Patents

Literature

36results about How to "No blemishes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cultivation technique for radishes

InactiveCN102090233AImprove qualityNo blemishesSeed and root treatmentHorticultureDiseasePest control

The invention relates to a cultivation technique for vegetables, specifically to a cultivation technique for radishes, belonging to the technical field of agricultures. The technique comprises the following steps such as variety breeding, fertilization and soil preparation, seed immersion and germination accelerating, disease and insect controlling and the like so as to improve the conventional culture technique, enable the yield of the radishes to 4000-5000kg / mu and ensure that the radishes have good quality and no spots; the raw radish has crisp taste; and the cooked radish is sweet, fine and smooth in mouth feel, so that the radishes can meet the demands of the market.

Owner:李秀云

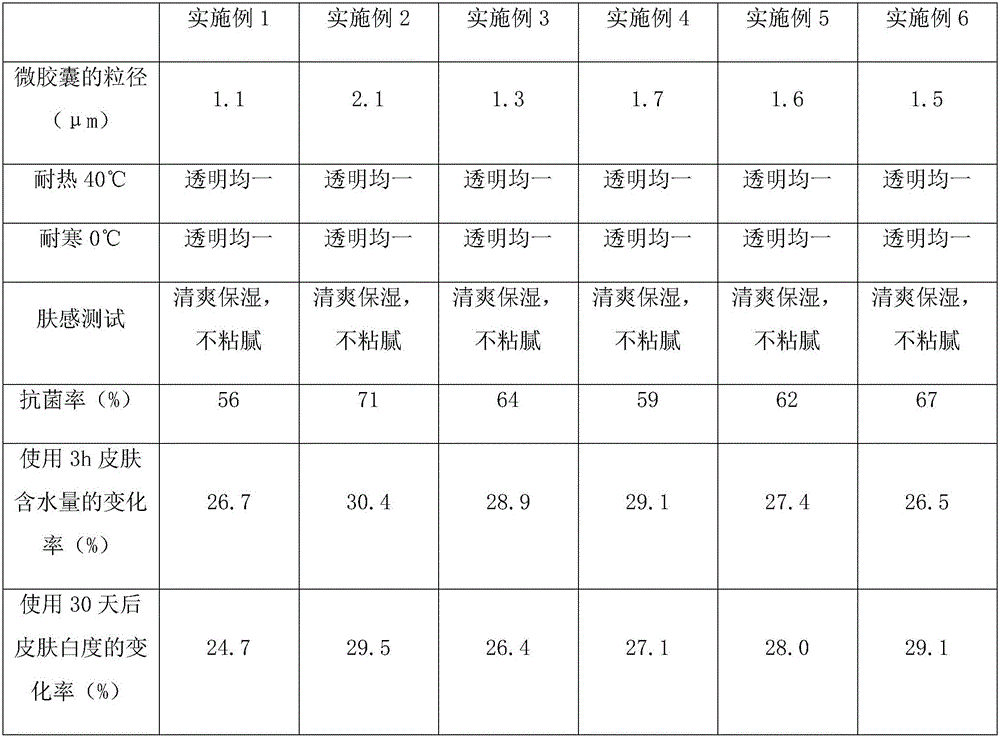

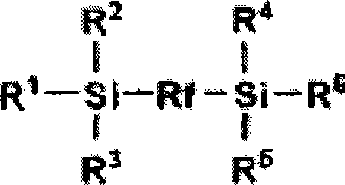

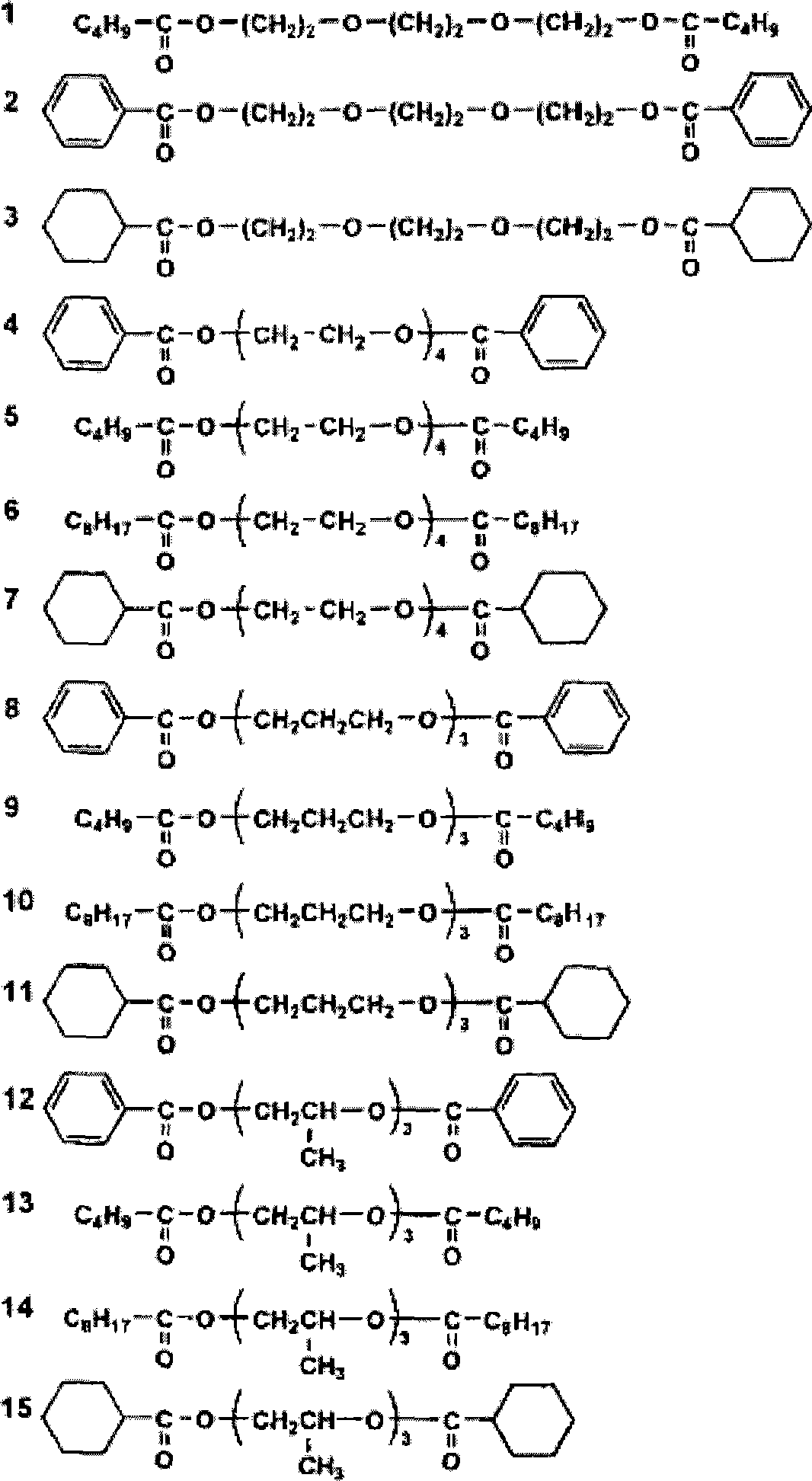

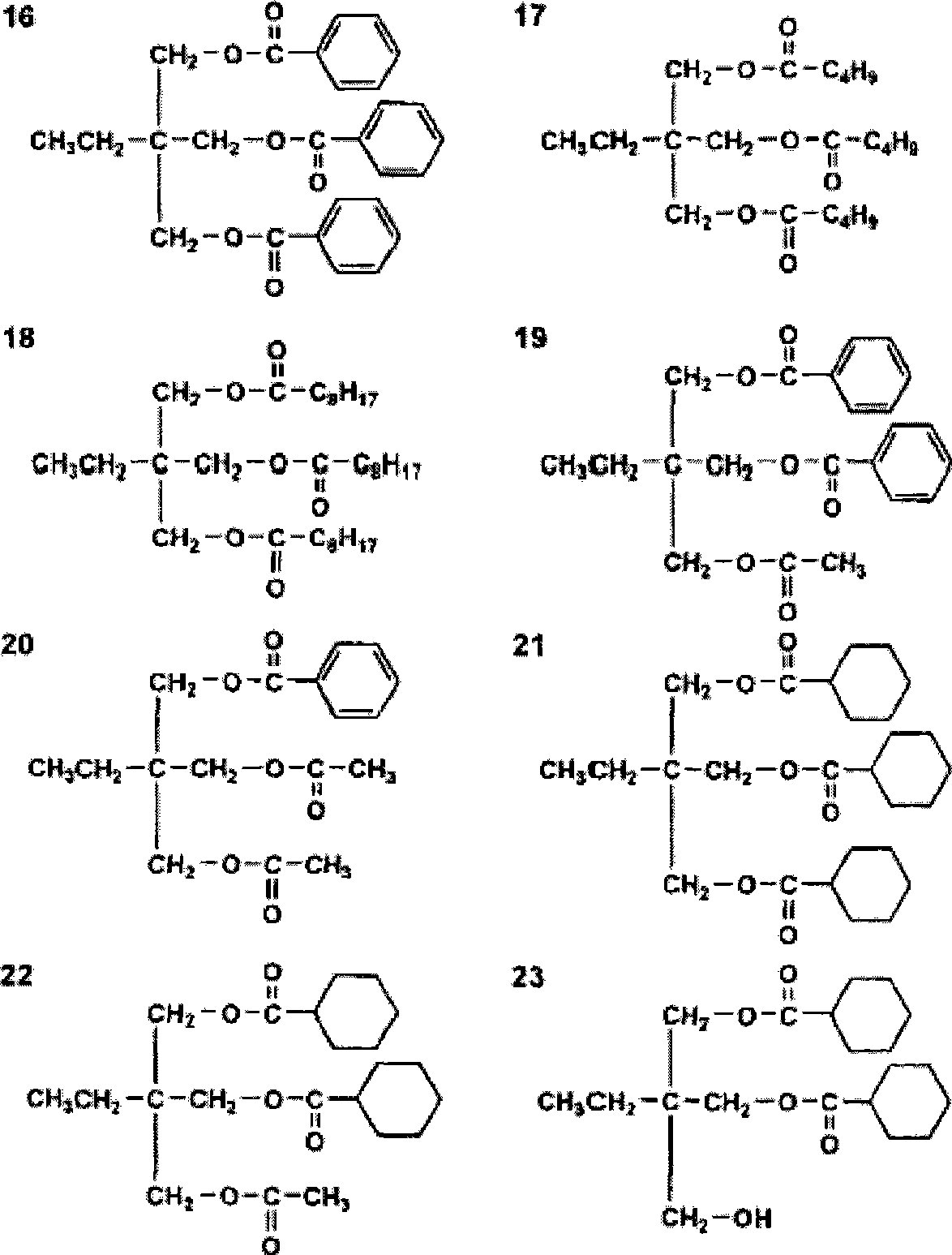

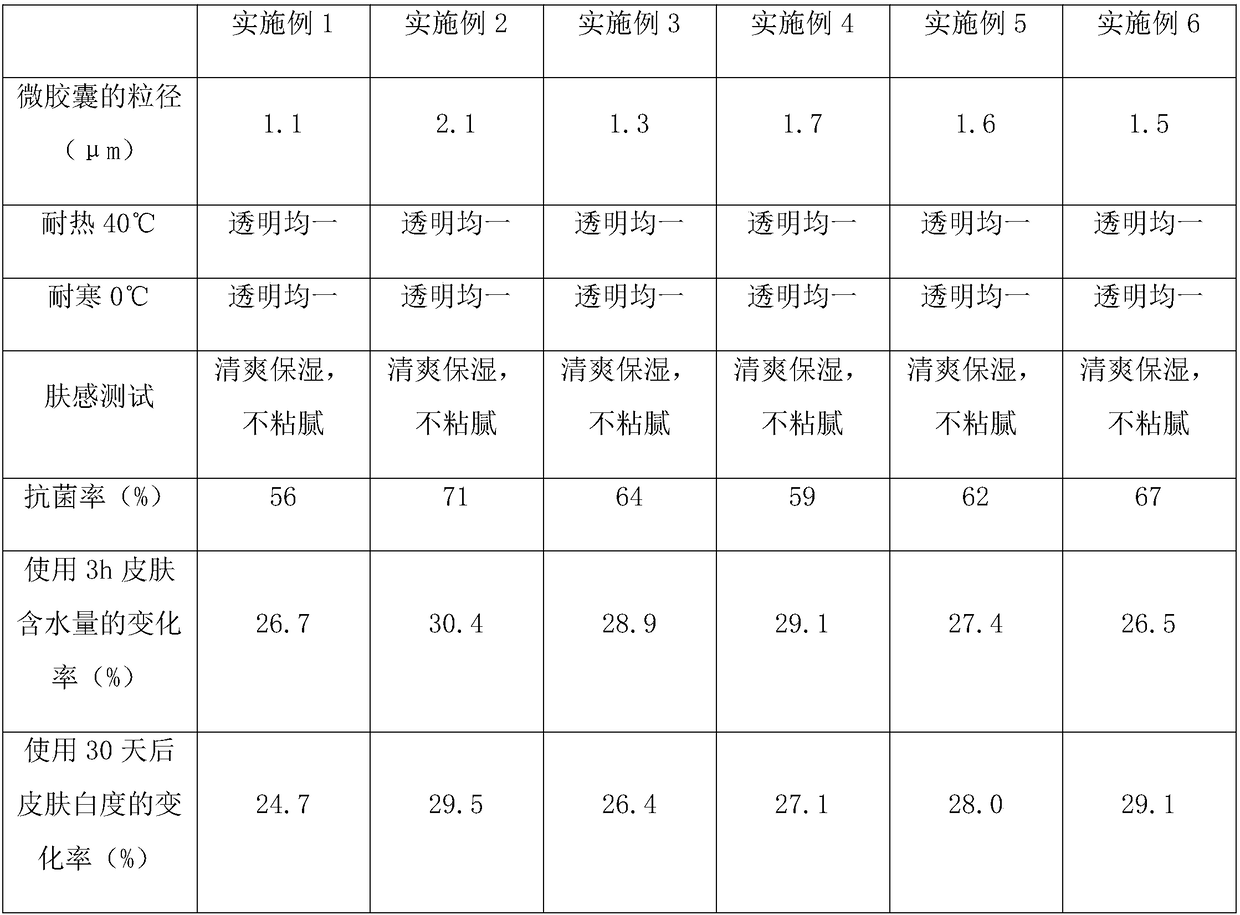

Herbaceous plant nutritive water based on emulsified microcapsule and preparation method of herbaceous plant nutritive water

InactiveCN105726456AGood skin tightening effectRich in nutrientsCosmetic preparationsToilet preparationsWater basedVegetable oil

The invention provides herbaceous plant nutritive water based on an emulsified microcapsule and a preparation method of the herbaceous plant nutritive water. The preparation method comprises the following specific steps: mixing hydrogenated vegetable oil, low erucic acid rapeseed oil , siloxane, microcrystalline wax and diglycerol, heating and uniformly stirring, and performing heat reservation and sterilization to obtain an oil phase; adding ethylene glycol, propylene glycol, glycine betaine, urea, poly-sodium glutamate, triethanolamine, caprylhydroxamic acid and hexylene glycol into deionized water, heating and uniformly stirring, performing heat preservation and sterilization to obtain a water phase; adding the oil phase into the water phase, performing heating, homogenization and low-speed stirring, adding cetyl ethyl hexanoate and stearic acid, then slowly adding PEG-40 hydrogenated castor oil and a microcapsule wall material, cooling, adding tremella, centella asiatica, polygonum cuspidatum, scutellaria baicalensis, tea leaves, glycyrrhiza glabra, female chrysanthemum, rosemary leaves, beer saccharomycete and grape fruit cell extract active components, and adding chondrus crispus extracts, bio-saccharide gum-1, diglycerol, palmitoyl tripeptide-1 and essence for mixing to obtain the herbaceous plant nutritive water based on the emulsified microcapsule.

Owner:广州市有喜化妆品有限公司

Antireflection film, process for producing antireflection film, hard coat film, polarizer, and display

InactiveCN101384927ANo blemishesPrevent sticking failureSynthetic resin layered productsPolarising elementsActinic RaysOLEYL ETHER

Owner:KONICA MINOLTA OPTO

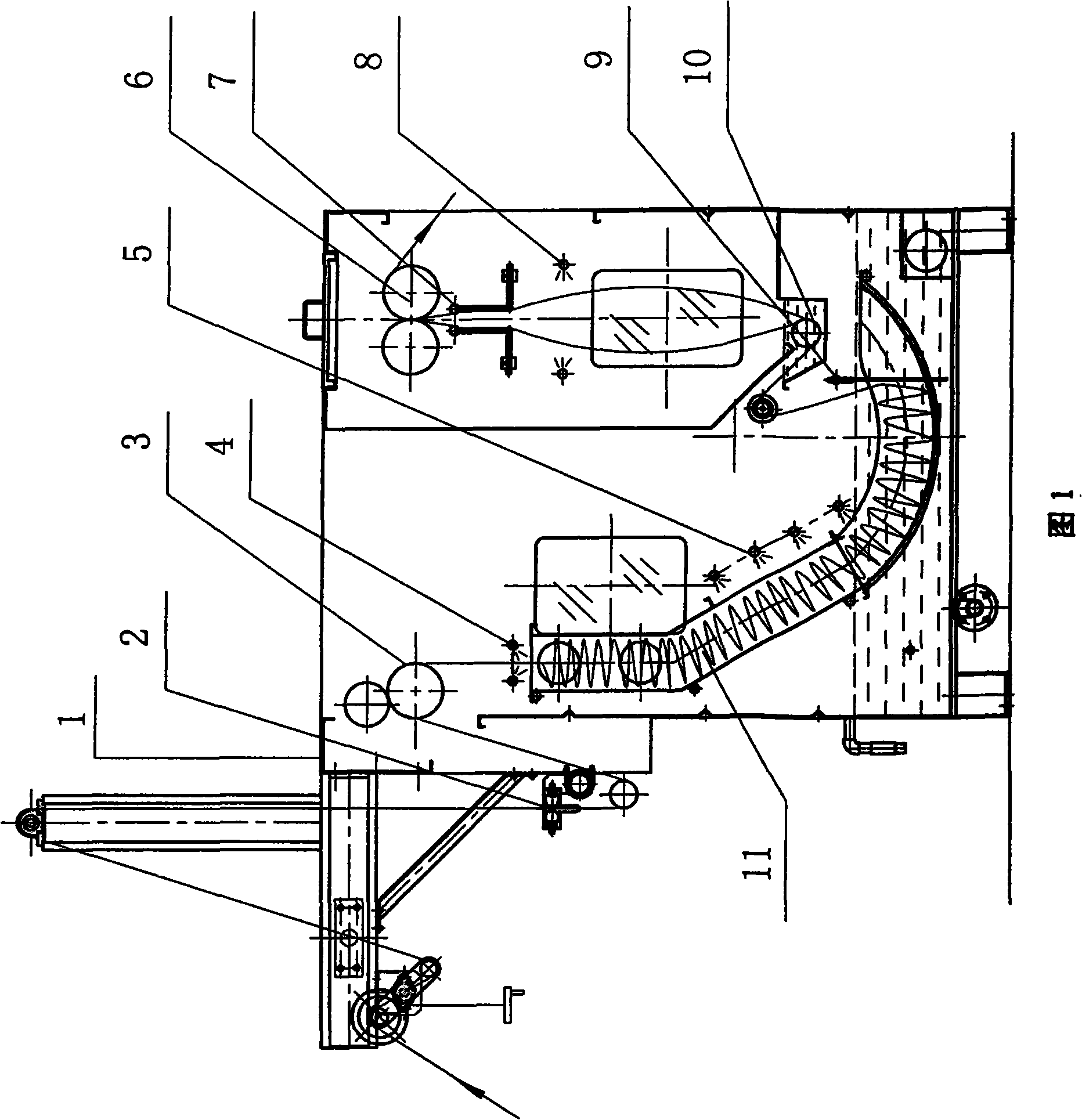

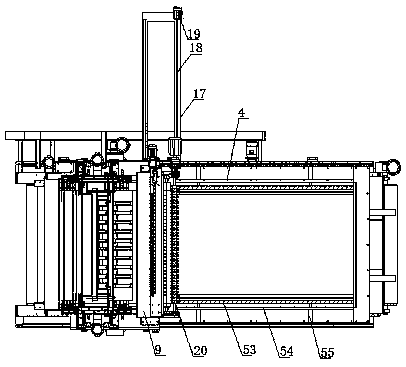

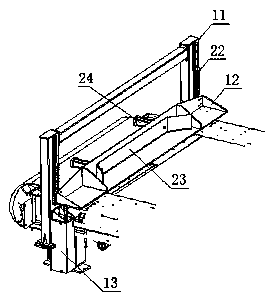

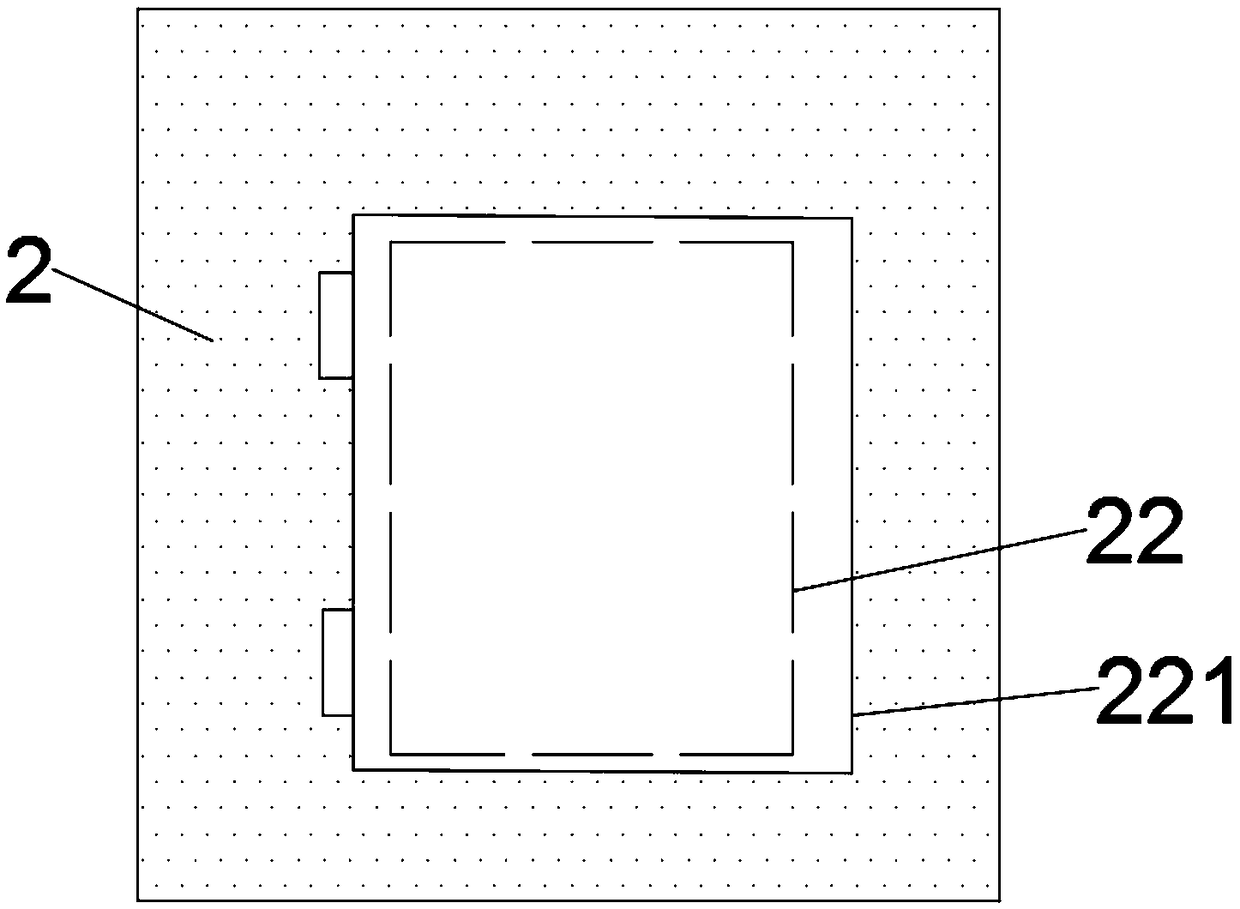

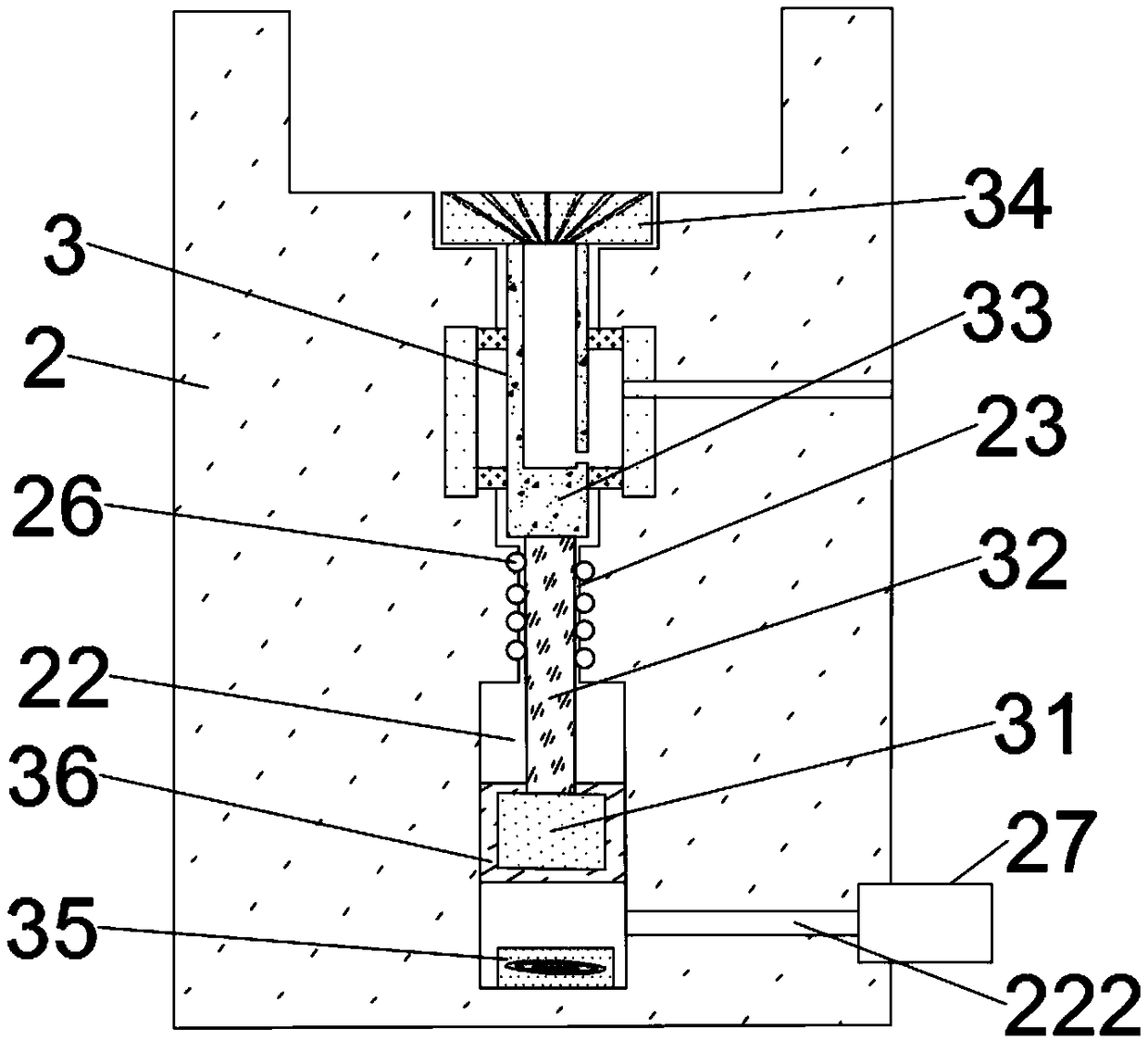

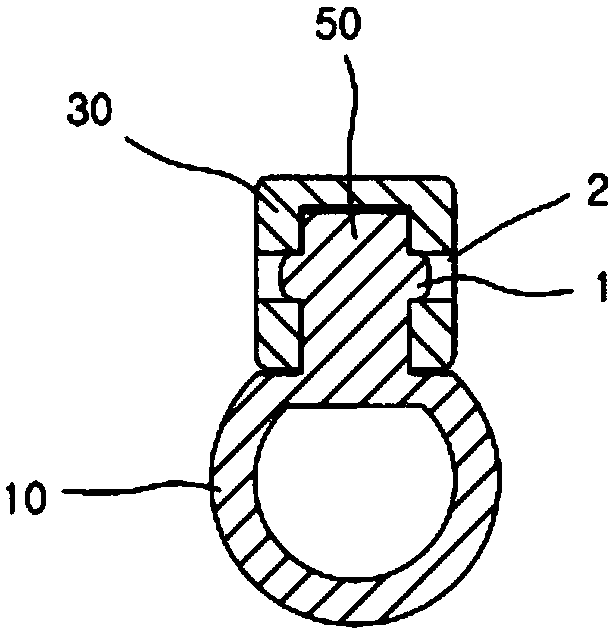

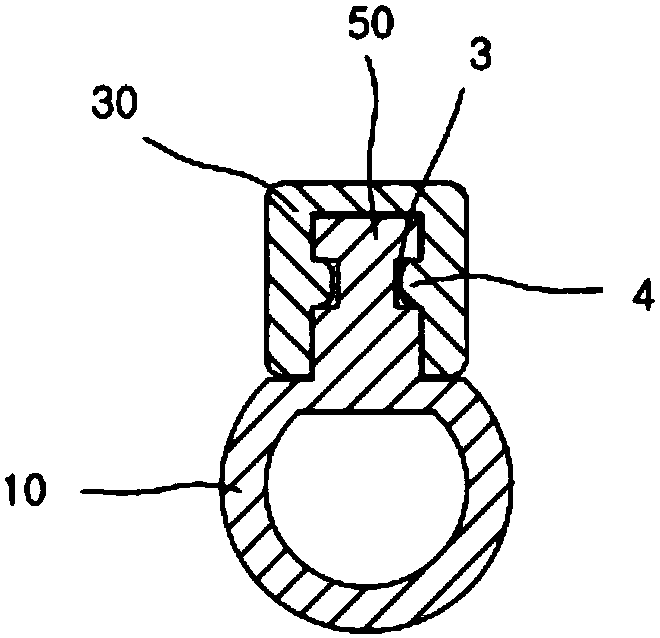

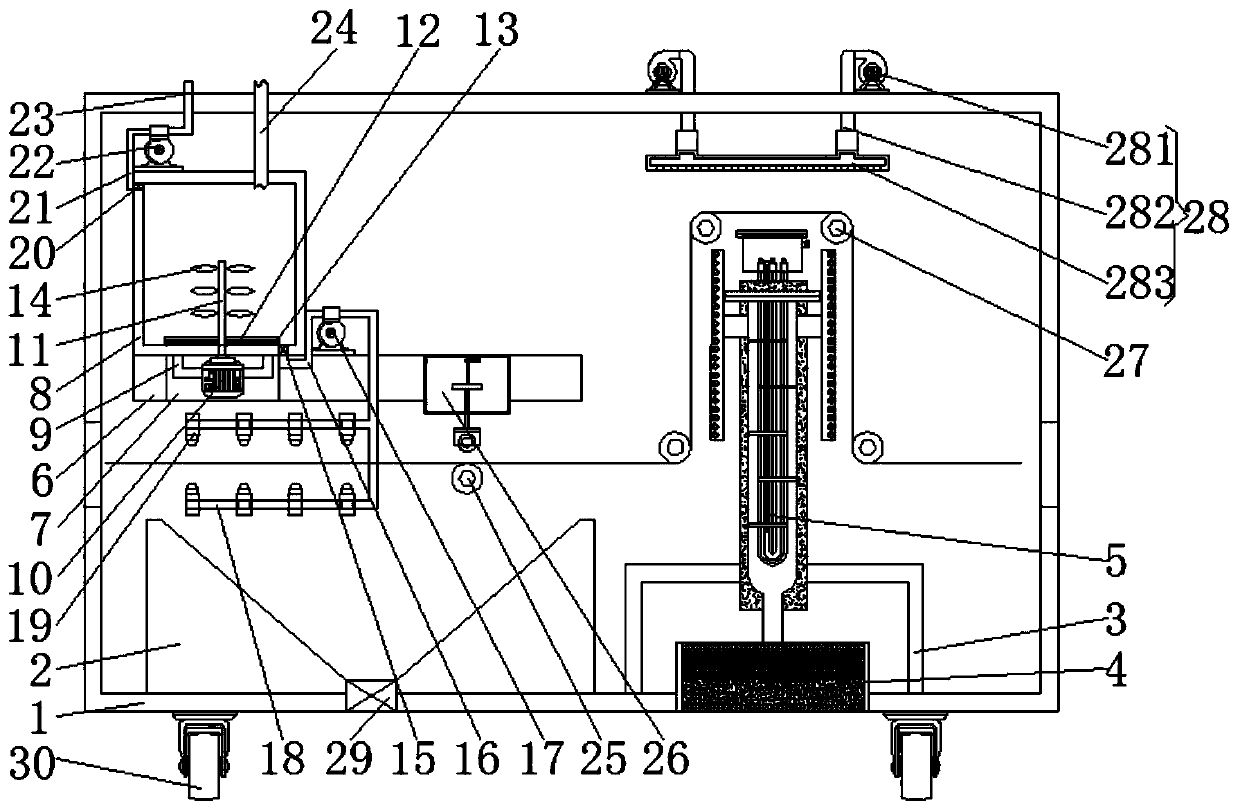

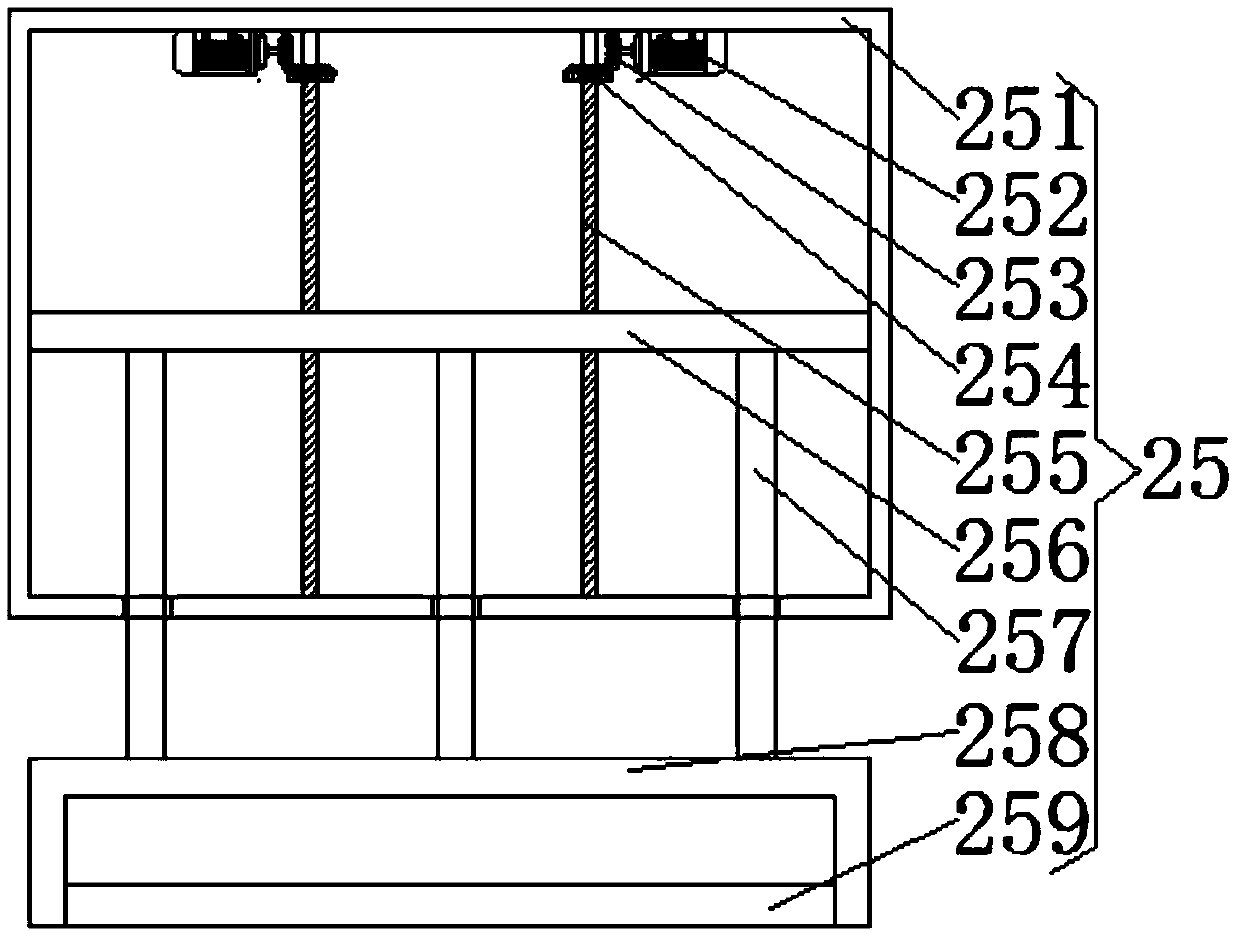

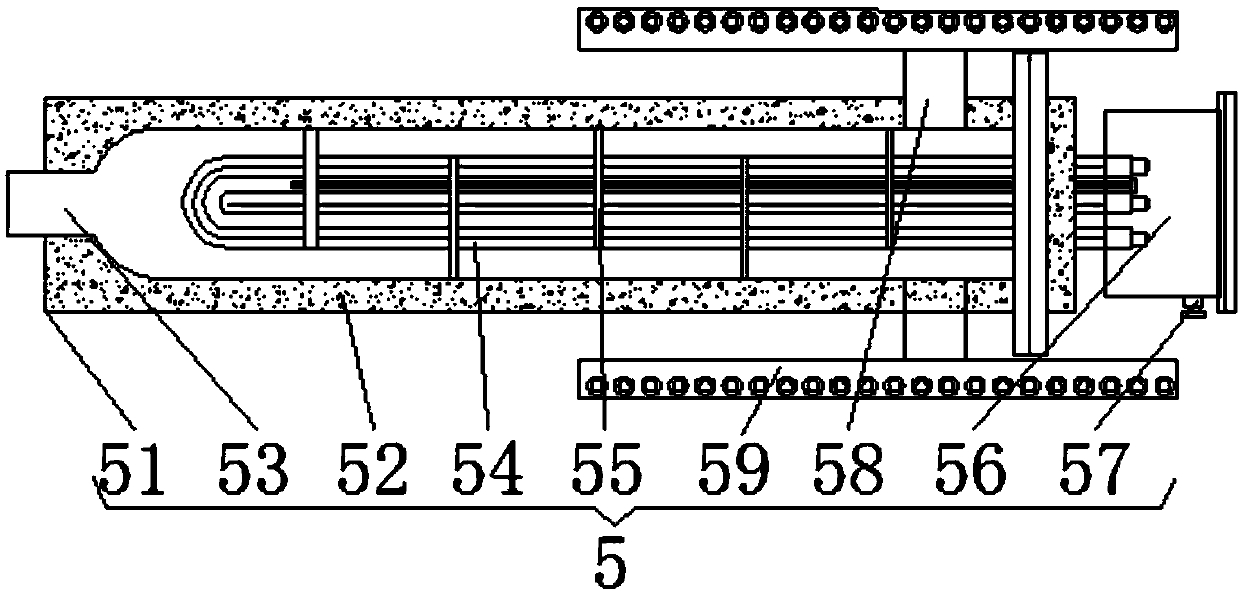

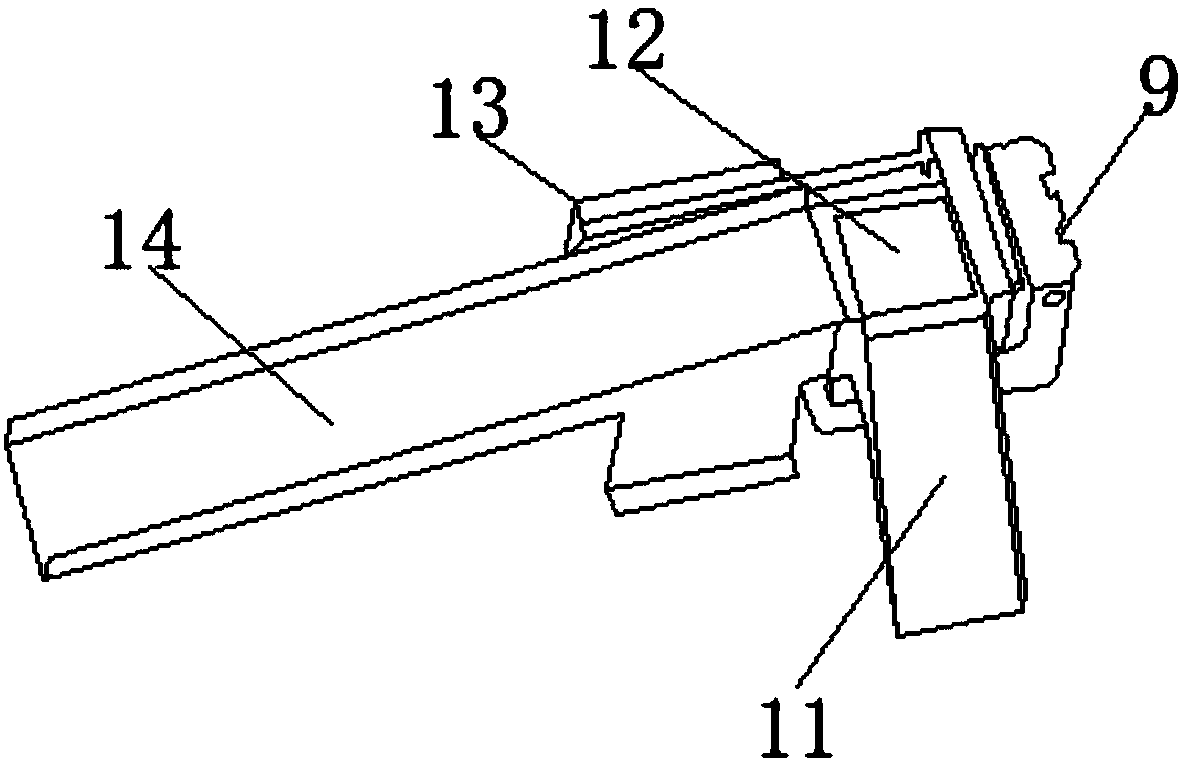

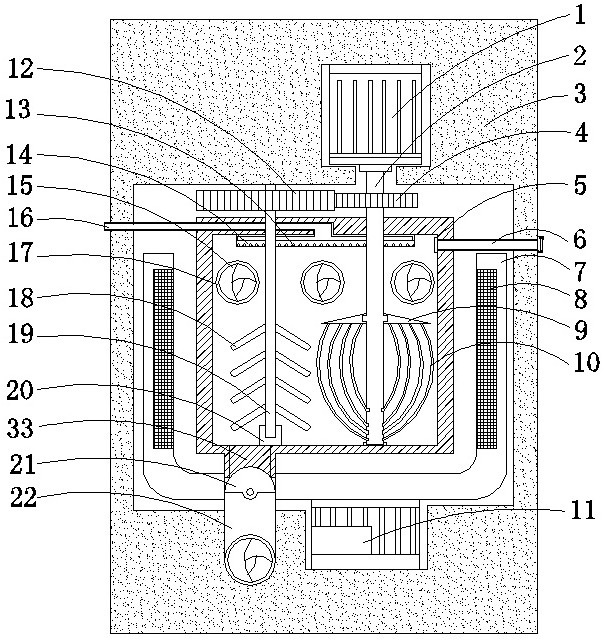

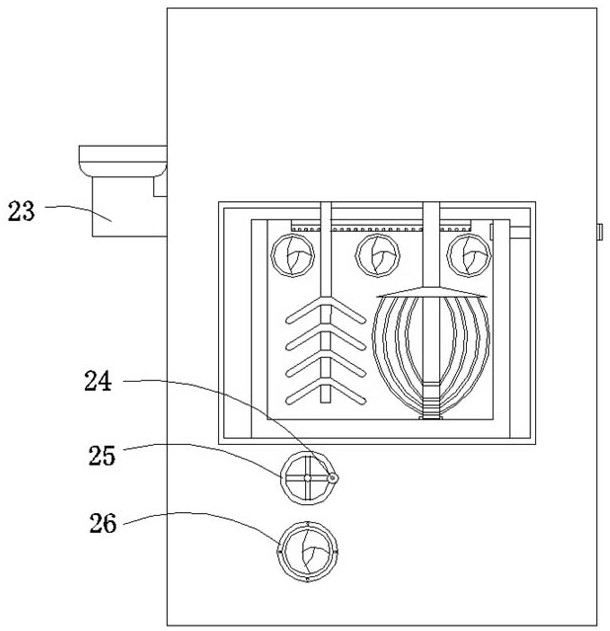

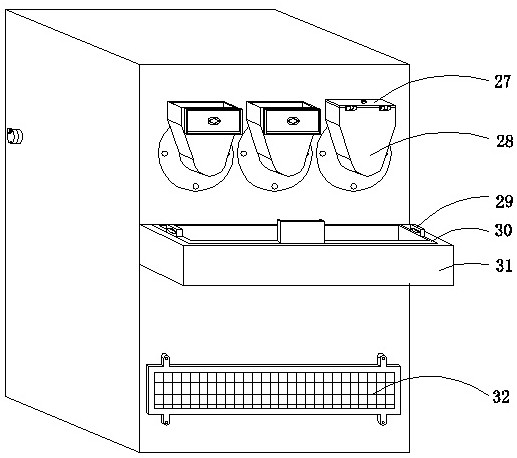

J-shape stacked pickling tank for knitting tubular open width refining rinsing combination machine

InactiveCN101289791ANo creaseNo blemishesLiquid/gas/vapor removal by squeezing rollersTextile treatment by spraying/projectingMechanical engineeringSmelting

The invention relates to a J-shaped stacking and steeping box for a knitted cylinder type open-width smelting and bleaching machine, comprising a steeping box body (1), a J-shaped stacking box (11), a cloth feeding spray device (4), a stacking spray device (5), an isochronous controller (9), a cloth discharge spray device (8), a blowing and bubbling device (7), water seals (10), a cloth feeding roller (3) and a cloth discharge roller (6), wherein, the cloth feeding spray device (4) is arranged above a grey cloth inlet of the J-shaped stacking box (11); the stacking spray device (5) is arranged on the side of the J-shaped stacking box (11); the isochronous controller (9) is arranged near a circular outlet of the J-shaped stacking box (11); the cloth discharge spray device (8) and the blowing and bubbling device (7) are arranged above the circular outlet of the J-shaped stacking box (11); and the water seals (10) are arranged under the cloth discharge spray device (8); the cloth feeding roller (3) is arranged on the upper front of the the cloth feeding spray device (4); and the cloth discharge roller (6) is arranged above the cloth discharge spray device (8) and the blowing and bubbling device (7). The J-shaped stacking and steeping box has the characteristics that: the surface of grey cloth can not be damaged and fuzzed and has no fold and grinding flaw; the water and the energy are saved; the efficiency is high; the production cost is low; the bleaching technique is stable; etc.

Owner:张琦

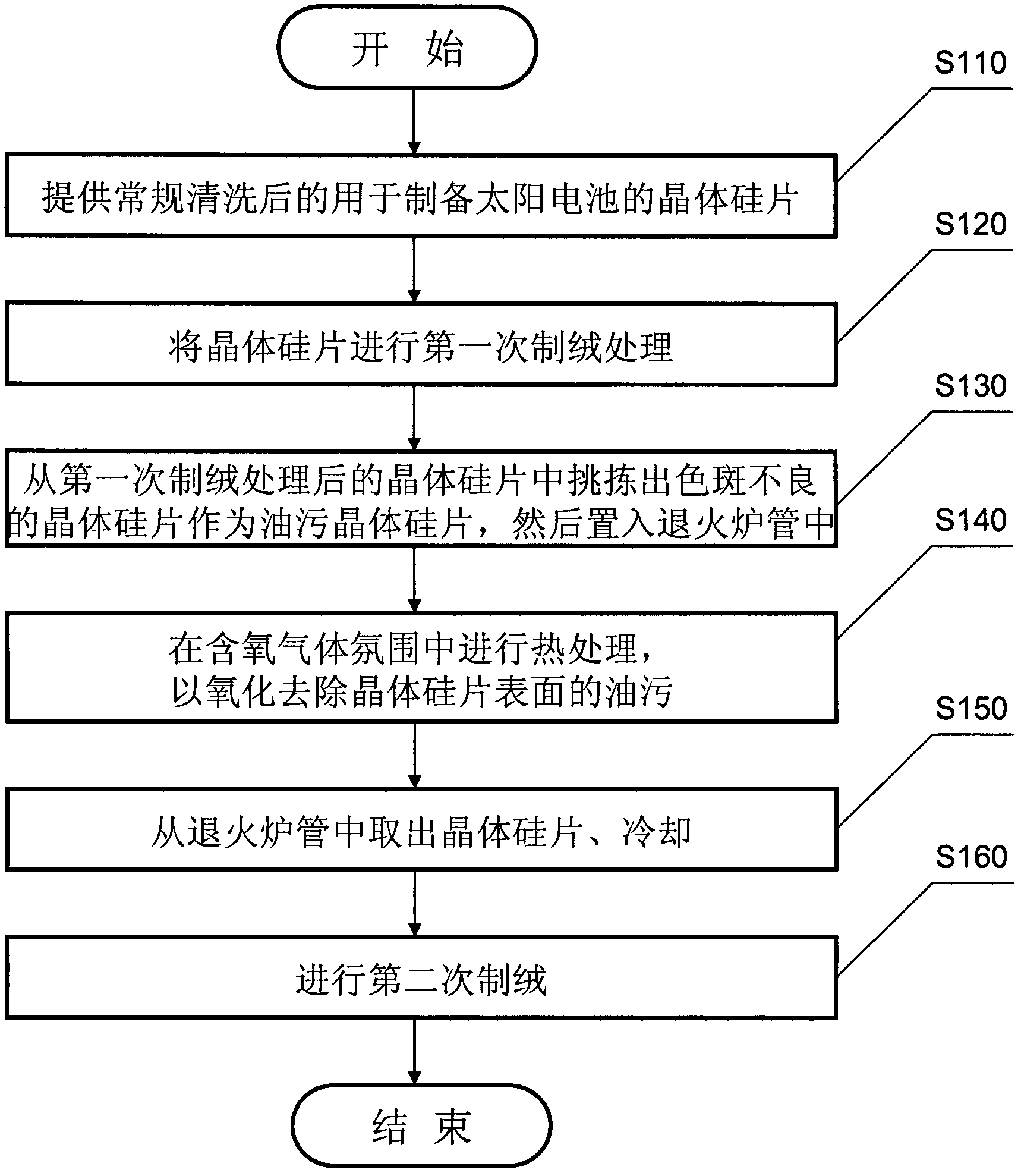

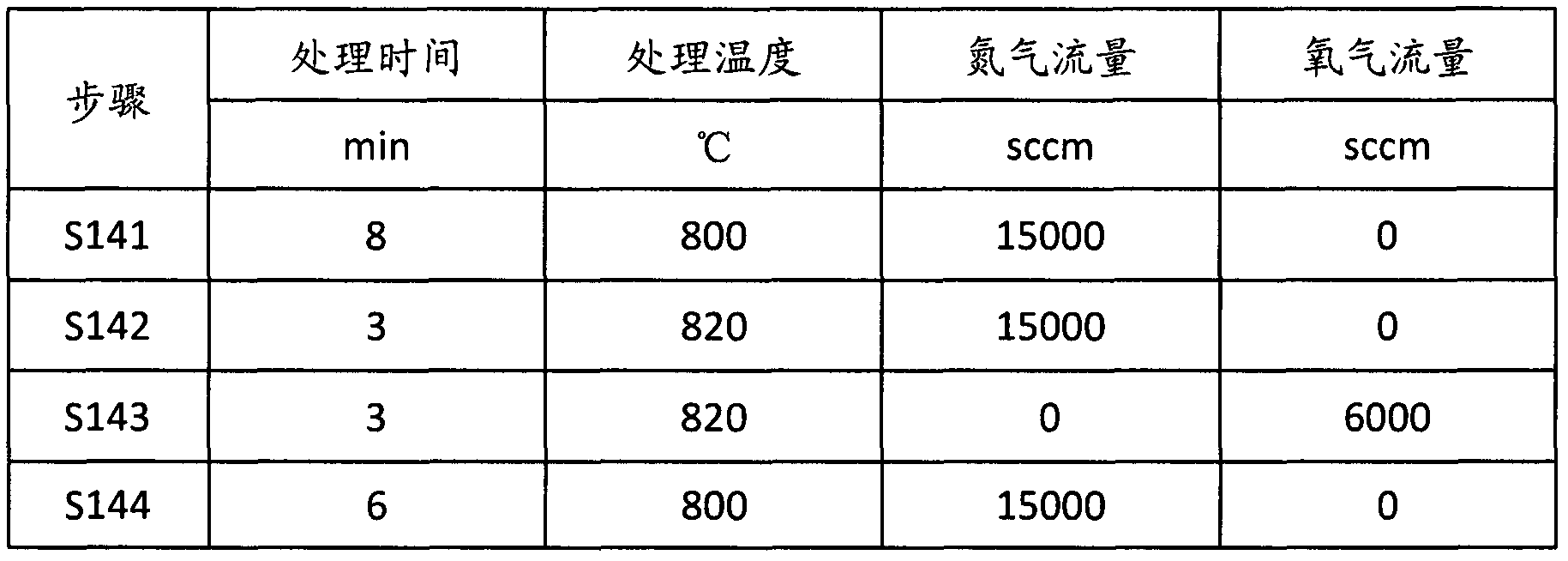

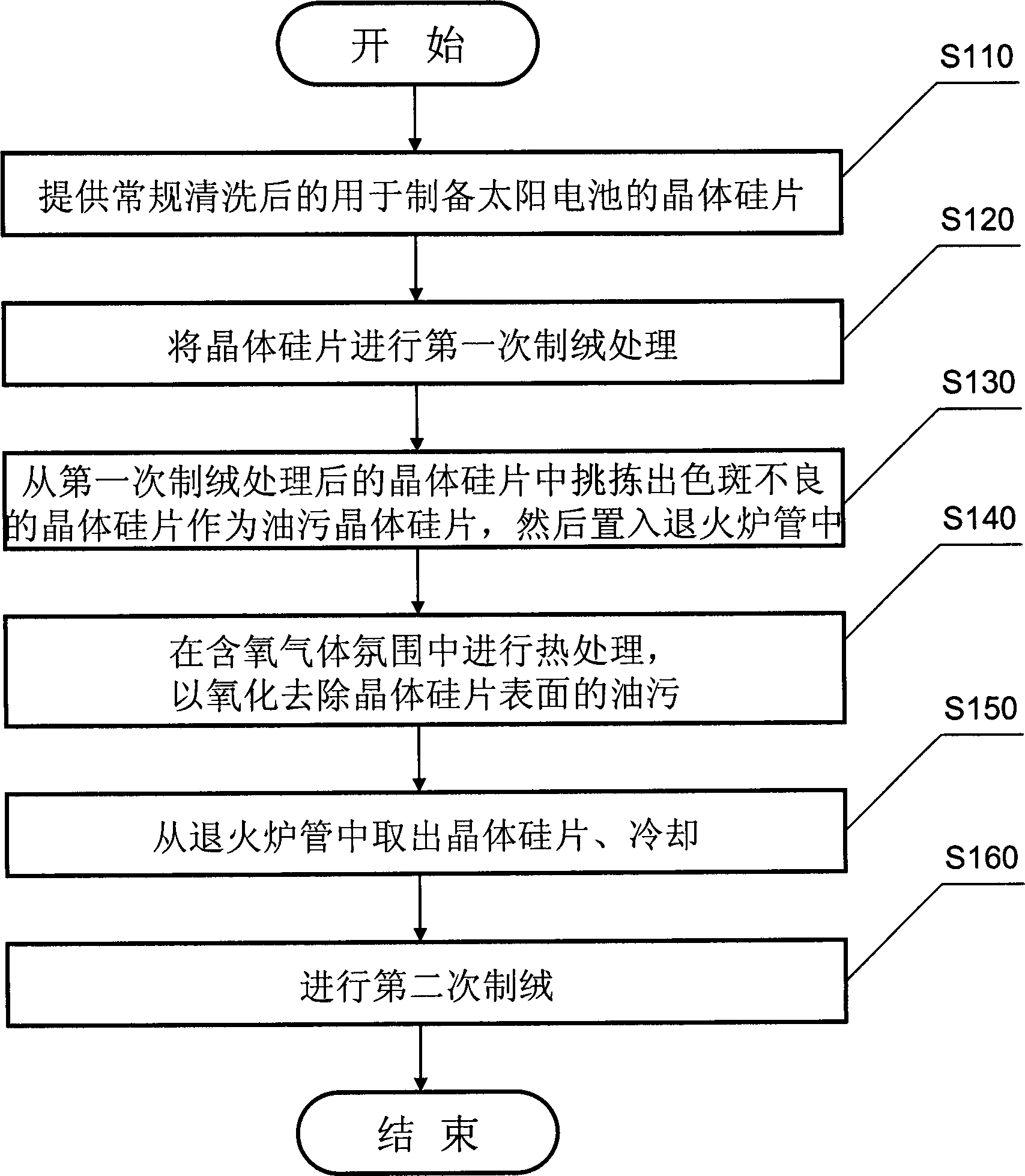

Treatment method and etching method of crystalline silicon wafer with oil stains

InactiveCN102653887AImprove finished product qualityEfficient removalAfter-treatment detailsCrystalline siliconMaterials science

The invention provides a treatment method and an etching method of a crystalline silicon wafer with oil stains, belonging to the technical field of solar cell manufacturing. In the oil stain treatment method, the crystalline silicon wafer is subjected to heat treatment in an oxygen-containing gas atmosphere to remove the oil stains by oxidation. The etching method comprises the following steps: removing the oil stains on the crystalline silicon wafer with oil stains by oxidation after the primary etching, and carrying out secondary etching. The treatment method can effectively remove oil stains on the crystalline silicon wafer surface; and in the etching method using the treatment method, after the crystalline silicon wafer subjected to oil stain removal by oxidation is subjected to secondary etching, the crystalline silicon wafer subjected to the secondary etching can not have the phenomenon of defective color spots, thereby enhancing the quality of the etching finished product.

Owner:WUXI SUNTECH POWER CO LTD +1

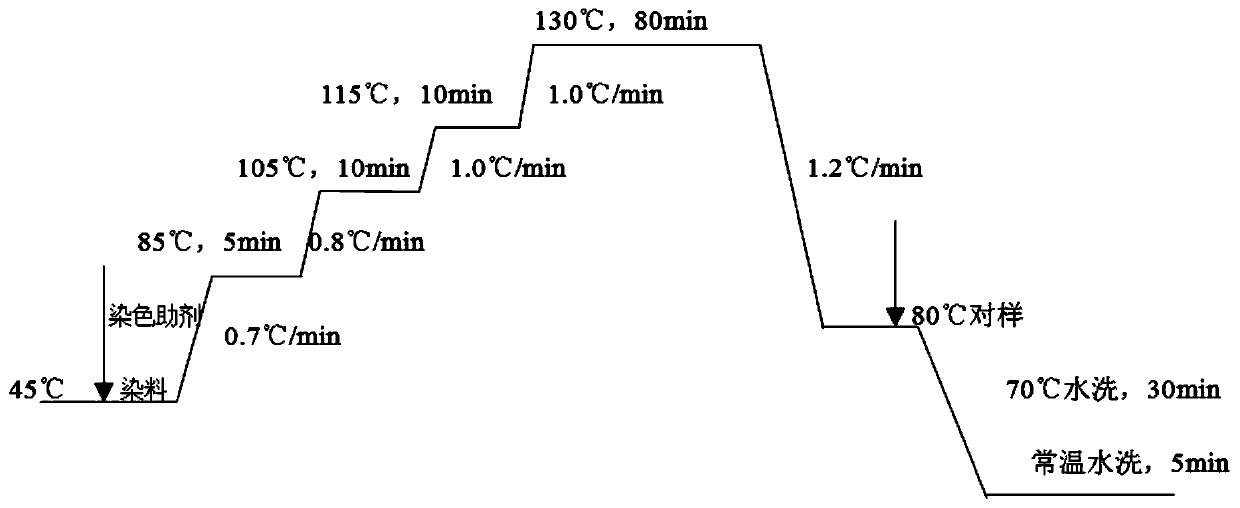

Dyeing process capable of forming PTT/PET composite fiber fabric with crepe feeling

The invention discloses a dyeing process capable of forming a PTT / PET composite fiber fabric with a crepe feeling. According to the dyeing process, an adopted dyeing agent consists of a dyeing assistant and a dye, and the dye is a disperse dye. In the dyeing process, a high-temperature and high-pressure airflow overflow dual-purpose dyeing machine is adopted for dyeing, and when the temperature ofa dyeing cylinder of the dyeing machine reaches 45 DEG C, the dyeing assistant and the disperse dye are separately injected; the dyeing process includes a dyeing stage and a water washing stage; in the dyeing stage, the dyeing machine stays in an airflow mode, and in the water washing stage, the dyeing machine stays in a gas-liquid mode. During dyeing, the temperature of the dyeing cylinder is increased to 85 DEG C at the temperature increase rate of 0.7 DEG C / min, and the temperature is set as the initial dyeing temperature. On the premise of ensuring the dyeing quality, not only can the dyed fabric have no flaws and defects, but also the fabric can be endowed with a zigzag crepe feeling, so that the fabric has an obvious airflow style, good color reproducibility and a soft hand feeling;moreover, the fabric has a shape memory function in the weft direction, the elastic effect is obvious, and the requirements for clothing are met.

Owner:SUZHOU XINMIN PRINTING&DYEING CO LTD

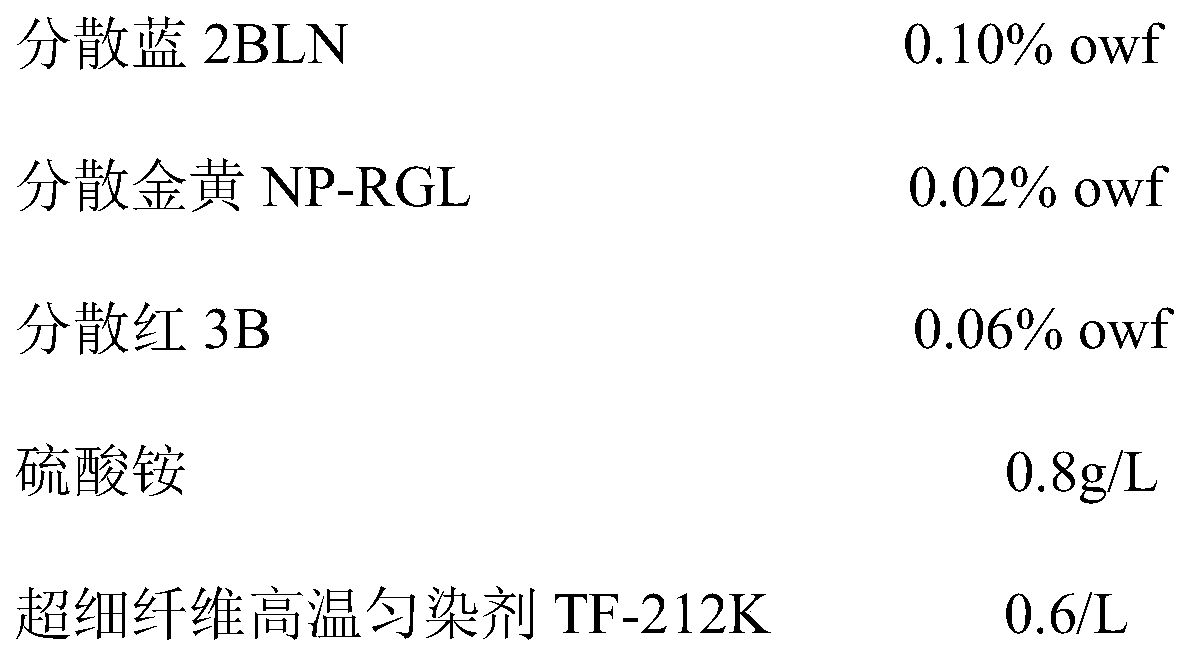

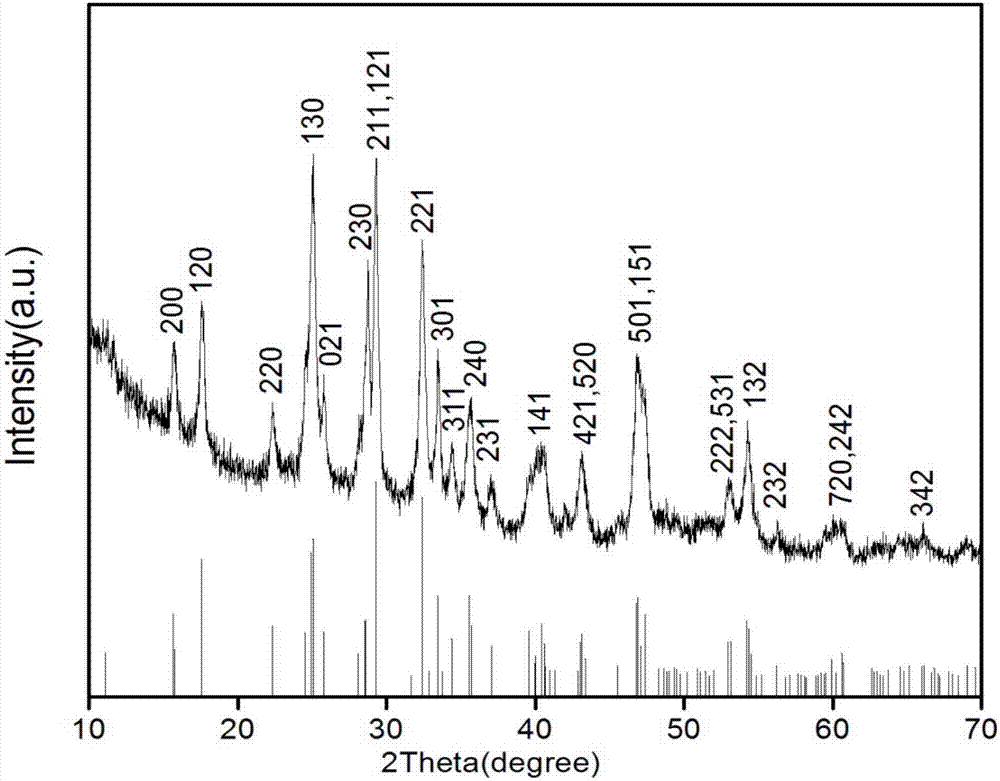

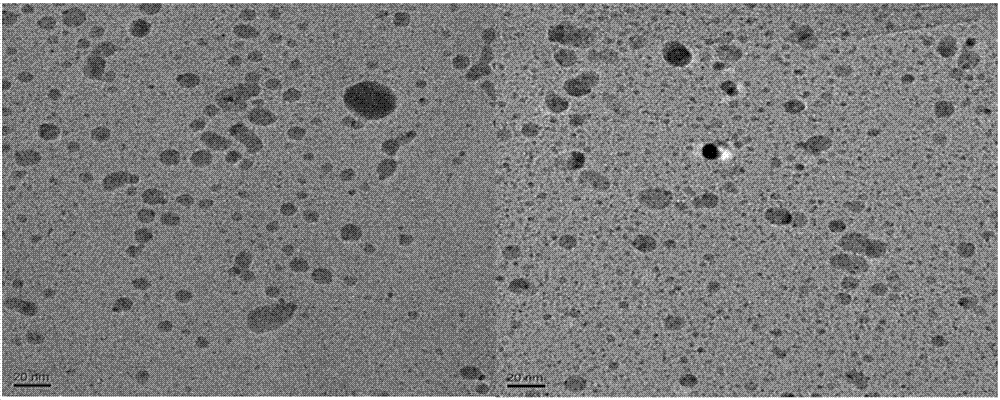

Semiconductor antimony sulfide nanocrystalline and preparing method thereof and photocatalysis hydrogen production performance testing method

InactiveCN107089681ANo pollution in the processSimple and fast operationMaterial nanotechnologyPhysical/chemical process catalystsPhotocatalysisCompound (substance)

The invention belongs to the technical field of semiconductor antimony sulfide (Sb2S3) nanocrystalline and a photocatalysis hydrogen production performance testing method. The chemical formula of semiconductor antimony sulfide is Sb2S3, the molecular weight is 339.68, the structure is an orthorhombic crystal system, and the space group number is Pcmn (62); the crystal particle is in an irregular spherical shape, the crystal particle distribution is narrow, and the crystal particle is 6.5nm-11.5 nm, the average size obtained after Gaussian fitting is 8.67 nm, the chemical component is relatively uniform, the structure is single, the surface is pure, and the direct band-gap value of semiconductor antimony sulfide nanocrystalline is about 1.74eV. The semiconductor antimony sulfide nanocrystalline and the preparing method thereof and the photocatalysis hydrogen production performance testing method have the advantages that the adopted amorphous metal alloy method is a physical compounding method, and compared with a chemical preparing method, has the advantages of being easy to operate, low in equipment price and free of pollution to environment, and semiconductor antimony sulfide nanocrystalline is easy to produce in large scale and the like.

Owner:WUHAN UNIV OF TECH

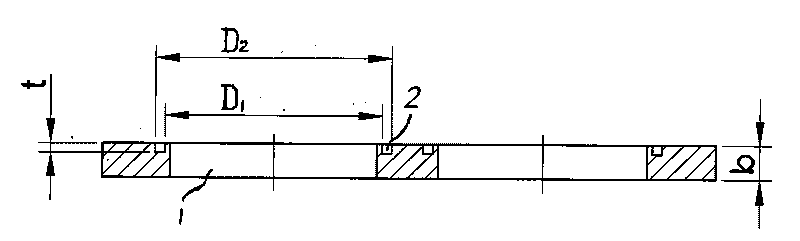

Welding method of damper plate and flow tube in Coriolis mass flowmeter

InactiveCN101745721AExempt from bringing your ownNo blemishesArc welding apparatusDirect mass flowmetersEngineeringLine defects

The invention relates to a welding method of a damper plate and a flow tube in a Coriolis mass flowmeter; the diameter of the flow tube is set as d, the tube wall thickness is delta which is more than or equal to 2mm, manual argon arc welding is carried out by the following steps: the thickness b of the damper plate is selected, b is equal to 4-5delta; a hole is arranged on the damper plate for leading the flow tube to penetrate through; a circular groove which has concentric circle with the hole is arranged on the damper plate; after the flow tube penetrates through the damper plate, the manual argon arc welding is carried out. The bore diameter d of the damper plate is equal to d (1+0.5 percent), the diameter of the inner ring of the circular groove is D+2delta, the diameter of the outer ring of the circular groove is D+5delta, and the depth of the circular groove is 1.5delta. the damper plate is thickened and the circular groove is arranged, so as to realize manual argon arc welding f the damper plate and the flow tube, a huge vacuum brazing furnace is omitted, even if the assembling clearance of the flow tube and the damper plate reaches 0.5mm, even wider clearance exists, welding can be carried out, secondary repair can be carried out to welding line defect, and the method is suitable for the mass flowmeter with more than 2mm of the flow tube wall.

Owner:SHANGHAI YINUO INSTR

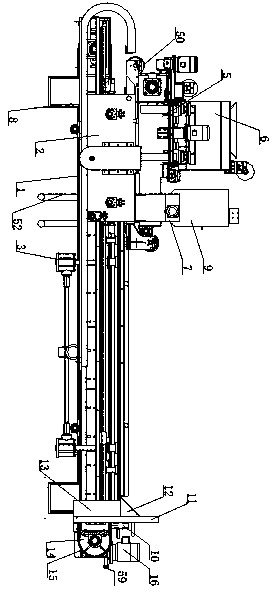

Powder spraying distributing machine

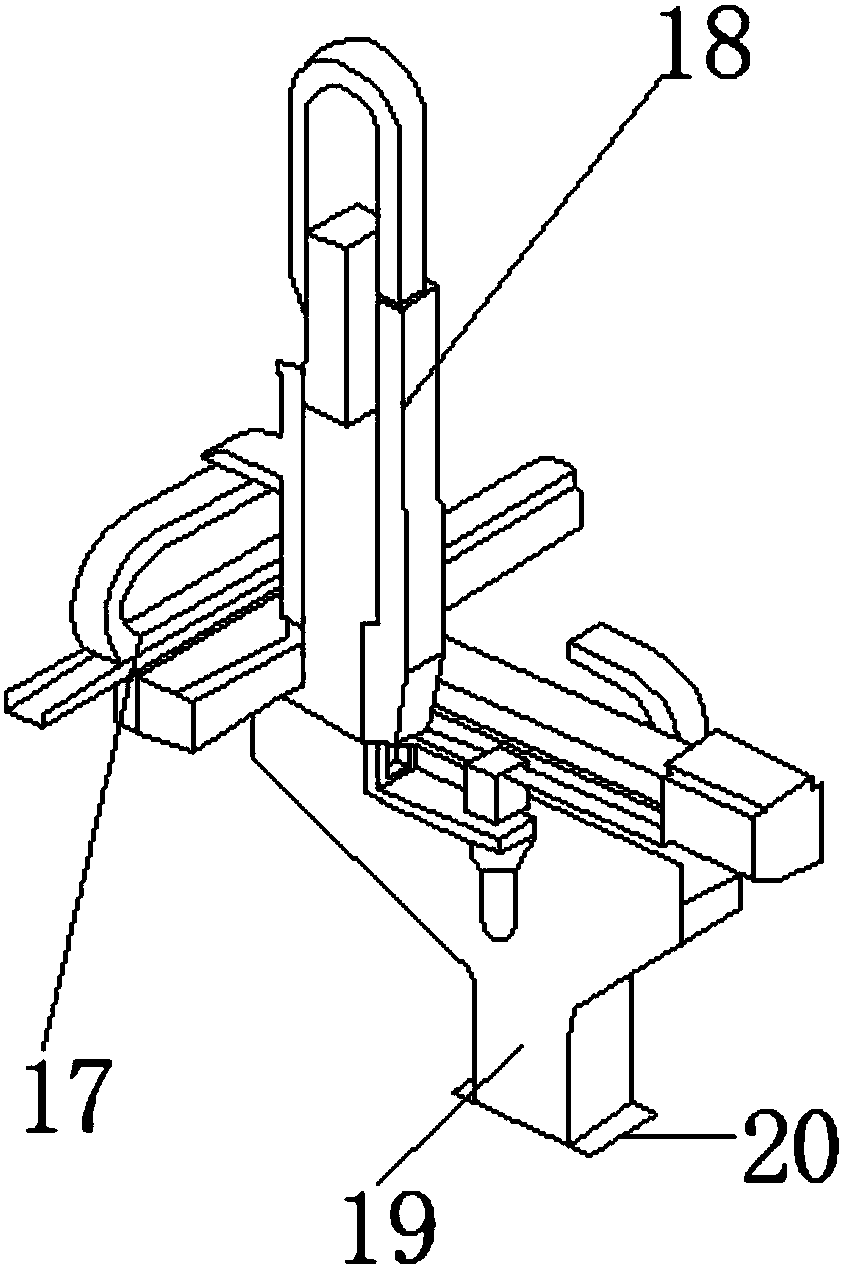

PendingCN111036509ATime consuming and laborious to clean upDifficult to clean upLiquid surface applicatorsCoatingsDrive wheelElectric machinery

The invention discloses a powder spraying distributing machine which comprises a distributing conveying platform, a sliding assembly, a mold frame lifting assembly, a distributing frame assembly, a distributing assembly, a hopper assembly, a color hopper frame, a platform support frame, a color powder hopper assembly part, a mold frame lifting limit switch seat, a guide rail support frame, a residual material recovery device, a residual material up-down driving cylinder, a driving wheel, a conveying belt, a driving wheel motor and a color hopper guide rail frame, wherein a trolley sliding railis arranged on the side surface of the distributing conveying platform, the sliding assembly is installed on the trolley sliding rail in a driving mode, and the distributing assembly is supported andinstalled on the sliding assembly. The powder spraying distributing machine has the beneficial effects that traditional distributing machines with two distributing ways of manual distributing and pattern distributing are integrated on the same equipment, disposable rolling adhesive paper is adopted for winding, defects can not be generated when the plate type is replaced for production, and a color powder recycling device is arranged, so that cleanness and sanitation are realized, and raw materials are saved.

Owner:肇庆威尼托机械有限公司 +2

Automobile adjuster mold assembly with reverse-ejecting mechanisms

ActiveCN108789969AAvoid sticking to the inner wall of the mold cavityHigh speedDomestic articlesAir pumpHigh pressure

The invention discloses an automobile adjuster mold assembly with reverse-ejecting mechanisms. The automobile adjuster mold assembly comprises an upper movable mold and a lower fixed mold, the interiors of the upper movable mold and the lower fixed mold are provided with the reverse-ejecting mechanisms through mounting layers respectively, wherein each mounting layer comprises a cylindrical sliding groove, a rectangular stop-rotating groove, a cylindrical rod groove and an ejecting block groove; and each reverse-ejecting mechanism comprises a cylindrical magnetic sliding block, a rectangular transmission rod, a hollow ejector rod and an ejecting block, wherein an electromagnetic seat is arranged at the bottom end of the cylindrical magnetic sliding block. A forming product is easily separated from a mold cavity under the thrust action of high-pressure gas, so that the integrity and the quality of the ejection forming product are guaranteed, energy is saved, and the ejection efficiencyis improved; and the reverse-ejecting mechanisms are enabled to eject the forming product through the two driving modes of the magnetic field force effect of the electromagnetic seat and the gas pressure action of a piston type air pump correspondingly, the diversity of the driving mode improves the error-tolerant rate of the reverse-ejecting mechanisms, so that the service life of the reverse-ejecting mechanisms is longer, the ejecting block can return to an initial position every time correspondingly, and a groove or a defect cannot be generated on a produced adjuster outer shell either.

Owner:芜湖众梦电子科技有限公司

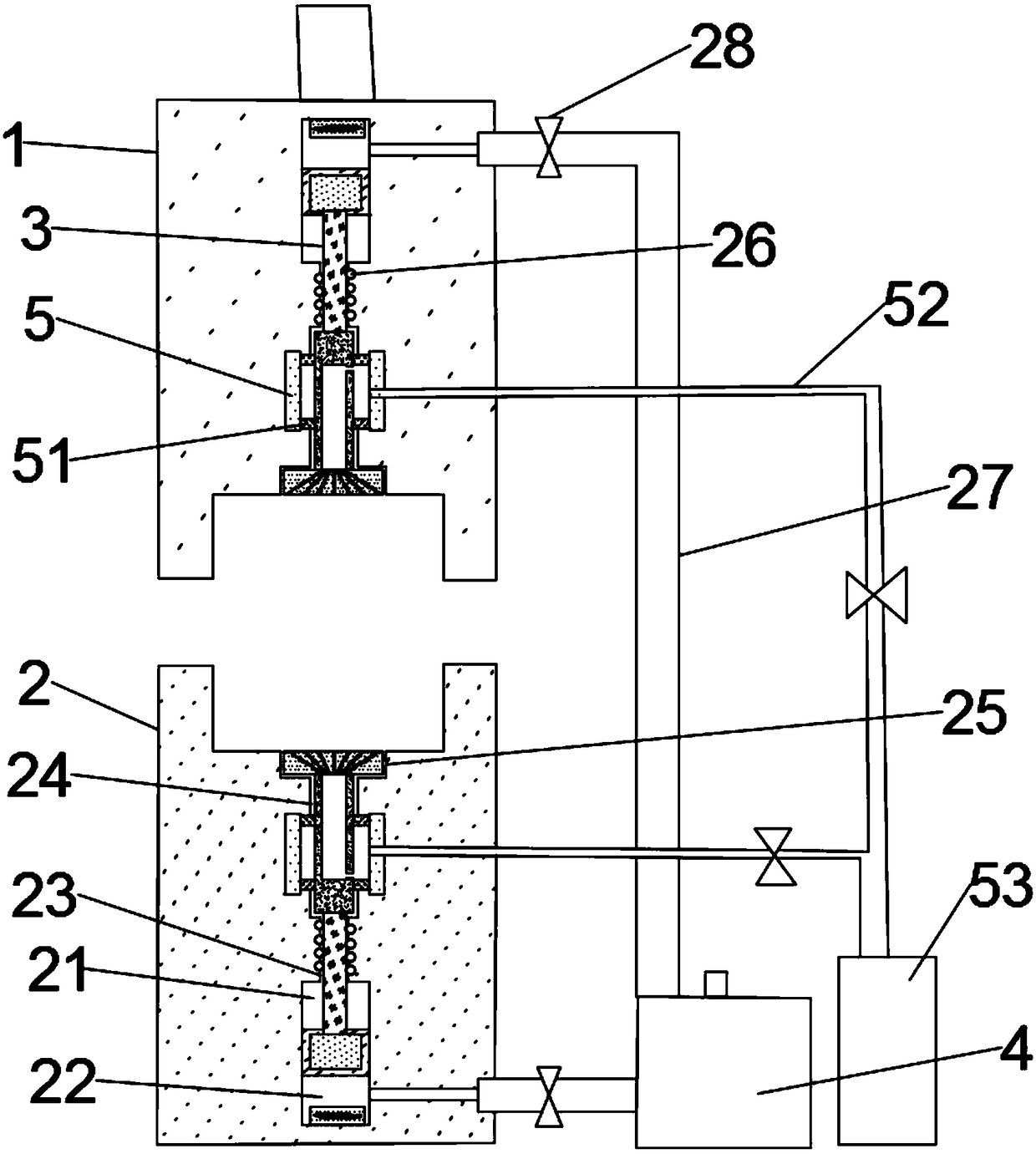

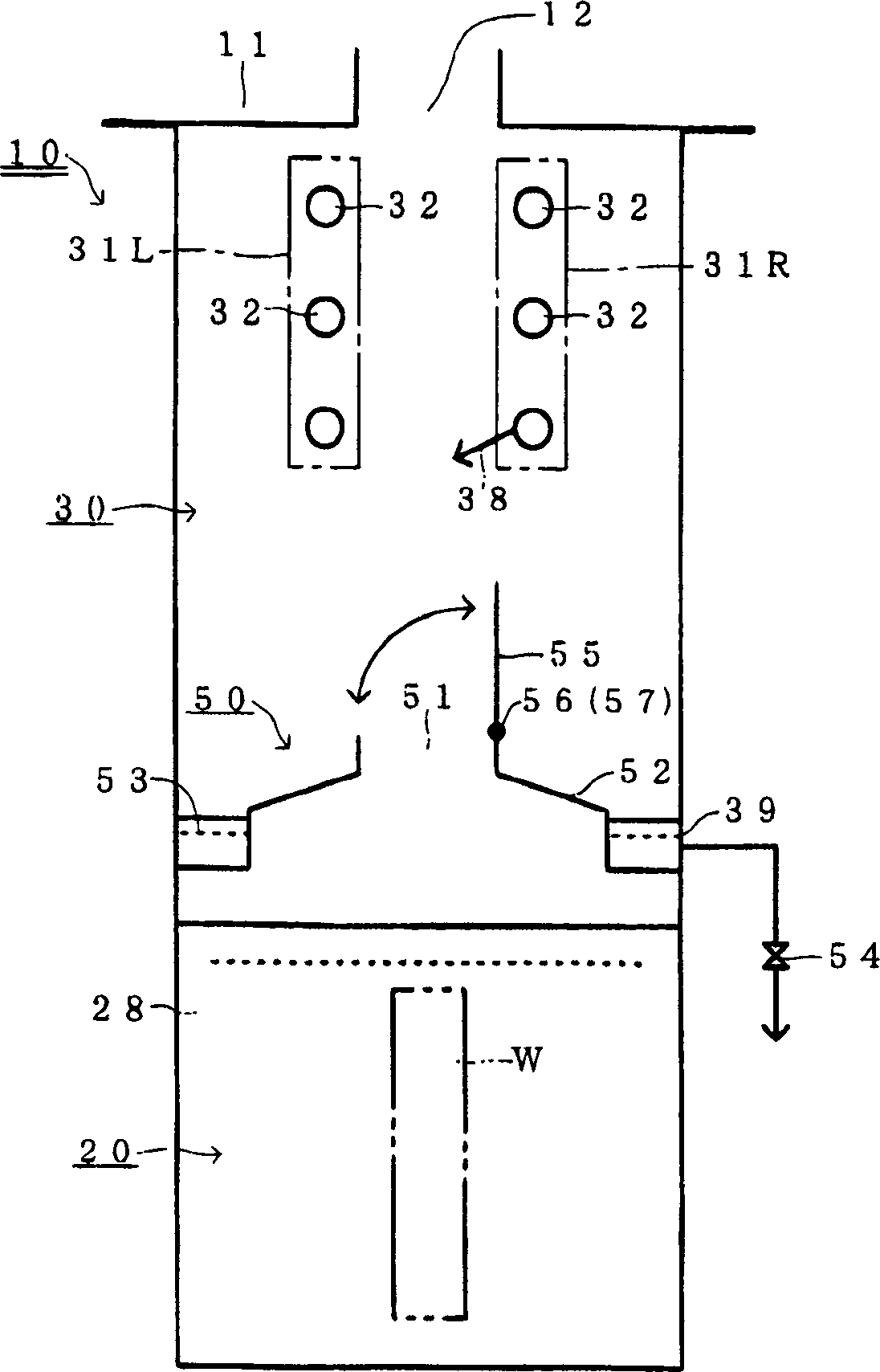

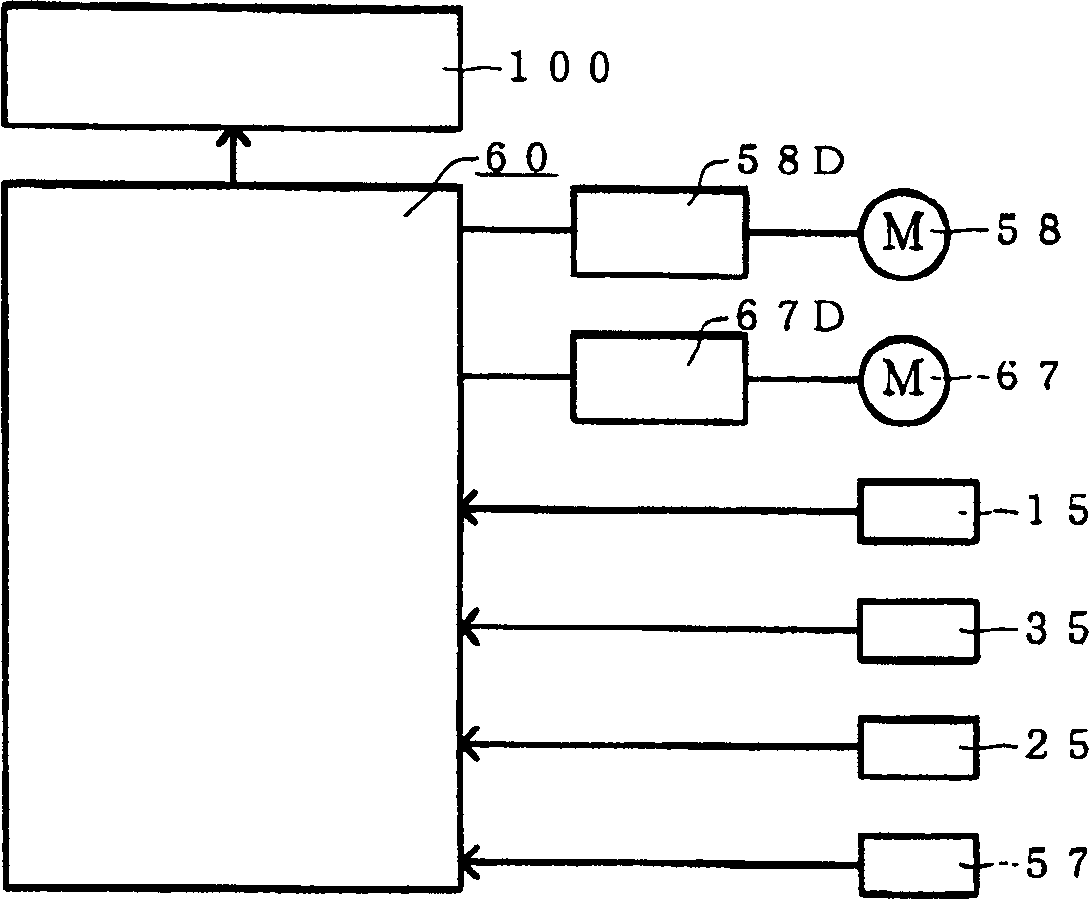

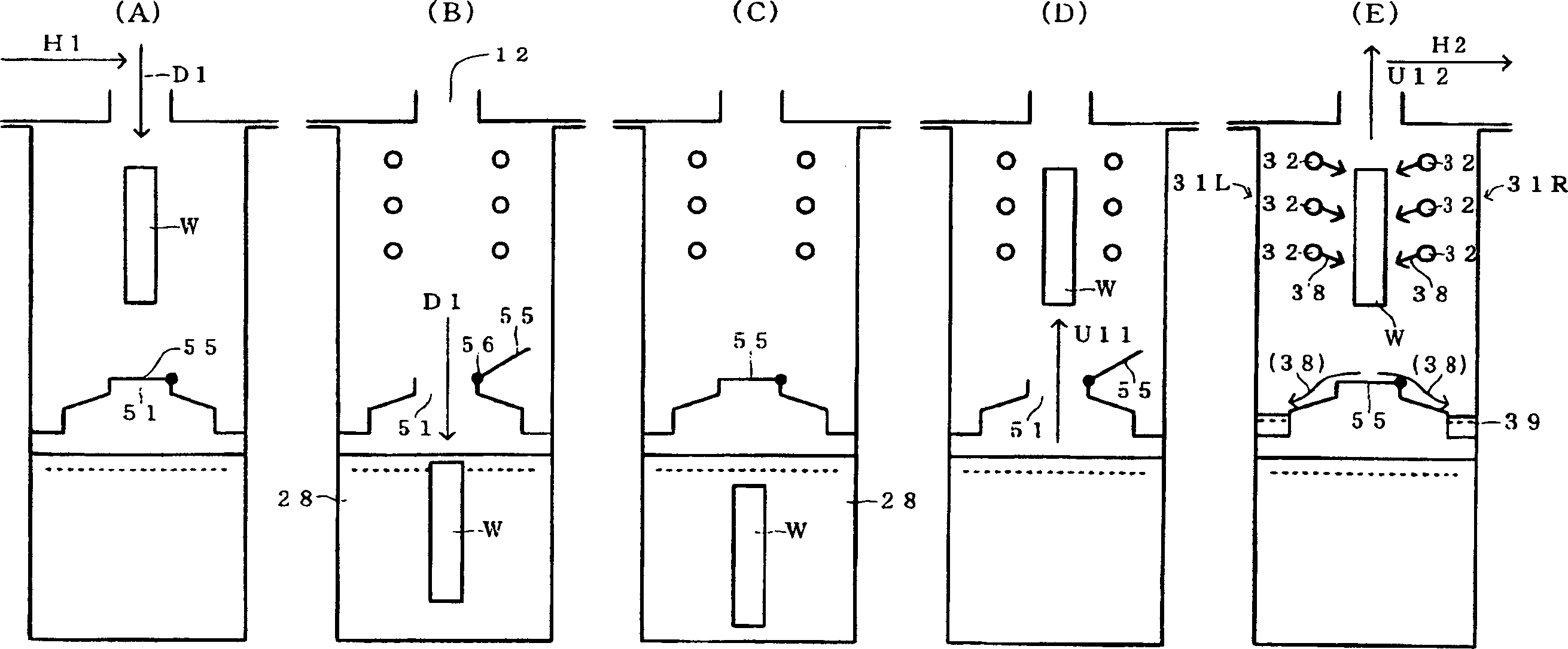

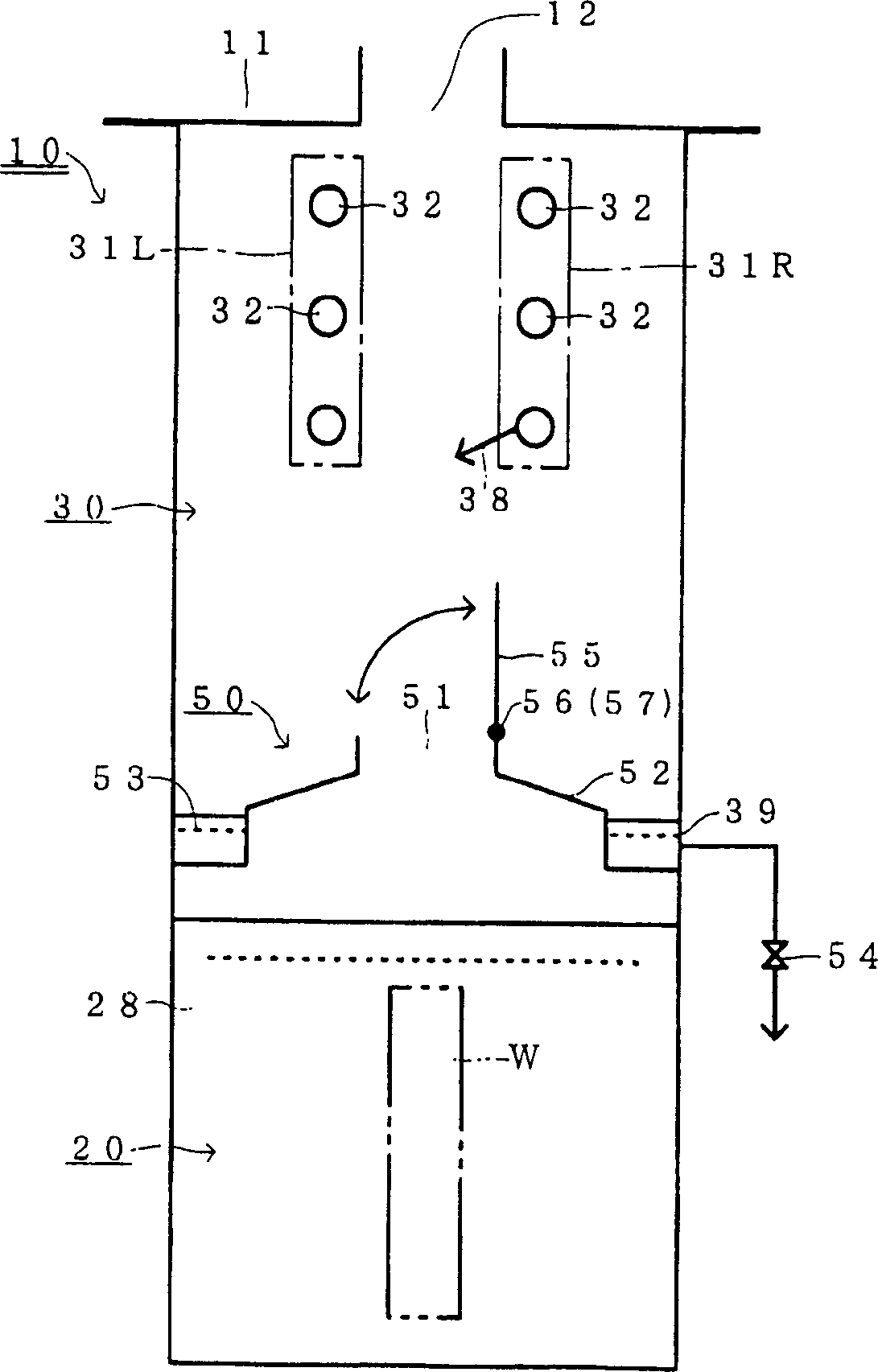

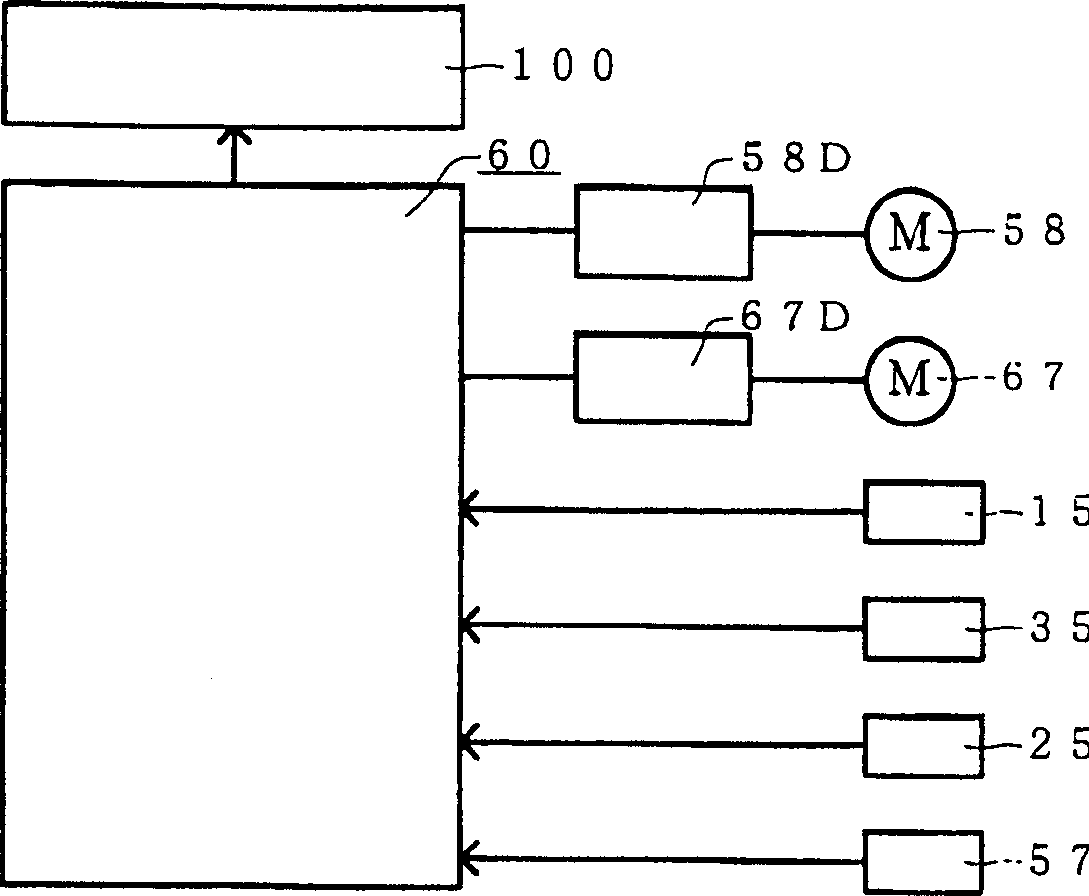

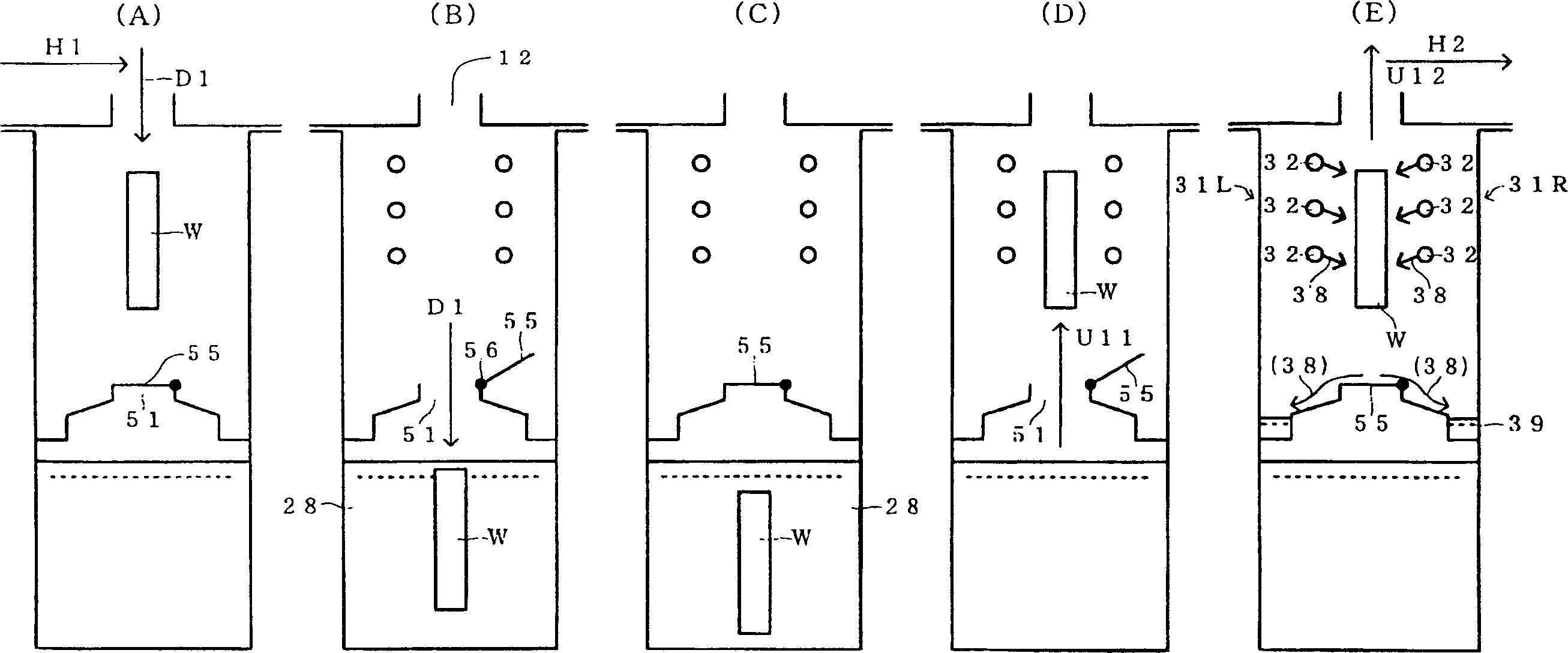

Surface treatment apparatus

InactiveCN1403629AShorten the timeImprove qualityPretreated surfacesCoatingsEngineeringSurface preparation

To shorten the exposing time from the end of a first surface treating process before the start of a second surface treating process. SOLUTION: The lower side of a booth 10 which is opened in the upper part and is intermediately partitioned by an intermediate partition 50 to form a first surface treating vessel 20 and the ascending side thereof is formed as a shower chamber 30. The intermediate partition 50 is provided with an aperture 51 which allows the passage of a work W in a vertical direction and an opening / closing cap 55 which is capable of opening and closing the aperture 51. The equipment is so formed that the first surface treating process step can be executed in the state that the work W is immersed into the first treating liquid 28 prepared in the first surface treating vessel 20 and in the state that the opening / closing cap 55 is held closed and the second surface treating process step can be executed while the work W is showered with the second treating liquid 38 in the shower chamber 30 in the state that the opening / closing cap 55 is held closed.

Owner:ALMEX PE INC

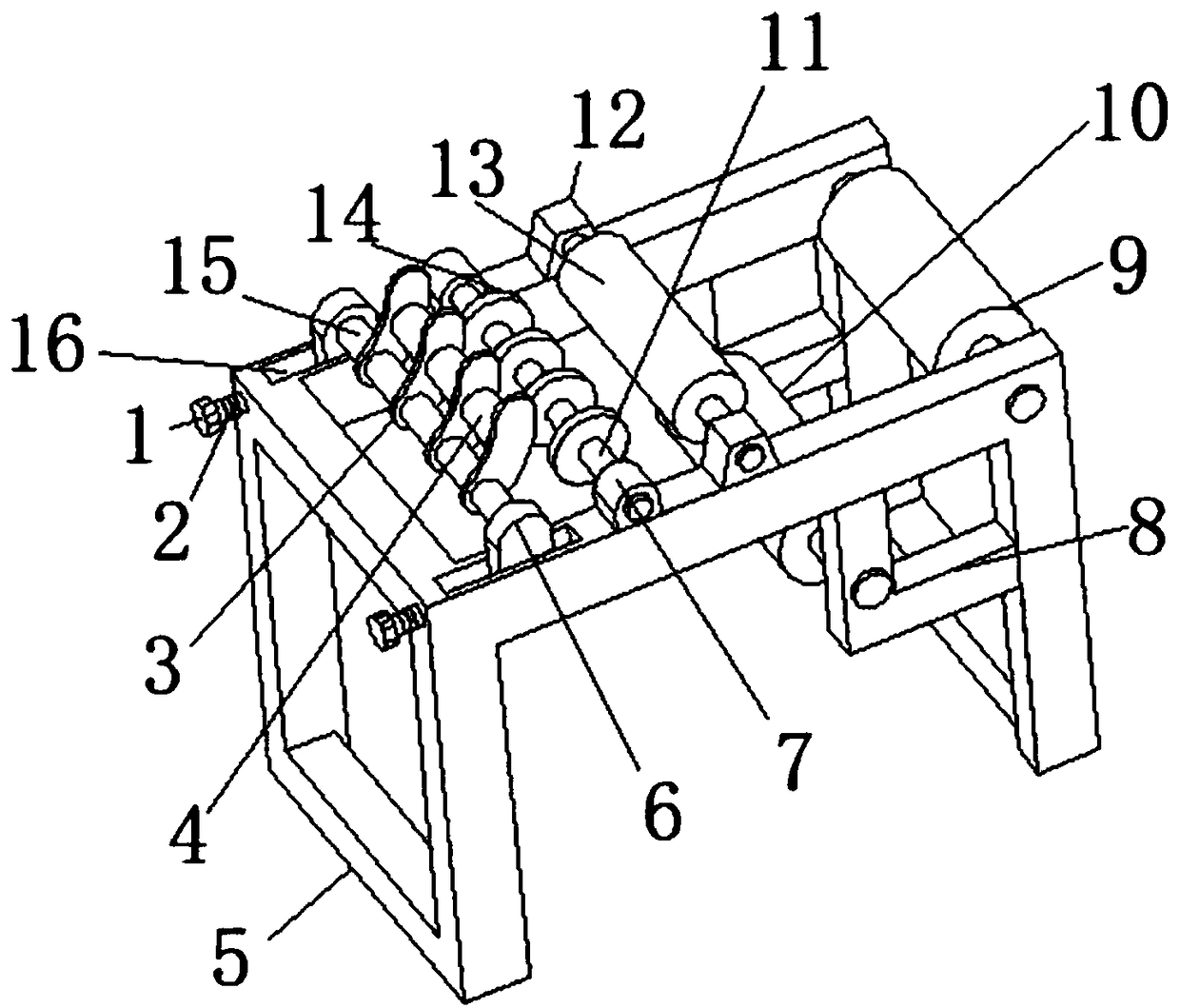

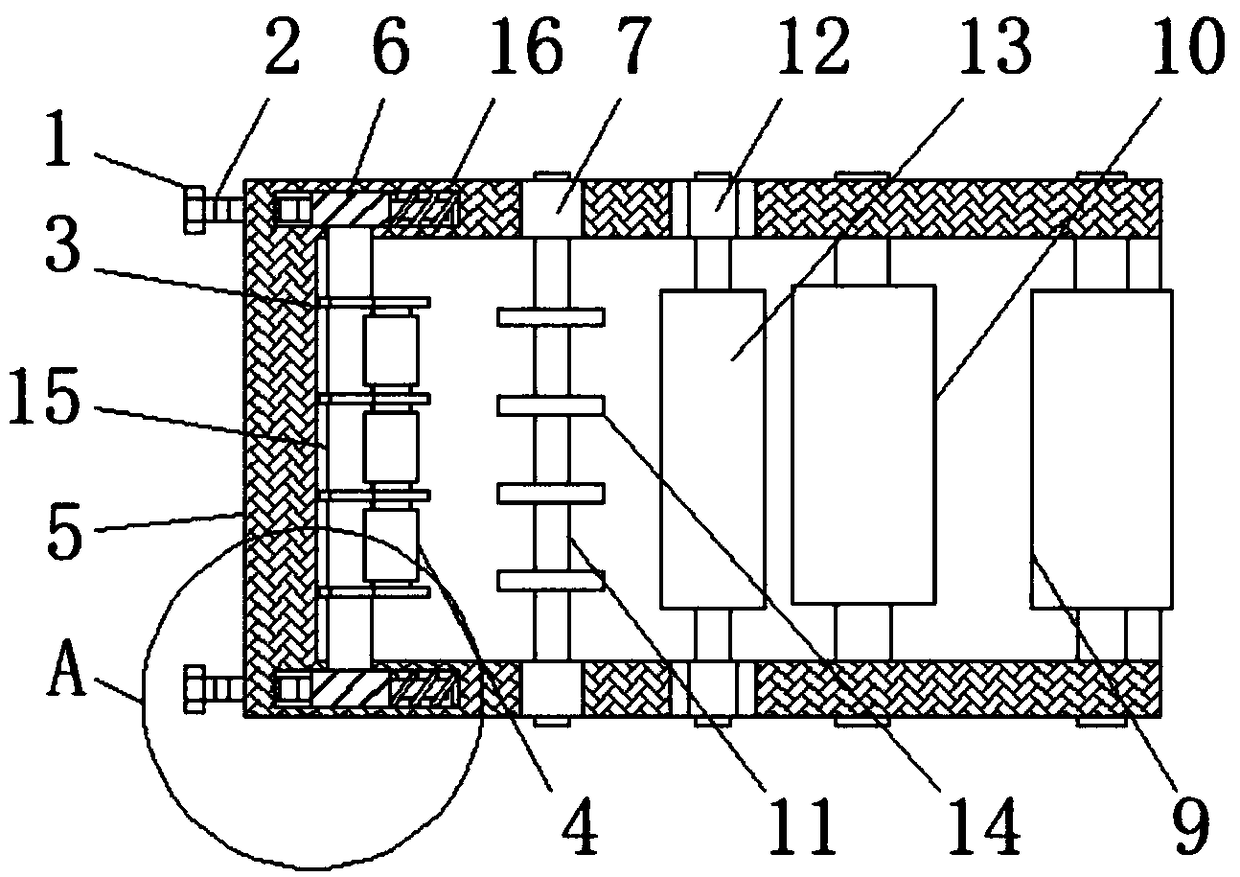

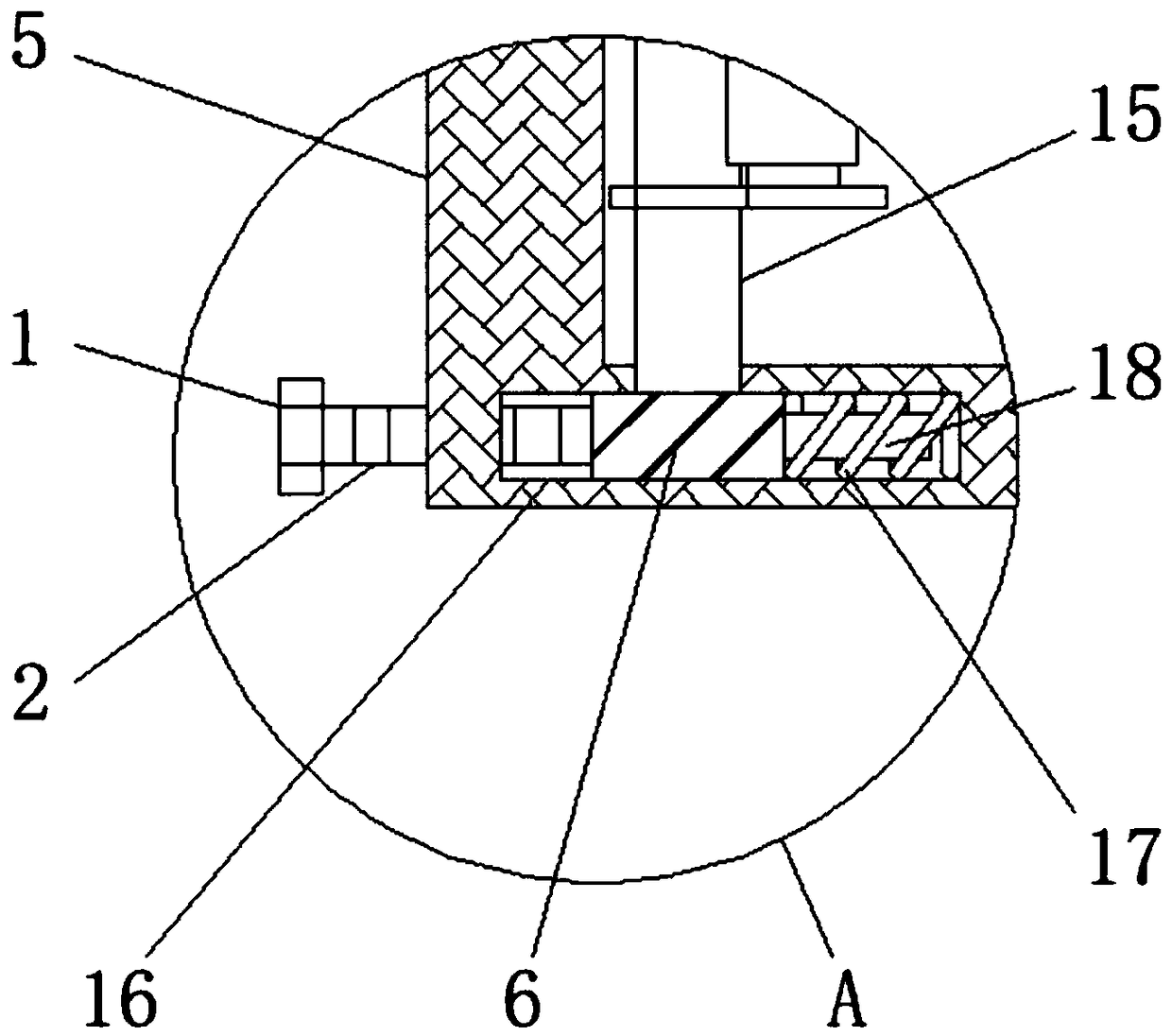

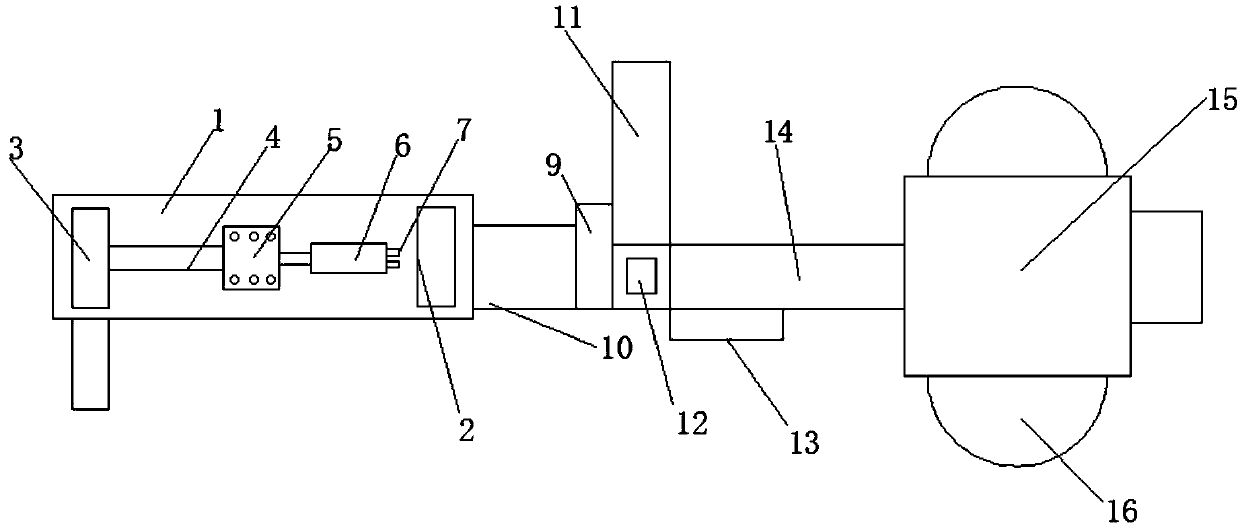

Winding drum adjusting device of lithium battery slitting machine

InactiveCN109368362APrecise cuttingImprove tightnessArticle deliveryWebs handlingPulp and paper industryConductor Coil

The invention discloses a winding drum adjusting device of a lithium battery slitting machine. The winding drum adjusting device comprises a machine frame, a paper feeding roller, a paper transferringroller and a tension roller, the paper feeding roller is connected with bearings on the machine frame through connecting shafts at the two ends of the outer wall of the paper feeding roller, L-shapedsupports are arranged on the two sides of the lower surface of the machine frame respectively, the paper transferring roller is connected with bearings on the L-shaped supports through connecting shafts at the two ends of the outer wall of the paper transferring roller, sliding grooves, fixing lugs and fixing blocks are arranged on the two sides of the upper surface of the machine frame respectively, and the sliding grooves, the fixing lugs and the fixing blocks are sequentially arranged from left to right; and the tension roller is connected with bearings on the fixing blocks through connecting shafts at the two ends of the outer wall of the tension roller, and the tension roller, the paper transferring roller and the paper feeding roller are sequentially arranged from left to right. According to the device, through the arrangement of a series of structures, the position of a winding drum on the lithium battery slitting machine is conveniently adjusted, the optimal degree of tightness of the winding drum during winding of slit membranes is achieved through the position adjustment, and the accuracy of slitting the membranes is improved.

Owner:江苏万达新能源科技股份有限公司

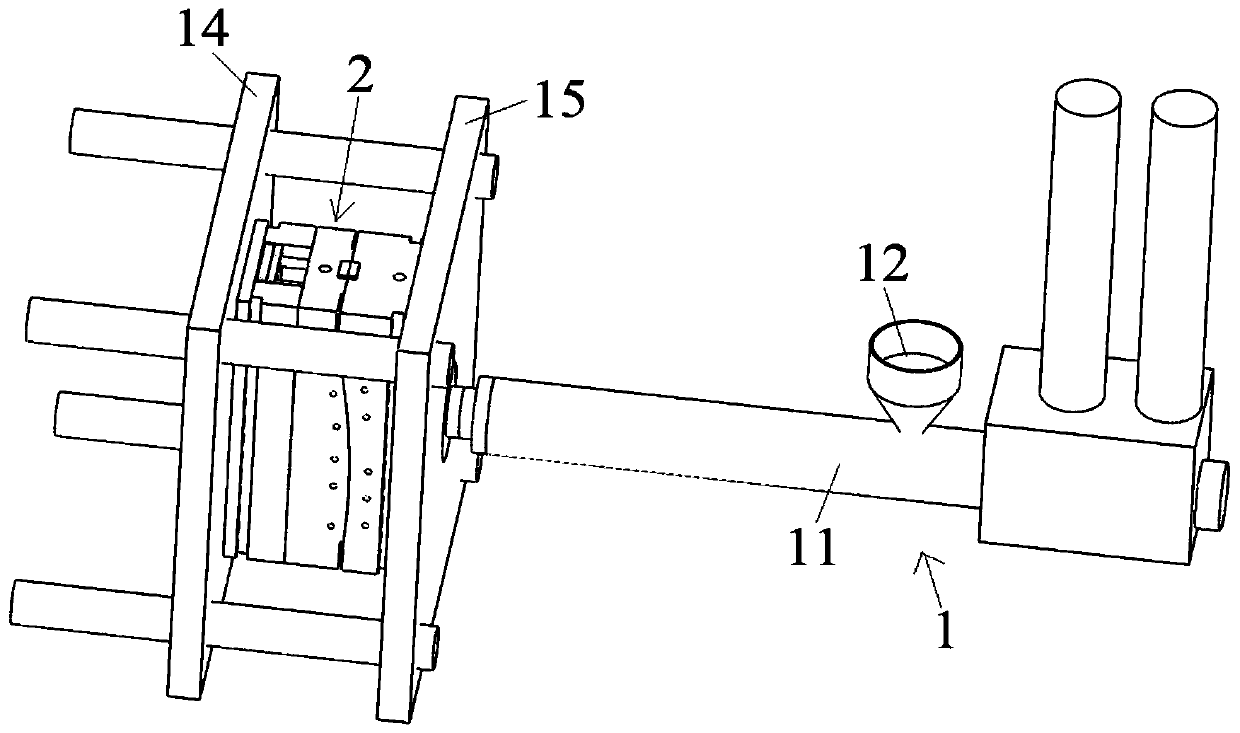

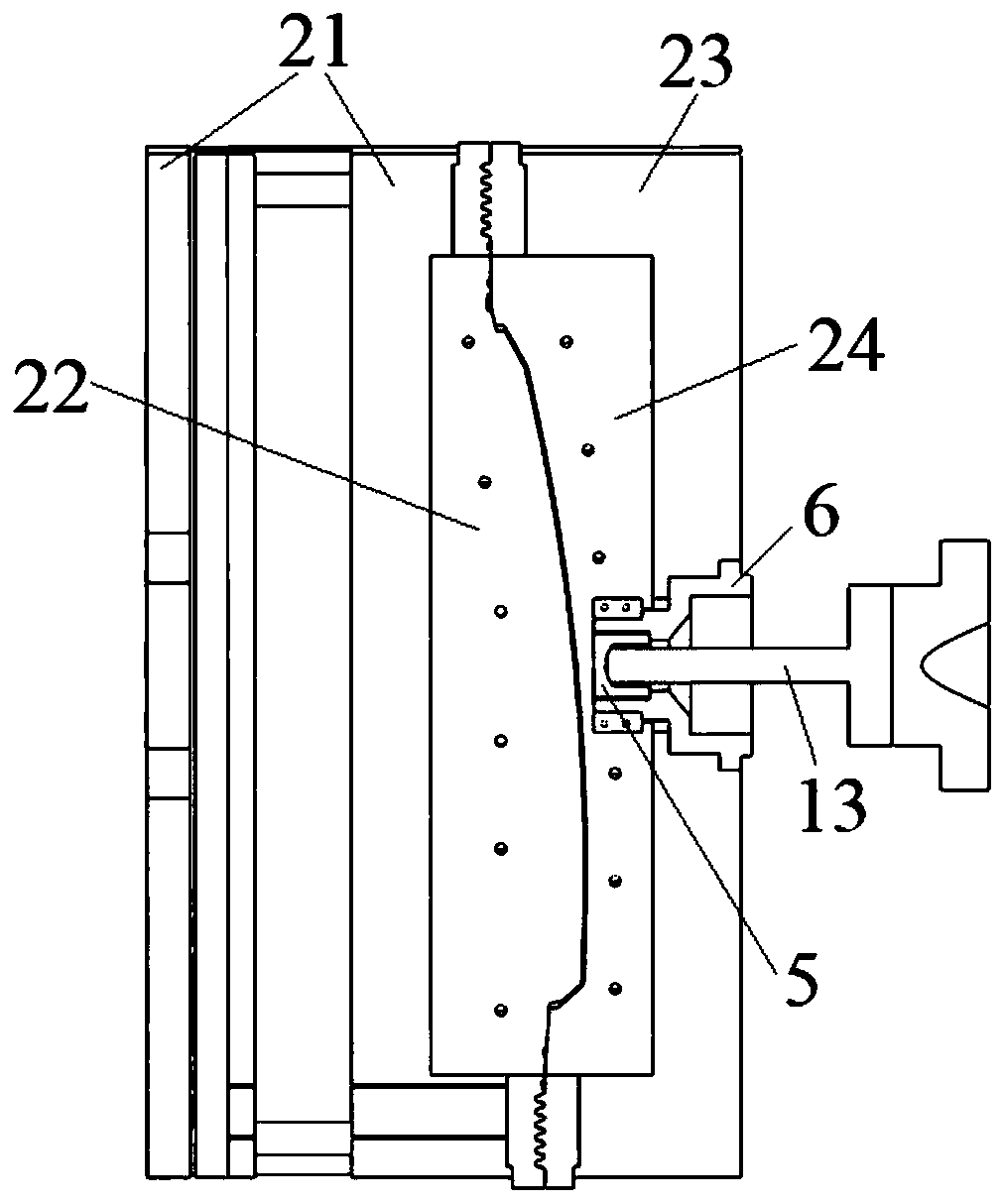

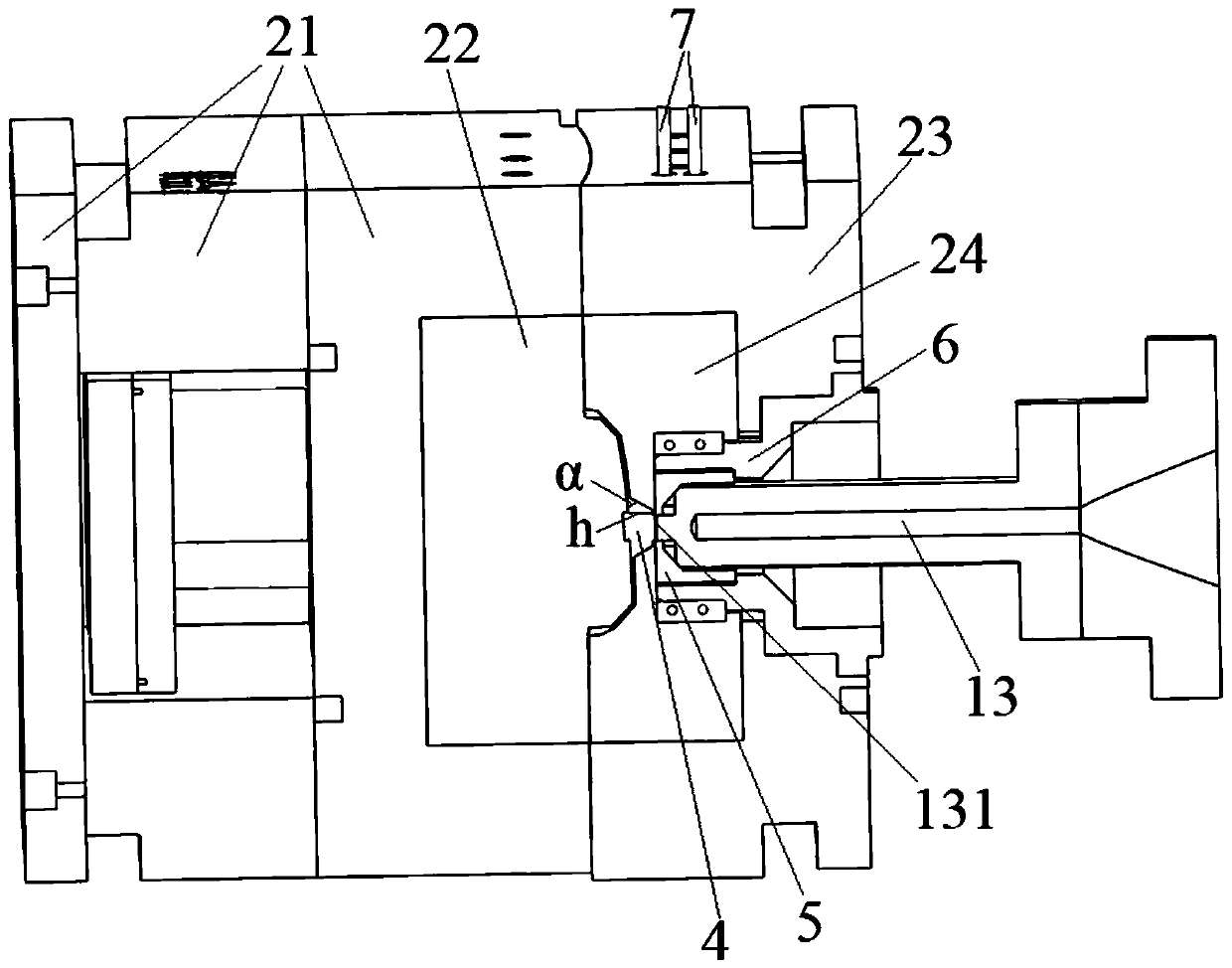

Device and method for realizing magnesium alloy injection molding

The invention discloses a device and a method for realizing magnesium alloy injection molding. The device comprises an injection molding machine and a molding mold, wherein the injection molding machine comprises a screw rod injection mechanism, a hopper, a long nozzle, a movable mold fixing plate and a fixed mold fixing plate; and the molding mold comprises a movable mold frame, a movable mold core, a fixed mold frame and a fixed mold core. The device is characterized in that a feed port is formed in the center of the fixed mold core; two opening ends of the feed port are respectively communicated with a cavity and an injection end of the long nozzle; and a cooling sleeve is sleeved at the injection end of the long nozzle. Semi-solid magnesium alloy materials are creatively and directly fed into the feed port in the center of the fixed mold core by the long nozzle to enter the cavity without adopting a runner mode for feeding, so that the device has such advantages as simple structure, few wastes, low material loss, good product quality and short molding period, is safe and environment-friendly in production, and is prominent in promotion of wide application of a magnesium alloy injection molding technology in the industrial field.

Owner:SHANGHAI WUTENG METAL PROD CO LTD

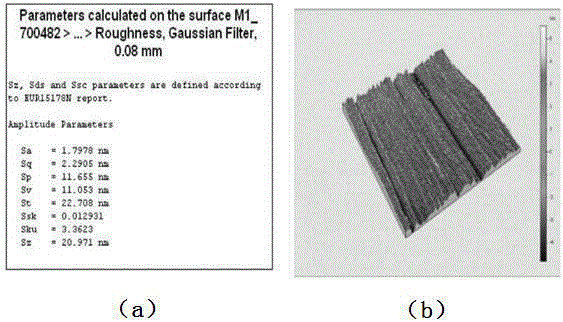

Layer paving type selective laser sintering fast forming method of linen

InactiveCN102632617AThe overall thickness is thinImprove machining accuracySelective laser sinteringSurface roughness

The invention provides a layer paving type selective laser sintering fast forming method of linen and relates to a selective laser sintering method. The method aims at overcoming the defects that when composite powder is adopted as raw materials of the selective laser sintering, the uniform powder mixing and the mutual adhesion gathering are frequently generated, so the powder paving thickness is not uniform, composite powder loss even occurs in certain point positions, and the relative wrapping rate, the internal stress and the surface roughness of parts are influenced. The method comprises the steps that: 1, a computer is used for building a model; 2, the linen is paved layer by layer, the solidifying liquid is sprayed and coated, and the selective laser sintering is carried out; 3, the step 2 is repeated; and 4, semi-finished products are soaked in toluene, then, the vacuum drying is carried out, next, the semi-finished products are placed into copper ammonia solution to be soaked and are then taken out to be flushed by clean water, the drying is carried out for 1 hour at 120 DEG C, and the layer paving type selective laser sintering is completed. The method is used for preparing processing parts or manufacturing molds through the selective laser sintering.

Owner:河北英曼卡科技有限公司

Herbal plant nutrient water emulsified microcapsules and preparation method thereof

InactiveCN105726456BGood skin tightening effectRich in nutrientsCosmetic preparationsToilet preparationsWater basedBetaine

The invention provides herbaceous plant nutritive water based on an emulsified microcapsule and a preparation method of the herbaceous plant nutritive water. The preparation method comprises the following specific steps: mixing hydrogenated vegetable oil, low erucic acid rapeseed oil , siloxane, microcrystalline wax and diglycerol, heating and uniformly stirring, and performing heat reservation and sterilization to obtain an oil phase; adding ethylene glycol, propylene glycol, glycine betaine, urea, poly-sodium glutamate, triethanolamine, caprylhydroxamic acid and hexylene glycol into deionized water, heating and uniformly stirring, performing heat preservation and sterilization to obtain a water phase; adding the oil phase into the water phase, performing heating, homogenization and low-speed stirring, adding cetyl ethyl hexanoate and stearic acid, then slowly adding PEG-40 hydrogenated castor oil and a microcapsule wall material, cooling, adding tremella, centella asiatica, polygonum cuspidatum, scutellaria baicalensis, tea leaves, glycyrrhiza glabra, female chrysanthemum, rosemary leaves, beer saccharomycete and grape fruit cell extract active components, and adding chondrus crispus extracts, bio-saccharide gum-1, diglycerol, palmitoyl tripeptide-1 and essence for mixing to obtain the herbaceous plant nutritive water based on the emulsified microcapsule.

Owner:广州市有喜化妆品有限公司

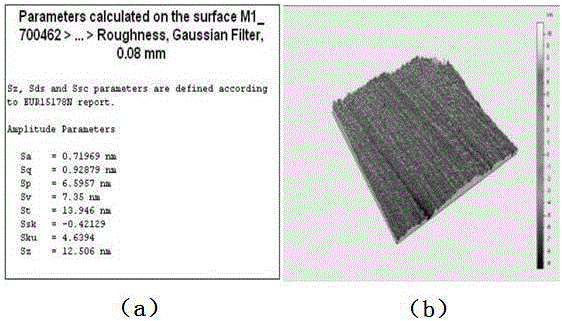

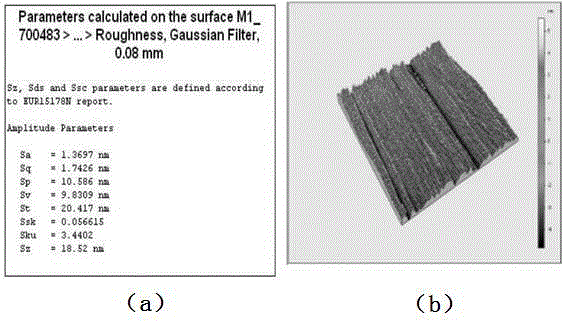

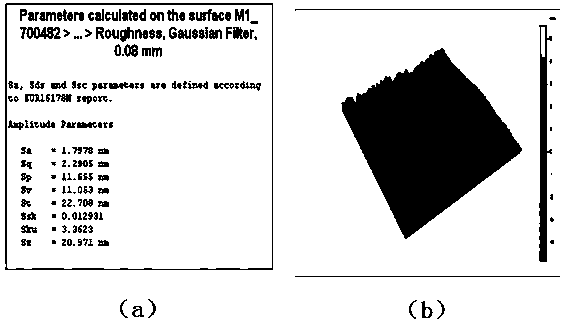

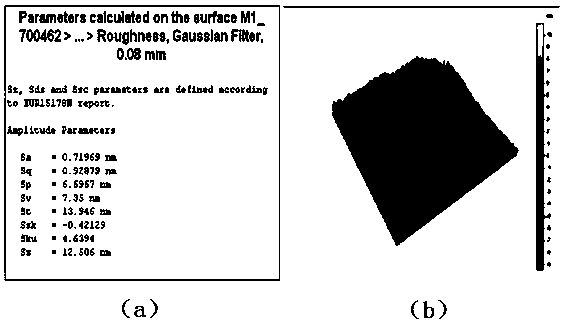

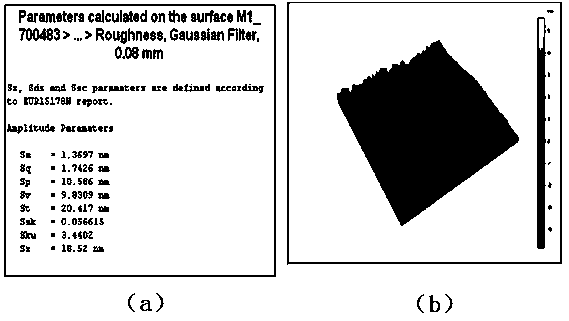

Method for planarization of potassium dihydrogen phosphate crystal optical surface

ActiveCN106835035AGood mechanical propertiesNo blemishesPolycrystalline material growthAfter-treatment detailsVacuum coolingSingle point

The invention relates to an optical element surface planarization method. The method mainly focuses on potassium dihydrogen phosphate (KH2PO4, also known as KDP) nonlinear optical crystal material after turning of a single point diamond lathe as a processing target, with the method of ion beam sputtering deposition, a layer of film of silicon or silicon dioxide or the composite of silicon dioxide and silicon is deposited on the optical surface of the potassium dihydrogen phosphate optical crystal material, and then after vacuum cooling, a layer of silicon film or silicon dioxide film or silicon dioxide and silicon composite film with low surface roughness is formed on the surface of the potassium dihydrogen phosphate optical crystal material, wherein the upper surface of the film layer is a flattened surface. According to the optical element surface planarization method, a layer of silicon film or silicon dioxide film or silicon dioxide and silicon composite film with good mechanical properties, stable properties, low surface roughness and compactness is formed on the surface of the potassium dihydrogen phosphate optical crystal material, the technological process is simple, the surface of the potassium dihydrogen phosphate can achieve a good planarization effect in a low-temperature vacuum environment, and a good foundation is made for later ion beam polishing of potassium dihydrogen phosphate crystals.

Owner:XIAN TECHNOLOGICAL UNIV

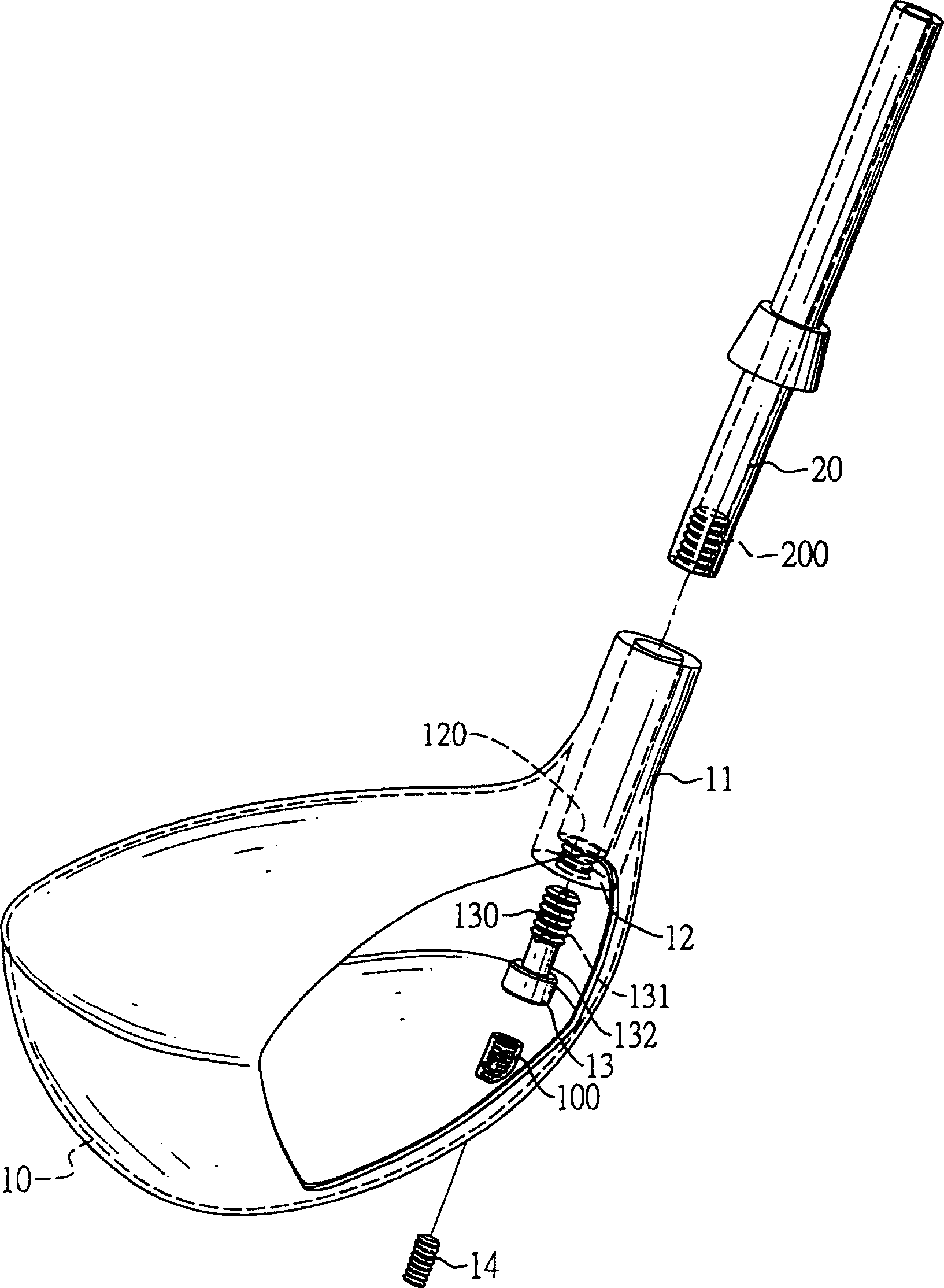

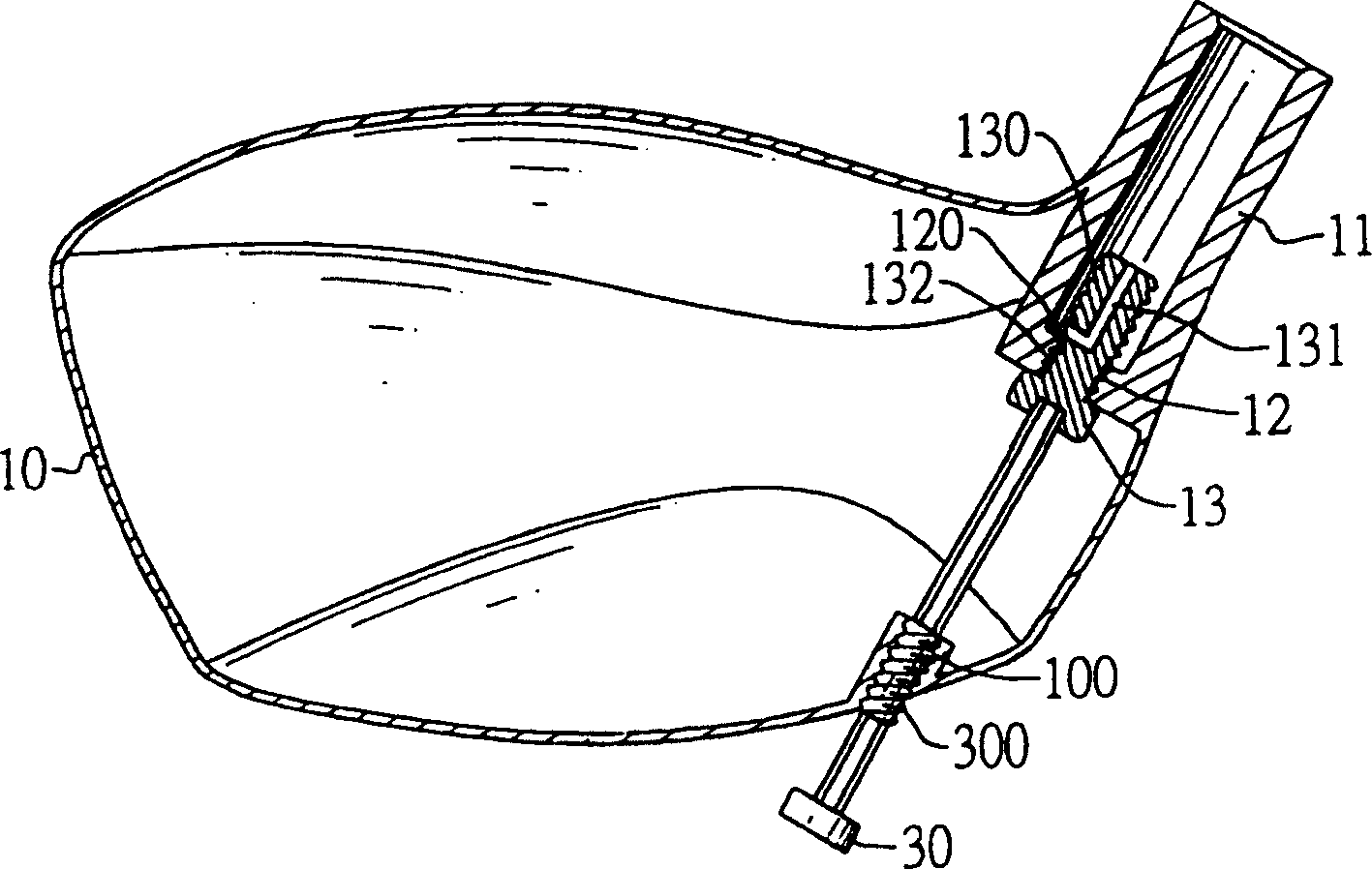

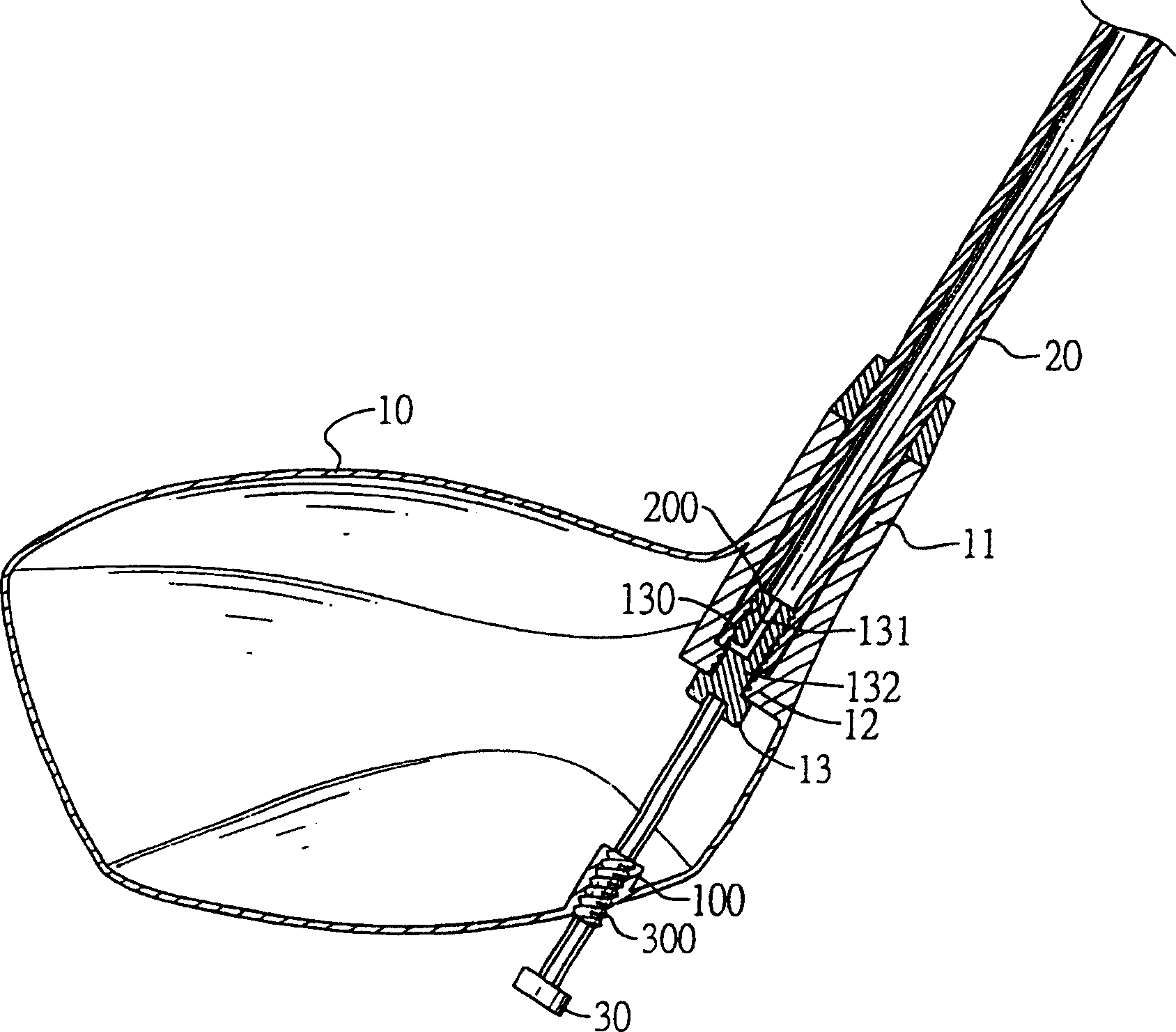

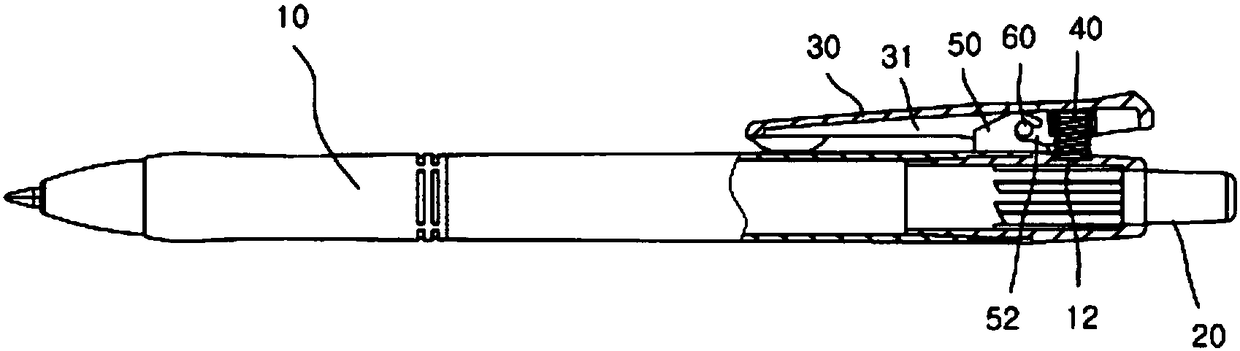

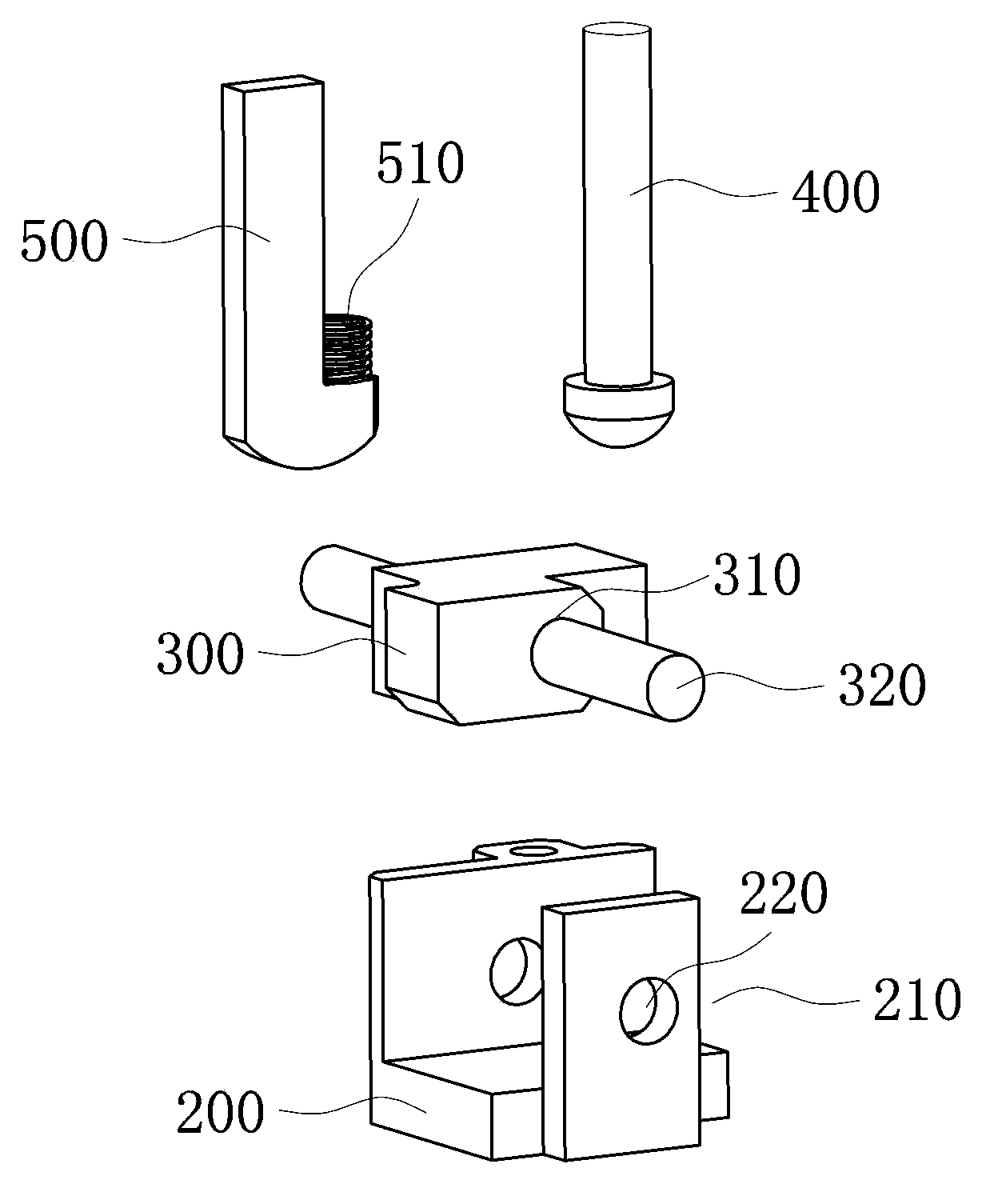

Writing tool with clip

ActiveCN108556518AImprove assembly efficiencyLow costBall-point pensOther pensInlet channelCoil spring

The invention relates to a writing tool with a clip. The writing tool comprises a cylindrical pen housing shaped in a hollow cylinder, a flowing axial clip arranged in the manner of standing on the outside support column of the pen housing and spiral springs arranged between the clip and the pen housing. The clip integrally forms a cylindrical hinge shaft along the direction of mutually connectingleft with right multiple sides. The support column is equipped with a hinge hole which receives and is inserted by the hinge shaft of the clip in the form of opening forwards. The support column is equipped with an opening part connected with the hinge hole. When the hinge hole is inserted by the hinge shaft, the hinge shaft can rotate. The opening part provides an inlet channel for insertion ofthe hinge shaft for the hinge hole. The upper part surface above the opening part is parallel to the shaft center of the pen housing. A gradient is formed by the lower surface below the opening part such that closer the insertion channel to the hinge hole, the channel is narrower. When the hinge shaft is arranged on one side of the hinge hole, the hinge shaft and the spiral springs are finished assembling due to horizontally-moving operation. Therefore, assembly efficiency is increased while cost is lowered.

Owner:CROWN BALLPEN

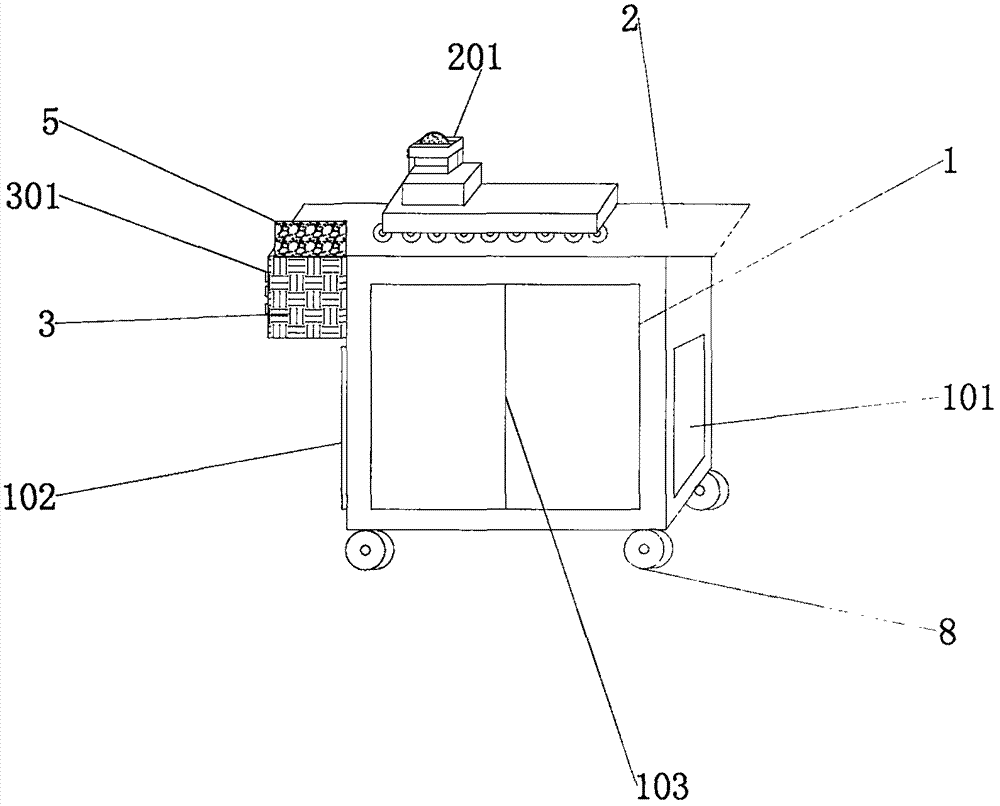

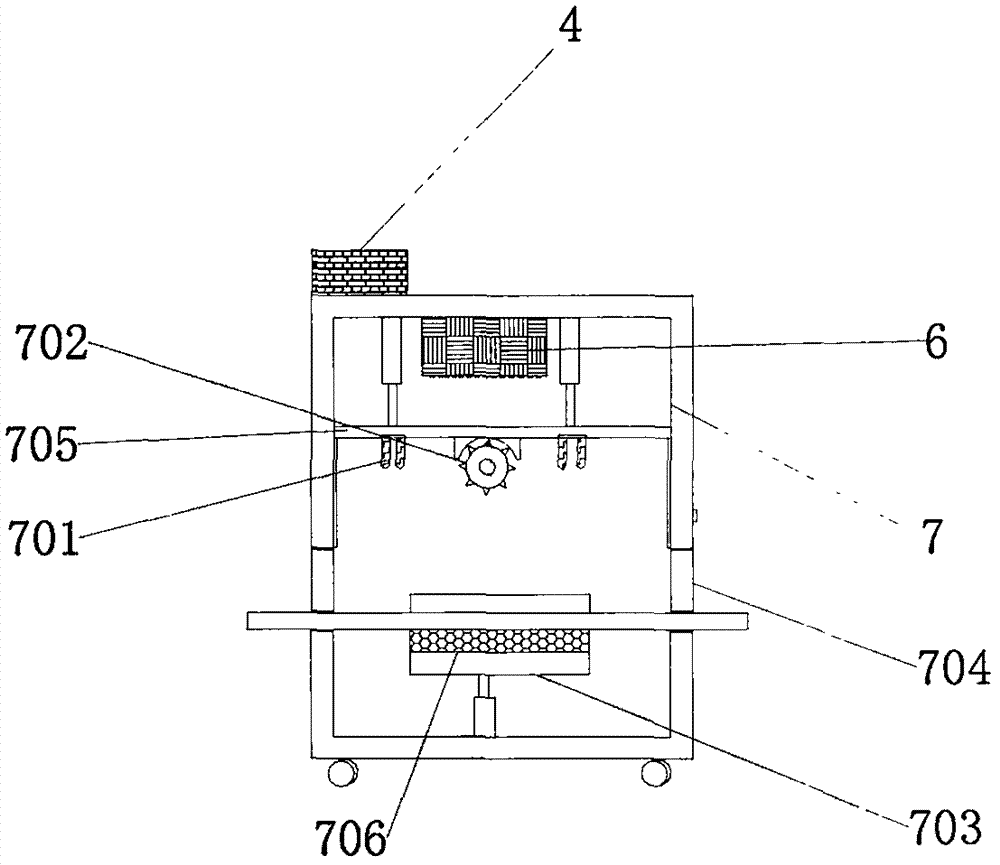

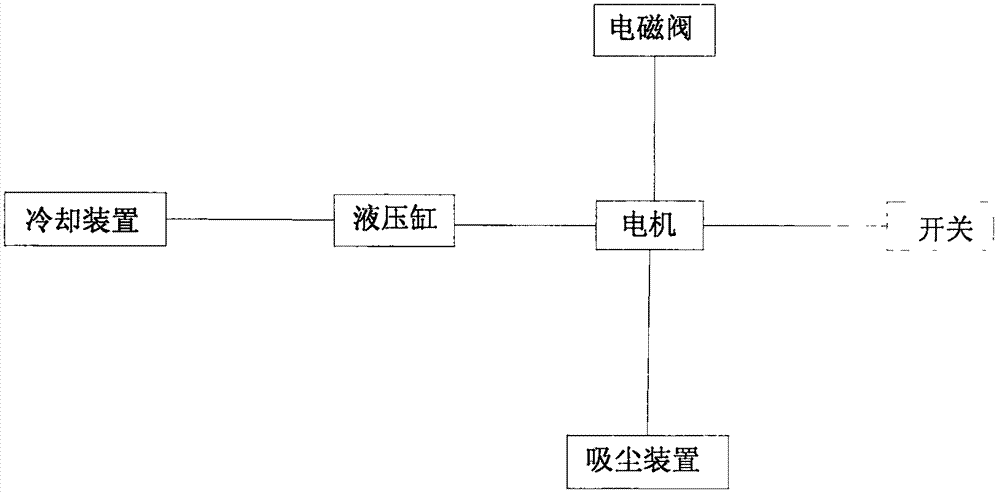

Automobile part rapid cutting-off machine

PendingCN107984019AQuick and easy to useFast truncationShearing machinesMaintainance and safety accessoriesEngineeringElectromagnetic valve

The invention discloses an automobile part rapid cutting-off machine. The machine comprises a cutting-off machine main body, a working table and a cutting-off device; the working table is arranged onthe upper side of the cutting-off machine main body and is fixedly connected with the cutting-off machine main body, the cutting-off device is arranged inside the cutting-off machine main body and isembedded in the cutting-off machine main body, and a motor is arranged on the left side of the cutting-off machine main body and is connected with the cutting-off machine main body in an embedding mode. According to the machine, a movable cutter can move left and right and up and down through a movable guide rail so that the cut-off position of a part can be more accurate and can not generate flaws, the rotary cutter is arranged so that the cutting speed can be higher, the efficiency can be higher, the automobile part can be cut off, the parts of other materials can also be cut off, the multipurpose performance of the machine is embodied, and a cooling device is further arranged in the cutting-off device so that cooling and dust clearing can be carried out on the cut part under the controlof an electromagnetic valve.

Owner:无锡市中吉橡塑机械有限公司

A textile dyeing device with drying effect

ActiveCN107503051BEasy to dryColoring firmLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by suctionAir filterEngineering

A textile dyeing device having drying effect comprises a box, one side of the bottom of an inner cavity of the box is fixedly connected with a drainage tank, a position, below a supporting frame, of the bottom of the inner cavity of the box is fixedly connected with an air filtering device, the top of the supporting frame is fixedly connected with an air heating device, the top, positioned on one side of a through groove, of a supporting plate is fixedly connected with a dye box, a nozzle is positioned between the supporting plate and the drainage tank, one side, away from the through groove, of the bottom of the supporting plate is fixedly connected with a water extruding device, and an exhaust device is fixedly connected at a position, right above the air heating device, of the top of the box. The invention relates to the technical field of textile processing. The textile dyeing device can quickly dry and dye cloth for the convenience of the next process, product quality is ensured, quick and efficient dyeing is realized, uniformity and thoroughness in dyeing are guaranteed, no flaw is about to be generated, and redundant water and dye are enabled to leave the cloth and can be recycled, so that resources are saved, and environment is protected.

Owner:天龙数码印染科技有限公司

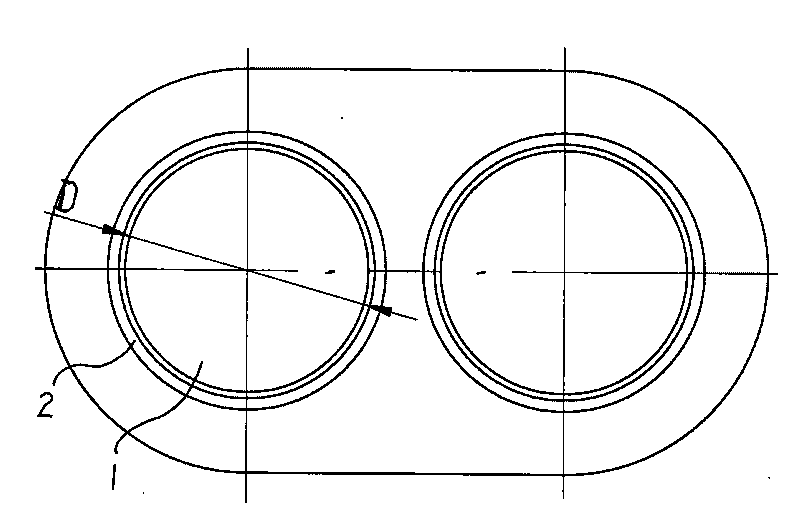

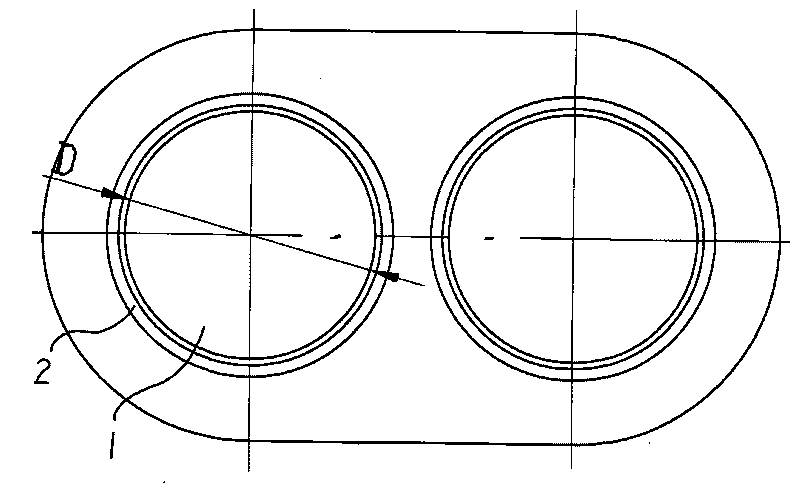

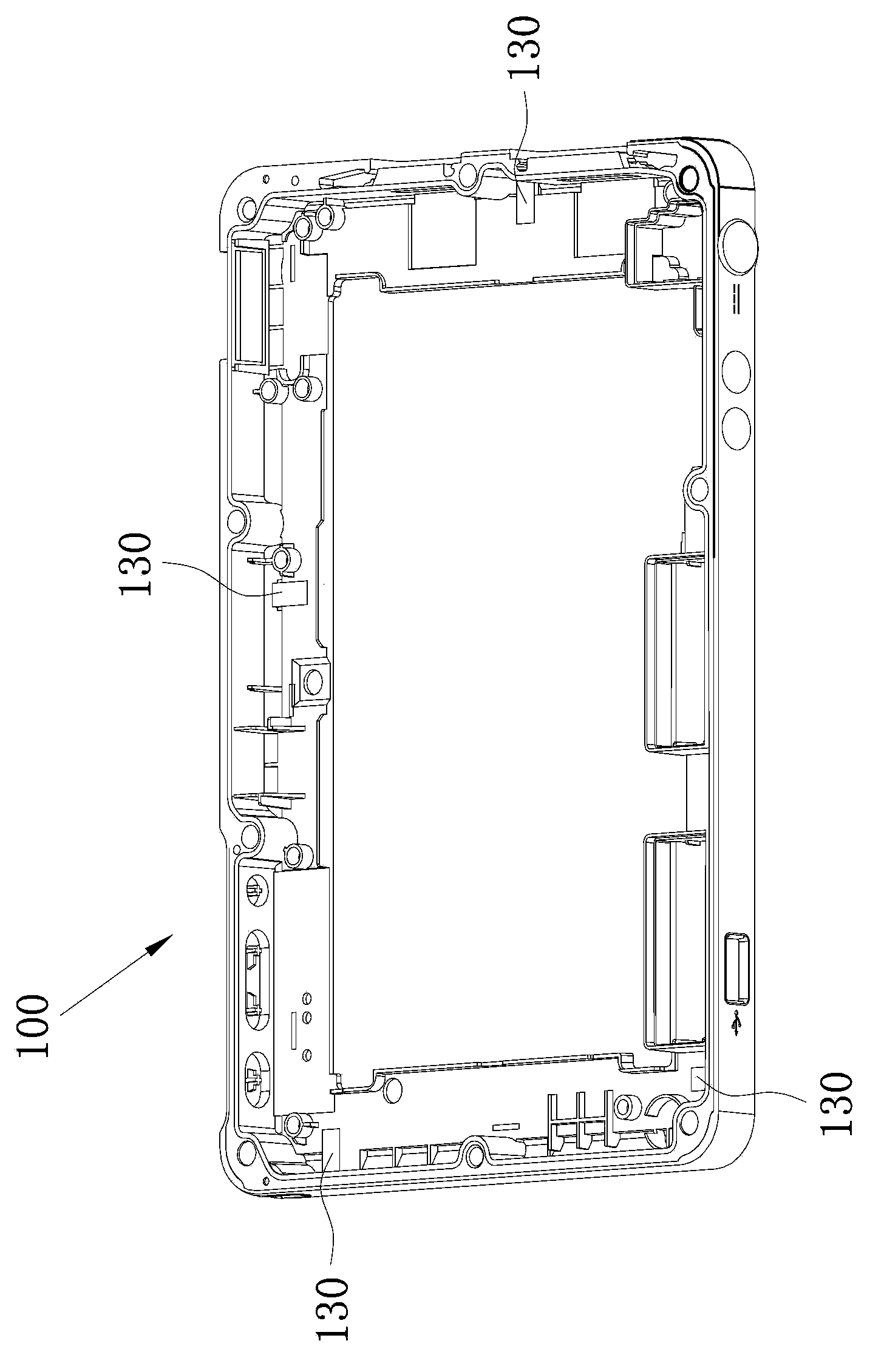

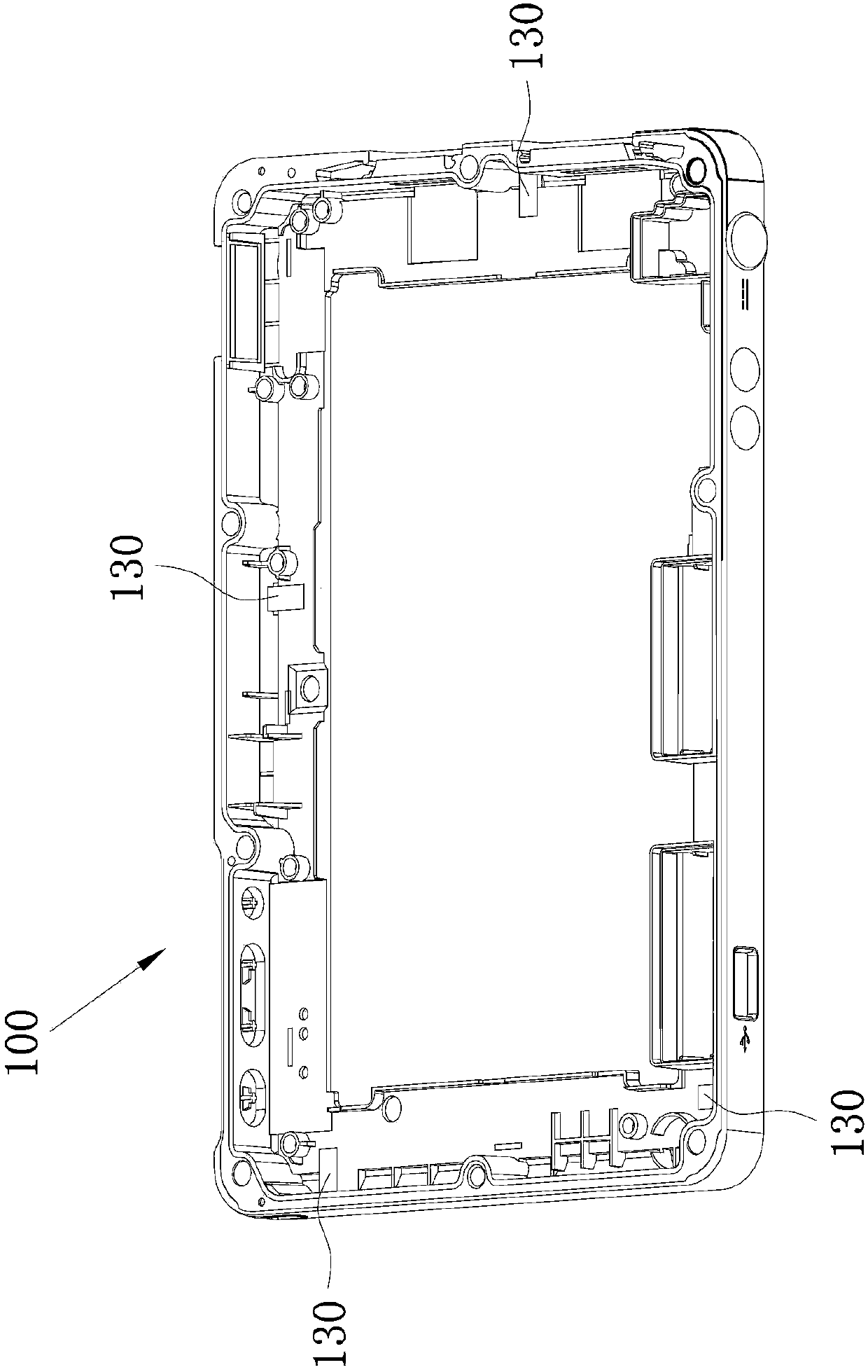

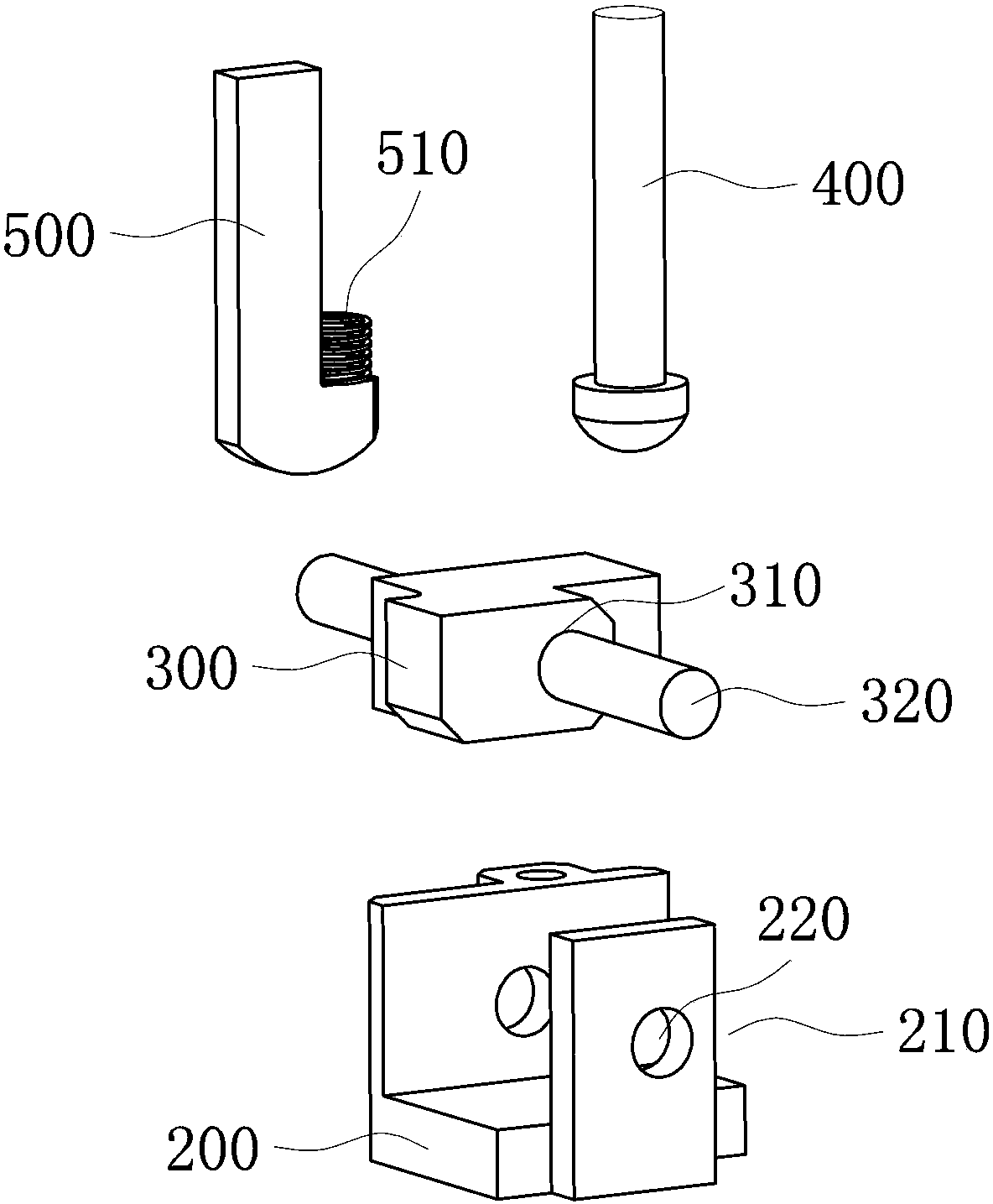

Bi-color mold lapping and gluing mechanism

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

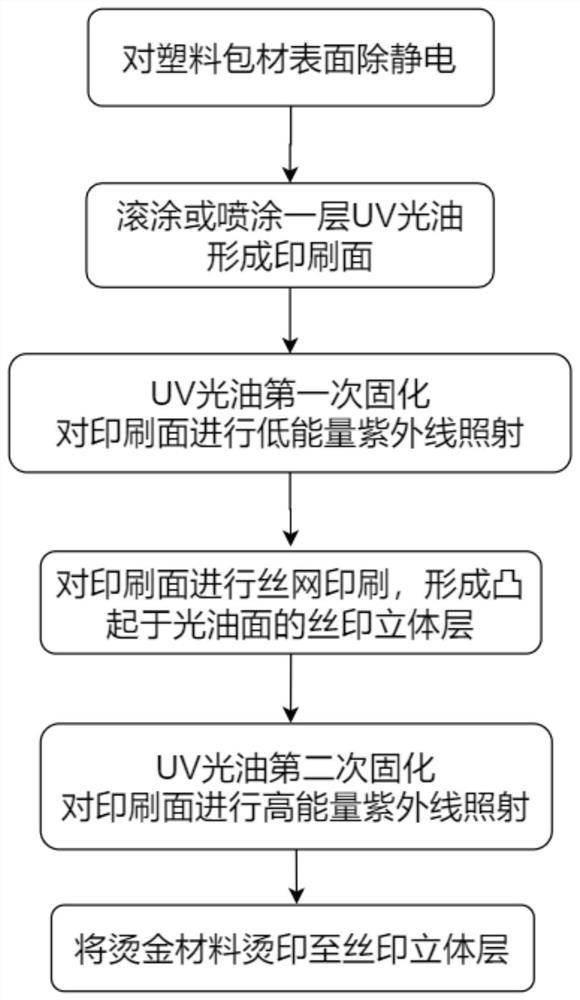

Three-dimensional gilding method for surface of plastic packing material

PendingCN112918143AThree-dimensionalNo bronzing residueDuplicating/marking methodsPattern printingScreen printingUltraviolet Radiations

The invention discloses a three-dimensional gilding method for the surface of a plastic packing material. The method is characterized in that UV gloss oil coated on the surface of the plastic packing material is irradiated twice by ultraviolet rays with different energies, and the smoothness of the gloss oil surface obtained by the two times of irradiation is different, so that silk-screen printing can be performed on the gloss oil surface after the first time of irradiation; and after the second time of irradiation, silk-screen printing ink is subjected to gilding, and a gilding material cannot be attached to the gloss oil surface. The method has the advantages that (1) the gilding effect on the surface of the plastic packing material has three-dimensional impression, and the gilding material is accurately gilded on three-dimensional lines of silk-screen printing, so that the impression is more delicate and finer; (2) gilding residues and flaws except printing lines are not generated, and the yield is extremely high; (3) large-scale mass production printing can be realized by adopting common offset printing, silk-screen printing and gilding equipment, the production cost is low, and the efficiency is high; and (4) the problems that the definition of small characters and line size and thickness cannot be unified in the gilding process can be well solved.

Owner:广州市威顿新材料包装有限公司

Surface treatment apparatus

InactiveCN1247815CNo blemishesImprove qualityPretreated surfacesCoatingsEngineeringSurface preparation

Owner:ALMEX PE INC

Self-inspection type car door lock assembly polishing equipment

PendingCN107695847AEasy to polishEasy to assembleGrinding carriagesGrinding machinesHuman safetyDistributor

The invention discloses self-inspection type car door lock assembly polishing equipment. The self-inspection type car door lock assembly polishing equipment comprises a working table, a rotation mechanism, a rotating shaft, a reduction box, an unqualified product discharging transporting belt, a qualified product discharging transporting belt and a distributor; and the rotation mechanism is arranged on the surface of the working table, the rotating shaft is arranged on one side of the rotation mechanism, the reduction box is arranged at one end of the rotating shaft, the unqualified product discharging transporting belt is arranged on one side of the reduction box, the qualified product discharging transporting belt is arranged on one side of the unqualified product discharging transporting belt, the distributor is arranged at one end of the qualified product discharging transporting belt, and one end of the reduction box is provided with a polishing barrel and a hole polishing columnarranged on the surface of the polishing barrel. The self-inspection type car door lock assembly polishing equipment is compact and reasonable in design structure, operation is simple, convenient andquick, the automatic operation level is greatly improved, meanwhile, the labor intensity of workers is reduced, the person safety is improved, the product yield is guaranteed, and the very good popularization value is achieved.

Owner:伟速达(荆州)汽车安全系统有限公司

A method for planarizing the optical surface of potassium dihydrogen phosphate crystal

ActiveCN106835035BImprove mechanical propertiesLow surface roughness and densePolycrystalline material growthAfter-treatment detailsNonlinear optical crystalComposite film

The invention relates to an optical element surface planarization method. The method mainly focuses on potassium dihydrogen phosphate (KH2PO4, also known as KDP) nonlinear optical crystal material after turning of a single point diamond lathe as a processing target, with the method of ion beam sputtering deposition, a layer of film of silicon or silicon dioxide or the composite of silicon dioxide and silicon is deposited on the optical surface of the potassium dihydrogen phosphate optical crystal material, and then after vacuum cooling, a layer of silicon film or silicon dioxide film or silicon dioxide and silicon composite film with low surface roughness is formed on the surface of the potassium dihydrogen phosphate optical crystal material, wherein the upper surface of the film layer is a flattened surface. According to the optical element surface planarization method, a layer of silicon film or silicon dioxide film or silicon dioxide and silicon composite film with good mechanical properties, stable properties, low surface roughness and compactness is formed on the surface of the potassium dihydrogen phosphate optical crystal material, the technological process is simple, the surface of the potassium dihydrogen phosphate can achieve a good planarization effect in a low-temperature vacuum environment, and a good foundation is made for later ion beam polishing of potassium dihydrogen phosphate crystals.

Owner:XIAN TECH UNIV

O-phenylphenol (opp) film transfer printing process

InactiveCN110421993AGood recoatabilityNo blemishesInk transfer from master sheetPrinting inkEngineering

The invention provides an o-phenylphenol (opp) film transfer printing process, which mainly solves the problems that common opp film transfer printing processes are prone to defects, and the recoatability of printed products after transferring is not good. Due to a low dyne value of opp film surface, transfer printing can be performed directly with a single coating. According to the process, nitrocotton system printing ink is used, the printing ink is printed on an opp film, then a printing coating is transferred to paper through wet process recombination, and a highlight transfer printing coating is obtained. Because of good film formation of the nitrocotton system printing ink, in the absence of a stripping layer, the coating can be completely transferred without defects, and the recoatability of the printed products after transferring is excellent.

Owner:哈尔滨大东方新材料科技股份有限公司

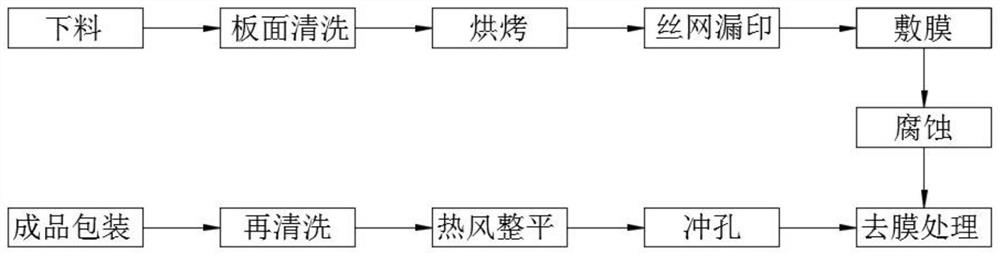

Binding board thick frame printing process

InactiveCN112055473AEasy to controlSmall side erosionPrinted circuit liquid treatmentConductive pattern formationSolder pasteMegasonic cleaning

The invention discloses a binding board thick frame printing process, and particularly relates to the technical field of circuit board printing, the binding board thick frame printing process comprises the following steps: S1, blanking, specifically, cutting a substrate into a required shape to prepare a binding board; s2, plate surface cleaning, specifically, putting the binding board into water,and cleaning the binding board in an ultrasonic cleaning mode; s3, baking, specifically, bakingthe cleaned binding board, and drying water; s4, silk screen skip printing, specifically, printing a required circuit diagram on the binding board through silk screen skip printing lead-free solder paste; and S5, coating, specifically, coating the binding board with a circuit diagram protection film, and preparing for corrosion. According to the circuit board printing process, printing is conducted on the binding board, board explosion and expansion and contraction are avoided through cleaning and drying, corrosion is achieved through spraying of spray heads, control is easy, lateral corrosion is small, the binding board can be effectively protected through hot air leveling, flaws are avoided when the high-precision circuit board is produced, the product reliability is high, and the production cost can be controlled at the normal level.

Owner:东莞市高迈电子有限公司

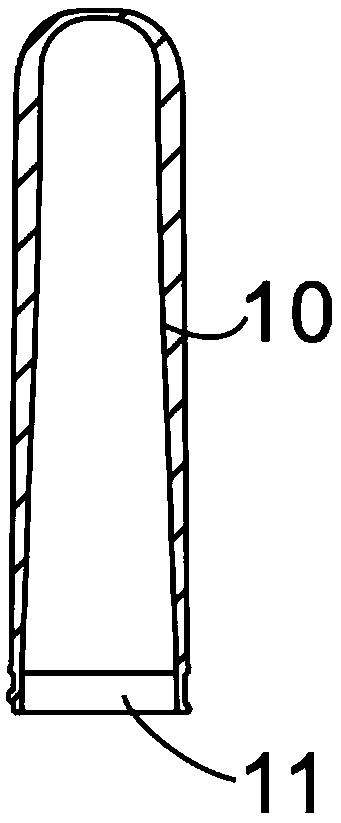

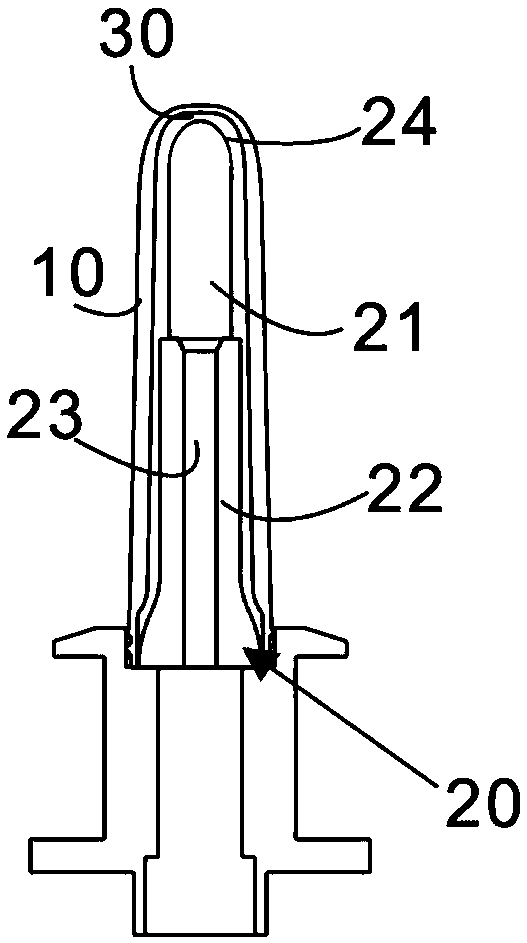

A manufacturing process of full-angle led plastic bulb lampshade

The invention discloses a manufacturing process of a full-angle LED plastic bulb lampshade, including S1. placing a positioning rod in a tubular embryo body, placing the tubular embryo body in a bulb blow mold, and the positioning rod includes a movable section and a fixed section , the fixed section is provided with a through hole for air intake; S2. Bake and soften the tubular embryo body to make it reach the Vicat softening point, and the tubular embryo body is baked to reach an expandable state; S3. From one end of the through hole of the fixed section Blow in compressed air, lift the movable section to open the other end of the through hole, inflate and soften the tubular embryo body, and at the same time, the spherical surface of the movable section is jacked up to make tangential contact with the inner wall of the tubular embryo, and then blow molded into a bulb lampshade. The invention makes the lampshade of the bulb uniform in thickness and does not produce spots, and can blow mold the lampshade of the large diameter and small opening type with a large inflation ratio, so that the LED lamp can emit light all around, and the light pattern and light effect meet the best requirements.

Owner:厦门普拉米达光电科技有限公司

Coating mixing device for interior decoration engineering

InactiveCN111871278AMix well and evenlyNo blemishesRotary stirring mixersTransportation and packagingBLENDER/MIXERElectric machinery

The invention provides a coating mixing device for interior decoration engineering. The coating mixing device comprises: a mixing stirrer; a mixing and stirring box which is arranged in the mixing andstirring machine; a motor, of which the top is fixedly connected to the top side of the interior of the mixing stirrer; and a heating machine, of which the bottom is fixedly connected to the bottom side of the interior of the mixing stirrer. Through the arrangement of the first stirring rod, the second stirring rod and two gears with different sizes, paint in the mixing and stirring box is stirred at the same time and at different speeds, the work that a worker holds a stirrer by hand is replaced, the working efficiency is improved, the working danger is reduced, and the paint cannot be splashed everywhere in the stirring process. A heating pipe is combined with a spray head, so that the device is cleaned more cleanly, and flaws cannot be generated in the next coating mixing process; andthe leaked material collecting box is used for collecting the scattered coating when the coating is injected, and can be used for the second time.

Owner:陕西闹闹馨馨知识产权服务有限公司

Two-color mold lap joint glue feeding mechanism

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com