Patents

Literature

108results about How to "Good oxygen barrier effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

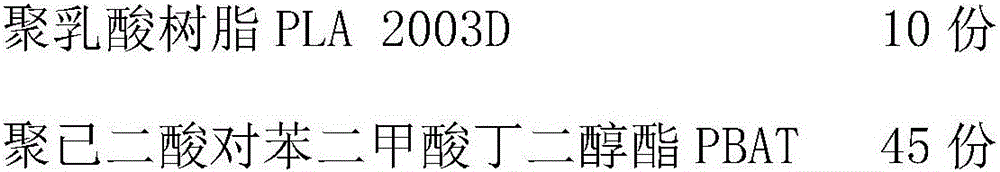

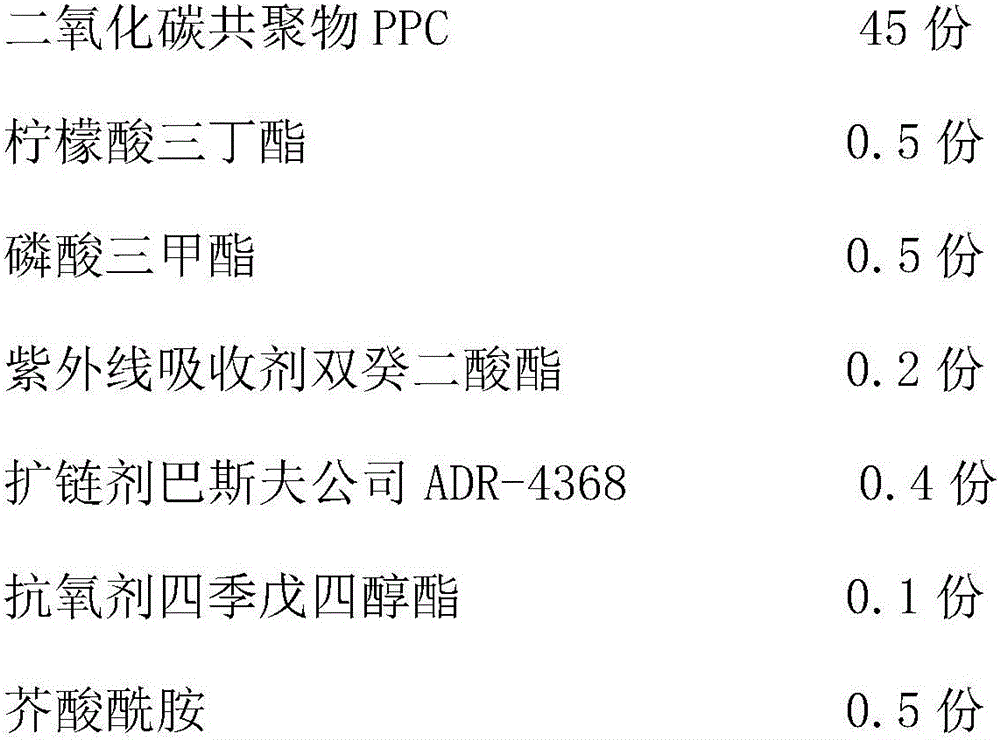

High-barrier-property biodegradable mulching film and preparation method thereof

InactiveCN106046725AFully biodegradableGood mechanical propertiesLow-density polyethyleneAntioxidant

The invention relates to a high-barrier-property biodegradable mulching film and a preparation method thereof, belonging to the field of high-polymer materials. The high-barrier-property biodegradable mulching film is prepared from a polylactic acid resin, a toughener, a heat stabilizer, an ultraviolet absorbent, a chain extender, an antioxidant, an opening agent and the like by using a film blowing machine set. The high-barrier-property biodegradable mulching film can be automatically degraded under the actions of rich oxygen and microbes, does not pollute the environment, has higher barrier property than the LDPE (low-density polyethylene) film with the same thickness by 1.5-2.0 times, and satisfies the functions of moisture retention, water preservation and yield increase for crops. The method has the advantages of simple production technique and high production efficiency, and can easily implement industrial production.

Owner:JILIN COFCO BIOCHEM

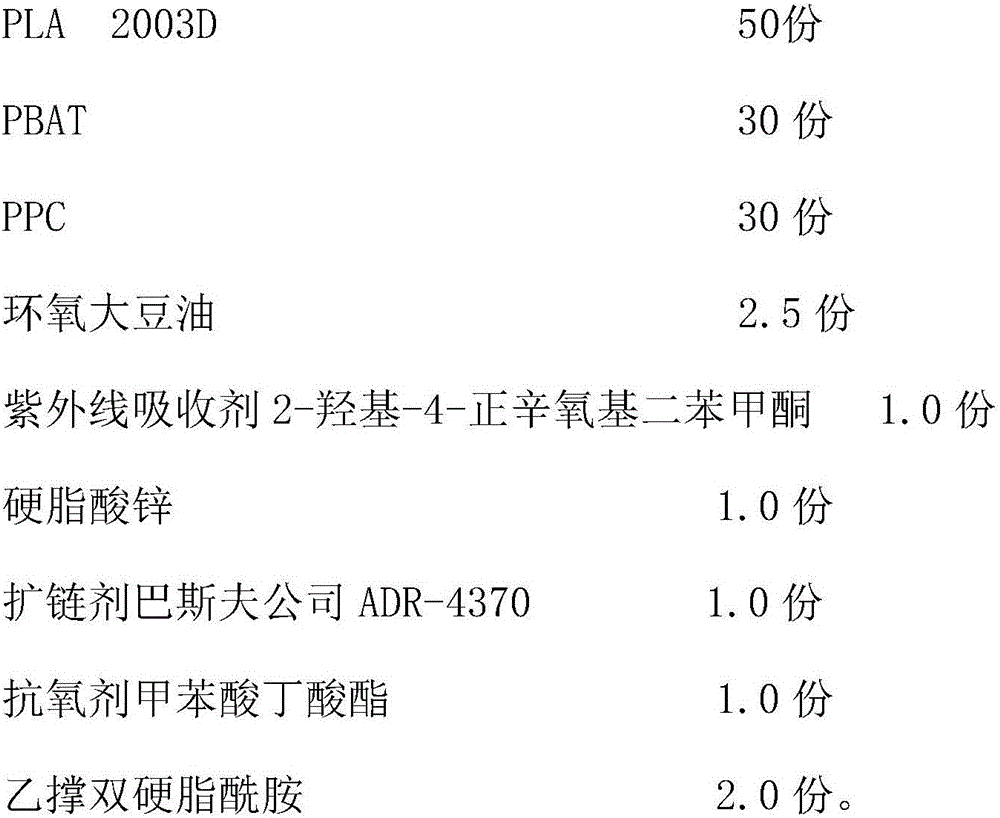

Double-layer thermal barrier/high-temperature low-infrared emissivity integrated coating, metal composite material with coating and preparation method thereof

ActiveCN110055486AGood oxygen barrier effectStop the spreadMolten spray coatingSuperimposed coating processEmissivityAlloy

The invention discloses a double-layer thermal barrier / high-temperature low-infrared emissivity integrated coating which is of a multilayer superposition structure. The multilayer superposition structure sequentially comprises a metal bonding layer, a thermal barrier ceramic inner layer, a thermal barrier ceramic outer layer and a low-infrared emissivity layer from inside to outside, and the thermal barrier ceramic inner layer is La2Zr2O7-8YSZ mixture layer, wherein the mass fraction of La2Zr2O7 powder in the mixture is not more than 45%, the thermal barrier ceramic outer layer is a rare earthzirconate layer, and the low-infrared emissivity layer is a Bi2O3-Al2O3-ZrO2-CaO-SiO2 glass coating comprising conductive phase AuPt alloy powder. The invention also provides a metal composite material with the coating and a preparation method thereof. The integrated coating has the characteristics of heat insulation performance, high-temperature low infrared emissivity, excellent thermal shock resistance and the like.

Owner:NAT UNIV OF DEFENSE TECH

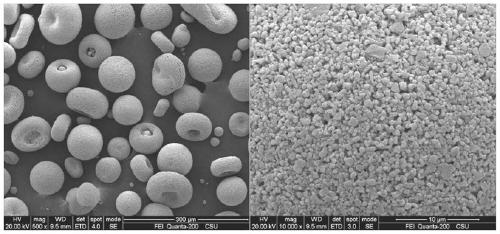

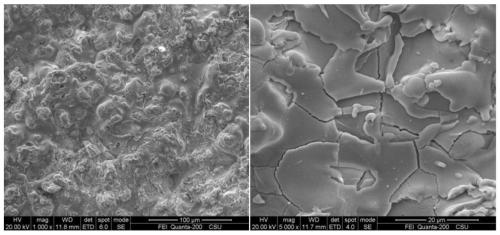

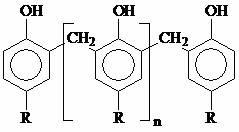

Halogen-free flame retardant containing linear phenolic aldehyde and polymer material containing halogen-free flame retardant

InactiveCN102504475AHigh synergistic flame retardant performanceLow costPolymer sciencePhosphoric acid

The invention relates to a halogen-free flame retardant containing linear phenolic aldehyde and a polymer material containing the halogen-free flame retardant. A small quantity of metal hydroxides can be added simultaneously for serving as synergistic flame retardants. Phosphorus pentoxide generated by the combustion of red phosphorus reacts with a phenolic hydroxyl group in the linear phenolic aldehyde, and phosphonic acid or metaphosphoric acid and the like are generated simultaneously; and the acids of the type are further used for catalyzing dehydration and char formation of phenolic resin, and are esterified with the phenolic hydroxyl group, so that an organic-inorganic hybrid barrier layer is formed. The barrier layer is used for blocking heat conduction, diffusion and permeation of oxygen and overflow of combustible matter and slowing material degradation and the like, so that combustion is stopped finally, and flame is extinguished. A flame retarding effect can be further improved by using a small quantity of hydroxides and inorganic flame retardants containing crystal water. A halogen-free flame retardant composition can be used for retarding combustion of polymers and polymer compositions. A halogen-free flame retardant system disclosed by the invention has the advantages of low cost, low toxicity, wide application and the like, and contributes to environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

Production technology for polycrystalline silicon

The invention discloses a production technology for polycrystalline silicon. The production technology includes the following steps: 1, a first coating, a second coating and a third coating are sequentially arranged on the surface of a crucible from inside to outside, and a crystalline silicone leftover material layer is laid; 2, a small quantity of raw polycrystalline silicon materials in the melted state is contained in the crucible, and the temperature of the crucible is controlled to be lower than the melting point of the crystalline silicone leftover material layer to enable the small quantity of melted raw polycrystalline silicon materials to form a crystallization protection layer; 3, in the vacuum environment, to-be-processed raw polycrystalline silicon materials are contained in the crucible, placed in a melting furnace with an electron beam generating device and processed through laser irradiation; 4, high-frequency induction heating is carried out in the vacuum environment, a slag forming constituent is added, plasma heating is carried out, steam-and-hydrogen-mixed argon is introduced, and directional solidification is carried out to obtain the polycrystalline silicon serving as the target product. By means of the production technology, the boron content, the phosphorous content and the metal impurity content can be effectively reduced, the complete polycrystalline silicon is prepared, long crystal dislocation is less, grain boundaries are proper, and the conversion rate of a polycrystalline silicon battery is increased.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

Application of nontoxic composite aluminum foil for exterior package of PVC or non-PVC soft packed transfusion agent

ActiveCN101033030AImprove barrier propertiesGood oxygen barrier effectFlexible coversWrappersMedicineAluminum foil

This invention relates to an atoxic compoune Al foil and its use in packaging PVC or non-PVC soft bag transfusion agent, in which, it is proved from the experiment of the proposer that as the bag of PVC or non-PVC soft bag transfusion agent, the medical compound Al foil has the advangtages of high blocking, high oxygen isolation, shading and high airproofing to solve the problem of stabilizing quality of remedy products that easily to be oxidized.

Owner:XIAN LIBANG PHARMA

Method for producing water soluble moistureproof film coating premixing agent

InactiveCN101584864AAppropriate proportionAppropriate sourceInorganic non-active ingredientsPolyethylene glycolMoisture resistance

The invention discloses a method for producing a water soluble moistureproof film coating premixing agent, which relates to a pharmaceutical excipient. The premixing agent consists of raw materials, namely polyvinyl alcohol, polyethyleneglycol, hydroxypropyl methylcellulose, castor oil, tween-80, color lake, titanium pigment and talcum. The raw materials are mixed according to certain weight percentage, and the premixing agent is produced according to the prior process for producing the film coating premixing agents. The method has the advantages that the water soluble moistureproof film coating premixing agent produced according to the formula has good film-forming property, firm combination of a coating layer and a medicament core, strict wrapping, uniform thickness and even coloration, is smooth and beautiful, has good moisture resistance and oxygen insulation, can avoid surface abrasion, edge cracking, peeling or adhesion of a finished coating agent product and the like, and can better meet various needs of film coatings of solid pharmaceutical preparations.

Owner:伦西全 +4

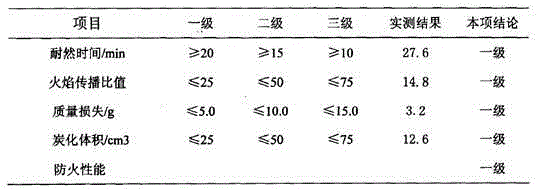

Water-resistant fireproof coating

The invention discloses a water-resistant fireproof coating. The coating comprises the following raw materials by weight: 20 to 50 parts of self-crosslinking elastic acrylic emulsion, 5 to 10 parts of copolymer emulsion of vinyl acetate and ethylene, 10 to 25 parts of a flame retardant, 10 to 25 parts of a pigment filler, 2 to 10 parts of propylene glycol, 0.2 to 1 part of 2-ethyl-4-methylimidazole, 0.5 to 1 part of polyvinylpyrrolidone, 0.2 to 1 part of sodium carboxymethylcellulose, 0.2 to 1.5 parts of 1,2-benzisothiazol-3-one, 0.3 to 1.2 parts of dodecyl mercaptan, 0.1 to 0.8 part of dodecyl dimethyl benzyl ammonium chloride, 0.5 to 1.5 parts of a defoaming agent, 0.5 to 2 parts of aluminium triphosphate and 25 to 40 parts of water. The water-resistant fireproof coating provided by the invention has the advantages of high strength, excellent fireproof property and water resistantce, strong adhesive force with a substrate, high bonding strength and long service life.

Owner:TIANCHANG YINHU PAINT

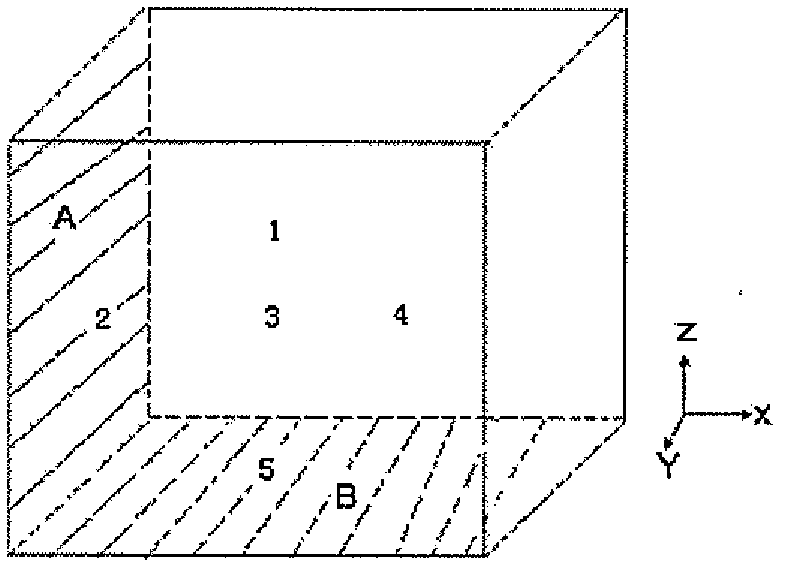

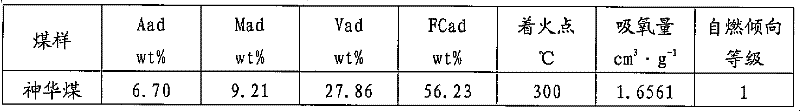

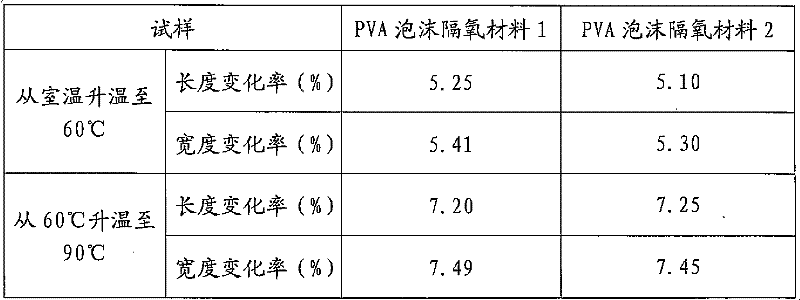

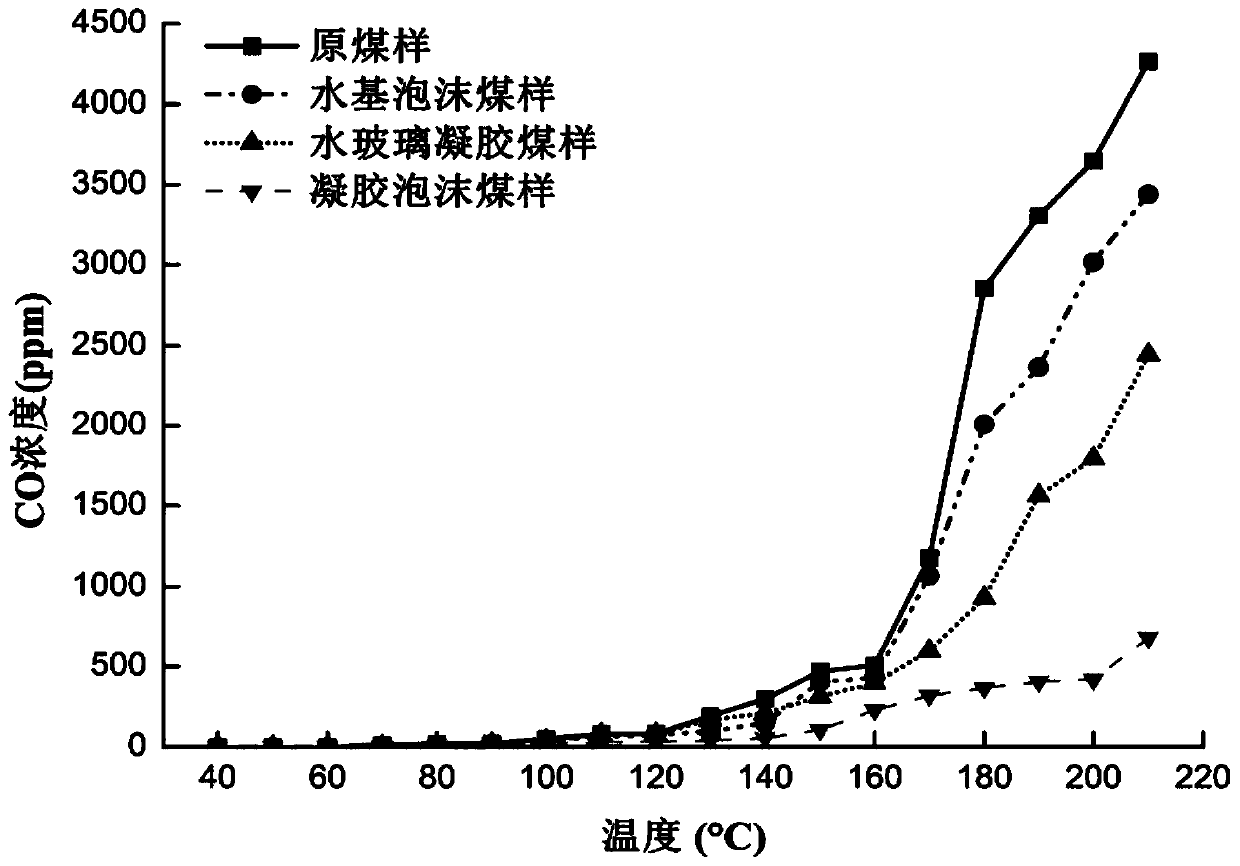

Polyvinyl alcohol foam oxygen insulation material and preparation method and application thereof

ActiveCN102336994AGood oxygen barrier effectSmall oxygen permeability coefficientDust removalFire preventionFoaming agentAlcohol

The invention discloses a polyvinyl alcohol foam oxygen insulation material, which comprises a component (A) and a component (B), wherein the component (A) comprises a solvent, and 3-8 percent by weight of polyvinyl alcohol, 0.5-1.5 percent by weight of linear hydrocarbon organic alcohol or ester and 0.04-0.10 percent by weight of foaming agent based on the total amount of the solvents contained in the component (A) and the component (B); the component (B) comprises 0.1-0.3 percent by weight of borate based on the total amount of solvents contained in the component (A) and the component (B); and the mass ratio of the solvent contained in the component (A) to the solvent contained in the component (B) is (5-9):1. A method for preparing the polyvinyl alcohol foam oxygen insulation material comprises the following steps of: dissolving polyvinyl alcohol into the solvent at constant temperature 70-95 DEG C, performing return flow agitation for 30-60 minutes, cooling to room temperature, and adding the linear hydrocarbon organic alcohol or ester and the foaming agent to obtain the component (A); adding borate into the solvent to obtain the component (B); and foaming the component (A), spraying onto a coal surface and spraying the component (B) to form a foam gel oxygen insulation material layer which plays a good role in sealing and insulating oxygen on the coal surface.

Owner:CHINA SHENHUA ENERGY CO LTD +1

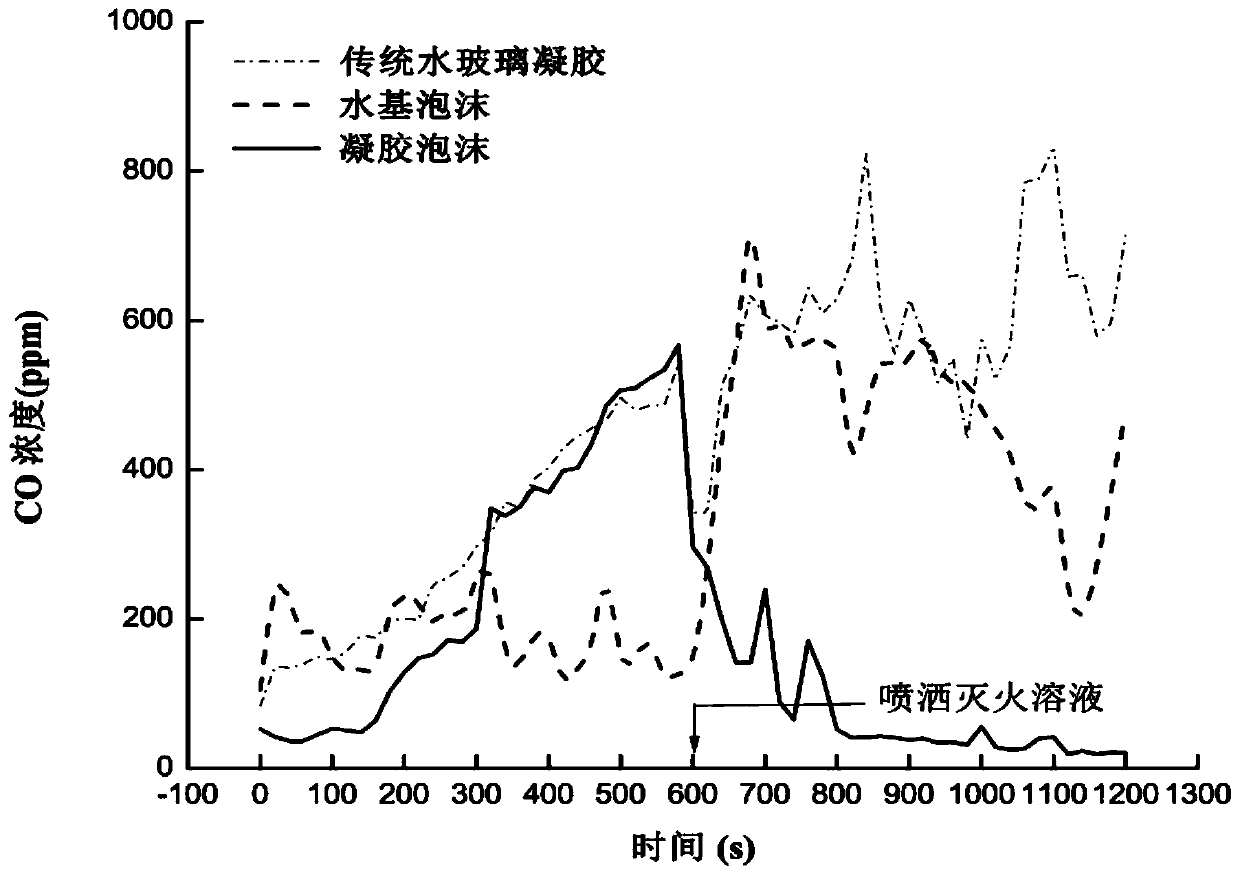

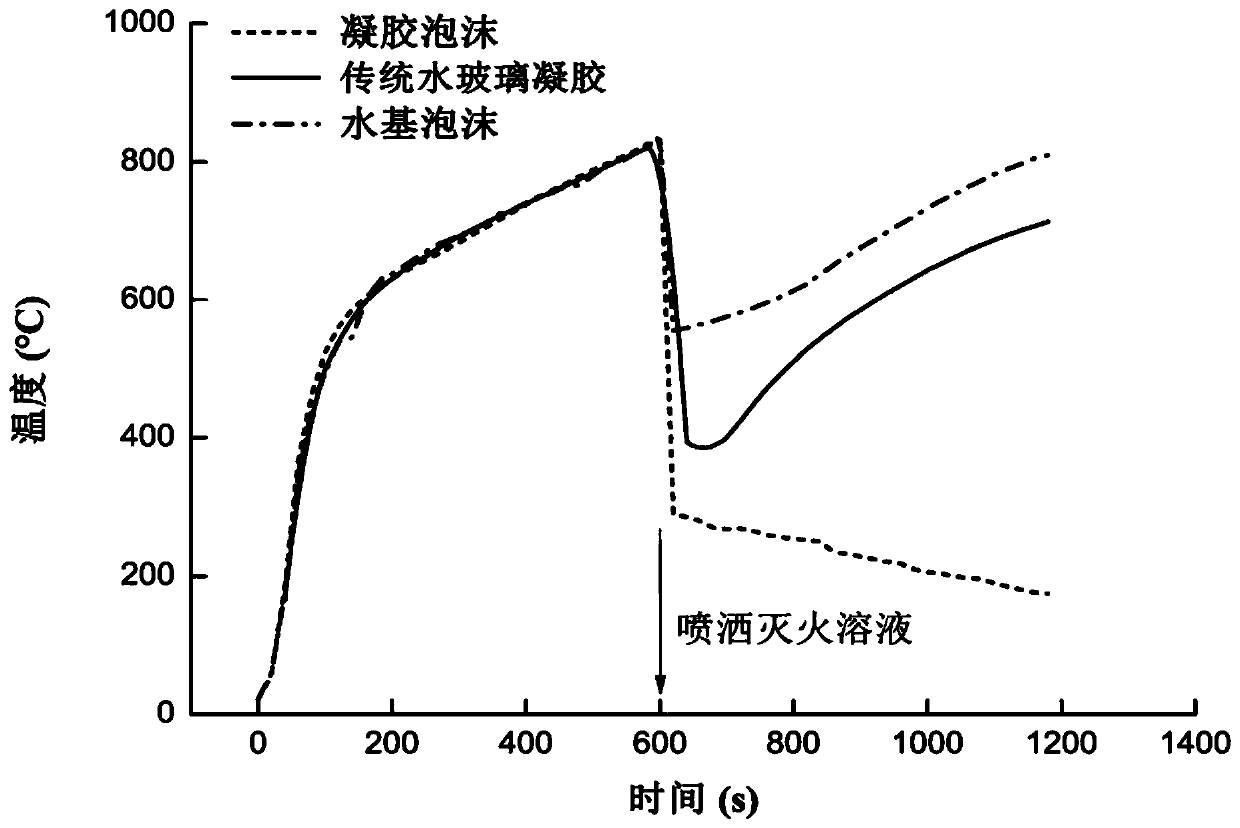

Economic and environment-friendly gel foam for preventing and curing coal spontaneous combustion

InactiveCN109899104APromote foam volumeSolve liquidity problemsMining devicesDust removalWater basedFoaming agent

The invention relates to the technical application field of coal mine fire preventing and extinguishing, and provides economic and environment-friendly gel foam for preventing and curing coal spontaneous combustion. The economic and environment-friendly gel foam is prepared from the components in percentage by weight: 4% to 35% of water glass, 0.4% to 3% of a foaming agent, 0.1% to 3% of a foam stabilizing agent, 1% to 5% of a coagulant, and the balance of water; and the foaming agent is formed by compounding two or more anionic-type foaming agents. According to the economic and environment-friendly gel foam for preventing and curing coal spontaneous combustion, the adopted foaming agent is formed by compounding two or more anionic-type foaming agents, an adopted gelatinizing system is composed of the water glass and the coagulant, the cost is low, economy and environmental protection are realized, and the gel foam is non-poisonous and harmless during using and has good economic benefits. The obtained gel foam maintains the advantages of high fluidity and good aggregation of water-based foam before gelatinizing, and after gelatinizing, the advantages of the outstanding cooling effect and the good leak sealing effect of water glass gel are maintained; and the gel foam is good in inhibition and fire extinguishing effect, the fire source temperature, thermal radiation and CO output can be significantly reduced, fire extinguishing is stable, and the reignition phenomenon does not occur.

Owner:SHANDONG UNIV OF SCI & TECH

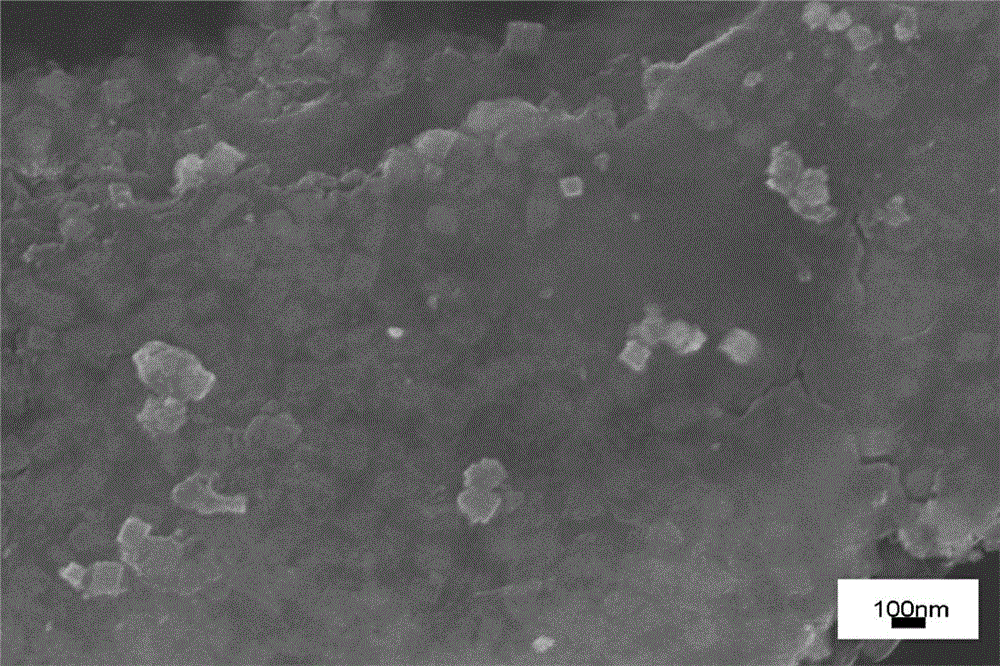

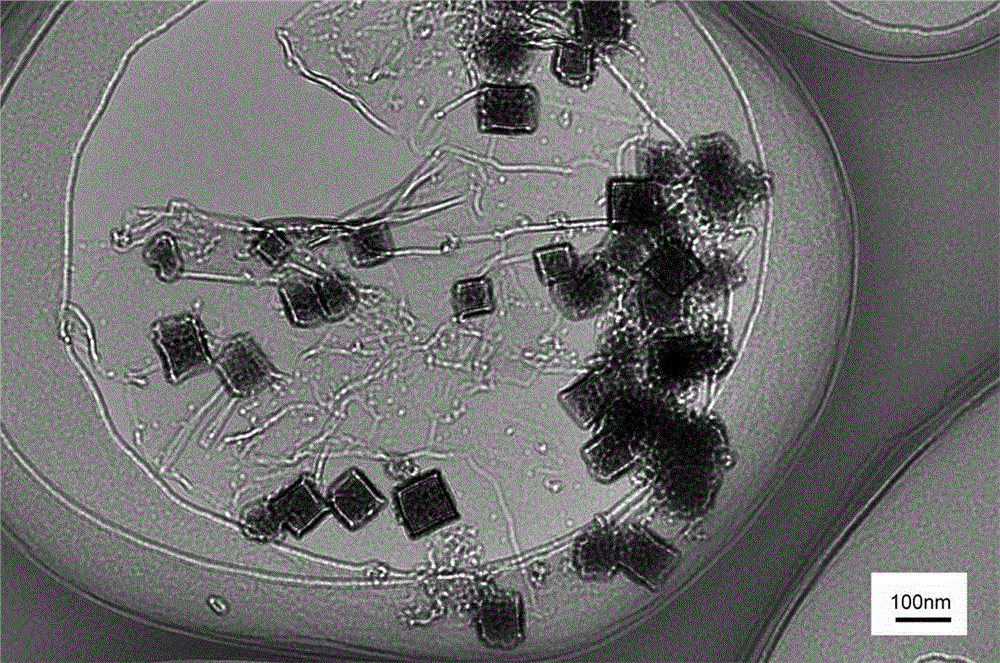

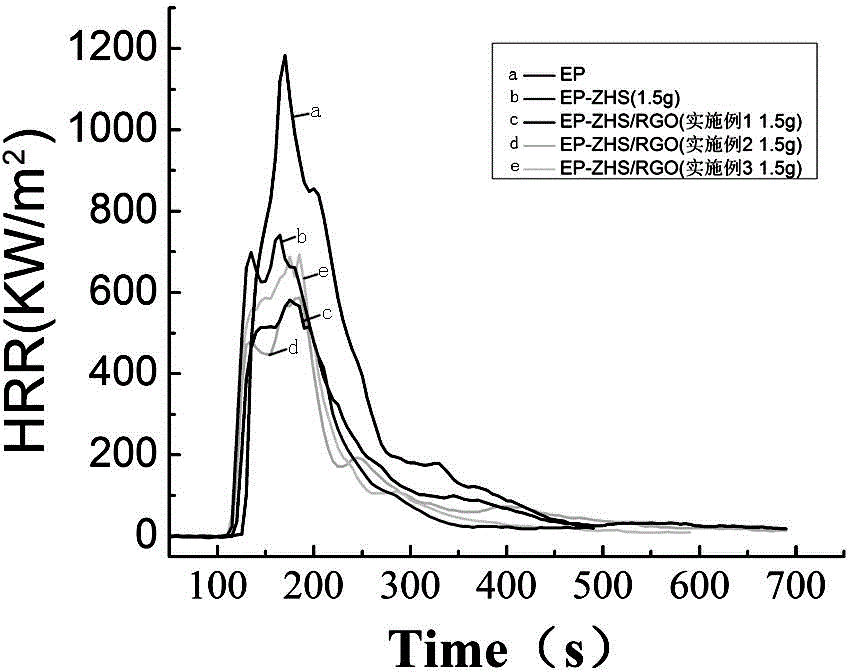

Preparation method and application of inorganic hybrid smoke-suppression flame retardant

The invention discloses a preparation method of an inorganic hybrid smoke-suppression flame retardant, which comprises the following steps: a) preparing a 0.4-0.6 mg / ml graphene oxide suspension; b) adding a soluble zinc salt into the graphene oxide suspension until the concentration of the soluble zinc salt is 2.5-9 mmol / L, stirring for 15-20 minutes, and adding a soluble stannate with the same mole number as the soluble zinc salt; stirring for 30-40 minutes to obtain a precursor solution; c) carrying out hydrothermal reaction on the precursor solution at 120-160 DEG C for 6-12 hours; and after the reaction finishes, cooling, filtering, washing with water and drying to obtain the inorganic hybrid smoke-suppression flame retardant. The invention also discloses application of the flame retardant in epoxy resins. The method is simple to operate, has the advantage of mild and controllable reaction conditions, and can easily implement large-scale production. The prepared flame retardant has favorable flame retardancy, overcomes the defects of low flame-retardant efficiency, high aggregation tendency, high addition amount and the like in the single graphene flame retardant. The flame-retardant material prepared by adding into the epoxy resin has flame-retardant and smoke-suppression functions.

Owner:HEBEI UNIVERSITY

Water-based intumescent fire-retardant coating for timber structure and preparation method of coating

InactiveCN104673036AImprove insulation performanceGood oxygen barrier effectFireproof paintsEpoxy resin coatingsPolymer sciencePtru catalyst

The invention discloses a water-based intumescent fire-retardant coating for a timber structure. The coating comprises a first component and a second component which are mixed in the ratio of (4-5):(1.2-1.5) in parts by weight, wherein the first component and the second component comprise components in parts by weight as follows: the first component comprises components in parts by weight as follows: a silicone-acrylate emulsion, a char-forming catalyst, a first component char-forming agent, a foaming agent, a pigment, a film-forming aid, a dispersing agent and an auxiliary material; the second component comprises components in parts by weight as follows: a composite emulsion, a second component char-forming agent, a flame retardant, a layered double hydroxide, filler, antimony trioxide, a film-forming agent, a thickening agent, an antifoaming agent and a curing agent. The coating has excellent physical and chemical properties, good fire retardance and a certain decoration property, is an efficient, environment-friendly and multifunctional fire-retardant coating and completely conforms to the development direction of the fire-retardant coating industry.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

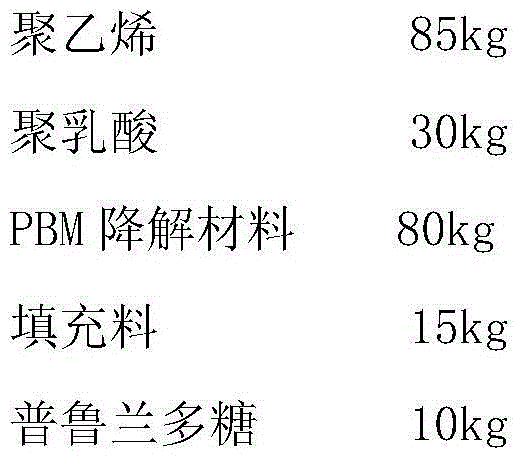

Biological nano plastic

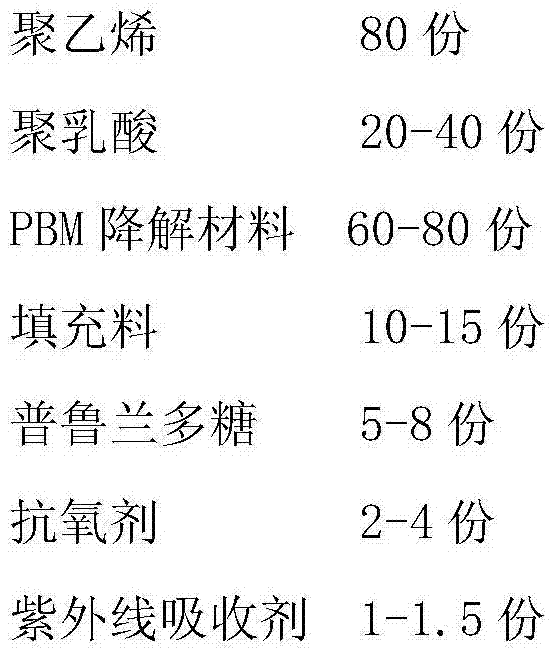

The invention discloses a biological nano plastic, which is characterized in that the plastic comprises the following raw material components in parts by weight: 45-60 parts of plant fiber starch, 4-6 parts of glycerine, 40 parts of polyethylene, 20-40 parts of a polylactic acid, 60-80 parts of synthetic resin, 10-15 parts of additives, 5-8 parts of Pulullan, 2-4 parts of an antioxidant, 1-1.5 parts of an ultraviolet light absorber, and the like.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

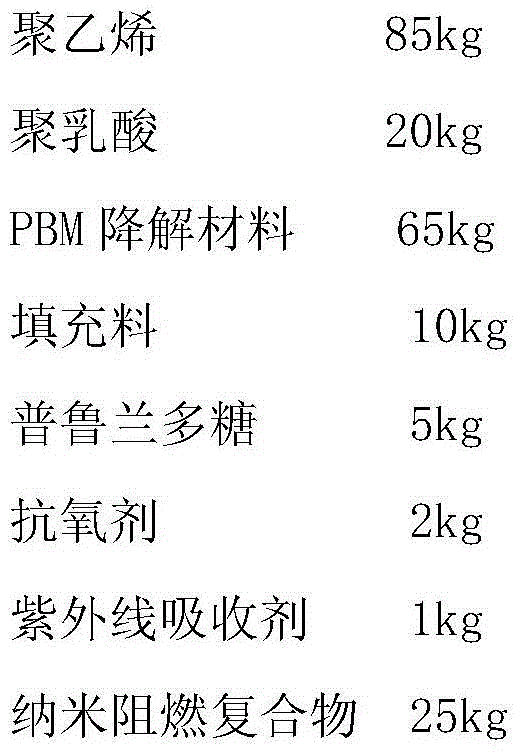

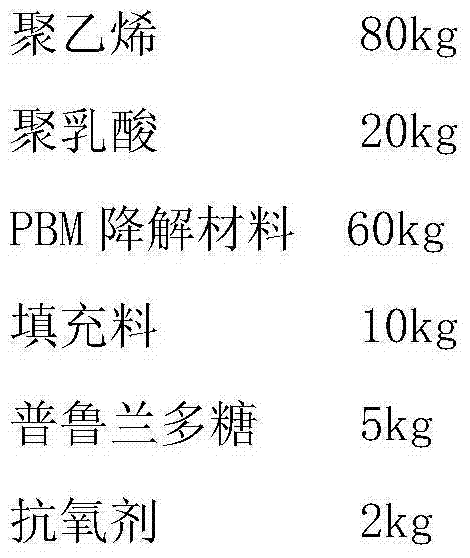

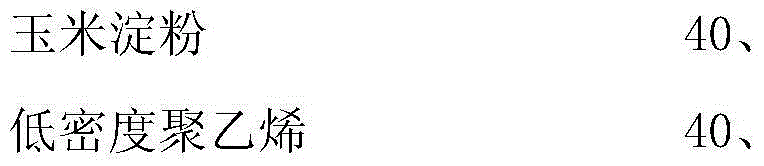

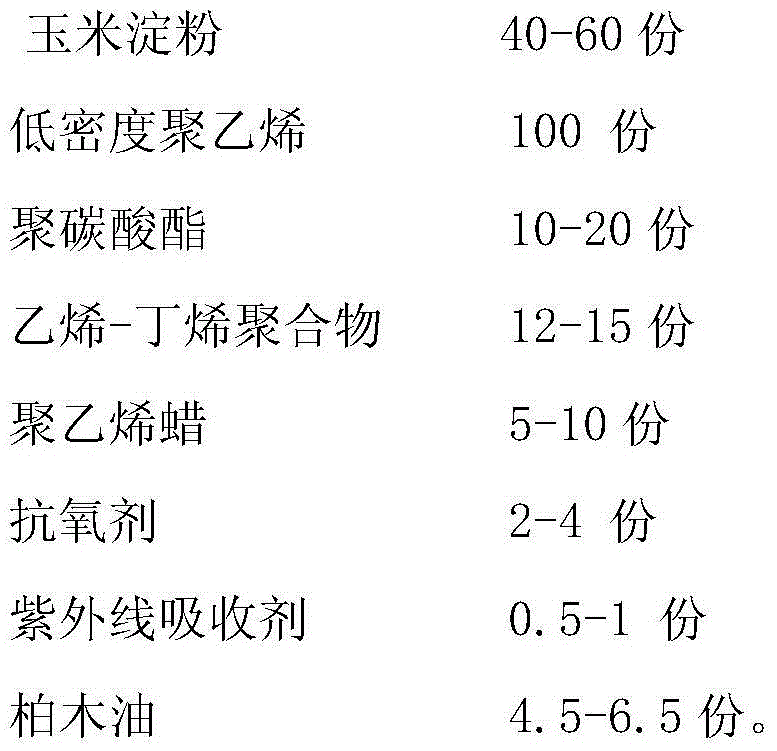

Preparation method for oxygen separating degradable plastic thin film

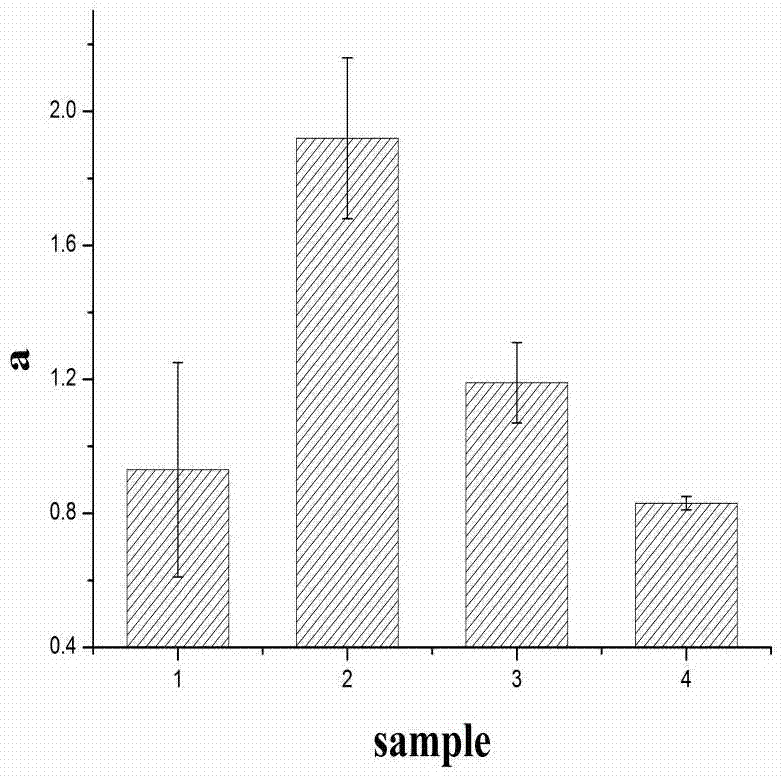

InactiveCN103205045AImprove mechanical propertiesAchieve environmental friendlinessLow-density polyethylenePullulan

The invention relates to a preparation method for an oxygen separating degradable plastic thin film. The method comprises the following steps of: (1) preparing a PBM (Plastic Master Batch) degradable material which is composited by full degradable natural high polymer material synthesized by main raw materials such as starch, plant grease and the like through special treatment with water soluble high polymer material and small amount of resin for later use; (2) mixing low density polyethylene, Pulullan and an antioxygen and an ultraviolet light absorber in a high speed mixer for 25-35 minutes; then, extruding and prilling in a twin-screw extruder to obtain master batch; and (3) mixing the master batch obtained by the step (1) with the PBM degradable material, and extruding and blowing by a plastic film blowing machine to obtain the product. According to the preparation method of the oxygen separating degradable plastic thin film, marketed mature modified starch degradable plastic master batch PBM and Pullulan and thin film grade LDPE are co-mixed, extruded and blown, so that the thin film has good mechanical property and degradability, and meanwhile has higher oxygen separating property.

Owner:天津超平新材料科技有限公司

A kind of topcoat for building curtain wall aluminum veneer and preparation method thereof

The invention relates to a finish for a building curtain wall aluminum veneer, and a preparation method thereof. The finish comprises 60 to 70% of FEVE fluorocarbon resin, 5 to 10% of an organic silicon resin, 0.05 to 0.1% of an acrylic acid levelling agent, 0.1 to 0.3% of an organosilicon levelling agent, 0.3 to 0.8% of benzotriazole ultraviolet absorbent, 0.3 to 0.8% of hindered amine light stabilizer, 0.1 to 0.3% of an organotin catalyst, 10 to 15% of butyl acetate, 10 to 15% of dimethylbenzene and 9 to 13% of an aliphatic isocyanate curing agent, wherein the aliphatic isocyanate curing agent needs to be individually packaged and stored and is added into a formula prior to construction for use. The FEVE fluorocarbon resin and the organic silicon resin are utilized as film-forming substances of the finish and the finish can be cured at normal temperature, and thus energy and labor are saved. Through a fluorine-silicon interpenetrating network structure, film surface tension is reduced and a water contact angle is reduced, and thus film anti-contamination properties are improved greatly. Through introduction of silicon atoms, film toughness is improved, and thus a film surface isnot easy to craze and temperature tolerance and endurance are further improved. In addition, the finish has the advantages of simple preparation method and low cost.

Owner:苏州金近幕墙有限公司

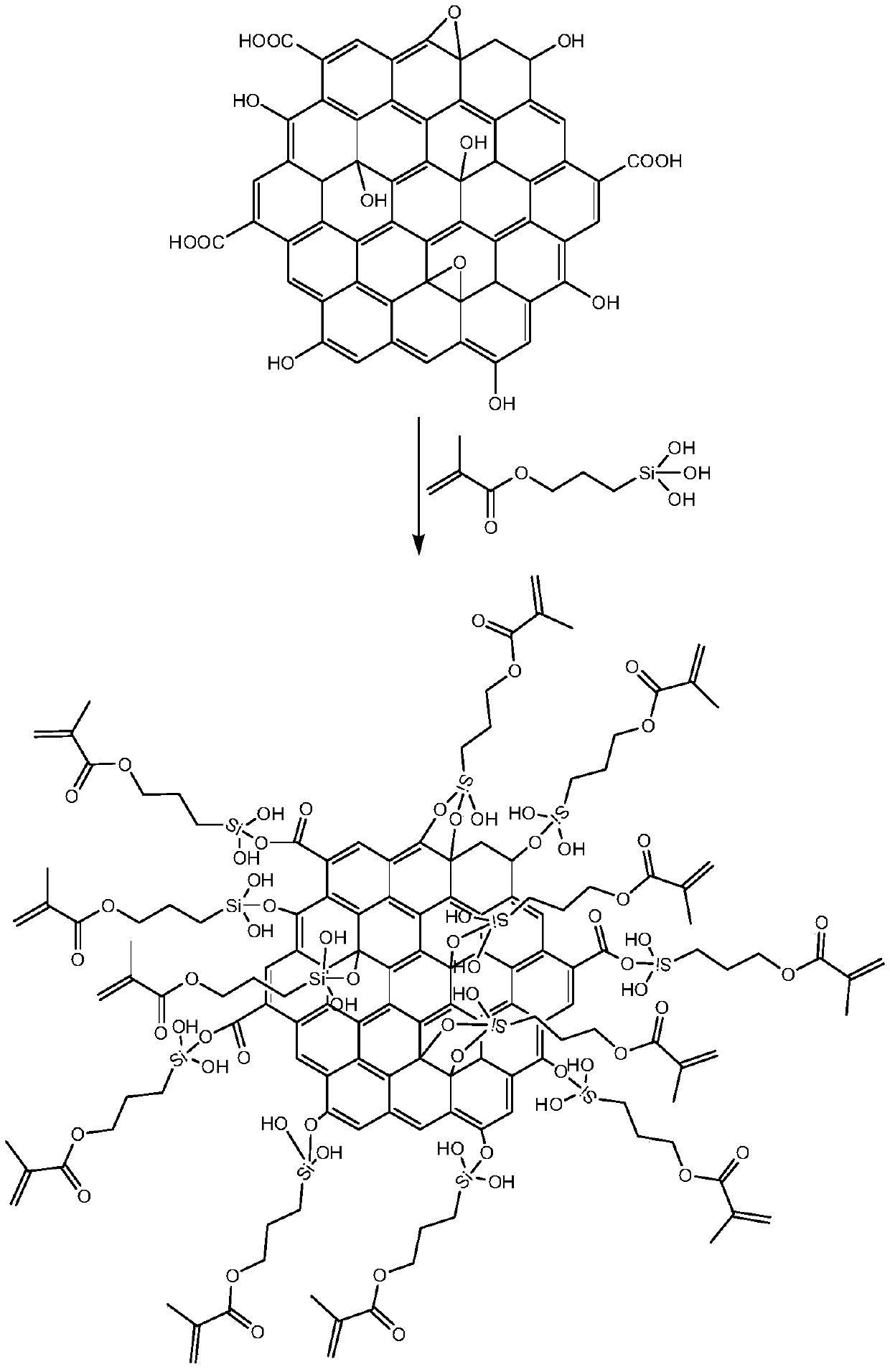

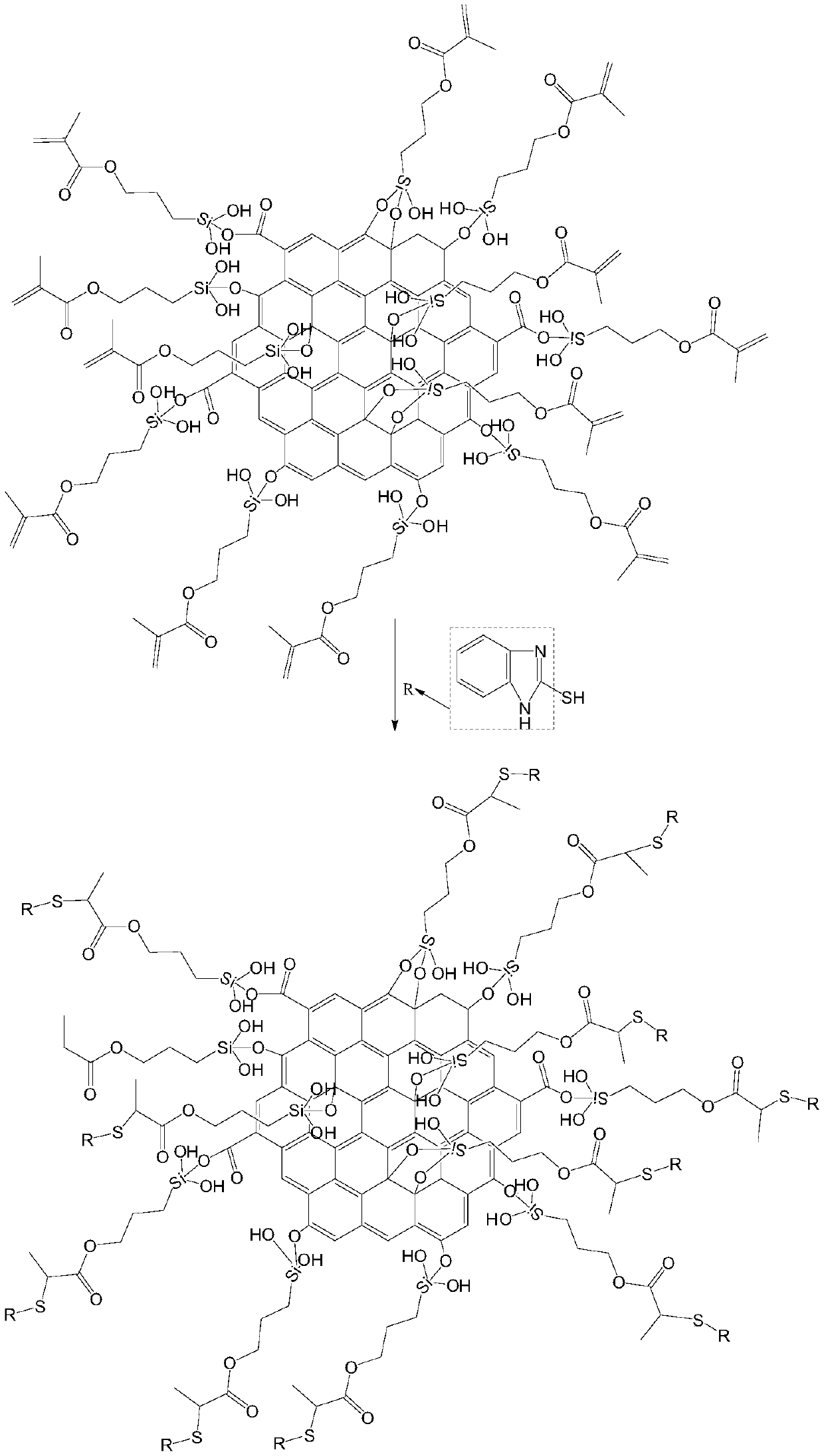

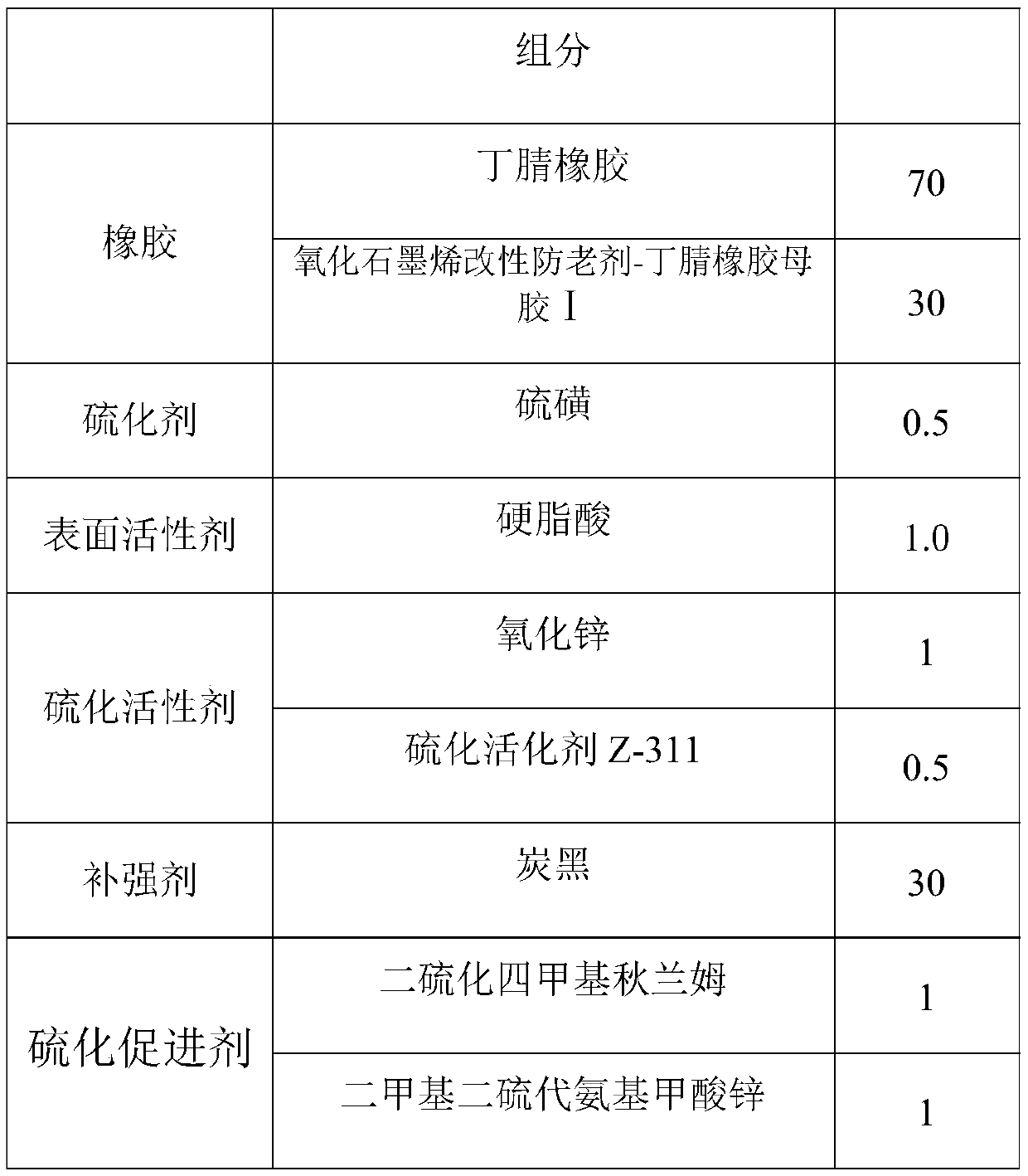

Graphene oxide modified anti-ageing agent, anti-thermo-oxidative-aging rubber containing graphene oxide modified anti-ageing agent and preparation method

ActiveCN110117390AExcellent heat and oxygen aging resistanceInhibit migrationAging resistanceDouble bond

The invention relates to the technical field of graphene rubber composite materials, in particular to a graphene oxide modified anti-ageing agent, anti-thermo-oxidative-aging rubber containing the graphene oxide modified anti-ageing agent and a preparation method. Organosilane containing carbon-carbon double bonds and graphene oxide are subjected to a dehydration condensation reaction to obtain anintermediate product, and the intermediate product and an anti-ageing agent containing mercapto groups are subjected to a click reaction to prepare the graphene oxide modified anti-ageing agent. Thegraphene oxide modified anti-ageing agent, can effectively reduce the using amount of the anti-ageing agent and is difficult to draw out, and the anti-thermo-oxidative-aging rubber prepared from the graphene oxide modified anti-ageing agent is high in mechanical strength and high in thermo-oxidative aging resistance.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

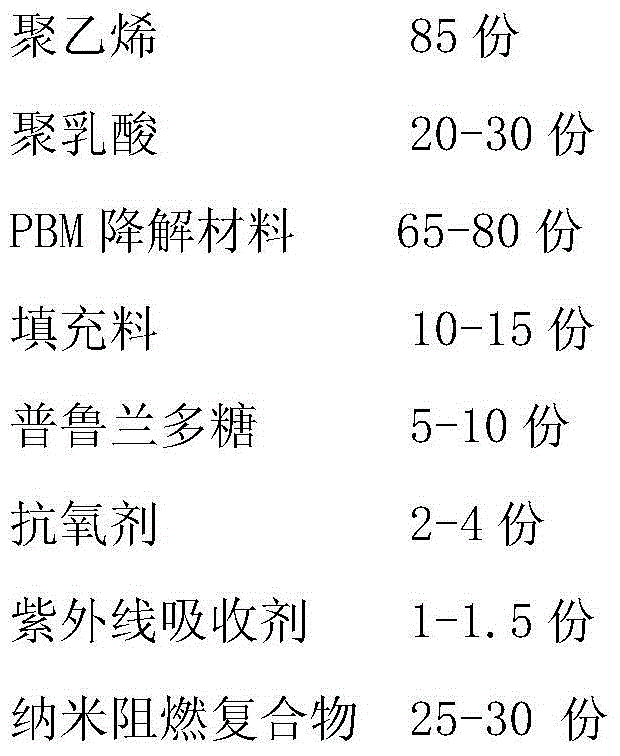

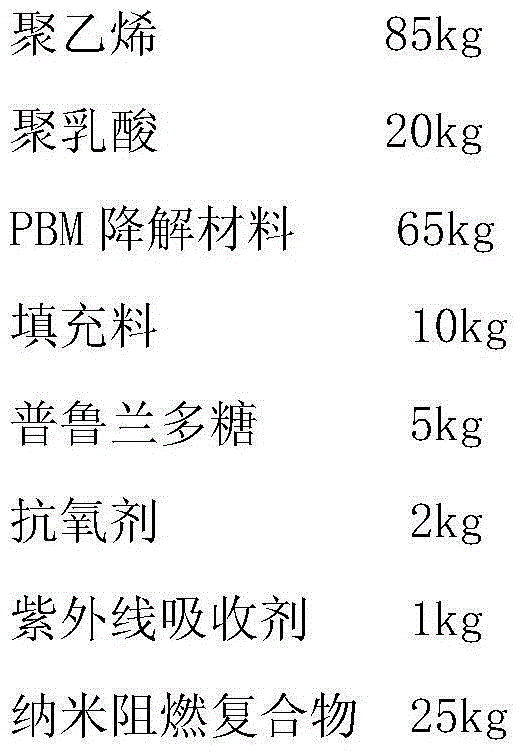

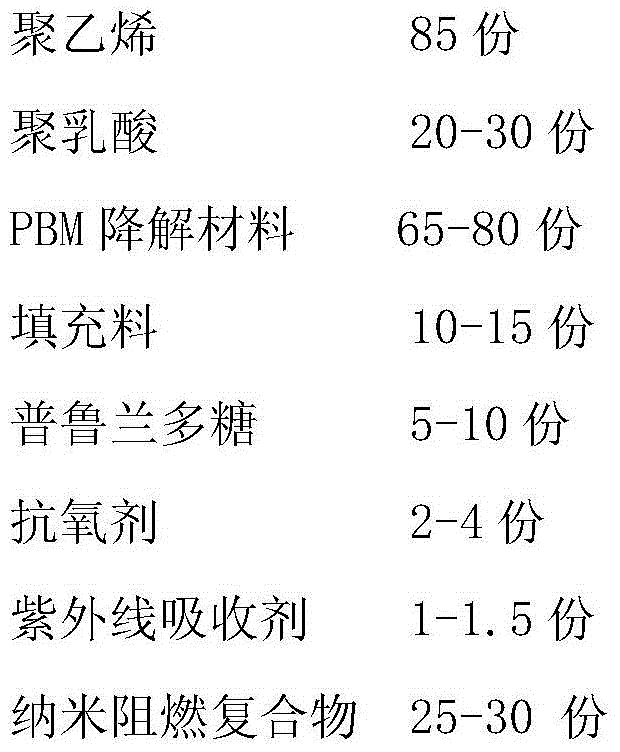

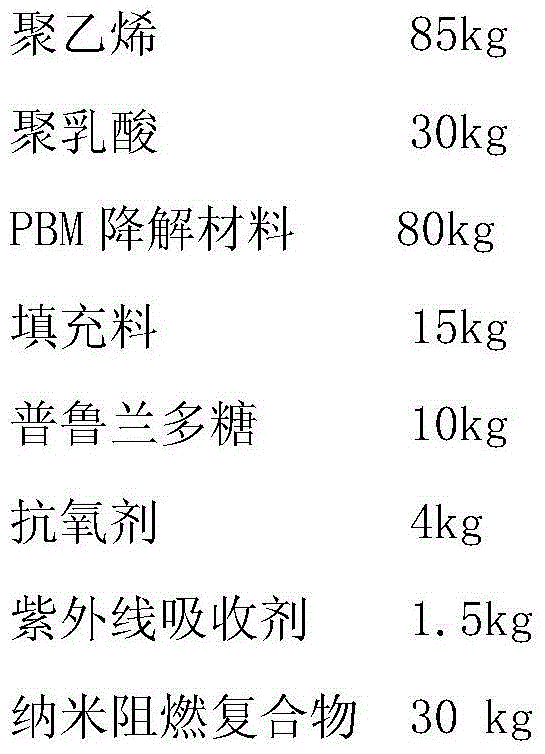

Biodegradable flame-retardant plastic film and preparation method thereof

InactiveCN104448495AGood mechanical propertiesAchieve environmental friendlinessPolymer sciencePullulan

The invention discloses a biodegradable flame-retardant plastic film, which is prepared from the following raw materials in parts by weight: 85 parts of polyethylene, 20-30 parts of polylactic acid, 65-80 parts of a PBM degradable material, 10-15 parts of packing, 5-10 parts of pullulan, 2-4 parts of an antioxidant, 1-1.5 parts of an ultraviolet light absorber and 25-30 parts of nano flame-retardant composites. The oxygen-isolating biodegradable plastic film disclosed by the invention is prepared by blending extrusion and film blowing of mature modified starch biodegradable plastic master batches PBM and pullulan and film-grade LDPE in the market at present in the preparation method; good mechanical property of the film is ensured by using the characteristics of the LDPE; the environment friendliness of the film material is achieved by using the biodegradability of the PBM and the pullulan; the oxygen isolating property of the film material is improved by using high oxygen isolating property of the pullulan; the overall compatibility of the plastic film material is improved by using the structure similarity of the starch and the pullulan as carbohydrates; and regulation and control of the oxygen isolating property, the biodegradability and the like can be achieved by controlling the blending ratio of the LDPE / PBM / Pullulan system.

Owner:TIANJIN KAIXUAN PLASTIC PROD

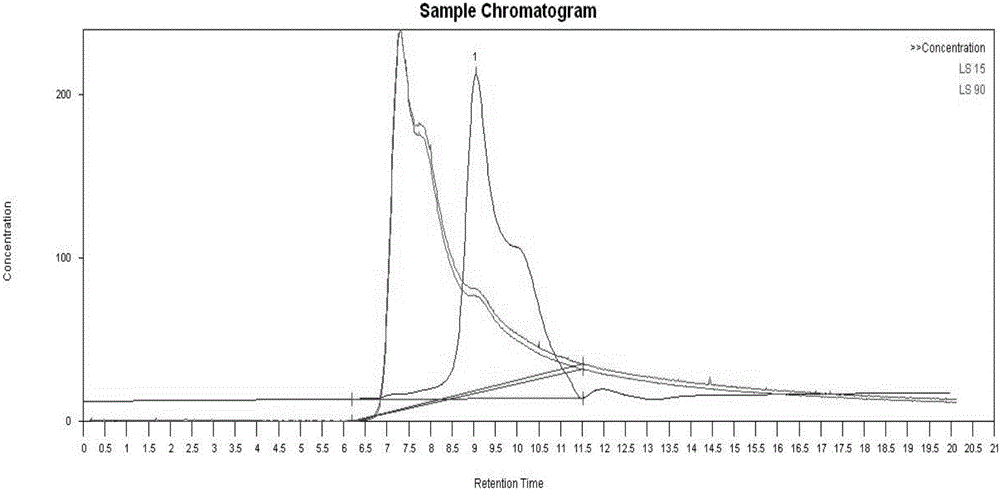

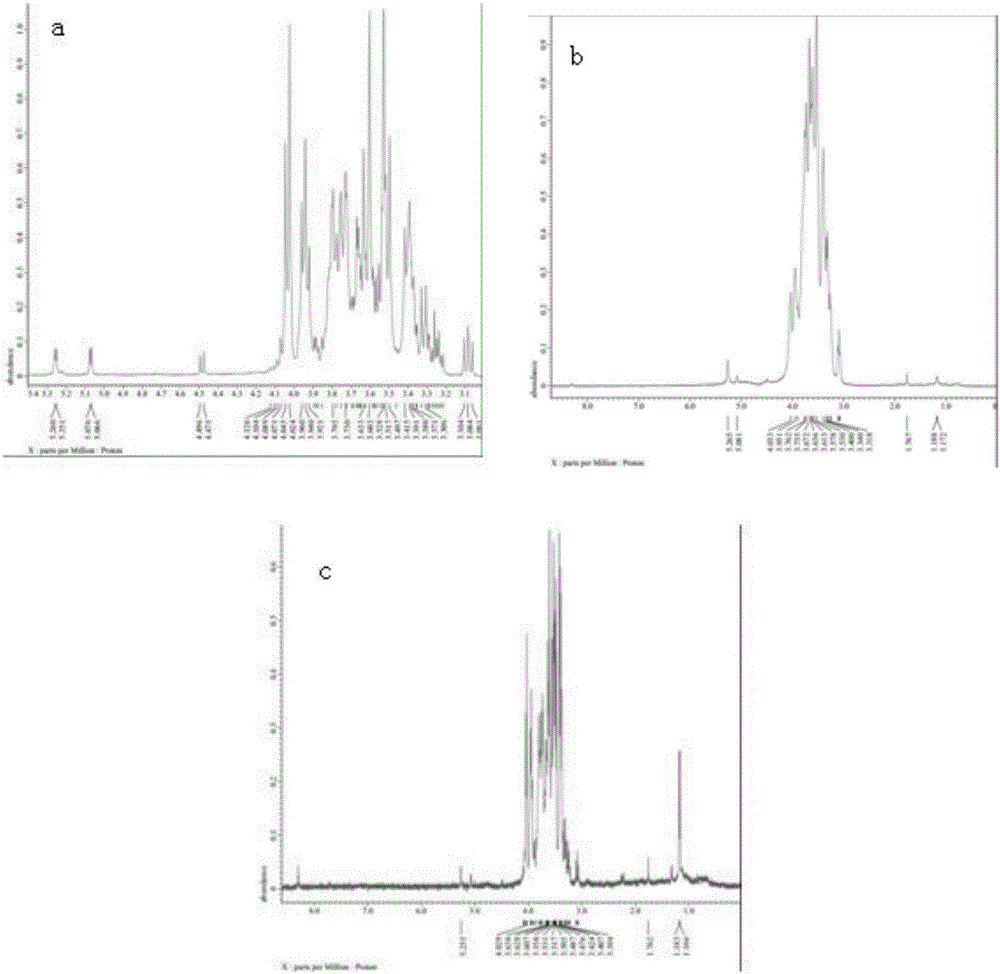

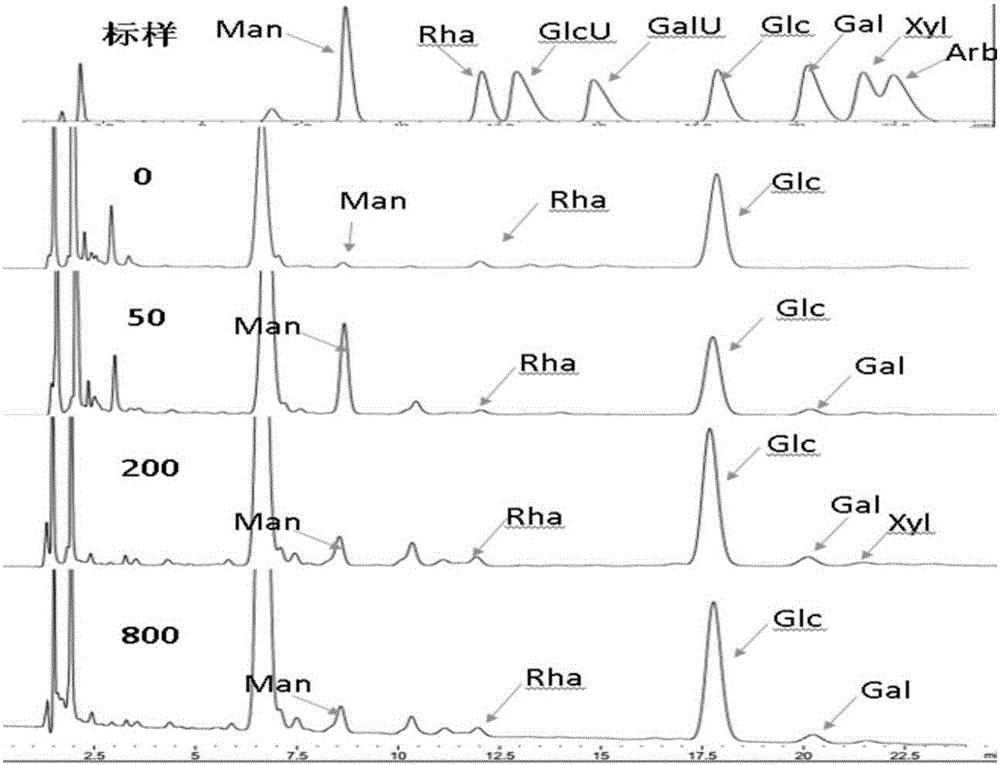

Bacillus amyloliquefaciens and preparation method of exopolysaccharides thereof

ActiveCN106520641ANon-irritatingAntigenicBacteriaMicroorganism based processesChromatographic separationBacillus amyloliquefaciens

The invention provides bacillus amyloliquefaciens EZ99. The bacillus amyloliquefaciens is gram positive bacteria, exists in plant rhizosphere soil, has no pathogenicity for people and plants, is collected from an orchard county, in the west of a Qilihe district in the Lanzhou city of the Gansu province, and has been identified, registered and preserved in the China common microorganism strain preservation center, and the preservation number is CGMCC No.13267. Component analysis is performed on bacterial colonies formed by the bacillus amyloliquefaciens on a PMA and MS culture medium, and it is found that the bacillus amyloliquefaciens has the characteristic of synthesizing and secreting exopolysaccharides. Optimal culture medium formulas and fermentation optimal conditions based on fermentation production of the exopolysaccharides of the strains are built, a fermentation solution is subjected to centrifuging, alcohol precipitation, dialysis and chromatographic separation, four purification polysaccharide components are obtained, and four-polysaccharide-component monosaccharide composition and monomer molecular weight are determined. The exopolysaccharides obtained through the strain and the method have the various applications of medicines, cosmetics, food additives, biological film raw materials and the like.

Owner:甘肃尚农生物科技有限公司

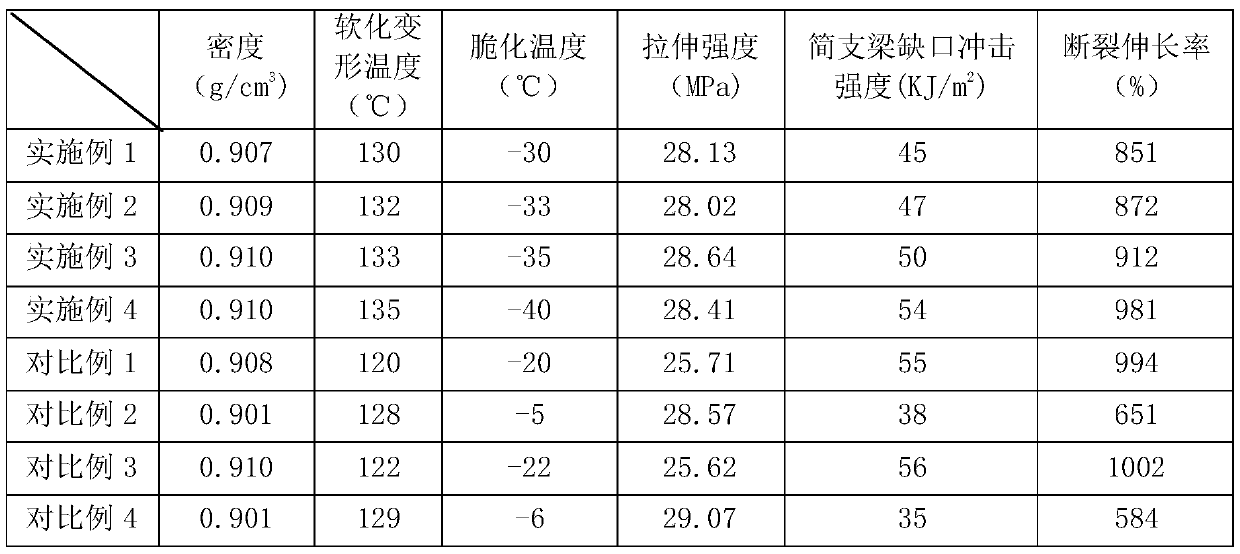

High-temperature steaming resistant and quick freezing resistant food packaging material and preparation method thereof

The invention belongs to the field of material science, and in particular relates to a high-temperature steaming resistant and quick freezing resistant food packaging material and a preparation method thereof. The packaging material is prepared from the following substances in parts by weight: 10 to 20 parts of homo-polypropylene, 60 to 70 parts of polypropylene randon copolymer, and 10 to 20 parts of high-density polyethylene. The preparation method comprises two steps of stirring for uniform mixing and mixing extrusion. According to the method disclosed by the method, the three materials such as homo-polypropylene, polypropylene randon copolymer and high-density polyethylene are mixed according to a specific ratio, thus obtaining the high-temperature steaming resistant and quick freezing resistant food packaging material which has the characteristics of high-temperature resistance, quick freezing resistance, high oxygen insulation property, high toughness and the like.

Owner:ANLU XINXIN MACHINERY EQUIP CO LTD

Flame-retardant polyacrylate emulsion and preparation method thereof

The invention relates to a flame-retardant polyacrylate emulsion and a preparation method thereof. The flame-retardant polyacrylate emulsion is prepared from, by weight, 40-50 parts of acrylate monomer, 5-10 parts of flame-retardant emulsion, 2-5 parts of emulsifier, 0.5-2 parts of initiator, 5-10 parts of antimony compound, 0.5-1 part of inorganic flame retardant, 0.5-1 part of intumescent flameretardant and 30-40 parts of deionized water. Compared with the prior art, the flame-retardant polyacrylate emulsion has the advantages of being excellent in flame retardancy and reaching V0 in flame-retardant grade.

Owner:浙江来往新材料有限公司

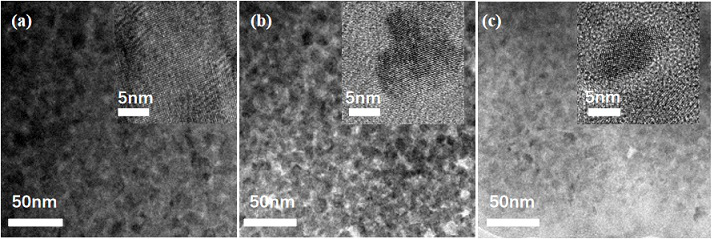

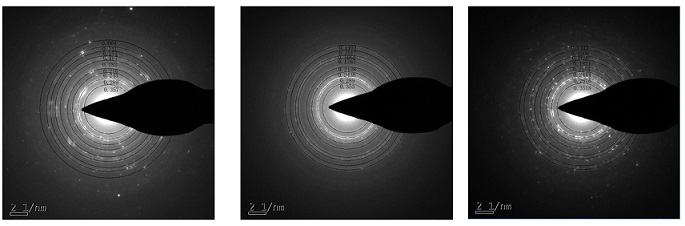

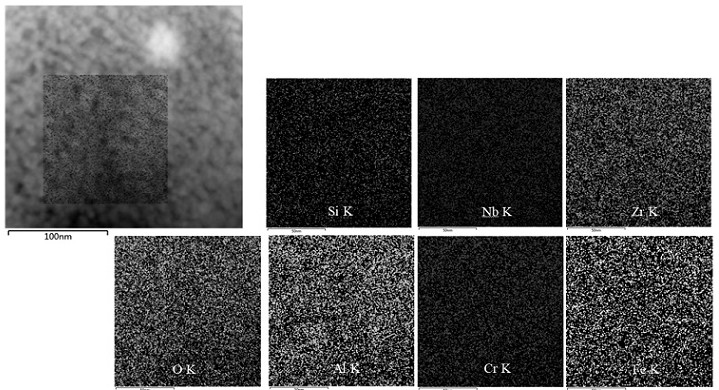

High-temperature self-transformation amorphous/nanocrystalline high-entropy oxide film, preparation method and application

ActiveCN112831751AHigh strengthHigh hardnessVacuum evaporation coatingSputtering coatingCrazingPhysical chemistry

The invention provides a high-temperature self-transformation amorphous / nanocrystalline high-entropy oxide thin film, a preparation method and application. The preparation method comprises the following steps that (1) a zirconium-based multi-element target material is cut and combined into a sputtering target material A, an Al-based multi-element target material is cut and combined into a sputtering target material B, the sputtering target material A is connected with a direct-current power source, the sputtering target material B is connected with a radio-frequency power source, and a high-entropy metal glass film is deposited by adopting a co-sputtering method after pre-sputtering; and (2) the obtained high-entropy metal glass film is placed in a muffle furnace, and calcining is carried out to obtain the amorphous / nanocrystalline high-entropy oxide film. The high-entropy thin film prepared through the method gradually achieves in-situ transformation at the high temperature, uniform and compact high-entropy oxide is formed, and cracks and coating failure are avoided. The high mixing entropy enhances the intersolubility among the elements and inhibits the formation of a single compound. Meanwhile, due to high interface energy and dynamic obstacles (slow kinetics) of atomic diffusion in the crystallization process, an amorphous / nanocrystalline system can stably exist.

Owner:ZHENGZHOU UNIV

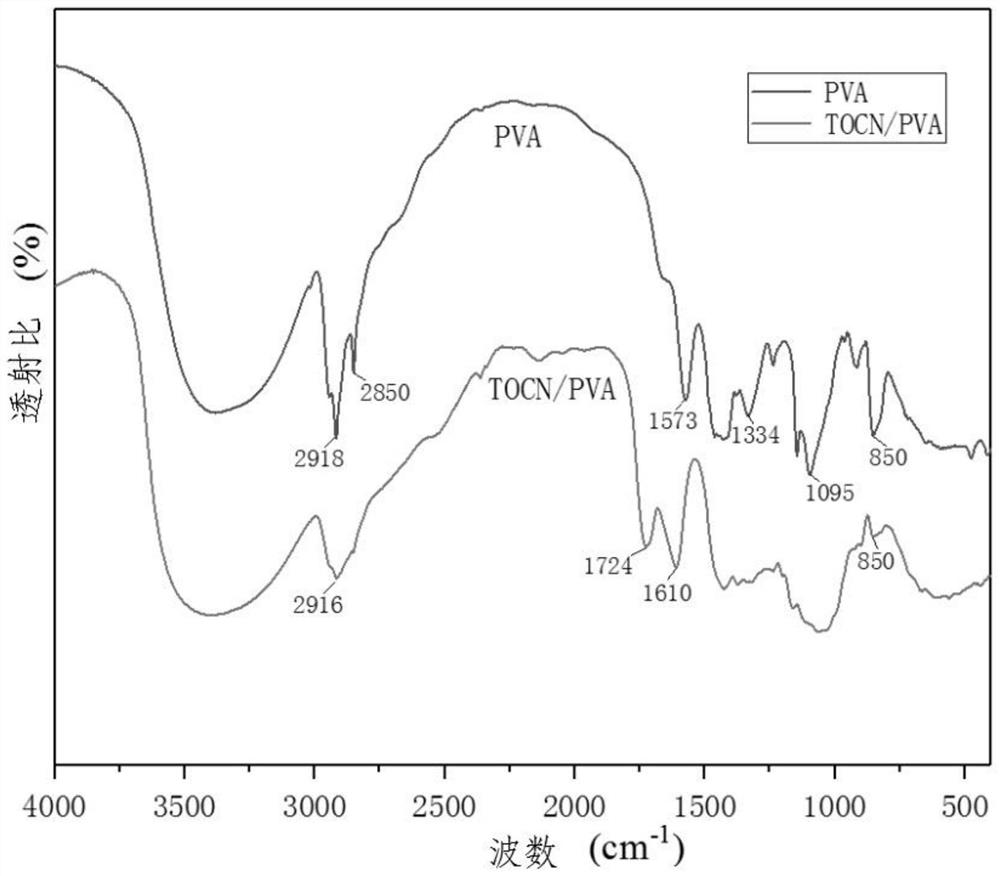

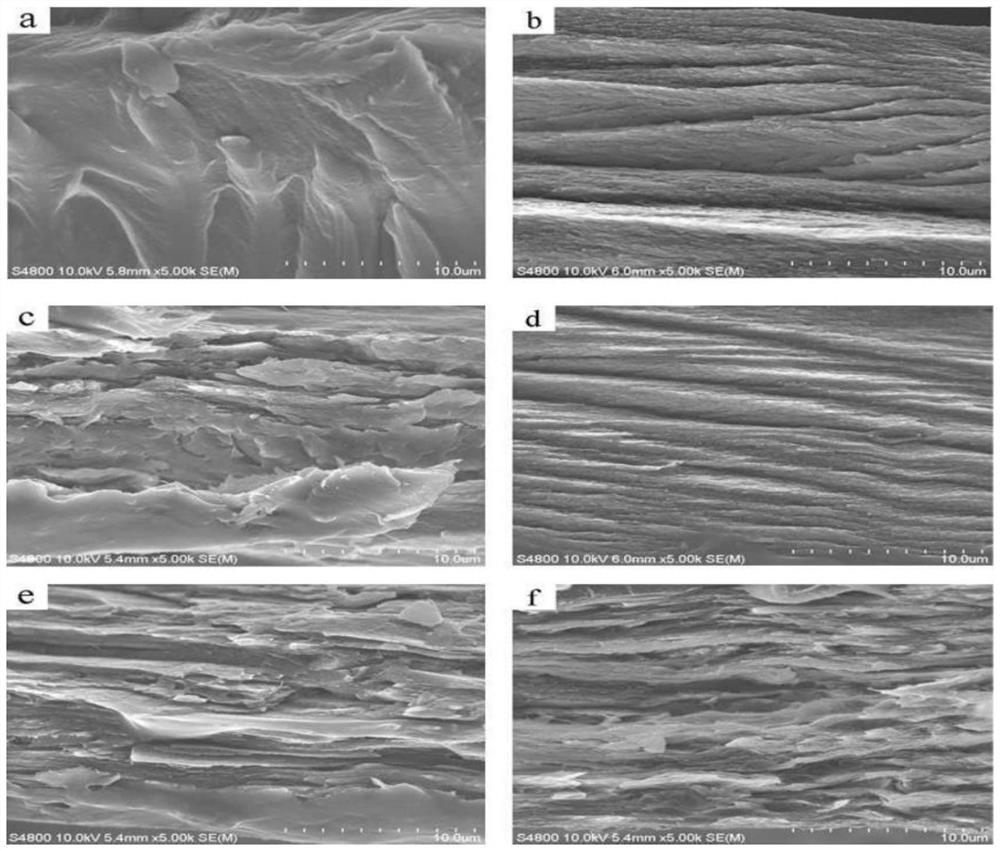

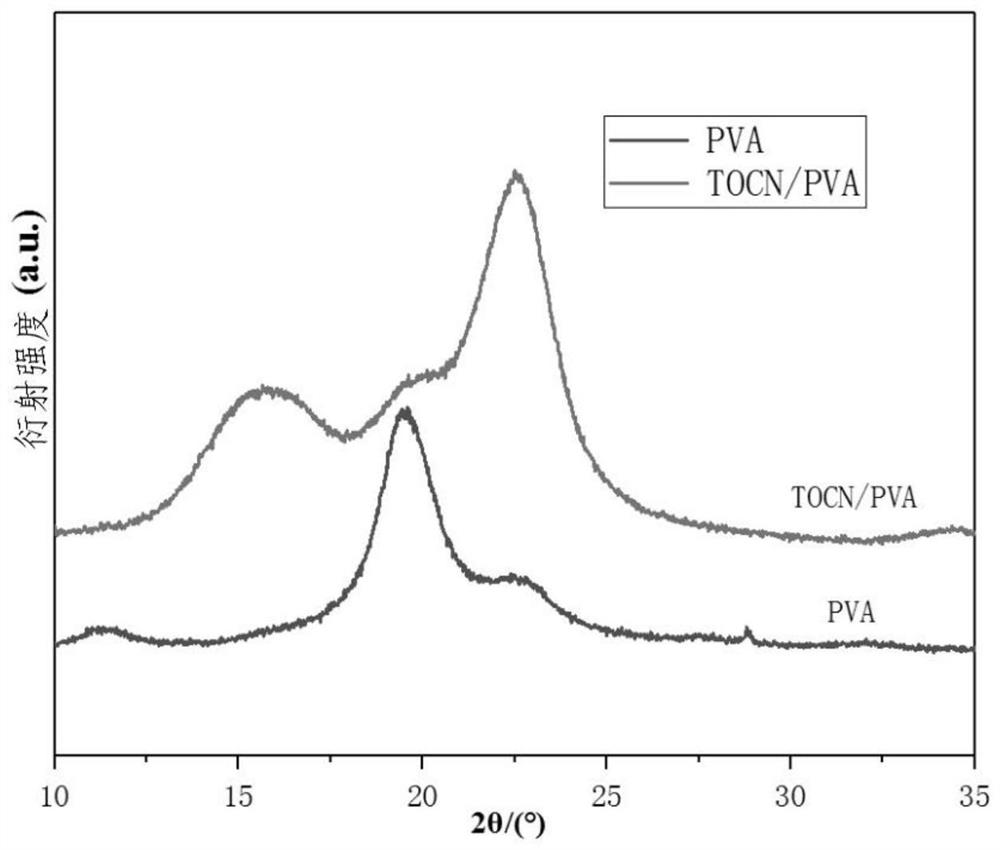

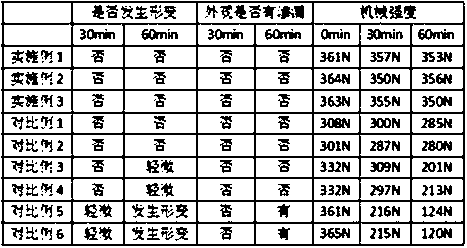

Preparation method of nano-cellulose-based oxygen isolation composite film

PendingCN112210225AExcellent oxygen barrier performanceGood water resistance and mechanical propertiesBio-packagingPolymer chemistryPolyvinyl alcohol

The invention provides a preparation method of a nanocellulose-based oxygen-isolating composite film. The method comprises the following steps: removing lignin from larch pulp powder to obtain lignocellulose, dissolving NaBr and tetramethylpiperidine oxide in a Na2CO3-NaHCO3 buffer solution, adding lignocellulose, dropwisely adding a NaClO solution, regulating the pH value, carrying out oxidationreaction, rinsing with deionized water, carrying out mechanical treatment, and obtaining carboxylated lignocellulose; adding deionized water and carboxylated lignocellulose into polyvinyl alcohol, mixing, and carrying out vacuum drying treatment to obtain a nanocellulose-based oxygen-isolating composite film, the mass ratio of polyvinyl alcohol to carboxylated lignocellulose being 3:7. The nano-cellulose-based oxygen isolation composite film prepared by the method has excellent oxygen isolation performance, and also has excellent water resistance and mechanical properties.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Edible environment-friendly bowl for instant noodle packaging

ActiveCN108328129AImprove securityImprove the environmentPackage recyclingTransportation and packagingFiberEngineering

The invention relates to an edible environment-friendly bowl for instant noodle packaging. The edible environment-friendly bowl comprises two parts, namely a bowl body and a bowl cover. The bowl bodyis made from edible materials and used as a base body, the bowl body is covered with a waterproof and oilproof layer made from an edible film, the exterior of the bowl body is packaged by a packagingfilm made from environment-friendly plant fiber to prevent pollution to the edible bowl body, and the bowl cover is made from an edible film. The bowl for instant noodle packaging is environmentally friendly and free of pollution, no substance harmful to body health is added, and the better mechanical strength, oil resistance, waterproof performance and oxygen resistance are achieved compared withmanufacturing materials of existing instant noodle bowls; and reuse can be achieved, the bowl can be naturally decomposed in nature after being abandoned if a user does not want to reuse it, no burden is caused to the environment, and the problems that materials used in instant noodle packaging bowls in the prior art are not healthy, not environmentally friendly and incapable of being reused aresolved.

Owner:淮安智品企业管理有限公司

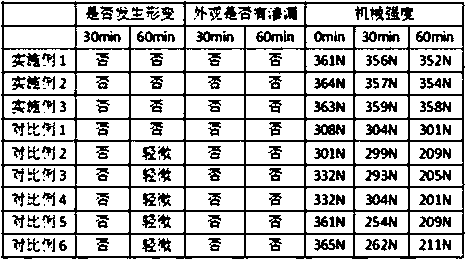

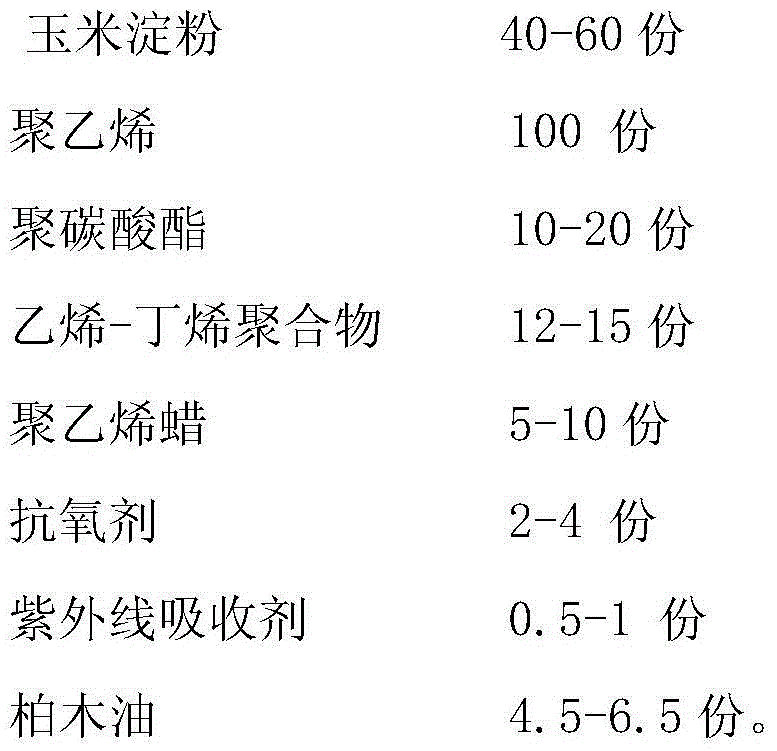

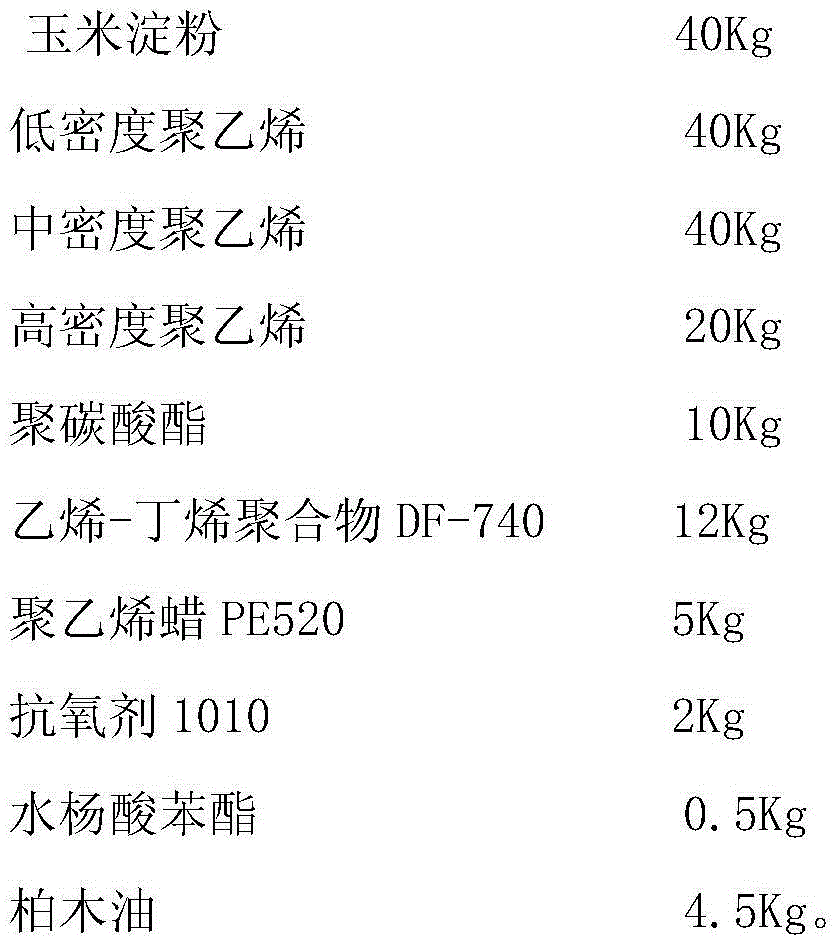

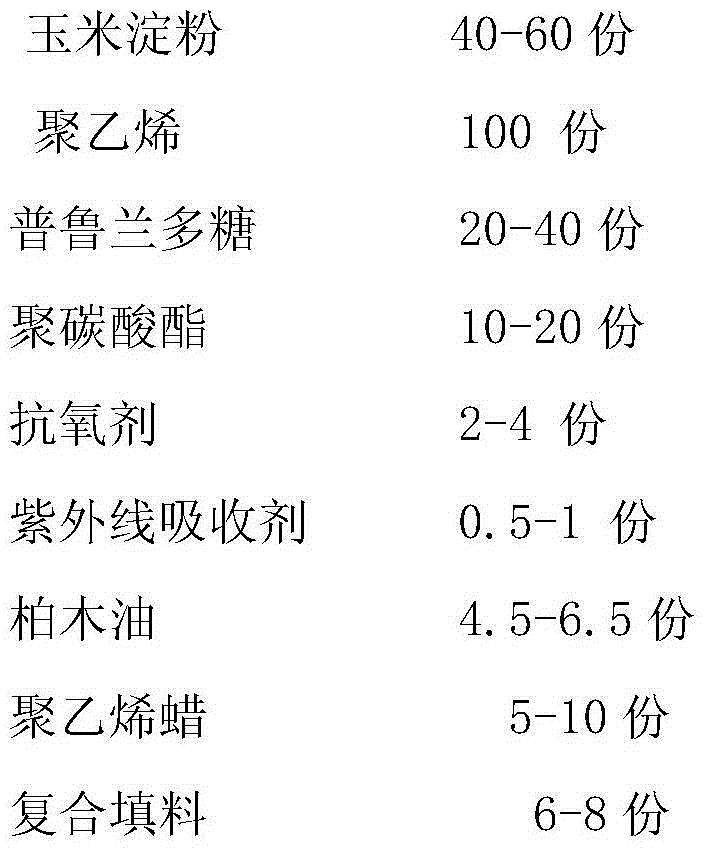

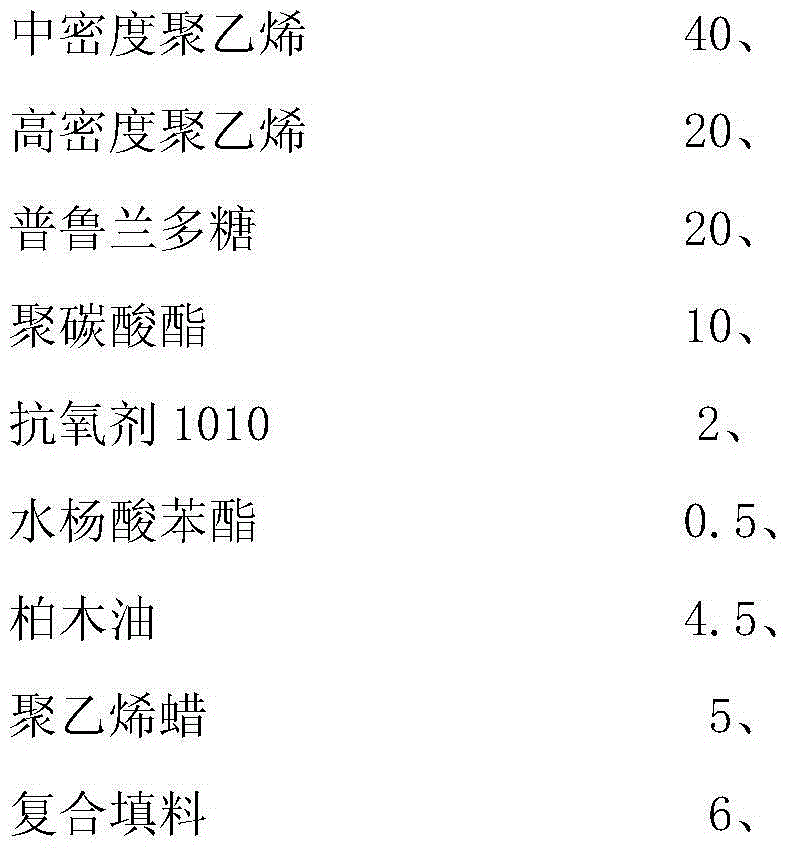

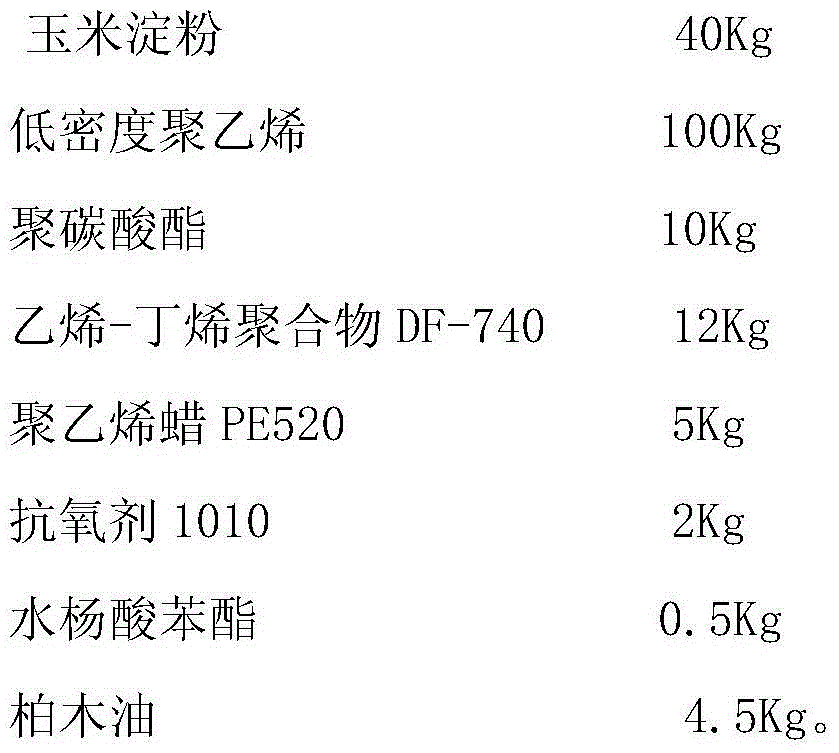

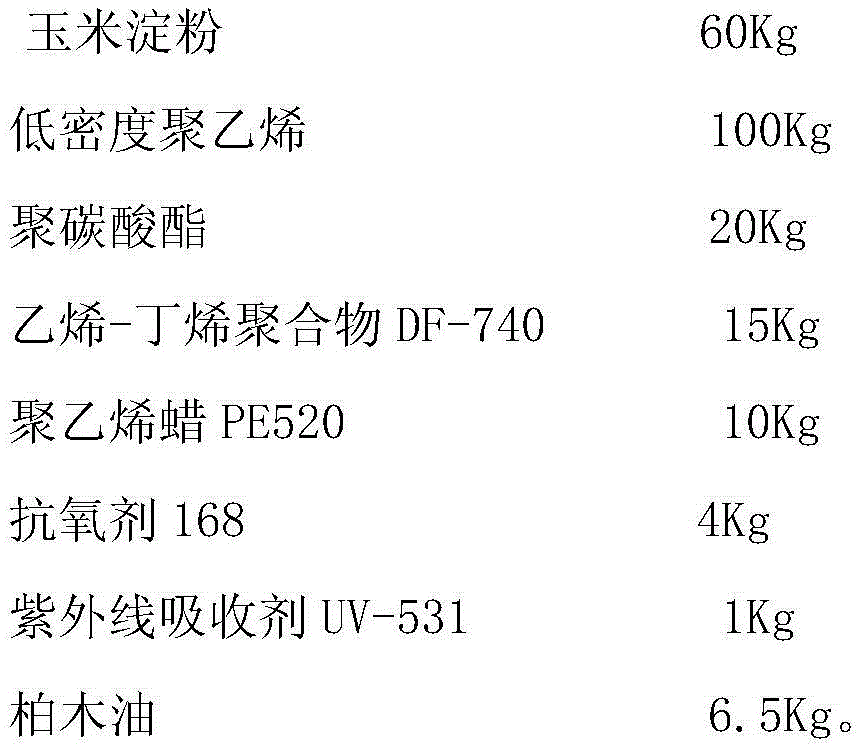

Plastic film

InactiveCN104151682AGood oxygen barrier effectIncrease productivityLow-density polyethyleneUltraviolet lights

The invention relates to a plastic film. The plastic film comprises the following components in parts by weight: 40-60 parts of corn starch, 100 parts of polyethylene, 10-20 parts of polycarbonates, 12-15 parts of thylene-butylene polymers, 5-10 parts of polyethylene wax, 2-4 parts of an anti-oxygen, 0.5-1 part of an ultraviolet light absorber and 4.5-6.5 parts of cedarwood oil. The oxygen isolating and degradable plastic film provided by the invention can be decomposed automatically under the influences of oxygen enrichment and microorganisms, the abandoned film can be degraded and digested completely through the microorganisms in nature to generate carbon dioxide and water ultimately, and compared with LDPE (low-density polyethylene) plastic film with same thicknesses, the oxygen isolating property can be improved by 40%. The preparation method of the plastic film provided by the invention has the advantages that the process is simple, the production efficiency is high, the implementations of the industrialization is easy and the plastic film can be produced through common plastic film blasting machines.

Owner:TIANJIN KAIXUAN PLASTIC PROD

Biodegradable plastic

ActiveCN103483850AGood mechanical propertiesAchieve environmental friendlinessFiberUltraviolet lights

Biodegradable plastic is characterized by including the following raw materials in parts by weight: 45-60 parts of plant fiber starch, 4-6 parts of glycerinum, 40 parts of polyethylene, 20-40 parts of polylactic acid, 60-80 parts of synthetic resin, 10-15 parts of auxiliaries, 5-8 parts of pulullan, 2-4 parts of an antioxidant and 1-1.5 parts of an ultraviolet light absorbent.

Owner:江苏湘园化工有限公司

Biodegradable flame-retardant plastic film

InactiveCN104448502AImprove mechanical propertiesAchieve environmental friendlinessPullulanAntioxidant

The invention discloses a biodegradable flame-retardant plastic film, which is prepared from the following raw materials in parts by weight: 85 parts of polyethylene, 20-30 parts of polylactic acid, 65-80 parts of a PBM degradable material, 10-15 parts of packing, 5-10 parts of pullulan, 2-4 parts of an antioxidant, 1-1.5 parts of an ultraviolet light absorber and 25-30 parts of nano flame-retardant composites. The oxygen-isolating biodegradable plastic film disclosed by the invention is prepared by blending extrusion and film blowing of mature modified starch biodegradable plastic master batches PBM and pullulan and film-grade LDPE in the market at present in the preparation method; good mechanical property of the film is ensured by using the characteristics of the LDPE; the environment friendliness of the film material is achieved by using the biodegradability of the PBM and the pullulan; the oxygen isolating property of the film material is improved by using high oxygen isolating property of the pullulan; the overall compatibility of the plastic film material is improved by using the structure similarity of starch and the pullulan as carbohydrates; and regulation and control of the oxygen isolating property, the biodegradability and the like can be achieved by controlling the blending ratio of the LDPE / PBM / Pullulan system.

Owner:TIANJIN KAIXUAN PLASTIC PROD

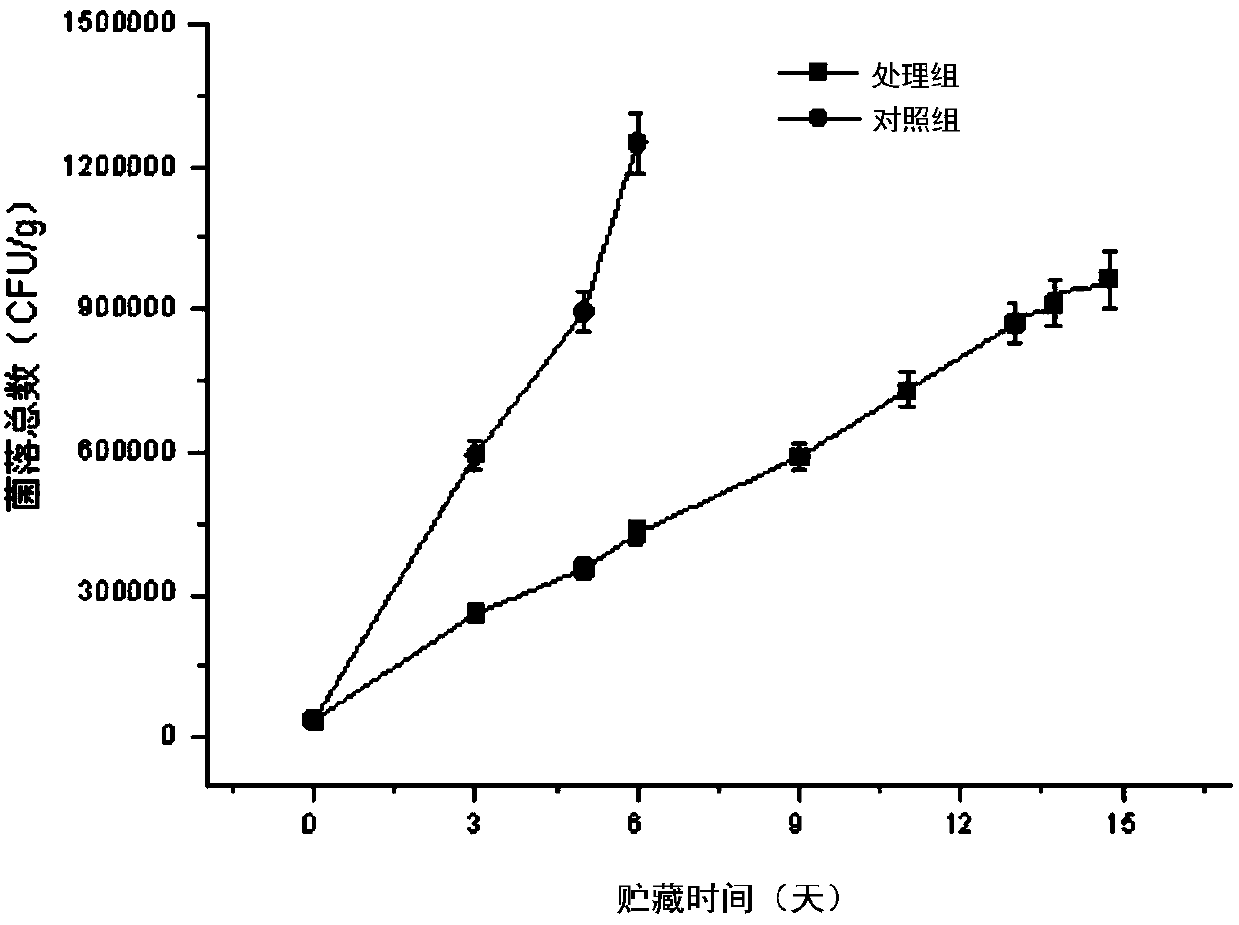

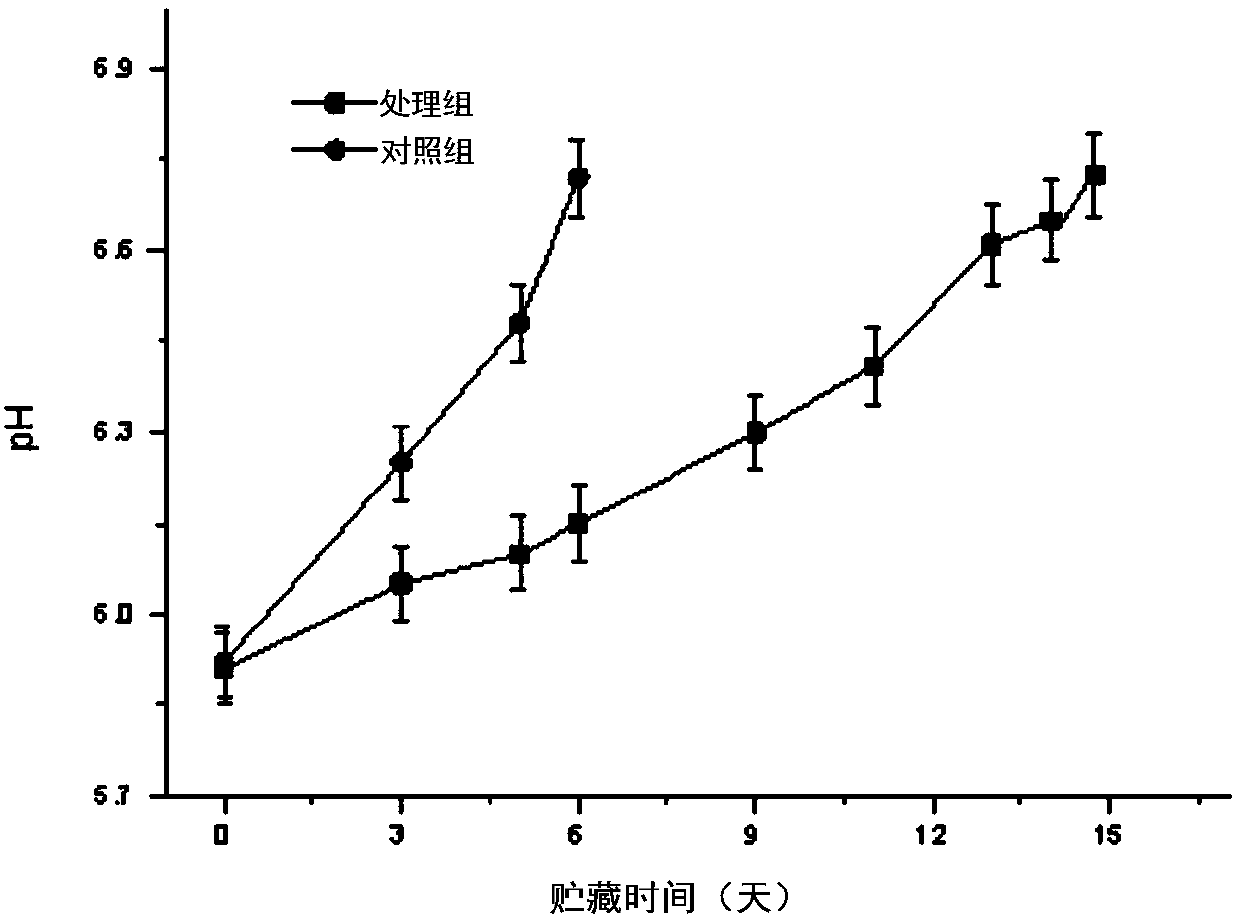

Biological fresh-keeping agent for chilled chicken

InactiveCN107853377AImprove antioxidant capacityAntioxidant is a new type of natural food antioxidantMeat/fish preservation by coatingNatural extract food ingredientsSolubilityAntioxidant

The invention provides a biological fresh-keeping agent for chilled chicken. Per 100mL of the biological fresh-keeping agent contains: 0.1-0.2g of a bamboo leaf antioxidant, 3-8g of whey protein, 0.01-0.025g of nisin, and the balance sterile water. The preparation method includes: (1) taking a clean 250mL beaker; (2) weighing 0.1-0.2g of the bamboo leaf antioxidant, 3-8g of whey protein and 0.01-0.025g of streptococcus lactis, and putting the substances into the beaker; (3) adding sterile water into the beaker to a constant volume of 100mL; and (4) conducting ultrasonic dissolving for 3-5min,at the same time performing stirring with a glass rod, thus obtaining the biological fresh-keeping agent. The biological fresh-keeping agent for chilled chicken provided by the invention can effectively prolong the shelf life of chilled chicken, also has good water solubility and simple and practicable preparation process, thus being suitable for mass preparation and use.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Method for preventing browning in production of konjak powder

InactiveCN104207298AImprove qualityGood oxygen barrier effectFood preservationFood ingredientsMoisturePapain

The invention discloses a method for preventing browning in production of konjak powder. The method particularly includes following steps: mixing konjak flying powder with papain and spraying the konjak flying powder and the papain on fresh cut konjak pieces for enabling the powder fully covers surfaces of the fresh cut konjak pieces. Glucomannan has a quite strong water-absorbing property and can absorb moisture on the surfaces of the fresh cut konjak piece to form a hydration film so that an oxygen-insulation effect is achieved. In addition, by means of color protection of the papain, a quite good color-protective effect is achieved. By means of the color-protective method combined with a conventional production technology of the konjak powder, an object of producing high-quality konjak powder is achieved.

Owner:HUBEI JIANSHI NONGTAI IND CO LTD

Biodegradable plastic film

InactiveCN104497398AGood mechanical propertiesAchieve environmental friendlinessPullulanUltraviolet lights

The invention discloses a biodegradable plastic film which respectively comprises the following raw material components in parts by weight: 80 parts of polyethylene, 20-40 parts of polylactic acid, 60-80 parts of a PBM degradable material, 10-15 parts of a filling material, 5-8 parts of Pullulan, 2-4 parts of an antioxidant and 1-1.5 parts of an ultraviolet light absorber. The oxygen-isolating and biodegradable plastic film provided by the invention has the advantages that the mature modified starch biodegradable plastic master batch PBM, the Pullulan and film-level LDPE in the market are selected to be subjected to blending extrusion and film blowing in the preparation method at present, the characteristics of LDPE are utilized, and good mechanical property of the film is guaranteed; by utilizing the biodegradability of PBM and Pullulan, the environment friendliness of the film material is realized; by utilizing high oxygen isolating property of the Pullulan, the oxygen isolation property of the film material is improved; by utilizing the structural similarity of the starch and Pullulan serving as saccharides, the overall compatibility of the plastic film material is improved; and moreover, the blending ratio of the LDPE / PBM / Pullulan system is controlled, so that the oxygen isolation property, the biodegradability and the like can be regulated.

Owner:TIANJIN KAIXUAN PLASTIC PROD

Agricultural insect killing and oxygen isolating environment-friendly degradable plastic film

InactiveCN104441881AGood oxygen barrier effectIncrease productivityBiocideSynthetic resin layered productsLow-density polyethyleneEnvironmental resistance

The invention provides an agricultural insect killing and oxygen isolating environment-friendly degradable plastic film. The agricultural insect killing and oxygen isolating environment-friendly degradable plastic film is prepared by coating both sides of a plastic film with an insecticide and comprises the following components in parts by weight: 40-60 parts of corn starch, 100 parts of low density polyethylene (LDPE), 20-40 parts of pulullan, 10-20 parts of polycarbonate, 2-4 parts of antioxidant, 0.5-1 part of ultraviolet absorber, 4.5-6.5 parts of cedar oil, 5-10 parts of polyethylene wax and 6-8 parts of composite filler. The film per m<2> is coated with 4-6g of insecticide slurry. The oxygen isolating degradable plastic film provided by the invention has the advantages and beneficial effects that the plastic film can be automatically decomposed under the actions of rich oxygen and microorganisms; the waste films can be completely decomposed and digested by microorganisms in the natural world to finally generate carbon dioxide and water; the oxygen isolating property of the plastic film can be improved by 40% compared with the oxygen isolating properties of LDPE films in the same thickness; a preparation method of the plastic film is simple in process and high in production efficiency, is easy to implement industrially and can be used for producing the plastic film by using a common plastic film blowing machine.

Owner:TIANJIN KAIXUAN PLASTIC PROD

Degradable plastic film

InactiveCN104151686AGood oxygen barrier effectIncrease productivityLow-density polyethyleneAntioxidant

The invention relates to a degradable plastic film which comprises the following components in parts by weight: 40-60 parts of corn starch, 100 parts of low density polyethylene (LEPD), 10-20 parts of polycarbonate, 12-15 parts of ethylene / butene polymer, 5-10 parts of polyethylene wax, 2-4 parts of an antioxidant, 0.5-1 part of a ultraviolet light absorber and 4.5-6.5 parts of cedarwood oil. The oxygen-separating degradable plastic film provided by the invention can be automatically decomposed under the actions of enriched oxygen and microorganisms; the wasted film can be completely degraded and digested by the microorganisms in a natural world and carbon dioxide and water are finally generated; compared with an LDPE film with the same thickness, the degradable plastic film has the advantage that the oxygen insulating performance can be improved by 40 percent. The degradable plastic film disclosed by the invention has the advantages of simple preparation method and process, high production efficiency and easy industrial implementation; the degradable film can be produced by a general plastic film blowing machine.

Owner:TIANJIN KAIXUAN PLASTIC PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com