Three-dimensional gilding method for surface of plastic packing material

A packaging material and plastic technology, which is applied in the field of three-dimensional hot stamping, can solve the problems of difficulty in precisely controlling the accuracy of positioning, the inability to obtain three-dimensional hot stamping effects, and the inability to use hot stamping, etc. It achieves exquisite and delicate appearance and solves the problem of fine text clarity in the hot stamping process And the effect that the lines cannot be uniform in size and thickness, and the production cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

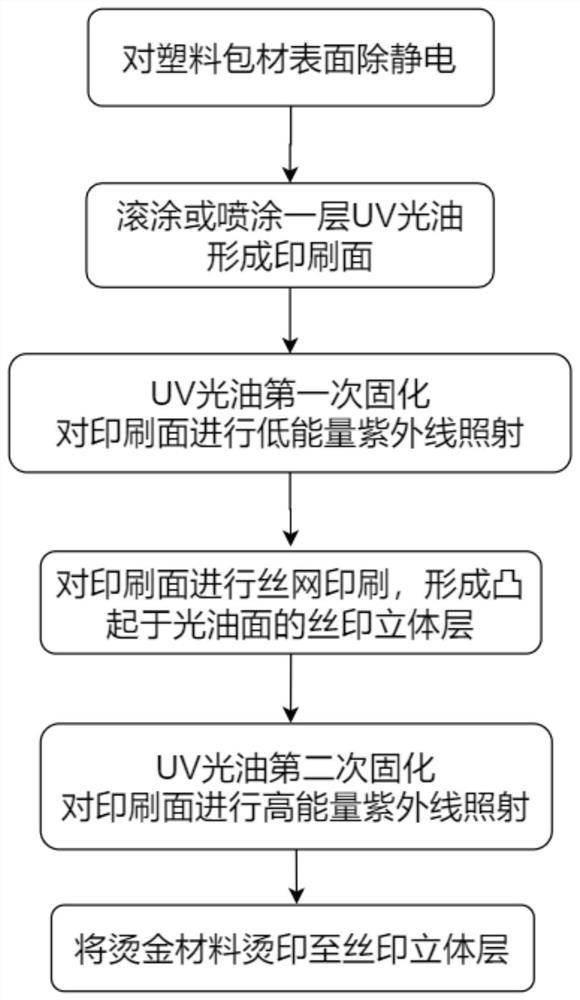

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] Based on the difficulties and unsolved problems of three-dimensional bronzing on the surface of plastic packaging materials (such as plastic hoses for cosmetics, etc.), the present invention groundbreakingly proposes a method for three-dimensional bronzing on the surface of plastic packaging materials. The UV varnish coated on the surface of the material is irradiated twice with ultraviolet rays of different energies. The smoothness of the varnish surface obtained by the two irradiations is different, so that silk screen printing can be performed on the varnish surface after the first irradiation, and the second irradiation After the second irradiation, the screen printing ink is bronzed and the varnish surface cannot be attached to the bronzing material. Using this method can obtain the following beneficial effects: (1) The ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com