Production process of polyester-cotton gathering warp knitting uniform fabric

A production process and pleating technology, which is applied in the field of production technology of polyester-cotton pleated warp knitted suit fabrics, can solve problems such as the production process of polyester-cotton pleated warp knitted suit fabrics that have never been seen before.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

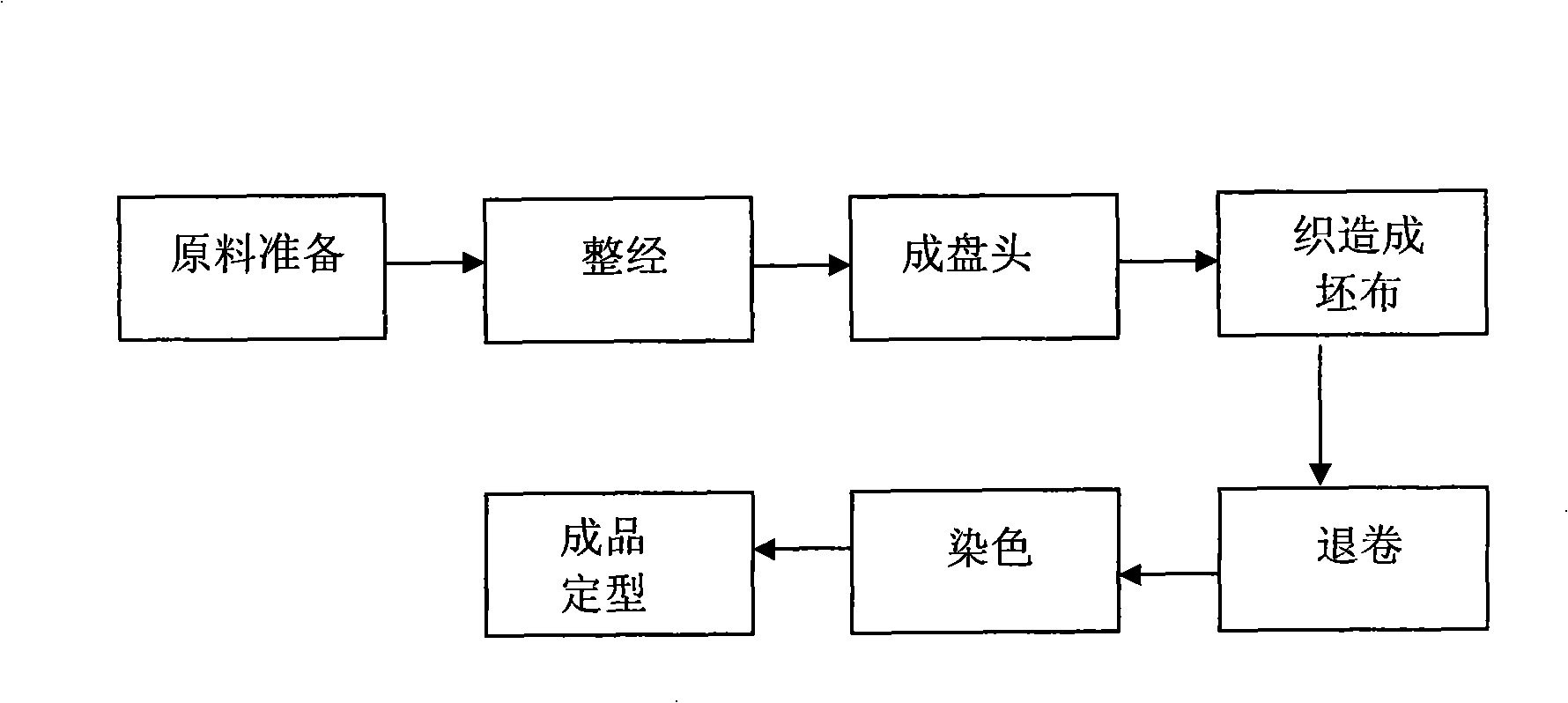

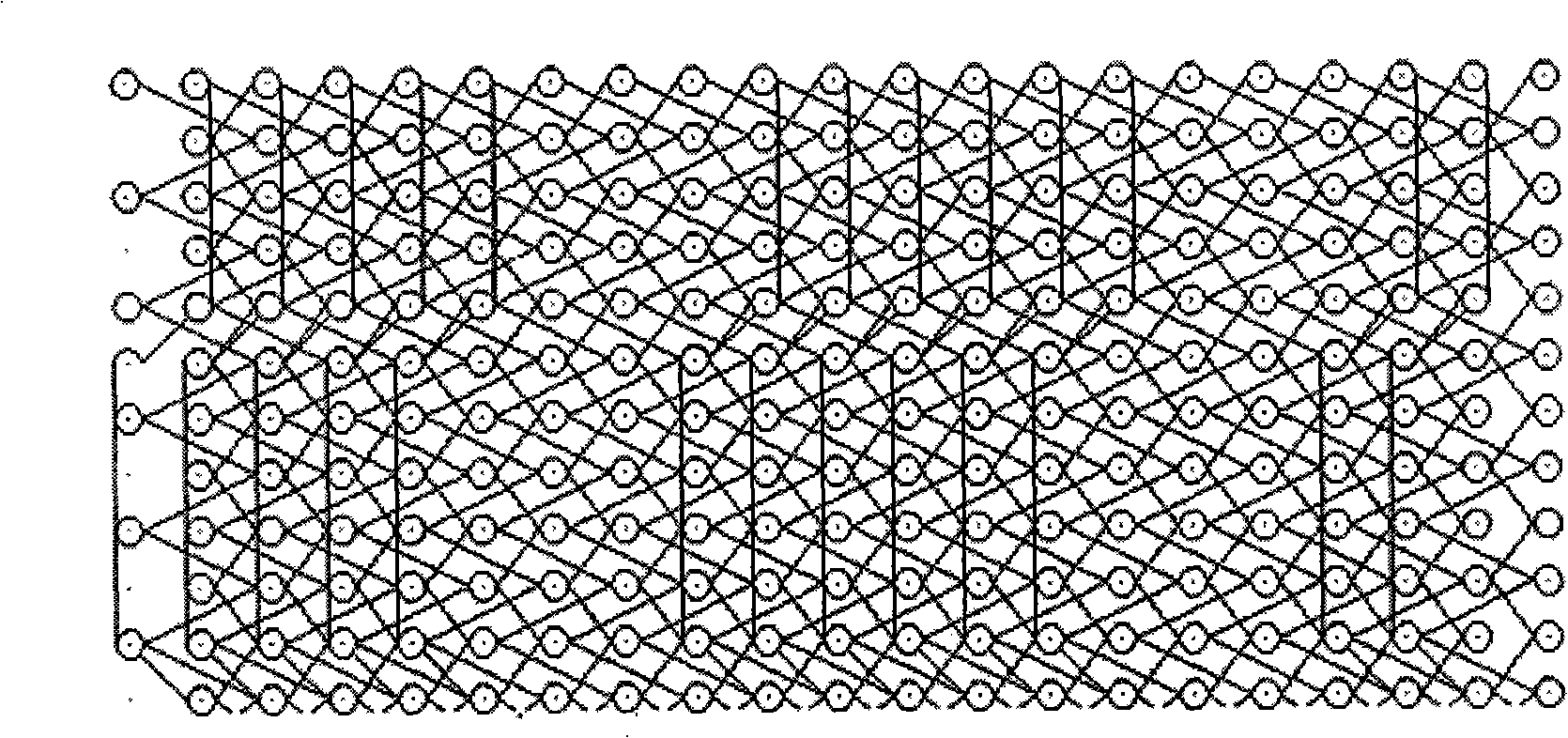

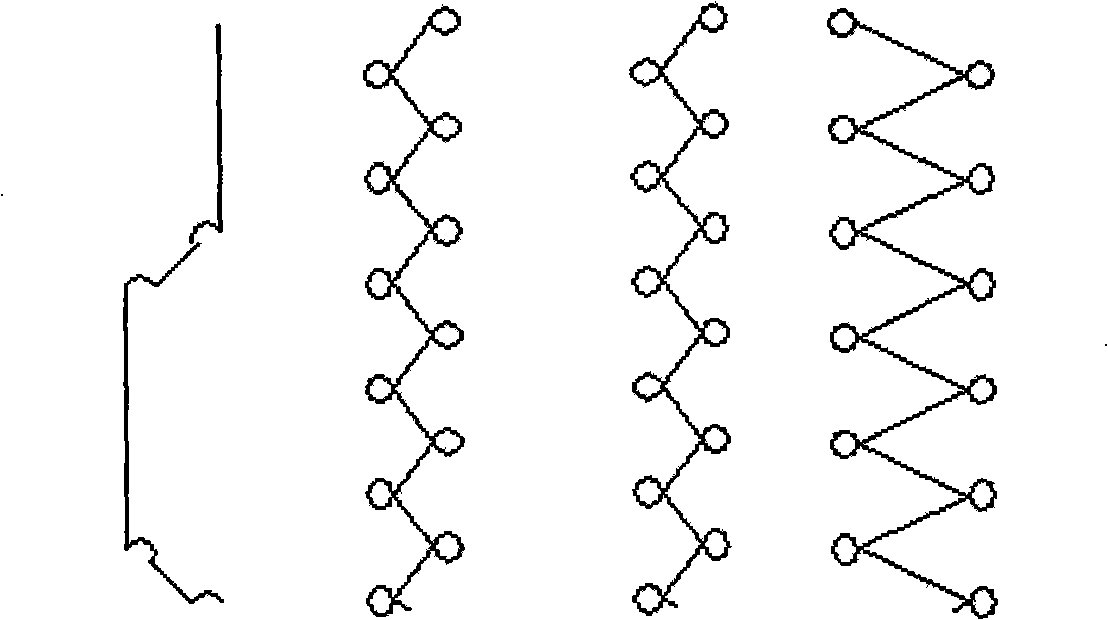

[0019] see figure 1 , the production process of the polyester-cotton pleated warp-knitted suit fabric of the embodiment of the present invention includes raw material preparation, warping, a complete set of pan heads, weaving into gray cloth, unwinding, dyeing, and final product setting. The described weaving into gray cloth adopts four Bar weaving, in which the first bar is made of polyester filament, 6 threads and 3 empty, through the combination of warp and padding (0-1 / 1-2 / 2-2 / 2-2 / 2-2 / 2 -2 / 2-1 / 1-0 / 0-0 / 0-0 / 0-0 / 0-0 / / ), forming horizontal pleats; the second bar is made of compact spun cotton yarn, 1 thread and 6 empty 1 thread and 1 empty, through flat double-strand weaving (1-2 / 1-0 / / ), forming a straight strip; the third bar is made of polyester low elastic yarn, 1 empty, 6 threaded, 1 empty and 1 threaded, also with The flat knitting method (1-2 / 1-0 / / ) fills the empty part of the second comb, and forms a straight two-color effect after dyeing; the fourth comb is also made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com