-consumption superfine wool yarn with the yarn counts of 120Nm / 2, and the yarn levelness of less than 15 percent and anti-pilling of more than or equal to the third level is successfully manufactured; and the number of the cross-section fibers of the fine yarn is only 28, which is far lower than the limit of the number of 36 in the international standard. The invention not only provides a new yarn product with excellent quality and high cost performance, but also provides a beneficial spinning method for sufficiently utilizing and reasonably developing tight wool resources.

Owner:ZHEJIANG ZHONGXIN WOOL TEXTILE

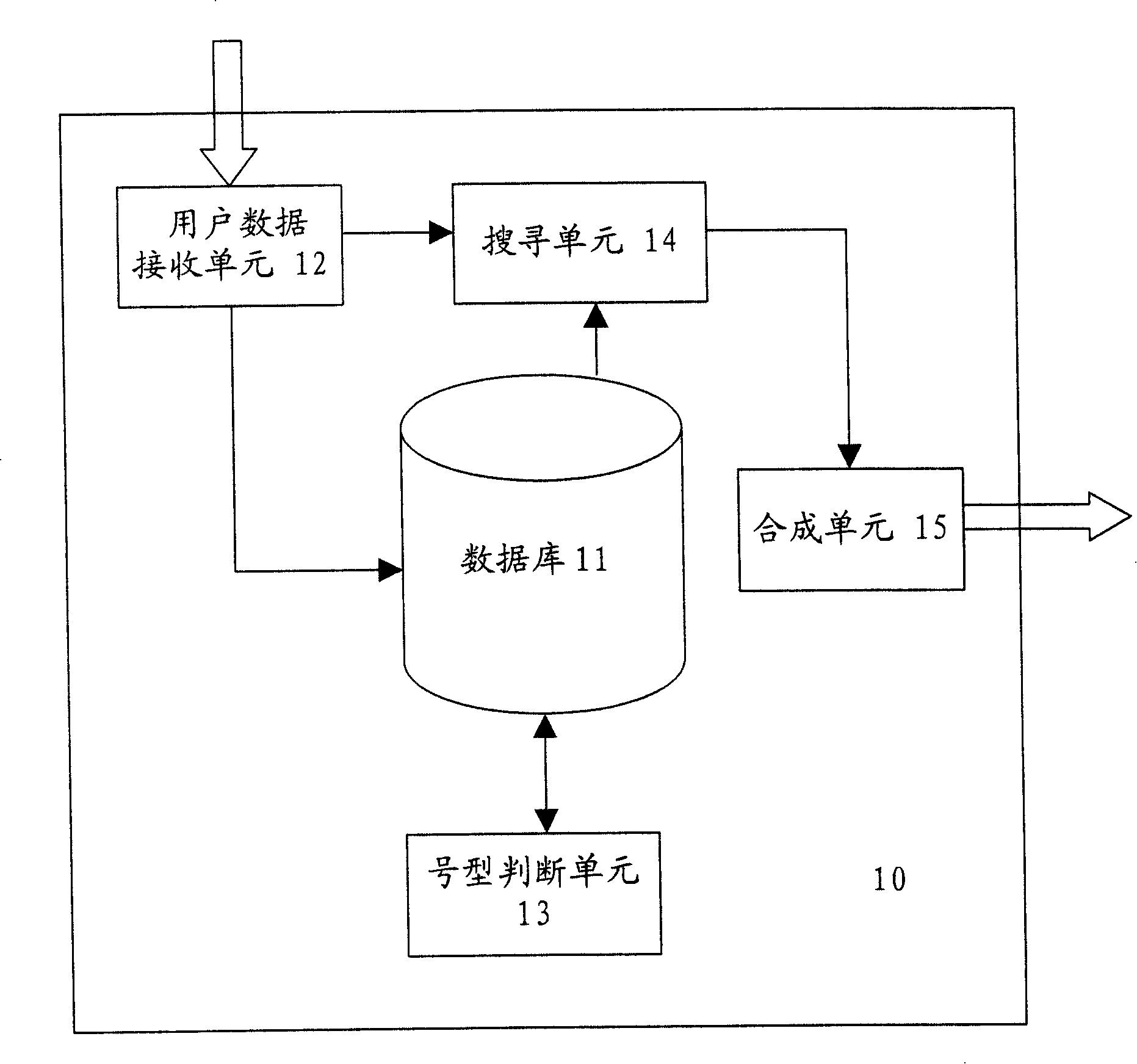

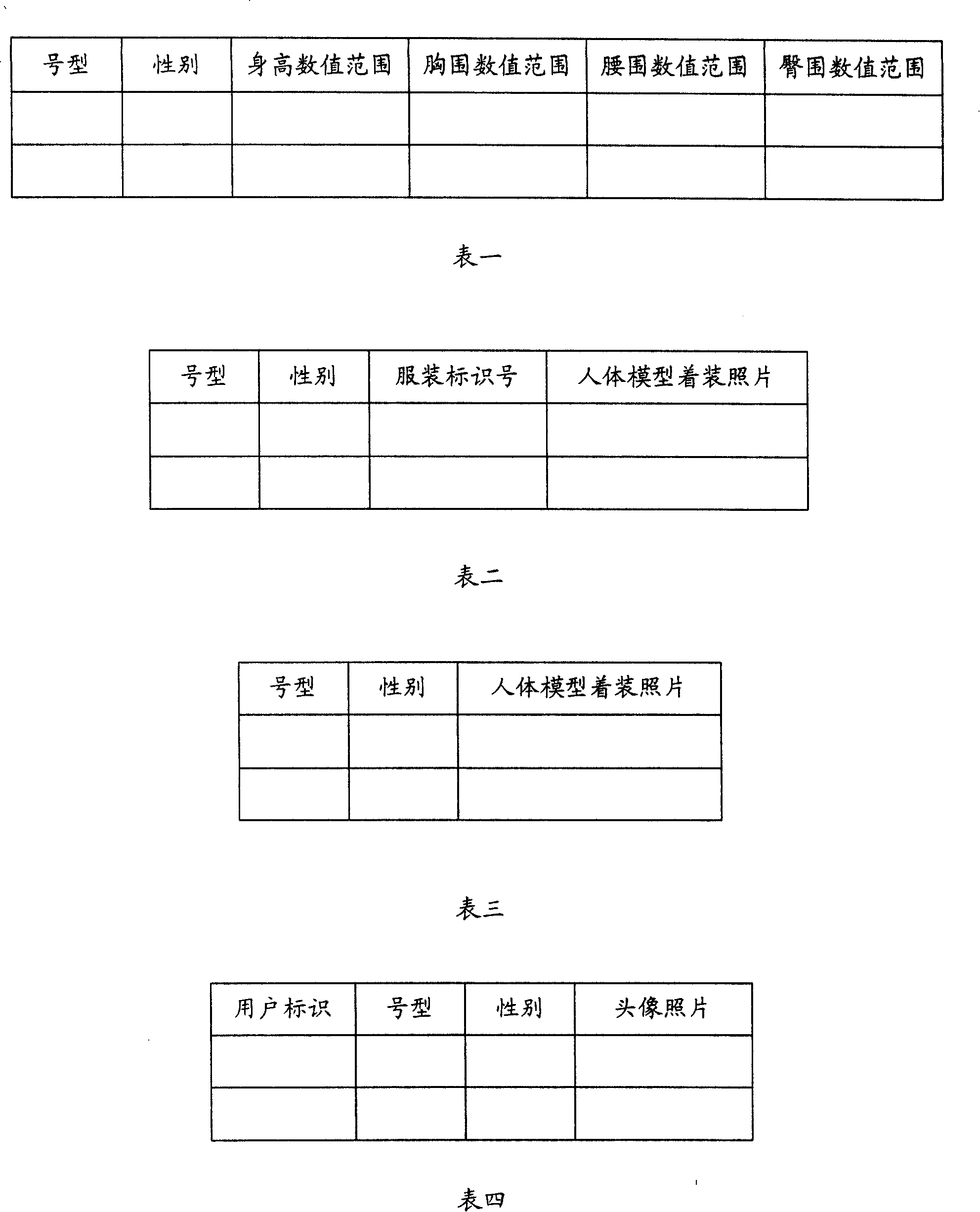

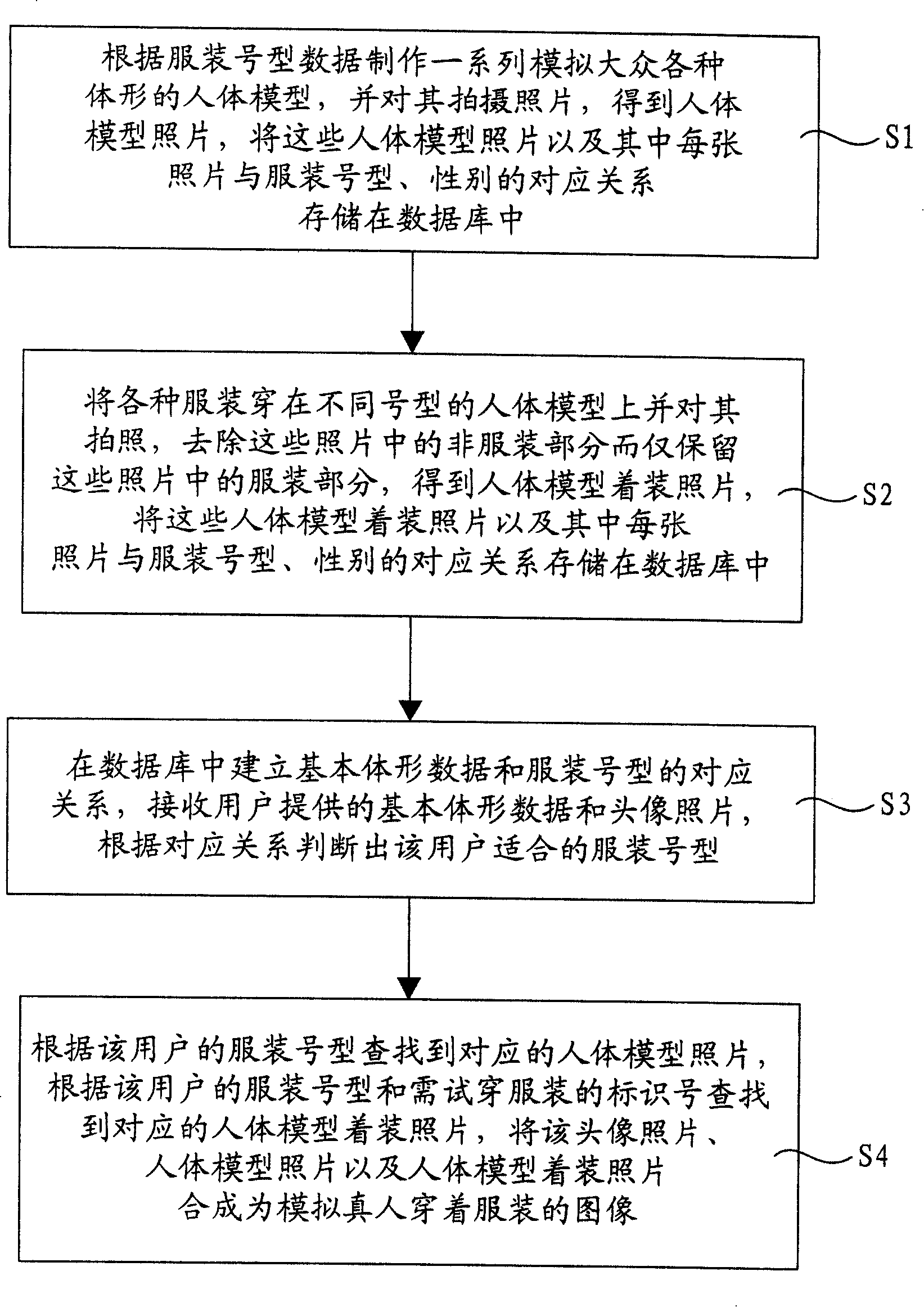

Virtual costume real man try-on system and constructing method thereof

InactiveCN101183450AReduce returnsIncrease salesCommerceSpecial data processing applicationsSimulationBuilding construction

The invention discloses a virtual clothing real trying-on system and the construction method, which solves the problem of online clothing real trying-on. The technical proposal of the invention is: the trying-on system comprises a data base storing dressing pictures of human model of a plurality of sizes and the corresponding human model pictures; a user data receiving element receiving the basic data, head portrait picture and the tried-on clothing which are provided by the user; a size-judging element judging out the size corresponding to the user's size according to the basic data received by the user data receiving element; a searching element finding out the human model picture and the dressing picture both corresponding to the judged size in the data base according to the judged size and the tried-on clothing by the size-judging element; a synthesis element synthesizing the received head portrait picture and the human model picture and the dressing picture by the searching element into an image simulating model dressed in the clothing. The invention is applied to the online clothing trying-on field.

Owner:朱滨

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com